Trace amount liquid viscosity measuring method and apparatus

A technology of trace liquid and measurement method, applied in the field of viscosity instruments, can solve the problems of unsuitable micro-flow liquid viscosity, high cost of constant temperature bath, large amount of experimental liquid, etc., achieving short measurement period, suitable for miniaturization, and liquid small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

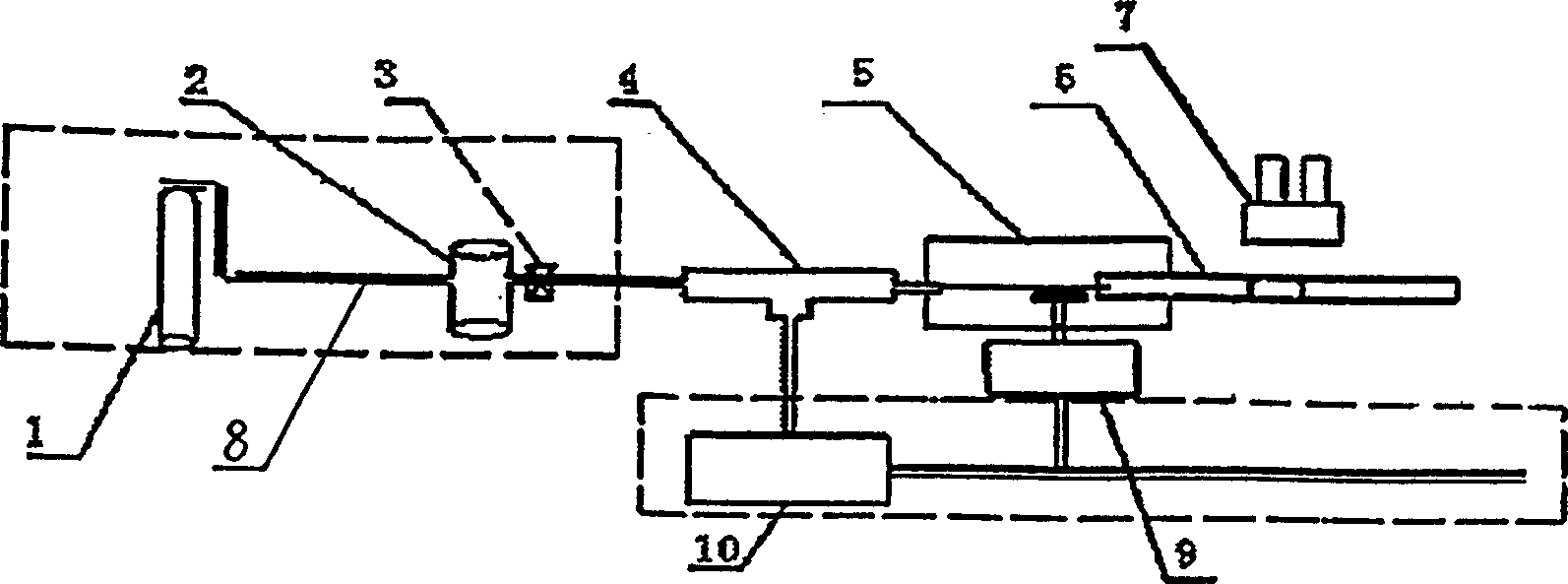

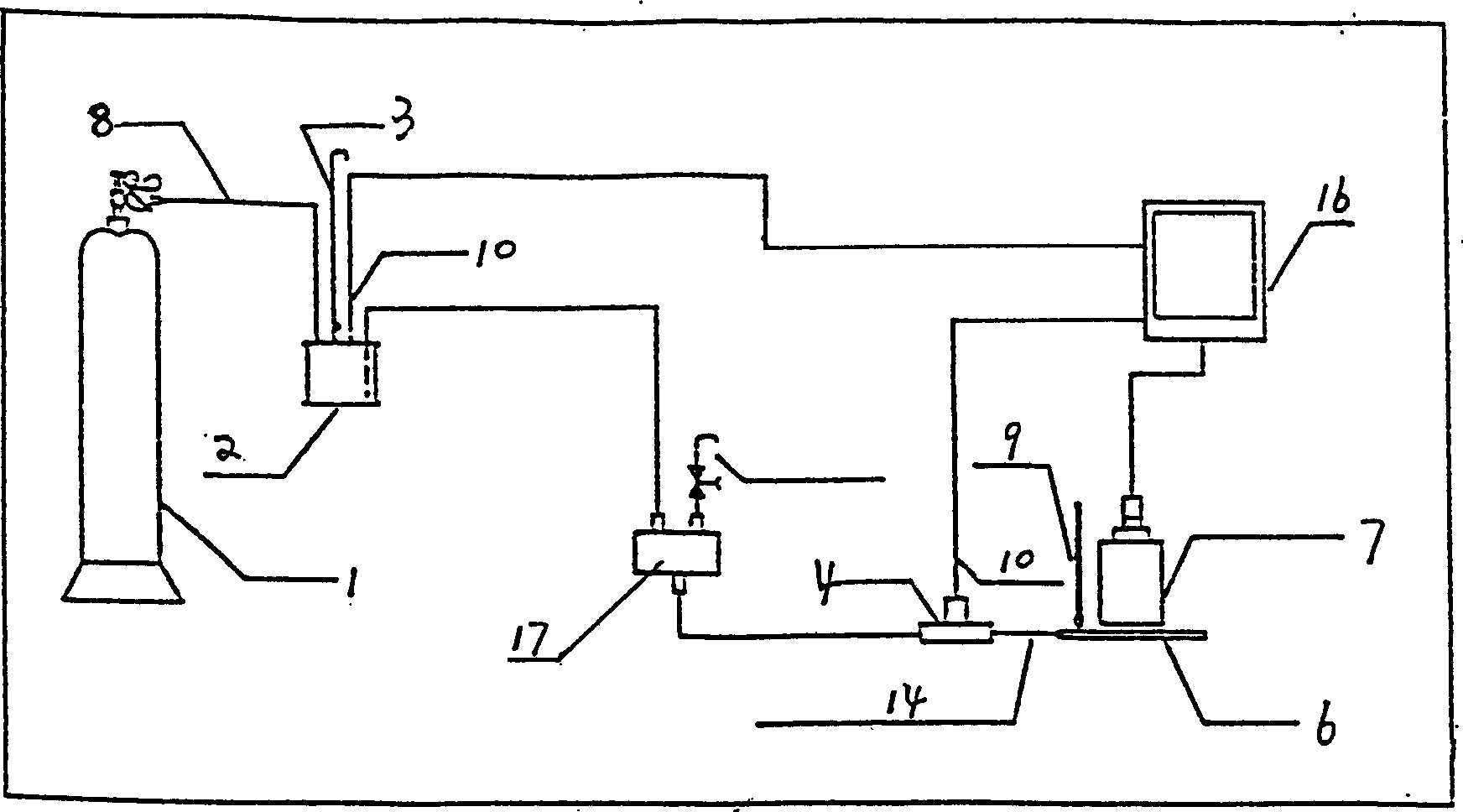

[0043] according to figure 1 To make a trace liquid viscosity measuring instrument, the gas storage cylinder 1 adopts a nitrogen cylinder, which communicates with the liquid storage tank 2 through a pipeline 8, and the liquid storage tank 2 is filled with water, and is connected to the tee 4 through the valve 3, and the two ports of the tee 4 Connect with the pressure sensor 10 and the micron pipe 14 bought in the market respectively; The other port of the glass displacement tube 5 of the displacement tube 6 passes through the temperature controller 5 and is directly connected to the atmosphere; the thermocouple 12 purchased in the market is placed close to the position of the micrometer pipe sleeve 13 wall, and measures the temperature in the sleeve cavity; The optical microscope 7 is arranged above the displacement tube 6 .

