Patents

Literature

443 results about "Antistatic Materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Substances that do not retain an electrostatic charge.

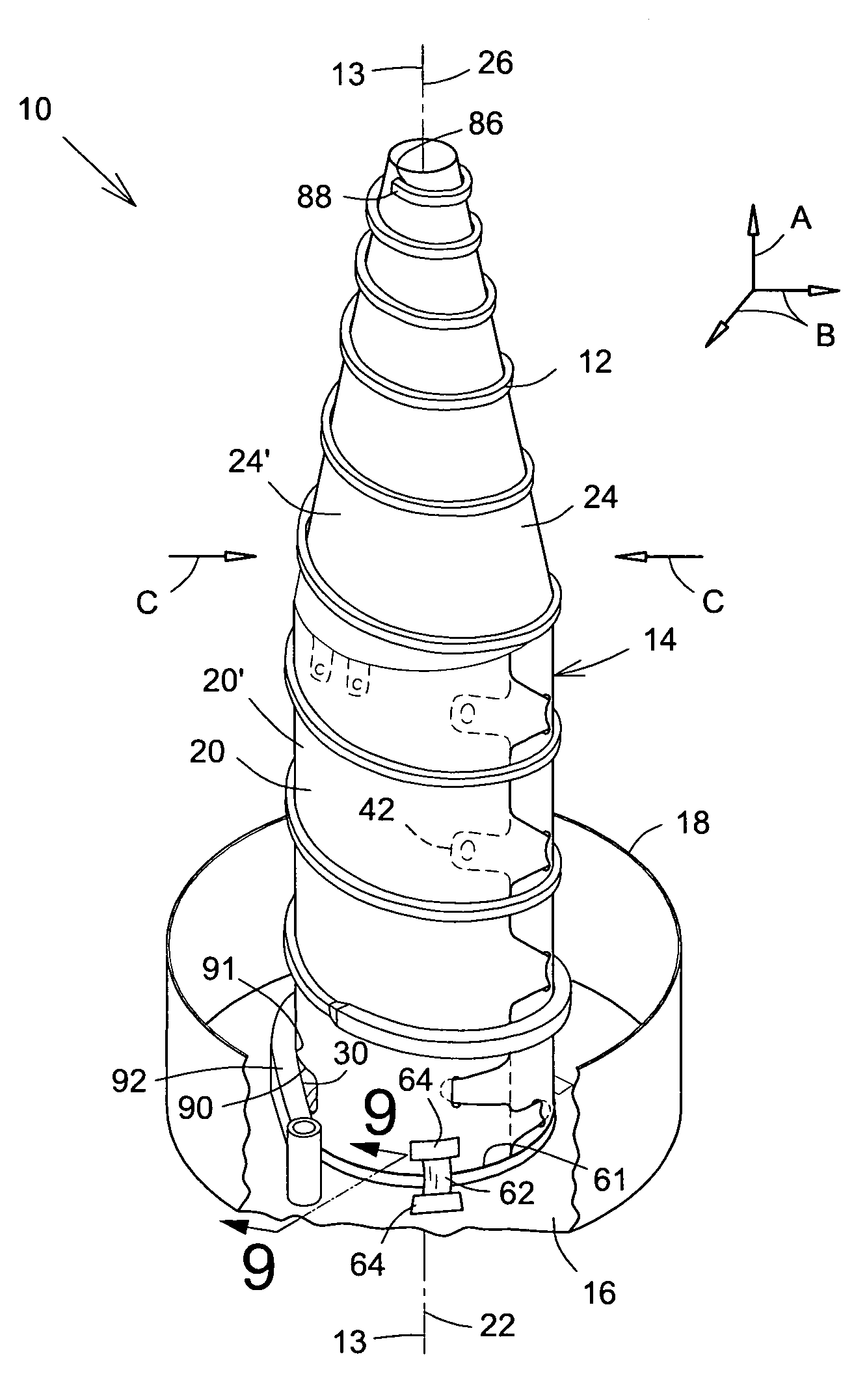

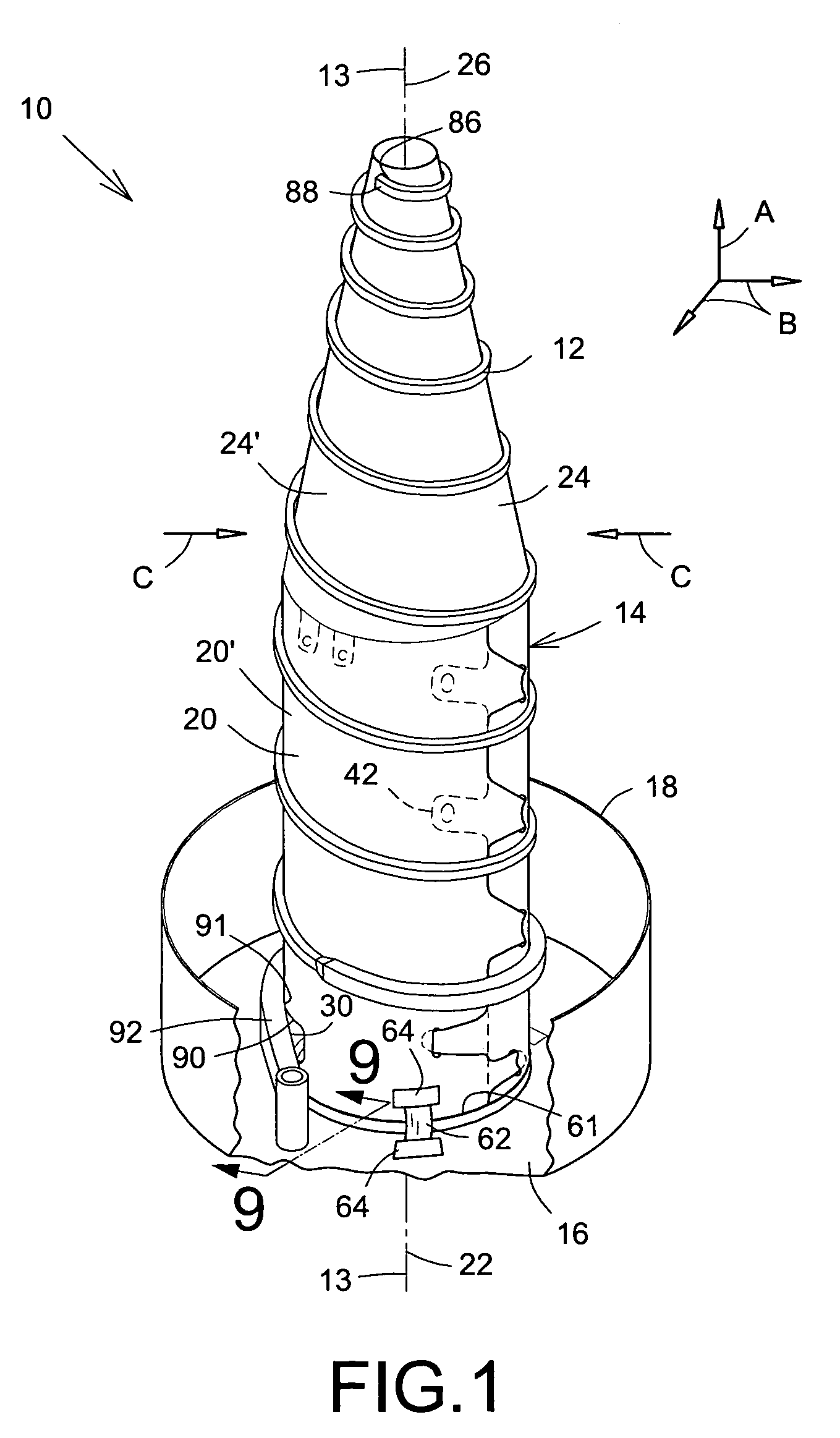

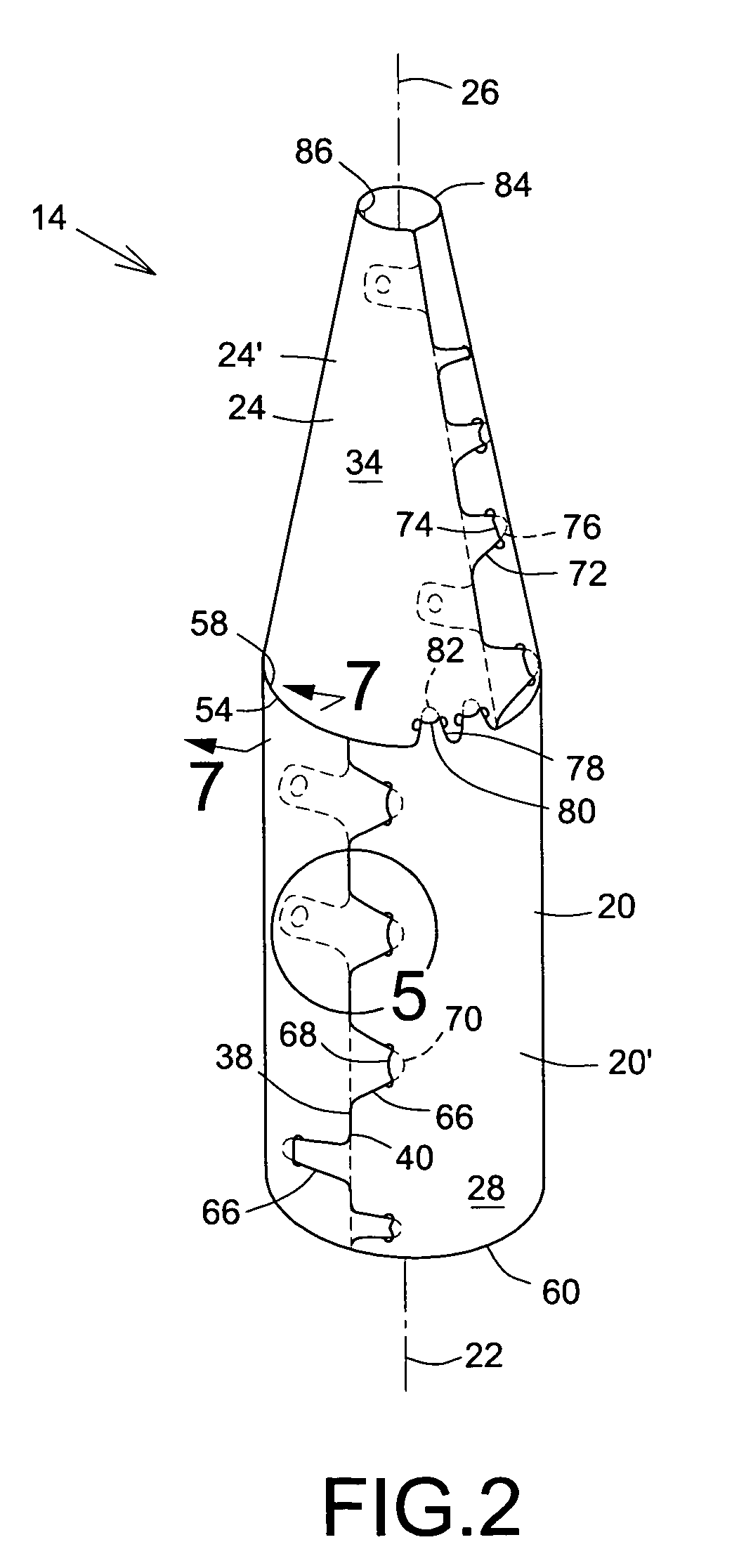

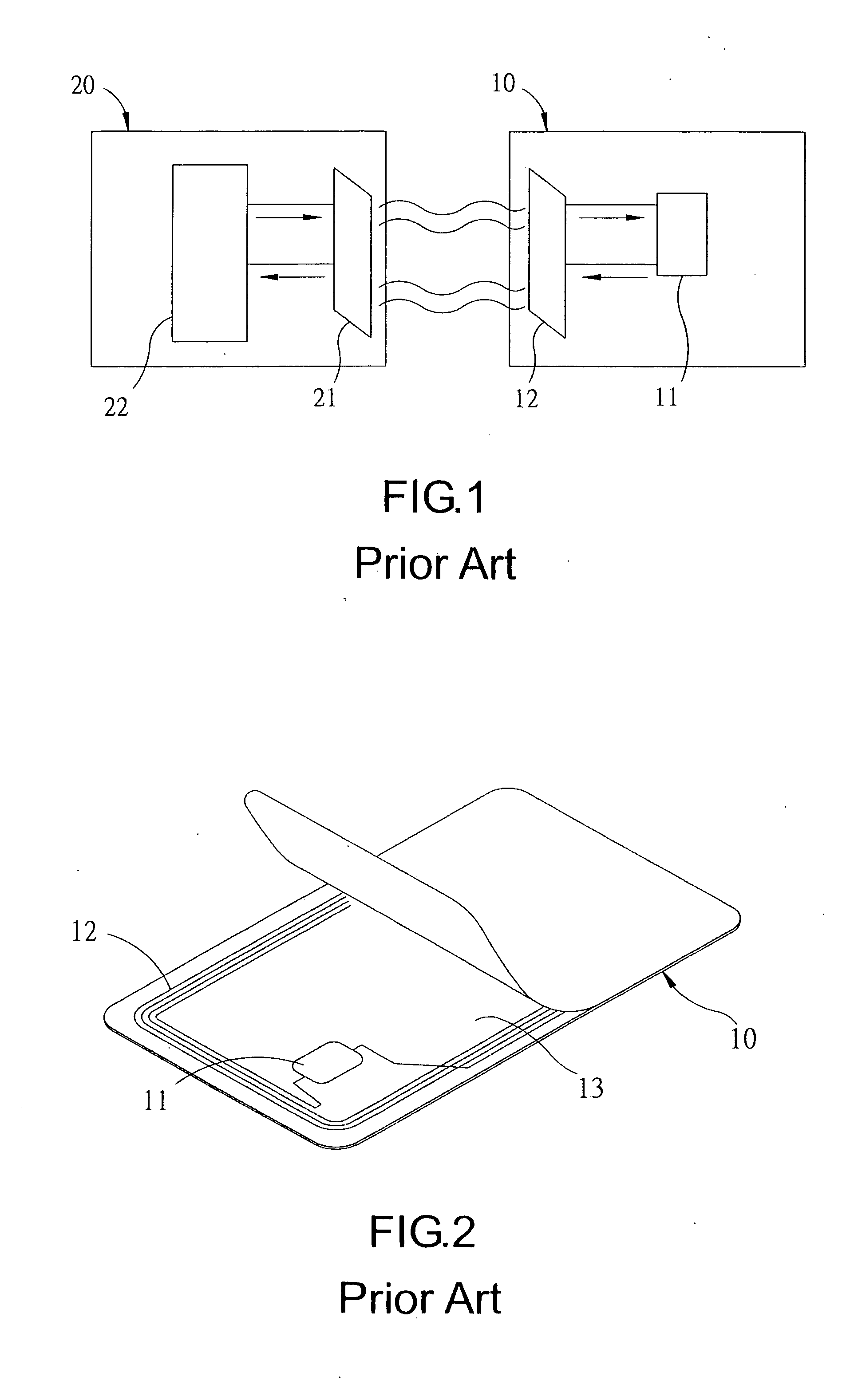

Helical antenna

ActiveUS7038636B2Light weightReduces dielectric lossLogperiodic antennasAntenna supports/mountingsLocking mechanismEngineering

A helical antenna has a helix supported by a helix support. The helix support includes at least one piece of flexible sheet having its two surfaces covered with a layer antistatic material. The flexible sheet is curlable into a revolution surface configuration to form a revolution surface-shaped support section for at least partially supporting a portion of the helix component there around. A grounding mechanism electrically grounds the external sheet surface to the helix and the two sheet surfaces to one another when in the revolution surface configuration while a locking mechanism locks the flexible sheet in the revolution surface configuration. The combination of the helix and the flexible support renders the antenna structurally relatively rigid in all directions.

Owner:MACDONALD DETTWILER & ASSOC CORP

Functional polymer nano composite material and preparation method and uses thereof

ActiveCN101161705AEvenly dispersedStable structureBiocideOther chemical processesEcological environmentPolymer solution

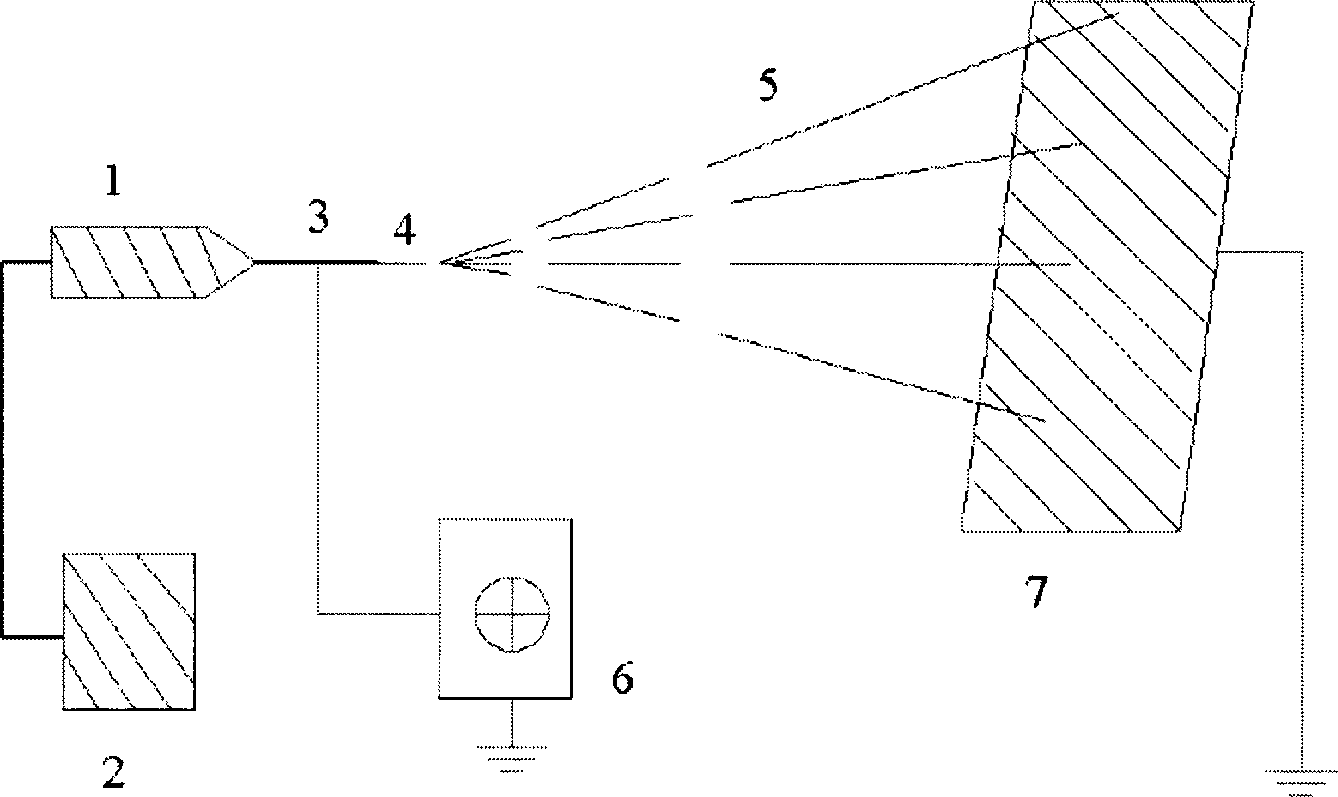

The present invention relates to a polymer nano-composite of the functional inorganic nano-particle with intermingle prepared by electrospinning method, and the use of the composite. The precursory sol of the functional inorganic nano-particle is prepared by the sol-gel method, and is mixed with the polymer solution to form spinning fluid, adding precursor of dopant if necessary, and then the mixed spinning fluid is sprayed on to the electric collecting board with the action of the electric field force by electrospinning method to obtain functional polymer nano-composite with intermingle. The equipment of the invention is simple, the operation is easy, the components, structure and characteristics of the composite is easy to control, the structure is stable, the inorganic nano-particle is dispersed uniformly. According to the difference of the functionality of the inorganic nano-particles, the composite can be used in conducting material, antistatic material, magnetic material, electrochromic material, photocatalysis and ecology environment material, antibiosis material and biomaterial.

