Patents

Literature

191results about How to "Avoid heavy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

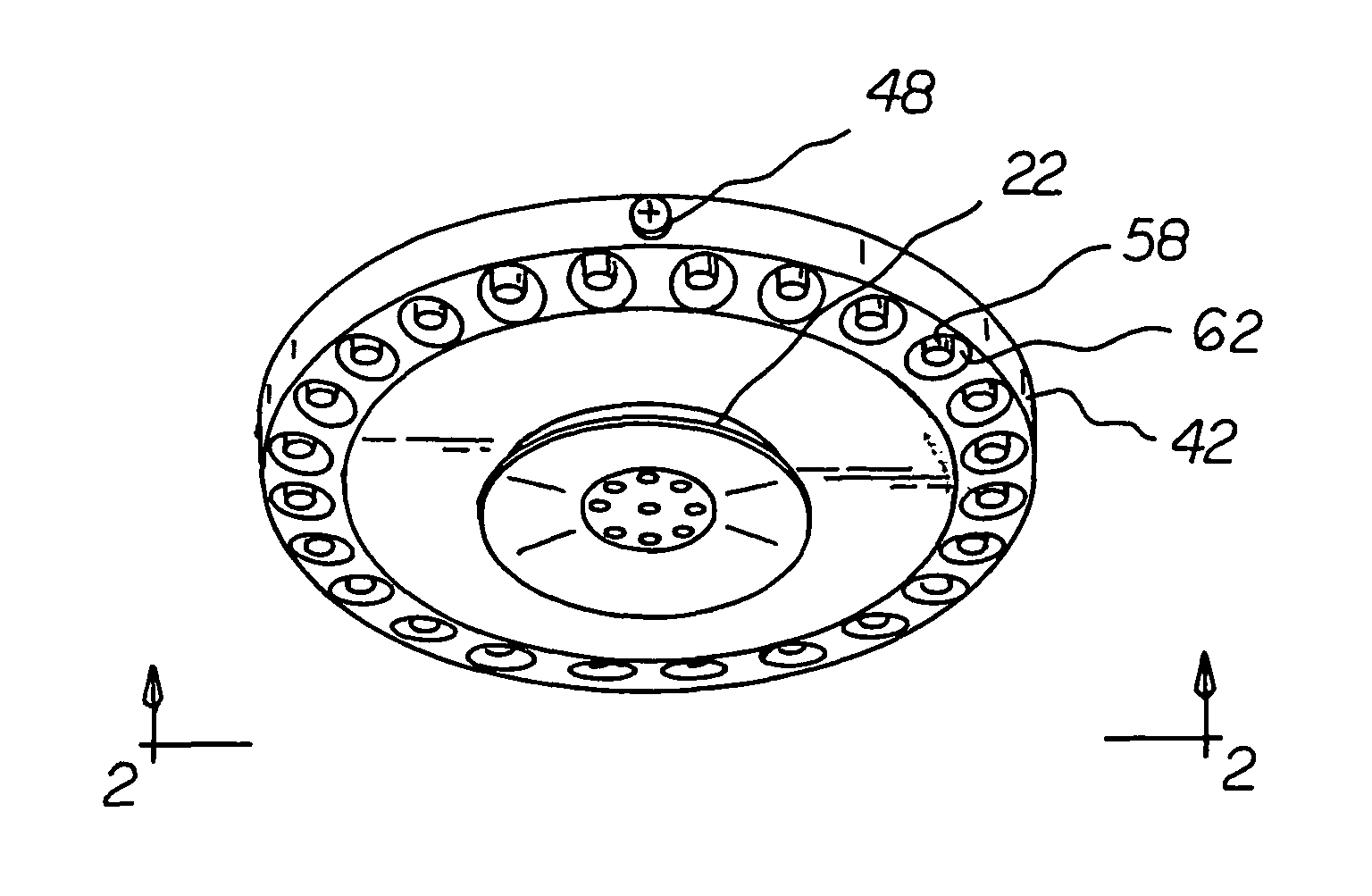

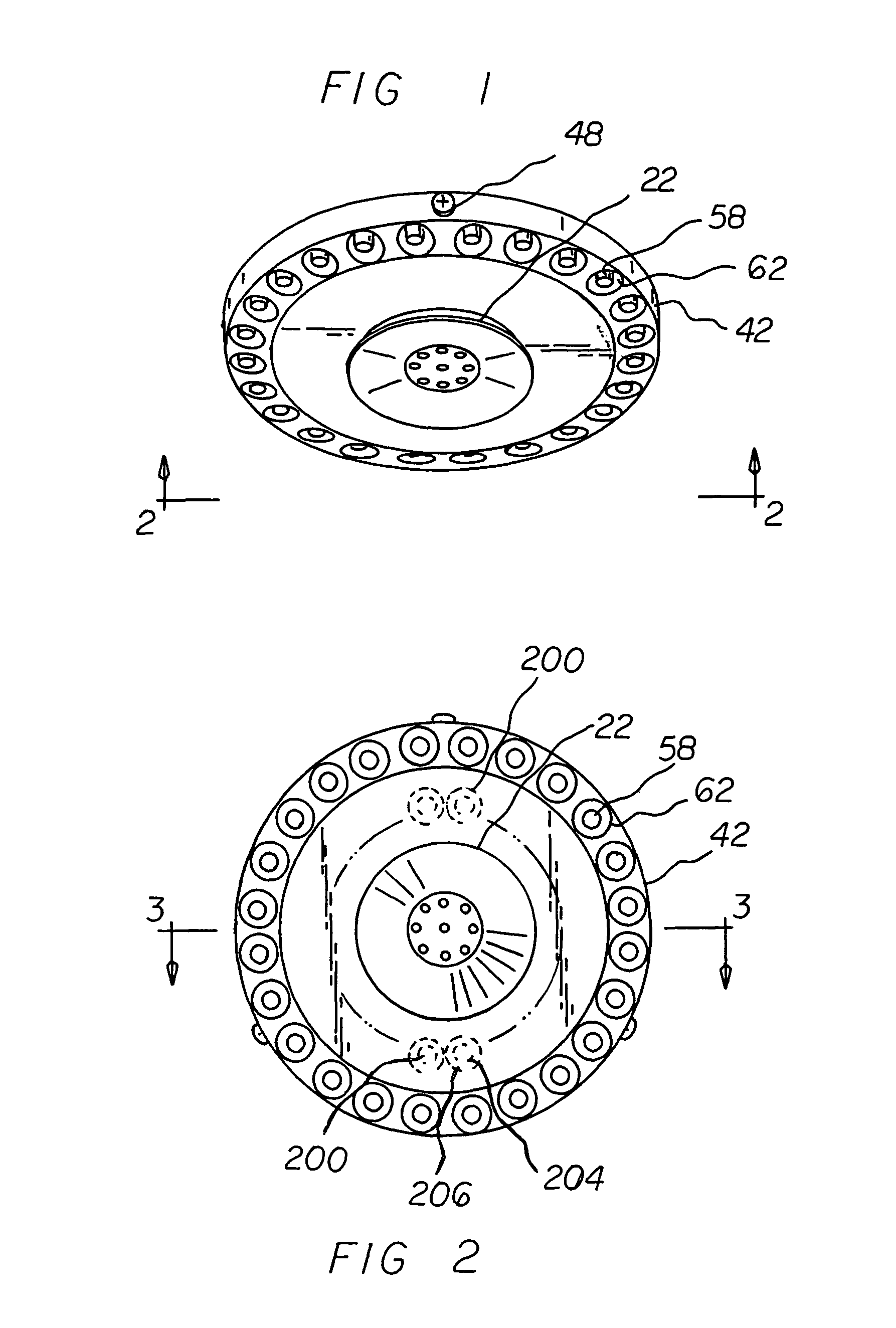

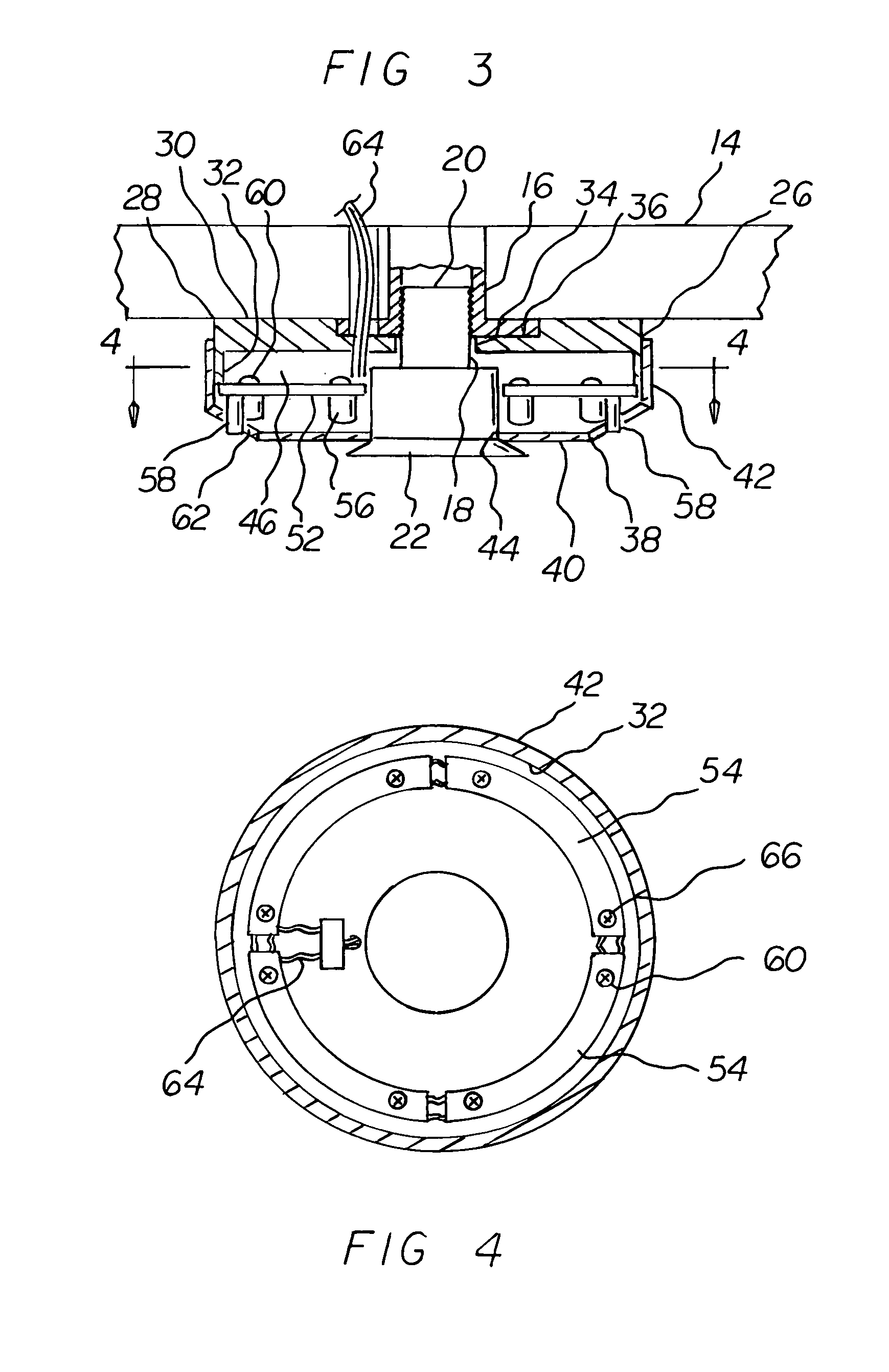

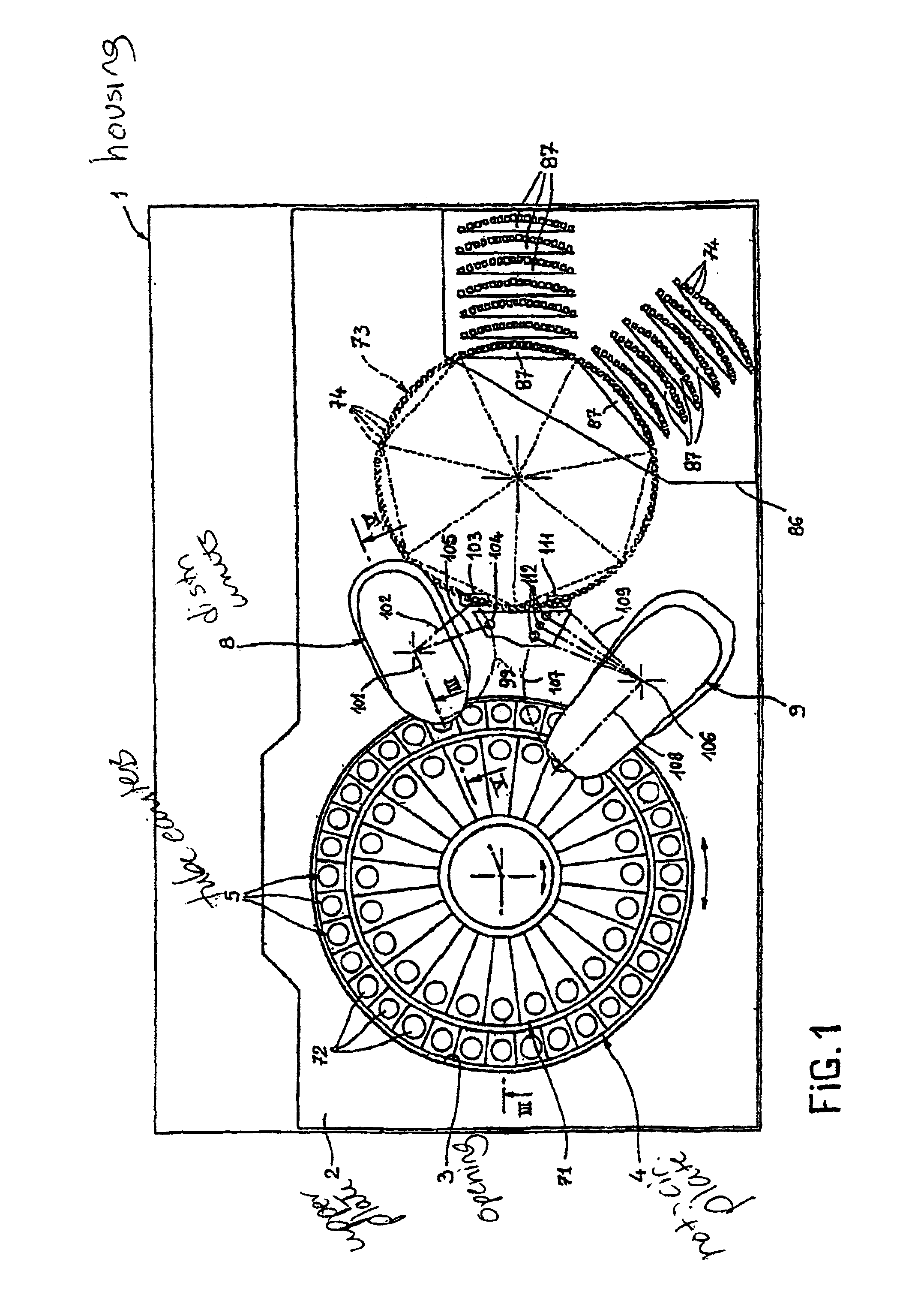

Light emitting diode system

InactiveUS8307472B1Easily and efficiently manufactured and marketedDurable and reliable constructionPoint-like light sourceBathsPrinted circuit boardEngineering

A housing has an upper component formed of an upper plate and a periphery. The upper plate has an upper central aperture. The housing has a lower component formed of a lower plate and a periphery. The lower plate has a lower central aperture. An annular printed circuit board is positioned within the housing. A plurality of light emitting diodes are secured to the printed circuit board and extend downwardly therefrom. A plurality of equally spaced small apertures in the lower plate of the lower component each receive one of the light emitting diodes for providing light.

Owner:SAXON THOMAS JASON +1

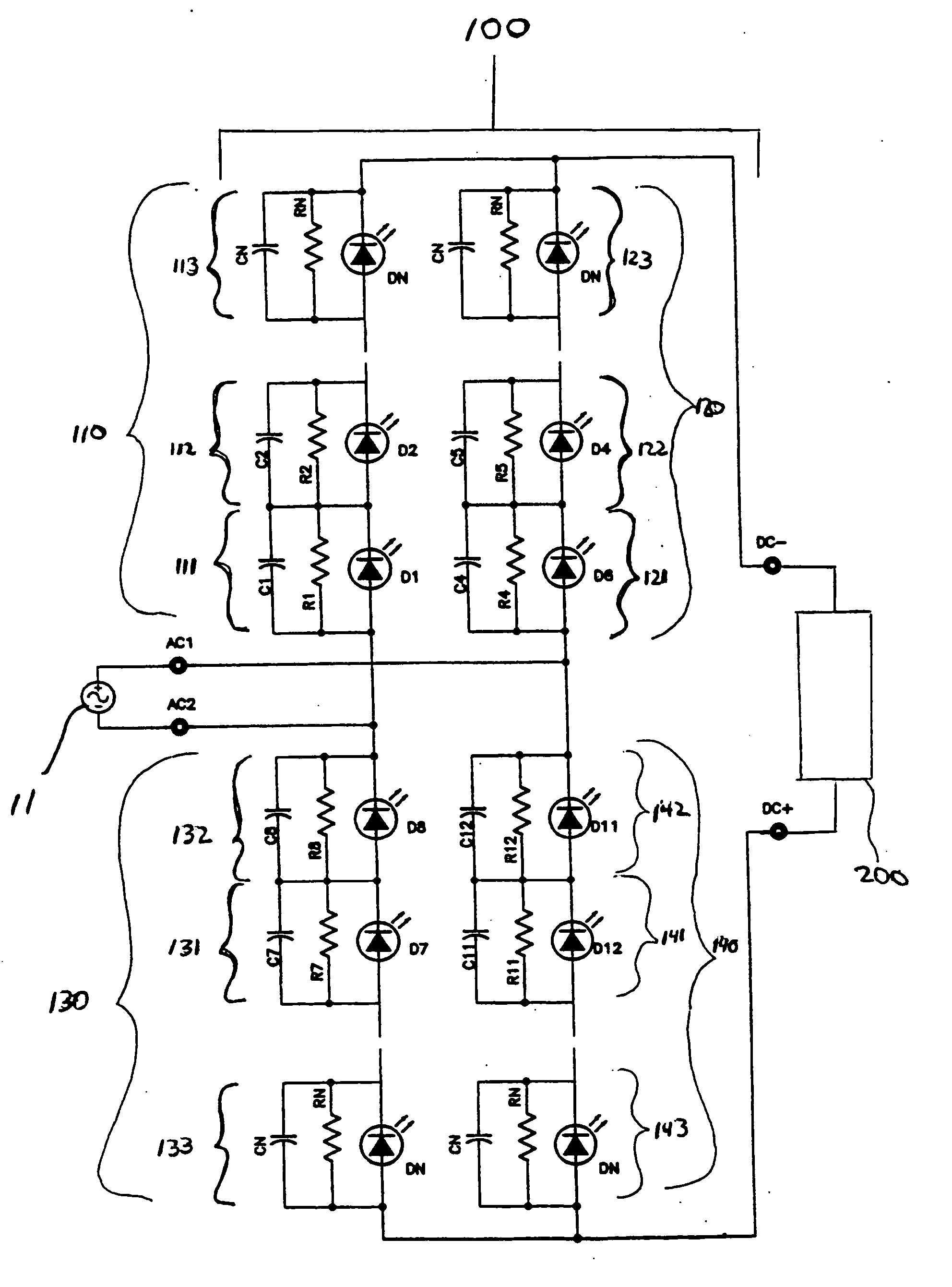

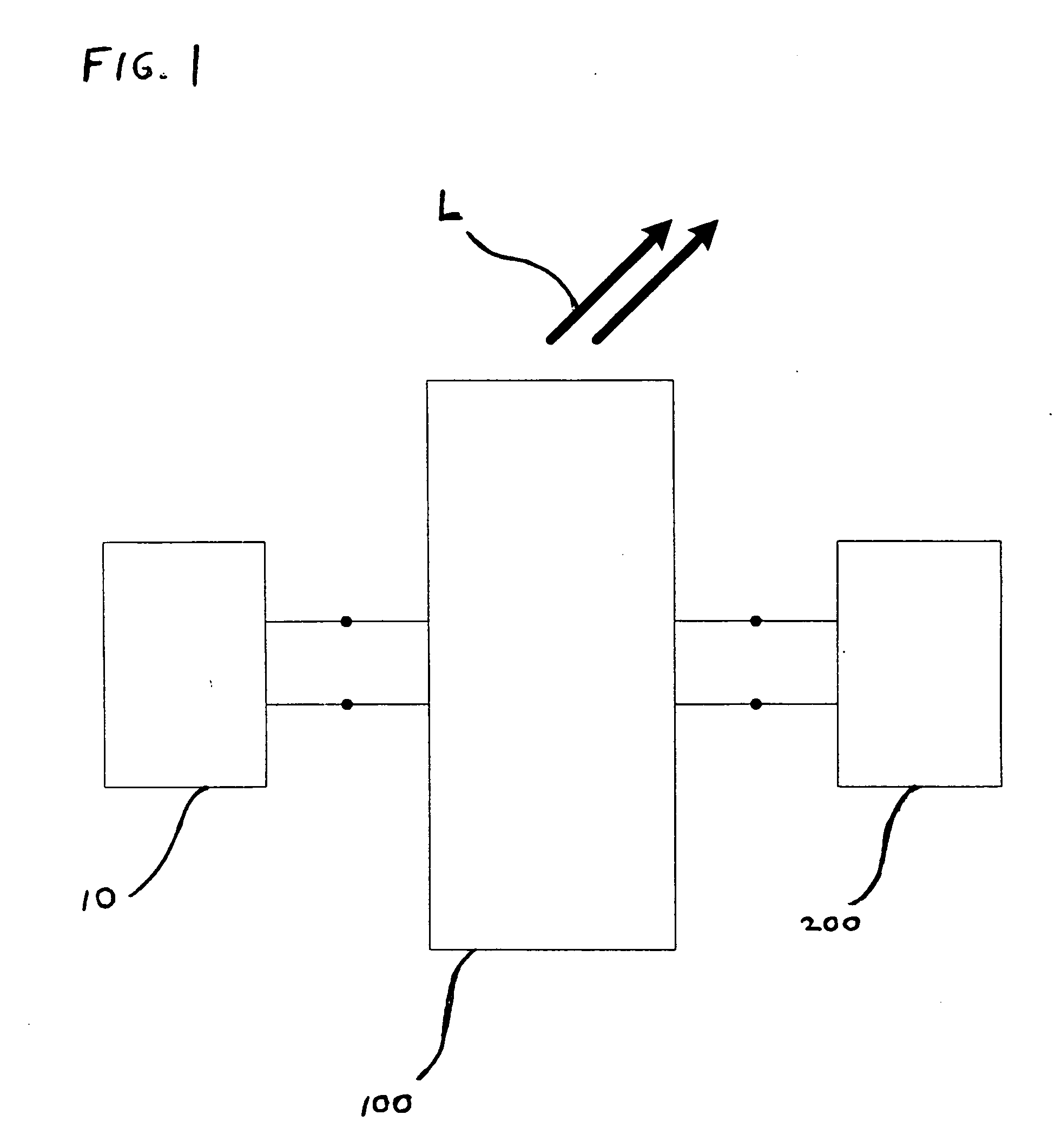

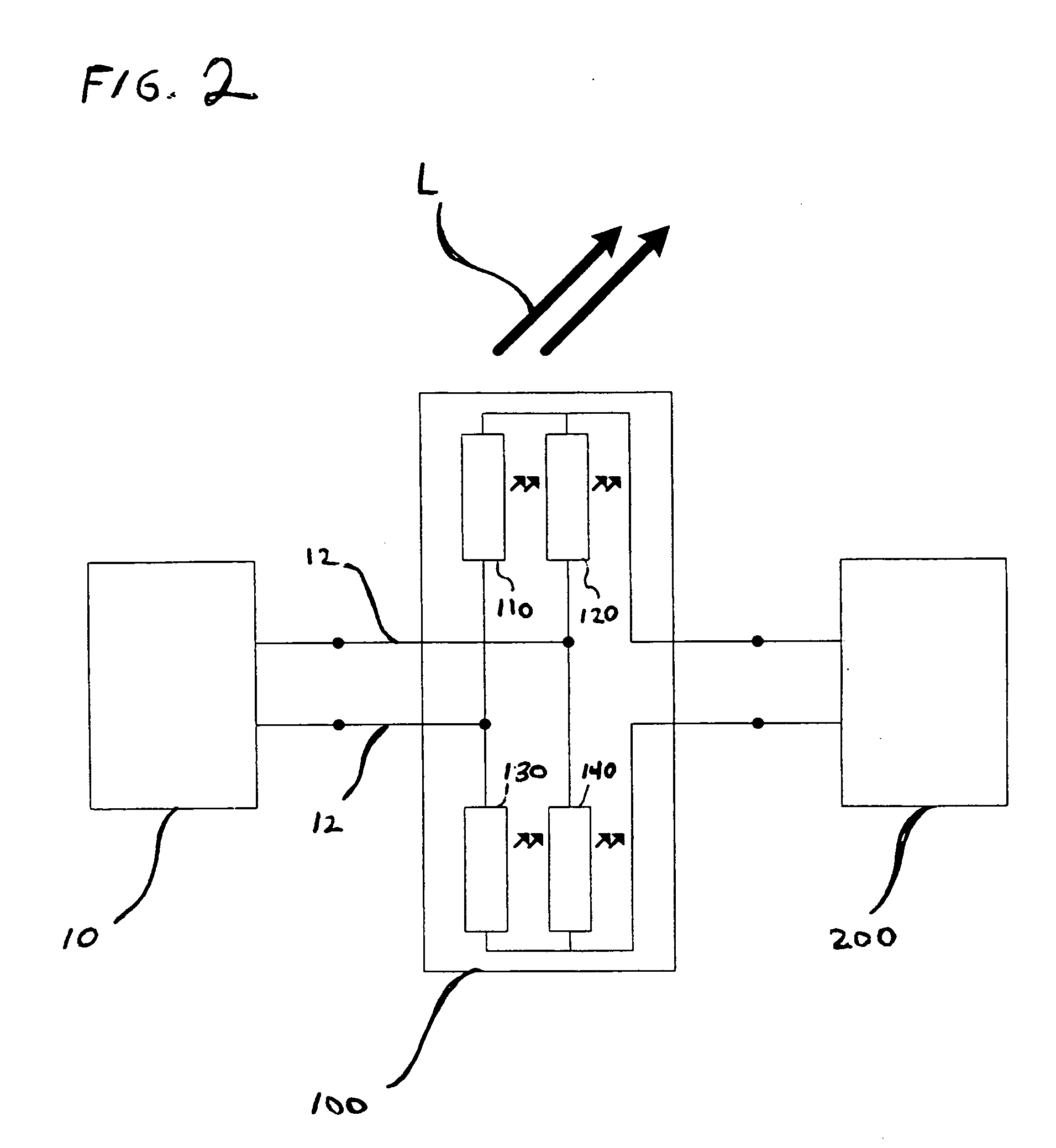

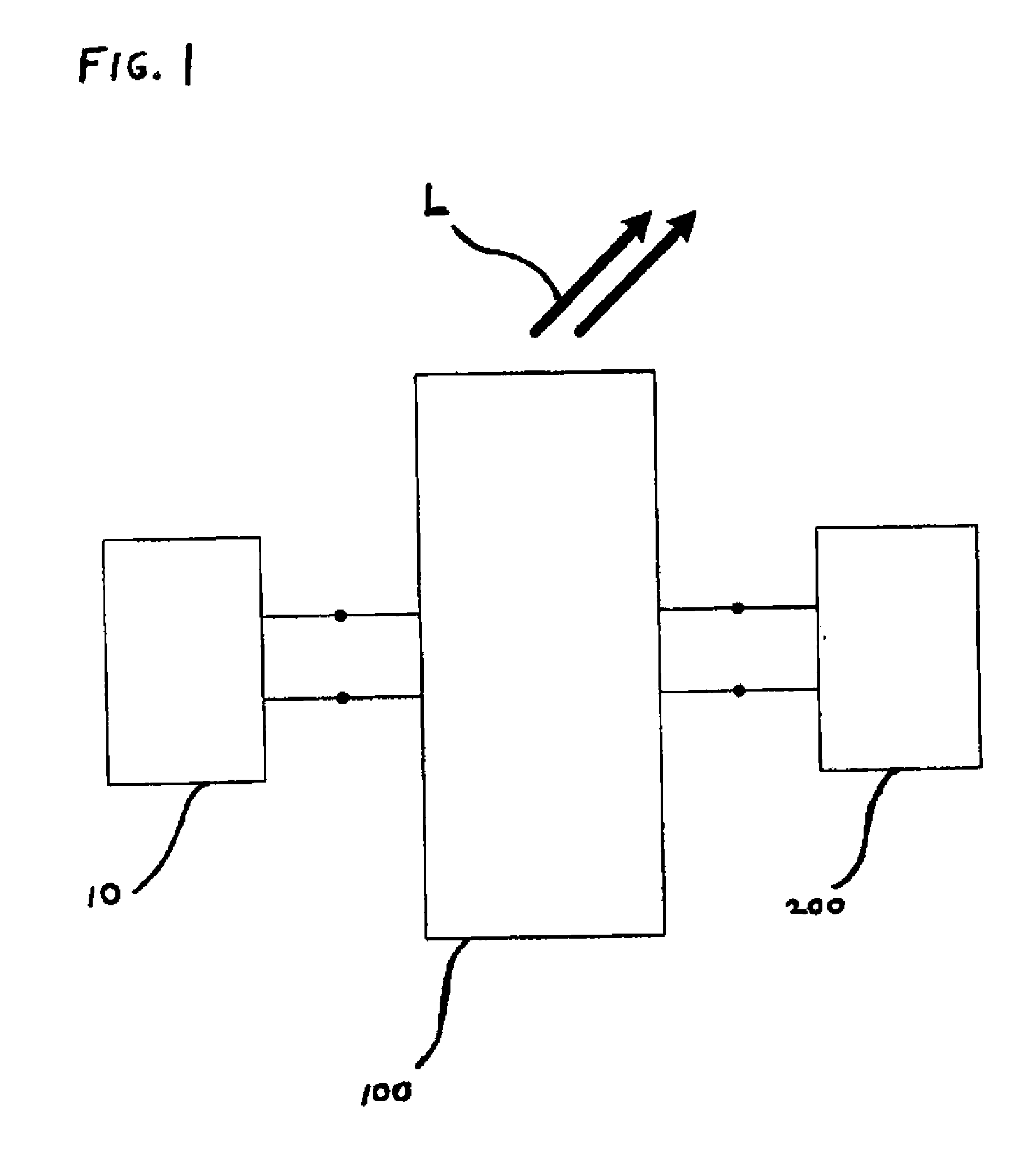

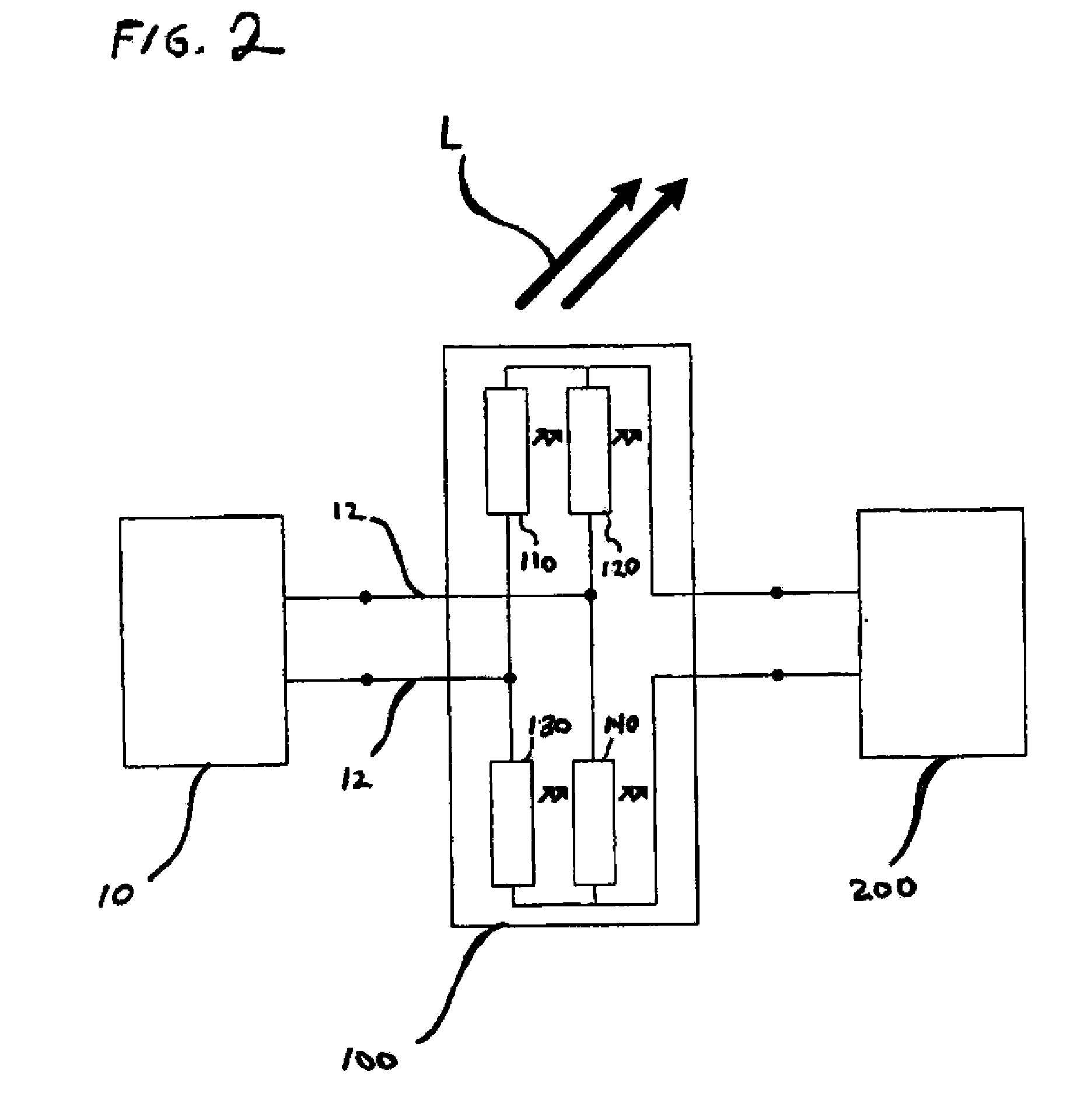

Solid state LED bridge rectifier light engine

InactiveUS20070069663A1Avoid heavyShorten the timeElectroluminescent light sourcesSolid-state devicesCurrent limitingPhosphor

A solid-state light engine comprised of light emitting diodes (LEDs) configured into a bridge rectifier with a current limiting module coupled to the LED bridge rectifier. The light engine may be packaged for high temperature operation. Optionally, the LEDs comprise wavelength-converting phosphors with a persistence that is a multiple of the peak to peak current period, to smooth and mask ripple frequency pulsation of emitted light.

