High-nitrogen nickel-free super double-phase stainless steel wire rope for high-speed elevator and manufacturing method thereof

A duplex stainless steel and high-speed elevator technology, which is applied in textile cables, textiles and auxiliary devices for papermaking and rope making, and can solve the problems of ordinary stainless steel wire ropes such as poor bearing capacity, non-wear-resistant production costs, and small breaking force , to achieve high strength, reduce product cost, and improve the breaking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

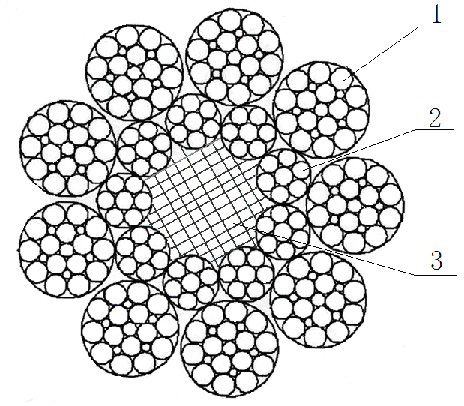

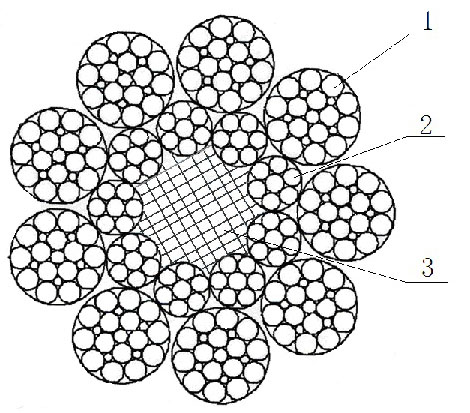

[0023] Example figure 1 As shown, this embodiment provides a 9×21Fi+PWRC (FC)-Φ8mm high-nitrogen nickel-free super duplex stainless steel wire rope for high-speed elevators and its manufacturing method. The steel wire rope includes outer strand 1, inner strand 2 and center Strand 3, outer layer strand 1 and inner layer strand 2 are made of high-nitrogen nickel-free super duplex stainless steel. ~0.48%N, ≤0.012%C, 0.12%Ce or Y, ≤1.0%Si, ≤0.01%S, ≤0.02%P, ≤0.01%B, the balance is Fe; the central strand 3 is made of polypropylene fiber material;

[0024] The outer layer strand 1 uses 9 filled steel wire strands. The strand structure is 10+5F+5+1, the strand diameter is 1.97mm, the strand lay length is 16.5mm, and the strand twist is leftward. When plying, a rear deformer must be used. The deformation roll distance is 30mm, the reduction is 2.2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com