Take-up device for woven fabric with rubber

A coiling device and fabric technology, applied in applications, household appliances, winding strips, etc., can solve the problems of insufficient productivity improvement and long replacement time, and achieve the effect of shortening replacement time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

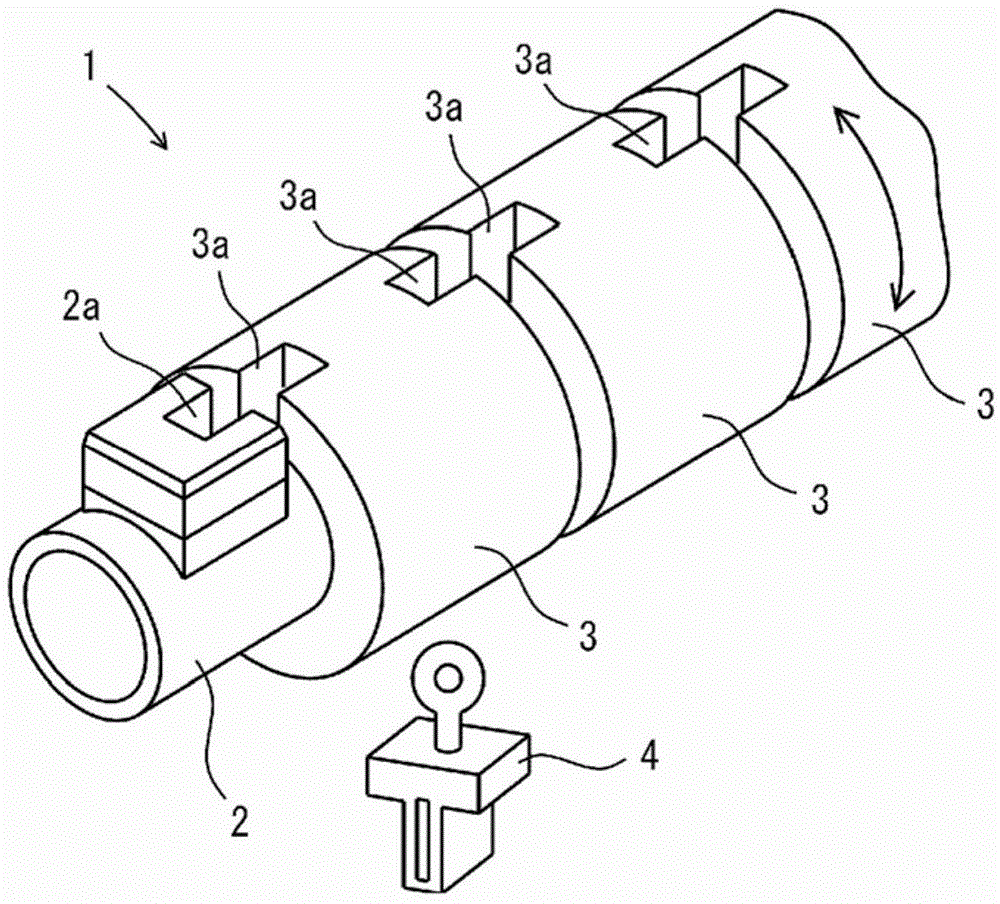

[0060] Hereinafter, the present invention will be specifically described based on examples.

[0061] 1. Production of JLB

[0062] (Example)