Owner:LIGHTING SCI GROUP

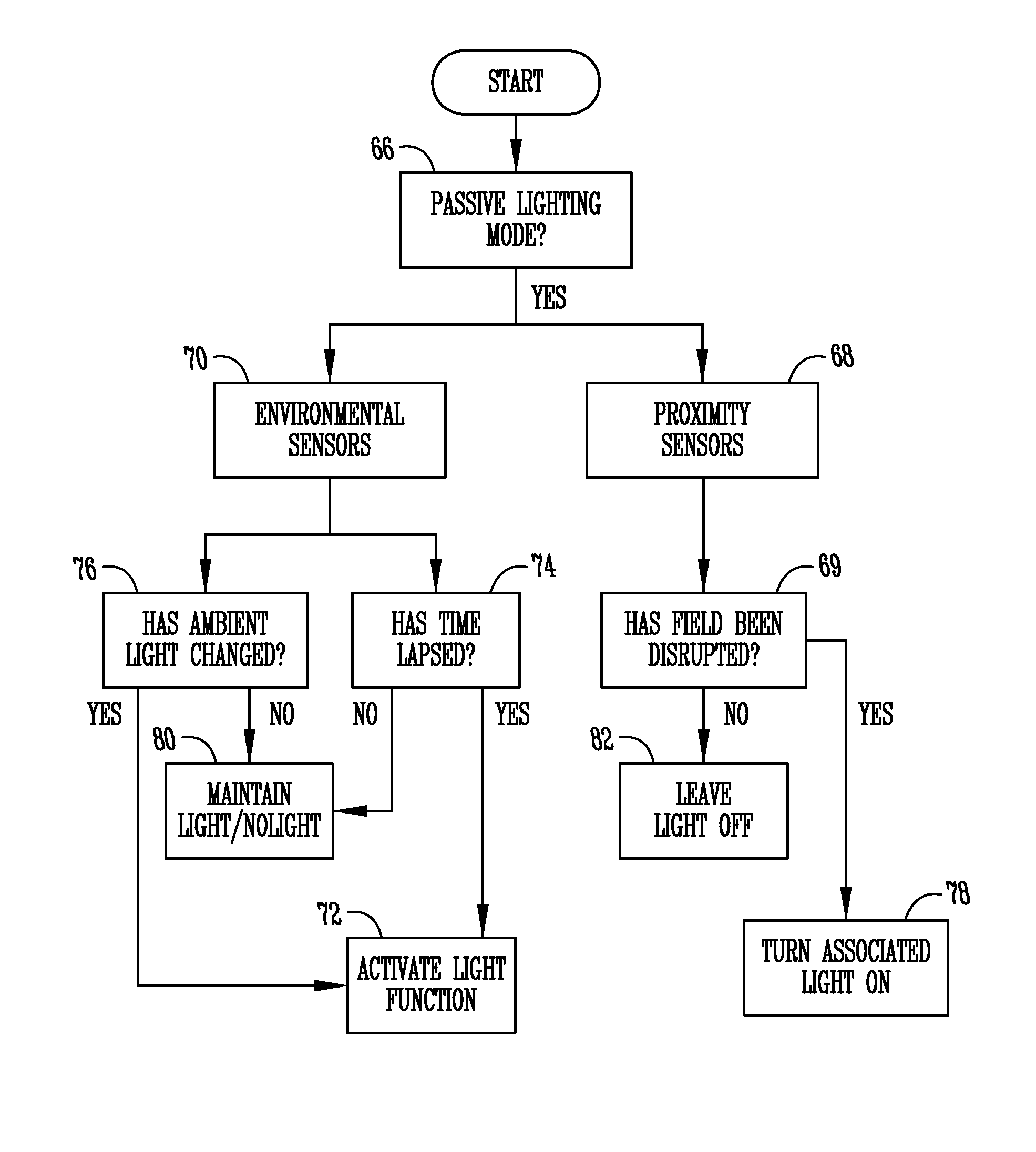

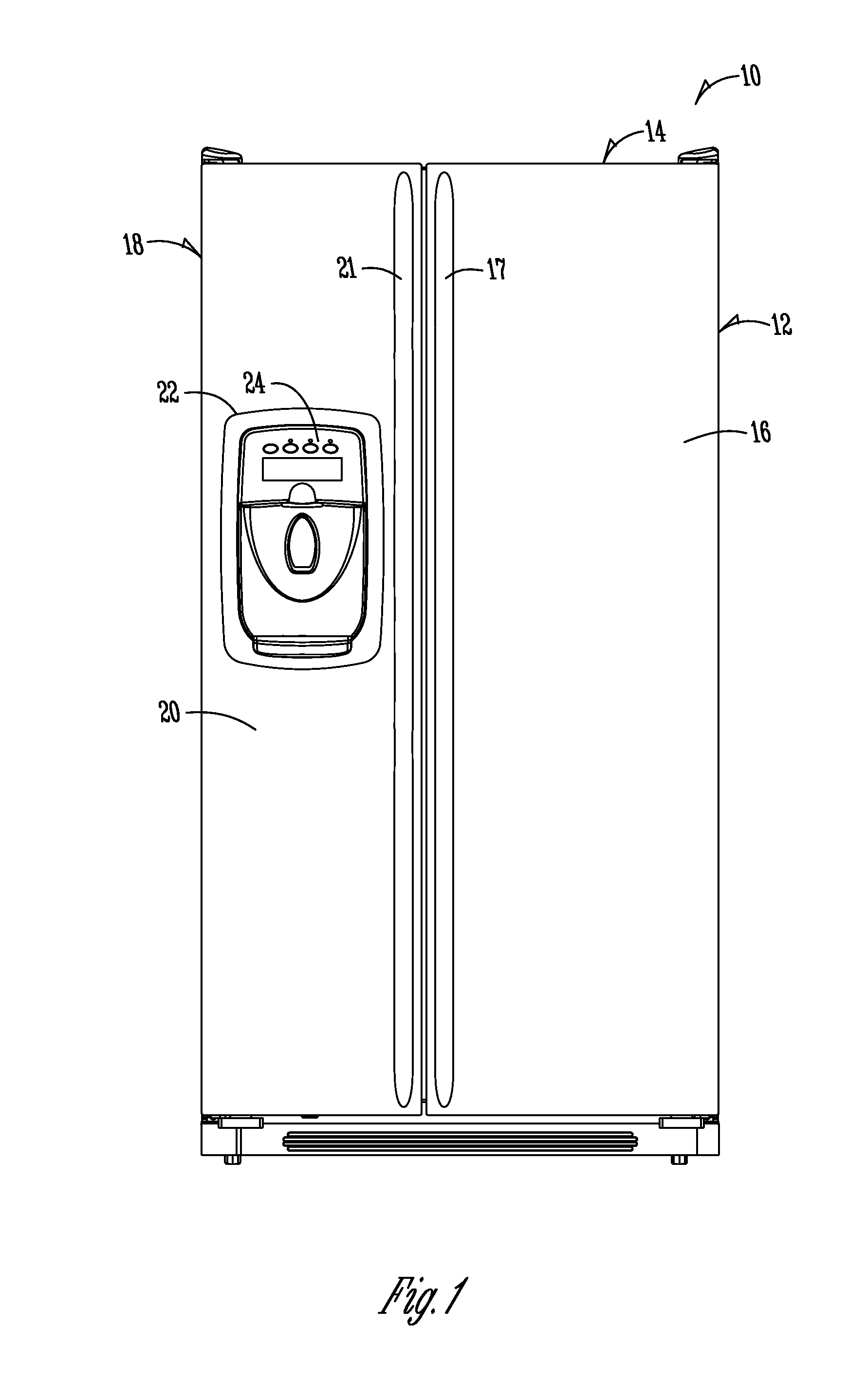

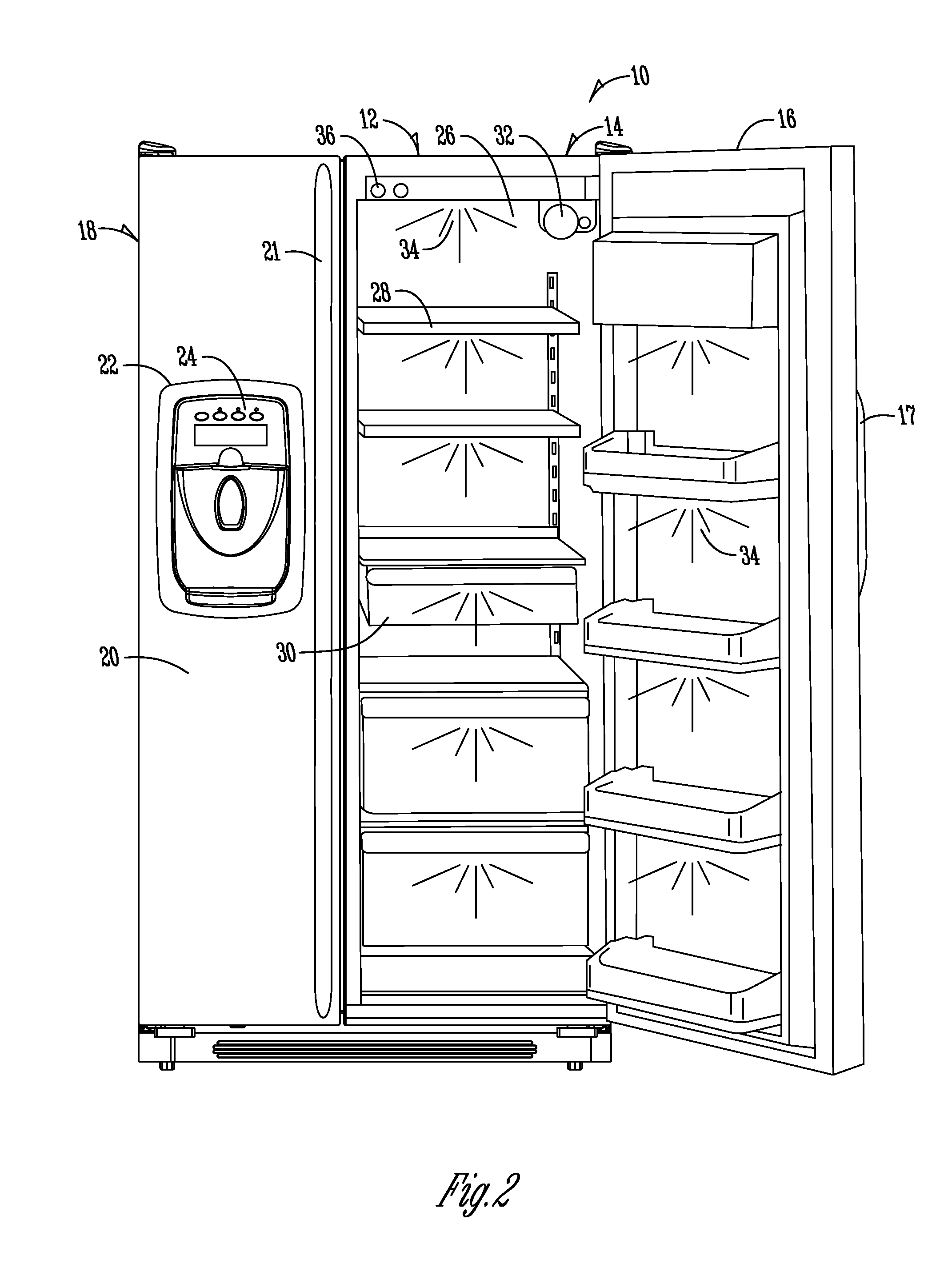

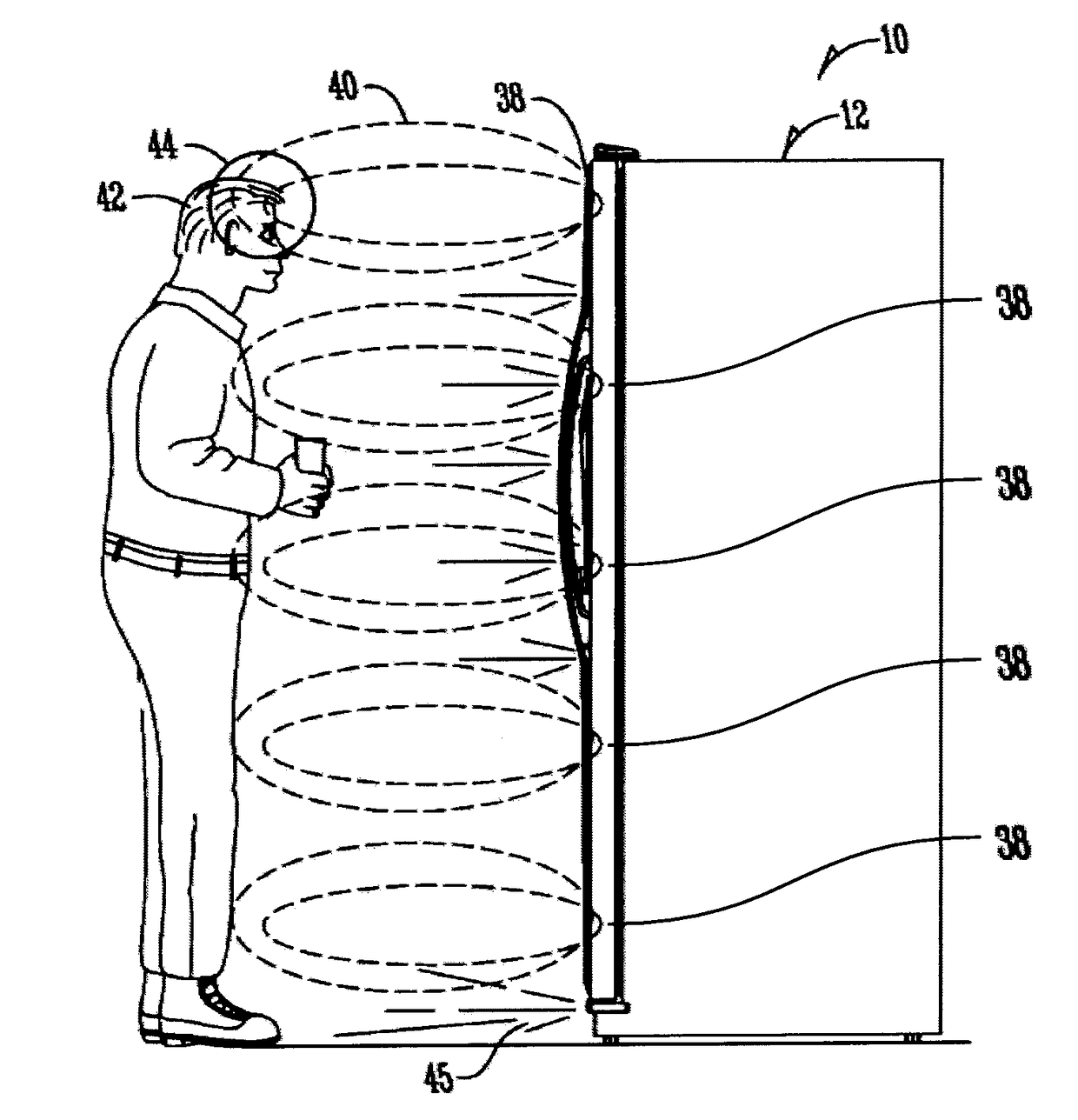

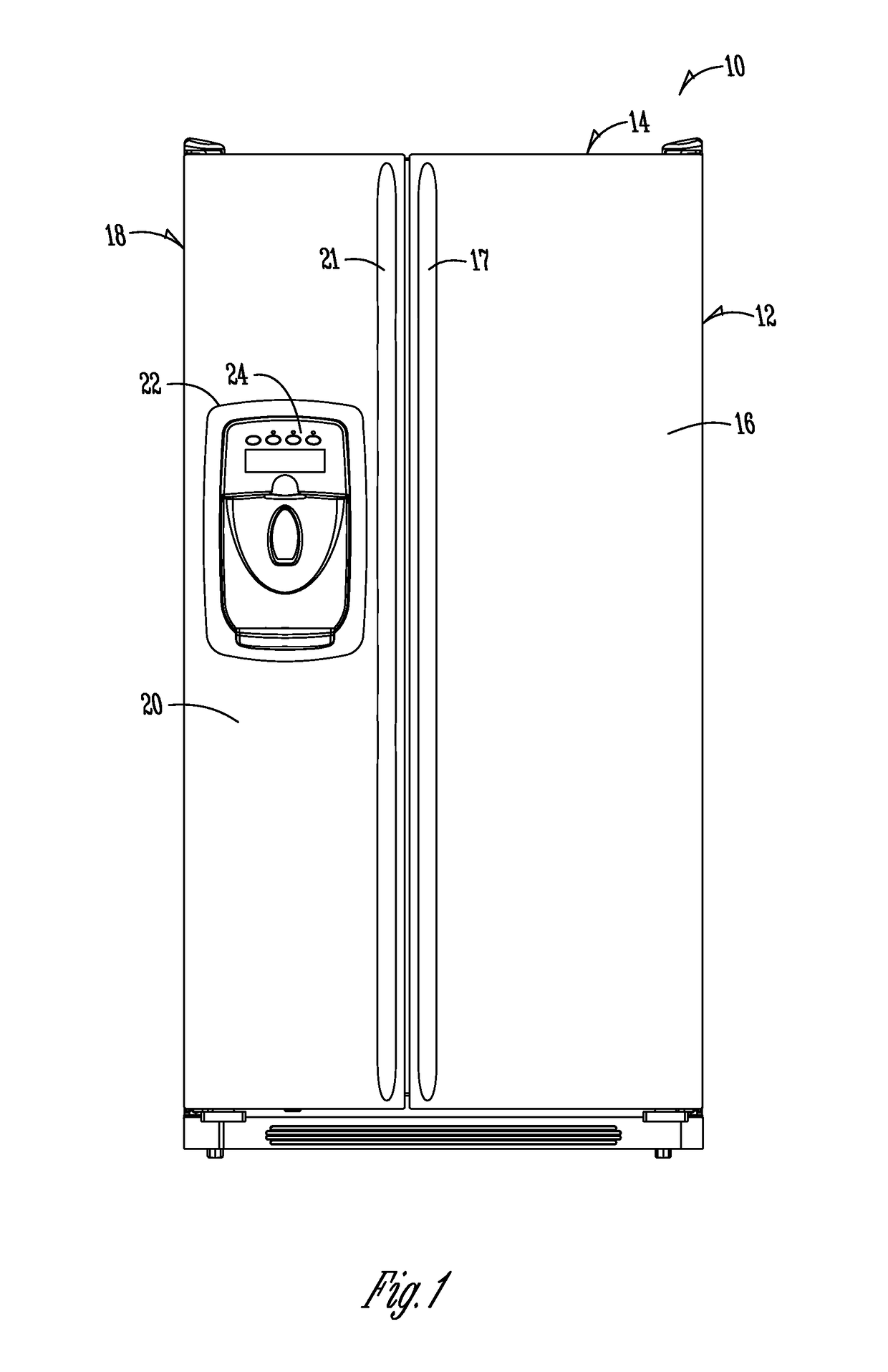

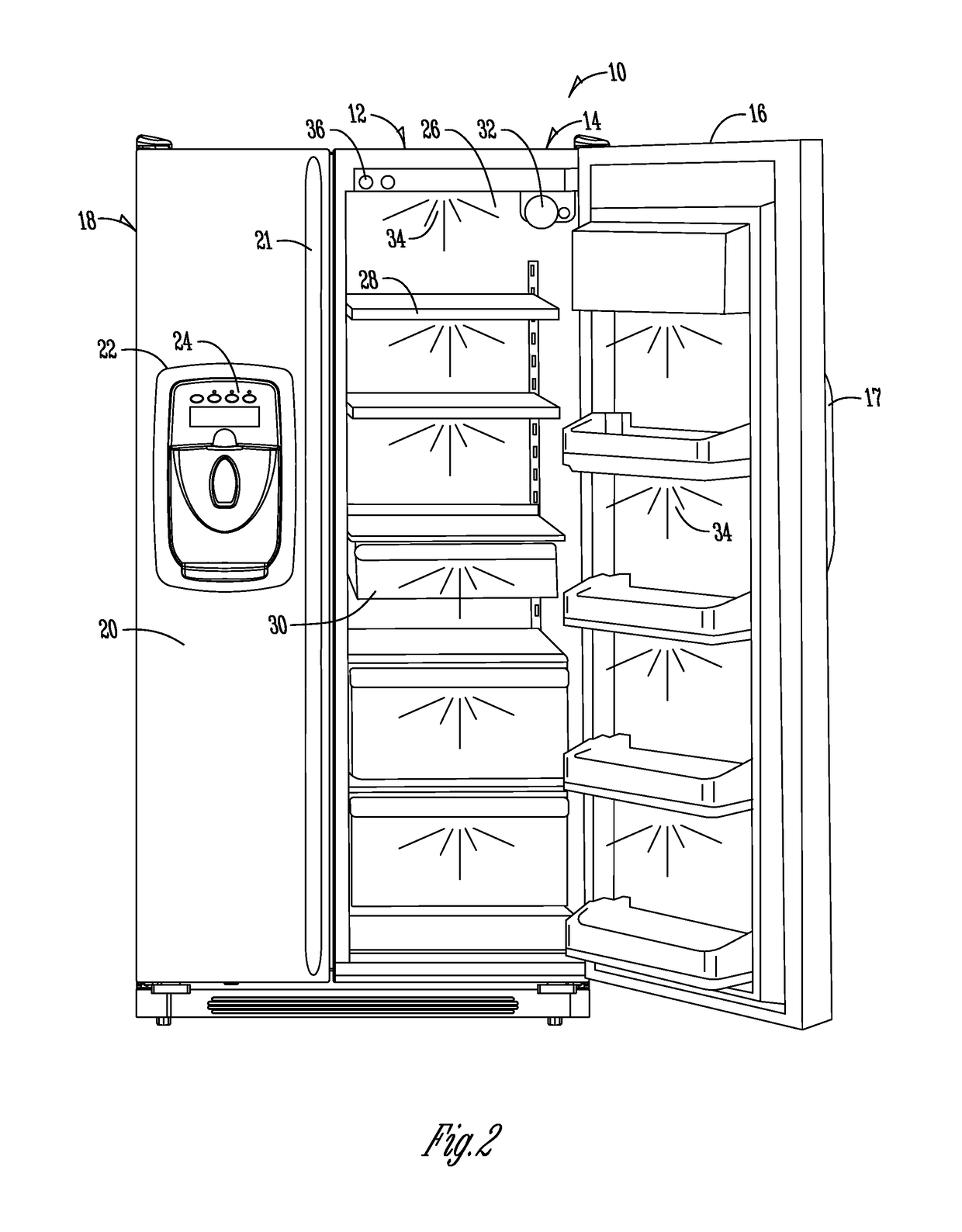

Sensor system for refrigerator

ActiveUS20140111118A1Avoid heavyOvercome deficienciesMechanical apparatusDomestic lightingElectricityEffect light

An interactive appliance is provided. The interactive appliance includes at least a housing, and an intelligent control disposed within the housing. One or more lighting devices are electrically connected to the intelligent control, as are one or more sensors. The sensors provide sensor data for the interactive appliance. The intelligent control is configured to alter operation of at least one of the one or more lighting devices based on data provided by the sensor to provide interactive feedback to a user of the interactive appliance. The feedback can include altering light intensity, color, consistency, or the like depending on the sensor data. Furthermore, the lighting device can be placed on a surface, such as an exterior surface of the housing of the appliance, or can be disposed within an interior portion of the appliance.

Owner:WHIRLPOOL CORP

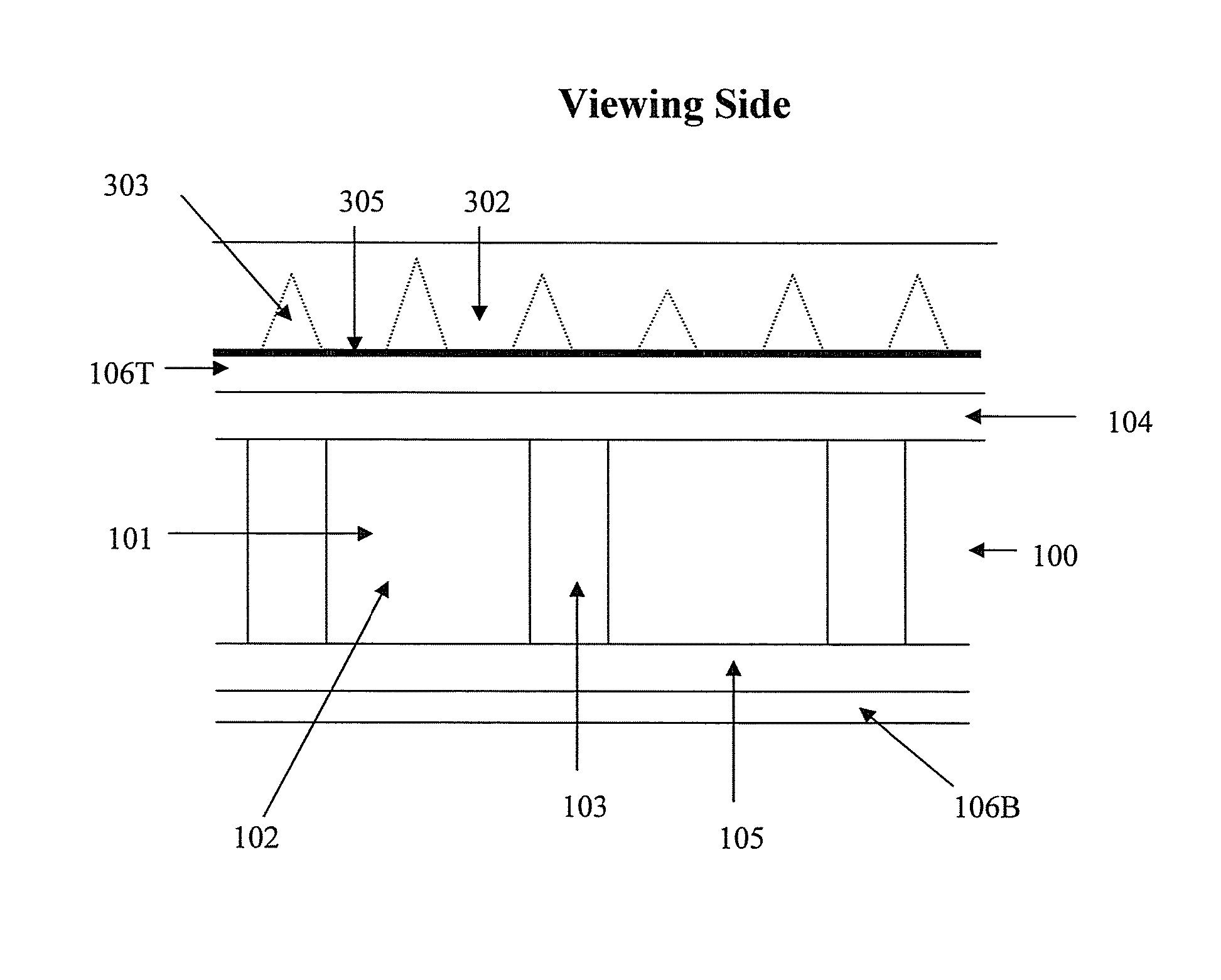

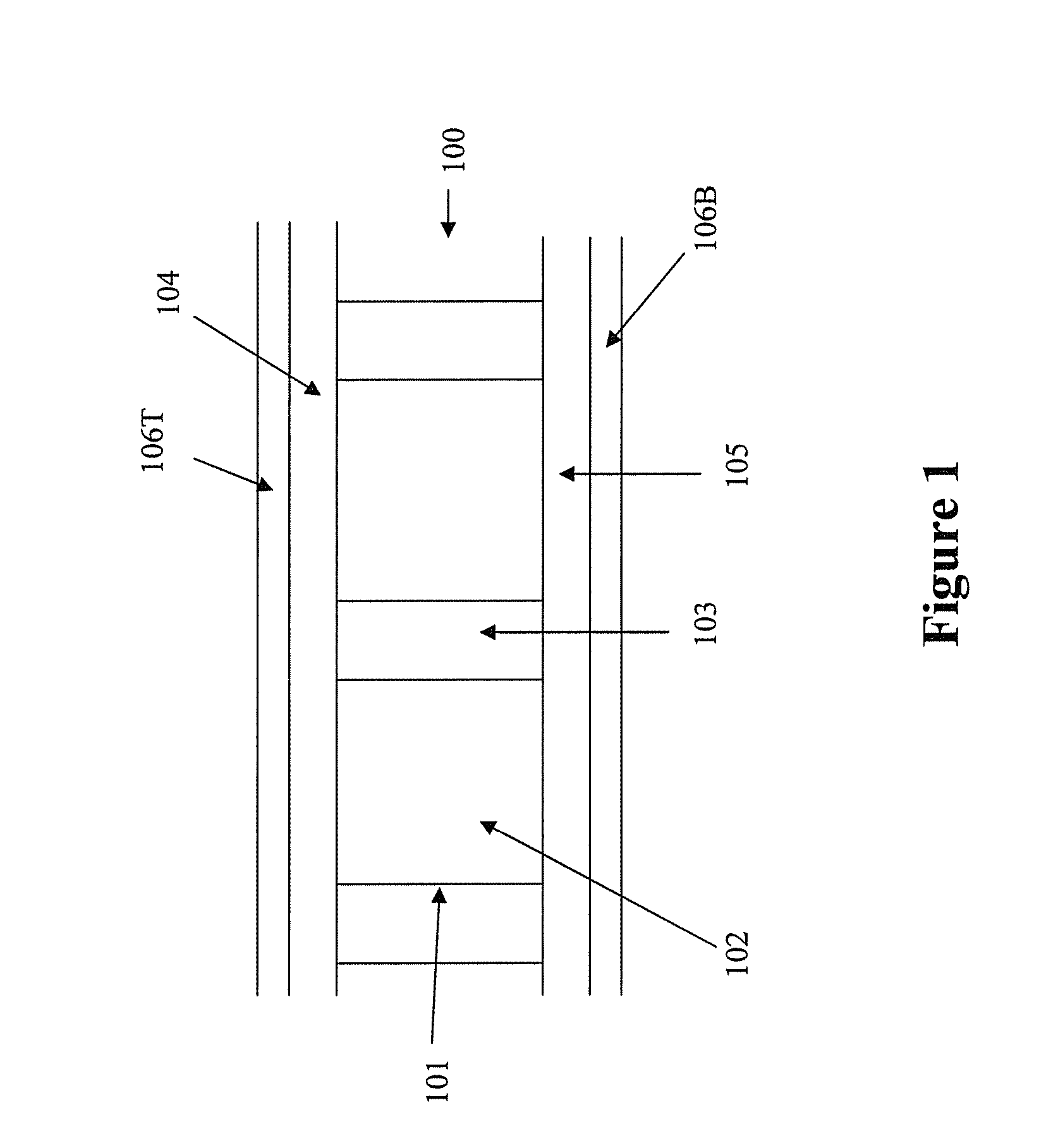

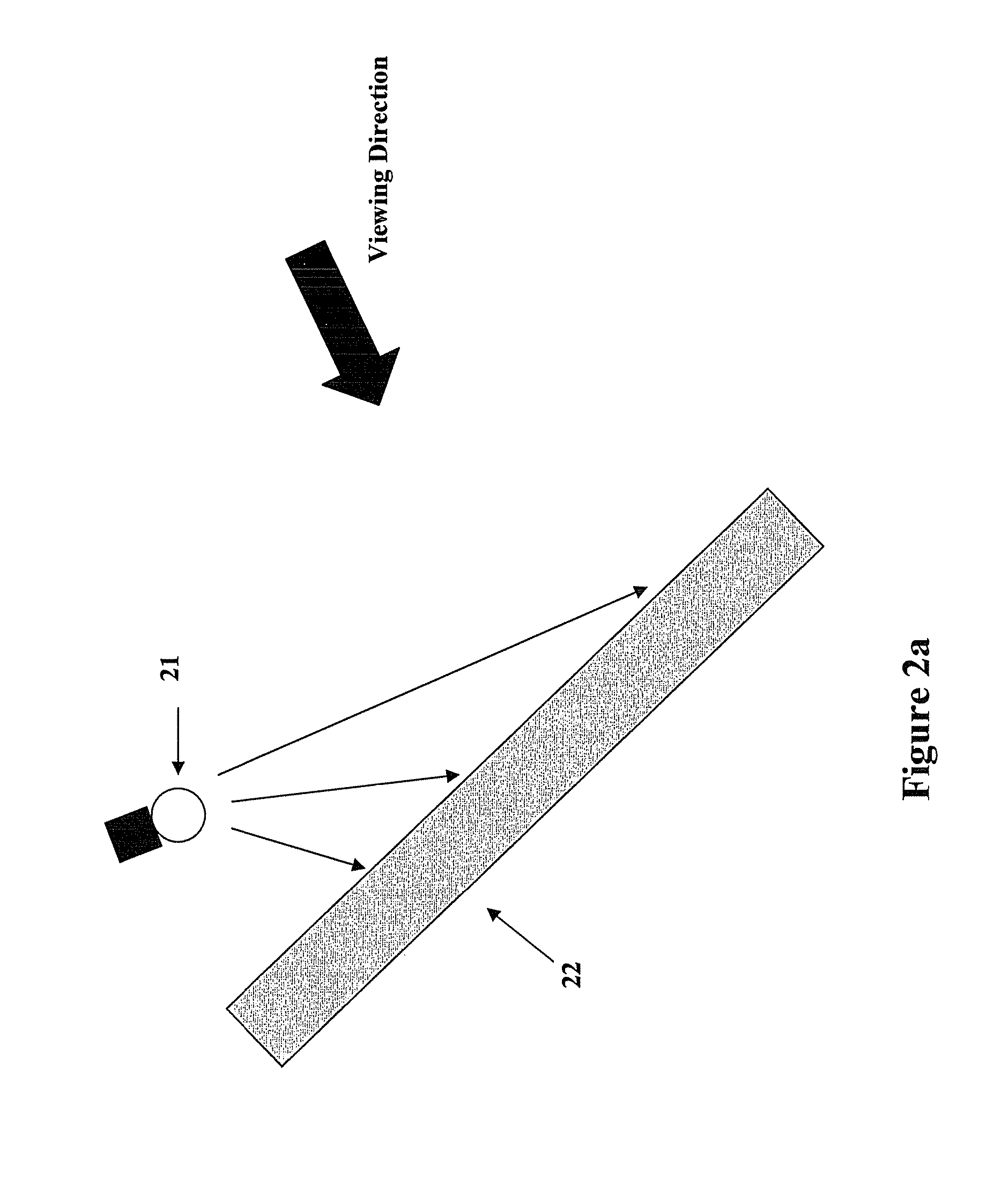

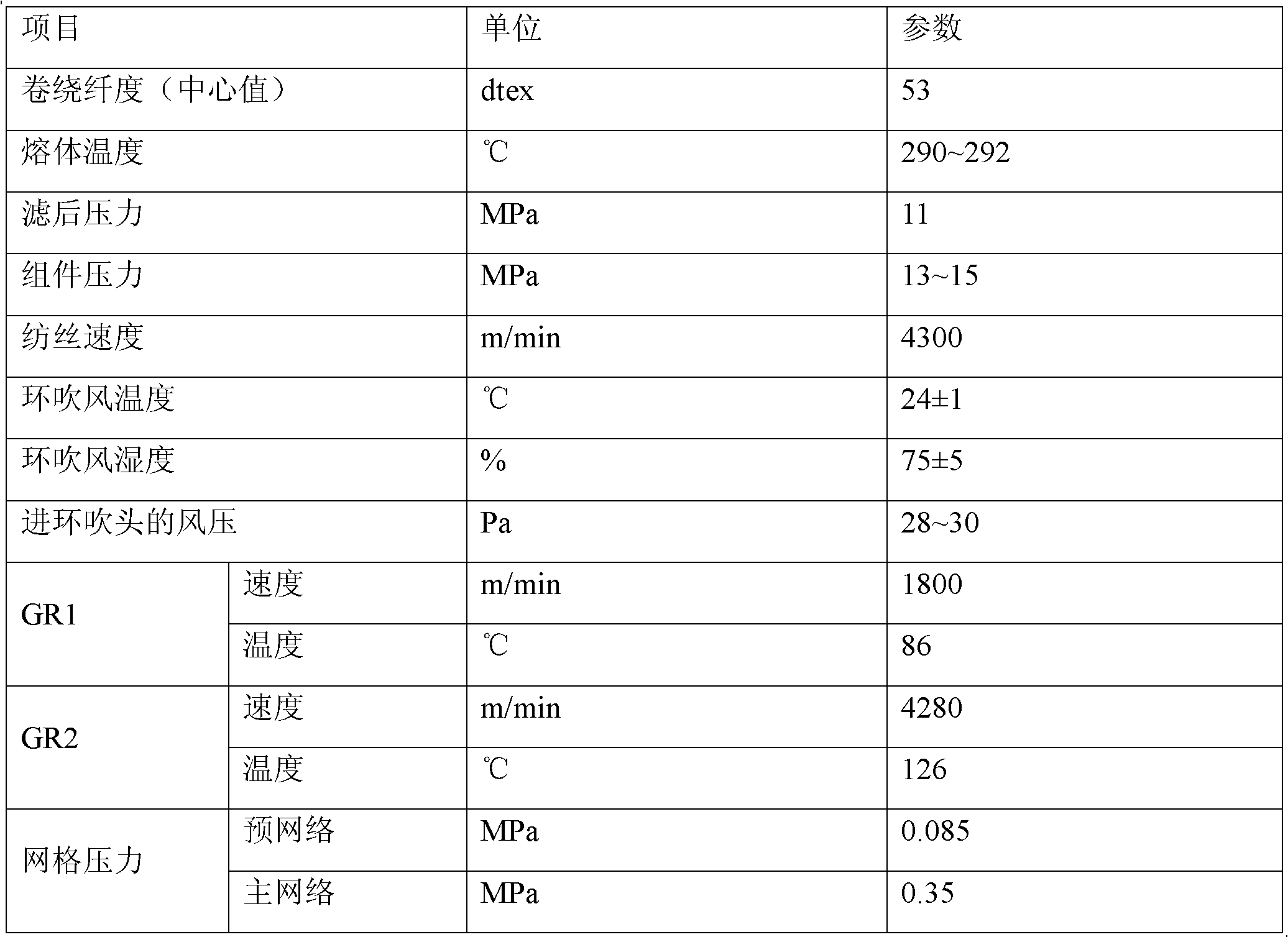

Display device assembly

ActiveUS8456589B1Avoid heavyImprove lighting conditionsOptical light guidesNon-linear opticsDisplay deviceComputer science

The present invention is directed to a display device which comprises a display device, a mechanical light and optionally a luminance enhancement structure. This type of display device assembly is particularly useful for e-books comprising a luminance enhancement structure designed to direct a significant amount of light towards the reader of the e-books.

