Rotational molding surfboard and manufacturing technology thereof

A manufacturing process and surfboard technology, applied in the field of rotomolding surfboards and its manufacturing process, can solve the problems of surfboards not being recyclable, small rudders unstable and easy to turn, increased difficulty, etc. The production process is difficult to operate, and the effect is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described here are only used to explain the present invention, not to limit the present invention.

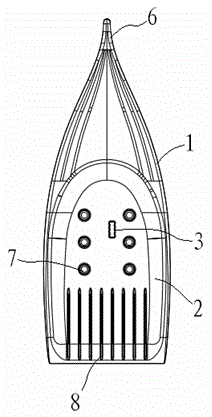

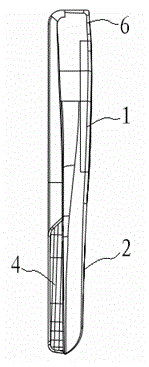

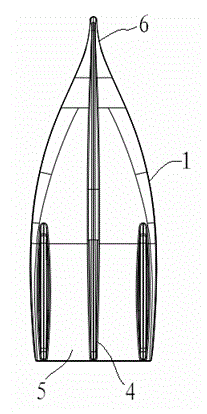

[0021] like Figure 1-4 As shown, a rotomolded surfboard with self-contained fin diversion of the present invention includes a surfboard body 1, the surfboard body 1 is a hollow structure with a pointed front and a leaf shape, and the head 6 is in the shape of a ship's bow , It reduces resistance and is easy to divert, and it is not easy to insert water and overturn. There is a streamlined recessed part 2 on the top. There are notches 3 for grippers in the recessed part 2. There are several backing plates on both sides of the recessed part 2. The mounting holes 7, the surface of the conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com