Patents

Literature

587results about How to "Improve rock breaking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

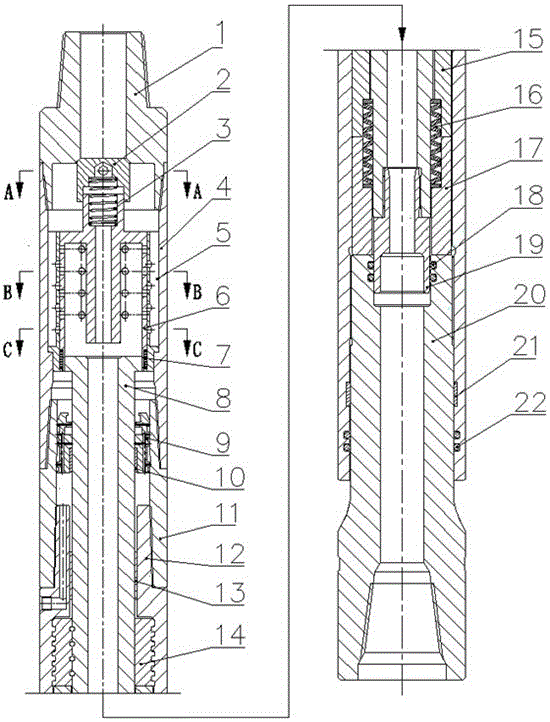

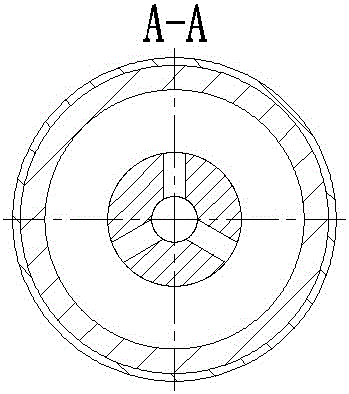

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

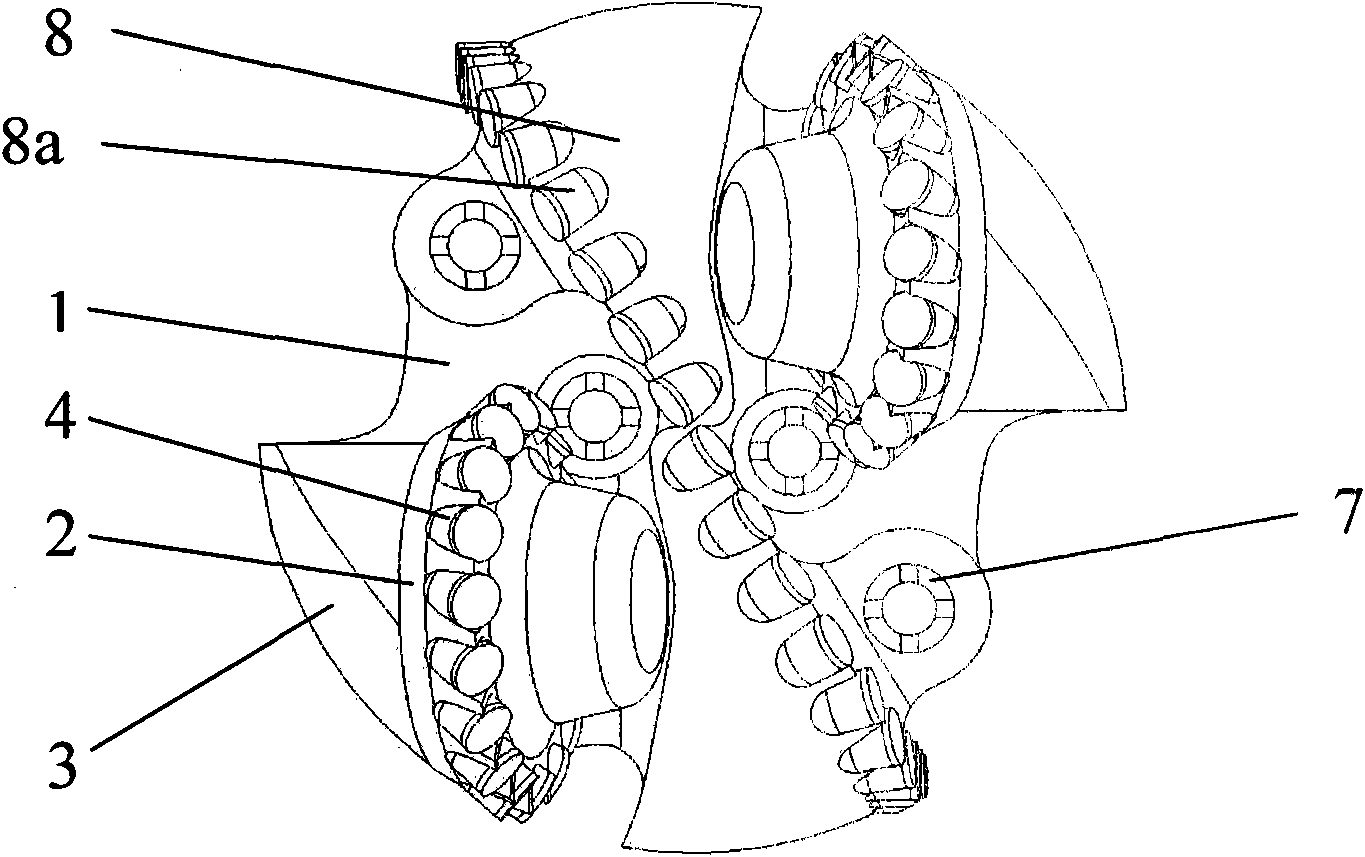

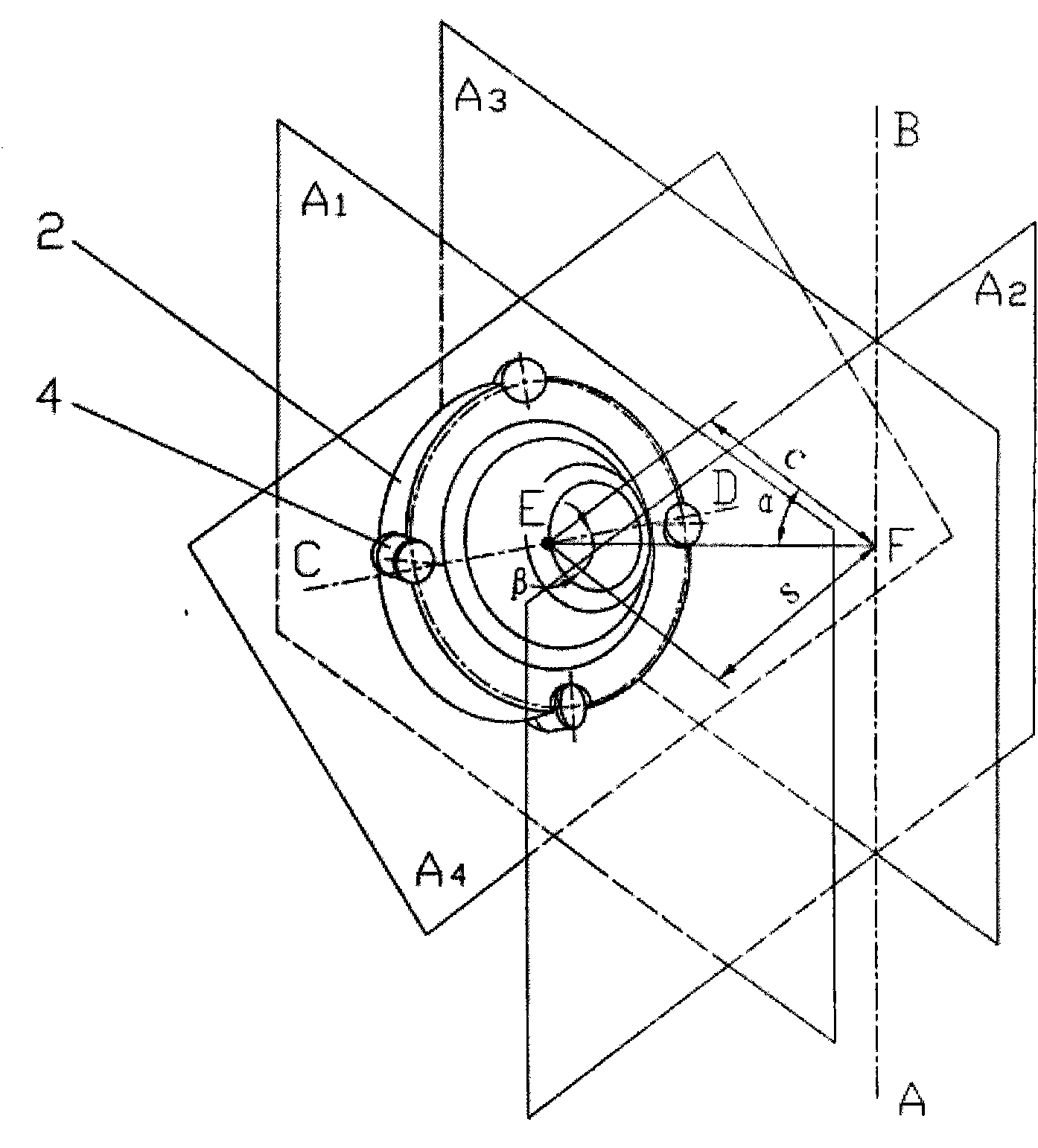

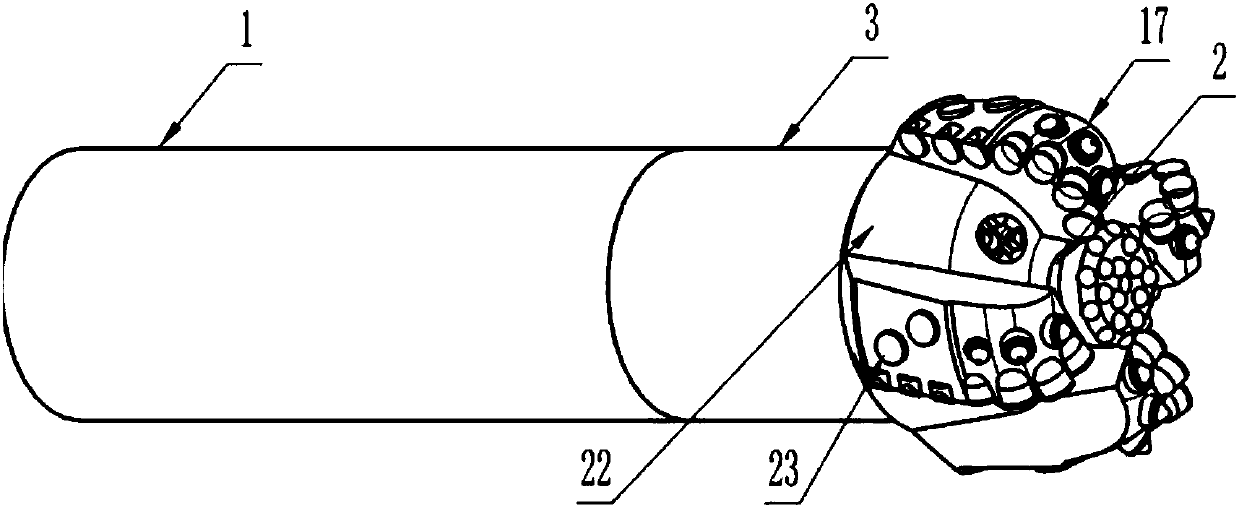

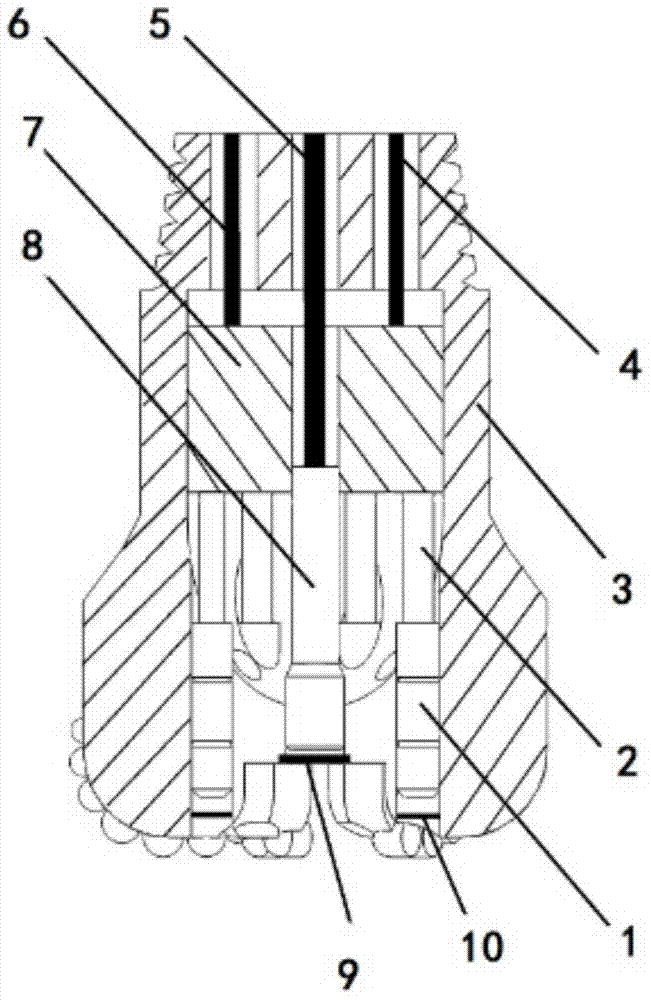

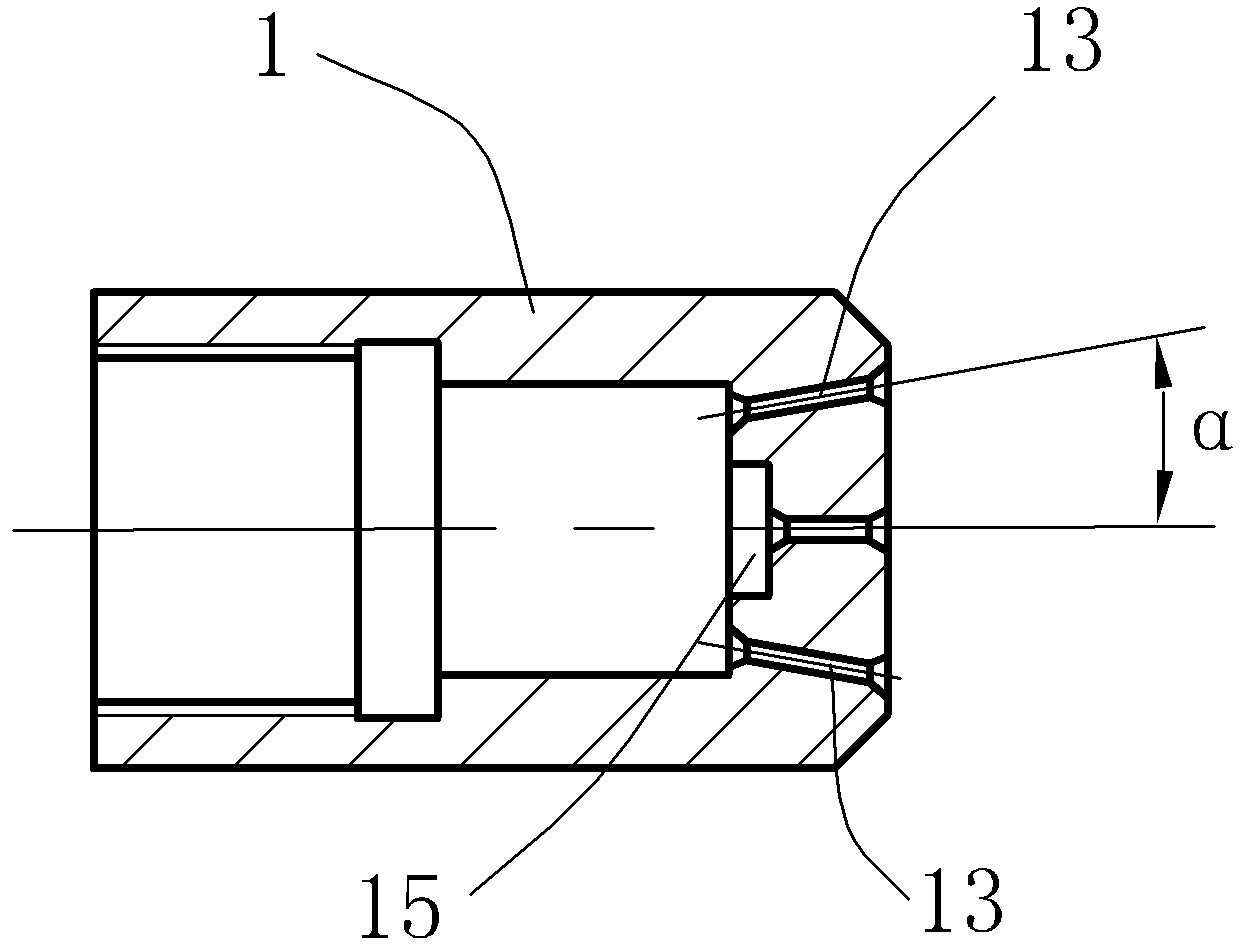

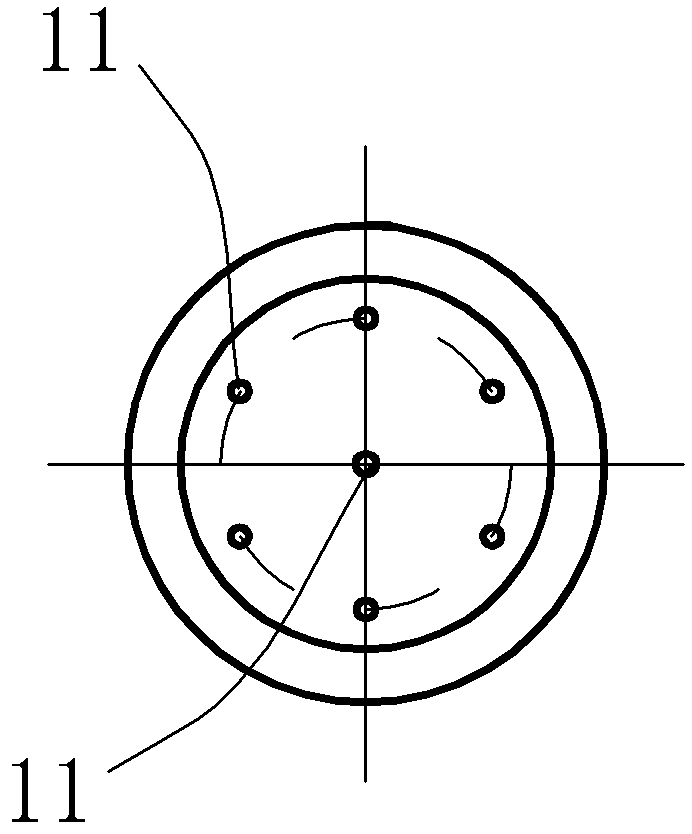

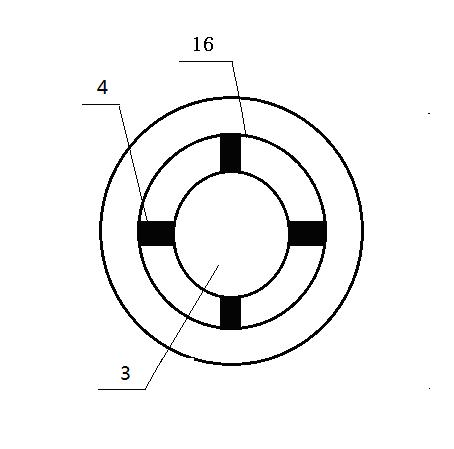

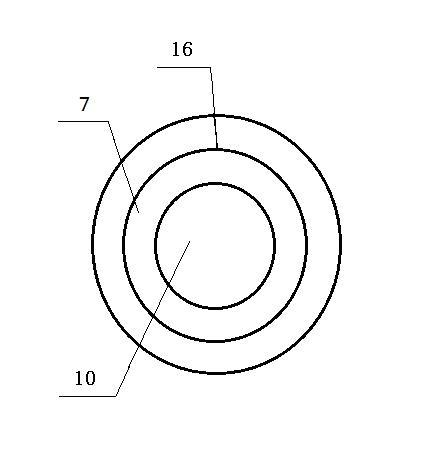

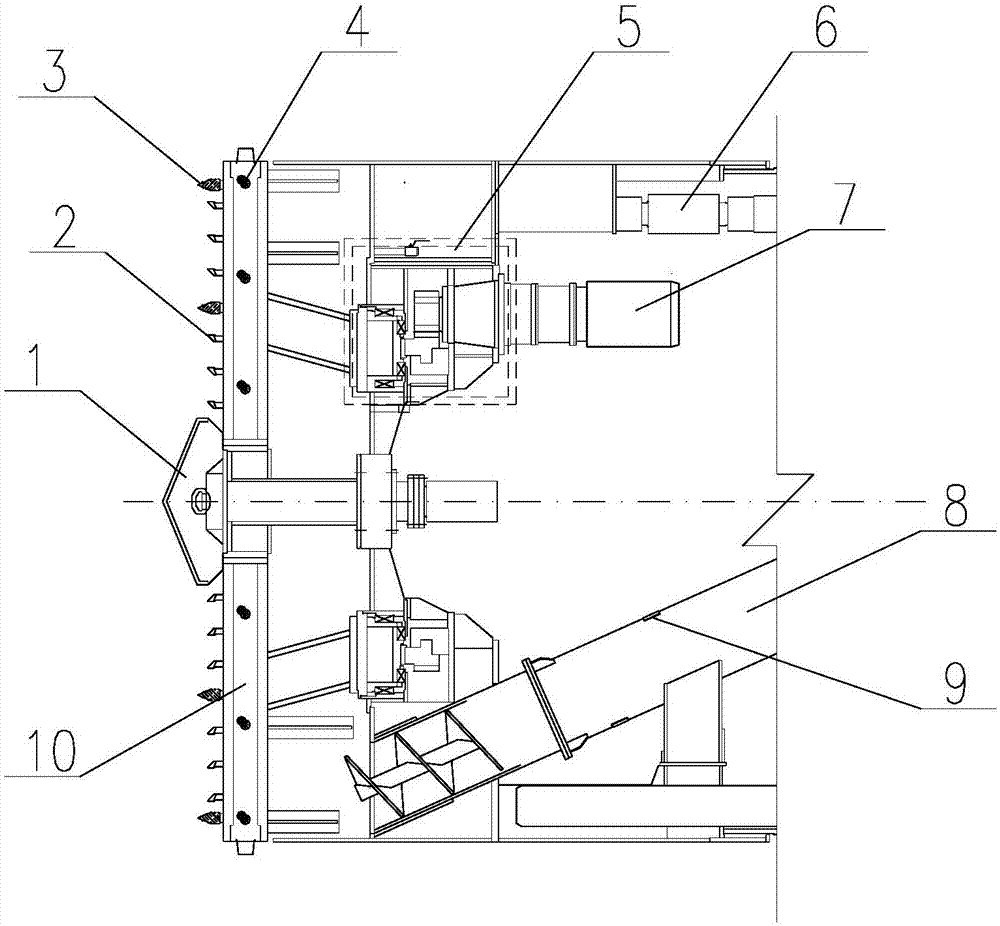

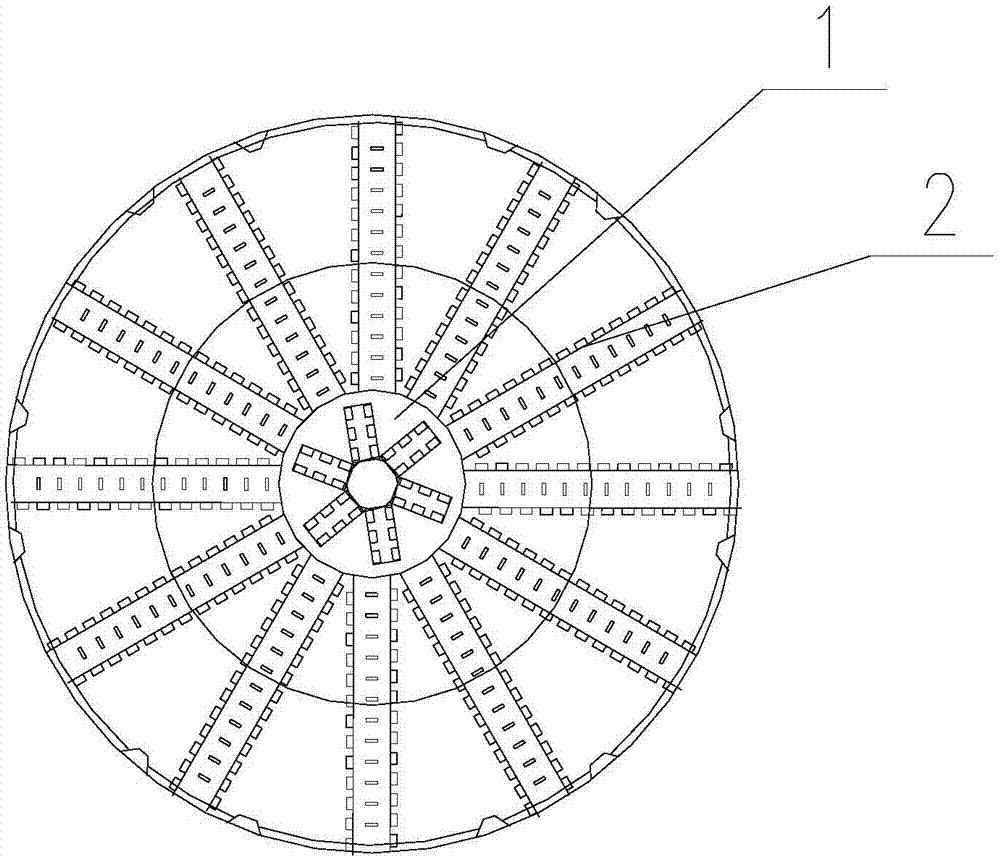

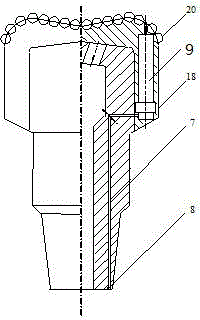

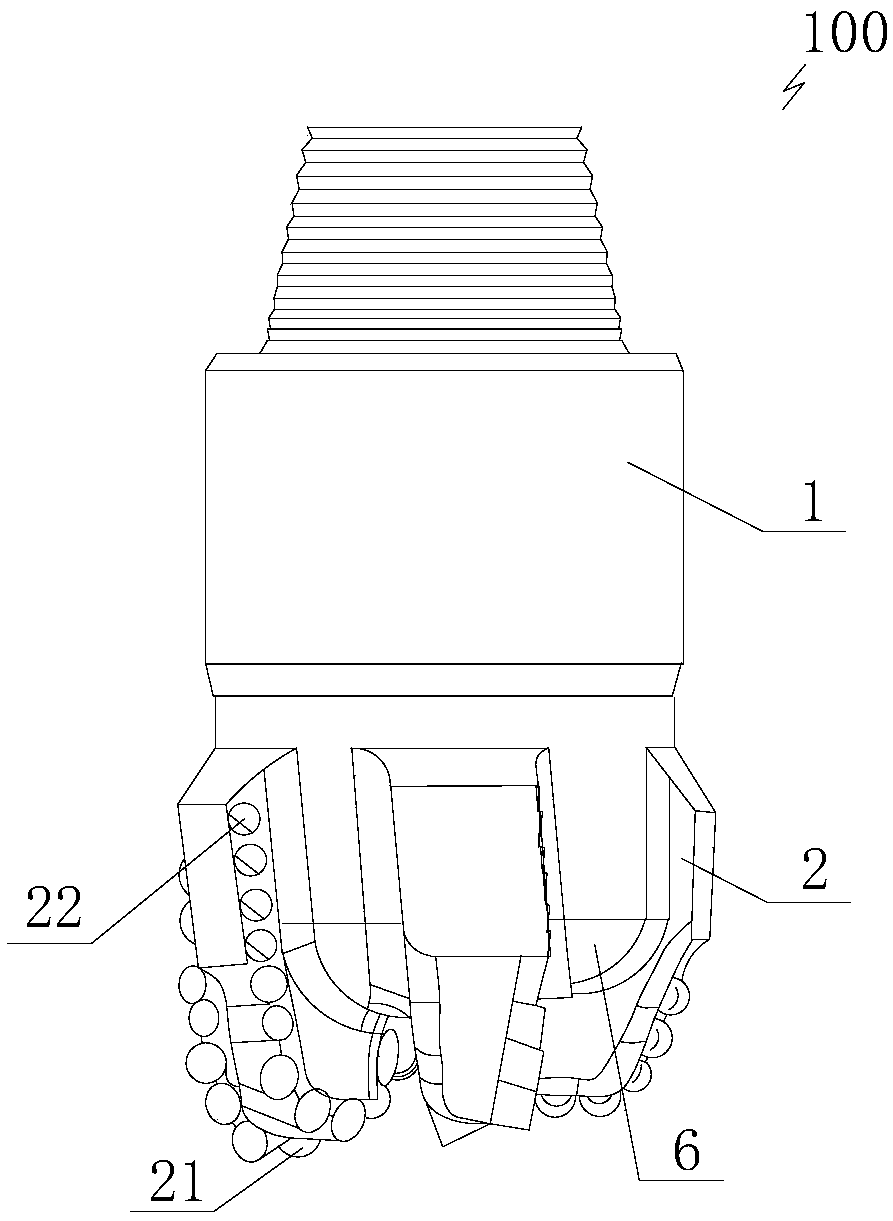

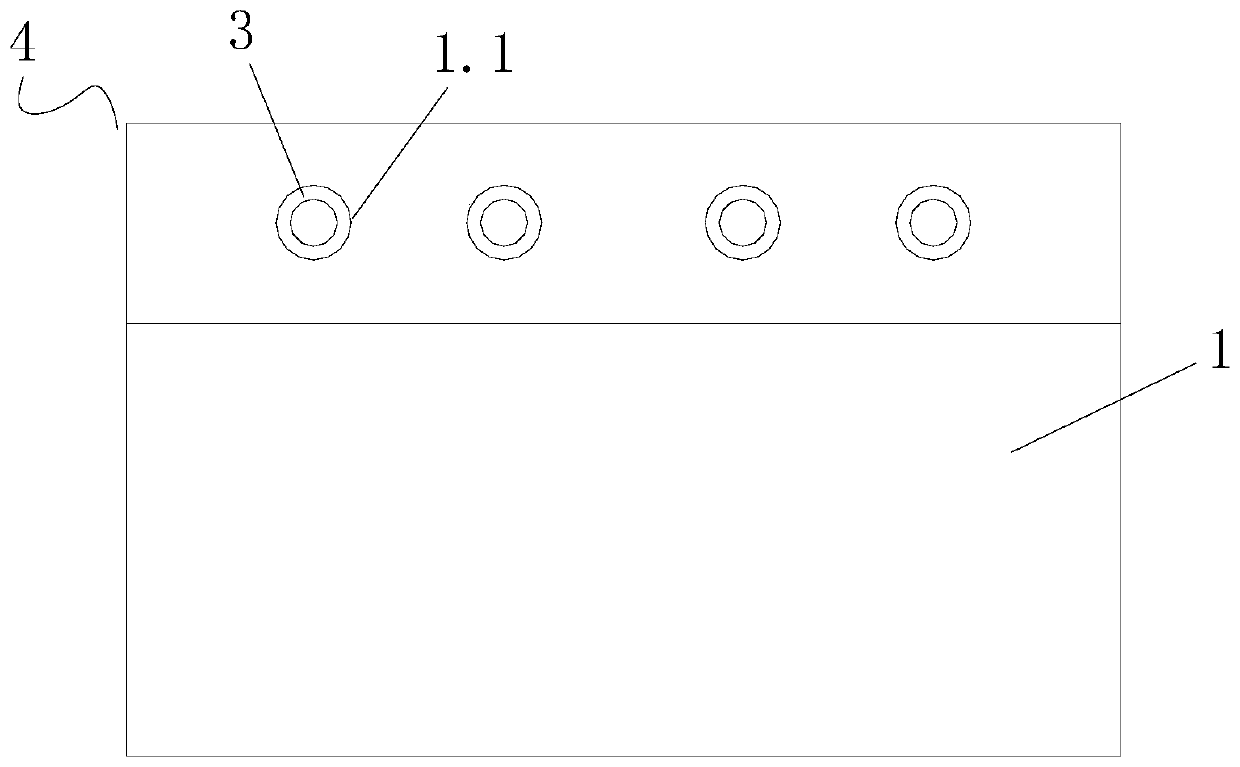

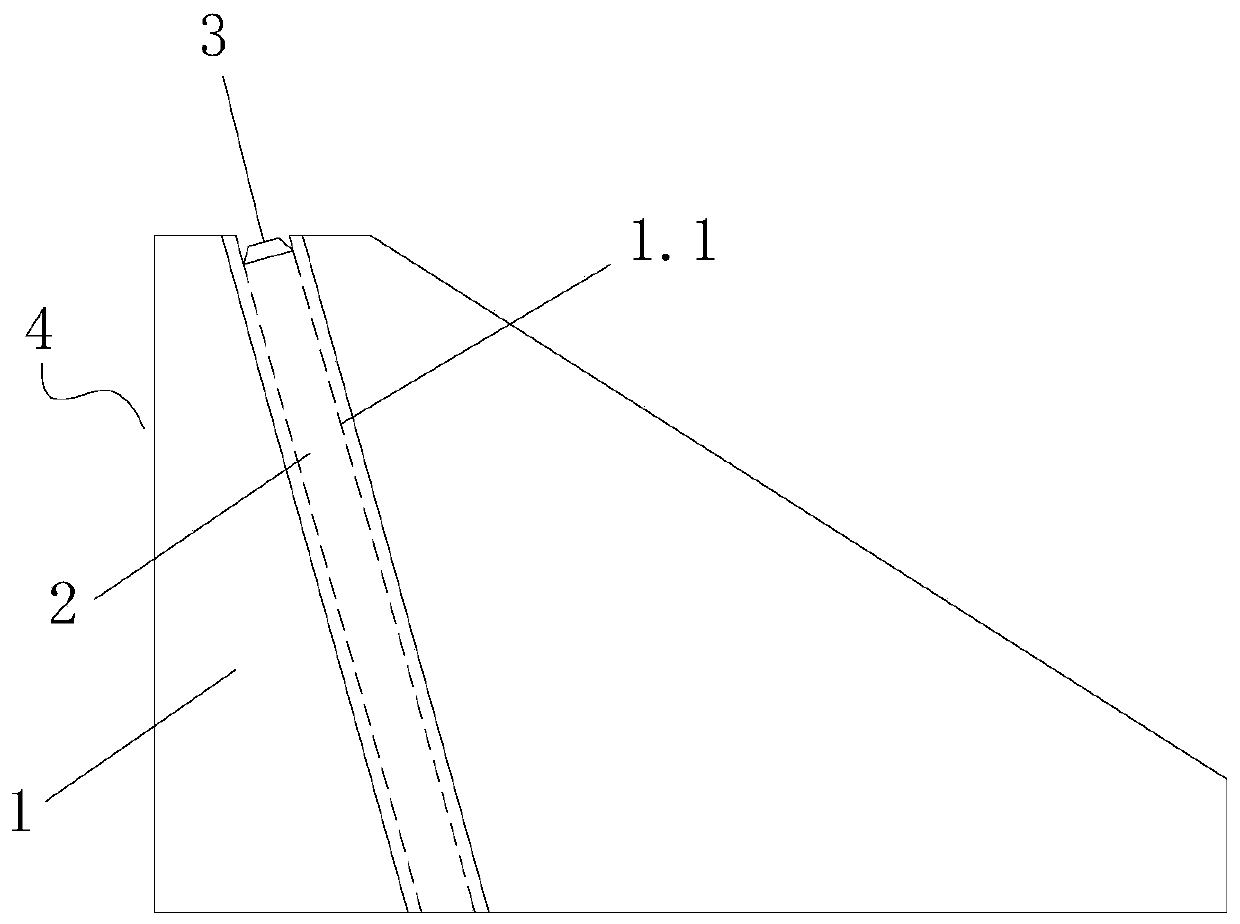

Combined drill breaking rocks by cutting method

ActiveCN101892810APromote fragmentationEffective intakeDrill bitsConstructionsWorking lifeCooling effect

The invention discloses a combined drill breaking rocks by a cutting method. The combined drill comprises a drill body (1) and a rotating wheel (2), wherein a wheel palm (3) is arranged on the drill body (1); the rotating wheel (2) is arranged on the shaft neck (6) of the wheel palm (3) and is in rotary connection with the wheel palm (3); an external row of cutting gear rings (4) are arranged on the rotating wheel (2); the deviation angle alpha of the rotating wheel (2) is in a range that the absolute value of alpha is more than or equal to 20 degrees and less than or equal to 90 degrees; and a fixed cutting structure (8) with fixed cutting teeth (8a) is arranged on the drill body (1). Cutting teeth on the rotating wheel break the rocks in an alternatively scraping mode and cooperates with the cutting teeth on the fixed cutting structure to form a net-like breaking region on the pit bottom rocks, so the combined drill has the advantages of high rock-breaking efficiency, uniform wear, good cooling effect, long service life of the teeth, long working life of the bearing and long service life of the drill.

