Patents

Literature

288 results about "Solid wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wall typically refers to masonry, brick, block, concrete structure, but in more modern construction solid laminated timber walls and other modern materials are considered solid walls as opposed to cavity walls, is timber frames cladded by gyprock (plaster), plywood, weatherboarded, cement sheeting, or other lining material.

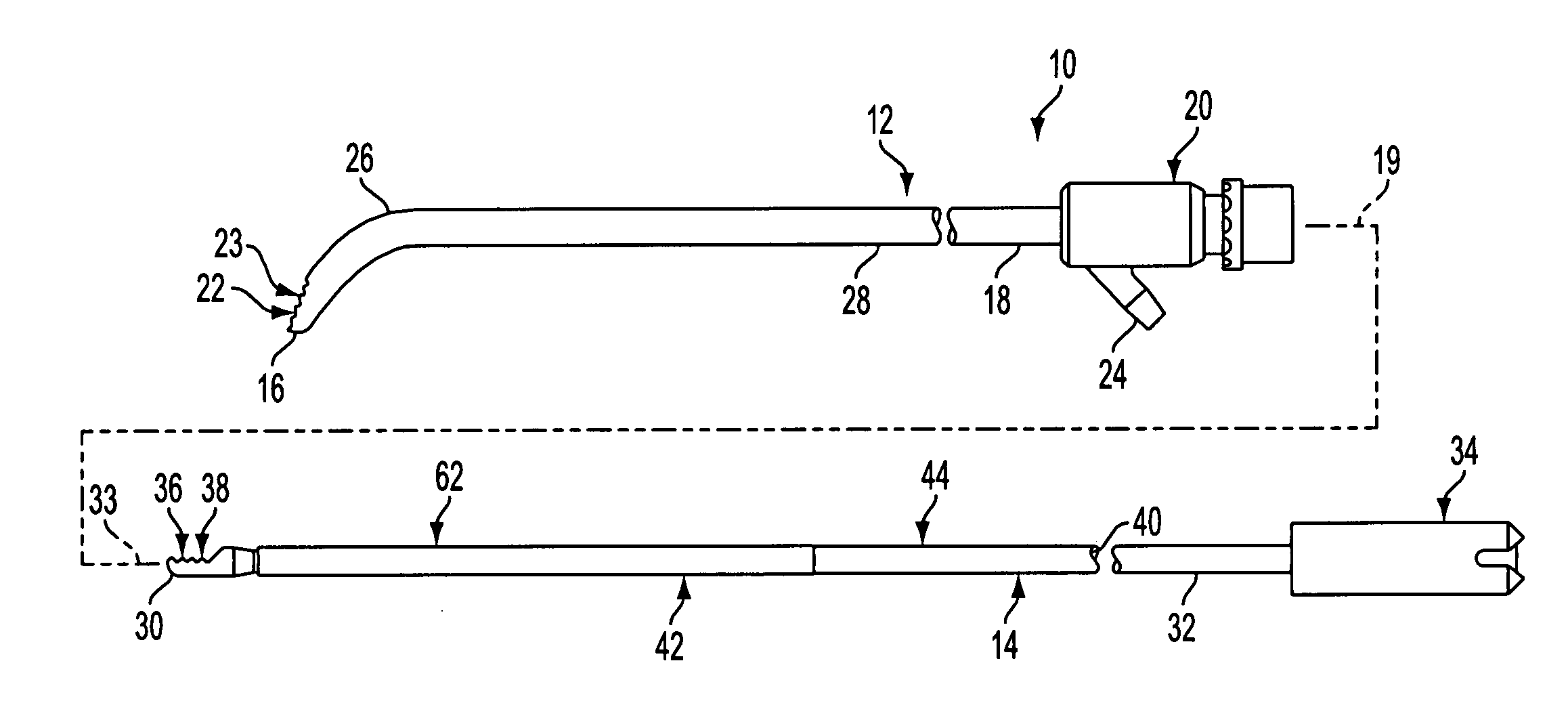

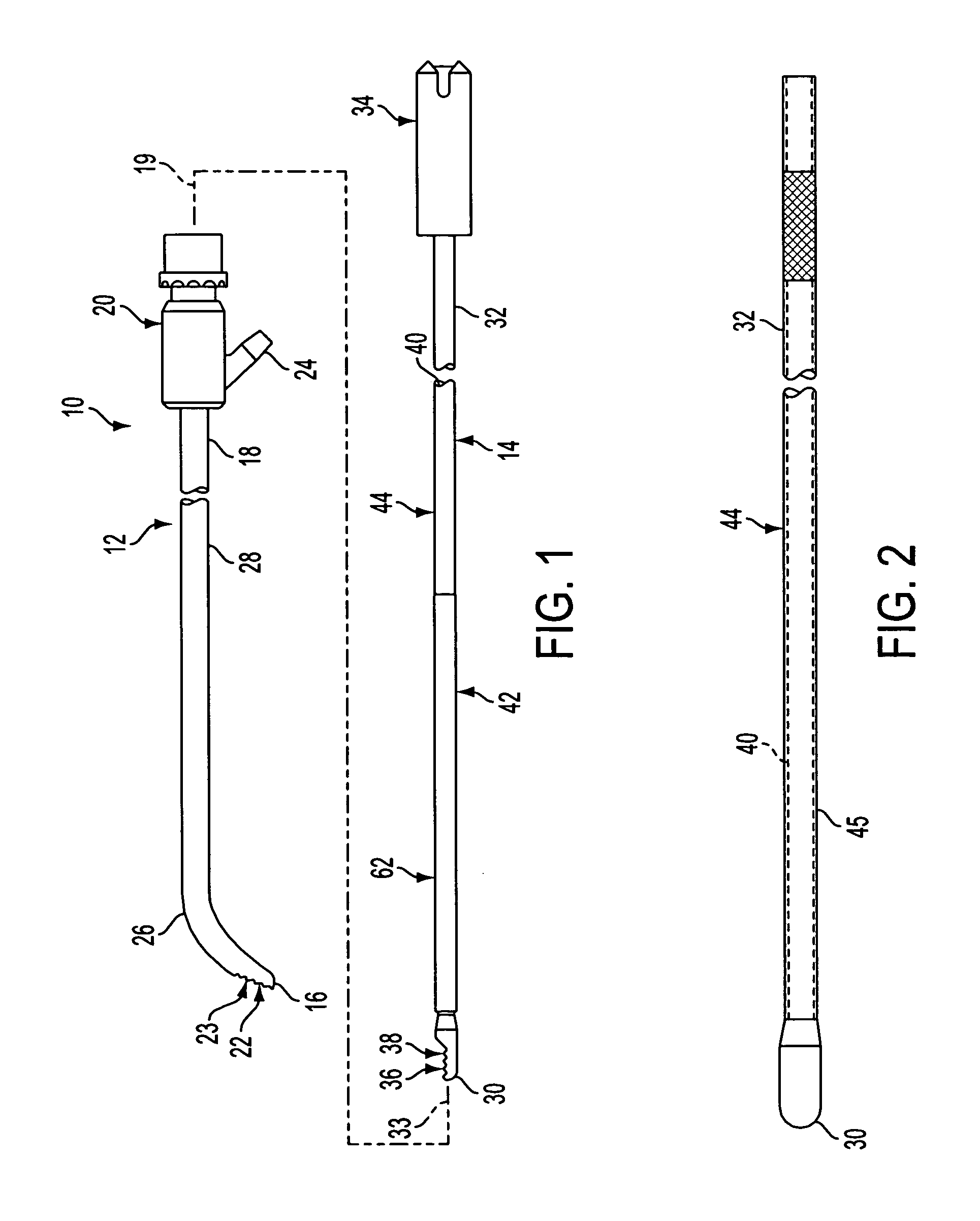

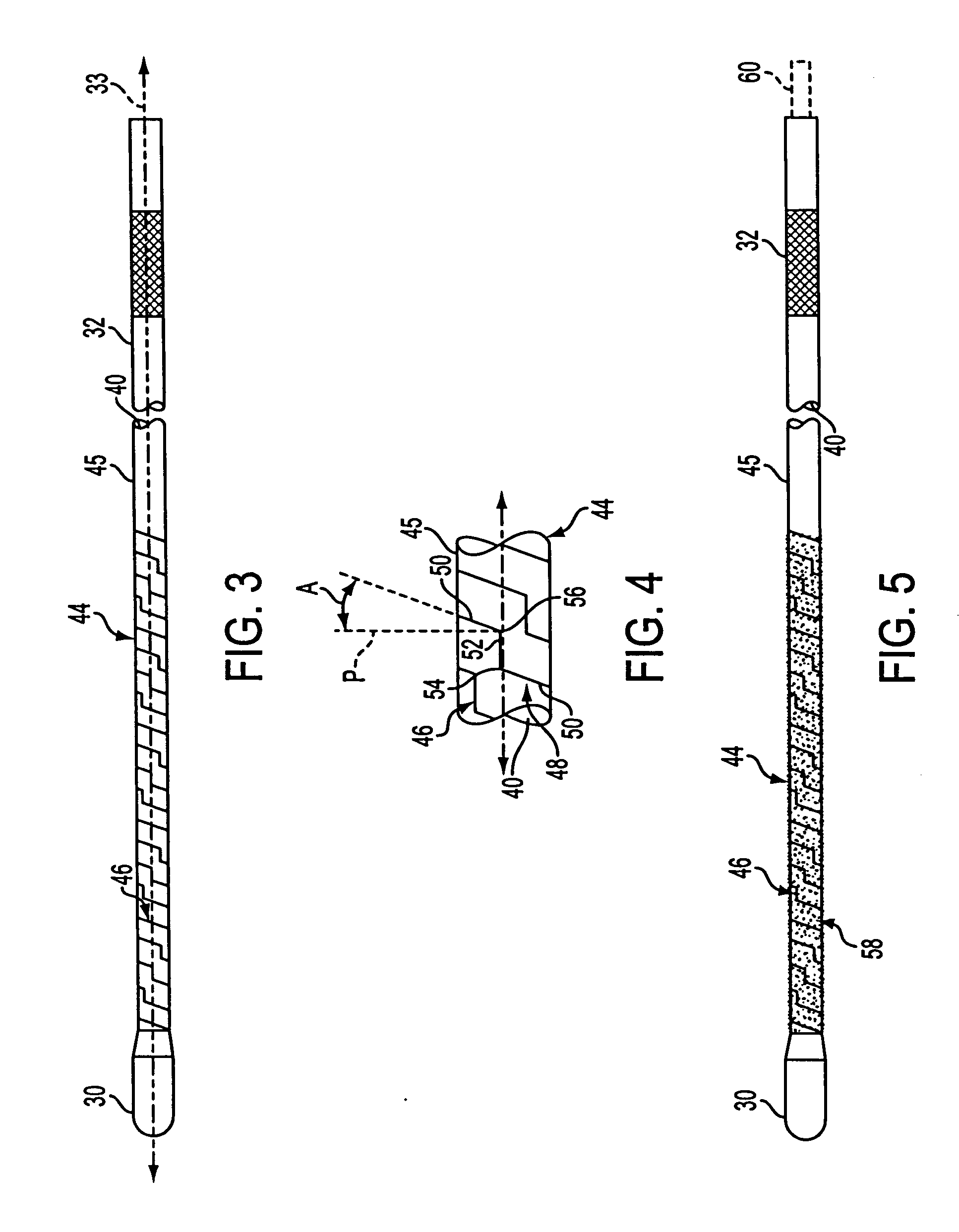

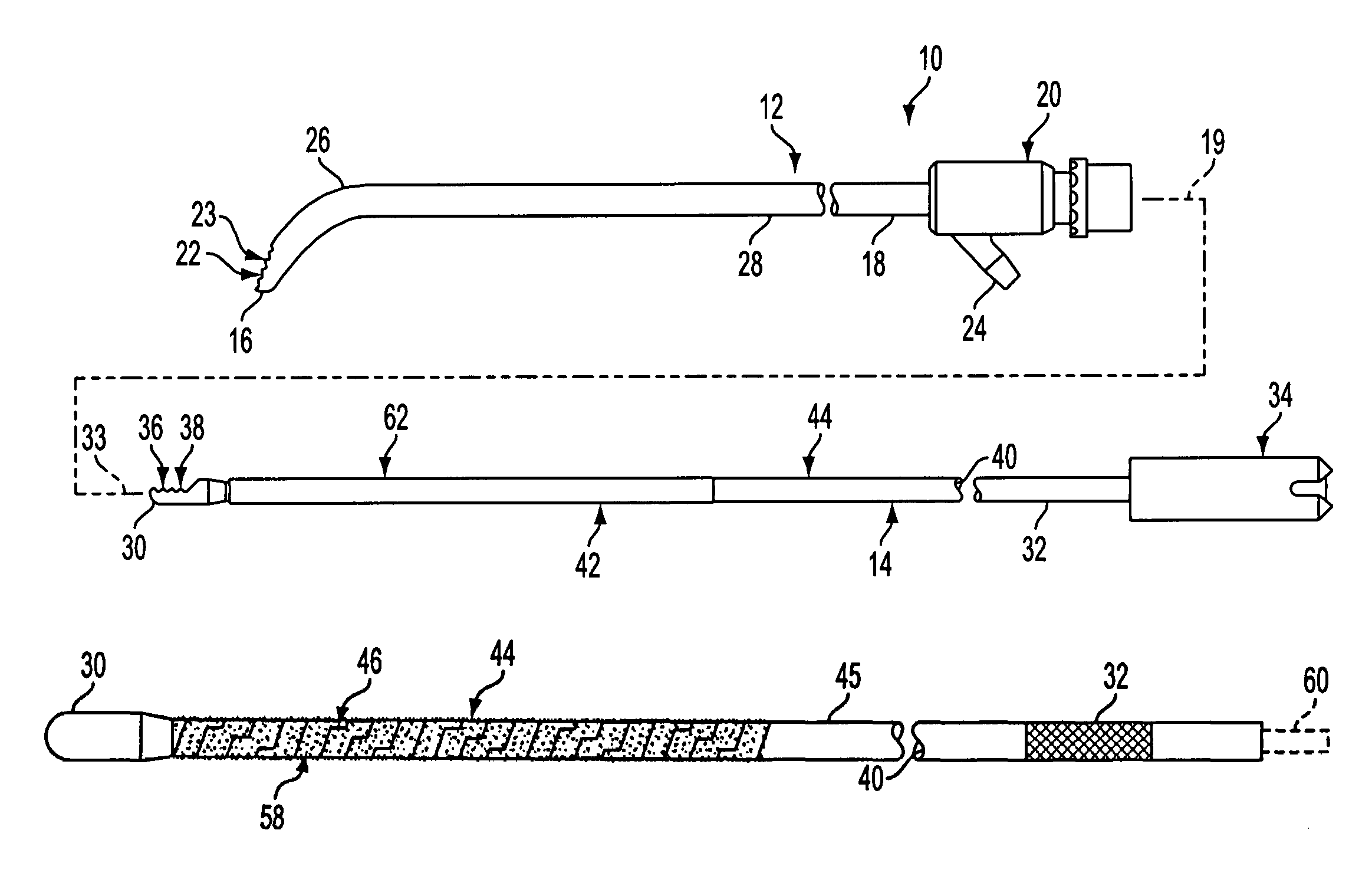

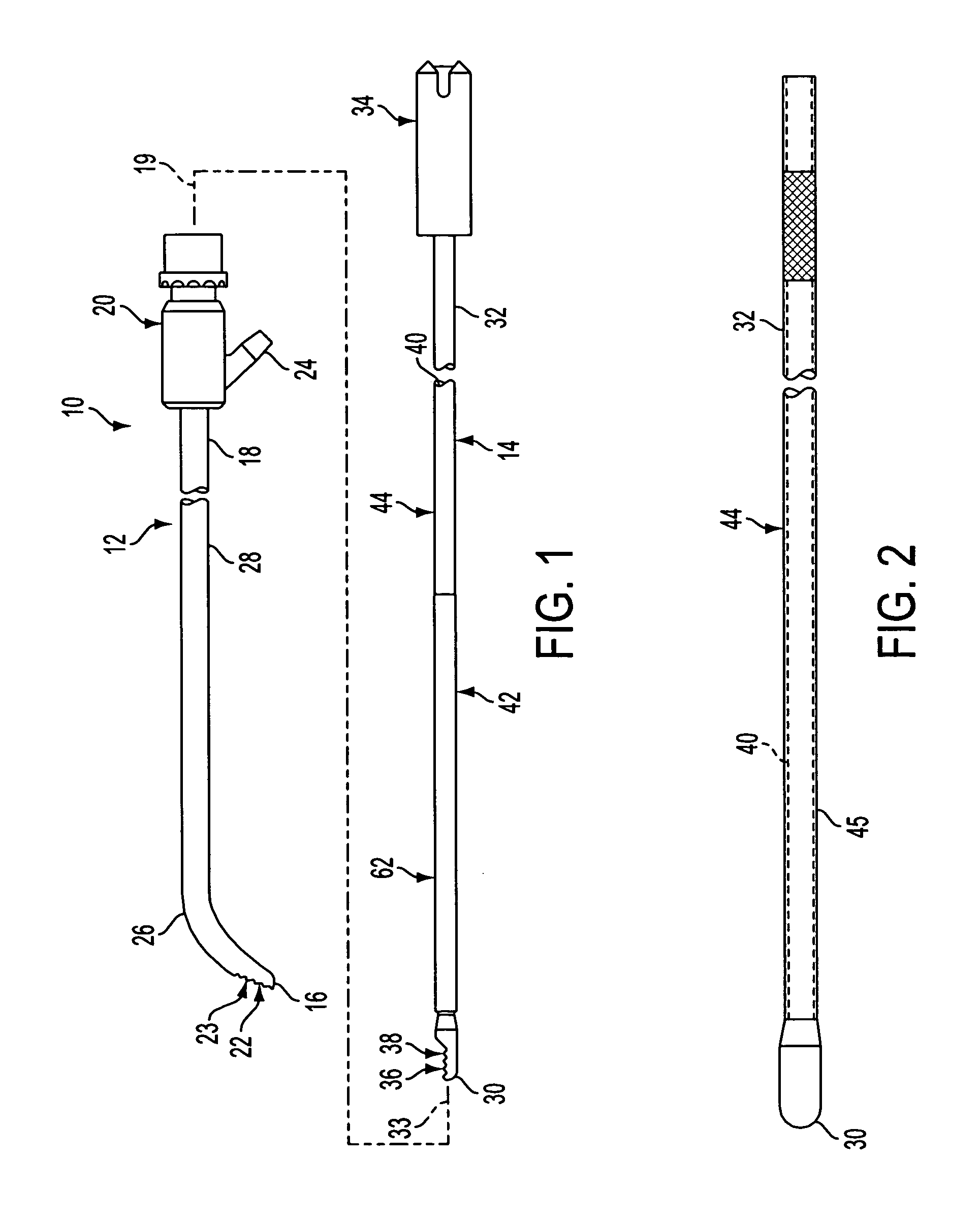

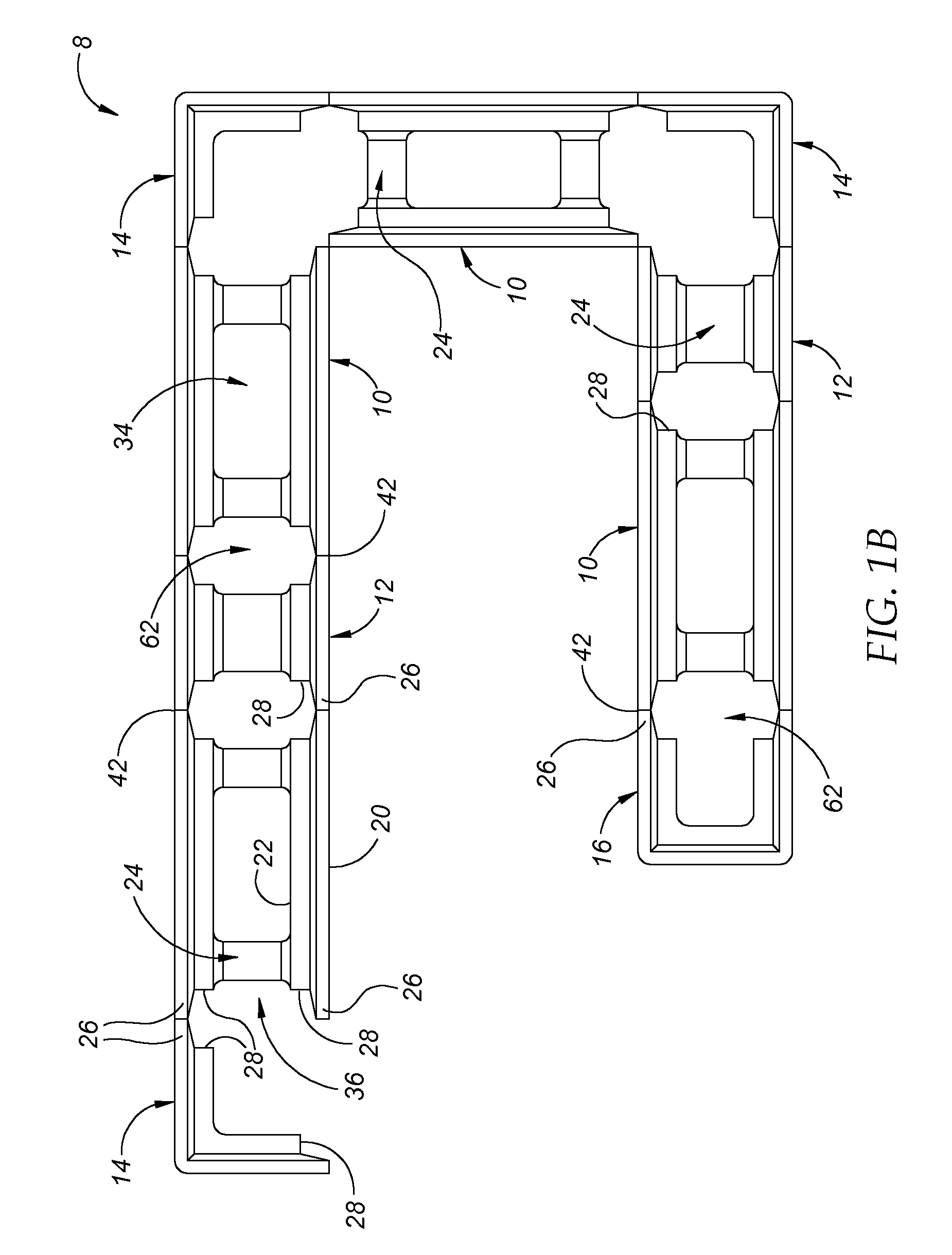

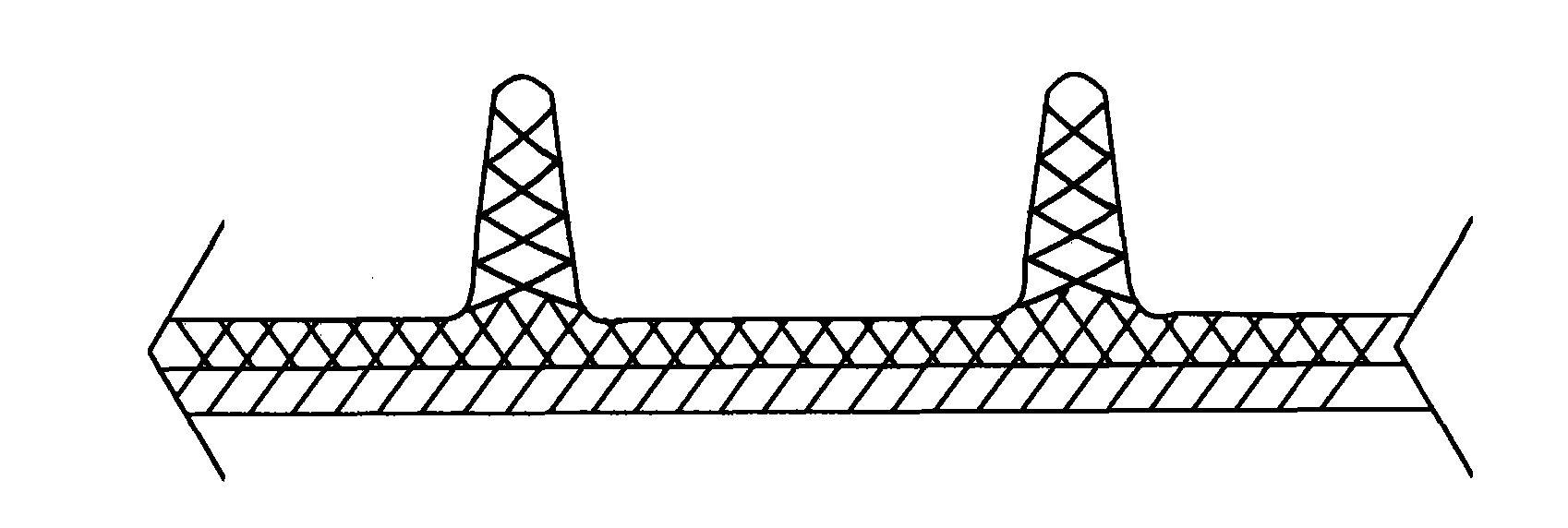

Angled tissue cutting instruments and method of fabricating angled tissue cutting instruments having flexible inner tubular members of tube and sleeve construction

ActiveUS20050090848A1Avoid inhalationAvoid flowEndoscopic cutting instrumentsSurgical sawsSolid wallEngineering

An angled tissue cutting instrument comprises an angled outer tubular member rotatably receiving a flexible inner tubular member. The inner member has a flexible region in correspondence with an angle of the outer member. The flexible region comprises a helically cut length portion of an elongate tubular body of the inner member and a continuous solid flexible surface secured to an outer surface of the body along the helically cut length portion. A method of fabricating a flexible inner tubular member involves forming a helical cut through the solid wall of a length portion of a tubular body and securing a continuous solid flexible surface to the outer surface of the body along the helically cut length portion to form a flexible region.

Owner:MEDTRONIC XOMED INC

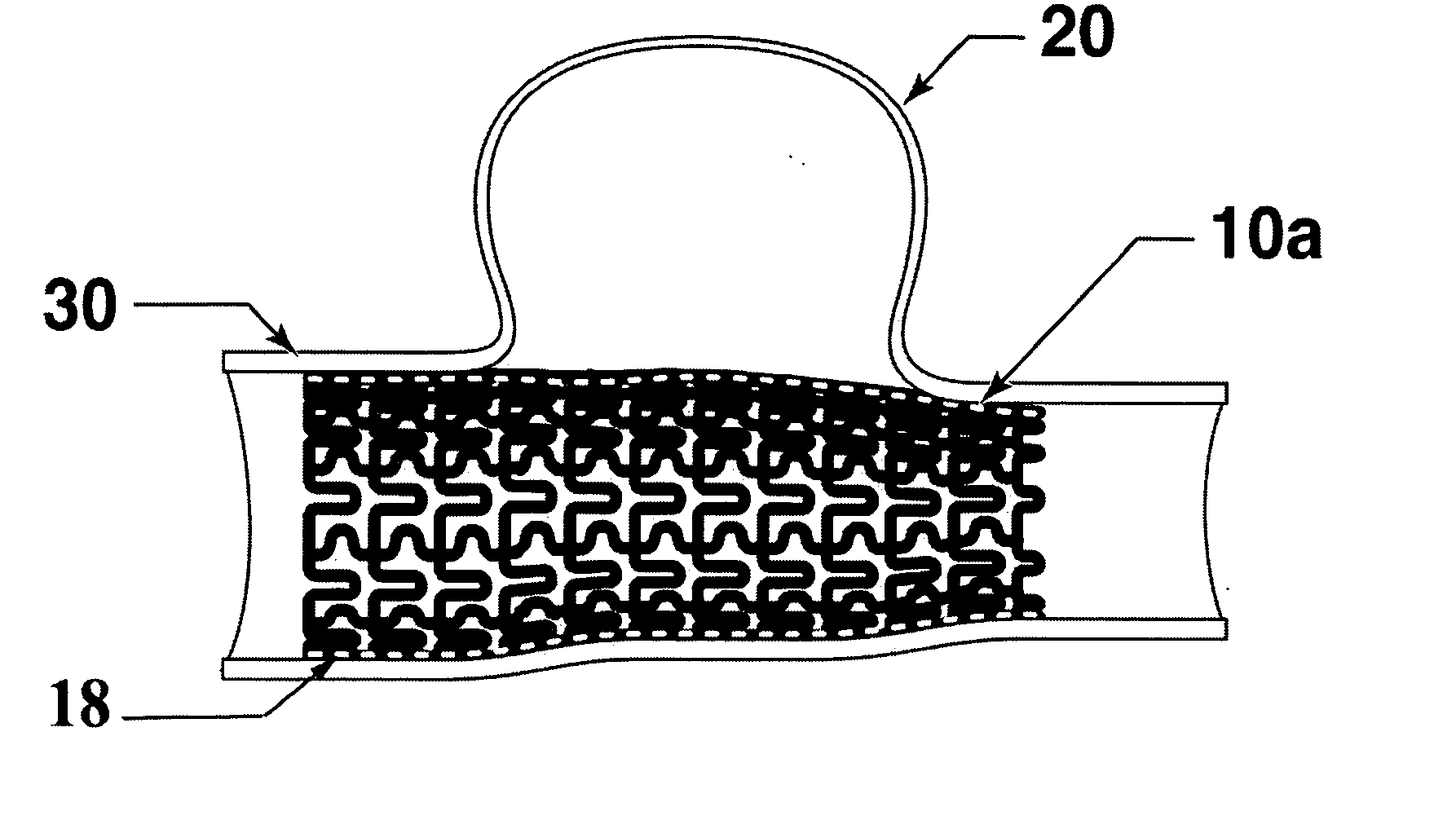

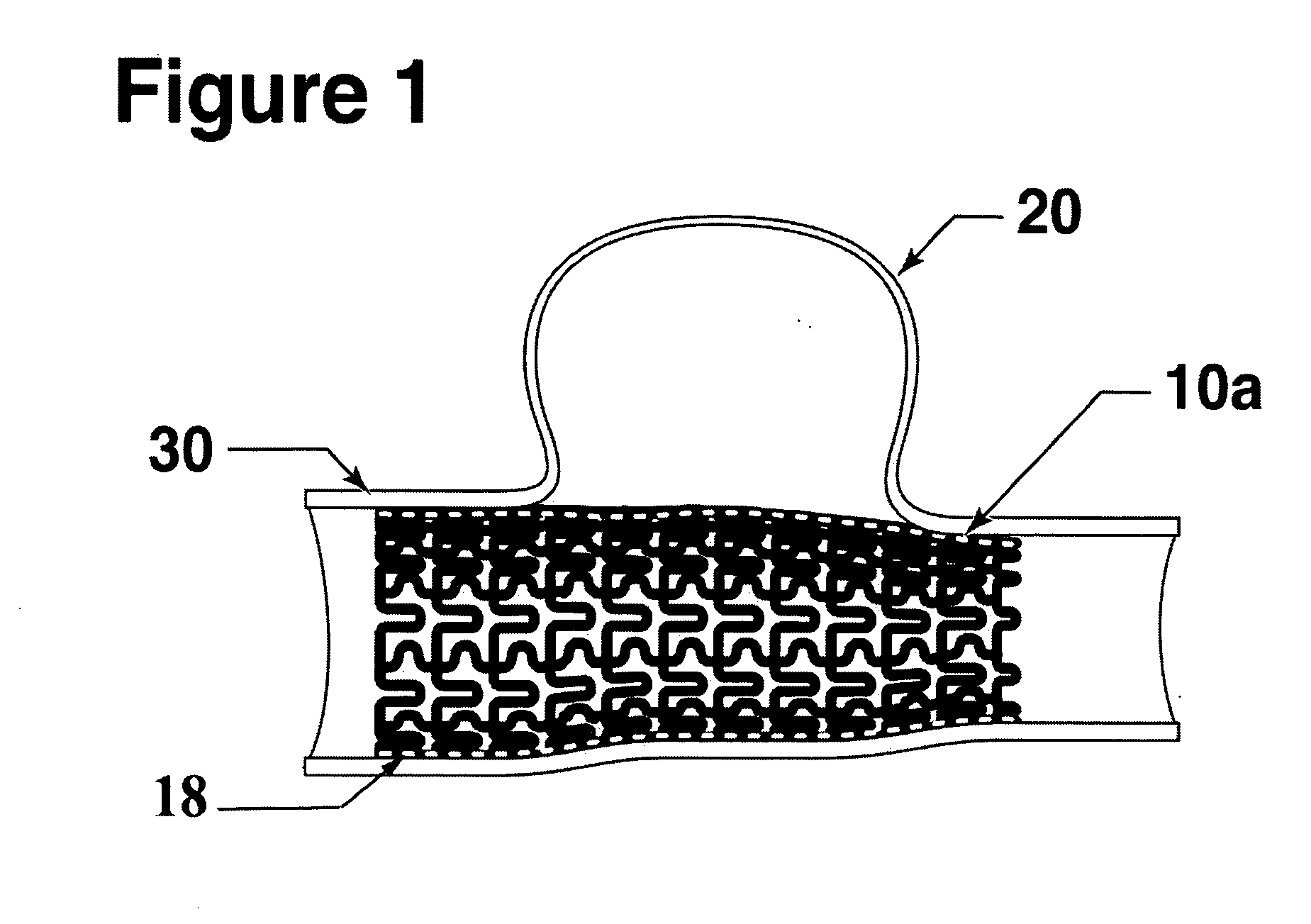

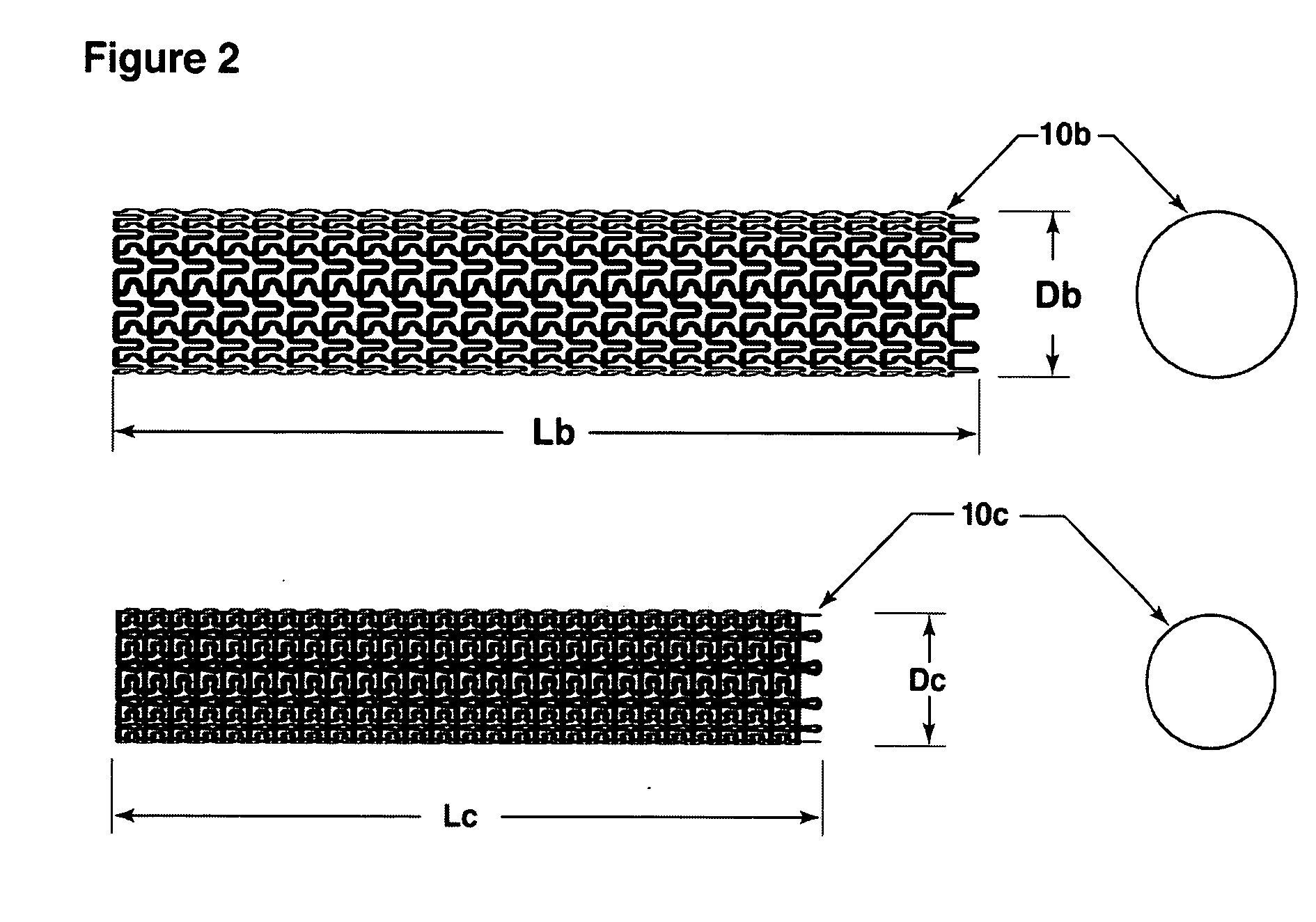

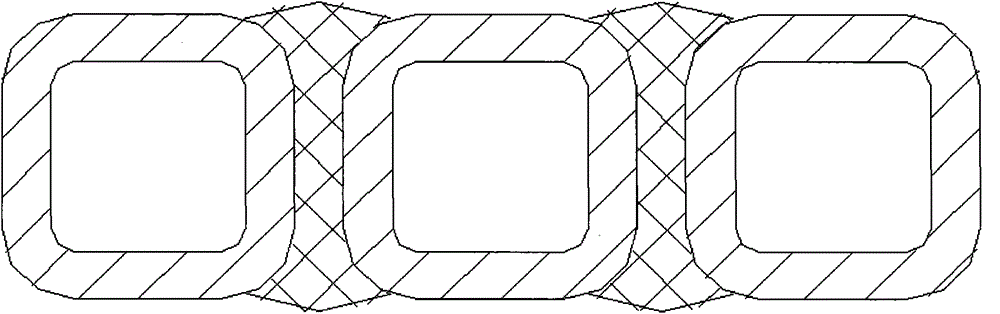

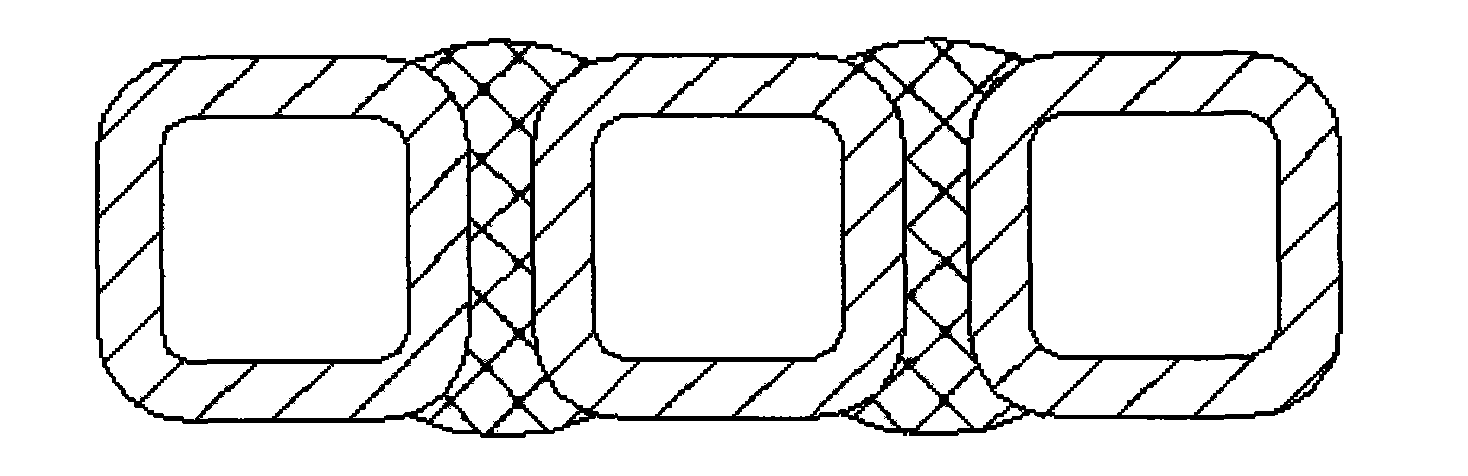

Micro-pleated stent assembly

InactiveUS20060155367A1Effective treatmentMore longitudinal flexibilityStentsBlood vesselsSolid wallInsertion stent

The present invention is directed to a micro-pleated medical device assembly, preferably a micro-pleated stent assembly, comprising a tube micro-pleated to a delivery diameter suitable for intraluminal delivery. The micro-pleated stent assembly of the present invention is designed to have a substantially solid wall, and is thus particularly suited for the treatment of neurovascular aneurysms, having the ability to block the neck of an aneurysm. Sections of the micro-pleated stent may be selected for expansion to variable diameters in order to optimally fit the configuration of the vessel.

