Patents

Literature

478results about "Flexible work arrangments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

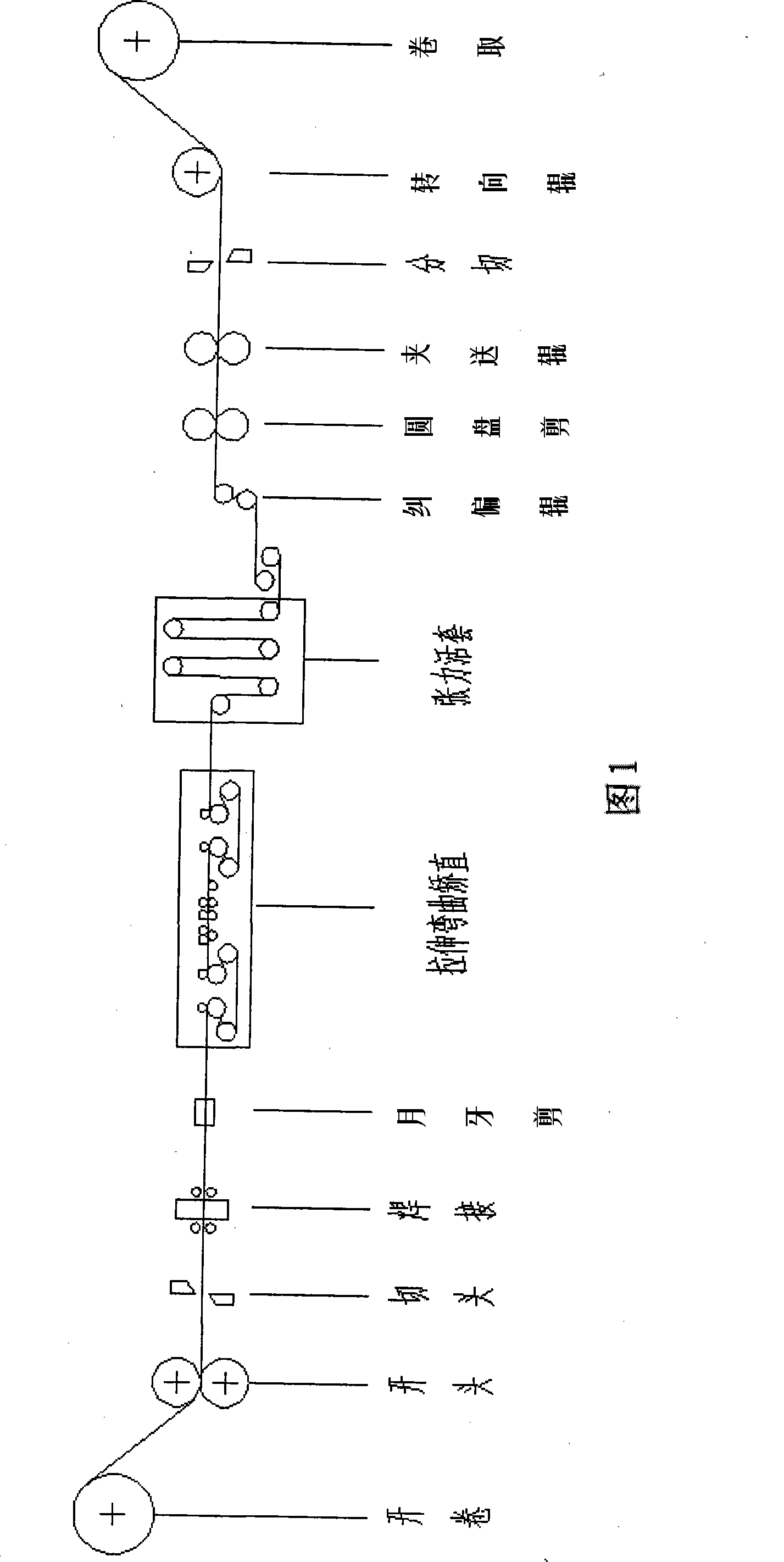

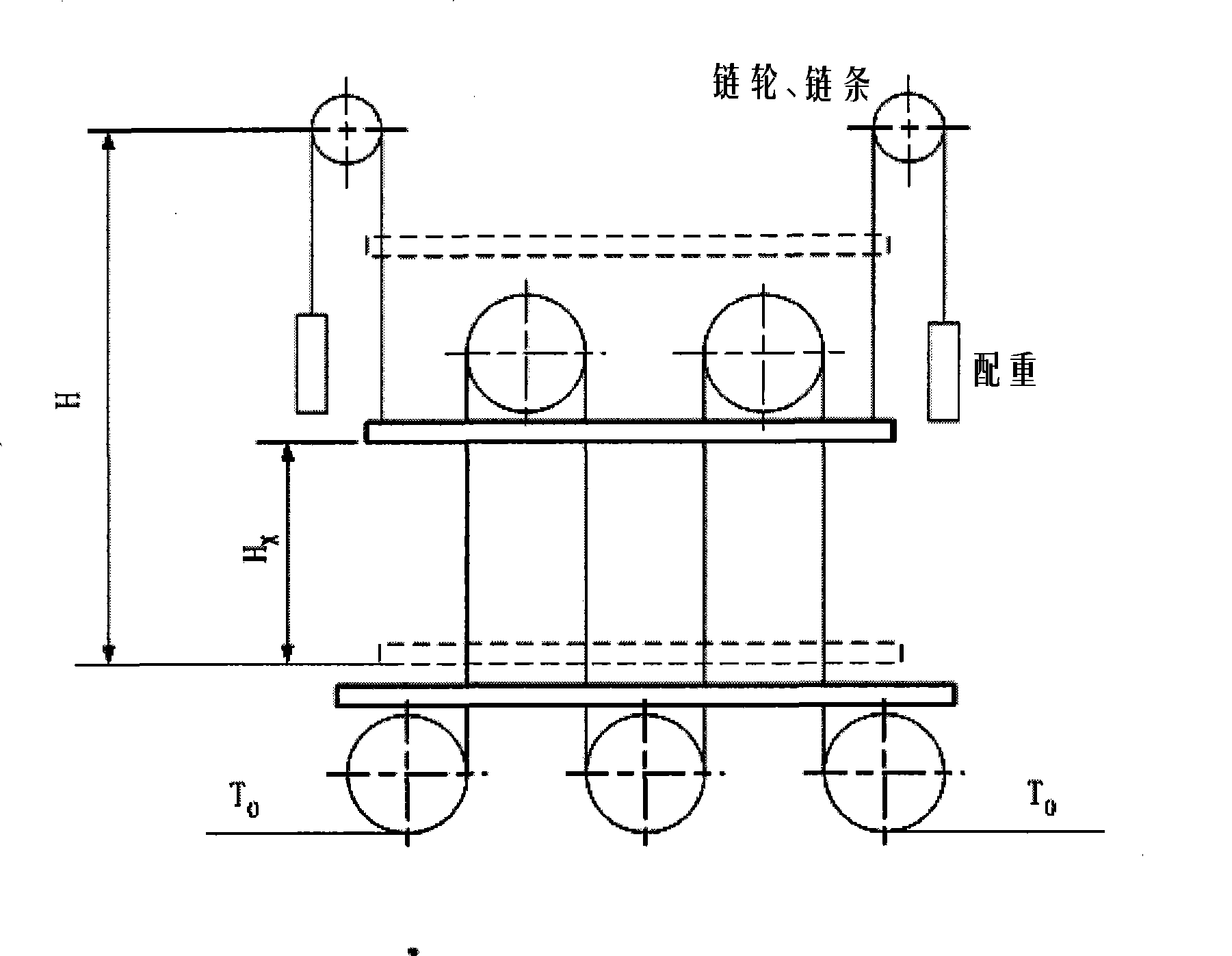

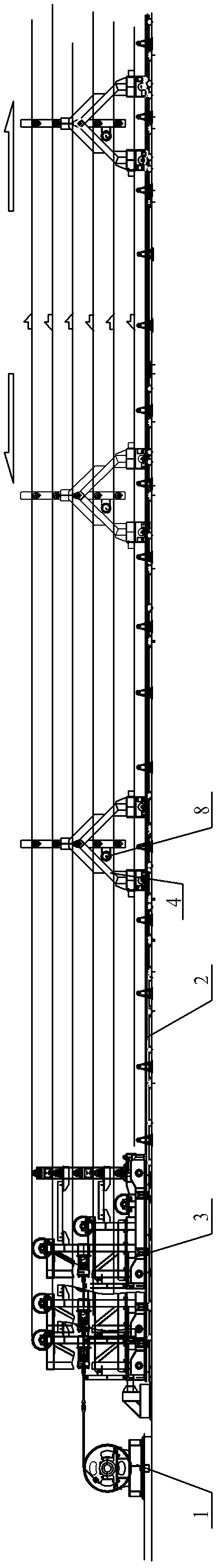

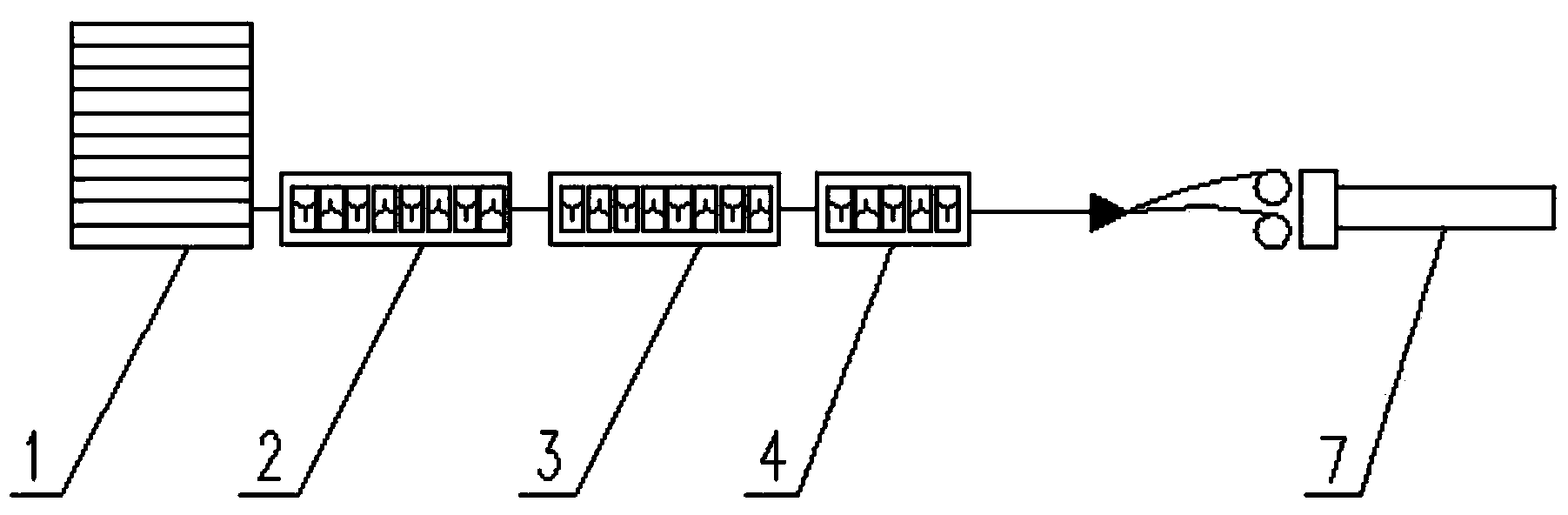

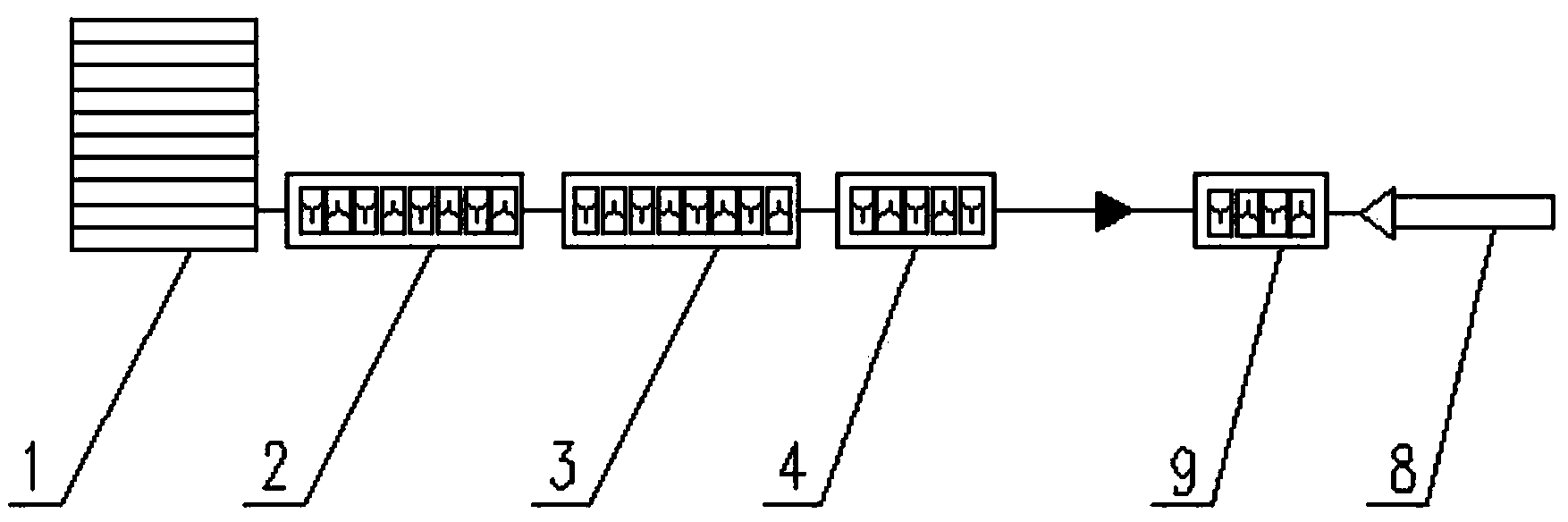

Machine unit process for stretch bending, straightening and rewinding

InactiveCN101439468AEliminate tension changesConstant tensionOther manufacturing equipments/toolsFlexible work arrangmentsCircular discLower limit

The invention provides a unit process used for finishing, tension-bending, straightening, and recoiling the metallurgical cold-rolling strips. The process is characterized in that the process comprises at least the steps as follows: roll-up, uncoiling, head cutting, welding, tension-bending and straightening, tensioning piston, rectification, trimming, separating, coiling and coil removing. When the unit produces normally, a coiler provides initial tension for an outlet tension roller; when the production line is shut down for coil separating, the coiler is shut down, the tensioning piston provides the initial tension equivalent to the coiling tension during the normal production for the outlet tension roller and a tension-bending, and straightening machine continues to straighten the strips; the straightened strips are stored in the tensioning piston; when the coiler removes the coils and re-produces the next finished coils, the straightened strips stored in the piston are coiled, the lifting roller unit of the movable sleeve falls to a lower limit position, the coiler loads the tension and shifts the initial tension of the tension-bending and straightening machine from the tensioning piston to the coiler at the same time, and then the whole unit produces at an accelerated speed. The process can overcome the defects generated on the disc shear by the strips when the tension is shifted between the coiler and the tensioning piston owning to the shutdown of the coil separating.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

