Patents

Literature

47results about How to "Increase winding length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

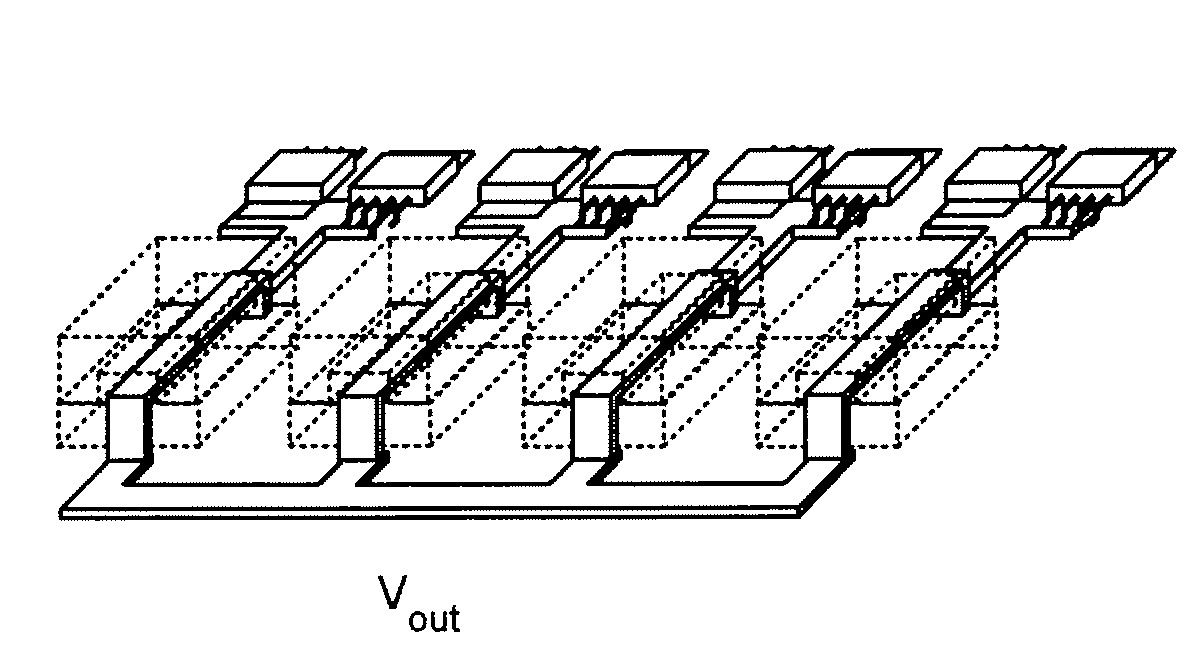

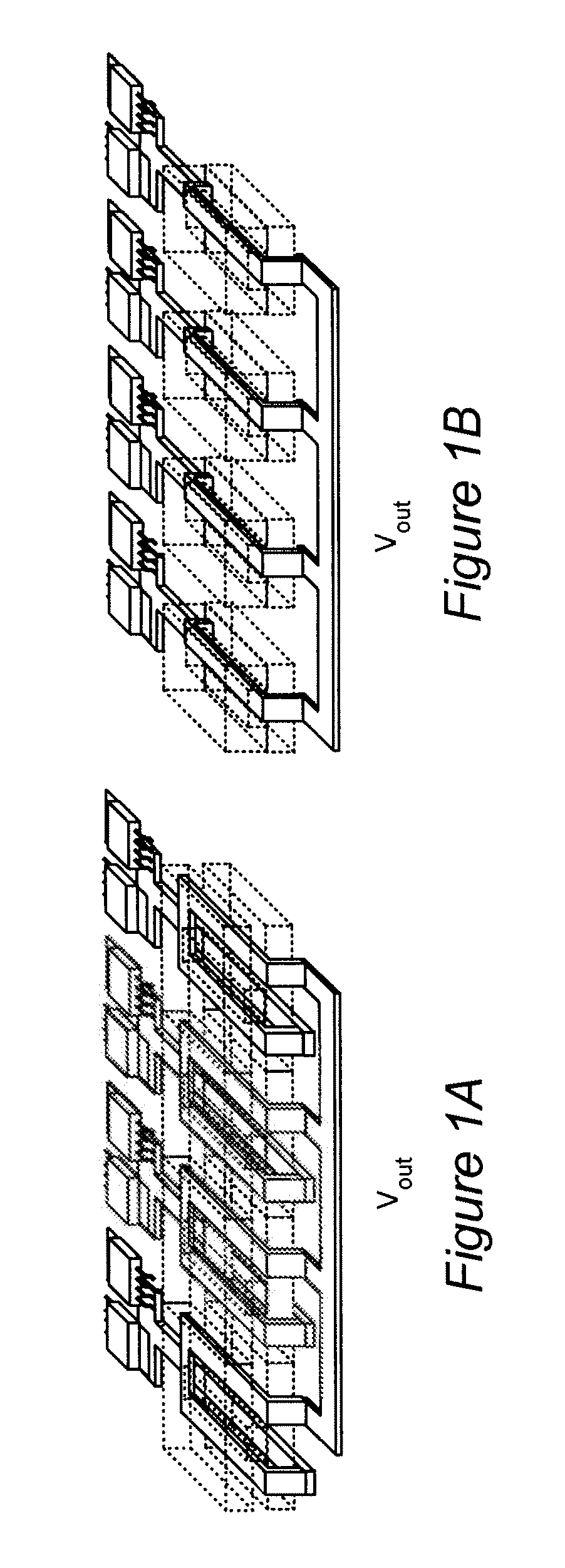

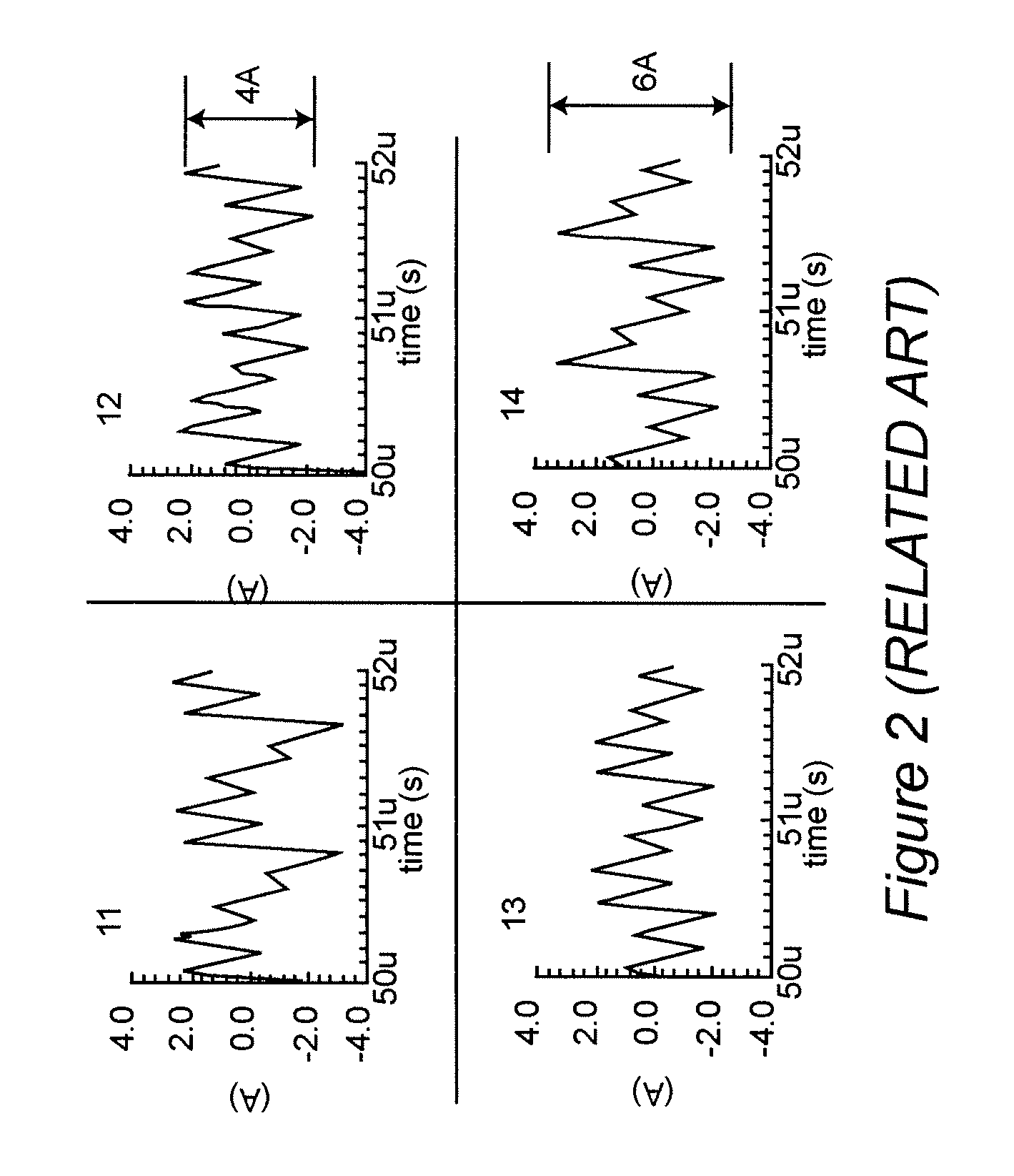

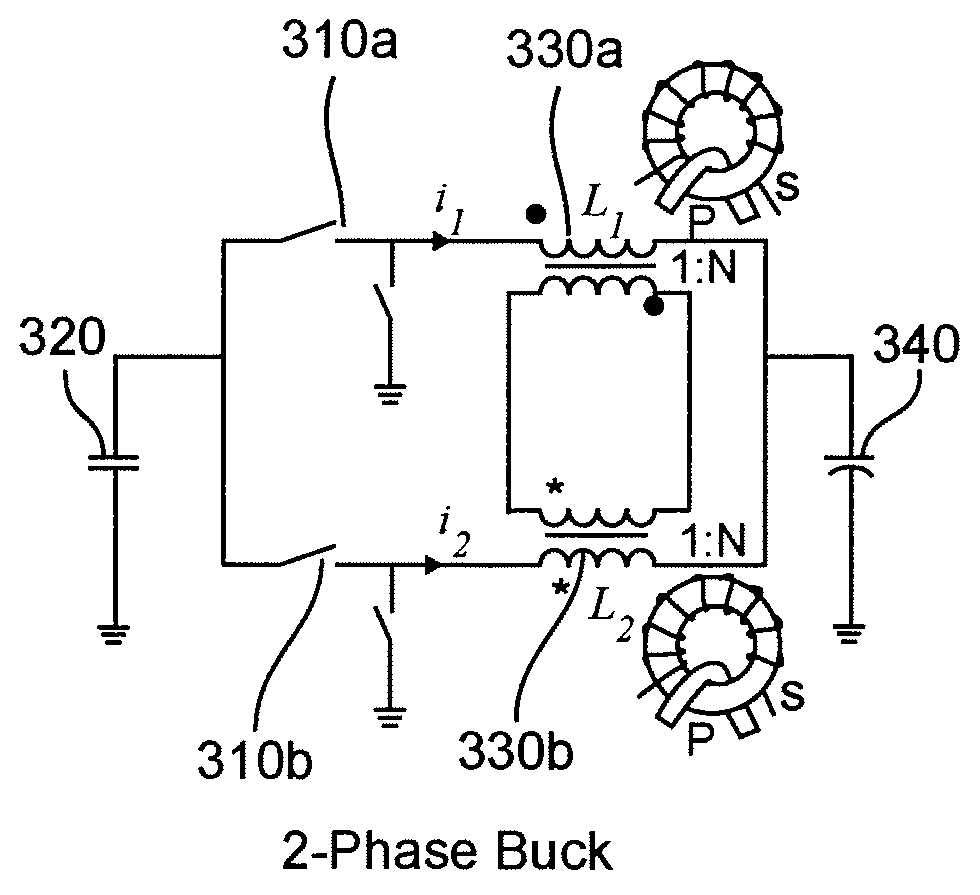

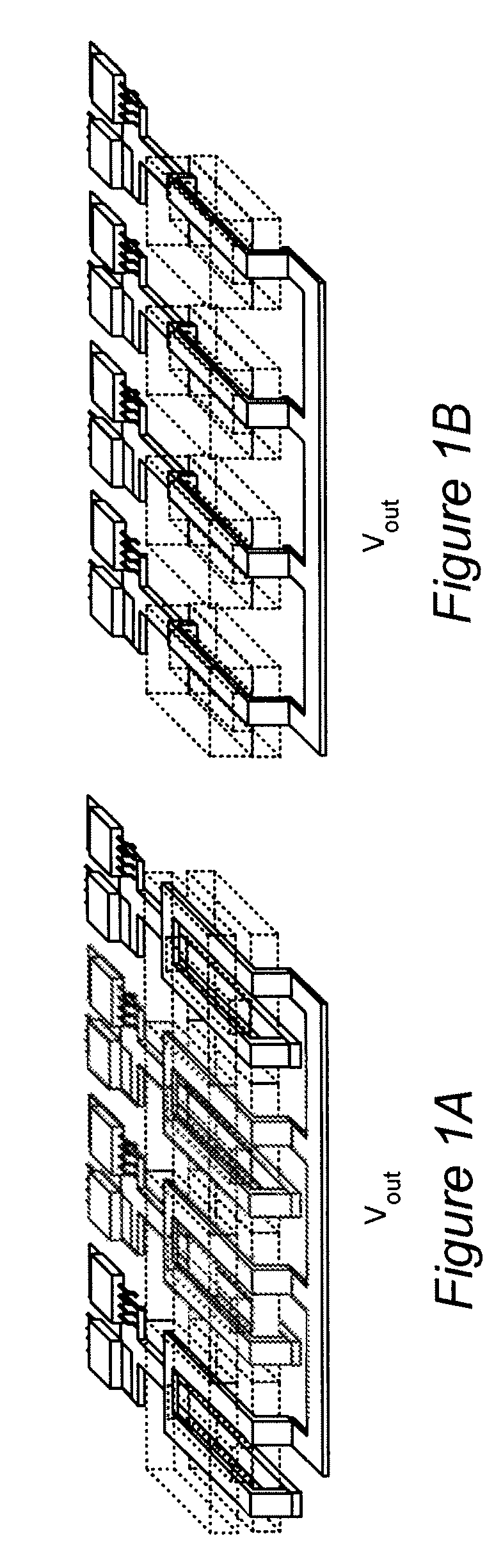

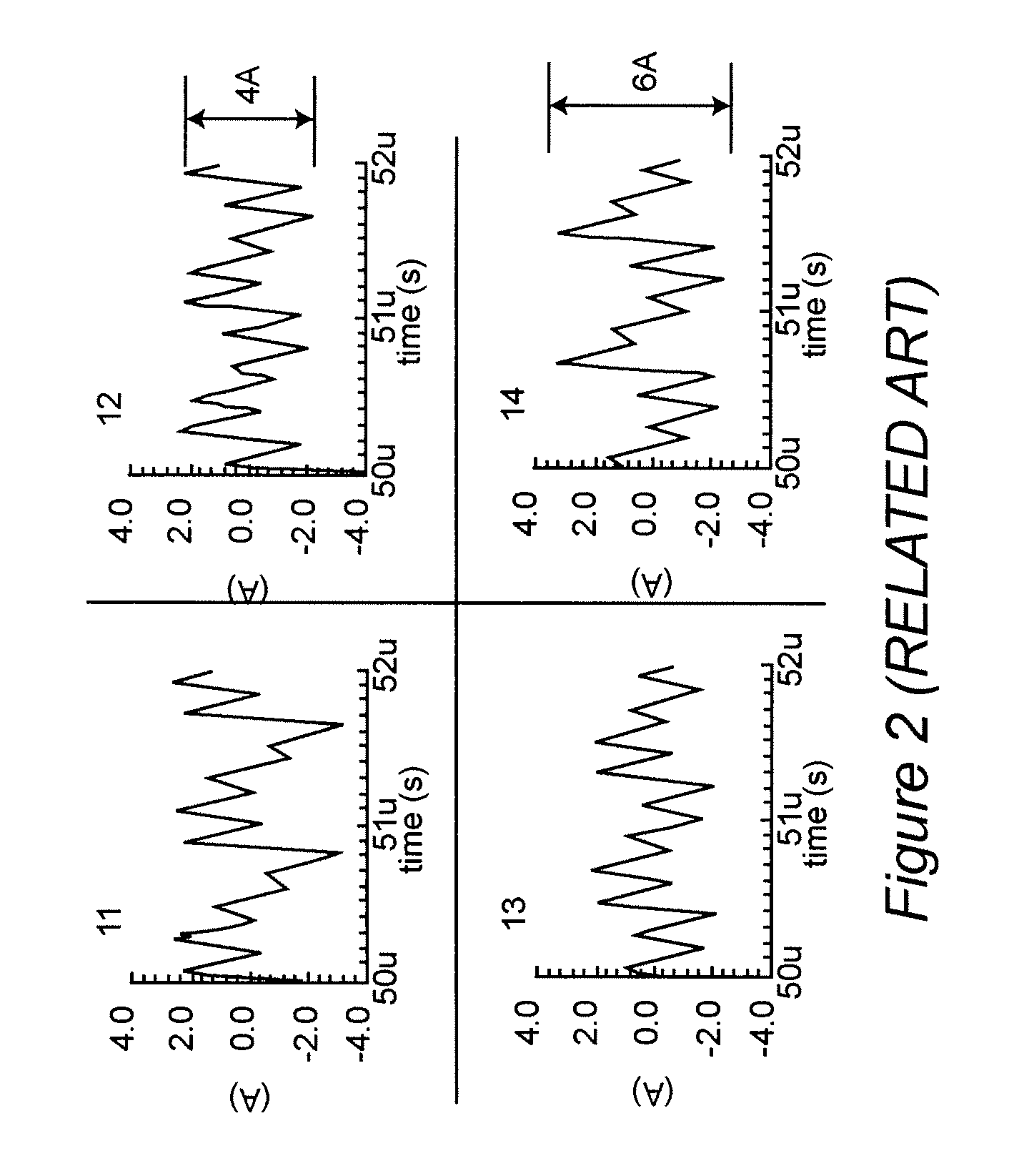

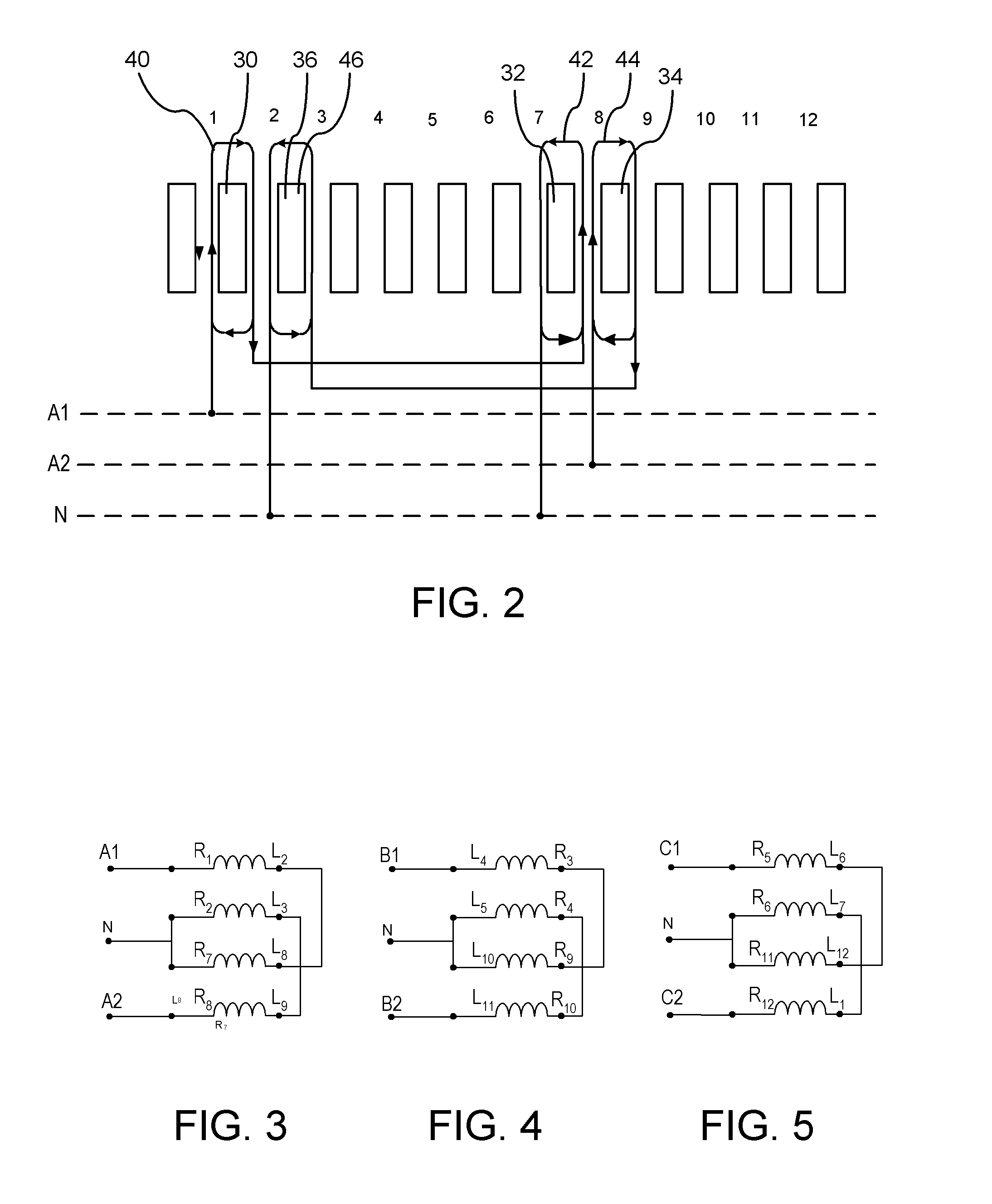

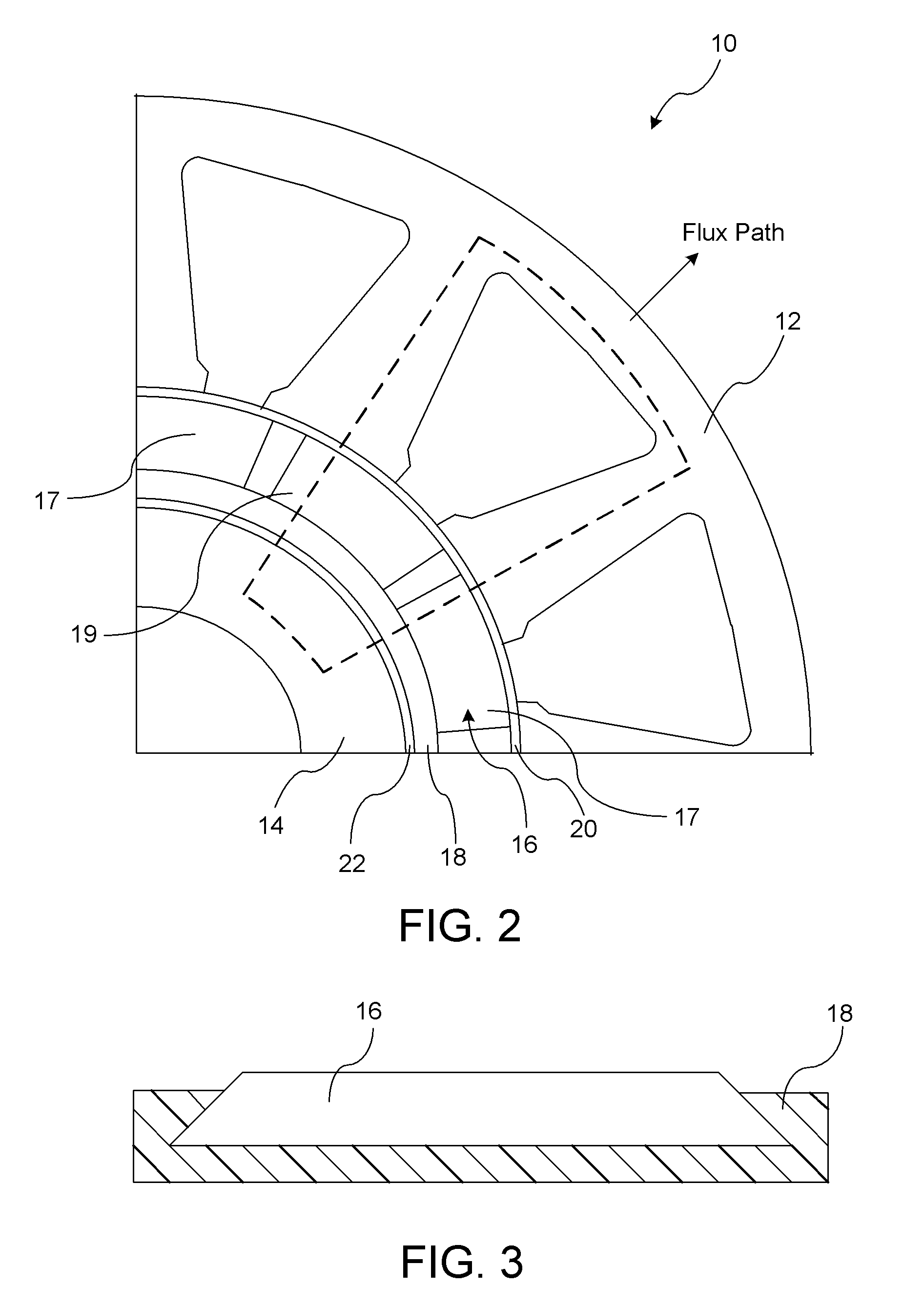

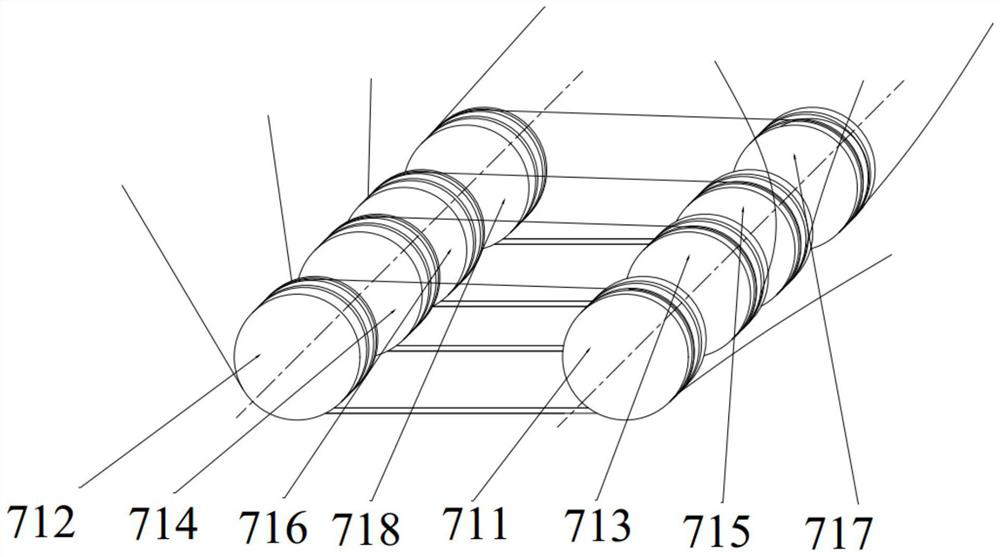

Coupled-Inductor Multi-Phase Buck Converters

InactiveUS20080205098A1Improved physical symmetryAvoid necessityDc-dc conversionFixed transformersTransformerConductor Coil

In a multi-phase power converter, efficiency is increased and ripple reduced while maintaining transient response and dynamic performance improved by electrically coupling secondary windings of transformers or provided for inductors of respective phases such that current to a load is induced in each phase by current in another phase. Magnetic coupling can also be provided between phases using a multi-aperture core of a configuration which minimizes primary winding length and copper losses. Efficiency at light load is enhanced by controlling current in the series connection of secondary windings in either binary or analog fashion.

