Patents

Literature

261results about How to "Solve consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for detecting an access point in a radio access system

InactiveUS20140066054A1Reduce power consumptionSolve consumptionAssess restrictionWireless commuication servicesCellular radioRadio access technology

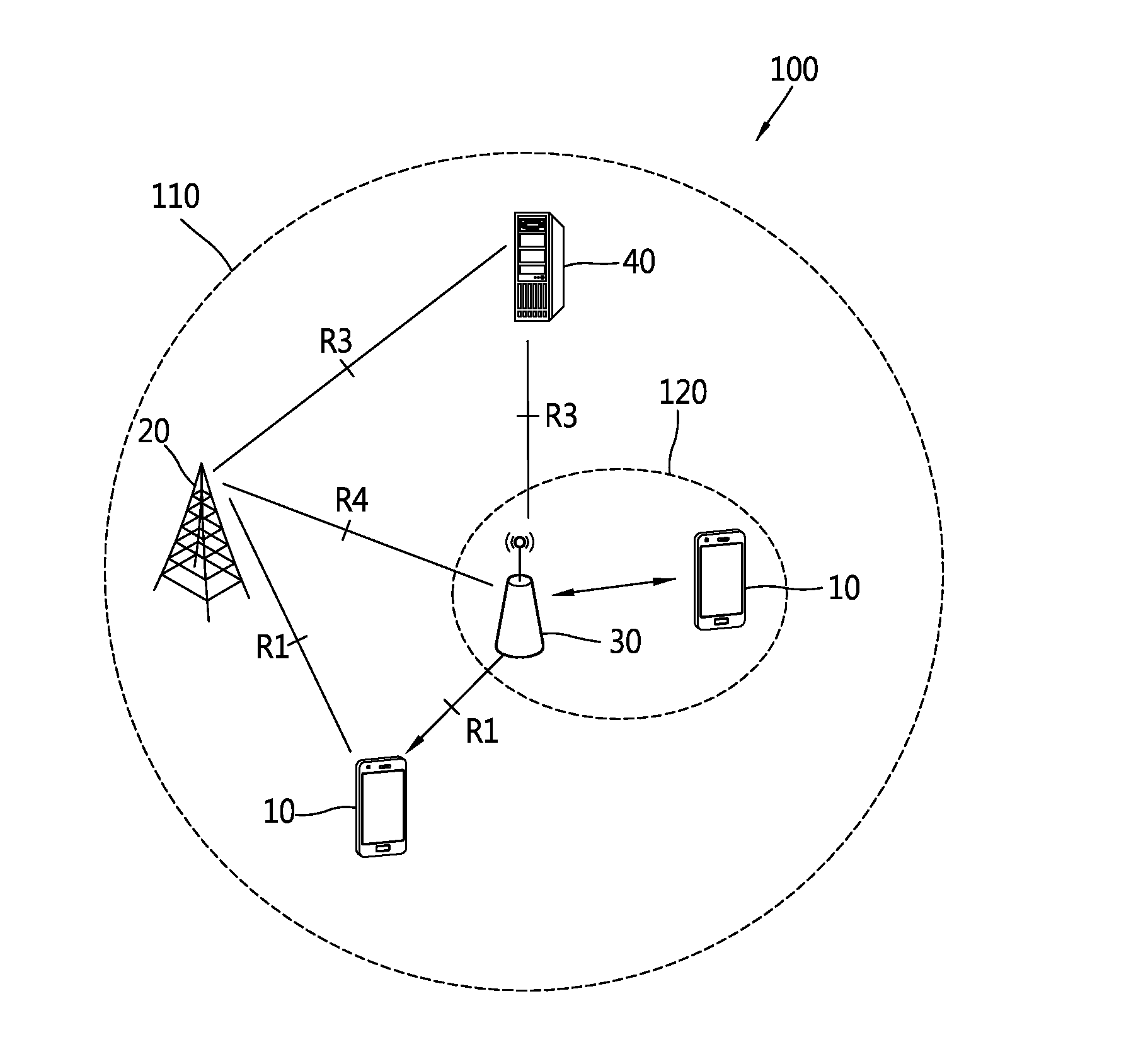

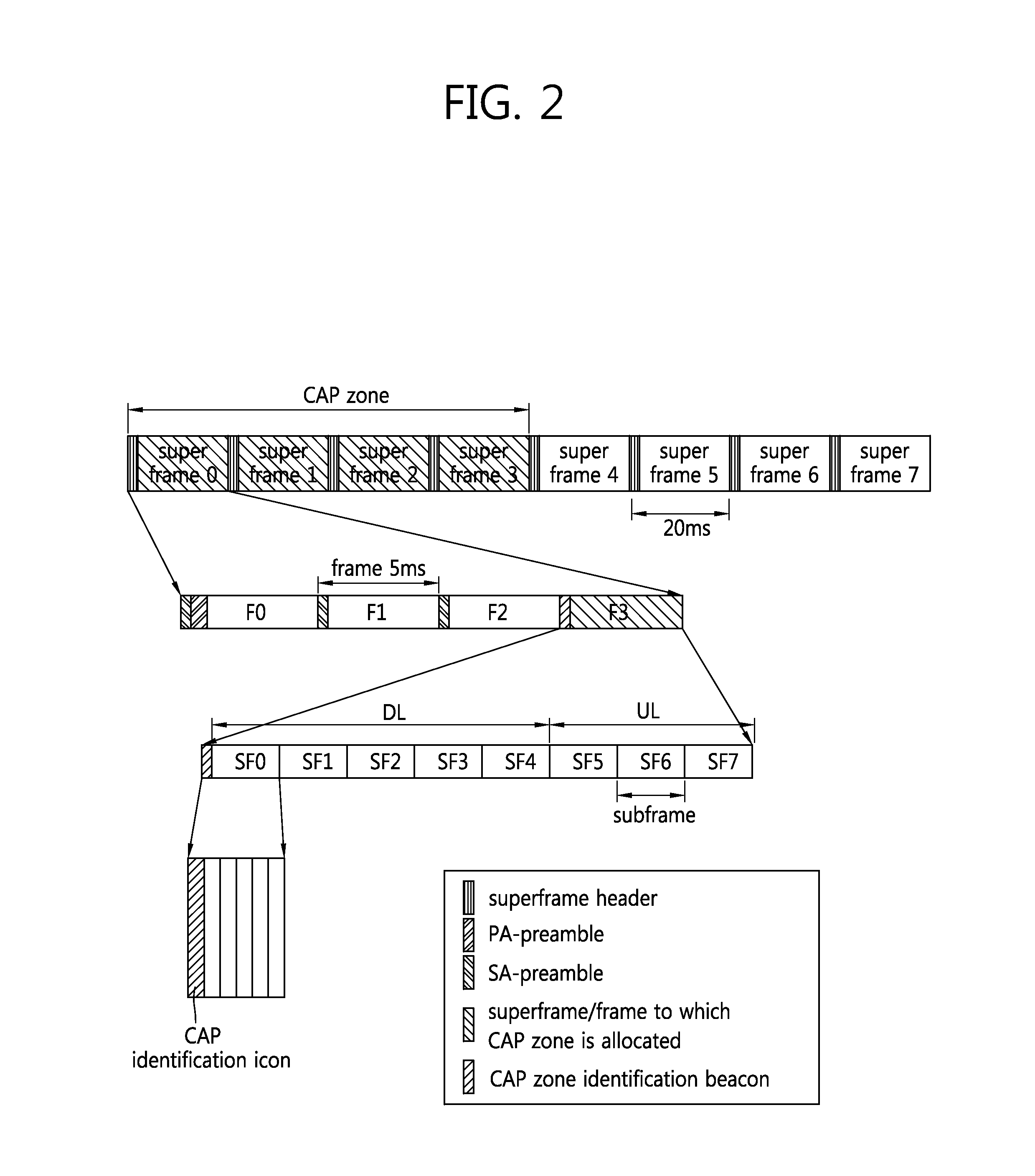

The present disclosure relates to a method for performing communication between a terminal and a base station in a radio access system supporting multi-radio access technology (RAT), the method being characterized in that it comprises the steps of performing an access procedure between a first base station supporting a cellular radio access technology and a second base station supporting a short-range radio access technology; the second base station receiving, from the first base station and through a first radio scanner, control information relating to the transmission of an identification signal (IDS) for detecting the second base station of the terminal; and the second base station transmitting the IDS through the first radio channel to the terminal based on the received control information, wherein the first radio channel is the radio channel corresponding to the first base station.