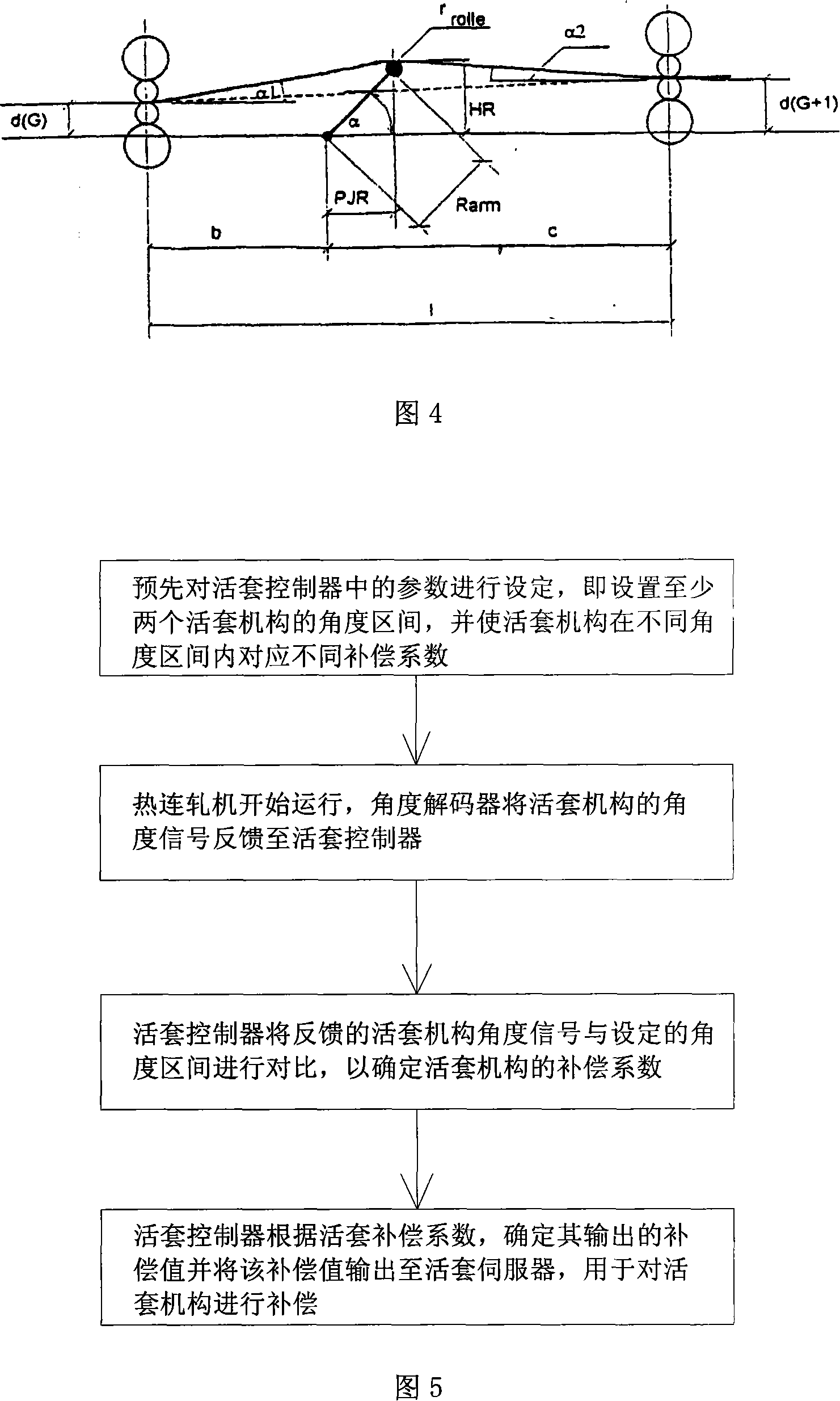

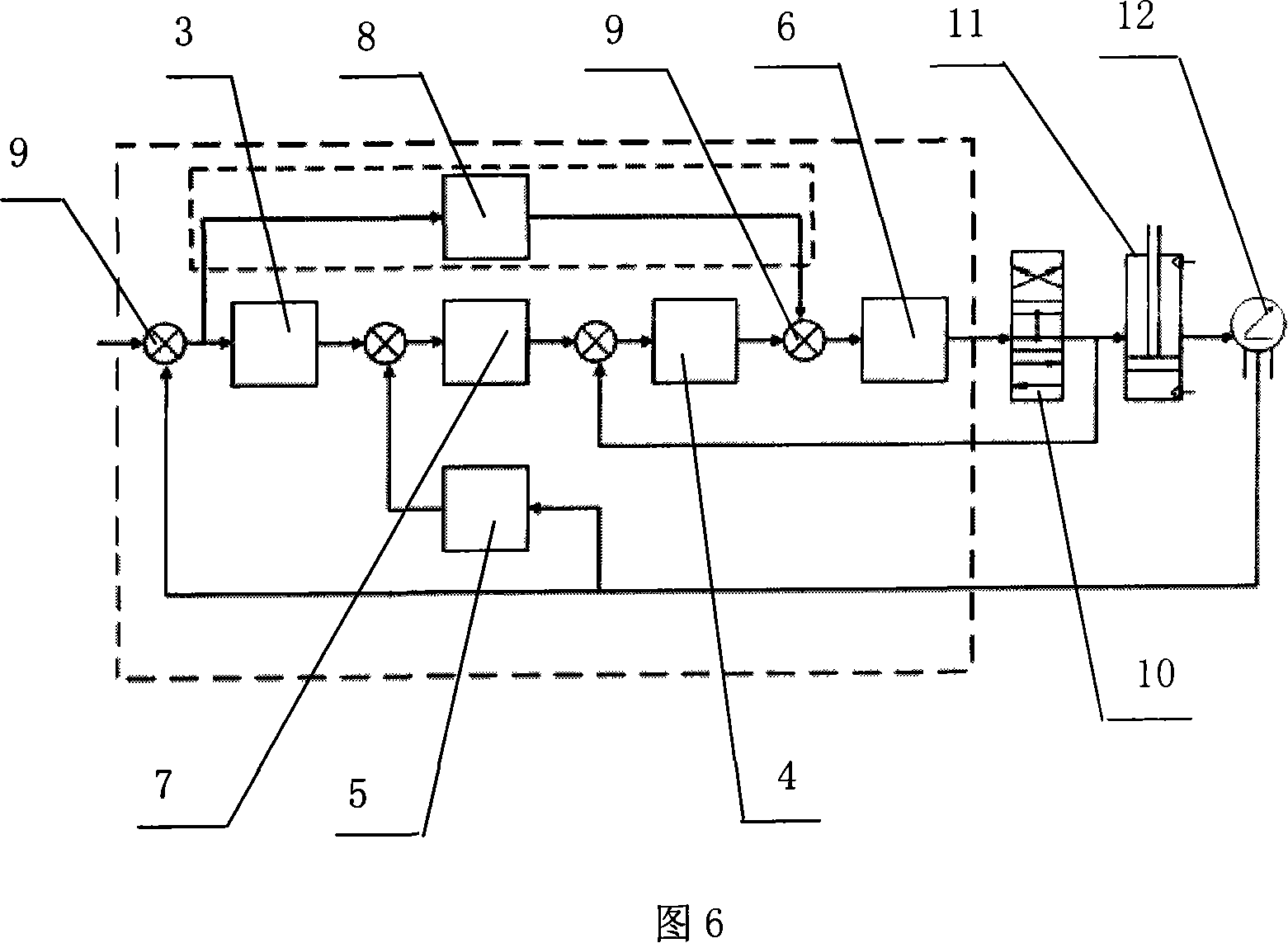

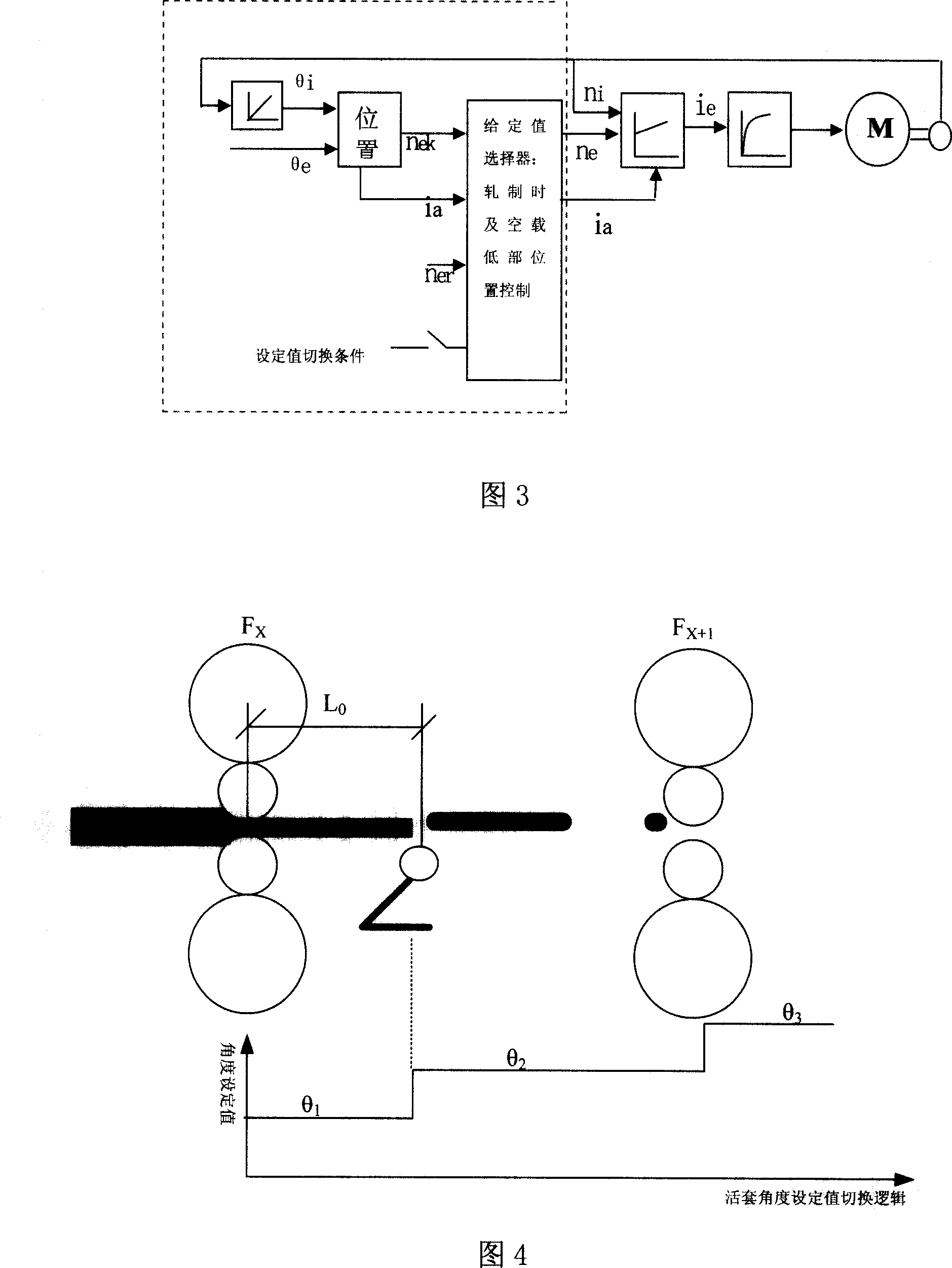

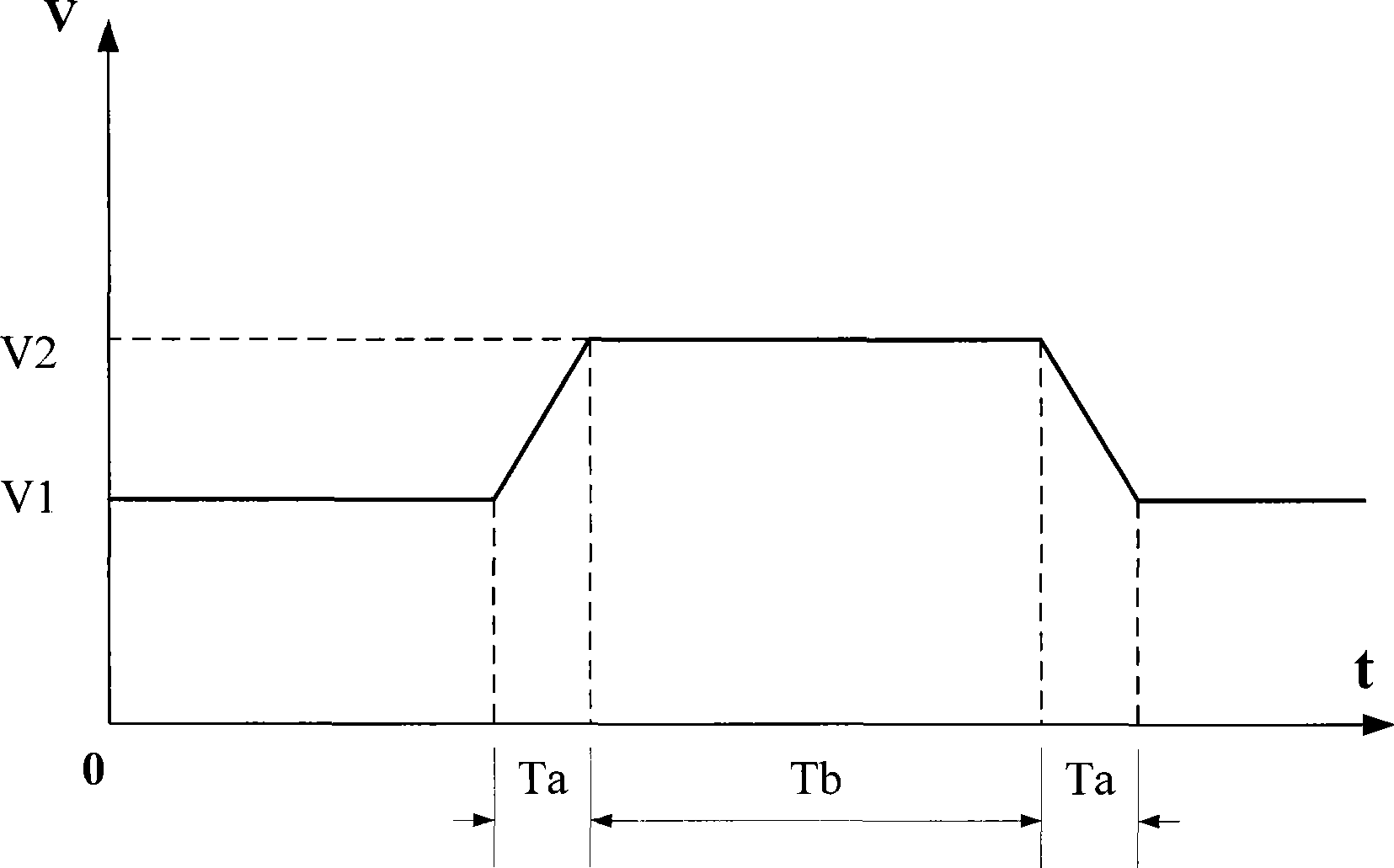

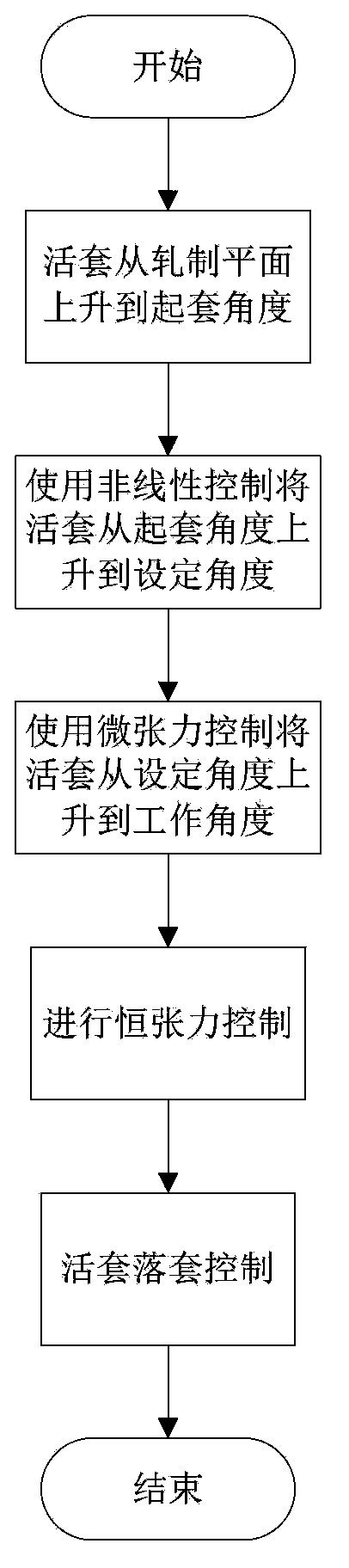

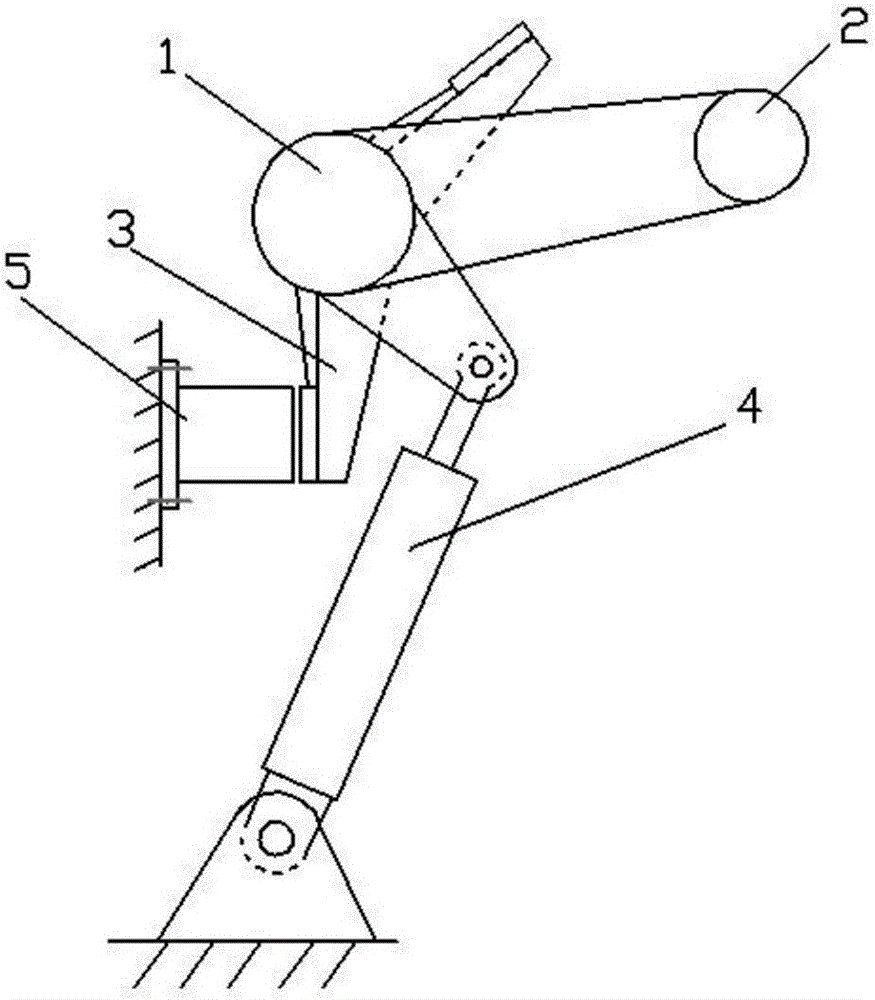

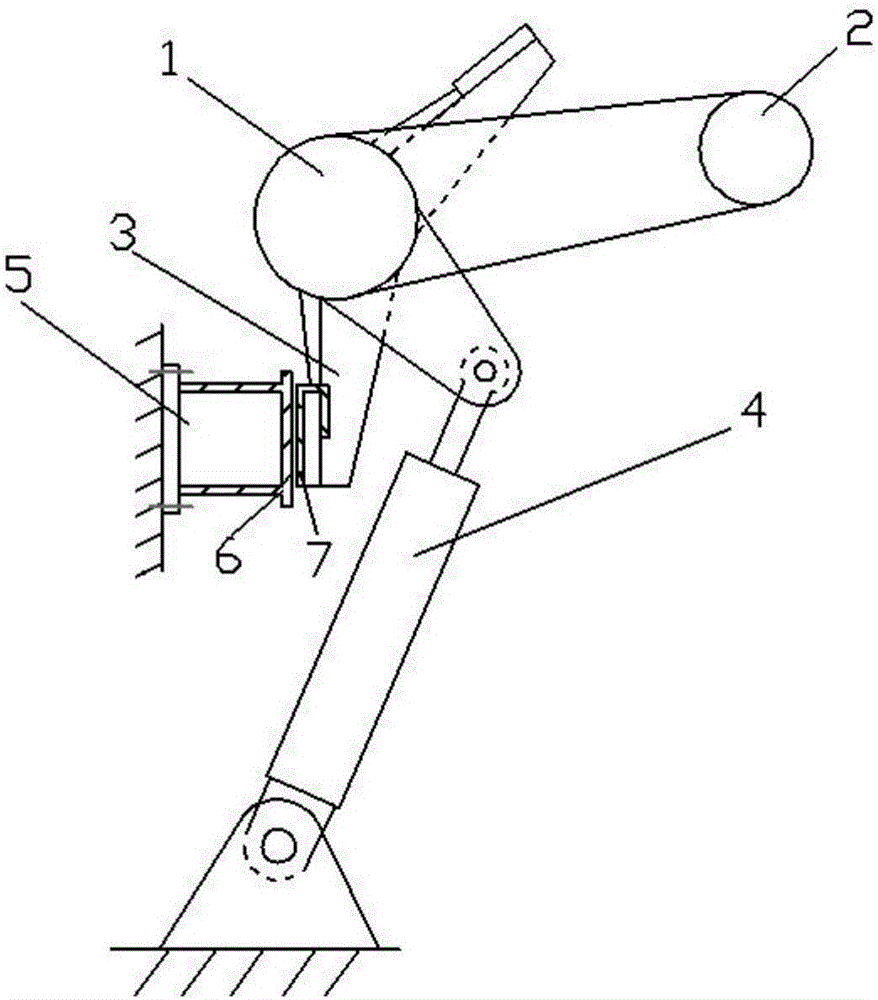

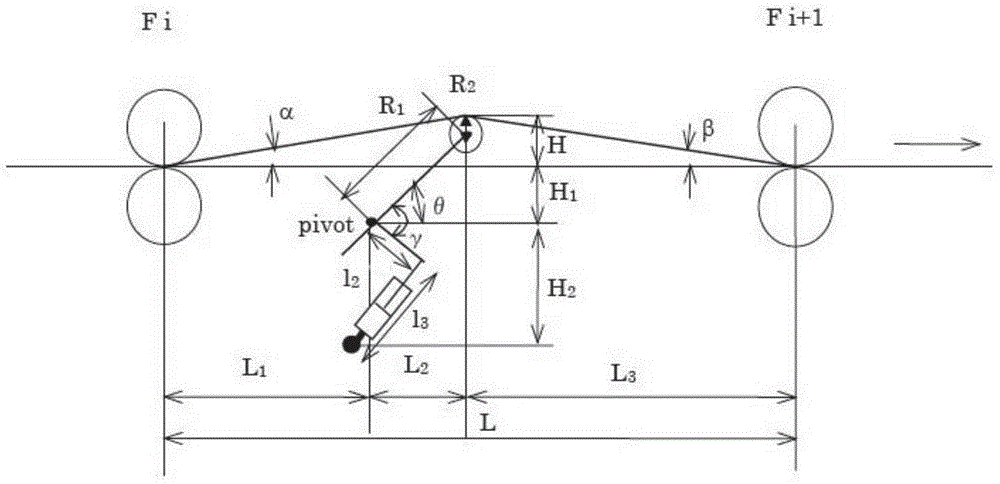

Hot continuous rolling mill loop control method and used controller

InactiveCN101219438AImprove control effectHigh control precisionFlexible work arrangmentsTension/compression control deviceLoop controlContinuous rolling

The invention discloses a control method for the loose cover of a hot strip mill, which comprises the steps that: a. the parameter in a controller of the loose cover is set in advance, namely at least two angle intervals of the loose cover device are set and the loose cover is arranged in different angle intervals with different corresponding compensation factors; b. the angle signals of the loose cover device are sent to the controller of the loose cover by an angle decoder when the hot strip mill starts to work; c. comparison is made between the angle signals of the loose cover and the set angle interval by the controller of the loose cover to determine the compensation factor of the loose cover device; d. an output compensation value is determined by the controller of the loose cover based on the compensation factor of the loose cover and output to a servo valve of the loose cover to make compensation to the loose cover device. The invention modifies the control property of the loose cover and promotes the stability thereof.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

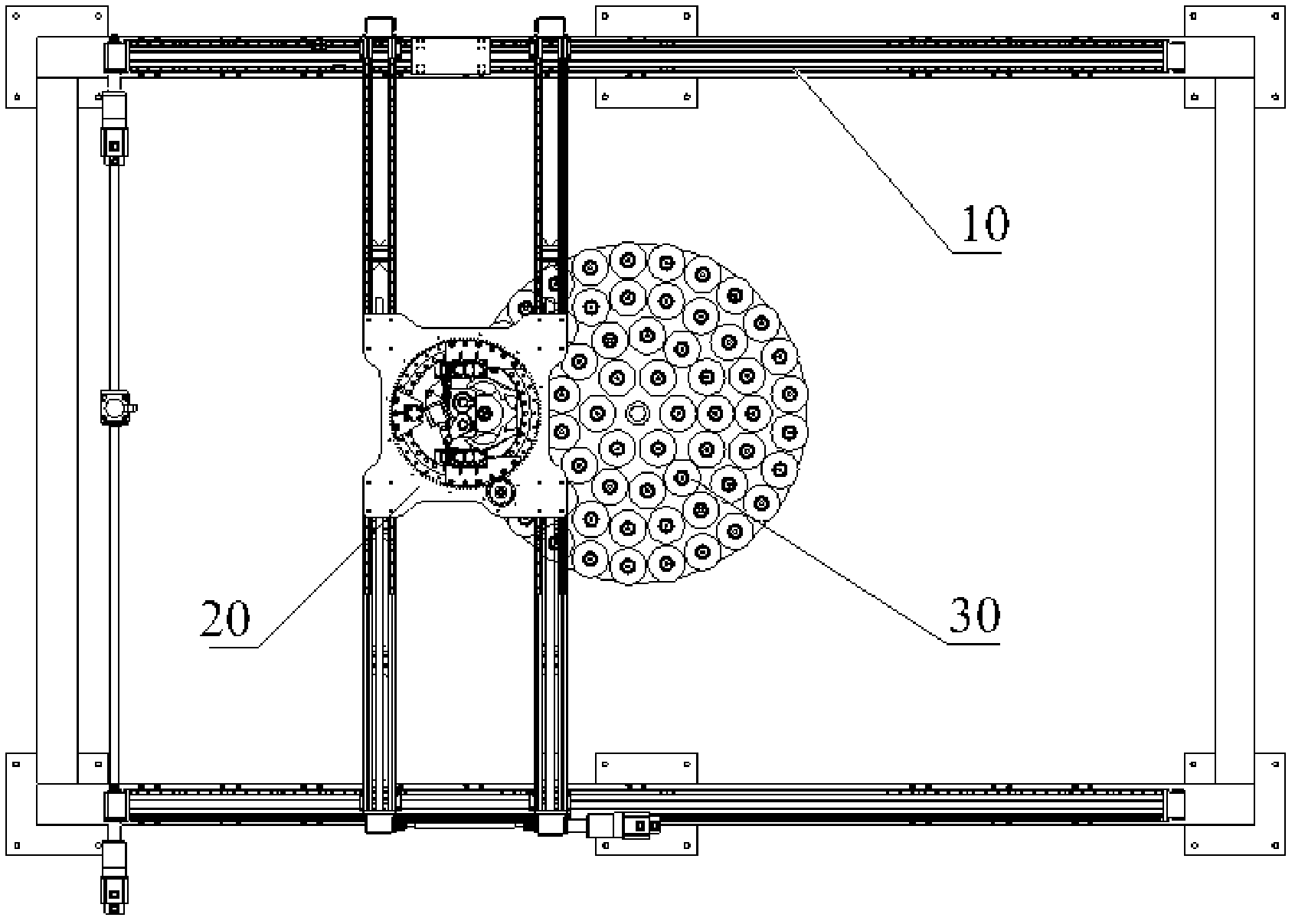

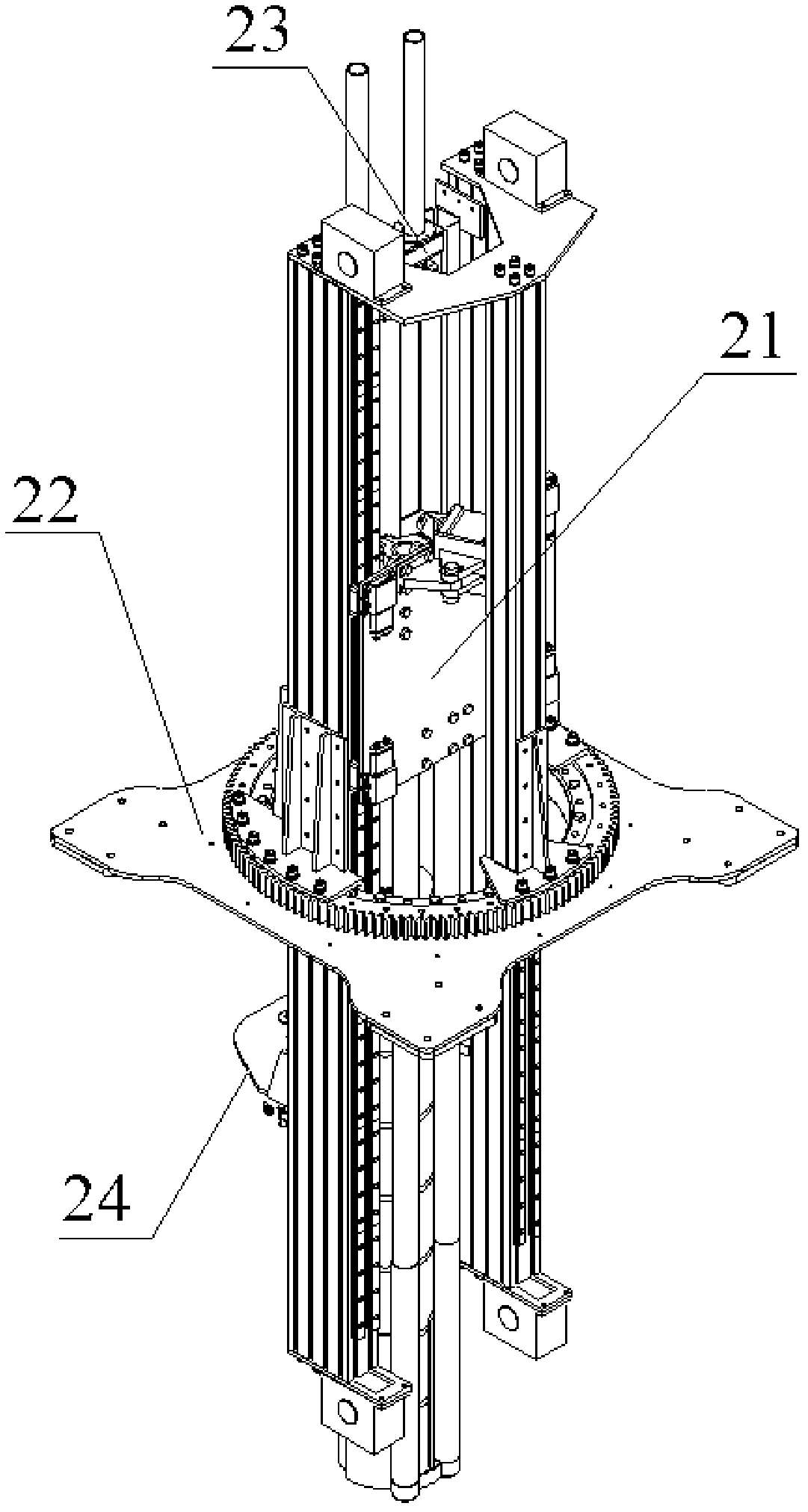

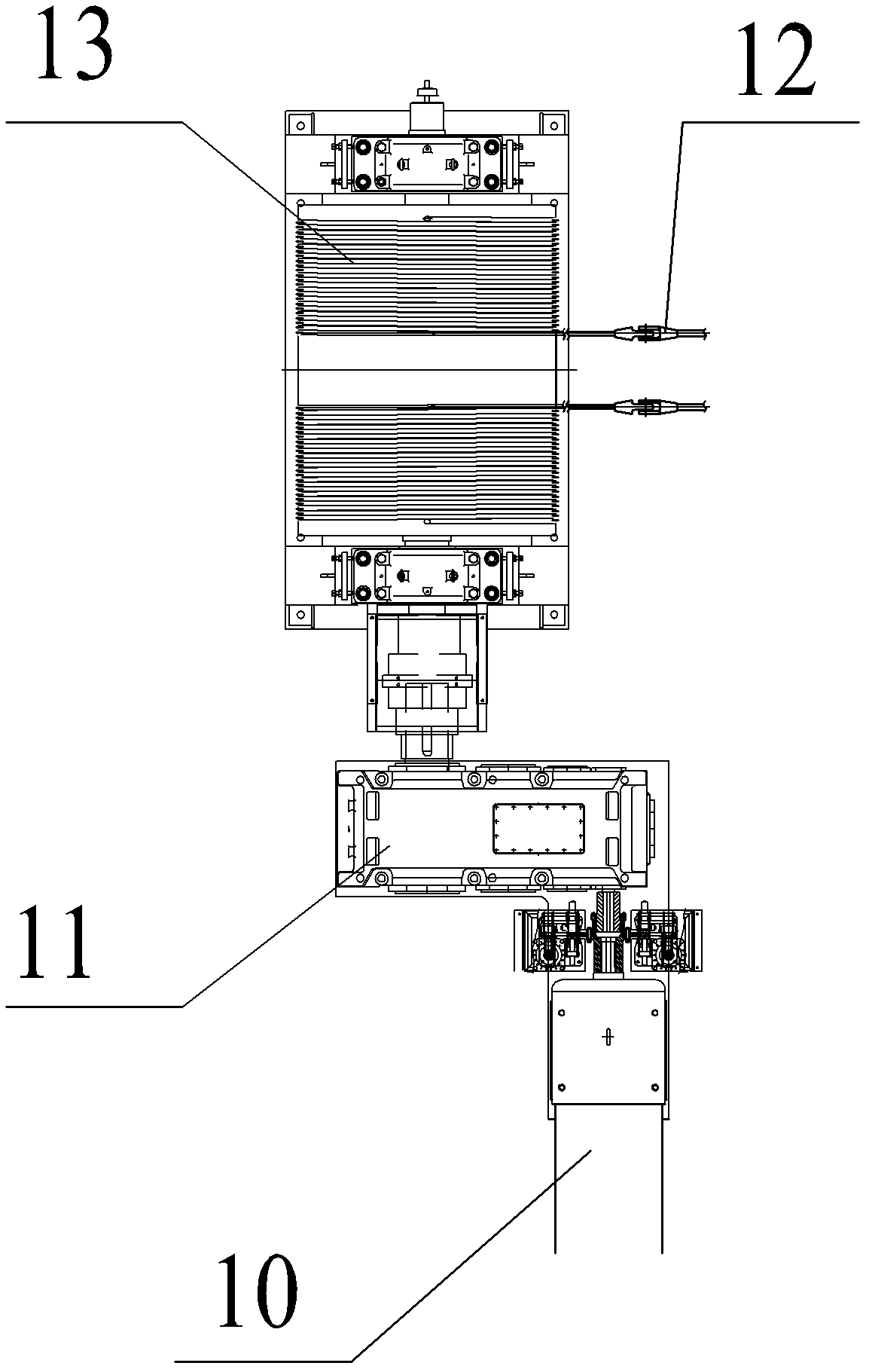

Automatic yarn grabbing machine and automatic yarn grabbing method

ActiveCN102583046AImprove efficiencyReduce labor costsProgramme-controlled manipulatorGripping headsYarnBobbin

The invention provides an automatic yarn grabbing machine and an automatic yarn grabbing method. The automatic yarn grabbing machine of the invention comprises a yarn grabbing unit comprising a clamping mechanism used for grabbing cheese and a rotary lifting mechanism used for driving the clamping mechanism to rotate and lift; and a planar moving mechanism used for driving the yarn grabbing unit to move on a horizontal plane. The automatic yarn grabbing machine of the invention mainly has the following advantages: yarns are grabbed in an automatic manner, so as to fill the blank in a bobbin dyeing procedure, improve efficiency and greatly save labor cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