Owner:CHENGDU WEIYI PETROLEUM TECH

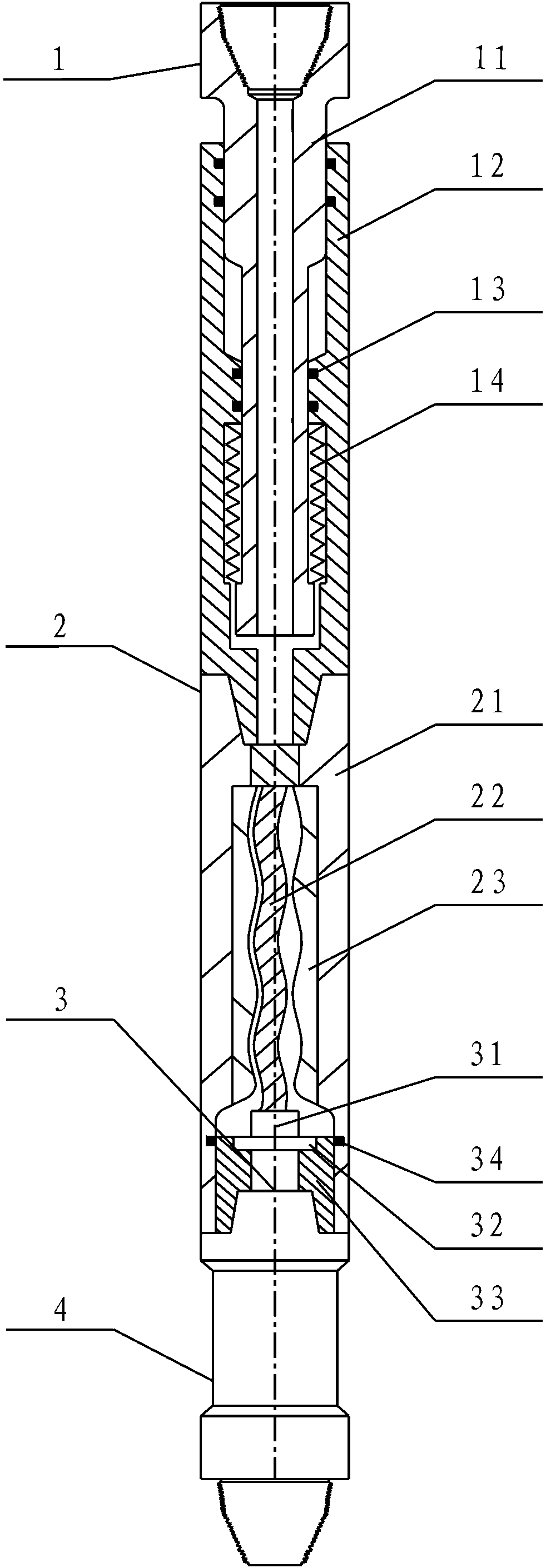

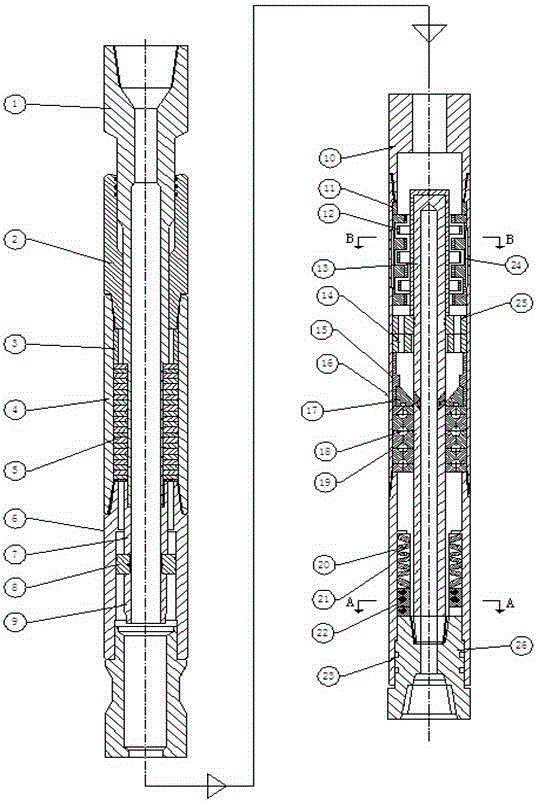

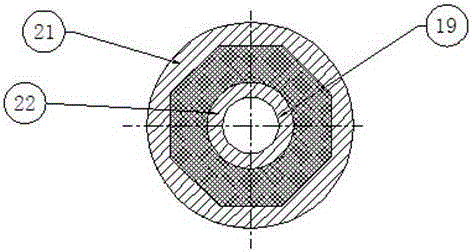

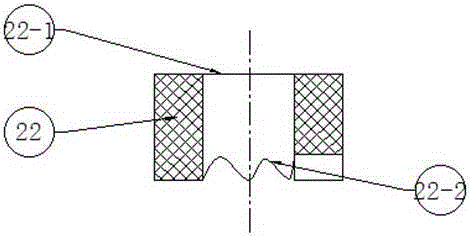

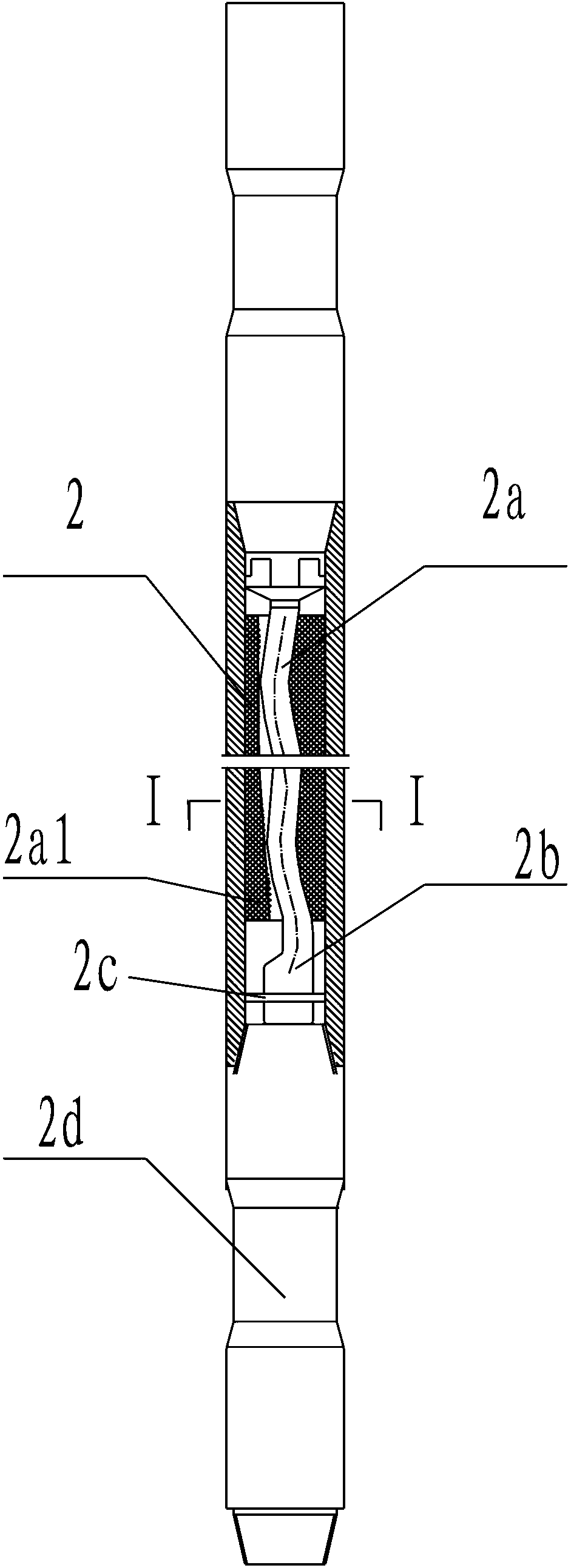

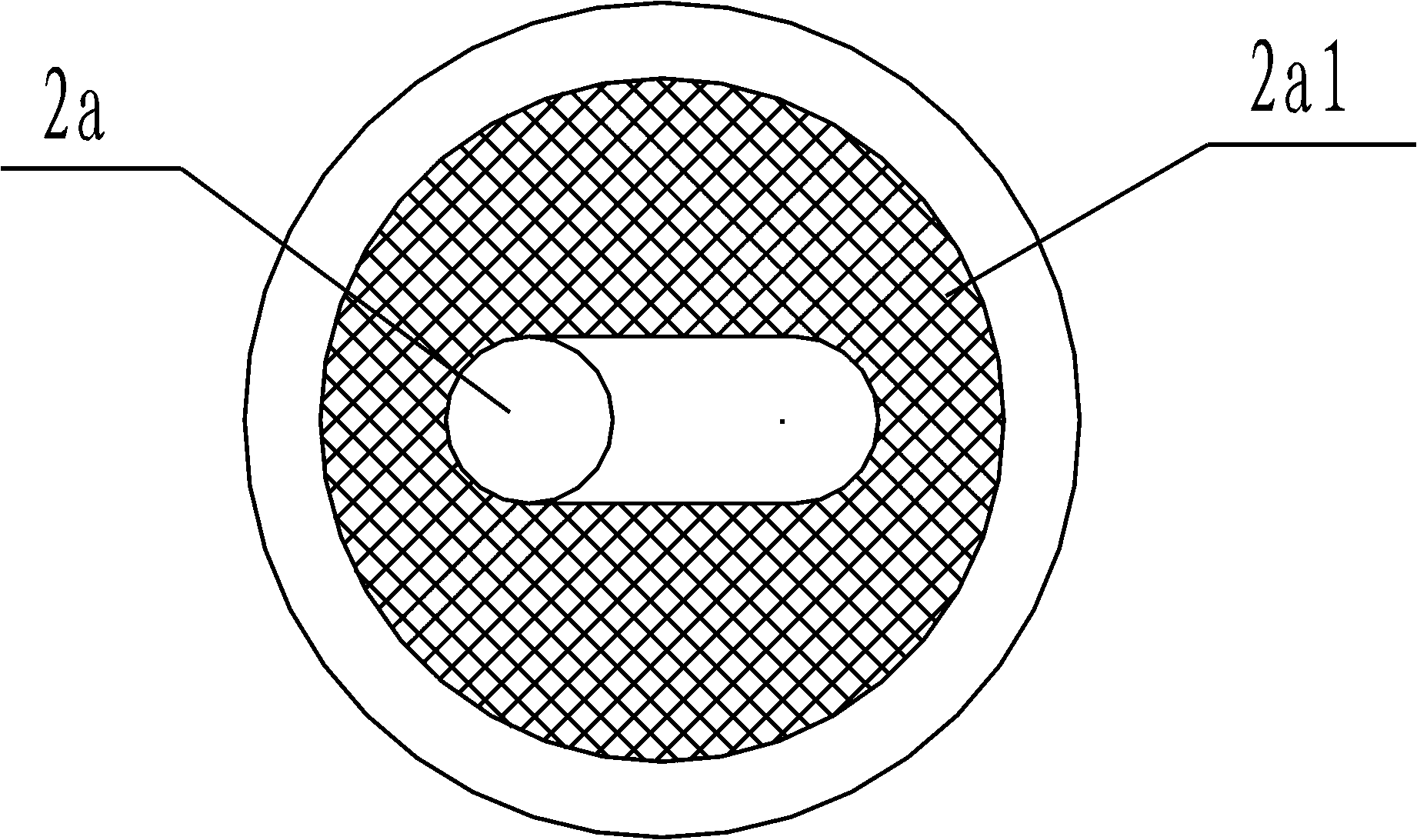

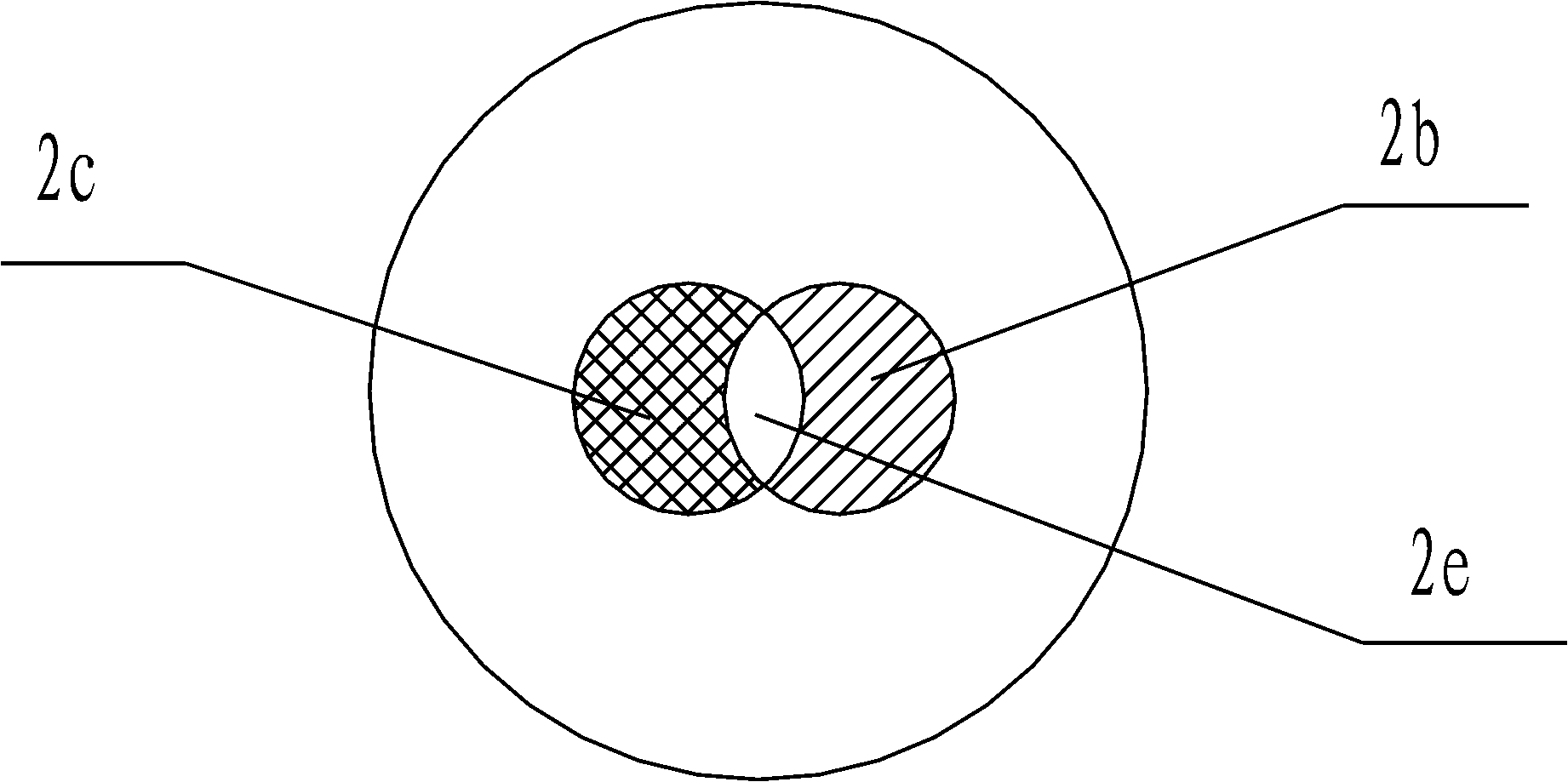

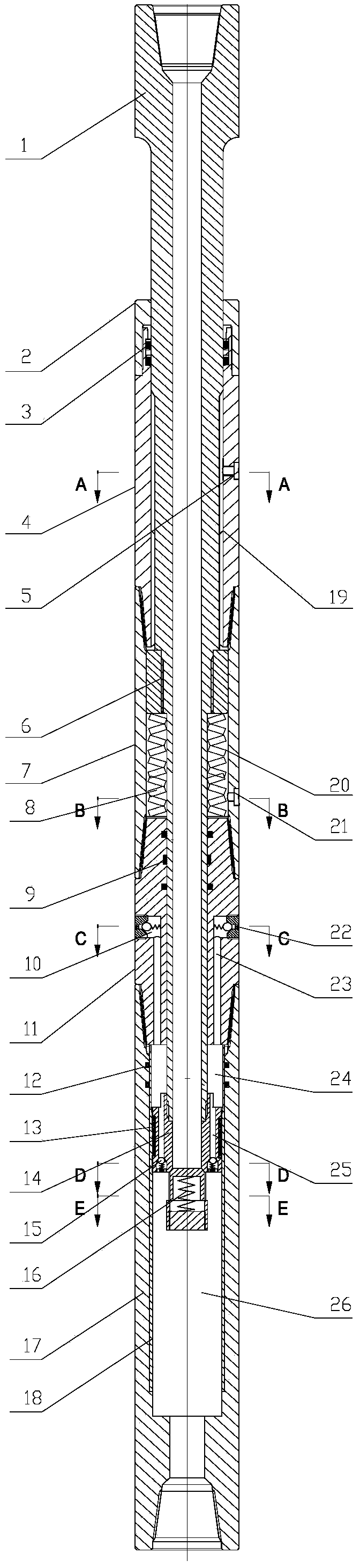

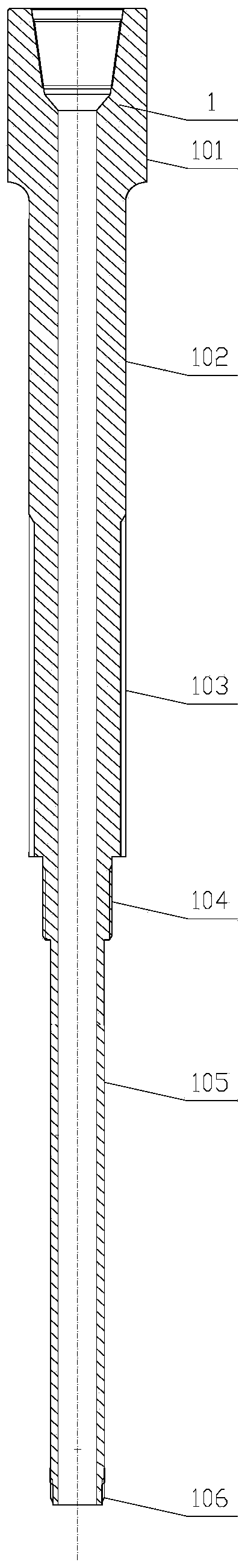

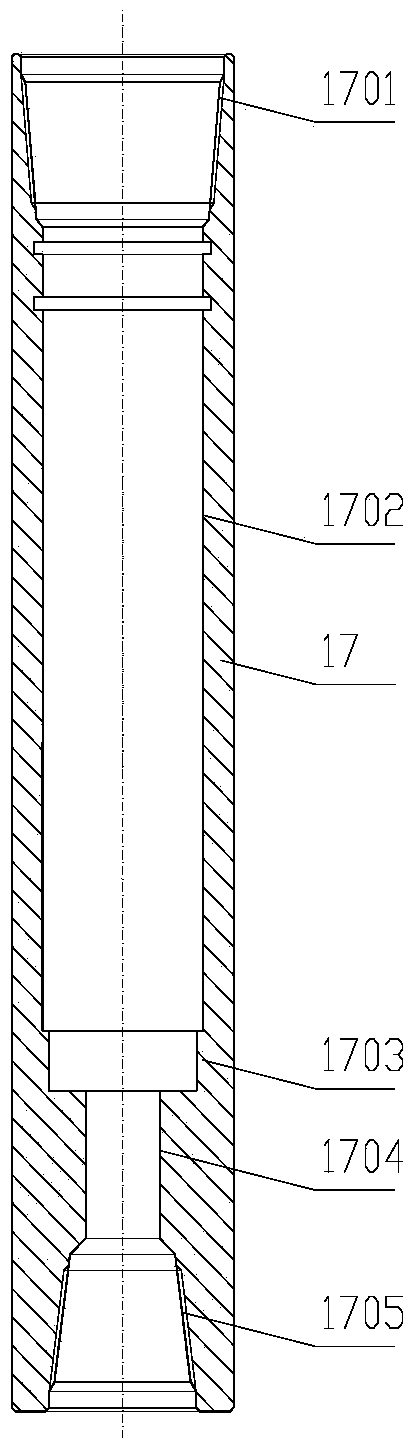

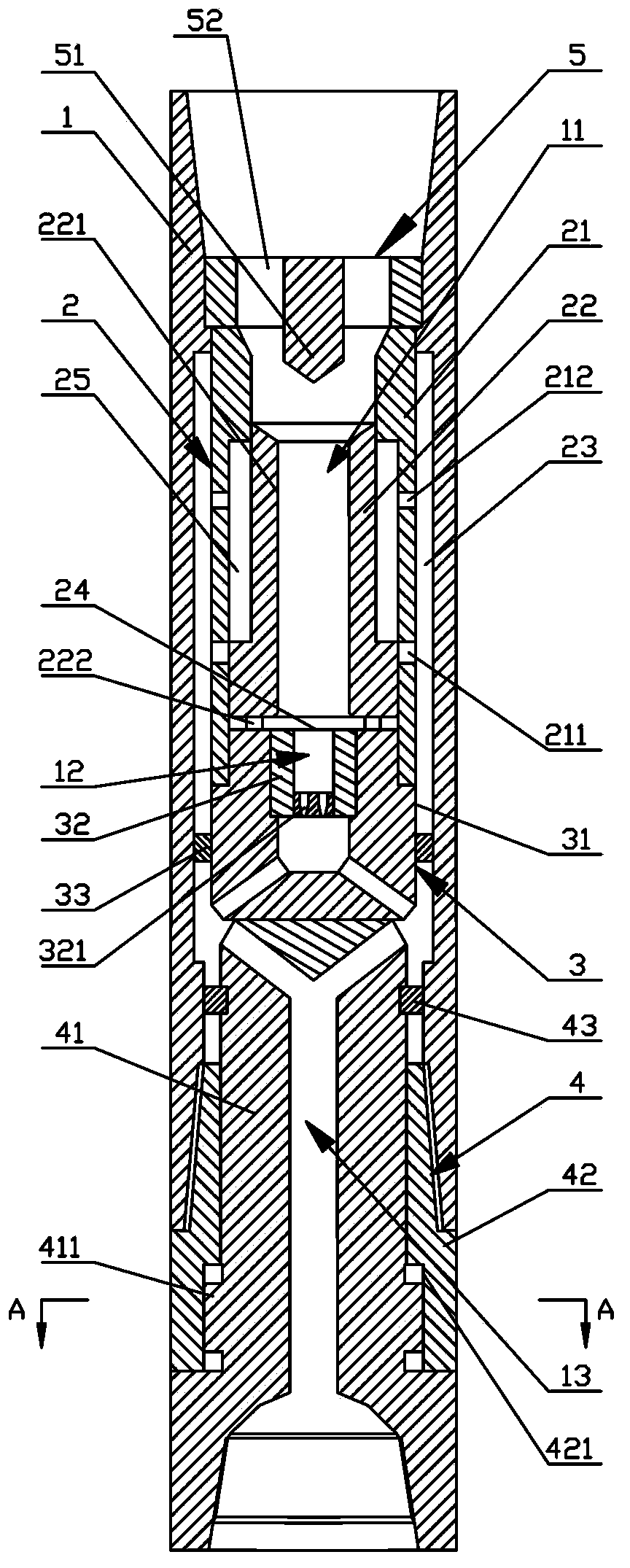

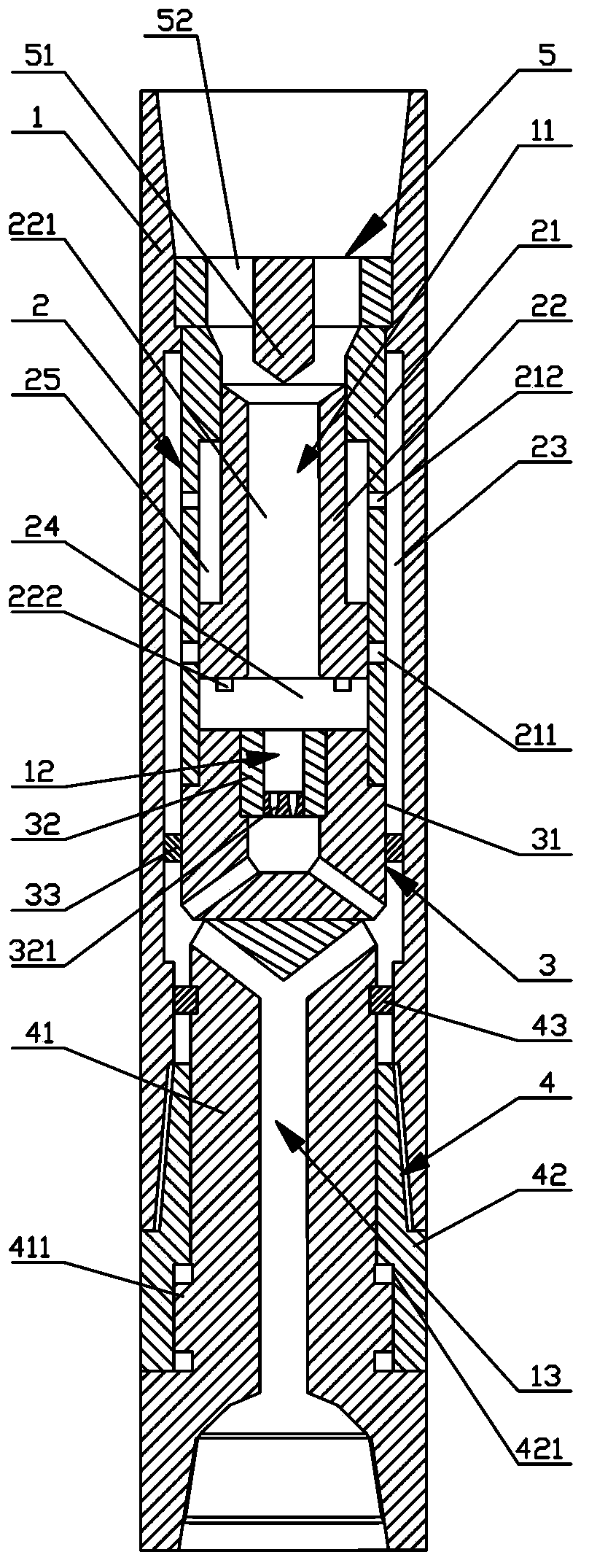

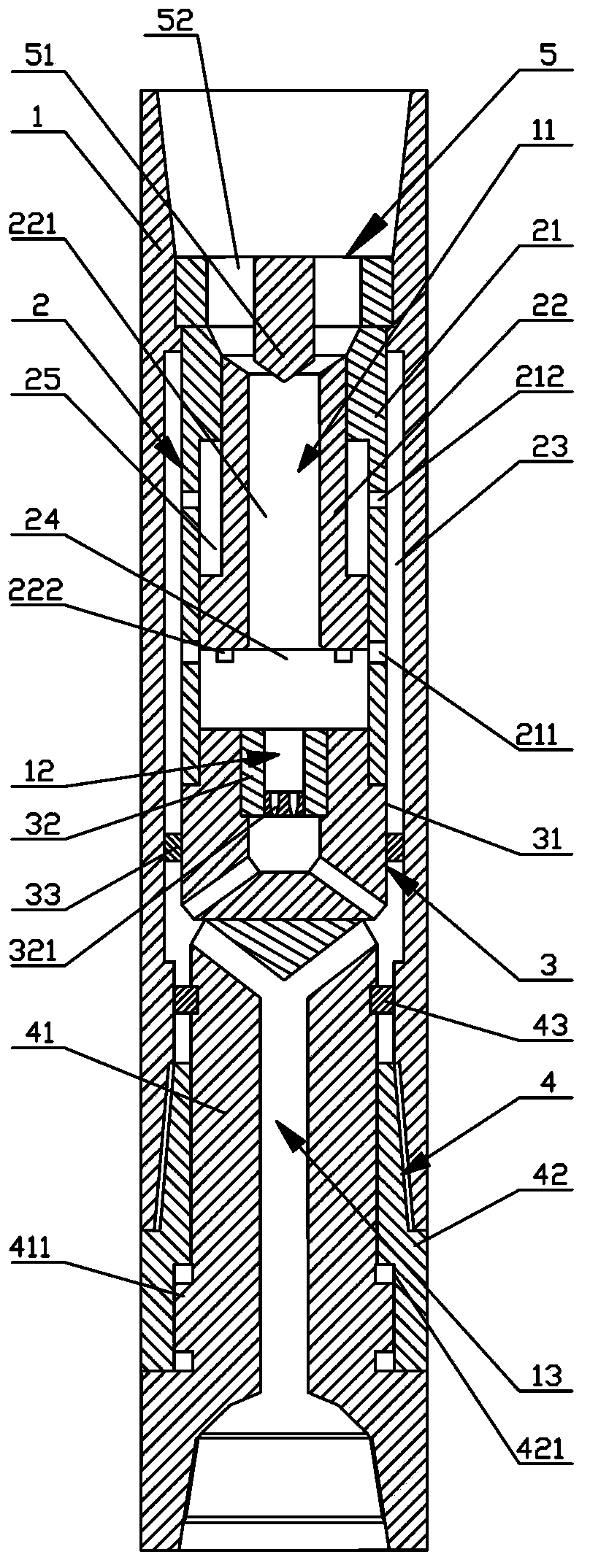

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

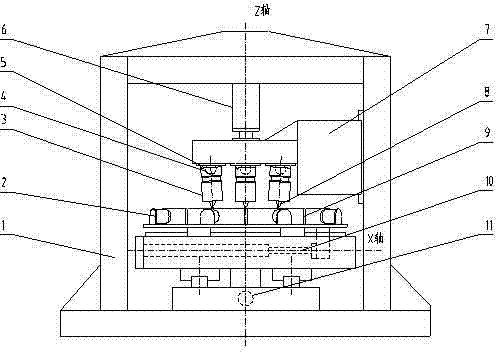

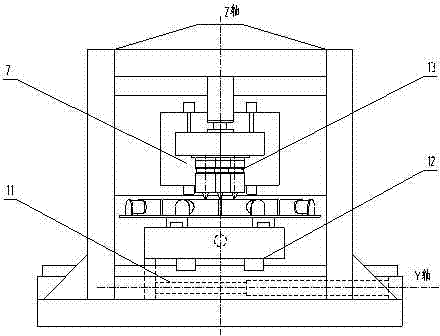

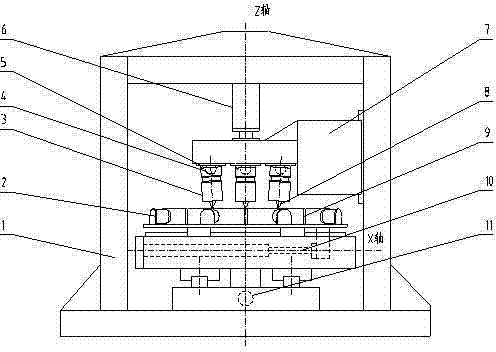

Multi-blade multi-angle rock breaking device for rock ripper

InactiveCN102445336AAccurate measurementImprove rock breaking efficiencyMachine part testingLateral moveTunnel construction

The invention discloses a multi-blade multi-angle rock breaking device for a rock ripper. The device comprises a self-reaction force frame body, an annular confining pressure loading workbench, a Z-direction servo actuator, an X-direction servo actuator, a Y-direction internal servo actuator, a horizontal dual-layer linear guide rail, a three-direction pressure sensor and the like, wherein the lateral moving direction of a rock test piece is set as an axis X; the propelling direction of the rock test piece is set as an axis Y; a direction which is vertical to the breaking surface of the rock test piece is set as an axis Z; the X-direction servo actuator is arranged between the horizontal dual-layer linear guide rail and the annular confining pressure loading workbench; the Y-direction internal servo actuator is arranged between the horizontal dual-layer linear guide rail and the self-reaction force frame body; and the Z-direction servo actuator is arranged between a guide rail guide mechanism and the self-reaction force frame body. In the device, the annular confining pressure loading function of rock is simulated, so that the rock test piece is closer to real geological conditions, parameter measuring values such as a blade distance and the like are more accurate, the design level of the rock ripper is raised, and tunnel construction accidents are controlled.

Owner:SHENYANG HEAVY MACHINERY GROUP

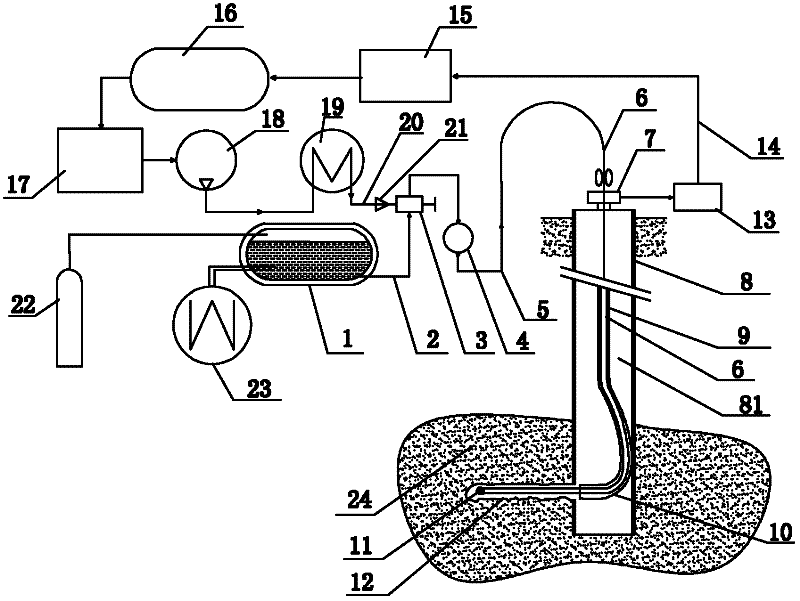

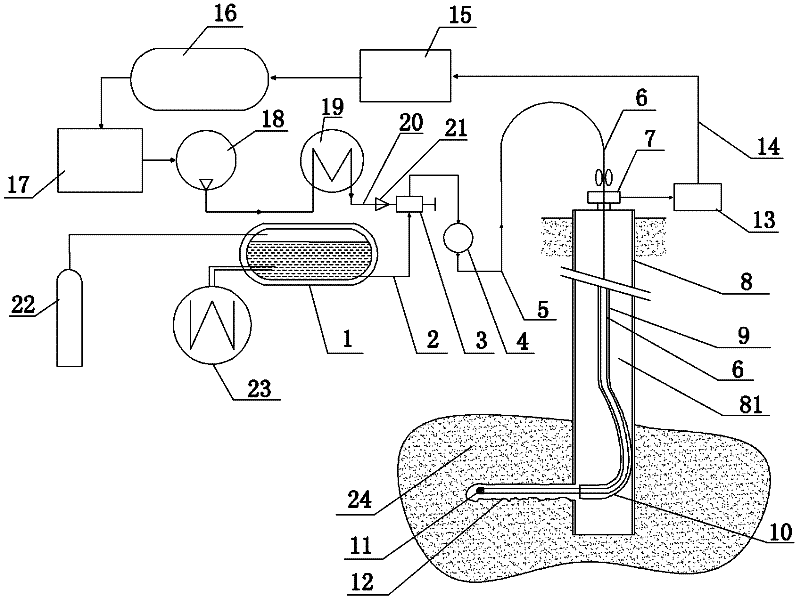

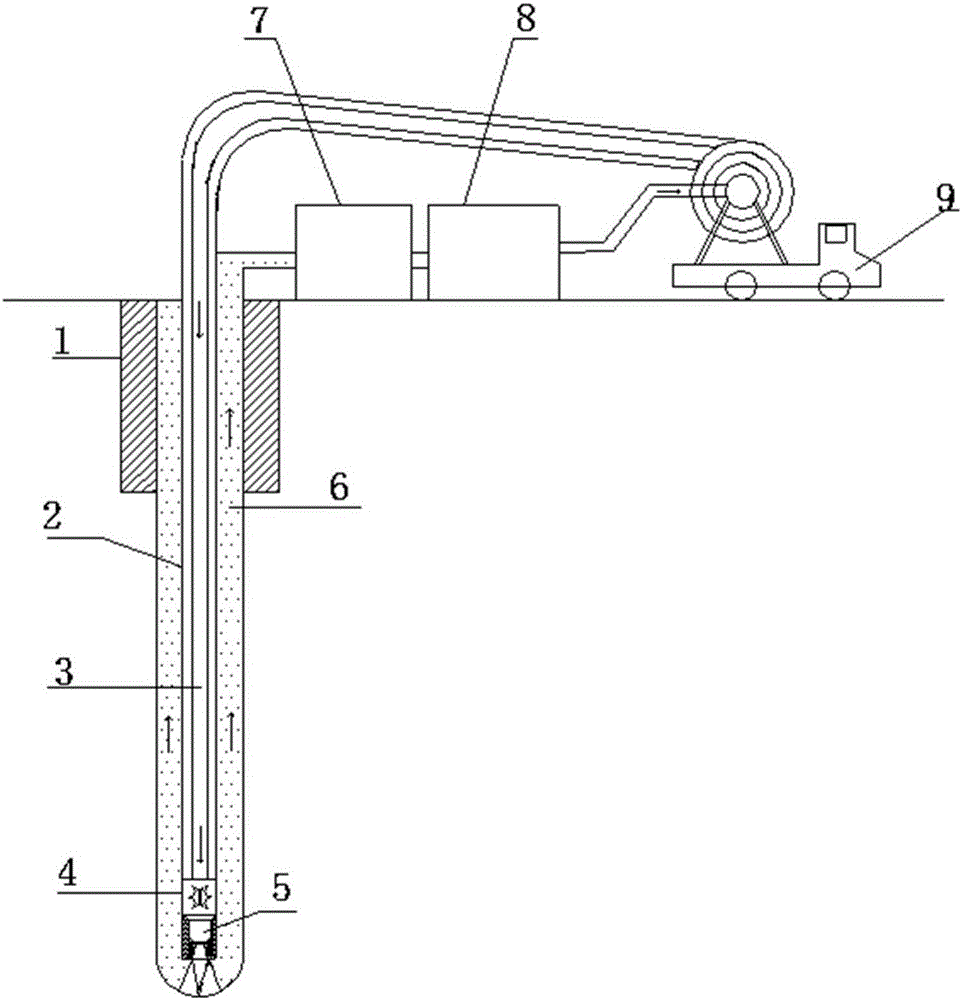

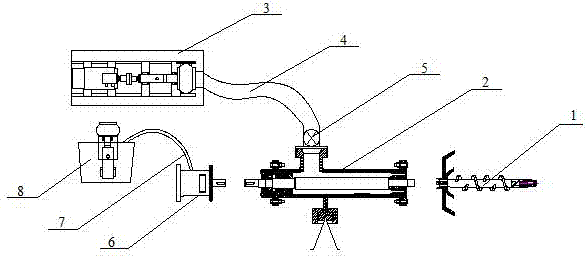

Radial horizontal drilling system using supercritical carbon dioxide and drilling method thereof

InactiveCN102409976ANo pollutionImprove protectionLiquid/gas jet drillingDirectional drillingUnconventional oilPollution

