Patents

Literature

166results about How to "Increase film thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

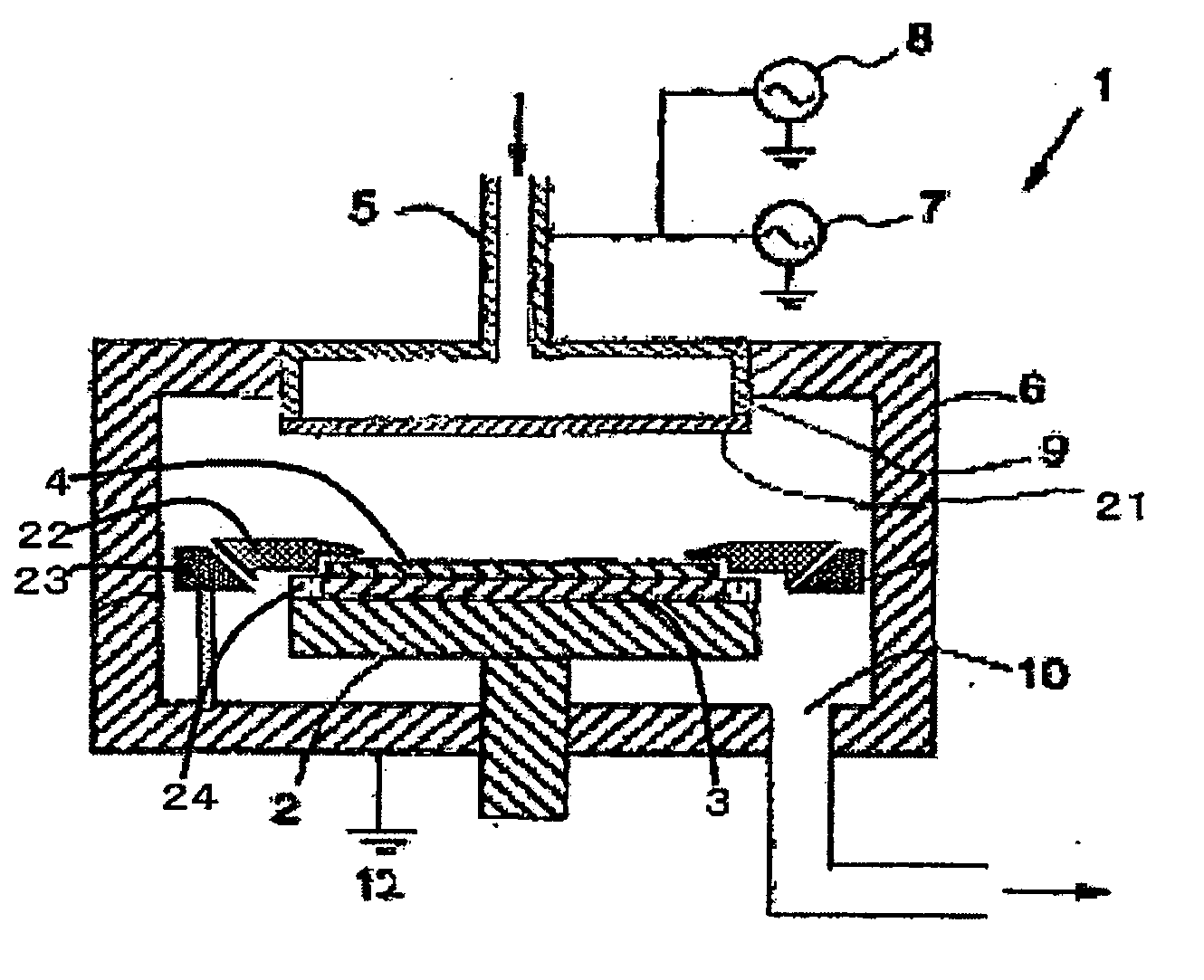

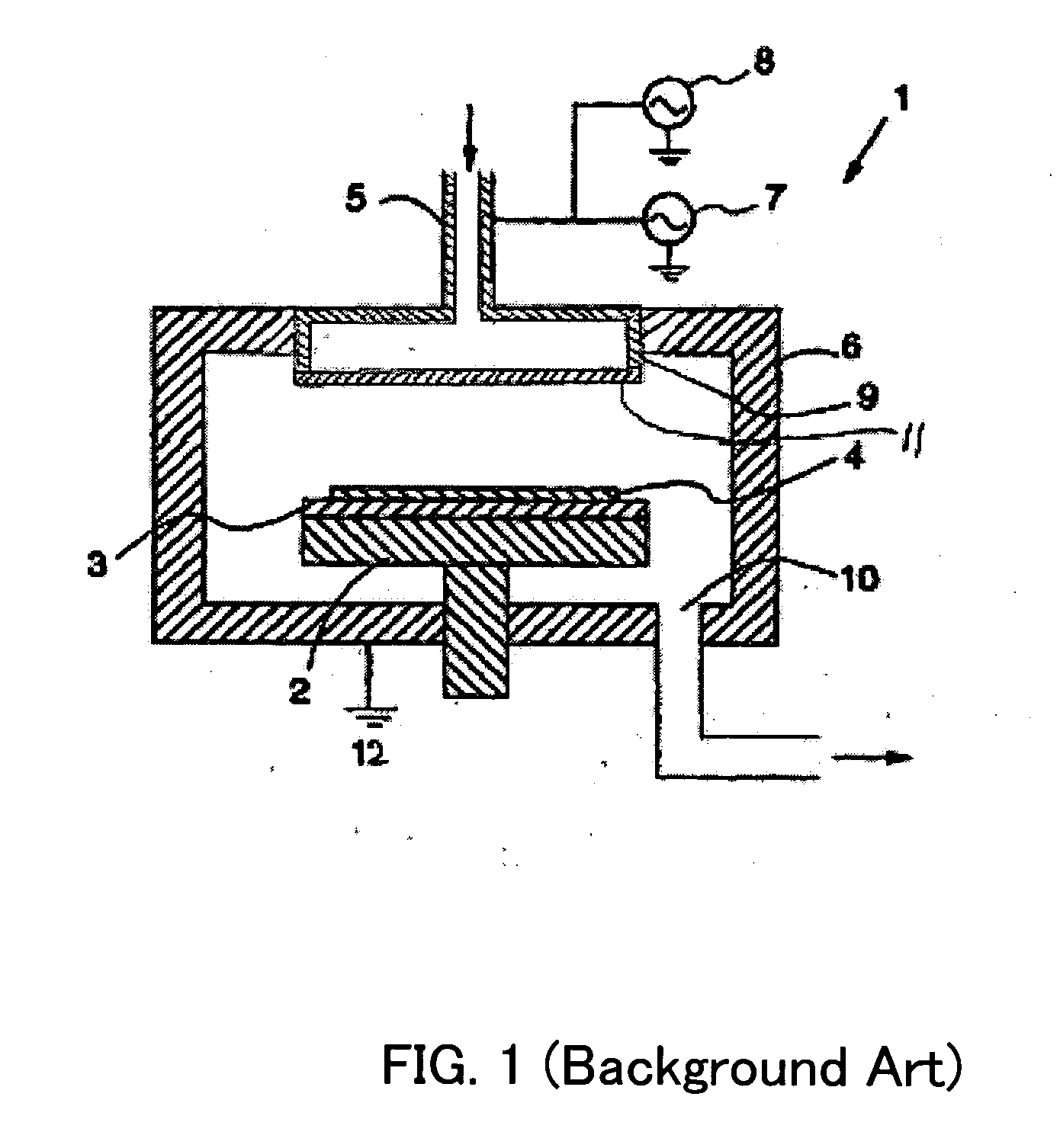

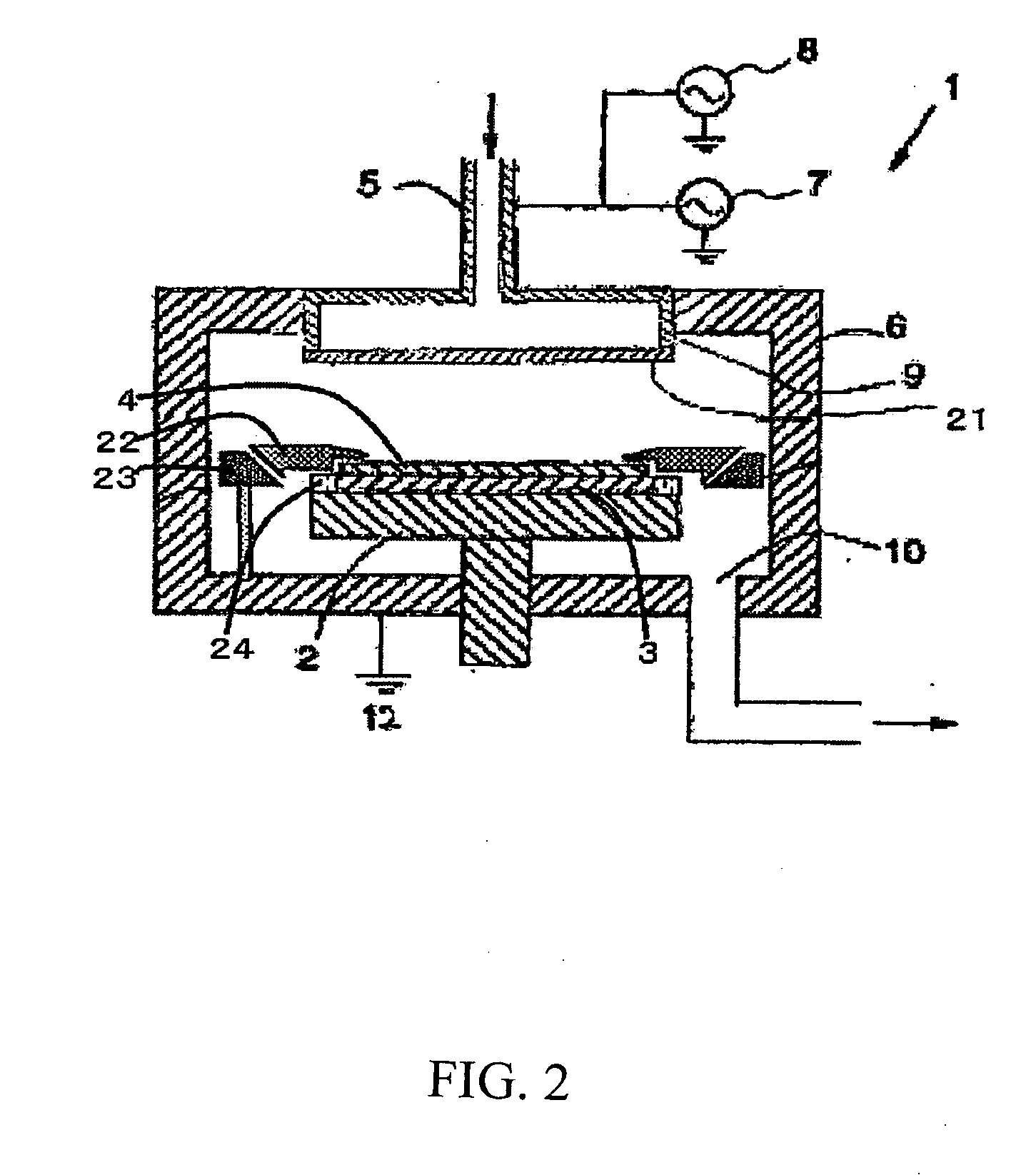

Plasma CVD film formation apparatus provided with mask

InactiveUS20070065597A1Uniform film thicknessUniform characteristicsElectric discharge tubesChemical vapor deposition coatingEngineeringVacuum chamber

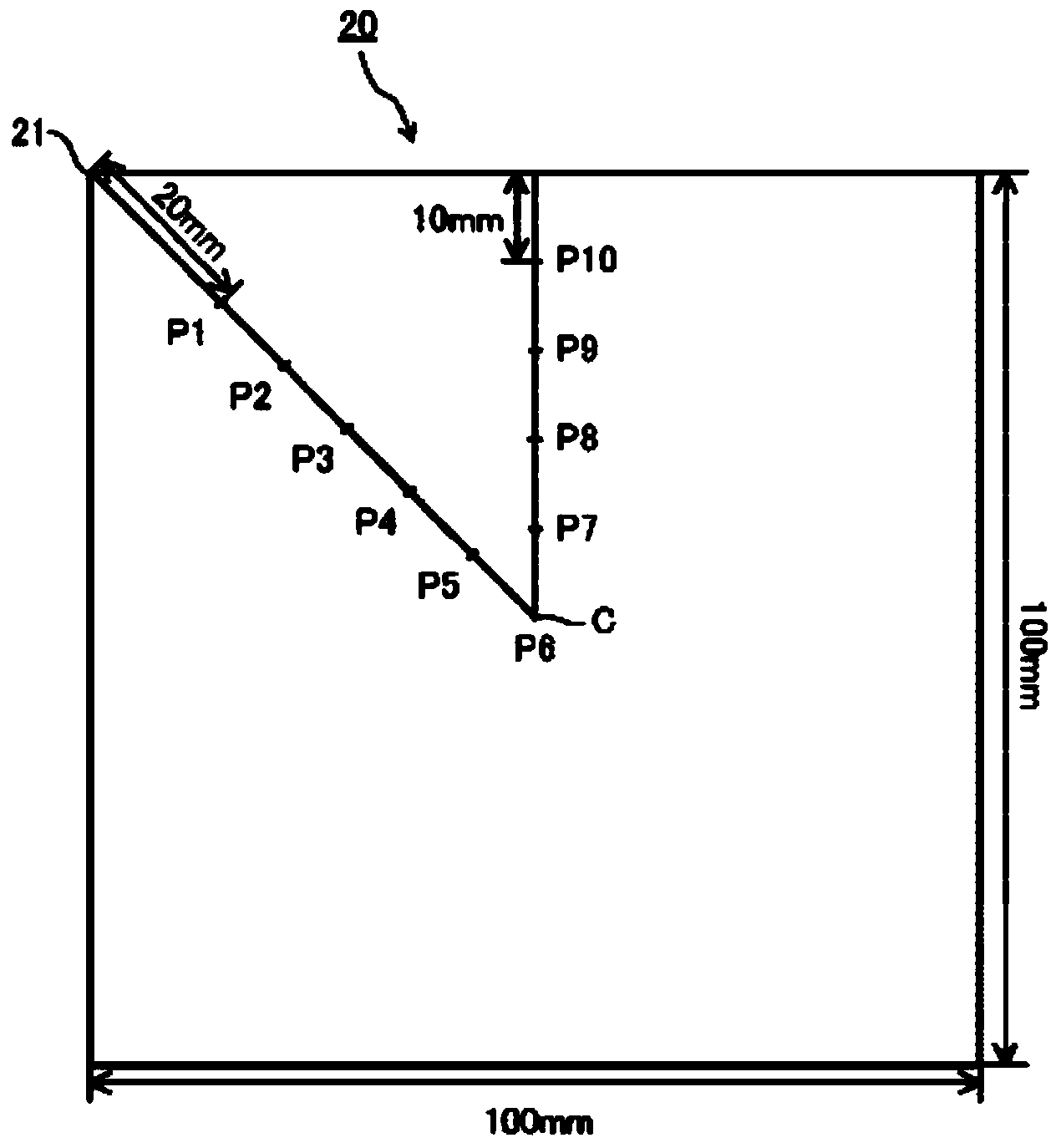

A plasma CVD apparatus for forming a thin film on a wafer having diameter Dw and thickness Tw, includes: a vacuum chamber; a shower plate; a top plate; a top mask portion for covering a top surface peripheral portion of the wafer; and a side mask portion for covering a side surface portion of the wafer. The side mask portion has an inner diameter of Dw+α, and the top mask portion is disposed at a clearance of Tw+β between a bottom surface of the top mask portion and a wafer-supporting surface of the top plate, wherein α is more than zero, and β is more than zero.

