Patents

Literature

327 results about "Viscosity measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

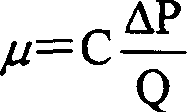

Viscosity is the measure of a substance's resistance to motion under an applied force. The formula for measuring viscosity is fairly simple: viscosity = shear stress / shear rate. The result is typically expressed in centipoise (cP), which is the equivalent of 1 mPa s (millipascal second).

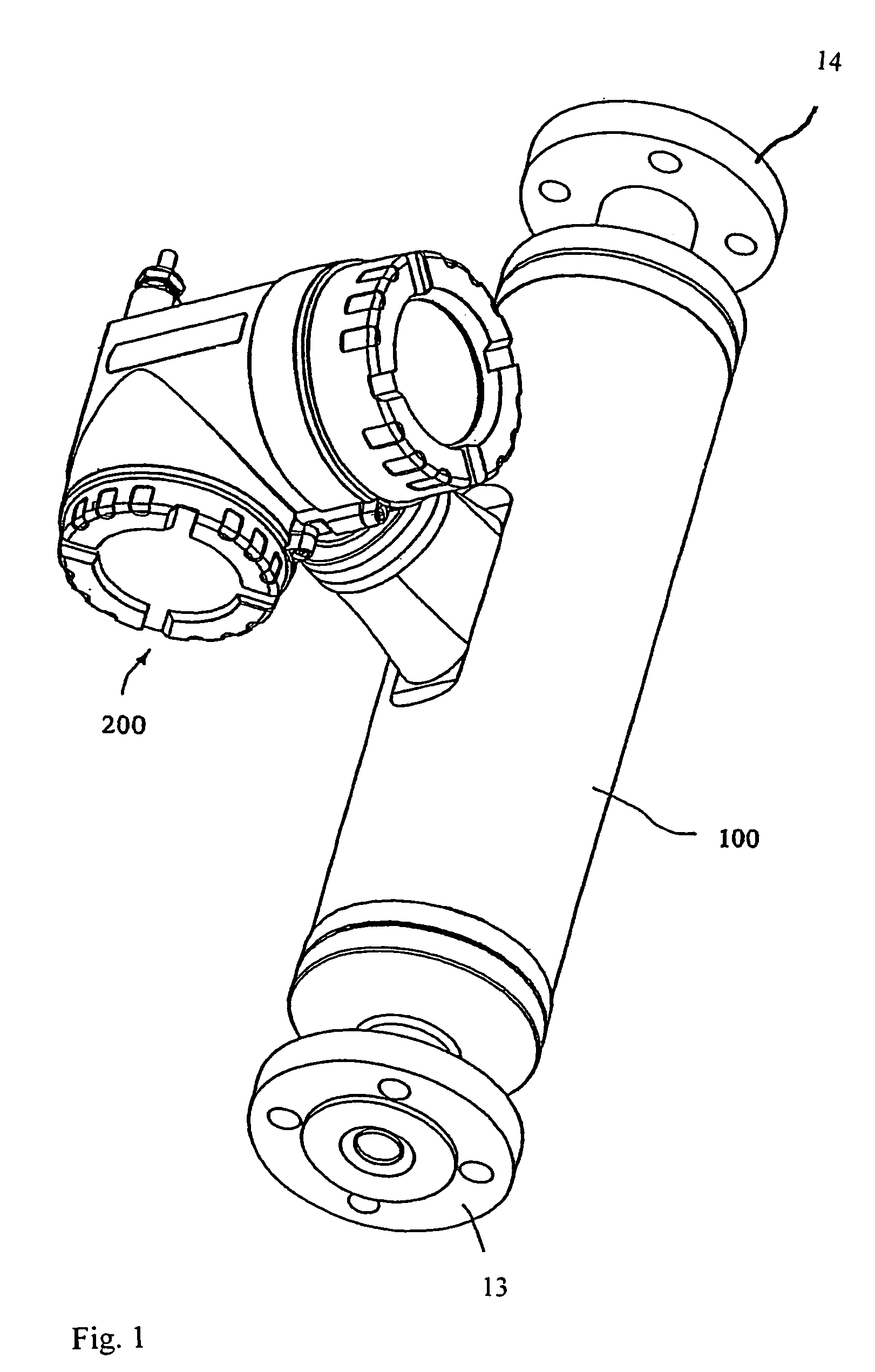

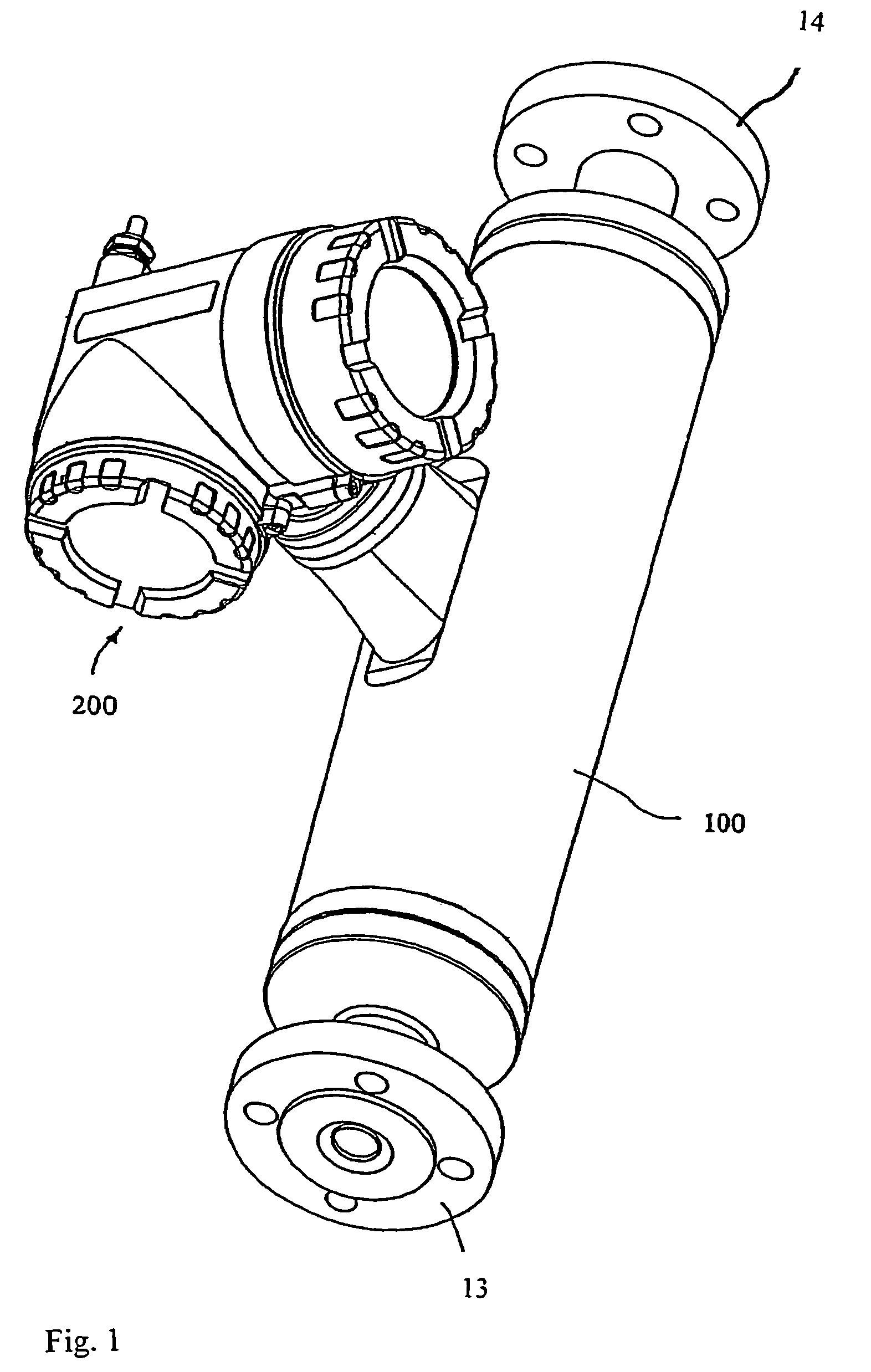

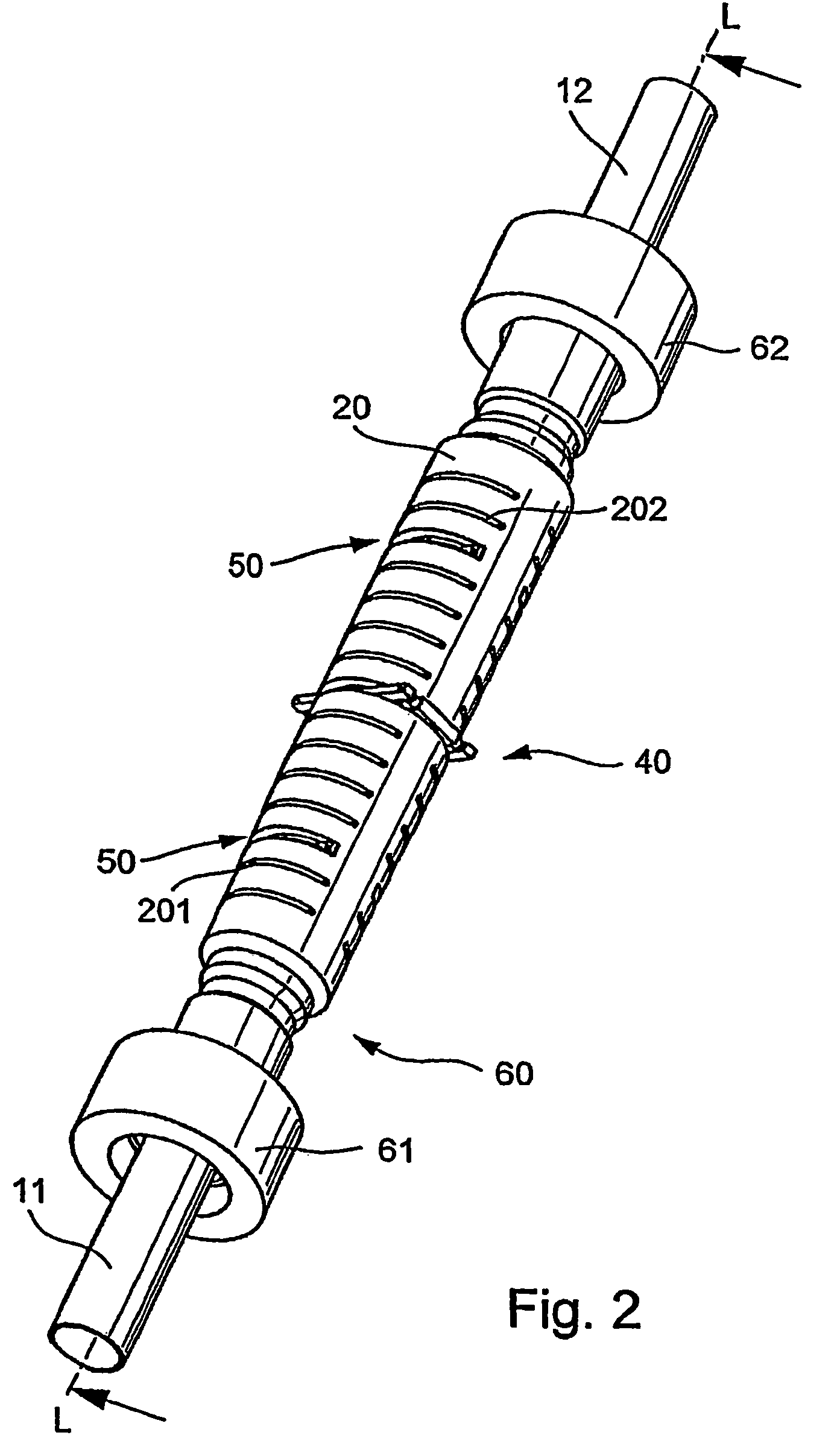

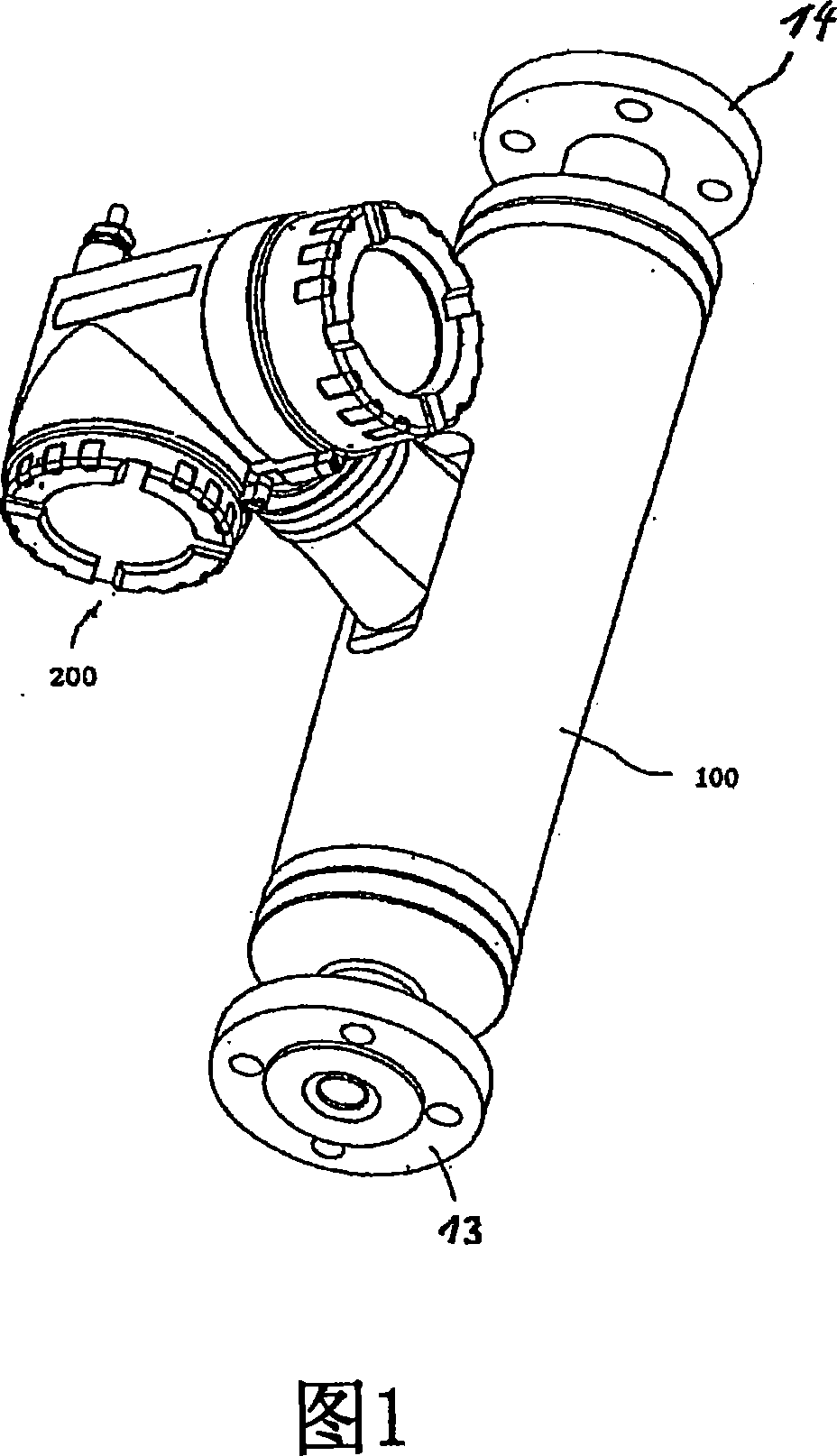

Vibratory transducer

InactiveUS6840109B2Simple and robust mannerSimplifies isolationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerEngineering

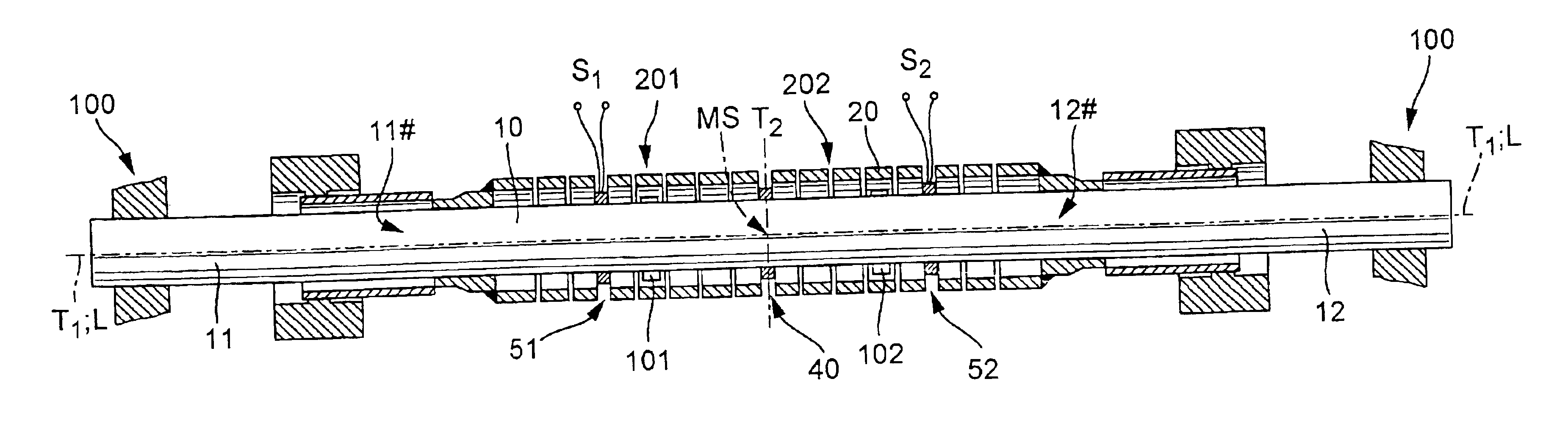

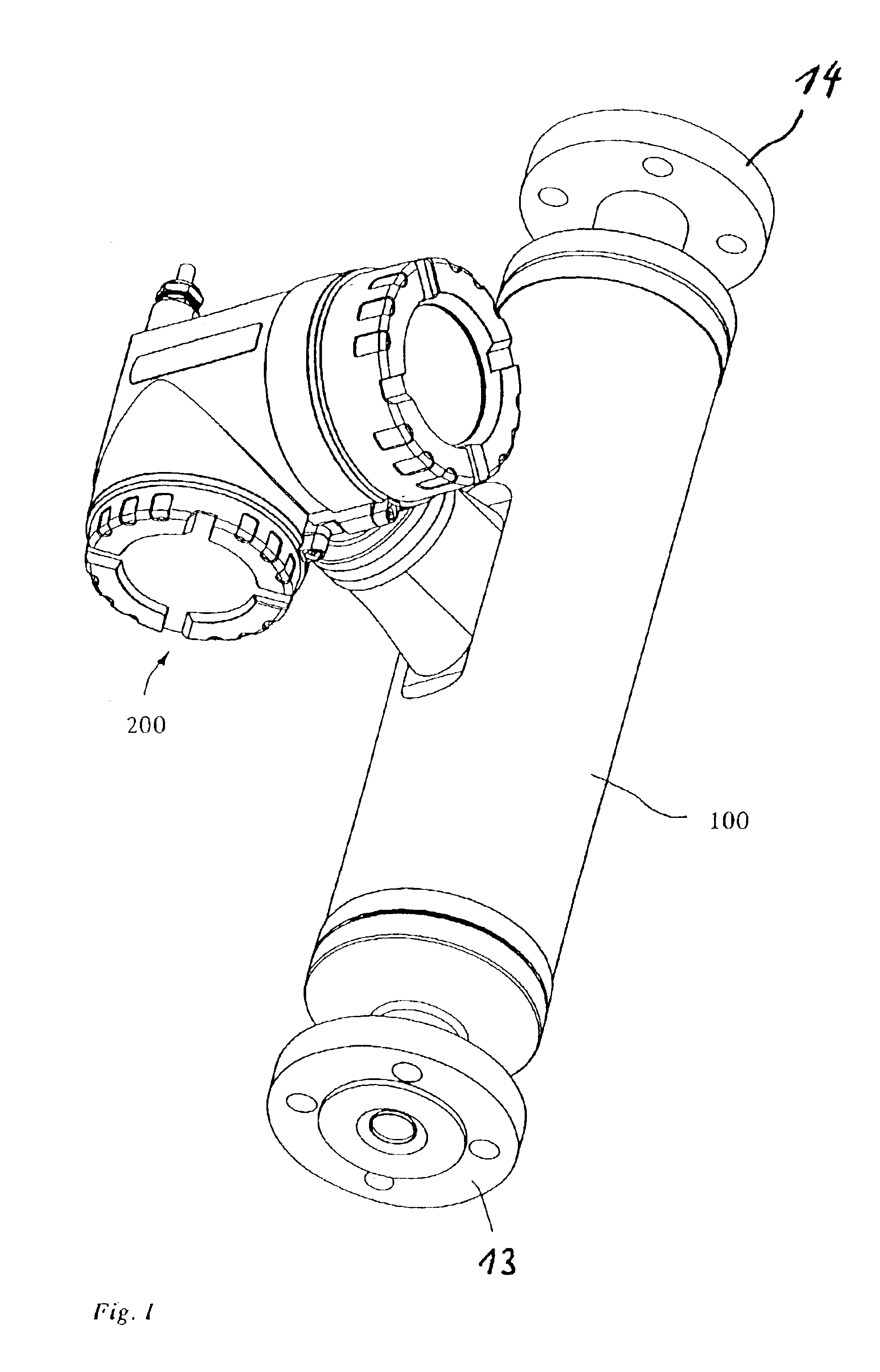

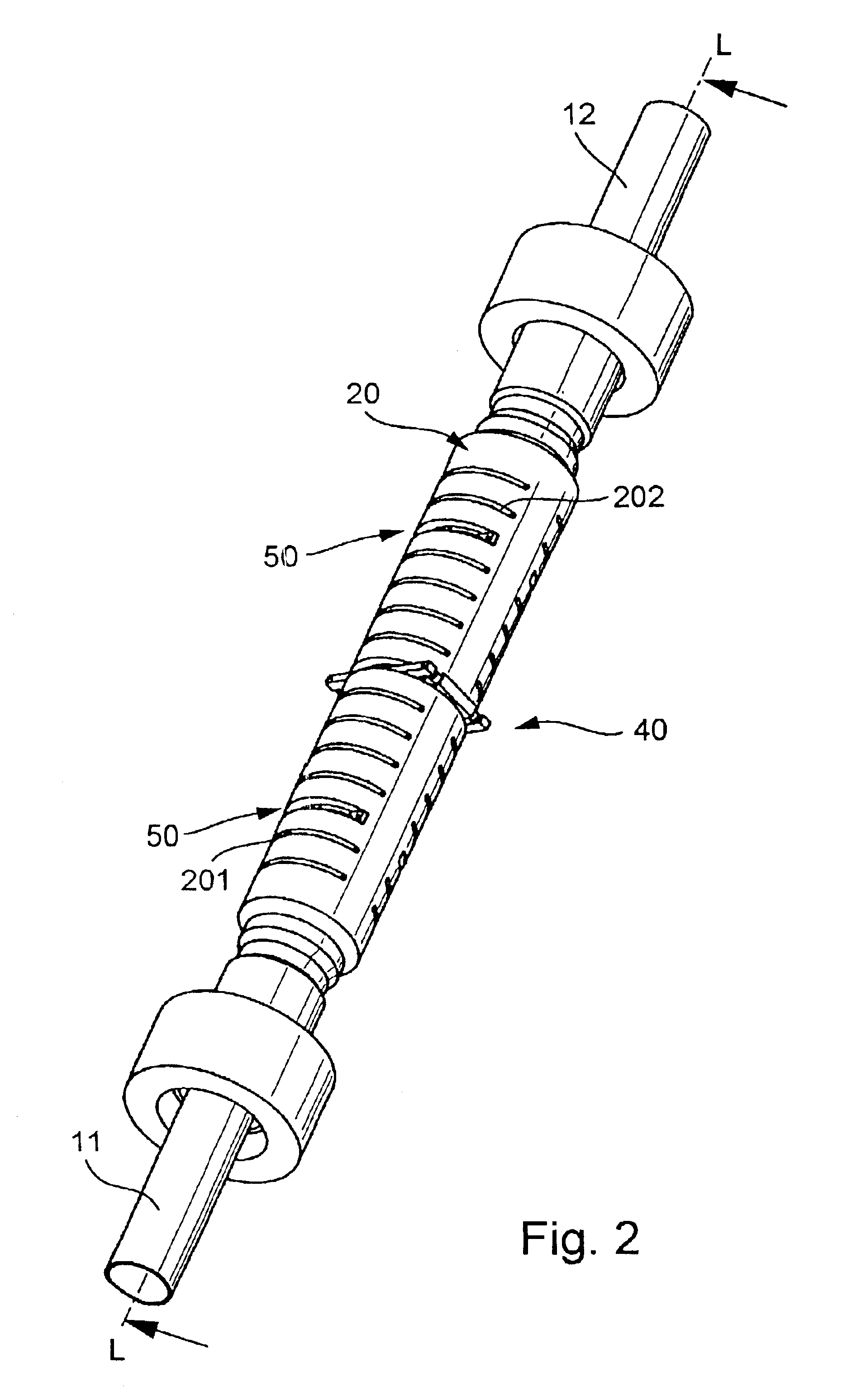

To conduct a fluid, the transducer has a flow tube which in operation vibrated by an excitation assembly. Inlet-side and outlet-side vibrations of the flow tube are sensed by means of a sensor arrangement. To produce shear forces in the fluid, the flow tube is at least intermittently excited into torsional vibrations about a longitudinal flow-tube axis. An internal portion of the transducer, formed at least by the flow tube, an antivibrator, the sensor arrangement, and the excitation assembly and mounted at least on the inlet and outlet tube sections, has a centroid which is located inside the flow tube. The transducer is suitable for use in viscometers or Coriolis mass flowmeter-viscometers. In spite of using only a single straight flow tube, it is dynamically well balanced in operation, and the development of bending moments by the torsionally vibrating flow tube is largely prevented. This also effectively prevents the transducer case or the connected pipe from being excited into sympathetic vibration. Measurement signals representative of mass flow rate are readily distinguishable from measurement signals representative of viscosity, particularly if the sensors used for the viscosity measurement are also used for the mass flow measurement.

Owner:ENDRESS HAUSER FLOWTEC AG

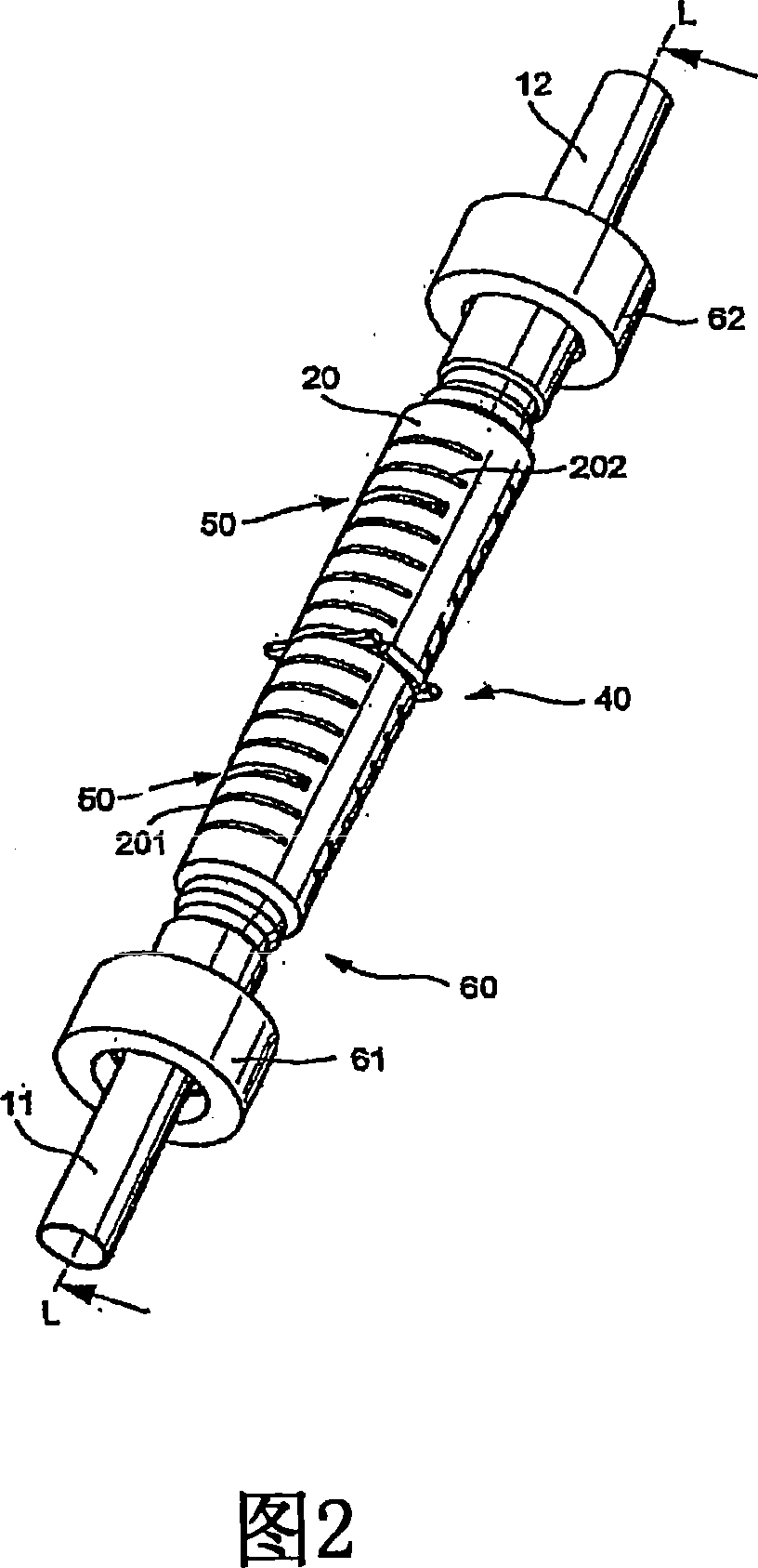

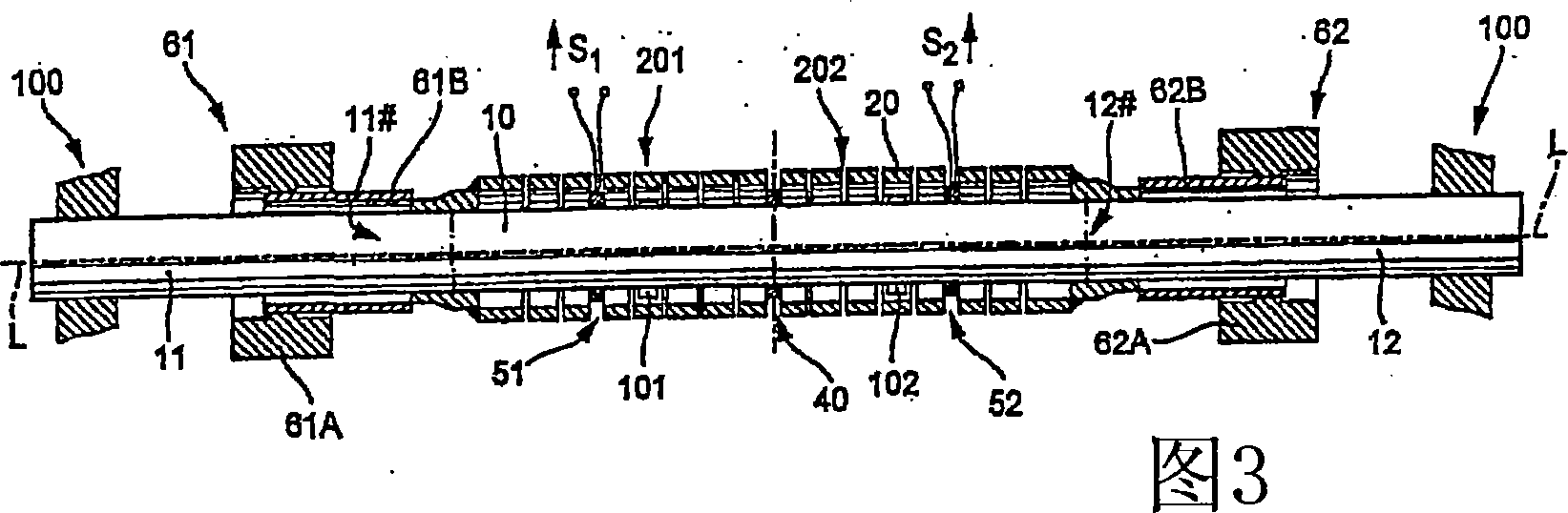

Coriolis mass measuring device

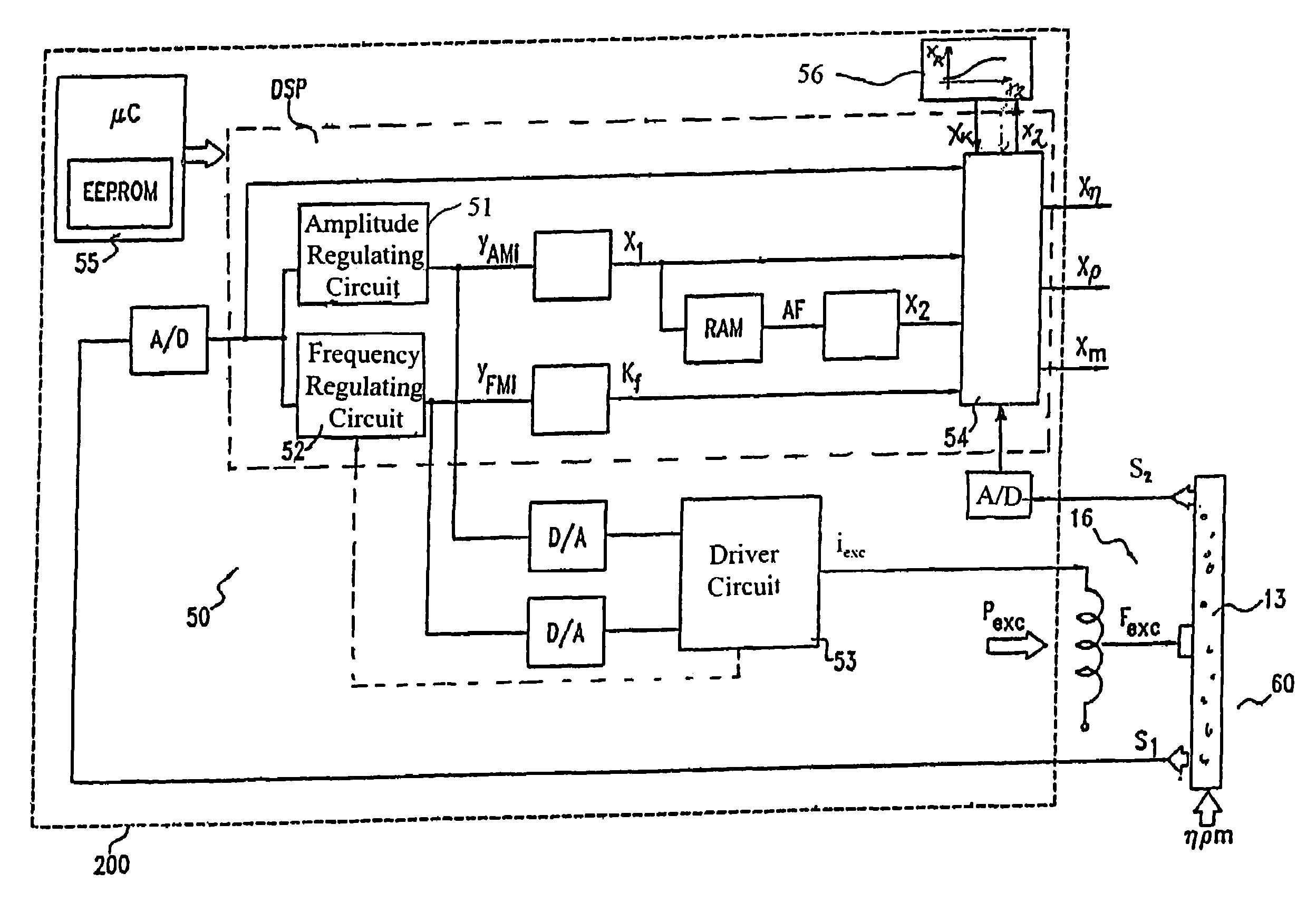

ActiveUS7040181B2Accurate measurementImprove accuracyFlow propertiesVolume meteringMeasurement deviceApparent viscosity

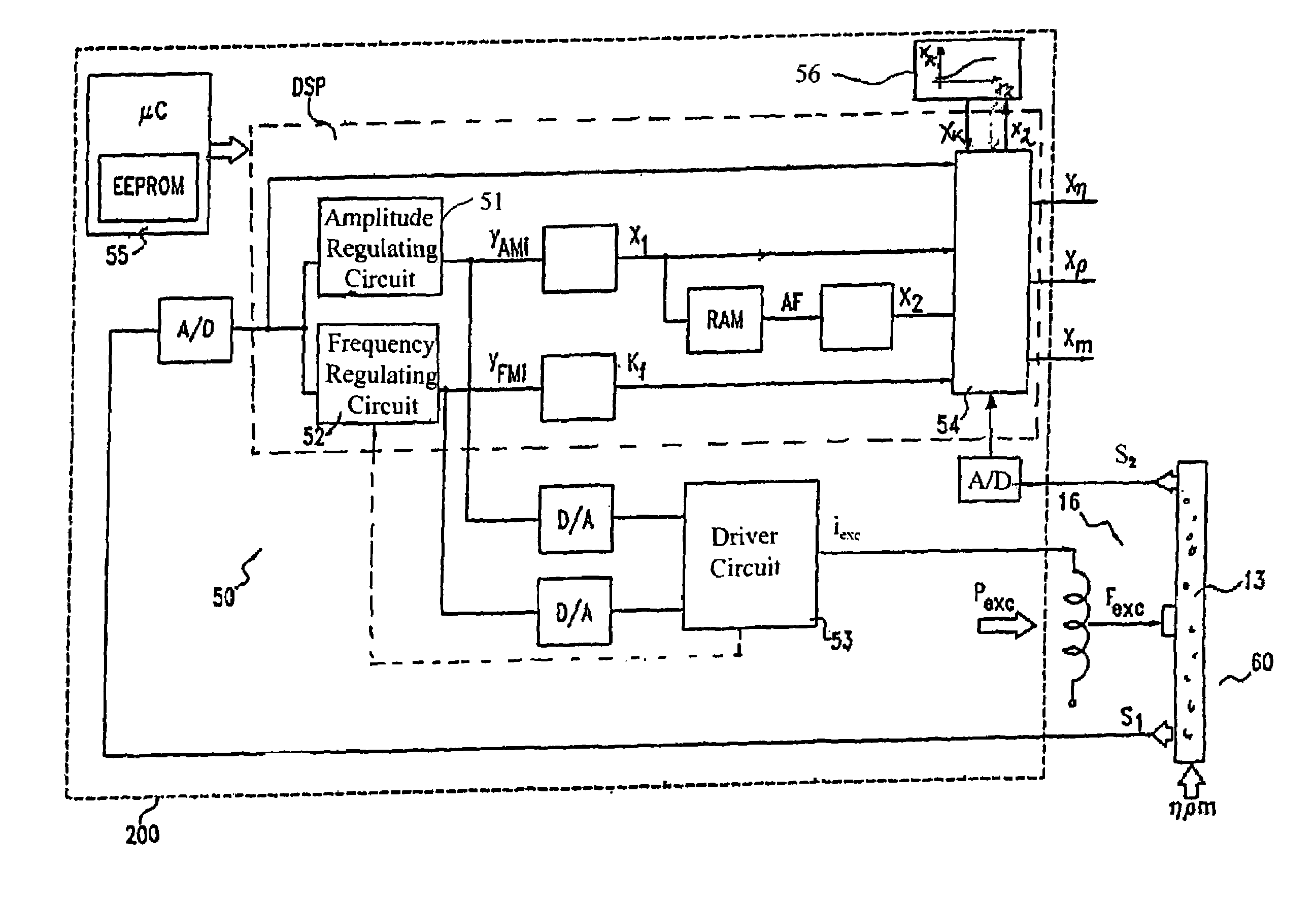

A Coriolis mass flow measuring device includes a vibratory measuring transducer having at least one measuring tube, which has medium flowing through it during operation. In operation, the measuring tube is caused by an exciter arrangement to undergo mechanical oscillations, especially bending oscillations. Additionally, the Coriolis mass flow measuring device includes a sensor arrangement for producing oscillation measurement signals (s1, S2) representing the inlet-end and outlet-end oscillations of the measuring tube. Measuring device electronics controlling the exciter arrangement produces an exciter current (iexc) and an intermediate value (X′m) derived from the oscillation measurement signals (s1, s2). This intermediate value represents an uncorrected mass flow. Derived from the exciter current and / or from a component of the exciter current (iexc), an intermediate value (X2) is produced, which corresponds to a damping of the oscillations of the measuring tube. This damping is especially a function of an apparent viscosity, and / or a viscosity-density product, of the medium guided in the measuring tube. Furthermore, a correction value (XK) is produced for the intermediate value (X′m) utilizing the intermediate value (X2) and a viscosity measurement value (Xη) determined initially or during operation. The viscosity measurement value (Xη) corresponds to a viscosity of the medium guided in the measuring tube and / or to a predetermined reference viscosity. On the basis of the intermediate value (X′m) and the correction value (XK), the measuring device electronics then produces an exact mass flow rate measurement value (Xm).

