Patents

Literature

91results about How to "Small arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

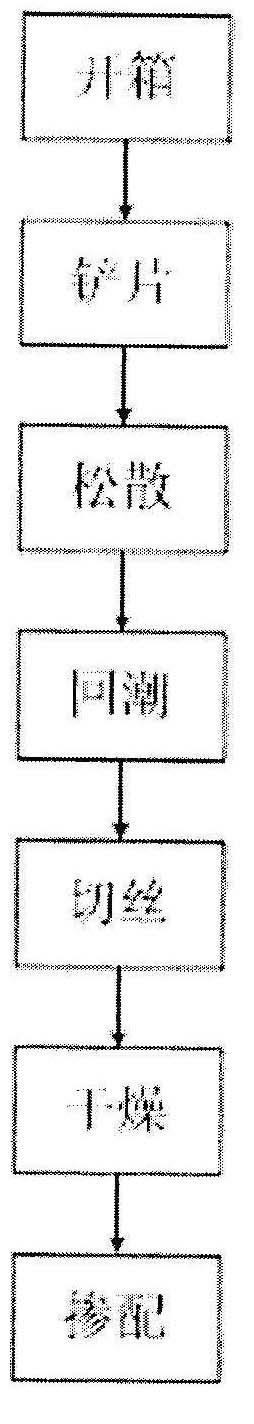

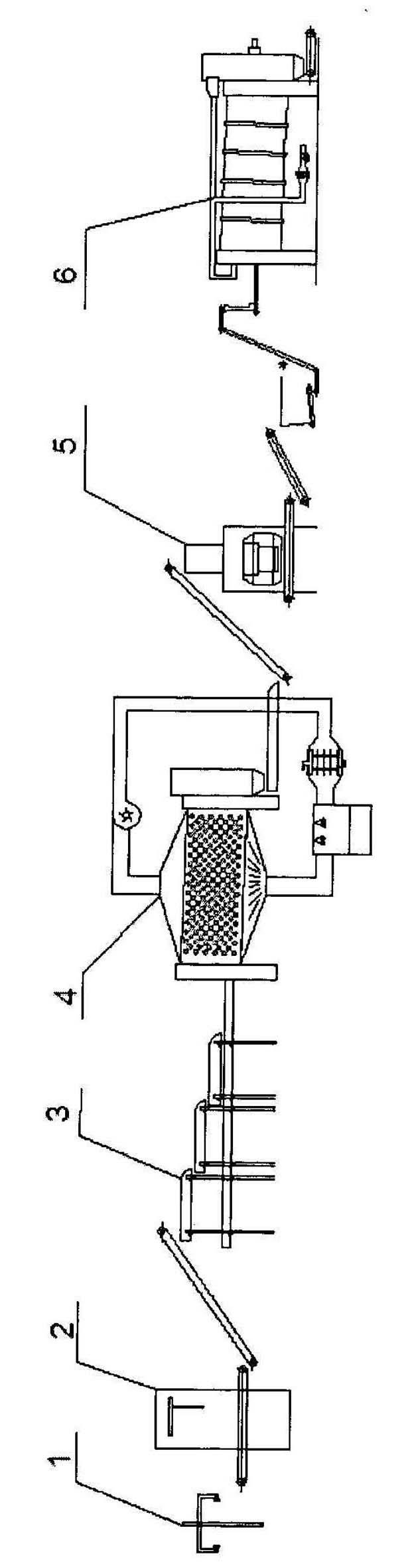

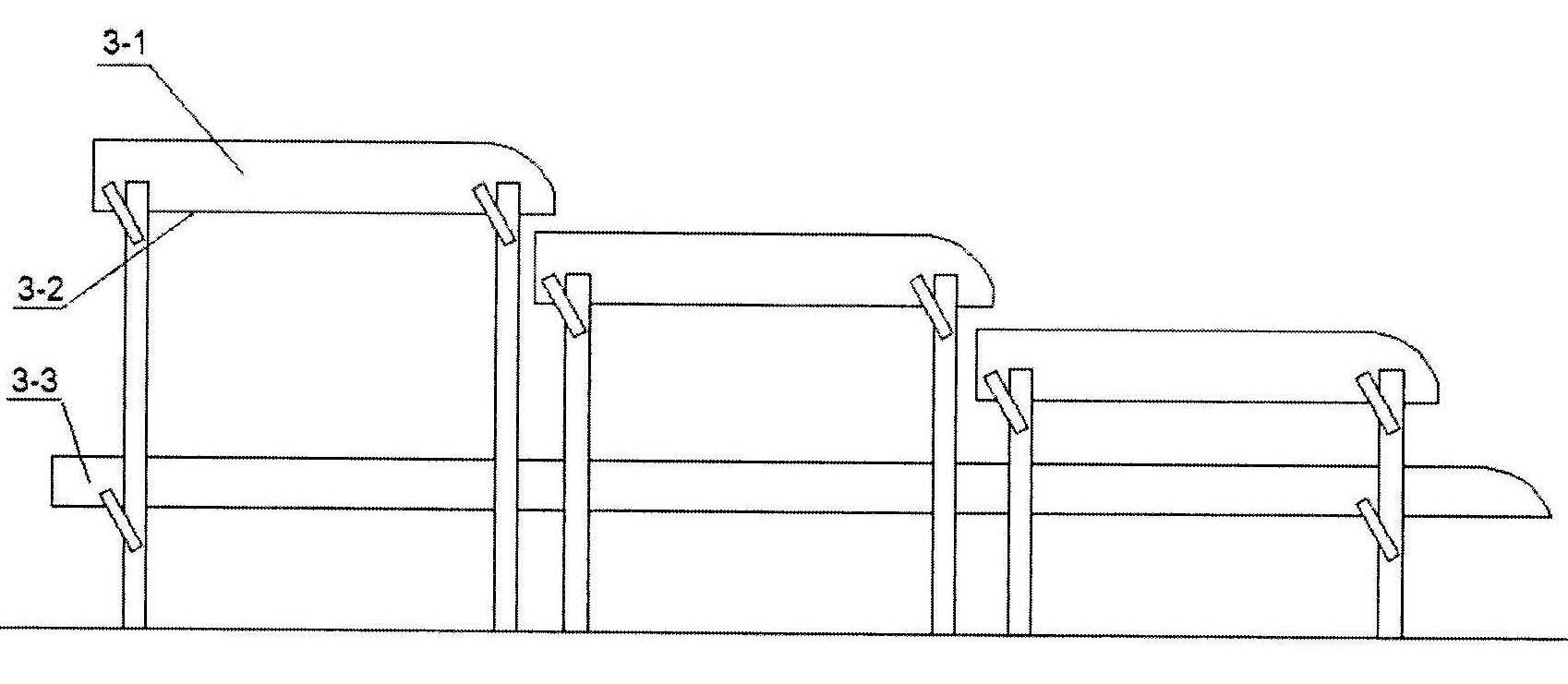

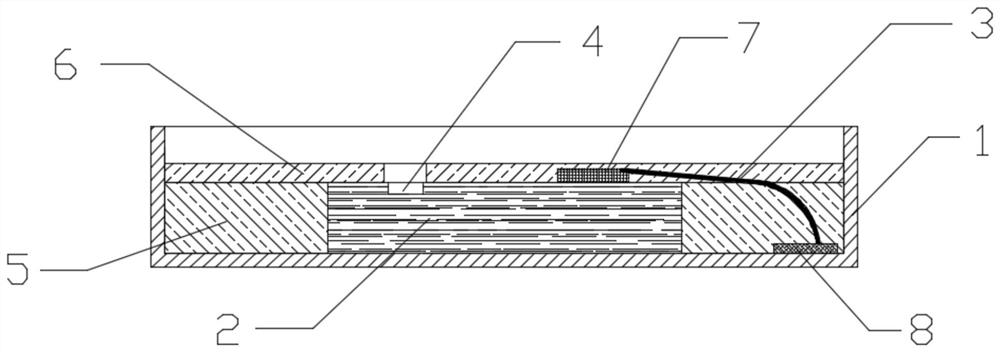

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

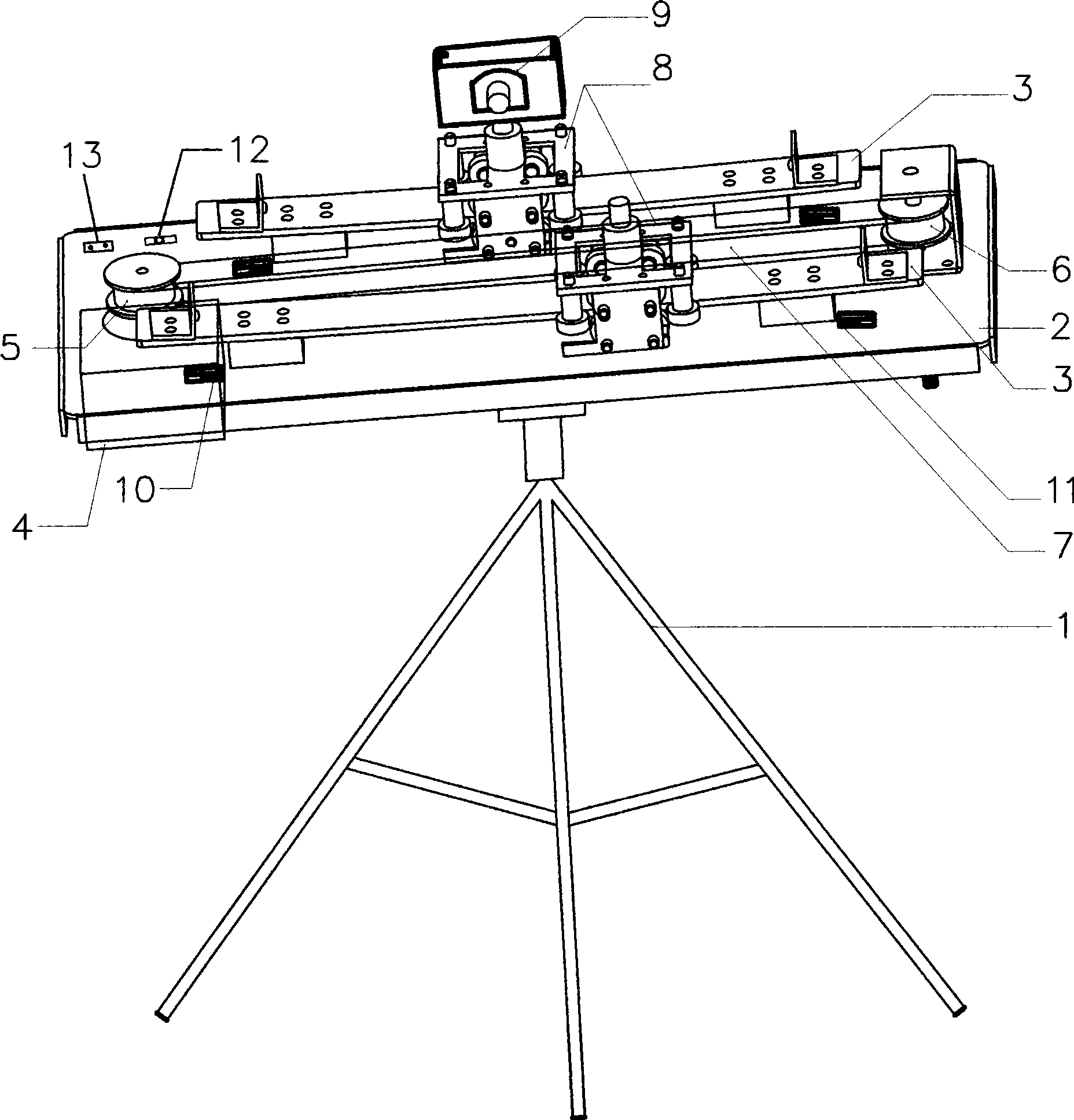

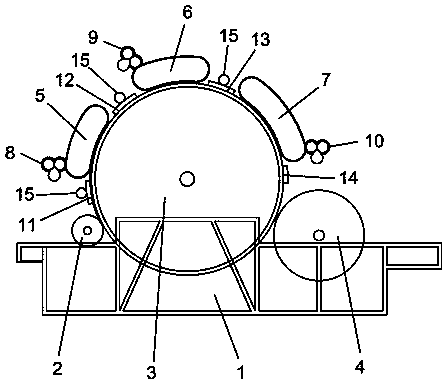

Stereoscopic image arc-shooting rail apparatus and its shooting method

InactiveCN101464615ASimple structureEasy to carryStands/trestlesStereoscopic photographyStereo cameraShooting method

The invention discloses an arc shooting track device for stereo images and a shooting method thereof. A slider is installed on the arc shooting track; a camera is installed on the slider; the control of the camera shutter and the control of the slider share a duplex control switch; and when the duplex switch of the camera shutter and the slider on the arc shooting track is open, the camera and the slider work synchronously. Through the control of the duplex switch, a continuous mode function of the camera can be utilized to cause the camera to move on the track and simultaneously conduct momentary continuous shooting in the arc direction, so as to achieve the shooting of the stereo images, and reach and surpass the stereo image effect shot by a multi-lens stereo camera.

