Patents

Literature

114 results about "Tensometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tensometer is a device used to evaluate the Young's modulus of a material and other tensile properties of materials, such as tensile strength. It is usually a universal testing machine loaded with a sample between 2 grips that are either adjusted manually or automatically to apply force to the specimen. The machine works either by driving a screw or by hydraulic ram. The latter have the great advantage of being able to create much more complex loading patterns, such as the cyclical loads needed for measurement of fatigue strength. Machines can also be equipped with environmental chambers for testing at different temperatures or variable humidity, for example.

Control method and control system of tension in the process of rolling periodic variable-thickness strips

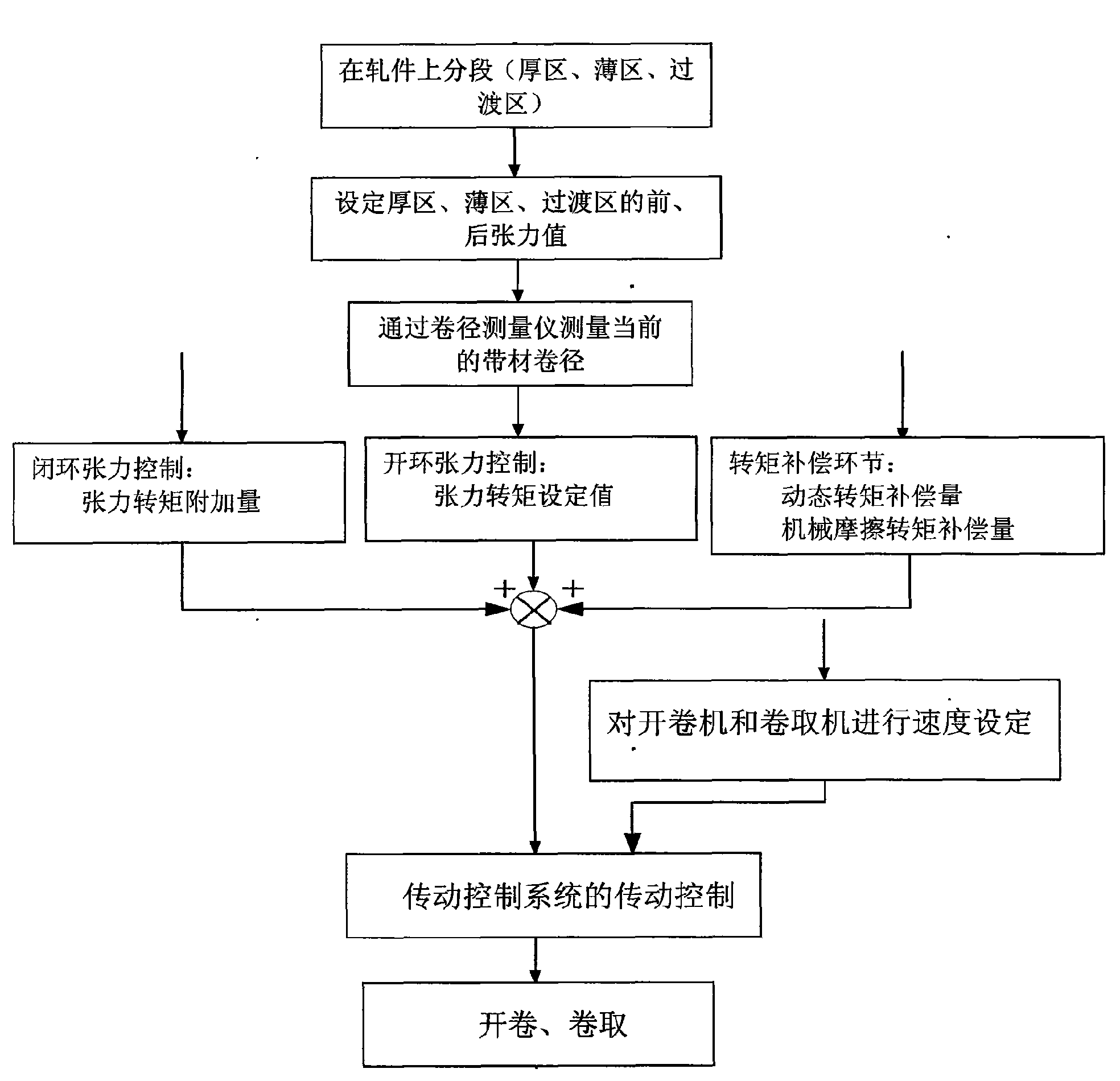

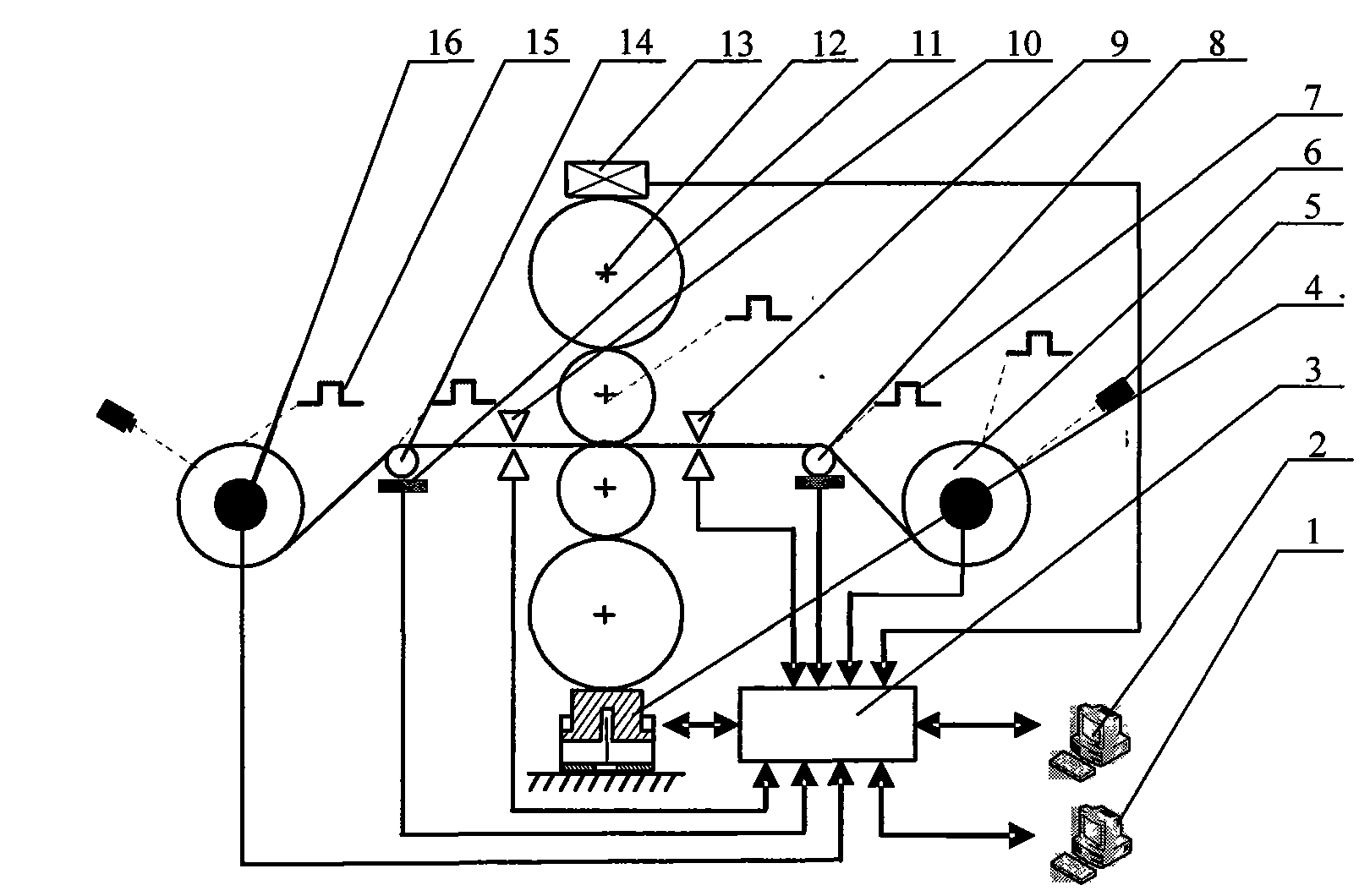

InactiveCN101602068AHigh precisionTension/compression control deviceMetal rolling arrangementsVariable thicknessMaximum torque

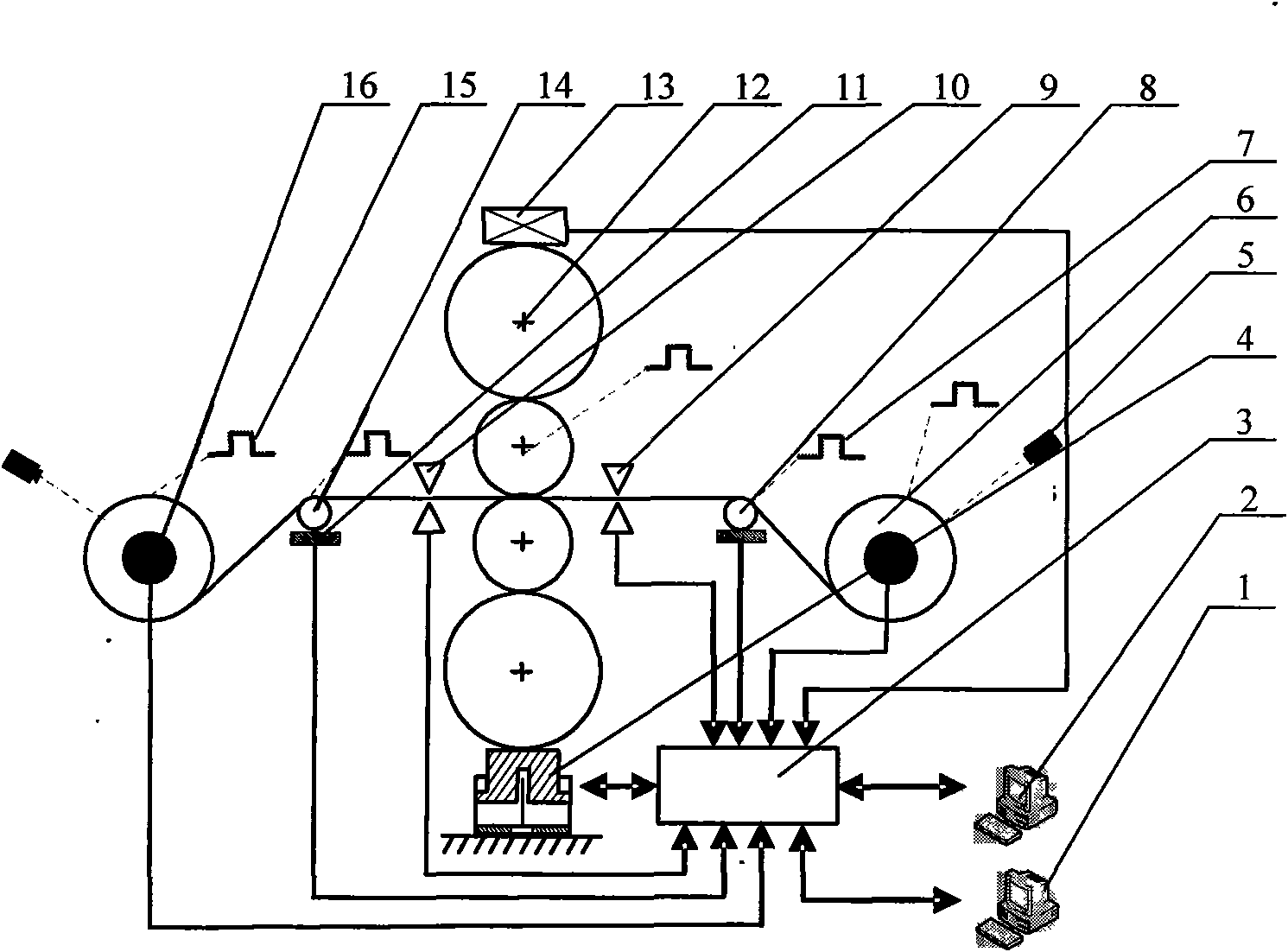

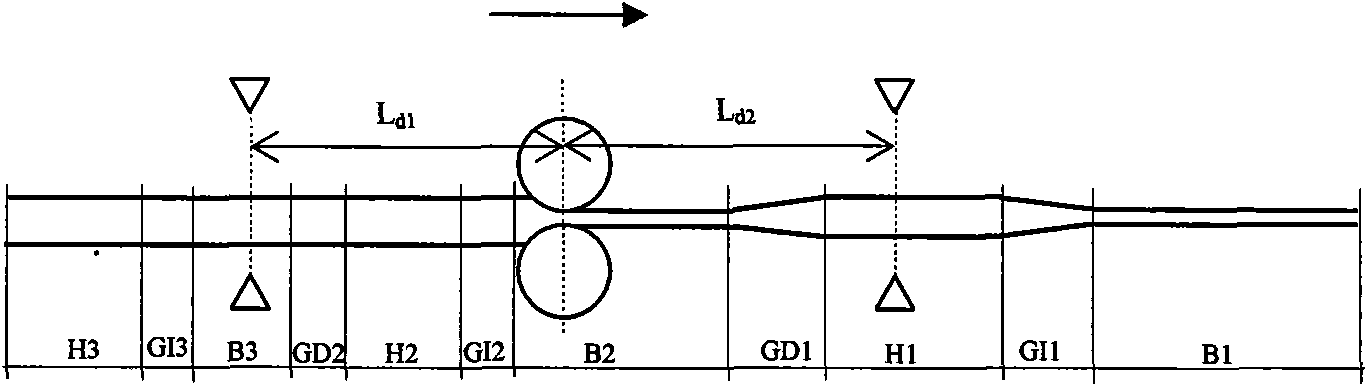

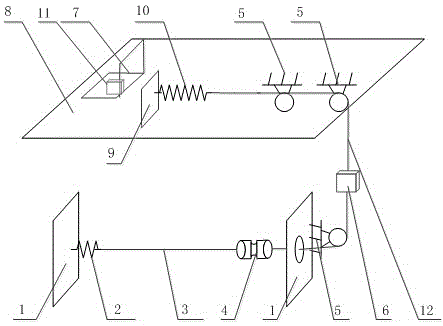

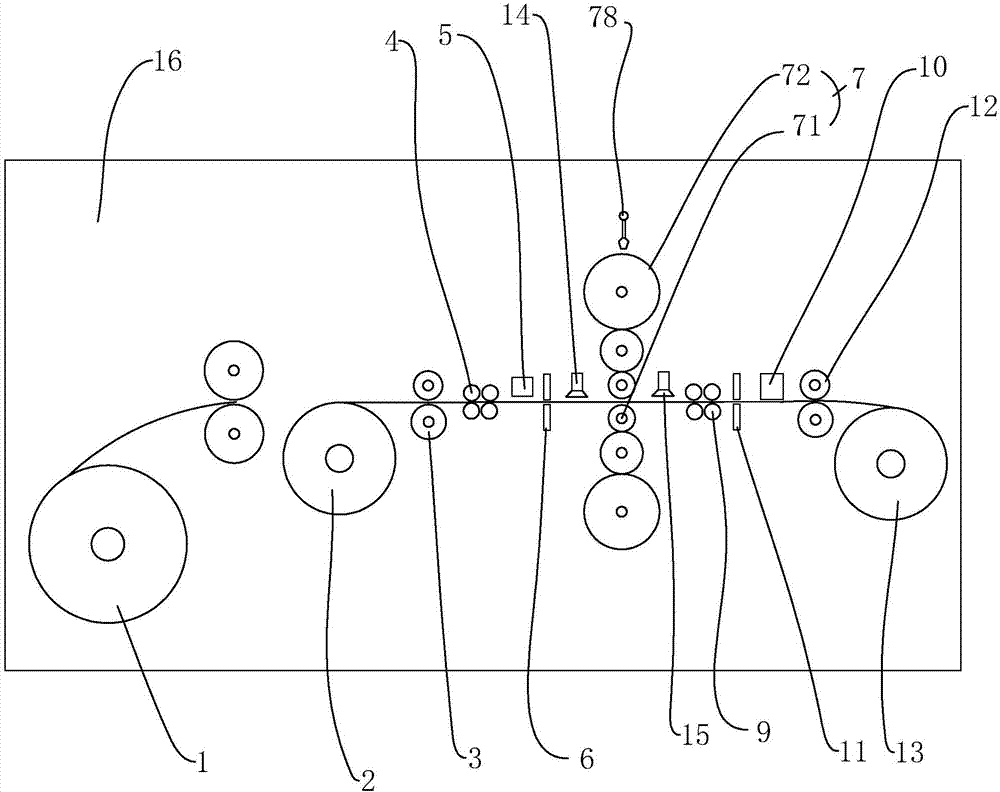

A control method and a control system of tension in the process of rolling periodic variable-thickness strips belong to the technical field of rolling. The method comprises the following steps: dividing segments on the rolled pieces, setting front and back tension values in each zone, realizing tension open-loop control and tension closed-loop control based on maximum torque limit and adding a dynamic torque compensation link and a mechanical friction torque compensation link; controlling torques of an uncoiler and a coiling machine motor and setting speed. The system comprises a rolling mill; coiling machines are arranged at both sides of the rolling mill respectively; length-measuring rollers are arranged between the coiling machines and the rolling mill; thickness gauges are arranged at both sides of the rolling mill respectively; coil diameter gauges are arranged on the coiling machines; a rolling force sensor and a hydraulic cylinder are arranged on the rolling mill; tensiometers are arranged below the length-measuring rollers and pulse coders are arranged on the length-measuring rollers; the thickness gauge, the coil diameter gauge, the rolling force sensor, a displacement sensor of the hydraulic cylinder, the tensiometer and the pulse coder are respectively connected with a computer control system.

Owner:NORTHEASTERN UNIV

Micro-tracking method and system of rolled pieces in the process of rolling periodic variable-thickness strips

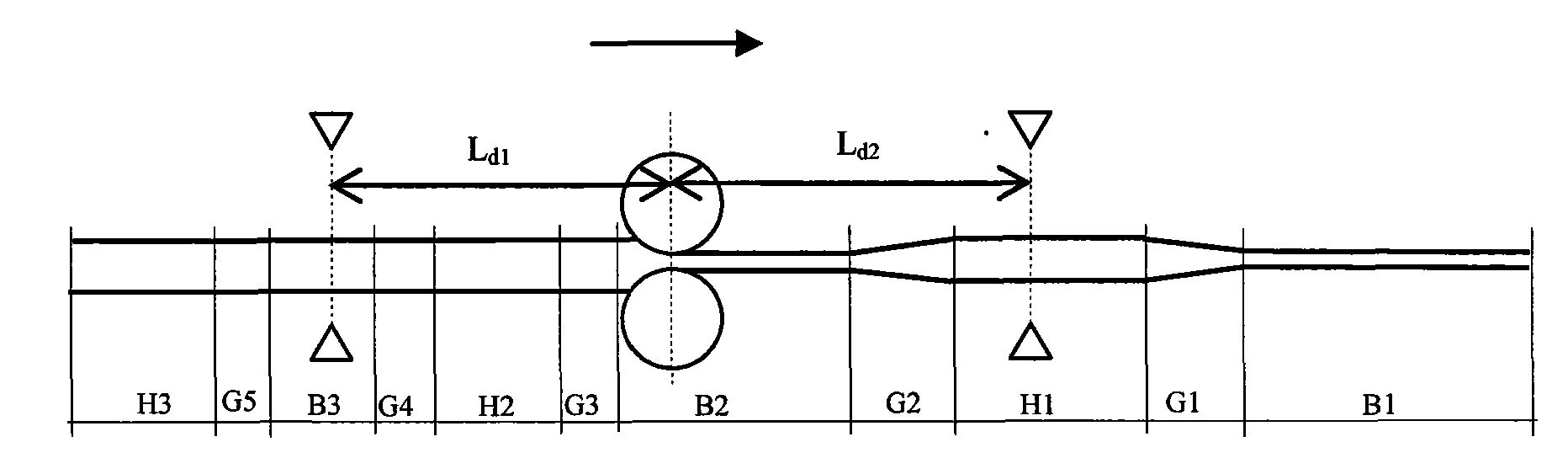

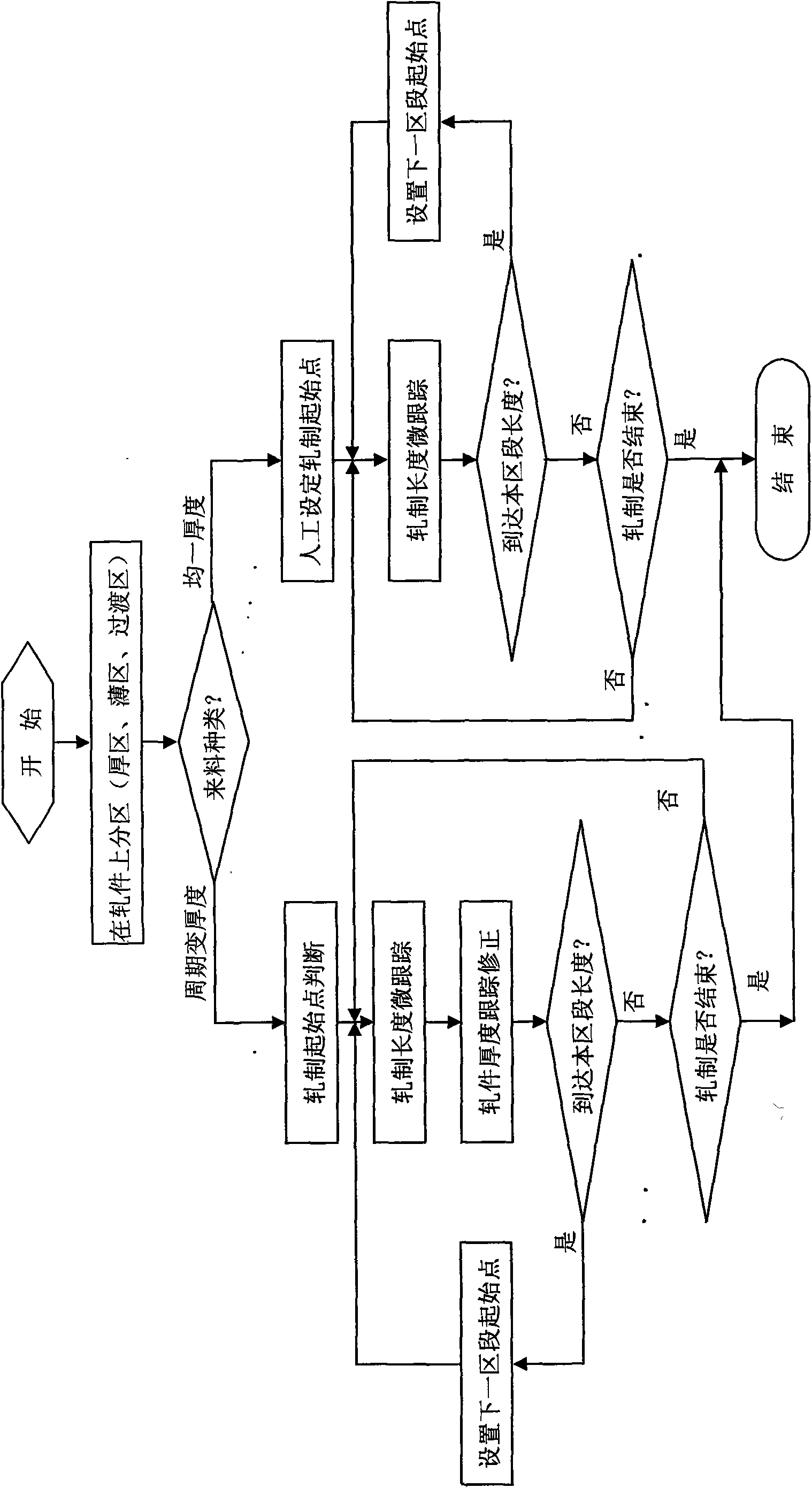

ActiveCN101602065AMeet the accuracy requirements for position trackingMeet the precision requirementsRoll mill control devicesProgramme control in sequence/logic controllersComputer control systemHydraulic cylinder

A micro-tracking method and a system of rolled pieces in the process of rolling periodic variable-thickness strips belong to the technical field of rolling. The method comprises the following steps: dividing thickness zones, thinness zones and transition zones on the rolled pieces of the periodic variable-thickness strips, setting whether the incoming materials are uniform-thickness rolled pieces or periodic variable-thickness rolled pieces, determining the starting point of rolling, micro-tracking the rolling length in the process of rolling and carrying out tracking correction on the periodic variable-thickness rolled pieces. The system comprises a rolling mill; coiling machines are arranged at both sides of the rolling mill respectively; length-measuring rollers are arranged between the coiling machines and the rolling mill; thickness gauges are arranged at both sides of the rolling mill respectively; coil diameter gauges are arranged on the coiling machines; a rolling force sensor and a hydraulic cylinder are arranged on the rolling mill; tensiometers are arranged below the length-measuring rollers and pulse coders are arranged on the length-measuring rollers; the thickness gauge, the coil diameter gauge, the rolling force sensor, a displacement sensor of the hydraulic cylinder, the tensiometer and the pulse coder are respectively connected with a computer control system.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

Device for testing characteristic curves and permeability coefficients of unsaturated coarse particle soil and water

InactiveCN103308435AEarth material testingPermeability/surface area analysisWater storageSoil science

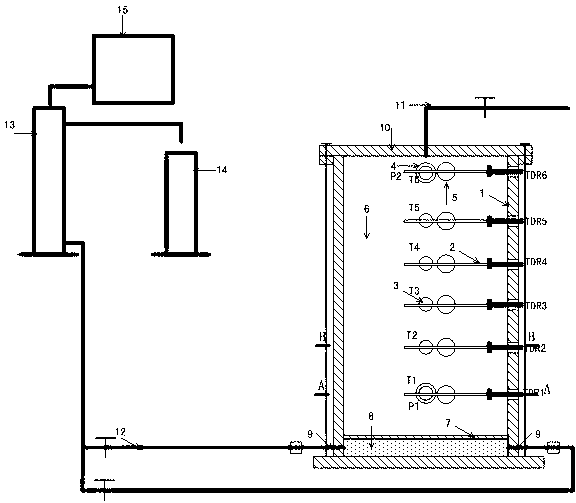

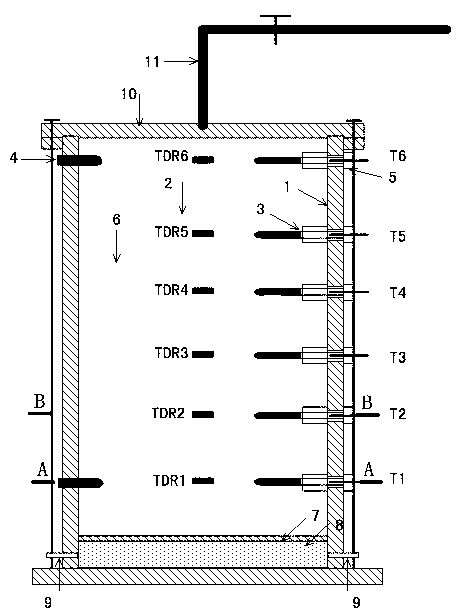

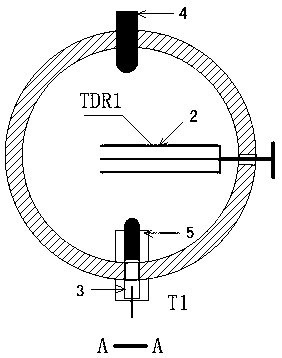

The invention discloses a device for testing characteristic curves and permeability coefficients of unsaturated coarse particle soil and water. A reversed filter is arranged at the bottom of a cylindrical rigid permeation column; six layers of compacted soil samples are arranged at the upper part of the reversed filter; a TDR (test data report) sensor, a tensiometer or a humidometer are buried at the same height on the same layer; pore pressure gauges are buried in the first layer and the sixth layer; the TDR sensor, and the tensiometer or the humidometer form 90 degrees; each pore pressure gauges and the tensiometer or the humidometer form 90 degrees; a waterhead stabilizer is externally connected with a water storage container and a water tank for providing a reference liquid level; the waterhead stabilizer is accessed into the reversed filter via a drainage valve; a top plate of the cylindrical rigid permeation column is connected with the drainage valve. Saturated ermeability coefficients of coarse particles can be obtained through the pore pressure gauges and the waterhead stabilizer after the sample is saturated; the change processes of of matric suctions and moisture contents of a soil body in each layer at different moments along with the time can be obtained through the corresponding tensiometer or the corresponding humidometer and the corresponding TDR sensor at the saturation, drainage and evaporation stages at the same time. Thus, mechanical parameters of the unsaturated coarse particle soil and water are obtained.