Owner:INST OF CHEM CHINESE ACAD OF SCI

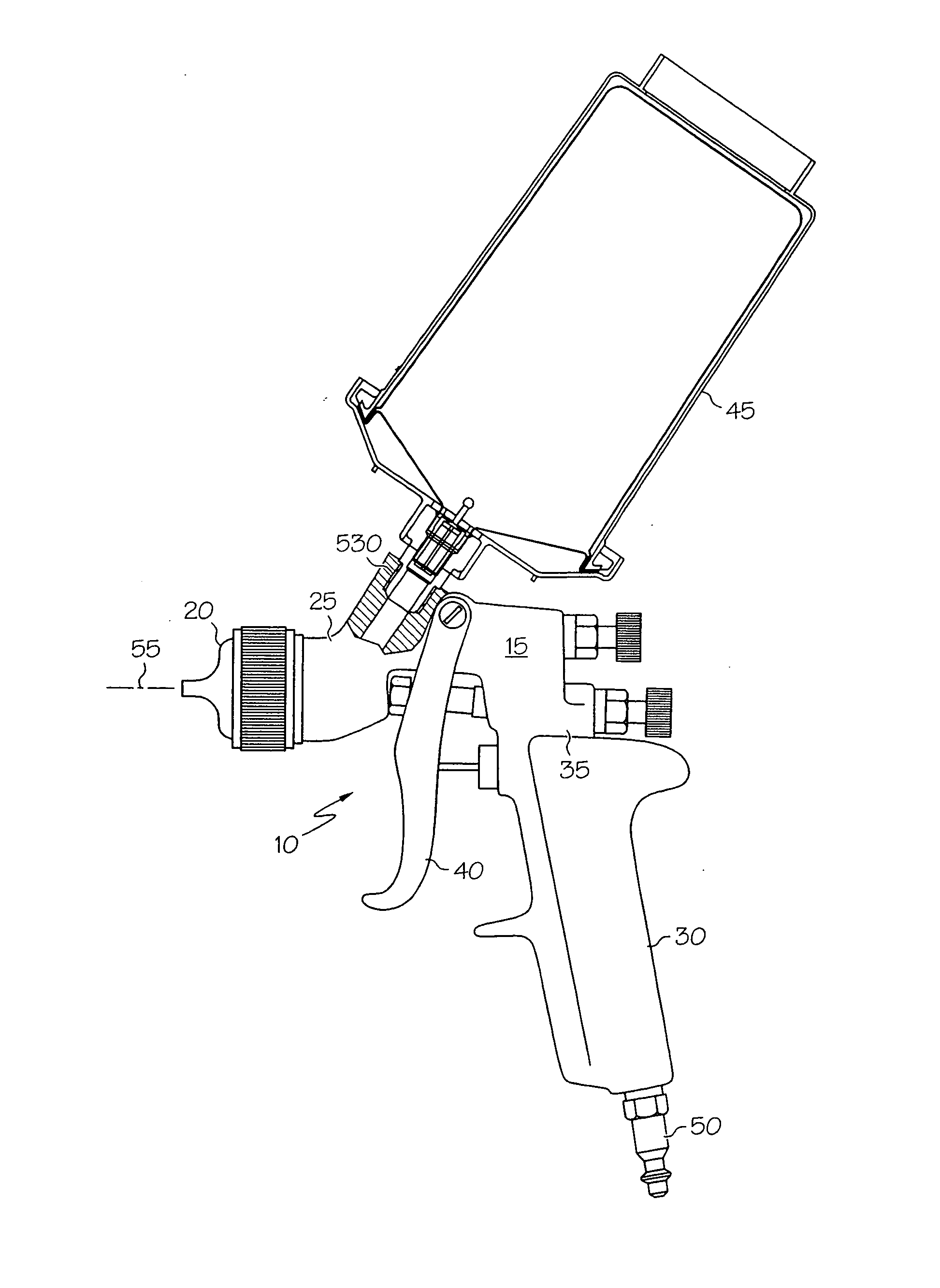

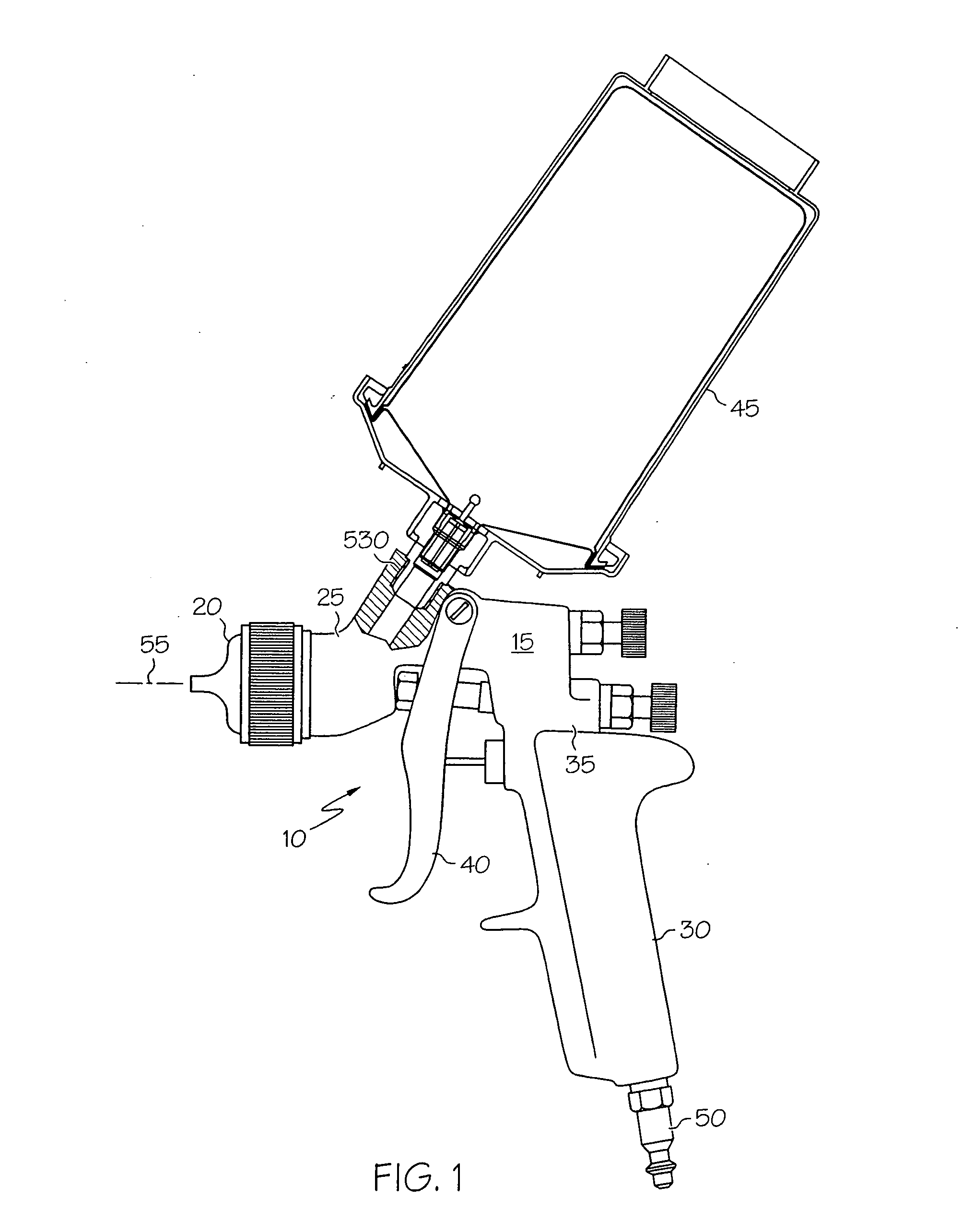

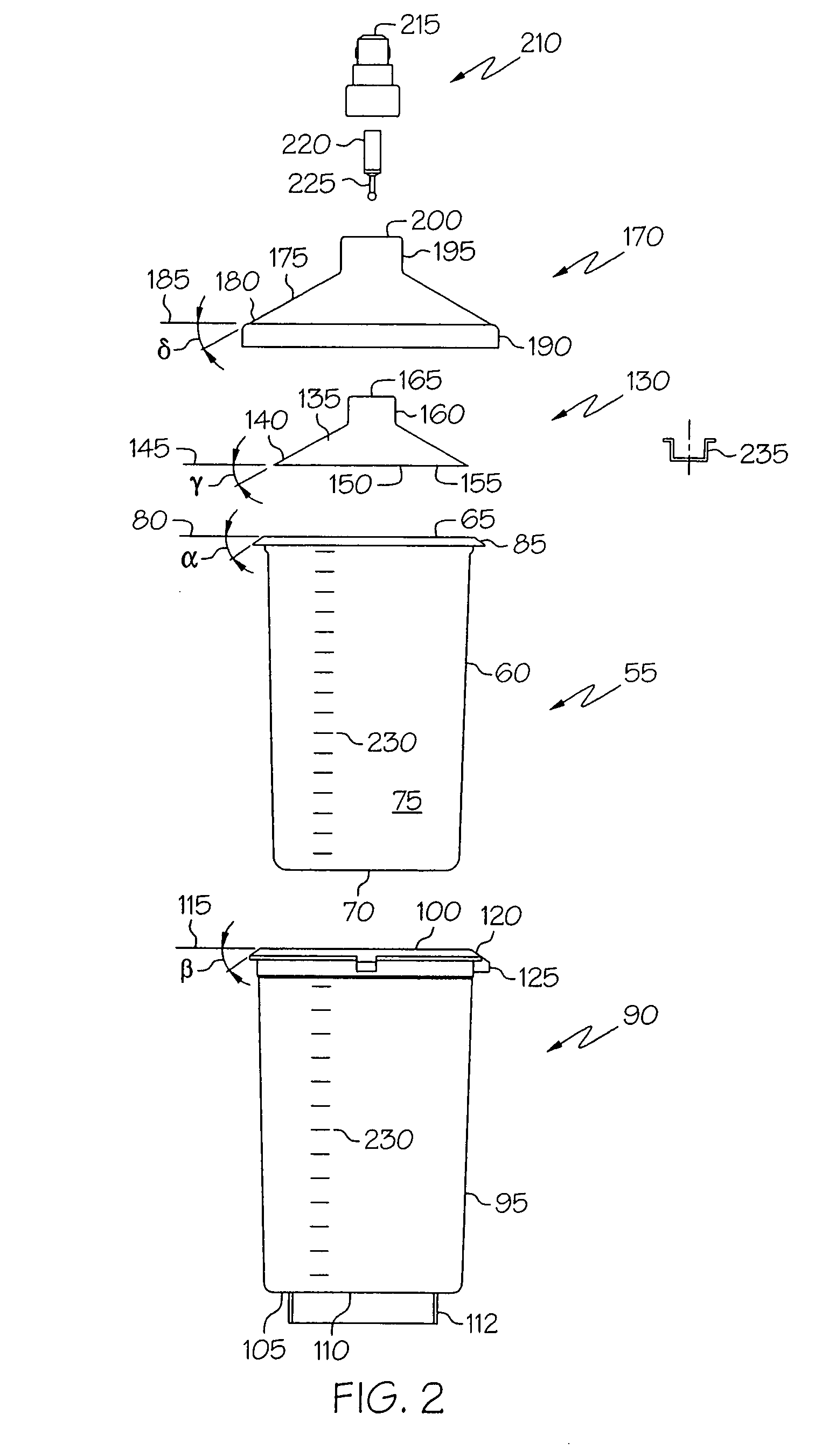

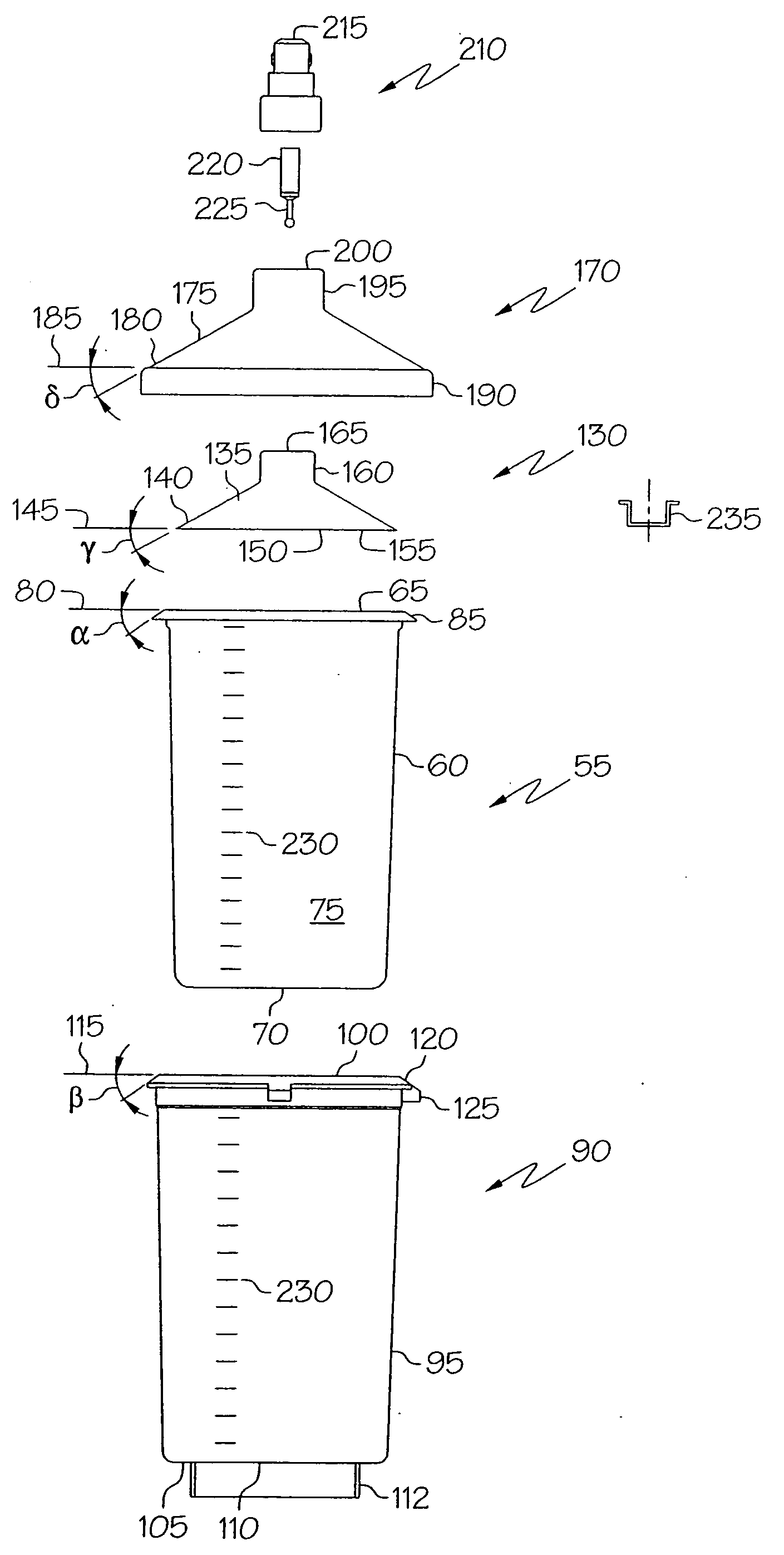

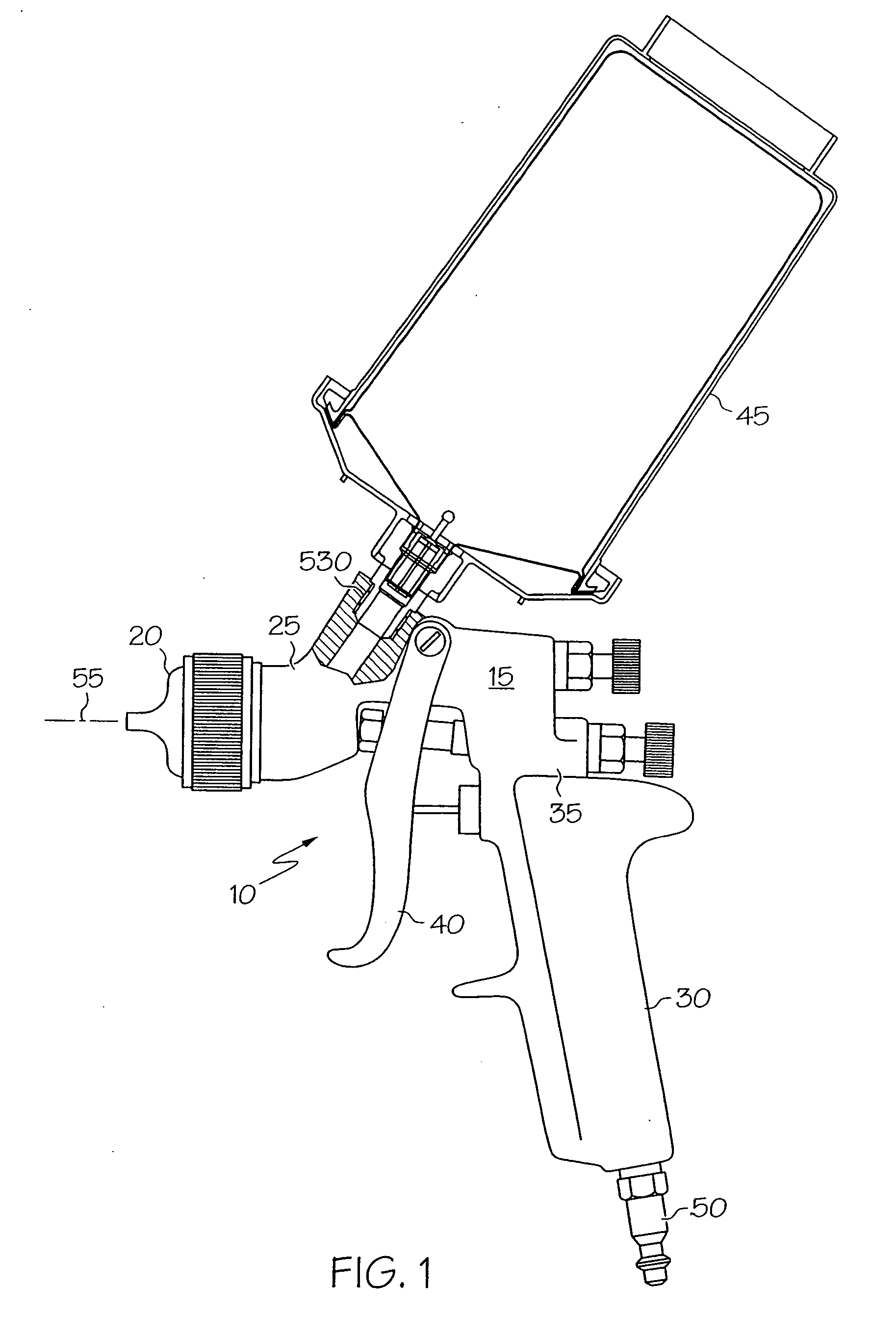

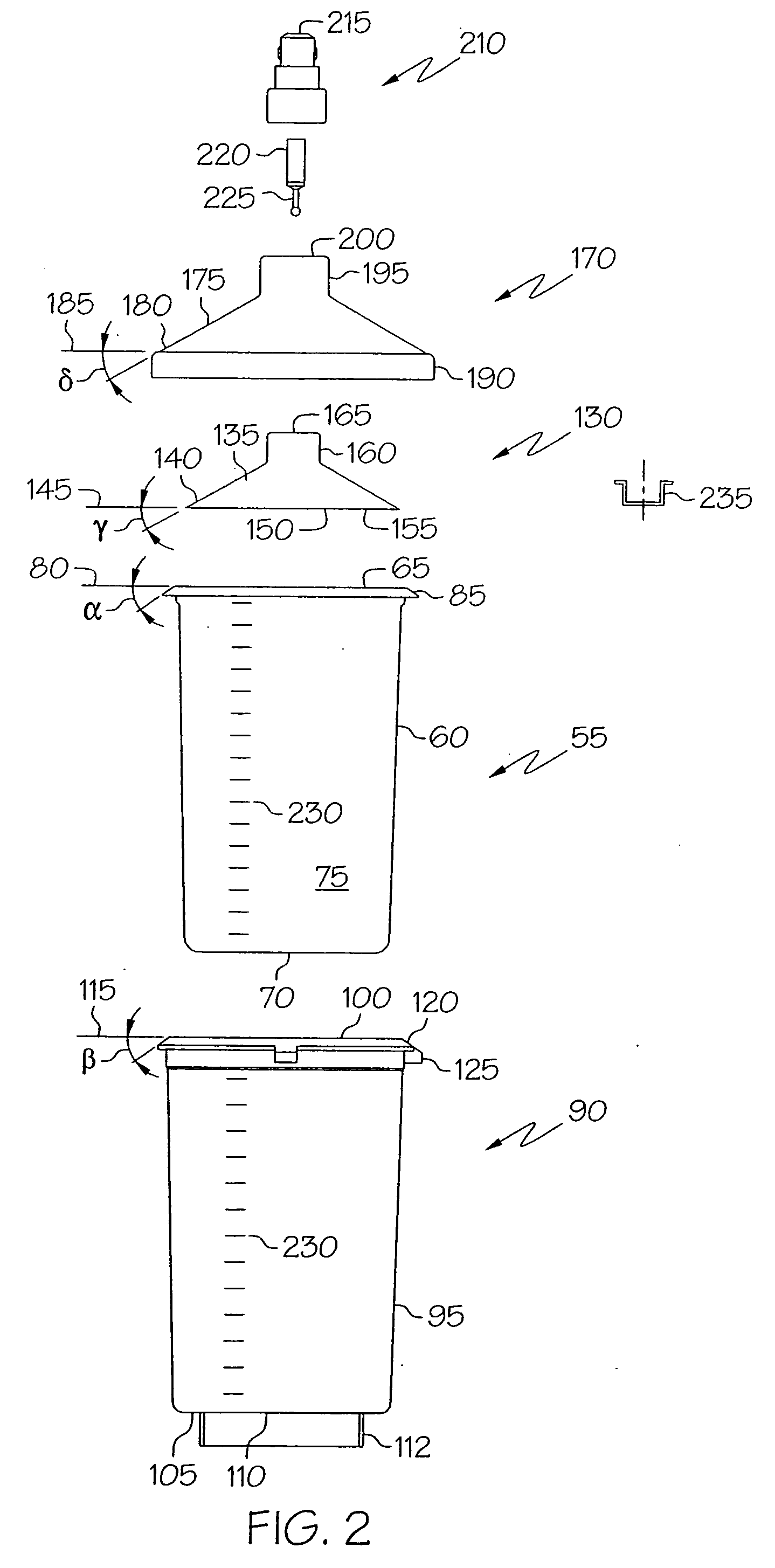

Antistatic paint cup

ActiveUS20050263614A1Liquid transferring devicesLiquid spraying apparatusDisposable cupAntistatic Materials

A flexible, disposable cup for use in a fluid supply assembly. The disposable cup is made of an antistatic material whereby chargeable particles in a coating mixture do not stick to the disposable cup so that uniformity of the coating mixture is maintained while it is dispensed. A method of maintaining the uniformity of a coating mixture during dispensing is also described.

