Patents

Literature

448results about How to "Increased ring stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

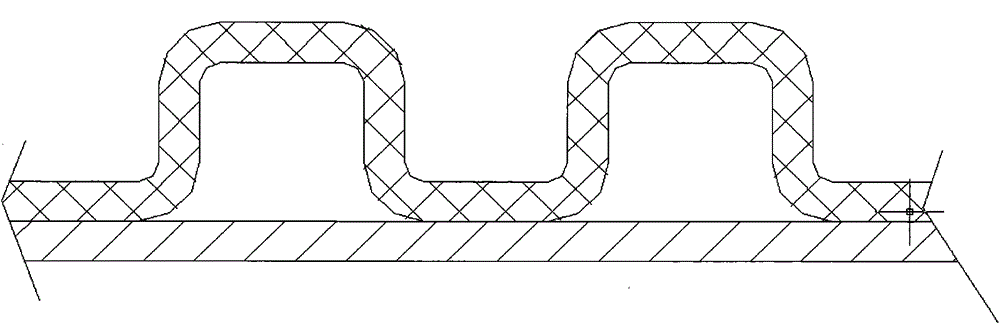

Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

InactiveCN101907207AIncrease the outer surface areaGood synergyRigid pipesTubular articlesMechanical engineeringHot-melt adhesive

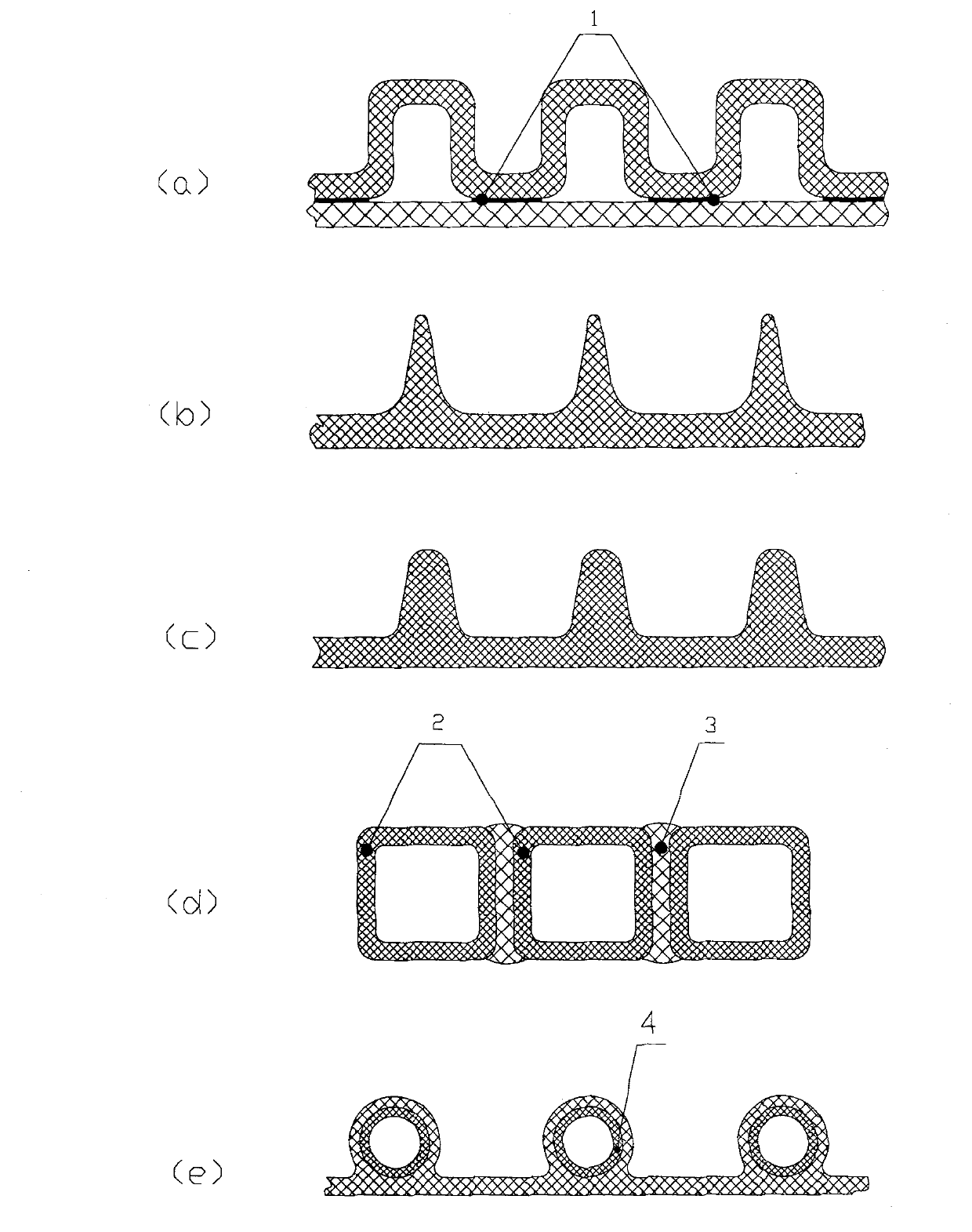

The invention relates to an internal rib reinforcing outer ripple type plastic spirally twining structured wall pipe, which comprises a cylindrical surfaced pipe main body and a reinforcing rib wound outside of the pipe main body. The reinforcing rib contains an inner reinforcing rib vertical to the pipe wall, wherein the inner rib divides the reinforcing rib into two parallel hollow cavities. The upper part of the reinforcing rib and the top of the inner rib are both provided with a solid bulge. A method for manufacturing the plastic reinforcing pipe of the invention comprises the steps of: continuously extruding a plastic abnormal strip with two tubular bulges and containing a hollow cavity inside through a first plastic extruder, continuously, regularly, spirally twining the plastic abnormal strip on a formed roller in parallel, at the same time, extruding fused plastic gel in a clearance between adjacent side walls of the spirally wound plastic abnormal strip through a second plastic extruder, rolling two projected tubular cavities corresponding to two sides of the clearances connected by fusing the adjacent plastic abnormal pipe through a rolling wheel which is arranged at the corresponding part on the periphery of the formed roller with a slot structure, forming an outer projected reinforcing rib of the pipe outer wall by fusing the two tubular bulges, and extruding the residual fused gel in the clearance by the rolling wheel so as to form the solid bulge.

Owner:戴爱清

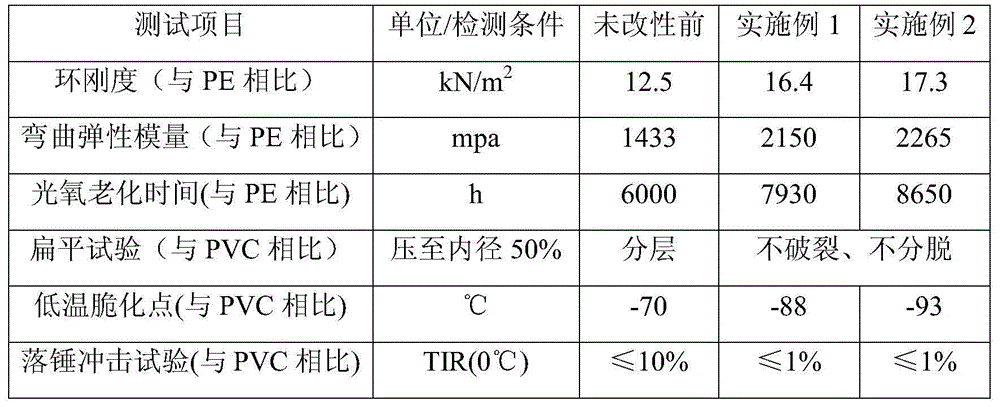

Polyethylene and polyvinyl chloride modified environment-friendly plastic check well and preparation method thereof

InactiveCN104356484AImprove impact resistanceIncreased ring stiffnessEnvironmental resistanceAntioxidant

The invention belongs to the field of a plastic check well and a preparation method thereof, and particularly relates to a polyethylene and polyvinyl chloride modified environment-friendly plastic check well and a preparation method thereof, aiming at solving the technical problem that the existing plastic check well is poor in impact strength, sensitive to temperature and bad for ring stiffness. According to the scheme for solving the technical problems, the invention provides the polyethylene and polyvinyl chloride modified environment-friendly plastic check well, which comprises the following compositions in parts by weight: 50-150 parts of polyethylene resin, 50-150 parts of polyvinyl chloride resin, 10-30 parts of nano materials, 0.5-5 parts of pigments, 2-20 parts of a lead-free stabilizer, 1-20 parts of processing aids, 1-5 parts of a lubricant, 0.5-5 parts of an antioxidant, 0.5-2 parts of a light stabilizer, 1-25 parts of a compatilizer, 1-15 parts of an impact modifier, 1-15 parts of an enhancer, and 0.5-10 parts of a coupling agent. The environment-friendly plastic check well is good in ring stiffness, high in impact strength, low in cost and long in service life.