Owner:ASM JAPAN +1

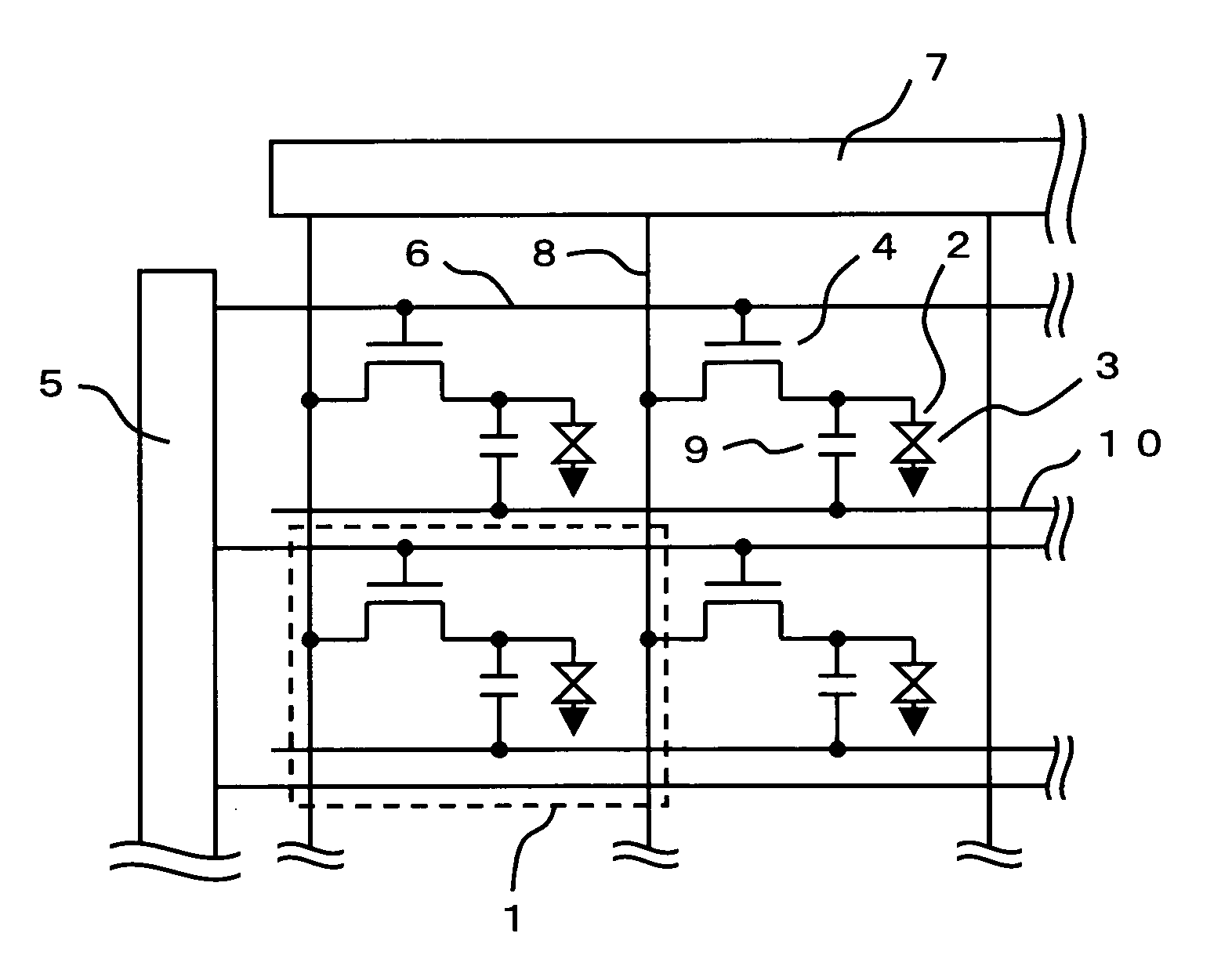

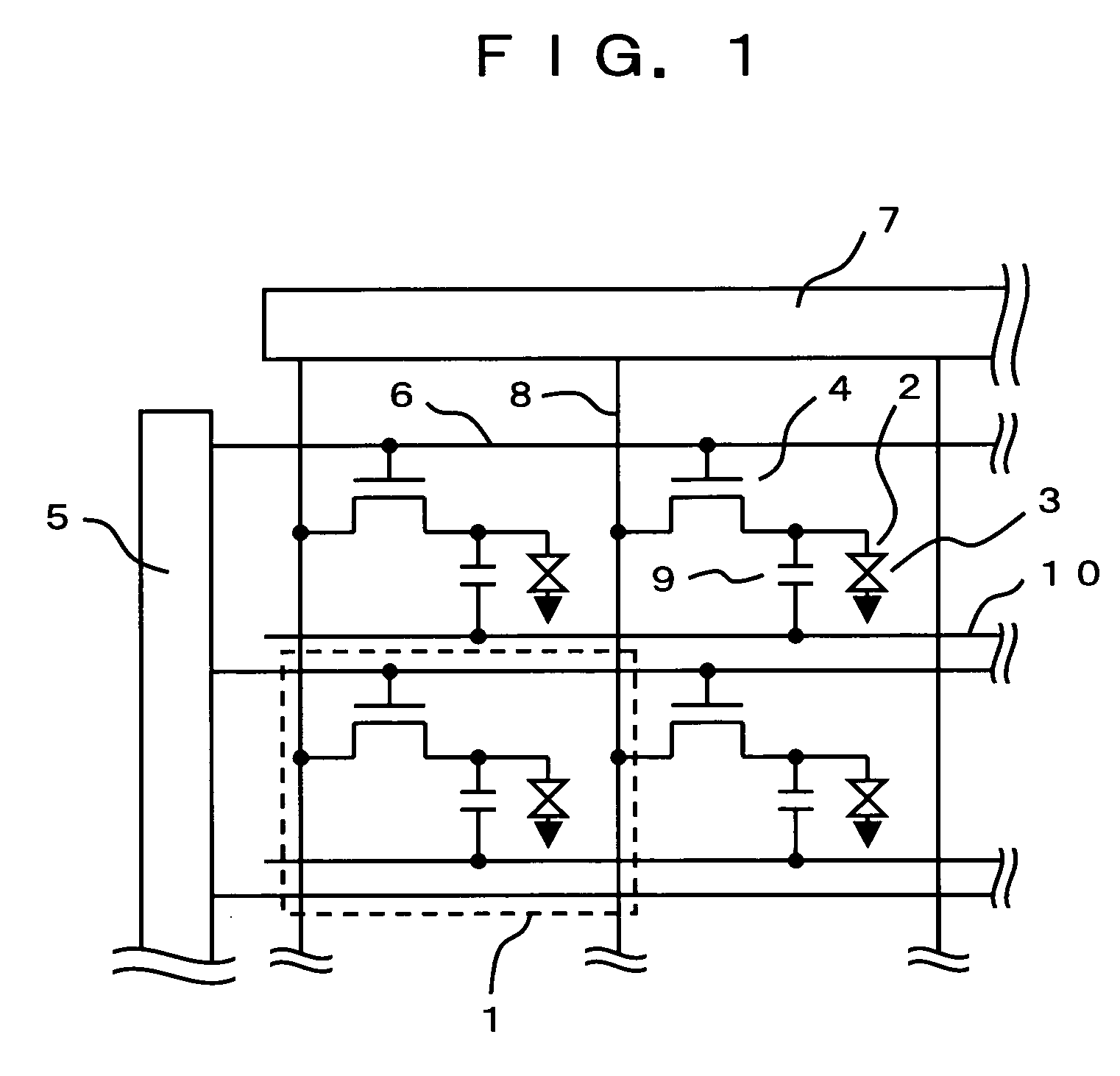

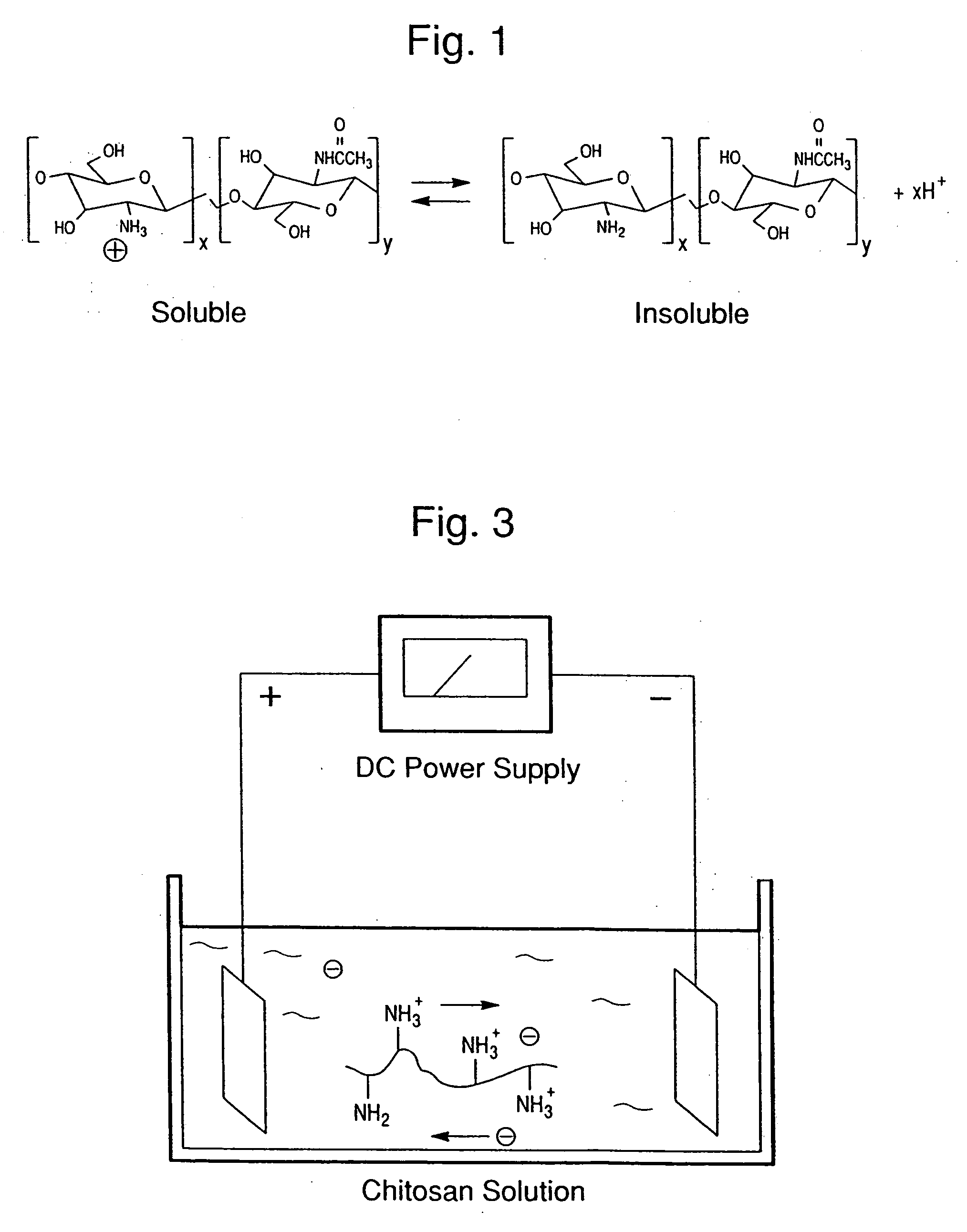

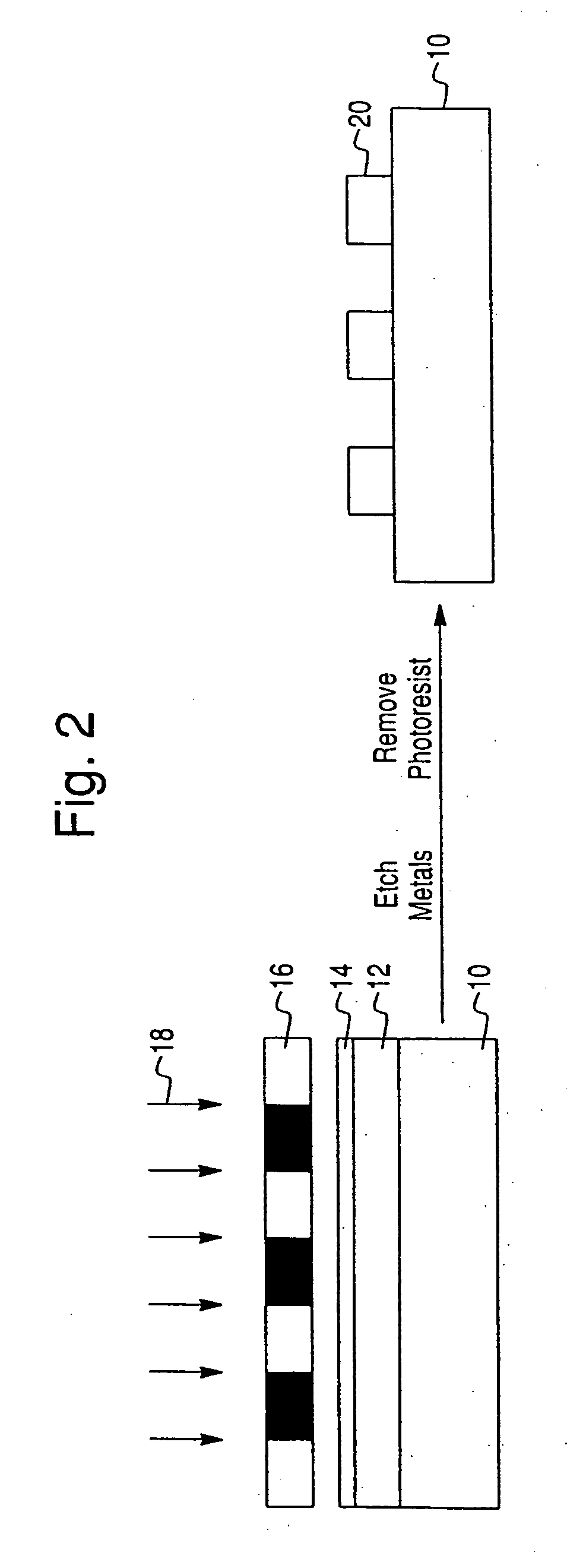

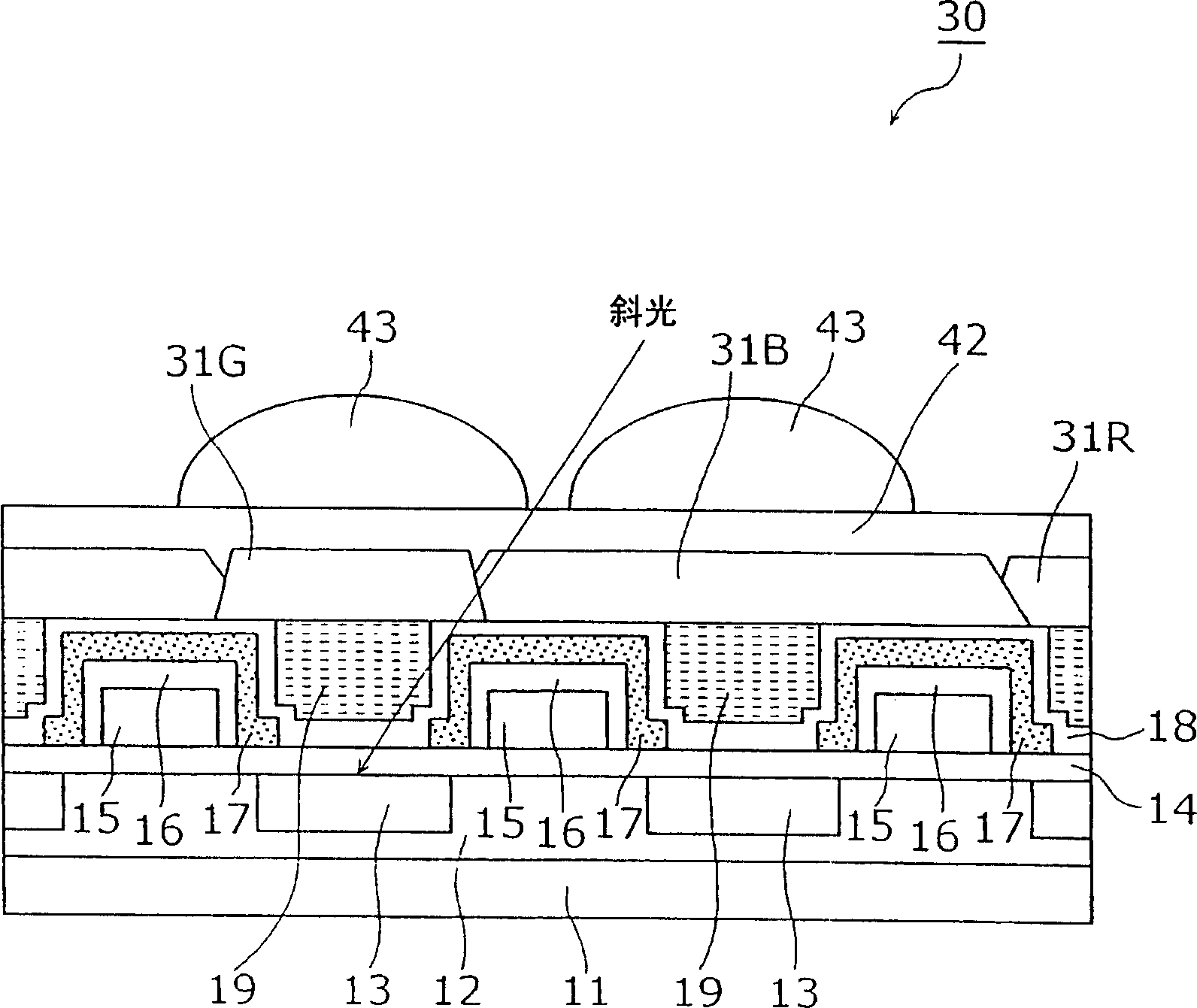

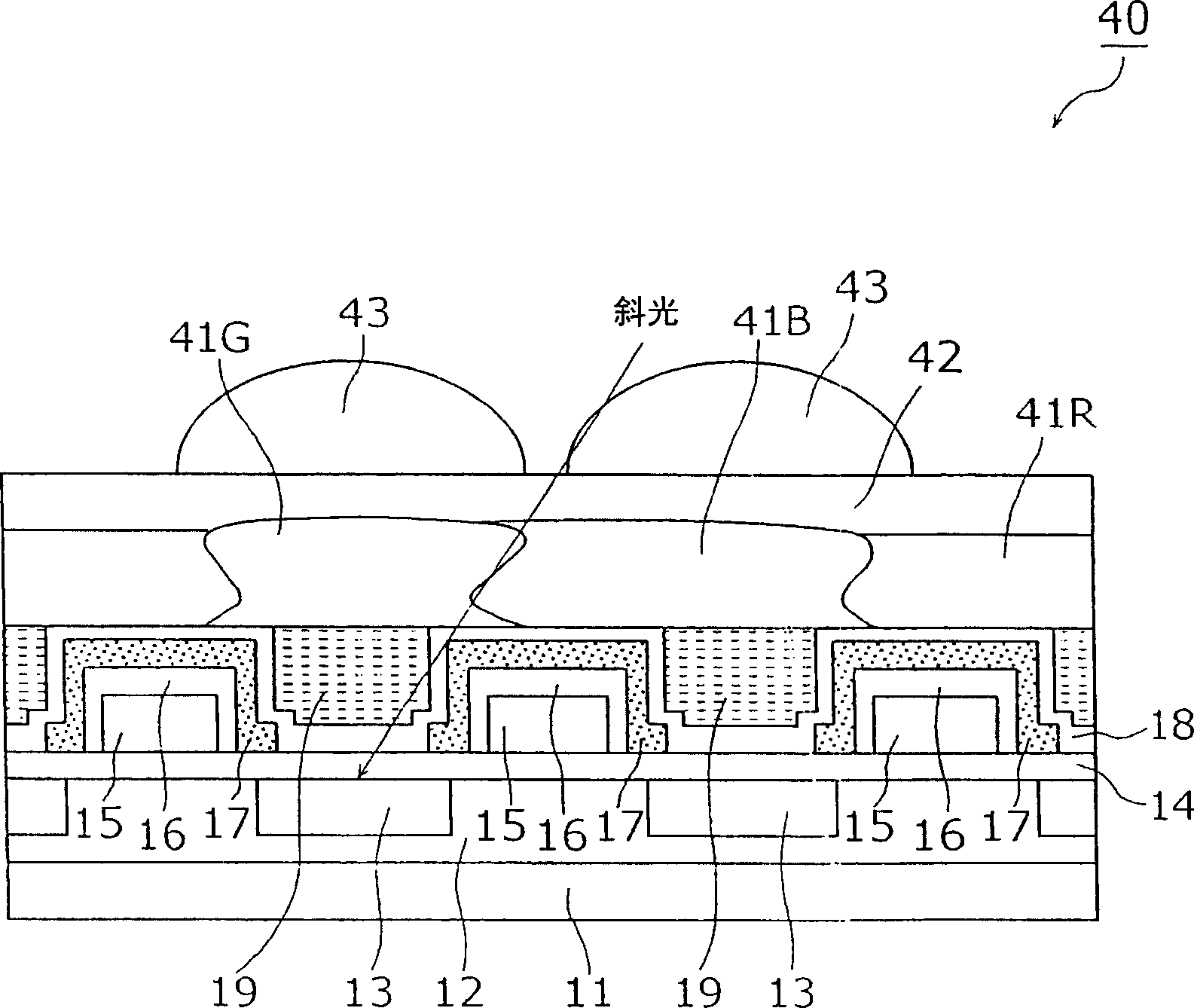

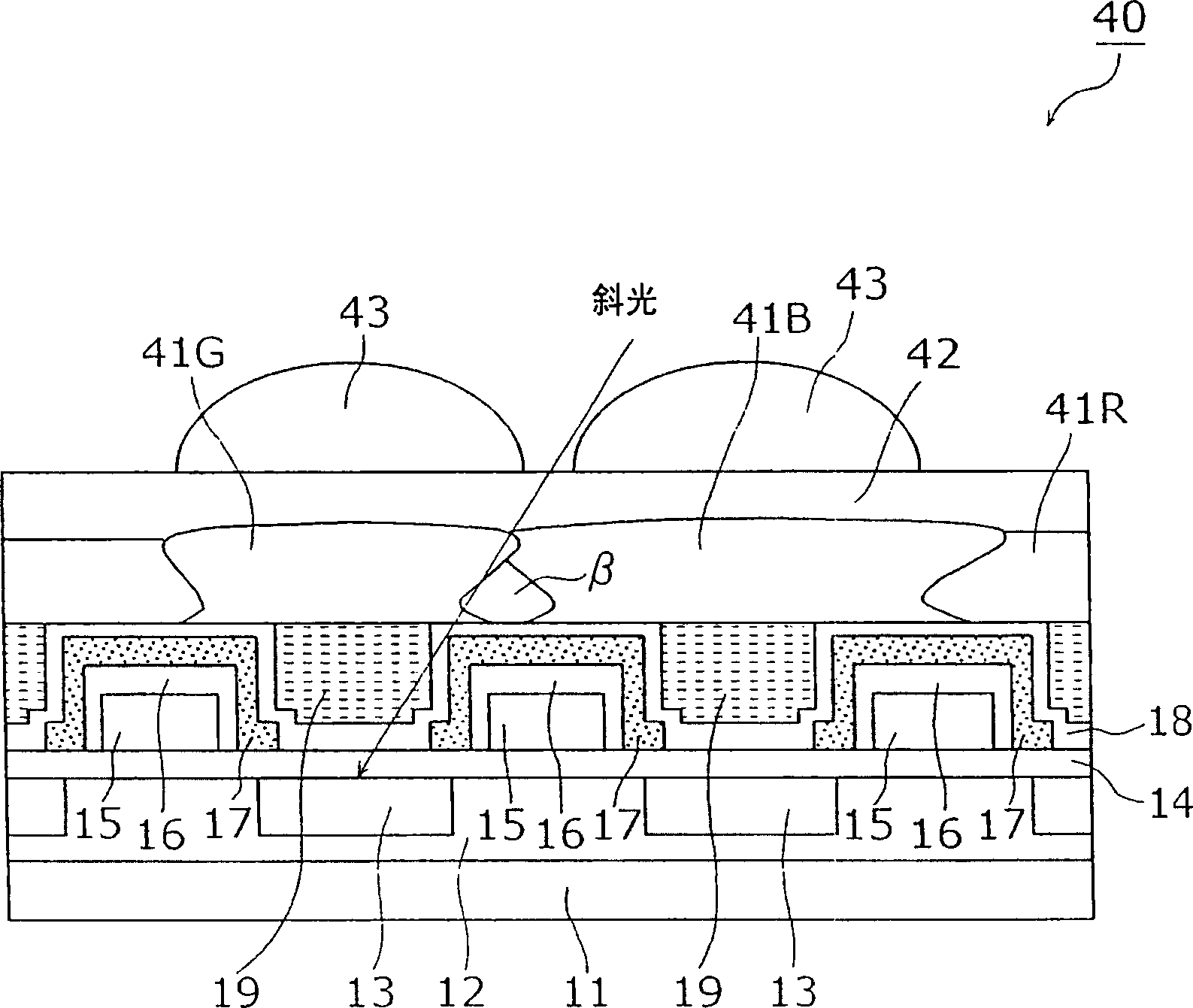

Liquid crystal display device and dielectric film usable in the liquid crystal display device

ActiveUS20070092661A1Efficient processLow dielectric constantLiquid crystal compositionsSemiconductor/solid-state device manufacturingVisibilityLiquid-crystal display

The present invention provides a liquid crystal display device with high image visibility at low power consumption and produced at low cost by using an interlayer dielectric film, which has low dielectric constant, high heat-resistant property, high optical transmissivity, high film thickness and high flattening property produced at low cost. An organic siloxane dielectric film is used as an interlayer dielectric film of the liquid crystal display device. A ratio of nitrogen content to silicon content (Ni content / Si content) in the interlayer dielectric film is controlled to 0.04 or more in the element ratio. The limiting film thickness to suppress and limit the cracking caused by the thickening of the interlayer dielectric film is set to 1.5 μm or more.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

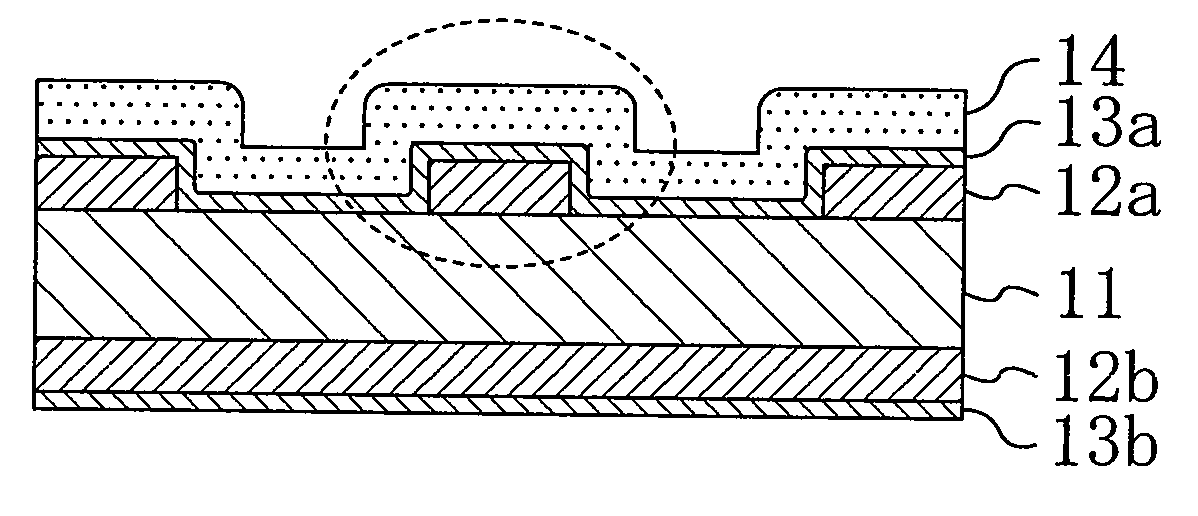

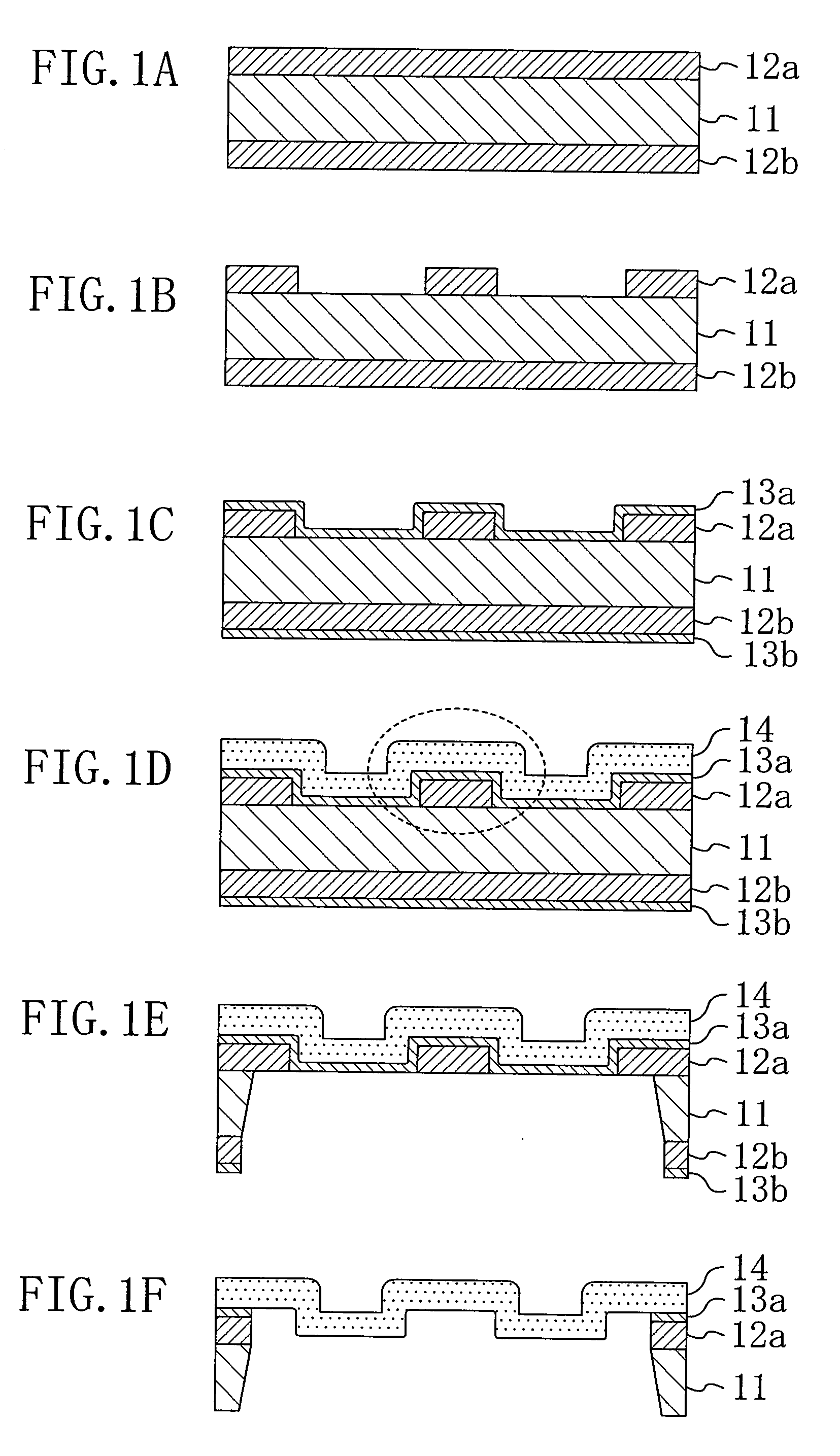

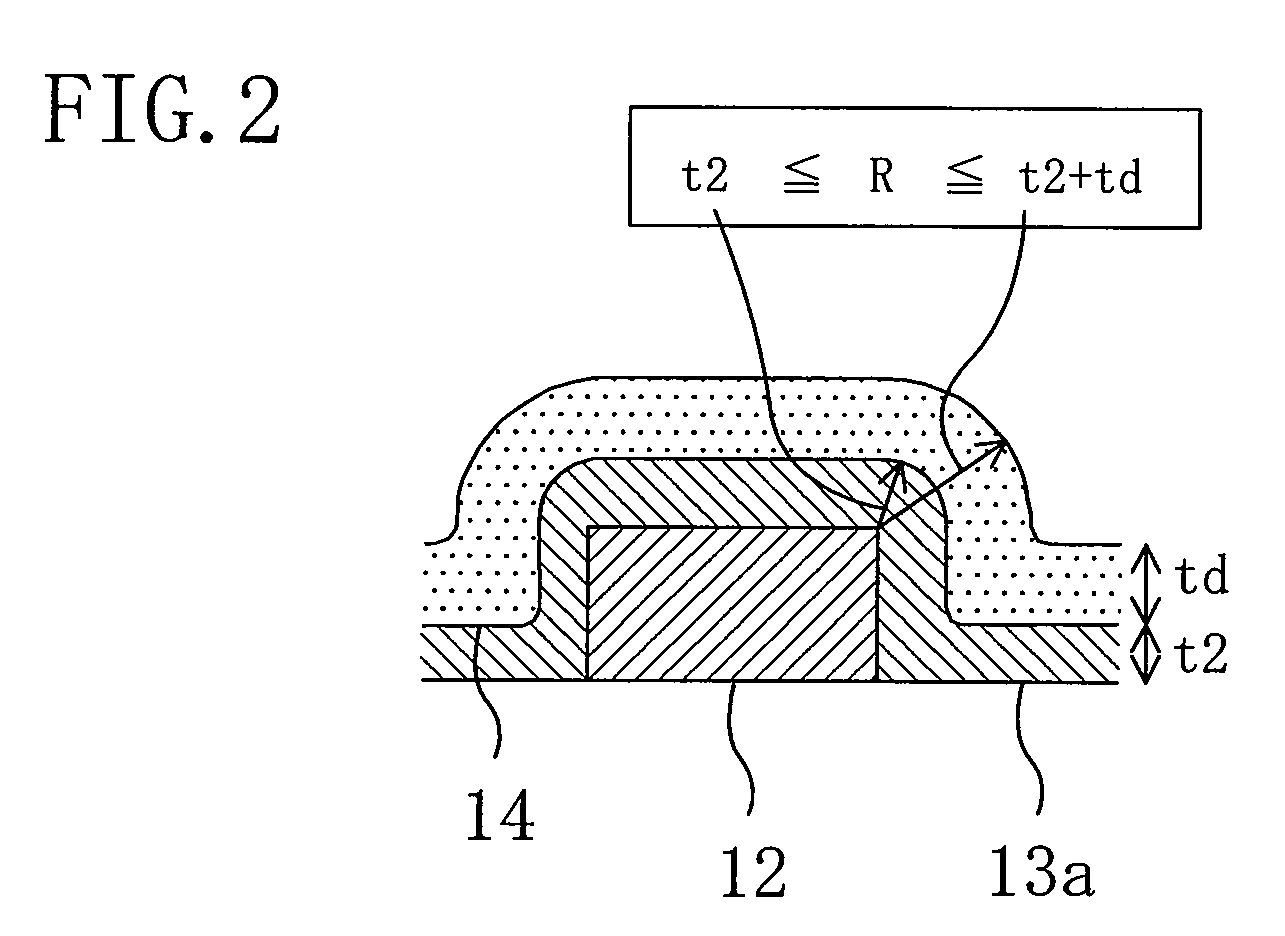

MEMS diaphragm structure and method for forming the same

InactiveUS20090116675A1Well formedEasily roundedPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersDiaphragm structureEngineering

