Magnetron sputtering device and magnetron sputtering method

A magnetron sputtering device and magnetron sputtering technology are applied in sputtering coating, ion implantation coating, metal material coating process, etc. The effect of uniform consumption rate and improved uniformity of film thickness and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

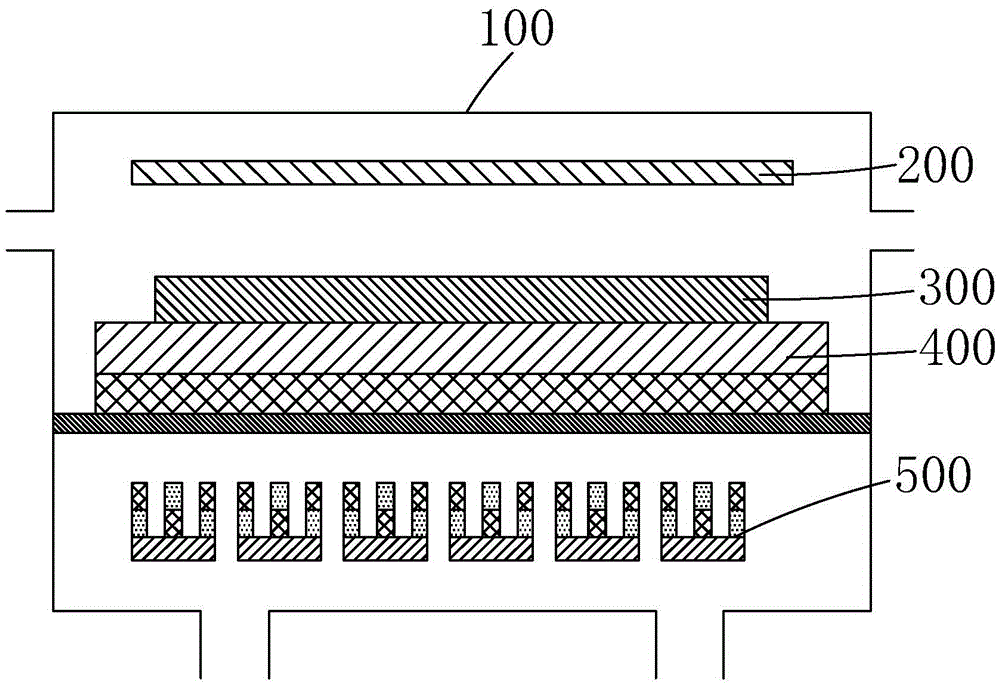

[0045] see Figure 7 , the present invention firstly provides a magnetron sputtering device, comprising a cavity 1, and a partition 20 disposed inside the cavity 1 and connected to the cavity 1, the partition 20 divides the cavity 1 divided into a first chamber 30 and a second chamber 40;

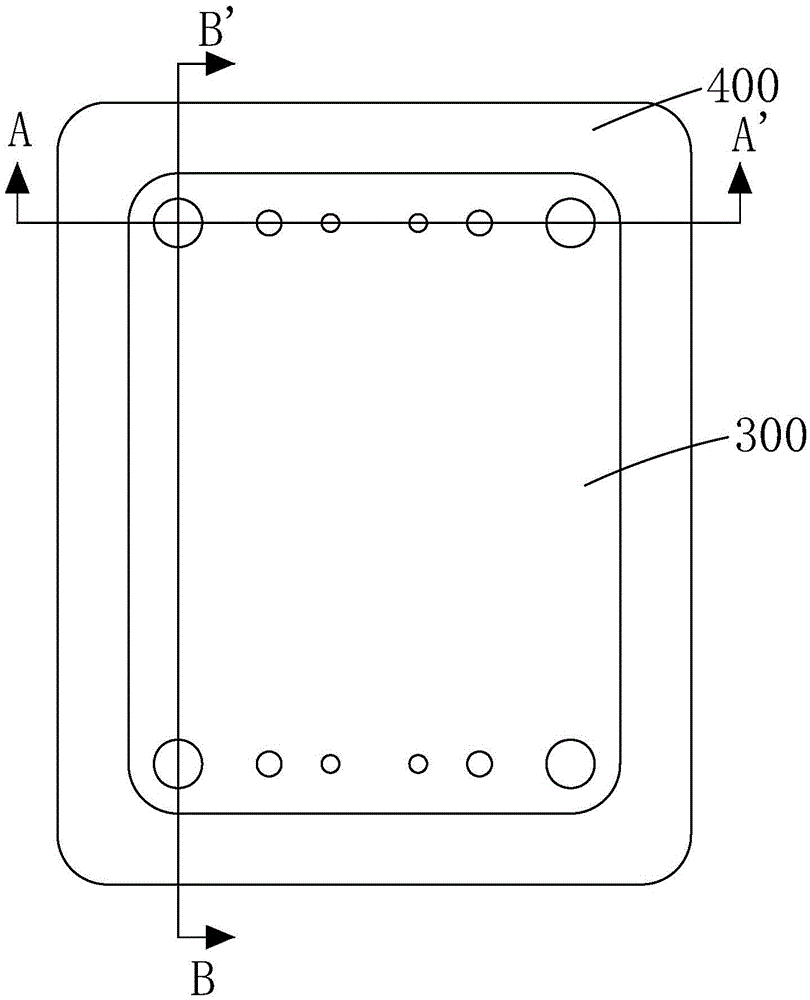

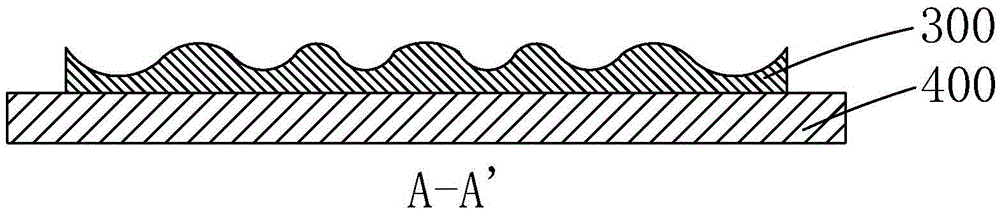

[0046] The first chamber 30 is provided with an anode plate 2, an insulating plate 35 on the separator 20, a back plate 4 on the insulating plate 35, and a back plate 4 on the back plate 4. The target material 3; the second chamber 40 is provided with a magnet group 5, and there is a distance between the magnet group 5 and the separator 20;

[0047] The magnet group 5 includes a magnetic conductor back plate 52 and several magnet units 51 that are spaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com