Owner:KANGTAI PLASTIC SCI & TECH GRP

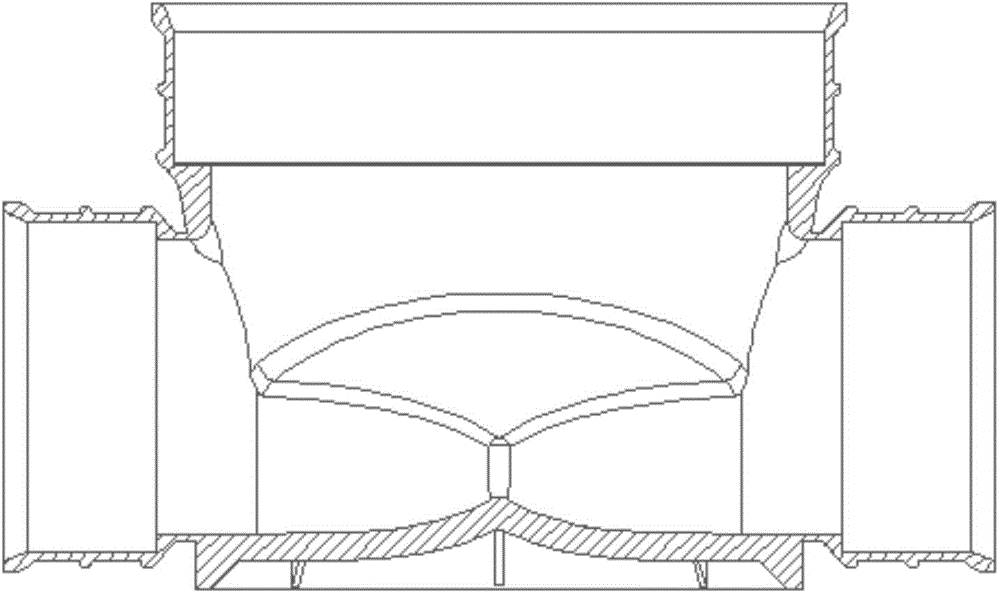

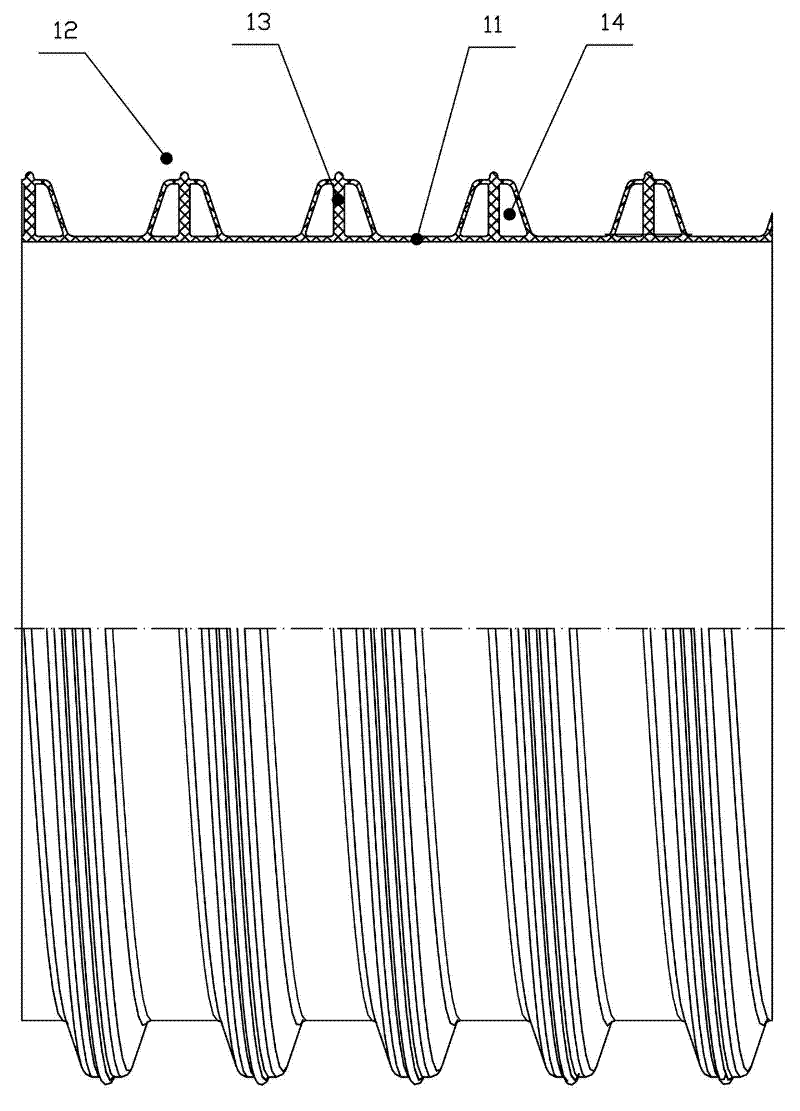

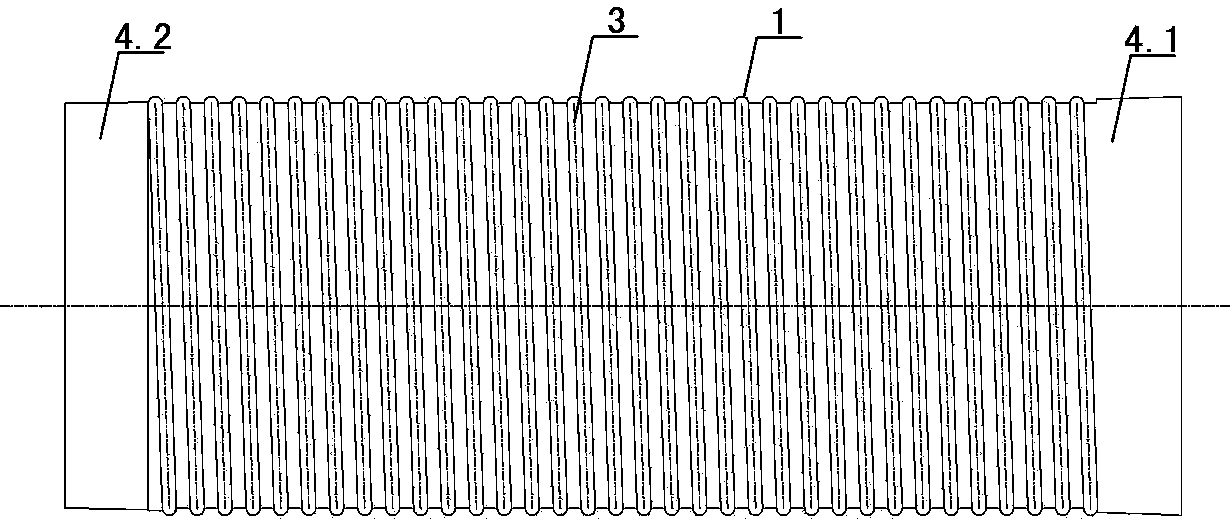

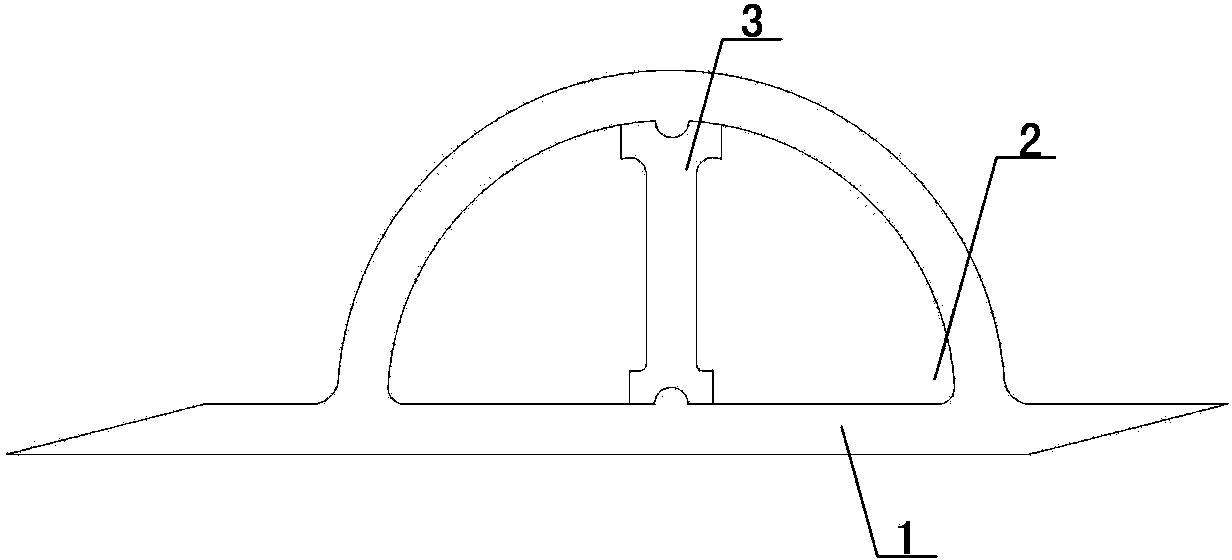

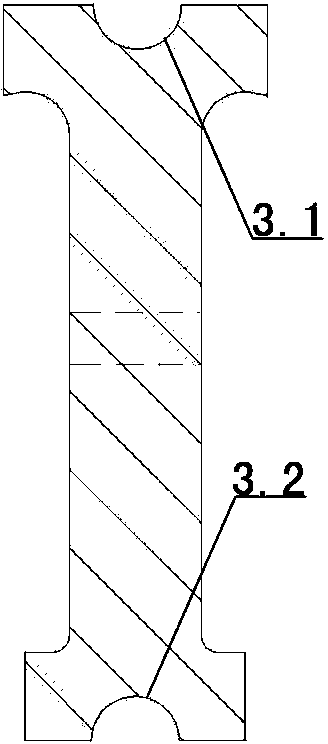

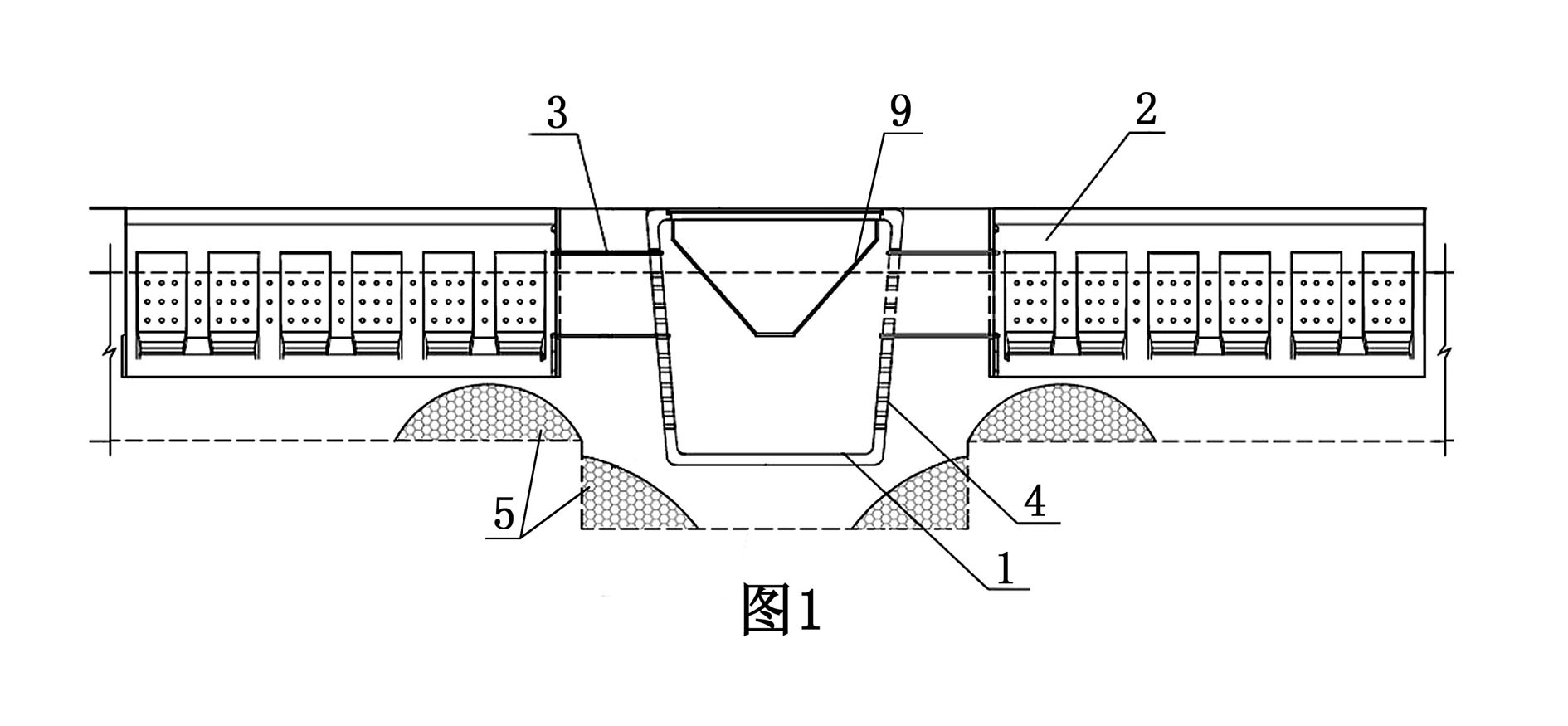

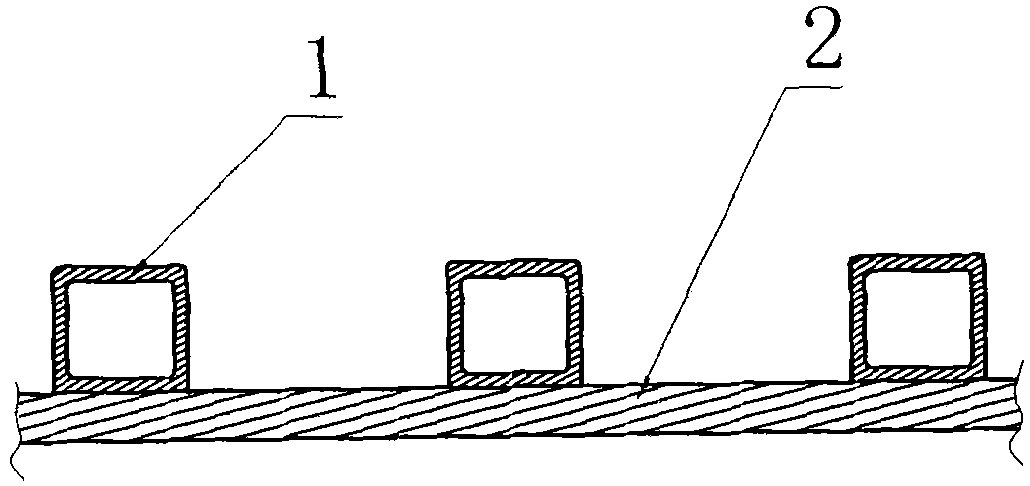

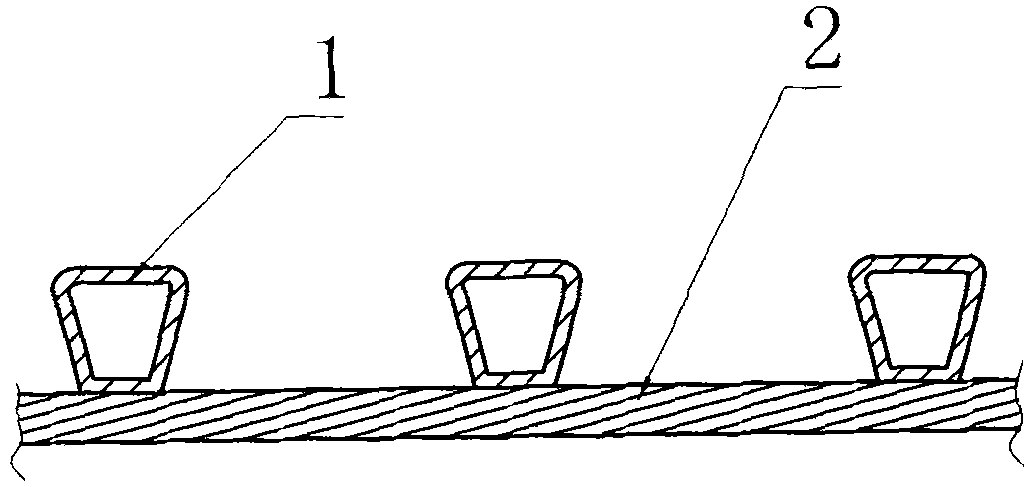

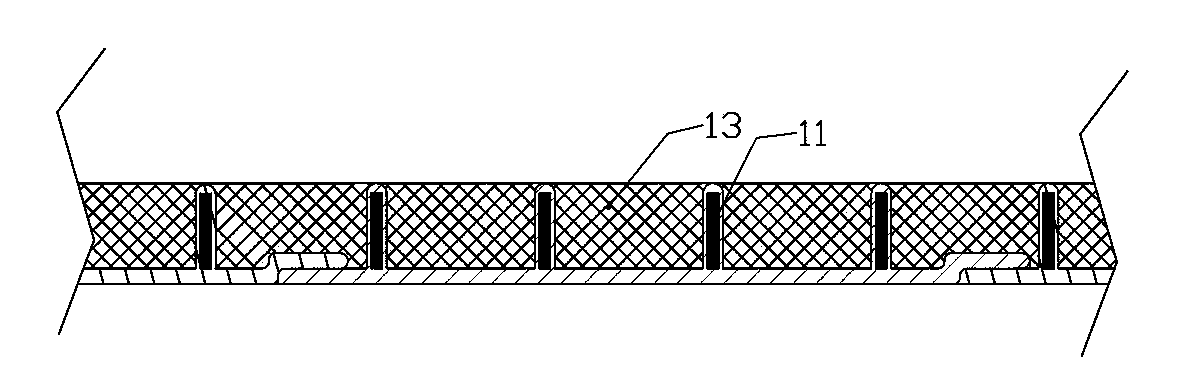

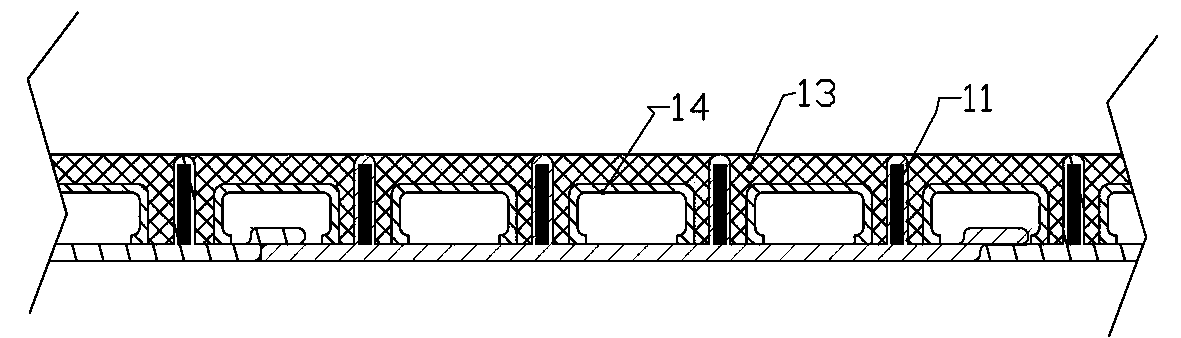

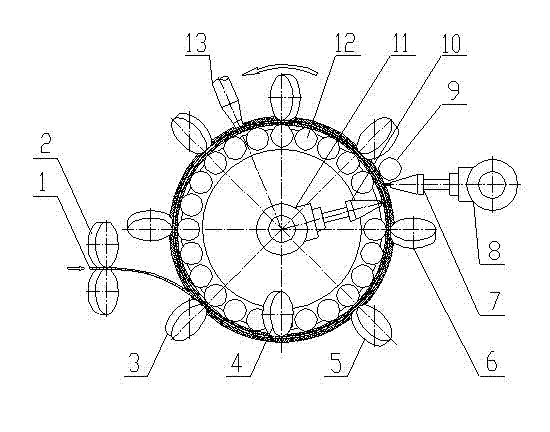

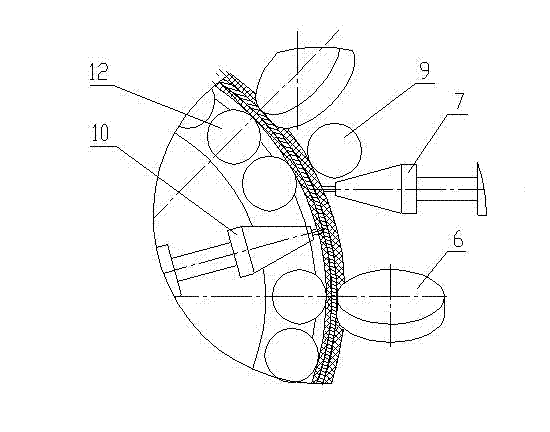

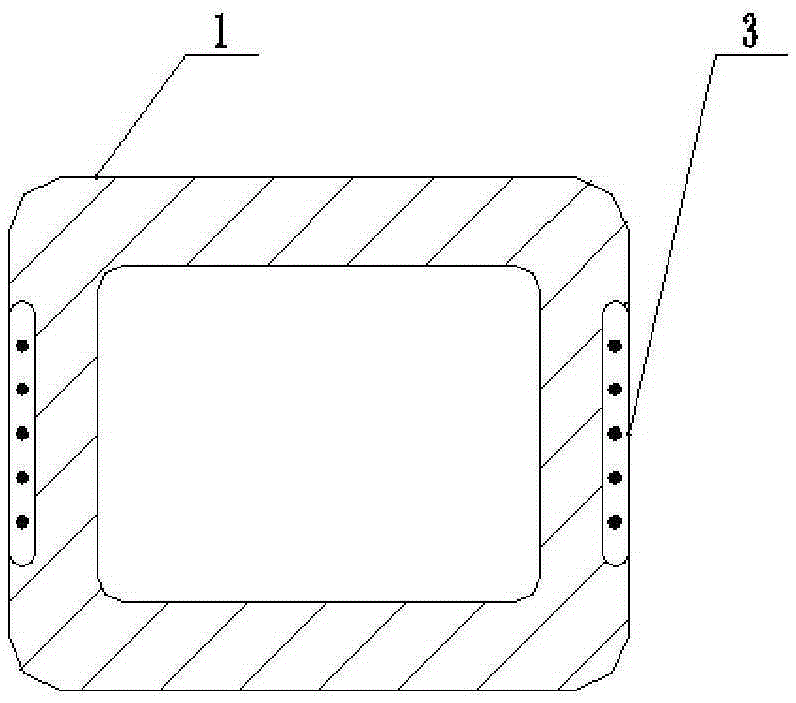

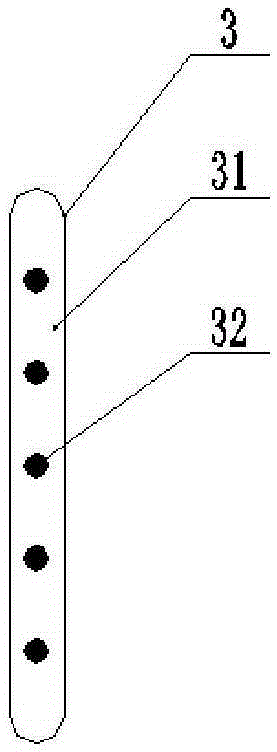

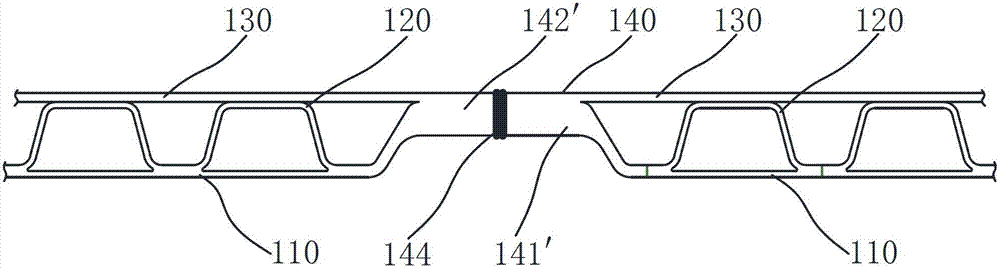

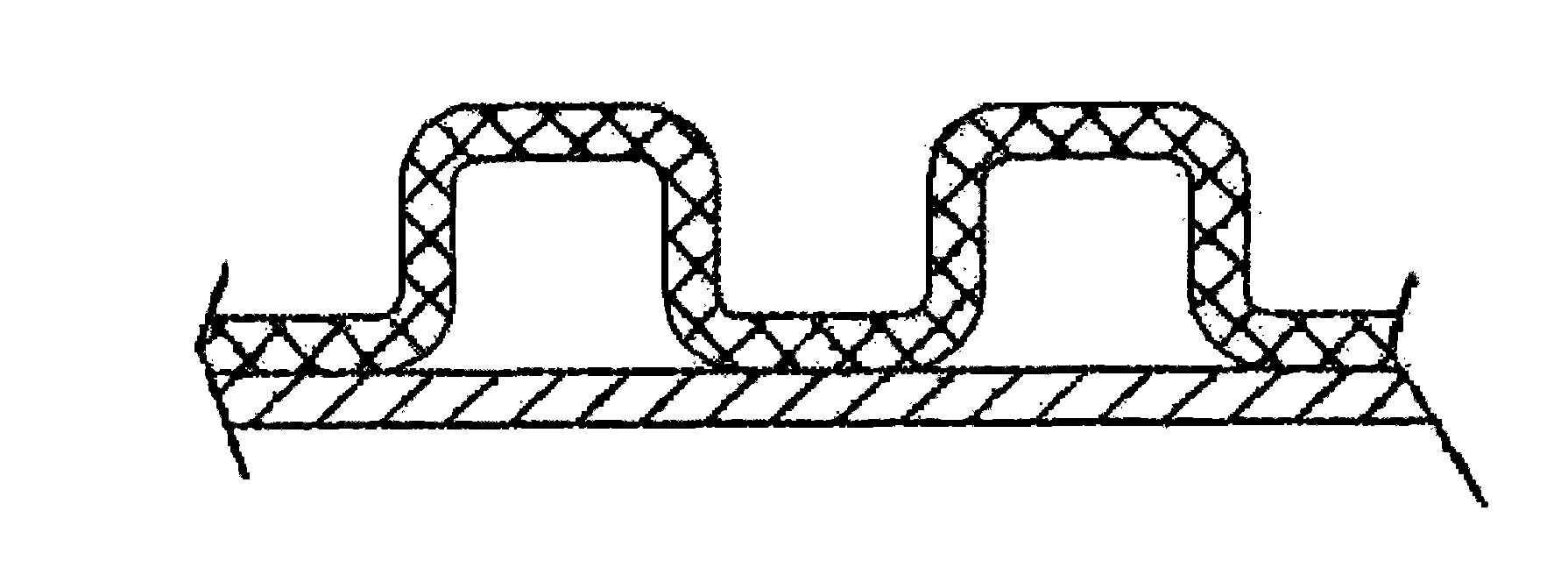

Internal rib-reinforced outer corrugated plastic wound structural wall pipe and manufacturing method thereof

