Patents

Literature

211results about How to "High breaking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

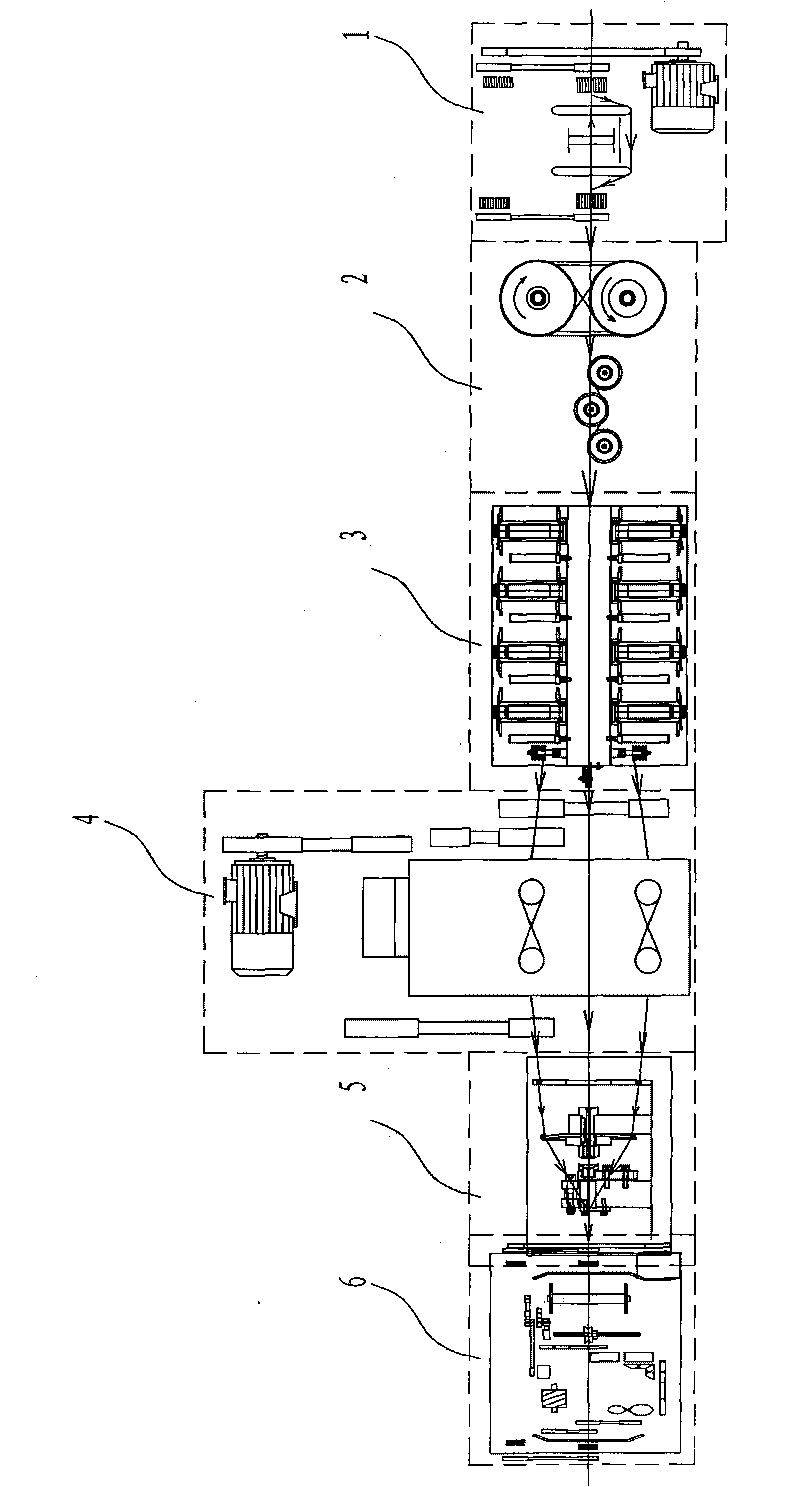

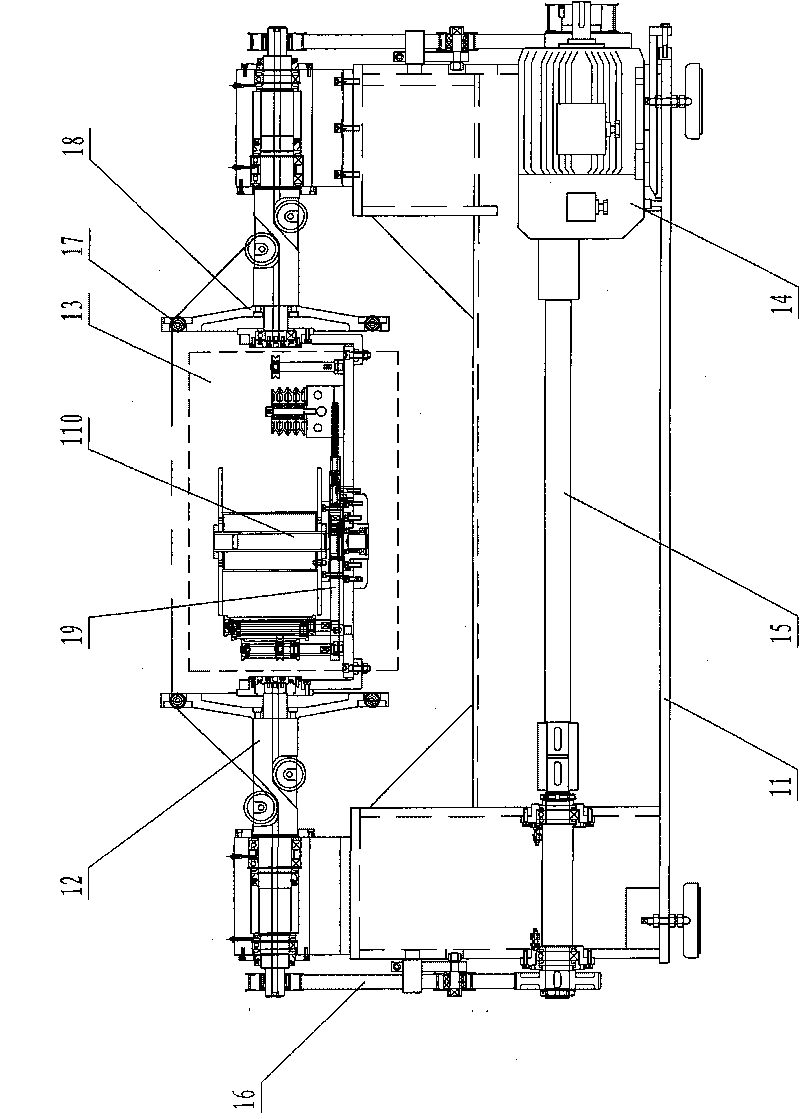

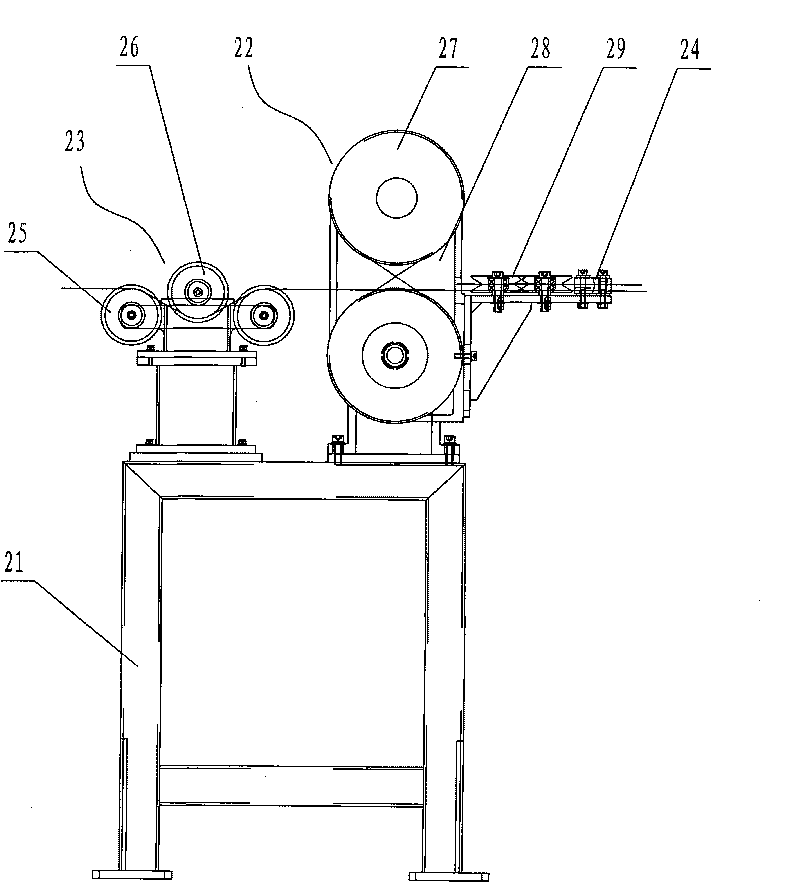

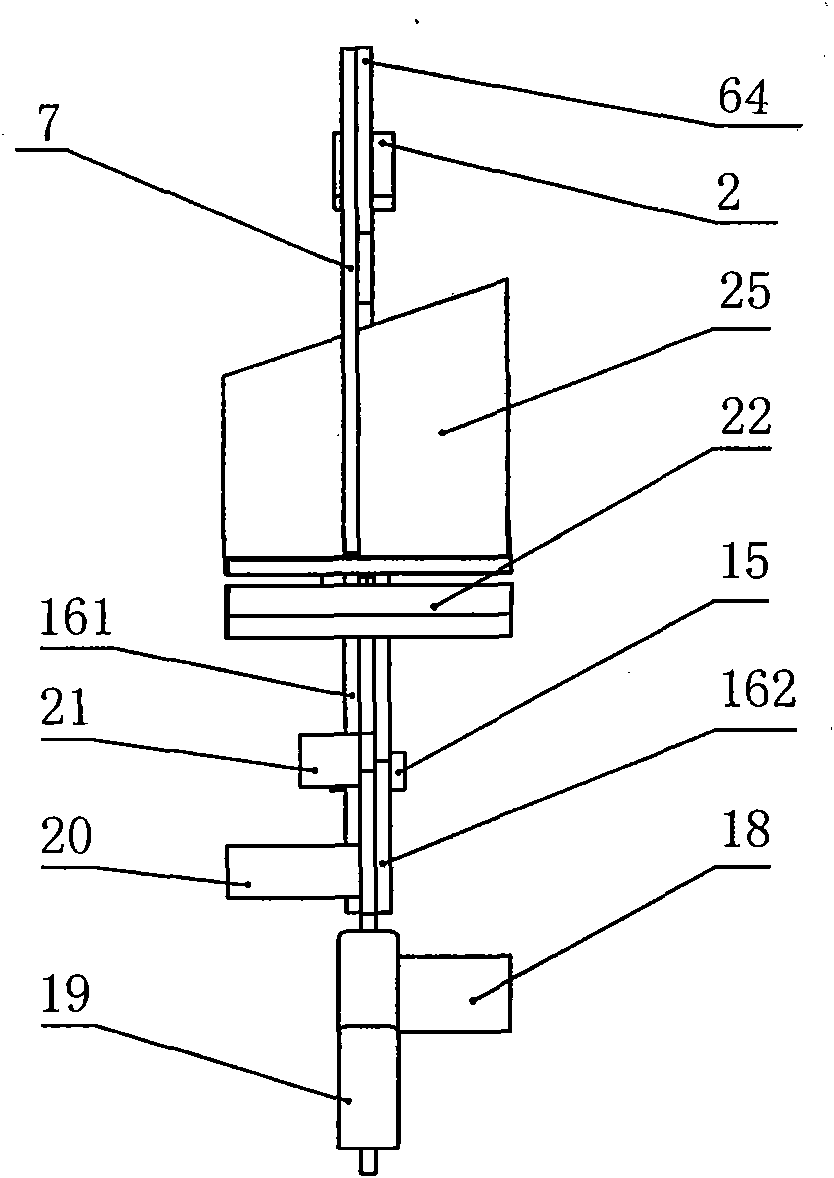

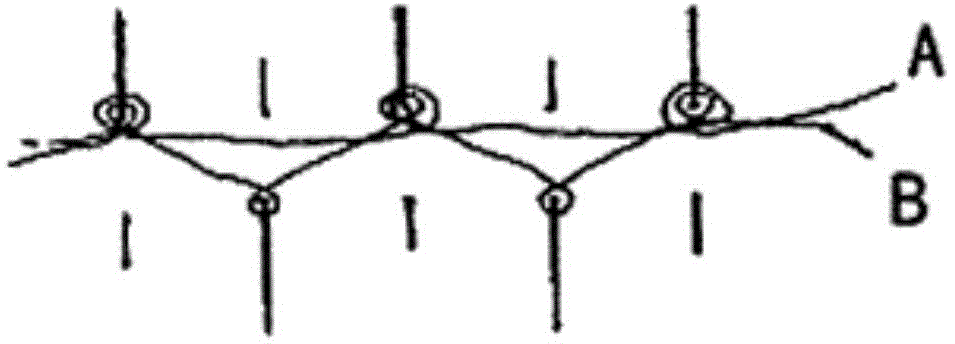

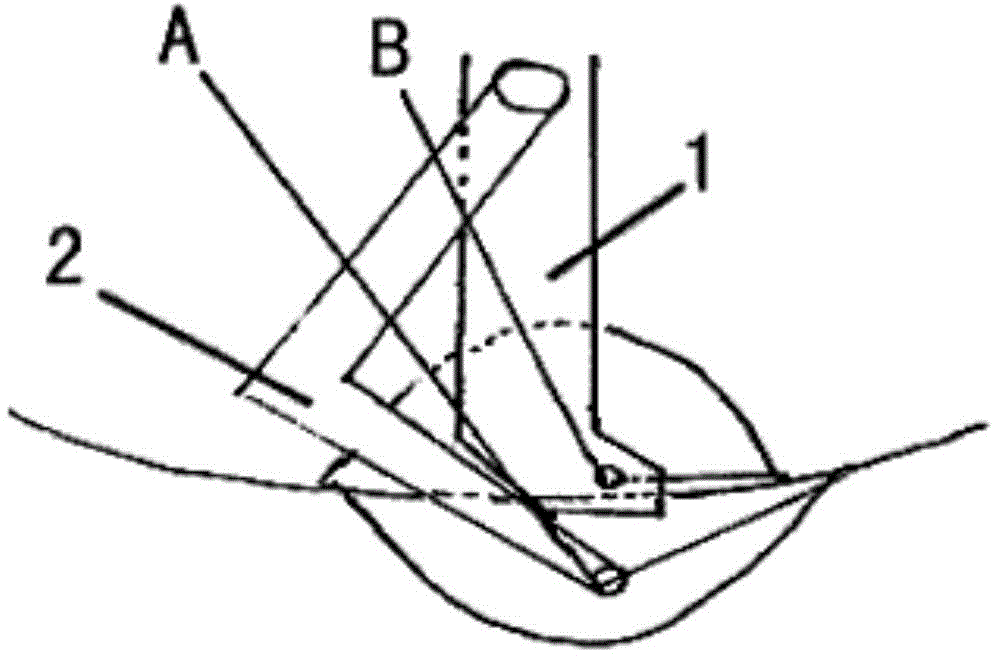

Double twisting rope laying machine

The invention discloses a double twisting rope laying machine which comprises a core wire laying machine, a core wire tension mechanism, a surface wire laying mechanism, a single wire pre-twisting machine, a wire collecting mechanism and a wire-rewinding machine arranged sequentially, wherein the core wire tension mechanism comprises a broken wire detecting device, a wire roller, a tension control device and a tension detecting device; the core wire output tension is detected by the tension detecting device, and if the tension exceeds a set tension range, the core wire output tension is adjusted by the tension control device to realize accurate control of the core wire laying tension; and the single wire pre-twisting machine comprises a motor, a transmission component and a plurality of groups of rotor components which are arranged at the front surface and the back surface of a stand. Through the rotation of each group of rotor components, the single wire pre-twisting process is realized and the single wire stress is eliminated, thereby being favorable to twisting and forming, and finally, the twisted cords have good straightness, stable residual torsion and high product quality and is difficult to loose; and the specifications of the producible cords are 3+9+15*0.22, 3+9+15*0.175 and 0.25+(6+12)*0.22.

