Wave-absorbing material based on grapheme and preparation method thereof

A wave absorbing material, graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of long time period, poor high temperature oxidation resistance, high quality of wave absorbing materials, etc., to enhance the ability of dielectric loss, The effect of strong absorbing ability and wide absorbing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

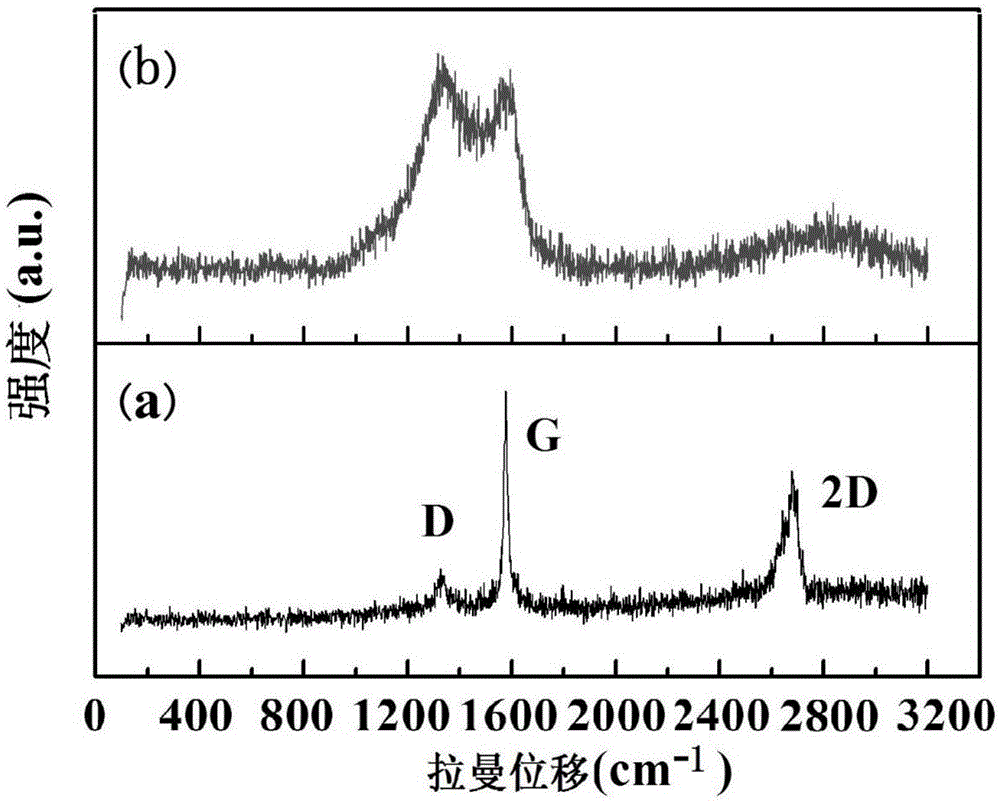

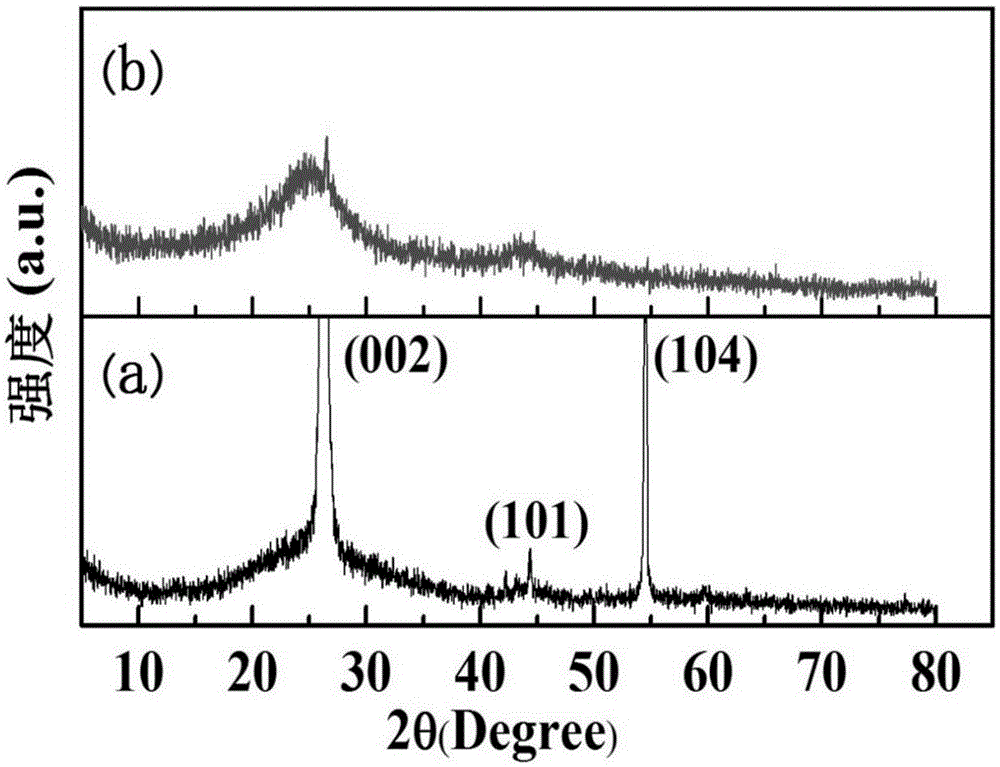

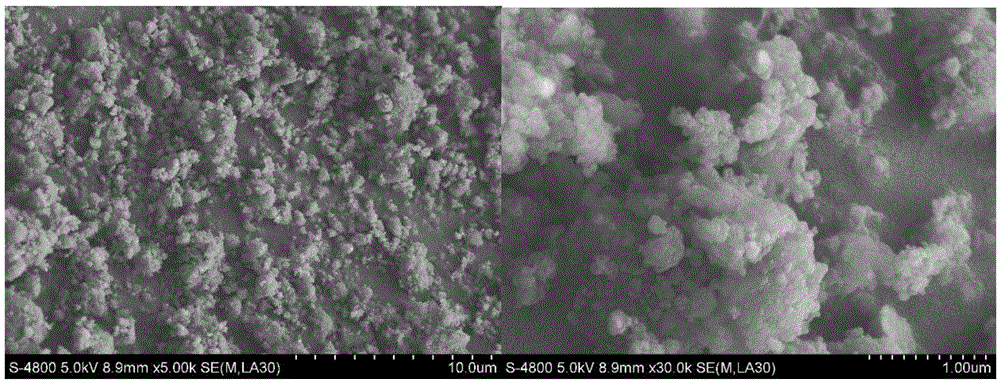

Embodiment 1

[0038] Mix 5g of flake graphite (325 mesh) with 30g of dry ice evenly, put it into a 1L stainless steel tank, and grind it in a planetary ball mill (the rotating speed of the turntable is 350rad / min, and the rotation speed of the steel tank is 700rpm), and the grinding time is 12 hours. Afterwards, graphene powder is obtained. The obtained sample was mixed with paraffin in a certain volume ratio (graphene powder:paraffin=7:3), and ultrasonically dispersed in n-butane system. The above-mentioned mixed samples were made into a ring with an outer diameter of 7mm, an inner diameter of 3.04mm, and a thickness of 3mm in a special mold. The microwave absorption performance of the material was tested with a Jielun E8363B vector network analyzer, and the test frequency range was 2 to 18GHz.

[0039] Measurement results: When the prepared graphene absorbing material has a matching thickness of 2.0mm, it can reach a maximum absorption of -23.34dB at 9.77GHz; when the matching thickness i...

Embodiment 2

