Conductive carbon black modified PP material and preparation method thereof

A conductive carbon black and modified technology, applied in the field of conductive carbon black modified PP material and its preparation, can solve problems such as not having very ideal results, and achieve the effects of easy processing, low price and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

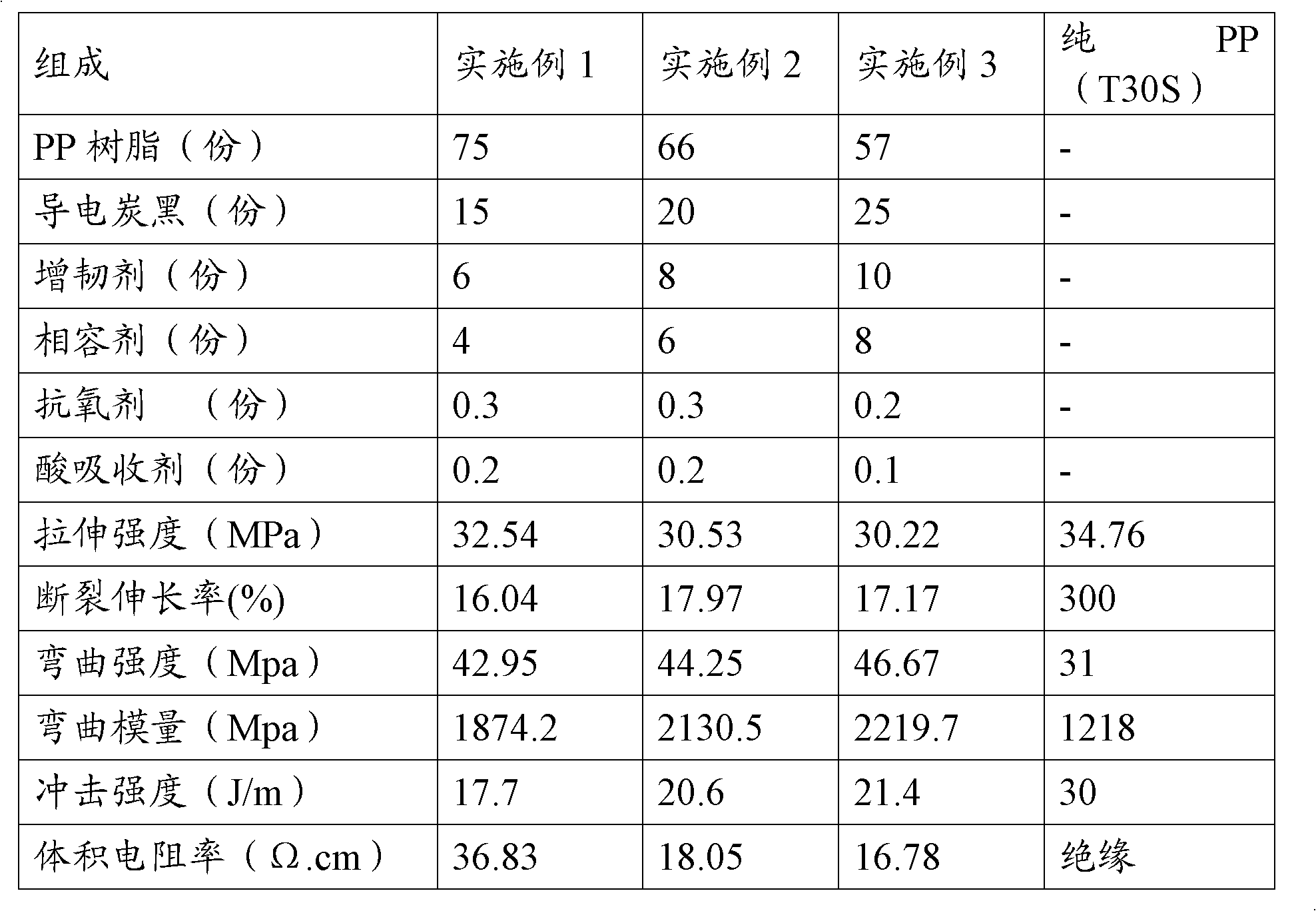

Embodiment 1

[0027] Weigh 75 parts of PP resin, 15 parts of conductive carbon black, 6 parts of toughening agent, 4 parts of compatibilizer, 0.3 part of antioxidant, and 0.2 part of acid absorbent in parts by weight. Pour the weighed components into a mixing tank and stir for 8 minutes at a stirring speed of 300r / min; put the stirred and mixed materials into the hopper of a twin-screw extruder, and melt and react to extrude and granulate; processing technology As follows: the temperature of twin-screw extruder zone 1 is 120°C, the temperature of zone 2 is 160°C, the temperature of zone 3 is 180°C, the temperature of zone 4 is 180°C, the temperature of zone 5 is 180°C, the temperature of zone 6 is 180°C, the temperature of zone 7 is 170°C, the temperature of zone 8 is 170°C, Zone temperature 170°C; screw speed 350r / min.

Embodiment 2

[0029] Weigh 66 parts of PP resin, 20 parts of conductive carbon black, 8 parts of toughening agent, 6 parts of compatibilizer, 0.3 part of antioxidant, and 0.2 part of acid absorbent in parts by weight. Pour the weighed components into a mixing tank and stir for 10 minutes at a stirring speed of 350r / min; put the stirred and mixed materials into the hopper of a twin-screw extruder, and melt and react to extrude and granulate; processing technology As follows: the temperature of twin-screw extruder zone 1 is 110°C, the temperature of zone 2 is 150°C, the temperature of zone 3 is 170°C, the temperature of zone 4 is 170°C, the temperature of zone 5 is 170°C, the temperature of zone 6 is 170°C, the temperature of zone 7 is 160°C, and the temperature of zone 8 is 160°C. Zone temperature 160°C; screw speed 330r / min.

Embodiment 3

[0031] Weigh 57 parts of PP resin, 25 parts of conductive carbon black, 10 parts of toughening agent, 8 parts of compatibilizer, 0.2 part of antioxidant, and 0.1 part of acid absorbent in parts by weight. Pour the weighed components into a mixing tank and stir for 15 minutes at a stirring speed of 380r / min; put the stirred and mixed materials into the hopper of a twin-screw extruder, and melt and react to extrude and granulate; processing technology As follows: the temperature of twin-screw extruder zone 1 is 100°C, the temperature of zone 2 is 140°C, the temperature of zone 3 is 160°C, the temperature of zone 4 is 160°C, the temperature of zone 5 is 160°C, the temperature of zone 6 is 160°C, the temperature of zone 7 is 150°C, zone 8 The temperature is 150°C; the screw speed is 300r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com