Owner:江苏泰隆机电科技有限公司

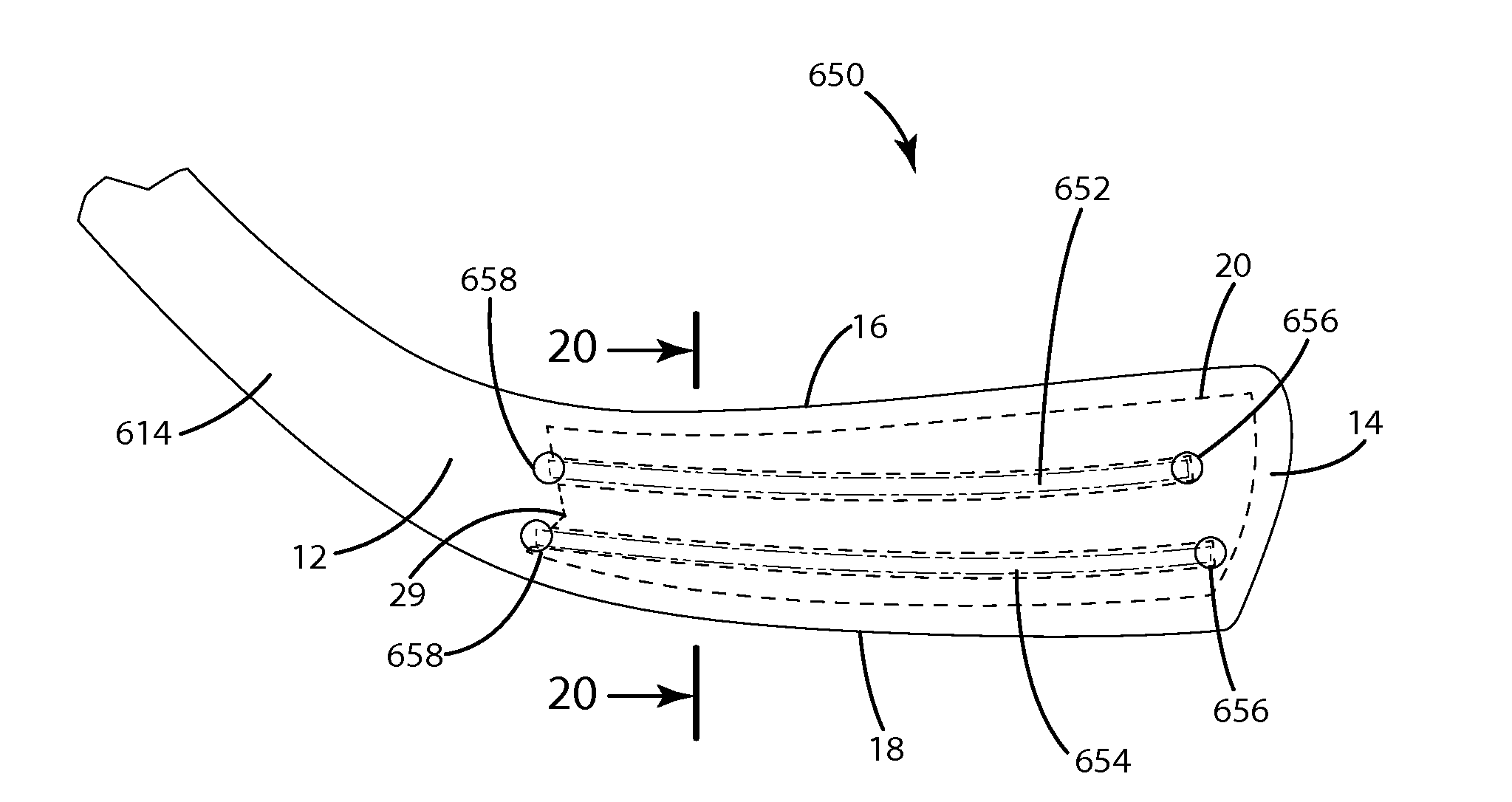

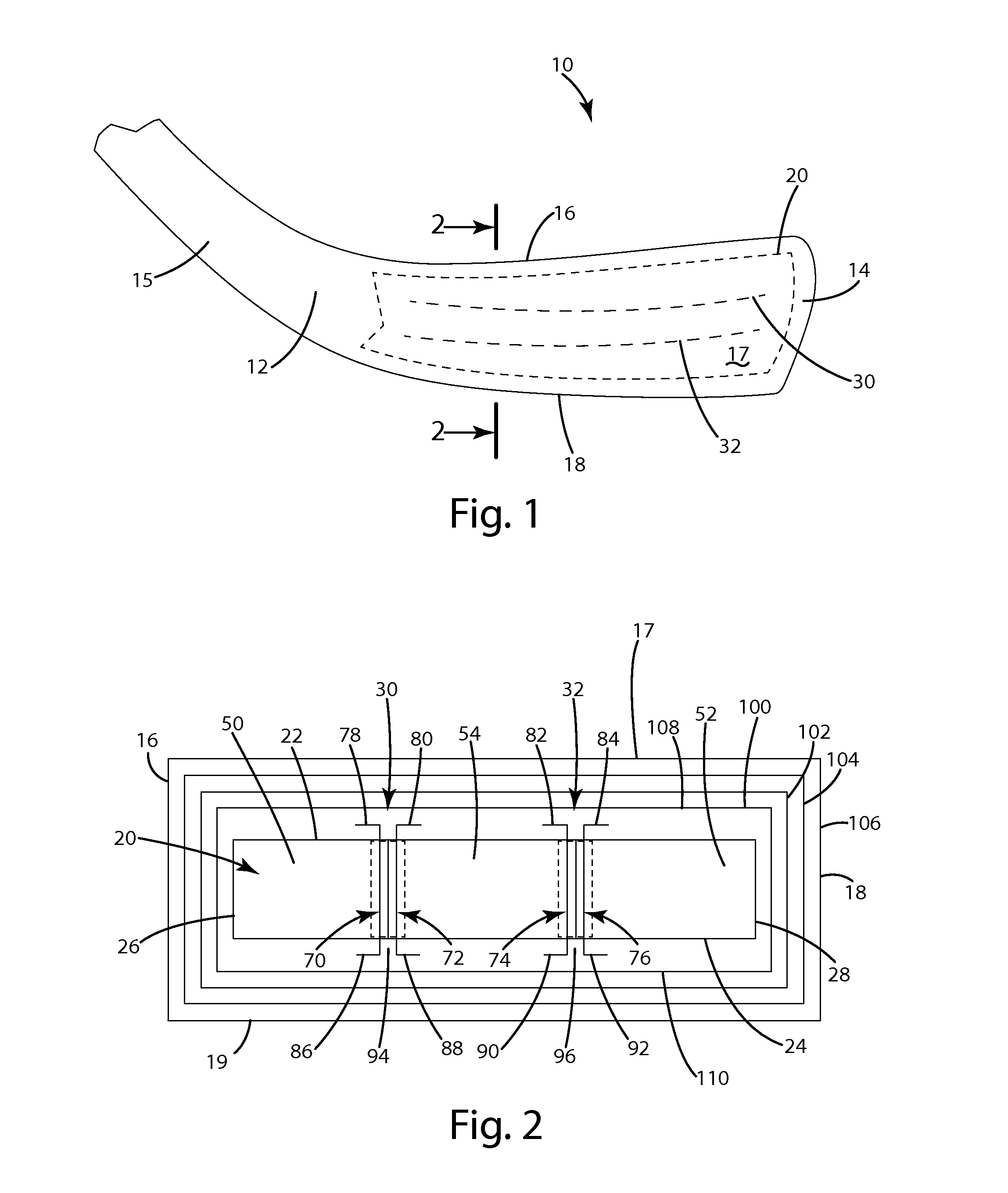

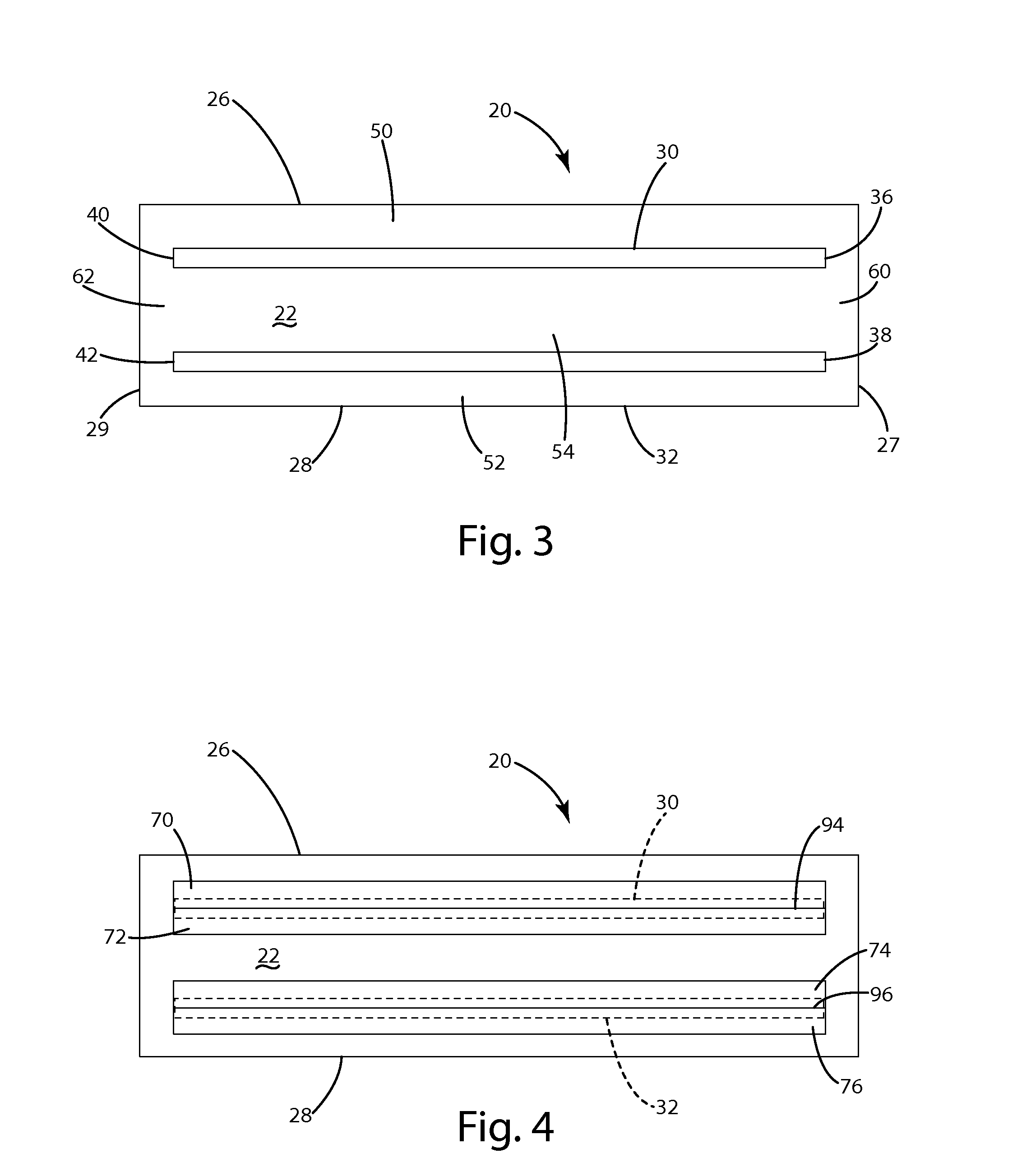

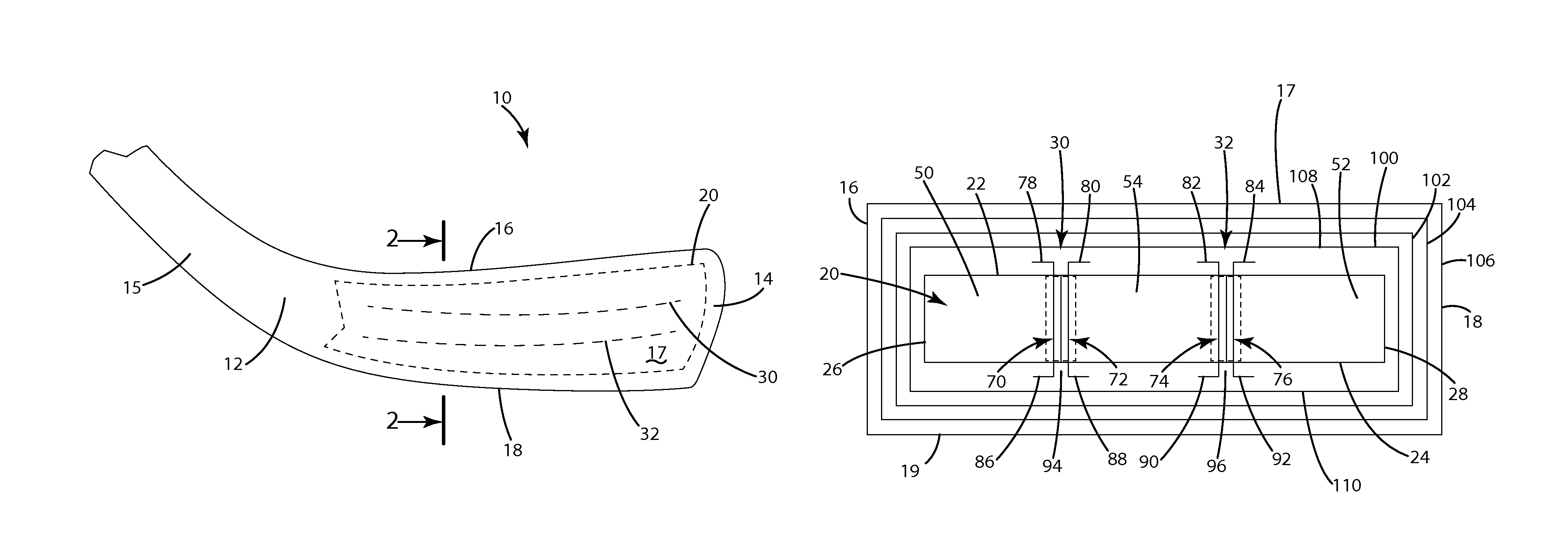

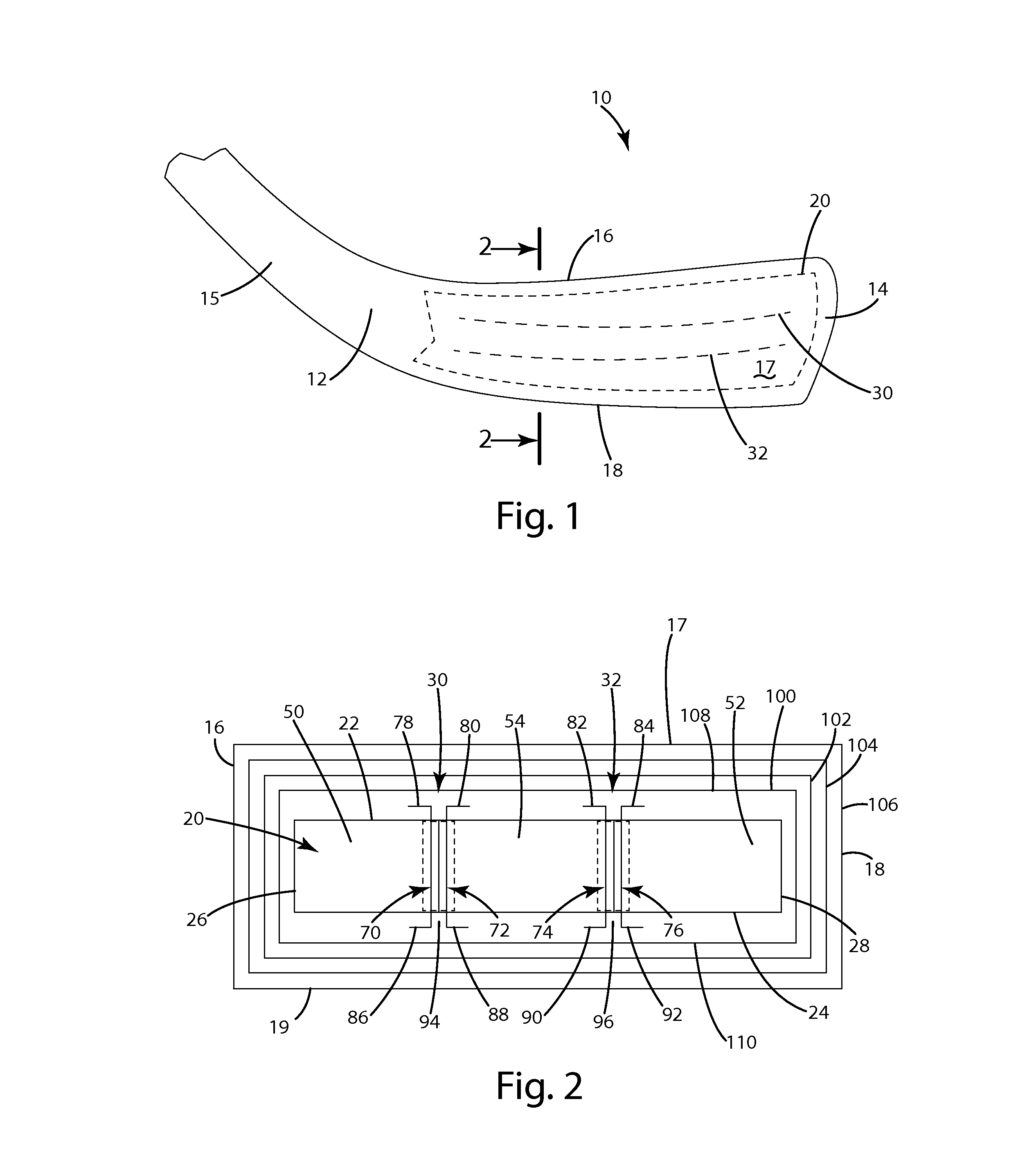

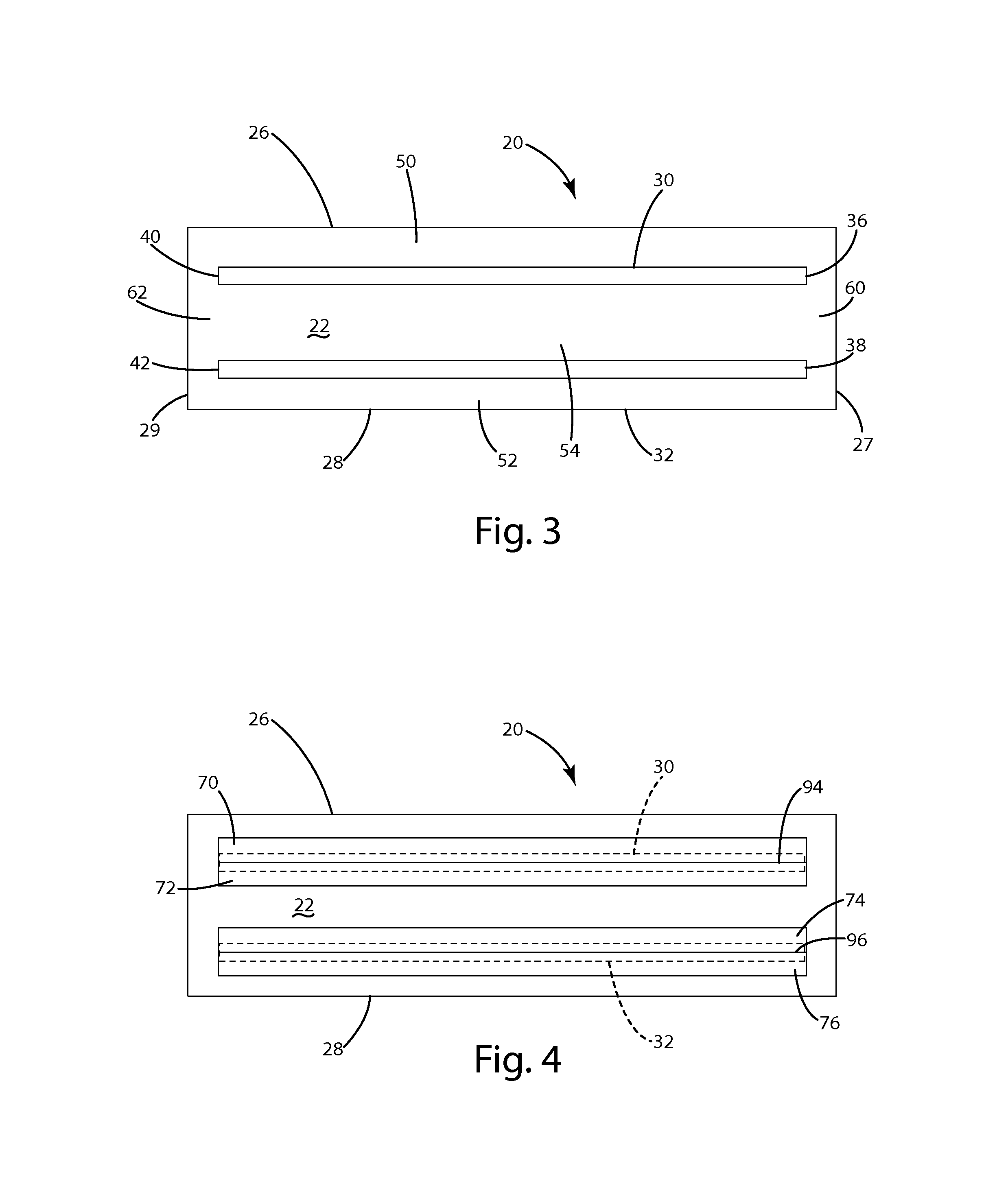

I-beam construction in a hockey blade core

ActiveUS20130116070A1Improve blade strengthIncreased durabilityDomestic articlesCoils manufactureEngineeringUltimate tensile strength

A reinforced hockey stick blade and a related method of manufacture are provided. The hockey stick blade can include a core element defining one or more longitudinal channels bounded by an upper core portion, a lower core portion, and a bridge portion interconnecting the upper and lower core portions. The hockey stick blade can additionally include a plurality of fiber-reinforced plies substantially encapsulating the core element and a reinforcing material received within the one or more longitudinal channels. The reinforcing material can extend longitudinally from a first channel end portion to a second channel end portion, and can include woven or unidirectional fiber-reinforced plies. The reinforcing material can additionally extend transversely across the channel to form a blade structure having increased blade strength and durability over existing composite hockey stick blades.