Owner:HINES RICHARD ALLEN

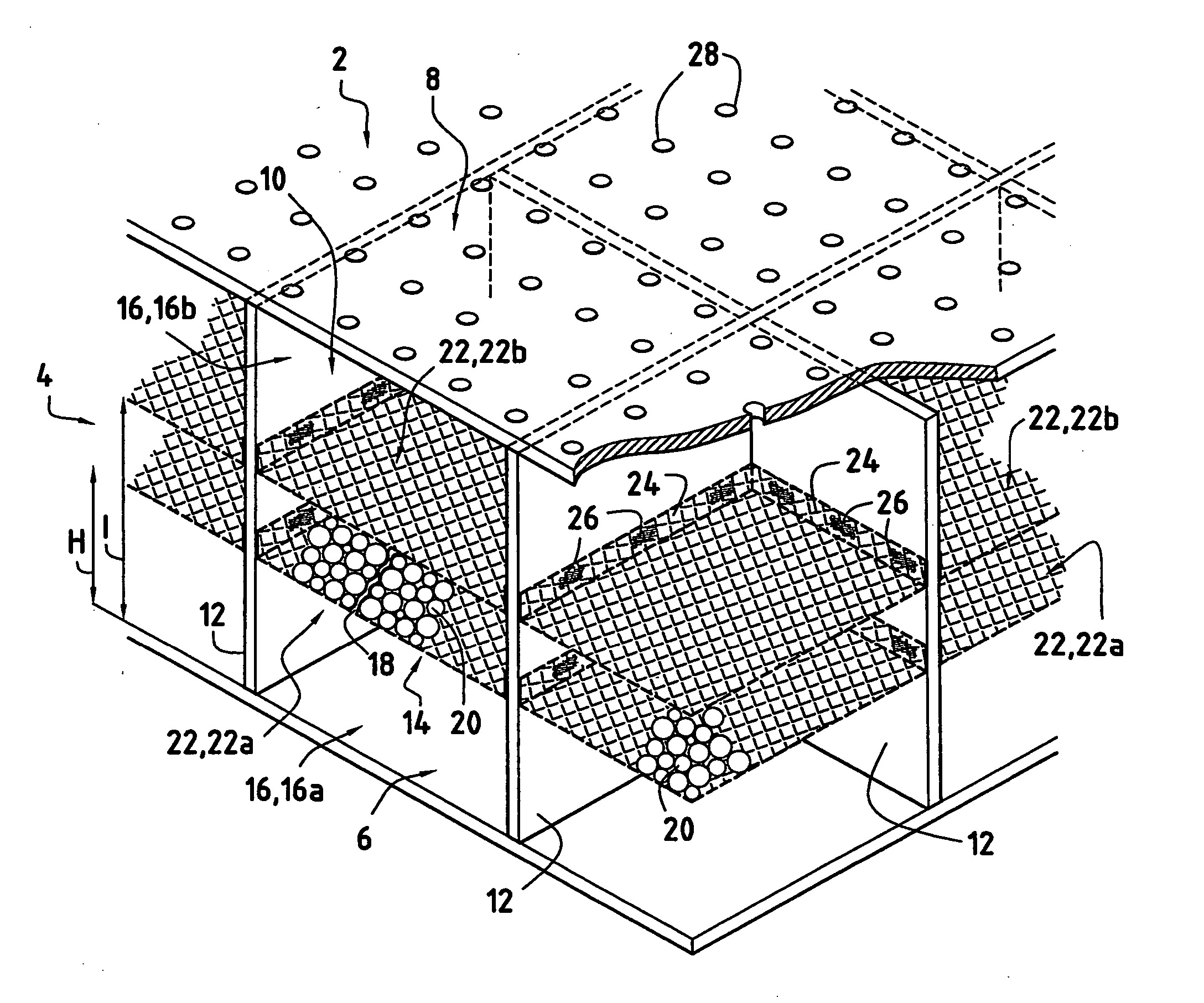

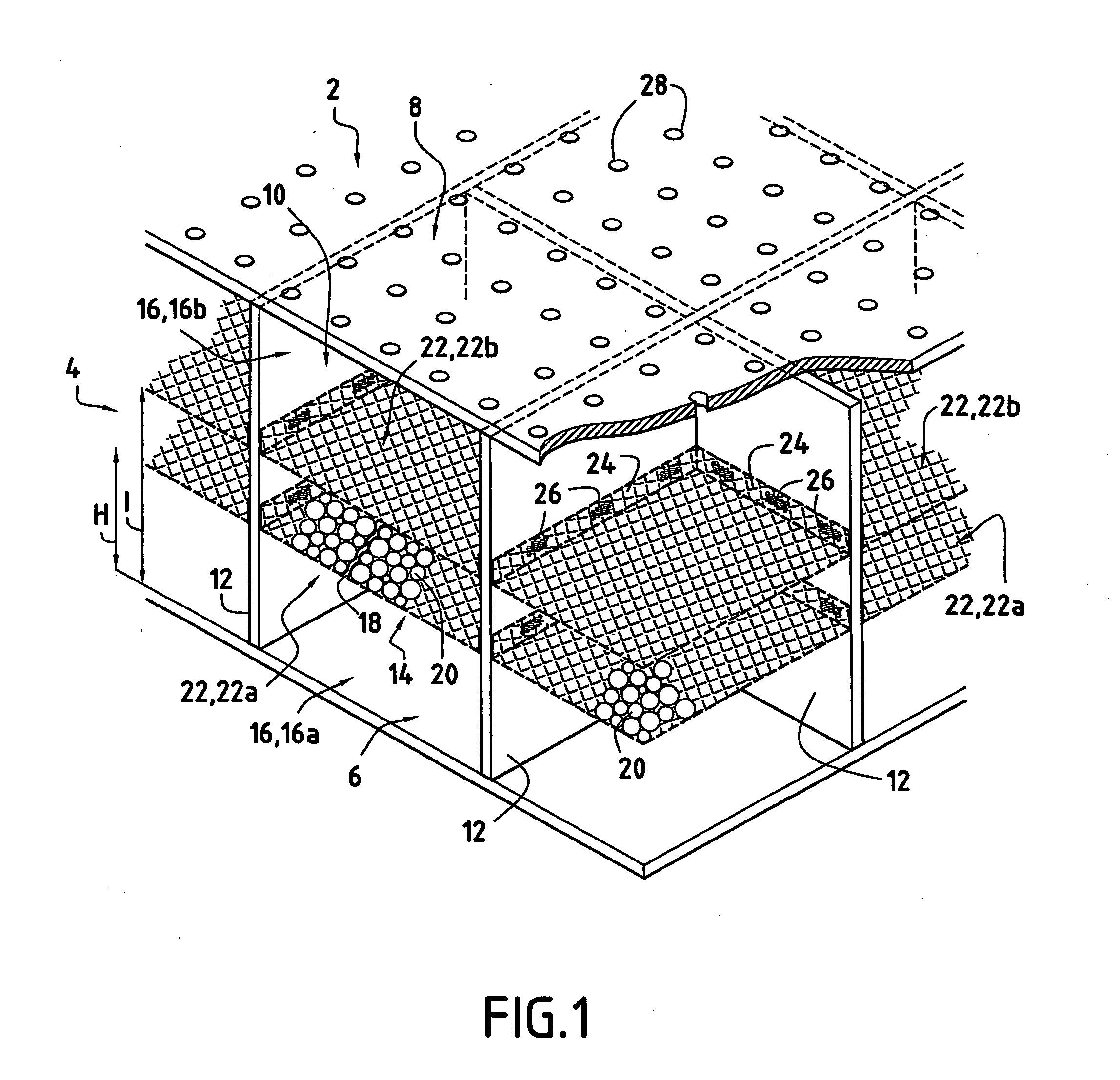

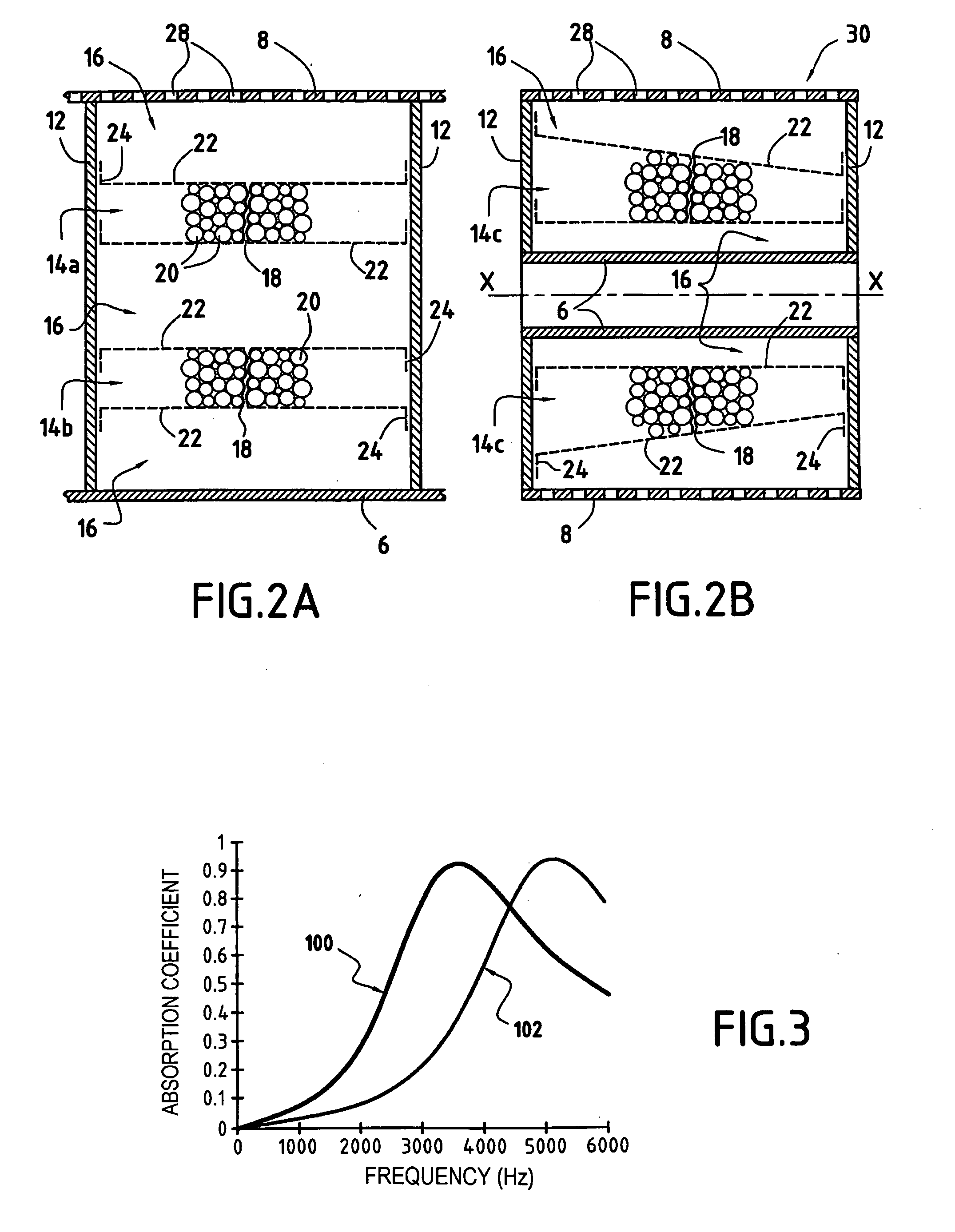

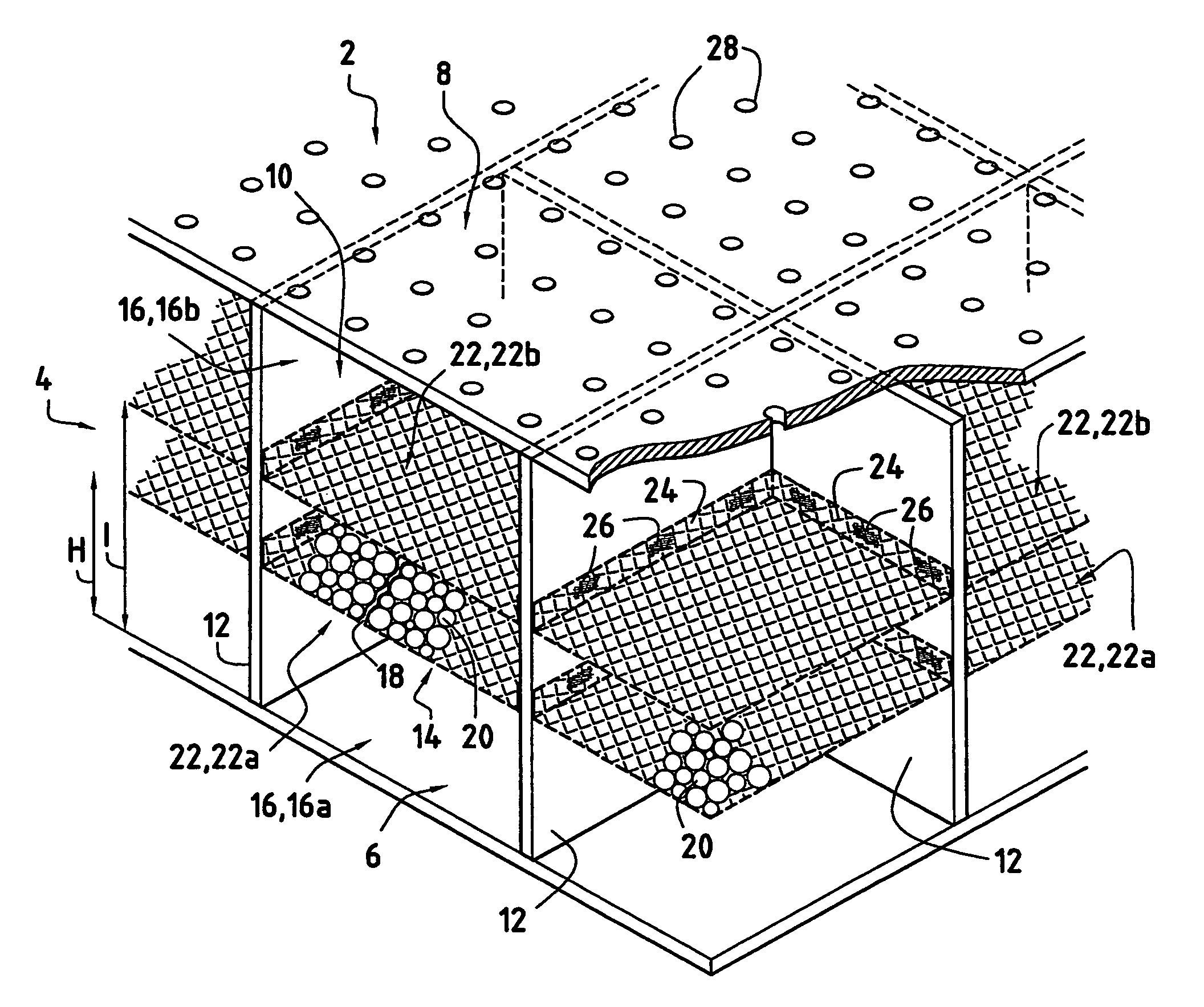

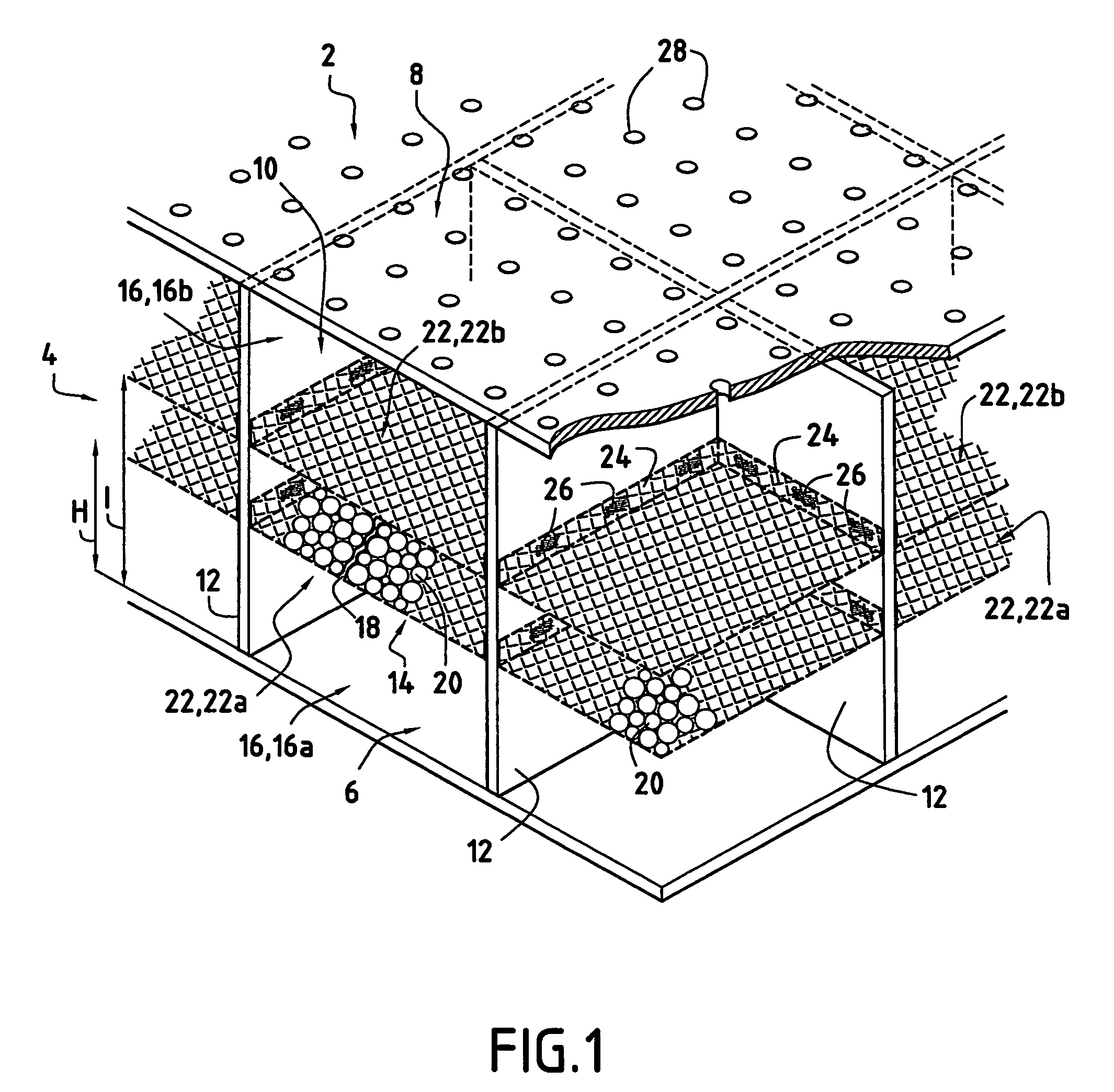

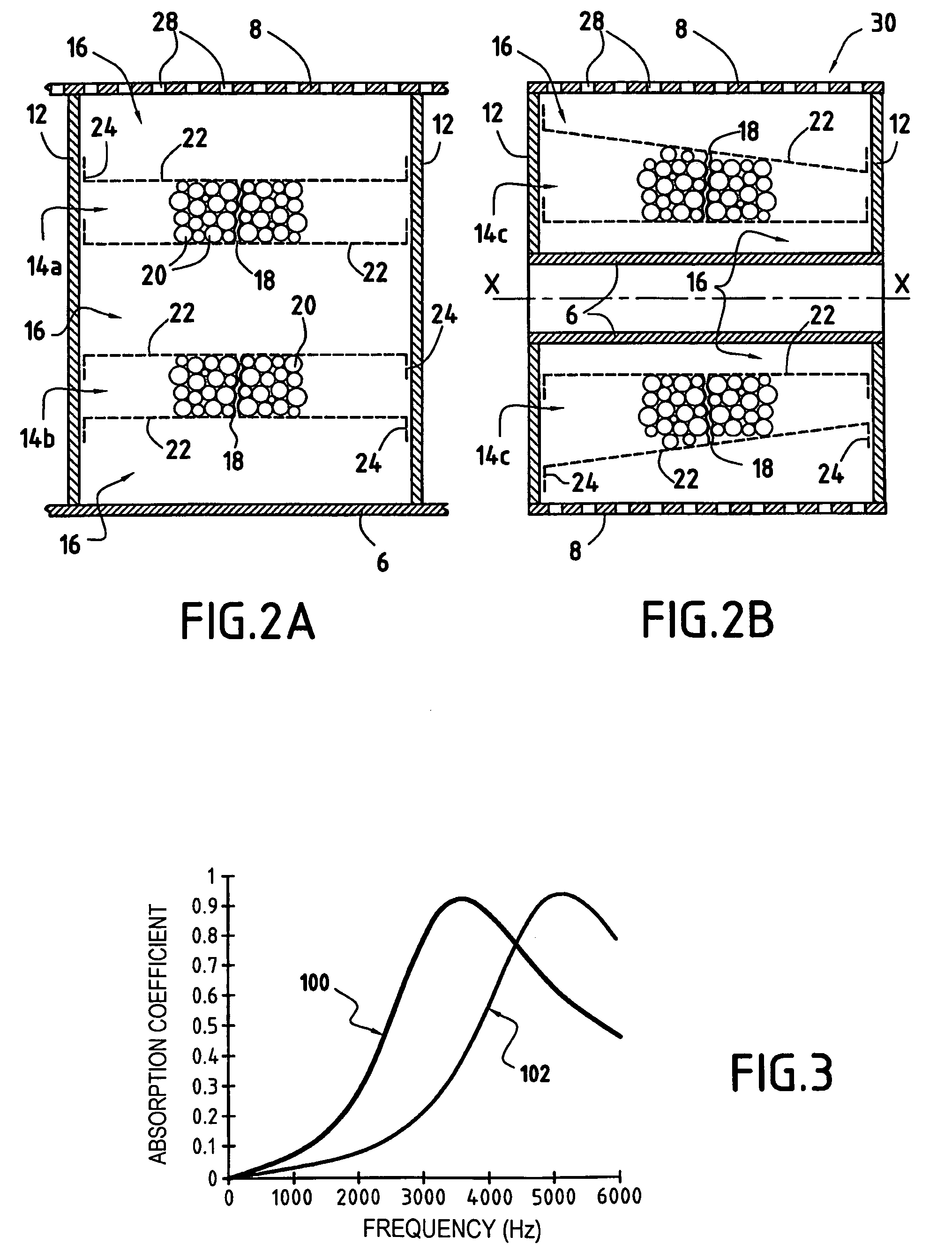

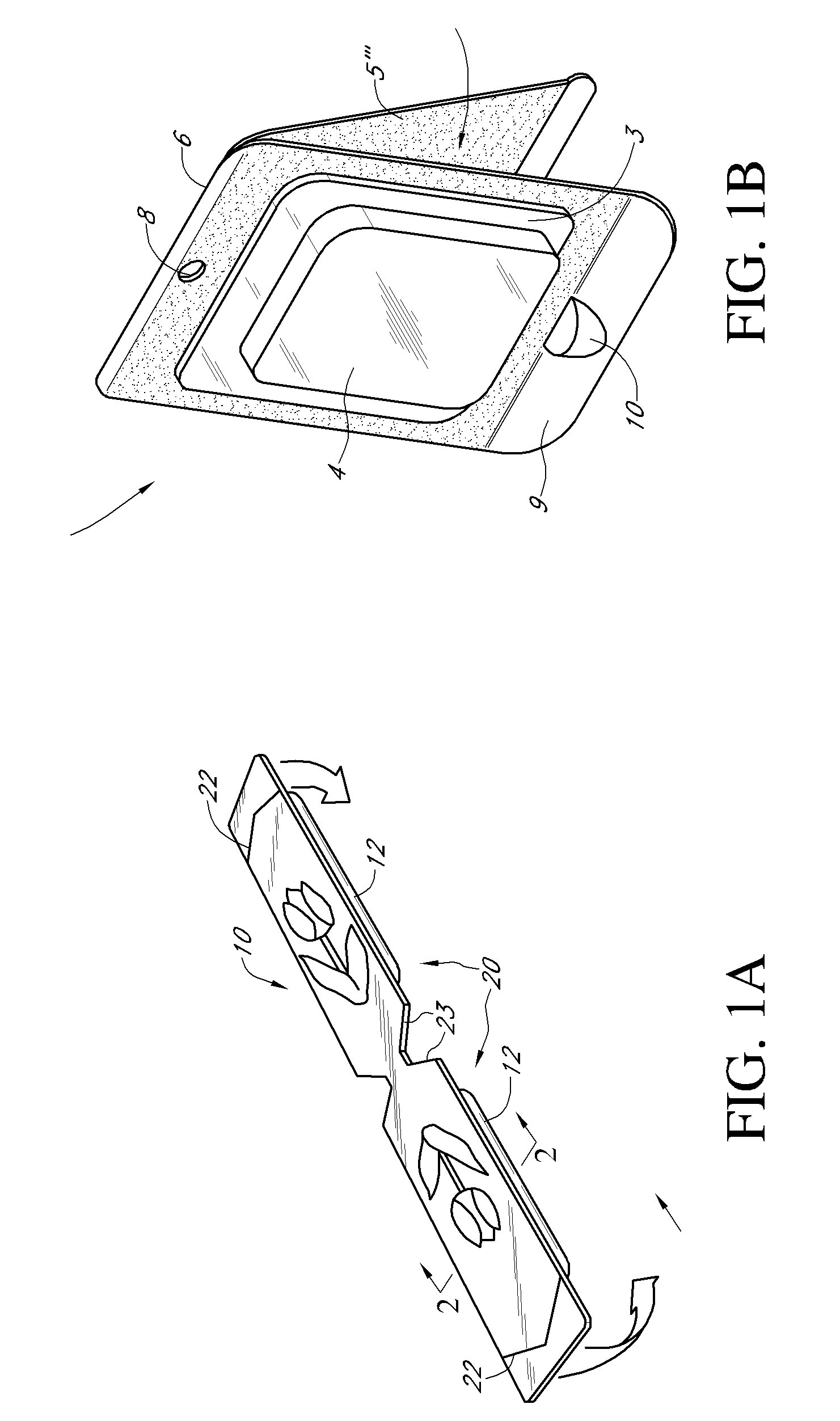

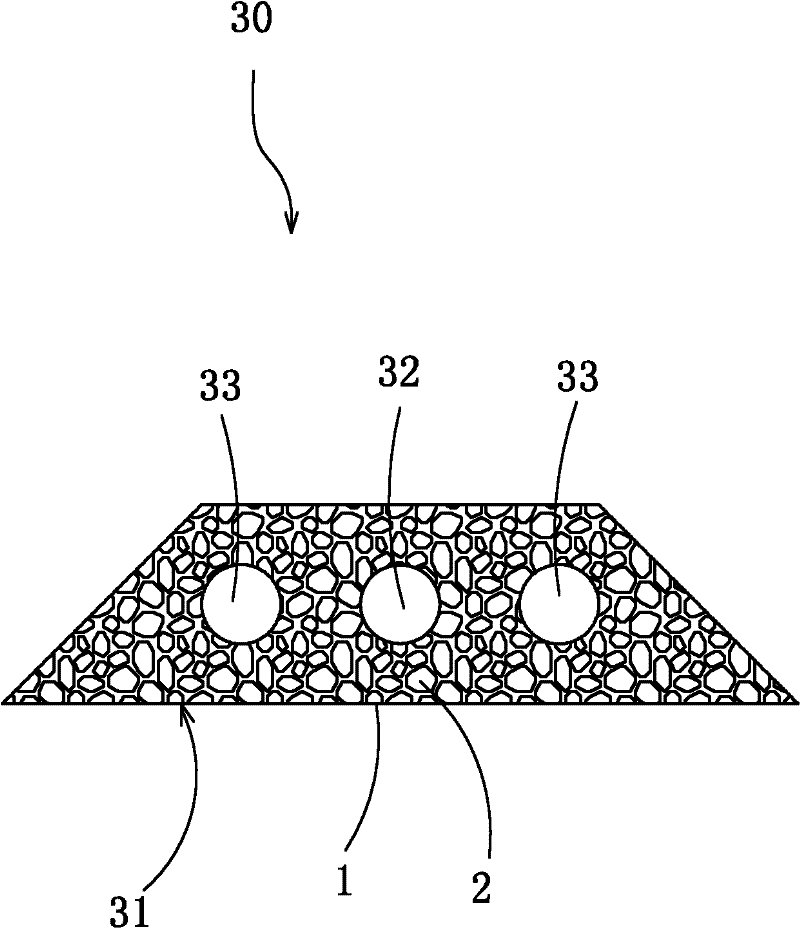

Soundproofing panel with beads, and a method of manufacture

ActiveUS20050109557A1Mitigate such drawbackImprove acoustic performanceCeilingsWallsSolid wallEngineering

A soundproofing panel (2) comprises a core (4) sandwiched between a solid wall (6) and a porous wall (8), the core being connected to the walls and comprising partitions (12) extending in the thickness direction between the two walls so as to form cells (10) each cell containing at least one sound energy dissipating layer (14), the dissipating layers (14) being constituted by hollow spherical beads (20) having mutually contacting walls that are porous and micro-perforated, and being held in position in the thickness direction between the two walls (6, 8) by nets (22) that are secured to the partitions.

Owner:ATECA +1

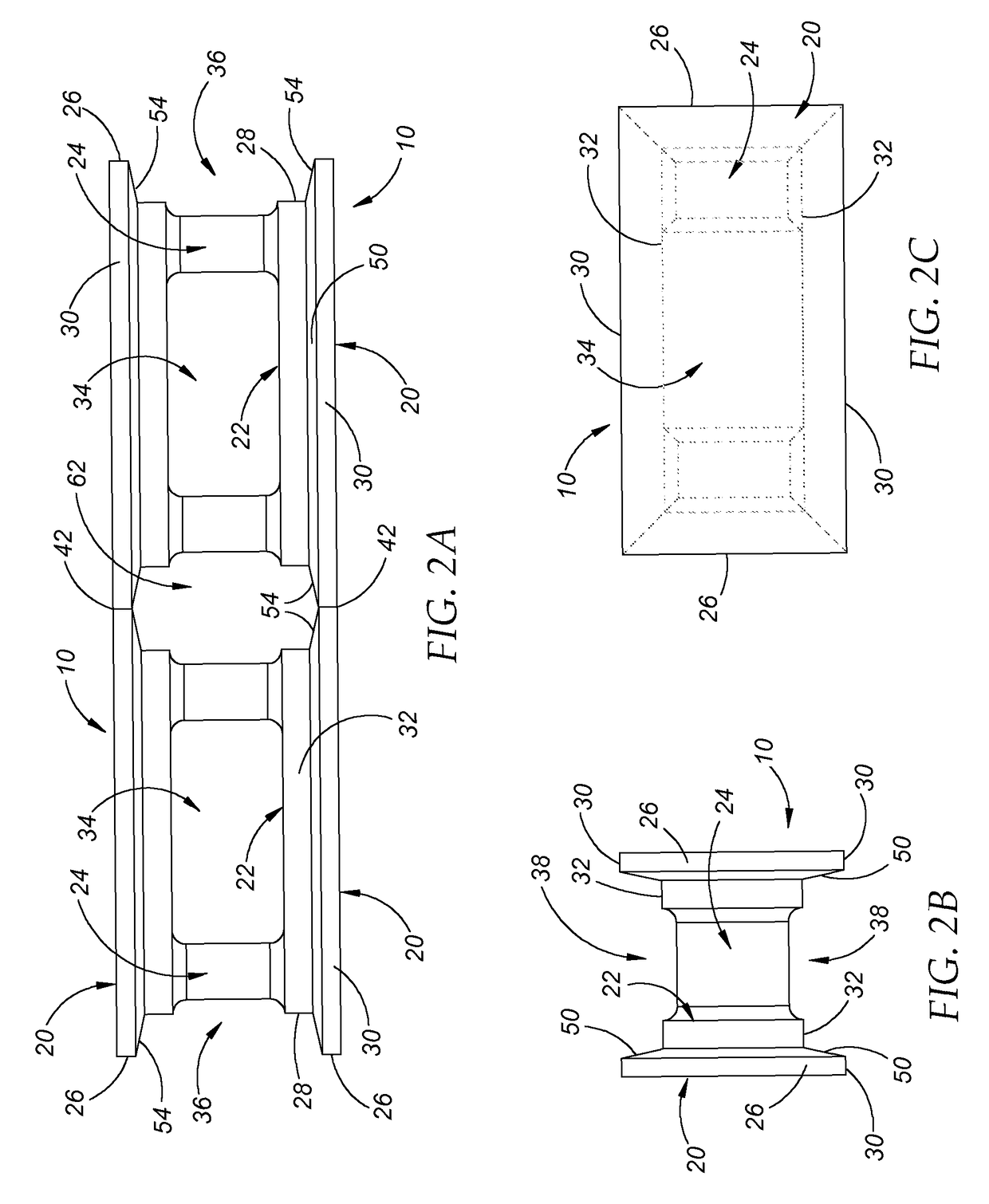

Angled tissue cutting instruments having flexible inner tubular members of tube and sleeve construction

ActiveUS7338495B2Reduce tanglingAvoid unwindingEndoscopic cutting instrumentsSurgical sawsSolid wallEngineering

An angled tissue cutting instrument comprises an angled outer tubular member rotatably receiving a flexible inner tubular member. The inner member has a flexible region in correspondence with an angle of the outer member. The flexible region comprises a helically cut length portion of an elongate tubular body of the inner member and a continuous solid flexible surface secured to an outer surface of the body along the helically cut length portion. A method of fabricating a flexible inner tubular member involves forming a helical cut through the solid wall of a length portion of a tubular body and securing a continuous solid flexible surface to the outer surface of the body along the helically cut length portion to form a flexible region.