Owner:CARLISLE FLUID TECH INC

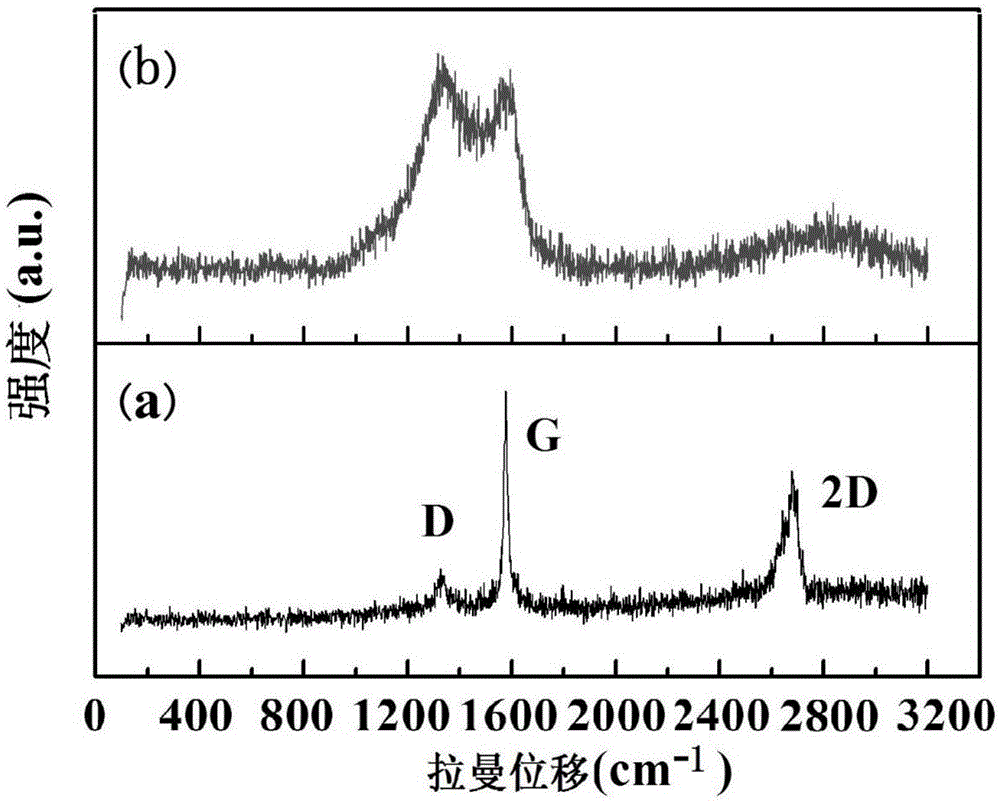

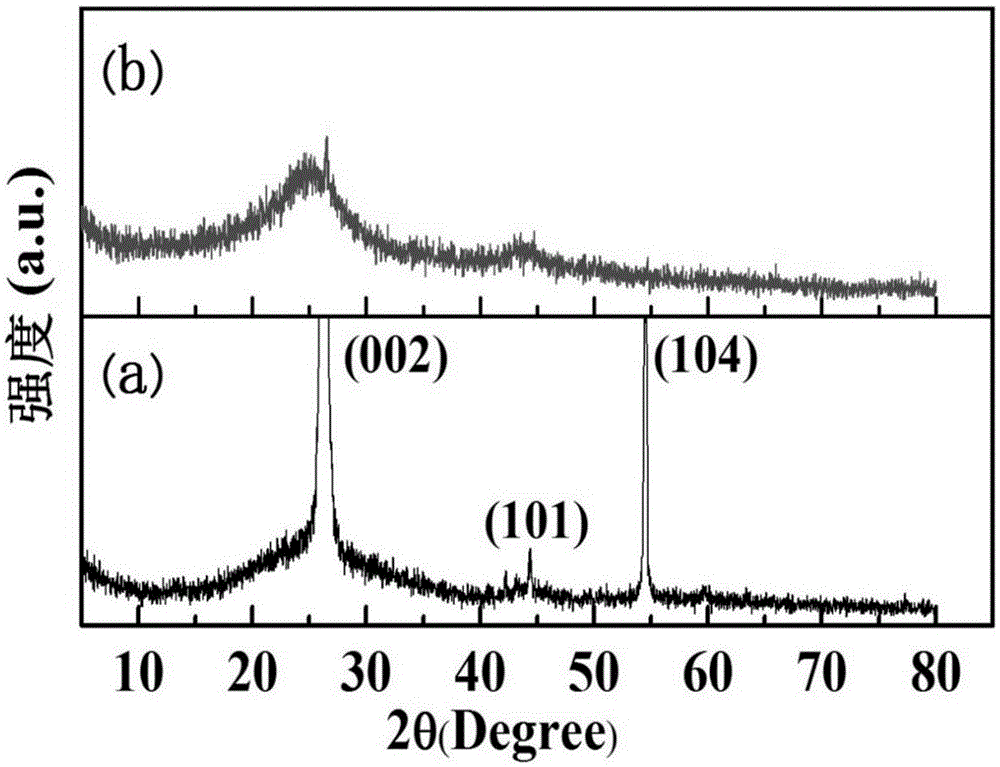

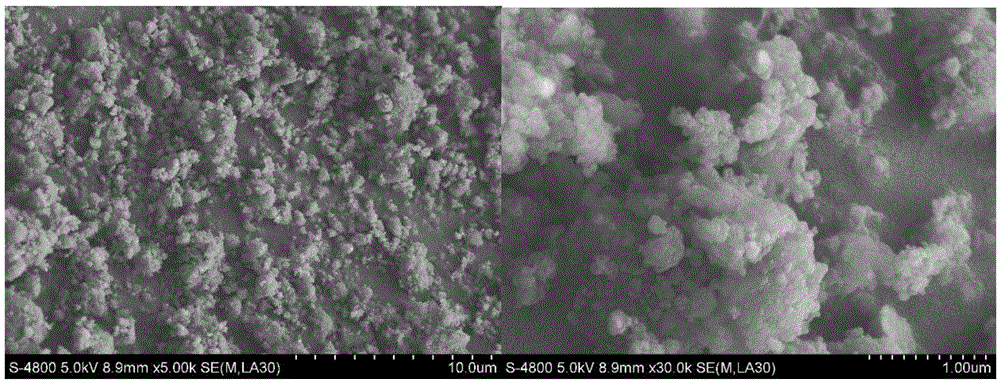

Wave-absorbing material based on grapheme and preparation method thereof

InactiveCN105647468AImprove absorbing abilityImprove absorbing performanceOther chemical processesDielectricElectromagnetic shielding

The invention discloses a wave-absorbing material based on grapheme and a preparation method thereof. The wave-absorbing material is formed by mixing graphite powder (or taking graphite powder as a main material) with one of three magnetic dielectric materials: ferrite, carbonyl iron powder and ultrafine metal powder, wherein the graphite powder is prepared by flake graphite through a mechanical stripping method and has a mass percentage content of 60-99 percent. The wave-absorbing material provided by the invention has the characteristics of being high in absorption strength, wide in absorption band, low in density and the like and has the excellent characteristics of the grapheme and the magnetic dielectric materials in electromagnetic performance; the preparation method is easy for large scale, low in cost, environment-friendly and suitable for industrialized production. The wave-absorbing material has wide application potential and market prospect in the fields of wave-absorbing materials, anti-electrostatic materials and electromagnetic shielding.

Owner:兰州天烁新能源有限公司

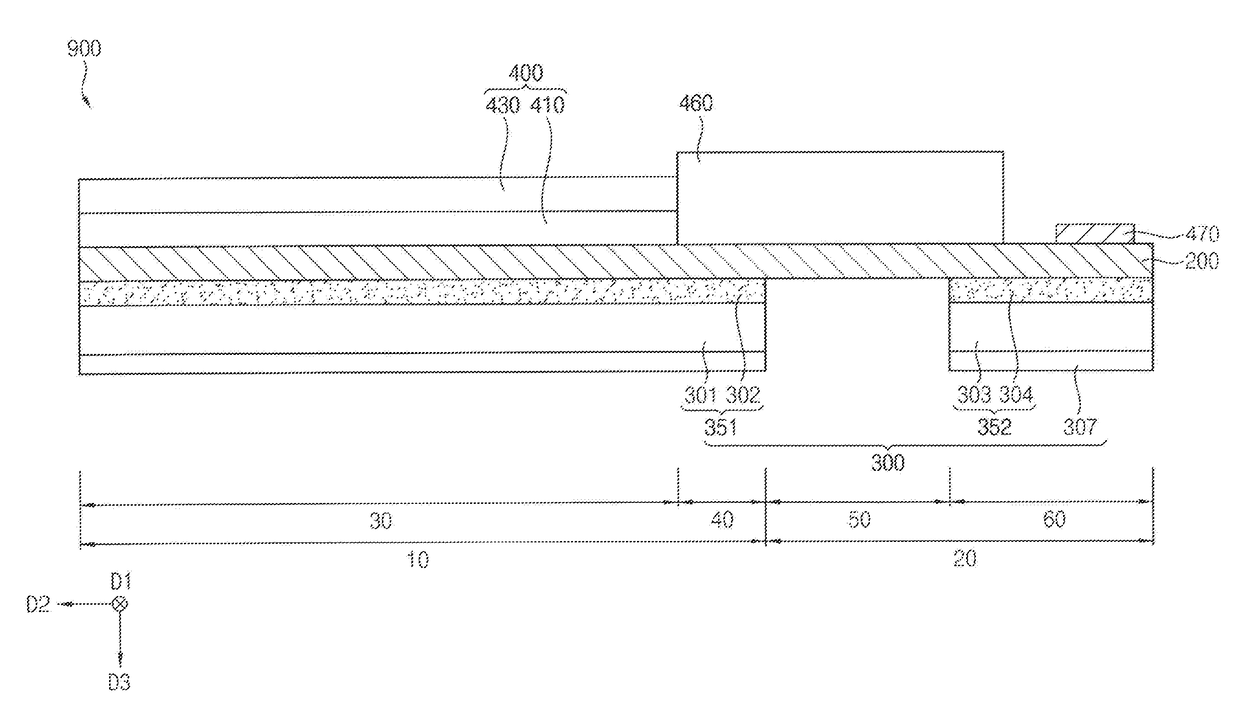

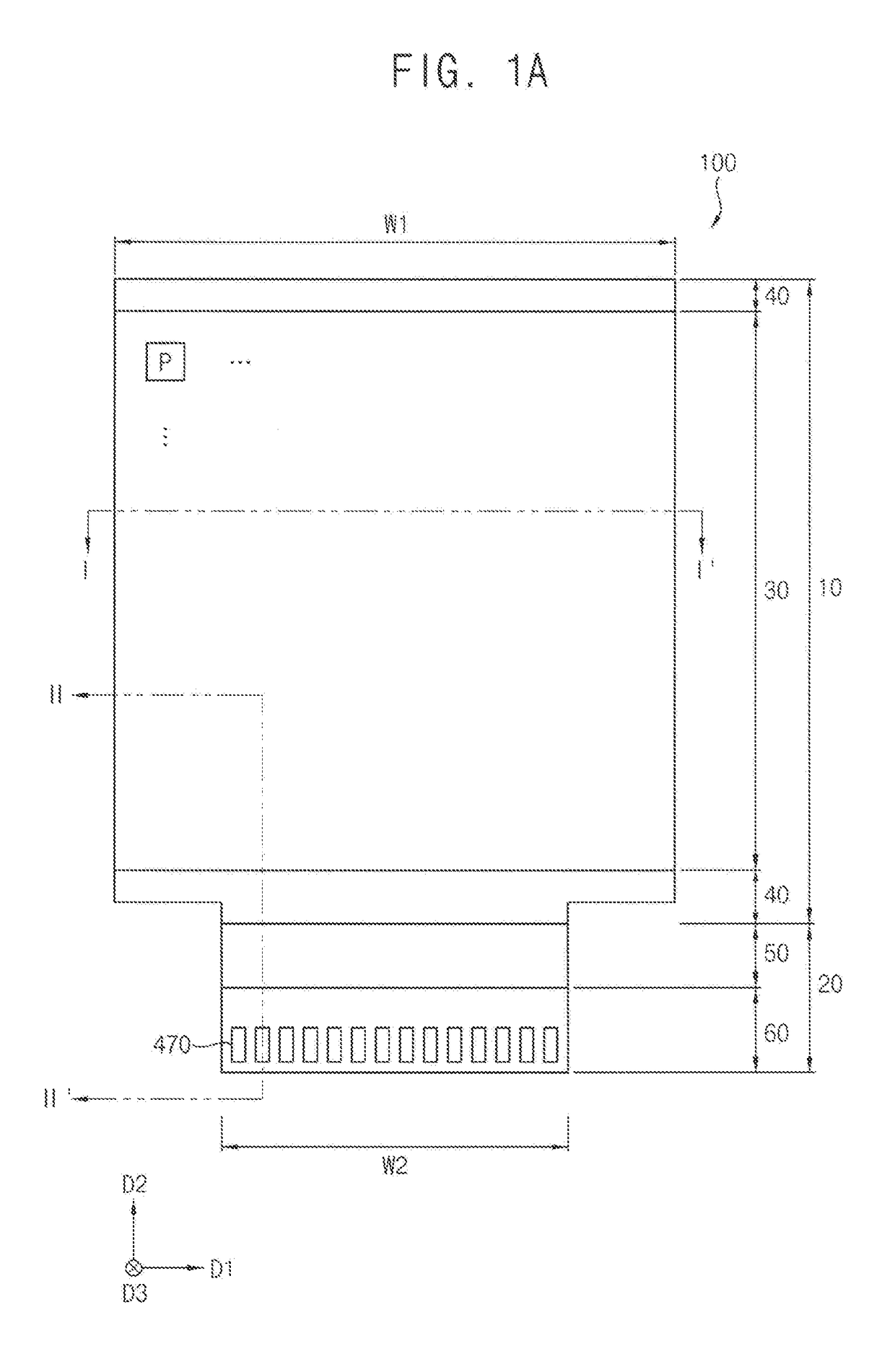

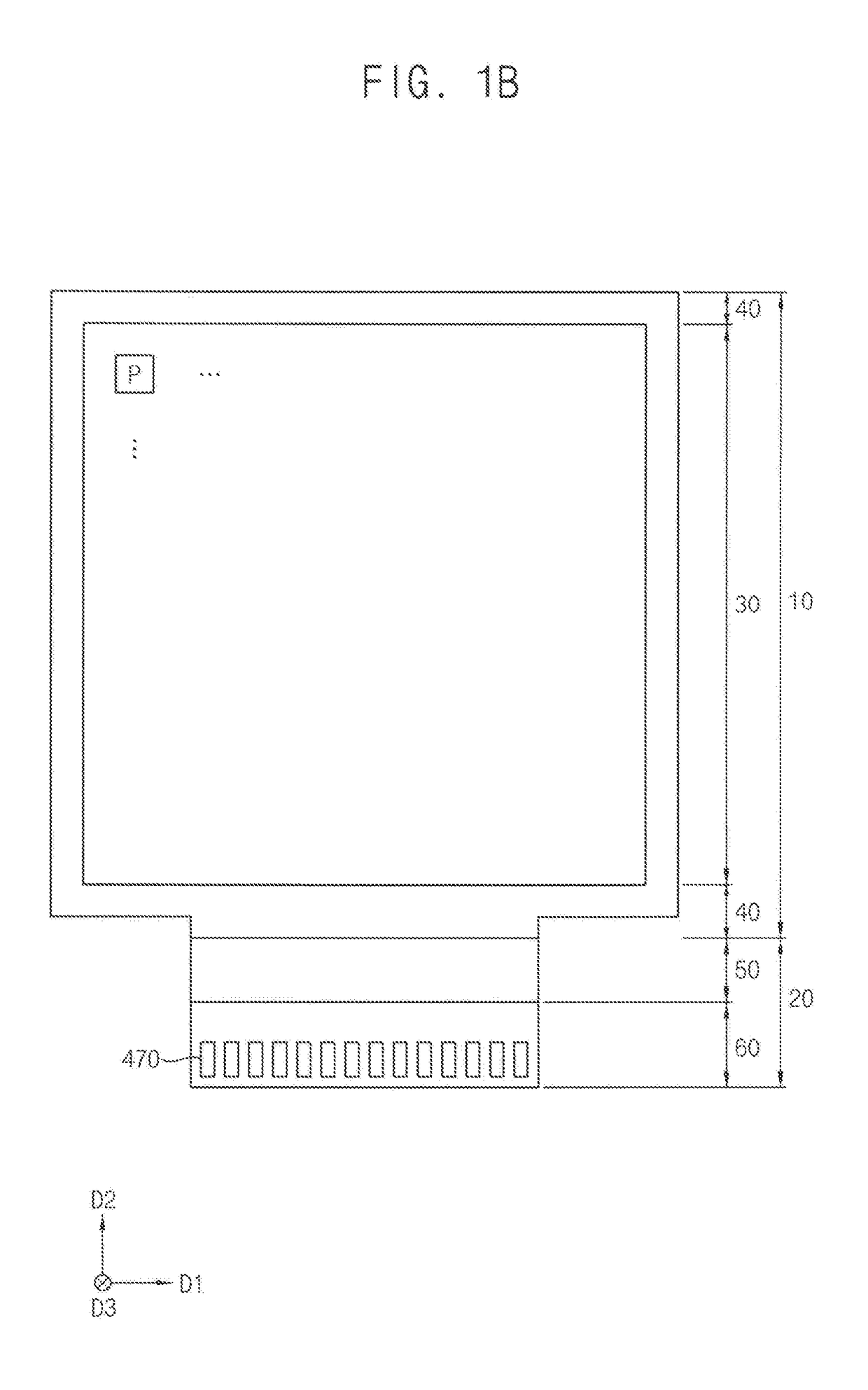

Organic light emitting display device

ActiveUS20180047938A1Improve device performanceEvenly distributedSemiconductor/solid-state device detailsSolid-state devicesCurve shapeDisplay device

An organic light emitting display device includes a flexible display panel having a display region where a plurality of pixels are disposed and a pad region where pad electrodes that are electrically connected to an external device are disposed, the pad region being located at a side of the display region, the display panel being configurable to have a curved shape where a flexible portion of the display region is bent, an upper structure in the display region of the display panel, and a lower protection film on a lower surface of the display panel, and including an adhesive layer and a protection layer. The adhesive layer is in direct contact with the lower surface of the display panel, and includes an antistatic material. The protection layer is disposed under the adhesive layer.

Owner:SAMSUNG DISPLAY CO LTD

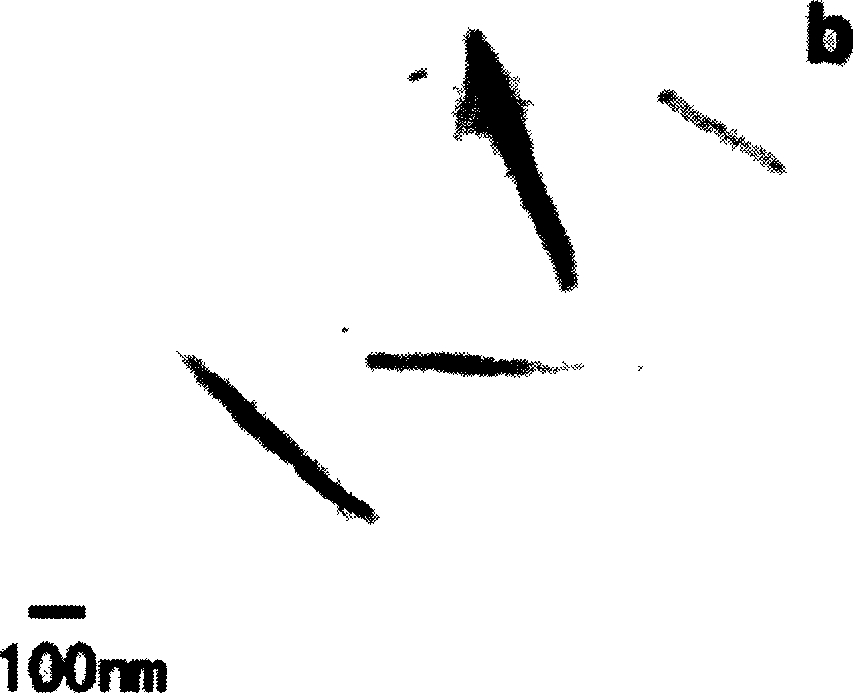

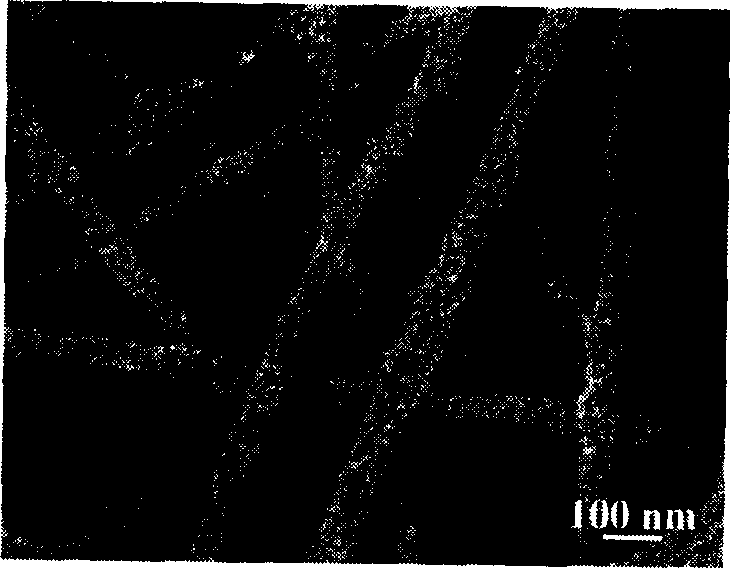

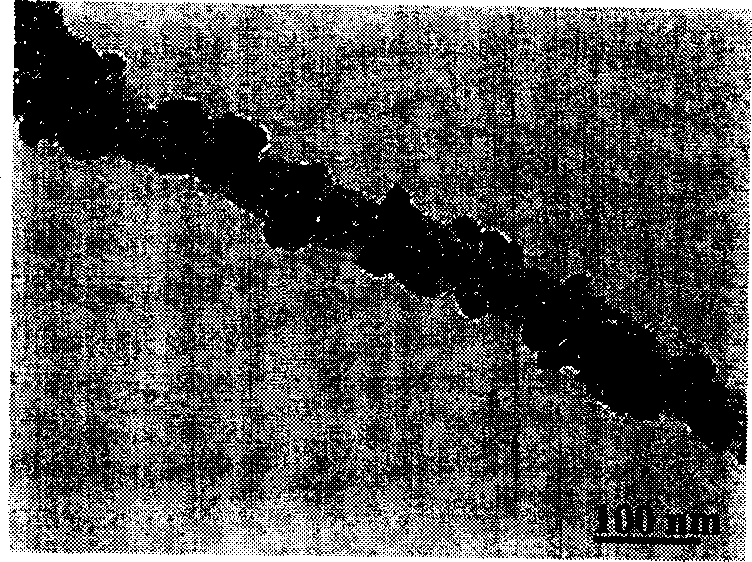

Carbon nanotube electrically conductive fibre and method for making same

The invention provides a carbon nanotube electrically conductive fibre and method for making same, wherein the conductive fiber comprises a carbon nano tube, dispersing agent and thermoplastic polymeric compound, the preparation comprises dispersing the carbon nano tube into water at the presence of the dispersing agent, mixing the carbon nano tube aqueous solution with thermoplastic polymer, drying, granulating and spinning.

Owner:DONGHUA UNIV

Antistatic paint cup

ActiveUS20060283861A1Avoid accumulationIncrease chanceWatering devicesLarge containersEngineeringAntistatic Materials

A flexible, disposable liner for use in a fluid supply assembly. The disposable liner is made of an antistatic material. In use, the chargeable particles in a coating mixture do not stick to the disposable liner so that uniformity of the coating mixture is maintained while it is dispensed. A method of maintaining the uniformity of a coating mixture during dispensing is also described.