ActiveCN102305316AImprove stabilityHigh strengthRigid pipesTubular articlesEngineeringUltimate tensile strength

The invention discloses an internal rib-reinforced outer corrugated plastic wound structural wall pipe and a manufacturing method thereof. The pipe comprises a pipe body formed by winding and welding special-shaped strips spirally, wherein the pipe body comprises a cylindrical pipe wall, a hollow reinforcing rib wound on the pipe wall spirally and a reinforced internal rib which is positioned in the hollow reinforcing rib and is perpendicular to the pipe wall; the reinforced internal rib divides the hollow reinforcing rib into two hollow cavities which are parallel; and the welded combinationsurface is positioned at the position of the reinforced internal rib. The pipe is formed by winding the plastic special-shaped strips of which two sides are provided with tubular bulges with the hollow cavities spirally and fusing by molten gel. In the manufacturing method, the pipe is formed by winding the plastic special-shaped strips of which the two sides are provided with the tubular bulges with the hollow cavities spirally and fusing by the molten gel, so an obtained plastic corrugated pipe is provided with the hollow reinforcing rib wound on the outer side of the pipe wall, and has high ring stiffness, the combined action of pipe clay and high strength. In addition, by a structure of the reinforced internal rib, the stability of the hollow reinforcing rib can be improved effectively, so that the stability of the wound corrugated pipe is superior to that of other wound corrugated pipes and dual-wall corrugated pipes.

Owner:戴爱清

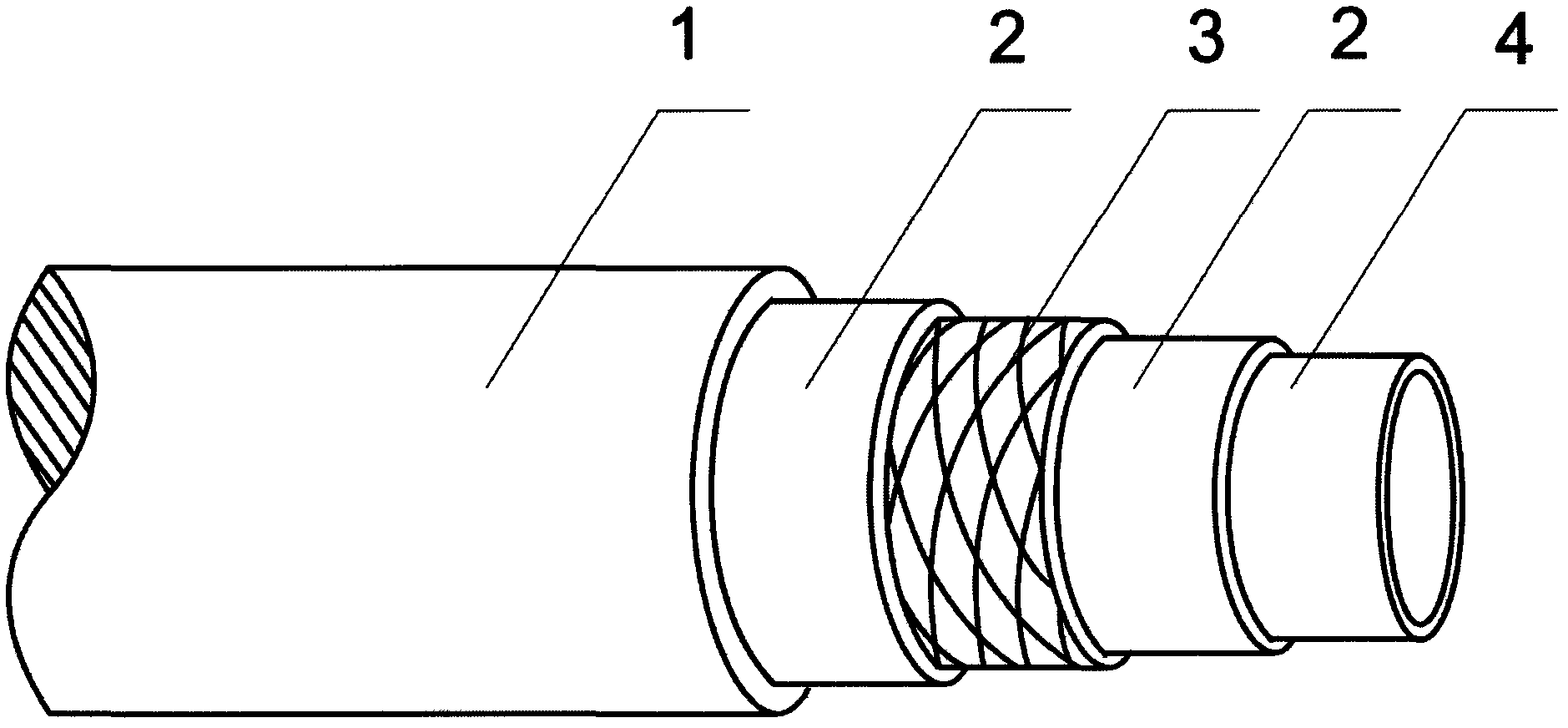

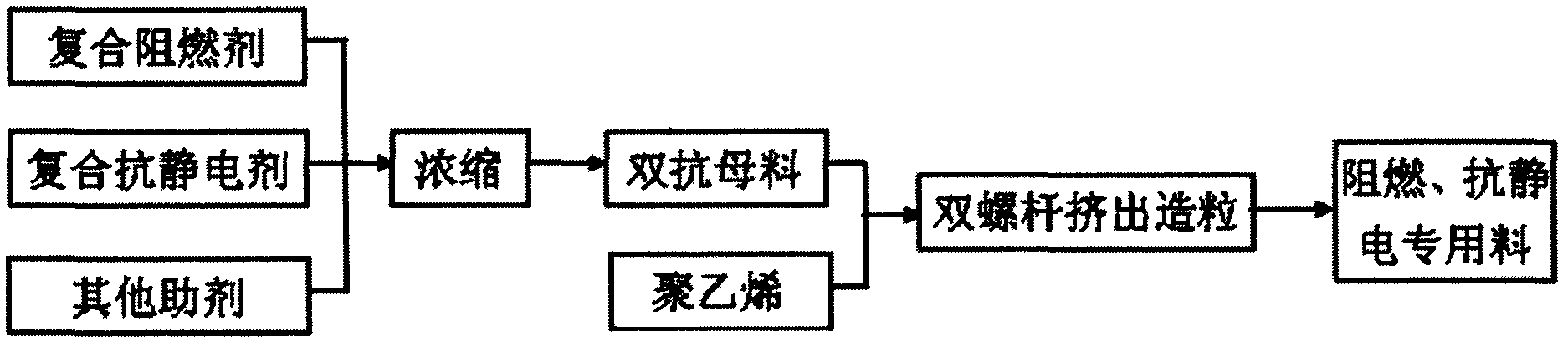

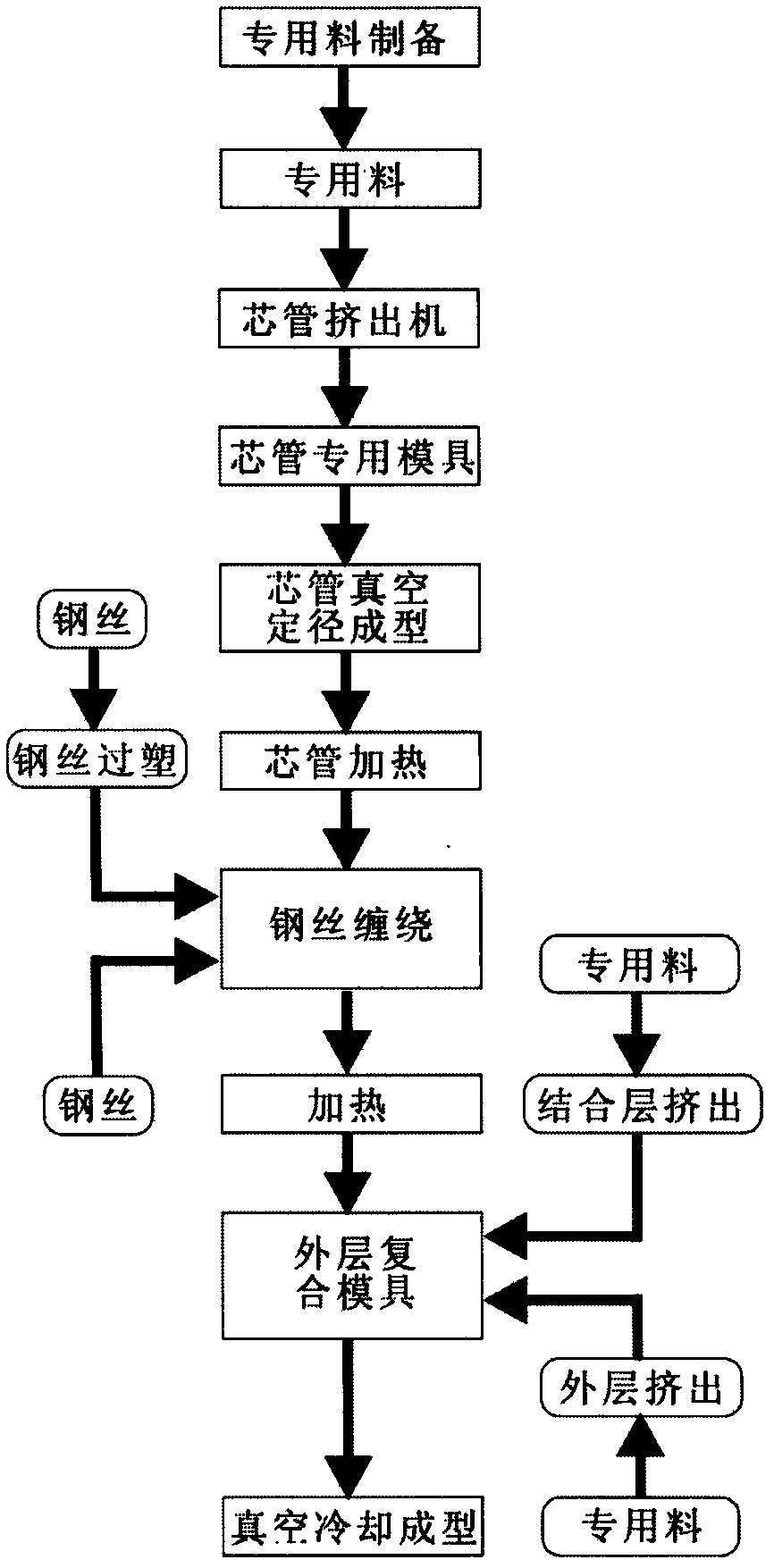

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

Nano-stage hard polyvinyl chloride pipe

InactiveCN101165089AImprove impact performanceIncreased ring stiffnessRigid pipesPolyvinyl chlorideWear resistance

The nanometer level hard polyvinyl chloride pipe material consists of polyvinyl chloride resin 100 weight portions, composite stabilizer 2-6 weight portions, machining assistant 1-6 weight portions, shock resisting agent 1-8 weight portions, and stuffing 20-30 weight portions. The present invention adopts nanometer level stuffing, such as nanometer level calcium carbonate material, to make the hard polyvinyl chloride pipe material possess low temperature shock resisting performance and cyclic rigidity higher than that of available similar pipe material. In addition, the nanometer level hard polyvinyl chloride pipe material has excellent wear resistance, low construction loss and high corrosion resistance.

Owner:上海正鸣塑胶管业有限公司

Double-plastics finned wound corrugated pipe and method for manufacturing same

InactiveCN103453240AGuaranteed Ring RigiditySecure connectionPipe connection arrangementsRigid pipesCorrosionEngineering

The invention discloses a double-plastics finned wound corrugated pipe and a method for manufacturing the same. A pipe wall of the double-plastics finned wound corrugated pipe is in the shape of a corrugated pipe which is squeezed and inflated and is integrated by means of spirally winding and hot melting, a bell socket and a spigot socket are respectively formed in two ends of the double-plastics finned wound corrugated pipe, cavities are arranged in corrugations of the pipe wall, strip-shaped plastic reinforcing ribs are arranged in the cavities and are perpendicular to the pipe wall, the outer edge of each plastic reinforcing rib is connected with a crest ring surface of the corresponding cavity by means of hot melting, and the inner edge of each plastic reinforcing rib is annularly connected with the other surface of the corresponding cavity by means of hot melting. The double-plastics finned wound corrugated pipe and the method have the advantages that the double-plastics finned wound corrugated pipe is good in ring stiffness and corrosion resistance and long in service life, and future maintenance investment is nearly zero; the bell socket and the spigot socket are connected with each other by means of electric hot melting, so that a system is good in airtight property, and forming machines implemented in a manufacturing procedure are simple and are low in investment and cost; the double-plastics finned wound corrugated pipe and the method can be widely applied to wall pipes with large and super-large apertures for drain and blowdown structures.

Owner:黄楠伟

Compound double-wall corrugated pipe and preparation process thereof

InactiveCN101761710AIncreased ring stiffnessImprove toughnessFlexible pipesPolymer scienceEngineering

The invention discloses a compound double-wall corrugated pipe, which is prepared from the following components in part by weight: 100 parts of mixture of polythene and polypropylene, 3-10 parts of coupling agent, 3-10 parts of rigid particle, 2-6 parts of master batch, 2-6 parts of blue batch and 3-9 parts of defoaming agent. The preparation process comprises the following steps of: evenly mixing the components in a high-speed mixer; after evenly mixing in a cold mixer, extruding tubes by using a double-host single screw extruder; modulizing, vacuumizing and cooling the tubes to form; and fixing the length and cutting and packaging the tubes. With the blending and the modification of polypropylene and polythene and the use of the rigid particles, the compound double-wall corrugated pipe well solves the problem of strong and unyielding balance, i.e. the tubes has higher toughness while having high annular rigidity. The tubes are made of completely non-toxic raw material and have good sanitary performance as well as the characteristic of simple production process.

Owner:山东华信塑胶股份有限公司

Preparation method for ultrastrong earthquake resistant polyvinyl chloride pipe material

ActiveCN102212237AHigh impact strengthIncreased ring stiffnessRigid pipesActive agentEngineering plastic

The invention discloses a preparation method for an ultrastrong earthquake resistant polyvinyl chloride pipe material, which is characterized in that the pipe material comprises 100 parts of polyvinyl chloride resin, 2-10 parts of acrylic acid resin, 3-10 parts of bismaleimide, 1-1.5 parts of active agent, 0.3-1 part of coupling agent, 1-2 parts of dispersing agent, 5-15 parts of nanometer material, 2-6 parts of stabilizing agent, 1-5 parts of compatibilizer, 6-13 parts of engineering plastics, 2-10 parts of filler, 5-10 parts of impact modifier and 1-2 parts of lubricating agent. The pipe material is extruded and formed by a mould after the components are mixed and stirred according to the weight part. Compared with the prior art, the invention has the advantages of high impact resistance strength, toughness of low temperature resistance, high ring stiffness, good performance of pressure resistance and long service life.

