Patents

Literature

298results about How to "Improve rolling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

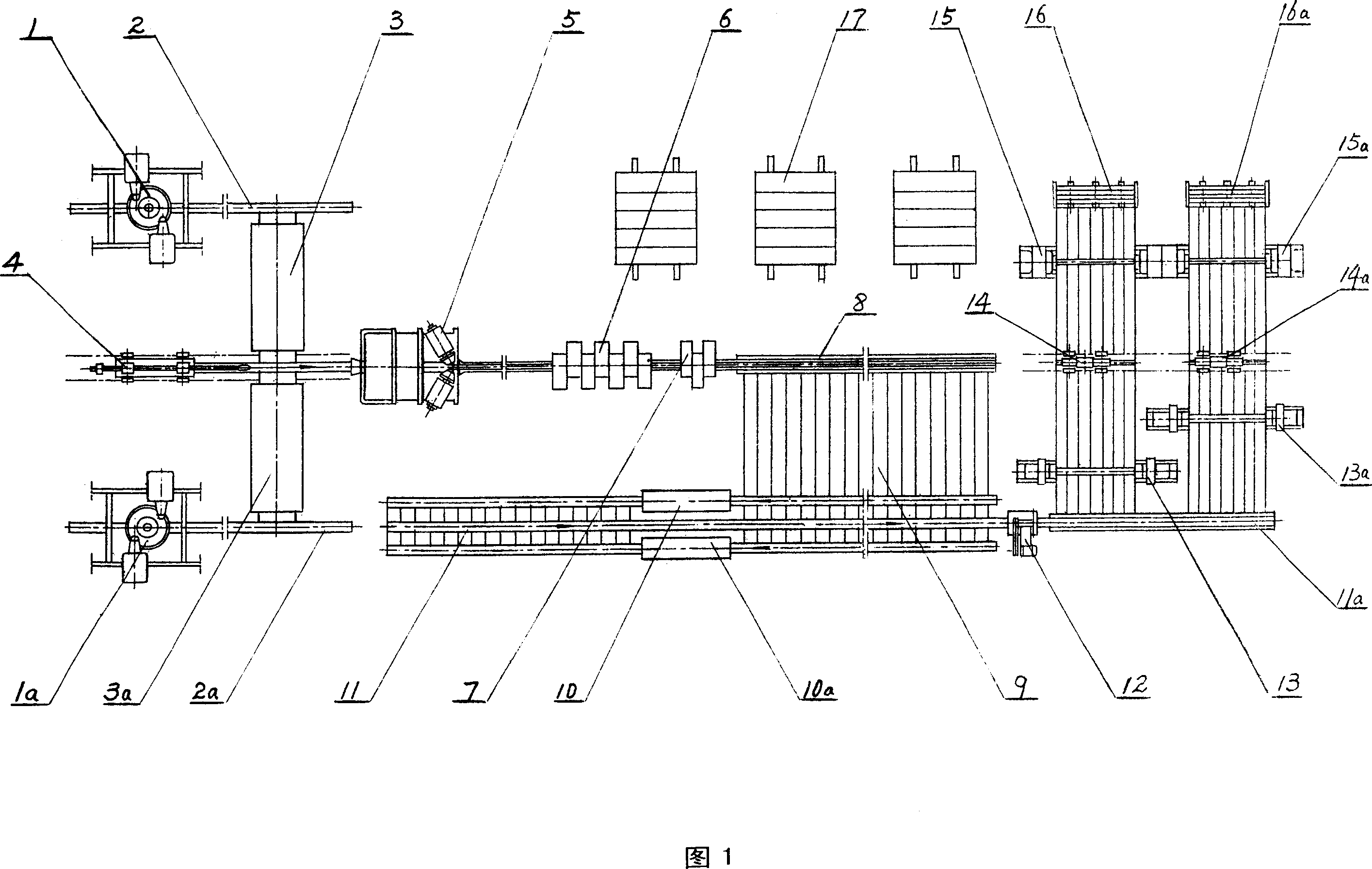

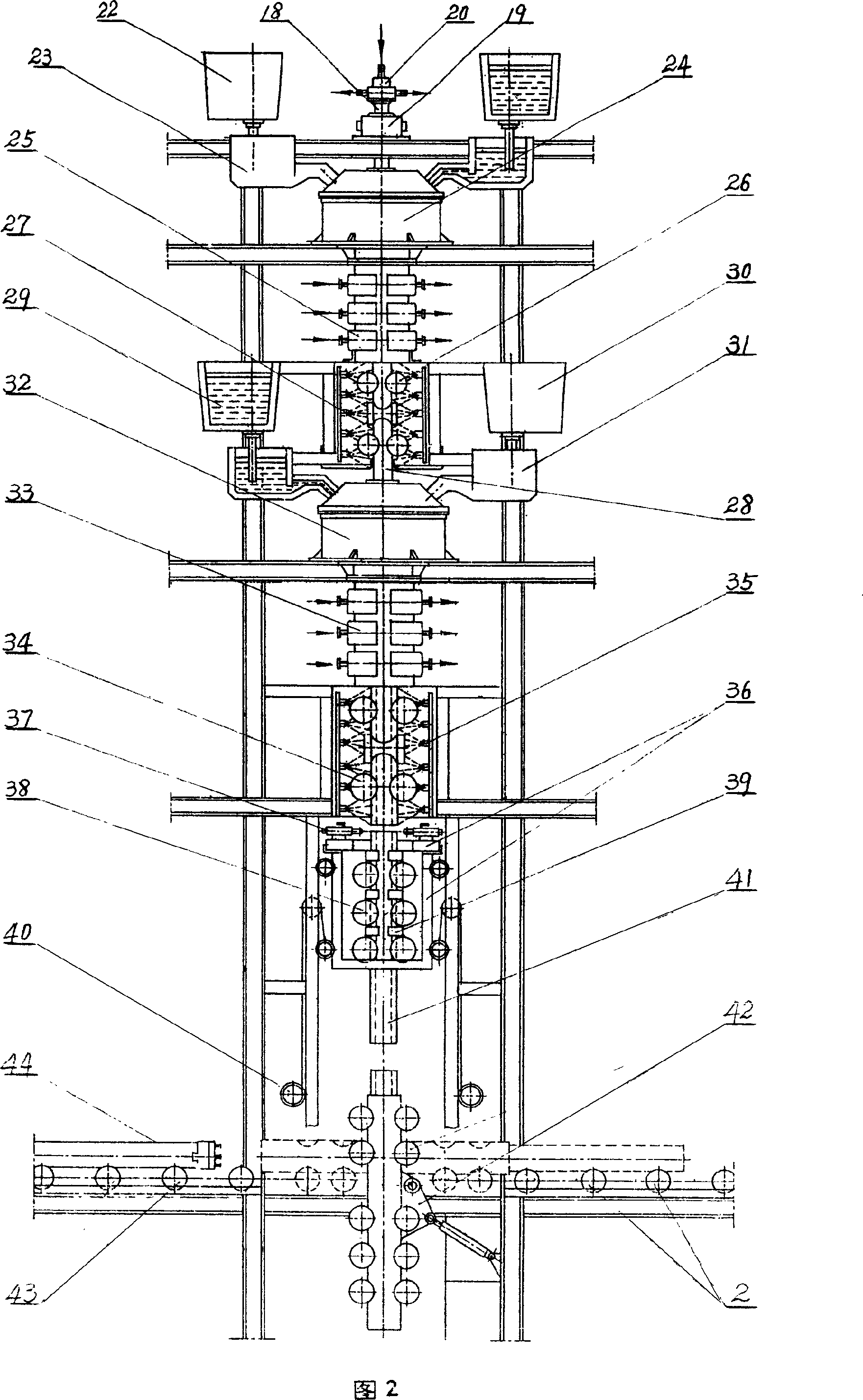

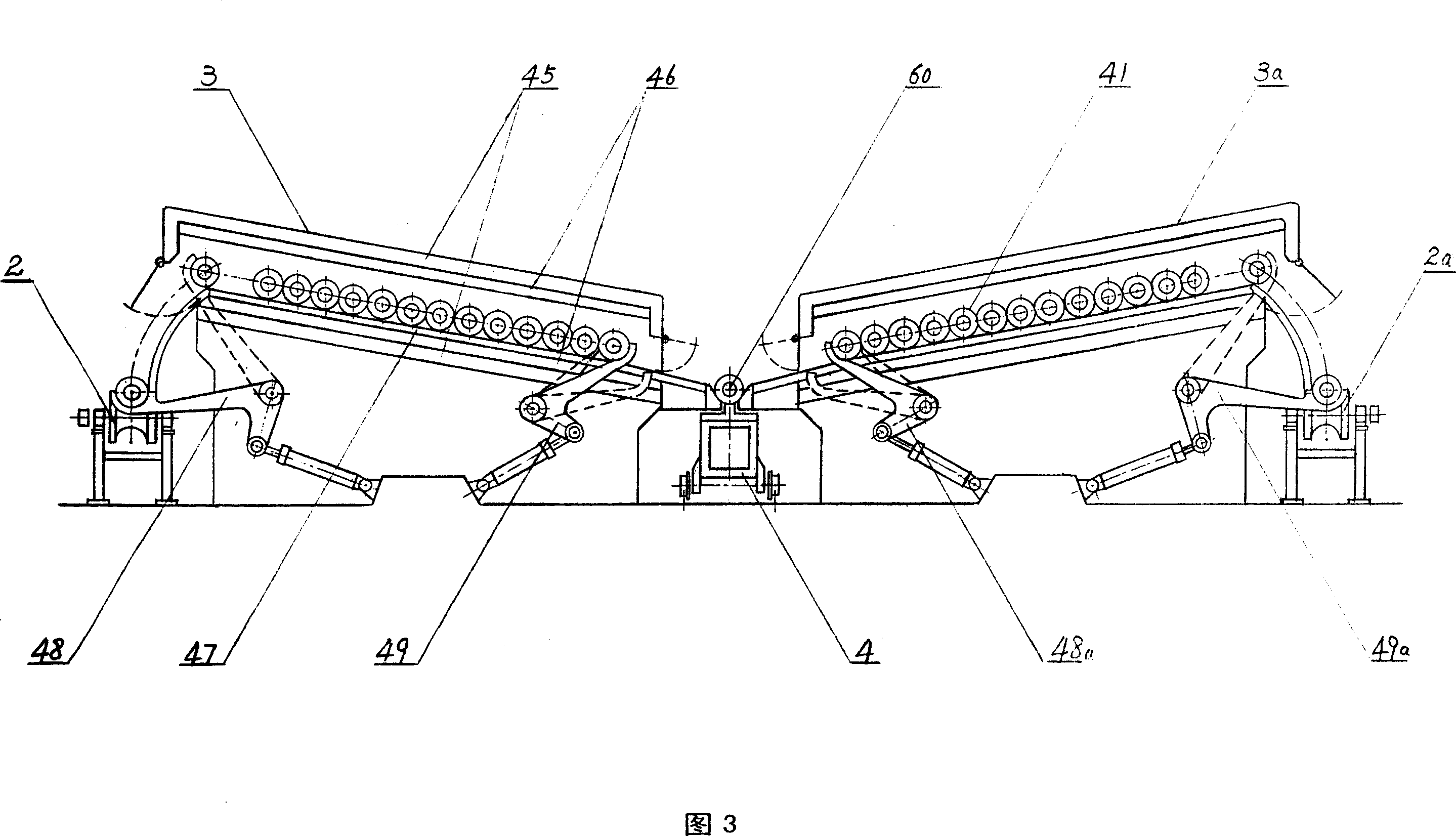

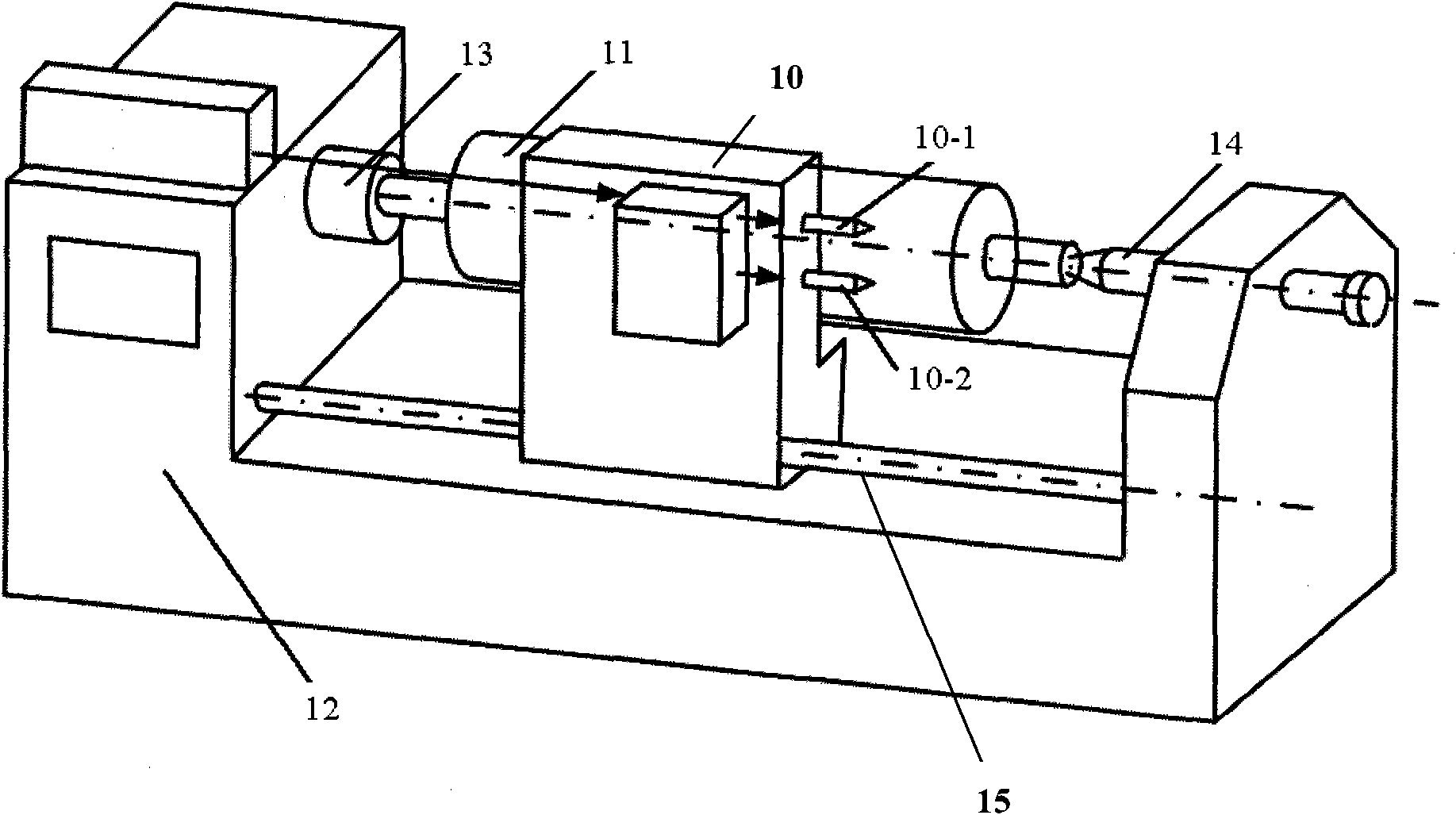

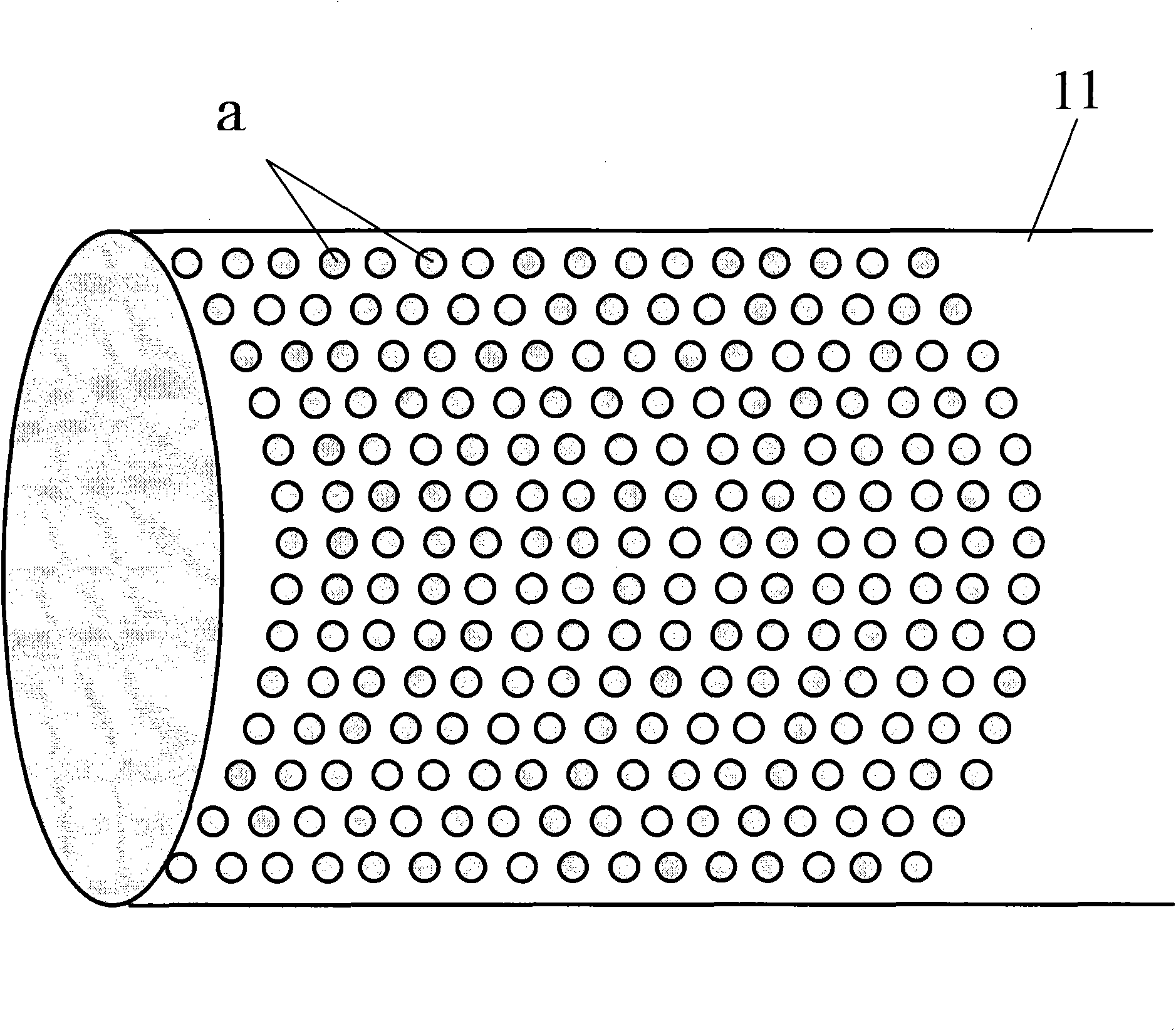

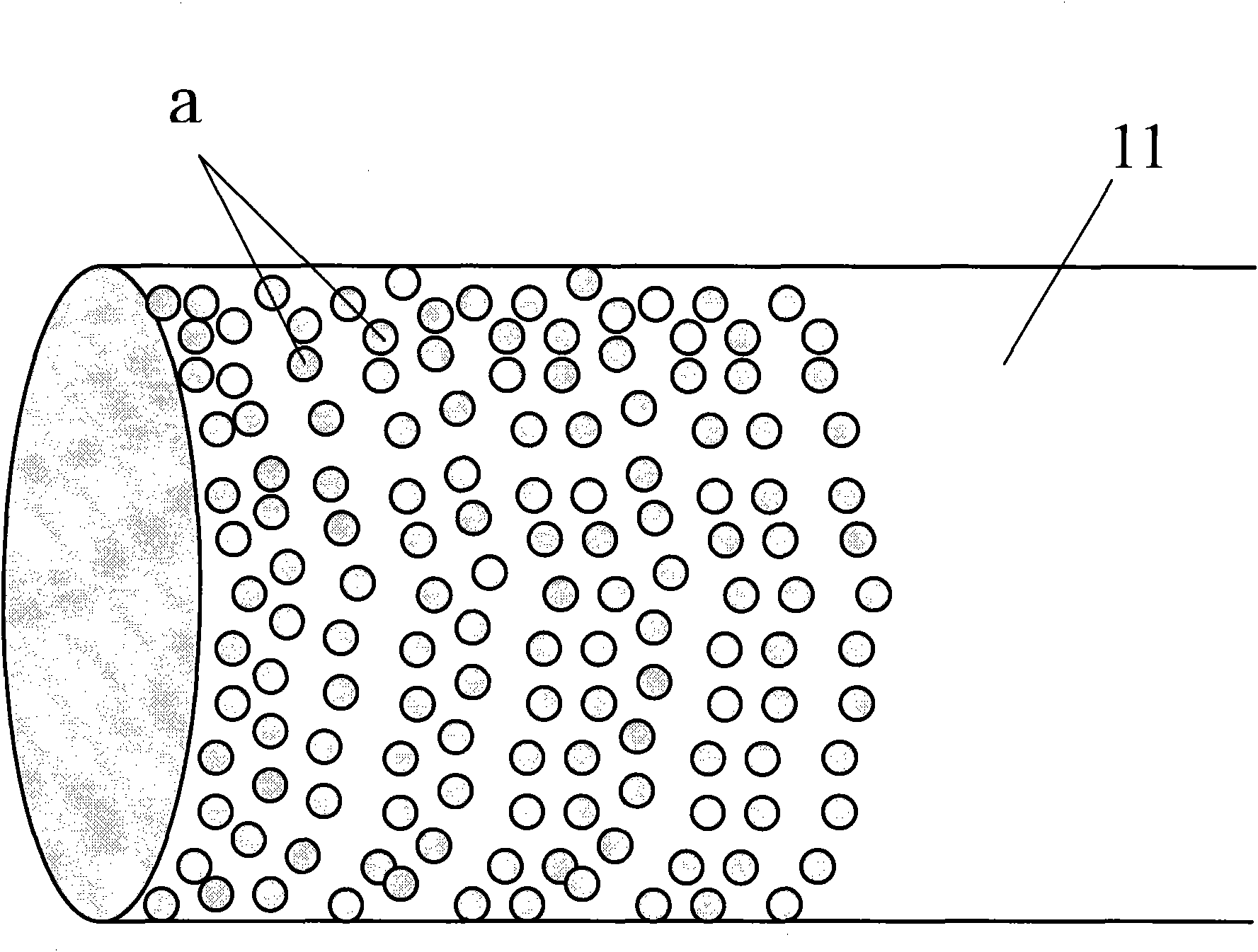

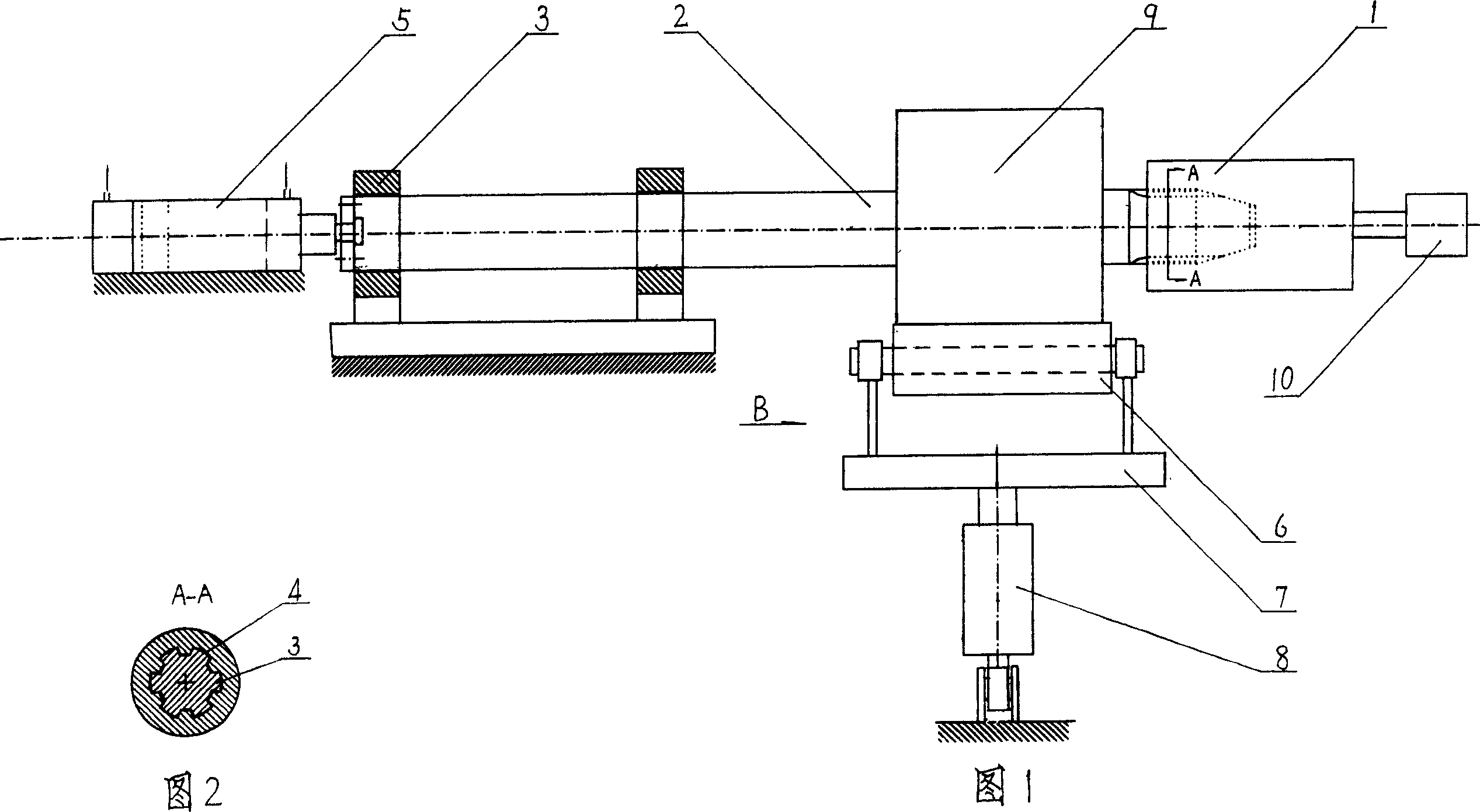

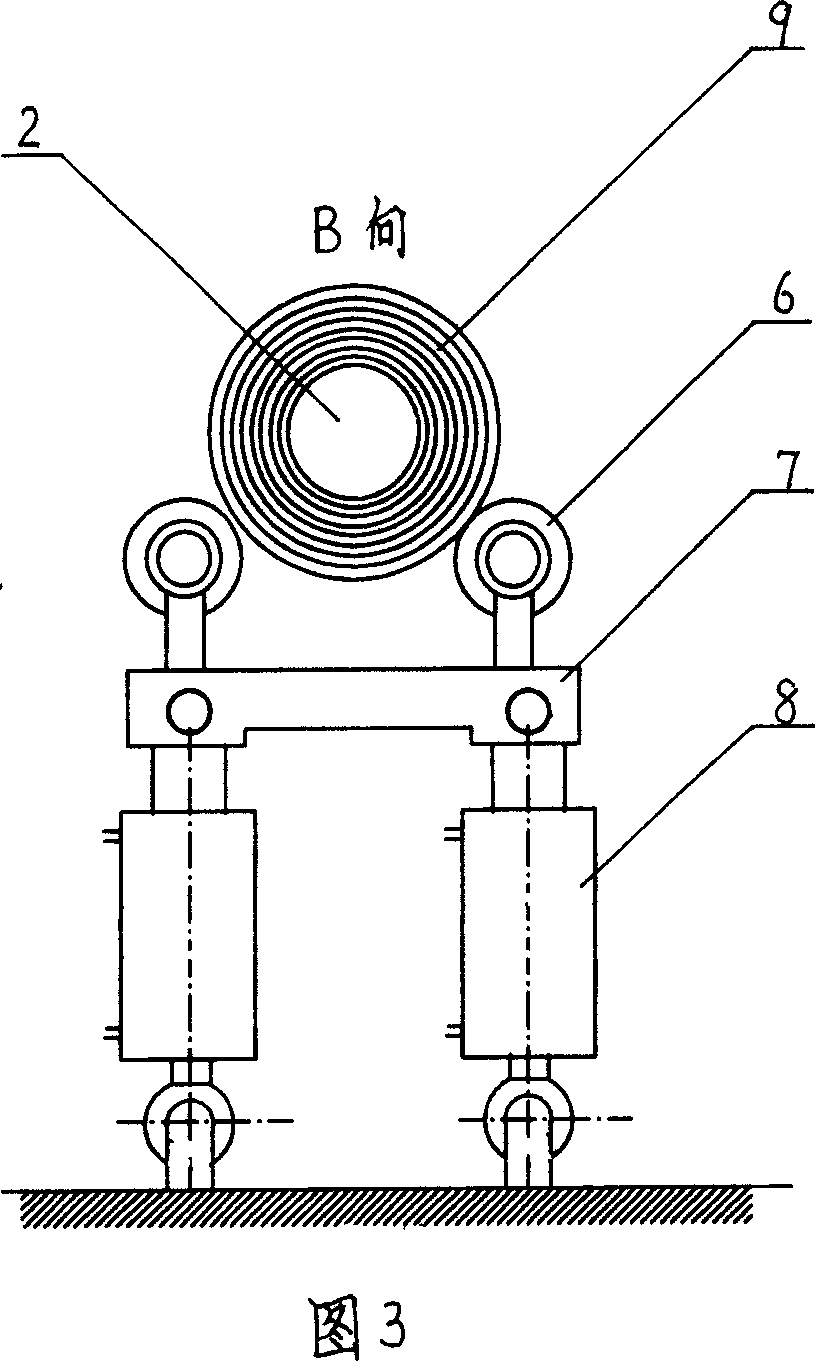

Continuous casting, continuous solling production method and apparatus for stainless steel seamless composite pipe

InactiveCN101024229AShort production processReduce equipment investmentMetal rolling arrangementsSteel tubeEnergy source

The invention relates to stainless steel seamless composite tube continuous casting tandem rolling producing method and device. Its features are that it uses two parallel vertical type hollow bloom continuous casting machines to directly cast out stainless steel composite hollow bloom, cut the high temperature tube blank into given size, and put into sloping bottom die casting furnace to adjust temperature; then the tube blank is taken out to sent into roller trio planet skew rolling mill, tension reducing mill, sizing mill to form finished tube; the finished tube is processed cooling, strengthening, scaling, packing. The invention can shorten production flow, reduce device investment, save energy sources, and increase production efficiency and steel tube rolling quality.