Owner:MEDTRONIC XOMED INC

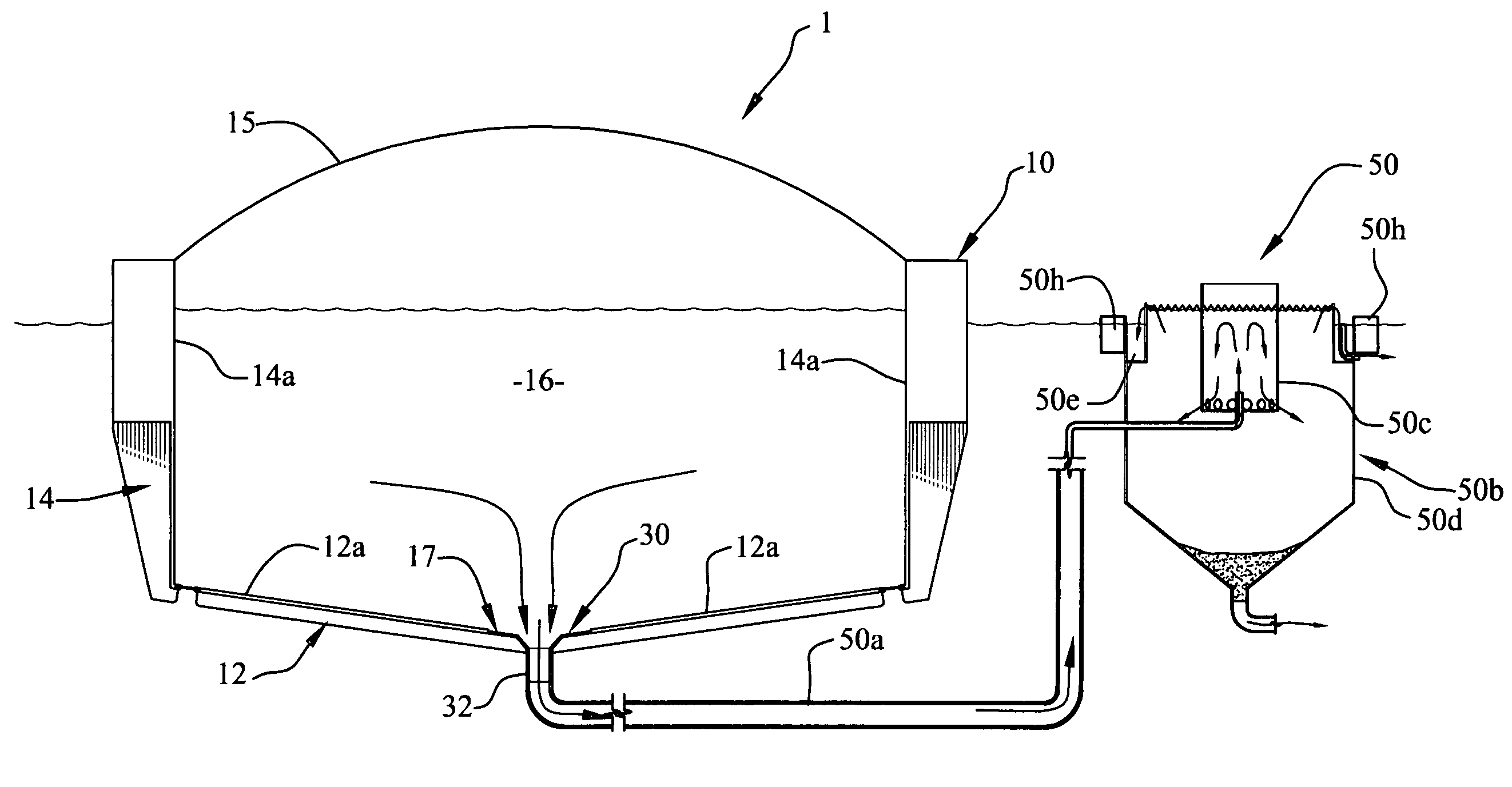

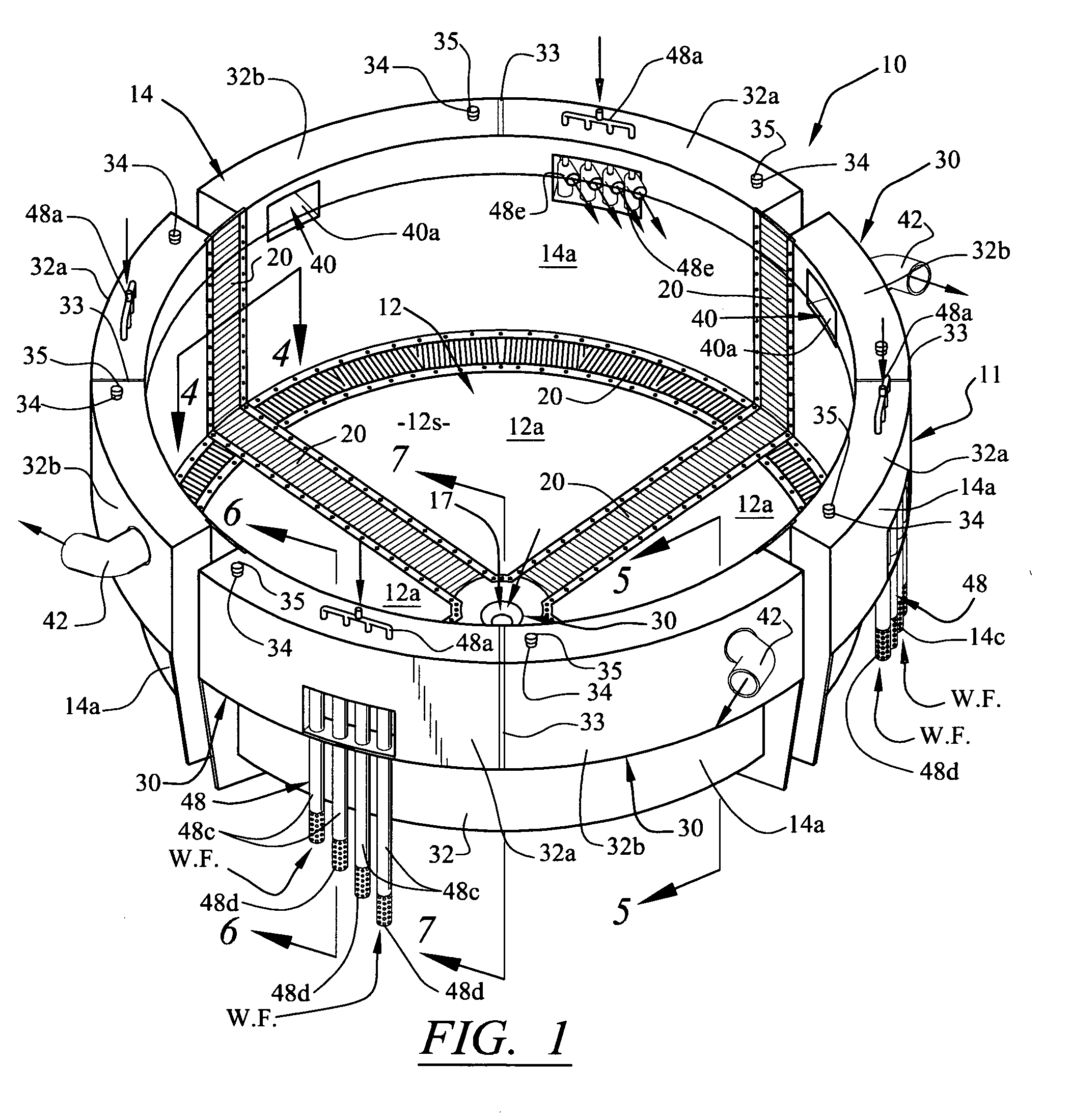

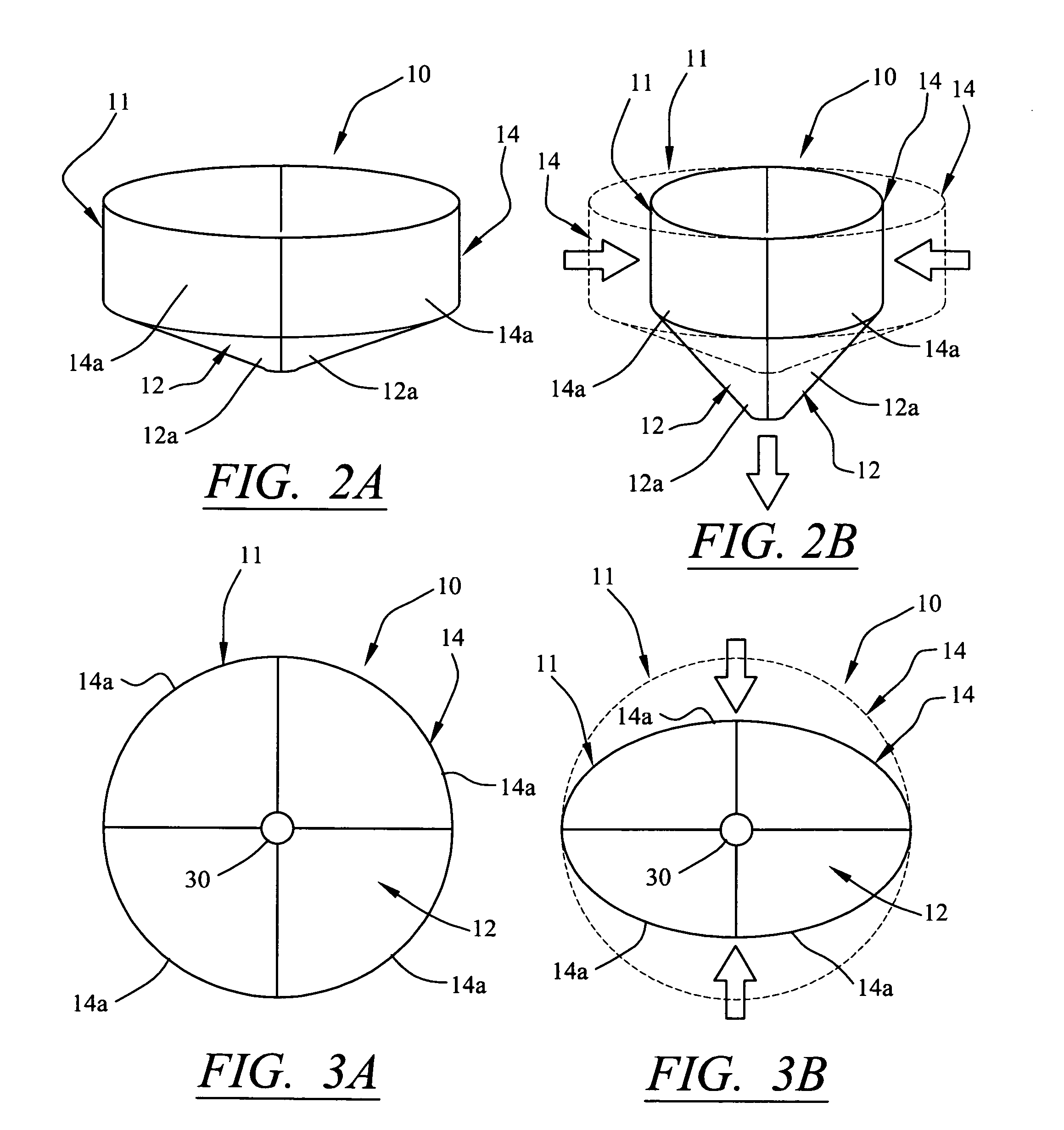

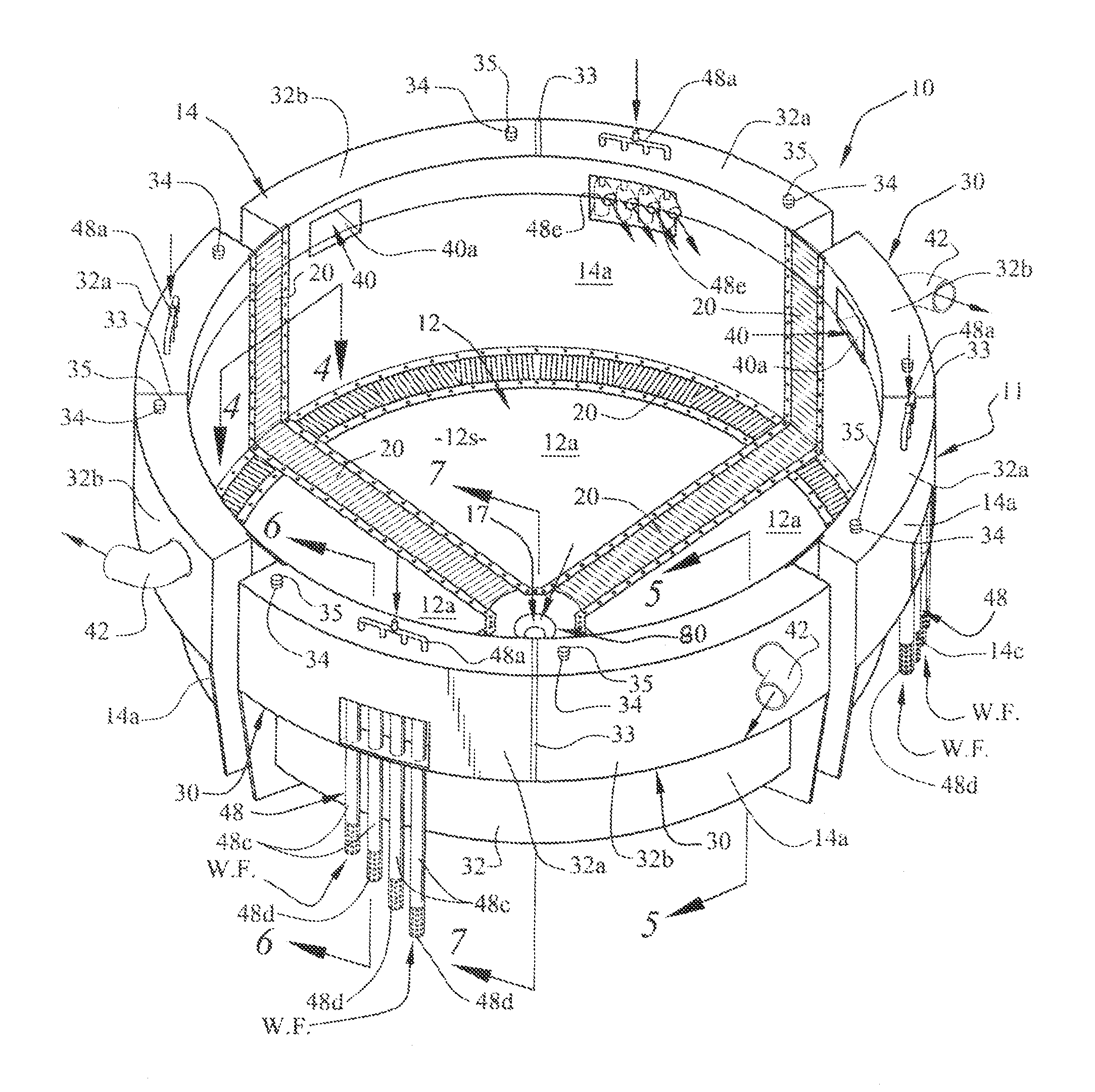

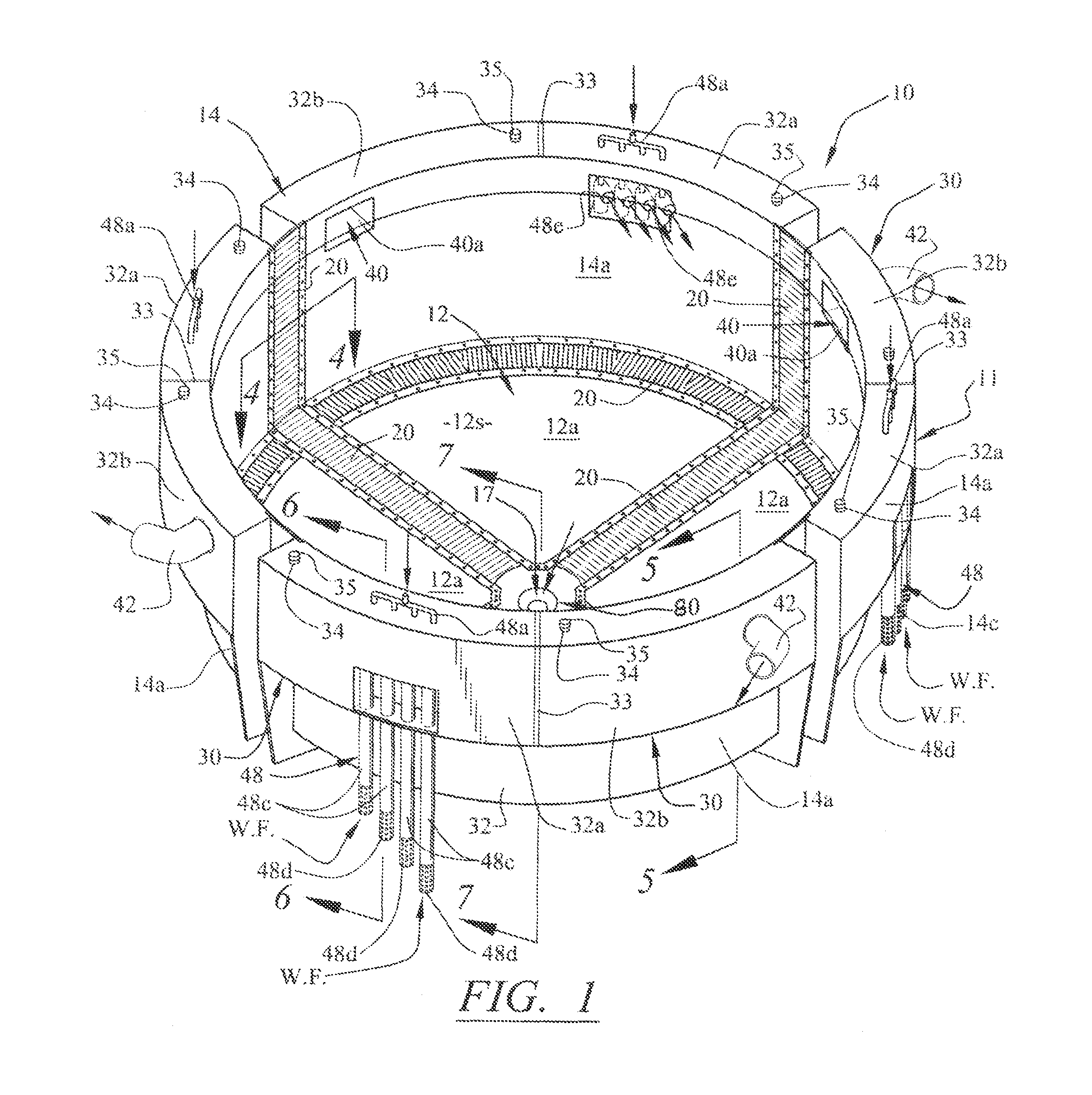

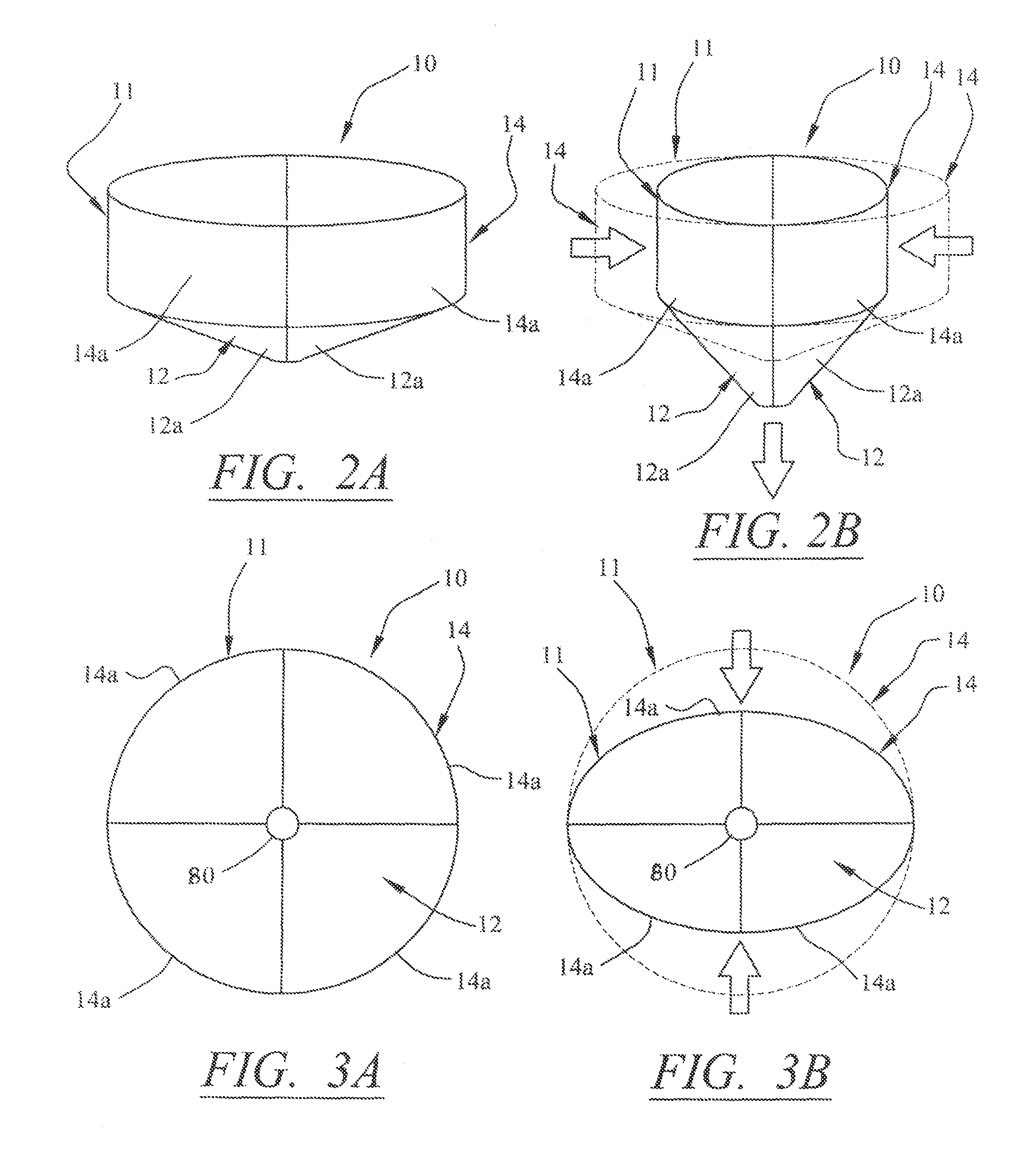

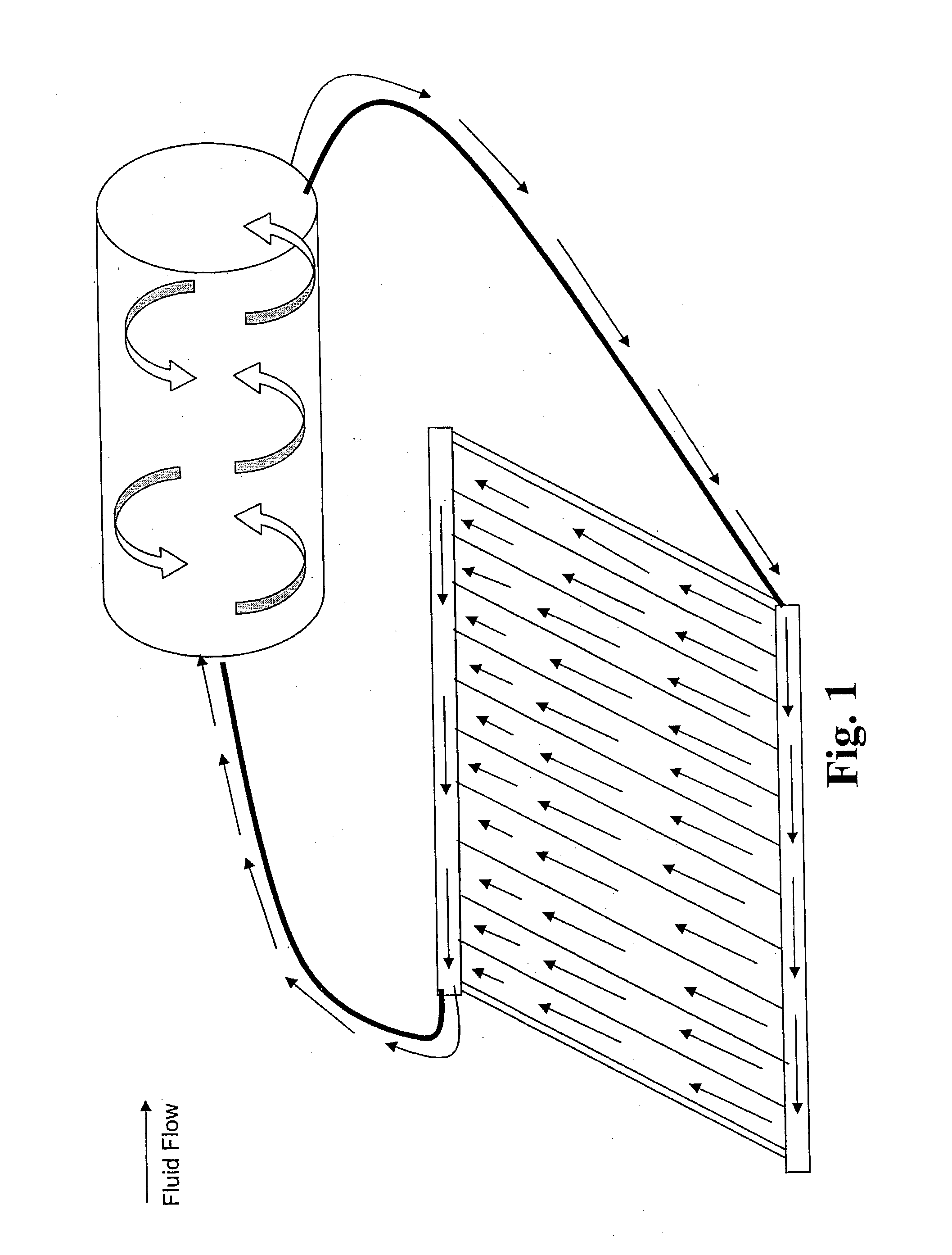

Aquaculture production system

InactiveUS20100224136A1Economically and environmentally superiorEconomically beneficialClimate change adaptationPisciculture and aquariaAquatic speciesSolid wall

A floating fish production system for placement within a body of water and being structured and disposed for containing fish and other aquatic animal, plant and algal species, the system including at least one primary containment tank having an arrangement of individual solid wall sections and an arrangement of individual solid floor sections. Flexible membranes span between and connect to adjacently positioned solid wall and floor sections to define flexible connecting joints that allow the individual solid wall and floor sections to move relative to one another in an articulating action. The flexible membranes allow the tank configuration to temporarily deform from a relaxed state in response to externally applied forces exerted on the tank (e.g., waves, wind, current) to thereby absorb the externally applied forces and reduce stress on the structural integrity on the tank. An air lift system including a high volume, low pressure blower and a spaced arrangement of vertically extending air lift pipes delivers water and oxygen from the exterior body of water and into the tank interior. A flexible main drain in a central area at the bottom of the tank connects to a waste recovery system for removing waste produced by the fish and other aquatic species.

Owner:PAPADOYIANIS ERNEST D +1

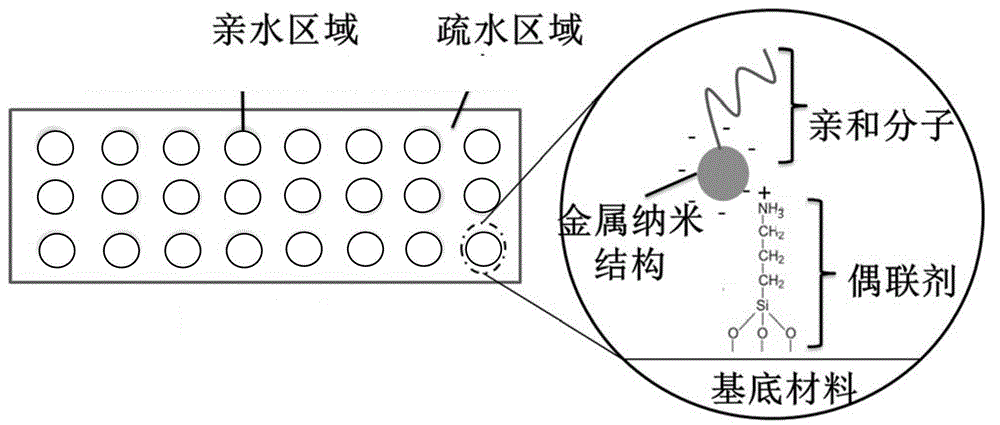

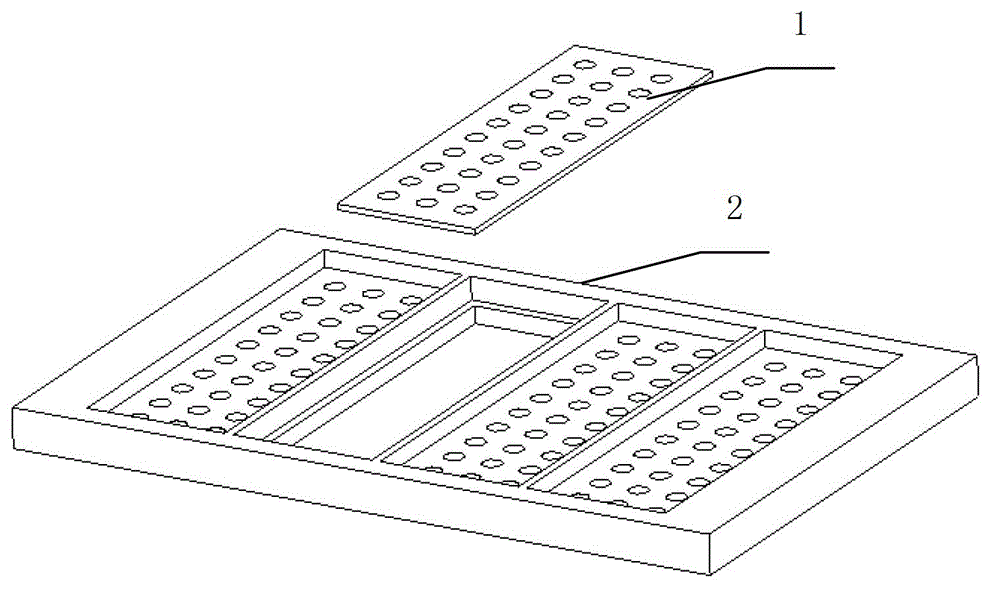

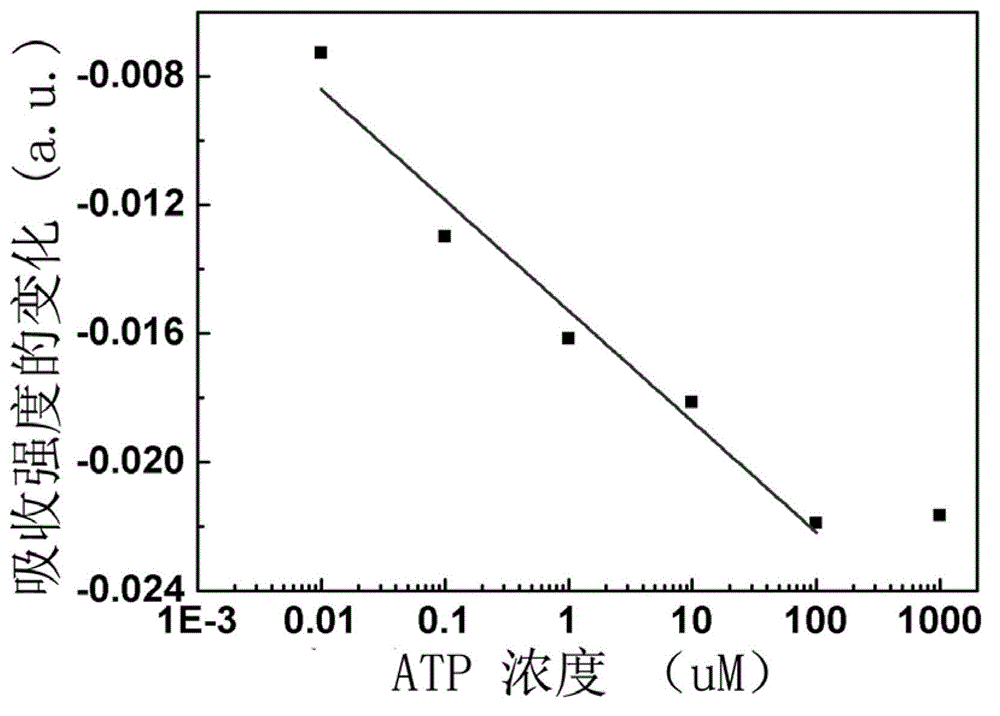

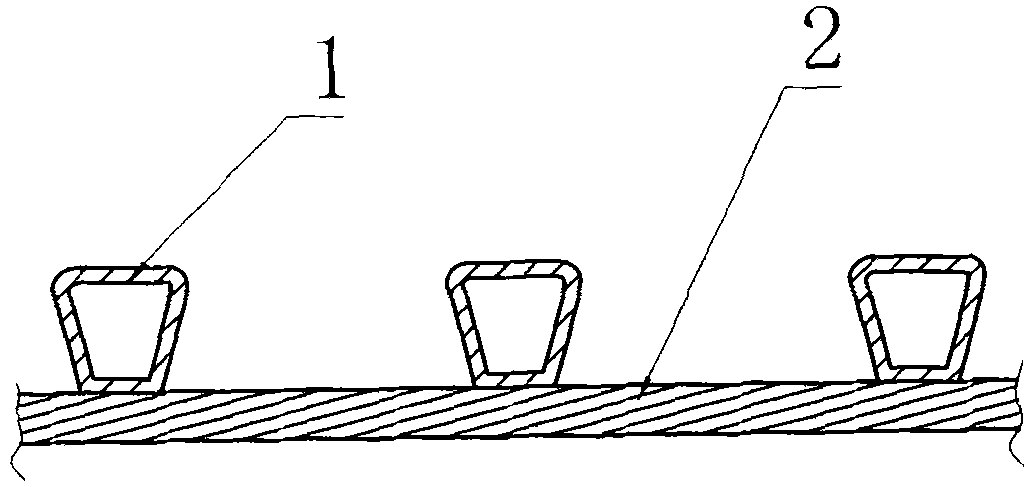

Microarray chip without solid wall based on LSPR (Localized Surface Plasmon Resonance) and application thereof

ActiveCN103335984ALow costSimple and fast operationScattering properties measurementsSolid wallMicroarray cgh

The invention discloses a microarray chip without solid walls based on LSPR (Localized Surface Plasmon Resonance) and application thereof. The substrate of the microarray chip is in a hydrophilic and hydrophobic mode and comprises a base, a plurality of hydrophilic regions and hydrophobic regions, wherein the hydrophilic regions are arranged on the base; the hydrophobic regions separate the hydrophilic regions; the surfaces of the hydrophilic regions are provided with metal nanometer material layers with local area surface plasma resonance attributes; the outer regions of the hydrophilic regions are not provided with the solid walls; the surfaces of the hydrophobic regions are provided with hydrophobic material layers. The microarray chip disclosed by the invention can be obtained by combining a peculiar affinitive molecule for detecting a substance to be detected on the substrate provided by the invention. The microarray chip disclosed by the invention has the advantages of easiness and convenience for use, low detection cost, accurate result, reusability, and the like, can be used for detecting multiple substances, such as micromolecules, heavy metal ions, proteins, bacteria, viruses, and the like, and has wide application prospect in the fields of medical health, environmental monitoring, scientific experiments, and the like.