Owner:VIRGINIA TECH INTPROP INC

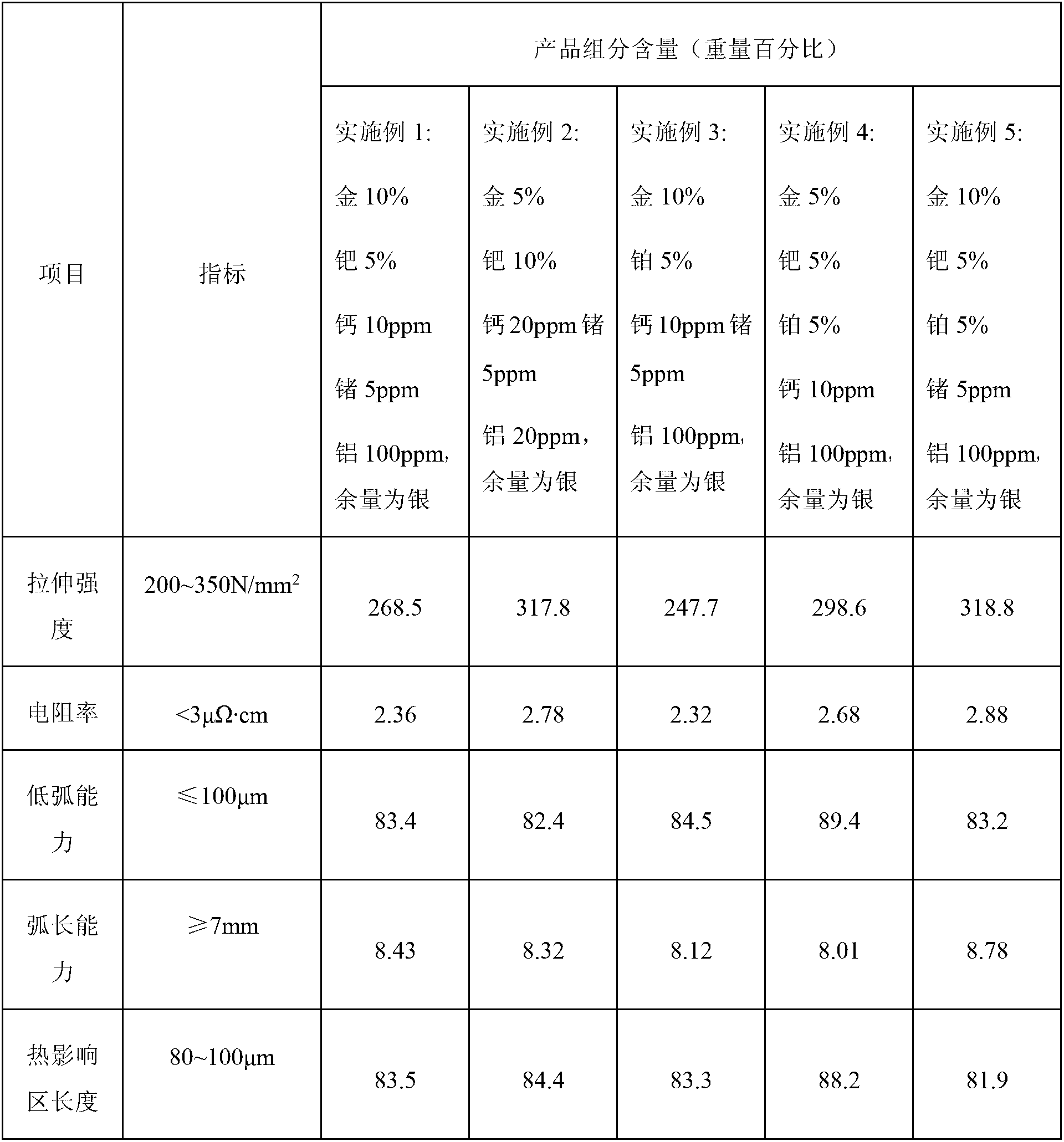

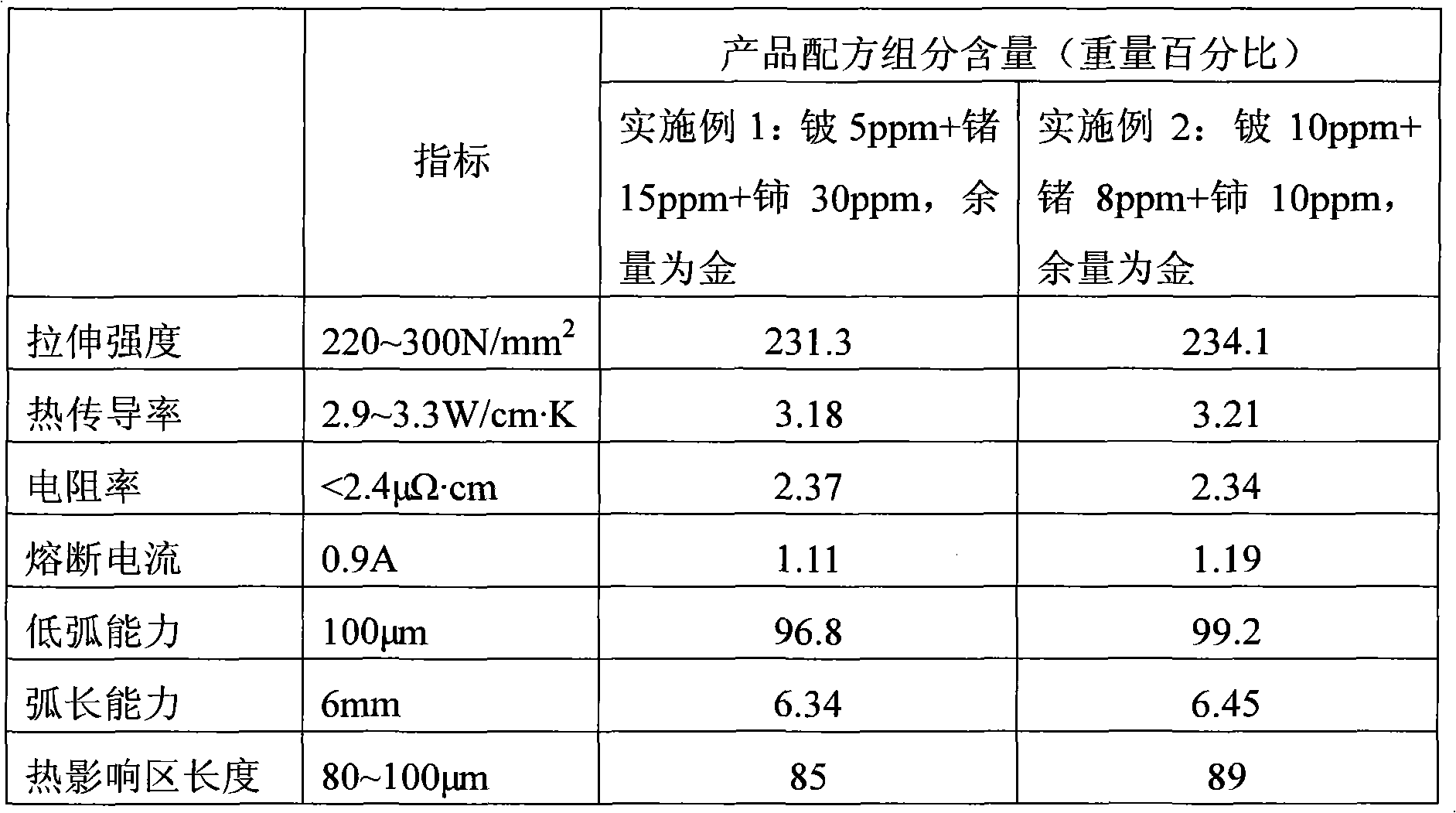

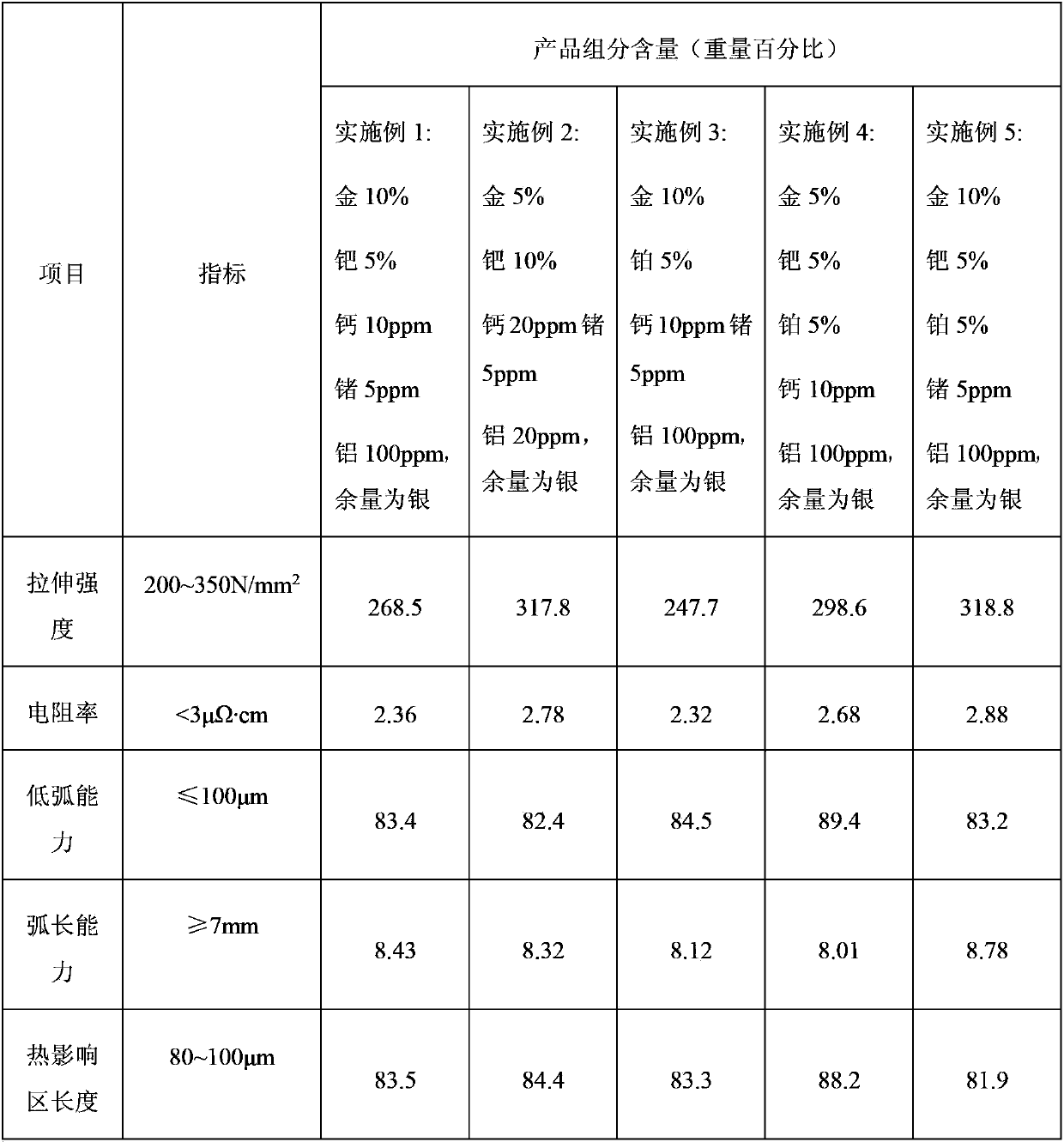

High-end packaging silver alloy bonding wire and method for manufacturing same

ActiveCN102912176AGood ball formingHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingPlatinumAlloy

The invention discloses a high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire is characterized by comprising 0.0001%-20% of gold, optional one or more than one of 0.0001%-20% of palladium, 0.0001%-20% of platinum, 0.0001%-0.015% of germanium, 0.0001%-0.015% of calcium and 0.0001%-1% of aluminum, and the balance silver. The invention further discloses a method for manufacturing the high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire has the advantages of high strength and low hardness and long-arc degree.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Coupled-inductor multi-phase buck converters

InactiveUS7791321B2Improved physical symmetryIncrease winding lengthDc-dc conversionFixed transformersTransformerConductor Coil

In a multi-phase power converter, efficiency is increased and ripple reduced while maintaining transient response and dynamic performance improved by electrically coupling secondary windings of transformers or provided for inductors of respective phases such that current to a load is induced in each phase by current in another phase. Magnetic coupling can also be provided between phases using a multi-aperture core of a configuration which minimizes primary winding length and copper losses. Efficiency at light load is enhanced by controlling current in the series connection of secondary windings in either binary or analog fashion.

Owner:VIRGINIA TECH INTPROP INC

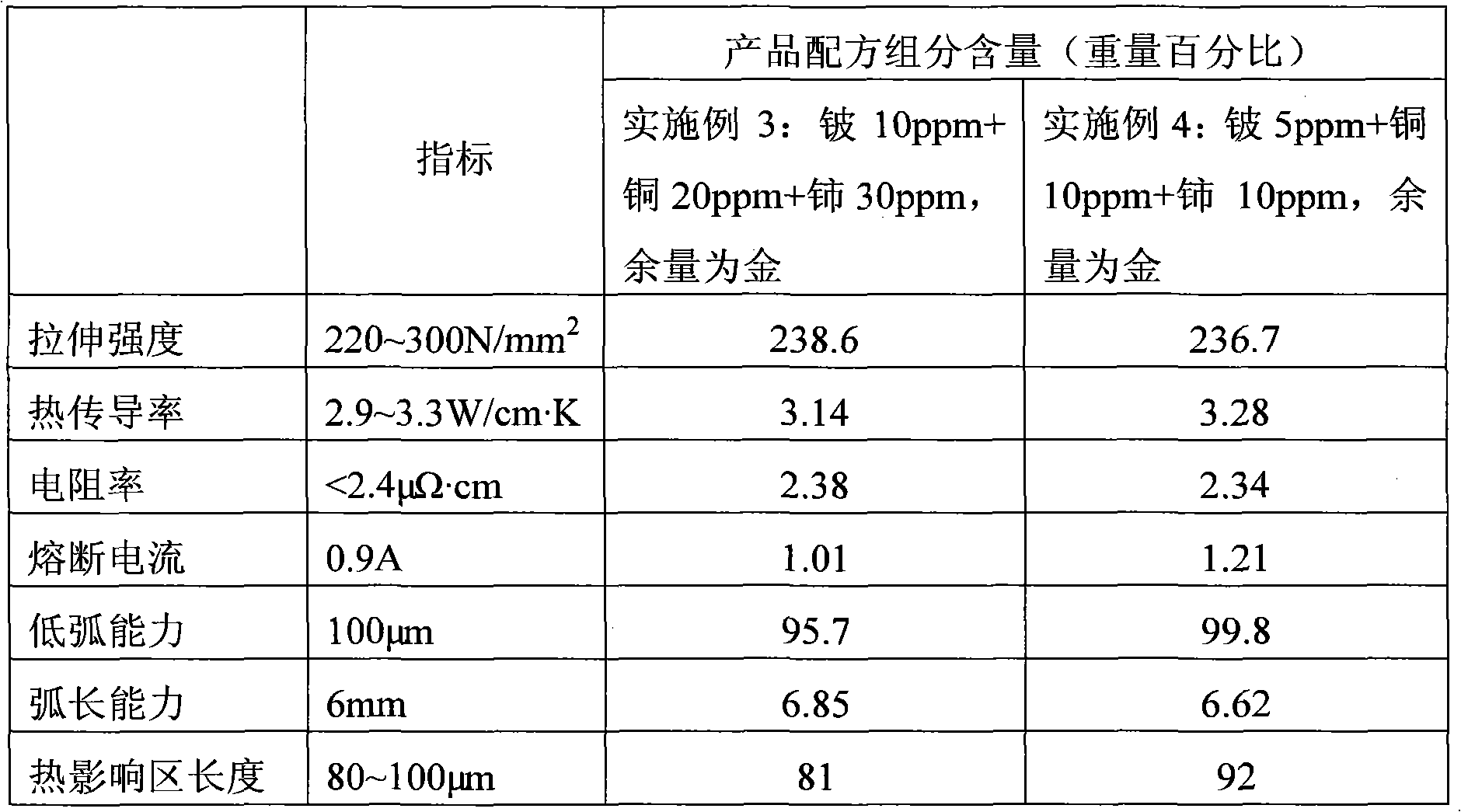

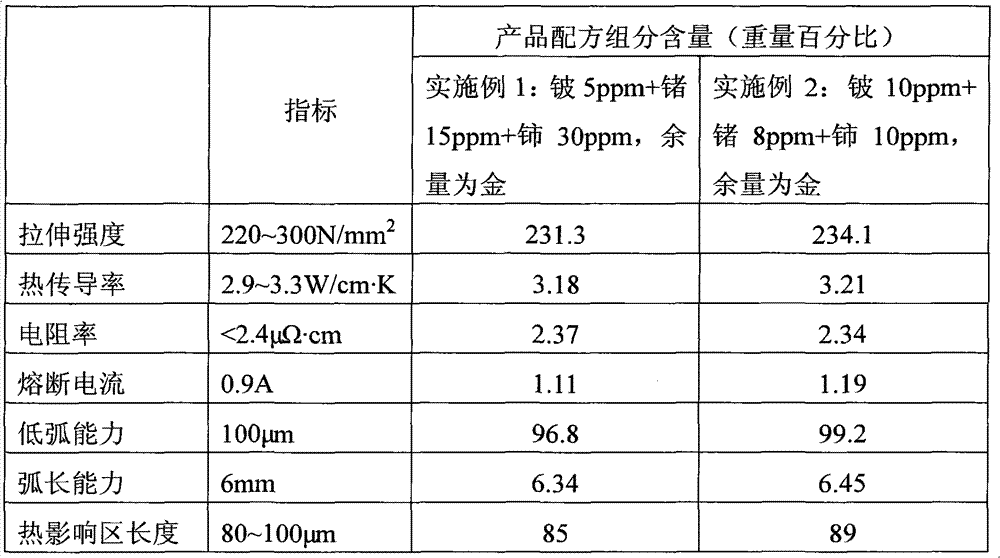

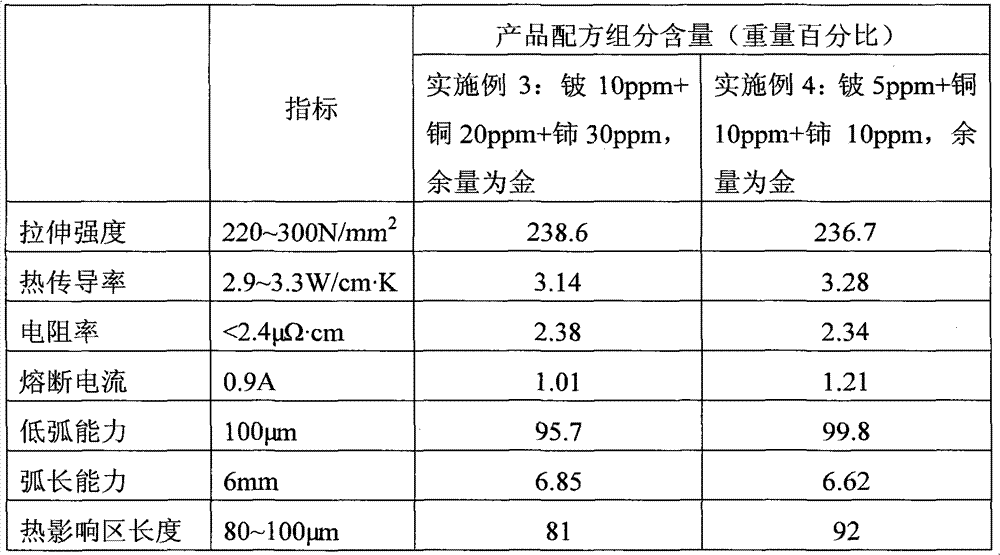

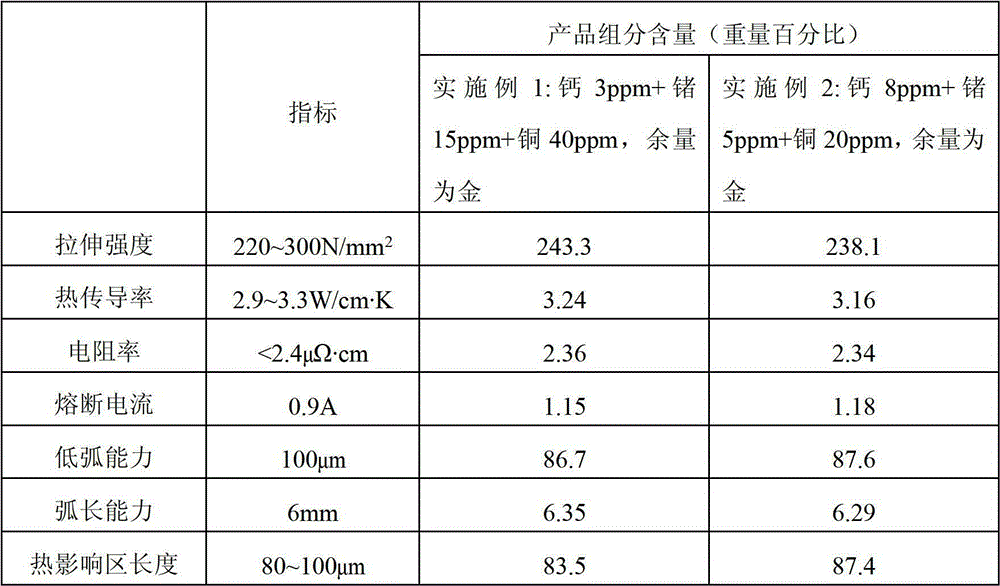

Gold bonding wire and preparation method thereof

ActiveCN102127663AHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method of the gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

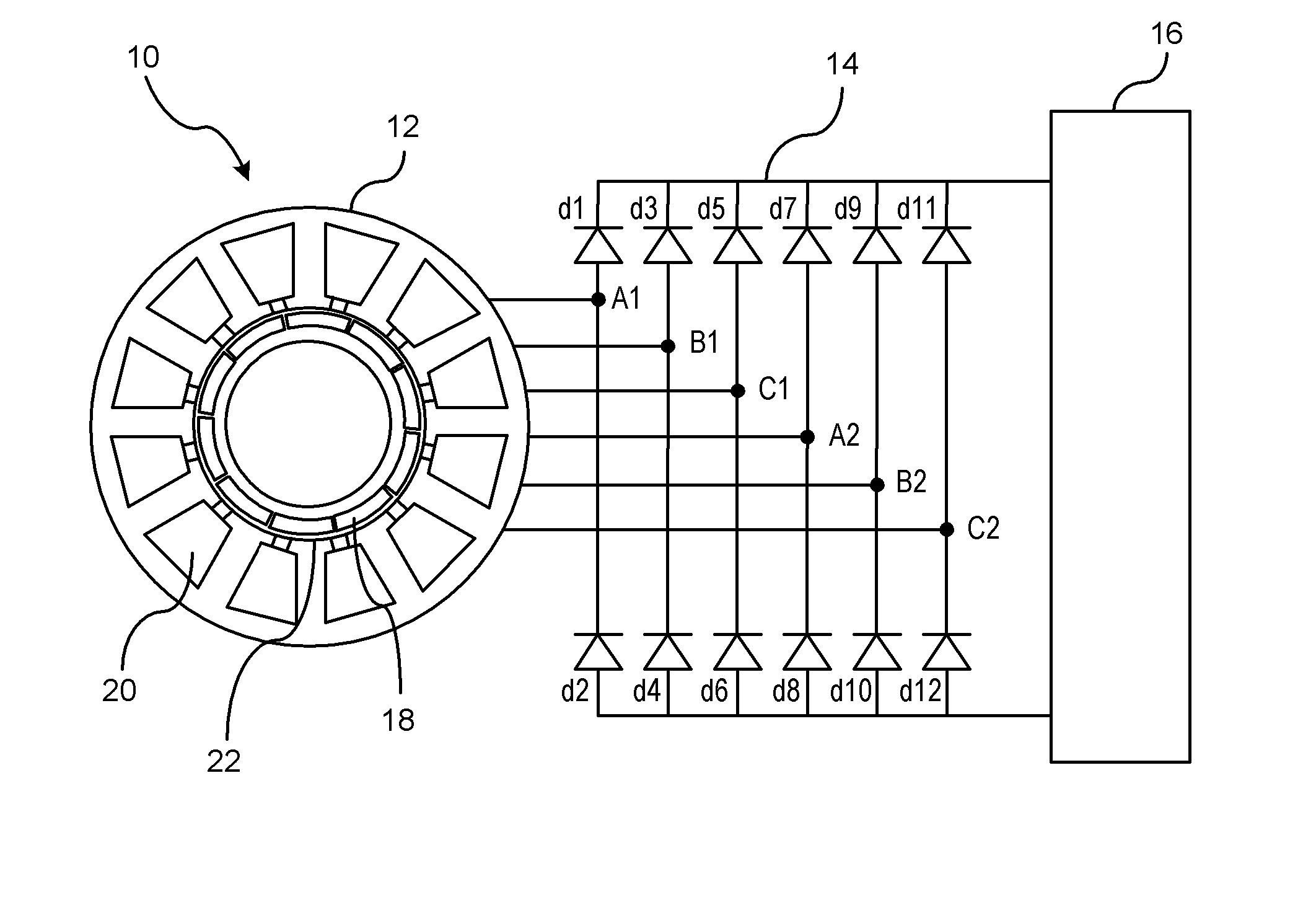

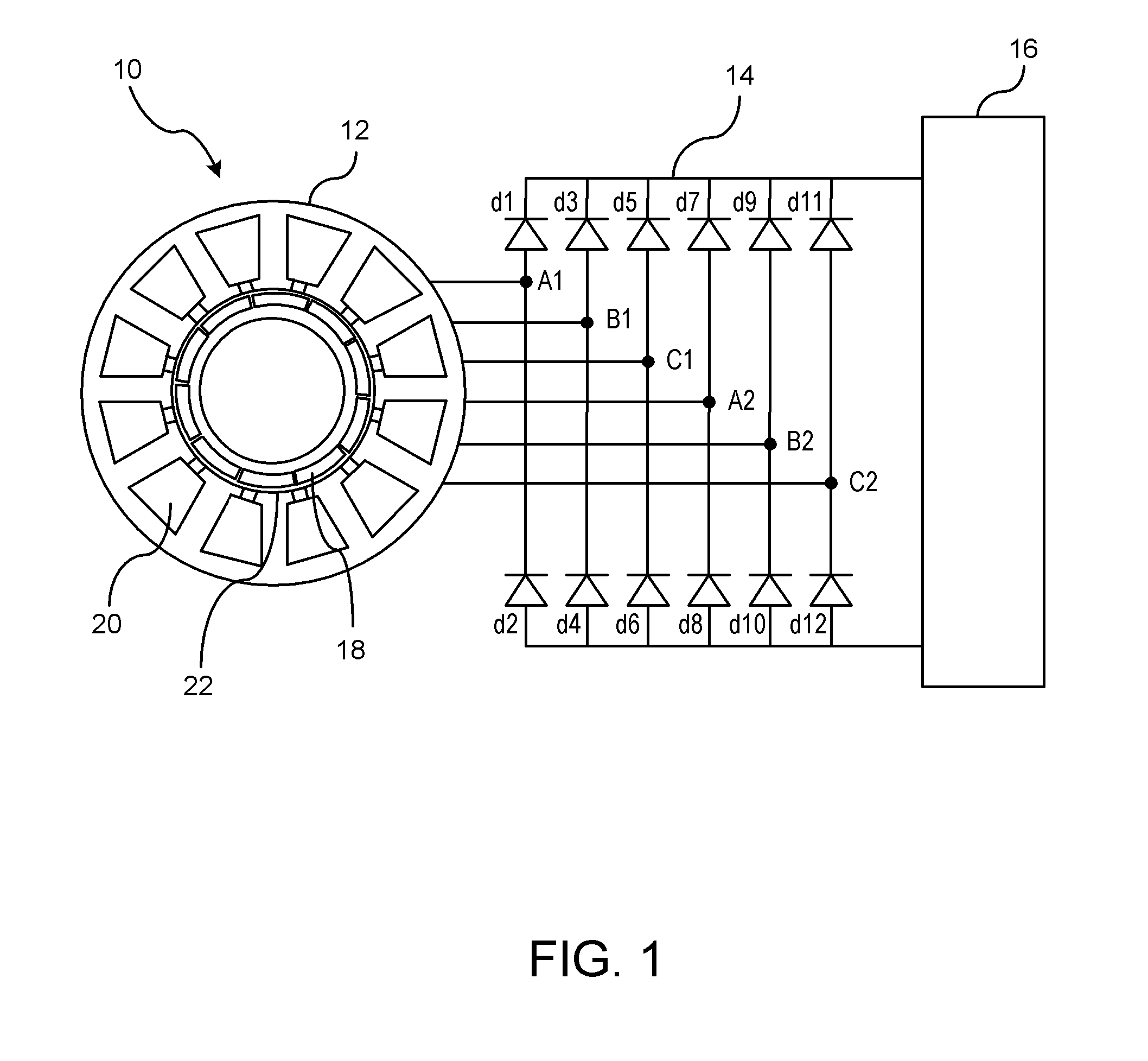

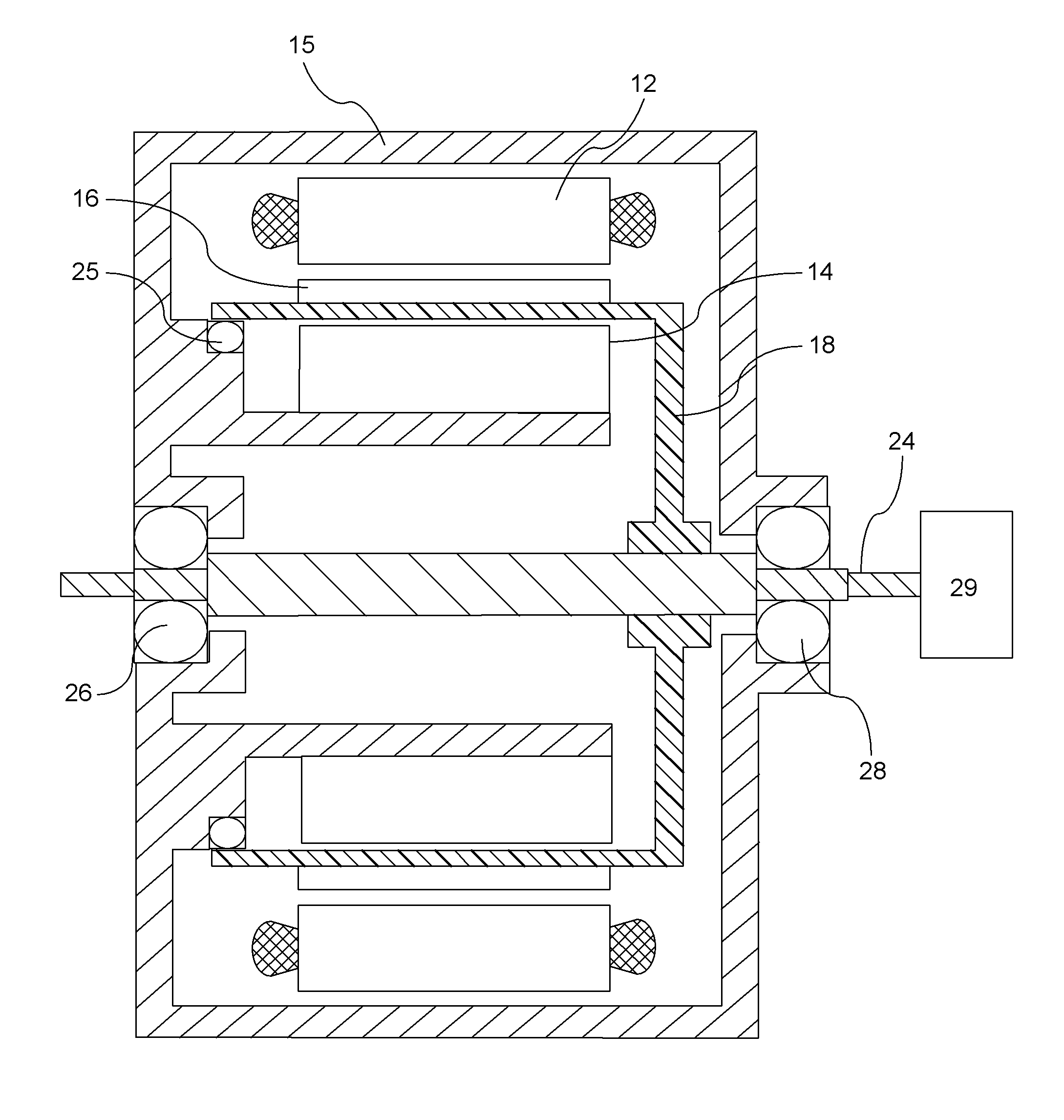

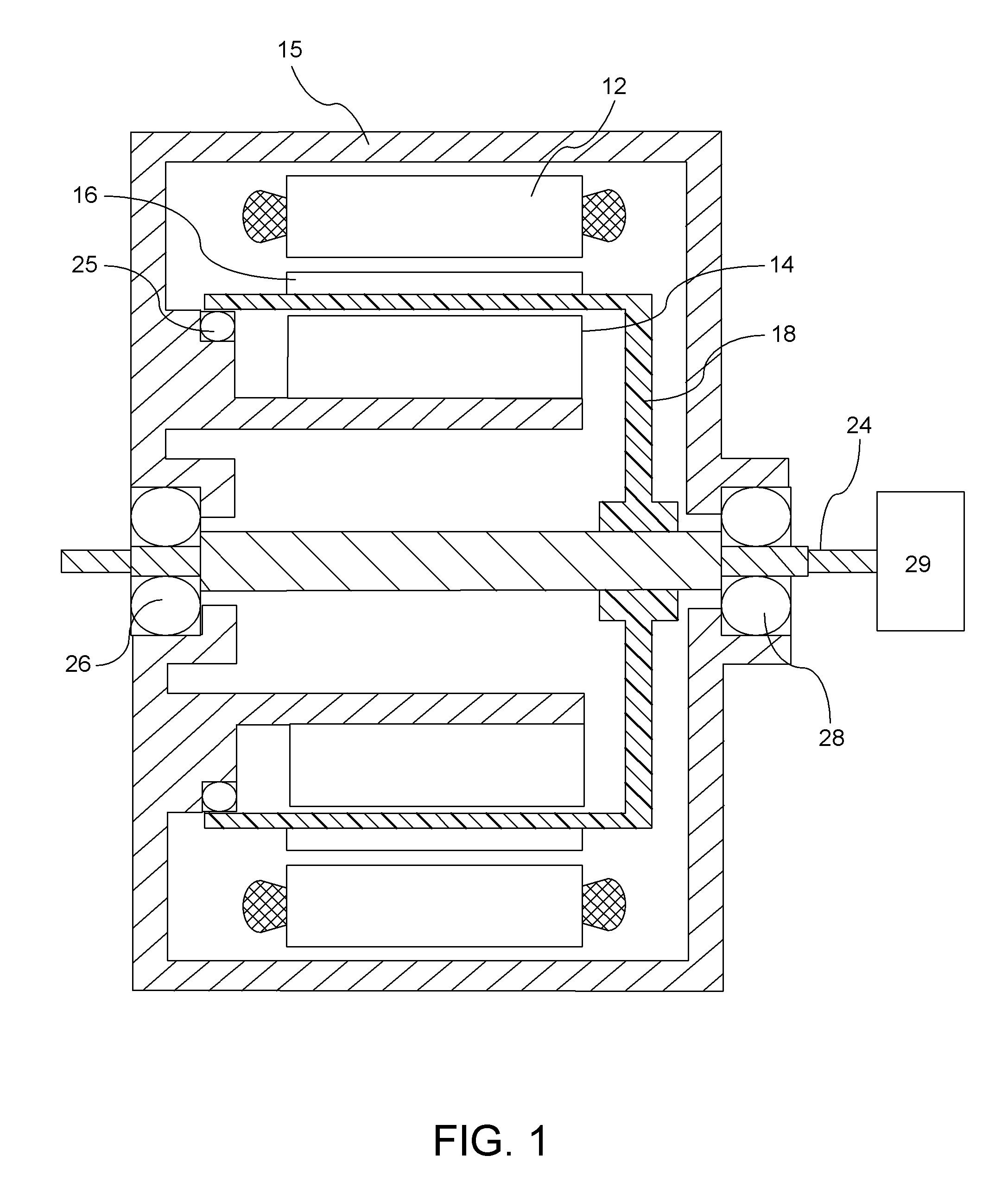

High Torque Density and Low Torque Ripple Actuator System

InactiveUS20120194040A1Optimal operating characteristicRaise the ratioSynchronous generatorsSynchronous machines with stationary armatures and rotating magnetsPhase shiftedEngineering

A permanent magnet electric machine drive system that includes a plurality of magnets for generating a first magnetic field and a stator is disposed radially outward from the plurality of magnets for generating a magnetic field. The stator includes a plurality of stator poles separated by slots with each respective stator pole having a concentrated winding with a respective number of turns formed around each respective stator pole. Each respective concentrated winding within the stator comprising non-overlapping phases. The concentrated windings form a dual three-phase winding configuration that includes a first set of three-balanced phase windings and a second set of three-balanced phase windings. The first set of three-balanced phase windings is phase shifted in the range of 15 to 45 electrical degrees from the second set of three-balanced phase windings for reducing the torque ripple.