Owner:李铁铎

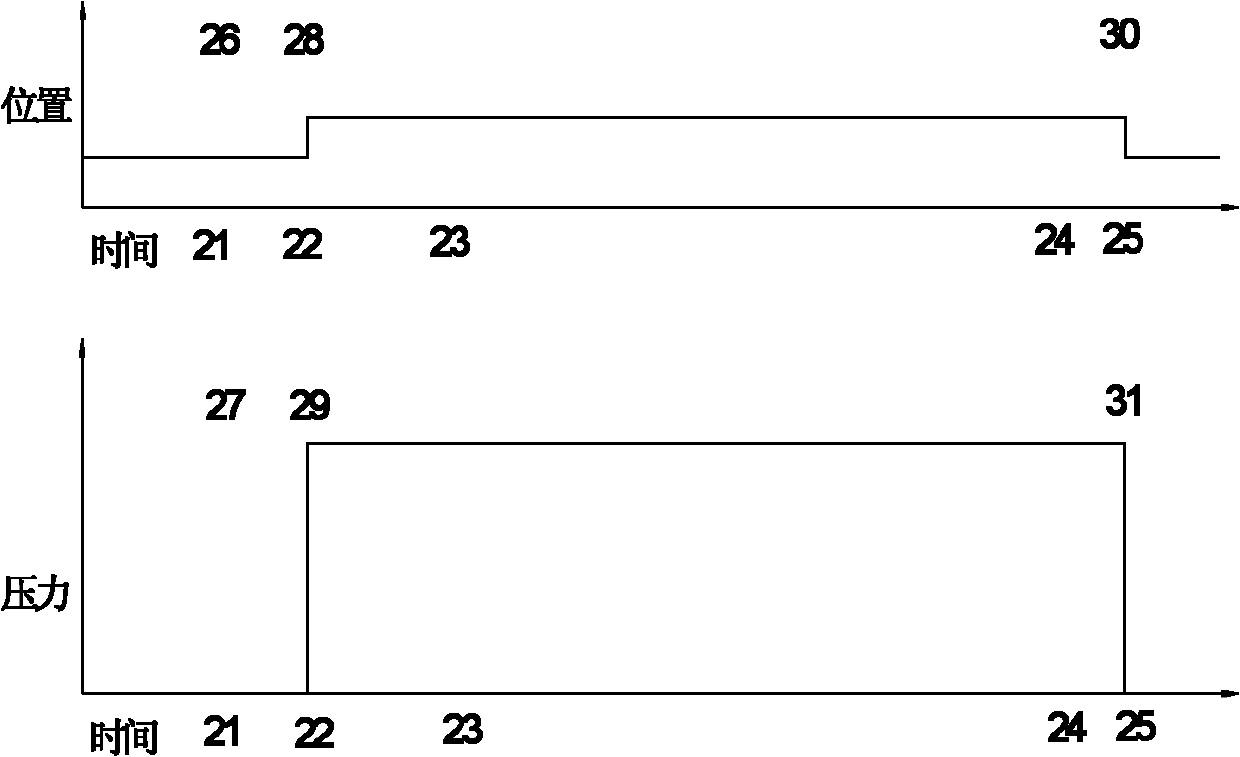

Hot-rolled coiler pinch roll controlling method

The invention relates to a hot-rolled coiler pinch roll controlling method. A pinch roll adopts position control or pressure control. The hot-rolled coiler pinch roll controlling method comprises the following steps that: step 1: before strip steel is gripped, the pinch roll adopts the position control; step 2: at the moment when a head part of the strip steel is gripped, the pinch roll adopts the pressure control; step 3: after the strip steel is wound on a wound roll and tension is formed, the pinch roll adopts the position control or the pressure control; and step 4: after the strip steel is tailed-out by a finishing front stander, the pinch roll adopts the pressure control. Due to adoption of the method, on the premise of the present precision control of roll-gap deviation at two sides of the pinch roll, the coiling quality of the tail part of a thin sheet can be improved, coiling flaws such as creasing, edge damage and surplus edge on the tail part of a steel coil can be reduced, damage on the surface of the pinch roll caused by the rolling cracking of the tail part of the strip steel can also be effectively reduced, the indentation flaw of the pinch roll can be reduced, and the high-strength steel wave-shaped flaw caused by the abrasion of the pinch roll can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

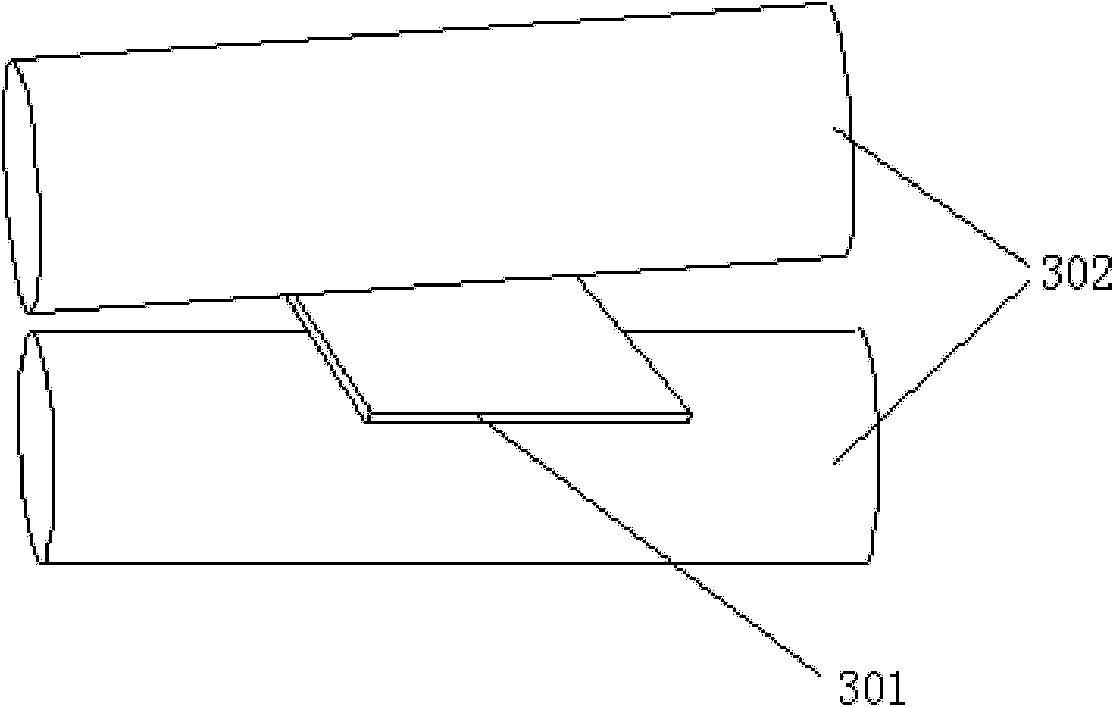

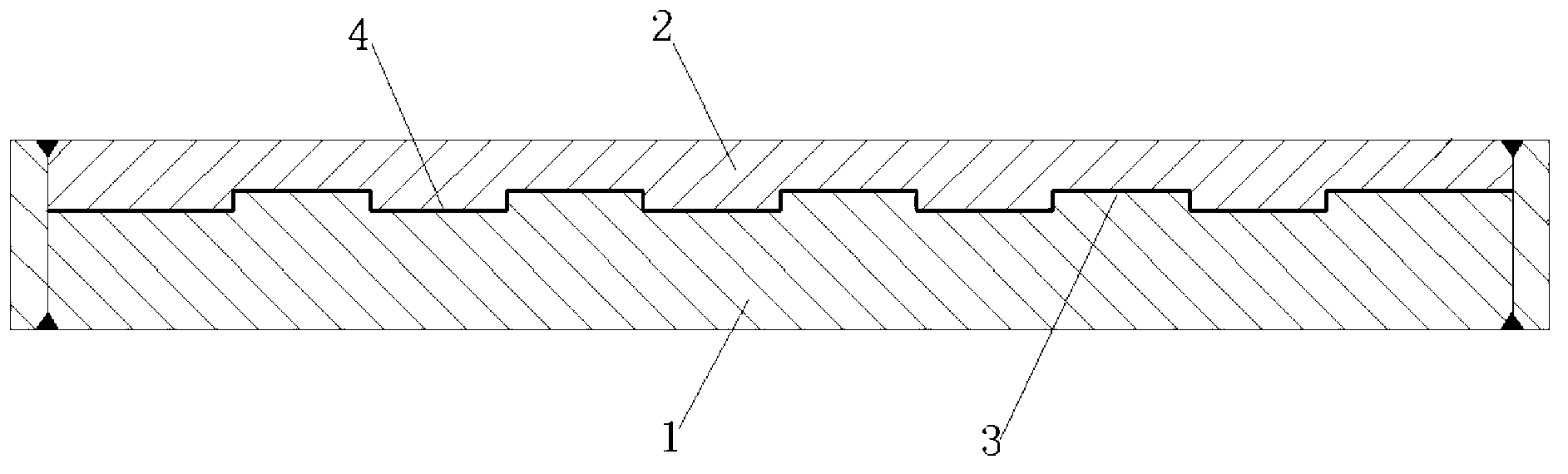

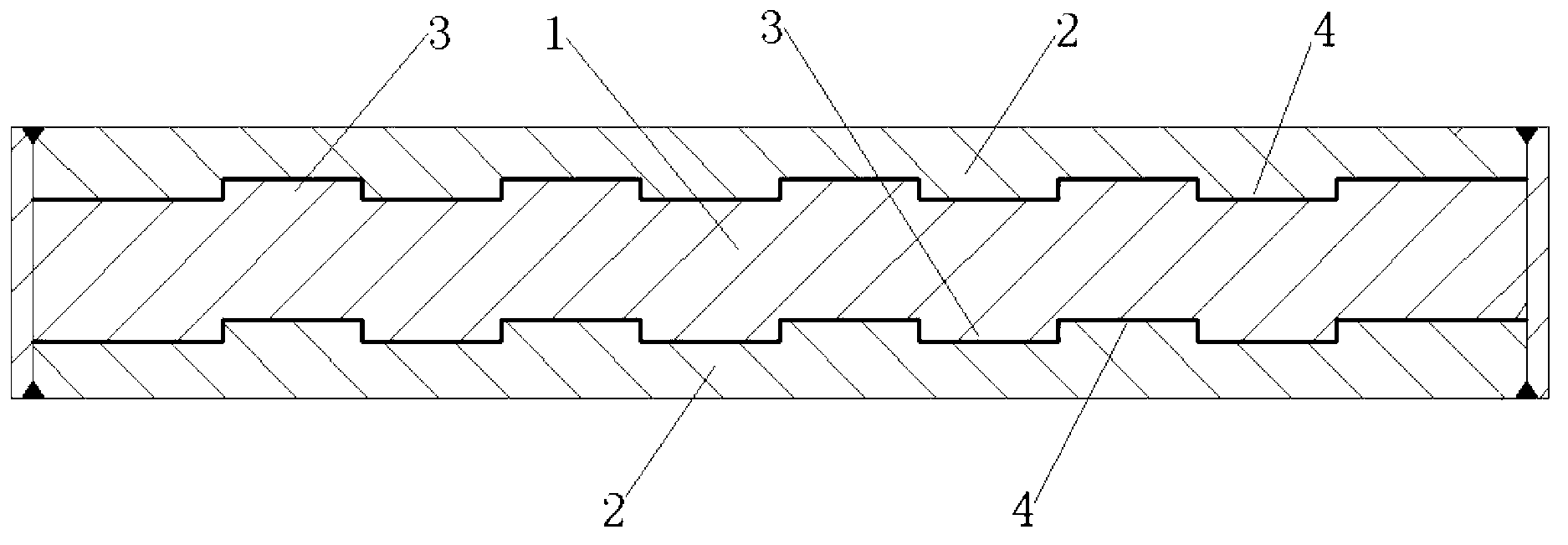

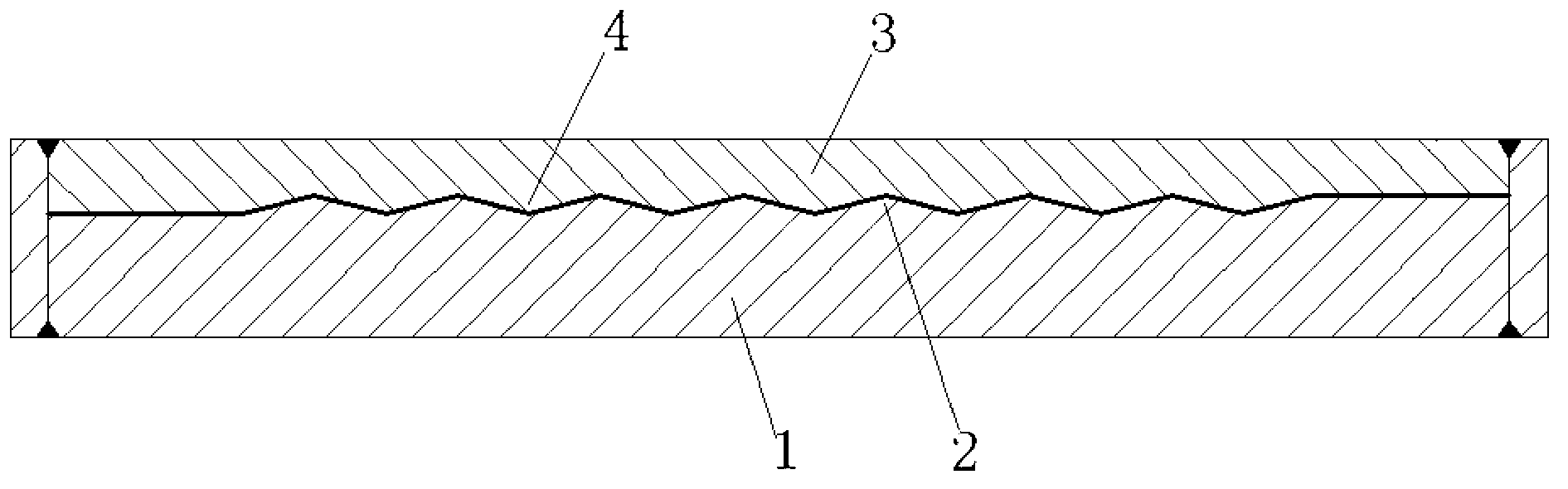

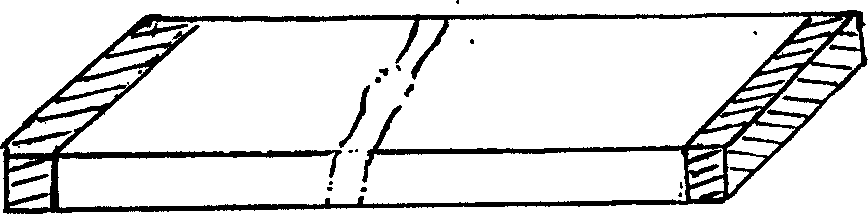

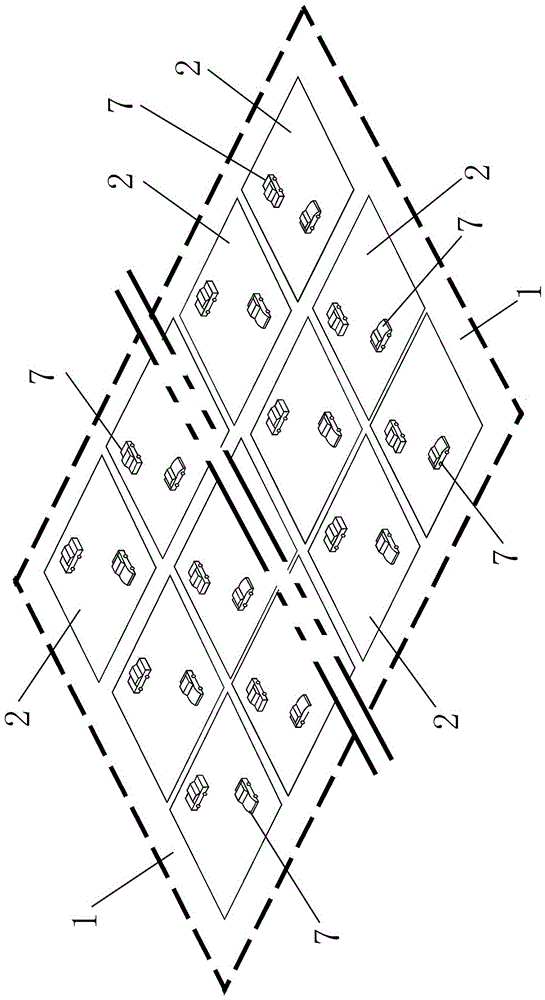

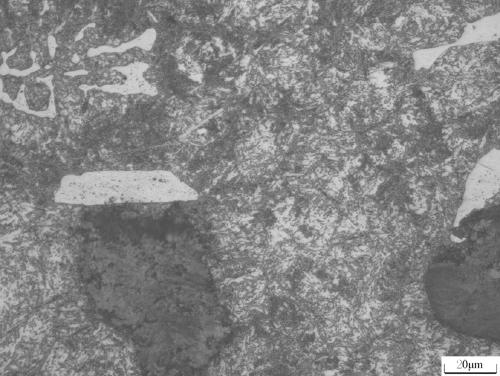

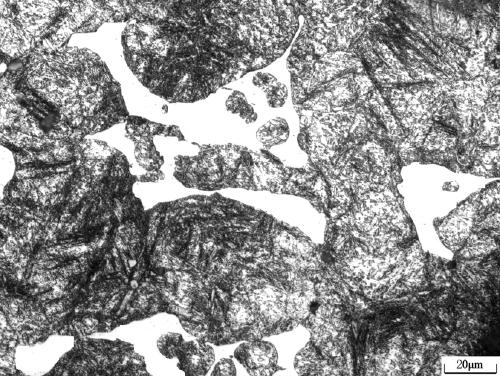

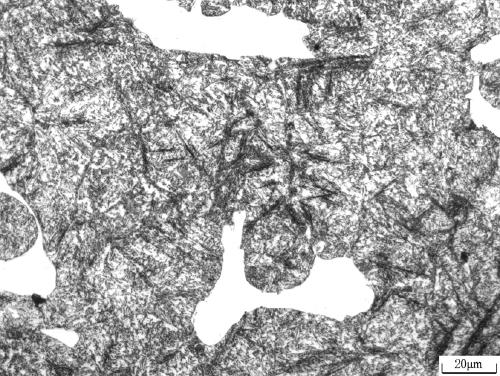

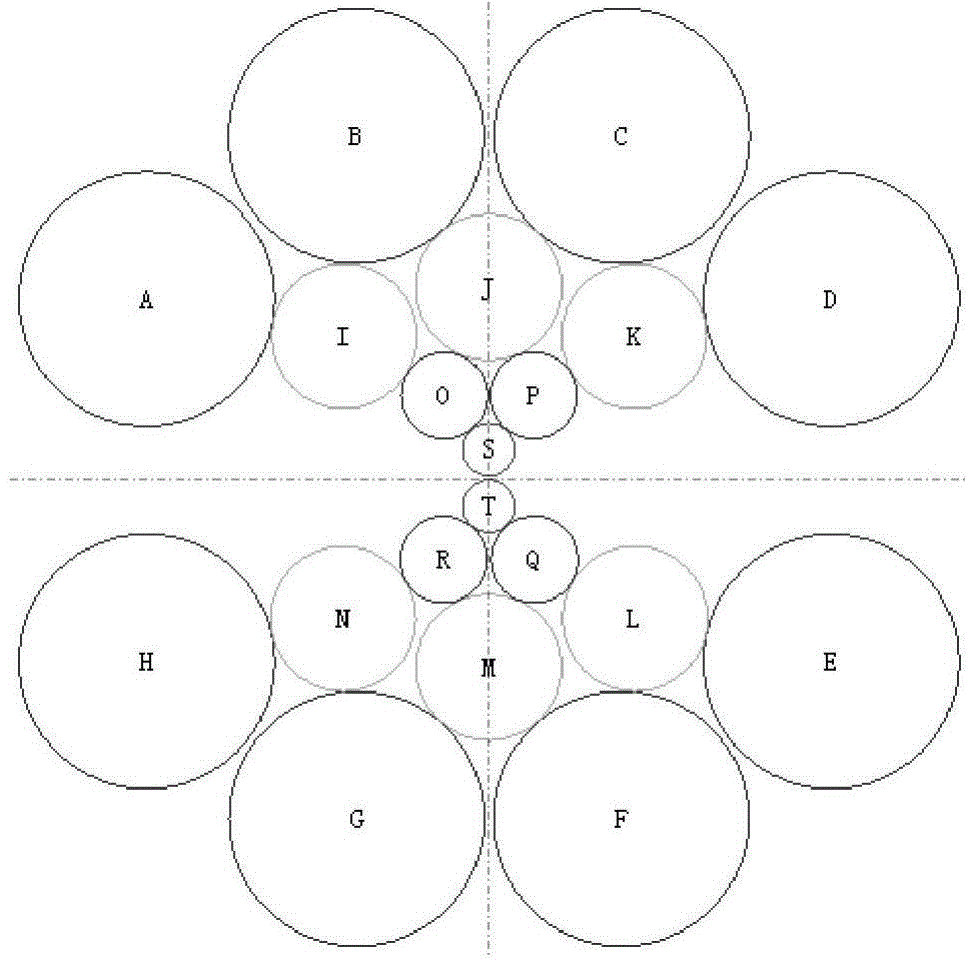

Meshing type composite plate vacuum rolling preparation method

InactiveCN103272842AImprove fitAvoid separationAuxillary arrangementsMetal rolling arrangementsComposite strengthComposite filter

The invention discloses a meshing type composite plate vacuum rolling preparation method. The meshing type composite plate vacuum rolling preparation method includes the steps: processing base plate protrusions and covering plate protrusions, which are matched mutually, on compositing surfaces of a base plate and a covering plate respectively; cleaning the compositing surfaces of the base plate and the covering plate; overlaying the base plate and the covering plate, and enabling the base plate protrusions on the base plate and the covering plate protrusions on the covering plate to be meshed mutually; obtaining a composite plate blank by means of blank assembly; and performing hot rolling so that a composite plate is obtained. The meshing type composite plate vacuum rolling preparation method has the advantages that the base plate protrusions and the covering plate protrusions which are matched mutually are processed on the compositing surfaces of the base plate and the covering plate respectively, so that fitting force between the base plate and the covering plate is increased by the aid of meshing force among the base plate protrusions and the covering plate protrusions, separation of the base plate from the covering plate during rolling is avoided, and rolling quality is improved while process is simple; meanwhile, contact area between the base plate and the covering plate is enlarged (namely, the area of a compositing interface is enlarged), so that compositing strength of the composite plate is enhanced; and the meshing type composite plate vacuum rolling preparation method is applicable to preparation of composite plates.

