OLED double-sided displayer and manufacturing method thereof

A technology of double-sided display and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of thick structure, high manufacturing cost, complicated process, etc. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

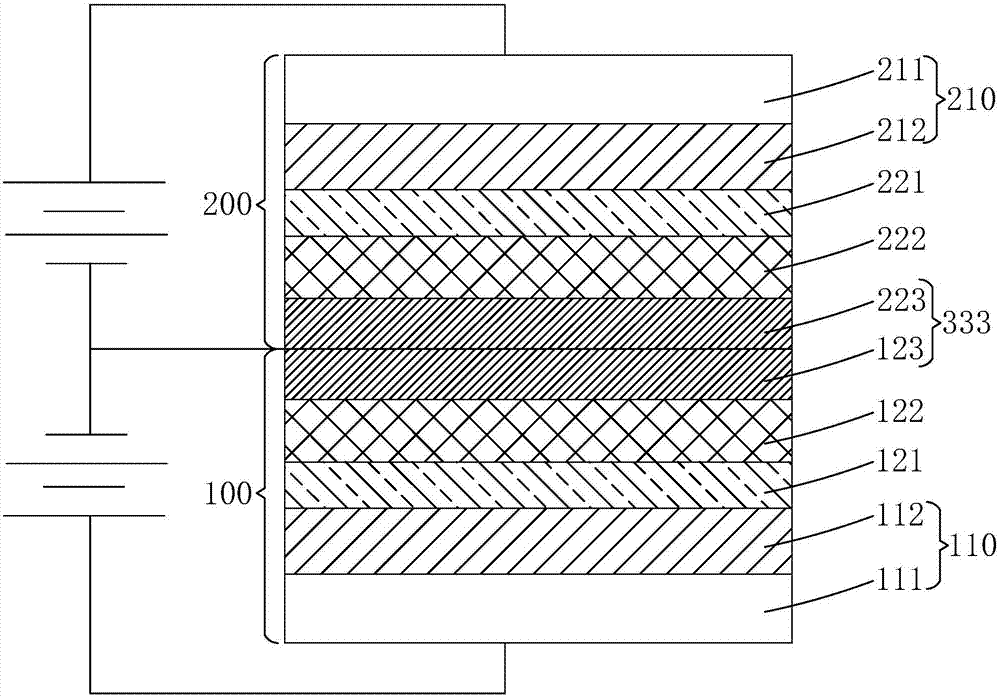

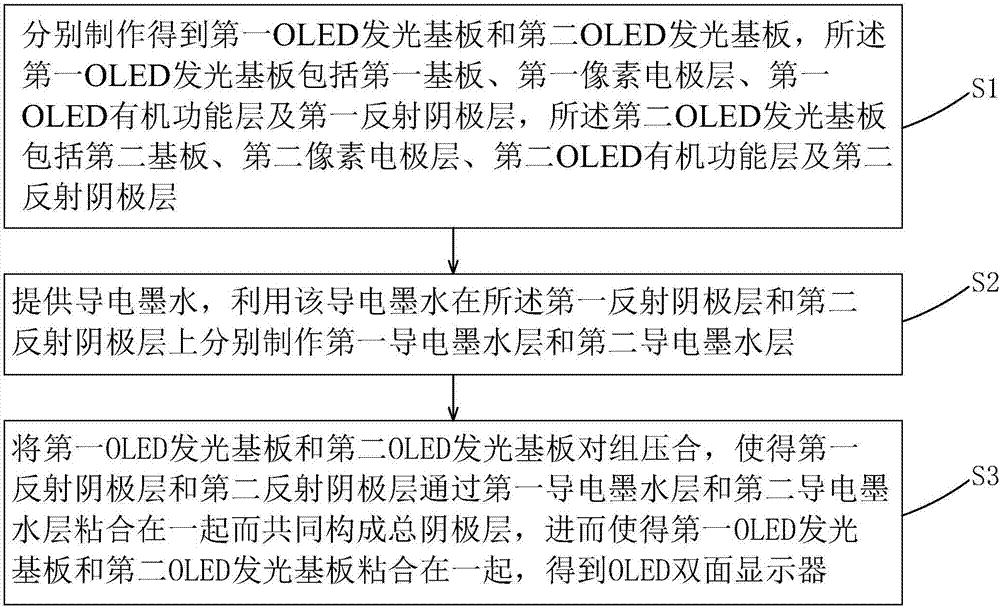

[0037] see figure 1 , the present invention firstly provides an OLED double-sided display, including a first OLED light-emitting substrate 100 and a second OLED light-emitting substrate 200 disposed opposite to each other;

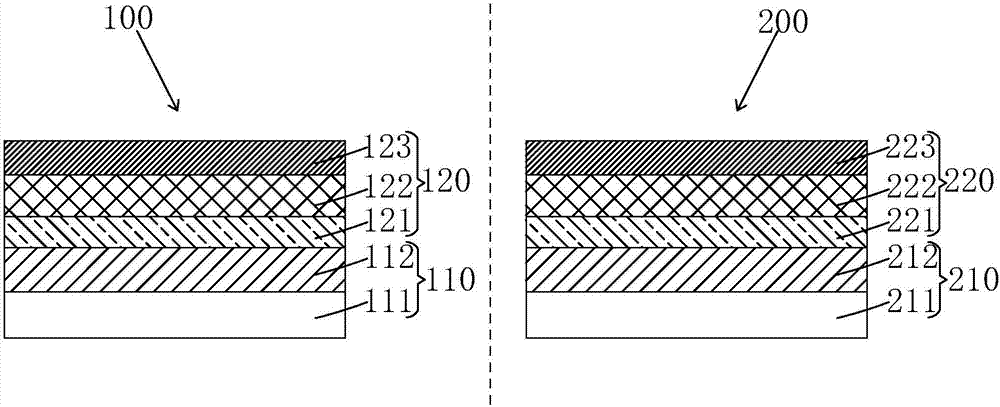

[0038] Wherein, the first OLED light-emitting substrate 100 includes a first substrate 110 and a first pixel electrode layer 121 and a first OLED organic functional layer 122 arranged in sequence on the side of the first substrate 110 close to the second OLED light-emitting substrate 200 and the first reflective cathode layer 123; thus the first pixel electrode layer 121, the first OLED organic functional layer 122 and the first reflective cathode layer 123 together constitute the first OLED light-emitting layer 120, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com