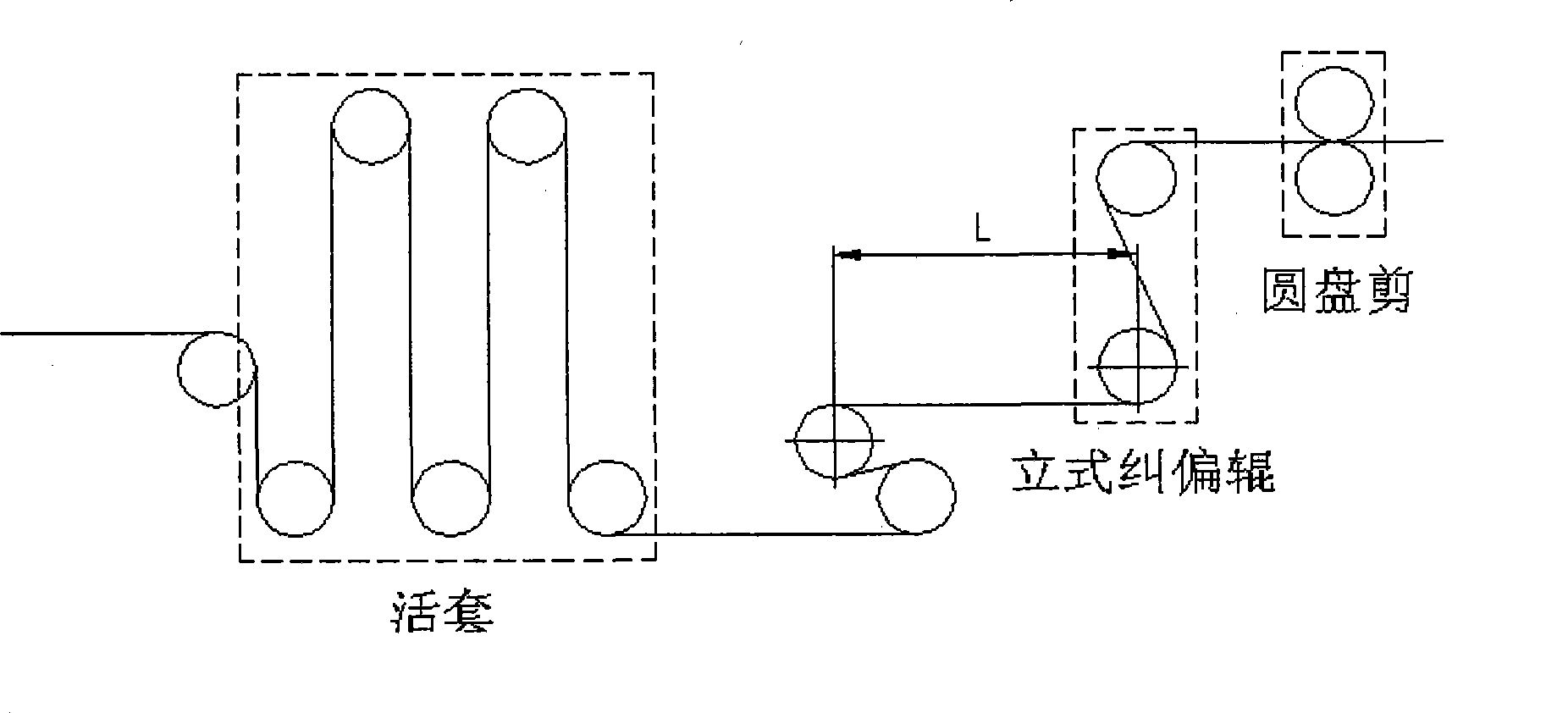

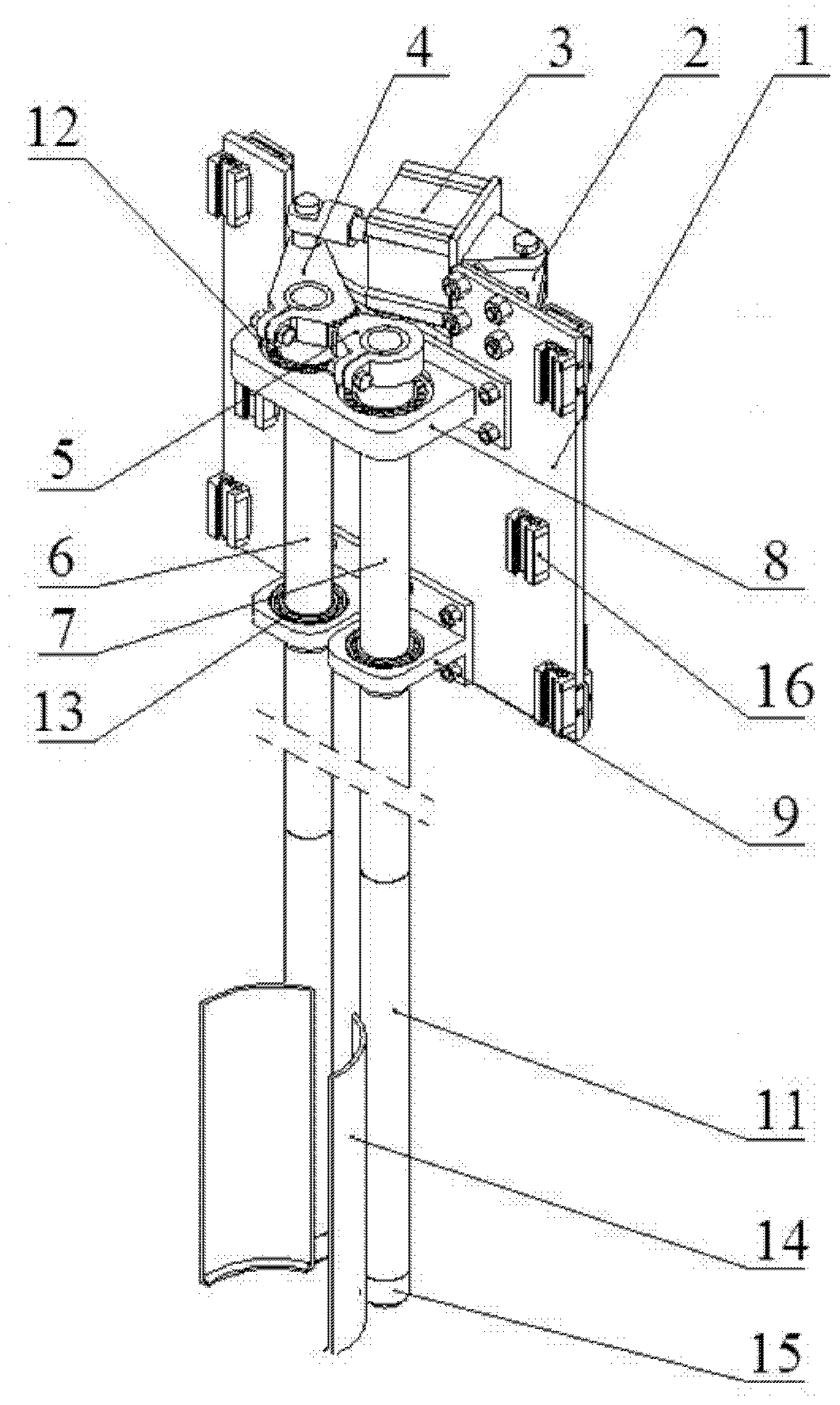

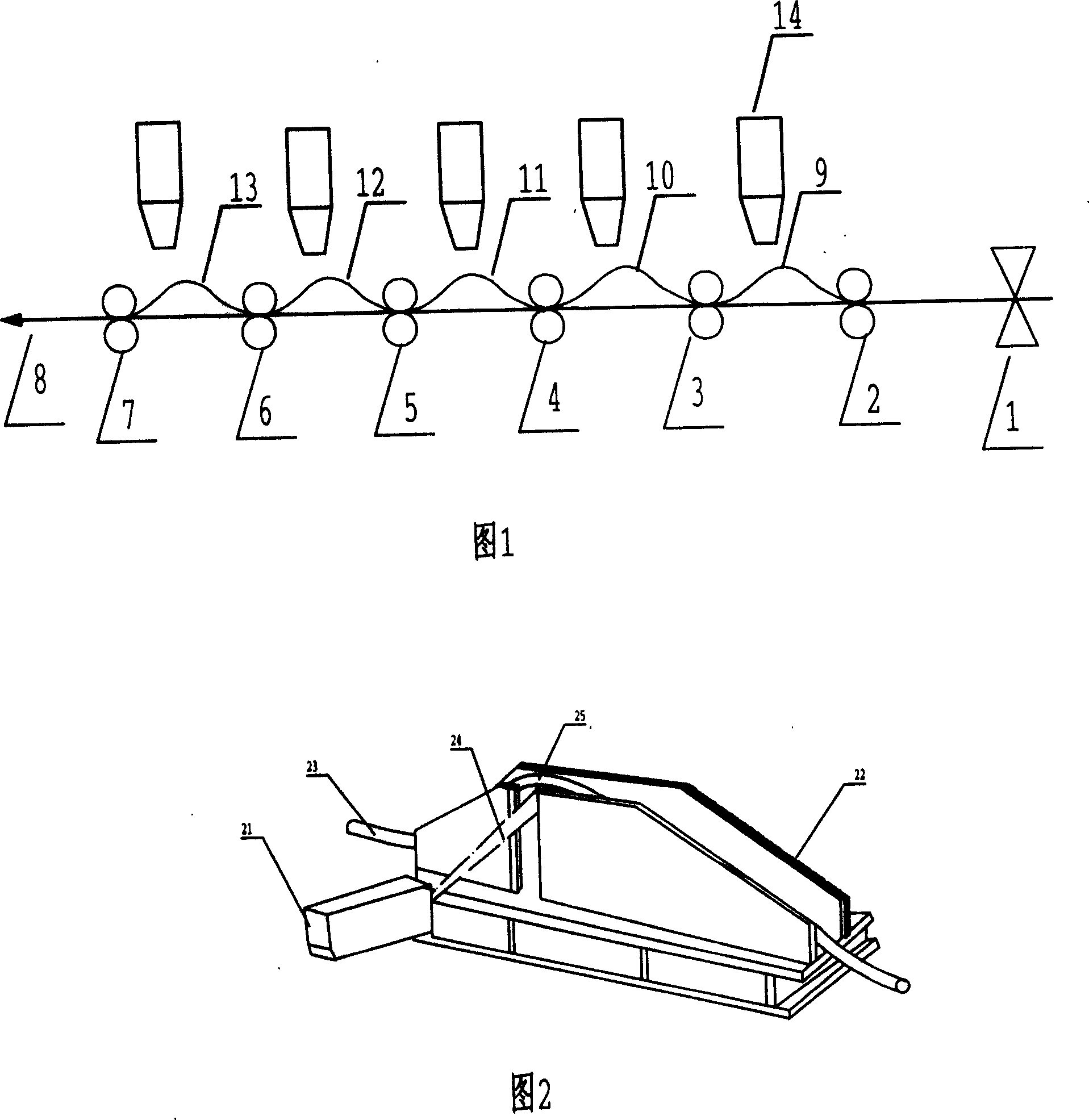

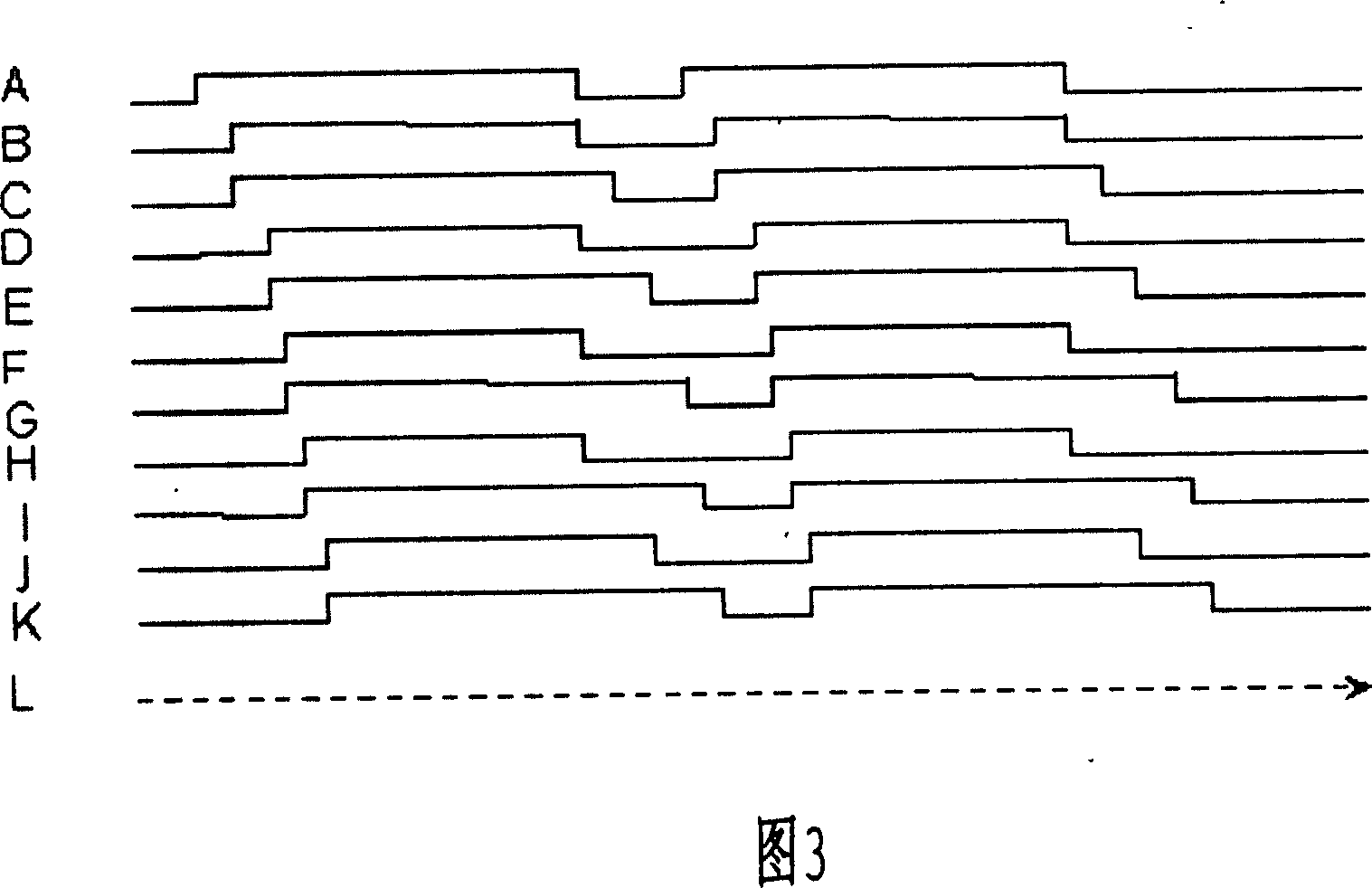

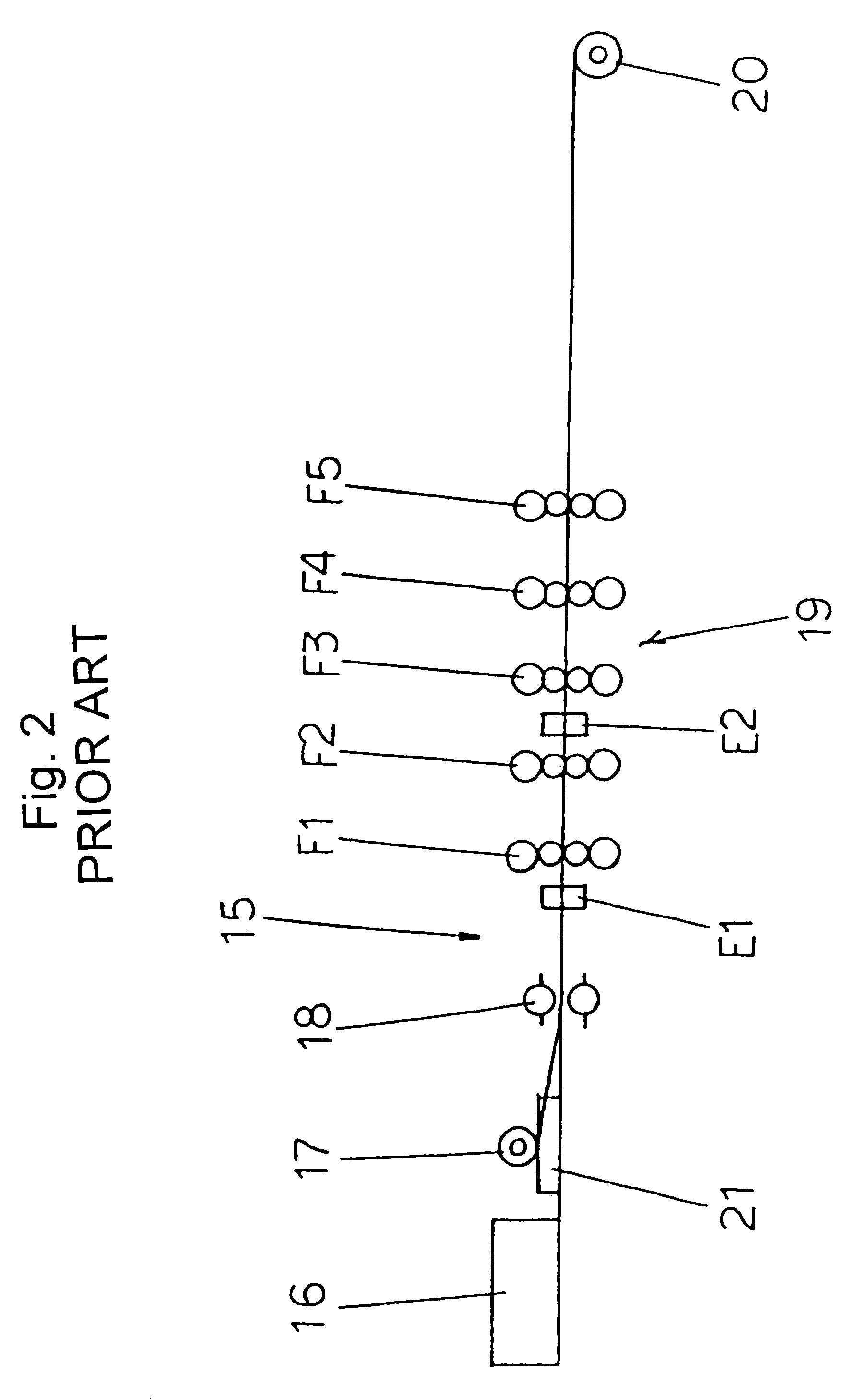

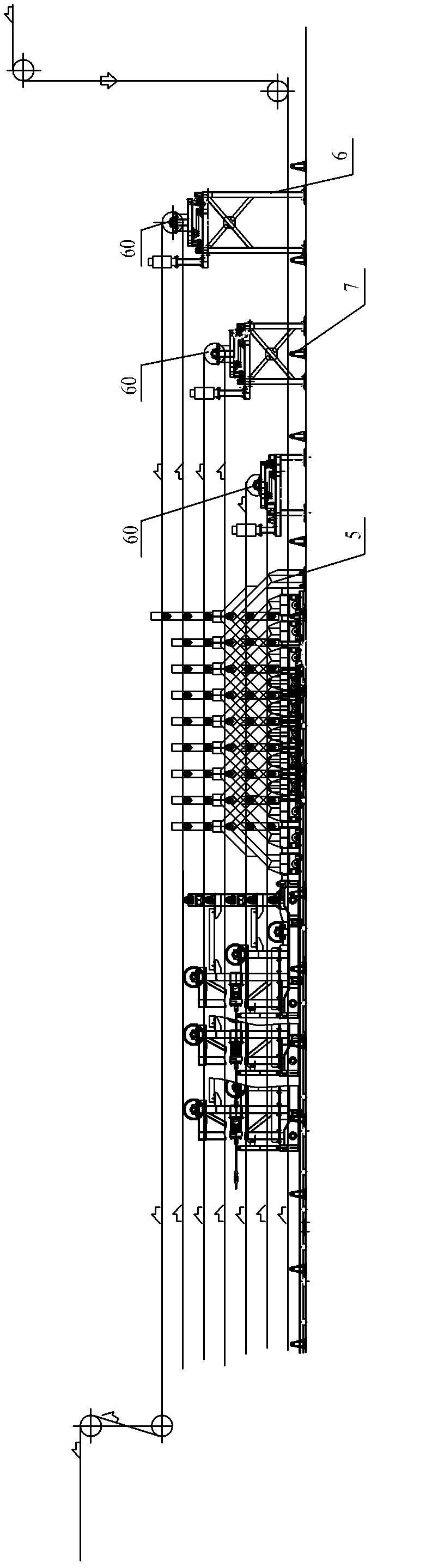

Finish rolling machine strip steel threading between frames movable sleeve controlling method

ActiveCN101099977AAvoid damageImprove surface qualityRoll mill control devicesFlexible work arrangmentsLoop controlAutomatic control

The loop control process for threading strip steel into finishing mill includes the following steps: making the looper roll in the initial angle automatically calibrated with the angle generator; making the loop in the stand-by angle when the strip steel enters to the front platen; making the looper roll in the threading angle after the head of the strip steel is sucked into the front platen and passed through the looper roll; raising the loop for the looper roll bus line to be lower than the lowest rolling line after the head of the strip steel enters to the back platen; and lowering the loop and entering to the ready position. The automatic control process can avoid faults in the strip steel effectively.

Owner:BAOSHAN IRON & STEEL CO LTD

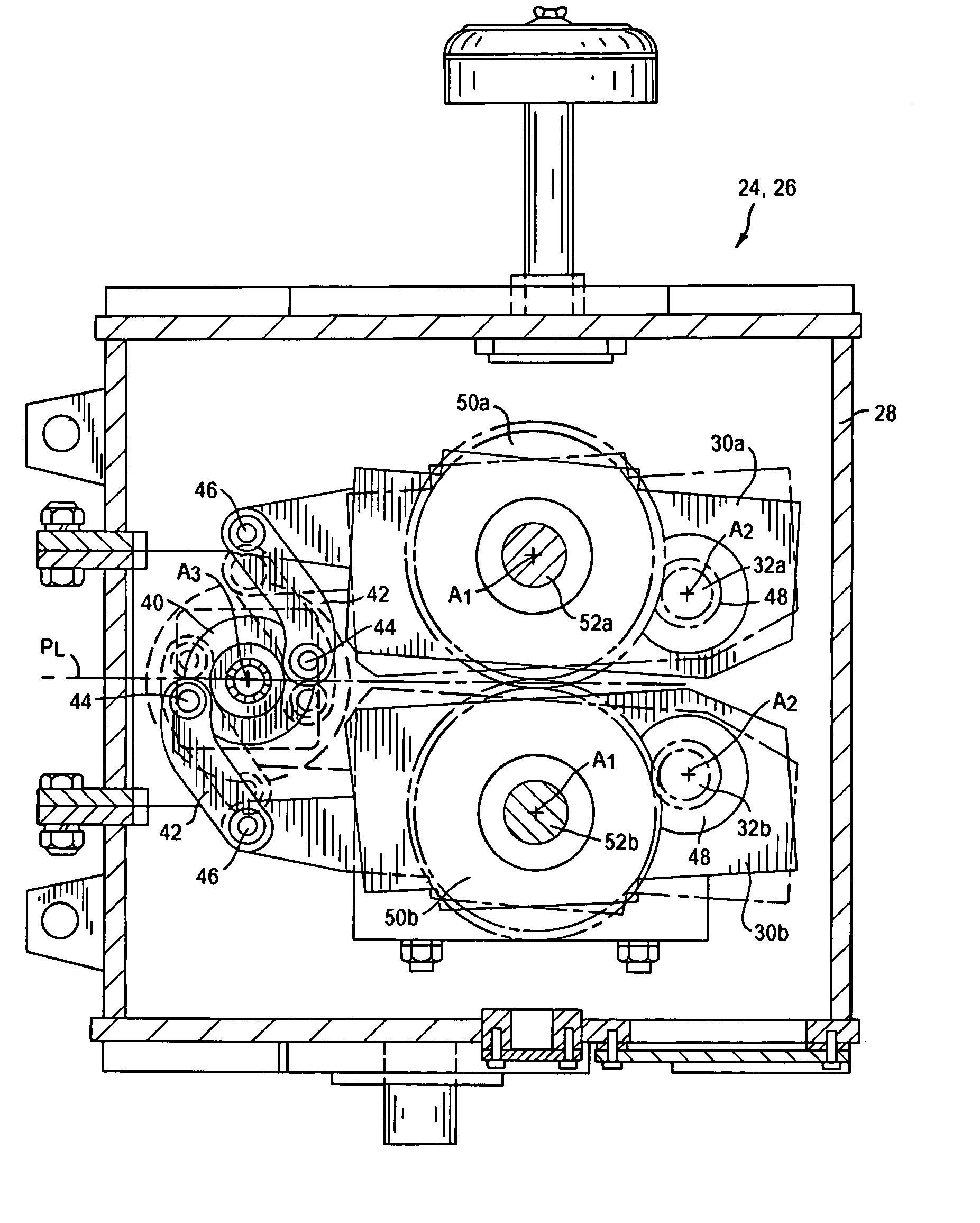

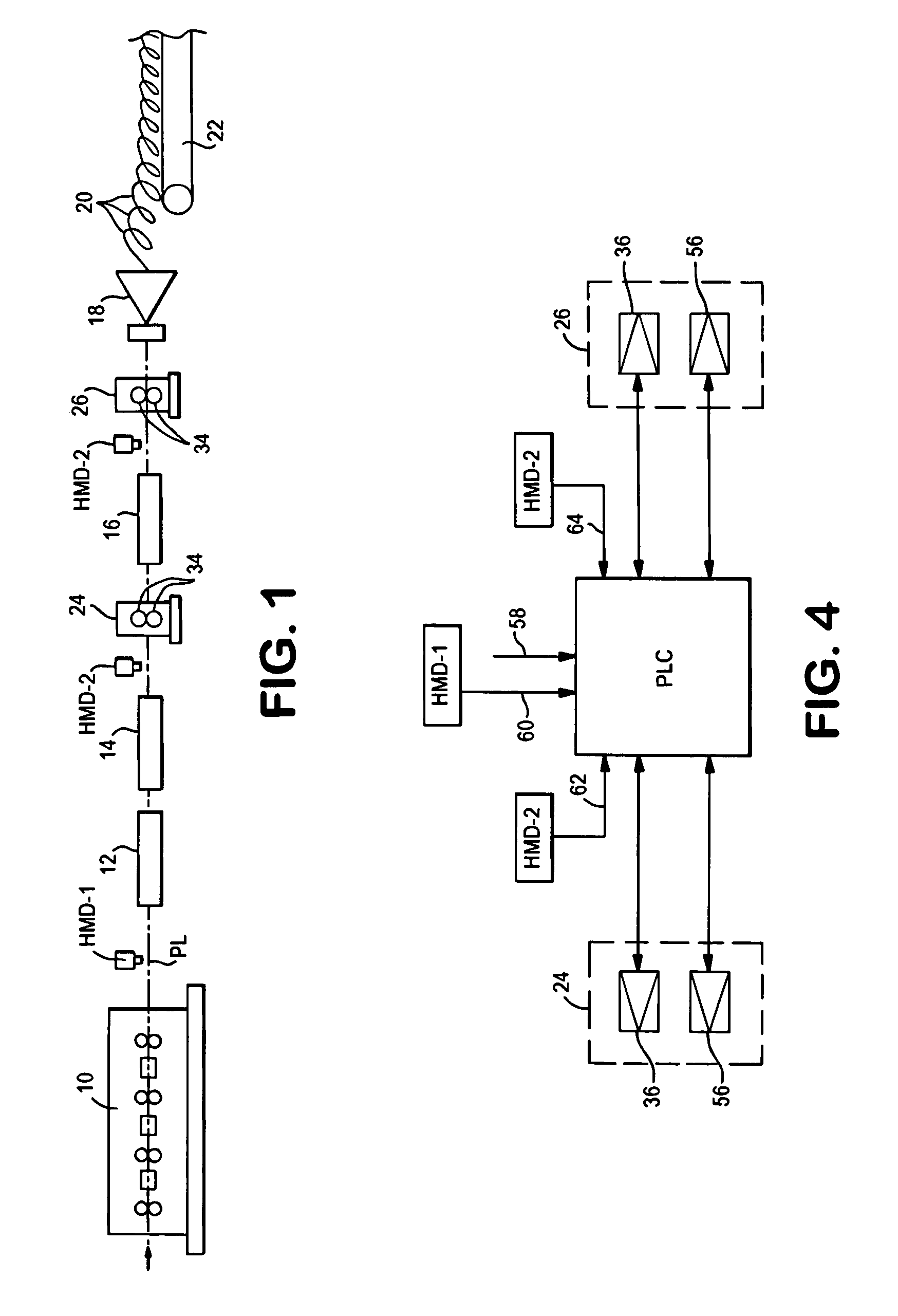

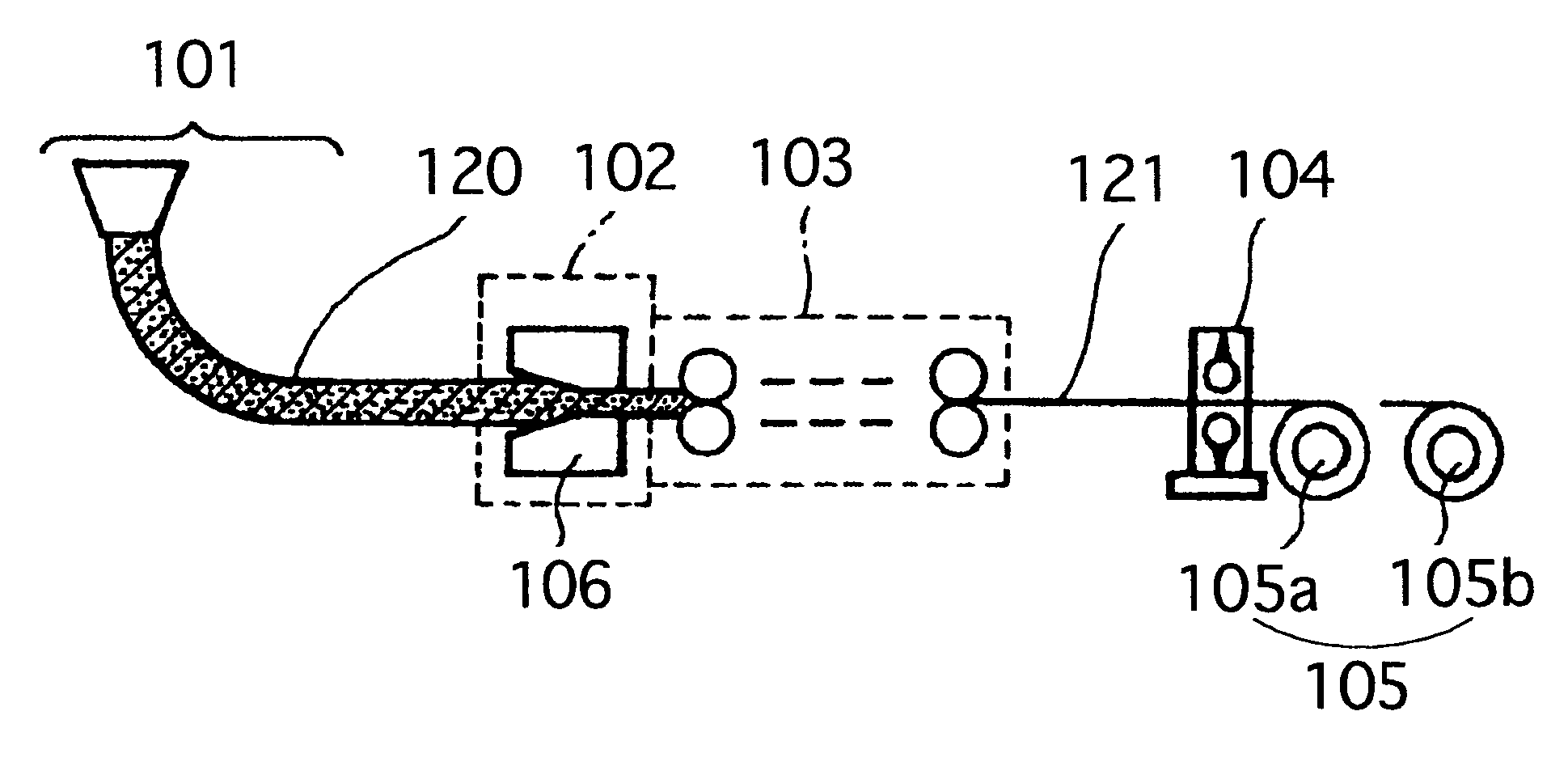

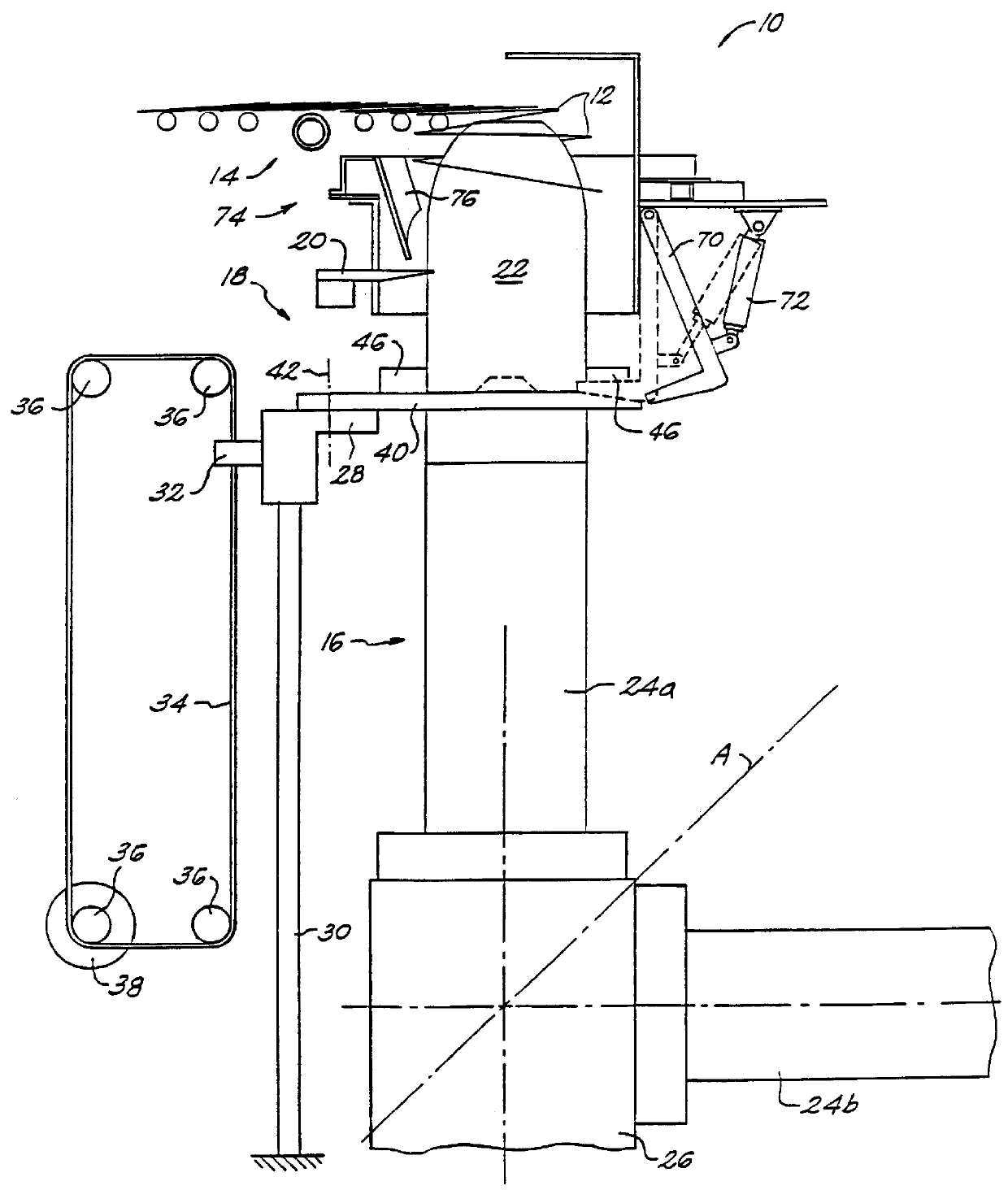

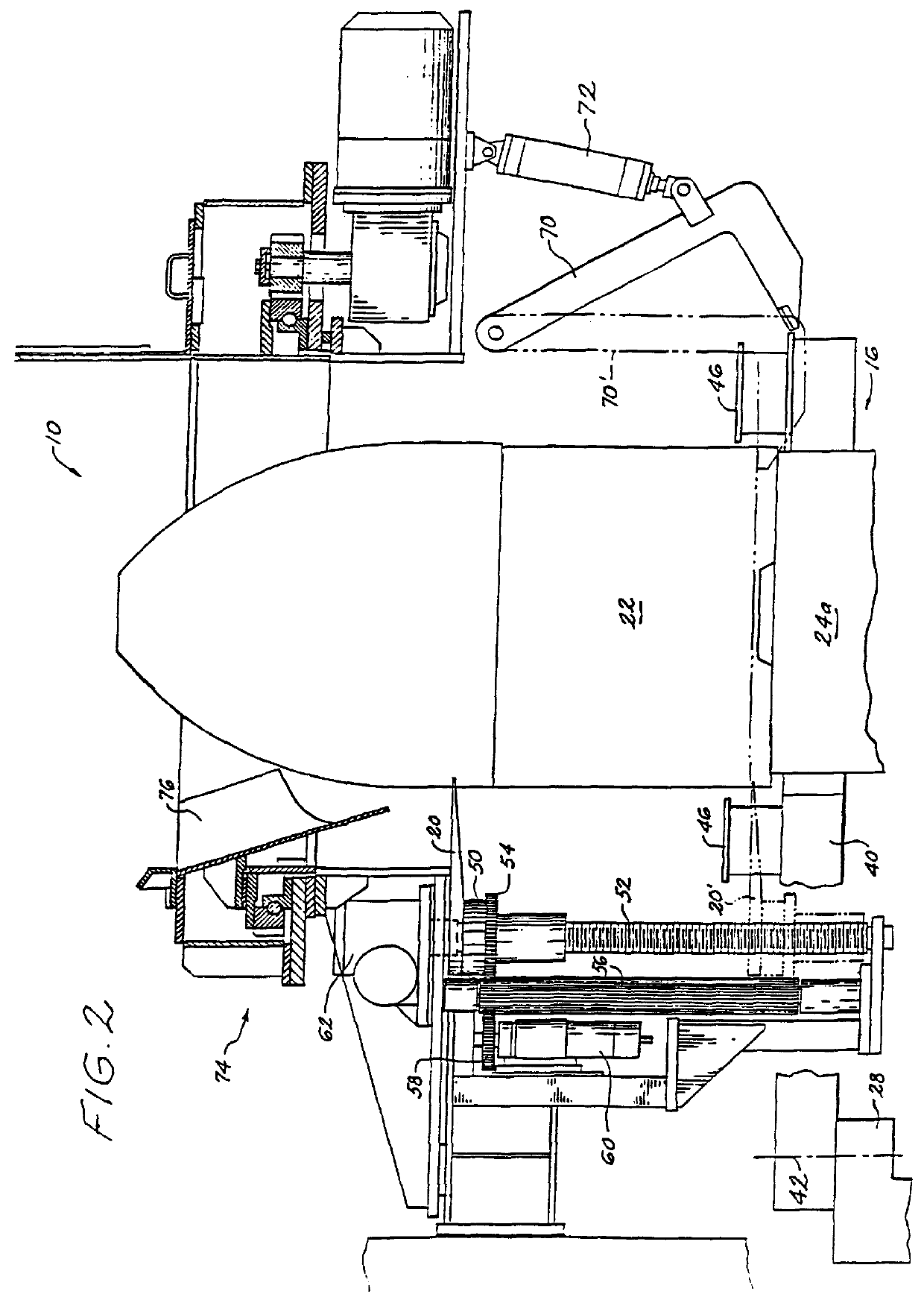

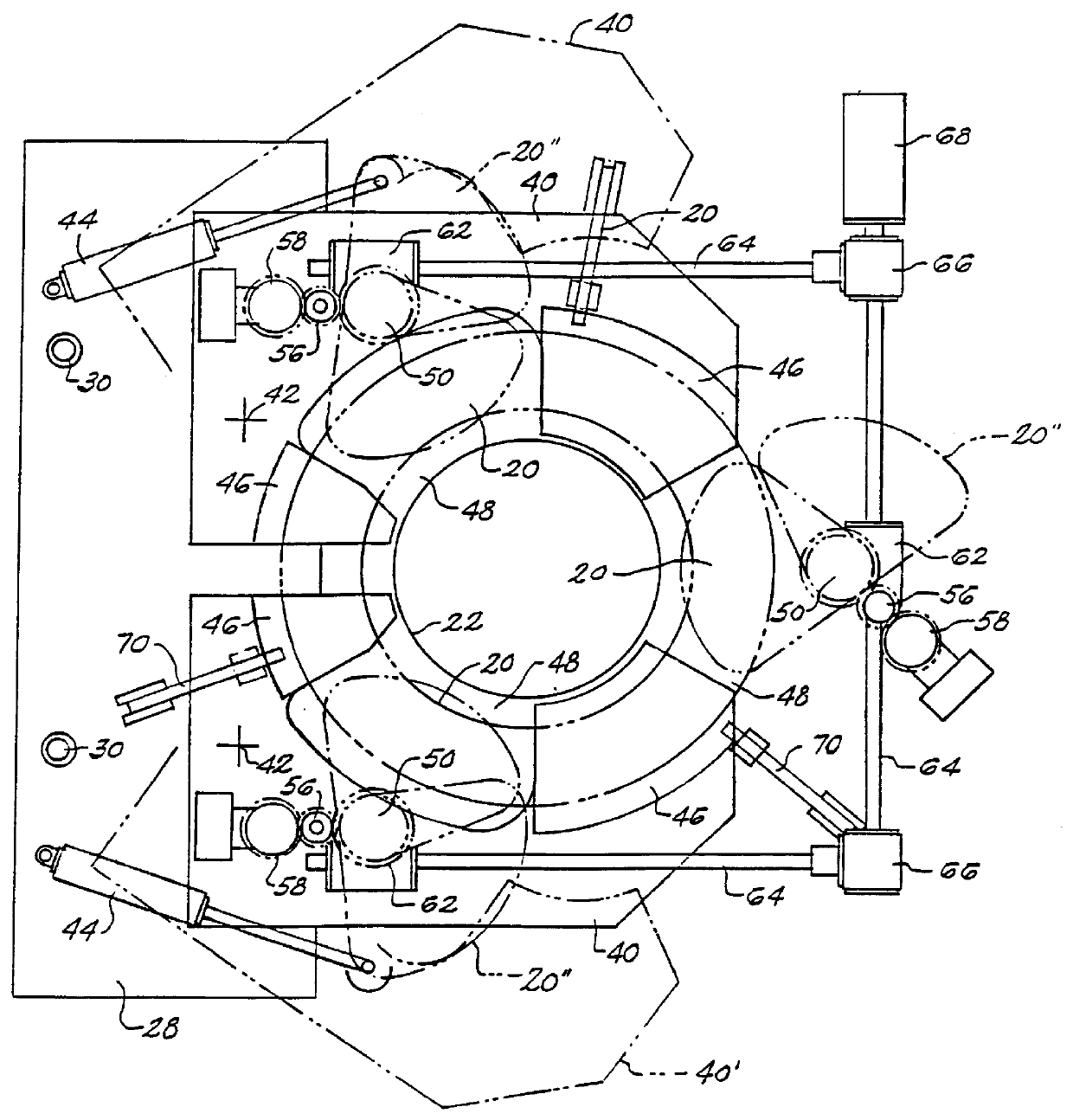

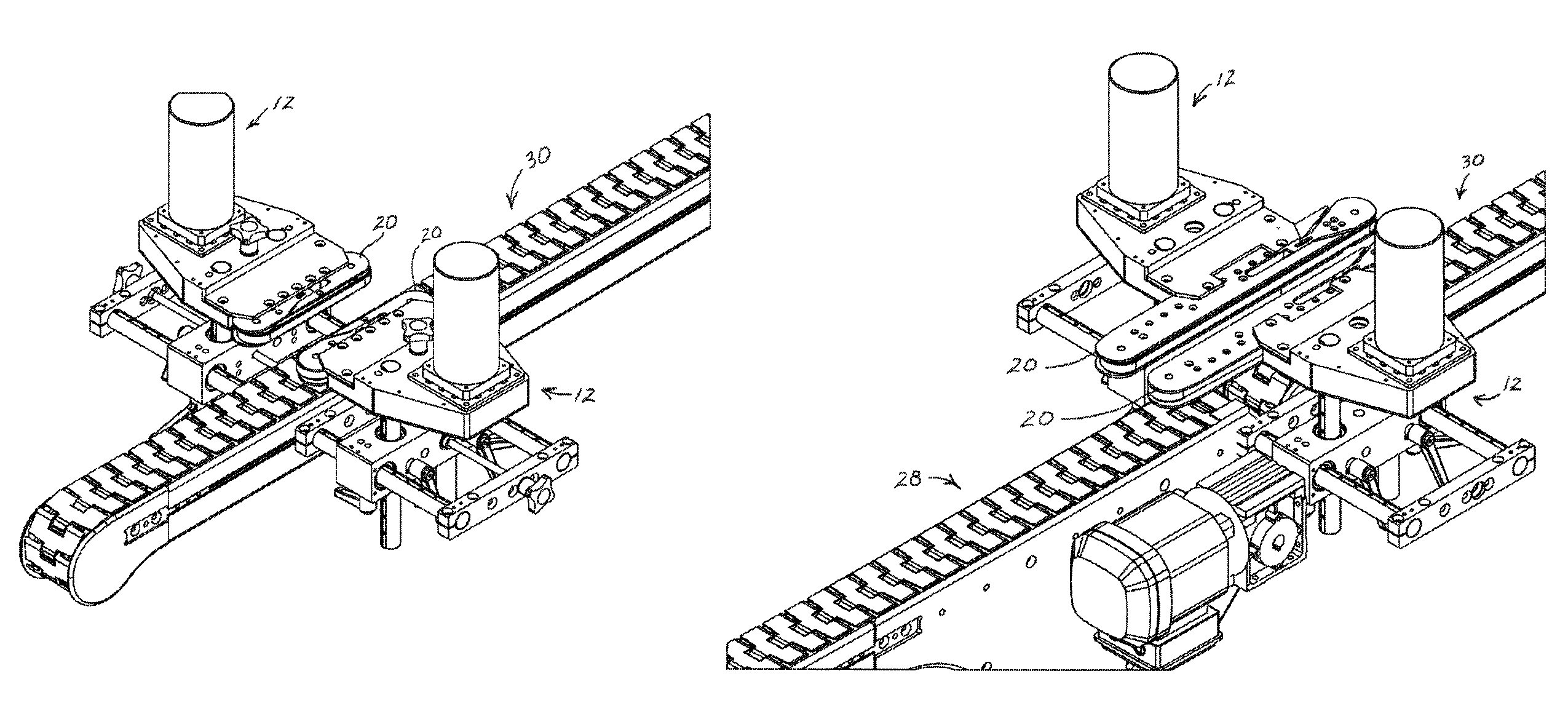

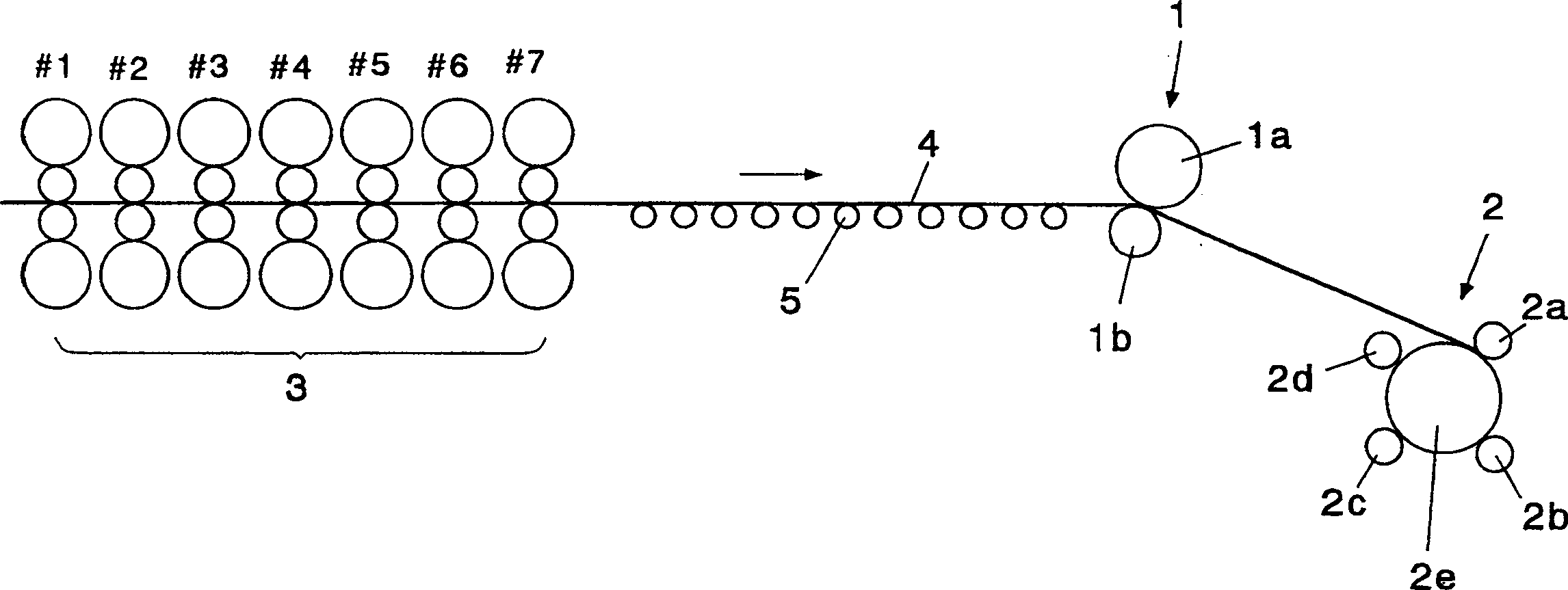

Method and apparatus for decelerating and temporarily accumulating a hot rolled product