Owner:武钢集团有限公司

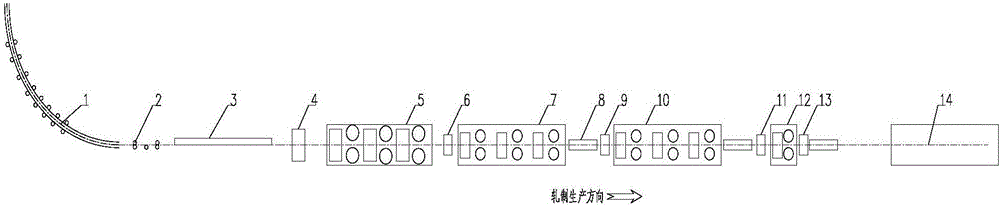

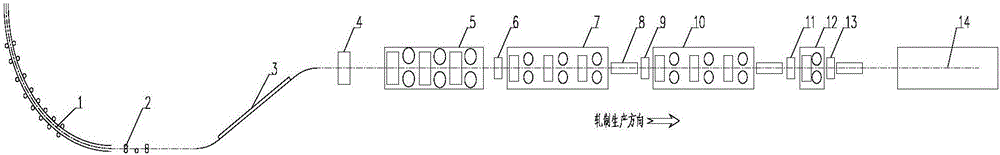

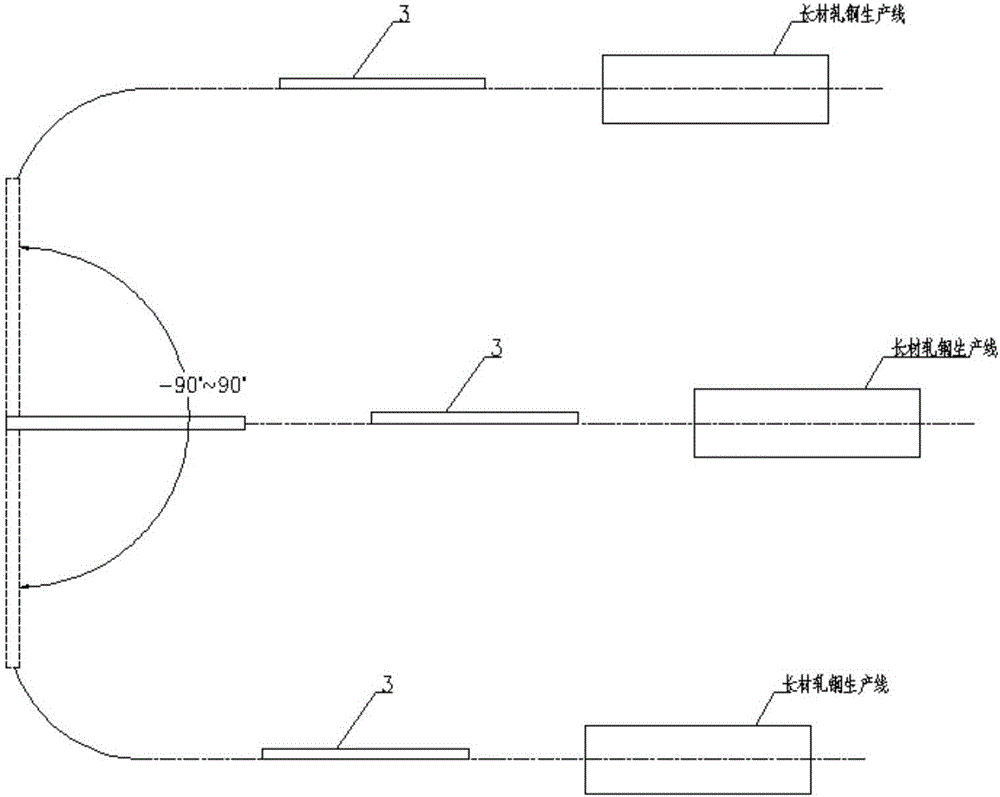

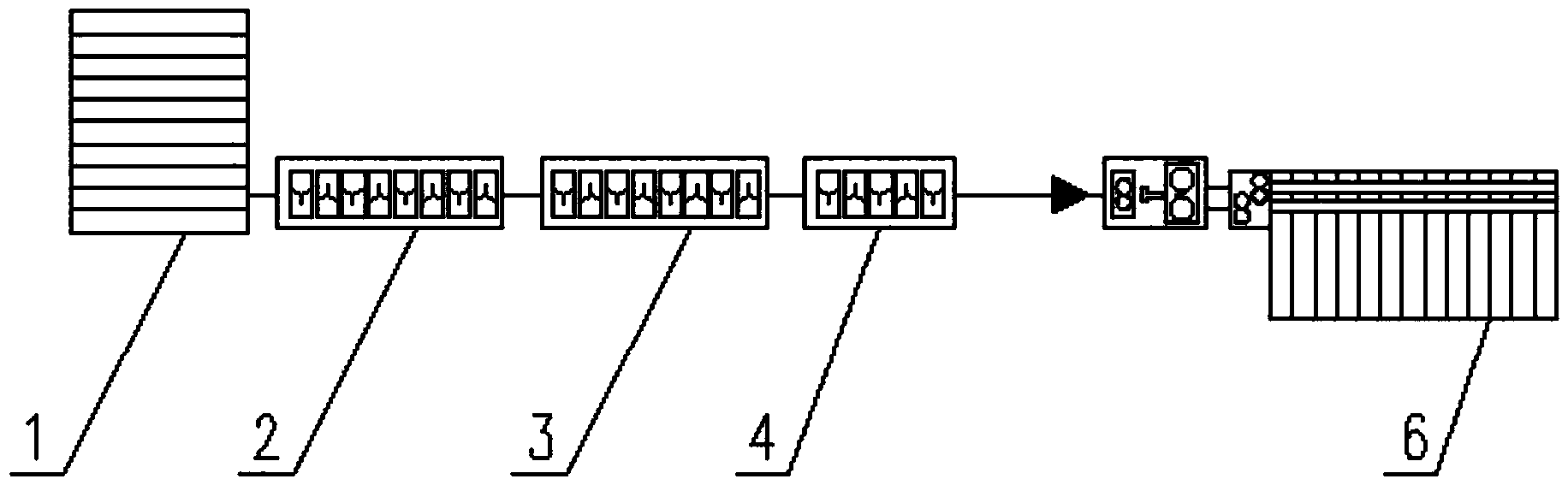

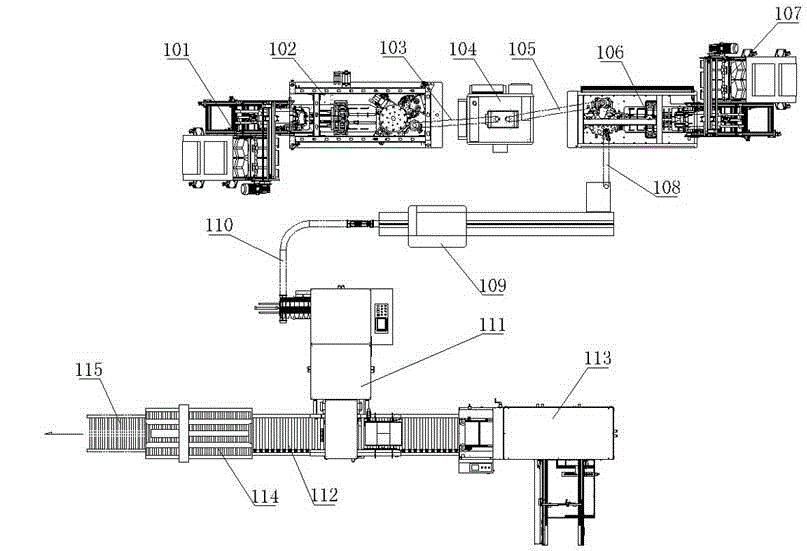

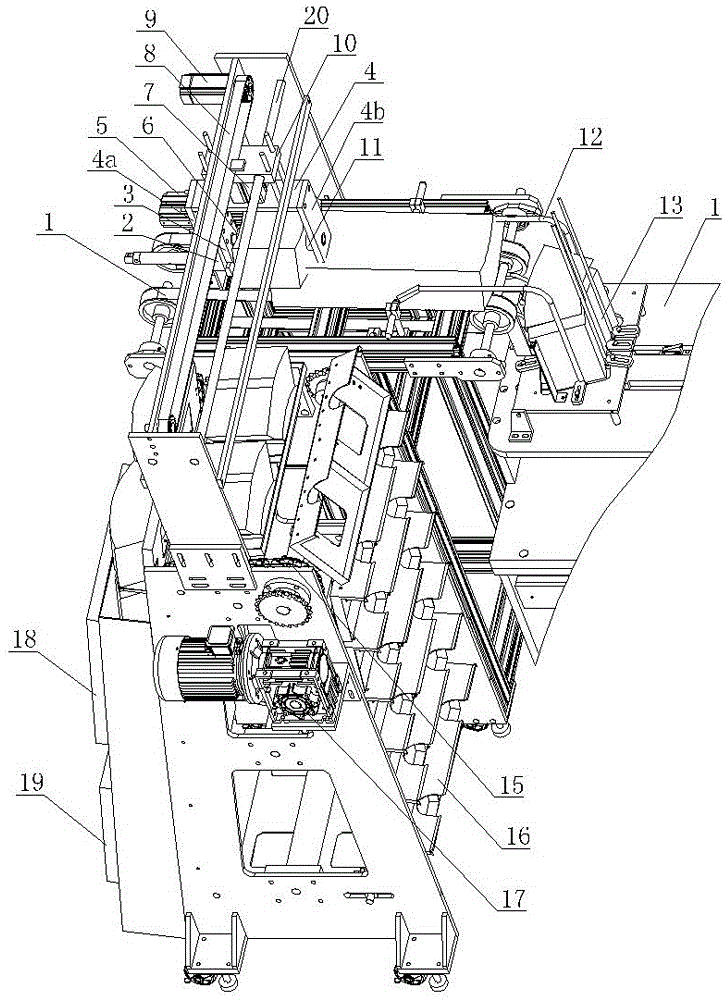

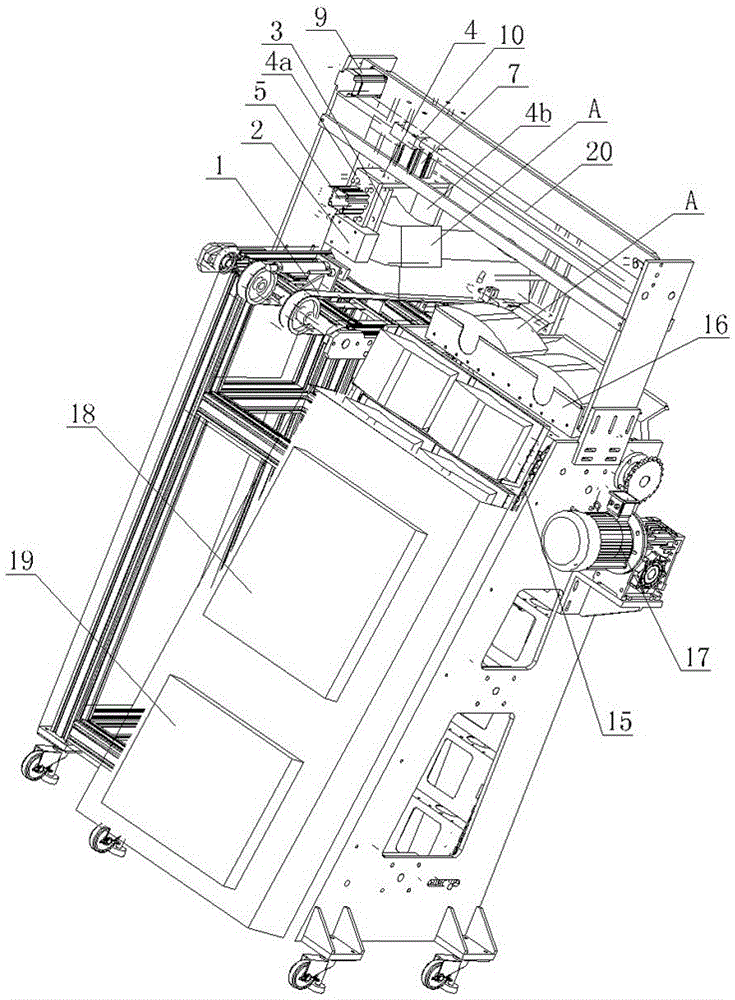

Long-bar rolling production line and production technology thereof

InactiveCN106269868AAvoid lostAvoid losses and achieve endless rollingMetal rolling arrangementsFailure rateProduction line

The invention discloses a long-bar rolling production line and a production technology thereof, and belongs to the technical field of bar rolling. The production line comprises a continuous casting machine, a withdrawal and straightening machine, a pre-rolling emergency shear, a roughing mill unit, a head cutting flying shear, an intermediate mill unit, a finishing mill unit, a reducing and sizing unit and a cooling bed which are connected by roller beds in sequence, wherein the continuous casting machine is a single-machine uniflow continuous casting machine; and the roller bed between the continuous casting machine and the roughing mill unit is a heat preservation roller bed. The production technology comprises the steps of: carrying out single-machine uniflow continuous casting, carrying out heat preservation by using the conveying roller bed, straightening by using the withdrawal and straightening machine, rolling by using the roughing mill unit, rolling by using the intermediate mill unit, rolling by using the finishing mill unit, rolling by using the reducing and sizing unit, cooling and collecting. The long-bar rolling production line and the production technology have the beneficial effects that round billets are directly rolled after the round billets are cast by using the single-machine uniflow continuous casting machine, thereby reducing middle working procedures and heat loss, realizing endless rolling, meanwhile omitting a heating surface and reducing a failure rate in a production process.

Owner:CISDI ENG CO LTD

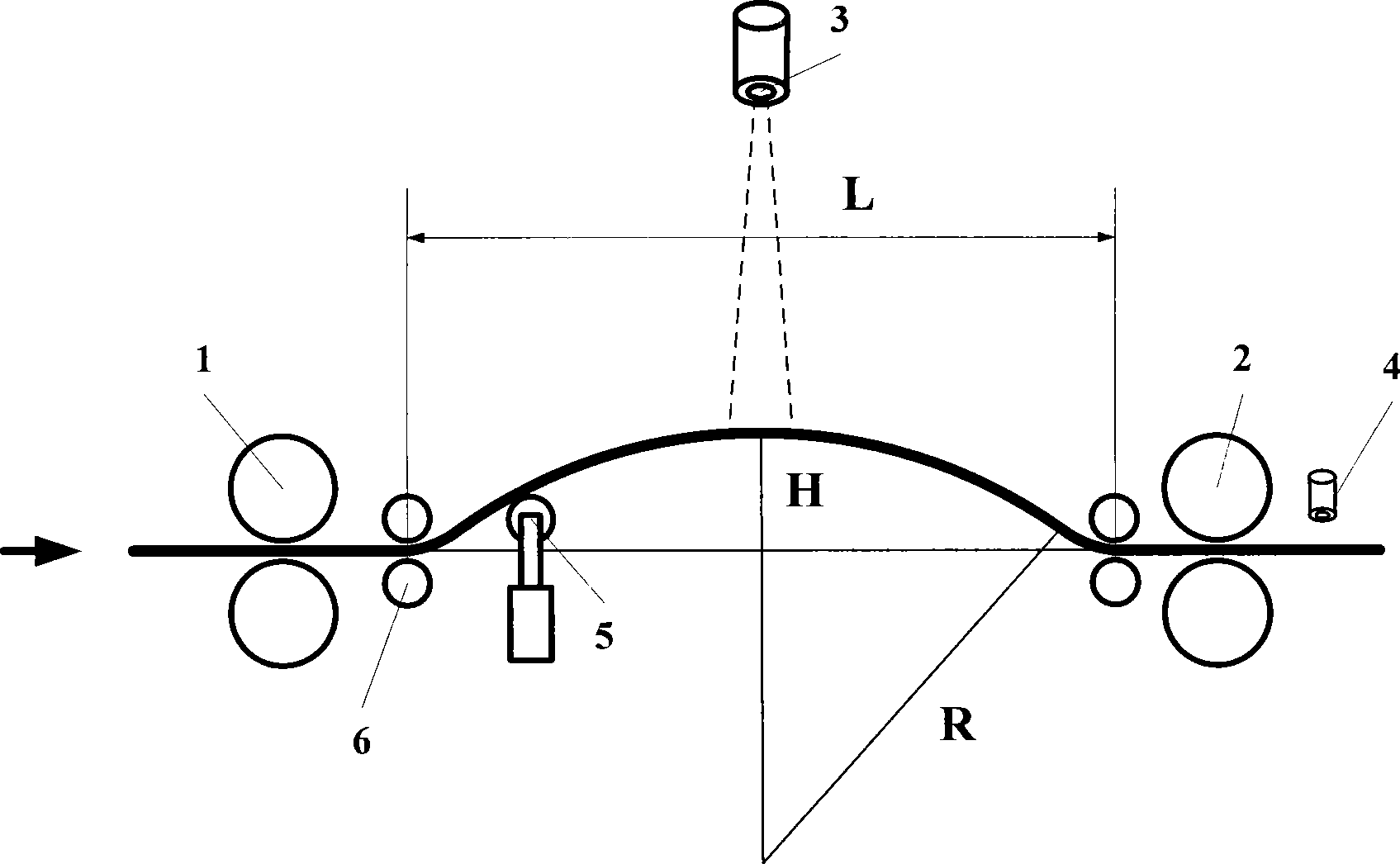

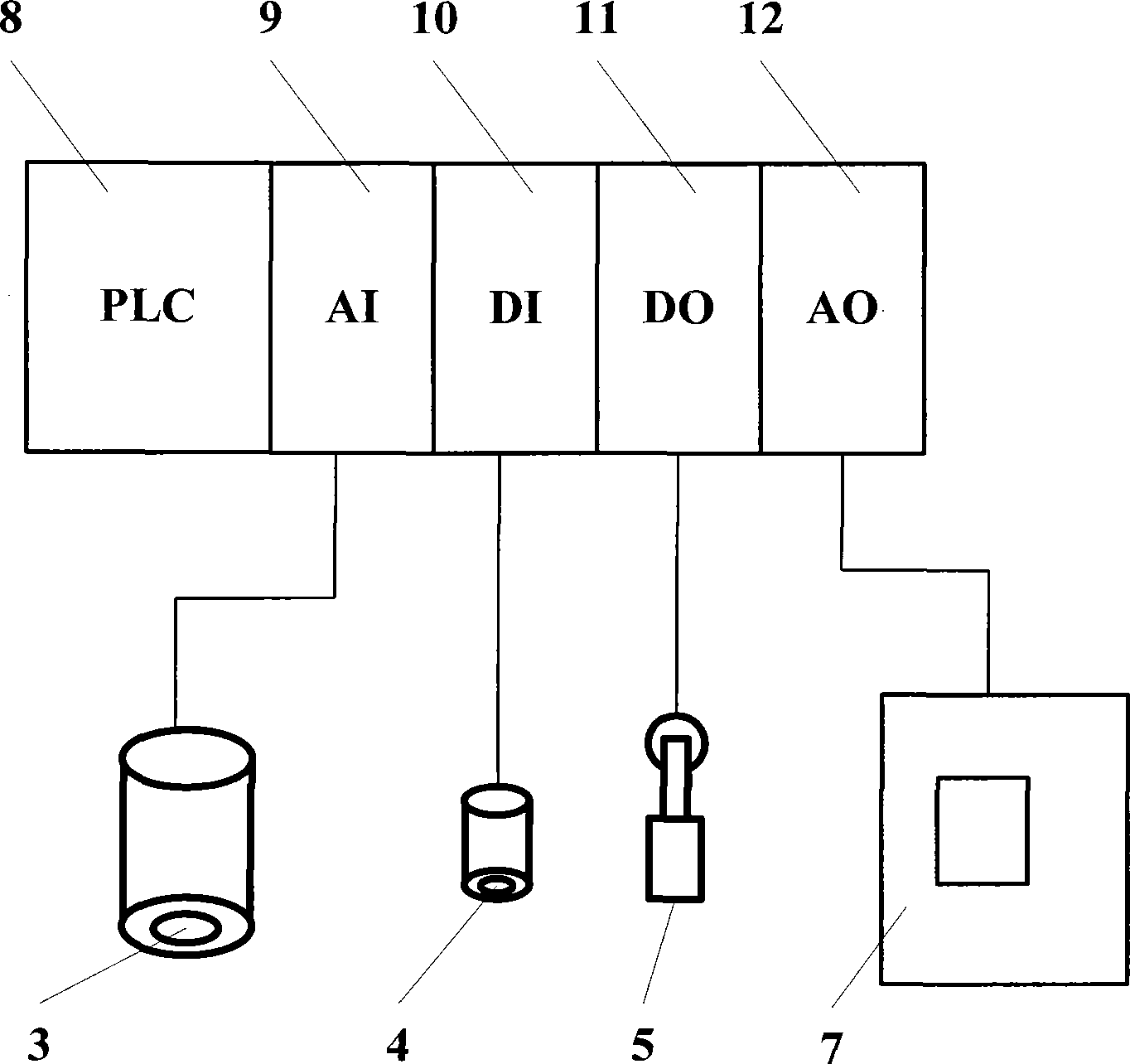

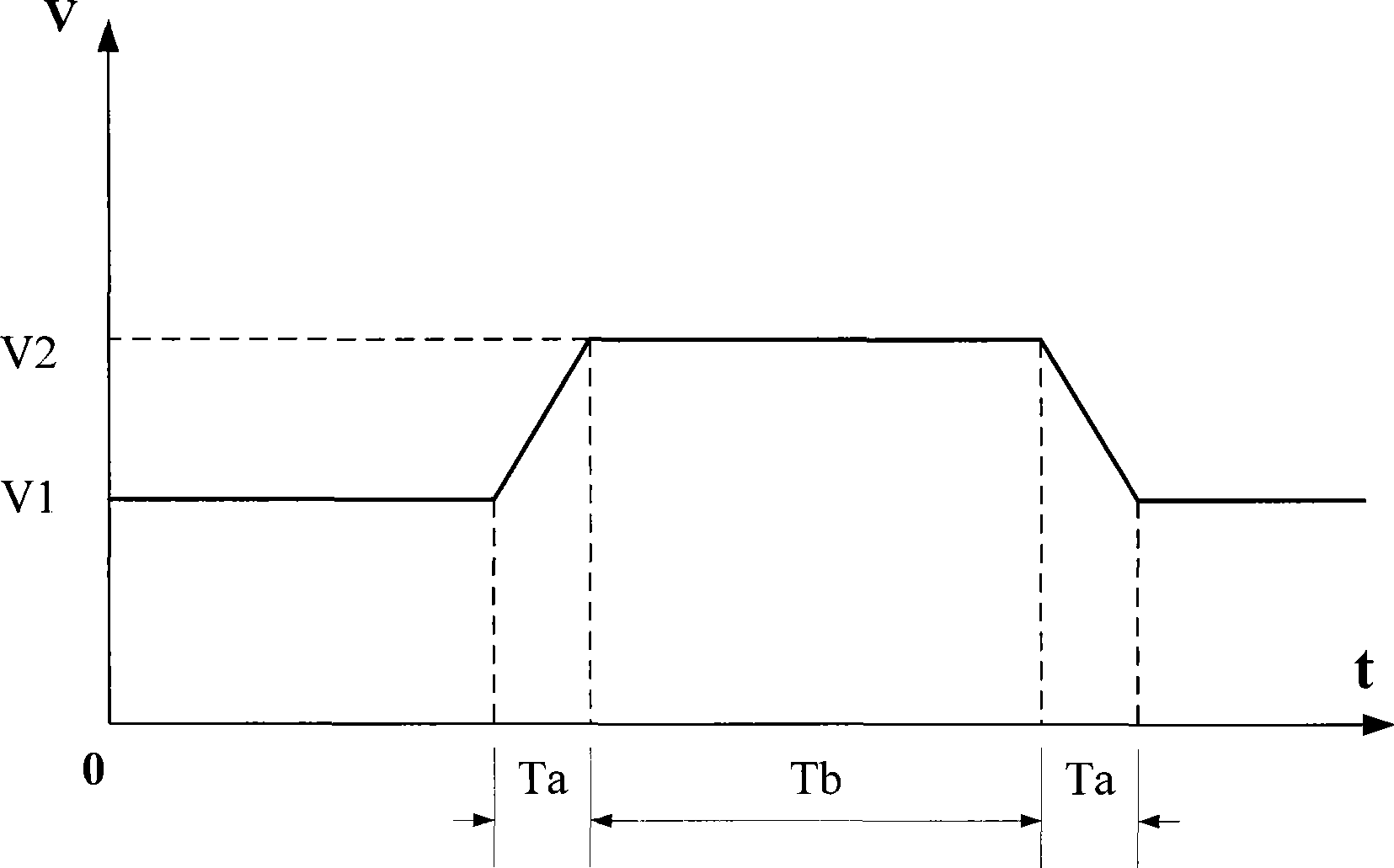

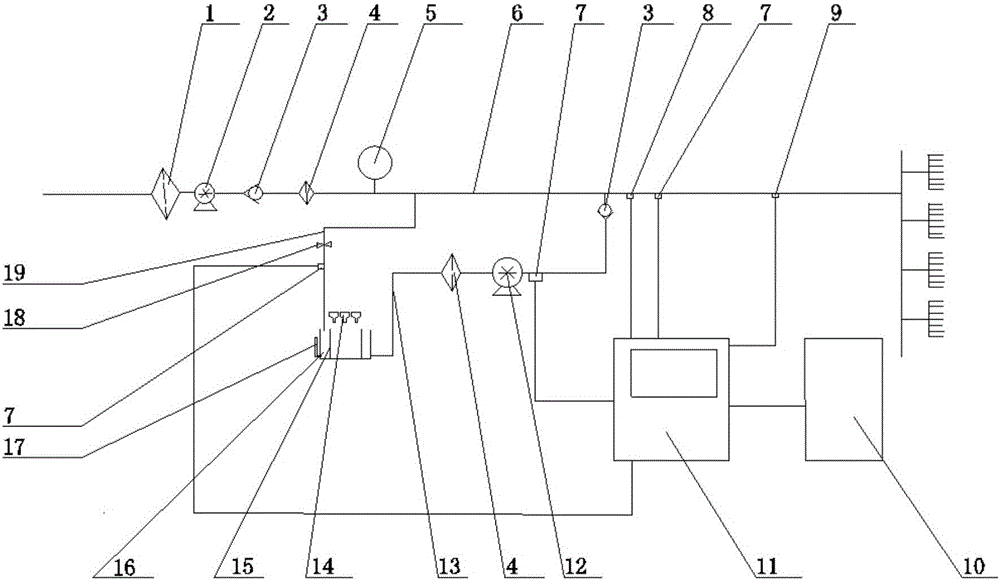

Loop control method for wire tandem rolling and device

InactiveCN101468361AImprove rolling qualitySimple structureRoll mill control devicesFlexible work arrangmentsWire rodLoop control

The invention discloses a method and a device for controlling a movable sleeve for the continuous rolling of a wire material. The method comprises: a guide wheel positioned between two adjacent rolling machines conducts the wire material to a rolling machine; a sleeve removing sensor arranged in an outlet of the rolling machine detects a reaching signal in the head of the wire material and emits a sleeve removing command; the sleeve is removed through a sleeve removing auxiliary cylinder; a programmable controller is adopted to adjust the speed of the rolling machine and control the stretching of the sleeve removing auxiliary cylinder for carrying out the sleeve removing according to calculated raising speed curve parameters of the rolling machine; and through a closed-loop PID digital control algorithm, the speed of the rolling machine is adjusted to control the height of the movable sleeve. The device comprises a first rolling machine, a second rolling machine, a movable sleeve scanner, a sleeve removing sensor, an auxiliary cylinder, and guide wheels; the movable sleeve scanner is positioned on the highest point of removing the movable sleeve between the first rolling machine and the second rolling machine; the sleeve removing sensor is arranged in the outlet end of the second rolling machine; the sleeve removing auxiliary cylinder is positioned in the outlet end of the first rolling machine; and the positions between the first rolling machine and the second rolling machine respectively close to the rolling machines are provided with the guide wheels. The device has the characteristics of simple structure, convenient use, and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

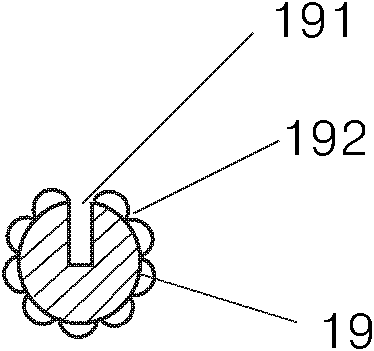

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

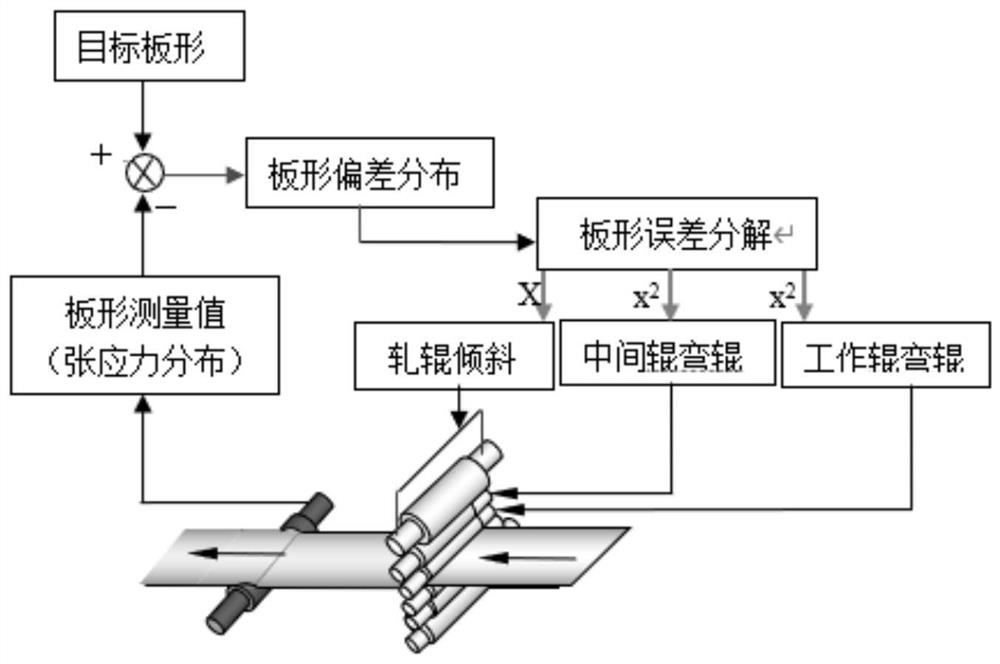

Edge shape control method

ActiveCN102909223AImprove rolling stabilityImprove rolling qualityProfile control deviceWork rollStrip steel

