Deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and implementing method of system

A deep foundation pit and pile body technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of prestress loss, poor safety, and many processes, avoiding prestress loss, short construction period, and good integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] The implementation method of the deep foundation pit pile-anchor support system with the anchor head placed on the pile body comprises the following steps:

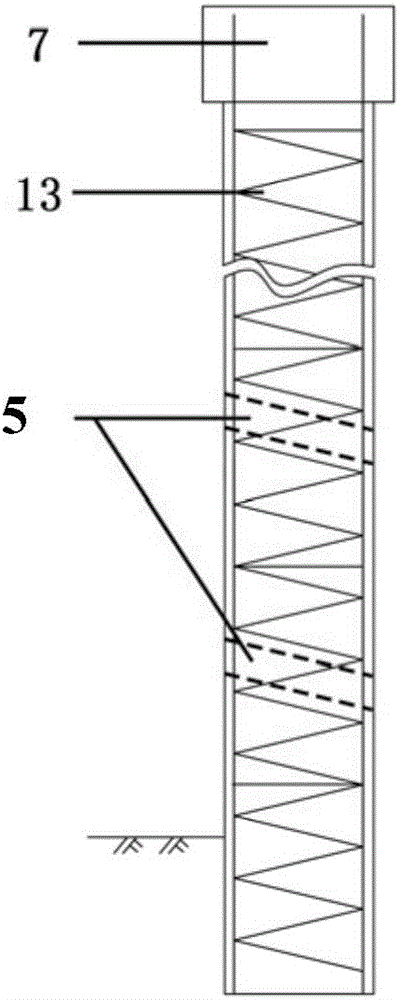

[0055] A, make the reinforcement cage 13 of retaining pile 1

[0056]When making the reinforcing cage 13 of retaining wall pile 1, the PVC pipe 5 that both ends are sealed with wooden plugs is preset at the design depth of the anchor rod 2 in the reinforcing cage 13, and the PVC pipe 5 is reliably connected with the reinforcing cage 13 by iron wire, so as to ensure that the PVC pipe 5 and the reinforcing cage 13 are reliably connected. The design angles of the anchor rods 2 should be kept consistent; the 5 places where the PVC pipes are preset in the reinforcement cage 13 should be treated with stirrup encryption, and the reinforcement of the retaining wall pile 1 has directionality, and the reinforcement cage 13 should be placed in strict accordance with the direction marked on the drawing.

[0057] B. Prefabricat...