Owner:GM GLOBAL TECH OPERATIONS LLC

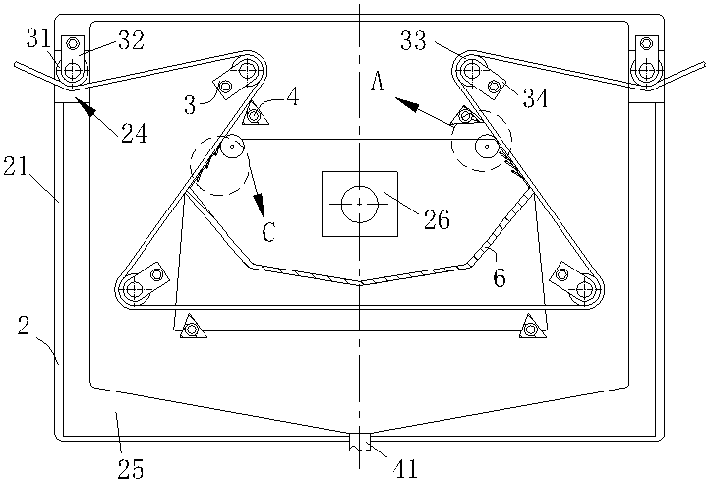

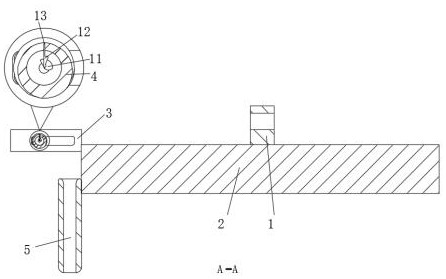

Direction changing type yarn textile working guide tensioning device and method

The invention relates to a direction changing type yarn textile working guide tensioning device and method. A bottom plate, direction changing pulley rods, an annular sliding groove, a connecting column, a connecting disc, anti-loosening devices and a rotating disc are included; the bottom plate is provided with the annular sliding groove, the annular sliding groove is connected with the directionchanging pulley rods in a sliding fit manner, the connecting column is installed in the middle portion of the bottom plate, the connecting column is located between the two direction changing pulleyrods, the upper end of the connecting column is provided with the connecting disc, the anti-loosening devices are evenly formed in the connecting disc in the circumferential direction, and the upper end of the connecting disc is provided with the rotating disc. According to the direction changing type yarn textile working guide tensioning device and method, yarns are synchronously supported to beopen through the anti-loosening devices, the winding length of the yarns is changed, and the yarns are wholly in the tightening state; and the conveying direction of the yarns is changed by position adjustment of the two direction changing pulley rods, friction generated when the yarns are subjected to direction-changing conveying, and the abrasion degree of the yarns is reduced.

Owner:福建石狮晨光化纤染织有限公司

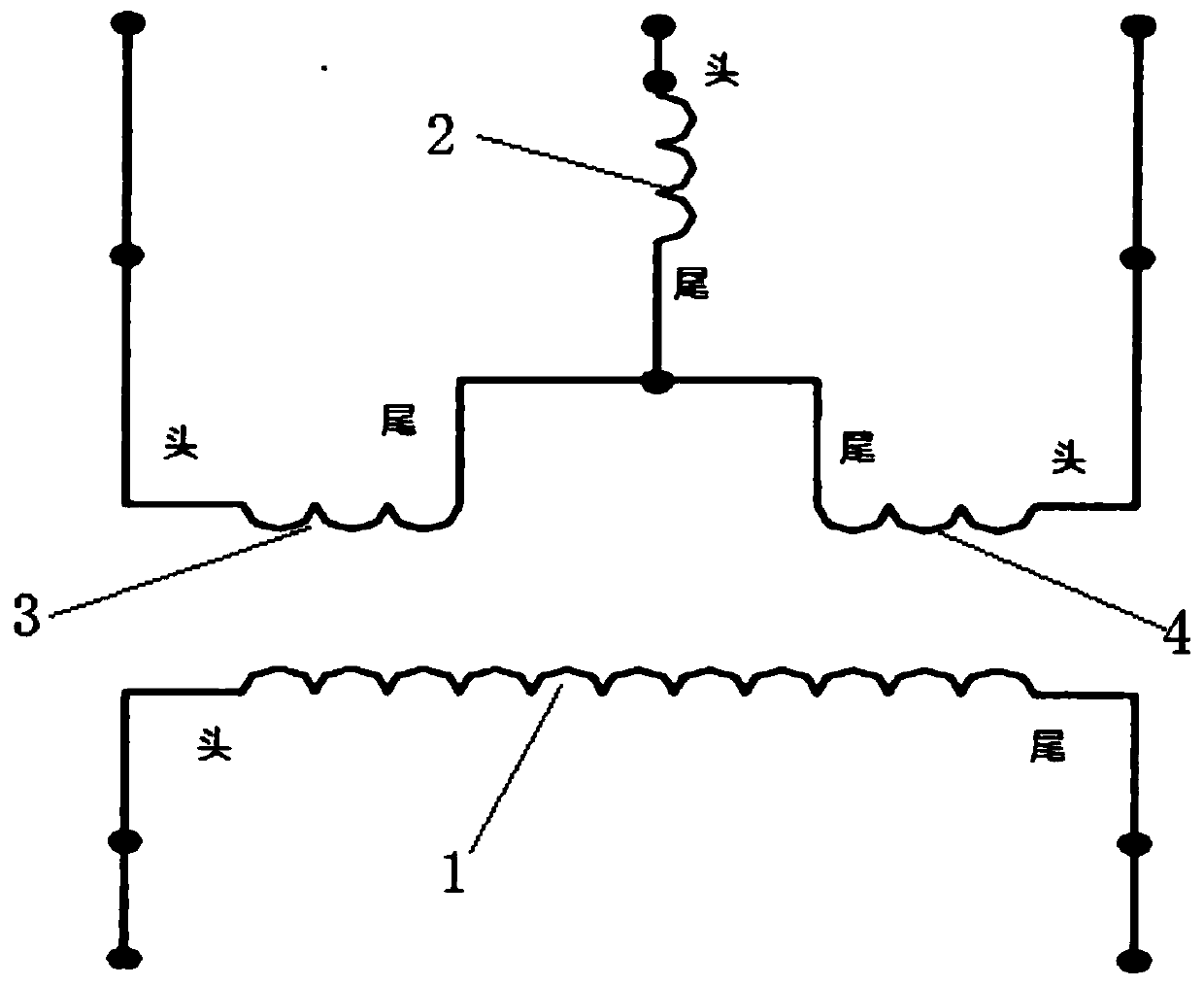

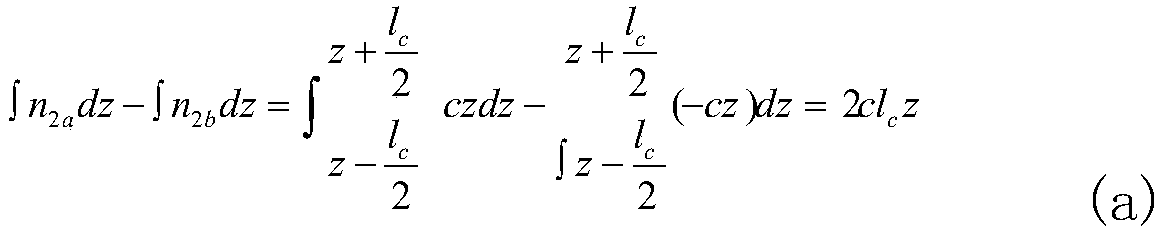

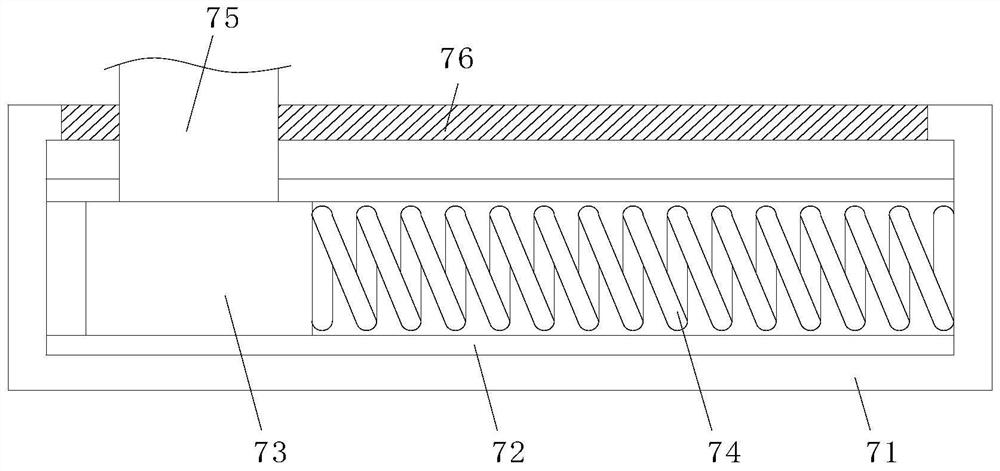

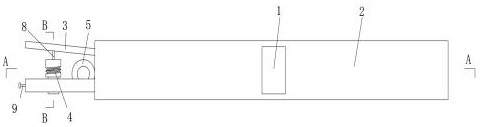

Small-stroke proportional output LVDT compensation coil process

InactiveCN109616313AIncrease winding lengthIncrease the lengthTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringConductor Coil

The invention relates to a small-stroke proportional output LVDT compensation coil process. The process comprises the following steps that step 1, the number of turns and the number of layer of primary coils are designed according to technical indexes for performing horizontal winding; step 2, a compensation coil WE is horizontally wound from left to right on the primary coils; and step 3, a secondary coil WA and a secondary coil WB are horizontally wound on the compensation coil WE according to a layer winding process. After the compensation coil is added, the wire winding length L and the length of an iron core can be increased, so that the performance of the LVDT can be improved; and the voltage value can be regulated, so that the requirements of technical indexes can be met.

Owner:安徽感航电子科技有限公司

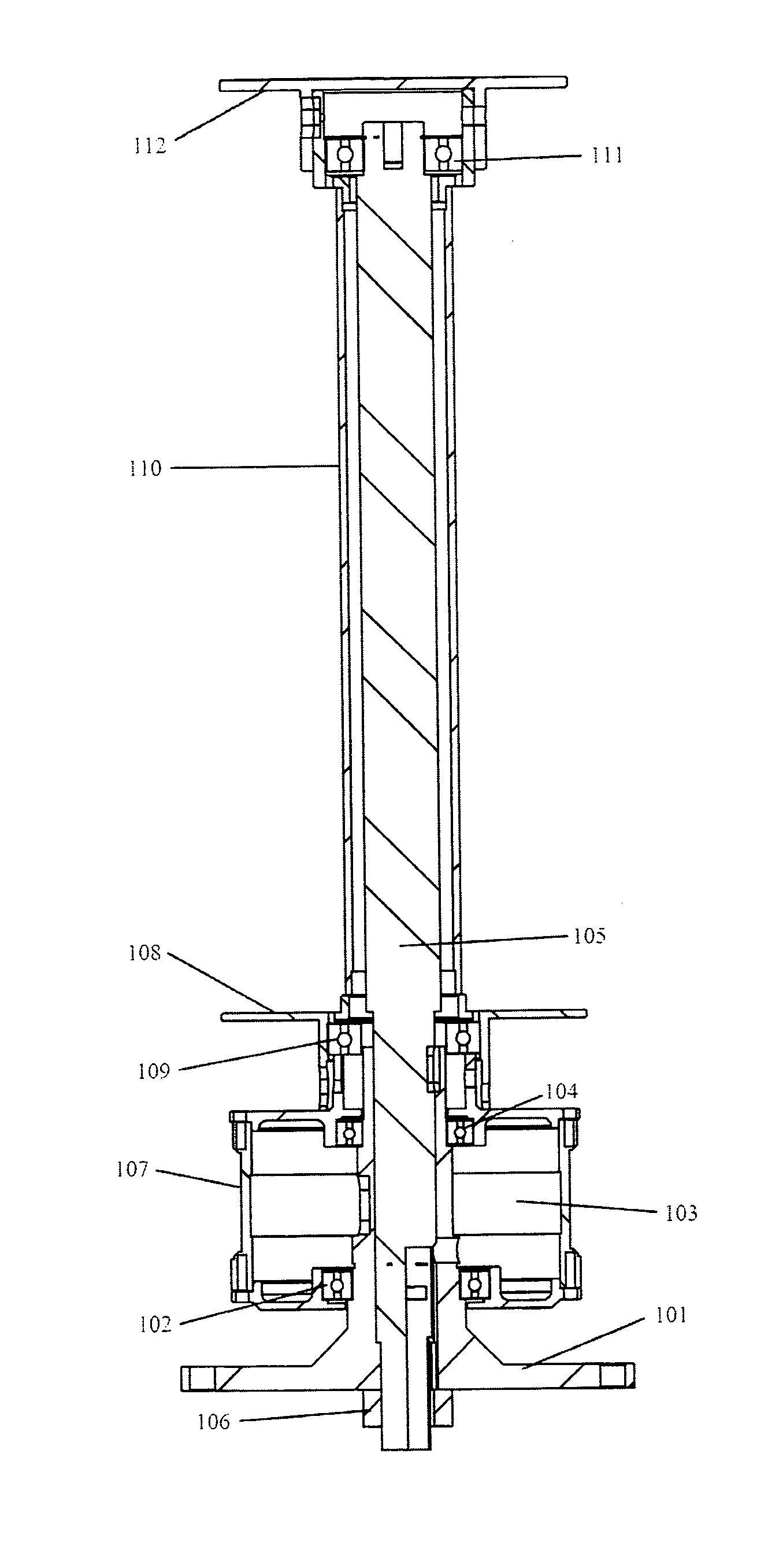

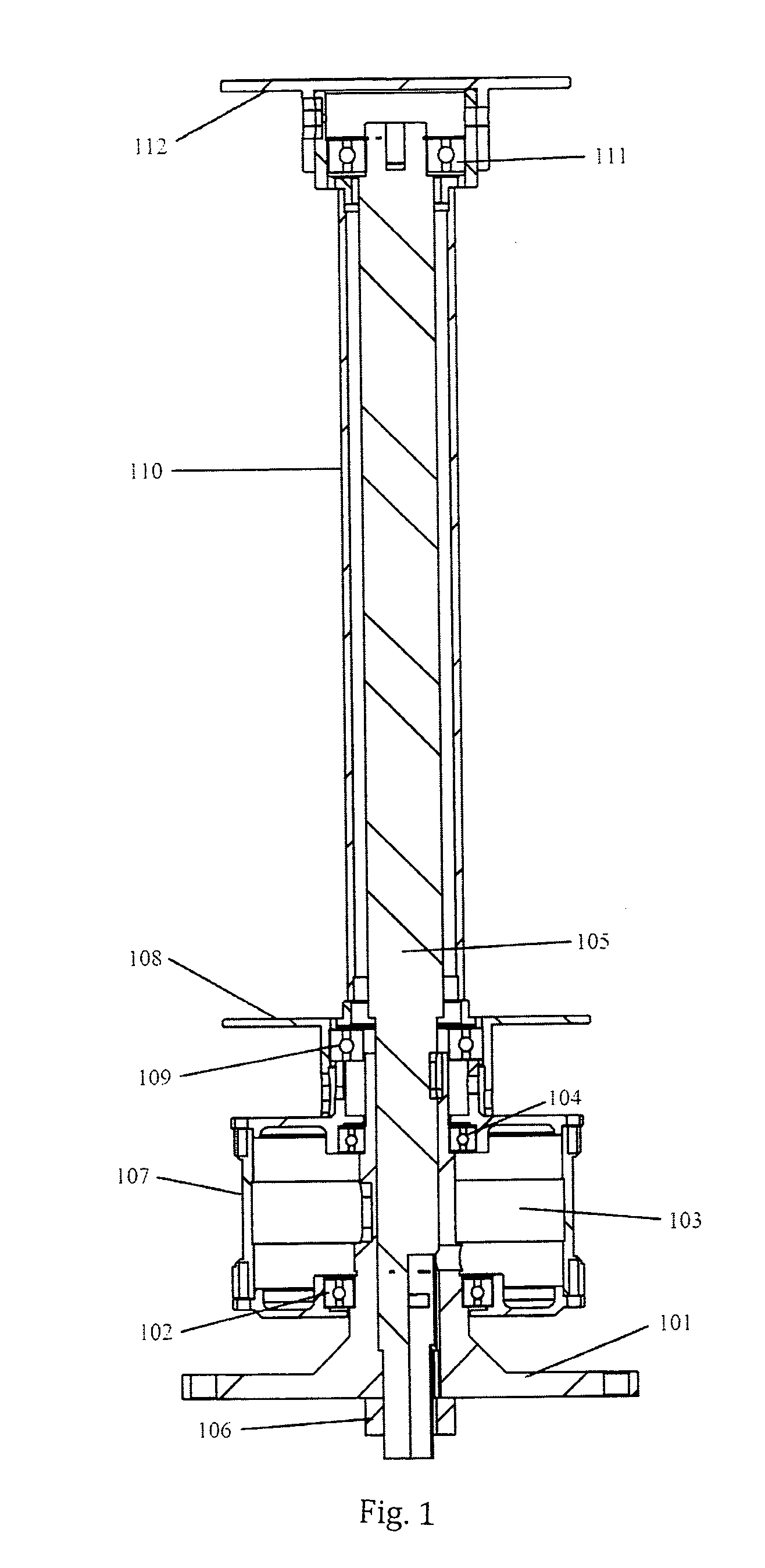

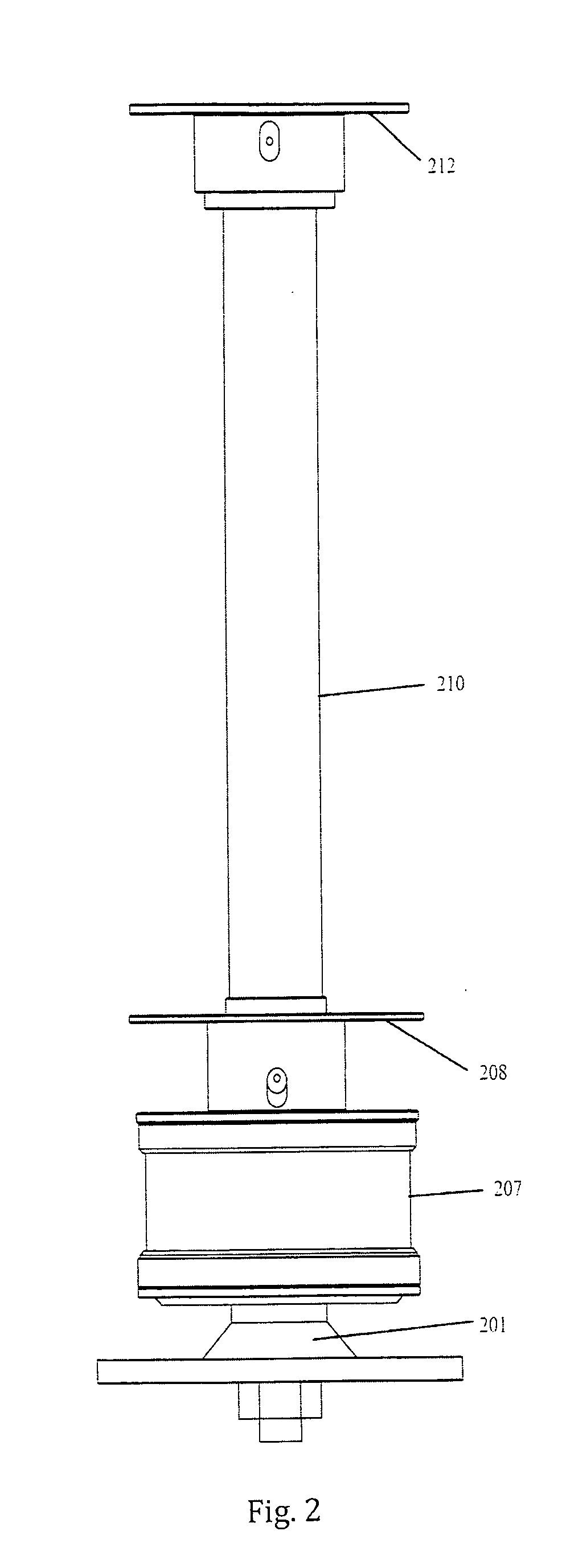

External Rotor Generator of Vertical Axis Wind Turbine

InactiveUS20120098270A1Decrease start up wind speed of windIncrease winding lengthFinal product manufactureWind motor supports/mountsVertical axis wind turbineWind force

A vertical axis wind turbine characterized in an external rotor generator comprising an external rotor generator and wind turbine arranged on the external rotor generator.

Owner:URBAN GREEN ENERGY

Optimized electric machine for smart actuators

InactiveUS8816556B2Optimal operating characteristicRaise the ratioSynchronous generatorsMagnetic circuit rotating partsElectric machineActuator

A single stator electric machine includes a plurality of magnets for generating a first magnetic field. Each respective magnet represents a respective rotor pole. A magnet holder retains the plurality of magnets. A stator is disposed radially outward from the plurality of magnets for generating a second magnetic field. The stator includes a plurality of stator poles separated by slots with each of the stator poles having a concentrated winding with a respective number of turns formed around each respective stator pole. Each respective concentrated winding within the stator comprises non-overlapping phases which increase an active length of the windings of the stator and reduce an overhang of each respective winding with respect to each stator pole for improving torque efficiency. A number of rotor poles is at least eight and the number of rotor poles and a number of stator slots have a least common multiple of at least 36.