Owner:ENDRESS HAUSER FLOWTEC AG

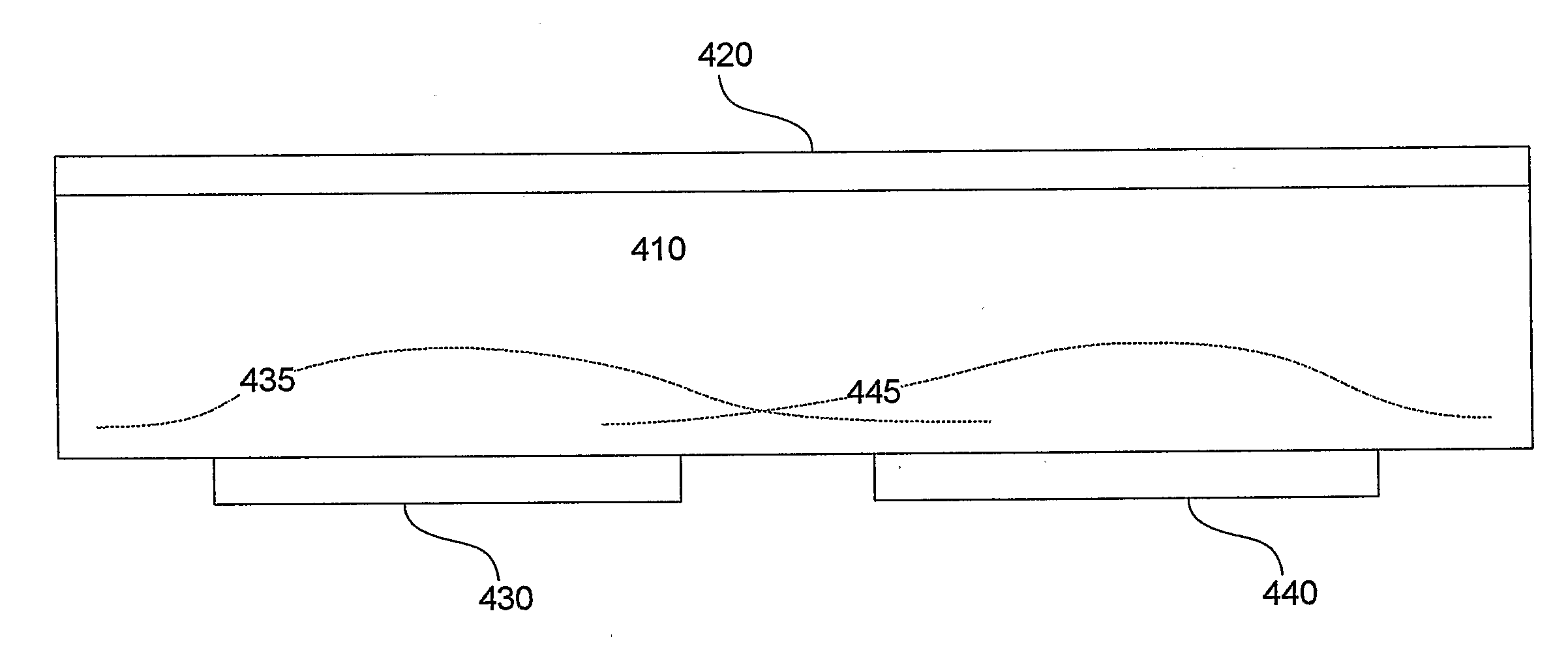

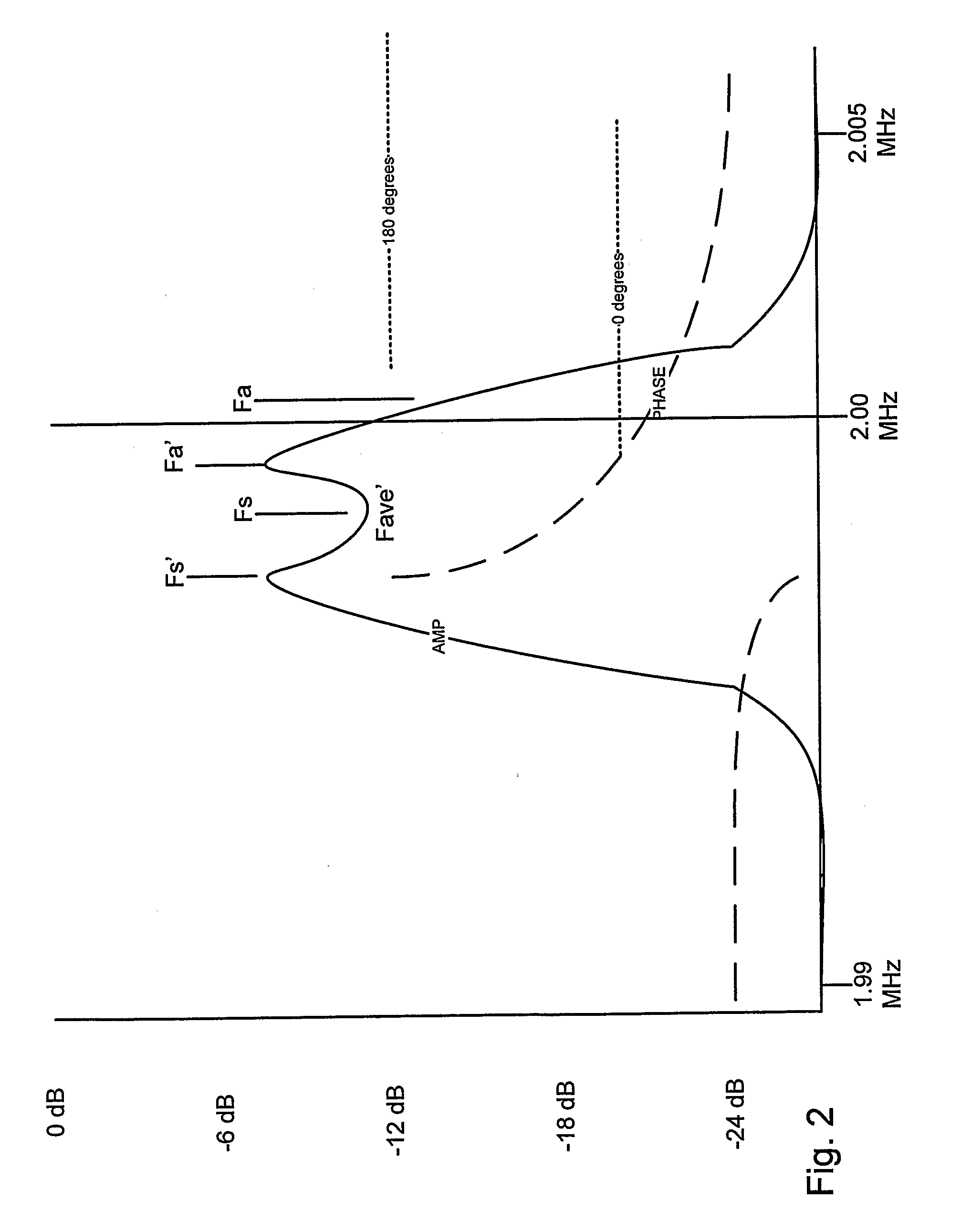

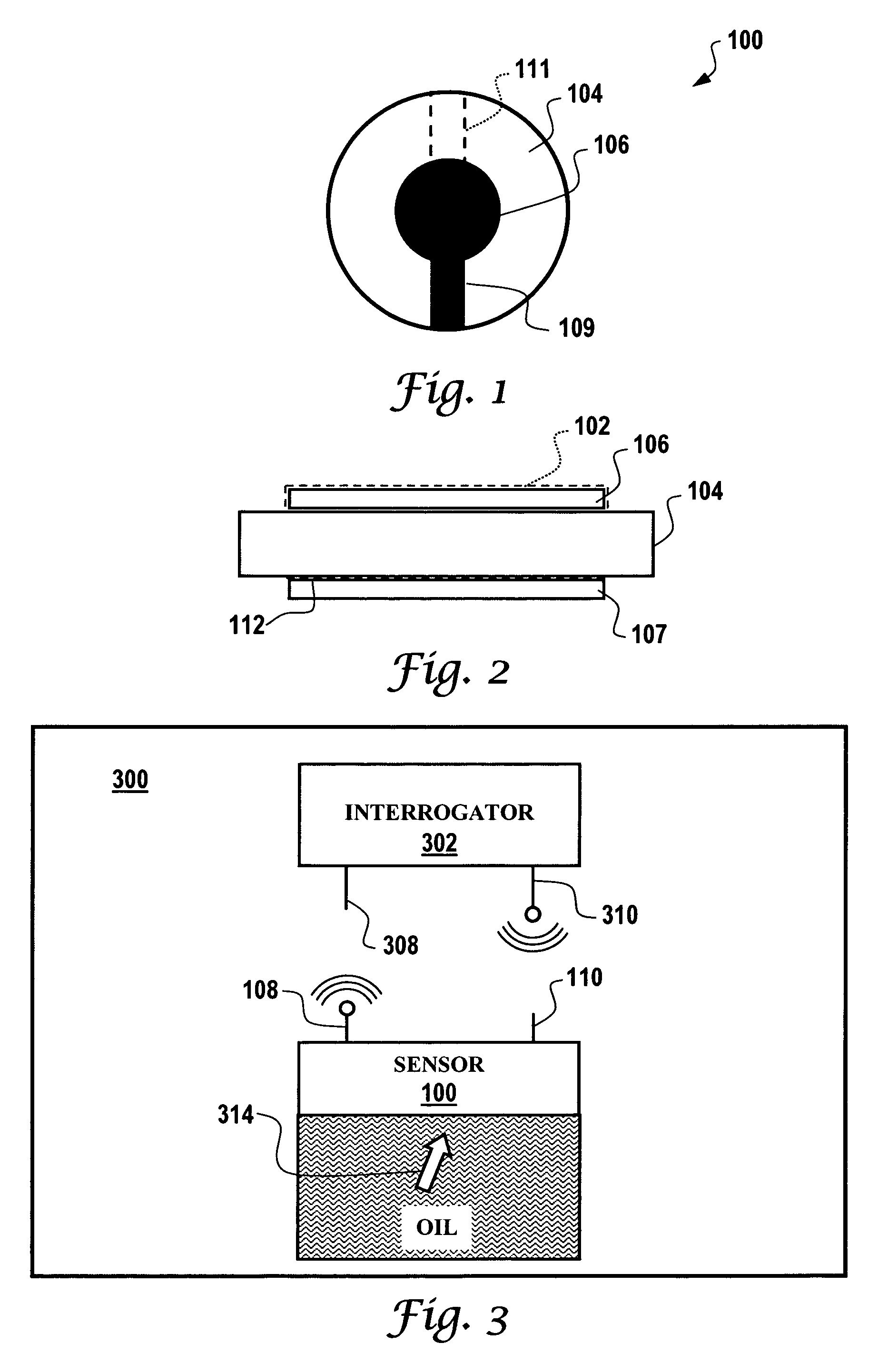

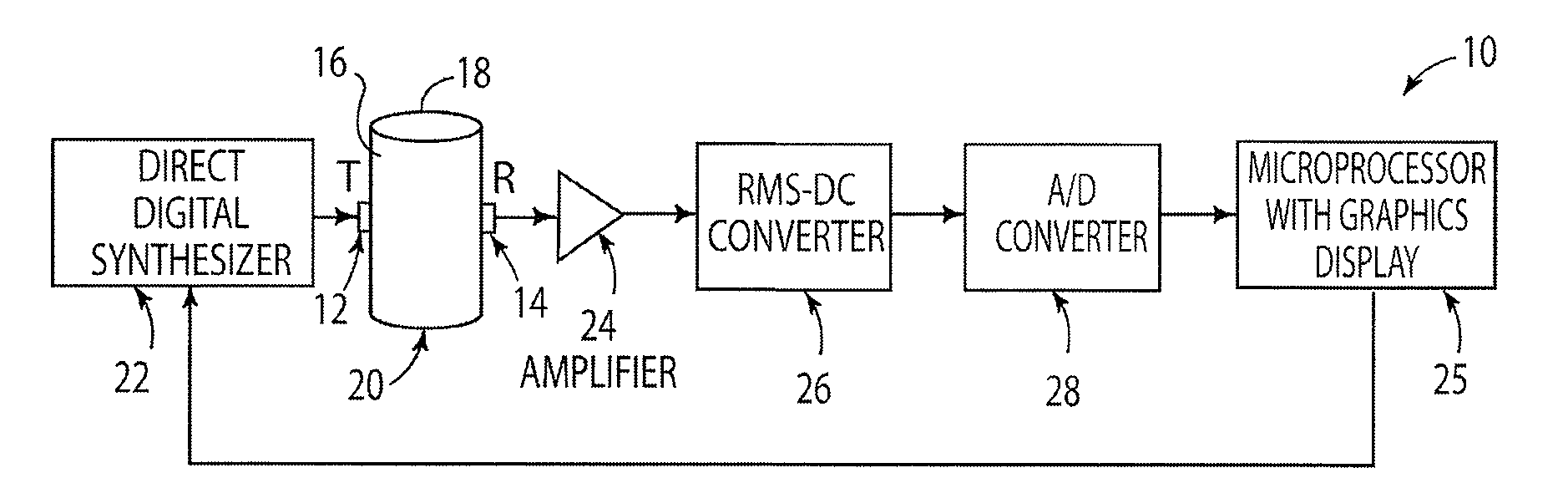

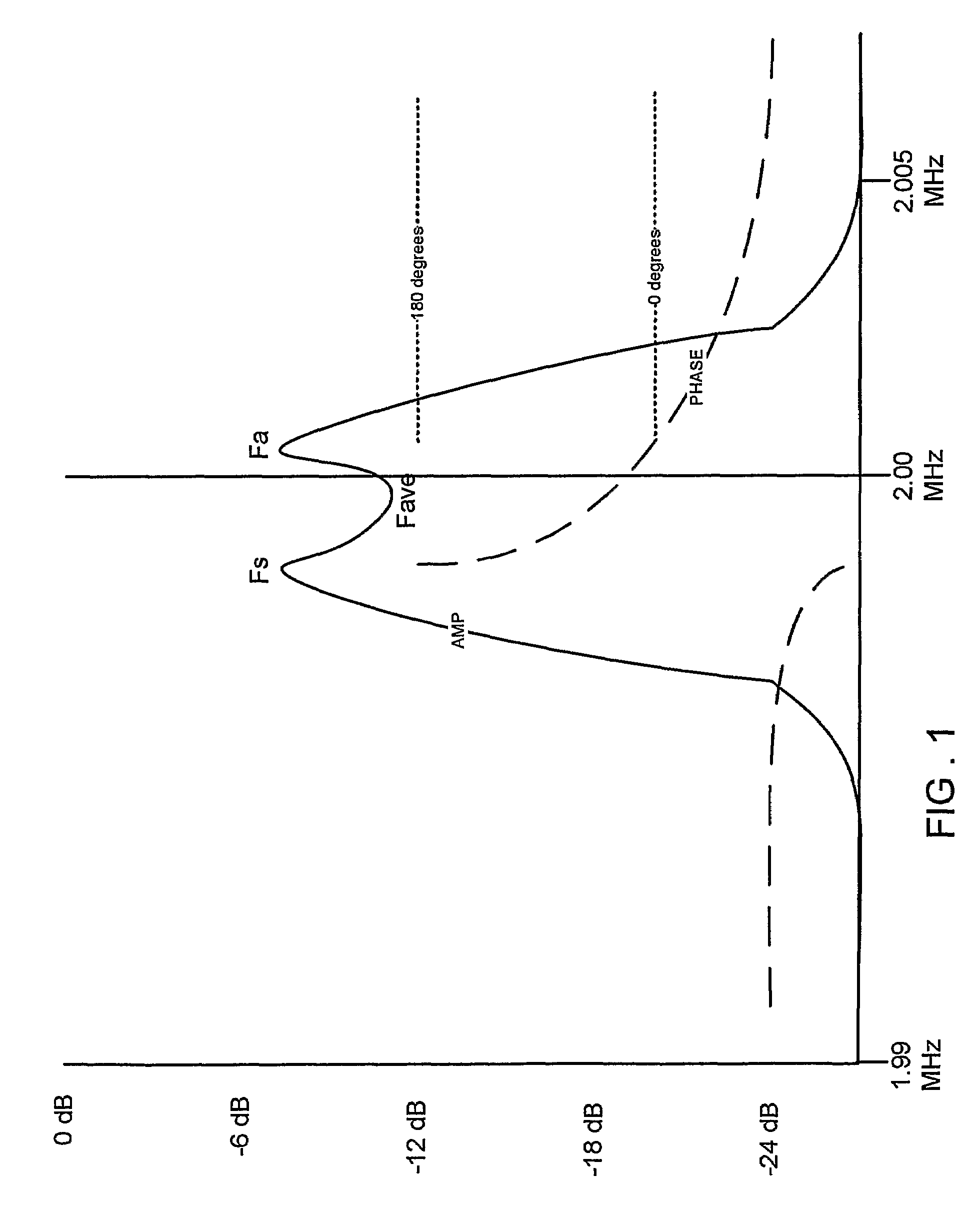

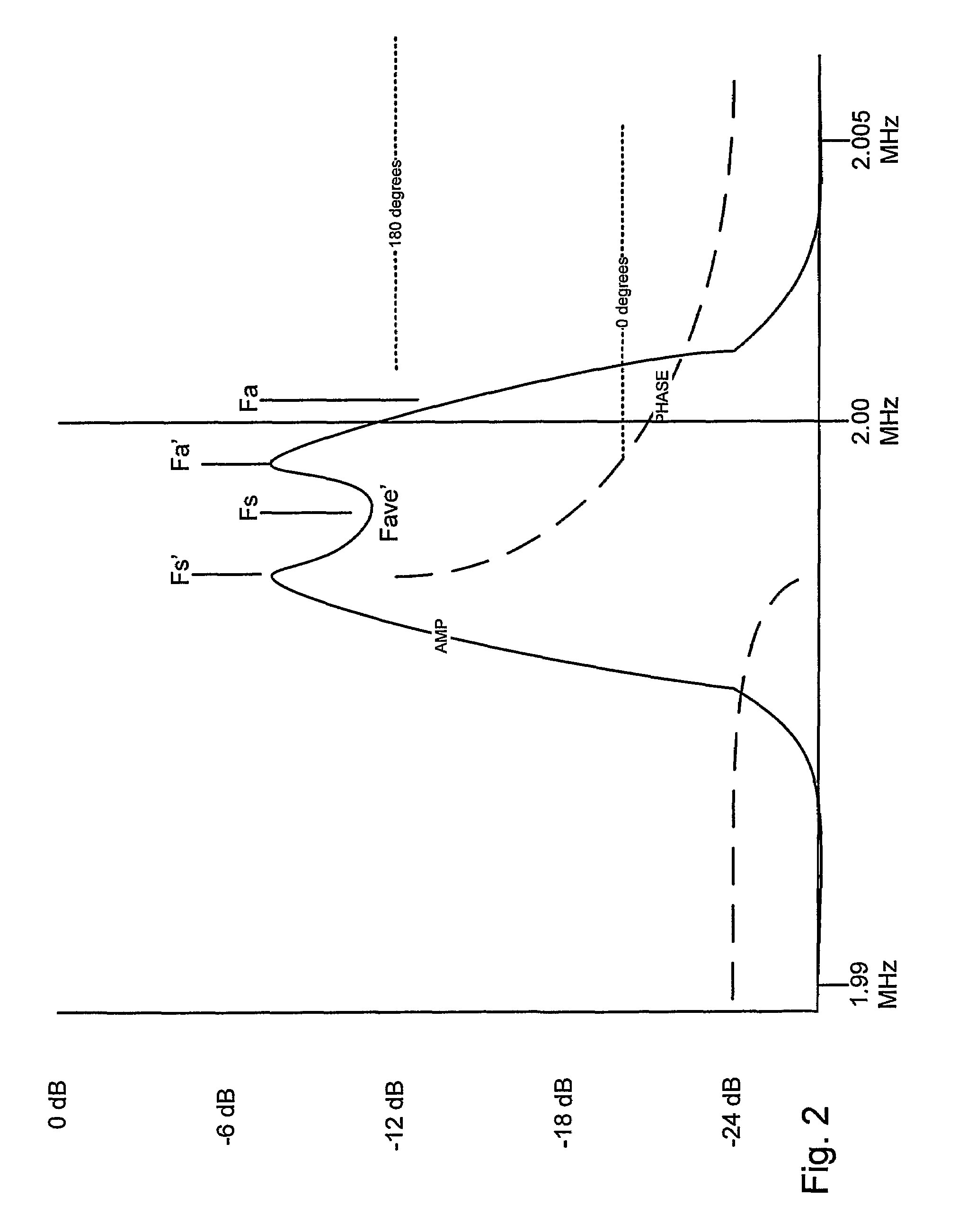

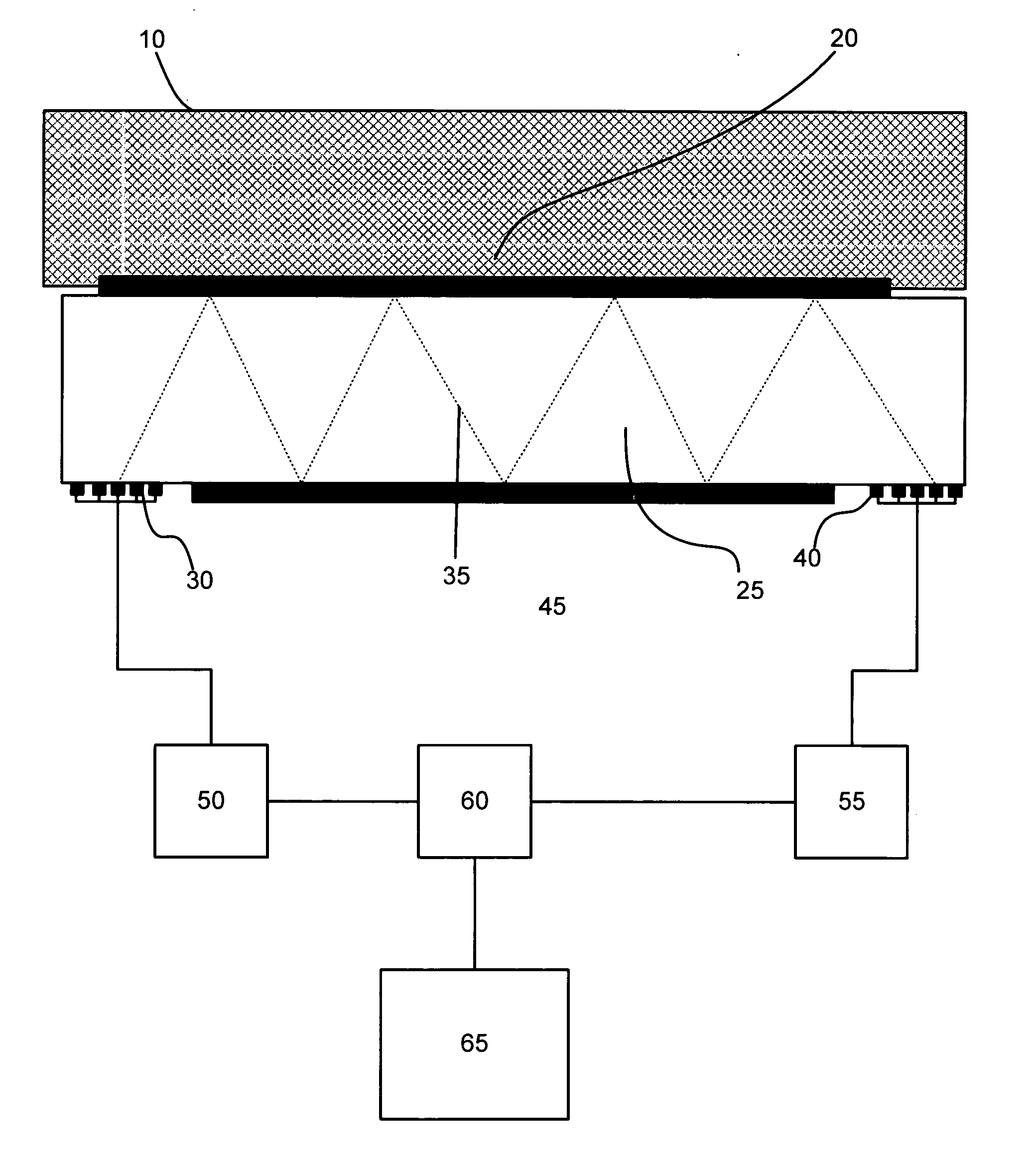

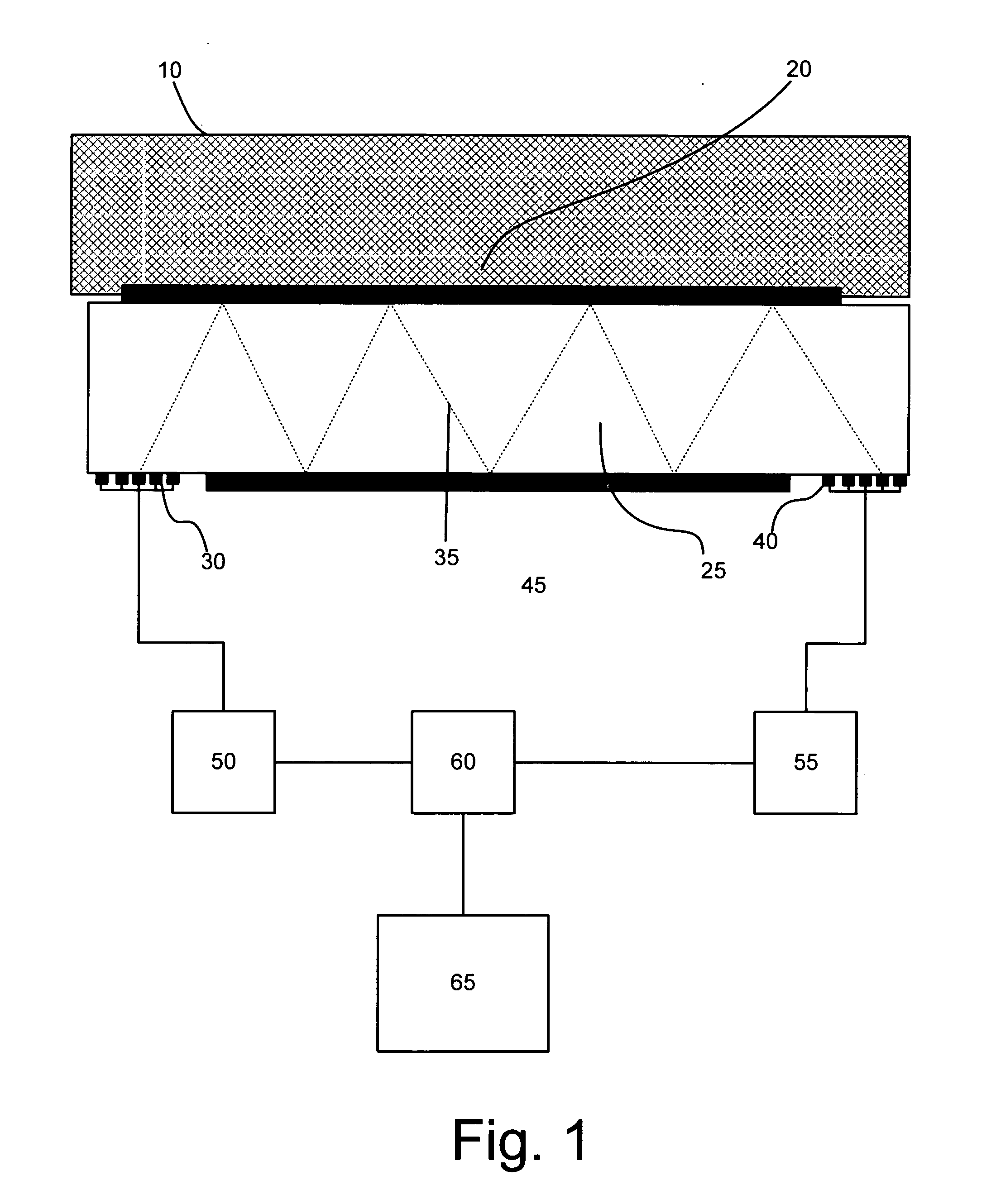

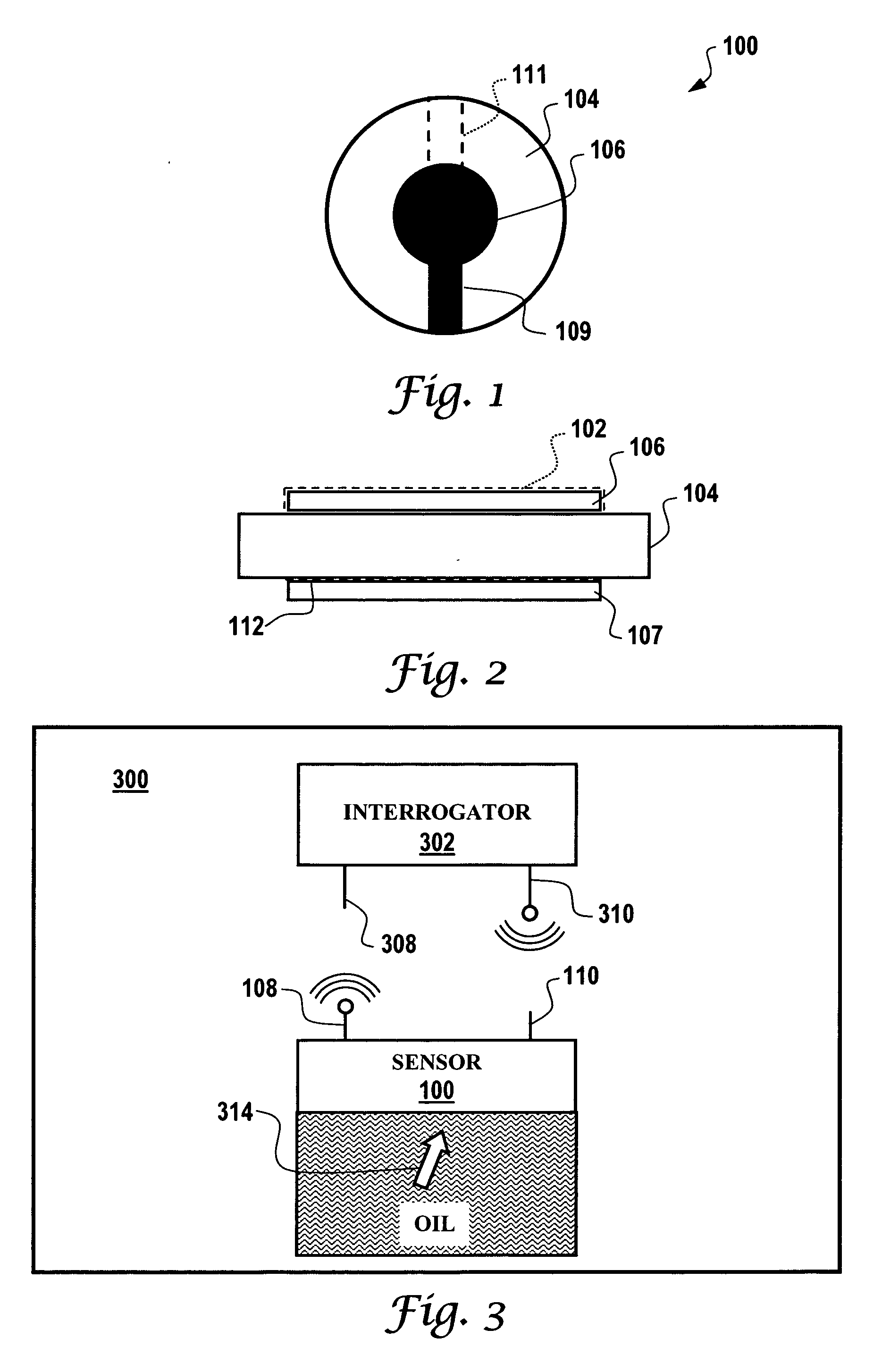

Measurement of density and viscoelasticity with a single acoustic wave sensor

InactiveUS20070144240A1Analysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesClose couplingMass loading

A sensor, method and system, for measuring certain characteristics of a fluid. The sensor utilizes a piezoelectric device having at least two tightly coupled resonators providing a two pole electric transfer function responsive to an electrical signal coupled to the input resonator. The piezoelectric sensor has a textured entrapment layer, constructed to entrap a known volume of fluid and impart motion to the entrapped fluid as well as to surrounding non-trapped fluid. The common mode frequency shift of the two resonant frequencies is related to mass loading due to the entrapped fluid, while the energy absorbed by the fluid, or a phase shift of one of the resonant frequencies, is related to the viscosity / density product of the fluid. Extracting the viscosity is a matter of mathematical manipulation. By controlling the energy level of the input electrical signal, the viscosity measurement may be conducted at a predetermined shear rate.