Owner:PANASONIC CORP

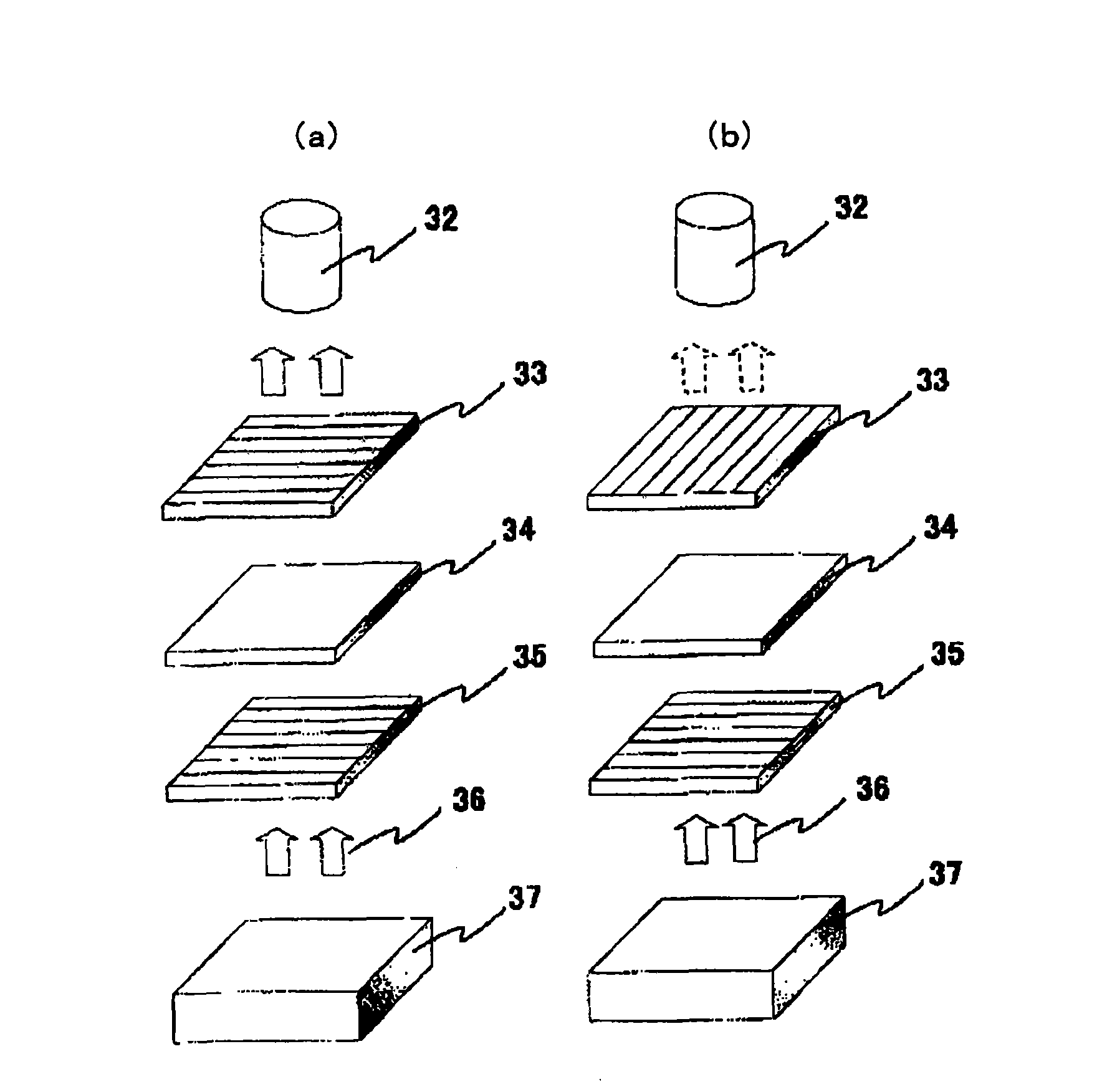

Pigment dispersion, coloring composition for color filter, color filter, liquid crystal display and organic EL display

ActiveCN101541898AImprove transmittanceIncrease contrastOptical filtersPhotosensitive materials for photomechanical apparatusDispersion stabilityPigment dispersion

Disclosed is a pigment dispersion exhibiting both high contrast and adequate dispersion stability, wherein a granulated pigment is used. Also disclosed is a coloring composition for color filters having good developability, which uses the pigment dispersion. Specifically disclosed is a pigment dispersion containing a pigment, a solvent and a dispersing agent, which is characterized in that the dispersing agent contains a block copolymer composed of a block A having an affinity for solvents and a block B having a functional group containing a nitrogen atom. This pigment dispersion is also characterized in that the dispersing agent has an amine number of not less than 80 mgKOH / g but not more than 150 mgKOH / g in terms of the effective solid content. Also specifically disclosed is a use of such a pigment dispersion.

Owner:MITSUBISHI RAYON CO LTD

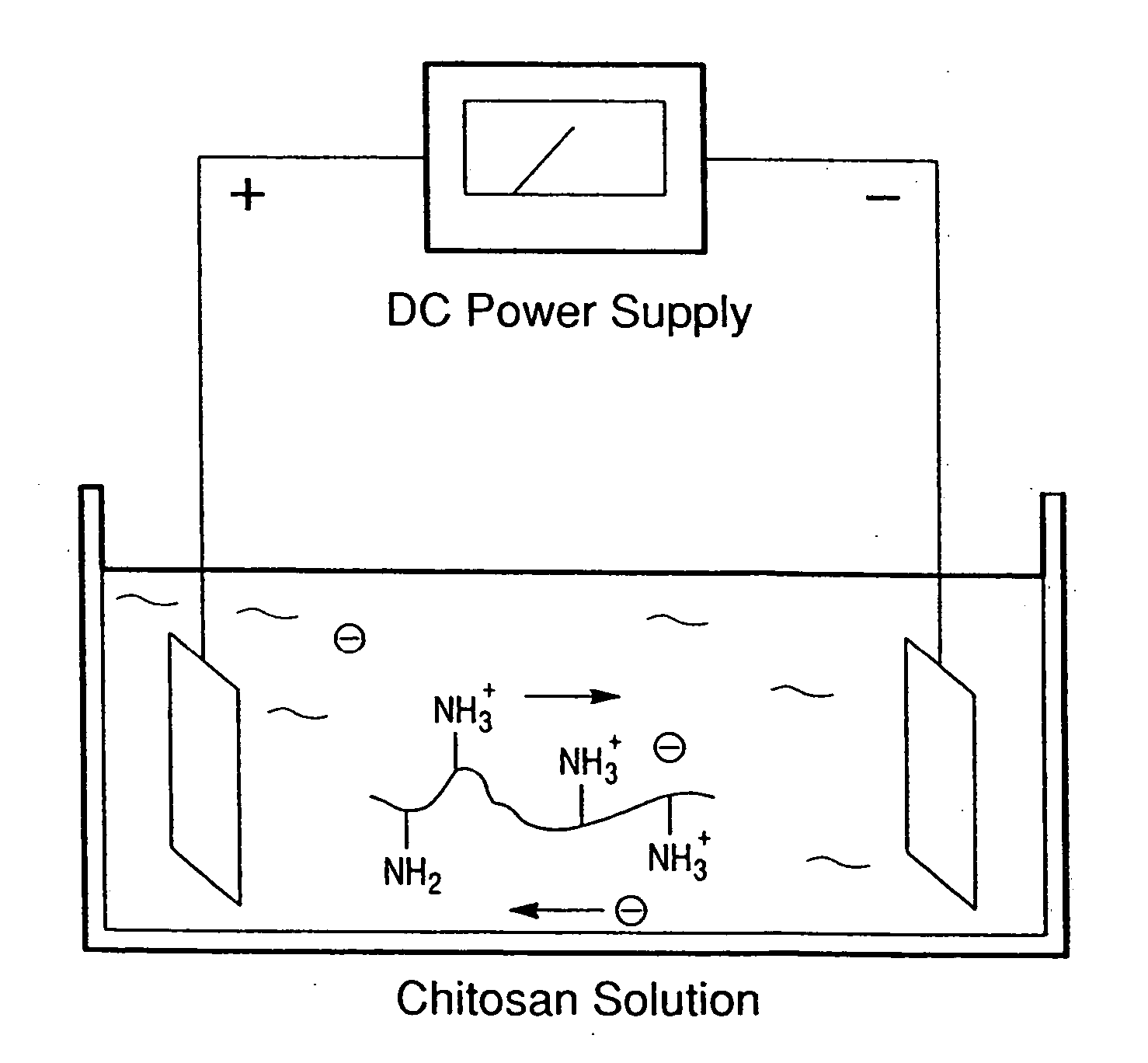

Spatially selective deposition of polysaccharide layer onto patterned template

InactiveUS20060102486A1Increase film thicknessStable adhesionSurface reaction electrolytic coatingElectrolytic organic material coatingChemistryElectrically conductive

A method is provided for electrochemically depositing a polymer with spatial selectivity. A substrate having a substrate surface is contacted with an aqueous solution containing a selectively insolubilizable polysaccharide, such as chitosan, which is subjected to electrochemically treatment to deposit, with spatial selectivity, the selectively insolubilizable polysaccharide on a patterned electrically conductive portion of the substrate surface.

Owner:MARYLAND BIOTECH INST UNIV OF +2

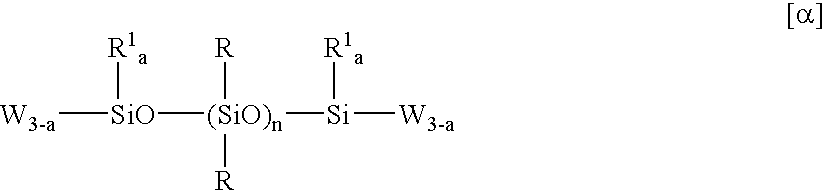

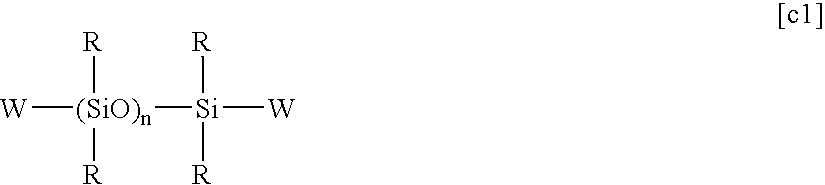

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

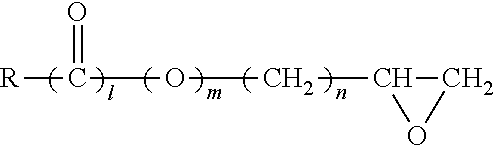

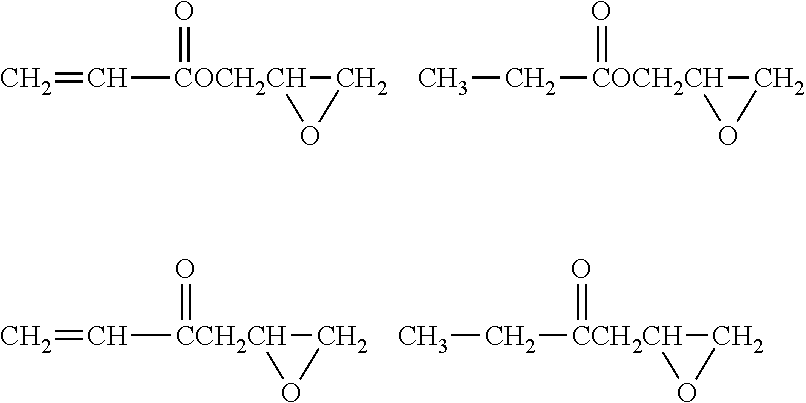

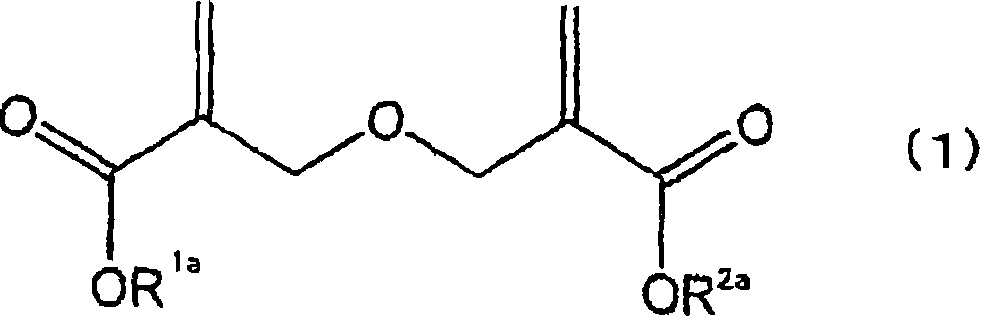

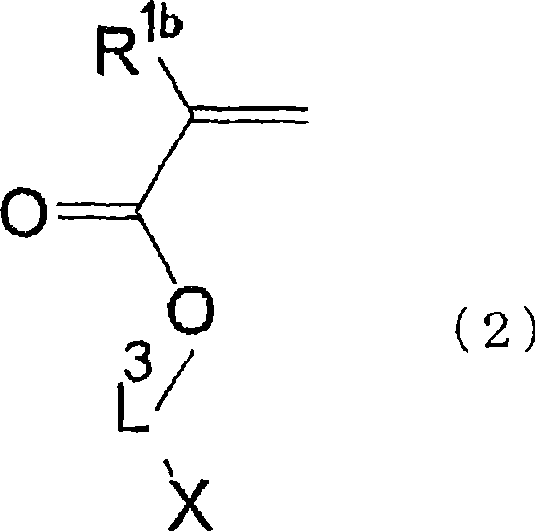

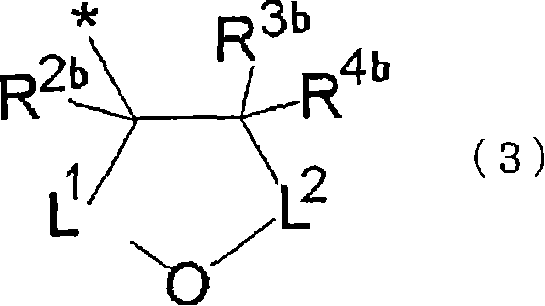

Composition for imprints, pattern and patterning method

InactiveUS20110183127A1Hardly worsening mold transferabilityImprove coating uniformityLayered productsDecorative surface effectsSiliconContamination

A composition for imprints comprising a polymerizable monomer, a photopolymerization initiator, and a polymer having a functional group with at least one of a fluorine atom or a silicon atom and having a polymerizable functional group, wherein the polymer has a weight-average molecular weight of at least 2000 and the amount of the polymer is from 0.01 to 20% by mass relative to the polymerizable monomer, is excellent in patternability and mold releasability, capable of forming good patterns and free from a problem of mold contamination.

Owner:FUJIFILM CORP

Composition for forming nitride coating film for hard mask

ActiveUS20070148557A1Low dry etching rateIncrease film thicknessPhotosensitive materialsSemiconductor/solid-state device manufacturingDevice materialCerium

There is provided an underlayer coating that causes no intermixing with photoresist layer, can be formed by a spin-coating method, and can be used as a hard mask in lithography process of manufacture of semiconductor device. Concretely, it is an underlayer coating forming composition used in manufacture of semiconductor device comprising metal nitride particles having an average particle diameter of 1 to 1000 nm, and an organic solvent. The metal nitride particles contain at least one element selected from the group consisting of titanium, silicon, tantalum, tungsten, cerium, germanium, hafnium, and gallium.

Owner:NISSAN CHEM IND LTD

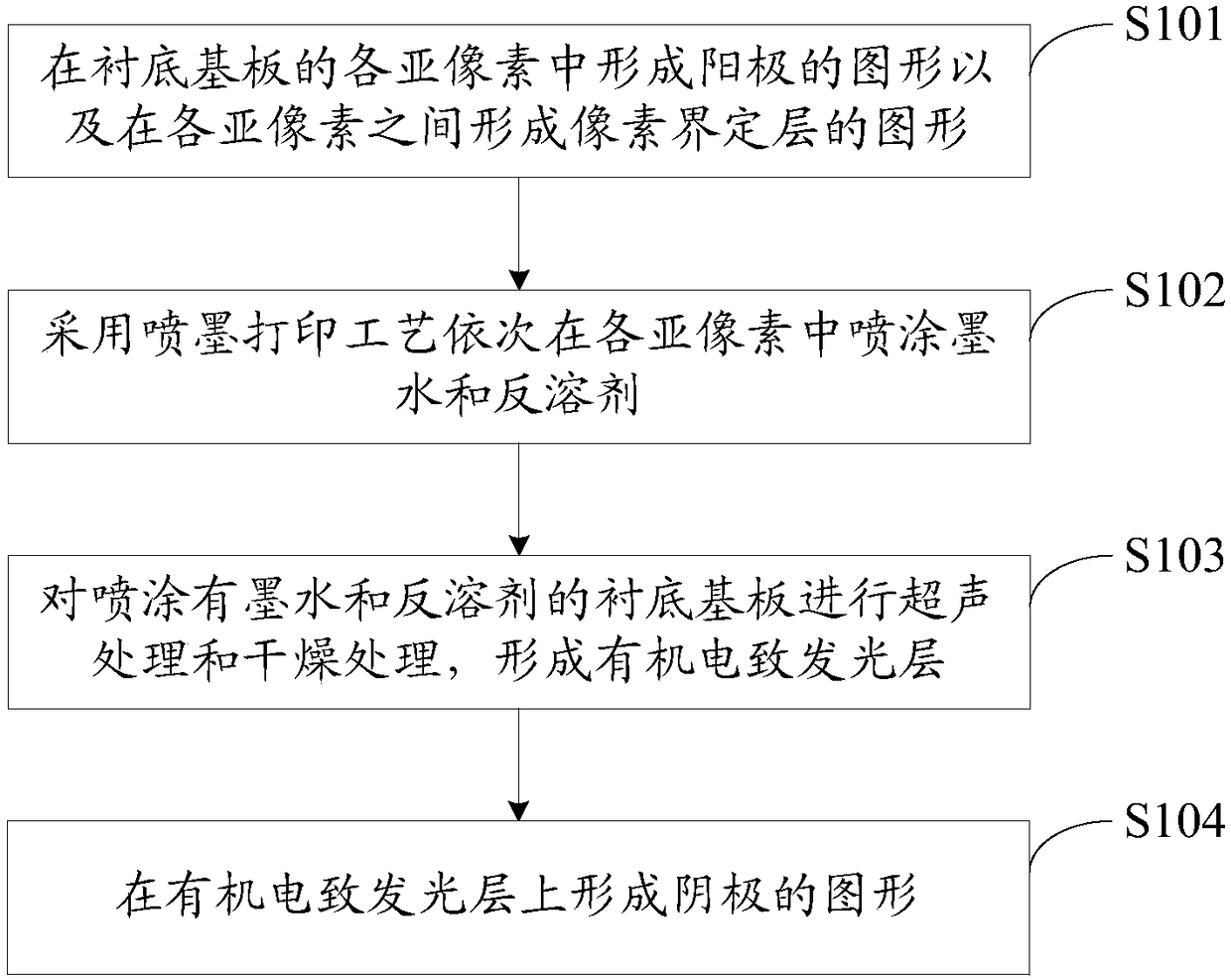

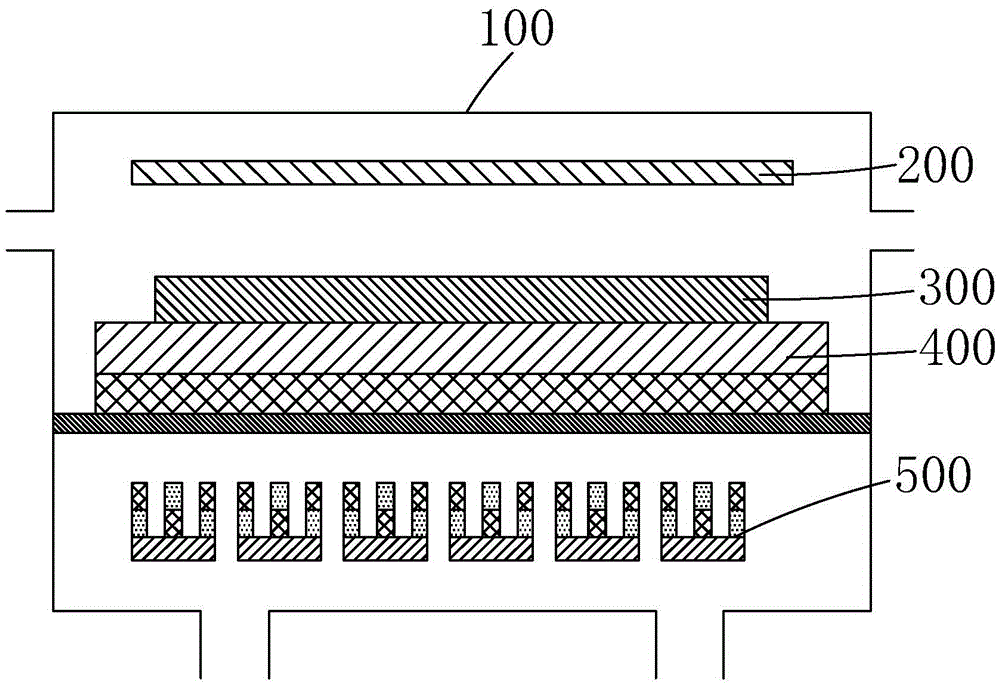

Electroluminescent display panel, preparation method thereof and display device

ActiveCN108389979AImprove the display effectIncrease film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingAnti solventCoffee ring effect

The invention discloses an electroluminescent display panel, a preparation method thereof and a display device. The preparation method comprises the steps of forming an anode in each sub-pixel of a substrate and a pixel defining layer between the sub-pixels; spraying ink and an anti-solvent on the anode of each sub-pixel by adopting an ink-jet printing process; performing ultrasonic treatment anddrying treatment on the substrate sprayed with the ink and anti-solvent to form an organic electroluminescent layer; and forming a cathode on the organic electroluminescent layer so as to form an electroluminescent display panel. The anode of each sub-pixel is sprayed with the ink and anti-solvent by adopting the ink-jet printing process, and a solute is separated out according to principles thatthe anti-solvent is mutually dissolved with a solvent and that the solute is not dissolved or slightly dissolved in the anti-solvent. The solute is enabled to be uniformly dispersed through the ultrasonic treatment, and then the solvent and the anti-solvent are removed through the drying treatment, so that the uniformity of the film thickness of the prepared organic electroluminescent layer is enabled to be improved, and a coffee-ring effect of the organic electroluminescent layer is avoided.