Owner:GM GLOBAL TECH OPERATIONS LLC

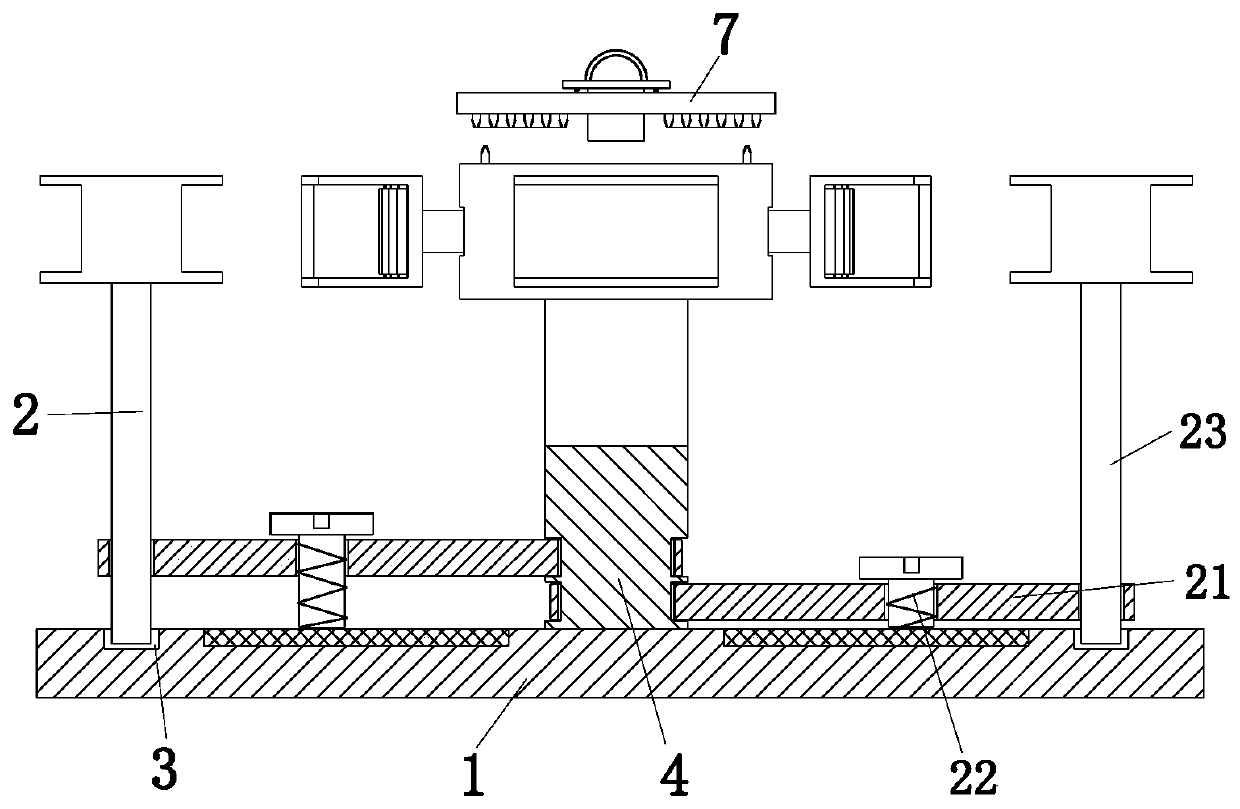

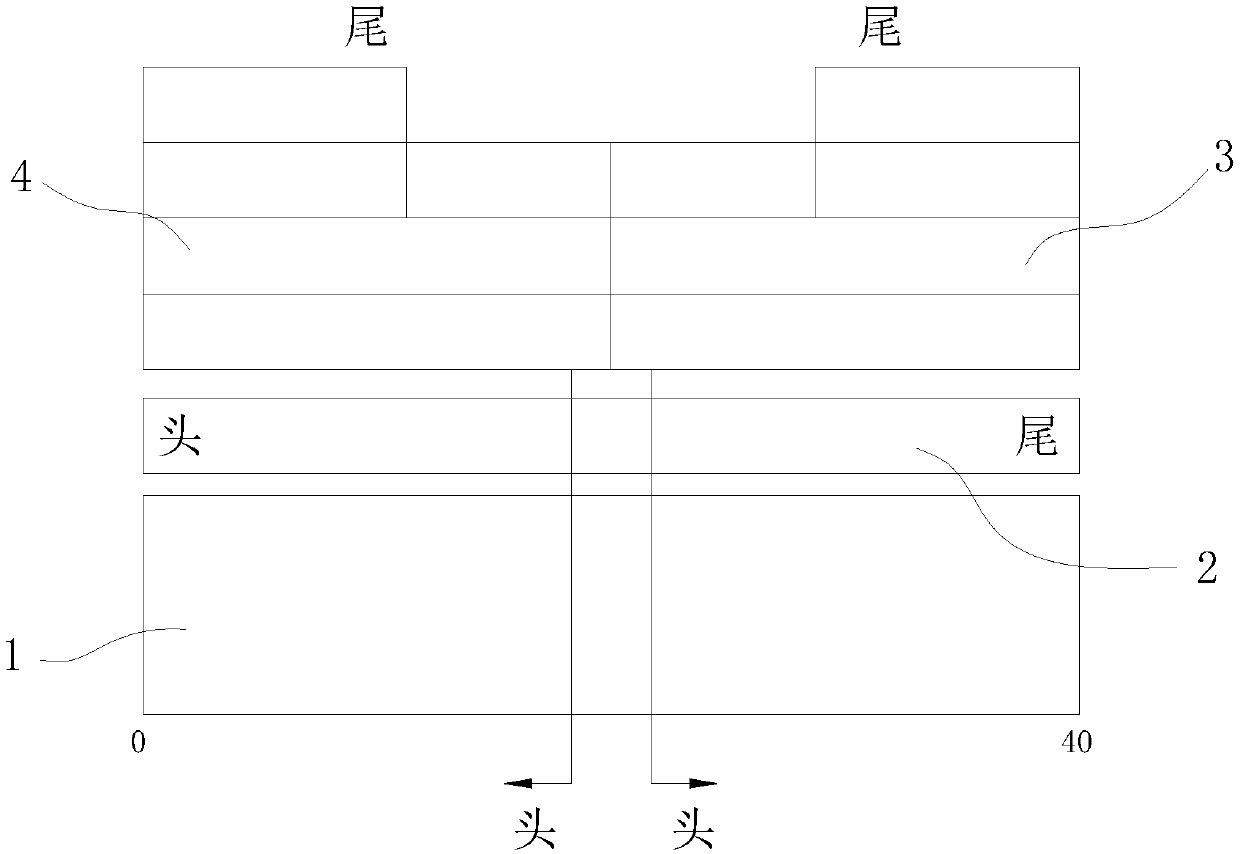

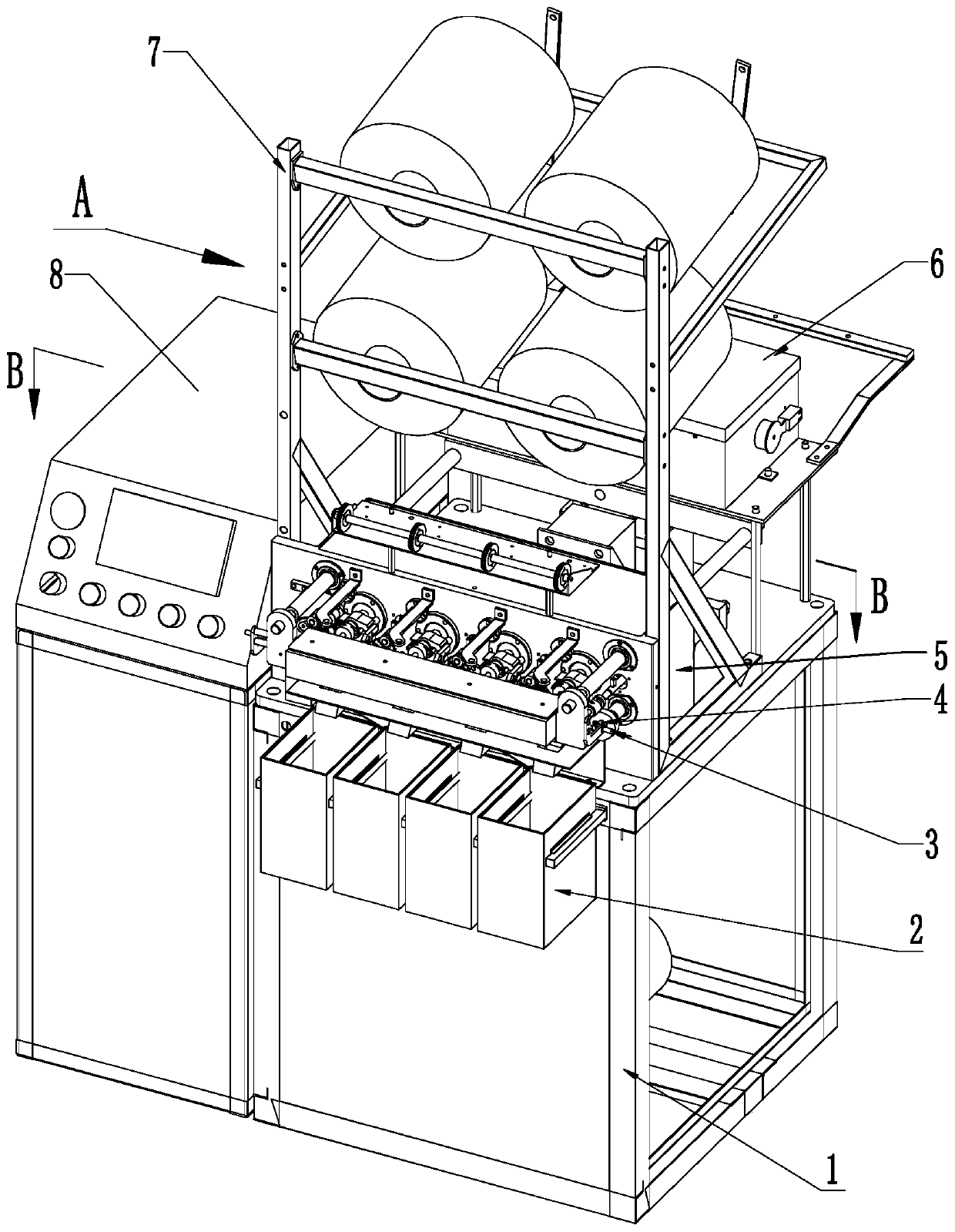

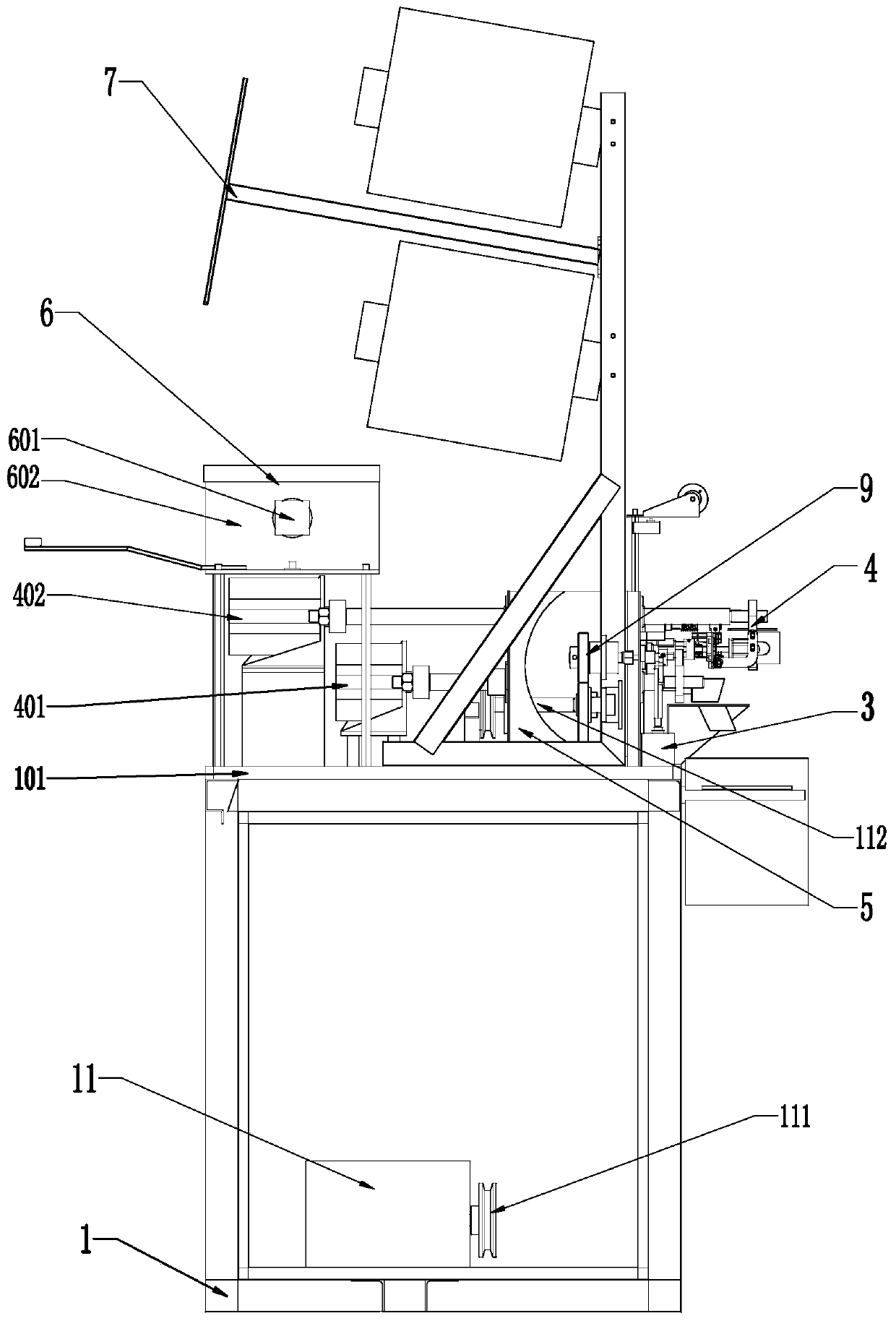

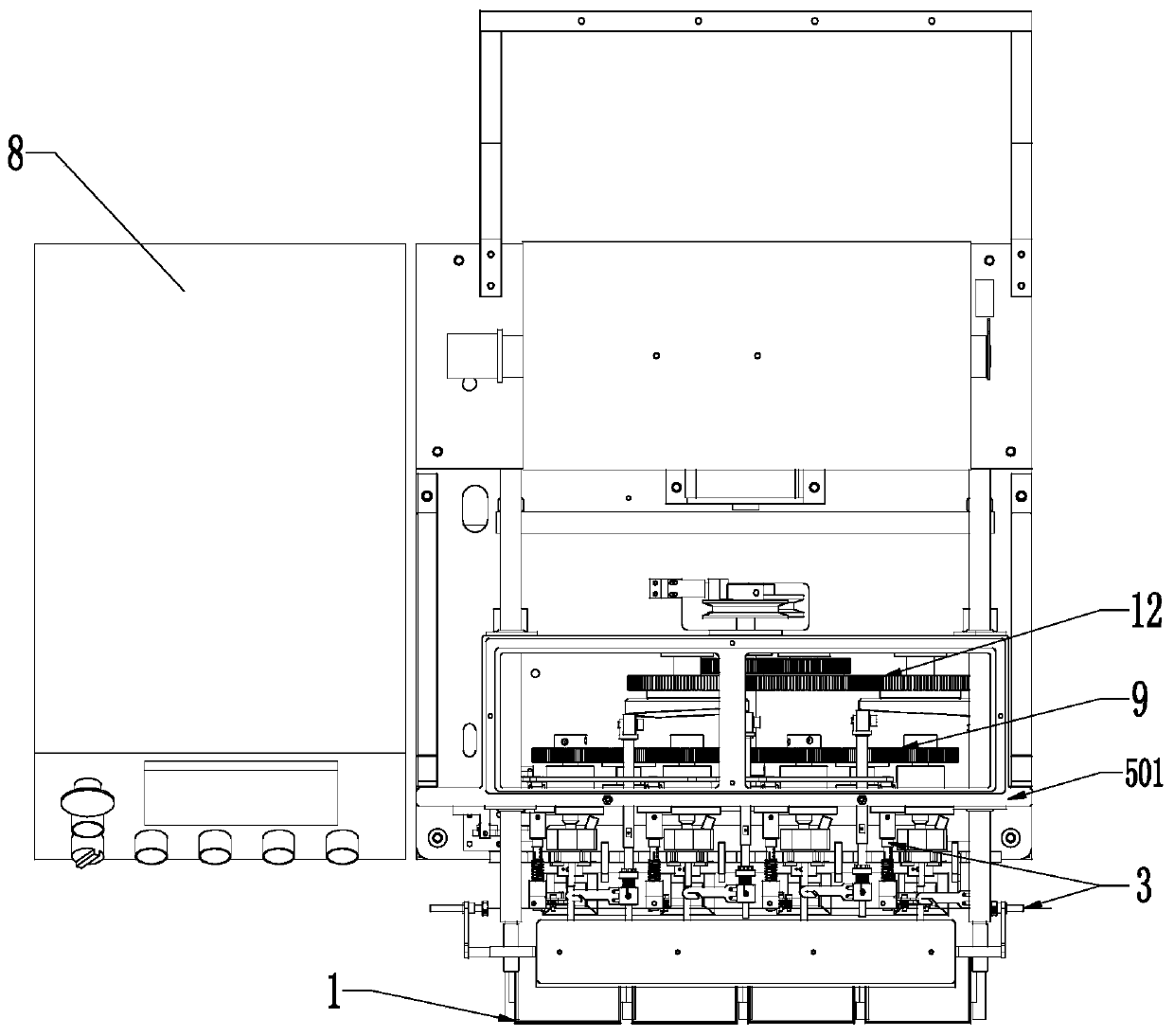

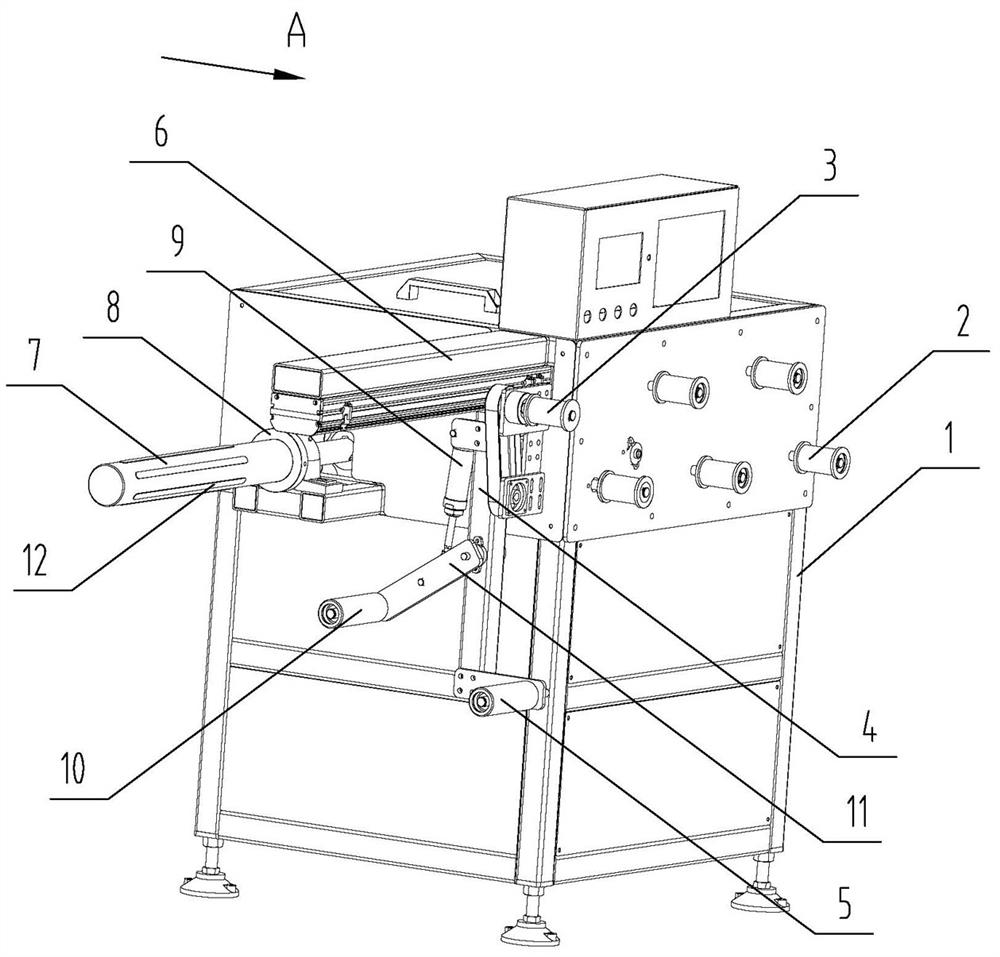

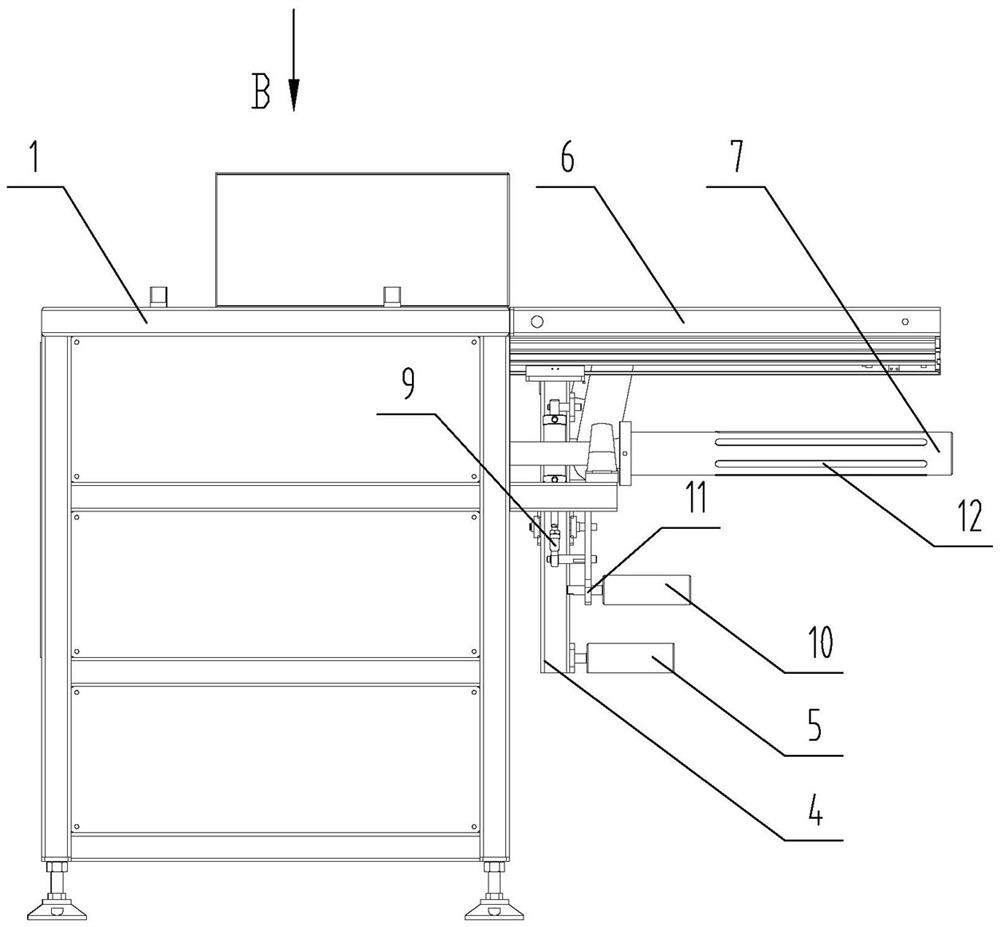

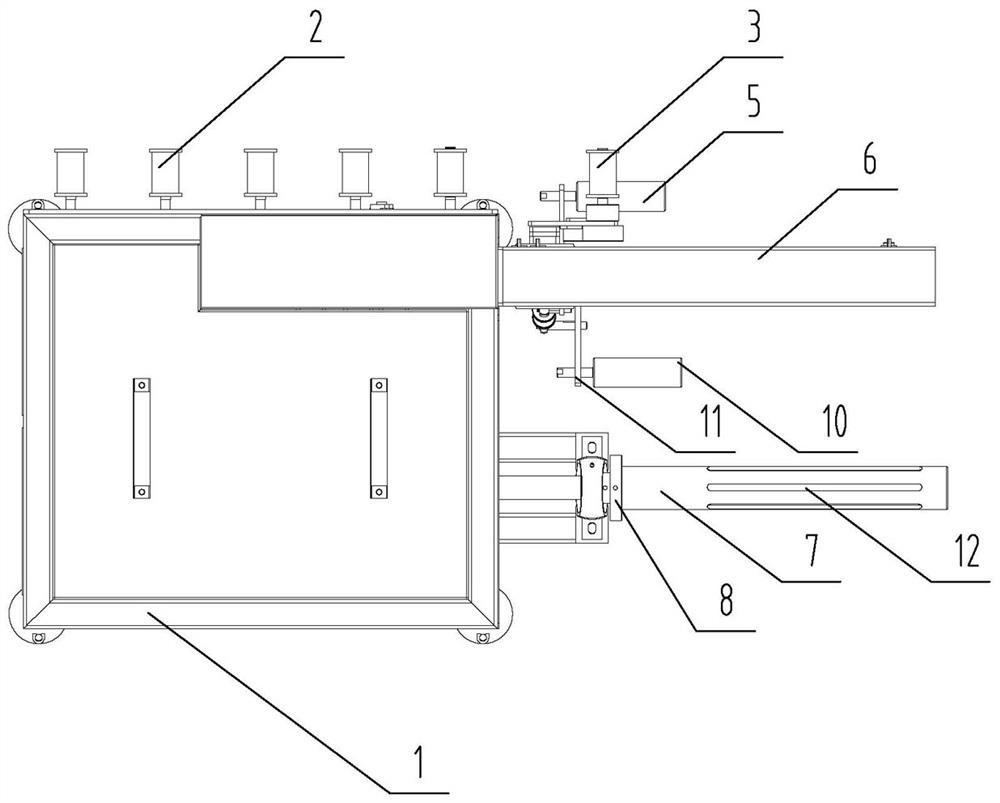

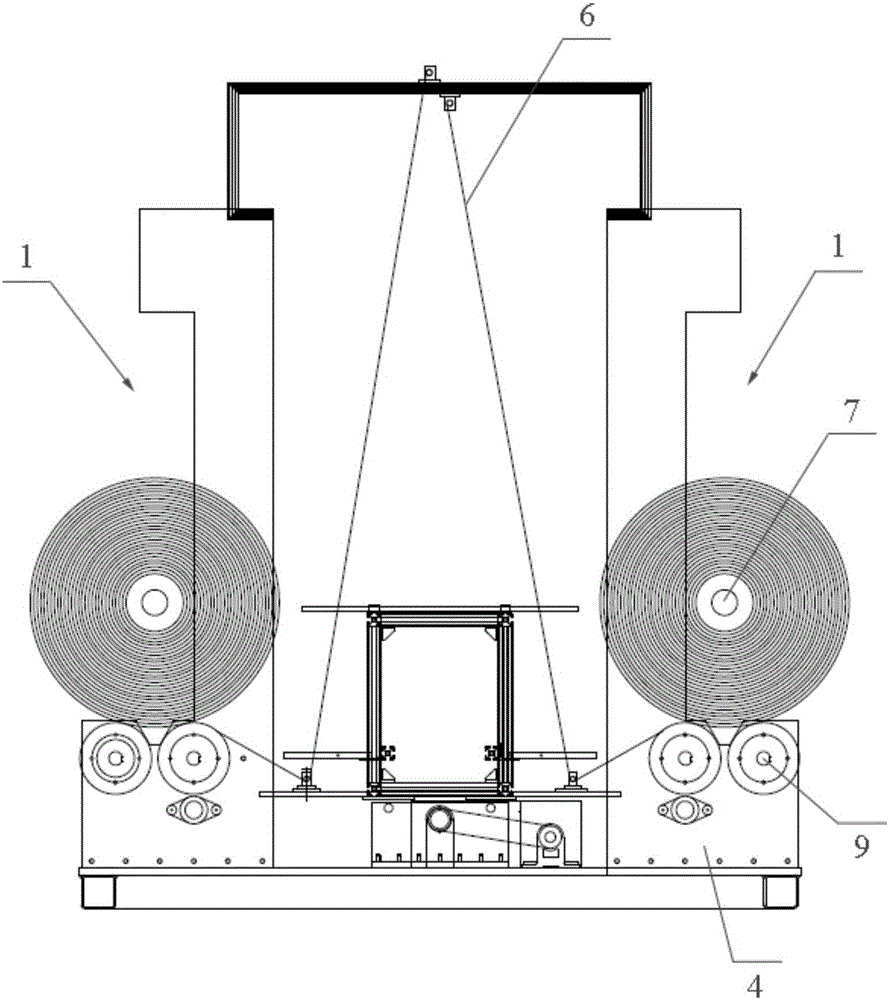

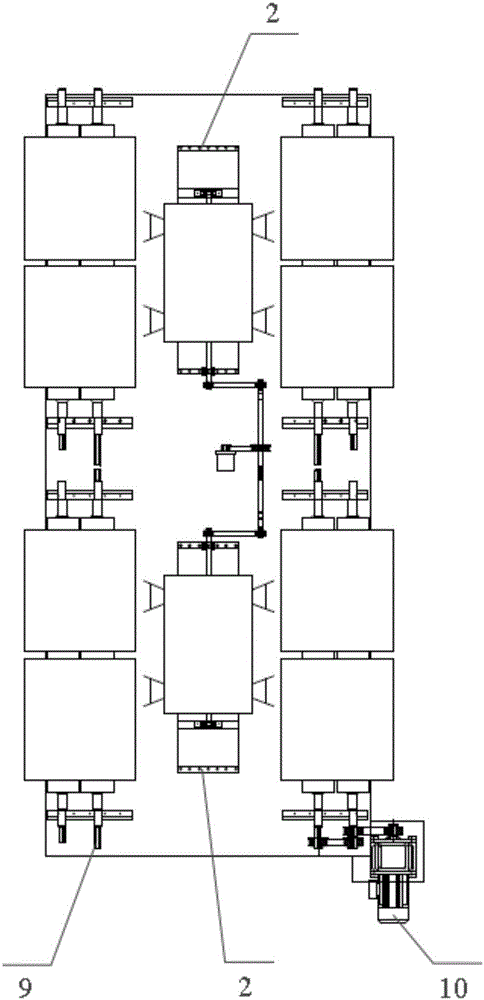

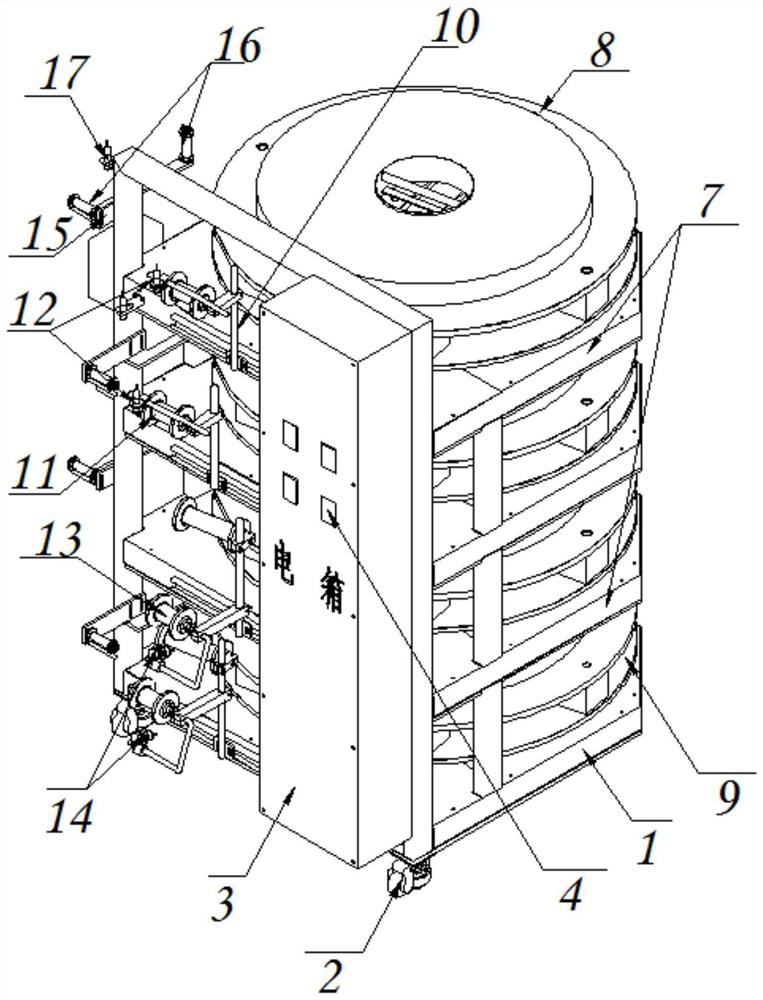

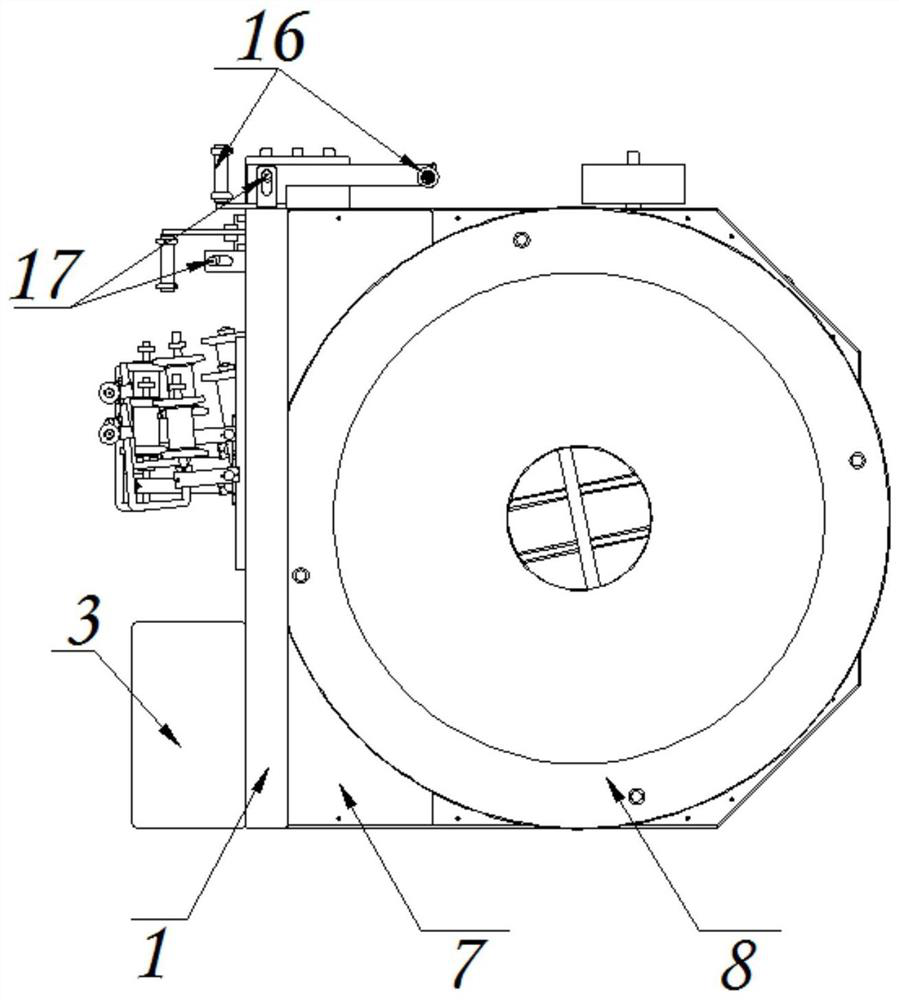

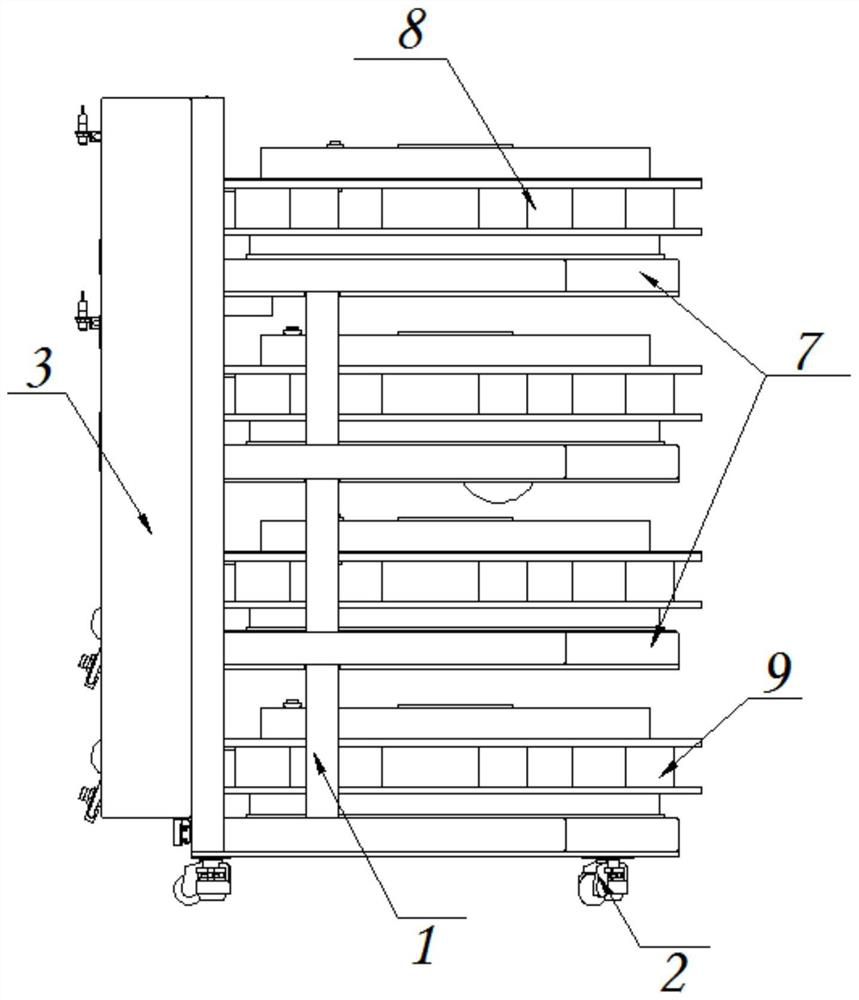

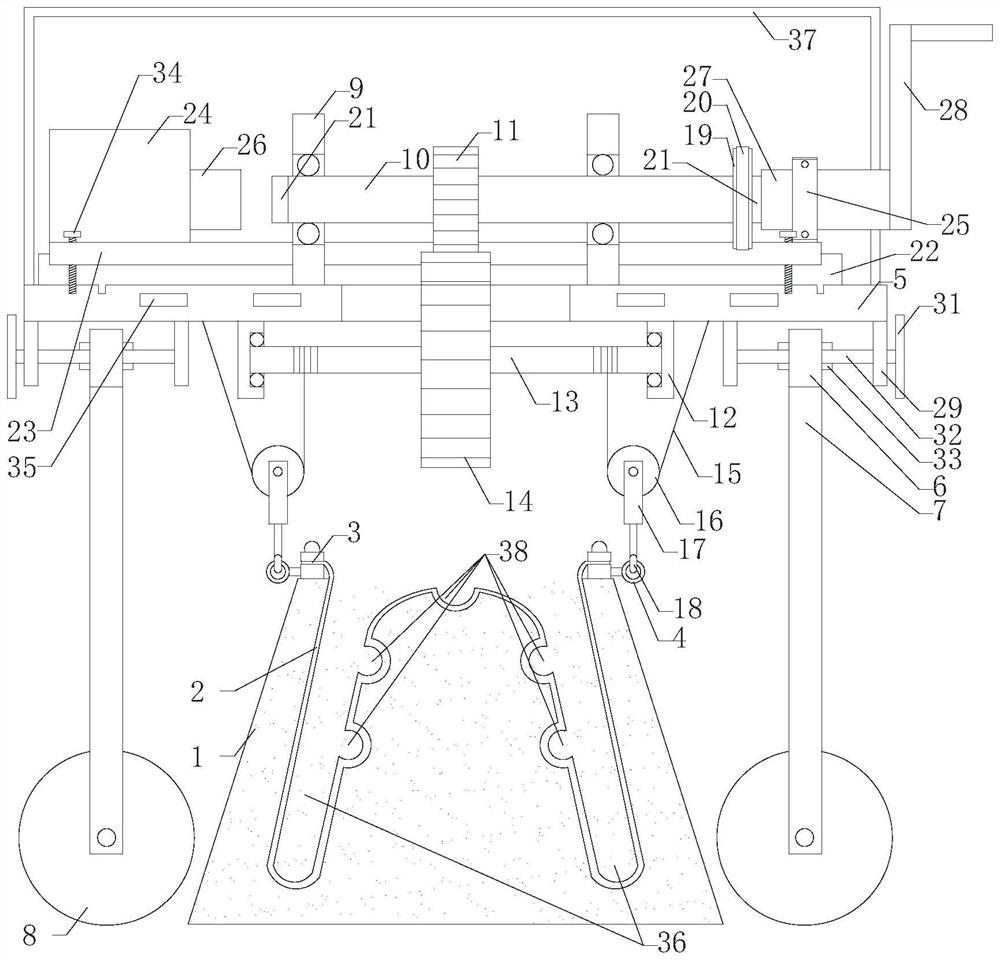

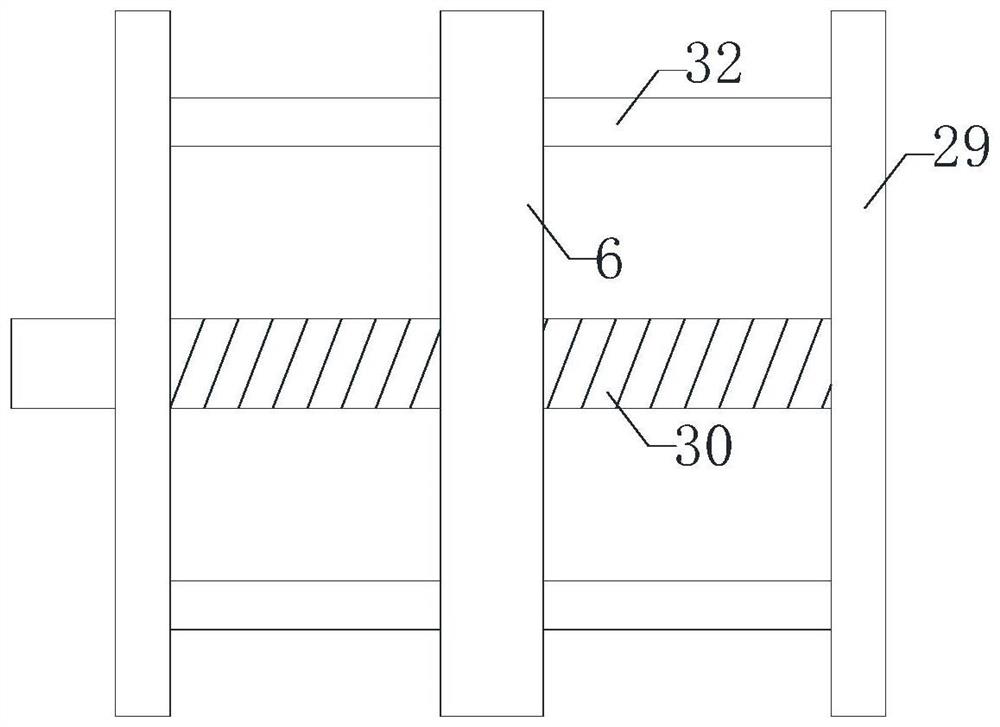

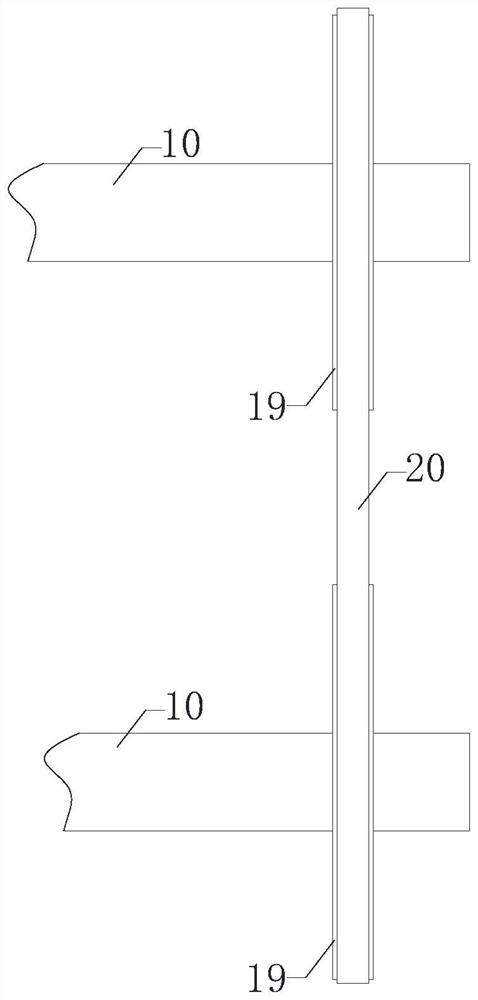

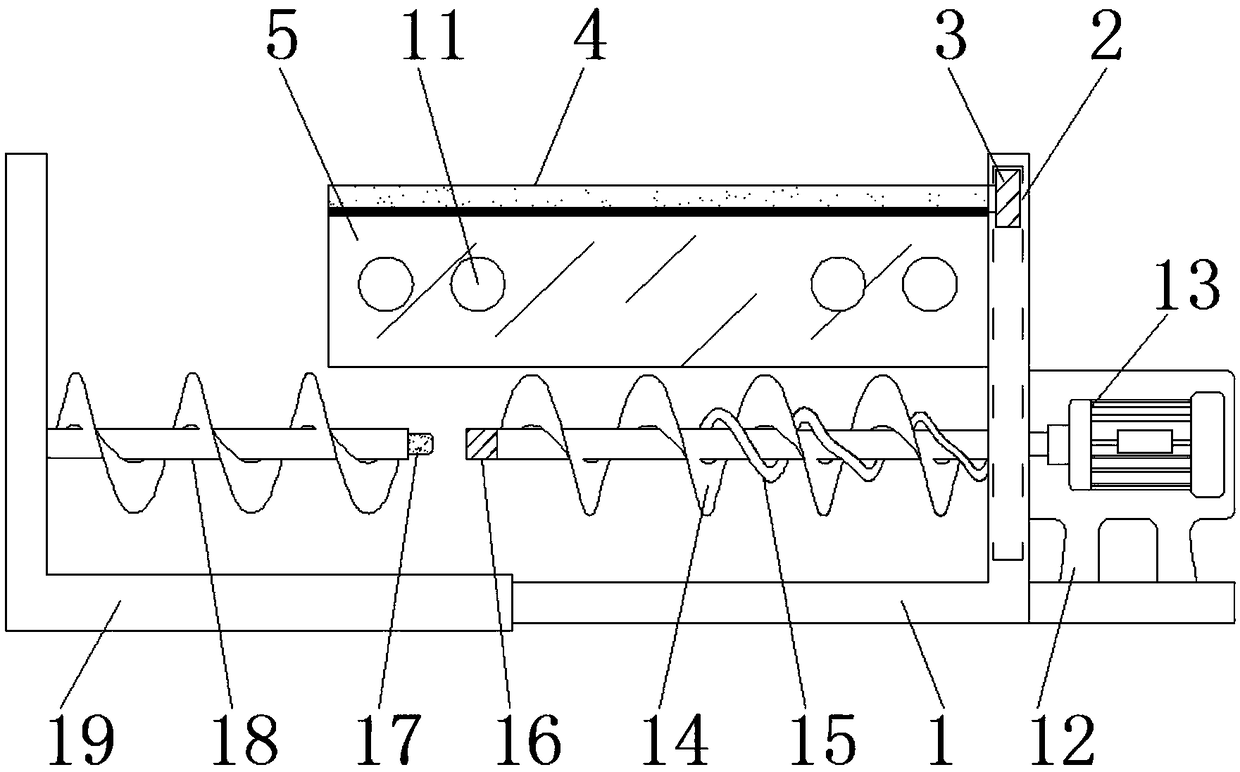

Full-automatic shuttle-core-free rotating shuttle bottom line winding machine

PendingCN110938946AIncrease winding lengthReduce downtime to replace the bottom lineBobbin-winding devicesWinding machineElectric machinery

The invention discloses a full-automatic shuttle-core-free rotating shuttle bottom line winding machine, and belongs to the technical field of sewing mechanical equipment and aims to solve the problems that an existing rotating shuttle bottom line winding machine is complex in overall structure and tedious in actual operation. A winding machine body is provided with a plurality of rotating shuttlebottom line winding systems; the plurality of rotating shuttle bottom line winding systems are connected with a winding power motor through a transmission mechanism by a winding transmission main shaft; each rotating shuttle bottom line winding system is connected with a bottom line shaping mechanism at the rear part of a slurry passing mechanism; the bottom line shaping mechanisms are connectedwith winding mechanisms; the winding