Owner:CARLISLE FLUID TECH INC

Modified ABS antistatic material and preparation method thereof

The invention discloses a modified ABS antistatic material and a preparation method thereof. The antistatic material is formed by melting the mixture in an injection machine after mixing PEEA, maleic anhydride grafted ABS resin (or styrene maleic anhydride copolymer SMA), ABS resin, zlnc oxide whisker, coupler and other additives according to a given proportion. The antistatic ABS material has the advantages of low surface resistance, permanent static resistance, light color and good mechanics performance; and moreover, the antistatic ABS material has appropriate cost, no toxicity and pollution, simple formation processing technology, easy realization and promising application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

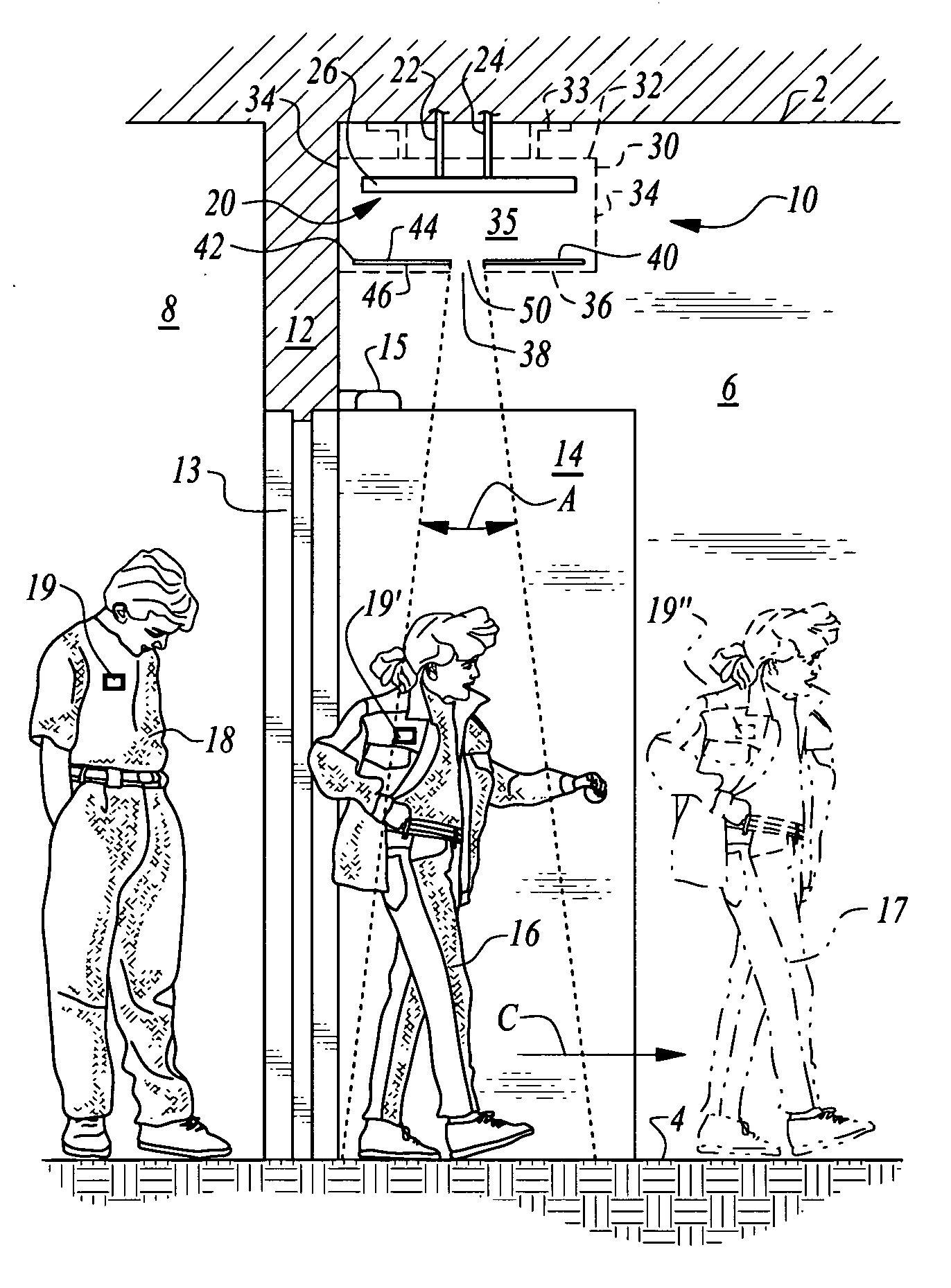

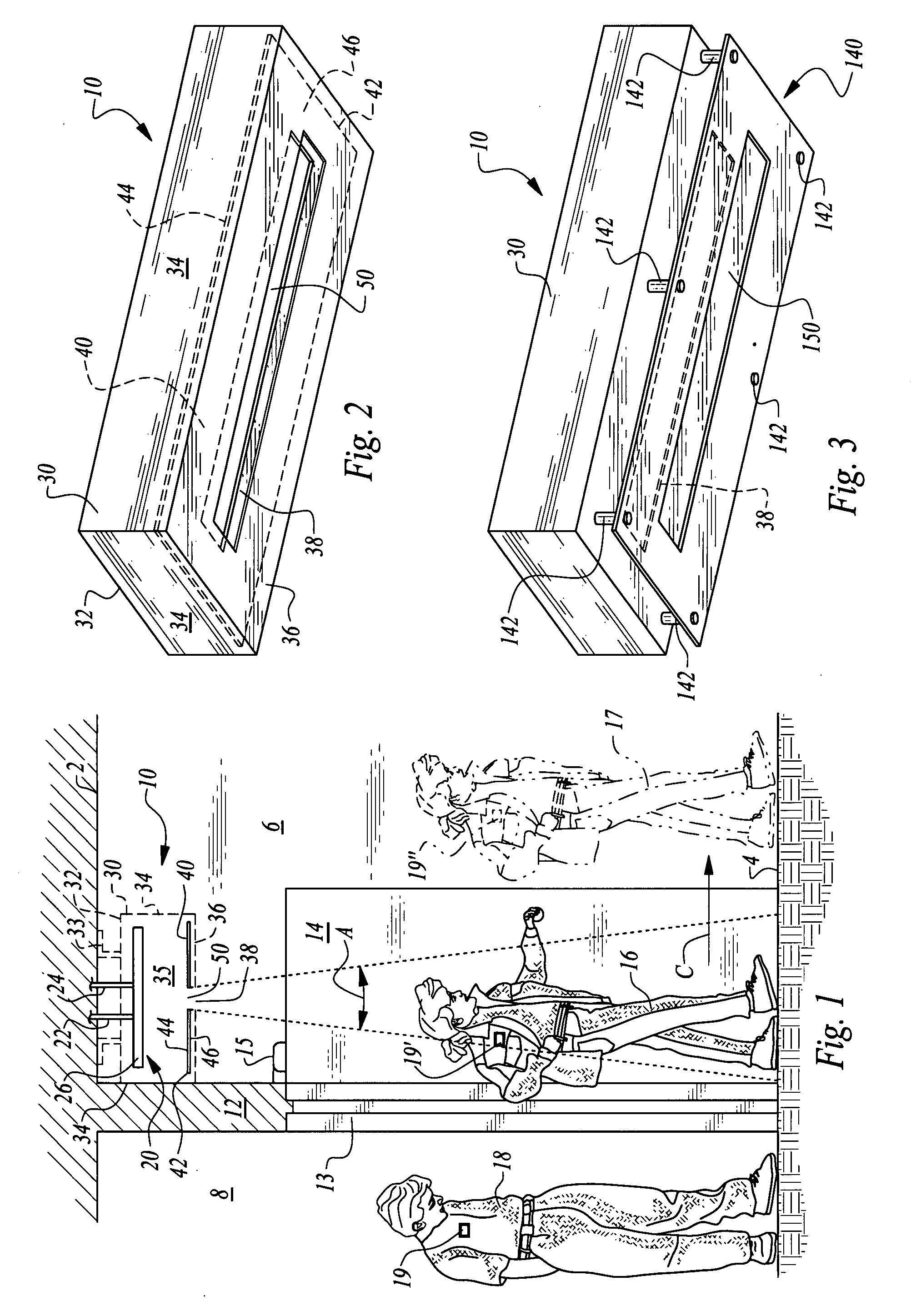

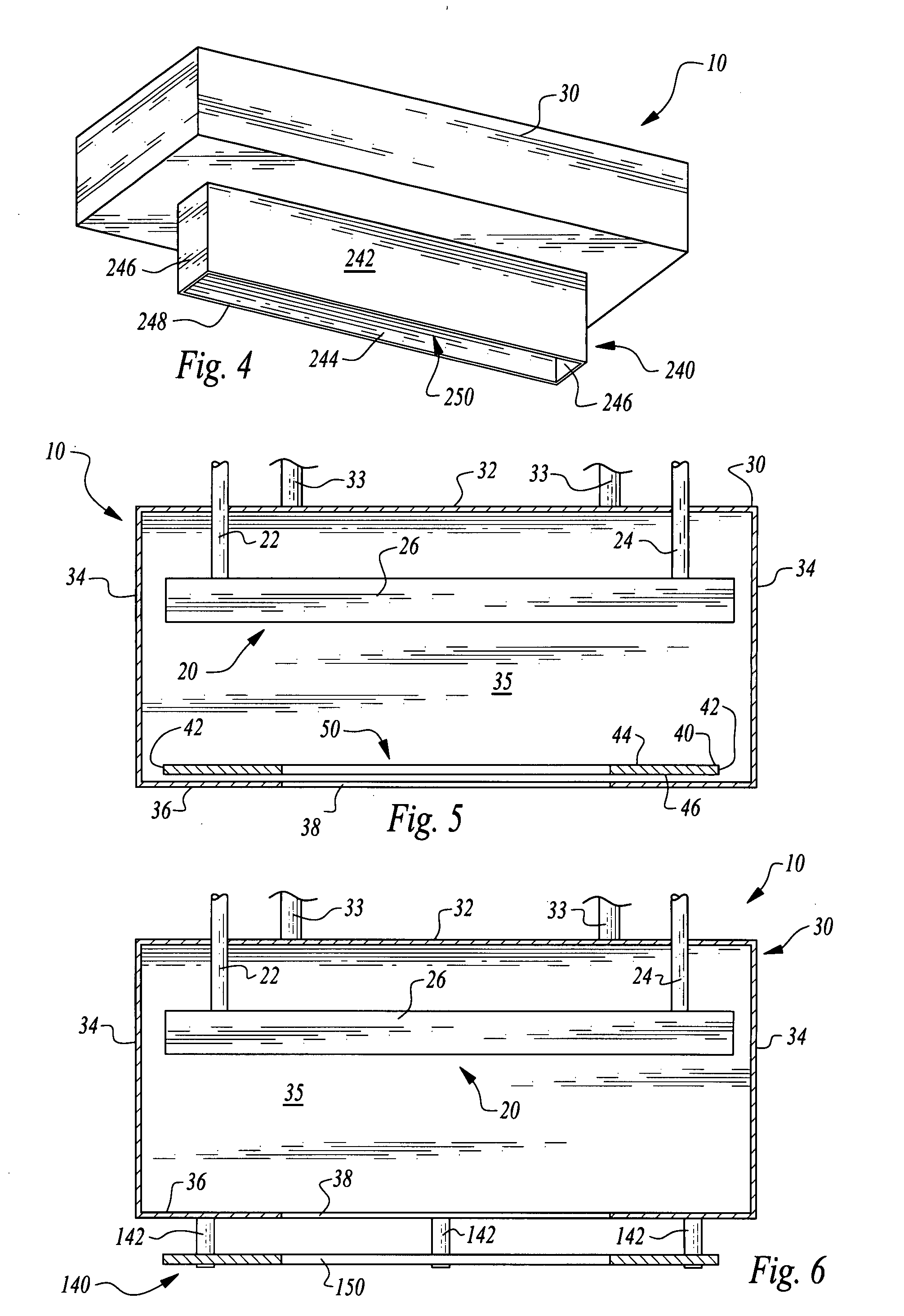

RFID transceiver sensitivity focusing system

InactiveUS20080185540A1Reduce sensitivityAccurate detectionMeasurement devicesShieldingRf fieldTransceiver

Shielding of a particular material and geometry is interposed between a radio frequency identification (“RFID”) antenna transceiver and a zone to be monitored by the antenna. The shielding has an aperture therein that to some extent defines a degree of focusing of the radio frequency (“RF”) field associated with the antenna. RFID tags having appropriate RFID circuitry are only detected by the antenna when they pass within the focused RF field. The shielding is formed of a thin metalized plastic material, such as film used in forming anti-static material for storage of sensitive electronics. One particular formulation is primarily polyethylene film with an aluminum coating or layer thereon.

Owner:INCOM CORP

Chitosan/carbon nanometer tube static spinning membrane preparation method

InactiveCN1730742AImprove solubilityGood film formingFilament/thread formingArtifical filament manufactureSolubilityPolyvinyl alcohol

The present invention is the preparation process of electrostatic spun chitosan / carbon nanotube film, and belongs to the field of antibiotic and antistatic material preparing technology. The preparation process includes the following steps: dissolving carbon nanotube in acid mixture to compound solution, heating the solution to boil, filtering, washing to weak acid and vacuum drying; dissolving chitosan inside glacial acetic acid solution to obtain yellowish glacial acetic acid solution of chitosan; mixing the carbon nanotube solution and the chitosan solution to obtain molecule level composite solution; mixing the molecule level composite solution with glacial acetic acid solution of PVA; and spinning. The preparation process is simple, and the obtained electrostatic spun chitosan / carbon nanotube material has high solubility, good filming performance, high conductivity, excellent antibiotic performance and excellent electromagnetic shielding performance.

Owner:TIANJIN UNIV

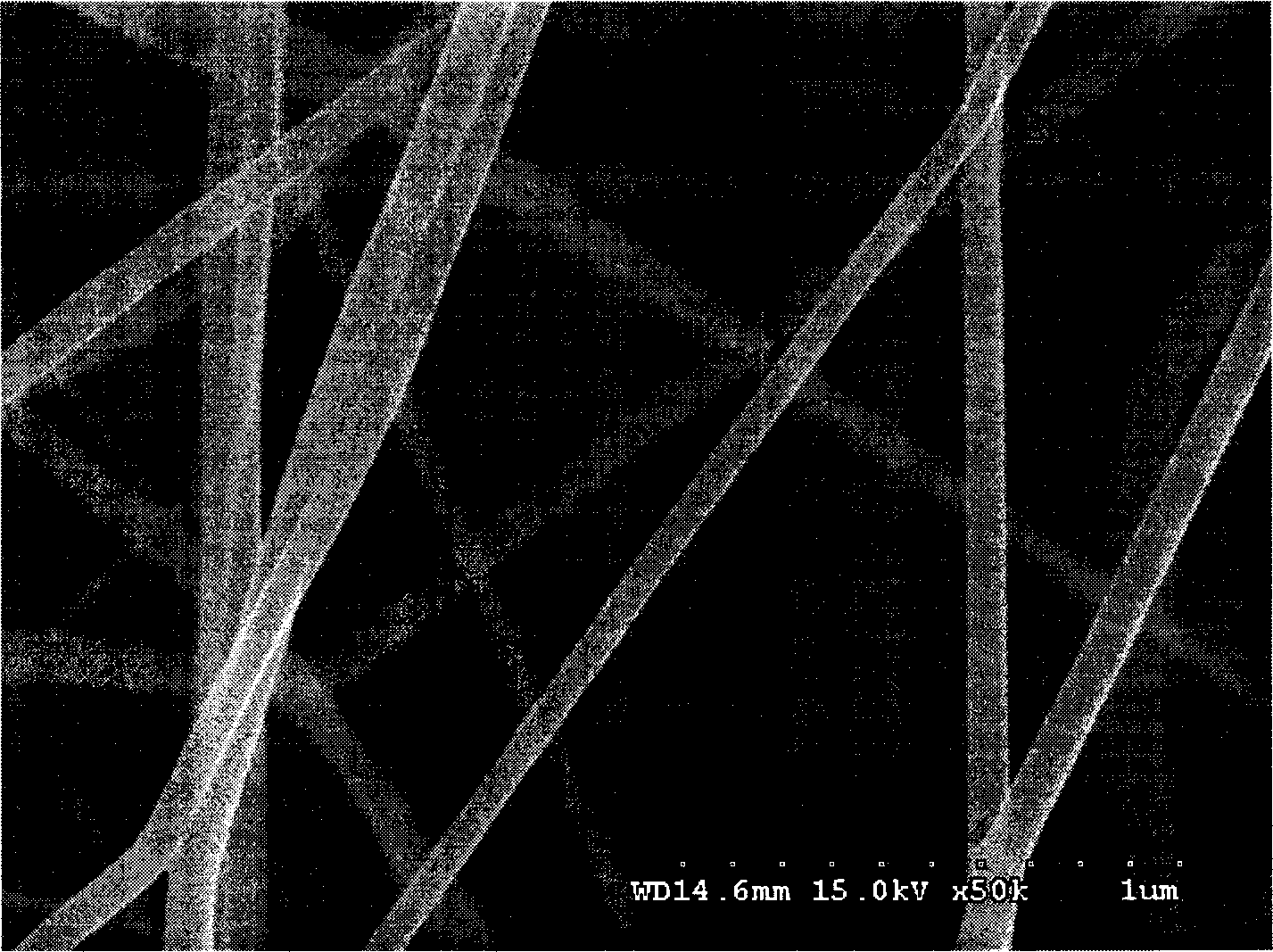

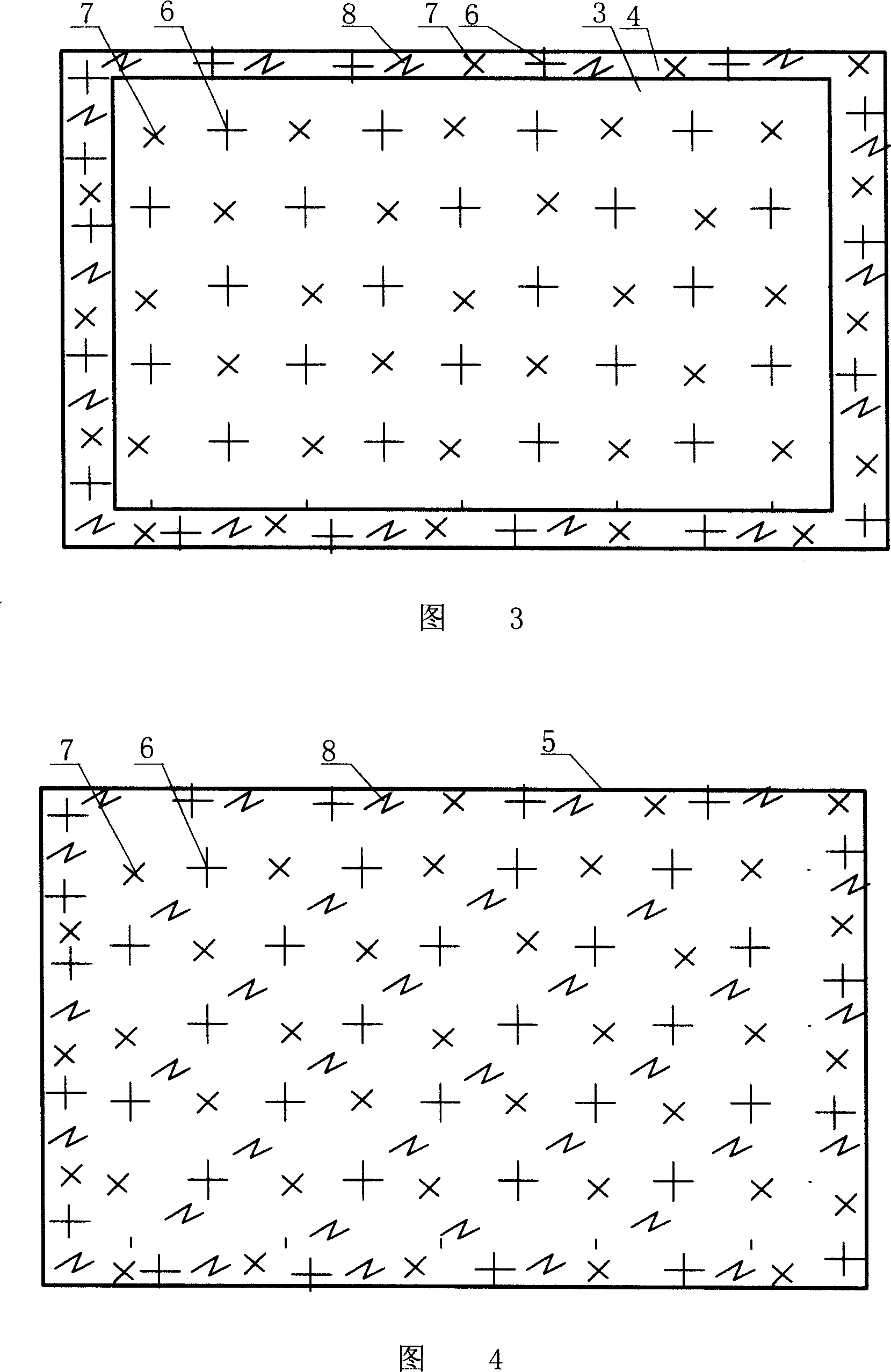

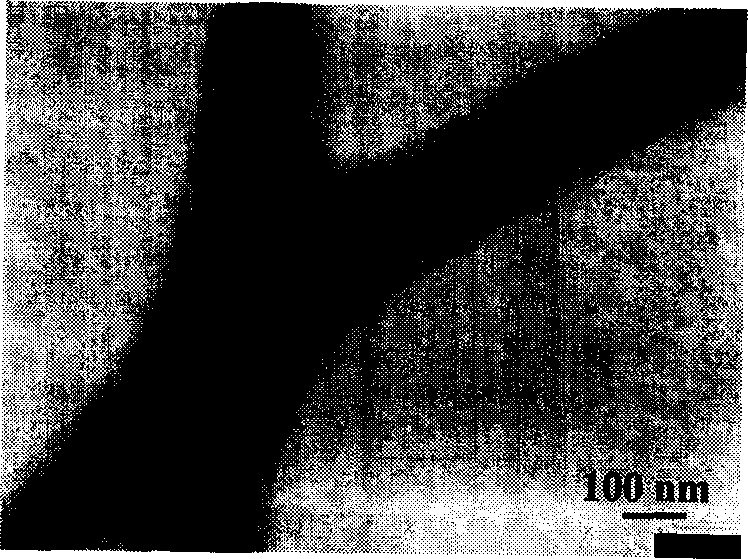

Fibre structure of polyester/carbone nanotube nano composite and its preparation method

InactiveCN1869291AGood orientationHigh strengthFilament/thread formingMonocomponent polyesters artificial filamentPolyesterElectrospinning

The invention relates to the fiber structure of polyester / carbon nanometer tube nanometer compound material that includes the fiber and the non-woven fabrics or film made by the fiber. Distributing the carbon nanometer tube and polyester into suitable polyester solution to form polyester / carbon nanometer tube solution or dispersing liquid, and gaining the fiber structure by static electric spinning that includes the non-woven fabrics or film of the fiber. The carbon nanometer occupies 0.001-90wt% in the material, and the diameter of the fiber is 1-10000nm, and optimization to 10-1000nm. The volume conductivity is 1*10-17-102S / cm. It has wide application prospect in kinds of fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Spray coating type fire-retardant antistatic polyurethane elastomer and preparation method thereof

ActiveCN103709362ALow viscosityImprove liquidityFireproof paintsPolyurea/polyurethane coatingsCarbon nanotubeSpray coating

The invention discloses a spray coating type fire-retardant antistatic polyurethane elastomer and a preparation method thereof. The spray coating type fire-retardant antistatic polyurethane elastomer comprises an A component and a B component, wherein the A component is composed of 40-60 parts of isocyanate and 40-60 parts of phosphorus-containing flame-retardant polyol, and the B component is composed of 0-30 parts of chain extender, 0-30 parts of polyether polyol, 10-75 parts of amine-terminated polyether, 0-30 parts of carbon nanotube slurry, 0-3 parts of pigment and 0-3 parts of assistant. The preparation method comprises the following steps: adding the phosphorus-containing flame-retardant polyol into a reaction kettle, heating up to 110 DEG C, vacuumizing for 3 hours, cooling to 30 DEG C, adding the isocyanate, heating up to 105 DEG C, and reacting for 3 hours to obtain a semi-prepolymer A component; sequentially adding the ingredients of the B component into a stirring tank, stirring uniformly, and grinding the mixture in a sand mill for 2.5 hours to prepare the B component; spray-coating the A component and the B component onto a surface through a high pressure spray coating machine, and quickly curing to form. According to the spray coating type fire-retardant antistatic polyurethane elastomer disclosed by the invention, film forming matters are stable, no fire retardant is separated out and the durability is good; a spray coating type fire-retardant antistatic material prepared by the preparation method disclosed by the invention has both fire resistance and anti-static function, so that the material is suitable for application on flame-retardant and explosion-proof occasions.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

