Patents

Literature

440 results about "Liquid viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid viscosity is a measure of the internal friction of a liquid. Liquids with high viscosities flow slowly, whereas low viscosity liquids flow quickly. Lava has a relatively high viscosity; water has a relatively low one. You can measure the viscosity of a liquid by measuring the velocity of a sphere as it falls through the liquid.

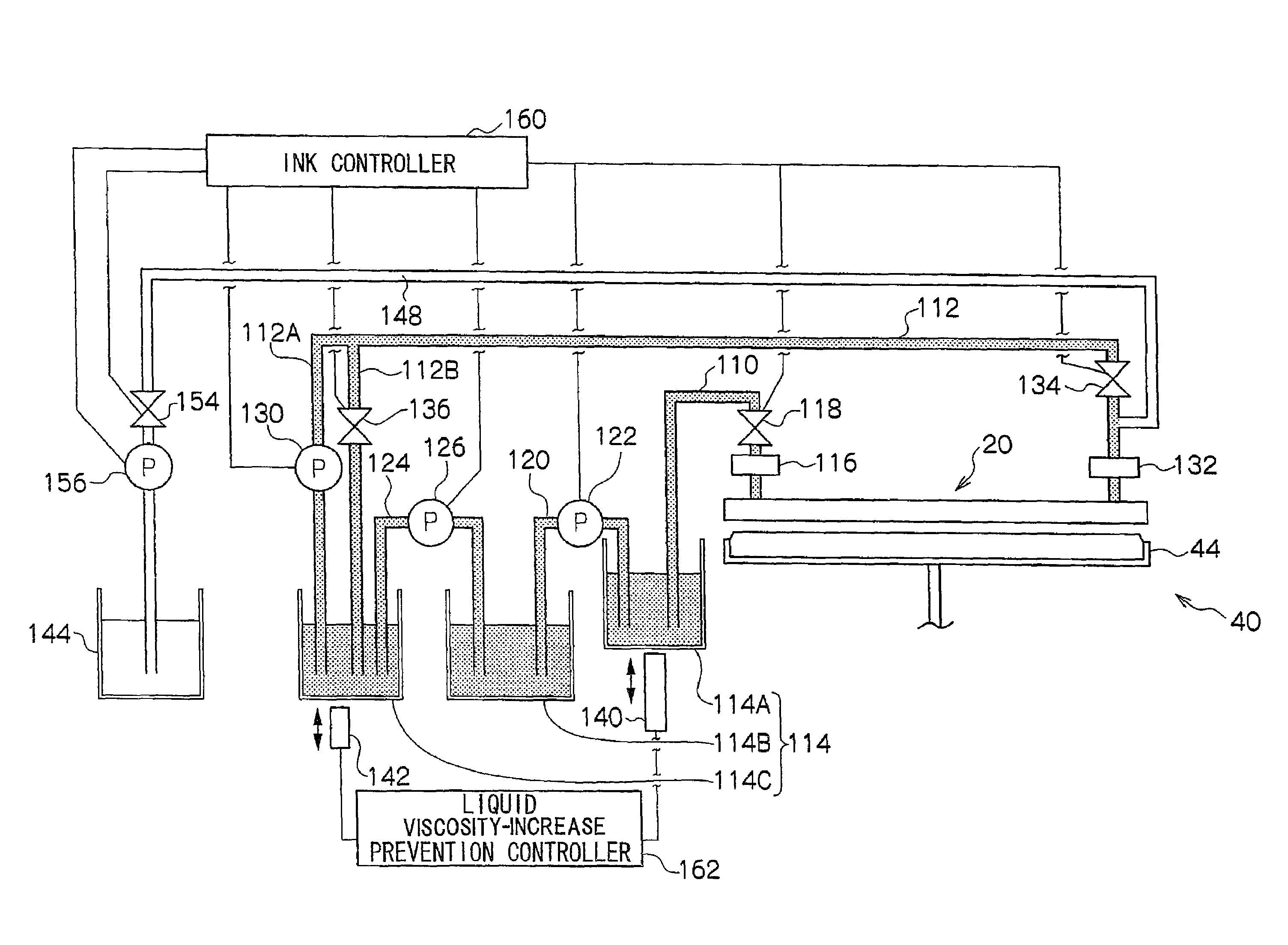

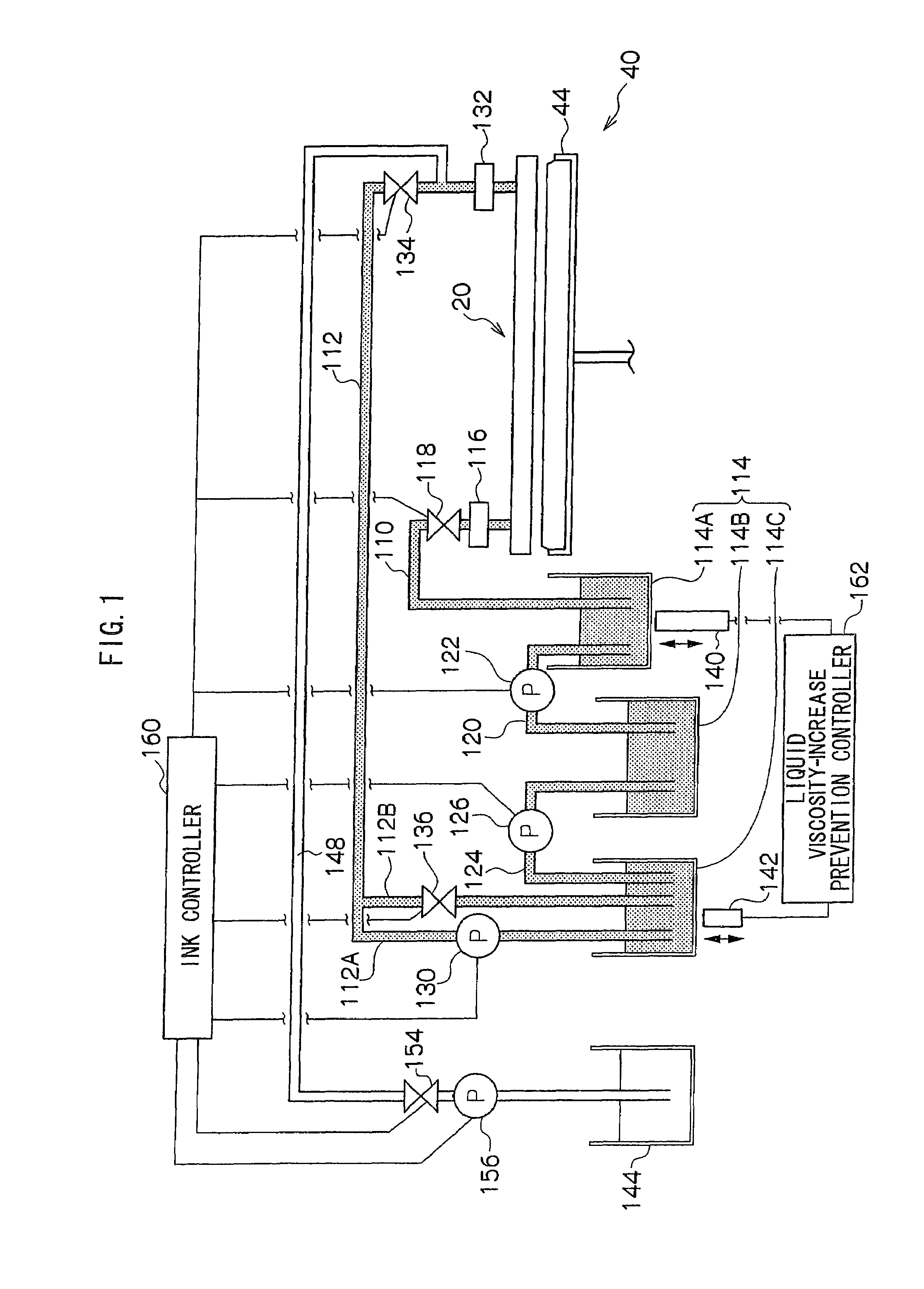

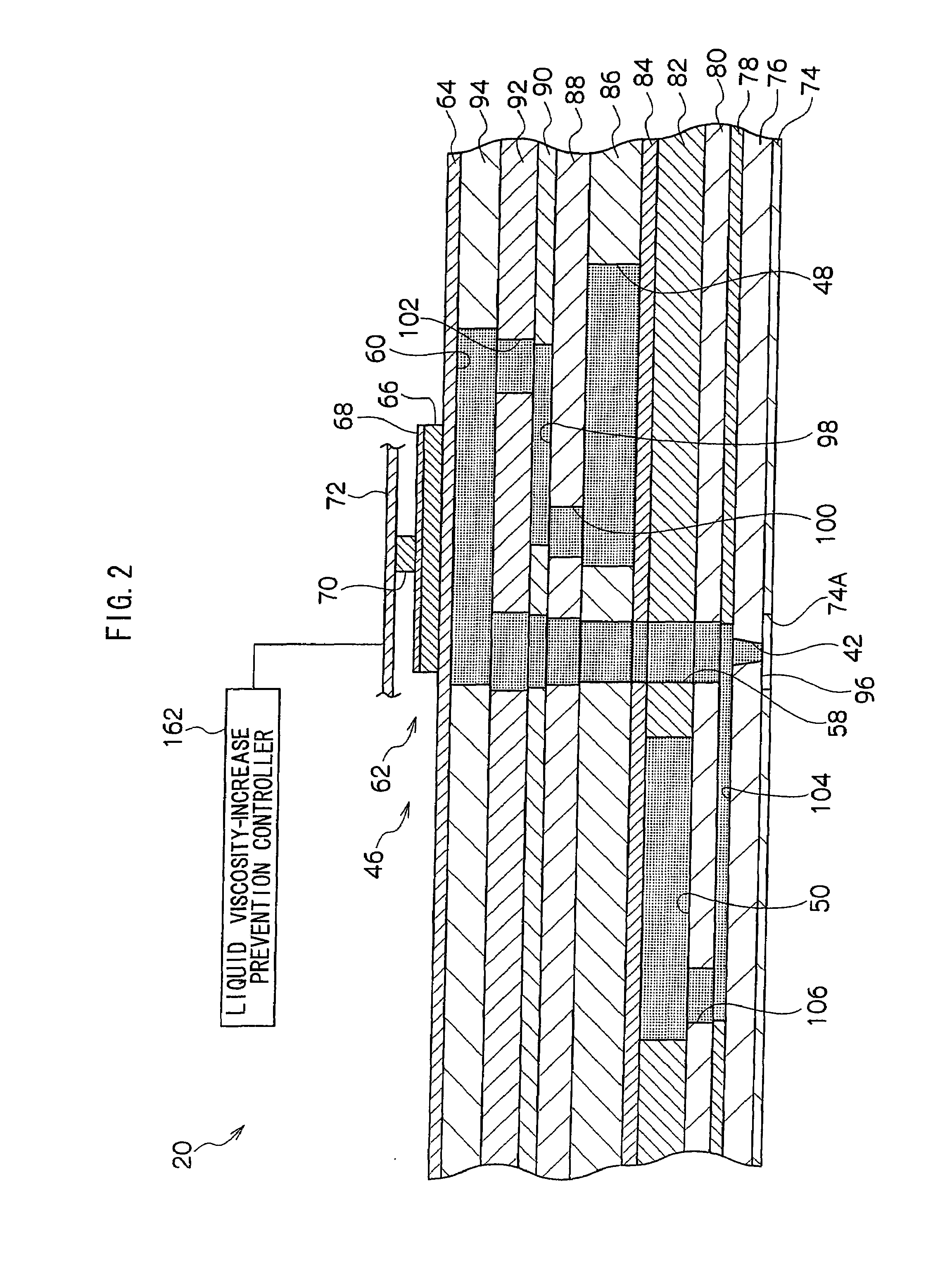

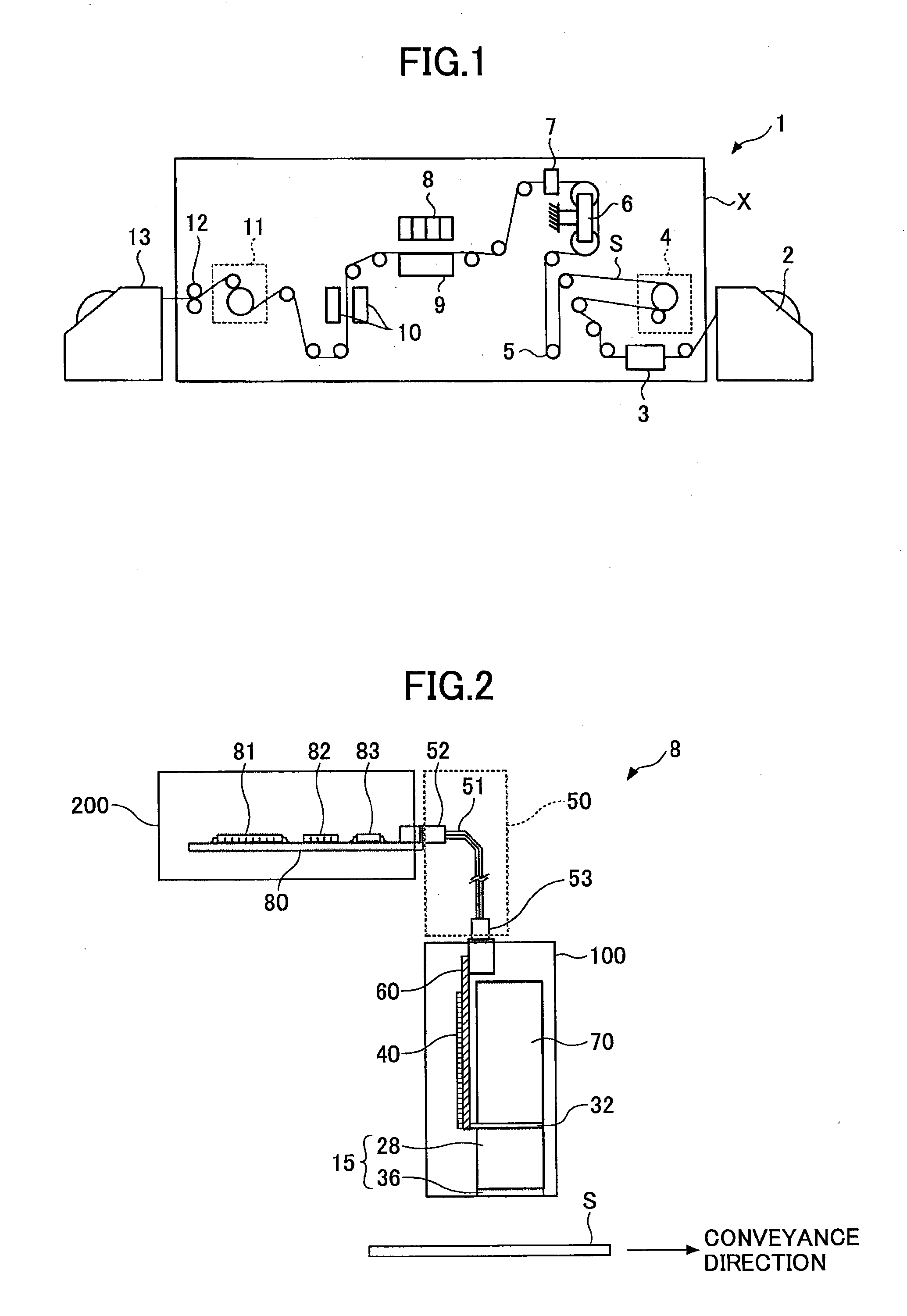

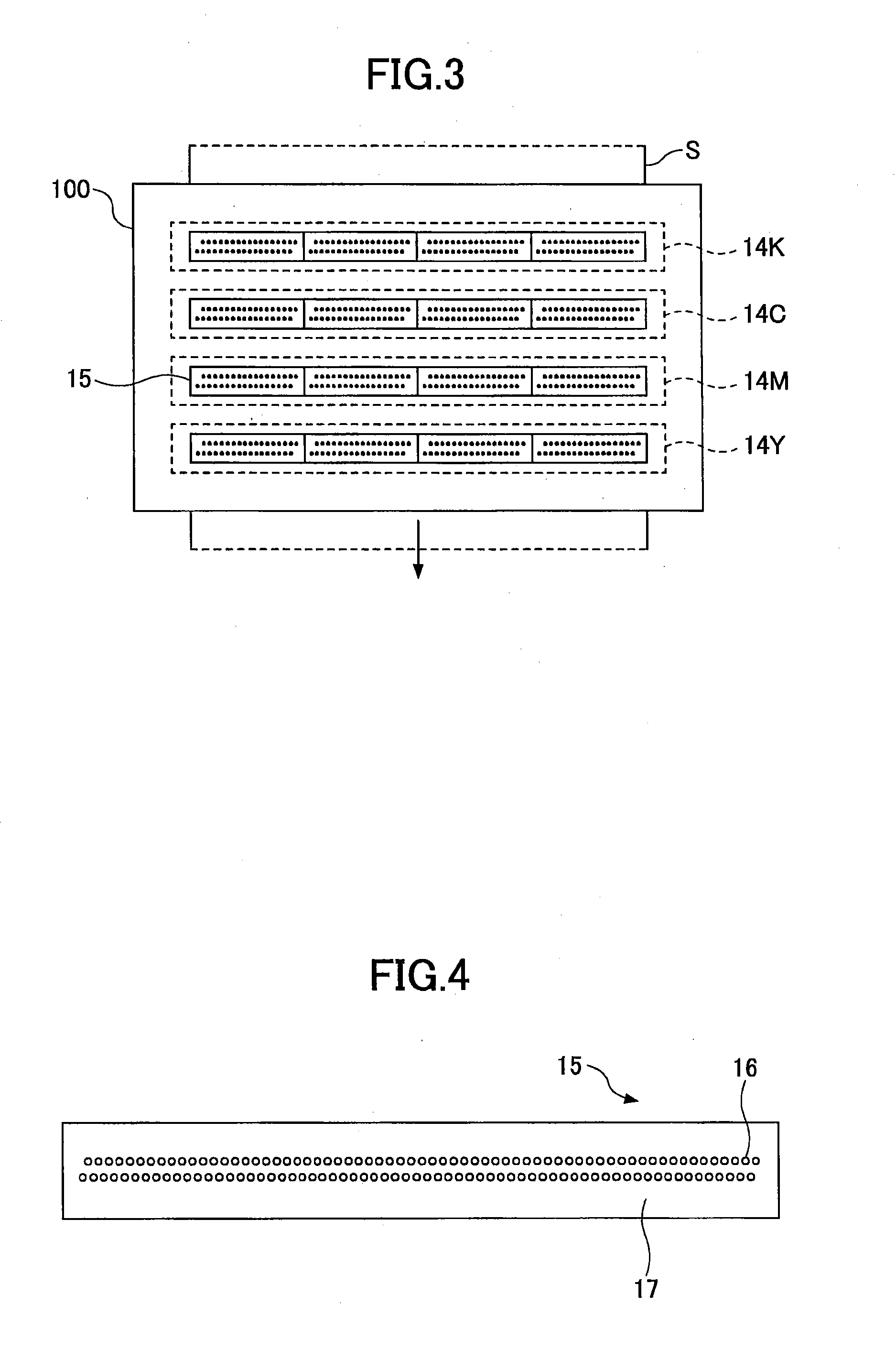

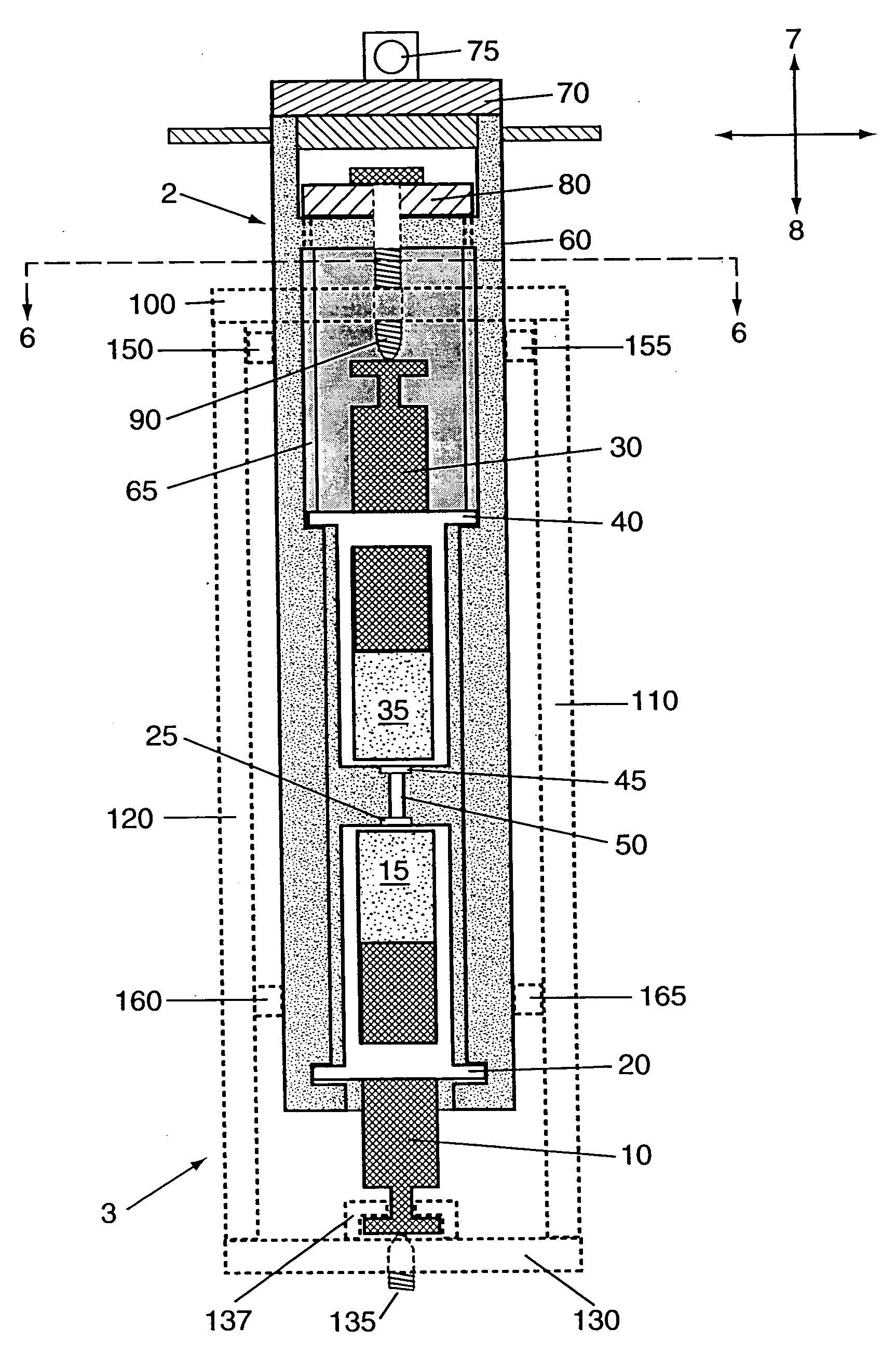

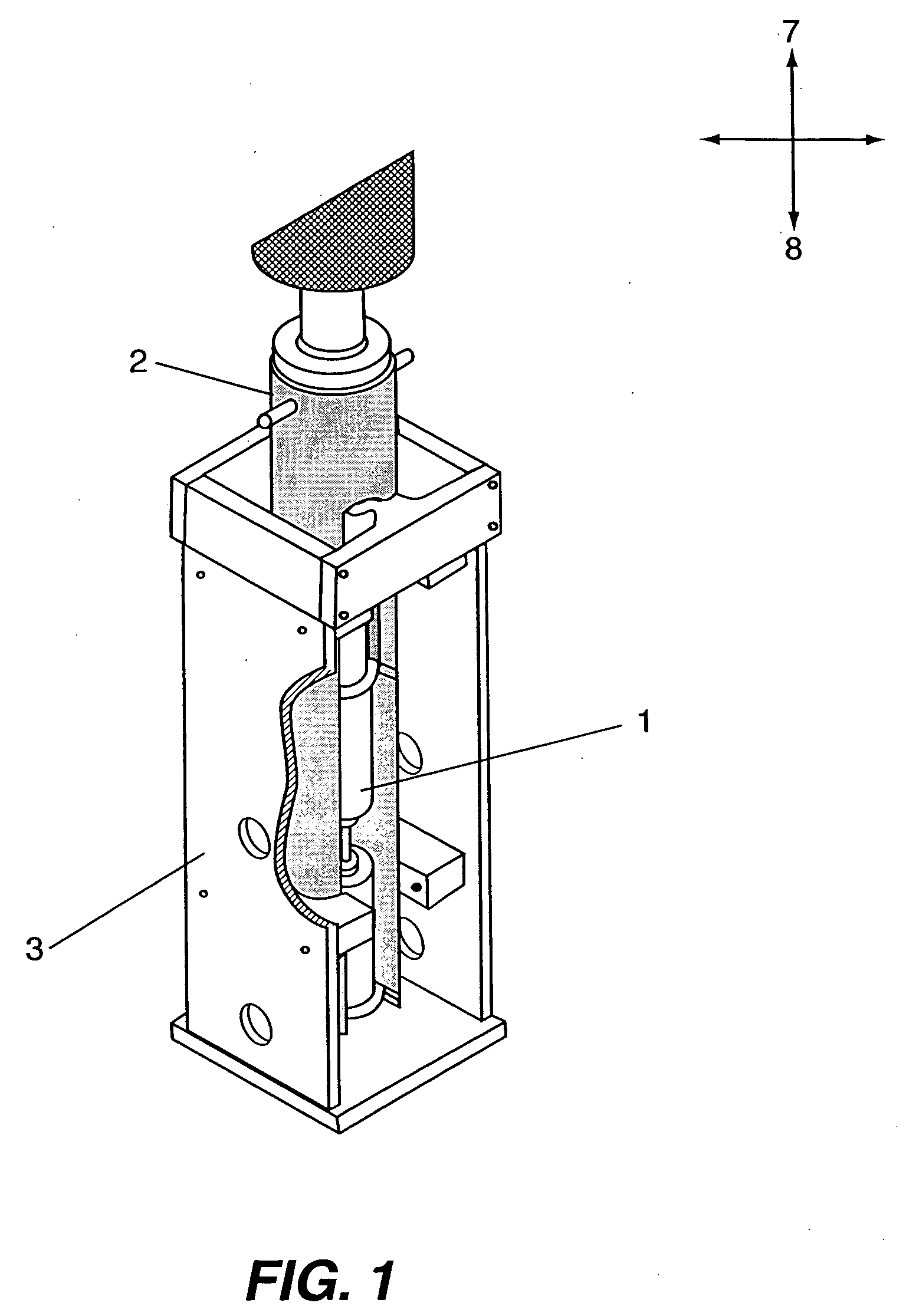

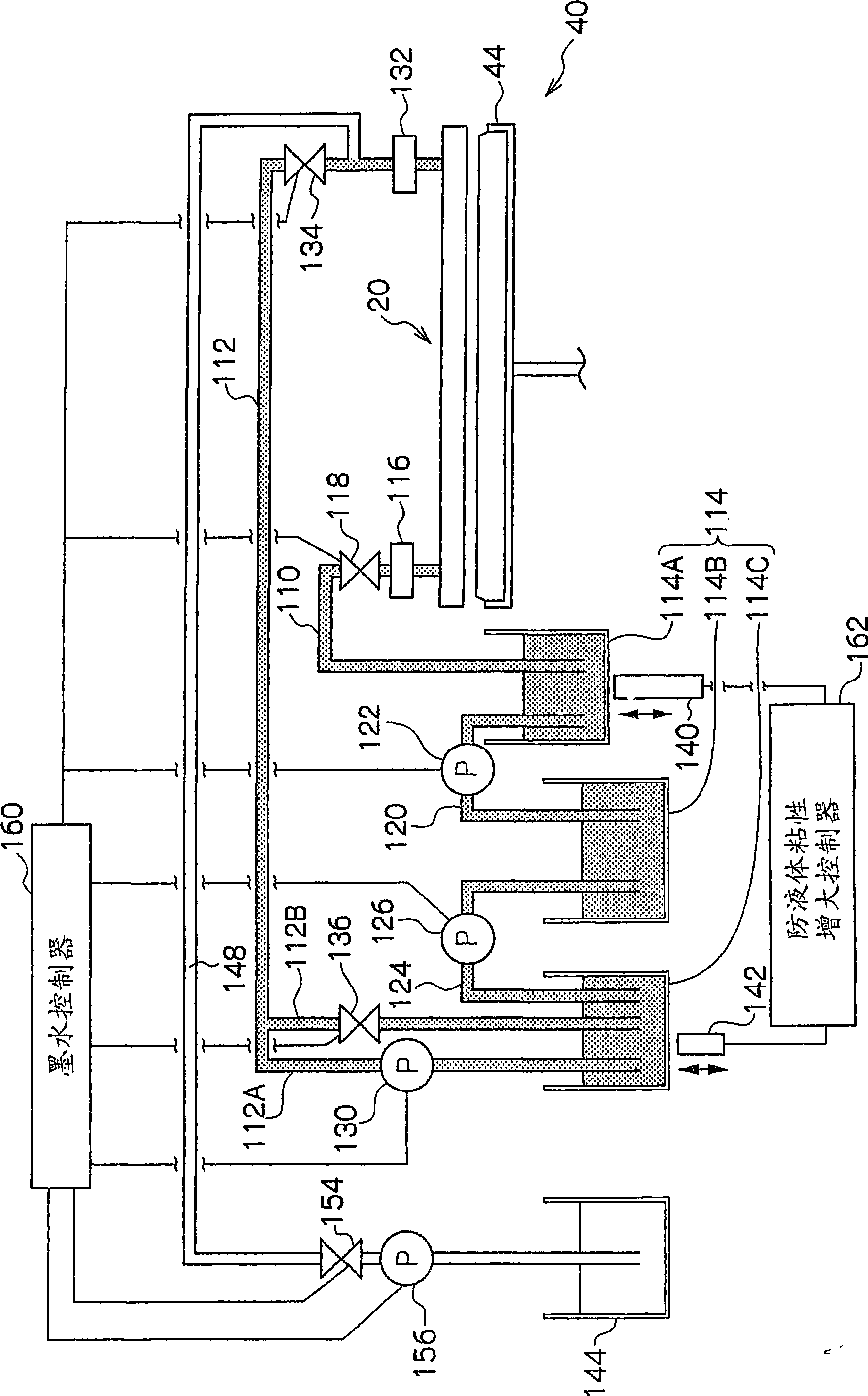

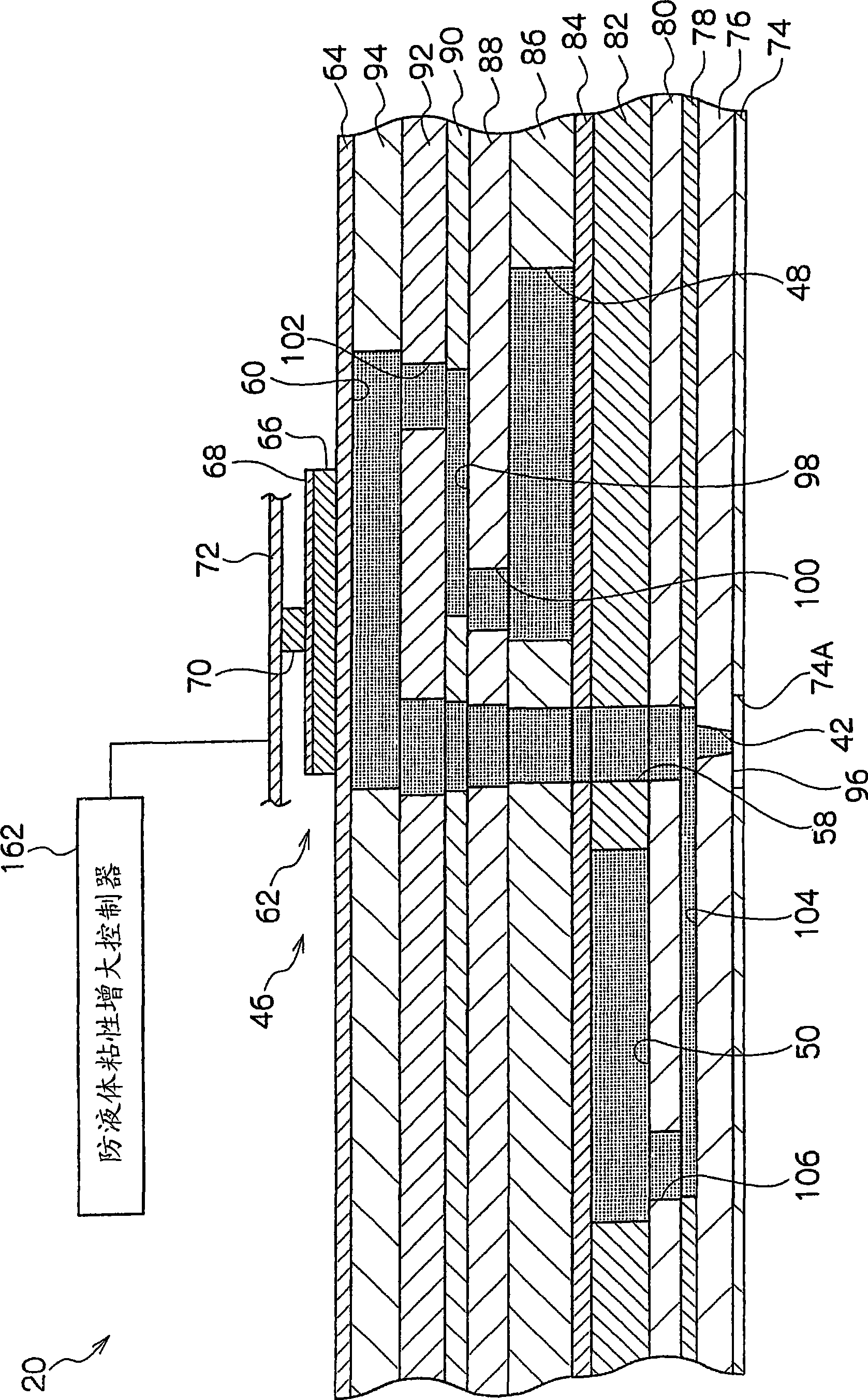

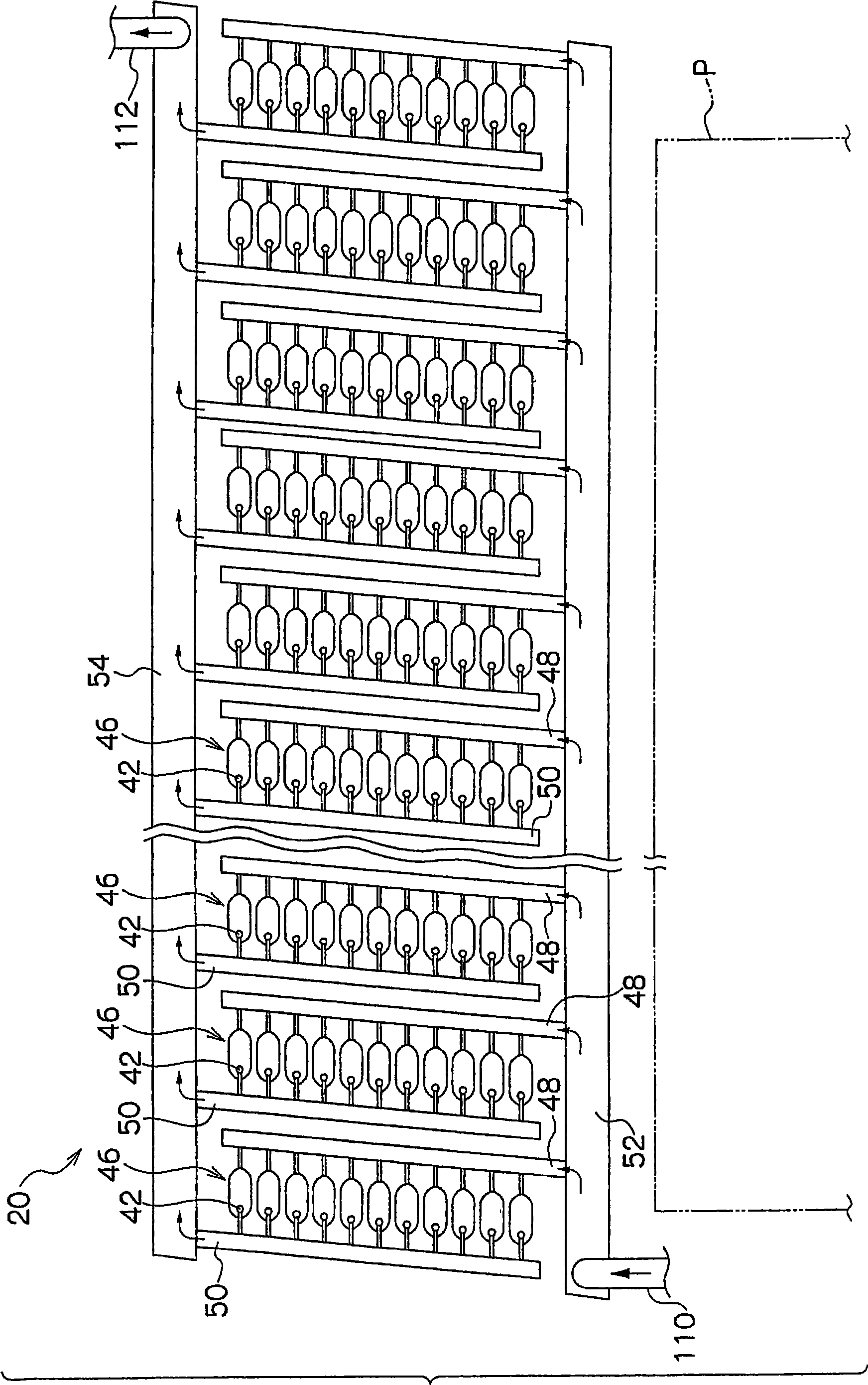

Liquid droplet ejection head and image forming apparatus having the same

InactiveUS20090160887A1Avoid problemsIncrease liquid viscosityInking apparatusOther printing apparatusLiquid viscosityEngineering

A liquid droplet ejection head comprises an ejector, a liquid viscosity-increase prevention structure and a liquid viscosity-increase prevention controller. The ejector includes a nozzle for ejecting a liquid droplet, a pressure chamber communicating with the nozzle through a communication path, and an actuator for applying pressure to a liquid in the pressure chamber. The liquid viscosity-increase prevention structure prevents an increase of viscosity of the liquid in the ejector. The liquid viscosity-increase prevention controller changes the operation frequency of the liquid viscosity-increase prevention structure between when the liquid droplet is ejected from the nozzle and when ejection of the liquid droplet is paused and no liquid droplet is being ejected from the nozzle.