mechanisms are connected with line swinging mechanisms and line breaking mechanisms; and an electric control cabinet is internally provided with automatic PLCs which are connected by electric wires and automatically control the winding power motor and the winding mechanisms, the line swinging mechanisms, the bottom line shaping mechanisms, the line breaking mechanisms and the slurry passing mechanisms in the rotating shuttle bottom line winding systems. The winding machine is novel and practical in overall structure, and is suitable for being equipped withsewing mechanical equipment such as a sewing machine, a quilting machine, an embroidery machine and a flat sewing machine.

Owner:河北德源九州机电科技有限公司

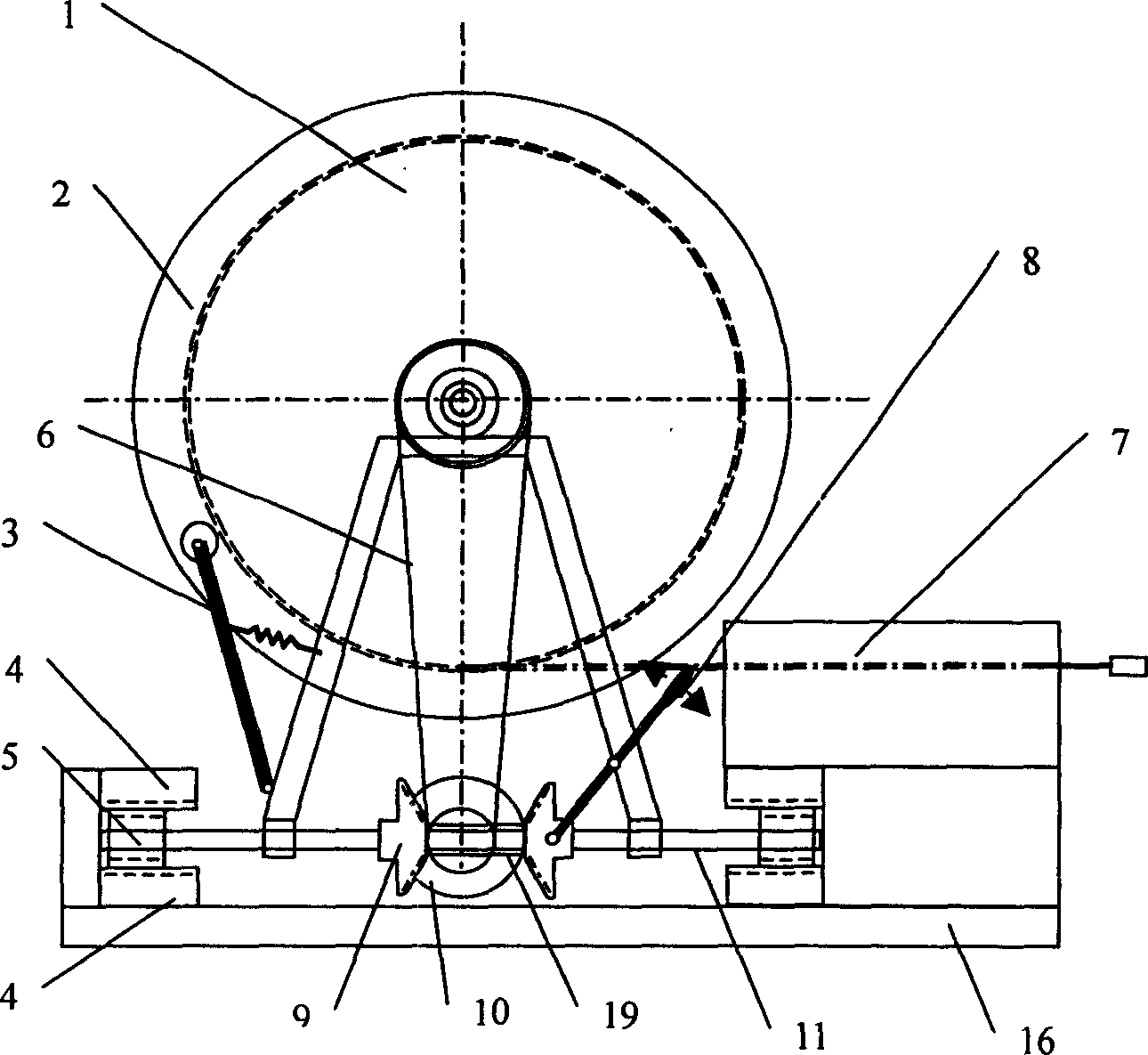

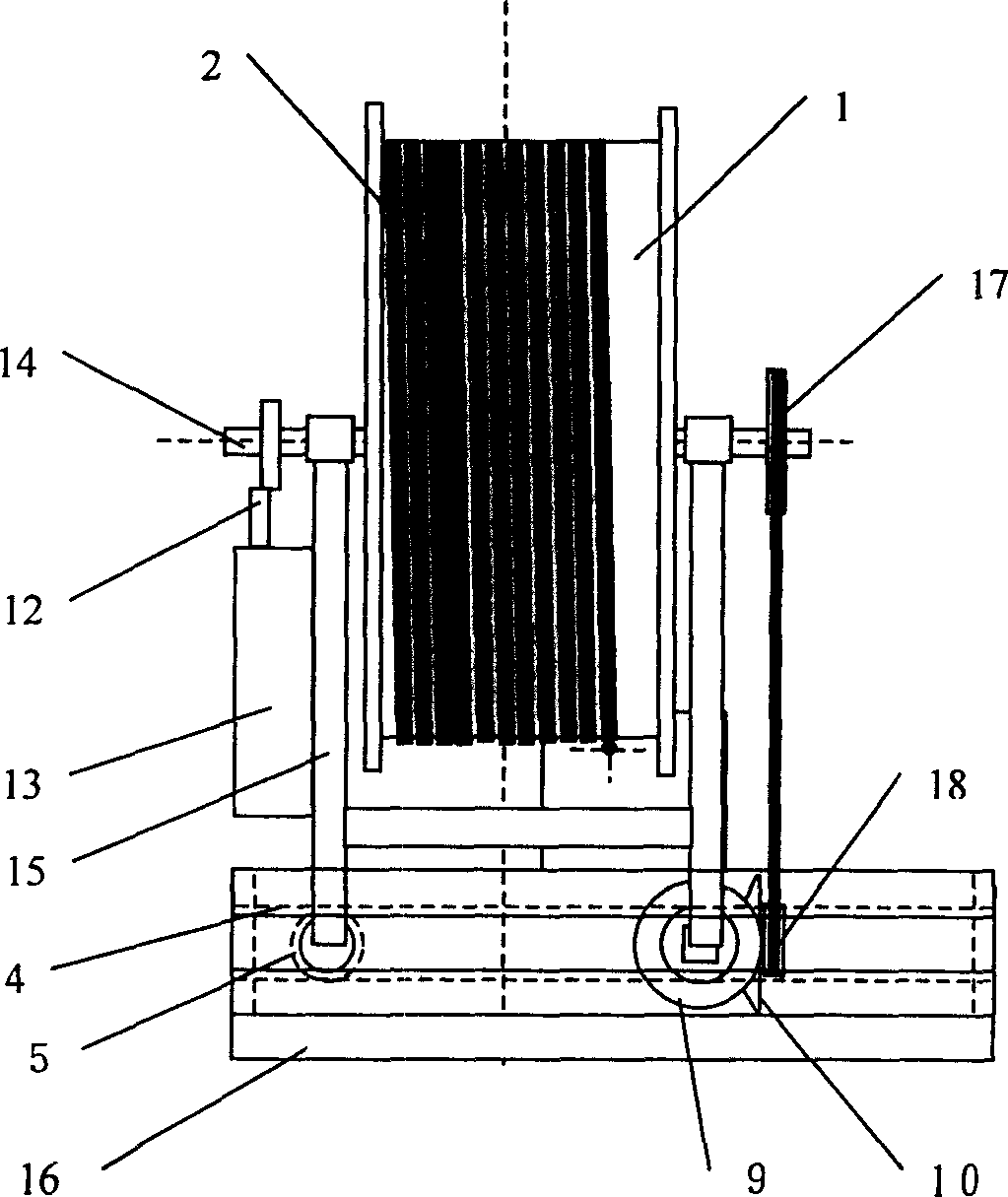

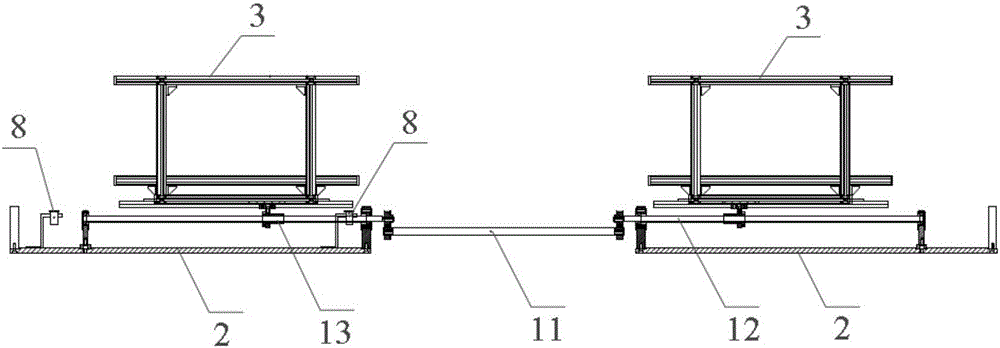

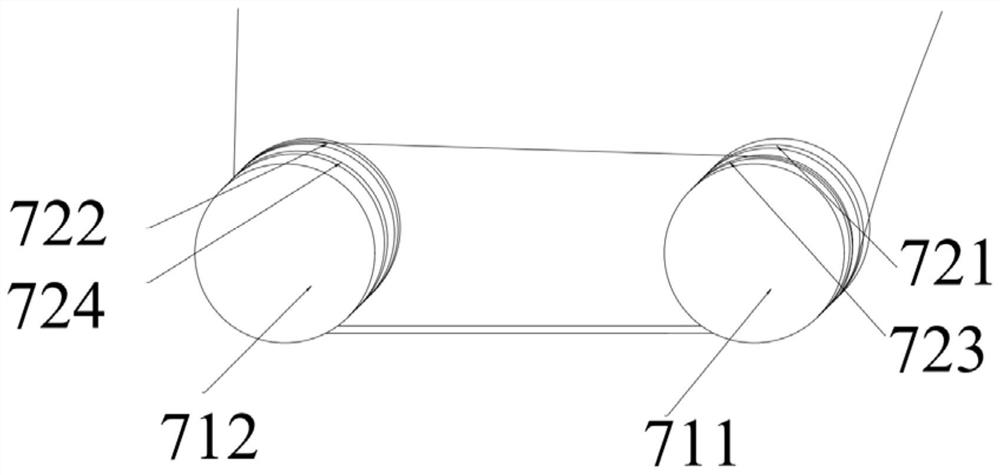

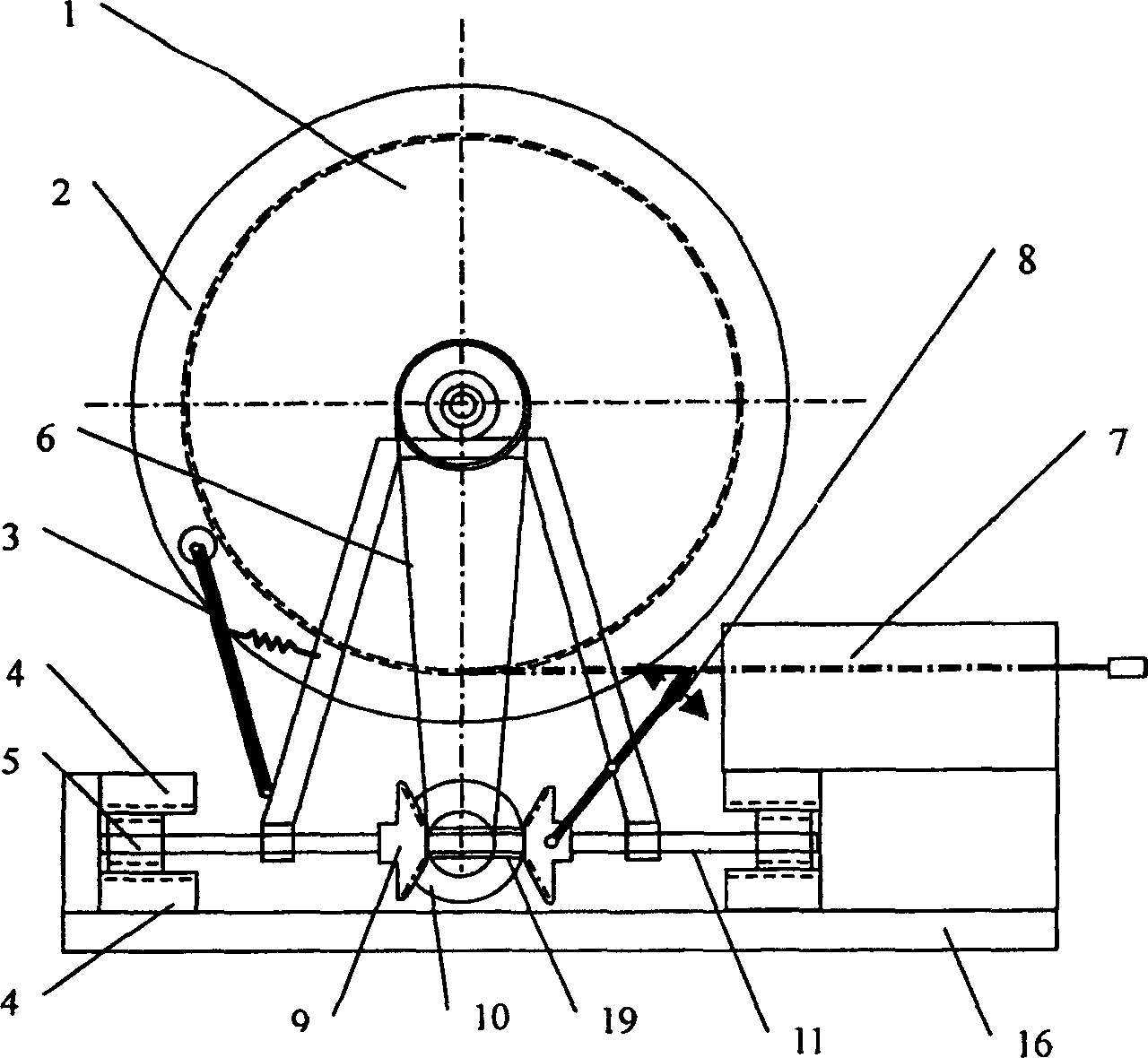

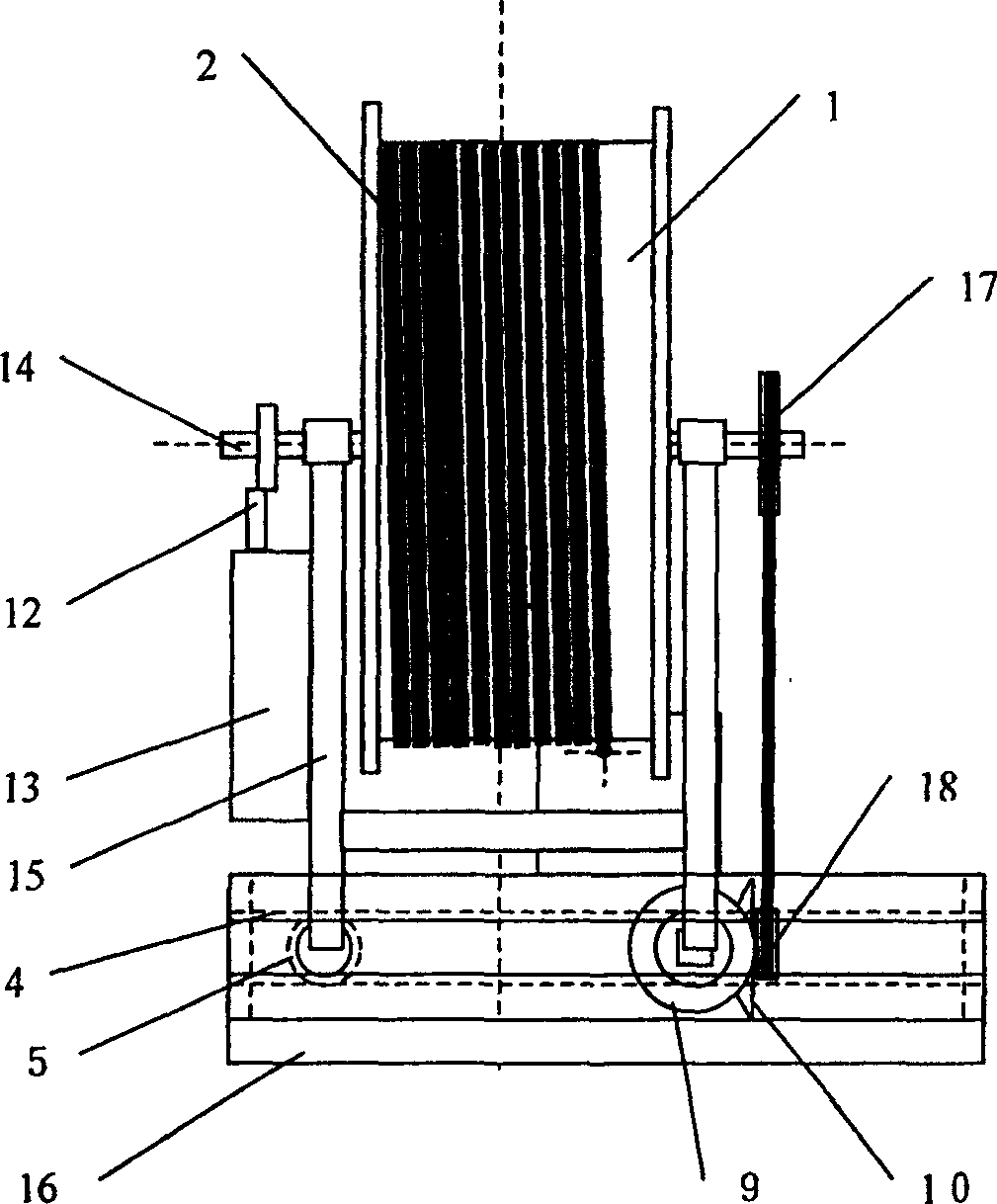

Multilayer winding device of continuous tube

InactiveCN1558083AReduce restrictionsIncrease winding lengthLiquid/gas jet drillingDirectional drillingSteel tubeDrill hole

The continuous tubular multi-layer winding apparatus is one kind of super-deep drilling apparatus for underground mineral exploitation, geological exploration, oil and gas exploitation, etc. The available single-layer winding apparatus limits the super-deep drilling construction. The continuous steel tube multi-layer winding apparatus consists of winding roller, frame, driving mechanism and power transmission gear, gear rack, etc. and is matched with steel tube driving apparatus to realize continuous steel tube multi-layer winding. The present invention makes it possible to increase greatly the continuous steel tube winding length without increasing the roller width.