Owner:ZHEJIANG UNIV

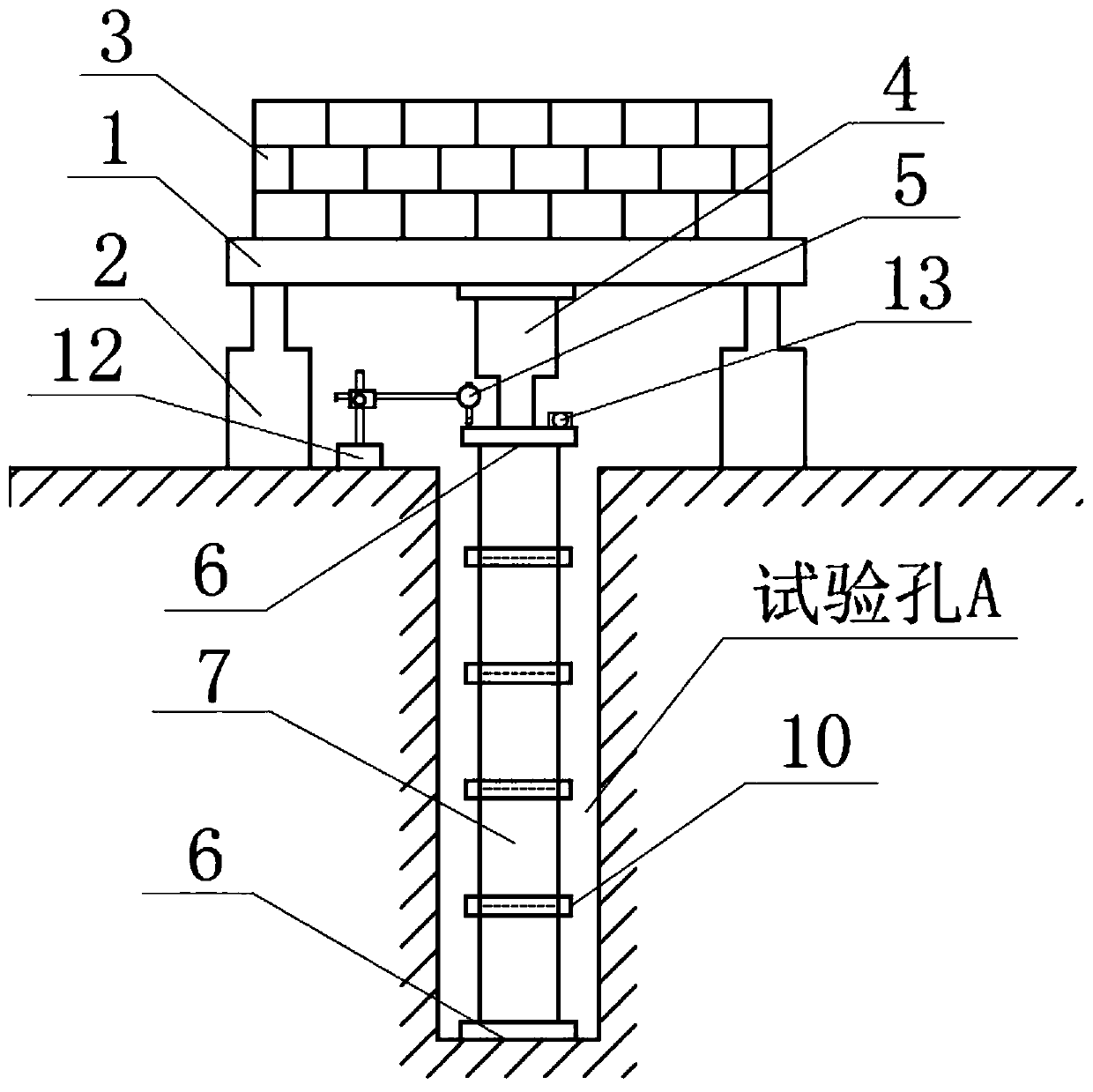

Testing device for conducting real-time observation on rock and soil mass cracks under suction measurement condition

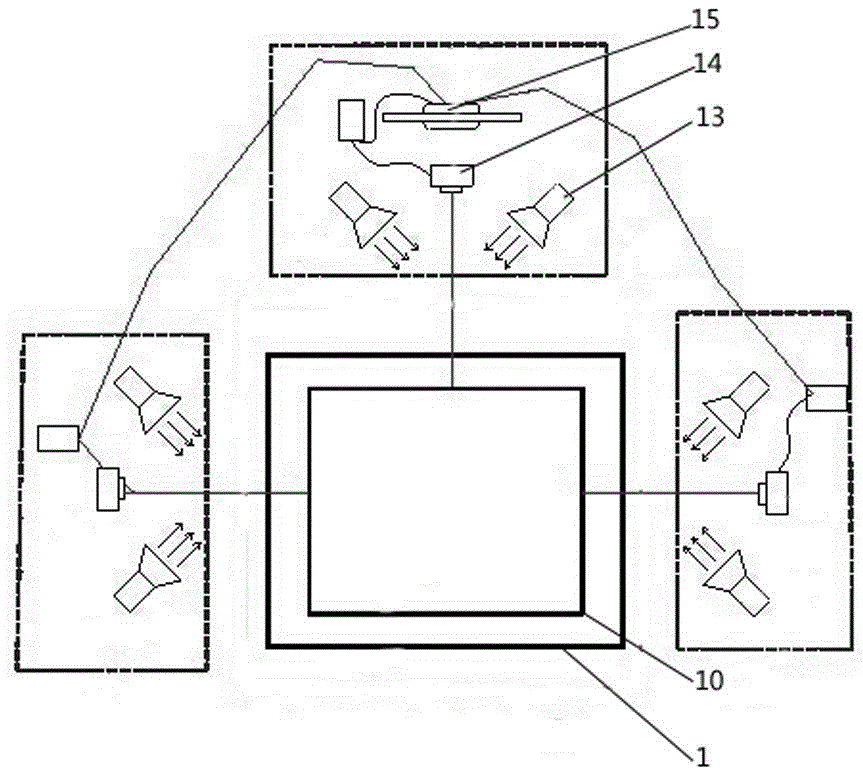

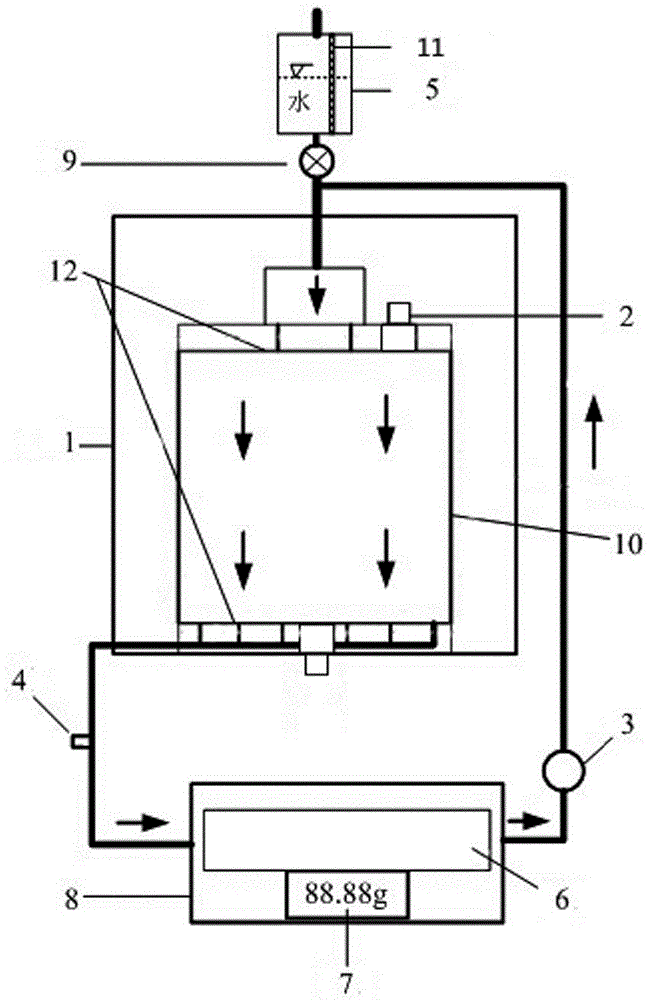

ActiveCN105823716AThe instrument structure is simpleEasy to operatePermeability/surface area analysisSoil scienceSuction stress

The invention discloses a testing device for conducting real-time observation on rock and soil mass cracks under the suction measurement condition. The testing device comprises an air circulation testing system and a PIV testing system. Compared with the prior art, the testing device can truly represent the drying and rainfall infiltrating process of soil masses in a natural state through the air circulation testing system and continuously measure the suction and moisture content of a soil test sample through a tensiometer and an electronic balance, and the testing time is greatly shortened through usage of an air circulation pump; meanwhile, by cooperatively applying the PIV system, the morphological characteristics of the rock and soil mass surface cracks can be observed in real time at multiple angles. The model testing device is convenient to operate, and the related instruments are simple in structure, high in adjustability and easy to master.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

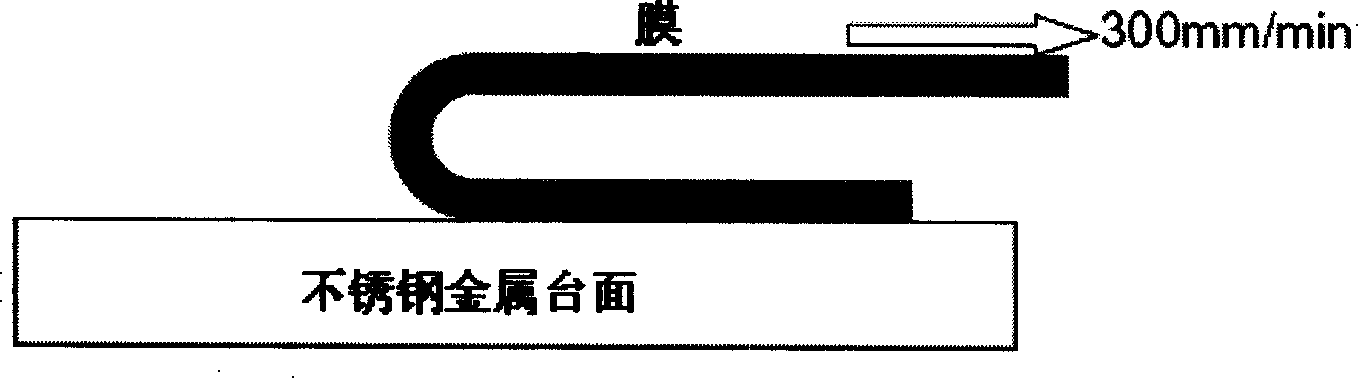

Membrane viscosity measurement method

ActiveCN101192505ASimple and fast operationEasy to operateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufacturing technologyQuality control

The invention discloses a method for measuring viscosity of a membrane. The invention includes the following steps: (1) a rubber belt is pasted and attached with the membrane to be measured by using pasting pressure and attaching pressure of a fixed roller on a sticking film machine; (2) the pasted membrane to be measured is fixed adhesively faceup on a working platform of the sticking film machine, and one end of the rubber belt is connected with a tensometer which is inversely fixed on the sticking film machine; and (3) the membrane to be measured is departed from the rubber belt by a movement with uniform speed of the working platform on the sticking film machine, and numerical value in the tensometer is read and taken as the result of measurement on the viscosity of the membrane to be measured. The invention admirably adopts the inherent function of sticking membrane in the present sticking film machine and device to carry out the quantitative measurement on the viscosity of all kinds of membranes used for being pasted and attached in silicon chips like the blue membrane, the UV membrane, etc. , with the advantages of easy and fast operation and low cost. The invention provides reliable evidences for the manufacturing technology condition and quality control of the semiconductor products.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

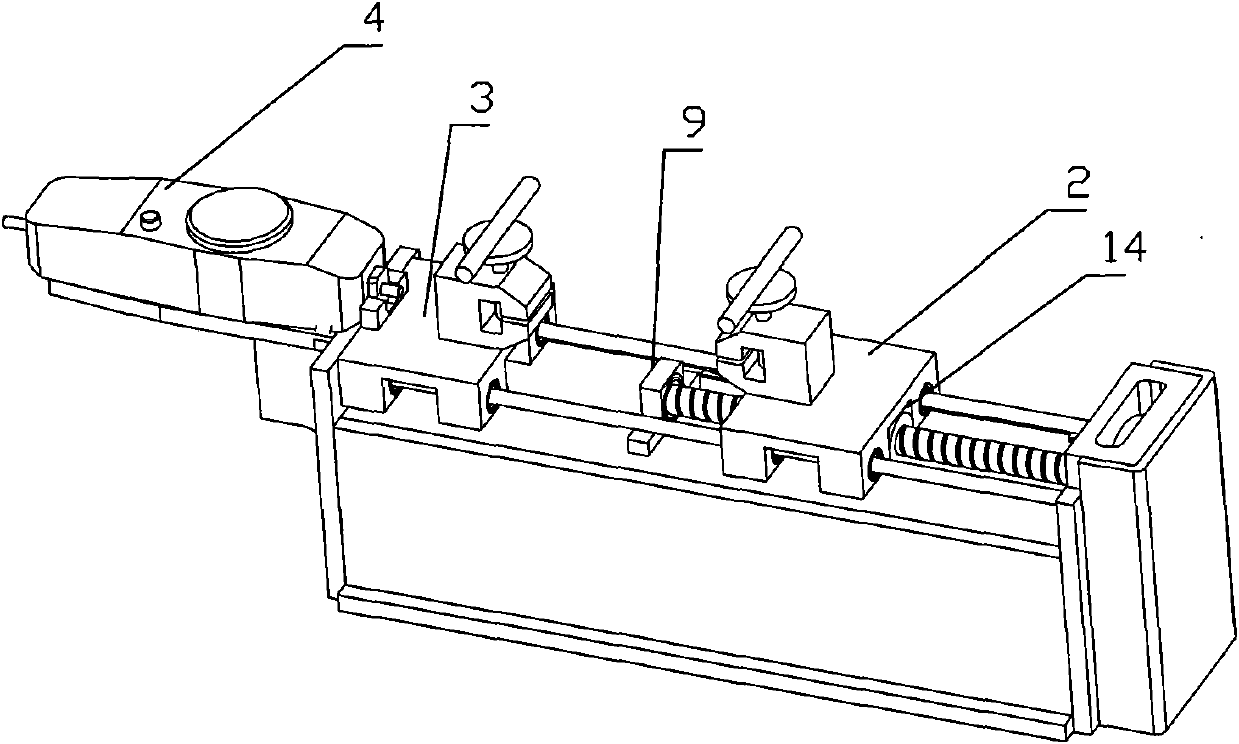

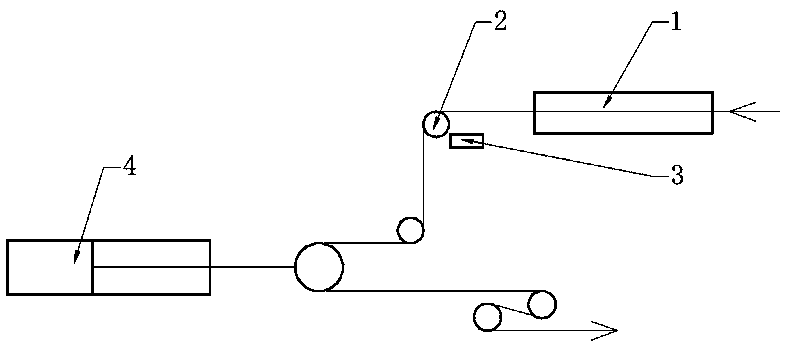

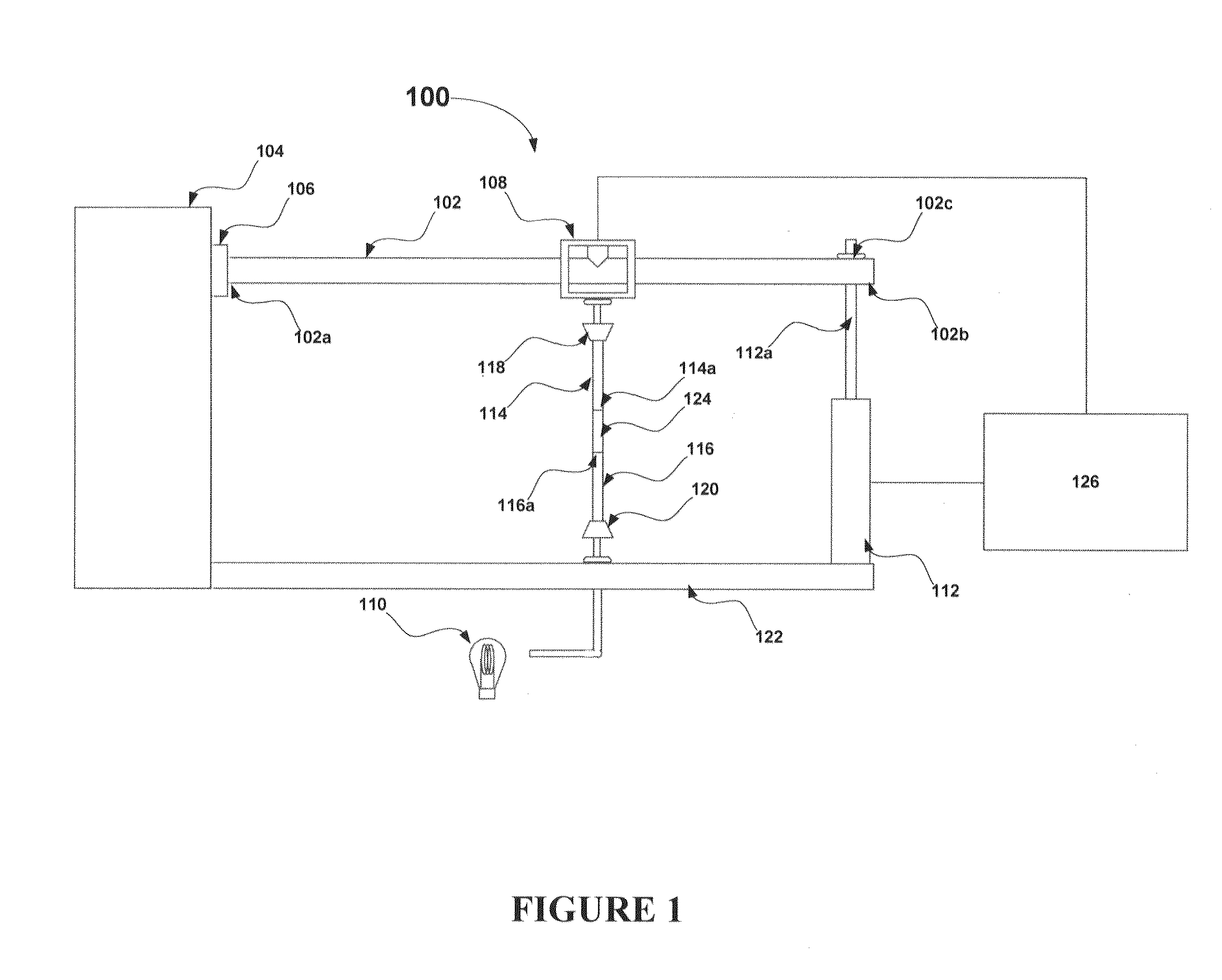

Device for testing tensile force of color strip

InactiveCN101907537AAvoid affecting test resultsFactors to Avoid Affecting Test ResultsMaterial strength using tensile/compressive forcesPull forceElectric machinery

The invention discloses a device for testing the tensile force of a color strip. The device is characterized by comprising a frame, a first movable block, a second movable block, a tensometer, a first clamping device and a second clamping device, wherein the first clamping device and the second clamping device are arranged on the first movable block and the second movable block respectively; two guide rails are horizontally arranged in parallel on the frame; the first movable block and the second movable block are arranged on the two guide rails; a screw rod is arranged in parallel with the guide rail on the frame; the outer end of the screw rod is in transmission connection with a motor through a transmission mechanism while the inner end is in threaded connection with a press block which can be contacted with the inside face of the first movable block; the press block is positioned between the first movable block and the second movable block; and the second movable block is connected with a measuring end of the tensometer. The device for testing the tensile force of the color strip has the advantages of preventing the influences of gravity factors and manual operation factors on a test result and improving test accuracy.

