Solid state LED bridge rectifier light engine

a technology of led bridge rectifier and solid state light, which is applied in the direction of electroluminescent light source, electric lighting source, and use of semiconductor lamps to speed up light pulsation, and achieve the effects of shortening or shortening the time duration, speeding up the light pulsation, and prolonging or shortening the persisten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

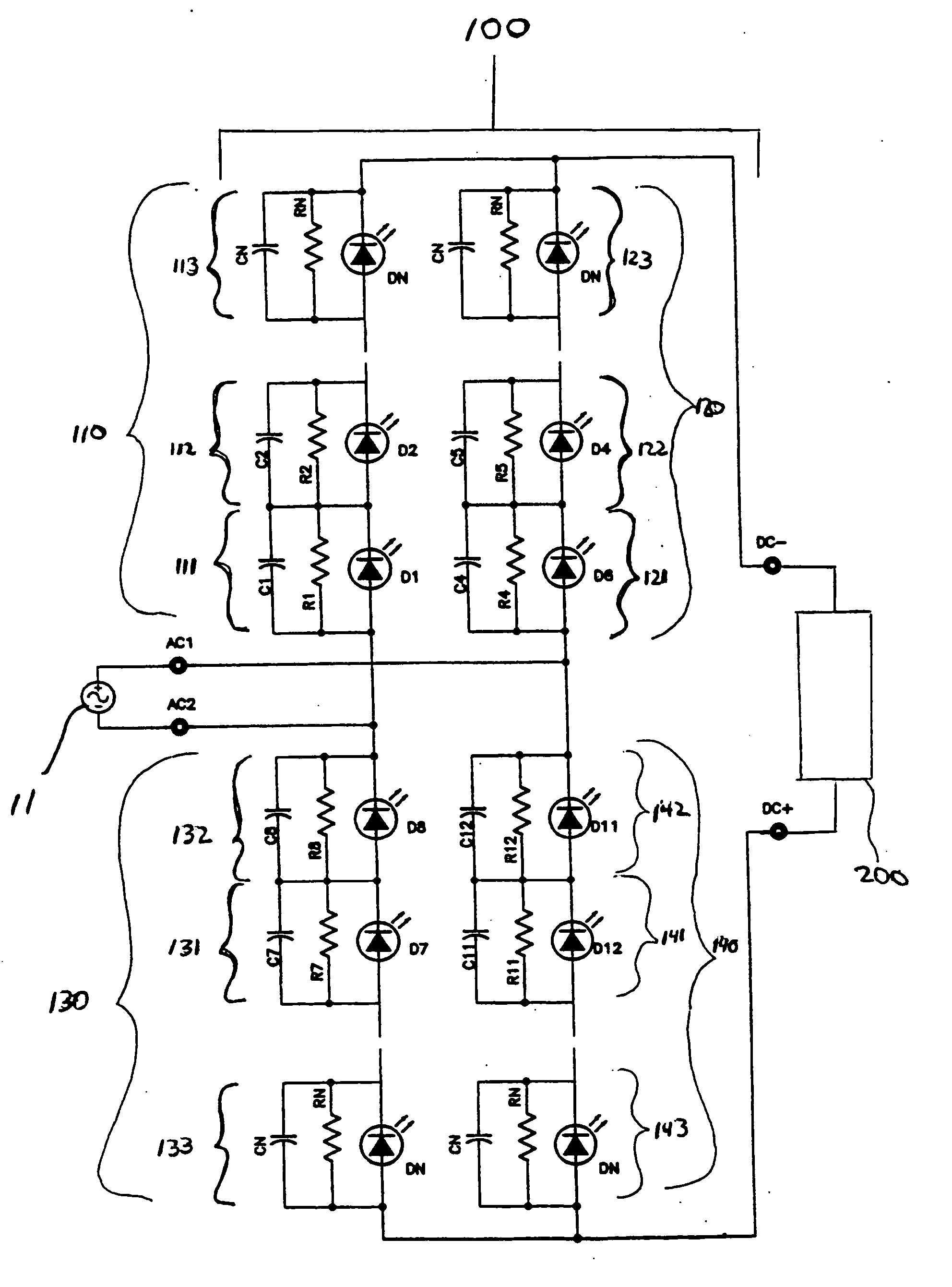

[0028] Embodiments of the invention are directed to a solid state light engine producing white or near white light that is constructed by using LEDs that emit blue or ultraviolet wavelength emission which stimulates a phosphor, or some mixture of phosphors, that emit light in the green, yellow and / or red wavelengths. The combination of all these wavelengths is perceived as white light by the human eye. If one were to look at just a monochrome color LED driven with an AC source, one would see the pulsation of the light at the 50 Hz or 60 Hz frequencies. Even if the pulsation is above the detectable threshold to 100 Hz or 120 Hz, the pulsation can still be detected when the light interacts with objects or images moving or pulsating at close to the LED pulse rate or harmonics of that rate. This is, at the least, annoying and, at worst, potentially dangerous. Strobing light could possibly make moving or spinning objects appear to be not moving at all. An example of this is a fluorescent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com