Owner:BOE TECH GRP CO LTD +1

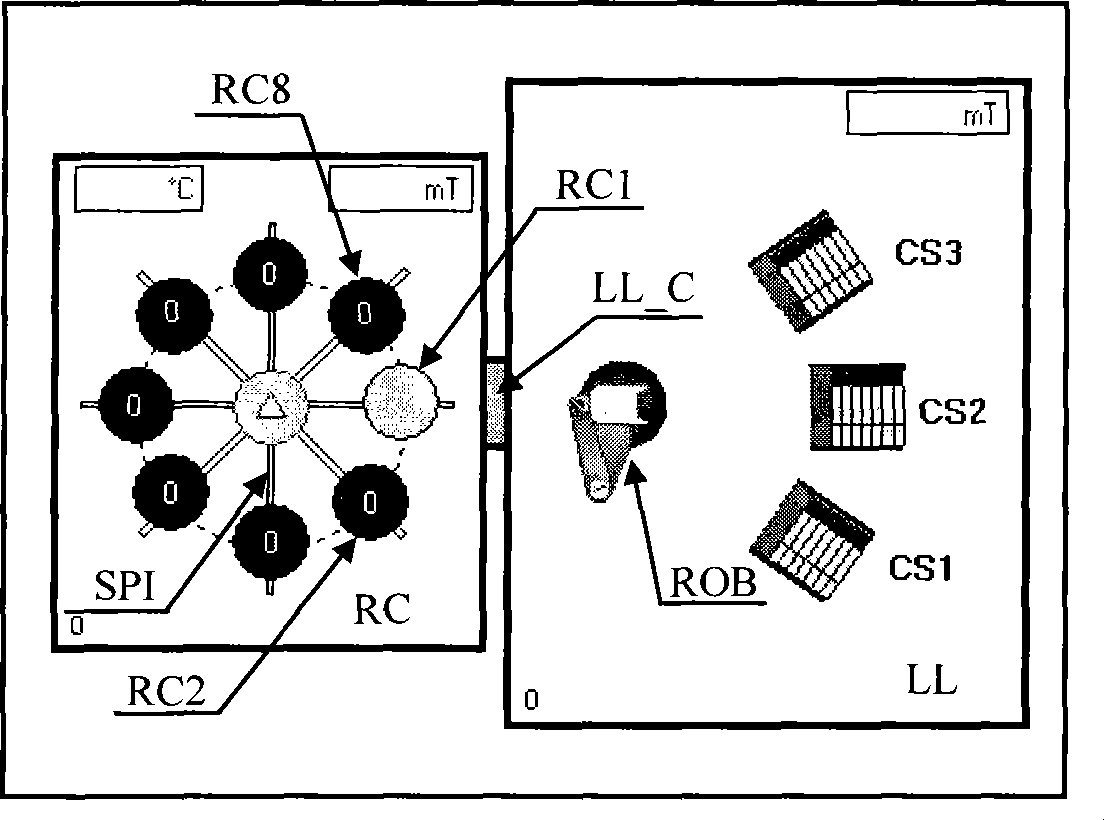

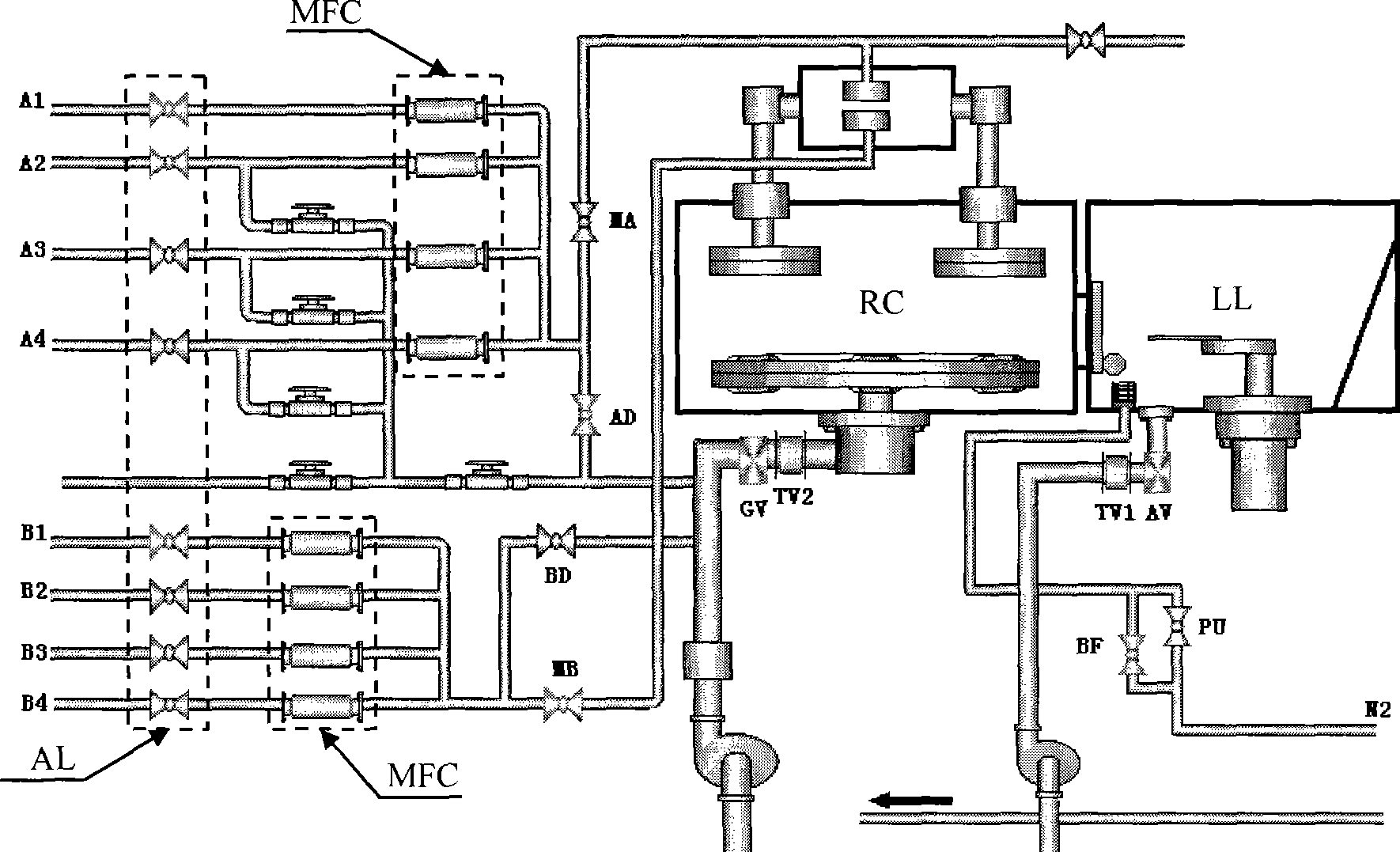

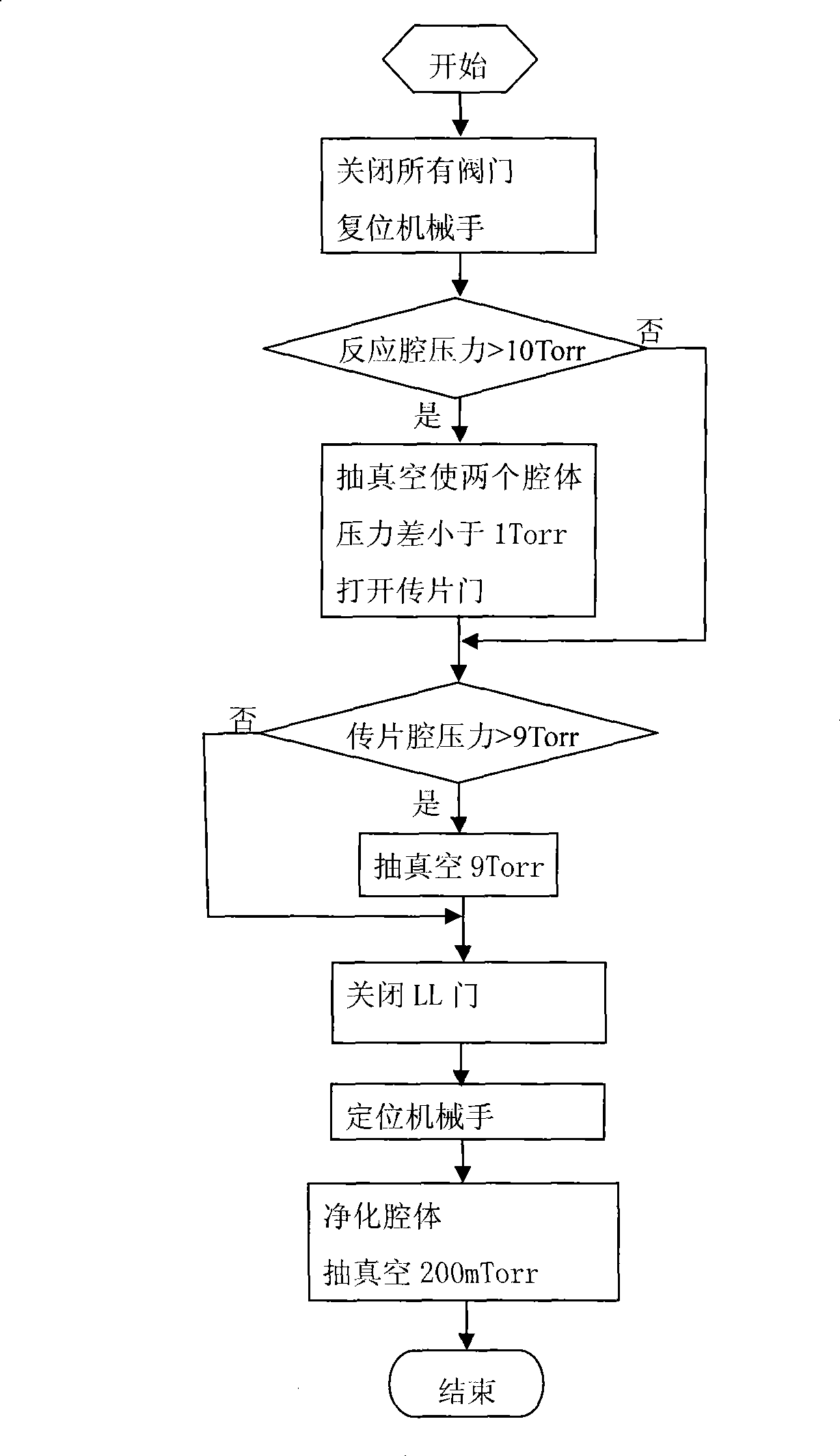

Control method for plasma reinforced chemical meteorology deposition apparatus

InactiveCN101469418AAddressing the needs of the future development of the processImprove deposition uniformityChemical vapor deposition coatingProcess mechanismEngineering

The invention belongs to a control system technique, in particular to a method for controlling plasma intensified chemical vapor phase deposition equipment. The method comprises the equipment initialization control, the wafer processing flow control and the equipment exception alarming control, wherein the equipment initialization control comprises the steps of starting a power supply of the equipment, turning on an alarm monitor, and sending initialization instructions of a sheet transmitting cavity and a reaction cavity; the wafer processing flow control comprises the steps of leading in a technique formulation, and using a batch or layer formulation to perform processing initialization, water processing and processing ending control; the equipment exception alarming control realizes the monitoring of equipment exception and failure, and performs the step treatment on the equipment alarming through an exception pretreating mechanism and an alarming response processing mechanism. The invention realizes the accurate process control to the chemical vapor phase deposition, and meets the process requirement in the process of manufacturing semiconductor devices.

Owner:MICROCYBER CORP +1

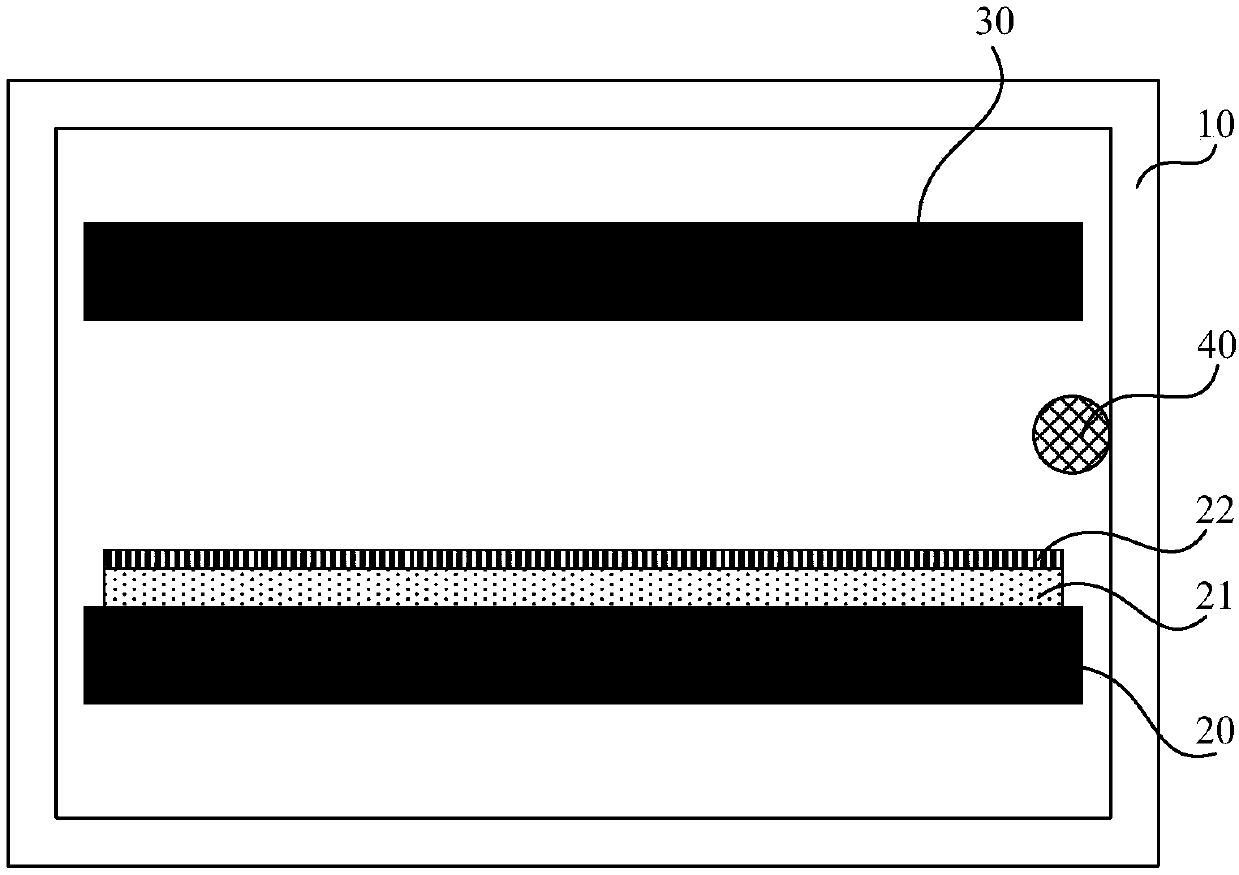

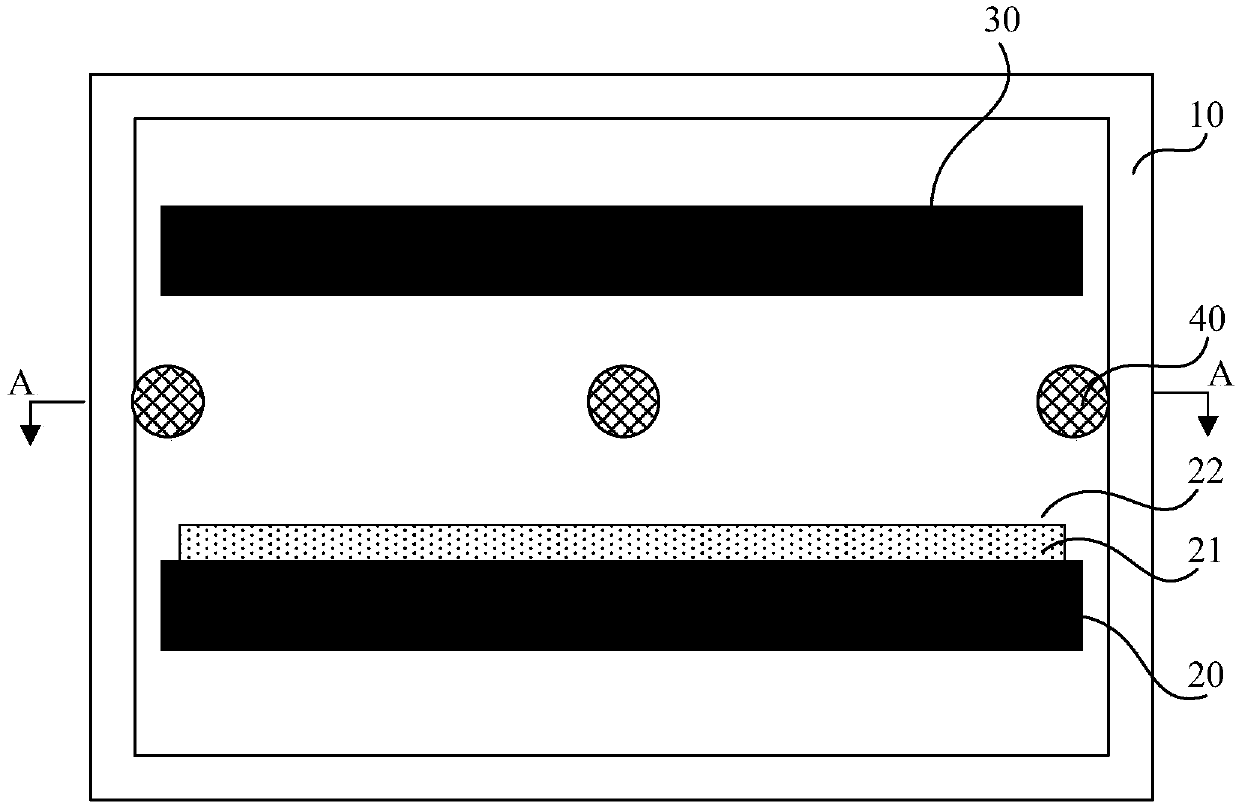

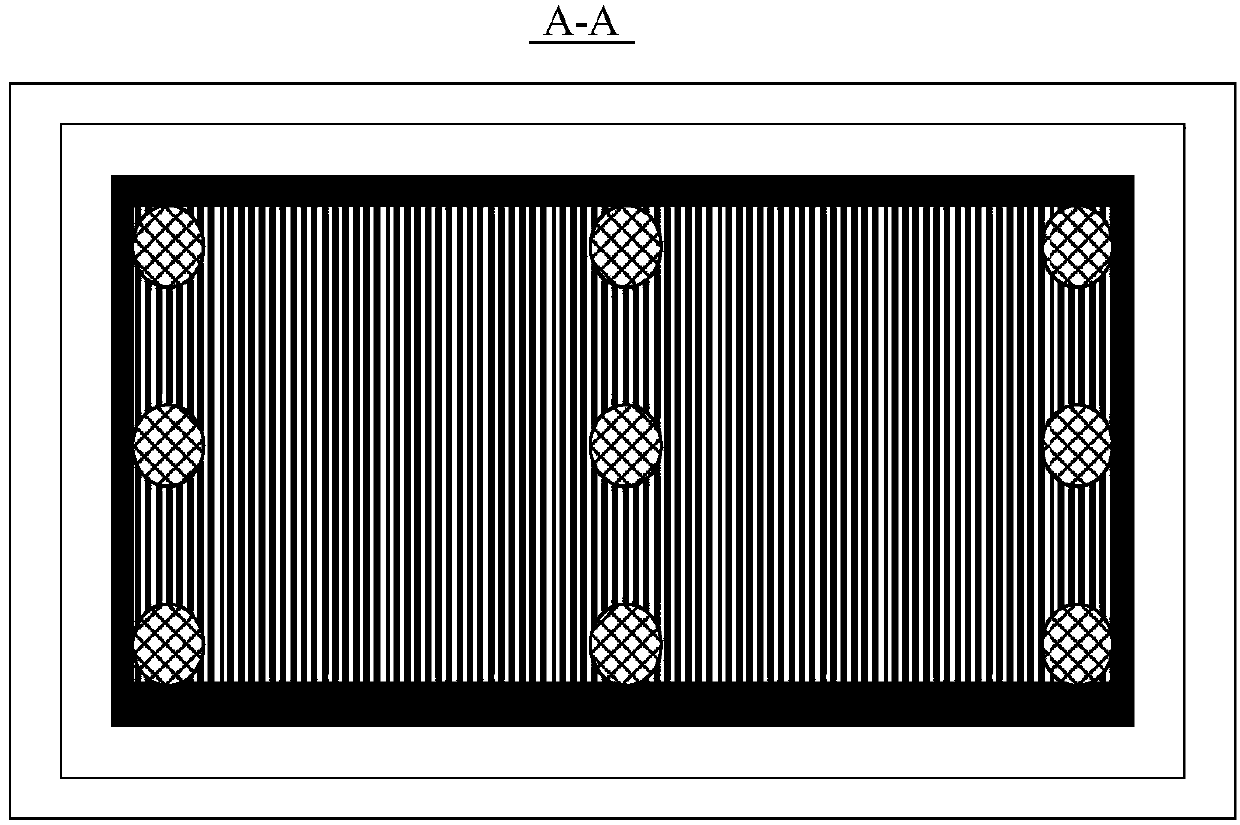

Vacuum drying cavity and vacuum drying device

ActiveCN107940904AIncrease film thicknessImproves evaporation rate uniformityDrying solid materials without heatOrganic solventEvaporation

The invention provides a vacuum drying cavity and a vacuum drying device, relates to the technical field of organic solution film formation, and can solve the problem of weak film thickness uniformityof dried substrate film layers caused by adjustment and judgment of the evaporation speed of organic solvent in the substrate film layers according to detected environmental vacuum degree in a traditional vacuum drying device. The vacuum drying cavity comprises a vacuum cavity, and a carrying table and a condensation plate oppositely arranged in the vacuum cavity; the carrying table is used for bearing substrates to be dried; the plate surface temperature of the condensation plate is lower than the table surface temperature of the carrying table; the surfaces of films layers to be dried of the substrates to be dried are towards the condensation plate; and an organic solvent concentration detector is arranged in the vacuum cavity.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

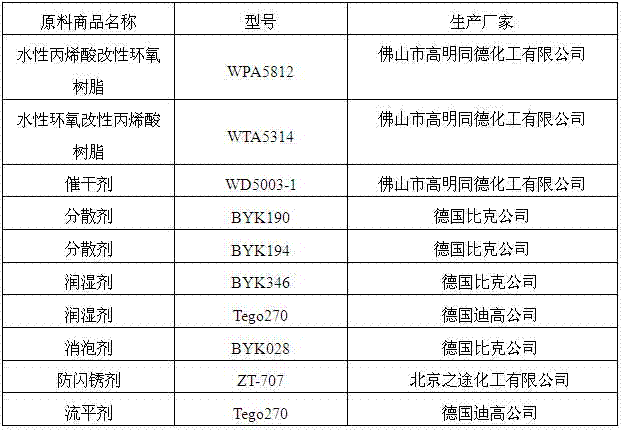

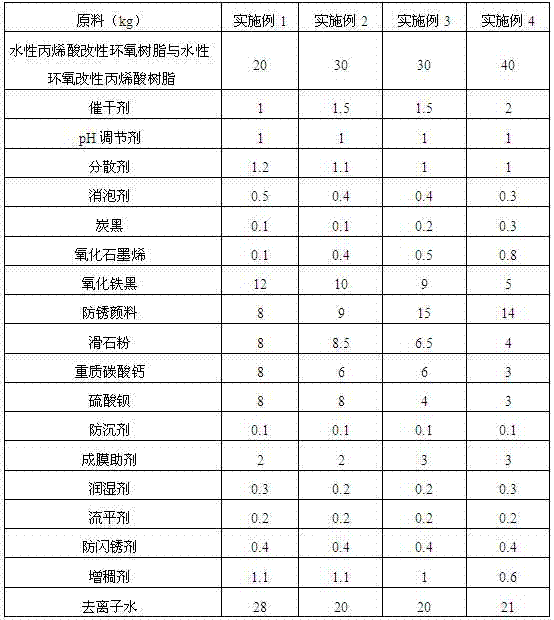

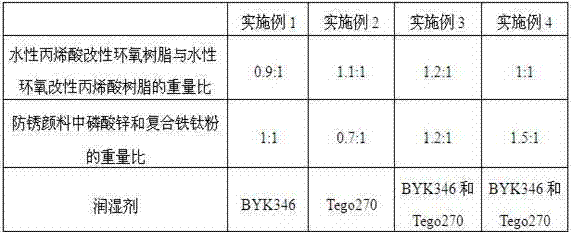

Dip-coating water-based paint for transmission shaft and preparation method thereof

InactiveCN106867368AWith cleanQuick-drying at room temperatureAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses dip-coating water-based paint for a transmission shaft and a preparation method thereof and relates to the technical field of metal water-based paint. The dip-coating water-based paint is prepared from the following raw materials in parts by weight: 20 to 40 parts of waterborne acrylic modified epoxy resin and epoxy modified acrylic resin, 0.3 to 3 parts of a drier, 0.4 to 1.5 parts of a pH (Potential of Hydrogen) regulator, 0.6 to 1.5 parts of a dispersant, 0.3 to 0.5 part of a de-foaming agent, 0.05 to 3 parts of carbon black, 0.01 to 1 part of graphene oxide, 4 to 12 parts of iron oxide black, 2 to 20 parts of antirust pigment, 3 to 8 parts of talcum powder, 0.5 to 8 parts of heavy calcium carbonate, 3 to 8 parts of barium sulfate, 0.05 to 0.15 part of an anti-sedimentation agent, 2 to 3 parts of a film forming auxiliary agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.5 part of a leveling agent, 0.1 to 0.5 part of a flash-rust resisting agent, 0.1 to 1.2 parts of a thickener and 10 to 28 parts of water. The water-based paint has the advantages of easiness of improving a film thickness, high rigidity, good wear-resisting and corrosion-preventing effects, capability of being rapidly dried at room temperature and extremely low VOC (Volatile Organic Compounds) content.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

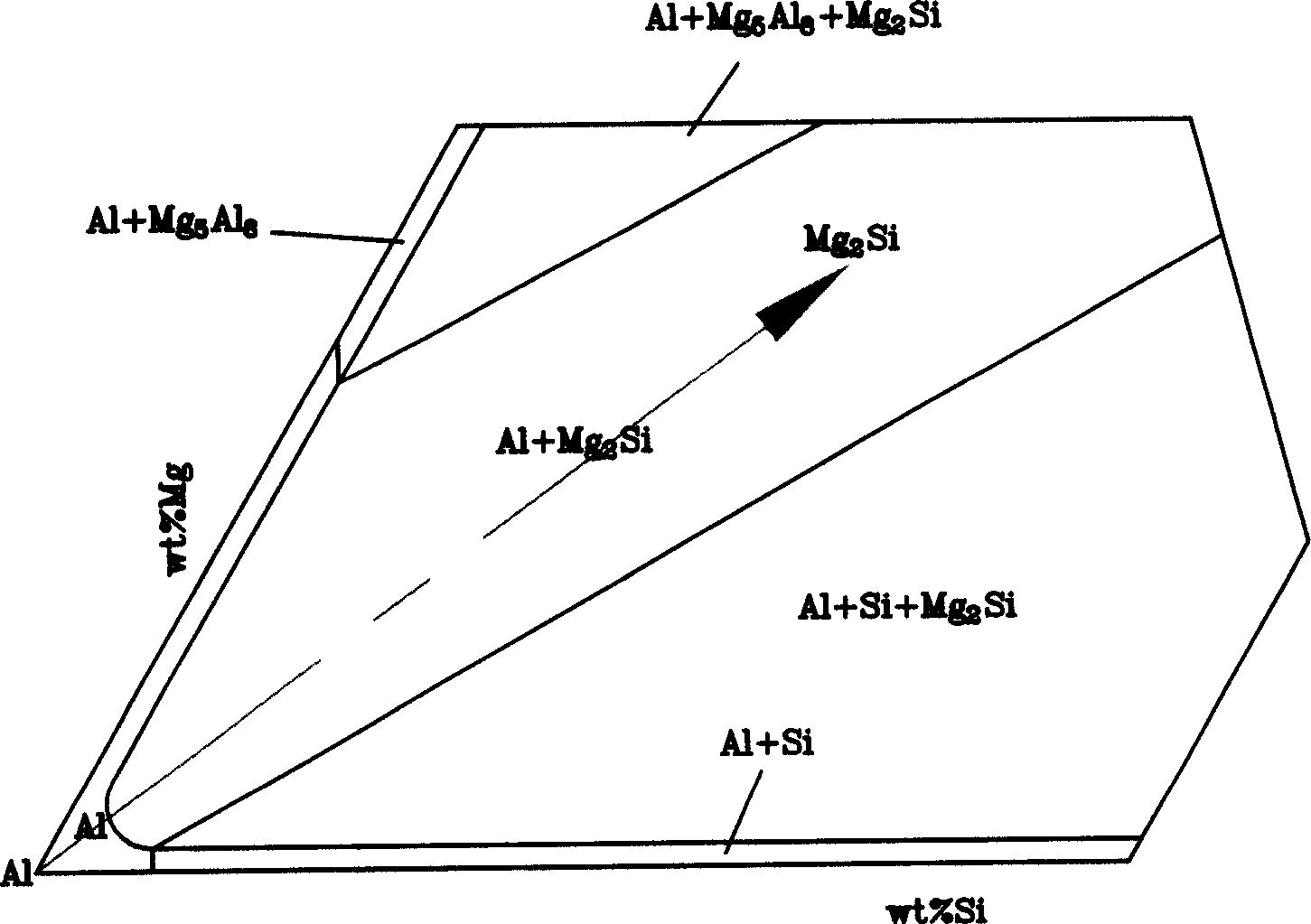

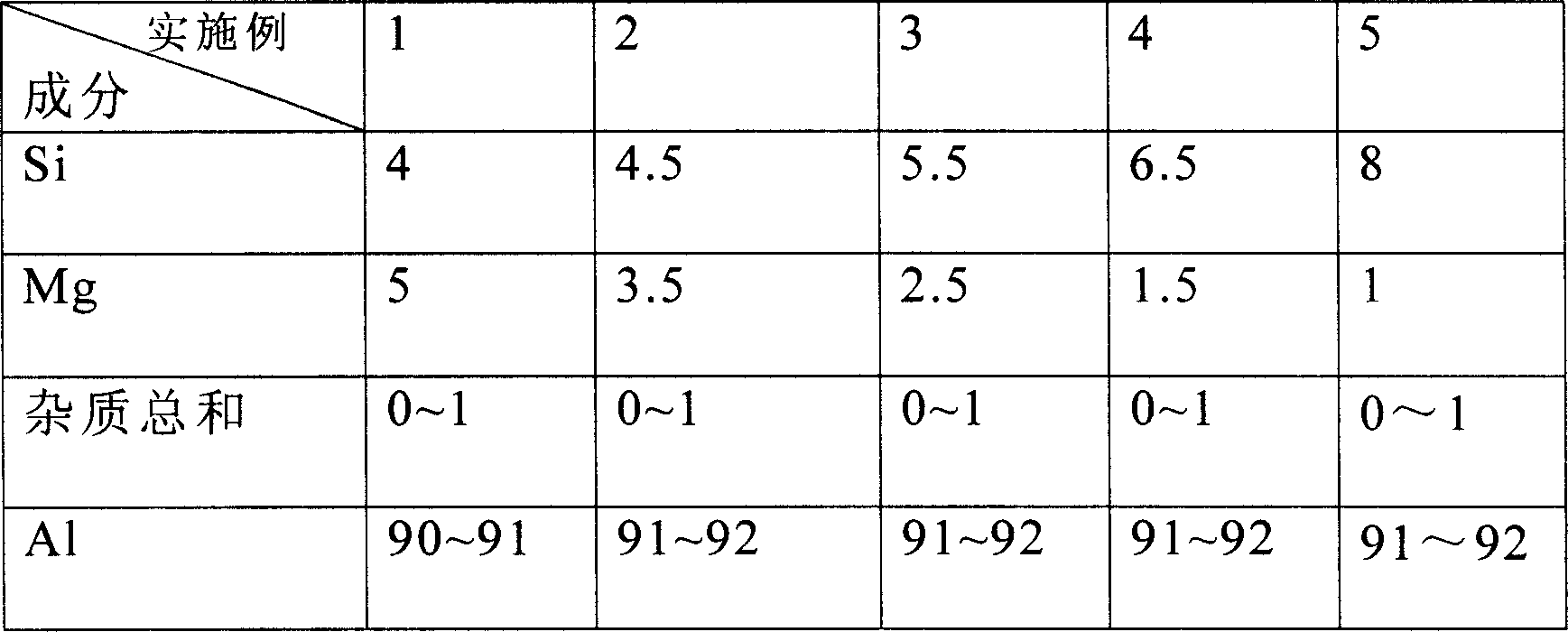

Pressure cast aluminium alloy and its application

The present invention provides one kind of pressure cast aluminum alloy and its application, and belongs to the field of material science. The pressure cast aluminum alloy consists of Si 4-8 wt%, Mg 1-5 wt%, and Al for the rest. The pressure cast aluminum alloy is applied to produce hard anodized oxide film through the following steps: smelting, pressure casting, modifying mechanically, and forming hard anodized oxide film. The pressure cast aluminum alloy has anodized oxide film with great thickness, high hardness and high corrosion resistance.