Owner:FUJIFILM BUSINESS INNOVATION CORP

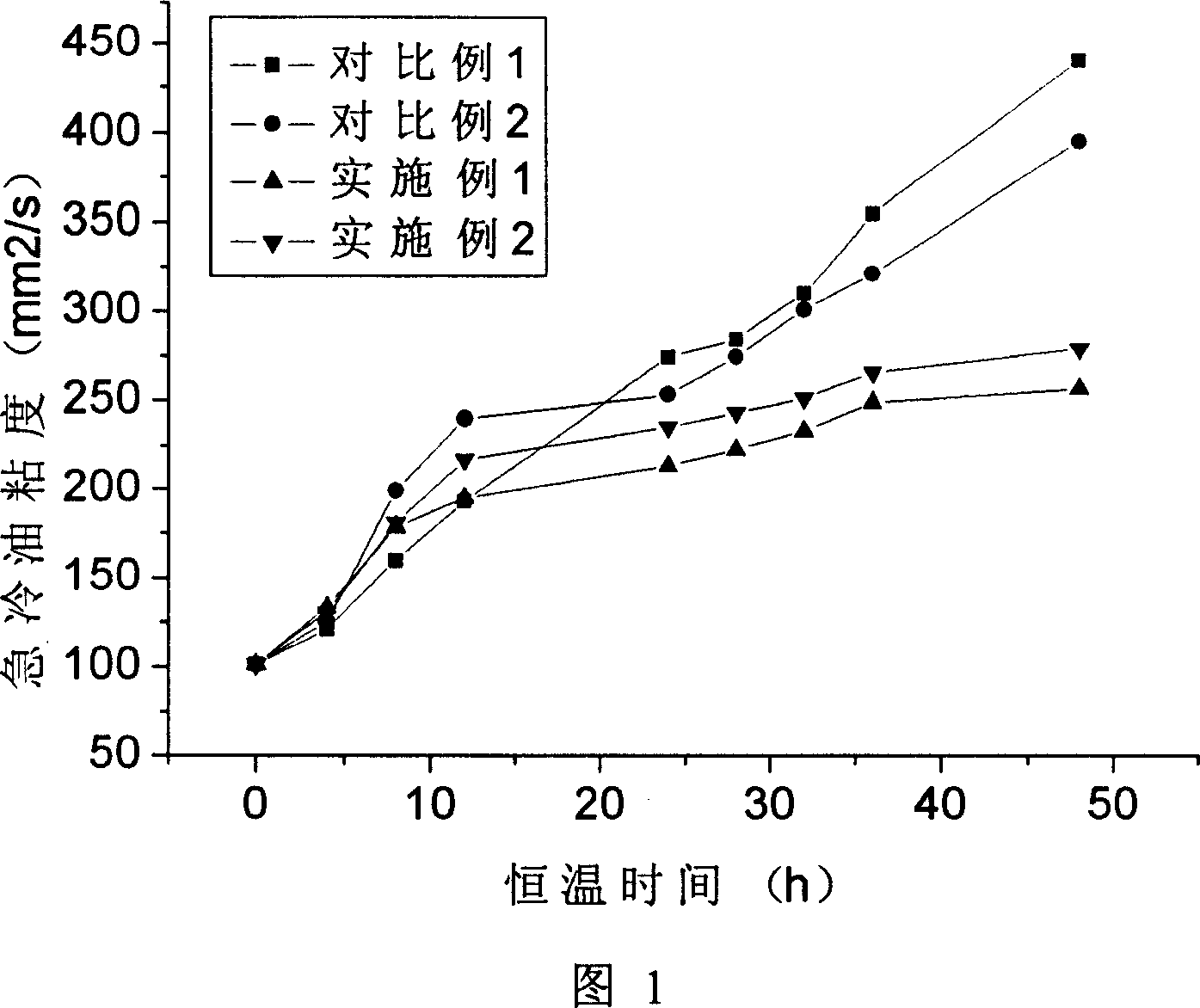

Ethylene device quench oil viscosity reductant

InactiveCN101062880AEasy to useDoes not cause emulsificationHydrocarbon purification/separationHydrocarbonsVisbreakerLiquid viscosity

The invention discloses an ethylene device quench oil viscosity reductant in inhibiting liquid viscosity intensification technical domain, which is characterized by the following: comprising with inhibitor, disperser and metal deactivator; possessing the function of aggregation inhibition, aggregation prevention and metallic surface deactivation; decreasing erosion and incrustation of quench system device; possessing little adding quantity and good stability; non-generating side effect of oil water emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

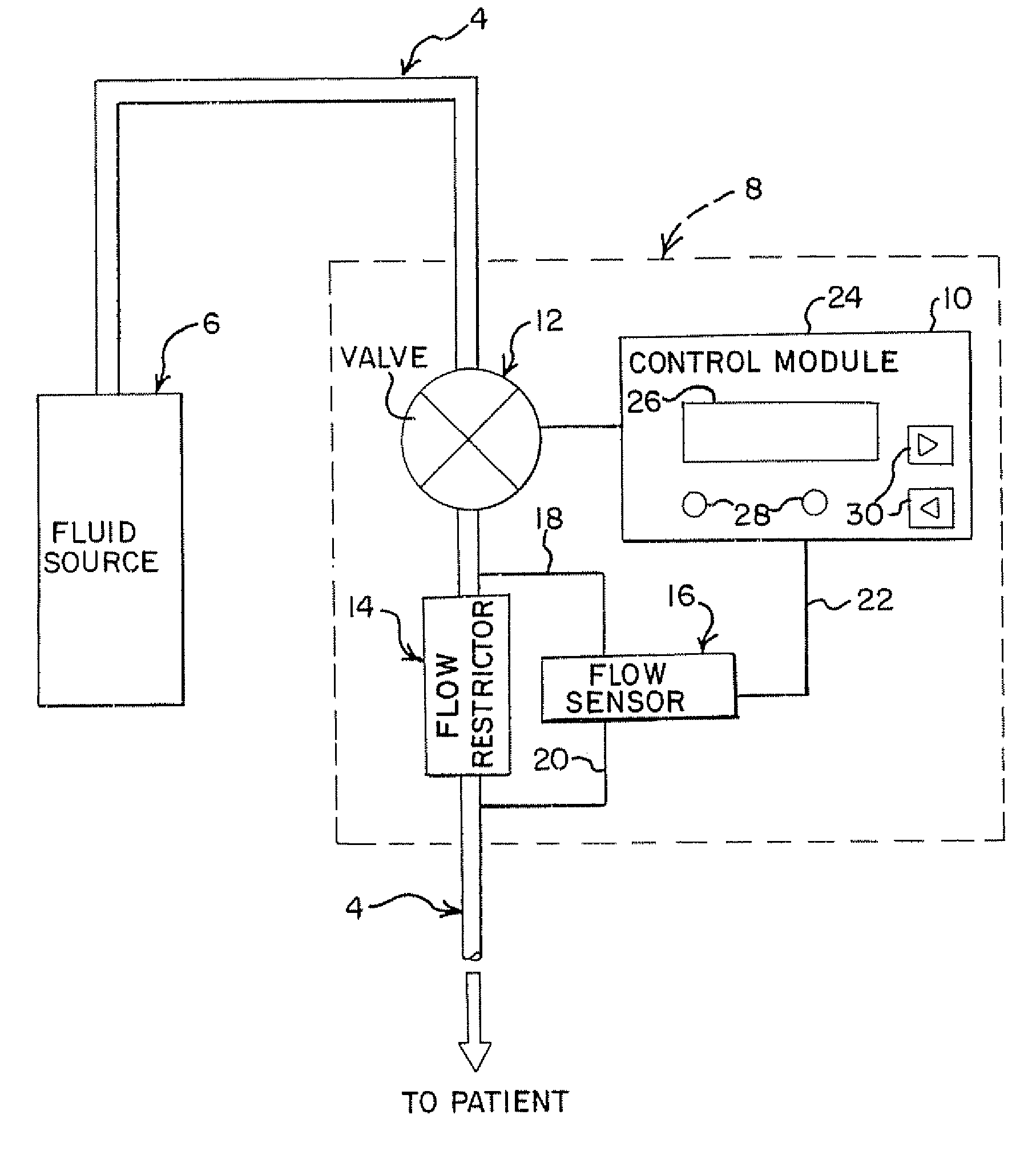

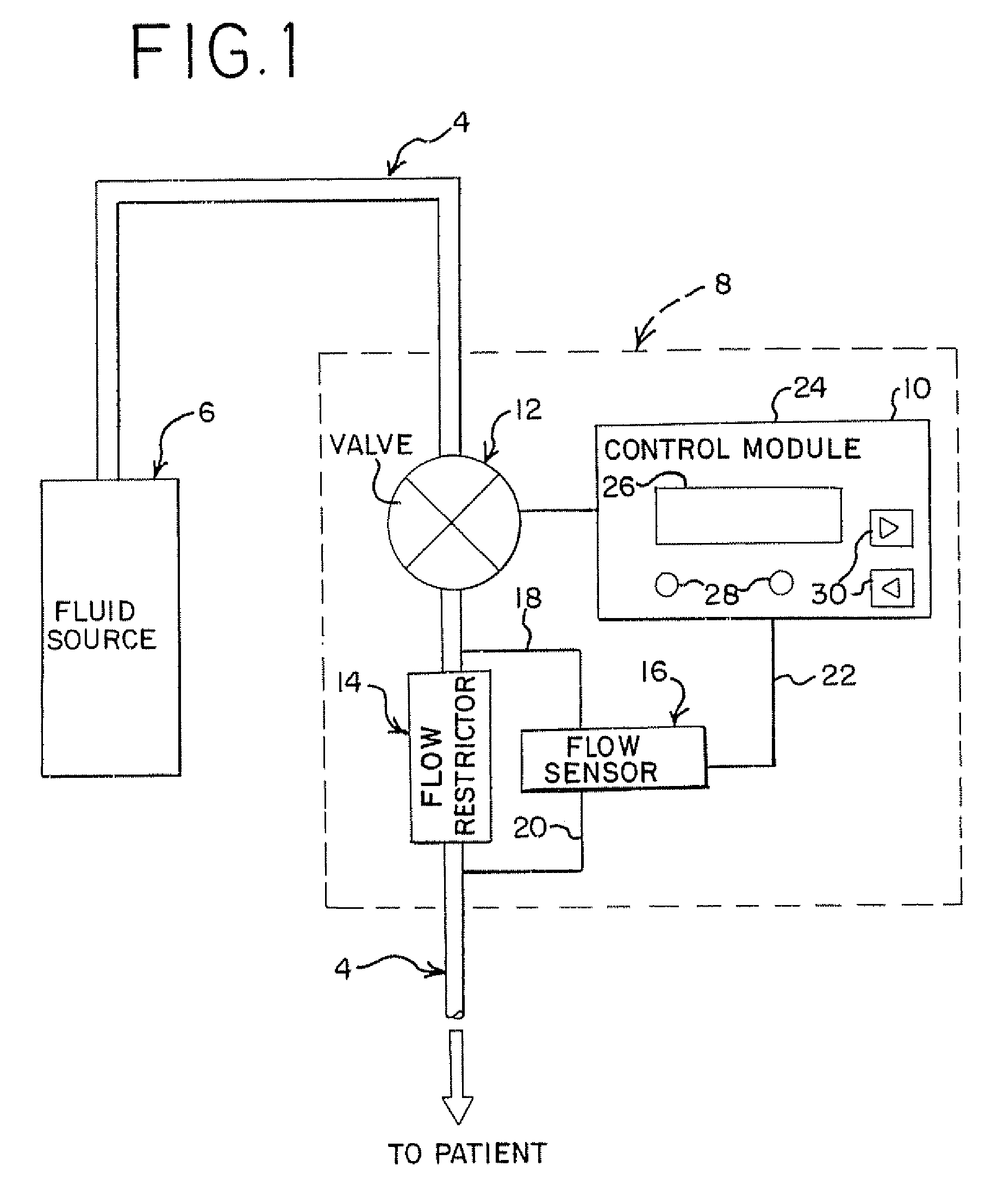

System and method for measuring liquid viscosity in a fluid delivery system

InactiveUS20090113996A1Conveniently performedIntravenous devicesDirect flow property measurementLiquid viscosityFluid viscosity

The present invention includes systems and methods for determining the viscosity of a fluid within a fluid flow path. Such method may comprise flowing fluid through the fluid flow path and past a fixed flow restriction therein. The method may also comprise first sensing of a fluid pressure within the fluid flow path at a selected location upstream of the flow restriction. The method may also include limiting fluid flow in the fluid flow path upstream of such selected location. The method may further comprise second sensing of a fluid pressure within the fluid flow path at such selected location after such limiting. Such method includes determining the viscosity of the fluid based, at least in part, on any pressure difference from such first and second sensing.