The invention provides an edge shape control method. The edge shape control method includes that a shape detector is used for detecting shape values of a working side and a drive side edge of strip steel; the shape values are amended to obtain a comprehensive plate shape value of the working side and the drive side of the strip steel; a working roll channeling roll value is amended according to the comprehensive shape value of the working side and the drive side; and according to the amended channeling roll value, an upper single taper working roll channeling roll and a lower single taper working roll channeling roll of an end rack are individually controlled on line. By the aid of the edge shape control method, the problem that about 70 mm (millimeter) fragmentary edge wave of a strip width side can not be eliminated by a conventional automatic shape control model is solved, and stability of rolling and quality of a product are improved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Laser texturing processing method on surface of roller

InactiveCN101642849AImprove rolling qualityImprove wear resistanceLaser beam welding apparatusSheet steelSlag

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized by leading focal light spots to randomly swing with low amplitude from left and right at a preset spiral line so as to produce the irregularly distributedtexturing spots on the surface of the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbed by texturing concave holes crisscross distributed on the peripheral directionof the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

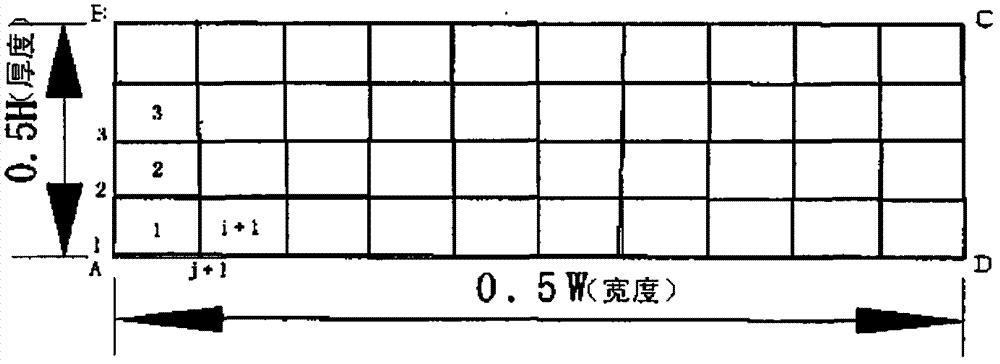

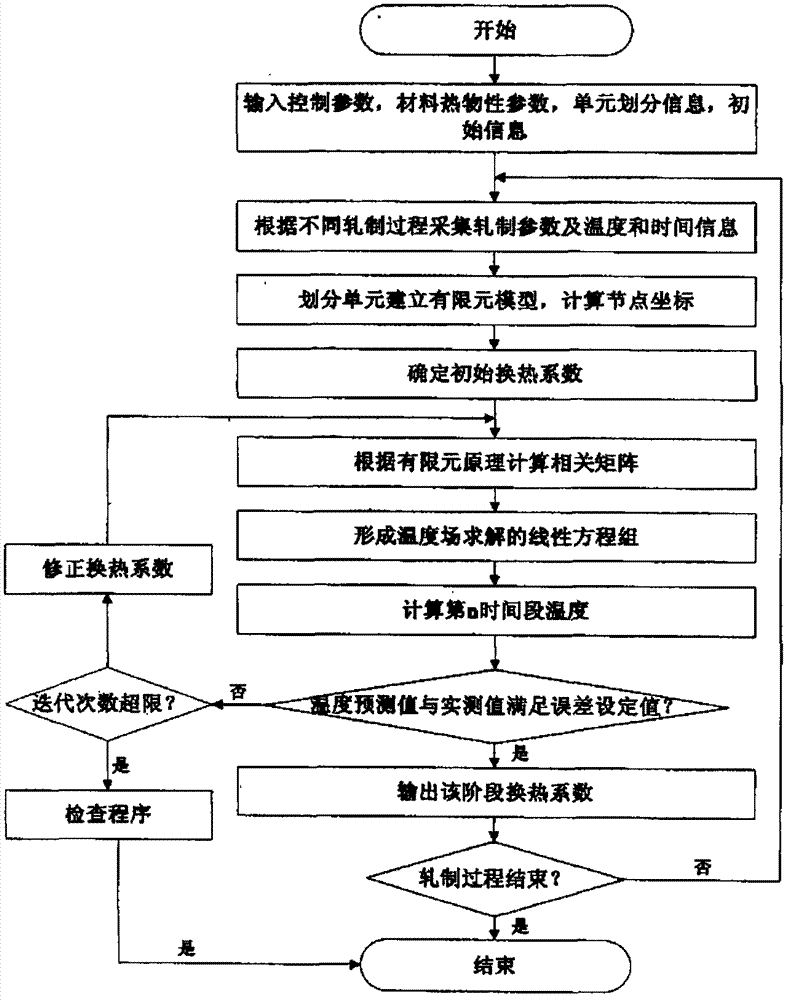

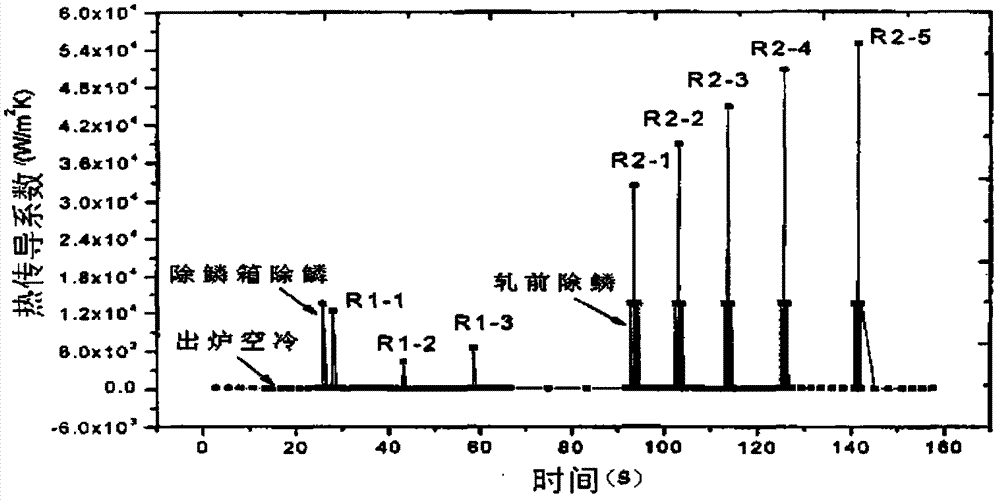

Method for predicting strip surface coefficients of heat transfer in hot rolling procedures

ActiveCN103761370AImprove forecast accuracyDetailed and accurate informationSpecial data processing applicationsElement modelPredictive methods

The invention discloses a method for predicting strip surface coefficients of heat transfer in hot rolling procedures. The method includes predicting strip surface coefficients of heat transfer by the aid of a finite-element model and heat transfer modifier formulas; determining the strip surface coefficients of heat transfer according to comparison values of measured temperatures and computed temperatures of strips. The method has the advantages that the method is specially used for predicting the strip surface coefficients of heat transfer in the strip hot rolling procedures, change of the strip surface coefficients of heat transfer in the integral rolling procedures can be acquired, information is detailed and accurate, the strip surface coefficients of heat transfer are high in prediction precision, and setting and optimizing parameters can be provided for the rolling procedures; the method is high in applicability and computational efficiency and is applicable to roughing mills and finishing mills in hot continuous rolling procedures.

Owner:NORTHEASTERN UNIV

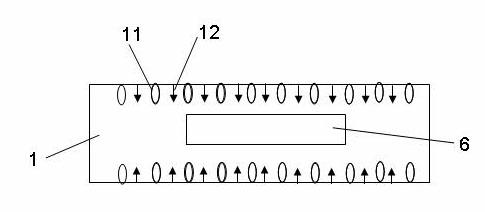

Locally reinforced heating method and device for hot rolling steel billet before discharging

InactiveCN1473945ASmall surface temperature differenceImprove productivityFurnace typesHeat treatment furnacesProduction rateHeating time

The local heating process for reinforced heating rolled steel billet includes the following steps: calculating the temperature distribution of discharged steel billet; calculating the reinforced heating time for the steel billet inside the furnace; establishing local reinforced heating area or chamber in the last end of the heating furnace based on the calculated data and heating the local 200-300 mm long areas in two ends of the steel billet at the temperature 80-120 deg.c higher than the average furnace temperature for 20-30 sec. The local heating apparatus features its at least one pair of burning nozzles installed on two side walls or top of the local heating area for the reinforced heating. The present invention can reduce the surface temperature difference in the steel billet to be rolled, raise the rolling temperature homogeneity and raise rolling quality.

Owner:SHANGHAI INST OF TECH

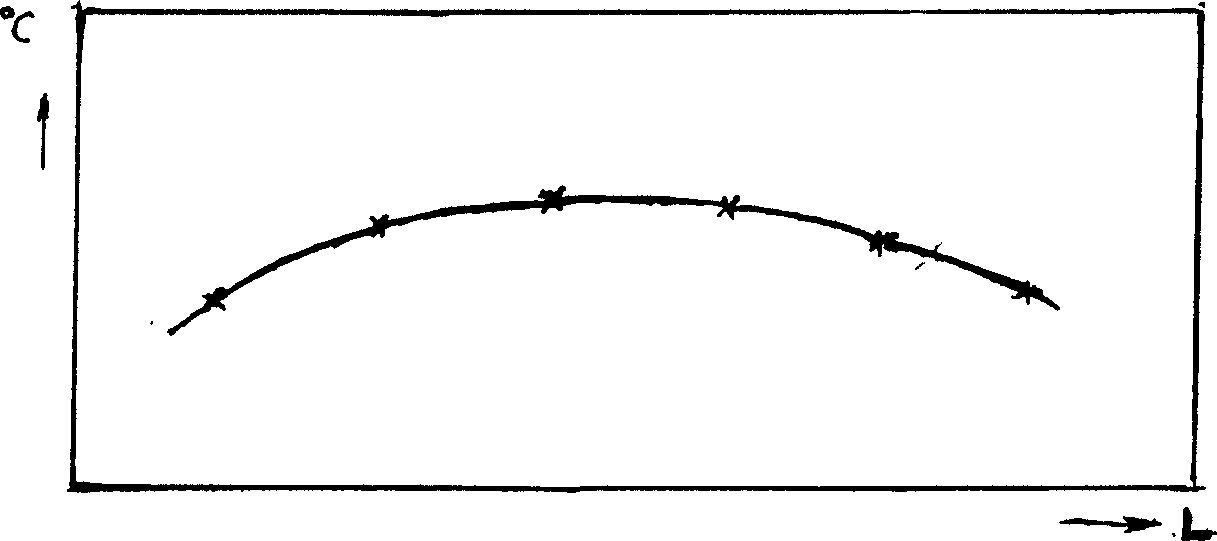

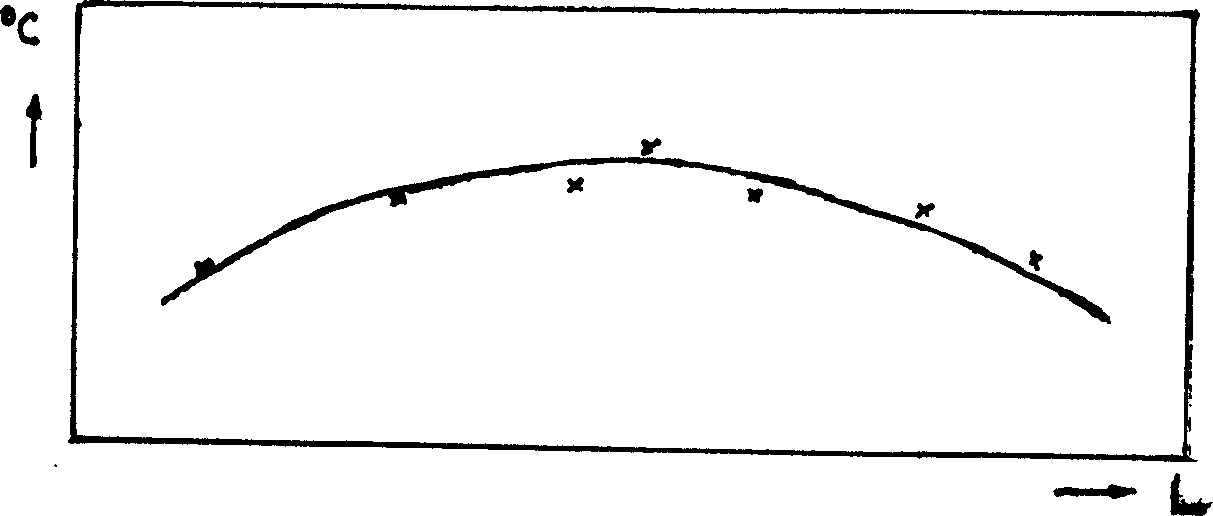

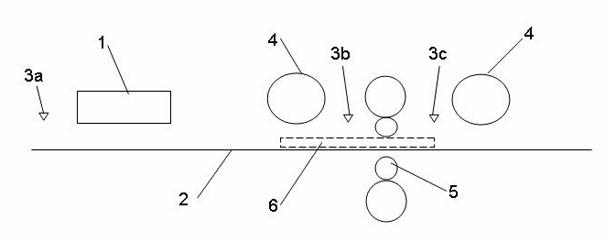

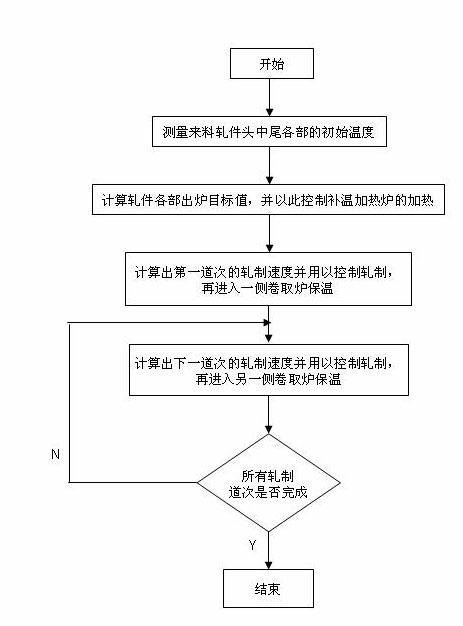

Temperature difference control method for rolling pieces for steckel mill

InactiveCN102601128AReduce temperature differenceImprove calculation accuracyTemperature control deviceProduction lineStrip mill

The invention discloses a temperature difference control method for rolling pieces for a steckel mill. The method includes steps of measuring initial temperature of the rolling pieces; calculating discharging target temperature value of a temperature complement furnace and heating the rolling pieces according to the target temperature value; calculating a set value of rolling speed of each rolling step and performing controlled rolling at each step according to the set value to reduce temperature difference; and measuring actual temperature of an exit and an entrance of a rolling mill and comparing the actual temperature with corresponding values to realize self-learning of the model and enhance calculating precision of the model. By the method, the temperature differences among the head, the middle and the tail of each rolling piece are reduced greatly, and rolling stability and quality of finished products and production ability of a production line are enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Casting-milling process method for manufacturing copper and copper alloy band

InactiveCN1730181AIncrease the elongation factorReduce energy consumptionWork treatment devicesMetal rolling arrangementsNitrogen gasDynamic recrystallization

The invention relates to a processing method for copper and copper alloy strip, which pertains to sheet metal strip casting, heat-rolling and machining technology. Specifically, the invention adopts continuous casting, hot rolling, thermomechanical treatment and machining principle and subjects band of horizontal continuous casting and downward continuous casting to heat preservation and samming, rapidly cooling after directly hot-rolling, on-line surface milling and rolling to built-up coil. Rolling is operated under the condition of exceeding recrystallization temperature and nitrogen protection. In the rolling, dynamic recrystallization of band structure takes place. The invention provides photo-quality and high-accuracy blank for cold rolling of end product.

Owner:JIANGSU XINGRONG HI TECH

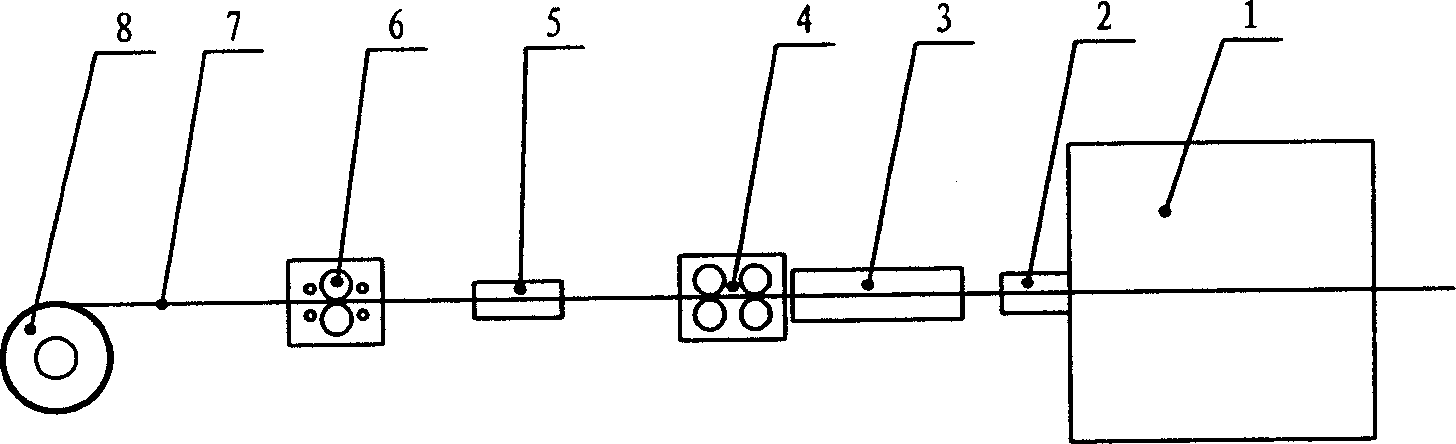

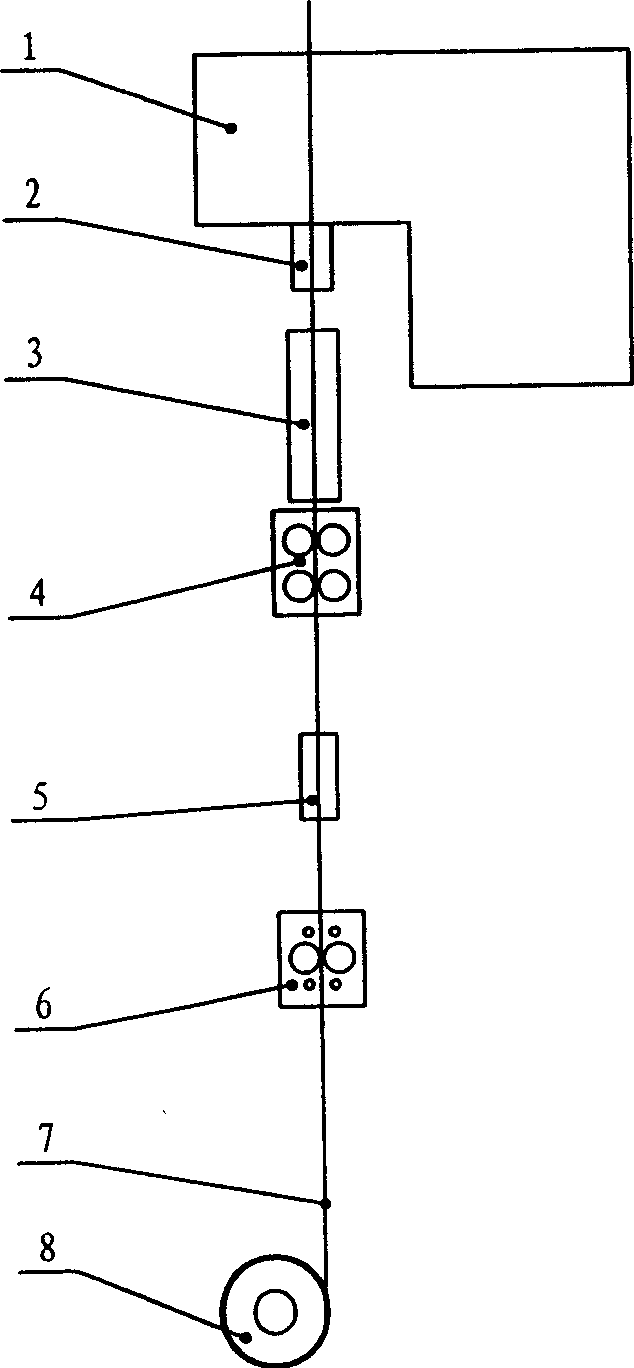

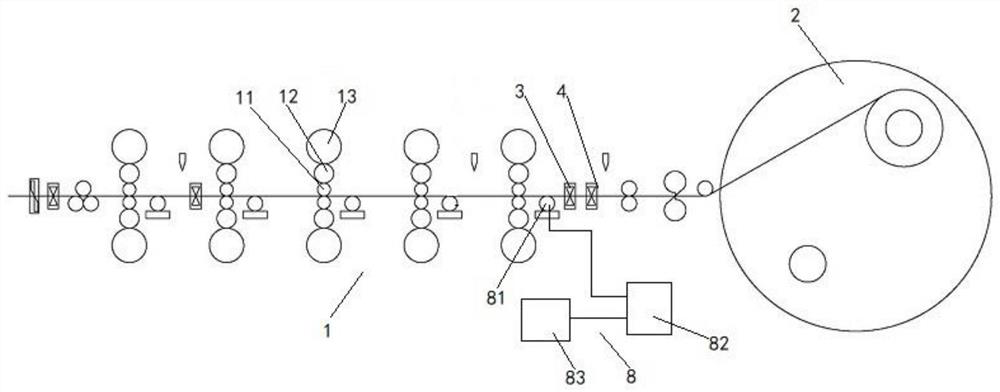

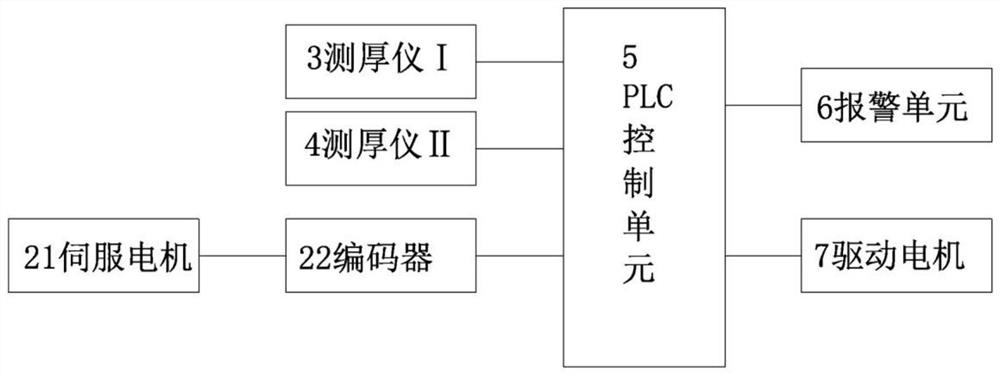

Non-oriented silicon steel cold continuous rolling device and thickness control method

PendingCN111604372AReduce contact pressureSmall amount of depressionMetal rolling stand detailsMeasuring devicesStrip steelMachine

The invention discloses a non-oriented silicon steel cold continuous rolling device and a thickness control method, and belongs to the technical field of non-oriented silicon steel cold rolling and forming. The non-oriented silicon steel cold continuous rolling device comprises a five-rack six-roller cold continuous rolling mill and a double-drum coiling machine, chamfers are correspondingly arranged at the end parts of intermediate rollers on each cold rolling unit of the five-rack six-roller cold continuous rolling mill, chamfers are correspondingly arranged at the end parts of working rollers of first, second and third cold rolling units of the five-rack six-roller cold continuous rolling mill, and the chamfering heights of the working rollers of the first cold rolling unit and the second cold rolling unit are correspondingly greater than the chamfering height of the working roller of the third cold rolling unit. The non-oriented silicon steel cold continuous rolling device has thebeneficial effects that the structure of the cold continuous rolling device and the process of cold continuous rolling are improved and optimized, the measuring accuracy of the longitudinal thicknessof strip steel is ensured, the control force of the transverse thickness of a non-oriented silicon steel strip is improved, the length of out of tolerance thickness of the steel strip head and tail isreduced, the edge thinning of the non-oriented silicon steel strip is reduced, and the qualification rate of longitudinal thickness and transverse thickness of the steel strip is increased.