Owner:佛山市顺德区高宝实业发展有限公司

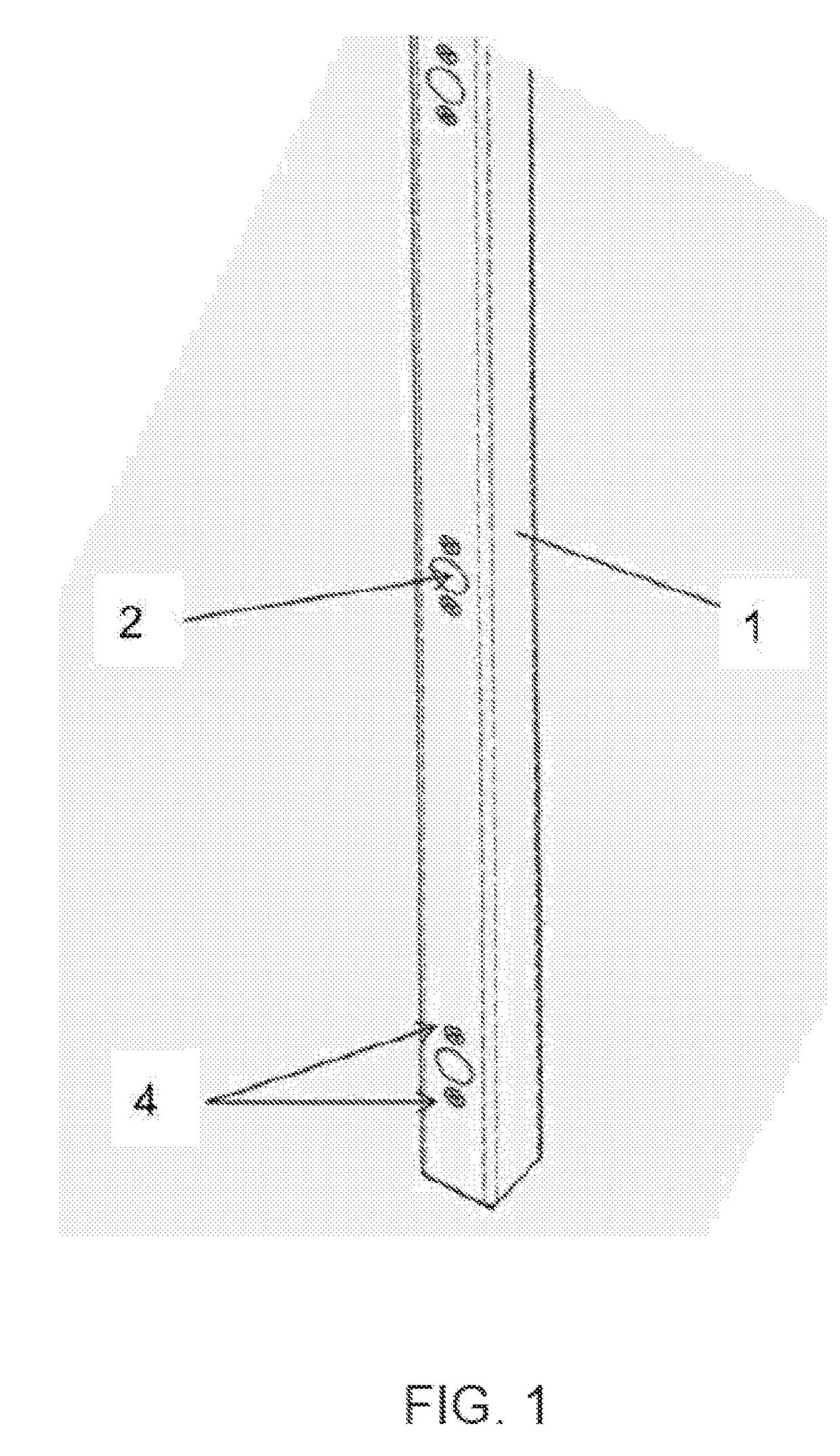

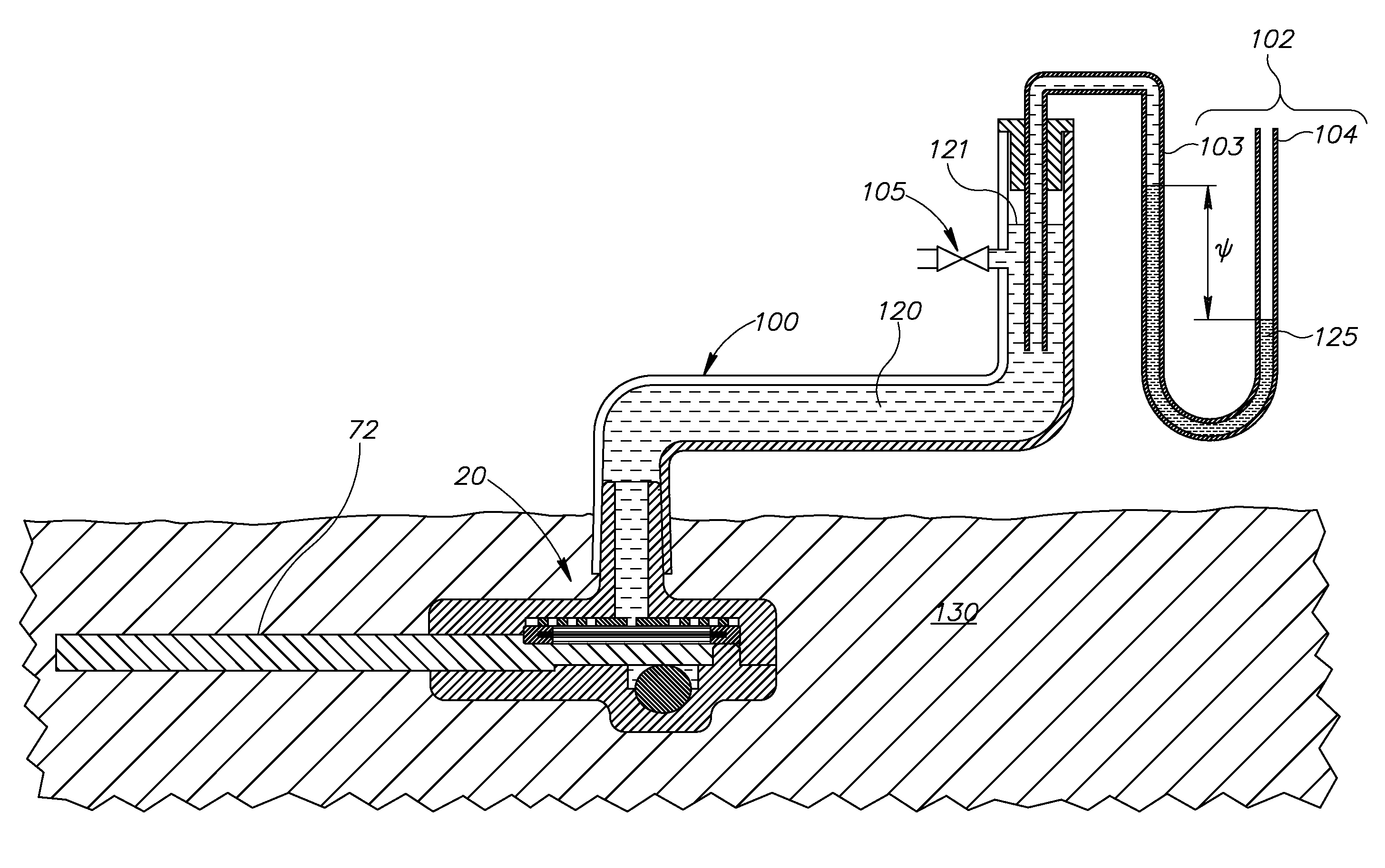

Tensiometer apparatus and method

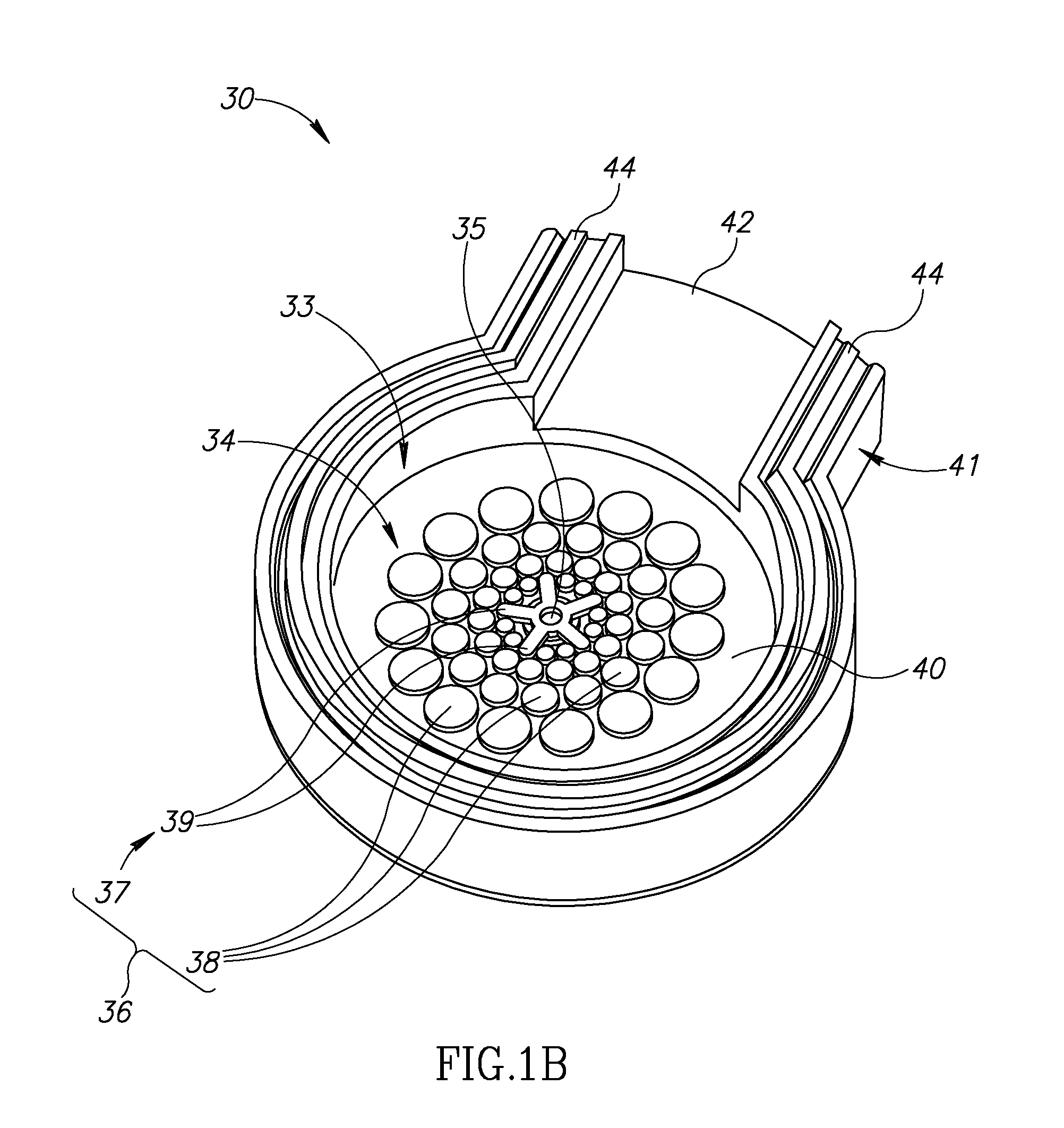

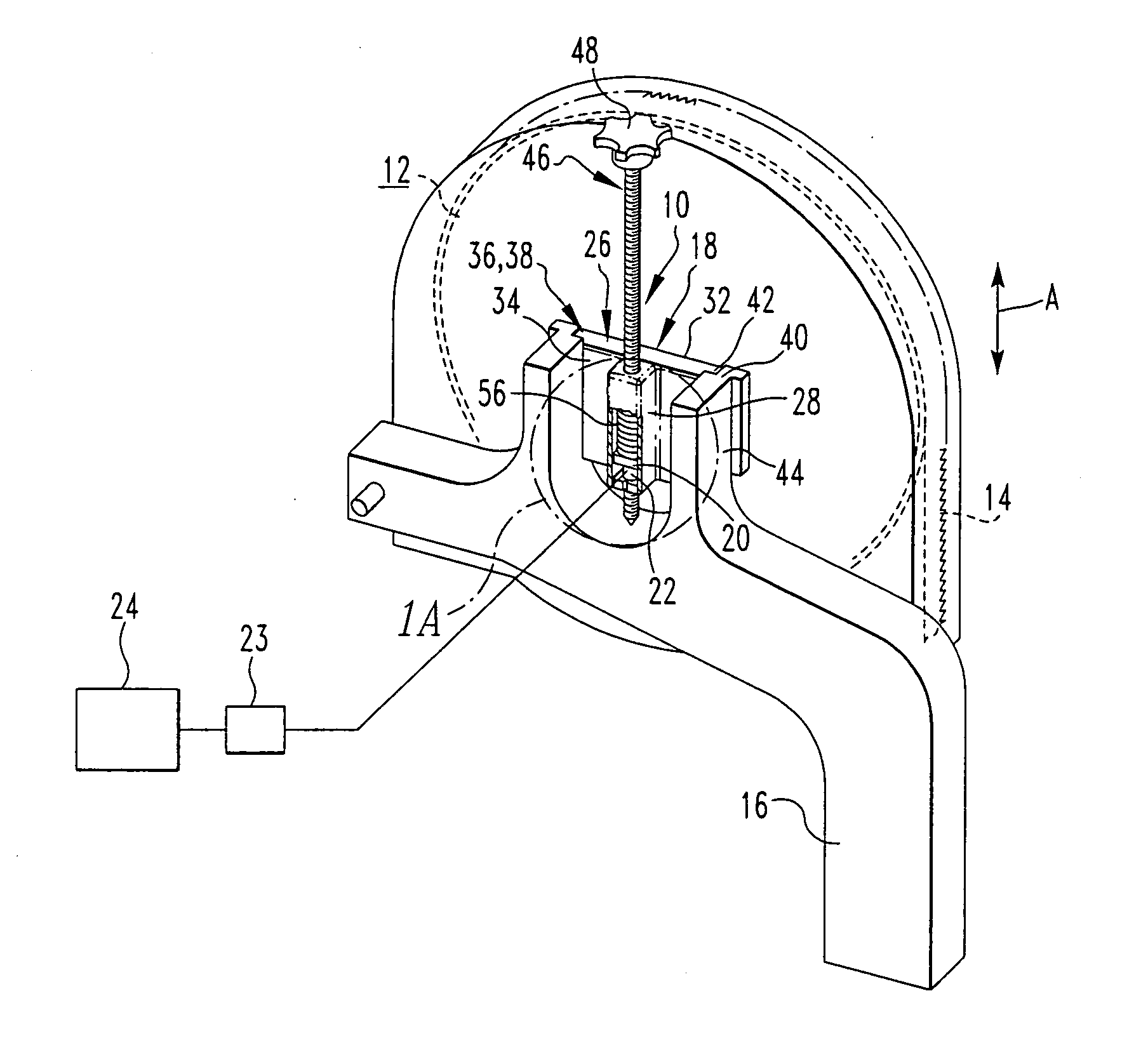

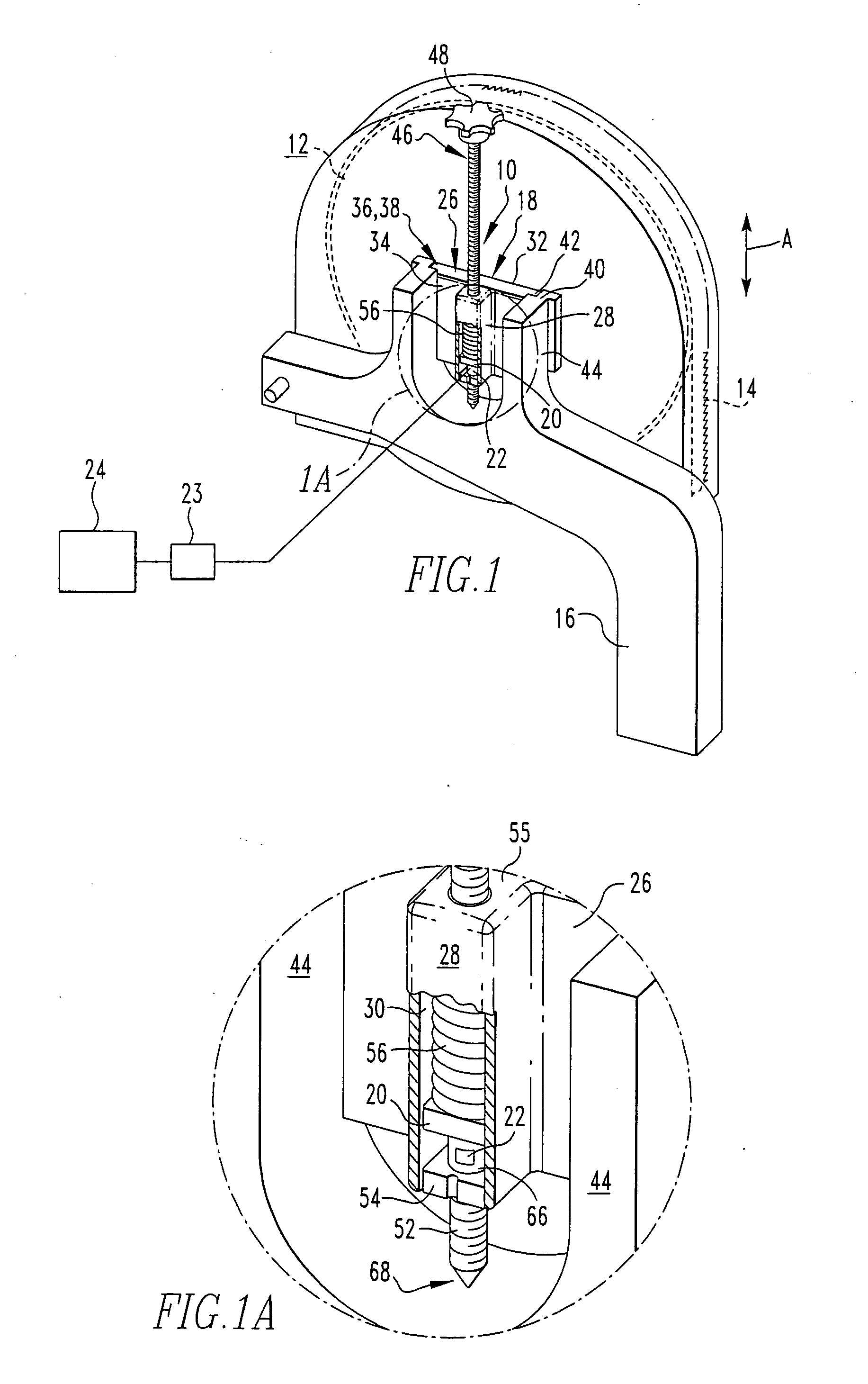

ActiveUS20180080861A1Fluid pressure measurement by electric/magnetic elementsForce measurementEngineeringMoisture

An elongated apparatus that measures soil water tension is disclosed, having a hydrogel chamber for receiving a plurality of macro-sized hydrogel particles through its open side and a sealed inner wall, the hydrogel held in the hydrogel chamber by a durable, hydrophilic, and porous window secured to the open side of the hydrogel chamber. The window, when the apparatus is received in soil, transmits moisture between the soil and the hydrogel chamber, causing variable pressure within the hydrogel chamber that can be converted to a measurement of soil water tension on the opposite side of the window. This pressure produces various mechanical effects, measurable by various types of sensors within the elongated probe. A method for measuring soil water tension at multiple depths within a soil profile is also disclosed.

Owner:LAFIAN JESSE

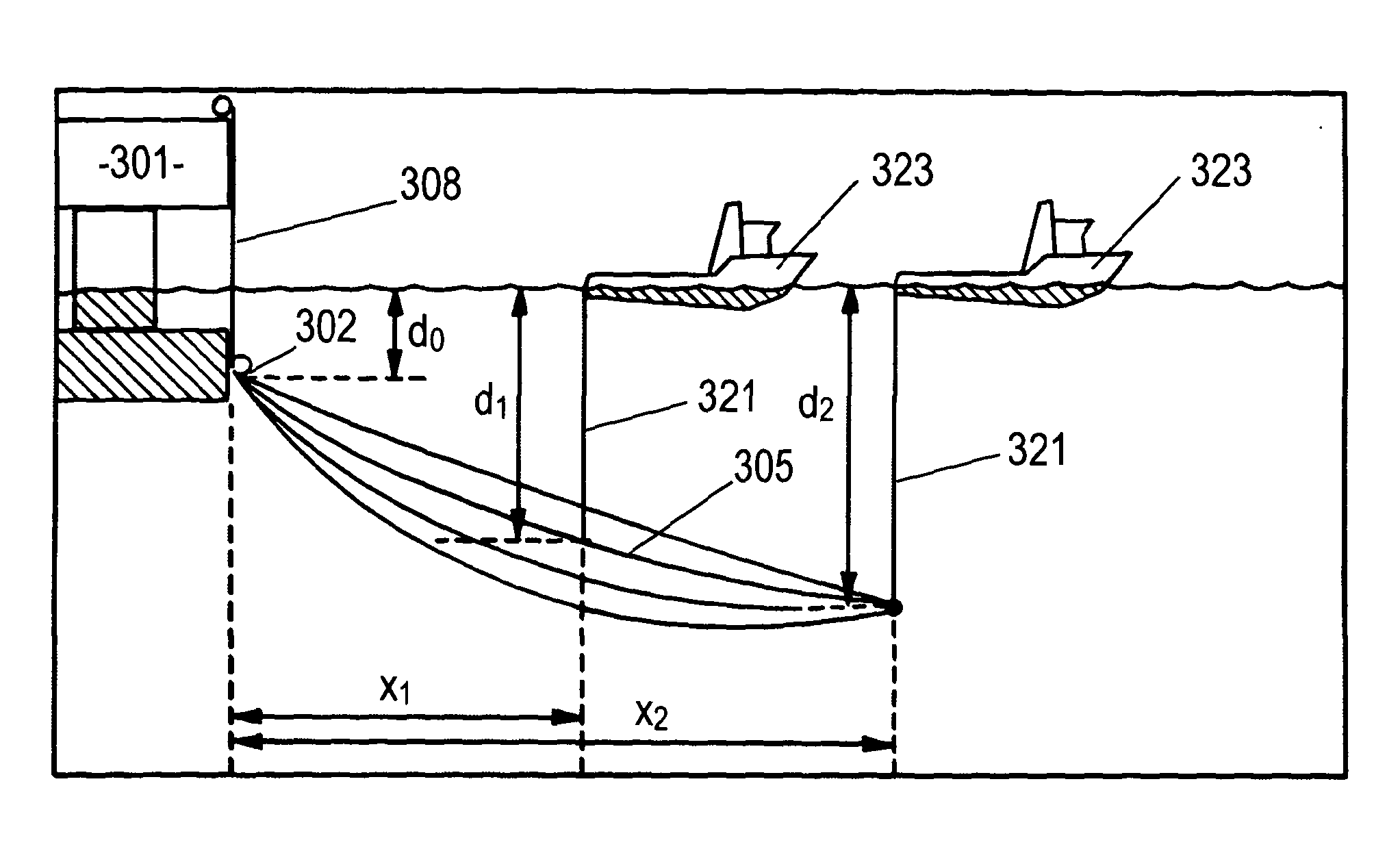

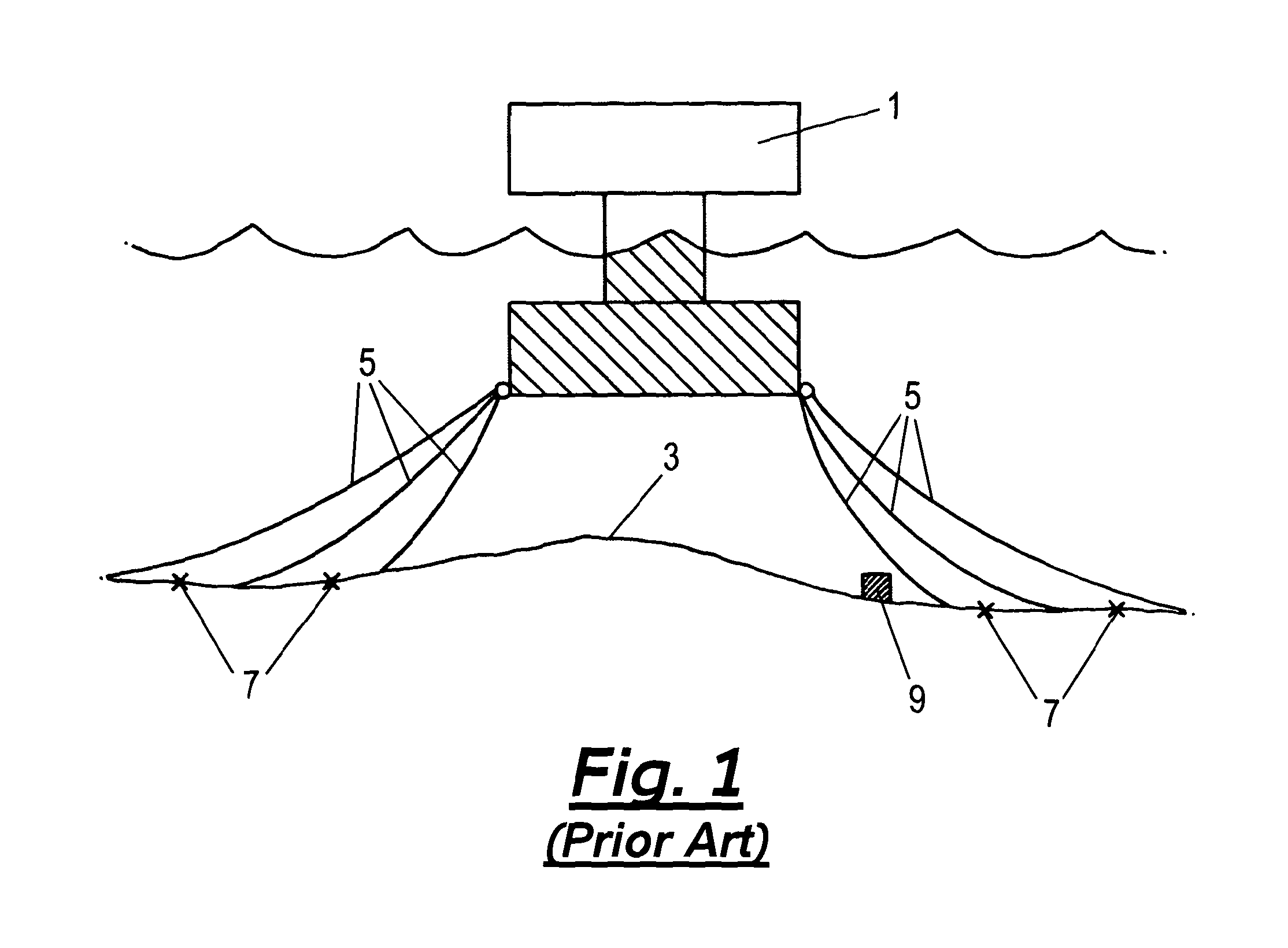

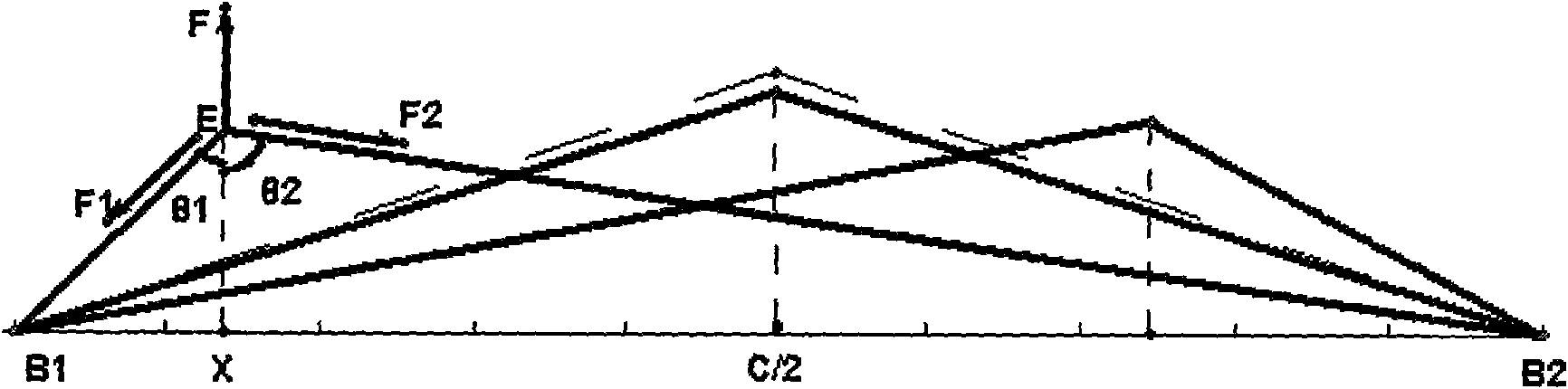

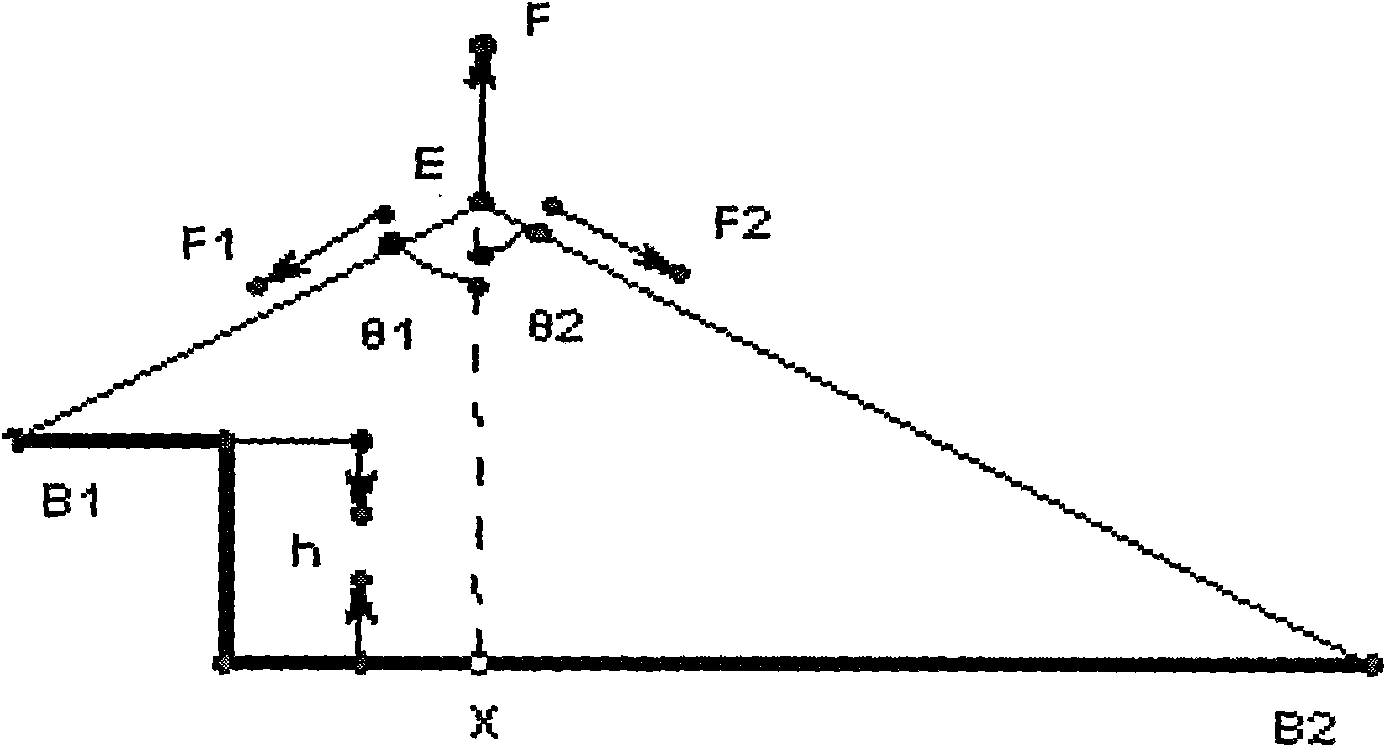

Method of determining the tension in a mooring line

InactiveUS20130239649A1Avoid the needWeighing apparatus testing/calibrationMaterial strength using tensile/compressive forcesMarine engineeringMonitoring system

A method of calibrating a tension meter arranged to measure the tension in a mooring line of a marine asset is described. The method comprises the step of determining at least one characteristic of the catenary trajectory formed by the mooring line, and determining the tension in the mooring line based on the at least one characteristic. The characteristic may be, for example, shape of the catenary trajectory or elastic response of the mooring line. The determined tension is compared with a corresponding tension measurement from the tension meter to allow the tension meter to be calibrated. The method may be carried out during normal operations of the marine asset, such as drilling or hydrocarbon production. Computer implemented methods are described, as are methods of deriving a position map of the mooring lines. The invention may be implemented in a real-time monitoring system which forms a long-term or permanent feature of the marine asset.

