Heavy caliber high-strength plastic wound pipe having pipe wall made of wrapping material and manufacture method therefor

A high-strength plastic and large-diameter technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of low hoop stress intensity, high longitudinal tensile strength of pipes, and large equipment investment, etc. Increased ring stress and ring stiffness, good flame retardant and static conductivity, increased effects of flame retardant and conductive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

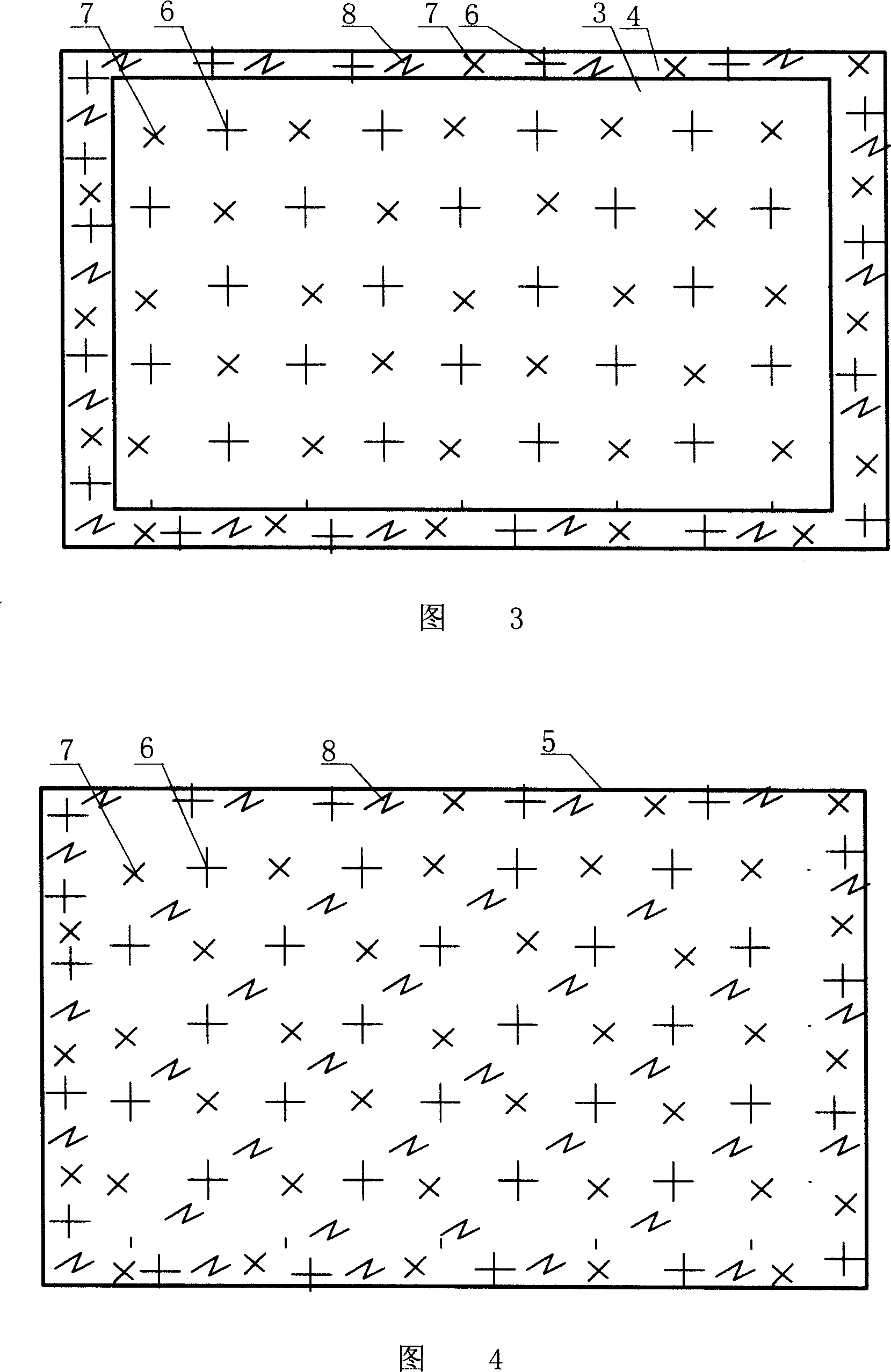

[0101] Weight ratio:

[0102] Plastic substrate: reinforcement material: flame retardant material: antistatic material = 1: 0.4: 0.1: 0.2;

[0103] Dosage: plastic substrate PE100 100kg;

[0104] Reinforcement glass fiber 40kg;

[0105] Flame retardant material decabromodiphenyl ether 6kg;

[0107] Antistatic material Conductive carbon black 20kg; raw materials are commercially available industrial products.