Owner:BAXTER INT INC +1

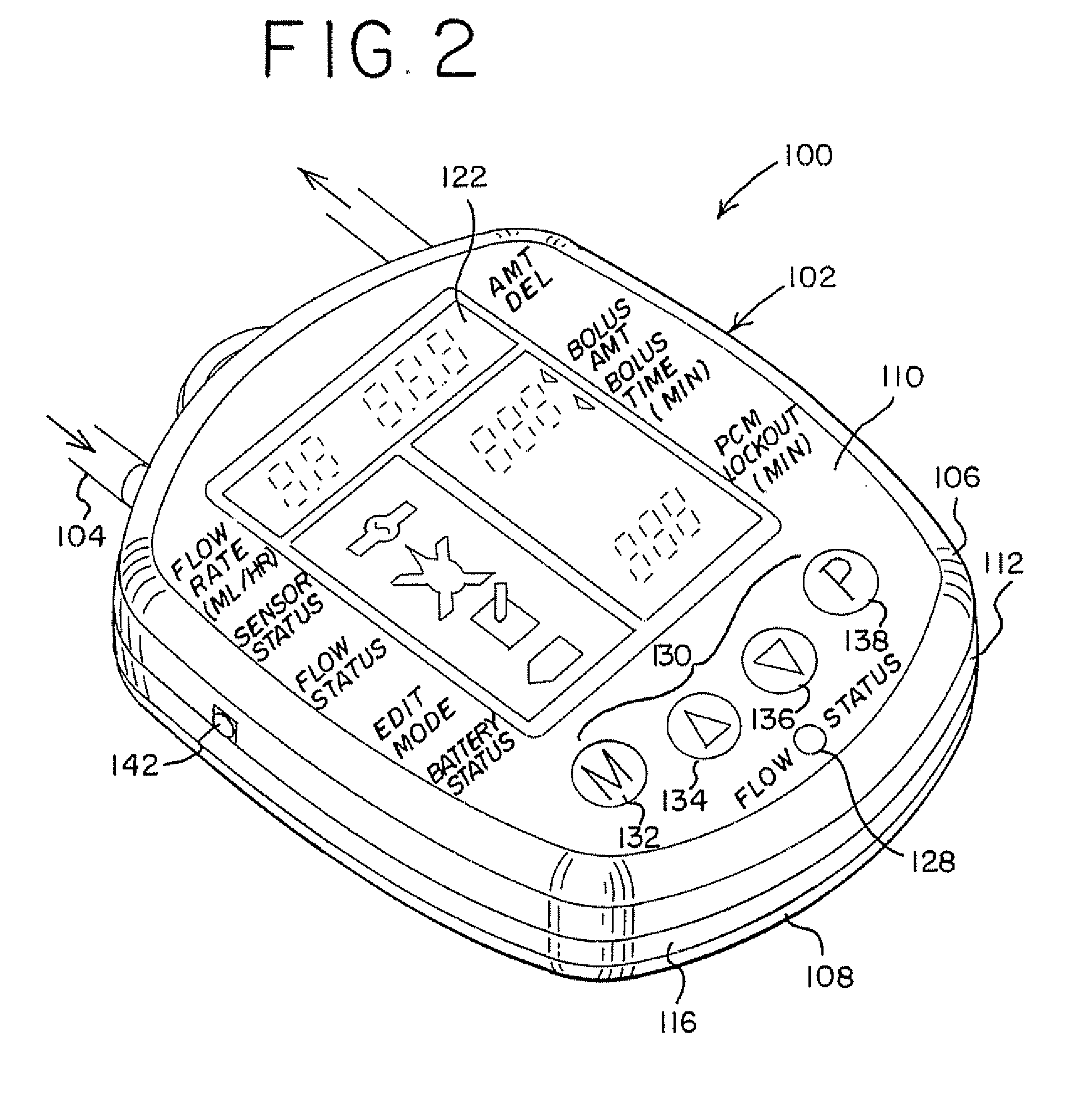

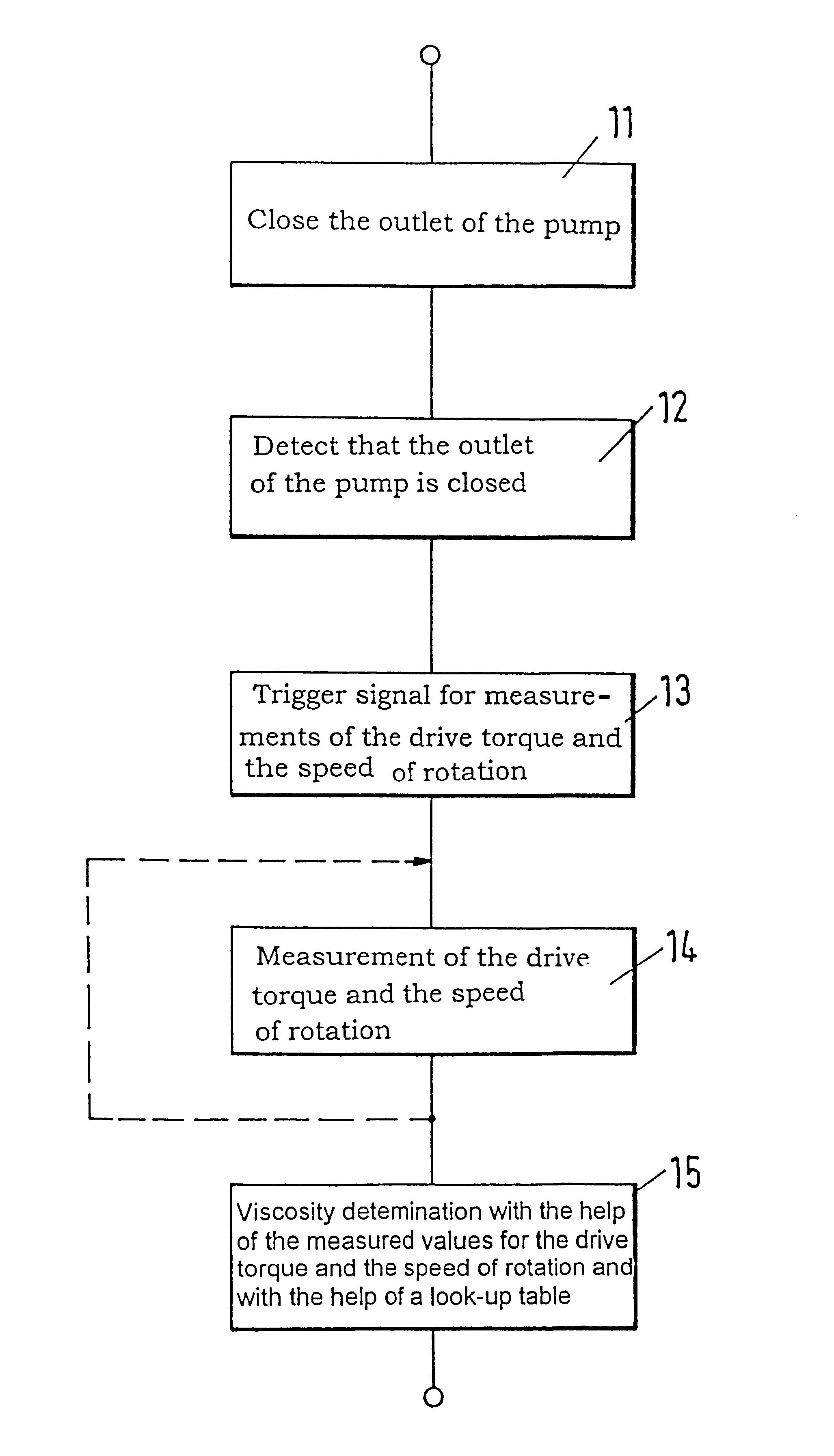

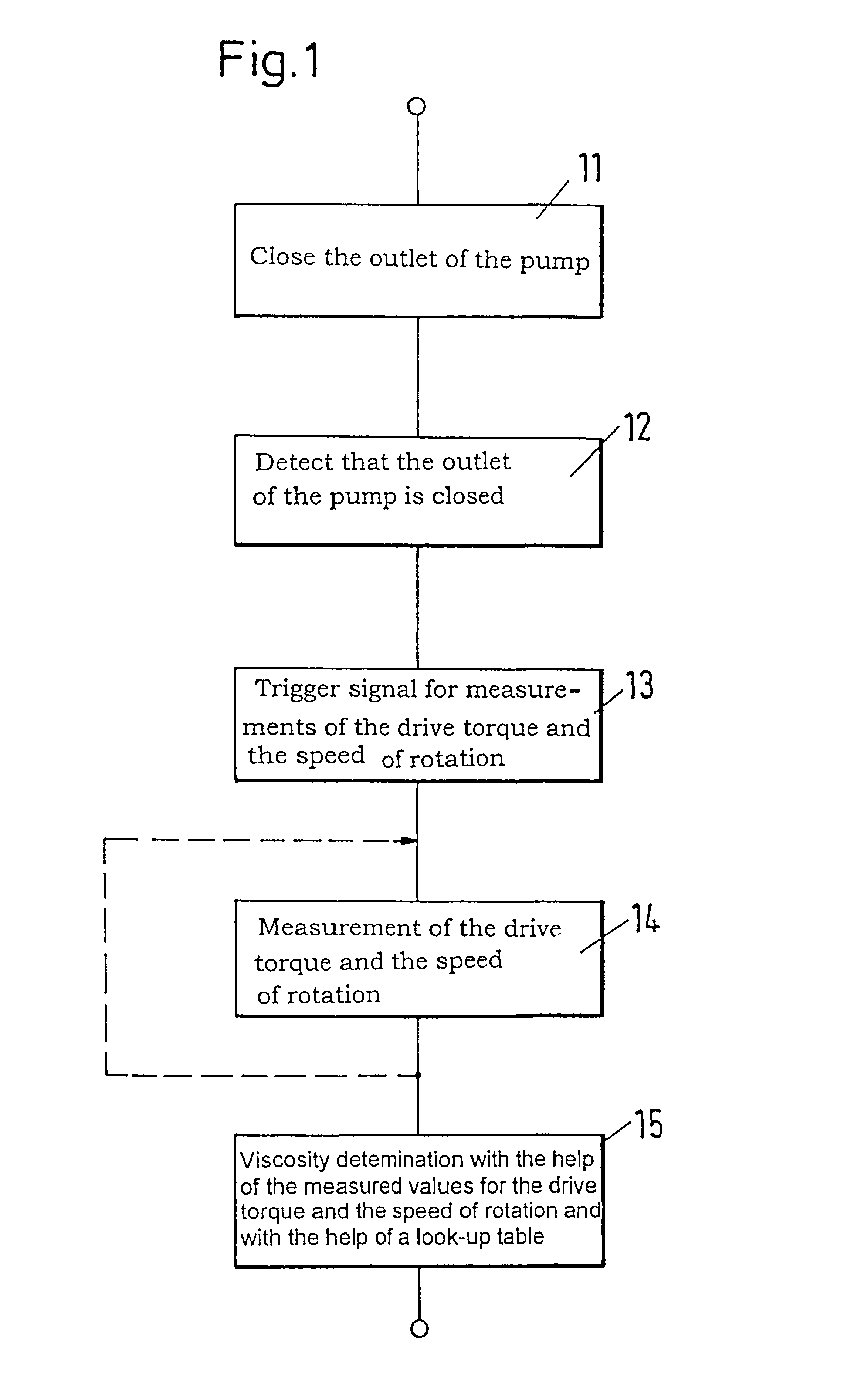

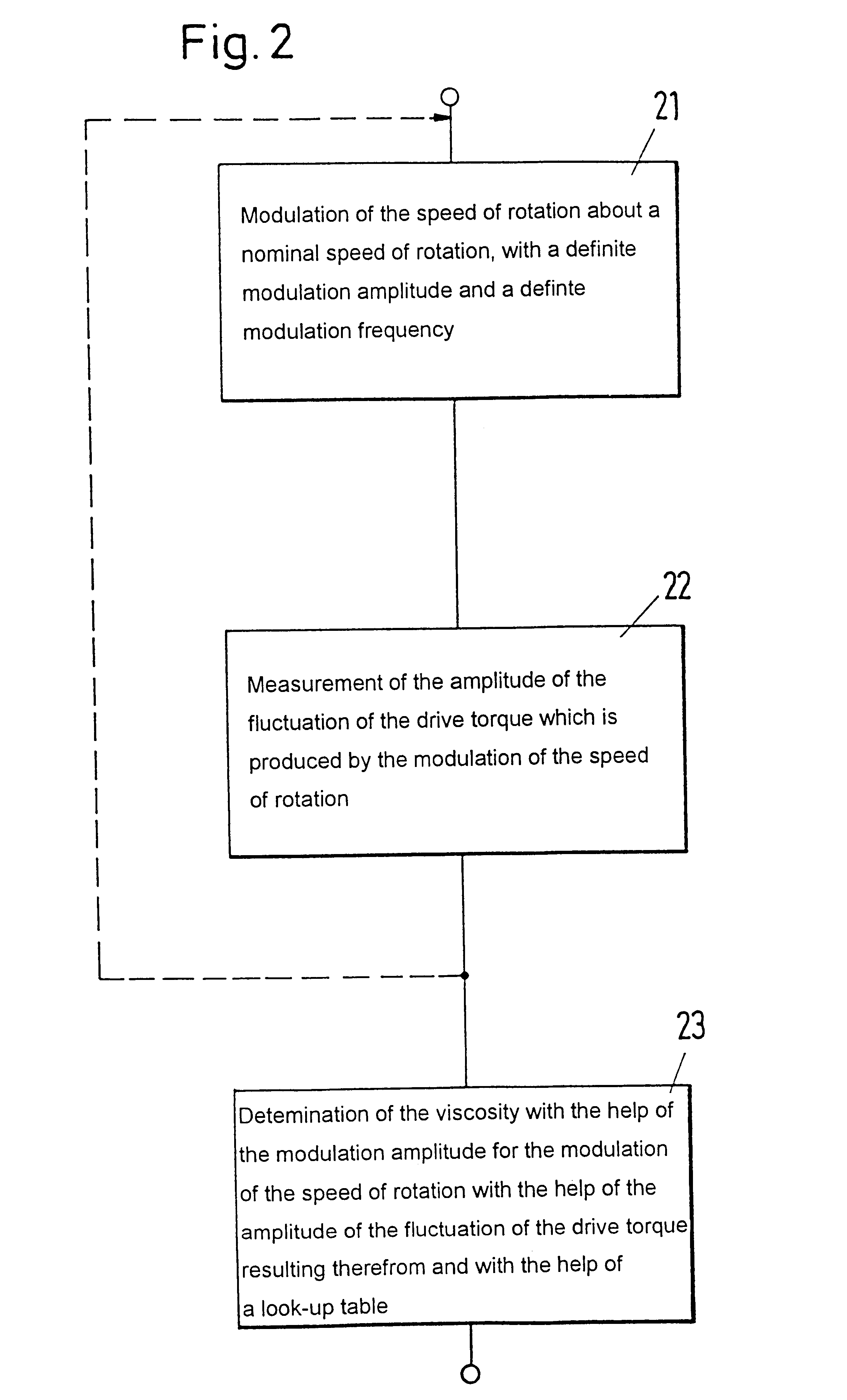

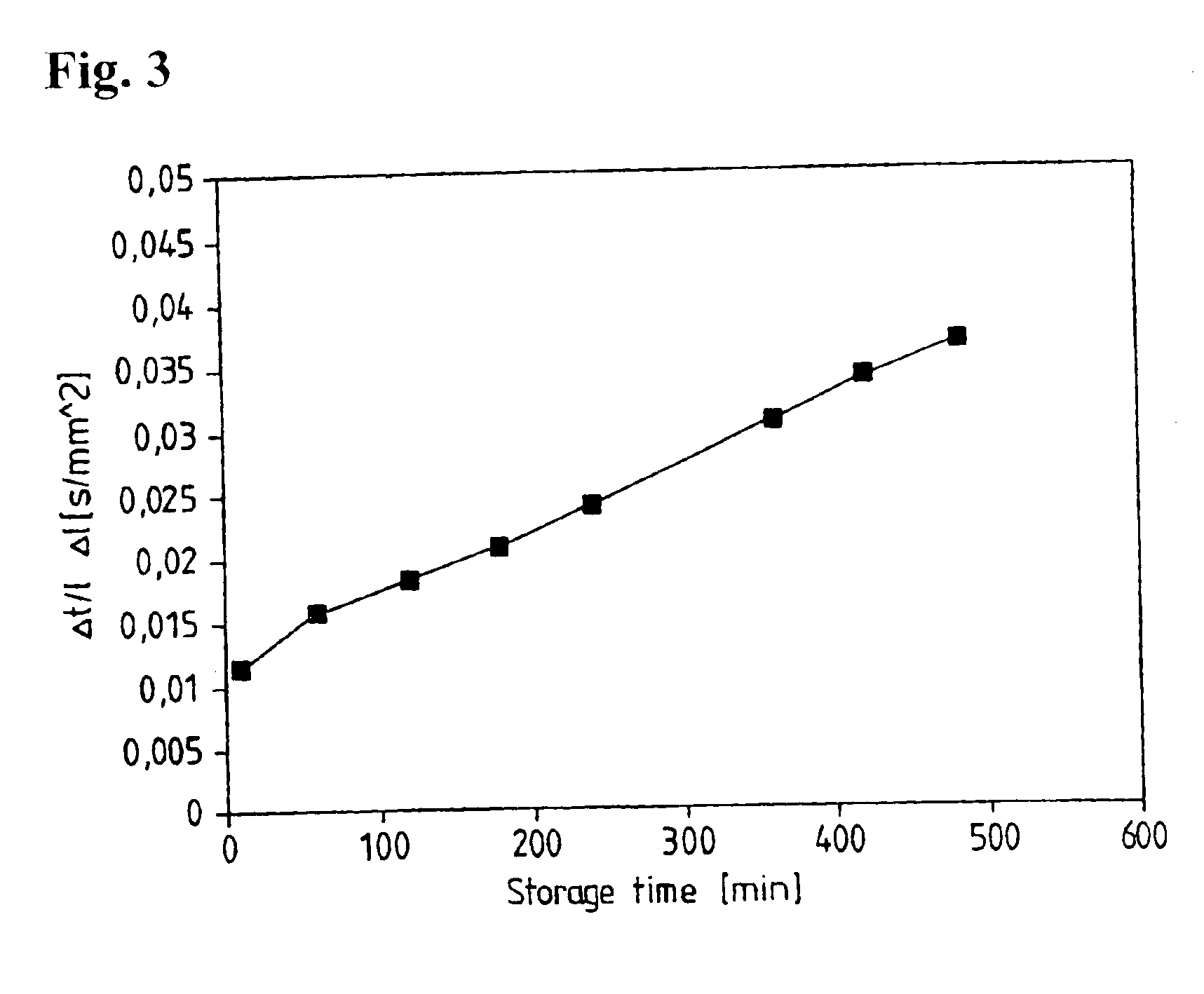

Method for the determination of the viscosity of a liquid such as blood

In a method for the determination of the viscosity (eta) of a liquid, e.g. of blood, which is forwarded by a pump, e.g. a blood pump, said pump having a rotor for the forwarding of the liquid from the inlet of the pump to the outlet, the rotor is used for the determination of the viscosity (eta). For the determination of the viscosity (eta) of the liquid no spatial deflection of the rotor from its operating position takes place, but rather the rotor is left in its operating position and the viscosity (eta) is determined from measurement parameters of the pump or of the rotor respectively.