Owner:新余钢铁股份有限公司

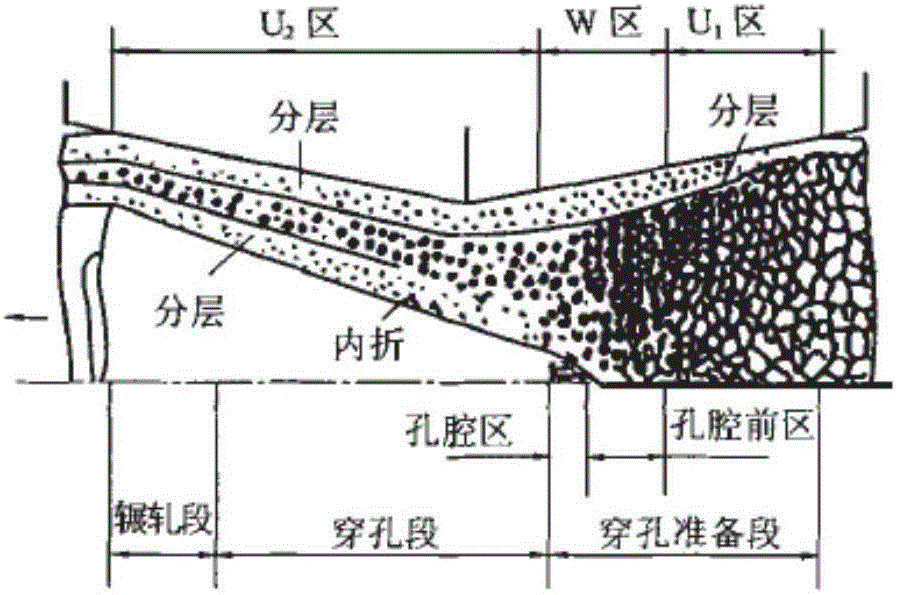

Process for preparing pipe by punching high temperature alloy bar

ActiveCN106180194ASmooth inner and outer surfacesImprove rolling qualityTemperature control deviceMetal rolling arrangementsHeating timeHigh frequency

The invention relates to a process for preparing a pipe by punching a high temperature alloy bar. Firstly, a high temperature alloy ingot is subjected to hammer cogging at 900-1200 DEG C to obtain a bar blank; secondly, bar blank induction heating is conducted under the condition that the heating temperature is 1000-1300 DEG C and the heating time is 10-60 min; and finally, ejection headers are arranged at the front ends of rollers of a three-roller planetary rolling mill, and the bar is directly punched into the pipe during rolling. The method for preparing the pipe is simple, steps are easy to implement, high-frequency induction heating is adopted during bar blank punching and rolling, the working efficiency is high, and pollution is avoided; the wall thickness of the punched pipe is even, the inner surface and the outer surface of the punched pipe are smooth, no crack is caused, and the application range of the specifications and materials of the bar blank is wide.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

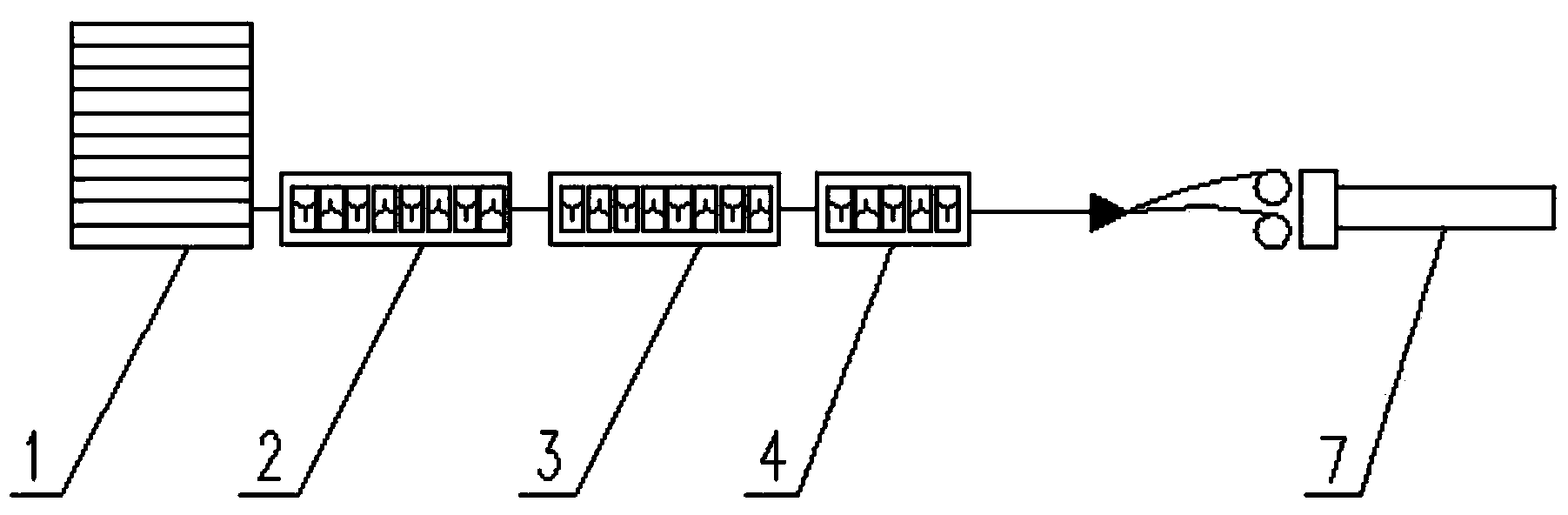

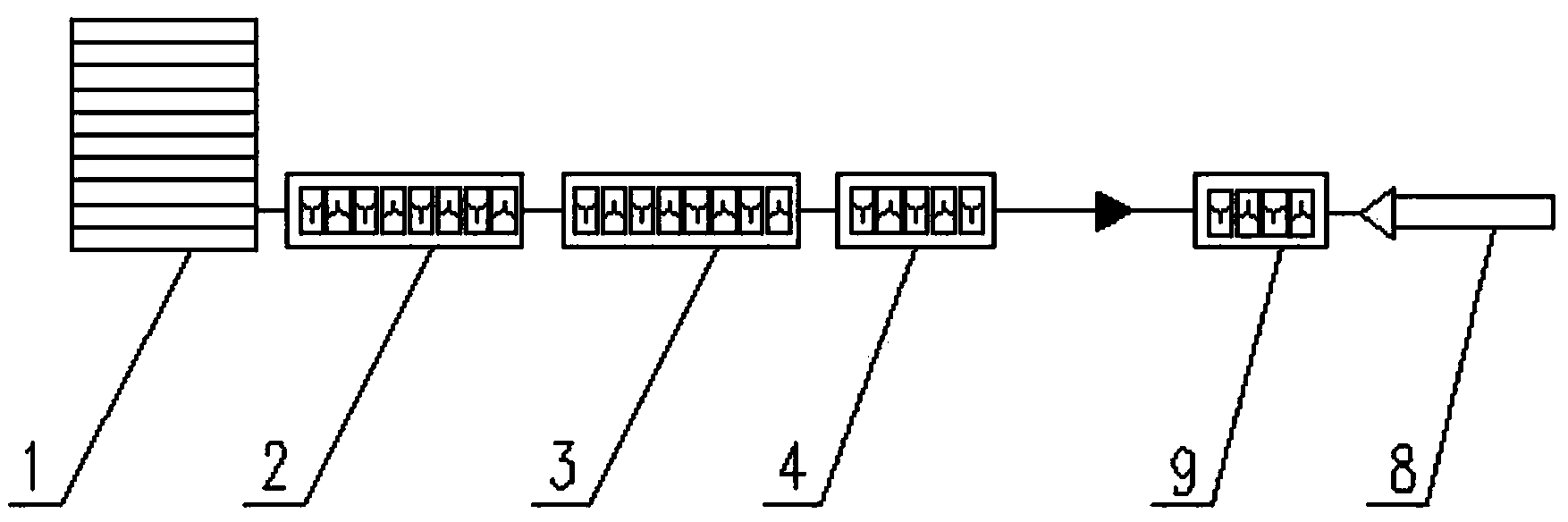

Compact wire and bar rolling production line

ActiveCN103706634AFlexible configurationIncrease flexibilityFlexible work arrangmentsMetal rolling arrangementsProduction lineEngineering

The invention relates to a compact wire and bar rolling production line which sequentially comprises a heating furnace, a rough rolling unit, an intermediate rolling unit, a finish rolling unit and a collecting system. The collecting system comprises at least one of a cooling bed, a coiling and collecting system and a wire collecting system. The rough rolling unit, the intermediate rolling unit and the finish rolling unit are respectively provided with a Y-type three-roll rolling mill and an inverted Y-type three-roll rolling mill, and the Y-type three-roll rolling mills and the inverted Y-type three-roll rolling mills are distributed in an alternating mode. A rolling machine set adopts the three-roll rolling mills of the same structural mode, the rolling machine set is universal, a wire and bar collecting system can be flexibly distributed, and flexibility of wire rolling is high. A high-speed steel feeding system is arranged so as to increase rolling speed of the rolling machine set and improve production efficiency, the brake sliding distance between high-speed rolled workpieces is shortened, the rolling length is further shortened, and investment is reduced. An arranged wire reducing sizing rolling unit further rolls and produces wires, and facilitates improvement of rolling quality of the wires and size precision of products.

Owner:CISDI ENG CO LTD

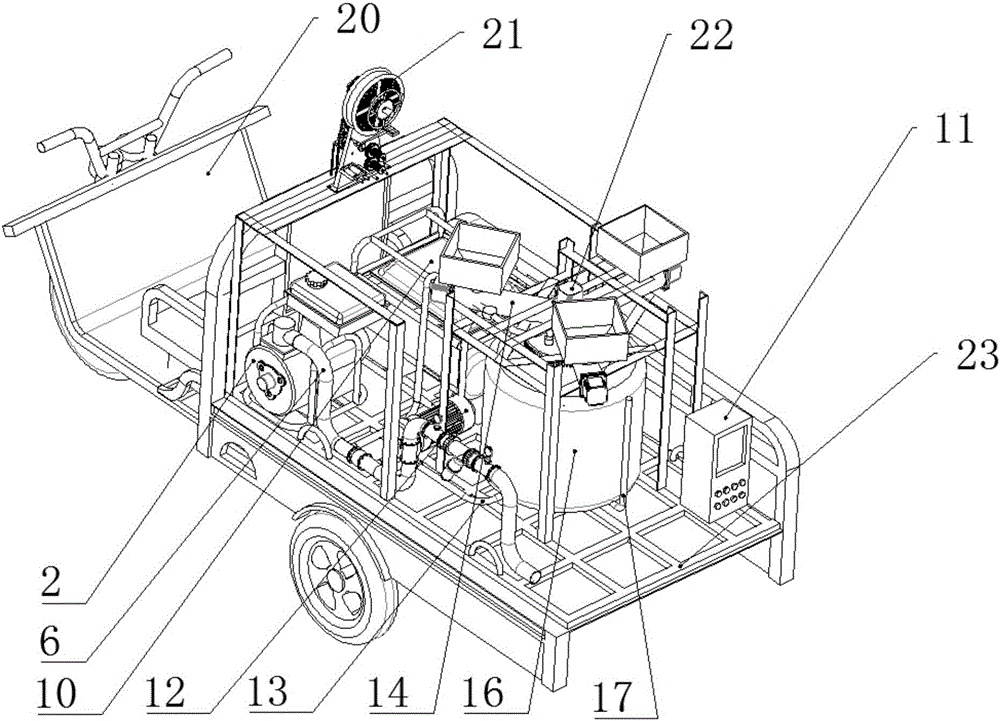

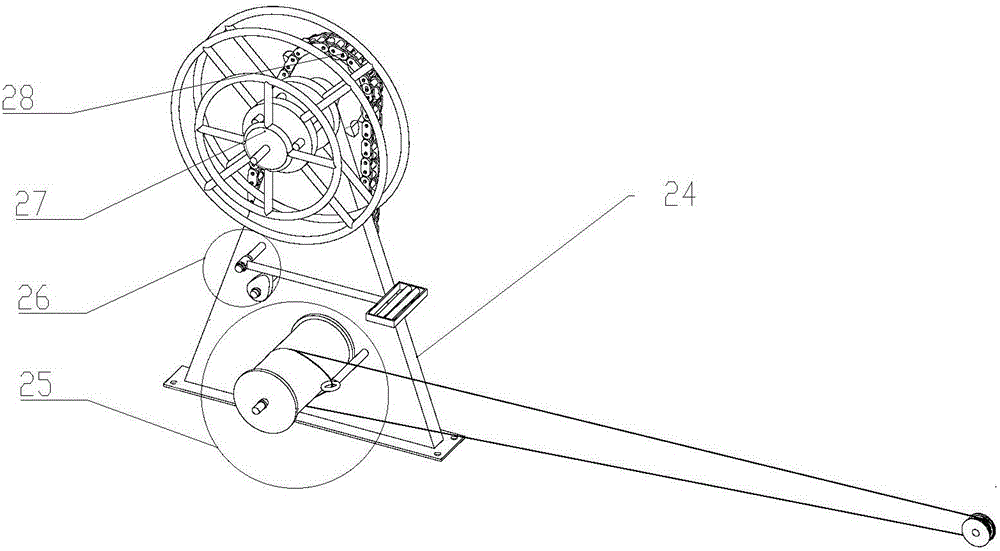

Movable micro-sprinkling irrigation water-fertilizer integrated comprehensive management system and control method thereof

ActiveCN105993855ARealize assortmentImprove continuityWatering devicesPressurised distribution of liquid fertiliserControl systemEngineering

The invention relates to a movable micro-sprinkling irrigation water-fertilizer integrated comprehensive management system and a control method thereof. The system comprises a movable device, a micro-sprinkling belt spreading / rolling device, a precision fertilizer preparation device, a head hub device, a control system and a power supply source, wherein the movable device comprises an electric tricycle and a movable bracket; the micro-sprinkling belt spreading / rolling device is used for paving and rolling a micro-sprinkling belt; the precision fertilizer preparation device is used for precisely ejecting fertilizer and preparing a concentration-controllable mother liquor; the head hub device is an integration of equipment for pressurization, adjustment, control, purification, fertilization, detection and the like and is used for conveying the irrigation water and fertilizer mother liquor; and the control system is used for controlling accurate operation of the micro-sprinkling belt spreading / rolling device, the precision fertilizer preparation device and the head hub device. According to the invention, the fertilizer can be automatically prepared, the ejection and preparation of mother liquor are realized at the same time, the working continuity of the device is improved, and the time and labor are saved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

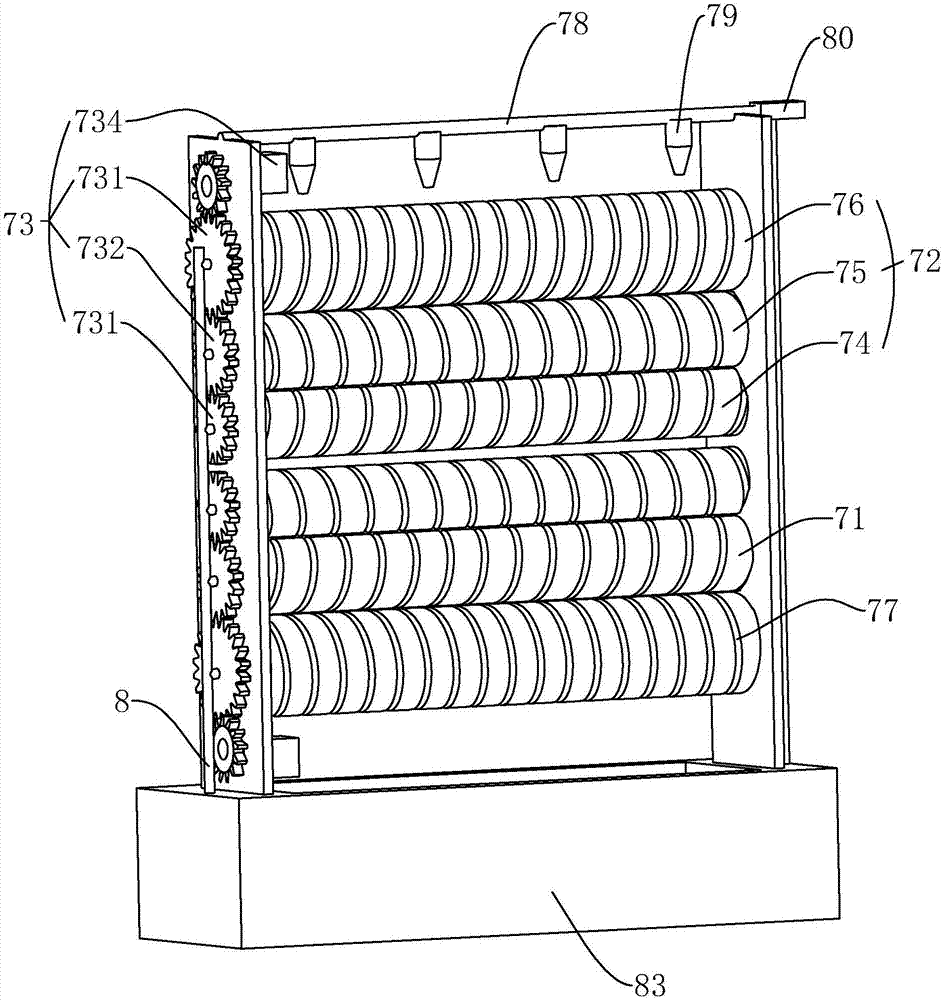

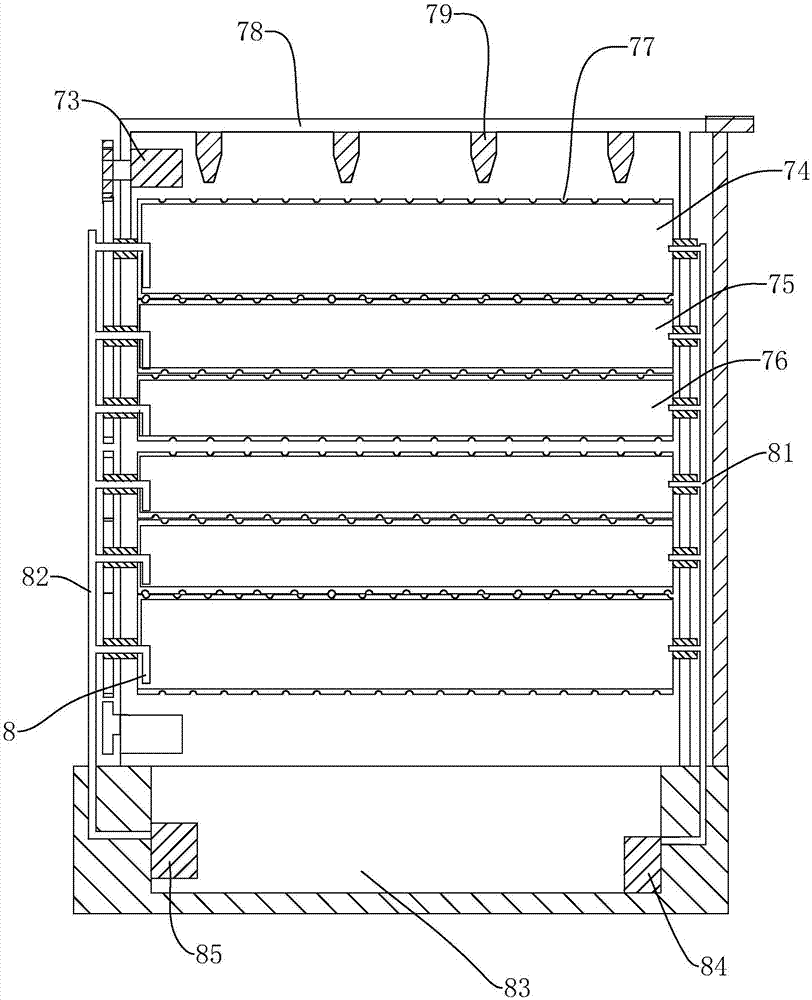

Continuous metal sheet winding apparatus

The invention discloses a continuous metal sheet coiler. It includes motor-driven roller, rolling plate axle laying one side of roller and installed on the same axial line with roller and can charge magnetism and demagnetizing, the end of said rolling plate axle which faces roller is equipped with connect key, the connect key and the key bed installed axially on the roller centre engage, and another end of rolling plate axle through frame are connected with horizontal draught device driving it move axially; rotate support device is equipped on the lower of rolling plate axle. The invention has reasonable design, easy operation and reliable work performance; it can achieve metal sheet continuous coiling operation, reduce energy consumption and improve work efficiency significantly.

Owner:宋儒钧

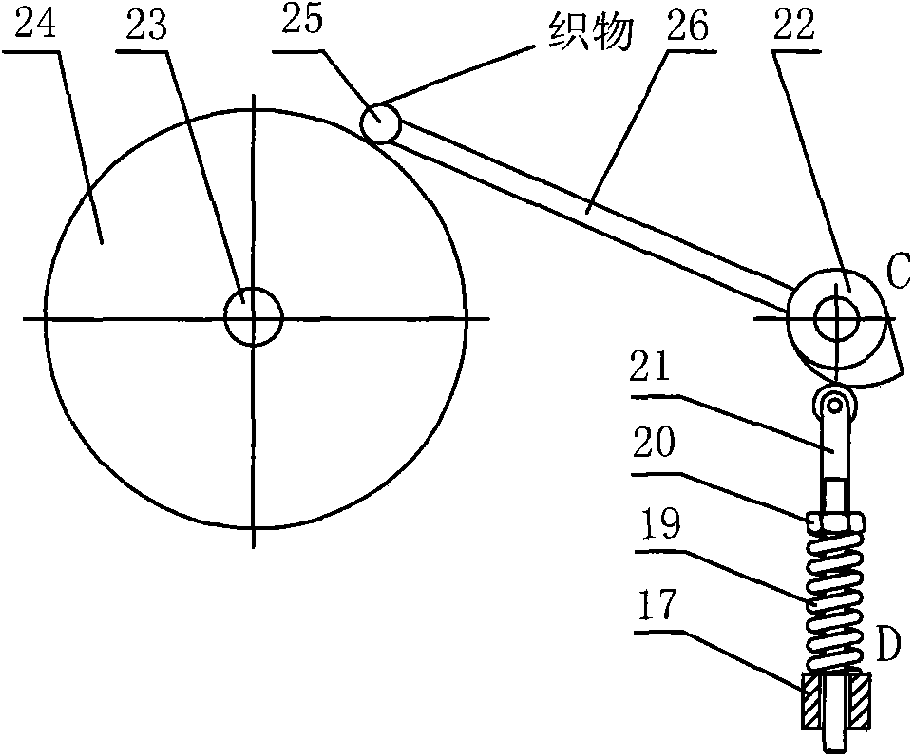

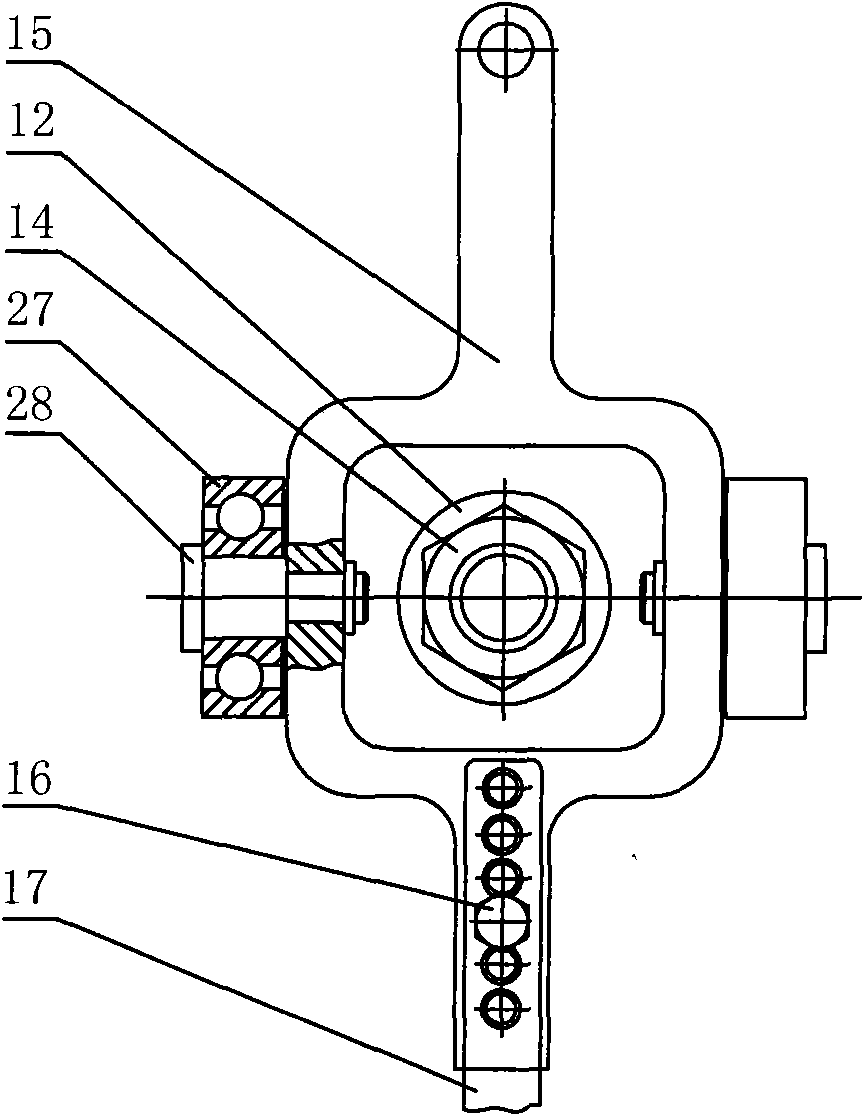

Cloth-rolling device of weaving machine

The invention discloses a cloth-rolling device of a weaving machine, which consists of a friction clutch connected with an input shaft and an output shaft, a cloth roll diameter detection mechanism, a loading mechanism and the like. In the cloth roll diameter detection mechanism, a cloth-pressing roller jointed with a cloth roll by compression is movably hinged with a swing link of the cloth-pressing roller, the swing link of the cloth-pressing roller is fixedly connected with a part of a cam, a cam carrier props against the part of the cam, a pressure spring is sheathed on the cam carrier, one end of the pressure spring props against an adjusting nut and the other end thereof props against a force-amplifying lever; and in the loading mechanism, one end of the force-amplifying lever is in gap junction with the cam carrier while the other end thereof is provided with an adjusting screw with adjustable position, the terminal of the adjusting screw props against a loading bar which is movably hinged with a fixed shaft, and loading power is transmitted to an active friction disc of the friction clutch by a loading bearing. The cloth-rolling device has simple structure, convenient manufacture, installation and maintenance, and low cost; and the fabric tension is controllable when the cloth roll is formed by winding, thus being beneficial to preventing the fabric in the cloth roll from creasing and beneficial to the post process of the fabric.

Owner:SUZHOU UNIV

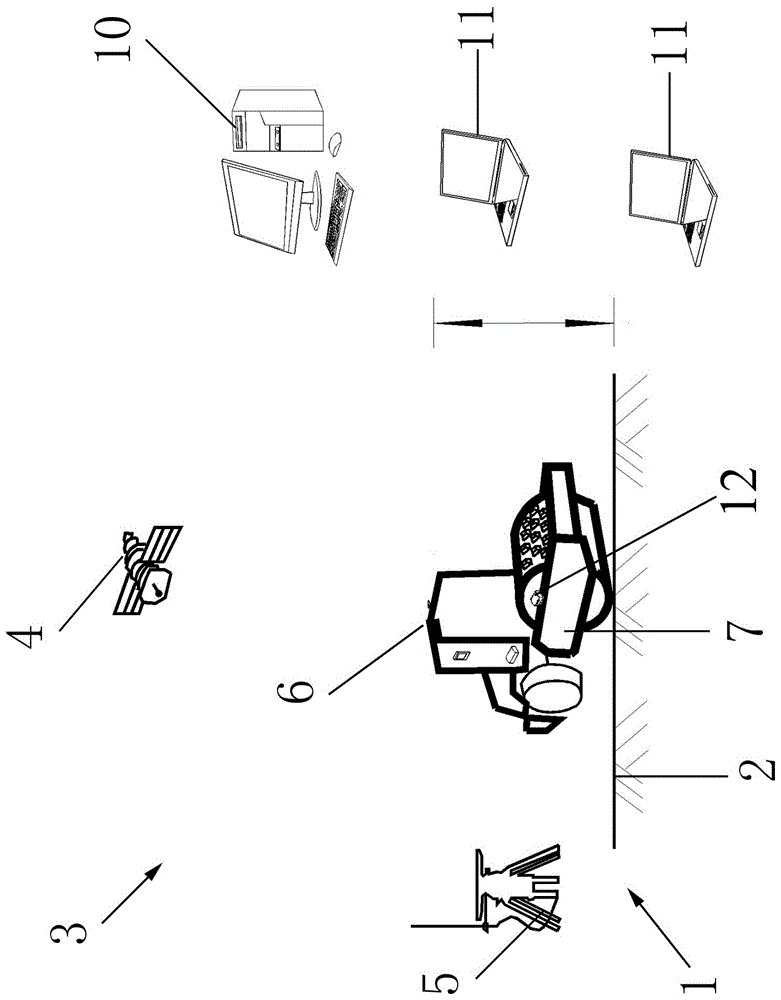

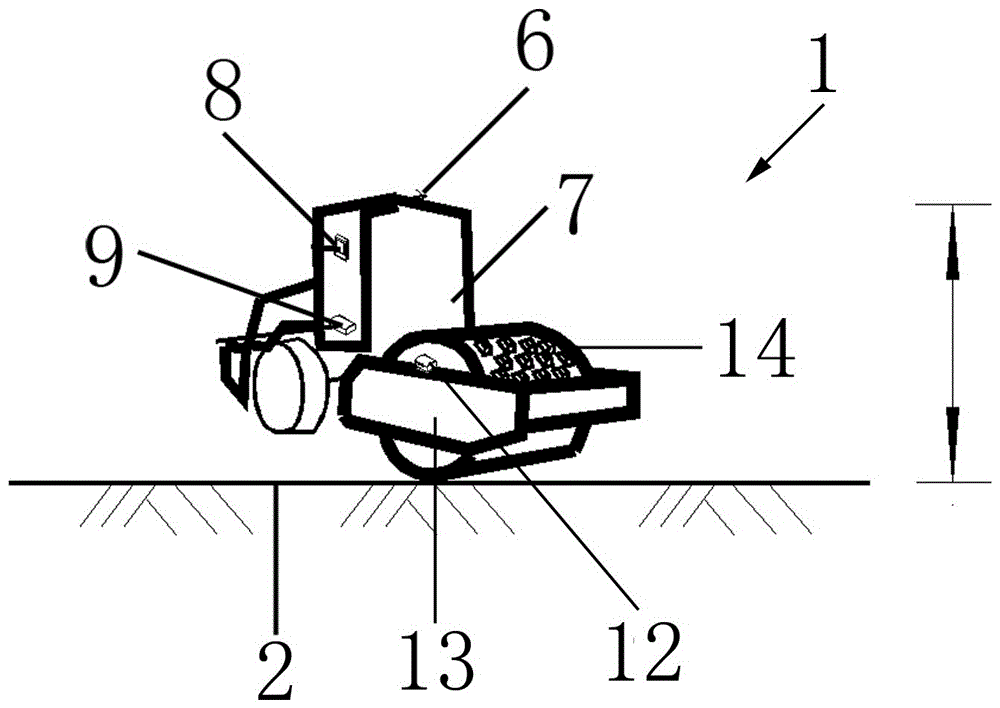

Rolling construction monitoring system and rolling construction monitoring method

InactiveCN106802640AShorten the timeSave human effortProgramme total factory controlSatelliteMonitoring data

The invention relates to a rolling construction monitoring system and a rolling construction monitoring method. Construction sections are divided in a construction area according to a design requirement, at least one construction section is set according to the design requirement, at least one construction roller is configured in each construction section, an RTK base station and a construction data processing mechanism are arranged in the construction area, a vehicle GPS mobile station is arranged on each construction roller, the RTK base station, the vehicle GPS mobile station and a GNSS satellite form a positioning system, and the rolling construction monitoring system is formed by the positioning system, the construction rollers, vehicle displays, vehicle controllers, the construction data processing mechanism, operation monitoring clients, and rolling degree detectors. According to the system and the method, the structure is simple, the design is scientific, the usage is convenient, the cost is low, the grasp is easy, monitoring data is accurate, the transmission is fast, the usage of equipment is long and durable, continuous, real-time and accurate rolling construction monitoring and rolling degree detection can be performed, and comprehensive control of the rolling process and the rolling quality is achieved.

