Loop control method for wire tandem rolling and device

A control method and looper technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems affecting steel bite, steel material scrapping, large overshoot, etc., achieve simple structure, improve steel bite The effect of success rate and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

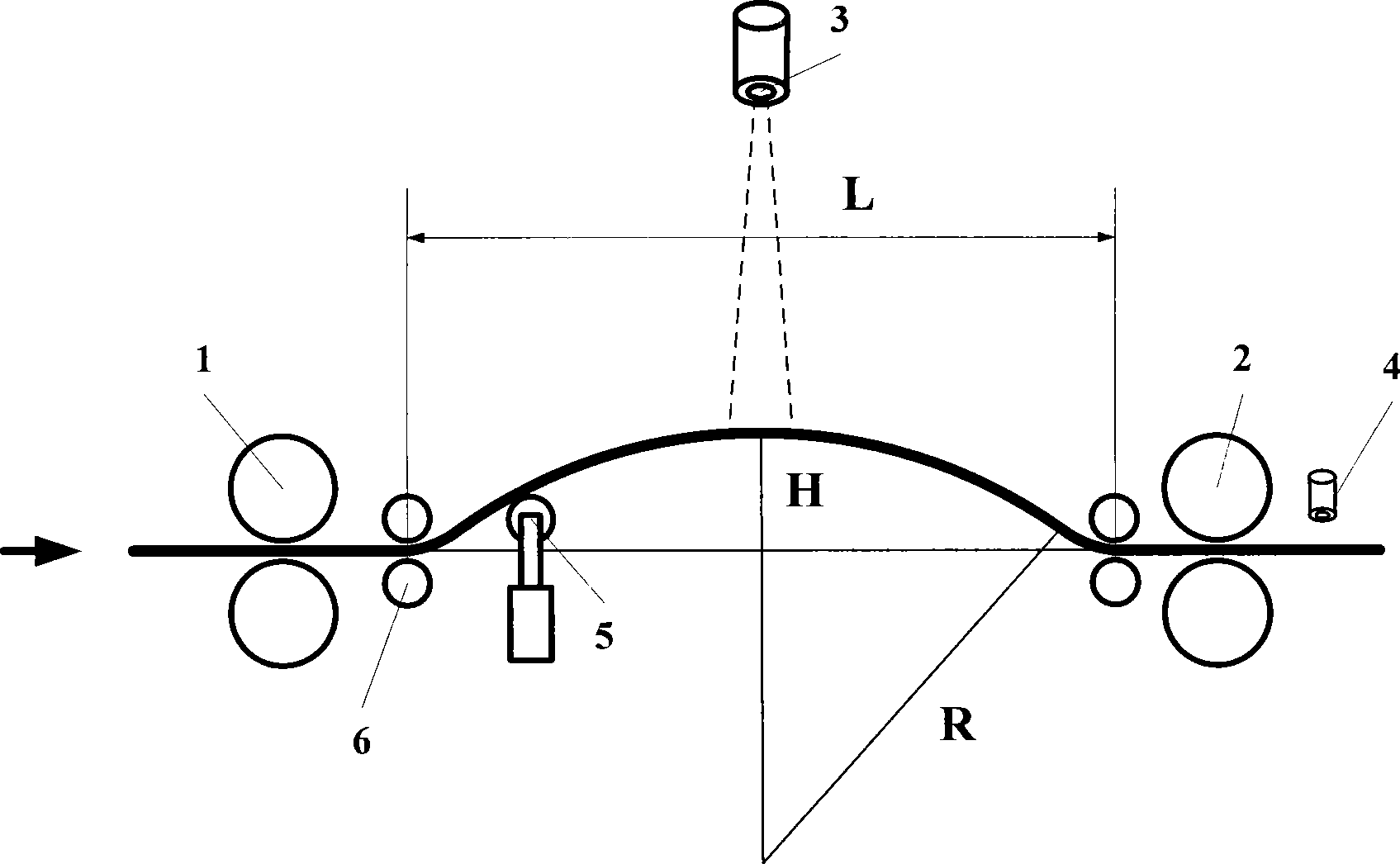

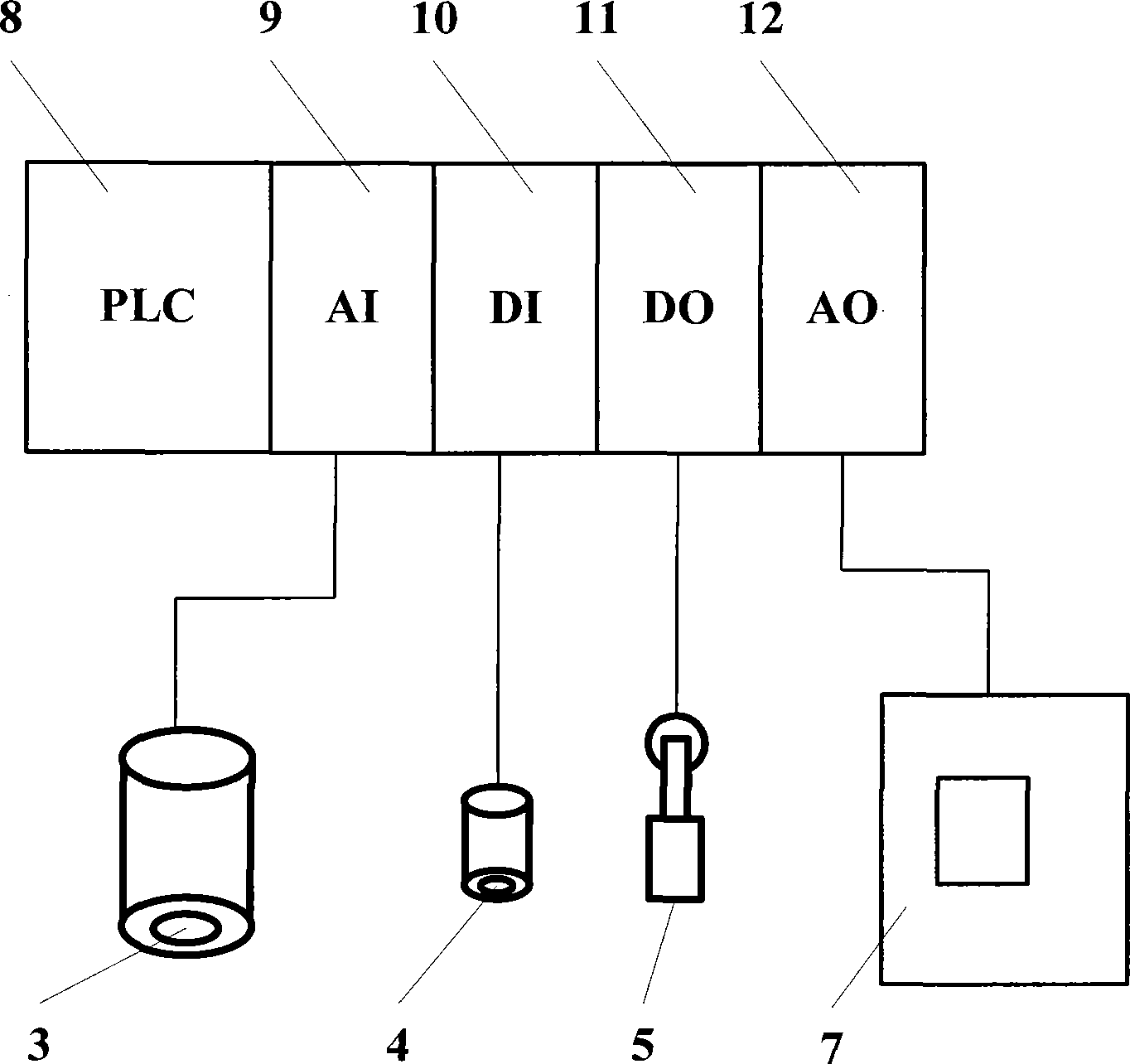

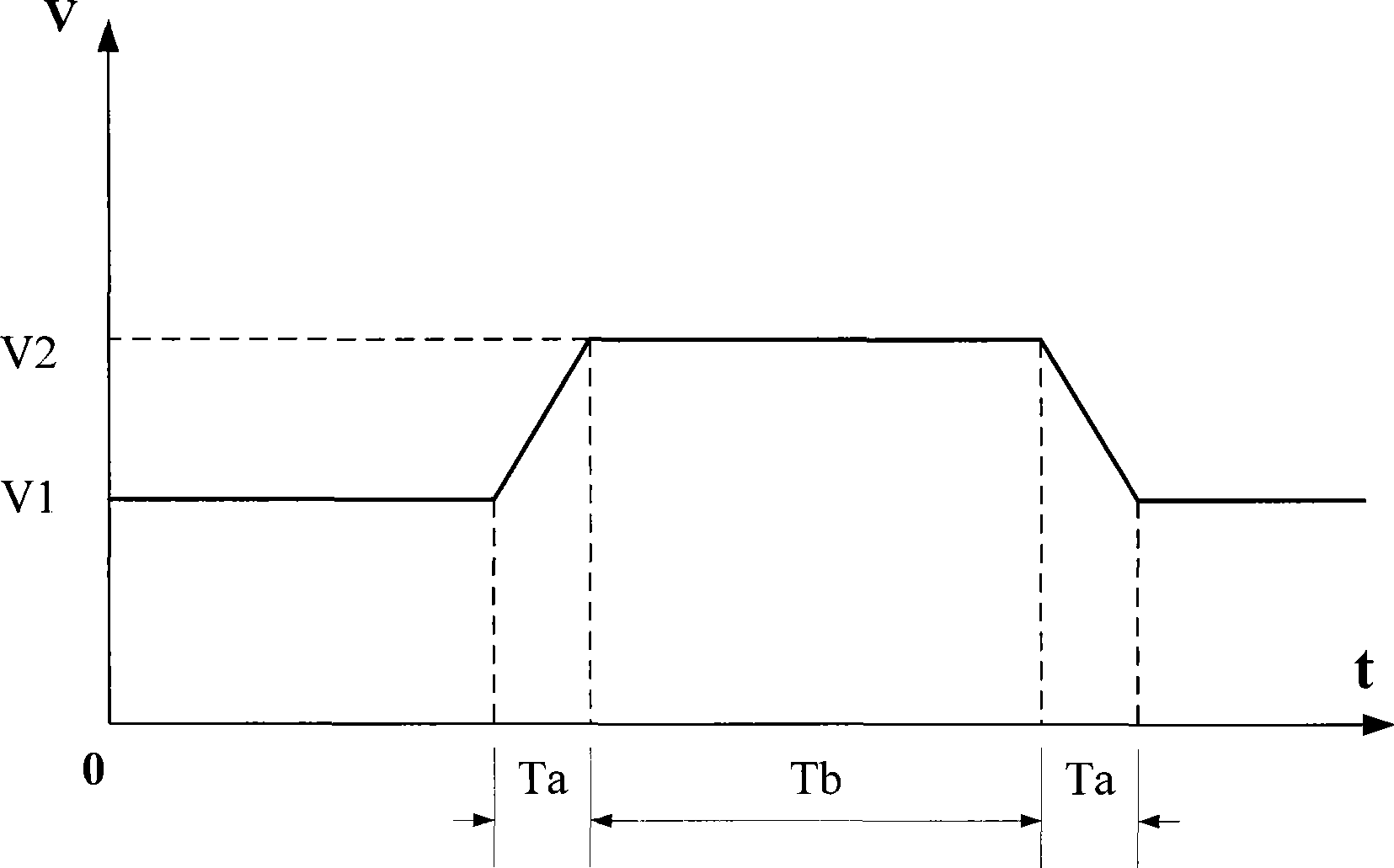

[0019] The control method of the present invention: use the guide wheel 6 located between two adjacent rolling mills to guide the wire into the rolling mill, the sheathing sensor 4 installed at the exit of the second rolling mill 2 detects the arrival signal of the head of the wire rod and issues a sheathing command, through the sheathing The auxiliary cylinder 5 is used to start the sleeve smoothly, and the programmable controller 8 is used to adjust the speed of the rolling mill according to the calculated rolling mill speed-up curve parameters and to control the extension of the auxiliary cylinder 5 to perform the sleeve start; after the sleeve start is completed, the closed-loop PID digital control Algorithms adjust the speed of the rolling mill to control the height of the looper. Since the actual height of the looper is equal to or close to the set looper height during closed-loop PID control, the overshoot of the looper control is very small, thereby effectively improvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com