Antistatic plastic for SMT carrier band, and preparation and use thereof

An anti-static, plastic technology, used in chemical instruments and methods, other chemical processes, packaging, etc., can solve the problems of high rigidity and flexural strength, small physical properties, and achieve good rigidity, easy processing, increased toughness and The effect of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Anti-static plastic for SMT carrier tape, the anti-static plastic is composed of the following components by weight percentage: conductive carbon black 20%, polystyrene 55%, styrene butadiene copolymer elastic SBS 20%, polyethylene reinforced Soft masterbatch 3%, antioxidant-AO-500.5%, coupling KH5701.5%.

[0027] The preparation method of the above-mentioned antistatic plastic particles, the method includes the following steps: according to the formula, kneading for 45 minutes under the condition of 55 ° C, feeding to the extruder for extrusion, the speed of the feeder is 500 rpm, and the extruded The temperature is 180°C, the rotation speed of the extruder is 600 rpm, and then it is obtained by cooling, pelletizing and drying.

Embodiment 2

[0029] Anti-static plastic for SMT carrier tape, the anti-static plastic is composed of the following components by weight percentage: conductive carbon black 15%, polystyrene 65%, styrene butadiene copolymer elastic SBS 10%, polyethylene reinforced Soft masterbatch 8%, antioxidant-AO-500.5%, coupling KH5701.5%.

[0030] The preparation method of the above-mentioned antistatic plastic particles, the method includes the following steps: according to the formula, kneading for 45 minutes under the condition of 55 ° C, feeding to the extruder for extrusion, the speed of the feeder is 500 rpm, and the extruded The temperature is 180°C, the rotation speed of the extruder is 600 rpm, and then it is obtained by cooling, pelletizing and drying.

Embodiment 3

[0032] Anti-static plastic for SMT carrier tape, the anti-static plastic is composed of the following components by weight percentage: conductive carbon black 10%, polystyrene 80%, styrene butadiene copolymer elastic SBS 5%, polyethylene reinforced Soft masterbatch 3%, antioxidant-AO-500.5%, coupling KH5701.5%.

[0033] The preparation method of the above-mentioned antistatic plastic particles, the method includes the following steps: according to the formula, kneading for 45 minutes under the condition of 55 ° C, feeding to the extruder for extrusion, the speed of the feeder is 500 rpm, and the extruded The temperature is 180°C, the rotation speed of the extruder is 600 rpm, and then it is obtained by cooling, pelletizing and drying.