Owner:VECTRON INT INC

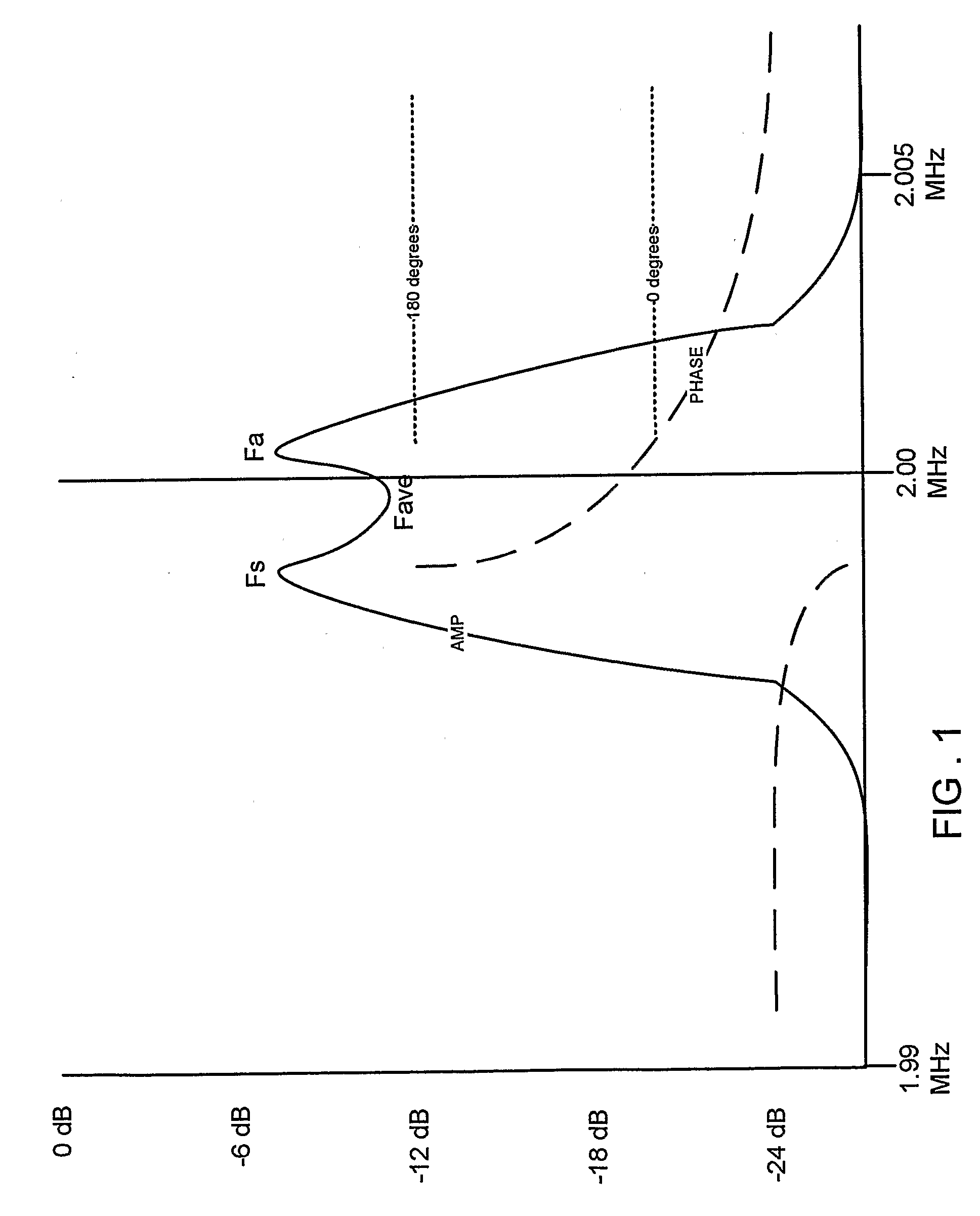

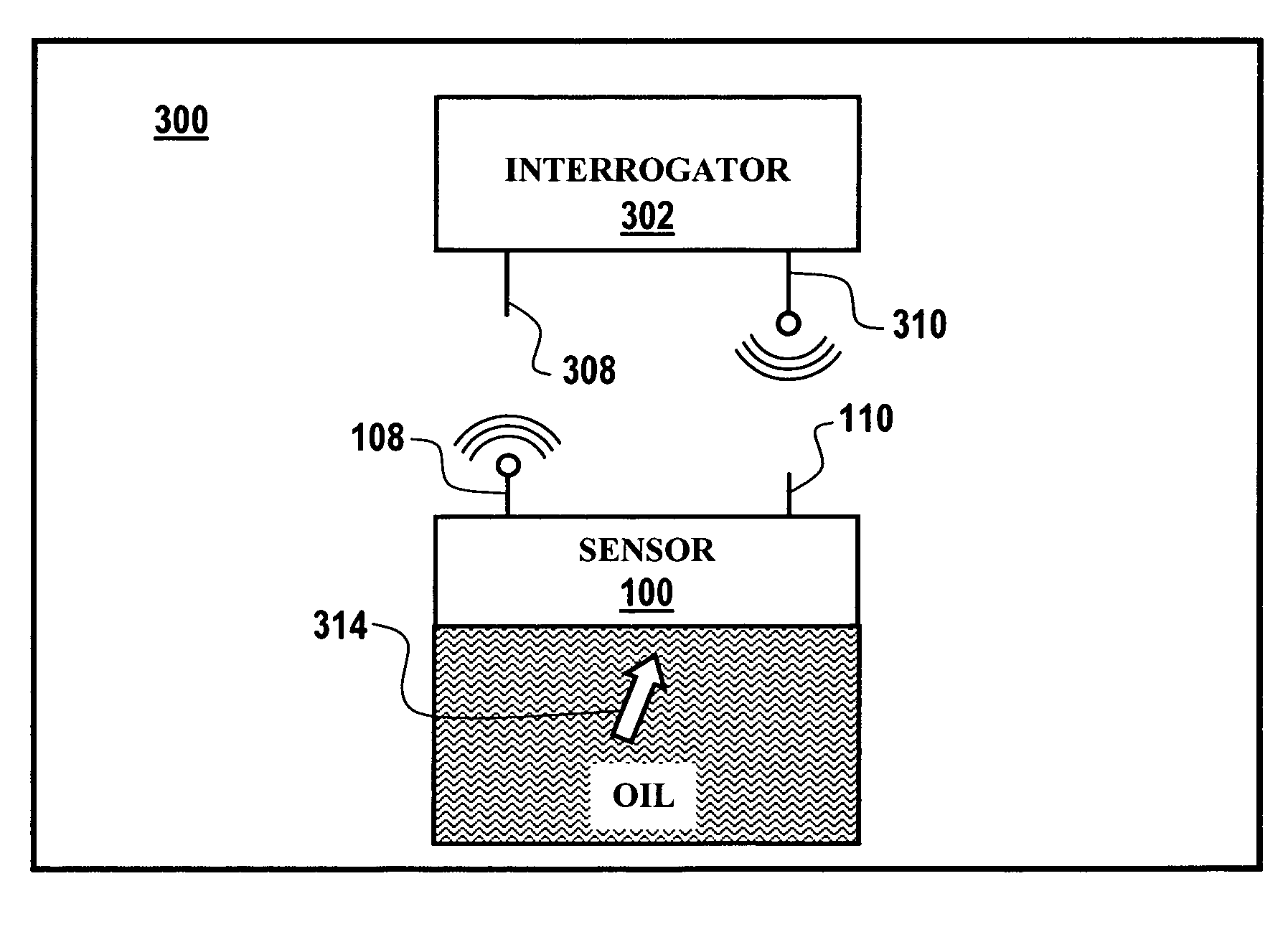

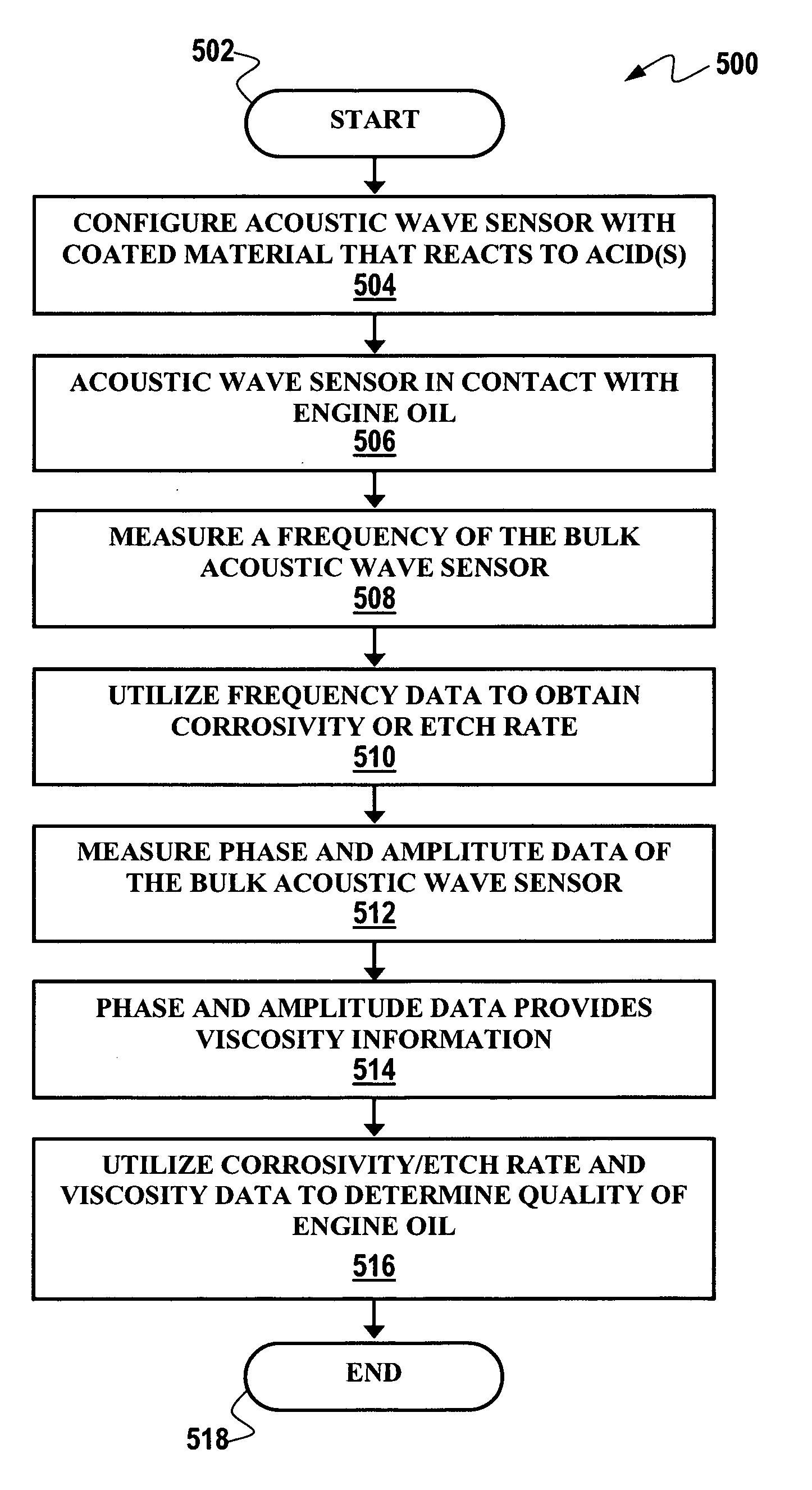

System and method to determine oil quality utilizing a single multi-function surface acoustic wave sensor

InactiveUS7219536B2Viscosity of the engine oil can additionally beAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesOil canFrequency measurements

A method and system for detecting oil quality. The quality of engine oil can be determined utilizing an acoustic wave sensor to obtain viscosity and corrosivity data associated with the engine oil. The acoustic wave sensor is coated with a material that selectively reacts to at least one type of an acid in order to provide data indicative of the presence of the acids in the engine oil. The etch rate or the corrosivity of the engine oil can be determined based on the frequency data obtained as a result of the frequency measurement utilizing the acoustic wave sensor. The viscosity of the engine oil can additionally be obtained based on a measurement of phase and amplitude obtained from the data utilizing the acoustic wave sensor. The etch rate and the viscosity measurement provide data indicative of the quality of the engine oil.

Owner:HONEYWELL INT INC

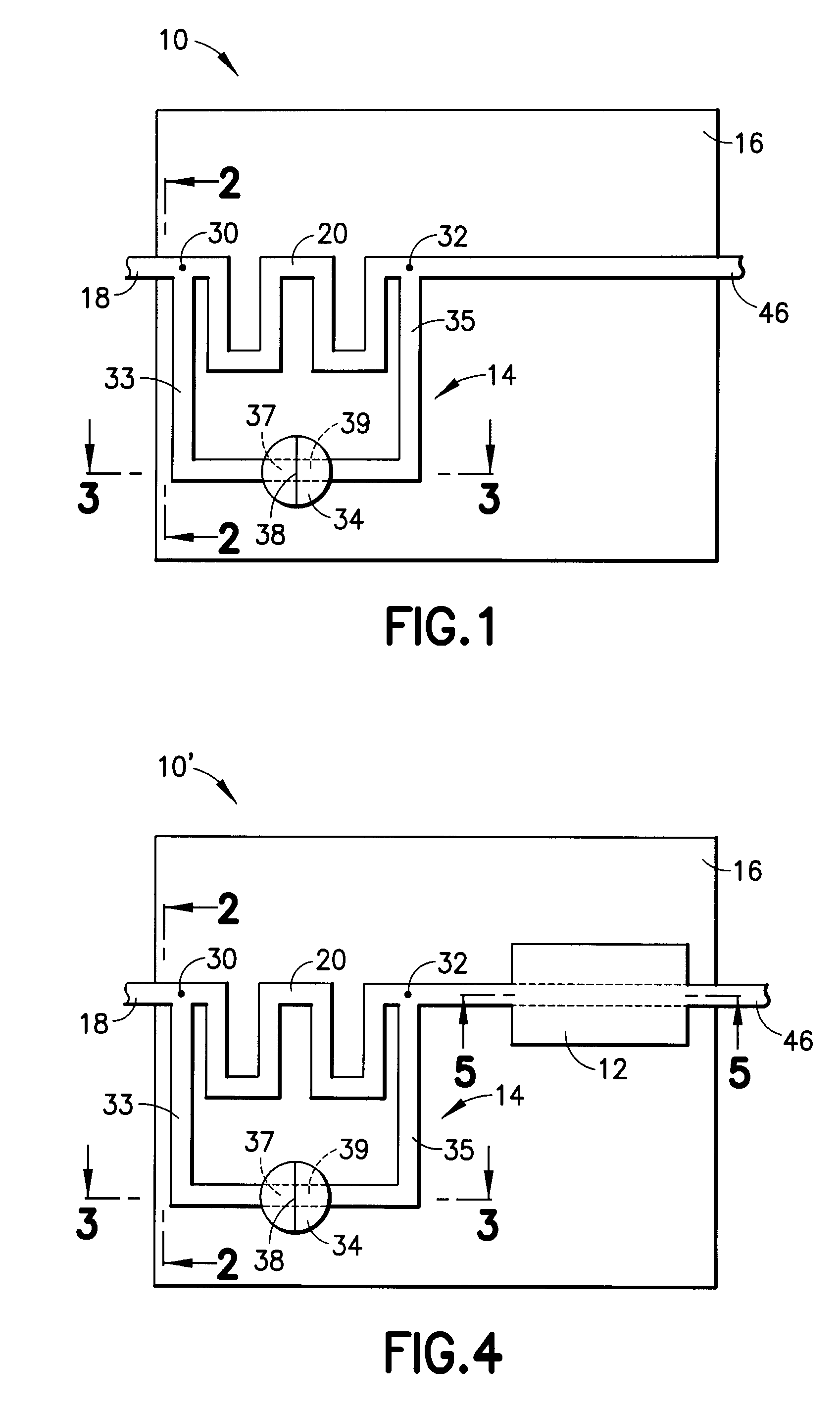

Viscosity measurement

ActiveUS7784330B2Material analysis by optical meansFluid pressure measurement by mechanical elementsDifferential pressureEngineering

A micro-fluidic device and methods for measuring one or more rheologic properties of a fluid. The micro-fluidic device includes a substrate and at least one cover bonded to a surface of the substrate with a fluid channel formed in at least one of the cover or the substrate. Further, the micro-fluidic device includes a first differential pressure gauge that can have a first differential pressure sensor in fluid communication with both a first pressure site and a second pressure site. Further still, the micro-fluidic device includes the first pressure site and the second pressure site that can be spaced apart by a first section of the fluid channel. Also, the micro-fluidic device includes a data processor communicatively coupled to the first differential pressure sensor, so as to receive data generated by the first differential pressure sensor.

Owner:SCHLUMBERGER TECH CORP

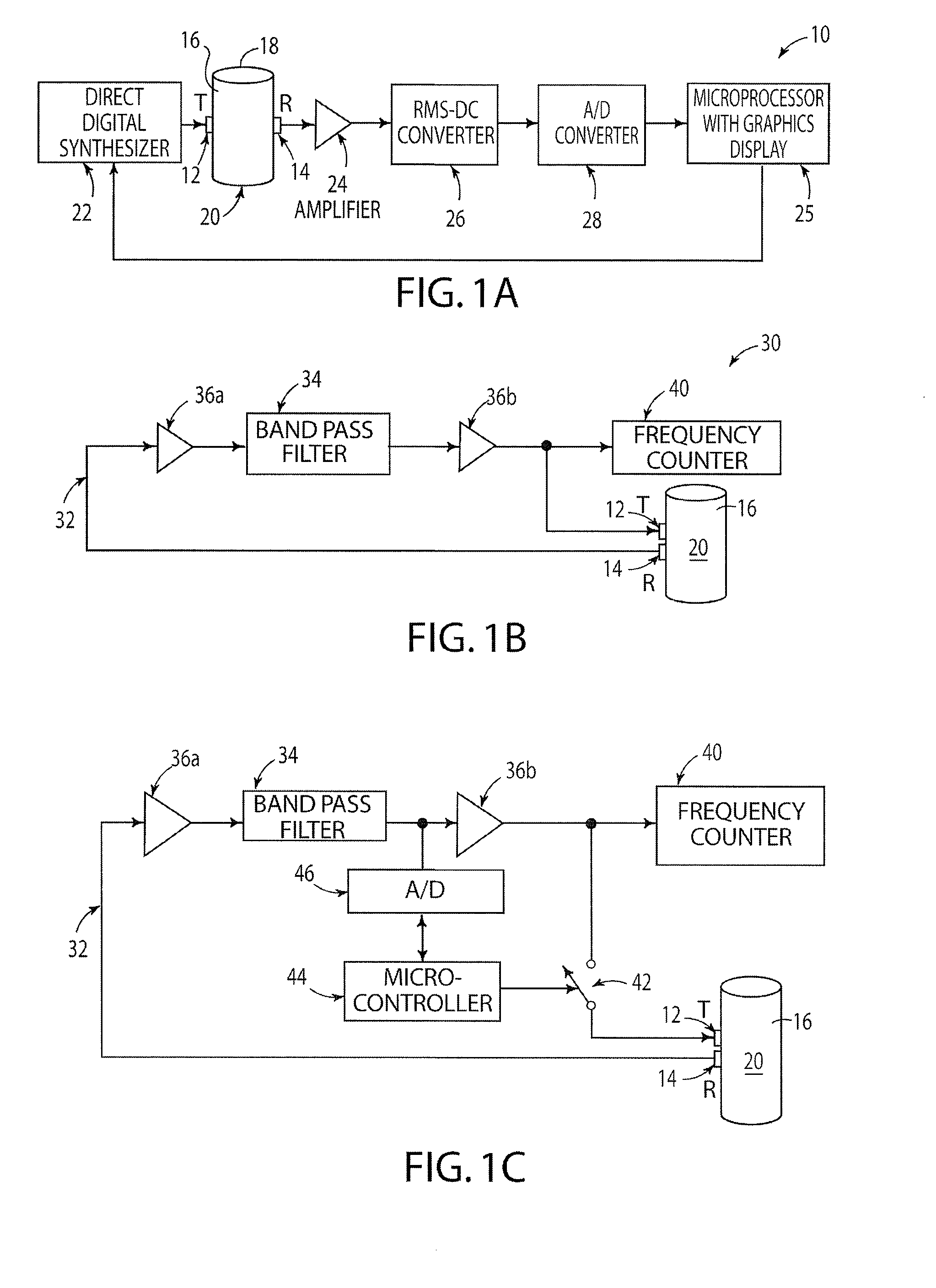

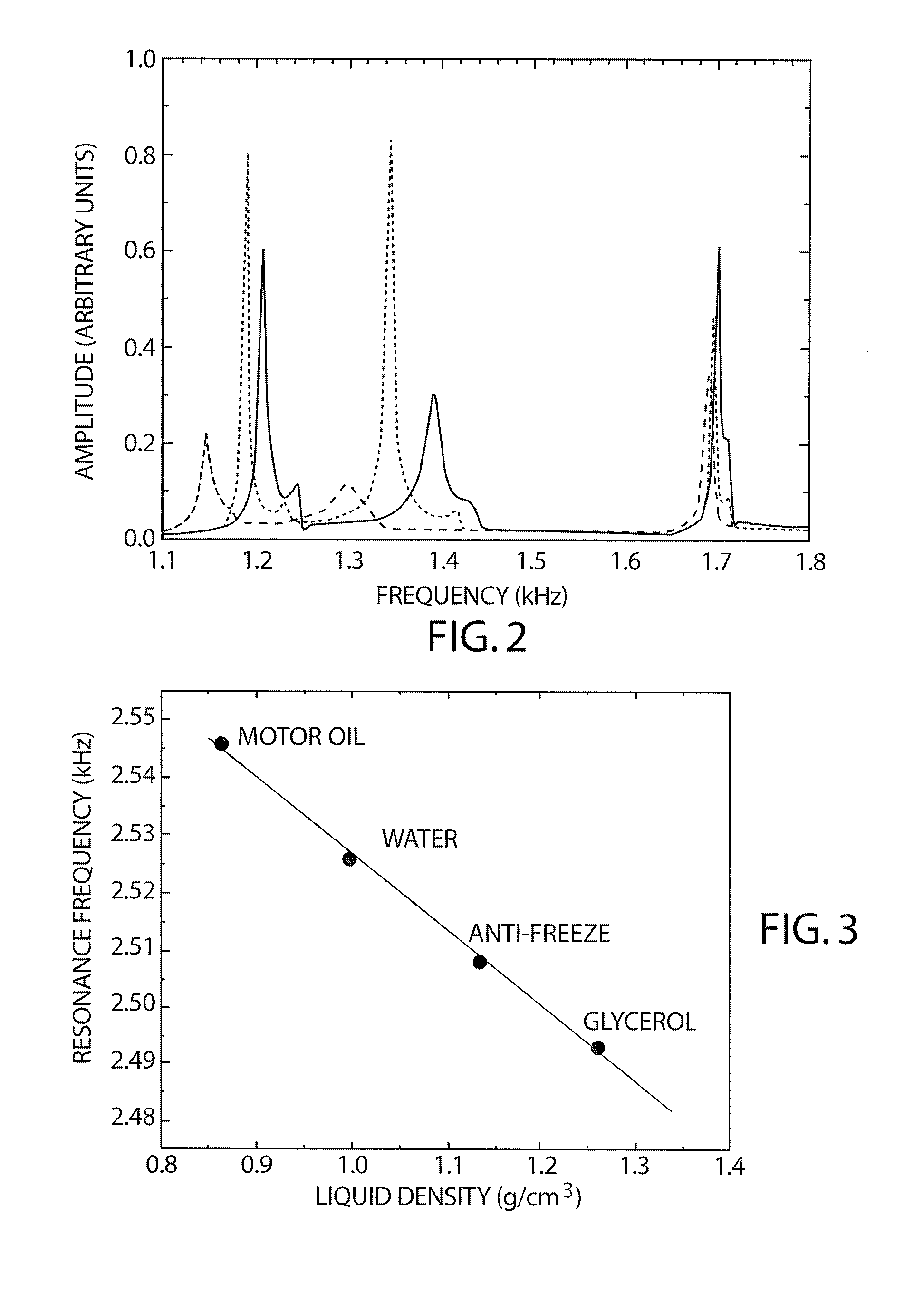

Non-invasive fluid density and viscosity measurement

ActiveUS20090084178A1Maintain integrityFlow propertiesSpecific gravity measurementResonanceNon invasive

The noninvasively measurement of the density and viscosity of static or flowing fluids in a section of pipe such that the pipe performs as the sensing apparatus, is described. Measurement of a suitable structural vibration resonance frequency of the pipe and the width of this resonance permits the density and viscosity to be determined, respectively. The viscosity may also be measured by monitoring the decay in time of a vibration resonance in the pipe.

Owner:TRIAD NAT SECURITY LLC

Viscosity measurement

ActiveUS20090090172A1Fluid pressure measurement by mechanical elementsMachines/enginesDifferential pressureEngineering

A micro-fluidic device and methods for measuring one or more rheologic properties of a fluid. The micro-fluidic device includes a substrate and at least one cover bonded to a surface of the substrate with a fluid channel formed in at least one of the cover or the substrate. Further, the micro-fluidic device includes a first differential pressure gauge that can have a first differential pressure sensor in fluid communication with both a first pressure site and a second pressure site. Further still, the micro-fluidic device includes the first pressure site and the second pressure site that can be spaced apart by a first section of the fluid channel. Also, the micro-fluidic device includes a data processor communicatively coupled to the first differential pressure sensor, so as to receive data generated by the first differential pressure sensor.

Owner:SCHLUMBERGER TECH CORP

Petroleum viscosity measurement and communication system and method

InactiveUS20080289400A1Flow propertiesMaterial analysis by electric/magnetic meansElectricityElectrical resistance and conductance

The disclosure presents an apparatus and method for measuring viscosity of a lubricating oil. The apparatus has a piezo-resistive cantilever sensor for sensing a first oil viscosity parameter. The sensor has a cantilever having a pressure receiving portion for receiving pressure exerted by the lubricating oil as the lubricating oil comes into contact with the pressure receiving portion. The cantilever also has first and second resistive portions in electrical communication with a first lead and a second lead, respectively, which are in electrical communication with an electrical circuit amplification element, for creating an output signal indicative of a change in the resistive characteristics of the first and second resistive portions of the cantilever as the lubricating oil comes into contact with the pressure receiving portion. The output signal can be used for determining oil viscosity. A processor and memory compare the output signal value with a stored resistance value to provide information relating to the quality of the lubricating oil.

Owner:RICHMOND CHEM CORP

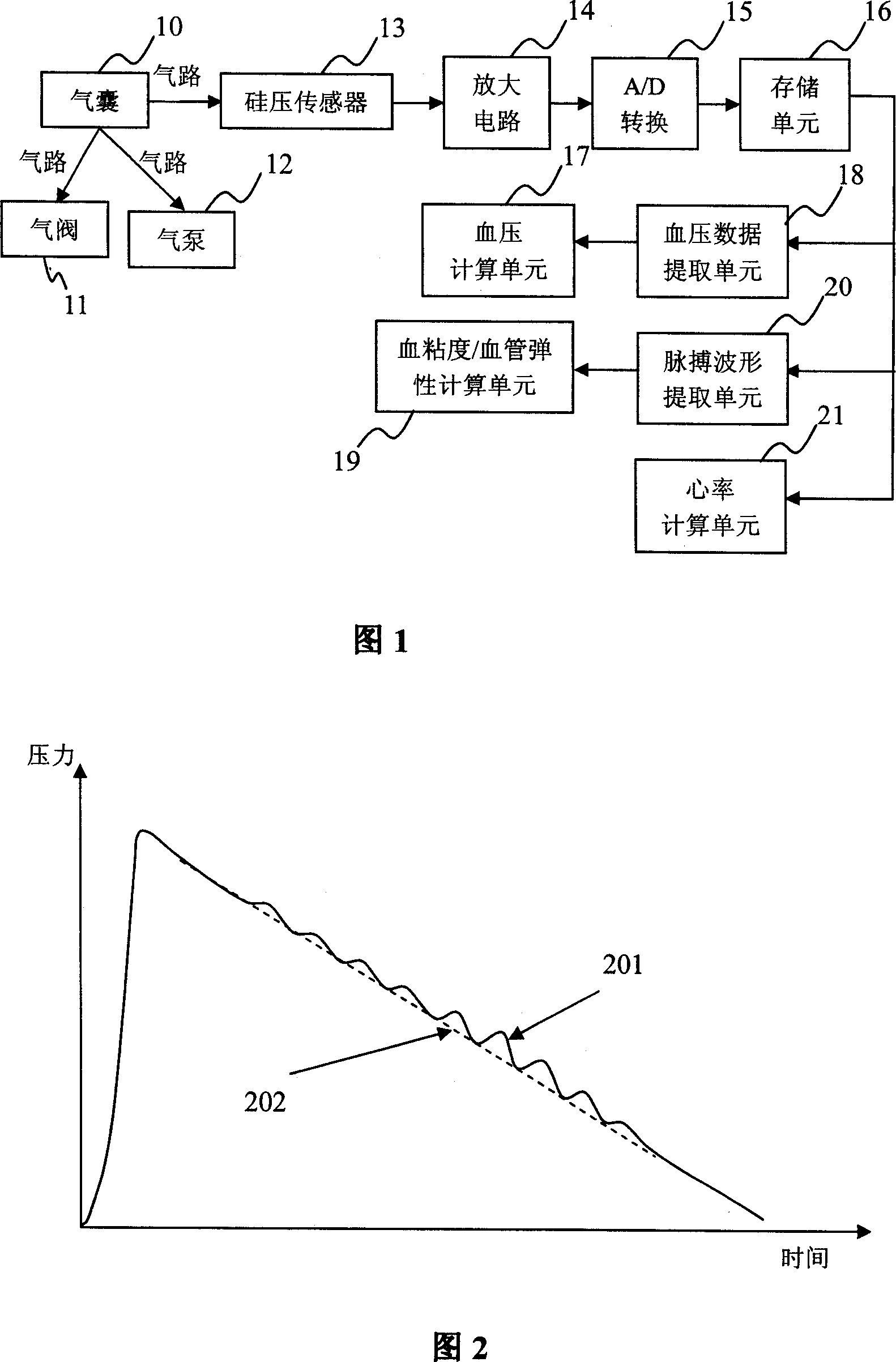

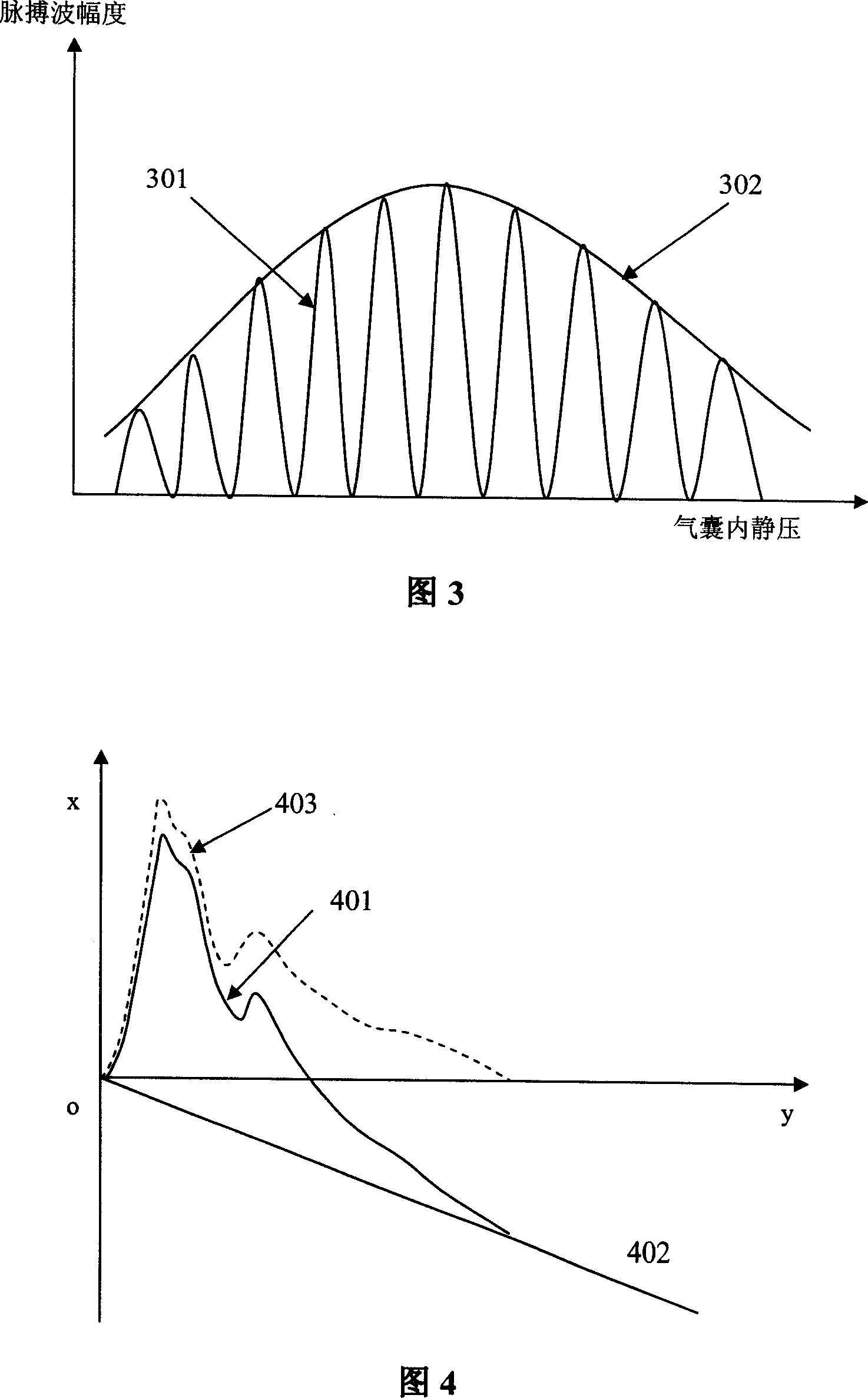

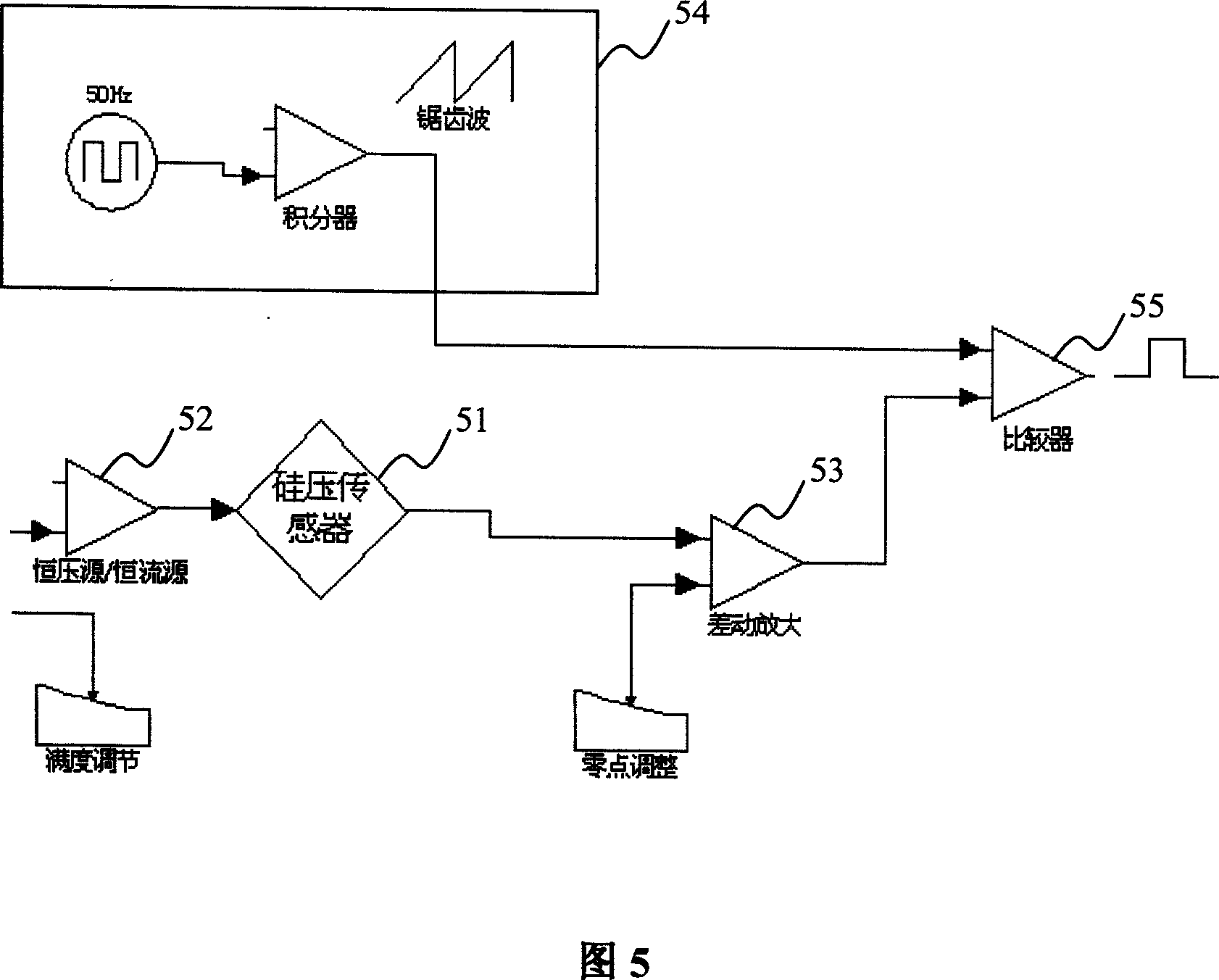

A device capable of measuring blood viscosity, vascular elasticity and blood pressure and measurement method thereof

InactiveCN101006917AQuick measurementSimple and fast operationEvaluation of blood vesselsCatheterOscillometryStrain gauge

The invention discloses an electronic meter device and realizing method, which comprises the following steps: utilizing fixed gas bag in the wrist belt to pressurize the wrist of detector; transmitting the pressure signal to electronic signal through silicon pressure sensor; amplifying signal to transmit; obtaining original pressure waveshape; separating blood pressure data and pulse wave data; gauging blood pressure, heart rate, blood viscosity and vessel elasticity.

