Method and system for controlling looping of finishing mill

A control method and finishing mill technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of large impact of strip steel, large impact of looper base, increased maintenance costs, etc., to achieve small impact and prolong service life Life, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

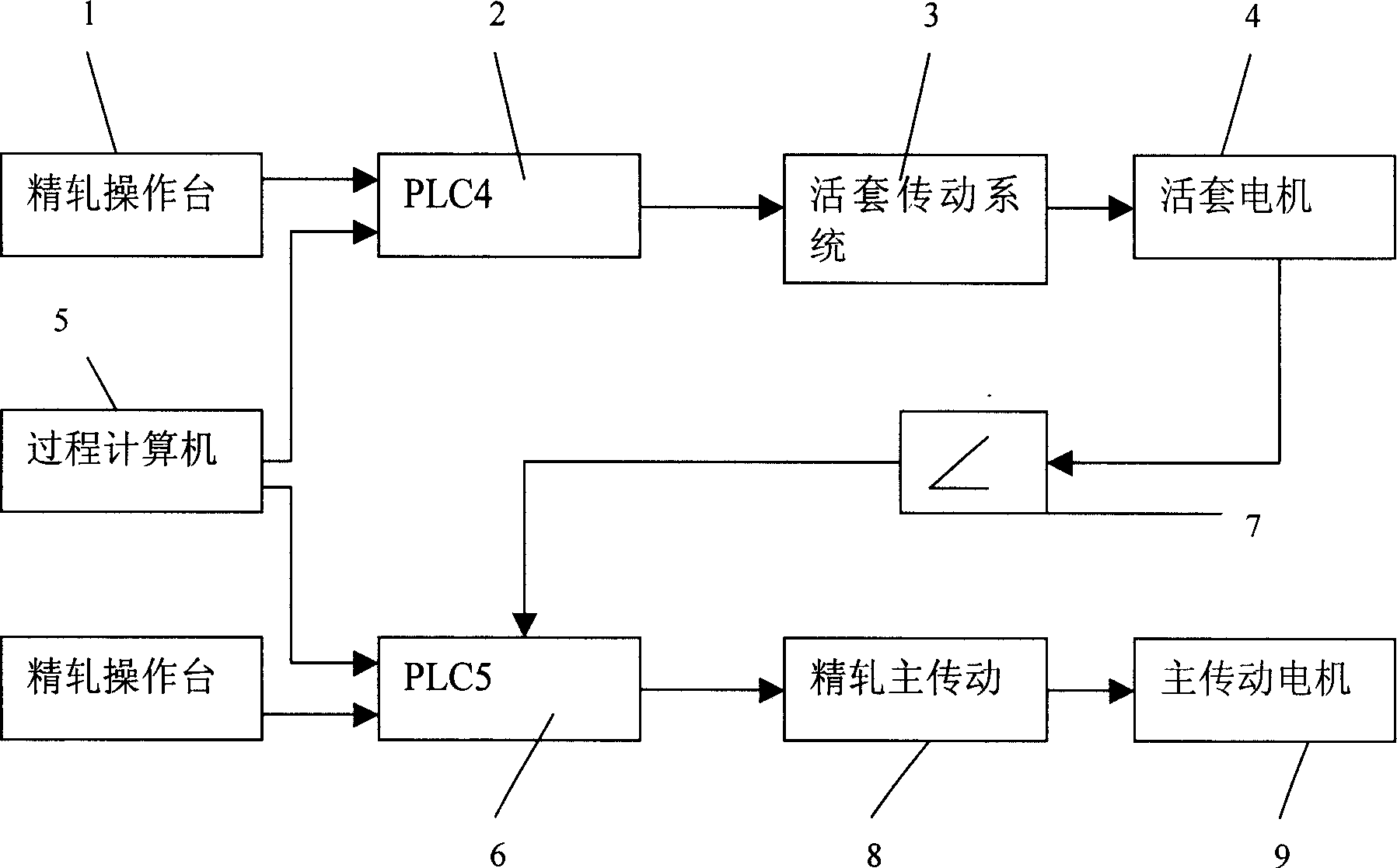

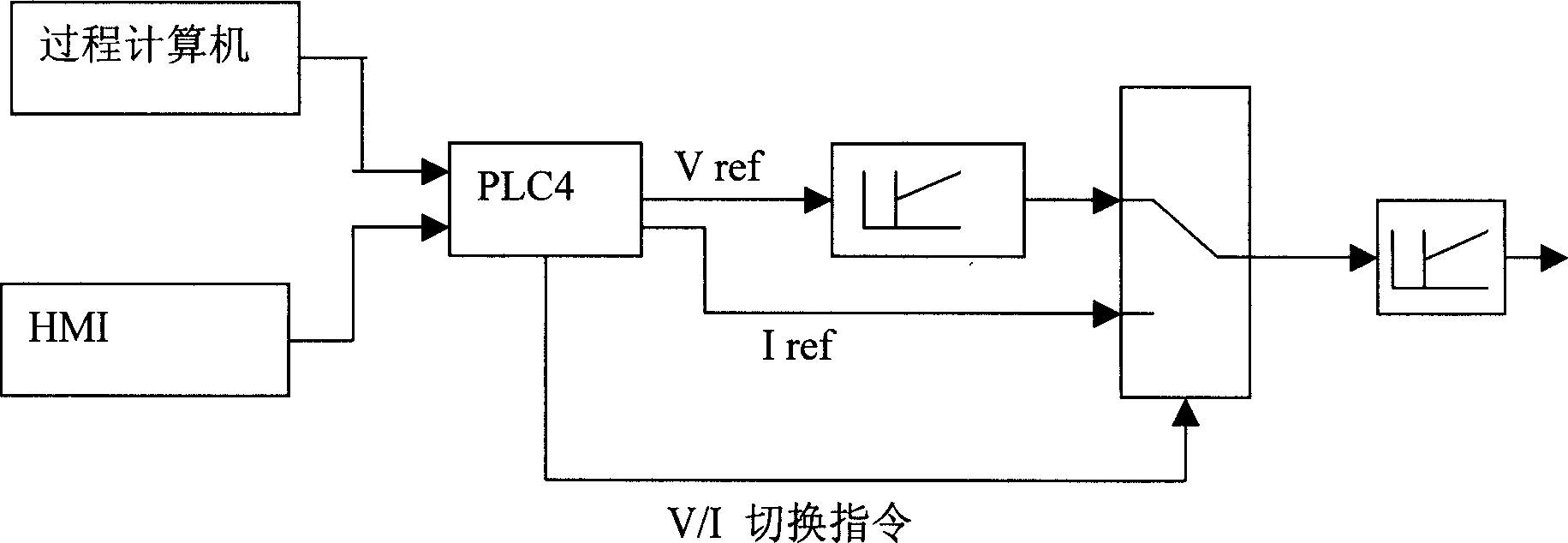

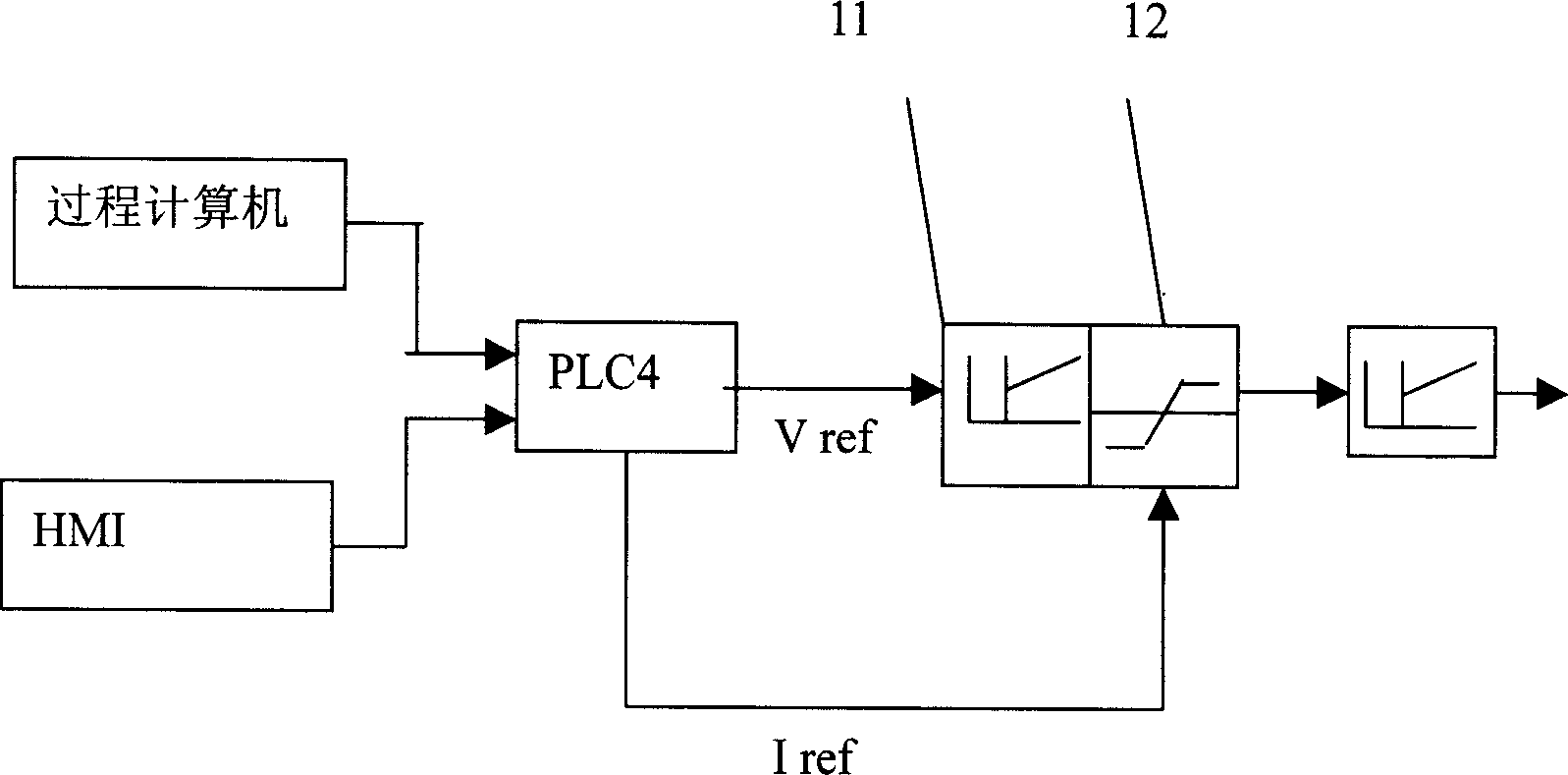

[0013] figure 1 For the control system as a whole, figure 2 for figure 1 part of the control system shown, figure 1 and figure 2 According to the prior art, switching is performed by a switching command between the tension given reference and the voltage given reference. The present invention as image 3 shown, yes figure 2 The control strategy shown is improved, the tension signal is used as the external limiter of the voltage signal, and then the current regulation is performed on the limited signal.

[0014] Such as figure 1 and image 3 , the programmable controller 2 mainly completes the looper lifting and torque control, and the programmable controller 6 mainly completes the speed control of the finishing mill and the closed-loop control of the looper height. The process computer 5 sets the tension of the looper for the programmable controller 2, and sets the working angle of the looper for the programmable controller 6, and the console 1 sends the operator se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com