Owner:TSINGHUA UNIV

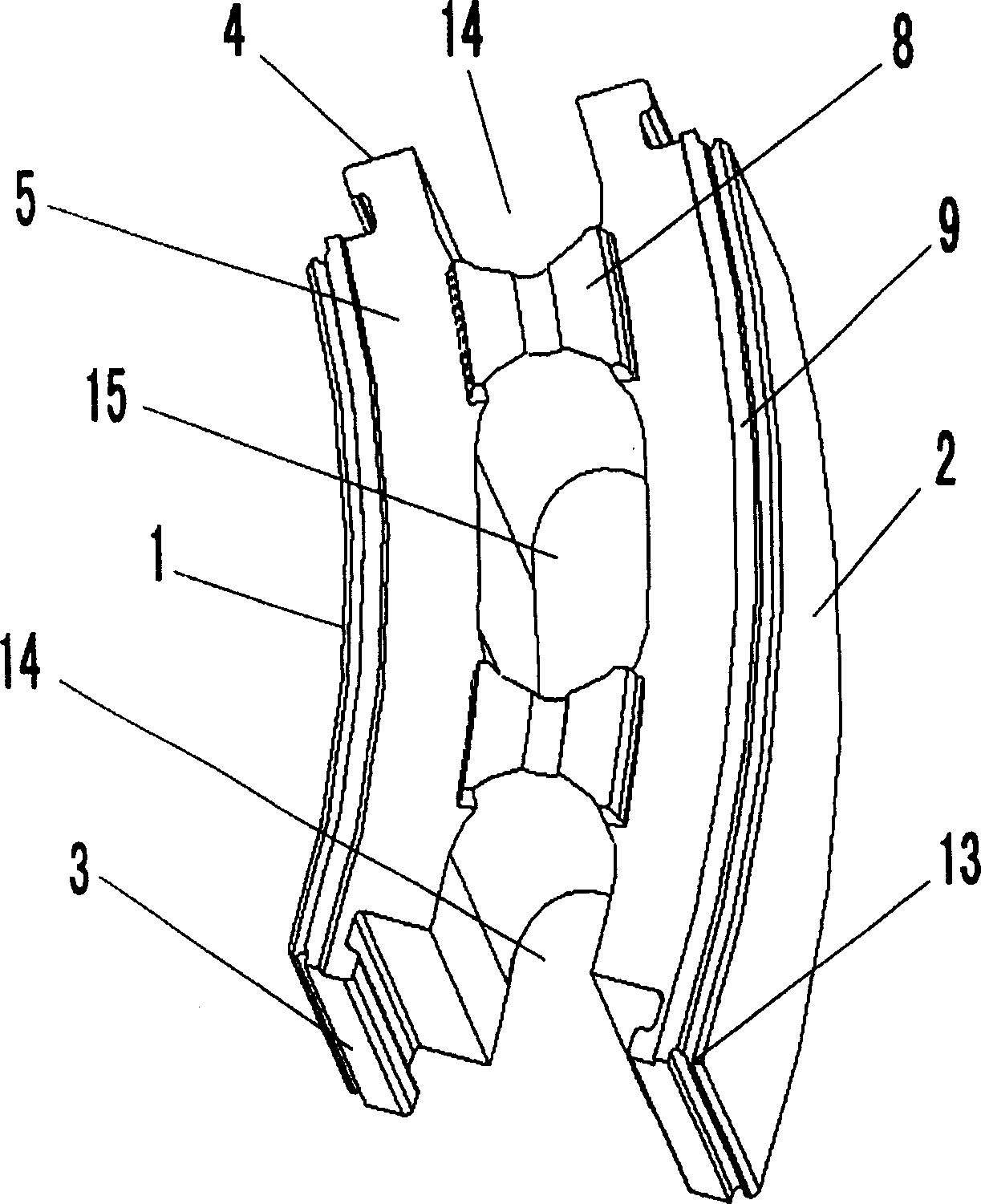

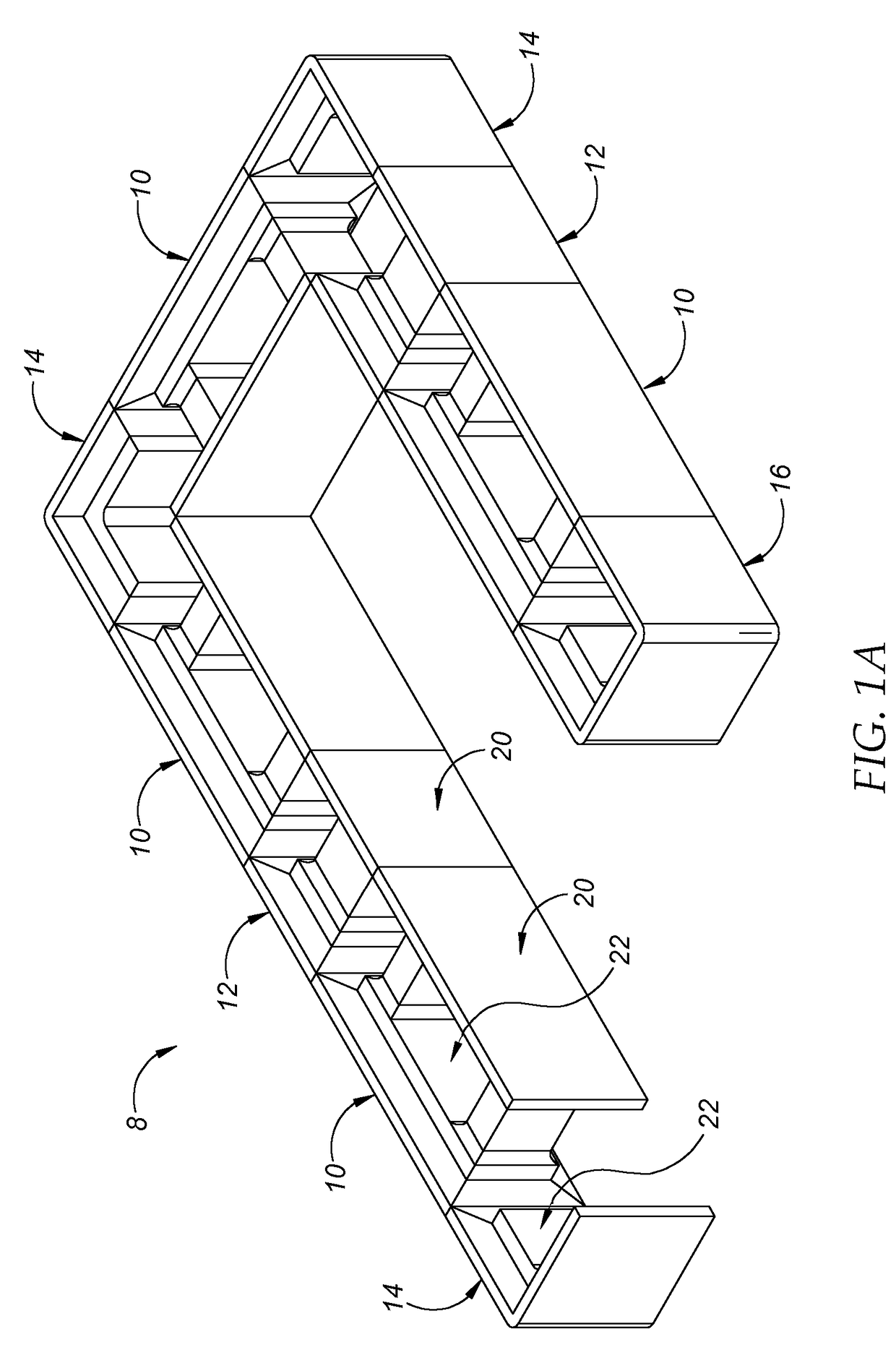

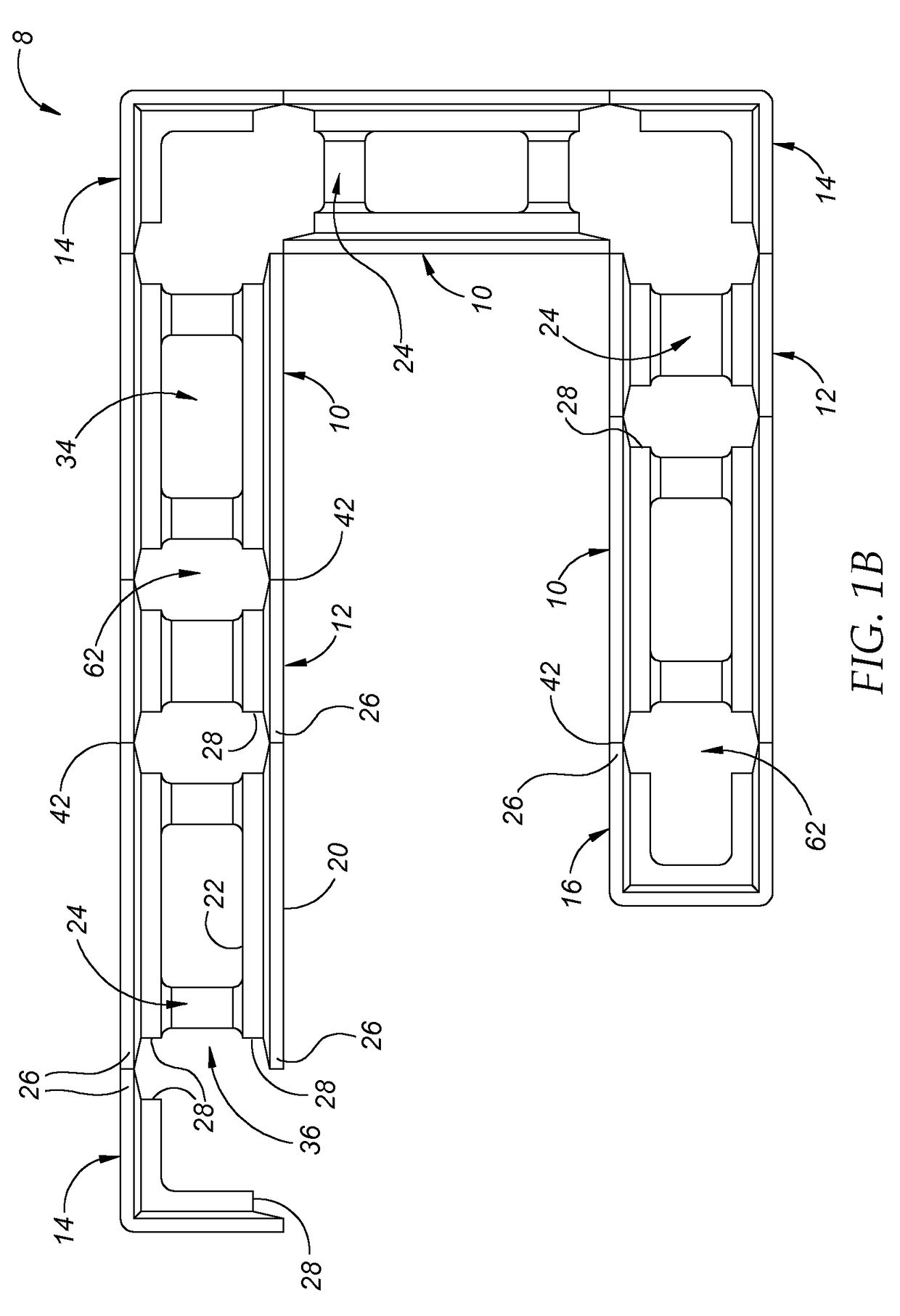

Interlocking mortarless structural concrete block building system

ActiveUS20070151191A1Improve efficiencyImprove performanceConstruction materialWallsSolid wallCavity wall

An interlocking modular building block system for mortarless cavity wall construction having blocks configured such that upon grouting, the cavity is solidly filled in a unified mass. Four block configurations are provided, namely runner, half, corner, and end block units. The runner has a length two times its width, and the other blocks have the same width and length as the width of the runner. Common to all blocks is a pair of parallel offset solid walls forming the outside and inside walls while creating vertical and horizontal positive and negative alignment features. The offset walls also form flat horizontal and vertical surfaces where successive units meet upon alignment. These walls are connected by one or more transverse membranes, with the exception of the corner block, where the walls are joined end to end at right angles.

Owner:AUGUST JOHN

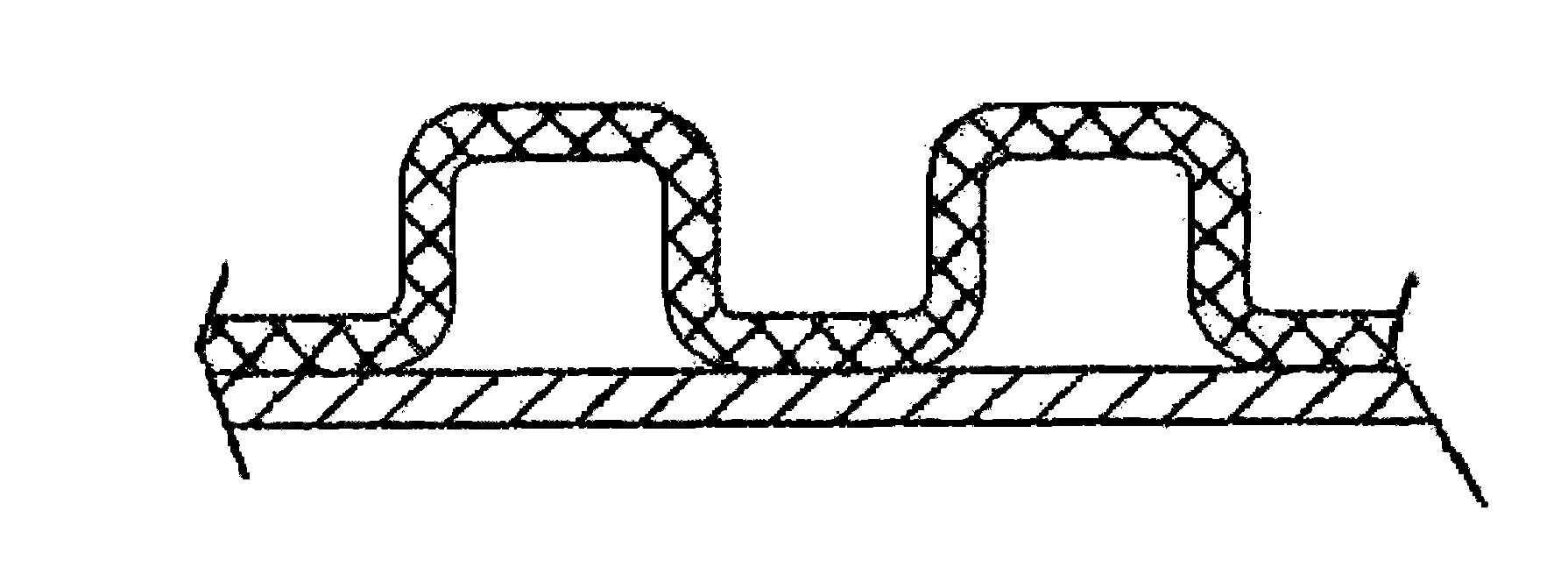

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

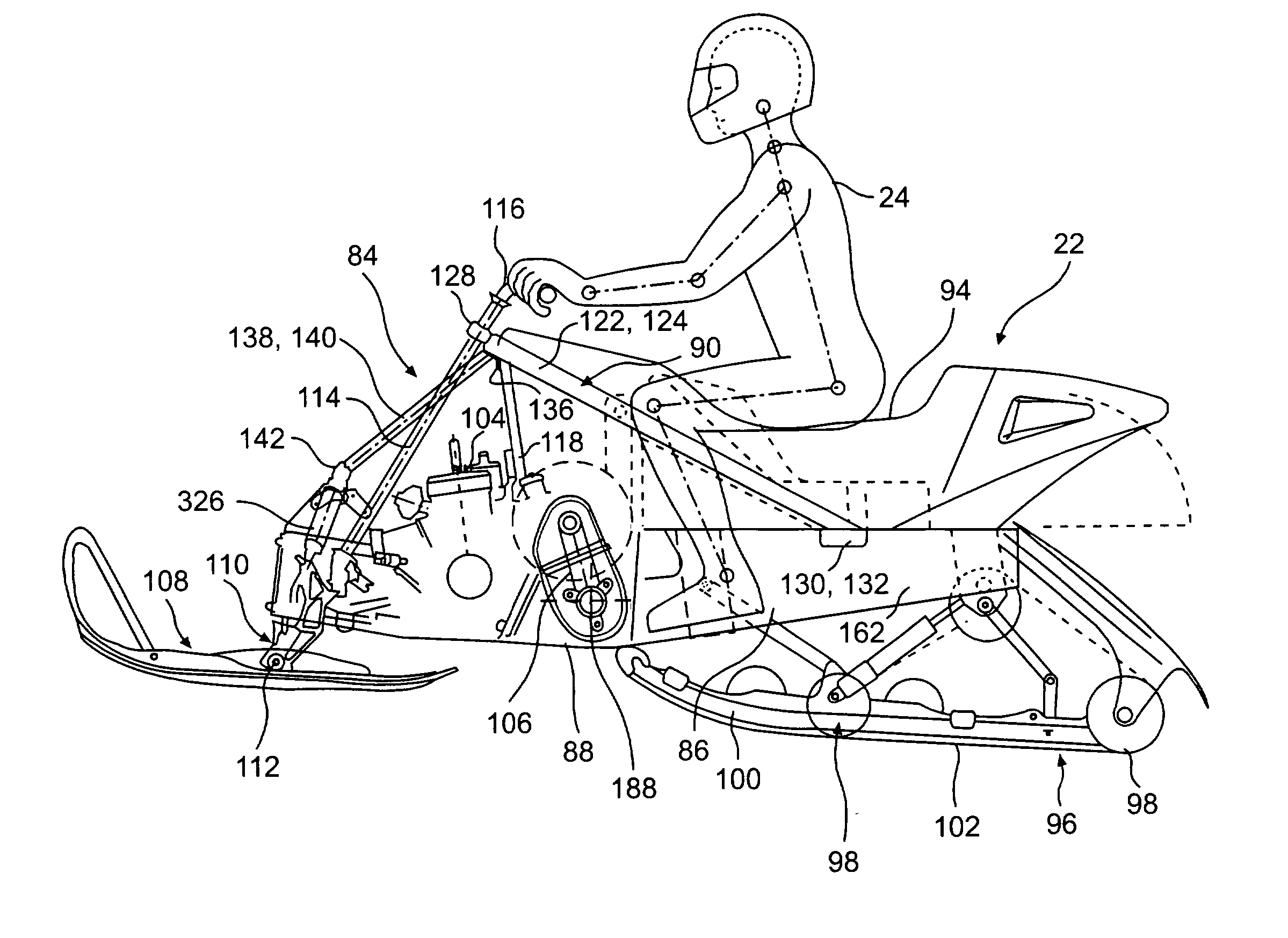

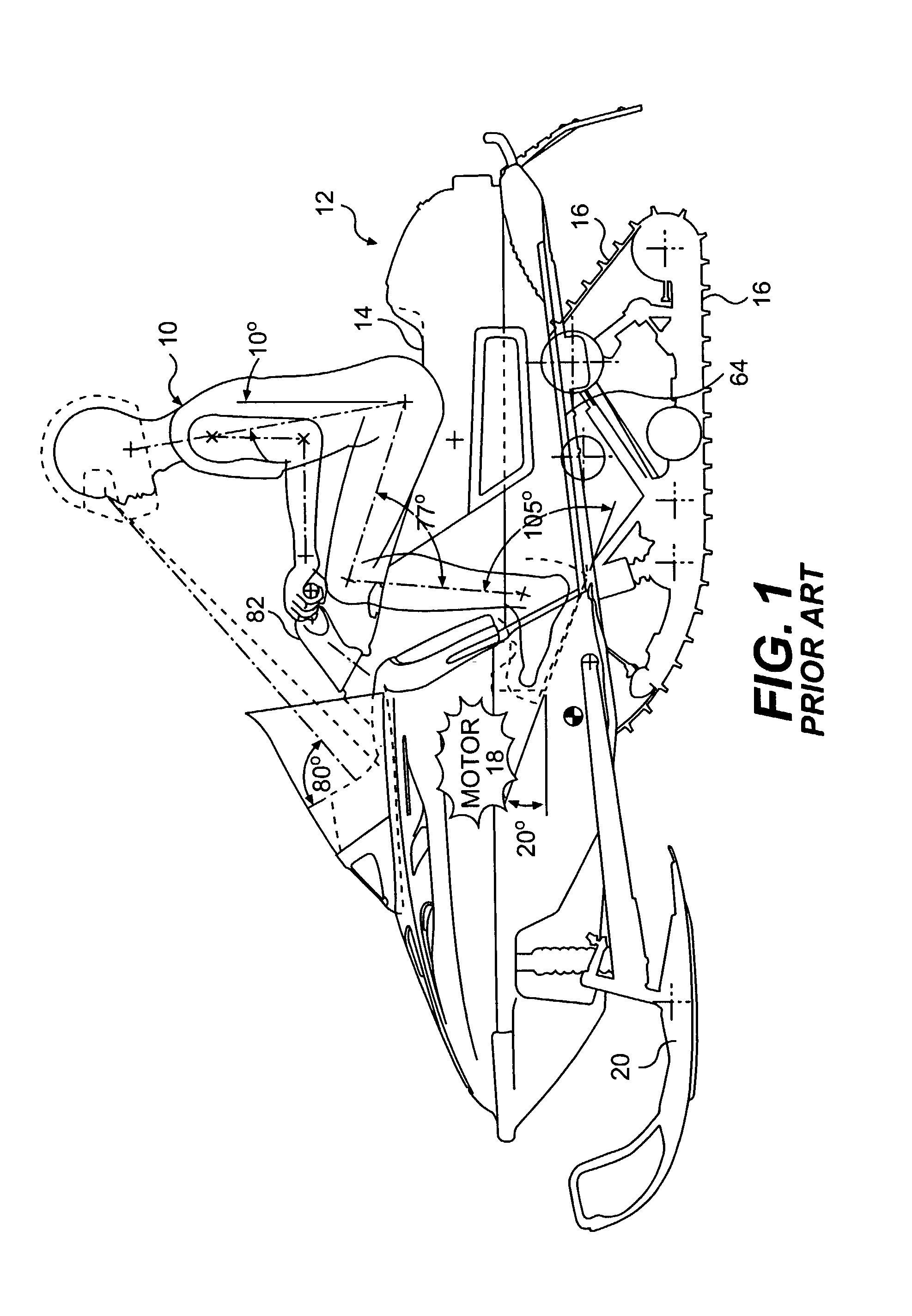

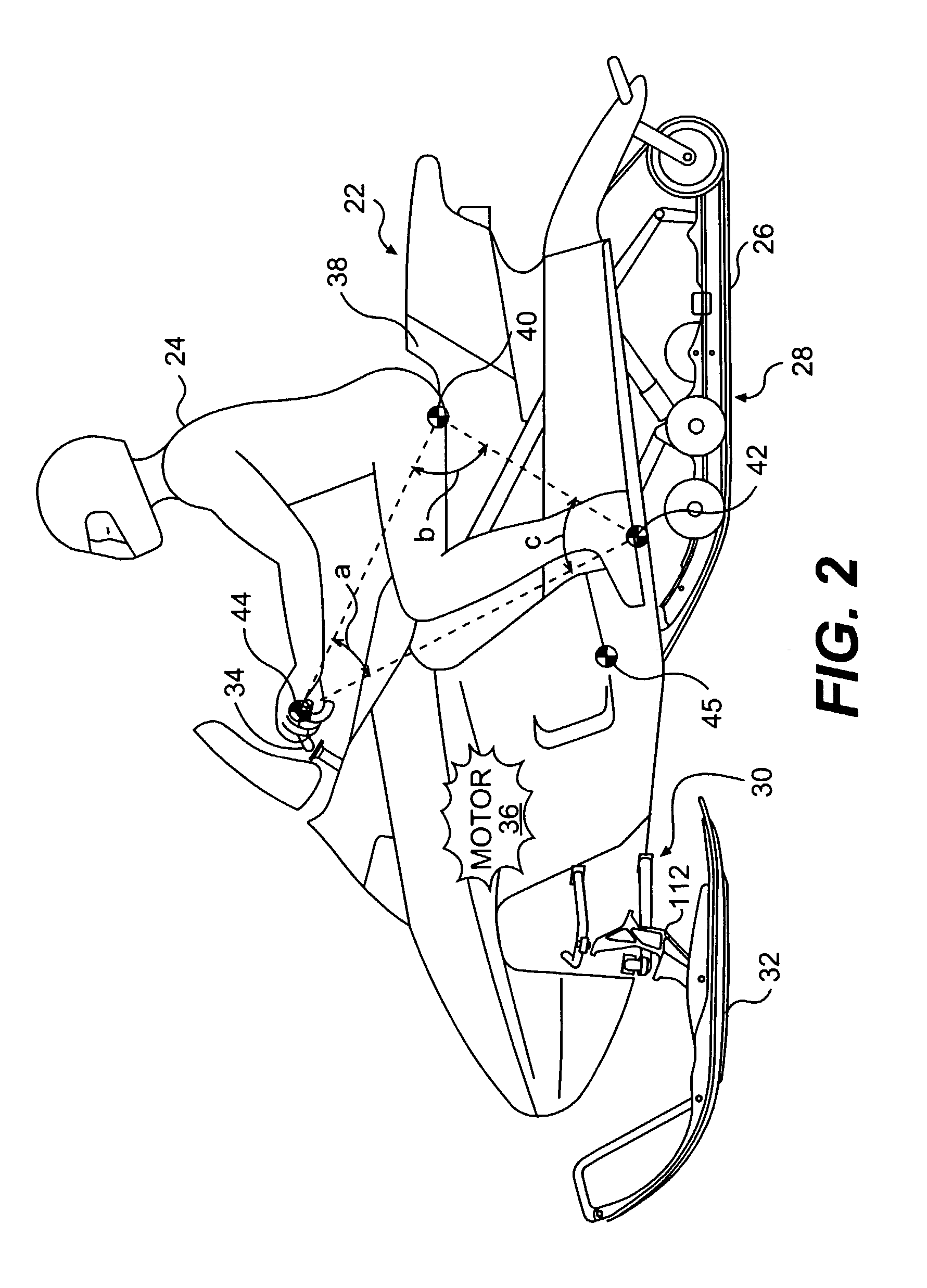

Snowmobile frame

An engine cradle adapted for receiving an engine includes a left side wall defining a C-shaped opening therein. The engine cradle also includes a right side wall, which is essentially a solid wall that provides a reflective surface for reflecting heat to the engine when contained within the engine cradle. The engine cradle also includes a front wall connected between forward portions of the left and right side walls. The engine cradle also includes a bottom panel and a rear panel connected between bottom portions of the front, left side, and right side walls.

Owner:BOMBARDIER RECREATIONAL PROD INC

Soundproofing panel with beads, and a method of manufacture

ActiveUS7520369B2Mitigate such drawbackImprove acoustic performanceCeilingsWallsSound energySolid wall

A soundproofing panel having a core sandwiched between a solid wall and a porous wall. The core being connected to the walls and having partitions extending in the thickness direction between the two walls so as to form cells. Each cell containing at least one sound energy dissipating layer constituted by hollow spherical beads having mutually contacting walls that are porous and micro-perforated, and being held in position in the thickness direction between the two walls by nets that are secured to the partitions.

Owner:ATECA +1

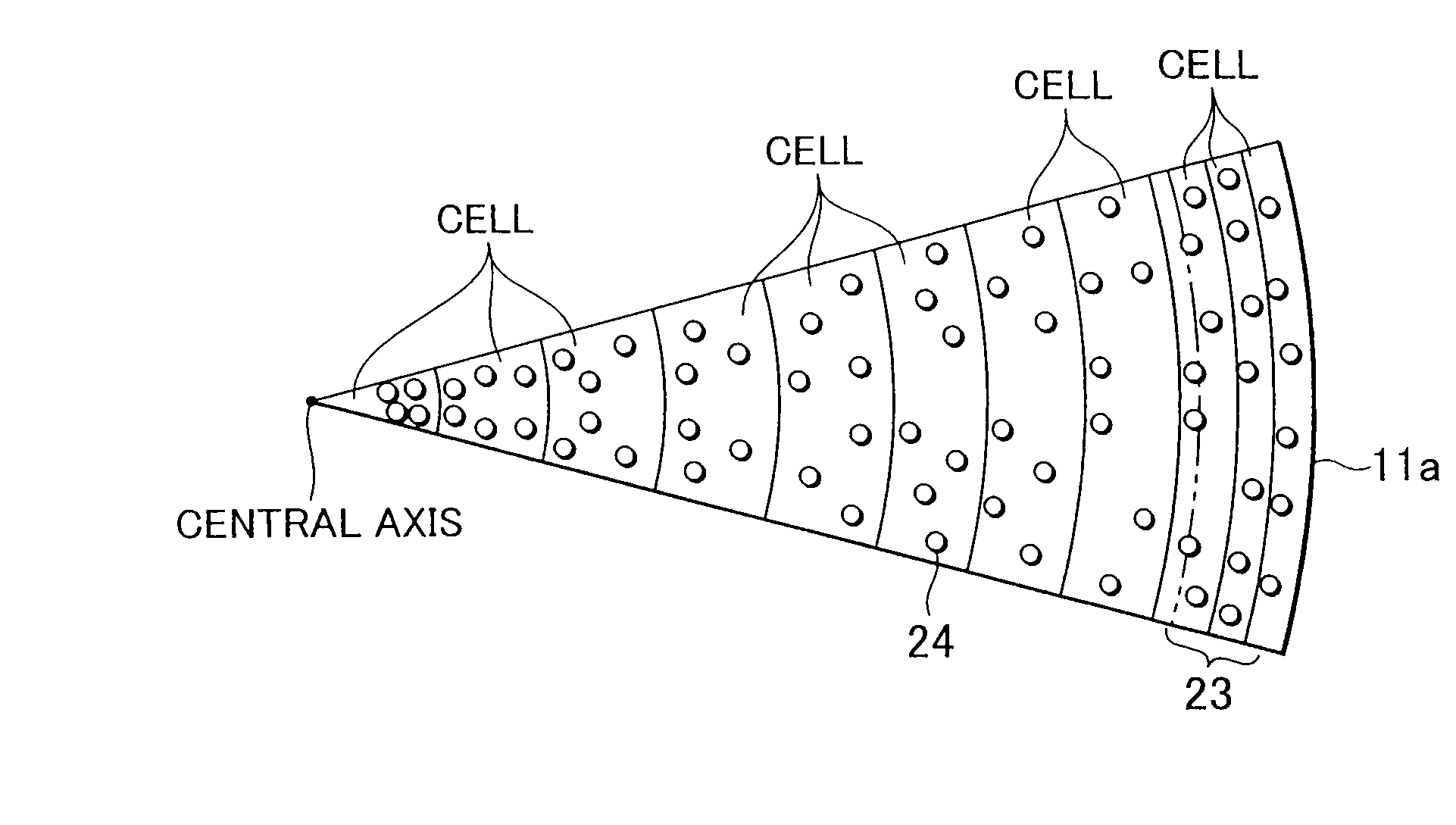

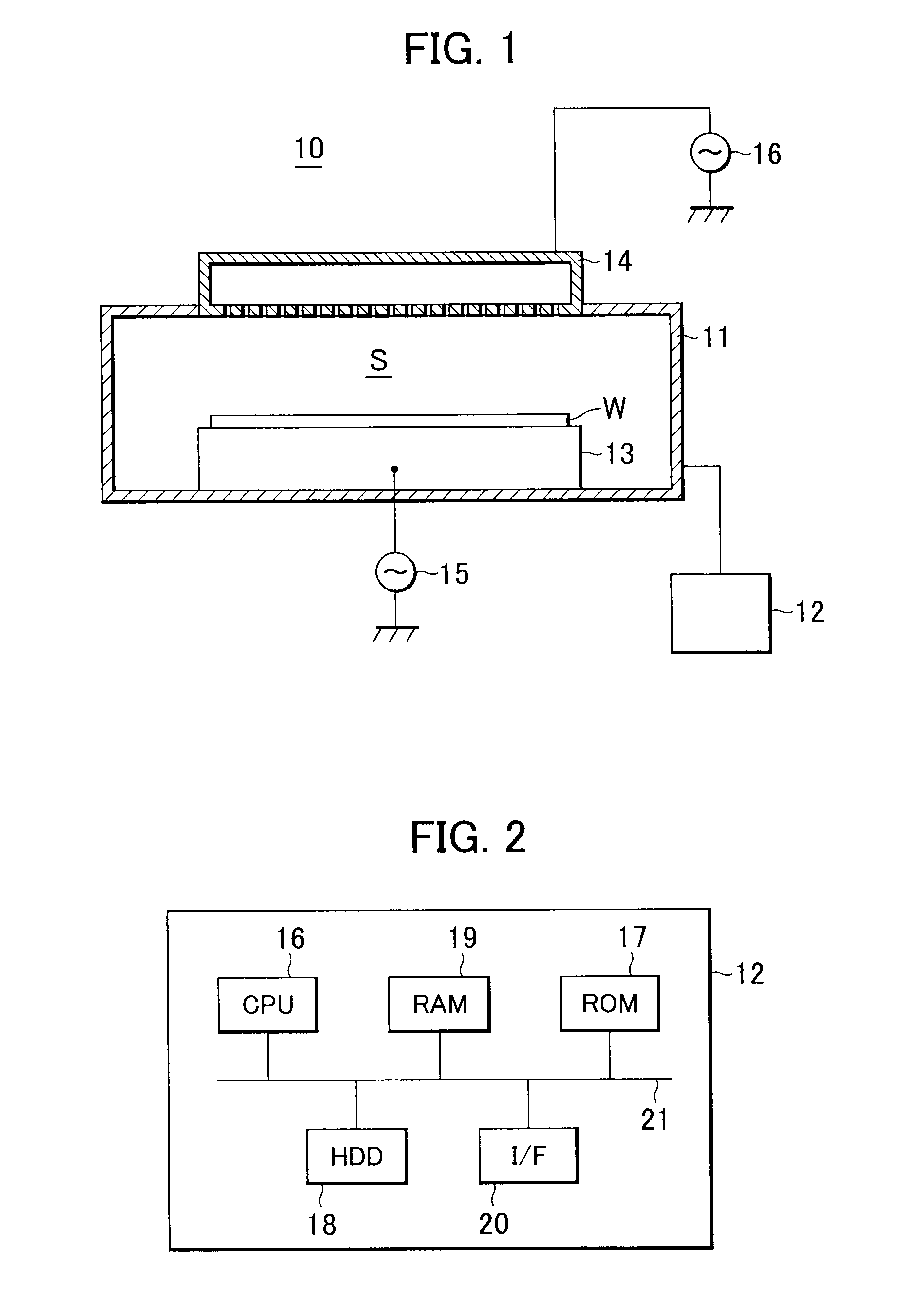

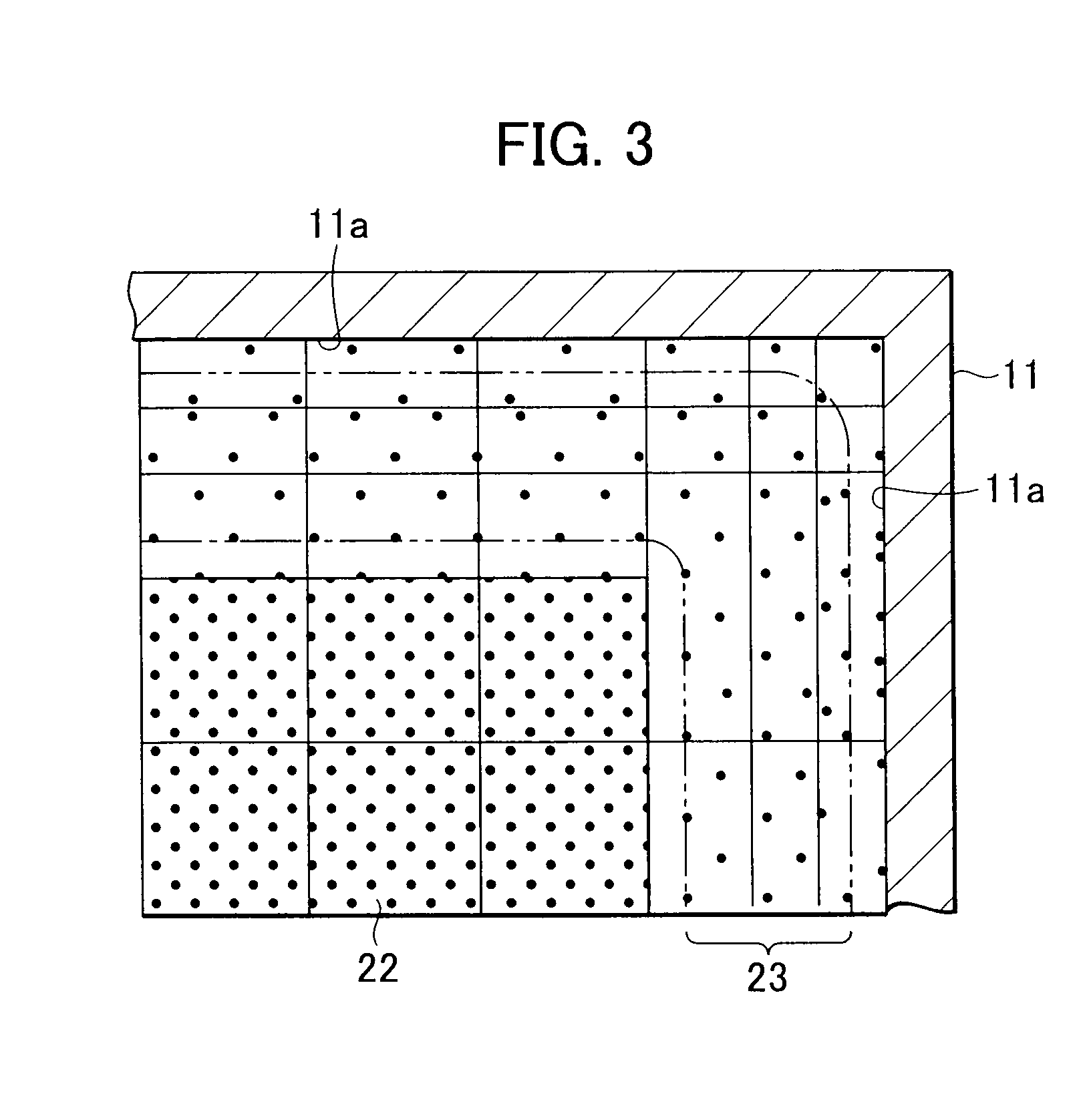

Method of plasma particle simulation, storage medium, plasma particle simulator and plasma processing apparatus

ActiveUS7847247B2Prevent a statistical error from becoming large in behavior calculationAvoid divergenceParticle separator tubesSemiconductor/solid-state device manufacturingSolid wallPlasma particle

A method of plasma particle simulation capable of preventing solution divergence. A space within a housing chamber of a plasma processing apparatus is divided into a plurality of cells. A weighting factor corresponding to the number of plasma particles represented by a superparticle is set in each of the divided cells. Superparticles are set in each of the divided cells using plasma particles contained in the divided cell and the set weighting factor. The behavior of the superparticles in each of the divided cells is calculated. The weighting factor becomes smaller as the divided cell is located closer to a solid wall surface of the housing chamber.