Owner:WARRIOR SPORTS INC

Surface palladium-plated bonding brass wire

ActiveCN102130067AGood ultimate plastic deformation abilityConsistent deformationSemiconductor/solid-state device detailsSolid-state devicesCost performanceBrass

The invention discloses a surface palladium-plated bonding brass wire comprising a brass core taking brass as a main component and a palladium layer formed by plating on the brass core. The surface palladium-plated bonding brass wire is characterized in that trace metal for improving the extension performance is added in the brass core taking the brass as the main component; a single crystal is smelt and drawn to form a brass alloy core wire; the palladium is plated on the surface of the brass alloy core wire; and the surface palladium-plated bonding brass wire is formed in a superfine drawing manner. Compared with the prior art, the invention has the benefits that the surface palladium-plated bonding brass wire has better final plasticity deformation capability in the subsequent superfine drawing process without intermediate annealing; the percentage elongation of the surface palladium-plated bonding brass wire is at least 11 percent; the deformation of a palladium-plated layer in the pressure processing flow is consistent; the surface of the surface palladium-plated bonding brass wire is uniform, compact and complete, which is especially beneficial to full deformation during welding bonding, and thus the pulling strength and the reliability are improved. In addition, the cost of products can be controlled to be about 6 yuan / 100 meters and the products have high cost performance.

Owner:SICHUAN WINNER SPECIAL ELECTRONICS MATERIALS

RFL film or adhesive dip coating comprising carbon nanotubes and yarn comprising such a coating

InactiveUS20090202764A1High breaking forcePretreated surfacesPneumatic tyre reinforcementsYarnRubber material

The invention relates to an RFL film or adhesive dip coating comprising carbon nanotubes.It also relates to a yarn coated or impregnated with a coating according to the invention.It also relates to the use of the yarn thus treated for reinforcing an article based on a rubber material, said article possibly being a belt, a tube, a hose, a pipe or a tire and generally any object subjected to shear stresses.

Owner:PORCHER INDUSTRIES

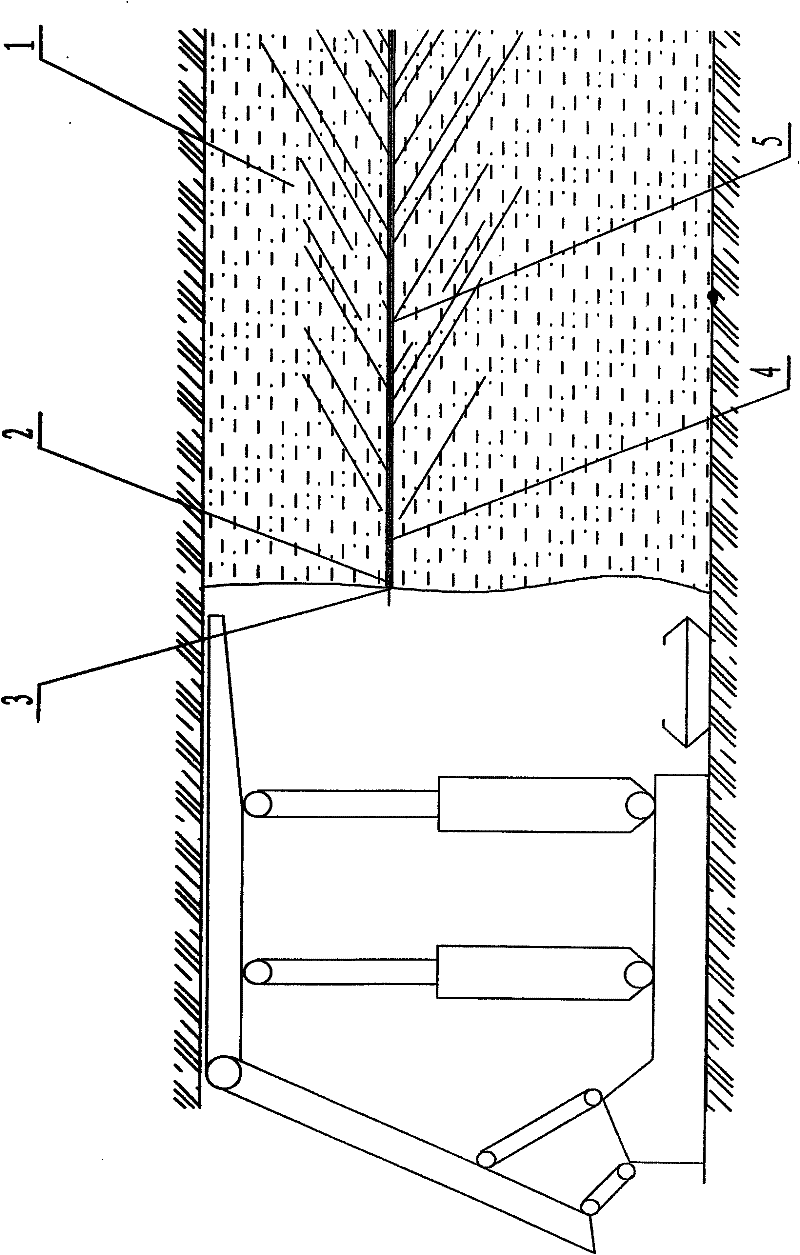

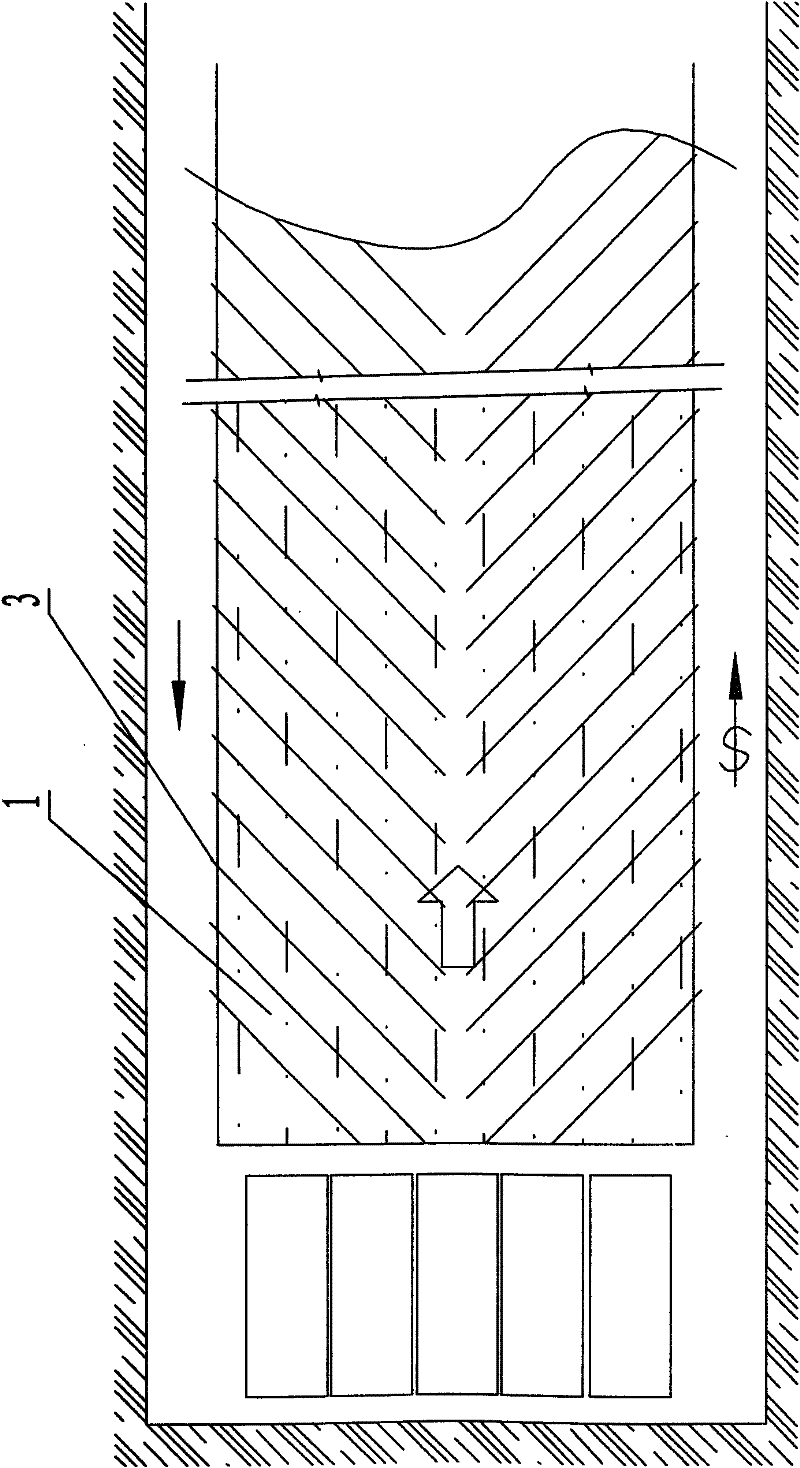

Method for reinforcing working surface of loose and soft coal bed by utilizing nonmetal grouting anchor cable

The invention discloses a method for reinforcing a working surface of a loose and soft coal bed by utilizing a nonmetal grouting anchor cable. The grouting anchor cable is made of a high-strength composite material carbon fiber / glass fiber. The reinforcement of the working surface of the loose and soft coal bed is realized through the processes of surveying and lofting, drilling holes in a coal body, manufacturing and arranging the grouting anchor cable, sealing an anchor cable hole, and grouting chemical grout in the hole and the like. As the grouting anchor cable is made of nonmetal materials, no sparks are generated when a coal-winning machine cuts, and the grouting anchor cable has the characteristics of flame retardancy, anti-static electricity, safety and reliability in use and hightensile strength, higher breaking force, light weight, and capability of being bent and coiled, and is higher than steel and convenient in transportation; and by utilizing the method, deep hole reinforcement and support on the working face can be carried out under the condition that the coal face can not be supported by using a metal anchor cable, the grouting support operation can be carried outon the working surface on site by combining a chemical grouting method, and the coal body of the working surface can be reinforced at the upper and lower tunnels of the working face by combining the chemical grouting in advance.

Owner:HEBEI TONGCHENG MINING TECH

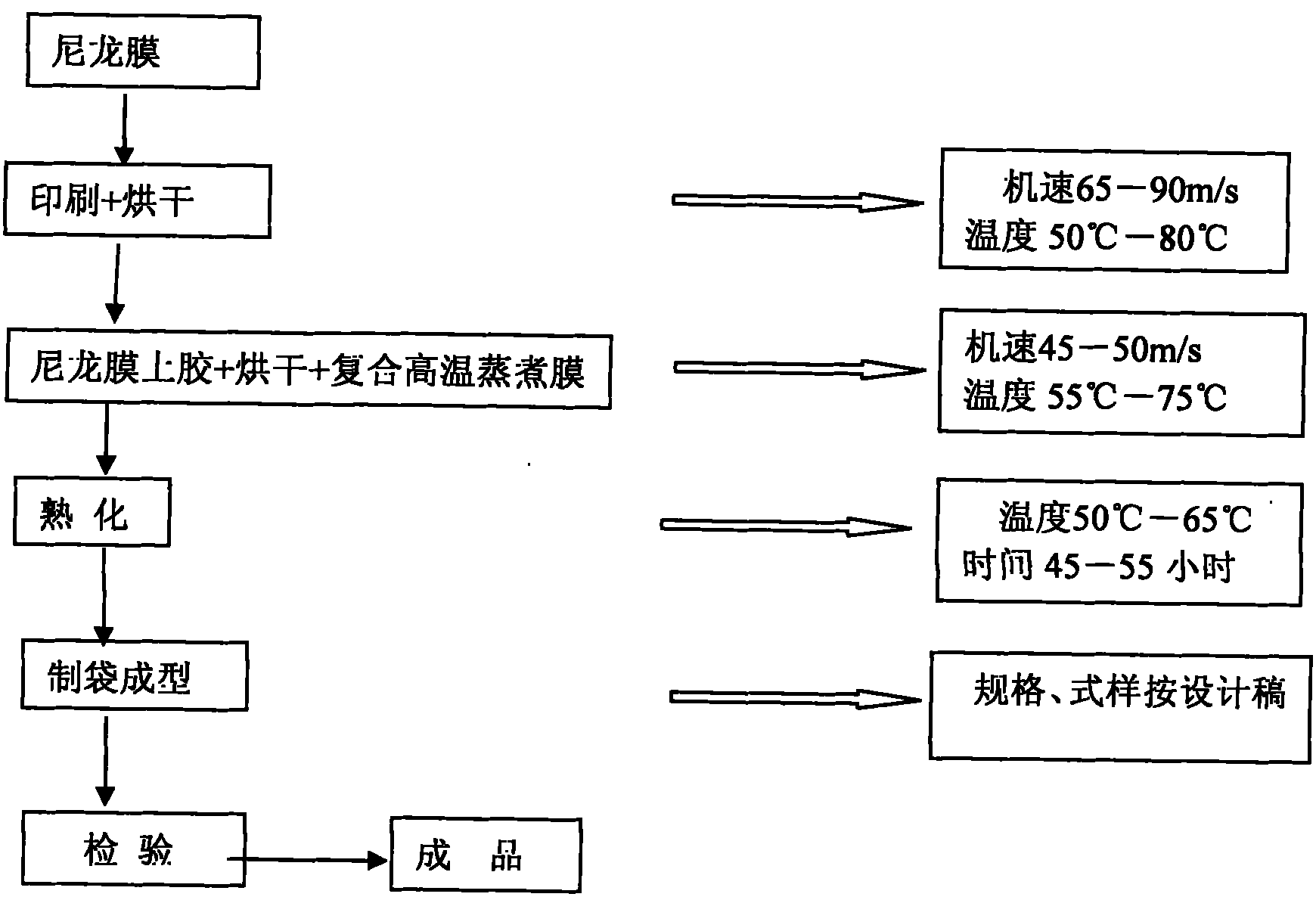

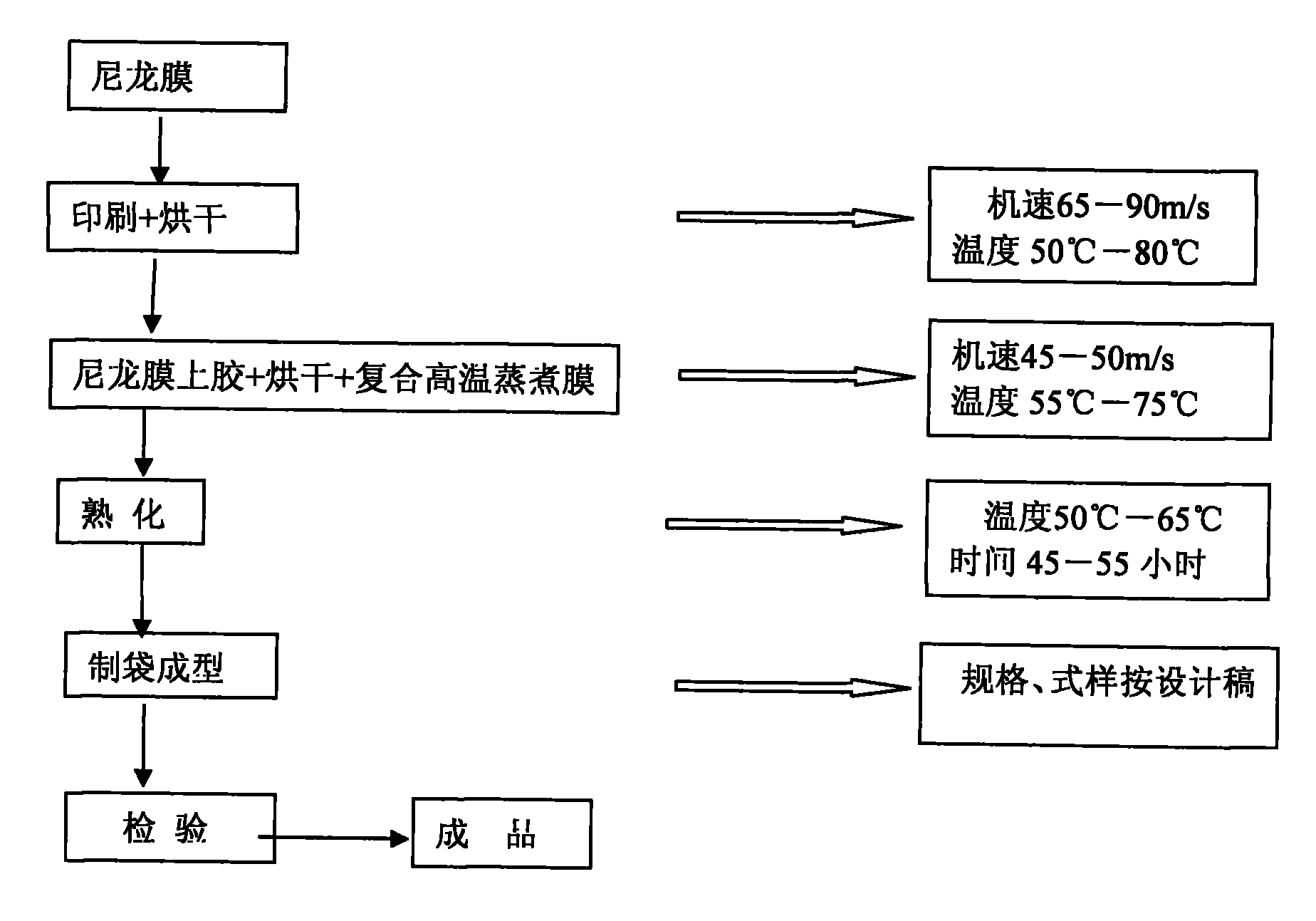

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

I-beam construction in a hockey blade core

ActiveUS9044658B2Increased durabilityHigh strengthDomestic articlesCoils manufactureEngineeringUltimate tensile strength

Owner:WARRIOR SPORTS INC

High-strength heat-resistant aluminum alloy single line and wire for smart power grid and processing process of single line

ActiveCN105369073AHigh strengthImprove the safety of useConductive materialInsulated cablesSmart gridPower grid

The invention discloses a high-strength heat-resistant aluminum alloy single line and wire for a smart power grid and a processing process of the single line. The high-stretching-rate high-strength heat-resistant aluminum alloy single line is prepared from, by weight percent, 0.05%-0.15% of Zr, 0.01%-0.30% of Y or La, 0.15%-0.30% of Fe, 0.01%-0.40 of Si, 0.01%-0.50% of Mg, 0.10% or less of other impurity elements and the balance aluminum. The strength of the wire formed by stranding single lines can be greatly increased, the draw-weight ratio can be increased, and the use safety of the wire can be improved; meanwhile, the operating temperature of the wire is greatly increased, the operating temperature of the wire is increased to 150 DEG C from conventional 70 DEG C, and therefore the carrying capacity is greatly improved; and the use requirements of high-capacity and large-span extra-high-voltage lines can be met.