The invention discloses a radial horizontal drilling system using supercritical carbon dioxide and a drilling method thereof. The drilling system comprises a liquid carbon dioxide supplying device, a drilling device, an in-well pressure control device, a solid, liquid and gas three-phase separating device and a carbon dioxide recycling device, wherein the drilling device is arranged in a shaft, and includes an oil pipe, a steering gear mounted at the bottom of the oil pipe, and a flexible drill stem sleeved in the oil pipe; the flexible drill stem passes through the steering gear and then realizes steering; the flexible drill stem has a hollow drill stem channel; a supercritical carbon dioxide jet drill is mounted at the end of the part, in a horizontal direction, of the flexible drill stem; a nozzle, which is communicated with the drill stem channel, is formed on the jet drill; the in-well pressure control device is disposed at the opening of a well; the solid, liquid and gas three-phase separating device and the carbon dioxide recycling device are disposed on the ground. The radial horizontal drilling system disclosed by the invention uses supercritical carbon dioxide fluid as rock breaking fluid, thus avoiding pollution to oil reservoir layers, effectively protecting the oil reservoir layers, greatly increasing rock breaking efficiency, and realizing cyclic utilization of the carbon dioxide; and the radial horizontal drilling system using supercritical carbon dioxide and the drilling method thereof have important application value to increase of production of old wells and to development of unconventional oil-gas reservoir.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

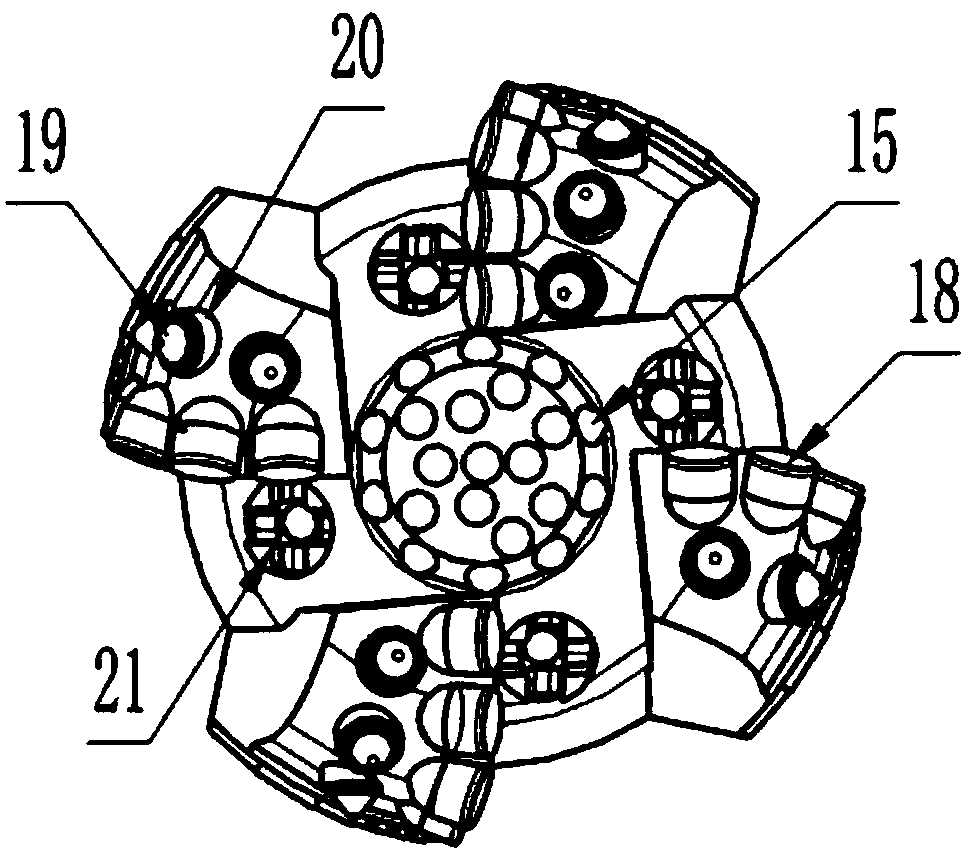

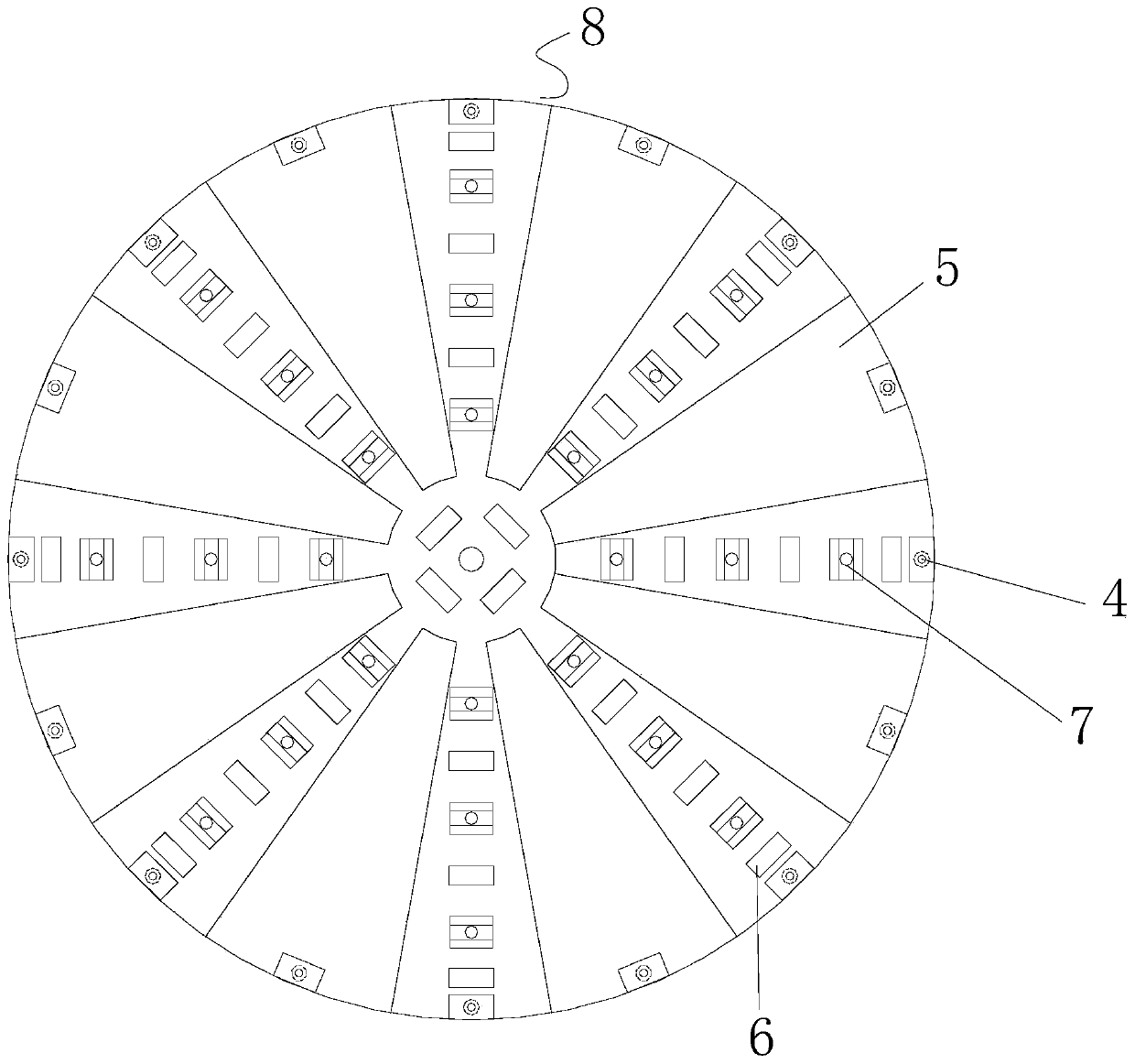

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

High-frequency torsion and axial bidirectional impactor

InactiveCN105672873AIncrease contact stressImprove rock breaking efficiencyBorehole drivesWell drillingRock breaking

The invention relates to a high-frequency torsion and axial bidirectional impactor, and belongs to the technical field of oil and gas field well drilling and well repairing tools. The high-frequency torsion and axial bidirectional impactor comprises a housing, a connector, an alignment bearing, a turbine shaft, an upper hammer body and a lower hammer body, wherein the connector is mounted at one end of the housing in a threaded manner; the lower hammer body is glidingly mounted at the other end of the housing through an end cover and a buffer spring, and the turbine shaft is mounted in the housing through a nut; a turbine rotor and a stator are mounted at one end of the turbine shaft, and the upper hammer body is mounted at the other end of the turbine shaft. By adopting the high-frequency torsion and axial bidirectional impactor, contact stress between a drill bit and rock can be effectively increased, and crack expansion in a broken pit can be effectively improved, so that the rock breaking efficiency of the drill bit can be improved; the problems that when a conventional rotating well drilling mode is adopted, the well drilling efficiency is degraded, the service life of the drill bit is shortened, the well drilling period is long and the cost is high when a hard stratum is encountered can be solved; the high-frequency torsion and axial bidirectional impactor has active popularization meanings in well-drilling efficiency improvement and well drilling cost reduction.