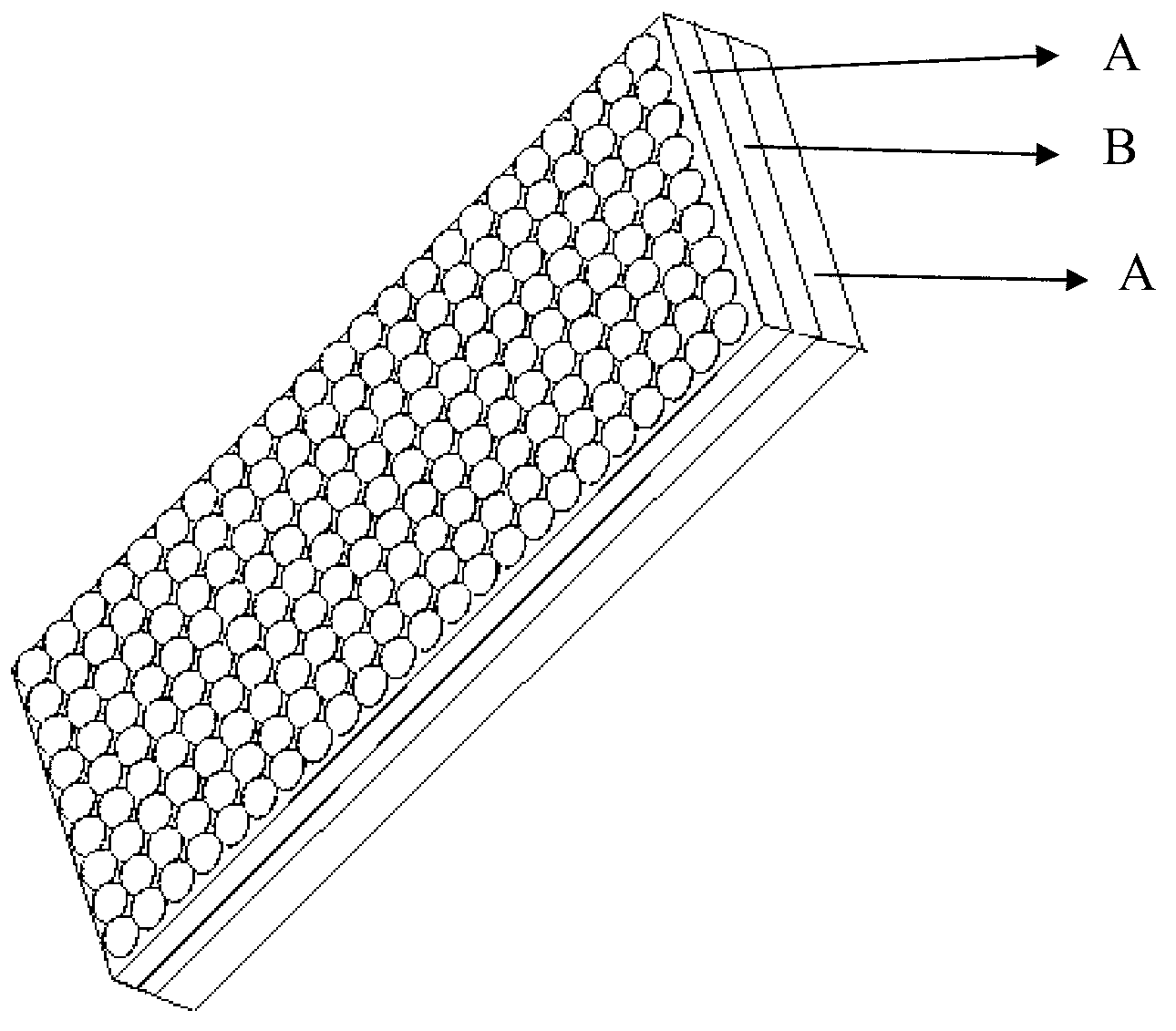

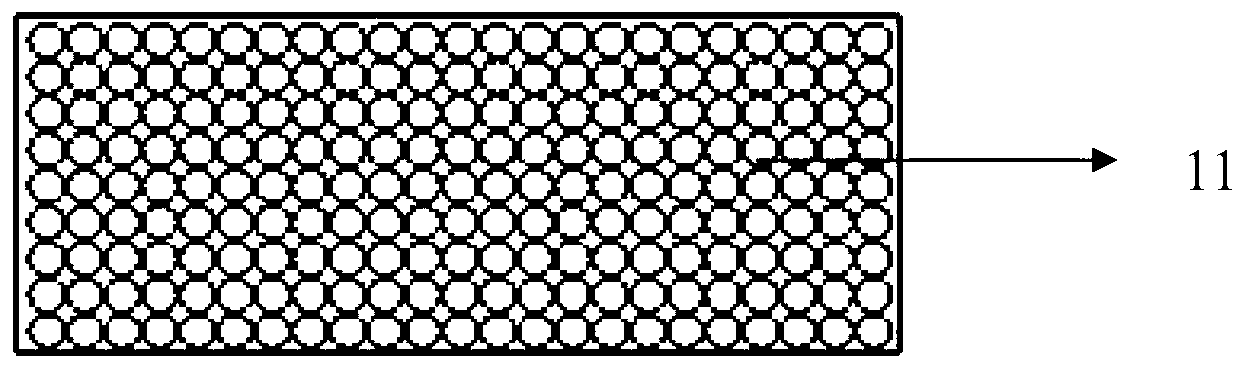

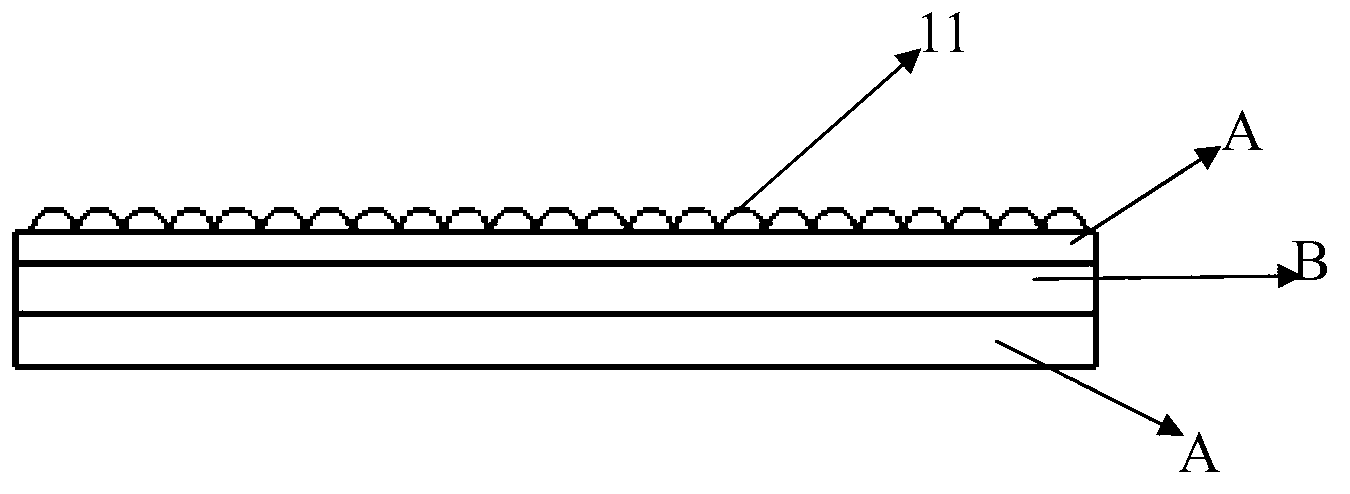

Antistatic plastic for SMT carrier band, and preparation and use thereof

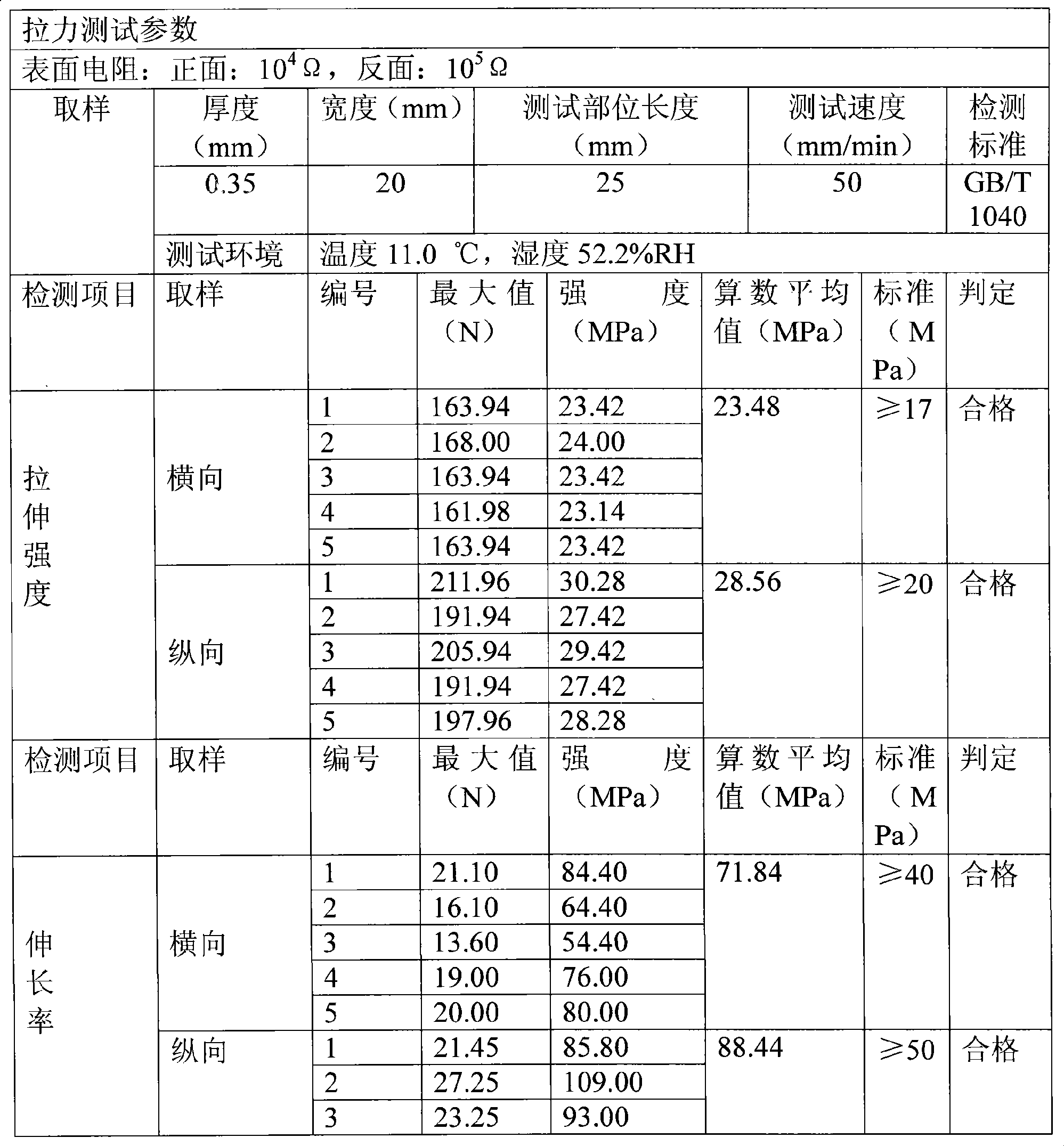

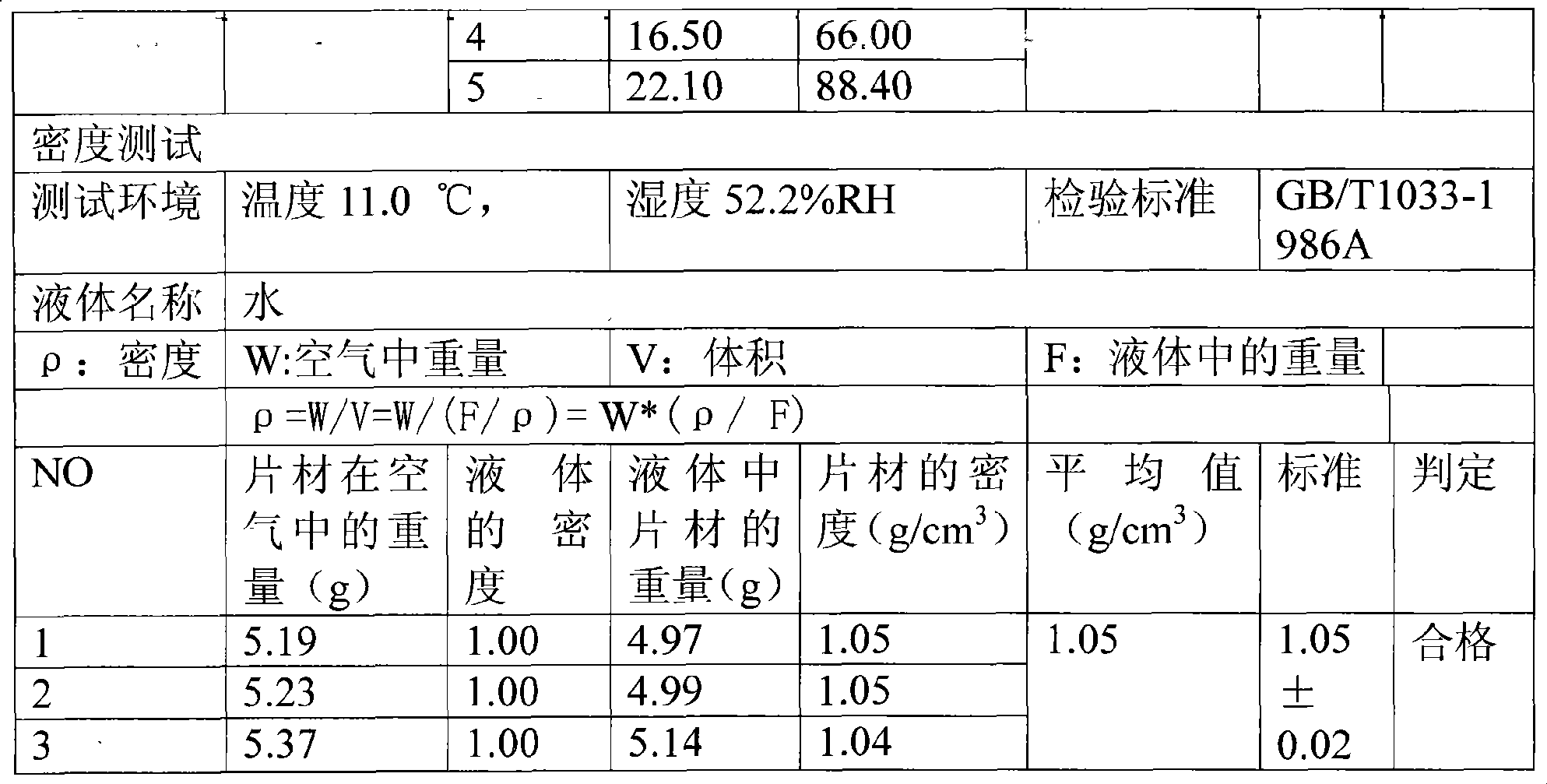

ActiveCN101475721AImprove rigidityImprove toughnessOther chemical processesSynthetic resin layered productsPolymer scienceButadiene Dioxide

The invention relates to an antistatic plastic for an SMT carrier band, a preparation method thereof, and a composite plastic sheet prepared from the antistatic plastic. The antistatic plastic for the SMT carrier band consists of the following compositions mixed in percentage by weight: 5 to 45 percent of conductive black carbon, 30 to 90 percent of polystyrene, 5 to 45 percent of styrene-butadiene copolymer elastic SBS, 1 to 13 percent of a toughening agent, 0.1 to 2.8 percent of an antioxidant, and 0.3 to 3.8 percent of a coupling agent. The invention also discloses the composite plastic sheet prepared from the antistatic plastic. The antistatic plastic has good rigidity, good toughness, good aging resistance and easy molding with surface antistatic index of between 10 and 10omega. The composite material with a three-layer structure saves use of the antistatic material on one side, and improves toughness and rigidity of the product on the other side, and is easy for processing. The composite material has tensile strength of between 22 and 24MPa widthwise and between 27 and 31MPa lengthwise, and has tensile stretch of between 54 and 84 percent widthwise and between 66 and 110 percent lengthwise.

Owner:浙江三和塑料有限公司

TPV (Thermoplastic Vulcanizate) elastomeric material with improved electrical property

ActiveCN102051000AMeet performance requirementsImprove electrical performanceThermoplasticCross-link

The invention discloses a TPV (Thermoplastic Vulcanizate) elastomeric material with improved electrical property, comprising the following components in percentage by weight: 15%-60% of polypropylene, 20%-60% ethylene propylene terpolymer rubber, 0.5%-10% of high-molecular compatibilizers, 0.1%-40% of fillers, 1%-60% of rubber extending oil, 0.5%-10% of modifiers, 0.5%-10% of cross-linking agents, 0.1%-10% of cross-linking auxiliary agents, 0.01%-2% of antioxidants and 0.01%-10% of processing auxiliary agents. The invention enables the carbon nanotubes to be gathered on continuous PP (PropenePolymer) phases to form a continuous conductive network structure by adopting the carbon nanotubes as the modifiers and utilizing a principle that the special phase-stage structure of TPV and the high-molecular compatibilizers are completely compatible with PP but incompletely compatible with cross-linking rubber, thereby obtaining ideal electrical property improving effect; surface resistance isreduced to 106 when an addition amount is 2 percent, and the surface resistance is reduced to 102 when the addition amount is 5 percent, therefore the effect is far higher than that the effect of thecommon conductive carbon black; and in addition, the invention keeps good processing flow property, extends the application of the TPV in the field of antistatic materials and conductive materials and has extensive application prospect.

Owner:KINGFA SCI & TECH CO LTD +2

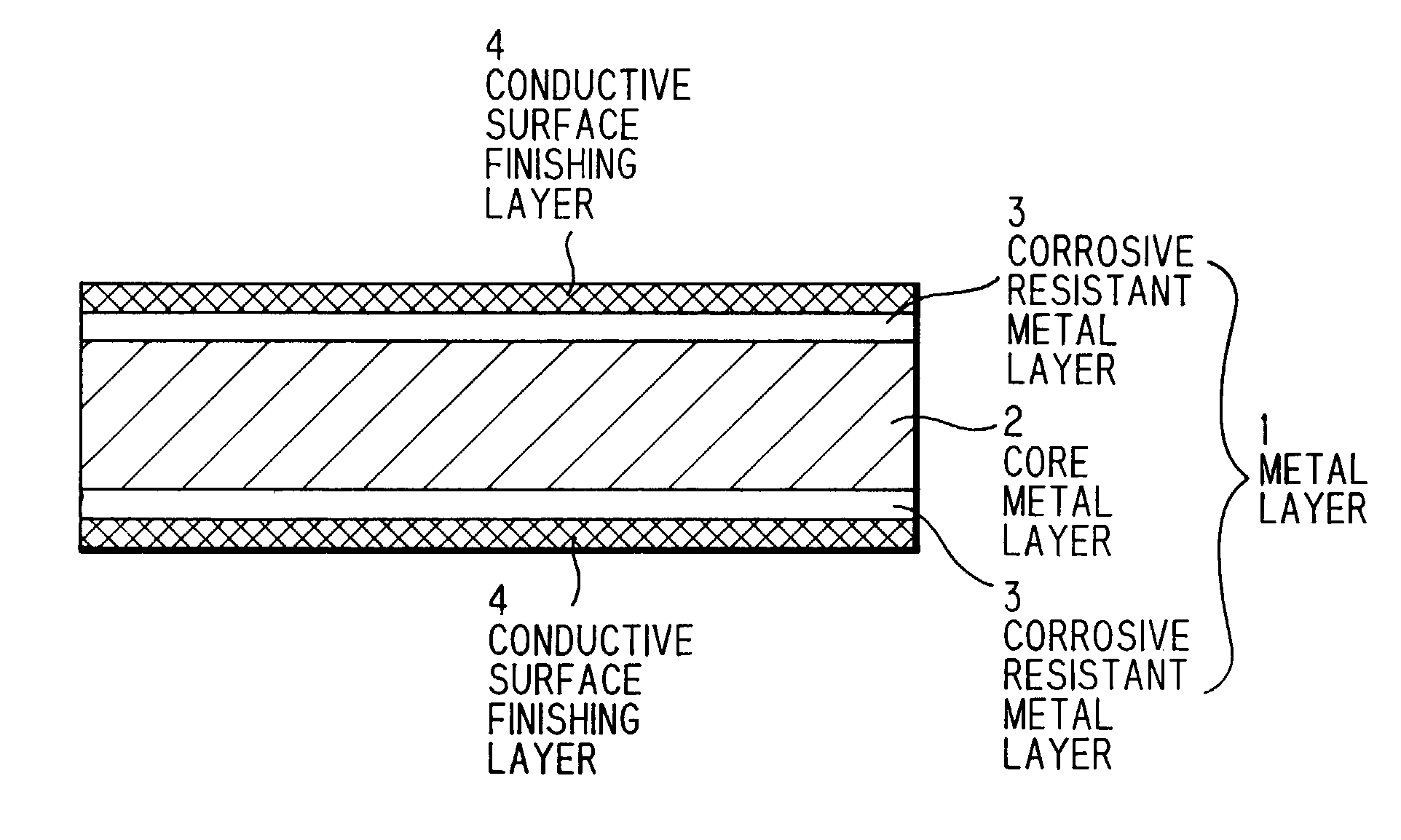

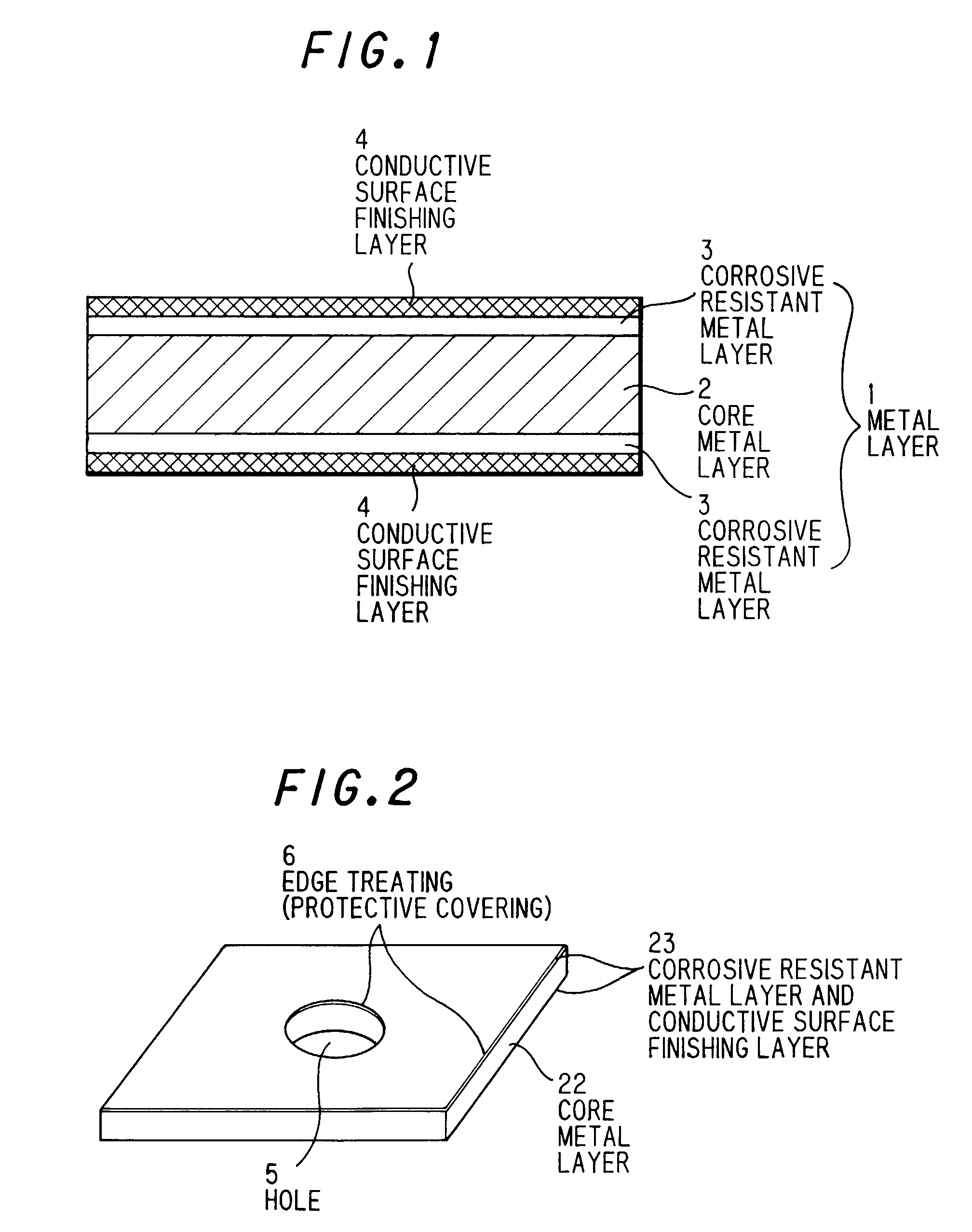

Corrosive resistant metal material covered with conductive substance

InactiveUS7399532B2Improve conductivityExcellent mold releasabilitySolid electrolyte fuel cellsFuel cell detailsNiobiumConductive materials

A corrosive resistant metal material covered with a conductive substance suitable for use in a component material requiring conductivity and corrosion resistance like electrical conductive material, electrical contact, electromagnetic wave shield, electrochemical electrode or antistatic material, specifically for component material requiring conductivity in sever condition of corrosive environment is provided. A corrosive resistant metal material covered with a conductive substance is formed by cladding a corrosive resistant metal selected from the group consisting of titanium, zirconium, tantalum, niobium and alloy thereof on a conductive metal selected from the group consisting of iron, aluminum, copper, titanium, magnesium, zirconium, tantalum, niobium, tungsten, nickel, chrome and alloy thereof, and covering a conductive surface finishing layer over surface of a corrosive resistant metal layer with a mixture of conductive substance and resinous binder.