Owner:CATENARY TESTING

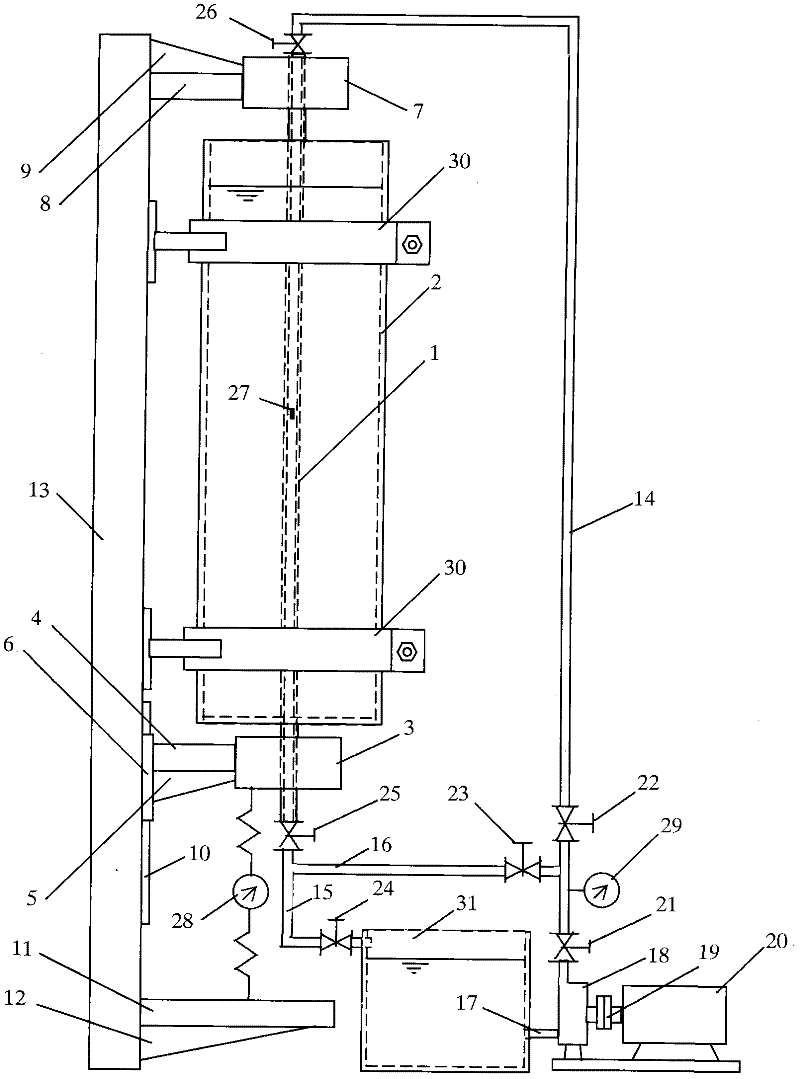

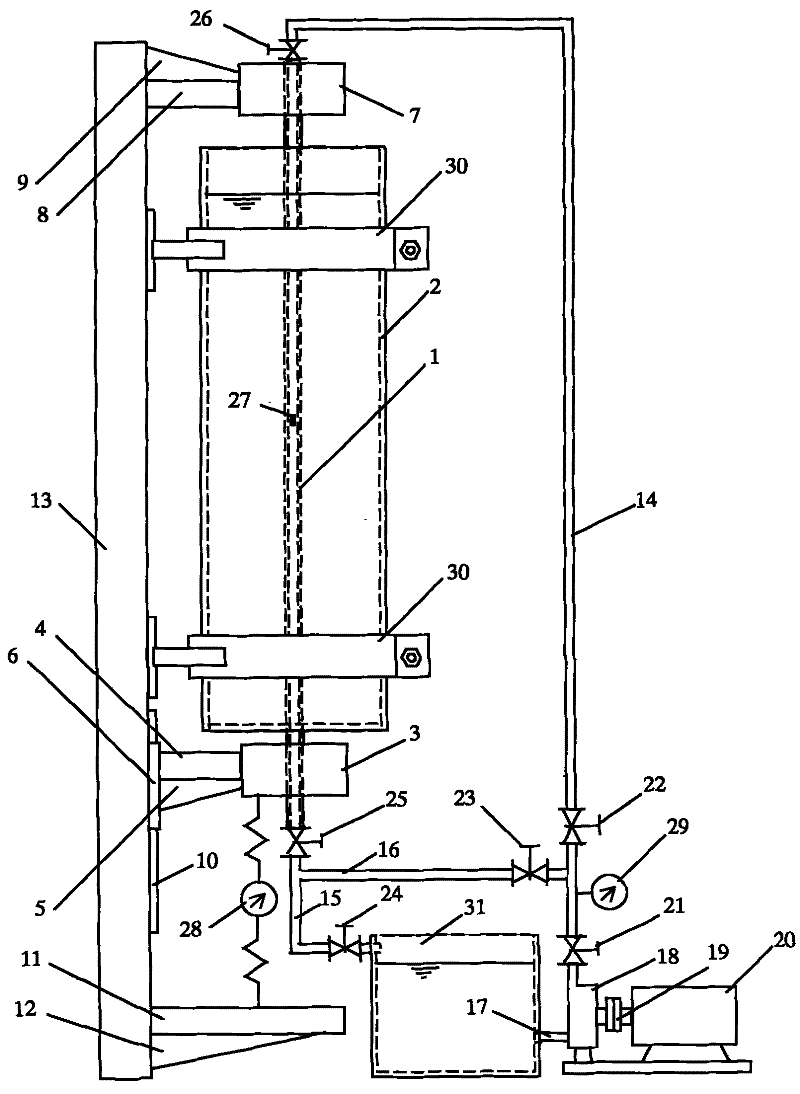

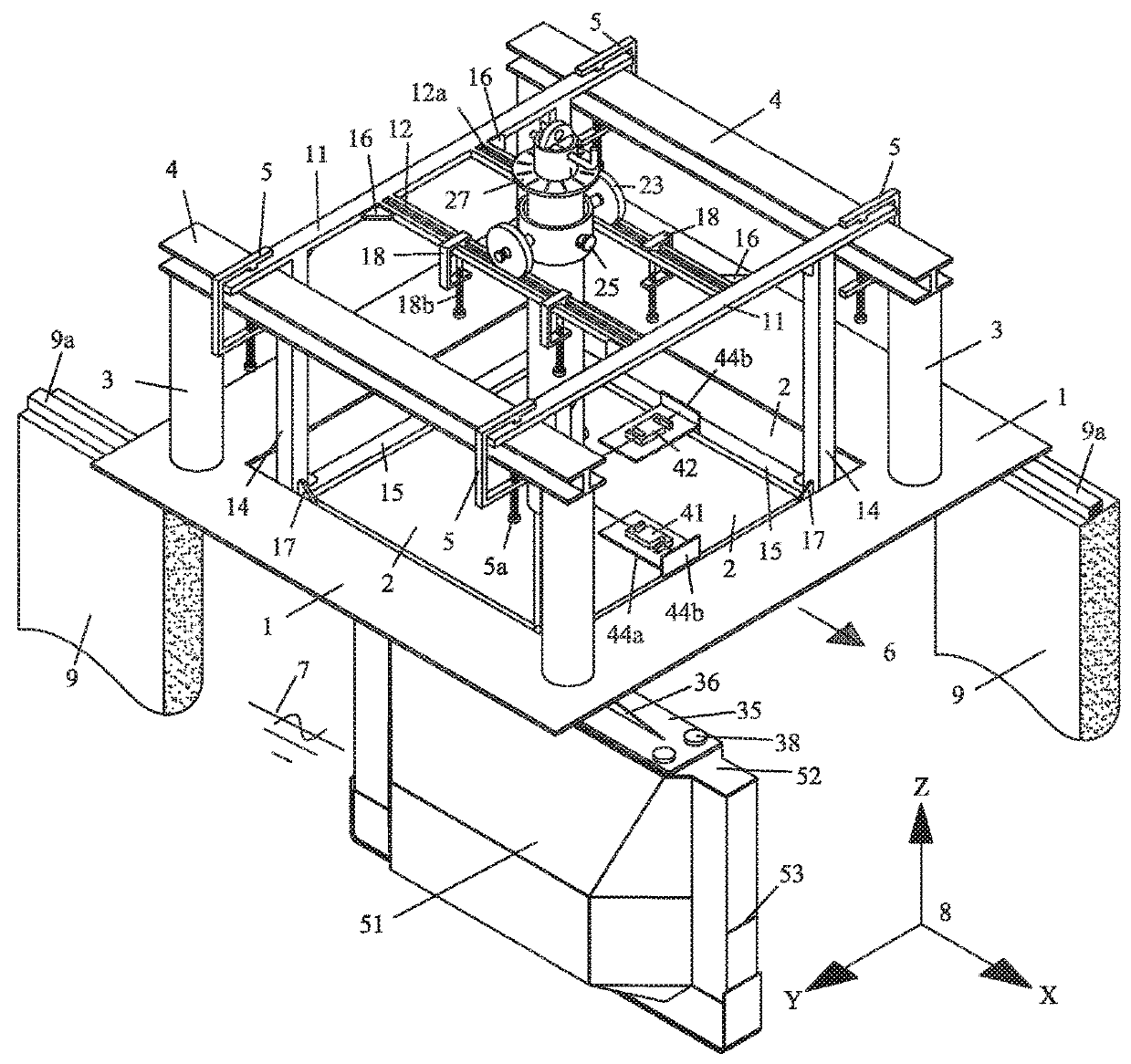

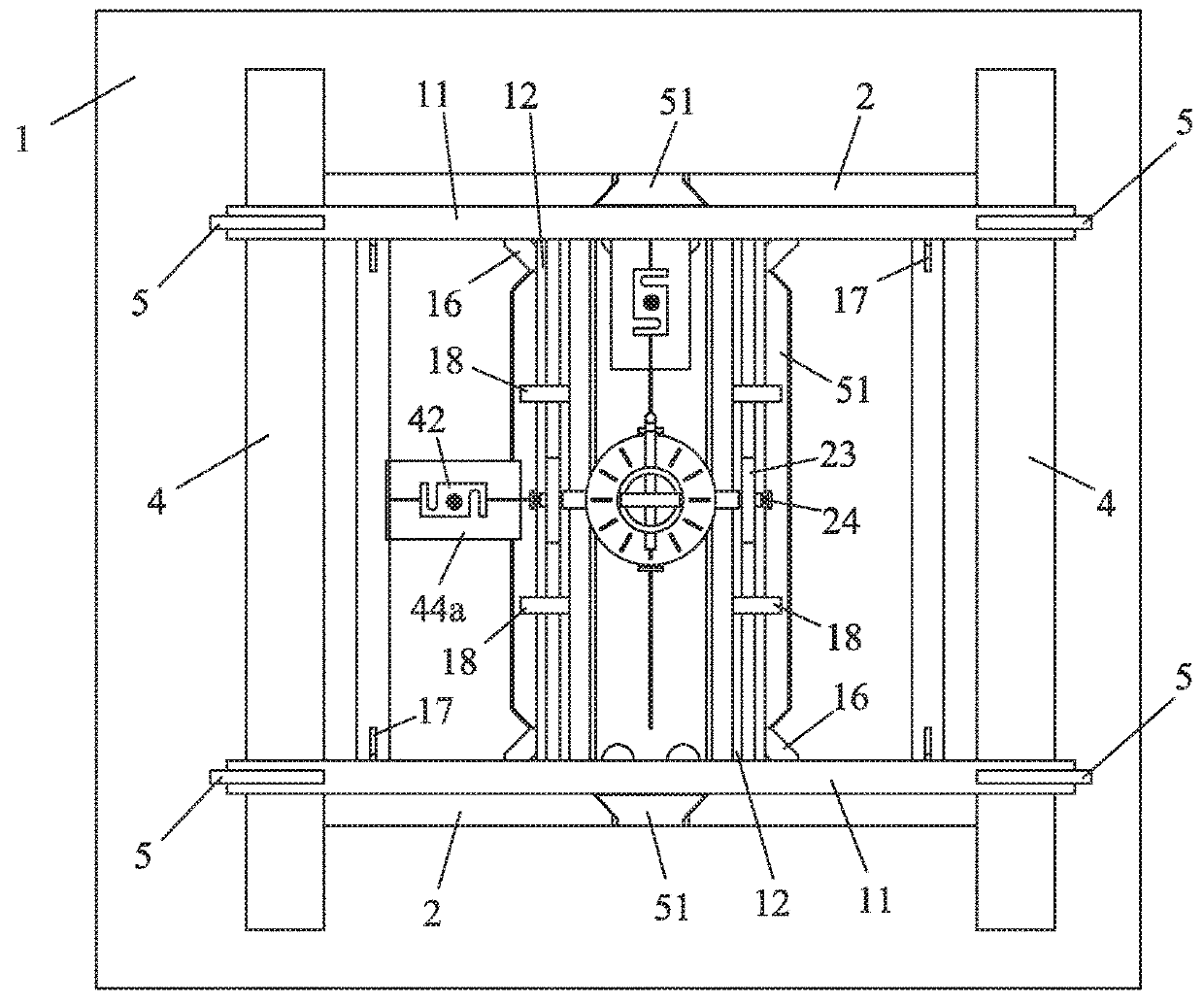

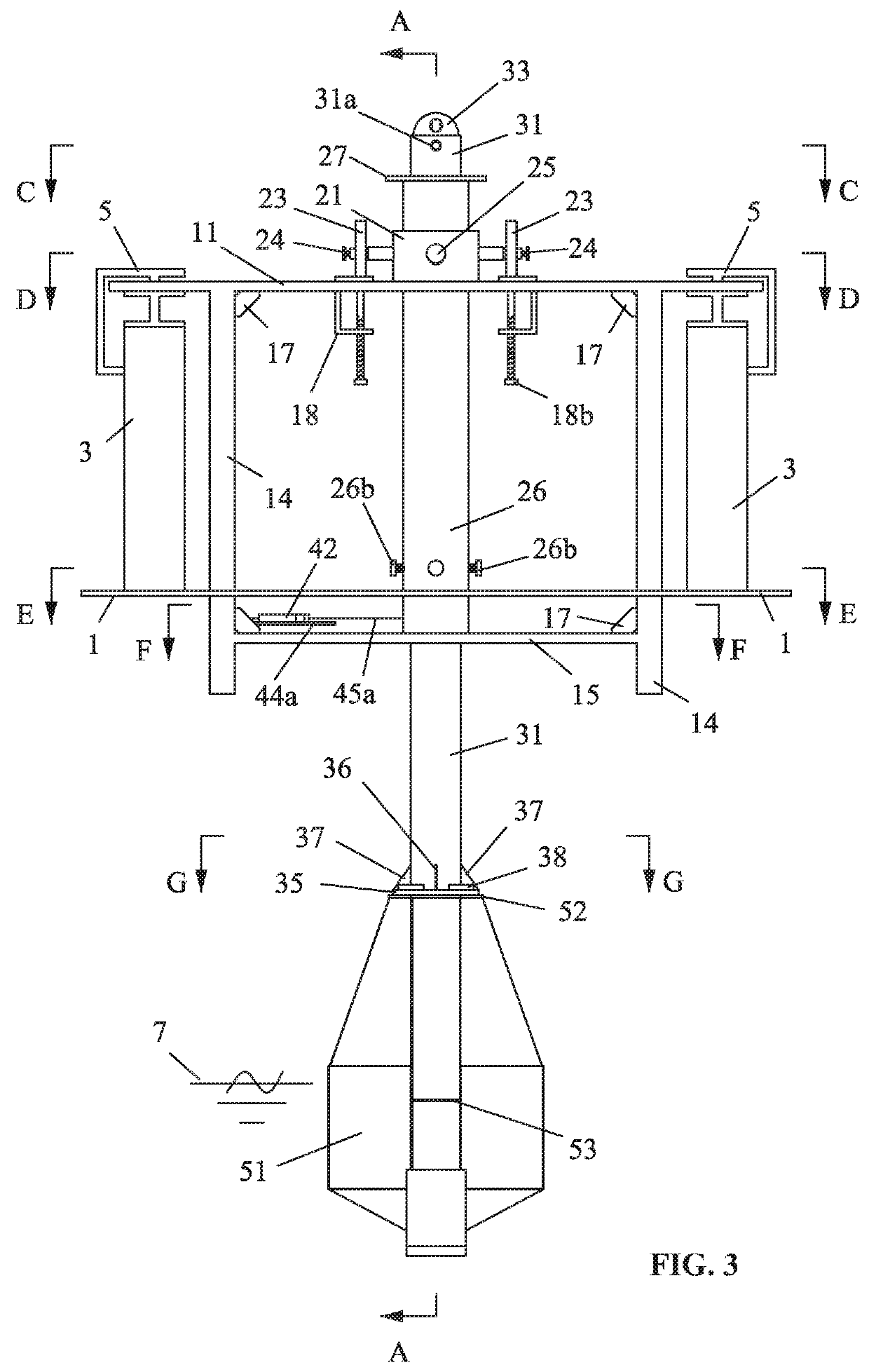

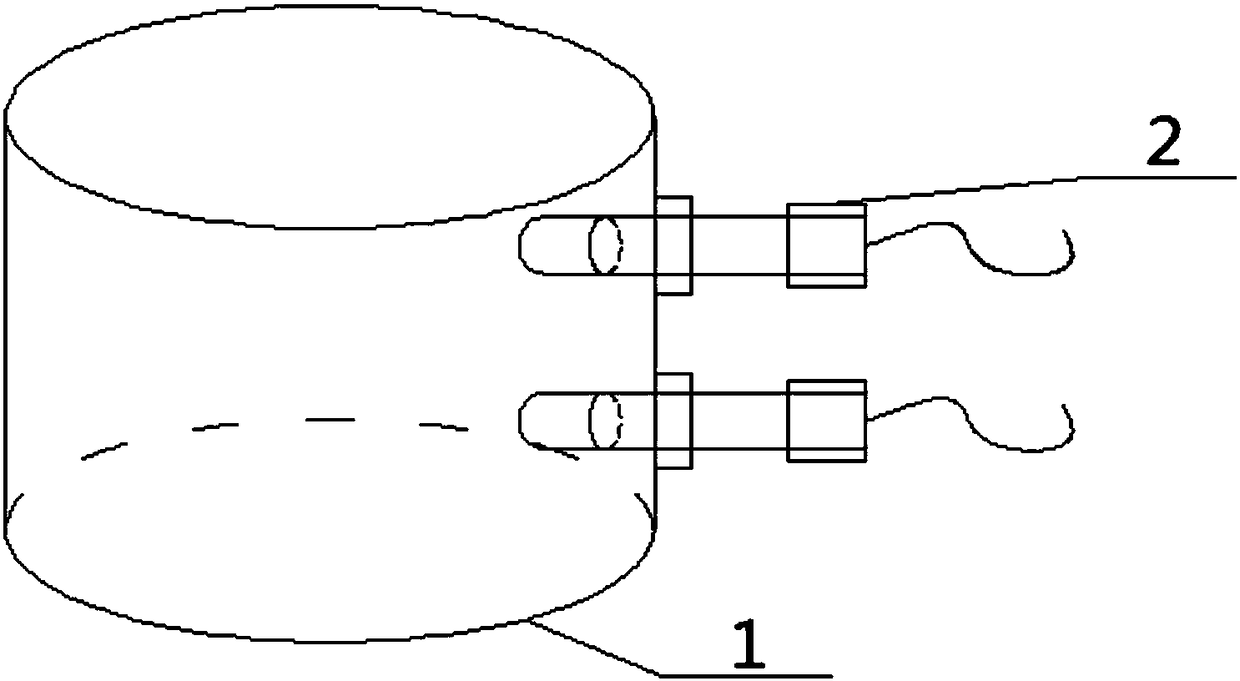

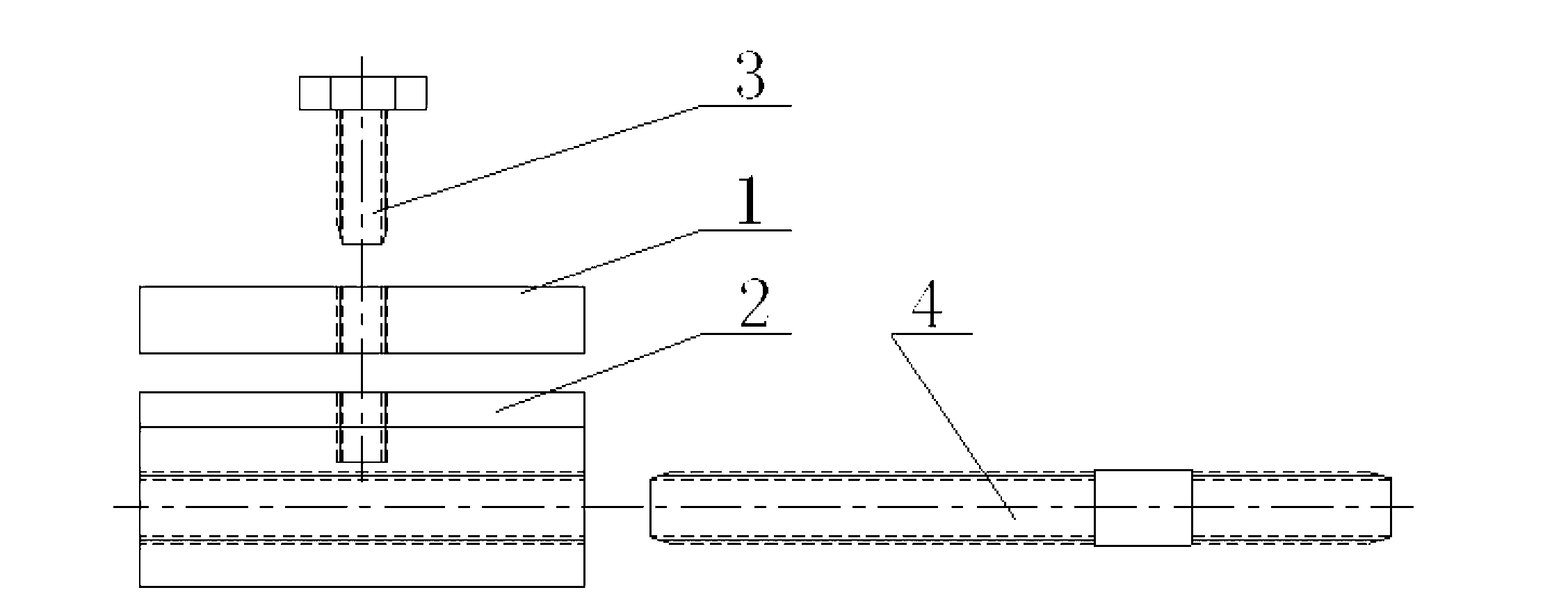

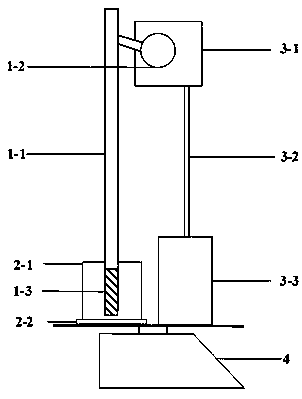

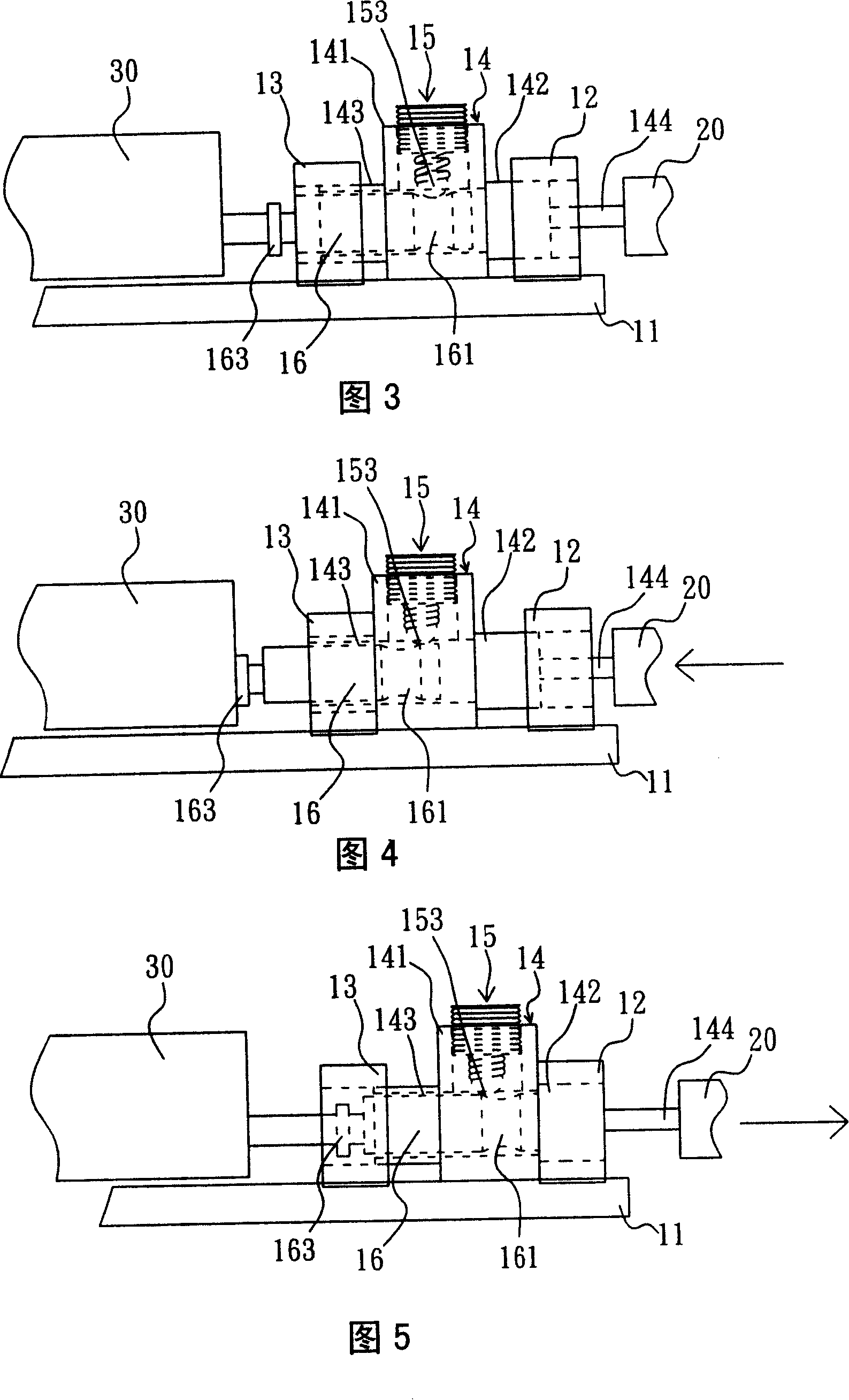

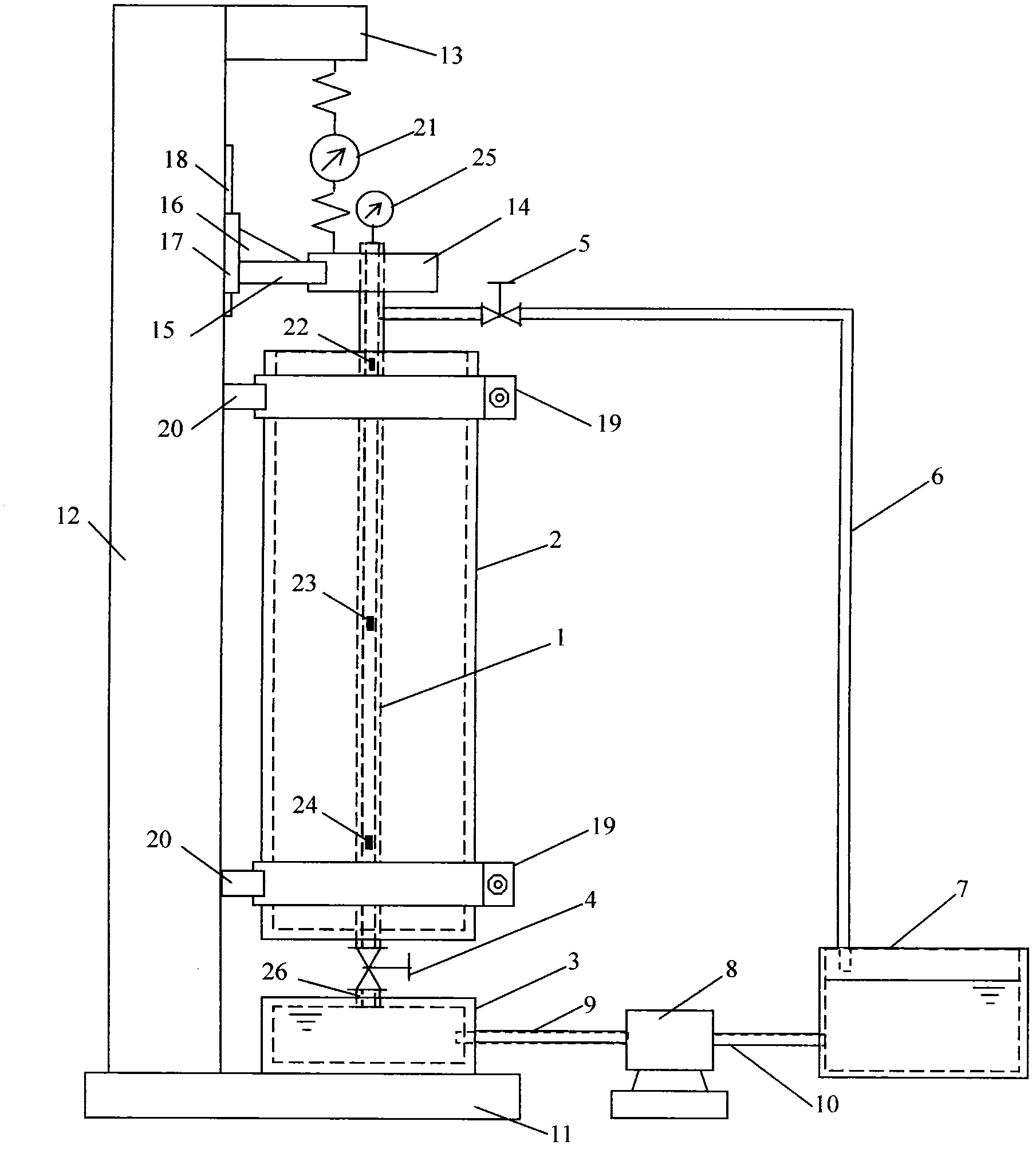

Geometric stiffness test device of deep water top tension type vertical pipe

InactiveCN102252907ARealize measurementRealize verificationMaterial strength using tensile/compressive forcesVertical tubeFixed frame

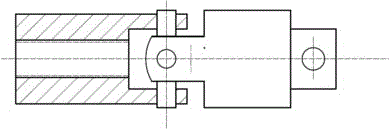

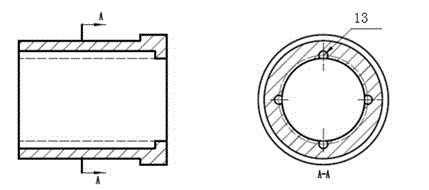

The invention relates to a research test device of an ocean deep water vertical pipe, in particular to a geometric stiffness test device of a deep water top tension type vertical pipe. In the device, a model pipeline is arranged on a fixed frame; a water barrel is arranged out of the model pipeline; the upper end and the lower end of the model pipeline are communicated with a water supply pipeline system; a reaction frame is arranged on the lower part of the fixed frame and is connected with a chuck arranged on the lower part of the model pipeline through a spring; a spring tensometer is arranged on the spring; and a strain foil for measuring wall tension and vibration response of the model pipeline is adhered to the model pipeline. The device can finish test research on the geometric stiffness of the deep water top tension type vertical pipe and provides basis and test verification for calculating the geometric stiffness of the deep water top tension type vertical pipe.

Owner:OCEAN UNIV OF CHINA

Irrigation control system

ActiveUS8051871B2Smooth connectionBroad spectrumRoot feedersSelf-acting watering devicesControl systemCoupling

A tensiometer for use in determining matric potential of a soil comprising: a water inlet; a hydraulic coupler comprising a porous material for providing hydraulic coupling between water that enters the inlet and the soil; and a septum that seals water that enters the inlet against ingress of air via the porous material.

Owner:NETAFIM LTD +1

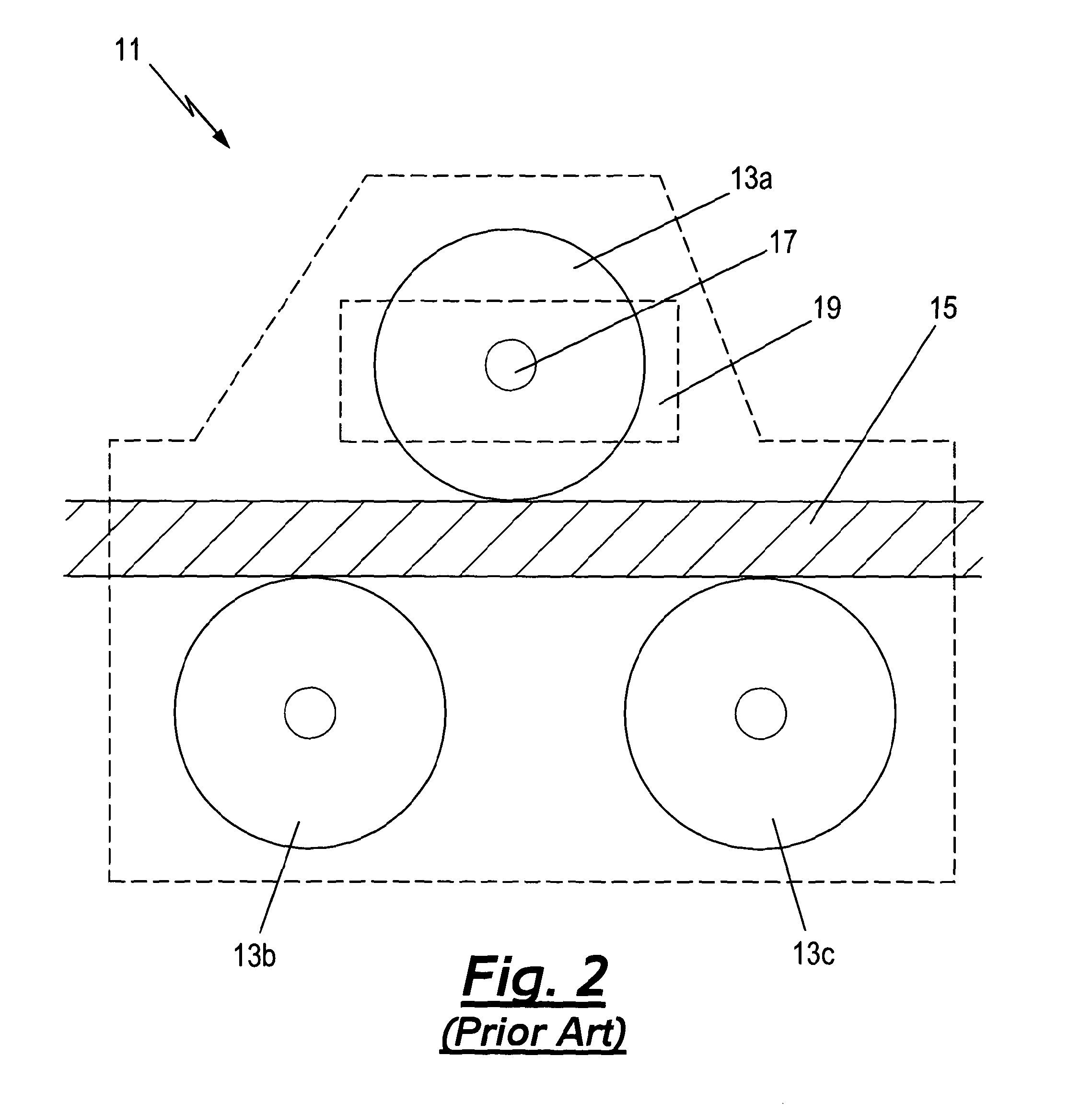

Blade tension gauge

Disclosed is a blade tension gauge for a band saw which provides a constant reading of the magnitude of the forces that act to put tension on the blade. The band saw includes a moveable wheel, a blade, and a frame, where movement of the moveable wheel in relation to the frame tensions the blade. The blade tension gauge includes a wheel positioning assembly rigidly connected to the moveable wheel and connected to the frame to be moveable relative to the frame. A load element is positioned to receive a load existing between the wheel positioning assembly and the frame. A sensor is configured to measure the load. A display is configured to display the tension value. Also disclosed is a method for outputting the tension of the blade of a band saw.

Owner:SNODGRASS JR HOWARD L

Testing device for model of floating gate and method of using the same

A testing device for a model of a floating gate, the device including: a towing carriage including a platform and a moon pool; a square support mechanism including two upper transversal beams, two upper longitudinal beams, two I-shaped longitudinal beams, four lower beams, and straight plates disposed on two of the four lower beams; a dynamometric mechanism including a longitudinal tensiometer, a transversal tensiometer, and a signal transmitting terminal; a data acquisition mechanism including a computer and a signal receiving terminal; a casing mechanism including two stepped shafts and two rolling wheels; and a guide rod mechanism including an inner sleeve, an outer sleeve, and a connecting plate. One end of the connecting plate is connected to the lower end of the inner sleeve, and the other end thereof is connected to a deck of the floating gate.

