Wiring mechanism, wire winding method and wire treatment device and method

A winding method and wire technology, applied in thin material processing, conveyor objects, transportation and packaging, etc., can solve the problems of high cost and low wire processing efficiency, and achieve the advantages of increasing residence time, increasing processing efficiency and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

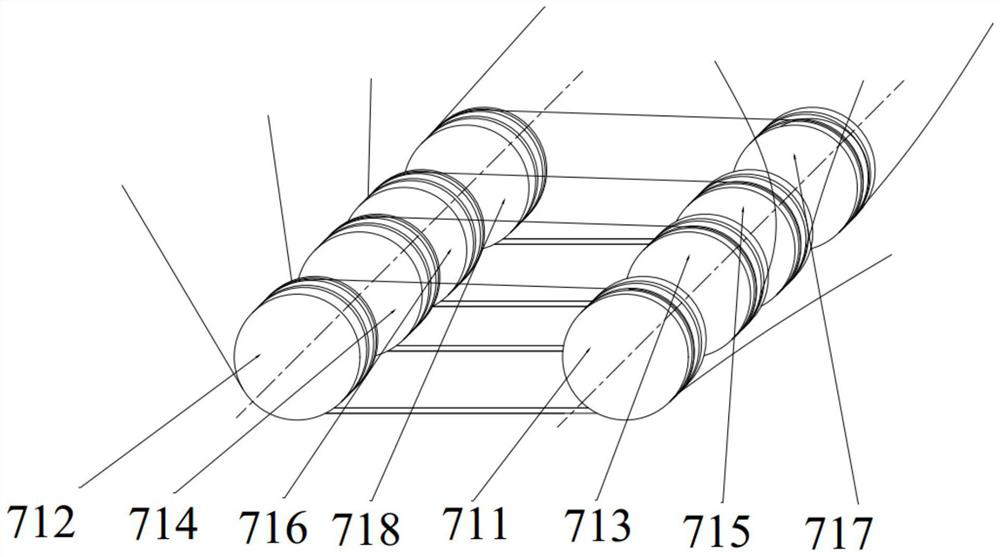

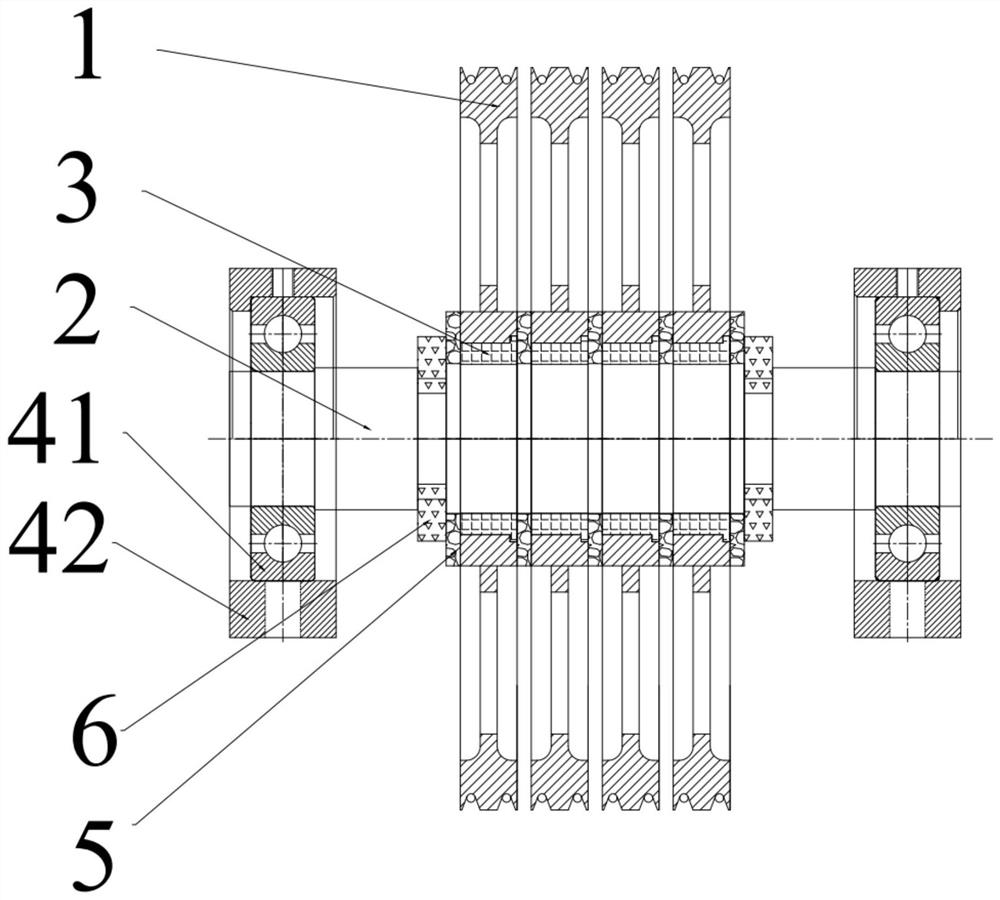

[0052] This embodiment provides a wiring mechanism, such as Figure 1 to Figure 4 As shown, it includes a support 42, a bearing 41, a rotating shaft 2, a shaft sleeve 3, a rotating wheel 1, a spacer 5 and a locking assembly. Wherein, two pairs of parallel bearings 42 are arranged on the mounting position, wherein, the following installation is described with the structure on each pair of bearings 42, specifically, on a pair of bearings 42, the bearings 41 and the rotating Shaft 2 is installed, and four rotating wheels 1 are arranged on each rotating shaft 2, and axle sleeve 3 is also provided between each rotating wheel 1 and rotating shaft 2; In addition, each rotating wheel 1 is provided with two sides The spacer 5 is used to separate adjacent rotating wheels 1 or other components; the locking assembly includes two sets of locking structures 6, and the locking structures 6 are arranged on the outer sides of the rotating wheels 1 on both ends of the coaxial, and the locking s...

Embodiment 2

[0065] This embodiment provides a wire winding method, using the routing mechanism in Embodiment 1, including the following steps:

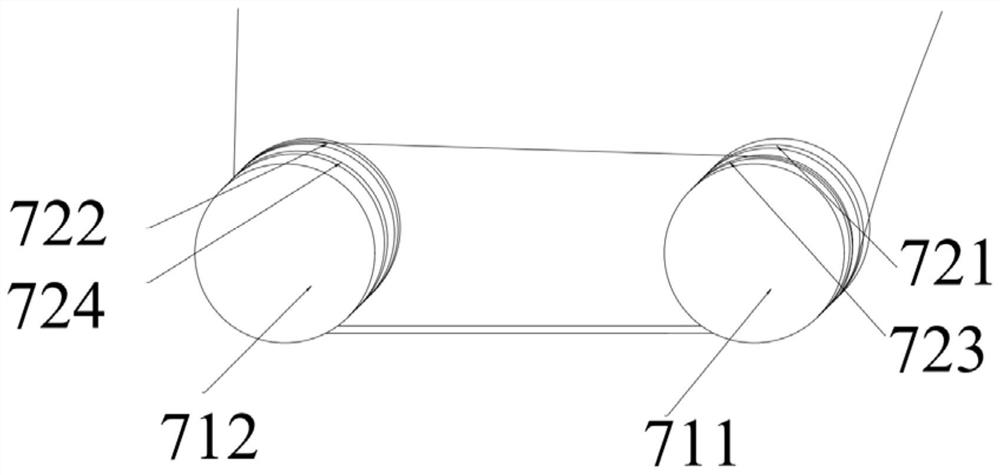