Owner:SHANGHAI YUANZHOU PIPE

Reinforced and modified corrugated power protection sleeve

The invention discloses a reinforced and modified corrugated power protection sleeve, which is produced by taking polyethylene or polypropylene or polyvinyl chloride as a main material and adding glass fibres, inorganic powder, an interface phase solvent, an impact modifier, a lubricant and toner to the main material. Among the components, the glass fibres and the inorganic powder can multiply the ring stiffness of a tubular product and reduce the manufacturing costs of the product, wherein the inorganic powder is one or a mixture of calcite master batch, a magnesium carbonate powder material or a calcium carbonate powder material; the interface phase solvent enables the components to be fully blended so as to facilitate granulation; and the impact modifier is a mixture of an acrylics impact modifier ACR and a chlorinated polyethylene impact modifier CPE, wherein the acrylics impact modifier ACR is excellent in workability and good in impact resistance and weather resistance and can be stable for a long time, the chlorinated polyethylene impact modifier CPE is a rubber body and is high in elasticity and excellent in impact resistance but is poor in workability and inferior to acrylics in weather resistance, but the synergistic effect of the two impact modifiers allows the good short-term impact resistance of the tubular products to be developed, and can ensure the long-term impact resistance of the tubular products.

Owner:ZHEJIANG FEILONG PIPE

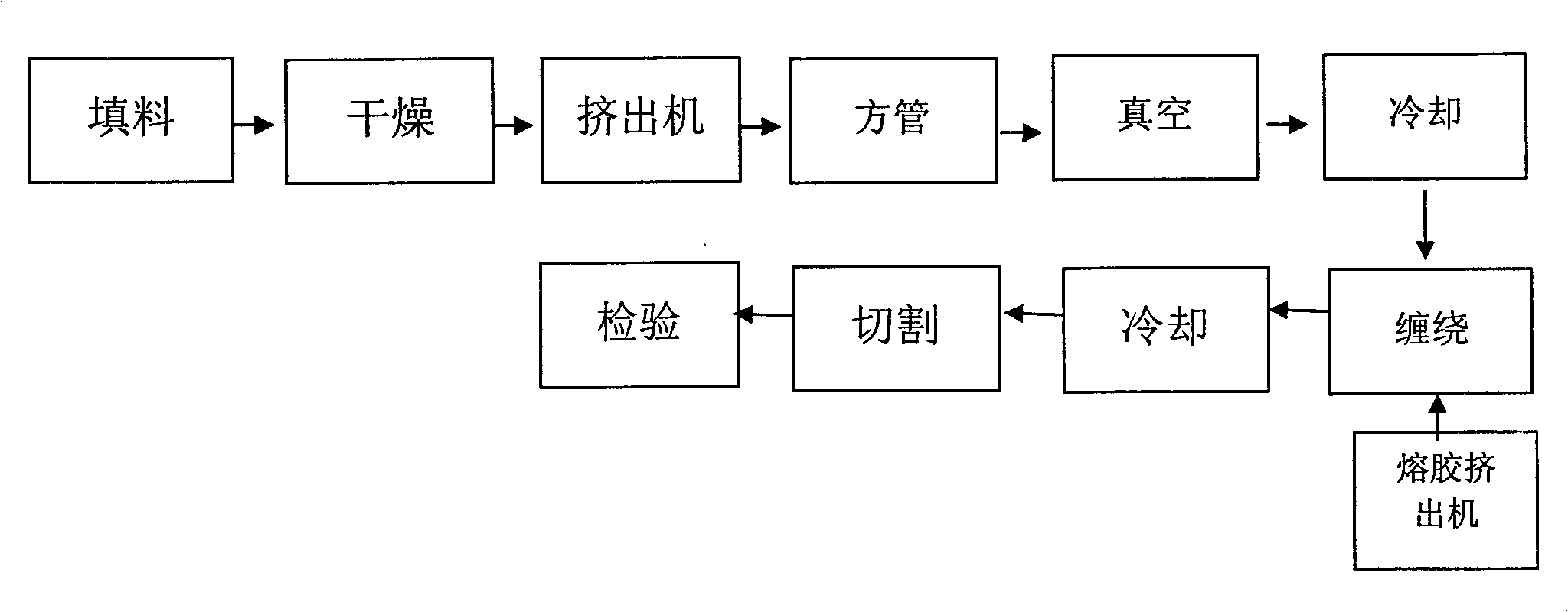

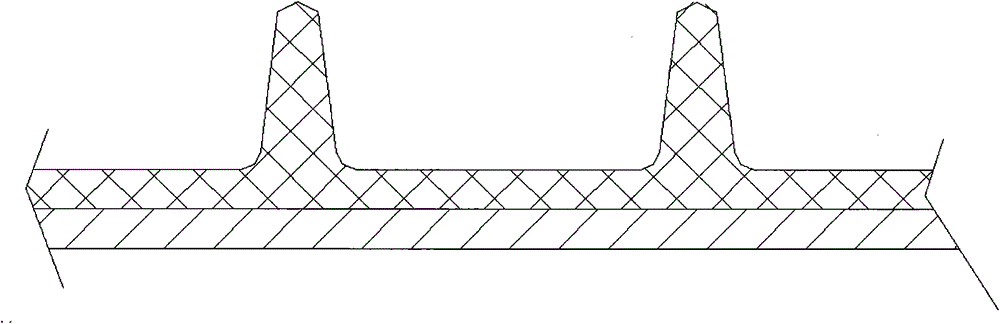

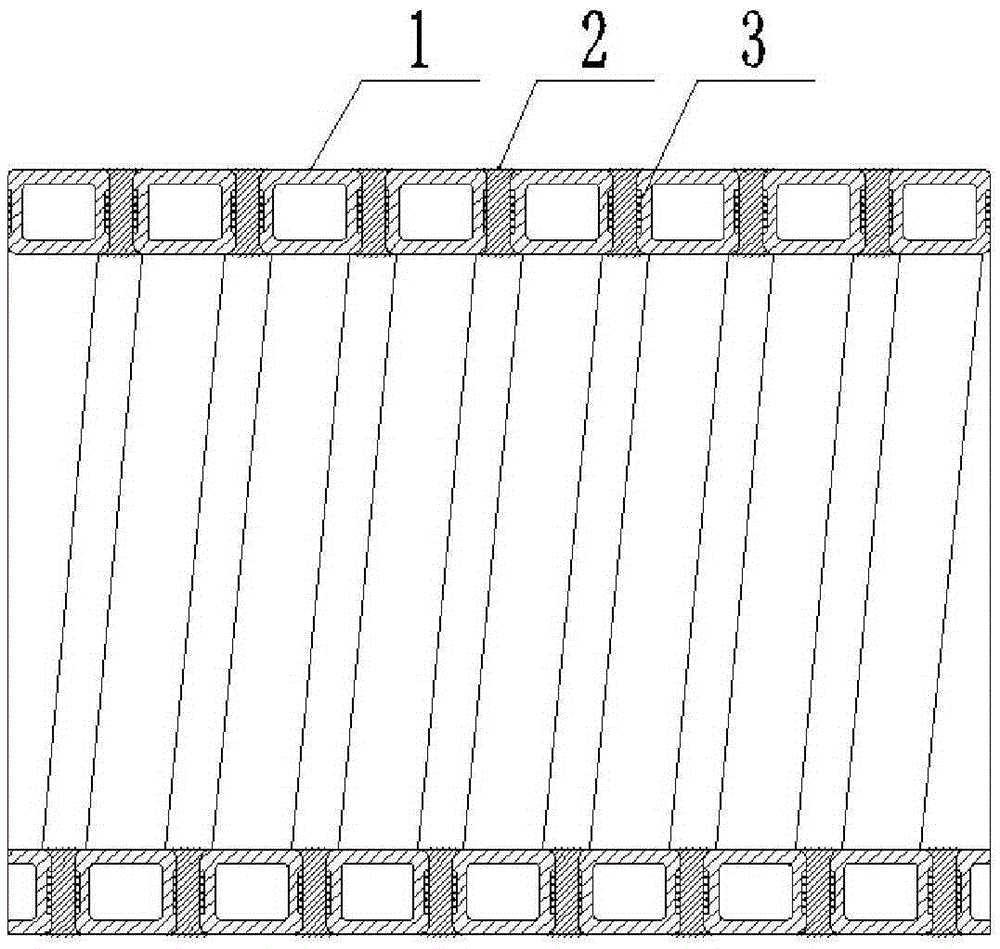

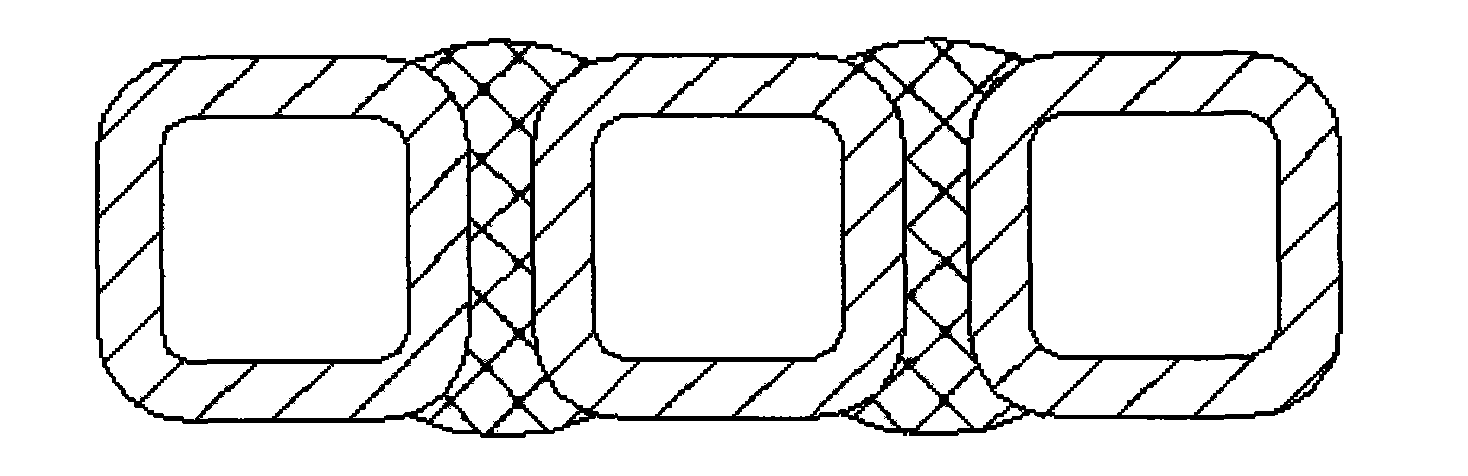

Preparation method of high density polyethylene hollow wrapped pipe

InactiveCN101358005AReduce manufacturing costImprove impact resistanceHollow wall articlesRigid pipesShock resistanceSewage

The invention discloses a manufacturing method of a high-density polyethylene hollow wall winding pipe which is used as a large-diameter sewage drain pipe. HDPE resin, modifier, defoamer and mixed pipe wall material are extruded by an extruder at 160 to 180 DEG C to produce small square tubes; after cooling stereotyping, the small square tubes are enwinded spirally to form sewage drain pipe walls; pipe wall material molten at 160 to 230 DEG C are used to bond the spirally enwinded square pipes to form sewage drain pipes. The sewage drain pipes is light weighted, shock resistant, highly intense, and uses calcium carbonate with low price as a modifier, greatly improves the shock resistance and ring stiffness of the sewage drain pipe and reduces the production cost of the sewage drain pipe without reducing the tenacity of the HDPE sewage drain pipe.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

Enhancement ultra-high molecular weight polyethylene wound pipe and manufacture method therefor

InactiveCN101016965AIncrease stressIncreased ring stiffnessRigid pipesHigh intensityAntistatic Materials

The invention relates to method for producing strengthen macromolecule polyethylene coil tube, which uses at least one layer of macromolecule polyethylene section material as coil material alternatively or irregularly arranged, and nearby side walls are fused to connected or adhered by fused material, to be screwed to form tube wall. The coil material is drawn to direct the molecule longitudinally. The macromolecule polyethylene base material is added with strength material and / or flameproof material and / or static resistance composed. The fusing connecting material is plastic polymer or added with strength material and / or flameproof material and / or static resistance, to form plastic fused material. The strength material is distributed in the coil material and / or fusing connecting material, directionally distributed along the screw of high-strength coil tube. The invention has high strength, flameproof property and static resistance.

Owner:淄博寿山特种塑料有限公司

Raw materials for preparing corrugated dual-wall hard PVC pipe

InactiveCN1346844AImprove the lubrication effectExcellent long-term heat resistanceParaffin waxPolyvinyl chloride

A material used for making hard corrugated PVC pipe is prepared from PVC (100 pts.wt.), trisalt (6.4-6.8 pts.wt.), lead stearate (0.42-0.47 pts.wt.), barium stearate (1.4-1.7 pts.wt.), stearic acid (0.42-0.47 pts.wt.), microcrystal paraffin (0.36-0.41 pts.wt.), polyvinyl wax (0.58-0.62 pts.wt.), ACR (401) (1.9-2.1 pts.wt.), chlorinated polyethylene (5.8-6.3 pts.wt.), superfine calcium carbonate (9-11 pts.wt.) and AC 316 (0.28-0.33 pts.wt.). Its advantages are high lubricating performance, impact strength, ring rigidity and Vicat softening temp, good demoulding nature, and excellent low-temp plasticity.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