InactiveUS7021103B2Guiding/positioning/aligning arrangementsFilament handlingEngineeringMechanical engineering

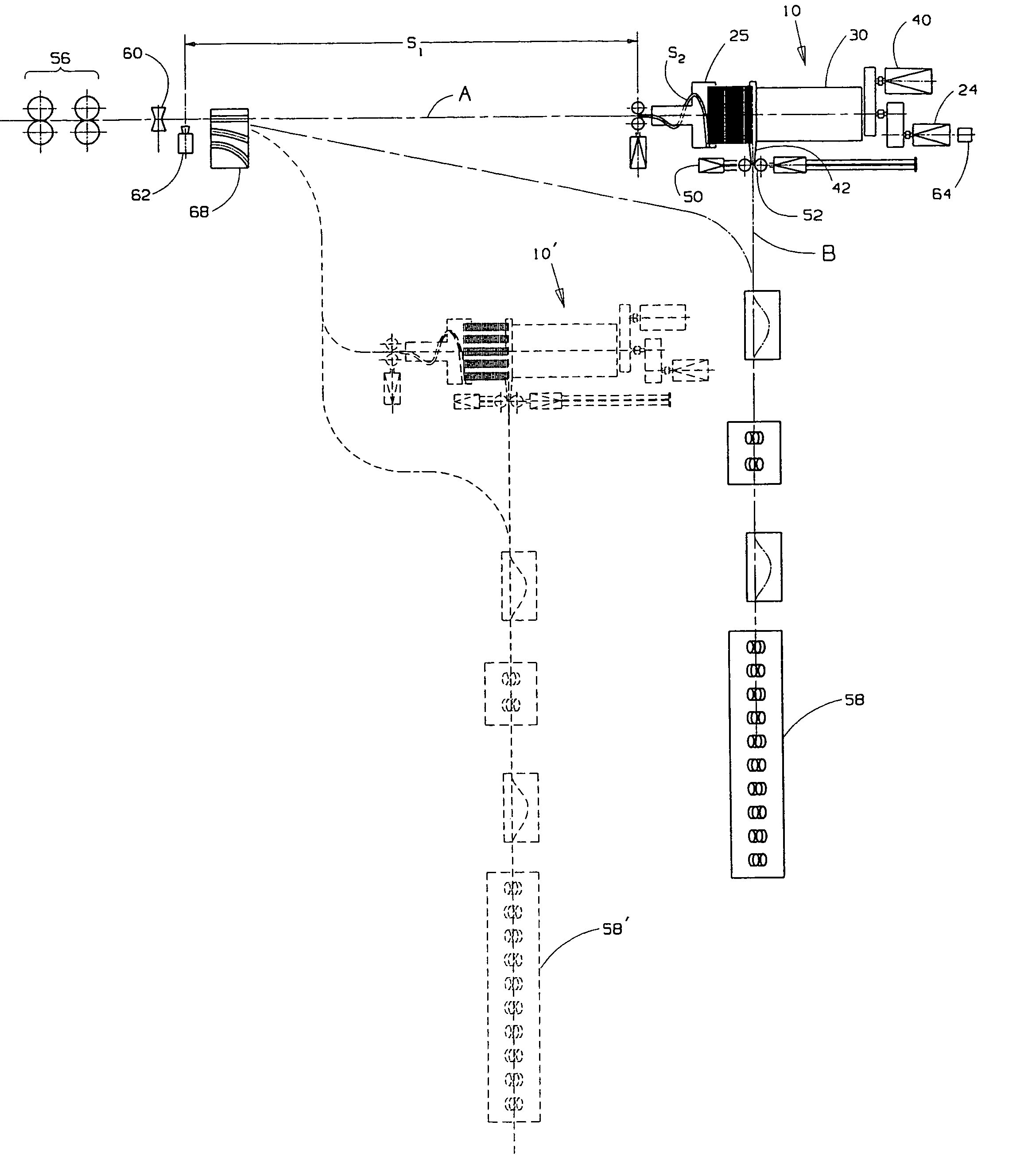

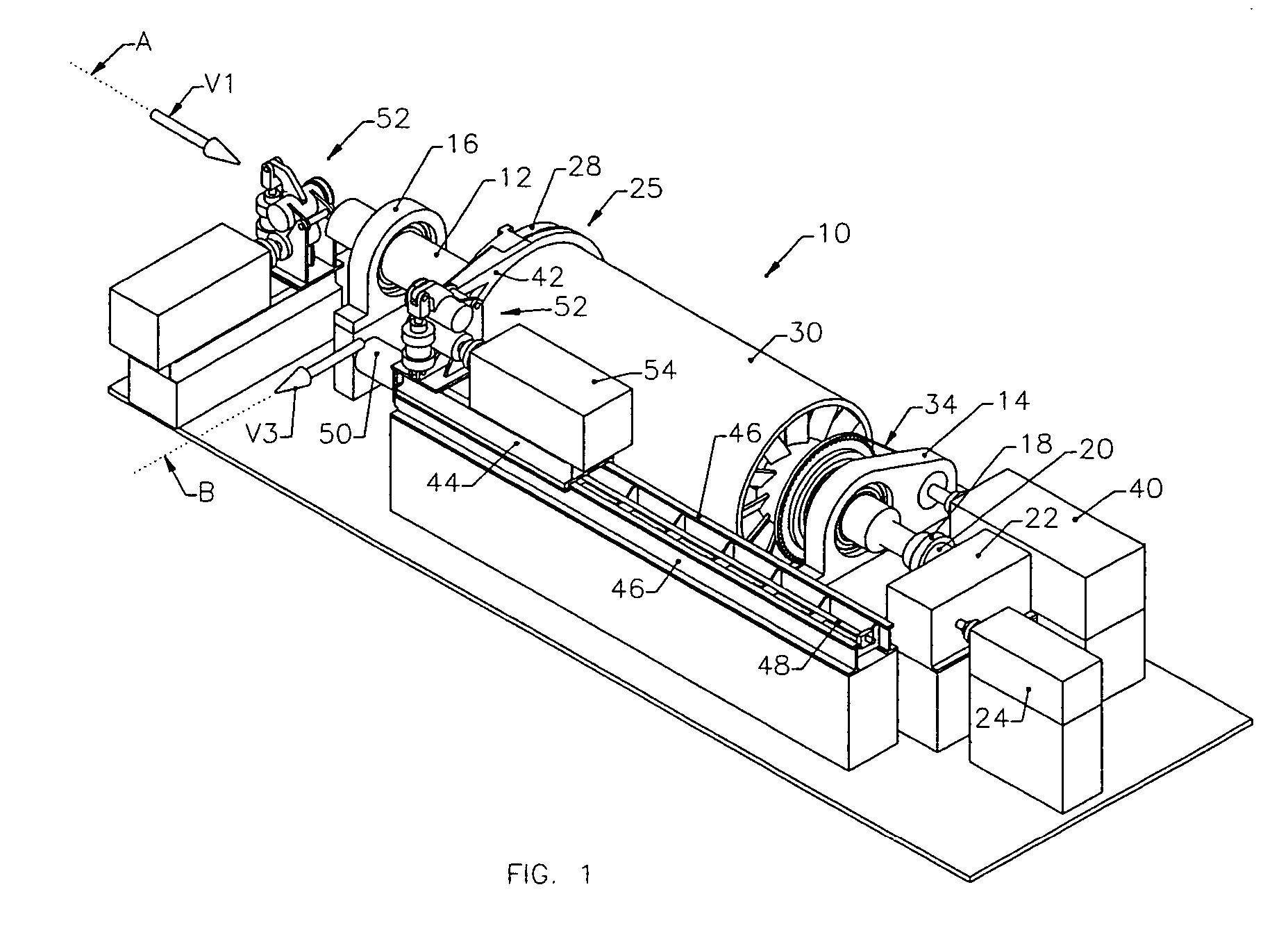

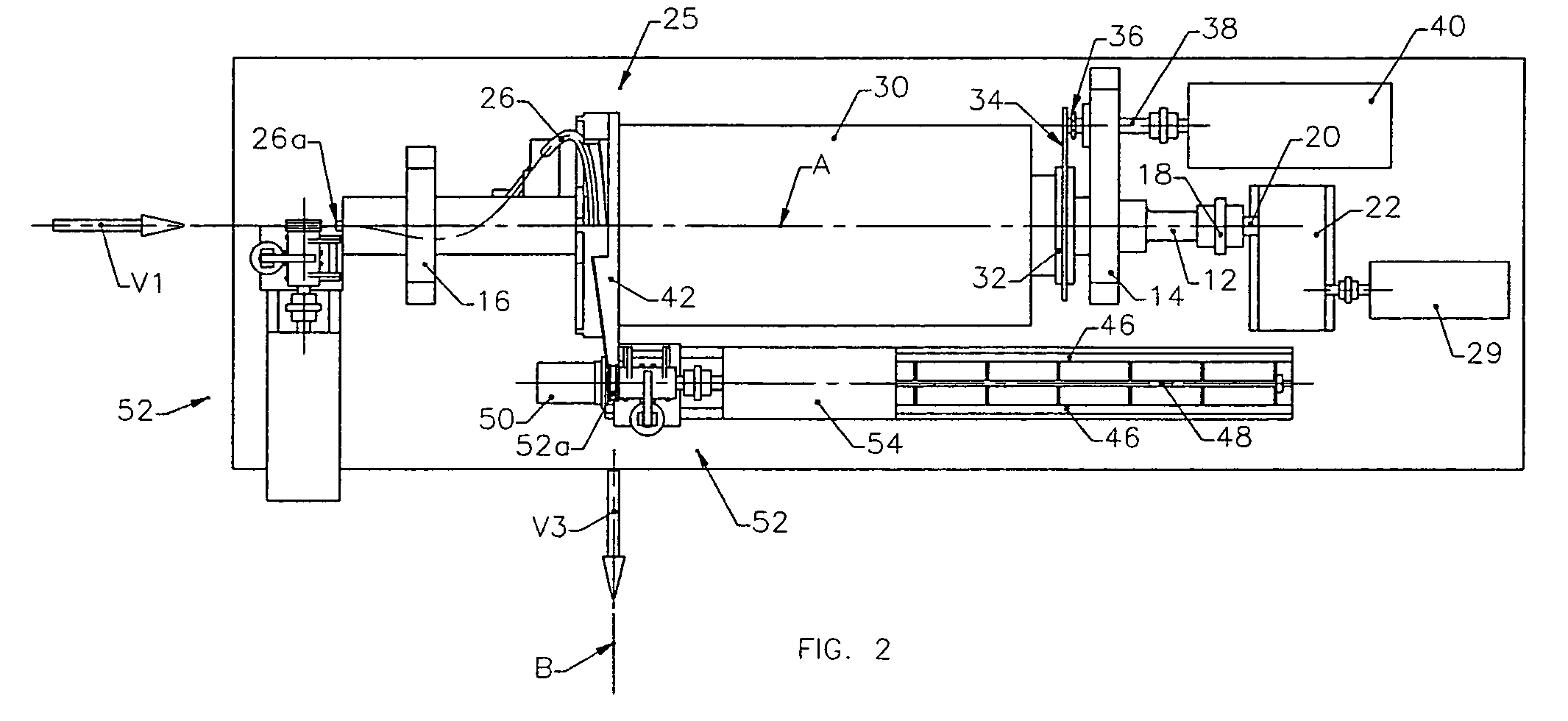

A method and apparatus is disclosed for decelerating and temporarily accumulating a hot rolled product moving longitudinally along a receiving axis at a first velocity V1. The product is directed through a curved guide having an entry end aligned with the receiving axis to receive the product, and an exit end spaced radially from the receiving axis and oriented to deliver the product in an exit direction transverse to the receiving axis. The curved guide is rotated about the receiving axis in a direction opposite to the exit direction of the product and at a speed at which the guide exit end has a velocity V2, thereby decelerating the product being delivered from the guide exit end to a reduced velocity V3 equal to V1−V2. The curvature of the guide and the orientation of its exit end is such as to form the delivered product into a helix deposited and temporarily accumulated on a cylindrical drum. The drum is rotated in a direction opposite to the direction of rotation of the curved guide to thereby unwind the product from the drum.

Owner:PRIMETALS TECH USA

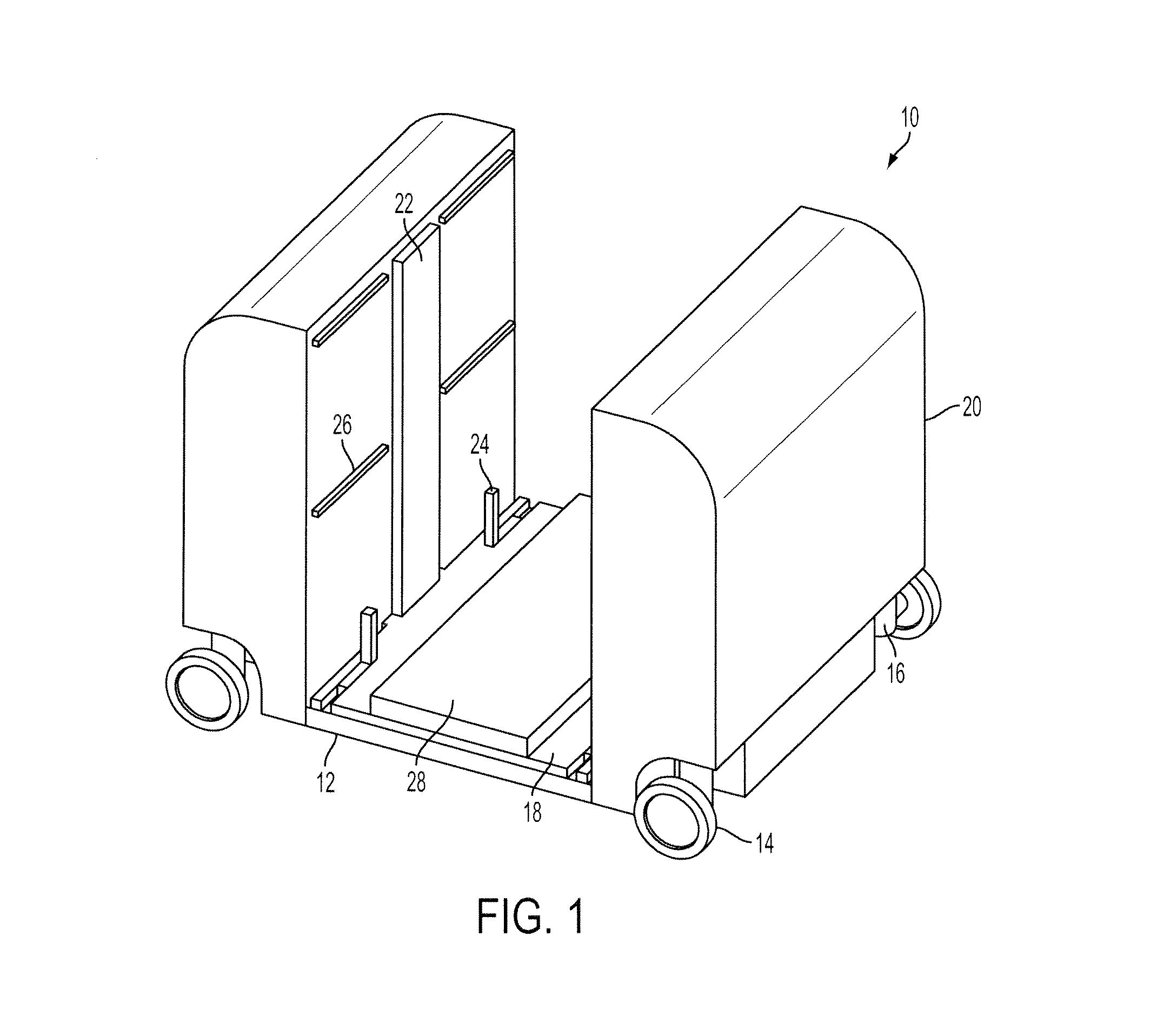

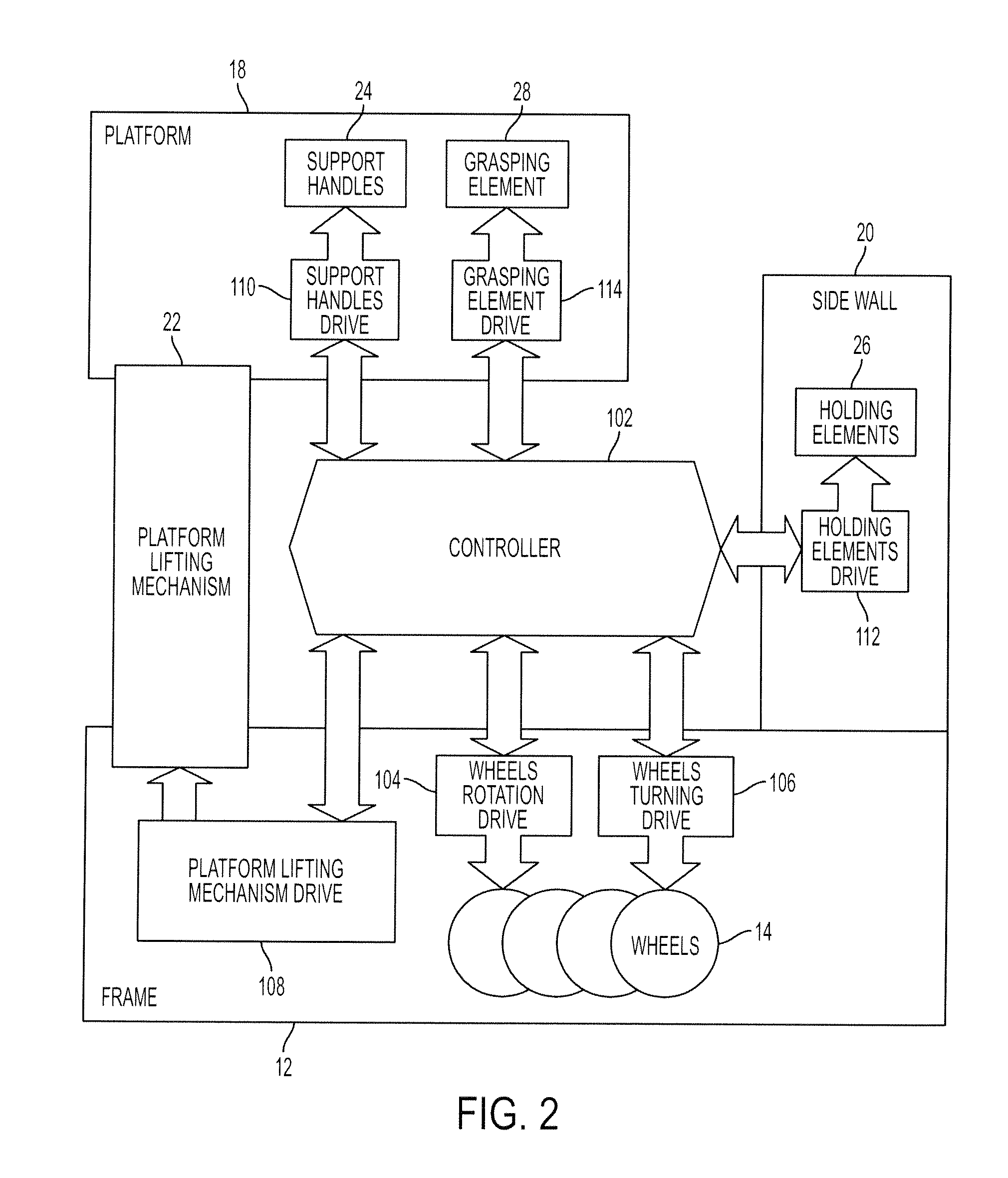

Self-lifting robotic device with load handling mechanism

Owner:ATOOL TRADING LTD

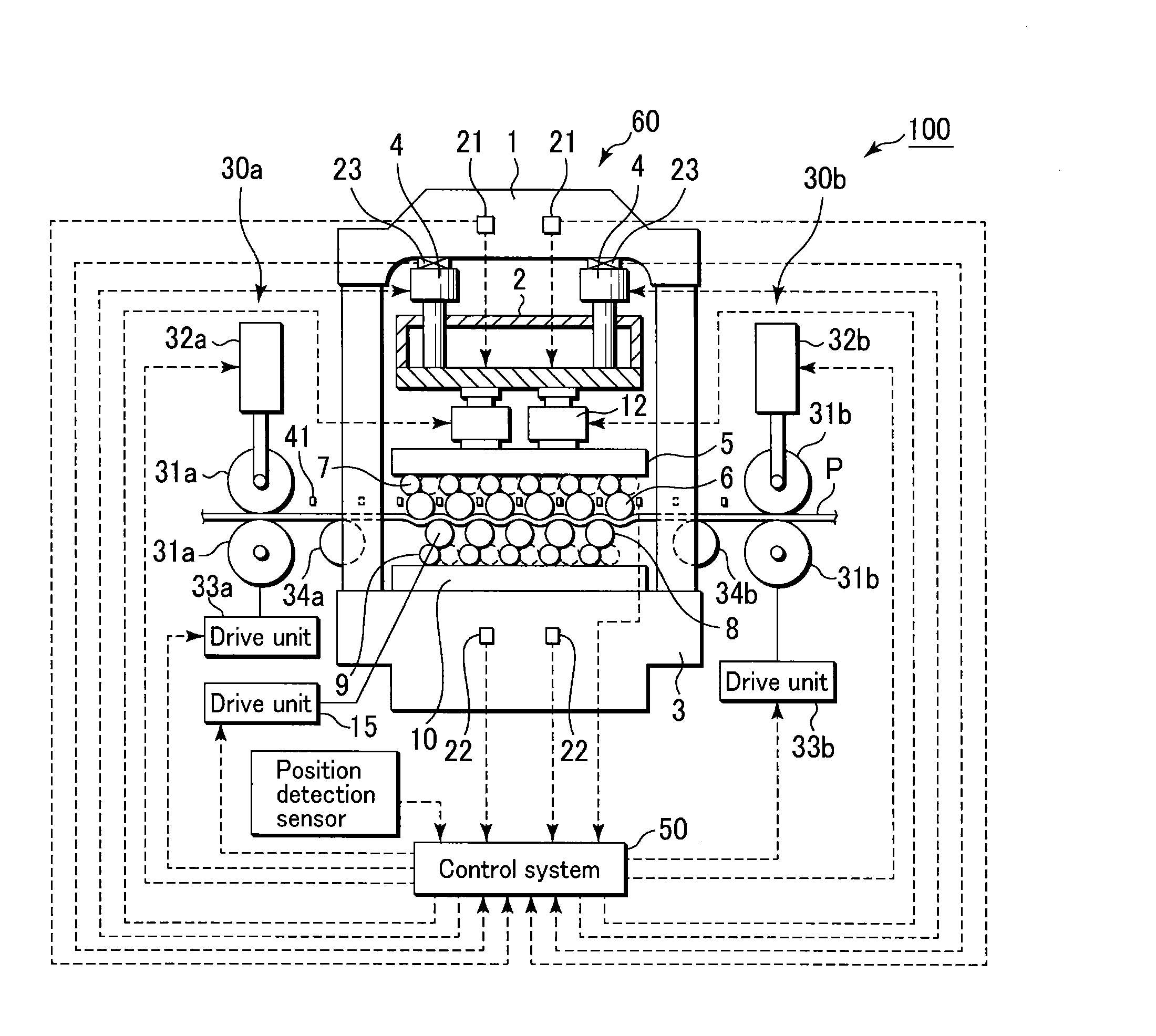

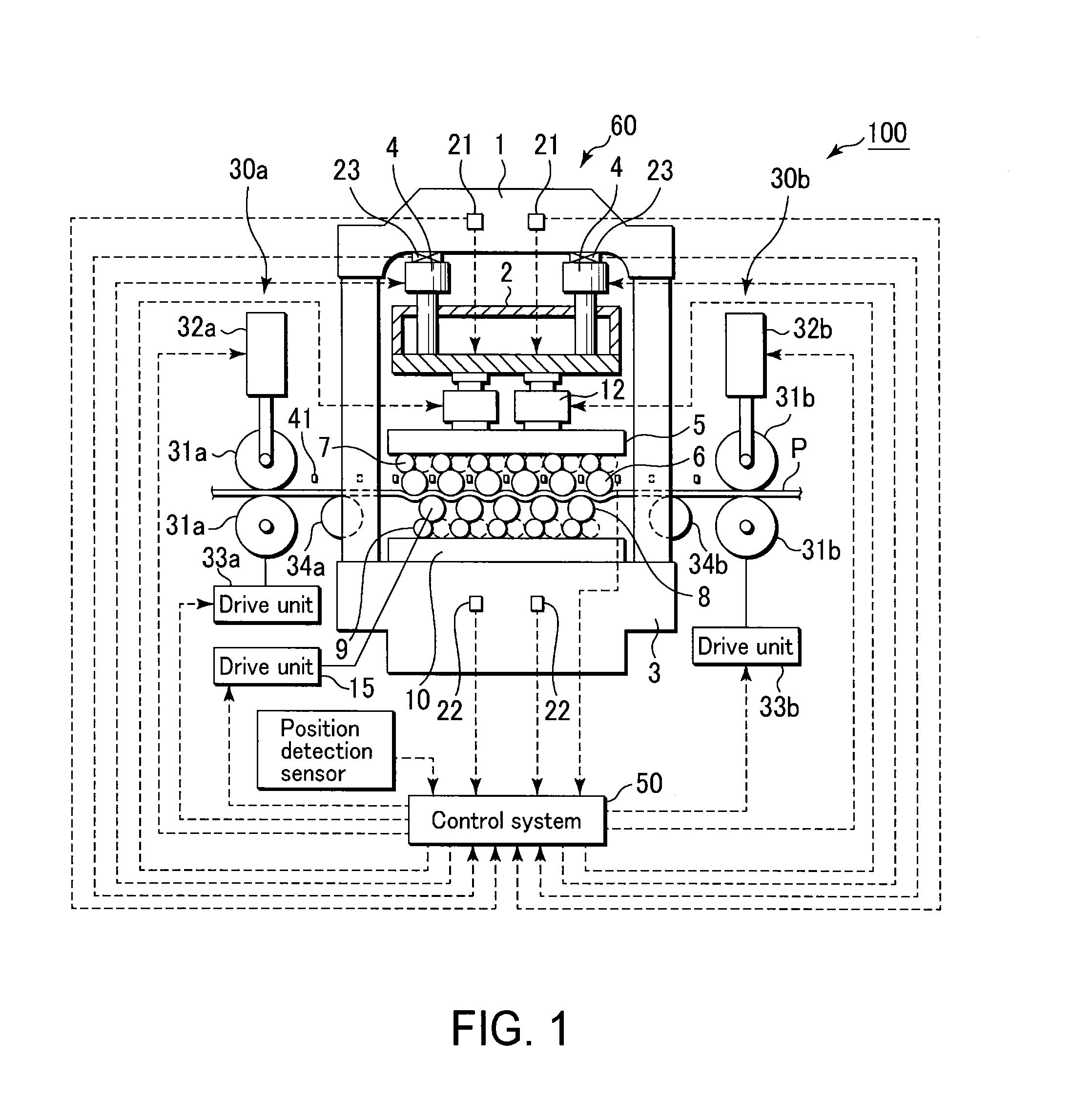

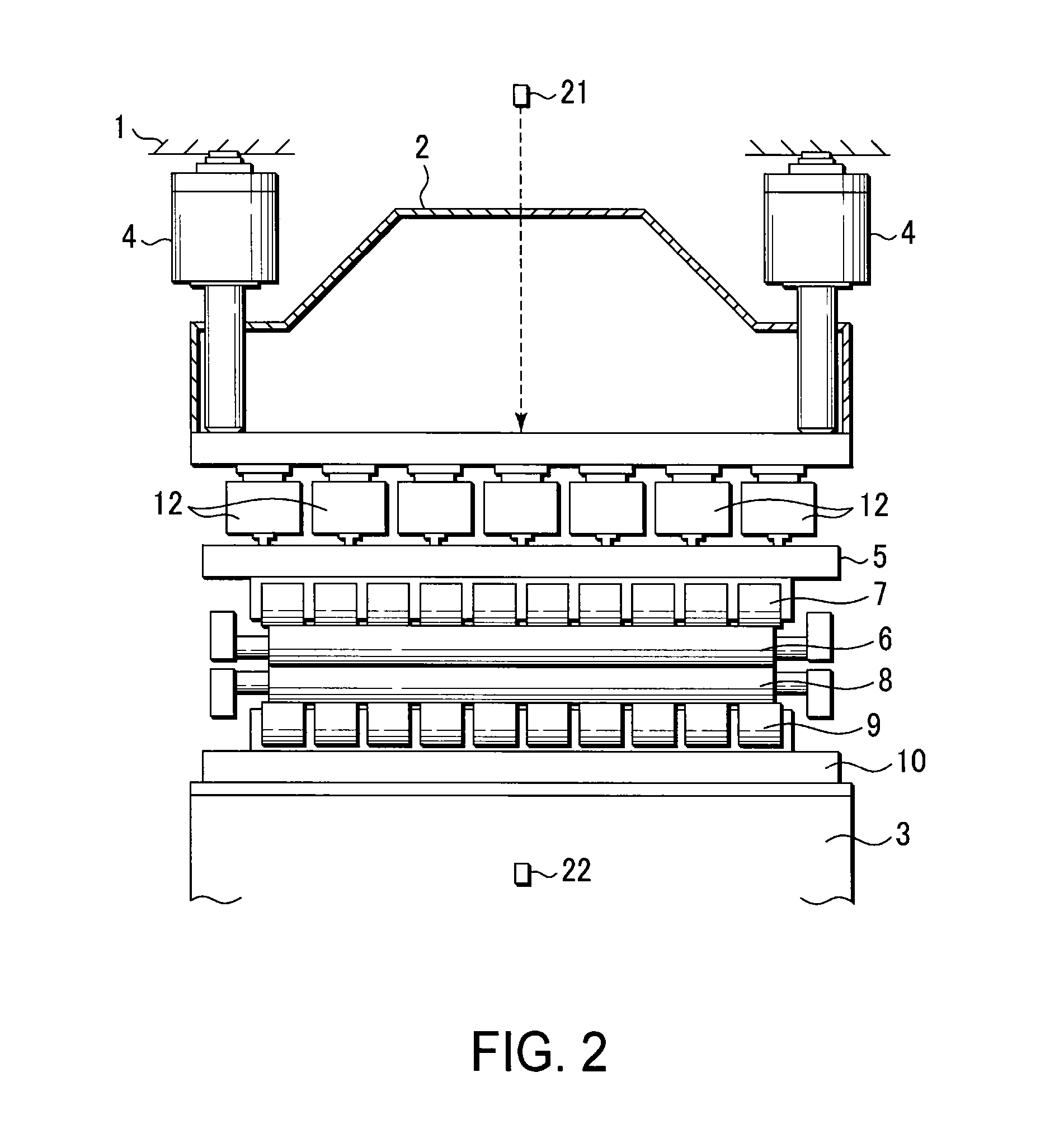

Roller leveler and metal sheet flattening method

ActiveUS20130327109A1Small thicknessLarge yield stressWire straightening devicesMetal rolling stand detailsPull forceMetal sheet

A roller leveler for flattening a metal sheet or plate having a cut-sheet form includes leveling rolls disposed in a staggered state on upper and lower sides of a pass line and configured to sandwich and flatten the metal sheet while pressing it therethrough, a hydraulic pressing cylinder configured to press the metal sheet via the leveling rolls, a drive unit configured to rotate the leveling rolls, and a pinch roll unit disposed on one side of a leveling roll array area and including a pair of pinch rolls. The pressing cylinder presses the metal sheet via the leveling rolls with a pressing amount necessary for flattening the metal sheet, while the metal sheet is passed by a drawing force applied by the pinch rolls and a driving force applied by the drive unit.