Owner:FAR EAST CABLE +2

Surface palladium-plated bonding brass wire

ActiveCN102130067BUniform surfaceFully deformedSemiconductor/solid-state device detailsVacuum evaporation coatingMinor metalsSingle crystal

The invention discloses a surface palladium-plated bonding brass wire comprising a brass core taking brass as a main component and a palladium layer formed by plating on the brass core. The surface palladium-plated bonding brass wire is characterized in that trace metal for improving the extension performance is added in the brass core taking the brass as the main component; a single crystal is smelt and drawn to form a brass alloy core wire; the palladium is plated on the surface of the brass alloy core wire; and the surface palladium-plated bonding brass wire is formed in a superfine drawing manner. Compared with the prior art, the invention has the benefits that the surface palladium-plated bonding brass wire has better final plasticity deformation capability in the subsequent superfine drawing process without intermediate annealing; the percentage elongation of the surface palladium-plated bonding brass wire is at least 11 percent; the deformation of a palladium-plated layer in the pressure processing flow is consistent; the surface of the surface palladium-plated bonding brass wire is uniform, compact and complete, which is especially beneficial to full deformation during welding bonding, and thus the pulling strength and the reliability are improved. In addition, the cost of products can be controlled to be about 6 yuan / 100 meters and the products have high cost performance.

Owner:SICHUAN WINNER SPECIAL ELECTRONICS MATERIALS

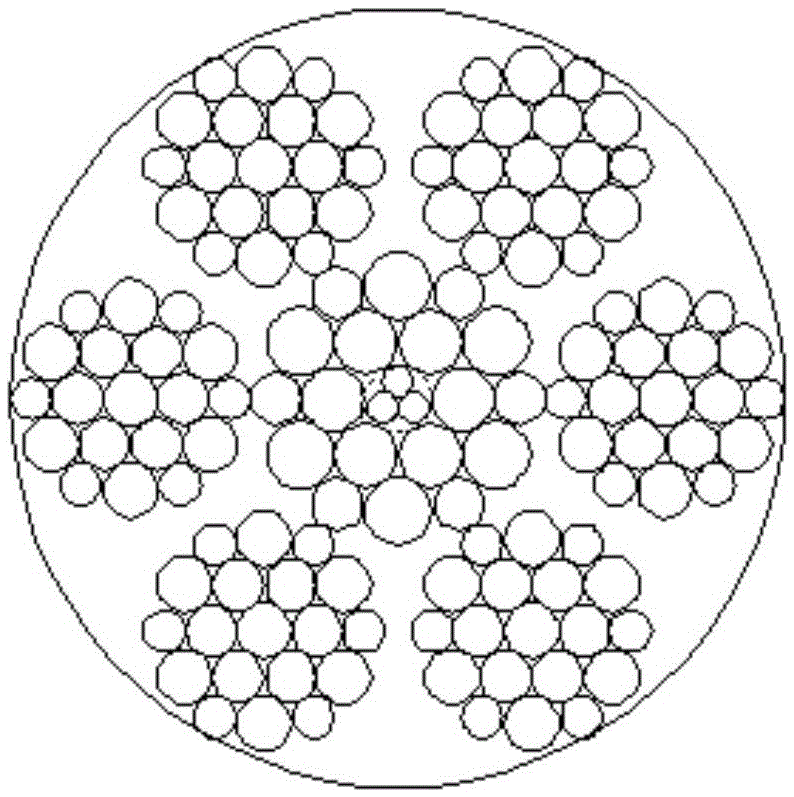

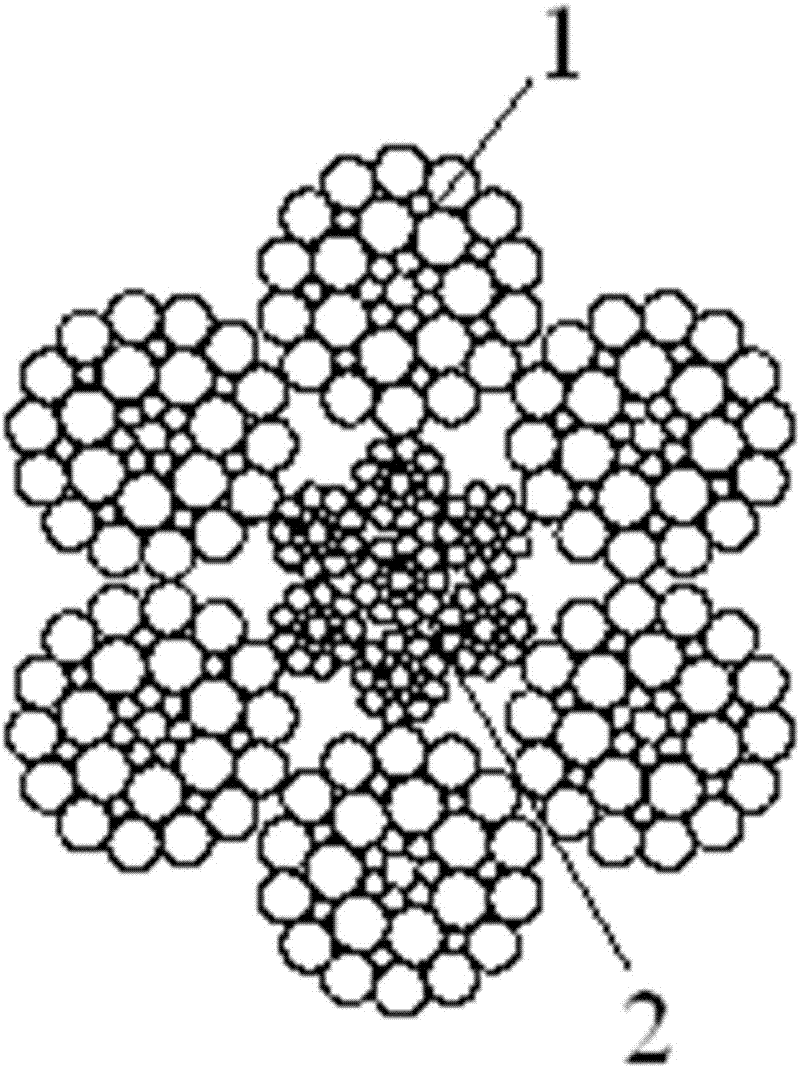

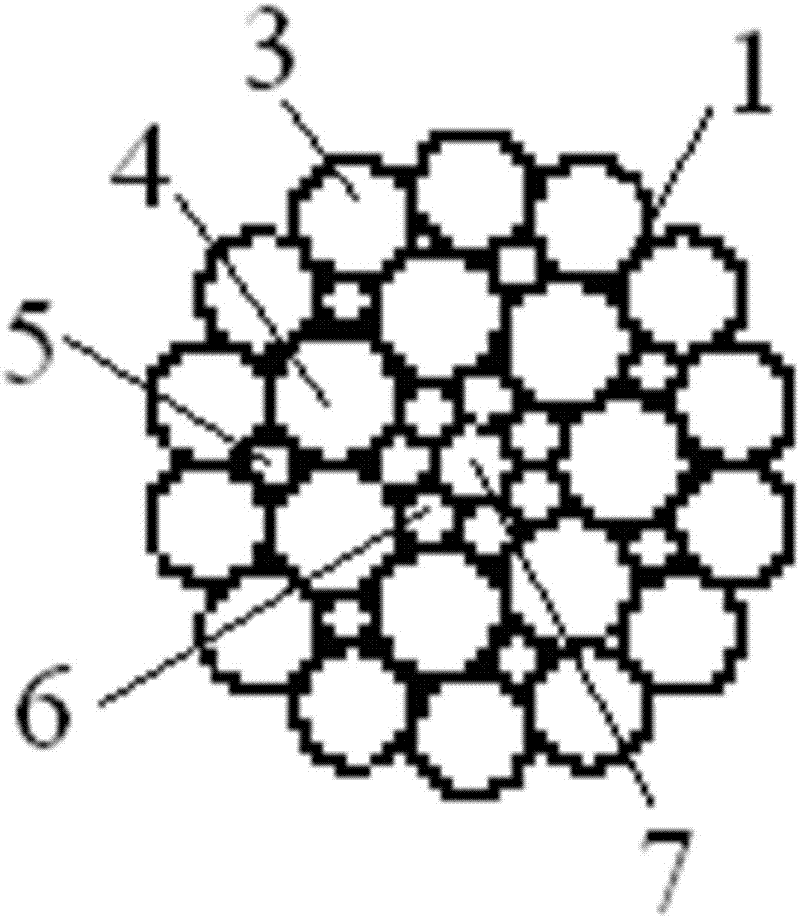

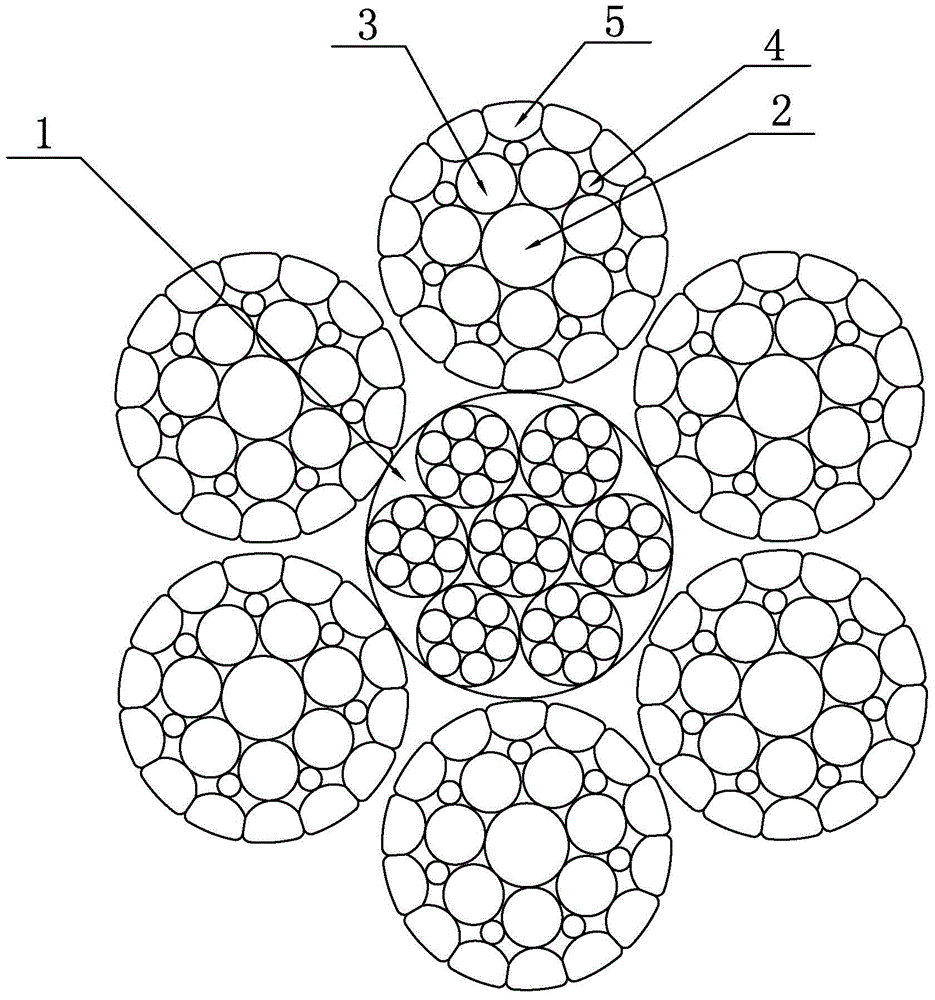

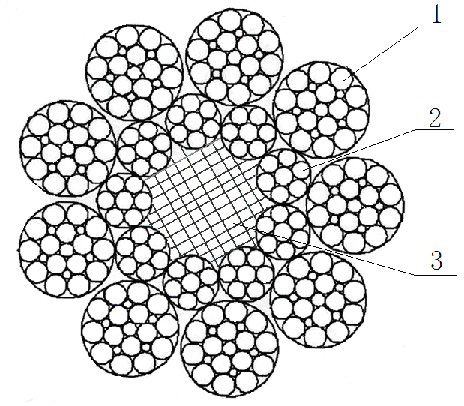

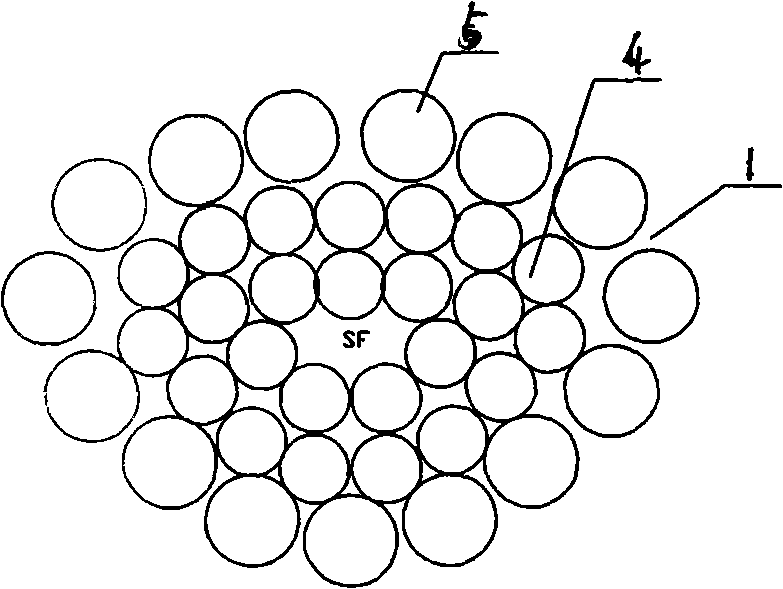

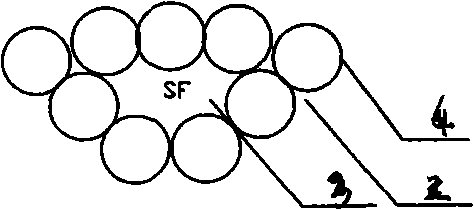

Ultrahigh strength steel wire rope and wire drawing method thereof

ActiveCN105537294AIncreased density coefficientHigh breaking forceHot-dipping/immersion processesDrawing diesUltimate tensile strengthWire rope

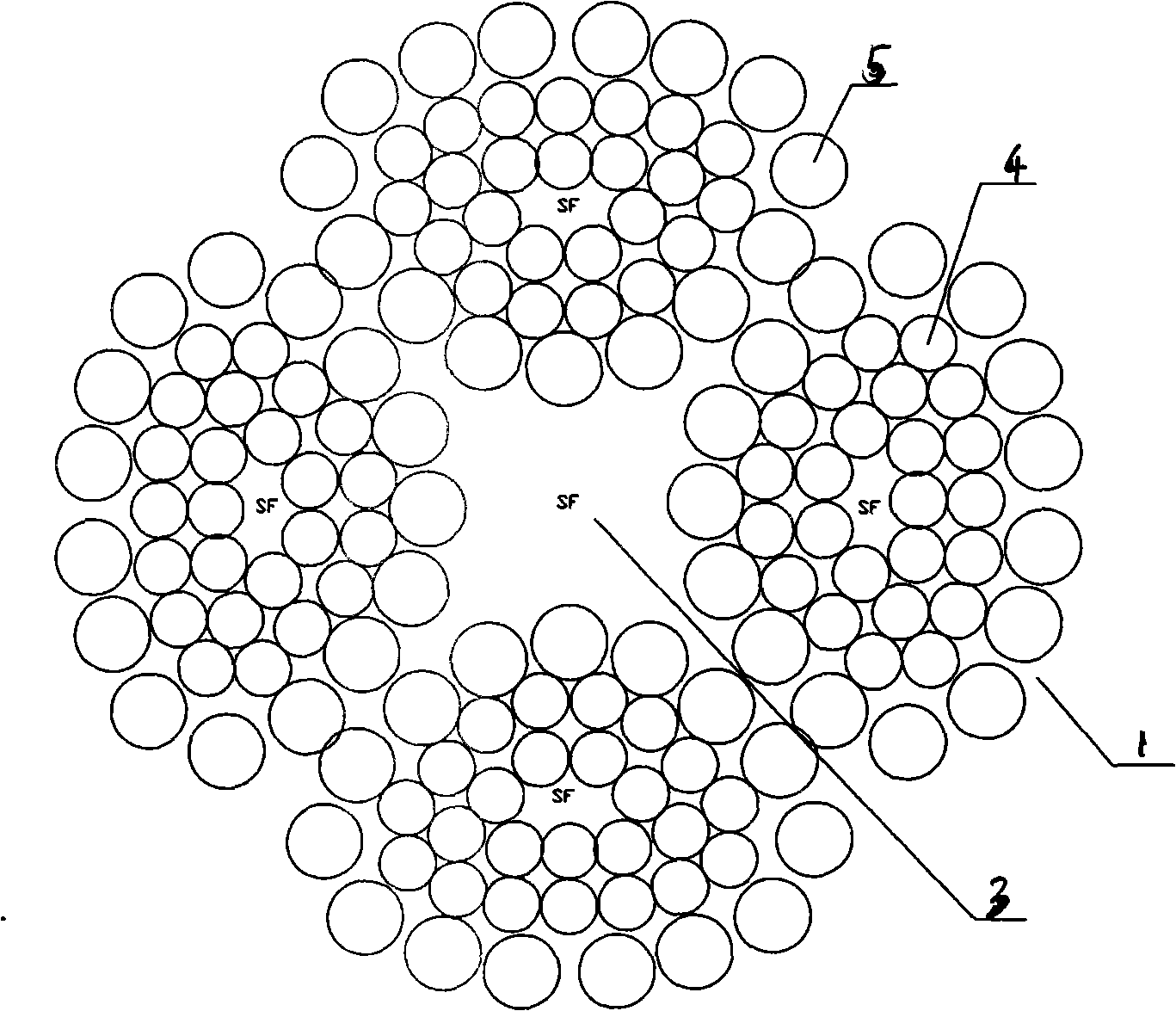

The invention discloses an ultrahigh strength steel wire rope and a wire drawing method thereof. The ultrahigh strength steel wire rope has a structure of 6*19W+21-phi 13.2mm. The ultrahigh strength steel wire rope comprises a core strand and edge strands. Each one of the core strand and edge strands orderly comprises central steel wires, inner layer steel wires and outer layer wires from inside to outside. The core strand has a steel strand structure comprising three central steel wires, six inner layer steel wires and 12 outer steel wires. The edge strand has a steel strand structure comprising one central steel wire, six inner layer steel wires and 12 outer steel wires. Each one of the central steel wire, inner layer steel wires and outer steel wires of the core strand and edge strands is prepared from a ultrahigh strength steel wire with the diameter of 2.60-2.80mm and a zinc layer with weight of 150-200g / m<2> on the surface of the steel wire by drawing. The wire drawing method simplifies a wire drawing process, steel wires of the core strand and edge strands have small diameter difference and under load, steel wire contact stress is reduced. The wire drawing method easily controls uniformity of zinc coating layer weight. The ultrahigh strength steel wire rope has a large density coefficient, a large breaking force and a long service life.