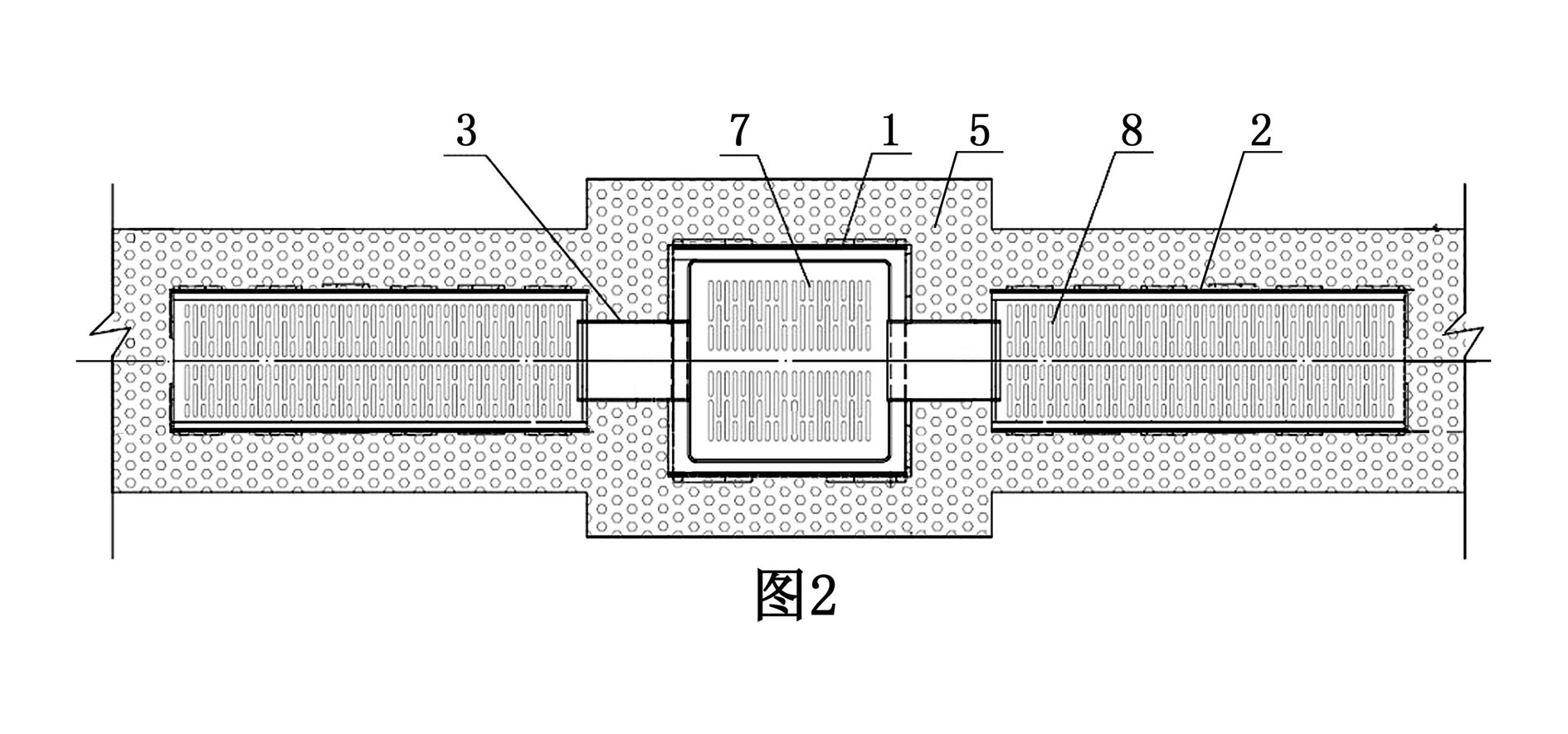

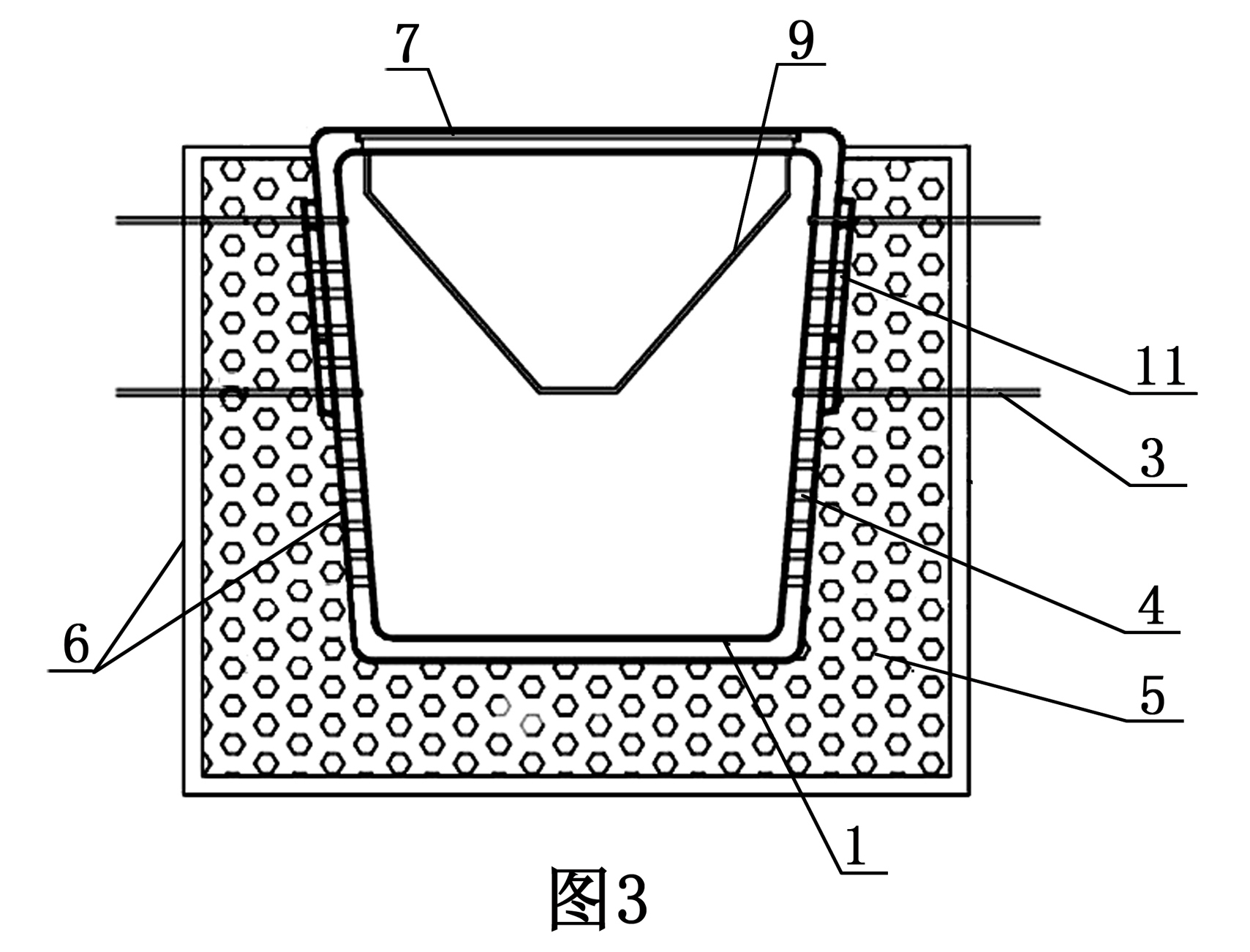

Rainwater penetrating-discharging integrated ecological system

InactiveCN101775839AReduce drainageImprove the ecological environmentSewerage structuresSewage drainingEnvironmental resource managementEcological environment

The invention discloses a rainwater penetrating-discharging integrated ecological system, which comprises penetration inspection wells distributed on the ground of residential areas, penetration drainage ditches which are in a network shape and connected on all the penetration inspection wells and transversal connecting pipes between the penetration inspection wells and the penetration drainage ditches. Permeable holes are formed on the side walls and at the bottoms of the penetration inspection wells, a gravel layer is laid in the peripheries of the penetration inspection wells, a layer of permeable geotextile is laid in the peripheries of the gravel layer, wellheads of the penetration inspection wells are provided with dirt-catching and sewage-blocking baskets therein and permeable well covers are covered on the wellheads; permeable holes are formed on the side walls of the penetration drainage ditches, the peripheries of the penetration drainage ditches are provided with the gravel layer, the peripheries of the gravel layers are provided with a layer of permeable geotexile, and the top parts of the penetration drainage ditches are covered with grate covers of the drainage ditches. The invention has the advantages of simple design principle and convenient construction. The invention can save water consumption, reduce rainwater runoff in a city and relieve municipal drainage pressure, thereby not only realizing early draining of rainwater, purifying water, but also realizing the penetration of rainwater, conserving underground water source and beautifying the peripheral ecological environment.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

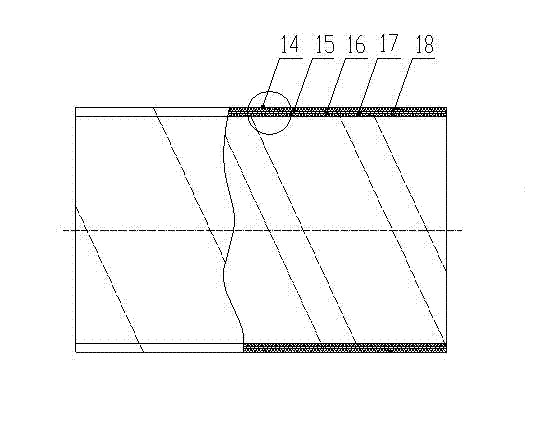

Polyethylene-wound structure wall tube and pipe without frame pipe and production method thereof

InactiveCN101852316AEnhanced centroid heightStrengthen heart distance heightRigid pipesSolid wallConductor Coil

The invention relates to a polyethylene-wound structure wall tube and pipe without a frame pipe, which is composed of an inner wall layer and an outer wall layer, wherein the inner wall layer is a continuous solid wall pipe formed by spirally winding a flaky polyethylene band, and adjacent band edges orderly being overlapped with each other; and the outer wall layer is composed of convex stiffening ribs formed by spirally winding a tubular polyethylene band on the external surface of the inner wall layer, and the tubular polyethylene band spirally presses across the overlap seam of each adjacent flaky polyethylene band edges. The production method comprises the following steps: extruding profiled bars, stretching, sizing, winding and fusing. The production method removes the original polypropylene frame pipe, can ensure the centroid distance of the stiffening rib tube, reduce the product weight by more than 20%, reduce raw material consumption, lower the product cost, greatly decrease the internal stress of the tube and pipe, reduce consumption and enhance ring stiff and ring flexibility.

Owner:韩路平 +2

Rigidity enhanced, modified dedicated material of plastic pipe material

This invention relates to a specific modification material for increasing the rigidity of plastic pipes. The specific modification material is composed of: ultra-fine talcum powder 20-30 parts, toughening agent 10-15 parts, coupling agent 1-2 parts, plasticizer 5-8 parts, dispersant 3-5 parts, and high density polyethylene (HDPE) 50-55 parts. Plastic pipes modified with the specific modification material have rigidity 5-6% higher than that of neat HDPE pipes, thus can solve the problems of easy deformation, large influence to ground smoothness and easy breakage of HDPE pipes. Besides, plastic pipes modified with the specific modification material have improved impact strength and physical properties. Talcum powder can partly replace synthetic resin to reduce the cost.