Owner:YANGTZE UNIVERSITY

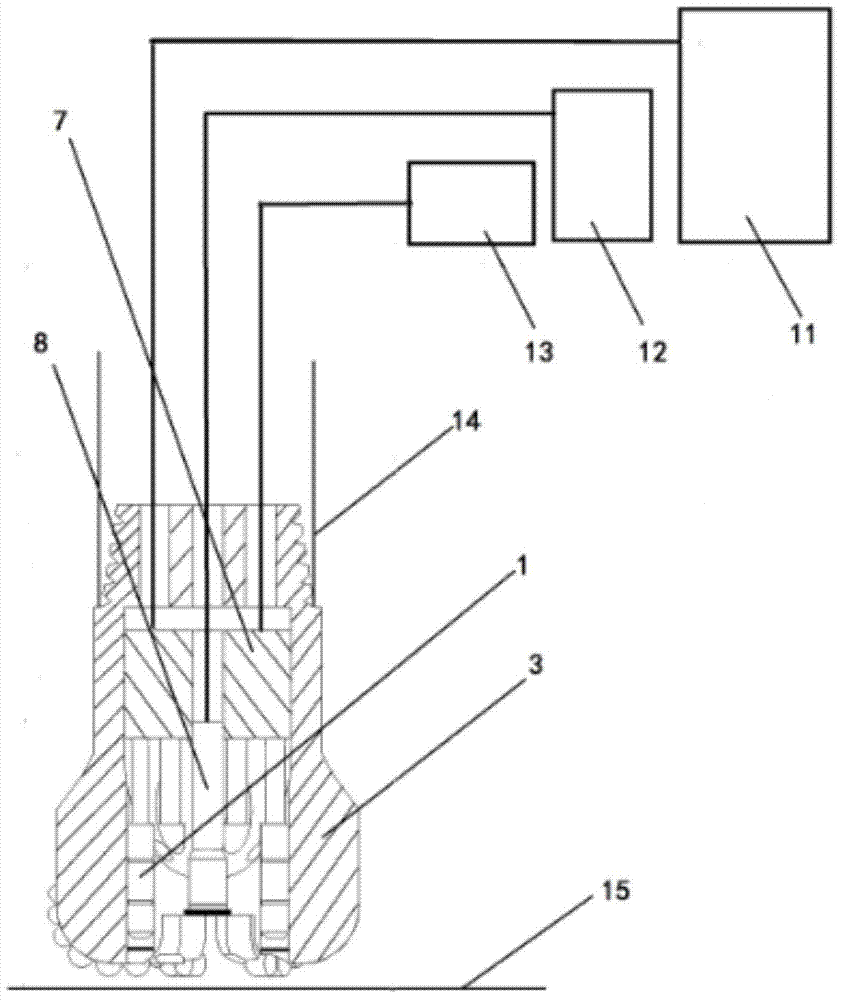

Laser drill, laser drilling tool and well drilling rock breaking method

The invention provides a laser drill, a laser drilling tool and a well drilling rock breaking method. The laser drill comprises a drill body (3); a camera (8) and a plurality of laser heads (1) are contained in the drill body (3); an adjusting bracket (7) capable of moving the camera (8) and / or the laser heads (1) is also contained in the drill body (3); through holes corresponding to the camera (8) and the laser heads (1) are formed in the head part of the drill body (3). The laser drilling tool containing the laser drill is provided with an underground night vision system and an aboveground control system; by the drilling rock breaking method, the problems that the hard rock stratum drilling and production efficiency is low, real-time observation cannot be performed underground, and the like are solved, the rock breaking efficiency is greatly increased, the loss of the drilling tool is reduced, and the cost is reduced.

Owner:PETROCHINA CO LTD

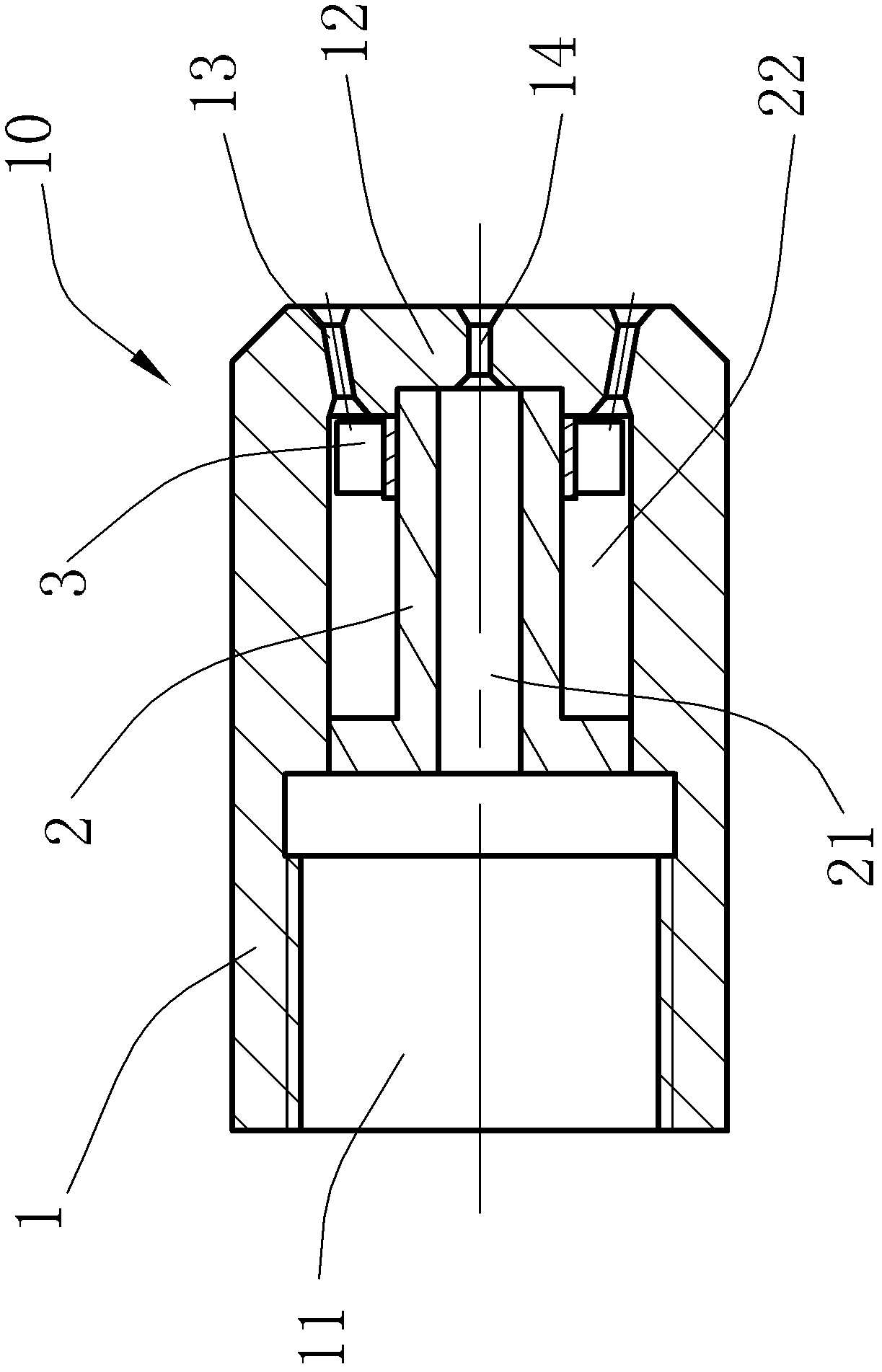

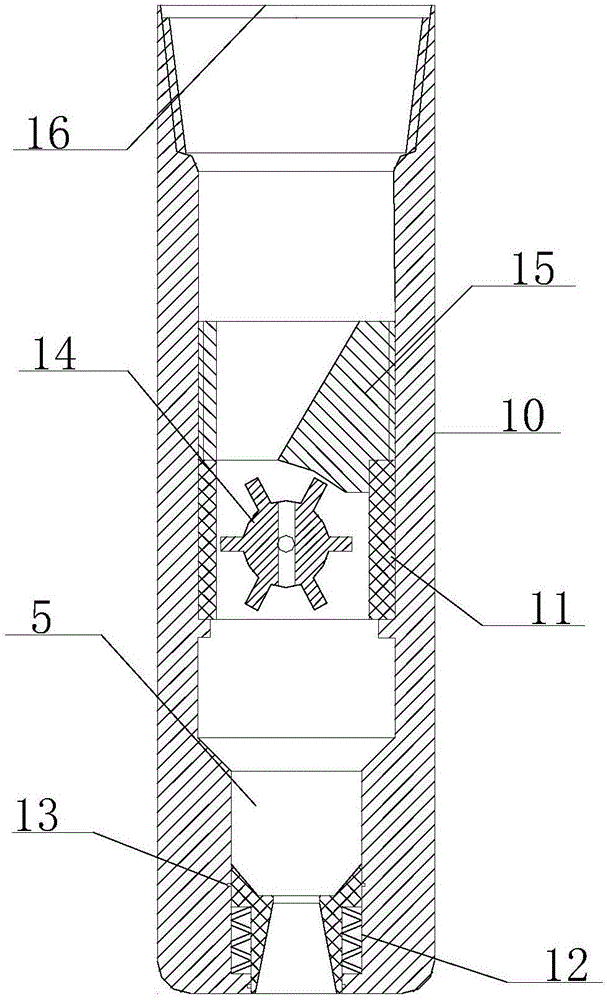

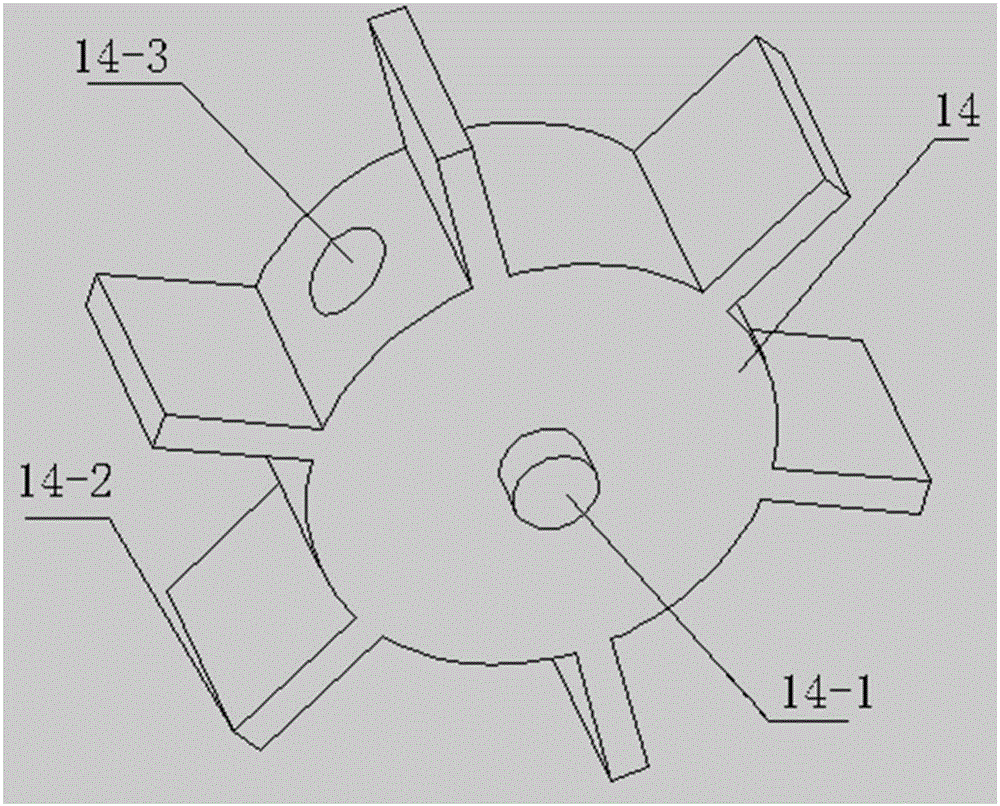

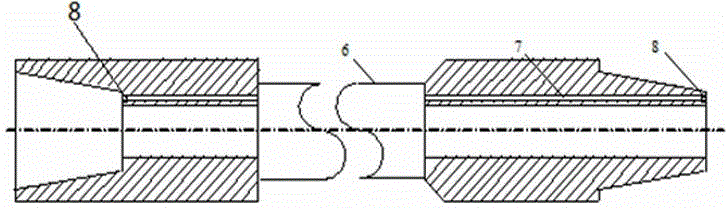

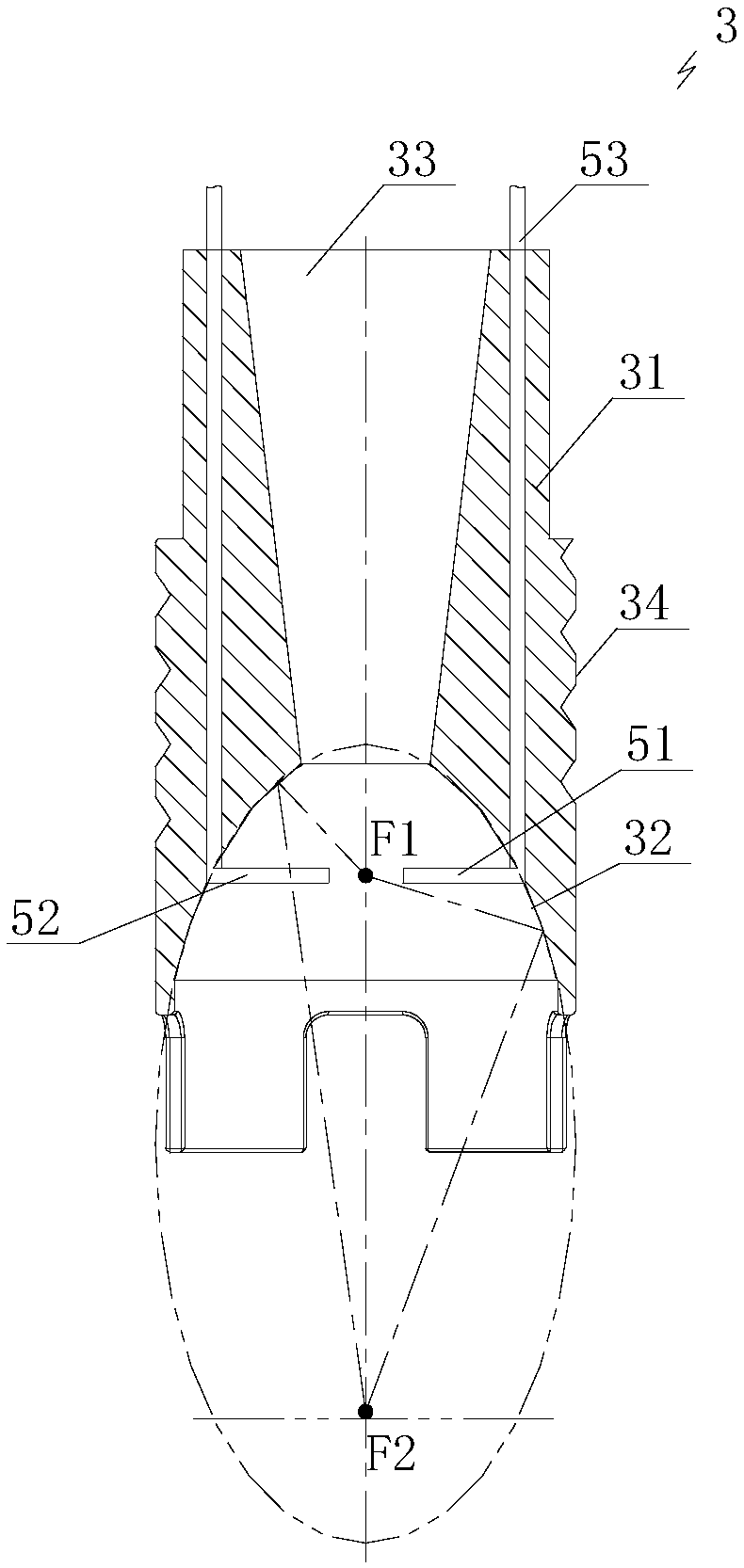

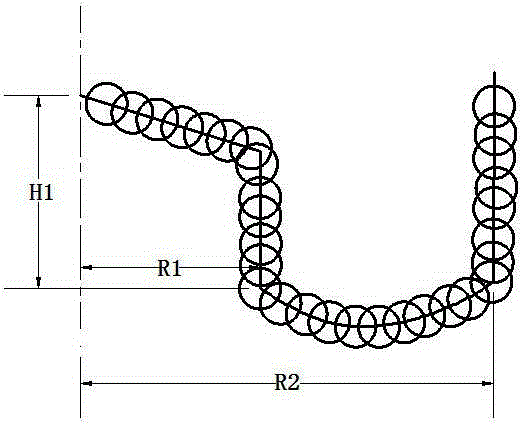

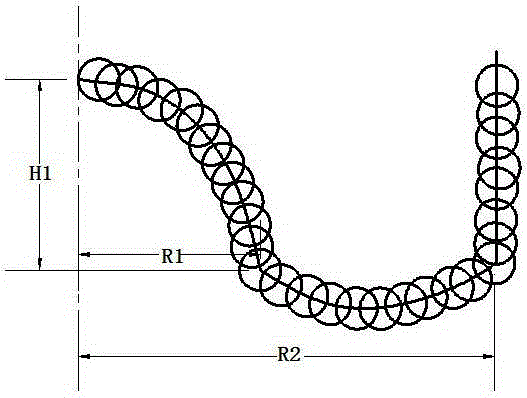

Pulse cavitation multiple jet nozzle

ActiveCN102434102ASimple structureEasy to manufactureSpray nozzlesLiquid/gas jet drillingImpellerCavitation

The invention relates to a pulse cavitation multiple jet nozzle, which comprises a nozzle body which is formed into an open end on one end and a jet end with a hollow cylinder on the other end, the open end is used for connecting with a fluid pipe, and the jet end is provided with a plurality of jet orifices; the central position of the jet end is provided with a central jet orifice, and a plurality of lateral jet orifices are arranged around the central jet orifice; the nozzle body is internally provided with an impeller being capable of rotating, a part of the fluid flowing into the nozzle passes through the center of the impeller and the central jet orifice to form continuous straight jet, the other part of the fluid impacts the blades of the impeller to cause the impeller to rotate so as to make flow field on the inlets of the lateral jet orifices around the central jet orifice generate regular disturbance, thus a pulse jet can be formed, vacuole can be produced, a cavitation jet can be formed, and the cavitation jet and the pulse jet are coupled to form a pulse cavitation jet to be ejected from the lateral jet orifices. The invention is simple in structure, and can greatly improve the efficiency of drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

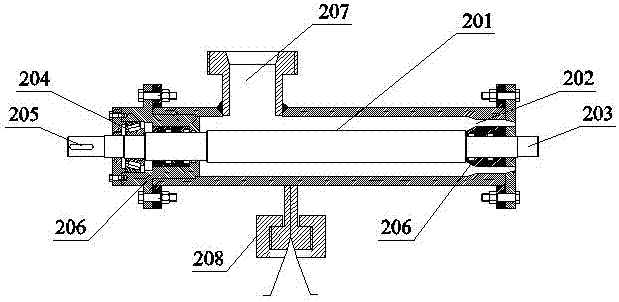

High-frequency pulsed jet flow resonance well drilling device and well drilling method thereof

InactiveCN102493768AIncrease compactionBuried deepLiquid/gas jet drillingMachines/enginesSteel jacketUltrasonic sensor

The invention relates to a high-frequency pulsed jet flow resonance well drilling device and a well drilling method thereof. The high-frequency pulsed jet flow resonance well drilling device comprises an outer steel jacket, wherein one end of the outer steel jacket is connected with an upper adapter; the other end of the outer steel jacket is connected with a lower adapter; the upper adapter is connected with a drill collar by a thread; the lower adapter is connected with a drill by the thread; a small hydrogenerator, a density logger, an acoustic logger, a controller and an ultrasonic transducer are successively installed from top to bottom in the outer steel jacket; the small hydrogenerator is composed of a blade and a generator; the blade is installed above the generator; the ultrasonic transducer comprises a fixed end, a transducer and an amplitude transformer; the position on the outer steel jacket, which corresponds to the amplitude transformer, is provided with a necking section; the density logger, the acoustic logger and the controller are mutually separated by cushion blocks; and after the density logger, the acoustic logger and the controller are connected, the inner cavities of the density logger, the acoustic logger and the controller are communicated to form a well drilling fluid path. According to the high-frequency pulsed jet flow resonance well drilling device, the mechanical drilling speed is drastically improved, the improvement amplitude is 1-2 times, and the well drilling cost is effectively lowered.

Owner:NORTHEAST GASOLINEEUM UNIV

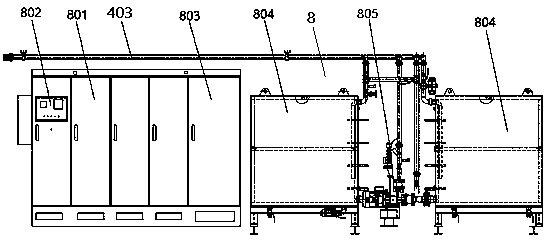

Laser-assisted tunnel boring machine and rock breaking method thereof

ActiveCN106884662AReduce wearImprove rock breaking efficiencyTunnelsIntelligent control systemTunnel engineering

The invention belongs to the technical field of tunnel engineering and discloses a laser-assisted tunnel boring machine and a rock-breaking method thereof. The machine is characterized by two rock breaking modes, a laser-hob rock breaking mode and a hob rock breaking mode. Identification and conversion of the two rock breaking modes can be achieved by an intelligent control system. The laser-hob rock breaking mode is used in hard rock sections for the improvement of rock breaking efficiency, while the hob rock breaking mode is used in soft rock sections. The main breaking mode of the laser-assisted rock breaking is hot-break, wherein a laser is used with a laser head installed on a cutter of the tunnel boring machine, supplemented by a water spray system, so that the goal of hot crack by laser irradiation with rapid cooling for assisting rock breaking by water spray and further excavation by mechanical rock breaking is achieved. With the reasonable selection of the rock breaking modes, the adaptation of the tunnel boring machine to complex geological conditions alternated with soft and hard rocks is improved, thereby the rock breaking efficiency is enhanced and the construction cost is saved.