Owner:THORATEC CORPORTION

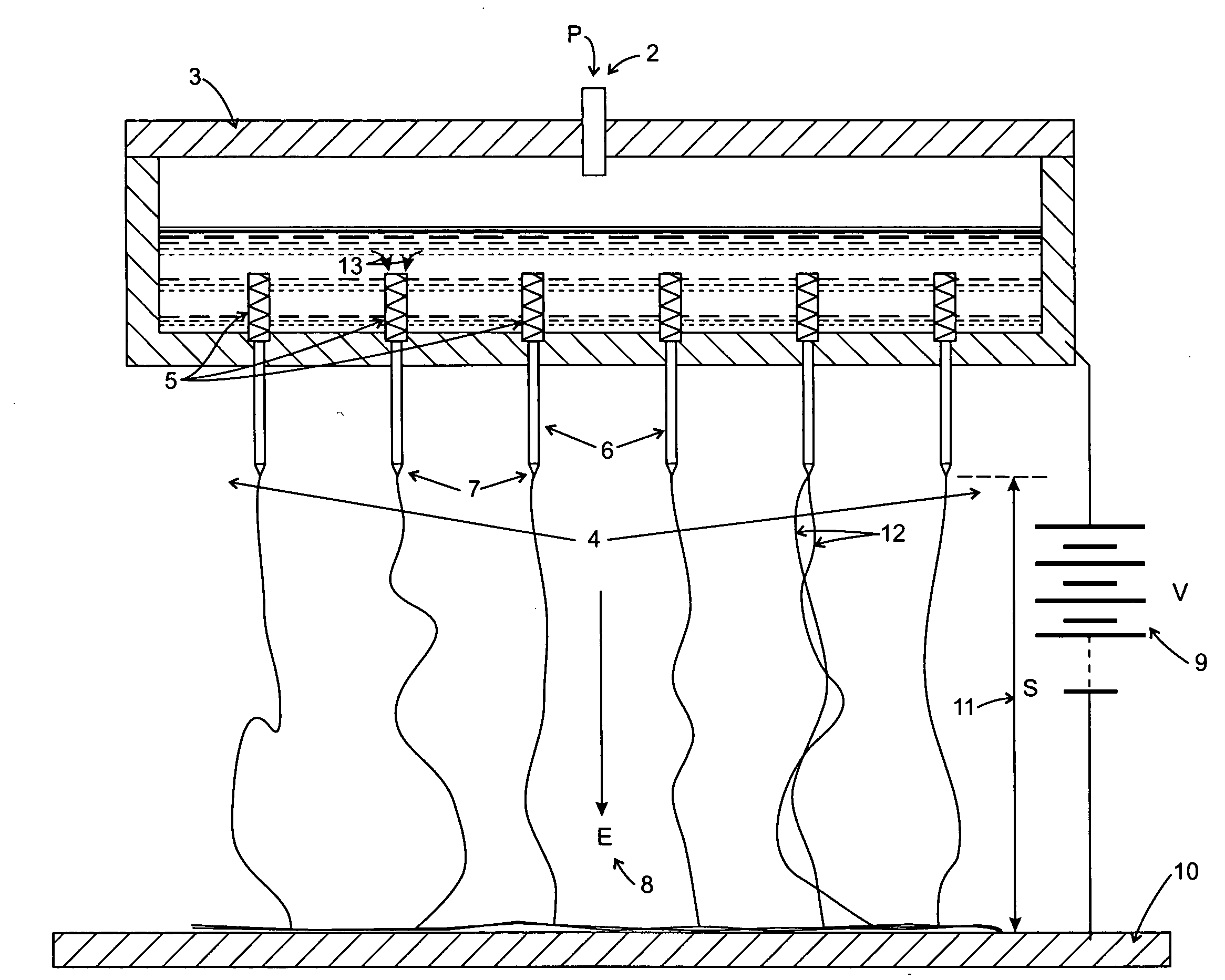

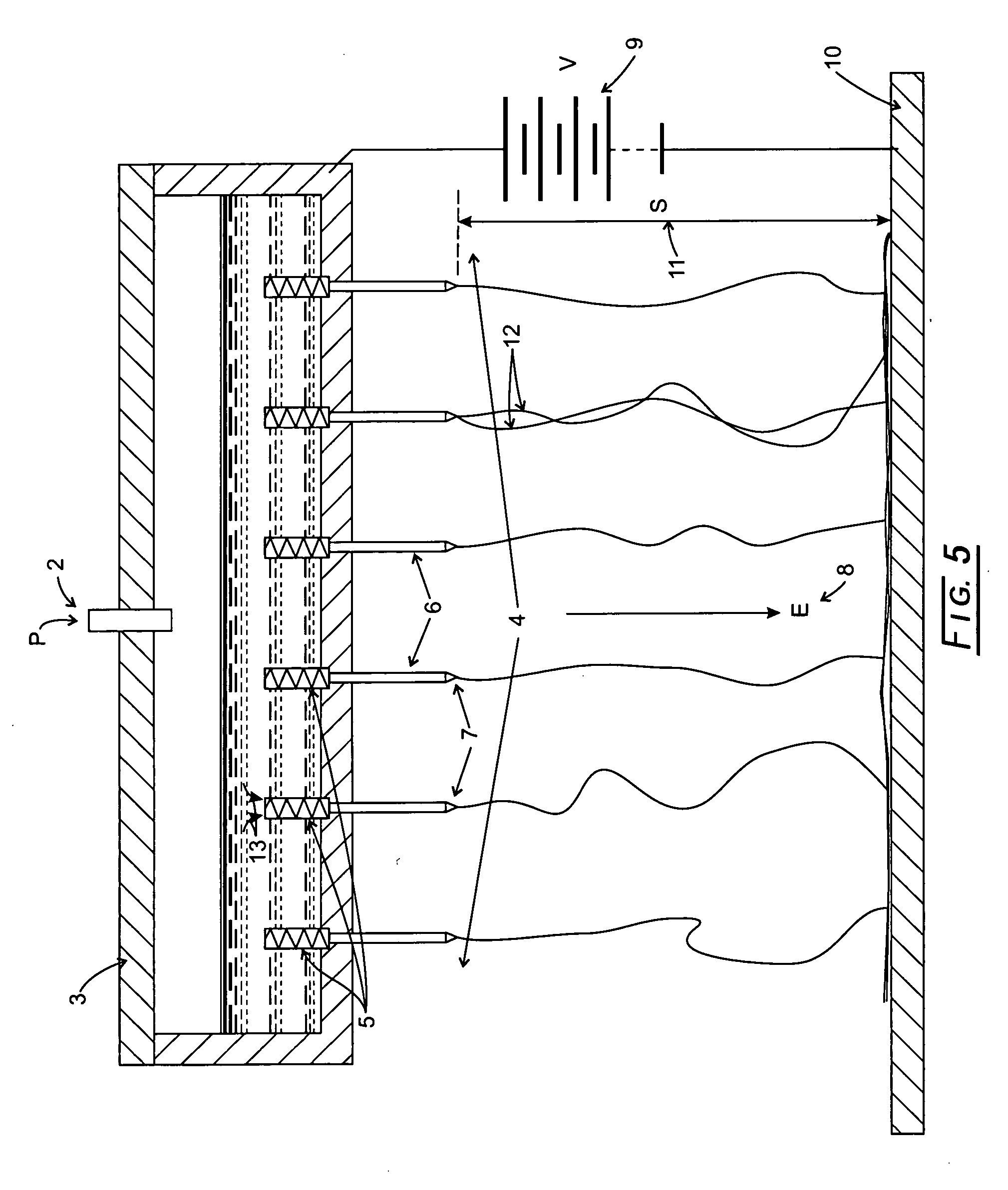

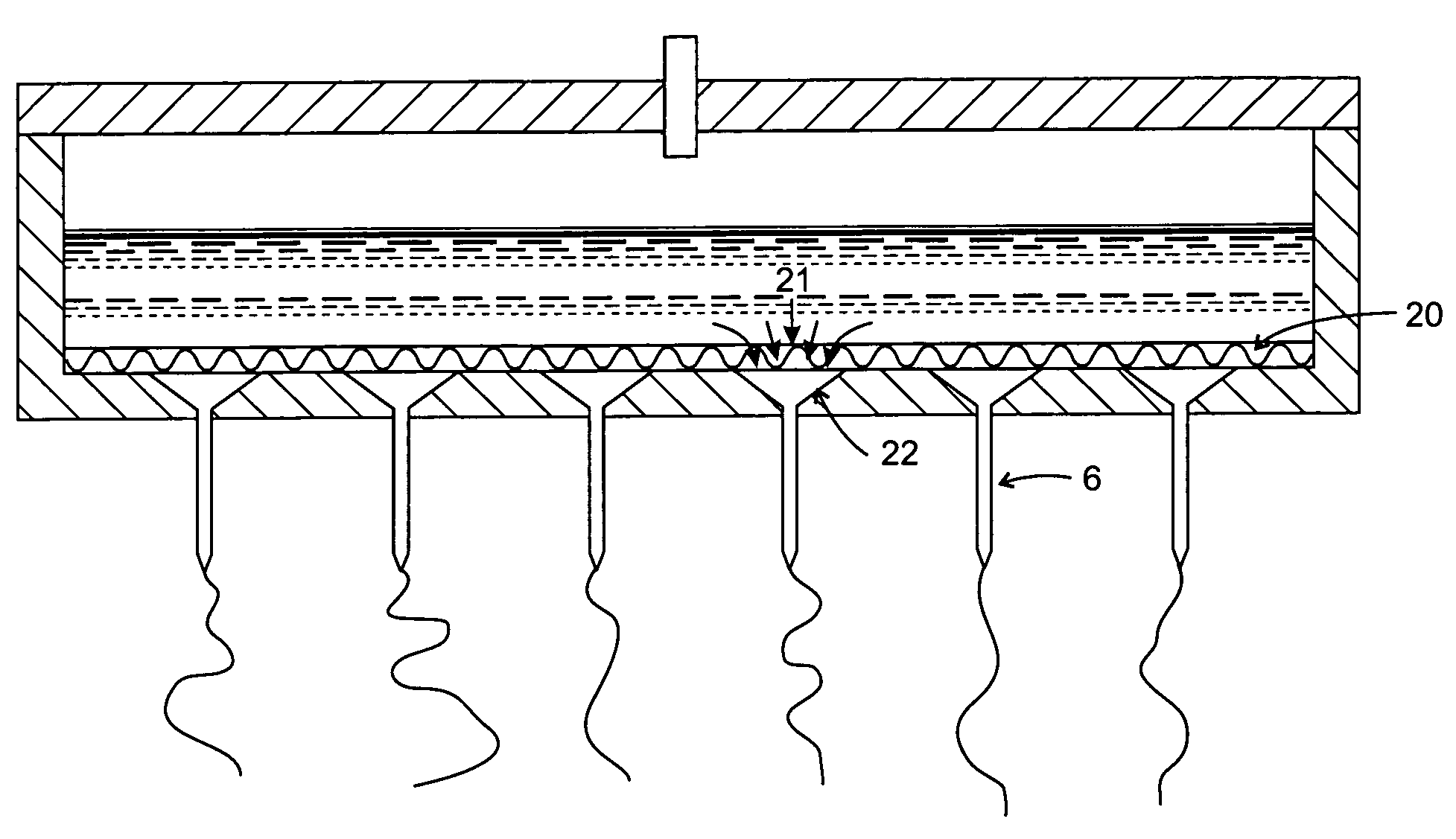

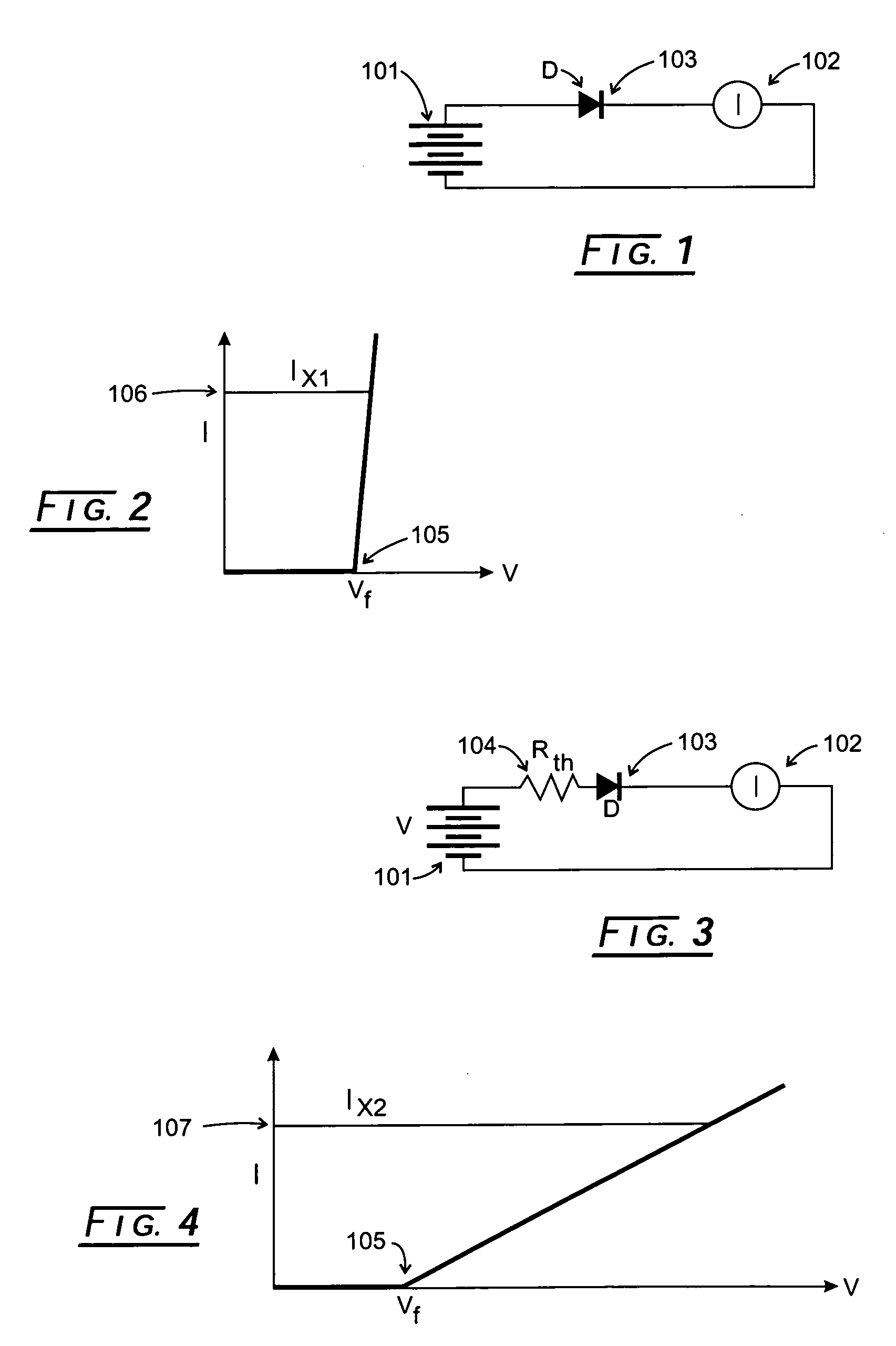

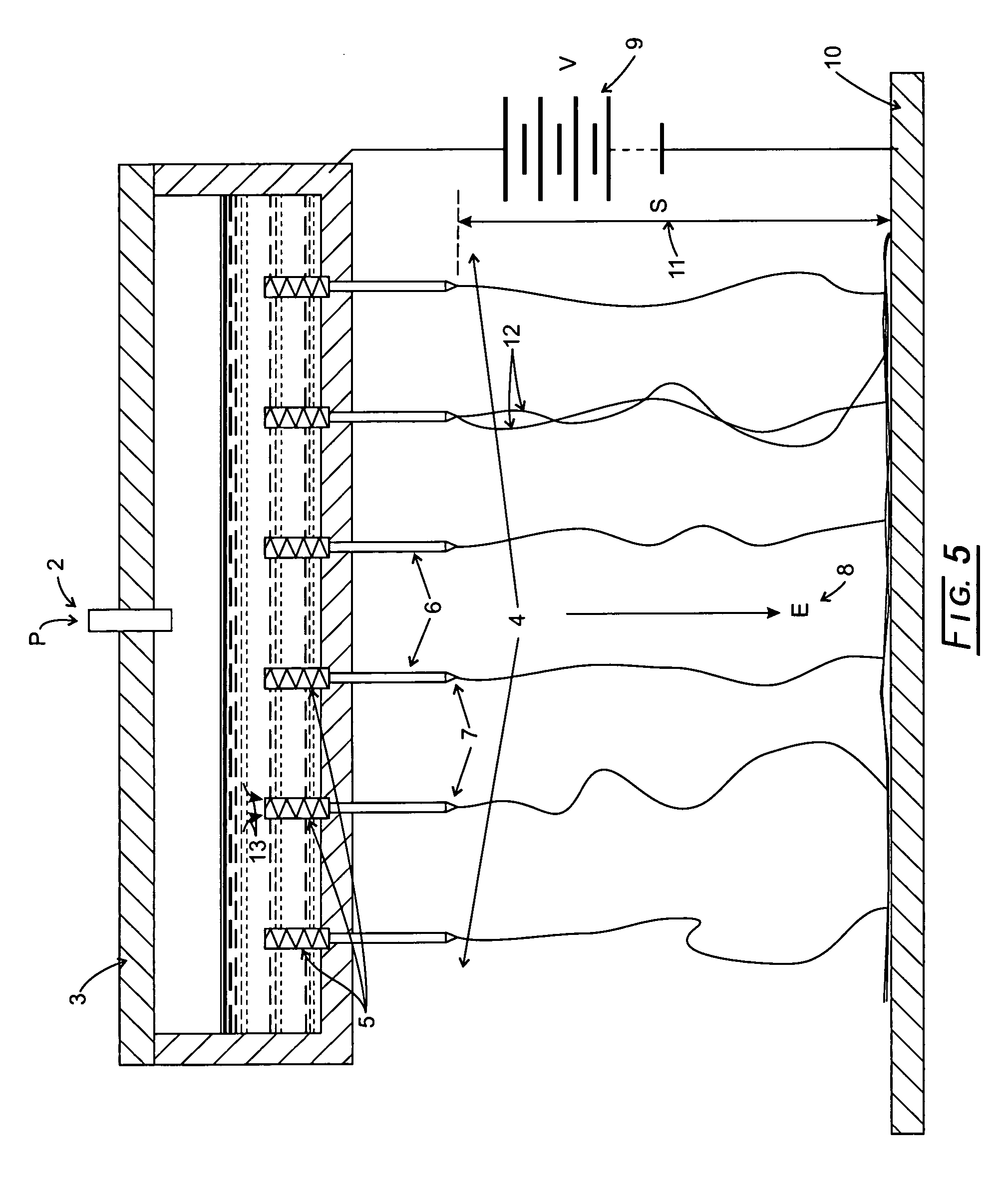

Electrospraying/electrospinning array utilizing a replacement array of individual tip flow restriction

InactiveUS20080131615A1Facilitate electrohydrodynamic (EHD) sprayingLess sensitiveLiquid surface applicatorsElectric shock equipmentsLiquid viscosityElectrospinning

An electrohydrodynamic spraying or spinning deposition system, which includes a common source of pressurized liquid within a manifold, and an array of 2 or more spraying tips, each tip being fed from the common source of pressurized liquid to create a liquid flow path. An individual flow impedance device is disposed within each tip's individual liquid flow path from the pressurized liquid source into each spraying tip. The individual flow impedance devices are disposed within a replaceable sheet, which can be easily cleaned or changed to accommodate the instance liquid viscosity and composition. A high voltage source is applied to create a high voltage potential applied between the tip array and a deposition surface.

Owner:DROPLETECH LLC

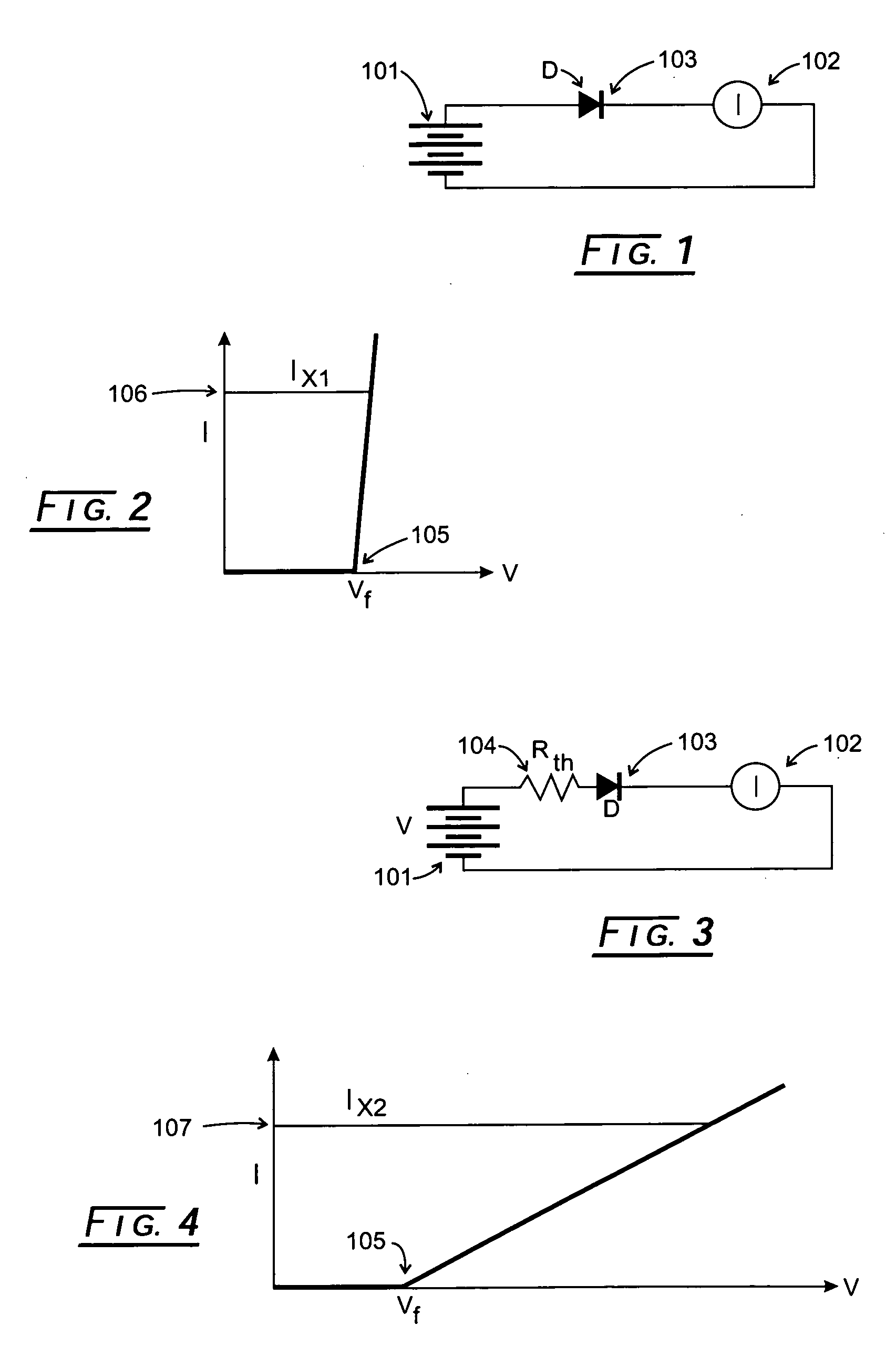

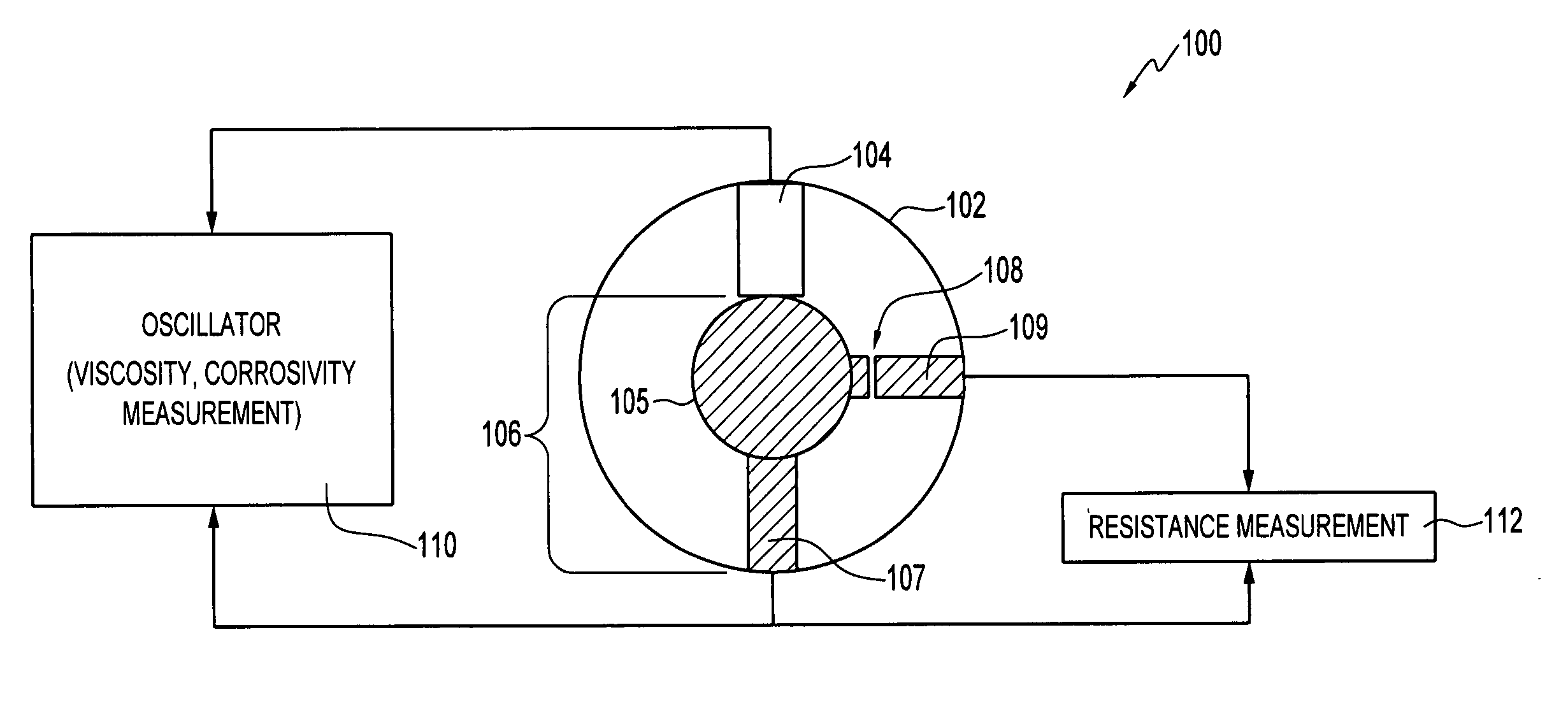

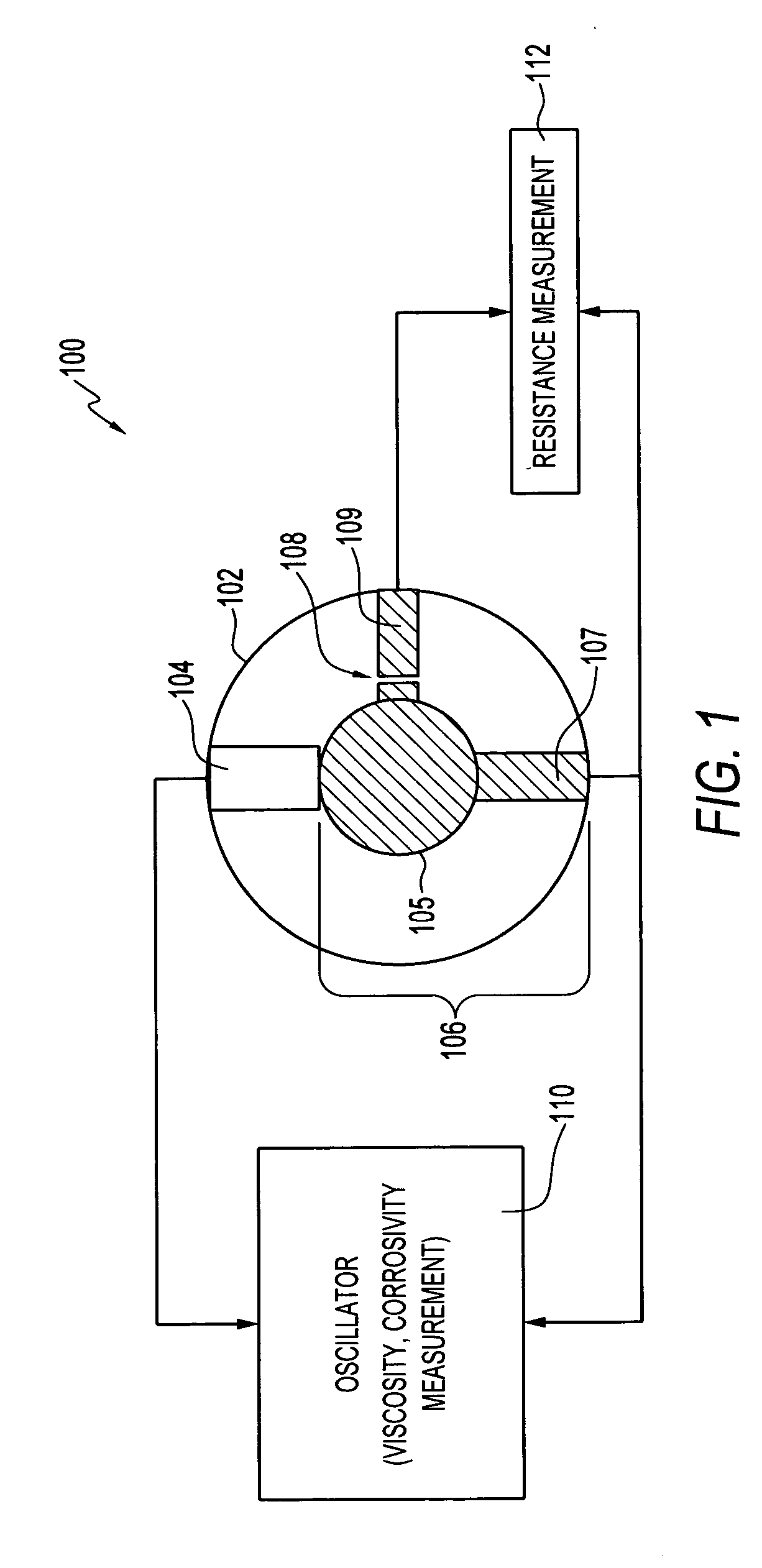

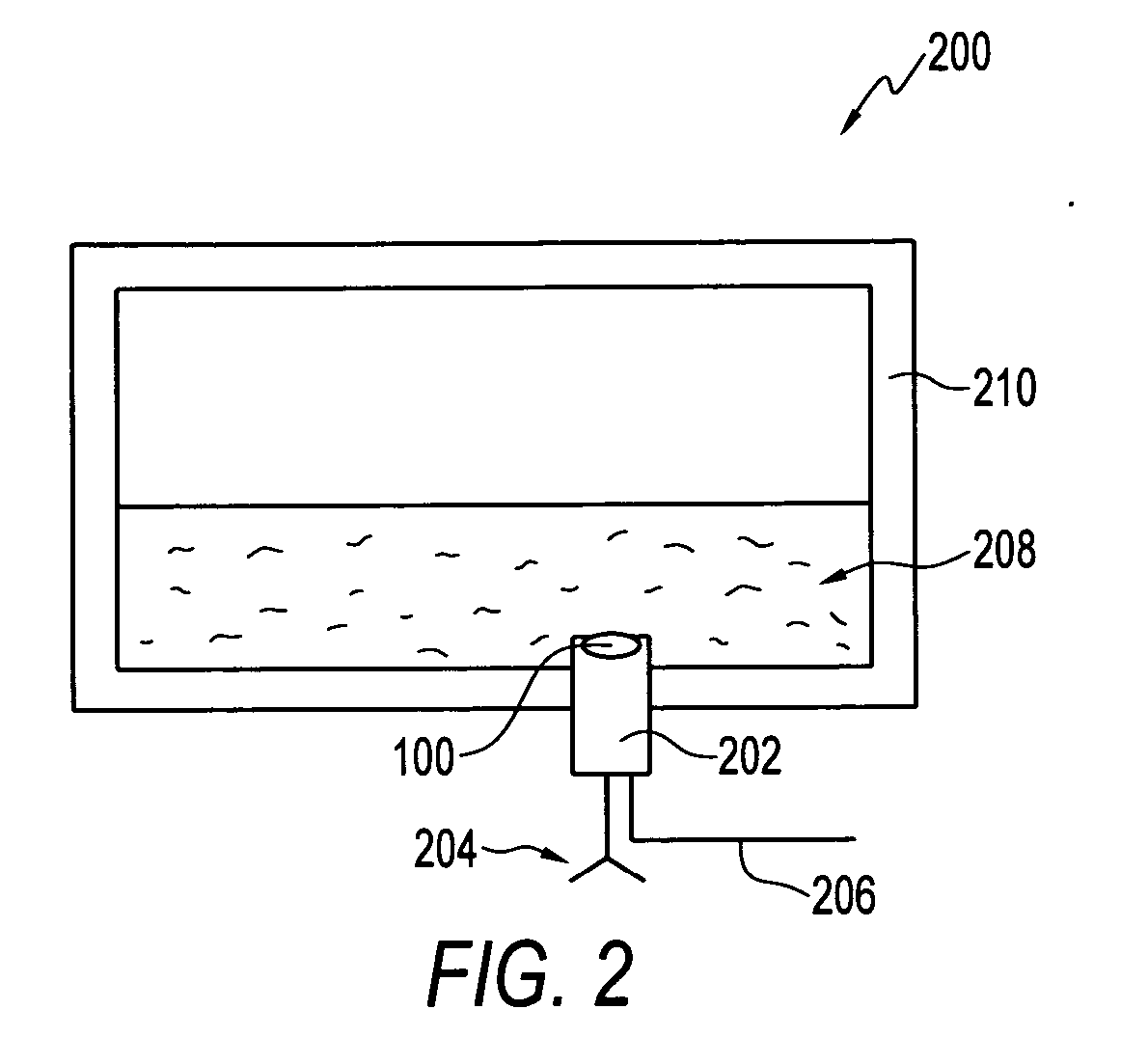

Engine wear and oil quality sensor

InactiveUS20070074563A1Material analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementLiquid viscosityEngineering

A viscosity and corrosivity sensor apparatus includes a substrate upon which one or more electrodes are configured. The electrode(s) are exposed to a liquid, such as automotive oil. An oscillator can be connected to the electrode, wherein the oscillator assists in providing data indicative of the corrosivity and data indicative of the viscosity of the liquid in contact with the electrode(s). A viscosity and corrosivity sensor is therefore provided in the same package.

Owner:HONEYWELL INT INC

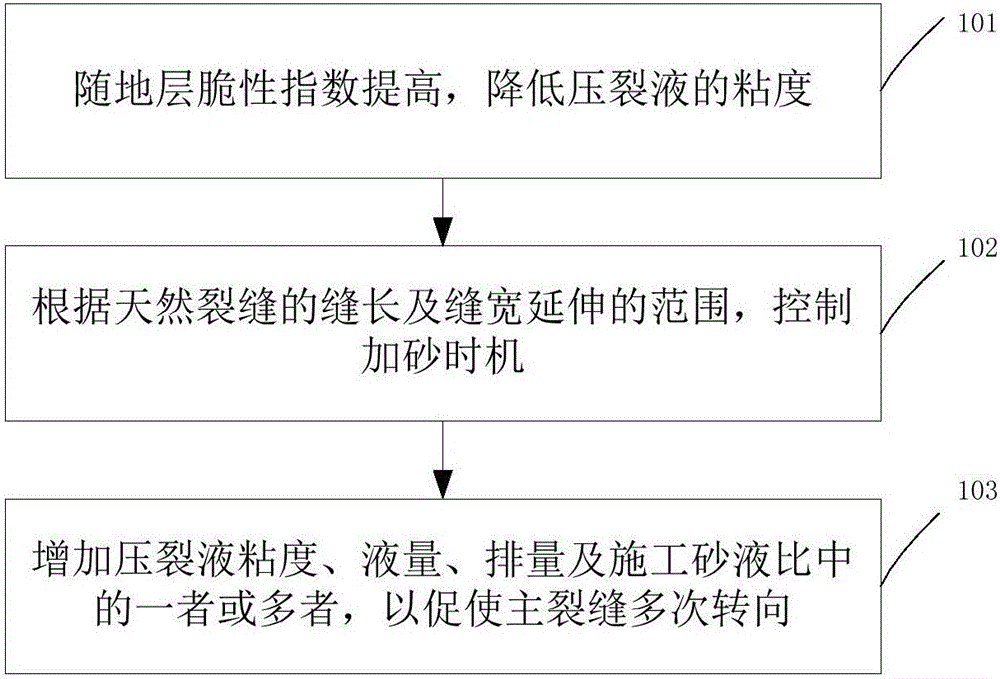

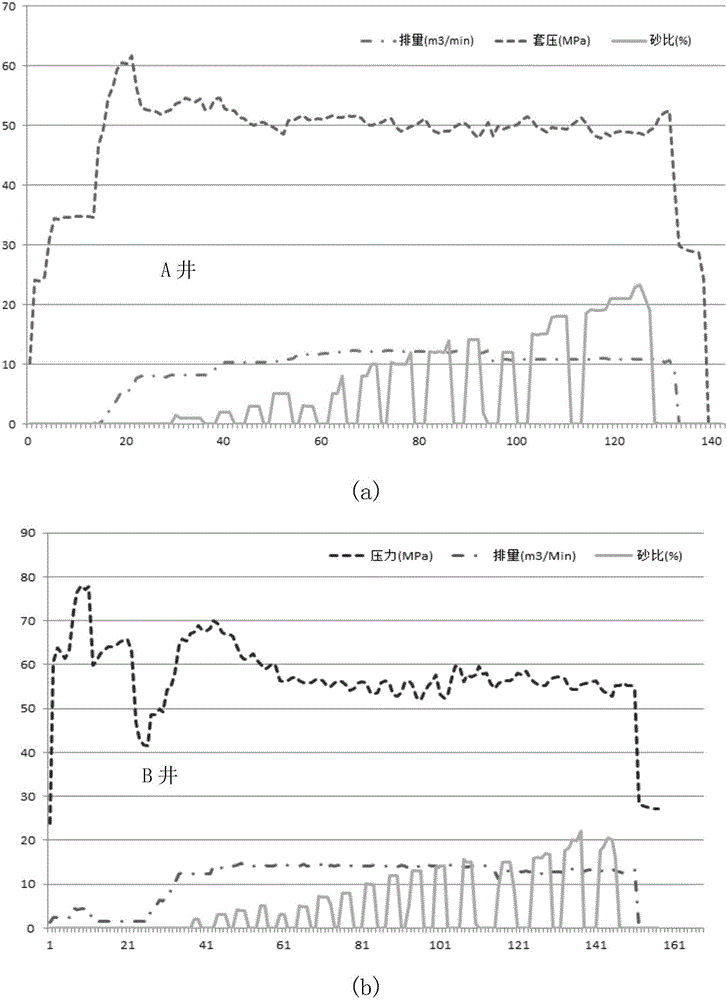

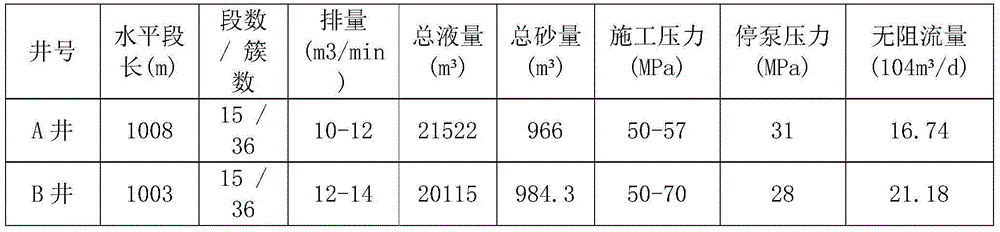

Method increasing shale gas fracturing crack complexity

A method increasing shale gas fracturing crack complexity comprises steps of reducing fracturing liquid viscosity with increase of stratum friability index, controlling sand adding time according to length of natural cracks and crack width extending range, and increasing either fracturing liquid viscosity, liquid volume, discharging volume or construction sand-liquid proportion or several of above to promote main cracks to turn time after time. By the use of the method, fracturing crack volume can be increased and segmental fracturing effect can be enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