Owner:LG ELECTRONICS INC

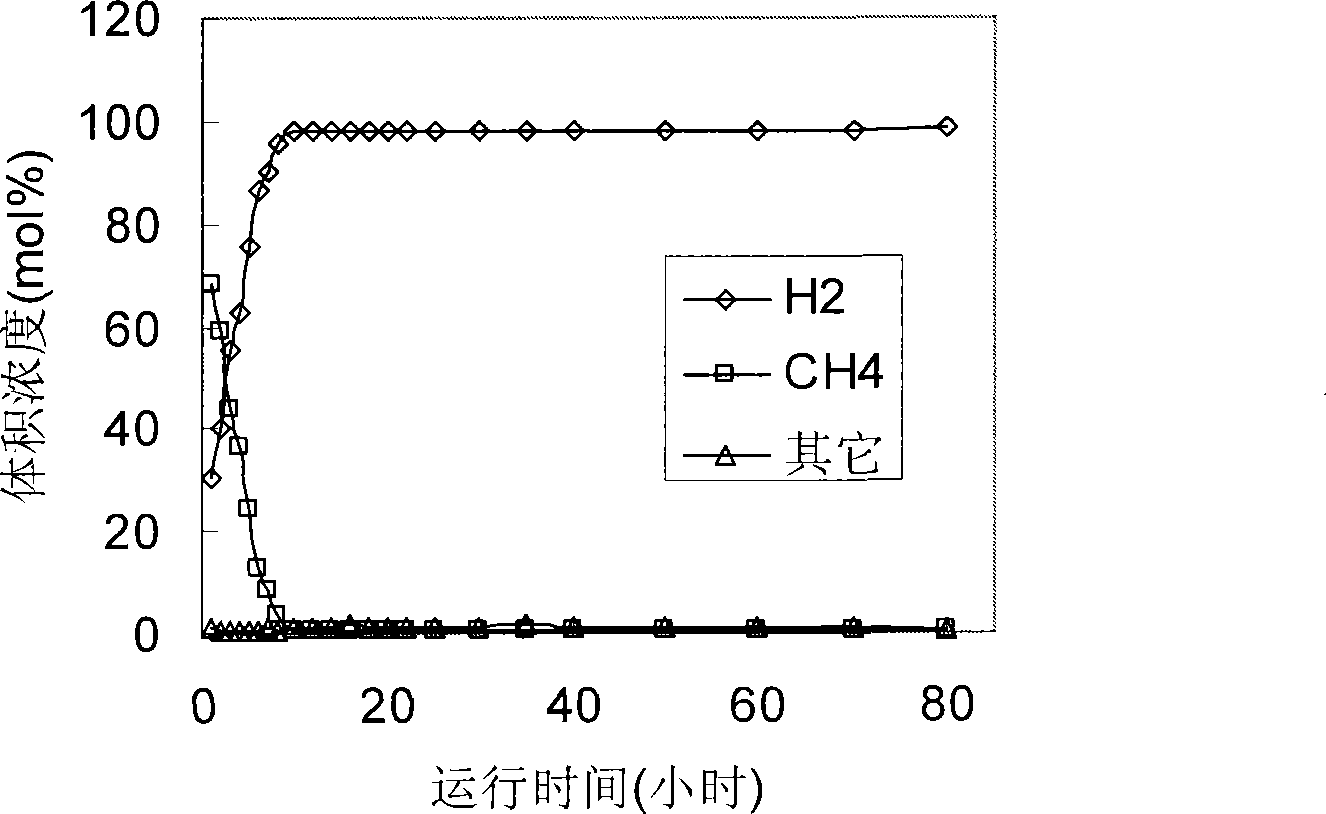

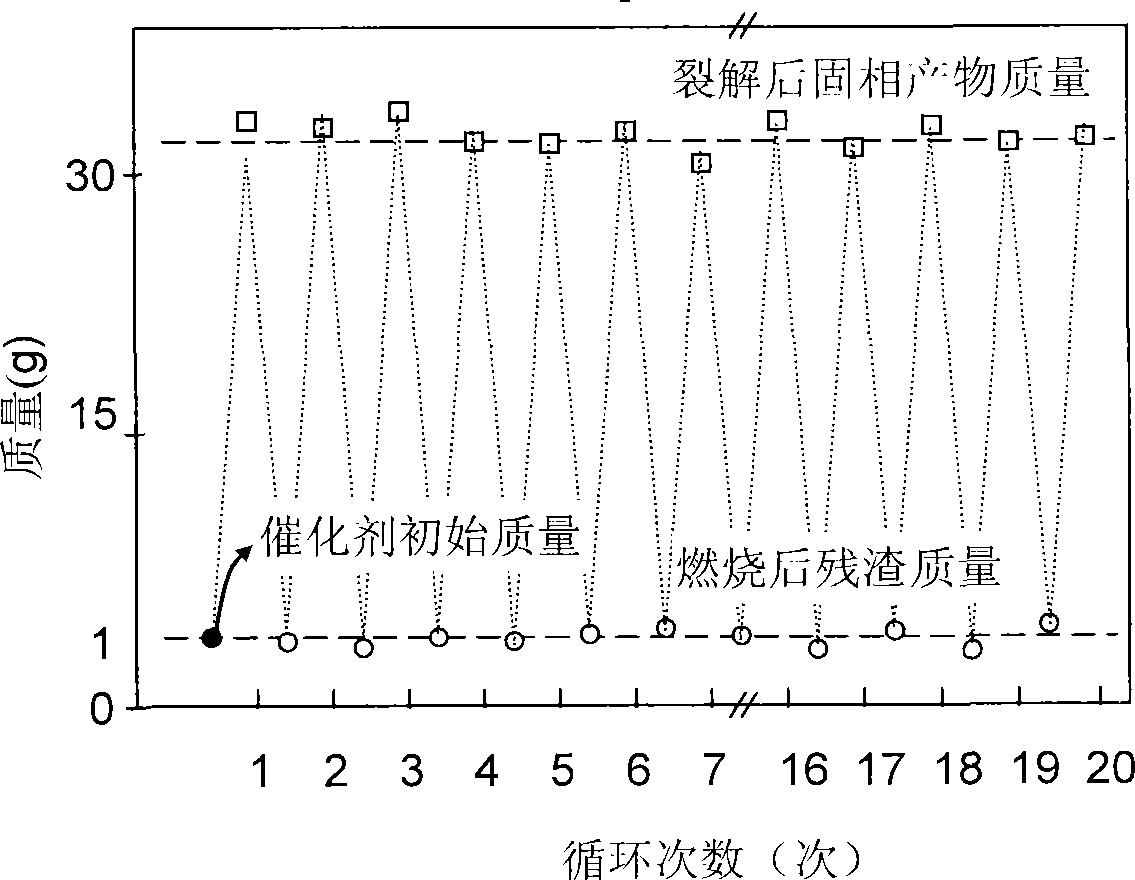

Technique for preparing hydrogen gas by hydrocarbons gases

The invention relates to a process for preparing hydrogen by hydrocarbon gases, which cracks the hydrocarbon gas to hydrogen and carbon / catalyst composite material by means of catalysis. The hydrogen is the product, and solid products are used as fuel to provide energy for the cracking process. Burned residue is recycled and cycled to be catalyst in the process of preparing the hydrogen. In the process of preparing the hydrogen of the invention, besides, the hydrogen with high purity and without CO and CO2 can be obtained, the catalyst is not consumed due to the recycling use of the catalyst, and problems that the catalyst losing activity results in an unstable system and the like are not existed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