Owner:ZHEJIANG SUPOR CO LTD

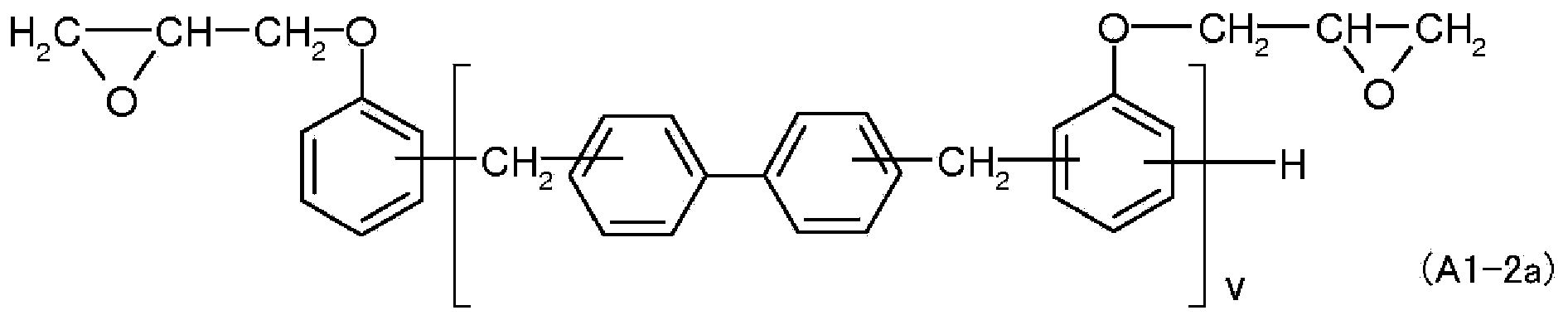

Pigment dispersion, coloring composition for color filter, color filter, liquid crystal display and organic el display

ActiveCN102719148AImprove transmittanceIncrease contrastOptical filtersOrganic dyesDispersion stabilityLiquid-crystal display

The objective of the present invention is to provide a pigment dispersion liquid in which both high contrast and dispersion stability are achieved when the pigment which is made into fine particles is used, and also to provide a colored composition for a color filter having good development property by using the same. The present invention provides a pigment dispersion liquid comprising a pigment, a solvent and a dispersant, wherein said dispersant comprises a block copolymer comprising a block A having a solvent affinity and a block B having a functional group comprising nitrogen atom, and an amine value of said dispersant is 80mg KOH / g or more and 150mg KOH / g or loss in terms of an effective solid content. The present invention also provides an application thereof.

Owner:MITSUBISHI RAYON CO LTD

Process for preparing carbon electrode array with high surface area and high gap filling capacity

InactiveCN1702887AIncrease film thicknessIncrease surface areaSemi-permeable membranesElectrode manufacturing processesMicrosphereMicroelectromechanical systems

This invention relates to carbon electrode array process method with large surface area and filling capacity in the field of micro machine system and micro battery, which comprises the following steps: adding some percentage of highly polymers expansion balls into the light etching glue and mixing them evenly; then coating it evenly on silicon slice, silicon nitride, earth silicon, quartz glass or metal underlay bottom surfaces; through drying, exploring, developing procedures; forming one graph thick film etching glue layer with certain deepness to width proportion; then processing light etching glue thermal carbon and forming hollow hole on the carbon electrode array; finally forming carbon electrode array structure with large surface area and filling capacitor.