Owner:TOKYO ELECTRON LTD

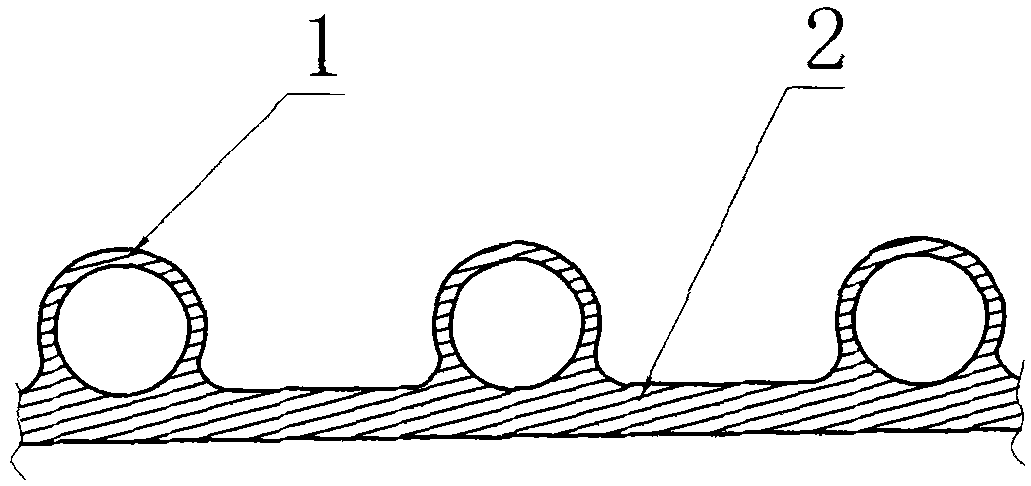

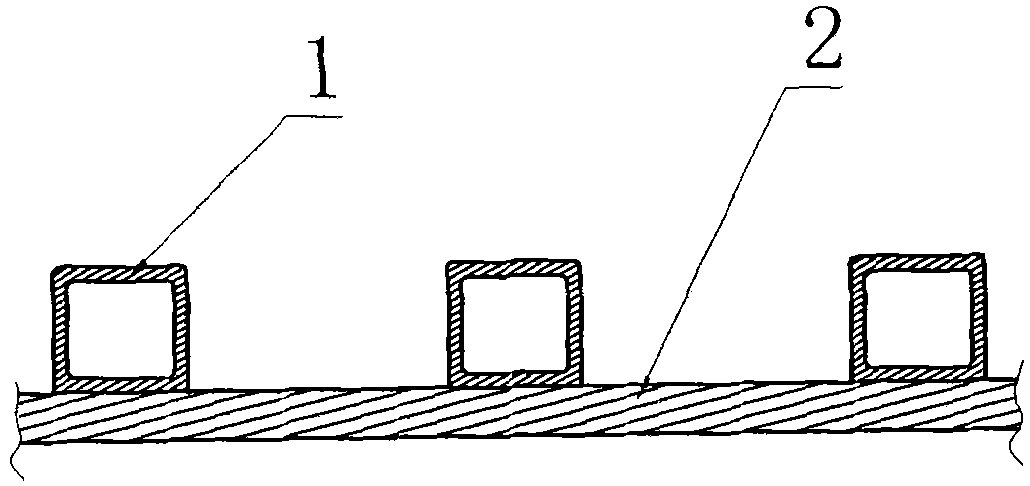

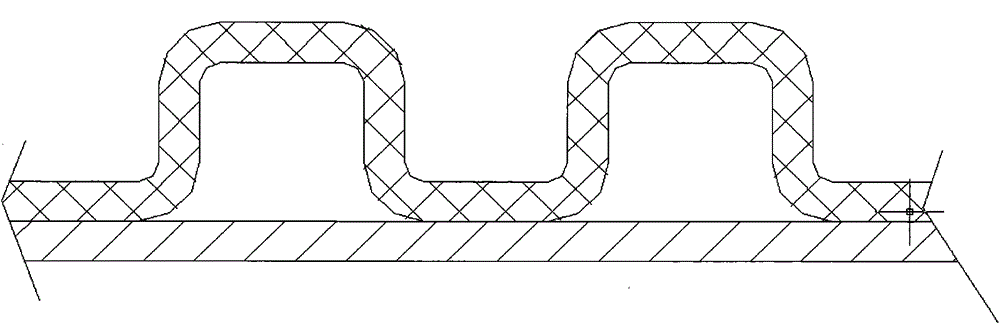

Polyethylene-wound structure wall tube and pipe without frame pipe and production method thereof

InactiveCN101852316AEnhanced centroid heightStrengthen heart distance heightRigid pipesSolid wallConductor Coil

The invention relates to a polyethylene-wound structure wall tube and pipe without a frame pipe, which is composed of an inner wall layer and an outer wall layer, wherein the inner wall layer is a continuous solid wall pipe formed by spirally winding a flaky polyethylene band, and adjacent band edges orderly being overlapped with each other; and the outer wall layer is composed of convex stiffening ribs formed by spirally winding a tubular polyethylene band on the external surface of the inner wall layer, and the tubular polyethylene band spirally presses across the overlap seam of each adjacent flaky polyethylene band edges. The production method comprises the following steps: extruding profiled bars, stretching, sizing, winding and fusing. The production method removes the original polypropylene frame pipe, can ensure the centroid distance of the stiffening rib tube, reduce the product weight by more than 20%, reduce raw material consumption, lower the product cost, greatly decrease the internal stress of the tube and pipe, reduce consumption and enhance ring stiff and ring flexibility.

Owner:韩路平 +2

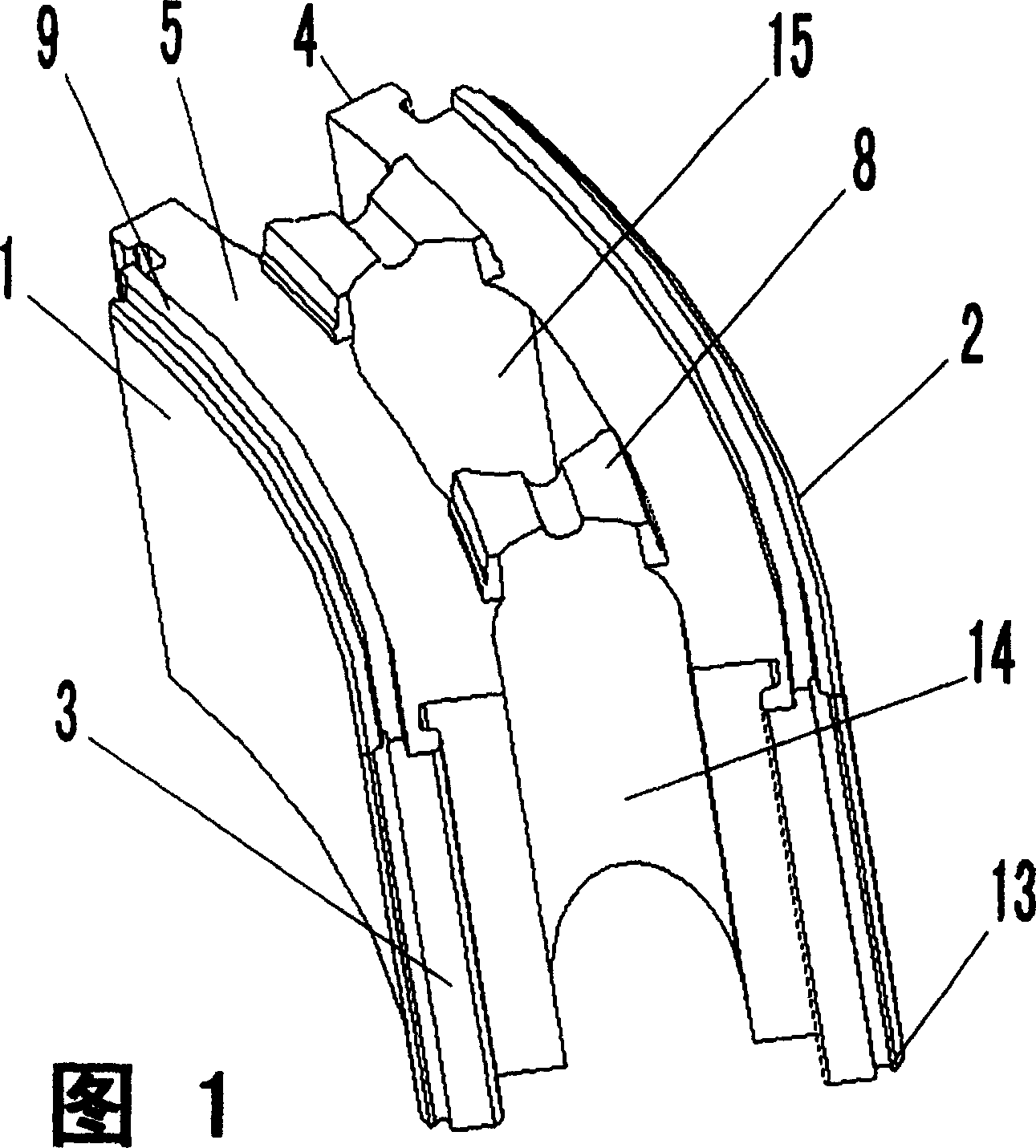

Wall module of well walls and method for building wall bodies of well walls by using module

InactiveCN1206429CPrevent subsidenceImprove sturdinessArtificial islandsBuilding componentsSolid wallLine tubing

The invention relates to a shaft wall module and a shaft wall construction method using the module. The object of the present invention is to provide a module with convenient construction and a firm shaft wall. The modules of the present invention realize the mutual alignment and clamping of the modules during the masonry process through the convex-concave structure arranged on the surface of the modules, and pour concrete into the holes and grooves reserved on the modules Using slurry and / or inserting reinforcing ribs to construct the well wall body into a whole with different load-bearing properties, so as to improve the strength of the well wall body. Through the predetermined connection mode with the auxiliary components, the flexible connection relationship with the steps and the connection port of the external pipeline is realized.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

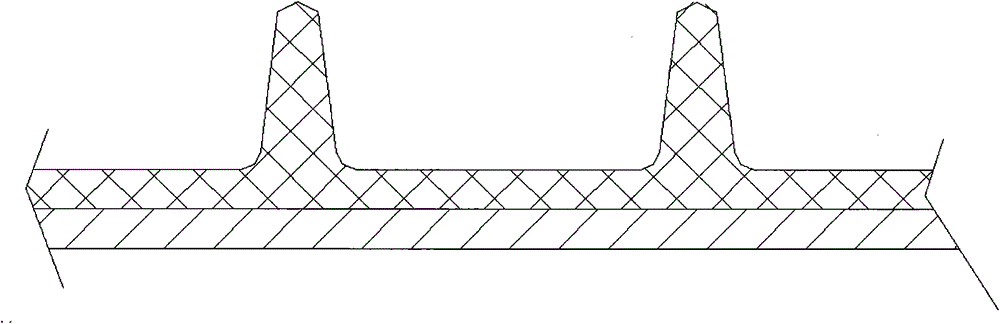

Continuous twining reinforced structure wall pipe, manufacturing equipment and manufacturing method

InactiveCN104061378AIncrease the outer surface areaGood synergyRigid pipesSolid wallPlastic materials

The invention provides a continuous twining reinforced structure wall pipe. The pipe wall of the continuous twining reinforced structure wall pipe is a spiral circumference; a center line is considered as an axis for specific strip-shaped plastic materials to twine in a spiral manner; the edges of the each adjacent specific strip-shaped plastic materials are overlapped to be integrated with each other to form a continuous solid wall pipe-shaped structure; reinforced adhesive materials which has the same spiral twining form is straddled and pressed on the positions on which overlapping joints of the adjacent specific strip-shaped materials are positioned; a specific single wall corrugated pipe which has the same spiral twining form is straddled and pressed on the reinforced adhesive materials; a strip-shaped material which has the same spiral twining form straddles the specific single wall corrugated pipe in a pressing manner, and adhesive to the pipe wall through a pressing wheel mechanism.

Owner:戴爱清 +1

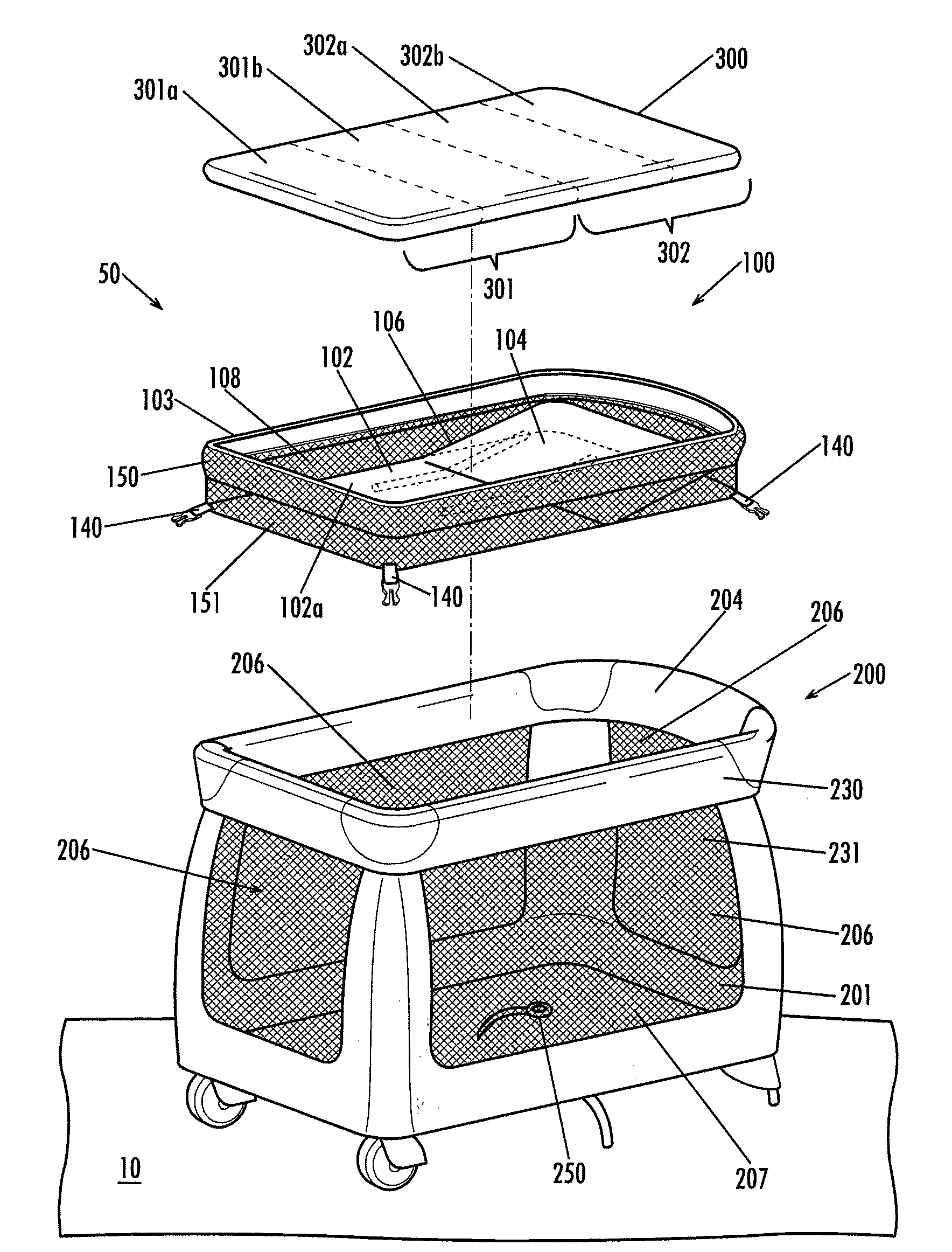

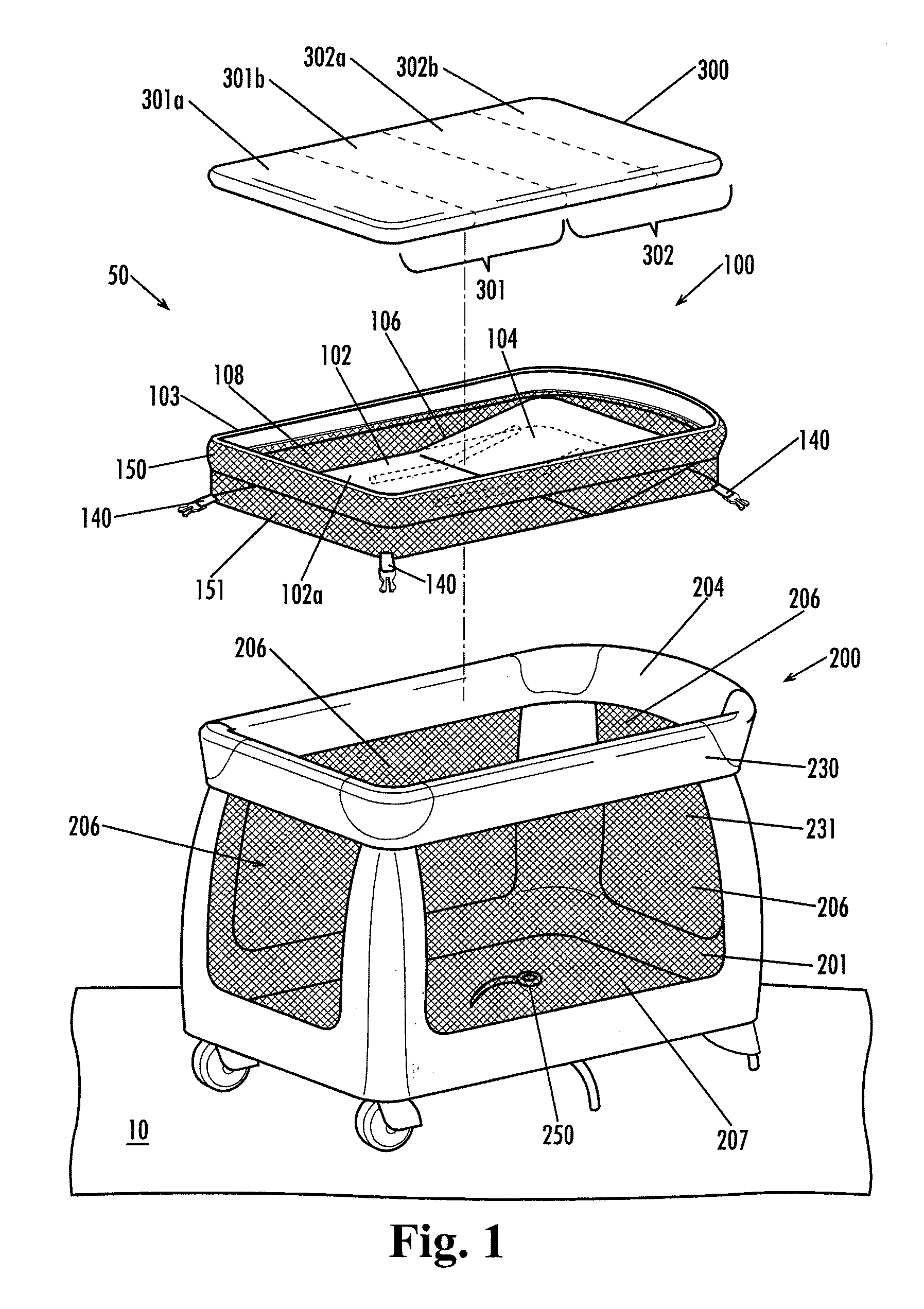

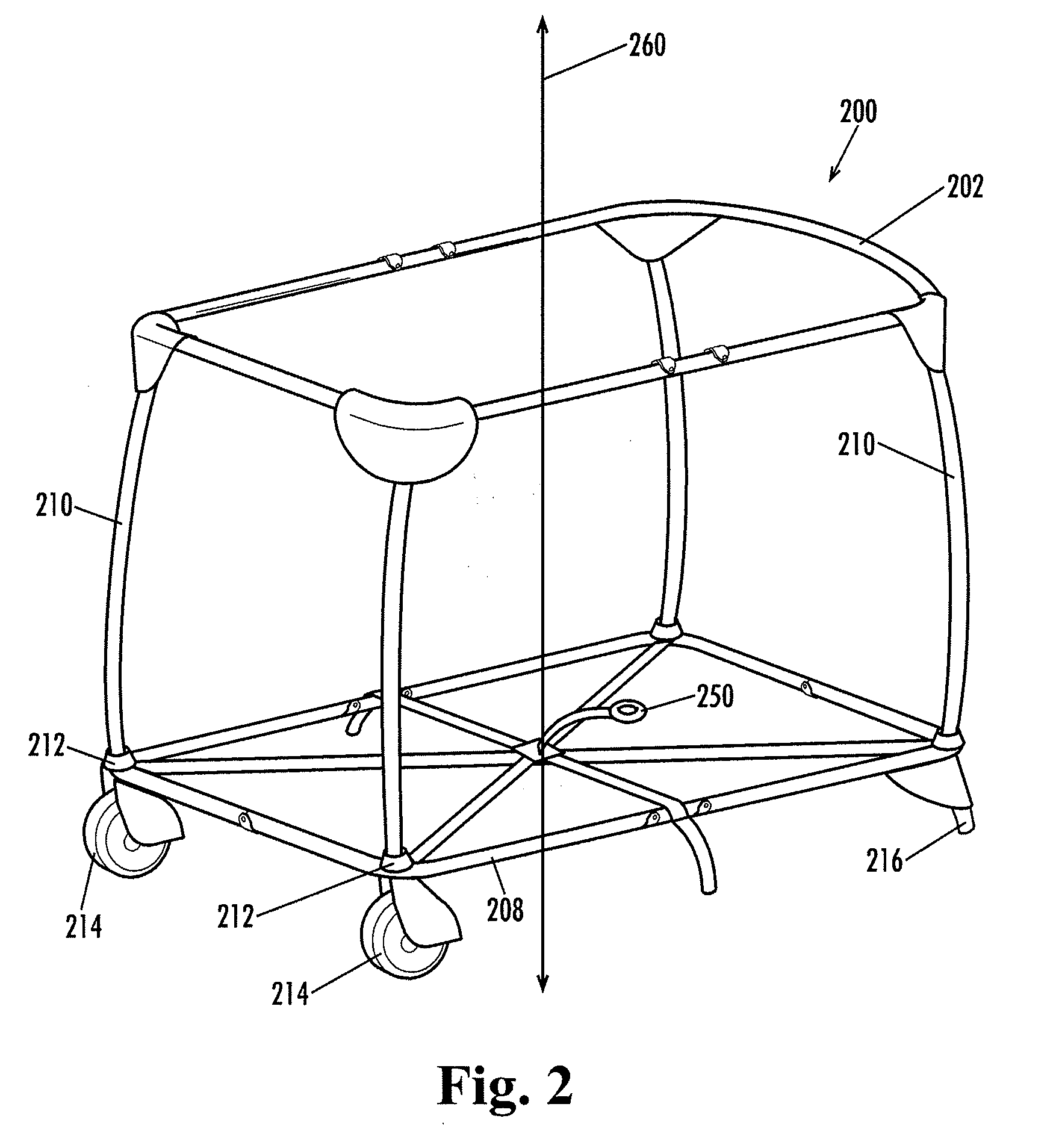

Mesh arrangement for bassinet assembly

According to various embodiments, a bassinet assembly includes a floor and one or more side walls that extend upwardly from a perimeter of the floor and surround the floor. Each side wall has an upper perimeter and includes a mesh portion that extends substantially the height of the side wall from the upper perimeter to the floor. Each side wall also includes a substantially solid wall portion that extends from the upper perimeter to an intermediate portion disposed between the upper perimeter and the floor. At least a portion of the side wall between the intermediate portion and the floor of the bassinet assembly is mesh to allow a child lying therein to breathe.

Owner:KIDS II INC

Interlocking mortarless structural concrete block building system

ActiveUS7905070B2Improve efficiencyImprove performanceConstruction materialWallsSolid wallCavity wall

