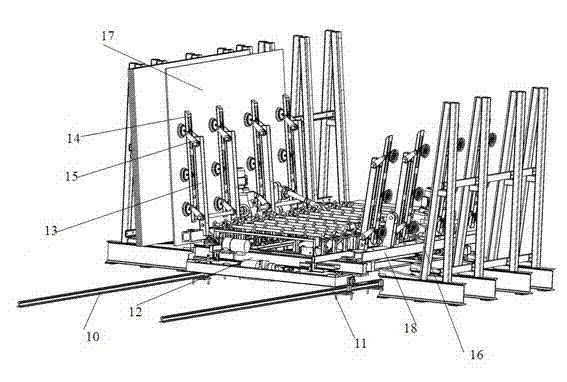

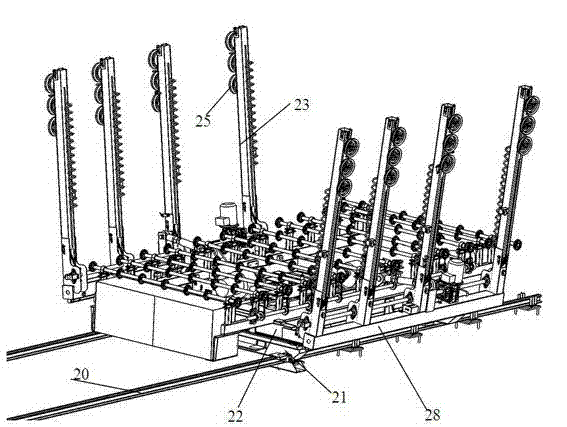

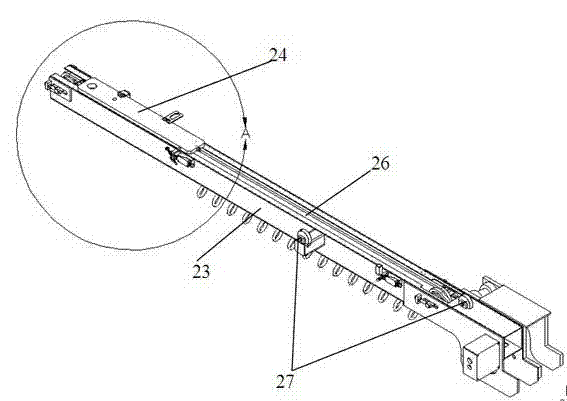

Flat material loading device

The technology of a flat plate and a deviation correction device is applied in the field of machinery, which can solve the problems of small up and down moving distance of the suction cup arm, high material cost and operating cost, long suction cup arm, etc., so as to increase the moving distance, low material cost and operating cost, The effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

[0046] The structure of the frame, the rotating arm support frame and the like of the third embodiment of the present invention are the same as those of the first embodiment, except that a suction cup is fixedly arranged above the outside of the suction cup base, and a There is a support plate made of spring plate or steel plate whose upper end is hinged with the suction cup base, the support plate can swing relative to the suction cup base, wherein two suction cups are fixedly connected with the support plate.

[0047] In this embodiment, when the flat material loading device of this embodiment is in operation, when the suction cup is in contact with the flat material and sucks the vacuum, because the suction cup fixed on the support plate is sucking the flat material, the deformation caused by the suction cup will simultaneously pull the support plate toward At this time, the suction cup fixed on the top of the suction cup base has sucked the flat material and achieved V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com