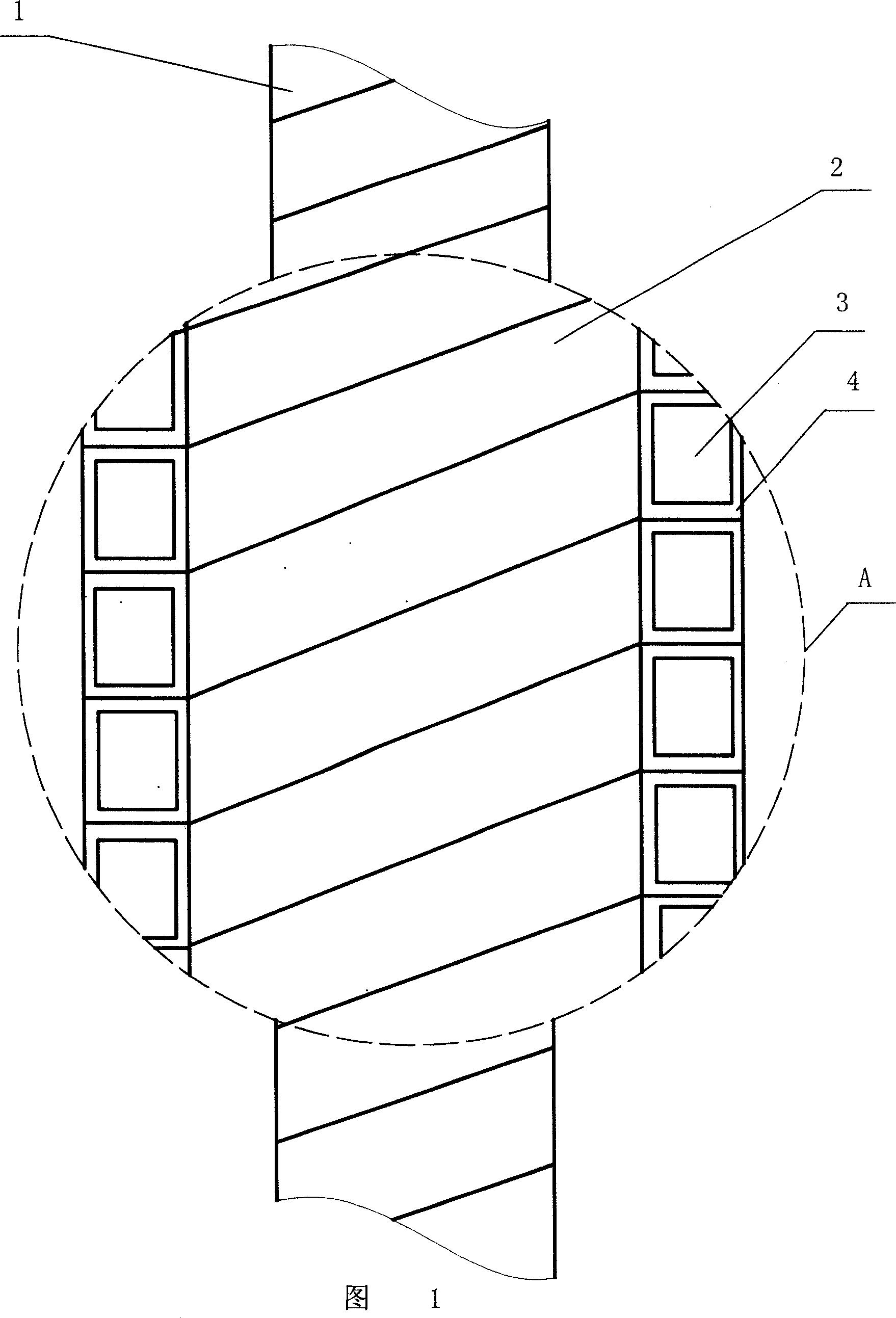

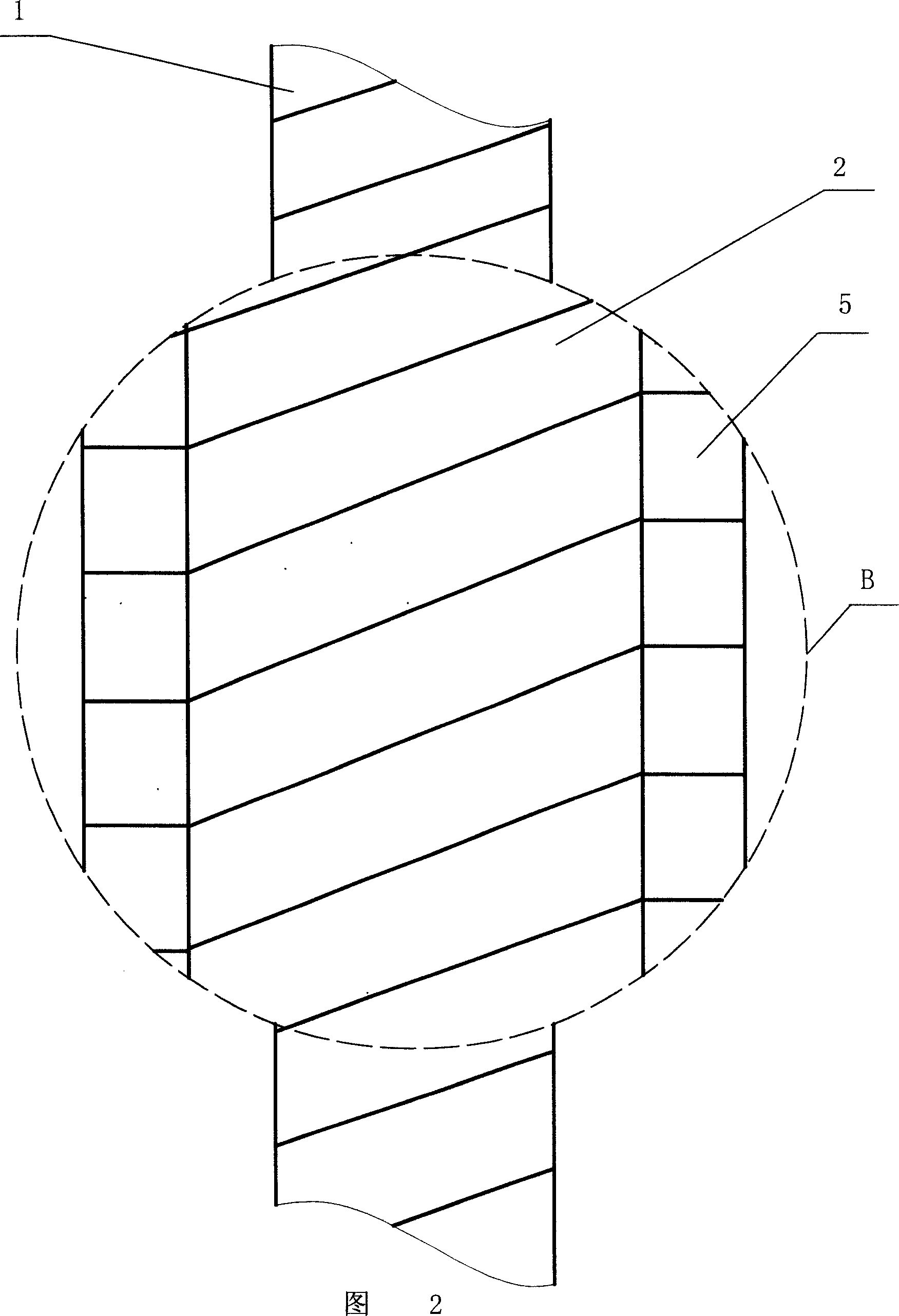

[0108] With the above ratio, make a winding pipe with a diameter of 2000mm.

[0109] Preparation method: mix the additives and the plastic base material evenly, and continuously extrude the solid plastic profile with the reinforcing material from the plastic extruder; at the same time, keep the temperature of the profile at 50-170°C and pull it to make the reinforcing material along the profile. Highly oriented in the longitudinal direction, producing high-strength plastic profiles.

[0110] There are two ways to make it, one is: using...

Embodiment 2

[0132] Weight ratio:

[0133] Plastic substrate: reinforcing material = 1:0.8;

[0134] Dosage: plastic substrate PE100 100kg;

[0135] Reinforcement glass fiber 80kg;

[0136] The compression ratio of the die head is set to: 70~100; the extrusion / drawing speed of the head of the plastic extruder is set to: 1000~2000mm / s;

[0137] Using the above proportions, the spiral pipe with a diameter of 2000mm and a standard size ratio (SDR) of 26.0 is produced. The results of its working pressure compared with pure PE100 and PE80 solid wall pipes are as follows:

[0138] standard size ratio