PUM

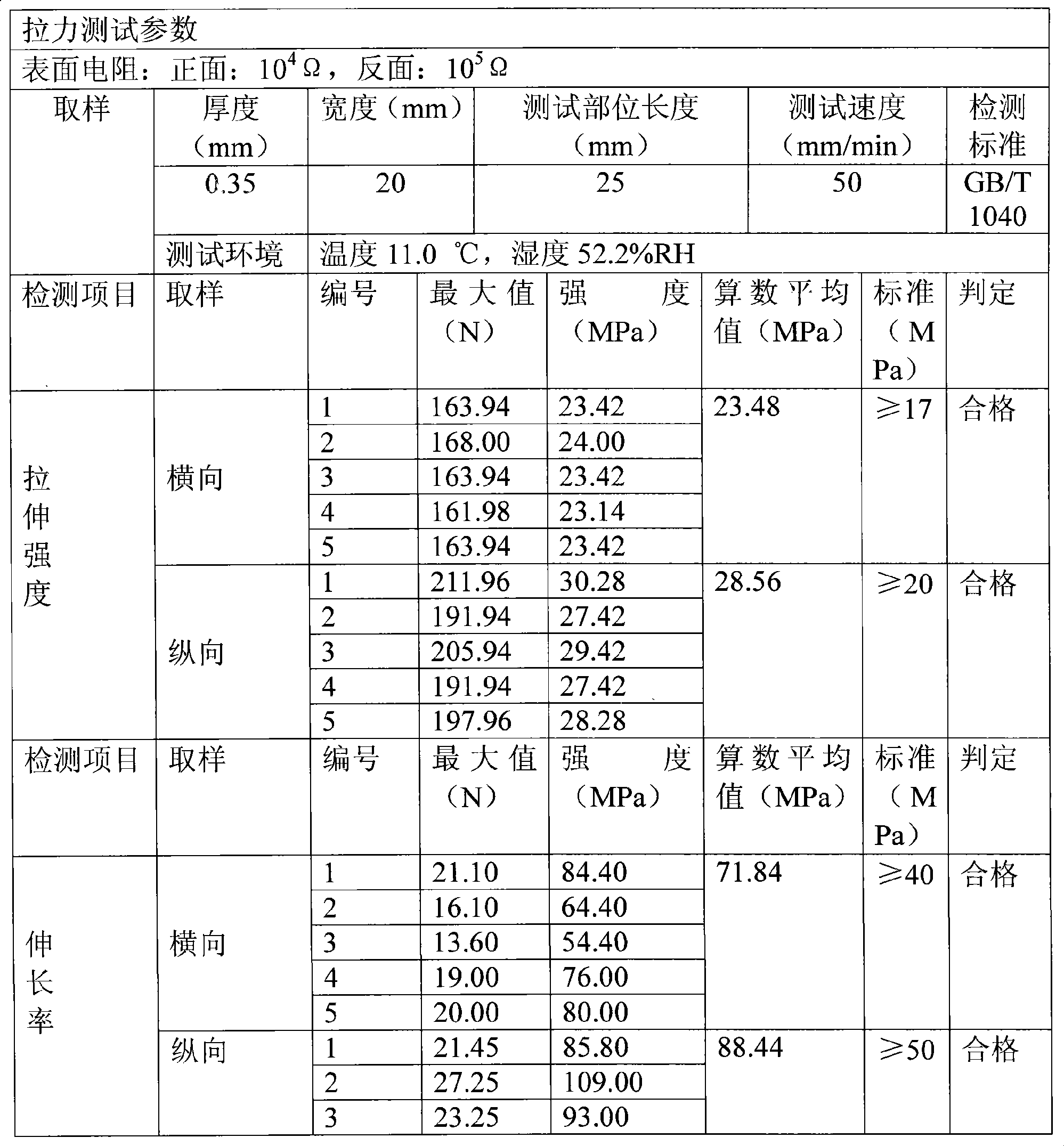

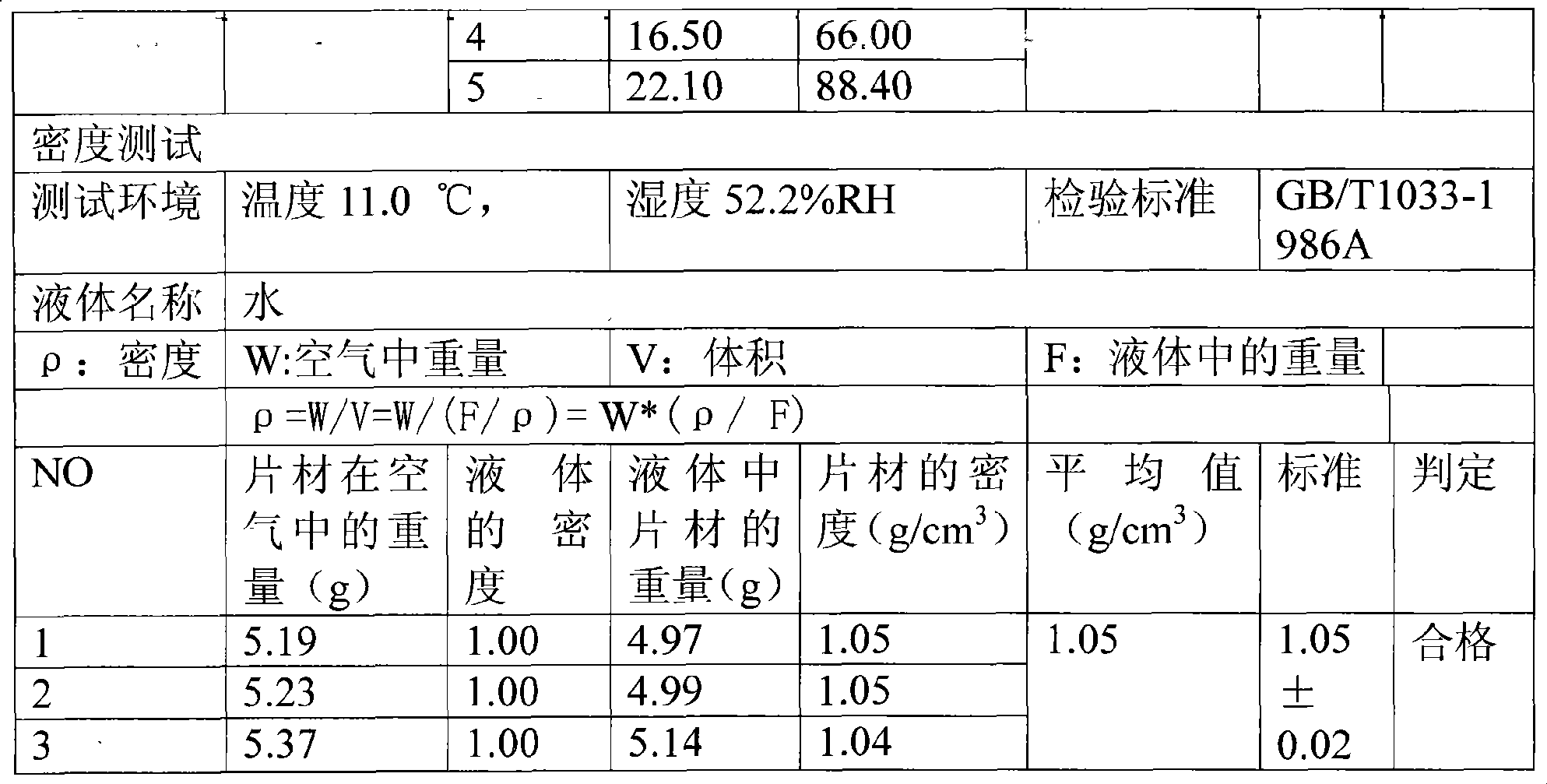

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com