Owner:ANDON HEALTH

Dermatological/cosmetic gels comprising at least one retinoid and benzoyl peroxide

ActiveUS20080181963A1Improve physical stabilityGood chemical stabilityBiocideCosmetic preparationsRetinoidBenzoyl peroxide

Owner:GALDERMA RES & DEV SNC

Measurement of density and viscoelasticity with a single acoustic wave sensor

A sensor, method and system, for measuring certain characteristics of a fluid. The sensor utilizes a piezoelectric device having at least two tightly coupled resonators providing a two pole electric transfer function responsive to an electrical signal coupled to the input resonator. The piezoelectric sensor has a textured entrapment layer, constructed to entrap a known volume of fluid and impart motion to the entrapped fluid as well as to surrounding non-trapped fluid. The common mode frequency shift of the two resonant frequencies is related to mass loading due to the entrapped fluid, while the energy absorbed by the fluid, or a phase shift of one of the resonant frequencies, is related to the viscosity / density product of the fluid. Extracting the viscosity is a matter of mathematical manipulation. By controlling the energy level of the input electrical signal, the viscosity measurement may be conducted at a predetermined shear rate.

Owner:VECTRON INT INC

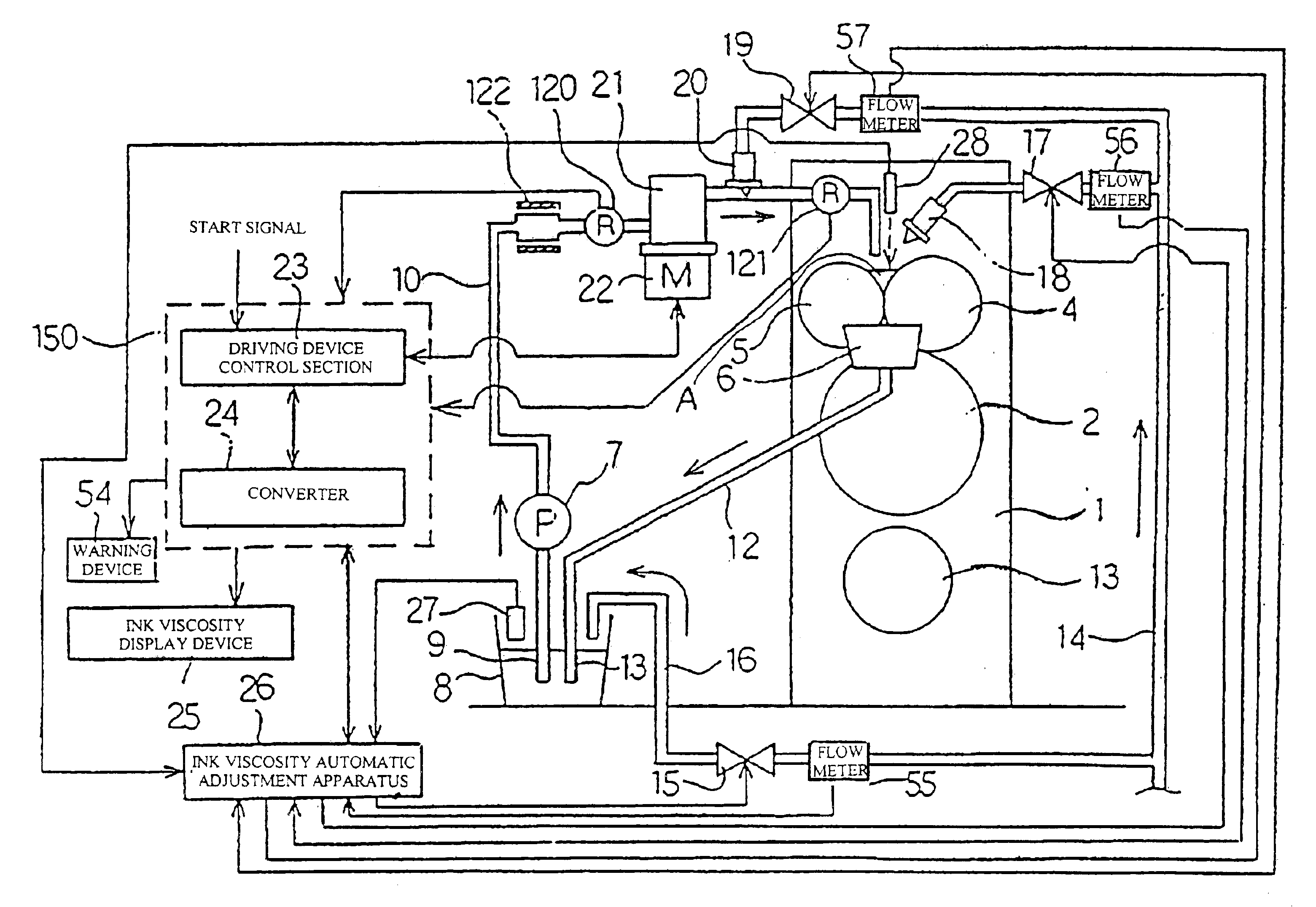

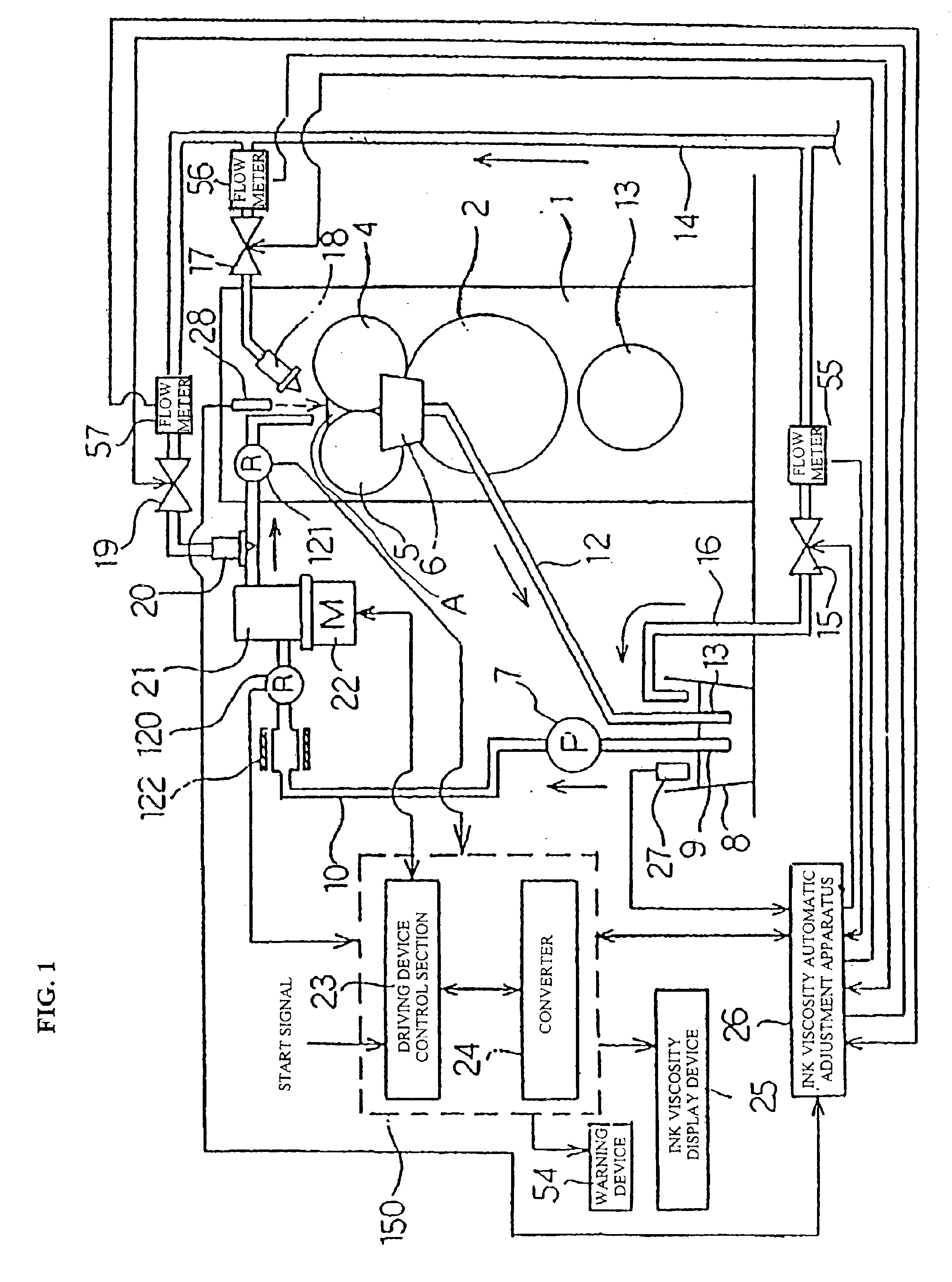

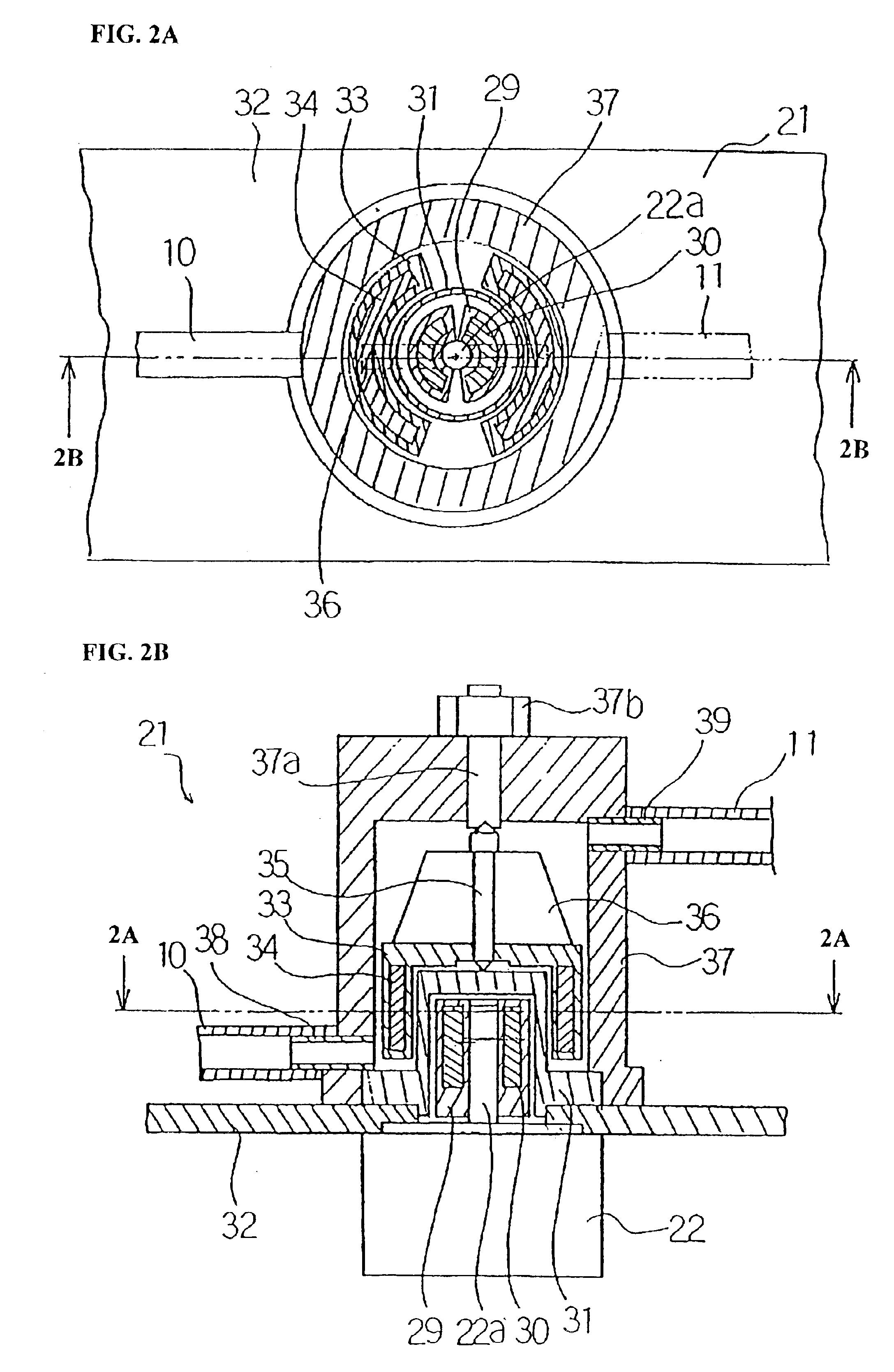

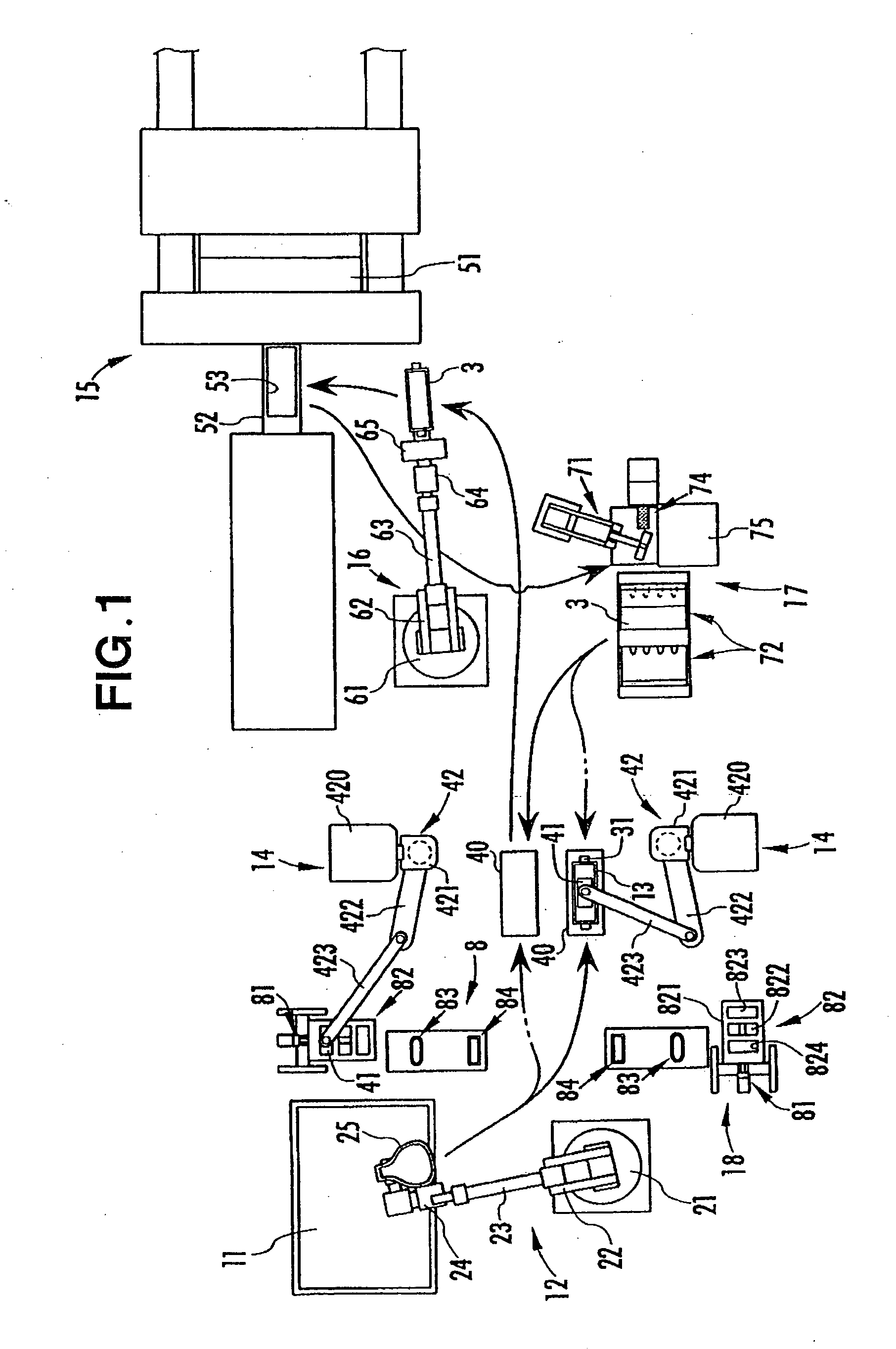

Ink viscosity measuring device, ink viscosity adjusting method and a device therefor, and a printing apparatus

InactiveUS6901861B2Complicated work partEnsure correct executionFlow propertiesPrinting press partsCardboardFree rotation

A cardboard sheet printing apparatus including: a rotating body that freely rotates inside an ink circulation passage through which ink flows, and a rotation-imparting assembly which is magnetically coupled with the rotating body outside the ink circulation passage and imparts rotation to the rotating body. When the rotating body is caused to rotate by the rotation-imparting assembly, the variation in the load current value that occurs upon changes in the viscosity of the ink that contacts the rotating body is detected; and this variation is compared with load current values that correspond to respective changes in the ink viscosity value stored in memory beforehand and is converted into an ink viscosity value and then displayed, so that the viscosity of the ink is adjusted based upon the calculated results.

Owner:ISOWA IND CO LTD

Coriolis mass measuring device

ActiveUS7357039B2Accurate measurementImprove accuracyFlow propertiesVolume meteringMeasurement deviceApparent viscosity

A Coriolis mass flow measuring device includes a vibratory measuring transducer having at least one measuring tube, which has medium flowing through it during operation. In operation, the measuring tube is caused by an exciter arrangement to undergo mechanical oscillations, especially bending oscillations. Additionally, the Coriolis mass flow measuring device includes a sensor arrangement for producing oscillation measurement signals (s1, s2) representing the inlet-end and outlet-end oscillations of the measuring tube. Measuring device electronics controlling the exciter arrangement produces an exciter current (iexc) and an intermediate value (X′m) derived from the oscillation measurement signals (s1, s2). This intermediate value represents an uncorrected mass flow. Derived from the exciter current and / or from a component of the exciter current (iexc), an intermediate value (X2) is produced, which corresponds to a damping of the oscillations of the measuring tube. This damping is especially a function of an apparent viscosity, and / or a viscosity-density product, of the medium guided in the measuring tube. Furthermore, a correction value (XK) is produced for the intermediate value (X′m) utilizing the intermediate value (X2) and a viscosity measurement value (Xη) determined initially or during operation. The viscosity measurement value (Xη) corresponds to a viscosity of the medium guided in the measuring tube and / or to a predetermined reference viscosity. On the basis of the intermediate value (X′m) and the correction value (XK), the measuring device electronics then produces an exact mass flow rate measurement value (Xm).

Owner:ENDRESS HAUSER FLOWTEC AG

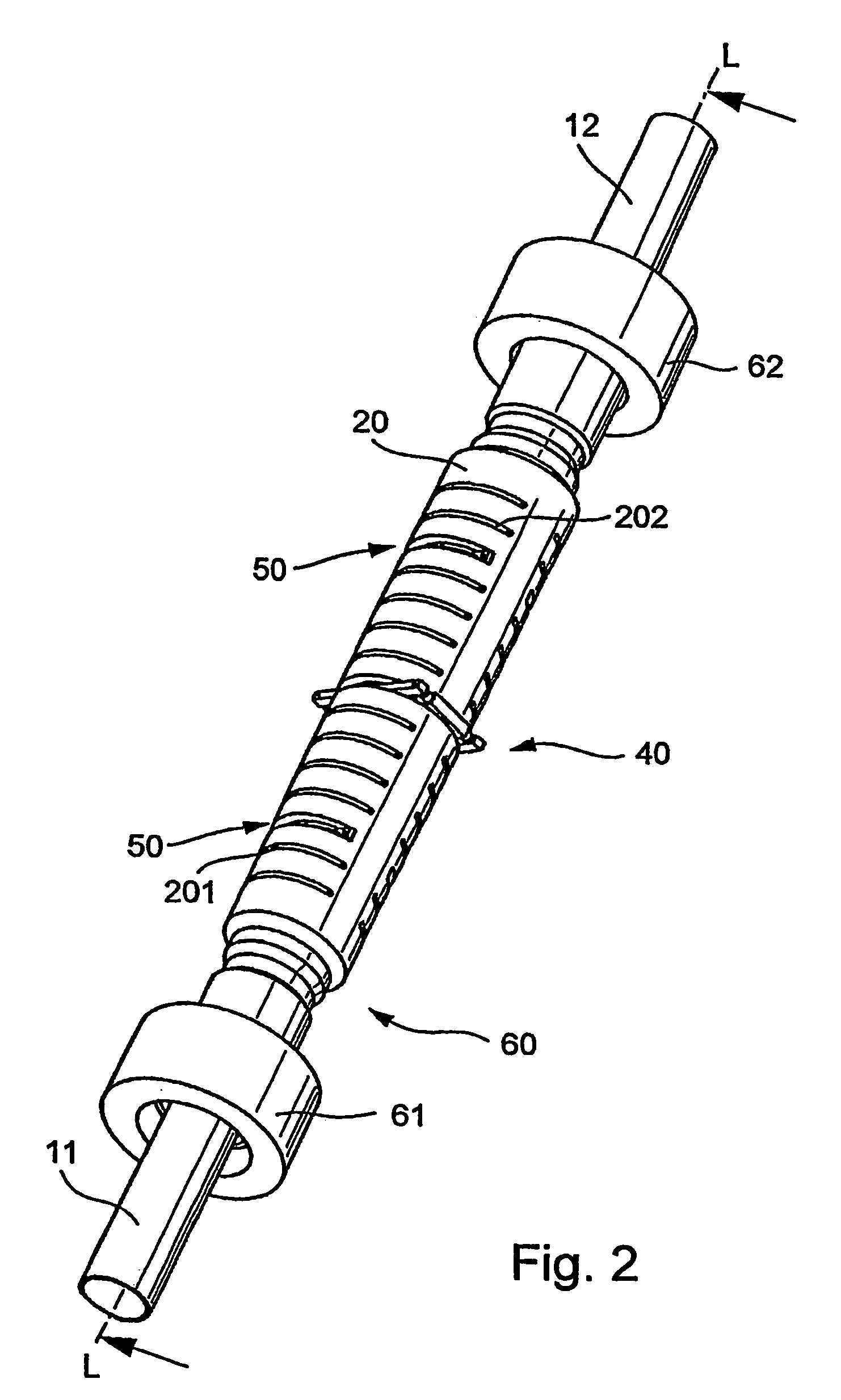

Coriolis mass flowmeter

ActiveCN1934425AAccurate measurementFlow propertiesVolume meteringApparent viscosityClassical mechanics

The invention relates to a Coriolis mass flowmeter comprising a vibration-type measuring sensor (1) comprising at least one measuring tube (10) through which a medium can flow during operation. During operation, the measuring tube moves by mechanical vibrations, especially bending vibrations, by means of an exciter arrangement (40). The Coriolis mass flowmeter also comprises a sensor arrangement (50) for generating vibration measuring signals (sl, s2) representing inlet-side and outlet-side vibrations of the measuring tube (10). Flowmeter electronics (2) controlling the exciter arrangement generate an intermediate value (X'm) which is derived from the vibration measuring signals (s1, s2) and represents an uncorrected mass flow, and an exciter current (iexc) driving the exciter arrangement. An intermediate value (X2) is derived from the exciter current and / or from part of the exciter current (iexc), said value corresponding to a dampening of the vibrations of the measuring tube (11), dependent on an apparent viscosity and / or a viscosity-density product of the medium guided in the measuring tube (11). Furthermore, a correction value (XK) for the intermediate value (X'm) is generated using the intermediate value (X2) and a viscosity measuring value (Xeta) that is determined previously or during operation and corresponds to a viscosity of the medium guided in the measuring tube and / or a pre-determined reference viscosity. On the basis of the intermediate value (X'm) and the correction value (XK), the flowmeter electronics can then generate an accurate mass flow measuring value (Xm).

Owner:ENDRESS HAUSER FLOWTEC AG

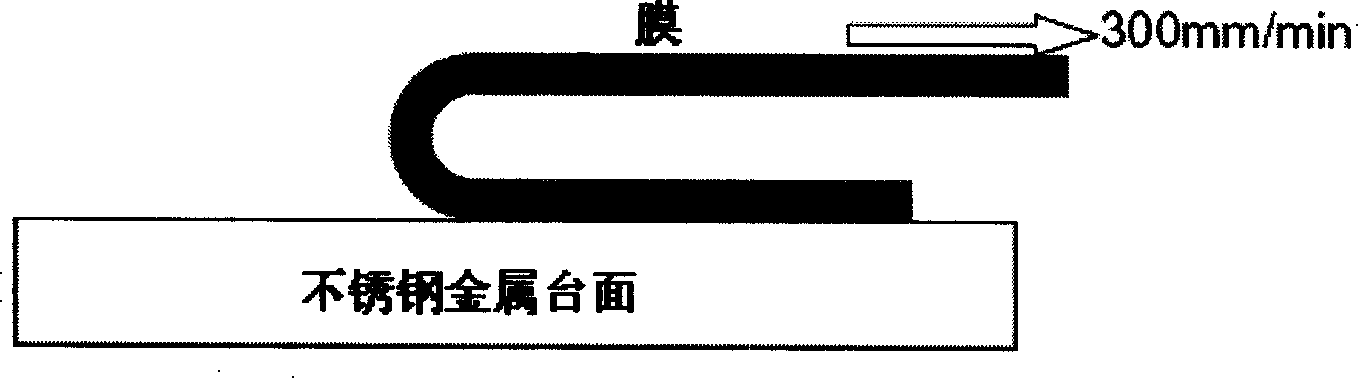

Membrane viscosity measurement method

ActiveCN101192505ASimple and fast operationEasy to operateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufacturing technologyQuality control

The invention discloses a method for measuring viscosity of a membrane. The invention includes the following steps: (1) a rubber belt is pasted and attached with the membrane to be measured by using pasting pressure and attaching pressure of a fixed roller on a sticking film machine; (2) the pasted membrane to be measured is fixed adhesively faceup on a working platform of the sticking film machine, and one end of the rubber belt is connected with a tensometer which is inversely fixed on the sticking film machine; and (3) the membrane to be measured is departed from the rubber belt by a movement with uniform speed of the working platform on the sticking film machine, and numerical value in the tensometer is read and taken as the result of measurement on the viscosity of the membrane to be measured. The invention admirably adopts the inherent function of sticking membrane in the present sticking film machine and device to carry out the quantitative measurement on the viscosity of all kinds of membranes used for being pasted and attached in silicon chips like the blue membrane, the UV membrane, etc. , with the advantages of easy and fast operation and low cost. The invention provides reliable evidences for the manufacturing technology condition and quality control of the semiconductor products.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