Owner:TSINGHUA UNIV

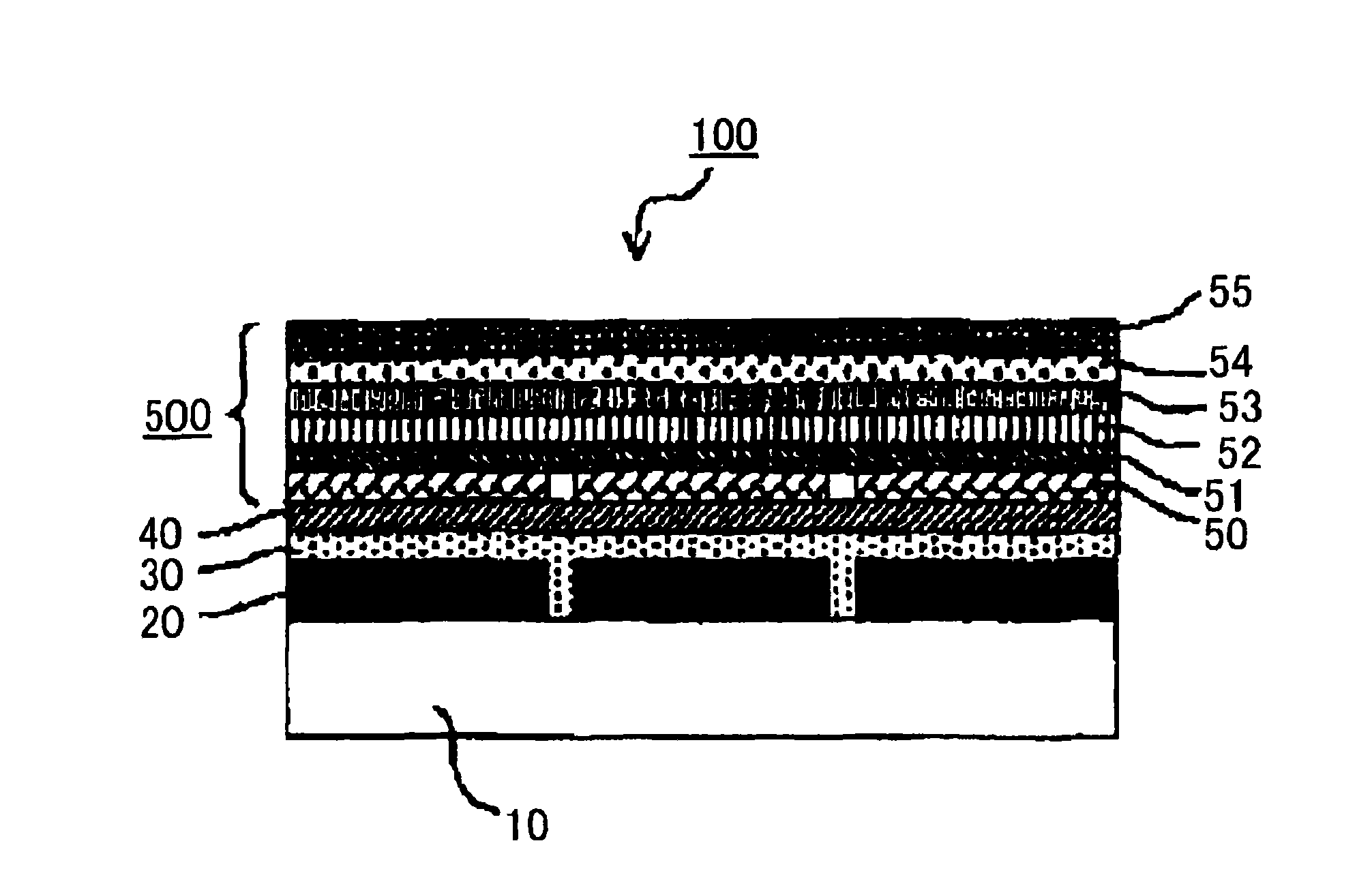

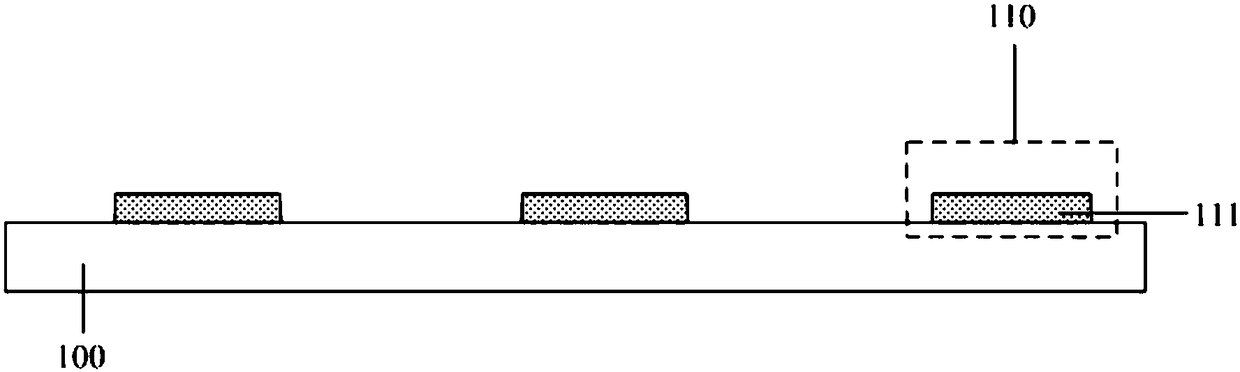

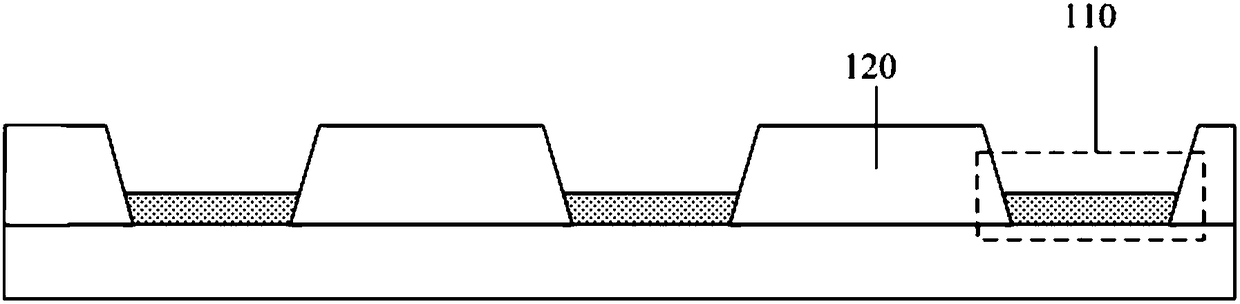

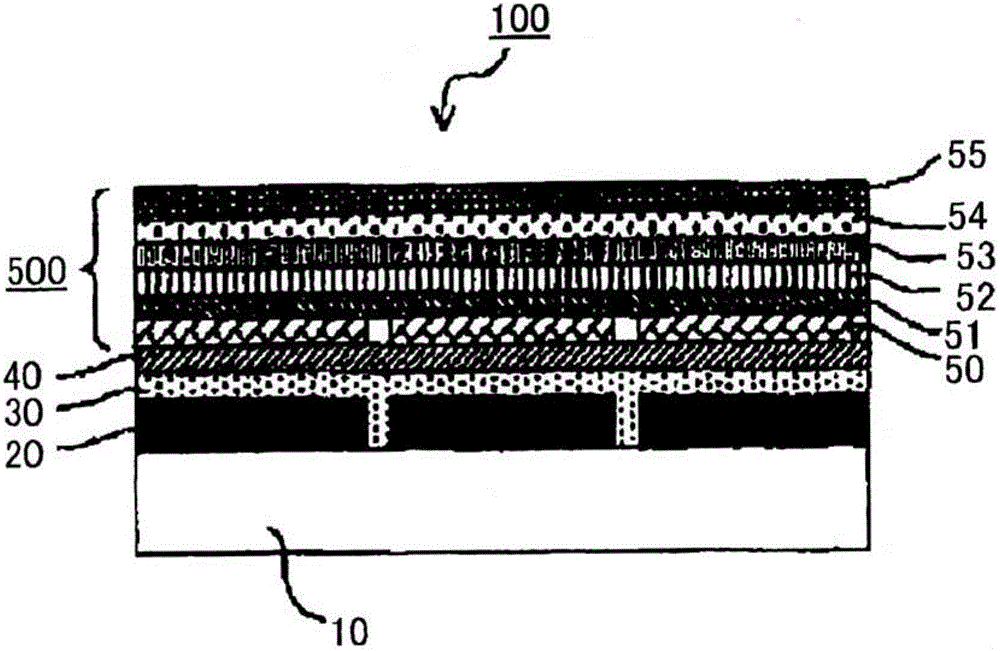

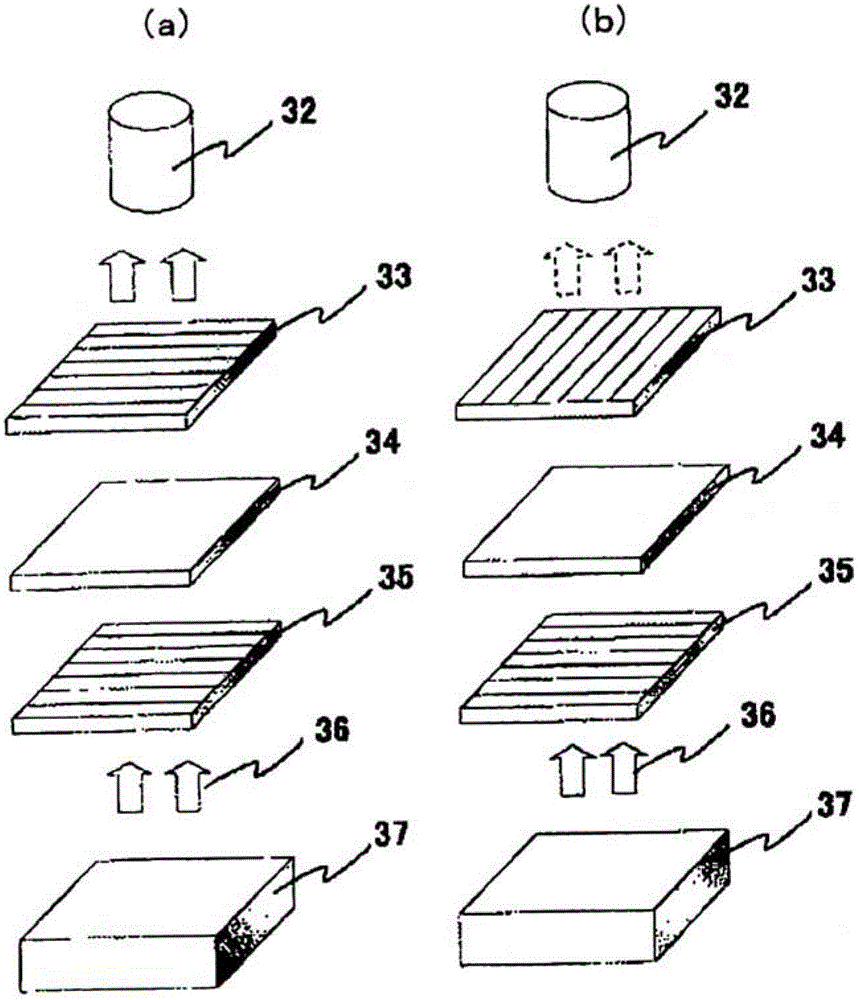

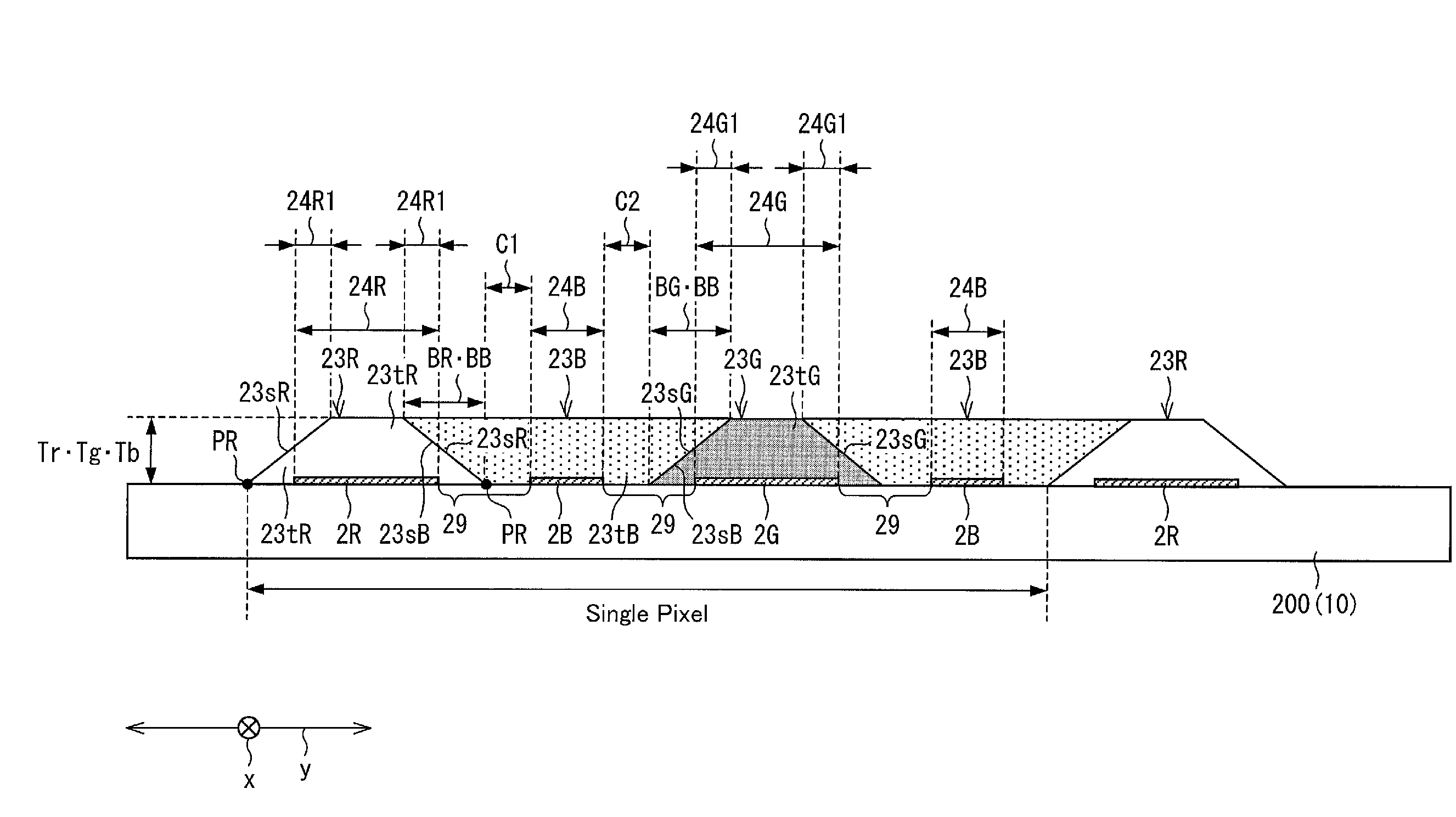

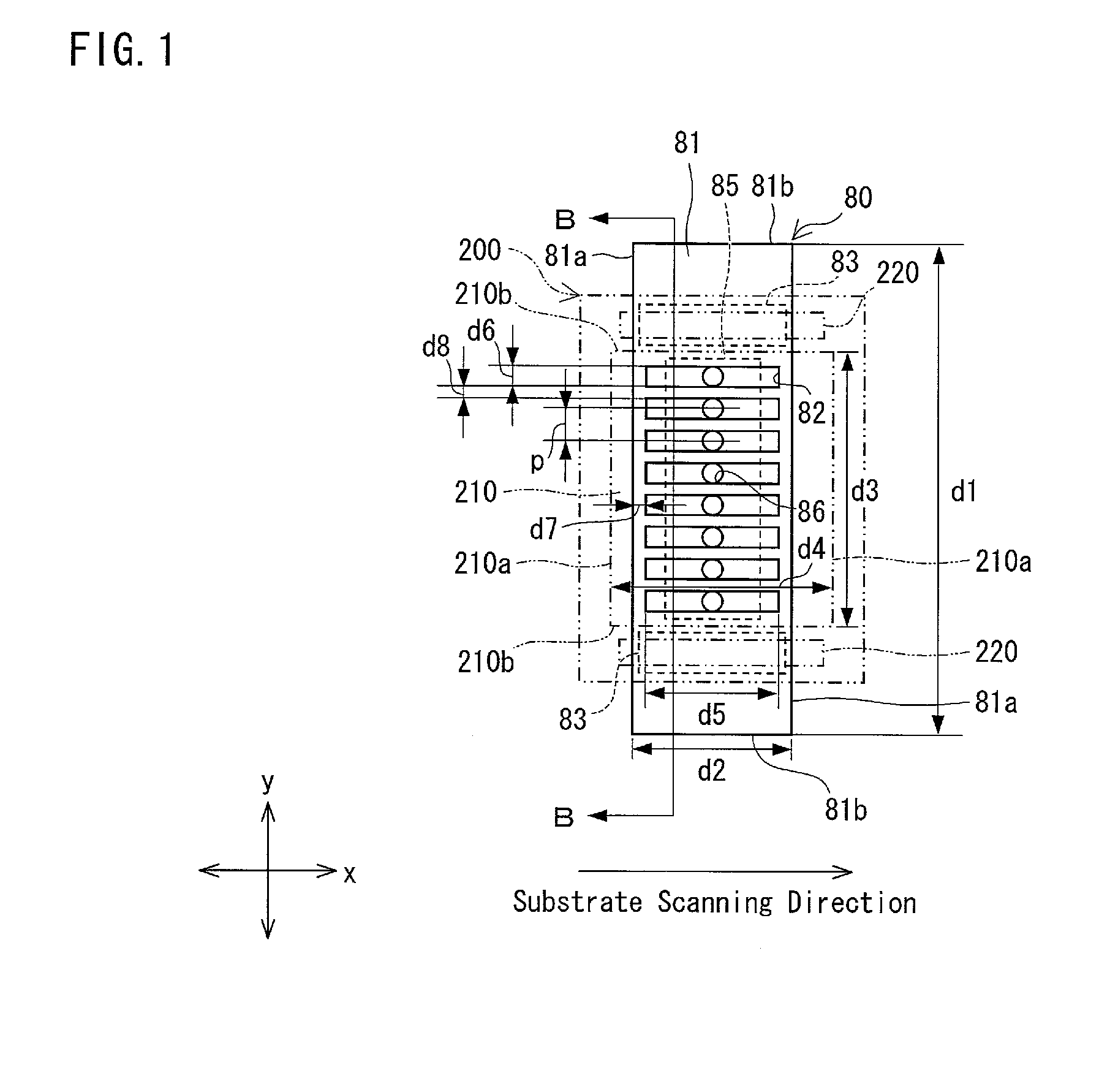

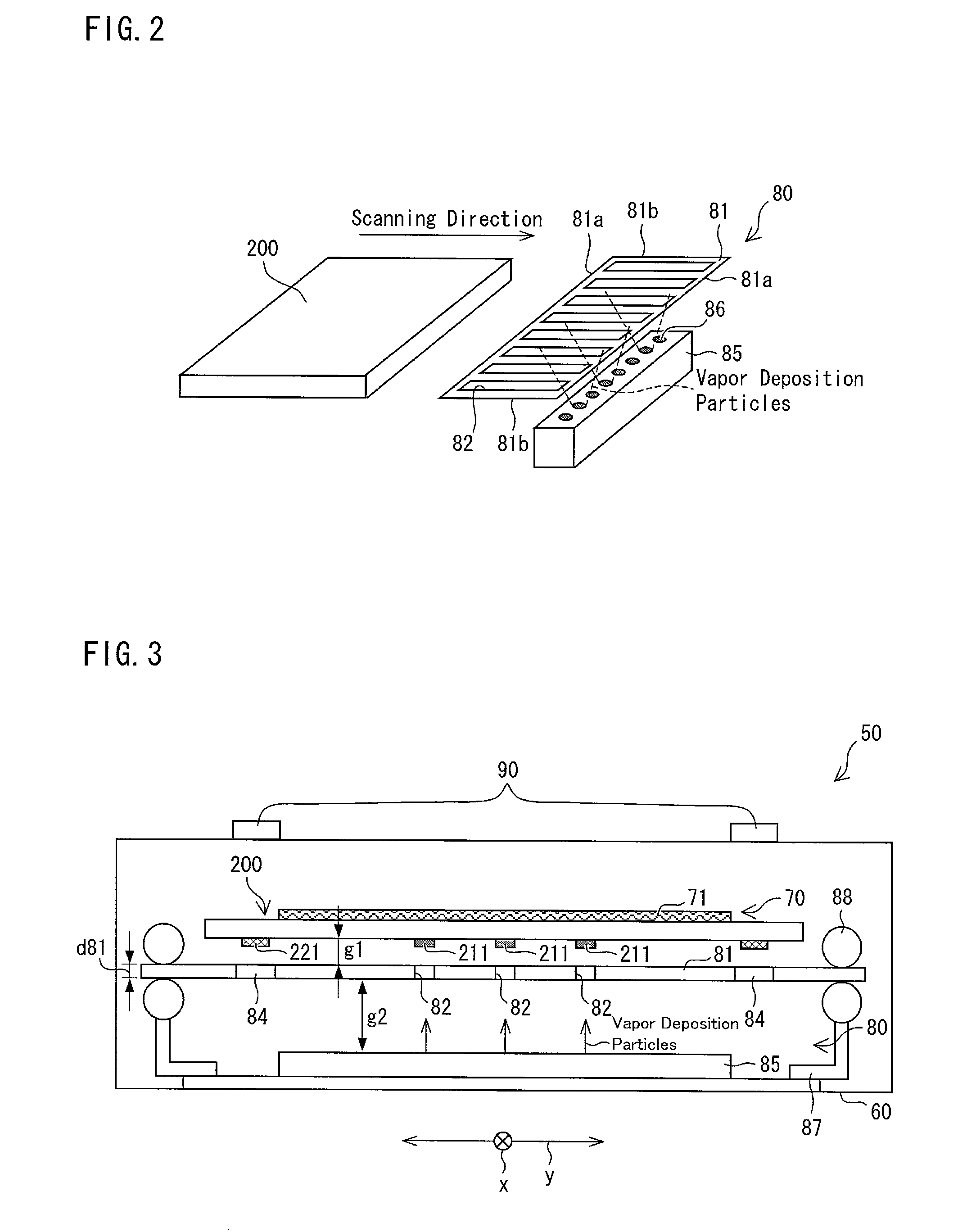

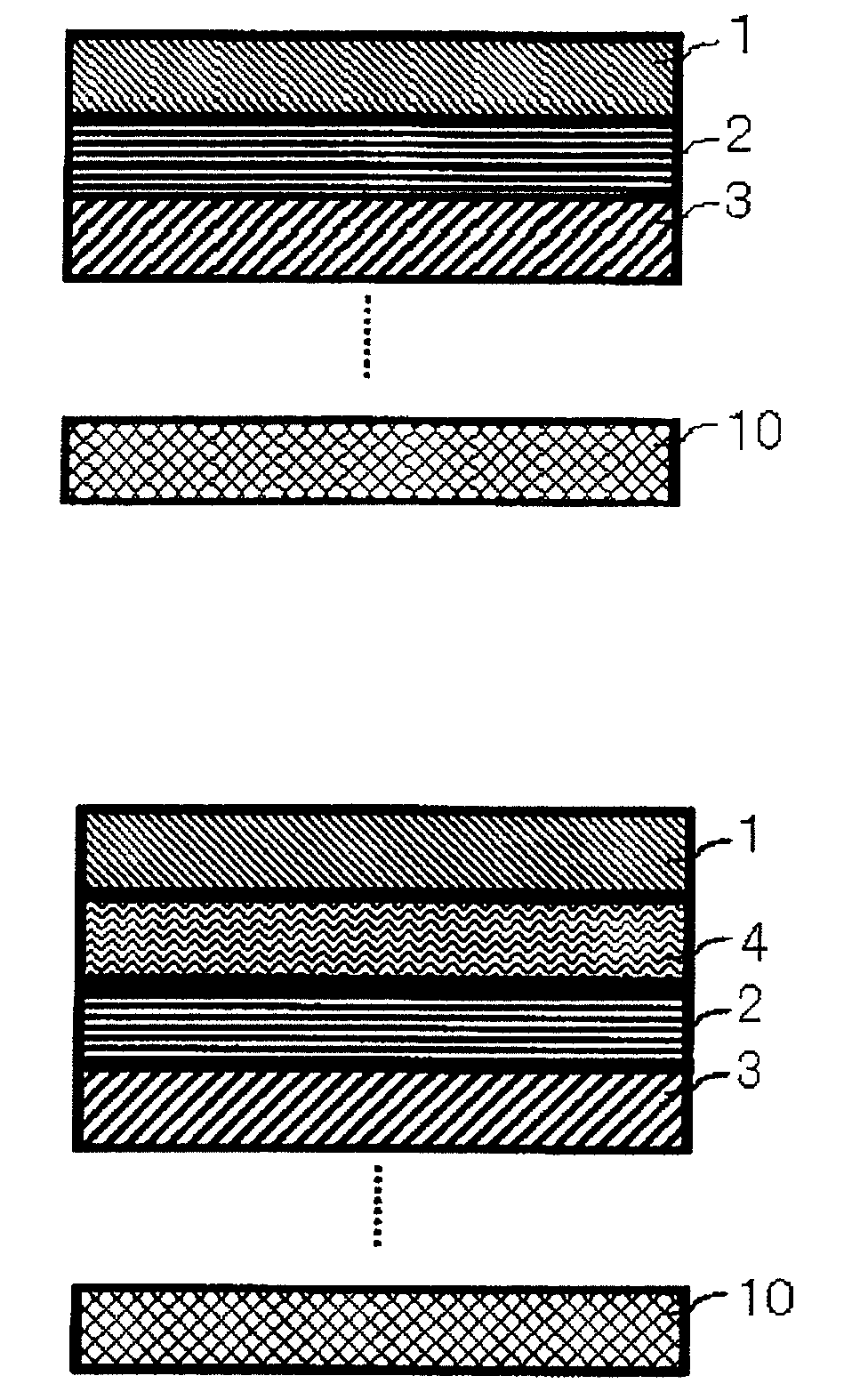

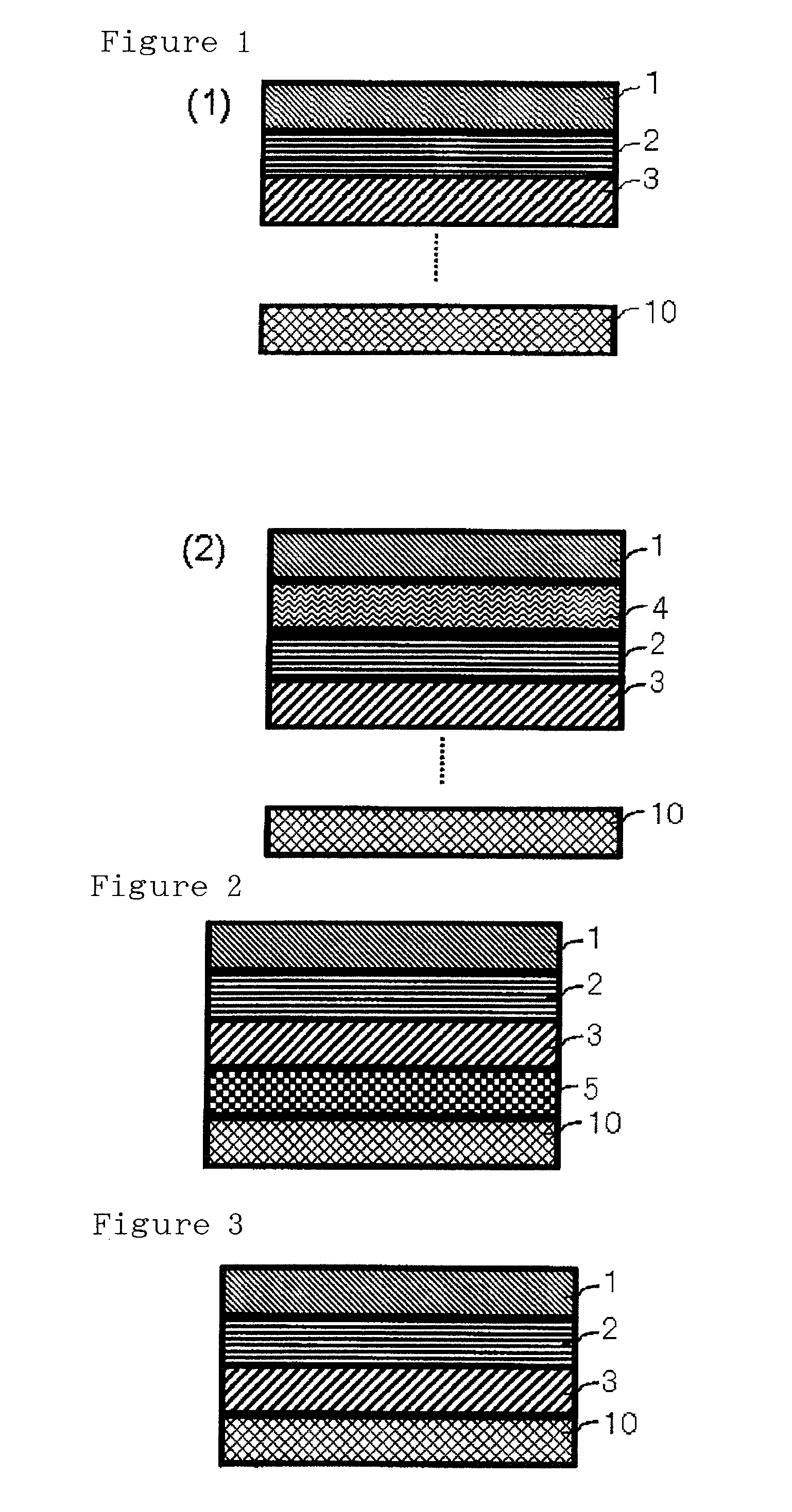

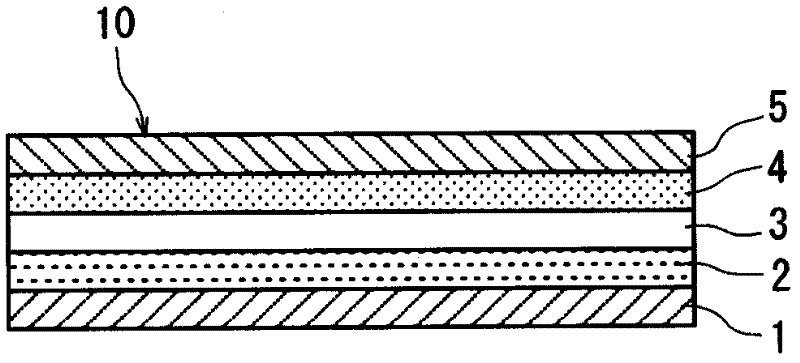

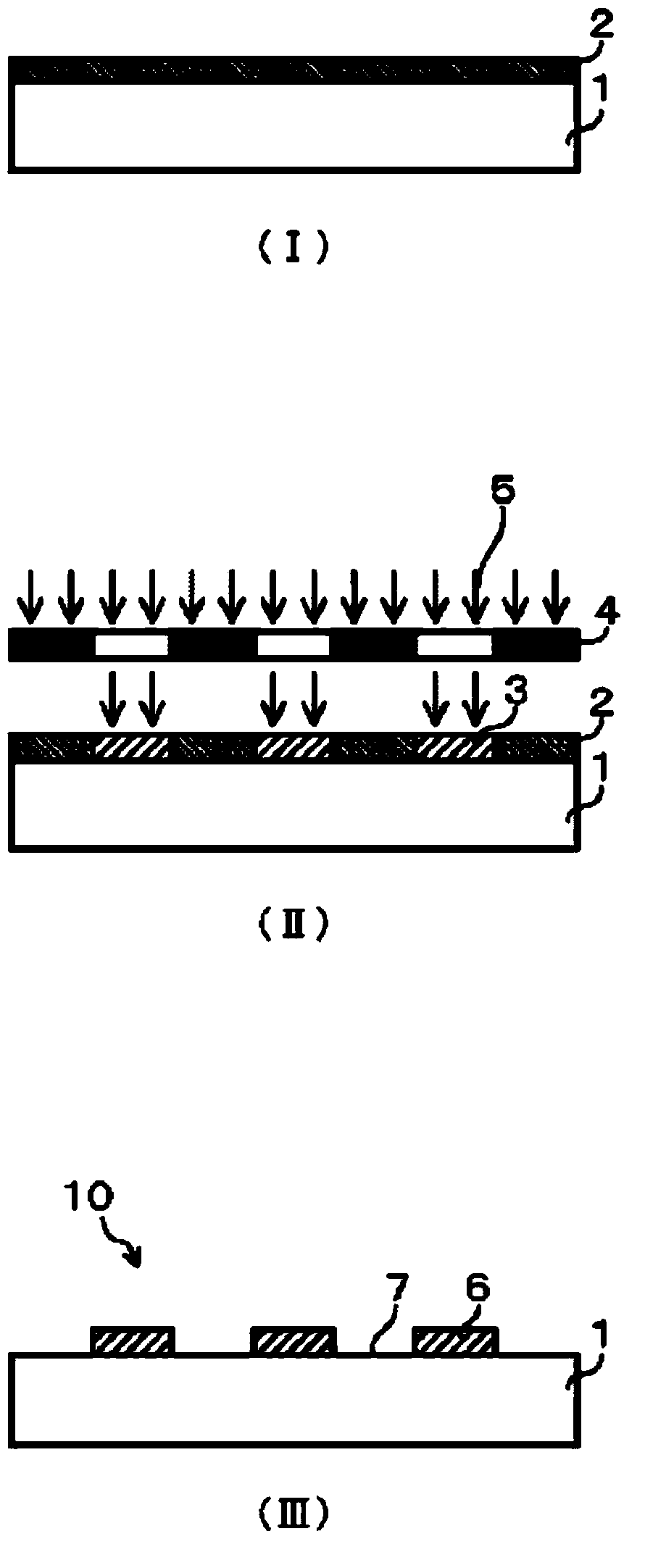

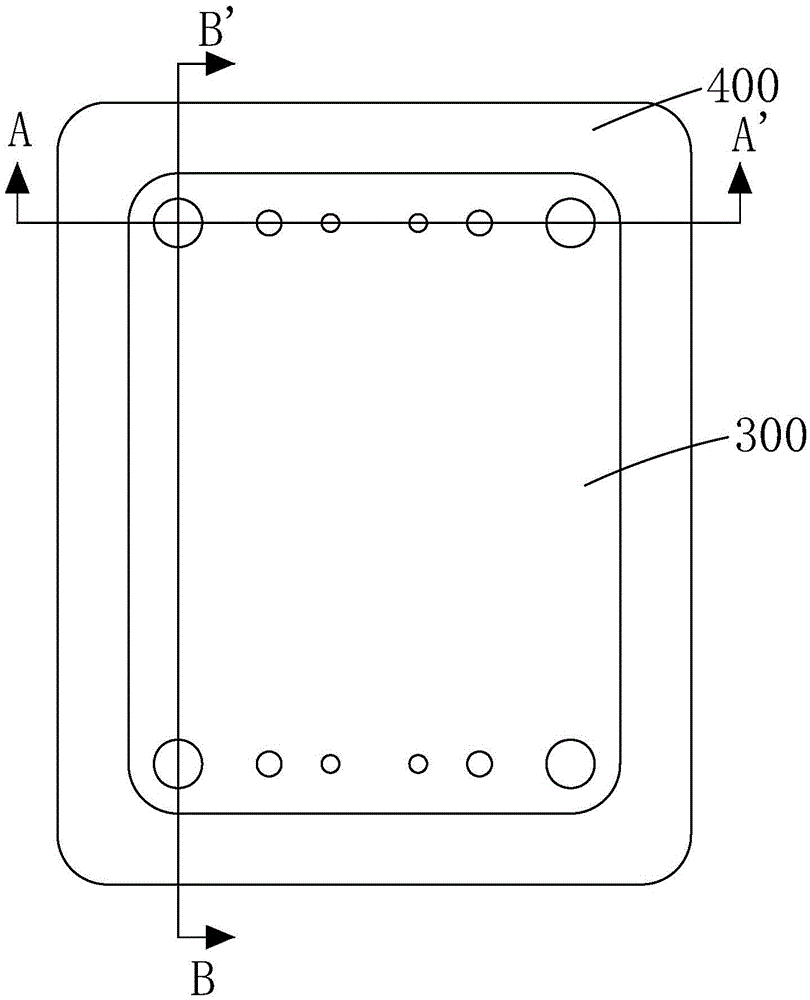

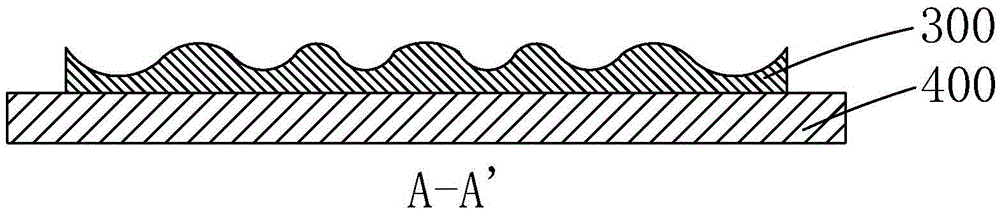

Substrate to which film is formed, method for production, and organic el display device

ActiveUS20130302572A1Reduce thicknessIncrease film thicknessElectrical apparatusLayered productsDisplay deviceEngineering

Owner:SHARP KK

Film for film capacitor and film capacitor

InactiveUS20110255210A1High mechanical strengthHigh dielectric constantFixed capacitor dielectricSynthetic resin layered productsInorganic particleInorganic particles

There is provided a thin highly dielectric film for a film capacitor being excellent in mechanical strength, in which highly dielectric inorganic particles can be blended to a dielectric resin at high ratio, and rubber particles (B) and preferably highly dielectric inorganic particles (C) are dispersed in a thermoplastic resin (A).

Owner:DAIKIN IND LTD

Photomask blank and method for manufacturing the same

ActiveUS20110081605A1Not easy to changeGood chemical resistanceSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentNumber densityOptoelectronics

The present invention provides a photomask blank in which a light-shielding film consisting of a plurality of layers is provided on a light transmissive substrate, wherein a layer that is provided to be closest to the front surface is made of CrO, CrON, CrN, CrOC or CrOCN, and wherein the atom number density of the front-surface portion of the light-shielding film is 9×1022 to 14×1022 atms / cm3.

Owner:HOYA CORP

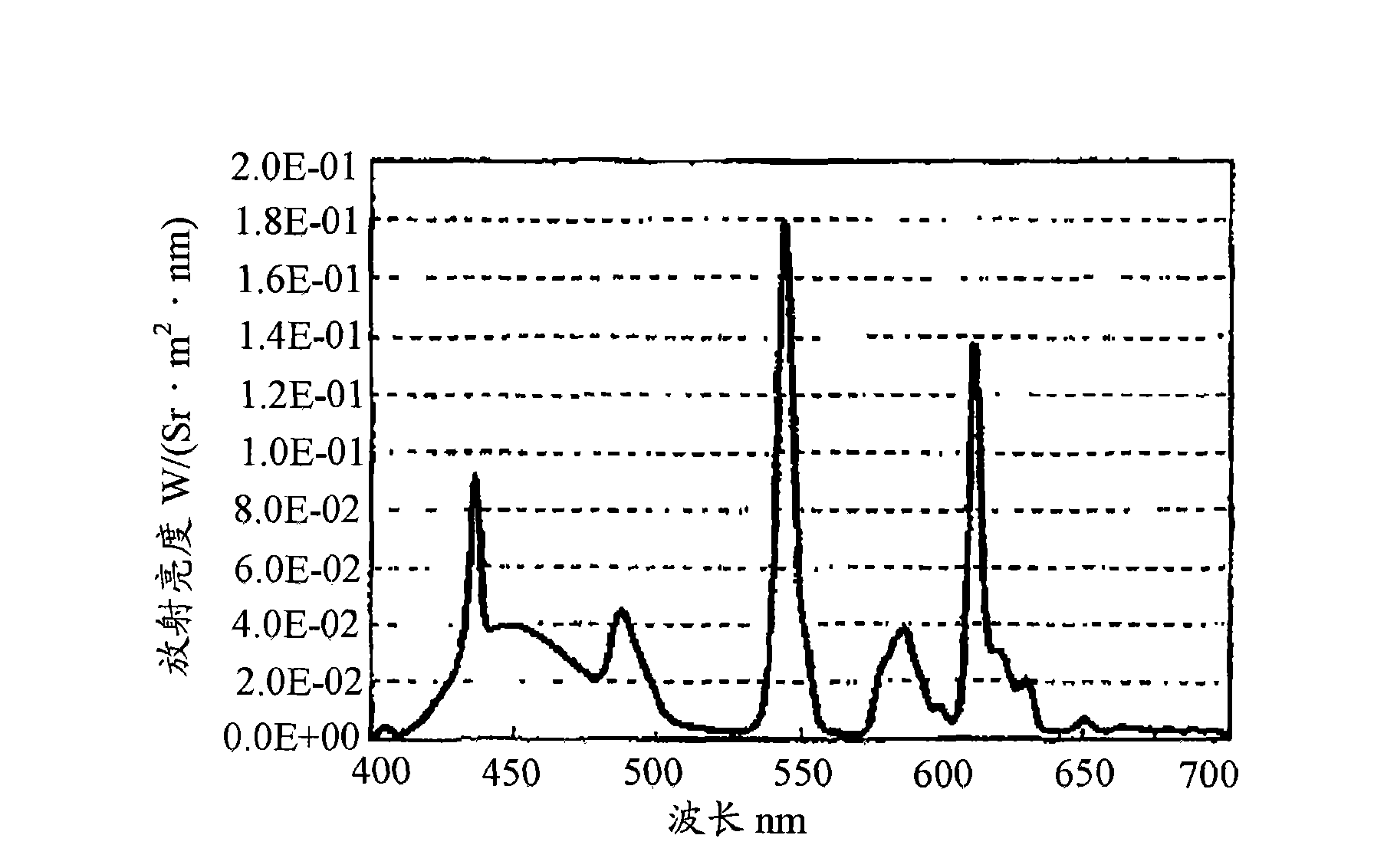

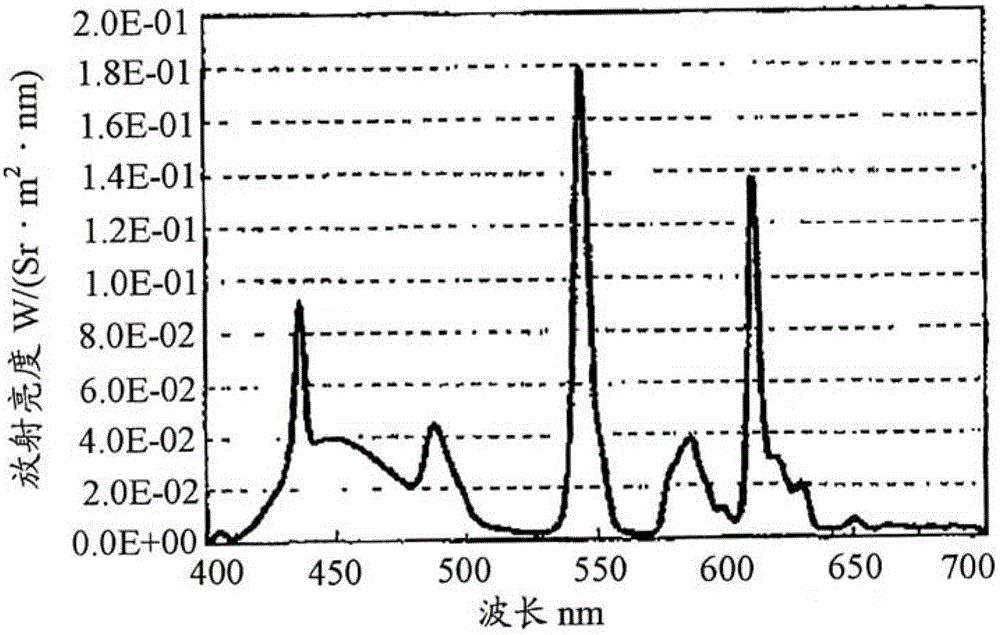

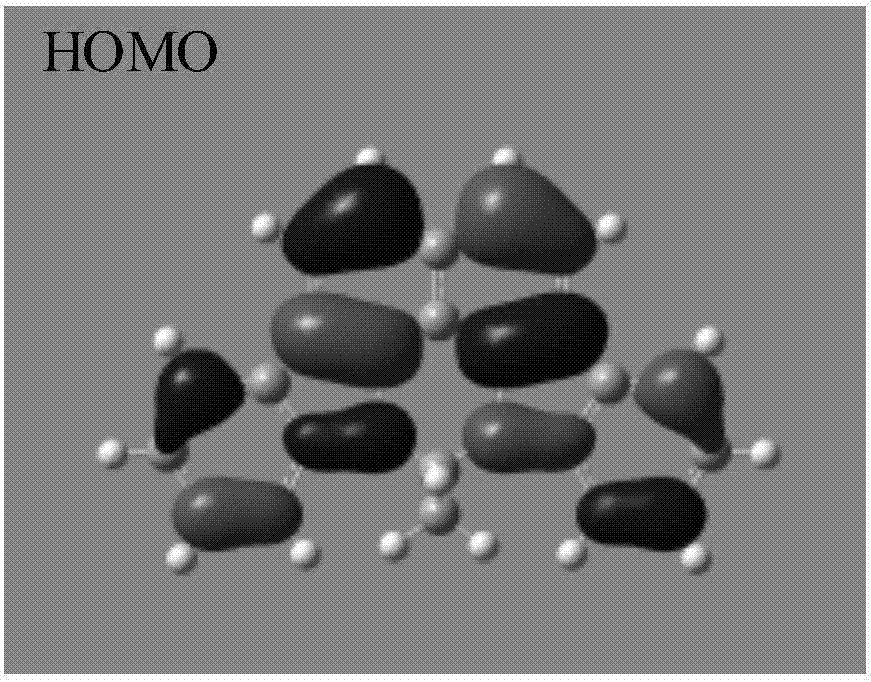

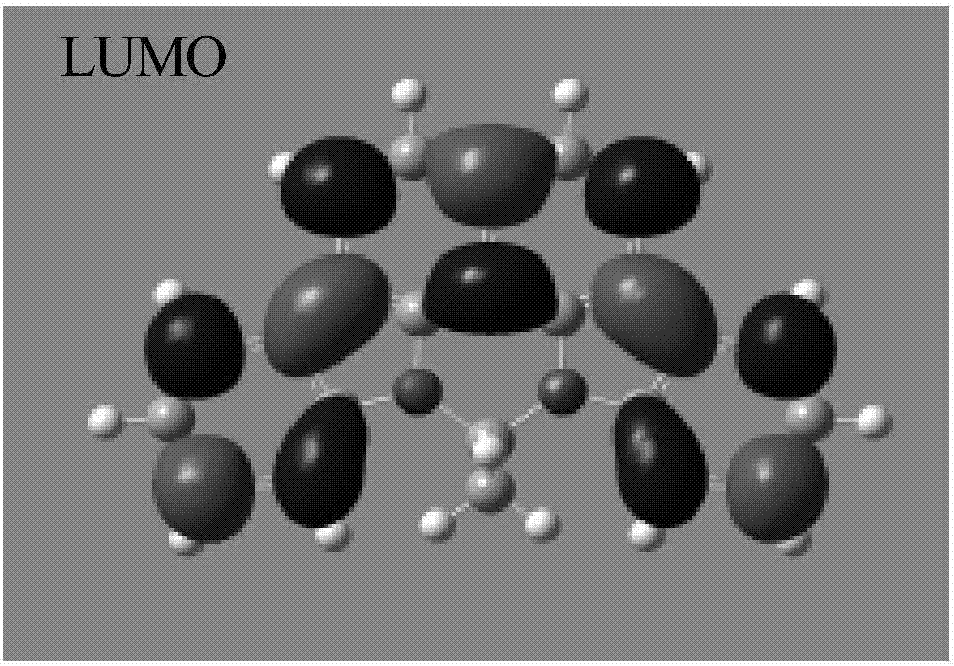

Novel organic electroluminescence device

ActiveCN107833974ALow working voltageImprove luminous efficiencyOrganic chemistrySolid-state devicesElectronic transmissionOrganic layer