Owner:SHANGHAI YIYING DIGITAL TECH

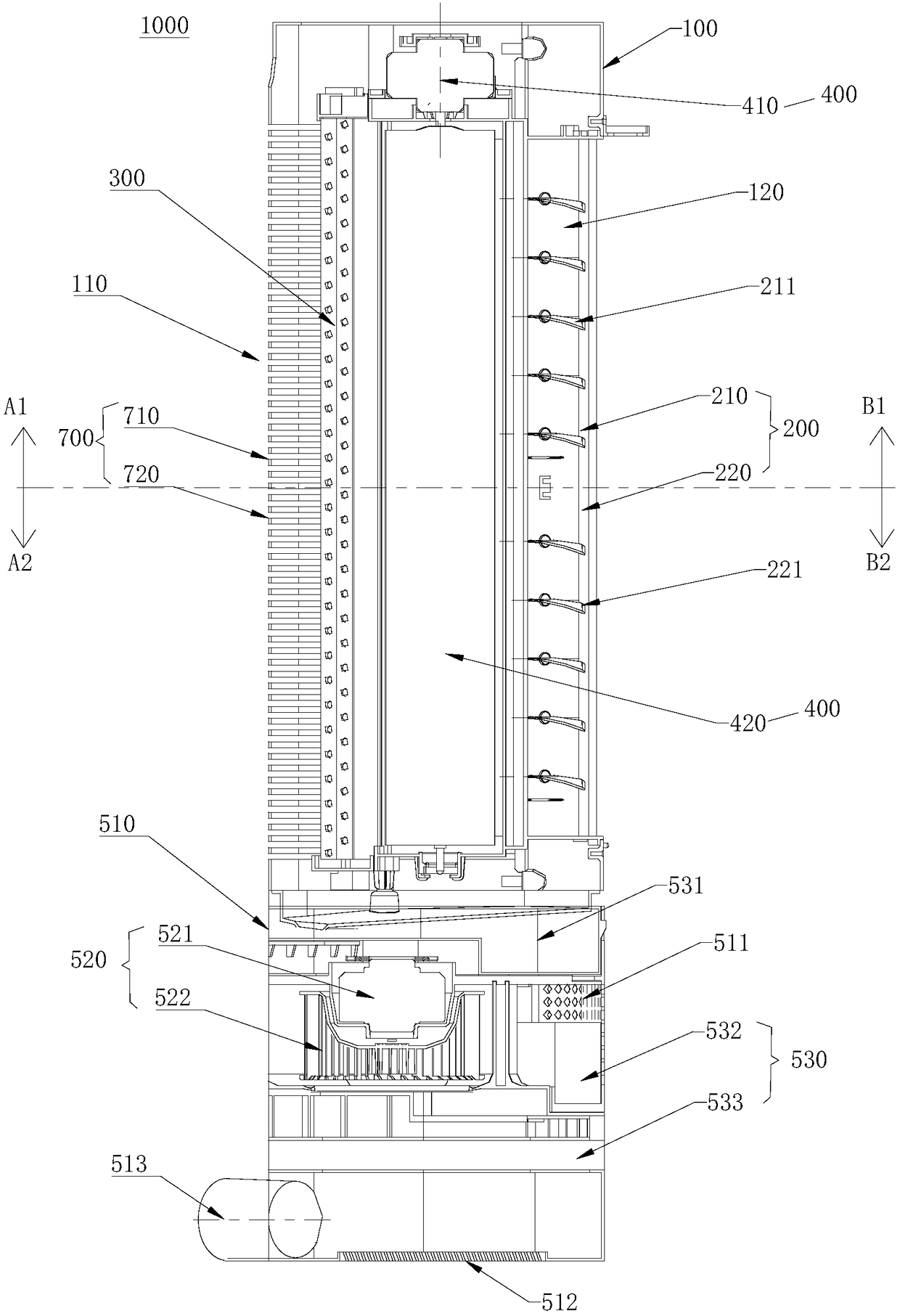

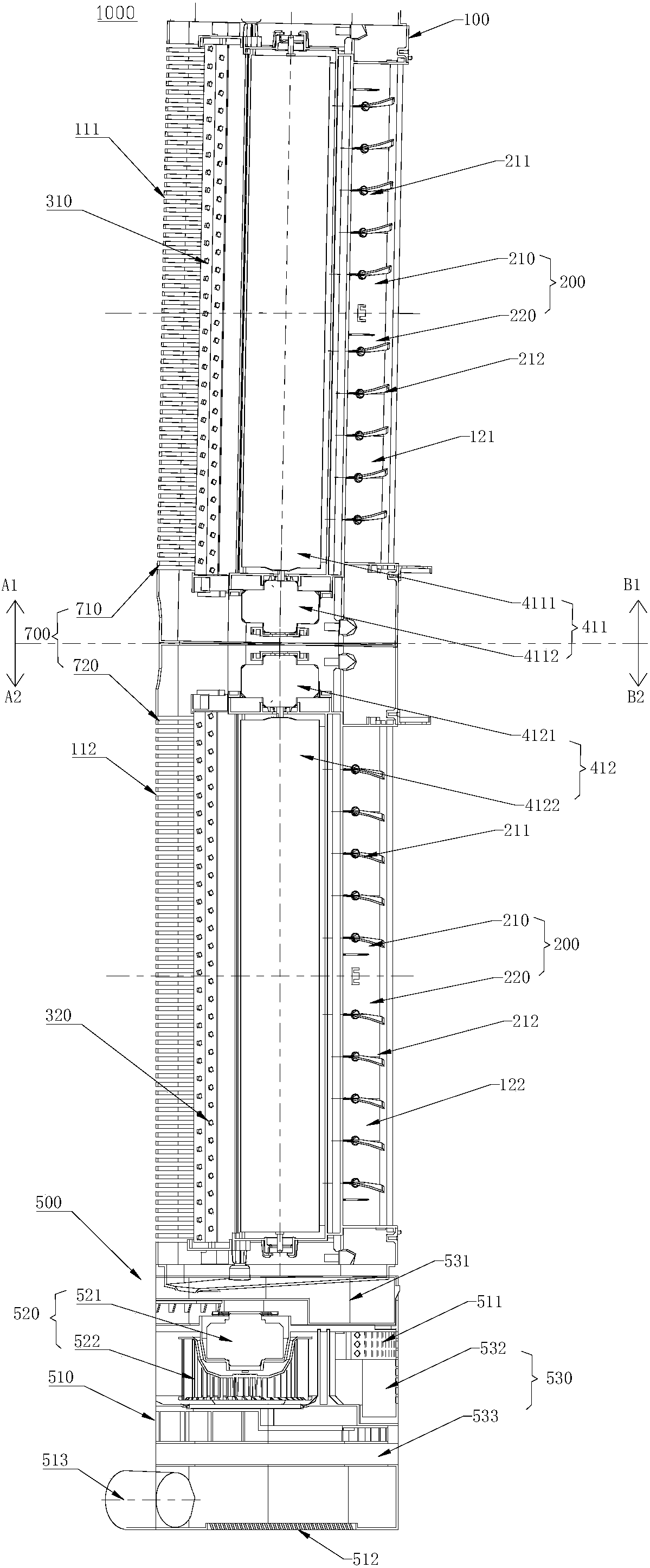

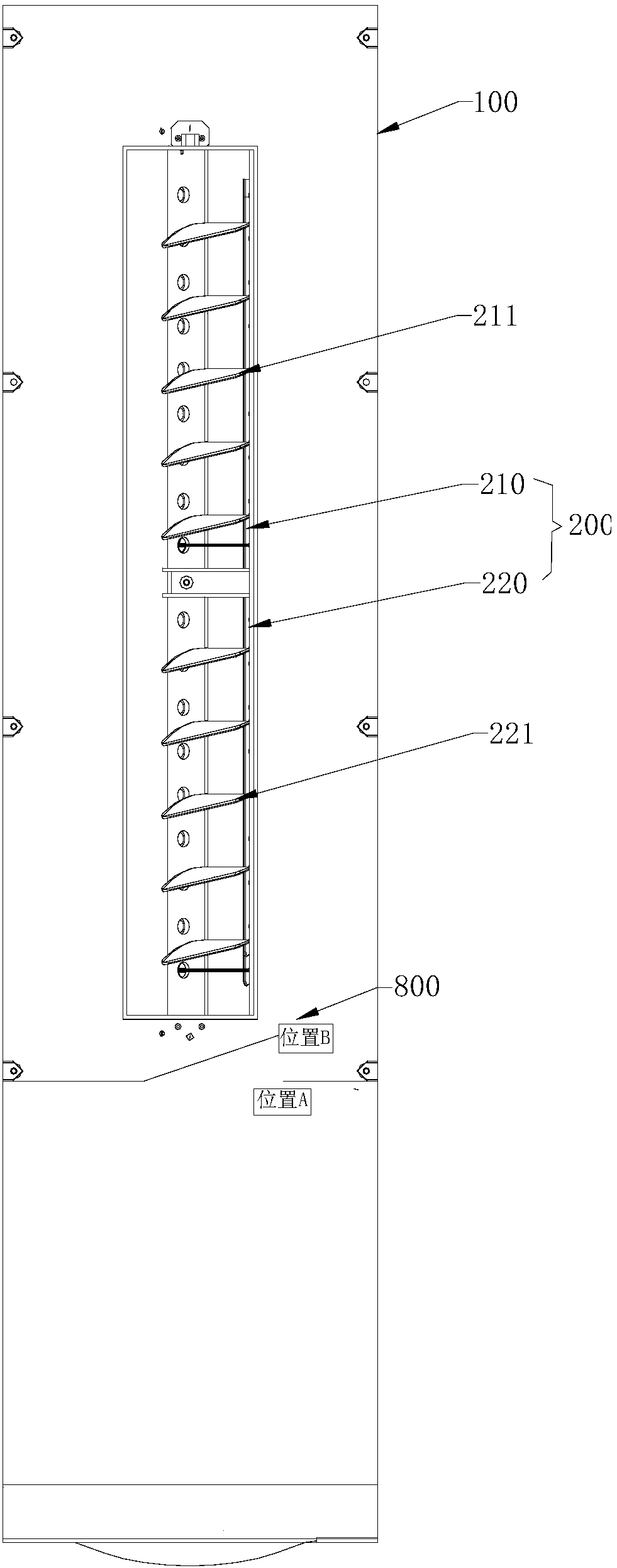

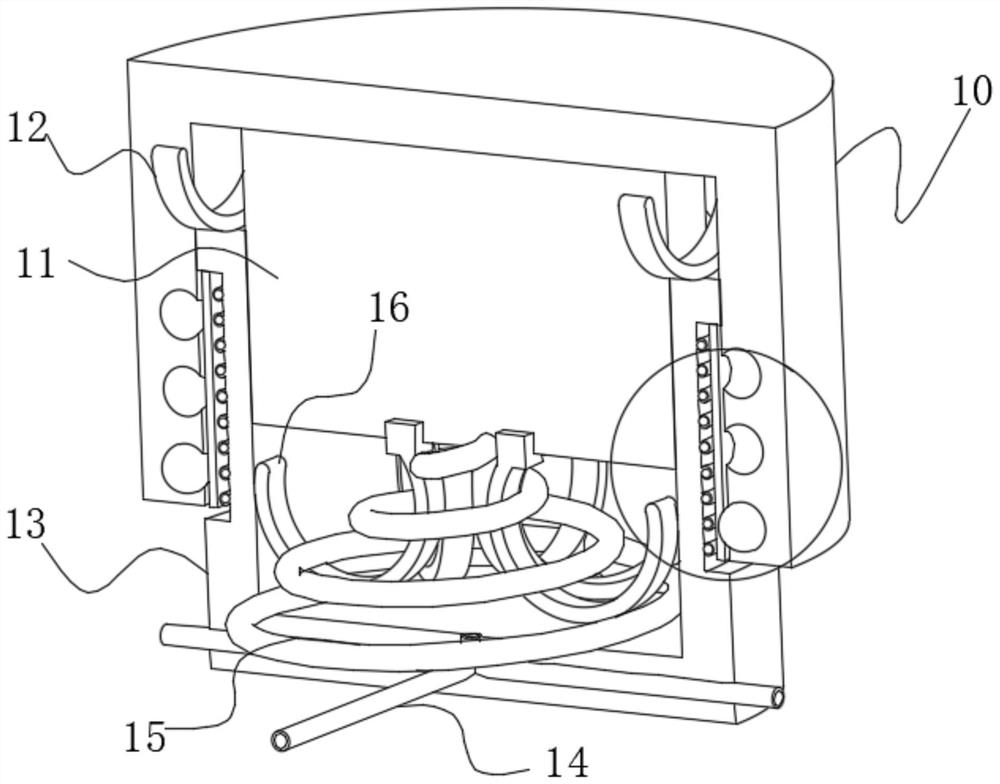

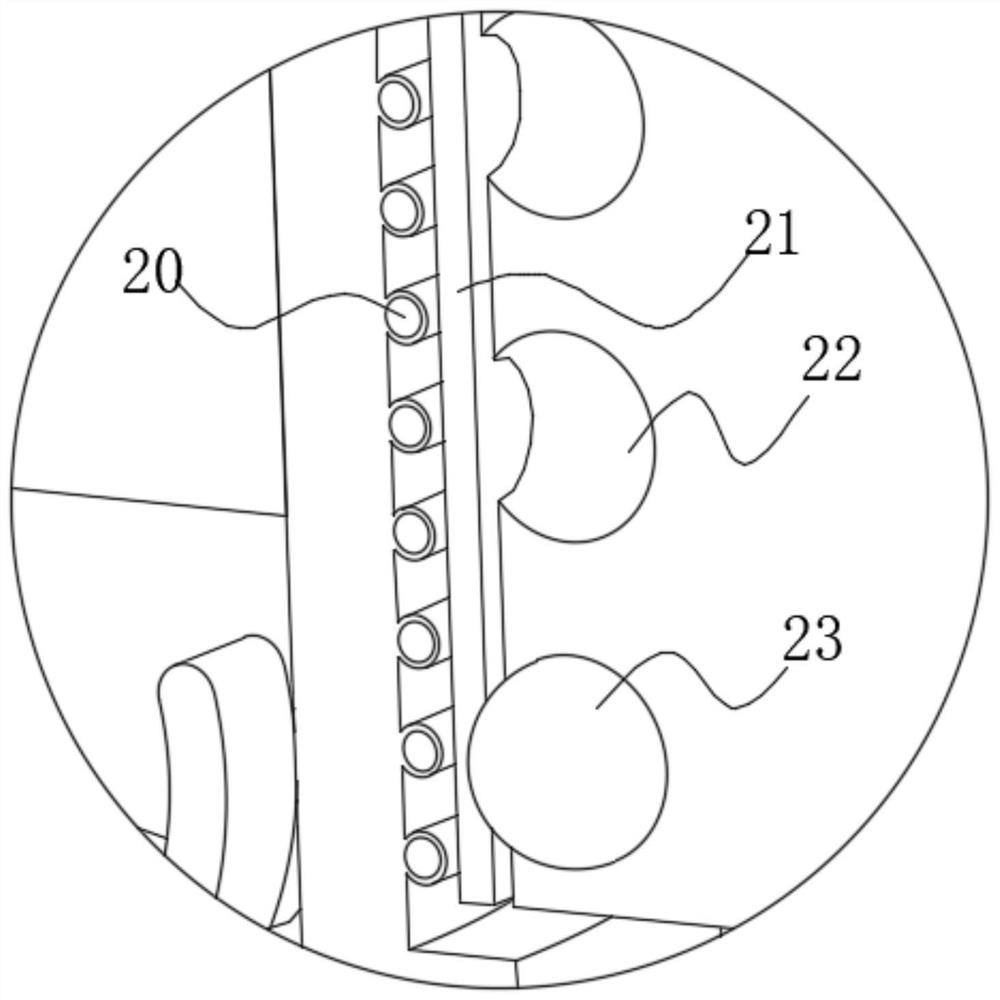

Air conditioner and control method and device of air conditioner

ActiveCN108488920AReduce working noiseDoes not affect appearanceDucting arrangementsMechanical apparatusThermal comfortFresh air

The invention discloses an air conditioner and a control method and device of the air conditioner. The air conditioner comprises an indoor unit. The indoor unit comprises a machine shell, an air handling module, multiple sets of air inlet adjusting assemblies and a switching valve. An air conditioning air flue is defined in the machine shell, and an air inlet is arranged on the machine shell. An upper air inlet area and a lower air inlet area are formed by the air inlet. The air handling module comprises a shell. A fresh air flue is defined in the shell. The method comprises the following steps that when the air conditioner operates by starting a heating mode, the air inlet is adjusted to be in the maximum air inlet state through the multiple sets of air inlet adjusting assemblies; the airinlet temperatures of the upper air inlet area and the lower air inlet area are acquired, and the temperature difference value is acquired; when the operation time reaches the first preset time, thetemperature difference value is judged; and if the temperature difference value is larger than the first preset temperature difference, the switching valve is controlled so as to control the air conditioning air flue to communicate with the fresh air flue, so that the indoor vertical temperature difference is reduced. The indoor heating power lamination phenomenon during heating operation of the air conditioner is effectively relieved, and therefore the indoor heat comfort is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

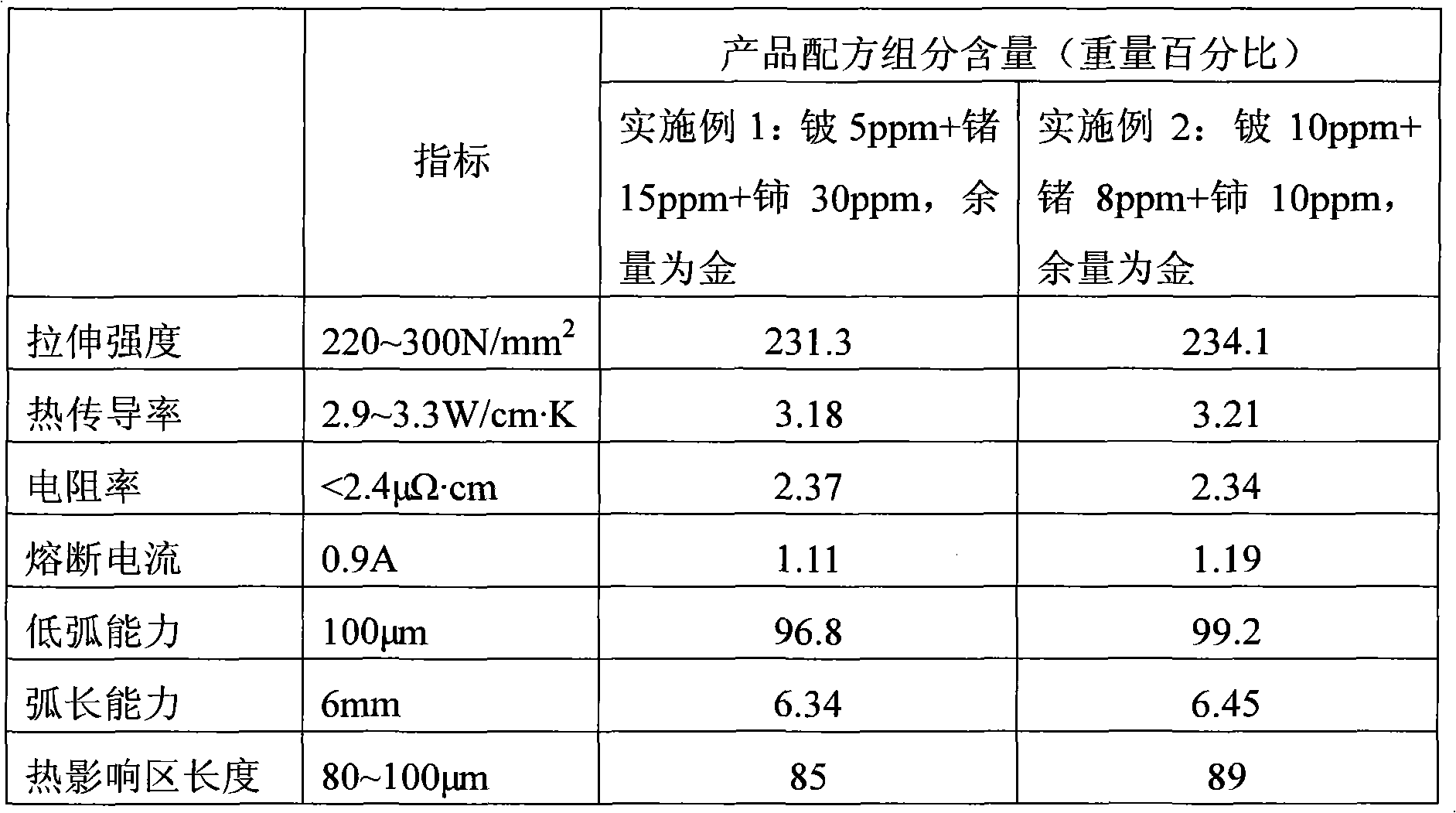

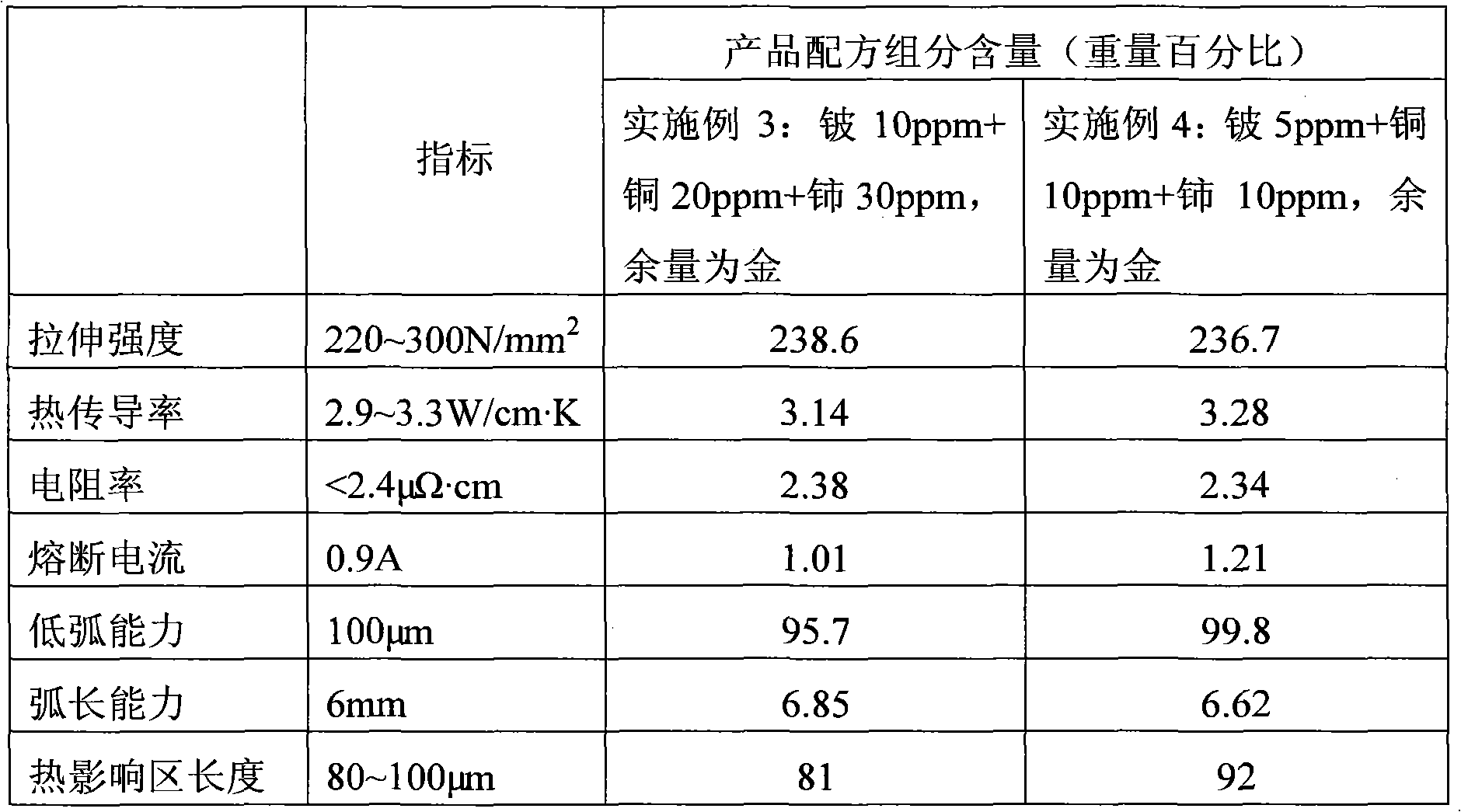

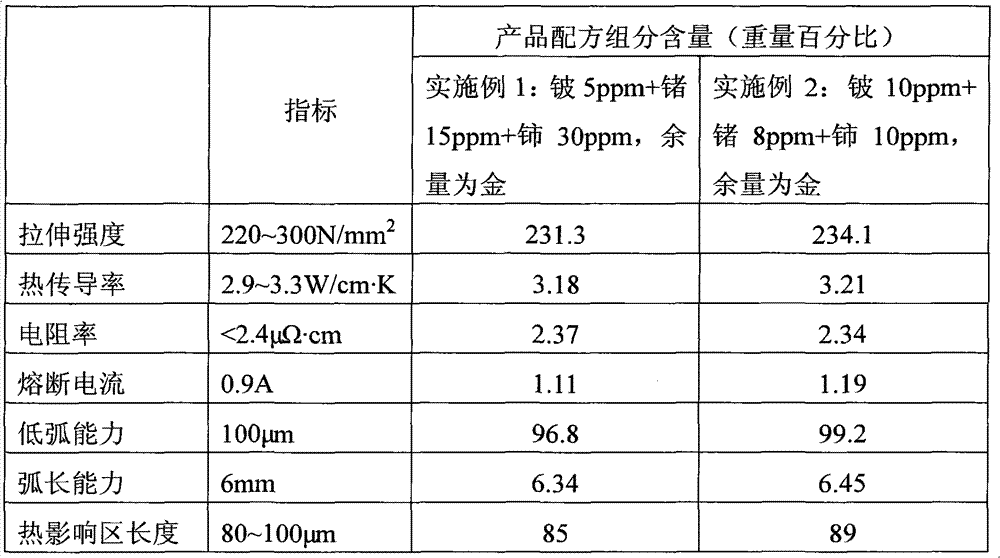

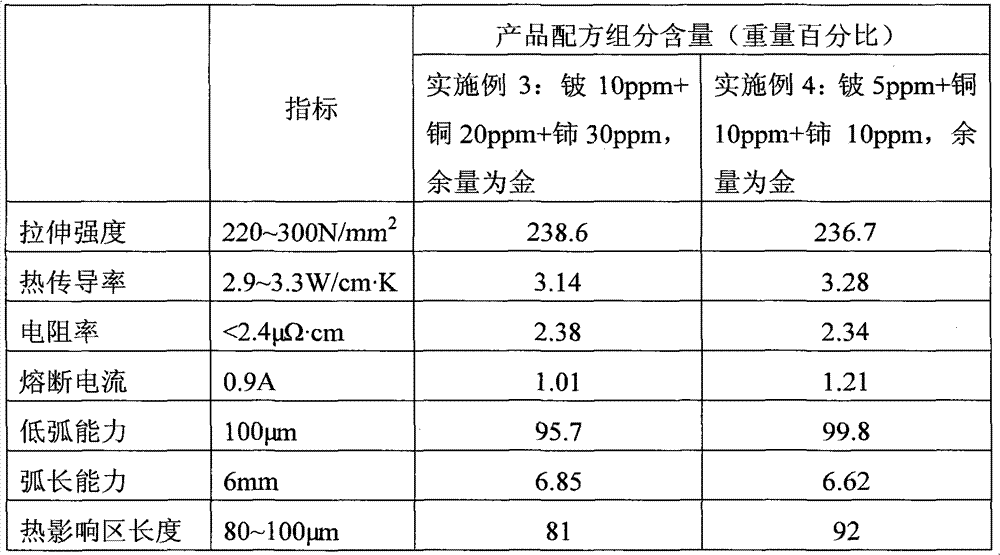

Gold bonding wire and preparation method thereof

ActiveCN102127663AHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method of the gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