Owner:TAIYUAN UNIV OF TECH

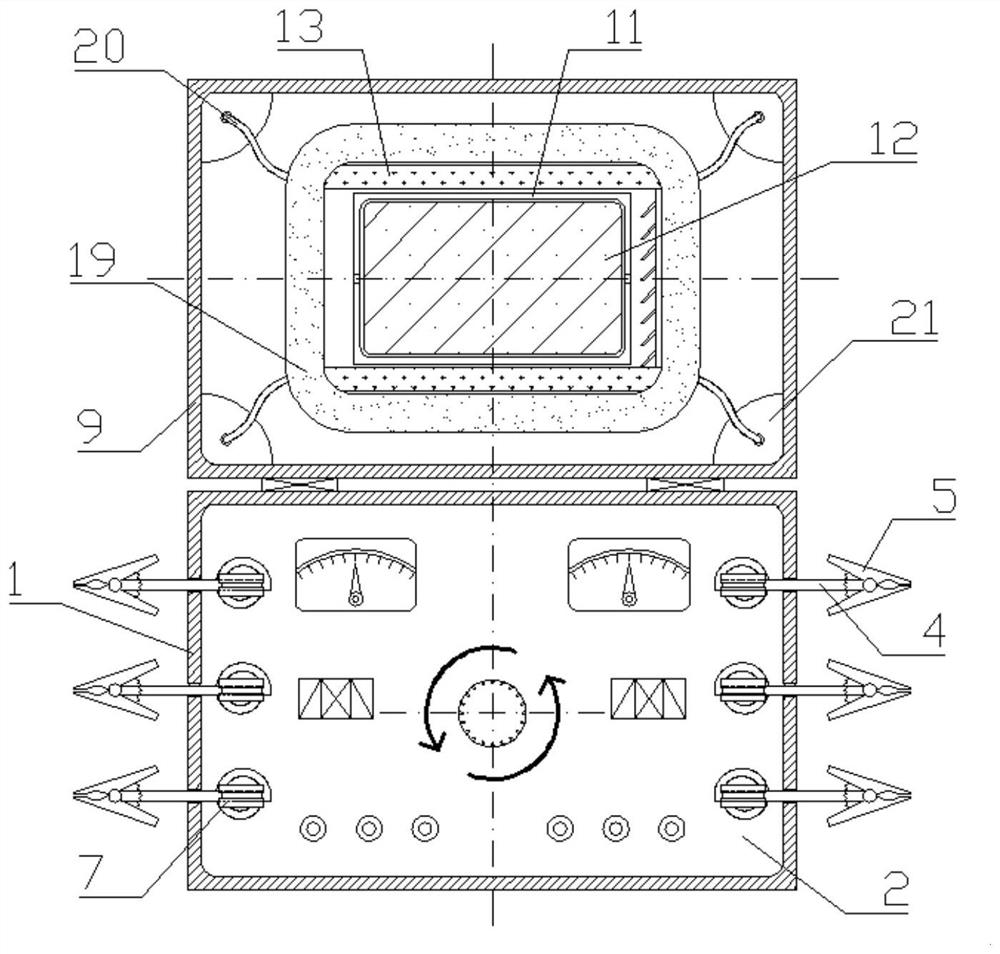

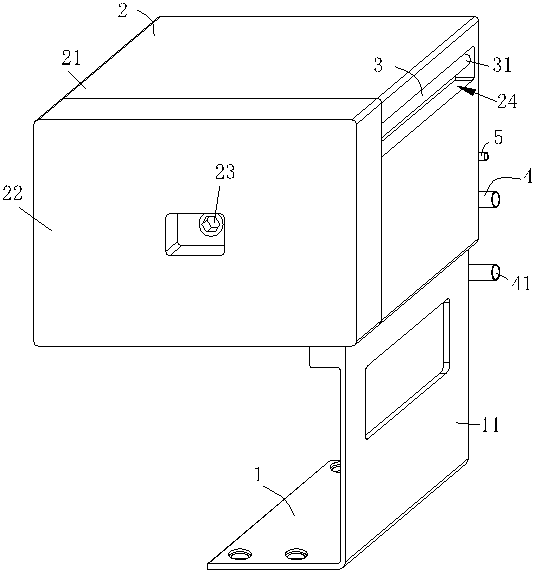

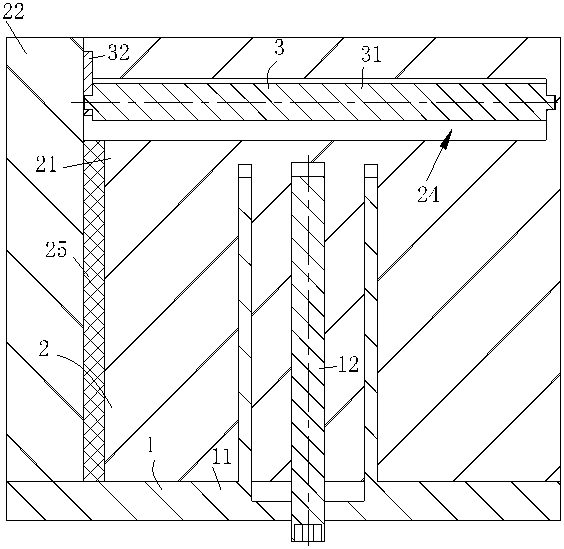

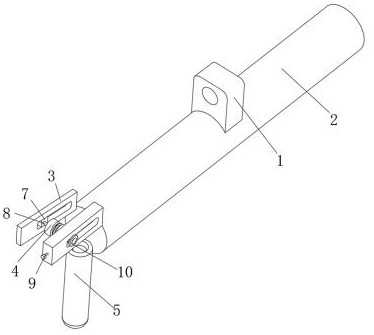

Portable cable partial discharge detection device

PendingCN112924835AIncrease winding lengthEasy to carryTesting dielectric strengthMeasurement instrument housingDamping functionEngineering

The present invention discloses a portable cable partial discharge detection device which comprises a detection box, a detection clamp, a box cover and a fixed box, an operation panel is installed in the detection box, the detection clamp for testing a cable is arranged at the end of a connecting line, and the top of a movable rod is connected with a limiting block; the box cover is hinged to the edge of the detection box, and a through groove is formed in the box cover; a fixed box is fixed to the inner side of the box cover, a movable groove allowing the movable shaft to move is formed in the side face of the fixed box, and the two ends of the movable shaft are sleeved with gears; and a protective air bag with a damping function is arranged on the box cover on the outer side of the fixed box. According to the portable cable partial discharge detection device, the detection device can be conveniently carried to different places for detection, the detection range and distance can be adjusted, and the damping strength of the internal protection structure can be adjusted according to the carrying condition of the detection device.

Owner:河南四达检测技术有限公司 +1

Gold bonding wire and preparation method thereof

ActiveCN102127663BHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method ofthe gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Electrode foil washing and cleaning device

ActiveCN111112204AEasy to layIncrease contact areaDrying gas arrangementsCleaning using toolsStorage structureEnvironmental engineering

The invention relates to the field of electrode foil cleaning devices, in particular to an electrode foil washing and cleaning device. The electrode foil washing and cleaning device comprises a supporting structure, a storage structure, a reversing structure, a washing structure, an air pipe, a flow guide sleeve, a driving structure and a cleaning structure, the reversing structure used for reversing and guiding the electrode foil is arranged in the storage structure, so that the electrode foil forms a combined body of two Z-shaped structures in the storage structure, the electrode foil is reversed, the winding length of the electrode foil in the storage structure is prolonged, and the electrode foil is convenient to wash; the electrode foil can be conveniently and quickly flushed and water drops on the electrode foil can be conveniently cleaned through the flushing structure; the driving structure is connected to the flow guide sleeve and is used for cleaning the cleaning structure for the waste chips and the water drops, so that the electrode foil drives the driving structure in the conveying process, the driving structure drives the cleaning structure to shake, the waste chips and the water drops are effectively prevented from being bonded on the cleaning structure, and the effect of cleaning the waste chips and the water drops by the cleaning structure is better.

Owner:JIANGSU RONGSHENG ELECTRONICS

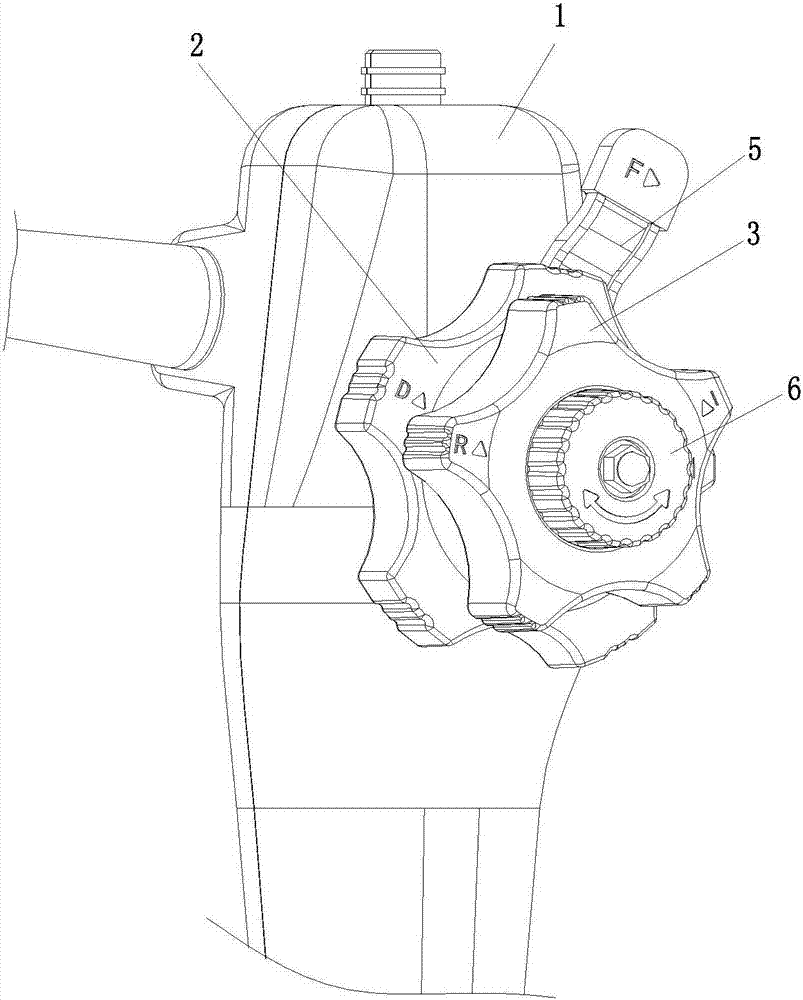

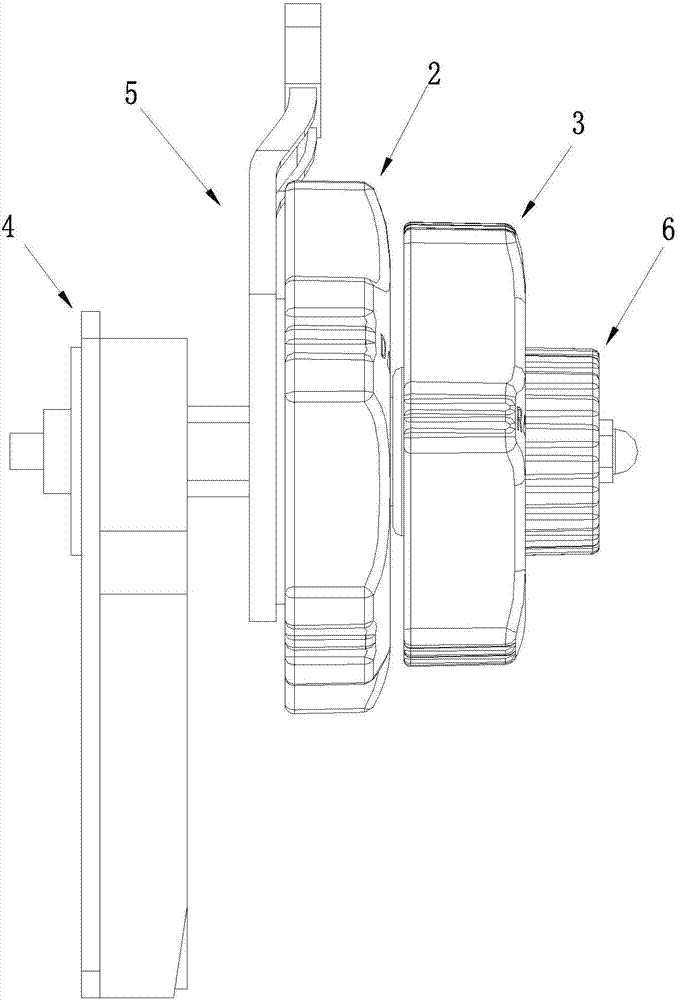

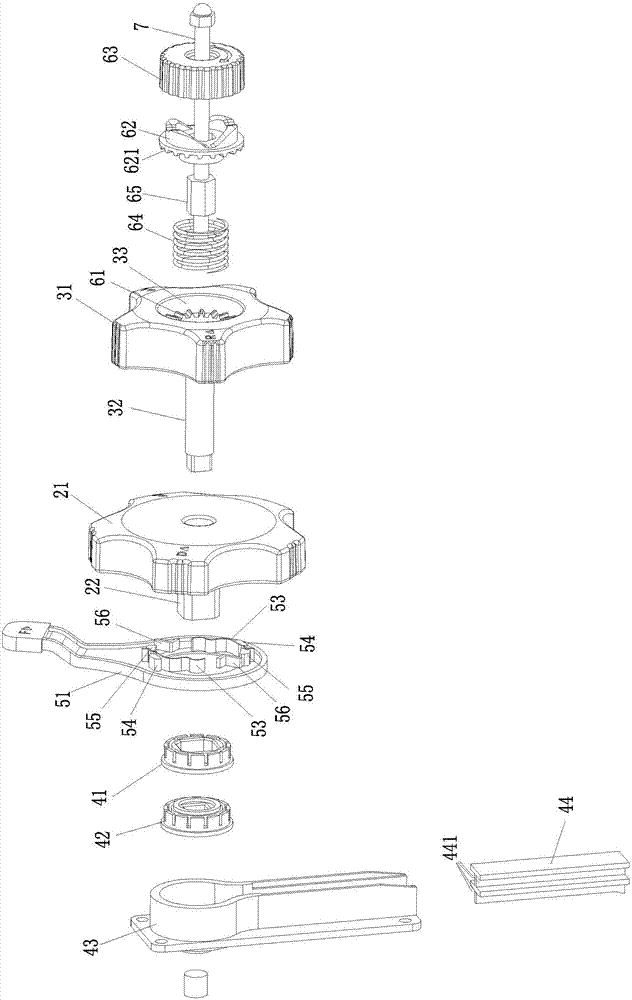

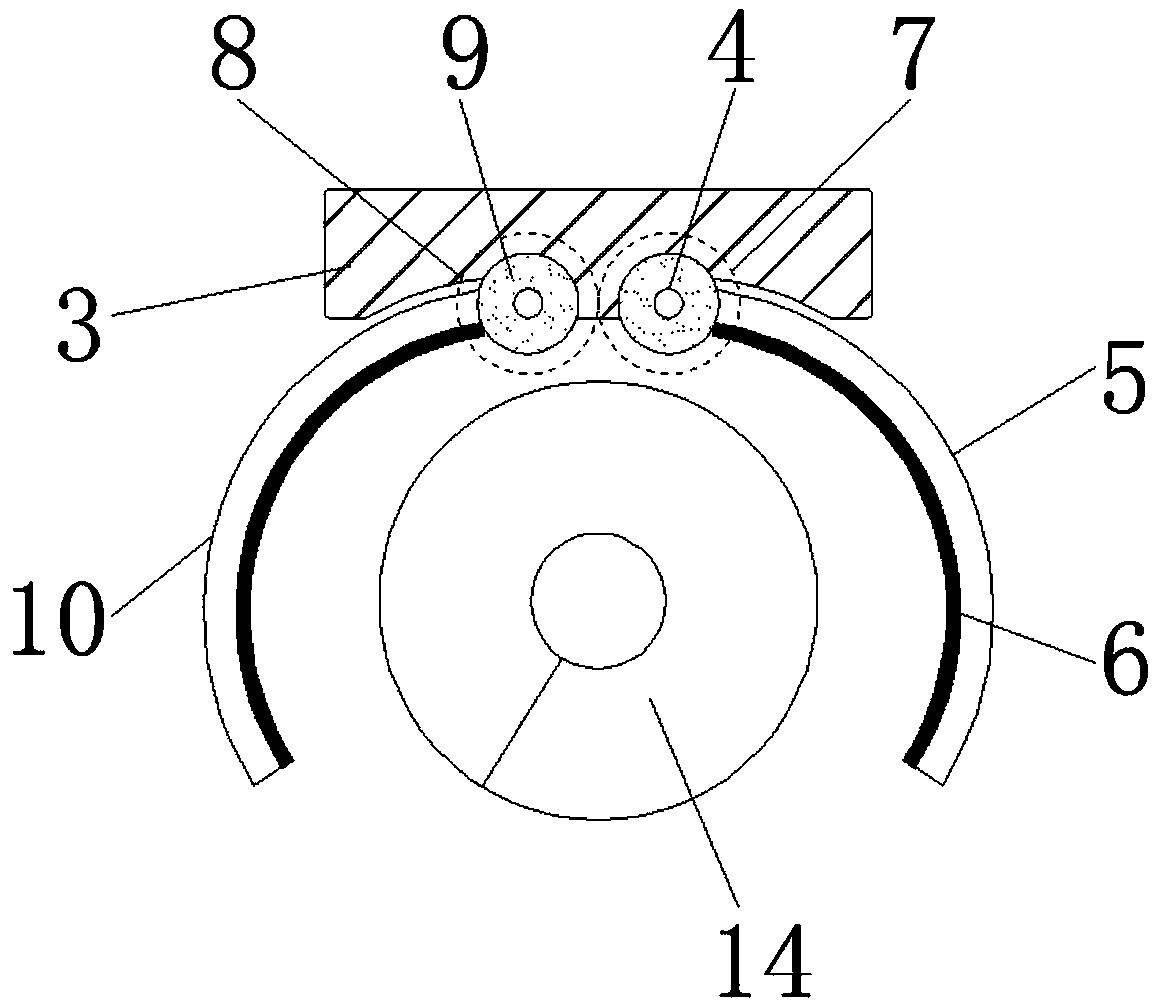

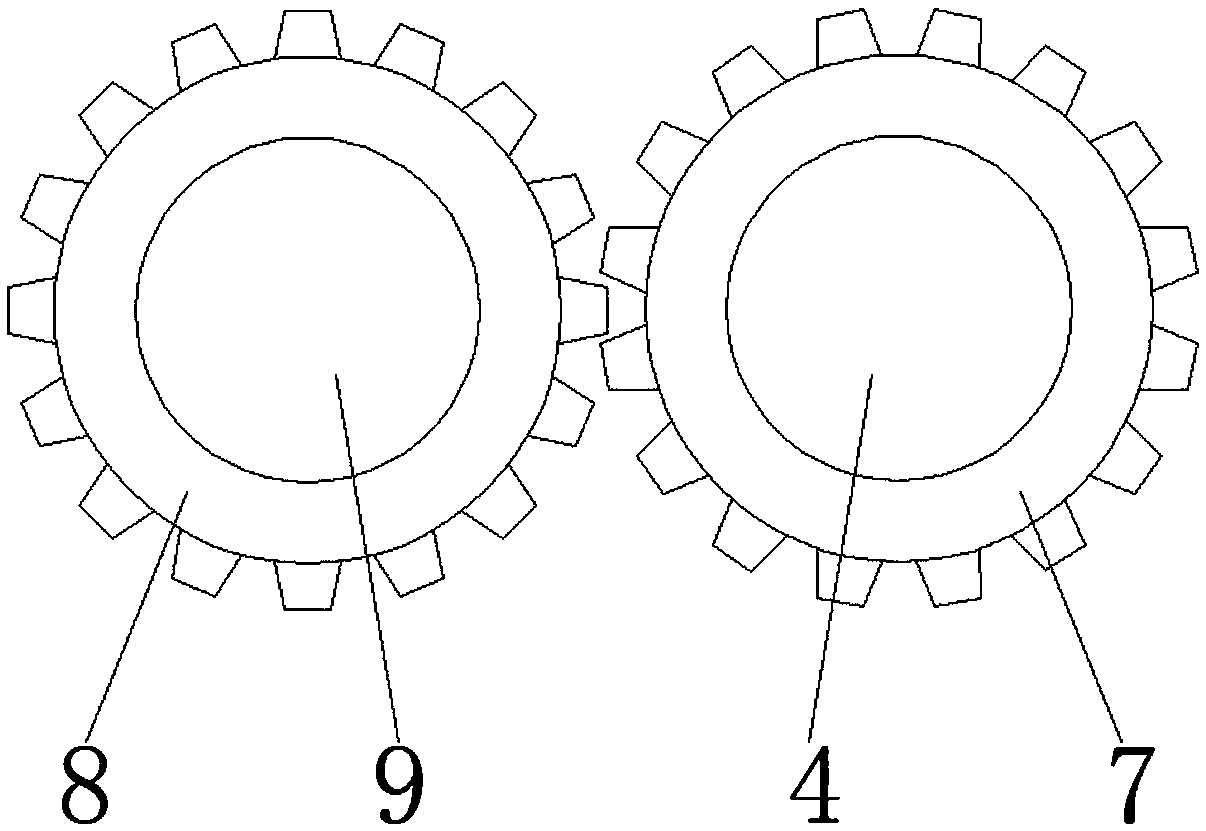

Medical endoscope control mechanism

PendingCN107088044ASimple structureIncrease frictionSurgeryEndoscopesConductor CoilMechanical engineering

The invention belongs to the technical field of endoscopes, and particularly relates to a medical endoscope control mechanism. The medical endoscope control mechanism comprises a first hand wheel assembly, a second hand wheel assembly, a winding assembly, a first locking component and a second locking component; the winding assembly comprises a first control wheel, a second control wheel and a wire bunching shell, and a control cable of an endoscope penetrates through the wire bunching groove, and is connected with an inserting component of the endoscope; the first hand wheel assembly comprises a first linkage rod and a first hand wheel, one end of the first linkage rod is fixedly connected with the first hand wheel, and the other end of the first linkage rod is in driving connection with the first control wheel; the second hand wheel assembly comprises a second linkage rod and a second hand wheel, the second linkage rod penetrates through the first hand wheel, the first linkage rod and the first control wheel, one end of the second linkage rod is fixedly connected with the second hand wheel, and the other end of the second linkage rod is in driving connection with the second control wheel. The medical endoscope control mechanism has the advantages of being simple in structure, firm in locking, and not prone to locking failure.

Owner:SHENZHEN XZING TECH CO LTD

A method and equipment for increasing the winding length of casings

Owner:青岛齐林智信自控技术有限公司

Spiral winding device

ActiveCN105129468AIncrease winding lengthReduce the frequency of refuelingWebs handlingWoven fabricConductor Coil

The invention discloses a spiral winding device and relates to the field of coiling and rolling of non-woven fabrics, air-laid paper and the like. The spiral winding device comprises at least one spiral winding system, wherein each spiral winding system comprises a sliding table, paper guiding supports arranged on the sliding table, a winding device arranged on one side of the sliding table and a first driving device; the paper guiding supports are connected with a product to be rolled; first driving devices are connected with the paper guiding supports and drive the paper guiding supports to slide back and forth on the sliding tables; each winding device comprises a winding shaft; and the products to be wound are connected with the winding shafts through the paper guiding supports. The spiral winding device can improve the working efficiency, increase the lengths of end product wound rolls and lower the work intensity.

Owner:南通优棉濠晨纺织品有限公司

Wiring mechanism, wire winding method and wire treatment device and method

PendingCN112061861AGuaranteed reliabilityAvoid interactionElectrolysis componentsFilament handlingWire rodWire wrap

Owner:NANTONG HUIFENG ELECTRONICS TECH

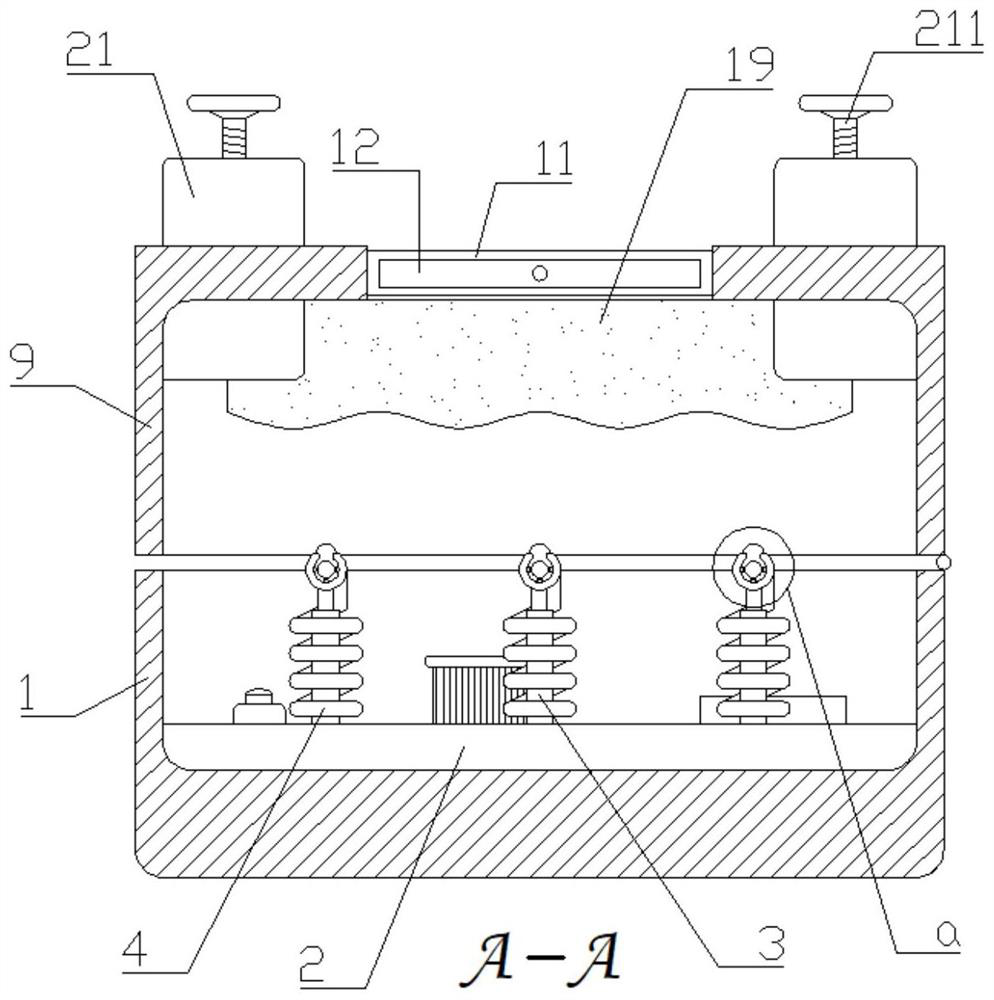

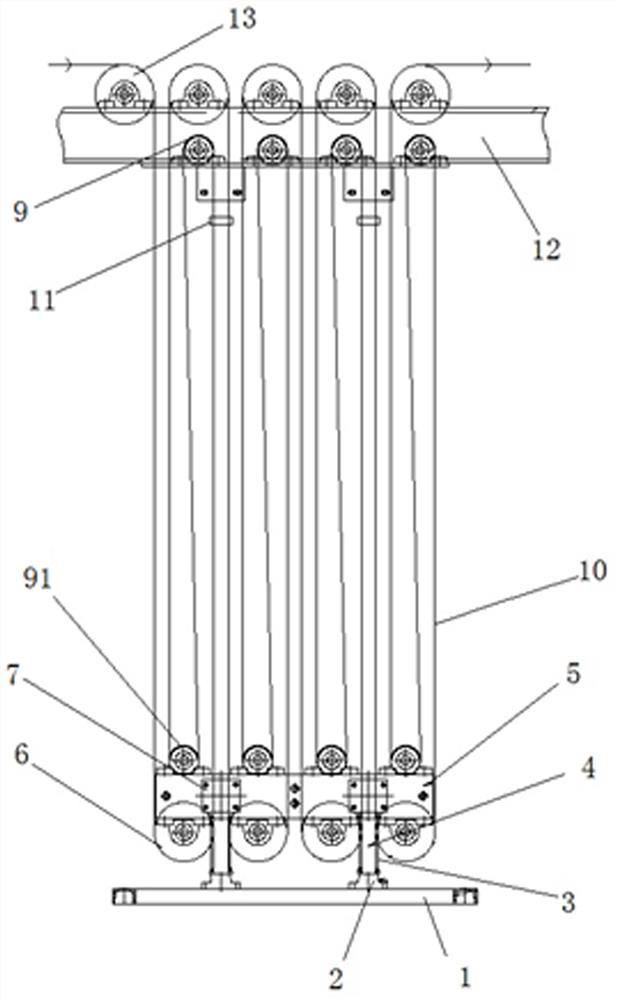

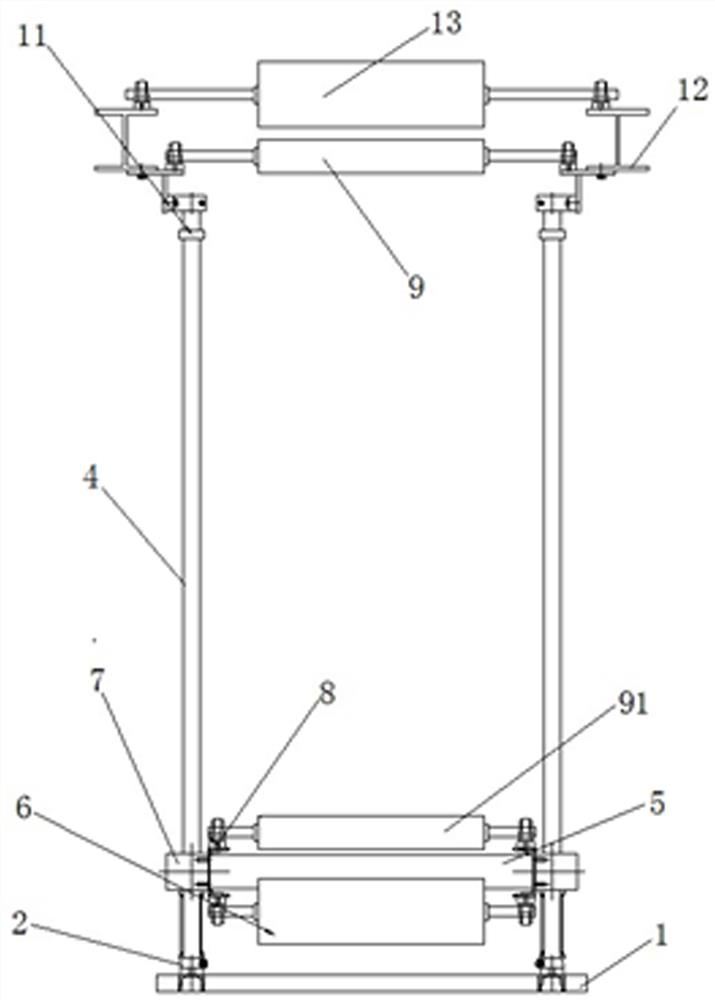

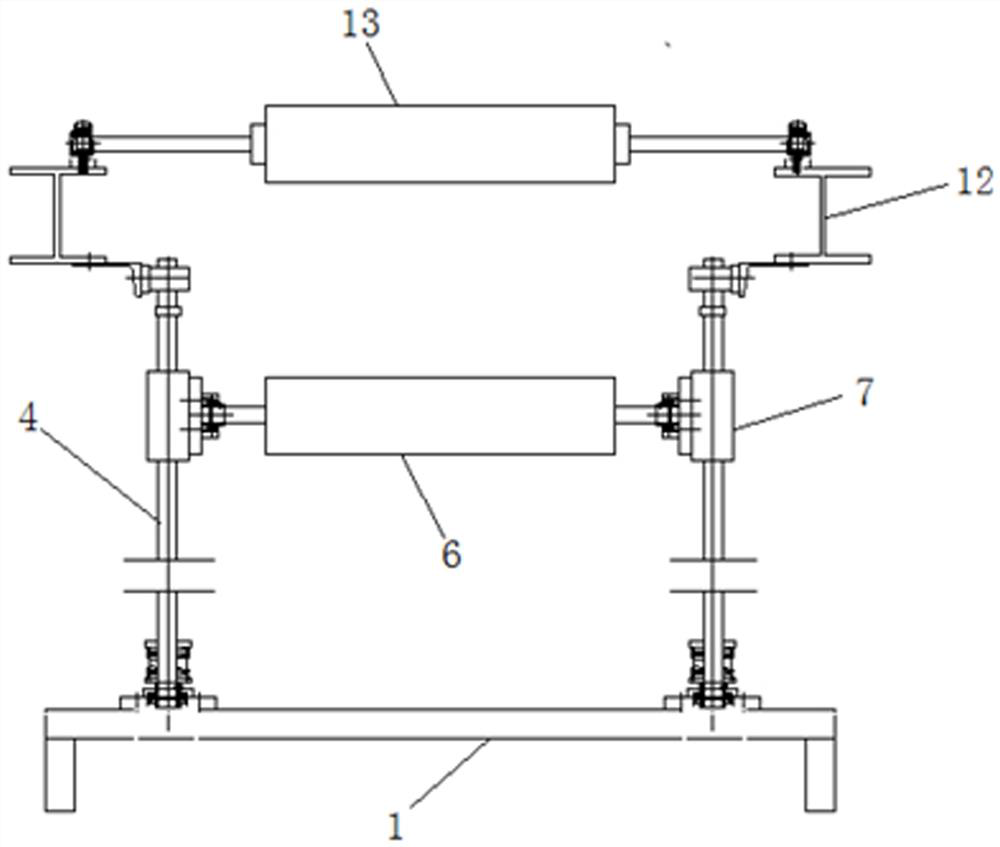

Floating frame device for medium-high voltage electronic aluminum production line and using method thereof