Owner:DALIAN UNIV OF TECH

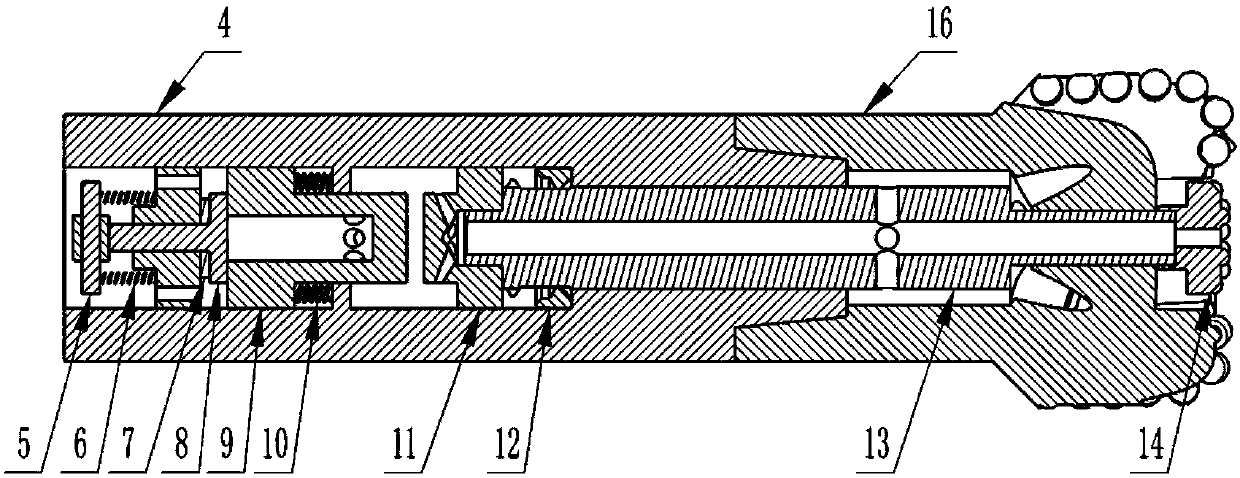

Drilling power tool, drilling tool and drilling method for forming boreholes

ActiveCN102705140AImprove rock breaking efficiencyReduce wearDrilling rodsMachines/enginesEngineeringHigh pressure

The invention discloses a drilling power tool, a drilling tool and a drilling method for forming boreholes. The drilling power tool comprises an energy conversion mechanism and a valve shaft system. The energy conversion mechanism is a rotary generator. The valve shaft system comprises a stator, a rotor, a movable valve sheet assembly, a fixed valve sheet assembly and a shaft assembly, wherein the rotor makes a reciprocating motion right and left and drives the movable valve sheet assembly directly connected with the rotor. The energy conversion mechanism is a screw rod or a turbine or an impeller. According to the invention, when a drilling bit is rotated, the drilling pressure at the drilling bit and the drilling pressure at the bottom of a drilling well are similar to the continuous gentle change of the sine law, which is favorable for the strength reduction of surrounding rocks and the development of fractures, so that the rock breaking efficiency can be improved obviously. In addition, because the pressure at the drilling bit and at the bottom of the drilling well is changed periodically, the negative-pressure injection and the high-pressure injection are generated alternately; and when the pressure becomes lower, the well drilling in an underbalance manner or by using the gas drilling fluid is carried out, so that the surrounding rock environment is changed, and the mechanical drilling rate is improved obviously.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Device for improving oil and gas well drilling speed

ActiveCN103899250ALoop does not affectCircular impactLiquid/gas jet drillingVibration drillingDepth in a wellWell drilling

The invention belongs to the field of petroleum engineering and particularly relates to a device for improving the oil and gas well drilling speed. The device for improving the oil and gas well drilling speed comprises a mandrel body, a spline outer barrel, a spring protection barrel, a spring assembly, a spring lower plugging connector, a piston assembly and a pressurization assembly outer barrel, and is characterized in that the mandrel body is connected with the piston assembly in a threaded mode, the spline outer barrel, the spring protection barrel, the spring lower plugging connector and the pressurization assembly outer barrel are connected together through threads, and the spring assembly is arranged in the spring protection barrel. Energy for working of the device is provided by vibration of a drill stem and is increased along with the increase of the depth of a well, and the adverse effect of vibration is reduced by the working process of the device; by adopting the device, both the rock breaking efficiency and the well bottom cutting carrying effect are improved; the device is simple in structure and stable in performance, and other risks will not be caused by drilling operation when the device is used; the structure of the drill stem does not need changing, normal use of the device will not be affected by the types of drills, and therefore the device is wide in application range and convenient to popularize and use.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