Owner:E INK CORPORATION

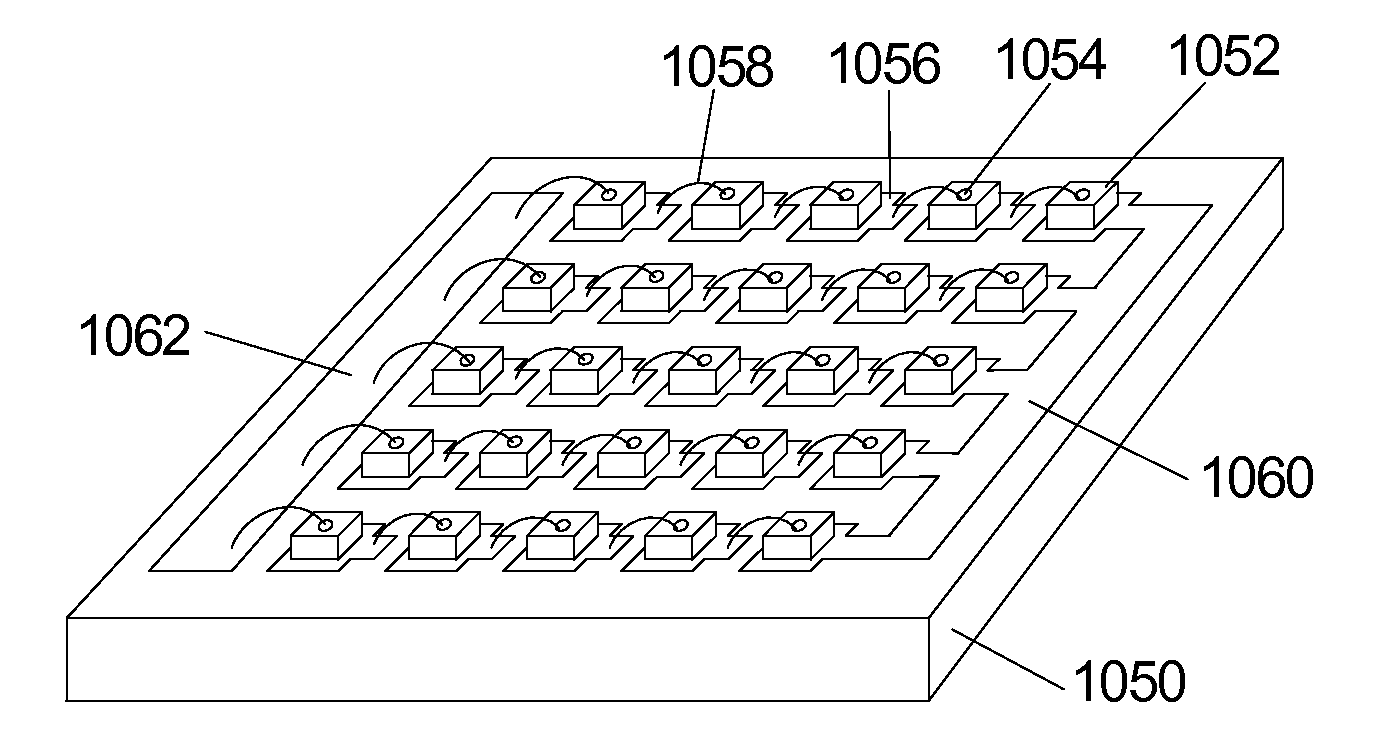

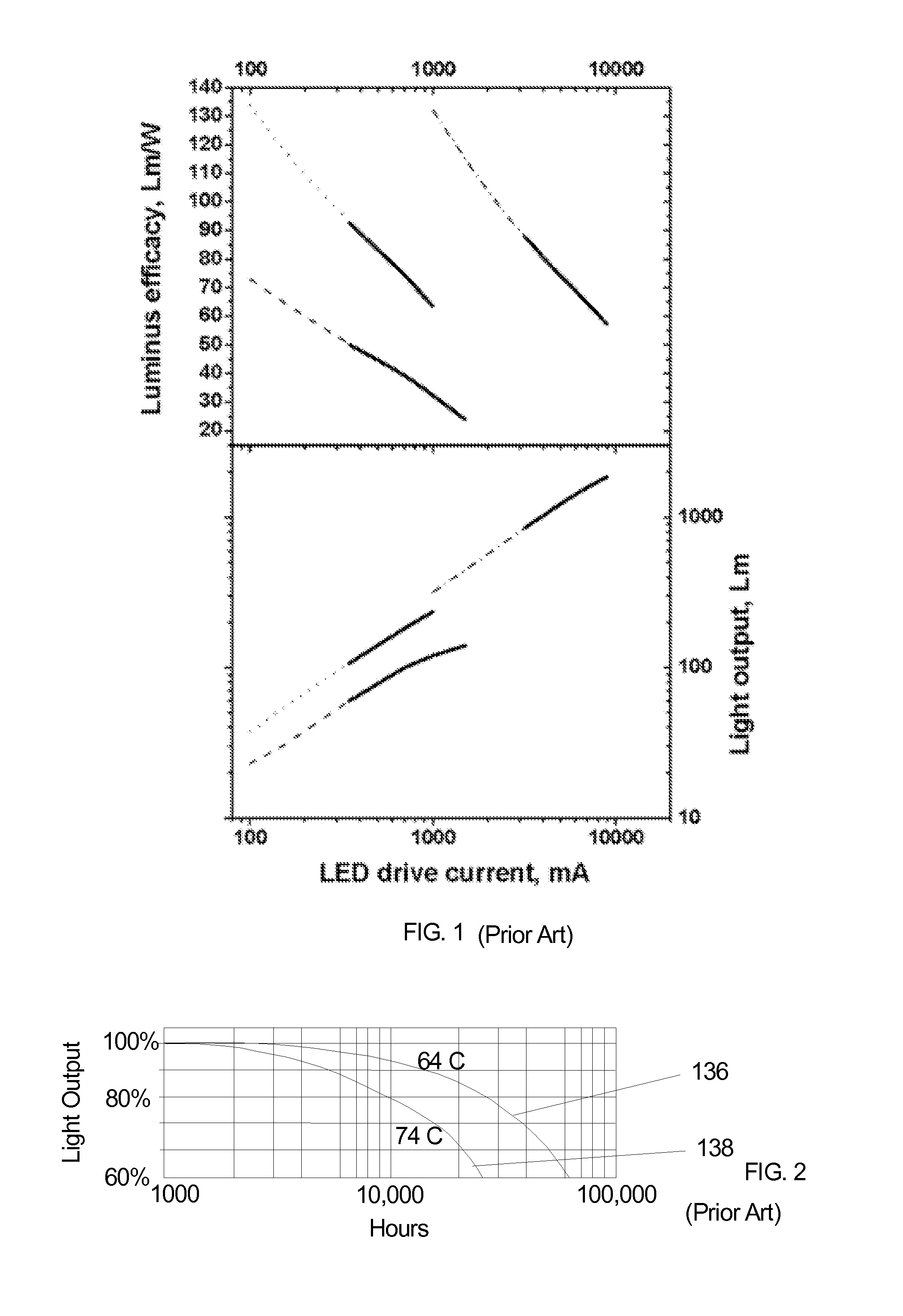

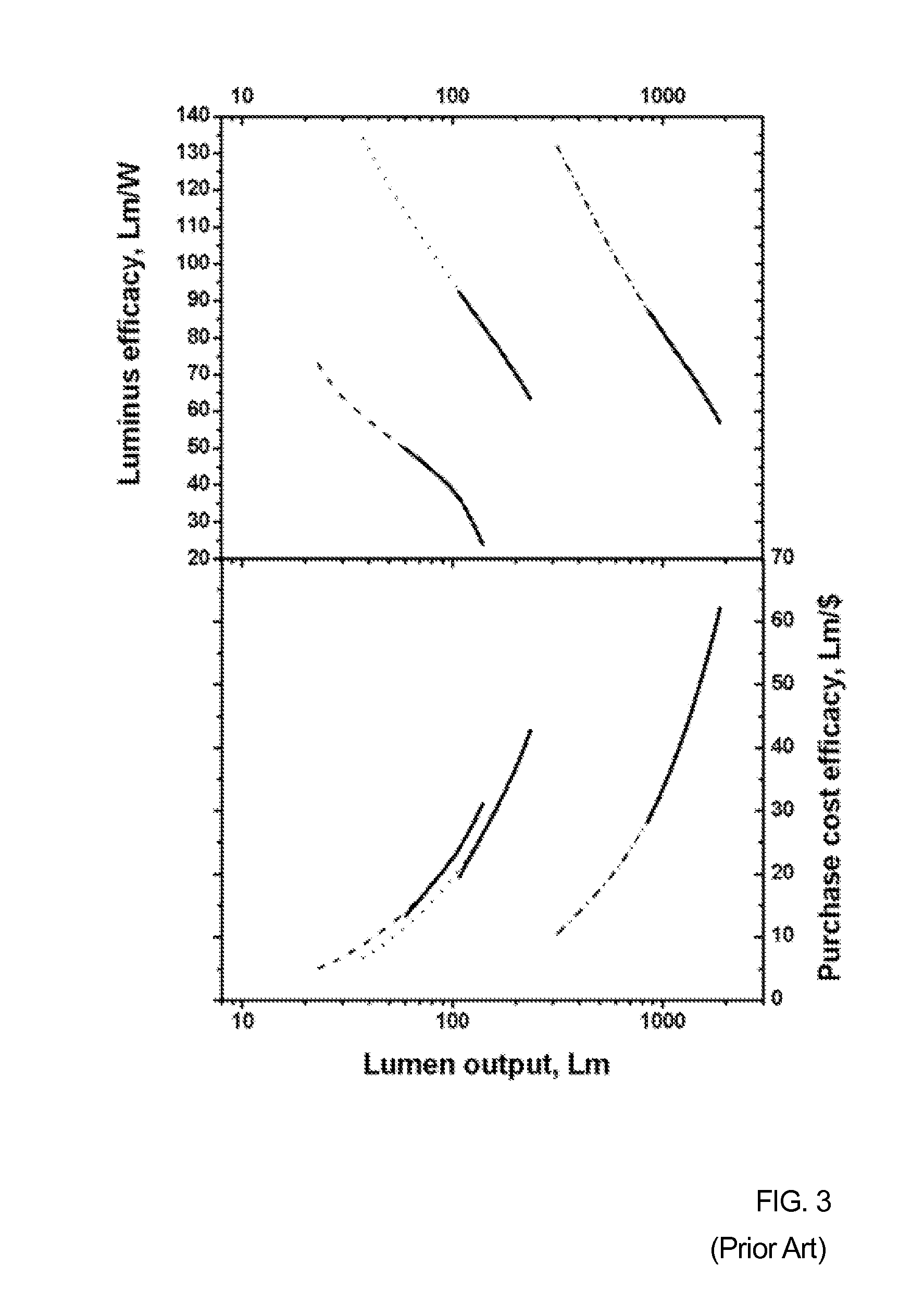

High efficiency leds and LED lamps

ActiveUS20120248477A1High light efficiencyReduce heatPlanar light sourcesPoint-like light sourceAdhesiveEngineering

Owner:COOLEDGE LIGHTING

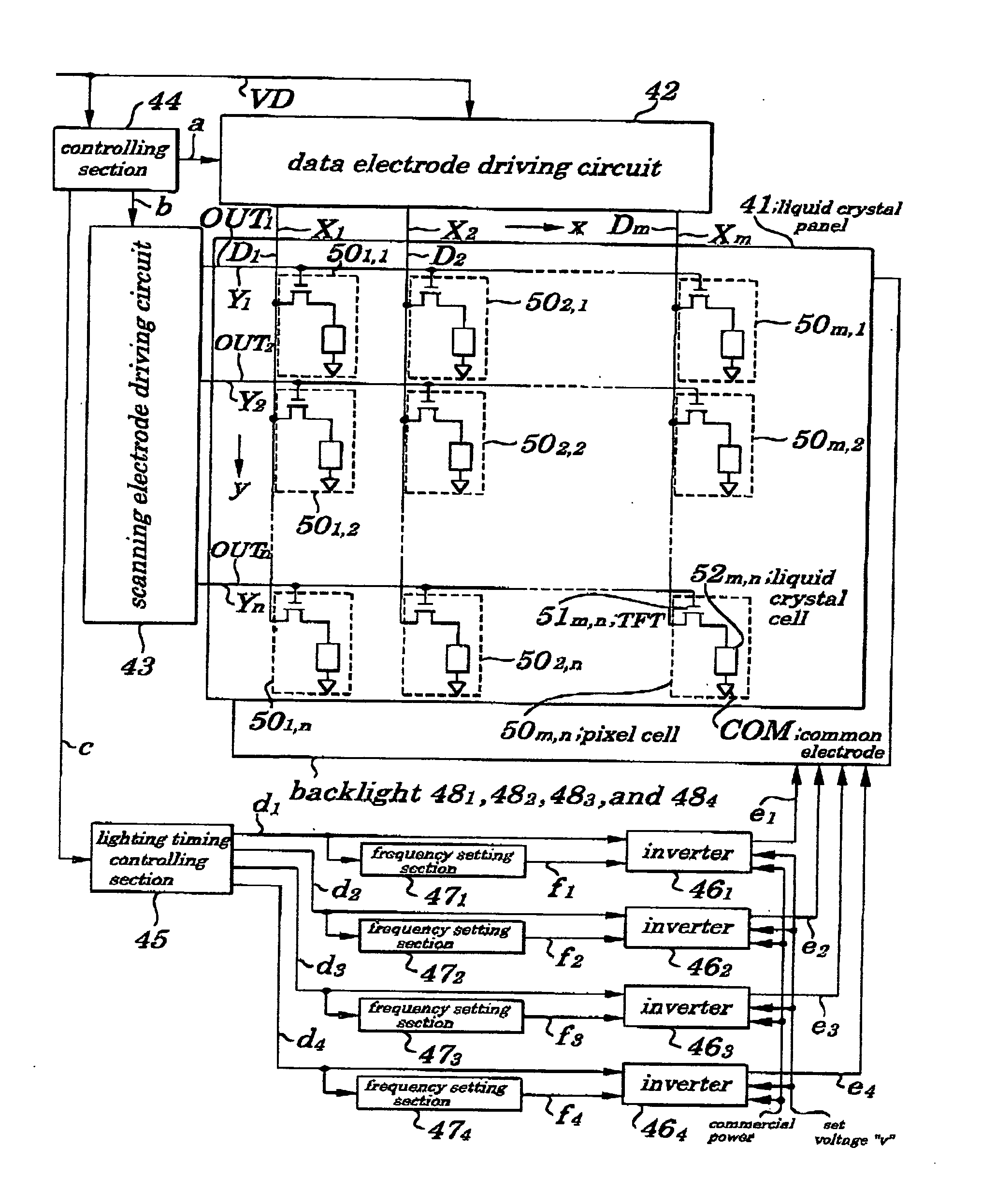

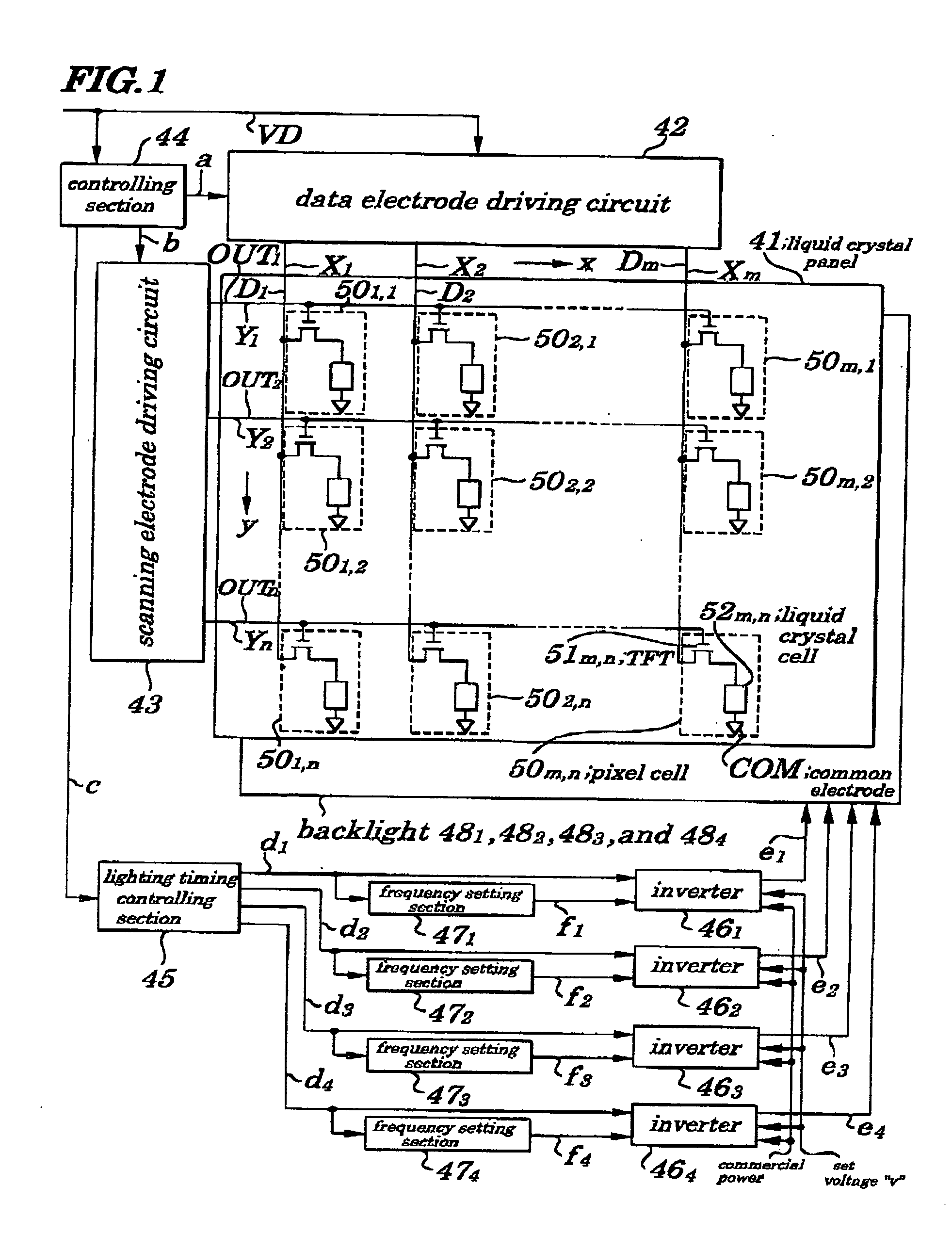

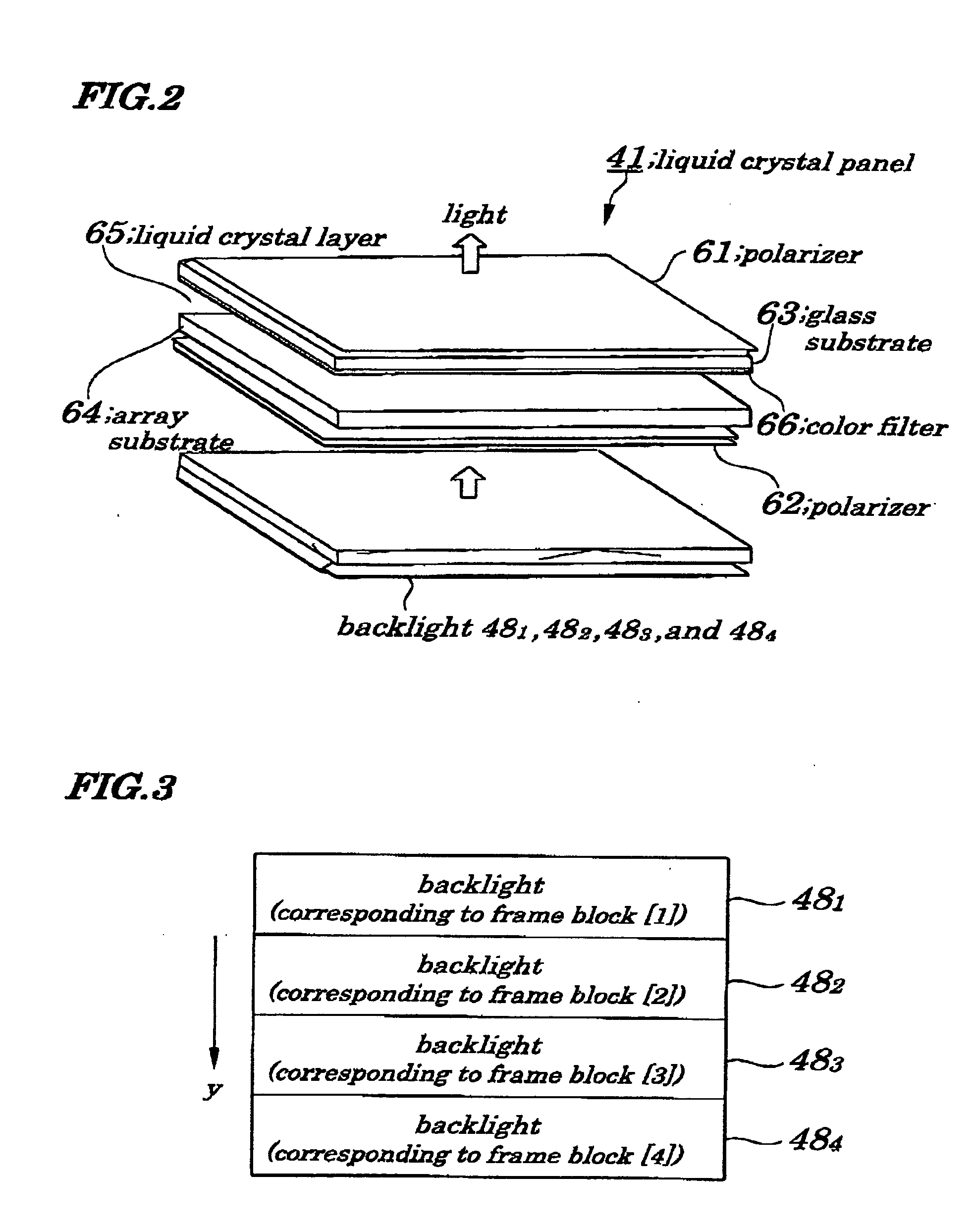

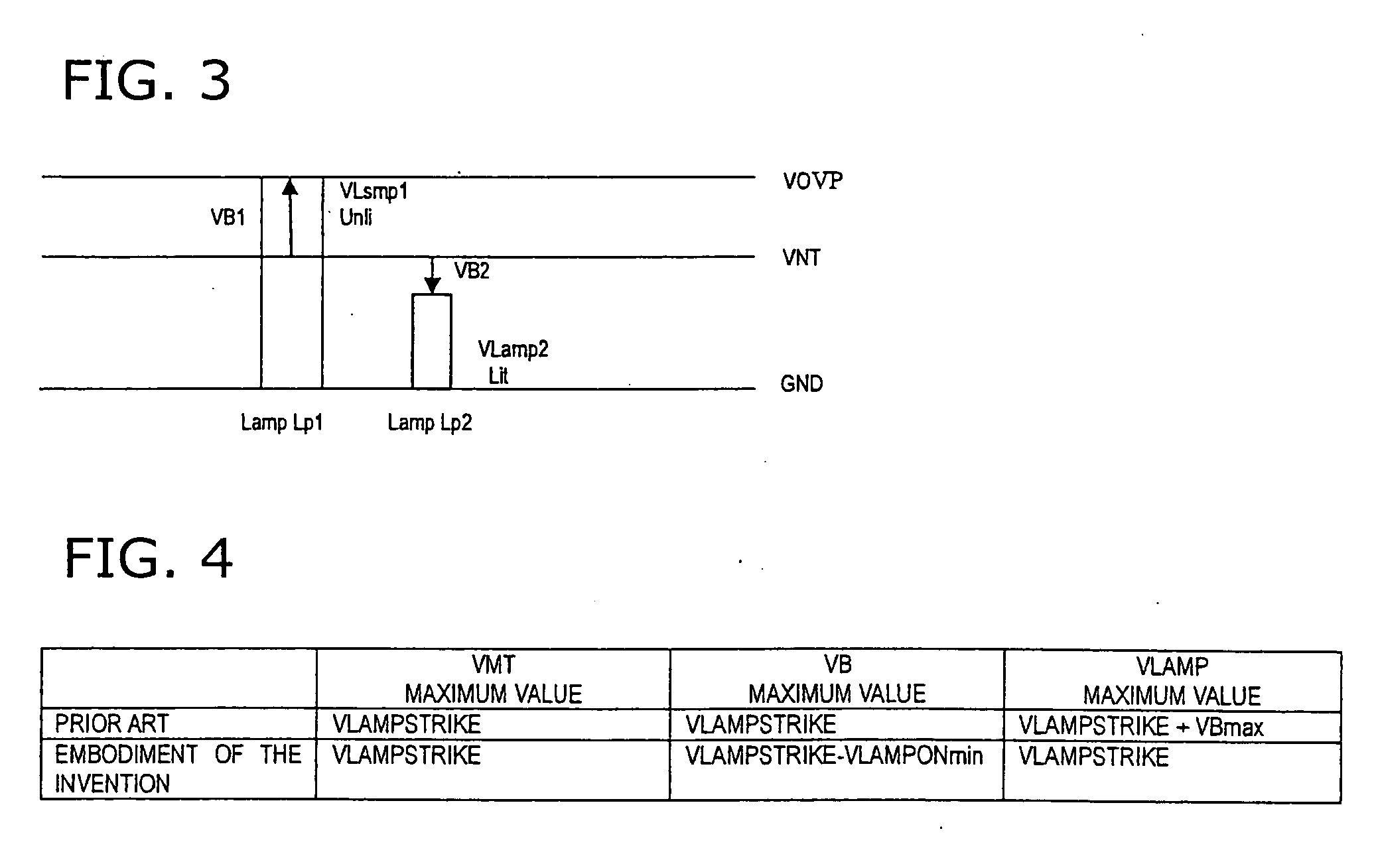

Liquid crystal display device and driving method to be used in same

InactiveUS20050083282A1Enhanced efficiencyEfficiency of feeding lightMechanical apparatusElectrical apparatusPulse voltageLiquid-crystal display

A liquid crystal display device is provided in which its cold cathode fluorescent tube serving as a surface light source block can reliably light up and efficiency of feeding light to a liquid crystal panel can be enhanced. When timing signals are fed to frequency setting sections, a frequency of each of driving pulse voltages becomes as high as a frequency being near to a resonant frequency corresponding to a floating capacitance occurring at start time of lighting of backlights and then becomes as low as a frequency being near to a resonant frequency corresponding to floating capacitance occurring at a stabilized period of lighting of the backlights. Therefore, the backlight, even if lighting duration of its cold cathode fluorescent tube is long, lights up reliably and a power factor is improved to improve efficiency of feeding light to the liquid crystal panel.