The invention discloses a novel organic electroluminescence device. The device comprises a first electrode, a second electrode and one or more layers of organic layers between the first electrode andthe second electrode. Each organic layer at least comprises a light emitting layer and an electronic transmission layer. The device is characterized in that the thickness of each electronic transmission layer is 5-100nm; each electronic transmission layer comprises at least one kind of compound shown by the formula (I) shown in the description, wherein L is selected from a chemical bond, an arylidene or sub-polycyclic aromatic hydrocarbon group of C6-C12, and a sub-heteroaryl or sub-polycyclic heteroaryl aromatic hydrocarbon group of C3-C12; the Ar1, the Ar2 and the Ar3 are respectively selected from the substituted or non-substituted aryl or polycyclic aromatic hydrocarbon group of C6-C30, and the substituted or non-substituted heteroaryl group or polycyclic heteroaryl aromatic hydrocarbon group of C3-C30; the R1, the R2, the R3 and the R4 are selected from hydrogen, the alkylene of C1-C10, the halogen, the cyan, the nitryl, the substituted or non-substituted aryl or polycyclic aromatic hydrocarbon group of C6-C30, and the substituted or non-substituted heteroaryl group or polycyclic heteroaryl aromatic hydrocarbon group of C3-C30; and the R3 can be connected with the R4, so an annular structure can be formed. According to the invention, the device is advantaged by low working voltage and high light emitting efficiency.

Owner:BEIJING ETERNAL MATERIAL TECH +1

UV-curing coating

InactiveCN105295669AImprove wettabilityHigh hardnessAnti-corrosive paintsEpoxy resin coatingsIrritationSolvent

The invention discloses an UV-curing coating. The UV-curing coating comprises the following components in parts by weight: 16-25 parts of bisphenol A epoxy acrylate resin, 4-10 parts of phenolic epoxy acrylate, 8-15 parts of epoxidation oil propionate, 10-25 parts of active diluents, 1-5 parts of photoinitiators, 6-12 parts of organic amine, 1-4 parts of auxiliary agents and 30-50 parts of a solvent. The UV-curing coating is used for making a printed circuit board and a substrate which has difficult adherence performance or a soft base material, the UV-curing coating has the advantages of fast light-curing speed of the coating, high coating hardness, good corrosion resistance, good heat resistance, good wetability, light irritation on skin, easy acquisition of the raw materials, and low cost.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Method for preparing nano crystal TiO2 porous film using high viscosity solvent

InactiveCN1648285AIncrease film thicknessImprove equipment efficiencyCatalyst activation/preparationTitanium dioxideSolventChemistry

The present invention discloses method of preparing porous nanometer crystal TiO2 film in high viscosity solvent. Inside mixed solvent of anhydrous alcohol and high viscosity reagent terpineol or inside solvent of high viscosity reagent decyl alcohol, butyl titanate as precursor and complexing agent NH(C2H5OH)2 are added, mixed water and ethanol solvent is dropped, and template agent PEG is added via strong stirring to form sol; and through further sol pre-treatment, soaking-drawing film coating and calcining, porous nano crystal TiO2 film is prepared. The said process has increased film thickness, raised apparatus utilization, raised regularity and orderliness of pore structure and increased specific surface area of film. The porous nano crystal TiO2 film may be used widely in photocatalysis, electrochromism, chemical sensitive device, solar cell, etc.

Owner:TIANJIN UNIV

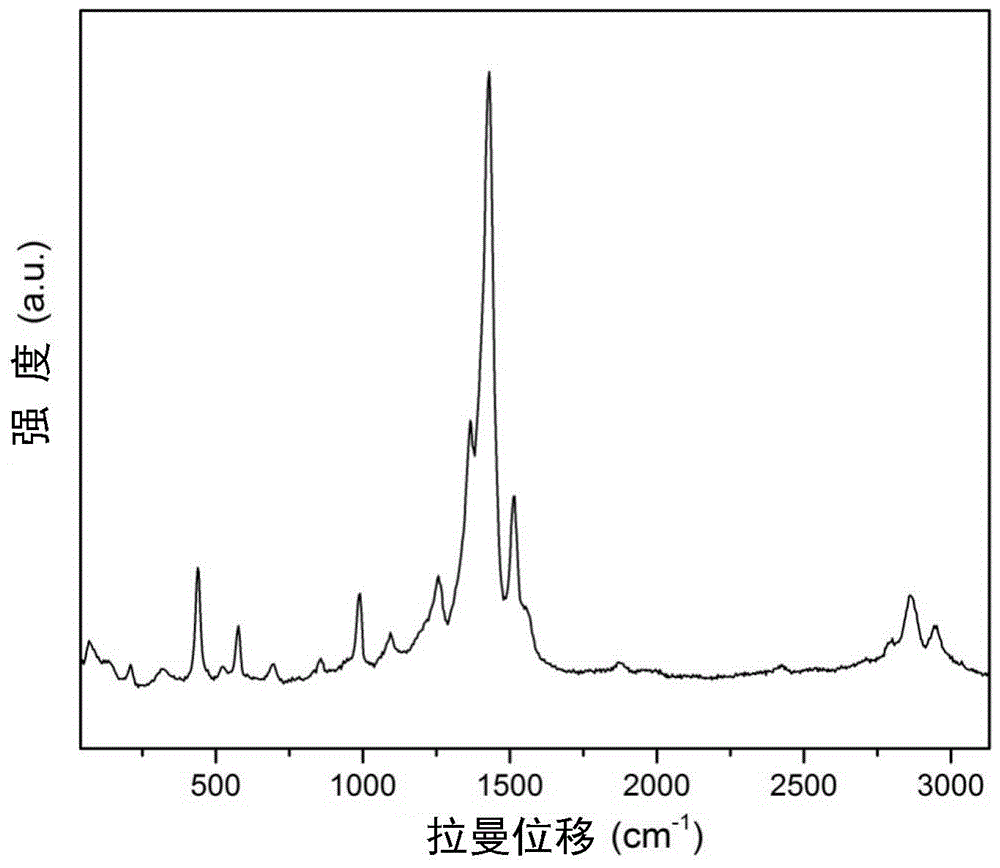

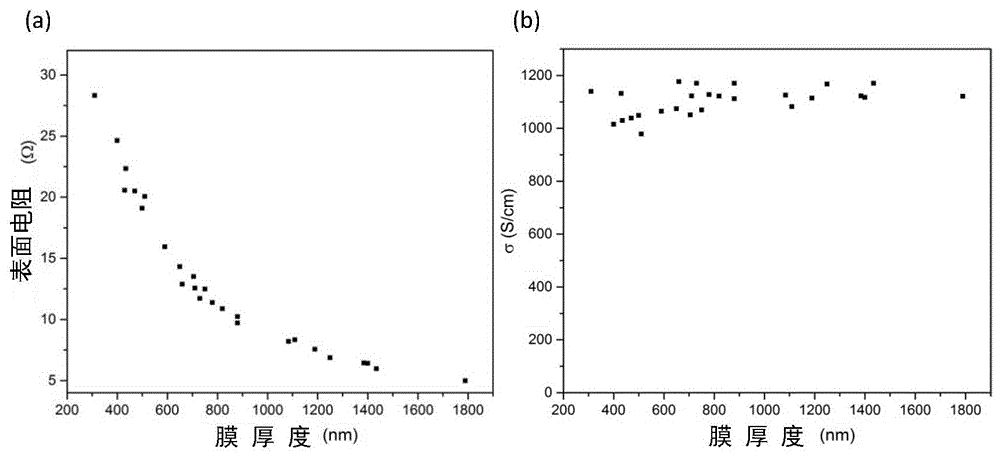

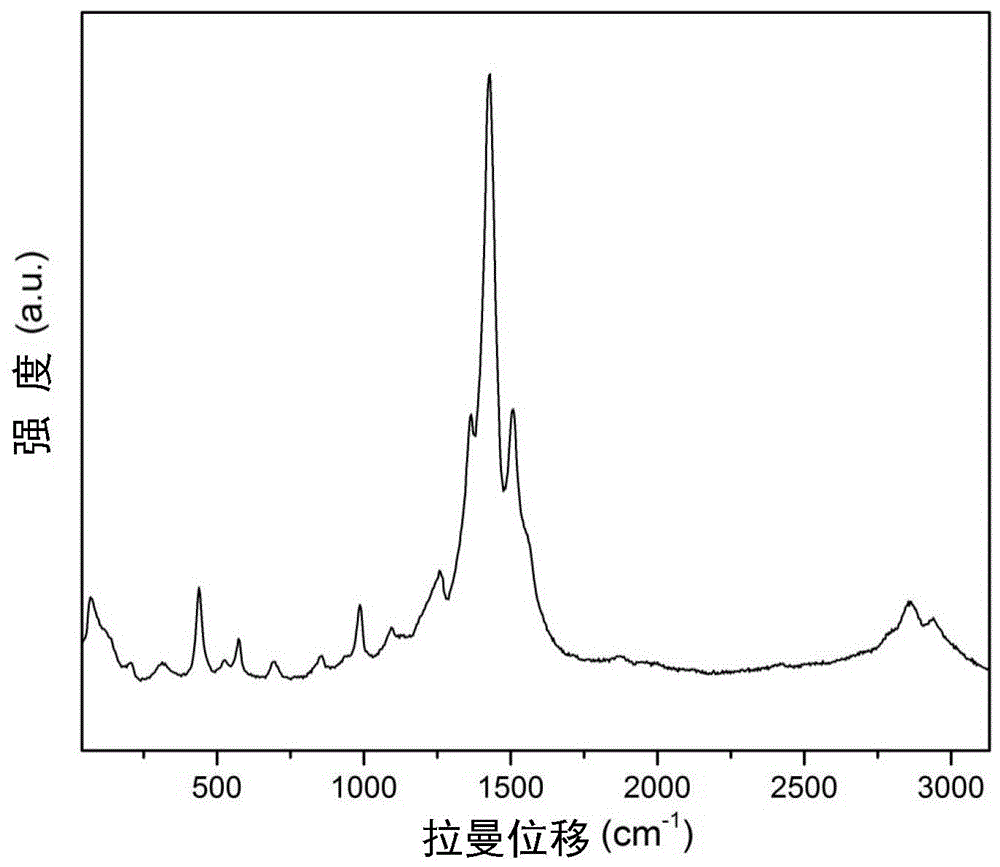

High-thickness and high-conductivity PEDOT film and preparation method thereof

ActiveCN106297968AIncrease film thicknessImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersElectro conductivityIon

The invention relates to a high-thickness and high-conductivity PEDOT film and a preparation method thereof. The PEDOT film containing PEDOT:X is prepared from an EDOT monomer as a raw material and a weak basic anion-containing high-alcohol-solubility ferric salt FeX<3> as an oxidizing agent by adopting a gas phase method or a solution method, wherein X is high-alcohol-solubility weak basic anions, preferably, at least one of camphosulfonate ions, long-chain alkylbenzene sulfonate ions, alkyl naphthalene sulfonate ions, dialkyl naphthalene sulfonate ions and dinonyl naphthalene disulfonate ions. According to the film and the preparation method thereof, by utilizing high alcohol solubility of a ferric salt oxidizing agent solution of a precursor, the concentration and viscosity of a spin-coating solution are improved, the crystallization of the oxidizing agent in a reaction process is inhibited, and copolymer anti-crystallization inhibitors (pyridine, PEPG and the like) do not need to be added, so that a high-thickness PEDOT film is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

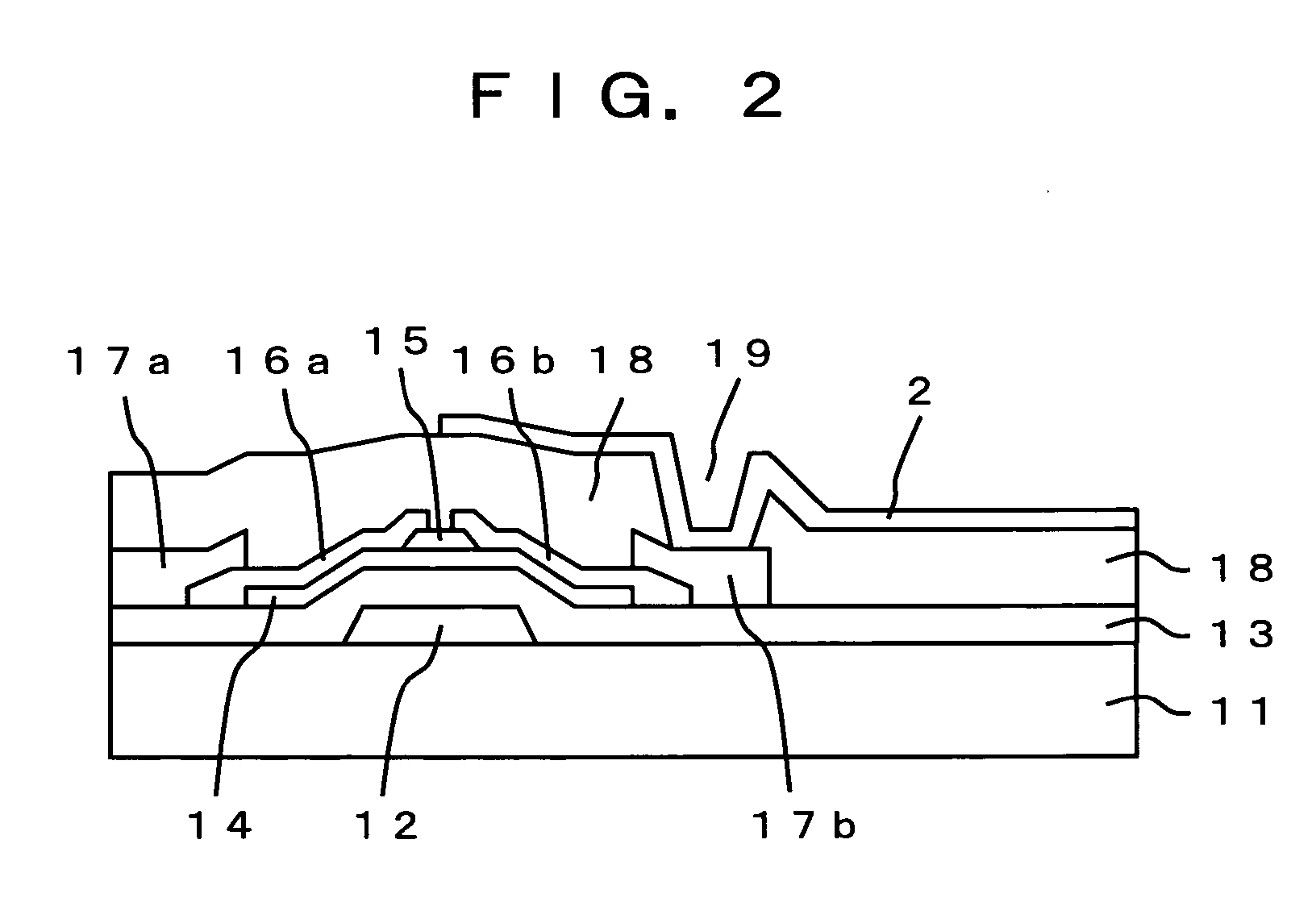

Solid-state imaging device and solid-state imaging device manufacturing method

InactiveCN1763963AImprove shadingImprove vertical accuracyOptical filtersSolid-state devicesSolid massEngineering

To provide a solid-state imaging device capable of improving color mixing, line shading, and sensitivity errors from adjacent color filter layers. It is a solid-state imaging device (1) in which a plurality of pixels having a photoelectric conversion element (13) and a color filter layer (21) formed on the photoelectric conversion element (13) are arranged in a matrix on a semiconductor substrate (11). ), in addition, on the boundary area with the adjacent photoelectric conversion element (13), there is a resin portion (20) formed protruding from the formation surface, and each color filter layer (21) is formed on the adjacent resin portion (20) ), the film thickness of each color filter layer (21) in the peripheral portion corresponding to the top portion is formed thinner than that in the central portion.

Owner:PANASONIC CORP

Coating composition, method for producing same, and laminate having hard coat layer

InactiveCN102272254AIncrease film thicknessGood dispersionCoatingsSpecial surfacesDiacetone alcoholHydrolysis

Provided is a coating composition which can form a hard coat layer with excellent transparency and excellent scratch resistance on the surface of an optical resin substrate such as a plastic lens, and which exhibits long-term storage stability. The coating composition comprises (A) composite metal oxide fine particles, (B') a hydrolyzate obtained by hydrolysis of (B) a hydrolyzable organosilicon component containing (B1) an epoxy-containing organosilicon compound such as gamma-glycidoxy-propyltrimethoxysilane, (C) water, (D1) a low-boiling and low-viscosity alcohol having three or fewer carbon atoms (such as methanol or ethanol), (D2) a low-boiling and high-viscosity alcohol (such as t-butanol), (D3) a high-boiling organic solvent having a boiling point of 150 DEG C or above and below 200 DEG C (such as diacetone alcohol), and (E) a curing catalyst such as tris(2, 4-pentanedionato)aluminum (III), wherein the (D1) / (C) mass ratio is 1.80 to 7.00; the (D2) / (C) mass ratio is 0.24 to 2.50; and the (D3) / (C) mass ratio is 1.10 to 4.40.