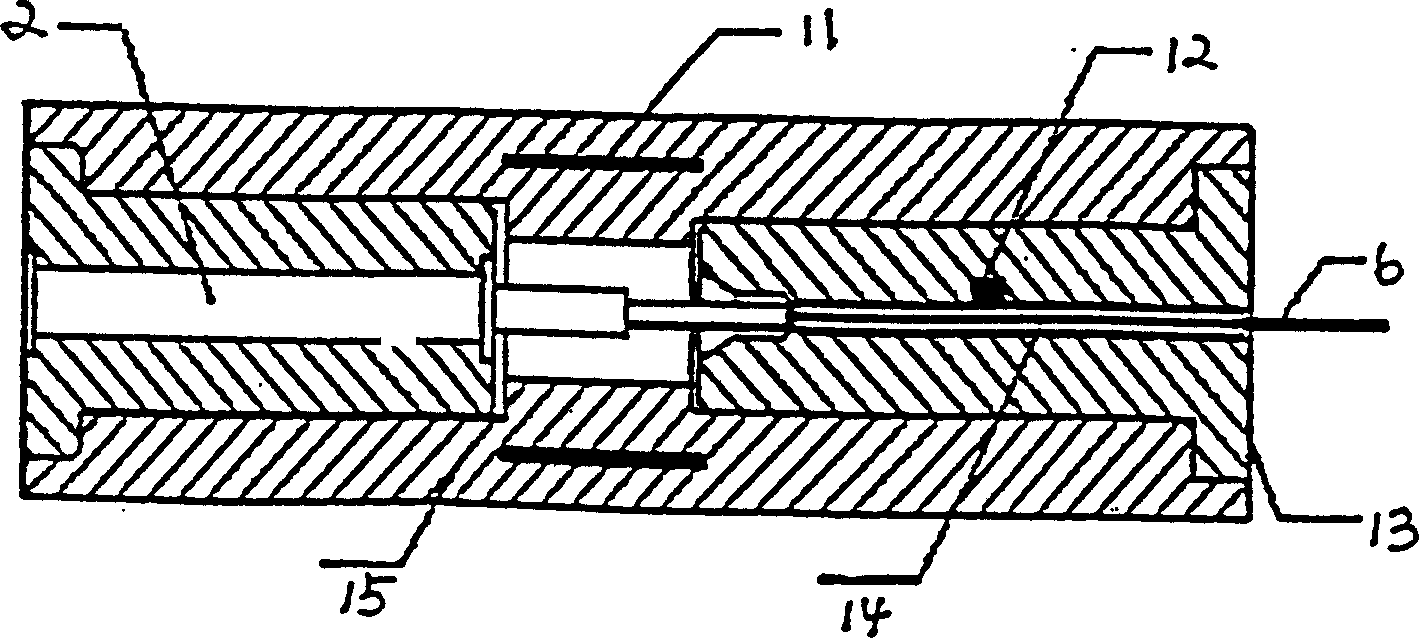

[0044] according to figure 2 To make a miniature adjustable constant temperature device for viscosity measurement, a rectangular copper plate with a l...

Embodiment 2

[0046] On the basis of embodiment 1, also increase computer 16, it is electrically connected with thermocouple 12, pressure sensor 10 and optical microscope 7 in temperature controller 5; Increase filter between liquid storage tank 2 and quartz tube 14 17. The filter membrane aperture is 0.2 μm, and the gas storage bottle 11, the liquid storage tank 2, and the filter 17 are connected with a high-pressure resistant plastic hose, and the joint adopts a hard seal.

Embodiment 4

[0051] Use the trace liquid viscometer in embodiment 2, in the scope of 10~40 ℃, measure the viscosity coefficient of carbon tetrahalide, carbon tetrahalide is housed in the liquid storage tank, the experiment adopts the nitrogen bottle of internal pressure 10Mpa and internal diameter is 25 μ m , A pipe with an outer diameter of 320μm and a length of about 4.7cm, with a pressure of 0.2Mpa. Measuring method and process are the same as embodiment 3. The experimental results show that: at the set target temperature, the viscosity measurement result is close to the theoretical value, and the error is only 0.6%-3.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com