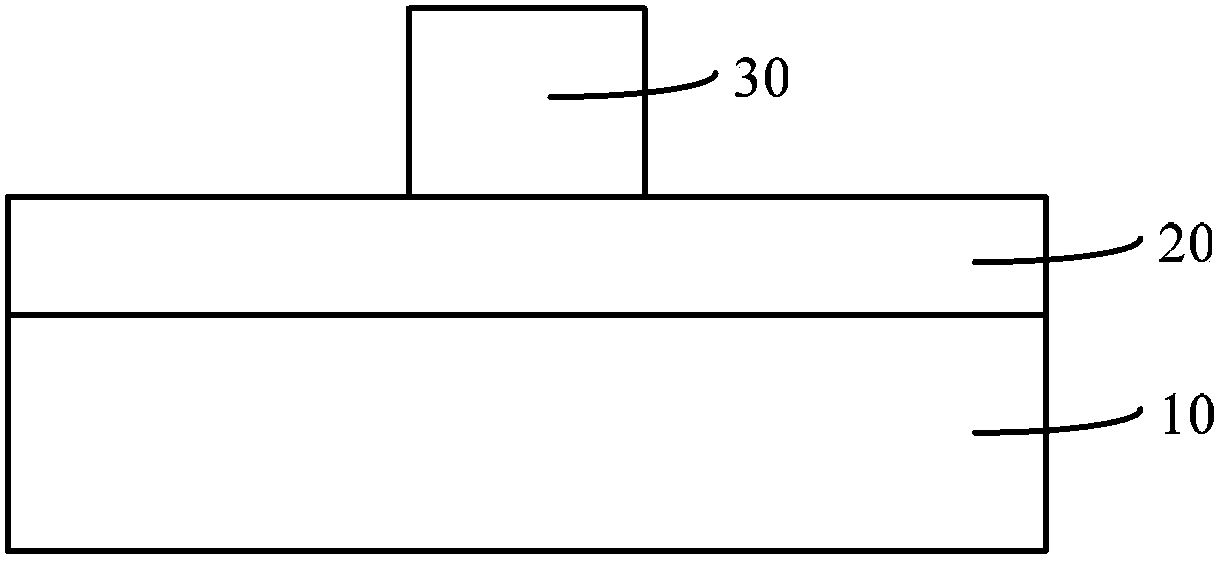

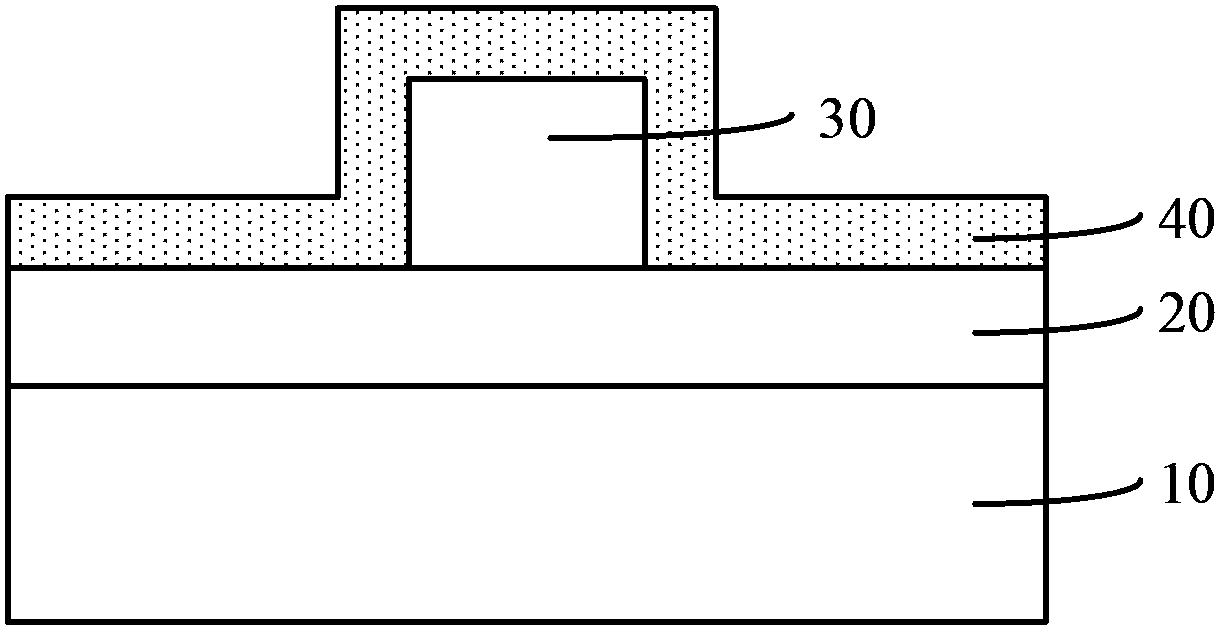

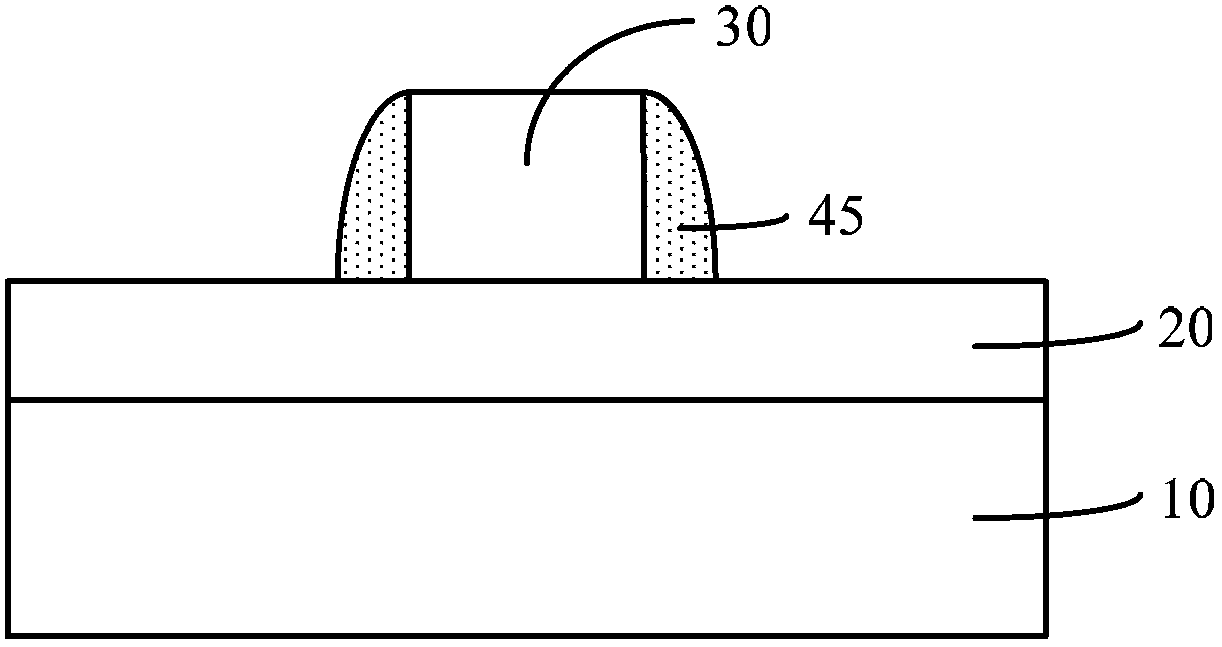

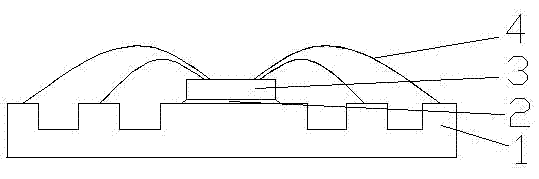

Forming method for multiple graphical mask layer and semiconductor structure

ActiveCN103578930ASmall arcMinimize the difference between topographySemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsMask layer

The invention relates to a forming method for a multiple graphical mask layer and a semiconductor structure. The forming method for the multiple graphical mask layer includes the steps that a semiconductor substrate is provided, and a material layer to be etched is formed on the semiconductor substrate; a plurality of discrete stack structures are formed on the surface of the material layer to be etched, and the stack structures comprise sacrificial layers and first mask layers located on the surfaces of the sacrificial layers; part of the sacrificial layers are etched back along the two sides of the stack structures, so that the profile image of the stack structures is in a T type; a second mask layer is formed on the surface of the material layer to be etched and covers the surfaces and the lateral walls of the T-type stack structures; the second mask layer is etched, and side walls are formed on the lateral walls of the sacrificial layers below the first mask layers of the T-type stack structures; the first mask layers and the sacrificial layers are removed, and the side walls are the multiple graphical mask layer. The side wall is formed on the lateral walls of the sacrificial layers of the T-type stack structures, so that morphology difference between lateral walls on the two sides of the side walls is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Gold bonding wire and production method thereof

ActiveCN106298721AHigh strengthShorten the lengthSemiconductor/solid-state device detailsSolid-state devicesRare-earth elementHeat-affected zone

The invention discloses a gold bonding wire and a production method thereof. The gold bonding wire comprises, by weight percentage, more than 99.99% of gold, 0.0010-0.0020% of silver, 0.0001-0.0010% of iron, 0.0005-0.0015% of lead, 0.0001-0.0010% of magnesium, 0.00010-0.0020% of copper, 0-0.0010% of silicon and 0.0003-0.0008% of rare-earth elements. The production method mainly includes: primary refining, secondary refining, continuous casting, drawing, cleaning, annealing, winding and packaging. The gold bonding wire has the advantages that the rare-earth elements are added on the basis of component optimization, process parameters are optimized, and accordingly the strength of the super-thin gold bonding wire is increased, the ductility and rupturing load of the gold bonding wire are increased, the length of a heat-affecting area is reduced greatly, radian is lowered effectively, the service life of the gold bonding wire is prolonged, and the application range of the gold bonding wire is expanded.

Owner:广东佳博电子科技有限公司

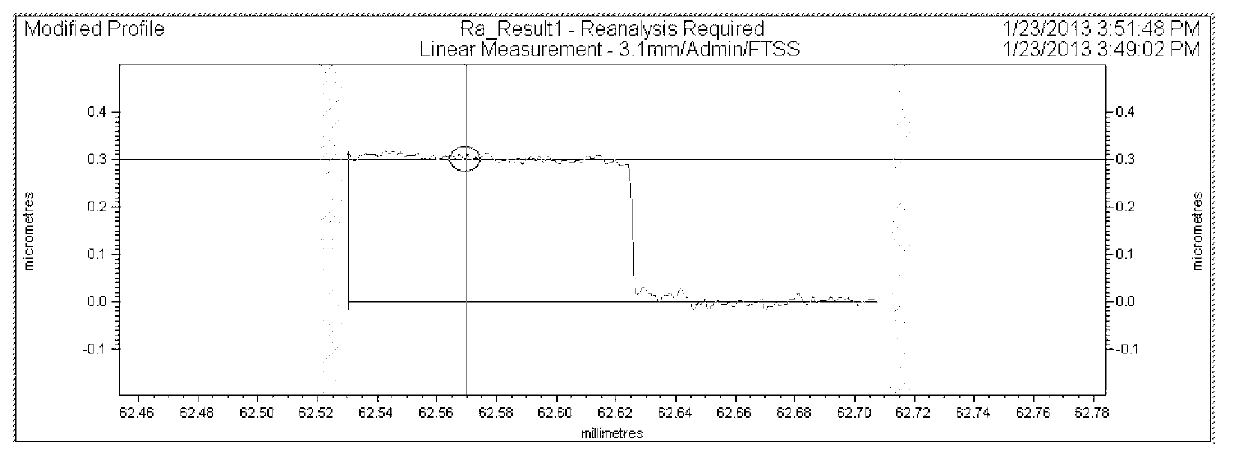

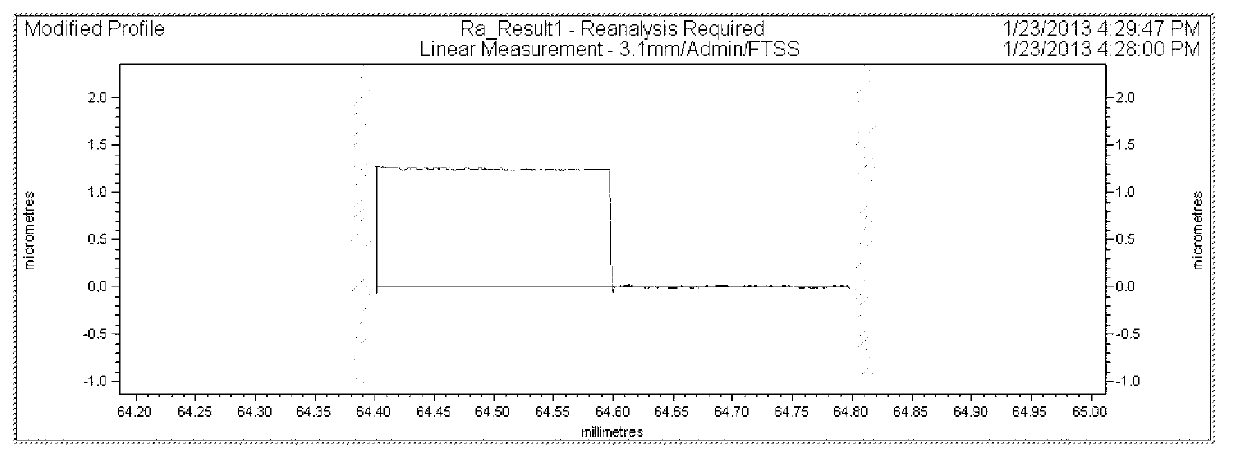

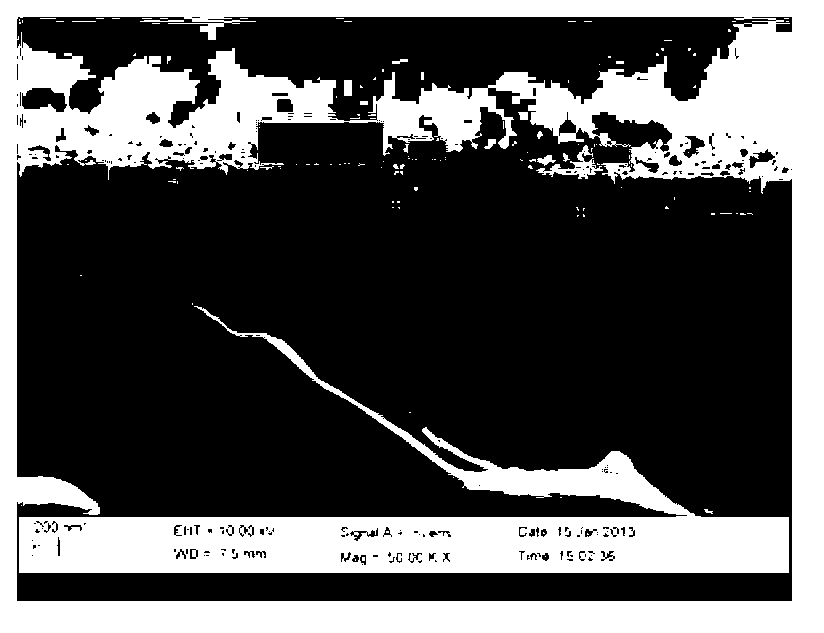

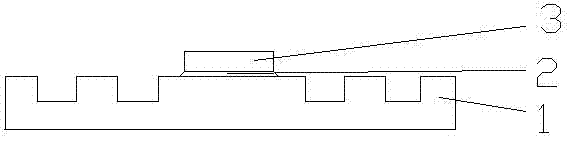

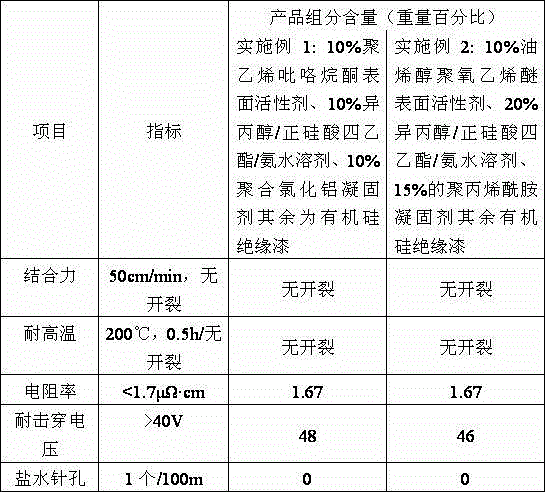

Metal film preparation method

InactiveCN103132039AFlat surfaceExcellent surface roughness Ra valueVacuum evaporation coatingSputtering coatingDiffractometerMetal substrate

The invention discloses a metal film preparation method. The method comprises the following steps: 1, coating an adhesive in a selected area on the surface of a metal substrate; 2, allowing the adhesive to stand for drying to form an adhesive layer, and coating a metal film on the surface of the metal substrate and the adhesive layer; and 3, infiltrating the metal substrate in an organic solvent after the coating completion to soften the adhesive layer, and carrying out ultrasonic treatment of the metal substrate in the organic solvent to remove the adhesive layer to obtain a metal film having a stepped structure. The adhesive is coated to protect the partial surface of the substrate, and steps are formed on the surface of the film through the adhesive removal mode, so the completeness and edge clearness of the stepped structure of the metal film are guaranteed. The metal film prepared in the invention is suitable for contourgraphs and scanning probe microscopes to measure the heights of the steps of the metal film and standardize the thickness of the film, and is also used for the metering calibration of non-contact direct thickness testers (such as X-ray diffractometers and X-ray fluorescence thickness testers).

Owner:GUANGDONG INST OF METROLOGY

Ceramic small outline package (CSOP) method

InactiveCN101740413AReduce distanceSmall arcSemiconductor/solid-state device manufacturingAviationBonding process

The invention discloses a ceramic small outline package (CSOP) method which comprises a cleaning process, a die bonding process, a bonding process, a before-package baking process, a package process and a printing process. An integrated circuit packaged by adopting the CSOP method has excellent electrical property and thermal property, small volume and light weight. The invention is widely applied to fields of aviation, astrogate and the like. When in application, solder paste is printed on a printed circuit board (PCB) welding pad, and the electrical connection is realized by sintering welding points through reflow welding.

Owner:TIANSHUI 749 ELECTRONICS

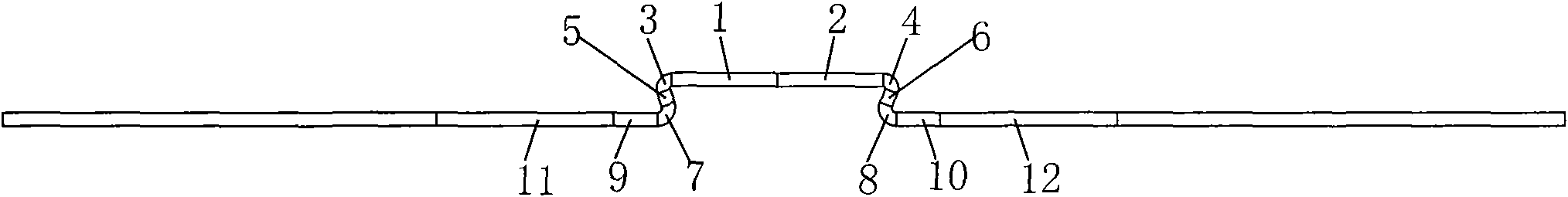

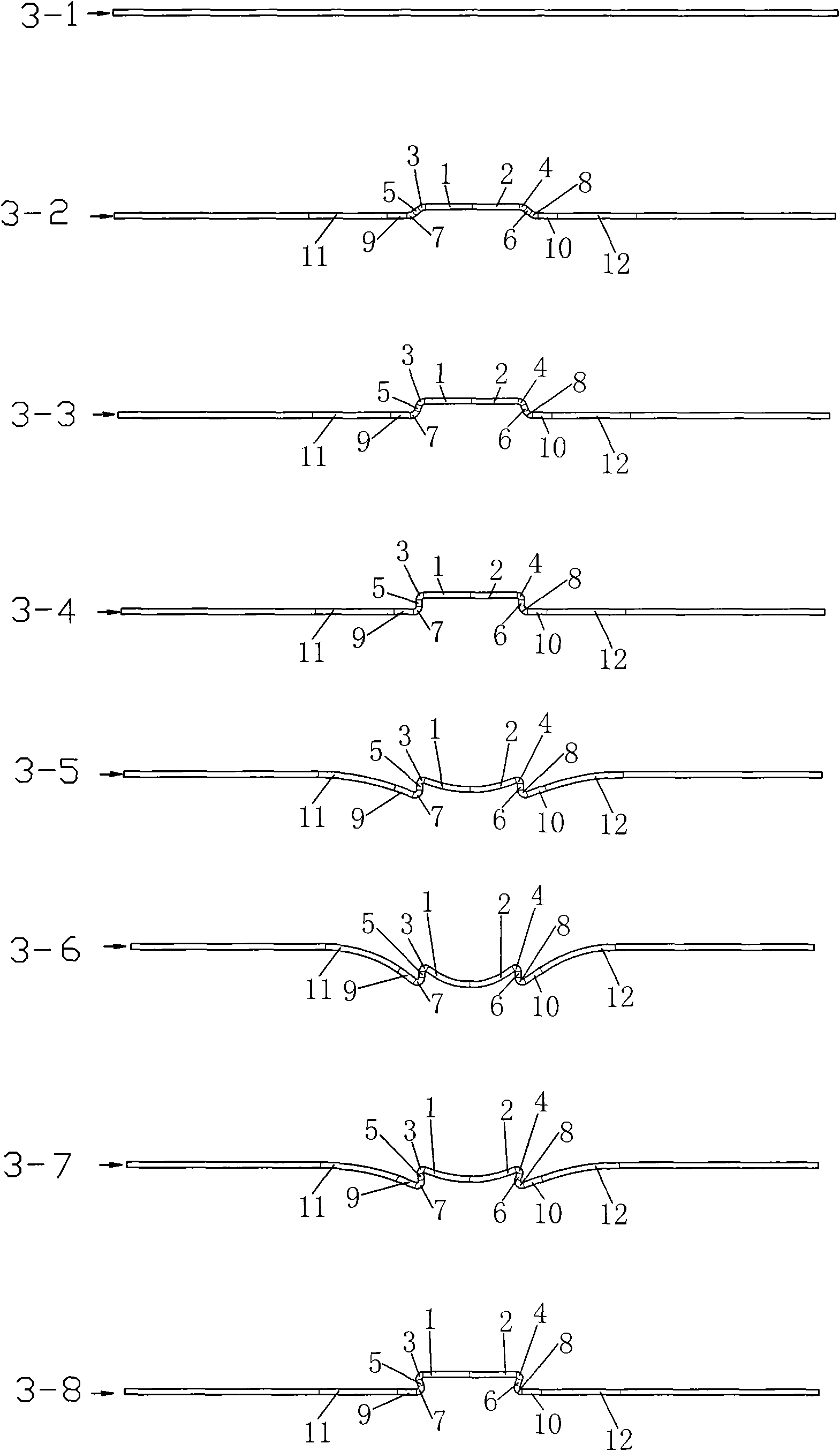

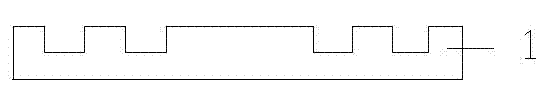

Method for cold-bending dovetail groove in fireproofing accurate steel materials and device thereof

The invention discloses a method for cold-bending dovetail groove in fireproofing accurate steel materials or other metal materials, the materials comprise right angle grooves of which the steel strip longitudinal roller is bent to be in cap shape, and the top part and the lateral part of the groove is bent backwards to arc shape until the bend angle achieves the requirements of the dovetail angle according to the product requirement, the arc part of the top part and the lateral part of the groove is pressed and planished ; the invention also discloses the equipment suitable for the method, as the bent section of the steel plate is located at the radial face of the roller, therefore, the bent point can be exerted with sufficient forming pressure with ease, the arc of the bent point is small, the equipment is simplified, and the production is stable and the forming speed is fast.

