Method for designing and manufacturing double-side colored jacquard fabrics by adopting complementary color principle

A technology of jacquard fabric and principle design, which is applied in the field of designing and manufacturing double-sided color jacquard fabrics by using the principle of complementary colors, which can solve the problems that double-sided jacquard fabrics cannot be produced, the fabric is heavy, and the yarns are complicated, etc., and the pattern is exquisite and elegant, avoiding Thickness, the effect of reducing the number of weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

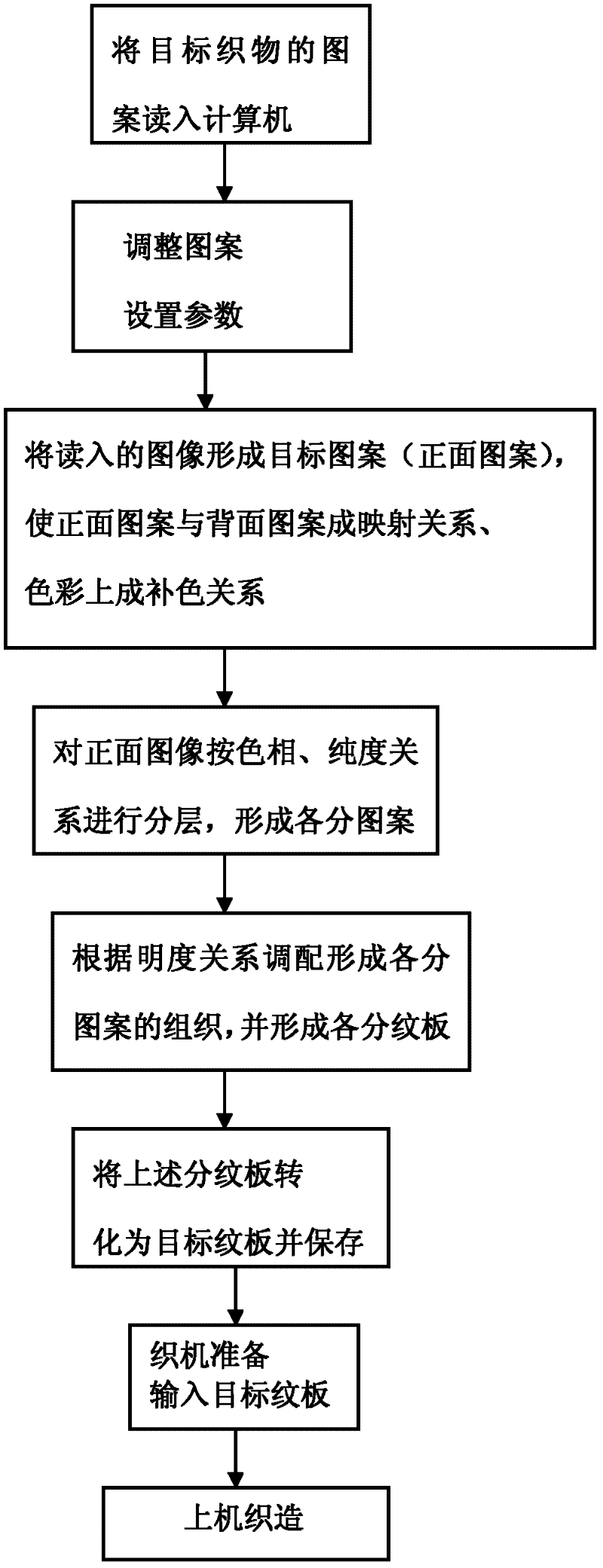

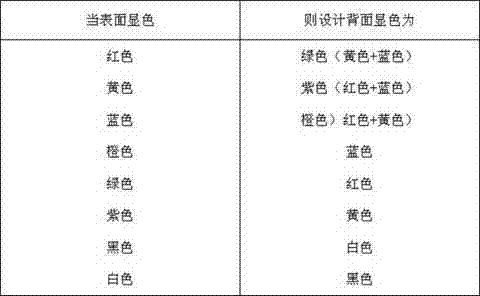

[0017] Example: A method for designing and manufacturing double-sided colored jacquard fabrics using the principle of complementary colors, the steps of which are (1), design and manufacture of patterns; (2), preparation of looms; (3), manufacturing on looms, wherein the pattern The design and manufacturing process includes: A. Reading the image of the jacquard fabric to be woven into the computer; B. Adjusting the read image, setting parameters, and giving the image value, and the pixel value corresponds to the number of warp and weft threads; C. Then do the screen modification design and adjustment; it is characterized in that: the design and production process of the pattern includes: D. Using the jacquard fabric computer aided design system, the aforementioned processed image is designed into the target pattern, that is, the formation The front pattern, and make it have a mapping relationship with the back pattern, and the color has a complementary color relationship; des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com