example

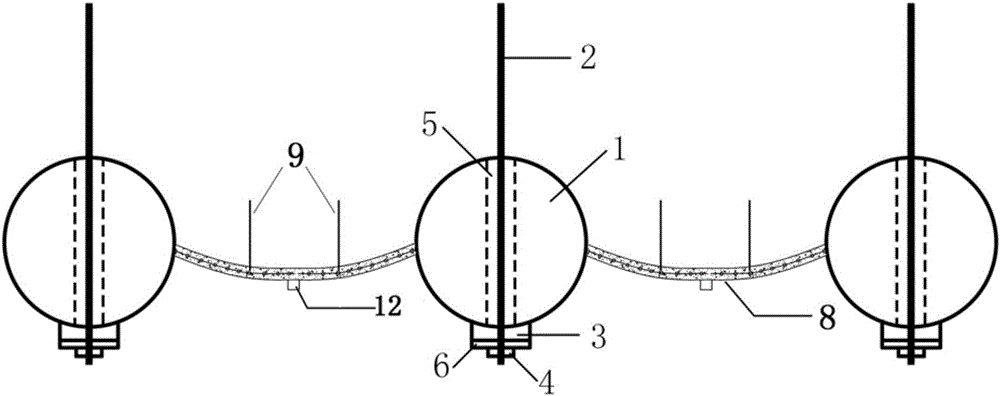

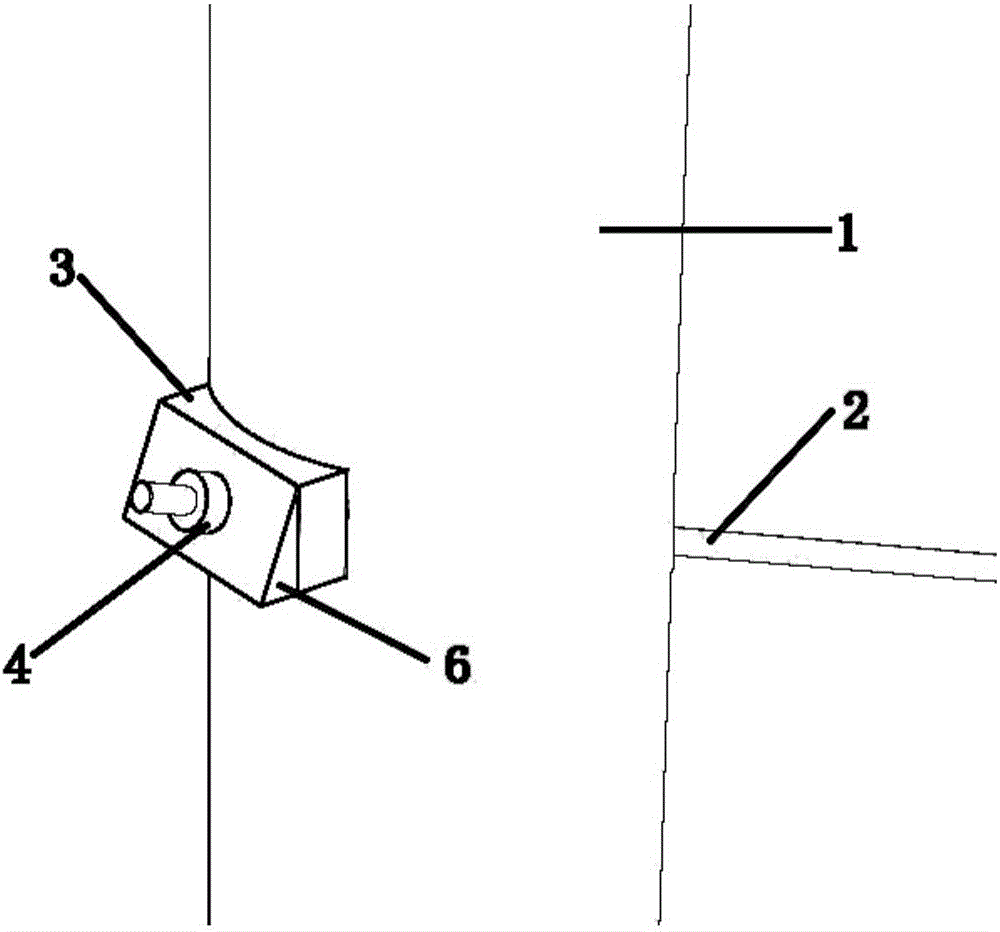

[0076] For deep foundation pit projects with poor geological conditions, pile-anchor support systems are usually used. like Figure 6-7 As shown, the depth of the foundation pit in this example is 12.4m, and the wall retaining pile 1 used is 15m long, 0.8m in pile diameter, and 1.6m in pile spacing. Rod 2 has an inclination angle of 15°.

[0077] Fully prepare for the construction, level the working surface, excavate the loose soil layer on the surface, and measure and position the 1 pile hole of the retaining pile.

[0078] like image 3 As shown, the hole digging operation is carried out after setting out the hole position, and the steel cage 13 is made at the same time. The main reinforcement of the steel cage 13 is HRB400 steel bar, fy=400MPa; the stirrup is HPB300 steel bar, Fy=300MPa; make retaining wall piles When the reinforcement cage 13 of 1, the PVC pipe 5 that both ends are sealed with wooden plugs is preset at the design depth of the anchor rod 2 in the reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com