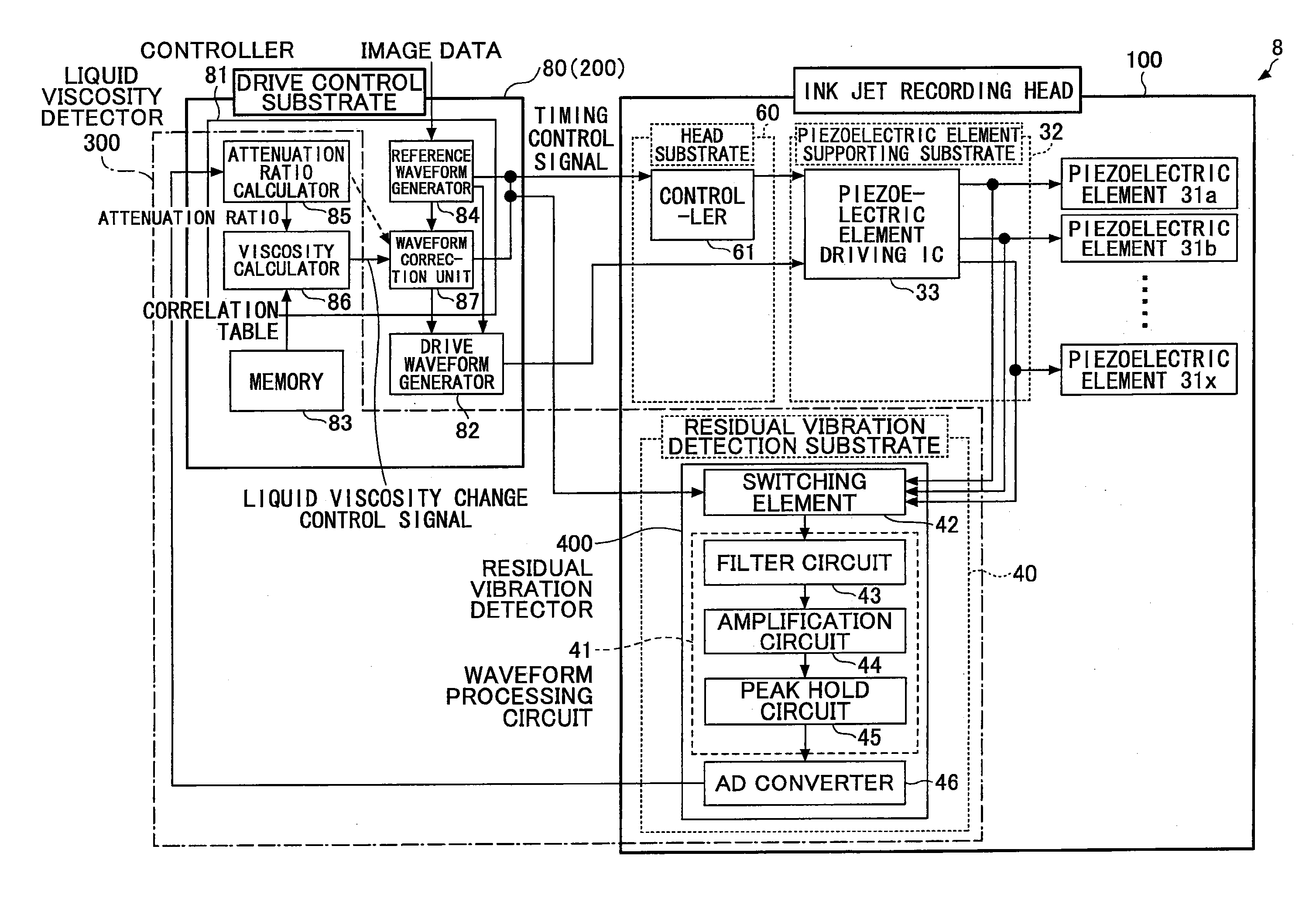

Liquid viscosity detecting method for liquid droplet ejecting device, control method for liquid droplet ejecting device, and liquid droplet ejecting device

A liquid viscosity detecting method is performed in a liquid droplet ejecting device that includes a piezoelectric type droplet ejecting head to which a drive waveform is applied to pressurize a liquid chamber to eject a liquid droplet, a drive waveform generator to apply the drive waveform to the droplet ejecting head, and a residual vibration detector. The method includes detecting, by the residual vibration detector, amplitude values of multiple cycles of a residual vibration waveform occurring within the liquid chamber after the drive waveform is applied; calculating an attenuation ratio based on the amplitude values; and calculating a liquid viscosity in the liquid chamber based on the attenuation ratio.

Owner:RICOH KK

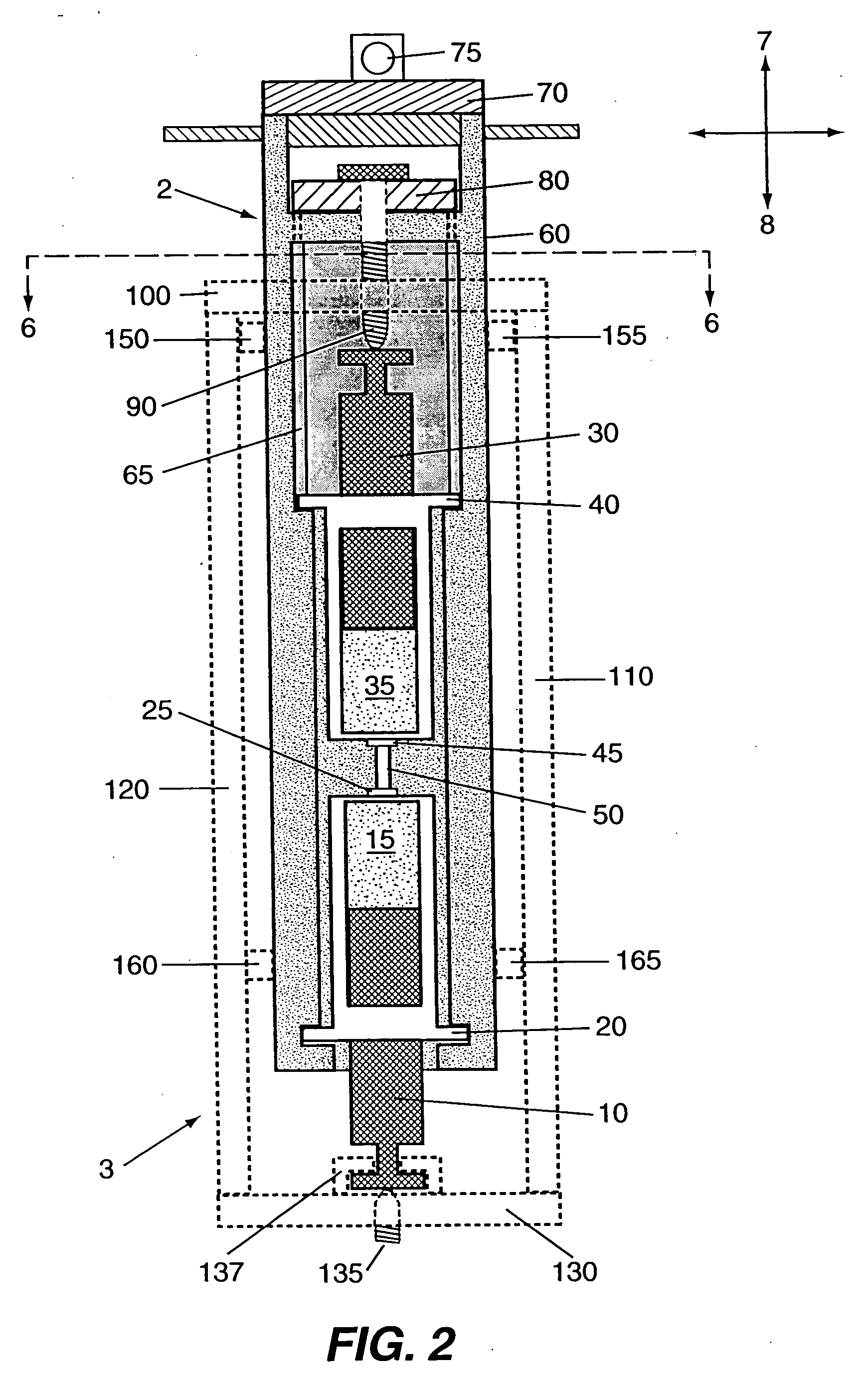

Mixing utility, liquid viscometric apparatus

An apparatus for foam emulsion processing, and / or determination of the rheological parameters of a given sample includes a syringe assembly, a movable assembly, and a platform assembly. The syringe assembly has a first and second syringe connected by a capillary tube (emulsion needle). The movable assembly includes a holder tube within which the syringe assembly is secured. The platform assembly restrains movement of the movable assembly to only one axis.

Owner:LOS ALAMOS NATIONAL SECURITY

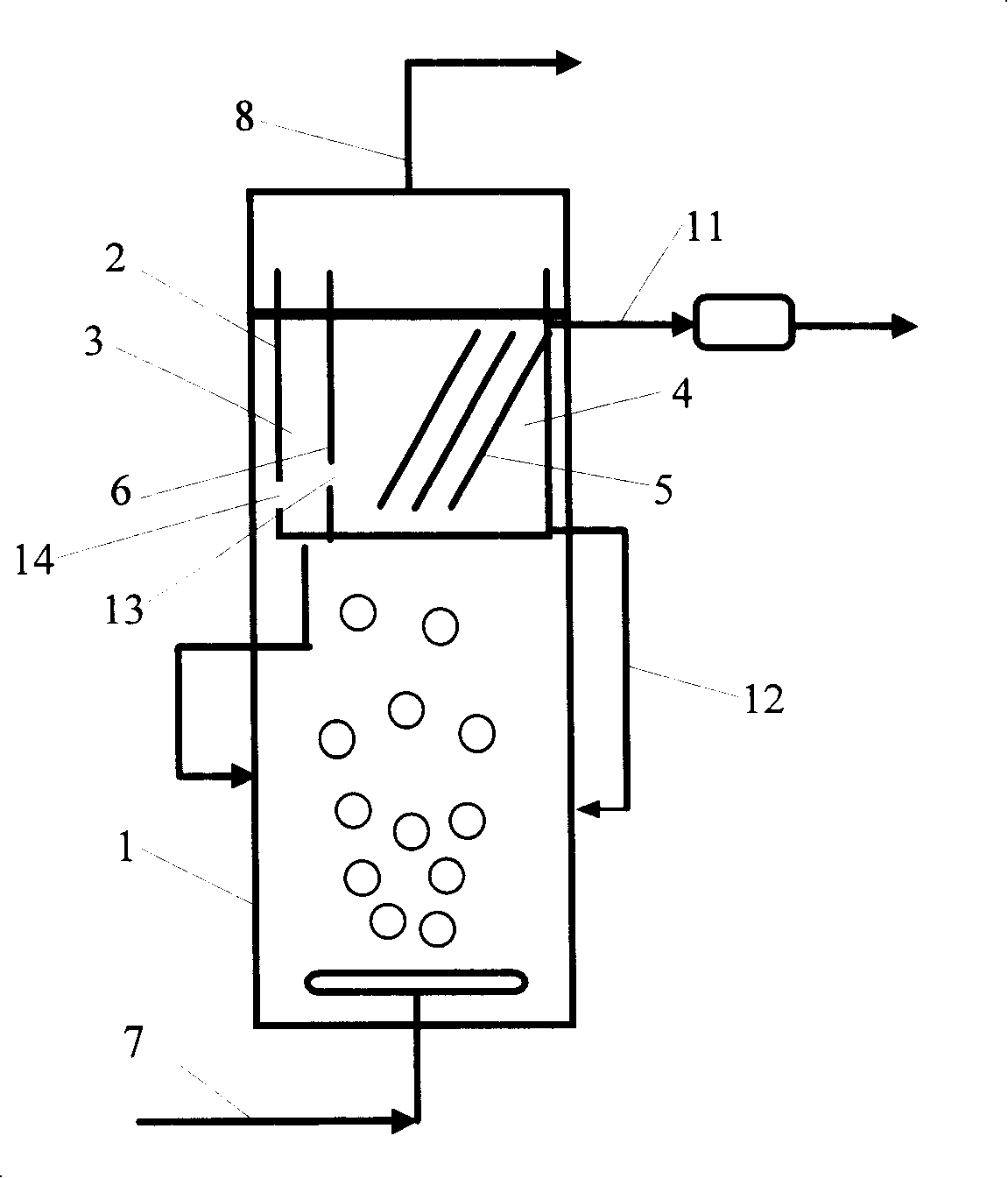

Method and equipment for liquid-solid continuously separation for slurry state bed reactor

ActiveCN101209403AAchieve continuous separationAchieve separationLiquid hydrocarbon mixture productionChemical/physical processesLiquid productLiquid viscosity

The invention discloses a method and a piece of equipment which are used for continuously separating liquid and solid of a serum-bed reactor. The contact reaction between materials and catalyst particles takes place in a serum-bed reactor, and suspension serum after the reaction is guided into a separation unit which comprises an inclined-plate settlement vessel and quickly separated into supernatant and concentrated serum in the inclined-plate settlement vessel, wherein, the concentrated serum returns to the reactor for continuing to participate in the reaction, and the supernatant flows upward into an upper part of the inclined-plate settlement vessel along gaps between the plates and is exhausted. The method provided by the invention implements the continuous separation and circular utilization of solid catalyst particles and liquid products in a smaller operation space and improves settlement efficiency. The equipment provided by the invention is applicable for separating suspension serum with smaller catalyst particles and larger liquid viscosity, occupies small space and has high separation efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

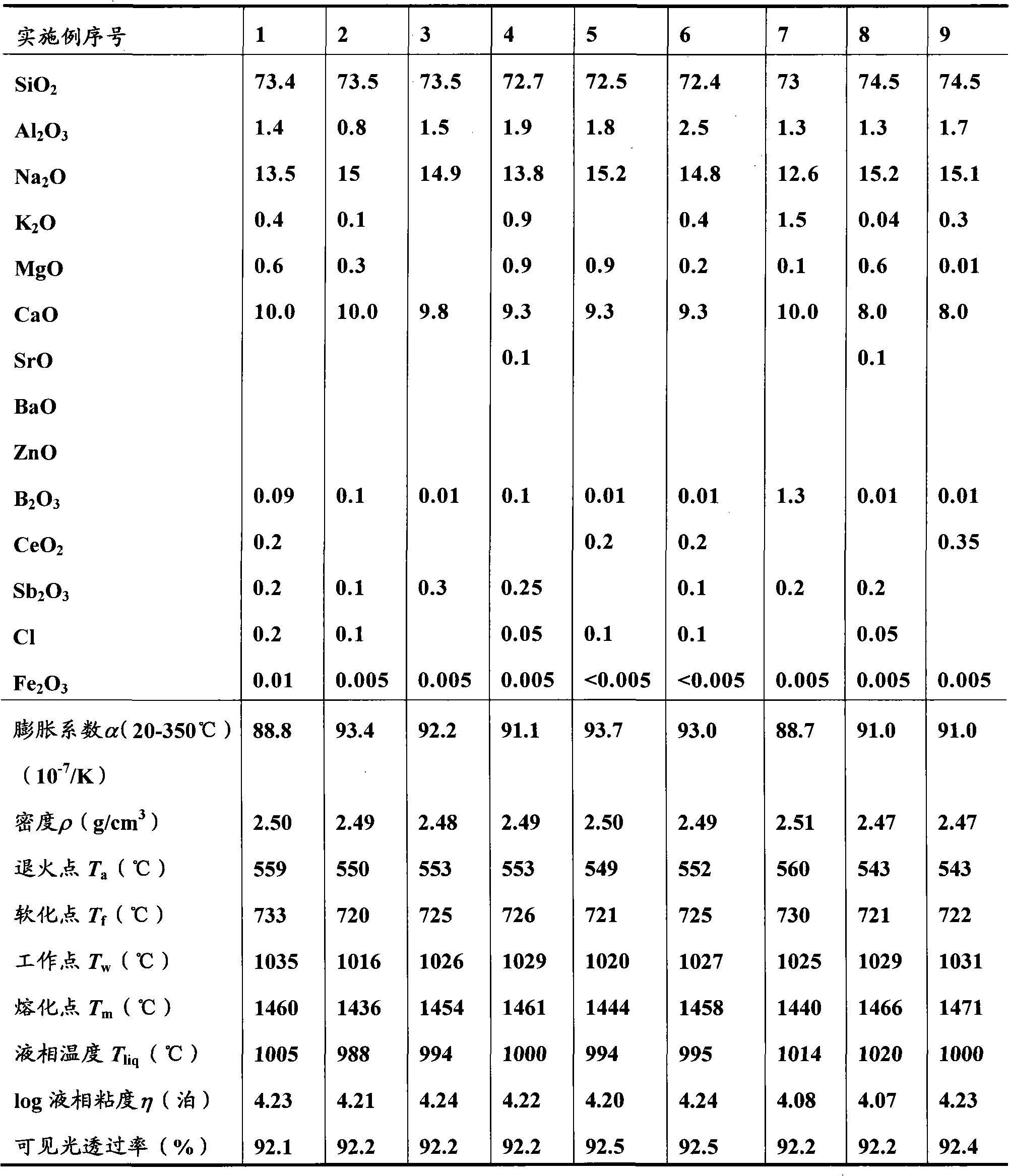

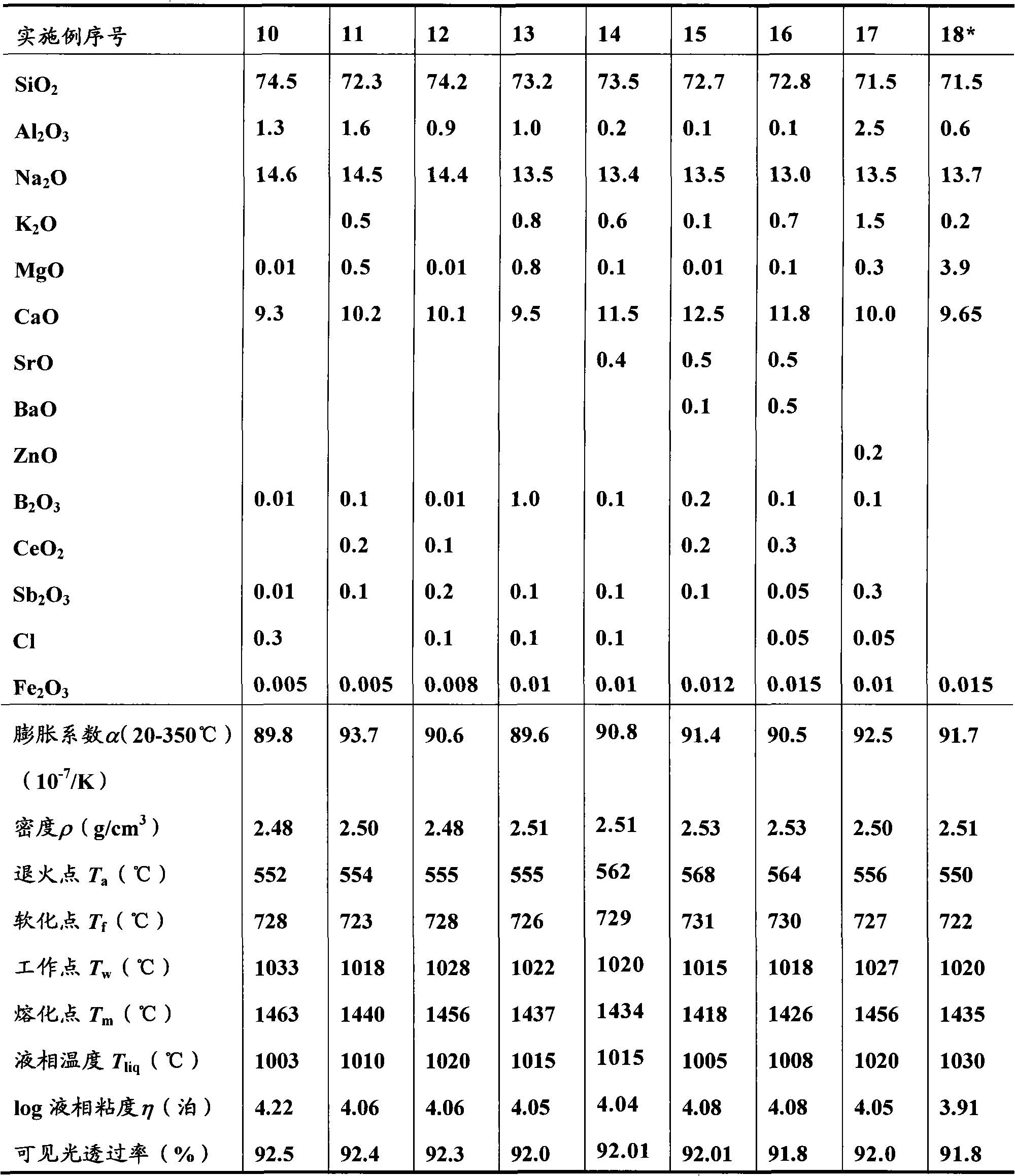

Sodium-calcium-silicate glass composition, its manufacturing method and use

The invention relates to a sodium-calcium silicate glass compound, which has high liquid viscosity and is suitable for manufacturing various glass plates, especially suitable for manufacturing glass plates used for solar cells; the invention also relates to a manufacturing method of the glass compound.

Owner:HENAN ANCAI HI-TECH

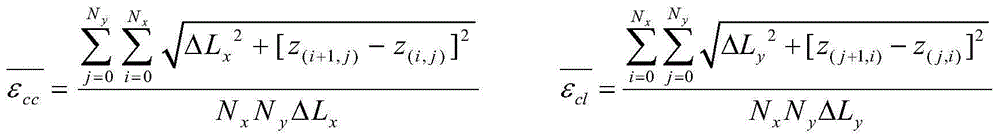

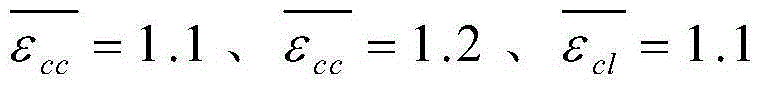

Method for evaluating etching forms of surface of rock plate in acid etching physical simulation test

ActiveCN104989364AGo digitalFluid removalSpecial data processing applicationsAcid etchingAcid fracturing

The invention discloses a method for evaluating the etching forms of the surface of a rock plate in an acid etching physical simulation test. The method sequentially comprises the following steps of: A, using a three-dimensional laser scanner to scan the rough surface of the rock plate subjected to acid etching to obtain three-dimensional data on the surface of the rock plate; B, calculating the transverse twisting ratio and the longitudinal twisting ratio of the surface of the rock plate; C, using the two parameters (the transverse twisting ratio and the longitudinal twisting ratio) to classify the etching forms of the surface of the rock plate; D, describing and evaluating various etching forms of the surface of the rock plate on the basis of the classification results; and E, sequentially sequencing various etching forms from the poorest one to the best one. The method has the advantages that a rock sample of an oil and gas reservoir is used for performing the acid etching physical simulation test; and rock samples with different etching forms are obtained through changing different test parameters (acid liquid viscosity, acid liquid concentration and acid injection discharge capacity). The principle is reliable; the operation is simple and convenient; and the guidance can be provided for acid fracturing construction parameter optimization.

Owner:SOUTHWEST PETROLEUM UNIV

Polishing liquid for grinding and polishing lithium niobate optical wafer

InactiveCN1858131AEasy to break awayIncrease viscosityOptical surface grinding machinesAqueous dispersionsLithiumLiquid viscosity

The present invention discloses polishing liquid for grinding and polishing optical lithium niobate wafer. The polishing liquid consists of silica sol 30-90 vol%, organic amine alkali 1-10 vol%, inorganic alkali 1-5 vol%, activator 0.5-5 vol%, chelating agent FA / O 0.5-5 vol%, and deionized water for the rest. Under CMP and high pH condition, lithium is formed into stable complex and water soluble niobate to raise polishing efficiency and surface quality. The present invention has organic alkali and lithium niobate surface matter to form soluble amine salt easy to separate from the reaction surface, and this avoids the increase in the abrasive granularity and polishing liquid viscosity to ensure no scoring, high flatness and no adsorbate.

Owner:HEBEI UNIV OF TECH

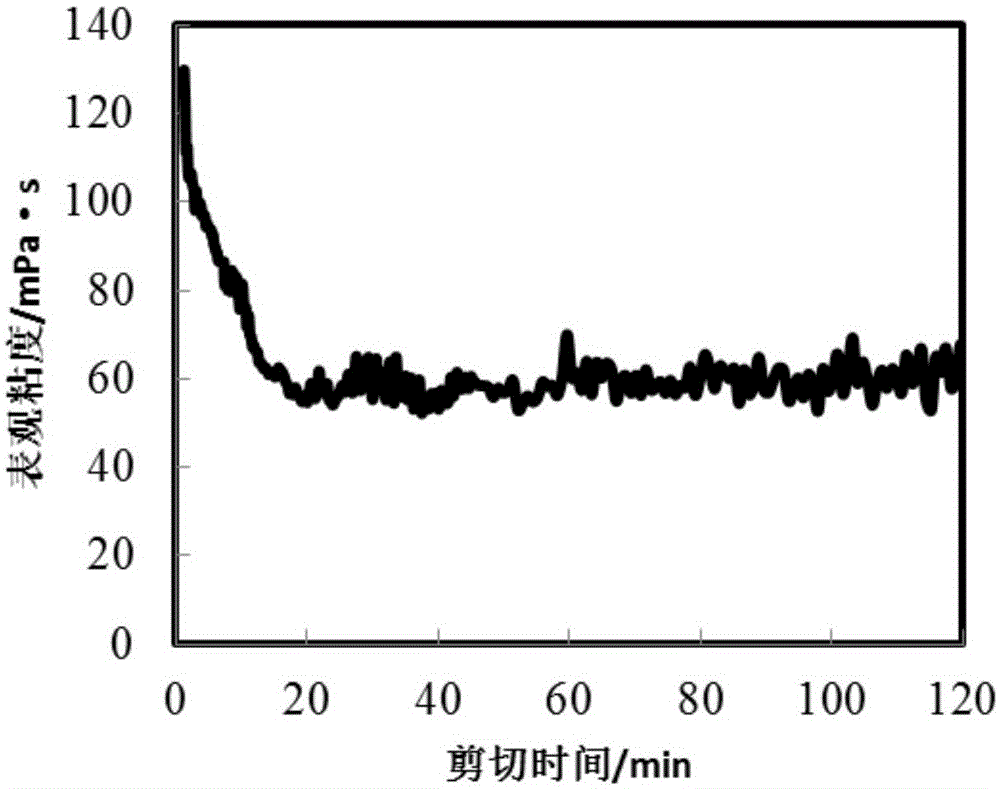

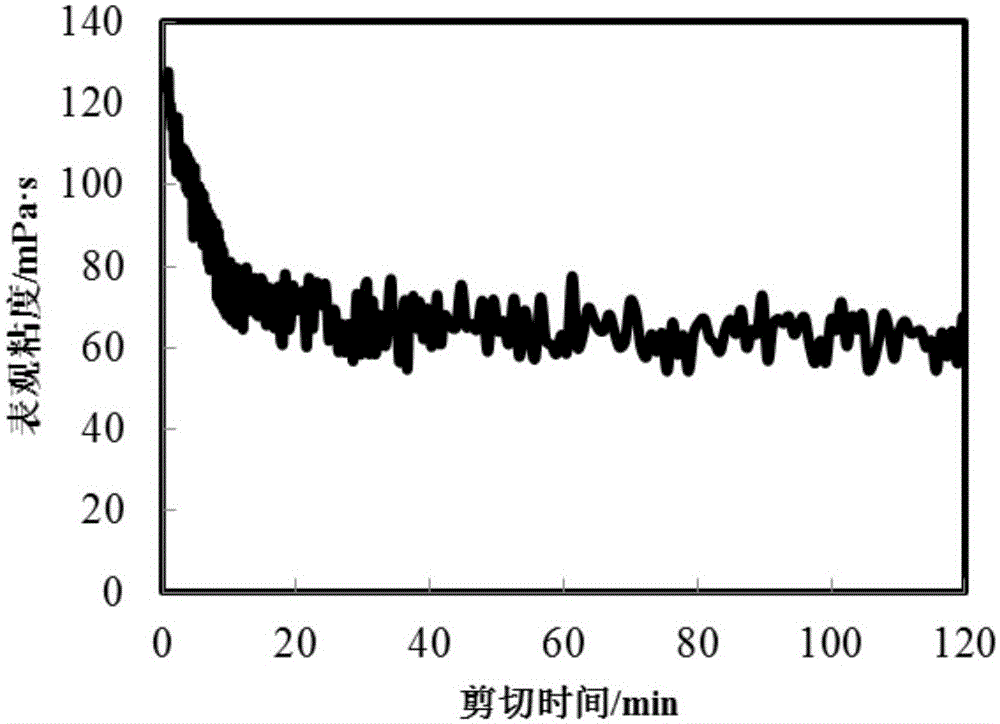

Supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C

The invention discloses supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C. The fracturing fluid is prepared from the following components in percentage by weight: 0.2 to 0.5 percent of thickening agent for the clean fracturing fluid, 0.1 to 0.5 percent of viscosity synergist, 0.2 to 0.4 percent of structural intensifier, 0.05 to 0.2 percent of deoxidant, 0.1 to 0.3 percent of metal ion chelating agent, 1 to 2 percent of clay stabilizer and the balance of fresh water. According to the clean fracturing fluid, a reversible supramolecular network structure is formed through the intermolecular interaction, and the thickening agent is low in use concentration and can be used for effectively controlling the viscosity of a base solution of the fracturing fluid and improving the pumping performance of the fluid; viscoelastic sand-carrying of the fracturing fluid is realized by low viscosity and high viscoelasticity; the temperature resistance can reach 170 DEG C under a long-term shear condition; the shear resistance is excellent, and the fluid viscosity and the structure after high shear can be effectively recovered; the construction friction is low, and the equipment load and the fracturing construction risk are reduced; the residue content is low, so that the damages to a reservoir stratum and prop fractures are greatly reduced, and the fracturing stimulation effect is greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Electrospraying/electrospinning array utilizing a replacement array of individual tip flow restriction

InactiveUS7629030B2Facilitate electrohydrodynamic (EHD) sprayingLess sensitiveLiquid surface applicatorsElectric shock equipmentsLiquid viscosityElectrospinning

An electrohydrodynamic spraying or spinning deposition system, which includes a common source of pressurized liquid within a manifold, and an array of 2 or more spraying tips, each tip being fed from the common source of pressurized liquid to create a liquid flow path. An individual flow impedance device is disposed within each tip's individual liquid flow path from the pressurized liquid source into each spraying tip. The individual flow impedance devices are disposed within a replaceable sheet, which can be easily cleaned or changed to accommodate the instance liquid viscosity and composition. A high voltage source is applied to create a high voltage potential applied between the tip array and a deposition surface.

