Wall liquid film and wall-free liquid film alternate structured filler adapting to viscous absorbent

A technology of structured packing and absorbent, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of not changing the overall macrostructure of corrugated packing, restrictions on the use of viscous absorbents, and unproposed To achieve the effect of improving anti-clogging performance, widening the viscosity range and increasing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

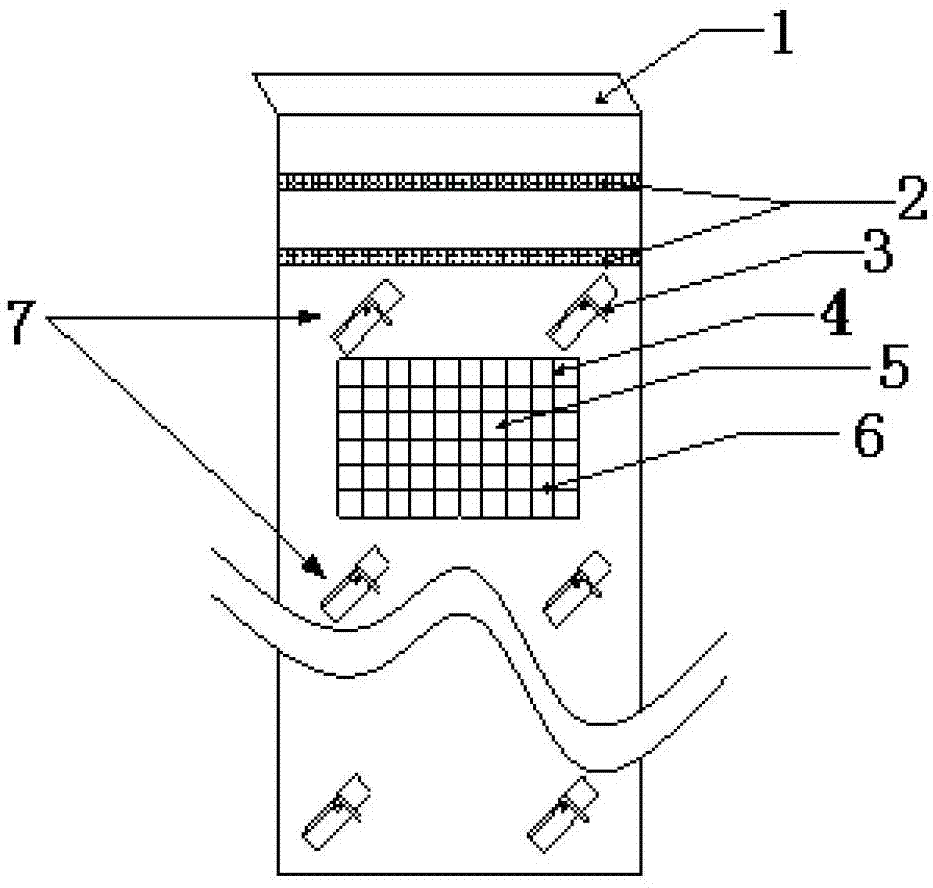

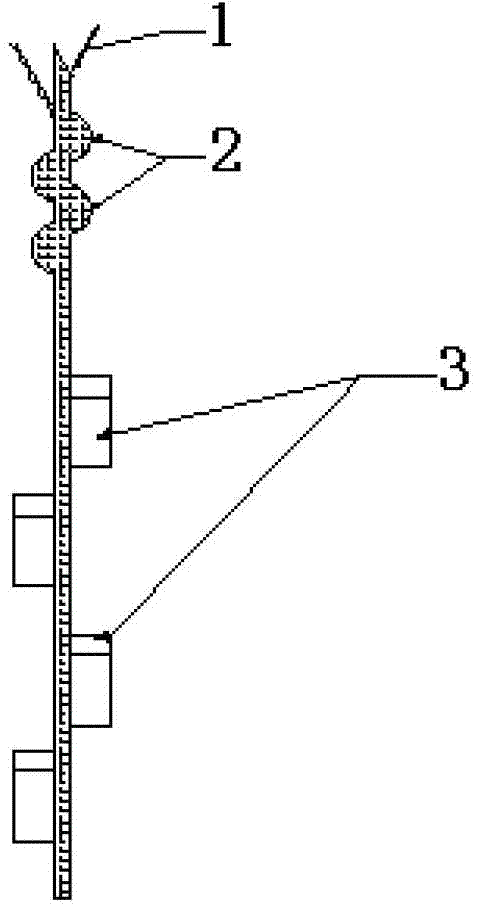

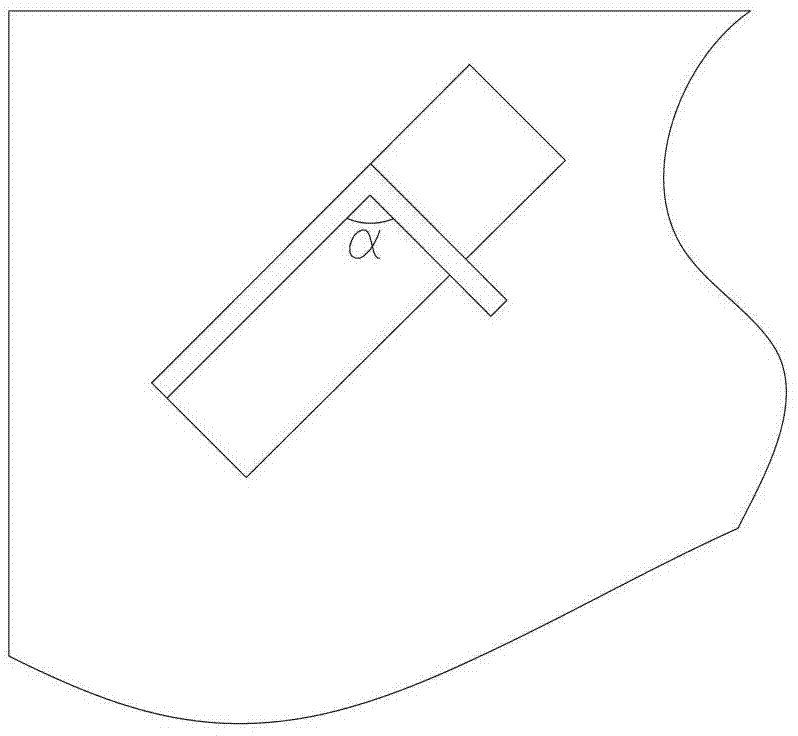

Embodiment 1

[0046] Oxygen desorption experiment, the liquid viscosity is about 1mPa.s, the tower diameter is 190mm, the packing used is the straight channel vertical plate structured packing of the present invention, and the specific surface area of the packing is 250m 2 / m 3 , the height of the packing layer is 500mm, the height of the packing plate is 125mm, the groove width of the liquid collection-primary distribution part on each piece of packing is 3mm, the groove depth is 8mm, the number of liquid uniform distribution parts is 2, the spacing is 15mm, and the proportion of holes in the total packing 25% of the area. The width of the tongue-shaped protrusion structure is 8mm, the length is 20mm, and the number is 4, which are evenly distributed near the four corners of the packing sheet. The liquid spray density is 10~38m 3 / (m 2 .h). The average number of theoretical plates obtained is 3-4 pieces / m, which greatly improves the separation efficiency compared with 2-3 pieces / m of...

Embodiment 2