Owner:TIANJIN WATER RESOURCES RES INST

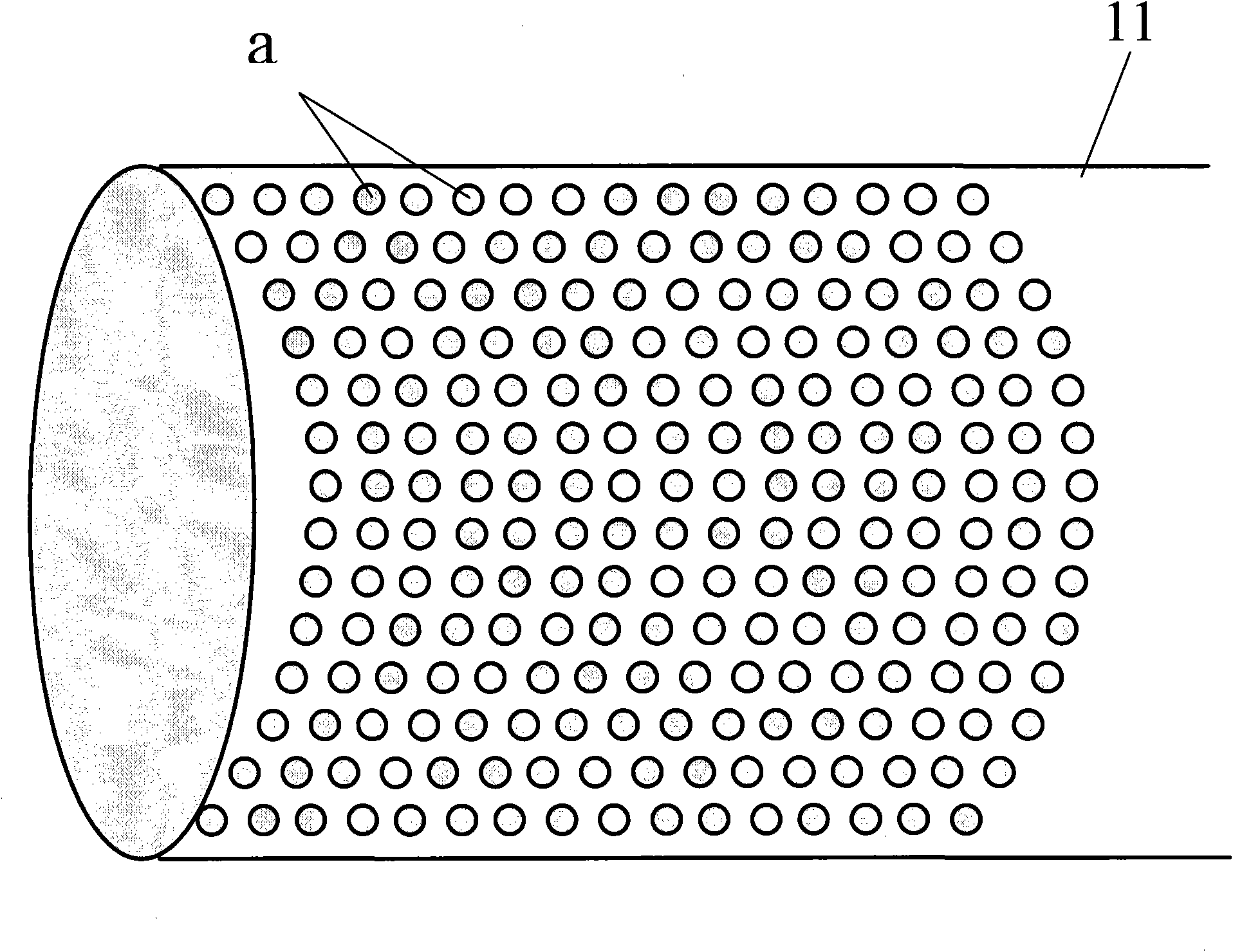

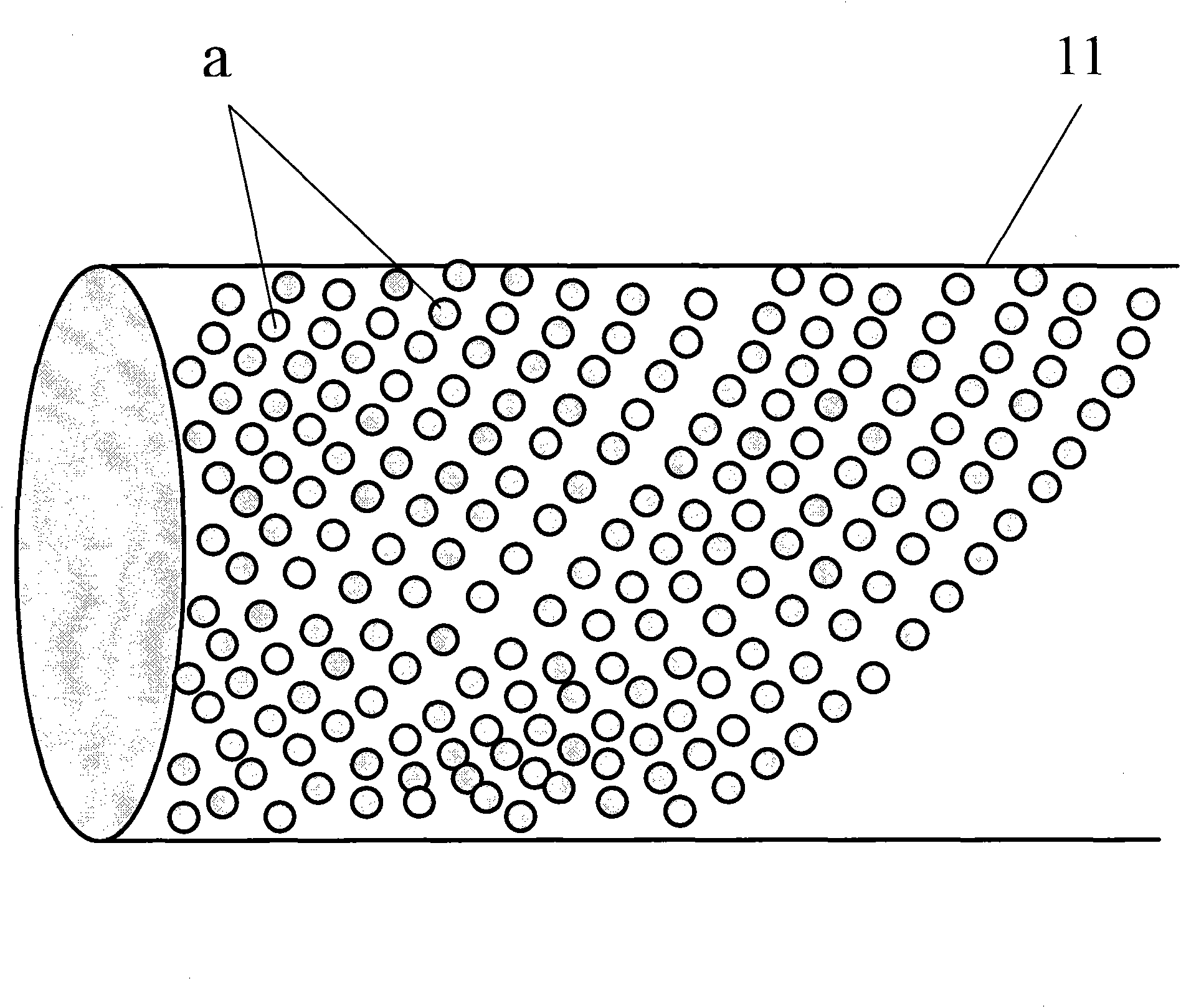

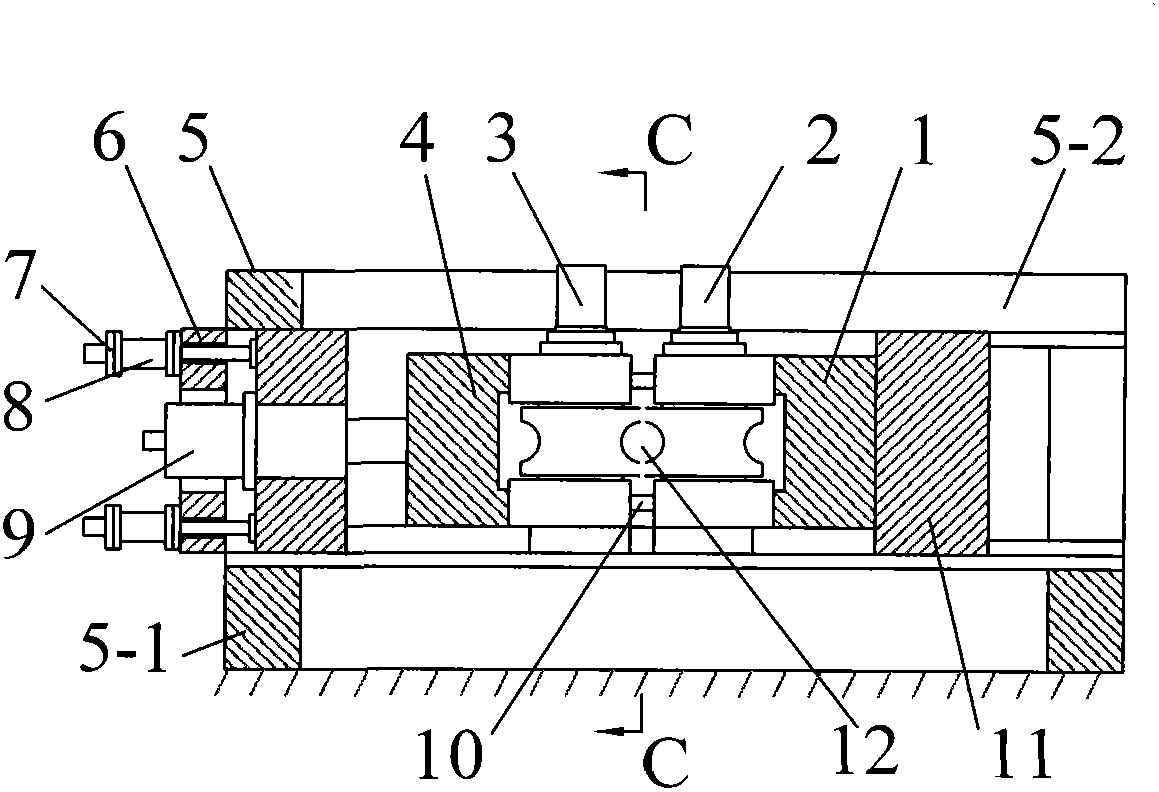

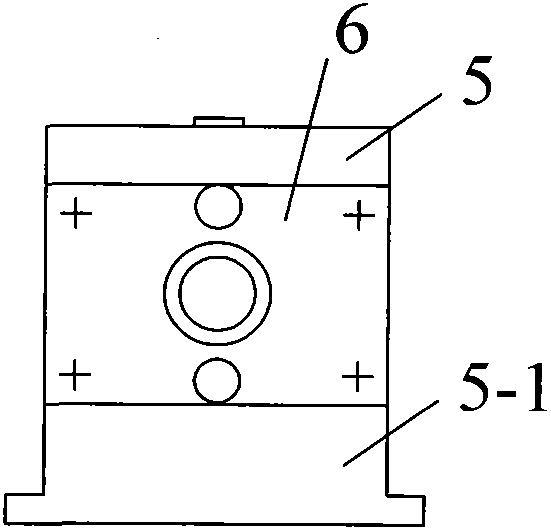

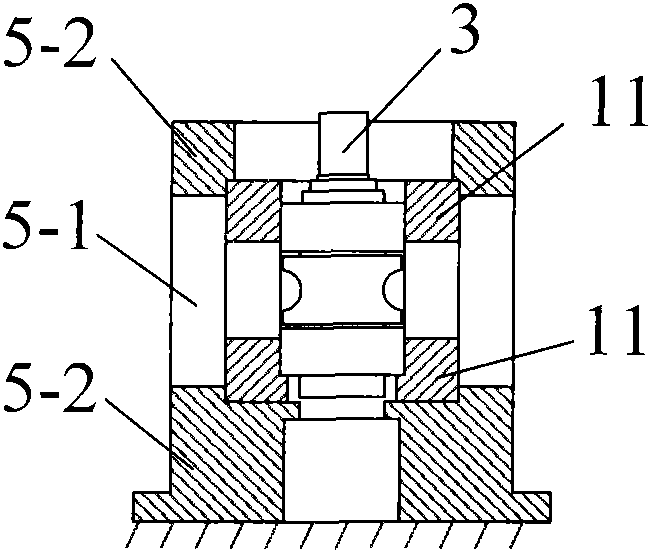

Two roller upright rolling mill

ActiveCN102581011AThe position of the center of the roll gap remains unchangedLess investmentMetal rolling stand detailsMetal rolling arrangementsStrip millRolling mill

The invention relates to a two roller upright rolling mill, which comprises a rolling mill base, a rolling mill rack, two upright mill rollers (3, 2) and a mill roller clearance regulating mechanism, wherein the two upright mill rollers (3, 2) are arranged inside the rolling mill rack in parallel; the rolling mill base (5) comprises an upright end plate (5-1) and horizontal transverse beams (5-2) which are connected with four angles of the upright end plate (5-1) respectively; the horizontal transverse beams (5-2) are vertical to the upright end plate and extend towards the same direction; the rolling mill base is a floating type rack (11) which is embedded among the four horizontal transverse beams of the rolling mill base; the mill roller clearance regulating mechanism is arranged at the transmission side or the operation side of the rolling mill; and a roller gap centering mechanism is also arranged at the same side with the mill roller clearance regulating mechanism. While the two mill rollers are subjected to clearance regulation, the roller gap between the two mill rollers is centered automatically; the device is simple and convenient to operate and maintain; and the rollers can be exchanged conveniently and rapidly.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

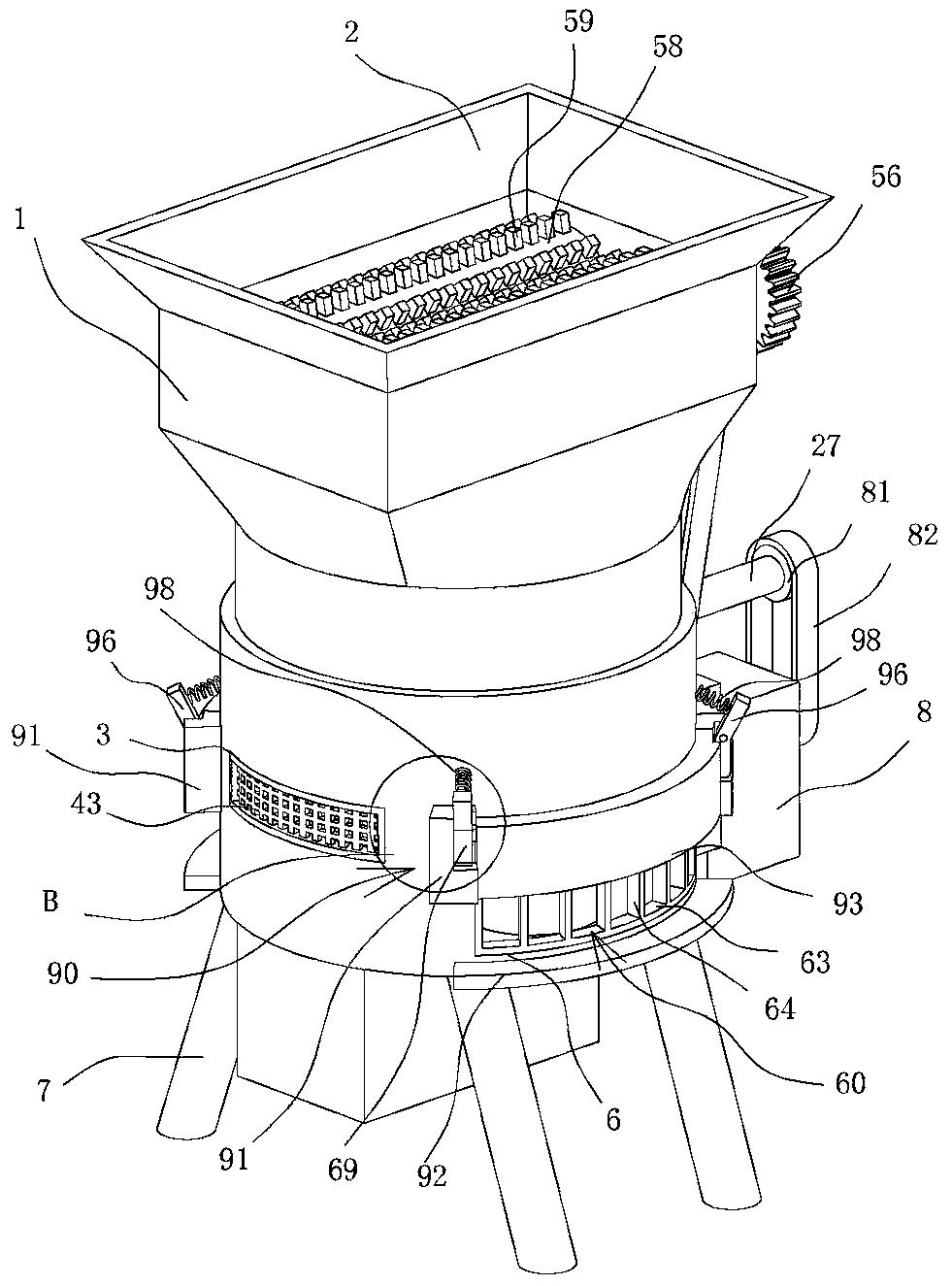

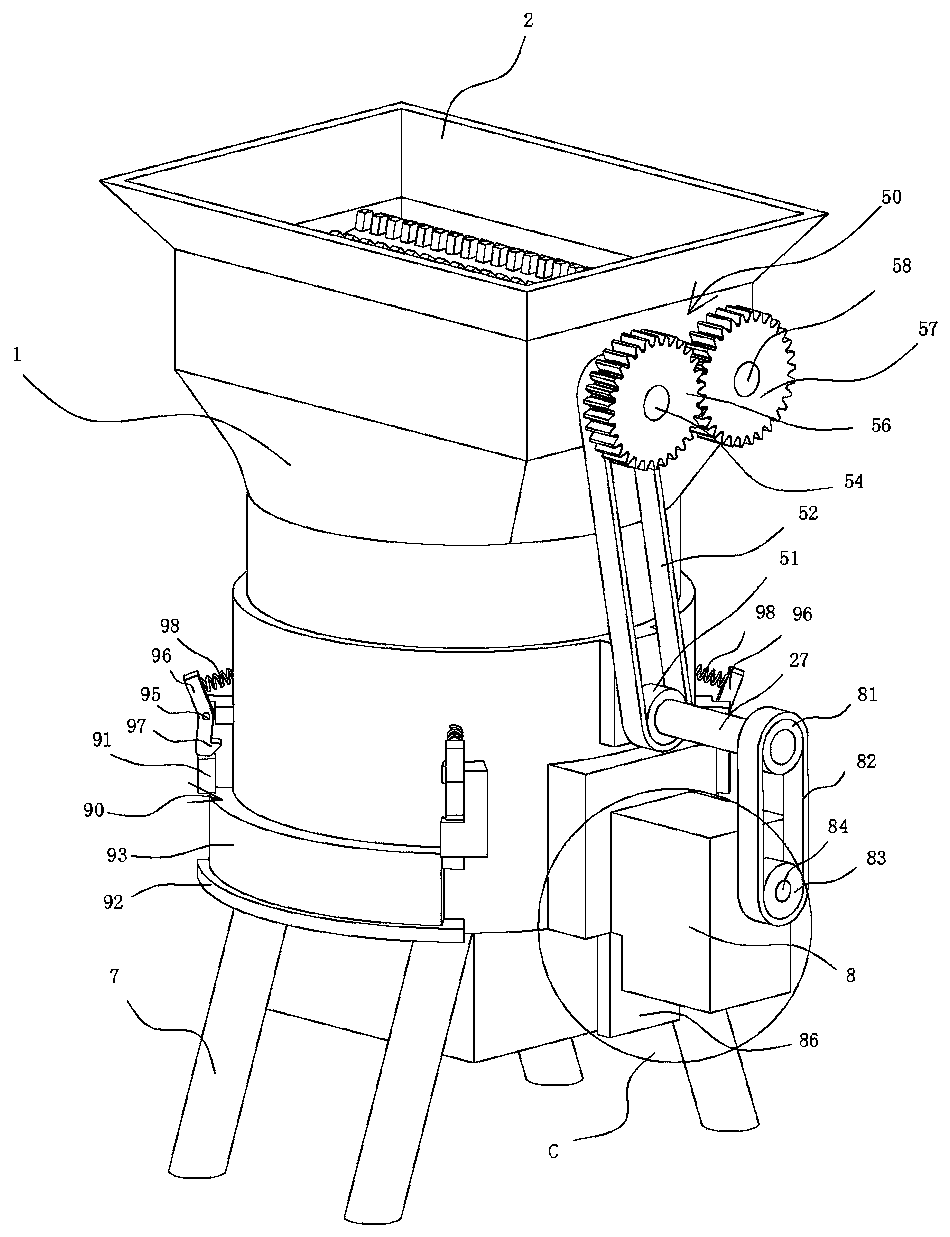

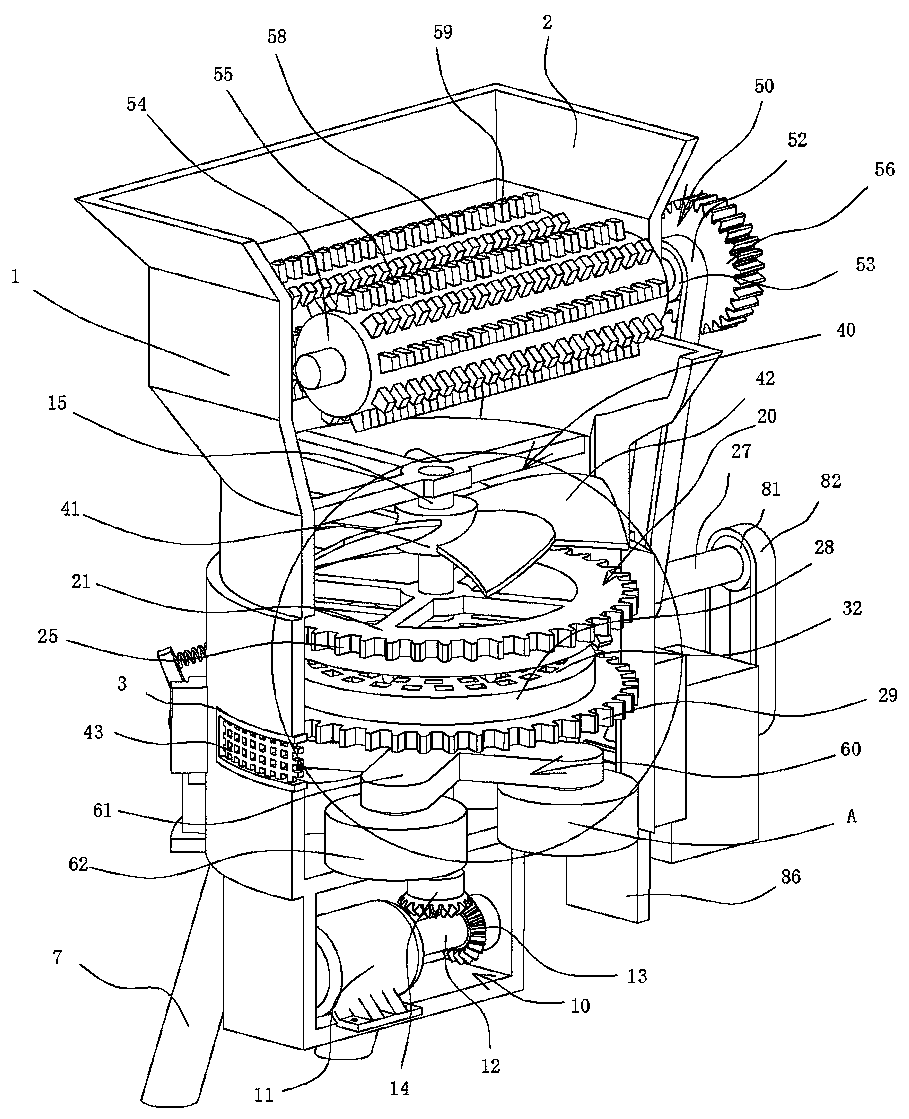

Straw processing device

InactiveCN110679303AImprove rolling qualityImprove grinding qualityBalingCuttersAgricultural engineeringGrinding mill

The invention discloses a straw processing device which comprises a frame. A feeding inlet is formed in one end of the frame, first discharging ports are formed in two sides of the frame, a second discharging port is formed in one end of the frame, a power mechanism is arranged at one inner end of the frame, a grinding mechanism is arranged on one side of the power mechanism, a cutting mechanism is arranged at one end of the power mechanism, a pressing mechanism is arranged at the other end of the power mechanism, straw pieces are extruded into blocks by the pressing mechanism, retaining mechanisms are arranged at the first discharging ports and arranged on one side of the pressing mechanism, a rolling mechanism is arranged on one side of the grinding mechanism, the other end of the rolling mechanism is arranged at the feeding inlet, a drying mechanism is arranged on the other side of the grinding mechanism, and the other end of the drying mechanism is arranged at the second discharging port. The straw processing device has the advantages that two-time broken straws can be further rolled, the crushing degree of the straws is improved, the straws can only pass the grinding mechanismfall into a forming cavity for briquetting after being crushed to a certain degree, and the quality of processed straw blocks is improved.