[0139] Using the above proportions, the spiral pipe with a diameter of 2000mm and an operating pressure (MOP) of 3.0MPa is produced. The results of comparing the standard size ratio (SDR) with pure PE100 and PE80 solid wall pipes are as follows:

[0140] standard size ratio

[0141] All the other are with embodiment 1.

Embodiment 3

[0143] Plastic substrate: reinforcing material: antistatic agent = 1: 0.6: 0.2;

[0144] Dosage: plastic substrate PE100 100kg;

[0145] Reinforcement glass fiber 60kg;

[0146] Antistatic material Conductive carbon black 20kg; raw materials are commercially available industrial products.

[0147] The compression ratio of the die head is set to: 2~50; the extrusion / drawing speed of the head of the plastic extruder is set to: 600~1500mm / s;

[0148] Using the above proportions, the spiral pipe with a diameter of 3000mm and a standard size ratio (SDR) of 26.0 is produced. The results of its working pressure compared with pure PE100 and PE80 solid wall pipes are as follows:

[0149] standard size ratio

[0150] Using the above proportions, the spiral pipe with a diameter of 3000mm and an operating pressure (MOP) of 3.6MPa is produced. The results of comparing the standard size ratio (SDR) with pure PE100 and PE80 solid wall pipes are as follows:

[0151] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com