Owner:DALIAN UNIV OF TECH

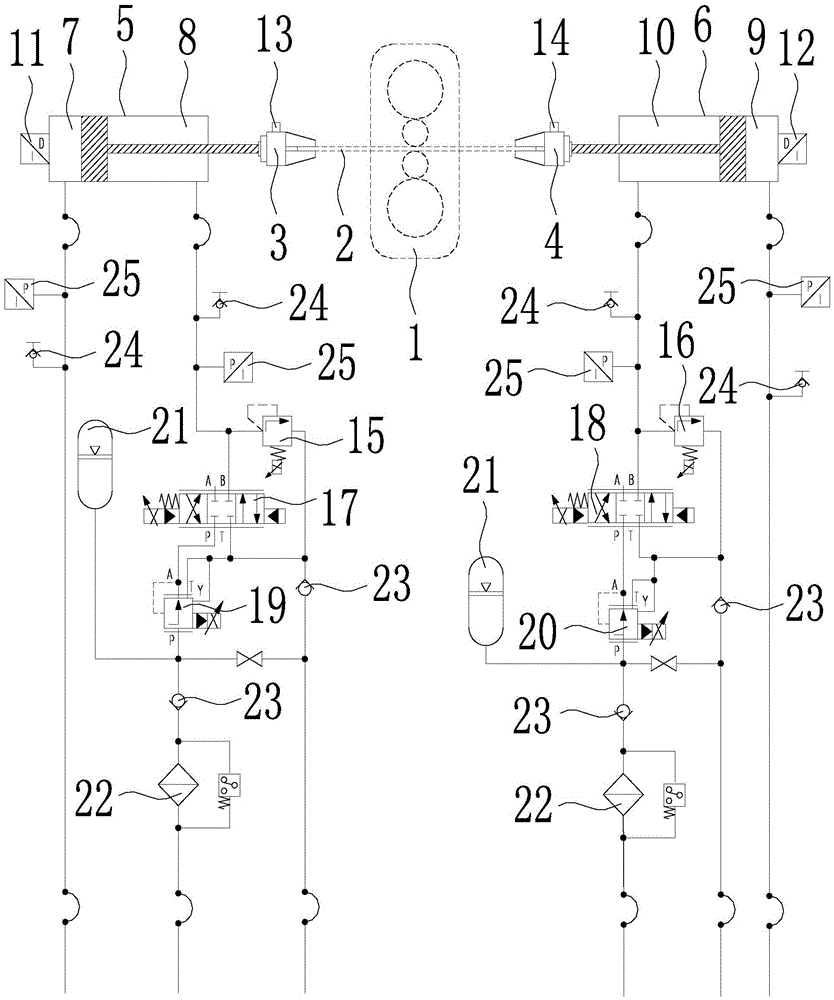

Micro-tension control system and method of hydraulic tension warm rolling mill

ActiveCN104815850AOvercome limitationsOvercome deficienciesTension/compression control deviceMetal stripsHydraulic cylinder

The invention relates to a micro-tension control system and method of a hydraulic tension warm rolling mill, and belongs to the technical field of tension control of hydraulic tension warm rolling mills. The micro-tension control system comprises a left tension hydraulic cylinder, a left hydraulic system, a right tension hydraulic cylinder and a right hydraulic system. Each hydraulic system comprises a proportional overflow valve, a servo valve and a proportional pressure-reducing valve. In the stage that tension of a rolled piece is established, the stage that the rolled piece is rolled, and the shutdown stage that pass rolling ends, the opening and closing states of the left proportional overflow valve, the left servo valve, the left proportional pressure-reducing valve, the right proportional overflow valve, the right servo valve and the right proportional pressure-reducing valve are controlled, corresponding control quantities are set for the valves, and therefore the tension hydraulic cylinders can conduct tension closed-loop adjustment through the proportional pressure-reducing valves and tensiometers, or through the proportional overflow valves and the tensiometers. In the feeding and discharging stages of the rolled piece, the tension hydraulic cylinders conduct position closed-loop adjustment through the servo valves and displacement sensors. According to the invention, the tension control mode is simpler and more efficient, the tension control accuracy is effectively guaranteed, and micro-tension rolling of high-fragility or difficult-to-deform metal strip materials is achieved.

Owner:NORTHEASTERN UNIV

Method for testing bond strength of materials

The invention discloses a method for testing bond strength of materials. The generally adopted method for measuring the bond strength is mainly a tensile test method of destructive wire bonding of double bonding points. Operating error can not be easily avoided in the actual operation, so that accurate bond strength can not be obtained. The method of the invention is different from the existing tensile test method of destructive wire bonding of double bonding points in which a lifting hook is hung in the middle of the wire. By adopting the tensile test method of destructive wire bond of a single bond point, a bonding point one and a bonding point two are measured individually, so that tension numerical value can be directly read on a tensometer. The accurate bond strength can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

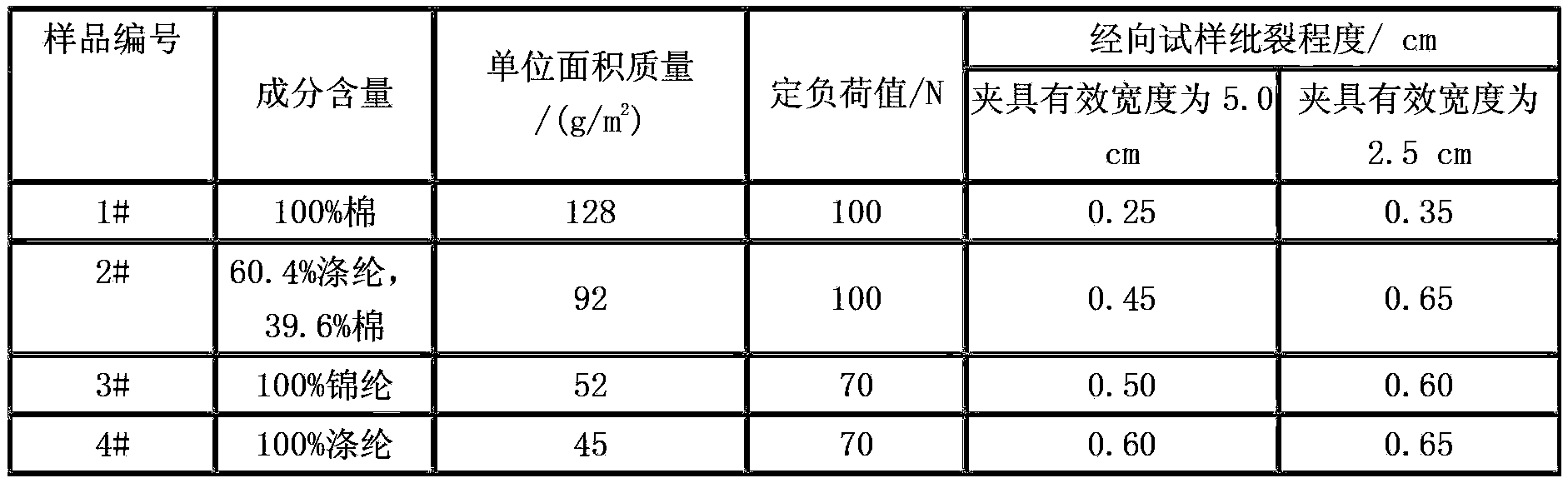

Method for testing stitch slipping of clothes

InactiveCN104062177ASimple processIn line with the actual situationMaterial strength using tensile/compressive forcesEngineeringInstrumentation

The invention relates to a method for testing stitch slipping of clothes, which concretely comprises: 1) apparatuses and tools for testing, 2)testing environment, 3) requirement and preparation of the testing sample, and 4) the concrete testing steps. The concrete steps comprise 1) separating two clamps of a tensometer to 10.0+ / -0.1cm, wherein the edge of two clamps should be parallel and perpendicular to the movement direction; 2)fixing a sample in the clamp, preloading 2N tension force so that a sample straight direction center line is mutually perpendicular to the edge of the clamp, and a seam line is positioned at the middle part of two clamps; if the fabrics and a lining are stitched, clamping fabrics and the lining together, loading according to loading prescription of fabrics; if fabrics and the lining are respectively stitched, respectively testing the fabrics and the lining; and 3)gradually increasing the load to a prescribed value at a speed of 5.0cm / min, or stopping movement of the clamp when the largest load is not reached and the percentage elongation of the sample can reach 30%, then vertically measuring the largest disconnection distance of the seam on the sample, and exacting the measured value to 0.05cm. The method for testing stitch slipping of clothes has the advantages of simple technology, easy popularization and high test precision.

Owner:HENGYUANXIANG GRP

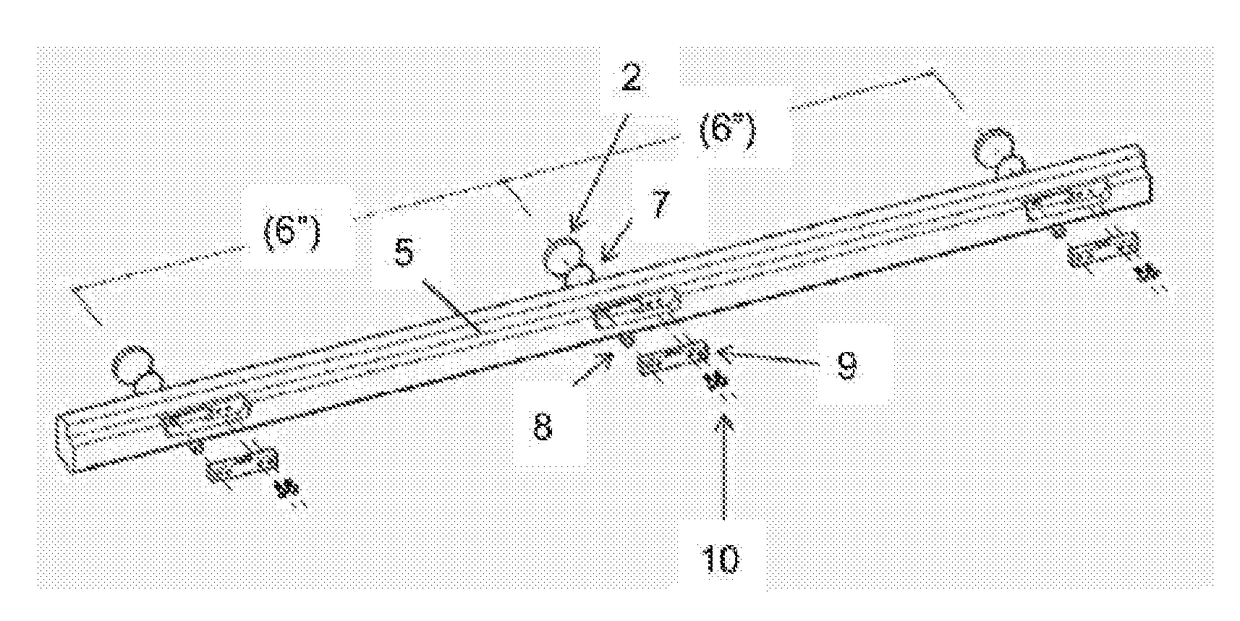

System for testing vortex-induced vibration traveling wave of structure with large length to diameter ratio

ActiveCN103954418ASave energyEasy to form traveling wavesVibration testingExperimental testingMeasurement device

The invention discloses a system for testing a vortex-induced vibration traveling wave of a structure with a large length to diameter ratio, and belongs to experiment testing systems of the technical field of ocean engineering. The system for testing the vortex-induced vibration traveling wave of the structure with the large length to diameter ratio comprises a trailer, an experimental model, a model restrain device, a tension device and a measuring device. The left end of the model is connected to the side plate of a carriage through a spring, and the right end of the model is connected to the spring of a mounting plate through a universal joint and three fixed pulleys. The spring of the mounting plate provides initial tension for the model. A grating strain sensor, a tensiometer and an acceleration sensor are arranged in the experimental model, the tension device and the mounting plate in a scattered mode. The model restrain mode of the system promote a structure model to generate vortex-induced vibration traveling waves under dragging of the trailer, the tension system of the system can achieve free control of the tension of the end portion of the model, and therefore traveling wave propagation situations under different tensions can be researched.

Owner:TAIYUAN UNIV OF TECH

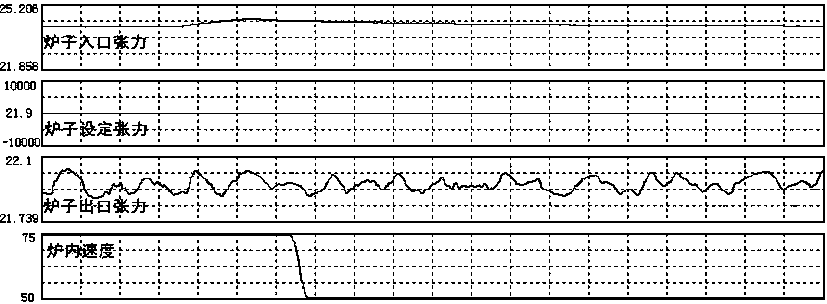

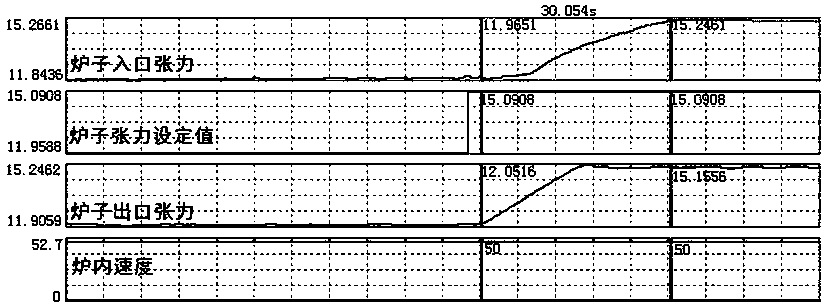

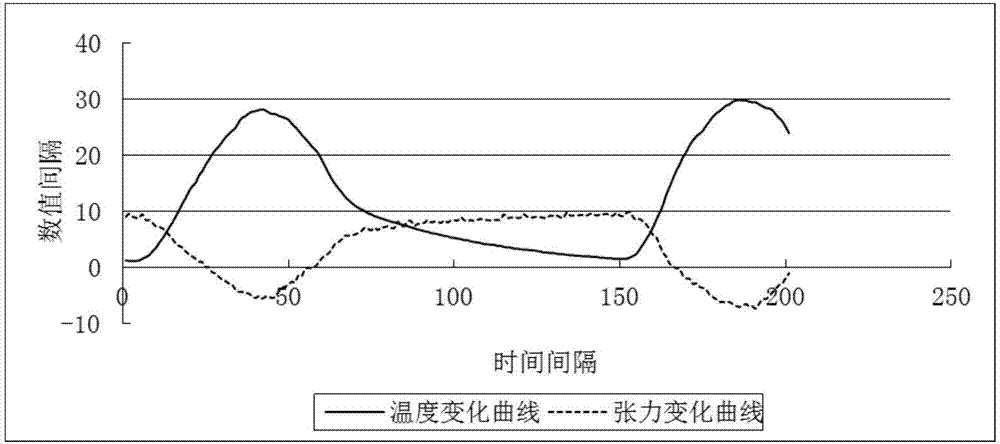

Inner-furnace tension compensation control method suitable for continuous rolling horizontal type annealing furnace

ActiveCN108677002AStable tension fluctuationAvoid damageFurnace typesHeat treatment process controlProduction lineMathematical model

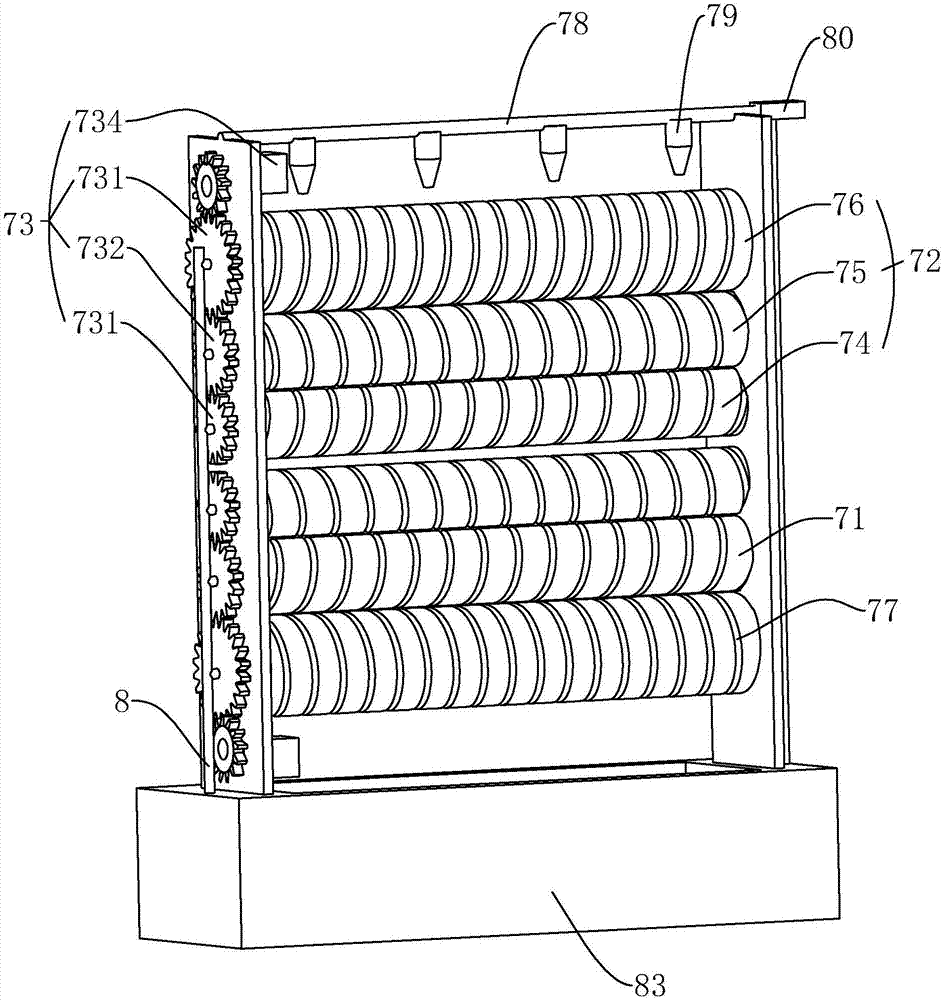

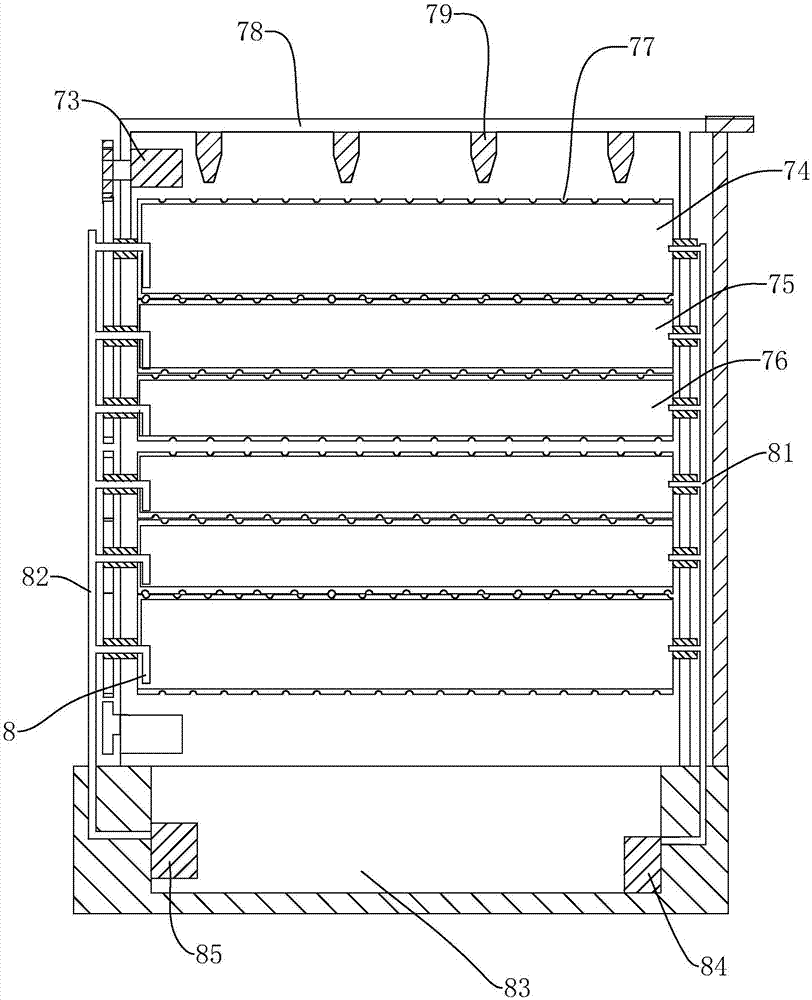

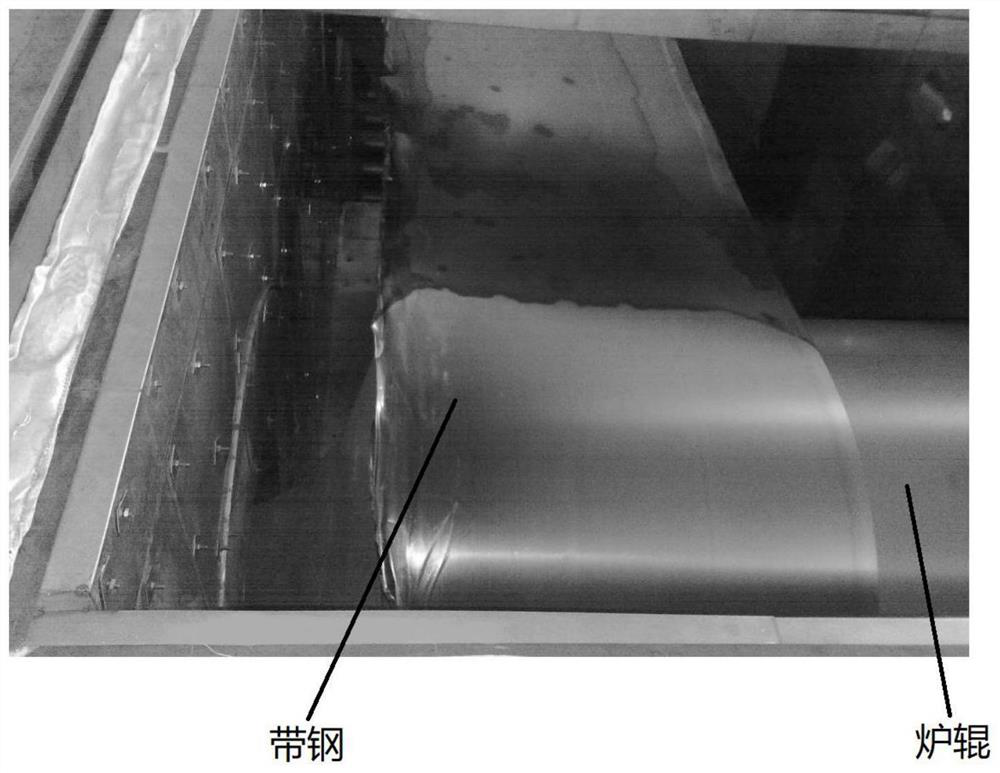

The invention provides an inner-furnace tension compensation control method suitable for a continuous rolling horizontal type annealing furnace and belongs to the technical field of continuous rollinghorizontal type annealing furnace production line. Technical problems of super long inner-furnace tension wave in the continuous rolling annealing furnace and smooth transition to a set value of tension when specifications of steel types vary are solved. The solution scheme includes the steps of a, a bouncing roller device is arranged at the outlet position of the continuous rolling horizontal type annealing furnace; the opening degree of a servo valve of the bouncing roller is controlled through the deviation of data collected by a tensometer and a pressure sensor from the set value; and corresponding compensation factors n are provided respectively; b, the inner-furnace steel belt speed v and the actual steel belt tension value are collected in real time, wherein according to the difference value-FACT between the collected actual tension value of the steel belt at the outlet of the continuous rolling horizontal type annealing furnace and the set tension value, mathematical models are established, and compensation value needed for the change of inner-furnace tension is calculated; and c, the tension value needed to be compensated is changed into the difference value between the set value of the gas pressure compensated and the on-the-spot feedback gas pressure; the opening degree of the servo valve of the bouncing roller is adjusted; and smooth and steady inner-furnace tension of the continuous rolling horizontal type annealing furnace is guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

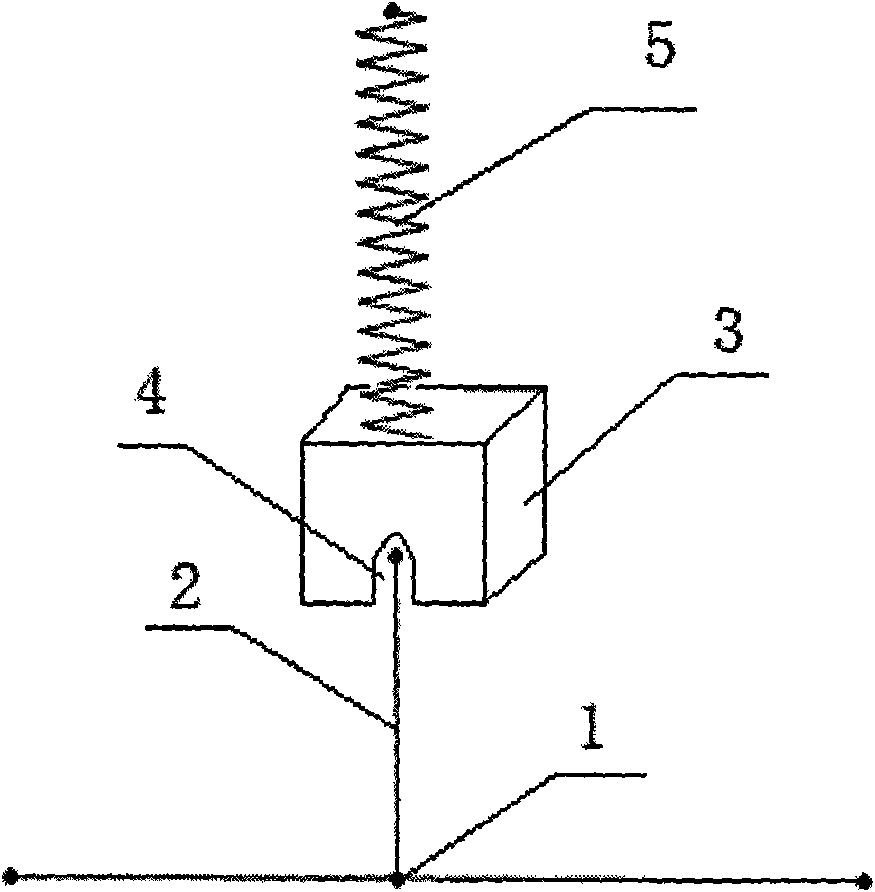

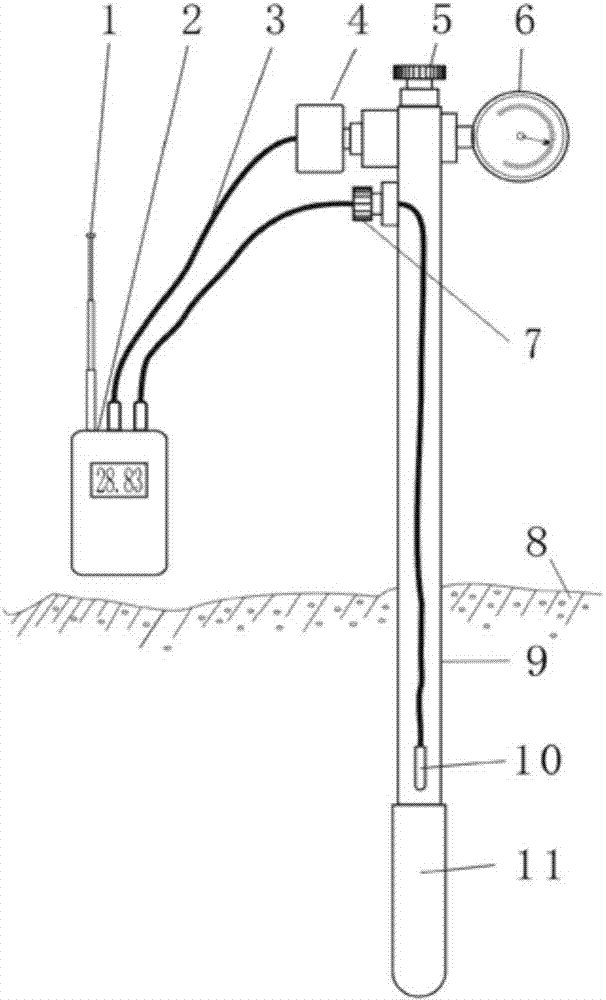

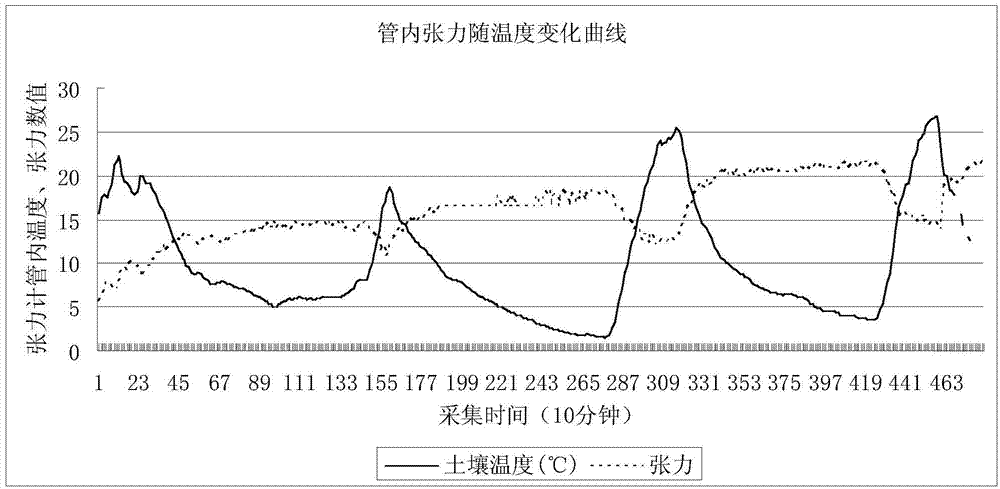

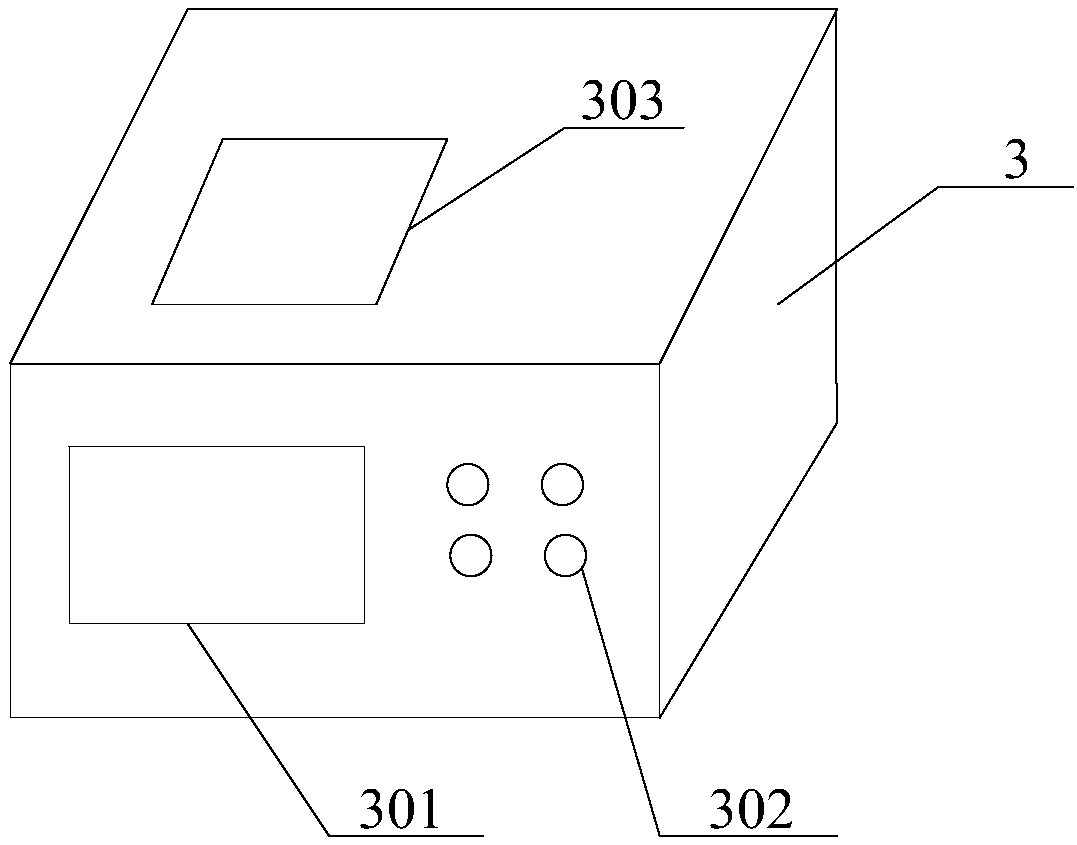

Automatic temperature compensation type soil water tension meter system and determination method