Owner:HITACHI CABLE +1

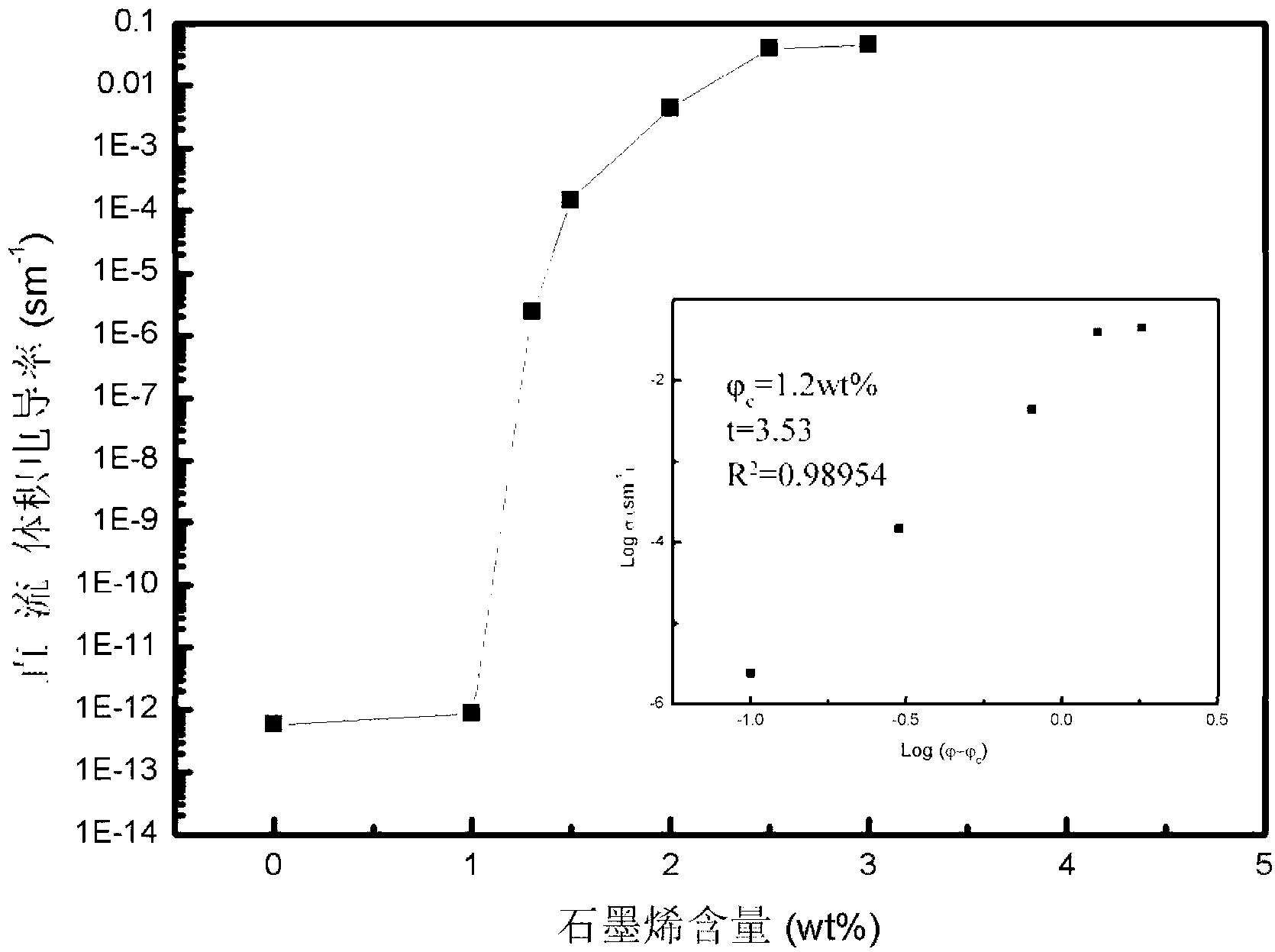

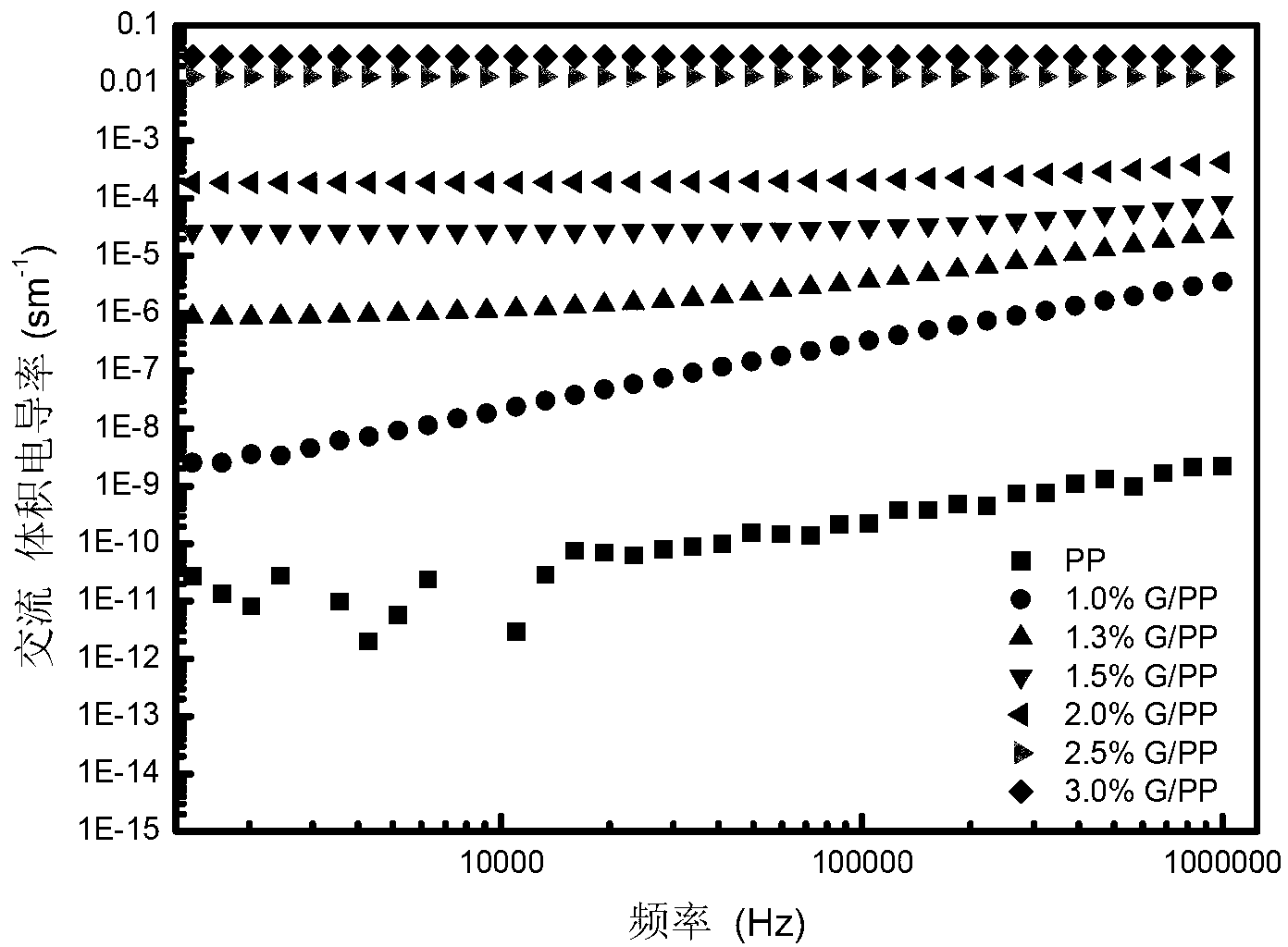

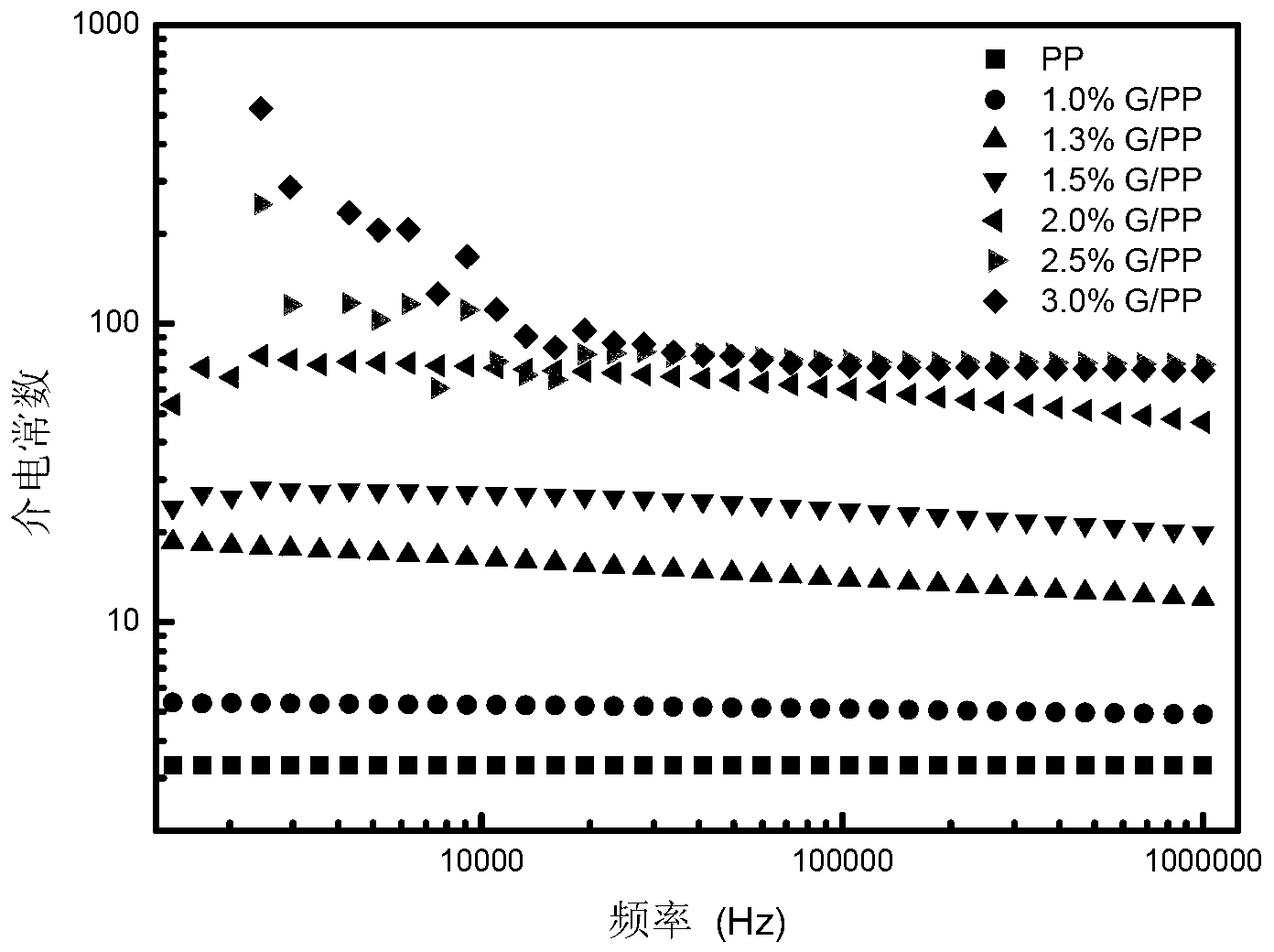

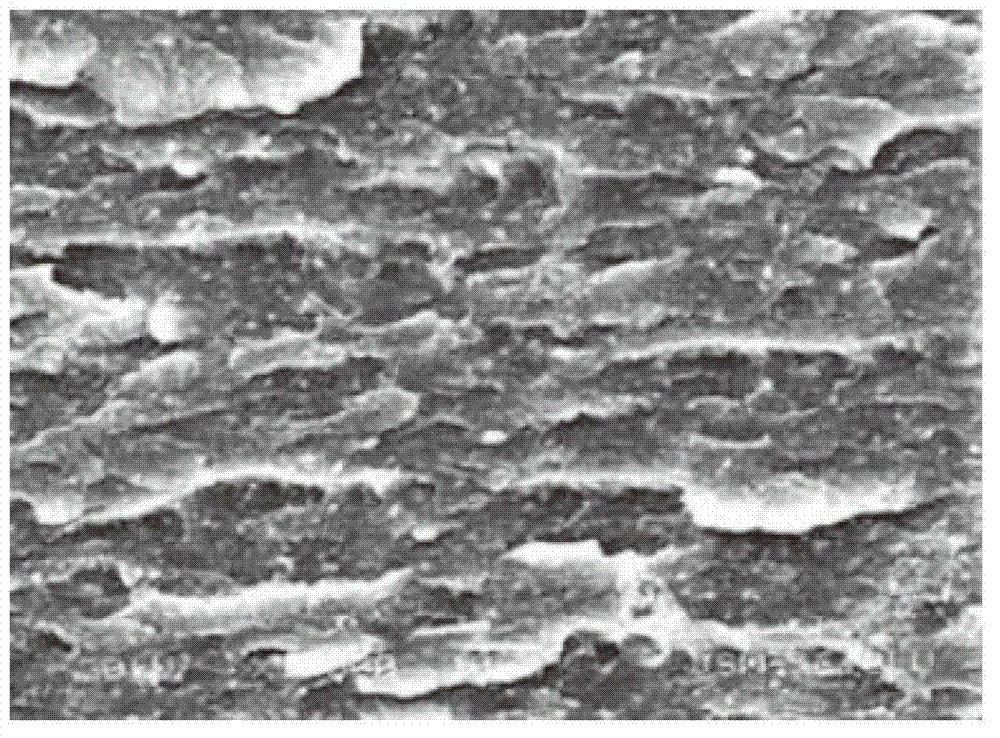

Graphene/polypropylene conductive nano composite material and preparation method thereof

The invention relates to a graphene / polypropylene conductive nano composite material and a preparation method thereof, belonging to the technical field of polymer nano composite materials. On the basis of 100 parts by mass, the graphene / polypropylene conductive nano composite material contains 92.5-97.5 parts by mass of polypropylene (as a base), 1-3 parts by mass of graphene (as a conductive filler) and 1.5-4.5 parts by mass of maleic anhydride grafted polypropylene (for promoting dispersion of the graphene); and the graphene / polypropylene conductive nano composite material is prepared by solution blending and hot pressing. A series of graphene / polypropylene conductive nano composite materials in different proportions can be obtained by changing the mass percent of the graphene in the composite system. The prepared graphene / polypropylene conductive nano composite material can be used in the fields of conductive materials, electromagnetic shielding materials, antistatic materials and the like.

Owner:JILIN UNIV +1

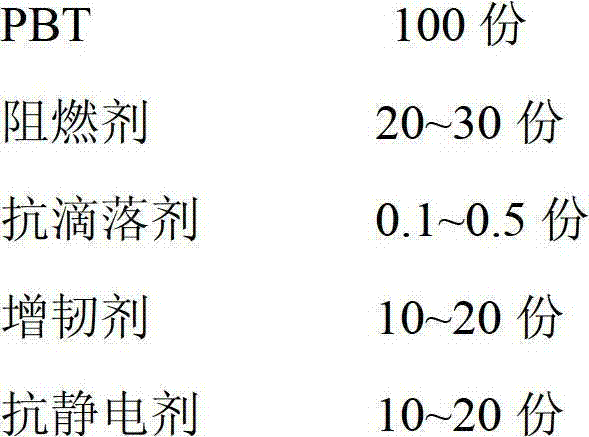

PBT (polybutylece terephthalate) composite and preparation method thereof

InactiveCN102924884AAvoid the phenomenon of floating fibersPerformance diversificationFiberPolyethylene terephthalate

The invention provides a high-performance halogen-free flame-resistant non-reinforced antistatic PBT (polybutylece terephthalate) composite and a preparation method thereof. The composite can still keep good flame-resistant, antistatic and mechanical properties under the condition that a reinforcing material is not added, and the phenomenon of fiber floating in the traditional reinforcing material system is avoided. The preparation method comprises the following steps that PBT resin, a fire retardant and a flexibilizer are dried, and a tackifier and an antistatic material are pretreated; the PBT resin and various padding are added into a low-speed mixer to be pre-mixed, the PBT resin and the padding are uniformly mixed and then are blend and extruded and pelleted through a double-screw extruder to be dried, and the halogen-free flame-resistant non-reinforced antistatic PBT material is obtained.

Owner:CHANGZHOU UNIV +1

Controllable synthesis method for polyaniline nano structure and use thereof

InactiveCN1667021AOptimal Control StructureThe synthesis method is simpleElectrical apparatusElectroluminescent light sourcesFiberSynthesis methods

This invention relates to a controllable synthesized method of new style polyaniline self-assembly nanostructure. The method is that poly reaction is happened at 100~2500C in autoclave, dopant is protonic acid of oxidative polymerization reaction, then polyaniline flake structure is got and order tactic polyaniline nanometer bar (fiber) array on its surface. The structure has great photism. The array can be used to electromagnetic wave shield materials, antistatic materials, big content capacitor material, triode, sensor material, gas separation material and high efficiency photism.

Owner:NANJING UNIV

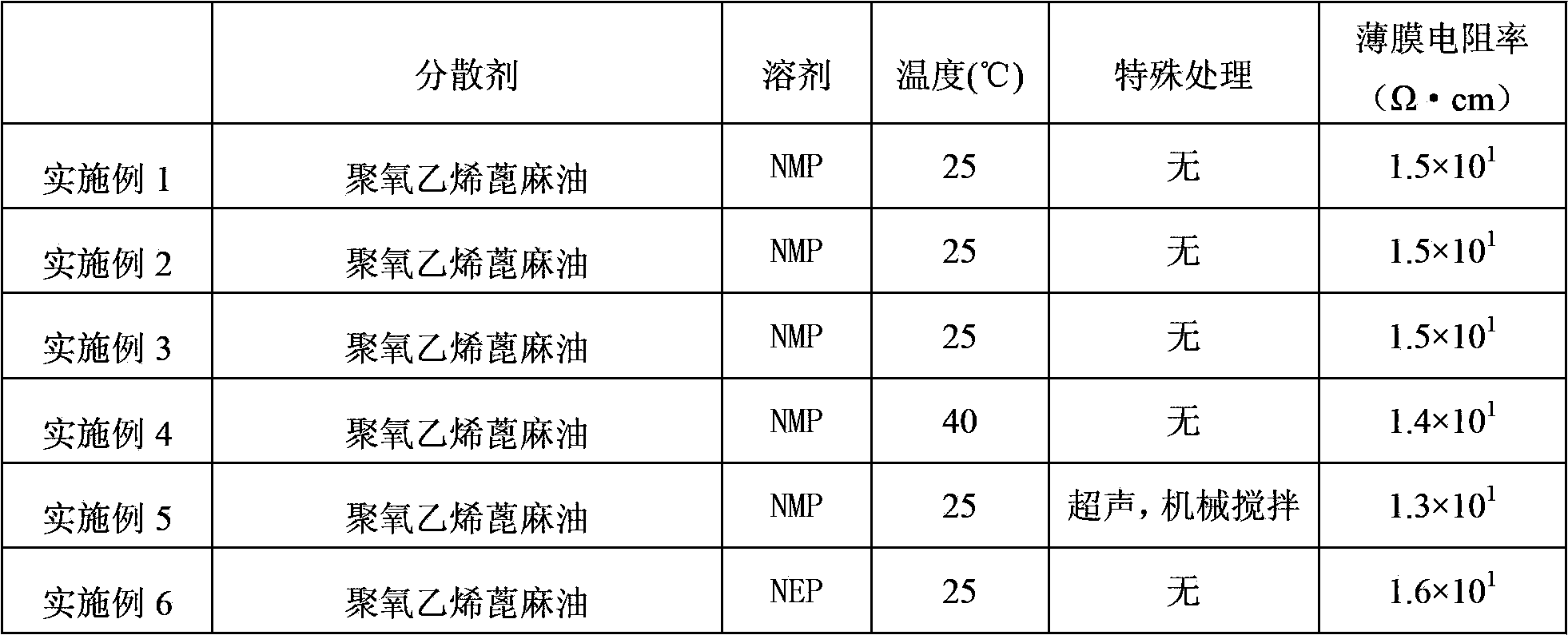

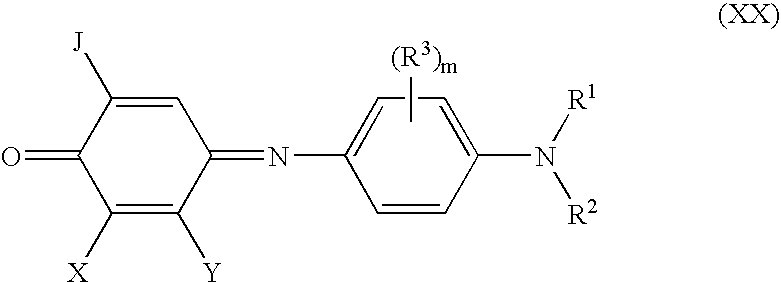

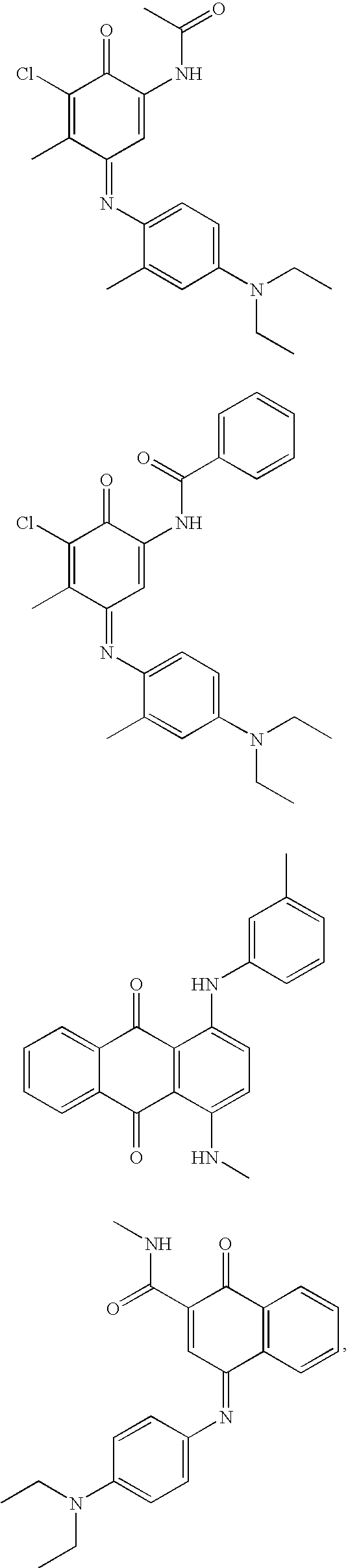

Graphene dispersion liquid and preparation method thereof

InactiveCN103725046AGood dispersionImprove conductivityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsMicrowaveElectromagnetic shielding

The invention relates to a graphene dispersion liquid and a preparation method thereof. The graphene dispersion liquid comprises graphene, a dispersant and a solvent. The dispersant is polyoxyethylated castor oil. Through use of the dispersant in graphene, the graphene dispersion liquid having good dispersibility is prepared. The graphene dispersion liquid has good electrical conductivity and can be used in fields of conductive materials, anti-static materials, electromagnetic shielding materials of electronic products, electrode materials of lithium ion batteries, and microwave absorption materials.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Antistatic material, self-cleaning light diffusion plate prepared therefrom, and preparation method of self-cleaning light diffusion plate

ActiveCN103242593ARaw materials are easy to getReduce manufacturing costOptical elementsAntioxidantAntistatic Materials

The invention relates to an antistatic material, a self-cleaning light diffusion plate prepared therefrom, and a preparation method of the self-cleaning light diffusion plate. The antistatic material comprises a matrix resin, a light diffusing agent, an antistatic agent, an antioxidant, a light stabilizer and a dispersing agent; the antistatic material has the resistivity up to 107 to 1011 and is remarkable in antistatic performance; the light diffusion plate prepared from such an antistatic material has high light transmission performance and high antistatic self-cleaning performance, effectively improves the light transmission performance and has long-term stability; in addition, raw materials are easy to obtain, the preparation cost is low, and the light diffusion plate is suitable for being applied to related fields of products requiring antistatic prevention and improvement of self-cleaning performance. The preparation method of the self-cleaning light diffusion plate, provided by the invention, is optimal in process, simple in operation, suitable for continuous production and manufacturing, low in economic cost, and suitable for popularization and application.