Owner:济宁长龙钢丝绳有限公司

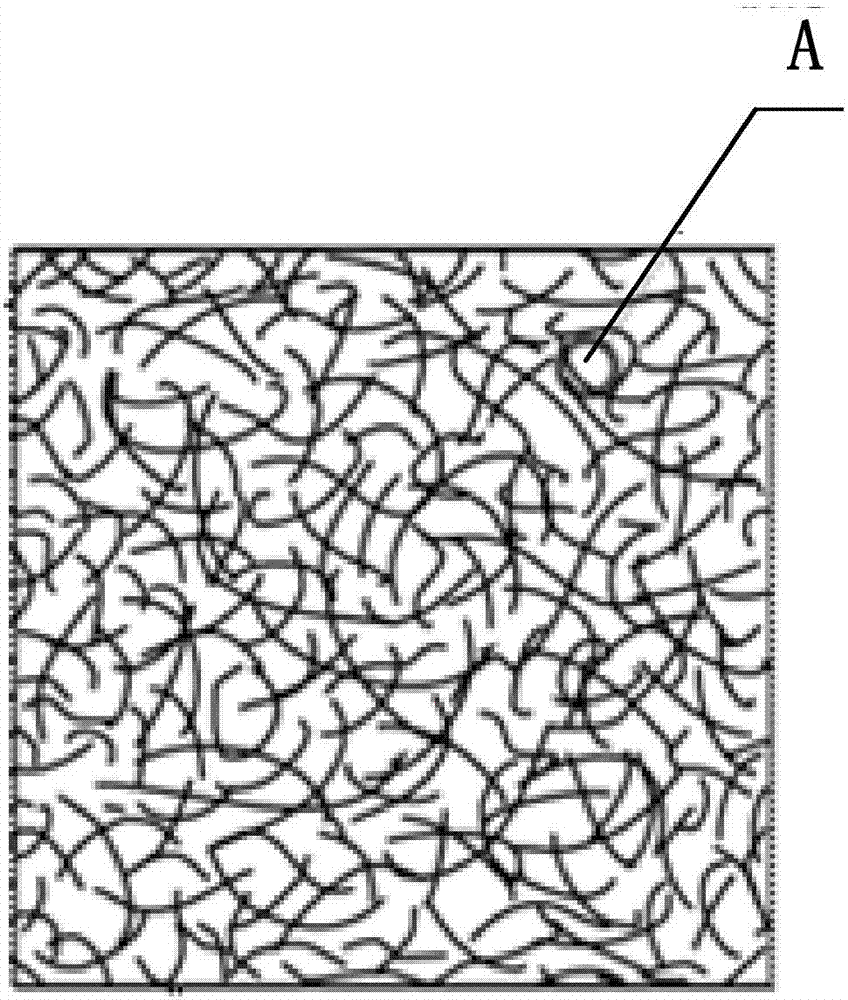

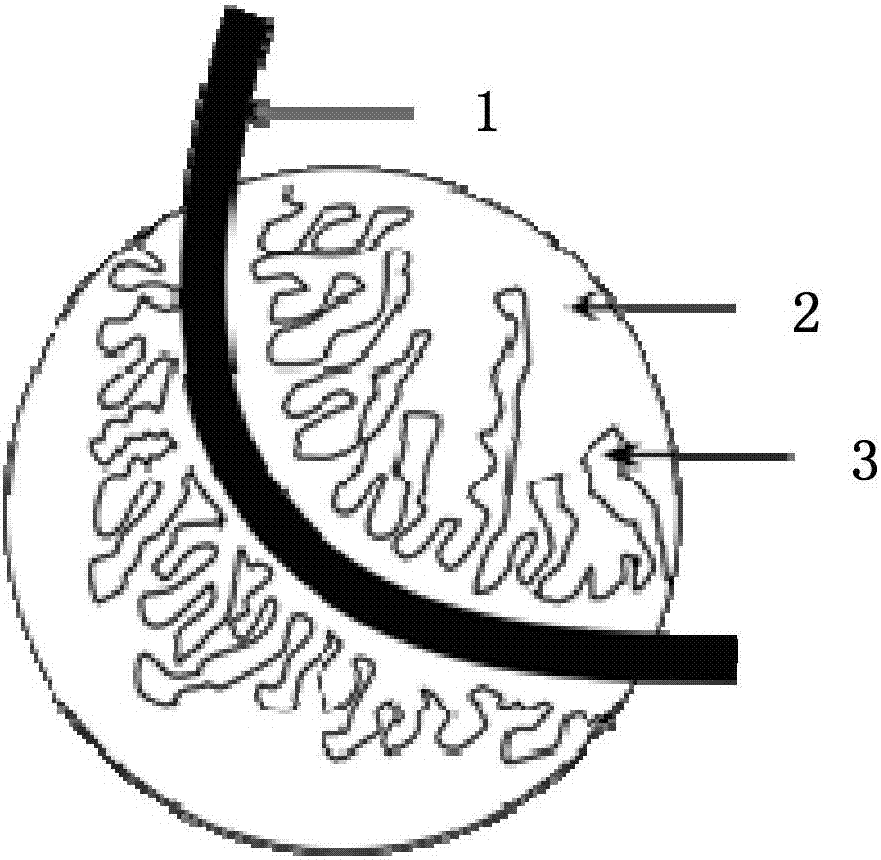

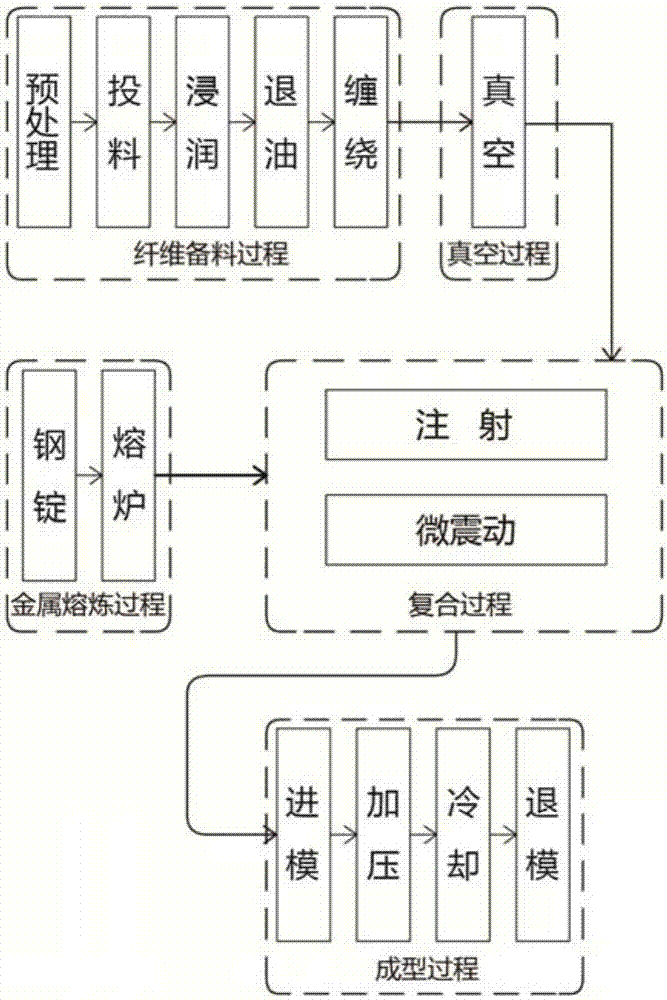

Steel-based carbon fibre composite material and preparation method thereof

ActiveCN107022724AEasy to prepareThe preparation method is reasonableAdhesiveUltimate tensile strength

The invention relates to a steel-based carbon fibre composite material and a preparation method thereof. The steel-based carbon fibre composite material comprises a plurality of bent carbon fibres which intertwine one another, a steel-based material and an adhesive which is adhered to the surface of the carbon fibres, wherein the carbon fibres, the adhesive and the steel-based material are formed by connecting through chemical bonds; a coral-like interface is formed between the adhesive which is adhered to the surfaces of the carbon fibres and the steel-based material through the chemical bonds; the preparation method for the steel-based carbon fibre composite material comprises the following steps: infiltrating the carbon fibres by utilizing the liquid adhesive; intertwining the carbon fibres after excessive adhesive is extruded away so that three-dimensional structural sponge-shaped carbon fibres which are adhered with the adhesive are formed; compounding the carbon fibres with the steel-base material after vacuumizing treatment is performed; finally, placing the composite material into a mould, pressurizing, cooling and moulding to obtain the steel-based carbon fibre composite material which is connected through the chemical bonds. The composite material prepared by the preparation method is far beyond the upper modulus limit of various types of conventional steel substrate materials; the rigidity, the tensile strength, the breaking power and the shearing strength are greatly improved.

Owner:靳普

Chain connecting link

InactiveCN101421538AImprove carrying capacitySimple structureChain fasteningsLongitudinal planeEngineering

The invention relates to a chain connecting link, which has two link brackets (4, 5) coupled via their limbs (6, 9), and a bar (14a-14c) that is inserted transversely between the limbs (6, 9) of the link brackets (4, 5). One limb (6) of each link bracket (4, 5) comprises a neck section (7) and a journal (8) thicker than the neck section, and a neck recess (10) and a journal recess (11) are provided in a matching fashion at the other limb (9) of the link bracket (4, 5). According to the invention, conically configured flank surfaces (12) with respect to the vertical central longitudinal plane (MLE) are provided at each journal (8) and at each journal recess (11).

Owner:THIELE GMBH & CO KG

Manufacture technology of steel wire cut pill

The invention discloses a technology for manufacturing a steel wire cut pill, which takes a waste steel wire rope as the manufacture raw material. The process flow comprises the following steps of: breaking the rope, breaking the strand, cutting the pill, decontaminating, derusting and screening. The technology can manufacture the steel wire cut pill with 0.2-4mm, has good performance and cleaning effect, is difficult to crush the pill, and has small consumption level and long service life. Meanwhile, the waste steel wire rope used as the raw material is the industrial waste material, so that the material source is abundant, the production cost is low, and the environment pollution can be reduced. Furthermore, the decontaminating and derusting method of the steel wire cut pill comprises the step of adding saw timber powder in a stirrer to abundantly mix and stir, thereby effectively removing the greasy dirt, the rust stain and the foreign matter on the surface with the porous absorption capability and the surface scrubbing capability of the saw timber powder, reducing the problems of high cost, water waste, uncleanness and environment pollution caused by using the conventional steel wire cut pill cleaning agent, and having prominent technical benefit, economic benefit and environmental benefit.

Owner:GUIZHOU UNIV

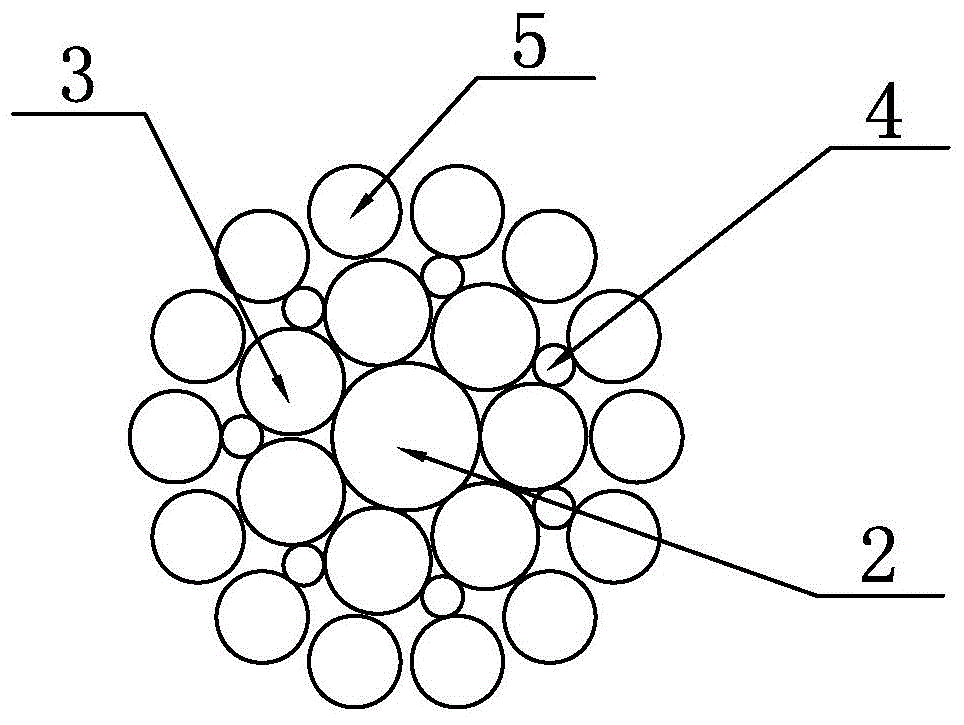

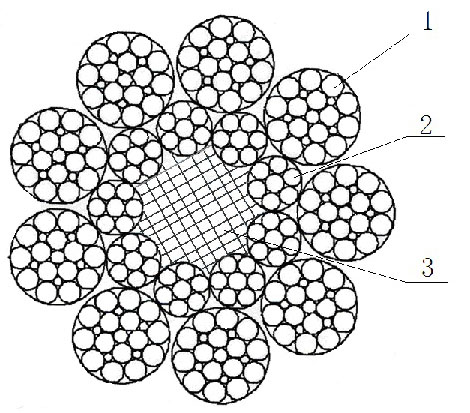

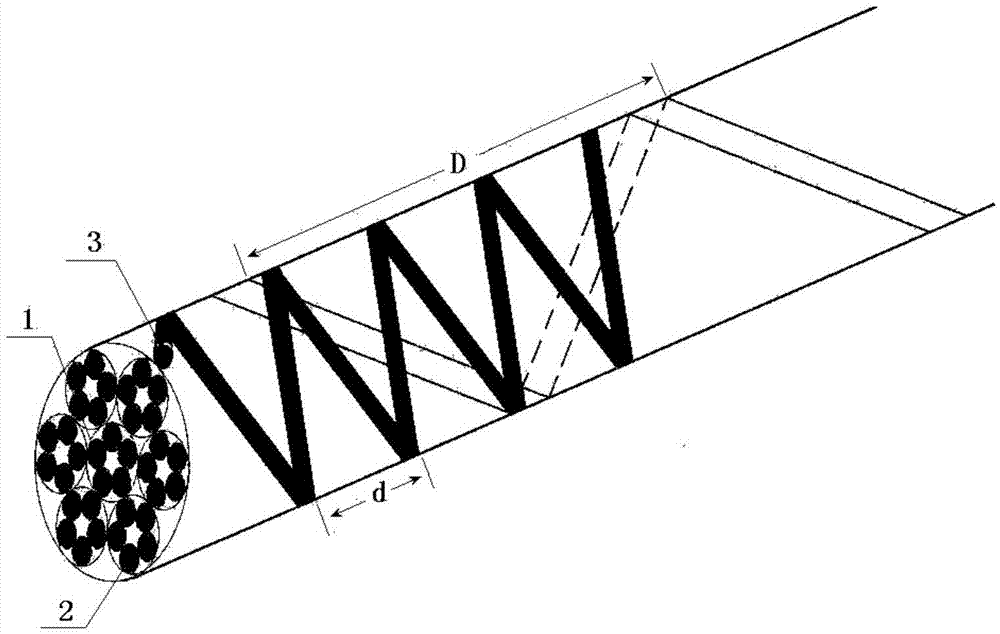

Parallel-laid steel wire rope for container equipment and manufacturing method thereof

The invention discloses a parallel twisted steel wire rope used for a container device and a manufacture method thereof. The steel wire rope comprises a rope core, wherein six strands of first outer-layer strands are arranged around the rope core, and the multiple of the lay length of the steel wire rope is 6.0-6.5 times. According to the structure and the diameter of the steel wire rope, steel wire breaking force summation and requirements on the value of gaps mutually between the twisted steel wires, the diameter of a finished product steel wire used in the steel wire rope is calculated according to the triangular geometry relationship formula; the spiral angle and the twisted circle of each layer of steel wires are calculated by the lay length; the proportional relation among different layers of steel wires can be deducted; the diameter of the raw material steel wire is calculated; a 65# wire rod of which the diameter is 6.5mm is processed and is drawn into the raw material steel wire; the raw material steel wire is drawn into the finished product steel wire after being subjected to heat treatment; and the finished product steel wire is twisted into the parallel twisted steel wire rope. The position of each steel wire in the steel wire rope is on the peak base of an adjacent steel wire on a lower layer, the position is very stable, the phenomena of abrading, breaking wires and breaking strands have small possibility of happening, and the service life is prolonged.