ActiveCN112872095AAchieving Floating Around FoilThe structure takes up little spaceProduction lineBraced frame

The invention discloses a floating frame device for a medium-high voltage electronic aluminum production line and a using method thereof. The floating frame device comprises a supporting frame, guide shafts, floating frames and a roller beam. The supporting frame is provided with the guide shafts, the roller beam is arranged at the tops of the guide shafts, transition rollers are uniformly distributed at the upper part of the roller beam, the two ends of each transition roller are respectively connected with the roller beam, the lower part of the roller beam is provided with small rollers A which are one less than the transition rollers, and the two ends of each small roller A are respectively connected with the roller beam. The floating frames are arranged in the middles of the guide shafts and are in sliding connection with the guide shafts through sliding blocks. The small rollers A are additionally arranged on the roller beam, large rollers and small rollers B are arranged on the floating frames to form a combination similar to a pulley block form, so that foil winding floating of the multiple sets of rollers is achieved. The foil winding mode of the large rollers, the small rollers A, the small rollers B, the transition rollers and the next set is adopted, the winding length of electronic aluminum foil is increased, the buffering time is prolonged, the foil winding structure is more compact, the occupied space of the foil winding structure is small, and meanwhile the stability of equipment is improved.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

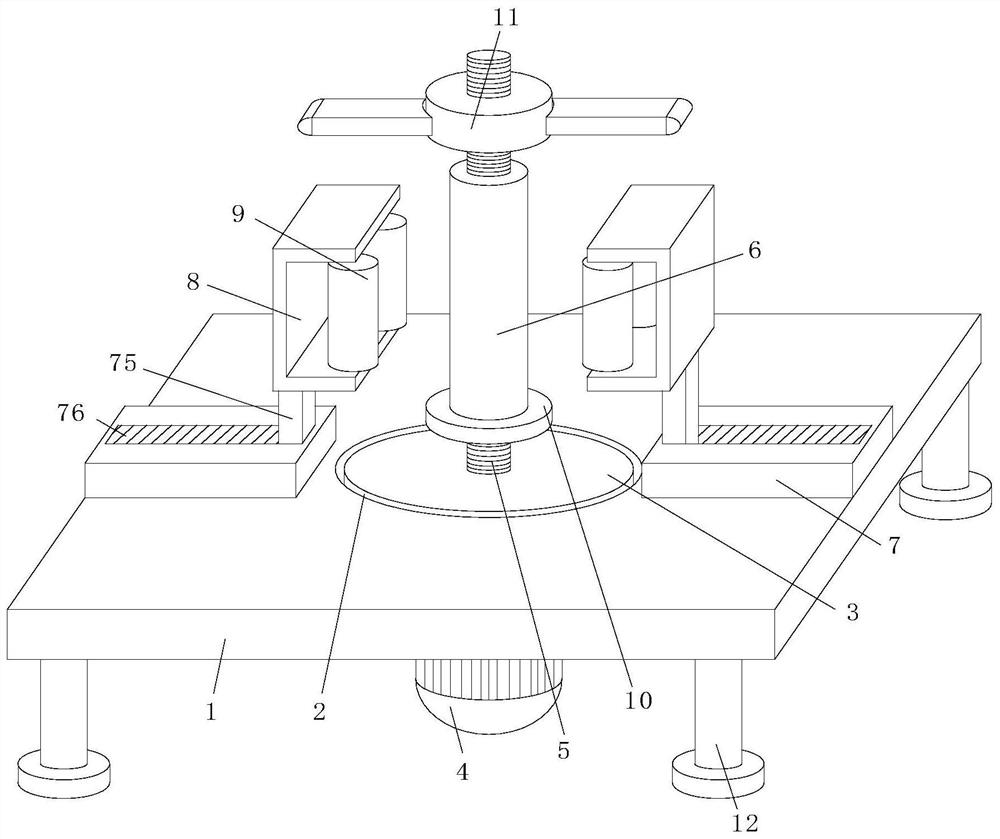

Cotton roll compacting device of lapper for spinning

The invention relates to the technical field of spinning, in particular to a cotton roll compacting device of a lapper for spinning. The cotton roll compacting device comprises a base plate, a turntable, a driving motor, a positioning screw rod, a winding drum, propelling mechanisms, installation frames, pressing rollers, a limiting plate, a fastener and bottom feet, wherein an installation grooveis formed at the middle position of the base plate; the bottom of the turntable is rotatably connected with the base plate through a bearing; the turntable is positioned in the interior of the installation groove; the driving motor is fixedly installed at the middle position of the bottom of the base plate; the output end of the driving motor is in transmission connection with the bottom of the turntable; and one end of the positioning screw rod is fixedly connected with the middle position of the top of the turntable. According to the cotton roll compacting device of the lapper for spinning,the purposes of avoiding the phenomena of loosening and expansion among winding layers of a cotton roll are achieved, the compact state of the cotton roll in the winding process is improved, and thetight fit among the cotton layers is ensured, so that the winding length of each cotton roll is increased, and the attractiveness of the cotton roll and the quality of the finished product are improved.

Owner:YANCHENG INST OF IND TECH

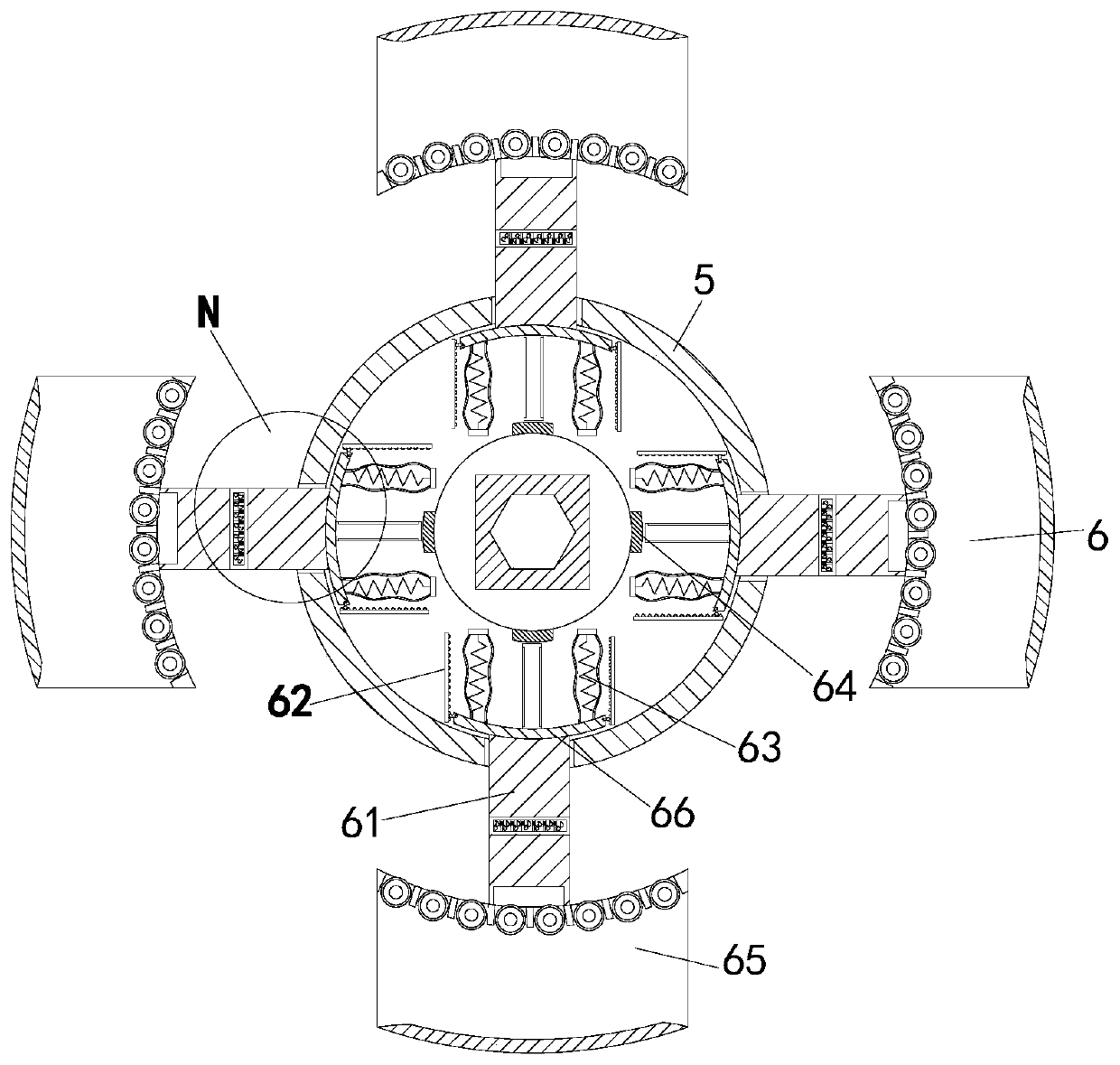

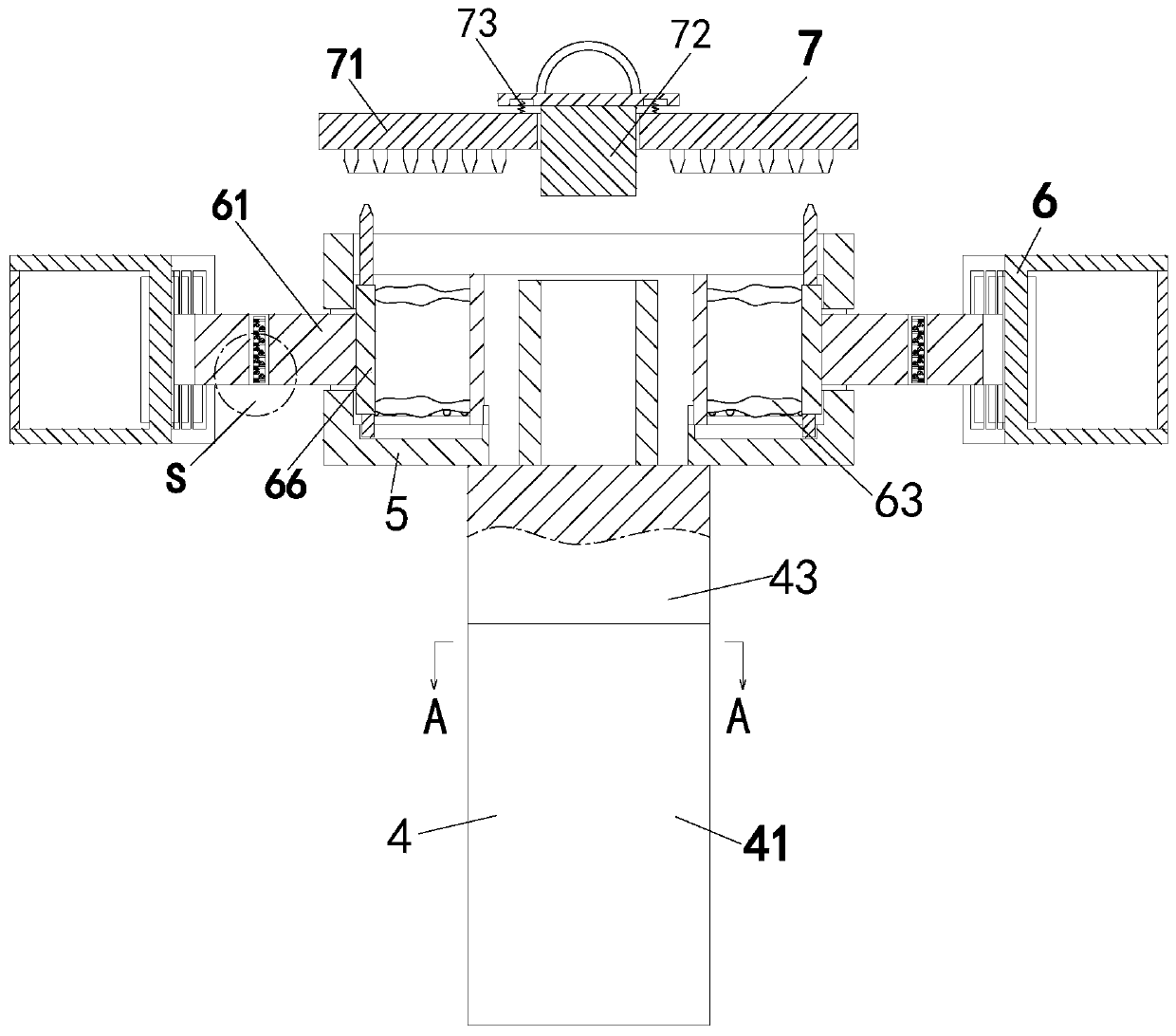

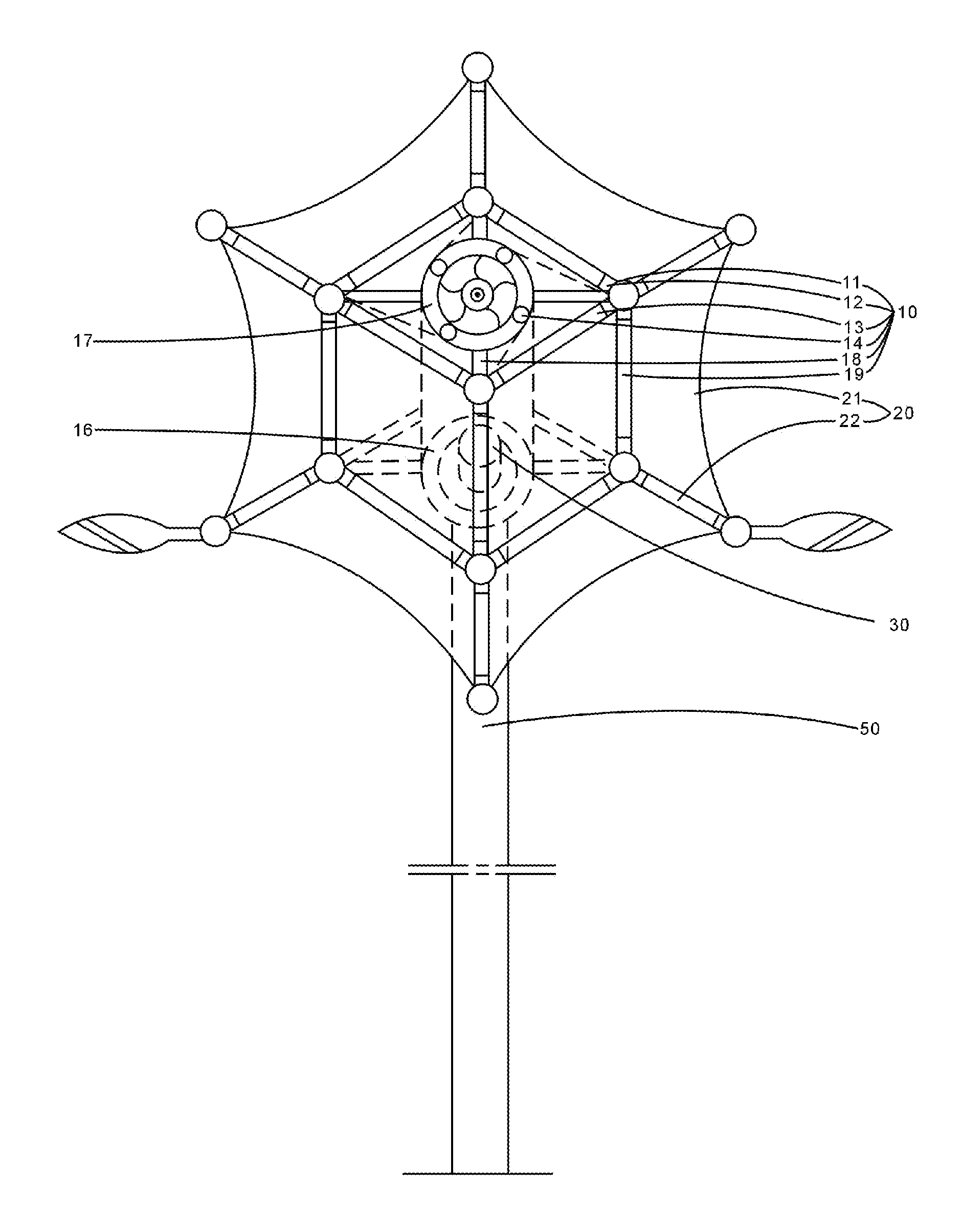

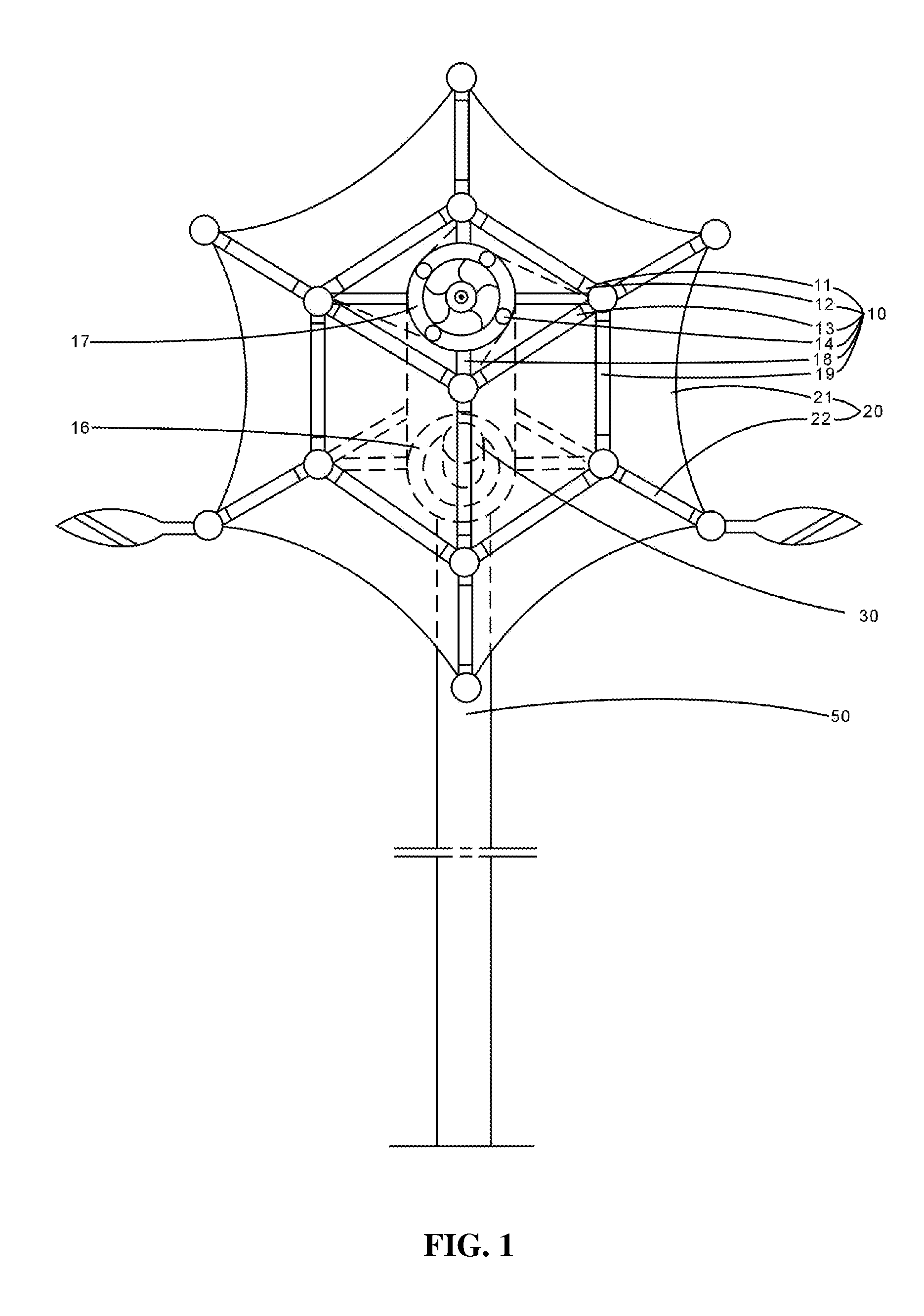

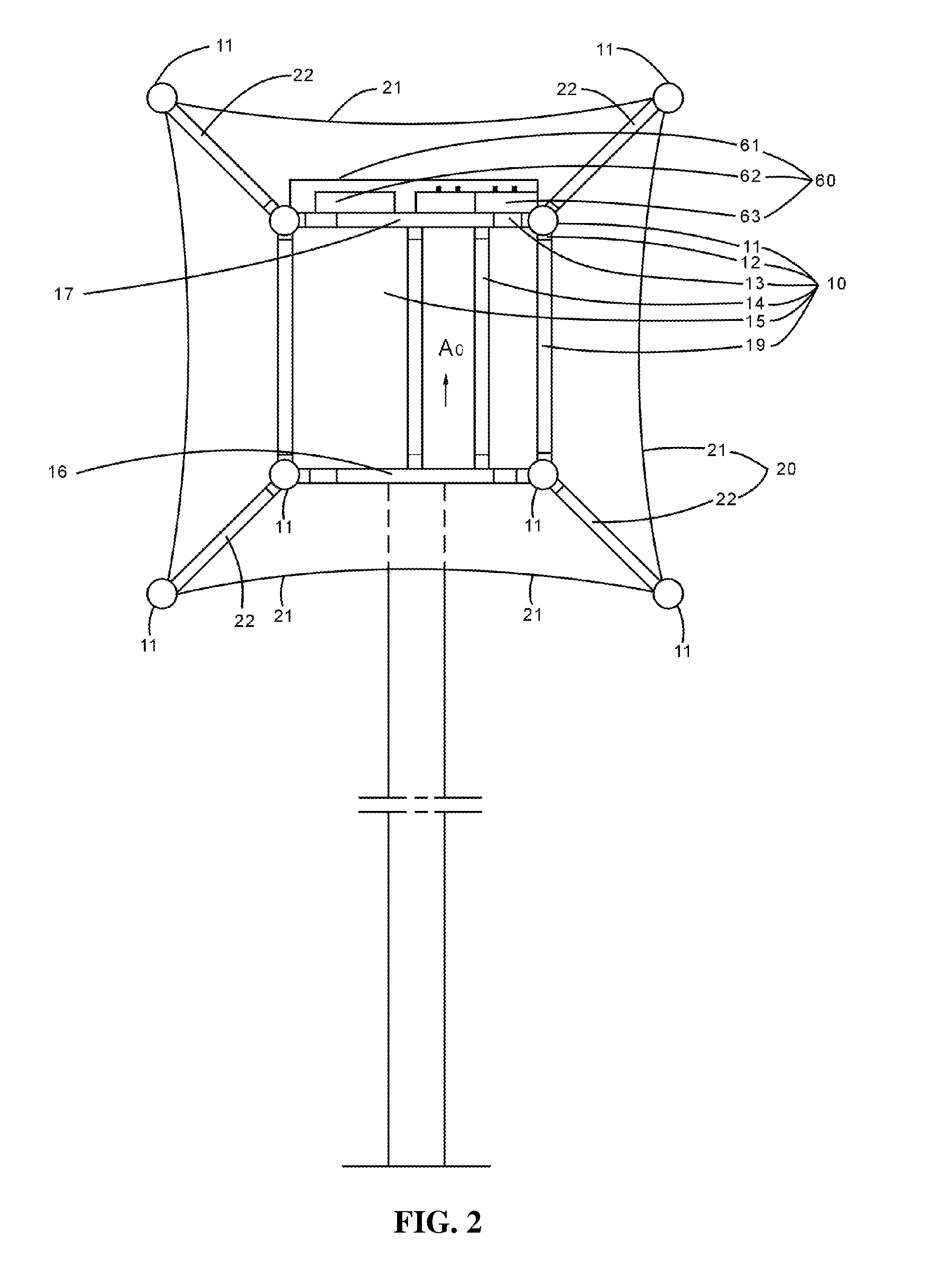

Three-dimensional wind-light congregating power generating system with spherical joints

ActiveUS8674547B2Improve efficiencyReduce areaSolar heating energySolar heat devicesEngineeringVertical axis wind turbine

A three-dimensional wind-light congregating power generating system with spherical joints includes a spherical joint wind-light congregating device (10), a spherical joint wind-light trapping device (20), both of which are assembled through spherical joints, and a vertical axis wind generator (30), wherein the profile of the spherical joint wind-light congregating device (10) is the shape of rectangular paralleling and comprises four wind lateral guiding boards (15) equally spaced around a center, a gradually narrowing wind inlet passage (150) is formed between adjacent wind lateral guiding boards (15), and the wind inlets of the wind inlet passages (150) are located respectively at the four sides of the spherical joint wind-light congregating device (10); the spherical joint wind-light trapping device (20) comprises wind-light trapping rods (22) and wind-light trapping films (21) for absorbing solar energy; the vertical axis wind generator (30) is mounted in the center of the spherical joint wind-light congregating device (10). The present power generating system applies an assembled structure with spherical joints, the components of the system can be produced in standardization and be assembled together by simple tools, and a plurality of miniwatt power generating systems can be assembled to a high power generating system; the power generating system can generate electricity efficiently all day even in the condition of gentle breeze and weak light.

Owner:SHEN WEIQING

High-end packaging silver alloy bonding wire and method for manufacturing same

ActiveCN102912176BGood ball formingHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingPlatinumAlloy

The invention discloses a high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire is characterized by comprising 0.0001%-20% of gold, optional one or more than one of 0.0001%-20% of palladium, 0.0001%-20% of platinum, 0.0001%-0.015% of germanium, 0.0001%-0.015% of calcium and 0.0001%-1% of aluminum, and the balance silver. The invention further discloses a method for manufacturing the high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire has the advantages of high strength and low hardness and long-arc degree.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Winding device for producing and processing motor stator

PendingCN114785069AReduce tensionAvoid breakingManufacturing stator/rotor bodiesPull forceSuction force

The invention relates to the related technical field of winding equipment, and discloses a winding device for producing and processing a motor stator, a guide wheel is provided with two grooved wire arranging grooves, and the guide wheel has resistance during movement through the magnetic attraction force of a resistance-adjusting magnetic block to the guide wheel, so that when an enameled wire is wound around the wire arranging grooves and is too loose, the enameled wire is prevented from being damaged. When the enameled wire is too tight, the guide wheel is far away from the resistance-adjusting magnetic block, so that the phenomenon that the enameled wire is too tight is reduced through the movement of the guide wheel, and the movement resistance of the guide wheel is reduced when the guide wheel is far away from the resistance-adjusting magnetic block; when the guide wheel rotates, the resistance of the guide wheel is reduced, so that the rotating speed of the guide wheel is increased, the tension of the wire arranging groove on the over-tight enameled wire is further weakened, the phenomenon that the enameled wire is snapped is avoided, and finally the purpose of self-adjusting the winding force is achieved.

Owner:江苏润杨精密制造有限公司

Improved high-molecular cluster pipe cable sleeve

InactiveCN108270180AIncrease profitIncrease winding lengthCable installations in underground tubesMolecular clusterMolecular materials

The invention relates to an improved high-molecular cluster pipe cable sleeve which comprises a cylindrical net sleeve with two end openings. The cylindrical net sleeve is composed of a net-shaped plate which is made of a high-molecular material. The net-shaped plate is obtained through interweaving warps and wefts. At least two net sleeves are superposed and fixed together. When the net sleeves are superposed and fixed together, the edge seam of the net-shaped plate is arranged at the inner part, thereby realizing no edge seam on the external surface of the cable sleeve. At least two superposed net sleeves are stitched together at the combining seam of the net-shaped plate. Furthermore a stitching line is arranged at the middle part of the net sleeve, thereby dividing the net sleeve intoa left part and a right part. At least two superposed net sleeves are stitched together at the edge seam of the net-shaped plate. Furthermore the stitching line exists at one side of the net sleeve. The outmost-layer net-shaped plate packages the edge seam of the inner net sleeve. The edge seam of the net-shaped plate is arranged at the inner part so that the edge seam of the net-shaped plate is packaged at the inner part, thereby realizing no edge seam on the outer surface of the cable sleeve. According to the cable sleeve, the mesh line on the edge seam does not easily fall off, and furthermore convenient construction is realized.

Owner:XIAOGAN GUANTIAN TECH INFORMATION CONSULTING

LED injection molding automatic material receiving and discharging machine capable of reducing roll lines and improving efficiency and yield

PendingCN114394457AAvoid breakingReduce sputteringArticle deliveryWebs handlingEmergency Stop ButtonSupport plane

The LED injection molding automatic winding and unwinding machine comprises a frame body horizontally placed above the ground, Foma wheels used for achieving movement are installed on the lower end face of the frame body, an electric box is fixedly installed on the outer side of the frame body, meanwhile, a speed adjusting panel is arranged on the outer side of the electric box, and the speed adjusting panel is connected with the frame body. An operation button and an emergency stop button are fixedly mounted on the outer side of the frame body and are used for realizing the operation and control of the equipment; the four supporting frames are vertically and fixedly installed on the outer side of the frame body at equal intervals, unwinding discs are installed on the upper surfaces of the two supporting frames on the upper layer, and winding discs are installed on the upper surfaces of the two supporting frames on the lower layer; and the four second brackets are fixedly mounted on the outer side of the frame body. The LED injection molding automatic winding and unwinding machine capable of reducing the roll lines and improving the efficiency and the yield is provided with the large-size material disc, the winding length can be effectively increased, the roll changing frequency and the roll line number can be reduced, meanwhile, double-channel equipment is adopted, the winding and unwinding efficiency of the device is effectively improved, and practicability is high.