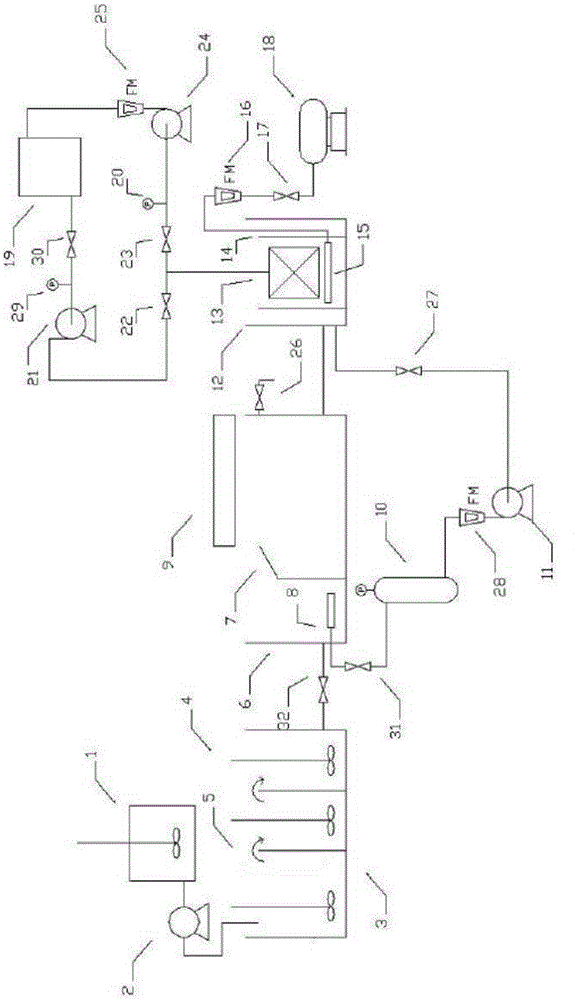

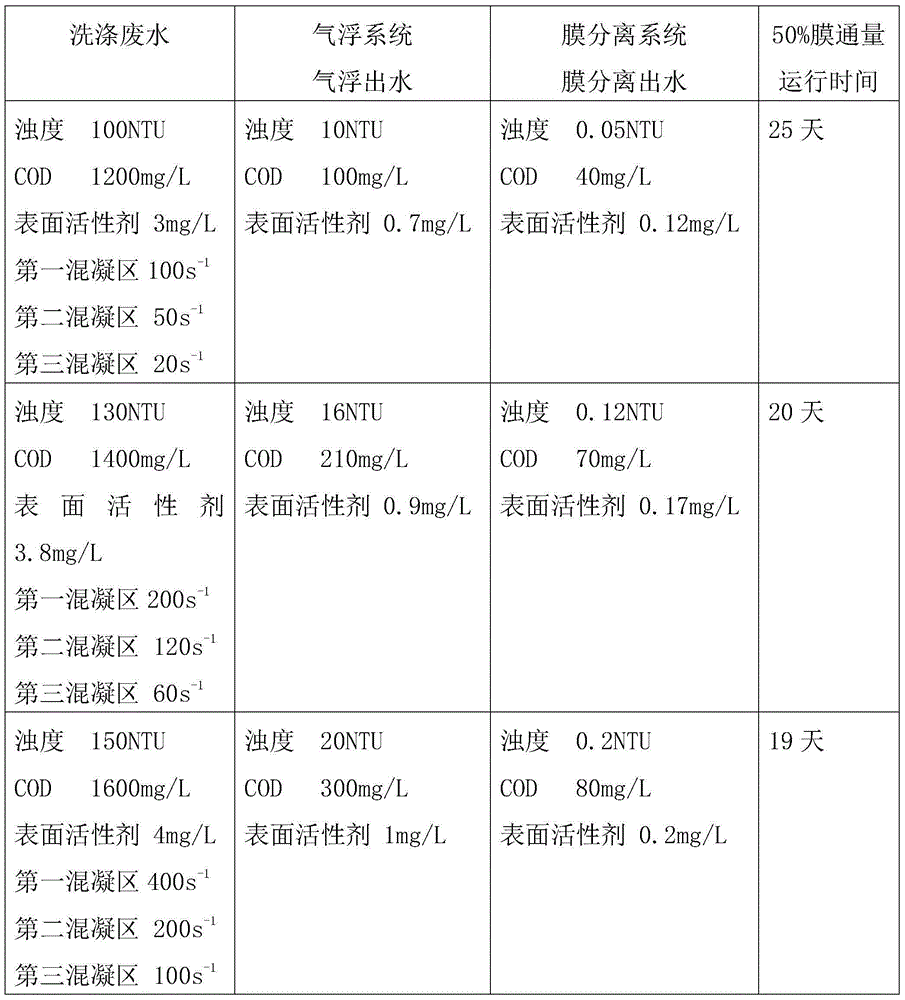

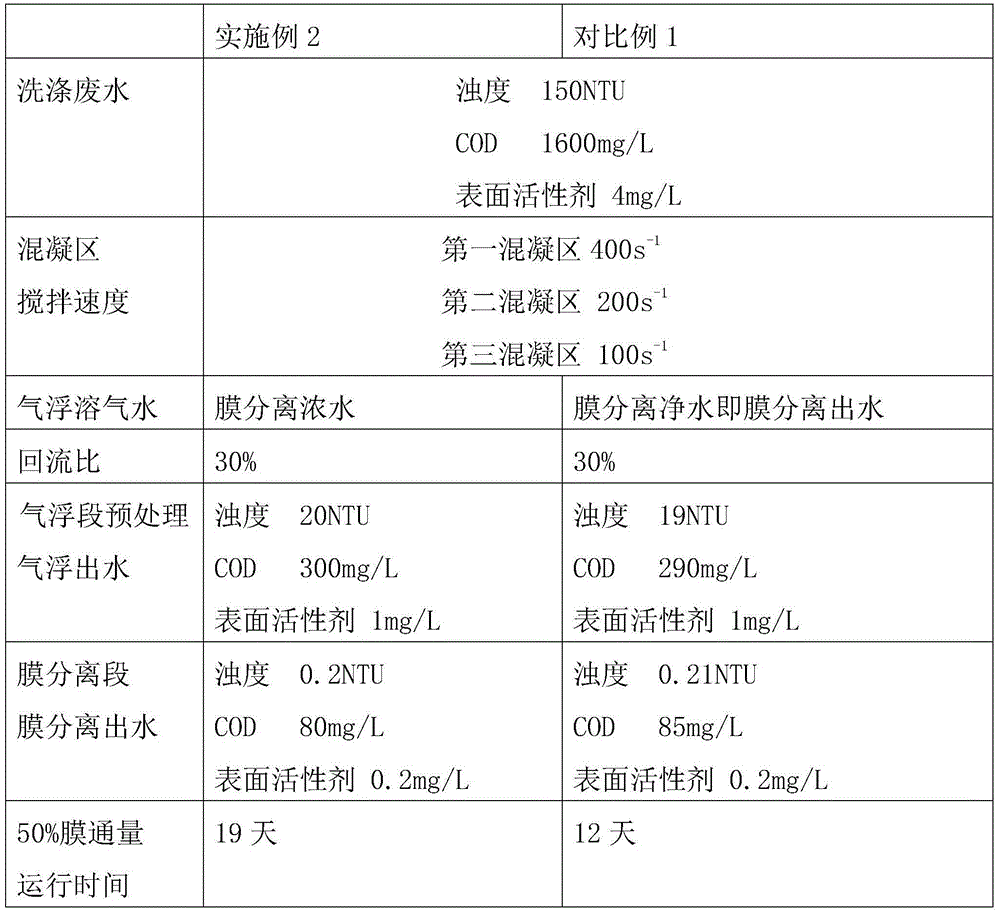

External circulation type pressurized dissolved air floatation-membrane separation water treatment method and device

ActiveCN103979706AReduce pollutionGuaranteed hydraulic retention timeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationWastewater

The invention discloses an external circulation type pressurized dissolved air floatation-membrane separation water treatment method, which comprises the following steps that a. chemicals are added into wastewater to be treated, and coagulation reaction is completed through a coagulation system; b. wastewater subjected to coagulation enters an air floatation system to be subjected to partial backflow pressurized dissolved-air air floatation; and c. air floatation outlet water subjected to air floatation treatment enters a membrane separation system, and completes the membrane separation process under the effect of a membrane assembly, treated purified water and concentrated water are obtained, and the concentrated water obtained after membrane separation is injected into a dissolved air tank of the air floatation system in the step b from the bottom of a membrane separation pool for forming dissolved air water. The method provided by the invention has the advantages that the membrane pollution can be effectively relieved; the membrane flux is improved; in addition, the problem of low air floatation efficiency in the existing membrane-air floatation equipment is solved; the air floatation effect is more effectively realized; and the method and the device can be applicable to deep treatment of higher-concentration wastewater.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

Method of producing propionic acid and propionate by microorganism fermentation

ActiveCN101748163AImprove securitySolve consumptionMicroorganism based processesCarboxylic acid salt preparationChemical synthesisPropanoic acid