Owner:甘肃金刚玻璃科技股份有限公司 +1

Copper linking wire and production method thereof

InactiveCN101487090ASmall arcReduce hardnessSolid-state devicesSemiconductor devicesCopper wireMiniaturization

The invention discloses a copper bonding wire and the weight percentages of components in the copper bonding wire are as follows: La accounts for 0.0008 to 0.002 wt percent, Ce accounts for 0.001 to 0.003 wt percent, Ca accounts for 0.002 to 0.004 wt percent, and Cu accounts for 99.99 to 99.995 percent. The copper bonding wire has low trajectory, low hardness and good oxidation resistance and avoids the oxidation of the copper bonding wire at normal temperature, so the copper wire can be stored for a long term at normal temperature, and the method can also meet the demand of high performance, multifunction, miniaturization and portable development of electronic packaging.

Owner:HENAN YOUK ELECTRONICS MATERIALS

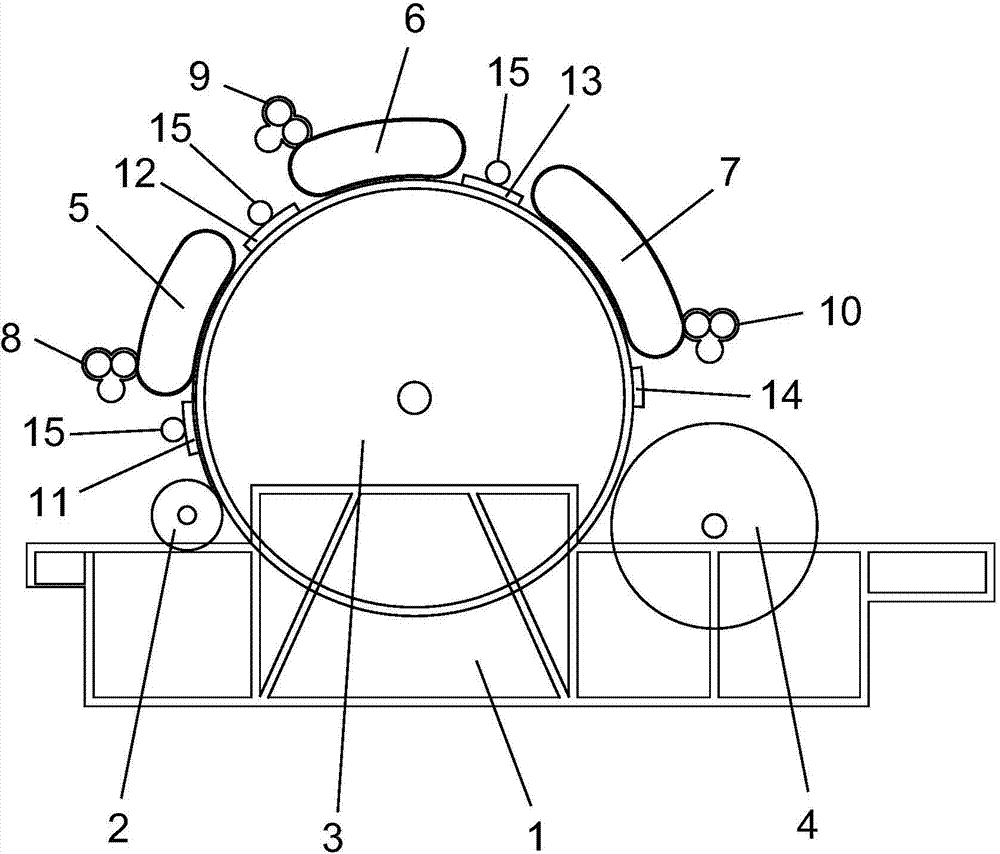

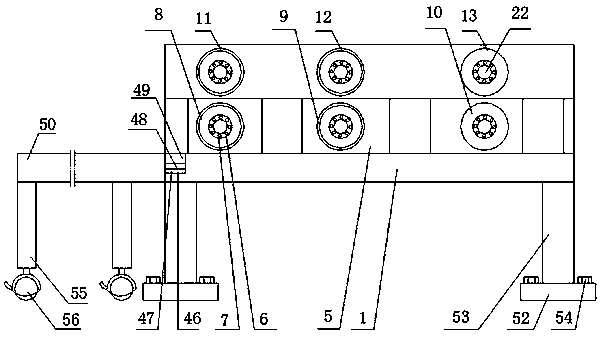

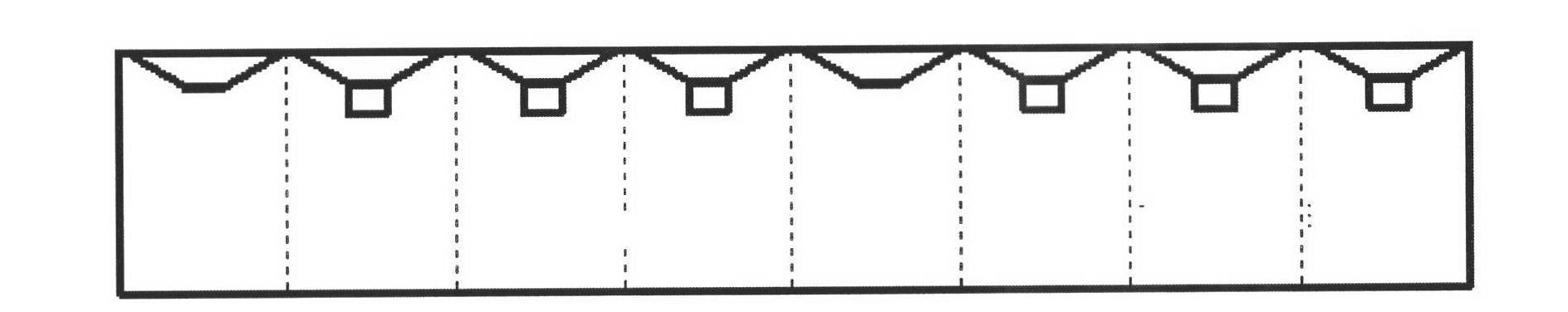

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

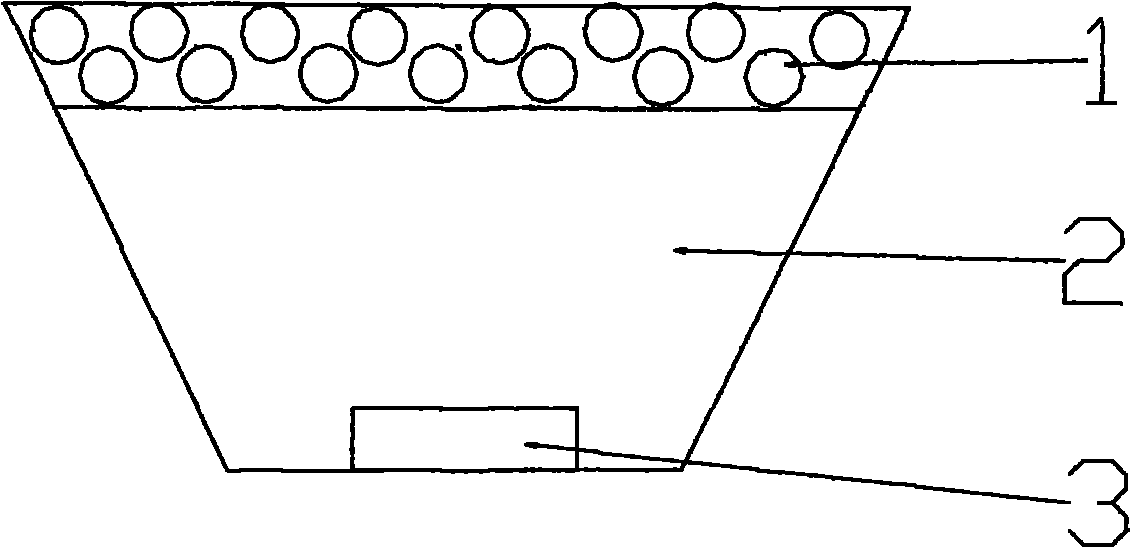

Split flange feeding gate of electronic quantitative weigh

InactiveCN1544893AShorten the opening and closing timeOpening and closing time is appropriateWeighing apparatus with automatic feed/dischargeDrive shaftEngineering

The invention provides an opposite feeding door of electronic determining weigh, including driving device installed on the frame, feeding door mechanism, and driving mechanism connected between feeding door and driving device, where the feeding door mechanism is composed of two feeding doors which are connected with each other through shaft and blanking cylinder, the driving mechanism includes a driving shaft with one end connected with the driving device and the other end installed on the frame through bearing, there is a swing block installed on the driving shaft, the upper and lower feeding doors are hinged with the inner and outer pull rods, respectively, the other two ends of the inner and outer pull rods are hinged with the swing block, respectively. It can cooperate with the high-speed weighing electronic determining weigh, implementing high speed multistage feeding.

Owner:HARBIN BOSHI AUTOMATION

AAQFN package part using electroplating process and manufacture process thereof

InactiveCN103094235AEliminate reflow soldering processReduce consumptionElectrolytic coatingsSemiconductor/solid-state device detailsSolder maskSolder ball

The invention discloses an AAQFN package part using an electroplating process and a manufacture process thereof. The package part is mainly composed of a copper lead framework, adhesive tape glue, a chip, a bonding wire, a plastic package material, a solder mask layer and a solder ball. The copper lead is etched to be adhered with the chip through the adhesive tape glue, the chip is connected with a pin of the copper lead framework through the bonding line and plastically packed by the plastic package materials, the solder mask layer is filled in a pin gap etched at the bottom of the copper lead framework, and the solder ball is electroplated on the pin. The manufacture process mainly comprises the following steps of semi etching a copper framework, thinning a wafer, scratching a wafer, bonding the chip, press soldering, plastically packing, framing, etching at the back, brushing the solder mask layer at the back, electroplating the solder ball and cutting. The manufacture process saves package cost and improves electric performance and product reliability.

Owner:HUATIAN TECH XIAN

4N bonding gold wire capable of being processed to phi 6 micrometers through wire drawing and preparation method of 4N bonding gold wire

ActiveCN111254311AHigh tensile strengthSmall arcPolycrystalline material growthFrom frozen solutionsSingle crystalAlloy

The invention belongs to the technical field of bonding gold wire processing, in particular to a 4N bonding gold wire capable of being processed to phi 6 micrometers through wire drawing and a preparation method of the 4N bonding gold wire. The 4N bonding gold wire comprises gold and an alloy additive. The alloy additive is formed by copper, vanadium, magnesium, palladium, silver, nickel, bismuth,beryllium, cerium, zinc, yttrium, calcium, gadolinium, aluminum and lead. According to the prepared bonding gold wire, the alloy additive of the specific components and content is added, the drawingstrength of the gold wire can be improved through the alloy additive, and the radian of the bonding gold wire can be reduced; the prepared bonding gold wire has the good low and long radian through adding of the additive and the reasonable proportion while guaranteeing high strength; the prepared gold wire has good drawing strength, heat conductivity, resistance and low and long arc length; and meanwhile, axial long crystals are formed after a single-crystal continuous casting method is adopted for casting, high purity and a continuous columnar crystal structure are achieved, a transverse crystal boundary is eliminated, casting defects are avoided, and the prepared gold wire can be processed to 6 micrometers.