Owner:NEC LCD TECH CORP

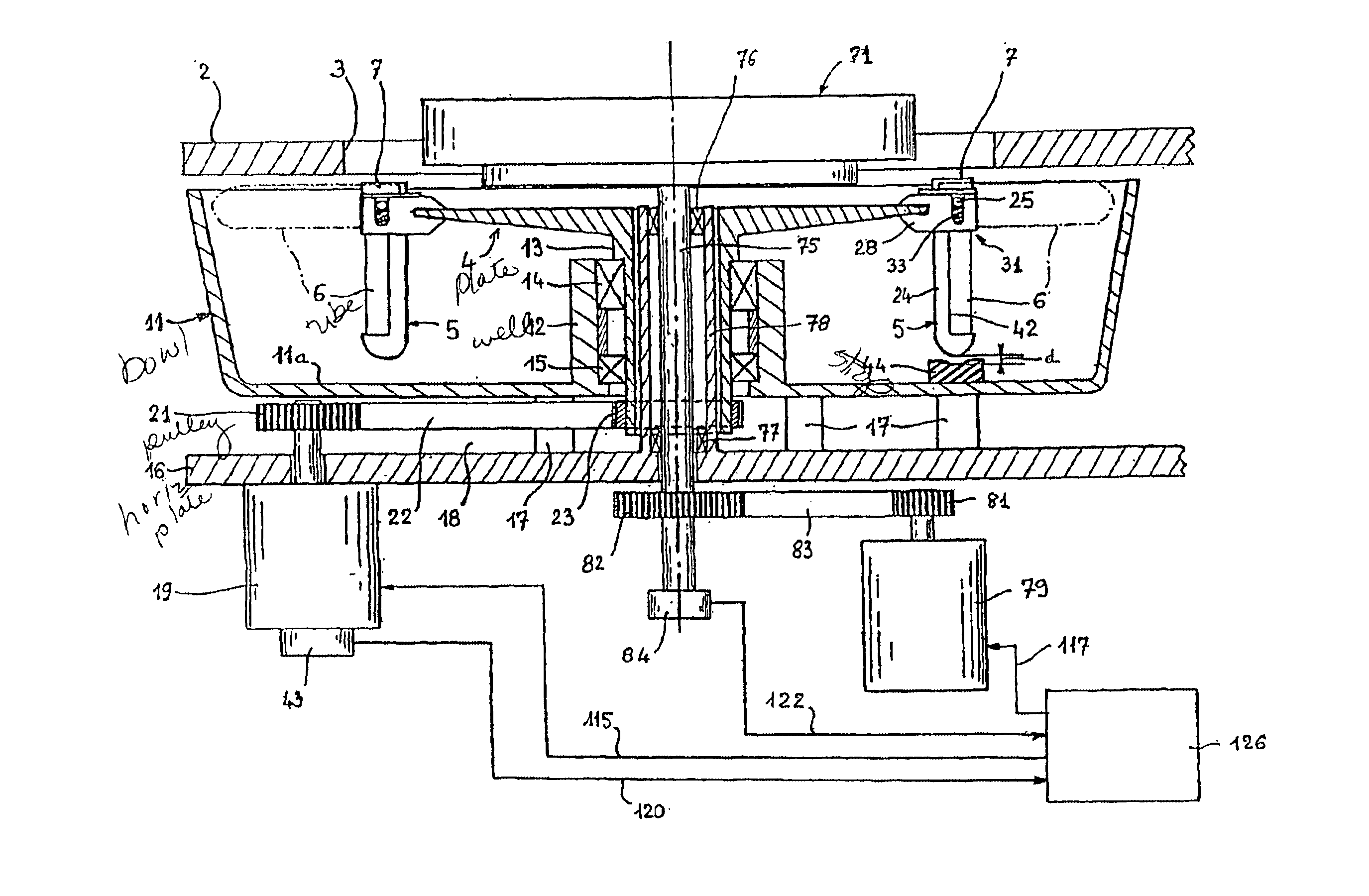

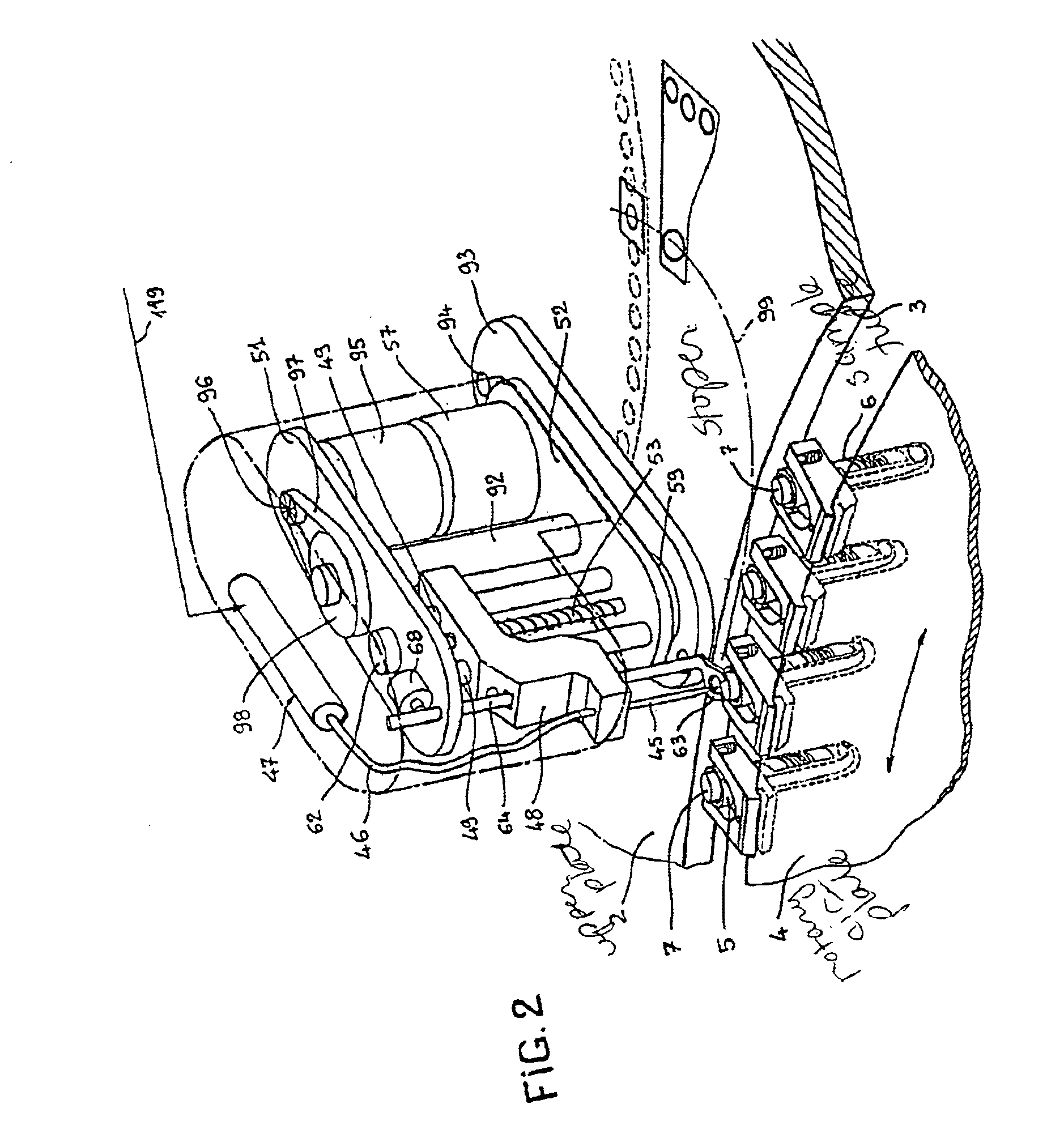

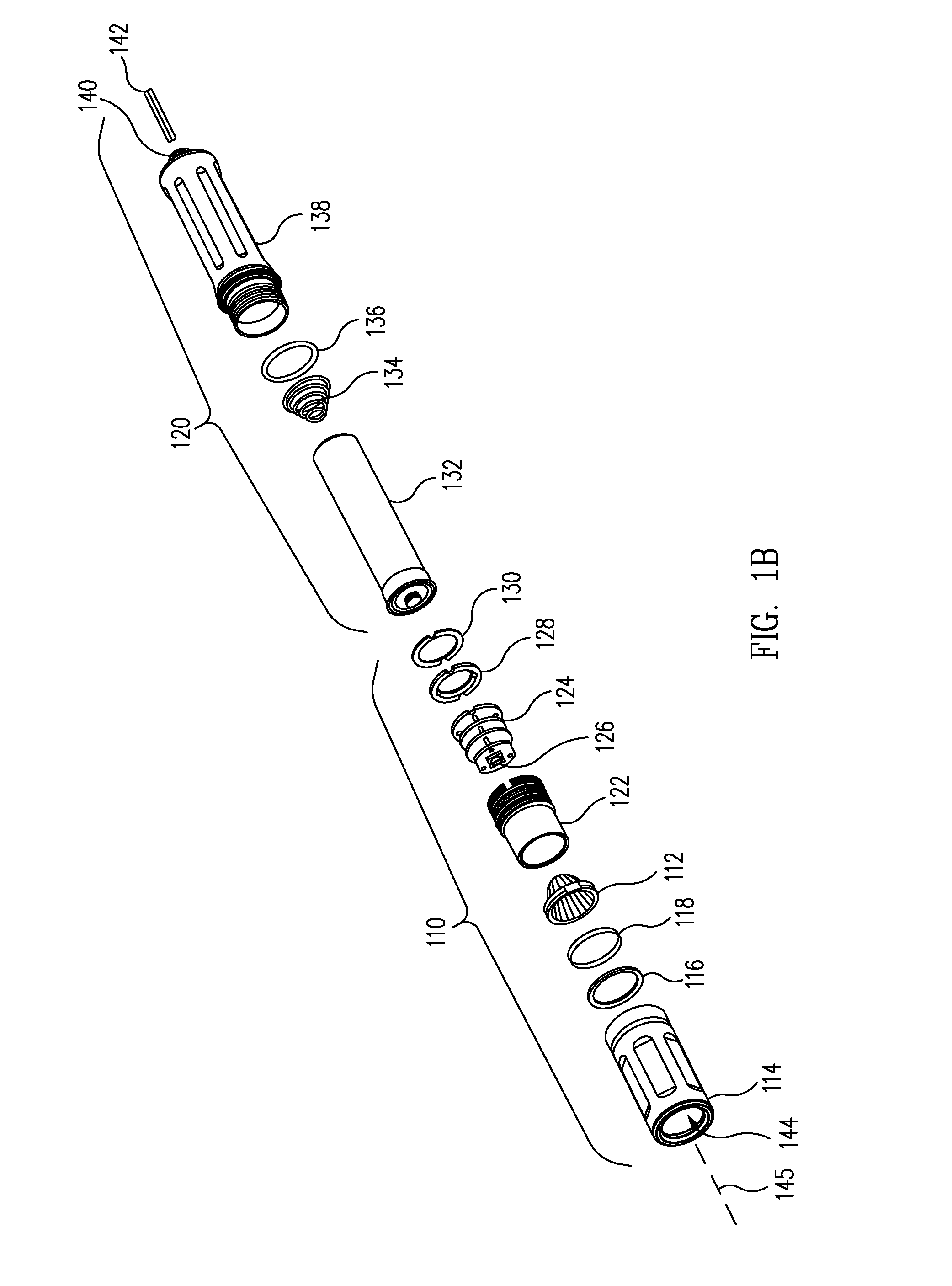

Sample analysis apparatus

InactiveUS6945129B2Significant processingImprove rigidityWithdrawing sample devicesSpecific gravity using centrifugal effectsEngineeringMechanical engineering

An apparatus for analyzing liquid samples packed in tubes (6) closed with a top (7) capable of being perforated, includes a support (4) for the tubes and a unit (8) for sampling an aliquot from each tube and delivering it into a receptacle for treatment and / or analysis, the unit (8) including a hollow needle (45) connected to a suction / delivery device and vertically mobile; the support (4) has a circular tray provided with several tube-holders (5) on its periphery and capable of rotating about a vertical axis to bring a position successively and selectively the tubes (6) borne by the tube-holders (5) in line with the unit (8); each tube-holder (5) is connected to the tray (4) through a linkage (31) with two degrees of freedom.

Owner:DIAGYR

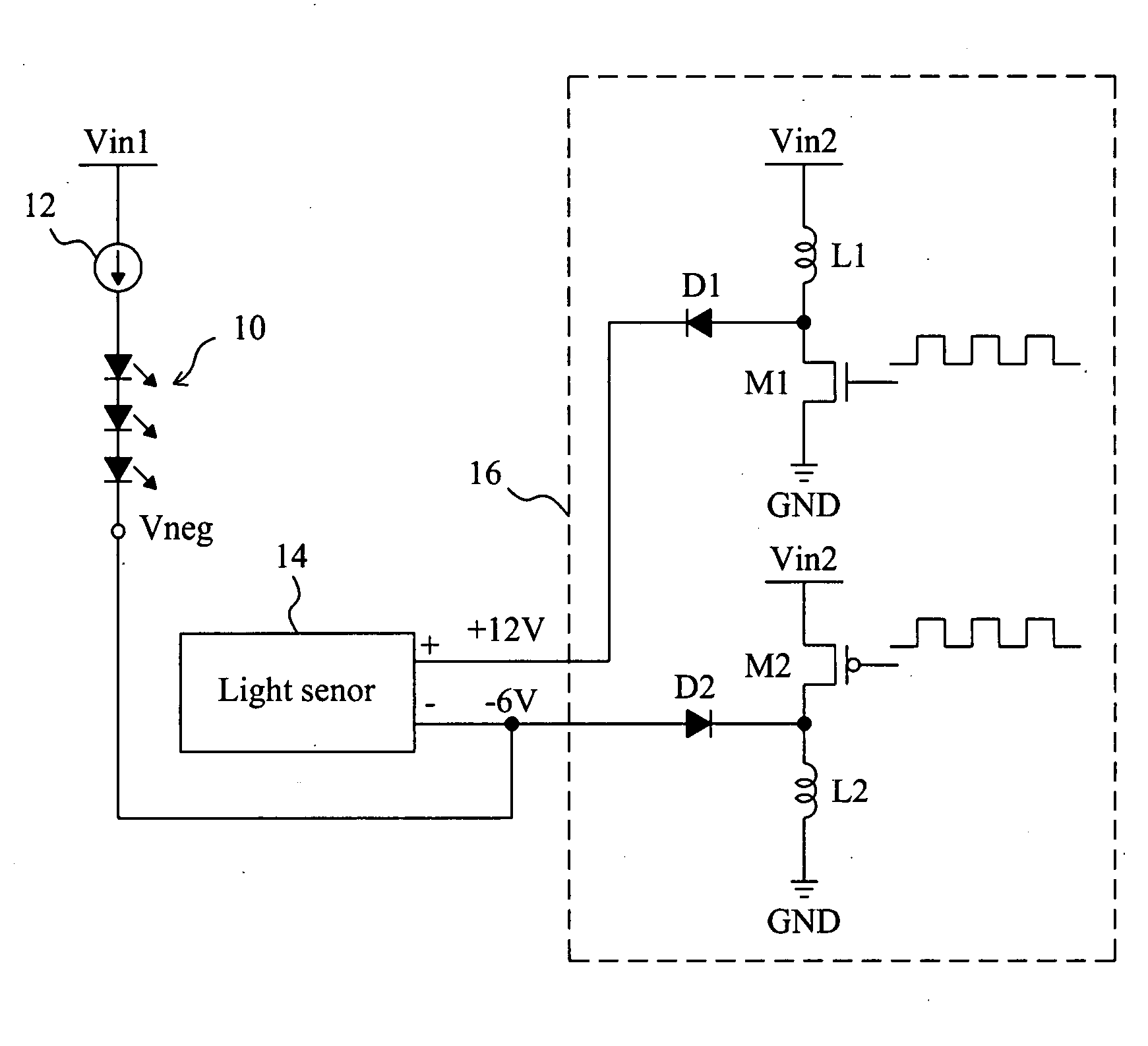

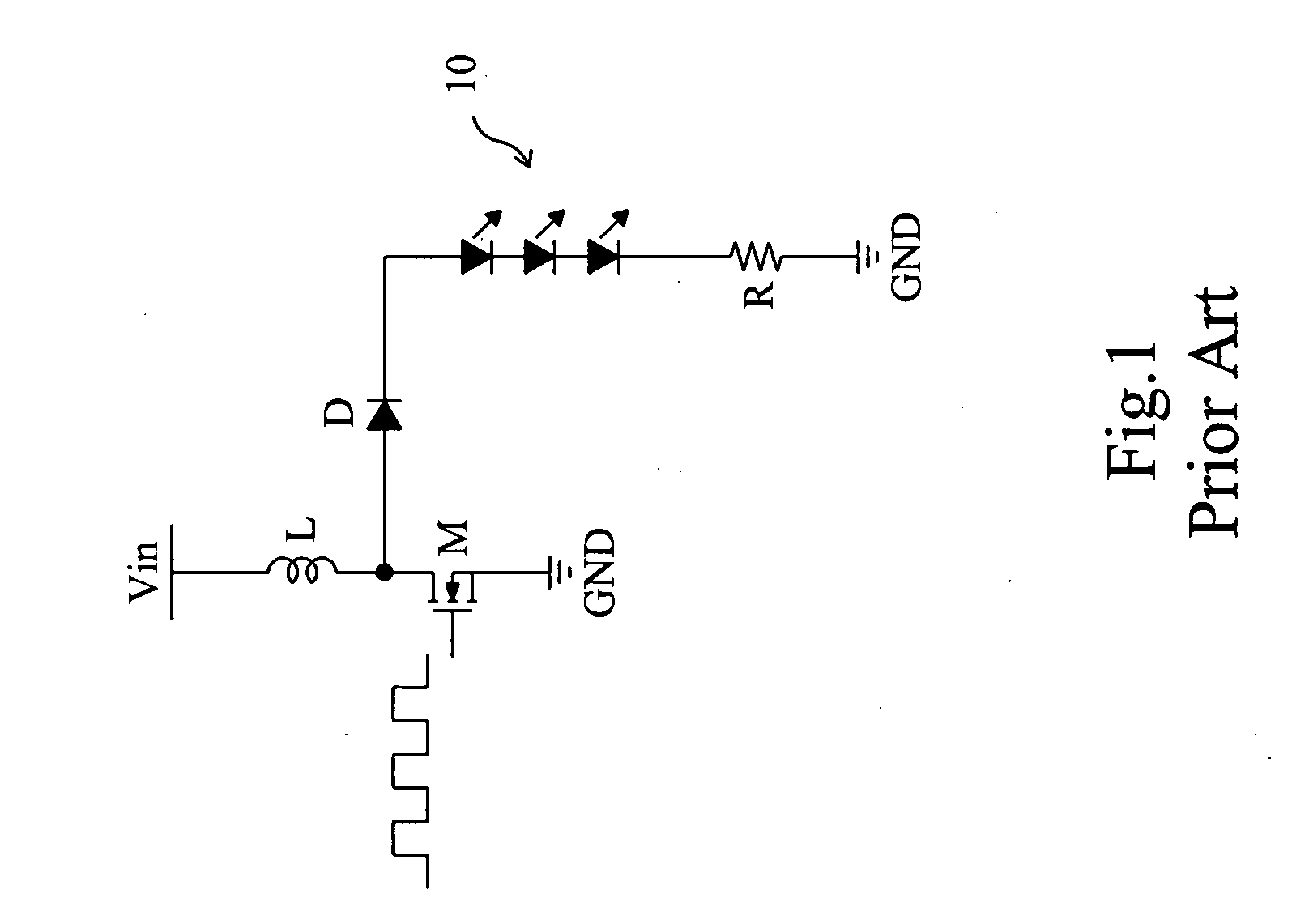

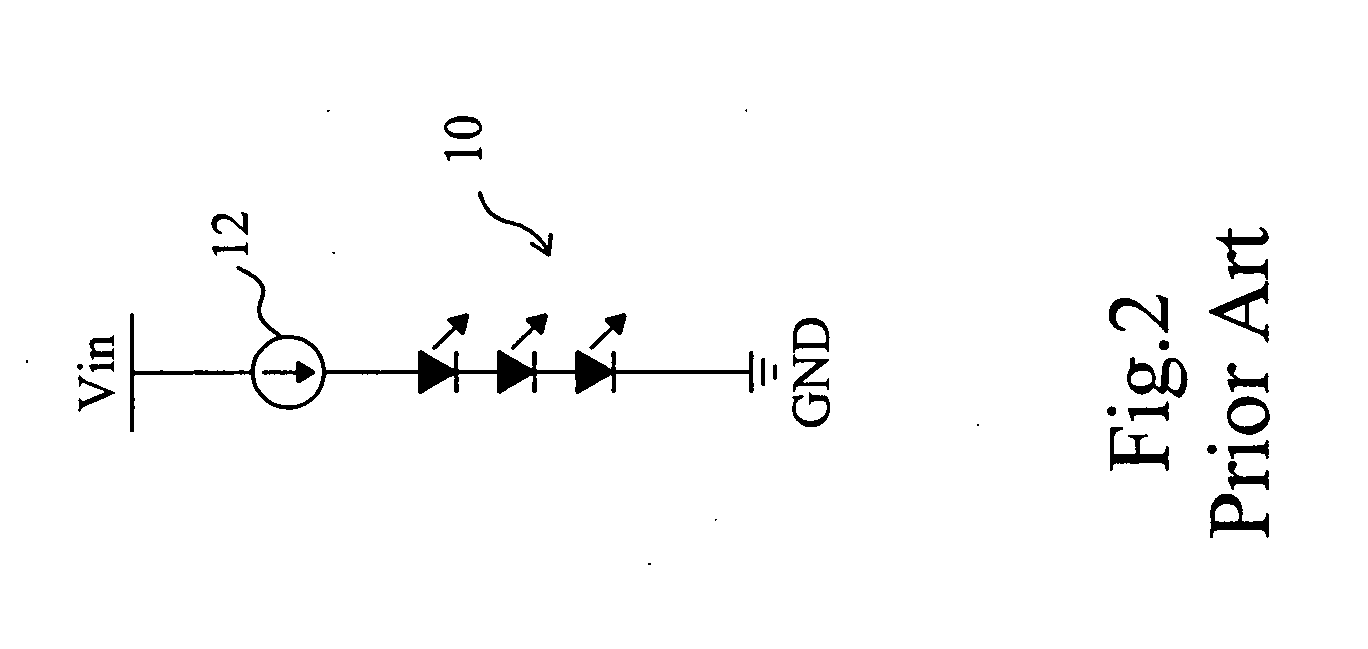

Led driving topology, light source moudle based thereon, and digital camera having the same

InactiveUS20090195187A1Great voltage differenceIncrease the differenceTelevision system detailsTelevision system scanning detailsElectricityLed array

A LED driving topology includes a LED array and a current source connected in series between two power inputs receiving a positive voltage and a negative voltage respectively. This topology increases the voltage difference across the LED array and hence has the capability of lighting up more serially connected LEDs, without requiring an additional boost circuit or a high voltage. In addition, the circuit of the current source can be made by a low-voltage manufacturing process.

Owner:RICHTEK TECH

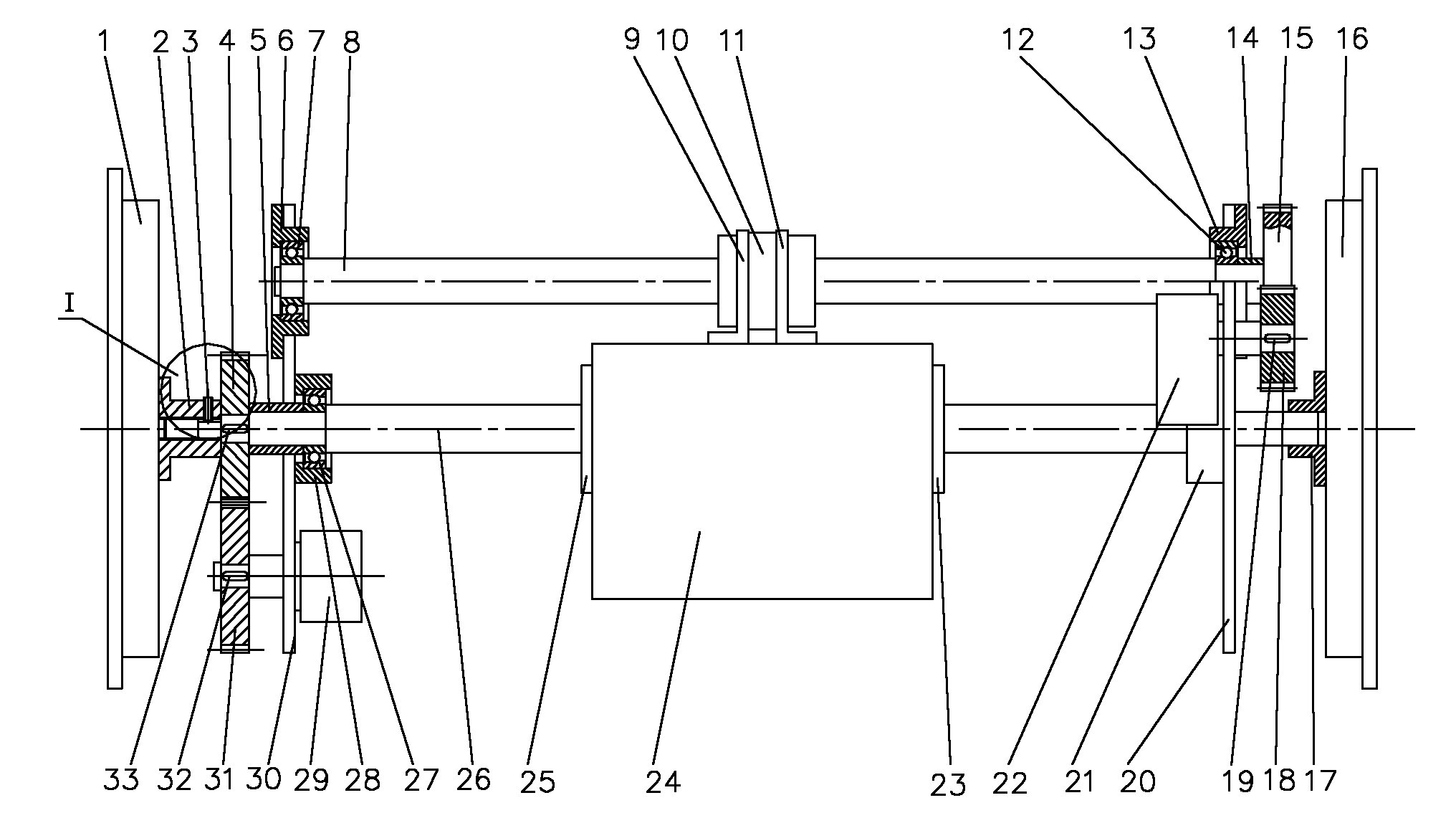

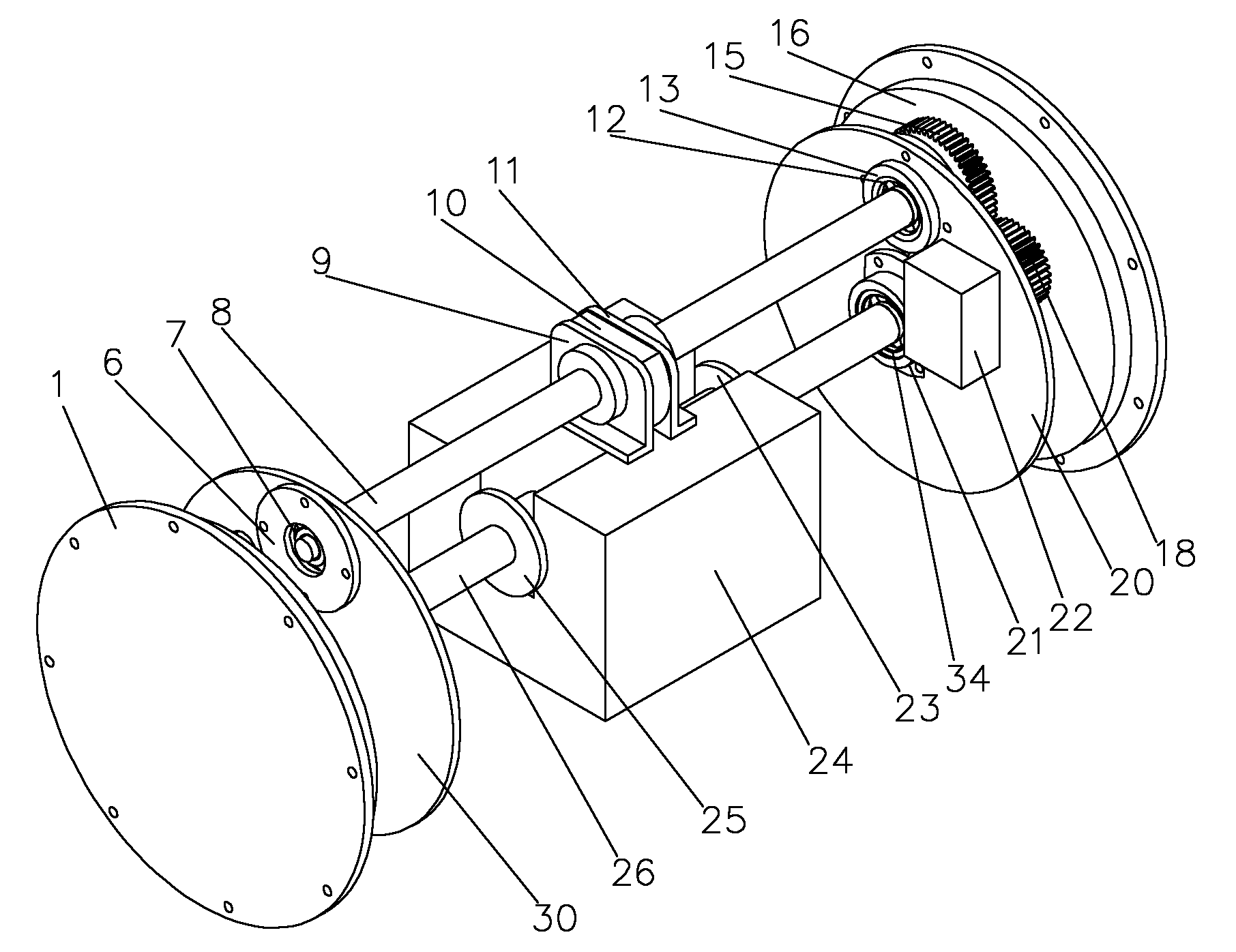

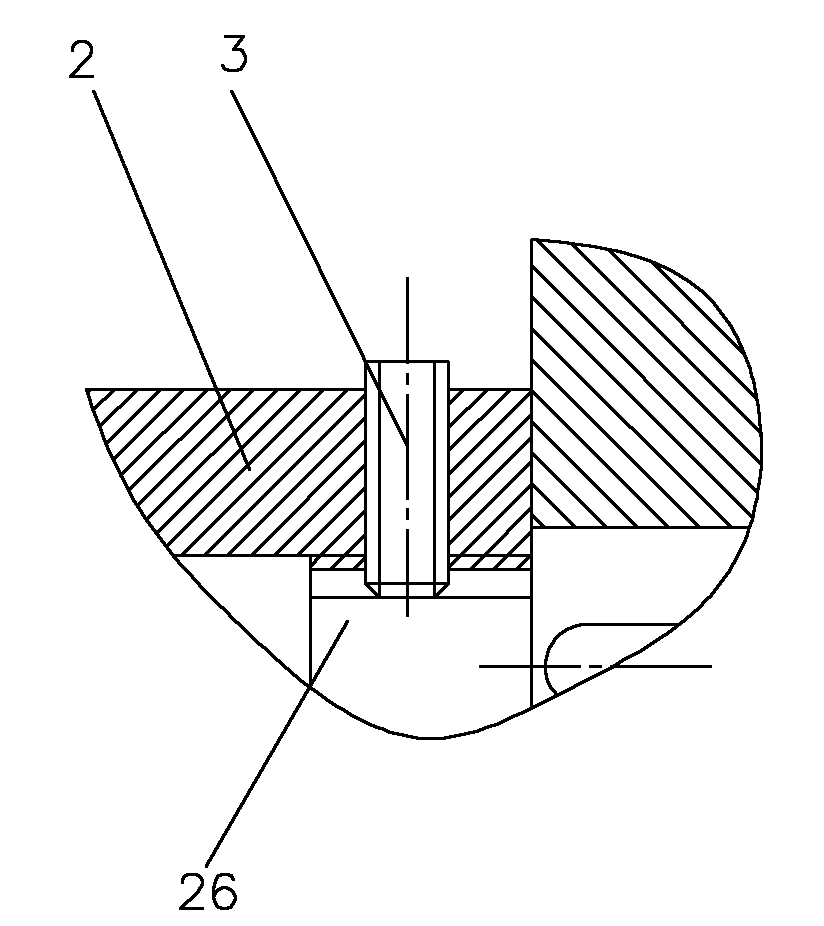

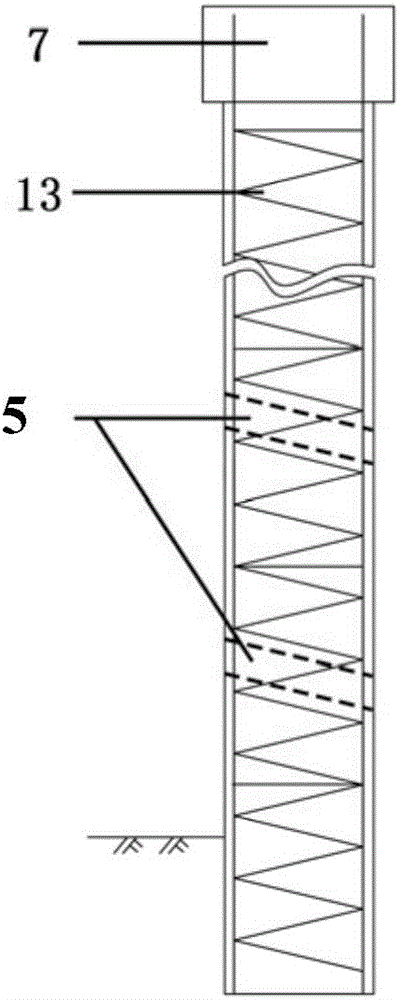

Gravity adjusting device for underwater robot

The invention provides a gravity adjusting device for an underwater robot. A central shaft is fixed between two end covers, and is provided with a left supporting disk and a right supporting disk, which can freely rotate around the central shaft, and an eccentric battery block; a screw rod is arranged between the left and the right supporting disks, and is provided with a ball nut; the ball nut is fixedly connected with the eccentric battery block through a connecting piece; the right supporting disk is provided with an axial adjusting motor; an axial position adjusting transmission mechanism is arranged between an output shaft of the axial adjusting motor and a ball screw rod; a rolling motor is arranged on the left supporting disk; and a rolling position adjusting transmission mechanism is arranged between an output shaft of the rolling motor and the central shaft. By adopting the gravity adjusting device, gravity adjustment of the underwater robot in two directions can be realized at the same time, i.e., the axial position and the rolling position of the gravity of the underwater robot can be adjusted, the service efficiency of the internal space of the robot is increased, and conditions for reducing the weight of the robot and enhancing the effective equipment carrying capability of the robot are provided.

