High-frequency torsion and axial bidirectional impactor

An impactor and axial technology, which is applied in earthwork drilling, driving devices for drilling in boreholes, drilling equipment, etc., can solve the problems of low drilling efficiency, long drilling cycle, and short life of drill bits, and achieve high drilling speed , reduce drilling cost, weaken the effect of drill bit torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

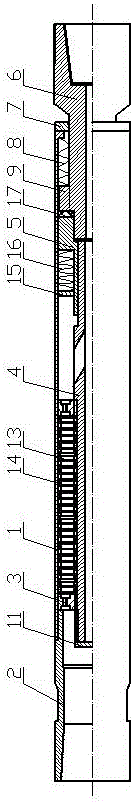

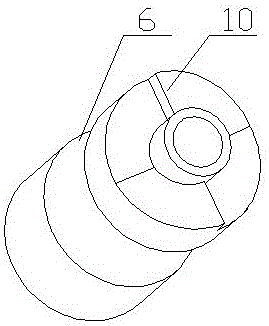

[0015] The high-frequency torsional and axial two-way impactor includes a casing 1 , a connecting head 2 , a centering bearing 3 , a turbine shaft 4 , an upper hammer body 5 and a lower hammer body 6 . One end of the casing 1 is threadedly mounted with a connector 2 ; the other end of the casing 1 is slidably mounted with a lower hammer body 6 through an end cover 7 and a buffer spring 8 . A limit protrusion 9 is arranged on the lower hammer body 6; two impact bosses 10 are arranged symmetrically on the inner end surface of the limit protrusion 9, and the impact bosses 10 are slope bosses.

[0016] The casing 1 on one side of the lower hammer body 6 is equipped with a turbine shaft 4 through a nut 11, the turbine shaft 4 is a reducing shaft, and the middle part of the turbine shaft 4 is radially evenly distributed with flow holes 12. A turbine rotor 13 and a stator 14 are installed on the circumference of one end of the turbine shaft 4 through symmetrically arranged centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com