[0041] 5g flake graphite (500 mesh) and 30g dry ice were mixed evenly, put into a 1L stainless steel tank, and ground in a planetary ball mill (the rotating speed of the turntable was 350rad / min, and the rotation speed of the steel tank was 700rpm), the grinding time was 8 hours, and cooled Afterwards, graphene powder is obtained. The subsequent preparation and testing methods of the absorbing material are the same as in Example 1.

[0042] Measurement results: When the prepared graphene absorbing material has a matching thickness of 1.92mm, it can reach a maximum absorption of -32.28dB at 8.69GHz; when the matching thickness is 1.0-5.0mm, the effective absorption band with a reflection loss lower than -10dB reaches 1.7GHz.

[0043] Figure 5 It is the graph of the absorbing performance of the graphene absorbing material under different matching thicknesses.

Embodiment 3

[0045] Mix 5g of flake graphite (1000 mesh) with 30g of dry ice, put it into a 1L stainless steel tank, and grind it in a planetary ball mill (the rotating speed of the turntable is 350rad / min, and the rotation speed of the steel tank is 700rpm), and the grinding time is 8 hours. Afterwards, graphene powder is obtained. The subsequent preparation and testing methods of the absorbing material are the same as in Example 1.

[0046] Test results: When the prepared graphene absorbing material has a matching thickness of 1.95mm, it can reach a maximum absorption of -10.57dB at 8.24GHz; when the matching thickness is 1.0-5.0mm, the effective absorption band with a reflection loss lower than -10dB reaches 1.3GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com