The invention relates to a method of producing propionic acid and propionate by microorganism fermentation, which is characterized by using microorganism fermentation technology to produce propionic acid; with propionibacterium, charging the nitrogen into basic fermentation culture medium which takes glycerin as a carbon source for anaerobic fermentation culture; movably adding the aqueous solution of calcium hydroxide, or the alkaline solution or the saline solution of sodium hydroxide and calcium carbonate with the ongoing of fermentation, adjusting the fermentation liquor and maintaining the pH value between 6.5 to 7.5; movably adding the aqueous solution of glycerin after the fermentation preformed for a period of time; the fermentation is finished when the content of glycerin stops increasing and is more than 35g / L; and then filtering the fermentation liquor through a pressure filter, getting the filtered solution, charging the filtered solution into a spray tower for spray drying, and the dried powder is the propionate product. The invention has the effects: the method can substitute the existing chemical synthesis to produce propionic acid, remarkably improving the safety of the propionic acid product, and is a green food additive; moreover, the problem of consumption of non-renewable resources (such as oil) can be solved without a secondary processing, the negative impact generated by chemical synthesis can be prevented, and the process flow and the cost can be saved; and the invention particularly opens up an industrialization stage of the propionic acid production by fermentation and the simultaneous production of the propionate.

Owner:意葆(上海)生物科技有限公司

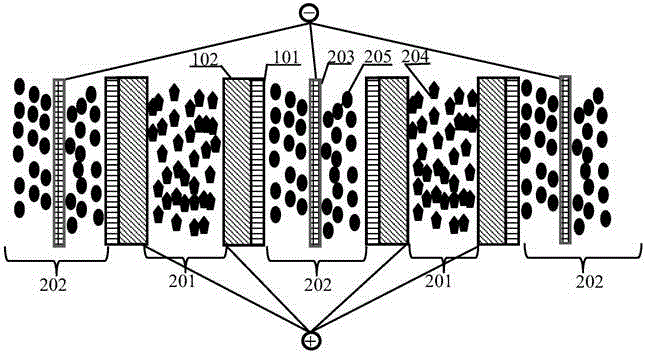

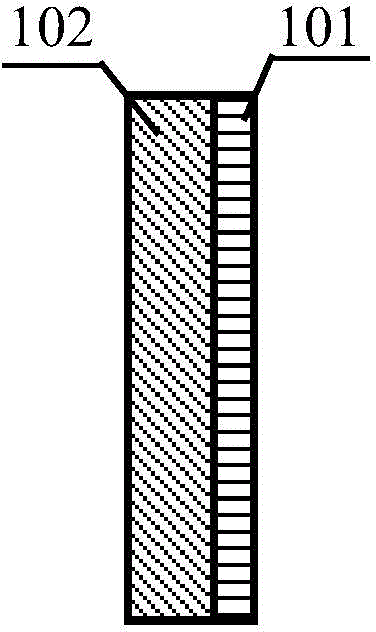

Lithium slurry battery reactor

ActiveCN106159302AThe height of the cavity can be adjusted arbitrarilySolve consumptionFuel cell auxillariesRegenerative fuel cellsLithiumDiaphragm structure

The invention provides a lithium slurry battery reactor. The lithium slurry battery reactor comprises positive pole reaction cavities, negative pole reaction cavities, unipolar diaphragms, negative pole current collectors, positive pole slurry and negative pole slurry, wherein each unipolar diaphragm is formed by an isolating layer and a positive pole porous current collector layer located on a single side of the isolating layer through close contacting, and a plurality of unipolar diaphragms are sequentially stacked in the sequence that isolation layers are placed oppositely; the distance between every two adjacent positive pole porous current collector layers is larger than 0 and preferably ranges from 1 mm to 10 mm, a gap between the every two adjacent positive pole porous current collector layers forms one positive pole reaction cavity, and the positive pole slurry is located in the positive pole reaction cavity; the distance between two adjacent isolating layers is larger than 0 and preferably ranges from 1 mm to 20 mm, and a gap between the adjacent isolating layers forms one negative pole reaction cavity; the negative pole current collectors are located in the negative pole reaction cavities, and the negative pole slurry is located between the negative pole current collectors and the isolating layers. With the adoption of the unipolar diaphragm structure, the problems of consumption of lithium ions and increasing of polarizing internal resistance due to deposition of metal lithium on the negative pole porous current collector layers in a bipolar diaphragm structure are solved.