Owner:HARBIN ENG UNIV

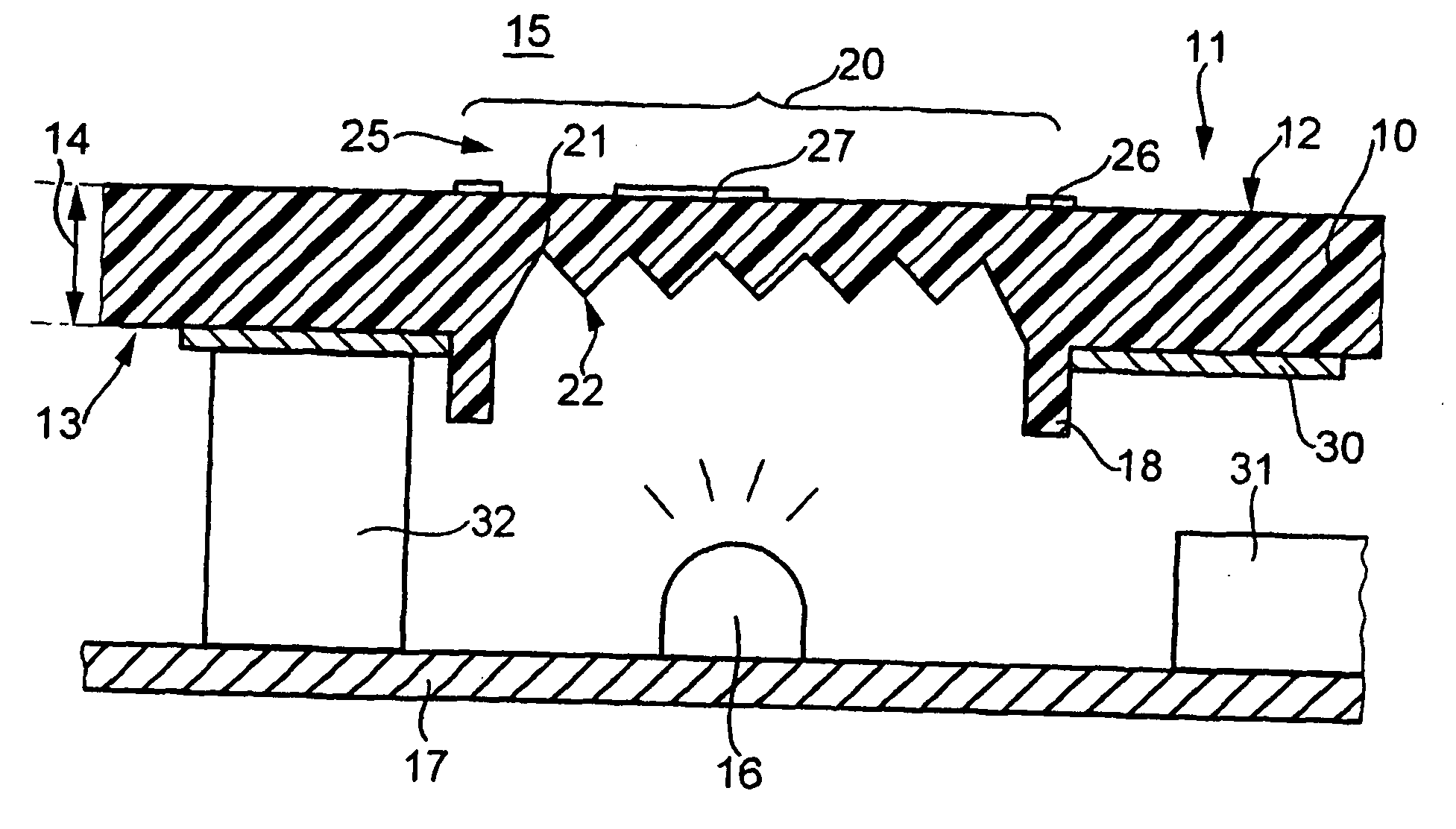

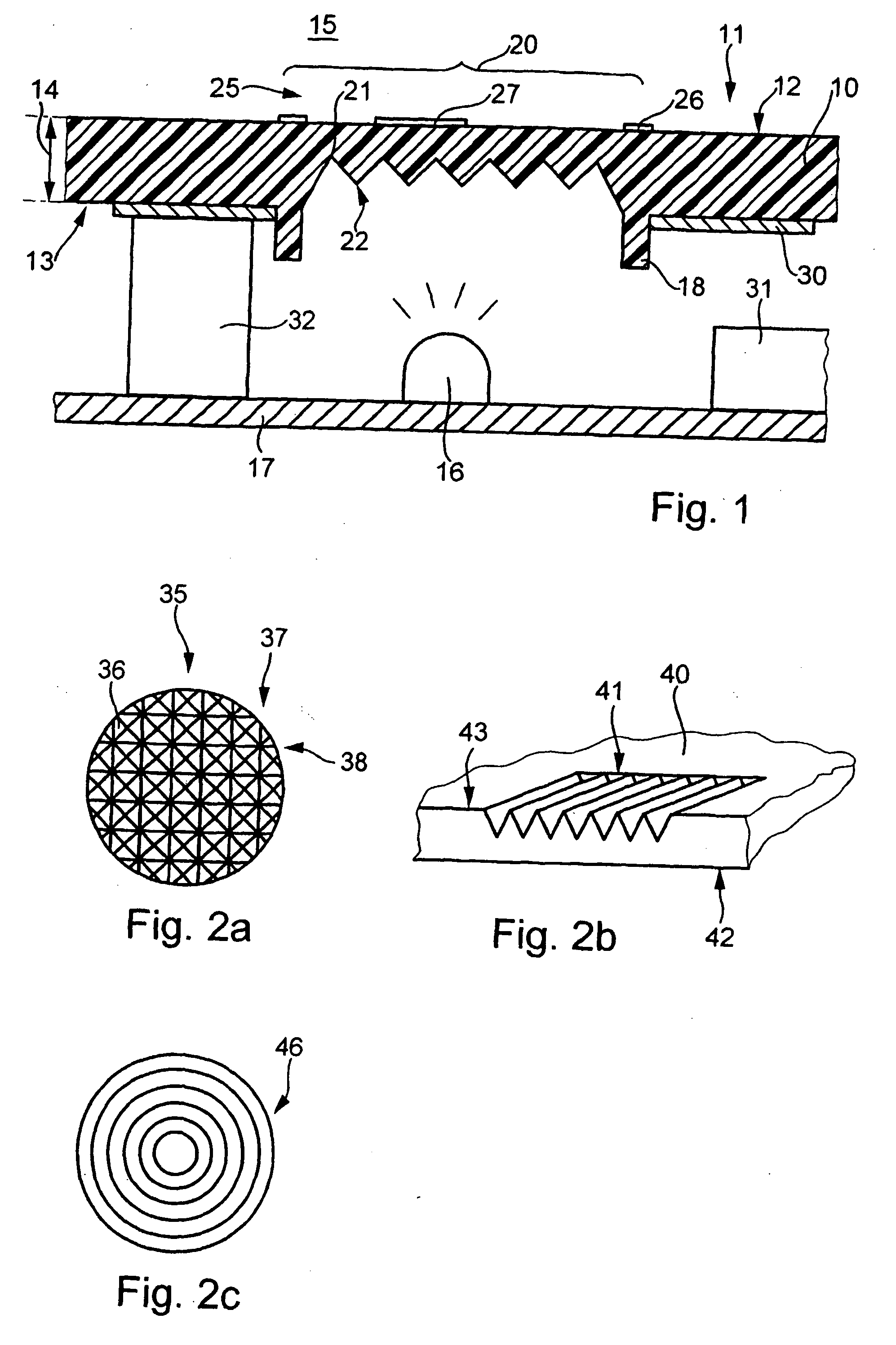

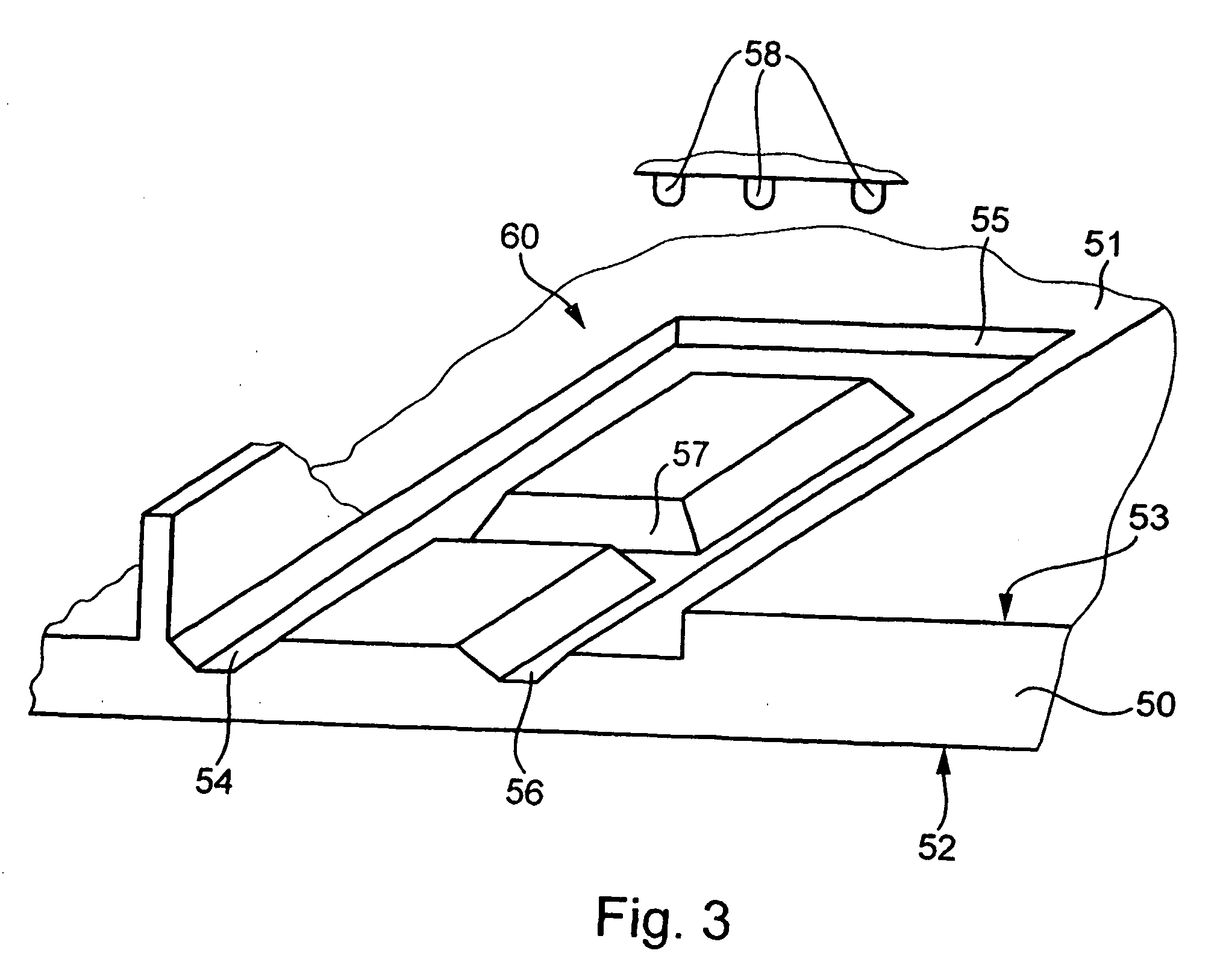

Electrical household appliance equipped with a control device and a display device

InactiveUS20060089732A1Large wall thicknessImprove stabilityDomestic stoves or rangesTableware washing/rinsing machine detailsDisplay deviceLight-emitting diode

One embodiment of the invention concerns an electrical household apparatus, for example a washing machine, equipped with a control device in the form of a panel, said panel comprising a display device for providing visual data to the user. Said panel (10) is made of a material which is substantially opaque when it has a normal thickness (14). One area specific to the display device (15) comprises at least one transparency zone (20) wherein the thickness of the panel material is reduced relative to the thickness of the material outside said transparency zone such that light from a light source (16), for example a light-emitting diode, located behind the panel may pass through said transparency zone. Such a configuration provides backlighted panels having a closed surface. In another embodiment, the control device is in the form of a turning knob (70, 80).

Owner:E G O CONTROL SYST

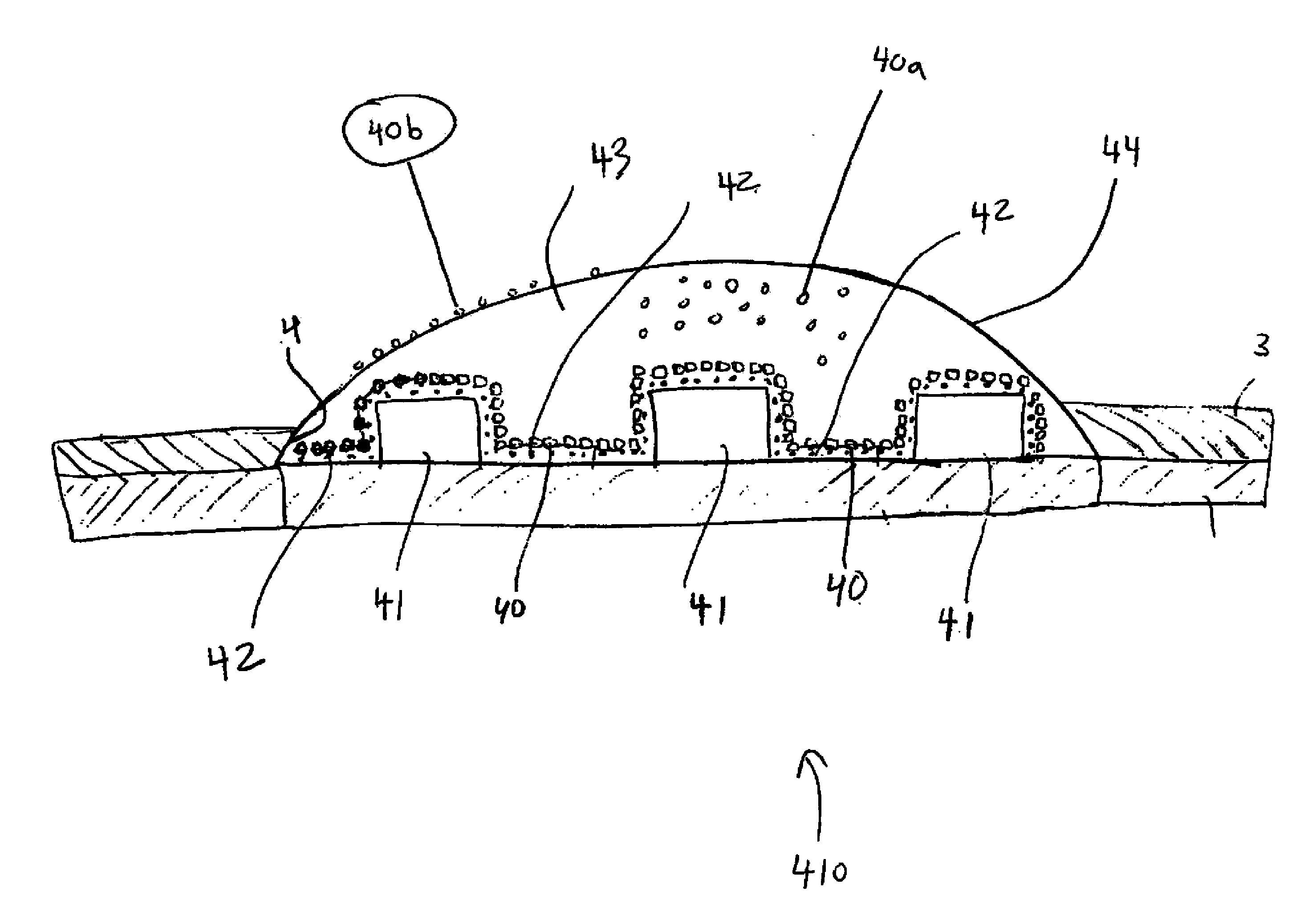

Profiled fire-retardant bright terylene FDY (Fully Drawn Yarn) filament and production process thereof

InactiveCN102586939AIncrease the areaImprove cooling effectFlame-proof filament manufactureFilament forming substance formingMasterbatchPolyethylene terephthalate glycol

The invention discloses a profiled fire-retardant bright terylene FDY (Fully Drawn Yarn) filament and a preparation process thereof. The raw materials of the fire-retardant bright terylene FDY filament comprises 92-94% of PET (Polyethylene Terephthalate) slice and 6-8% of fire-retardant masterbatch. The profiled fire-retardant bright terylene FDY filament produced by the invention has good fire-retardant performance and special cross section; a gap between the surfaces of single filaments can form a good capillary effect, so that the filament has a good moisture absorption function; and the filament has a bright performance so as to be particularly suitable for the production of high-grade clothes. According to the invention, through the control to the processes of crystallizing and drying the slices, melting, cooling yarn strips, bundling, applying oil, drawing and forming, and the like, the preparation process is simple, broken filaments of a prepared product are fewer, and the dyeing is uniform.

Owner:JIANG SU TIANDI CHEM FIBER

Solid state LED bridge rectifier light engine

ActiveUS20090289267A1Avoid heavyShorten the timeElectroluminescent light sourcesSolid-state devicesCurrent limitingPhosphor

A solid-state light engine comprised of light emitting diodes (LEDs) configured into a bridge rectifier with a current limiting module coupled to the LED bridge rectifier. The light engine may be packaged for high temperature operation. Optionally, the LEDs comprise wavelength-converting phosphors with a persistence that is a multiple of the peak to peak current period, to smooth and mask ripple frequency pulsation of emitted light.

Owner:LIGHTING SCI GROUP

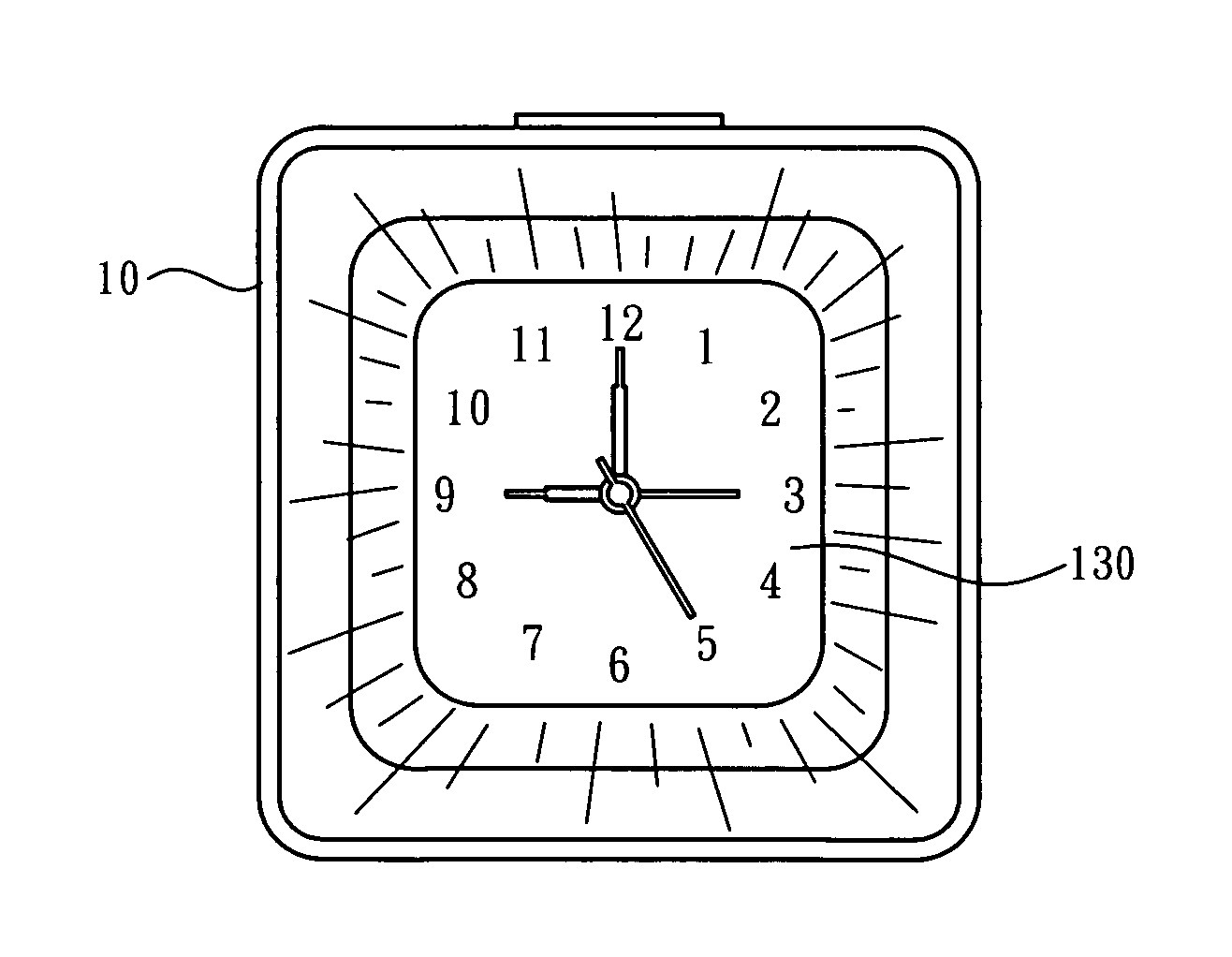

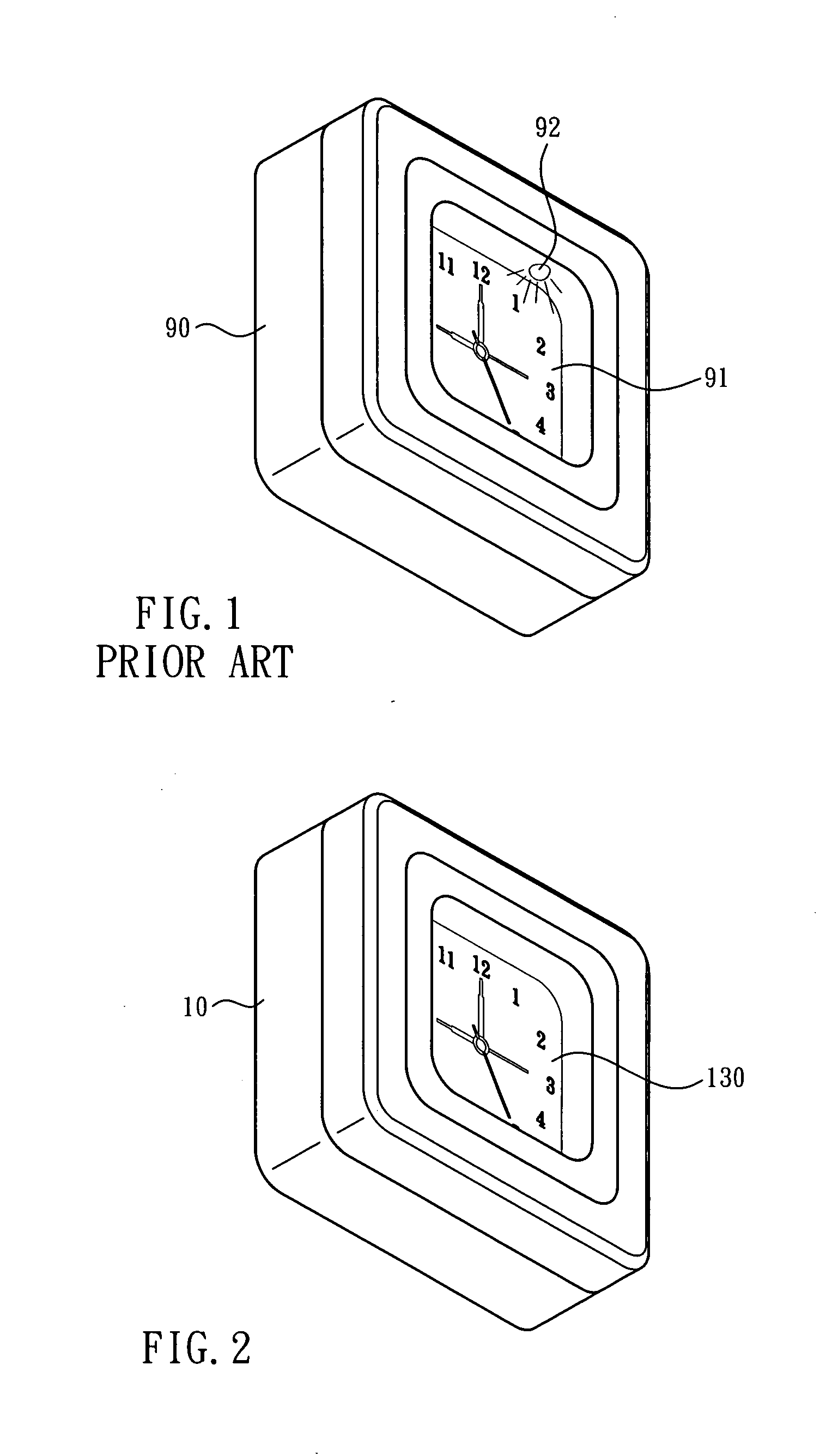

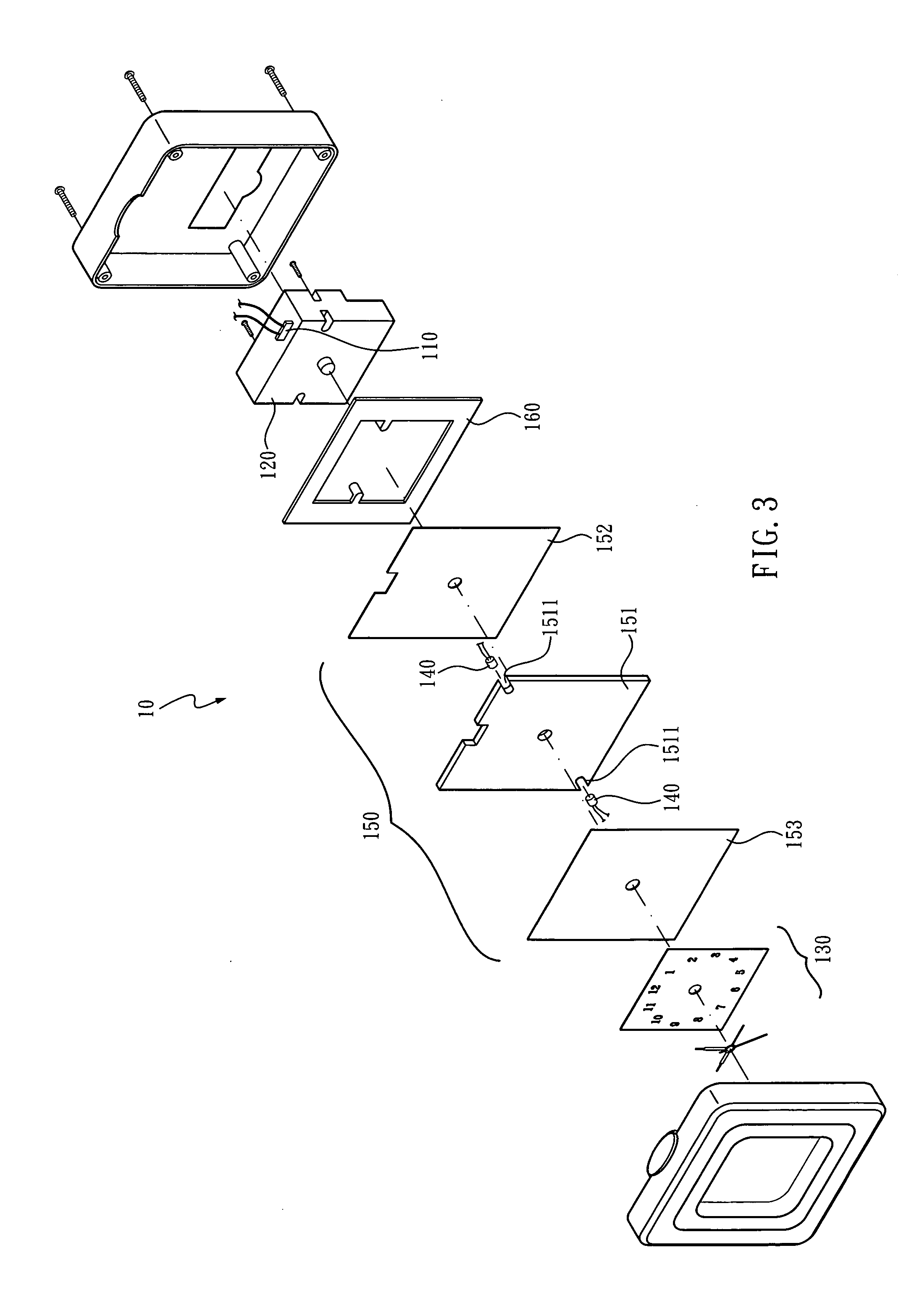

Indicator timepiece having light diffusing effect

InactiveUS20110280110A1Simple structureReduce manufacturing costVisual indicationLight diffractionOptoelectronics

An indicator timepiece having a light diffraction function is provided. Therein a light diffusion unit is provided between a timepiece movement and a time indicating unit of the indicator timepiece for receiving a lighting device and providing at least light diffraction to a light generated from the lighting device. Thereby the light diffraction of the light diffusion unit converts the light into a sheet-like lighting presented on the time indicating unit.