[0048] Glycerin aqueous solution cold model test, the liquid viscosity is 17mPa.s. Packed column size and packing parameters are as in Example 1. The liquid spray density is 10~30m 3 / (m 2 .h). at 15m 3 / (m 2 .h), 22m 3 / (m 2 .h), 30m 3 / (m 2 .h) under the spray density, within the normal operating range, the average pressure drop of the straight channel vertical plate structured packing is only 54.4%, 39.6%, 25.5% of the wire mesh corrugated packing, and 31.5% of the plastic corrugated packing , 16.2%, 6.21%. The flood point F factors of the straight channel vertical plate structured packing are 2.48, 1.57, and 1.50 times that of the wire mesh corrugated packing, and 2.48, 1.57, and 1.50 times that of the plastic corrugated packing. The comparison shows that the effect of the present invention is obvious.

Embodiment 3

[0050] High viscosity (concentrated) diethanolamine (DEA) aqueous solution absorbs CO 2 Comparative Experiment. In the gas absorption device, the mass fraction of 5% to 63% and the corresponding viscosity of 1.1 to 25.3mPa.s diethanolamine (DEA) solution absorption volume fraction of 15% to 45% CO 2 Comparative Experiment. Both plates are made of 304 stainless steel plates with a thickness of 0.2mm. The total gas-liquid contact area of the two plates is 2*100*600mm. The test plate 1 is a solid plate, and the test plate 2 is a straight channel vertical channel proposed by the patent of the present invention. Plate structured packing, that is, three holes of 80*80mm are opened on the basis of plate 1, and the distance between adjacent holes is 60mm. In order to ensure stable film formation and uniform liquid distribution when the absorption liquid flows through the holes, vertical guide rods with a diameter of 0.1mm and a distance of 6mm and horizontal diverter rods are weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com