Owner:WUXI LEIDE ENVIRONMENTAL PROTECTION EQUIP

Multilayer winding device of continuous tube

InactiveCN1271306CReduce restrictionsIncrease winding lengthLiquid/gas jet drillingDirectional drillingEngineeringGeological exploration

The continuous tubular multi-layer winding apparatus is one kind of super-deep drilling apparatus for underground mineral exploitation, geological exploration, oil and gas exploitation, etc. The available single-layer winding apparatus limits the super-deep drilling construction. The continuous steel tube multi-layer winding apparatus consists of winding roller, frame, driving mechanism and power transmission gear, gear rack, etc. and is matched with steel tube driving apparatus to realize continuous steel tube multi-layer winding. The present invention makes it possible to increase greatly the continuous steel tube winding length without increasing the roller width.

Owner:TAIYUAN UNIV OF TECH

Net type planting device for underground rhizome crops

InactiveCN114431036AIncrease winding lengthIncrease the lengthHarvestersAgriculture gas emission reductionAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural planting accessory devices, in particular to a net type planting device for underground rhizome crops, which is characterized in that crops are planted in a hollow net surface, and the net surface is lifted out during harvesting, so that the crops can be quickly harvested; comprising field ridges made of soil, grooves are formed in the field ridges, hollowed-out net faces are laid on the inner walls of the grooves, the net faces are covered with light filler mixed with organic fertilizer, the effect of fixing sowing materials is achieved, connecting pieces are fixed to the two ends of each net face through a plurality of screws, and a plurality of hanging rings are fixed to the other ends of the connecting pieces; adjusting mechanisms are arranged on the left side and the right side of the bottom of the flat plate, adjusting plates are installed at the output ends of the adjusting mechanisms, supporting legs are installed at the two ends of each adjusting plate, and universal wheels are installed at the other ends of the supporting legs; a plurality of driving mechanisms are arranged on the flat plate, each driving mechanism comprises two supporting rods fixed to the flat plate, a driving shaft is rotationally installed on each supporting rod, and a small gear is fixed to each driving shaft.

Owner:恩施市盛元食品有限责任公司

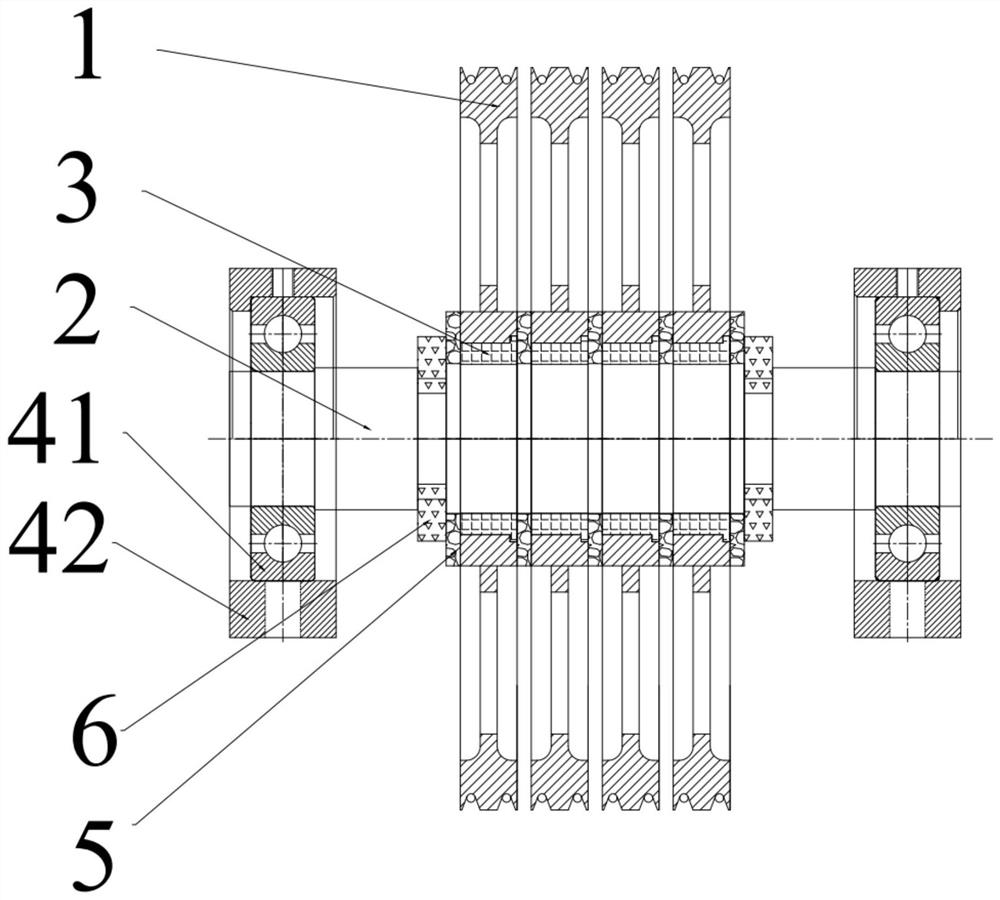

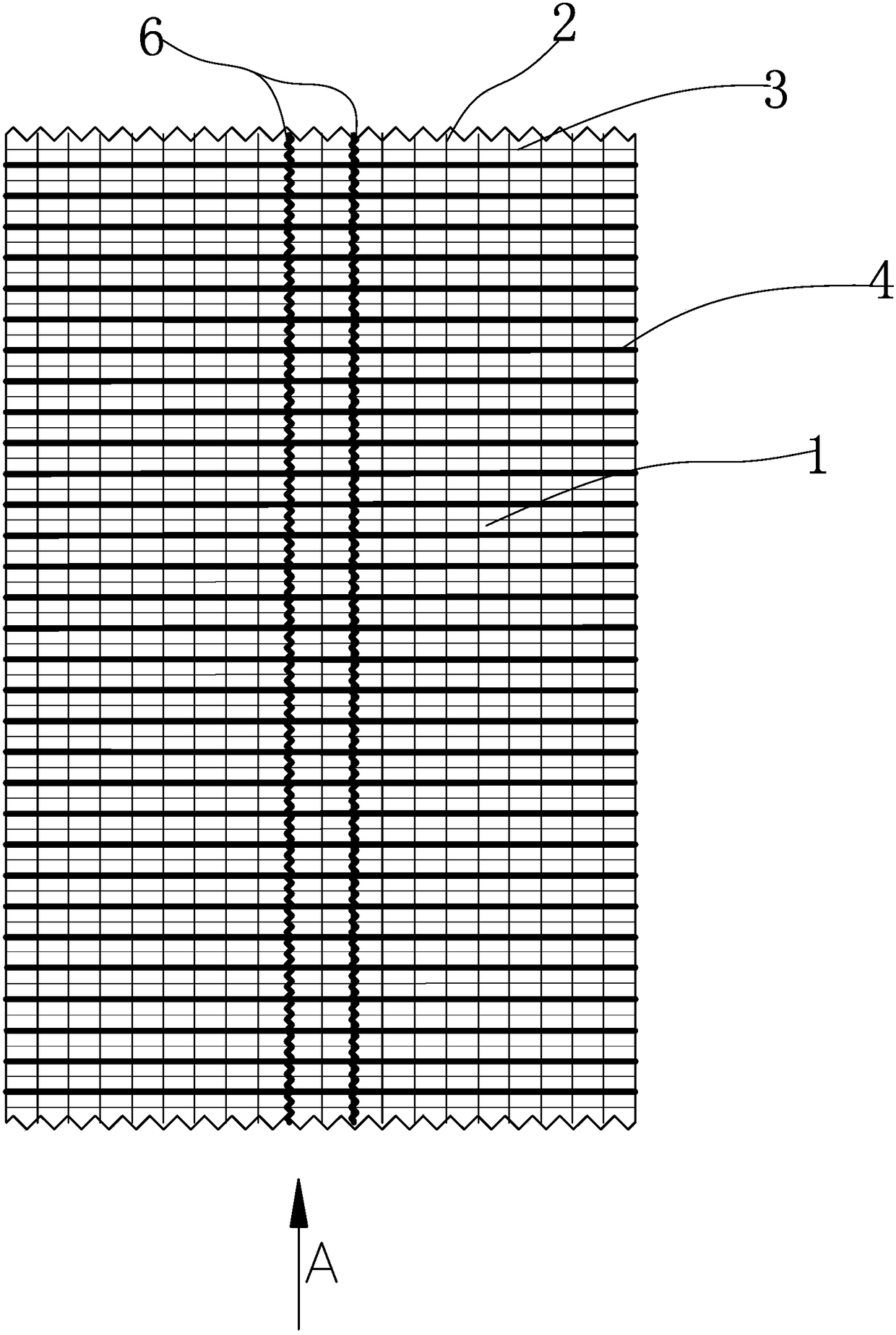

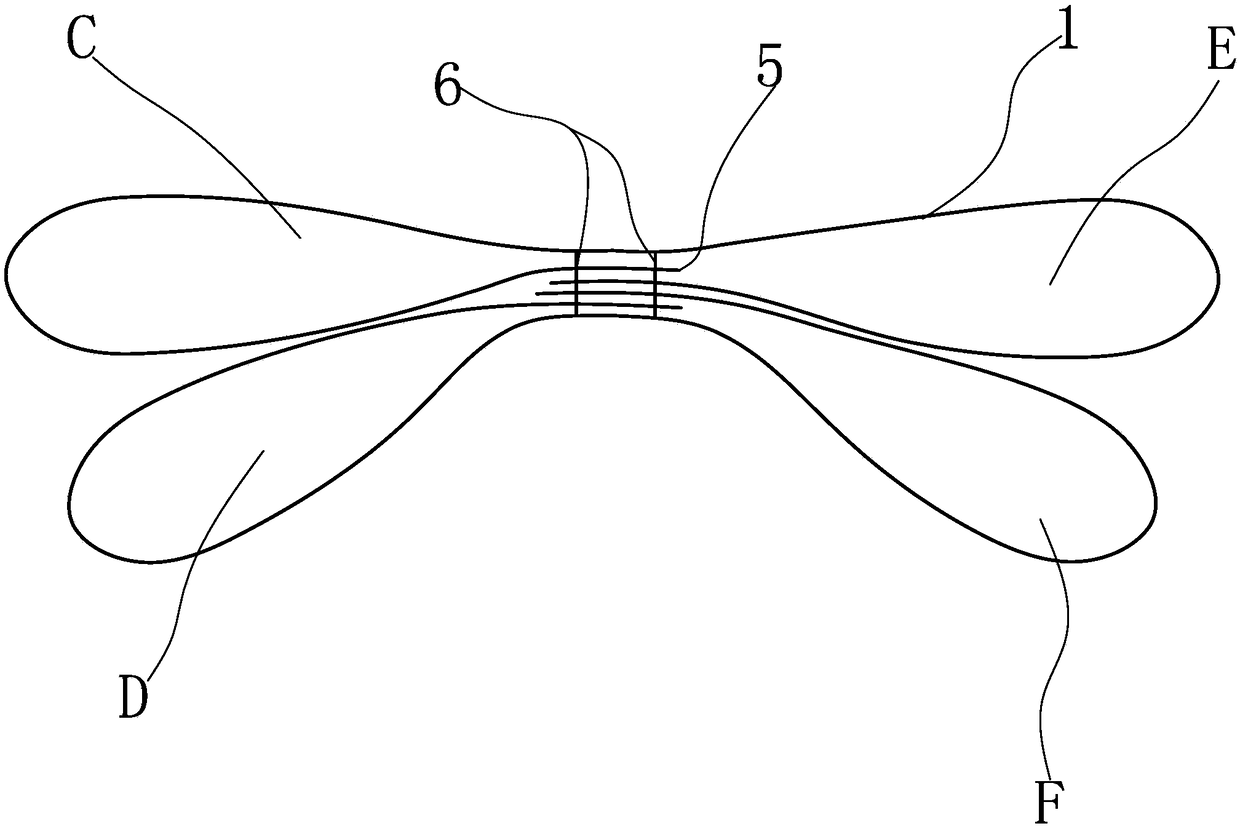

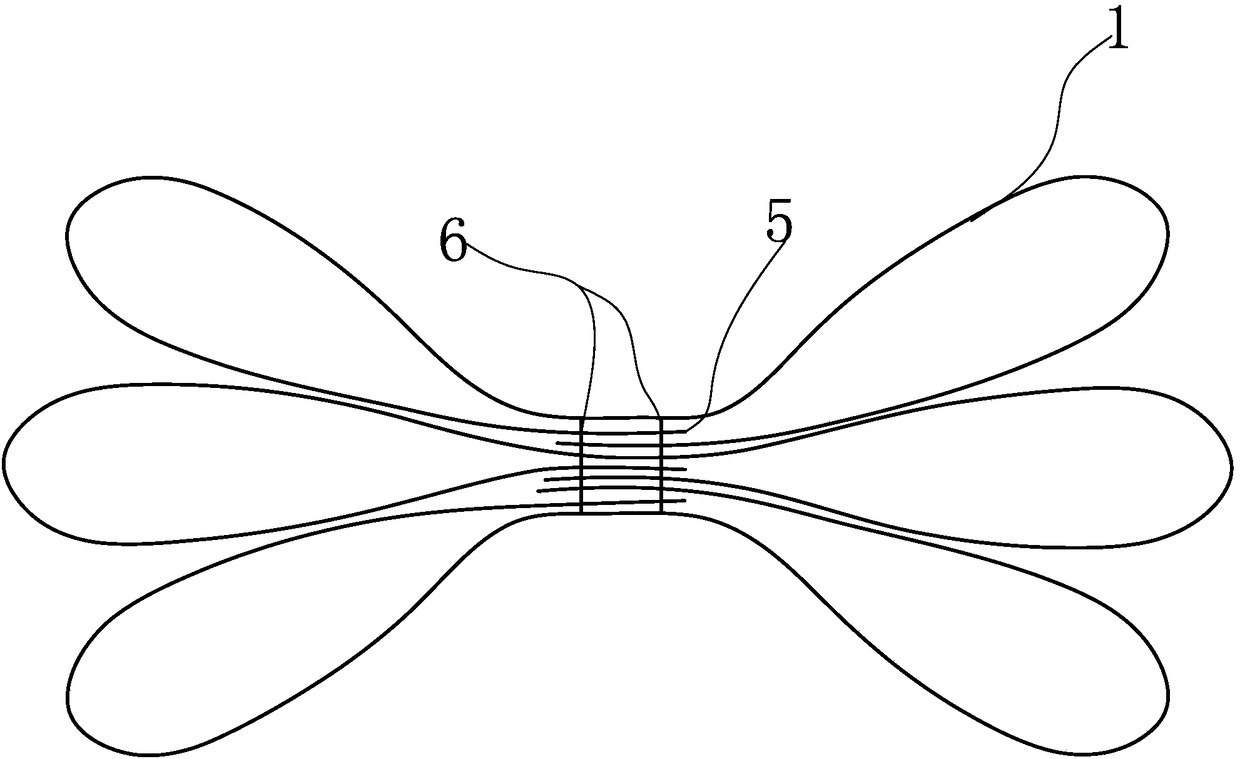

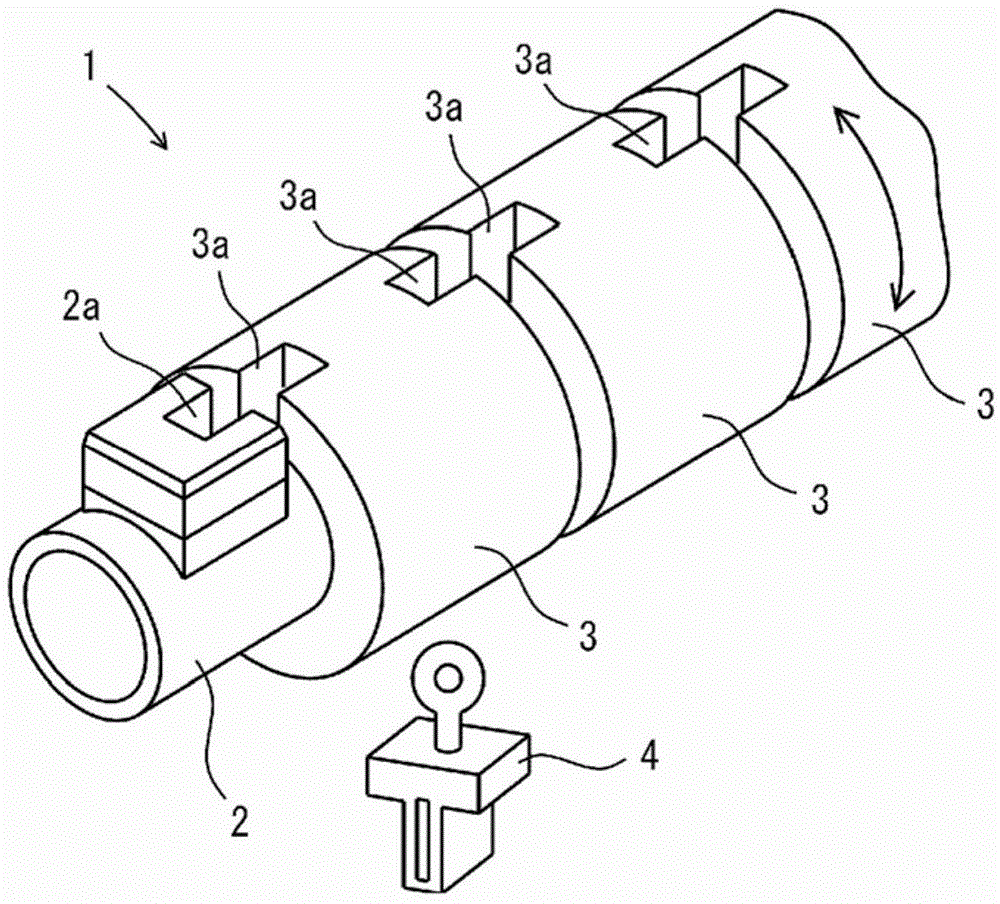

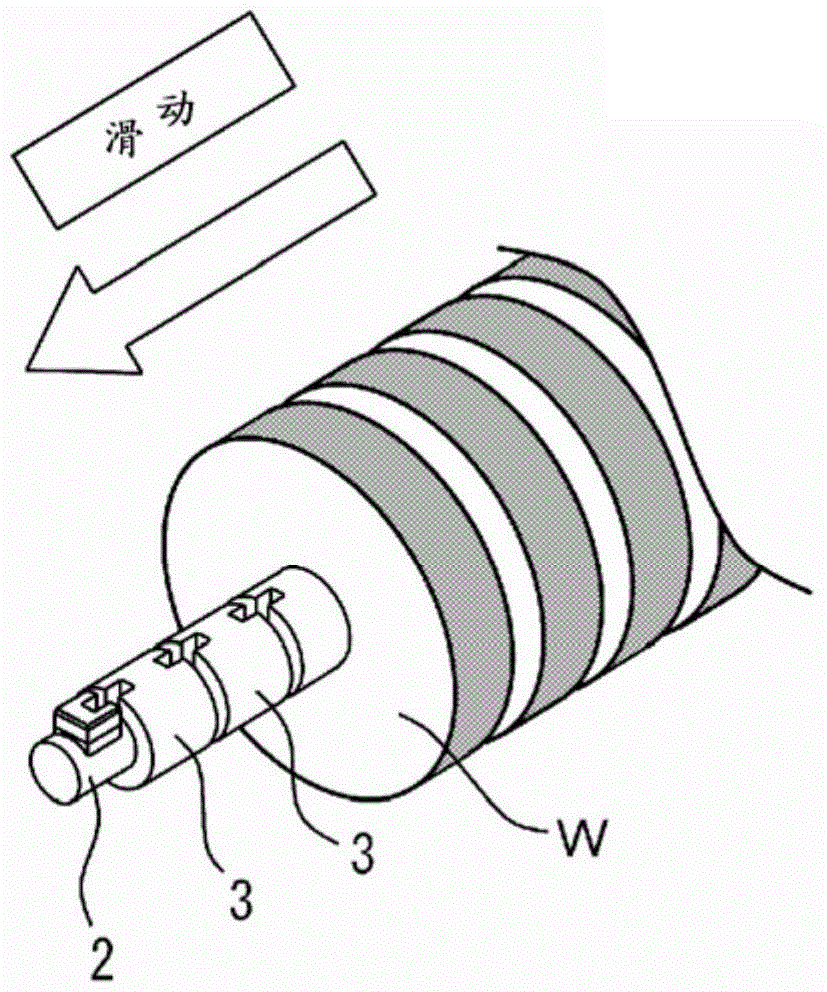

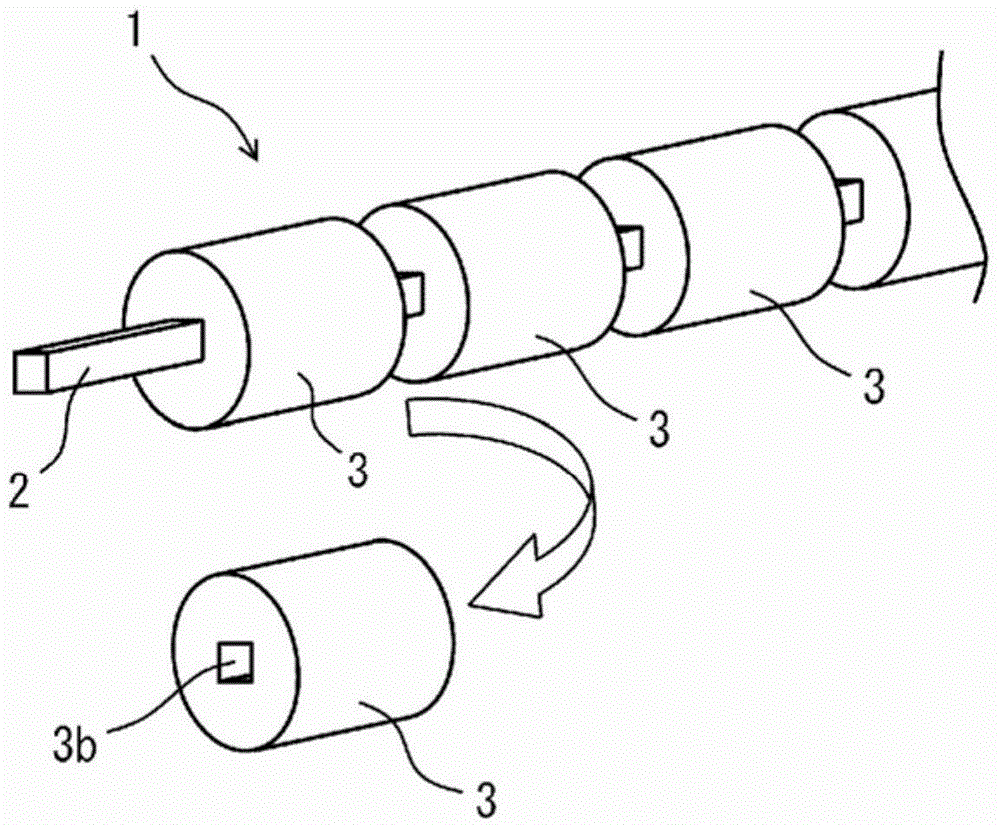

Take-up device for woven fabric with rubber

InactiveCN104039670AReduce replacement timeImprove productivityTyresWebs handlingEngineeringMechanical engineering

A take-up device (1) for a woven fabric (W) with rubber comprises a rotating shaft (2), and a plurality of take-up boxes (3) mounted to the rotating shaft (2). The take-up boxes (3) are rotatable with respect to the rotating shaft (2). When a coupling key (4) is inserted into an insertion opening (2a) of the rotating shaft and an insertion opening (3a) of the take-up box (3) so as to span the insertion openings (2a, 3a), and another coupling key (4) is inserted so as to span the insertion openings (3a) of the adjacent take-up boxes (3), the take-up boxes (3) are locked with respect to the rotating shaft (2). By integral rotation of the rotating shaft (2) and the take-up boxes (3), each one of a plurality of woven fabrics (W) with rubber is simultaneously wound around each of the take-up boxes (3). After the coupling key (4) is taken out of the insertion openings (2a, 3a), the woven fabric (W) with rubber is unwound from the take-up box (3) by the rotation of the take-up box (3) with respect to the rotating shaft (2).

Owner:SUMITOMO RUBBER IND LTD

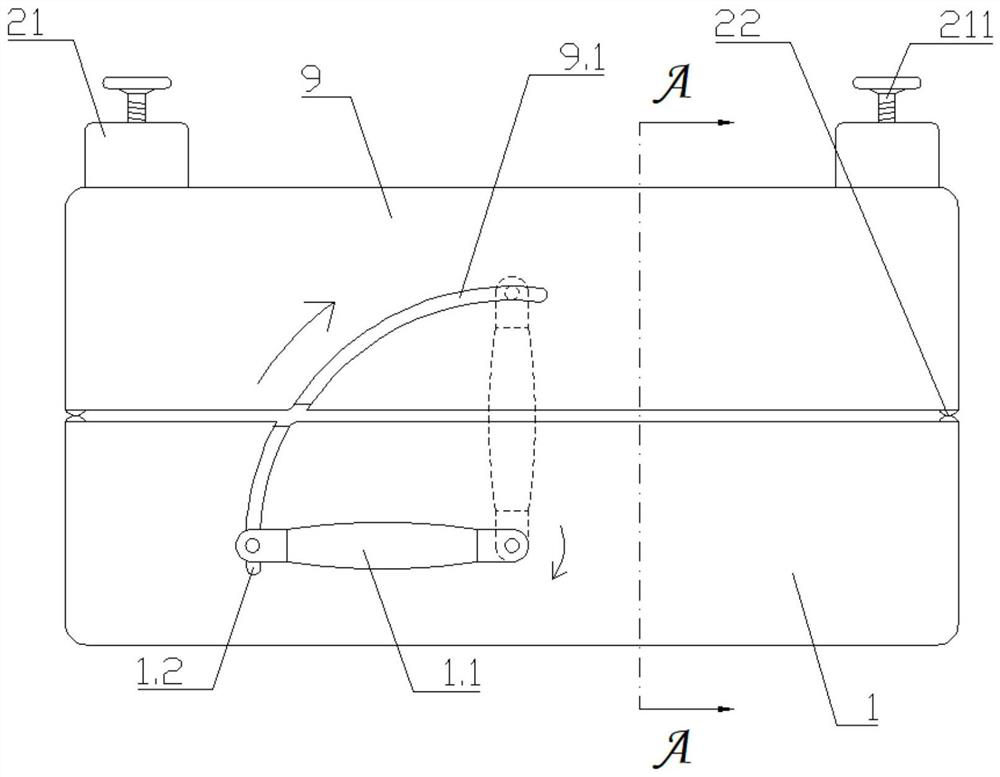

Knotting-preventing take-up device for yellow phosphorus furnace water hose

InactiveCN109230834ANot easy to squeeze each otherAdjust the winding lengthFilament handlingInternal connectionExtrusion

The invention discloses a knotting-preventing take-up device for a yellow phosphorus furnace water hose. The knotting-preventing take-up device comprises a right supporting plate, a mounting base anda concave block, wherein the right end of the right supporting plate is internally provided with a sliding groove, a first rotary shaft is connected in a sliding block, a sponge layer is adhered and connected to the inner surface of a right clamping plate, a second fluted disc is connected to a first fluted disc, the outer surface of a second rotary shaft is welded with a left clamping plate, themounting base is located at the right end of the right supporting plate, a first take-up rod is connected to a motor, the concave block is located at the left end of the first take-up rod, a convex block is arranged at the left end of the concave block and is welded at the right of a second take-up pipe, and the left end of the second take-up pipe is connected with a left supporting plate. The knotting-preventing take-up device for the yellow phosphorus furnace water hose can adjust take-up length and increase the take-up amount, a winding mode is reasonable, mutual extrusion of the water hoseis not possibly caused, and a water hose inclusion device is provided to prevent loosening of the water hose after winding.

Owner:贵州新天鑫化工有限公司

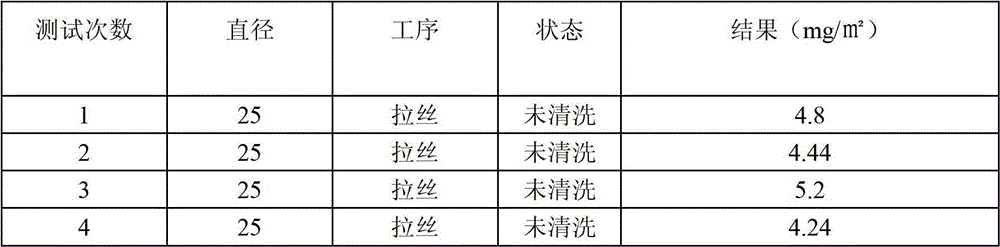

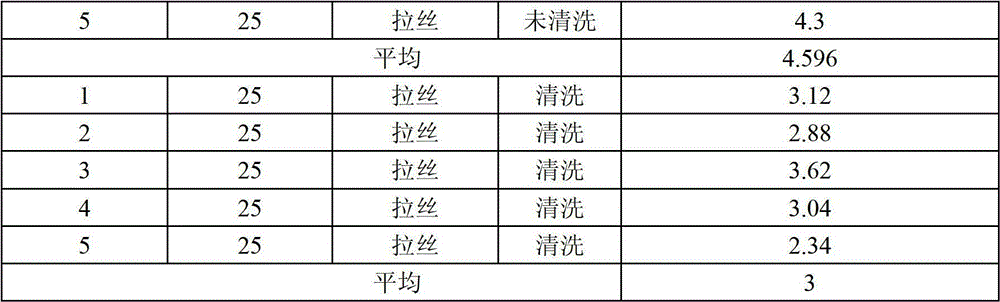

Gold bonding wire and preparation method thereof

ActiveCN102121077BHigh strengthImprove high temperature strengthSemiconductor/solid-state device detailsSolid-state devicesHigh pressure waterAlloy

The invention discloses a gold bonding wire which comprises the following components in percentage by weight: 0.0003-0.0008 percent of calcium, 0.002-0.004 percent of copper, 0.0005-0.0015 percent of germanium and the balance of gold, wherein the purity of the gold is larger than or equal to 99.99 weight percent. The invention also discloses a preparation method of the gold bonding wire. The method mainly comprises the following step of after a wire drawing step and before an annealing step: loading a gold wire obtained after wire drawing into a high-pressure water washing system for washing,wherein the water pressure of the washing system is 2-4kg, i.e. 0.2-0.4MPa, and the water temperature is 40-60 DEG C. The gold bonding wire has the advantages of high strength and low and long arc and can meet the high requirement on gold bonding wires of the semiconductor industry; and moreover, in the preparation process, lubricating agents on the surfaces of the gold bonding wires can be effectively washed, therefore, the use effect of a final product is guaranteed.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com