Owner:JP STEEL PLANTECH

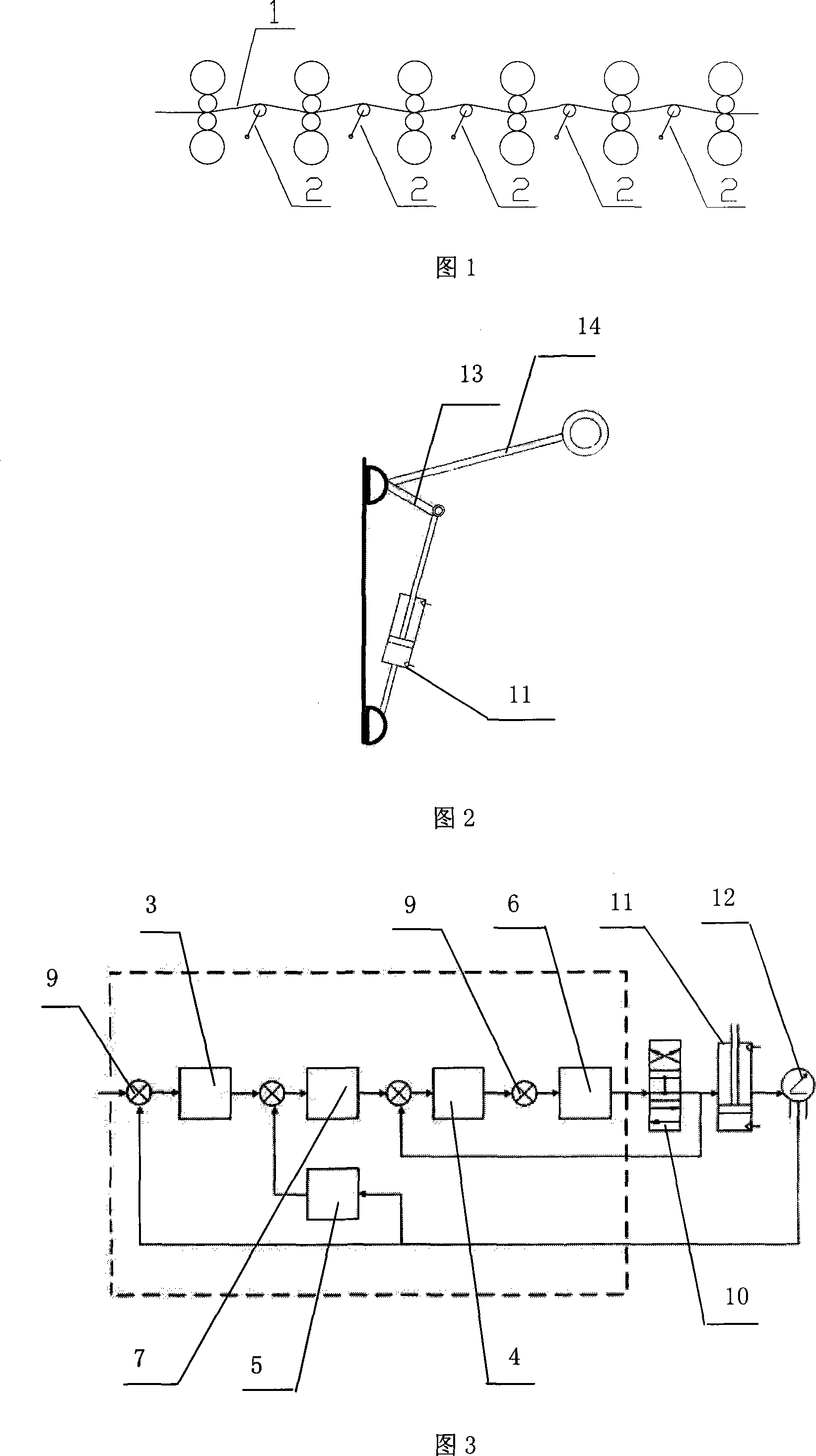

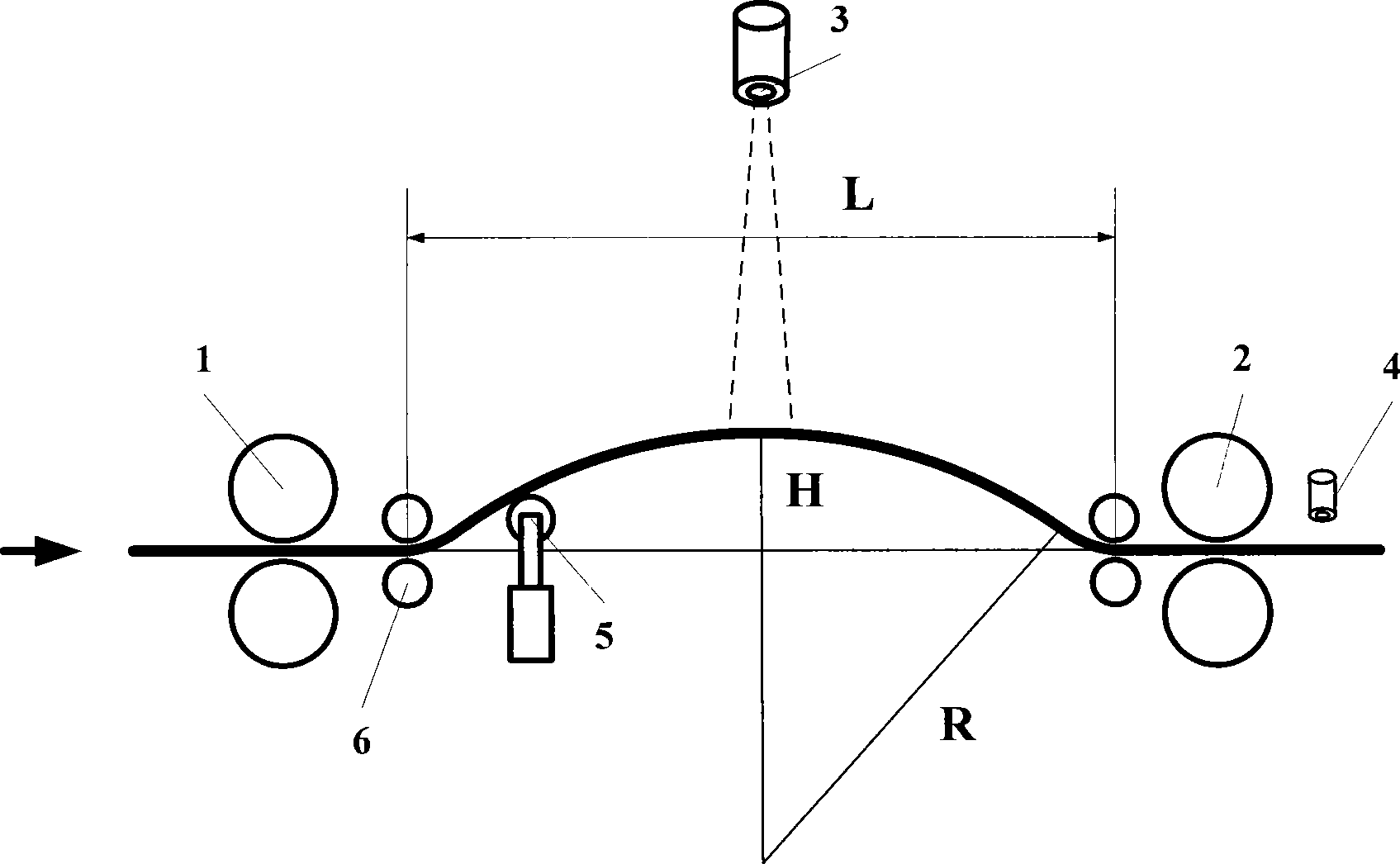

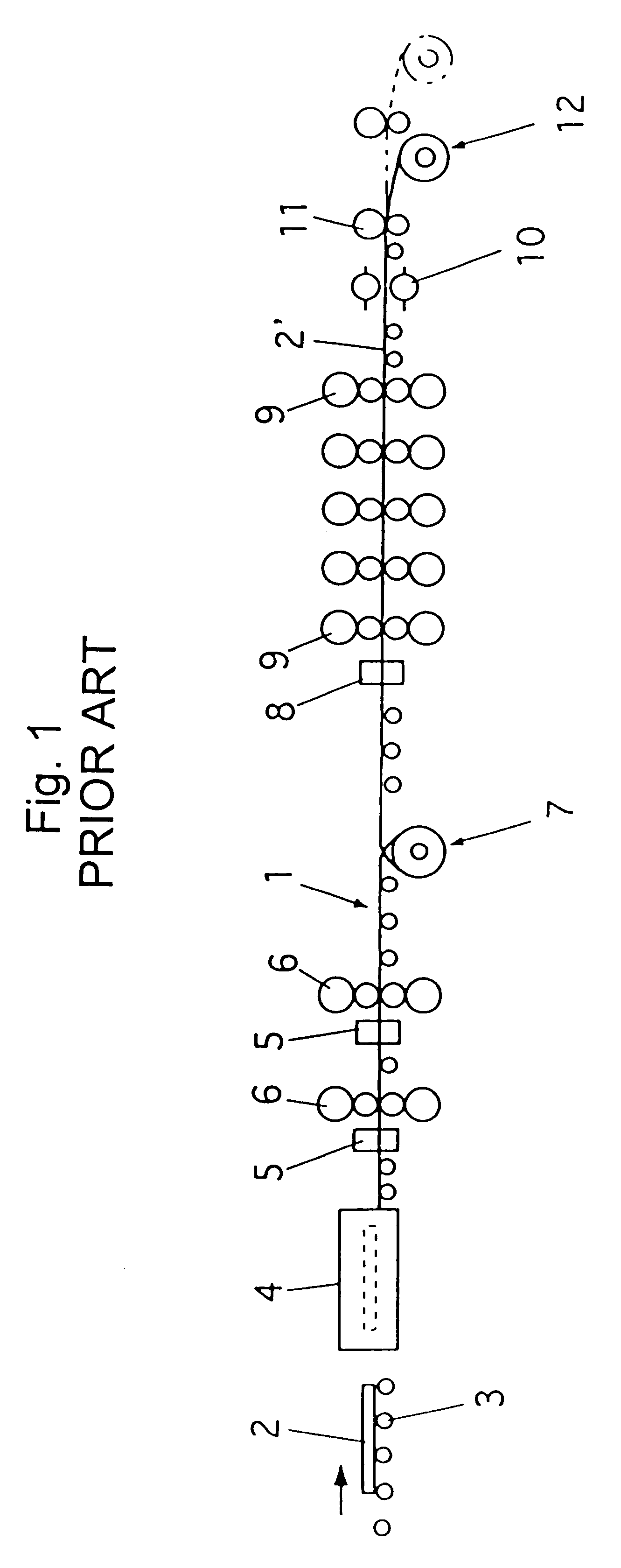

Loop control method for wire tandem rolling and device

InactiveCN101468361AImprove rolling qualitySimple structureRoll mill control devicesFlexible work arrangmentsWire rodLoop control

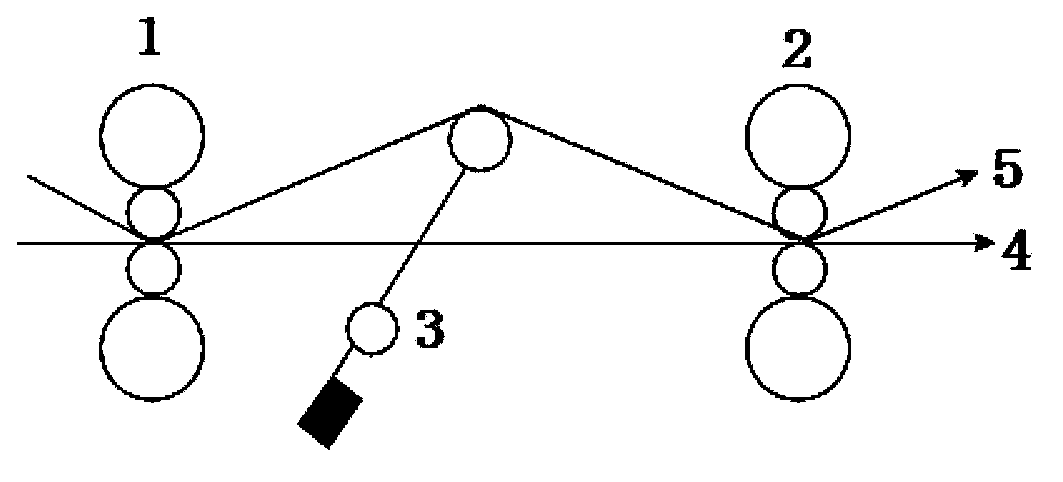

The invention discloses a method and a device for controlling a movable sleeve for the continuous rolling of a wire material. The method comprises: a guide wheel positioned between two adjacent rolling machines conducts the wire material to a rolling machine; a sleeve removing sensor arranged in an outlet of the rolling machine detects a reaching signal in the head of the wire material and emits a sleeve removing command; the sleeve is removed through a sleeve removing auxiliary cylinder; a programmable controller is adopted to adjust the speed of the rolling machine and control the stretching of the sleeve removing auxiliary cylinder for carrying out the sleeve removing according to calculated raising speed curve parameters of the rolling machine; and through a closed-loop PID digital control algorithm, the speed of the rolling machine is adjusted to control the height of the movable sleeve. The device comprises a first rolling machine, a second rolling machine, a movable sleeve scanner, a sleeve removing sensor, an auxiliary cylinder, and guide wheels; the movable sleeve scanner is positioned on the highest point of removing the movable sleeve between the first rolling machine and the second rolling machine; the sleeve removing sensor is arranged in the outlet end of the second rolling machine; the sleeve removing auxiliary cylinder is positioned in the outlet end of the first rolling machine; and the positions between the first rolling machine and the second rolling machine respectively close to the rolling machines are provided with the guide wheels. The device has the characteristics of simple structure, convenient use, and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

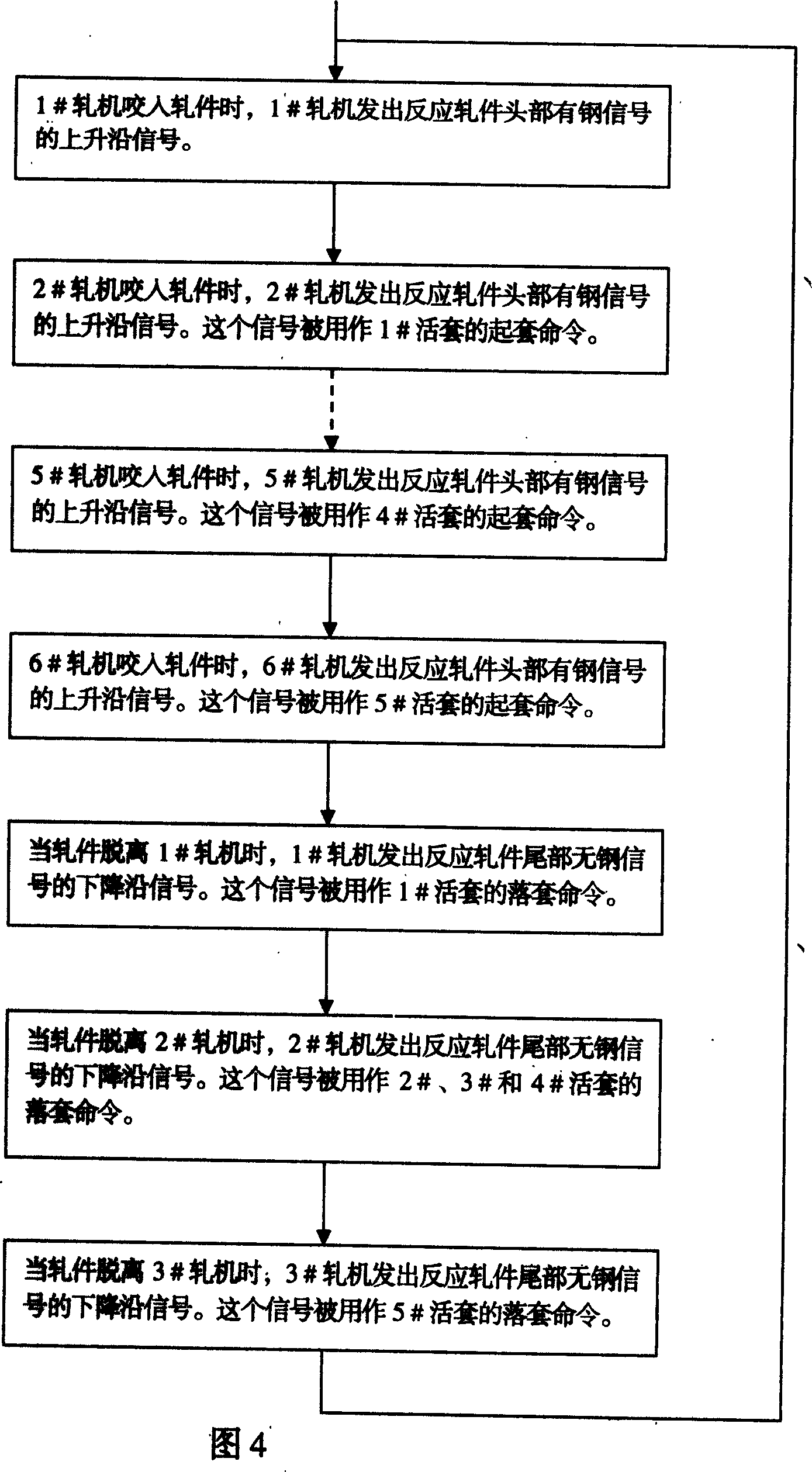

Method for solving difficulty of looping tail at steel rolling production-line

InactiveCN101003064ASolve the tail flick problemReduce steel pile accidentsRare end control deviceFlexible work arrangmentsProduction lineControl signal

A method for preventing the loops from not containing the steel tail features that the load head signal of down stream rolling mill is used as the loop lifting command, the load tail signal of upstream rolling mill is used as the loop lowering command, and the load signal of the first rolling mill is directly used as the control signal of the loop lifters for the next three rolling mills.

Owner:HEBEI IRON AND STEEL

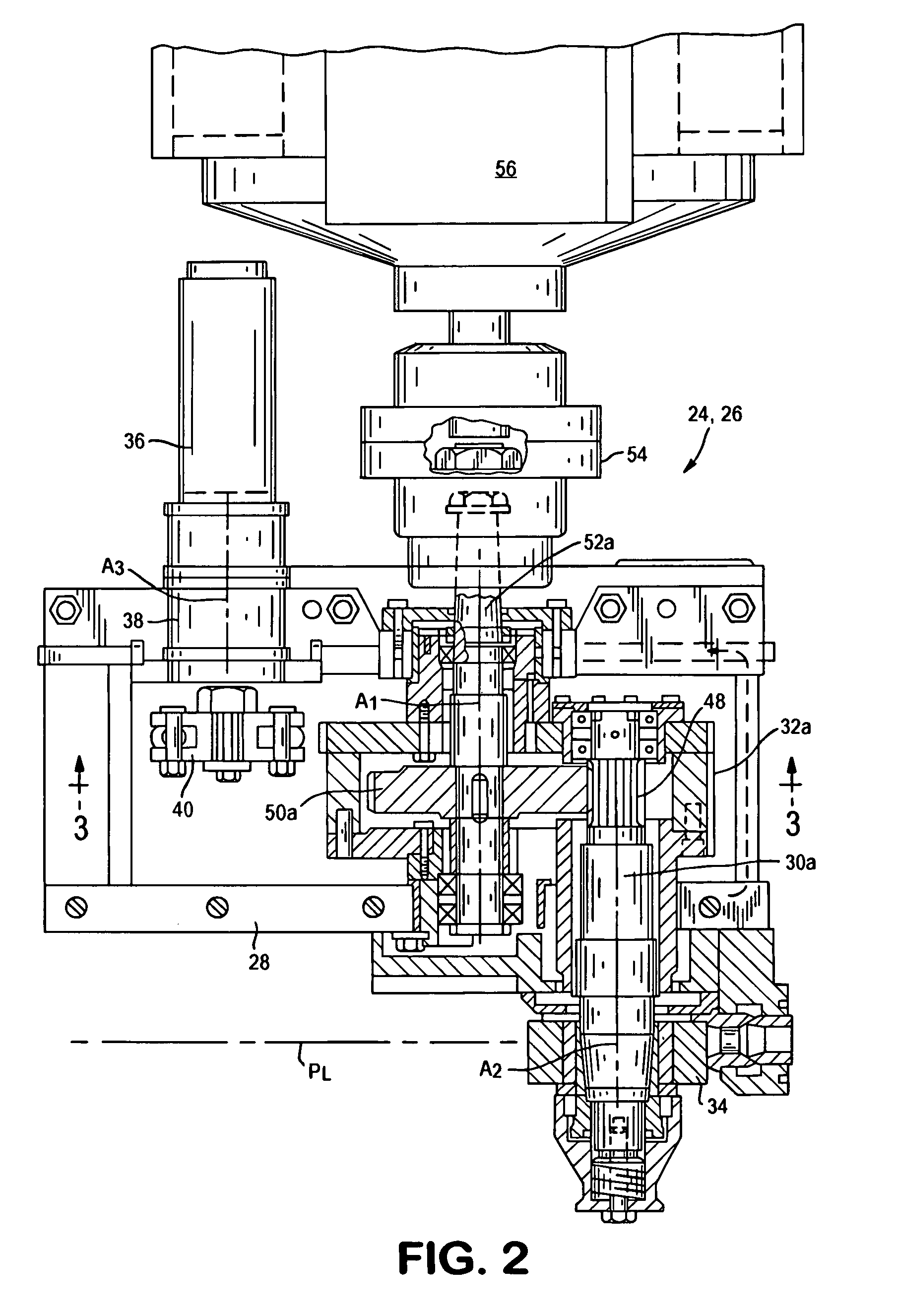

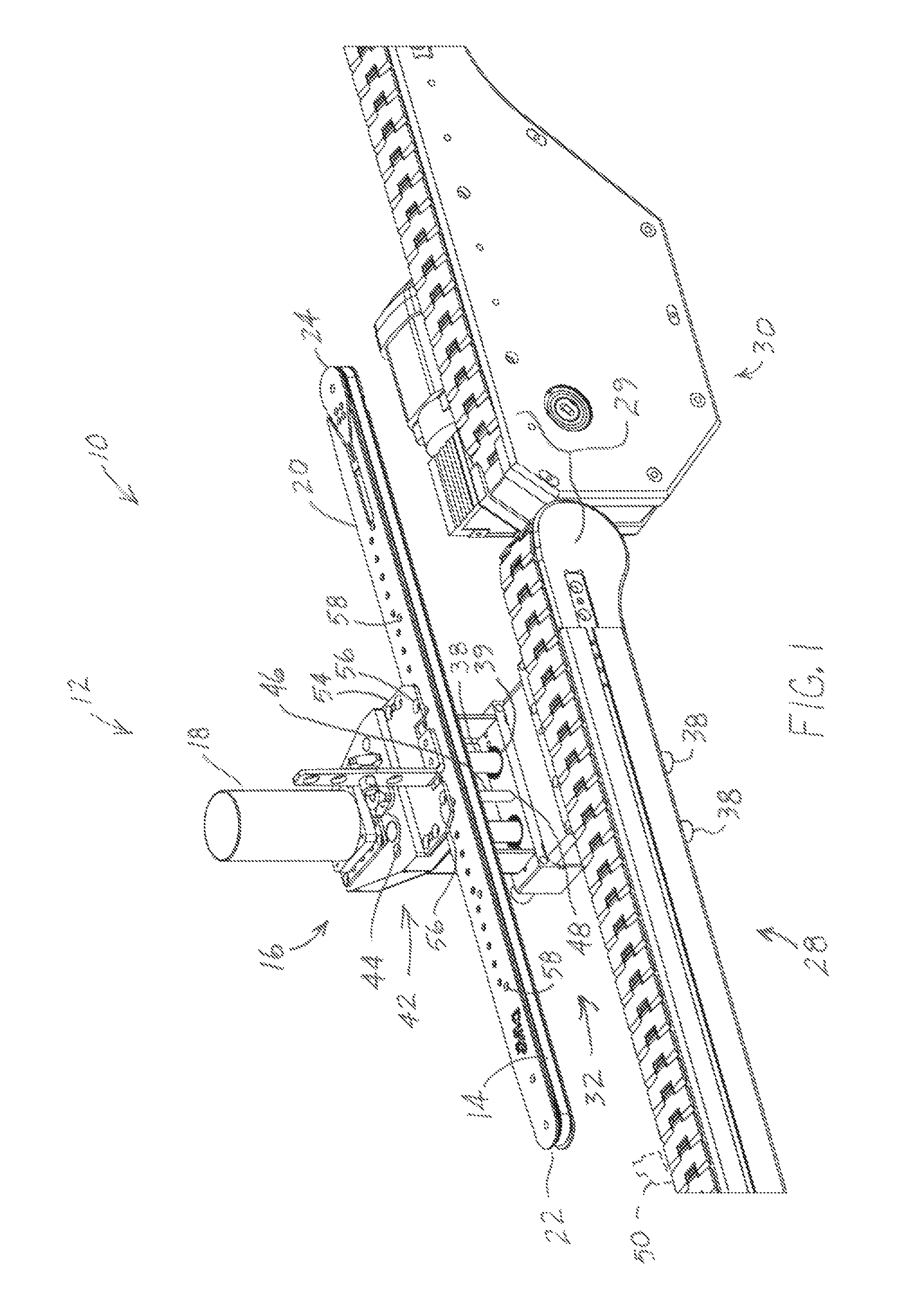

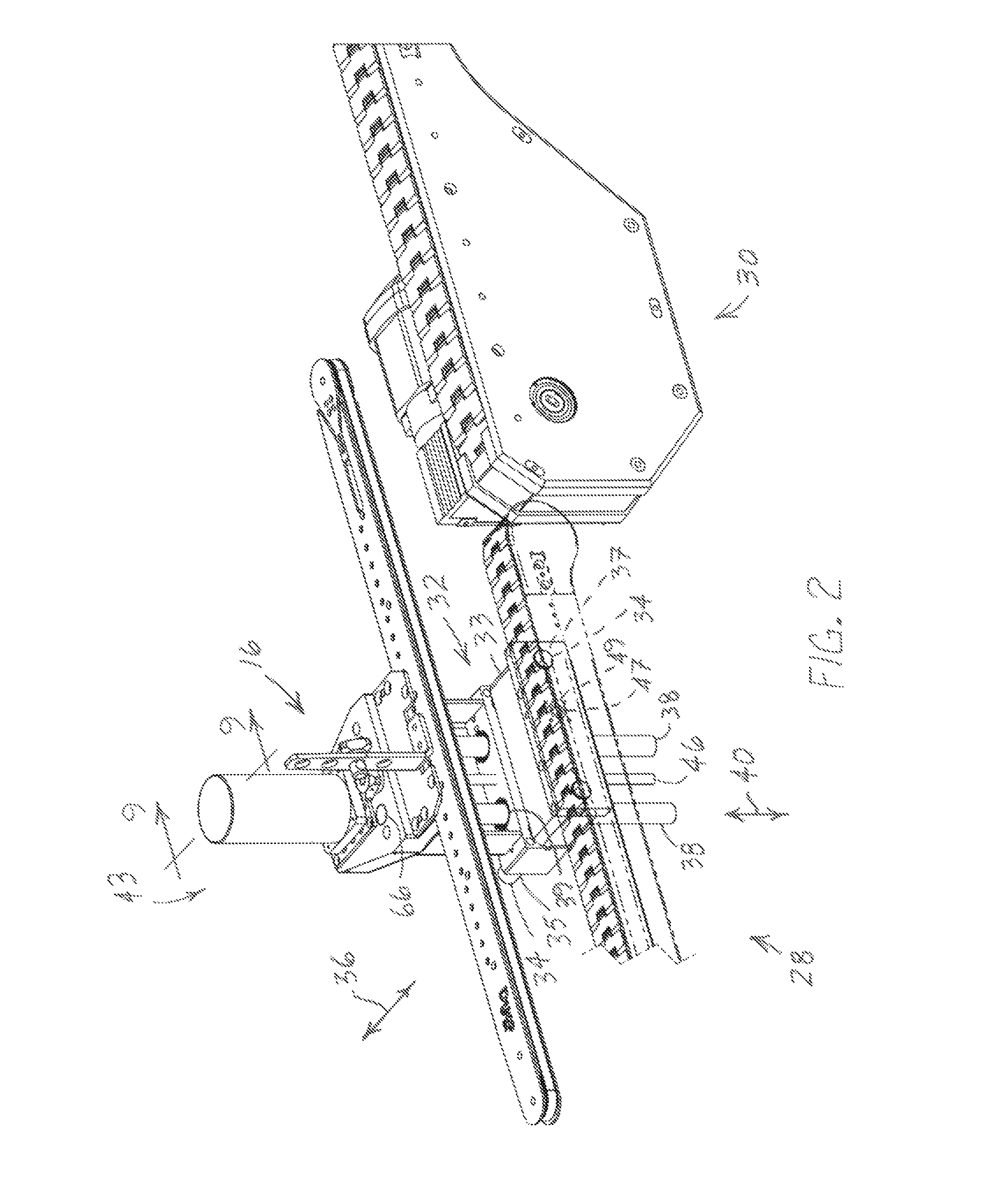

Pinch roll unit

A pinch roll unit for either propelling or retarding a product moving along the pass line of a rolling mill comprises a pair of levers mounted for rotation about parallel first axes. Roll shafts are carried by the levers with each roll shaft being journalled for rotation about a second axis parallel to the first axis of its respective lever. Pinch rolls are carried by the roll shafts and are positioned to define a gap therebetween for receiving the product. An electrically powered first motor operates via a linkage to rotate the levers about the first axes and to move the pinch rolls between open positions spaced from the product, and closed positions contacting and gripping the product therebetween. An electrically powered second motor rotatably drives the pinch rolls.

