Method and device for detecting viscosity of fluid passing pipe

A technology of measuring devices and measuring methods, applied in the direction of measuring devices, flow characteristics, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

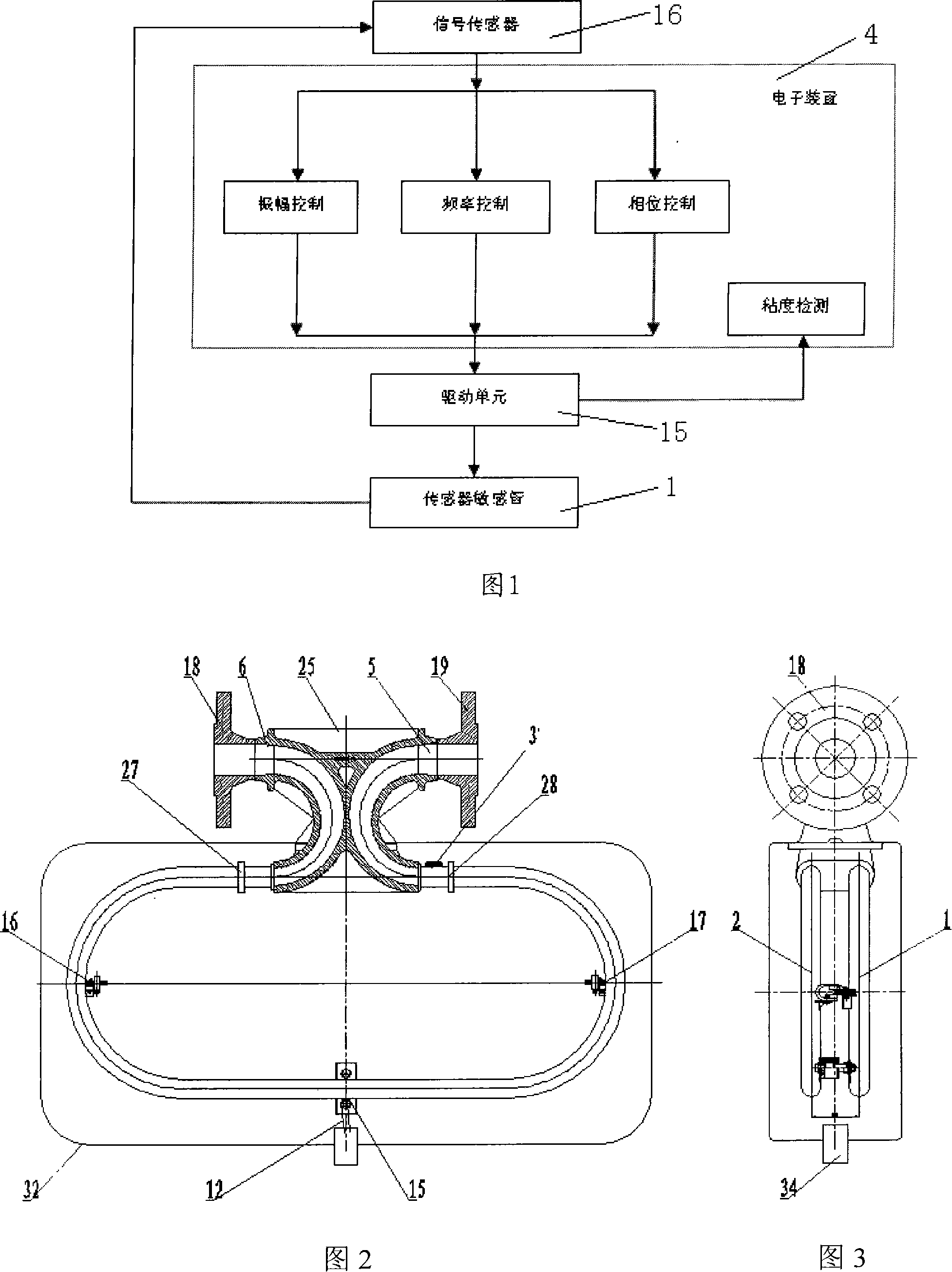

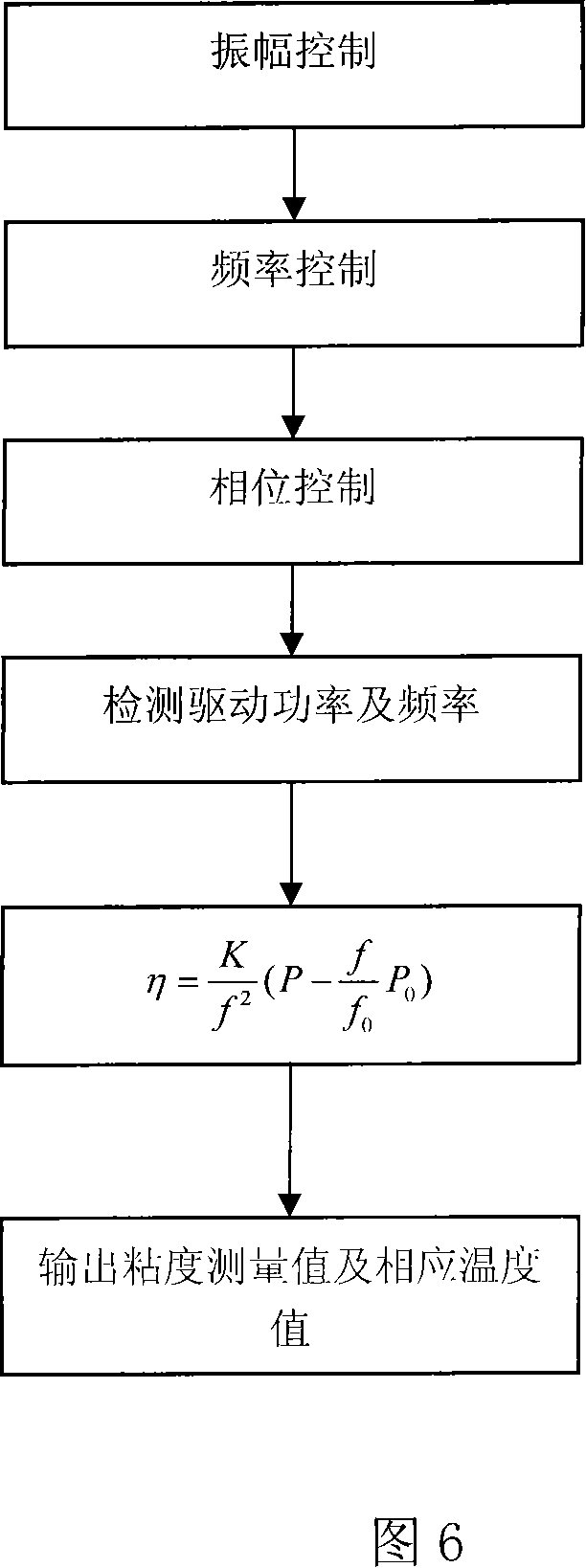

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

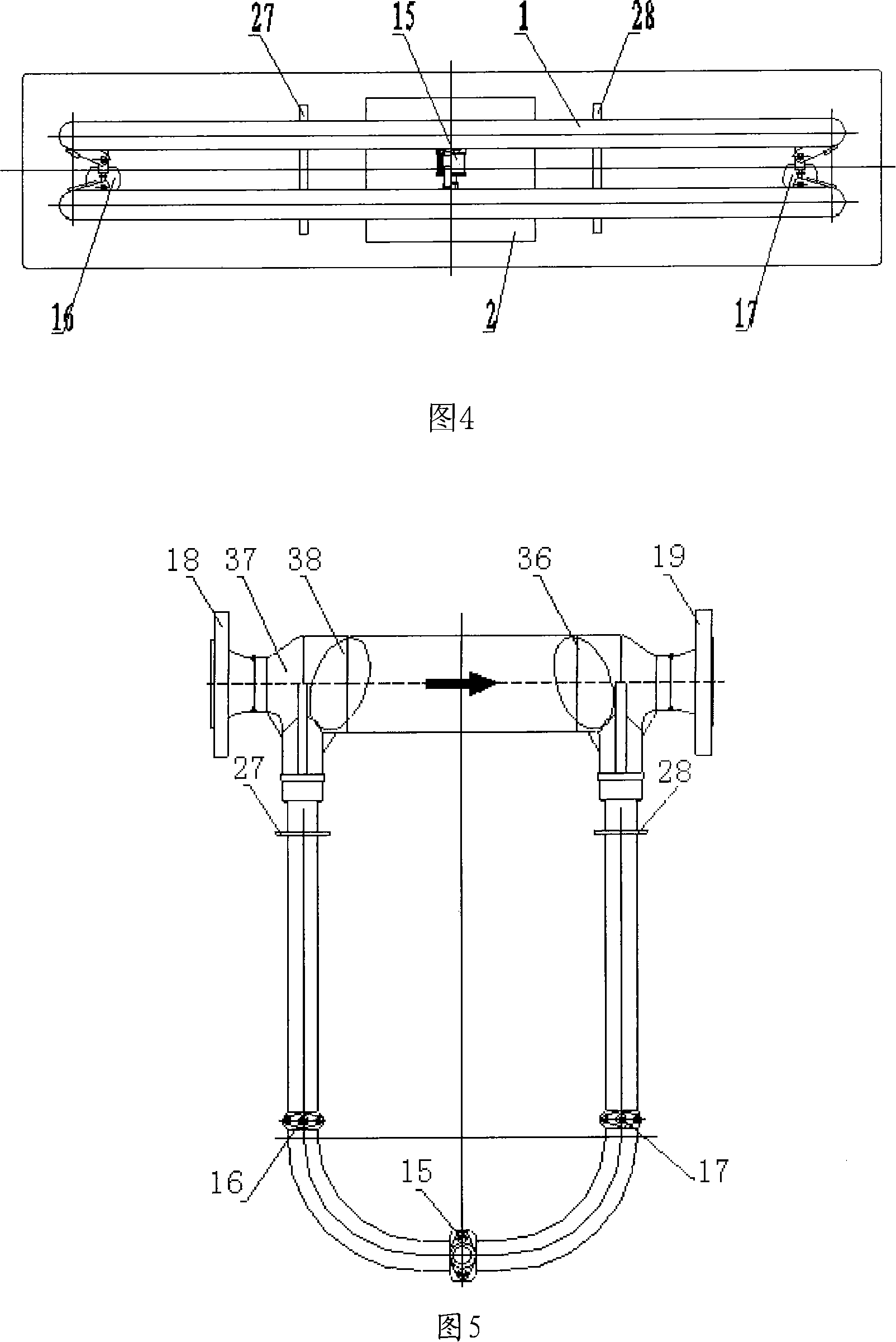

[0054] Referring to Figures 2-4, Figure 2 is a schematic structural view of a double C-type Coriolis mass flowmeter; the present invention can be implemented on this patent 200410073046.2, as shown in Figure 2, it includes two parallel C-type sensitive tubes 1 and 2. The fluid to be measured enters the flowmeter from the main pipe 25 of the main body and is divided into two parts, flows into the sensitive tubes 1 and 2, and then flows into the main body from the outlets of the sensitive tubes 1 and 2 to be combined into one, and is output by the main tube. The mouth 6 flows to the external pipe through the flange 18, and the drive unit 15 is installed in the middle section of the sensitive tube 1 and 2. When working, the two sensitive tubes resonate, and the displacement signal devices 16 and 17 are symmetrically installed in the middle part of the arc of the sensitive tube 1 and 2. , to detect a phase difference signal proportional to Coriolis.

[0055] Fixing plates 27 and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com