Owner:辽宁艾海滑石有限公司

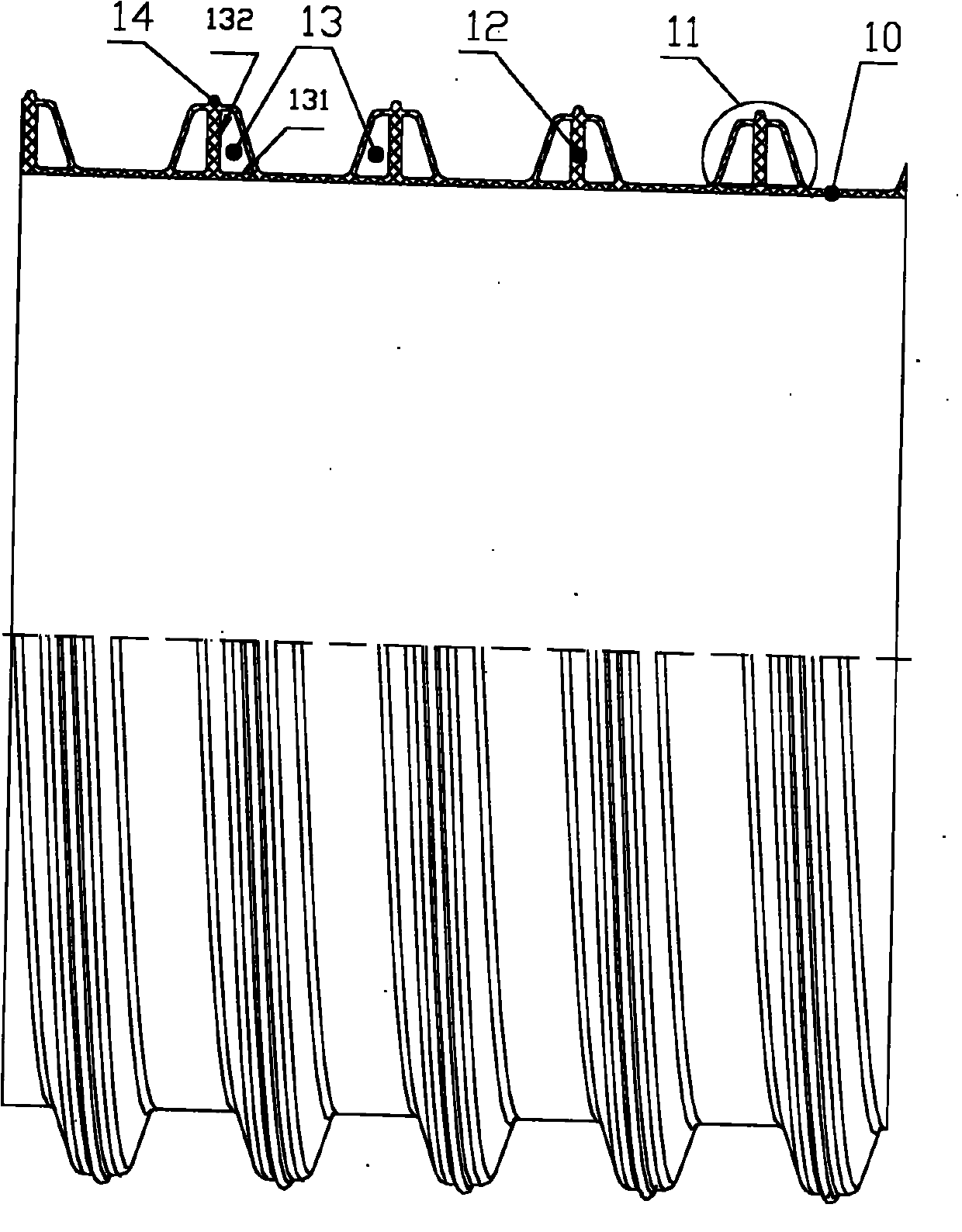

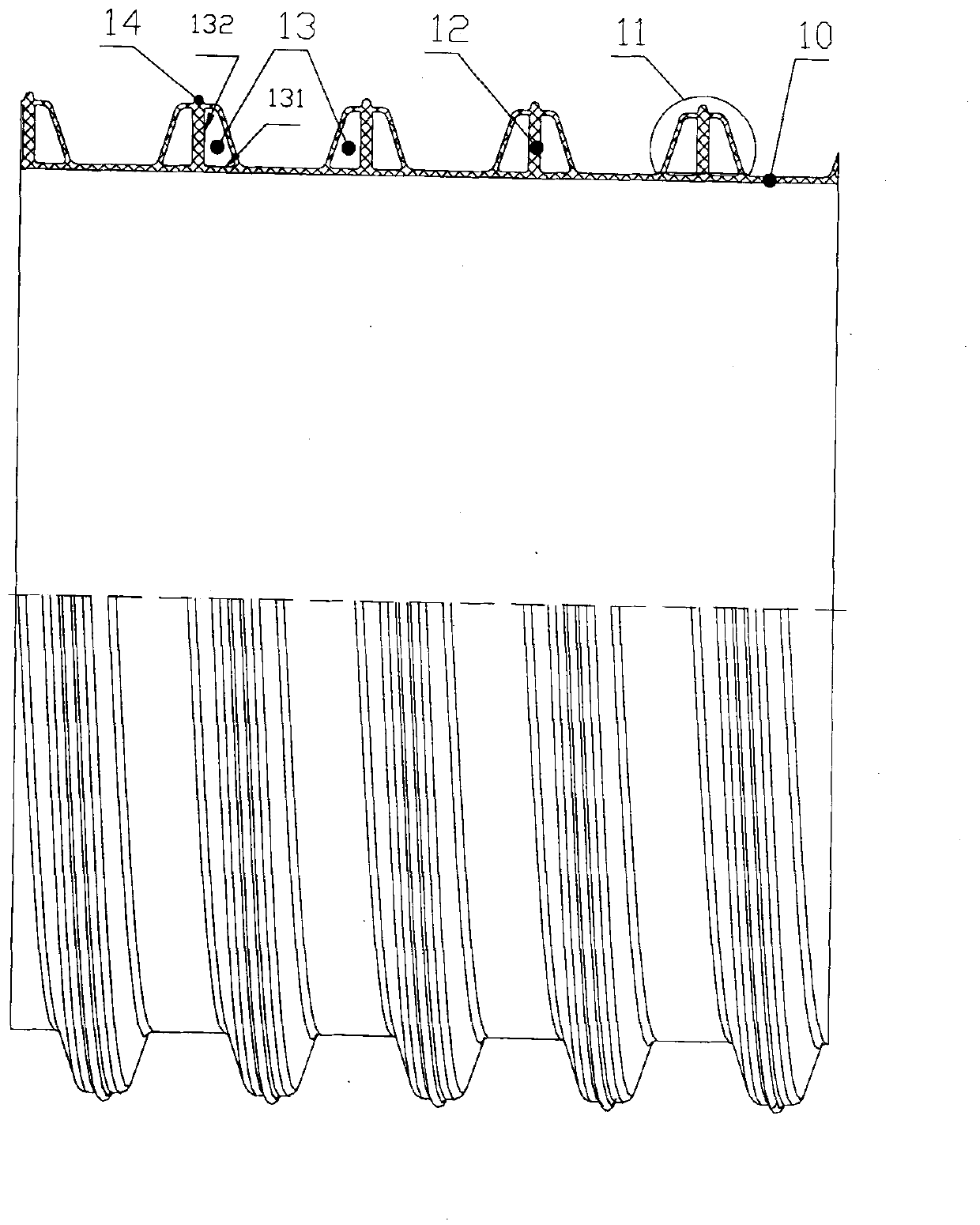

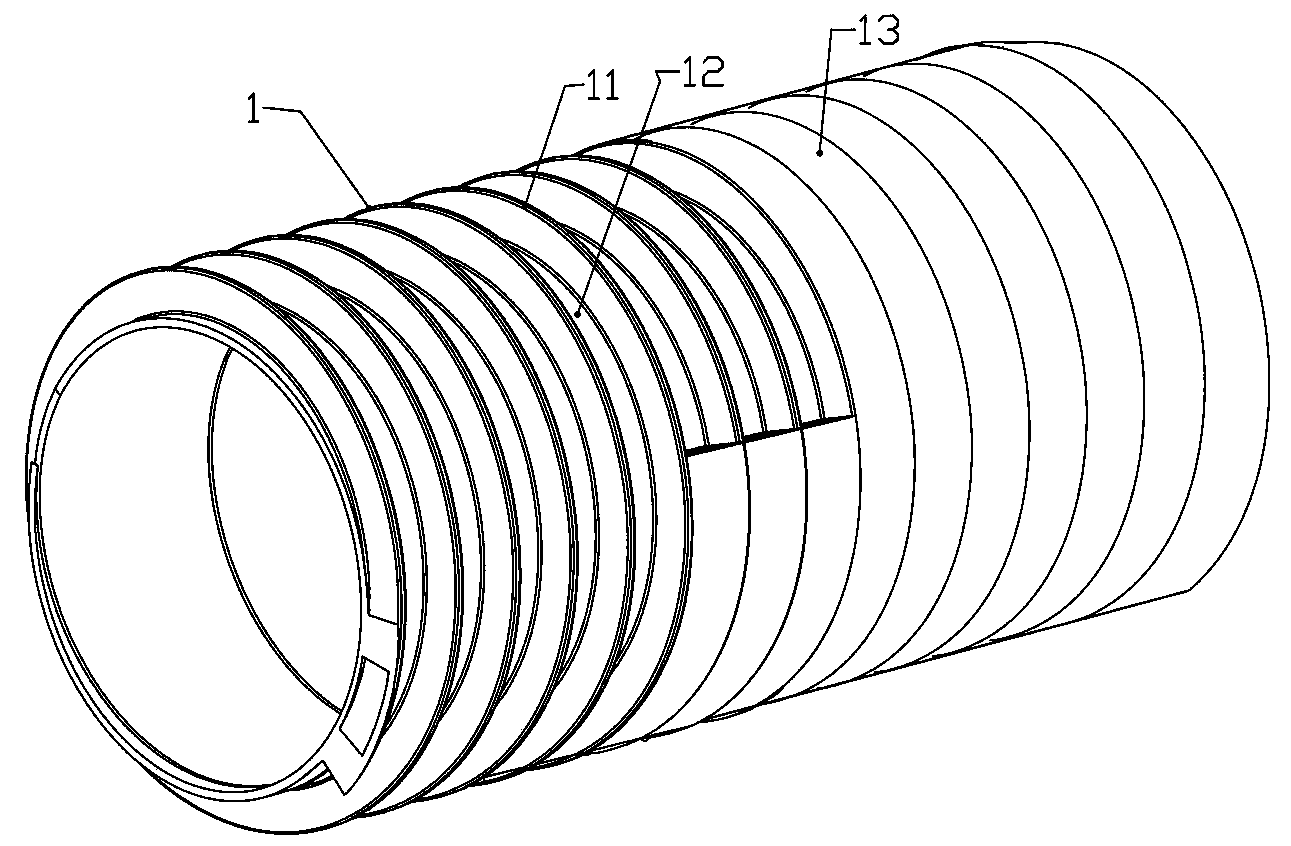

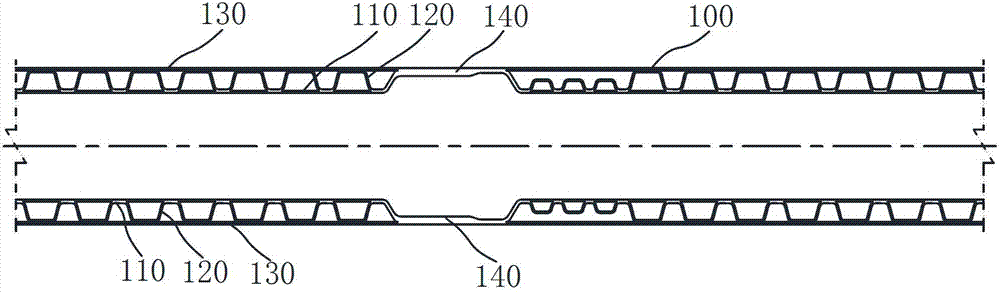

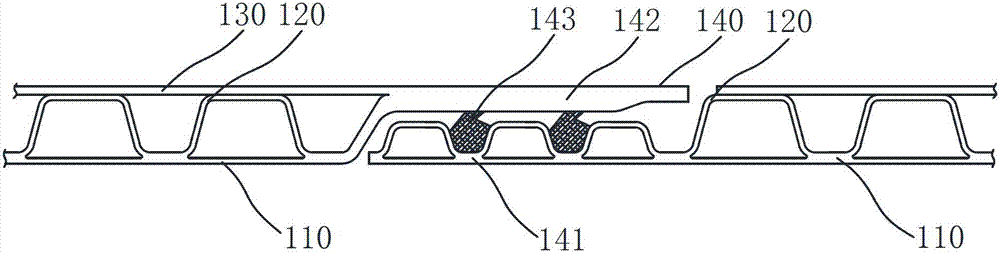

Continuous twining reinforced structure wall pipe, manufacturing equipment and manufacturing method

InactiveCN104061378AIncrease the outer surface areaGood synergyRigid pipesSolid wallPlastic materials

The invention provides a continuous twining reinforced structure wall pipe. The pipe wall of the continuous twining reinforced structure wall pipe is a spiral circumference; a center line is considered as an axis for specific strip-shaped plastic materials to twine in a spiral manner; the edges of the each adjacent specific strip-shaped plastic materials are overlapped to be integrated with each other to form a continuous solid wall pipe-shaped structure; reinforced adhesive materials which has the same spiral twining form is straddled and pressed on the positions on which overlapping joints of the adjacent specific strip-shaped materials are positioned; a specific single wall corrugated pipe which has the same spiral twining form is straddled and pressed on the reinforced adhesive materials; a strip-shaped material which has the same spiral twining form straddles the specific single wall corrugated pipe in a pressing manner, and adhesive to the pipe wall through a pressing wheel mechanism.

Owner:戴爱清 +1

Steel-plastic wound multiple pipe and manufacturing device and manufacturing technique of steel-plastic wound multiple pipe

InactiveCN103644394AIncreased ring stiffnessHigh strengthRigid pipesFilling materialsUltimate tensile strength

The invention discloses a steel-plastic wound multiple pipe, and a manufacturing device and a manufacturing technique of the steel-plastic wound multiple pipe. The steel-plastic wound multiple pipe comprises a steel-plastic wound multiple pipe substrate, wherein the steel-plastic wound multiple pipe substrate is wound by a steel-plastic band material and is welded through hot melting to form a spiral shape; vertical reinforcing ribs are arranged on the outer surface of the steel-plastic wound multiple pipe substrate. The steel-plastic wound multiple pipe is characterized in that spiral plastic filling materials, which are stuffed in a thermoplastic manner and formed through condensation, are arranged in the grooves between every two reinforcing ribs on the outer surface of the steel-plastic wound multiple pipe substrate. The invention further discloses the manufacturing device and the manufacturing technique of the pipe. The pipe has the advantages of high strength, easiness in manufacturing, and fold increase in bearing capacity of the pipe; meanwhile, the pipe is very low in transforming cost, has a relatively wide applicable scope, and can be widely applied to upgrade and transforming of various steel-plastic wound pipes.

Owner:山东天迈管业有限公司

Double wall corrugated pipe

InactiveCN102002179AIncreased ring stiffnessReduce formulation costsFlexible pipesLinear low-density polyethyleneHigh density

The invention discloses a factory formula of a double wall corrugated pipe. The pipe wall of the corrugated pipe consists of internal and external layers. The external layer comprises the following components in parts by weight: 50-80 parts of HDPE high density polyvinyl resin, 15-30 parts of special enhancing master batch, 10-25 parts of special modifying master batch, 2-5 parts of moisture absorbing master batch and 1-3 parts of colour master batch. The internal layer comprises the following components in parts by weight: 50-80 parts of HDPE high density polyvinyl resin, 15-30 parts of metallocene linear low density polyethylene, 20-45 parts of special modifying master batch, 1-3 parts of moisture absorbing master batch and 1-3 parts of color master batch. The HDPE double wall corrugated pipe produced by the formula has high rigidity, other performance indexes can reach the standard and the formula cost is reduced greatly.

Owner:ANHUI ZHONGHONG PIPE IND TECH

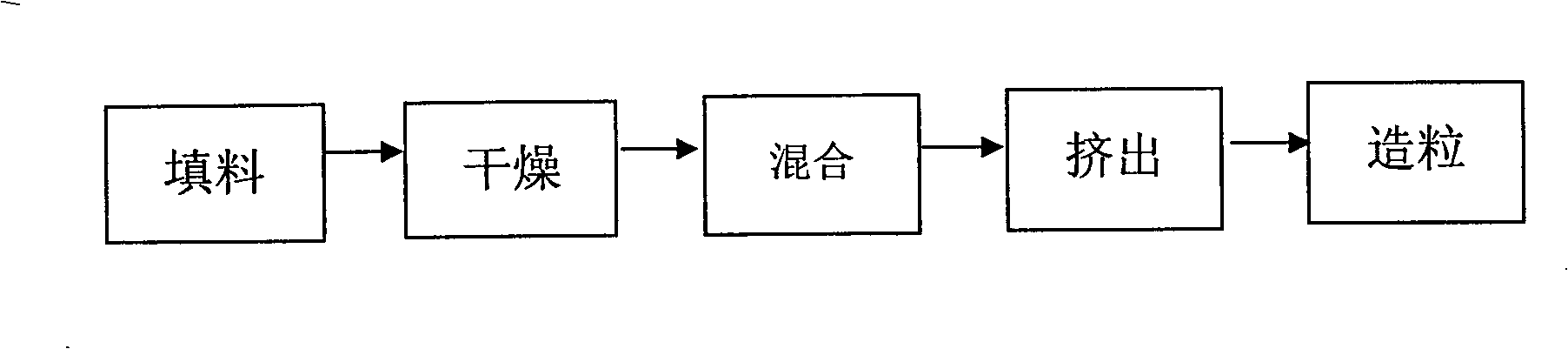

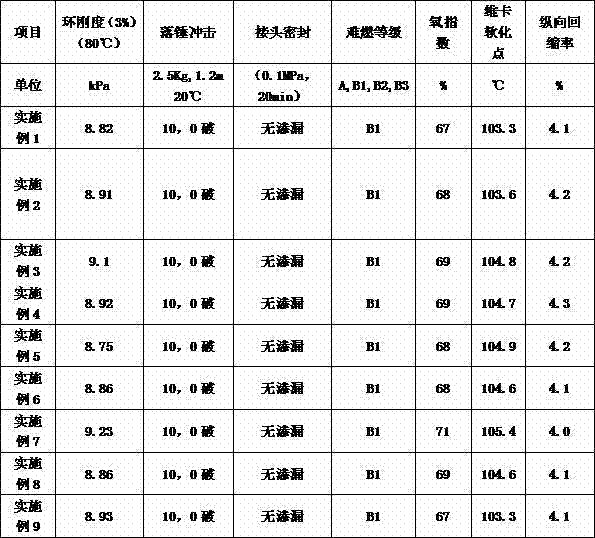

CPVC used for high Vicat power cable sleeve and its preparation method

The invention discloses a CPVC used for a high Vicat power cable sleeve and its preparation method. The CPVC is composed of the following raw materials by weight: 80-90 parts of CPVC resin, 10-20 parts of PVC resin, 5-7 parts of composite lead salt stabilizing agent, 1.2-1.8 parts of inner lubricant, 2-4 parts of outer lubricant, 5-8 parts of anti-punching modifier, 2-5 parts of processing auxiliary agent, 20-30 parts of filling material and 0.05-0.1 part of pigment. According to the prepared CPVC sleeve, the Vicat softening temperature can reach more than 103 DEG C, the temperature can reach as high as 80 DEG C for long-term usage, the CPVC sleeve is more suitable for severe environment, the mechanical strength is larger, the ring stiffness of the CPVC sleeve is higher by 12-15% than that of the national standard, the flame resistance is better, the oxygen index can reach as high as 71, the cost is low, and the CPVC used for the high Vicat power cable sleeve and its preparation method are convenient for popularization.

Owner:山东高信化学股份有限公司

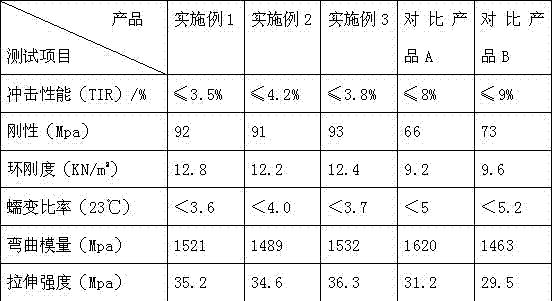

Reinforced HDPE double-wall corrugated pipe and production method thereof

The invention discloses a formula of a reinforced HDPE double-wall corrugated pipe. The formula comprises, by weight, 280 parts of high density polyethylene, 80 parts of chopped glass fibers, 8 parts of elastomer, 12 parts of phenolic resin, 30 parts of wood powder, 8 parts of a coupling agent, 10 parts of calcium carbonate, 10 parts of nanometer silicon oxide, 1 part of an antioxidant, 26 parts of methylsilicone oil and 4 parts of a lubricant. A manufacturing method of the reinforced HDPE double-wall corrugated pipe comprises the following steps: wood powder processing, plasticizing treatment, batch mixing, granulation and compression molding. The reinforced HDPE double-wall corrugated pipe has the advantages of good rigidity and strength, low creep deformation ratio and good impact performance, so the use amount of materials is effectively reduced on the premise of guaranteeing the use performances of the pipe, thereby the cost is saved, and the pipe has very high practical values.

Owner:贵州枫叶管业有限公司

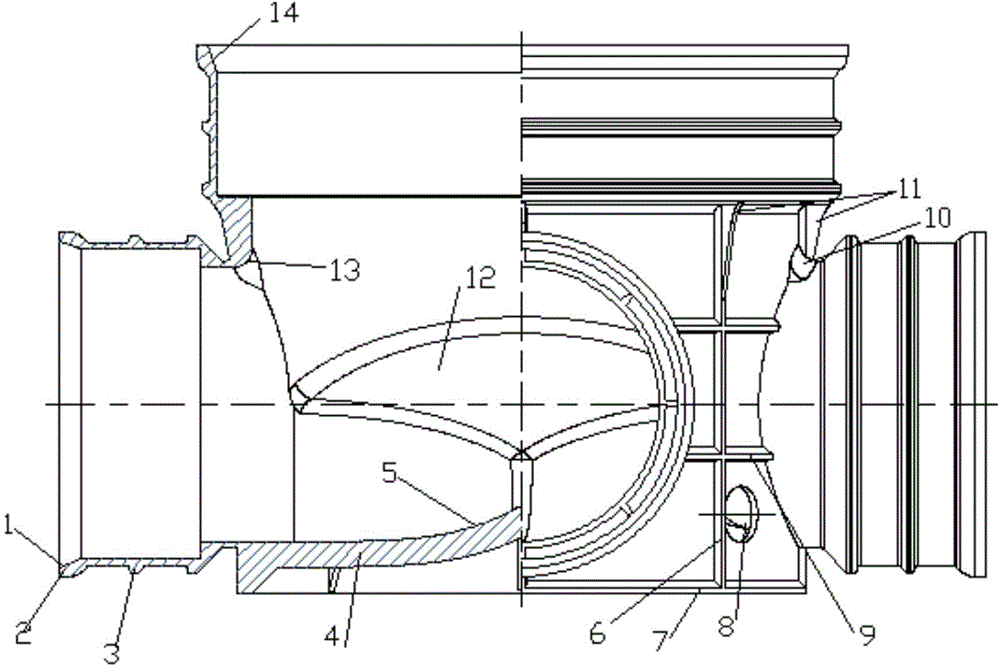

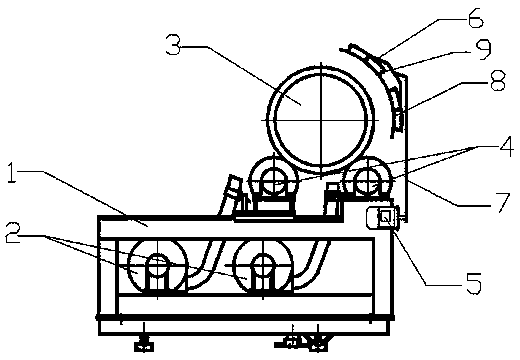

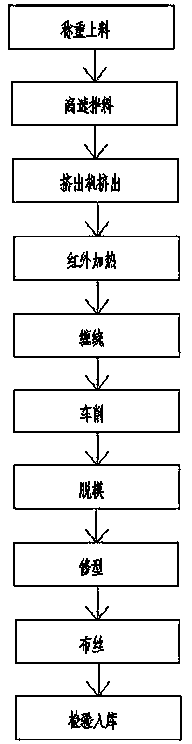

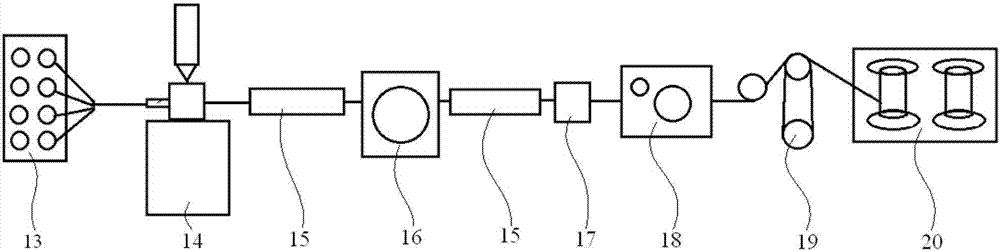

Production equipment and production technology for HDPE (high density polyethylene)spirally enwound structure-wall pipe (Krah pipe)

ActiveCN103963325AReduce manufacturing costImprove heating efficiencyTubular articlesElectric fusesProcess engineering

The invention discloses production equipment and a production technology for an HDPE (high density polyethylene) spirally enwound structure-wall pipe (Krah pipe).The equipment comprises a base trolley, cooling fans, a mold roller, rolling wheels, a servo motor, an infrared heating device and a rotating rod. The technology comprises material mixing, feeding, vacuum feeding, extrusion, enwinding, turning, demolding, modification, electric fuse distribution, inspection and storage. According to the production equipment and the production technology, infrared high-frequency heating is adopted, the heating efficiency is high, the cost is low, and the operation is simple and convenient; the ring stiffness is increased by above 30% due to addition of short-glass-fiber master batches; characteristics of HDPE are adopted, so that the comprehensive performance of the pipe is improved; the weld seam quality of the pipe is guaranteed, and the weld seam quality and the overall external pressure resistance of the pipe are also improved.