Owner:AUGUST JOHN

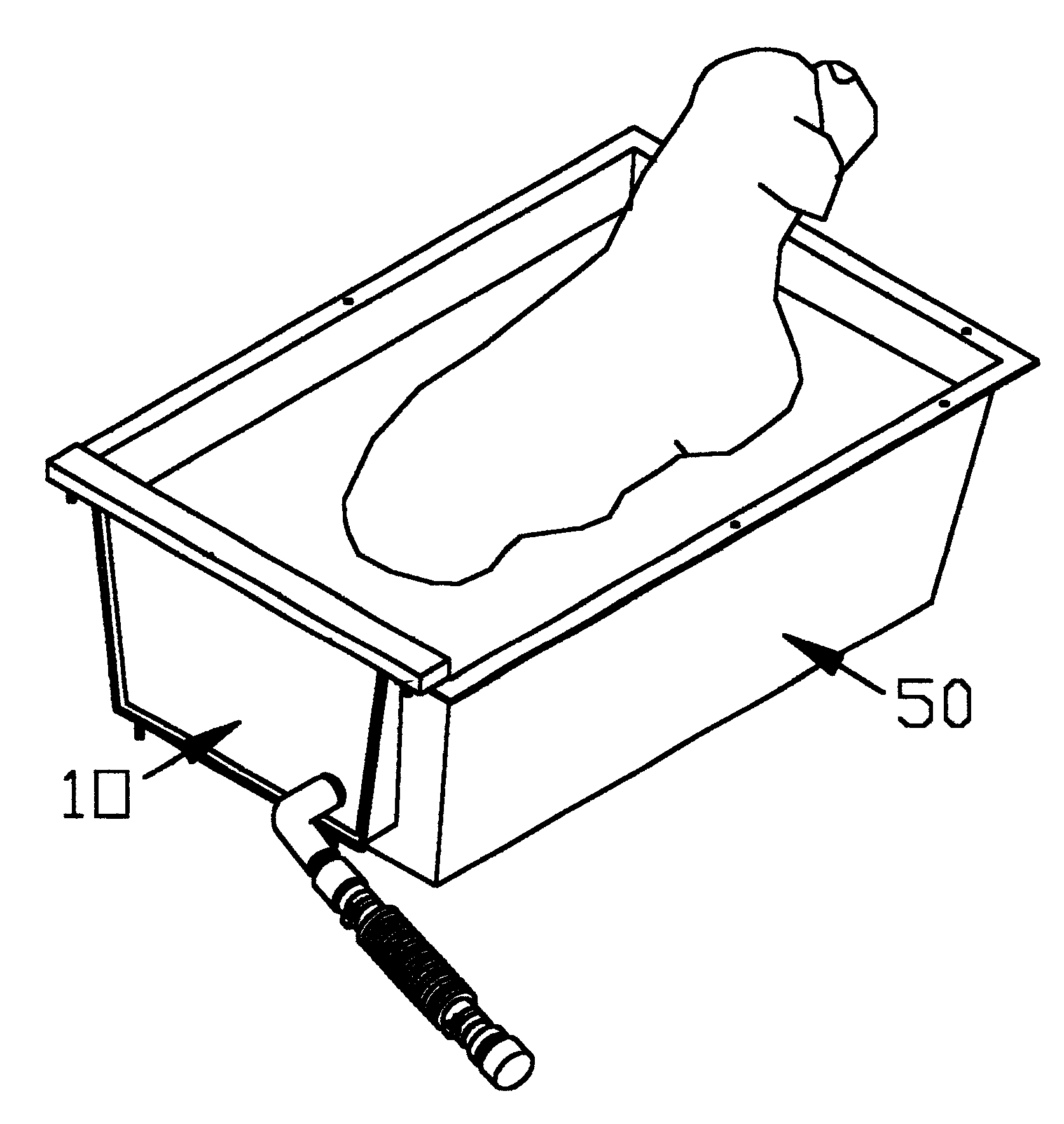

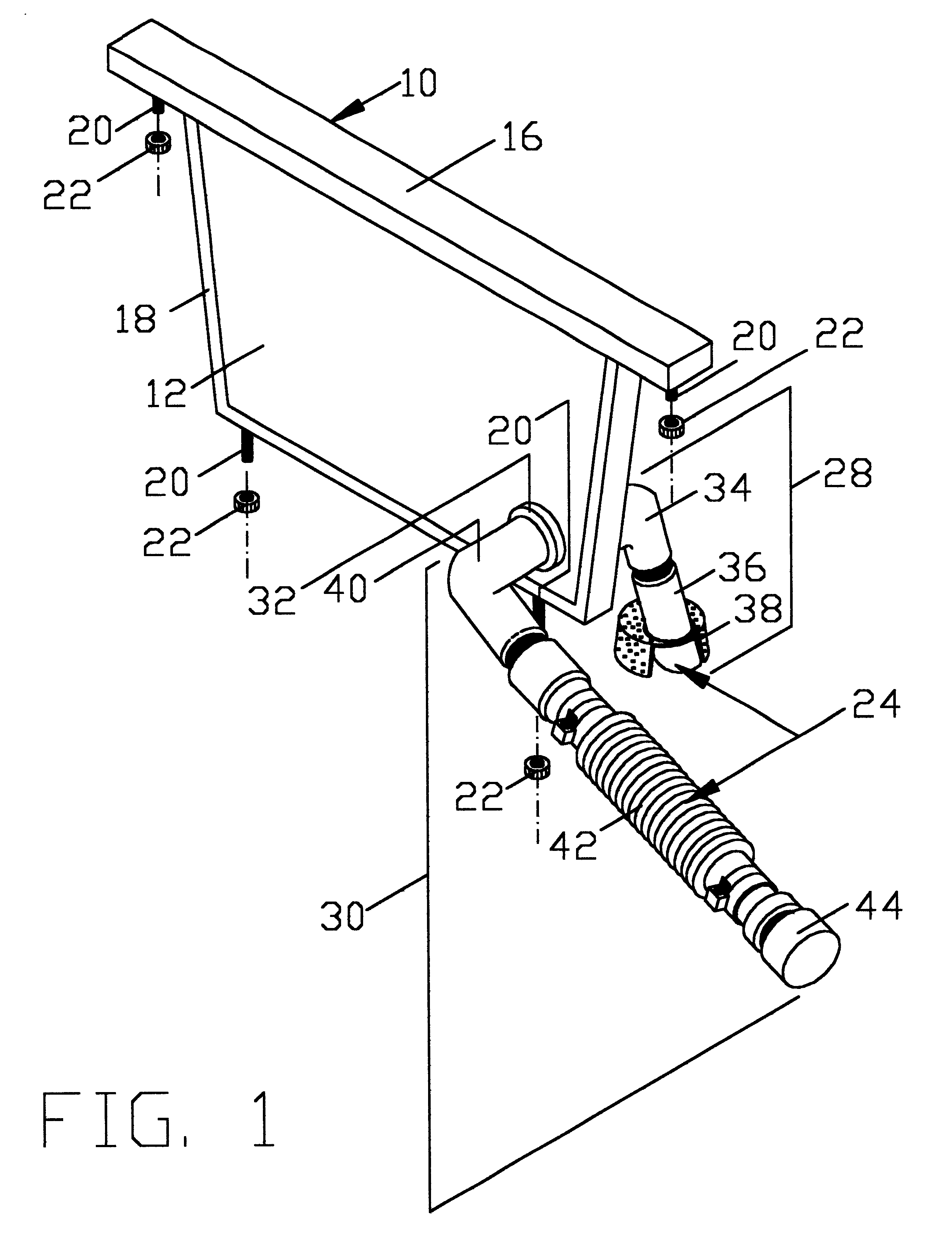

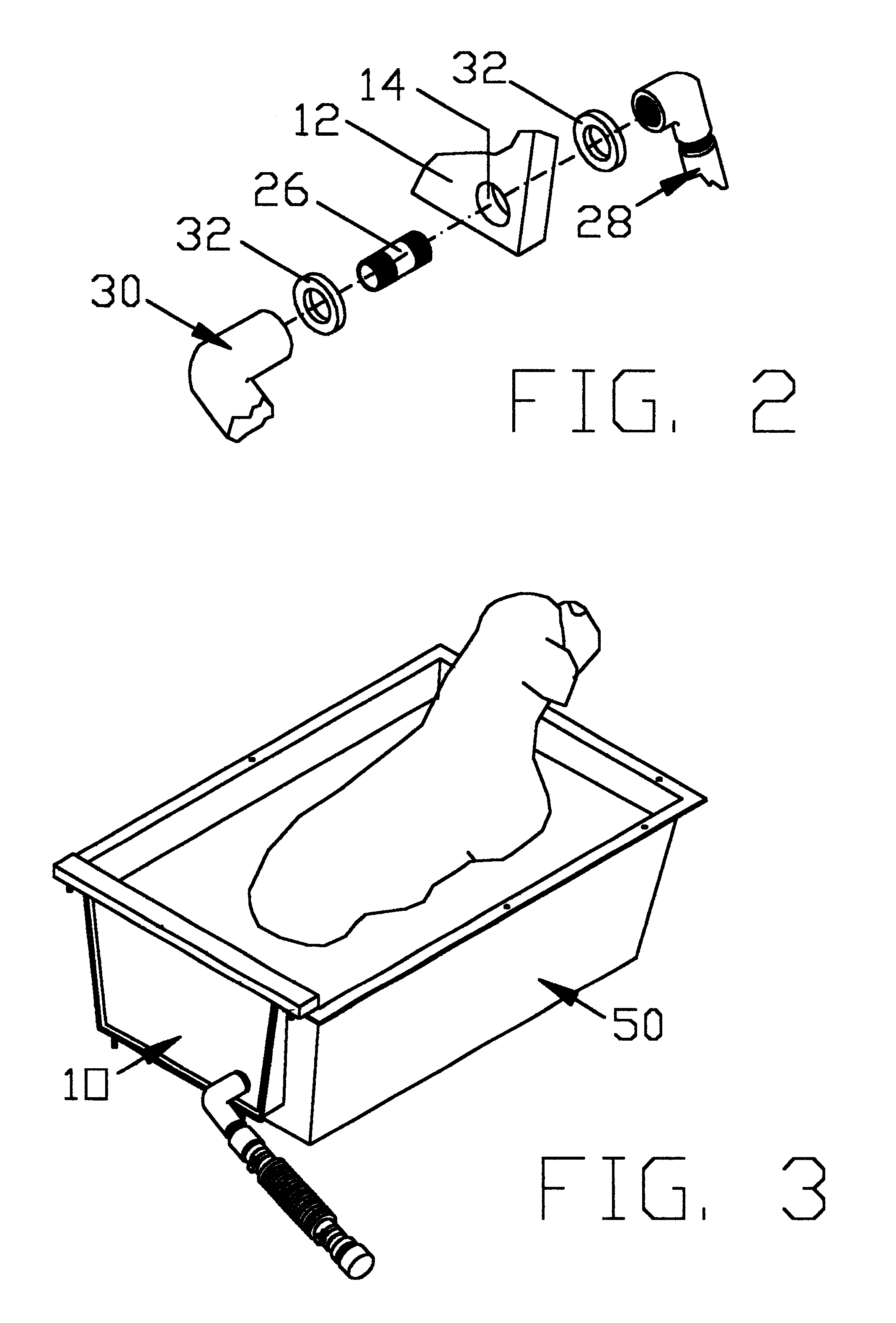

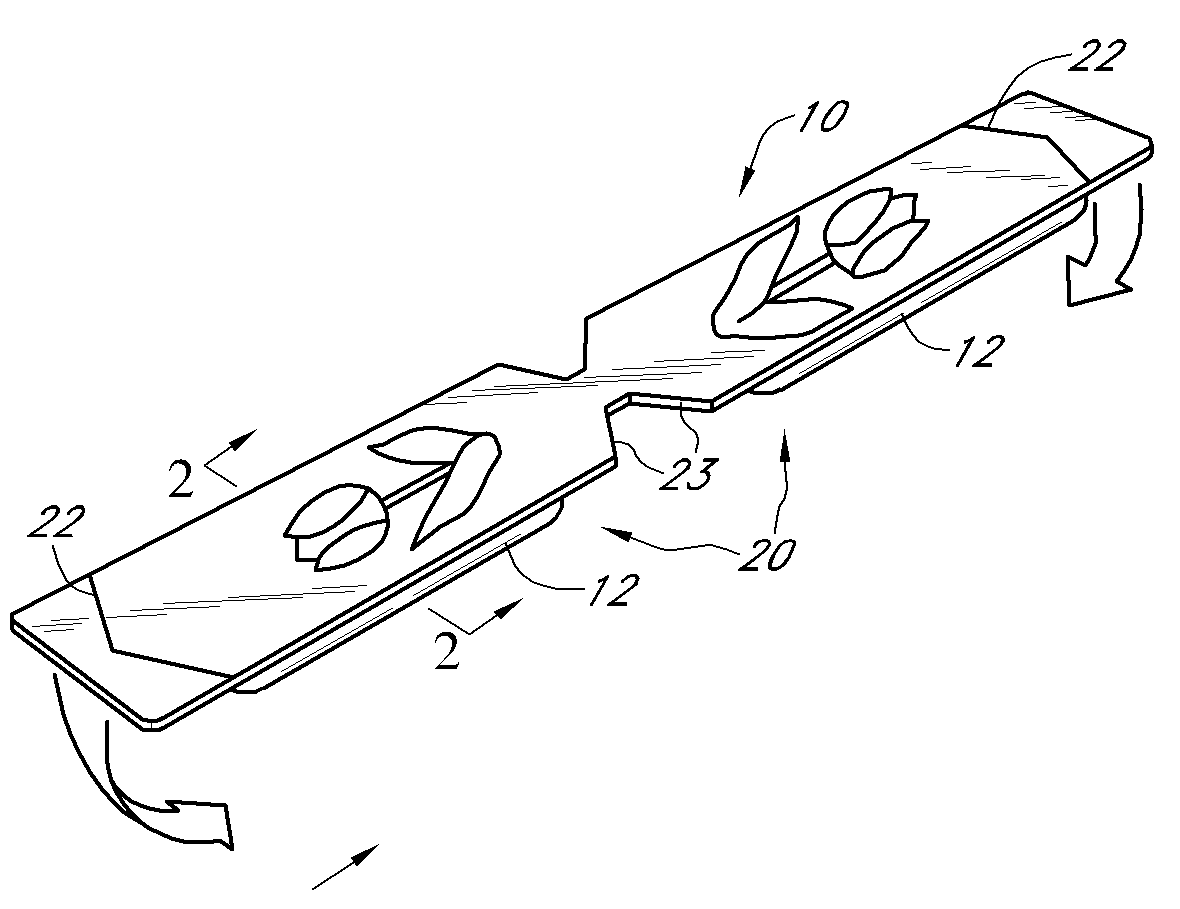

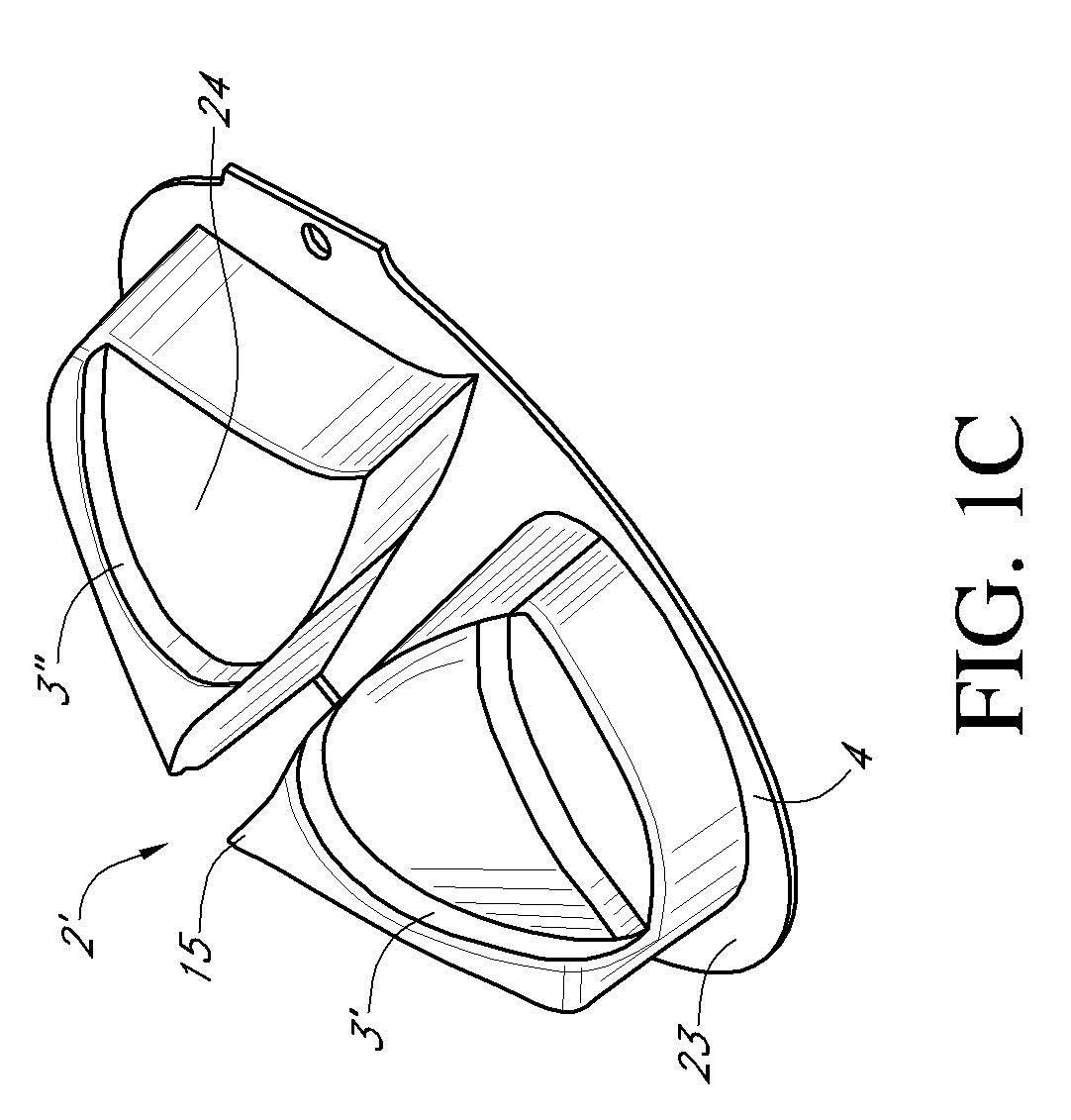

Crate DAM

A removable device that is used with the bottom part, or crate bottom (50), of modular dog crates having a plurality of solid walls and an additional wall with an entryway cutout (52) to create a temporary pet bathtub enclosed on all sides. The device comprises, in part, a rigid, waterproof panel (12) with an elongated transom (16) affixed to its top edge. A gasket (18) is affixed to the edges of the panel (12) which abut the entryway cutout (52) to ensure a watertight seal between the panel (12) and the perimeter lip of the entryway cutout (52). Alignment hardware (20) and fastening devices (22) are affixed to the panel (12) and transom (16) to aid in the positioning and securing in place of the device in the entryway cutout (52). One or more drain assemblies (24) pass through the face of the panel (12) to provide a means of draining the crate bottom (50) after it has been filled with water.

Owner:WINCHESTER ANNE M

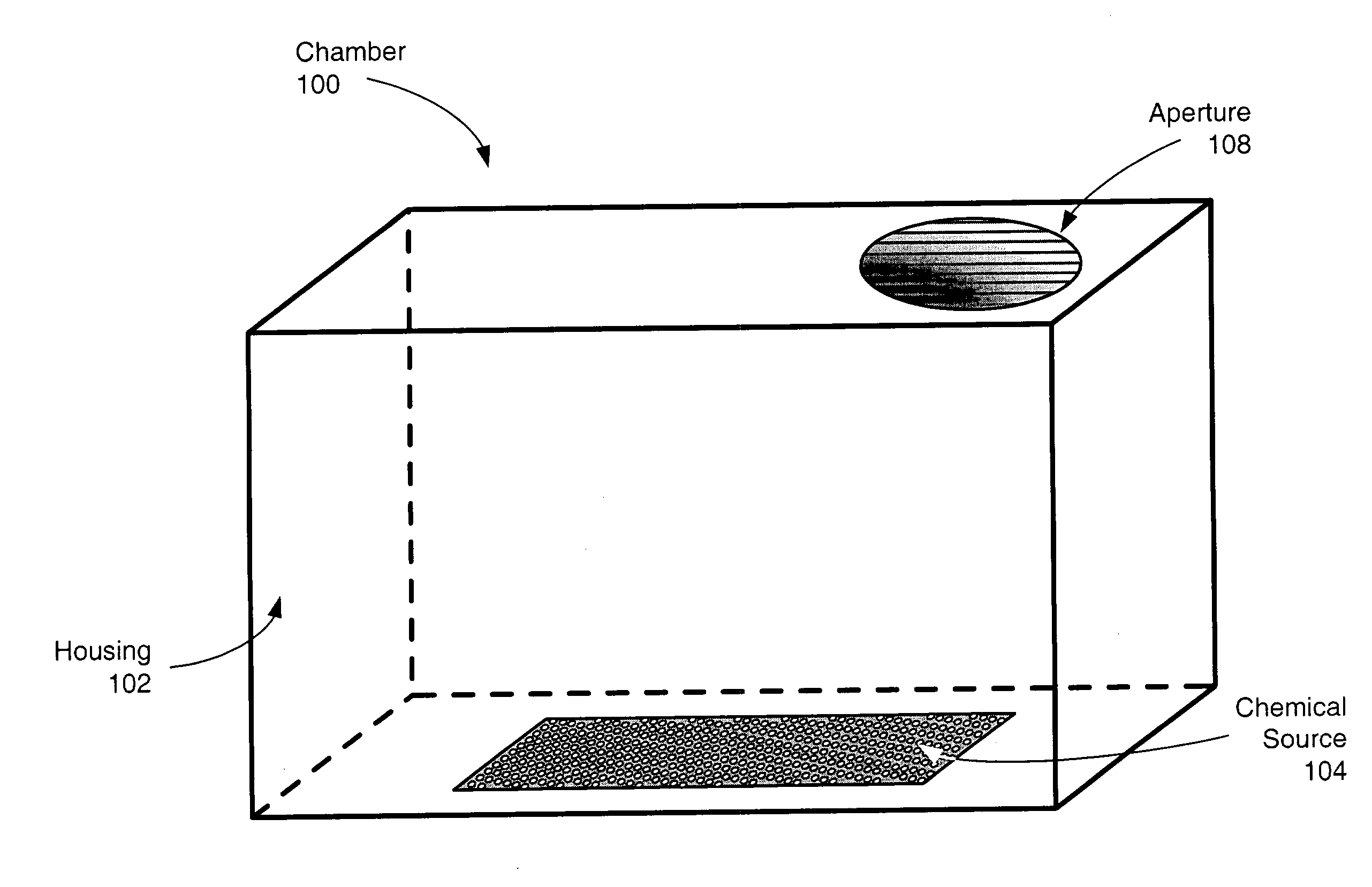

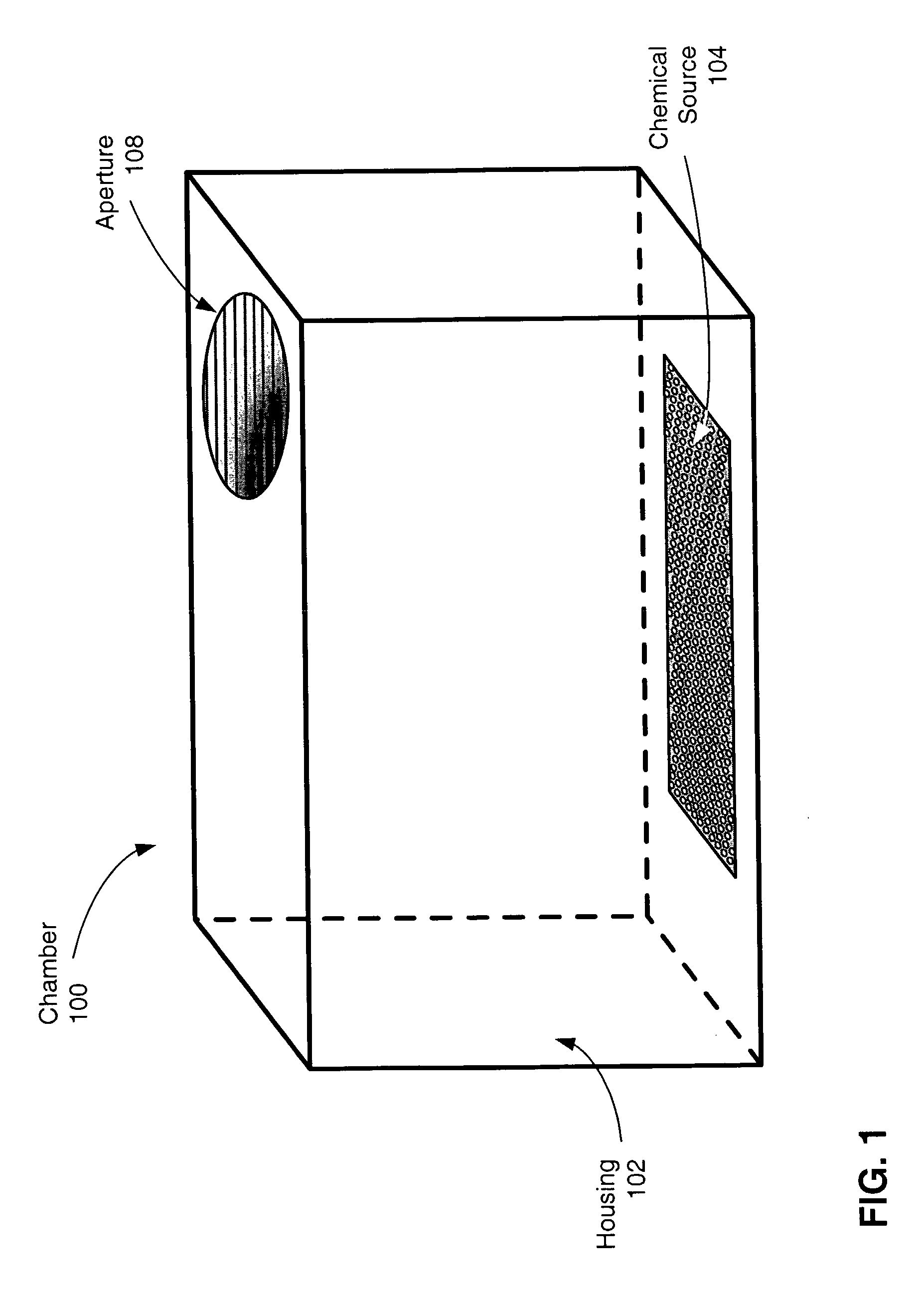

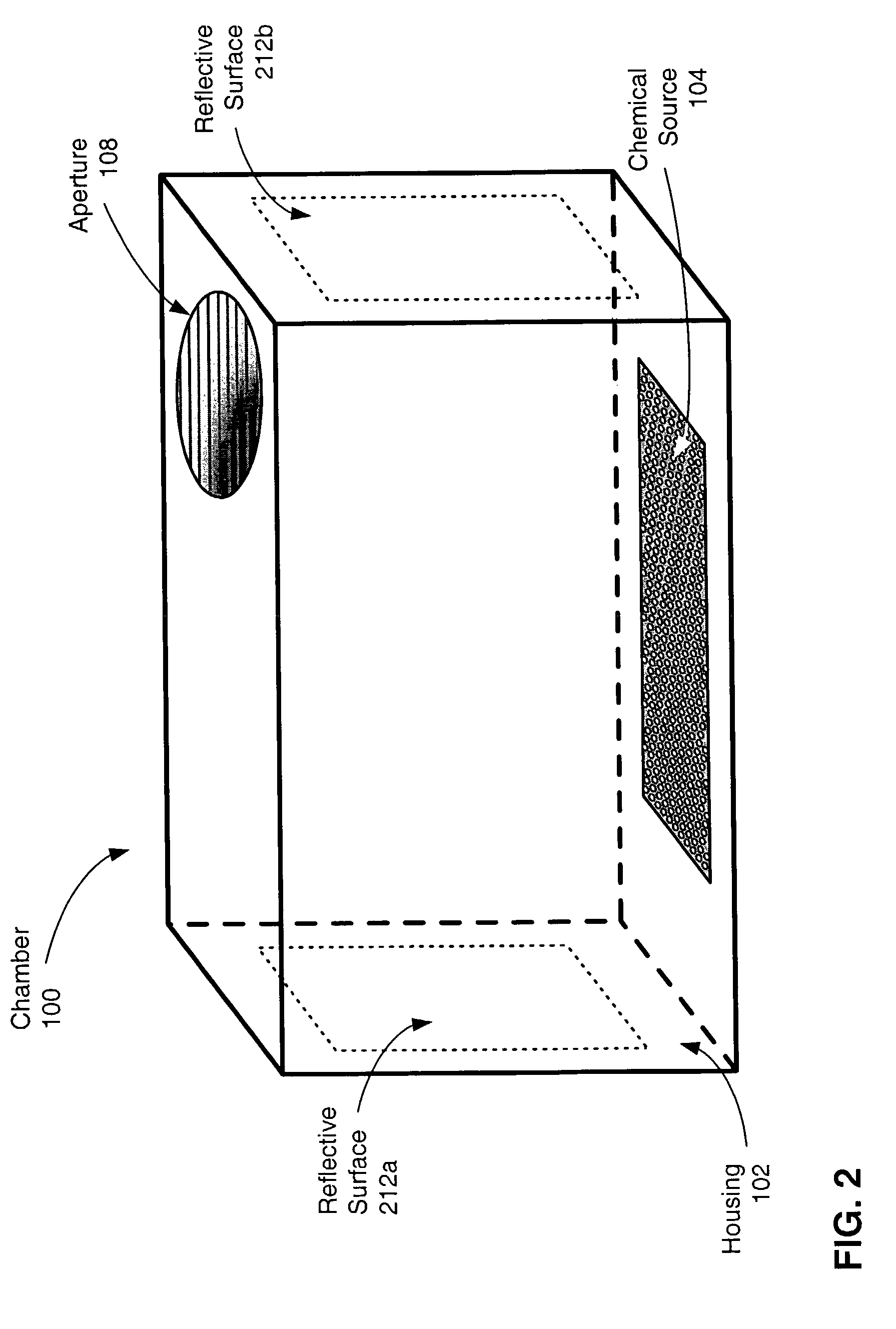

System for trapping insects

An insect trap is described. The insect trap includes a container that has solid walls defining a substantially rectangular or spherical closed space. The container has a hole. The container has at least two parallel walls in the rectangular embodiment. The two parallel walls or the spherical walls are at least partially covered with a reflective surface on the inside of the container. A semiochemical or an odorant is situated in said container. A permeable flap covers the hole.

Owner:TECH SG

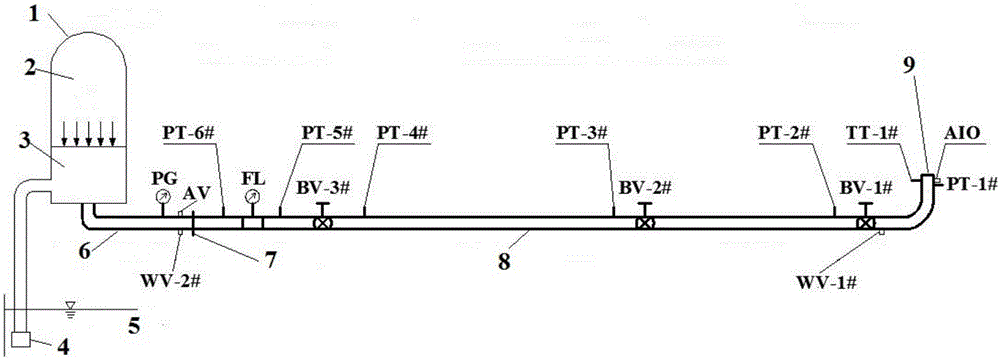

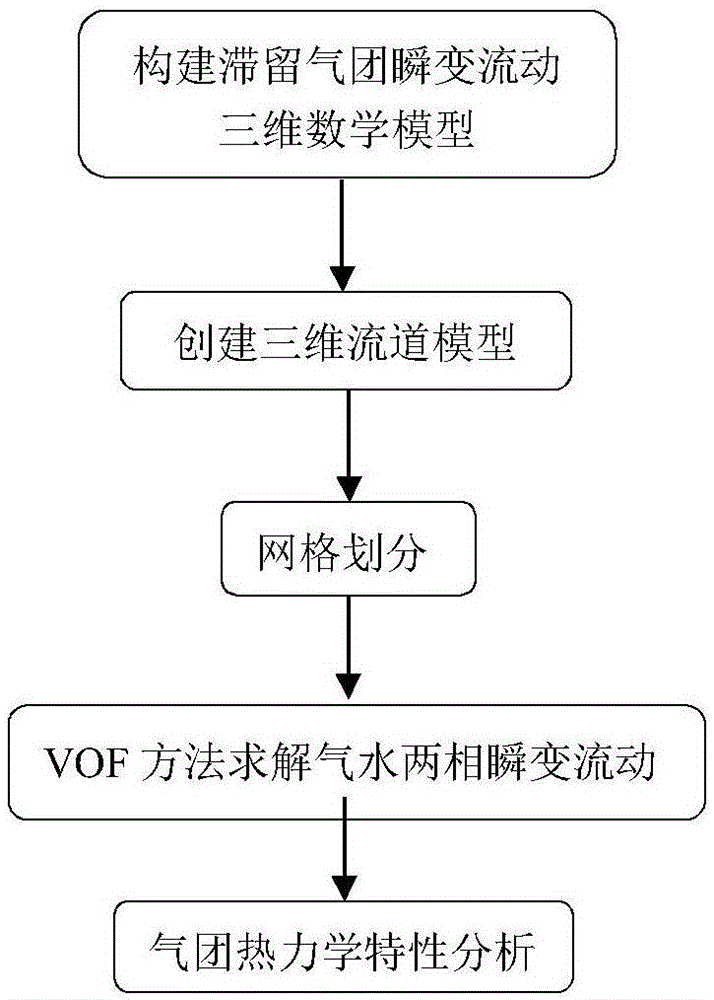

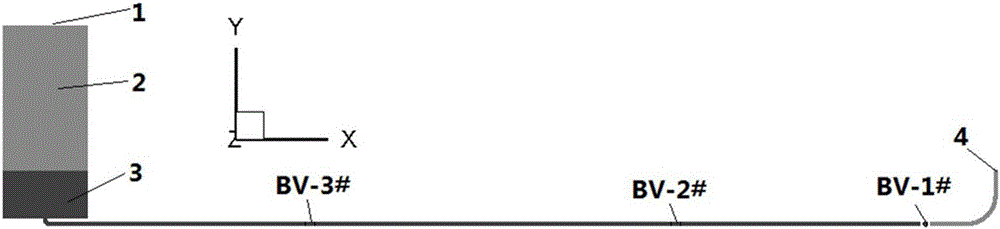

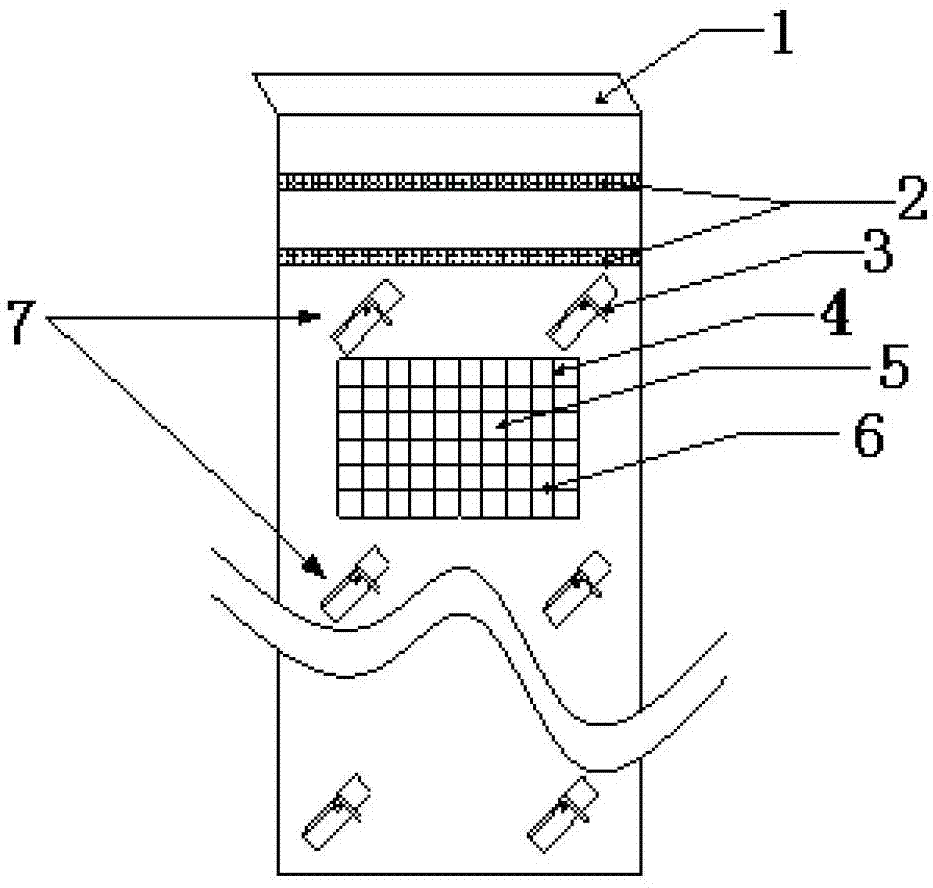

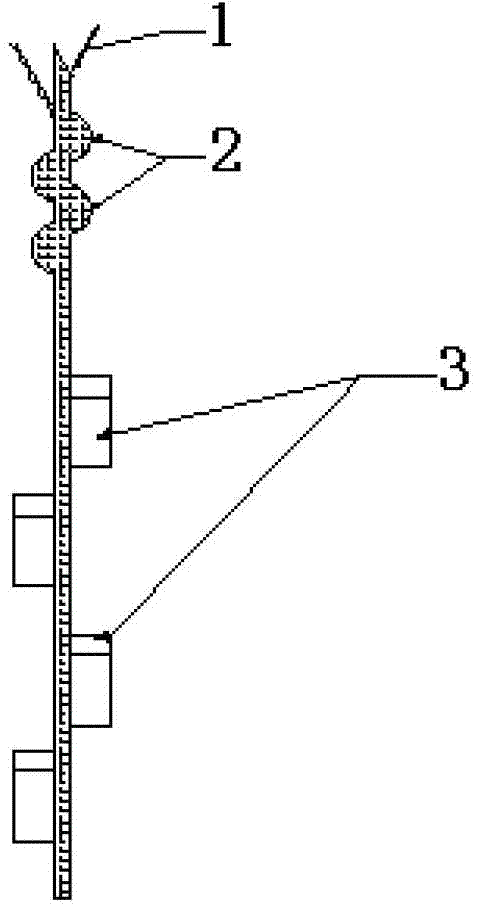

Trapped air mass thermodynamic characteristic simulation method based on three-dimensional CFD

ActiveCN106844913ADynamic Observation Compression-ExpansionDynamic observation splitGeometric CADSpecial data processing applicationsSolid wallCompressibility

The invention discloses a method for simulating trapped air mass thermodynamic characteristic in the pipeline rapid water filling process on the basis of computational fluid dynamics (CFD). Firstly, three-dimensional modeling and mesh generation are conducted, and a volume of fluid (VOF) method is adopted for conducting gas and water two-phase transient flow calculation; finally, post-processing software is used for processing a calculated result. According to the method, on the basis that the compressibility of water and the compressibility of gas are considered at the same time, the heat conduction among water, gas and a solid wall surface and the convective heat transferring effect are considered, energy dissipation in the rapid water filling process can be more accurately simulated, and then the gas-water coupling effect and the air mass thermodynamic characteristic in the process are more deeply studied.

Owner:HOHAI UNIV

Wall liquid film and wall-free liquid film alternate structured filler adapting to viscous absorbent

InactiveCN103191692AAvoid Wall Flow EffectsImprove anti-clogging performanceChemical/physical/physico-chemical processesViscous liquidLiquid viscosity

The invention relates to a wall liquid film and wall-free liquid film alternate structured filler adapting to a viscous absorbent. The wall liquid film and wall-free liquid film alternate structured filler is a perpendicular plate structured filler comprising alternate wall-attached films and free films. The wall liquid film and wall-free liquid film alternate structured filler mainly comprises a liquid collection-primary distribution member, a liquid uniform-distribution member, structured solid wall surfaces and holes having a plurality of shapes, and is characterized in that when sprayed liquid flows downward and flows through the wall liquid film and wall-free liquid film alternate structured filler, the liquid enters into the liquid collection-primary distribution member and is subjected to primary distribution and then enters into the liquid uniform-distribution member and is subjected to film-type uniform distribution; and the falling liquid film enters into channels formed from the alternate structured solid wall surfaces and the holes and contacts with gas concurrent flows or gas countercurrent flows. The channels for liquid flowing are regular so that a viscous liquid can smoothly pass through the channels and does not produce foam, emulsification and blocking and thus adaptability to processing liquid viscosity is greatly improved. Through special flow behaviors of the free film and interaction of the free film with the wall-attached film, high-viscosity absorbent mass transfer performances are improved obviously.