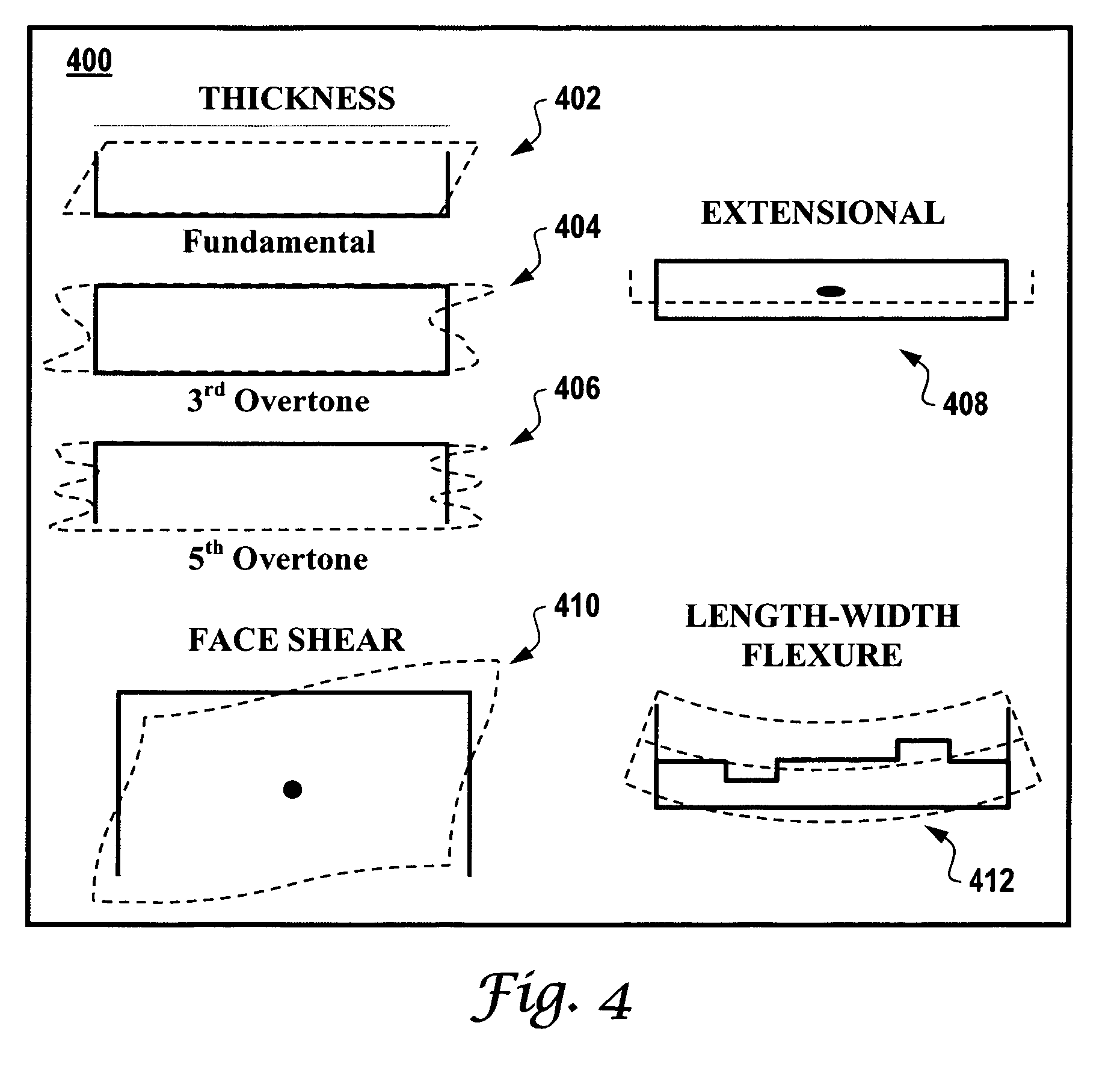

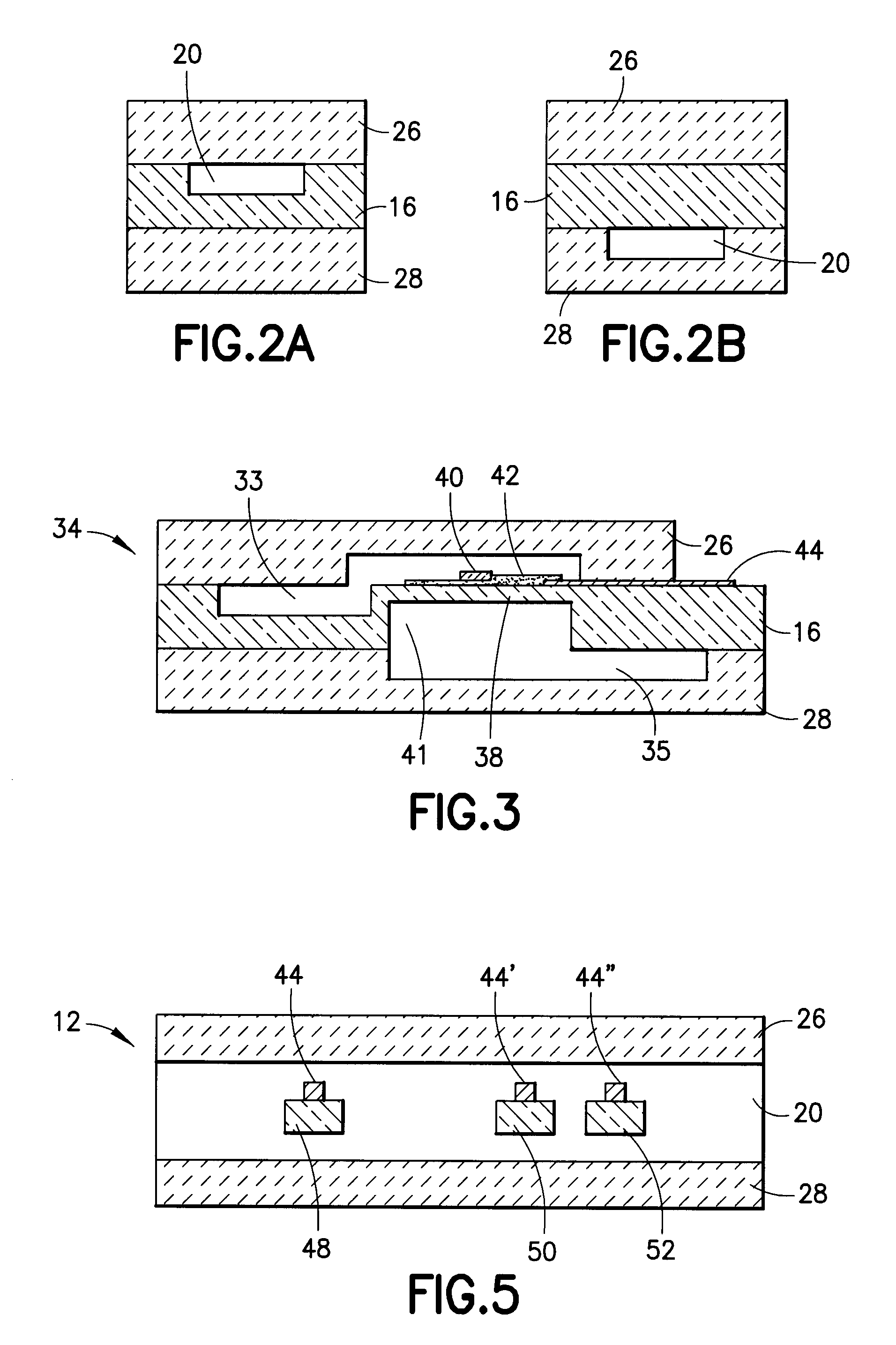

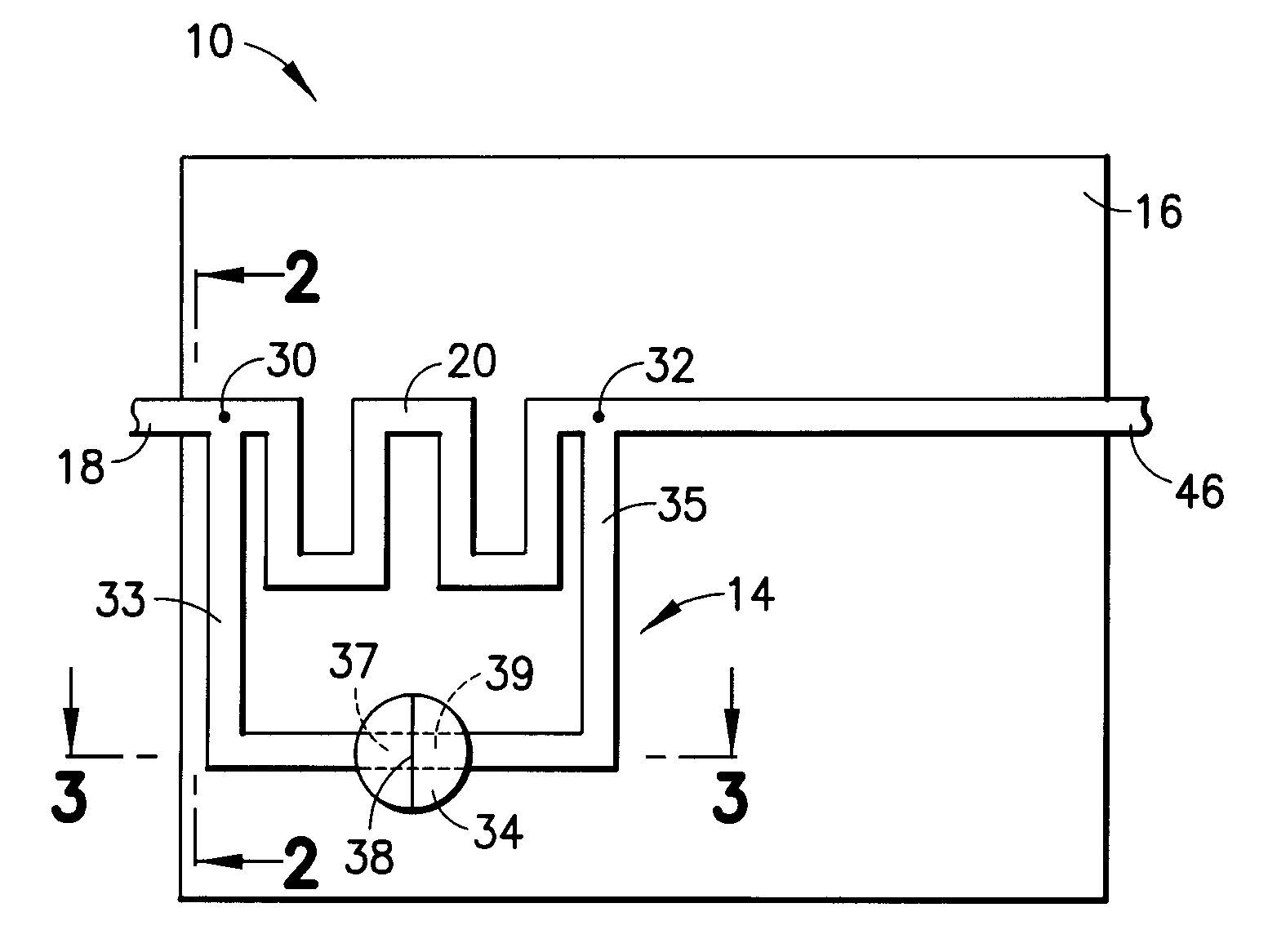

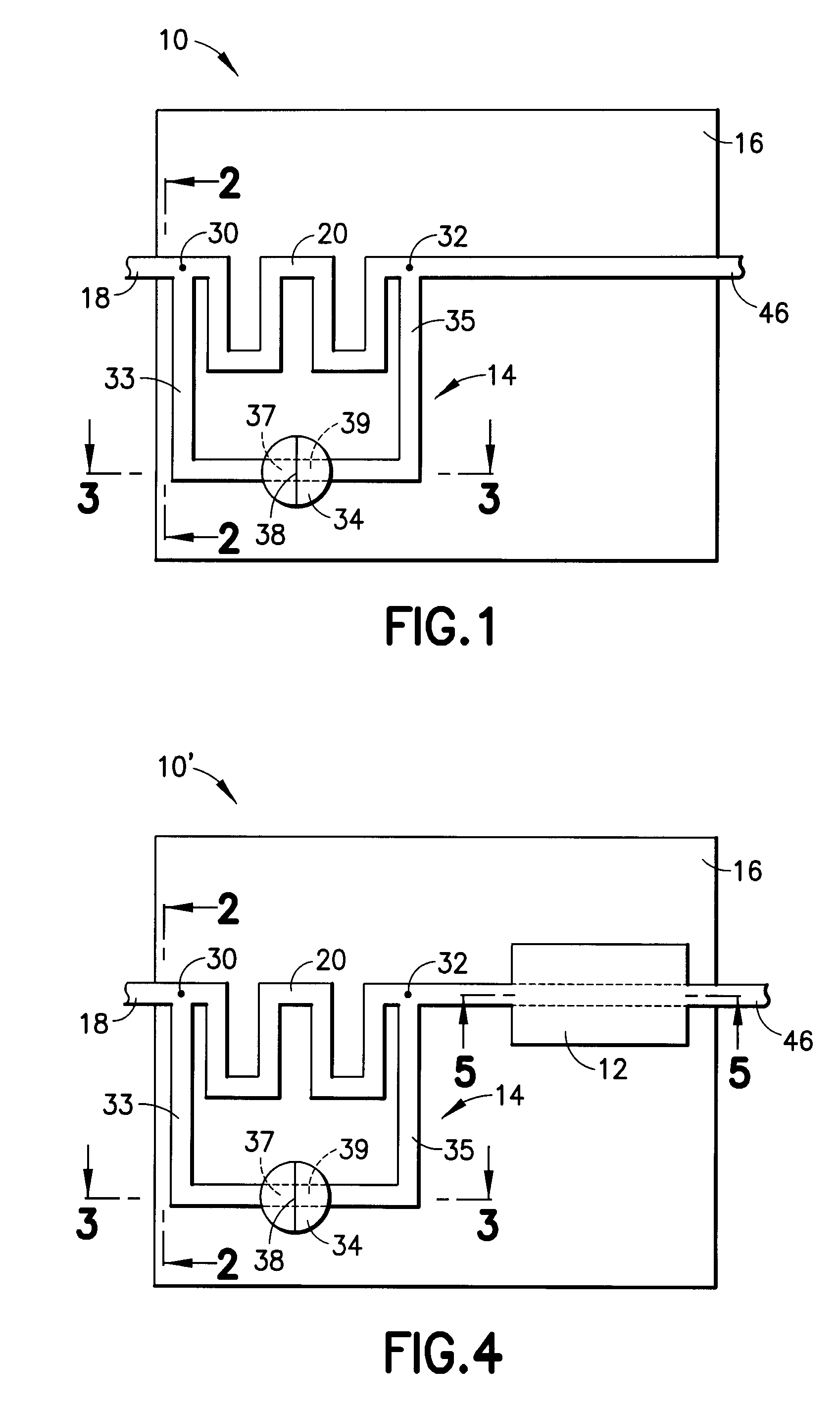

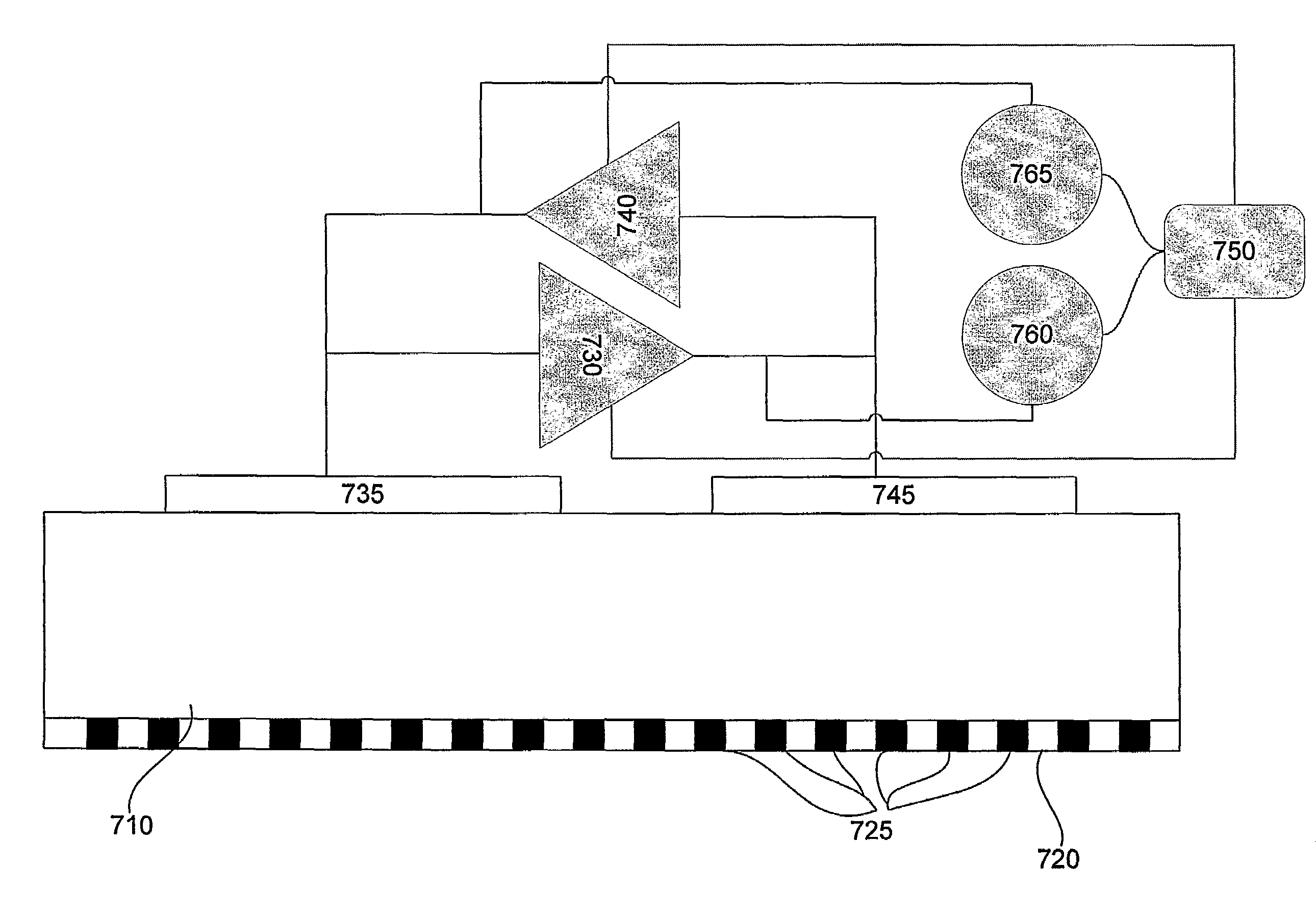

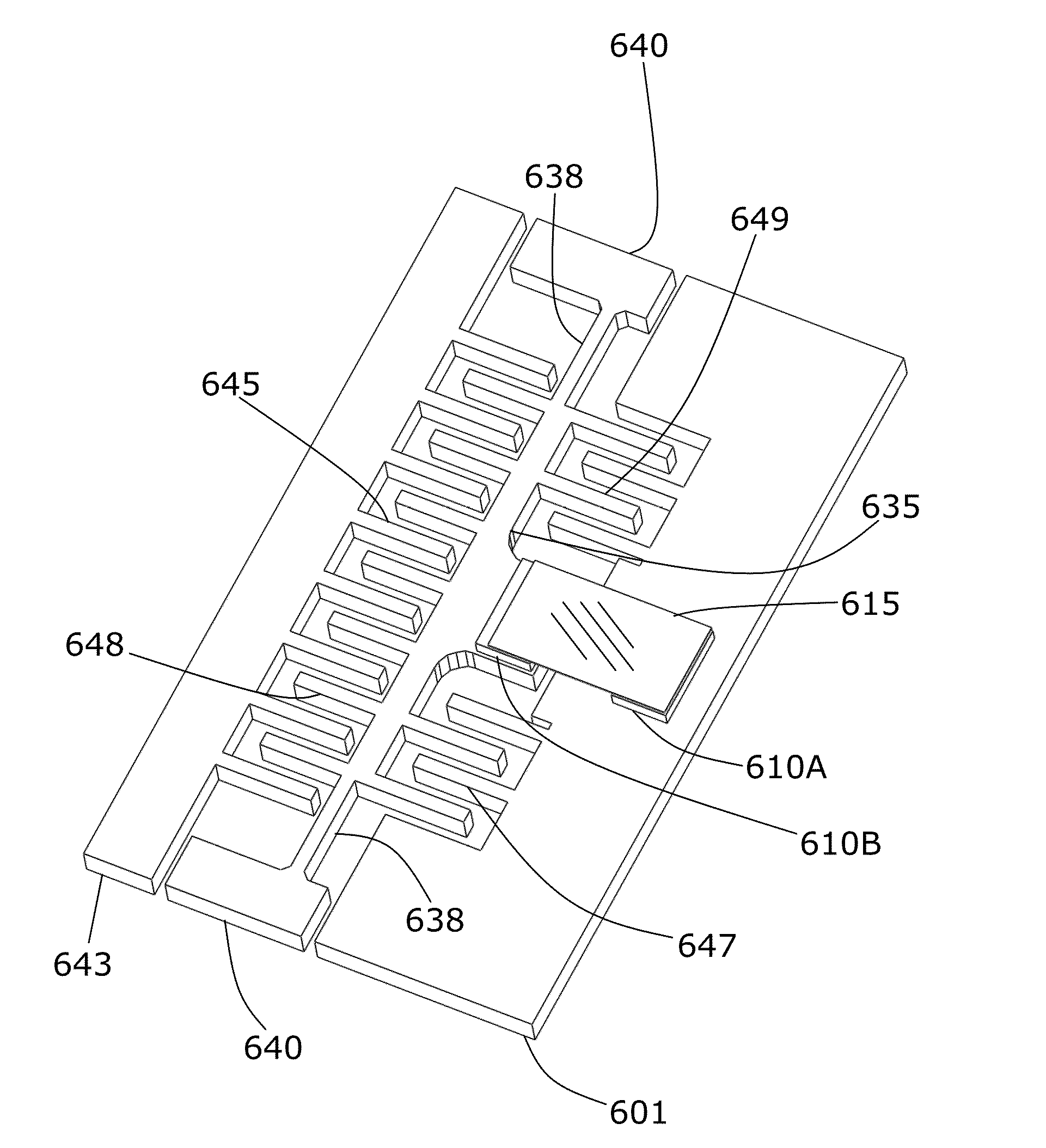

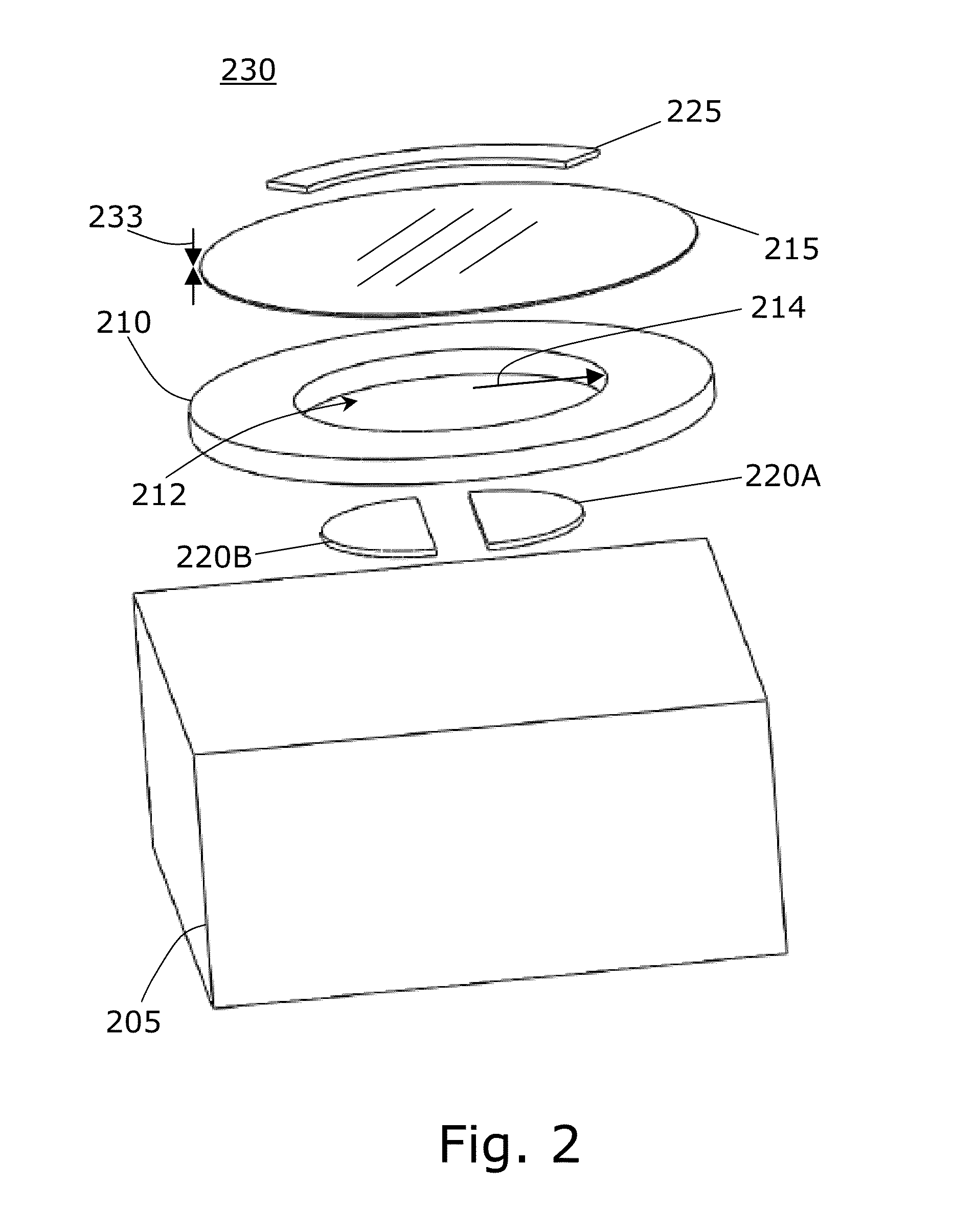

Microfabricated resonant fluid density and viscosity sensor

ActiveUS9038443B1Fast trackLarge structureAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesMicron scaleResonant sensor

Determination of fluid properties is important in a variety of research and industrial applications. Real-time measurements in operating fluidic systems are performed for monitoring, diagnosis, and feedback-control. A simplified, microfabricated resonant sensor for separate density and viscosity measurements of a fluid with a common sensor is disclosed. The sensor is micron-scale, so as to produce a minimum of perturbation to the fluid under test, and may be arrayed to probe viscosity and density across a flowstream or vessel. Measurement is performed at resonance peaks, and geometry or operating conditions of sensor are varied to produce different resonance responses useful for separate sensing of density and viscosity of a fluid. Another embodiment includes a method for reducing quiescent in-plate elastic strain in a plate or membrane so as to allow bending-stiffness dominated behavior of a resonator.

Owner:PACE MARIA ESTHER +1

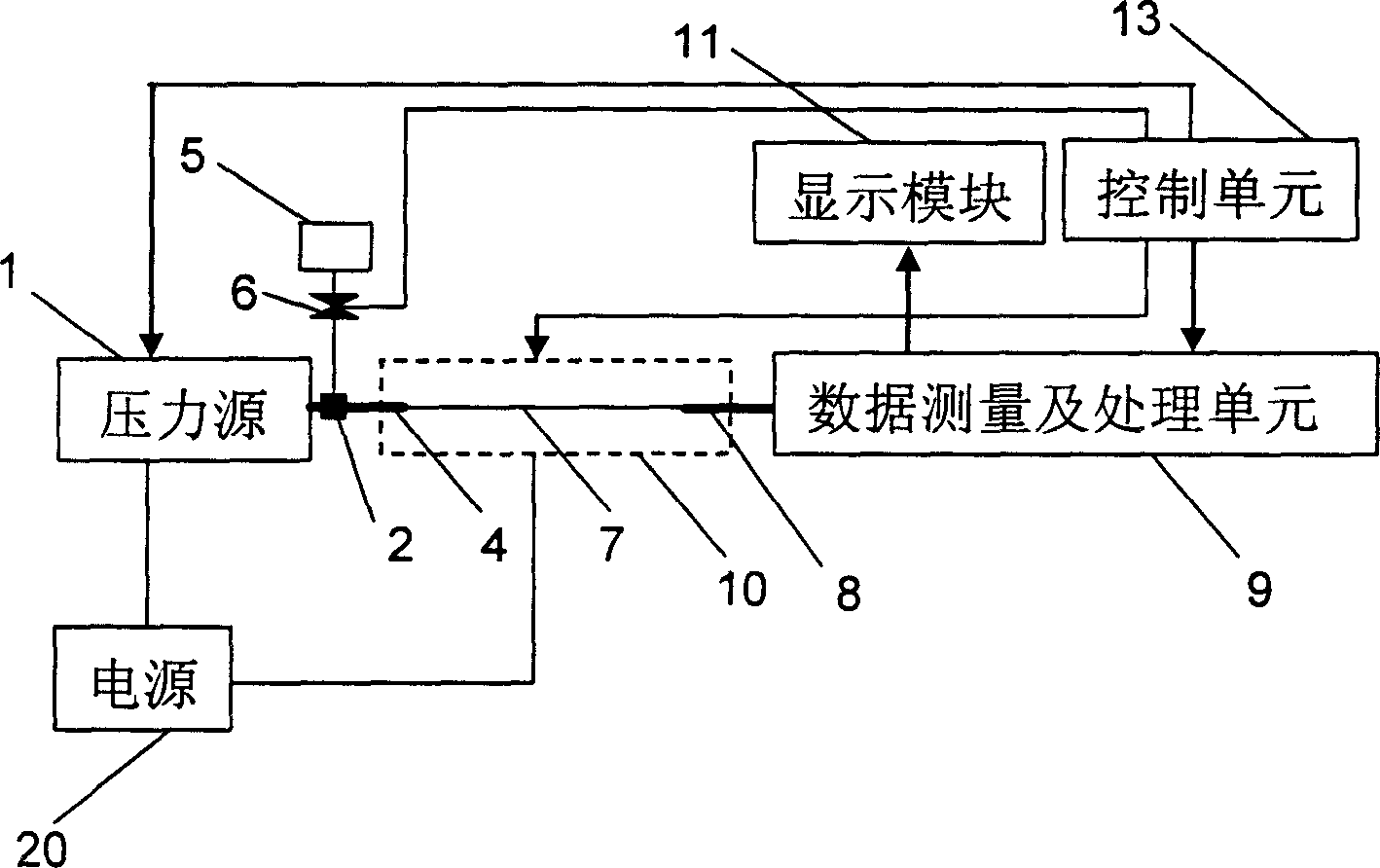

Real-time body blood viscosity measuring instrument

InactiveCN1847849AImprove detection accuracyHigh degree of detection automationBiological testingDirect flow property measurementInfusion catheterTemperature control

The present invention relates to real-time body blood viscosity measuring instrument. The measuring instrument includes pressure source, infusion catheter, micron tube, transparent capillary tube, calibrating liquid container, temperature control unit, data measuring and processing unit, display module and control unit, with the transparent capillary tube being inside data measuring and processing unit. The viscosity measurement has relatively measuring method adopted. The present invention has high detection precision, automatic measurement, small blood consumption of only 20 microliter, disposable infusion catheter, micron tube and transparent capillary tube to avoid cross infection and simple operation, and is portable and suitable for use in hospital and household.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

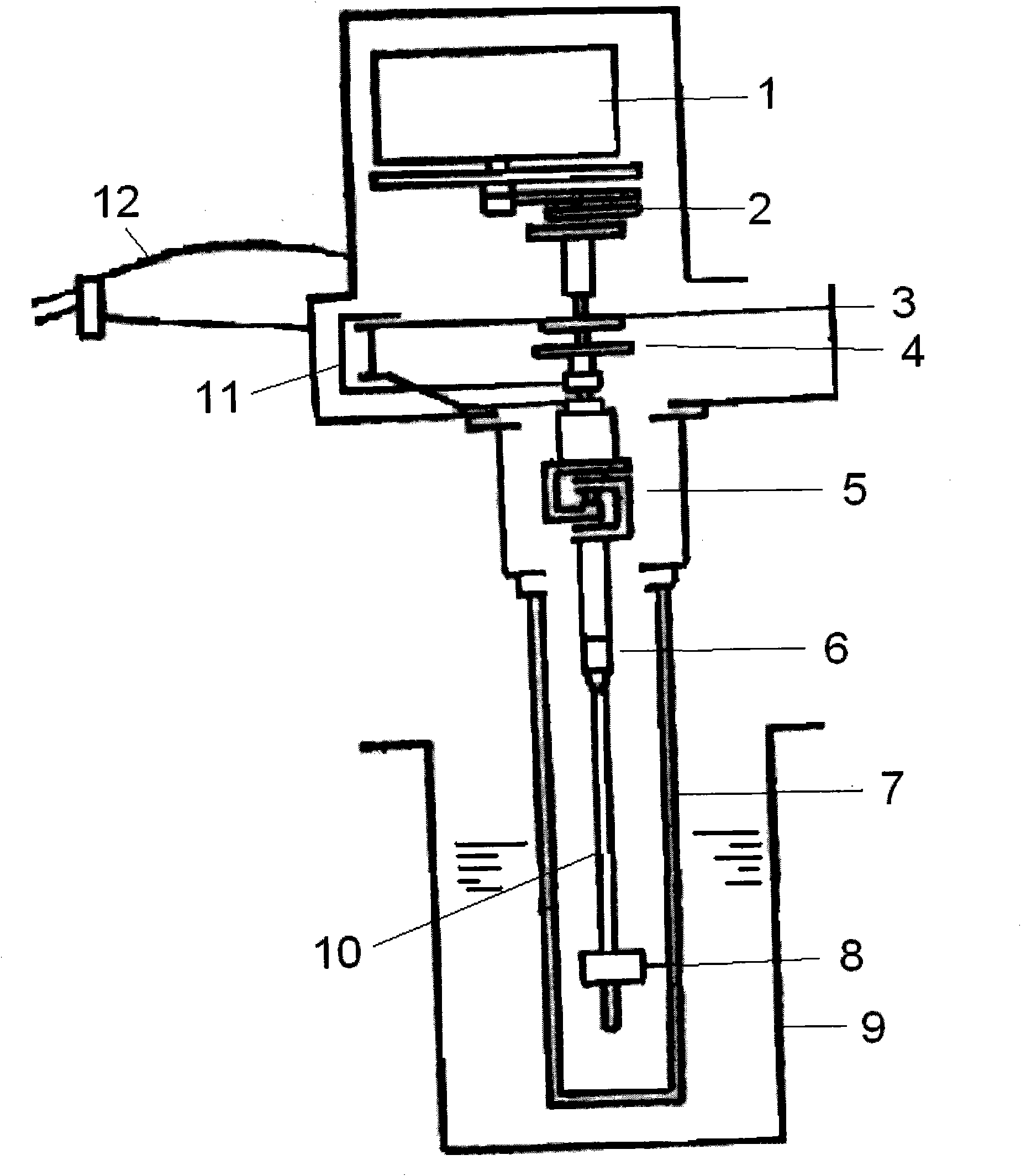

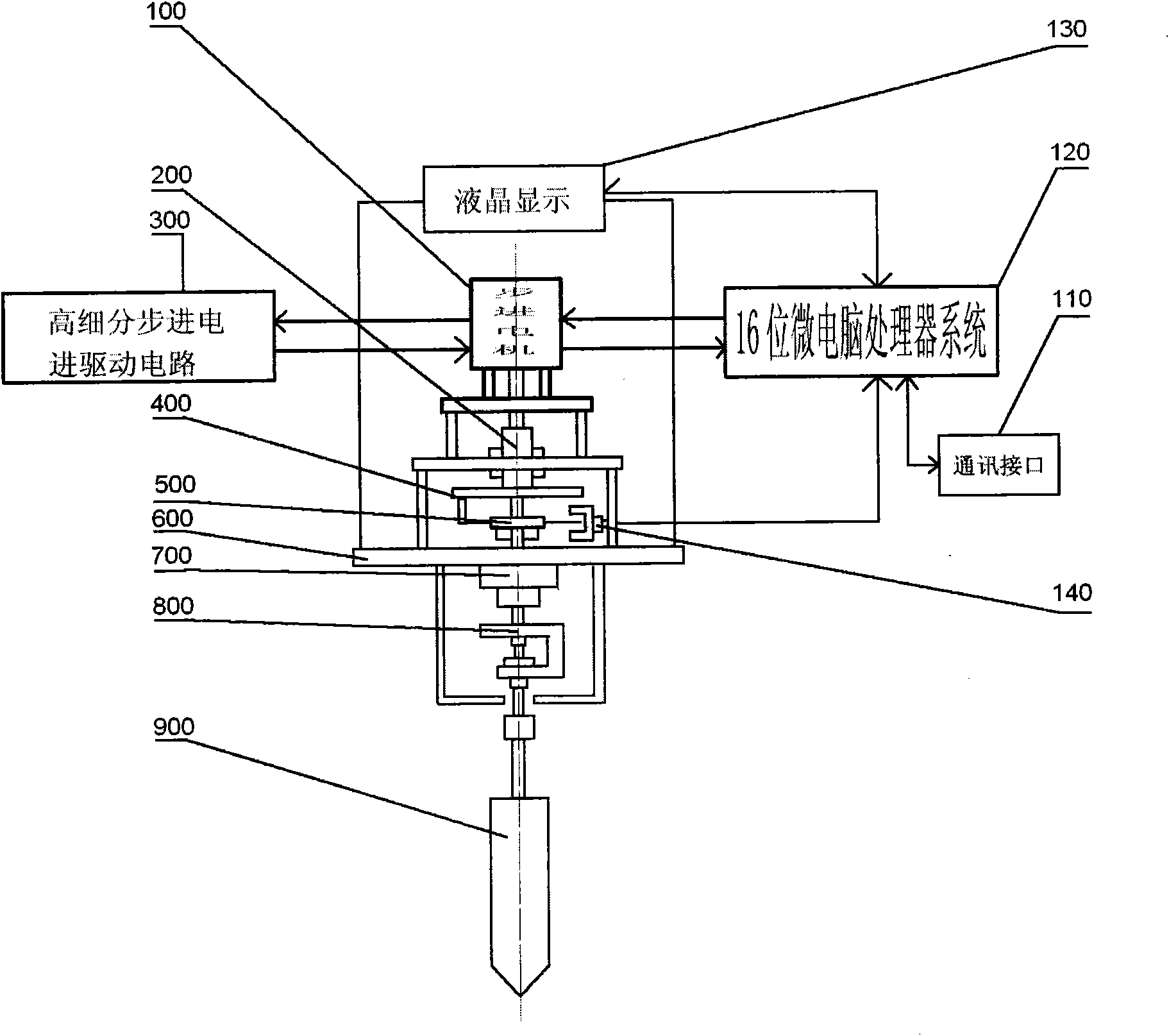

Instrument for measuring rheological property and viscosity of fluid

InactiveCN101655438AGuaranteed accuracyReduce the influence of human factorsFlow propertiesMotor driveRemote control

The invention relates to an instrument for measuring rheological property and viscosity of fluid, which comprises a mounting plate, a central connecting mechanism arranged on the mounting plate, and ajewelled bearing mechanism and a rotor which are arranged below the installation plate and on the central connecting mechanism in sequence. The instrument also comprises a torque sensor, a torque displacement adjusting mechanism and a bearing mechanism which are arranged above the mounting plate and on the central connecting mechanism in sequence, wherein the bearing mechanism is connected with astepper motor driven by a driving circuit of a high subdivision stepper motor; and the side of the torque senor is provided with a non-contact photoelectric sensor which is connected with a computerprocessor control system. The instrument for measuring the rheological property and the viscosity of the fluid has the advantages of simpler structure, no noise, convenient speed variation and good reliability, ensures the accuracy of the measured viscosity; and the instrument is operated through remote control in a non-contact remote control mode to ensure that the horizontal state of the instrument is influenced by human factors as little as possible, and ensure the accuracy of the measurement.