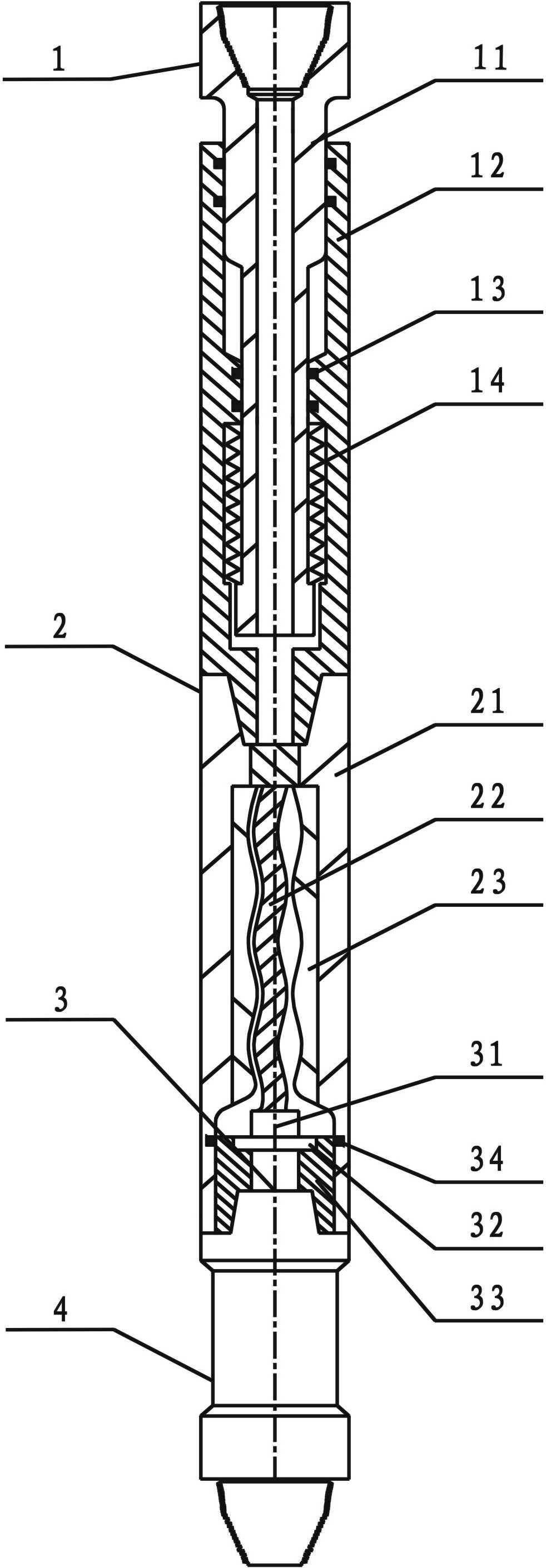

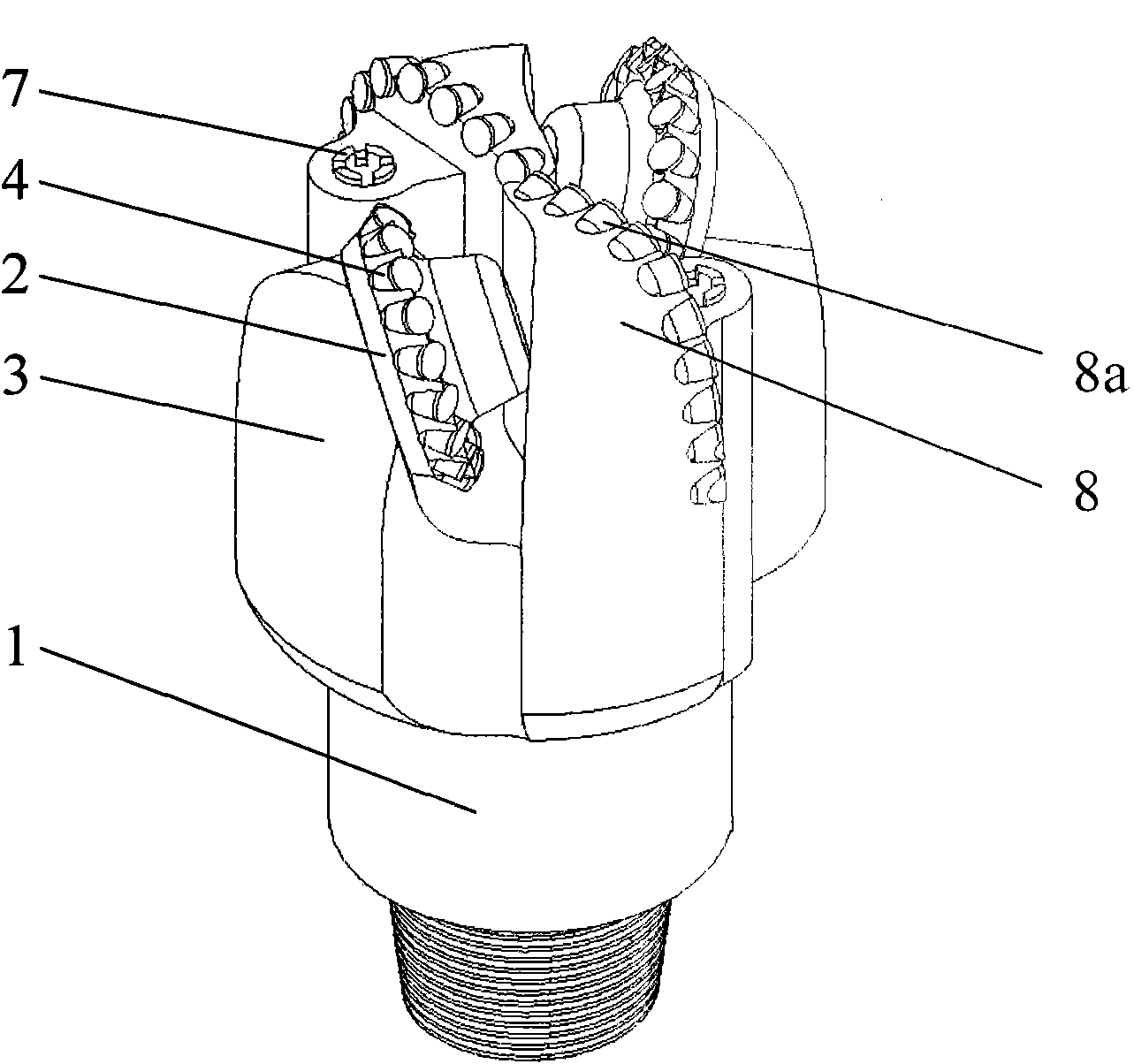

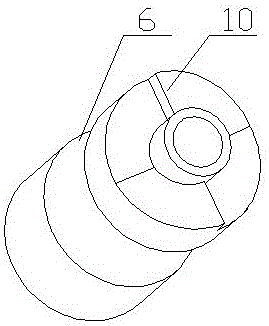

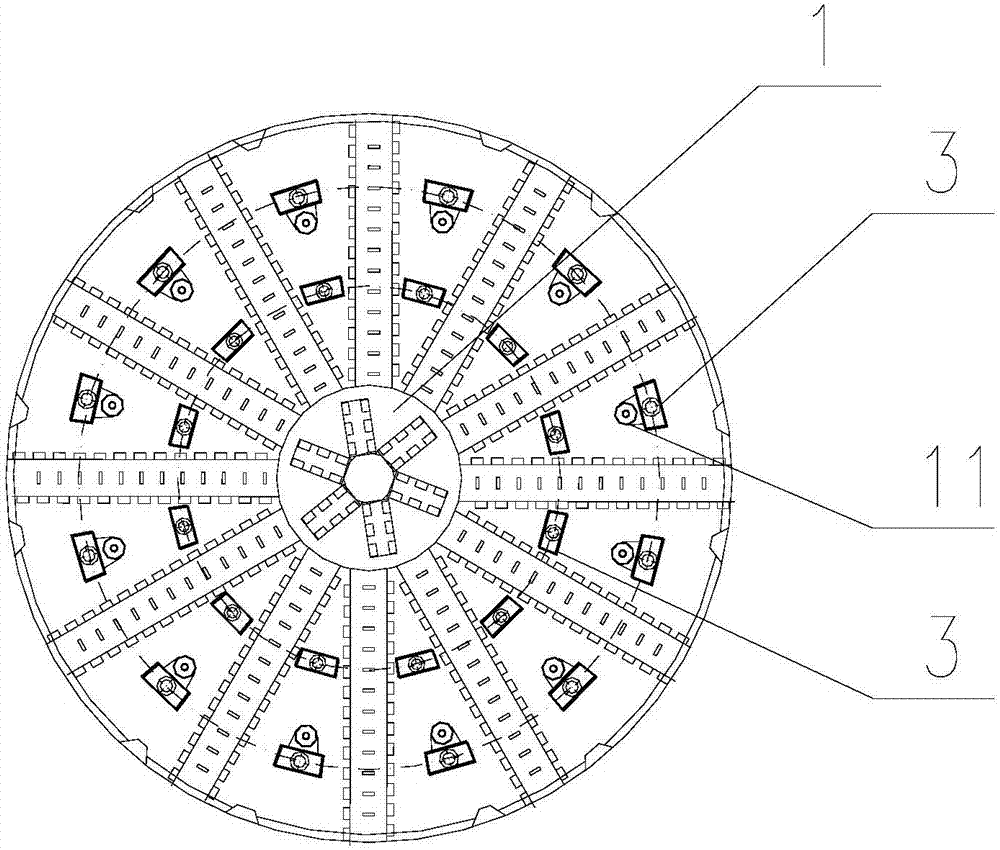

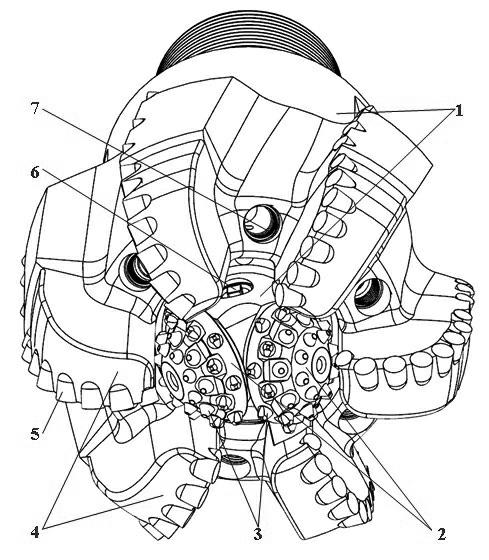

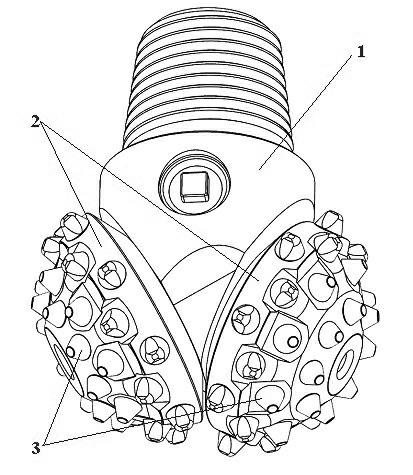

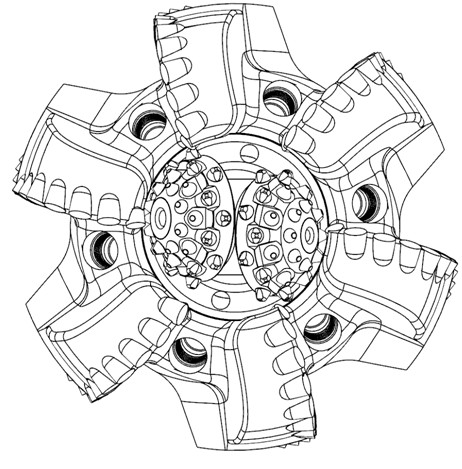

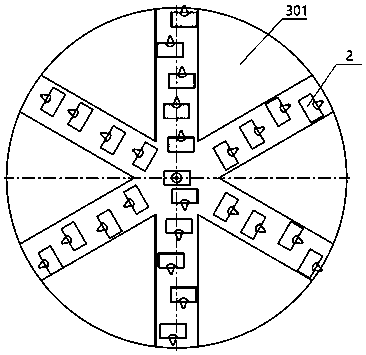

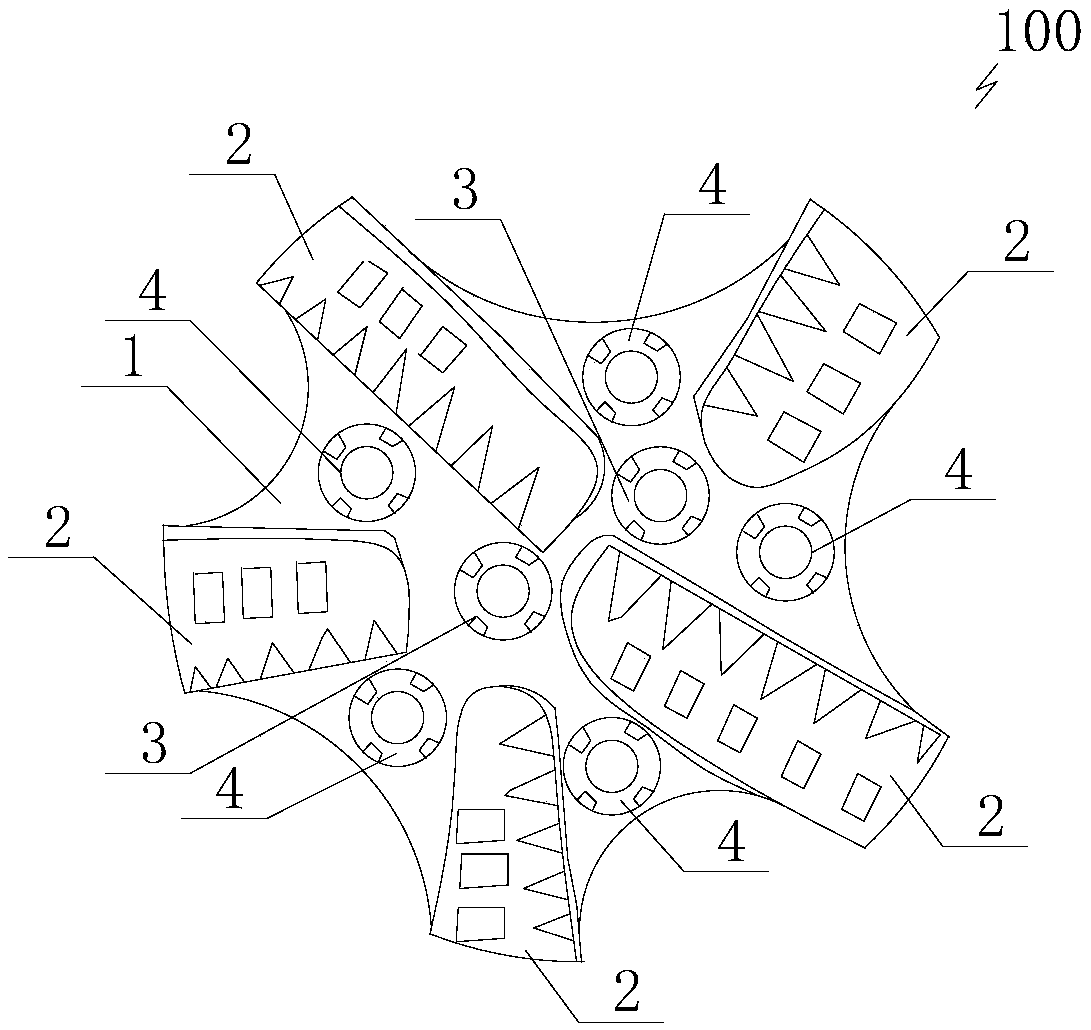

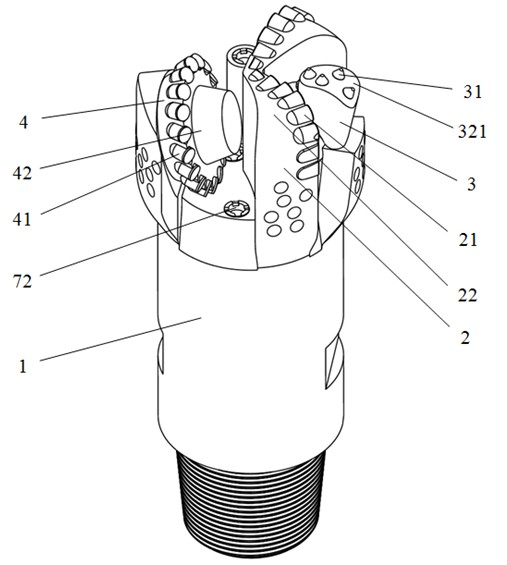

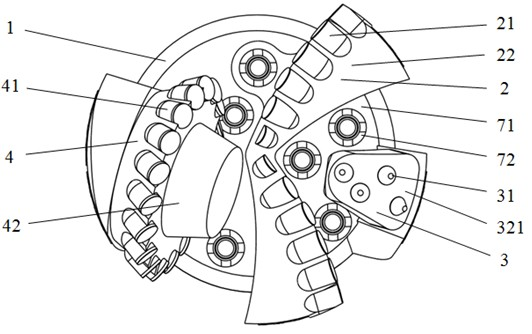

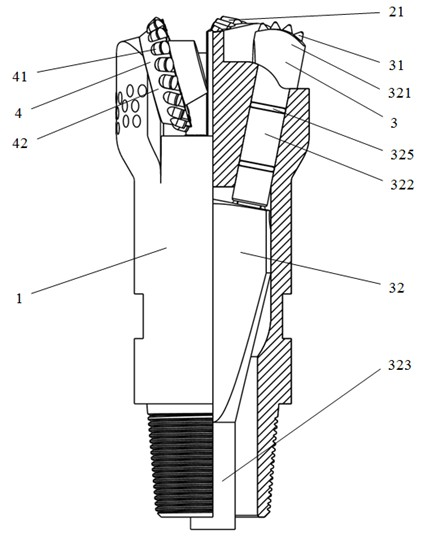

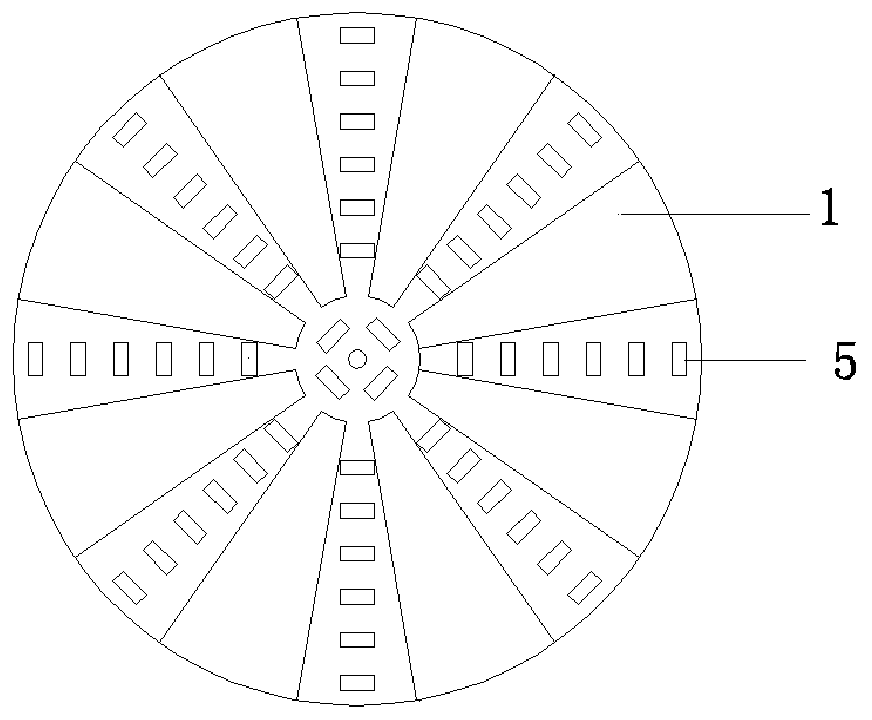

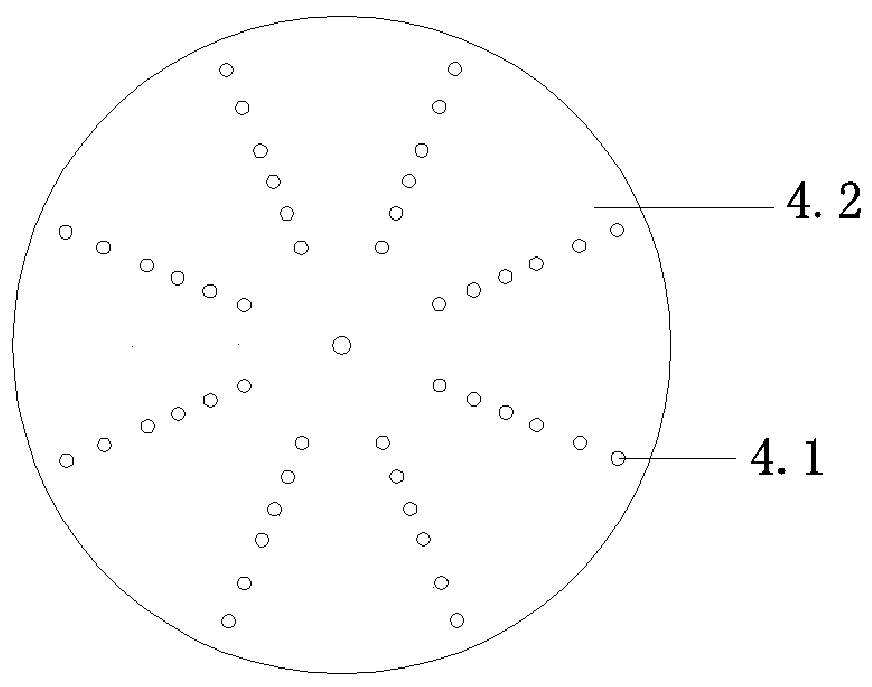

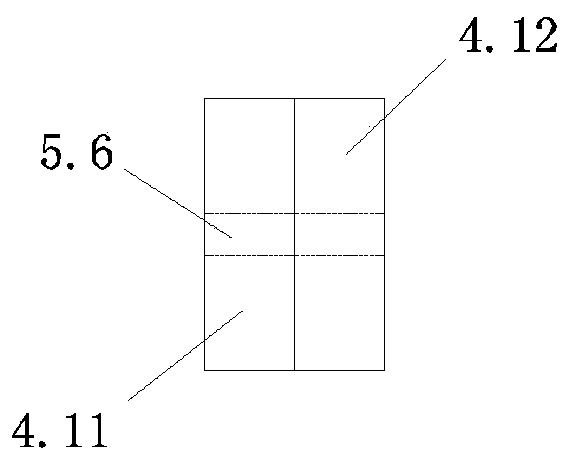

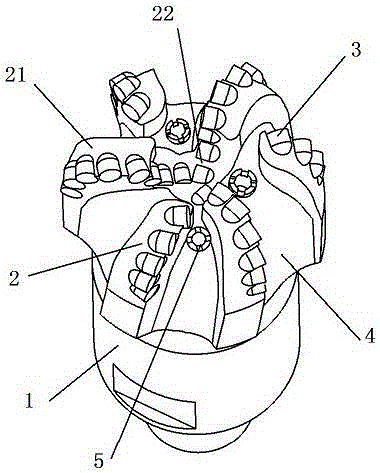

Composite bit with rotary cut rock-breaking function

ActiveCN102434105AExtended service lifeGood gauge effectDrill bitsConstructionsAgricultural engineeringPolycrystalline diamond

The invention discloses a composite bit with a rotary cut rock-breaking function, which comprises the composition of a rotary cut bit, a polycrystalline diamond compact (PDC) bit and a roller cone bit. The composite bit with the rotary cut rock-breaking function comprises a main body (1), a rotary cut bit roller cone (2), rotary cut bit cutting teeth (3), a PDC bit knife wing (4), PDC cutting teeth (5), an oil storage capsule (6) and a spray nozzle (7). The bit main body (1) comprises a roller cone shaft neck, a wiper block, a high-pressure mud channel and connecting screw threads. The composite bit with the rotary cut rock-breaking function has the advantages that the rotary cut bit cutting teeth in the composite bit impact, crush and cut rocks in rotary cut mode, central rock breaking efficiency is high, mechanical drilling speed is high, the composite bit has better dynamics performance, and the abrasion is even. Simultaneously, a bit bearing structure is improved, service life of the bit is prolonged while improvement of the rock-breaking efficiency is guaranteed, and the gauge protection effect is good. Different composite structures in the composite bit can achieve the effects of high central rock breaking efficiency, high mechanical drilling speed and good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

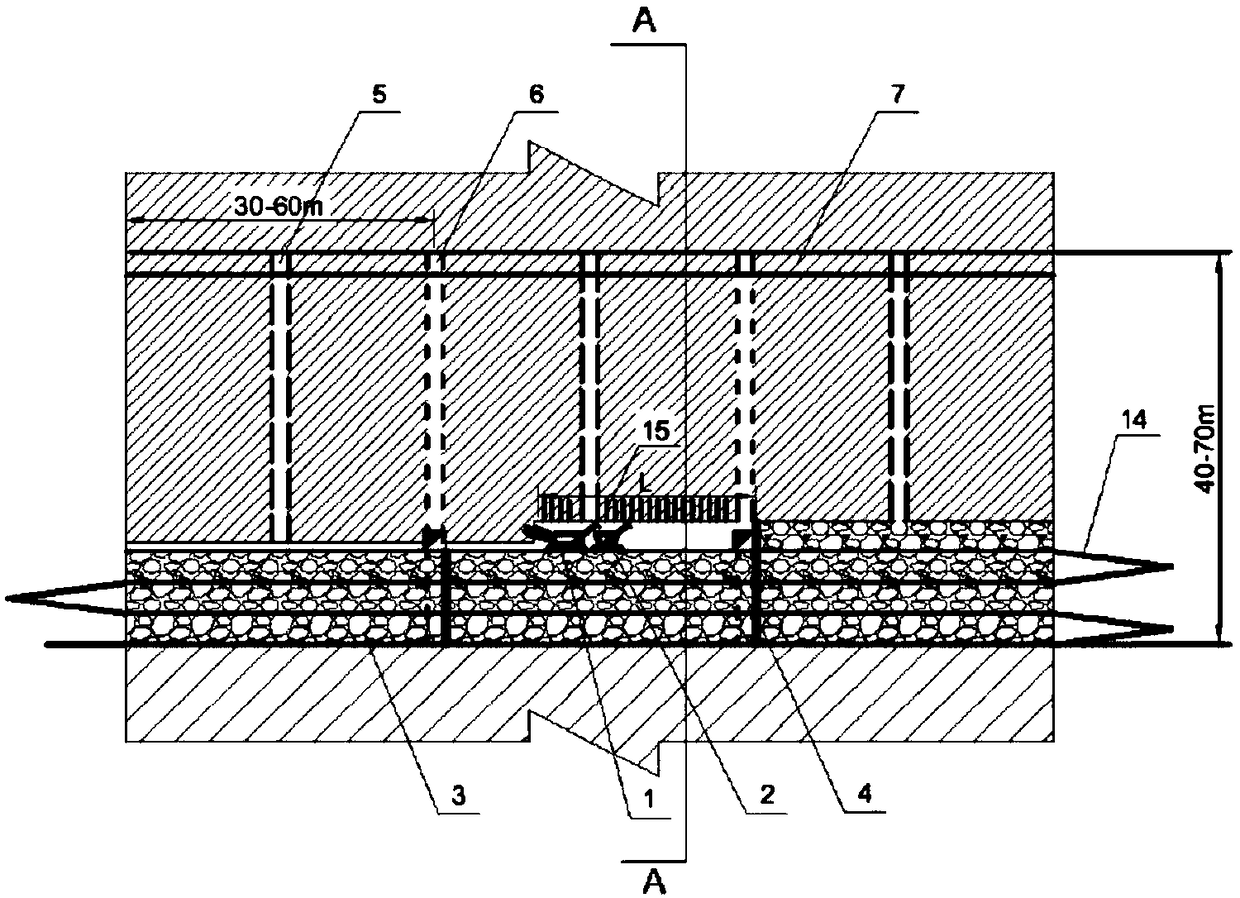

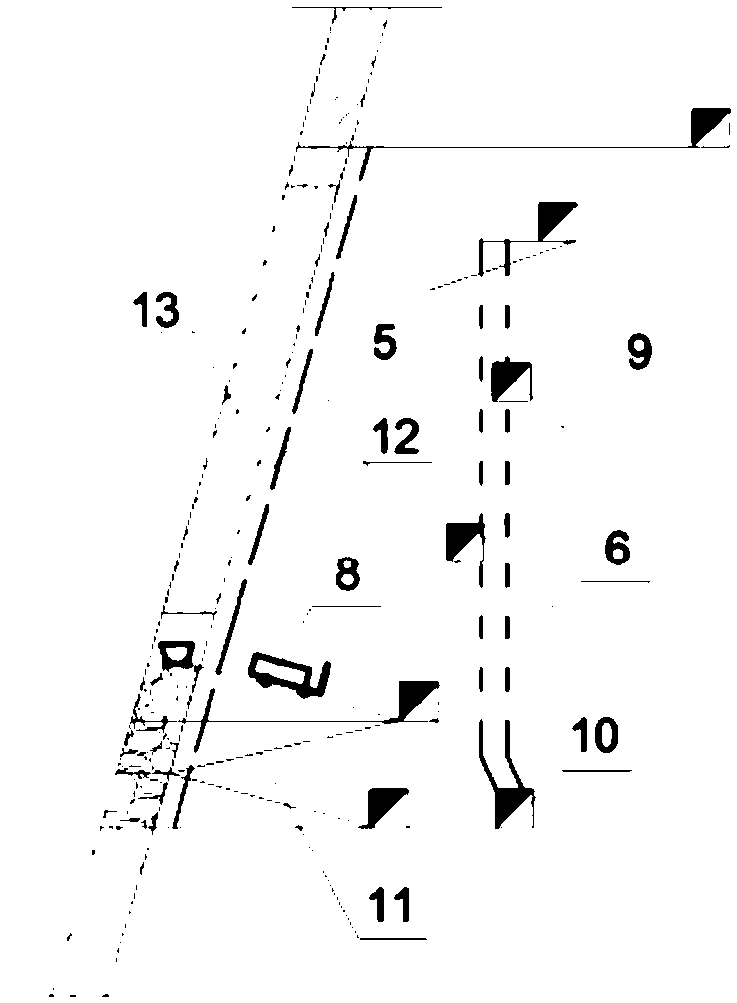

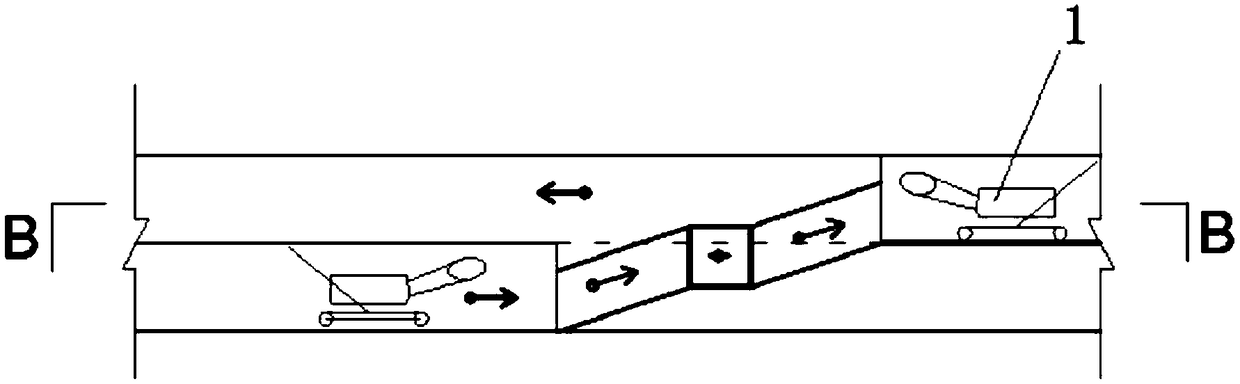

Dipping or high-dipping thin ore cantilever-type tunneling machine ore breaking continuous mining method

ActiveCN108643911AImprove rock breaking efficiencySurrounding rock disturbance is smallUnderground miningSurface miningGlass fiberIntrinsic safety

The invention discloses a dipping or high-dipping thin ore mechanical ore breaking continuous mining method. Tunneling machine mechanical ore breaking, goaf filling, stope carrying, supporting operation and the like all achieve parallel operation around a mining technology of a single mining operation face. Continuous ore drawing is achieved by moving a transferring ore bin, a tunneling machine conducts layer transferring returning at the ore end through a Y-shaped mining preparation structure and does not travel back, cutting engineering is avoided, point pillars and studs are not reserved, supporting is conducted only through fiberglass anchor bolts with good cuttability and meshes, and a dust-removal fan, a mobile substation and the like do not enter a stope and are all movably arrangedin mining preparation engineering. Mining and cutting engineering, all mining technologies and equipment power supplying are matched and then are mutually matched with the mechanical ore breaking efficiency, the technological continuity is improved, the efficiency of the tunneling machine is exerted to the greatest extent, and the mining mode of blasting ore breaking is changed basically. The mechanization degree is high, operating personnel are reduced greatly, the labor intensity is lowered, the goaf exposure time is short, and the mine intrinsic safety is improved. Through the highly-intensive parallel operation, the tunneling speed is high, the production efficiency is high, and the ore breaking cost is low.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