Owner:EAST CHINA UNIV OF SCI & TECH

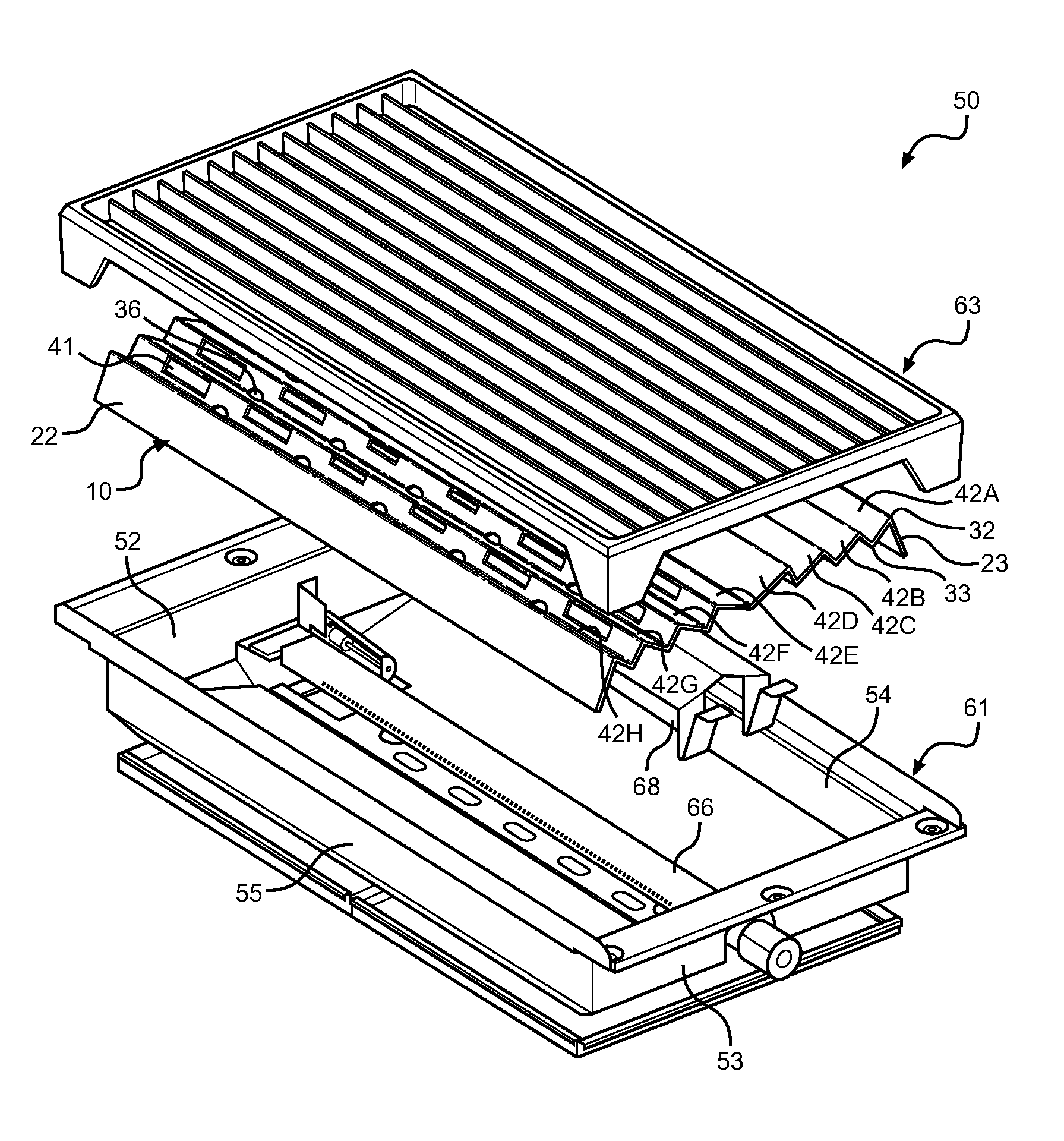

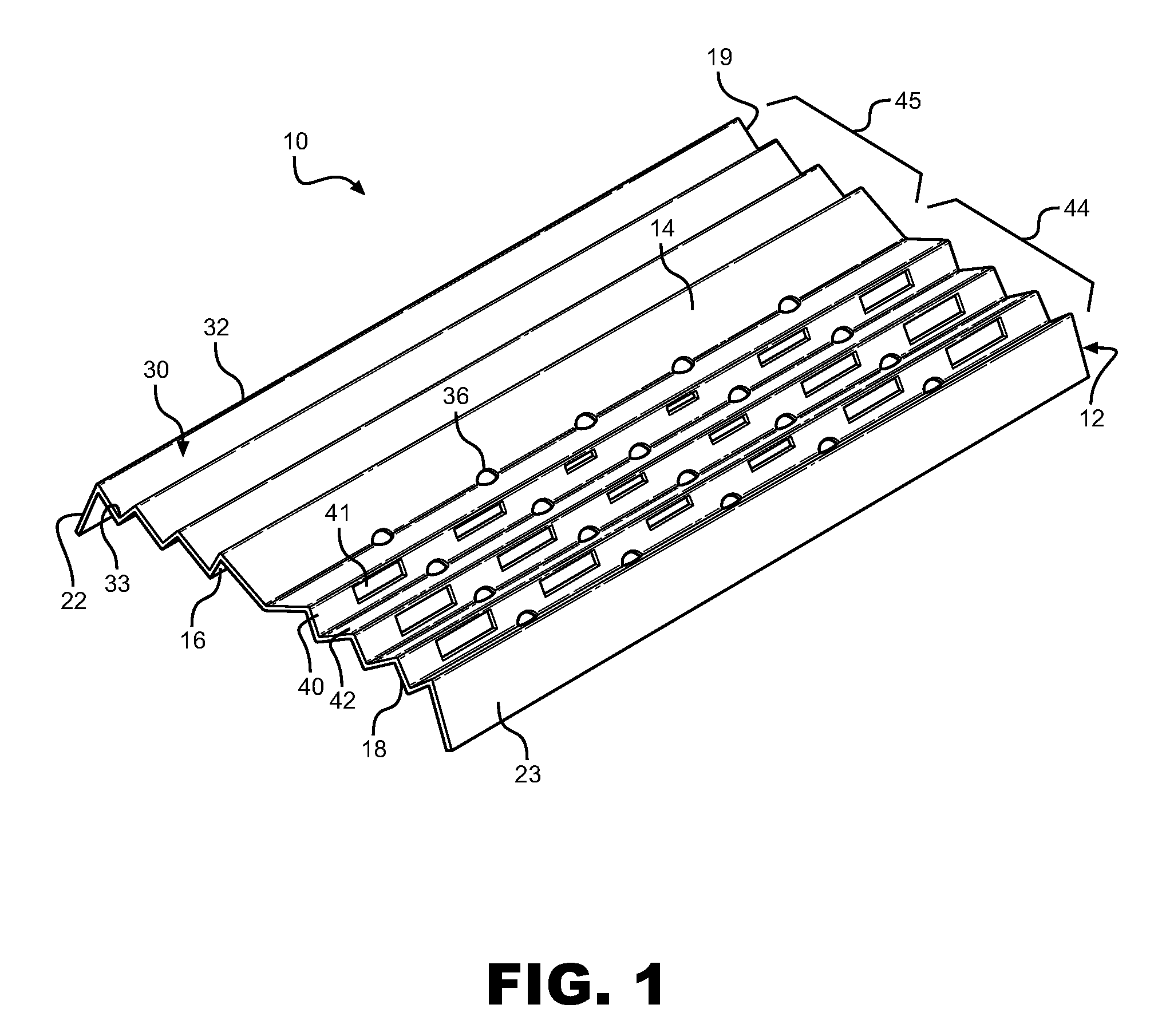

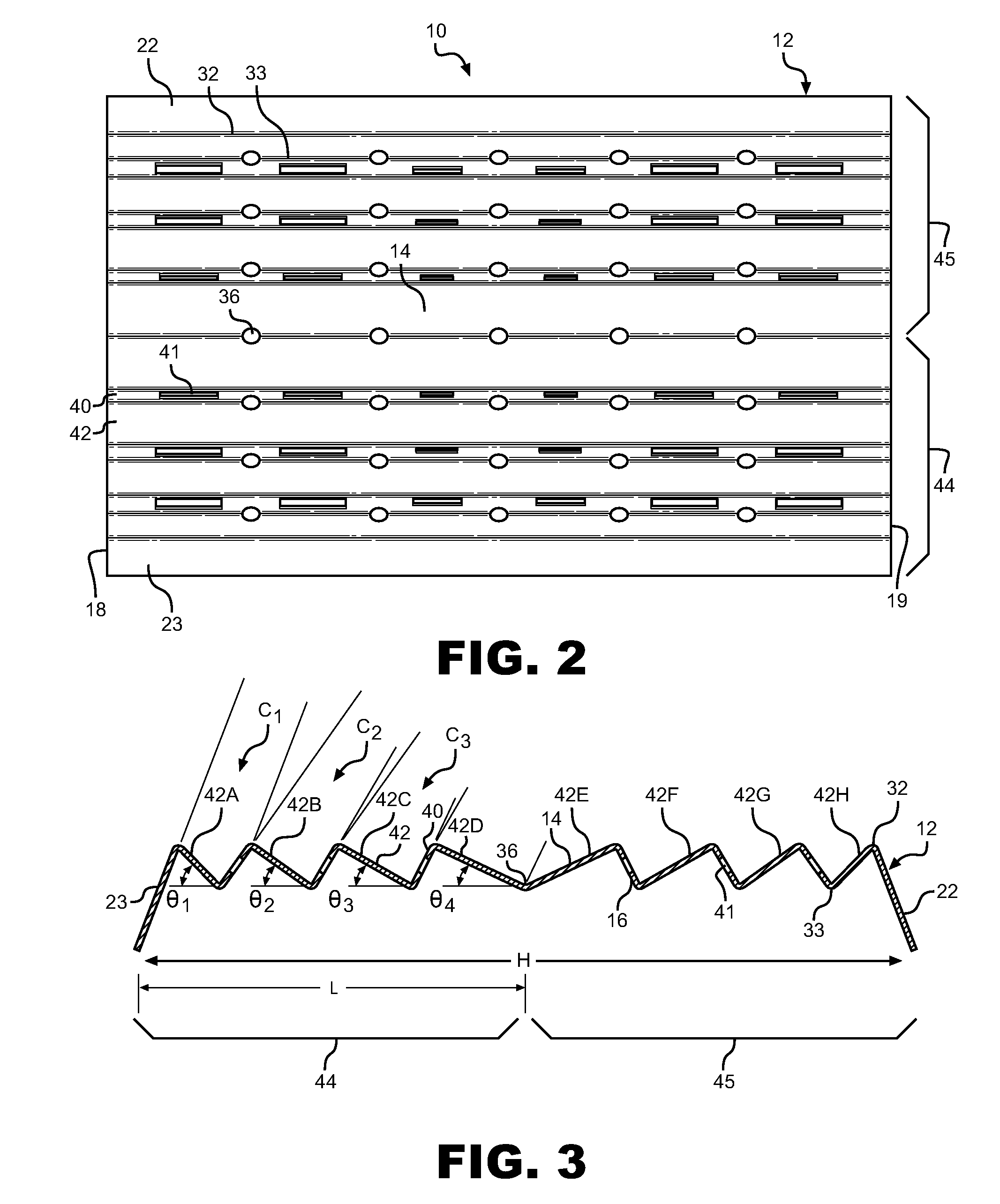

Heat distributing wave tray for a grill

A heat distributing tray for use in a barbecue grill includes a corrugated unitary body of heat conducting material having alternating solid and grated walls which define channels. More specifically, the body includes first and second side portions defined by both solid walls which extend at gradually decreasing angles with respect to a common horizontal plane and varying length grated walls interconnecting the solid walls. In use, the tray is placed over one or more heating elements in a barbecue housing, with radiant and convective heat from the heating element being optimally distributed throughout the entire interior portion of the barbecue grill due to the relative structure and configuration of the solid walls in relation to the grated walls.

Owner:WHIRLPOOL CORP

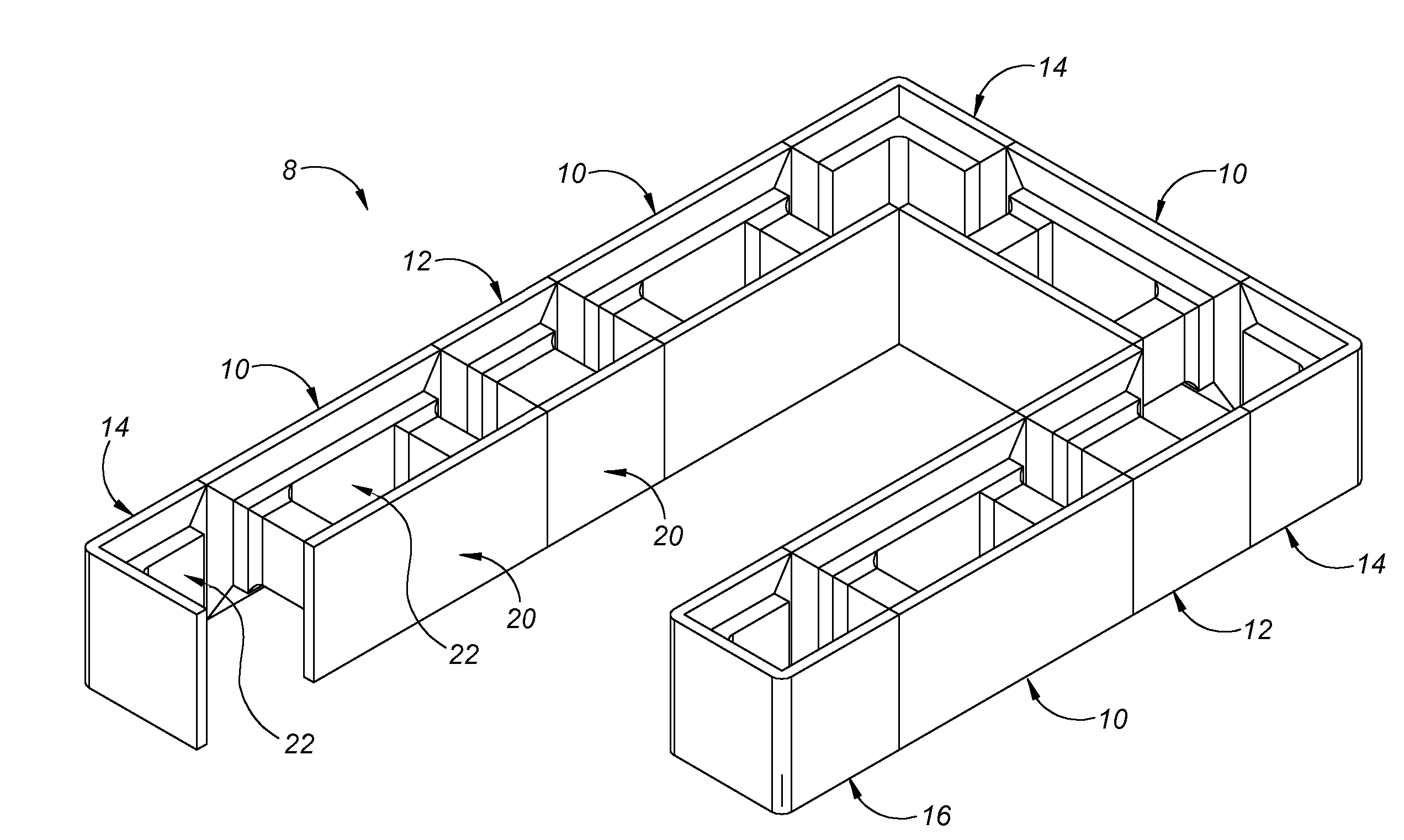

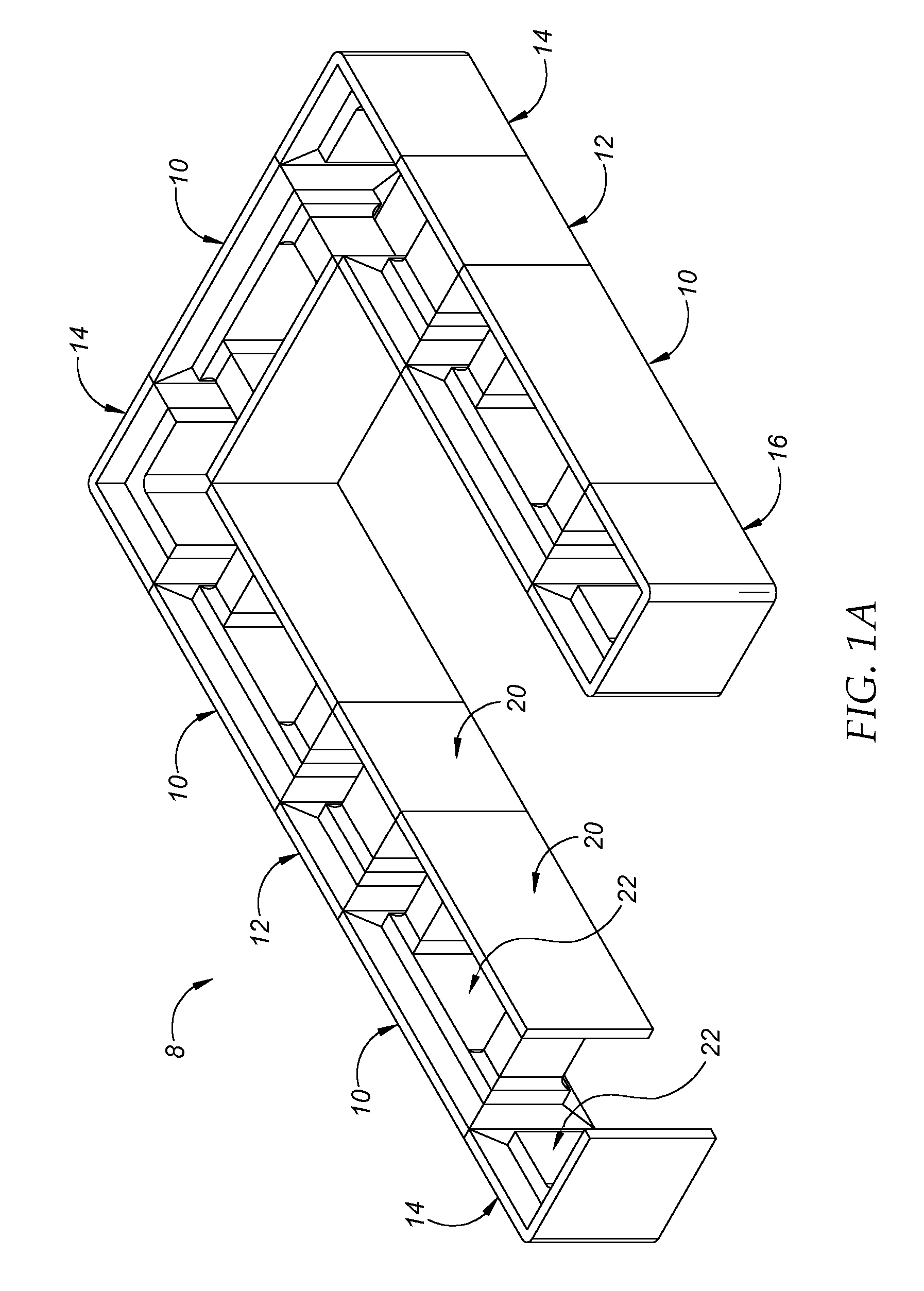

Aquaculture production system

A floating fish production system for placement within a body of water and being structured and disposed for containing fish and other aquatic animal, plant and algal species, the system including at least one primary containment tank having an arrangement of individual solid wall sections and an arrangement of individual solid floor sections. Flexible membranes span between and connect to adjacently positioned solid wall and floor sections to define flexible connecting joints that allow the individual solid wall and floor sections to move relative to one another in an articulating action. The flexible membranes allow the tank configuration to temporarily deform from a relaxed state in response to externally applied forces exerted on the tank (e.g., waves, wind, current) to thereby absorb the externally applied forces and reduce stress on the structural integrity on the tank. An air lift system including a high volume, low pressure blower and a spaced arrangement of vertically extending air lift pipes delivers water and oxygen from the exterior body of water and into the tank interior. A flexible main drain in a central area at the bottom of the tank connects to a waste recovery system for removing waste produced by the fish and other aquatic species.

Owner:PAPADOYIANIS ERNEST D +1

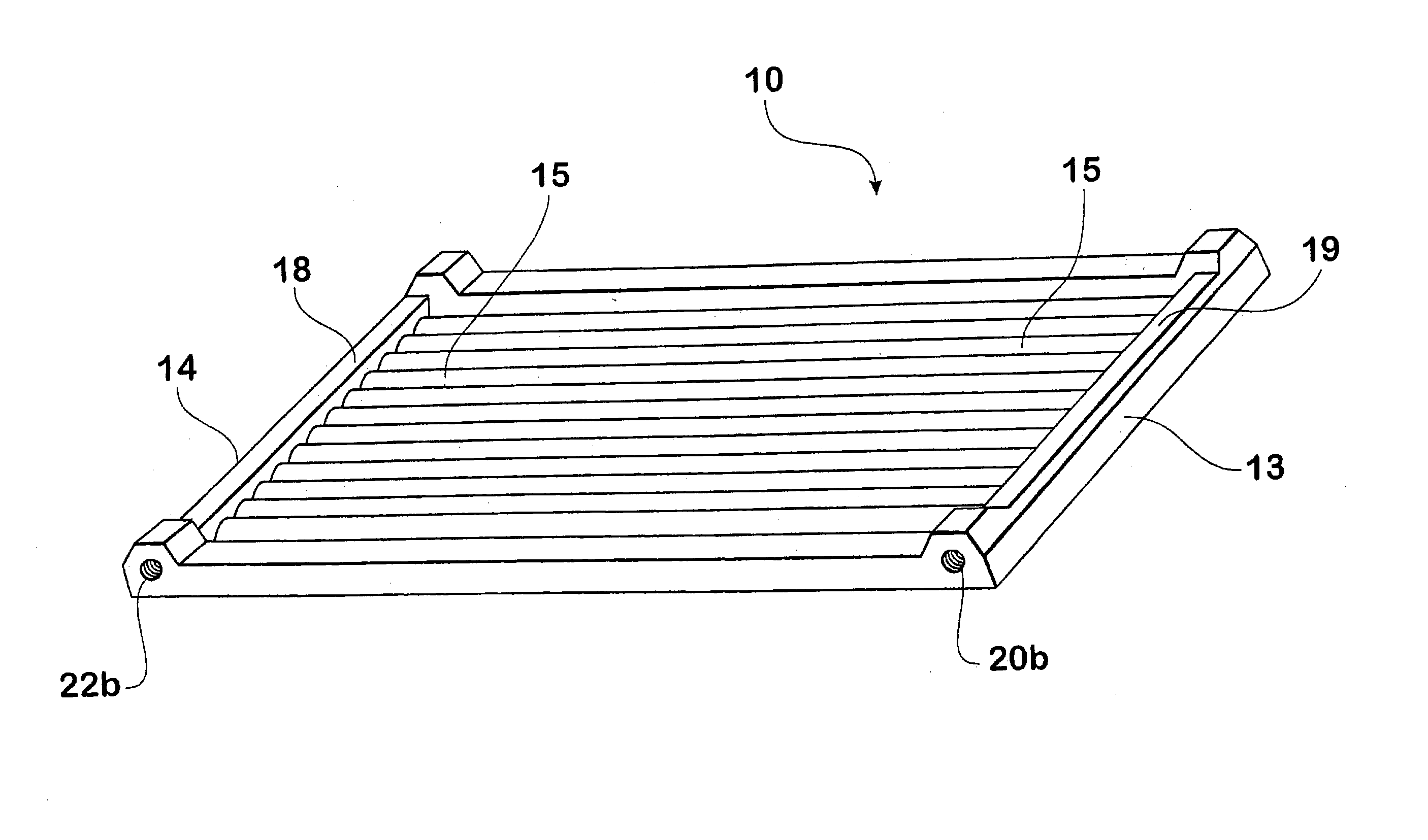

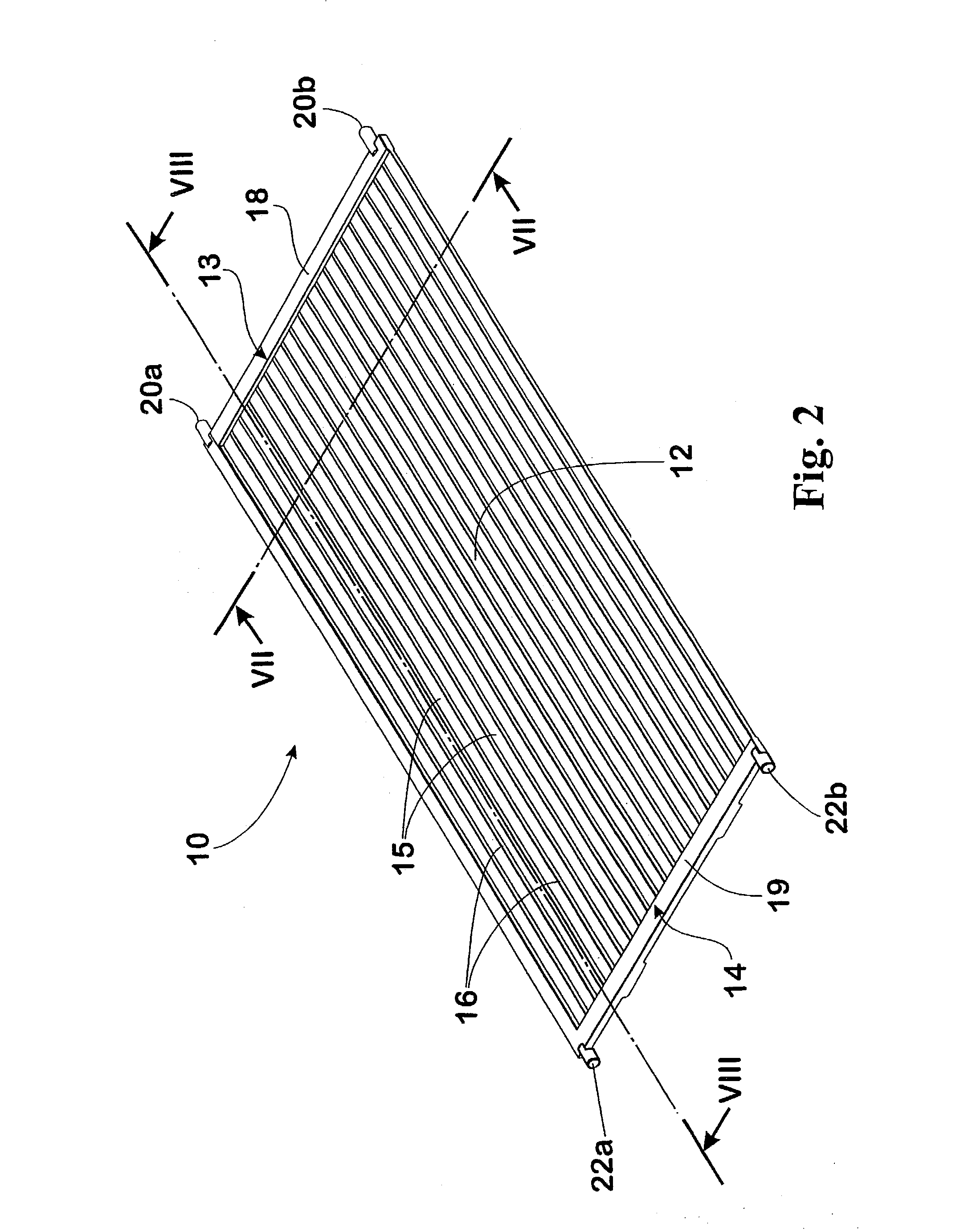

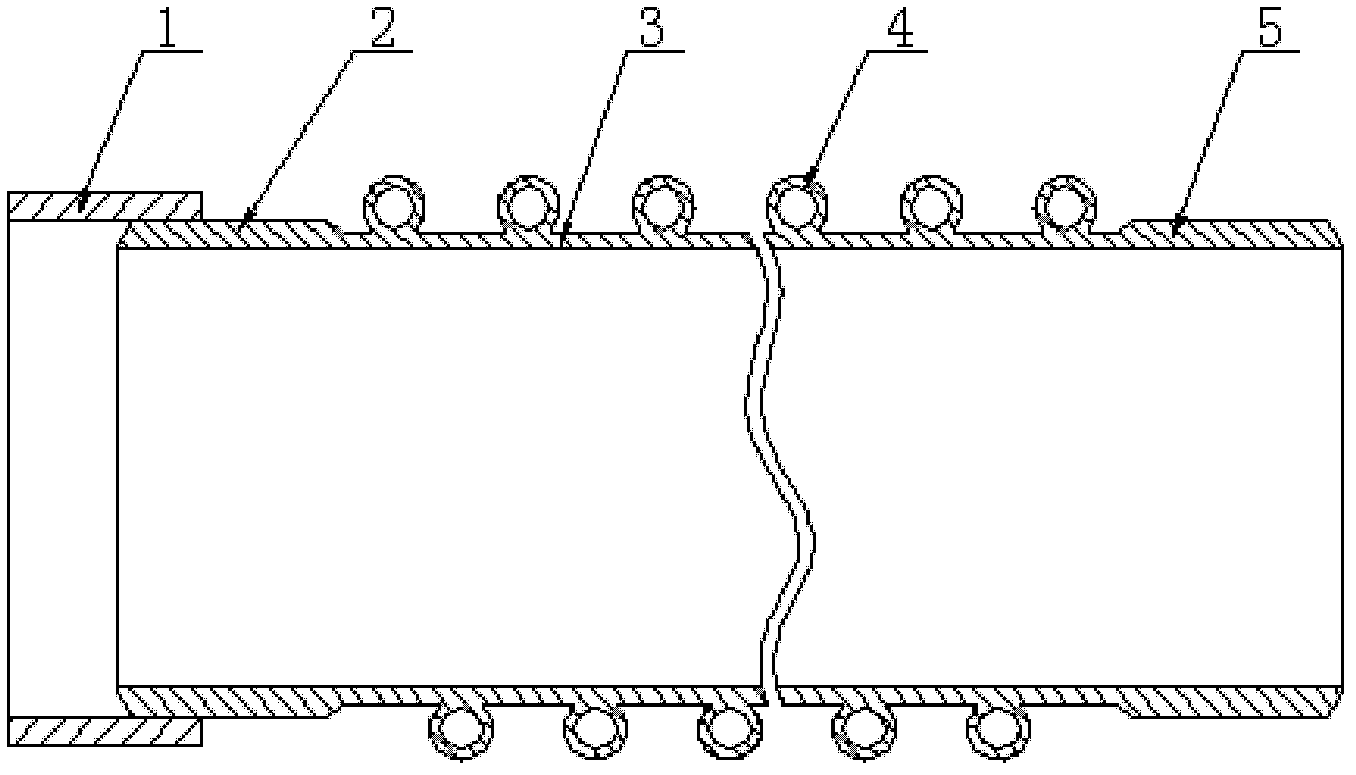

Method of manufacturing a solar collector panel

A method of manufacturing an integral one-piece solar collector panel by a rotational moulding process is disclosed. The solar collector panel has a plurality of fluid ways extending between opposed ends and transverse headers opening into the open ends of the fluid ways. The panel is moulded by a rotational moulding process using mould faces with a non planar topography, eg in the form of a plurality of lines projecting outwardly proud of the remainder of the mould plate. This enables areas of the moulded body to be formed that are not hollow and form a solid wall in the moulded panel and other areas of the body to be formed that are hollow and form the fluid ways and headers. After the moulding of the panel has taken place the two opposed mould faces are moved towards each other to cause the contacting layers of mould material to firmly adhere to each other. This post moulding treatment step is not used in standard rotational moulding processes. The manufacturing process of the invention enables collector panels to be produced at substantially less cost than known prior art methods of making collector panels.

Owner:SOLARTHERM INT

Wall tube with reinforced polyethylene-wound structure as well as manufacturing device and manufacturing method thereof

ActiveCN102384318ARealize continuous online productionReduce consumptionRigid pipesSolid wallEngineering

The invention relates to a wall tube with a reinforced polyethylene-wound structure. The wall tube is composed of a tube body, and a socket and a faucet at the two ends of the tube body, wherein the tube body is composed of an inner wall layer and an outer wall layer; the inner wall layer is a continuous solid wall tube formed by spirally winding the sheet-shaped polyethylene strips, and the edges of adjacent strips are mutually overlapped and fused in succession; and the outer wall layer is a convex reinforced rib formed by spirally winding tubular polyethylene strips on the outer surface of the inner wall layer; and the tubular polyethylene strips are spirally pressed at places on which the edges of the adjacent sheet-shaped polyethylene strips are overlapped and fused in a bridged mode. The innovation of the invention lies in that both ends of the inner wall layer of the tube body are provided with a faucet, and a faucet at one end of the inner wall layer of the tube body is coaxially provided with a socket. The socket and the faucet can be produced in an online continuous mode, thus realizing easiness in processing and high production efficiency; and moreover the socket and the faucet are easy to install, has good sealing reliability after being connected. Meanwhile, the tube uses a structure without a skeleton, and has the advantages of small raw material consumption, short processing time, light product weight, low cost and the like. The invention also relates to a manufacturing device and a manufacturing method of the wall tube with the reinforced polyethylene-wound structure.

Owner:韩路平 +2

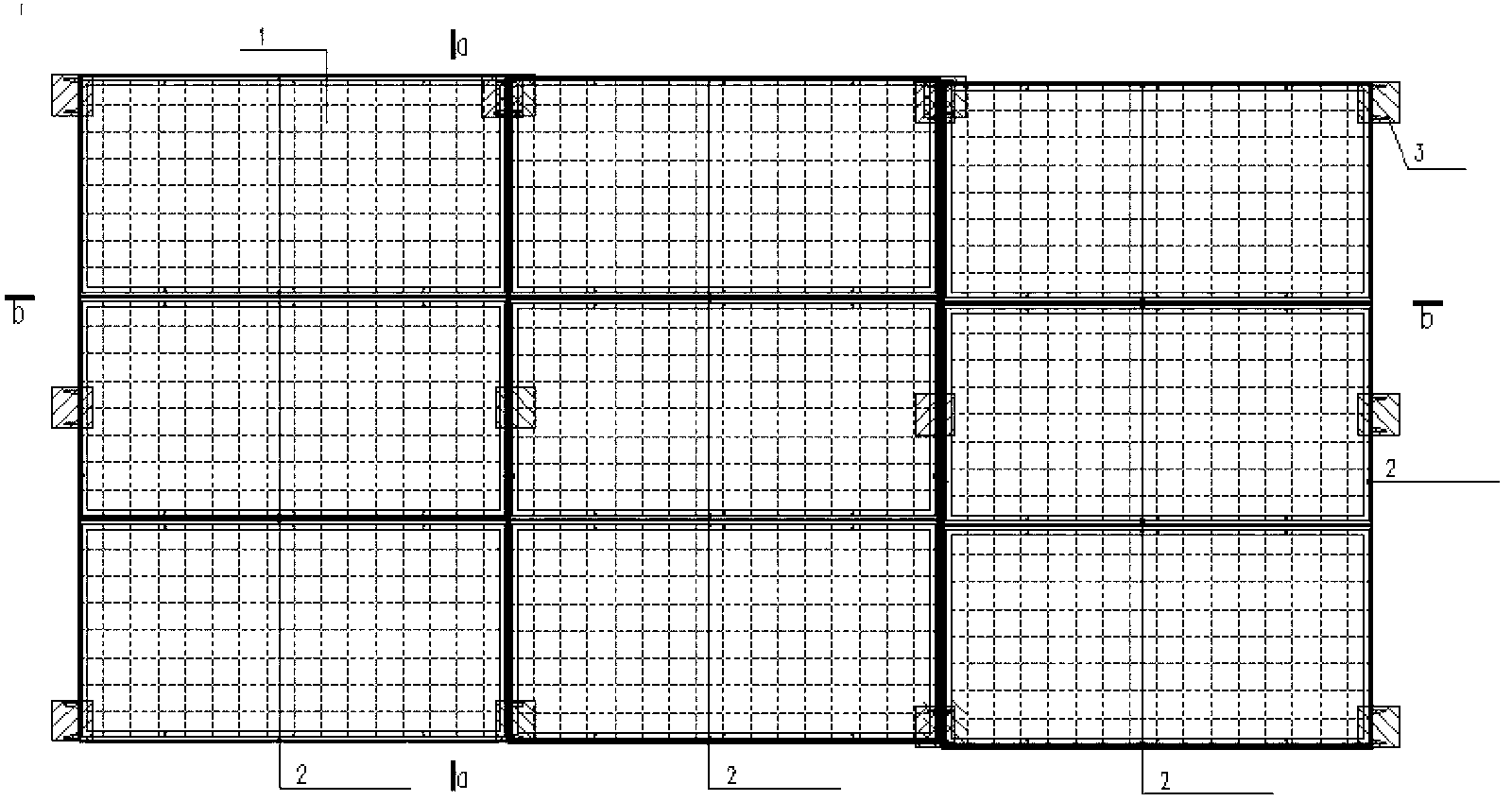

Combined curtain wall

The invention relates to a combined curtain wall which is characterized by comprising an aluminum single veneer curtain wall, a heat-insulated transparent frame glass curtain wall, a stone curtain wall, a steel plate structure and aluminum alloy doors and windows. The aluminum single veneer curtain wall is positioned at the aluminum plate part between a porch and the windows and a large area of shearing wall parts; the stone curtain wall is positioned on a solid wall on the lower part; and the rest part of the combined curtain wall is the heat-insulated transparent frame glass curtain wall. The combined curtain wall can effectively prevent the electric erosion and the earthquake while strengthening the viewing effect, reduce the precision requirement of the construction and better achieve the effects of heat preservation and insulation.