Owner:上杭县紫金佳博电子新材料科技有限公司

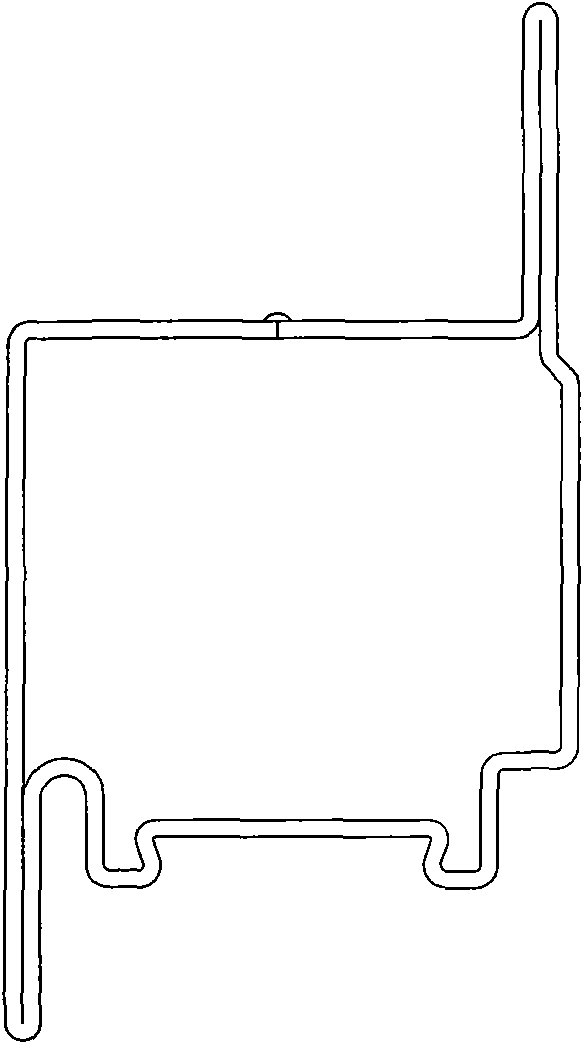

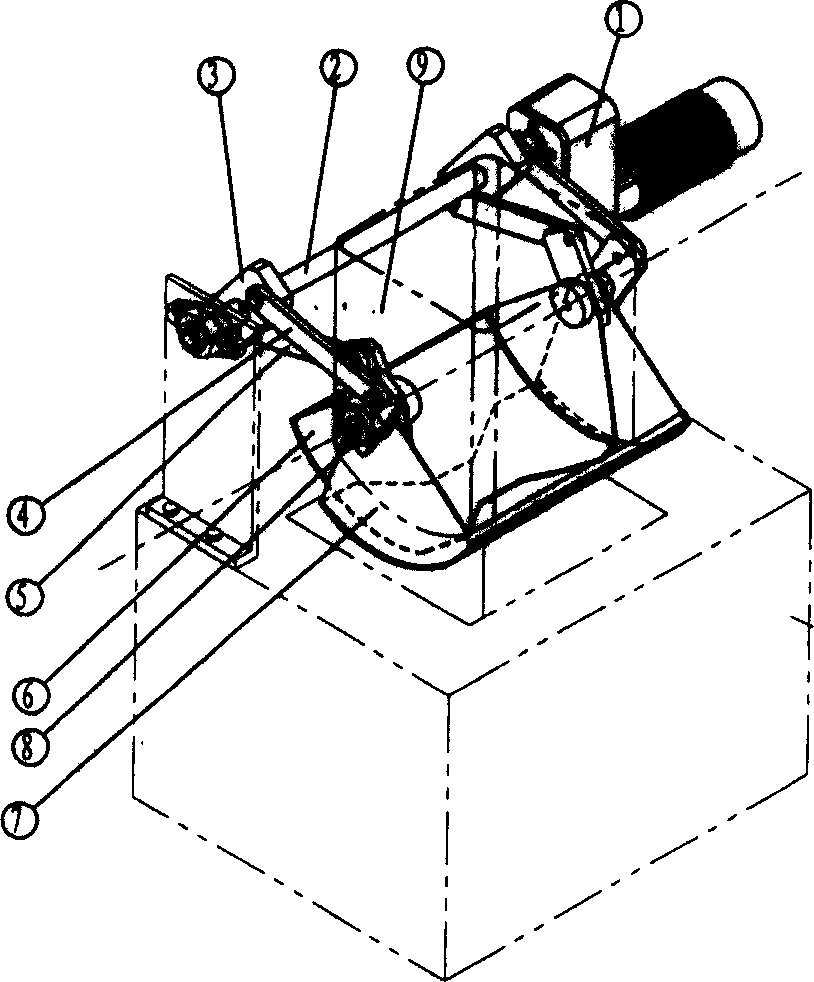

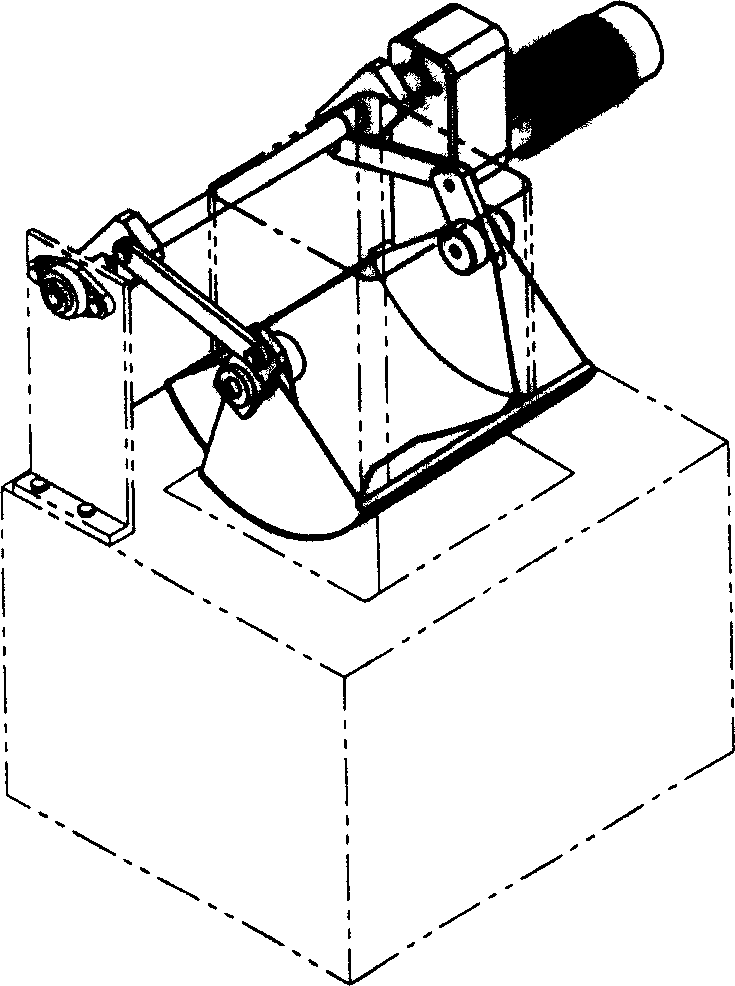

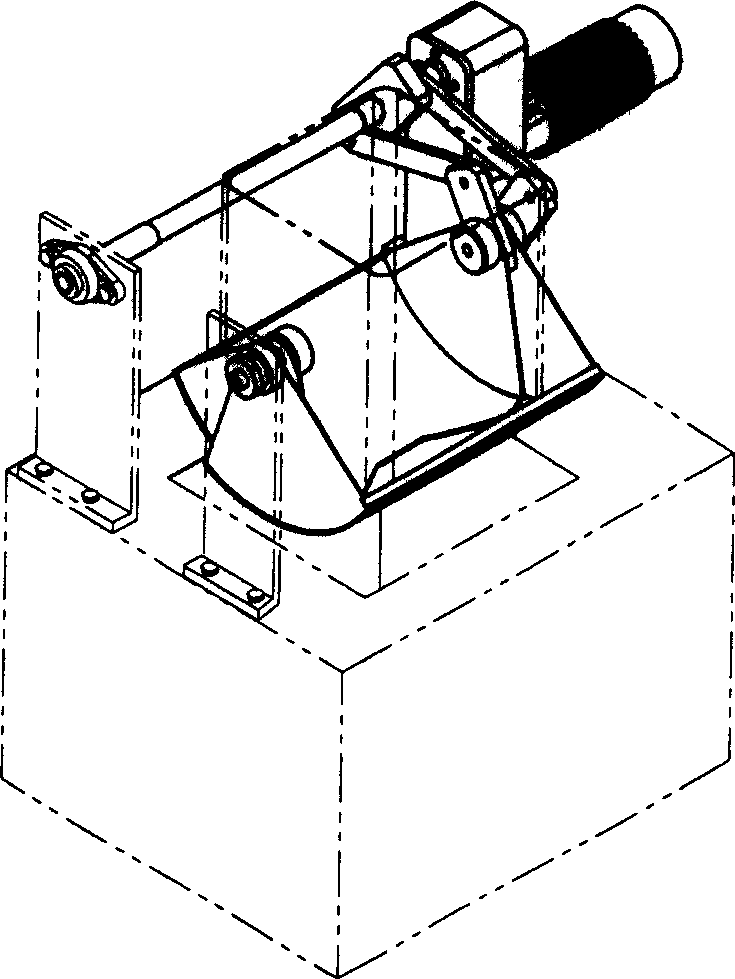

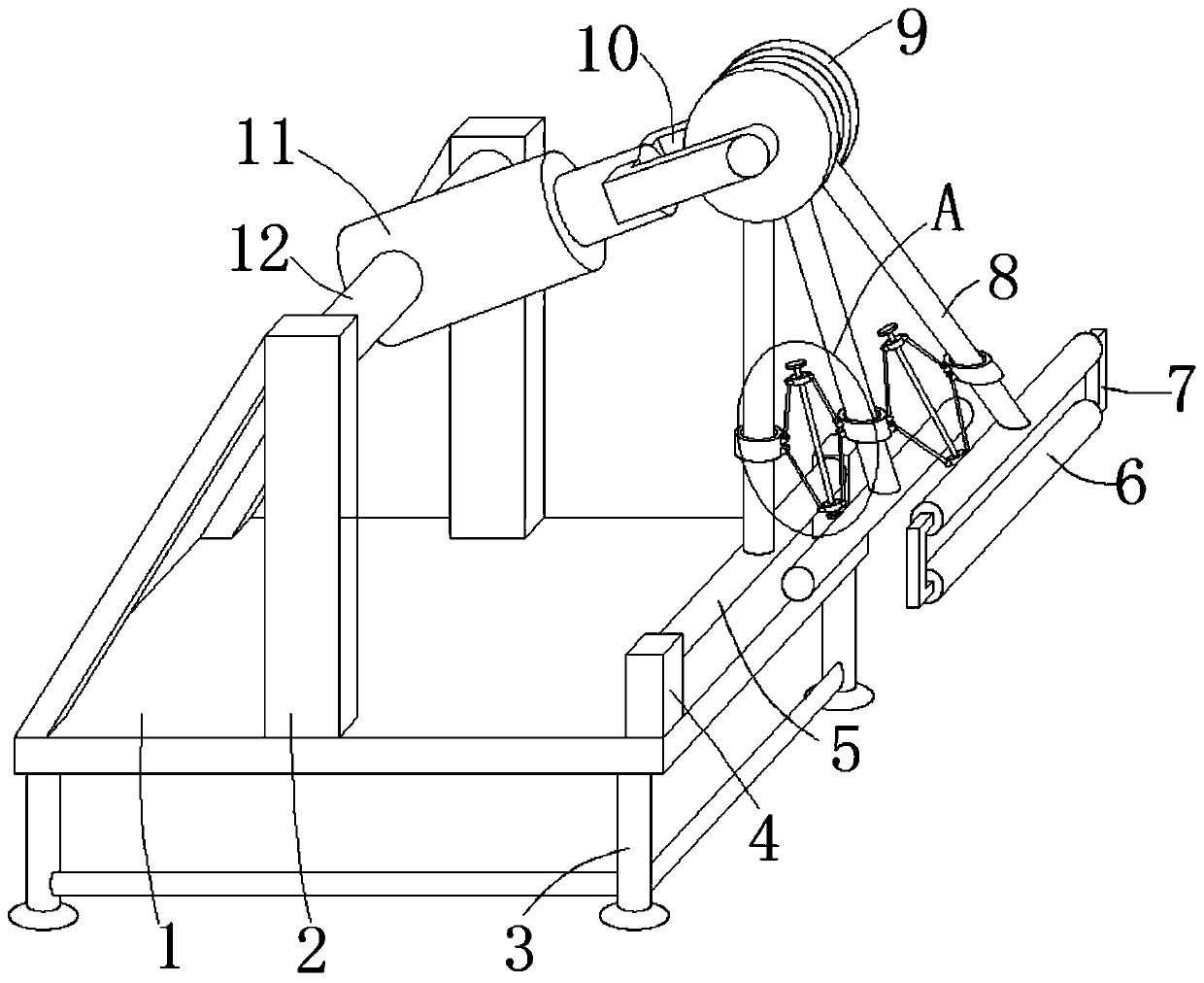

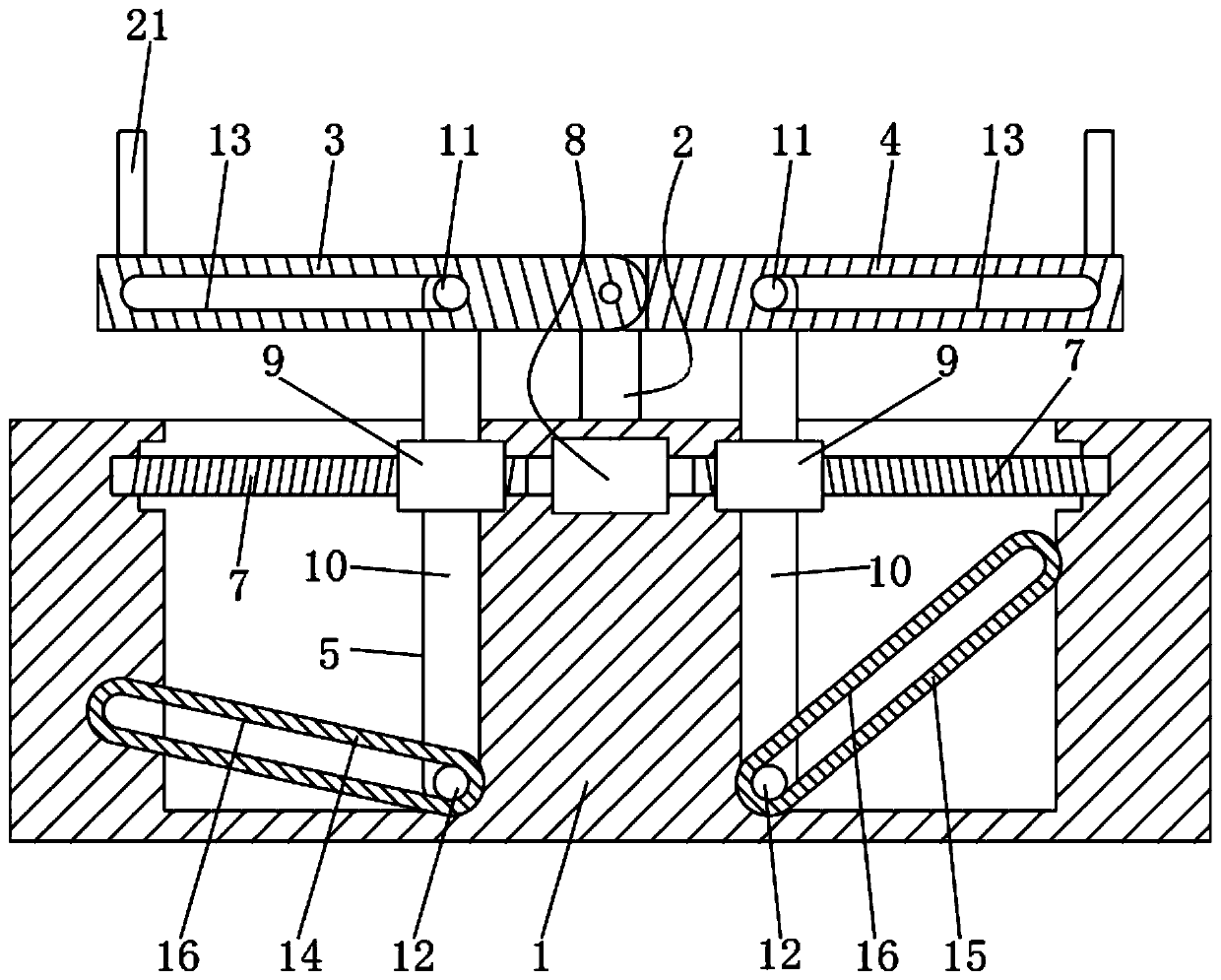

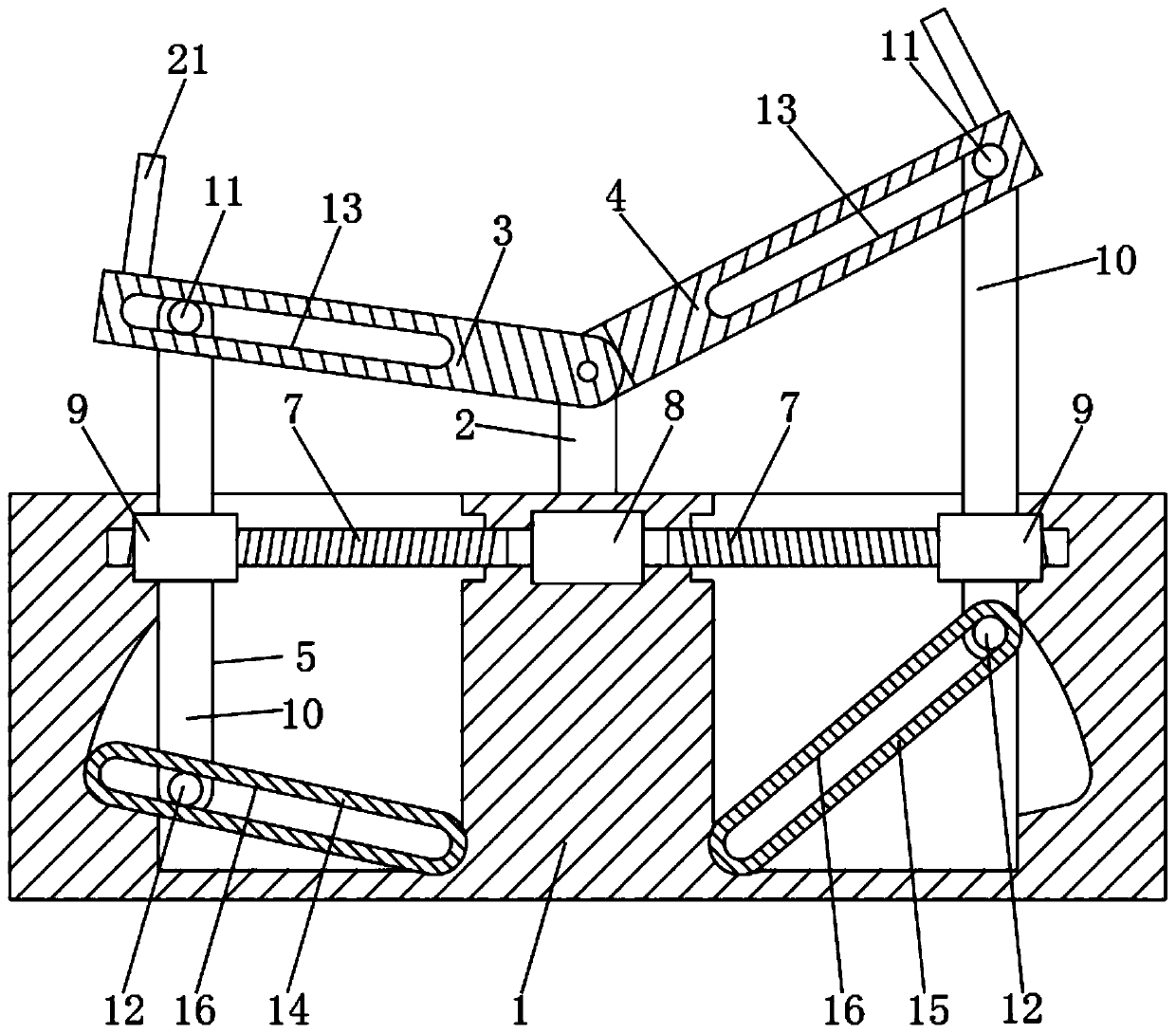

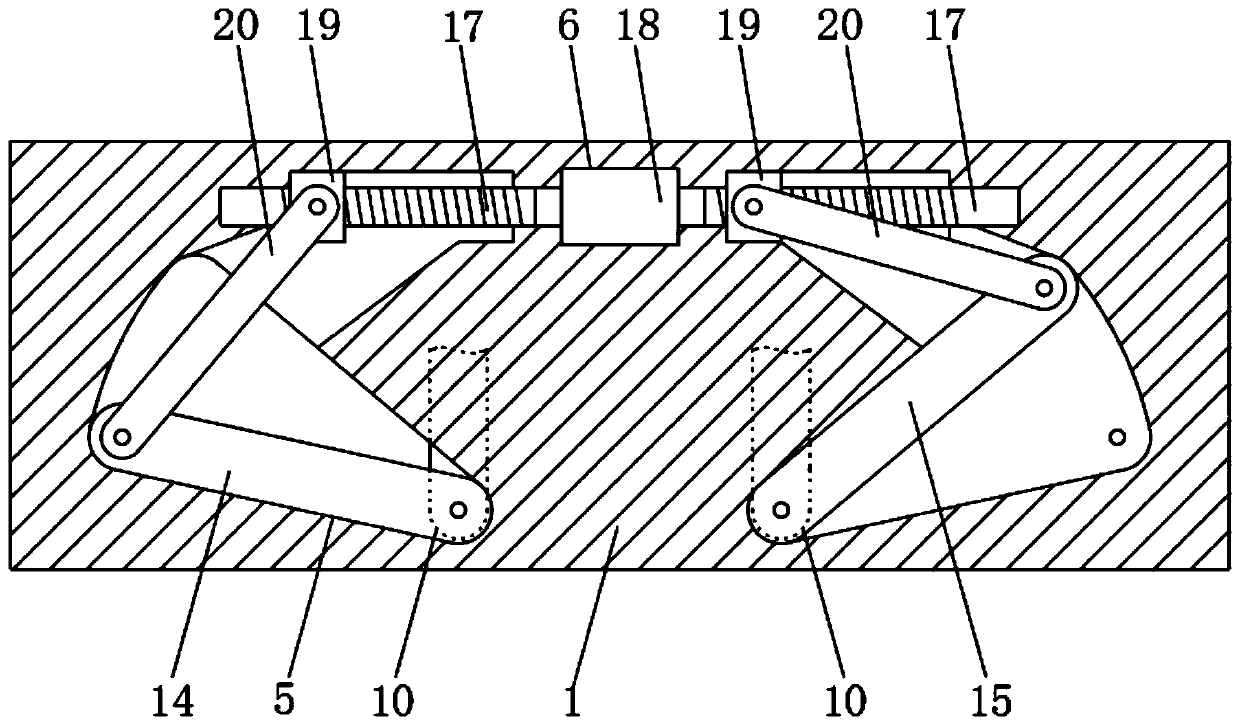

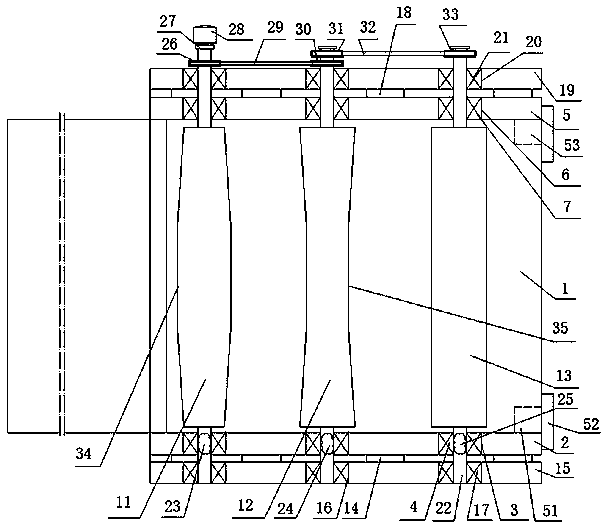

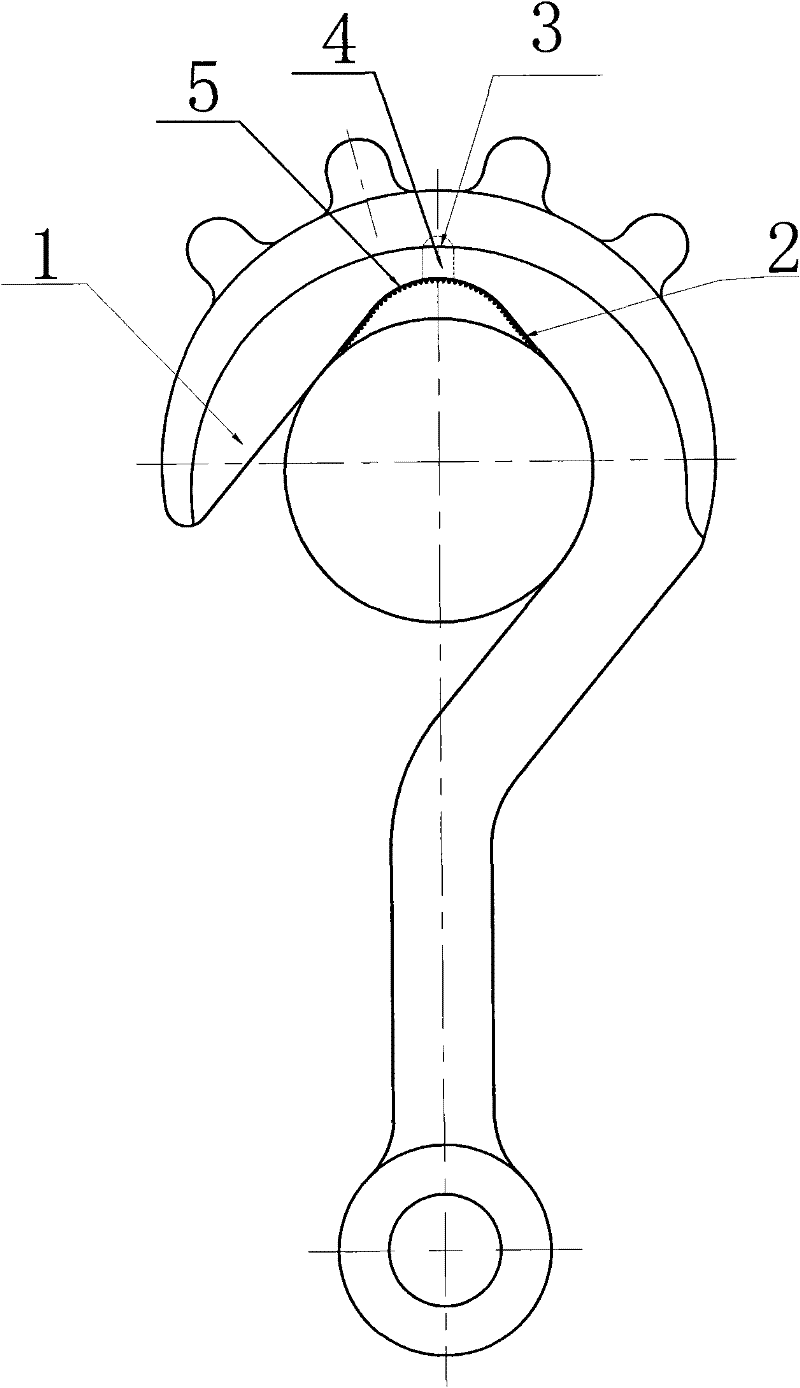

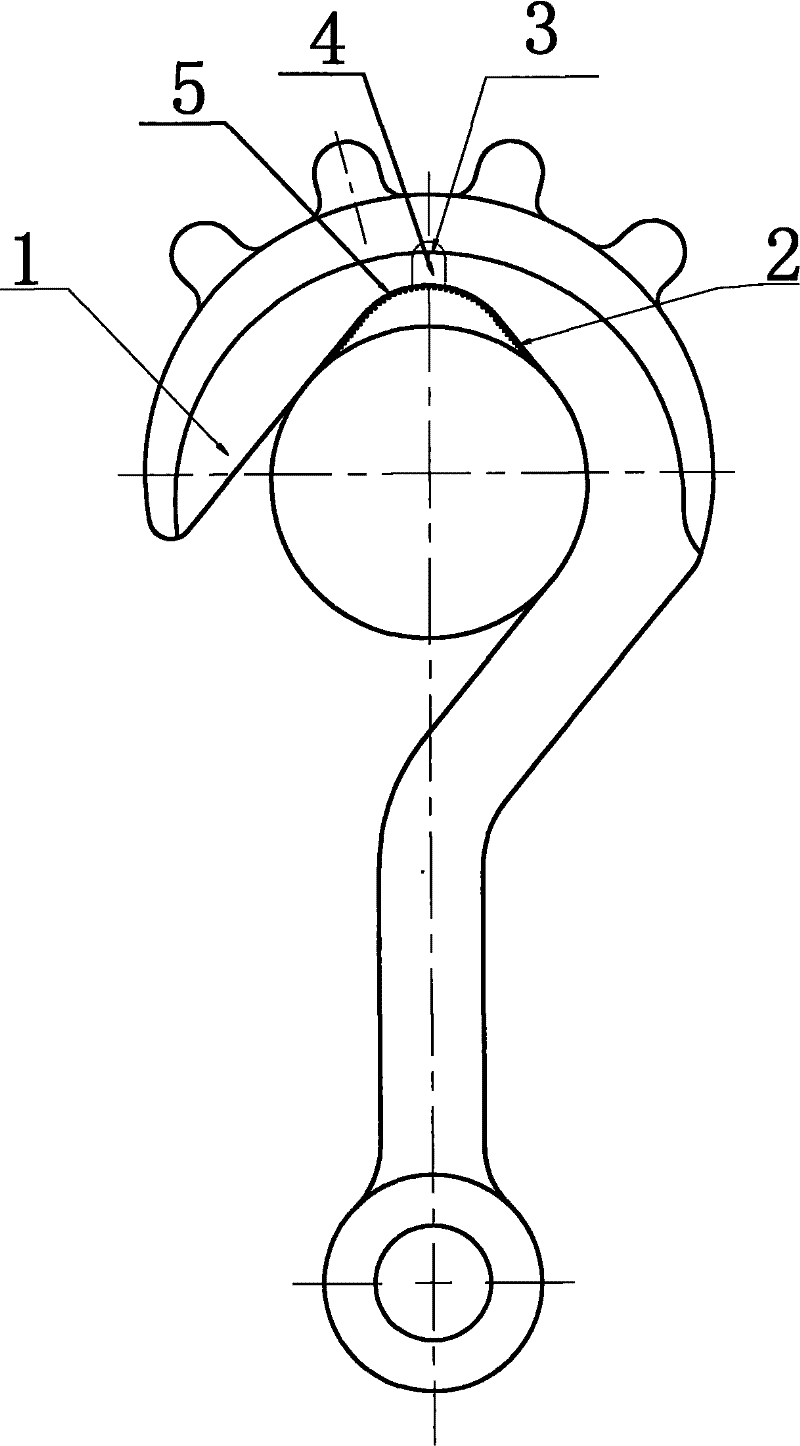

Mould frame bending machine

The invention discloses a mould frame bending machine. The mould frame bending machine comprises a bending base and a plurality of adjusting mechanisms, wherein front and rear sides of the top end surface of the bending base are perpendicularly equipped with supporting stand columns; the tip end of a hydraulic cylinder is rotatably hinged with an inverted-H-shaped wheel through a connecting frame;a plurality of slide blocks are blocked between two ring-shaped slide slots in a sliding mode; the outer wall of each slide block is welded with a regulating rod in a radial direction of the inverted-H-shaped wheel; the outer wall of each regulating rod is in sliding sleeving connection to a hollow sleeve; each regulating mechanism is separately positioned on a position between adjacent two hollow sleeves; the bottom end of each regulating rod is welded with a bending guide rod which is distributed in the horizontal direction; front and rear ends of the bending guide rod at the leftmost sideare rotatably arranged on the right side of the top end surface of the bending base through hinged frames; front and rear ends of the bending guide rod at the rightmost side are perpendicularly equipped with hanging rods; and a rolling guide rod is rotatably arranged between side walls of the bottom ends of the two hanging rods. The mould frame bending machine disclosed by the invention conveniently meets bending operation, with different bending needs, of a mould frame.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