Owner:CHEN MING HSIEN

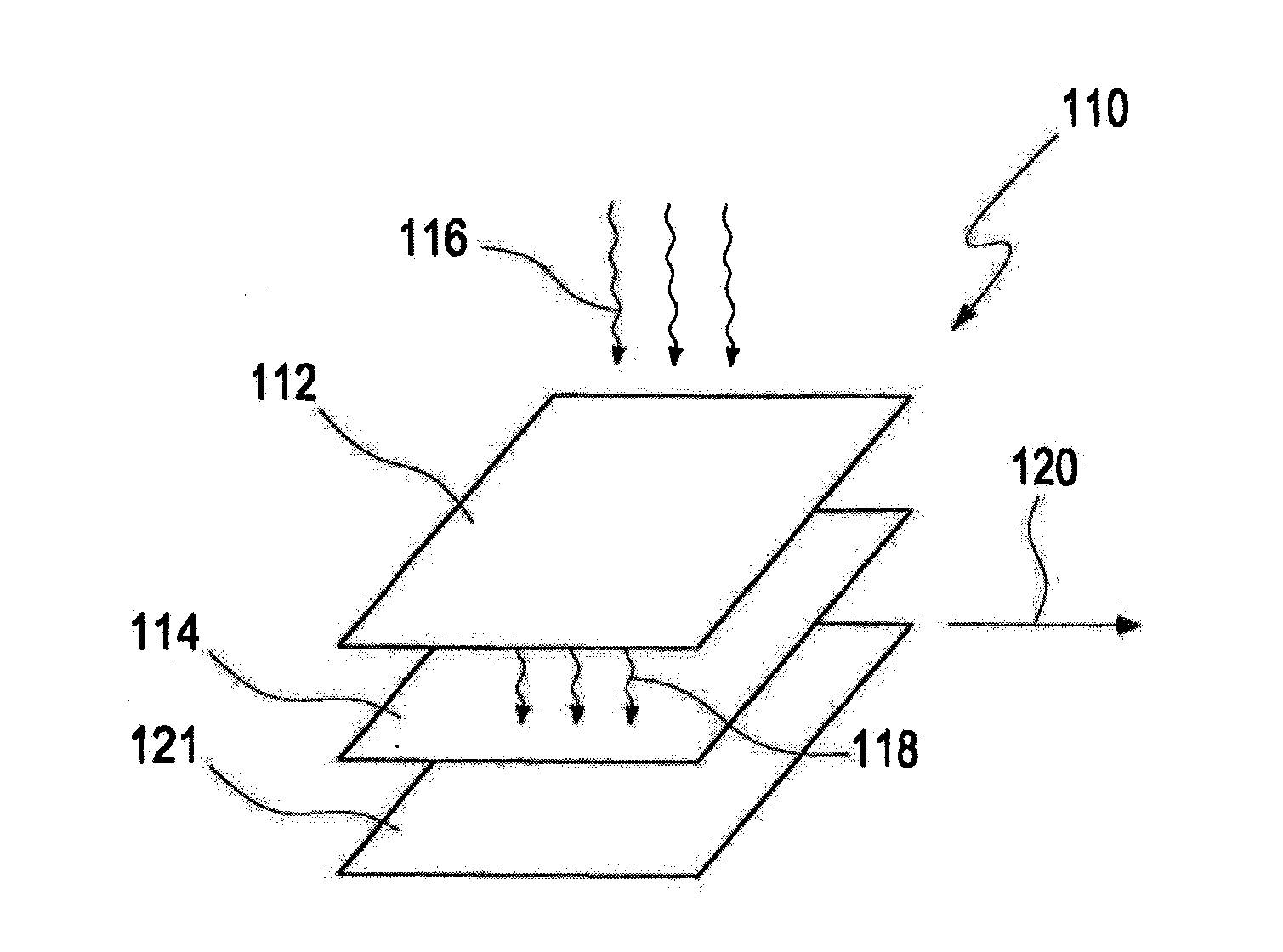

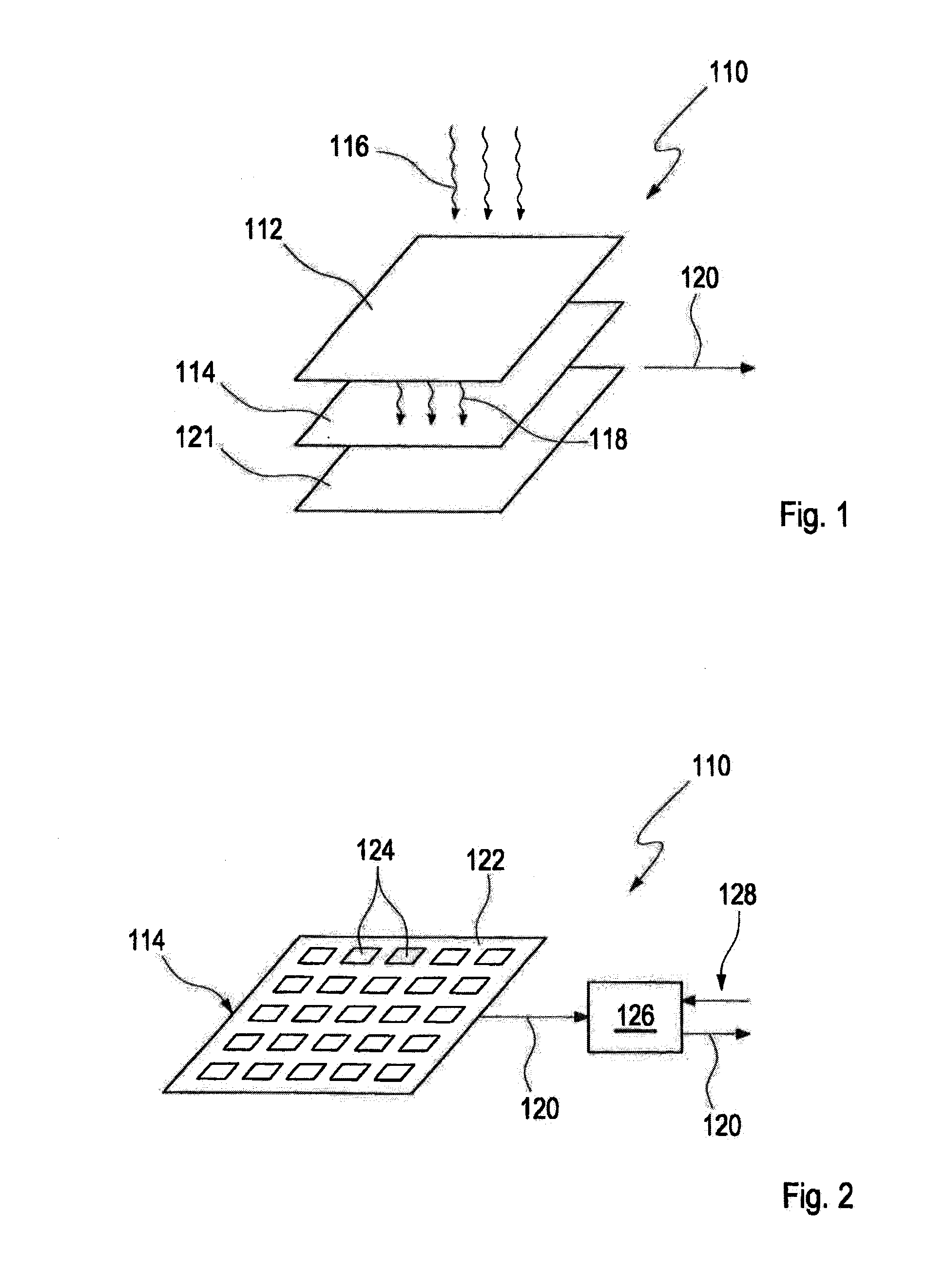

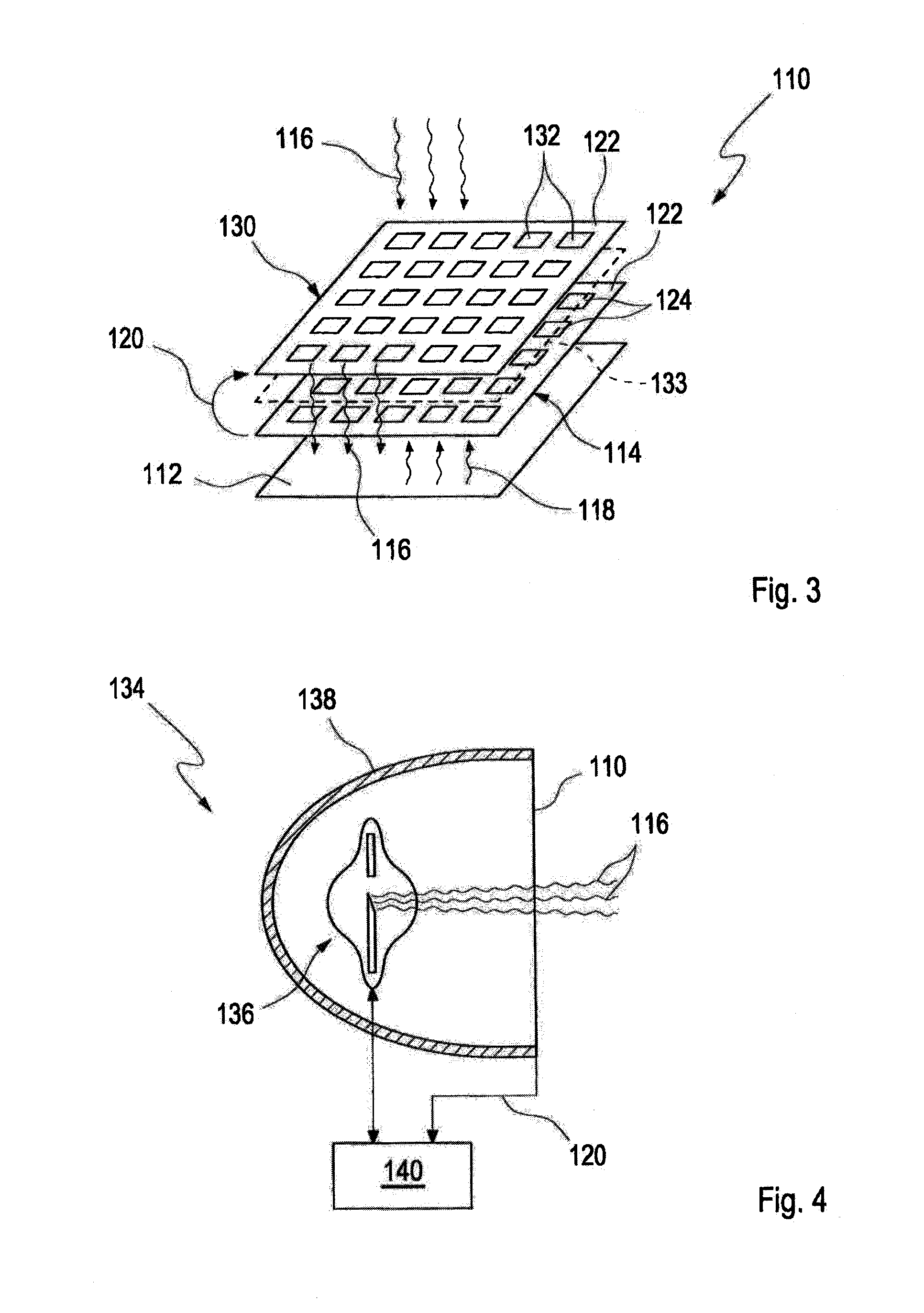

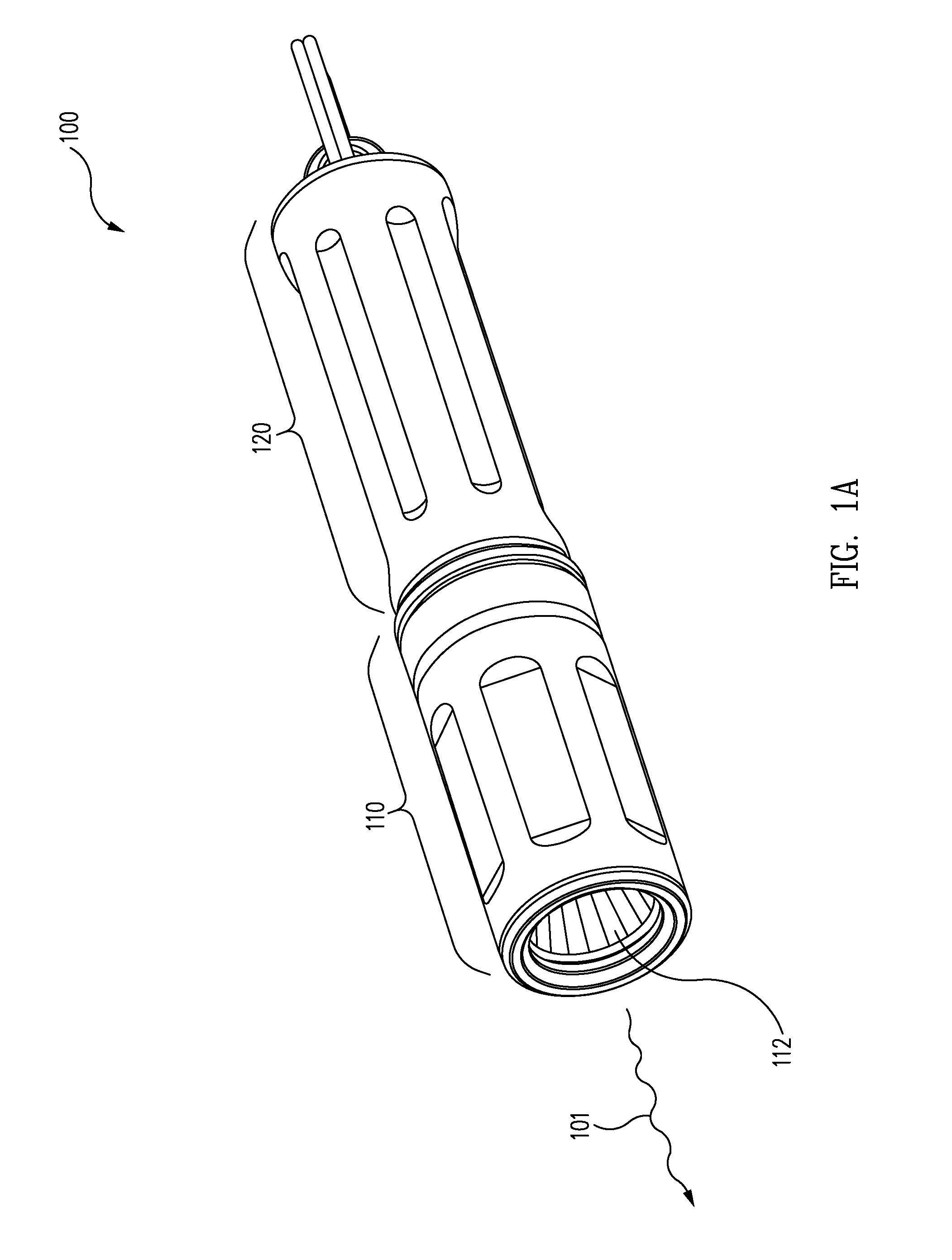

Detector for the detection of ionizing radiation

InactiveUS20120241628A1Easy to manufactureReduce absorptionSolid-state devicesMaterial analysis by optical meansElectromagnetic radiationScintillator

The invention relates to a detector (110) for the detection of ionizing radiation (116). The detector (110) comprises at least one scintillator (112) which is adapted to convert the ionizing radiation (116) to electromagnetic radiation (118), especially to visible, ultraviolet or infrared light. The detector (110) further comprises at least one organic photovoltaic element (114) which is adapted to convert the electromagnetic radiation (118) to at least one electrical signal (120).

Owner:ION BEAM APPL

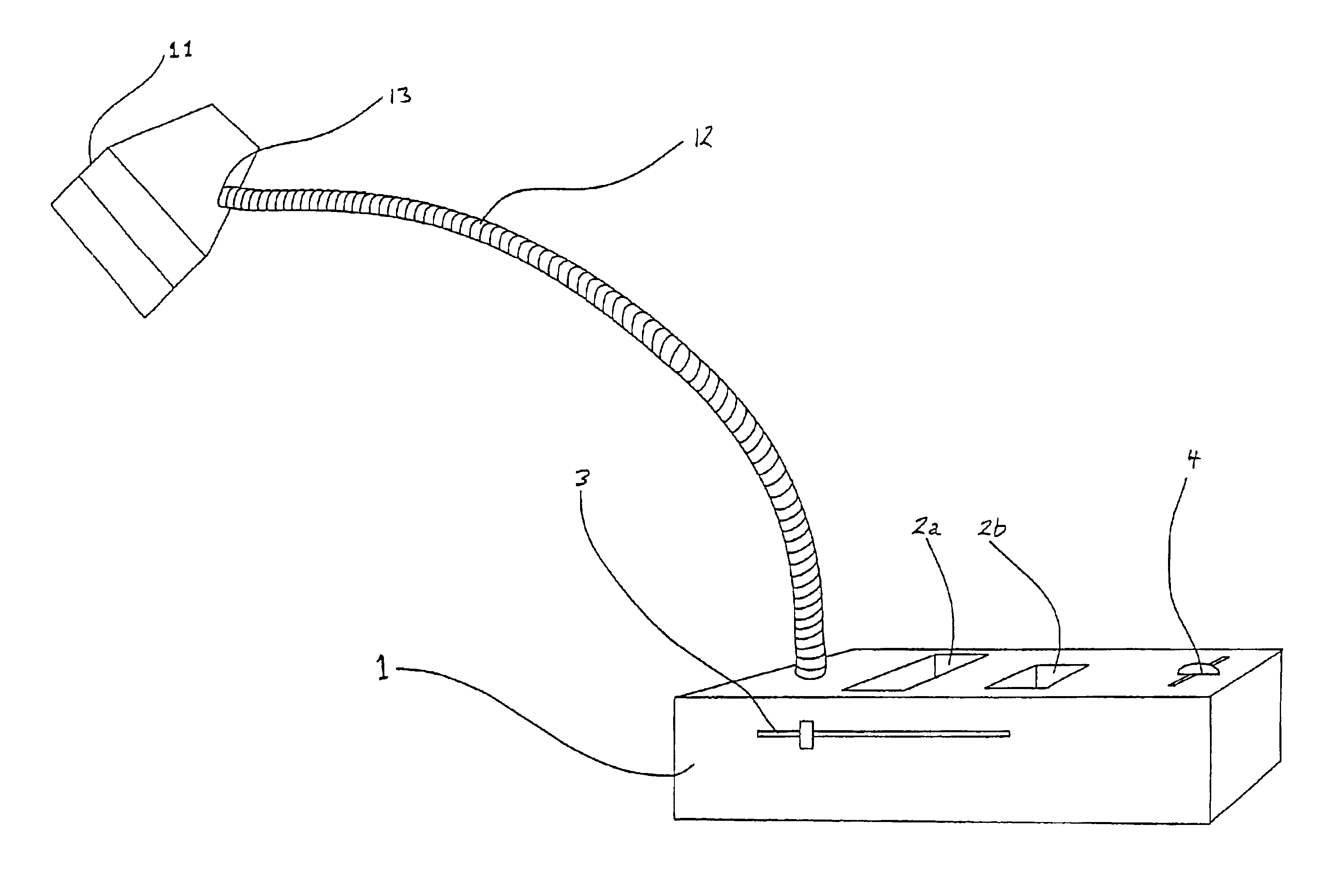

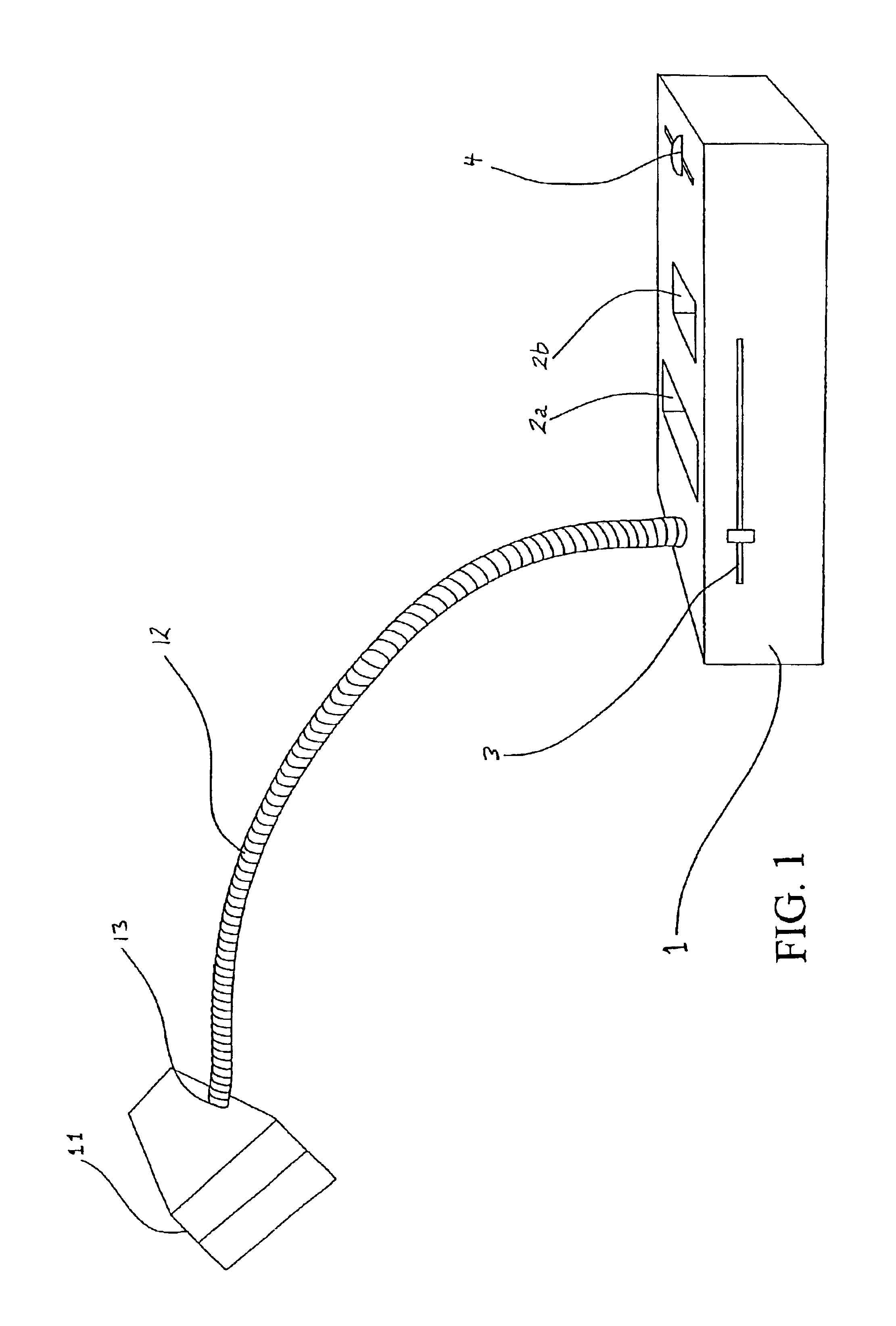

Charging station for pagers with night light

InactiveUS6897785B2Save a lot of energyAvoid injuryBatteries circuit arrangementsWith electric batteriesPagerLight beam

A recharging stand for pagers with a night light designed for the particular needs of emergency response personnel such as firemen. The light is preferably activated only in response to a signal to the pager. Also, the light is a focused beam that is adjustable in direction as needed by the user. Optionally, the light may be attached to a timer, which deactivates the light after a set amount of time since activation has lapsed.

Owner:CORBUS FRLIN

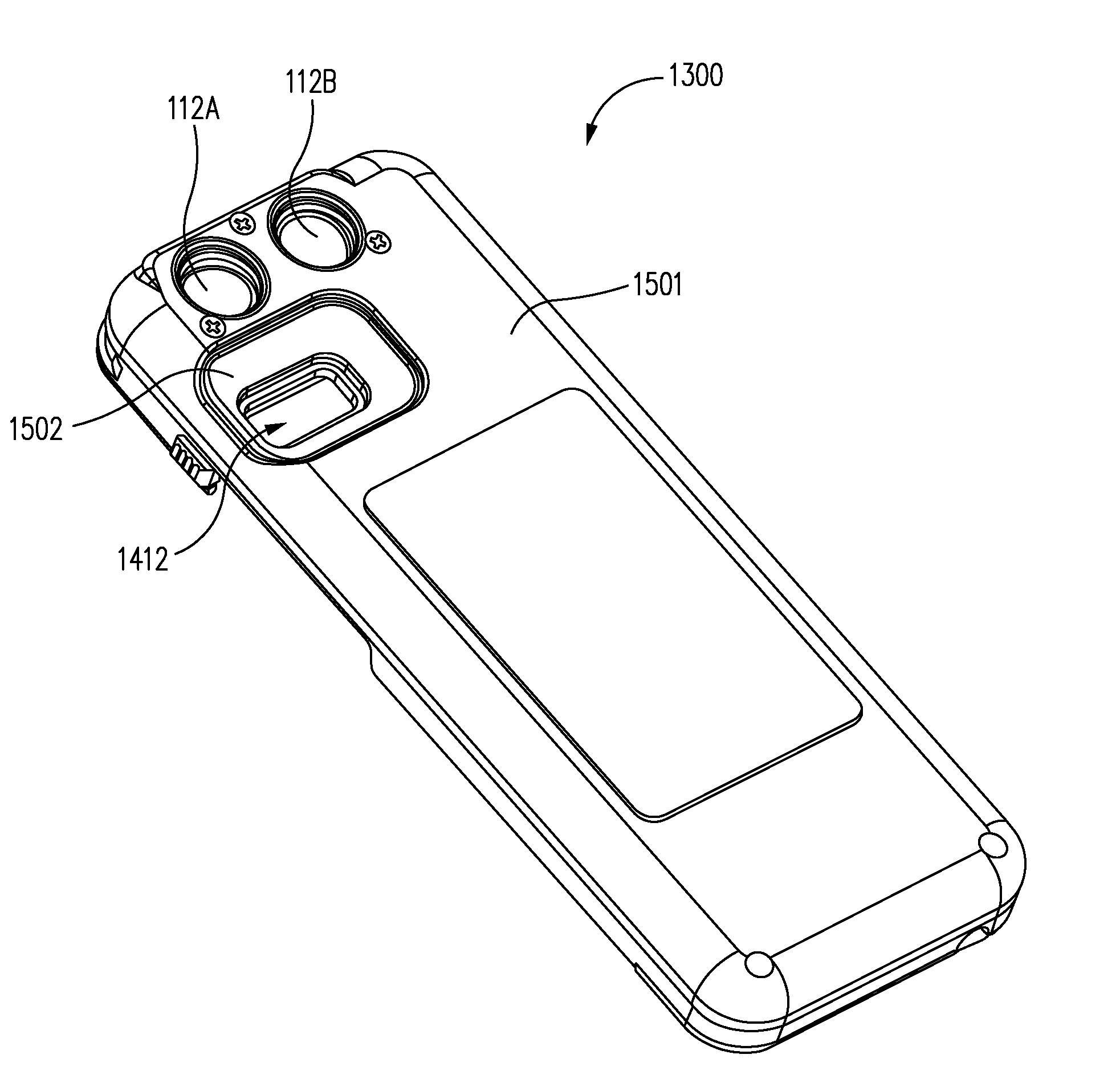

Lighting device attachment for mobile devices

InactiveUS20160209025A1Eliminate structureReducing angular extentLighting elementsWith electric batteriesLight equipmentElectrical battery

A lighting device attachment for a mobile device may include a housing that defines a cavity or an external coupling member configured to receive the mobile device, a light source within the housing, and an optical element adapted to project light from the light source to illuminate an external scene. The attachment may include multiple light sources and multiple associated optical elements to generate a combined beam for illuminating the external scene which may include the field of view of a camera of the mobile device. The camera and the light sources may be cooperated to capture still or video images. The attachment may include a battery that provides power to the light sources and / or the mobile device and may charge a battery of the mobile device. The light sources may be operated by a control device of the attachment and / or by the mobile device. Related methods are provided.

Owner:SUREFIRE LLC

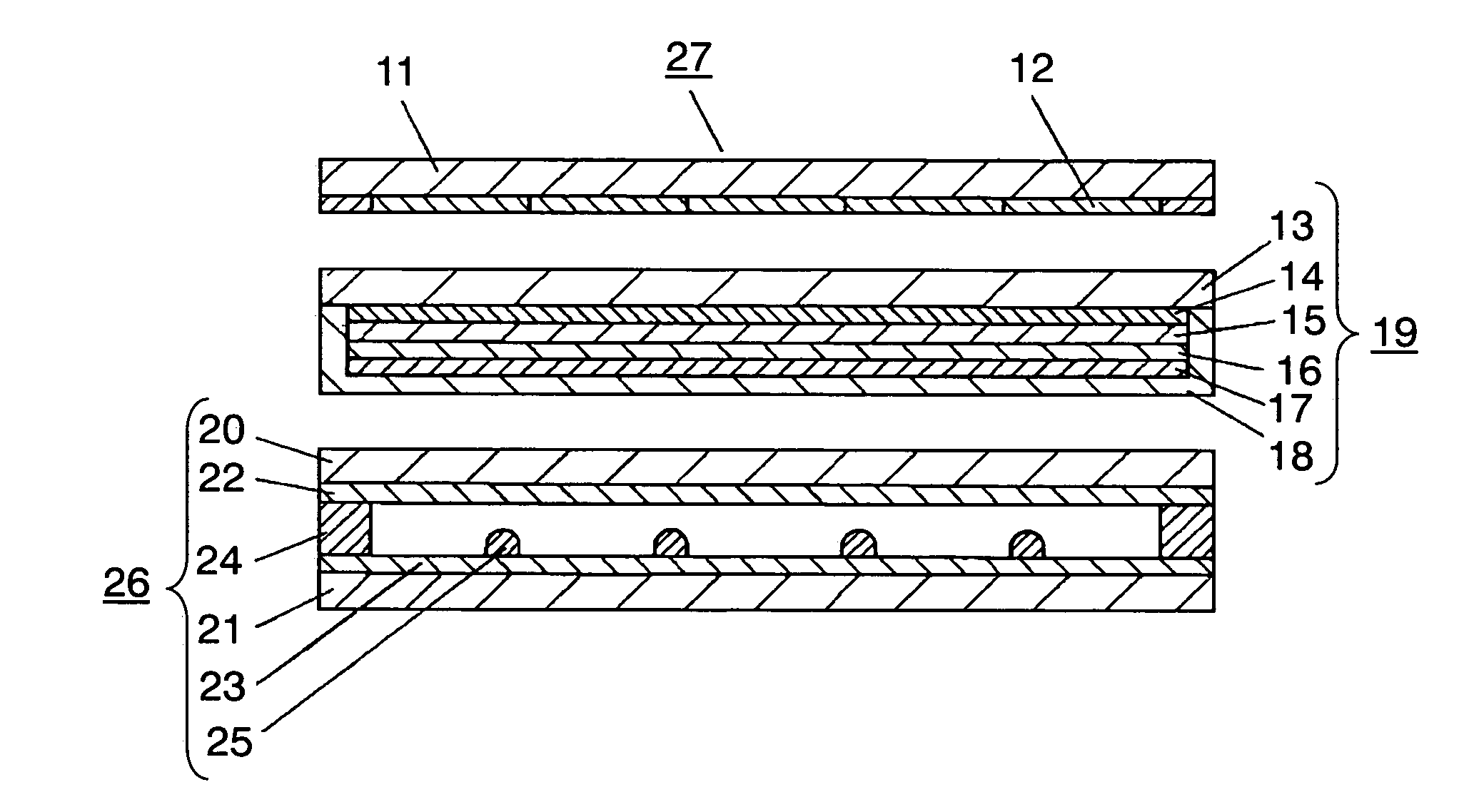

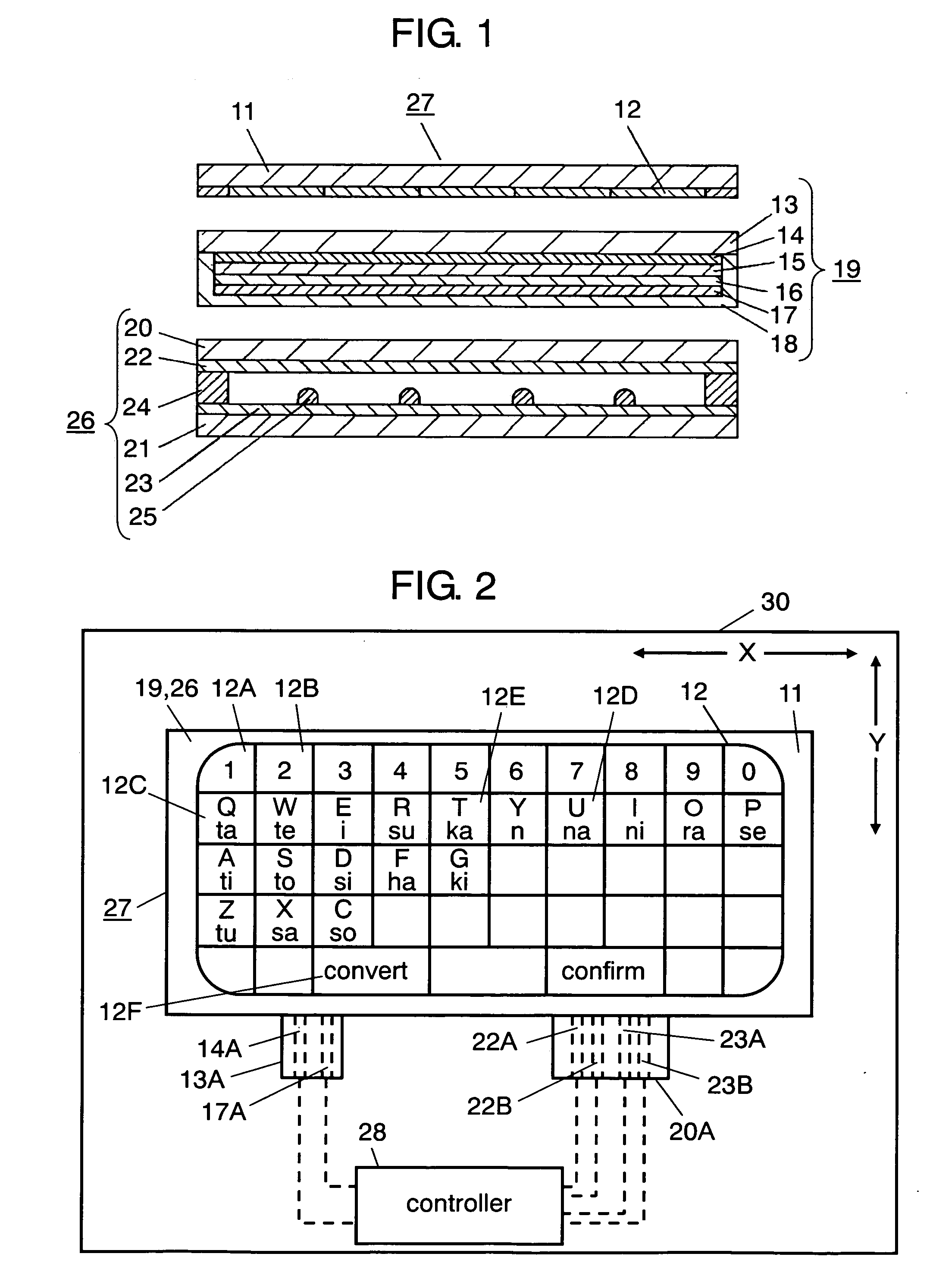

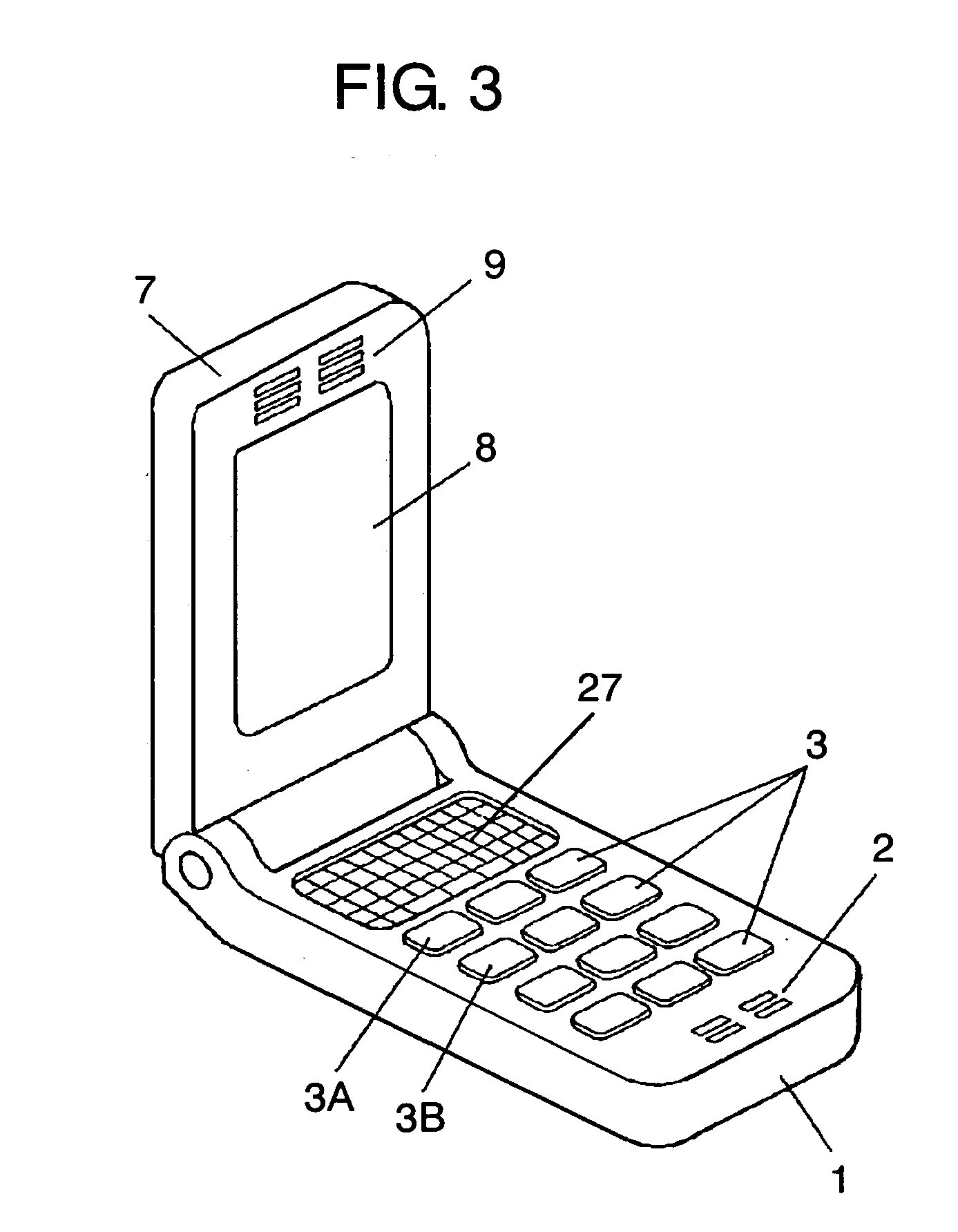

Input device and mobile phone using the same

InactiveUS20060044279A1Input operation becomes easyUniform lightInput/output for user-computer interactionLegendsVisibilityTouchpad

An input device having a data entry section and a controller. The data entry section has a layered structure of “keyboard”-equipped printed input portion, EL device, and touch panel. The controller controls the EL device and the touch panel. Since the printed input portion has keyboard layout, users can input data with ease. Furthermore, the surface lighting of EL device can provide the input device with uniform lighting, increasing visibility of the entire device.