Owner:葛汉明

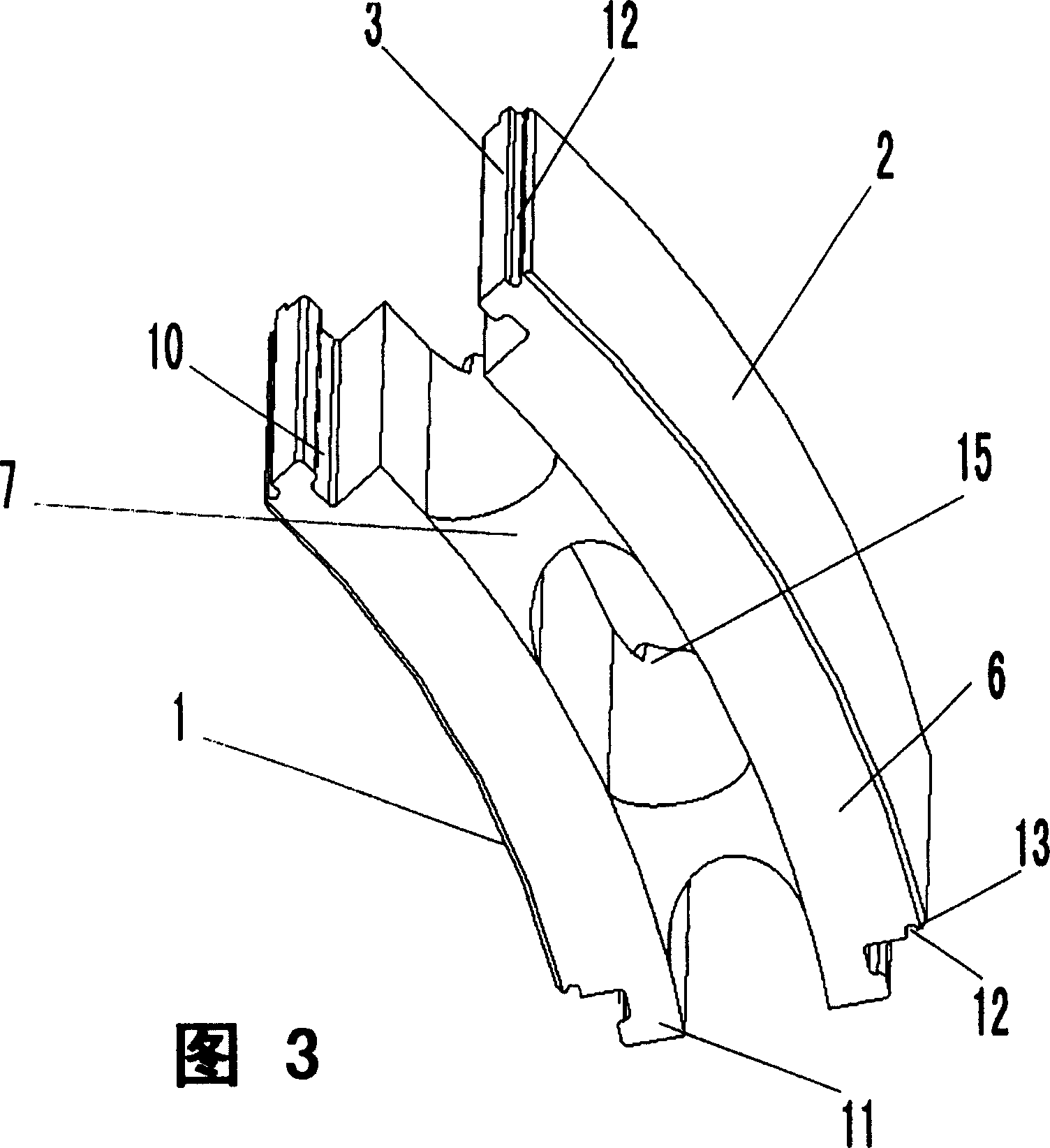

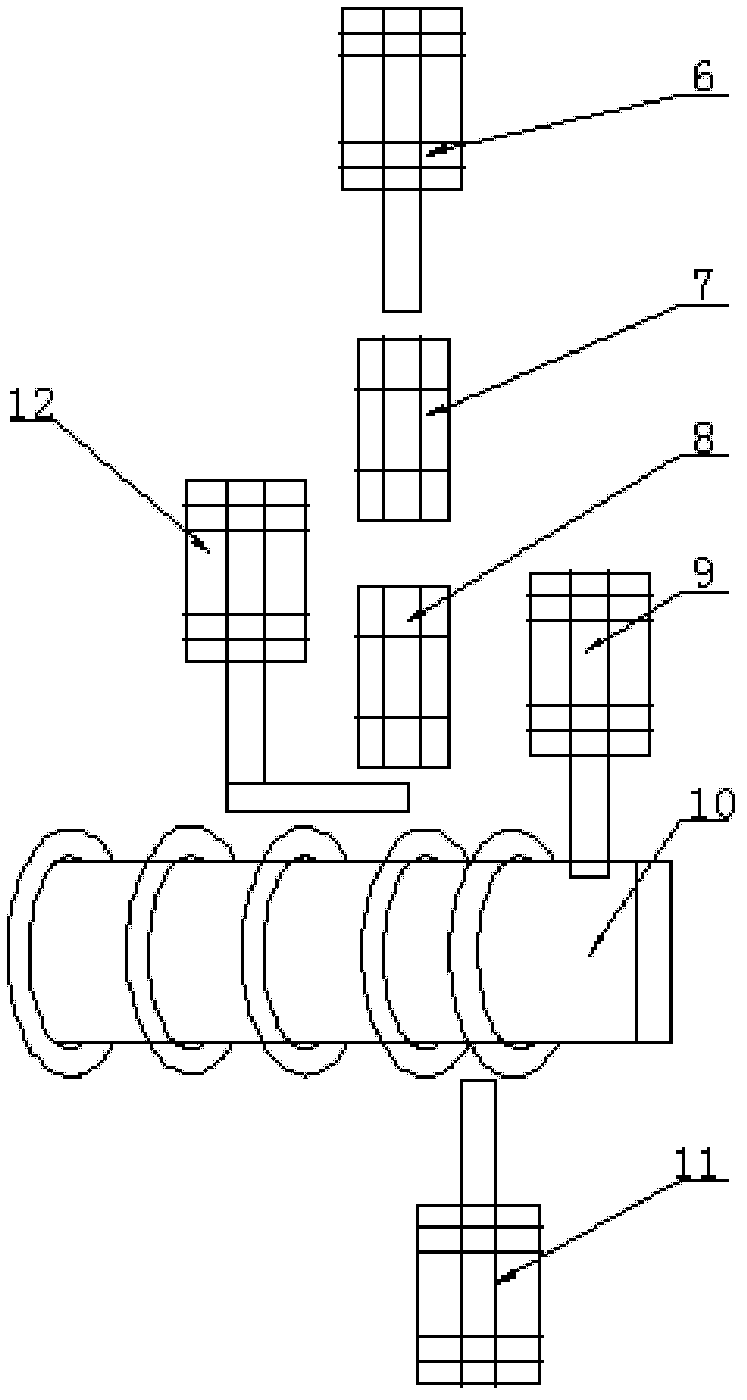

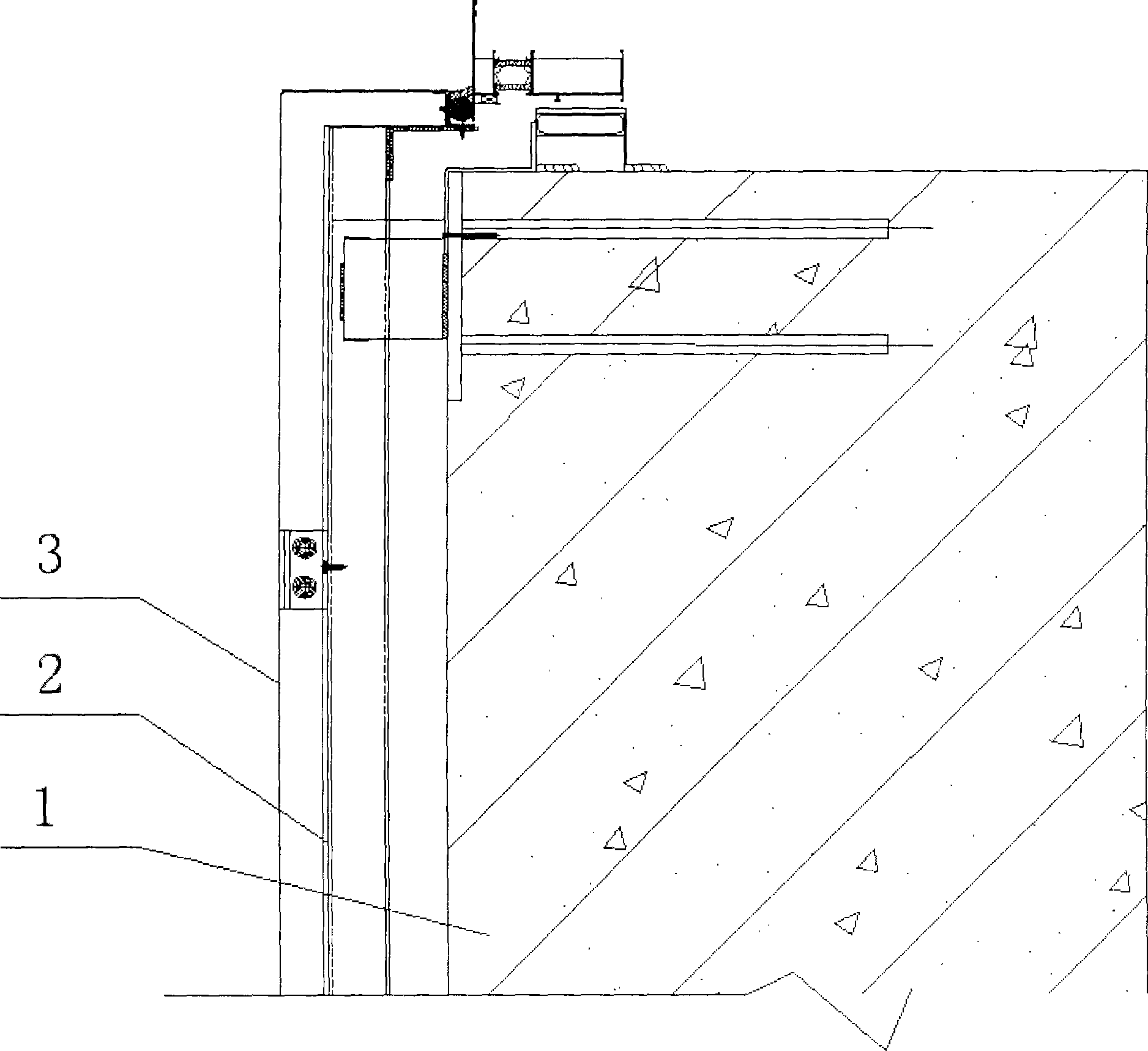

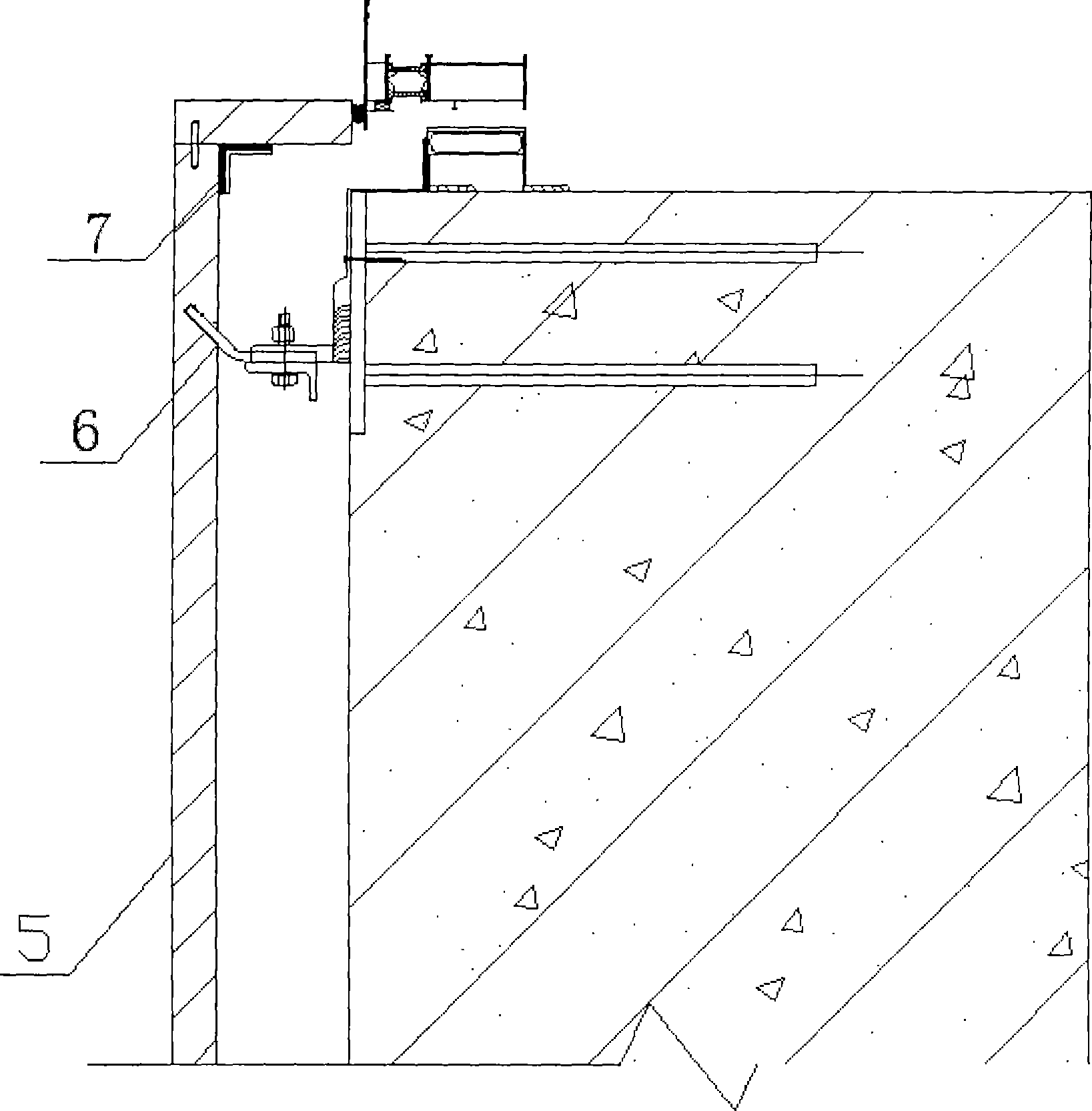

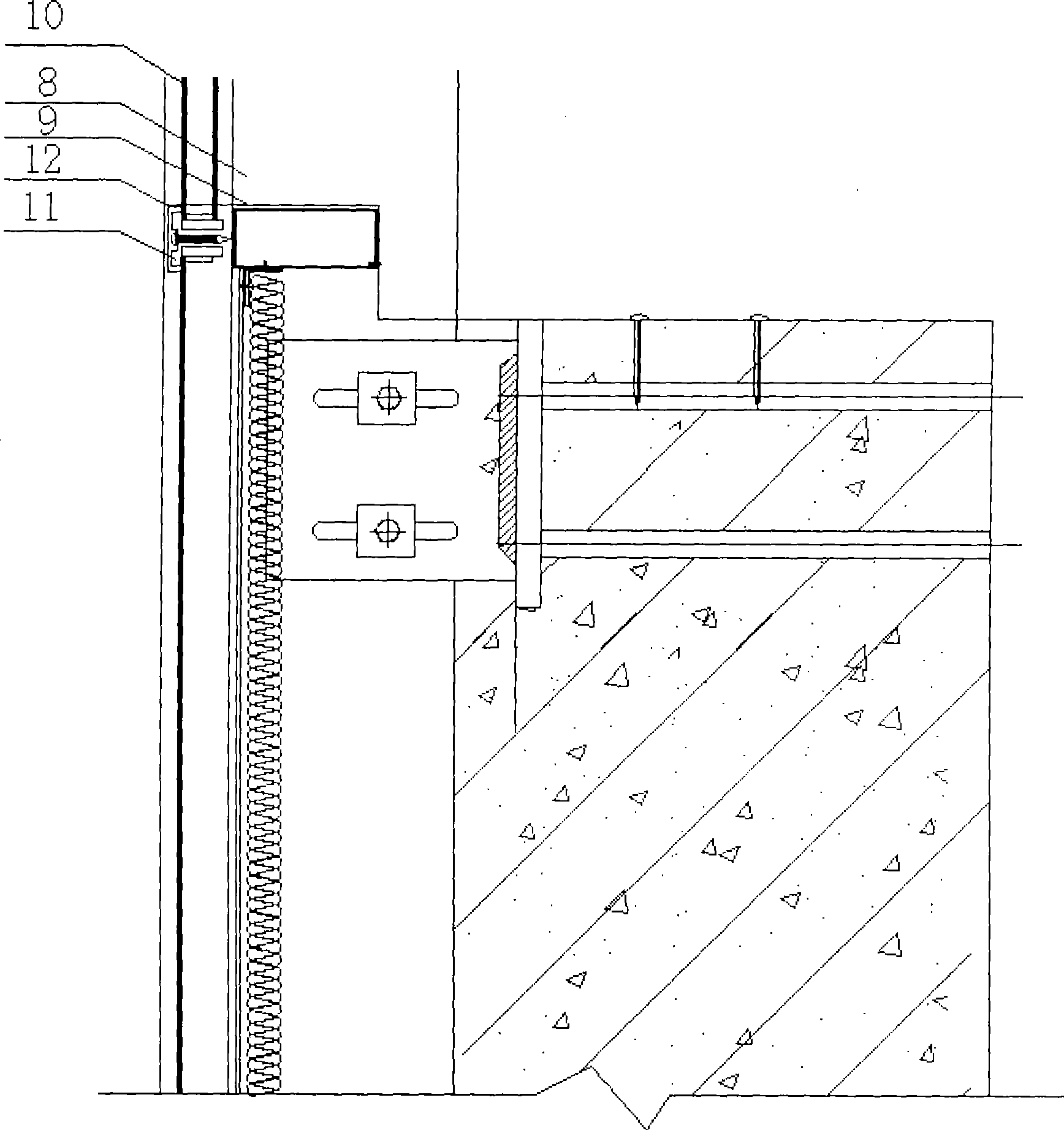

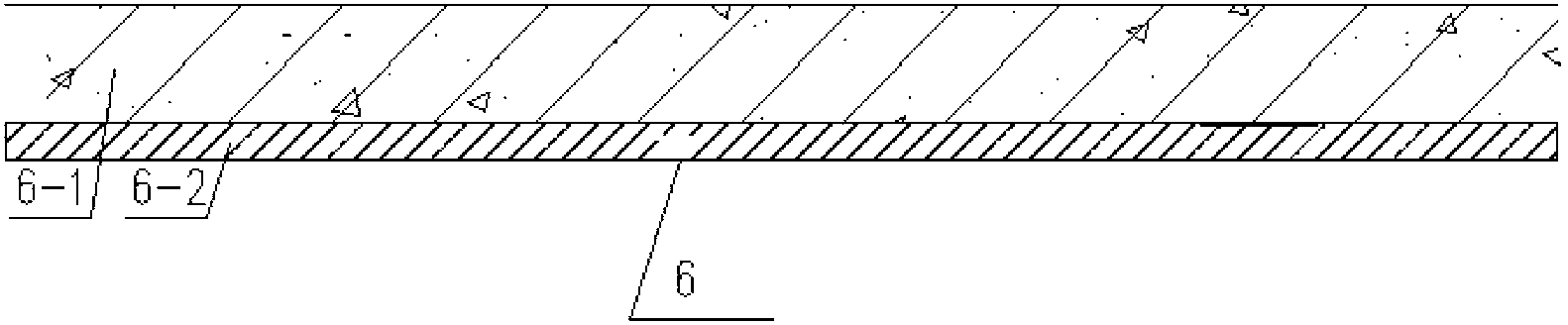

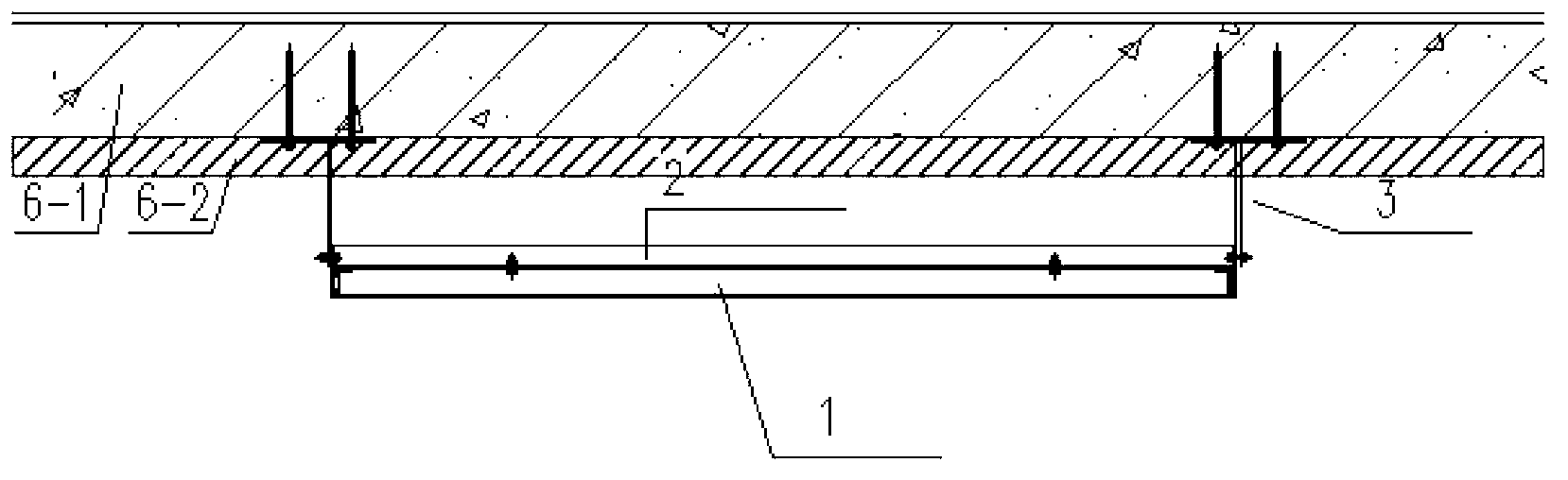

Narrow-channel double-layer ventilation external wall utilizing photovoltaic power generation

InactiveCN103233530AReduce heat radiation effectLower working temperatureWallsClimate change adaptationSolid wallInlet valve

The invention discloses a narrow-channel double-layer ventilation external wall utilizing photovoltaic power generation, and belongs to the technical field of solar power generation BIPV (building integrated photovoltaics). The external wall comprises a solid wall (6) and a solar cell panel (1) which is fixedly connected with the outer side of the solid wall (6) through a chemical anchor bolt (3), wherein a cavity (5) is reserved between the solid wall (6) and the solar cell panel (1); an air outlet is formed above the cavity (5) and is provided with an air outlet valve (7); and an air inlet is formed below the cavity (5) and is provided with an air inlet valve (8). Aiming at the BIPV manner combining the solar cell panel and the external solid wall, one cavity is reserved between the solar cell panel and the external solid wall, and the heat yield in a power generation process of the solar cell panel is taken away through forced ventilation of a direct current fan, so that the heat radiation effect on external walls of buildings is reduced.

Owner:BEIJING VALEEN LEADING GREEN BUILDING TECH

Continuously wound reinforced corrugated pipe and manufacturing method thereof

ActiveCN104279379AIncrease the outer surface areaIncreased structural wall thicknessCorrugation articlesFlexible pipesSolid wallAdhesive

The invention discloses a continuously wound reinforced corrugated pipe and a preparation method thereof. The pipe comprises a continuous solid-wall cylindrical pipe body formed by lapping and fusing a plurality of spirally wound special rods of which the two sides are provided with butting wings through the wings; a plurality of hollow reinforcing ribs are spirally wound on the pipe wall of the cylindrical pipe body; each hollow reinforcing rib comprises at least one special single-wall corrugated reinforcement pipe which is spirally wound on the pipe wall of the cylindrical pipe body through a reinforcement adhesive layer, and an outer reinforcement layer which is spirally wound, spans and presses on the special single-wall corrugated reinforcement pipe and of which two ends are adhered to the pipe wall of the cylindrical pipe body; the center line of each hollow reinforcing rib is overlapped with the center line of a lapping and fusing part of wings of an adjacent special rod. The pipe is high in stability and welding effect, the crest height of the pipe is higher than that of a double-wall corrugated pipe, the continuously wound reinforced corrugated pipe can be produced by matching common wound pipe production equipment with a suitable die, and equipment investment is small.

Owner:戴爱清 +1

Volatile substances diffuser

ActiveUS8062598B2Enhancing evaporation and diffusionReduce equipment costsMechanical apparatusAir-treating devicesSolid wallEvaporation

Owner:ZOBELE HLDG SPA

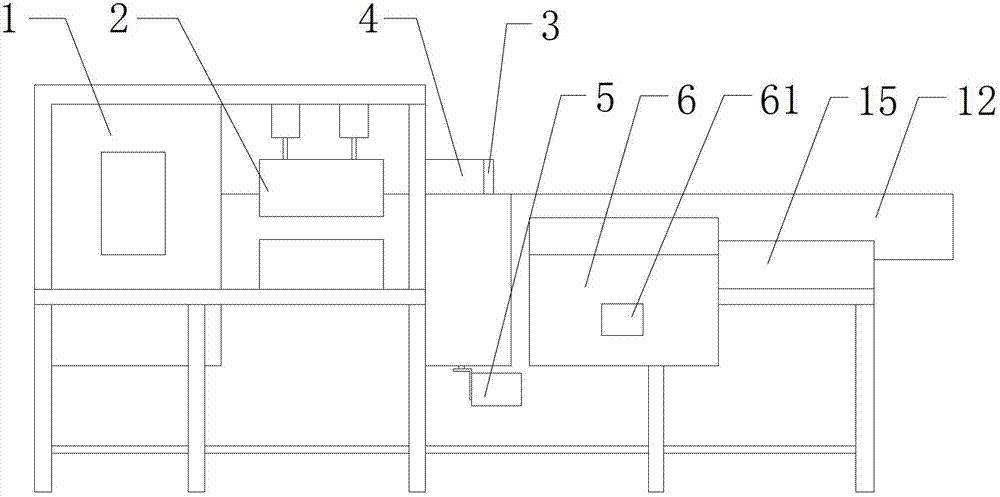

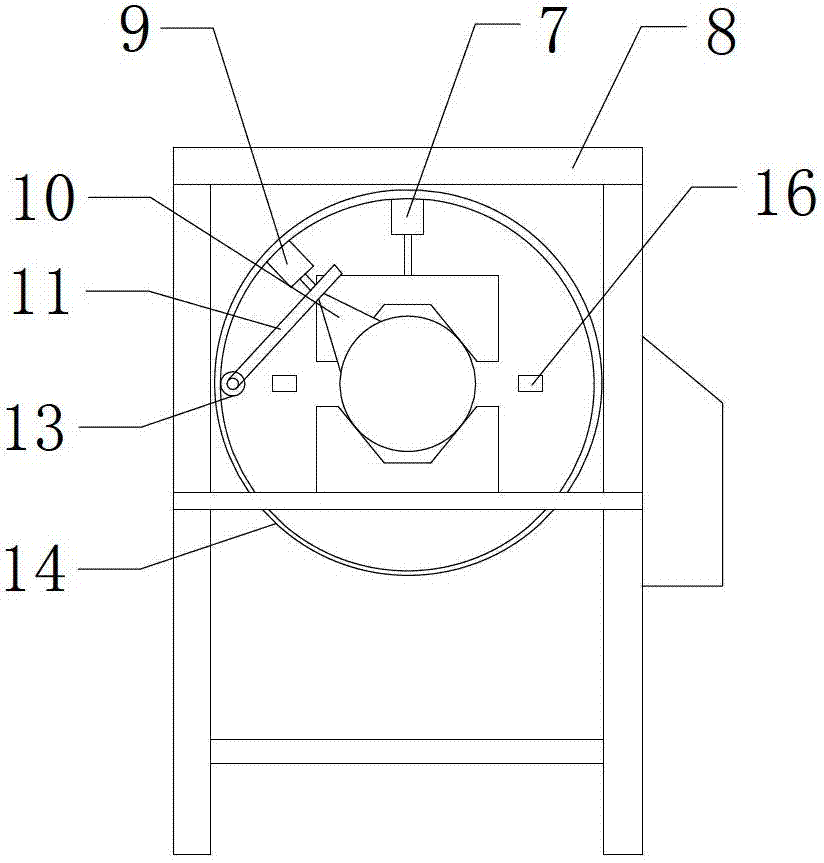

Chipless cutting-off machine for plastic solid-wall pipe

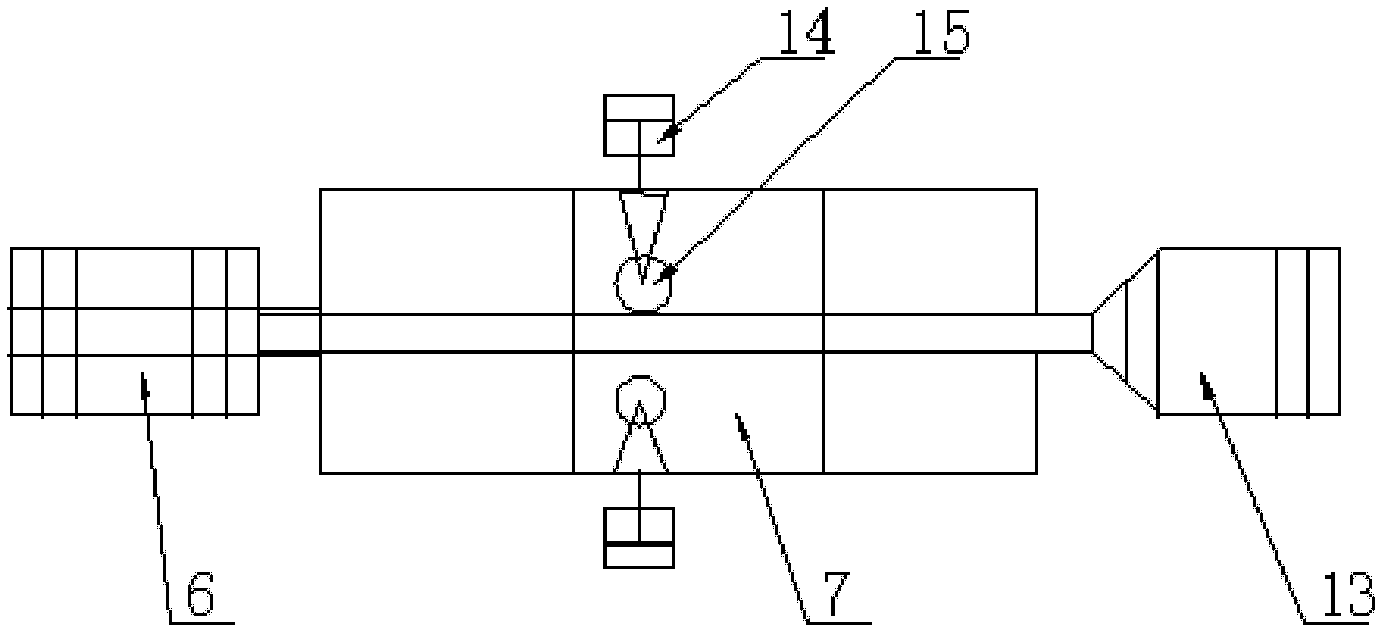

ActiveCN102785267AImprove work efficiencyImprove securityMetal working apparatusSolid wallEngineering

The invention provides a chipless cutting-off machine for plastic solid-wall pipes, which comprises a machine frame, wherein a clamping and feeding device for transporting the pipes, a compressing device for compressing the pipes and a cutting device for cutting the pipes are sequentially arranged on the machine frame, and an electric control box for controlling the working of the clamping and feeding device, the compressing device and the cutting device is arranged on the machine frame. The chipless cutting-off machine has high work efficiency of waste-pipe recovery and good safety factors, and the economic cost can be saved.

Owner:浙江永达电力实业股份有限公司

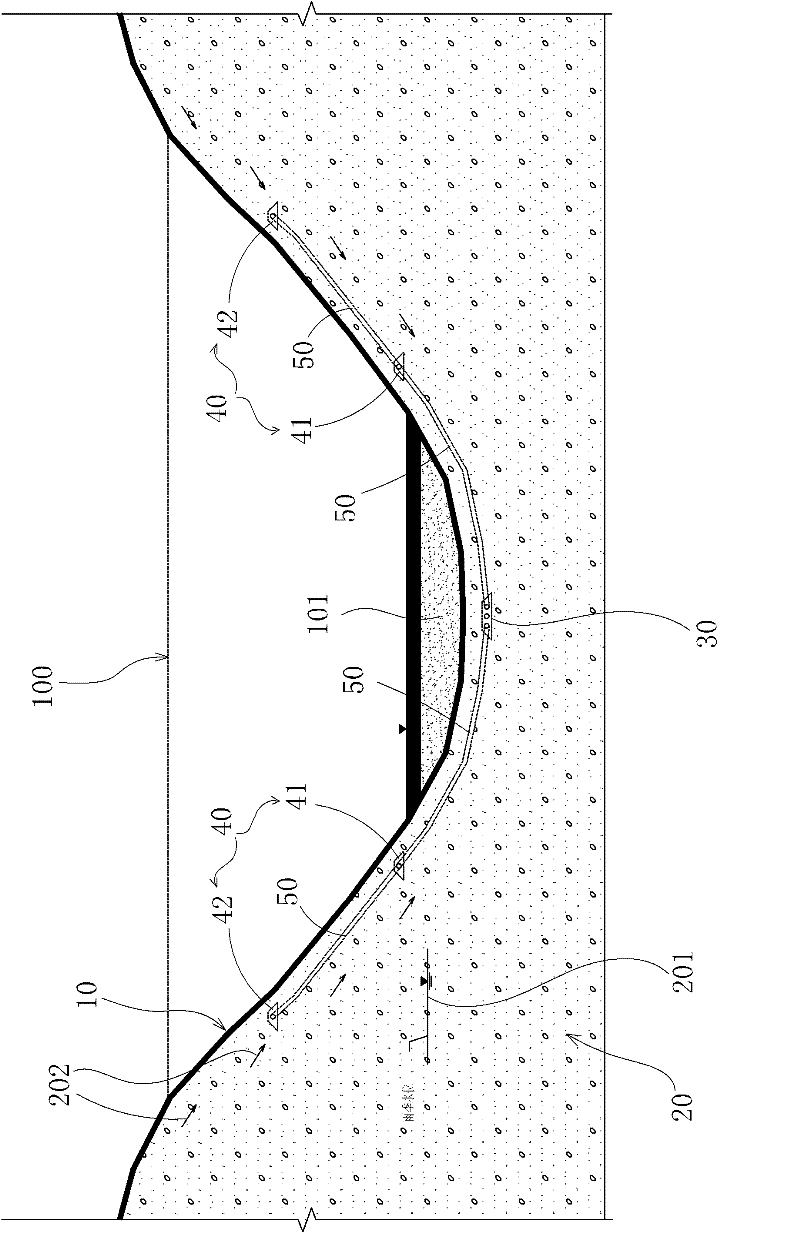

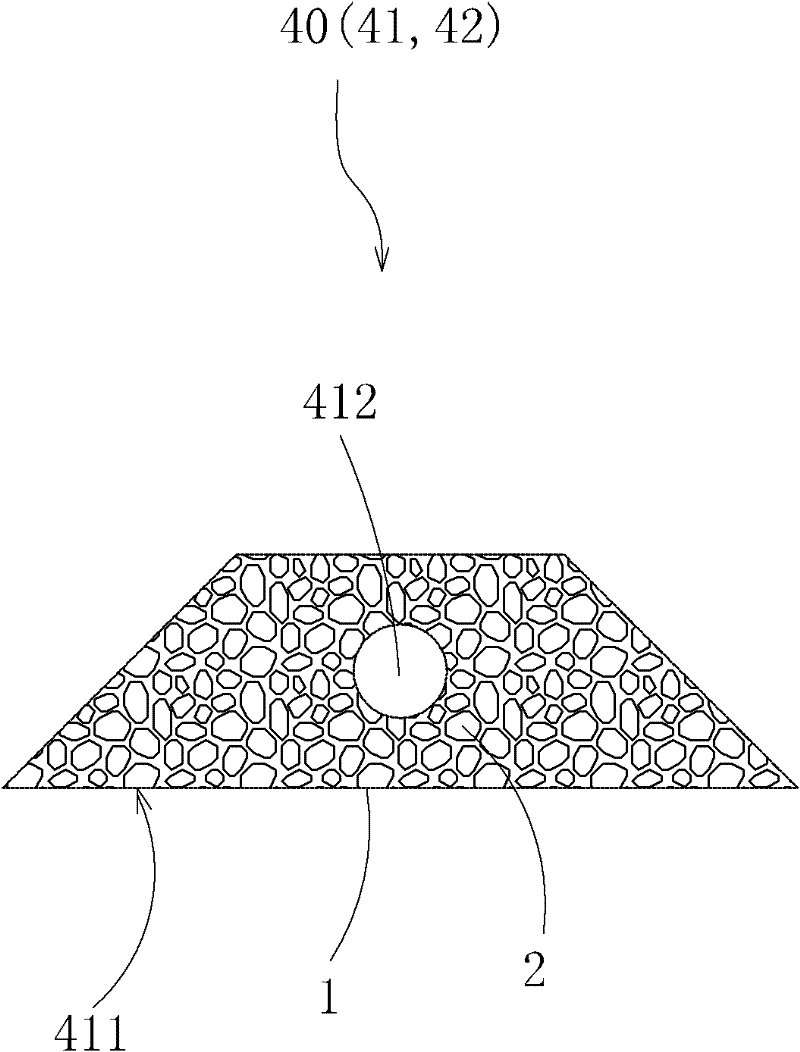

Underground water guiding and draining system under impermeable membrane of industrial waste residue storage yard

InactiveCN102182208AJacking uplift preventionAvoid bumpingSewerage structuresProtective foundationLeaking waterSolid wall

An underground water guiding and draining system under an impermeable membrane of an industrial waste residue storage yard is arranged in a mountain body (20) below a impermeable membrane (10) in a storage yard, and comprises a main guiding-leaking blind ditch (30), a branch guiding-leaking blind ditch (40) and a water guiding blind ditch (50), wherein the main guiding-leaking blind ditch is arranged at the lowest position of a valley, and the length of the main guiding-leaking blind ditch extends to the downstream of the storage yard along the tail end of the storage yard; the branch guiding-leaking blind ditch is arranged by surrounding the storage yard along the hillside surrounding the storage yard, a plurality of leaking water grooves for containing water leaking from the hillside are arranged on a guiding-leaking pipe in the branch guiding-leaking blind ditch, and a water outlet is arranged at one end of the branch guiding-leaking blind ditch positioned at the downstream of the storage yard; and the branch guiding-leaking blind ditch and the main guiding-leaking blind ditch are communicated with each other by a plurality of water guiding blind ditches or solid-wall HDPE (High-Density Polyethylene) water guiding pipes, which are arranged at intervals. The underground water guiding and draining system forms spider net shape under the impermeable membrane of the waste residue storage yard, so that underground water can be drained effectively, the support force on the impermeable membrane caused by underground water can be reduced, the upheaval and cracking of the impermeable membrane can be prevented, so that the completeness of the impermeable membrane can be kept, and the impermeable function of the impermeable membrane can be guaranteed.

Owner:中城建胜义(深圳)环境科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com