Owner:HUNAN QIANYUAN NEW MATERIAL

Method for utilizing waste HDPE plastic to prepare large-caliber double-wall bellow

InactiveCN101549535AHigh mechanical strengthIncreased ring stiffnessPlastic recyclingElastomerDouble wall

The invention discloses a method for utilizing waste HDPE plastic to prepare a large-caliber double-wall bellow, essentially comprising the following steps of: using waste high-density polyethylene (HDPE) to prepare a double-wall bellow with the caliber of 1200mm; carrying out cooperative combination to strip, fibrous and spherical fillers; adopting novel elastomer as basic resin; preparing modified master batch which has functions of reinforcing and toughening to the waste HDPE; and using the functional master batch to carry out modification to the waste HDPE so as to lead the mechanical performance thereof to reach the level of new resin of HDPE; and an extrusion mould of the large-caliber double-wall bellow adopts arc structure at peak part, thus improving the ring stiffness of the product and leading the product parameters to meet standard requirements.

Owner:江苏和远电力科技有限公司

HDPE (high-density polyethylene) double-wall corrugated pipe with high ring stiffness

InactiveCN102786730AIncreased ring stiffnessStrong water absorptionElongated constructional elementsLow-density polyethyleneAcrylic resin

The invention discloses an HDPE (high-density polyethylene) double-wall corrugated pipe with high ring stiffness. The HDPE double-wall corrugated pipe comprises the following raw materials in parts by weight: 47 to 49 parts of high-density polyethylene, 17 to 19 parts of high modulus propene polymer (PP), 3 to 5 parts of attapulgite, rigidity-reinforcing and tenacity-reinforcing master batch and the like. Due to the adoption of the formula of the HDPE double-wall corrugated pipe, the ring stiffness of the HDPE double-wall corrugated pipe can be greatly improved; due to the adoption of the attapulgite in the formula, the HDPE double-wall corrugated pipe has high water absorptivity and slurry making property; and due to the adoption of modified acrylic resin which has certain cohesiveness, the machining property is high.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Large-caliber spiral welding steel plastic composite pressure pipe and manufacturing method thereof

The invention relates to the technical field of steel plastic composite steel pipe manufacturing, in particular to a large-caliber spiral welding steel plastic composite pressure pipe and a manufacturing method thereof, and the problems that the manufacturing method of the existing steel plastic composite steel pipe is single, the structural strength of the pipe body is not ideal, and the adhesion strength of a plastic composite layer is poor are solved. The large-caliber spiral welding steel plastic composite pressure pipe is formed by compounding five or more than five layers of materials with different characteristics, wherein the middle layer is a spirally formed welded steel pipe, the inner surface and the outer surface of the spirally formed welded steel pipe are respectively provided with an inner hot melt adhesive layer and an outer hot melt adhesive layer, the outer hot melt adhesive layer of the spirally formed welded steel pipe is provided with an outer wound plastic layer, and the inner hot melt adhesive layer of the spirally formed welded steel pipe is provided with an inner wound plastic layer. The large-caliber spiral welding steel plastic composite pressure pipe has large integral structure strength and ring stiffness, good rigidity, high bearing pressure, and smooth inner and outer wall surfaces, and the manufacturing method is suitable for manufacturing large-caliber steel plastic composite pressure pipes.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