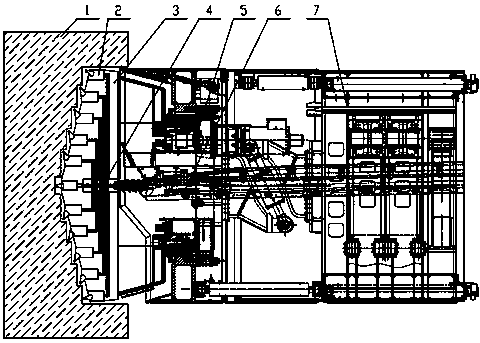

Tunneling machine using laser for rock breaking

InactiveCN108561148ASolve the problem of abnormal damage proneImprove rock breaking efficiencyTunnelsElectricitySlag

The invention discloses a tunneling machine using laser for rock breaking. The tunneling machine structurally comprises a tunneling machine host and a water and electricity output system matched withthe tunneling machine host, wherein a cutter head system is arranged at the front part of the tunneling machine host; a plurality of laser generators are uniformly arranged on a cutterhead of the cutterhead system along the movement track; the emitting ends of the laser generators form an inclined angle with the tunnel face rock in the digging position; the laser generators are connected with thewater and electricity output system through a conveying and distribution pipe of a water and electricity conveying and distribution system; the conveying and distribution pipe is a porous pipeline integrating a water pipe and an electric wire pipe; the middle part of the tunneling machine host is provided with a driving system for driving the cutterhead system; a slag discharging system matched with the cutterhead system is arranged inside the tunneling machine host; a step system is arranged on the tunneling machine host. A laser ray system is used for solving the problem that the abnormal damage can easily occur during the rock cutting by a metal cutter; the suspension cutting rock breaking is used, so that the digging efficiency is improved; the digging cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

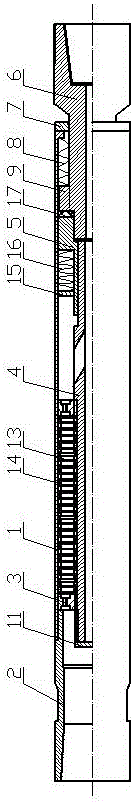

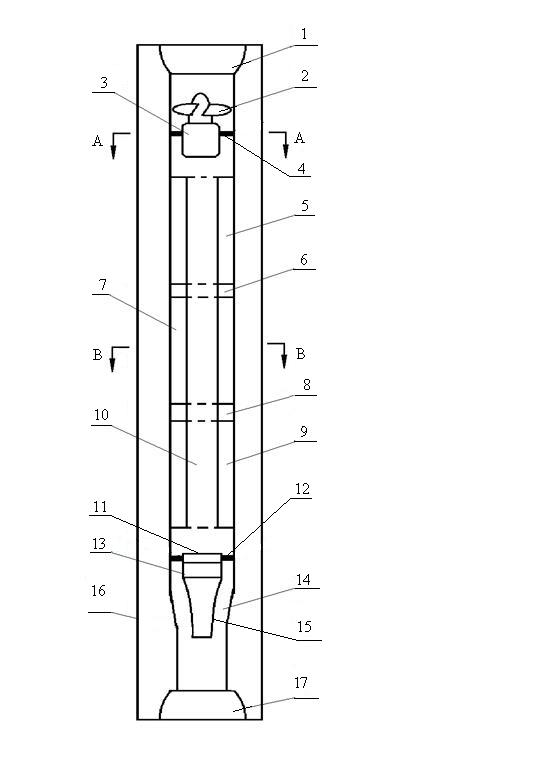

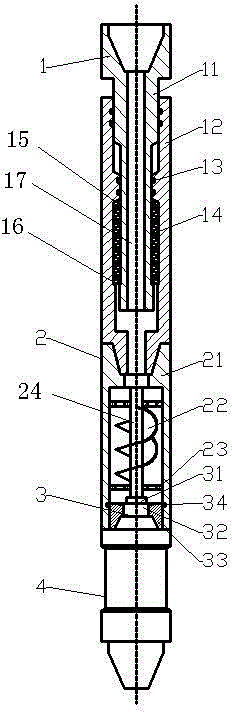

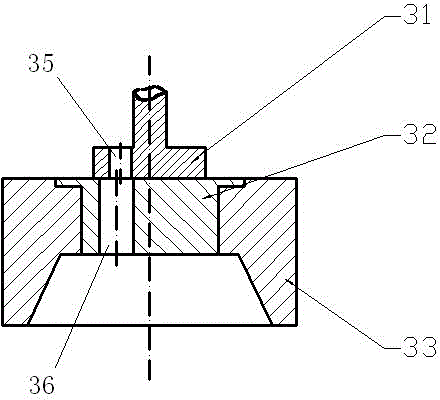

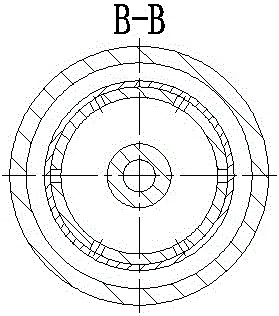

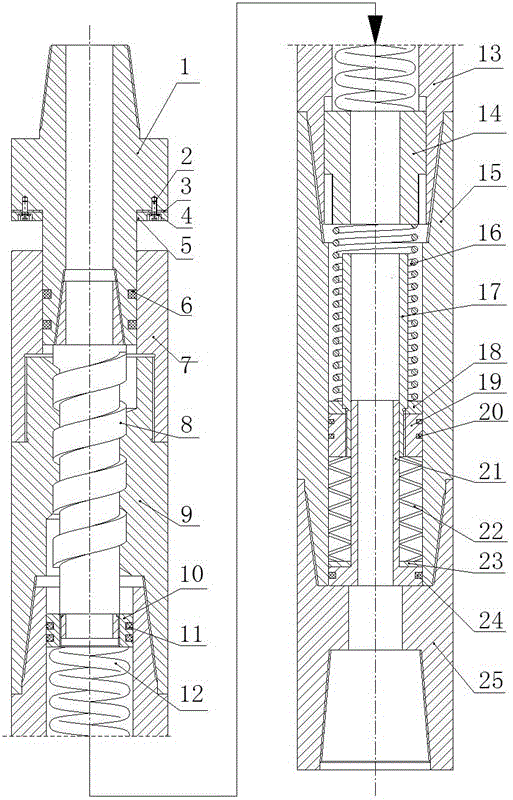

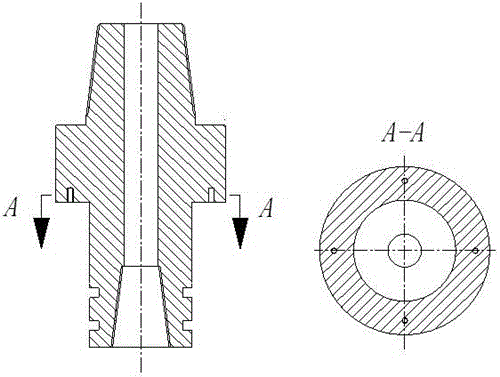

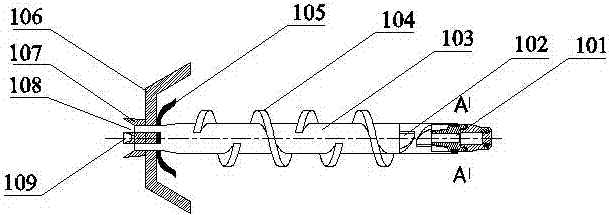

Hydraulic simple harmonic oscillator for well drilling

InactiveCN104405288ASimple structureStructure does not affectVibration drillingWell drillingSpiral blade

The invention discloses a hydraulic simple harmonic oscillator for well drilling. The hydraulic simple harmonic oscillator consists of a power assembly, a valve assembly, a bottom assembly and an elastic short section, wherein the elastic short section is connected with the power assembly; a spiral blade is connected with a valve block; a fixed valve is mounted on the bottom assembly; a power shell is connected with the bottom assembly. Well drilling liquid drives the spiral blade to rotate, and the spiral blade drives the valve block to rotate, so that circulating holes of the valve block and the fixed valve are staggered to modulate simple harmonic pressure waves; the pressure waves are upwards transmitted to the elastic short section part to drive the power shell to generate continuous simple harmonic oscillation in the axial direction; therefore the friction between a drilling column and the well wall is effectively improved, and the drilling speed is increased. Oscillation impact force is downwards transmitted to a drilling head for jetting, so that rock breaking pressure is periodically changed, and rocks can be effectively broken. The hydraulic simple harmonic oscillator has the characteristics of simple structure, convenience in operation, safety, reliability, low pressure drop, high adaptability, no influence on the drill structure and the like and has an important significance in increasing the drilling speed and lowering the cost.