Owner:杭州易岚永道景观设计有限公司

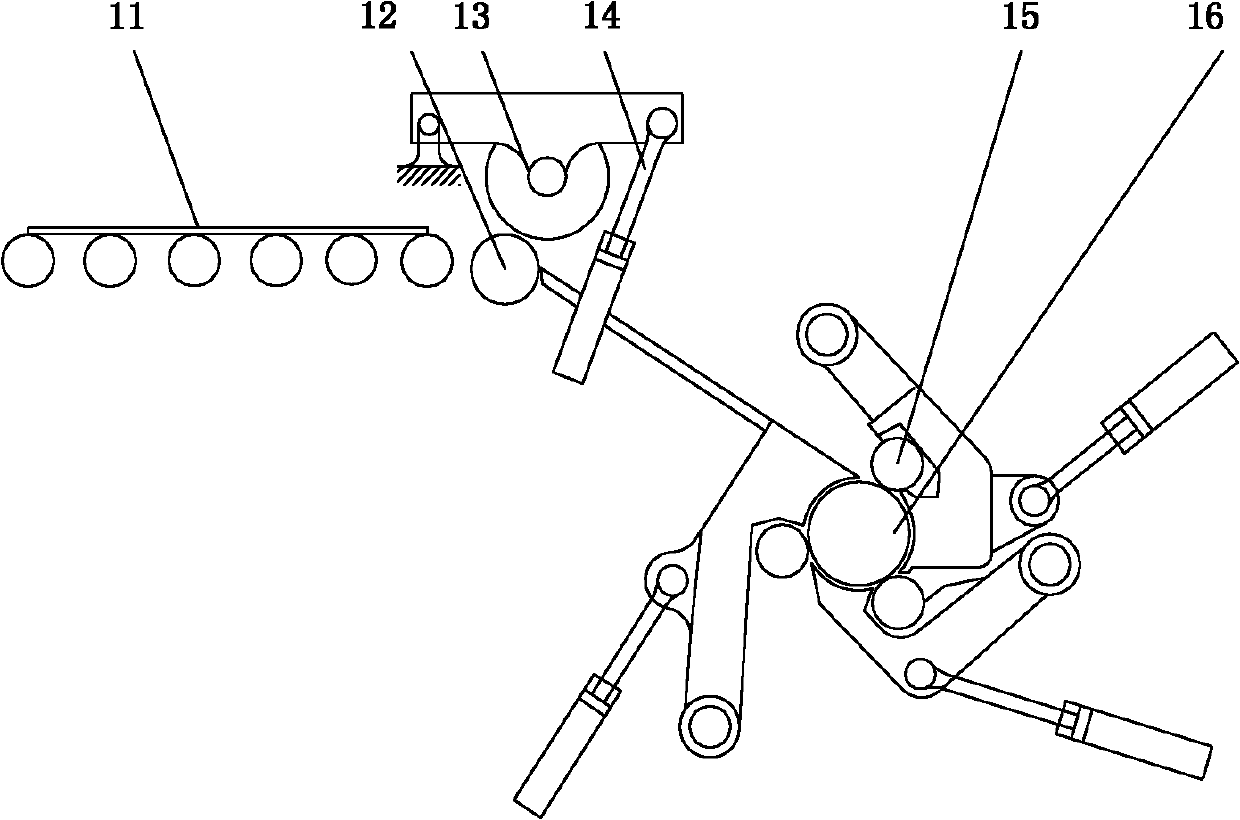

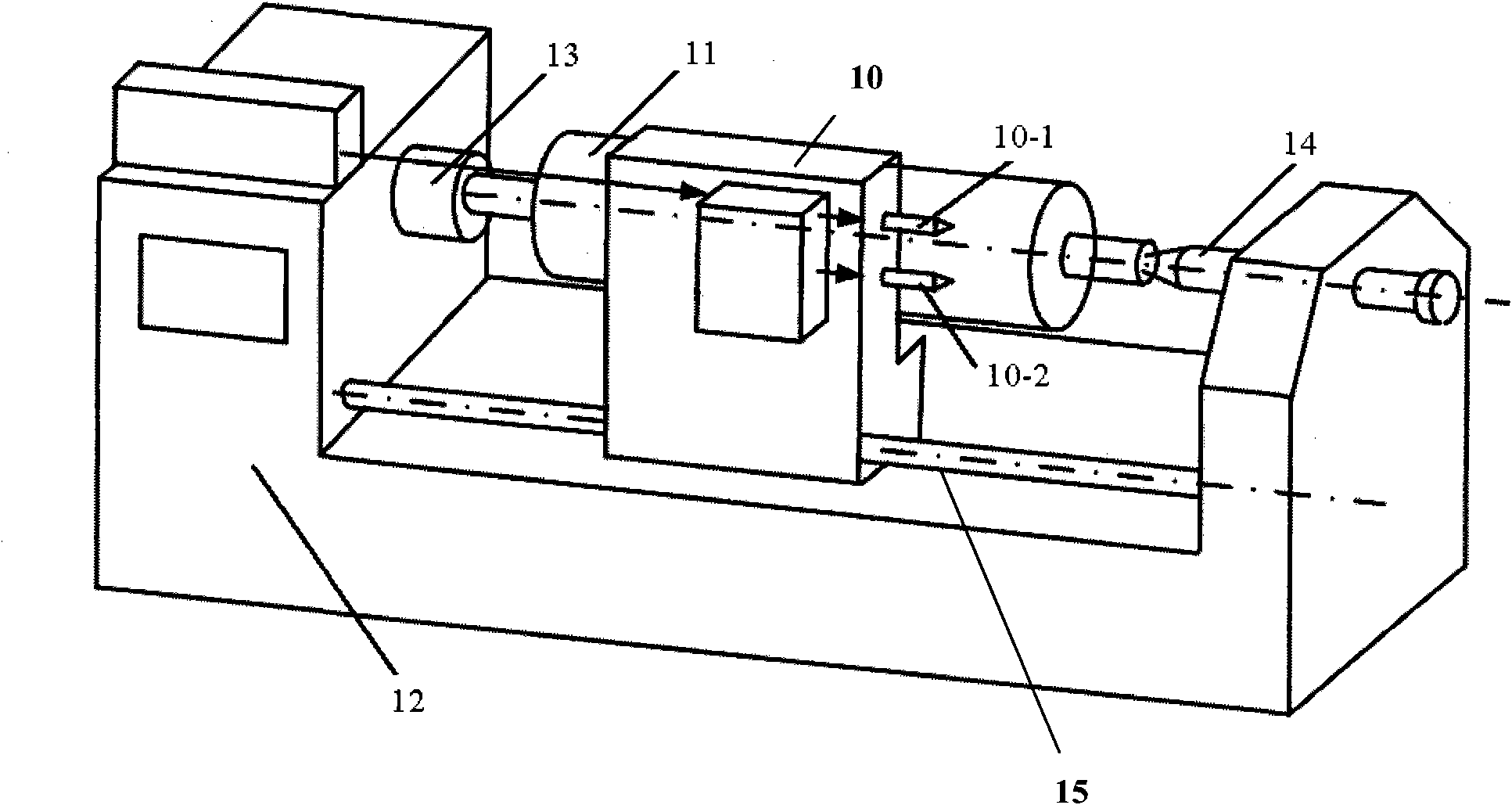

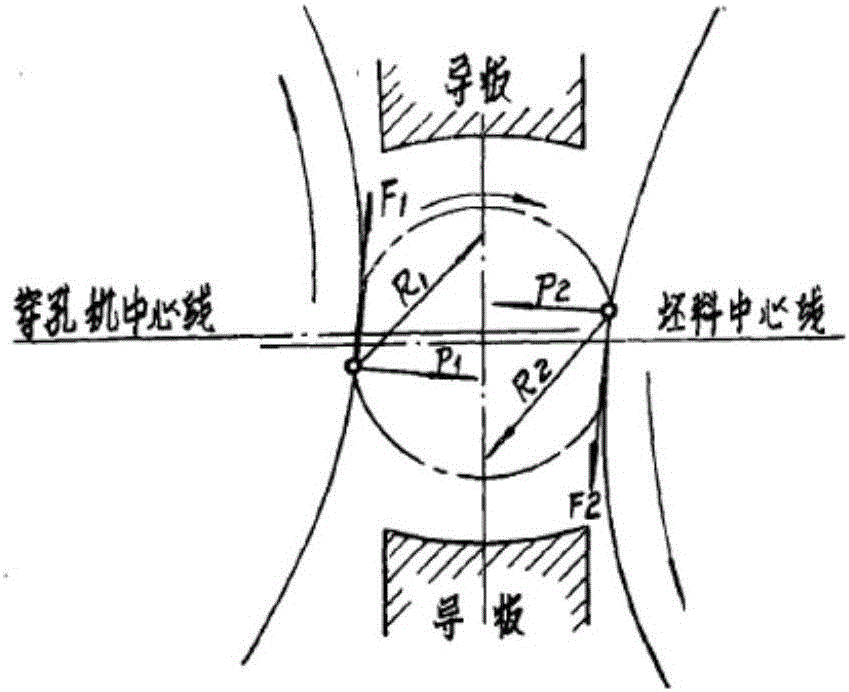

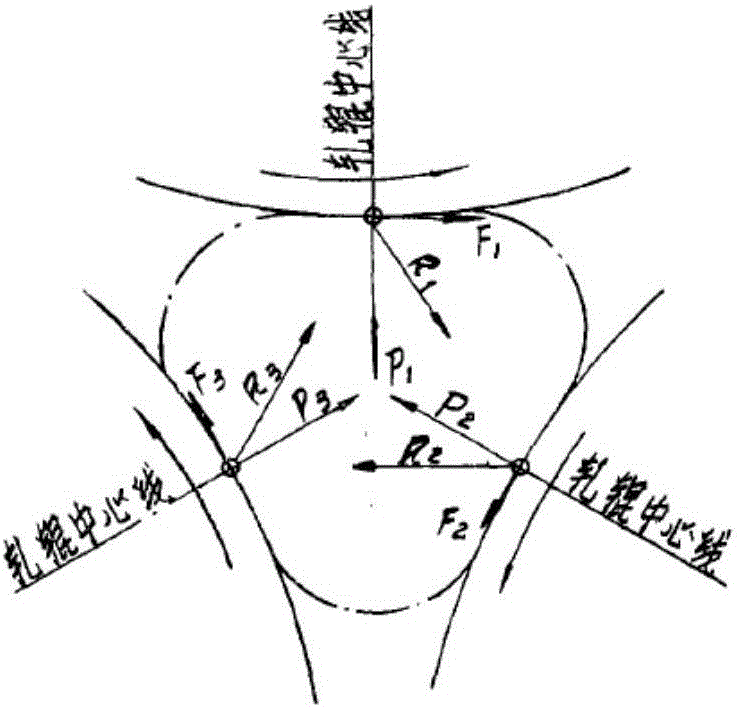

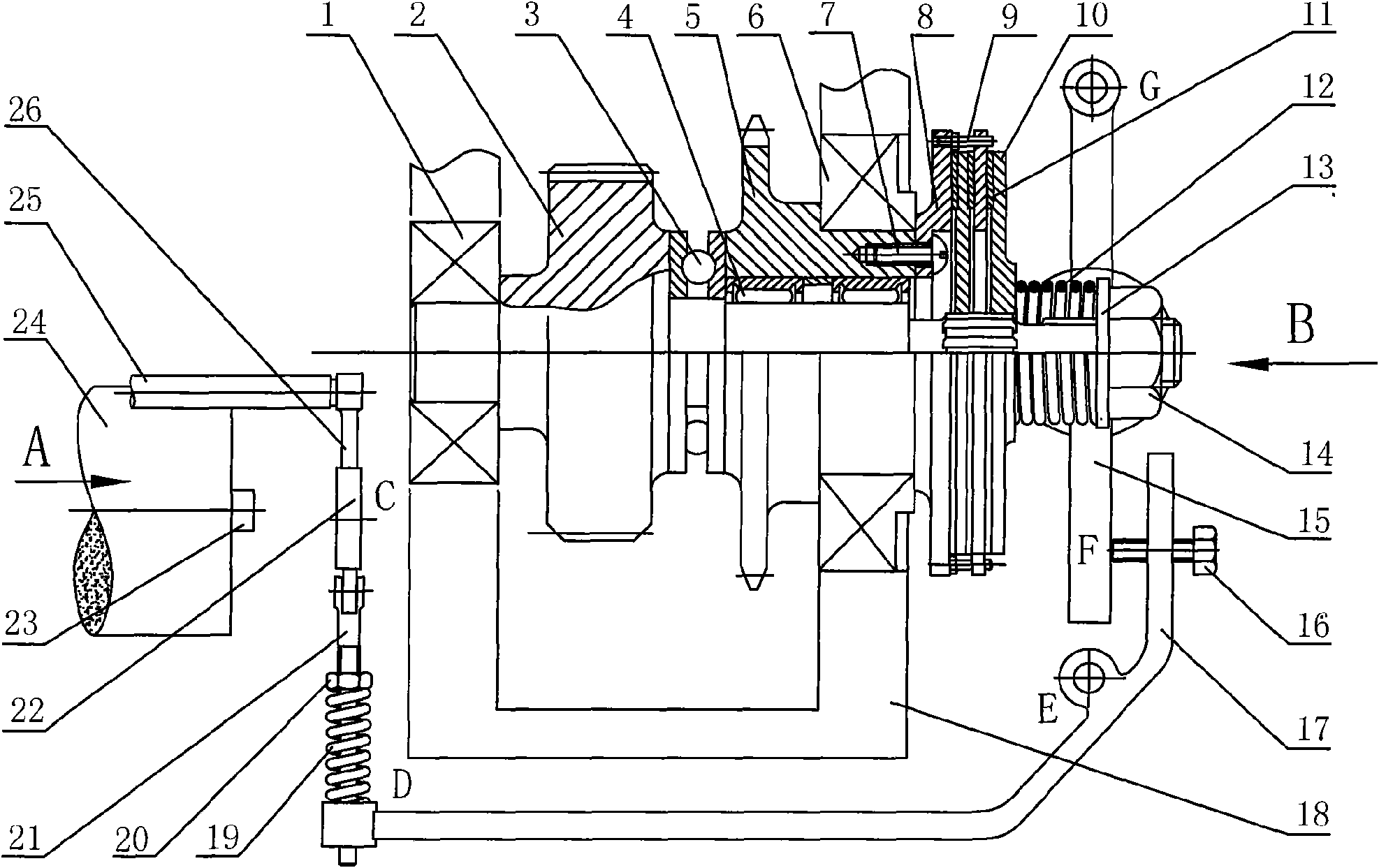

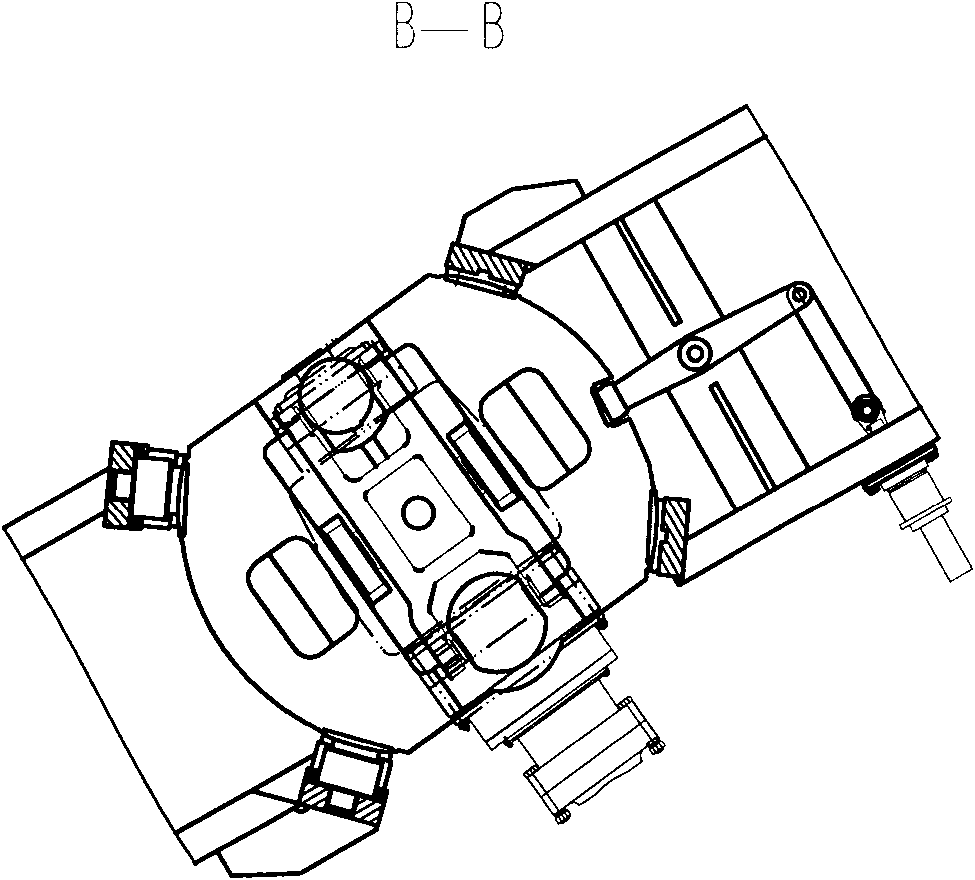

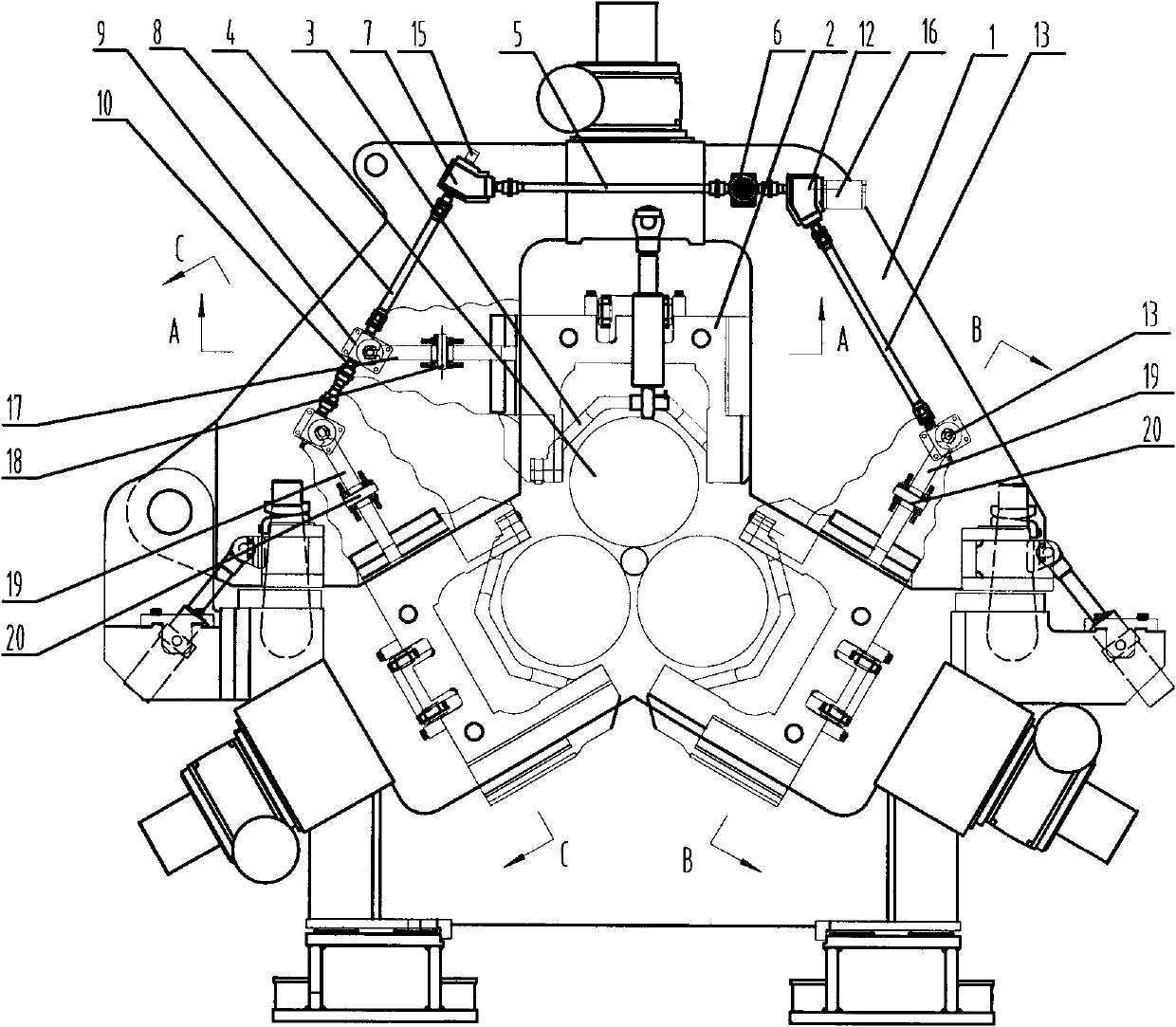

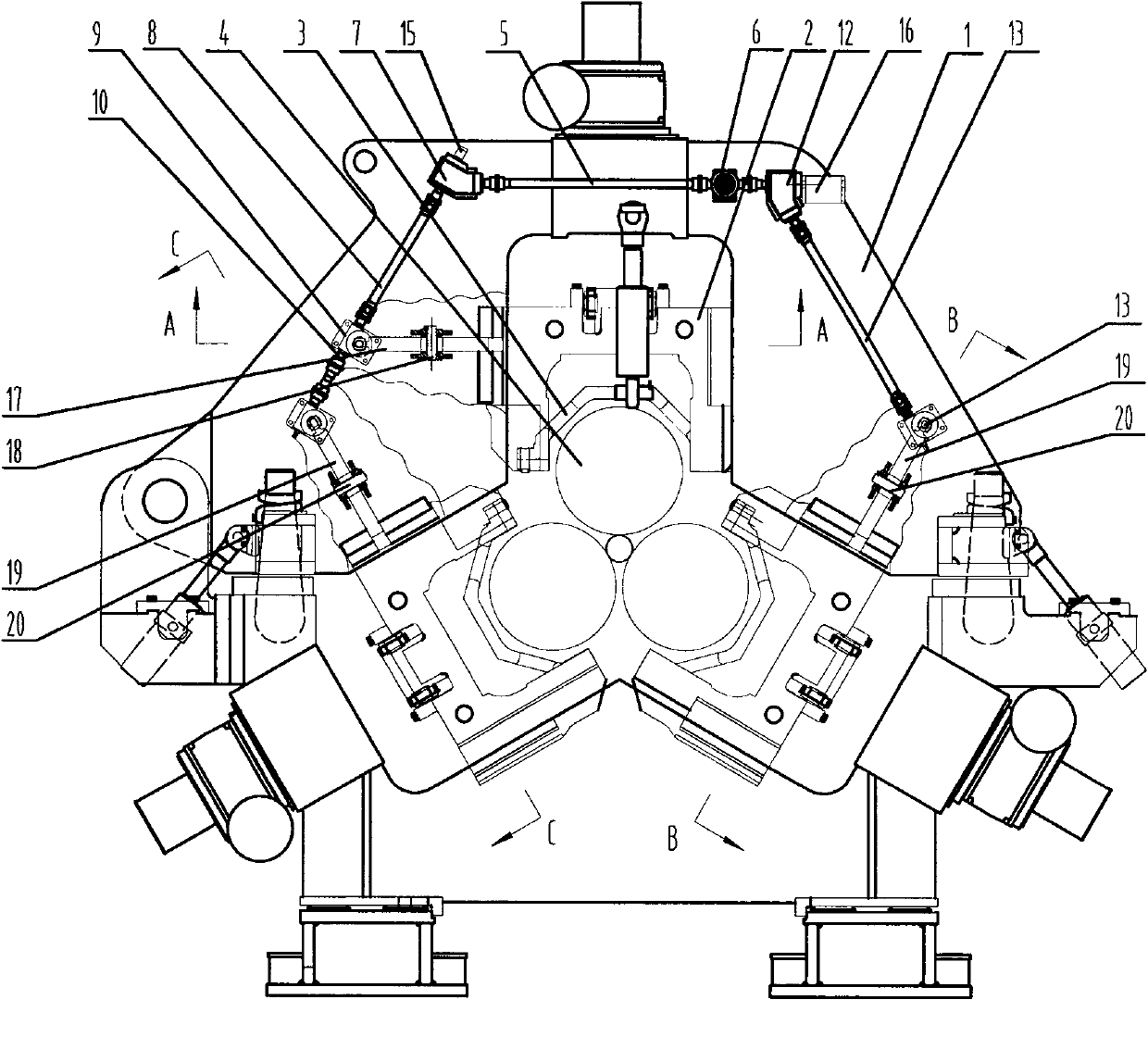

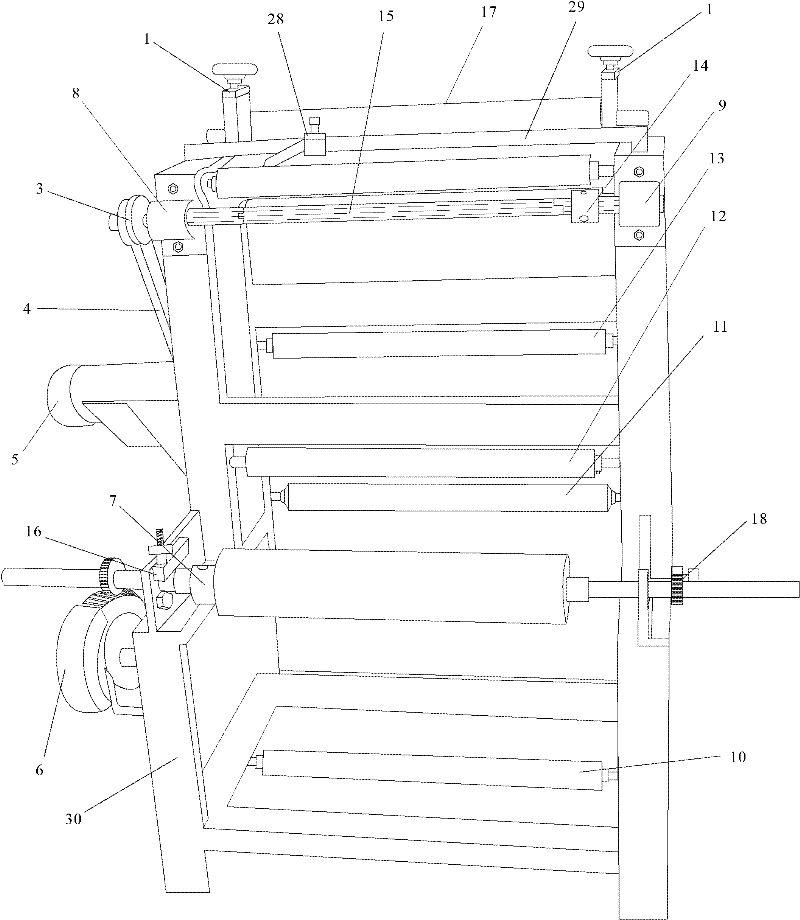

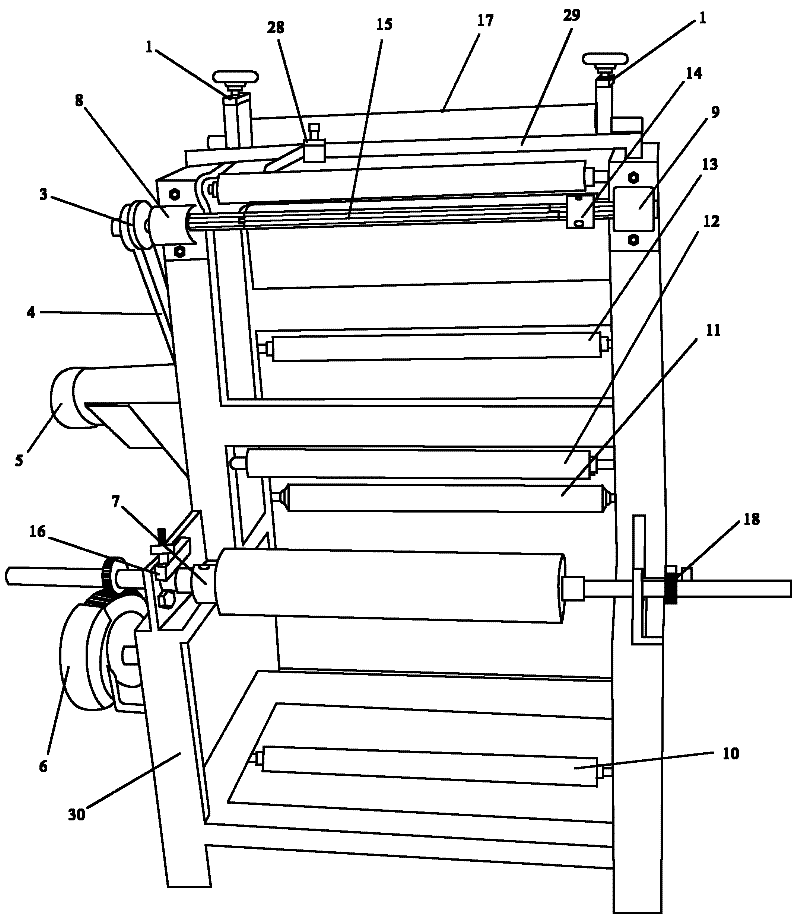

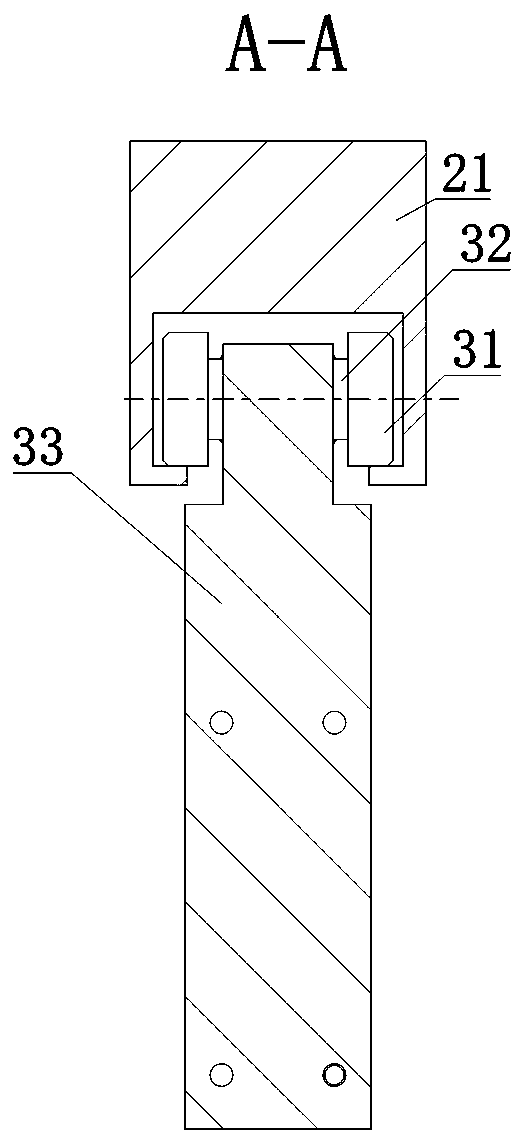

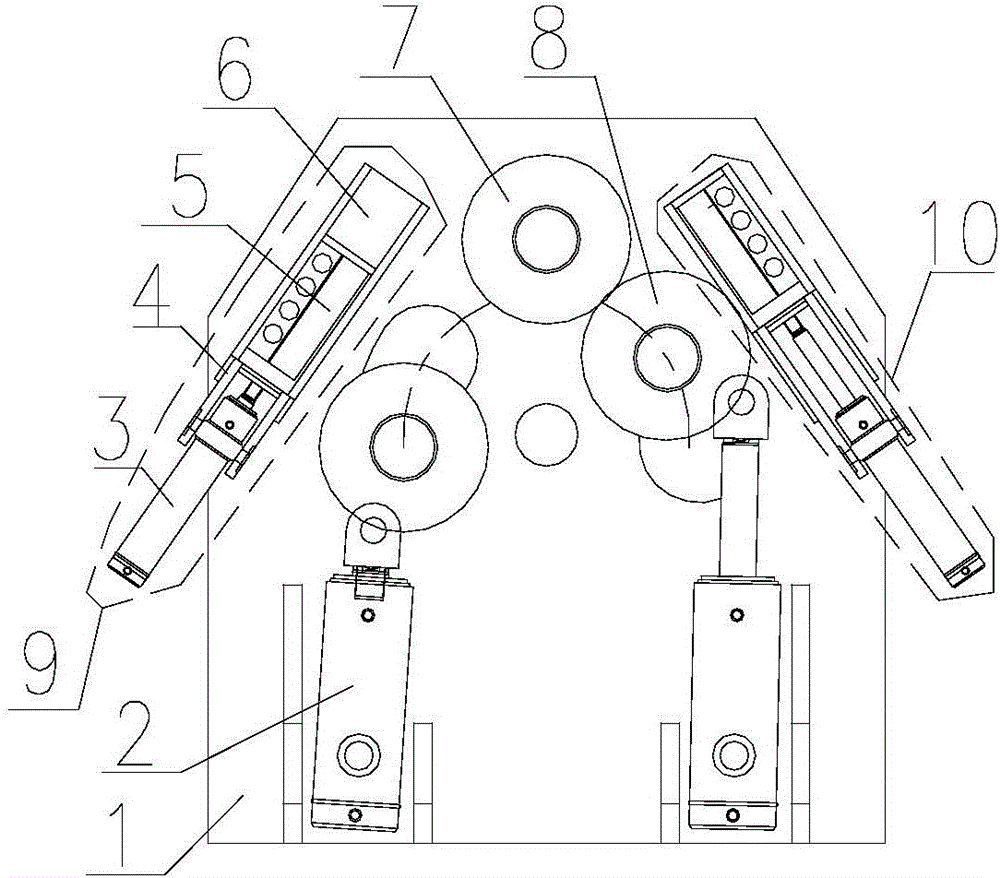

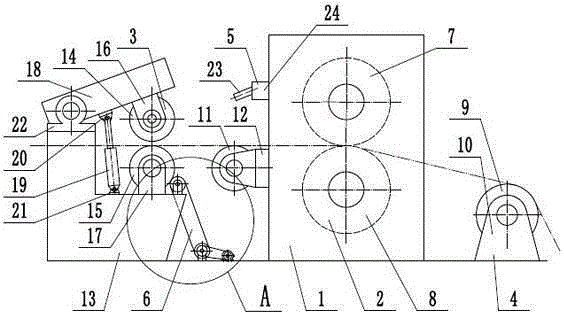

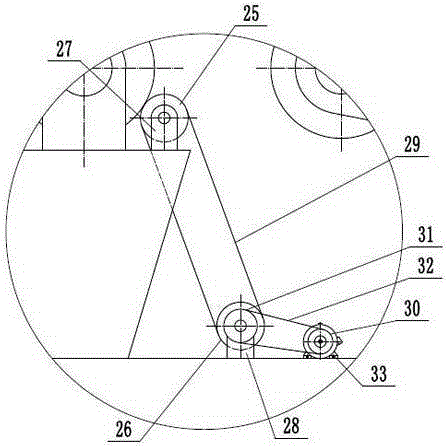

Feeding angle adjusting device of three-roller skew rolling mill

InactiveCN101947554AImprove rolling qualityMetal rolling stand detailsMetal rolling arrangementsCouplingElectric machine

The invention discloses a feeding angle adjusting device of a three-roller skew rolling mill, which solves the problem of the prior art that the adjustment of the feeding angles of three rollers cannot be synchronized with the same accuracy. The feeding angle adjusting device comprises a dual-output shaft driving motor (6) and three worm lifts, wherein the dual-output shaft driving motor (6) and the three worm lifts are fixed on a frame (1) respectively; the dual-output shaft driving motor (6) is connected with the input shafts of the three worm lifts through three couplings in turn respectively; the three worm lifts are connected with three drum devices through respective swing bars and hinges respectively; and three sets of swing devices synchronously swing in set directions. According to the invention, synchronous and centralized adjustment of the feeding angle of the three-roller skew rolling mill can be realized.

Owner:TAIYUAN TONGZE HEAVY IND

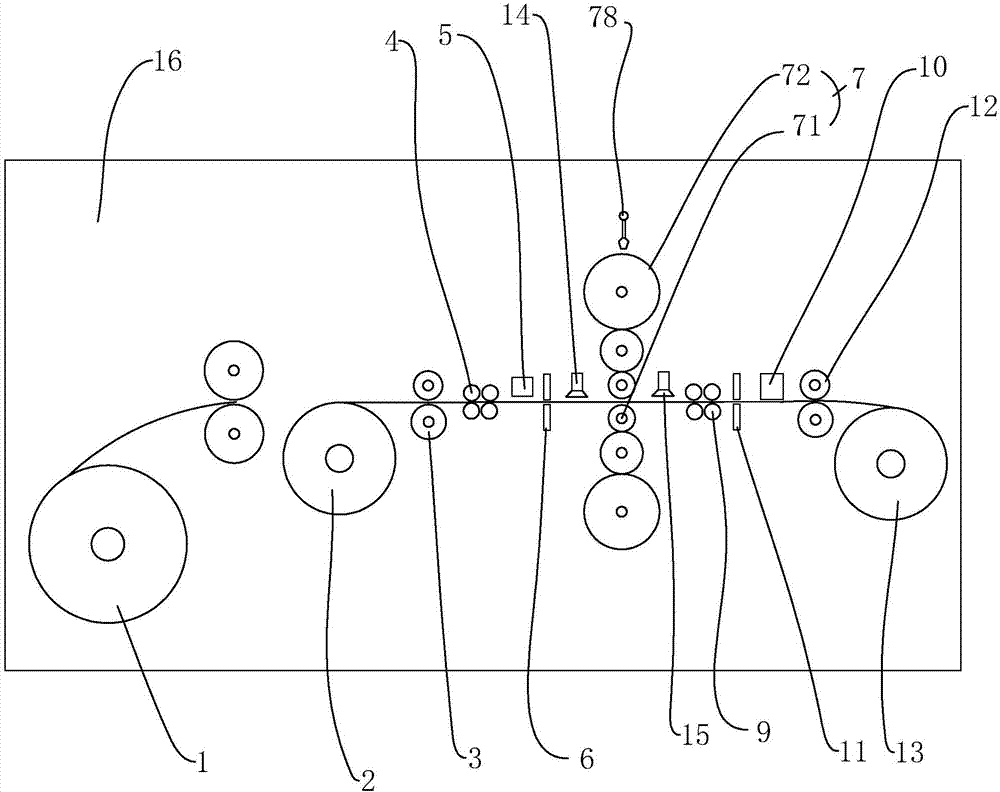

Fully-automatic intelligent heat insulation paper cup production line

ActiveCN105109109ARealize automatic controlHigh degree of automationPaper/cardboard articlesWrapper twisting/gatheringProduction lineCarton

The invention discloses a fully-automatic intelligent heat insulation paper cup production line. The production line is characterized by being composed of an inner cup forming machine, an inner cup detecting machine, a heat insulation cup externally-bonding machine, an automatic bagging machine and an automatic boxing machine which are connected in sequence, the inner cup forming machine and the inner cup detecting machine are connected through a first connecting and conveying pipe, the inner cup detecting machine and the heat insulation cup externally-bonding machine are connected through a second connecting and conveying pipe, the heat insulation cup externally-bonding machine and the automatic bagging machine are connected through a third connecting and conveying pipe, and the automatic bagging machine and the automatic boxing machine are connected through a fourth connecting and conveying pipe; the automatic boxing machine and a carton conveying platform are connected, an inlet of the carton conveying platform and an automatic carton forming machine are connected, an outlet of the carton conveying platform is connected with an automatic cover folding tape sealing machine, the automatic cover folding tape sealing machine and a carton output conveyer are connected, and the inner cup forming machine and the heat insulation cup externally-bonding machine are connected with an automatic paper feeding device. By the adoption of the production line, unmanned operation is adopted for the whole process from automatic paper feeding to heat insulation paper cup boxing, automation degree is high, and heat insulation paper cup forming quality is high.

Owner:ZHEJIANG SINI MACHINERY

Cylinder-less paper winder

The invention relates to a cylinder-less paper winder, which comprises a frame type stander, a driving motor, a transmission mechanism, a plurality of rollers, an charging device, a paper winding shaft and a control device, wherein the plurality of rollers are arranged in parallel and in pairs; the charging device can be used for holding a paper tube to be wound and the paper tube to be wound can rotate on the charging device so as to unfold external layer paper web in sequence; the paper winding shaft is in a driving connection with the driving motor through the transmission device; and the paper winding shaft is composed of three sections which can be coaxially connected so as to wind the paper tube and can be disconnected to unload the paper tube from the paper winding shaft. The paper winder has a reasonable structure, is easy to manufacture, is simple and convenient for winding operation and can obtain better core-less winding quality, particularly the wound paper tube can be directly dismounted from the paper winding shaft; the working space required by the overall machine is small; and the manufacturing cost is low.

Owner:CANGNAN JIAHE WALLPAPER

Cold-rolled steel strip processing technology

InactiveCN107052049AImprove rolling qualityImprove rolling plasticityRollsTension/compression control deviceWinding machineStrip steel

The invention discloses a cold-rolled steel strip processing technology. The cold-rolled steel strip processing technology is characterized by comprising the following steps of: conveying a steel strip of which the thickness is 3mm to a left winding machine through an unwinding machine rotating forwards; enabling the steel strip to pass through a left turning roll, and conveying the steel strip into a left tensiometer for tension test; conveying the steel strip into a left speed meter for speed measurement; conveying the steel strip into a left thickness gauge for thickness test; conveying the steel strip into a six-roll reversible cold rolling mill for rolling; enabling the steel strip to pass through a cooling device on the six-roll reversible cold rolling mill for cooling; conveying the steel strip to a right tensiometer for tension test; conveying the steel strip into a right speed meter for speed measurement; conveying the steel strip into a right thickness gauge for thickness test; performing reverse motion for rolling; and after rolling for seven times, winding the steel strip through a right winding machine to complete the rolling process. The cold-rolled steel strip processing technology has the effects that the rolled plasticity of the steel strip is improved, and the rolling quality of the steel strip is further improved.

Owner:浙江协和陶瓷有限公司

Working roller for wire and bar roughing mill stand and manufacturing method thereof

ActiveCN111101053AIncrease Ni contentImprove thermal cracking resistanceFurnace typesRollsCarbideDuctile iron