InactiveCN103884830AReduce mistakesMonitor temperature in real timeEarth material testingData acquisitionEngineering

The invention relates to an automatic temperature compensation type soil water tension meter system and a determination method. The system is composed of a tension meter end and a control center end, wherein the tension meter end and the control center end transmit by virtue of a wireless signal; the tension meter end comprises a tension meter and a data acquisition and processing transmitter; the tension meter is internally provided with a pressure sensor and a temperature sensor; all the sensors are connected with the data acquisition and processing transmitter; the control center end comprises a computer and a receiver; the receiver and the data acquisition and processing transmitter of the tension meter end wirelessly transmit data or instructions. According to the automatic temperature compensation type soil water tension meter system and the determination method, the errors of the tension meter system, caused by the change of environment temperatures, are reduced. Meanwhile, temperature and water content conditions of a soil environment can be subjected to all-weather real-time monitoring; the data acquisition amount is great and the data can be automatically uploaded to a central controller to realize water management.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

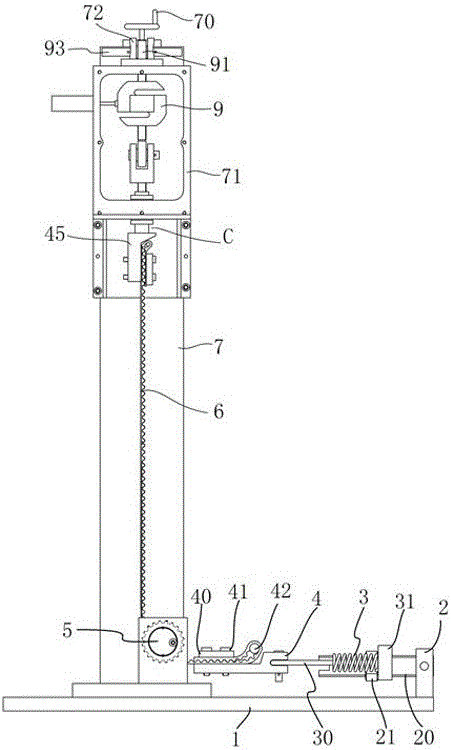

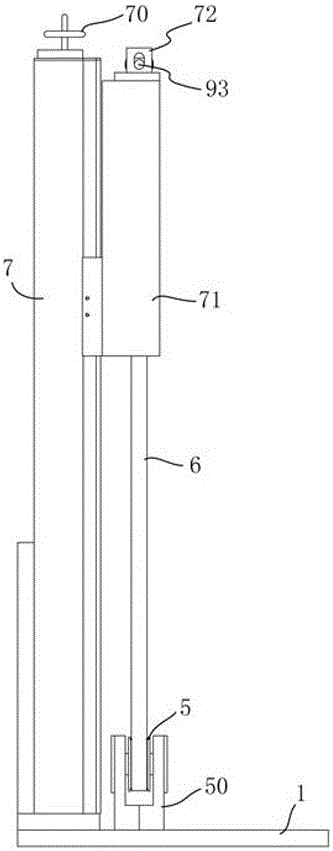

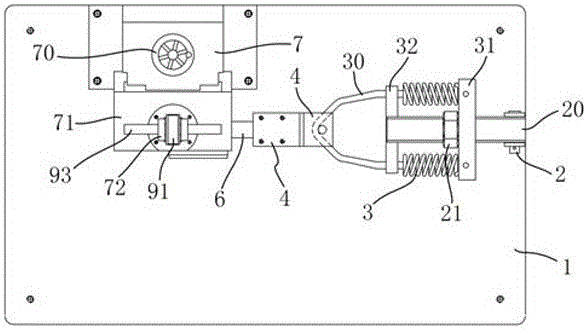

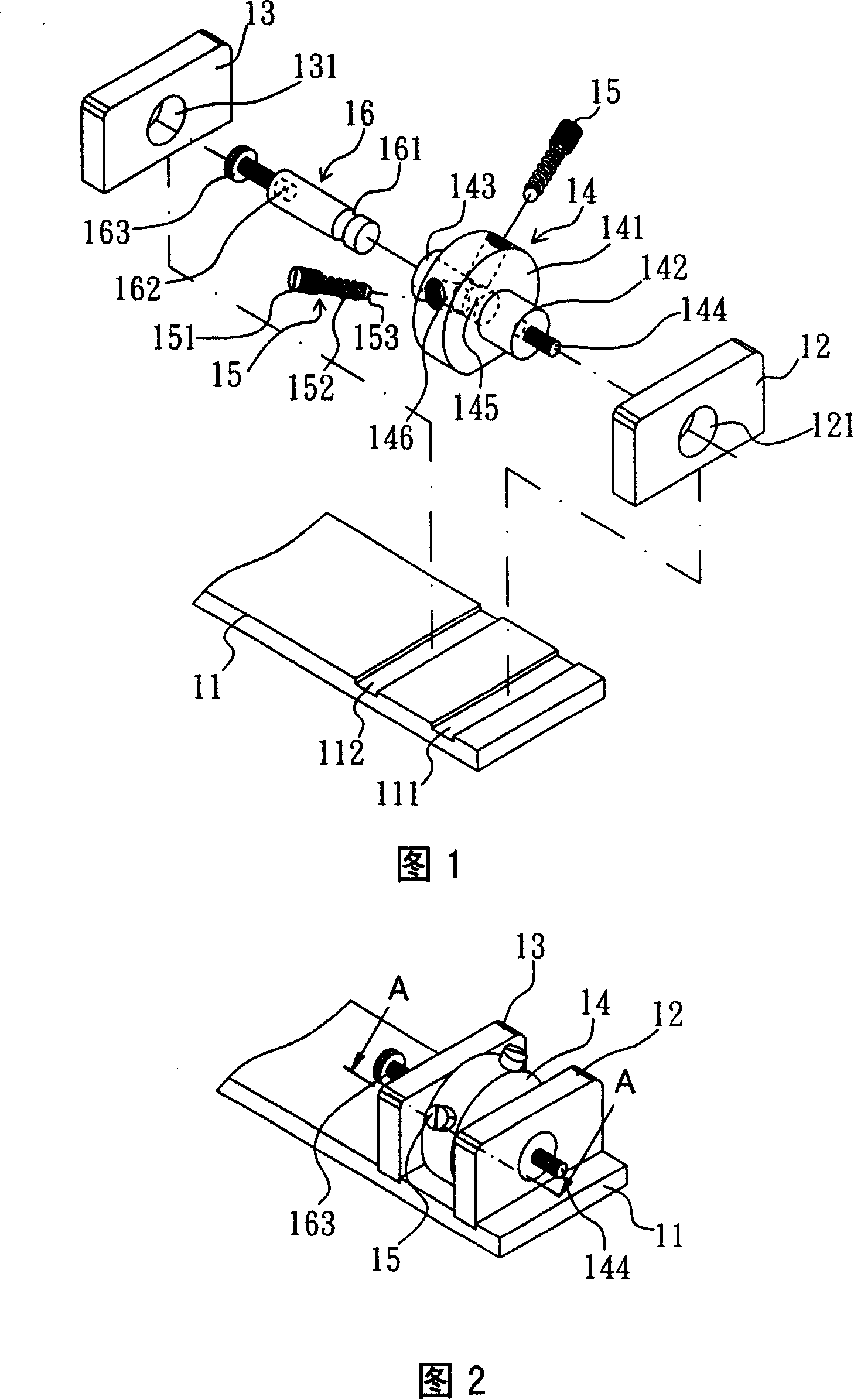

Tension meter calibration device and check device applied to same

ActiveCN105784267APrevent movementForce/torque/work measurement apparatus calibration/testingEngineeringTransfer mechanism

The invention provides a tension meter calibration device and a check device applied to the same. The tension meter calibration device comprises a base and a force transducer arranged on the base. The base is equipped with a force transducer mounting frame. The force transducer mounting frame is provided with a limiting structure used for stopping the upper force bearing end of the force transducer in the downward direction, and is further provided with an avoiding space allowing the upper force bearing end of the force transducer to move upwards. The avoiding space enables the check device to directly apply an action force to the upper force bearing end of the force transducer when the force transducer is mounted on the tension meter calibration device, the action force can be transferred to a force standard through a force transfer mechanism to facilitate calibration of the force transducer, and there is no need to disassemble the force transducer.

Owner:HENAN PROVINCE INST OF METROLOGY +1

Cold-rolled steel strip processing technology

InactiveCN107052049AImprove rolling qualityImprove rolling plasticityRollsTension/compression control deviceWinding machineStrip steel

The invention discloses a cold-rolled steel strip processing technology. The cold-rolled steel strip processing technology is characterized by comprising the following steps of: conveying a steel strip of which the thickness is 3mm to a left winding machine through an unwinding machine rotating forwards; enabling the steel strip to pass through a left turning roll, and conveying the steel strip into a left tensiometer for tension test; conveying the steel strip into a left speed meter for speed measurement; conveying the steel strip into a left thickness gauge for thickness test; conveying the steel strip into a six-roll reversible cold rolling mill for rolling; enabling the steel strip to pass through a cooling device on the six-roll reversible cold rolling mill for cooling; conveying the steel strip to a right tensiometer for tension test; conveying the steel strip into a right speed meter for speed measurement; conveying the steel strip into a right thickness gauge for thickness test; performing reverse motion for rolling; and after rolling for seven times, winding the steel strip through a right winding machine to complete the rolling process. The cold-rolled steel strip processing technology has the effects that the rolled plasticity of the steel strip is improved, and the rolling quality of the steel strip is further improved.

Owner:浙江协和陶瓷有限公司

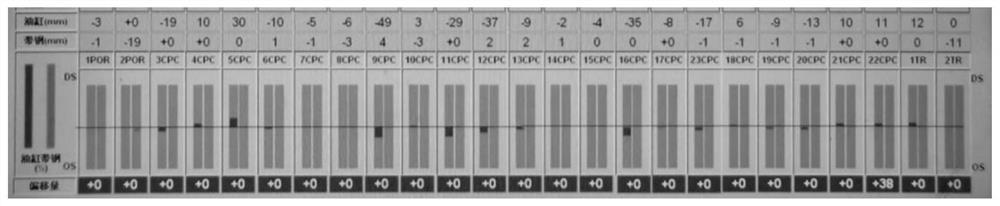

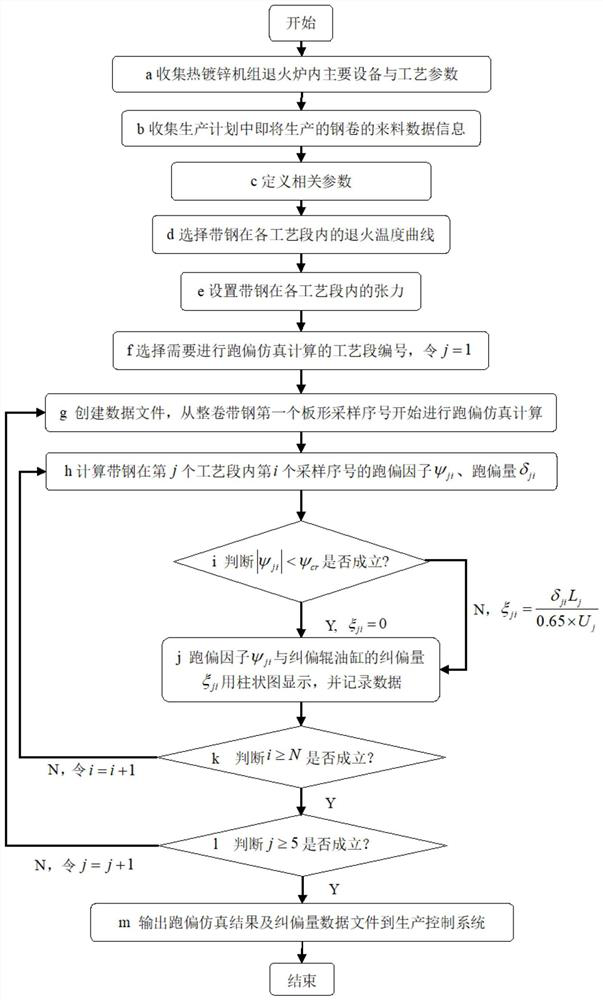

Strip steel deviation simulation system of continuous hot galvanizing unit annealing furnace and control method

PendingCN112446130ARealize deviation predictionImprove stabilityDigital data information retrievalFurnace typesProcess engineeringStrip steel

The invention provides a strip steel deviation simulation system of a continuous hot galvanizing unit annealing furnace and a control method. The method comprises the following steps: obtaining process parameters of selected process sections; obtaining incoming material data information of the strip steel; setting the sampling serial number of the sampling point of each process section, and setting the annealing temperature and tension of the strip steel in each process section; calculating a deviation factor and a deviation amount of each sampling sequence number in each process section, judging whether the deviation factor exceeds a deviation critical value or not, and calculating a deviation correction amount for the deviation factor which exceeds the deviation critical value; and summarizing the deviation correction amount of each process section to pre-adjust the deviation correction roller oil cylinder. According to the method, deviation prediction of the whole roll of strip steel in all process sections can be achieved according to different plate shape sampling points of the whole roll of strip steel, meanwhile, the deviation correction amount of the deviation correction roller is calculated according to the deviated sampling points, the deviation correction roller is pre-adjusted, prediction and control over deviation of the strip steel in the annealing furnace are achieved, compared with the hysteresis problem of a deviation rectifying method of firstly monitoring and then adjusting in the current production, the occurrence of deviation is effectively avoided.

Owner:宝钢日铁汽车板有限公司 +2

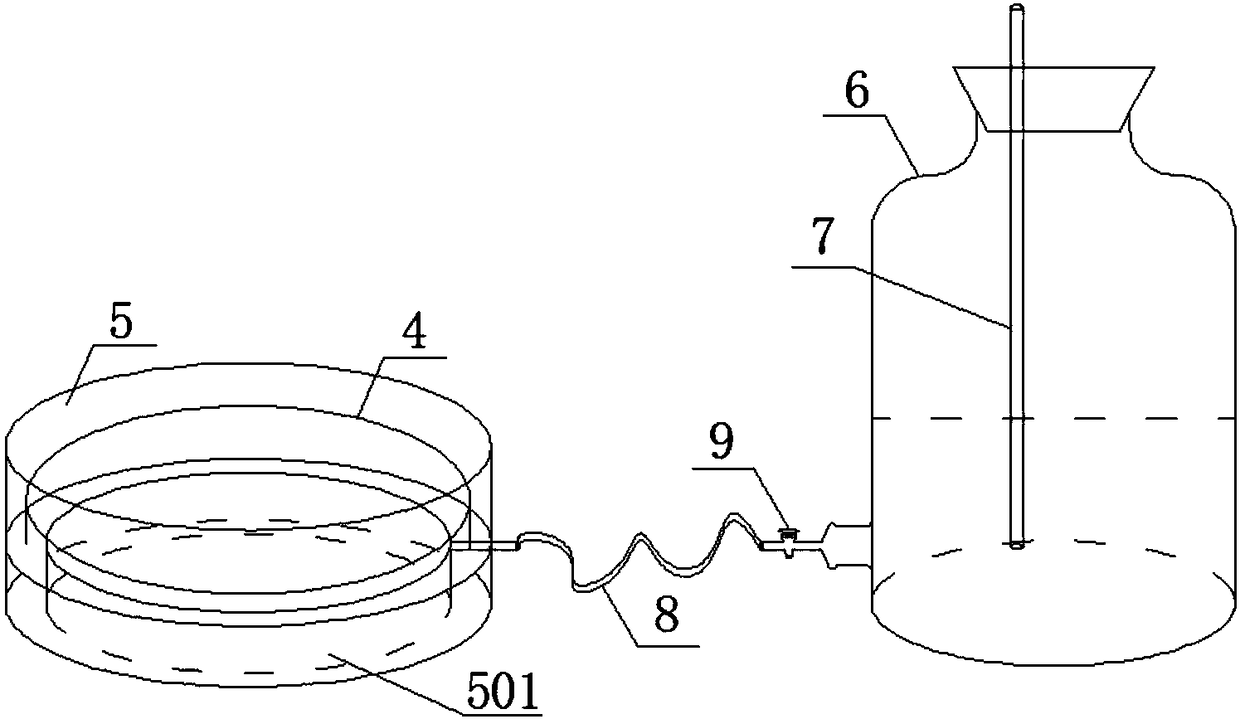

Device and method for measuring moisture characteristic curve in soil dehumidification and moisture absorption processes

ActiveCN108287121ARealize determinationWeighing by removing componentSurface/boundary effectMeasuring instrumentMoisture absorption

The invention provides a device and a method for measuring a moisture characteristic curve in the soil dehumidification and moisture absorption processes. The device comprises a cutting ring, two tension meters, a measuring instrument, a ceramic plate and a first vessel, wherein two open pores positioned at different heights of the side wall are formed in the side wall of the cutting ring, and thecutting ring sleeves the exterior of soil to be measured; the two tension meters are configured to be applicable for being inserted into soil through the two open pores respectively and measuring thetension of soil; the ceramic plate is placed in the first vessel for supporting the cutting ring; the first vessel is configured to keep water inside the first vessel and the upper end face of the ceramic plate to be at the same height all the time when the moisture characteristic curve in the soil dehumidification and moisture absorption processes is measured; the measuring instrument is configured to measure and record the weight of the cutting ring and the weight of soil corresponding to a plurality of preset moments, or the weight of the cutting ring, the weight of the first vessel, the weight of the ceramic plate and the weight of the soil, and record the displayed numbers of the two tension meters corresponding to the preset moments. The device and the method can be used for measuring the moisture characteristic curve corresponding to the soil dehumidification and moisture absorption processes.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

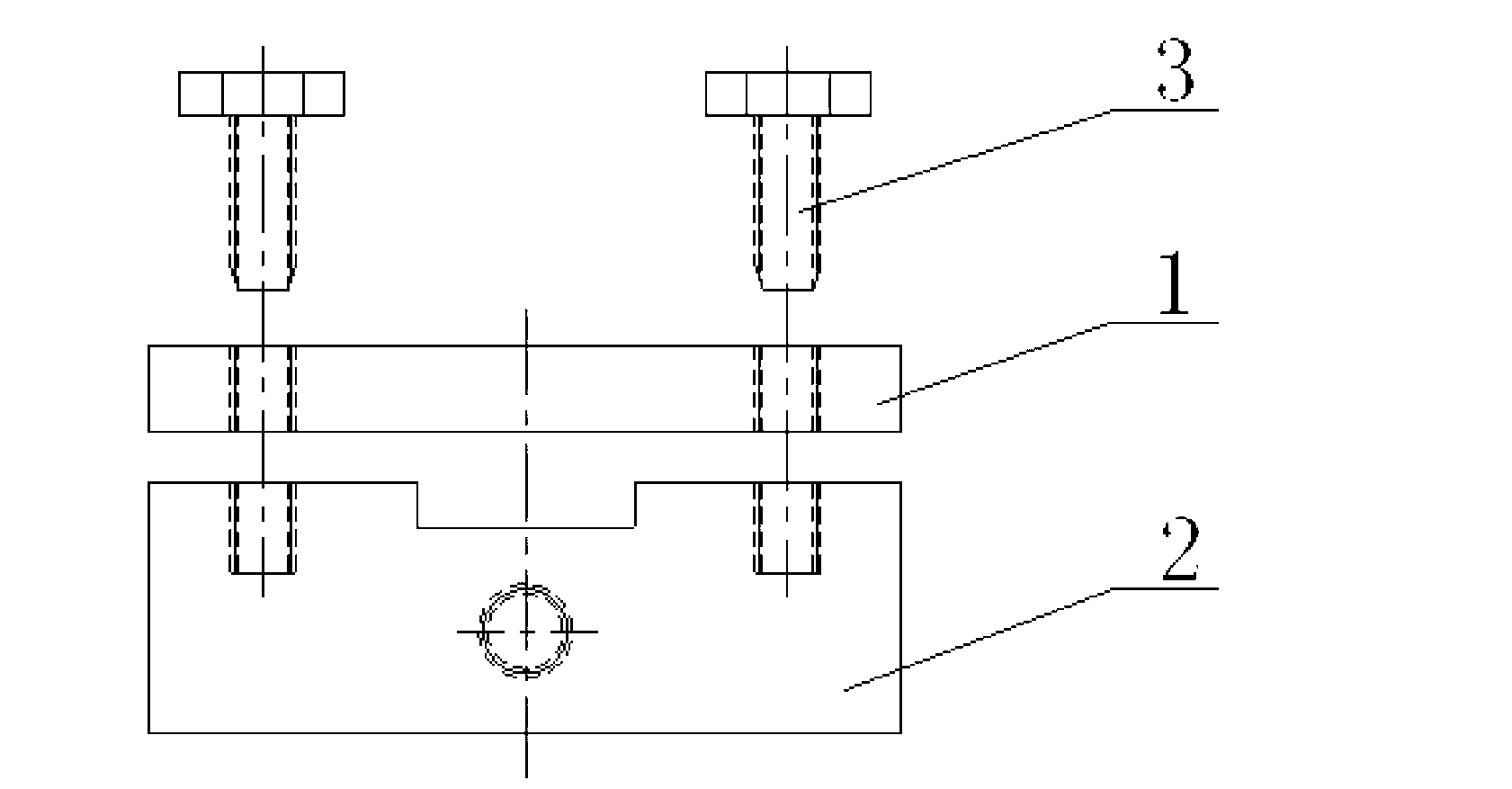

Tension detecting device

The invention discloses a tension detecting device, comprising an upper pressing plate, a lower pressing block, paired bolts and a connecting screw rod, wherein the upper side face of the lower pressing block is provided with a square slot for communicating the left side face and the right side face of the lower pressing block, and the upper pressing plate and the lower pressing block are fixed through the bolts; the lower side face of the square slot and the lower side face of the upper pressing plate positioned on the lower side face of the square slot form a seal face of the upper side face and the lower side face of a detected fixed part; the paired bolts are respectively positioned on opposite positions at front and back sides of the square slot; and the left end of the connecting screw rod is fixed with the lower pressing block through a threading structure, the right end of the connecting screw rod is fixed with a measuring head of a tensometer through a threading structure, and the central axis of the connecting screw rod is consistent with the central axis of the measuring head of the tensometer. The tension detecting device disclosed by the invention has a simple structure and is convenient to use; and by adopting the tension detecting device, the detected fixed part can be ensured to be effectively fixed without generating additional force on a detected movable part, the accuracy of the force application direction can be improved when the detected part is detected, the measurement process is convenient, and the measurement precision is improved.

Owner:昆山沪光汽车电器股份有限公司

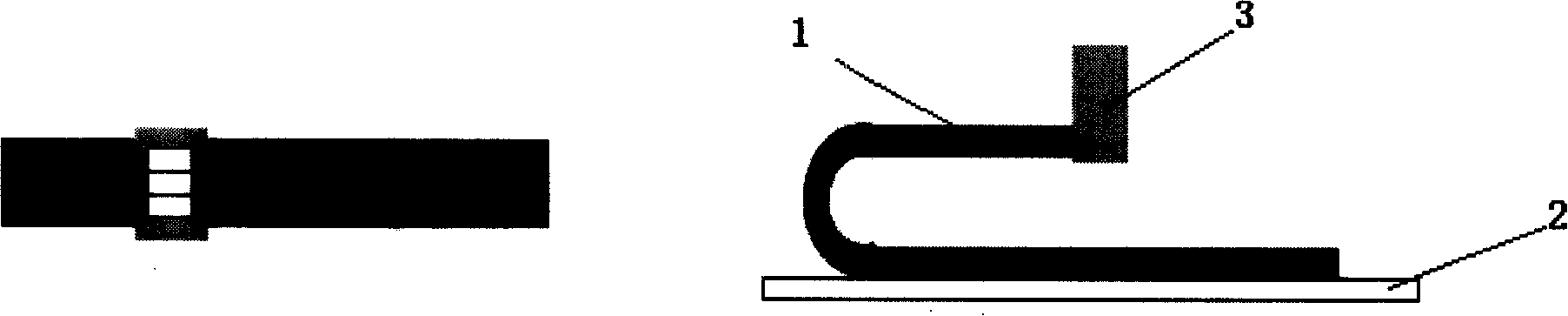

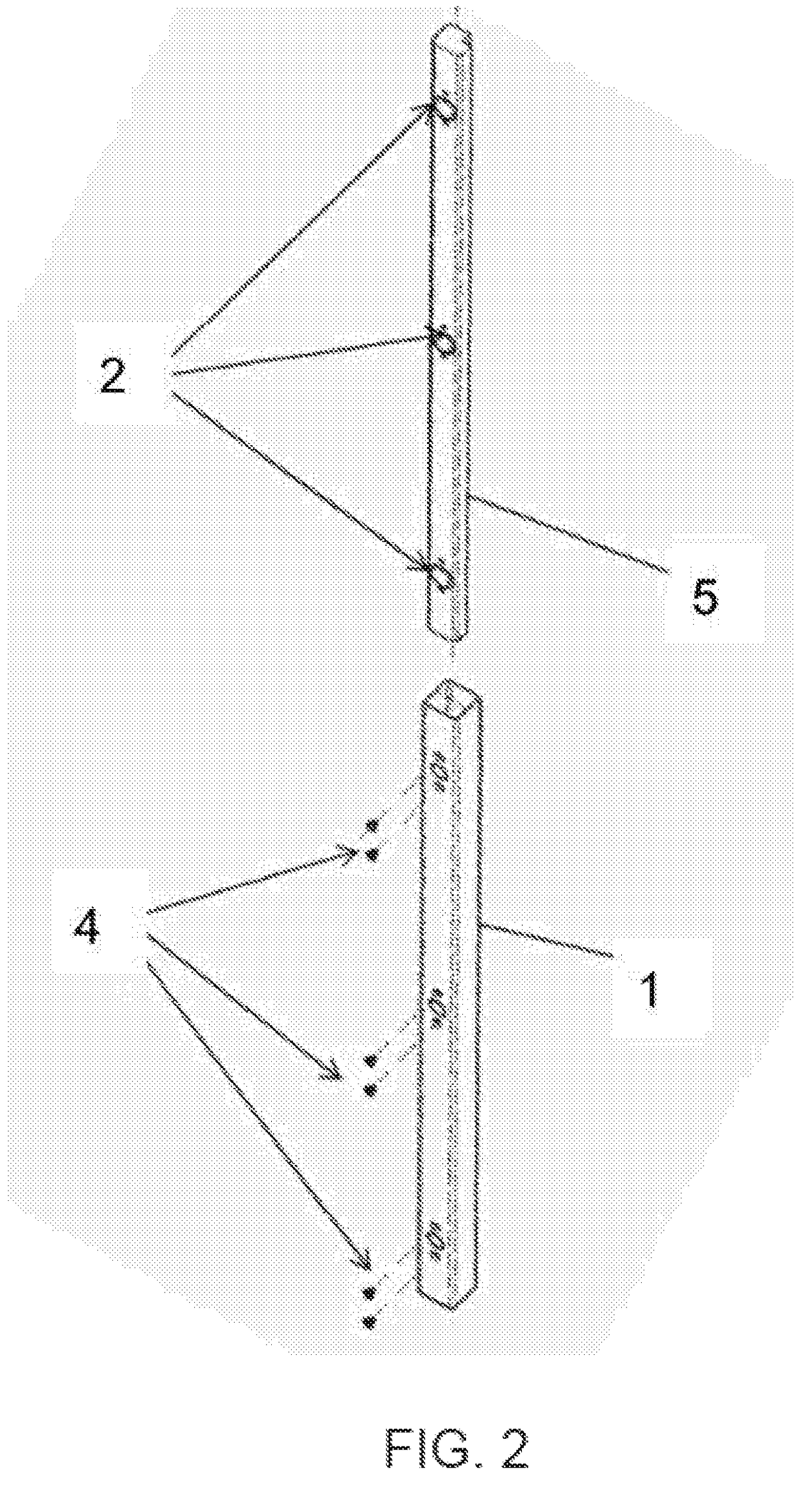

Measurement device for drawing soil moisture characteristic curve and use method thereof

InactiveCN109900589AAvoid Shrinkage SituationsEasy to assembleWeighing by removing componentMeasurement deviceEngineering

The invention discloses a measurement device for drawing a soil moisture characteristic curve. The device comprises a tensiometer, a ring cutter, a detachable support and an electronic balance. The tensiometer is formed by a probe tube, a negative pressure meter and a clay head. The ring cutter comprises a ring cutter body and a solid cover. The detachable support is formed by a fixation frame, asupport rod and a base. The negative pressure meter is fixedly arranged on the fixation frame. The clay head is inserted into a saturated soil sample in the ring cutter. The lower end of the support rod is fixedly arranged on the base, and the upper end thereof is fixedly provided with the fixation frame. The base and the ring cutter are arranged on the electronic balance. The use method of the measurement device comprises the following steps: 1) measuring basic data of the device; 2) assembling the measurement device; 3) recording experiment data; 4) calculating daily volume moisture content;and 5) drawing the soil moisture characteristic curve according to the daily soil volume moisture content omega1, omega2, omega3... and tensiometer values P1, P2, P3....