Owner:BEIJING UNIV OF CHEM TECH

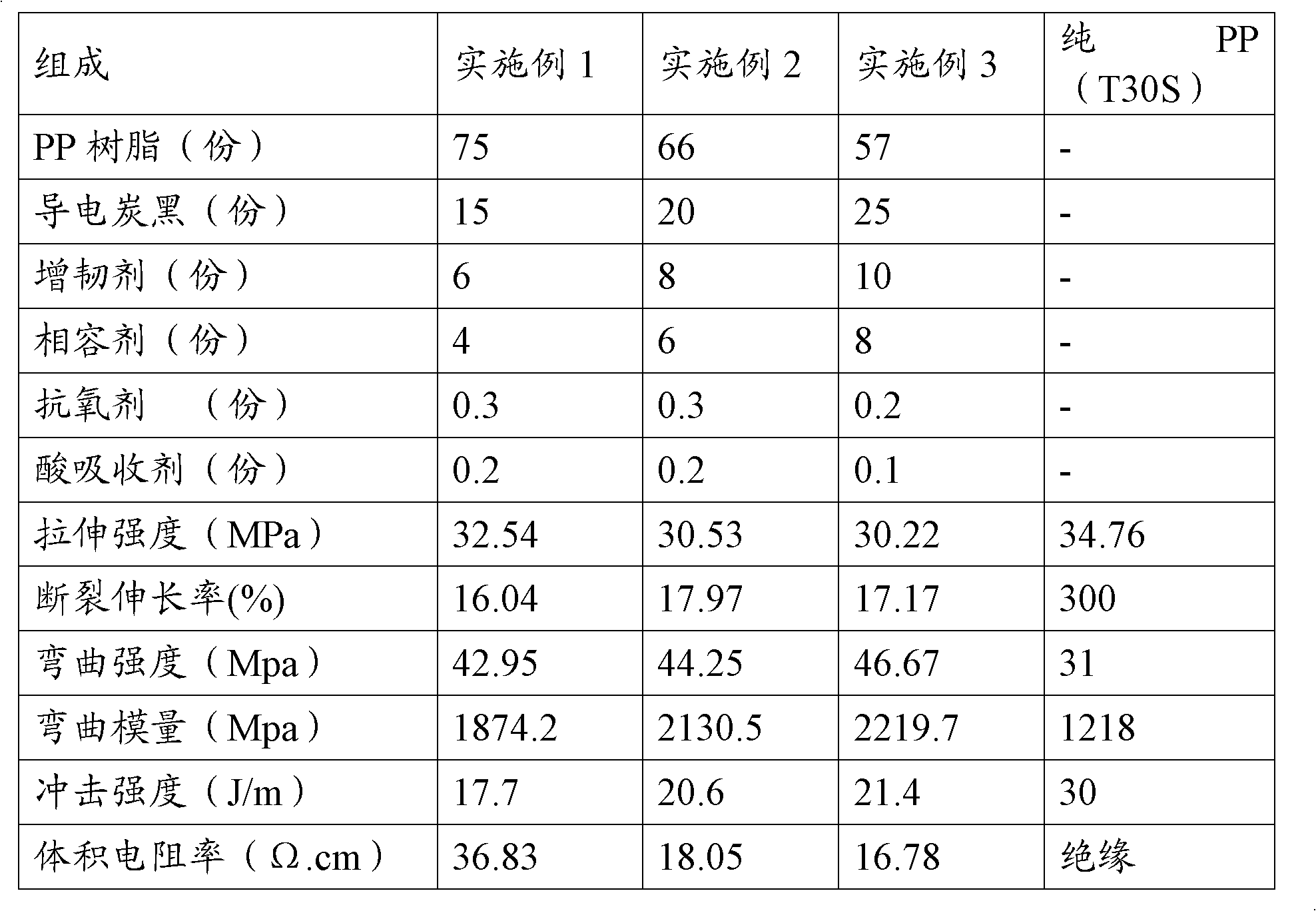

Conductive carbon black modified PP material and preparation method thereof

The invention discloses a conductive carbon black modified PP material and a preparation method thereof. The conductive PP material is prepared from components of, by weight: 55 to 75 parts of PP resin, 15 to 25 parts of conductive carbon black, 6 to 10 parts of a toughening agent, 4 to 8 parts of a compatibilizer, 0.2 to 0.4 parts of an antioxidant, and 0.1 to 0.3 parts of an acid absorbent. According to the invention, carbon black is added into PP resin, and the materials are processed through blending modification, such that a permanently conductive plastic material with adjustable resistivity is obtained. The material has permanently stable conductivity. The resistivity of the material can be adjusted within a relatively large range. The plastic material has good performance as thermoplastics, and has low price. The material is an ideal antistatic material which can be widely applied in antistatic reusable containers, pallets, wafer carriers, and film sacs in processing procedures of precise electronic components of integrated circuits, wafers, and sensor sheaths. The material can also be used in industries of electronic product EMI shielding housings in fields of telecommunications, computers, automation systems, industrial electronic products, consumption electronic products, and automobile electronic products.

Owner:SHENZHEN KEJU NEW MATERIAL

Antistatic decorated board

The invention provides an antistatic decorated board, relates to an artificial board material, in particular to a decorated board which is made of bamboo or wooden material and has antistatic function. The antistatic decorated board uses a flakeboard, a directional structural flakeboard or a fiber board as a base material, and uses decorative impregnated paper as a surface layer and a bottom layer to produce the antistatic decorated board through hot-press gluing. The antistatic decorated board is characterized in that an antistatic material is added into the flakeboard, the directional structural flakeboard or the fiber board; a impregnated material of the decorative impregnated paper of the surface layer and the bottom layer is antistatic resin adhesive; the surface resistance of the antistatic decorated board is less than 10 ohms. The antistatic decorated board has a nice appearance, maintains the corresponding performance of the structural board, has double antistatic effect, low cost, corrosion resistance and the surface resistance is less than 10 ohms of, therefore the invention is the best choice for an electronic environment decorated board material.

Owner:云南永利发林业有限公司

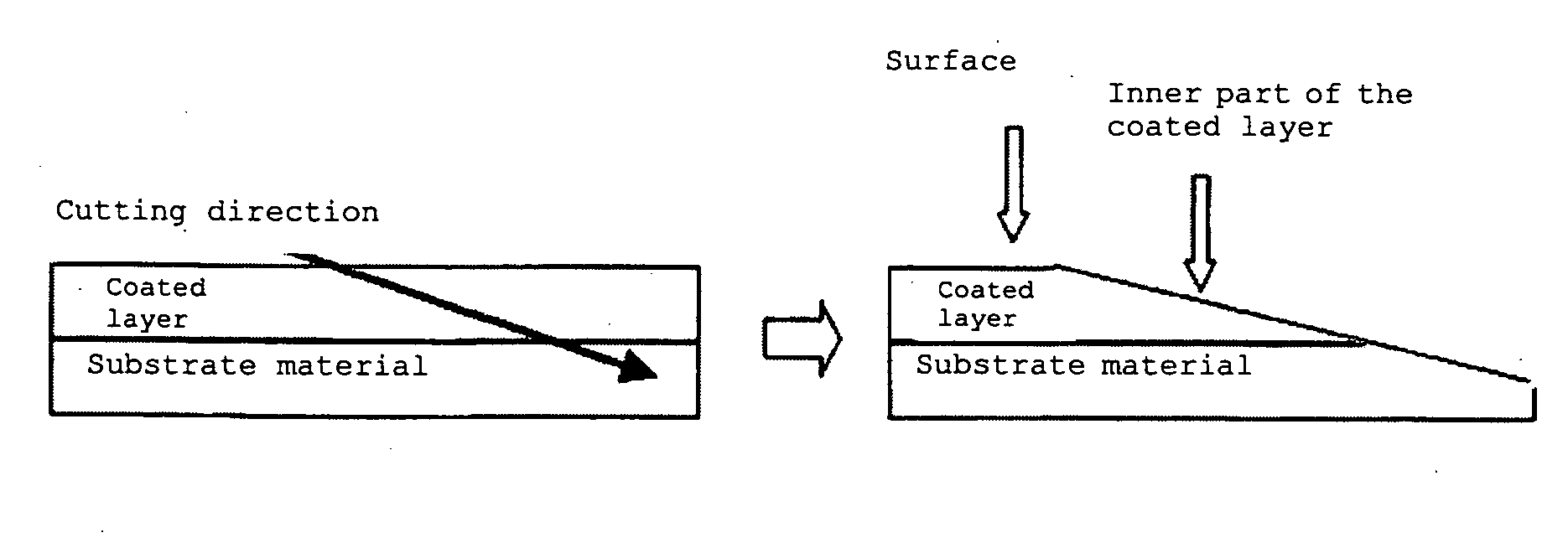

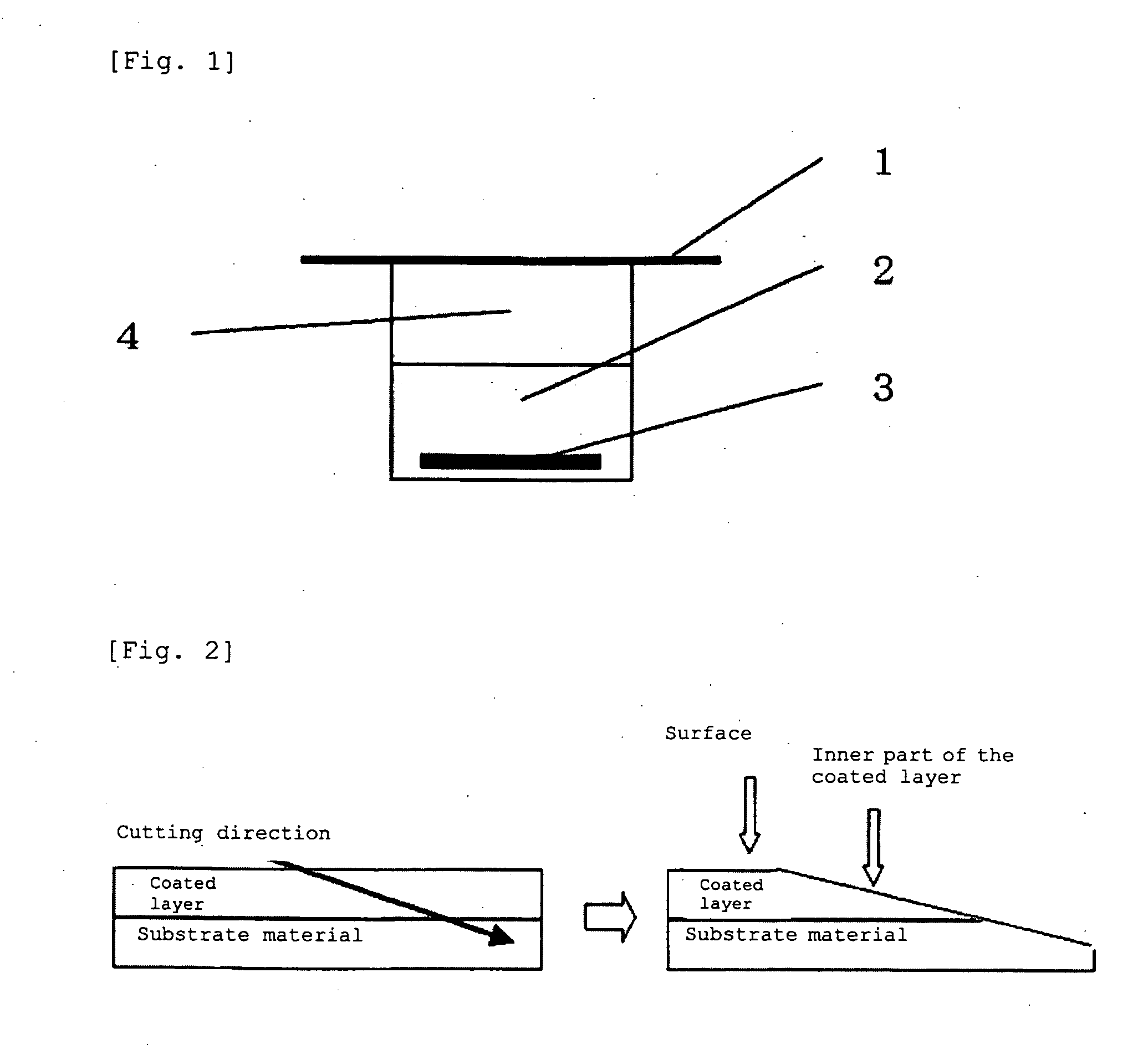

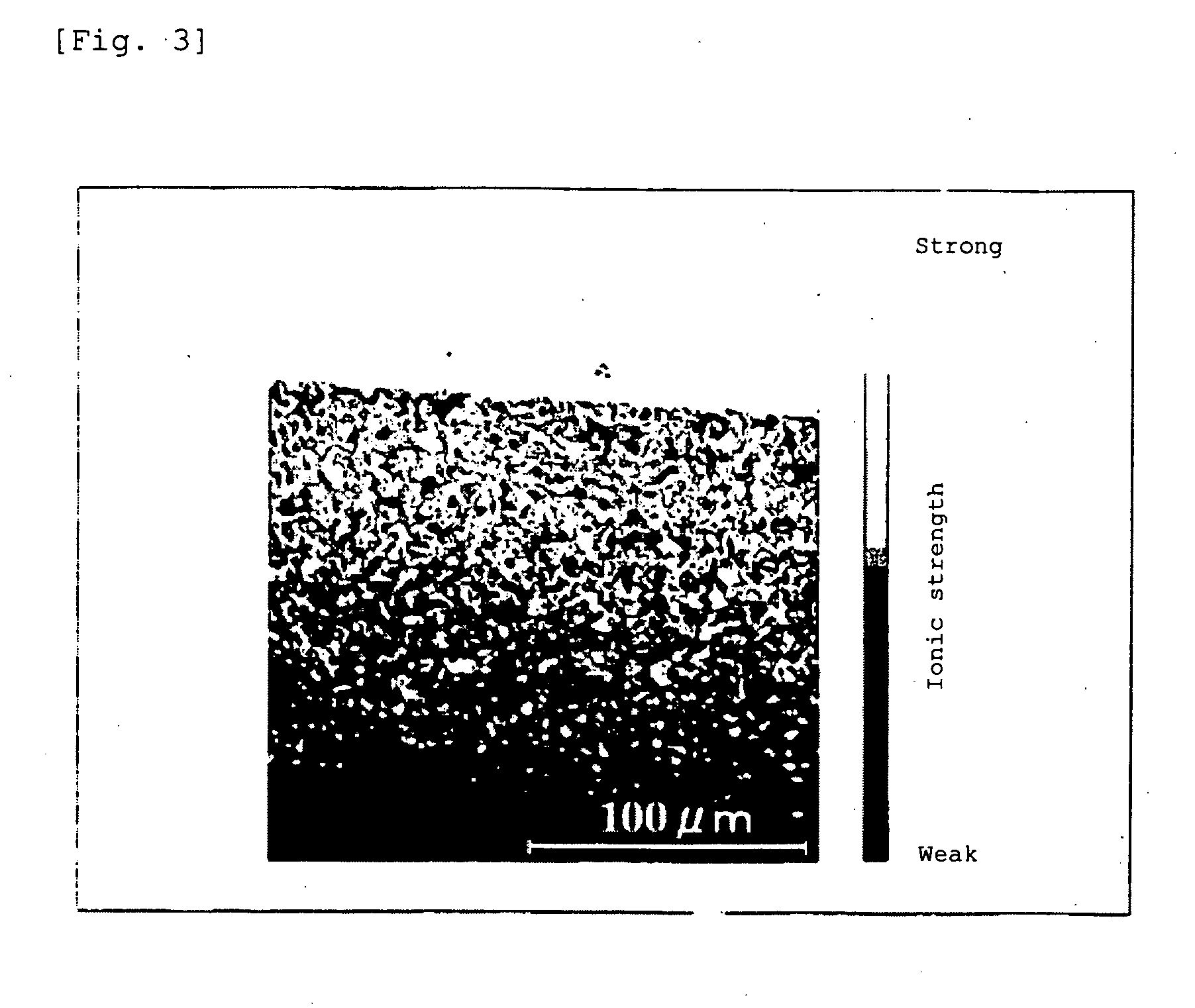

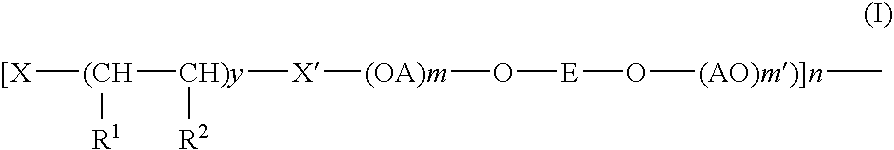

Single Layer Film and Hydrophilic Material Comprising the Same

InactiveUS20090191373A1Other chemical processesSynthetic resin layered productsMeth-Carboxyl radical

A single layer film containing at least one anionic hydrophilic group selected from a sulfonic acid group, a carboxyl group and a phosphate group, wherein an anion concentration ratio (Sa / Da) of an anion concentration at a surface (Sa) to an anion concentration at a deep part (Da) is 1.1 or more. The single layer film is a copolymer prepared by polymerizing a composition containing a compound (I) represented by the general formula (1) ([X]s[M1]1[M2]m (1)) and a compound (II) having two or more (meth)acryloyl groups in a molecule at a molar ratio of 15:1 to 1:30 and having a water contact angle of 30° or less. Such a single layer film has high hydrophilicity and surface hardness and is excellent in antifogging property, antifouling property and antistatic property, thus is useful as an antifogging material, an antifouling material, an antistatic material and a multilayer body.

Owner:MITSUI CHEM INC

Conductive type polyaniline composite film, prepn. method and use thereof

InactiveCN1831033AImprove self-cleaning abilityNot affectedPlastic/resin/waxes insulatorsOther chemical processesFiberJet aeroplane

The invention relates to the current conducting ployaniline composite membrane having the framework of the lotus leaf genus. It is the cancellated film composed by the nm fibre with microsphere and has the tuber on the surface of the fibre and the microsphere. The producing process of the composite includes the below steps: the eigenstate polyaniline is dissolved into the solvent; the insoluble substance is rejected, the adulterating acid is added; then, the polystyrene is added; the current conducting polyaniline mixed liquor is gained; finally, the petrified urrent conducting ployaniline composite membrance is gained one the receiving system using the electrostatic spinning technique. The composite membrane is indicative of the contact angle of 160 degree and the roll angle of below 5 degree to the pure water, the acid and the alkaline solution in the range of the entirely PH value and express the sky high ability of self purging; at the same time, the conductivity of the conducting macromolecule composite membrane don't change with the acid and alkaline solution. The conducting composite membrane can be used for producing the resisting electromagnetic shielding material, the antistatic stuff, the anticorrosion stuff, the anti fouling stuff of the shipping and the airplane, the latent stuff, the liquid transmission without the loss and the micro-flow stuff.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heavy caliber high-strength plastic wound pipe having pipe wall made of wrapping material and manufacture method therefor

The invention relates to a method for producing big high strength plastic coil tube which uses coil material to form tube wall, wherein the coil material is a composite plastic section bar formed by an inner core and an outer layer, which is alternatively or irregularly arranged, and nearby side walls are fused to connected or adhered by fused material, to be screwed to form tube wall. The coil material is drawn to direct the molecule longitudinally. The outer layer is thermal plastic, while the inner corn is strength material and / or flameproof material and / or static resistance composed in plastic base material. The fusing connecting material is plastic polymer or added with strength material and / or flameproof material and / or static resistance, to form plastic fused material. The strength material is distributed in the coil material and / or fusing connecting material, directionally distributed along the screw of high-strength coil tube. The invention has high strength, flameproof property and static resistance.

Owner:淄博寿山特种塑料有限公司

Super-hydrophotic magnetic carbon film, its preparing method and use

InactiveCN1850356AMeet the needs of different applicationsExhibit superhydrophobic propertiesPretreated surfacesCoatingsCarbon filmFiber

The present invention relates to a superhydrophobic magnetic carbon membrane. Its surface has net-like structure formed from spherical projection nano fibre, in which the diameter of nano fibre is 60-100 nano, the diameter of spherical projection is 20-30 nano. Said superhydrophobic magnetic carbon membrane is prepared by using electrostatic spinning technique and low-temperature carburization technique. Said superhydrophobic magnetic carbon membrane has electric conductivity, its conductivity is 0.31-5.6 s / cm. It can be used for treatment of antifouling and water-proofing surface, also can be used in sensor, nano probe, antistatic material and wave-absorbing material.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Extrudable antistatic tielayers

ActiveUS20080220353A1Improve adhesionAvoid layeringDiffusion transfer processesPhotosensitive materialsEngineeringAntistatic Materials

The present invention relates to an extruded imaging element comprising an extruded support bearing an extruded image receiving layer and an extruded antistatic tie layer between the extruded support and the extruded image receiving layer, wherein the extruded tie layer absorbs less than 3 weight % of moisture at 80% RH and 70 F (22.78° C.) comprises 5-30% polyether-containing antistatic material in a matrix polymer, and a method for making the same.

