Cold-rolled steel strip processing technology

A processing technology and technology of cold-rolled strip steel, applied in metal processing equipment, rolls, metal rolling, etc., can solve the problems affecting the quality of rolling of steel strips and reduce the plasticity of steel strips, so as to improve the plasticity of rolling and improve the quality of steel strips. Strip rolling quality, the effect of improving the rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~28

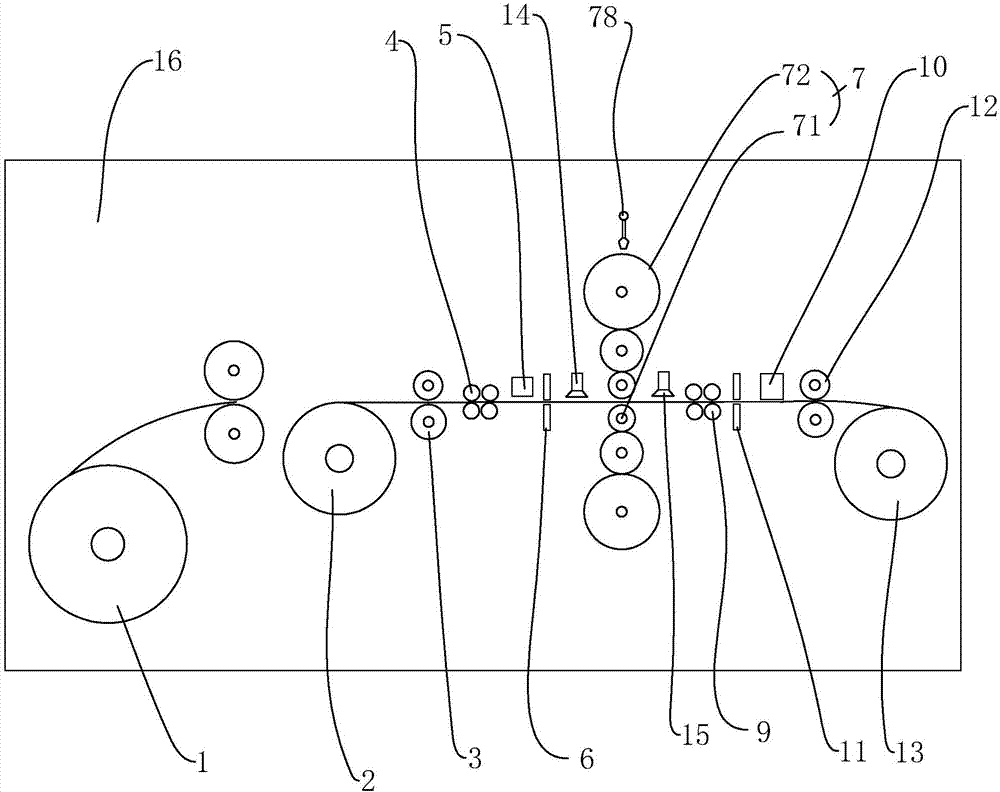

[0039] Embodiment 1~28: a kind of cold-rolled steel strip processing technology, combine figure 1 shown, including the following steps:

[0040] S1. The steel strip with a thickness of 3mm is sent to the left coiler 2 through the forward-rotating uncoiler 1, and then enters the left tension meter 4 for tension testing after passing through the left steering roller 3, and enters the left speedometer 5 for speed measurement. , Enter the left thickness gauge 6 for thickness testing, and then enter the six-roll reversible cold rolling mill 7 for the first rolling, the tension of the left tension gauge 4 is 5 ~ 8kgf / mm 2 ; During rolling, the first cooling is carried out through the cooling device 8 arranged on the six-roller reversible cold rolling mill 7. After rolling and cooling, it enters the right tensiometer 9 for tension testing, enters the right speedometer 10 for speed measurement, and enters the right tension meter 10 for speed measurement. Thickness tester 11 conducts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com