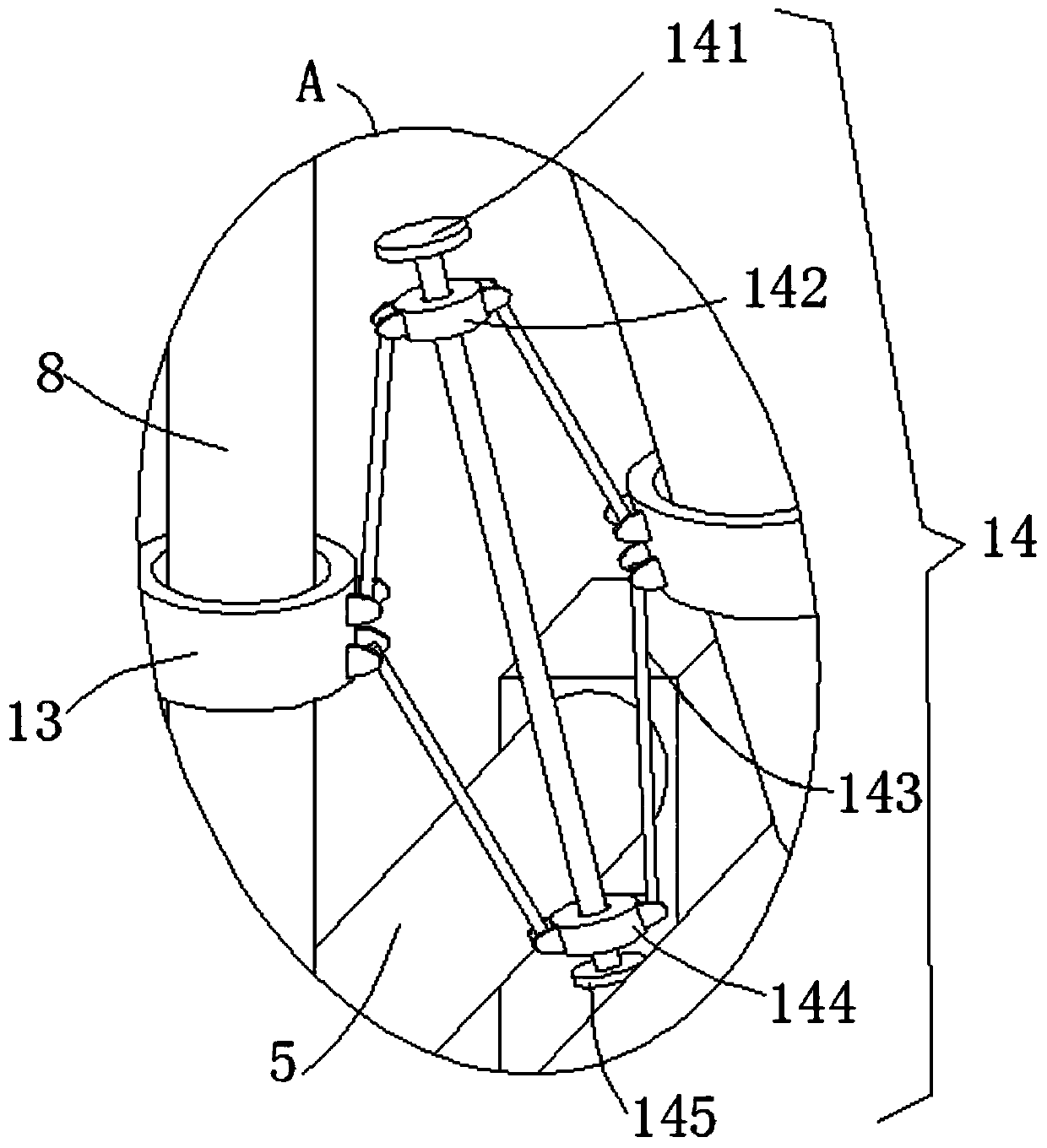

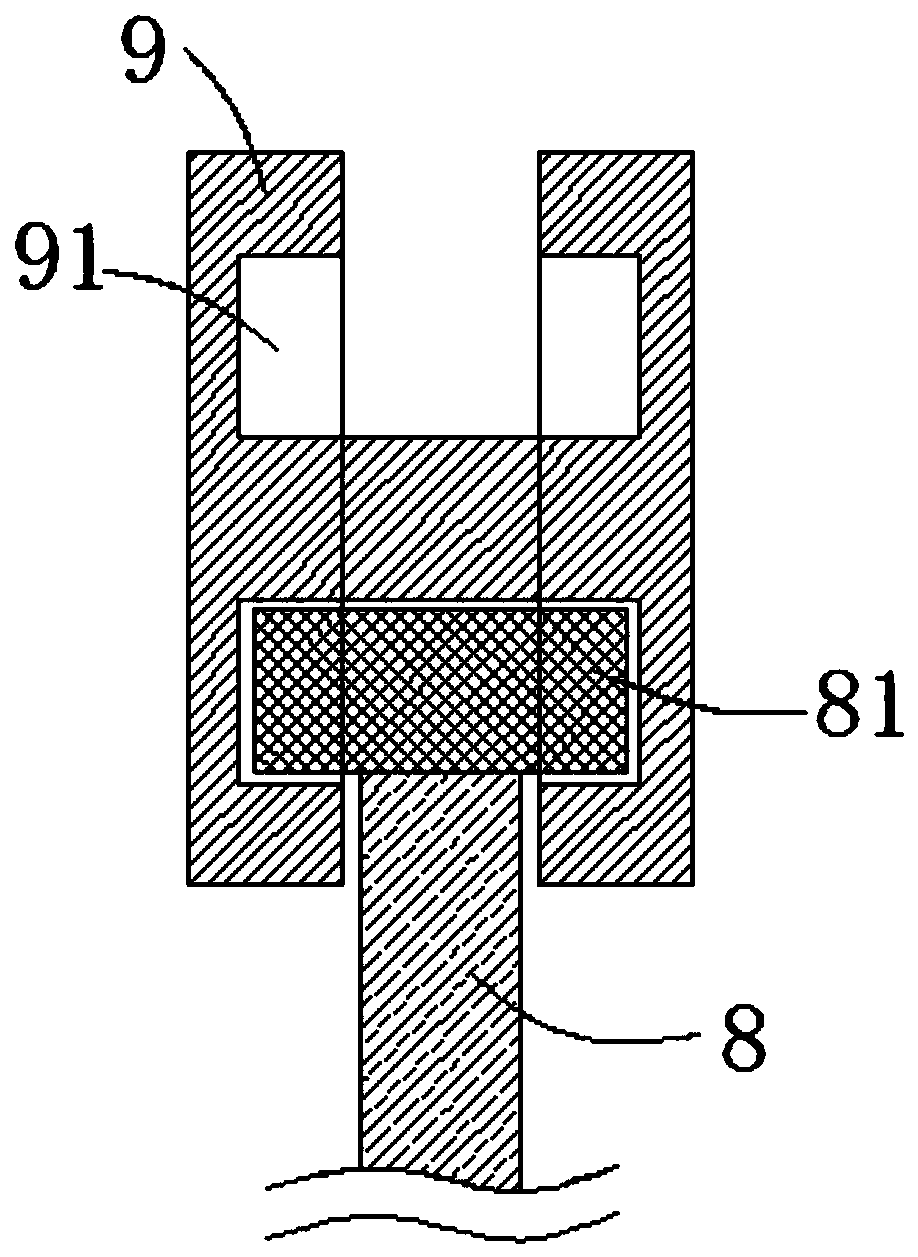

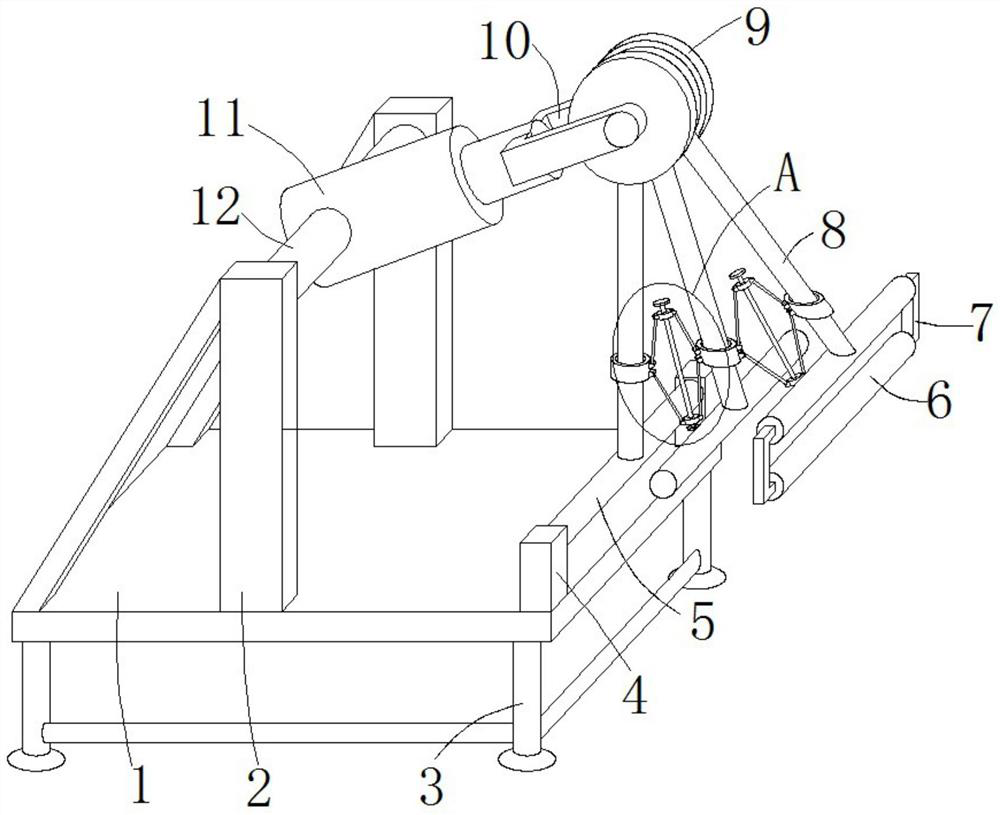

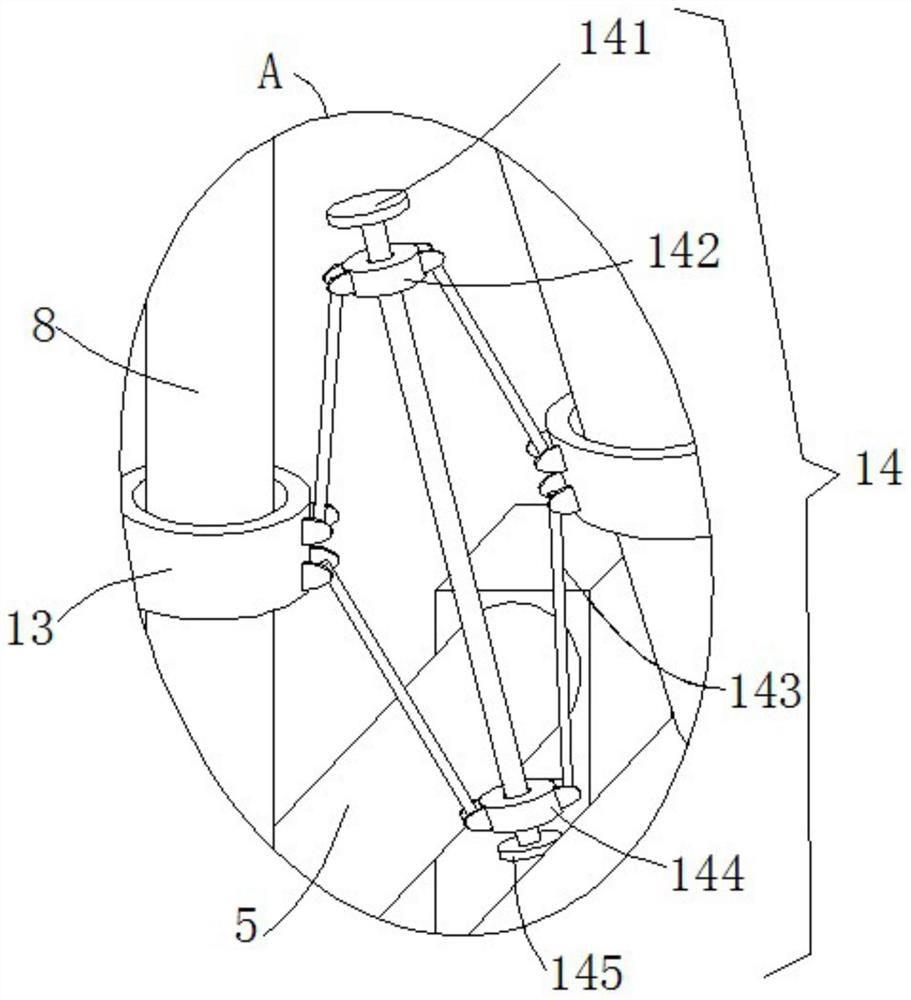

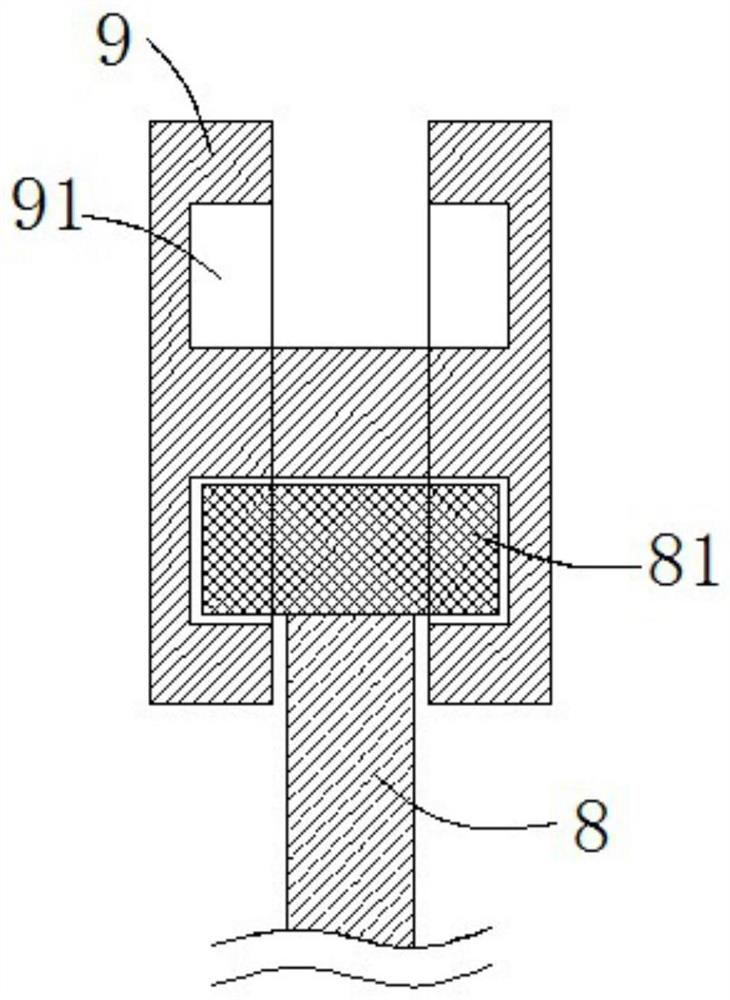

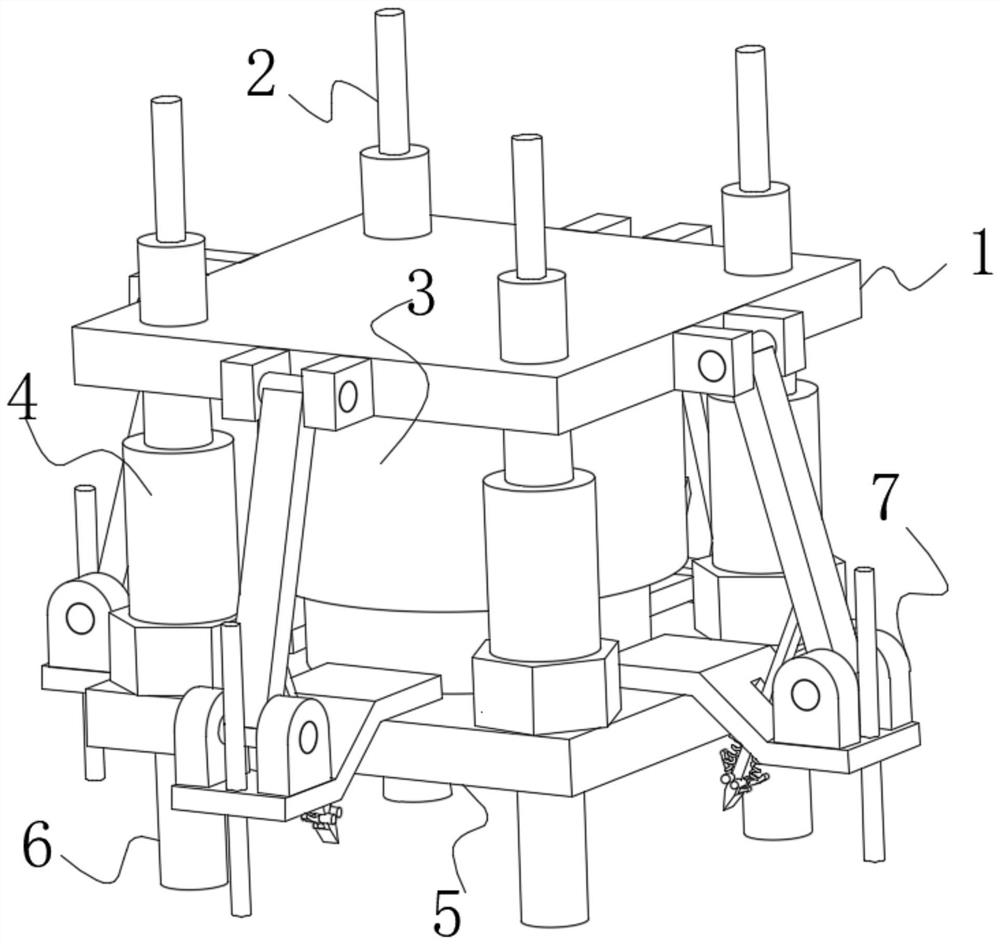

A formwork bending machine

Disclosed is a mold frame bending machine, comprising a bending base (1) and a plurality of adjusting mechanisms (14), wherein the front side and the rear side of the top end face of the bending base are respectively vertically provided with a supporting stand column (2); the tip end of a hydraulic cylinder (11) is rotatably provided with an I-shaped wheel (9) in a hinged manner by means of a connecting frame (10); a plurality of sliding blocks (81) are slidably clamped between two annular sliding grooves (91) formed in the inner side of the I-shaped wheel; the outer wall of each sliding block is provided with an adjustment rod (8) in a welded manner in the radial direction of the I-shaped wheel; the outer wall of each adjustment rod is slidably sheathed in a hollow sleeve (13); each adjusting mechanism is located at a position between every two adjacent hollow sleeves; a bending guide rod (5) that is distributed at the front and back is welded to the bottom end of each adjustment rod; the front end and the rear end of the bending guide rod at the far left are rotatably arranged on the right side of the top end face of the bending base by means of a hinge frame (4); the front end and the rear end of the bending guide rod at the far right are respectively provided with a hanging rod (7) in a perpendicular manner; and a rolling guide rod (6) is rotatably arranged between the side walls of the bottom ends of the two hanging rods. The mold frame bending machine facilitates the achievement of the bending operation on mold frames with various bending requirements.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

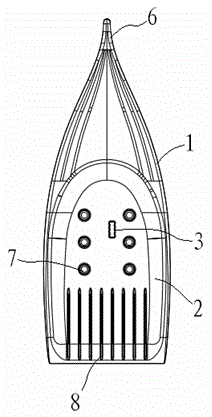

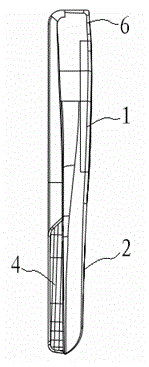

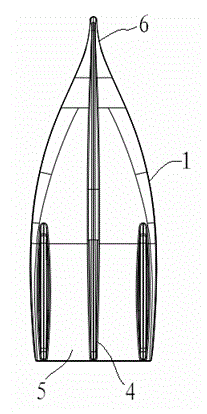

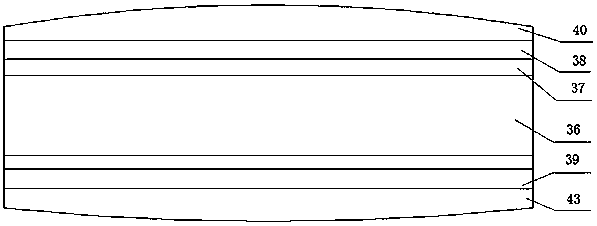

Rotational molding surfboard and manufacturing technology thereof

InactiveCN104139835AReduce resistanceChange the height of the arc and use the defectWaterborne vesselsCoatingsSurfboardingEngineering

The invention discloses a rotational molding surfboard and a manufacturing technology of the rotational molding surfboard. The rotational molding surfboard comprises a surfboard body, wherein the surfboard body is of a hollow structure with the front pointed and the rear blunt and is in the shape of a leaf, a streamlined concave portion is arranged on the top of the surfboard body, a plurality of convex tail fins are arranged at the bottom of the surfboard body, and a finished product of the surfboard is made through rotational molding hollow mold opening, material feeding, heating and rotation, forming and mold release, spraying, cooling, mold release and edge scraping processing. The rotational molding surfboard is simple in structure; because the rotational molding surfboard is provided with the tail fins, the effects that the surfboard is safe, durable and easy to operate can be achieved, production efficiency of the surfboard is improved, technological operation difficulty is reduced, and the purposes of standardization and batching are achieved.

