Plate processing flattening arrangement device and use method

A sorting device and plate processing technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unsatisfactory use effect, unqualified processing quality, and reduced yield rate, etc., and achieve good effect and smoothness High degree, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

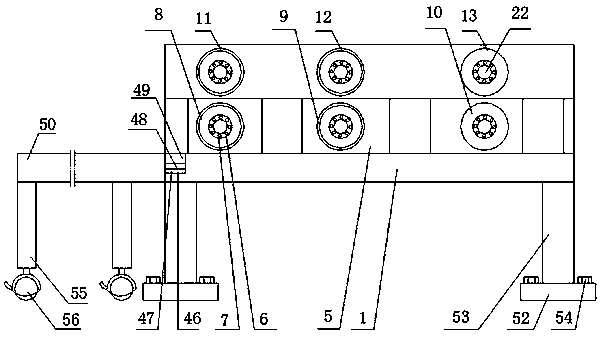

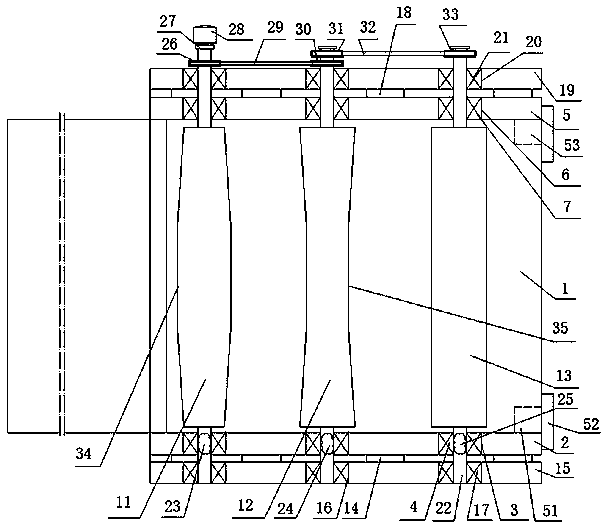

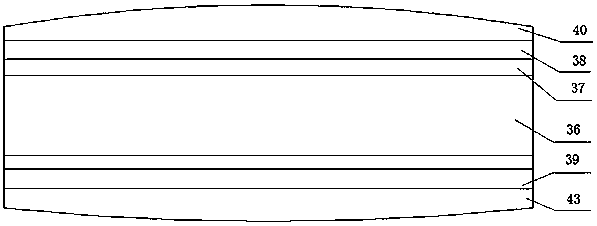

[0027] A plate processing and flattening device, which consists of: a bottom fixing plate 1, the left side of the bottom fixing plate is fixed and vertically connected to the left support plate 2, and the left support plate is provided with a group of horizontally arranged left shaft holes 3. The left shaft hole is connected to the left bearing 4, the right side of the bottom fixing plate is fixed and vertically connected to the right support plate 5, and the right support plate has a set of right shaft holes 6 arranged horizontally. The right shaft hole is connected to the right bearing 7, the left bearing and the right bearing are connected through a lower horizontal shaft, and the lower horizontal shaft is connected to the lower pressure roller, and the lower pressure roller includes a lower convex pressure roller 8, the lower middle concave pressure roller 9, the lower flat pressure roller 10, and according to the arrangement of the lower middle convex pressure roller, the ...

Embodiment 2

[0031] In the plate processing and flattening device described in Embodiment 1, a group of left magnetic plates 14 arranged in horizontal rows are connected to the outside of the left support plate, and the left magnetic plates are attracted to the left adjustable support iron plate 15. The left adjustment support iron plate is provided with a left jack 16, the left jack is connected to the left upper bearing 17, and the outside of the right support plate is connected to a group of right magnetic plates 18 arranged in rows, and the right magnetic plates are sucked together. The right adjustment support iron plate 19, the right adjustment support iron plate has a right socket 20, the right socket is connected to the upper right bearing 21, the upper left bearing and the upper right bearing pass through the upper horizontal shaft 22, the upper horizontal axis is respectively connected to the upper middle convex pressure roller, the upper middle concave pressure roller, and the up...

Embodiment 3

[0034] In the plate processing flattening device described in Example 1, the lower horizontal shafts include No. 1 lower horizontal shaft 23, No. 2 lower horizontal shaft 24, and No. 3 lower horizontal shaft 25, and the No. 1 lower horizontal shaft is connected to The lower center convex pressure roller, the No. 2 lower horizontal shaft is connected to the lower center concave pressure roller, the No. 3 lower horizontal shaft is connected to the lower flat pressure roller, and the No. 1 lower horizontal shaft is connected to the lower flat pressure roller. The shaft is connected with the No. 1 pulley 26, the No. 1 lower horizontal shaft is connected with the shaft coupling 27, and the shaft coupling is connected with the motor 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com