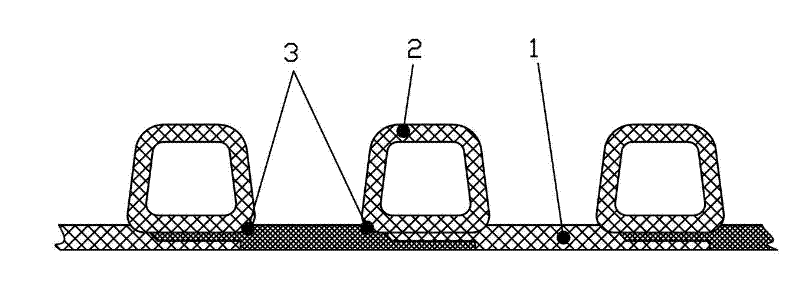

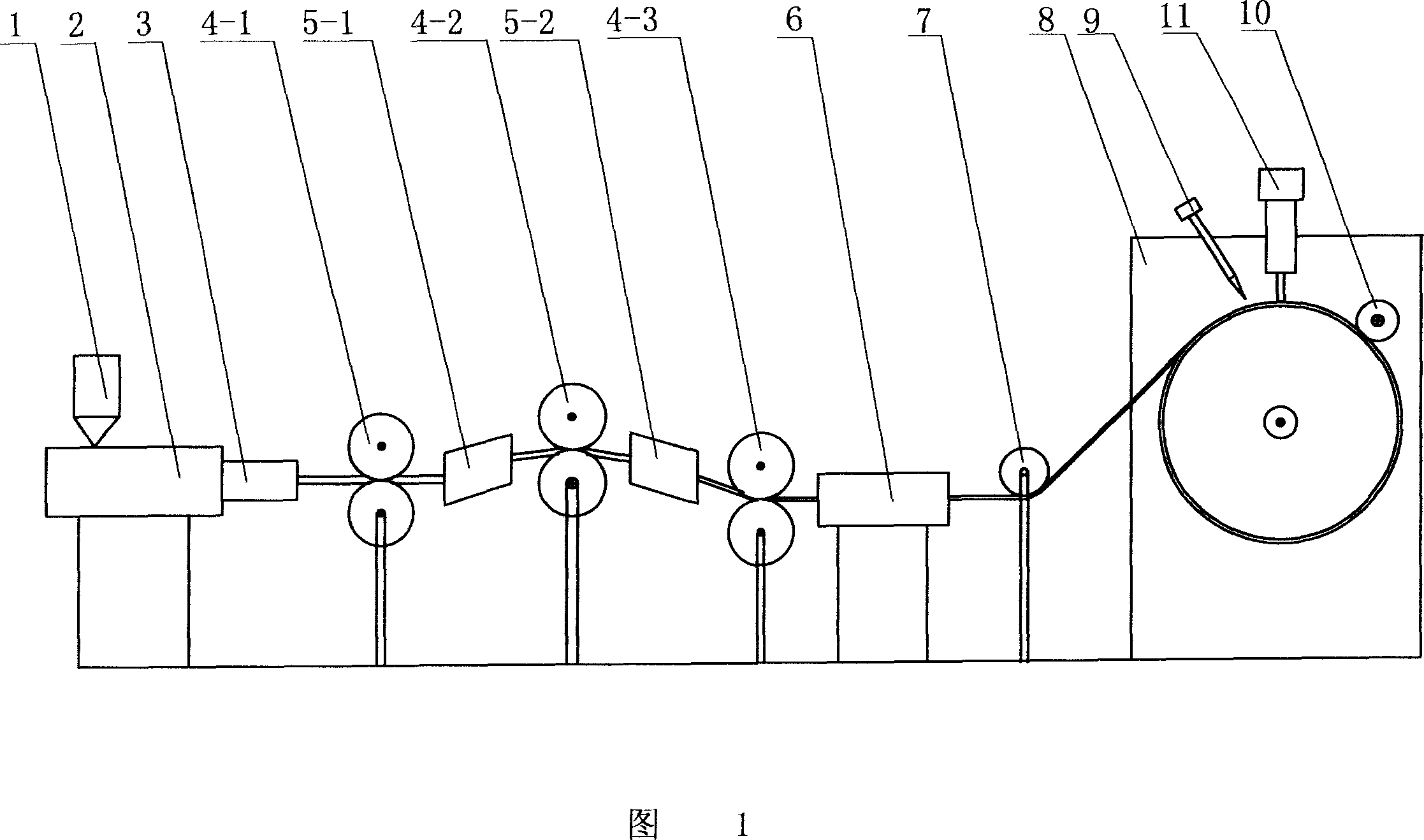

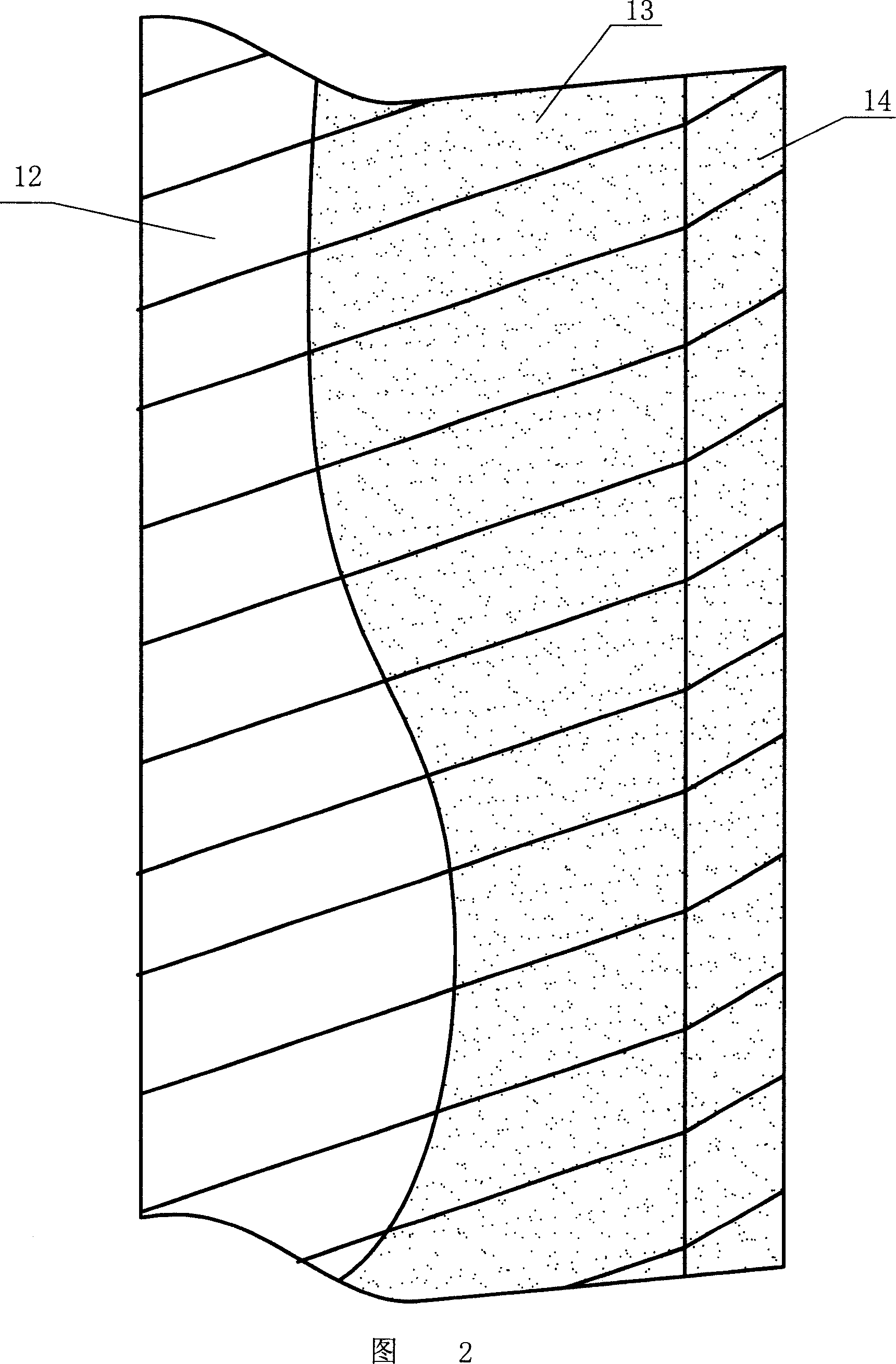

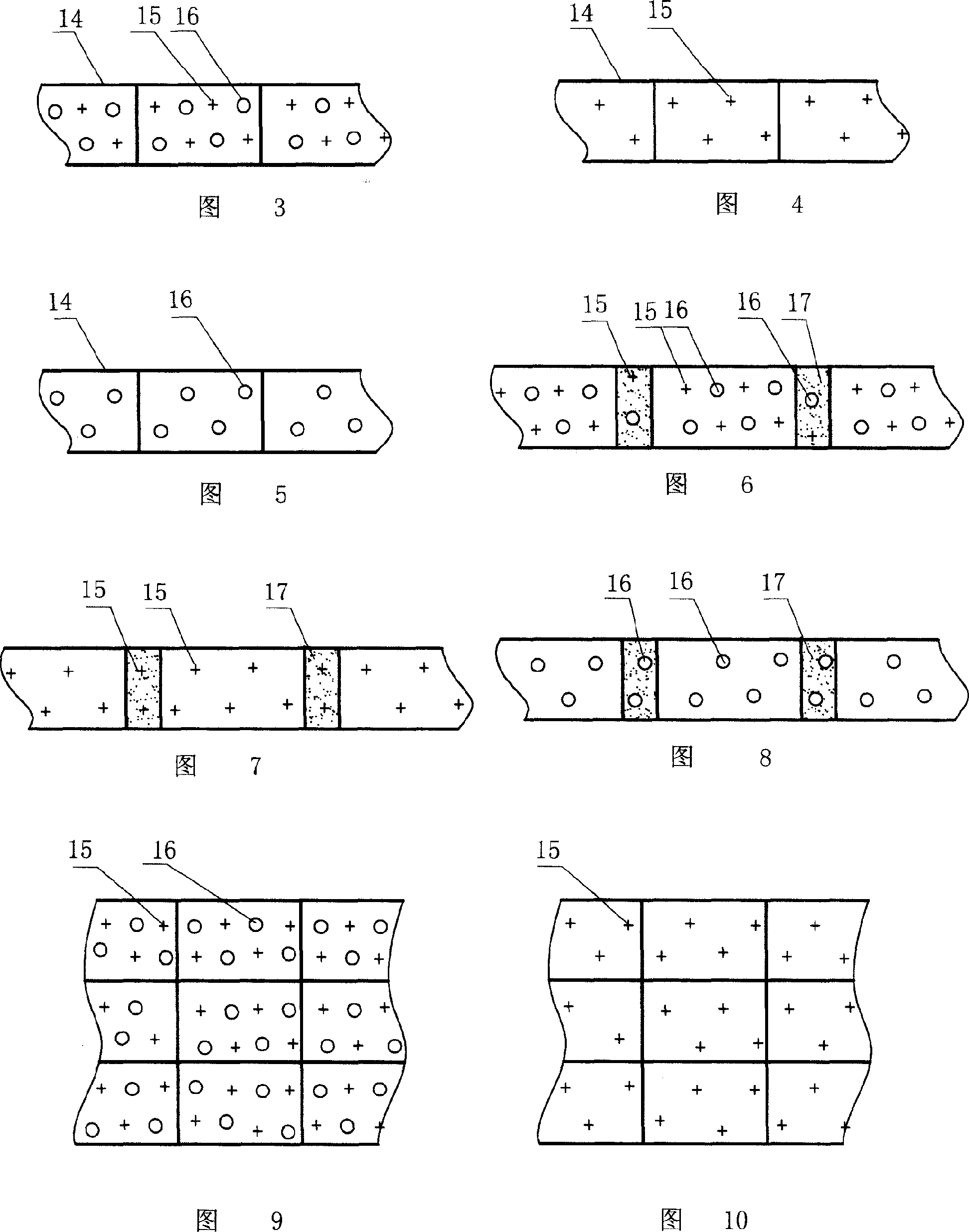

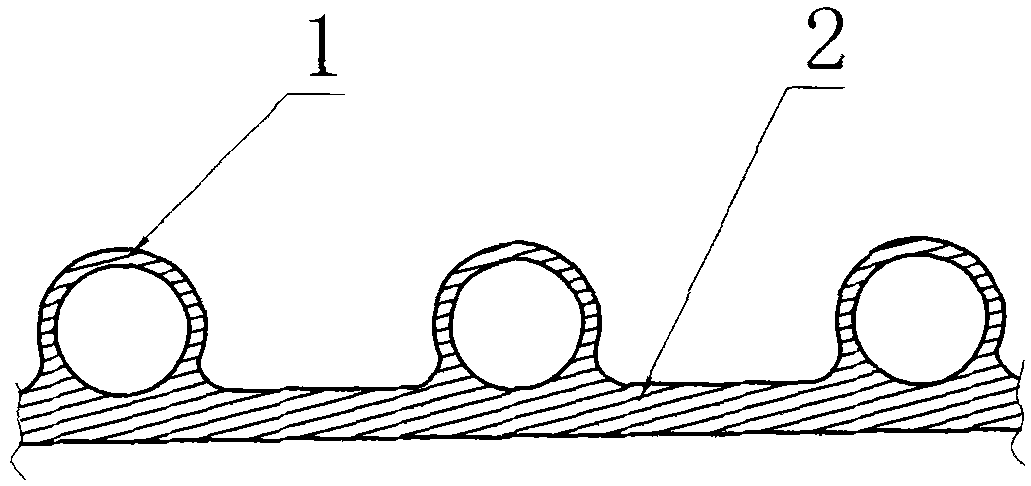

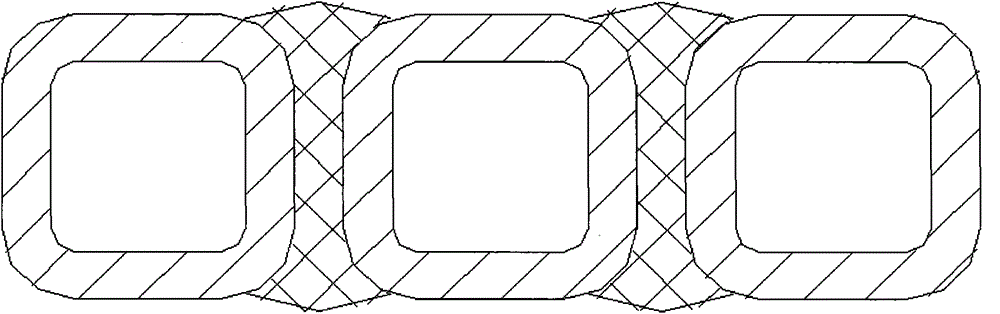

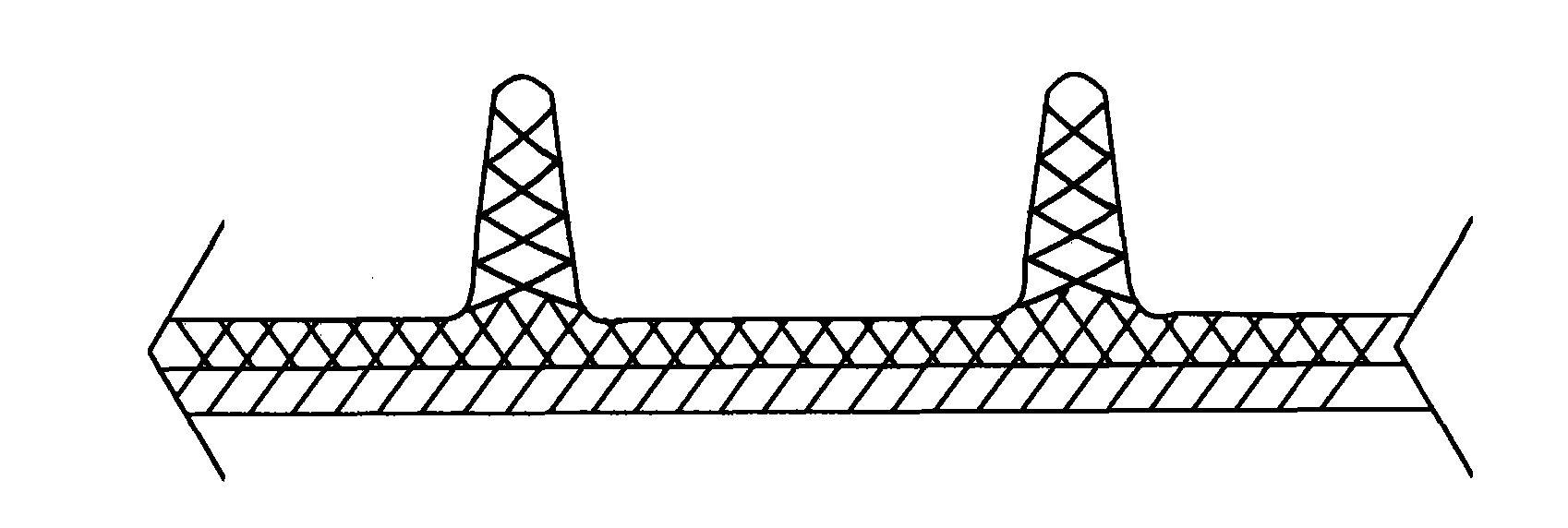

Plastic covered belt reinforced hollow-wall wound pipe and manufacturing method thereof

ActiveCN105318116ARice weightIncreased ring stiffnessFlexible pipesTubular articlesPipeMechanical engineering

The invention discloses a plastic covered belt reinforced hollow-wall wound pipe and a manufacturing method thereof. The plastic covered belt reinforced hollow-wall wound pipe comprises a square pipe, molten glue and a plastic covered belt. The plastic covered belt is longitudinal placed on one side face or two sides of the square pipe to form the plastic covered belt reinforced square pipe. The plastic covered belt reinforced square pipe is arranged on a roller mold to be spirally wound, the molten glue in a molten state is extruded to bond gaps, and therefore the plastic covered belt reinforced hollow-wall wound pipe is formed. The manufacturing method of the plastic covered belt reinforced hollow-wall wound pipe mainly comprises the steps of extruding shaping of the square pipe, attaching of the plastic covered reinforcement belt and winding forming. The plastic covered belt reinforced hollow-wall wound pipe is simple in structure, low in weight per meter and simple in production process, and has the characteristics of saving energy and being environmentally friendly.

Owner:GUANGDONG YONGGAO PLASTIC INDUSTRY DEVELOPMENT CO LTD

Three-wall corrugated pipe and manufacturing equipment thereof

The invention discloses a three-wall corrugated pipe and manufacturing equipment thereof. The pipe includes a pipe body, which includes a smooth inner wall layer, a corrugated intermediate layer and a smooth outer wall layer. The inner wall layer and the outer wall layer are closely connected with the crests or troughs of the intermediate layer, and the pipe body is provided with connection ports for mutual connection. Compared with prior arts, the inventive corrugated pipe has a smooth outer wall, which facilitates dragging and rolling during transportation and construction processes and avoids outer wall corrugation breakage and recess to further influence pipe use. Meanwhile, the outer wall layer is covered, in a molten state, on the outer wall of a double-wall corrugated pipe, which increases the pipe wave height and the moment of inertia to realize higher ring stiffness of the pipe and production of pipes with higher strength requirements on one hand, and increases the longitudinal bending strength of the pipe and improves the ring flexibility of the pipe on the other hand, thus realizing the purpose of the invention.

Owner:公元管道(上海)有限公司

HDPE (High-Density Polyethylene) double-wall corrugated pipe

InactiveCN102494203AIncreased ring stiffnessReduce formulation costsRigid pipesLow-density polyethyleneLinear low-density polyethylene

The invention discloses an HDPE (High-Density Polyethylene) double-wall corrugated pipe. The walls of the HDPE double-wall corrugated pipe are respectively composed of an inner layer and an outer layer, wherein the outer layer comprises the following components in parts by weight: 50-80 parts of HDPE resin, 15-30 parts of special reinforced master batches, 10-25 parts of special modified master batches, 2-5 parts of moisture absorption master batches and 1-3 parts of color master batches, and the inner layer comprises the following components in parts by weight: 50-80 parts of HDPE resin, 15-30 parts of metallocene linear low-density polyethylene, 20-45 parts of special modified master batches, 1-3 parts of moisture absorption master batches and 1-3 parts of color master batches. The HDPE double-wall corrugated pipe provided by the invention has high ring stiffness, all other performance indexes can be up to the standard, and the production cost is greatly reduced.

Owner:合肥安诺新型建材有限公司

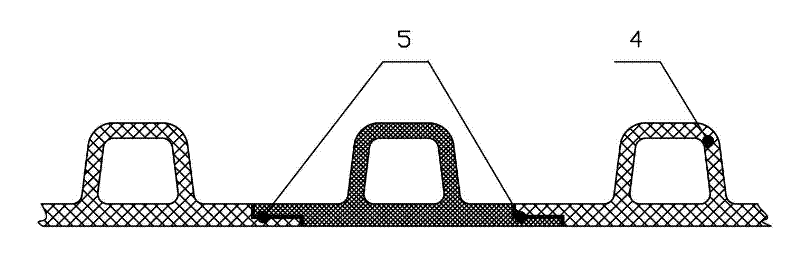

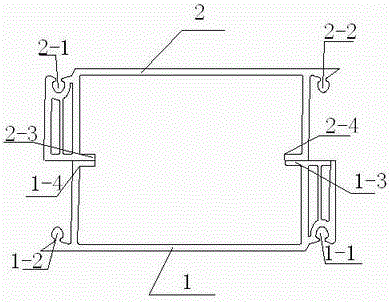

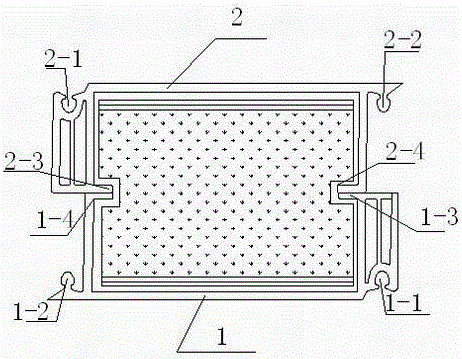

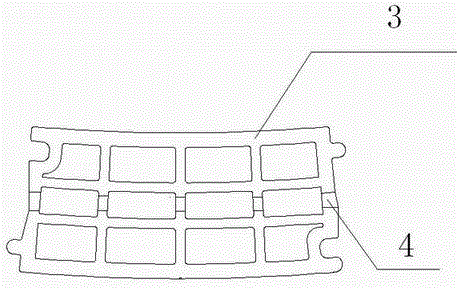

PVC modular high-ring stiffness spiral winding pipe and production method thereof

The invention discloses a PVC modular high-ring stiffness spiral winding pipe and a production method thereof. The PVC modular high-ring stiffness spiral winding pipe comprises a pipe integrally wound by a first frame profile and a second frame profile; the first frame profile is a pipe outer layer; the second frame profile is a pipe inner layer; multiple ring stiffness reinforcing modules are hung or inlaid between the first frame profile and the second frame profile; the ring stiffness reinforcing modules have grooves and bosses matched and fixed with each other; the grooves and the bosses are automatically clamped when the second frame profile clockwise or anticlockwise rotates; the first frame profile, the second frame profile and the ring stiffness reinforcing module are combined to form a ring stiffness reinforcing layer; each ring stiffness reinforcing module is fan-shaped; and the ring stiffness reinforcing layer is a ring, and is spirally wound to form a large-caliber pipe through a winding machine. The device is higher in ring stiffness, excellent in displacement resistance, low in production cost, convenient for transportation and capable of realizing the field operation.

Owner:CHONGQING LICHENG PIPE

Continuously wound reinforced corrugated pipe and manufacturing method thereof

ActiveCN104279379AIncrease the outer surface areaIncreased structural wall thicknessCorrugation articlesFlexible pipesSolid wallAdhesive

The invention discloses a continuously wound reinforced corrugated pipe and a preparation method thereof. The pipe comprises a continuous solid-wall cylindrical pipe body formed by lapping and fusing a plurality of spirally wound special rods of which the two sides are provided with butting wings through the wings; a plurality of hollow reinforcing ribs are spirally wound on the pipe wall of the cylindrical pipe body; each hollow reinforcing rib comprises at least one special single-wall corrugated reinforcement pipe which is spirally wound on the pipe wall of the cylindrical pipe body through a reinforcement adhesive layer, and an outer reinforcement layer which is spirally wound, spans and presses on the special single-wall corrugated reinforcement pipe and of which two ends are adhered to the pipe wall of the cylindrical pipe body; the center line of each hollow reinforcing rib is overlapped with the center line of a lapping and fusing part of wings of an adjacent special rod. The pipe is high in stability and welding effect, the crest height of the pipe is higher than that of a double-wall corrugated pipe, the continuously wound reinforced corrugated pipe can be produced by matching common wound pipe production equipment with a suitable die, and equipment investment is small.

Owner:戴爱清 +1

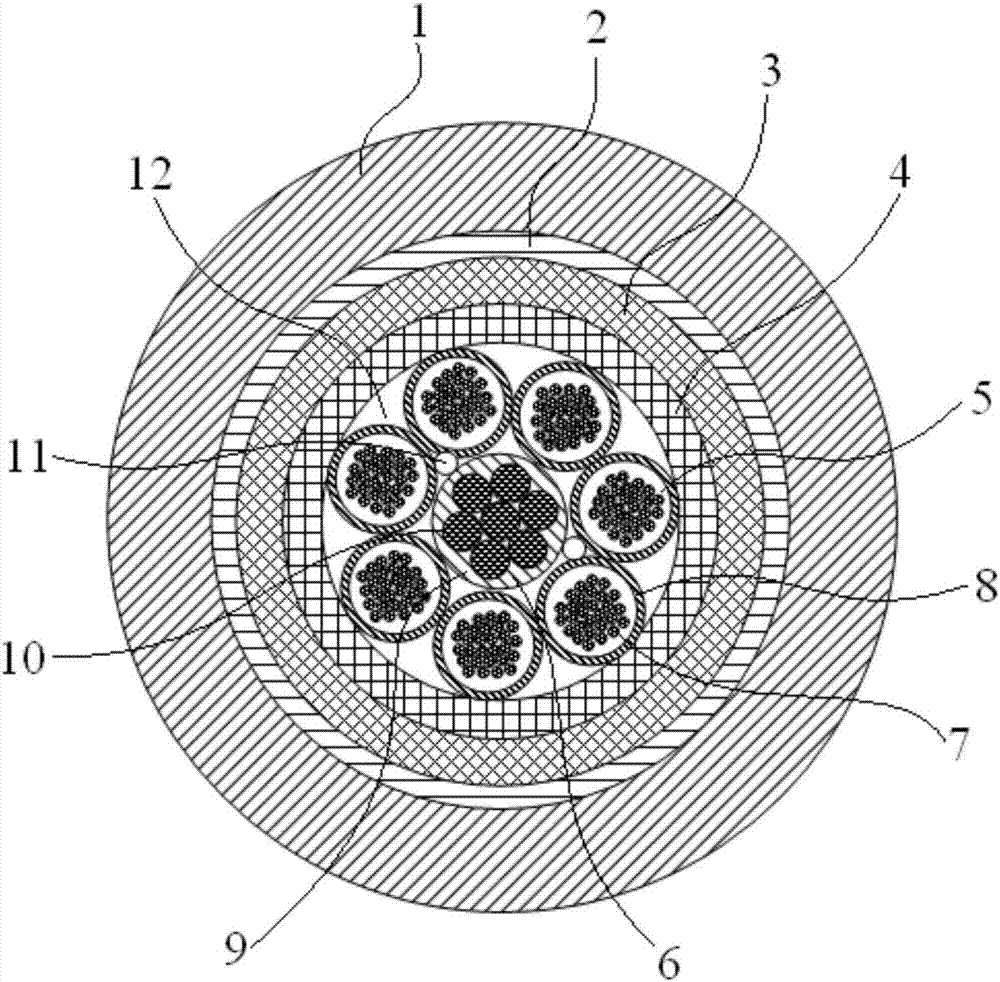

Ultra-soft temperature-resistant bulletproof optical cable and production method thereof

ActiveCN107422435AIngenious structural designImprove flexibilityFibre mechanical structuresThermal insulationPliability

The invention relates to an ultra-soft temperature-resistant bulletproof optical cable and a production method thereof. The optical cable comprises a cable core, a plastic foaming layer, a bulletproof armored layer and an outer sheath layer, the surface of the cable core is provided with the plastic foaming layer, the outside of the plastic foaming layer is provided with the bulletproof armored layer, the outside of the bulletproof armored layer is provided with the outer sheath layer, the cable core comprises optical fiber units and a central reinforcing element which are twisted in an SZ twisting manner, each optical fiber unit comprises coated optical fibers and a buffer tube, the external parts of the coated optical fibers are wrapped by the buffer tube, the central reinforcing element comprises flexible reinforcing members and a PE sheath layer wrapping the external parts of the flexible reinforcing members, and the outer sheath layer is a bellows sheath. According to the optical cable, good thermal insulation performance is achieved by employing the plastic foaming layer structure, the impact force of the exterior on the optical cable can be effectively buffered, the optical fiber has good flexibility and good bulletproof performance by employing the bulletproof armored layer, the overall bending resistance of the optical fiber can be effectively improved by employing the bellows outer sheath, and the bending recovery toughness can be improved.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com