Chipless cutting-off machine for plastic solid-wall pipe

A solid-wall pipe and cutting machine technology, applied in the field of machinery, can solve the problems of low work efficiency, waste of resources, cost recovery, frequent safety accidents, etc., and achieve the effect of high work efficiency, good safety factor, and economic cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

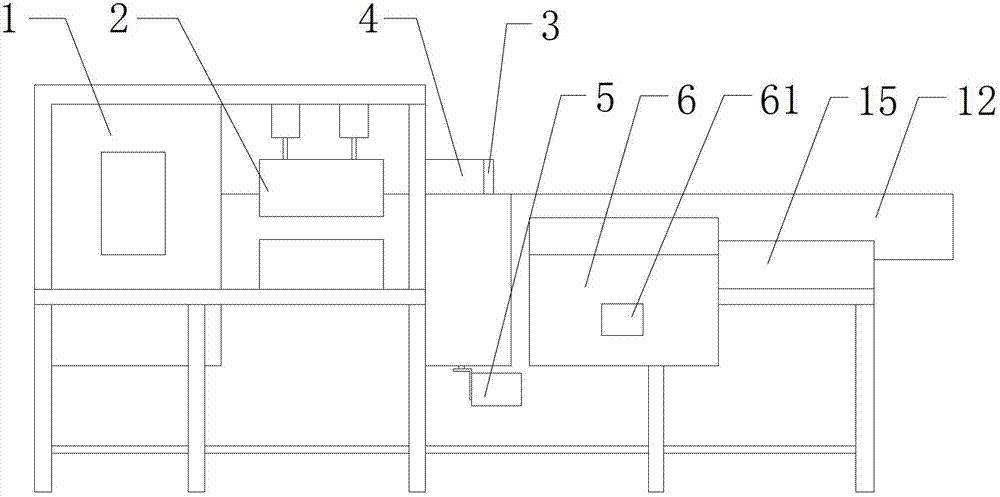

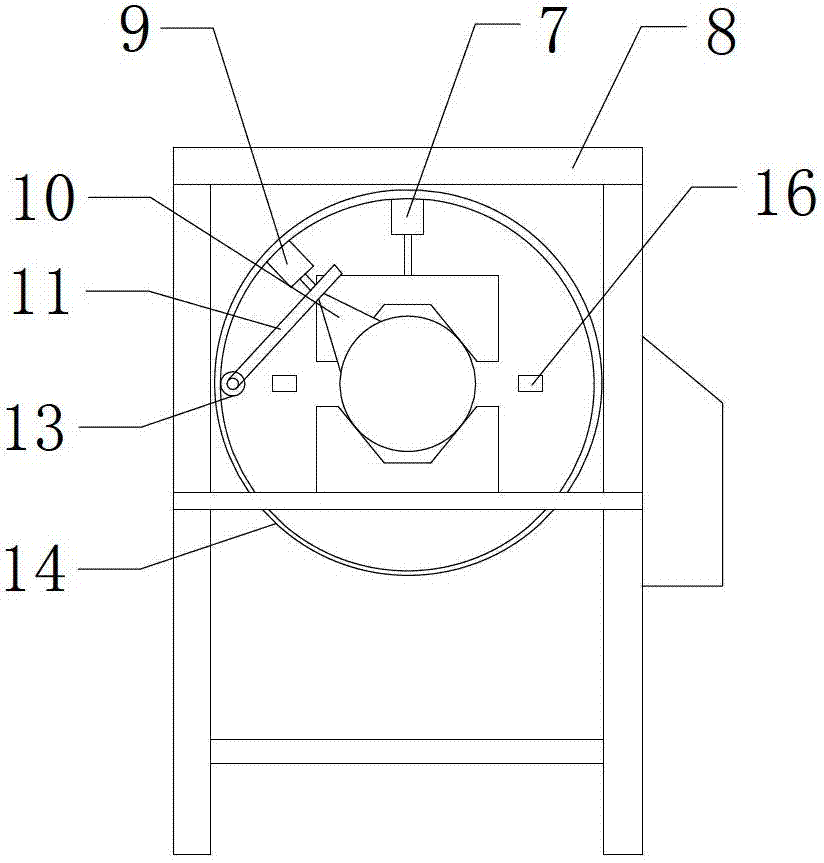

[0018] Such as figure 1 with figure 2 As shown, a chip-free cutting machine for plastic solid-walled pipes includes a frame 8 on which a clamping and feeding device for transporting pipes 12, a pressing device for pressing pipes 12, and a cutting pipe 12 are sequentially arranged. The cutting device 1, the frame 8 is provided with a control electric box 6 for controlling the operation of the clamping and feeding device, the pressing device and the cutting device 1. The clamping and feeding device is at least two feeding rubber rollers 4 arranged on the frame 8, and the driving feeding rubber rollers 4 are provided on the frame 8 to clamp and position the pipe material 12 and rotate to drive the pipe material 12 to move The feed motor 5, the control electric box 6 controls the feed motor 5 to work. The feeding rubber roller 4 is provided with a tension sensor 3 that senses the clamping force of the feeding rubber roller 4 , and the control electric box 6 controls the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com