Owner:SHANGHAI NIRUN INTELLIGENT TECH

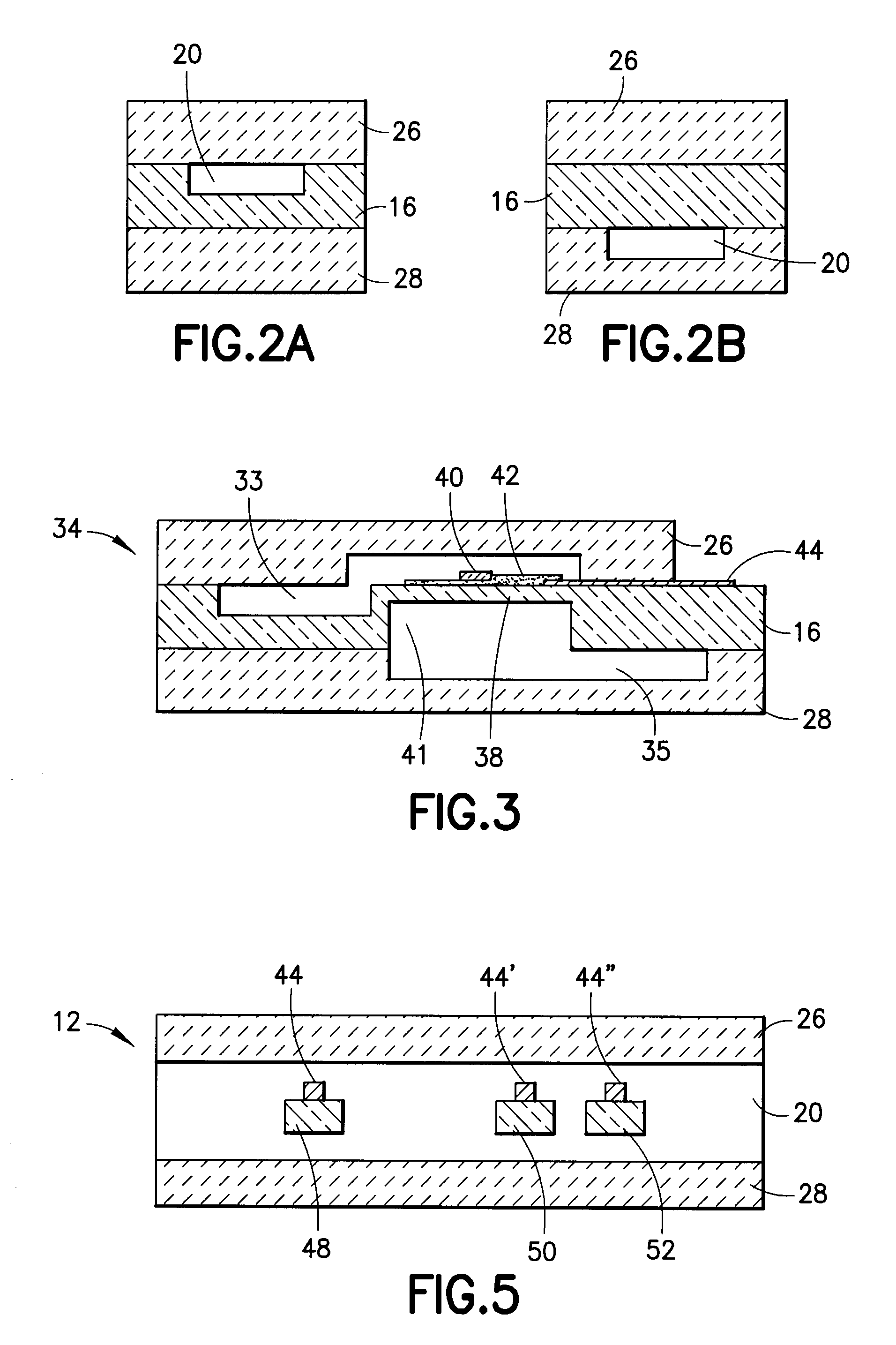

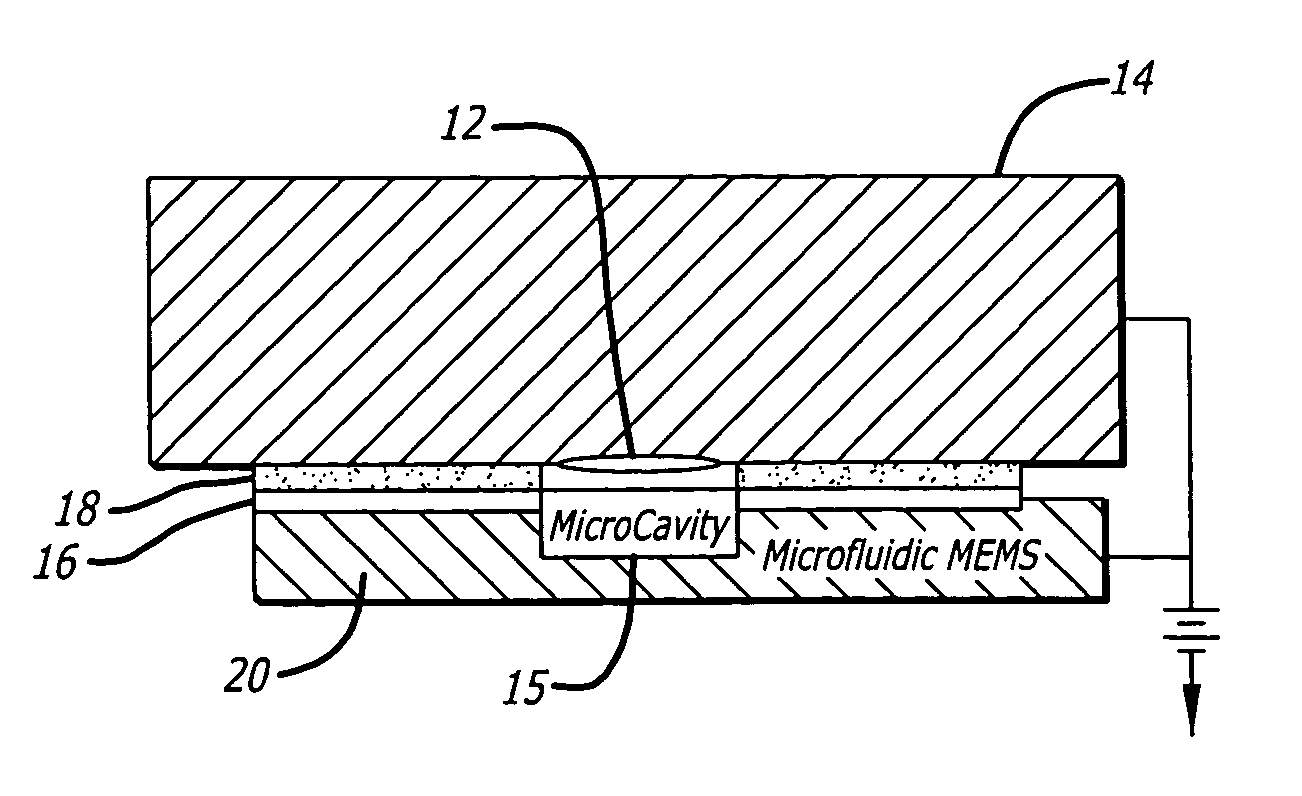

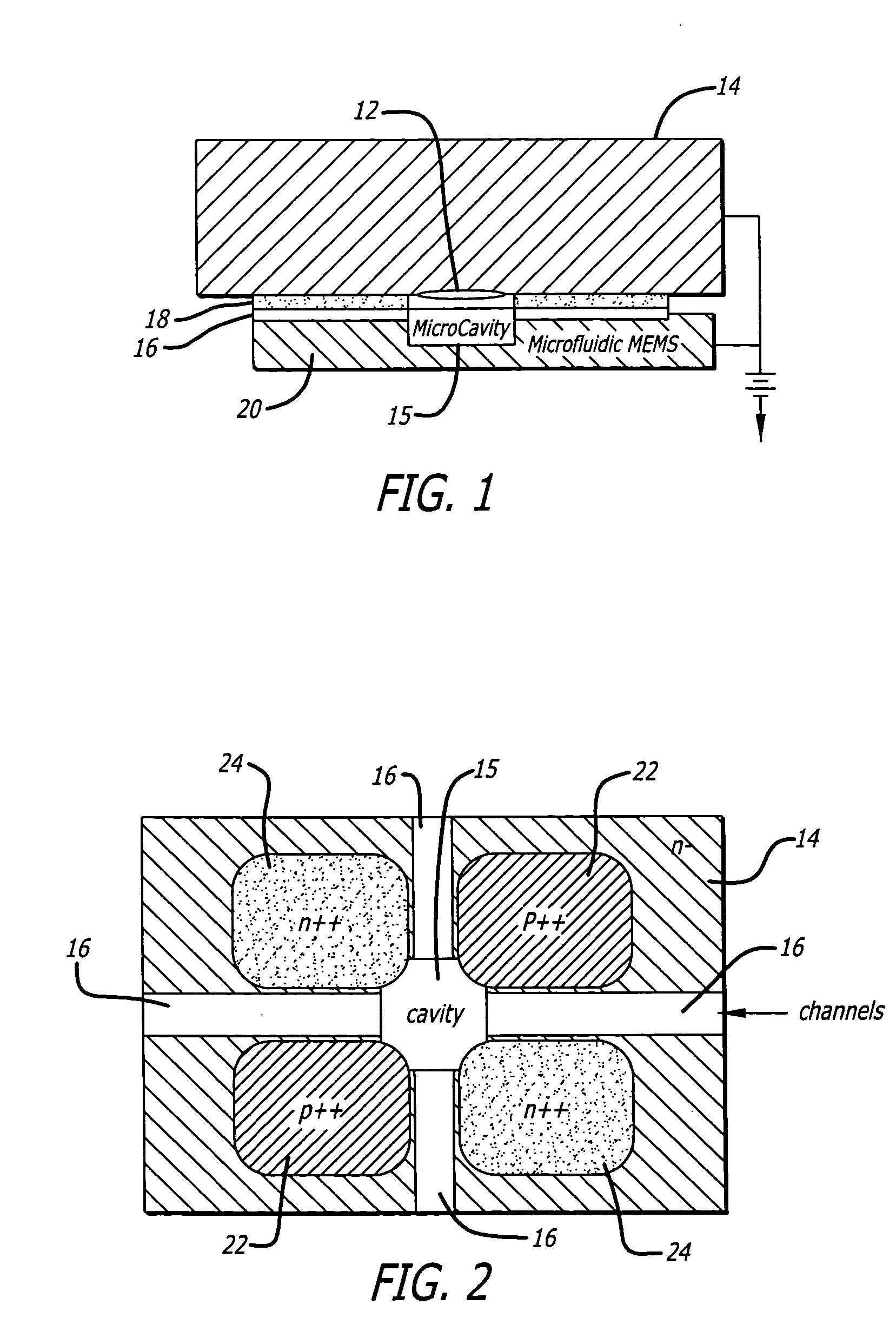

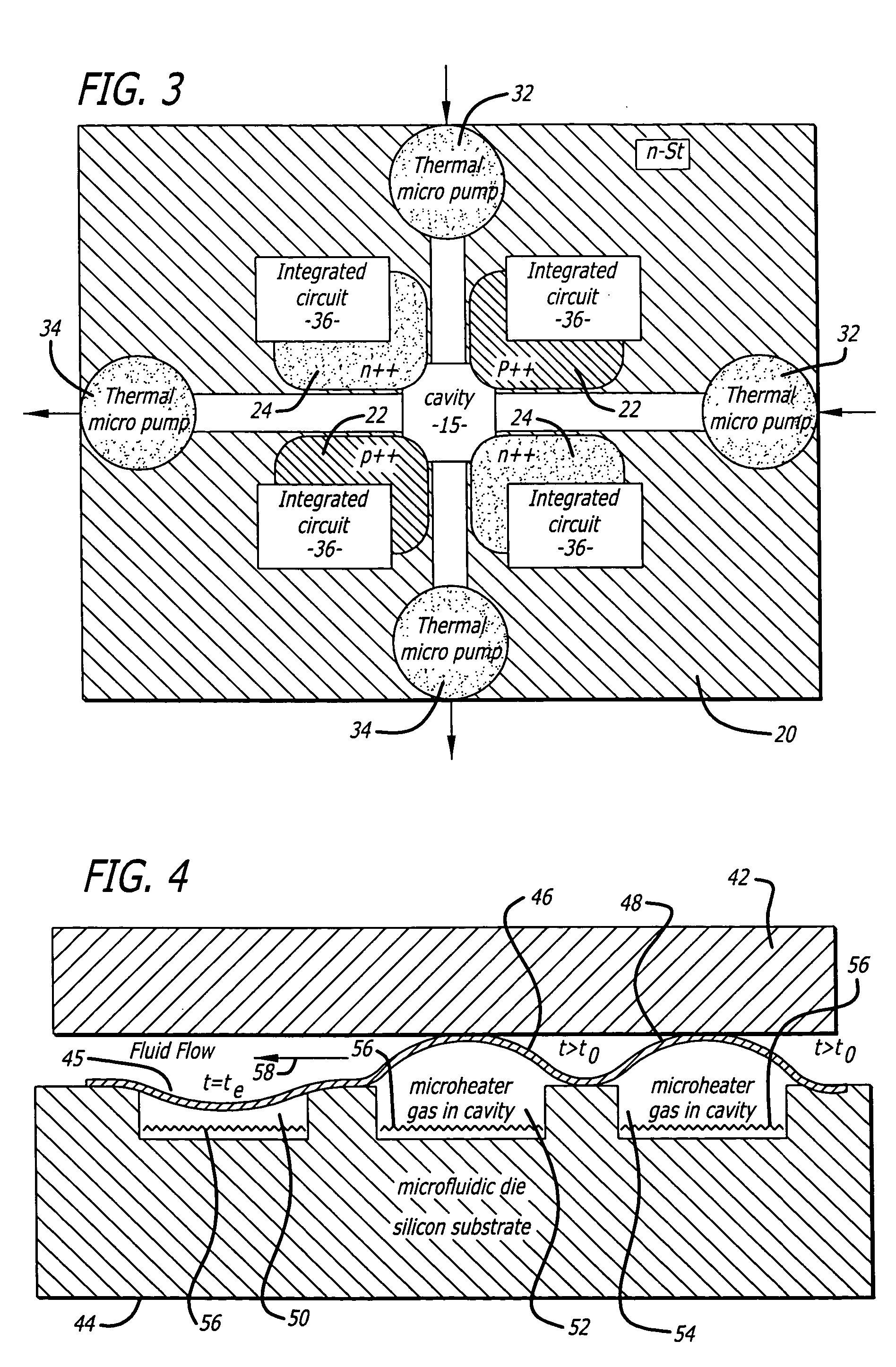

Microfluidic system

InactiveUS20050223783A1Small volumeEasy to useFlexible member pumpsPositive-displacement liquid enginesSemiconductor electrodeCapacitance

A system for measuring viscosity includes microfluidic passageways coupled to a micro-cavity, and semiconductive electrodes for applying an electric field across said electrodes. The resultant pressure increase and deflection of the diaphragm changes the capacitance of the MEMS capacitor. Pumps such as a thermal pump or a surface acoustic wave pump control flow of fluid to be measured to and from the micro-cavity. Semiconductor device fabrication techniques are employed to produce the viscosity measurement system.

Owner:KAVLICO CORP

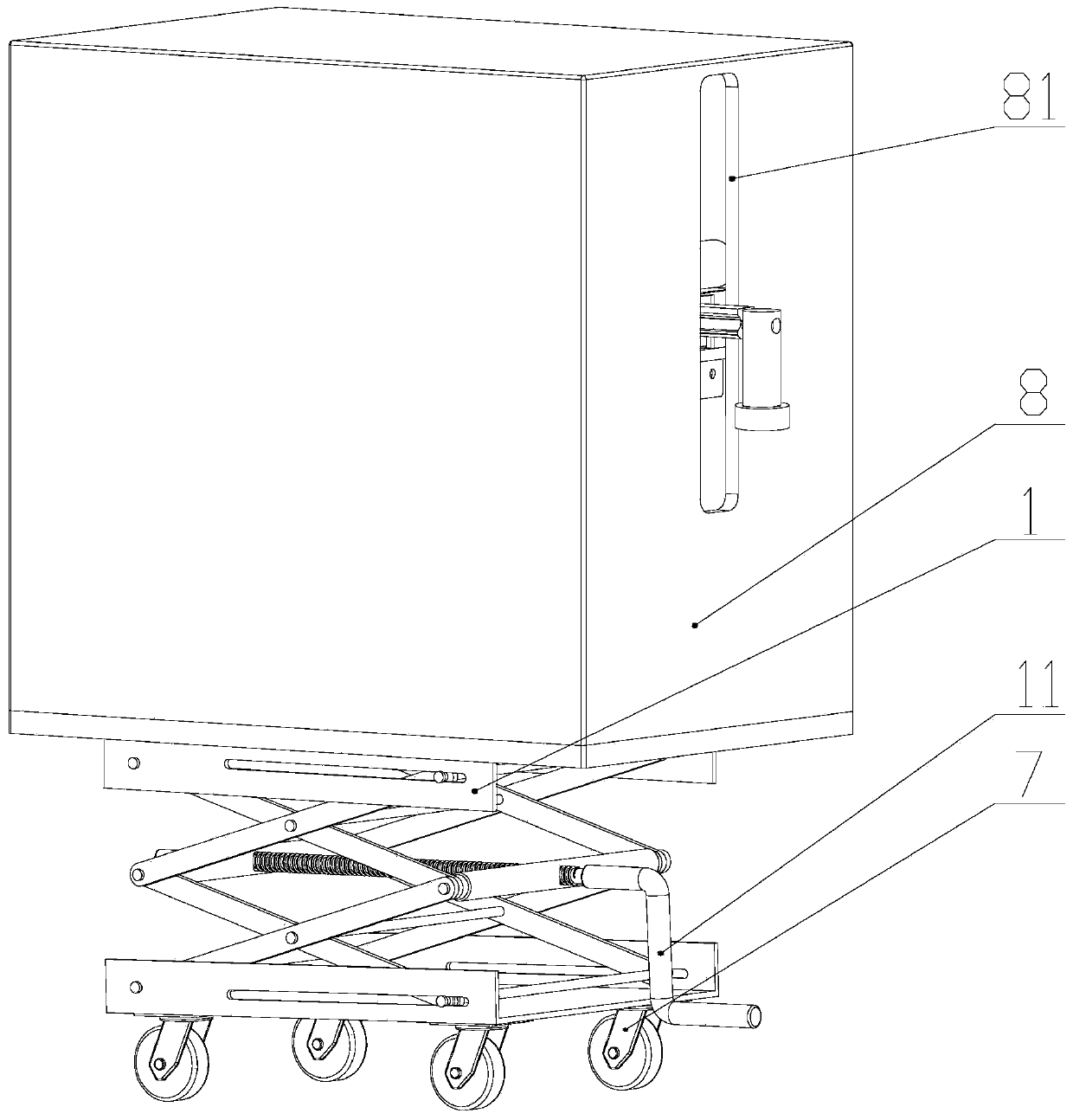

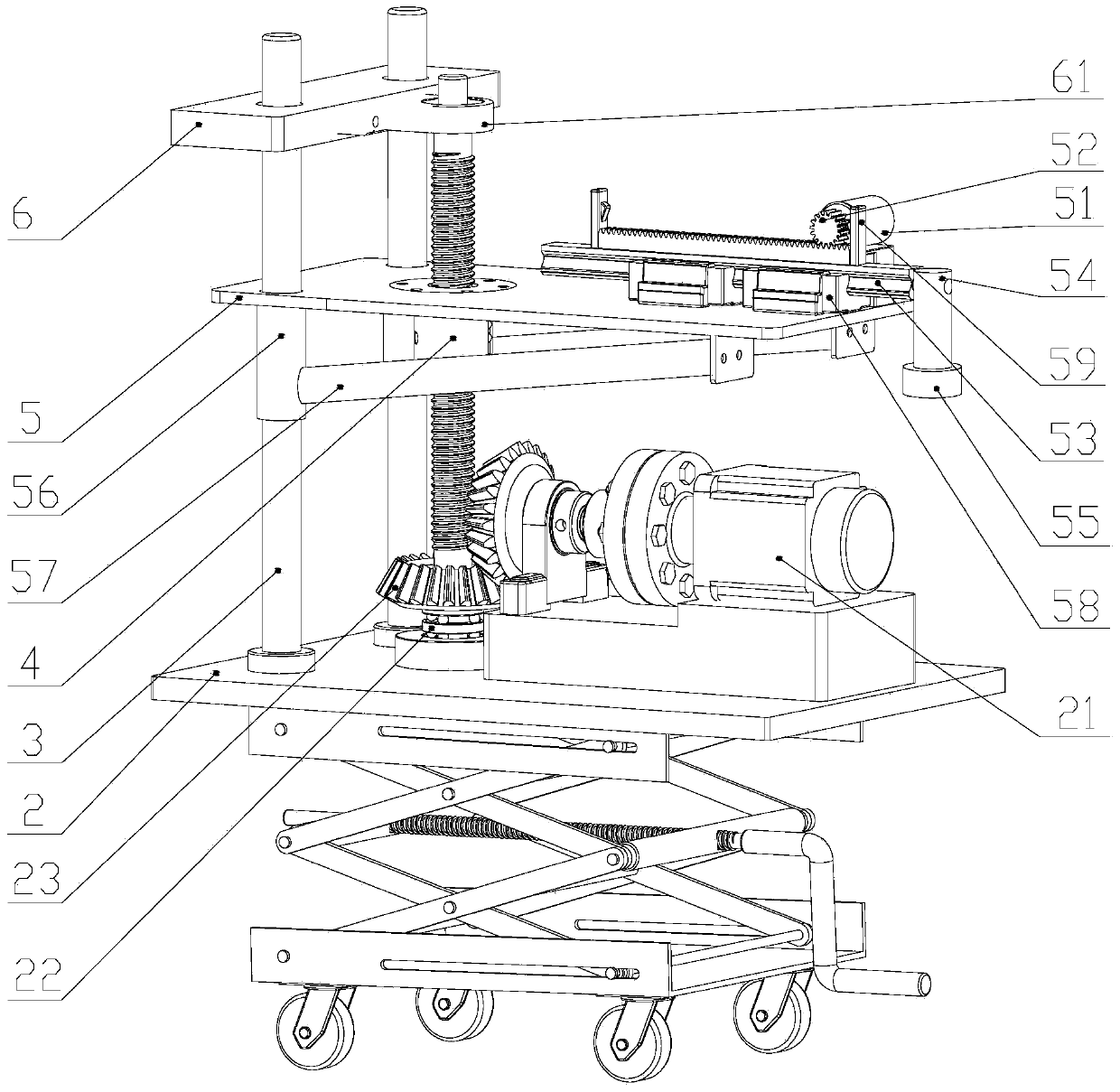

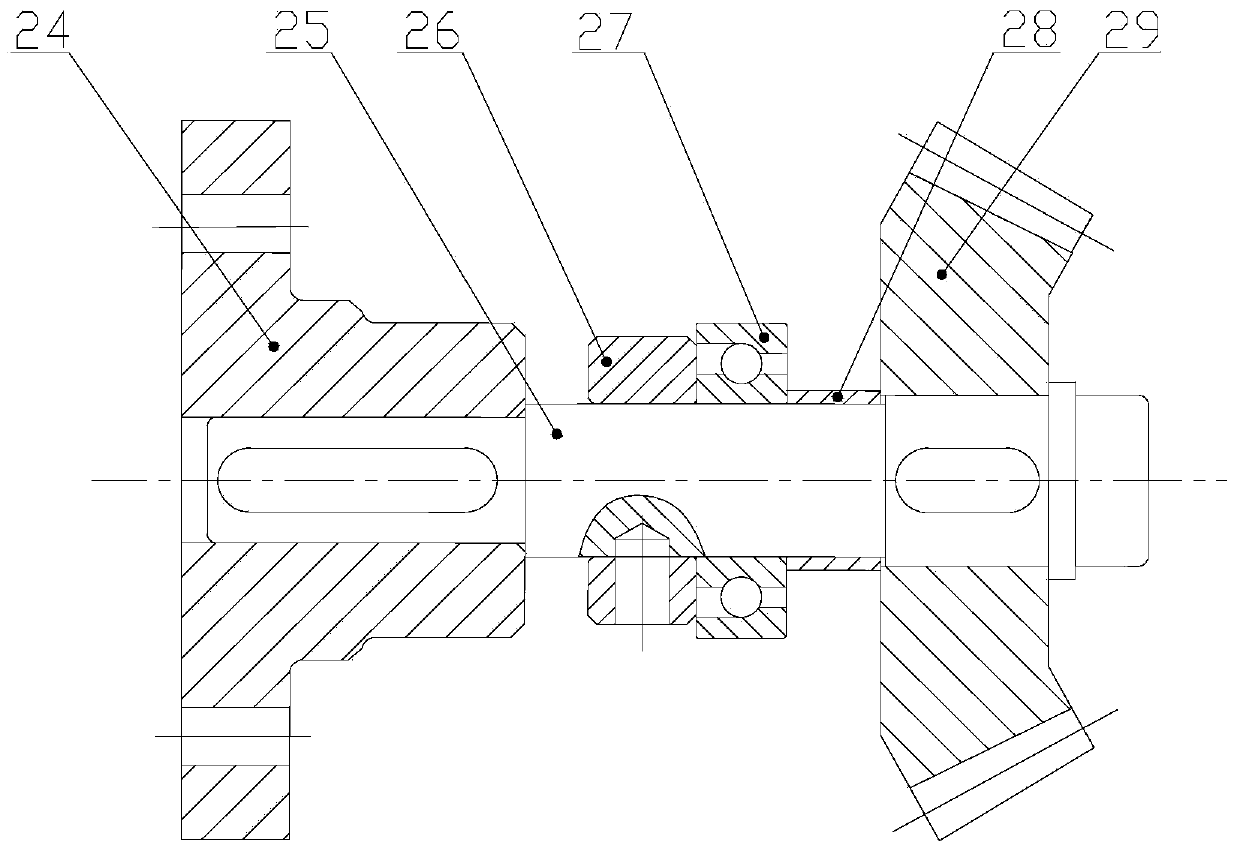

Lining viscosity measurement instrument

The invention relates to a lining viscosity measurement instrument which is provided with a shear type lifting table (1), wherein a bottom plate (2) is arranged at the top of the shear type lifting table (1); a guide light rod (3) and a ball screw nut pair (4) are arranged on the bottom plate (2); a platform (5) is arranged above the bottom plate (2) and is driven by the ball screw nut pair (4) to move up or down; power of the ball screw nut pair (4) is provided by a first motor (21) mounted on the bottom plate (2); a second motor (51), a gear rack mechanism (52) and a linear guide rail (53) are mounted on the platform (5); a pressing head (54) is mounted at the end part of the linear guide rail (53); a sensor (55) is arranged on the pressing head (54) and connected with a controller and a display; the gear rack mechanism (52) is driven by the second motor (51) to push the linear guide rail (53) to horizontally move. According to the device, the lining viscosity can be quickly measured.

Owner:HUZHOU TEACHERS COLLEGE

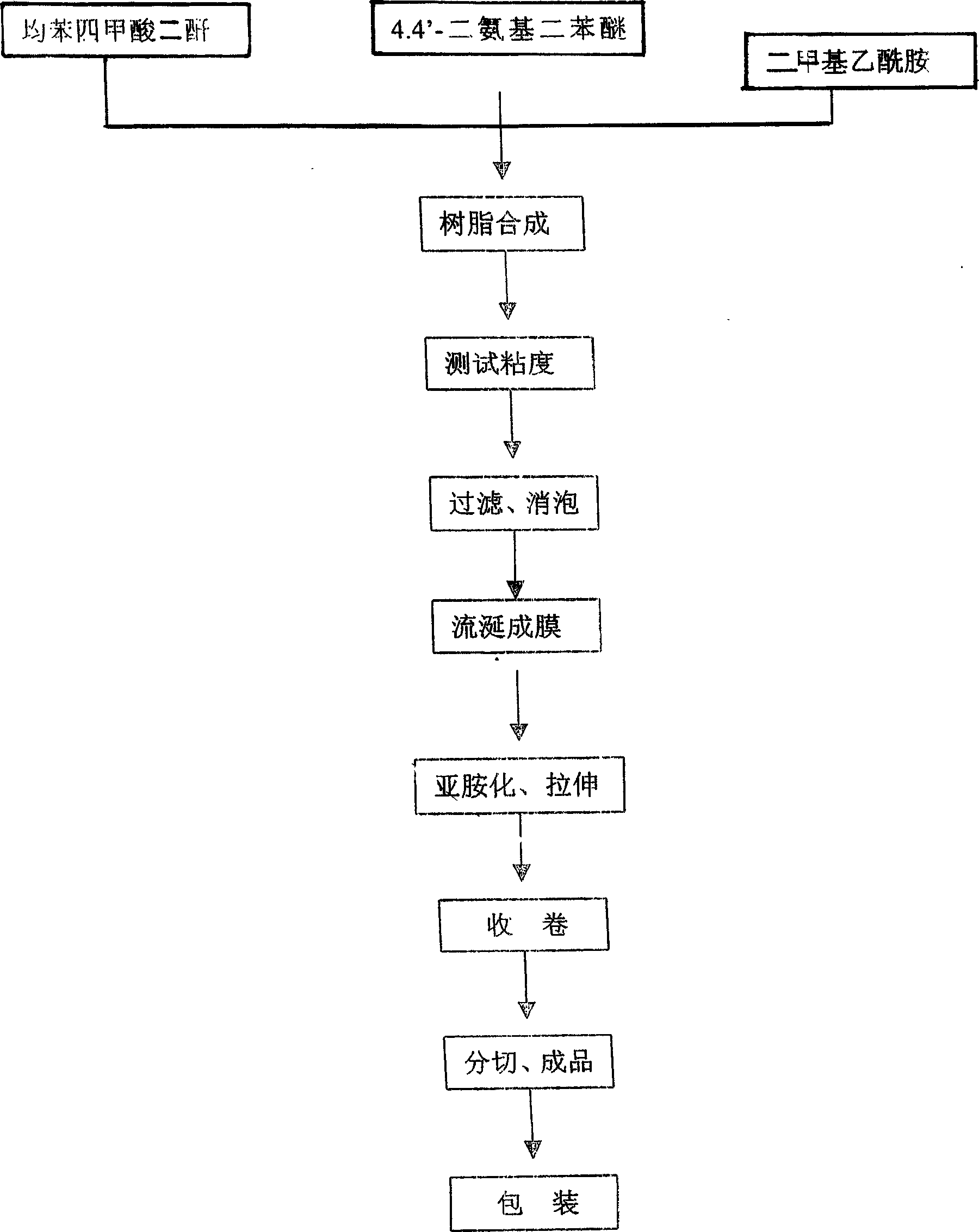

Polyimide film and its producing process

InactiveCN1748985AOrientation crystallization is goodMeet the marketFlat articlesDiaminodiphenyl etherPolymer science

The polyimide film and its production process belong to the field of insulating material producing technology. The production process has pyromellitic dianhydride as main material, and 4, 4-diaminodiphenyl ether and dimethylacetamide as supplementary material, and includes the main steps of: resin synthesis, viscosity measurement, filter, debubbling, casting to form film, winding and cutting. The present invention features the polyimide film with thickness of 0.25-0.35 mm and width of 1250-1500 m, the reaction of pyromellitic dianhydride and 4, 4-diaminodiphenyl ether in dimethylacetamide and the optimized technological process to make the product meet the requirement of producing flexible printed circuit board and other information industry production.