Owner:佛山市顺德区和鼎塑料制品有限公司

Antioxidation bonding copper wire and method for preparing same

ActiveCN104835798AHigh elongationImprove high temperature strengthSemiconductor/solid-state device detailsSolid-state devicesCopper wireOrganic matter

The present invention discloses an antioxidation bonding copper wire, and the surface of the copper wire is coated with an organic matter layer of which the thickness is between 5 nanometers and 60 nanometers. The present invention also discloses a method for preparing the antioxidation bonding copper wire. The method comprises the steps of purification, alloy making, vertical smelting, wire drawing, annealing, coating and packaging. The antioxidation bonding copper wire prepared by the method possesses a better low long radian, and can be prevented from being oxidized effectively, so that the prepared bonding copper wire is not oxidized during the storage and transportation. Moreover, a coating material can withstand a high temperature more than 200 DEG C, thereby solving the copper wire oxidation problem effectively.

Owner:SHANDONG KEDADINGXIN ELECTRONICS TECH

Postoperative nursing bed for thoracic surgery

The invention discloses a postoperative nursing bed for thoracic surgery, and belongs to the technical field of hospital bed care. The postoperative nursing bed includes a supporting shell, two supporting seats are fixedly connected to the upper surface, close to the middle part, of the supporting shell, and a side-turning mechanism and an adjustment mechanism are fixedly installed on the inner wall of the supporting shell. According to the postoperative nursing bed, through the cooperation between the structures, two bed boards can be turned over simultaneously by being controlled by a singledrive mechanism, so that the side slipping phenomenon can be prevented during the process of turning a patient to one side while the patient is turned to the side, possible dangers are avoided, meanwhile, the turning-over speed of the bed board on the side for turning the patient on the side is slower relative to that of the bed board on the other side and the arc is smaller, it is ensured that the patient cannot be squeezed and crushed by the angle between the two bed boards, and the problems that the patient lies on his side only with the help of family members or medical personnel at present, a wound of the patient is prone to being injured through artificial methods, and the side-turning process is more troublesome are solved.

Owner:李素霞

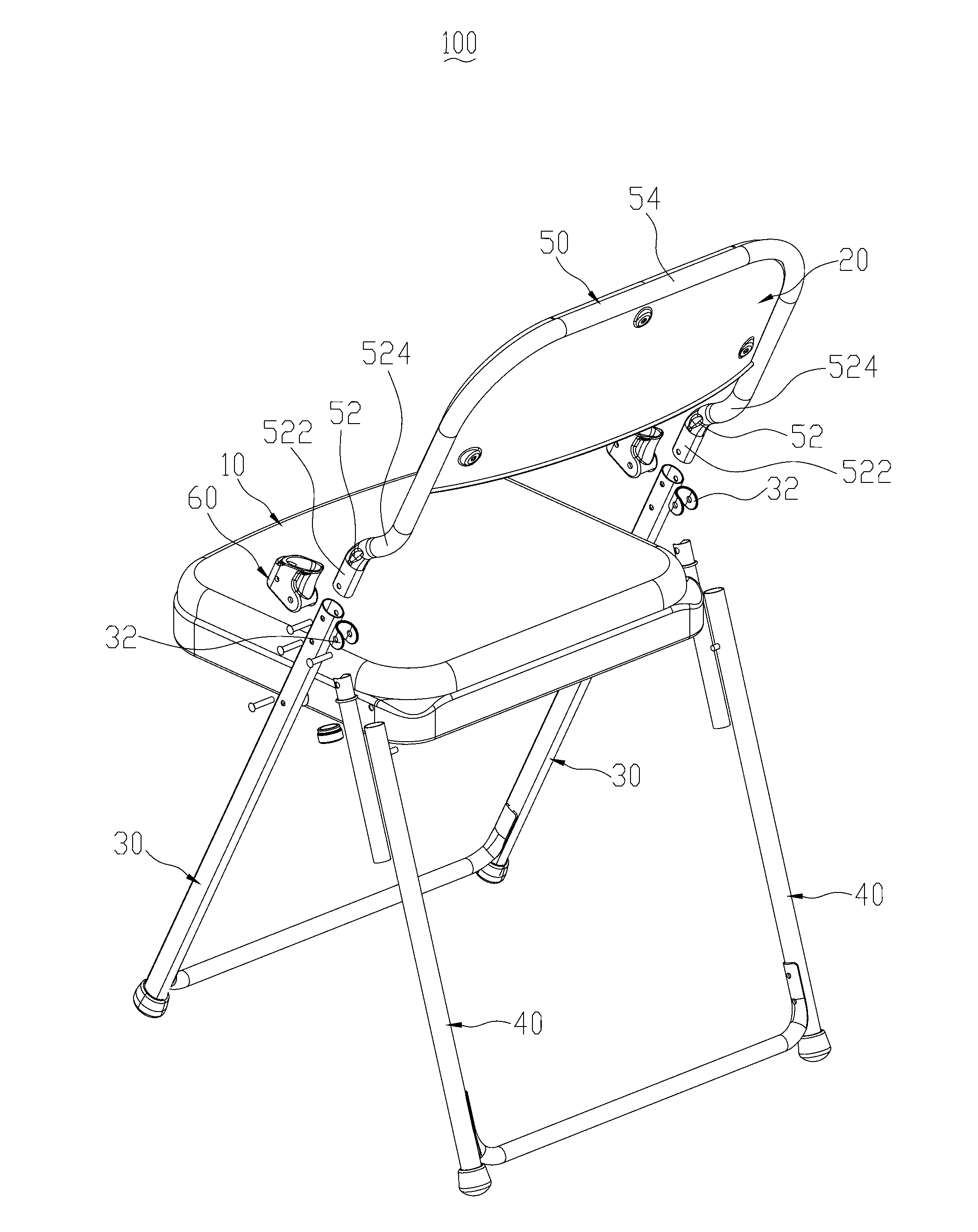

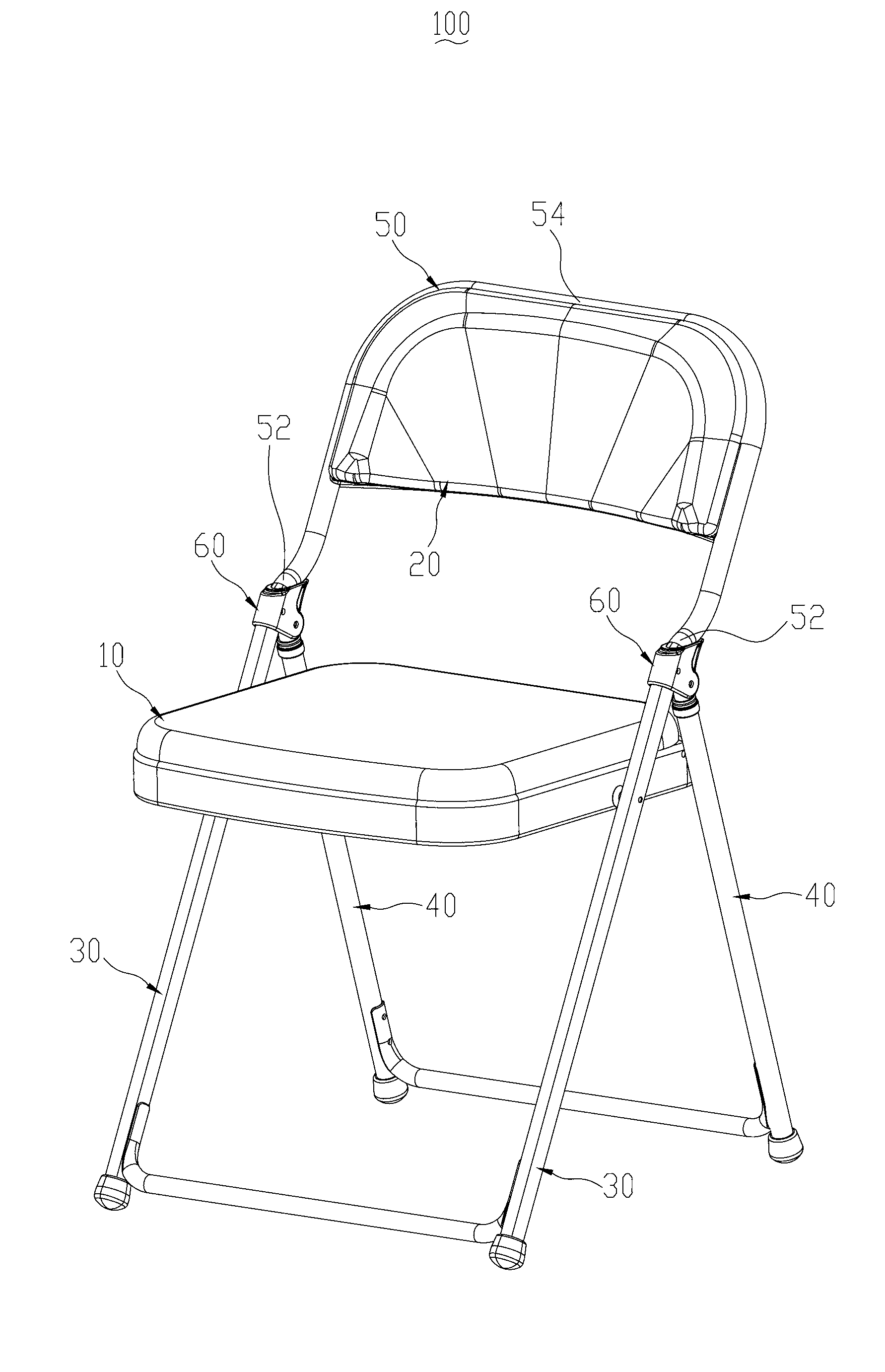

Foldable chair

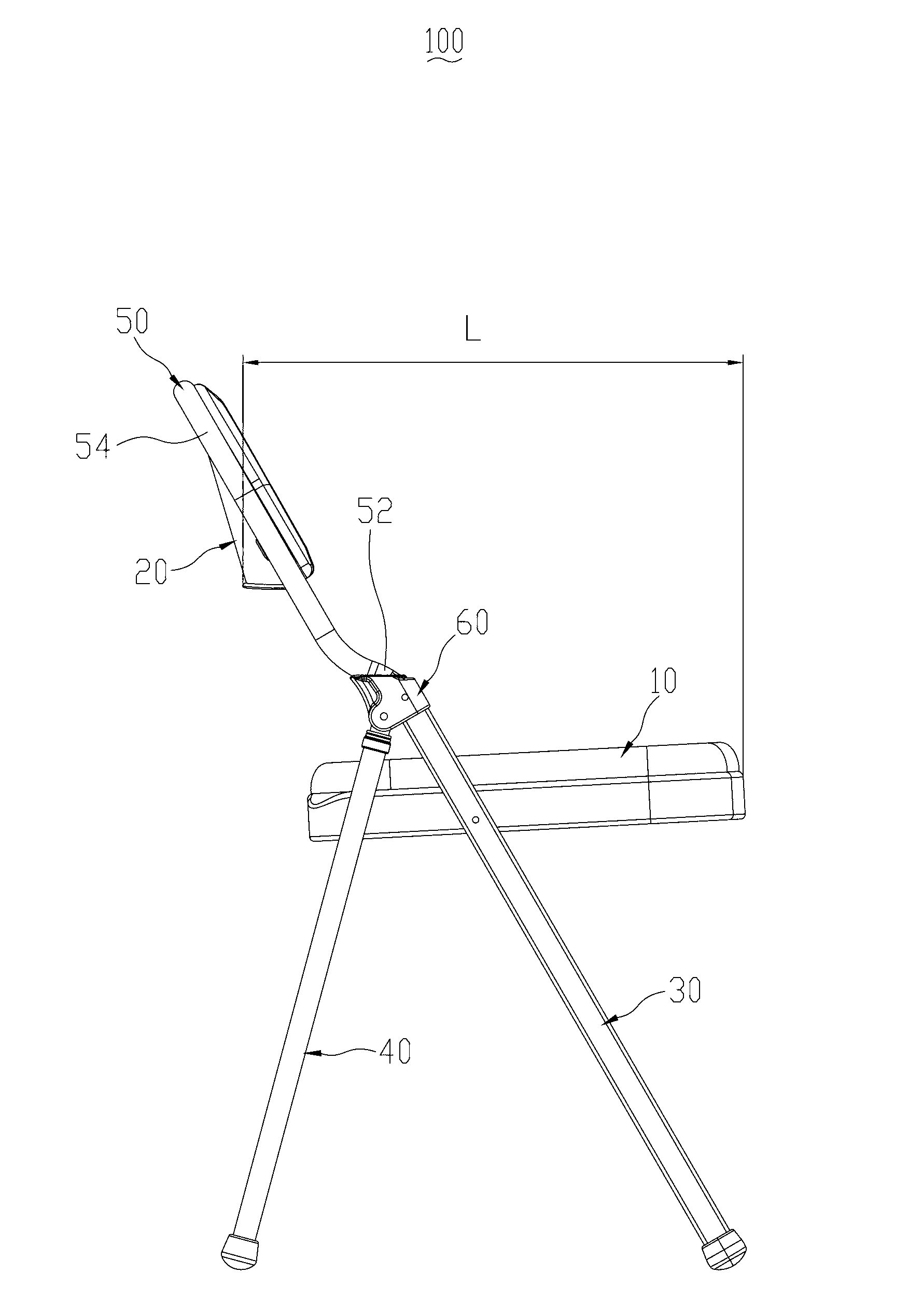

InactiveCN103040263ABigger and deeperImprove comfortDismountable chairsFoldable chairsEngineeringMechanical engineering

The invention discloses a foldable chair which comprises a seat board, a backrest, two front legs and two rear legs, wherein the upper parts of the front and rear legs are respectively connected with the rear parts of the left and right side edges of the seat board; the upper parts of the two front legs are respectively connected with the middle parts of the left and right side edges of the seat board; the upper ends of the rear legs are rotatably pivoted with the upper ends of the front legs; the chair further comprises a U-shaped tube piece; the U-shaped tube piece comprises a U-shaped section for fixing the backrest and fixed sections which are used for being connected with the front legs respectively; the two fixed sections are arranged in a mode of respectively extending and tilting outwards from the opening of the U-shaped section; the U-shaped section and the front legs are not arranged on one same straight line; and the U-shaped section deviates to one sides of the rear legs. As the U-shaped section and the front legs are not arranged on one same straight line, and the U-shaped section deviates to one sides of the rear legs, the distance between the backrest and the front end of the seat board is greatly increased, and the foldable chair has larger sitting depth, so that the human body conformability is greatly improved.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Laserwelding method for repairing penetrating defect of base metal

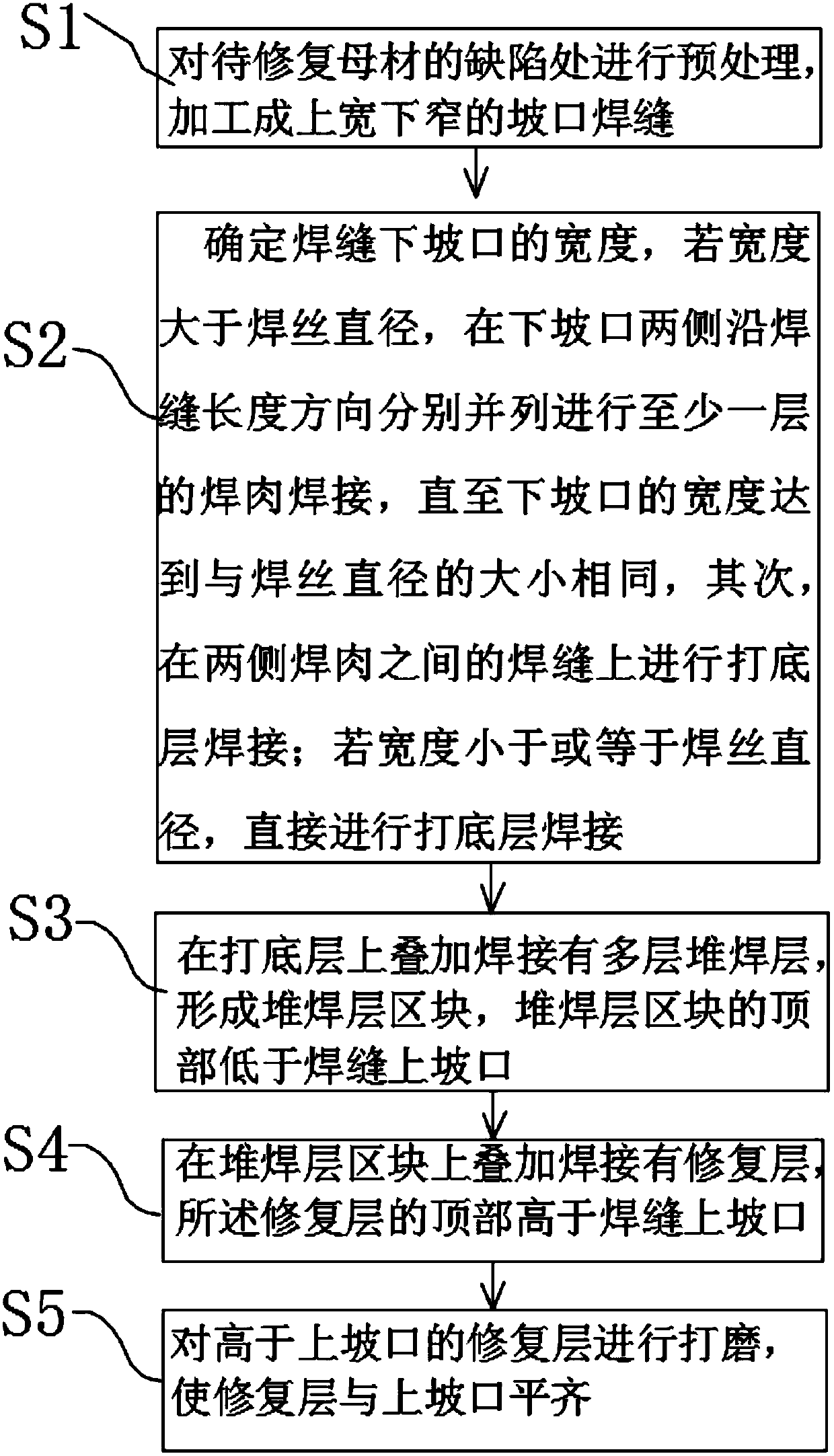

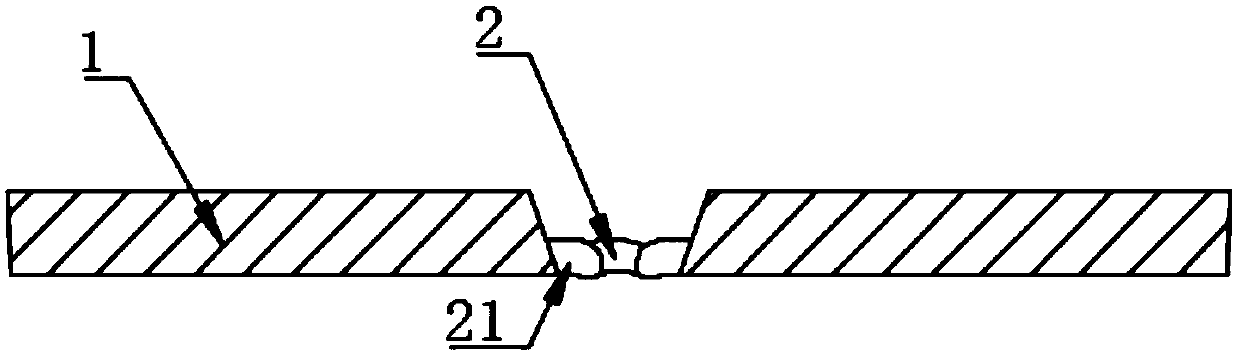

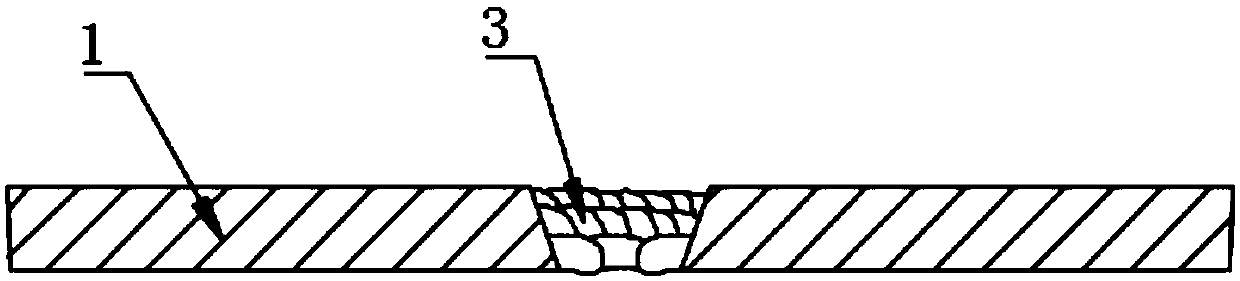

ActiveCN109664023AEnsure normal exposureAvoid crack defectsLaser beam welding apparatusWorkpiece edge portionsArchitectural engineeringLaser

The invention relates to a laser welding method for a repairing penetrating defect of base metal. The method comprises the following steps that S1, the to-be-repaired defect of the base material is pretreated and machined into a groove weld joint with a wide upper portion and a thin lower portion; S2, the width of a weld joint lower groove is determined, if the width of the lower groove is greaterthan the diameter of a welding wire, at least one layer of convex weld welding are conducted on the two sides of the lower groove side by side in the length direction of the weld joint until the width of the lower groove is the same as the diameter of the welding wire, then priming layer welding is conducted on the weld joint between convex welds on the two sides, and if the width is smaller thanor equal to the diameter of the welding wire, the priming layer is directly welded; S3, multiple welding layers are superimposed and welded on the priming layer, a welding layer zone is formed, and the top of a welding layer block is lower than a weld joint upper groove; S4, a repair layer is superimposed and welded on the welding layer block, and the top of the repair layer is higher than the weld joint upper groove; and S5, the repair layer higher than the upper groove is ground, and thus the repair layer is flush with the upper groove.