Owner:缪宏

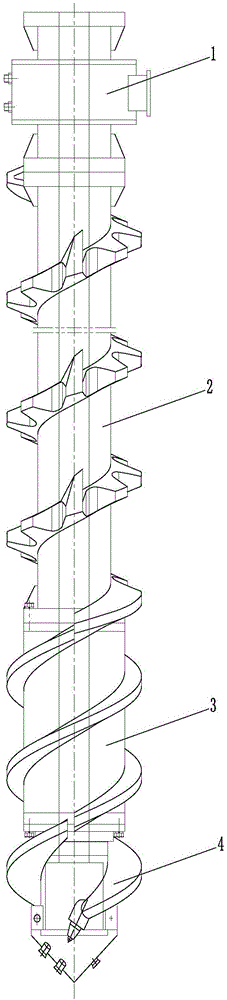

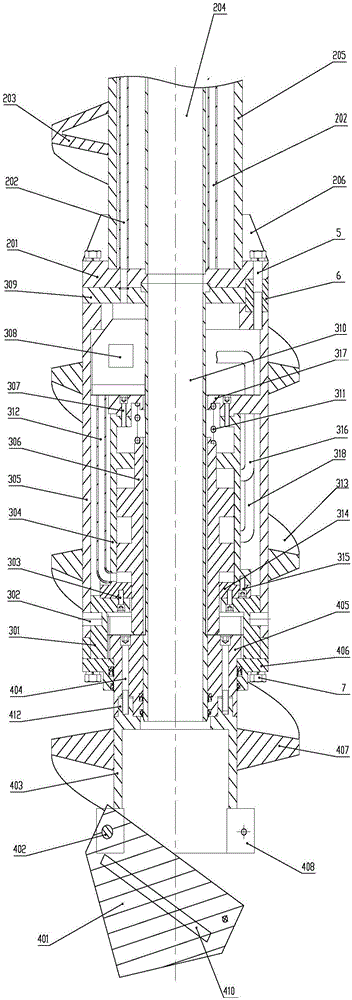

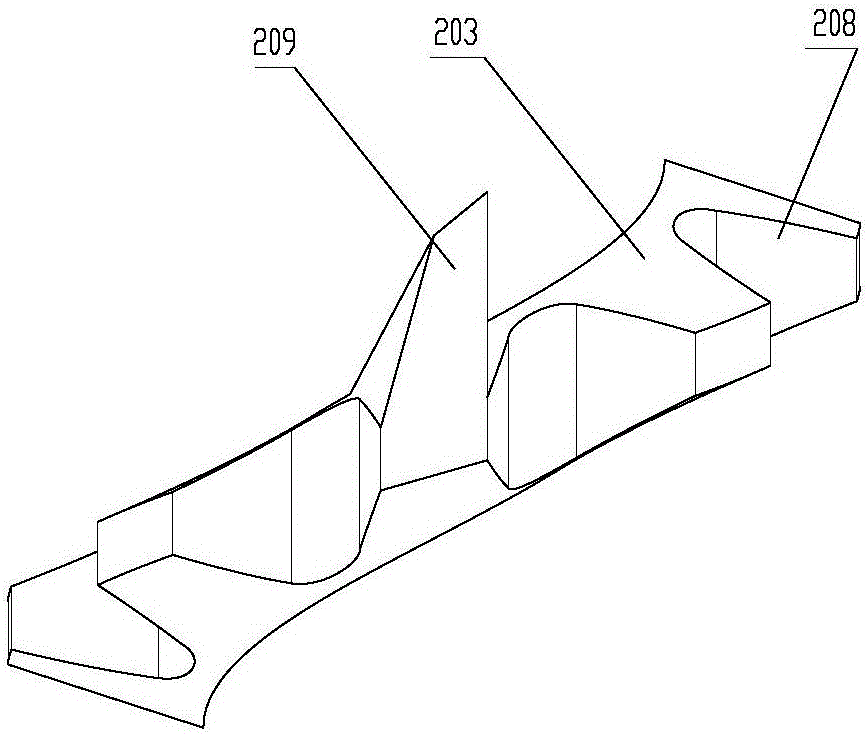

Spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing

InactiveCN105909166AReduce supplyImprove rock breaking efficiencyReciprocating drilling machinesConstructionsUpper jointSpray nozzle

The invention relates to a spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing in the fields of oil drilling, geological drilling and the like. The pressure of slurry can be converted into spiral impact of a center pipe. The spiral double-stage compounding impacting device has the technical scheme that an upper joint, an upper casing, a middle joint, a lower casing and a lower joint are sequentially matched through screw threads; a cavity is formed after the fixation; a valve body, a valve body spring, a driving hammer, a center pipe, a disc spring and an impact spray nozzle are sequentially arranged in the cavity from top to bottom; the driving hammer and an inner tube realize the axial positioning through an inner tube spring; through holes are uniformly formed in the peripheral direction; and a spiral bearing groove is formed in the outer surface of the center pipe. According to the tool, the driving hammer is driven to move in the axial direction through slurry pressure; the center pipe is subjected to axial impact; under the joint effects of the driving hammer, the disc spring and a spiral bearing, the center pipe drives the impact spray nozzle to generate the periodic spiral impact on the lower joint, and the impact acts on a lower part drilling tool; the rock breaking efficiency of a drill bit can be effectively improved; the drilling cost is reduced; and meanwhile, the occurrence of a stick-slip phenomenon is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Drilling device and method for efficient rock breaking by using liquid nitrogen jet flow

InactiveCN106382097AEffective damageImprove drilling efficiencyLiquid/gas jet drillingJet flowWell drilling

The invention discloses a drilling device and method for efficient rock breaking by using liquid nitrogen jet flow. The method comprises the following steps that liquid nitrogen is used as a jet flow medium and is sprayed out from a high-pressure jet flow spray nozzle in a pulse form; pulse waves further press a disc spring arranged in an opening position of the high-pressure jet flow spray nozzle, so that the disc spring generates vibration to drive the whole spray nozzle to vibrate; the generation of ice bags is avoided. The system is provided with a continuous oil pipe, a liquid nitrogen injection pipeline, an annular sleeve pipe, a liquid nitrogen compressor, a liquid nitrogen pump group, a continuous oil pipe operation car and a drilling device. The drilling device and the drilling method have the advantages that the acting principle of the liquid nitrogen at the stratum is utilized; a jet flow technology using the liquid nitrogen as the jet flow medium is combined with a continuous pipe technology; the stratum efficient rock breaking can be realized; the rock can be broken effectively, so that the drilling efficiency is higher; the cost is lower.

Owner:SOUTHWEST PETROLEUM UNIV

Microwave-assisted rock breaking drill bit, electricity conductive drill rod and microwave-assisted rock breaking device

InactiveCN104563883AReduce the difficulty of rock breakingExtended service lifeDrill bitsDrilling rodsElectricityWell drilling

The invention discloses a microwave-assisted rock breaking drill bit, an electricity conductive drill rod and a microwave-assisted rock breaking device. The microwave-assisted rock breaking drill bit comprises a drill bit inserting body, cutter wings, cutting teeth and connectors, wherein the cutter wings, the cutting teeth and the connectors are distributed on the drill bit inserting body, assisted rock breaking microwave generators are embedded in the cutter wings, cables are embedded in the drill bit inserting body, independent electricity conductive coils are embedded at the positions of the connectors, and the cables are connected between the electricity conductive coils and the assisted rock breaking microwave generators; the inserting conductive drill rod comprises a drill rod body and connectors connected to two ends of the drill rod body, wherein the cables are embedded in the drill rod body, and the independent electricity conductive coils are embedded at the positions of the connectors of the drill rod; the microwave-assisted rock breaking device comprises a drill machine, a power supply system and a control system, wherein the control system comprises a microwave generation controller. For the microwave-assisted rock breaking drill bit, the electricity conductive drill rod and the microwave-assisted rock breaking device, heat generated by microwave radiation is applied to reduce the strength of rock or directly break the rock, so that not only the mechanical drilling rate can be increased, but also vibration in a drilling process can be effectively reduced, the service life of the drill bit is prolonged, and the costs of drilling a well and breaking the rock are reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Liquid phase discharge plasma impact wave PDC drill bit

The invention relates to a liquid phase discharge plasma impact wave PDC drill bit, which comprises a drill bit body. Drill bit cutter wings are arranged at one end of the drill bit body at intervalsin the circumferential direction, cutting teeth capable of mechanically cutting rock are arranged on the drill bit cutter wings, and a well drilling liquid flowing channel is formed in the center of the drill bit body; a center water hole communicating with the well drilling liquid flowing channel is formed in the center of one end of the drill bit body in a penetrating mode, a center impact wavegenerator is arranged in the center water hole in a connected mode, and an edge water hole communicating with the well drilling liquid flowing channel is formed in the side wall of one end of the drill bit body in a penetrating mode; and an edge impact wave generator is arranged in the edge water hole in a connected mode, and the center impact wave generator and the edge impact wave generator areused for generating liquid phase discharge plasma impact waves capable of impacting and crushing the rock. According to the liquid phase discharge plasma impact wave PDC drill bit, by taking rock crushing through the liquid phase discharge plasma impact waves as the main and mechanical rock crushing as the auxiliary, rock drillability is improved, the well drilling speed is increased, the rock crushing efficiency of hard strata is improved, the service life of the drill bit is long, and use and promotion are facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Viscous motion preventing instrument capable of realizing friction reduction, drag reduction, energy saving and synergy

InactiveCN105569577ARealize normal drilling functionSimple structureEarth drilling toolsFriction reductionEngineering

The invention relates to a viscous motion preventing instrument capable of realizing friction reduction, drag reduction, energy saving and synergy. The viscous motion preventing instrument is fixedly installed at the upper part of a drill bit and comprises an upper contact assembly, a drive assembly, a vibration absorption assembly and a lower contact, wherein the drive assembly is installed at the front end of the upper contact assembly and the vibration absorption assembly is connected with the front end of the drive assembly. A screw short piece and a screw outer tube are matched to transmit torque to the drill bit. When the drill bit is stuck, the torque on bit gradually increases and reacts on the viscous motion preventing instrument so that a torsion spring is loaded and distorts, a spline moves forward, a spring and a disc spring are compressed, the torsion spring restores when the spring and disc spring are compressed to limit, the screw outer tube produces reversing rotation through the spline, and the screw outer tube moves rearward relative to the screw short piece. Thus, the torque on bit is decreased and keeps in balance with the torque of the upper instrument again, and the drill bit works normally. The viscous motion preventing instrument capable of realizing friction reduction, drag reduction, energy saving and synergy has the advantages of stable working performance, good vibration absorption effect and good structural performance and transmits drilling pressure and torque through screw drive.

Owner:SOUTHWEST PETROLEUM UNIV

Crossed scraping-impacting composite drill bit

ActiveCN102678053AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringHydraulic structure

The invention discloses a crossed scraping-impacting composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The crossed scraping-impacting composite drill bit comprises a drill bit body, a fixed cutting structure, a disc cutter cutting structure and a hydraulic structure, wherein the fixed cutting structure, the disc cutter cutting structure and the hydraulic structure are arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact forces and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit for blasting a rock in a cutting way, the crossed scraping-impacting composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

Spiral soil-squeezing downhole rock embedding device and pile forming method

ActiveCN106246099AImprove construction efficiencyReduce construction costsDrill bitsDrilling rodsFlangeDrill bit

The invention relates to a spiral soil-squeezing downhole rock embedding device and a pile forming method. The spiral soil-squeezing downhole rock embedding device is composed of a rotating unit, a standard soil squeezing drill rig, an impactor and a drill bit. The rotating unit is mounted at the upper end of the standard soil squeezing drill rig. The standard soil squeezing drill rig and the impactor are connected with an upper connecting plate through a standard flange. The impactor and the drill bit are positioned through a guiding spline between a lower body and an upper body, and the lower body, a pile casing and the upper body are connected into a whole through bolts and flanges. An impacting unit mounted in the impactor is movably connected with the upper body, and an inner tube II penetrates through the impactor and the drill bit. By means of the pile forming method, a rock-embedded pile with the rock bearing capacity larger than 500 Kpa is constructed, the construction quality is guaranteed, construction efficiency is improved, and the requirements for energy saving and environmental protection are met.

Owner:东营正诺技术服务有限公司

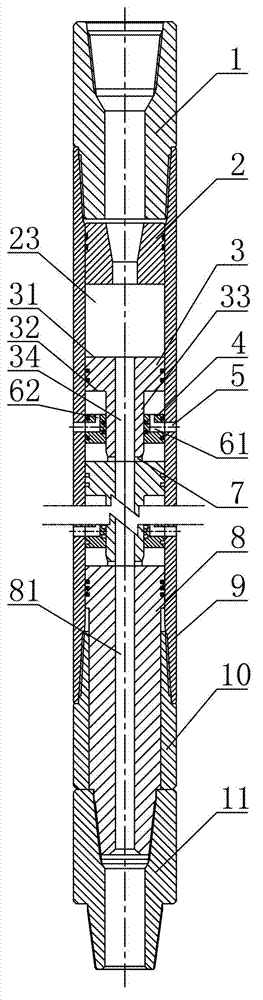

Vibration and pressure well drilling tool

ActiveCN102733756AEliminates "stick-slip" phenomenonIncrease stressVibration drillingWell drillingPolycrystalline diamond

The invention discloses a vibration and pressure well drilling tool. An upper connector and a nozzle are arranged at the upper end of a sleeve; a driving rod is arranged at the lower end of the sleeve in a sliding manner; the lower end of the driving rod is fixedly connected with a lower connector; a plurality of stages of piston separation ring structures are arranged between the nozzle and the driving rod in the sleeve; each stage of piston separation ring structure comprises a piston approximately in a T-shaped structure, and a separation ring fixedly arranged in the sleeve and sleeved at a guide rod part of each piston; piston pressure transmitting holes communicated with a piston runner are arranged at the lower ends of the guide rod parts of the pistons; radial separation ring holes and axial separation ring holes are arranged in the separation rings; and sleeve flow guide holes are arranged in the sleeve, corresponding to the radial separation ring holes. According to the invention, shock vibration is innovatively introduced for ''stick-slip'' vibration of a drill bit, so that the stick-slip in the drilling process of the PDC (polycrystalline diamond compact) drill bit is eliminated, the PDC drill bit exerts a high-frequency and low-amplitude shock effect on the rock below, the stress status of the rock is improved, and the rock breaking efficiency is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Lithology identification based mechanical-hydraulic combined rock breaking TBM real-time tunneling method

ActiveCN110318765AReduce energy consumptionImprove rock breaking efficiencyTunnelsLaser rangingRock breaking

The invention discloses a lithology identification based mechanical-hydraulic combined rock breaking TBM real-time tunneling method. The method comprises the following steps that mechanical-hydrauliccombined rock breaking cutterhead TBM construction prepares are made; construction is started; TBM cutterhead propulsion is carried out; a mechanical cutter pushes and presses the face; a module detection hobbing cutter device applies detection pushing force; cutter laser ranging and timing and sensor lithology index feedback are carried out; a TBM rear end control processor processes information;a TBM cutterhead control center makes responses; a hydraulic cutting hobbing cutter acquires and adjusts parameters; and a TBM cutterhead breaks rock. The method has the advantages of being energy-saving, efficient, high in rock breaking efficiency and small in cutterhead consumption.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

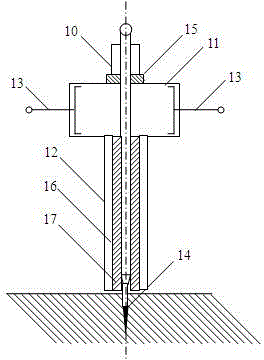

Self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method

PendingCN107476814AImprove rock drilling or rock breaking efficiencyDrilling speed is fastAnchoring boltsDrill bitHigh pressure

The invention discloses self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method. The equipment is composed of a self-vibrating flow-jetting and grouting anchor rod, a high-pressure rotary slurry mixing device, a grouting device and a hydraulic driving device. The self-vibrating flow-jetting and grouting anchor rod is a hollow rod body with a screw-edge stirring piece, and the front end of the anchor rod is provided with a vibration generator which is connected with a drill bit; the upper portion of the high-pressure rotary slurry mixing device is provided with a feed hole, the bottom of the high-pressure rotary slurry mixing device is provided with a rotary supporting leg which can freely lift and rotate, the front portion of the high-pressure rotary slurry mixing device is provided with a flow-jetting spray pipe, an inner cavity is provided with a rotating shaft, the front end of the rotating shaft is provided with a connection plug, the connection plug is cooperated and connected with a connection inserted groove of the self-vibrating flow-jetting and grouting anchor rod, the rear end of the rotating shaft is provided with a bearing, and the two ends of the rotating shaft are provided with high-pressure sealing boxes. The grouting device adjusts the grouting amount and the grouting pressure at any time, and the hydraulic driving device provides rotating power. The equipment and the method is widely used in support and reinforcement engineering in mines, transportation, water conservancy and other engineering fields, the application prospect is broad and the economic benefit is remarkable.

Owner:BINZHOU UNIV

Double-stage drill bit

InactiveCN105221077APrevent left and right movementImprove stabilityDrill bitsConstructionsLarge sizeDouble stage

The invention discloses a double-stage drill bit. The double-stage drill bit comprises a drill bit body, fixed blades, fixed cutting teeth, chip grooves, nozzles and the like and is characterized in that the core of the drill bit is inwardly concave to form a core cutting structure, and the core cutting structure and an outer cutting structure form the stepped double-stage drill bit. By the structure, the double-stage drill bit has the advantages that the problems that the drill bit is low in mechanical drilling speed and poor in stability when the drill bit is in a large well hole of a deep stratum are solved effectively, the outer cutting structure cuts annular crushed zones in the well hole first to form annular stress release faces in well-bottom rock, and drill bit rock breaking efficiency is increased favorably; protruded rock is formed at the core area of the drill bit, and drill bit stability is increased favorably; the well-bottom drilling parameters of large-size drill bits can be changed, double-stage cutting structure drilling pressure and torque proportion can be reasonably adjusted and allocated, and drilling efficiency is increased.

Owner:SOUTHWEST PETROLEUM UNIV

Hydraulic impactor

The invention discloses a hydraulic impactor. Pressure difference formed between the upper end and the lower end of an impacting body by drilling fluid flowing inside an impactor body achieves guide effects on the impacting body and meanwhile enables the impacting body to move axially and reciprocatingly, and a throttle device and an impact transfer device can transmit impact force generated by the impacting body to a drill bit, so that the impacting body can exert the impact force at a certain frequency onto the drill bit. Compared with an existing hydraulic impactor, the hydraulic impactor omits a reversing unit, a working valve and a driving device, thereby being simple in structure and high in use reliability.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-pressure water jet edge cutter and combined rock breaking and escaping TBM cutterhead and method thereof

The invention discloses a high-pressure water jet edge cutter which comprises an edge cutter mechanical structure, an edge cutter high-pressure water jet pipeline and an edge cutter high-pressure water jet nozzle. The edge cutter high-pressure water jet pipeline is located in the edge cutter mechanical structure. The edge cutter high-pressure water jet nozzle is embedded in the edge cutter mechanical structure and communicates with the edge cutter high-pressure water jet pipeline. The high-pressure water jet edge cutter has the advantages of realizing rock breaking through high-pressure waterjet and solving the problem that a TBM gets stuck. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping TBM cutterhead. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping method.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com