Owner:PRIMETALS TECH USA

Loop control method of special thick steel at low temperature

InactiveCN102430591AEnsure automatic controlRealize automatic controlMeasuring devicesFlexible work arrangmentsLoop controlHeight difference

A loop control method of special thick steel at low temperature is disclosed, and aims to overcome the loop oscillation among precision rolling frames and ensure normal production of hot rolling. The method comprises the steps of: determining the control parameters of the loop among the frames by a first level computer according to the following formula if the target temperature at the strip steel precision rolling outlet is lower than 830 DEG C and the thickness of the product is greater than 7mm: Yn=Yn-1+Kp*{[1+TA / TN]*deltaYn-deltaYn-1}, wherein Yn is the additional quantity m / s of the loop height to the frame speed at sampling moment n; TA is program scanning time; TN is time of integration; Kp is proportional coefficient; deltaYn is loop height difference mm at sampling movement n; and transmitting downward by a second level computer to distinguish the loop tension set values of steels so as to give the torque of the loop.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

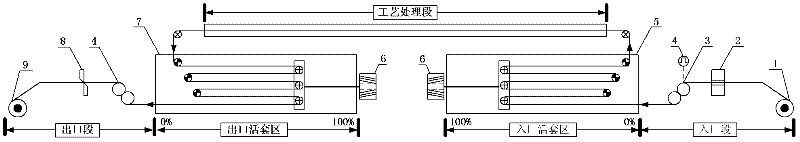

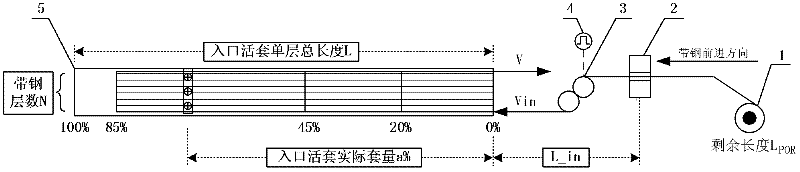

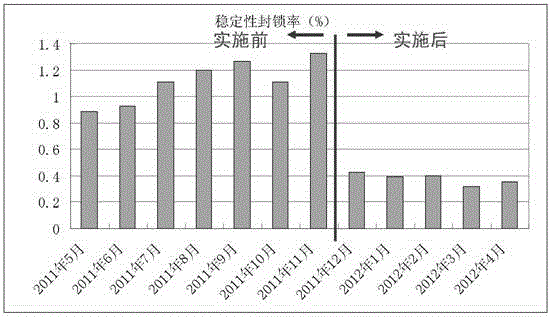

Automatic dynamic adjustment method for synchronous extension of loop of cold rolling continuous processing line

ActiveCN102553948AThere is no need to dynamically adjust the set value of synchronous setsPrevent deviationFlexible work arrangmentsMetal rolling arrangementsBreakage probabilityExtension set

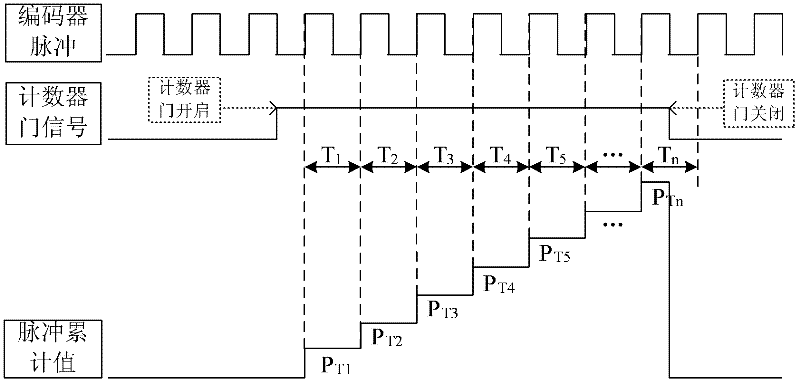

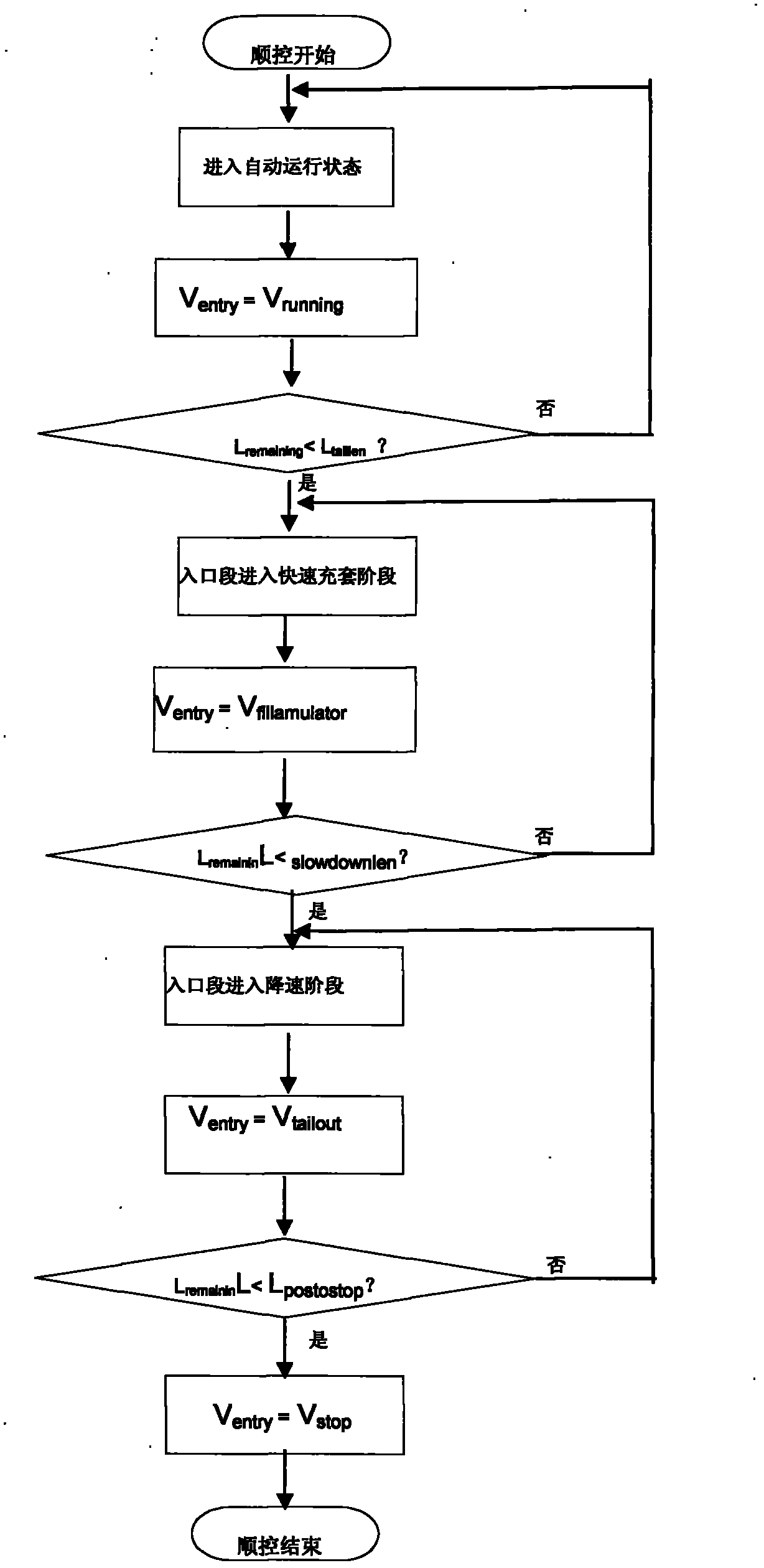

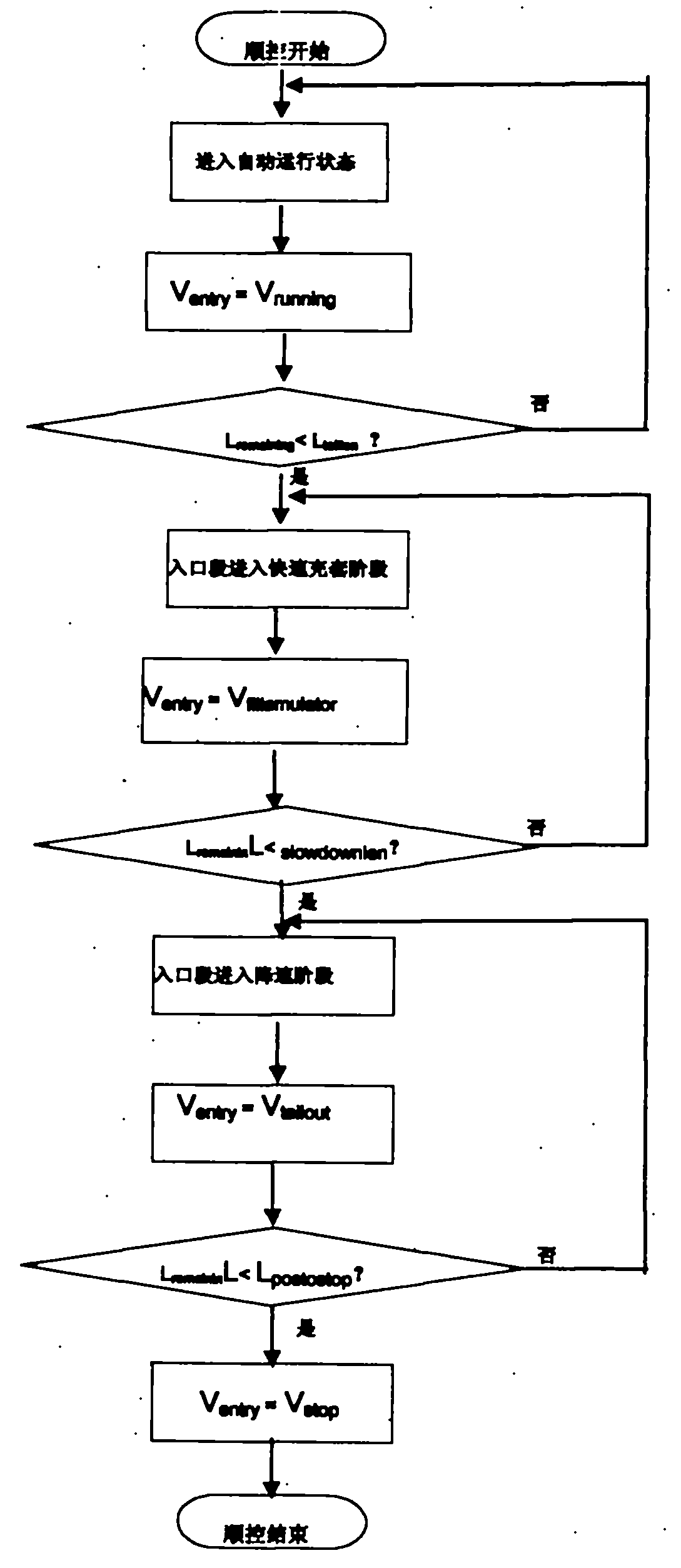

The invention relates to an automatic dynamic adjustment method for synchronous extension of a loop of a cold rolling continuous processing line. The automatic dynamic adjustment method specifically comprises the following steps of: at a non-drift stage of an uncoiling machine, acquiring a pulse encoder signal on an inlet tension roller, calculating the actual traveling distance of strip steel and thereby judging the relative position of a weld joint and the loop, and automatically adjusting a synchronous extension set value of the loop; at a drift stage of the uncoiling machine, calculating length of strip steel to be replenished according to a target set value and a current actual value for the synchronous extension of the loop, comparing the length of the strip steel with that of the remaining strip steel on the inlet uncoiling machine, and automatically adjusting the synchronous extension set value of the loop; and finally, arranging a functional module in a cold rolling continuous processing line control system to realize an undisturbed automatic switching function of the synchronous extension set value of the loop. According to the automatic dynamic adjustment method, deviation of the strip steel in the loop can be prevented, and the strip breakage probability of the strip steel in the loop is reduced; the production efficiency of the processing line can be increased and the working intensity of operation personnel is reduced; and the disposal difficulty for strip breakage accidents in the loop can be reduced and the accident recovery time is shortened.

Owner:WISDRI WUHAN AUTOMATION

Method for solving problem of loop charging and drifting of production line of pickling-rolling coupled machine

ActiveCN101934293AGuaranteed to proceed normallyUse adequate and accurateRare end control deviceFlexible work arrangmentsLiquid coreProduction line

The invention relates to a sector segment actuating mechanism taking pressure as a control target, belonging to the technical field of continuous casting equipment in a metallurgy industry. The sector segment actuating mechanism comprises a displacement sensor, a hydraulic cylinder, a pressure sensor, an electric control system, a hydraulic system and a sector segment, wherein the hydraulic cylinder of the sector segment is provided with the displacement sensor and the pressure sensor which are matched with the hydraulic cylinder; the signal output ends of the displacement sensor and the pressure sensor are connected with the electric control system; the output of the electric control system is connected with the hydraulic system; and the hydraulic system is connected with the hydraulic cylinder of the sector segment. The sector segment can reflect the stress of a casting blank in real time by taking the pressure as the control target, solve the problems of errors caused by sensor drifting and initial roll gap setting, prevent the casting blank from internally cracking and the sector segment from being damaged due to overload because of superabundant shrinkage mass and also ensure good casting blank quality through the force analysis of the casting blank. Besides, the method can also be used for judging the position of a liquid core of the casting blank and providing accurate feedback data for the application of a dynamic soft reduction technology.

Owner:HEBEI IRON AND STEEL

Loop control method and rolling method of hot rolling mill

ActiveCN103909095AImprove production stabilityImprove product qualityRoll mill control devicesFlexible work arrangmentsLinear controlLoop control

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

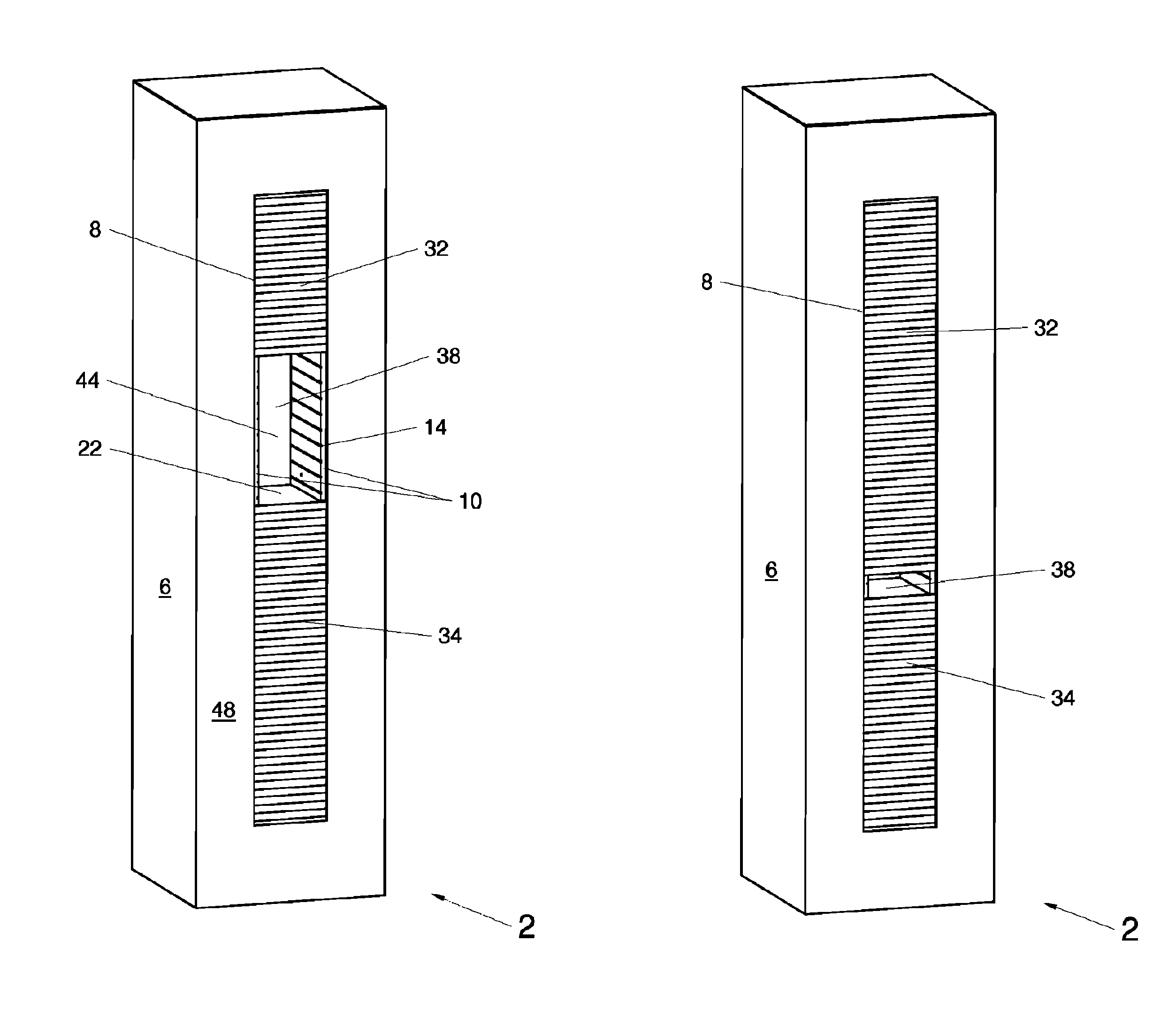

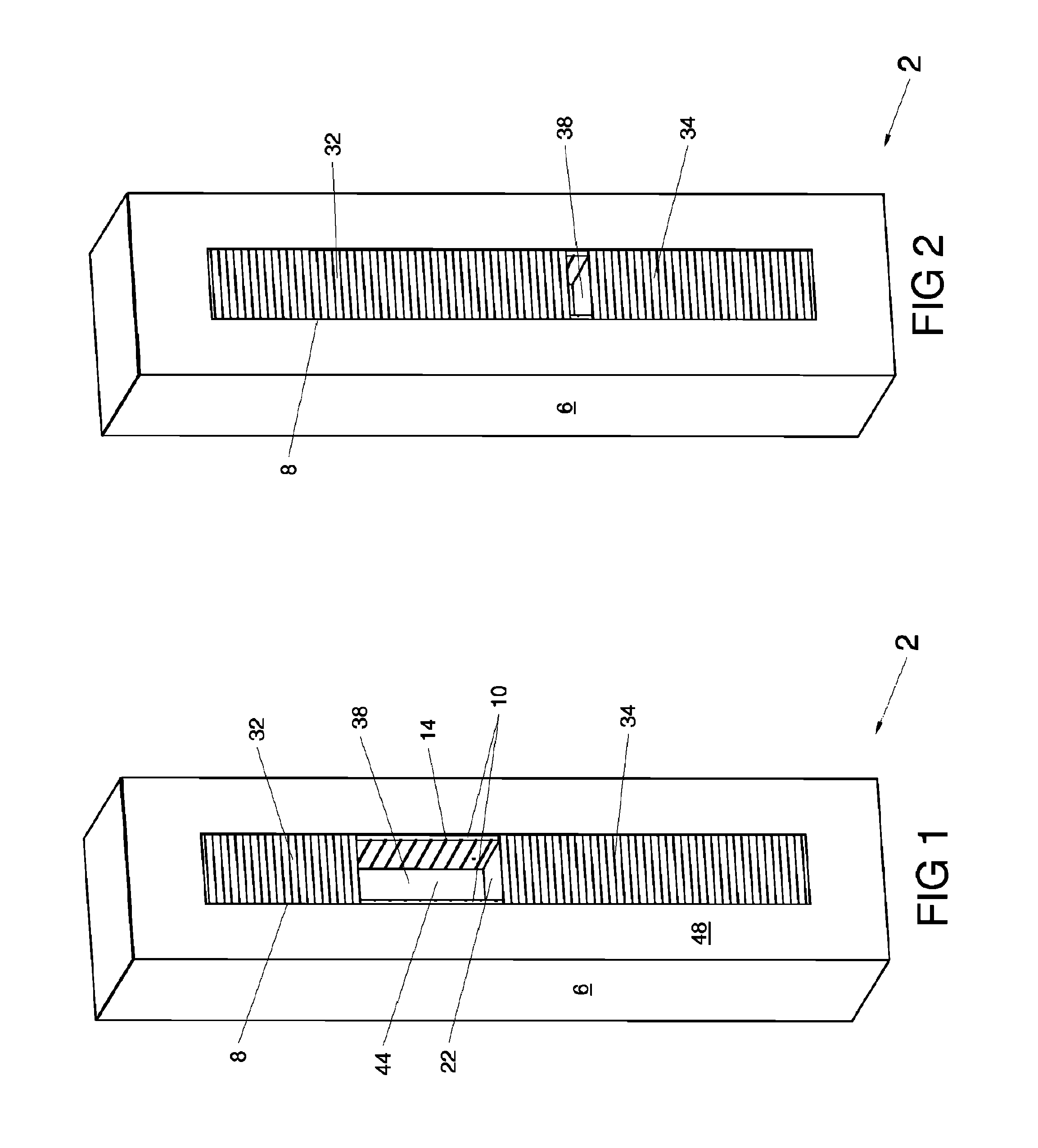

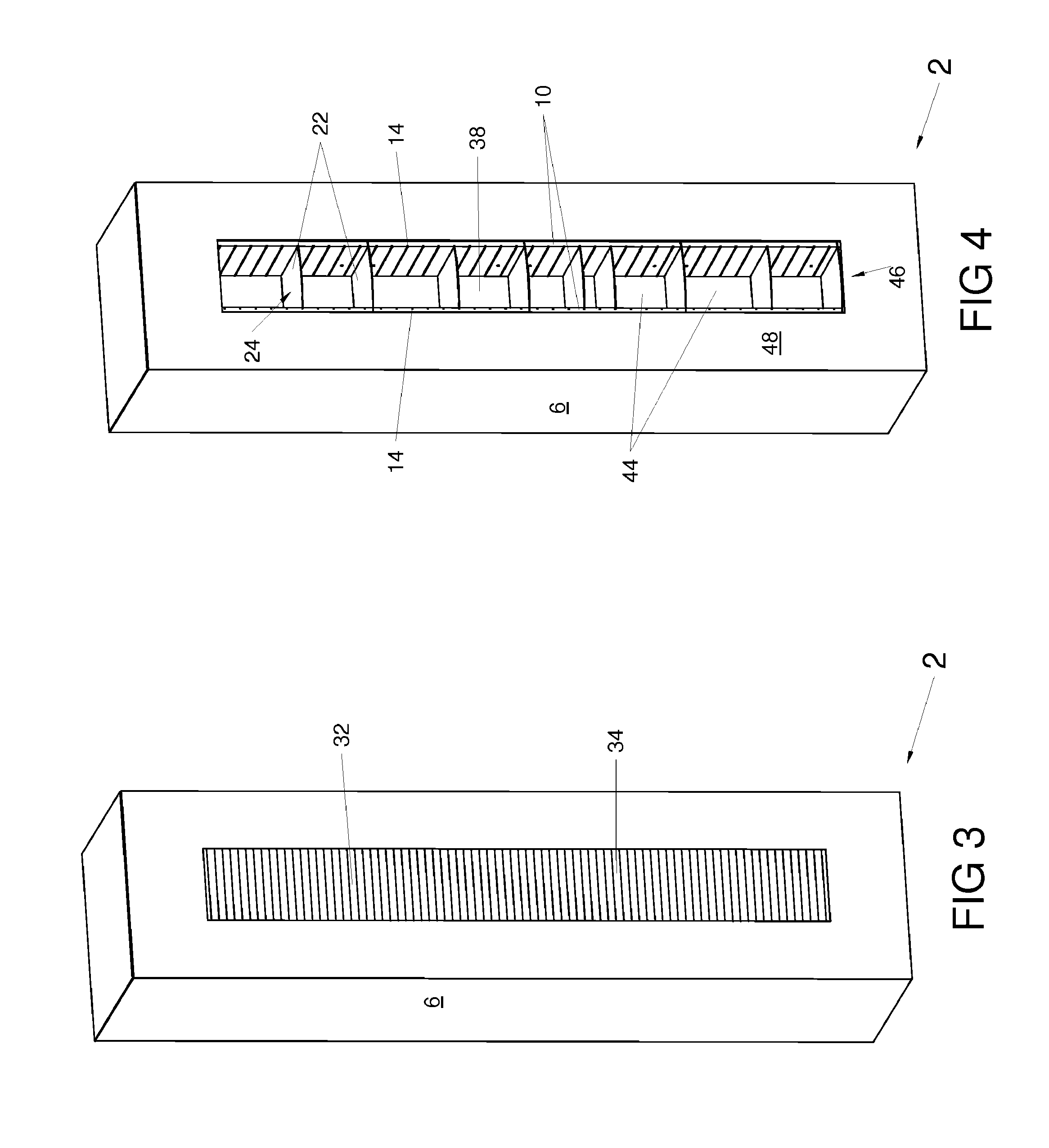

Storage and retrieval machine with variable-height door opening

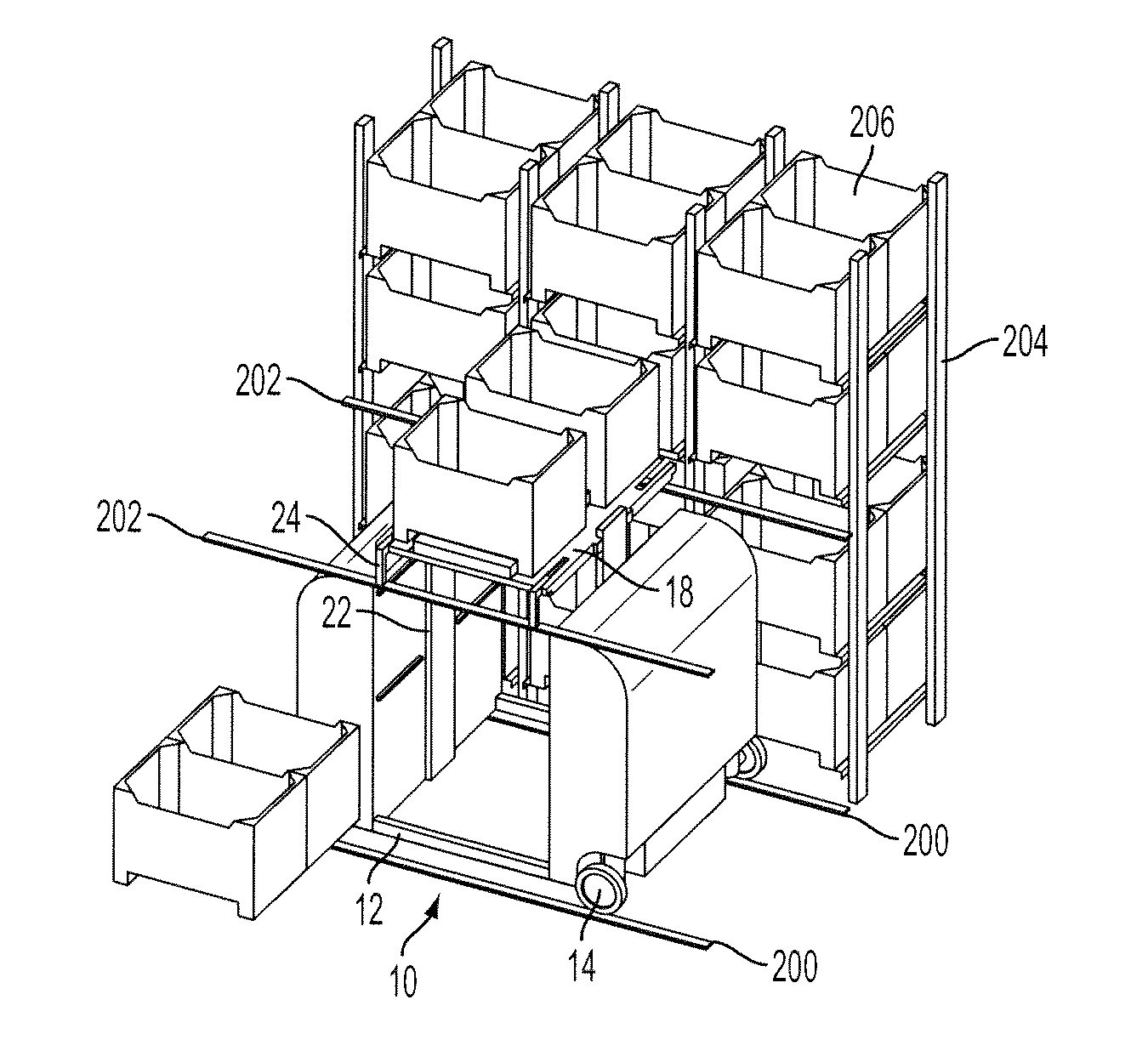

ActiveUS8714669B1SunshadesShutters/ movable grillesElectrical and Electronics engineeringVertical Dimensions

This storage and retrieval machine consists of an enclosure with an enclosure opening and two independently positionable doors, which move vertically to block or provide access into the storage machine. The enclosure contains one or more shelf stacks, where each shelf stack has multiple, easily adjustable, drawer-style shelves to form storage areas of various vertical dimensions. One may combine several shelf stacks to form a rotatable storage cylinder. Shelves used with either the fixed or rotatable shelf supports can be blocked by one or both doors to prohibit their repositioning.

Owner:ROTARY STORAGE & RETRIEVAL LLC

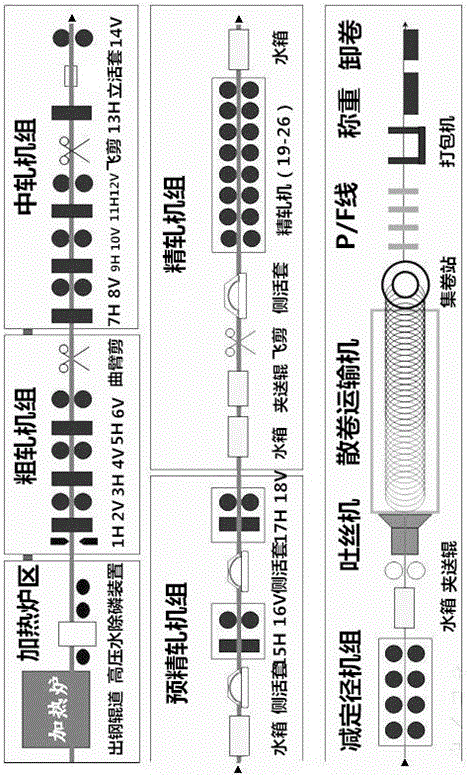

Coil production method and production line thereof

ActiveCN105665442AHigh strengthImprove plasticityTemperature control deviceWork cooling devicesProduction lineHeating furnace

The invention discloses a coil production method and a production line thereof. The production line comprises a heating furnace, a rough rolling unit, a medium rolling unit, a pre-finish rolling unit, a finish rolling unit, a reducing and sizing unit, a spinning machine, an air-cooling line, a reel collecting station and other devices. A blank is subjected to the first step of heating, the second step of rough rolling and medium rolling, the third step of pre-finish rolling and finish rolling, the fourth step of reducing and sizing, the fifth step of spinning, the sixth step of fast cooling after spinning, the seventh step of air-cooling line controlled cooling and the eighth step of reel collecting and packaging in sequence on the above devices. Controlled rolling in a critical austenite area is achieved by accurately controlling the rolling temperature, the low-temperature phase change is achieved, a rolled piece directly enters the spinning machine without being subjected to water cooling after reducing and sizing are conducted, the phenomenon of water blocking caused during small-specification water passing is effectively avoided, the production fault rate is reduced, the distance between the reducing and sizing unit and the spinning machine is shortened, and the length of the cooling line is reduced; and due to the combination of two sections of water cooling and air cooling after spinning, the cooling efficiency is improved, transformation of a control structure is achieved, investment is reduced, and the market competitiveness is improved.

Owner:CISDI ENG CO LTD

Apparatus and methods for manufacturing hot rolled steel sheets

InactiveUS6463652B1DesignedReduce vibrationForging/pressing devicesMetal rolling stand detailsProduction rateSheet steel

A high-quality hot rolled steel sheet is manufactured with a high production efficiency and a low cost, from a long, hot slab, using a combination of continuous casting facilities and a plate reduction press machine.

Owner:IHI CORP +2

Coil forming apparatus and method

A method and apparatus is disclosed for receiving a helical formation of rings free falling from the delivery end of a conveyor and for gathering the rings into an upstanding cylindrical coil, The free falling rings encircle a vertically disposed guide and are supported initially on elevated intercepting elements. The interceptor elements are gradually lowered past a coil plate onto which the accumulated rings are transferred. The coil plate is then lowered to accommodate continued formation of the coil, and the intercepting elements are returned to their elevated position.