Owner:TOKUYAMA CORP

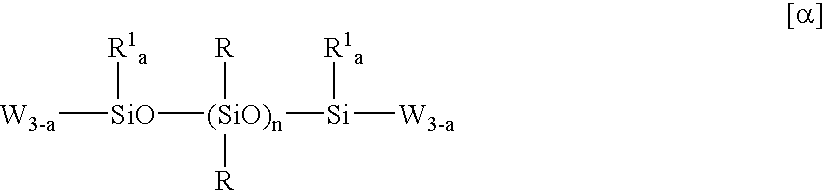

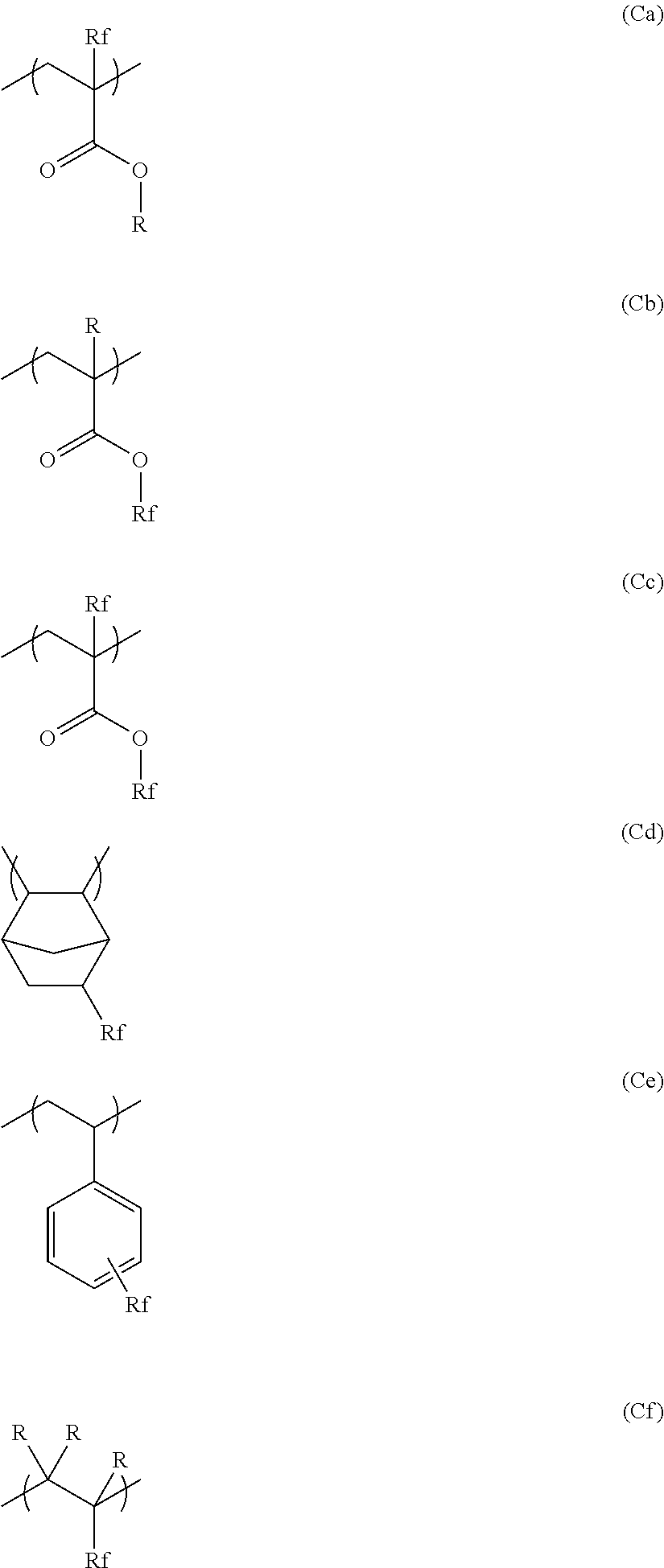

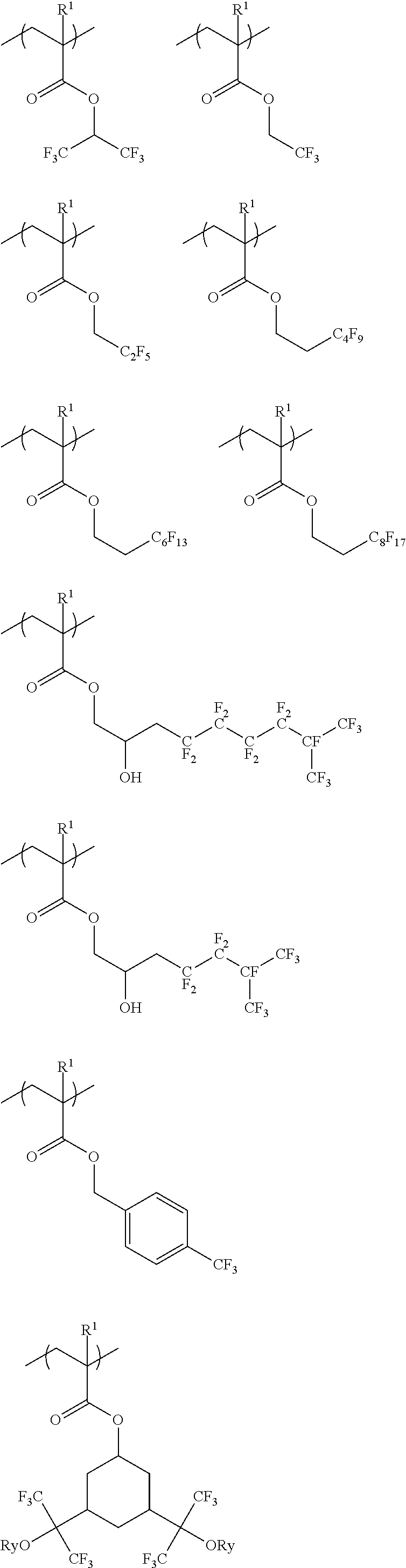

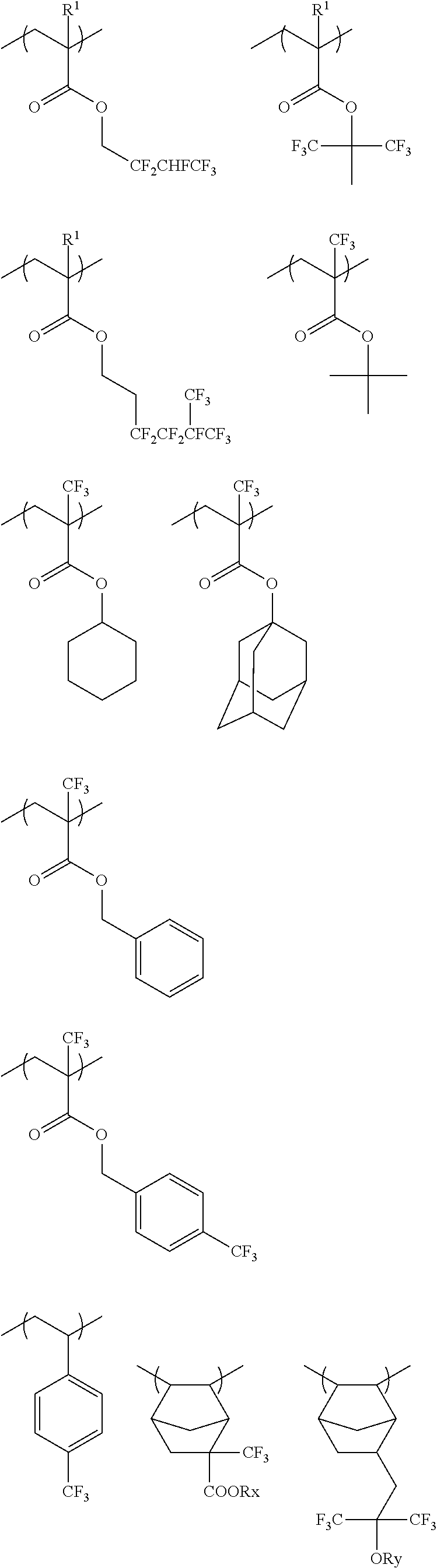

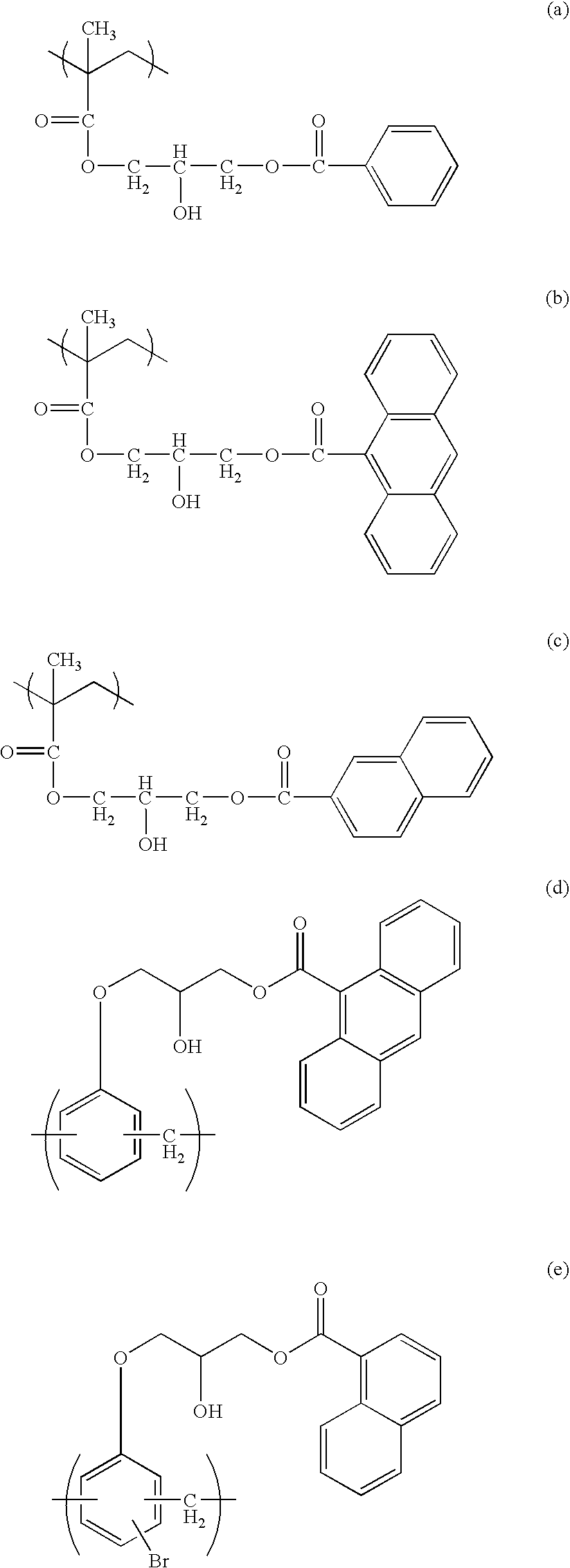

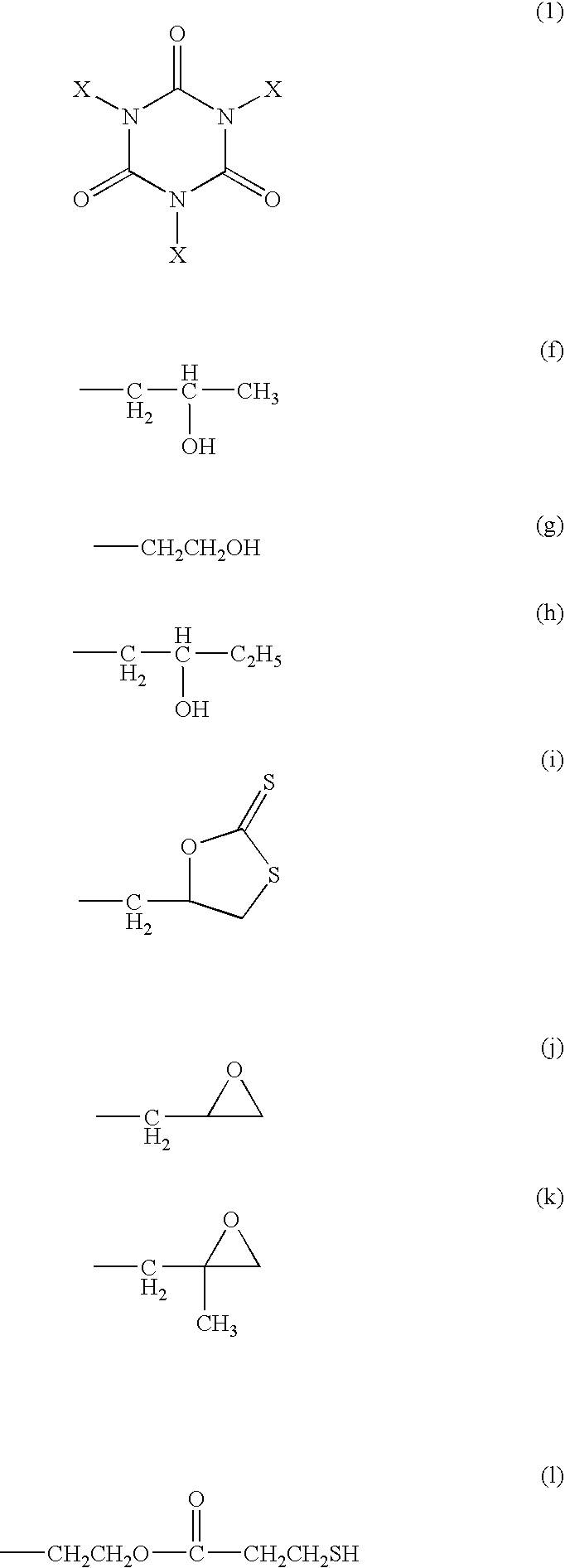

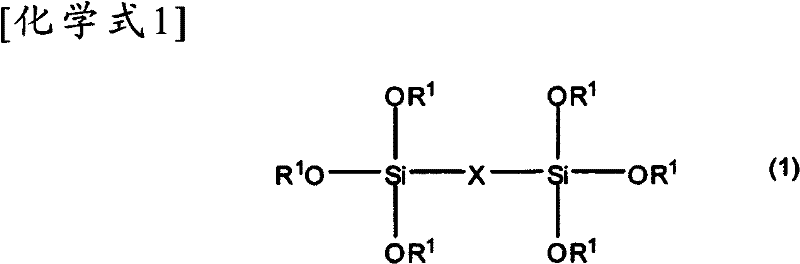

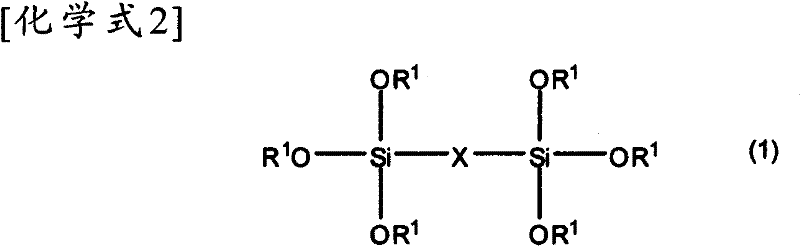

Negative photosensitive resin composition, partition wall and optical element

ActiveCN103765314AGood ink repellencyIncrease film thicknessElectroluminescent light sourcesOptical filtersSilane compoundsBoiling point

Provided is a negative photosensitive resin composition which is capable of producing a partition wall that has good ink repellency and is capable of maintaining the ink repellency even after being irradiated with ultraviolet light / ozone. This negative photosensitive resin also has good coating properties so that a film, which is obtained by coating and drying the negative photosensitive resin composition when a partition wall is produced, has uniform and even film thickness and so that the surface of the film is free from agglomerates. Also provided are: a partition wall which is formed using the negative photosensitive resin composition; and an optical element. A negative photosensitive resin composition which contains an alkali-soluble resin (A), a photopolymerization initiator (B), an ink-repellent agent (C) and a solvent (D) and is characterized in that the ink-repellent agent (C) is composed of a fluorine-containing silane compound and the solvent (D) contains a solvent (D1) that has a boiling point of 165-210 DEG C in an amount of 10-100% by mass relative to the total mass of the solvent (D); and a partition wall which is formed of a cured film of the negative photosensitive resin composition so as to have a shape that divides the surface of a substrate into a plurality of compartments.

Owner:ASAHI GLASS CO LTD

Perimidine derivative and application thereof

InactiveCN107880049ASimple manufacturing processRaw materials are easy to getSilicon organic compoundsSolid-state devicesArylHalogen

The invention provides a compound of general formulae (I) and (II), wherein A1 and A2 are independently selected from C1-12 alkyl, C6-60 substituted or unsubstituted aryl and C10-60 substituted or unsubstituted condensed ring aryl, separately; the substituted aryl specifically means that the substituent is selected from C1-6 alkyl, halogen and CN or Si(R2)3, and R2 is selected from C1-6 alkyl; andthe substituted condensed ring aryl specifically means that the substituent is selected from C1-6 alkyl, halogen and CN or Si(R2)3, and R2 is selected from C1-6 alkyl. The compound of the general formulae can be used in organic electroluminescence devices.

Owner:BEIJING ETERNAL MATERIAL TECH +1

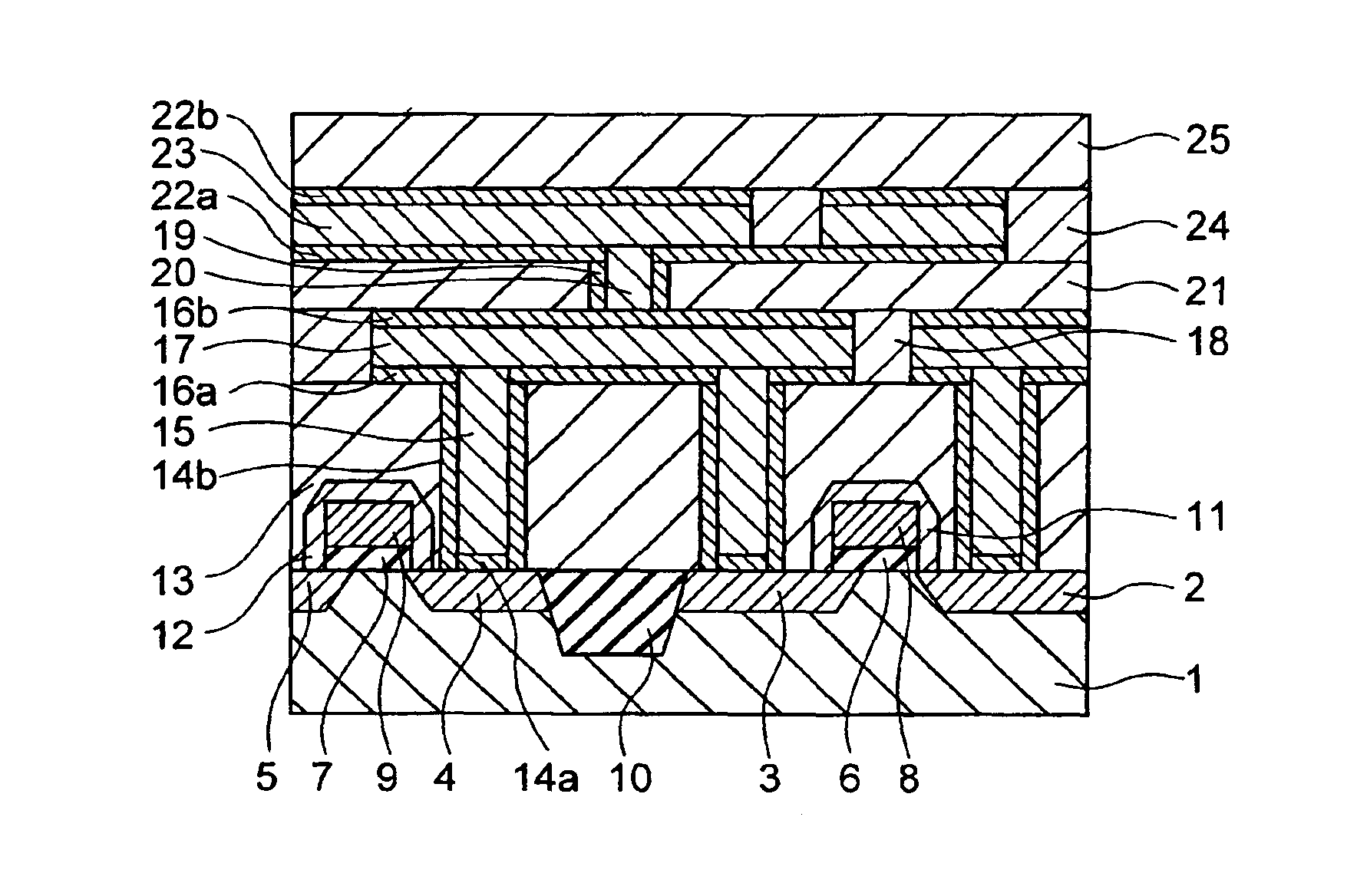

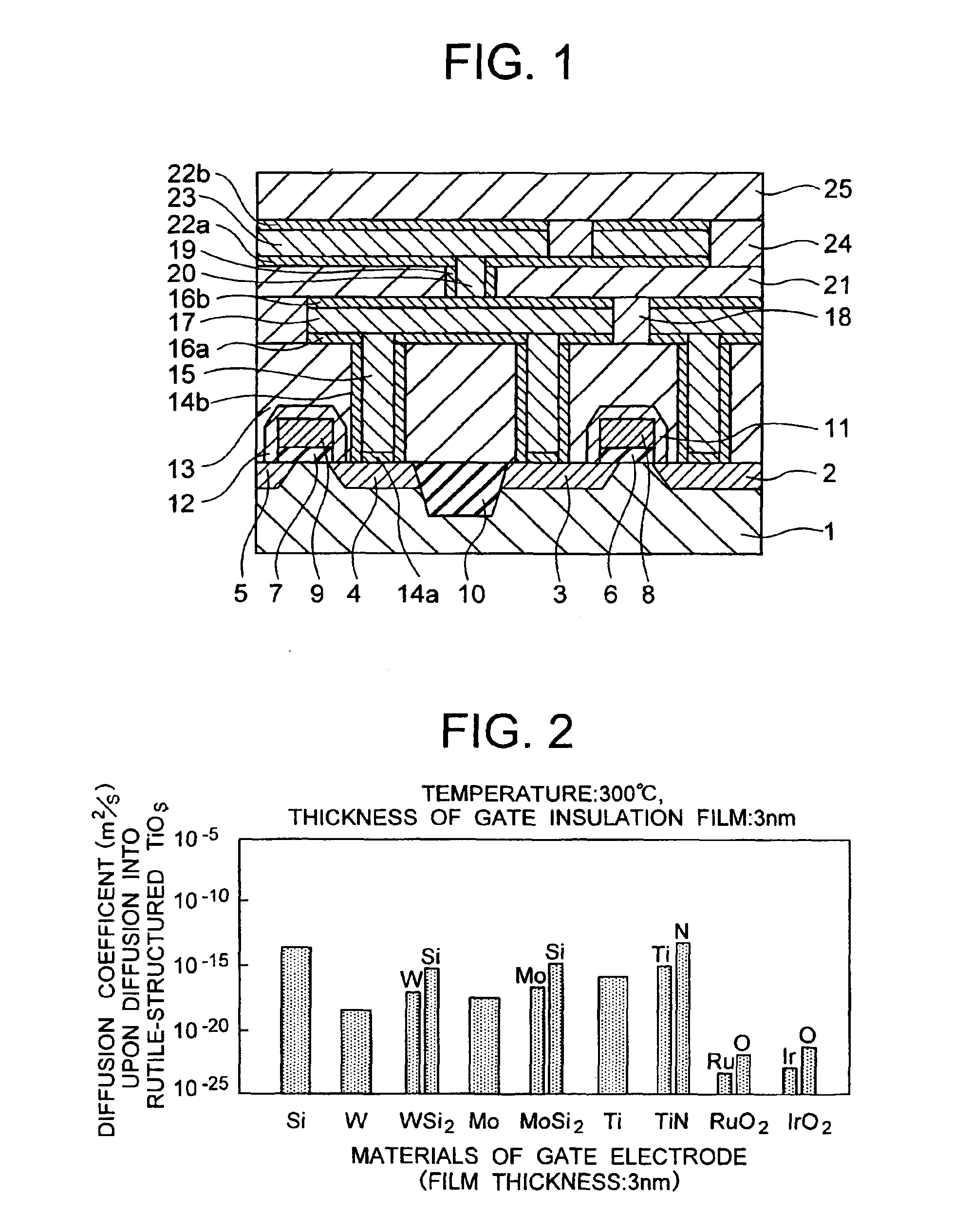

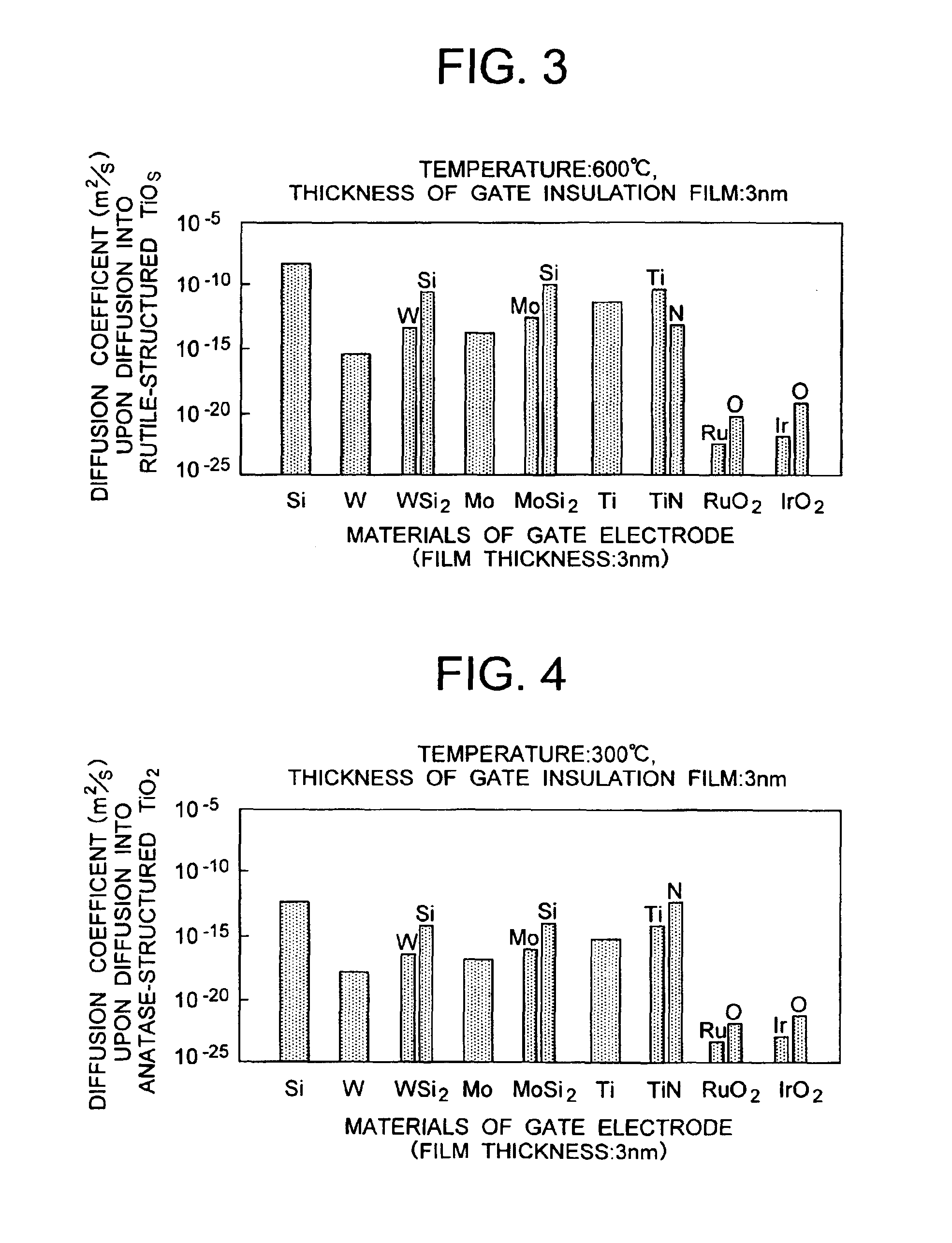

Semiconductor device and method of manufacturing the same

InactiveUS6943076B2Increase film thicknessMaintenance characteristicTransistorSolid-state devicesElectrically conductiveTitanium oxide

Gate insulation films each containing titanium oxide as a primary constituent material are formed on one major surface of a semiconductor substrate. Gate electrode films are formed in contact with the gate insulation films. The gate electrode films contain ruthenium oxide or alternatively iridium oxide as a primary constituent material. In order to prevent electrically conductive elements from diffusing into titanium oxide of the gate insulation films, ruthenium oxide or iridium oxide is effectively used as a primary constituent material of the gate electrodes. A semiconductor device can be realized in which occurrence of a leak current is suppressed by increasing a physical film thickness while sustaining desired dielectric characteristic.

Owner:RENESAS ELECTRONICS CORP

Colorant dispersion liquid, colored resin composition, color filter and liquid crystal display

InactiveCN1918250AExcellent adhesionInhibit dry condensationOptical filtersOrganic dyesSolventLiquid-crystal display

Disclosed is a colorant dispersion liquid which enables to reduce the amount of undissolved photosensitive colored composition remaining in non-image portions on a substrate when it is applied over the substrate. The colorant dispersion liquid has excellent adhesion to the substrate and does not deteriorate image-forming properties such as curability, so that it enables to produce a color filter having high concentration and low film thickness. In addition, since drying / clogging at a die lip edge is suppressed during application of this colorant dispersion liquid by die coating, this colorant dispersion liquid enables to produce a color filter with high yield. Specifically disclosed is a colorant dispersion liquid containing a colorant (A), a dispersing agent (B) and a solvent (C) which is characterized in that the dispersing agent (B) contains at least a graft copolymer (a) containing a nitrogen atom and a polymer (b) which is obtained by polymerizing a monomer component essentially containing a specific compound.

Owner:MITSUBISHI CHEM CORP

Magnetron sputtering device and magnetron sputtering method

ActiveCN105568240AEven consumptionAverage consumption rateVacuum evaporation coatingSputtering coatingSputteringReciprocating motion

The invention provides a magnetron sputtering device and a magnetron sputtering method. A magnet set in the magnetron sputtering device is set to have a plurality of magnet units which are arranged at intervals and distributed in a matrix way, and the S poles and the N poles of the plurality of magnet units in each line and each row of the magnet set are alternatively distributed to form a uniform magnetic filed with matrix periodicity, so that the wear rates of all regions of a target are uniform, target utilization rate is greatly improved, and the film thickness and stress uniformity of film formation are improved; and meanwhile, during magnetron sputtering processing, a motor can drive the whole magnet set to reciprocate in front-back and left-right directions in a horizontal direction, and a plurality of motors can control the plurality of magnet units to respectively move up and down, so that the consumption of the target is more uniform, and the service life of the target is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Chromium-free passivation method for galvanized steel sheet by using molybdate/polyphosphate composite system

InactiveCN102747360AImprove corrosion resistanceStop pittingMetallic material coating processesAcid etchingChromium free

The invention relates to a chromium-free passivation method for a galvanized steel sheet by using a molybdate / polyphosphate composite system. The method overcomes the problems of high cost and insufficient corrosion resistance of a passive film in the prior art and realizes passivation of a galvanized steel sheet through the two steps of acid etching and passivation so as to achieve the purposes of protection and decoration. Molybdate and polyphosphate are utilized as main salts for a passivation solution used in the method and are assisted by other additives, and the passivation solution can form a compact passive film on the galvanized steel sheet so as to realize chromium-free passivation of the galvanized steel sheet. Steps of the method comprise: a degreasing procedure, an acid pickling procedure, a passivation procedure, at least a rinsing procedure and a drying procedure. According to the invention, a novel composite passivation system is used, an obtained passivation layer has better corrosion resistance and can provide good protection for the galvanized steel sheet, and the advantages of reduction in production cost, decrease in environmental pollution and easiness in realization of industrialization are obtained.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com