Owner:甘肃新实创科技有限公司

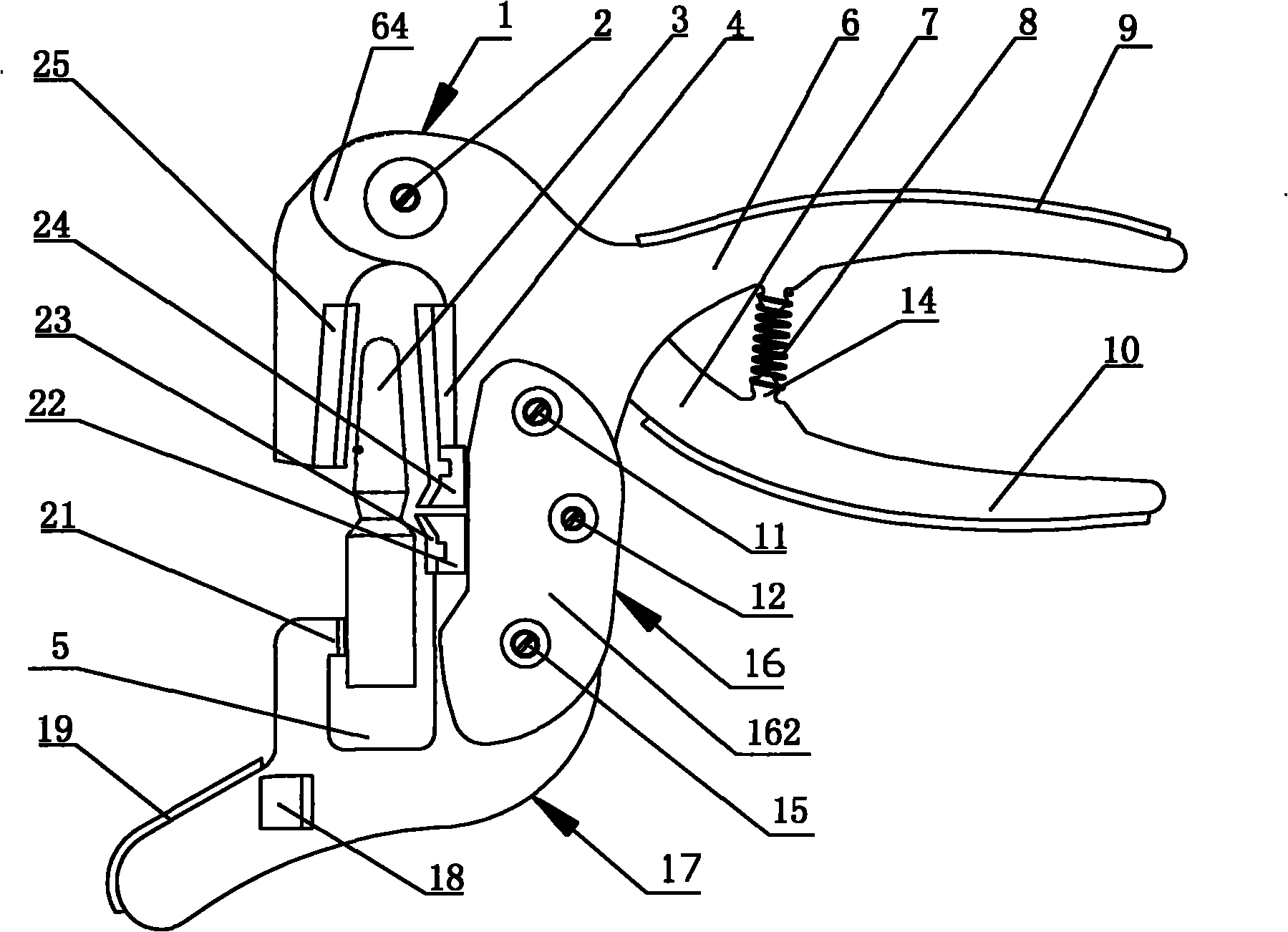

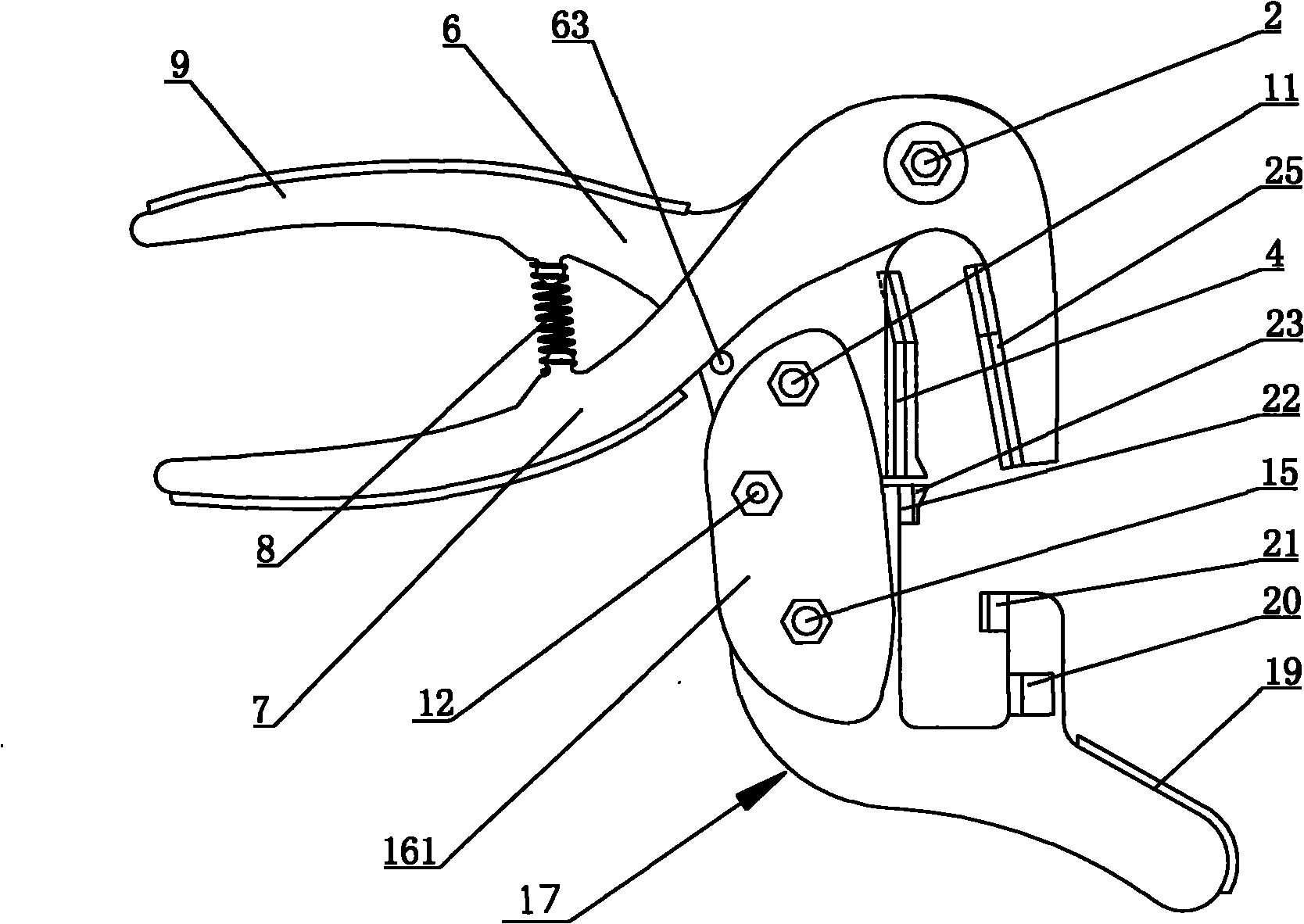

Ampoule splitter

InactiveCN101973505AHigh breaking forceGuaranteed against damageOpening closed containersBottle/container closureEngineeringBottle neck

The invention discloses an ampoule splitter which is a manual-operation type or full-automatic type ampoule splitter. The ampoule splitter comprises a bottle bubble clamp, a positioning frame and a bottle body frame and is characterized in that the upper part of the positioning frame is provided with the bottle bubble clamp used for clamping an ampoule bottle bubble and splitting the ampoule bottle bubble through a lever, and the bottle bubble clamp is formed by crosswise and movably connecting an upper clamp body and a lower clamp body through a clamp pin shaft. The lower part of the positioning frame is provided with the bottle body frame used for positioning and clamping the ampoule bottle body, and the bottle body frame comprise a connecting plate, a bottle neck lower force arm and a bottle body force arm. The positioning frame is formed by assembling the bottle bubble clamp and the bottle body frame together through double shafts in a linkage way, and the bottle bubble clamp is movably connected with the bottle body frame through the positioning frame. By using the ampoule splitter of the invention, fine glass fragments cannot be generated, the phenomena of hands injuring and medicinal liquid spilling are prevented, the table type or full-automatic type ampoule splitter can be used for splitting two or three ampoule bottles at the same time. The ampoule splitter has the advantages of convenient and rapid operation and meets the professional requirements of medical treatment.

Owner:向永川

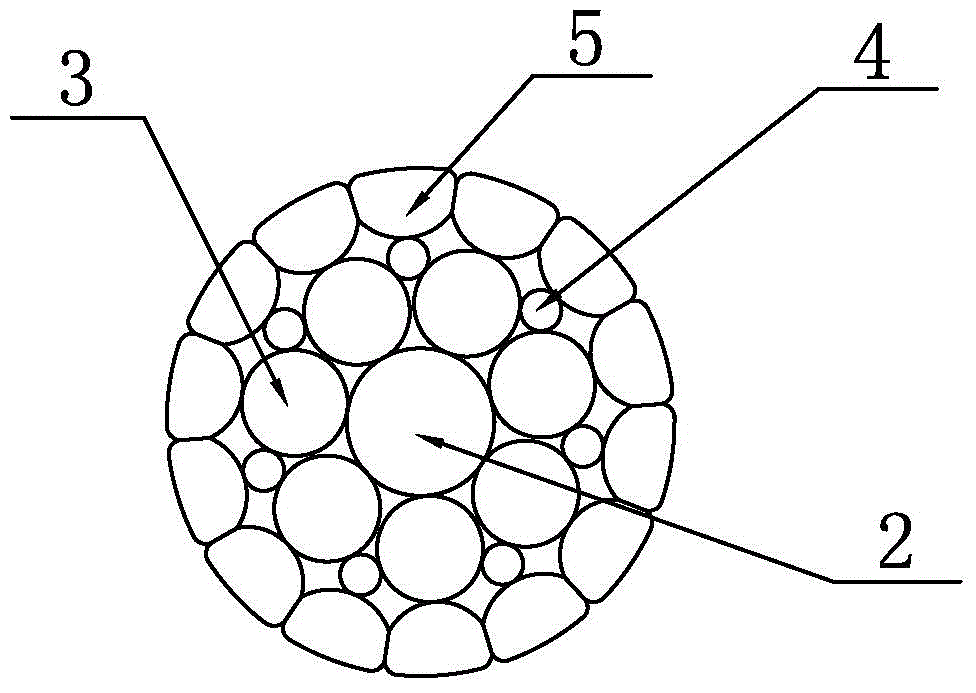

Novel double-compacted steel wire rope and production technology thereof

The invention relates to a novel double-compacted steel wire rope and a production technology thereof, and aims to provide a steel wire rope which is stable in physical property and is compacted tightly as well as a production technology of the steel wire rope. All pickled and phosphatized steel wires are drawn for the first time, then annealed, dried and drawn again after dried, and various finished steel wire products are formed. Third center steel wires, inner-layer steel wires, filling steel wires and third outer-layer steel wires are twisted and then rolled, steel wire rope first outer-layer strands are produced and twisted on the outer side of a rope core in a wrapping manner, a steel wire rope is twisted, the twisted steel wire rope is forged, and the forged steel wire rope is warehoused. The section area of each steel wire rope first outer-layer strand after rolling is 8%-10% smaller than that before rolling, and the section area of the steel wire rope after forging is 10%-13% smaller than that before forging. The rope core adopts 7*7 independent steel cores.

Owner:天津市新天钢钢线钢缆有限公司

Composite core half-hard aluminum conductor and manufacturing method thereof

ActiveCN105869786AHigh breaking forceImprove delivery capacityNon-insulated conductorsConductive materialHardnessThermal treatment

The invention discloses a composite core half-hard aluminum conductor and a manufacturing method thereof. The manufacturing method comprises the following steps: I, processing so as to manufacture an aluminum rod; II, drawing the aluminum rod into hard aluminum wires; III, performing high-temperature thermal treatment on the hard aluminum wires so as to obtain half-hard aluminum wires; IV, concentrically twisting a plurality of half-hard aluminum wires and carbon fiber composite cores, thereby obtaining the finished carbon fiber composite core half-hard aluminum conductor. As the composite cores and the intermediate state aluminum wires are combined, and a specific process is provided, the produced carbon fiber composite core half-hard aluminum conductor has the characteristics of large pulling strength, large draw-weight ratio, good conductivity, relatively large surface hardness, low probability of scratching in laying, small sagging and the like, and the line security can be greatly improved.

Owner:FAR EAST CABLE +2

High-nitrogen nickel-free super double-phase stainless steel wire rope for high-speed elevator and manufacturing method thereof

InactiveCN102444041AIncrease the cross-sectional area of the metalIncrease contact areaRope making machinesElevatorsDouble phaseNitrogen

The invention provides a high-nitrogen nickel-free super double-phase stainless steel wire rope for a high-speed elevator and a manufacturing method thereof. The high-nitrogen nickel-free super double-phase stainless steel wire rope comprises an outer-layer strand, an inner-layer strand and a central strand, wherein the outer-layer strand and the inner-layer strand are made of high-nitrogen nickel-free super double-phase stainless steel materials, and the central strand is made of polypropylene fibre materials; and protective grease is filled between the central strand and the inner-layer strand or between the central strand and the outer-layer strand and between the inner-layer strand and the outer-layer strand. According to the invention, the cost of a product is reduced, the contact stress between the stainless steel wire rope and a wheel groove is reduced, the strength is high, the wear resistance and the safety are greatly improved, and the service life is prolonged.

Owner:江苏亚盛金属制品有限公司

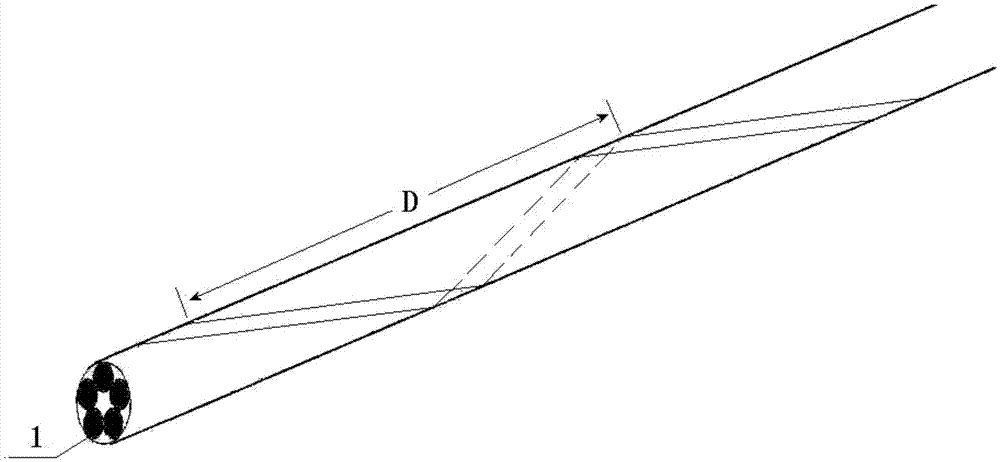

Preparation process of Ti alloy wire rope for marine engineering

InactiveCN110387486AIntensity exceedsStrong corrosion resistanceTextile cablesCorrosion resistantWire rope

The invention provides a preparation process of a Ti alloy wire rope for marine engineering. The preparation process comprises the following steps: step 1, electing sponge Ti, sponge Zr, Al shots, anAl-Mo intermediate alloy and an Al-Nb intermediate alloy according to the composition amount, and uniformly mixing the above raw materials; step 2, preparing an electrode by extruding the mixed materials obtained in step 1, cutting off a riser after smelting, and preparing a polished ingot by the adoption of machining; step 3, carrying out wire material preparation by subjecting the polished ingotprepared in step 2 to two stages: hot drawing of a coarse wire and hot drawing at room temperature, so as to obtain alloy fine wires; and step 4, stranding and braiding the alloy fine wires obtainedin step 3 in the form of point contact, so as to obtain the Ti alloy wire rope finally. According to the preparation process provided by the invention, the Ti alloy wire rope is prepared by adopting the Ti alloy material; the corrosion-resistance performance of the Ti alloy wire rope is relatively strong; compared with a steel wire rope, the Ti alloy wire rope has the advantages that the corrosionproblem is solved and the equipment running safety is guaranteed; meanwhile, the maintenance and replacement cost is greatly reduced; and the Ti alloy wire rope is widely applicable to marine engineering and other corrosion environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

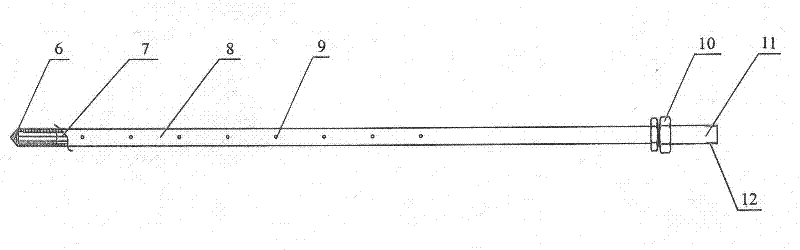

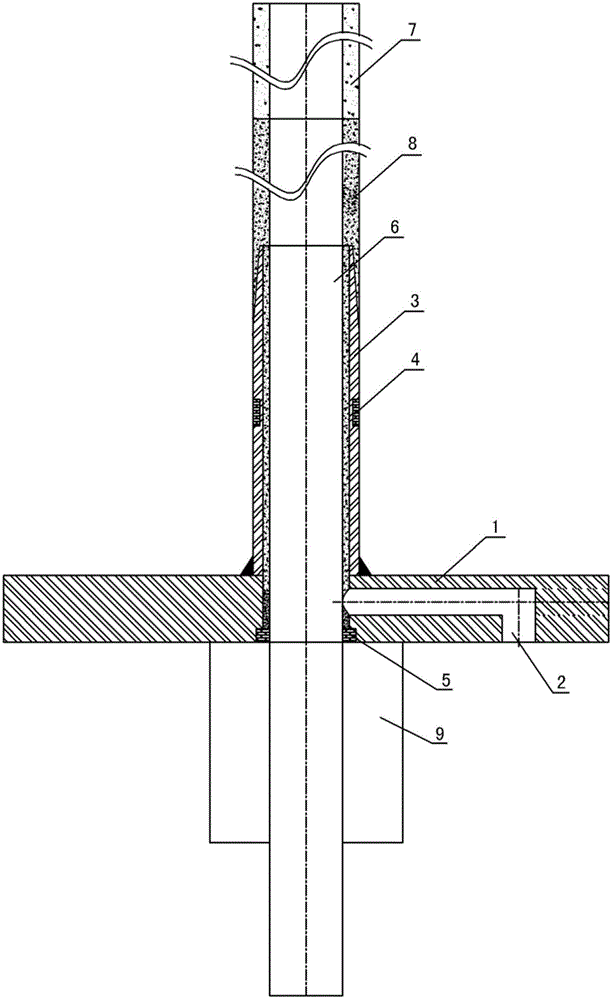

Hole wall grouting anchor cable

InactiveCN102748048AImprove support strength or breaking forceImprove anchor strengthAnchoring boltsDrill holeGrout

The invention discloses a hole wall grouting anchor cable which is characterized in that an L-shaped grouting hole is formed in an anchor cable supporting plate and on the periphery of a steel strand mounting hole, wherein one end of the grouting hole is communicated with an anchor cable hole in the anchor cable supporting plate and is communicated with an annular grouting cavity between a steel strand and a hole drilling wall through the anchor cable hole, and the other end of the grouting hole is located on the surface of the anchor cable supporting plate and is connected with an external grouting pipe; a hole pipe located in a drilled hole is connected with the anchor cable supporting plate; and a groove is turned on the periphery of the hole pipe and is internally provided with a hole wall sealing ring. The hole wall grouting anchor cable disclosed by the invention can effectively improve the grout anchoring strength of an anchor cable and reduces the manufacturing cost of the anchor cable.