Owner:MORGAN CONSTR CO

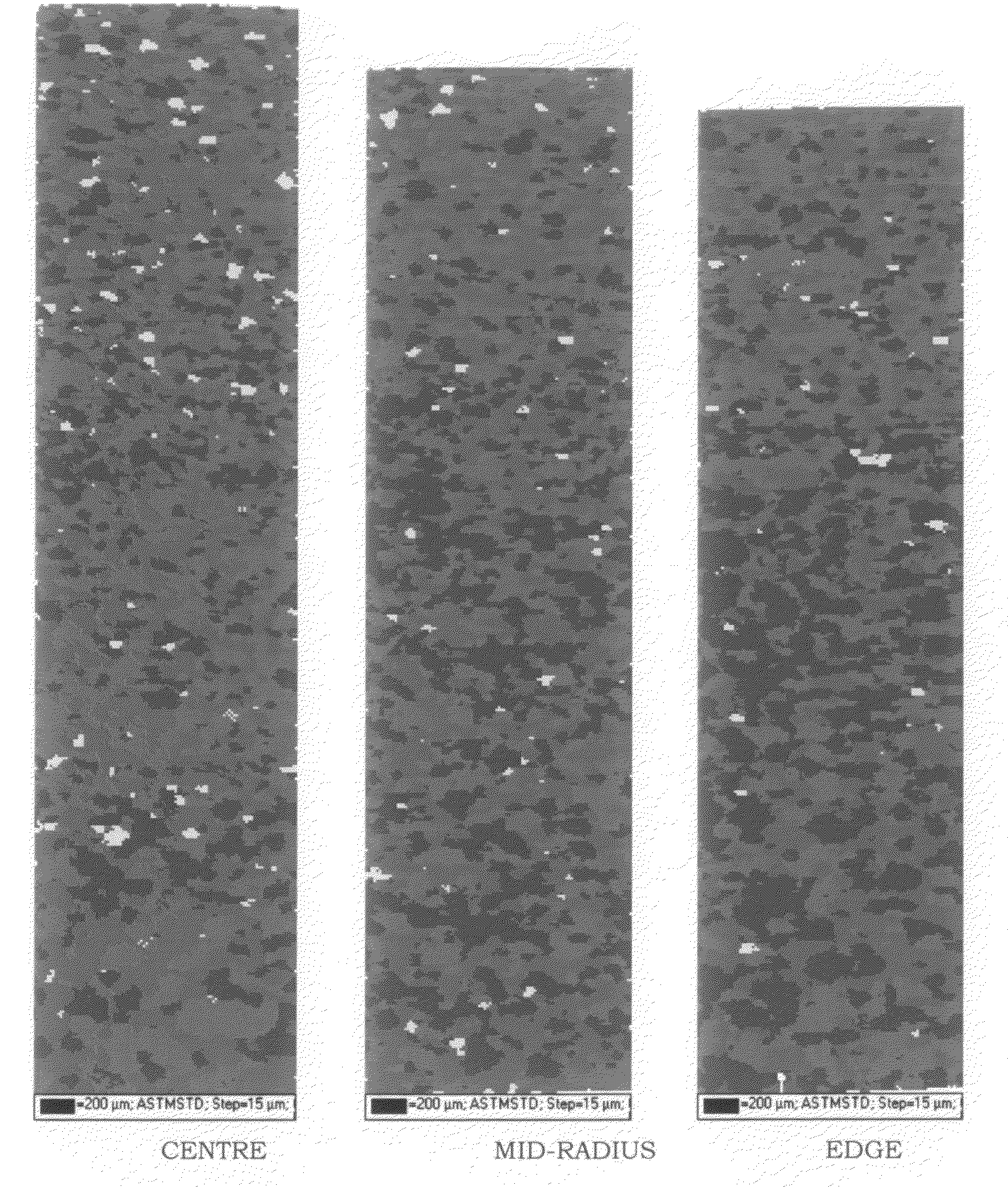

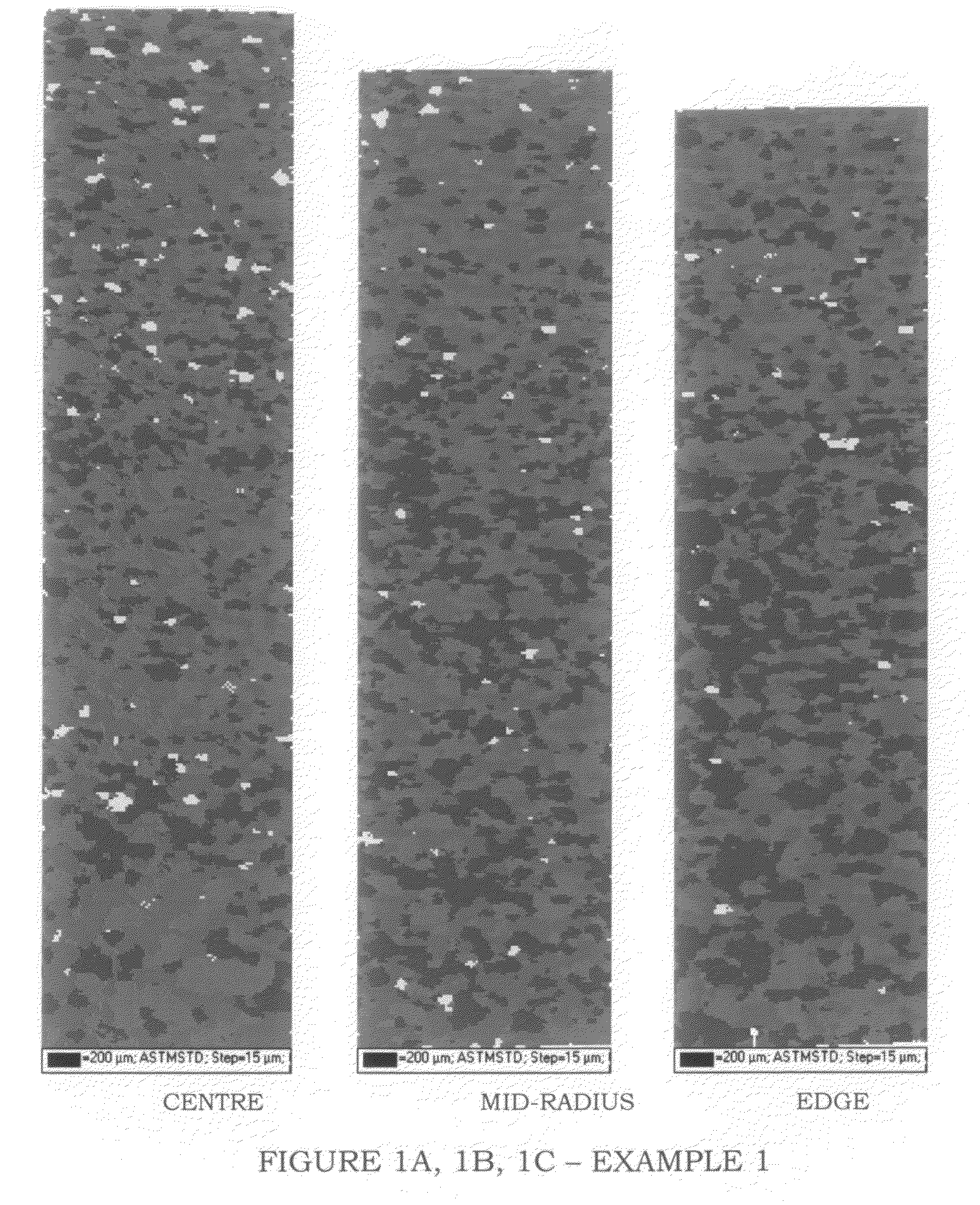

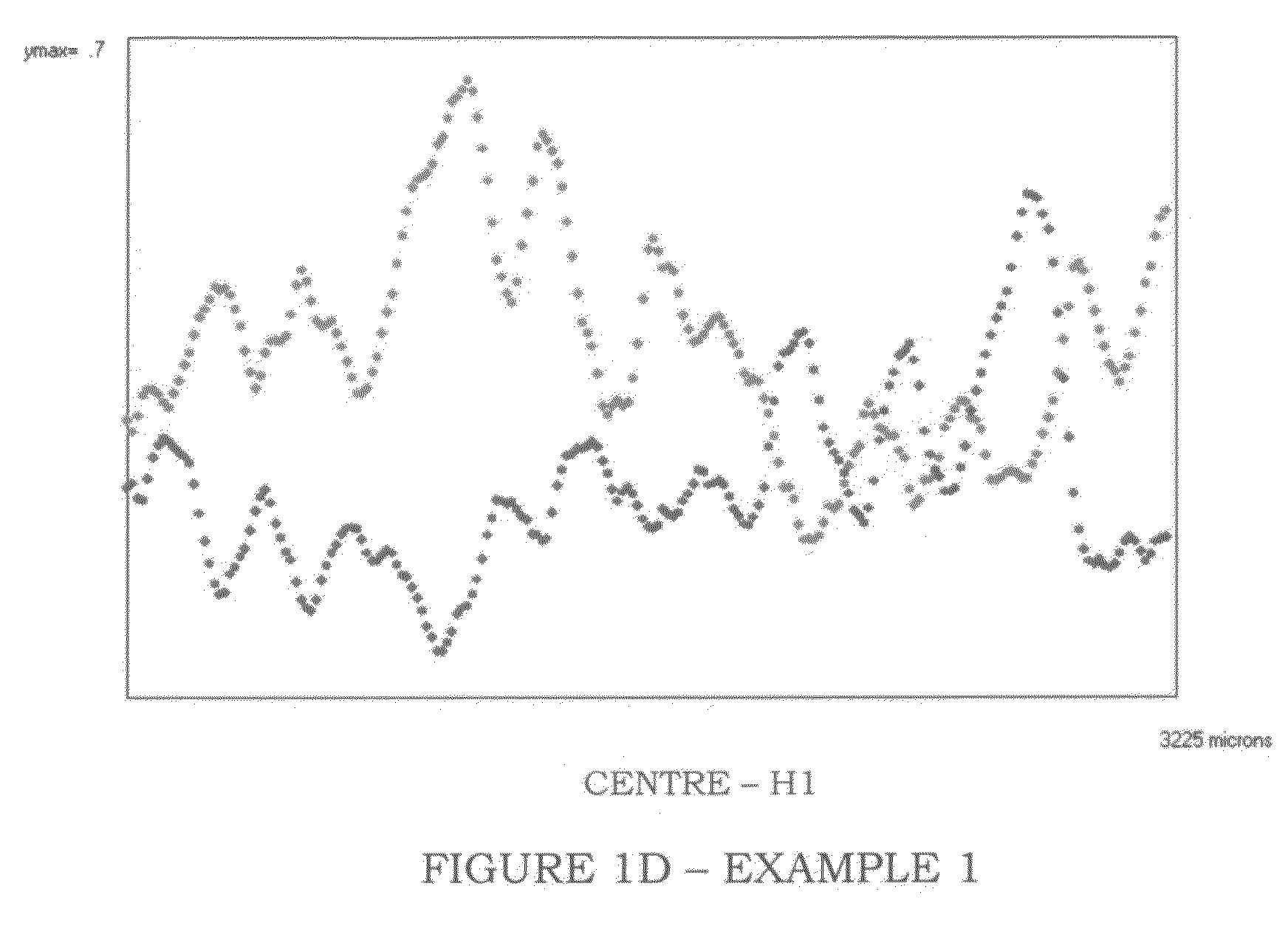

Refractory metal plates with improved uniformity of texture

ActiveUS20090038362A1Increase film thicknessImprove predictabilityPig casting plantsVacuum evaporation coatingMetalCrystallization

A refractory metal plate is provided. The plate has a center, a thickness, an edge, a top surface and a bottom surface, and has a crystallographic texture (as characterized by through thickness gradient, banding severity; and variation across the plate, for each of the texture components 100 / / ND and 111 / / ND, which is substantially uniform throughout the plate.

Owner:GLAS TRUST +1

Article metering device

An article metering device for use in a conveyor system includes a continuous belt, a body, a motor operatively connected to the body for drivingly moving the belt and a guide belt. The belt guide has opposed ends operatively connected to and continuously supported by the body in at least two directions, the belt guide having a support surface for continuously supporting the belt between the opposed ends. The belt guide has a different coefficient of expansion / contraction than the body. The belt guide is operatively connected to the body such that the belt guide can freely expand / contract relative to the body without distorting the support surface. The belt guide extends between adjacent conveyor sections of the conveyor system or between different positions of a conveyor section of the conveyor system.

Owner:DYCO

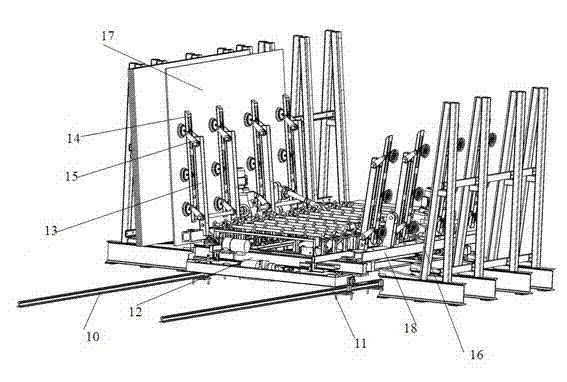

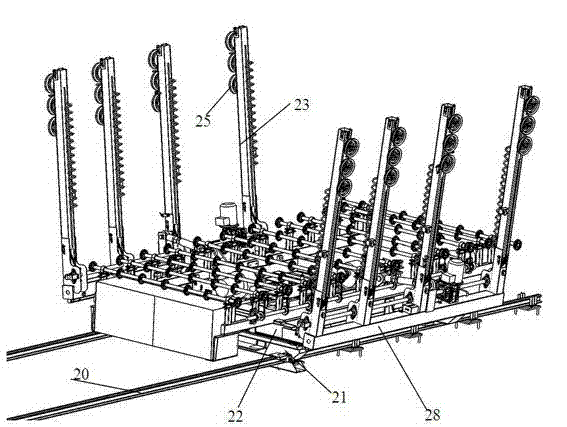

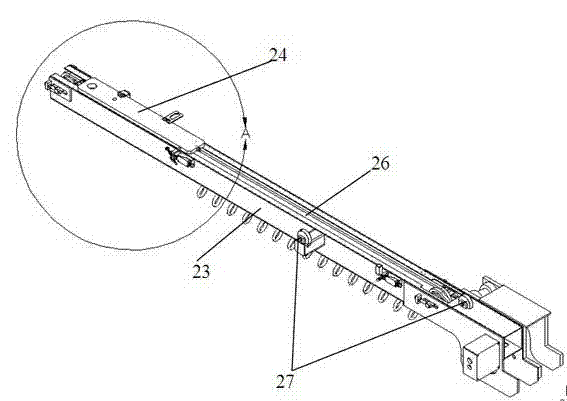

Flat material loading device

InactiveCN102862835ALow costLow running costConveyorsFlexible work arrangmentsEngineeringMechanical engineering

The invention discloses a flat material loading device. The device comprises a rack, a turning arm support frame and a plurality of turning arms, wherein the turning arm support frame can move horizontally along the rack, one ends of the plurality of turning arms are fixedly connected with a turning arm base which is rotatably connected with the turning arm support frame, sucker bases capable of moving up and down under driving along the extending directions of the turning arms are arranged on the turning arms, and at least one sucker is arranged on each sucker base. According to the device, the sucker bases are used for replacing sucker arms, the length and mass are reduced, simultaneously, positions of the suckers are concentrated, therefore when the flat materials are sucked and separated, actions happened to the flat materials are swing with the lower portions still, namely, a V-type separation, scrapes to following flat materials are avoided, simultaneously, the sucker bases can move up and down on the turning arms, so that the flat material suction specification is the same on the datum side and the non-datum side, and the sucking range during suction of the flat materials on the non-datum side is increased.

Owner:GLASTONTIANJINCO

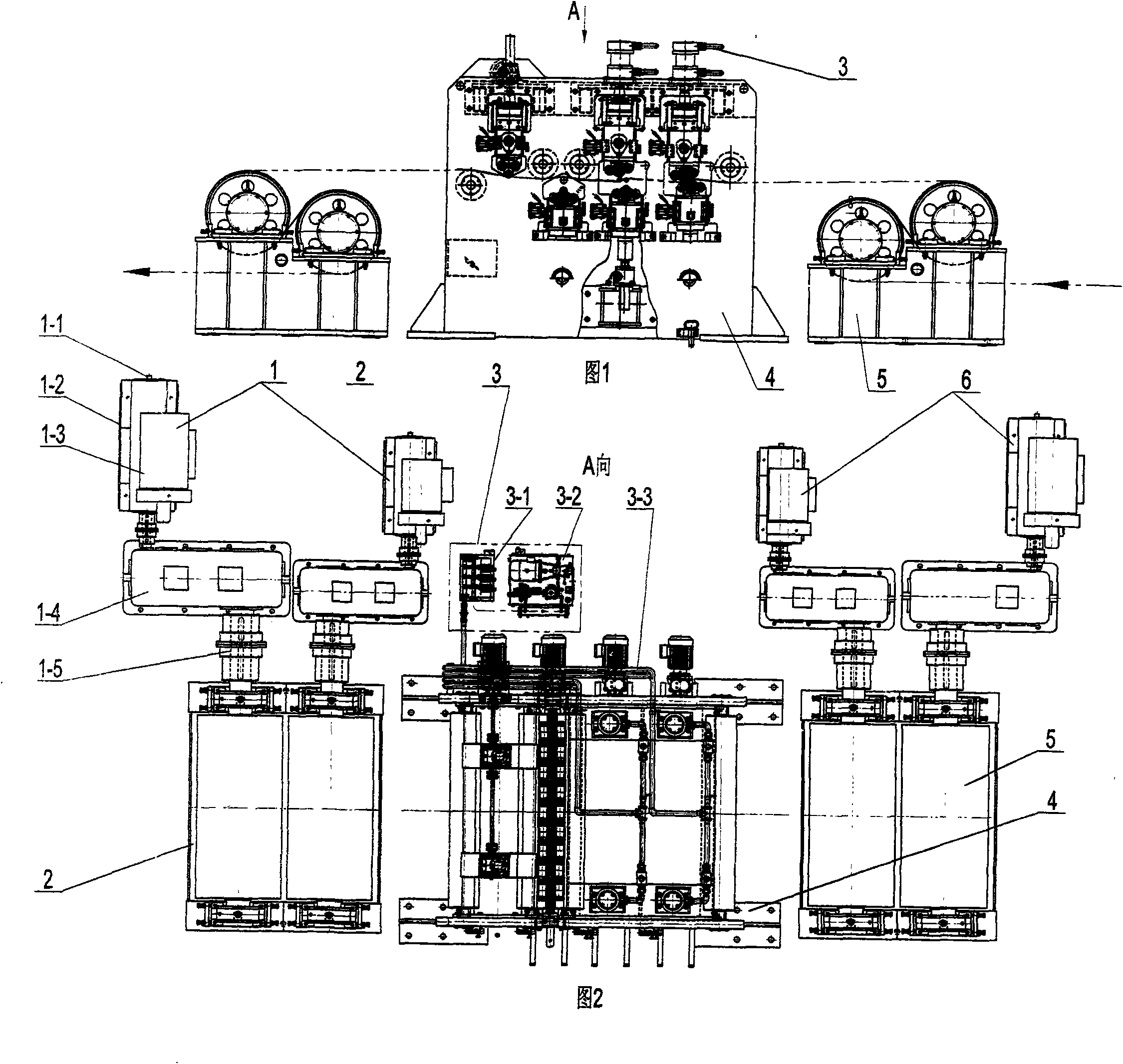

Horizontal loop device with support vehicles

ActiveCN102430592ASimple structureGuaranteed uptimeFlexible work arrangmentsMetal rolling arrangementsEngineeringLoop device

The invention discloses a horizontal loop device with support vehicles. The horizontal loop device with the support vehicles comprises a transmission device, a track device, a loop vehicles capable of running along the track device, a steering deviation rectification device which is fixedly mounted on a loop foundation platform and a plurality of ground support rollers, and the horizontal loop device with the support vehicles further comprises a fixed support device which is fixedly mounted on the loop foundation platform and a plurality of support vehicles capable of running along the track device, wherein the fixed support device is arranged between the support vehicles and the steering deviation rectification device. The horizontal loop device with the support vehicles, disclosed by the invention, is simple in structure, stable in running and easy to control and maintain in loop charging and discharging processes.

Owner:WISDRI ENG & RES INC LTD

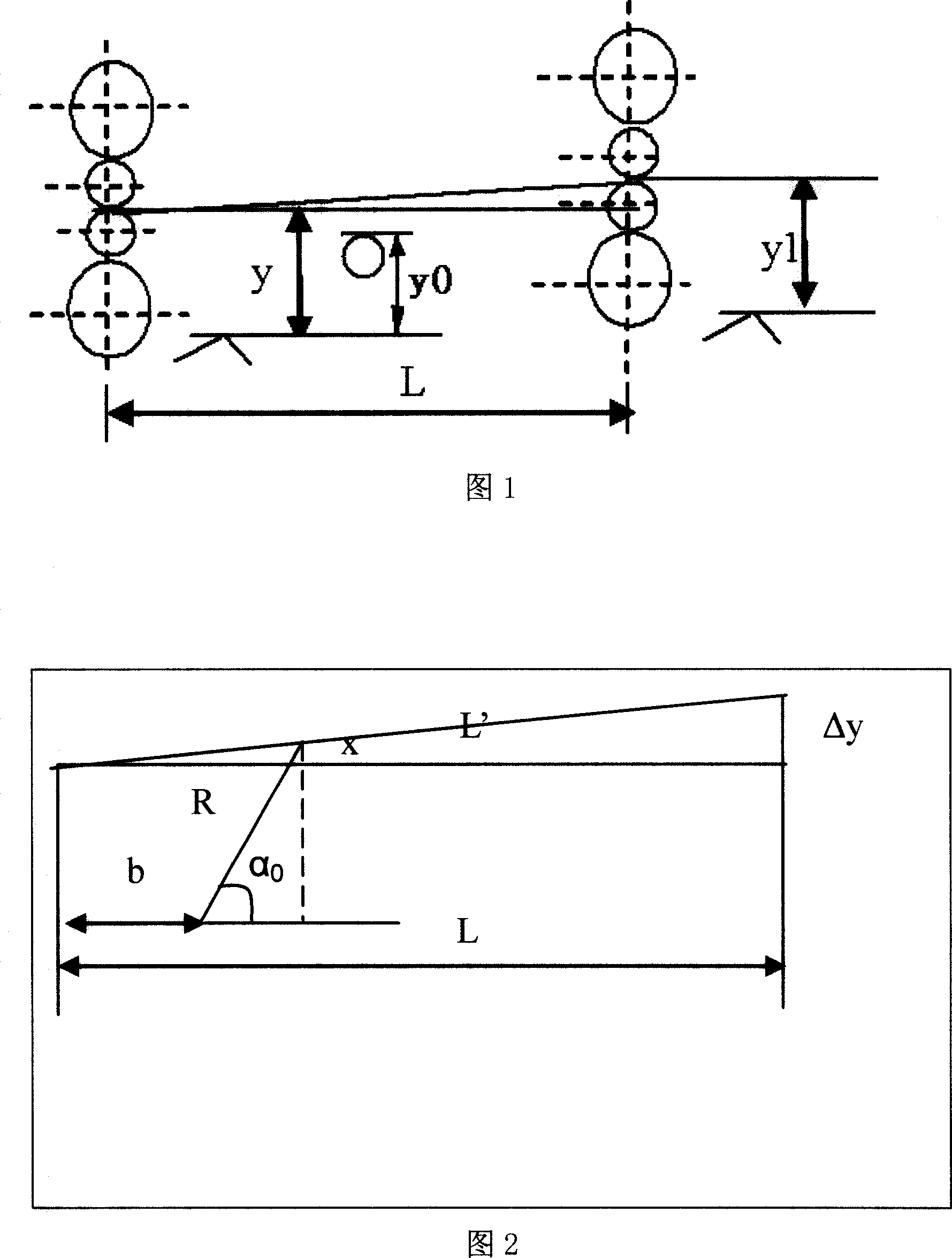

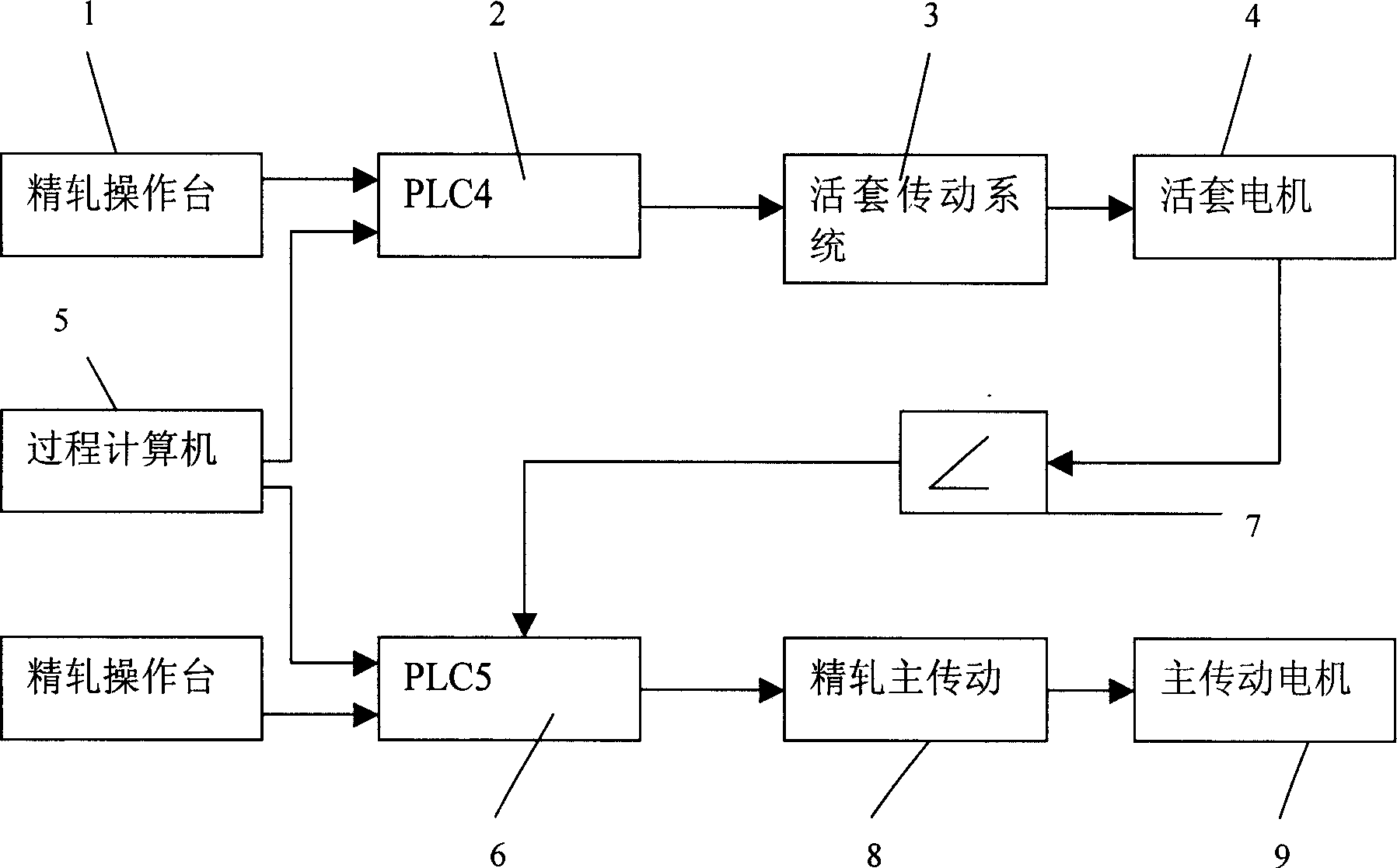

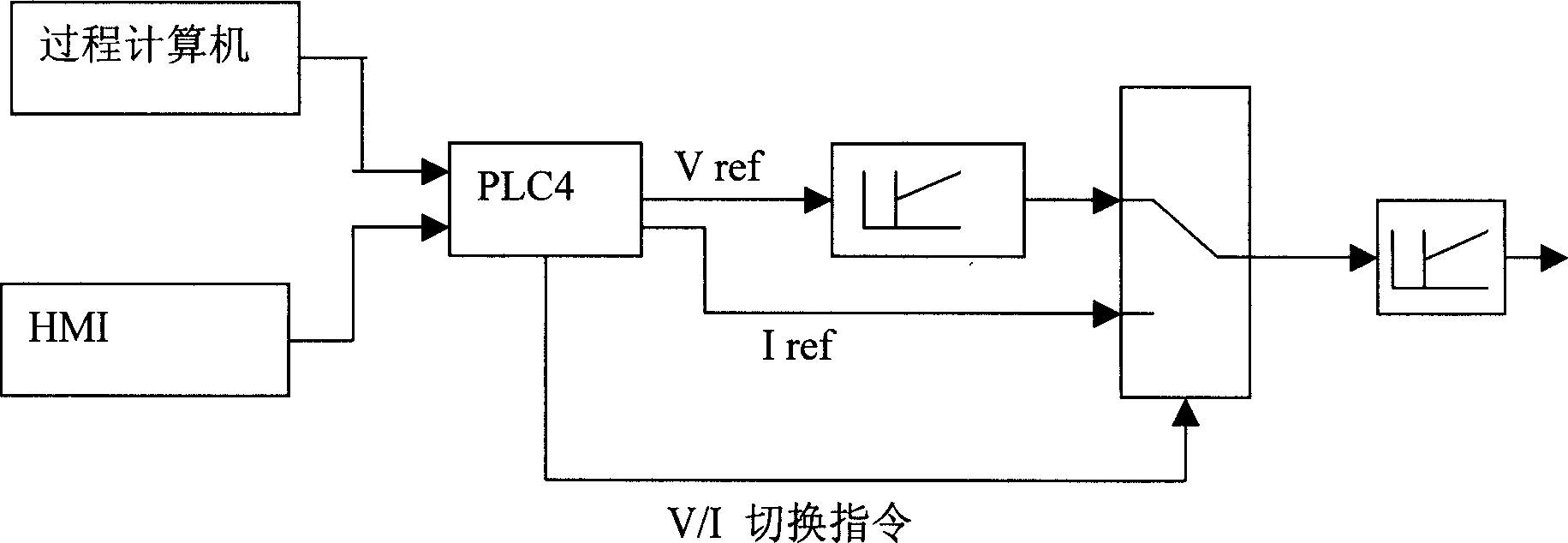

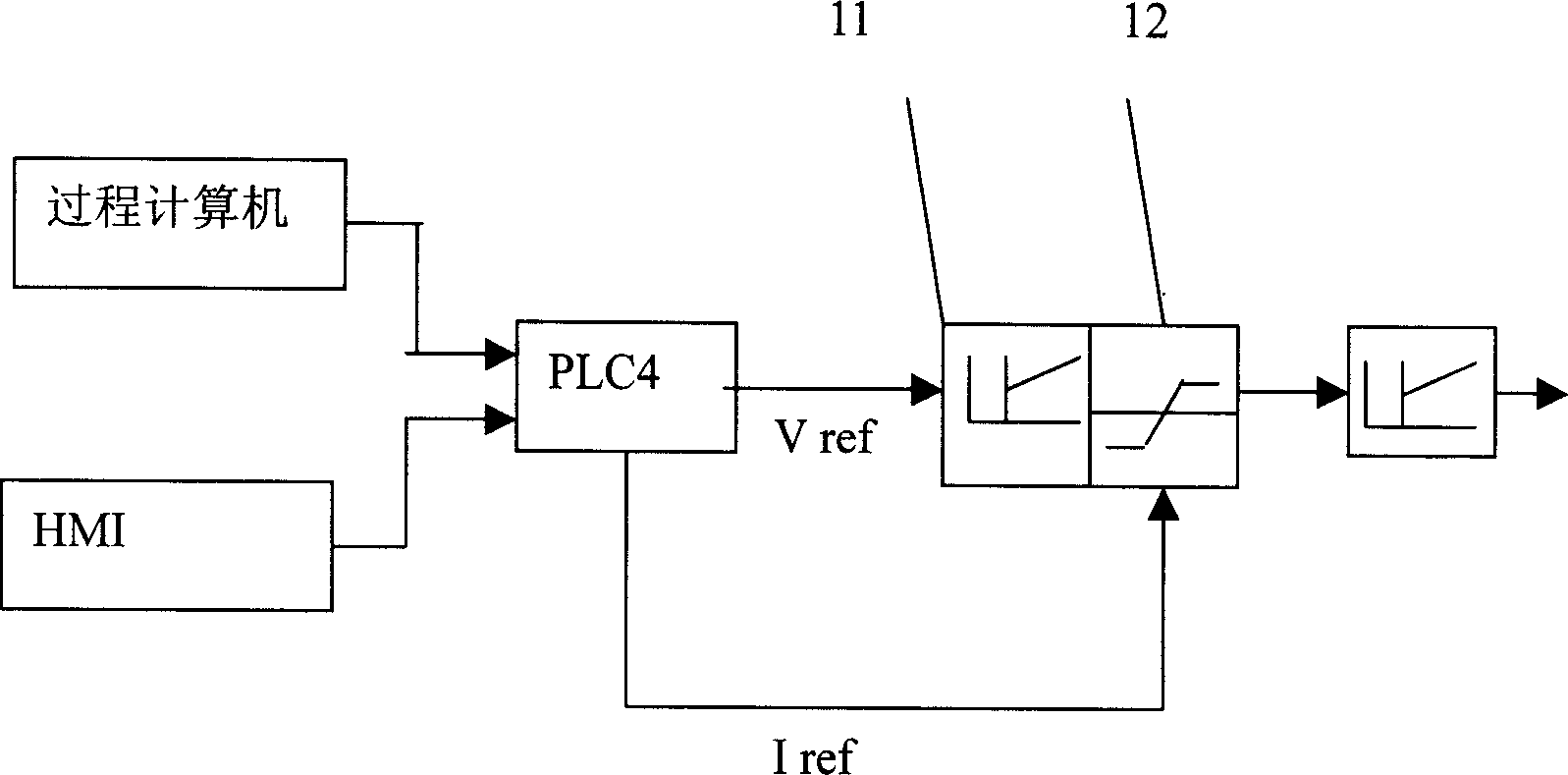

Method and system for controlling looping of finishing mill

InactiveCN1623700AReduce shockNo tension surgeFlexible work arrangmentsMetal rolling arrangementsPower flowVoltage loop

A method and system for controlling the movable sleeve of finishing mill in order to implement the soft contact and decrease the impact to base and band steel features that the tension ring control and voltage loop control are used. The tension signal is used to externally limit the ampletude of voltage signals and the current of limited signal is regulated for controlling the motor of movable sleeve.

Owner:攀枝花新钢钒股份有限公司热轧板厂

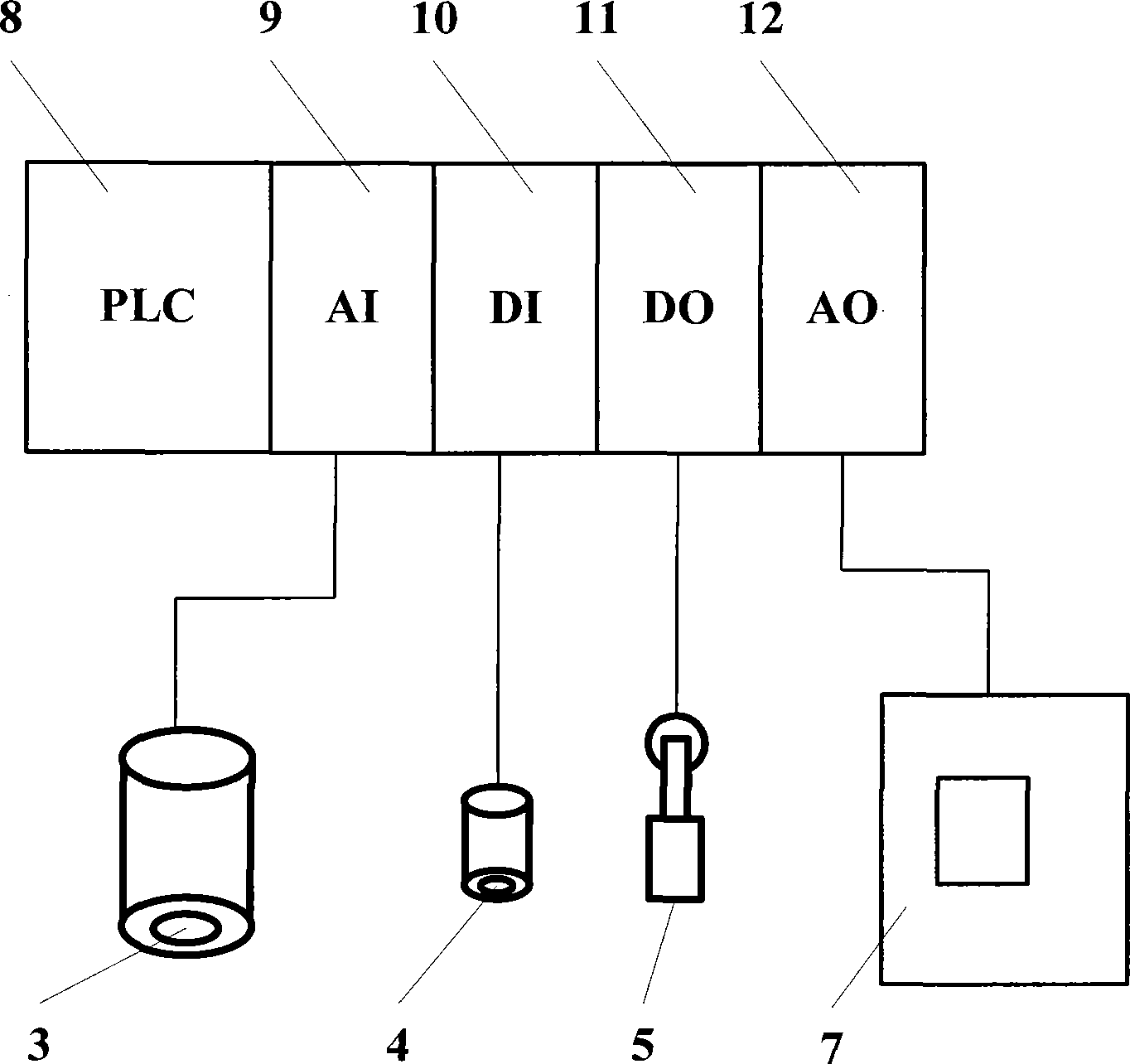

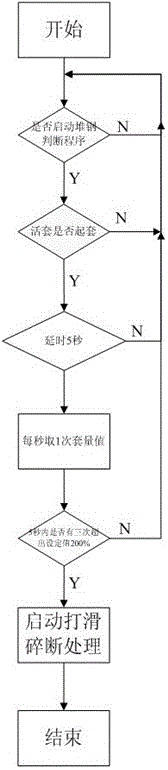

Detection system for high-speed wire rod steel heaping and judgment method

ActiveCN106040752AAccurate judgmentShorten the timeRolling equipment maintainenceMeasuring devicesWire rodProduction line

The invention discloses a detection system for high-speed wire rod steel heaping and a judgment method of the detection system. The detection system comprises a PLC control system, detection loops, loop detectors and accident shears. The loop detectors are mounted on the detection loops. The detection loops are correspondingly mounted on a pre-finishing mill group and a finishing mill group of a rolling production line. The loop detectors and the accident shears are connected to the PLC control system through circuits. The detection system for high-speed wire rod steel heaping and the judgment method mainly aim at the steel heaping failure of a segment from a pre-finishing mill to a finishing mill in the large-scale steel rolling process; and in the type of steel heaping failure, the finishing line failure cannot be judged in time, excessive steel heaping is caused, so that whether steel heaping happens or not is judged by detecting the loop quantity between the pre-finishing mill and the finishing mill, accordingly the judgment can be made in advance, the judgment is precise, and the failure treatment time is shortened.