Owner:DROPLETECH LLC

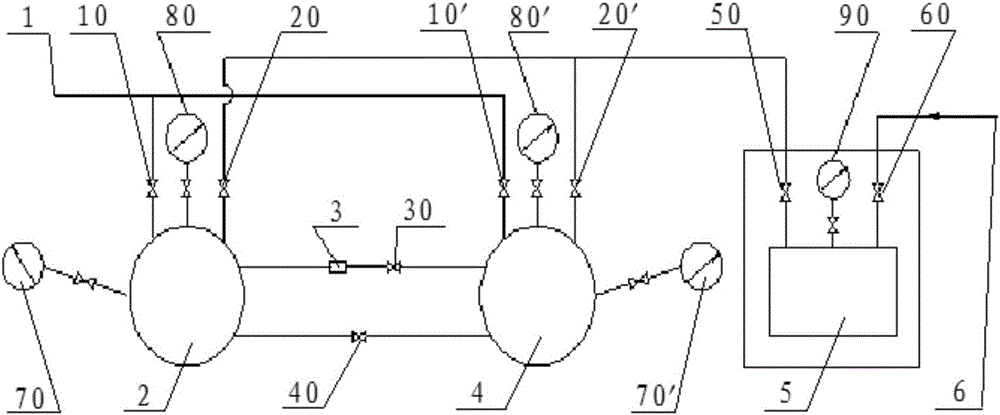

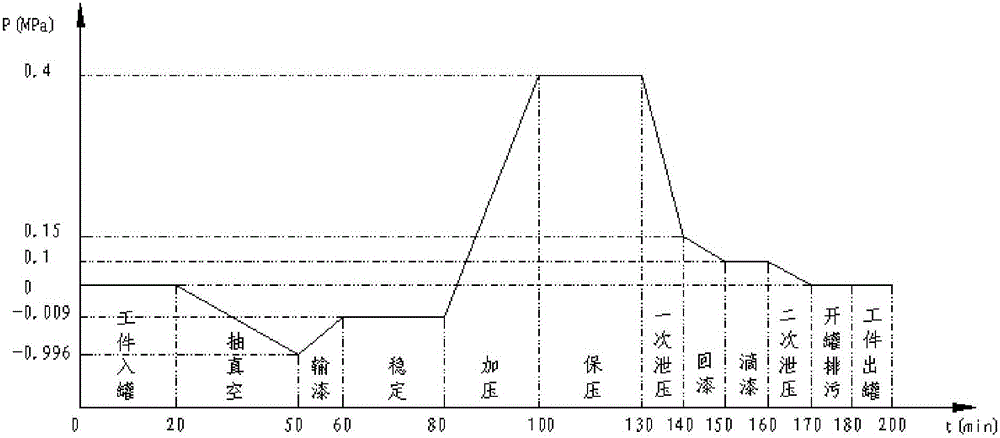

Vacuum pressure paint-soaking process for dry-type transformer coil

ActiveCN105097272AImprove insulation performanceEnsure moisture resistancePretreated surfacesCoatingsLiquid viscosityVacuum pressure

The invention discloses a vacuum pressure paint-soaking process for a dry-type transformer coil. The vacuum pressure paint-soaking process sequentially comprises the following procedures: a paint liquid viscosity adjusting procedure, a drying procedure before paint soaking, a first paint-soaking procedure, a drying procedure, a second paint-soaking procedure and a curing procedure; and the first paint-soaking procedure adopts a pressure paint-soaking mode, and sequentially comprises the following steps: a vacuum supply step, a paint transfer step, a pressurized paint-soaking step and a paint dripping step. According to the vacuum pressure paint-soaking process for the dry-type transformer coil disclosed by the invention, second paint-soaking is adopted; the pressure paint-soaking mode is adopted by the first paint-soaking procedure; and an atmospheric pressure paint-soaking mode or the pressure paint-soaking mode is adopted by the second paint-soaking procedure, so that the condition that the transformer coil is covered with an insulating paint in an omnibearing manner can be ensured; the insulating effect of the transformer is further improved; and the anti-moisture performance, the heat resistance, the conductivity, the magnetic conductivity and the mechanical property are ensured.

Owner:ZHONGBIAN GRP SHANGHAI TRANSFORMER CO LTD

Process for production of core-shell particles, core-shell particles, and paste composition and sheet composition which contain same

InactiveCN102574934ANo viscosity increaseNon-insulated conductorsMagnetic/electric field screeningOrganic acidPhosphate

Disclosed is a process which comprises bringing an acidic organic substance or phosphoric acid into contact with a metal to form, on the surface of the metal, a layer that contains either an organic acid salt formed from both the acidic organic substance and the metal or a phosphoric acid salt formed from both the phosphoric acid and the metal. In the process, the layer can be selectively formed only on the surface of the metal. When the process is applied to the production of core-shell particles, neither agglomeration of the particles nor viscosity increase of the fluid occurs, while when the process is applied to the production of a covered metal-wiring circuit board, the layer can be selectively formed only in the metal area to be covered.

Owner:TORAY IND INC

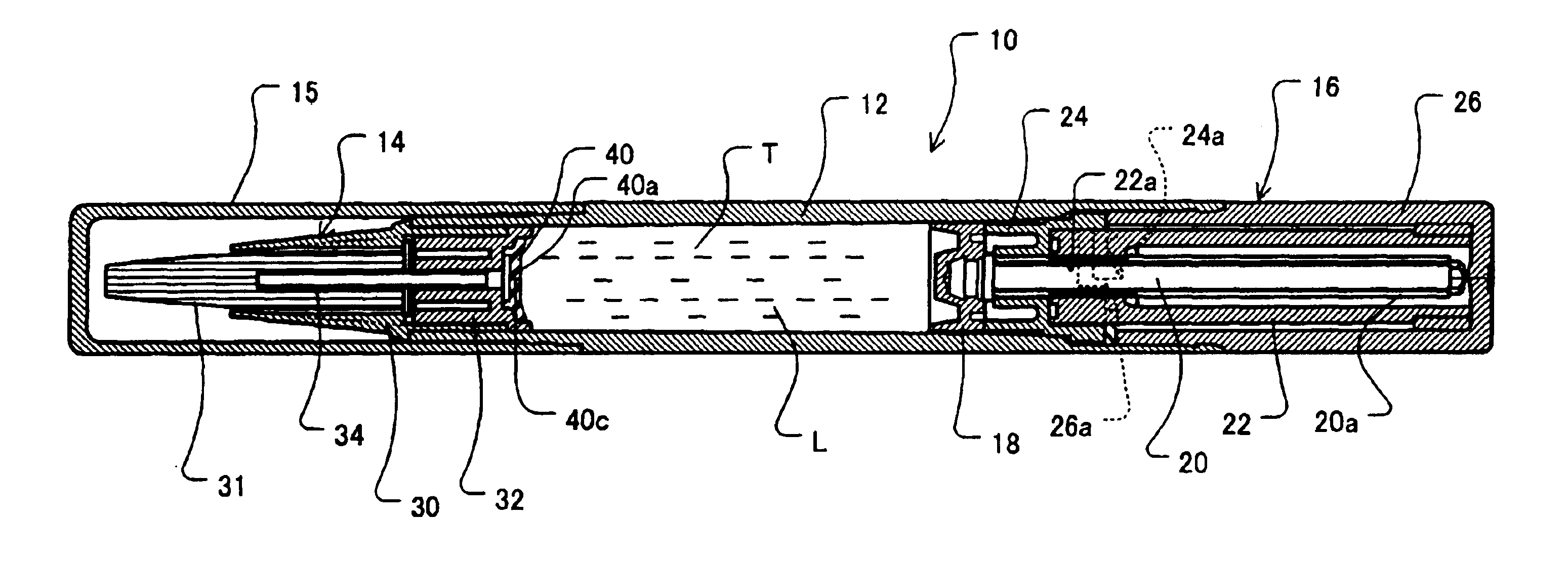

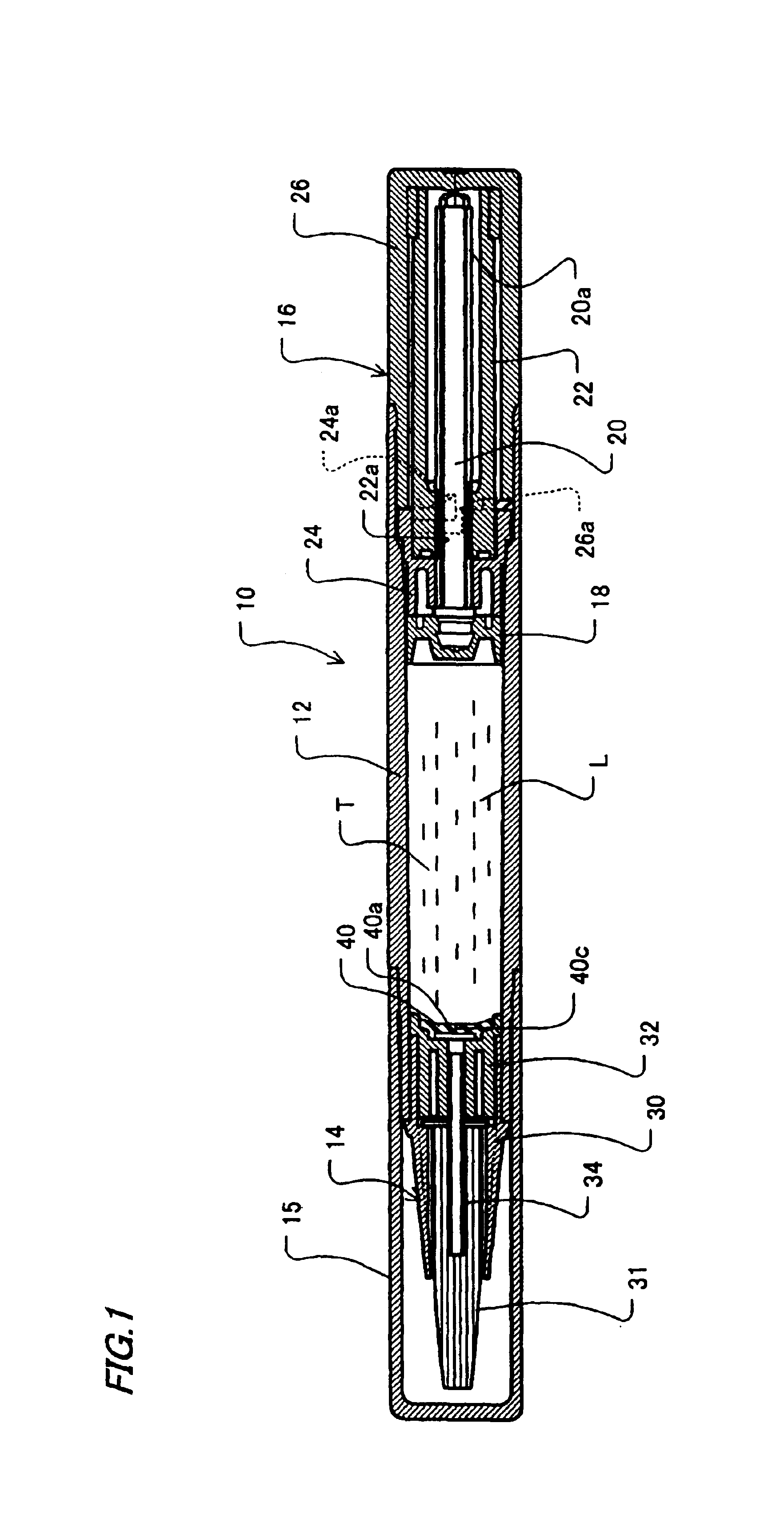

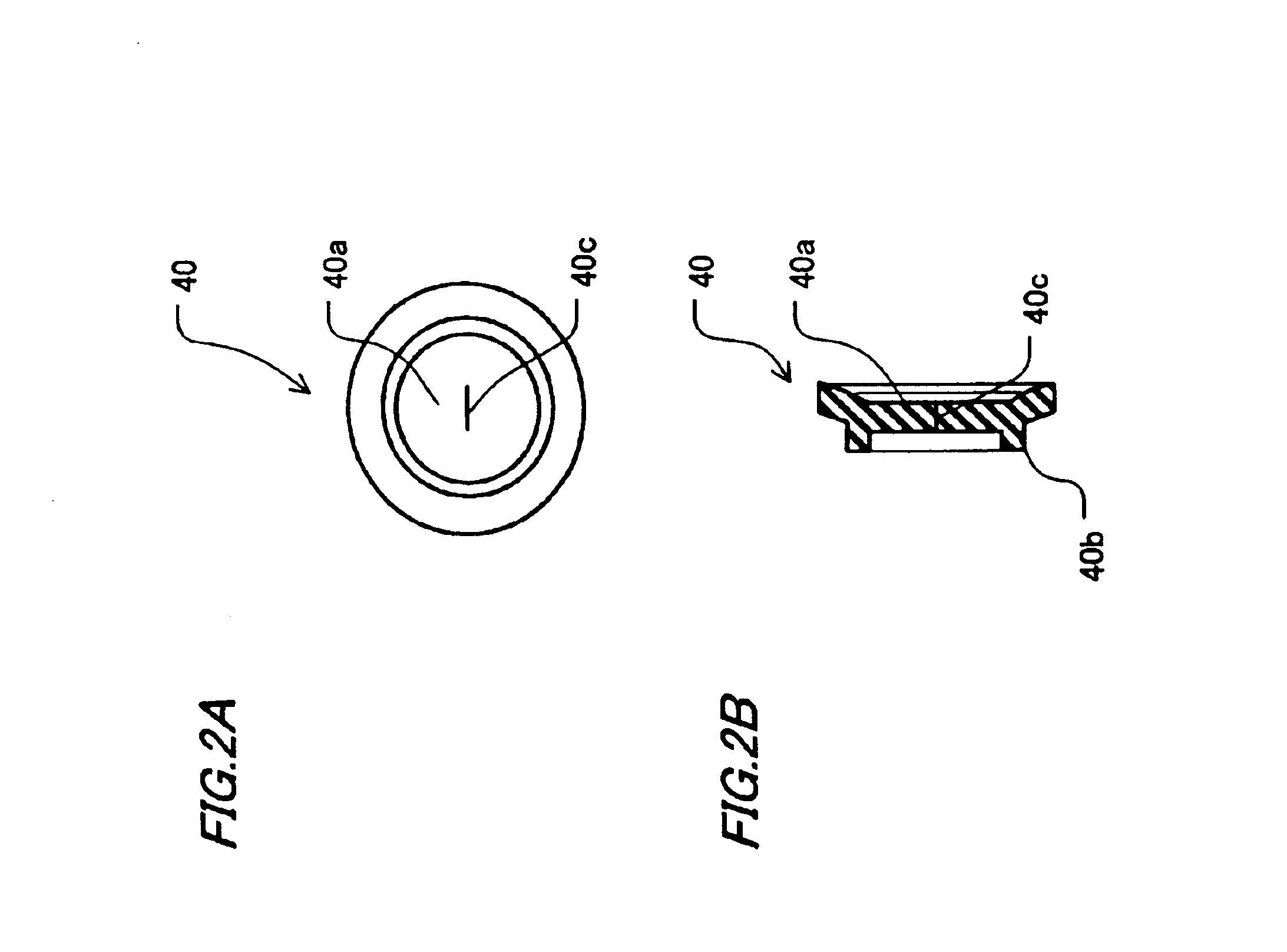

Liquid container

InactiveUS6918515B2Prevent leakageEffective volumeLarge containersCleaning machinesLiquid viscosityEngineering

In a liquid container, the dimension of inside diameter of a liquid supply portion is not subject to any restriction, and also a liquid leakage suppressing mechanism that is not subject to any restriction by the viscosity of stored liquid is provided. A liquid container includes a body having a tank for storing a liquid; a supply mechanism which is connected to the tip end portion of the body and has a brush for supplying the liquid; and a drive mechanism for pushing out the liquid L in the tank T to the supply mechanism. A valve which is normally closed and can be opened only when the drive mechanism is operated is provided between the tank and the supply mechanism.