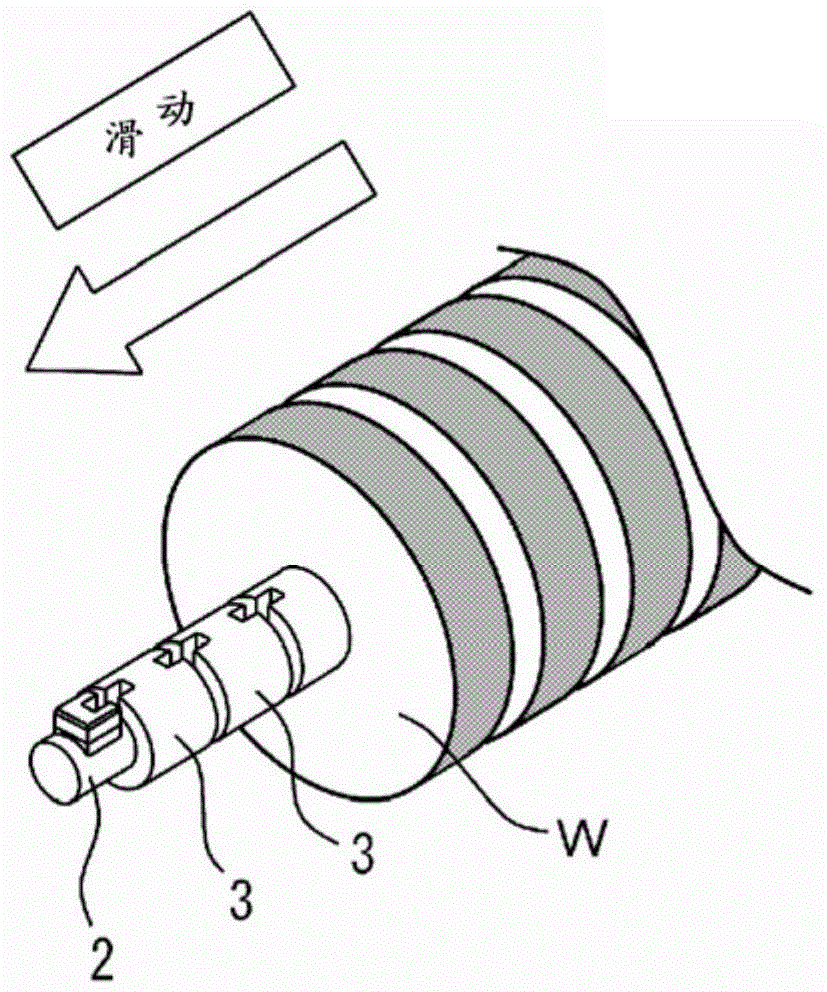

[0063] In this example, the rubber cord fabric with a width of 1440mm and a length of 600m was cut into a width of 80mm in the rough cutting process. After making 18 JLB base materials, the winding drum and rotary The shaft-integrated winding device winds the JLB base material to each winding drum for 600 m.

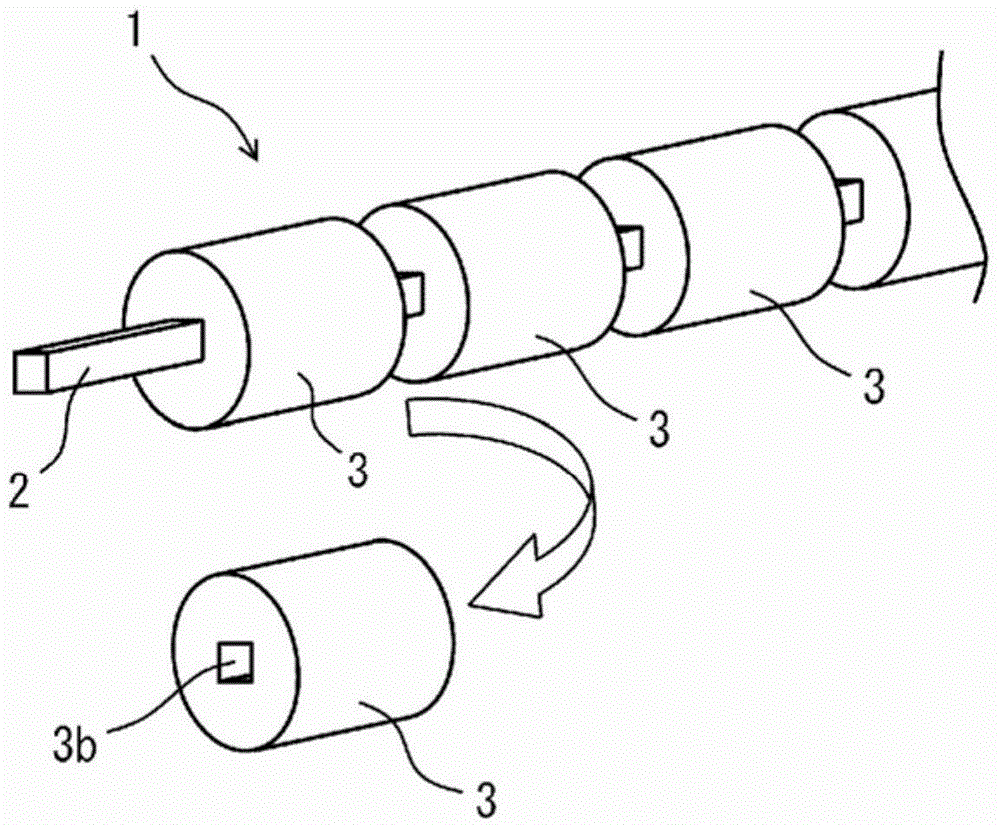

[0064] Next, the JLB base material wound on the take-up drum is transported to the fine cutting process together with the rotating shaft using a hoist, and cut into a width of 10mm, and 8 JLBs are produced for each take-up drum. The replacement of the JLB base material is performed by sliding the rotating shaft on which the JLB base material is wound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com