Owner:KODAK ALARIS INC

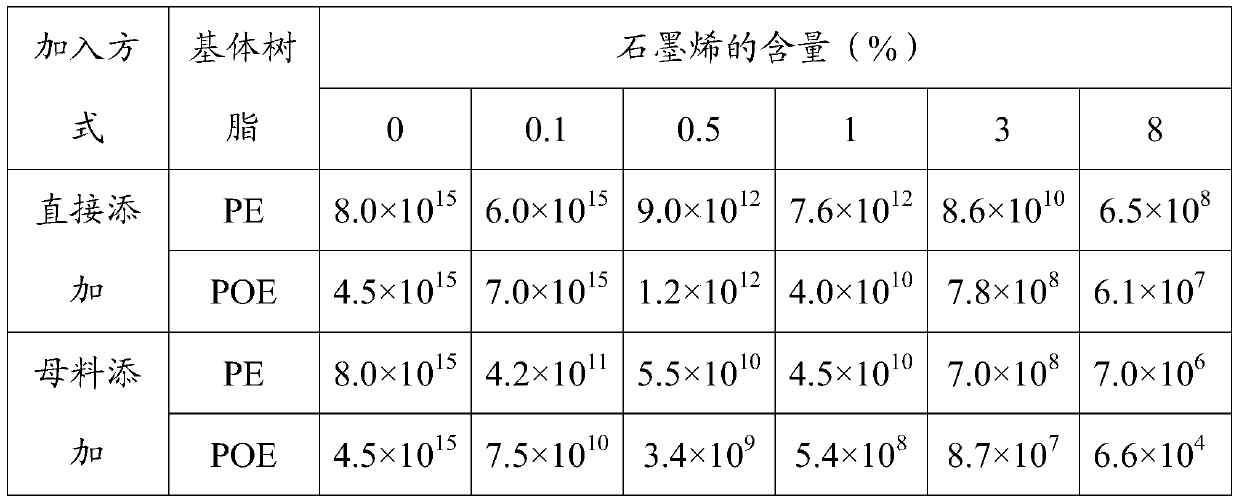

Graphene/polyolefin elastomer master batch and graphene antistatic composite material as well as preparation methods thereof

The invention discloses a graphene / polyolefin elastomer master batch and a graphene antistatic composite material as well as preparation methods thereof. The graphene / polyolefin elastomer master batch is prepared from the following raw materials in parts by weight: 1-100 parts of polyolefin elastomer (POE) or grafted polyolefin elastomer (m-POE), 1-10 parts of graphene and 0.01-1 part of silane coupling agent. The graphene / POE master batch has better electrical property; a polyethylene (PE) antistatic material prepared by adding 1-10% of graphene / POE master batch has the surface resistance less than 1011 omega, so that the use safety of engineering plastics of high-voltage-resistant parts in electrical products can be improved; therefore, the graphene / polyolefin elastomer master batch has remarkable industrial application value.

Owner:余姚中国塑料城塑料研究院有限公司

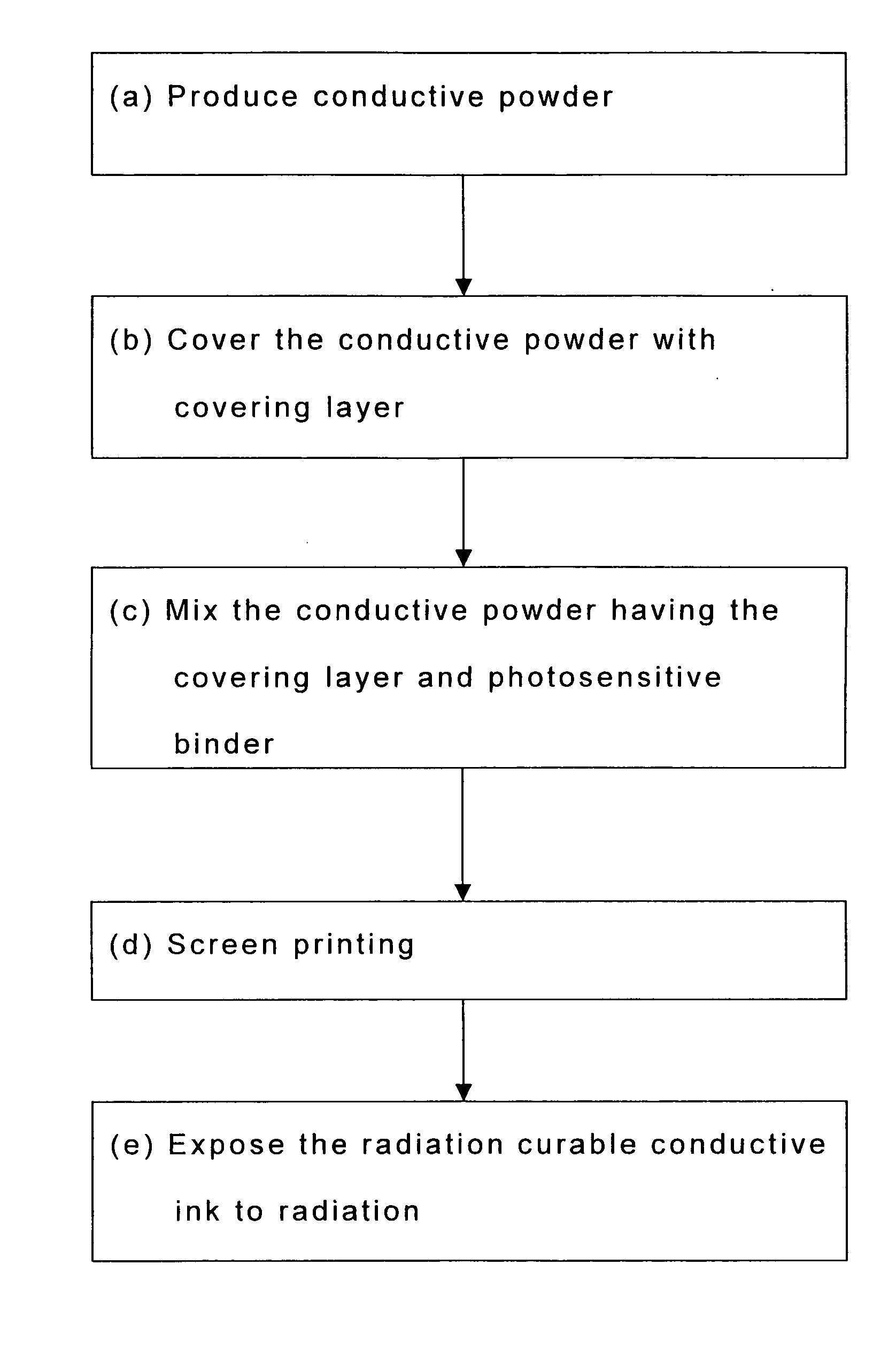

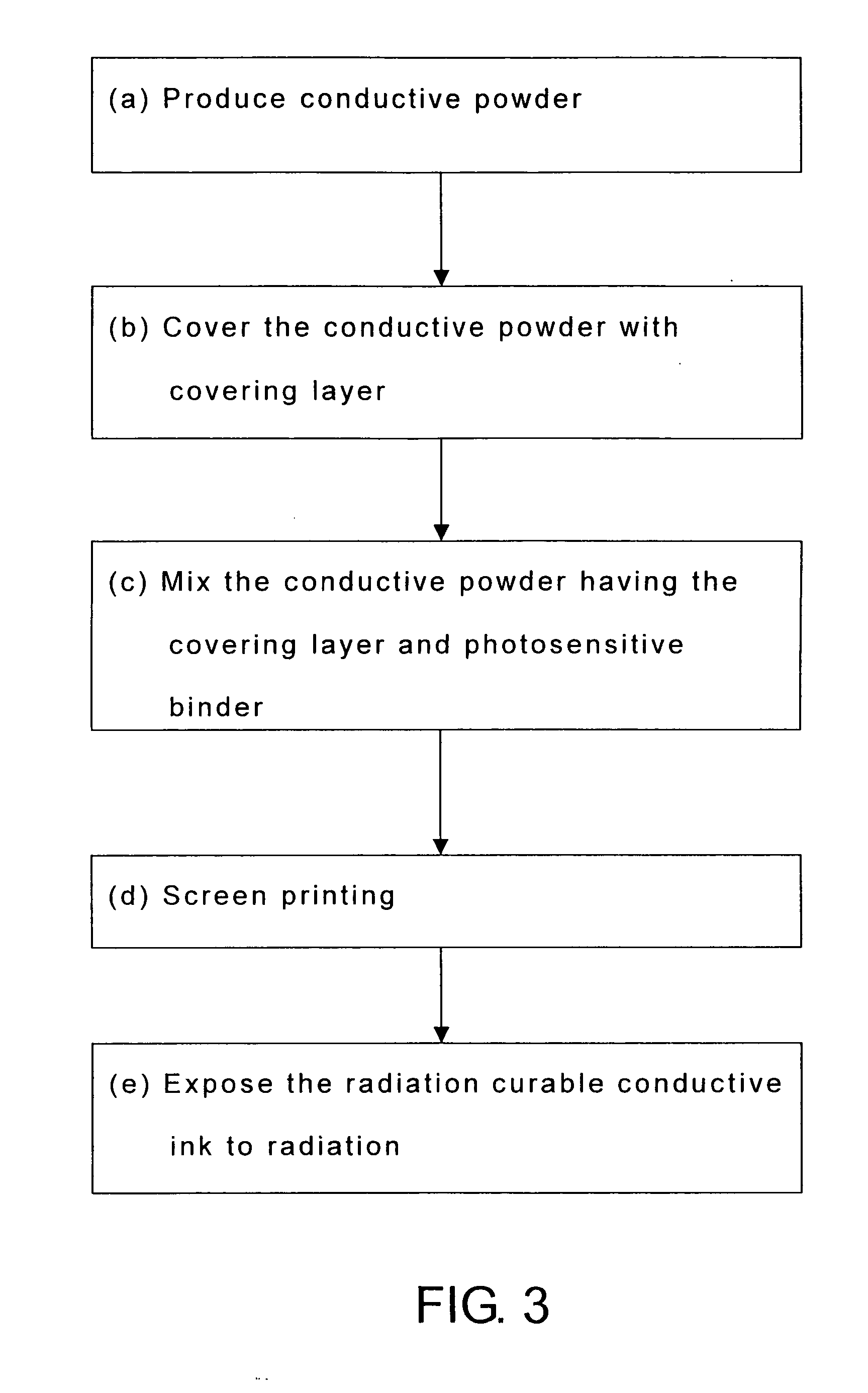

Radiation curable conductive ink and manufacturing method for using the same

The present invention provides a radiation curable conductive ink and a manufacturing method for conductive substrate using the conductive ink, wherein components of the radiation curable conductive ink contain at least conductive powder having a covering layer and a photosensitive binder. The radiation curable conductive ink is printed on surface of a substrate using a screen printing method, and a chemical crosslinking reaction is achieved by irradiating the conductive ink with ultraviolet ray, visible light or electron beam, thereby forming a conductive substrate. The conductive substrate is particularly applicable for use in laminate type electronic devices, including radio frequency identification (RFID) antenna, printed-circuit boards, smart cards (non-contact chip cards) components, smart labels, printed electronics, anti-electromagnetic interference (EMI) and anti-electrostatic materials.

Owner:YANG YUNG SHU

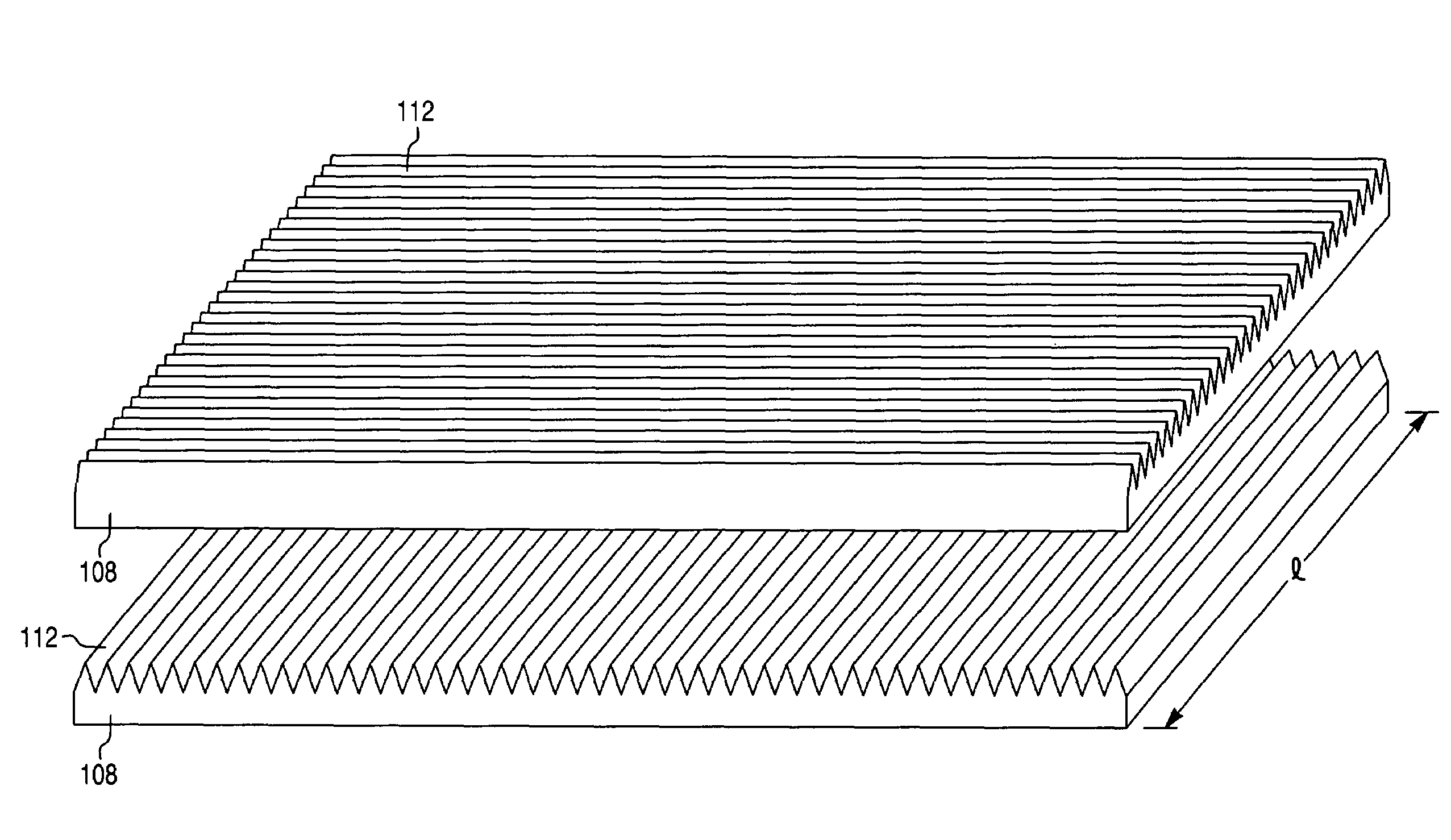

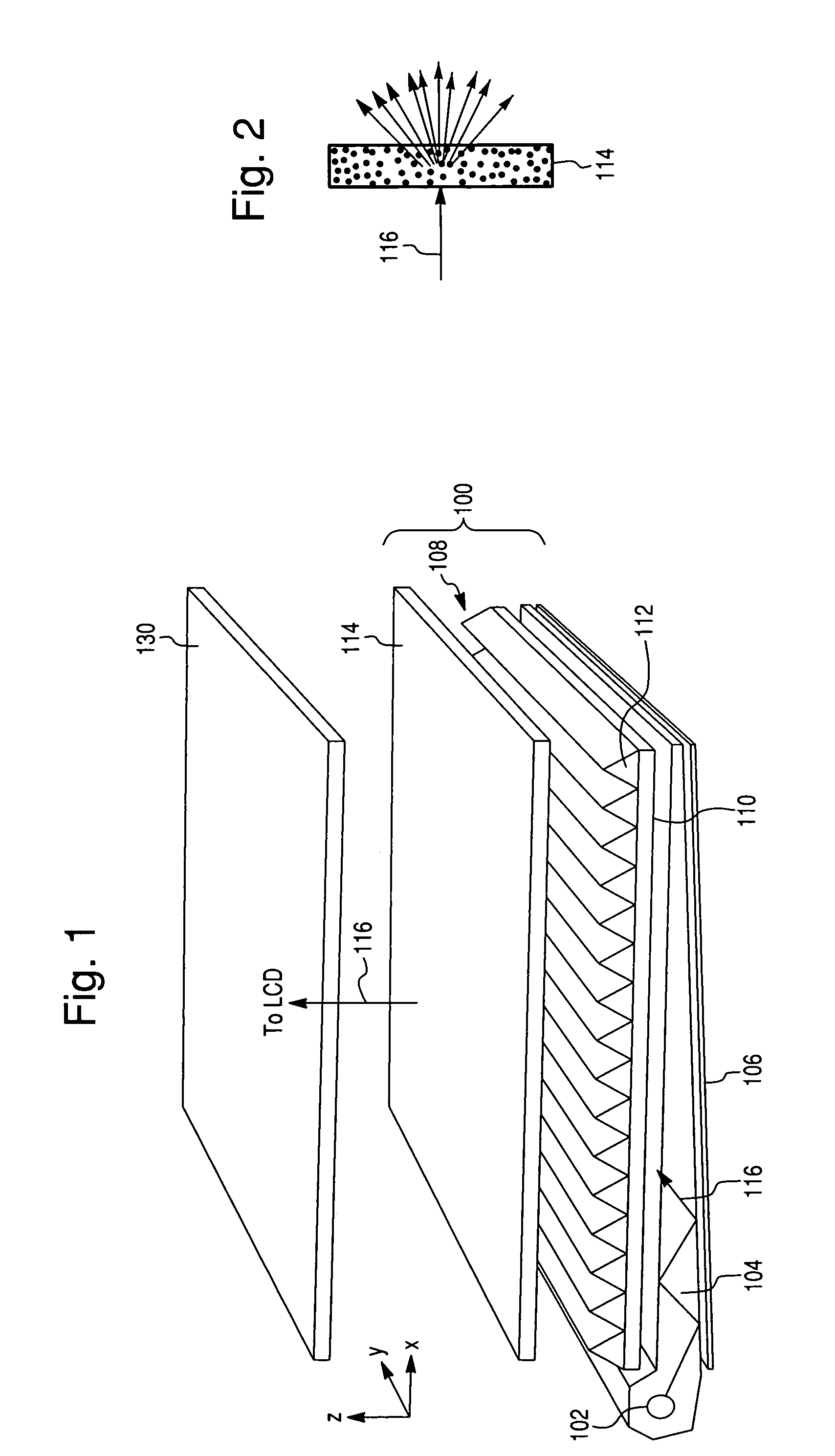

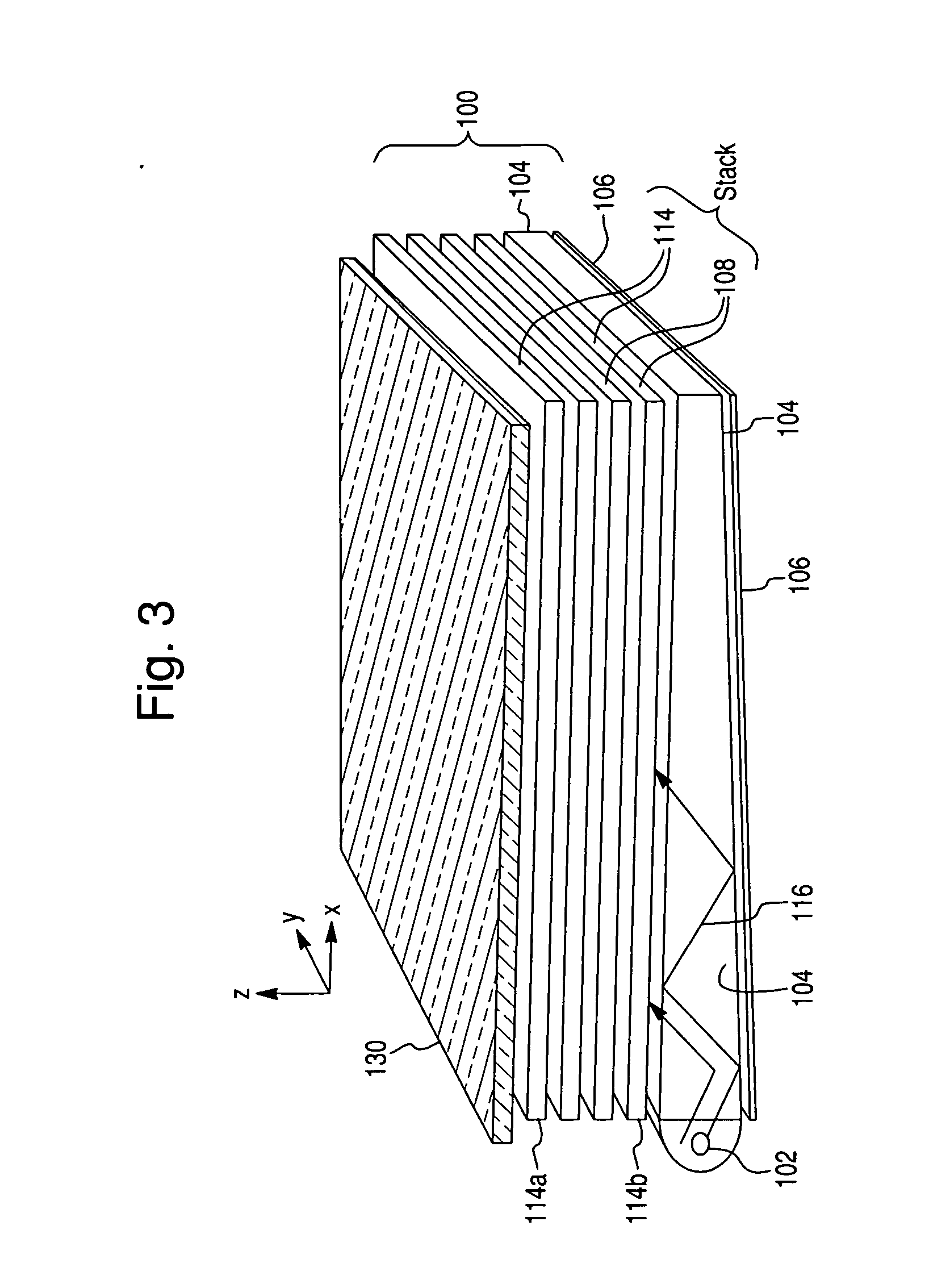

Diffuser for flat panel display

ActiveUS7314652B2Prevent discolorationReduce scatterLiquid crystal compositionsPrismsSulfonatePhosphonium

A light diffusing film for a back light display is described. The light diffusing film includes a unitary film consisting essentially of polycarbonate and a uniformly dispersed anti-static material in an amount sufficient to impart anti-static properties to the film. The anti-static material may comprise a fluorinated phosphonium sulfonate. The film may additionally include at least one textured surface for the low scattering of light. Alternatively, the film may additionally include a uniformly dispersed acrylic bulk scattering additive of particles having a mean particle size of from about 3 to about 10 microns and present in an amount from about 2 to about 7 percent by weight percent for the high scattering of light.

Owner:SABIC GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com