Owner:JIANGSU YABAO INSULATION MATERIAL

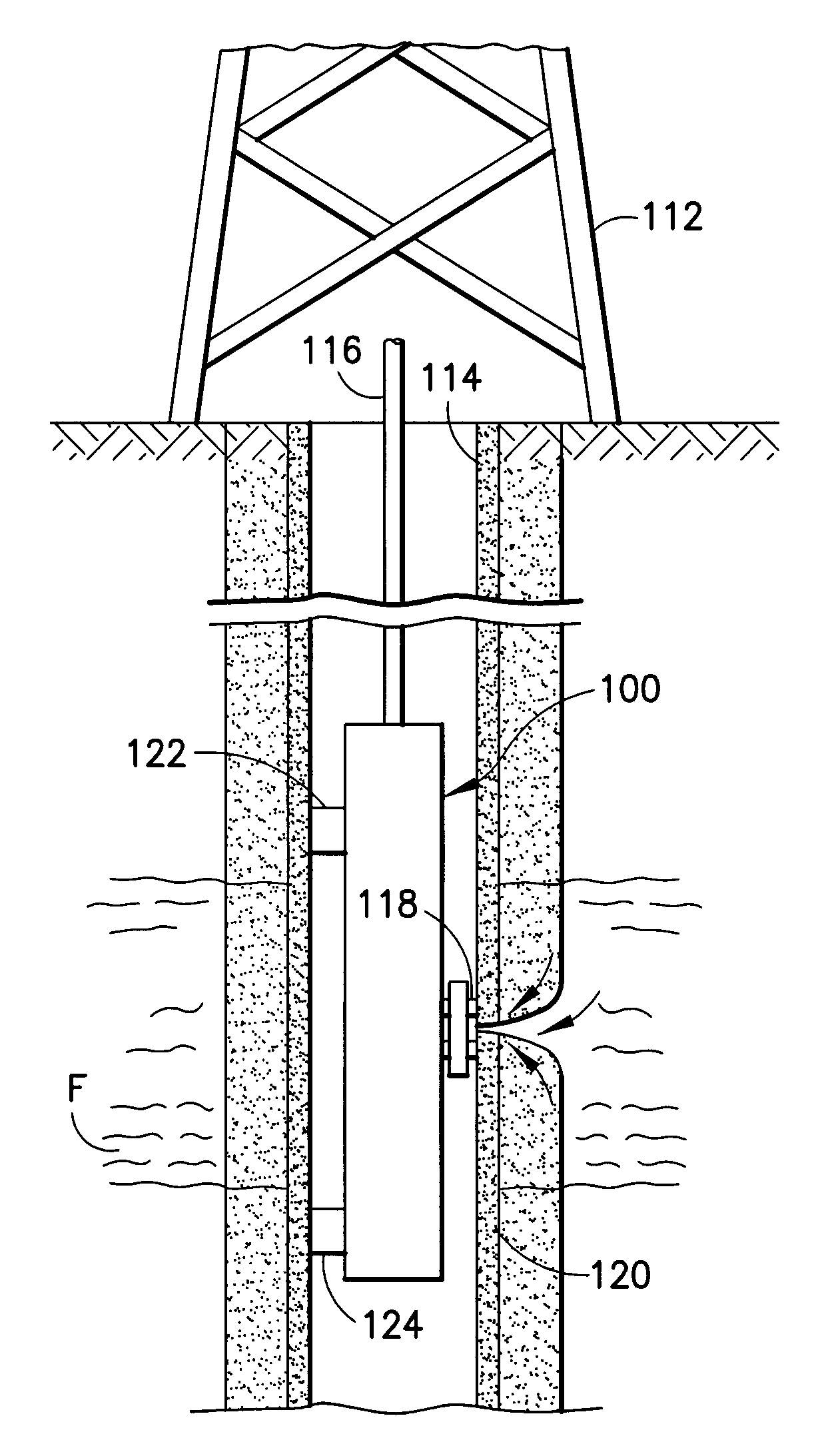

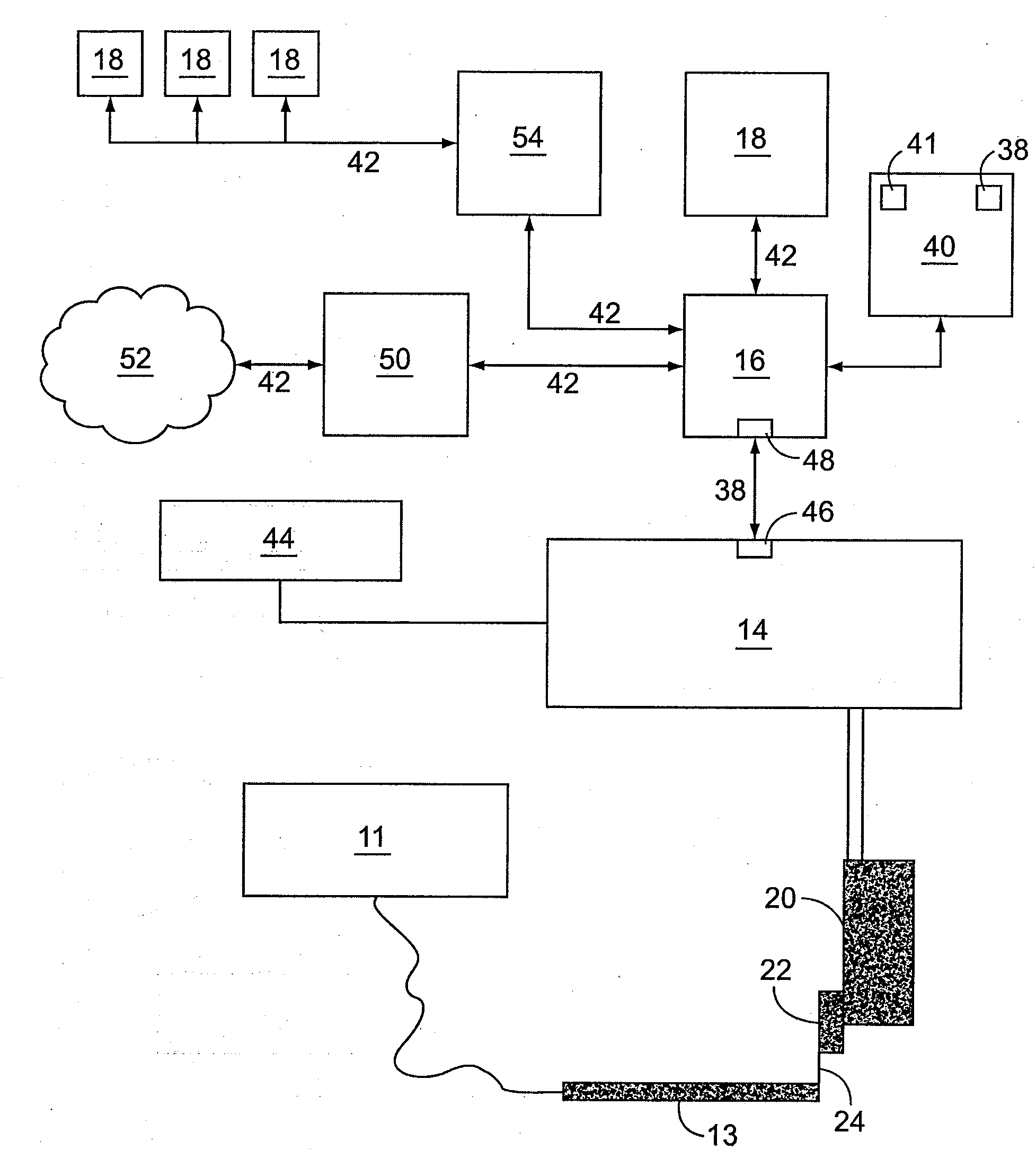

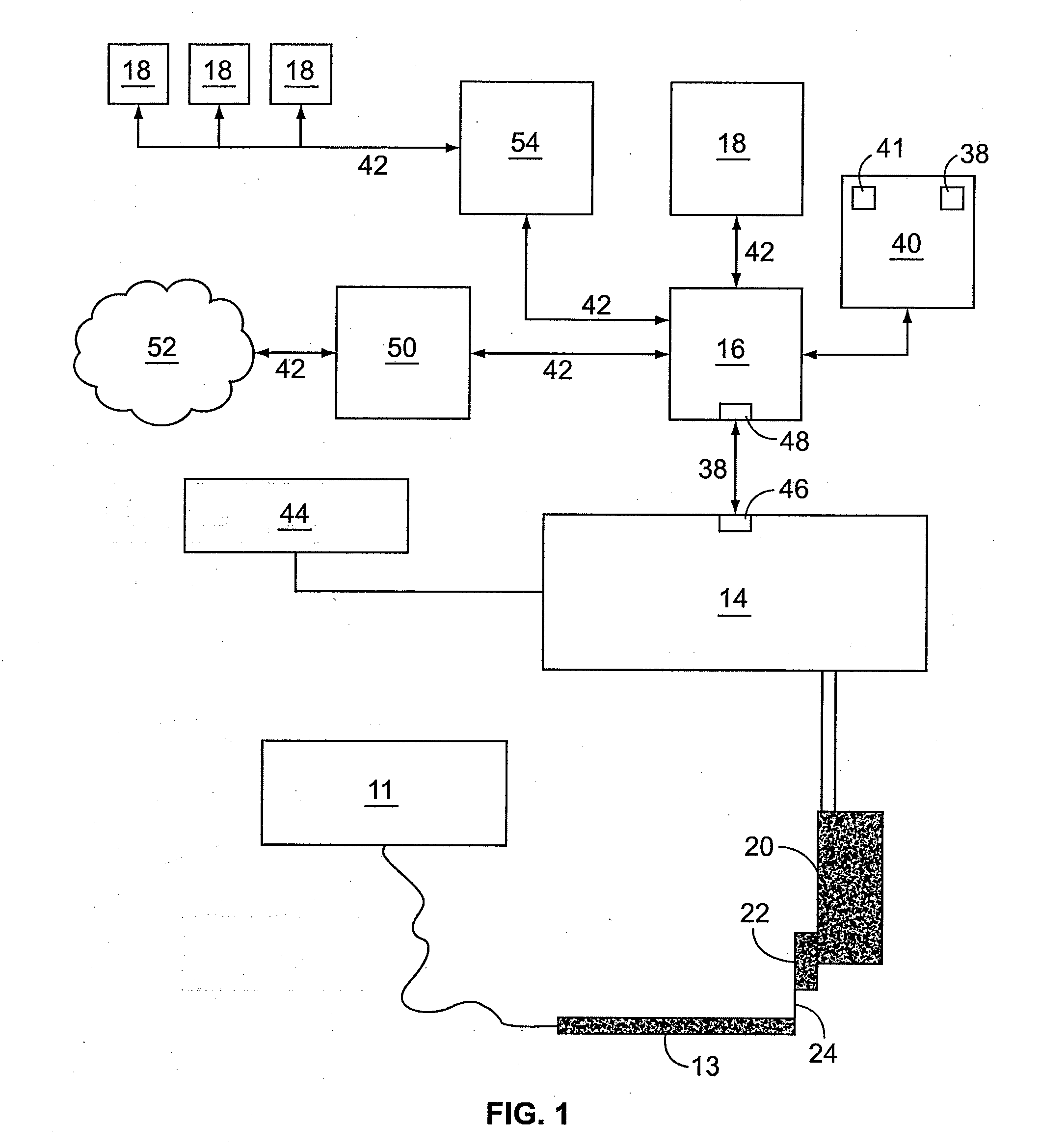

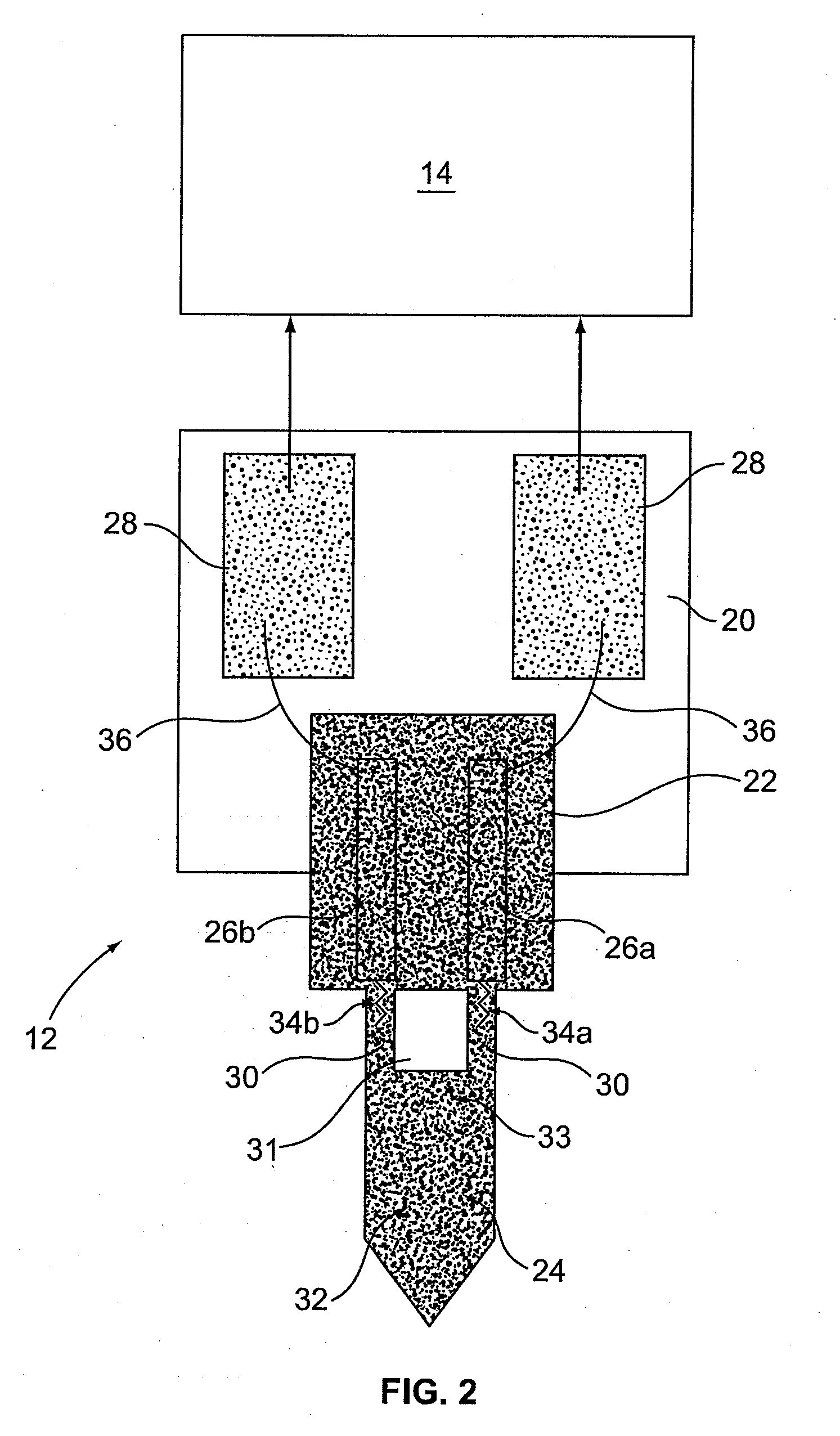

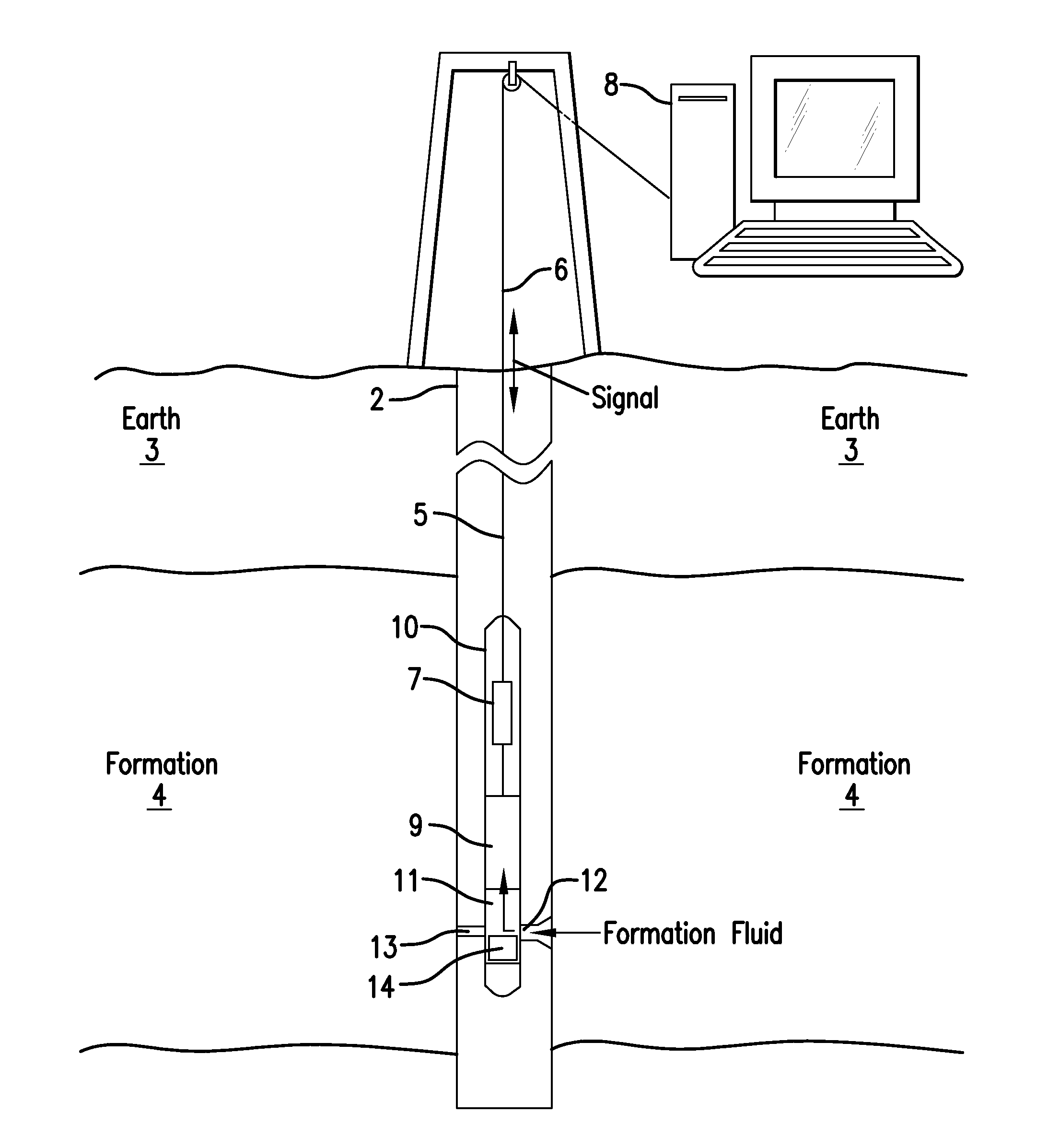

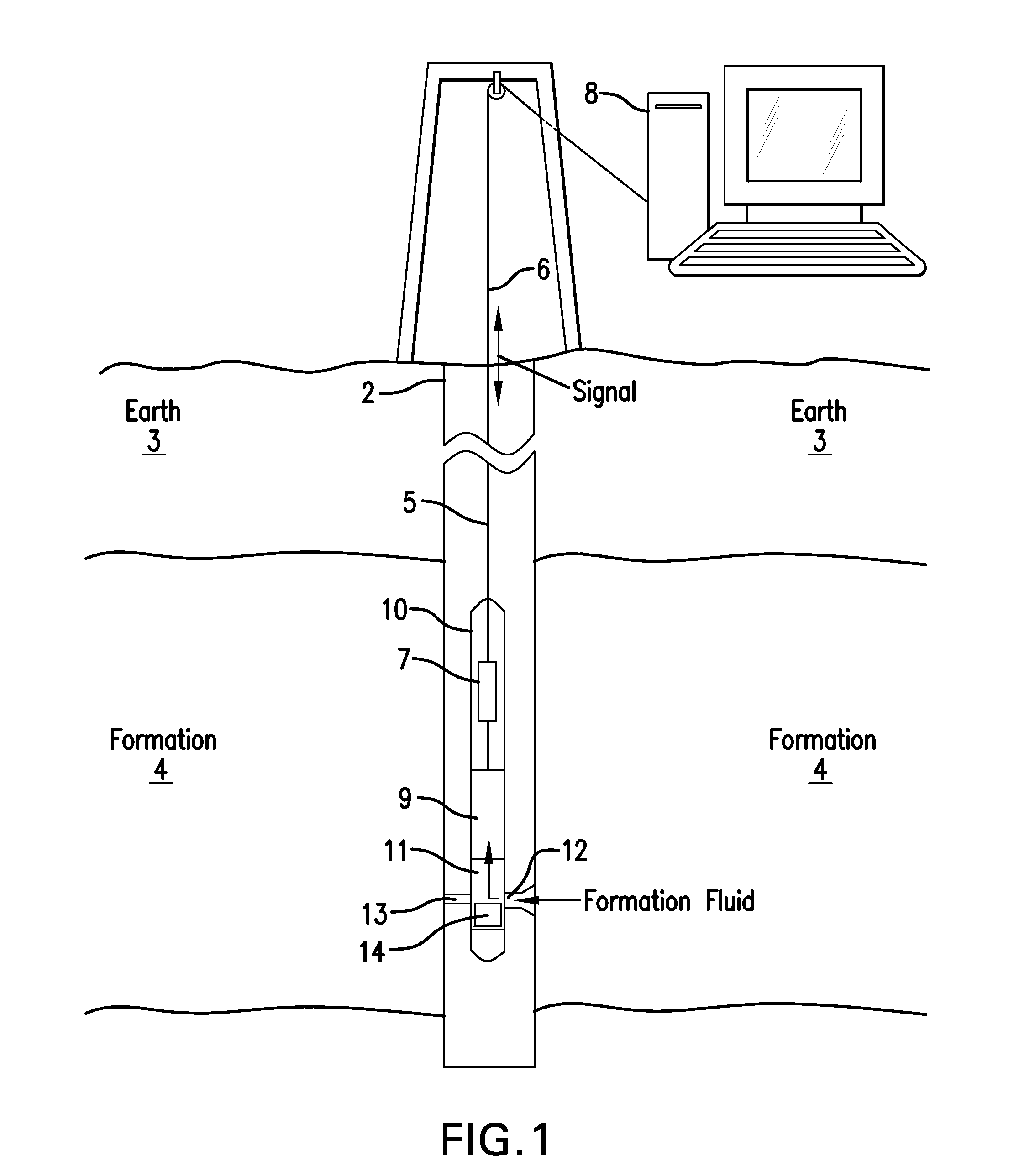

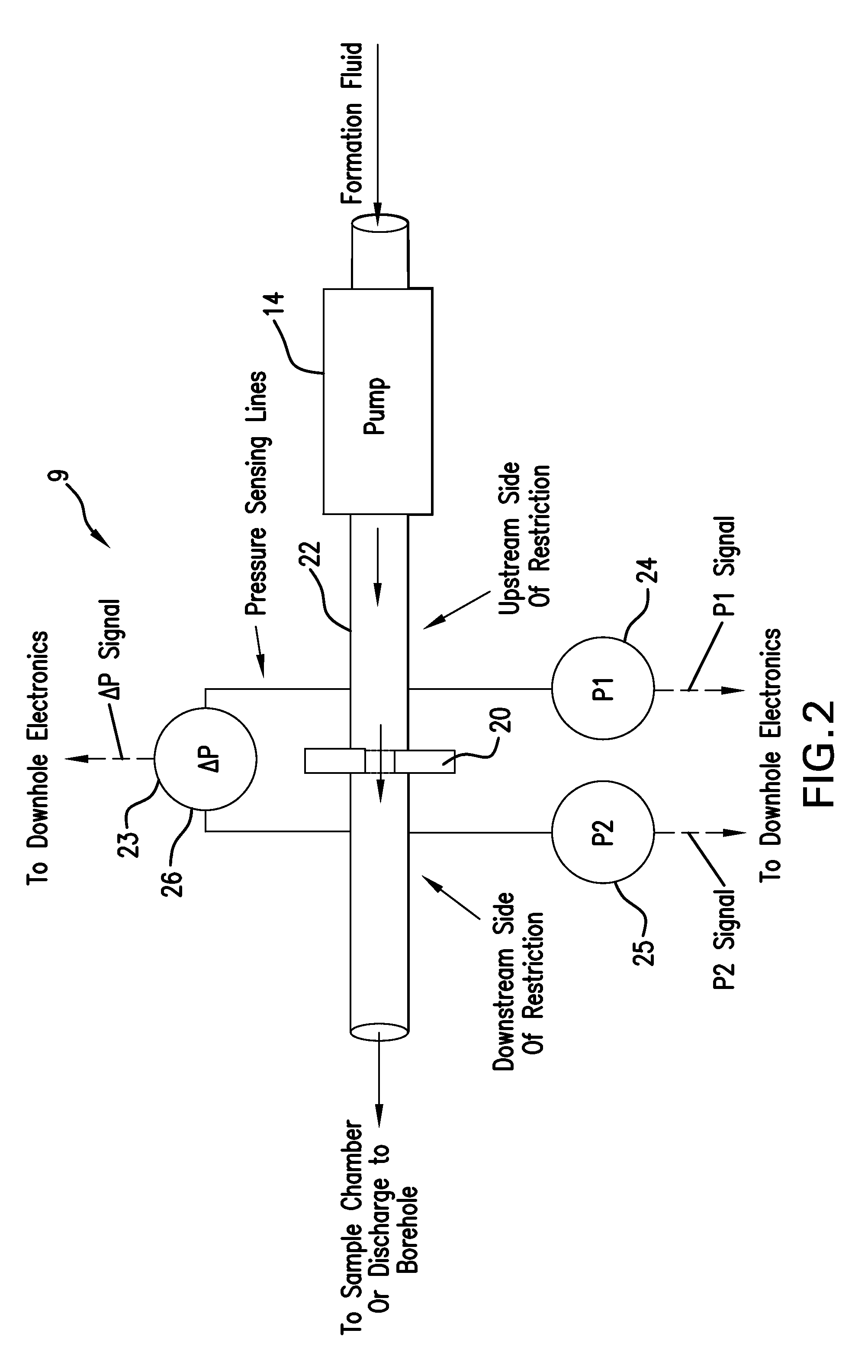

Viscosity measurement in a fluid analyzer sampling tool

ActiveUS20130019673A1Reduce pressureSurveySpecific gravity by measuring pressure differencesDifferential pressureEngineering

An apparatus for estimating a viscosity or density of a fluid downhole includes a carrier configured to be conveyed through a borehole penetrating the earth. A pump is disposed at the carrier and configured to pump the fluid. A flow restriction element is configured to receive a flow of the fluid pumped by the pump and to reduce pressure of the fluid flowing through the flow restriction element. A sensor is configured to measure a differential pressure across the flow restriction element and to provide an output that is used to estimate the viscosity or density.

Owner:BAKER HUGHES INC

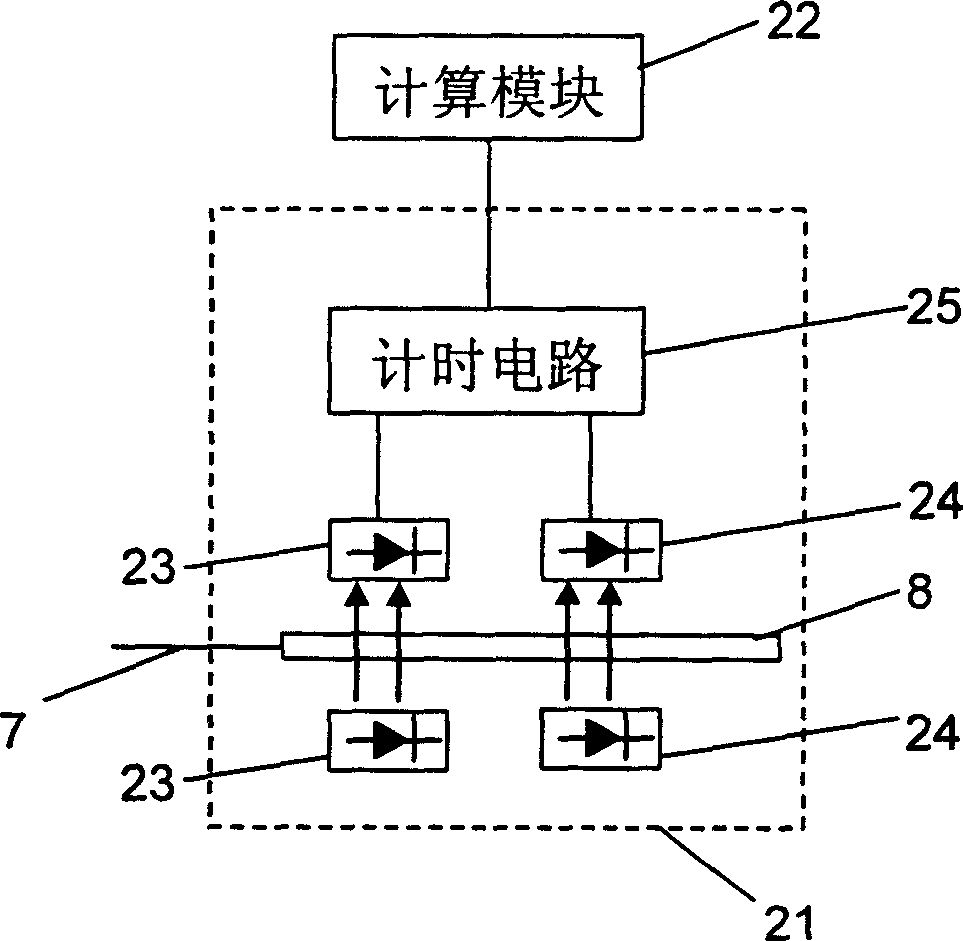

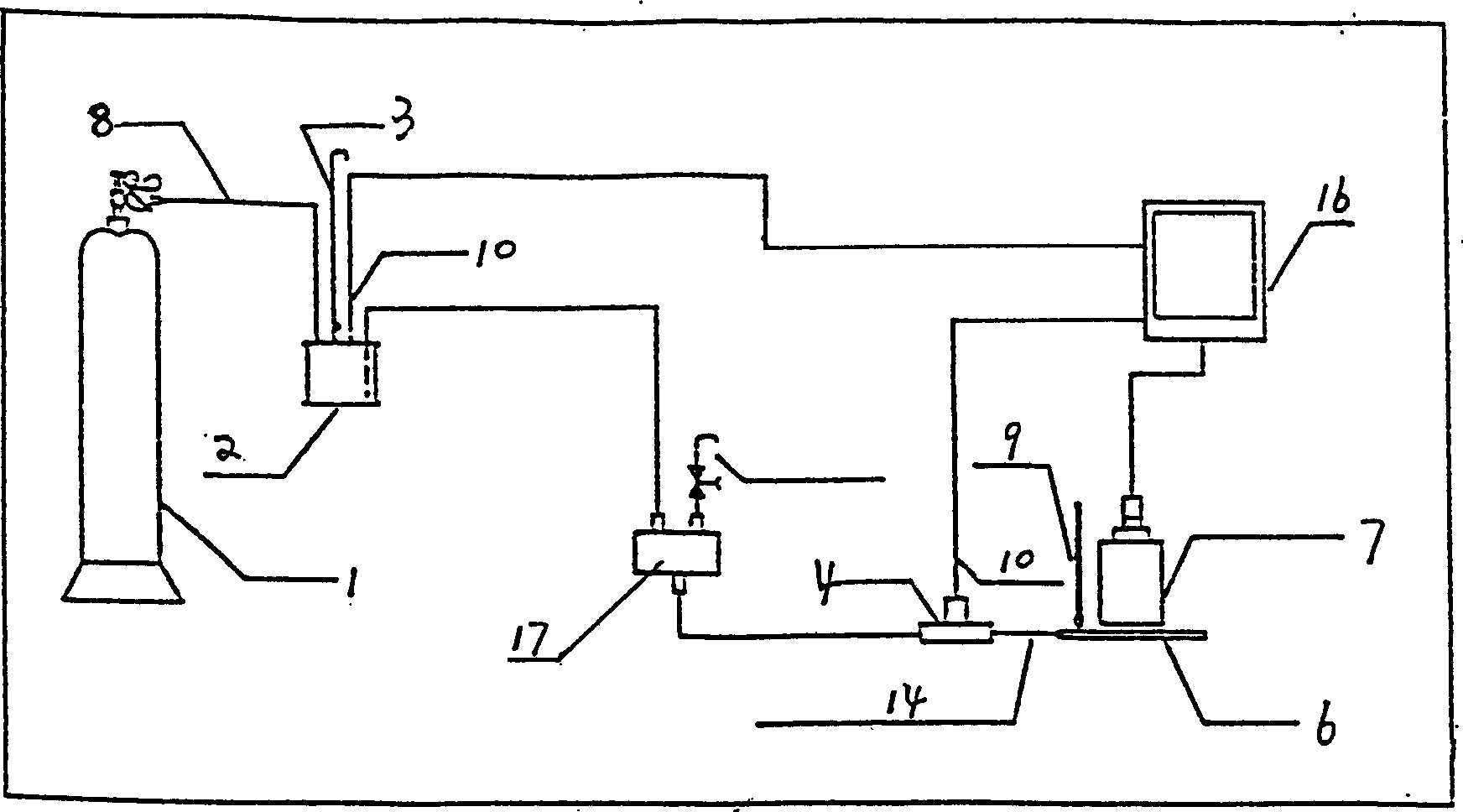

Trace amount liquid viscosity measuring method and apparatus

InactiveCN1501061AReduce dosageEasy to controlDirect flow property measurementTemperature controlLiquid viscosity

The present invention relates to micro liquid viscosity measuring method and unit. The present invention measures the viscosity of liquid indirectly via measuring the flow rate-pressure relationship of liquid in micron pipe, and the method is superior to available one, which adopts large amount of test liquid and expensive constant temperature bath. One micro liquid viscosity measuring instrument with small amount of test liquid, simple constant temperature device and short measurement period is provided. The measuring instrument consists of low pressure micro flow experimental apparatus and temperature controller, and has the structure including gas storage, liquid tank, T-pipe, pressure detector, temperature controller, micron pipeline inside the temperature controller, transparent displacement pipe with one end connected to the micron pipeline and the other end communicated to atmosphere via the temperature controller, and optical microscope on the transparent displacement pipe.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

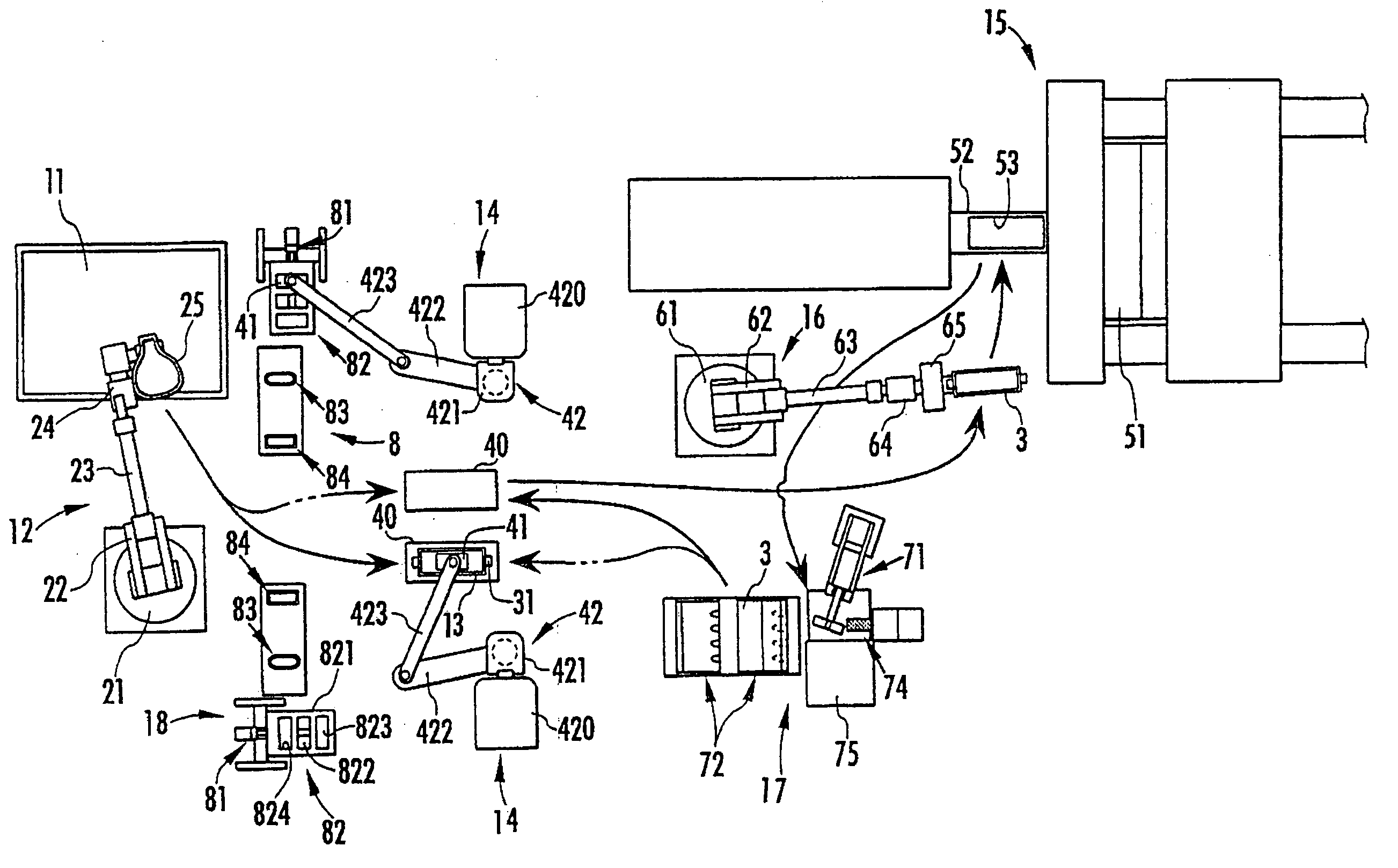

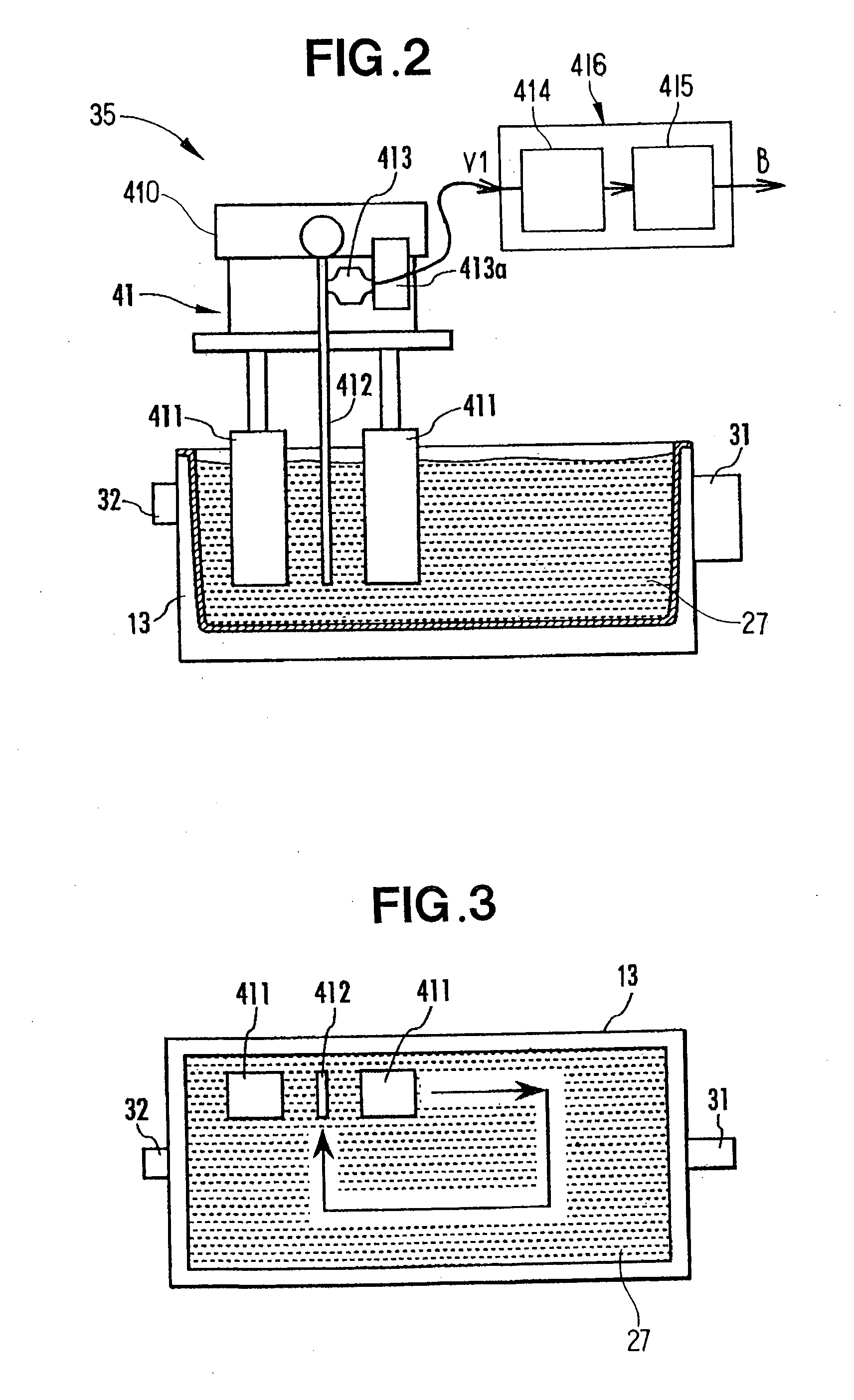

Molding of slurry-form semi-solidified metal

ActiveUS20060151137A1Exclude influenceInhibitionMelt-holding vesselsCasting safety devicesSemi solidSlurry

Made up of a step of preparing a map expressing a correlation between solid phase percentage and viscosity of a slurry-form semi-solid metal (27) for a given metal composition; a step of setting a target viscosity corresponding to a target solid phase percentage using this map; a viscosity measuring step of measuring the viscosity of a semi-solid metal in a vessel (13) while cooling it; and a step of carrying out cooling until this viscosity reaches the target viscosity, by these steps being carried out in from the preparation of the map expressing the correlation between solid phase percentage and viscosity of the semi-solid metal to the end of cooling of the semi-solid metal the solid phase percentage of the semi-solid metal is made to match the target solid phase percentage. Because the viscosity is detected, the affects of cooling rate changes and time can be eliminated, and it is possible to raise management accuracy of the solid phase percentage of the semi-solid metal much further than with related art management based on time.

Owner:HONDA MOTOR CO LTD

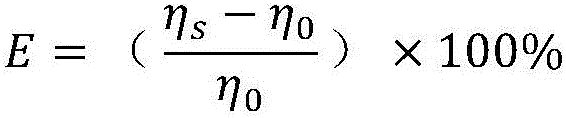

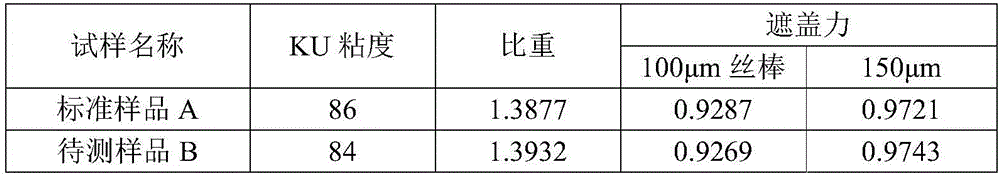

Method measuring inter-batch stability of latex paint by using rotational rheometer

ActiveCN105758766AQuality improvementReaction feeding accuracyFlow propertiesPaint productViscosity measurement

The invention discloses a method measuring inter-batch stability of latex paint by using a rotational rheometer, comprising the following steps: (1), providing the rotational rheometer, a standard latex paint sample and a latex paint sample to be tested; (2), measuring viscosity of the standard latex paint sample at a preset shearing rate by using the rotational rheometer; (3), preparing the homogenously disposed latex paint sample to be detected; (4), measuring viscosity of the latex paint sample to be detected, at a preset shearing rate by using the rotational rheometer; (5), comparing the viscosity measurement of the latex paint sample to be detected with that of the standard latex paint sample, and calculating a deviation of the latex paint sample to be detected with respect to the standard latex paint sample so as to evaluate production stability of sample latex paint.The method enables feeding accuracy in the production process of latex paint products to be accurately reflected, thus improving total quality of paint production.