Owner:KOTOBUKI & CO LTD

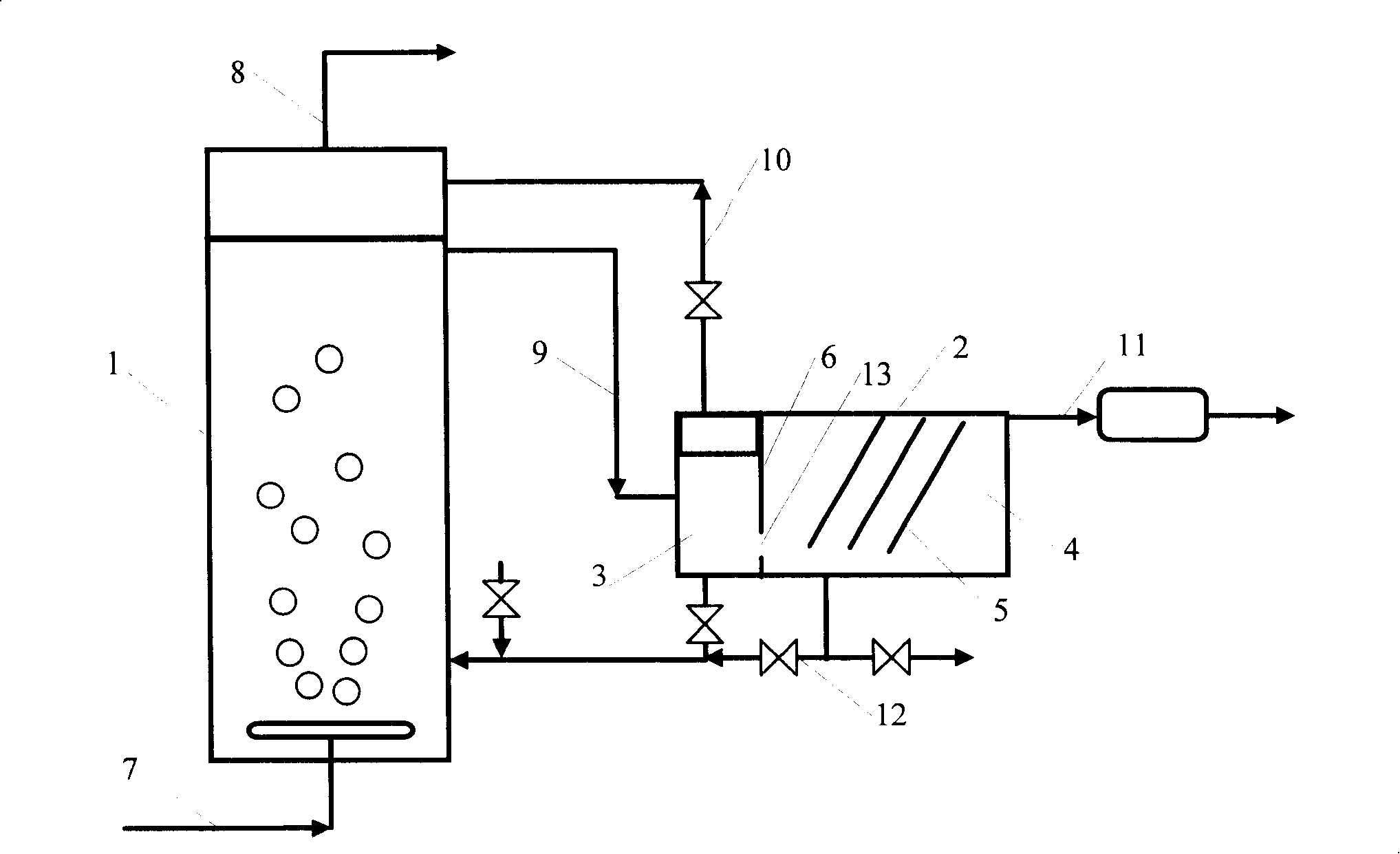

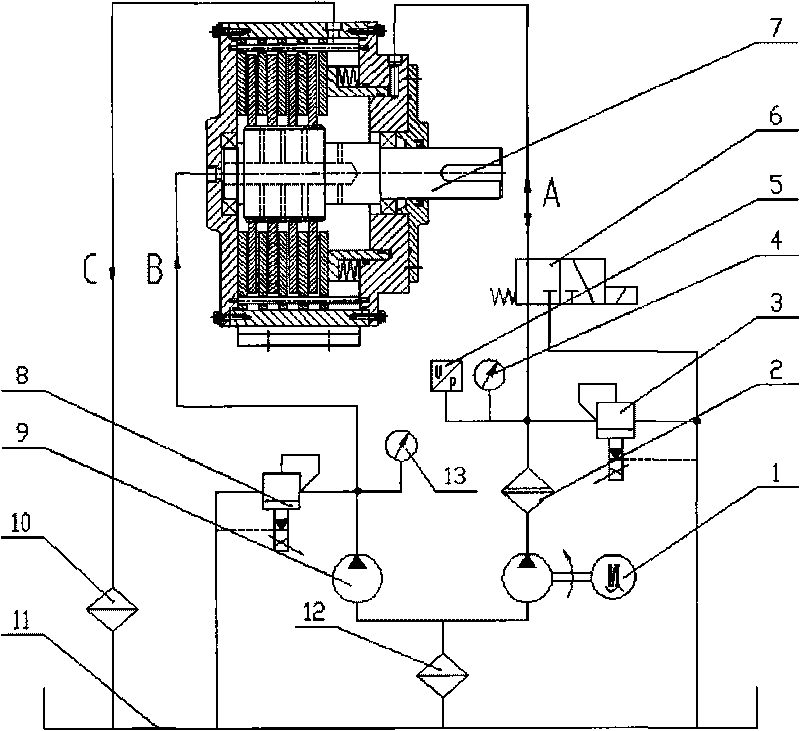

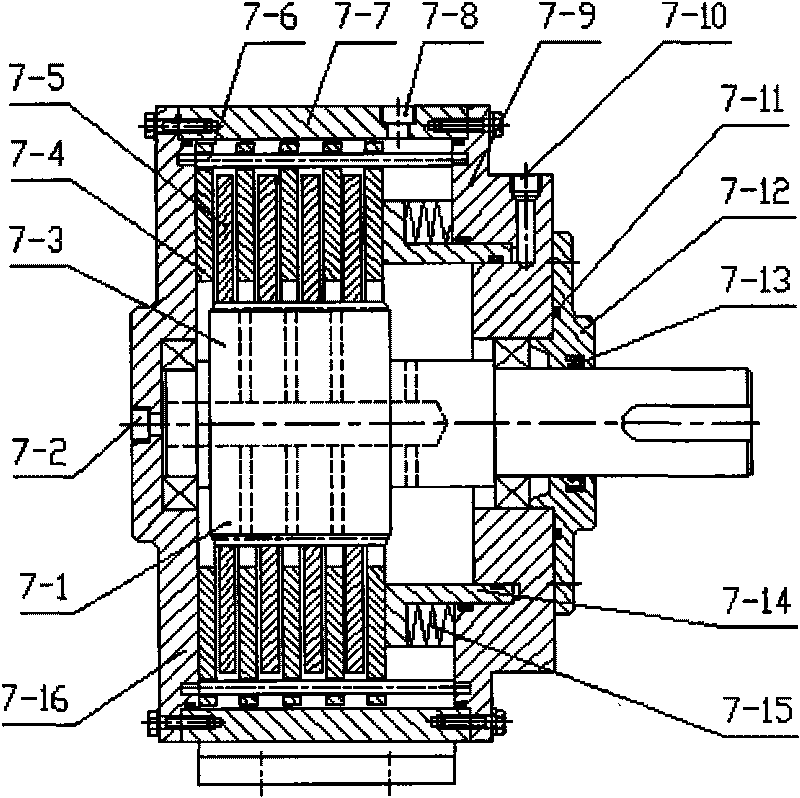

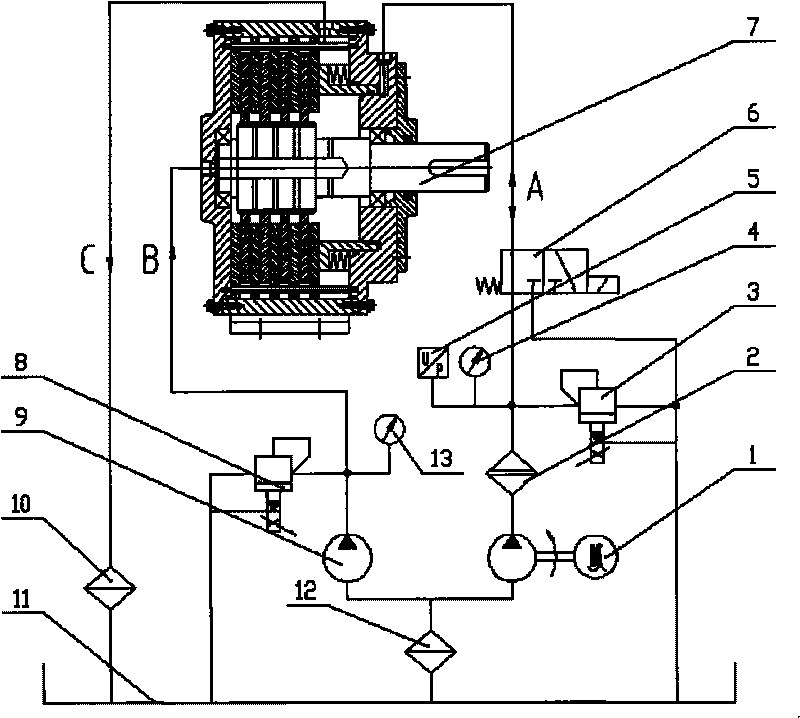

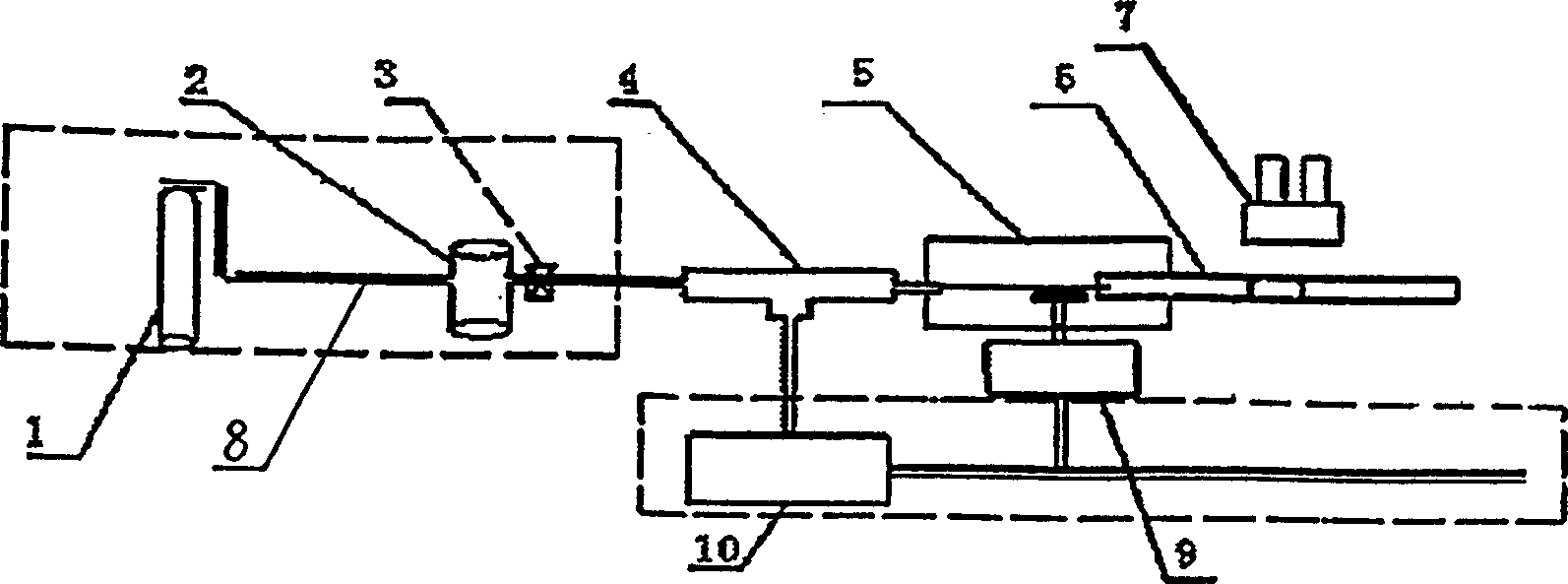

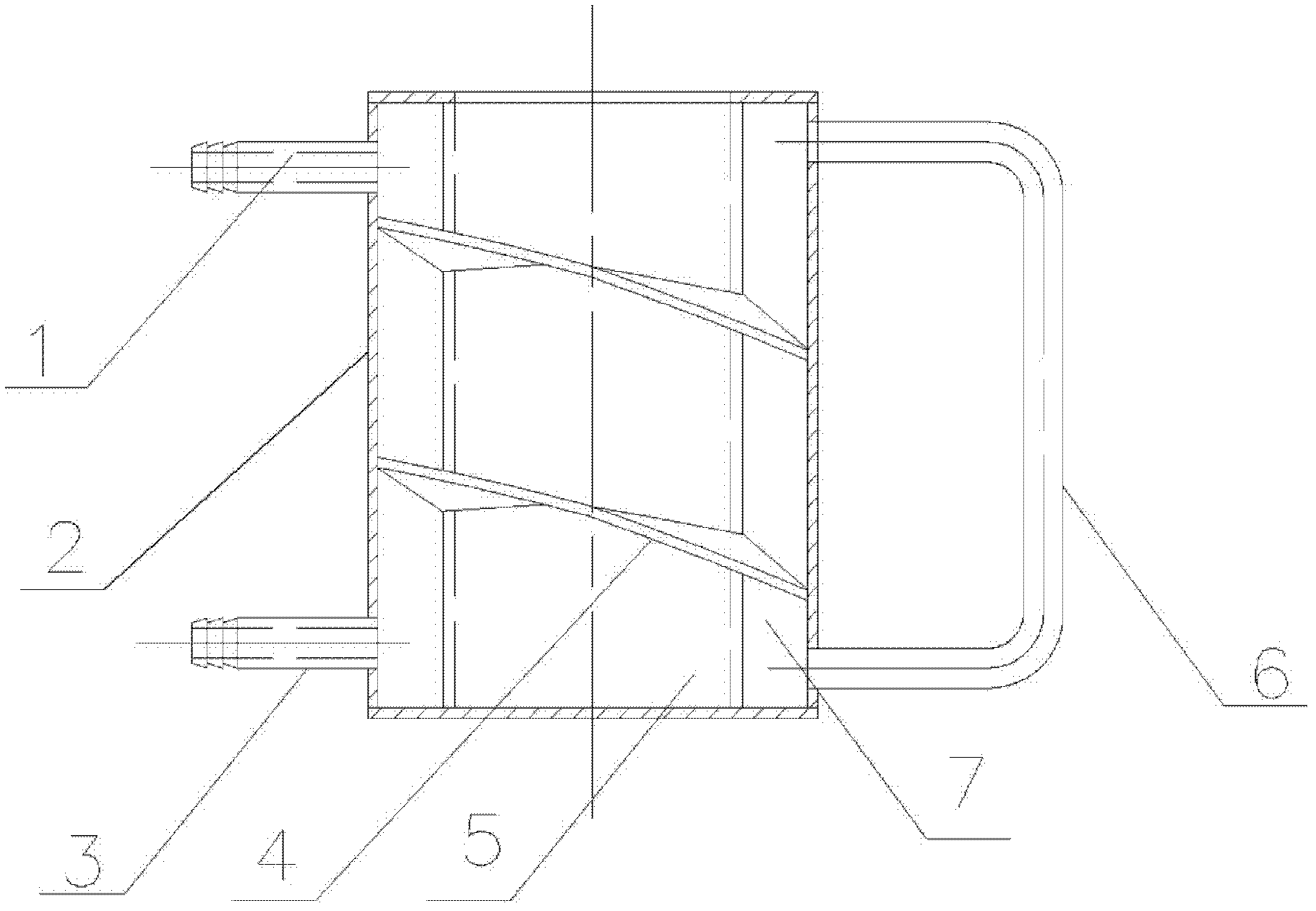

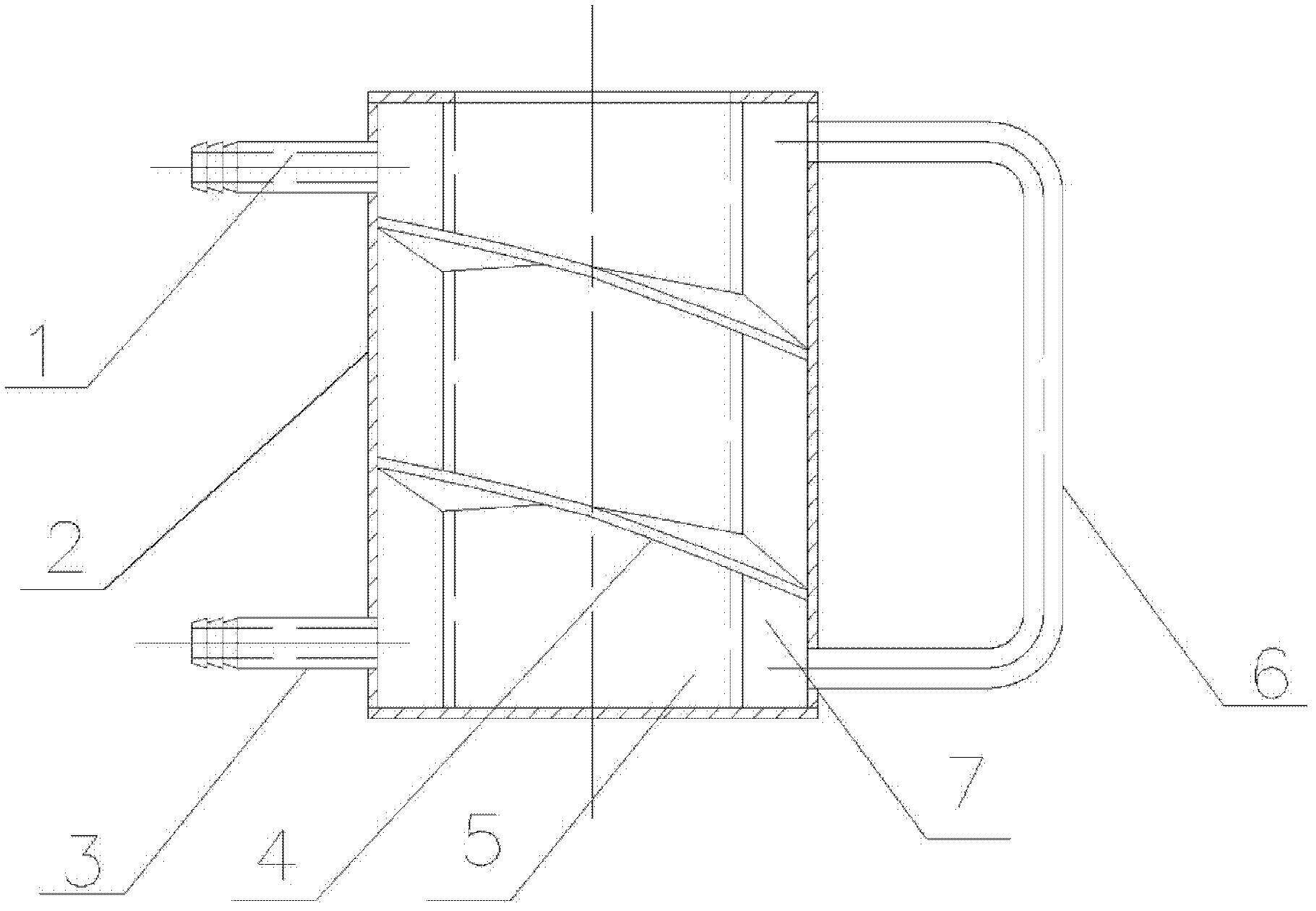

Liquid-viscosity loading system

The invention relates to a liquid-viscosity loading system which is suitable for applying load moment to the rotating shafts rotating at various speed. The liquid-viscosity loading system mainly comprises a hydraulic control system and a liquid-viscosity loading device which is connected with the hydraulic control system. The hydraulic control system comprises an electric motor, an double pump, an electrohydraulic proportional overflow valve, an electromagnetic reversing valve, a filter, a pressure detecting element, a pressure gauge, a lubricating oil tank and the like. The liquid-viscosity loading device comprises an inputting shaft, a piston, an external friction plate, an internal friction plate, a resetting spring, a shell, an end over, a sealing cover, a sealing assembly and the like. The power is transmitted by using the viscosity of the lubricating oil film between the friction plates or the shearing force, the load moment is regulated by changing the thickness of the lubricating oil film, a lubricating oil passageway is formed in such a way that the electric motor drives the double pump to be connected with the liquid-viscosity loading device, and the lubricating oil pressure and the load moment are controlled through the electromagnetic reversing valve, the electrohydraulic proportional overflow valve and the like. The liquid-viscosity loading system has the advantages of simple structure, steady loading, long service life, convenient operation and good effect.

Owner:XUZHOU WUYANG TECH

Environmentally benign non-toxic fire flooding agents

Fire flooding and extinguishing agents and detoxifiers which are environmentally safe and non-toxic in both natural form and in fire exposed degraded forms are disclosed. The flooding and streaming-type fire extinguishing agents are rich in low boiling, unsaturated halocarbon compounds having low liquid viscosities, and low boiling alkenes as detoxifying agents. The detoxifiers are conjugated double bond hydrocarbons.

Owner:LACOVIA

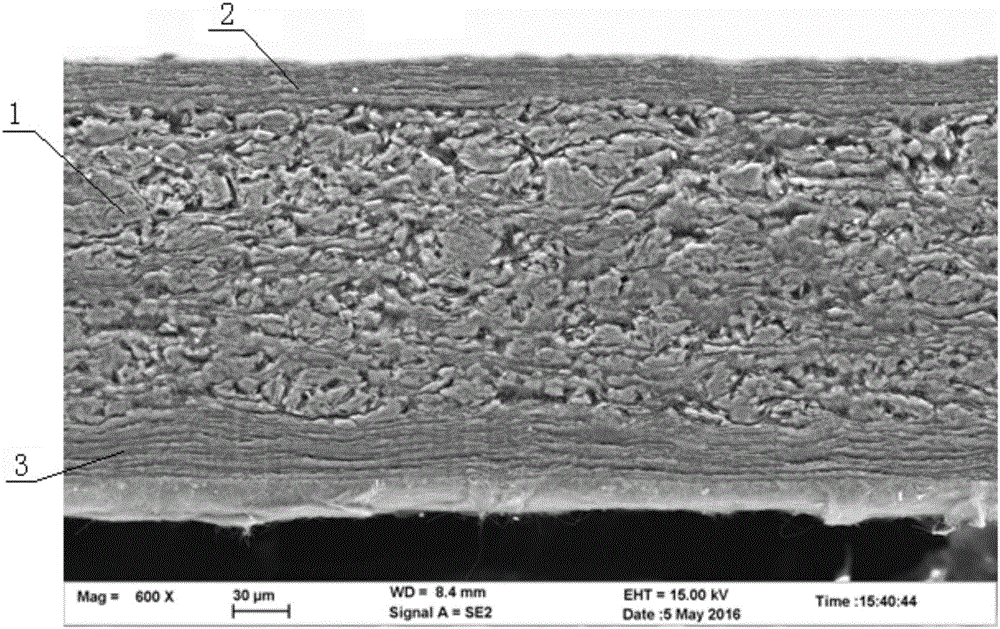

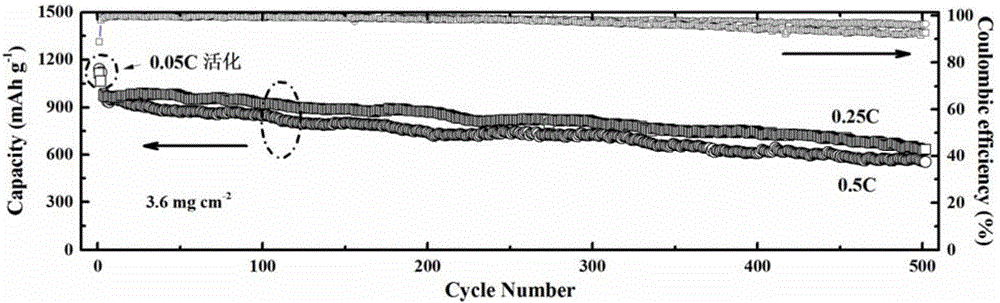

Electrode of lithium sulfur battery and preparation method thereof

InactiveCN106058150ALarge specific surface areaImprove conductivityNon-aqueous electrolyte accumulator electrodesFiberPorosity

The invention discloses an electrode of a lithium sulfur battery and a preparation method thereof. The electrode of the lithium sulfur battery includes an active substance layer containing sulfur, and conductive hydroxyl or carboxyl layers are formed on the upper surface and the lower surface of the active substance layer respectively; the active substance layer and the conductive hydroxyl are combined, or the active substance layer and the conductive carboxyl layers are combined, through external pressure, a surface substance of the active substance layer generates cross-linking interaction and hydrogen bond interaction with a fiber component of the conductive hydroxyl or carboxyl layers. The hydroxyl or carboxyl layers have high specific surface area, can adsorb polysulfide and inhibit a back-and-forth shuttling effect. The three-layer electrode structure has higher porosity, can store more electrolyte liquids, is conducive to slow down dissolution of sulfur and polysulfide, thereby ensuring occurrence of positive electrode reactions and improving the discharge capacity of the battery. Increase of the electrolyte liquid viscosity due to dissolution of the sulfur and polysulfide is also effectively alleviated. The preparation method is simple, and is easy to popularize and apply.

Owner:柔电(武汉)科技有限公司

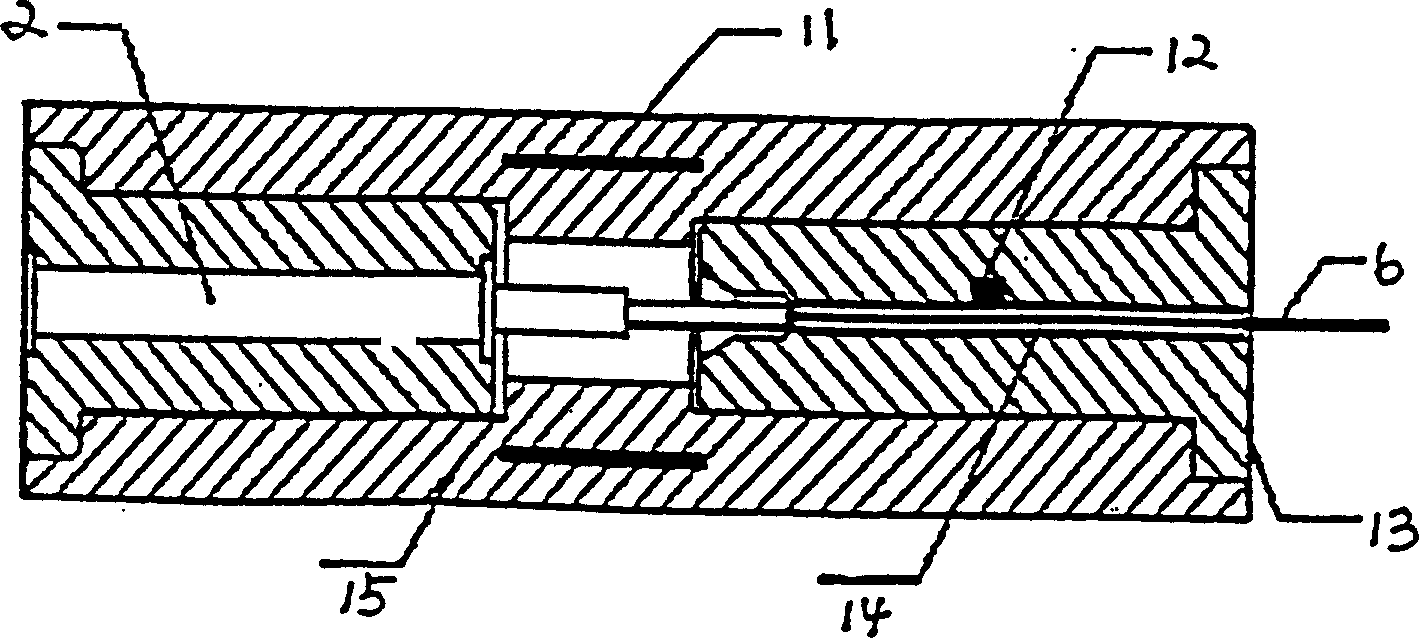

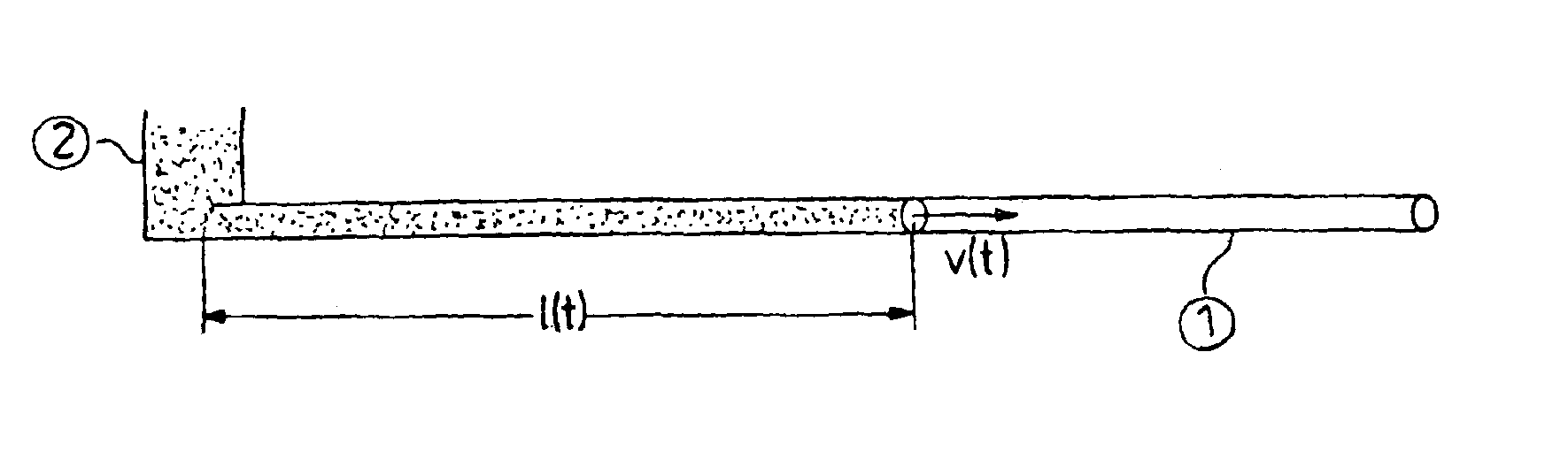

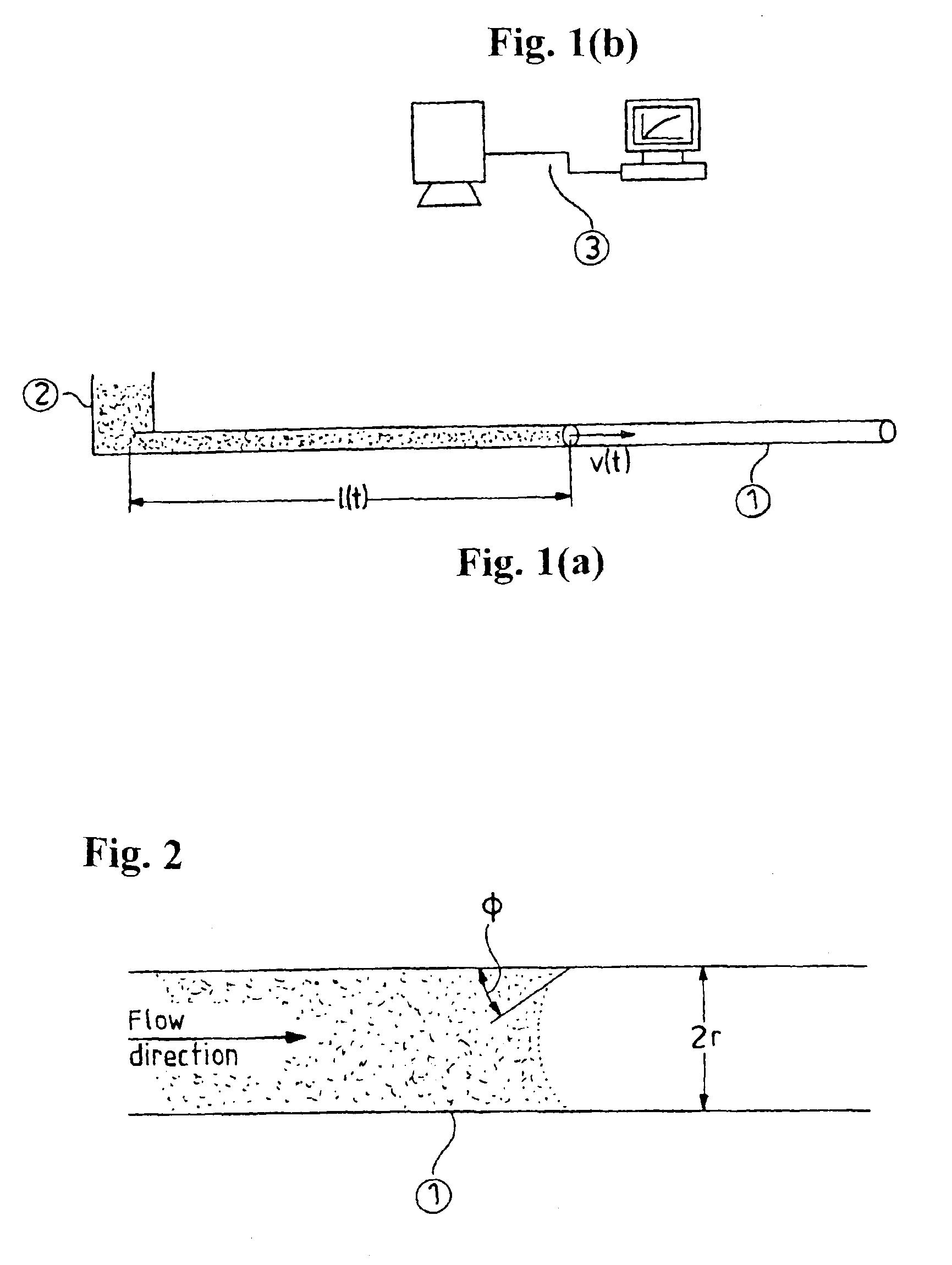

Trace amount liquid viscosity measuring method and apparatus

InactiveCN1501061AReduce dosageEasy to controlDirect flow property measurementTemperature controlLiquid viscosity

The present invention relates to micro liquid viscosity measuring method and unit. The present invention measures the viscosity of liquid indirectly via measuring the flow rate-pressure relationship of liquid in micron pipe, and the method is superior to available one, which adopts large amount of test liquid and expensive constant temperature bath. One micro liquid viscosity measuring instrument with small amount of test liquid, simple constant temperature device and short measurement period is provided. The measuring instrument consists of low pressure micro flow experimental apparatus and temperature controller, and has the structure including gas storage, liquid tank, T-pipe, pressure detector, temperature controller, micron pipeline inside the temperature controller, transparent displacement pipe with one end connected to the micron pipeline and the other end communicated to atmosphere via the temperature controller, and optical microscope on the transparent displacement pipe.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