Owner:PANASONIC CORP

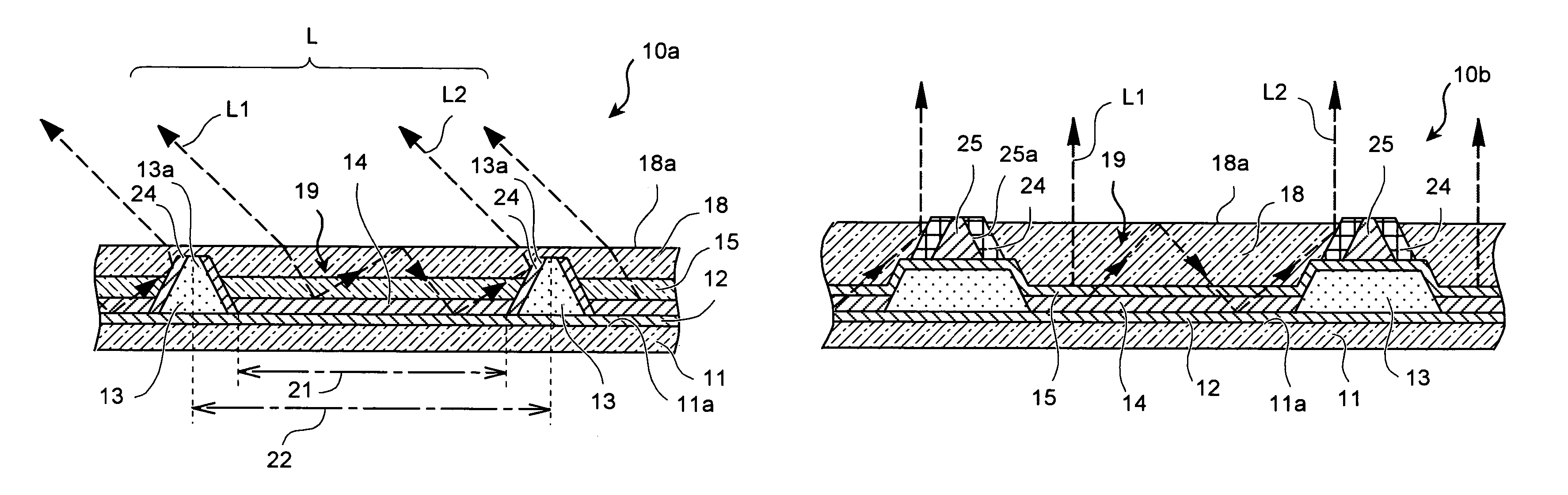

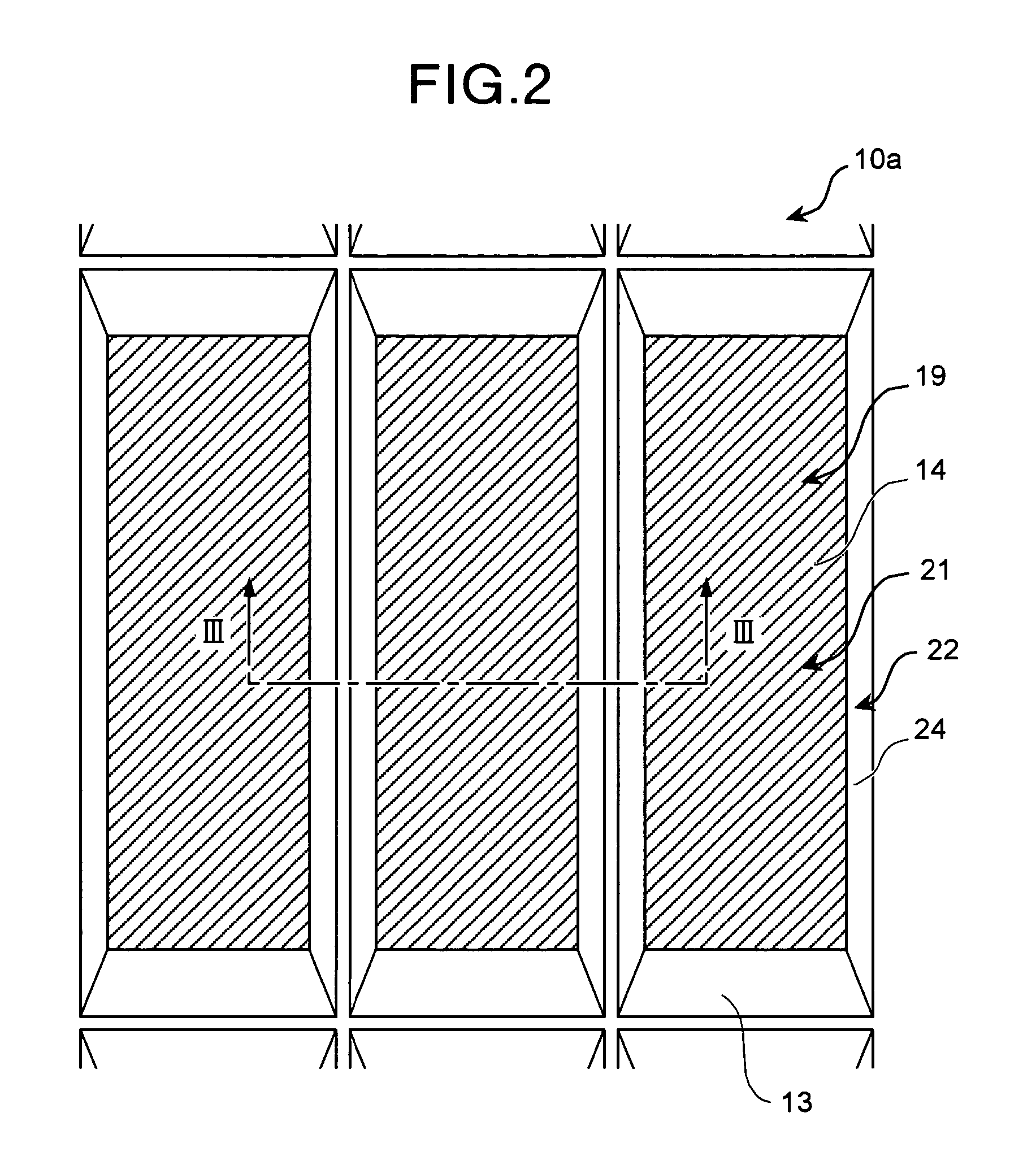

Self-emitting element, display panel, display apparatus, and method of manufacturing self-emitting element

ActiveUS7492092B2Reduces incidence of lightReduce lossesDischarge tube luminescnet screensElectroluminescent light sourcesReflective layerProtection layer

A display panel includes a light-emitting layer, a protective layer, a reflective layer, and a reflective surface. The protective layer is deposited on an emitting side of the light-emitting layer and forms an interface with an external medium. The protective layer has a thickness that allows the light emitted from the light-emitting layer to undergo total reflection at least once at the interface in an area of the light-emitting layer. The reflective layer is deposited on an opposite side of the protective layer with respect to the light-emitting layer. The reflective surface is at a periphery of the light-emitting layer and changes the direction of the light propagating inside the protective layer emitted from the light-emitting layer.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

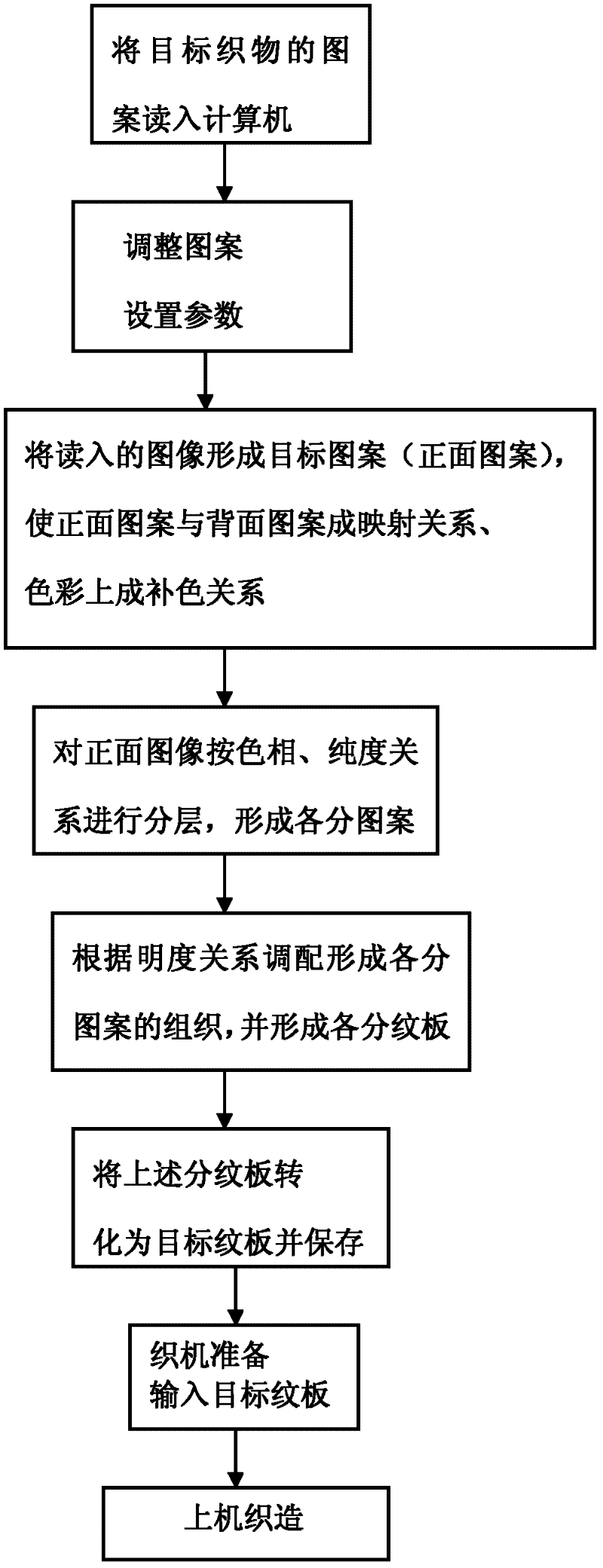

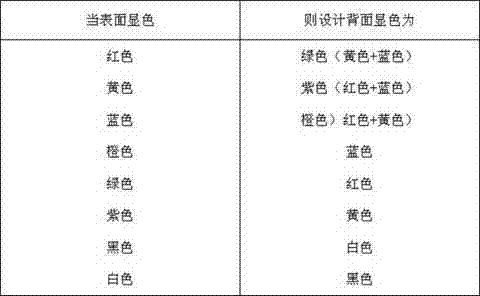

Method for designing and manufacturing double-side colored jacquard fabrics by adopting complementary color principle

ActiveCN102505243AReduce the number of picksLayeredJacquardsWoven fabricsComputer Aided DesignSurface pattern

The invention relates to a method for designing and manufacturing double-side colored jacquard fabrics by adopting the complementary color principle. The method comprises the steps of pattern plate design and manufacture work procedures and is characterized in that the work procedures comprise the following processes of: A, reading images of jacquard fabrics to be woven into a computer; B, regulating read images, setting parameters and giving out pixel value, wherein the pixel value corresponds to the number of warps and wefts; C, carrying out image modification design and regulation; and D, designing processed images into target patterns and carrying out pattern plate manufacture by using a jacquard fabric computer aided design system. The method has the prominent substantial characteristics that the method adopts the complementary color principle, back side patterns are woven by wefts which are not used by surface patterns, the complementary color relationship is shown, and in addition, the brightness change is shown, so the fabric patterns have the stereovision, in addition, the weft insertion quantity is small, the woven fabrics are in a single-layer structure, the thickness and the heavy weight are avoided, the color is improved, and the patterns are exquisite and elegant.

Owner:李加林

Sensor system for refrigerator

ActiveUS9642214B2Overcome deficienciesAvoid heavyMechanical apparatusDomestic stoves or rangesElectricityLight equipment

Owner:WHIRLPOOL CORP

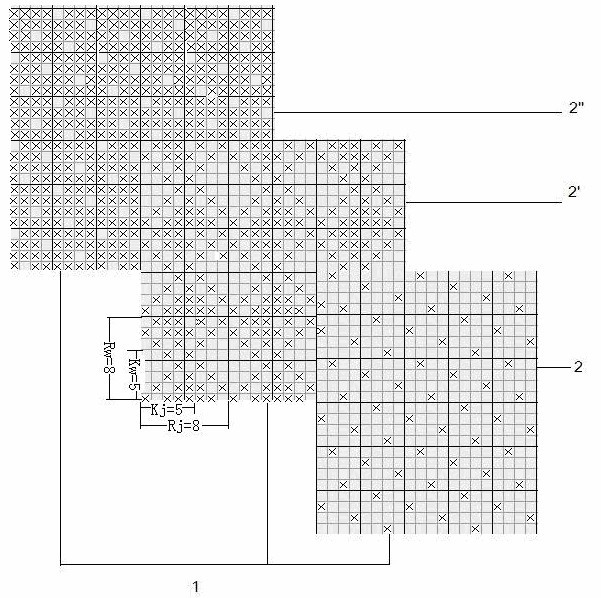

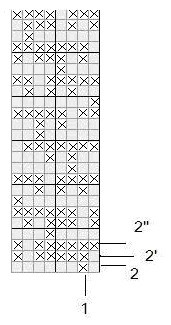

Method for preparing warm composite woven fabric

InactiveCN102181986AElasticIncreased warmth and bulkinessMulti-ply fabricsSwivel-woven fabricsYarnSurface layer

The invention relates to a method for preparing warm composite woven fabric. The warm composite woven fabric is prepared by interweaving a group of warp yarns (1) and three groups of filling yarns in an overlapped way, wherein the three groups of filling yarns are respectively face weft (2), intermediate weft (2') and back weft (2''), the face weft (2), the intermediate weft (2') and the back weft (2'') are arranged according to the proportion of 1:1:1, the warp yarn (1) and the face weft (2) are woven into satin weave which has 8 lines and 5 step weft faces and serves as a surface layer according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the back weft (2'') are woven into satin weave which has 8 lines and 5 step weft faces and serves as a lining according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the intermediate weft (2') take honeycomb weave as an intermediate layer in terms of Rj equal to Rw and equal to 8, and the Rj and the Rw are respectively the circulated yarn numbers of warp weave and weft weave. The warm composite woven fabric prepared by the method integrates the characteristics of light weight, super warm property, softness, comfortableness, moisture absorption, air permeability, bacterial resistance and bacterial restraint, and the production is simple and easy to implement.

Owner:江苏保丹服饰有限公司

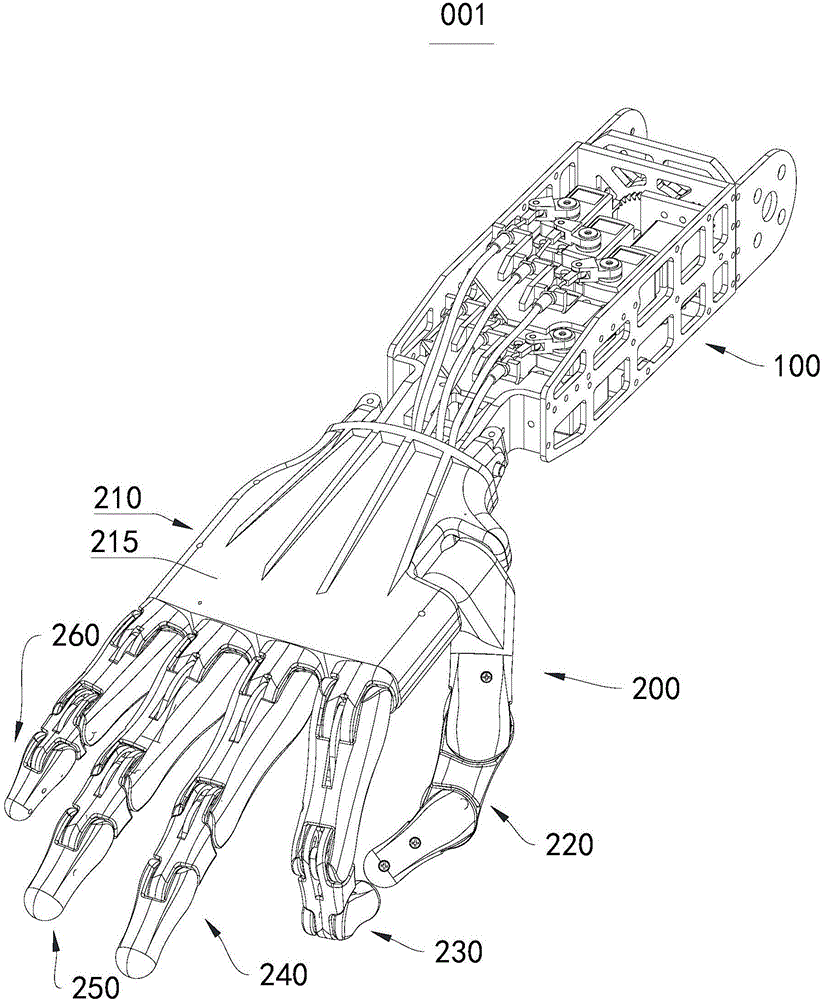

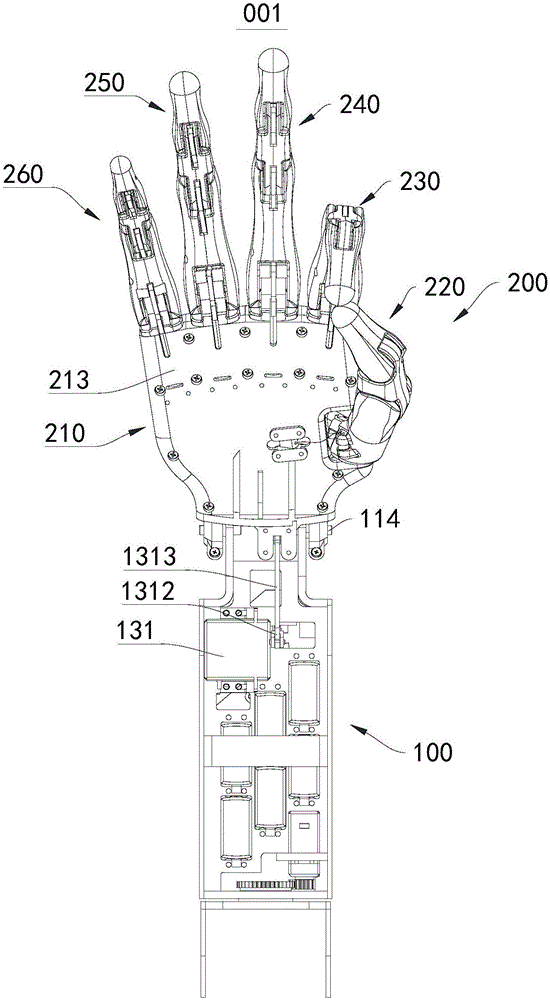

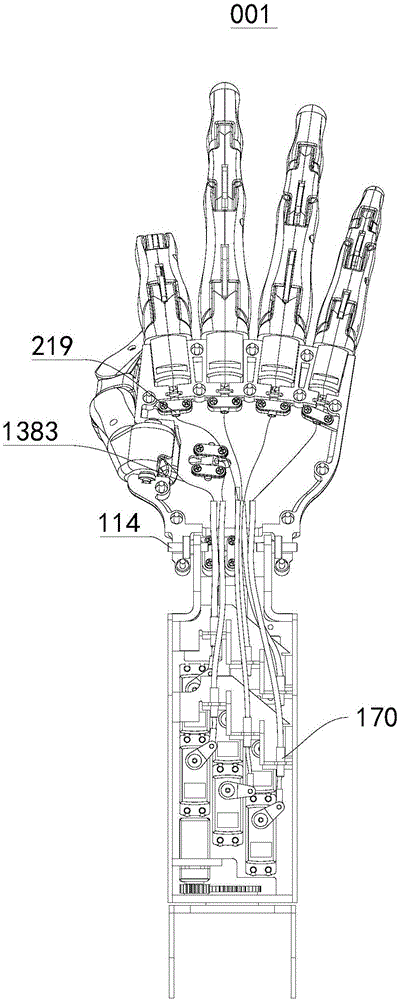

Bionic mechanical arm and robot

The invention provides a bionic mechanical arm and a robot and belongs to the field of artificial intelligence. The bionic mechanical arm comprises a palm assembly. The palm assembly comprises a middle finger assembly which is fixedly connected with the palm assembly. The middle finger assembly comprises a first middle finger connecting rod, a first middle finger section, a second middle finger section and a third middle finger section, wherein one end of the first middle finger section is fixedly connected with the palm assembly; and the first middle finger section, the second middle finger section and the third middle finger section are hinged in sequence. One end of the first middle finger connecting rod is fixedly connected to the first middle finger section, and the other end of the first middle finger connecting rod is fixedly connected to the third middle finger section. The robot comprises the bionic mechanical arm and a trunk. The bionic mechanical arm provided by the invention has the advantages of being light in structure, fast in action response and accurate in action control.

Owner:CHANGZHOU JINGANG NETWORK TECH

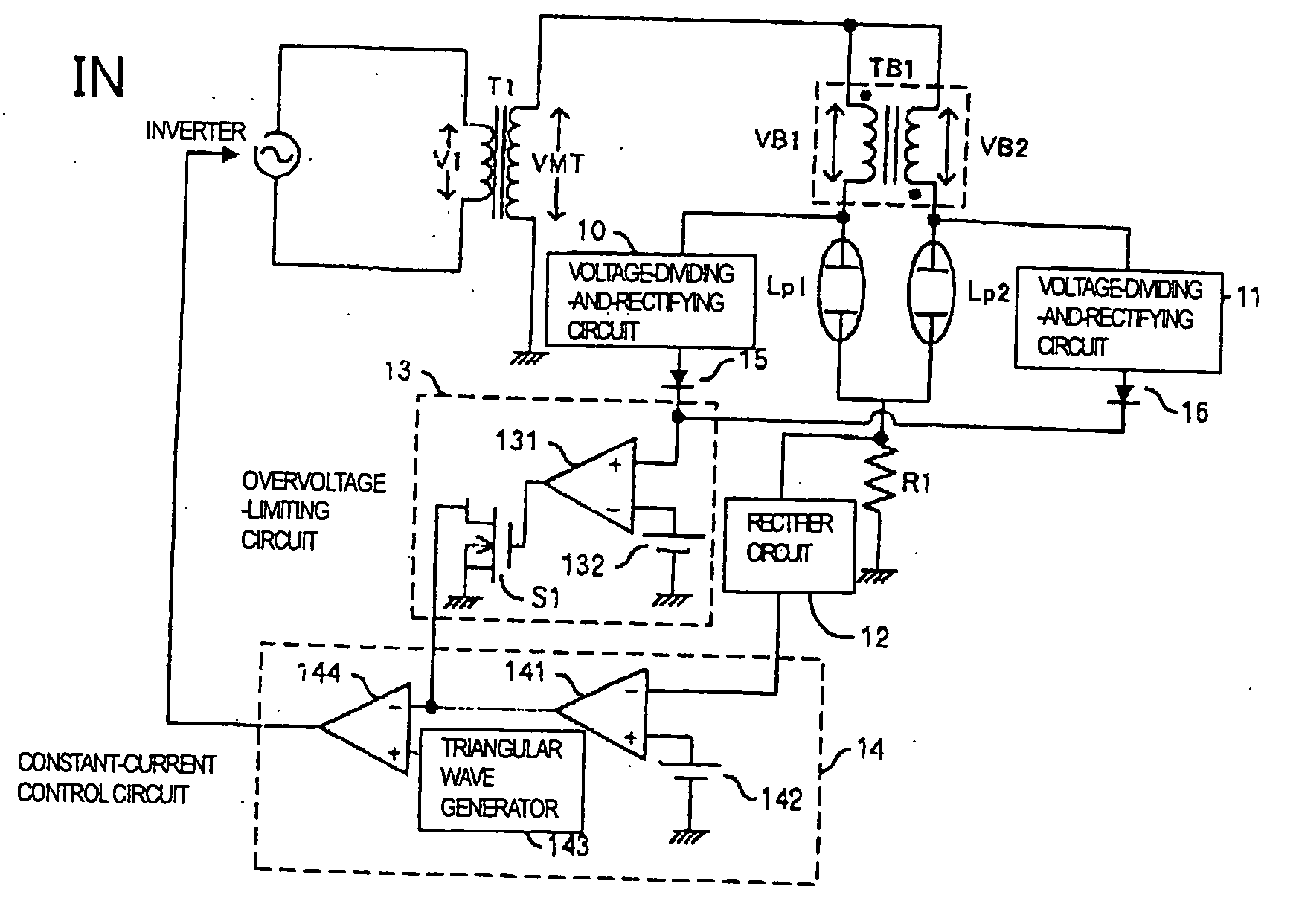

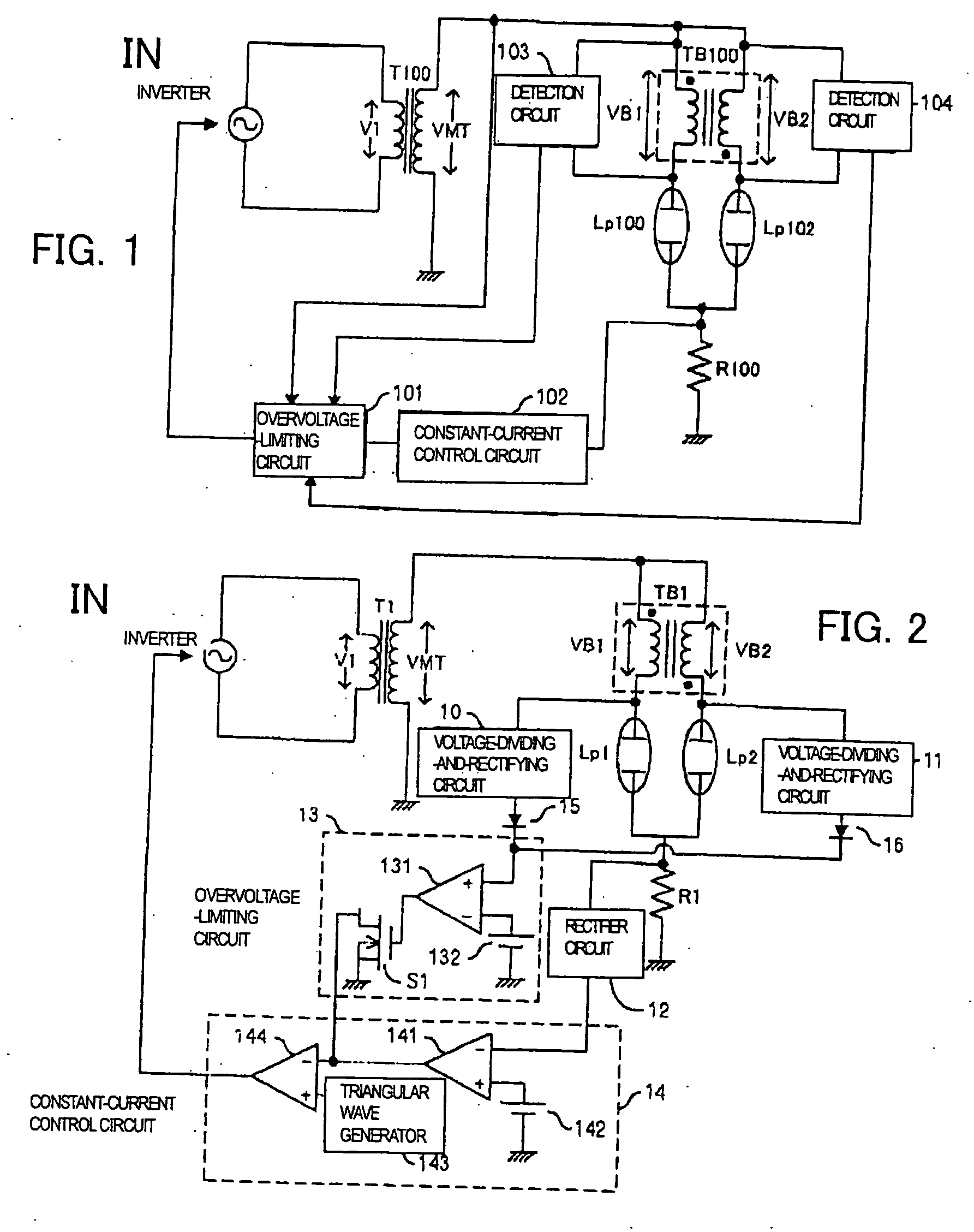

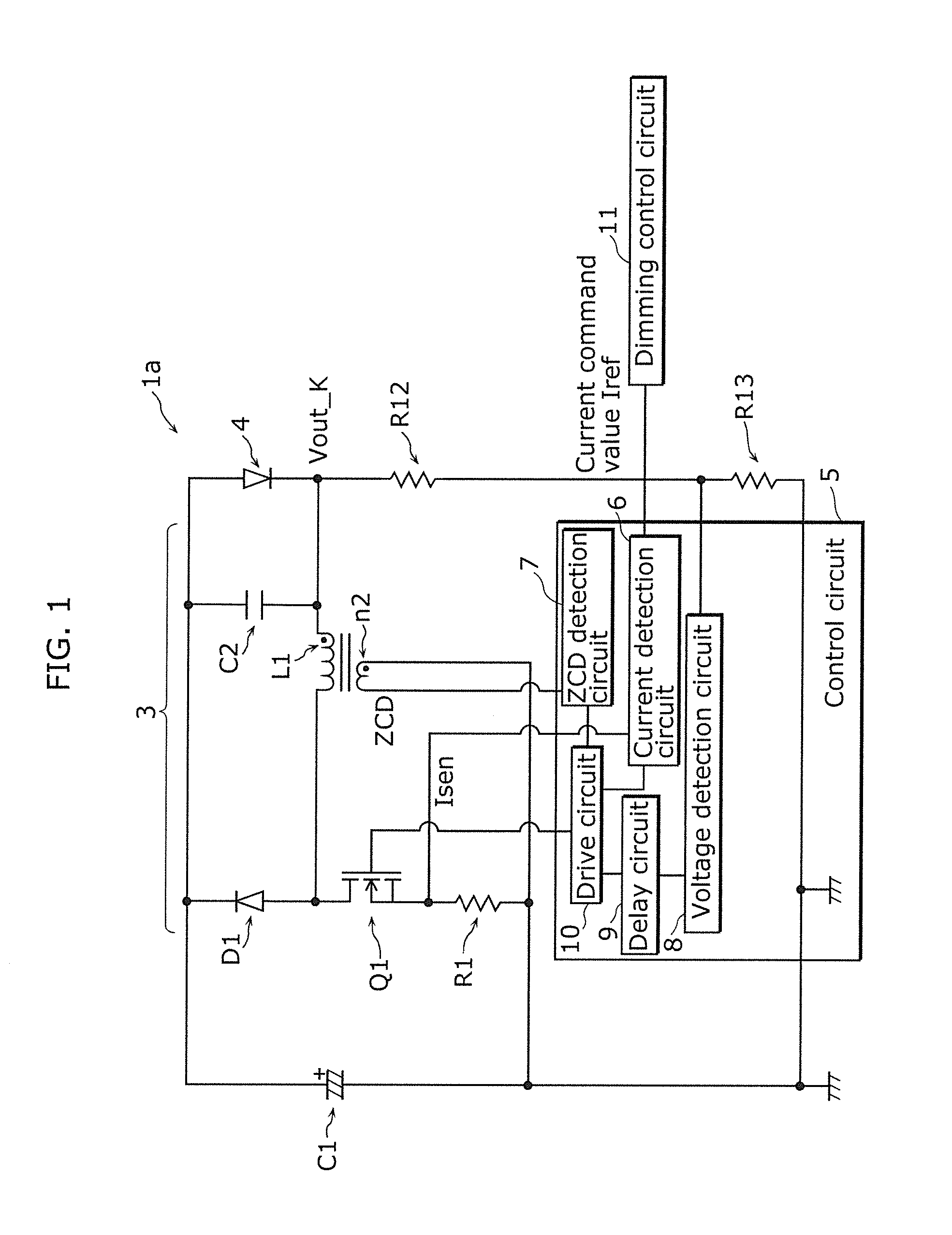

Lamp-lighting apparatus

ActiveUS20060158124A1Reduce equipment costsImprove securityElectrical apparatusElectric light circuit arrangementTransformerControl signal

An economical device for lighting lamps such as discharge tubes. The lamp-lighting apparatus has an inverter transformer, a switching circuit connected with the primary winding of the inverter transformer and acting to perform switching for converting a voltage from an input power supply, a shunt transformer connected in series with the secondary winding of the inverter transformer, lamps connected in series with the shunt transformers, and a control circuit for producing a control signal to control the switching performed by the switching circuit based on the voltages at the junctions of the shunt transformer and each of the lamps without directly detecting the voltage applied to the secondary winding of the inverter transformer. The number of protective circuits can be reduced. Consequently, the cost can be reduced.

Owner:TAIYO YUDEN KK

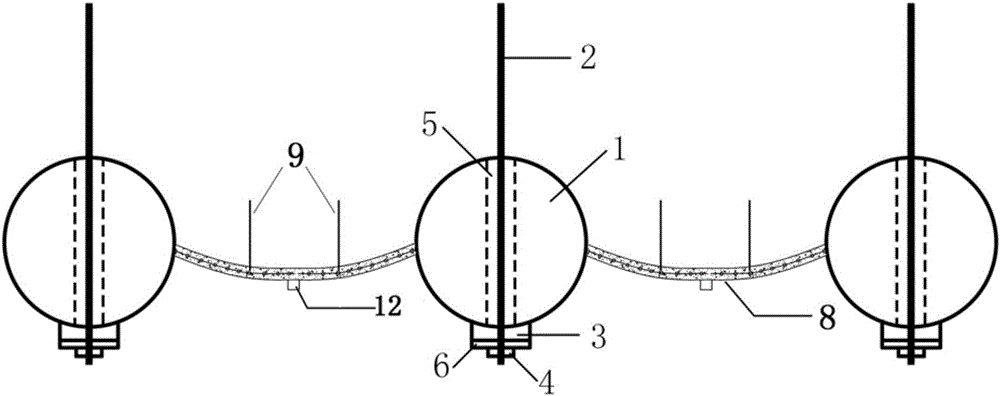

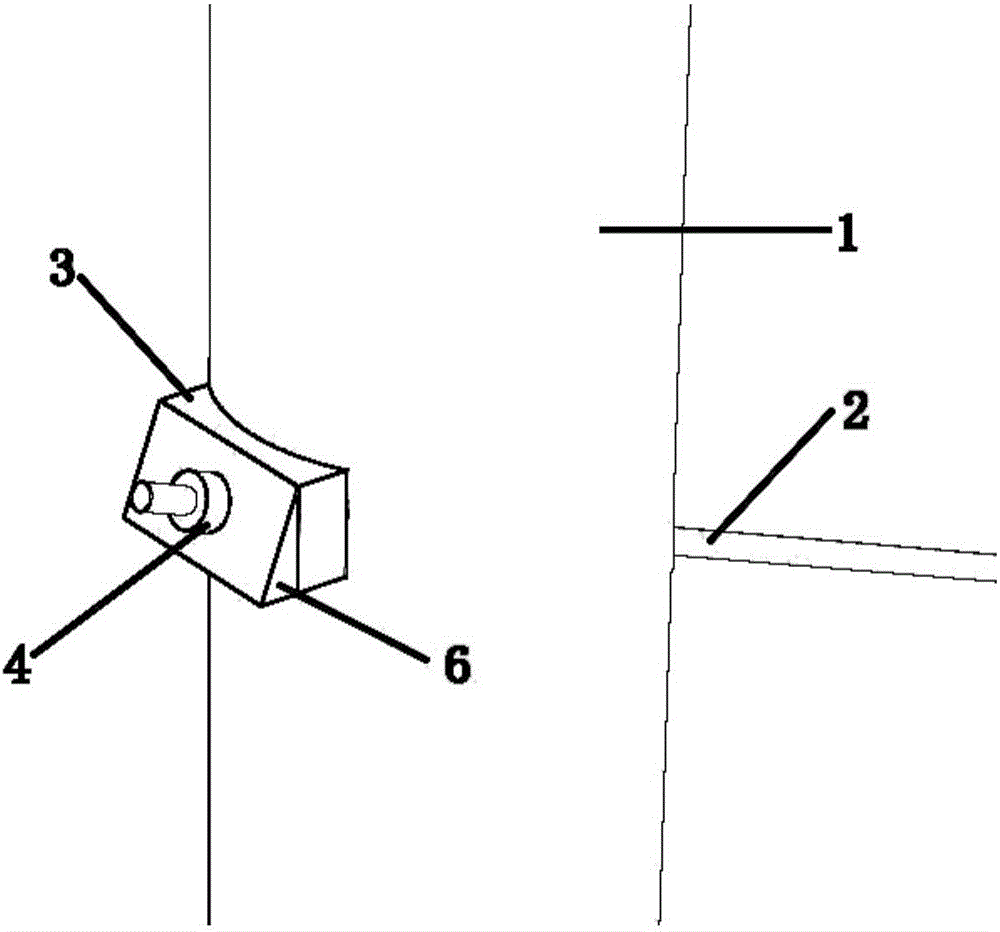

Deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and implementing method of system

The invention discloses a deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and an implementing method of the system. The supporting system comprises retaining piles, anchor rods, saddle-shaped cushion blocks, anchor devices, PVC pipes, wedges and locking beams; the PVC pipes are arranged inside the retaining piles in advance; inner ends of the anchor rods penetrate through the PVC pipes and are inserted in the foundation pit wall, and outer ends of the anchor rods are fixedly connected with the anchor devices; and included angles being 15-25 degrees are formed between axes of the anchor devices and the horizontal plane and are kept consistent with inclination angles of the anchor rods. Waist beams in a traditional pile-anchor system are canceled, so that the prestress loss caused by deformation of the waist beams is avoided. The force of the anchor rods is directly transferred to the retaining piles, the anchor rods and the retaining piles can be better integrally and synergistically stressed, and a supporting structure is better in integrity, safe and reliable. A lot of connecting batten plates and welding rods are canceled, so that profile steel materials and the electricity consumption are greatly saved. Heavy and dangerous waist beam mounting work is avoided, procedures are simplified, and the construction period is shortened.