Owner:ANHUI PROVINCE COAL SCI RES INST

Production method and plus material of high strength and double face polyester peach skin cotton knitting fabric

InactiveCN104032462ASoft touchHigh strengthWeft knittingHeating/cooling textile fabricsPolyesterDyeing

Owner:NINGBO DAQIAN TEXTILE

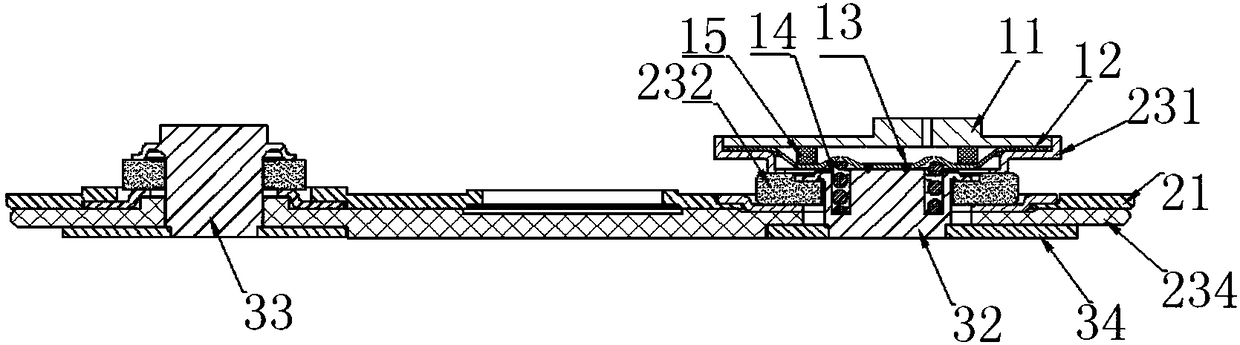

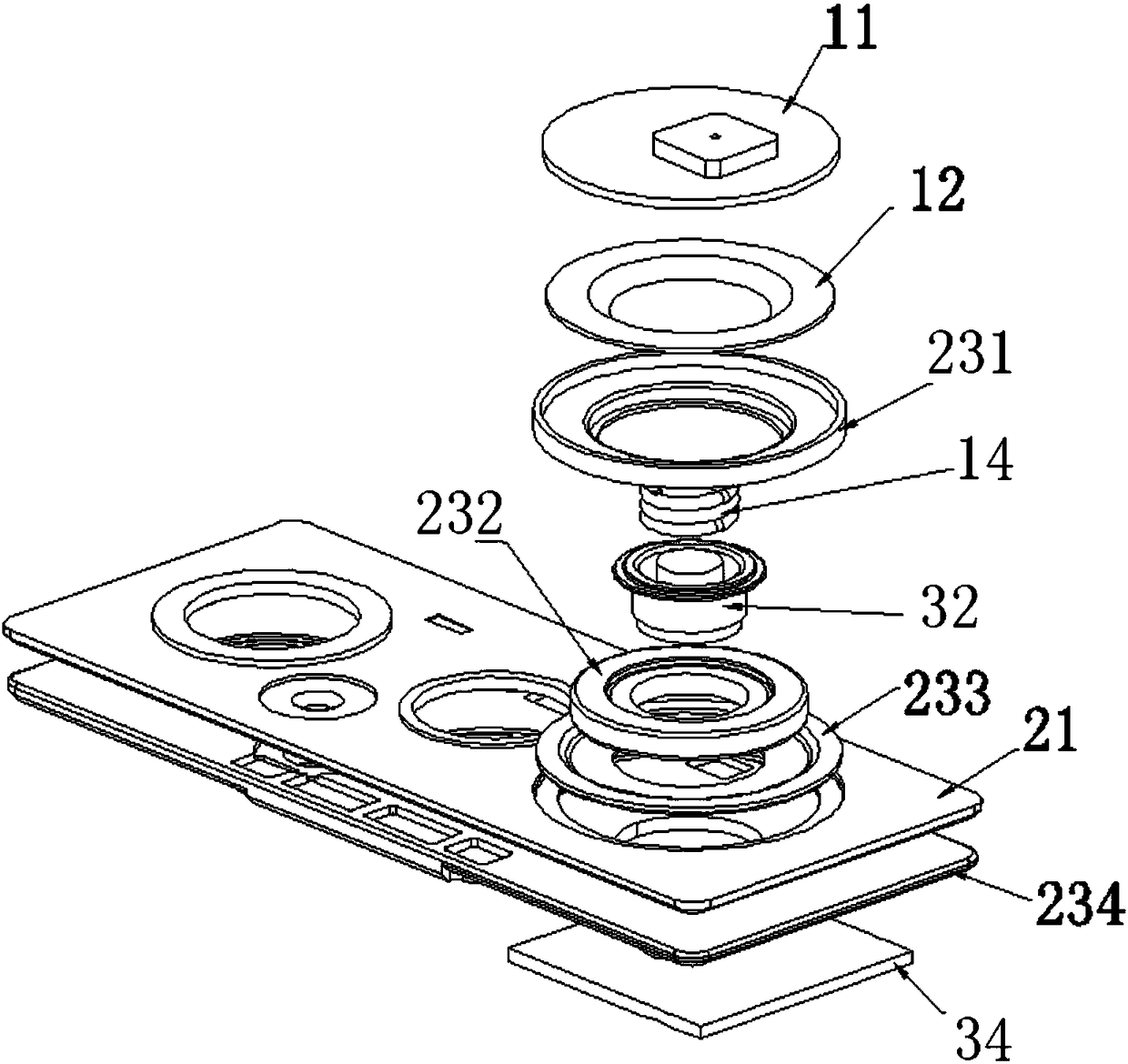

Battery electrode assembly, cover plate assembly and battery

ActiveCN108511670AImprove flow capacityImprove performanceCell component detailsBatteriesTemperature controlElectricity

The invention provides a battery electrode assembly, a cover plate assembly and a battery. A temperature memory elastic element is arranged between an electrode terminal and a conducting strip and canelastically extend and act on the conducting strip so as to break electrical connection between the electrode terminal and a cap when the internal temperature of a battery is higher than a preset temperature control threshold value. When abnormal conditions such as collision, extrusion, overcharging and internal short circuit occur inside the battery, the internal temperature of the battery rises, and when the temperature reaches 60 to 80 DEG C, the temperature memory elastic member deforms and is elongated and thus pushes the conducting strip to break the connection between the electrode terminal and the conducting strip, thereby realizing the disconnection of an internal circuit of the battery. The trigger condition for battery protection via the battery electrode assembly is temperature instead of pressure, and the tensile force of the conducting strip is improved via the temperature memory elastic member; and on the premise of protection of the battery, the thickness of the conducting strip is ensured, the overcurrent capability of the battery is improved, and the performance of the battery is optimized.

Owner:BYD CO LTD

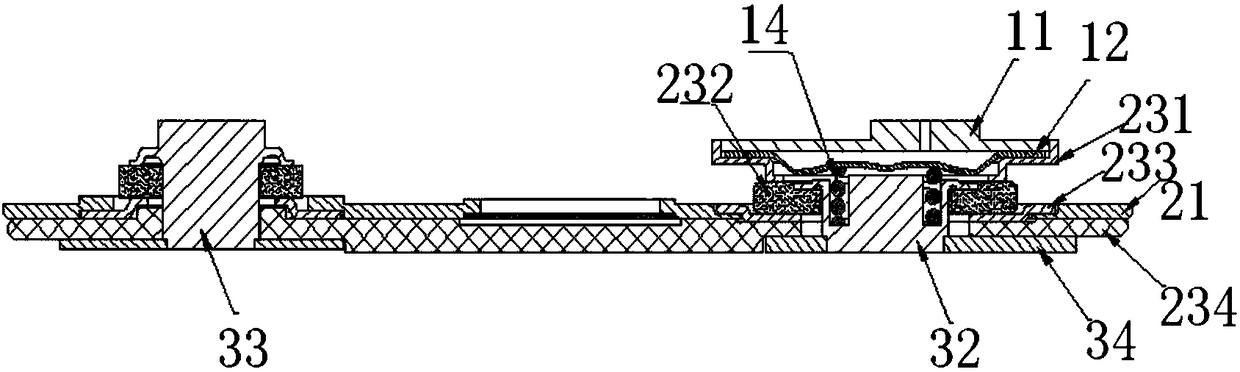

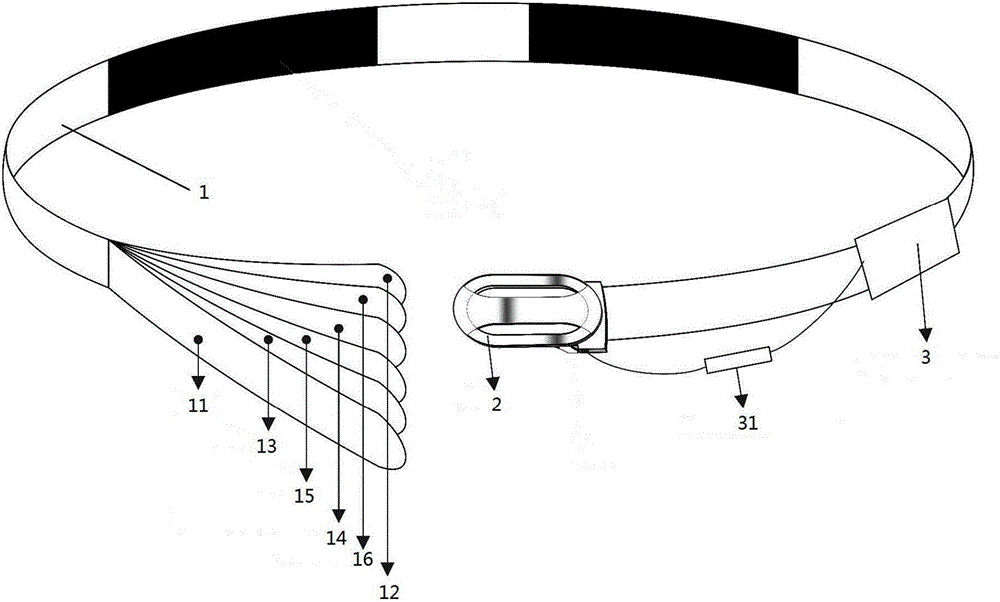

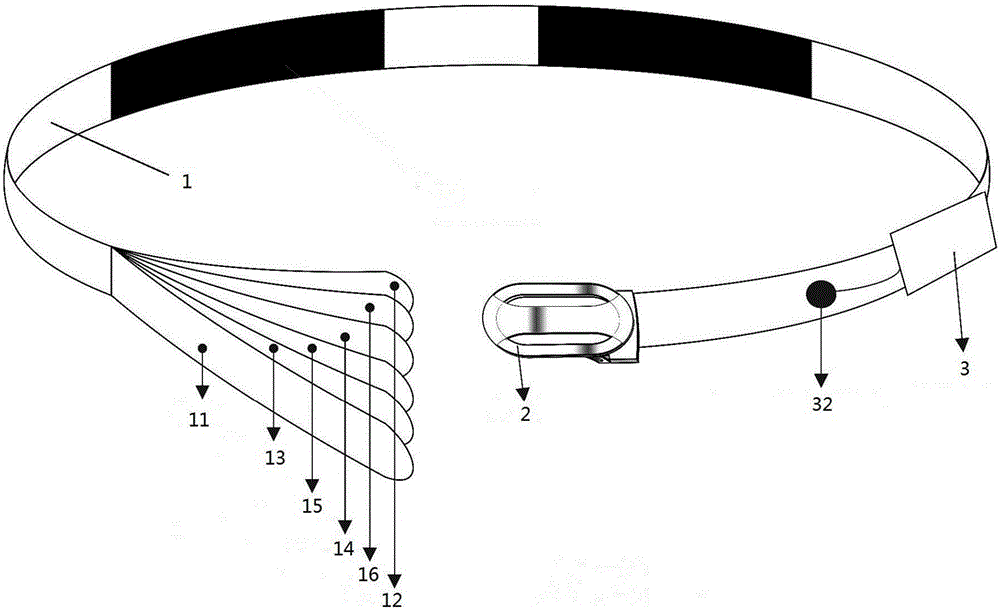

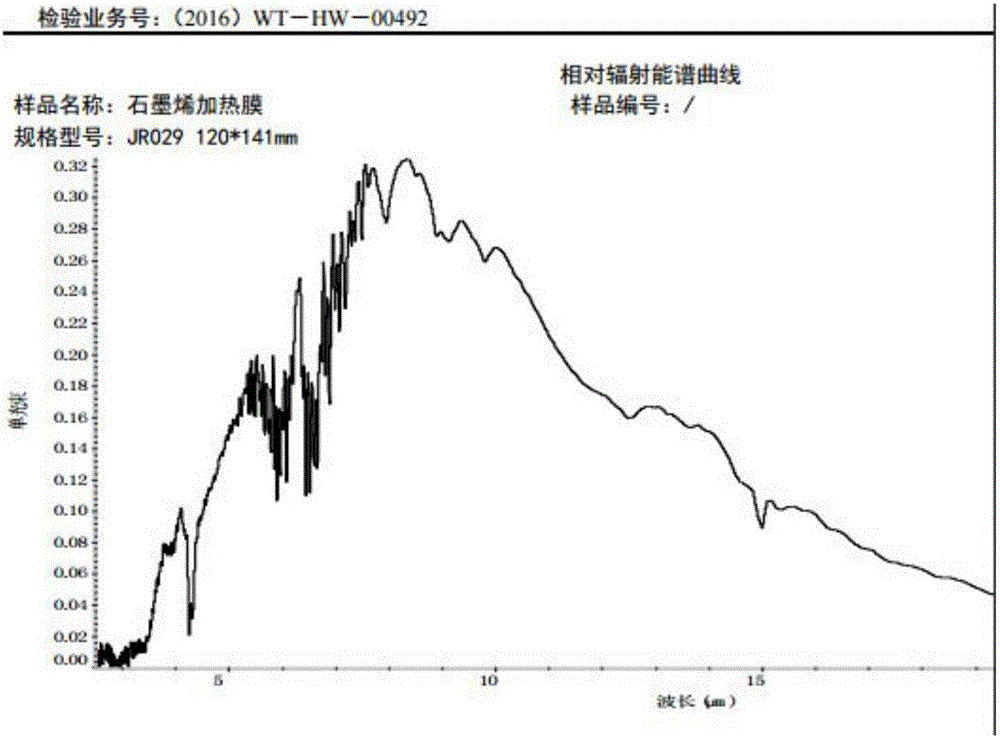

Intelligent graphene waistband suitable for daily life and manufacturing process of intelligent graphene waistband

ActiveCN106562497AAvoid heavyHigh breaking forceGarment beltsTherapeutic coolingHeating filmAcupuncture point

The invention provides an intelligent graphene waistband suitable for daily life and a manufacturing process of the intelligent graphene waistband. The intelligent graphene waistband comprises a waistband body and a belt buckle which is connected to one end of the waistband body, wherein the waistband body comprises a waistband fabric which is arranged at the outer side and a backing material which is arranged at the inner side; an interlayer is arranged between the waistband fabric and the backing material; a flexible circuit and a graphene heating film are arranged between the interlayer and the backing material; the graphene heating film is electrically connected to a portable power supply which is hung on the waistband body by virtue of the circuit; and the graphene heating film can generate heat through power supplied by the portable power supply. According to the intelligent graphene waistband suitable for daily life provided by the invention, heat, which is generated from the two-dimensional graphene heating film, can act on the waist and acupuncture points of a human body, so that effects of protecting the human body against cold and conducting physiotherapy are achieved; in addition, the problem of conventional health care physiotherapy waistbands which are thick is avoided; and breaking power of the waistband body is enhanced, and the strength and the practicability of the waistband body are improved.

Owner:GUANGZHOU YIKESHU NETWORK TECH CO LTD

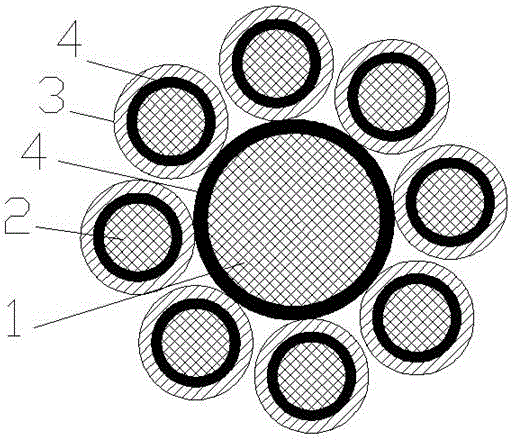

Compound rope with eight steel cores

The invention discloses a compound rope with eight steel cores. The compound rope comprises a central strand and eight peripheral strands surrounding the central strand, wherein the steel core, which is formed by twisting multiple strands of stainless steel wires, is arranged as the central strand; the peripheral strands are formed by twisting multiple strands of chemical fiber ropes; the eight peripheral strands are mutually weaved and coated on the surface of the central strand; the stainless steel wire twisted layers are coated on the outer layers of the eight peripheral strands; the stainless steel wire twisted layers are formed by twisting stainless steel wires. According to the invention, a method of covering the steel cores with chemical fibers is adopted; the compound rope is characterized by light specific gravity, high breaking force and light weight; two stainless steel wire twisted layers are also covered on the outer layers of the peripheral strands, so that the compound rope is suitable for wearable environment; the inner steel cores can cause the elongation to be only 2%-3%; the safety factor is high and the service life is long; the compound rope has the advantages of high flexibility and corrosion resistance of pure chemical fiber rope and the advantages of corrosion resistance and scraping and breaking resistance of the steel wire rope.