[0066] S11: The first adjacent routing: the wire member first winds clockwise along the first limiting channel of the first rotating wheel, then outputs from the first limiting channel, and goes to the second limiting channel of the second rotating wheel Winding direction clockwise;

[0067] S12: The first cross-wire routing: After the wire member is wound half a turn in the second limiting channel, it is output from the second limiting channel, and extends toward the third limiting channel of the first rotating wheel, and so that the wire member is arranged in the third limiting passage and wound clockwise;

[0068] S13: the second adjacent wiring; the wire member is output from the third limiting channel, and then the wire member extends toward the fourth limiting channel on the second rotating wheel, and the wire member is wound clockwise in ...

Embodiment 3

[0071] In this embodiment, a cable routing mechanism is provided, which is different from Embodiment 1 in that: the first rotating wheel, the third rotating wheel, the fifth rotating wheel and the seventh rotating wheel are arranged on different rotating shafts. The second rotating wheel, the fourth rotating wheel, the sixth rotating wheel and the eighth rotating wheel are arranged on the same rotating shaft. It is also possible to realize the transmission of multiple groups of wire members at different wire speeds.

[0072] Of course, in other optional embodiments, the number of rotating wheels can be set according to the needs of use, for example, three rotating wheels with different rotating shafts can be set, and three rotating wheels with the same rotating shaft can be set for winding Three different wire components.

[0073] When the above wire routing mechanism winds wires, the method adopted can be similar to the method in embodiment 2, as long as the wire members cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com