Owner:DALIAN JIAOTONG UNIVERSITY

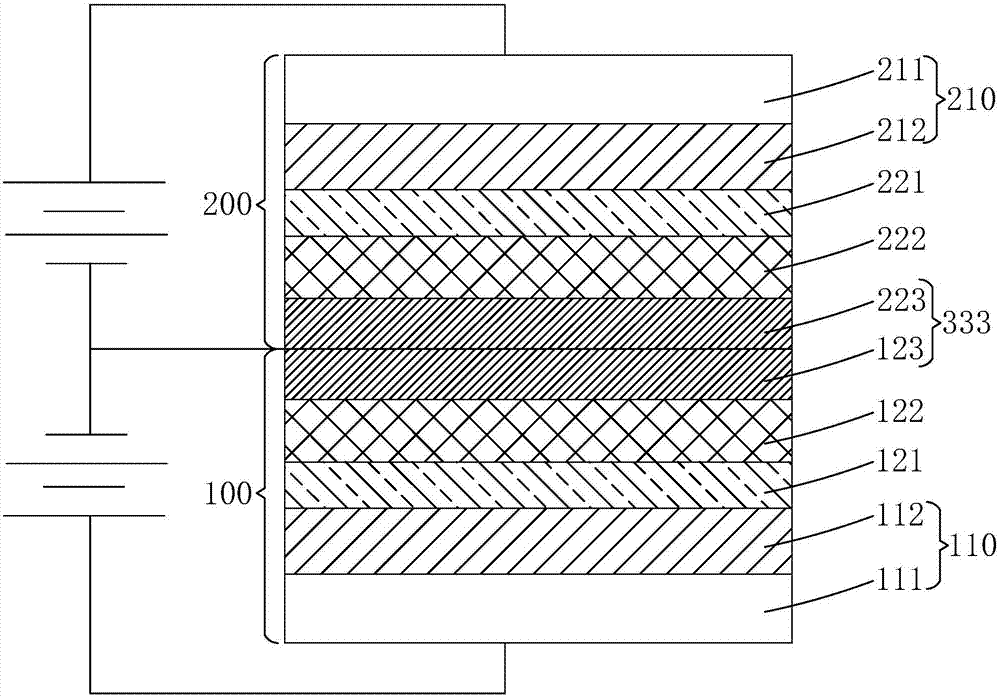

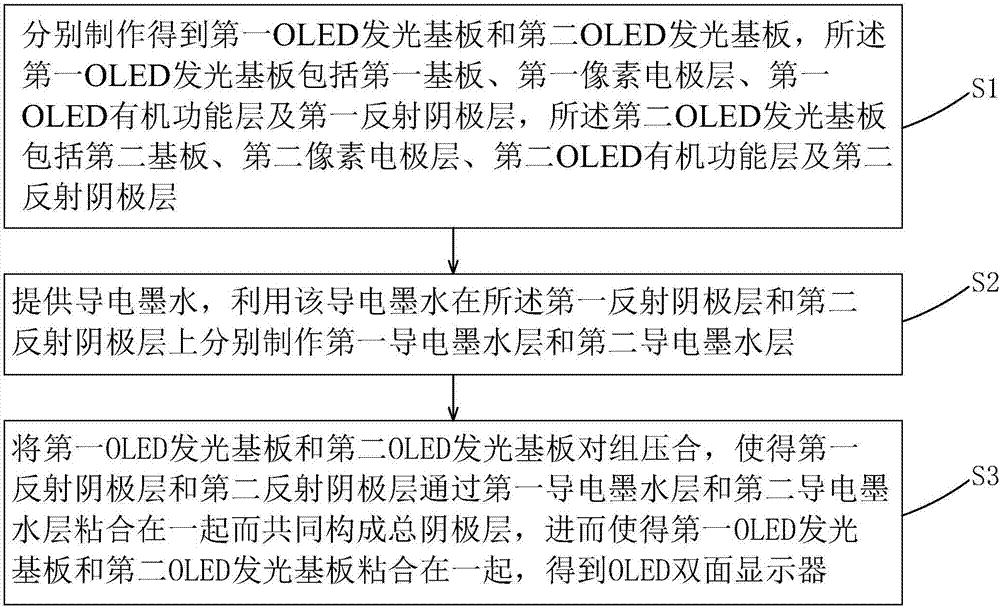

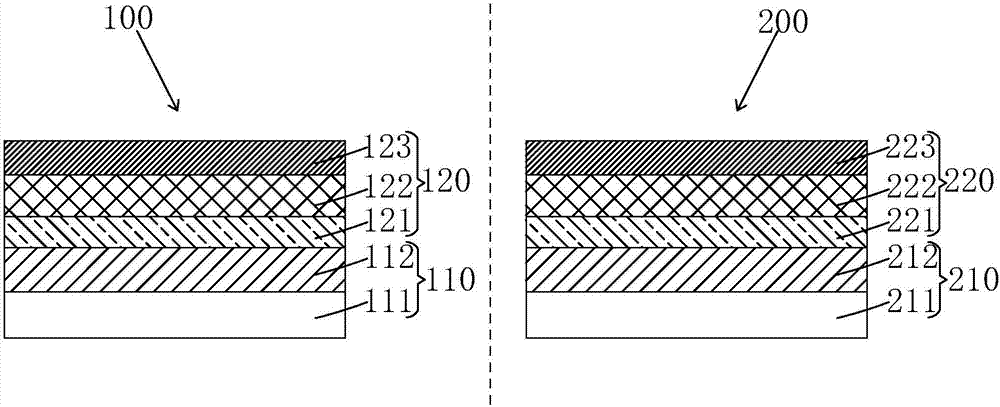

OLED double-sided displayer and manufacturing method thereof

InactiveCN107331687AAvoid heavyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides an OLED double-sided displayer and a manufacturing method thereof. The OLED double-sided displayer comprises a first OLED light-emitting substrate and a second OLED light-emitting substrate which are oppositely arranged. The respective first reflecting cathode layer and the second reflecting cathode layer of the first OLED light-emitting substrate and the second OLED light-emitting substrate are adhered together through conductive ink so as to form a total cathode layer together, and then the first OLED light-emitting substrate and the second OLED light-emitting substrate are adhered together through the conductive ink in a facing way. The manufacturing method is simple, the cost is low, the problems of thickness and weight of the present double-sided displayer can be effectively solved, and the front and rear surfaces of the OLED double-sided displayer are enabled to display different frames simultaneously.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

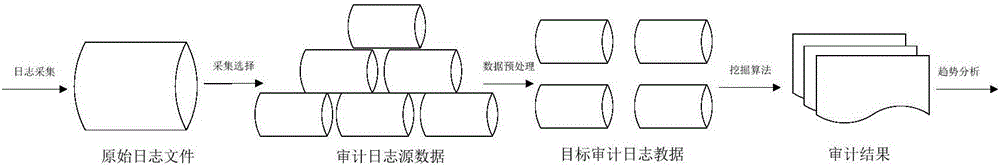

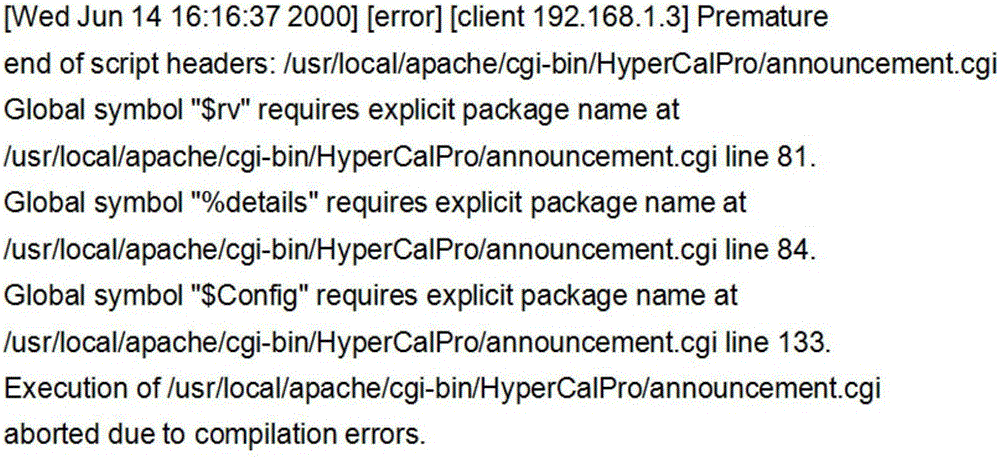

Hierarchical clustering-based log audit method

ActiveCN106446076AAvoid heavyImprove experienceSpecial data processing applicationsCluster basedData mining

The invention discloses a hierarchical clustering-based log audit method. A system reads log information; a keyword in the log information is analyzed according to the read log information; the log information is subjected to word vector transformation according to the obtained keyword; and the system performs cluster analysis on obtained word vectors and displays small abnormal information obtained by analysis. According to the method, heavy work of manual log audit is avoided and abnormal log information can be automatically filtered, so that the user experience effect is enhanced.

Owner:NANJING UNIV OF SCI & TECH

Multicomponent and multiple boundary layer composite heat insulation material and its producing method

InactiveCN1899814AGood warmth retentionHigh heat retentionHollow filament manufactureLayered productsPolyesterAir trapping

The present invention relates to a kind of multicomponent and multiple boundary layer composite heat insulating material and its production process. The composite heat insulating material is produced through arranging and adhering the following layers: superfine polypropylene non-woven fabric layer as the main air blocking layer, infrared radiation layer, down-like polyester / polypropylene layer as the main air trapping layer, infrared radiation and air blocking layer, and air holding hollow 3D crimping polyester layer. It has the thermal protection quality of 1.03-1.45clo, vapor transfer rate of 6200-8214g / sq m .24h, and air permeability of 2617-3267 ml / sq m .s. The composite heat insulating material has the advantages of being waterproof, poromeric, wind-proof, heat insulating and light.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

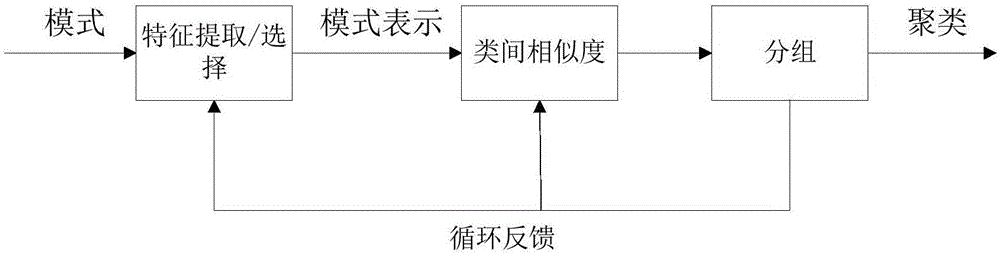

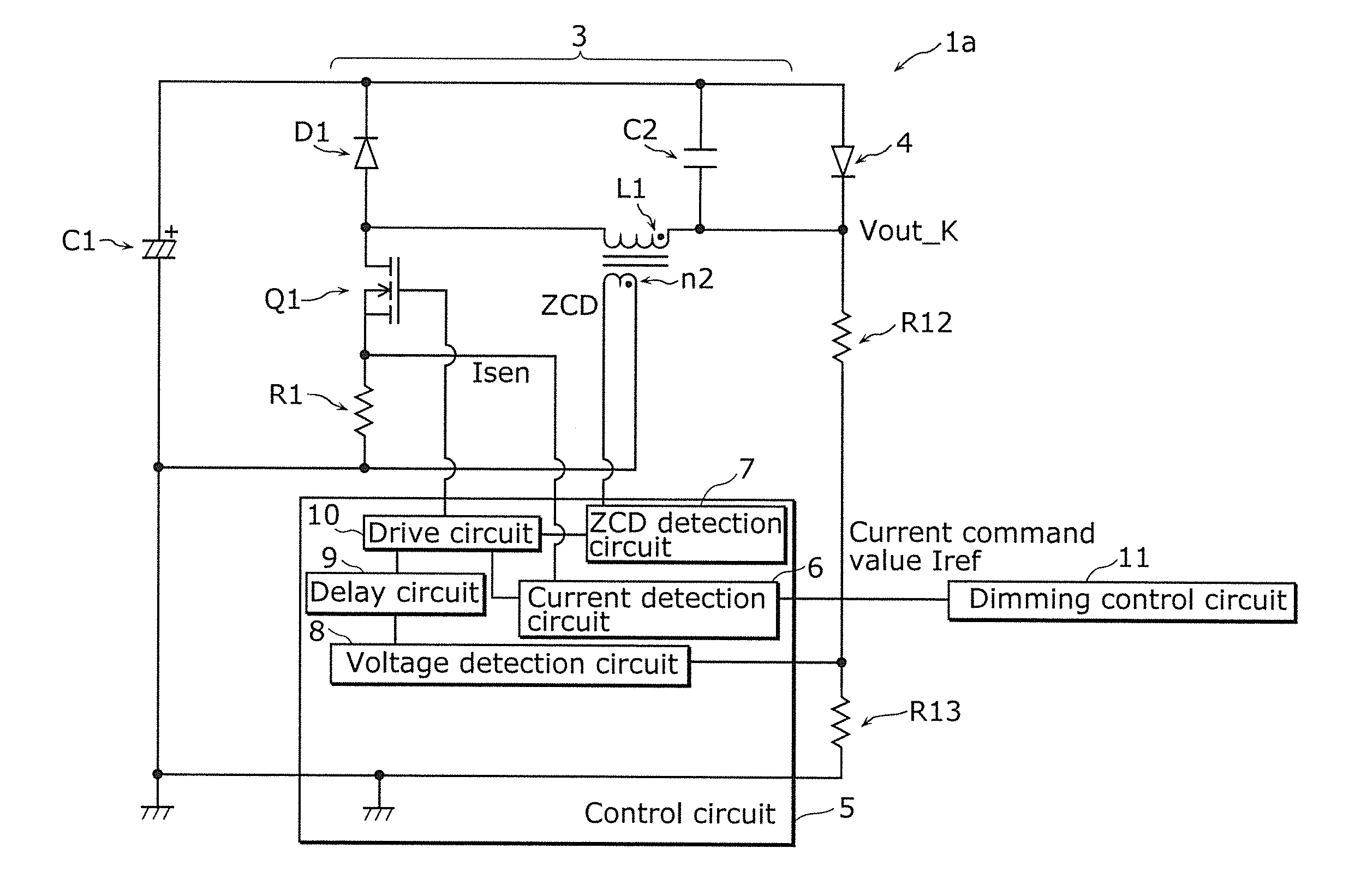

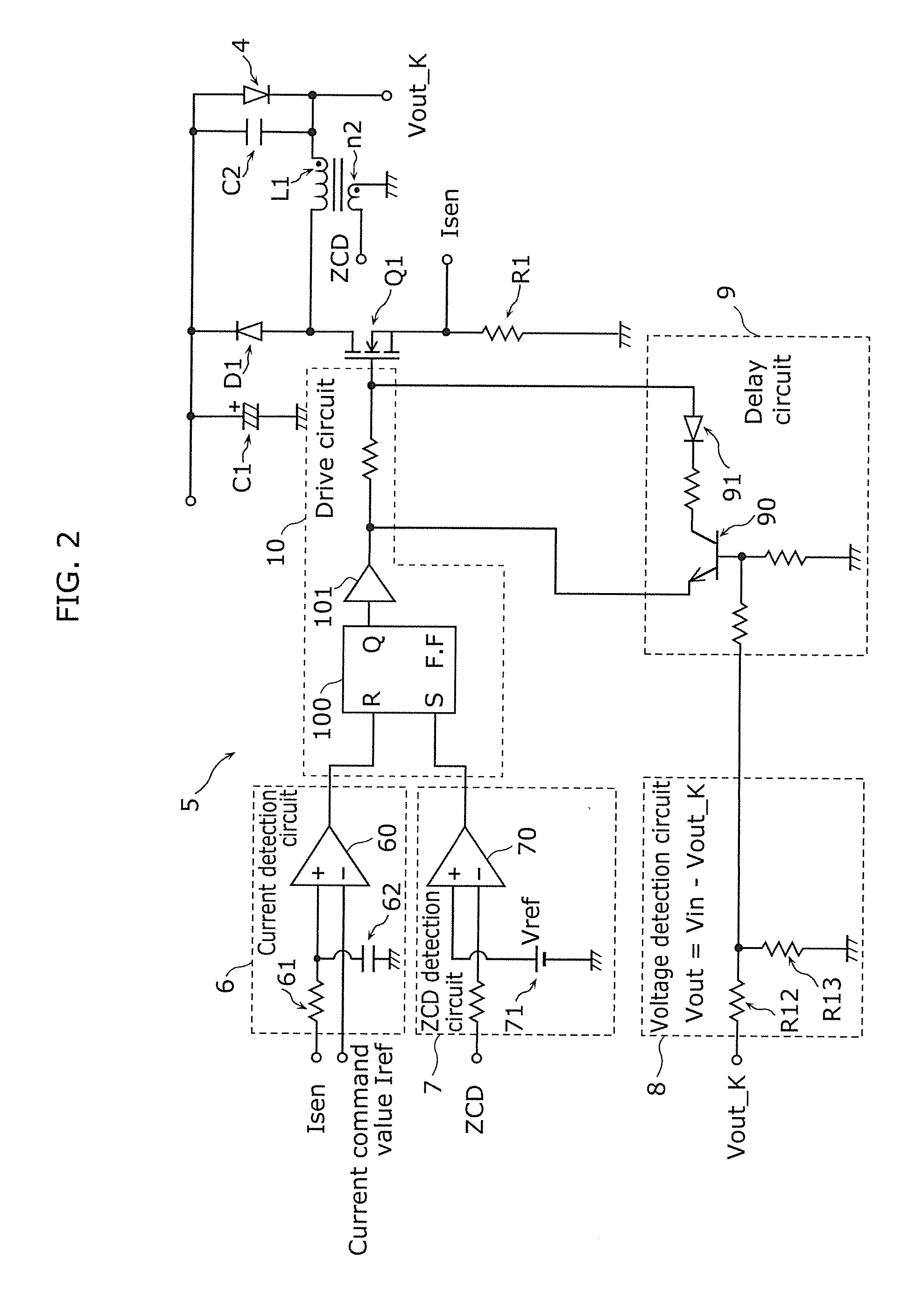

Lighting device and luminaire

ActiveUS20150035446A1Stably lightingSuppress mutationElectrical apparatusElectroluminescent light sourcesPower flowControl signal

A lighting device that lights up an LED and includes a DC power source, a buck converter and a control circuit. The buck converter includes a switching element, an inductor and a diode. The control circuit includes a current detection circuit that detects an electric current flowing through the switching element, a voltage detection circuit that detects a voltage across the inductor, a delay circuit that generates a delay time according to the voltage detected by the voltage detection circuit, and a drive circuit that generates and outputs a control signal to the switching element, the control signal turning OFF the switching element after a lapse of the delay time generated by the delay circuit from when the electric current detected by the current detection circuit reaches a predetermined current command value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

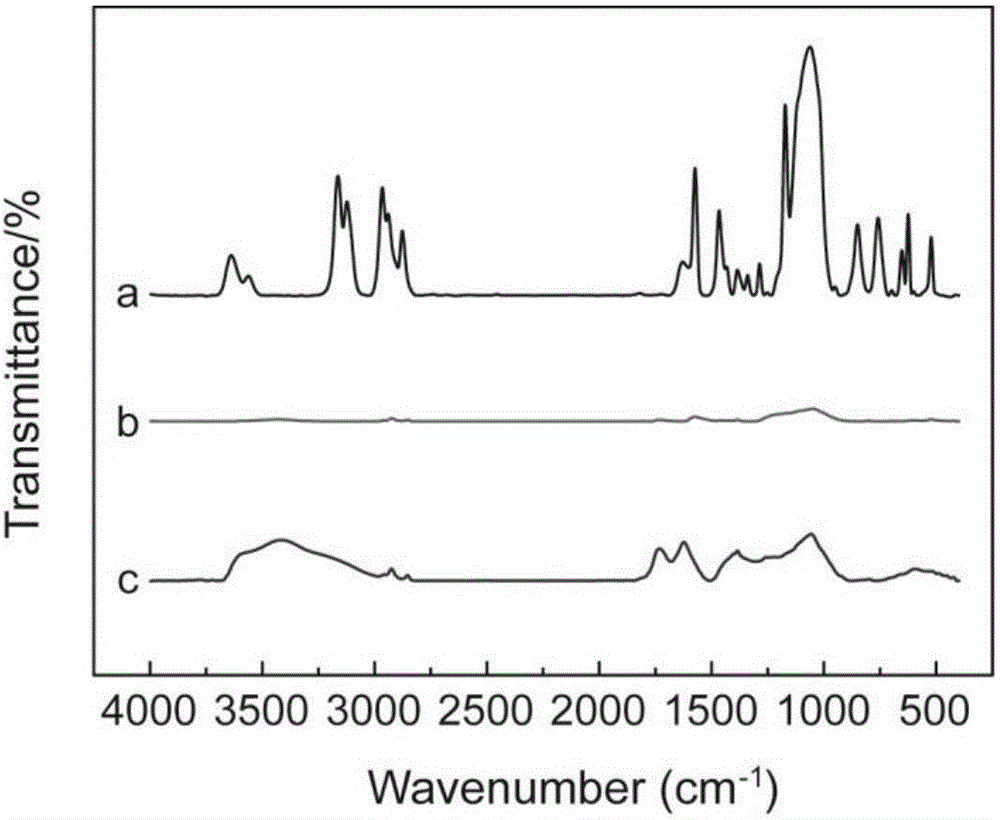

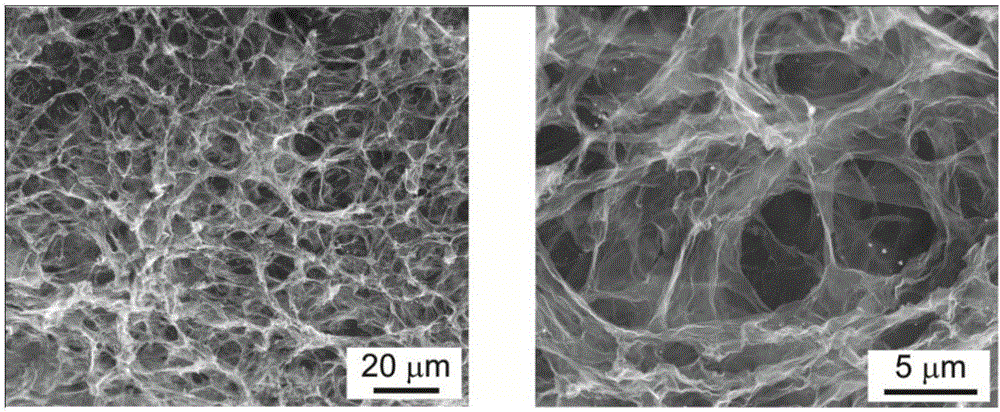

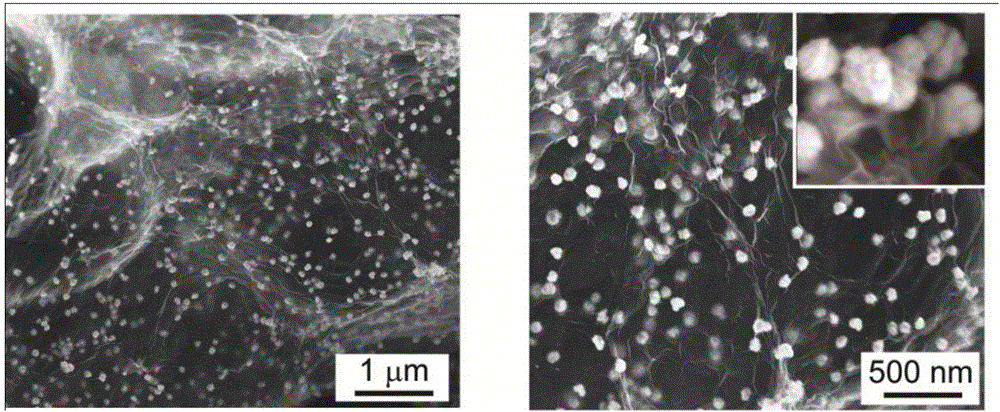

Gold nanoflower modified ionic liquid functionalized graphene paper electrode as well as preparation method and application thereof

ActiveCN106814123AImprove stabilityGood dispersionMaterial electrochemical variablesPorous grapheneReactive oxygen radicals

The invention discloses a gold nanoflower modified ionic liquid functionalized graphene paper electrode as well as a preparation method and application thereof in electrochemical detection of breast cancer cells. The electrocatalytic active component of the composite paper electrode is gold nanoflower; and a catalyst carrier is a three-dimensional porous graphene skeleton. In the invention, a gold nanoflower modified ionic liquid functionalized graphene composite is prepared by use of dopamine assisting one-pot self-assembly; and water is adopted for disperse suction filtration to obtain functionalized graphene paper. The process of the method is simple and easy to control, and a functionalized graphene product with controllable morphology can be obtained. Due to the unique structural properties and synergistic effect of different components in the gold nanoflower / ionic liquid-graphene composite, the functionalized graphene paper electrode has good performance when adopted to detect small-molecule metabolite active oxygen radical, hydrogen peroxide (H2O2).

Owner:HUAZHONG UNIV OF SCI & TECH

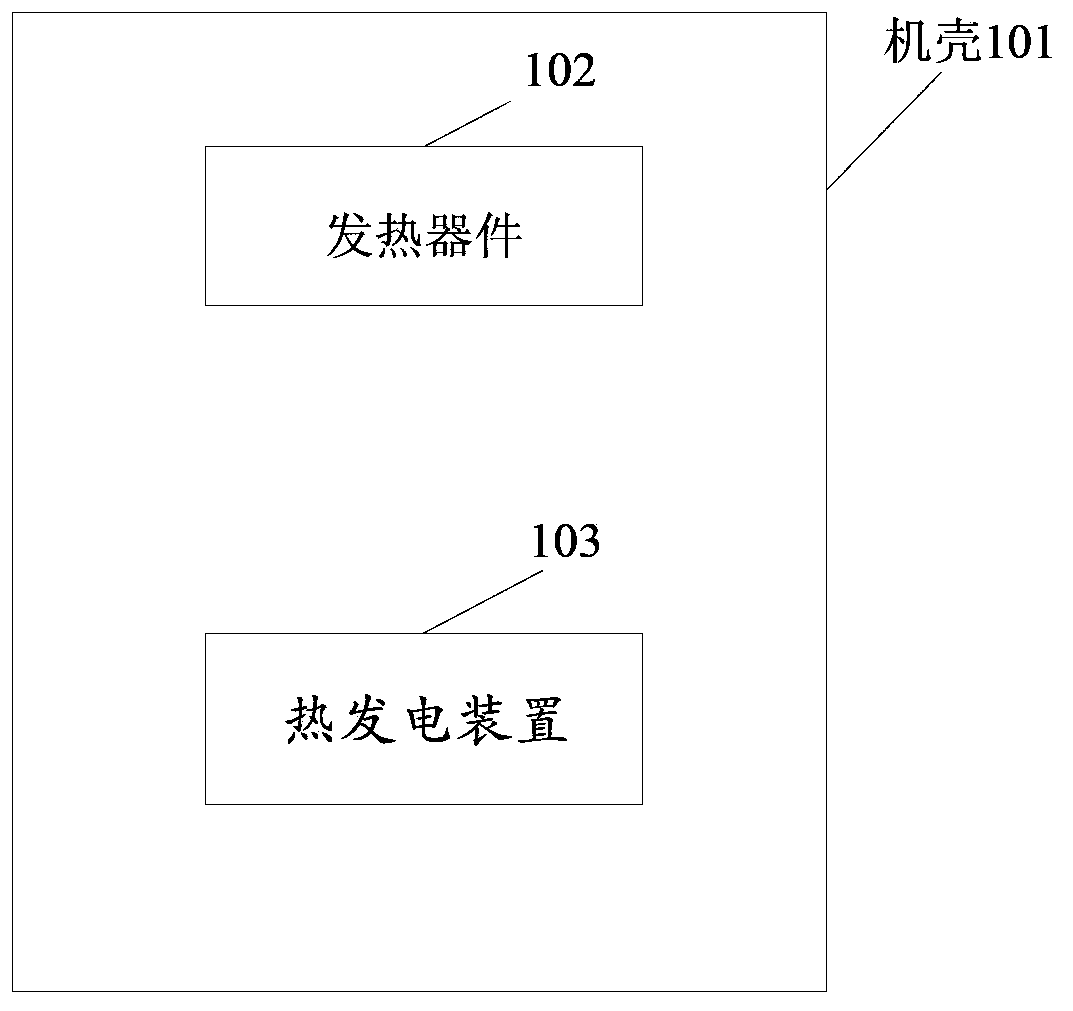

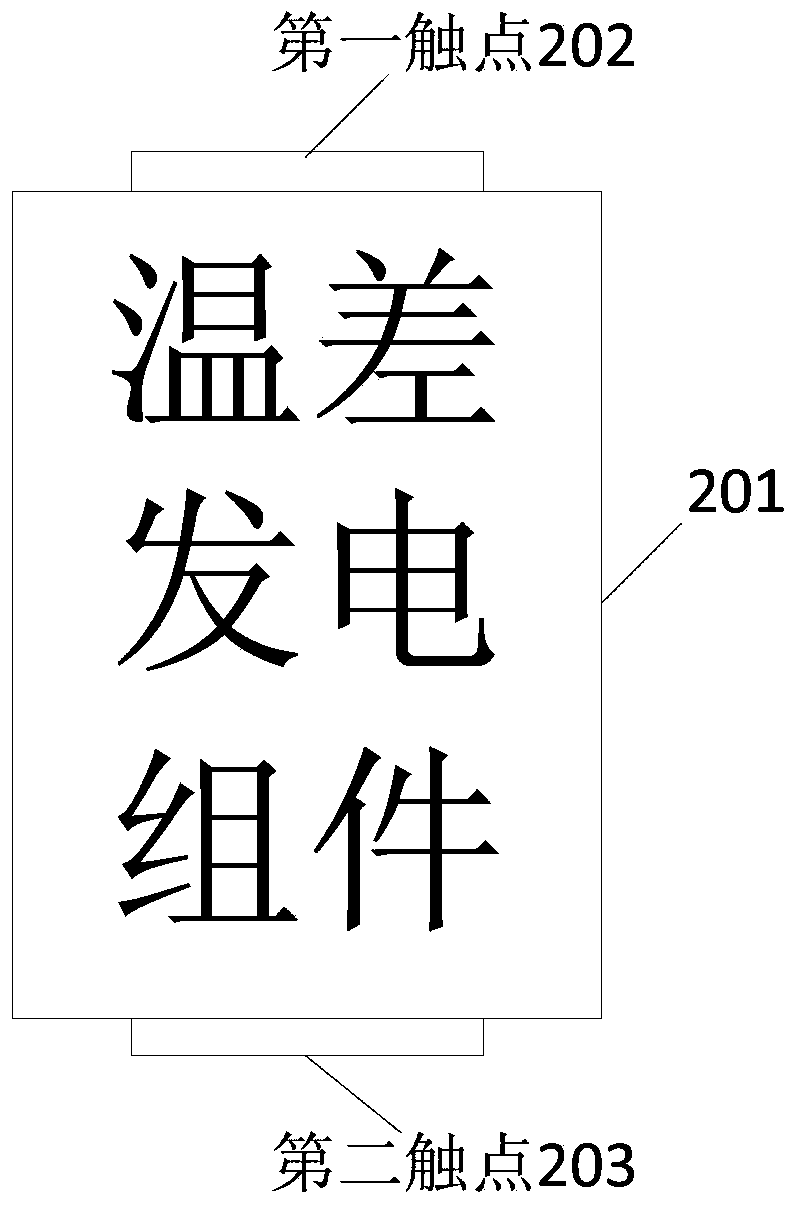

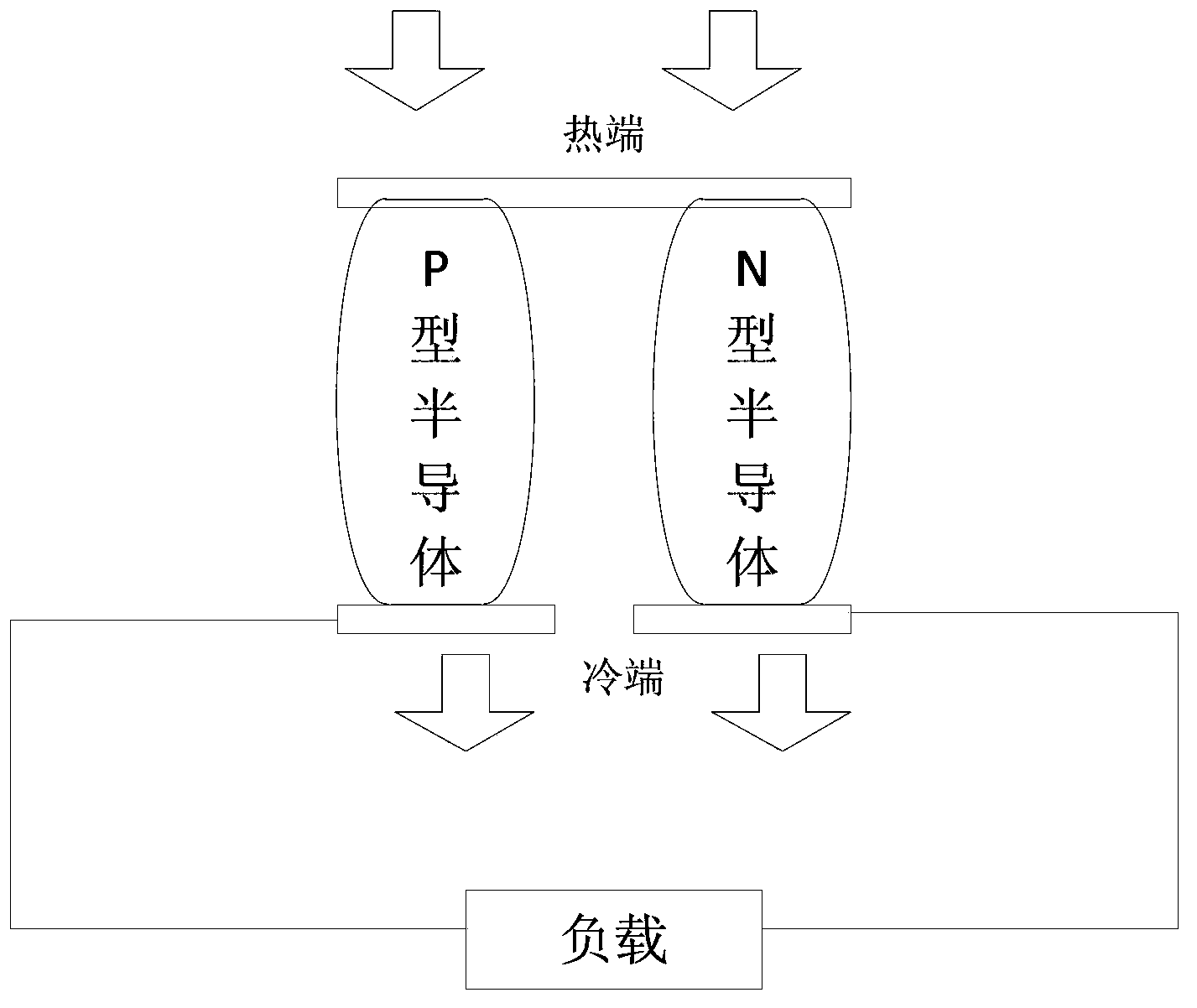

Electronic device and method for controlling temperature

ActiveCN103853214ATroubleshoot noisy technical issuesReduce noiseAuxillary controllers with auxillary heating devicesGenerators/motorsEngineeringElectronic equipment

The invention discloses an electronic device for controlling temperature. The electronic device comprises a device shell, at least one heating component and a thermal power generation device, the at least one heating component is arranged in the device shell, the thermal power generation device is arranged in the device shell, and when the electronic device is in a working state, the at least one heating component will generate heat. The thermal power generation device absorbs the heat and converts the heat into electric energy, and then the temperature of the at least one heating component is controlled to be within a preset temperature range. In addition, the invention further discloses a method, corresponding to the electronic device, for controlling the temperature.

Owner:LENOVO (BEIJING) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com