Owner:SHANXI AGRI UNIV

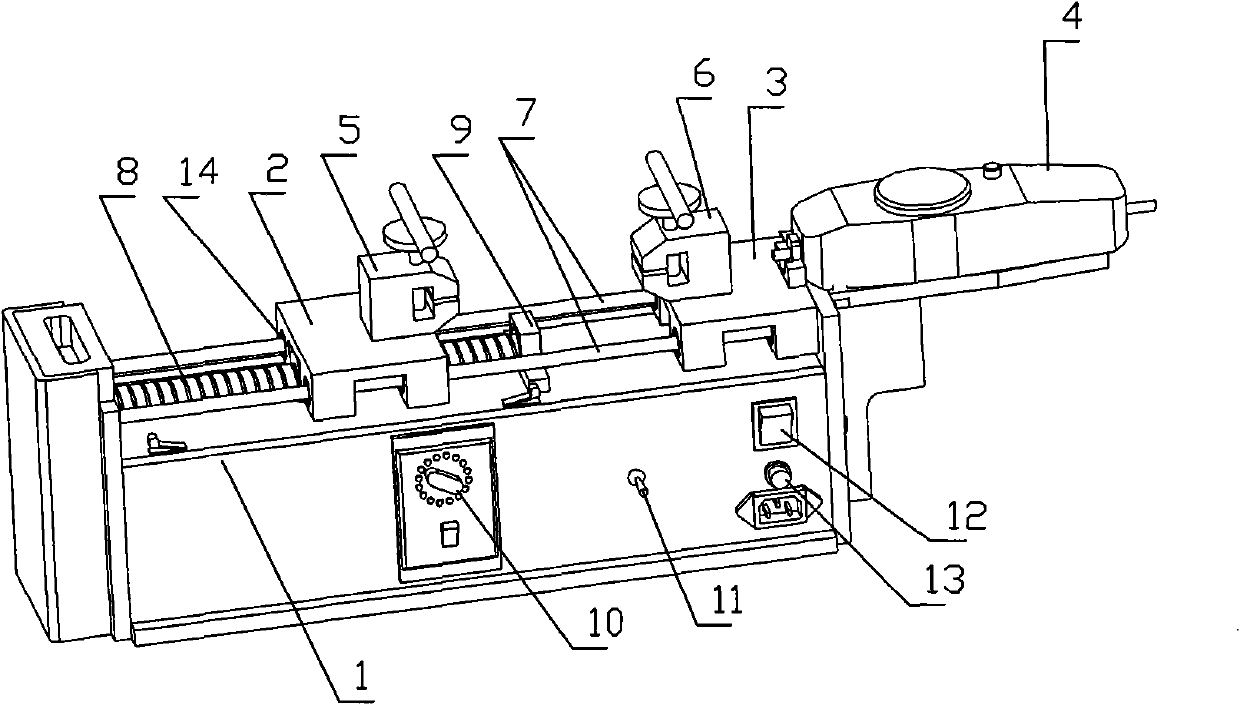

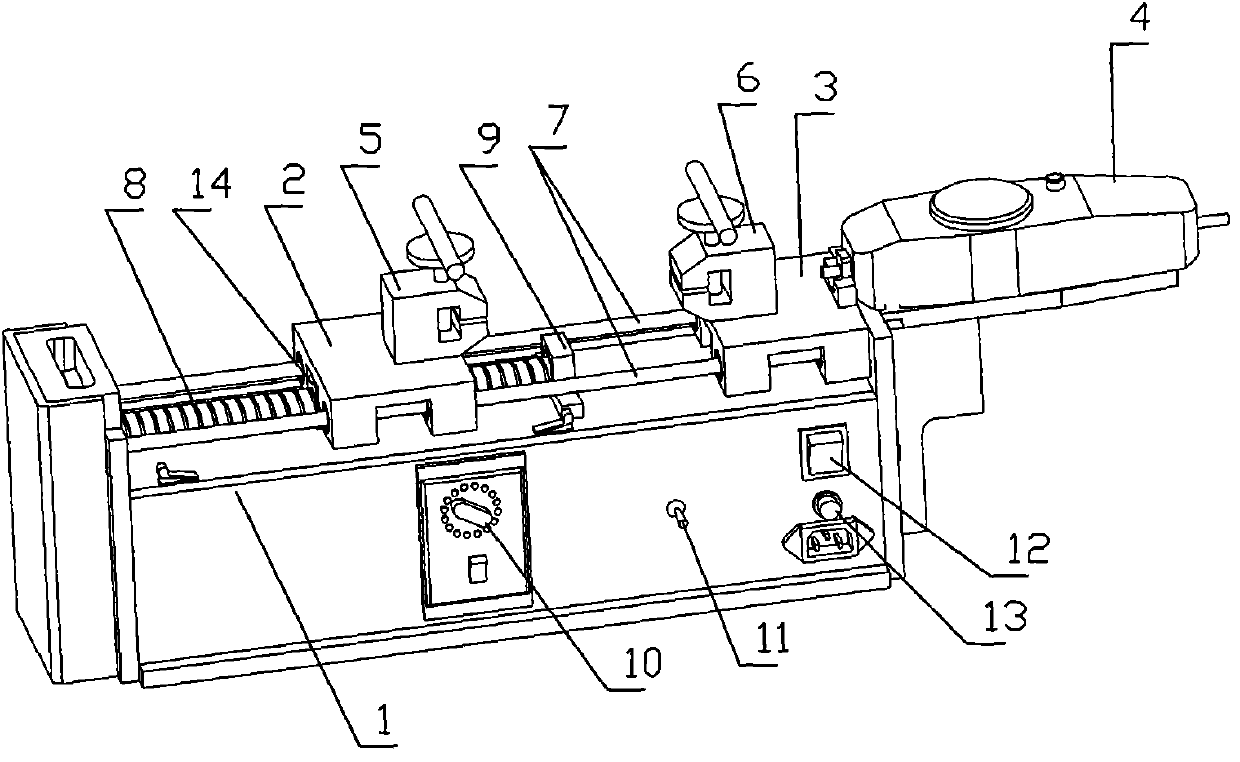

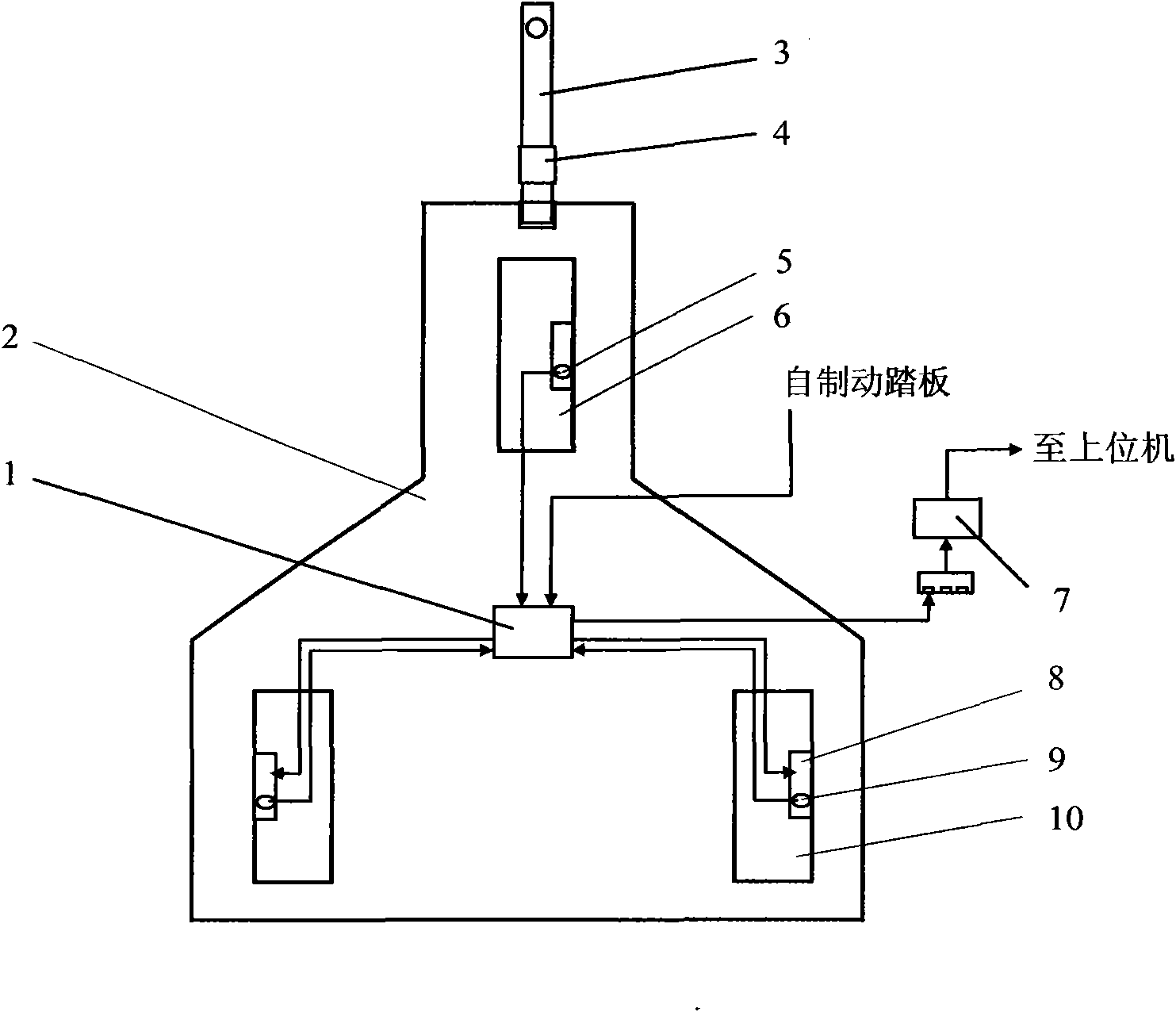

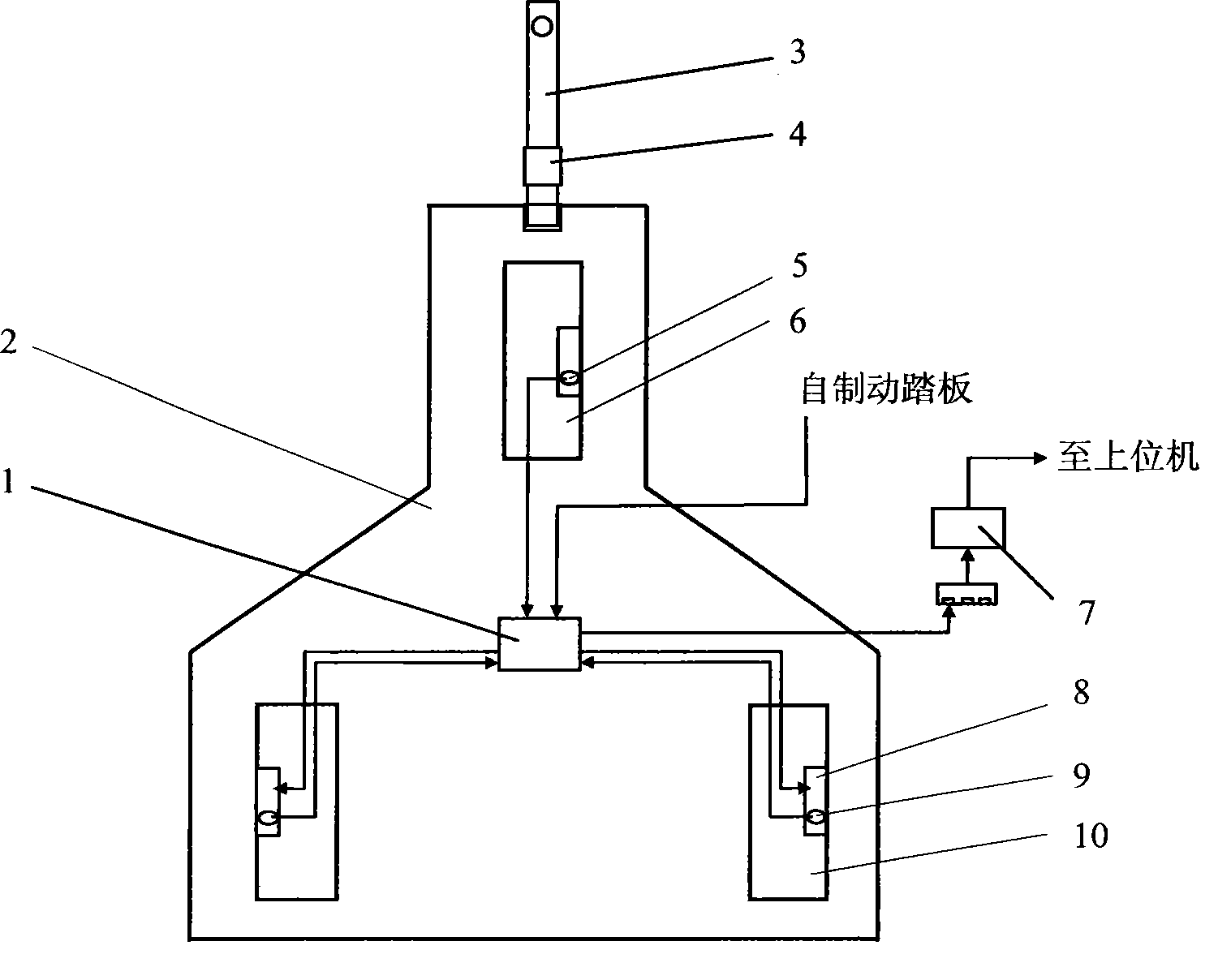

ABS/EBD comprehensive test system of automobile

InactiveCN101793609AVehicle testingApparatus for force/torque/work measurementCombined testWheel speed sensor

The invention discloses an ABS / EBD comprehensive test system of an automobile. The main body structure of the system is composed of a comprehensive tester rack 2, a draw bar 3, a comprehensive tester front wheel 6 and comprehensive tester rear wheels 10, wherein the front wheel 6 is installed on the comprehensive tester rack 2 by a forerake steering king pin, two rear wheels adopt the same wheel 10, a brake 8 and a wheel speed sensor 9, and two wheels can brake and control by respective brake 8 arranged thereon; the comprehensive tester can be dragged by a vehicle via the draw bar 3, and two rear wheels 10 can serve as brake control objects researched by the test; a tensometer 4 measures wheel braking force, and the front wheel 6 can serve as a fifth wheel gauge and serve as the ABS and EBD control test research and comprehensive test system; when brake control is not carried out on two rear wheels 10 of the comprehensive tester, the front wheel serves as the fifth wheel gauge and can carry out the finished-automobile ABS and EBD control test research and comprehensive test on a tow vehicle.

Owner:CHINA AGRI UNIV

Overload safeguard for tensometer

InactiveCN101131341AAvoid damageMaterial strength using tensile/compressive forcesPush and pullPull force

Owner:KINPO ELECTRONICS

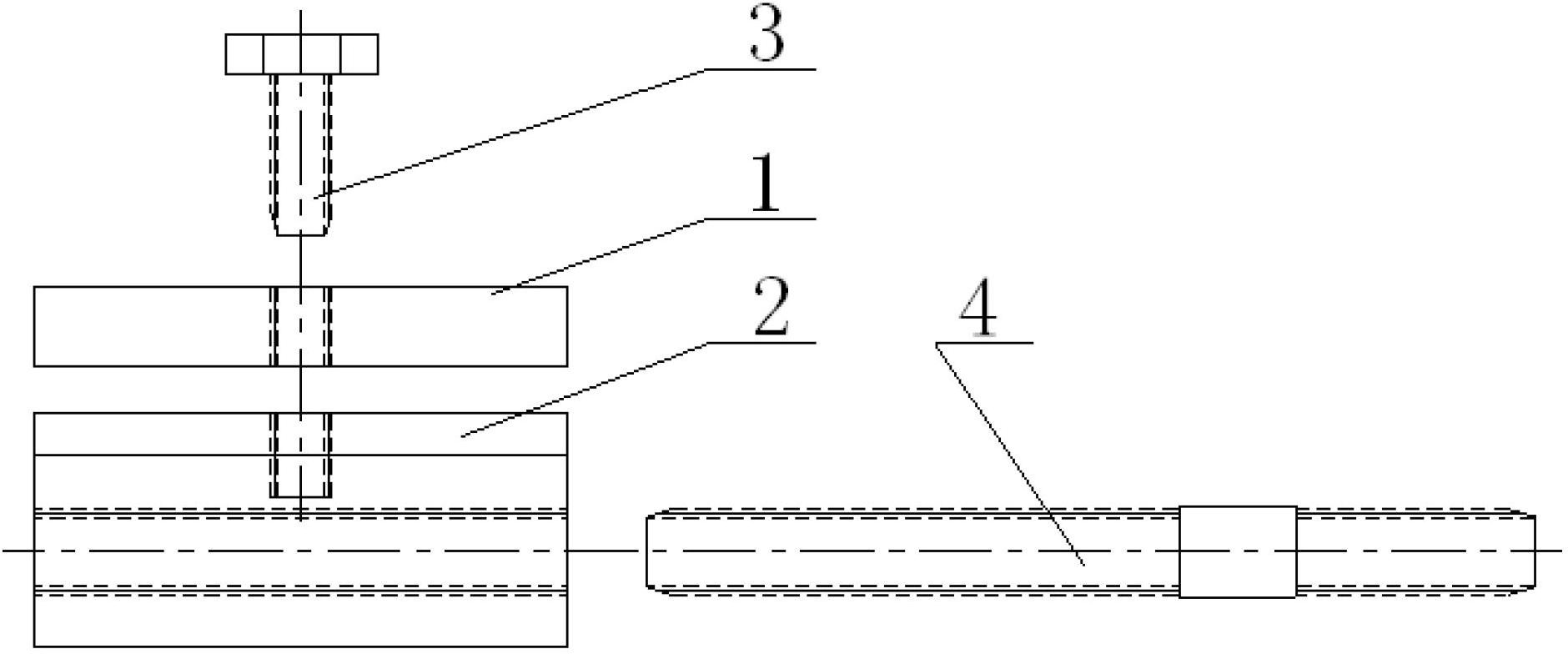

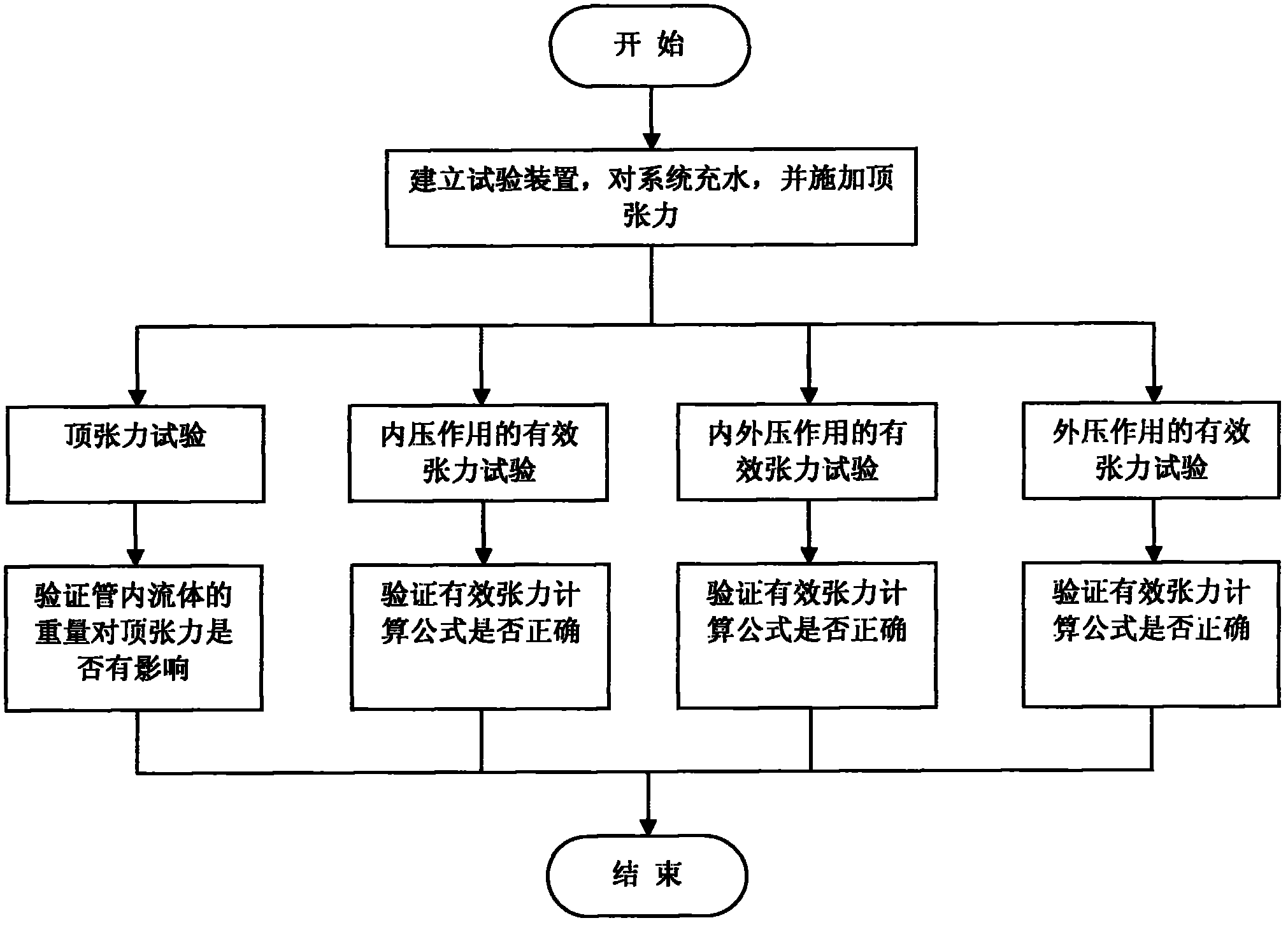

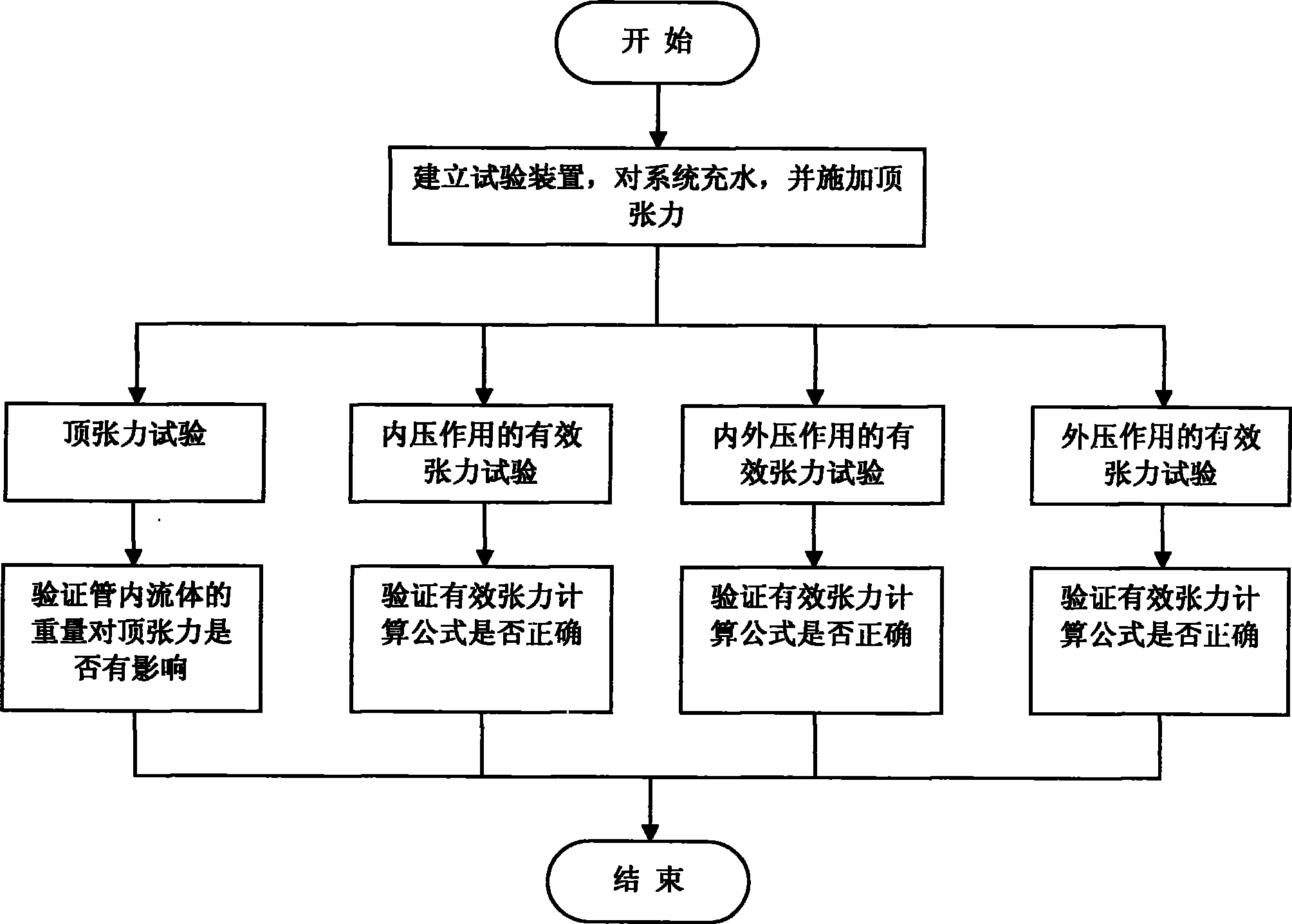

A test method for top tension and effective tension of deep water top tension riser

The invention relates to a research test method of a marine deep-water stand pipe and particularly relates to a method for testing top tension and effective tension of a deep-water top tension type stand pipe. The method comprises the following steps of: fastening the lower end of a model pipeline to an internal pressure water tank and connecting the upper end of the model pipeline to a spring tensometer, arranging an external pressure water tank outside the model pipeline, arranging strain gauges in different positions on the model pipeline, and arranging a pressure gauge for measuring the internal pressure of the pipeline; then, performing a top tension text, the effective tension test of internal pressure action, the effective tension test with both internal and external pressure actions, and the effective tension test of external pressure action. The method is capable of completing the test researches on the top tension and effective tension of the deep-water top tension type stand pipe, thereby providing a basis and a test verification for the top tension and effective tension calculation of the deep-water top tension type stand pipe.