The invention discloses a working roller for a wire and bar roughing mill stand. The working roller comprises, by weight, 2.9-3.6% of C, 1.2-2.0% of Si, 0.3-0.8% of Mn, 0.2-1.0% of Cr, 1.0-2.0% of Ni,0.2-0.5% of Mo, less than or equal to 0.15% of P, less than or equal to 0.3% of S, and the balance being Fe and inevitable impurities. A manufacturing method is characterized in that a pearlitic ductile cast iron blank manufactured through integral casting is subjected to rough machining and then quenching heat treatment to obtain the working roller with the structure of bainite, tempered sorbiteand carbide for the roughing mill stand. The pearlitic ductile cast iron blank manufactured through integral casting is subjected to rough machining and then quenching heat treatment, so that not only is the hardness drop inside and outside a working layer reduced, but also the wear resistance is improved, and the probability of occurrence of hot cracks at the bottom of a roller groove is reduced.

Owner:邢台轧辊线棒辊有限责任公司

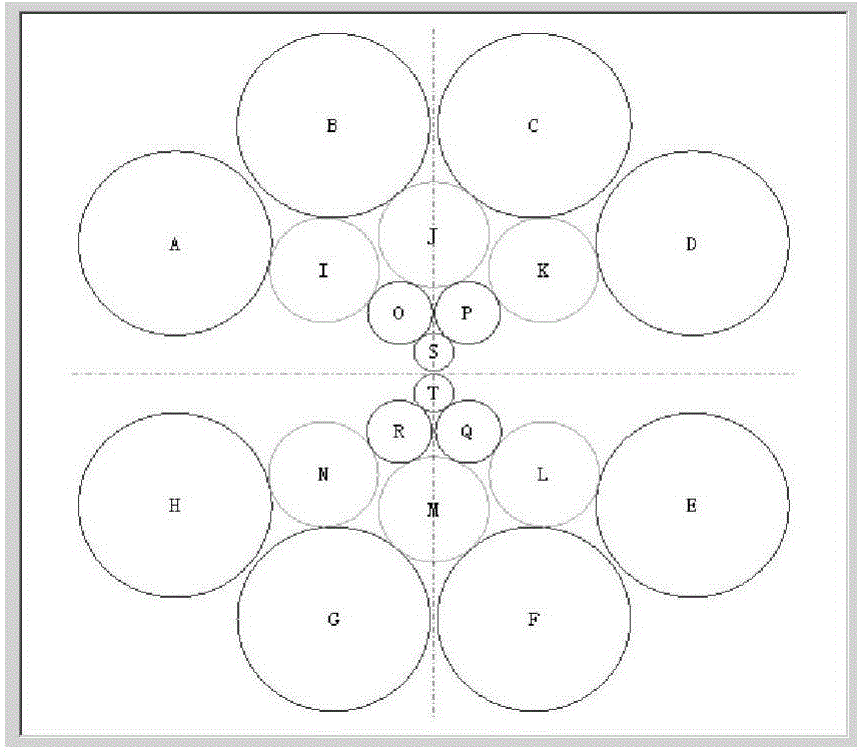

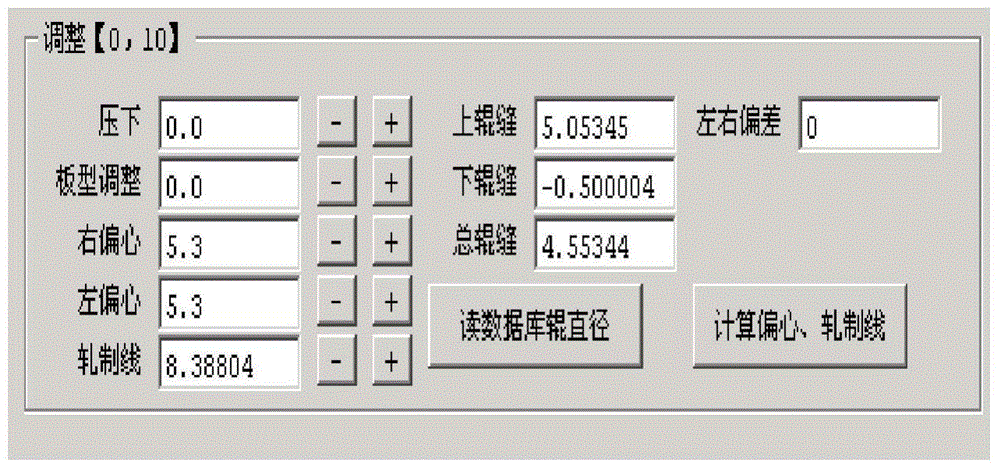

Online roll matching method and system of working rolls of twenty-roll Sendzimir mill

InactiveCN106180201AQuality improvementImprove efficiencyMetal rolling stand detailsRolling equipment maintainenceWork rollControl system

The invention discloses an online roll matching method and system of working rolls of a twenty-roll Sendzimir mill, and belongs to control systems. The method comprises the steps of forming a working roll database according to diameters of ground working rolls, and linking the working roll database with a roll system database system of the mill to achieve data sharing; calculating left and right eccentricity data and a rolling line of an entire mill roll system, and performing optimization and adjustment; checking mutual interference situations among the rolls in the roll system; calculating upper roll gap, lower roll gap and total roll gap values according to diameter data of the rolls in the actual roll system, and performing analog display; calculating the diameter range of upper and lower working rolls matched with the group of rolls according to the actual parameters of the rolls in the roll system, and determining a roll matching table of corresponding residual rolls; forming a dynamic roll matching table according to the calculation result of roll matching data of the working rolls; selecting the corresponding working rolls and carrying out roll changing operation according to an allowable matched roll diameter range of the upper and lower working rolls and roll numbers of the working rolls, which are given in the dynamic roll matching table.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

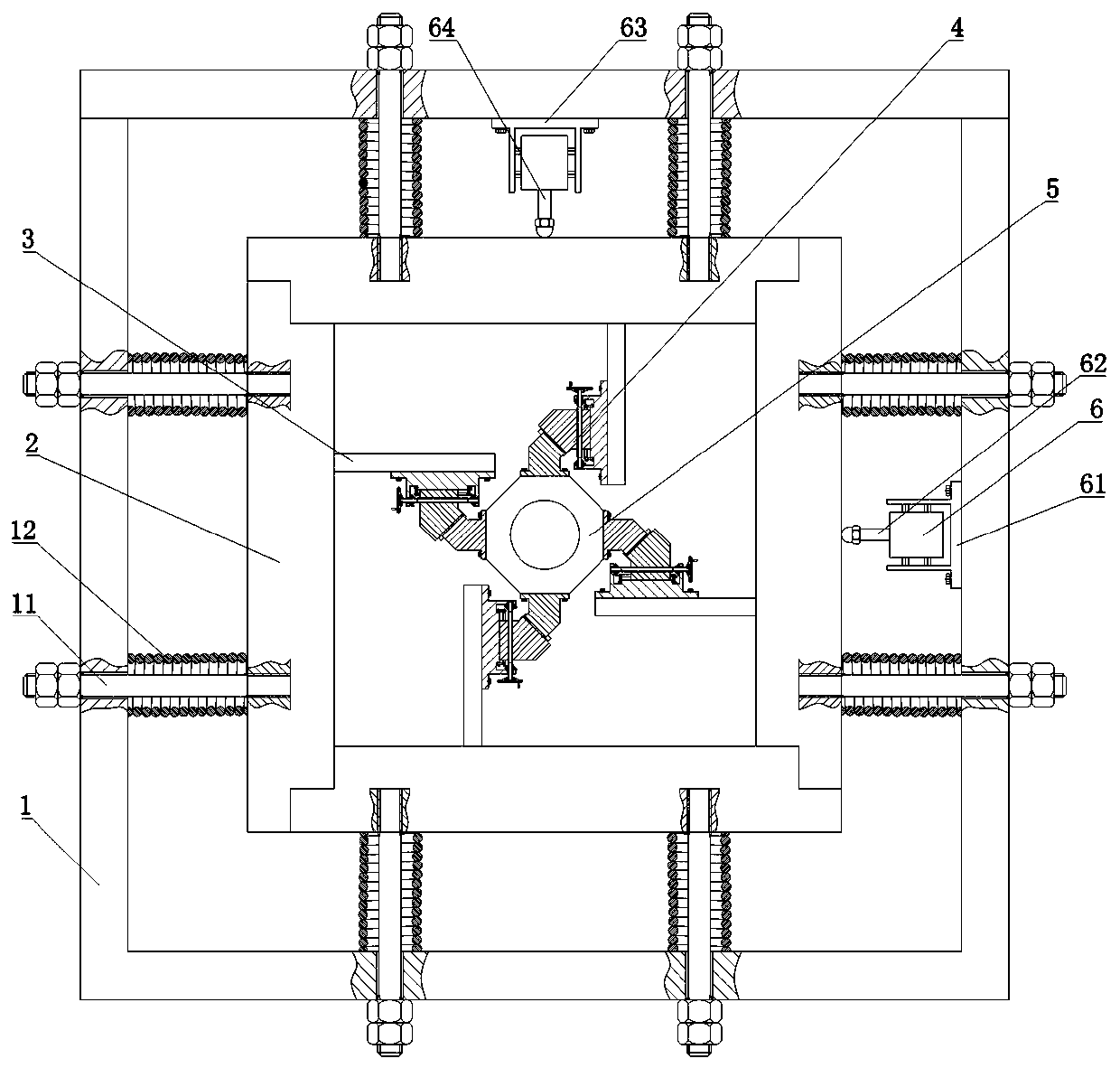

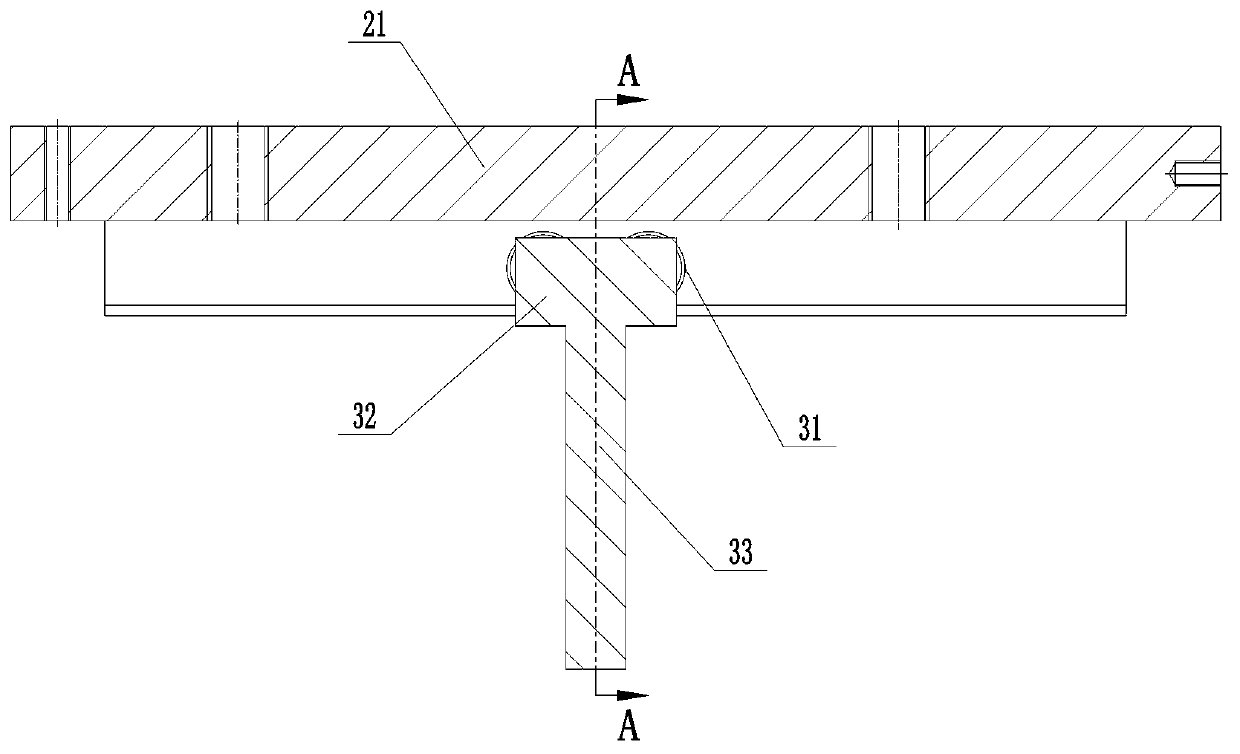

Adjusting device of roller test center of rolling mill

ActiveCN109877163AAchieve coarse adjustmentFulfilling adjustment requirementsMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The invention discloses an adjusting device of a roller test center of a rolling mill. The adjusting device comprises a guide framework, follow-up structures, fine adjustment modules and a roller bearing pedestal. A center adjusting mechanism comprises the follow-up structures and the fine adjustment modules. The number of the fine adjustment modules is four, and the fine adjustment modules are arranged in rotational symmetry about the axis of the roller bearing pedestal. The fine adjustment modules are in sliding connection with the guide framework through the follow-up structures. Accordingto the adjusting device of the roller test center of the rolling mill, the roller bearing pedestal of the rolling mill can be subjected to self aligning in the single motion direction and the composite motion direction through the fine adjustment modules, and therefore deviation happening to the roller mounting center is corrected; and the center position of a roller of the rolling mill can be changed by adjusting the fine adjustment modules, and the work condition of the roller of the rolling mill in an eccentric state can be simulated.

Owner:HENAN POLYTECHNIC UNIV

Carrier roller device of profile bender

InactiveCN104096732AAddressing Structural ComplexitySolve the inconvenience of installationHydraulic cylinderEngineering

The invention belongs to the technical field of profile forming equipment, particularly relates to a carrier roller device of a profile bender, and aims to solve the technical problem that a carrier roller device of an existing profile bender is complicated in structure, inconvenient to mount and poor in profile rolling quality. The carrier roller device of the profile bender comprises a rack, an upper working roller, a pair of lower working rollers, a pair of hydraulic cylinders, a left carrier roller device and a right carrier roller device, and the left carrier roller device and the right carrier roller device are respectively mounted on the rack on two sides of the pair of lower working rollers, and arranged along the direction that the lower working rollers located at the highest positions are tangential to the upper working roller. The carrier roller device of the profile bender has the advantages of simple structure, convenience in mounting, good using effect, low cost and high rolled profile quality.

Owner:长治市泽洋锻压机械有限公司

Aluminum plate rolling device

ActiveCN105195513AAchieve orientationAchieve coolingRolling equipment maintainenceGuiding/positioning/aligning arrangementsTransverse beamNozzle

The invention provides an aluminum plate rolling device, which belongs to the technical field of metal processing, and comprises a first rolling component, a second rolling component, a guiding component, a cooling component and a cleaning component, a first upper press roll and a first lower press roll which are arranged on the first rolling component are up and down adjacent but not contacted, a feeding guide roll of the guiding component is rotatably arranged on a feeding guide roll support, a discharge guide roll is rotatably arranged on a discharge guide roll support, the left end of a transverse beam of the second rolling component is hinged on a bearing support seat, the second upper press roll is rotatably arranged on a second upper support, the upper and the lower ends of a driving air cylinder are respectively hinged on an air cylinder upper support seat and an air cylinder lower support seat, an air nozzle of the cleaning component is rotatably arranged on a nozzle support, an upper cleaning roll of the cleaning component and a second lower press roll are adjacent but not contacted, and a cleaning curtain is encircled on the upper cleaning roll and a lower cleaning rolls. The aluminum plate rolling device achieves real-time cleaning of the surface of the second lower press roll, and improves rolling quality of an aluminum plate.

Owner:南通市中京机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com