Owner:JIANGSU YONGGANG GROUP CO LTD

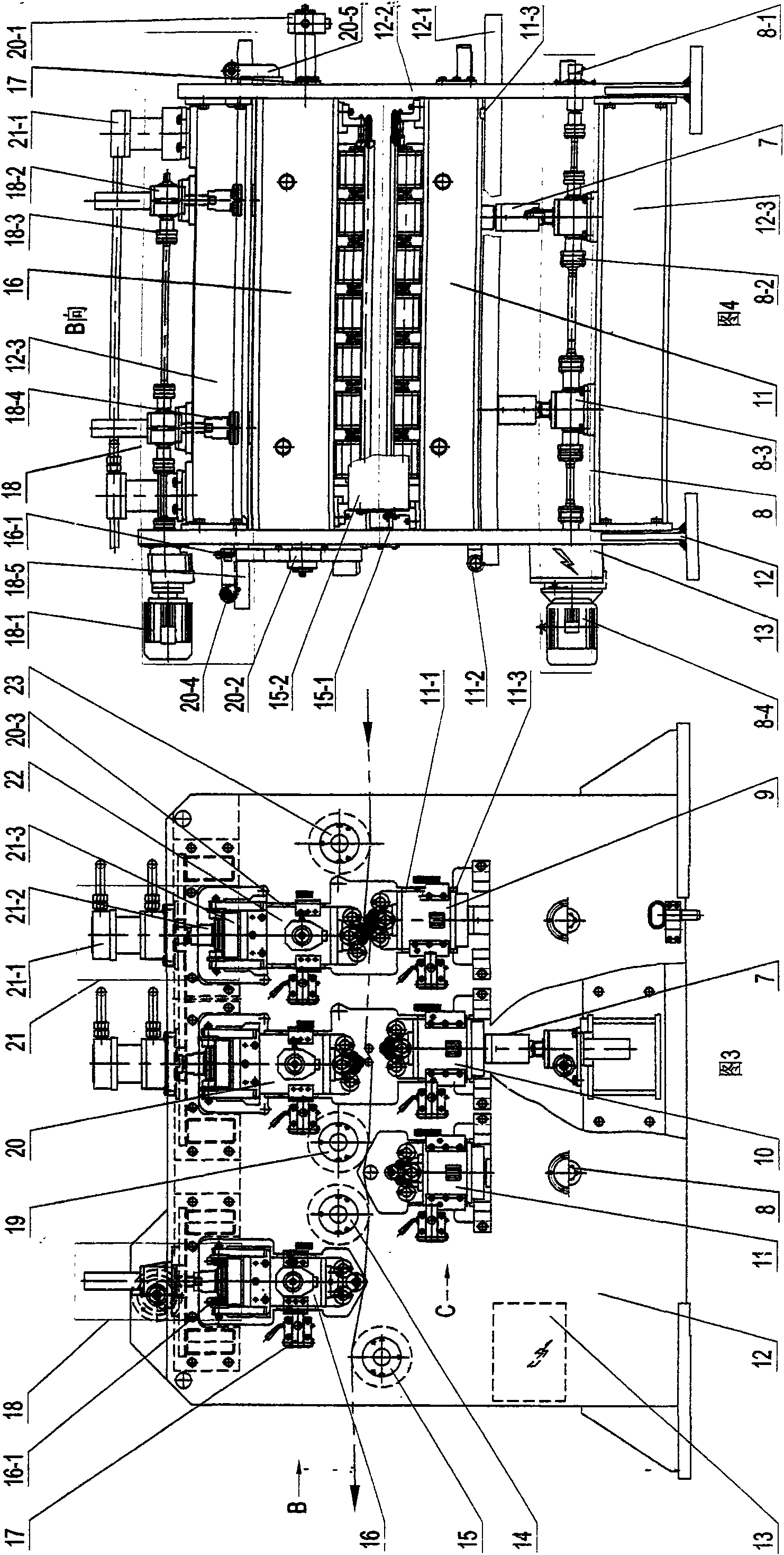

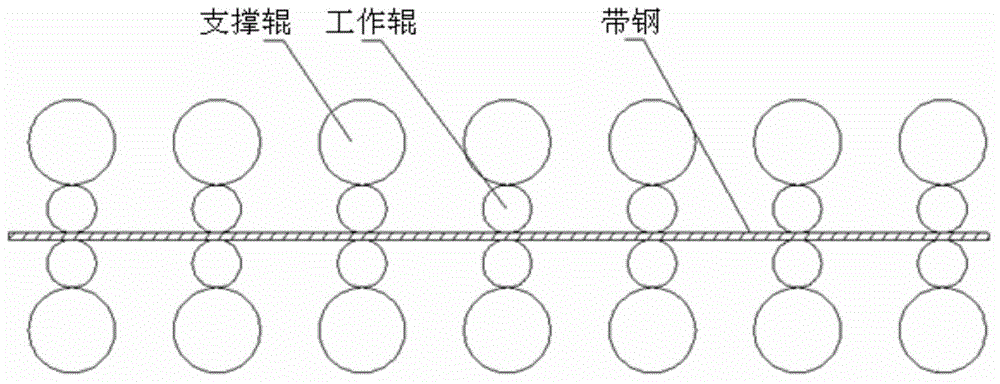

Stretch bending-straightening machine

ActiveCN101767126AOpen quicklyFast rigid couplingMetal rolling stand detailsFlexible work arrangmentsThrust bearingIron industry

The invention discloses a stretch bending-straightening machine, which is used for continuously straightening a steel strip in the iron industry. The stretch bending-straightening machine consists of an outlet / inlet main drive, a tension device, a hydraulic system and a main body. The main body is additionally provided with a fast open oil cylinder, a support roller, a rotary joint and a limitation stop base, wherein the fast open oil cylinder can be instantaneously and fast opened when a welding gap of the strip steel passes through the main body and can be instantaneously reset to normally work, thereby preventing the surface of a roller and the strip steel from being mutually scrubbed; the support roller changes the installation on a roller box from line contact into face contact, thereby being capable of keeping the precision for long time use and guaranteeing the straightening quality of the strip steel; the rotary joint is in a pretightening type structure which adopts a combined type quill roller thrust bearing with large carrying capability, wherein the rotary joint and a top rod of the stop base are tightly contacted with each other under the function of a spring without impact force caused by axial pulsation when a work roller and a middle roller work, thereby prolonging the service life; and the limitation stop base conveniently changes a single roller on an upper roller box and unscrews screw nails of a lower roller box, so that a plurality of front top rods simultaneously and automatically withdraw from the rotary joint under the function of the spring, thereby being capable of conveniently changing a work roller assembly and a middle roller assembly.

Owner:襄阳博亚精工机器有限公司

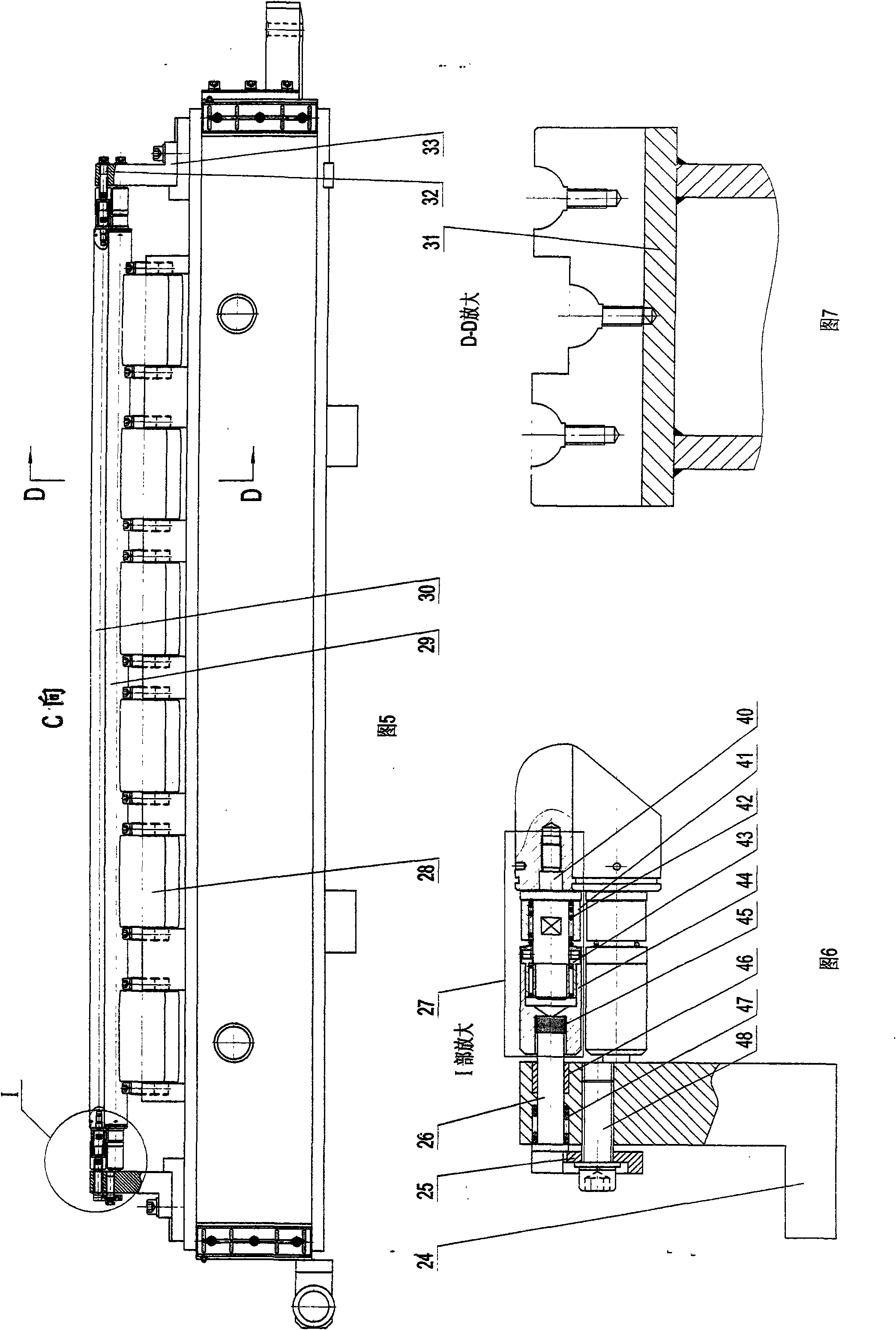

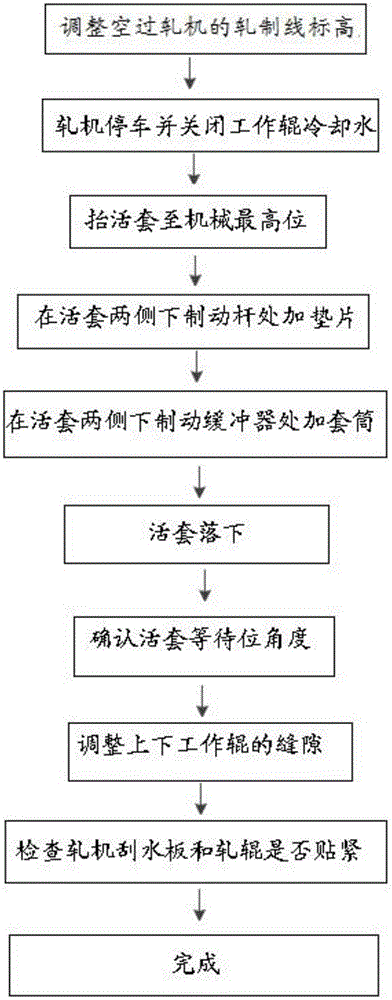

Method of preventing heavy gauge strip steel from being scratched among finishing mill racks

ActiveCN105728460AAvoid compressionSolve the scratchMetal rolling stand detailsFlexible work arrangmentsPosition angleStrip steel

The invention provides a method of preventing heavy gauge strip steel from being scratched among finishing mill racks. The method comprises the following steps of: adjusting the elevation of a rolling line of an idle rolling mill to right elevation; and adjusting the mechanical position of a downstream loop of the idle rolling mill, to be specific, lifting the loop to the mechanical highest position, arranging a gasket on a brake bar below the loop and a sleeve on a buffer below the loop, dropping down the loop, and identifying the waiting position angle of the loop. The method has the beneficial effects that the rolling line is in the right elevation, and strip steel is lifted; the waiting position angle of the loop is increased by adjusting the mechanical position of the downstream loop of the idle rolling mill, thereby preventing the lower surface of the strip steel from scratching a lower guide plate of a rolling mill outlet, completely solving the surface scratching problem of the strip steel, greatly increasing the percent of pass of strip steel quality and ensuring the smooth production.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

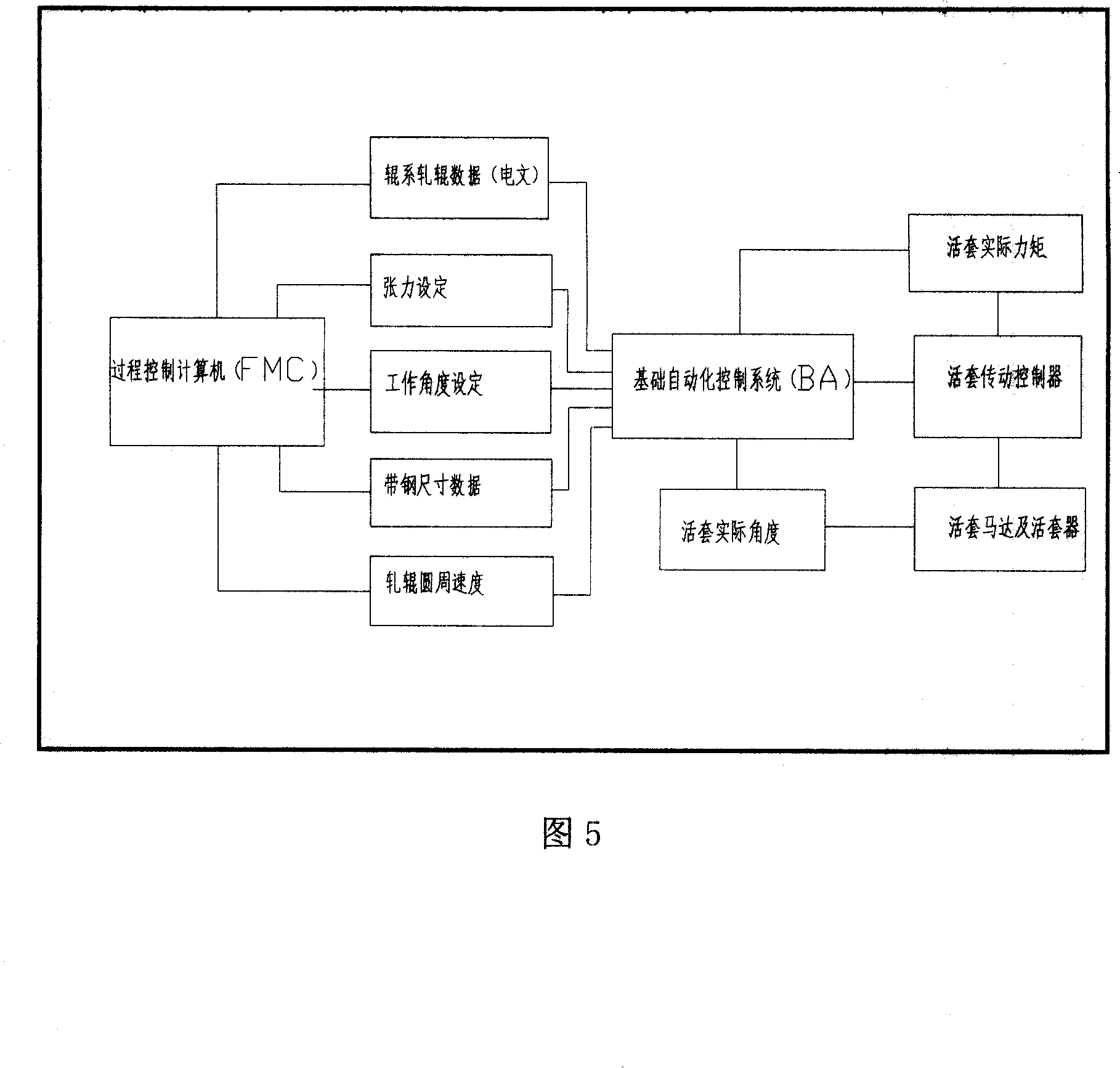

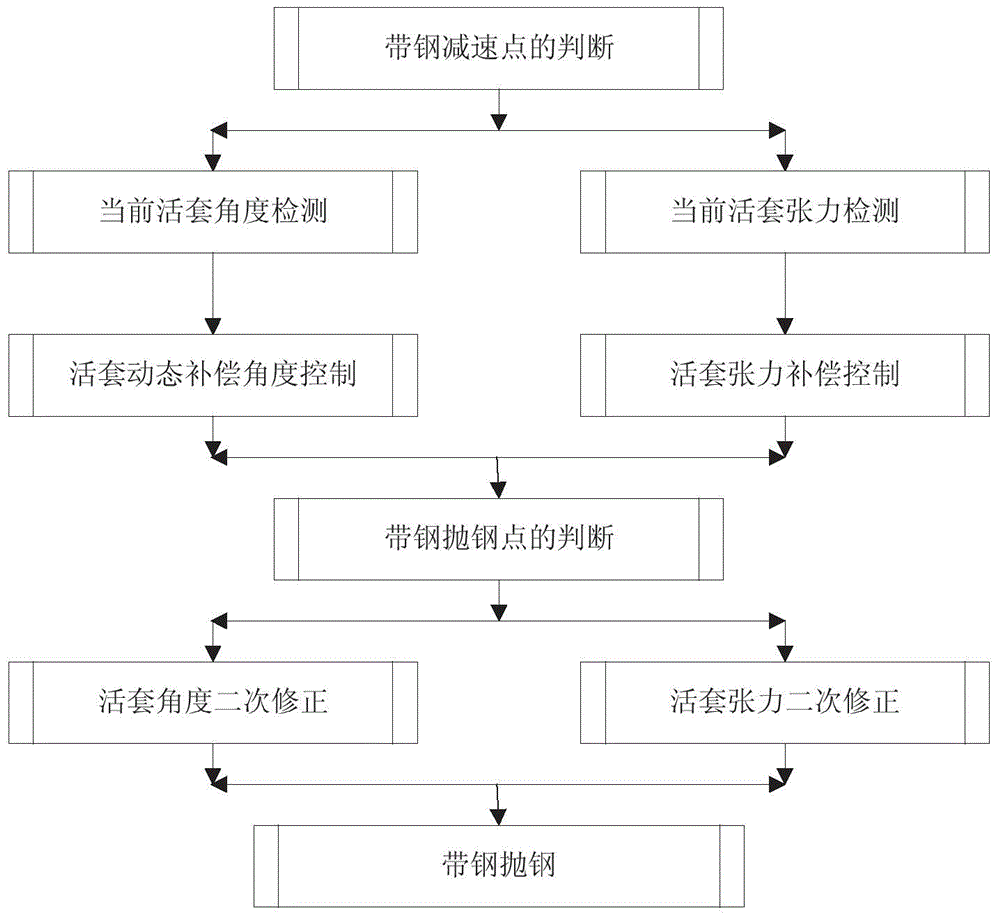

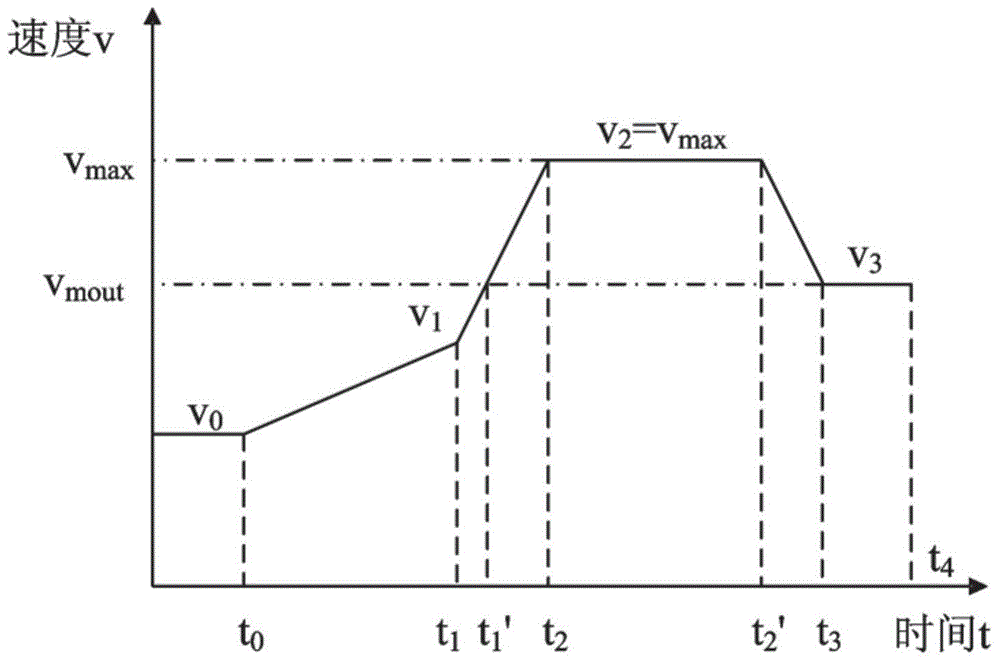

Method for dynamically controlling loop angle of hot continuous rolling mill

ActiveCN104801547AImplementation angleAchieve tension controlRoll mill control devicesFlexible work arrangmentsEngineeringDynamic Tension

A method for dynamically controlling a loop angle of a hot continuous rolling mill adopts a strip steel rolling force detector, a strip steel speed detector, a loop angle detector, a strip steel tension detector, a basic automatic level control machine and a process control machine to conduct dynamic control on angles of six loops among seven continuous rolling mills according to the set process requirements, accordingly the stability of the loops during strip steel throwing is improved, specifically variable-angle control before strip steel throwing and a unary function loop angle compensation method are adopted to achieve continuous dynamic control in the control process according to change of angle and tension control, meanwhile synchronous and dynamic tension control is achieved in the tension control process according to angle change, and the stability of the loops in the strip steel throwing process is improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

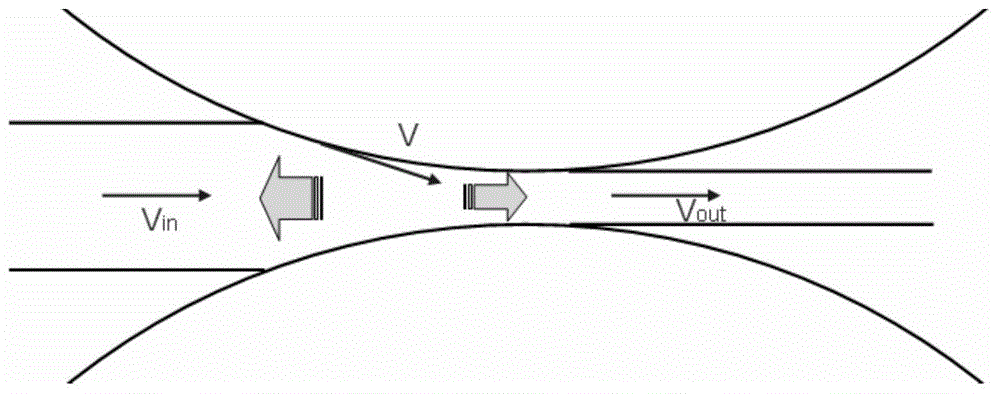

Method for automatically improving per-second flow balance of strip steel in hot continuous rolling strip threading process

ActiveCN104801548AIntelligent adjustment of speed ratioAdapt to changes in external working conditionsFlexible work arrangmentsMass flow control deviceLoop lengthEngineering

The invention provides a method for automatically improving per-second flow balance of strip steel in the hot continuous rolling strip threading process. Due to the fact that 'later' intervention of an operator is basically correct, the per-second flow balance can be changed more reasonable, an ideal rack speed matching value of a piece of steel is calculated by analysis the loop length and manual invention amount of the operator in the strip threading process and used for correcting setting of a next piece of same-specification steel. Compared with routine techniques, the method is characterized in that 'later intervention' is converted into accurate 'advanced correction', accordingly a complicated and tedious forward slip formula is omitted, and racks can have an 'intelligent learning' function on the speed aspect. According to the method, the complicated and tedious forward slip formula is omitted, and a method for automatically adjusting per-second flow matching between racks is found. The method is used for improving the per-second flow balance in the hot continuous rolling strip threading process and improving rolling stability so as to decrease strip steel head rolling breakage times and width decrease times. In addition, automation degree of strip threading is improved, and the working load of the operator is decreased.

Owner:BAOSHAN IRON & STEEL CO LTD

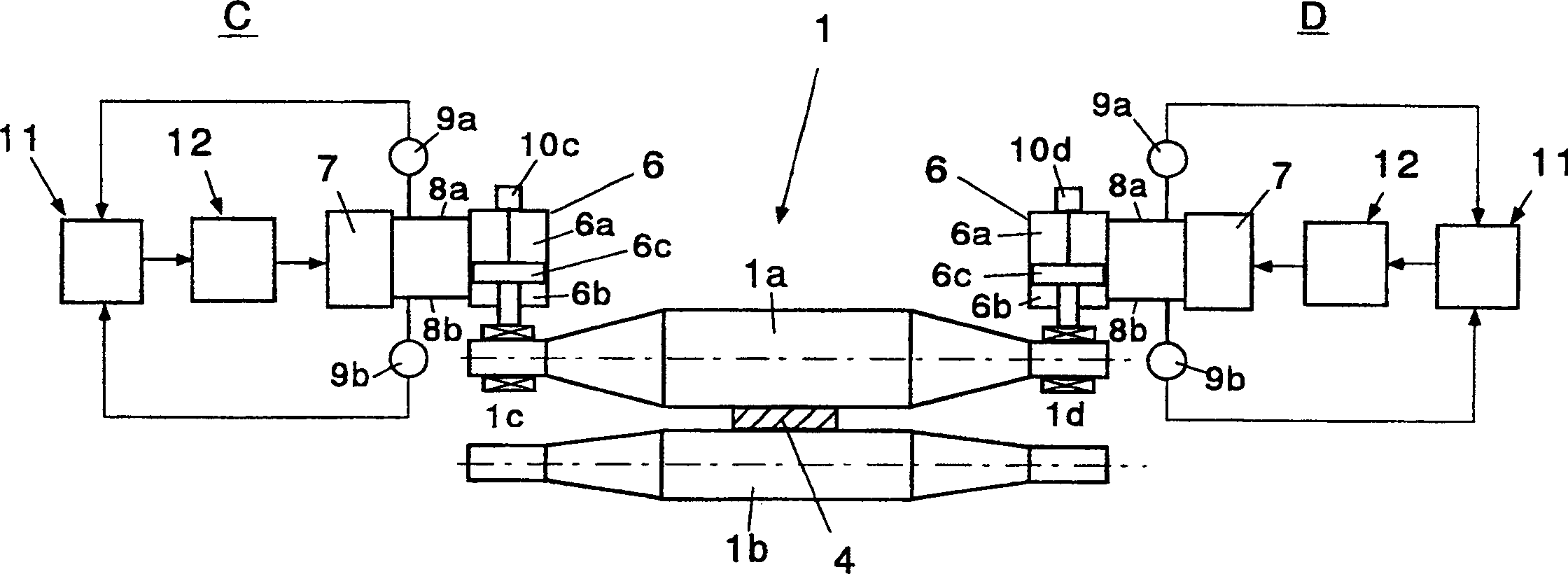

Control method for hydraulic pinch roll and controll apparatus thereof

The present invention is the control method and controller for hydraulic pinch roll. The controller is provided with position detector for detecting the positions of the pistons in the right and left cylinders, calculator for calculating the difference between the outputs, control unit for processing and giving correction output and addition and subtraction calculator for operation based on the set extrusion force. The control method includes applying correcting output from the controller to one side of the pinch roll for increasing the extruding interval and applying corresponding correcting output from the controller to the opposite side of the pinch roll for decreasing the extruding interval so as to control the extrusion and improve the winding shape.

Owner:IHI CORP

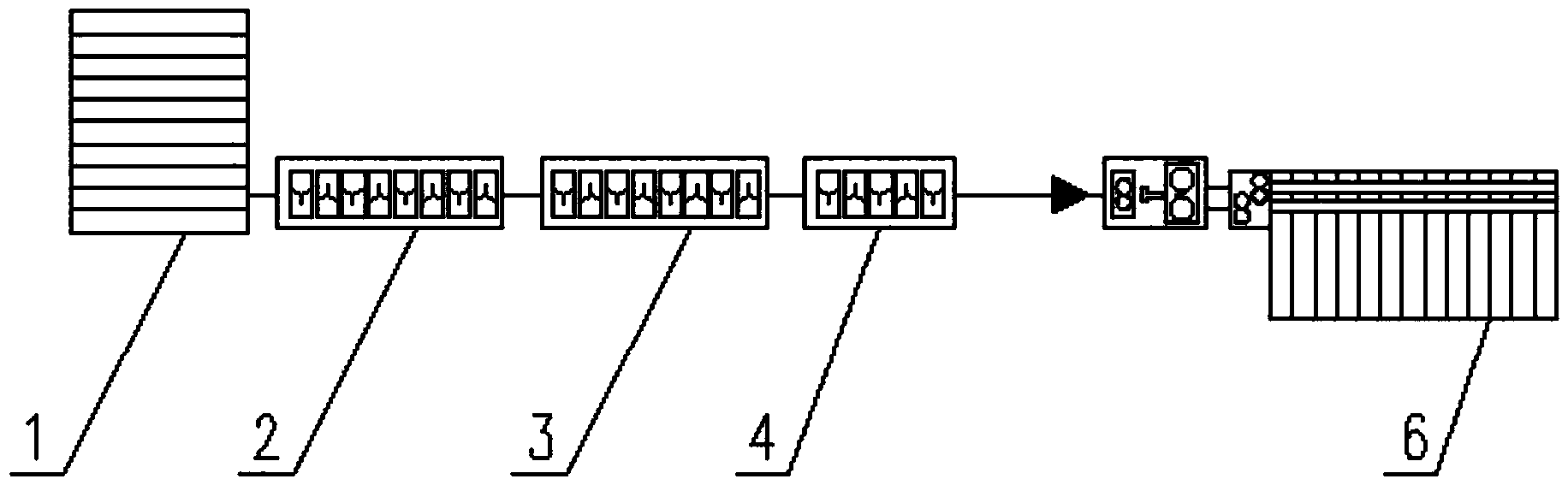

Compact wire and bar rolling production line

ActiveCN103706634AFlexible configurationIncrease flexibilityFlexible work arrangmentsMetal rolling arrangementsProduction lineEngineering

The invention relates to a compact wire and bar rolling production line which sequentially comprises a heating furnace, a rough rolling unit, an intermediate rolling unit, a finish rolling unit and a collecting system. The collecting system comprises at least one of a cooling bed, a coiling and collecting system and a wire collecting system. The rough rolling unit, the intermediate rolling unit and the finish rolling unit are respectively provided with a Y-type three-roll rolling mill and an inverted Y-type three-roll rolling mill, and the Y-type three-roll rolling mills and the inverted Y-type three-roll rolling mills are distributed in an alternating mode. A rolling machine set adopts the three-roll rolling mills of the same structural mode, the rolling machine set is universal, a wire and bar collecting system can be flexibly distributed, and flexibility of wire rolling is high. A high-speed steel feeding system is arranged so as to increase rolling speed of the rolling machine set and improve production efficiency, the brake sliding distance between high-speed rolled workpieces is shortened, the rolling length is further shortened, and investment is reduced. An arranged wire reducing sizing rolling unit further rolls and produces wires, and facilitates improvement of rolling quality of the wires and size precision of products.

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com