Owner:YANGZHOU XINGLUN ROPE CABLE CO LTD

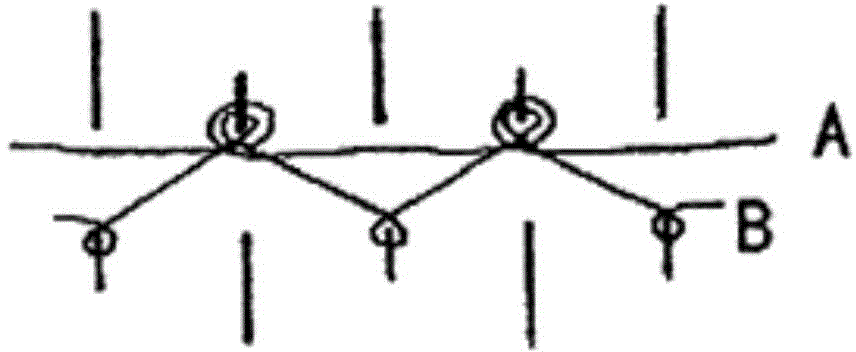

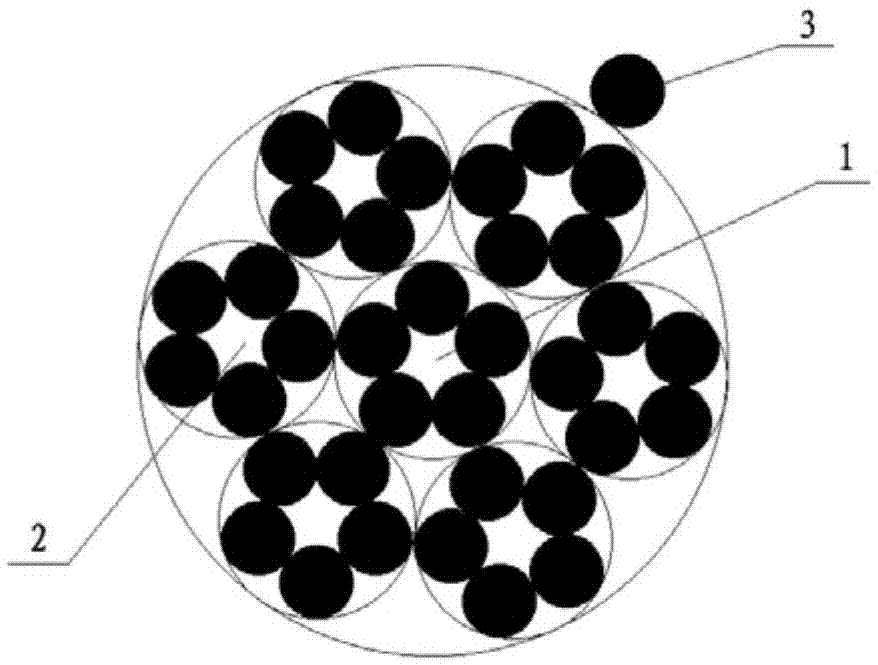

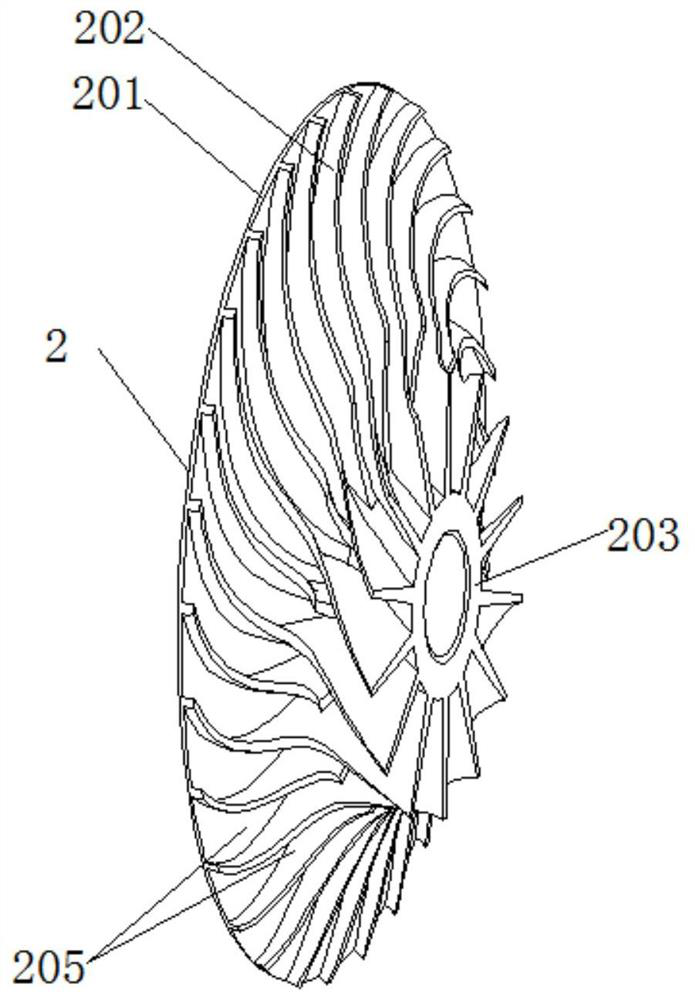

Seven-strand steel cord for engineering tire

InactiveCN105442362AHigh breaking forceImprove carrying capacityTextile cablesUltimate tensile strengthWear resistance

The invention discloses a seven-strand steel cord for an engineering tire. The seven-strand steel cord is formed by weaving and twisting steel wires and comprises a core wire strand and outer layer strands, the seven-strand steel cord is formed by weaving and twisting seven strands of steel wires and then adding a winding steel wire, and the twisting direction of the winding steel wire is the S twisting direction. After the seven strands of steel wires are twisted, the structure that the six outer layer strands are evenly arrayed around the core wire strand, and the twisting direction is the Z twisting direction, and the section is round. The core wire strand and the outer layer strands are each formed by weaving and twisting five steel wires, and the twisting directions are each the S twisting direction. The steel cord is high in strength, resistant to puncture and good in wear resistance, and while breaking force of the steel cord is improved, the proportion of the steel cord in the tire is reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

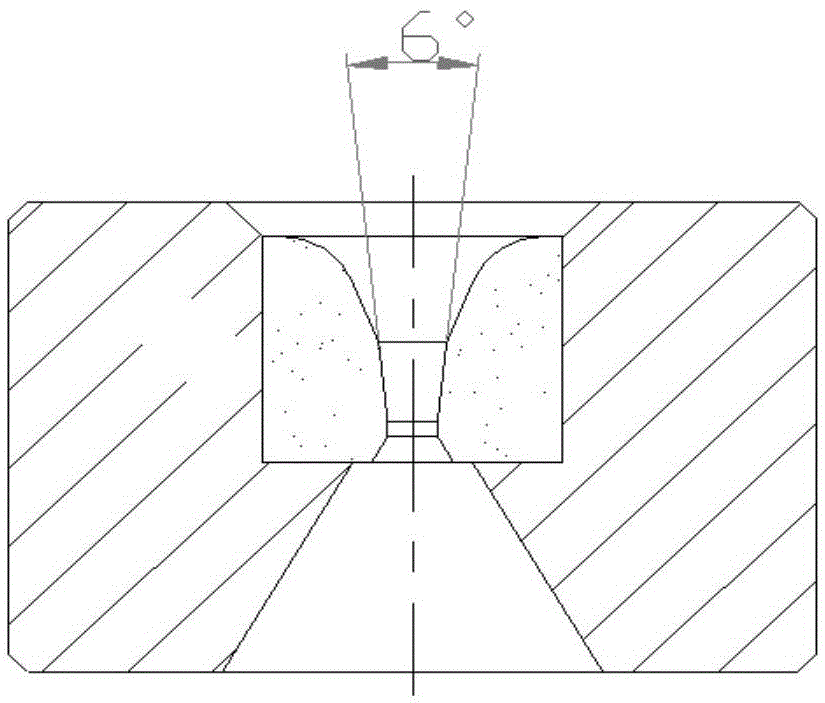

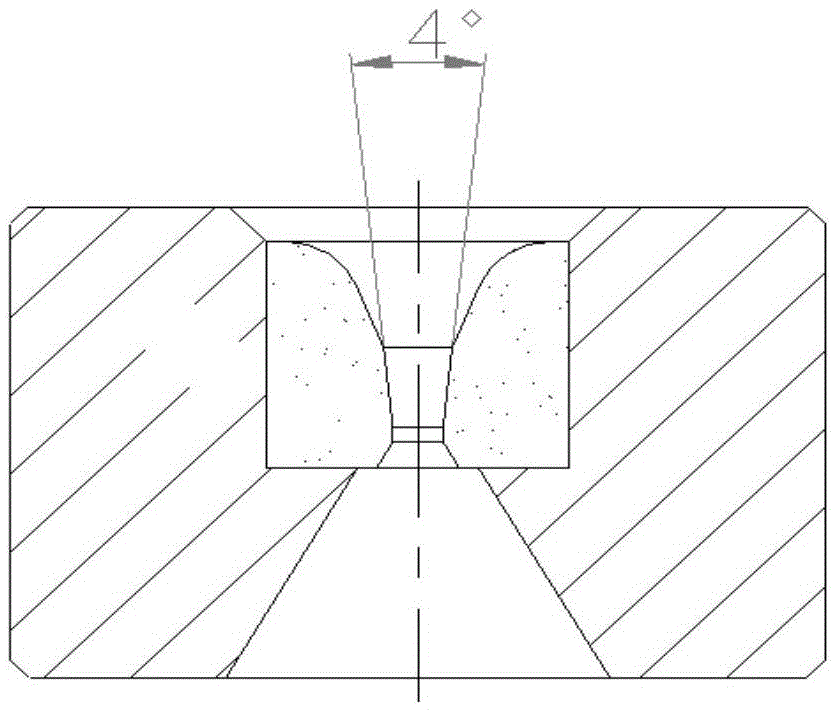

Pouring experiment method for overall breaking force of steel wire rope

InactiveCN101750249AHigh breaking forceSimple designMaterial strength using tensile/compressive forcesEpoxyPull force

The invention relates to a pouring experiment method for overall breaking force of a steel wire rope. In the method, an epoxy resin pouring method is adopted for a tensile test; and raw materials adopted by the method comprise the following components according to parts by weight: 8-15 parts of epoxy resin, 0.2-0.6 part of ethidene diamine, 3-8 parts of DBP, 4-8 parts of quartz sand and 1-5 parts of talcum powder. Compared with the prior art, the method has the beneficial effect that a contrast experiment is carried out by steel wire ropes with five types of structures such as 6V*34+NF, 6V*37S+NF and the like as well as more than 30 specifications by two methods; resin pouring can improve the breaking force of the whole steel wire rope by 10% compared with alloy pouring; the test data of the method is closer to the real breaking force of the steel wire rope, which is more favourable for design of the steel wire rope and determination of technological parameters; and raw material cost is lower.

Owner:ANGANG STEEL WIRE ROPE

Easily-degradable anti-shrinkage polypropylene master batch and preparation method thereof

InactiveCN106674728AImprove high temperature resistanceImproves shrink resistanceFungiMicroorganism based processesPolypropyleneAntioxidant

The invention discloses an easily-degradable anti-shrinkage polypropylene master batch, wherein polypropylene serves as a base material, the types and the formula of the master batch are optimized, and a production process is improved. A complex antioxidant which contains a biologic antioxidant, modified nanocarbon which can obviously improve high temperature resistance, shrinkage resistance, relative tensile load, strength and toughness and elasticity modulus of the polypropylene master batch, calcium fruit fibers which can obviously improve shock resistance of the polypropylene master batch, are easily biodegradable and lower production cost, polyethylene / winter rye peptide complexes which can greatly improve low temperature resistance of the polypropylene master batch and bitter almond oil which can effectively improve lubricating property and oxidation resistance of the polypropylene master batch are scientifically compounded; the obtained compound has a synergistic effect with other processing aids; finally, the environment-friendly easily-degradable anti-shrinkage polypropylene master batch with good physical property is obtained.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

Steel wire rope for nacelle and manufacturing method thereof

The invention relates to a steel wire rope for a nacelle and a manufacturing method thereof. The steel wire rope is in a seale type structure, the external surface of the steel wire rope is in a sector shape, and the steel wire rope comprises four upper strands and one synthetic fiber core, wherein the four upper strands are symmetrically twisted on the synthetic fiber core, and the sector surface is outward. The preparation method comprises the following steps: firstly, twisting a light-gage steel wire on one synthetic fiber core to form an initial lower strand, and sequentially and symmetrically winding a light-gage steel wire and a heavy-gage steel wire in a seale type on the outer layer of the initial lower strand to form the upper strand; then twisting four upper strands on one synthetic fiber core into a rope to form the product, namely, the steel wire rope for the nacelle; and extruding steel wire rope for the nacelle into a sector shape by two groups of orthogonal sizing tools during rope twisting. The four steel wire ropes with different shapes provided by the steel wire rope for the nacelle and the manufacturing method thereof of the invention have good rotation-resisting performance and basically realize no rotation of the steel wire ropes, a sector strand has a large contact surface with a pulley and good wear resistance, and by tightening a deformed steel wire rope, the breaking force is improved by one level compared with a round strand steel wire rope at the same level.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

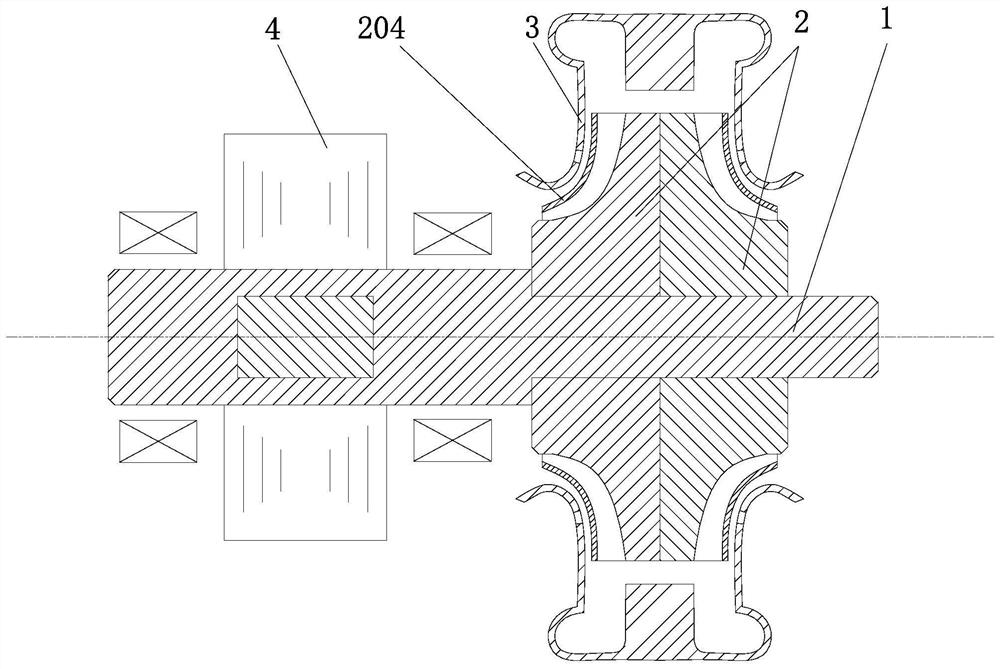

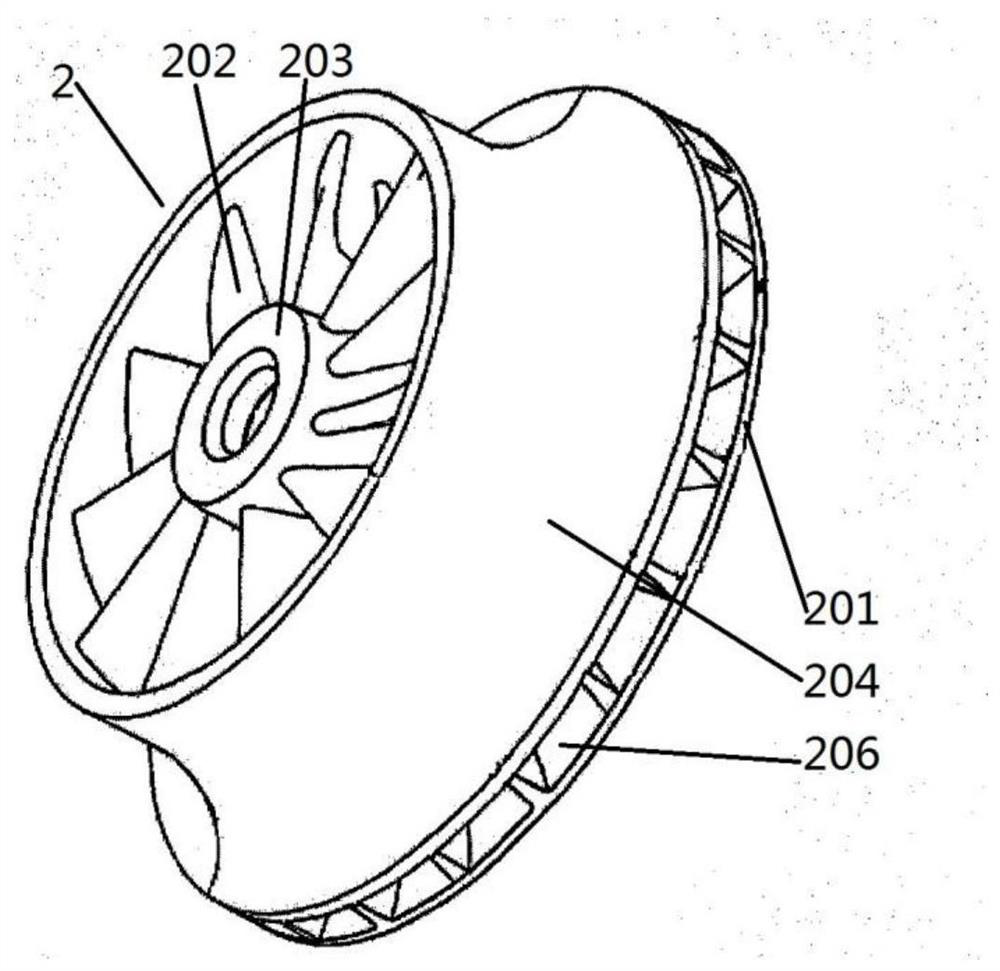

Back-to-back air compressor

PendingCN112503004AHigh strengthImprove machine efficiencyPump componentsPump installationsImpellerAir bearing

The invention discloses a back-to-back air compressor which comprises a rotating shaft. The rotating shaft is sleeved with an impeller set and a motor, the impeller set is covered with a stator, the impeller group comprises a pair of impellers, the air back surfaces of the pair of impellers are opposite to each other, are in contact with each other, and are mutually fixed into a whole or are integrally formed through casting, and furthermore, impellers are provided with front covers, and the front covers are in a circular truncated cone ring shape. The air inlet surfaces of the front covers are curved surfaces in smooth transition along the outline of a blade ridge line, and grooves matched with the end part of a blade are formed in the air back surfaces. Furthermore, one or more circles of air holes are evenly formed in the portion, right opposite to the impellers or the front covers, of the stator, air can be decomposed into axial airflow and radial airflow after entering the air holes, the impellers are suspended in the stator to stably rotate through the radial airflow, the impellers are pushed backwards through the axial airflow, and the stator is used as an air bearing and plays a role of a radial bearing and a thrust bearing at the same time. The back-to-back air compressor adopts a double-sided air inlet mode and has the advantages of being large in flow, small in size,capable of balancing axial force and the like.

Owner:刘慕华

High-nitrogen low-nickel super two-phase stainless steel

The invention provides high-nitrogen low-nickel super two-phase stainless steel, comprising the following components in percentage by weight: 24-26% of Cr, 14-20% of Mn, 2.0-4.0% of Mo, 0.30-0.55% of N, 0.01-0.03% of C, 0.05-0.2% of Ce or Y, 2-3.2% of Ni, less than or equal to 1.0% of Si, less than or equal to 0.01% of S, less than or equal to 0.02% of P, less than or equal to 0.01% of B and the balance of Fe. The high-nitrogen low-nickel super two-phase stainless steel has the characteristics of low manufacturing cost, high strength, high toughness, corrosion resistance and wearing resistance, can be widely applied in equipment of the manufacturing industries such as petroleum, chemical engineering, ship building, papermaking, food, medicines and the like and the fields such as environmental protection, aerospace, urban rail transit and the like, and products such as stainless steel corrosion-resistance alloy plates, pipes, steel wire ropes, casting and forging pieces and the like.

Owner:江苏亚盛金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com