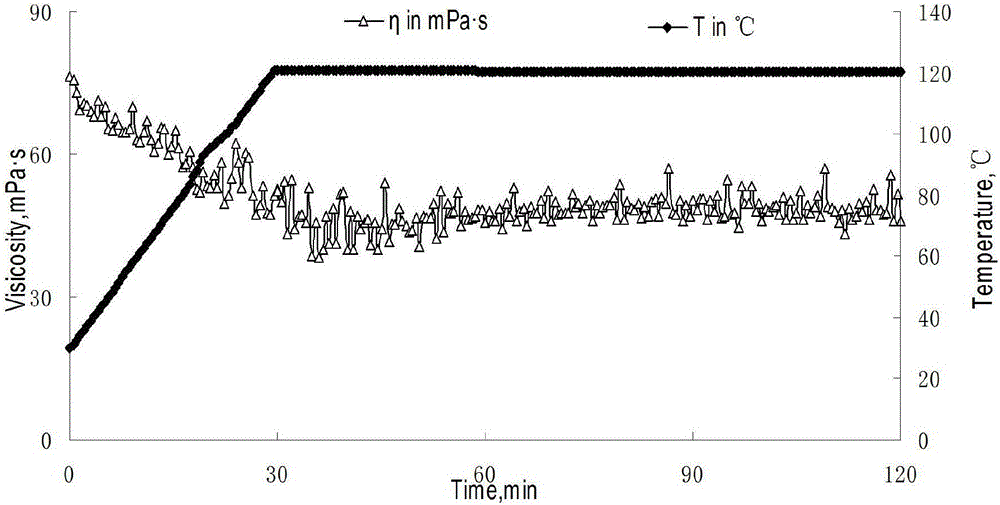

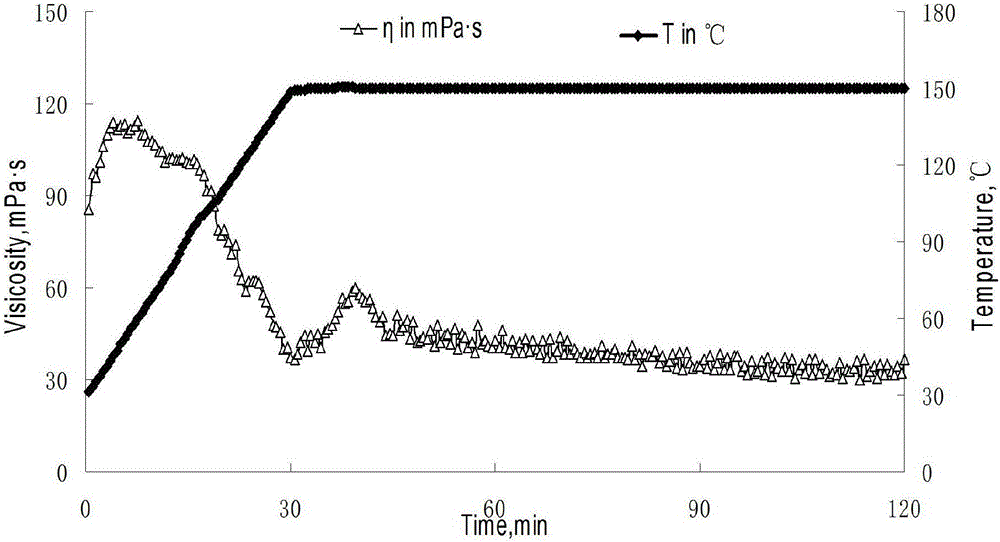

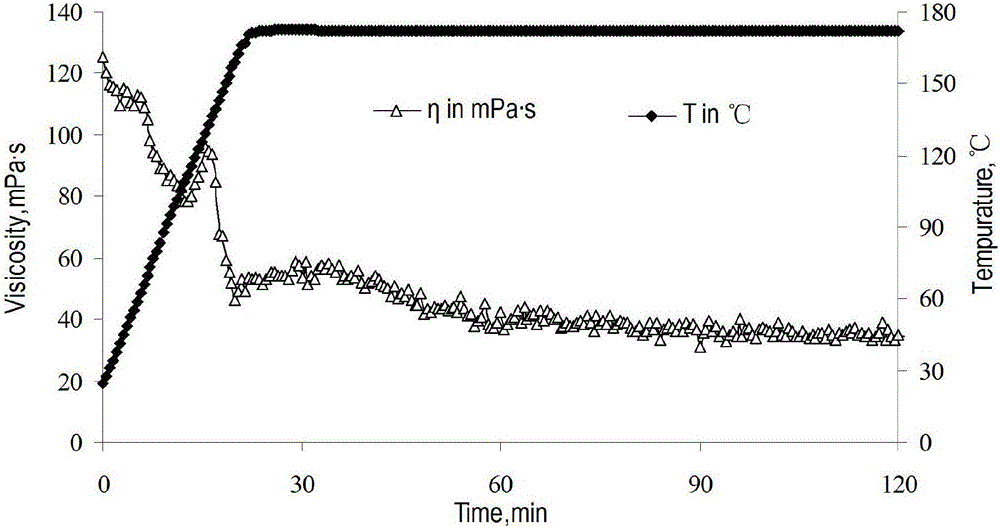

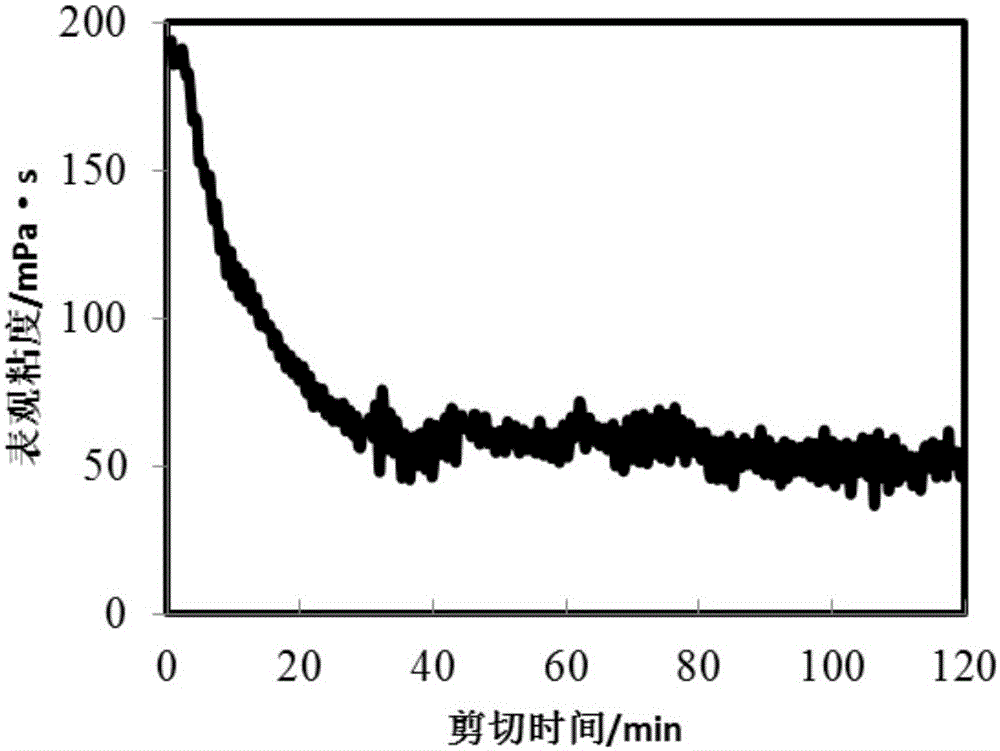

Reversible physical crosslinking polymer fracturing fluid and preparation method thereof

InactiveCN106318365AReversible crosslinkingDestroy rheologyDrilling compositionPolymer scienceLiquid viscosity

The invention relates to a reversible physical crosslinking polymer fracturing fluid and a preparation method thereof. The fracturing fluid is composed of 0.3% to 0.6% of a polymer thickening agent, 0.12% to 0.3% of a reversible physical crosslinking agent, 0.1% to 0.5% of a clay stabilizing agent and 0.001% to 0.05% of an ammonium persulfate gel breaking agent, with the balance being water. The reversible physical crosslinking polymer fracturing fluid can be applied in fracturing construction of a reservoir at 120 to 160 DEG C, and does not need addition of a temperature stabilizing agent, a cleanup agent, a defoaming agent and a bactericide, so the cost of the fracturing fluid is saved; meanwhile, the fracturing fluid has a gel breaking liquid viscosity less than 2 mPa-s, a gel breaking liquid surface tension lower than or equal to 28 mN / m, a residue content less than or equal to 100 mg / L, and a damage rate less than 10%.

Owner:CHINA PETROLEUM & CHEM CORP +1

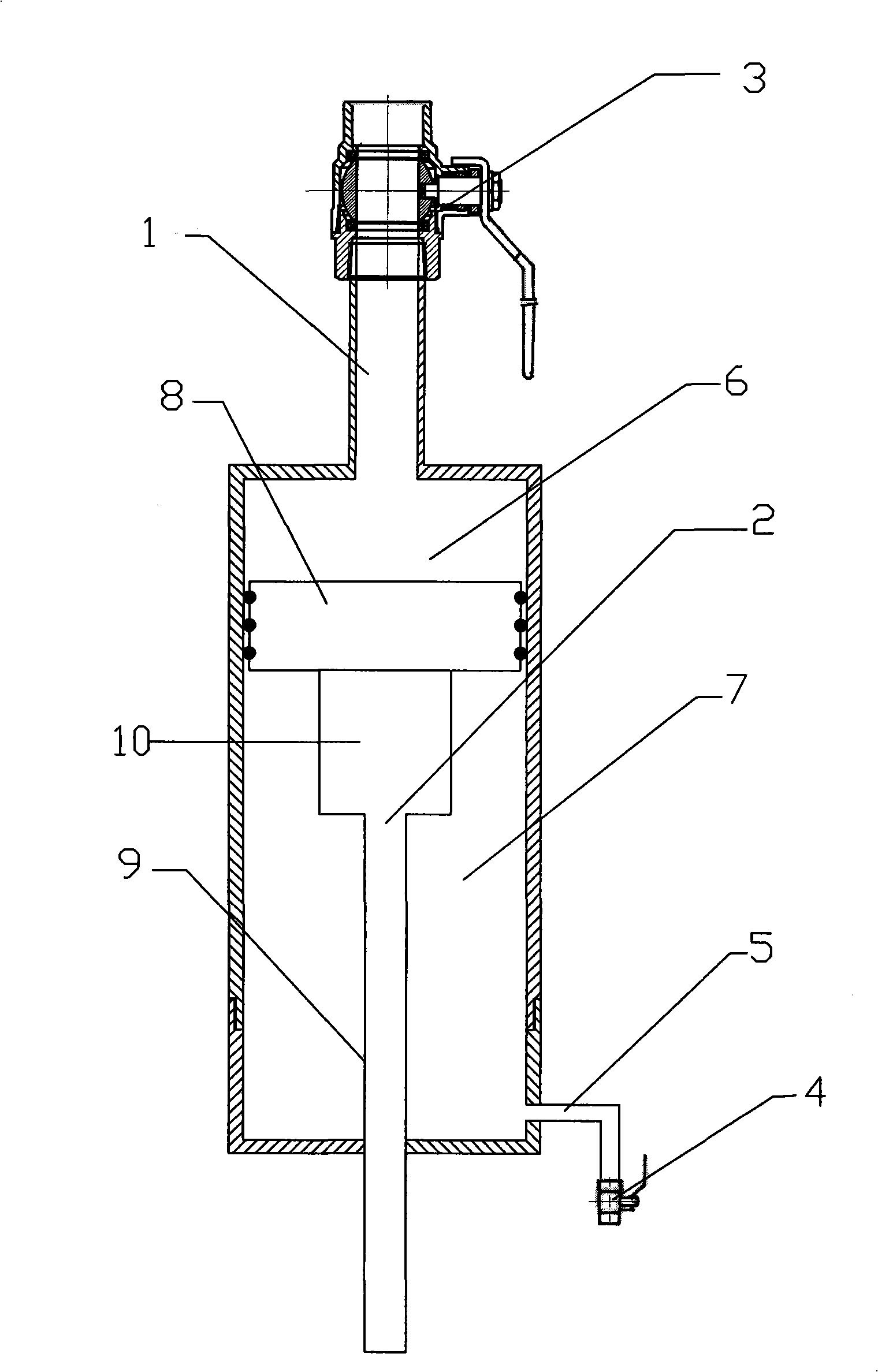

Hydraulic-control high-pressure environment liquid sampler

InactiveCN101526444AHigh viscosity retentionEasy to sampleWithdrawing sample devicesLiquid viscosityEngineering

The present invention discloses a hydraulic-control high-pressure environment liquid sampler. The hydraulic-control high-pressure environment liquid sampler of the invention comprises the following components: a sealed barrel which is composed of a main chamber and a sampling chamber (1), a piston (2), a sampling valve (3), a control valve (4) and a liquid inlet / outlet pipe (5). One end of the piston is positioned in the main chamber and divides the main chamber to a liquid inlet chamber (6) and a cushion chamber (7). The other end of piston extends out through an opening on the main chamber. The side surface of main chamber is provided with a liquid inlet which is communicated with the liquid inlet / outlet pipe. The sampling chamber is provided with a sampling opening controlled by the sampling valve. The control valve is installed at the free end of the liquid inlet / outlet pipe. The moving speed of piston can be controlled through controlling the liquid discharge velocity of control valve thereby controlling the flow velocity of high-pressure liquid into the liquid inlet chamber and reducing the shearing of high pressure to the viscosity of liquid. The hydraulic-control high-pressure environment liquid sampler of the invention has the advantages of simple structure and convenient sampling. The shearing caused by the entering of liquid into the sampler in the high-pressure environment can be effectively prevented and the liquid entering into the sampler can be accurately measured.

Owner:CHINA NAT OFFSHORE OIL CORP +1

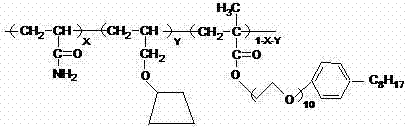

Temperature and salt-resistant AM/ACD/AE copolymer and its preparation method

InactiveCN102229692AThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionPotassium persulfatePolymer science

The invention relates to a temperature and salt-resistant AM / ACD / AE copolymer used as an oil displacement agent in the petroleum exploitation and a preparation method thereof. The temperature and salt-resistant AM / ACD / AE copolymer can meet the requirements of the injected liquid viscosity with the incessant increasing of the oil reservoir temperature and the stratum mineralization. The technical scheme of the invention is characterized in that the mole ratio of the raw materials used in the preparation of the copolymer comprises, by mole percentage, 88.2-91.4% of an AM monomer, 8-11% of an ACD monomer, 0.6-0.8% of an AE monomer, an oxidizing agent potassium persulphate which accounts for 0.3-0.5% of the total weight of the monomers, and a reducing agent sodium bisulfite which accounts for0.35-0.45% of the total weight of the monomers. The preparation method provided by the invention comprises the following steps of: adding AM, ACD and AE into a container, adding water to produce a solution at the concentration of 15%, dissolving with stirring, adding the oxidizing agent and the reducing agent with uniformly blending, deoxygenizing by filling nitrogen, reacting at the temperature of 40-50 DEG C for 4-5 hours, washing and drying to obtain the AM / ACD / AE copolymer. The preparation method provided by the invention is simple and feasible with mild reaction conditions; the product prepared by the method has inclusion and aggregation functions as well as temperature and salt-resistant performance, and can be used in tertiary oil extraction.

Owner:SOUTHWEST PETROLEUM UNIV

Liquid droplet ejection head and image forming apparatus having the same

InactiveCN101468547AIncrease stickinessIncreased viscosity against liquidsInking apparatusLiquid viscosityEngineering

A liquid droplet ejection head comprises an ejector, a liquid viscosity-increase prevention structure and a liquid viscosity-increase prevention controller. The ejector includes a nozzle for ejecting a liquid droplet, a pressure chamber communicating with the nozzle through a communication path, and an actuator for applying pressure to a liquid in the pressure chamber. The liquid viscosity-increase prevention structure prevents an increase of viscosity of the liquid in the ejector. The liquid viscosity-increase prevention controller changes the operation frequency of the liquid viscosity-increase prevention structure between when the liquid droplet is ejected from the nozzle and when ejection of the liquid droplet is paused and no liquid droplet is being ejected from the nozzle.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Wall liquid film and wall-free liquid film alternate structured filler adapting to viscous absorbent

InactiveCN103191692AAvoid Wall Flow EffectsImprove anti-clogging performanceChemical/physical/physico-chemical processesViscous liquidLiquid viscosity

The invention relates to a wall liquid film and wall-free liquid film alternate structured filler adapting to a viscous absorbent. The wall liquid film and wall-free liquid film alternate structured filler is a perpendicular plate structured filler comprising alternate wall-attached films and free films. The wall liquid film and wall-free liquid film alternate structured filler mainly comprises a liquid collection-primary distribution member, a liquid uniform-distribution member, structured solid wall surfaces and holes having a plurality of shapes, and is characterized in that when sprayed liquid flows downward and flows through the wall liquid film and wall-free liquid film alternate structured filler, the liquid enters into the liquid collection-primary distribution member and is subjected to primary distribution and then enters into the liquid uniform-distribution member and is subjected to film-type uniform distribution; and the falling liquid film enters into channels formed from the alternate structured solid wall surfaces and the holes and contacts with gas concurrent flows or gas countercurrent flows. The channels for liquid flowing are regular so that a viscous liquid can smoothly pass through the channels and does not produce foam, emulsification and blocking and thus adaptability to processing liquid viscosity is greatly improved. Through special flow behaviors of the free film and interaction of the free film with the wall-attached film, high-viscosity absorbent mass transfer performances are improved obviously.

Owner:EAST CHINA UNIV OF SCI & TECH

Device and method for determining the viscosities of liquids by means of the capillary force

The invention relates to a device and a method for automated and simultaneous determination of the viscosity of a plurality of liquids.

Owner:BAYER AG

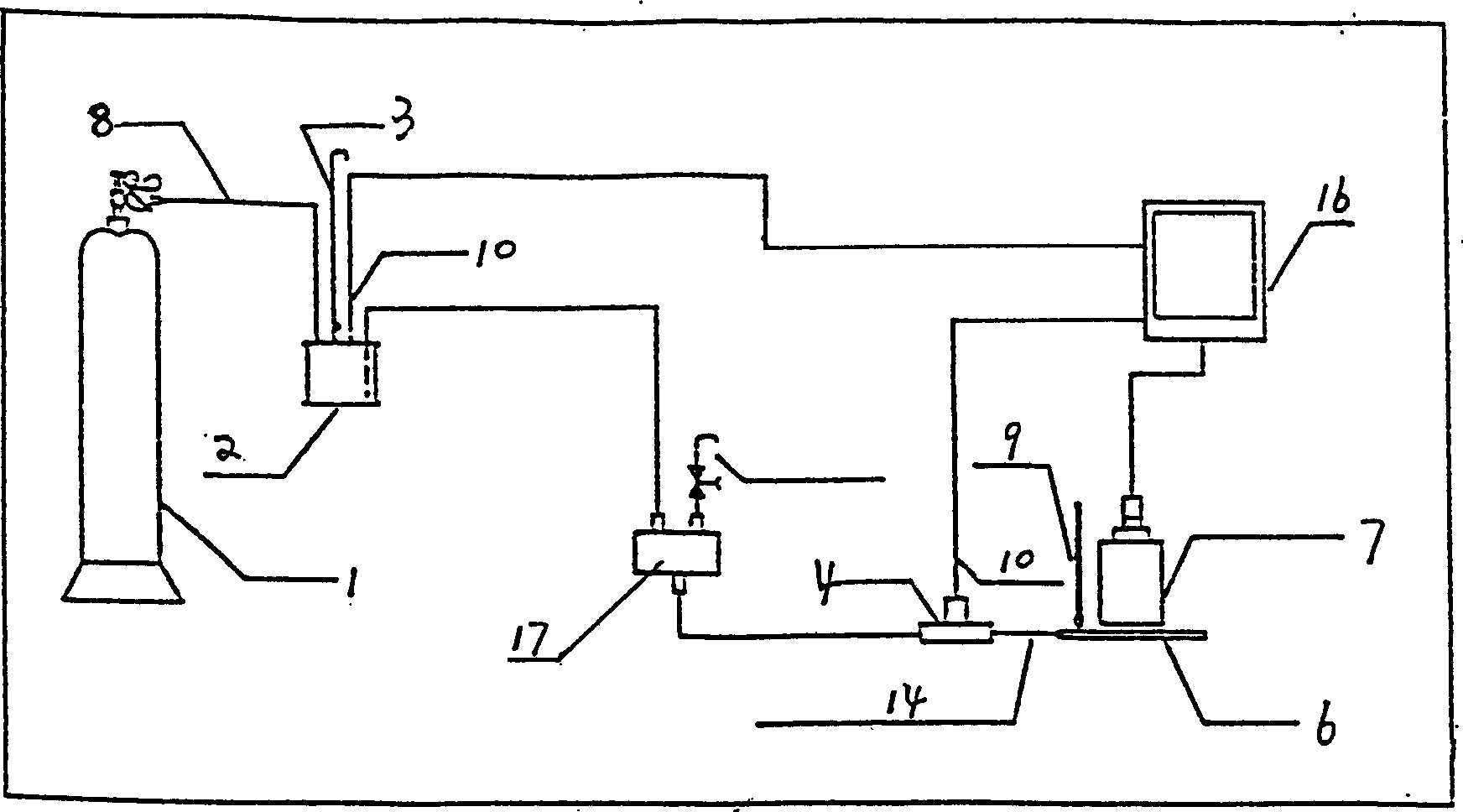

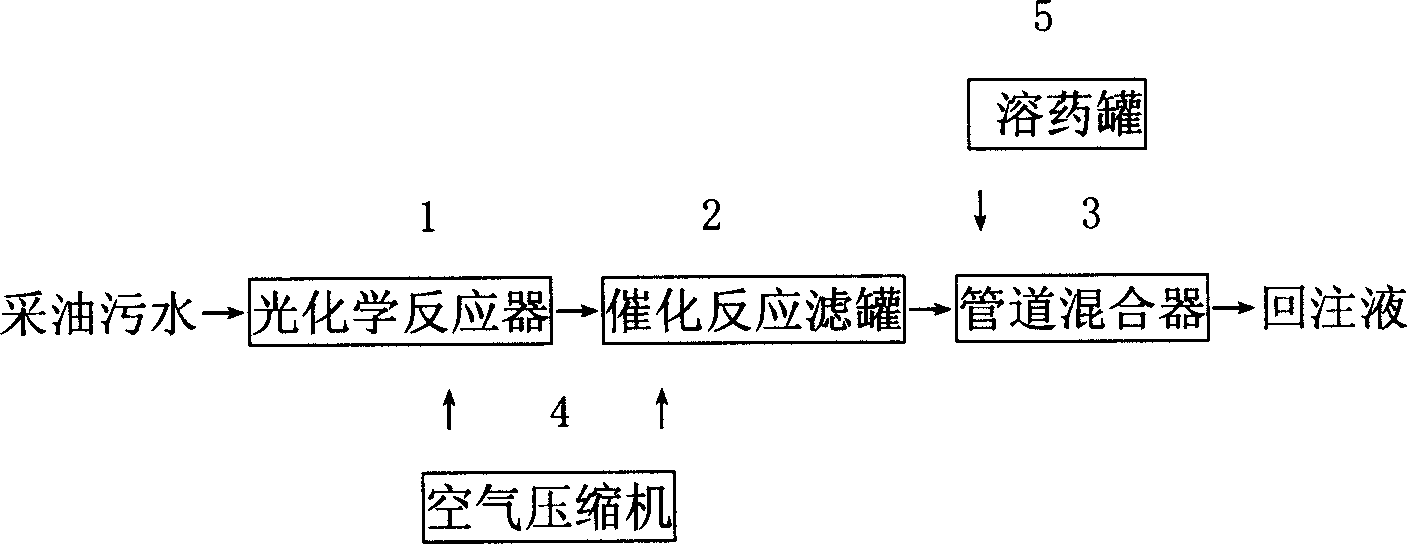

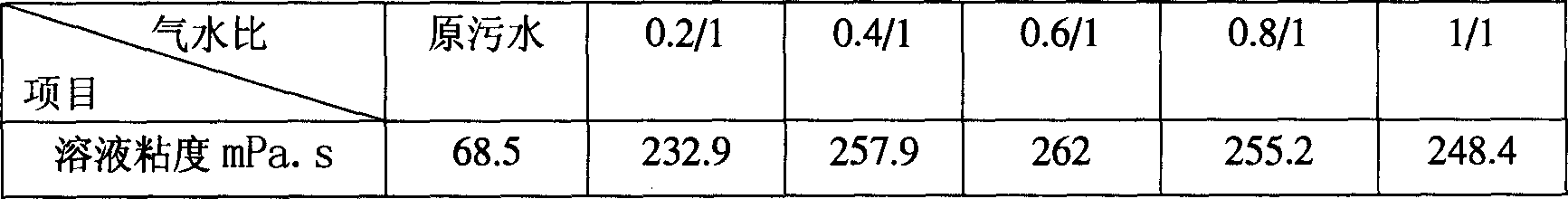

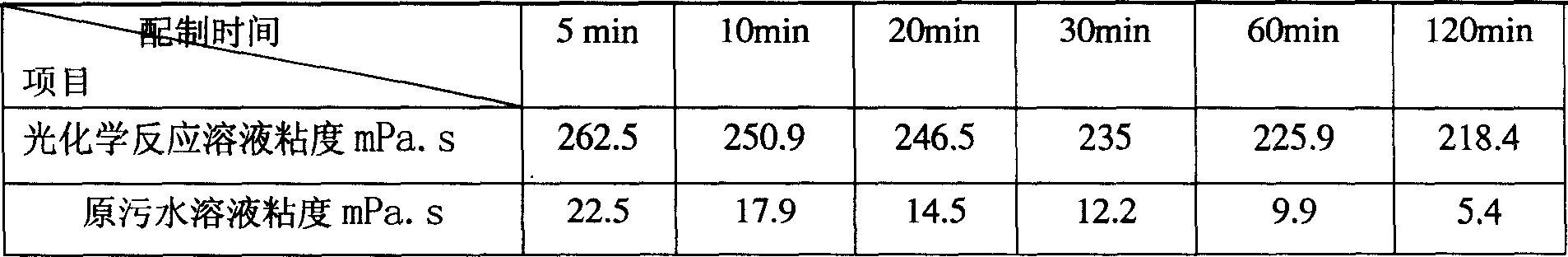

Photochemical oxidation method for increasing oilfield sewage prepared polymer solution viscosity

InactiveCN1803676AReduce dosageHigh viscosityWaste water treatment from quariesTreatment using aerobic processesLiquid viscosityCatalytic oxidation

The disclosed sewage treatment method increase sewage matched polymer solution viscosity for tertiary oil recovery comprises: connecting the optical chemical reactor, a catalysis reaction filter tank and a pipeline mixer by turns; inputting the sewage into the reactor for aeration on bottom; lifting the outlet water into said filter tank for catalysis oxidation and filter to output water on bottom to enter into said pipeline mixer; adding PAM from dissolved-drug tank in front of the mixer by a metering pump, mixing and preparing polymer reinjection liquid, and using high-pressure pump to inject into strata for oil recovery. This invention eliminates lots of high-active material in sewage, improves injection liquid viscosity, and is simple and cheap with no secondary pollution.

Owner:NANKAI UNIV

Constant-temperature device for measuring liquid viscosity

The invention provides a constant-temperature device for measuring liquid viscosity. The constant-temperature device for testing liquid viscosity can effectively control a temperature of a sample needing to be tested in liquid viscosity measurement, and guarantee the accuracy of measured data. The constant-temperature device for testing liquid viscosity comprises a sample measuring cup and a constant-temperature water bath. The constant-temperature water bath comprises a bath tank and a circulating pump which is connected to the bath tank through a pipe and is utilized for driving a liquid in the bath tank to flow circularly. The bath tank of the constant-temperature water bath is provided with a water inlet and a water outlet. The sample measuring cup comprises an inner cylinder and an outer cylinder, wherein the outer cylinder is coaxially sleeved on the inner cylinder. The inner cylinder is utilized for loading a liquid sample. The outer cylinder is provided with a water outlet pipe and a water inlet pipe. The water inlet pipe is connected to the water outlet of the constant-temperature water bath. The water outlet pipe is connected to the water inlet of the constant-temperature water bath. An interlayer space between the inner cylinder and the outer cylinder forms a constant temperature layer. The constant temperature layer is communicated with the bath tank of the constant-temperature water bath by the water outlet pipe and the water inlet pipe.

Owner:CHONGQING POLYCOMP INT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com