Owner:LANGFANG NIPPON PAINT

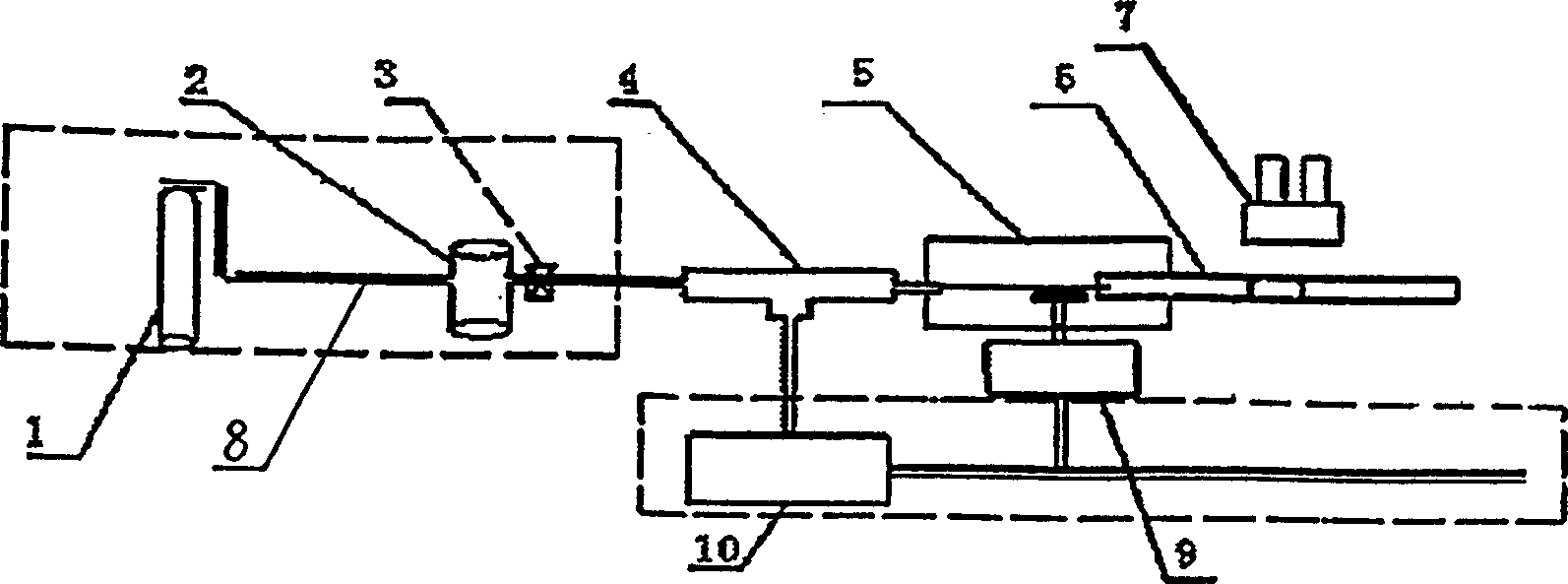

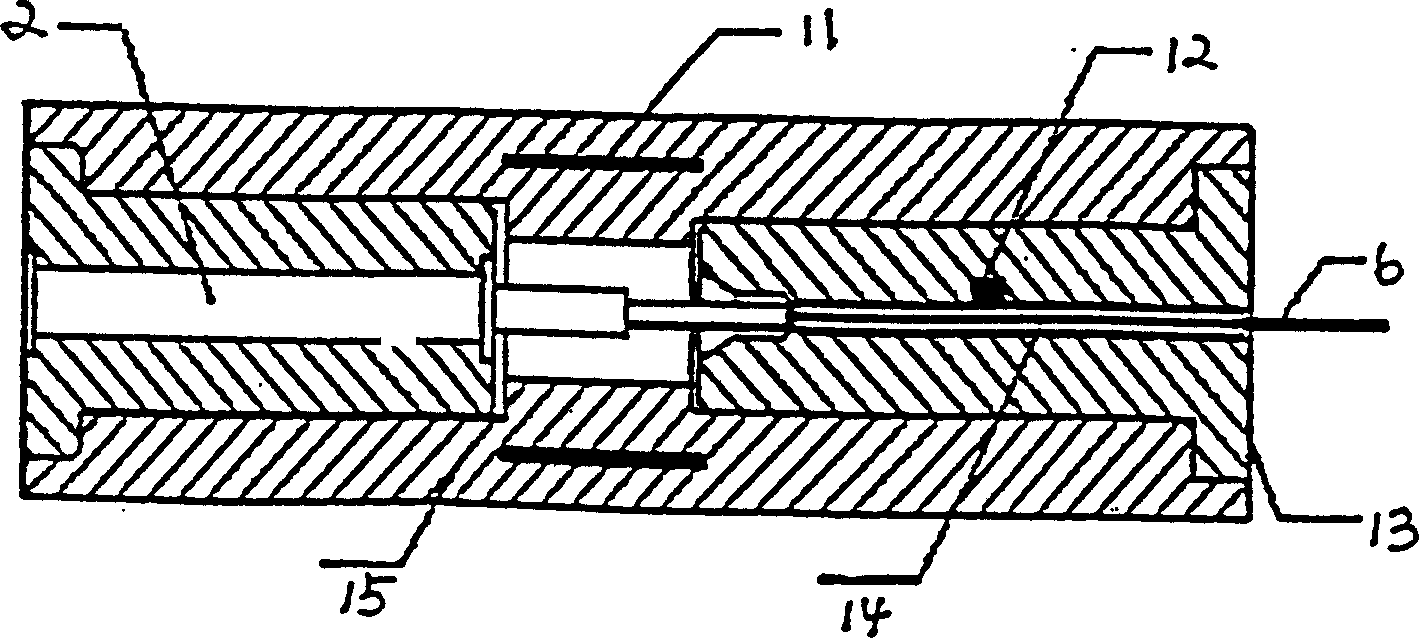

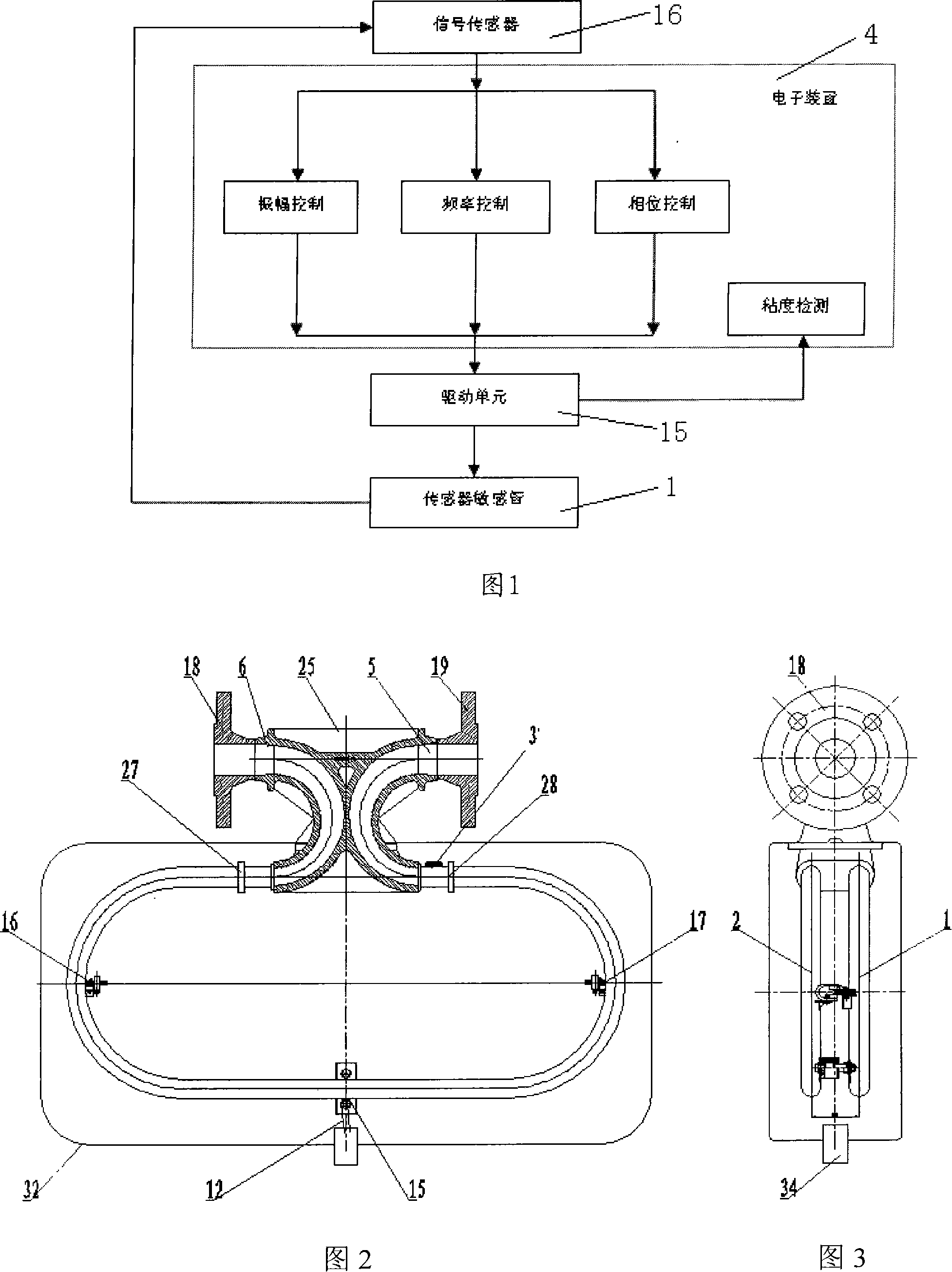

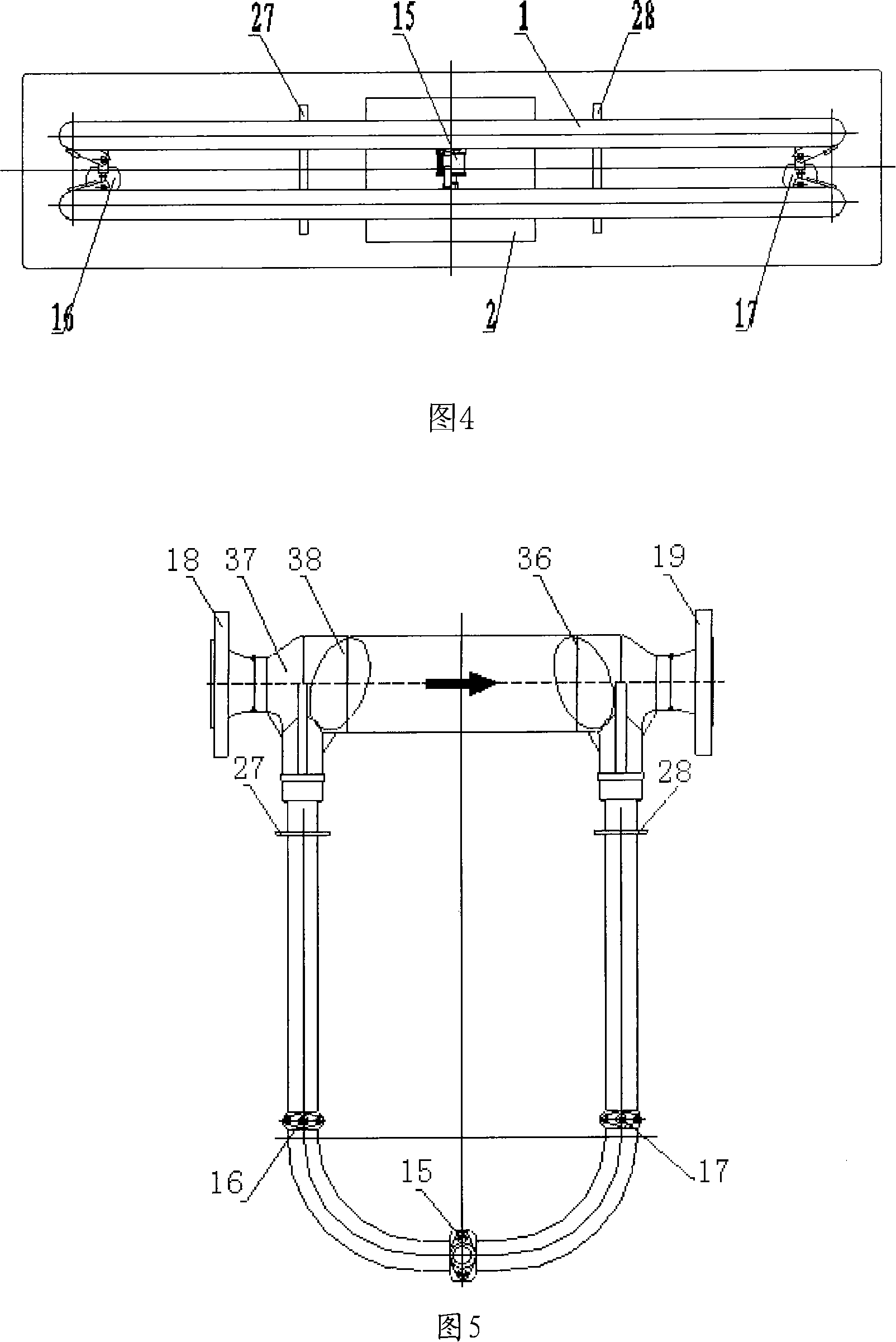

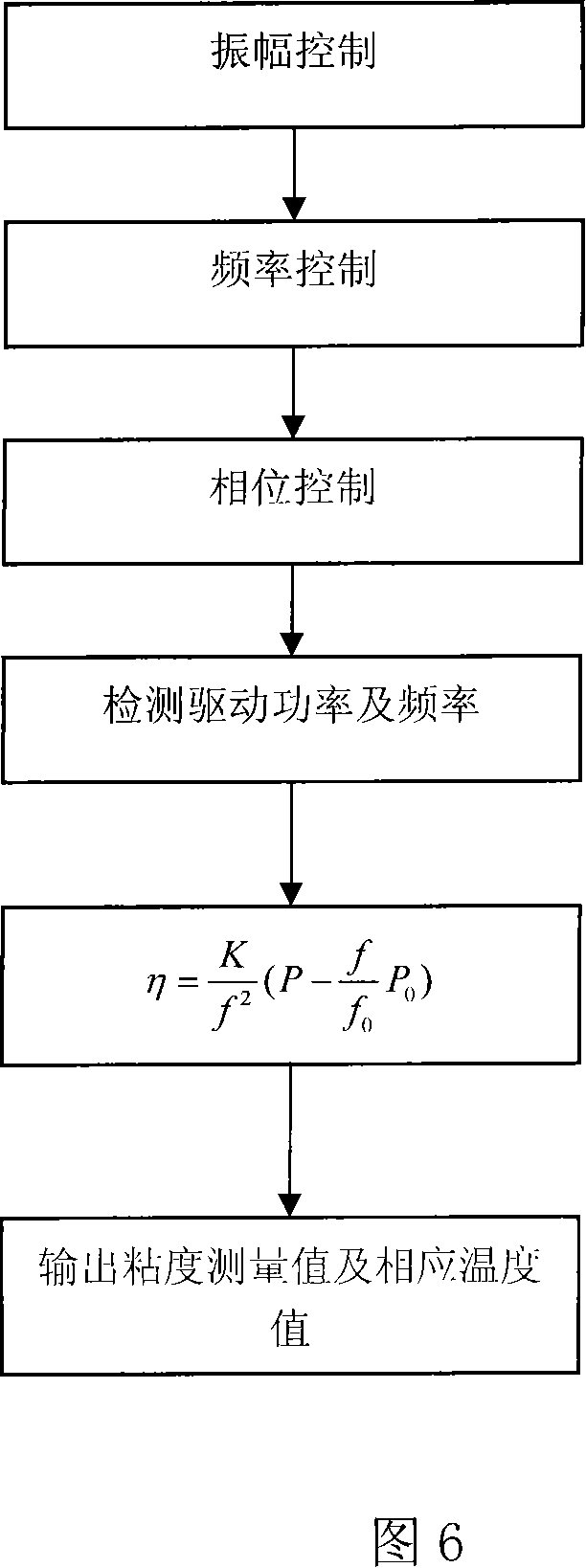

Method and device for detecting viscosity of fluid passing pipe

The invention relates to a device and method for testing the viscosity of a fluid passing a pipe. For a prior viscosity tester, for example, American patent 4,524,610, a drive makes a sensor sensitive pipe to generate twisting and vibration, so as to generate frictional force in the fluid; and by measuring the drive current, the dynamic viscosity measurement of the fluid can be obtained, and the dynamic viscosity can be obtained by measuring the fluid density. However, for implementing the patent on other instruments, it needs a lot of changes to meet the implementing condition. The present invention is a device allows to get continuous viscosity value, which can be realized on a Coriolis mass flowmeter and comprises at least a sensor sensitive pipe without changing greatly original device, in addition, by measuring the fluid density, the dynamic viscosity of the fluid can be obtained. The invention is to measure the viscosity of a fluid by making the fluid to reach its optimal harmonic-oscillation point and then taking use of different information at the point. The invention is of simple structure, easy to operate. The method is of simple procedures and accurate test results.

Owner:XIAN DONGFENG MACHINERY & ELECTRONICS

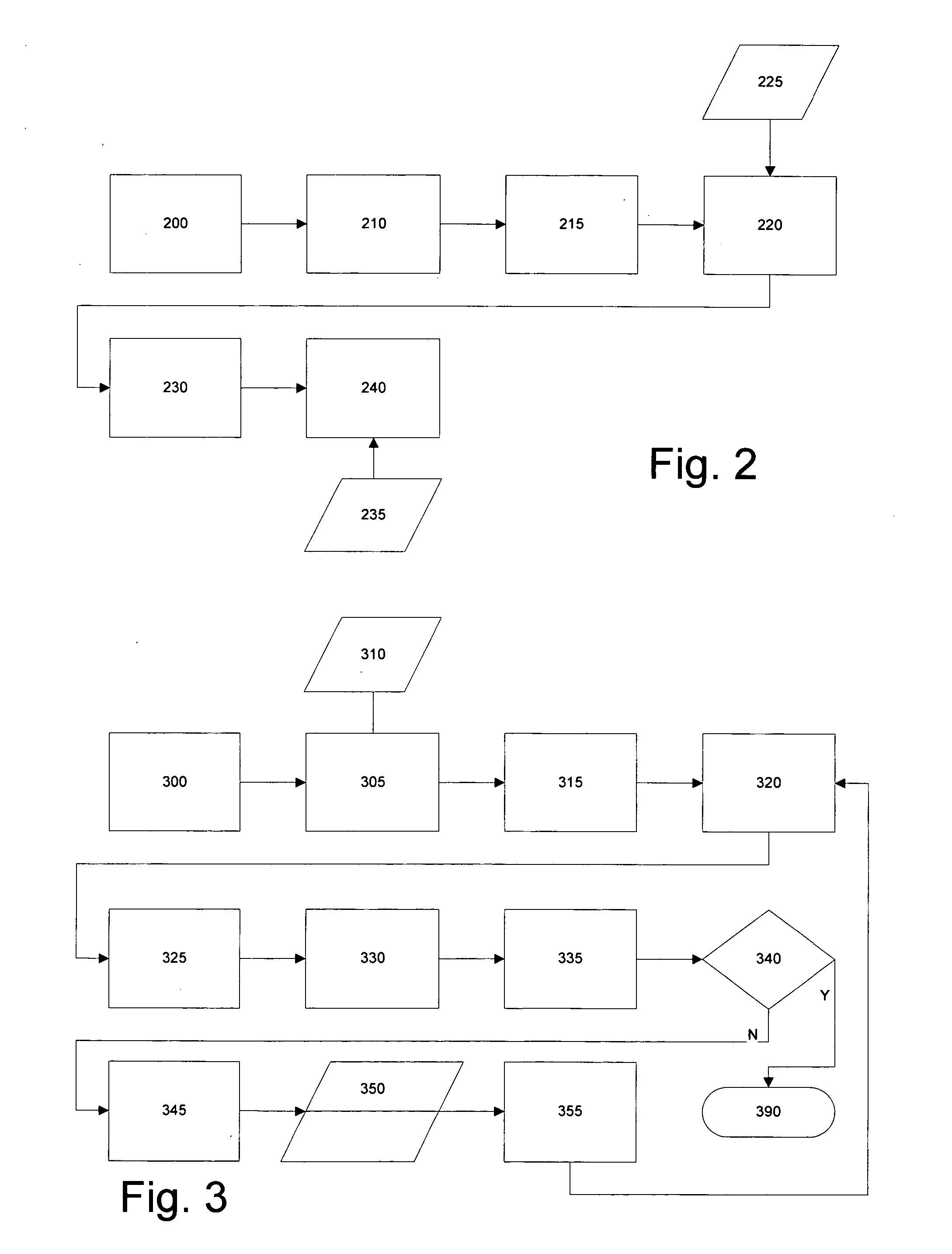

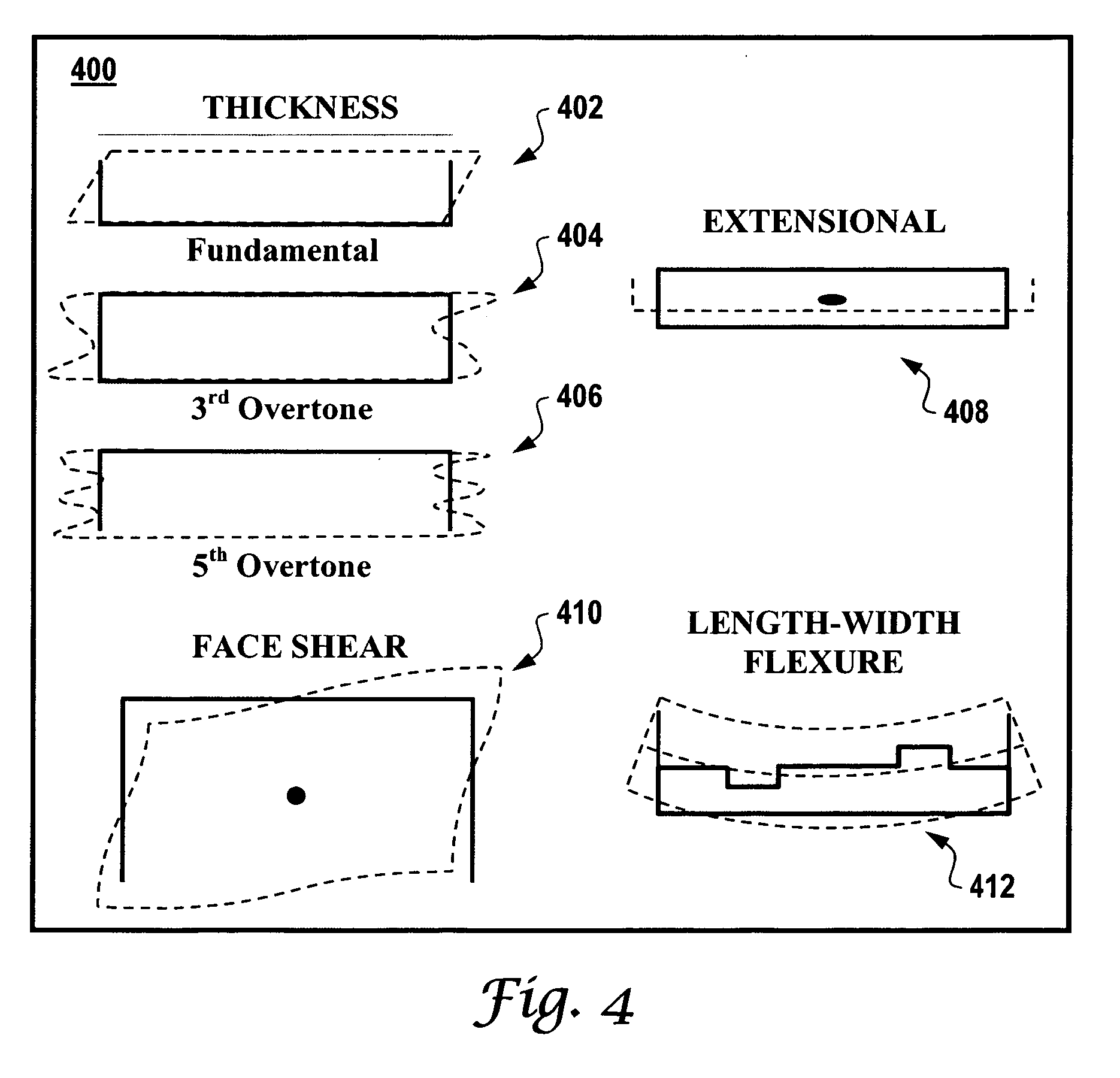

Measurement, compensation and control of equivalent shear rate in acoustic wave sensors

InactiveUS20050132784A1Analysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesShear rateAcoustic wave

A method for measuring viscosity and shear rate at which the measurement is performed is provided, by utilizing an acoustic wave sensor, and calculating the shear rate as a function of the characteristic rate of quartz movement in response to a given power transmitted to a fluid, and the viscosity of the fluid. Related aspects of the invention provide for methods for controlling the shear rate at which a viscosity measurement is performed, and characterizing viscoelastic fluids at a plurality of shear rates.

Owner:VECTRON INT INC

Multiple-function acoustic wave oil quality sensor

InactiveUS20060243032A1Viscosity of the engine oil can additionally beAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesOil canFrequency measurements

A method and system for detecting oil quality. The quality of engine oil can be determined utilizing an acoustic wave sensor to obtain viscosity and corrosivity data associated with the engine oil. The acoustic wave sensor is coated with a material that selectively reacts to at least one type of an acid in order to provide data indicative of the presence of the acids in the engine oil. The etch rate or the corrosivity of the engine oil can be determined based on the frequency data obtained as a result of the frequency measurement utilizing the acoustic wave sensor. The viscosity of the engine oil can additionally be obtained based on a measurement of phase and amplitude obtained from the data utilizing the acoustic wave sensor. The etch rate and the viscosity measurement provide data indicative of the quality of the engine oil.

Owner:HONEYWELL INT INC

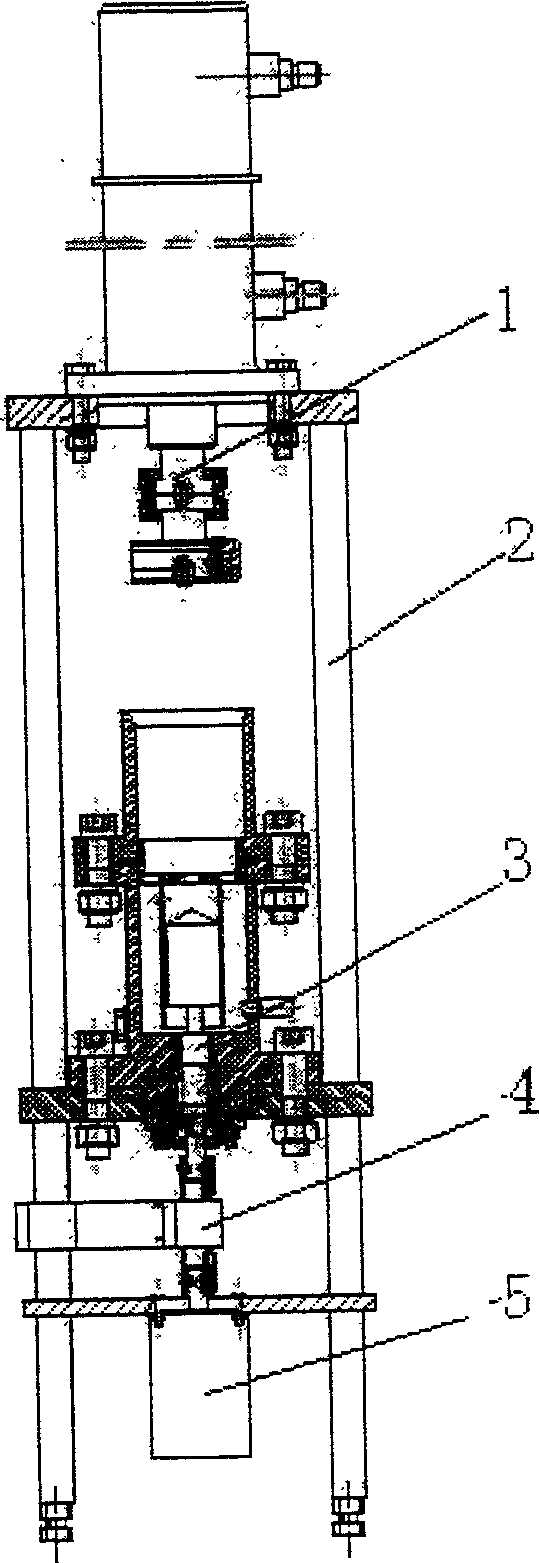

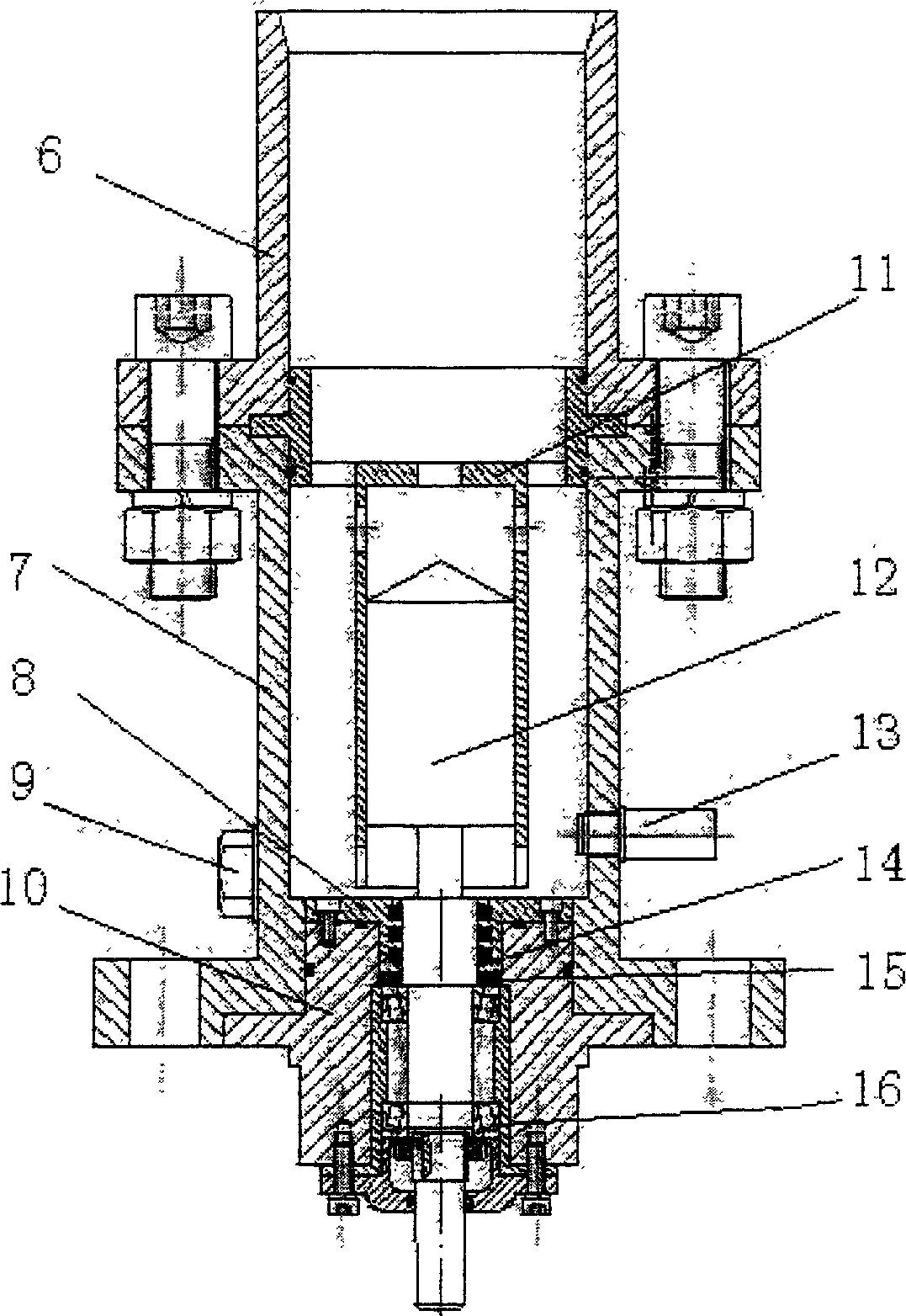

Pressurizing rotary rheometer

A pressurizing rotary rheometer used in viscosity measurement of high-concentration viscous homogeneous fluid can aims at the rheological measurement of high-concentration viscous slurry containing big particles under pressurizing state. The instrument comprises servo-motor driving system, viscosity measuring system, hydraulic drive system and so on. In the viscosity measuring system, the hydraulic cylinder part, viscosity measuring part, torque sensor and AC servo-motor are coaxially installed on a vertical type bracket orderly.

Owner:ZHANGKUANG ELECTROMECHANICAL ENG TECH INST BEIJING

Method of evaluating the wear of engine oil taking into account the addition of fresh oil

InactiveUS20030172722A1Flow propertiesFluid pressure measurement by mechanical elementsOil viscosityViscosity measurement

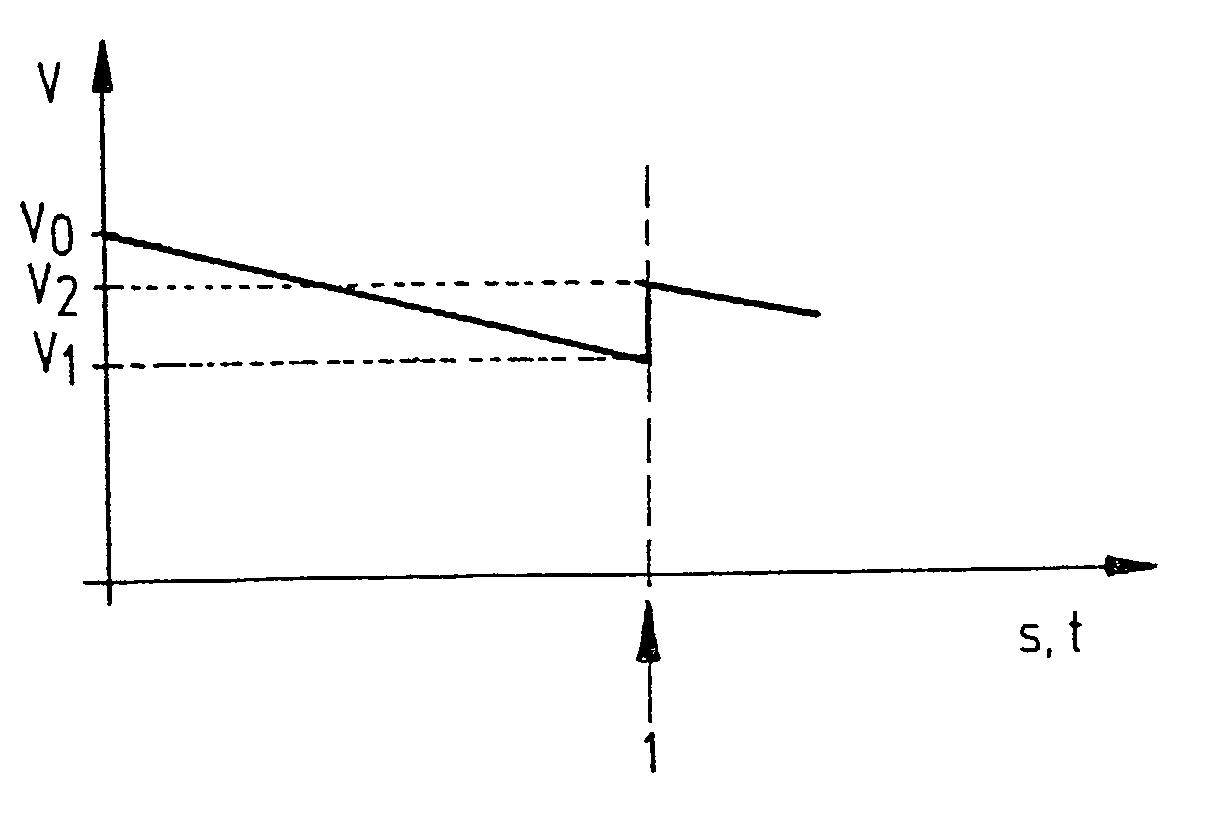

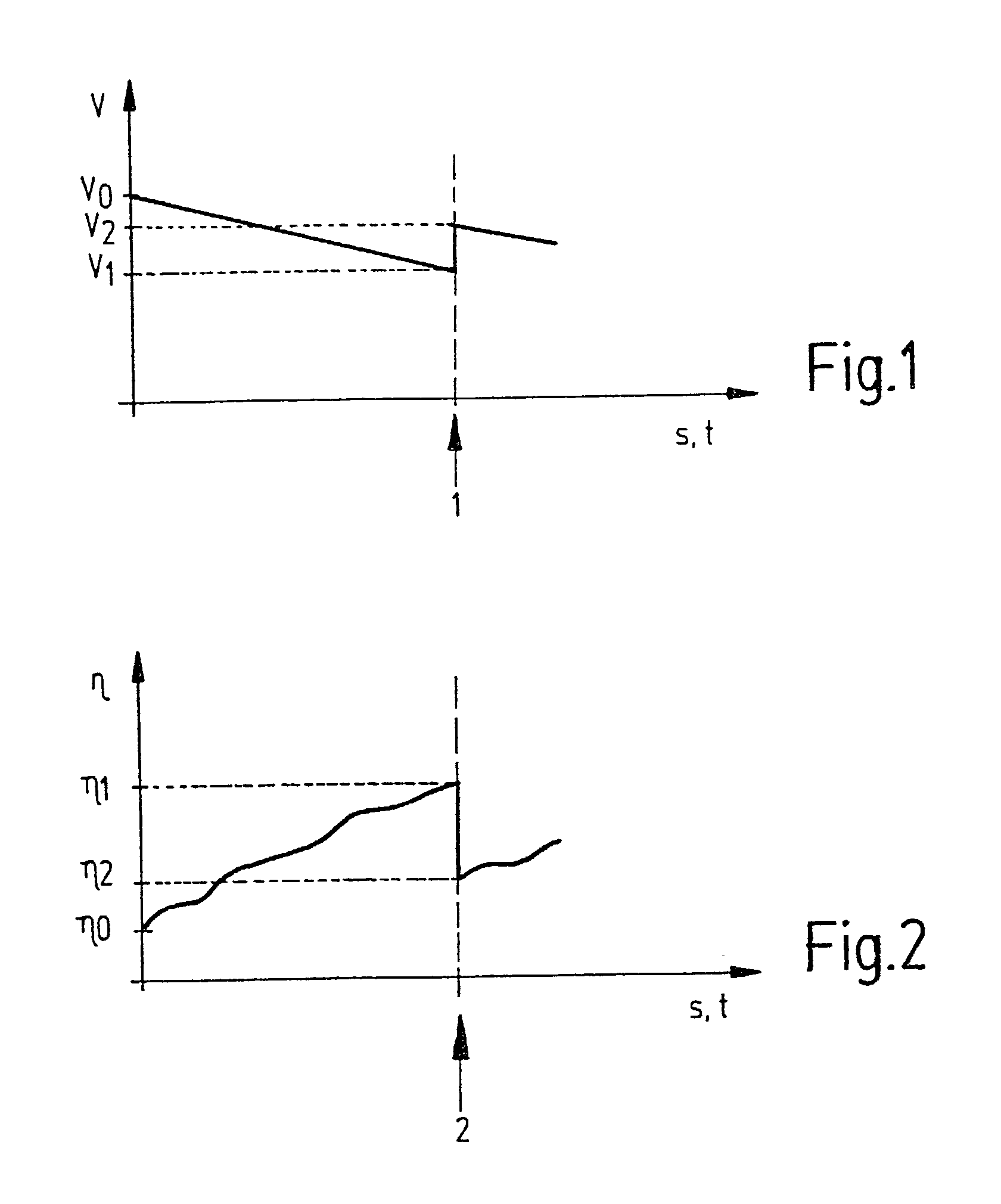

A method of evaluating engine oil wear on the basis of viscosity measurement, taking into account the addition of fresh oil is described. First, using the oil viscosity sensor, the amount of oil added in the addition of fresh oil is detected, then the oil viscosity sensor determines the viscosity of the oil mixture (eta2) of the engine oil and fresh oil; the quantity (Vn) of fresh oil added is determined in the electronic analyzer from the difference between the old oil level, i.e., the oil volume (V1), and the new oil level, i.e., oil volume (V2); and the viscosity (etan) of the fresh oil is determined from the viscosity (eta1) of the old engine oil immediately before the point in time of the addition of fresh oil and from the viscosity (eta2) after the addition; and a hypothetical initial viscosity (eta'0) is calculated as a new corrected reference value from the known value of the viscosity (eta0) of the old engine oil in the new condition, the quantity (V1) of the engine oil still present at the point in time of the addition, the calculated viscosity (etan) of the fresh oil and the calculated quantity (Vn) of the fresh oil.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com