Owner:OCEAN UNIV OF CHINA

Method and apparatus for inspecting optical filter adhesion in lens mould set

InactiveCN101075084AGuaranteed qualityAdhesion detection method is simpleWork measurementTorque measurementCamera lensEngineering

A method for detecting adhesive force of filter in lens module includes providing a lens module with filter and lens component in lens cone, attaching said filter on one side surface of adjacent lens component, providing a tensometer with a screen and pulling rod, connecting one end of pulling rod to said screen and jointing another end with said filter through binding, exerting an acting force to pull said filter open from surface of lens component and recording indication on tensometer when said filter is pulled to be open.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

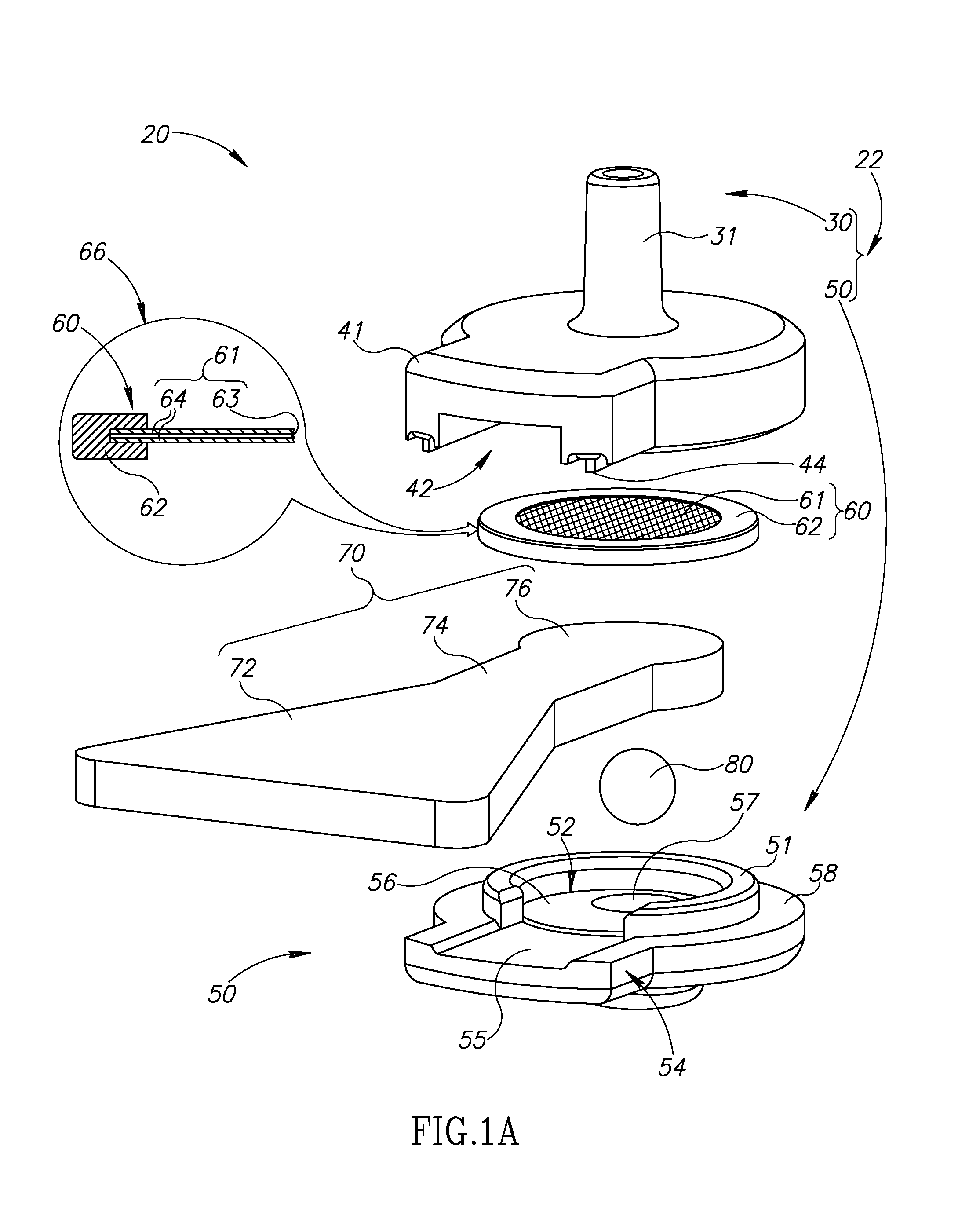

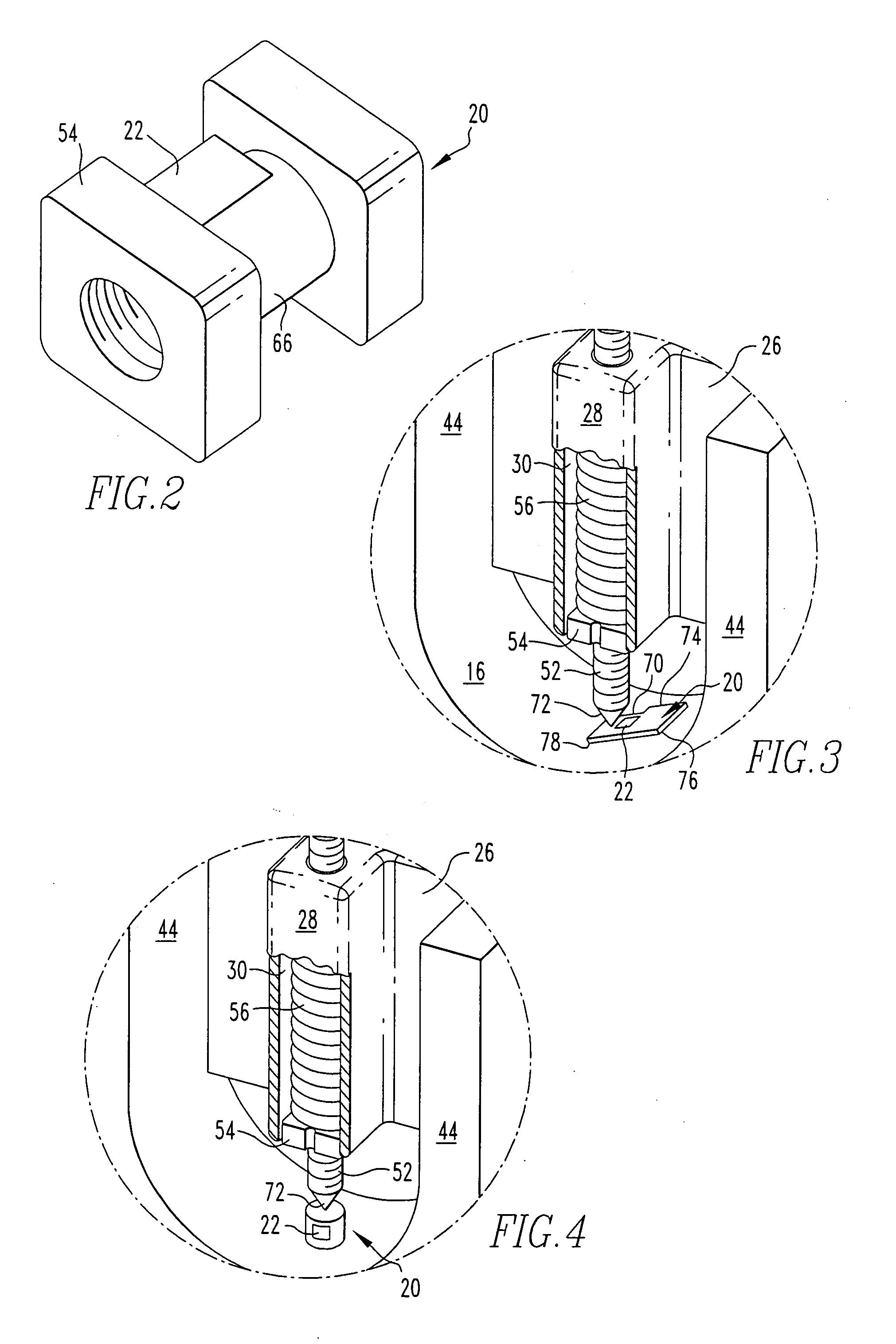

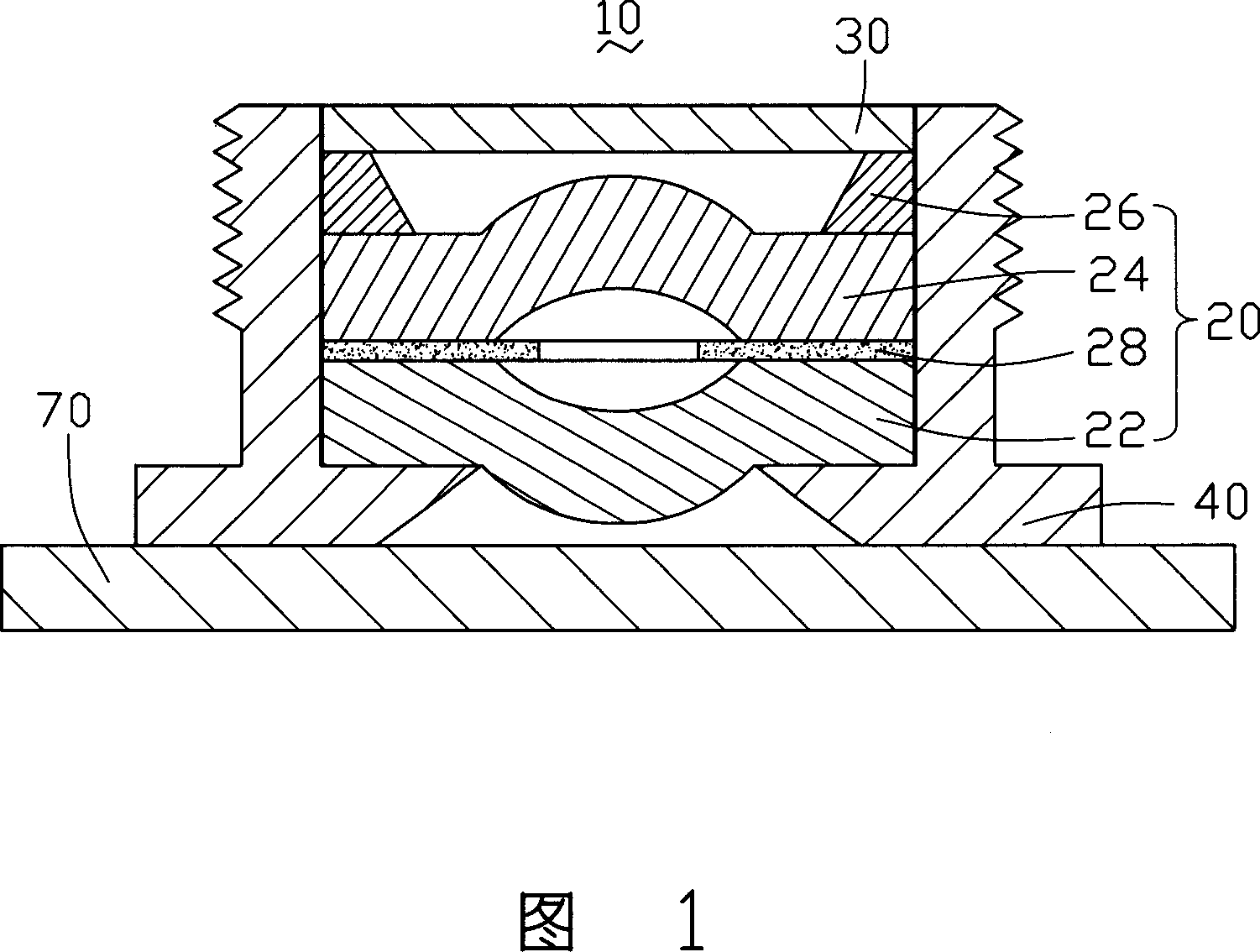

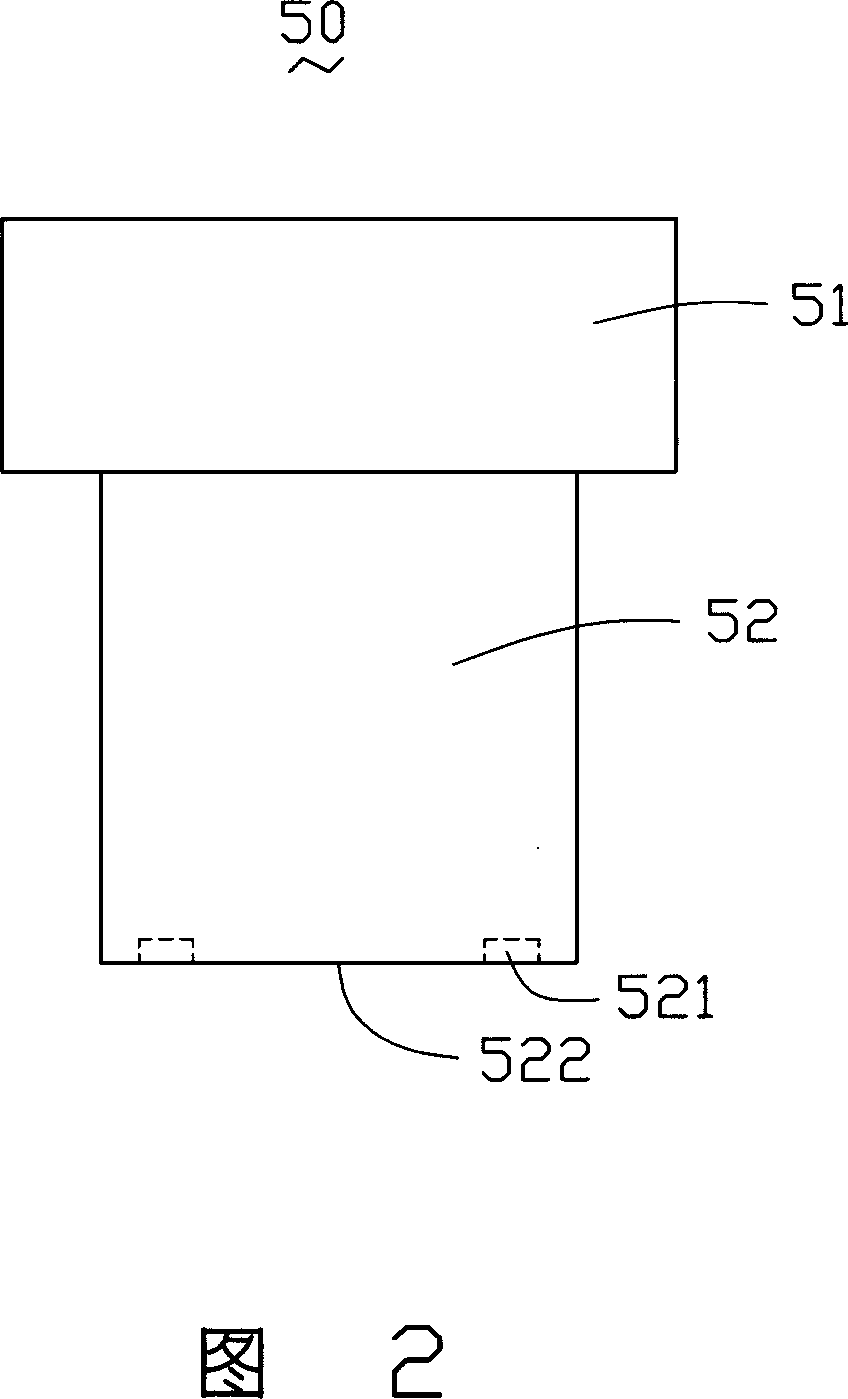

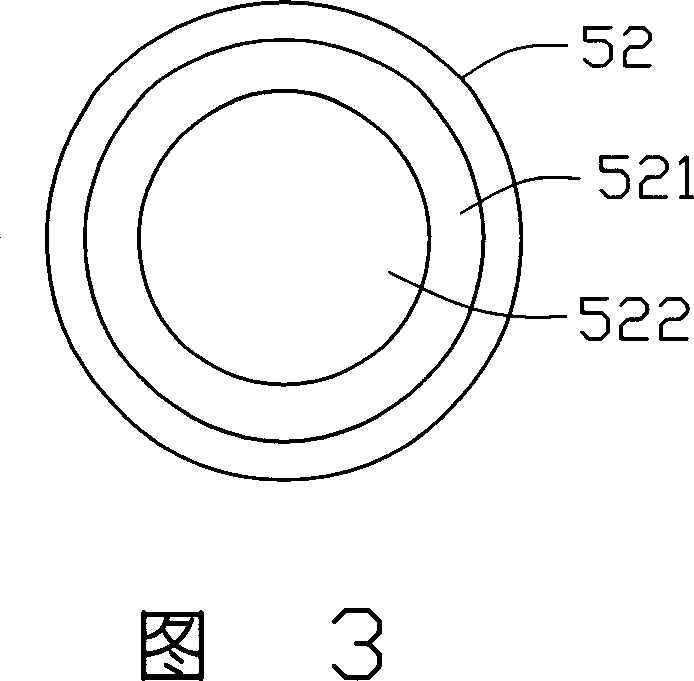

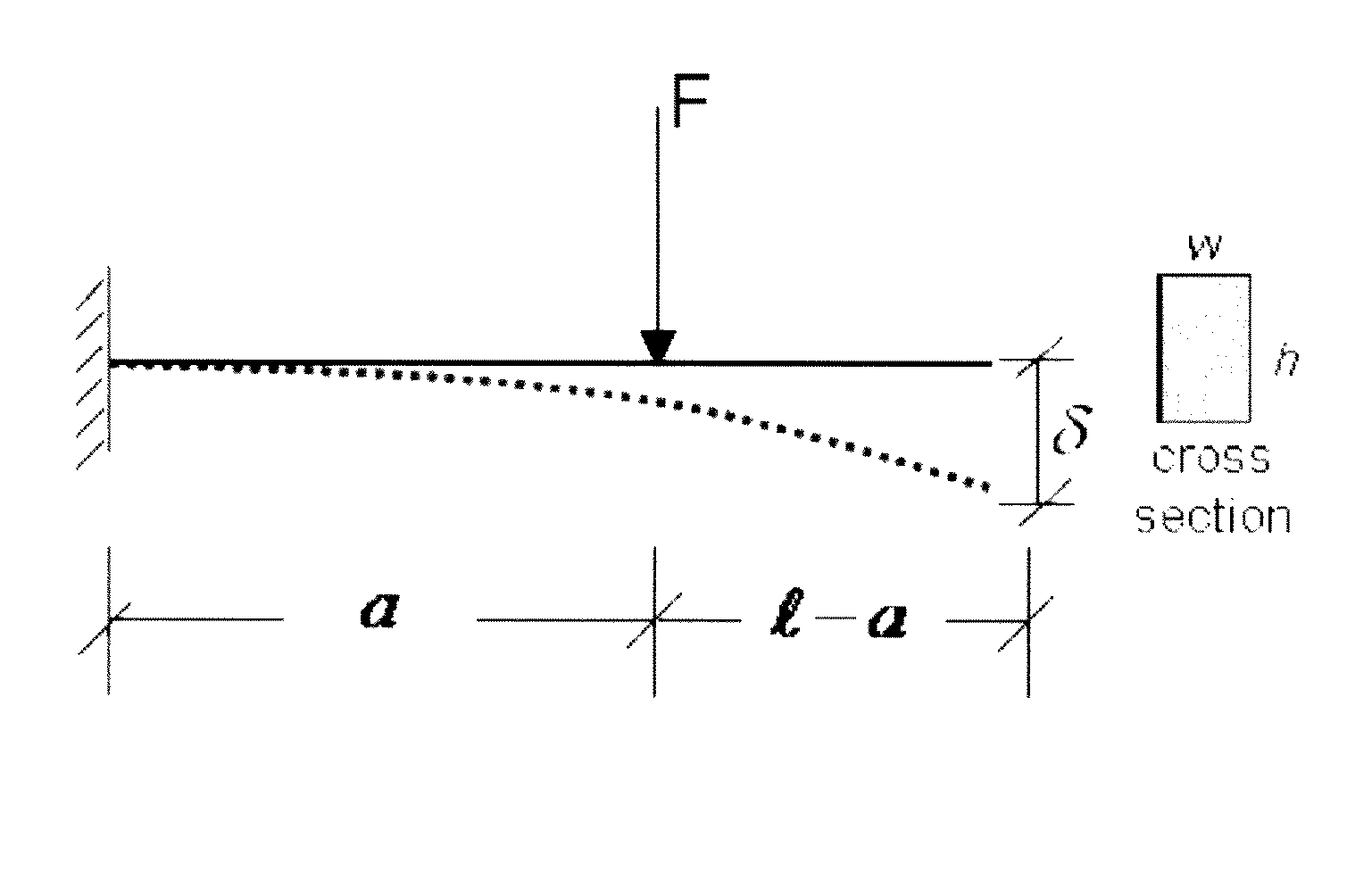

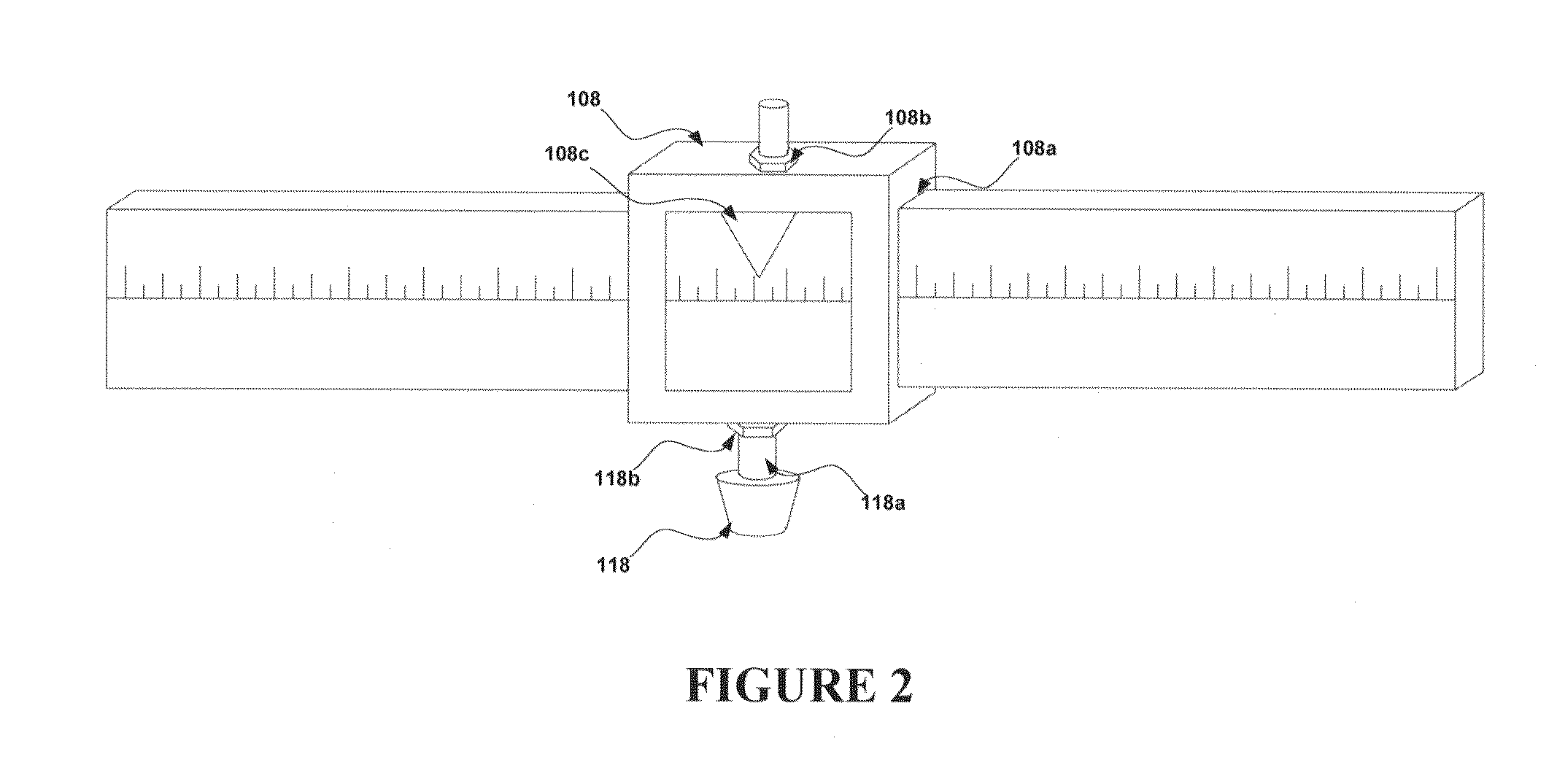

Tensometer for simultaneously evaluating polymerization stresses, shrinkage and modulus development

ActiveUS8857266B2Material strength using tensile/compressive forcesMaterial strength using steady bending forcesCantileverDental restoration

The present invention relates to apparatus and method for evaluating the development of PS during polymerization of dental restorative composites, which includes using a tensometer for measuring deflection of a calibrated cantilever beam induced by PS and calculating PS from the measured deflection. A tensometer according to an embodiment of the present invention can be used to quantify PS at varying beam locations and heights, and determine trend in PS development as a function of beam length. More importantly, in the present invention, the development of polymerization shrinkage and the elastic modulus can be simultaneously obtained in real time.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF COMMERCE THE NAT INST OF STANDARDS & TEHCNOLOGY

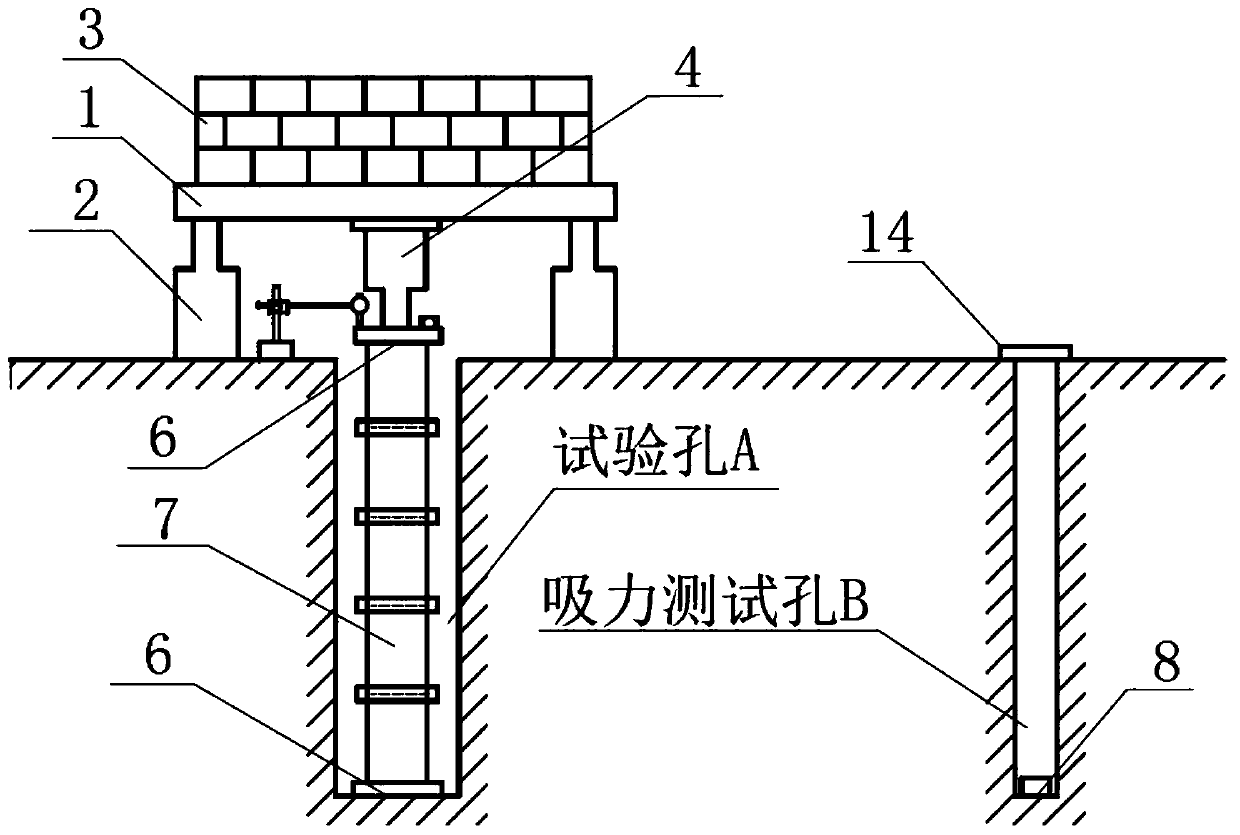

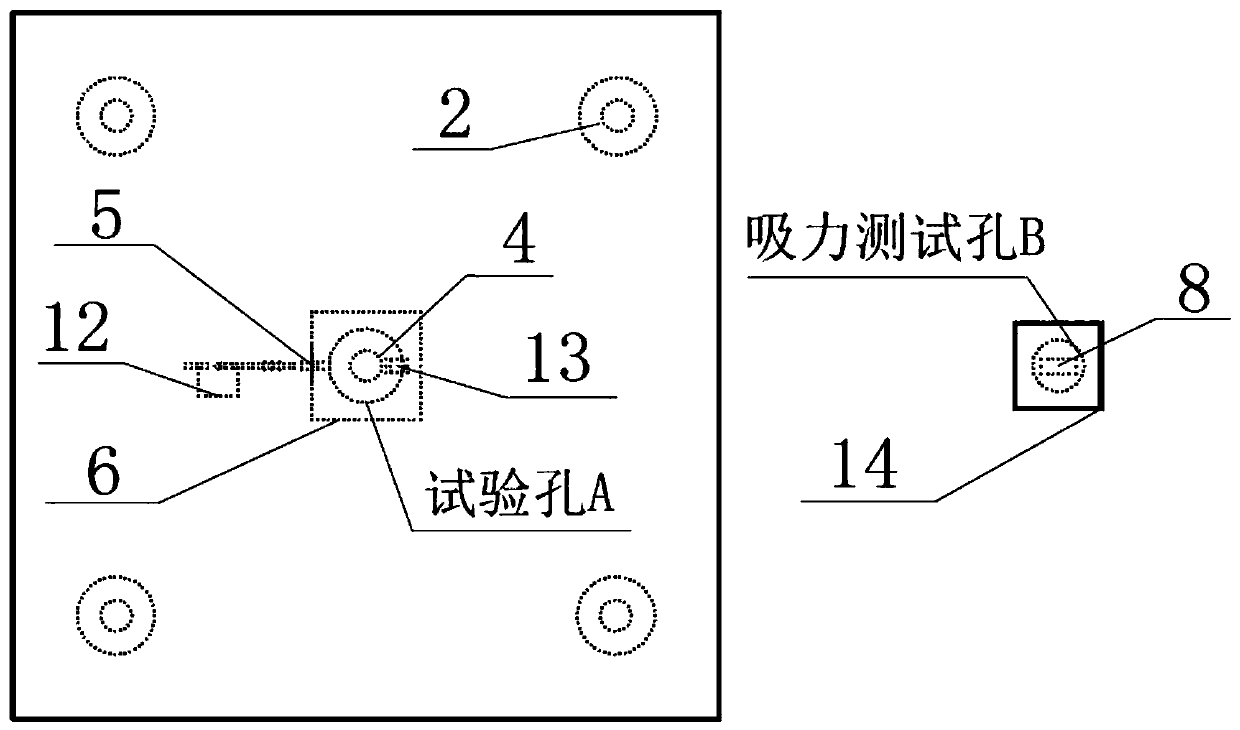

Field test and measurement method of strength characteristics of unsaturated soil

ActiveCN109799140AReduce disturbanceReduce construction areaMaterial strength using tensile/compressive forcesSoil scienceMeasurement test

The invention relates to a field test and measurement method of strength characteristics of unsaturated soil, which comprises: digging a test hole A and a suction test hole B with a Luoyang shovel, setting a measuring device of strength characteristics of unsaturated soil above the test hole A, setting a tensiometer at the bottom of the suction test hole B, carrying out loading test in the test hole A, observing changes in the reading of the tensiometer in the suction test hole B, drawing a load-settlement curve, and carrying out other steps. Field test and measurement from the Luoyang shovel-formed holes to strength characteristics of unsaturated soil are achieved herein; the field test and measurement method and device to acquire strength characteristics of unsaturated soil through the loading test and the tensiometer measurement test are provided; the load-settlement curve under different suction levels is drawn through groups of unsaturated soil loading tests under different suction levels so that strength characteristic parameters of unsaturated soil are attained; therefore, strength of the unsaturated soil under any suction level is calculated.

Owner:HAINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com