Owner:丁二纲

Broadening rolling method with dynamic roll gap control

InactiveCN103252357AReduce arcReduce head and tail arcsRoll force/gap control deviceSheet steelHydraulic pressure

The invention discloses a broadening rolling method with dynamic roll gap control. The broadening rolling method comprises the following steps of improving hydraulic pressure response speed, when a steel plate is in a last pass of broadening passes, lifting up a roll gap 1-2mm in the process of biting steel, pressing the roll gap 3-4mm in the process of steel plate rolling after normal biting steel, and pressing the roll gap when 400mm length of the steel plate is achieved through normal rolling. When the steel plate is close to the tail, the roll gap is lifted up 3-4mm to obtain a steel plate which is U-shaped. By the adoption of the broadening rolling method with the dynamic roll gap control, circular arcs of the head and the tail of the steel plate can be reduced, non-planed size is reduced, and yield is improved.

Owner:NANJING IRON & STEEL CO LTD

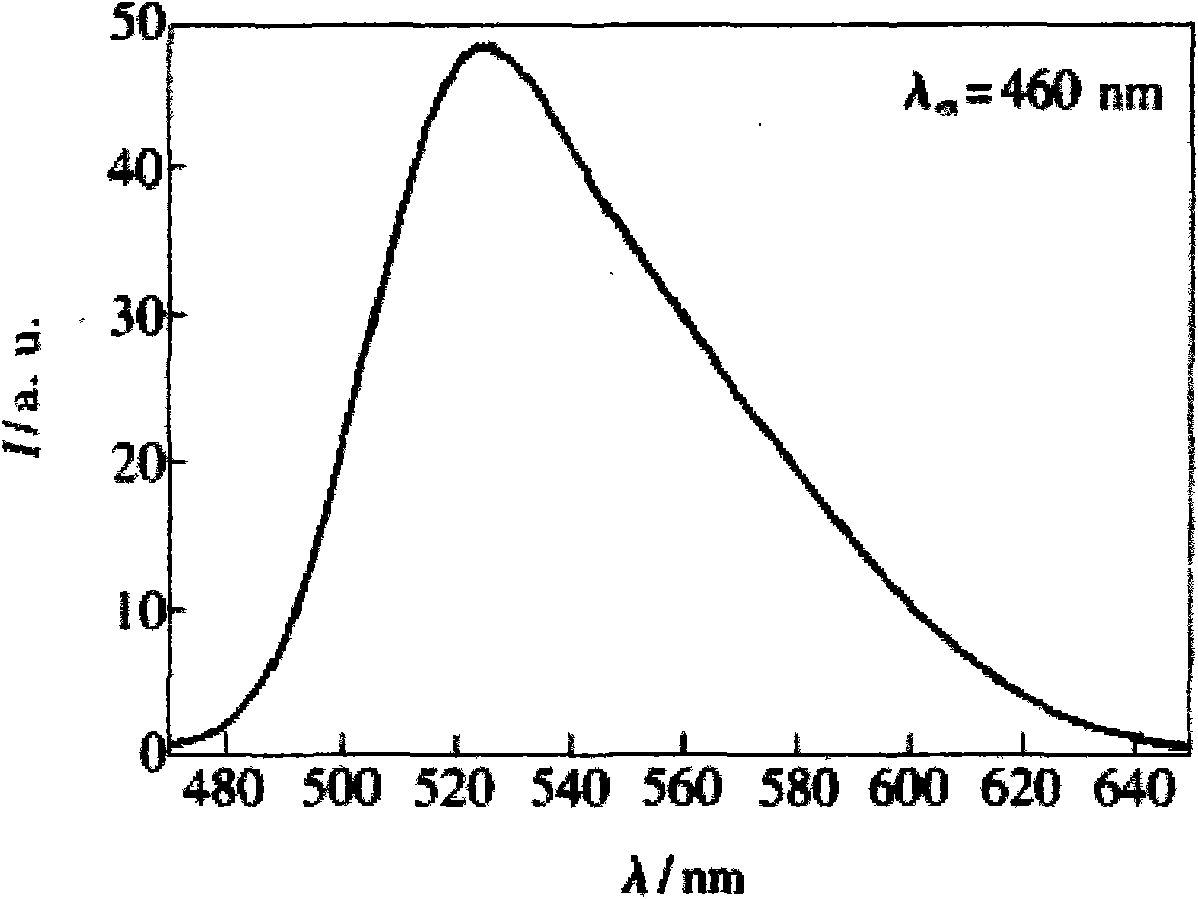

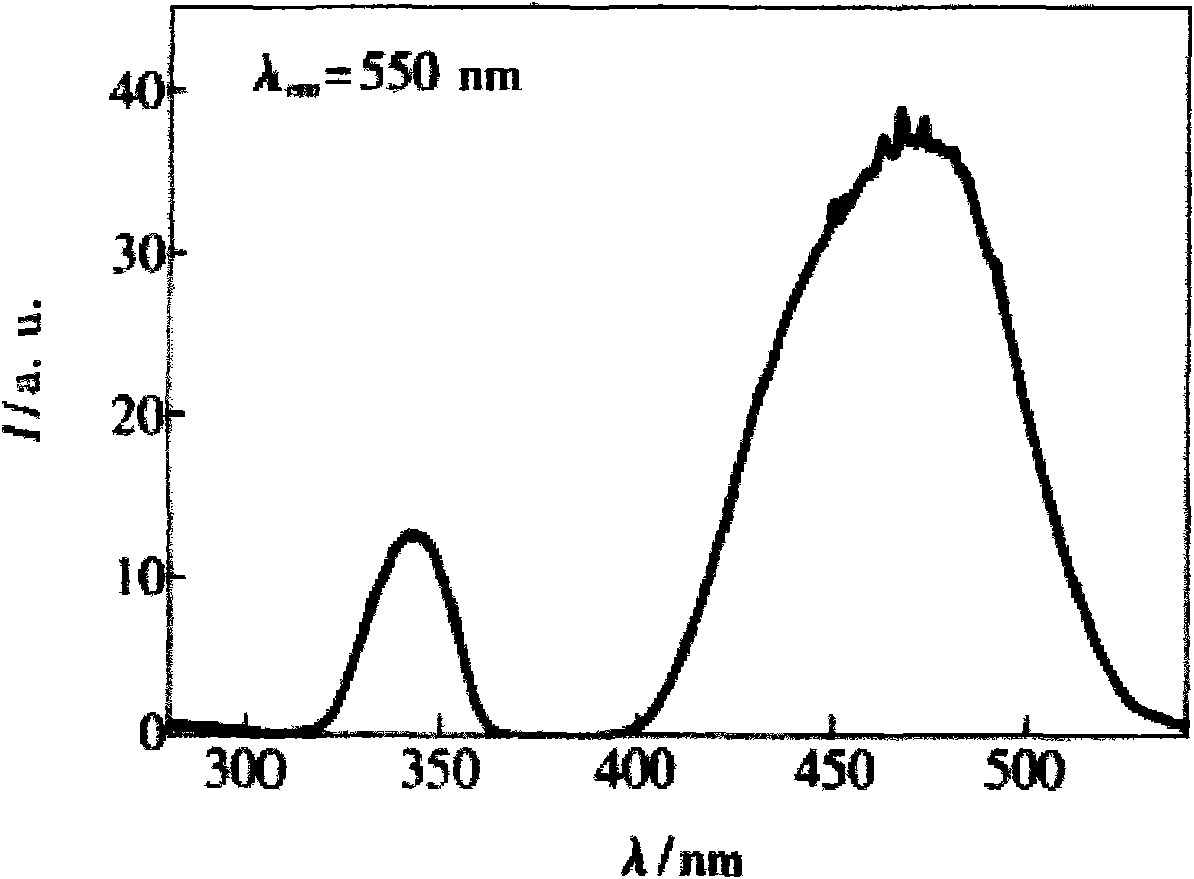

Method for manufacturing light-emitting diode (LED) structure

The invention discloses a method for manufacturing a light-emitting diode (LED) structure. The method comprises the following steps of: 1) preparing a cured and encapsulated blue LED chip and a corresponding lead wire structure, wherein the blue LED chip is electrically connected and fixed with the lead wire of the lead wire structure; 2) coating transparent epoxy resin on the blue LED chip which is fixed and connected with the lead wire structure and then performing curing, wherein the epoxy resin does not comprise fluorescent powder; 3) mixing yellow fluorescent powder and the epoxy resin uniformly and coating the yellow fluorescent powder and the epoxy resin which are mixed uniformly on the cured epoxy resin in the step 2) to perform secondary curing; and 4) performing encapsulation by using the epoxy resin. The method for manufacturing the LED structure has the advantages of effectively improving the luminous efficiency of a white LED and homogenizing the emitted light.

Owner:JIANGXI HUAYE ENERGY SAVING LIGHTING

Assembled bridge support

InactiveCN113699879AReduce distanceSmall arcBridge structural detailsAxial pressureClassical mechanics

The invention belongs to the field of bridge supports, and particularly relates to an assembled bridge support which comprises a top plate. A top connecting rod is fixedly connected to the upper surface of the top plate, the outer surface of the top connecting rod makes contact with the inner surface of the bridge, and a main supporting mechanism is arranged at the bottom of the top connecting rod. According to the assembled bridge support, by arranging the limiting mechanism, when the main supporting mechanism and the auxiliary supporting mechanism retract, a push-pull rod downwards extrudes the upper surface of a pressing plate, the pressing plate increases the contact area between the bottom of the support and the top of a pier and increases friction force, a fixing pin is vertically embedded into the pier, and the axial stability is improved, an inclined rod is obliquely and downwards inserted into the pier through the action of a pushing-pulling rod; when an axial pressure is reduced, the inclined rods move upwards in an inclined mode, the clamping jaws abut against the interior of the pier, the springback amplitude of the support is reduced, meanwhile, the axial and radial stability of the support is improved, and the problems that when the internal pressure of a traditional bridge support is too large, springback is prone to occurring, and therefore, the structural stability of the support is influenced.

Owner:朱鹏程

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are successively mounted on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are successively mounted on the top of the cylinder from front to back and correspond to the rack; a gap is formed between the first carding region cover plate and the second carding region cover plate; and a gap is also formed between the second carding region cover plate and the third carding region cover plate. The carding machine is provided with the three carding cover plates, three carding regions are formed, the first carding region has main effects of neatening, smoothly carding fibers and preliminarily discharging impurities andlower piles, the second carding region is further used for neatening, carding the fibers and preliminarily discharging the impurities and the lower piles, the third carding region has main effects ofprecisely carding and further discharging the impurities and lower piles, each of the three carding region cover plates is provided with a cover plate cleaning device, the three carding region cover plates can be cleaned independently, and after being cleaned, the carding cover plates can be rapidly and efficiently used in carding operation. The carding machine is divided into three portions, radian occupied by each carding cover plate is also reduced, the carding cover plates can be cleaned as quickly as possible, the cover plate cleaning efficiency is further improved, and a carding effect is ensured.

Owner:乐陵市佳和纺织有限公司

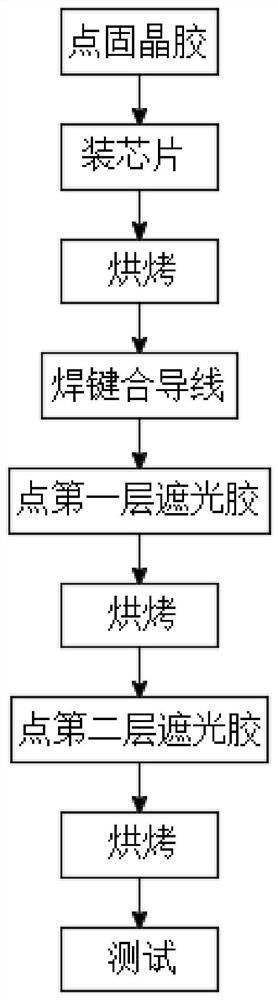

RCLED lamp bead packaging process

ActiveCN113284988AEliminates reflective effectsImprove the effect of emitting light spotsElectric circuit arrangementsCoatingsLight spotEngineering

The invention discloses an RCLED lamp bead packaging process, which comprises the following steps of dispensing solid crystal glue, mounting a chip, baking, welding a bonding wire, dispensing a first layer of anti-reflection glue, baking, dispensing a second layer of anti-reflection glue, baking and testing. The anti-reflection glue is dispensed in a corresponding area of an RCLED lamp bead, so that a part capable of reflecting light in the RCLED lamp bead is shielded; the reflection effect of the RCLED lamp bead is effectively eliminated, the light spot emitting effect of the RCLED lamp bead is improved, and the light spots are clearer and more accurate. And the viscosity of the first layer of anti-reflection glue has certain flowability, so that the anti-reflection glue can be rapidly filled in a specified area, and the production efficiency is high. And the second layer of anti-reflection glue is relatively high in viscosity and flows slowly after glue dispensing, so that the glue dispensing precision is improved, and the anti-reflection glue can be effectively prevented from shielding a light-emitting hole of the RCLED chip. When the bonding wire is welded, the support is the first welding spot, and the PAD of the RCLED chip is the second welding spot, so that the radian of the bonding wire is lower, the lamp bead has a good appearance, the dispensing amount is reduced, and the production cost is saved.

Owner:PSG OPTO DEV CO LTD

Plate processing flattening arrangement device and use method

The invention discloses a plate processing flattening arrangement device and a use method. The device comprises a bottom fixing plate, the left side of the bottom fixing plate is fixedly connected with a left supporting plate in a perpendicular mode, a group of left shaft holes which are transversely arranged are formed in the left supporting plate, the left shaft holes are connected with left bearings, the right side of the bottom fixing plate is fixedly connected with a right supporting plate, and the right side of the bottom fixing plate is fixedly connected with a right supporting plate ina perpendicular mode, a group of right shaft holes which are transversely arranged are formed in the right supporting plate, and the right shaft holes are connected with right bearings; and the leftbearings and the right bearings are connected through lower transverse shafts, the lower transverse shafts are connected with lower pressing rollers, the lower pressing rollers comprise the lower middle convex pressing roller, a lower middle concave pressing roller and a lower flat pressing roller, moreover, the lower middle convex pressing roller, the lower middle concave pressing roller and thelower flat pressing roller are arranged in sequence, the lower middle concave pressing roller is corresponding to an upper middle concave pressing roller, the lower middle convex pressing roller is corresponding to an upper middle convex pressing roller, and the lower flat pressing roller is corresponding to an upper flat pressing roller. The device and the method are used for plate processing flattening arrangement.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Gold bonding wire and preparation method thereof

ActiveCN102127663BHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method ofthe gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

A pre-twisted damping anti-vibration hammer

InactiveCN102280846AImprove slip resistanceThe installation position is accurateDevices for damping mechanical oscillationsEngineeringHooking

A pre-twisted damping anti-vibration hammer. The invention relates to the improvement of a pre-twisted anti-vibration hammer upper wire clip structure. It can effectively enhance the anti-loosening and anti-slip capabilities of the anti-vibration hammer, ensure the accurate installation position of the anti-vibration hammer and protect the cable from damage. It includes a wire clip, the upper part of which is hook-shaped, and the hook-shaped hook surface is a wire clamping surface, and a damping anti-skid pad is provided on the wire clamping surface. The invention increases the sliding friction force between the anti-vibration hammer and the cable, improves the anti-sliding ability of the anti-vibration hammer, ensures the correct installation position of the anti-vibration hammer, and can protect the cable from damage. In order to ensure the reliability of the connection between the damping anti-slip pad and the clamp, a bump and a mounting hole are provided, and the elasticity of the material of the damping anti-slip pad is used to embed the bump into the mounting hole; it can prevent the damping pad from slipping relative to the anti-vibration hammer verb: move. In order to increase the reliability of the connection with the wire, the curvature of the upper part of the clamping surface is also reduced to be smaller than the curvature of the wire, which is equivalent to clamping the wire in a small arc.

Owner:江苏华厦电力成套设备有限公司

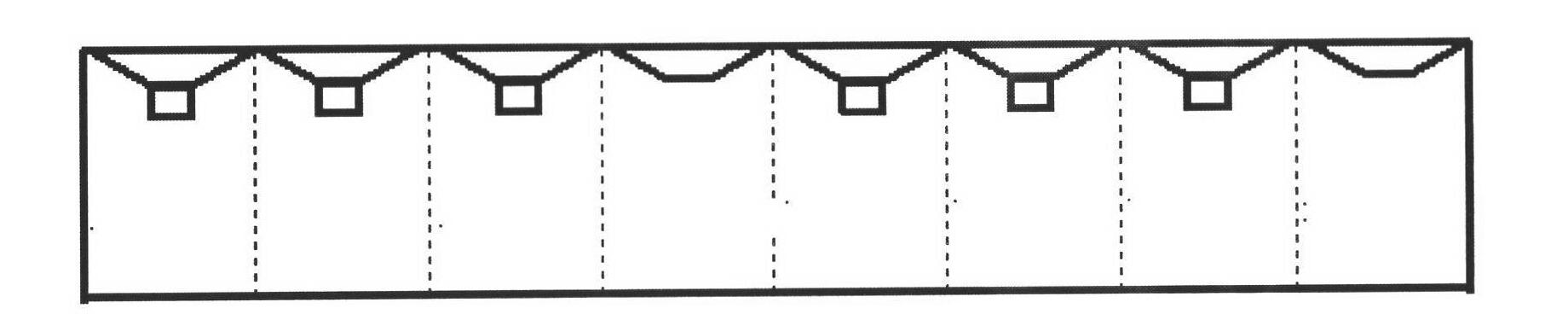

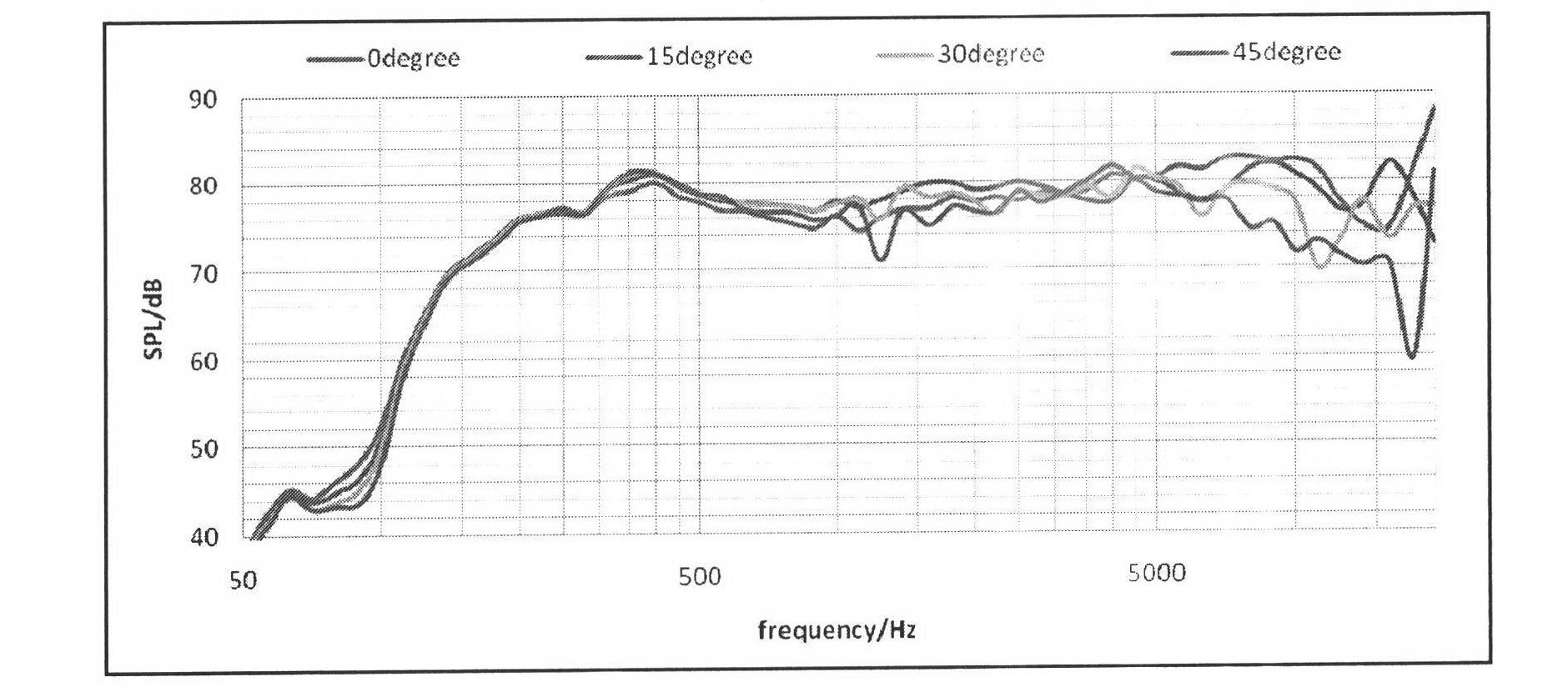

Speaker system with eight acoustic radiators

InactiveCN102158791AWide radiation angleImprove low frequency responsePublic address systemsPassive radiatorEngineering

The invention discloses a speaker system with eight acoustic radiators, wherein six of the eight acoustic radiators and two passive radiators are successively arranged based on a certain rule to constitute the speaker system with an array consisting of eight acoustic radiators, and the two passive radiators are respectively arranged in a first position and a fifth position in the array. The speaker system in the invention can have a wider radiator angle in the working frequency range of the speaker system, and the low frequency response is improved. The speaker system has the advantages of wider radiation angle in the working frequency range, uniform radiation sound field, ideal low frequency response, simple design method, low cost and convenience in use.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com