Owner:南京竞予能源有限公司

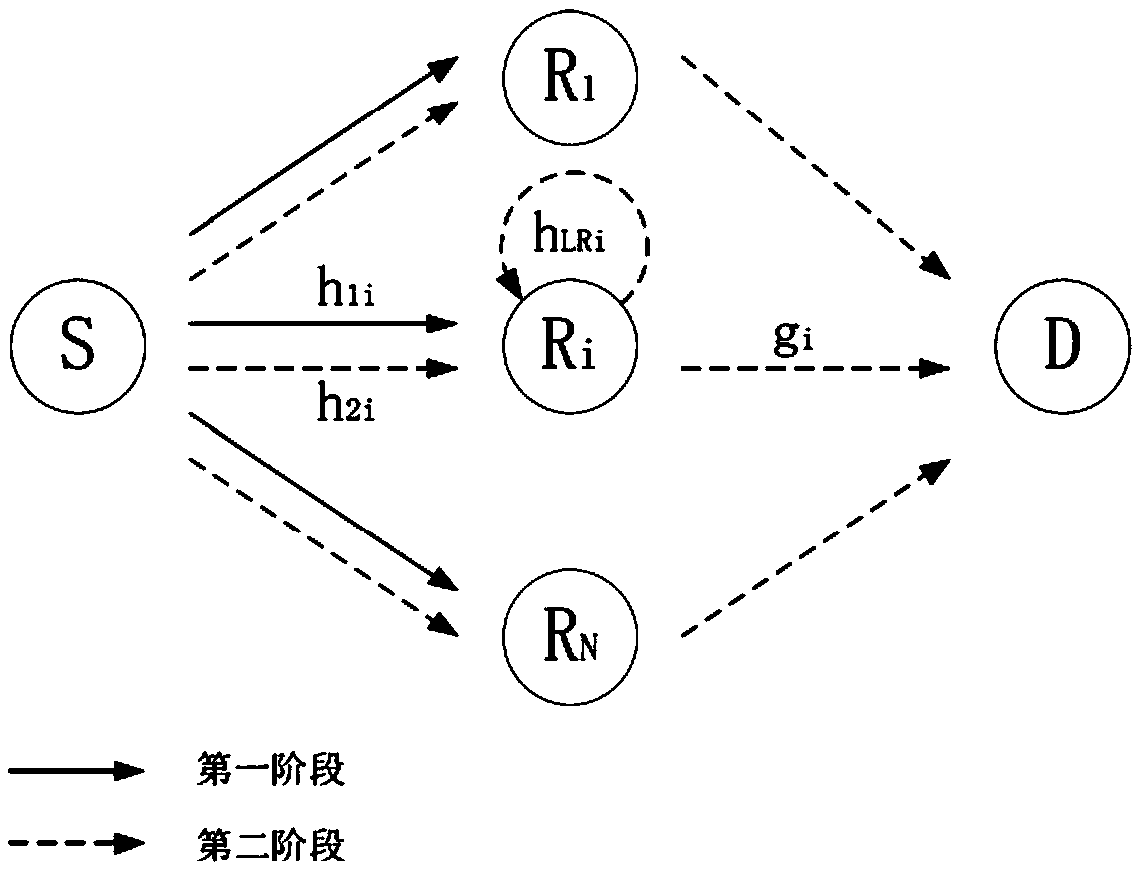

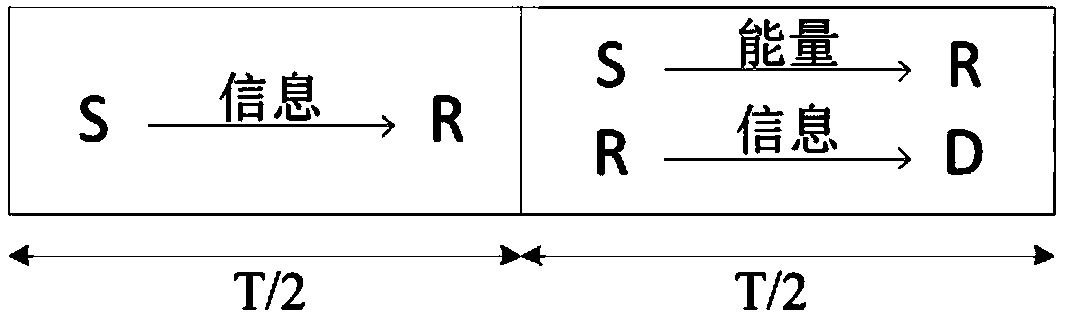

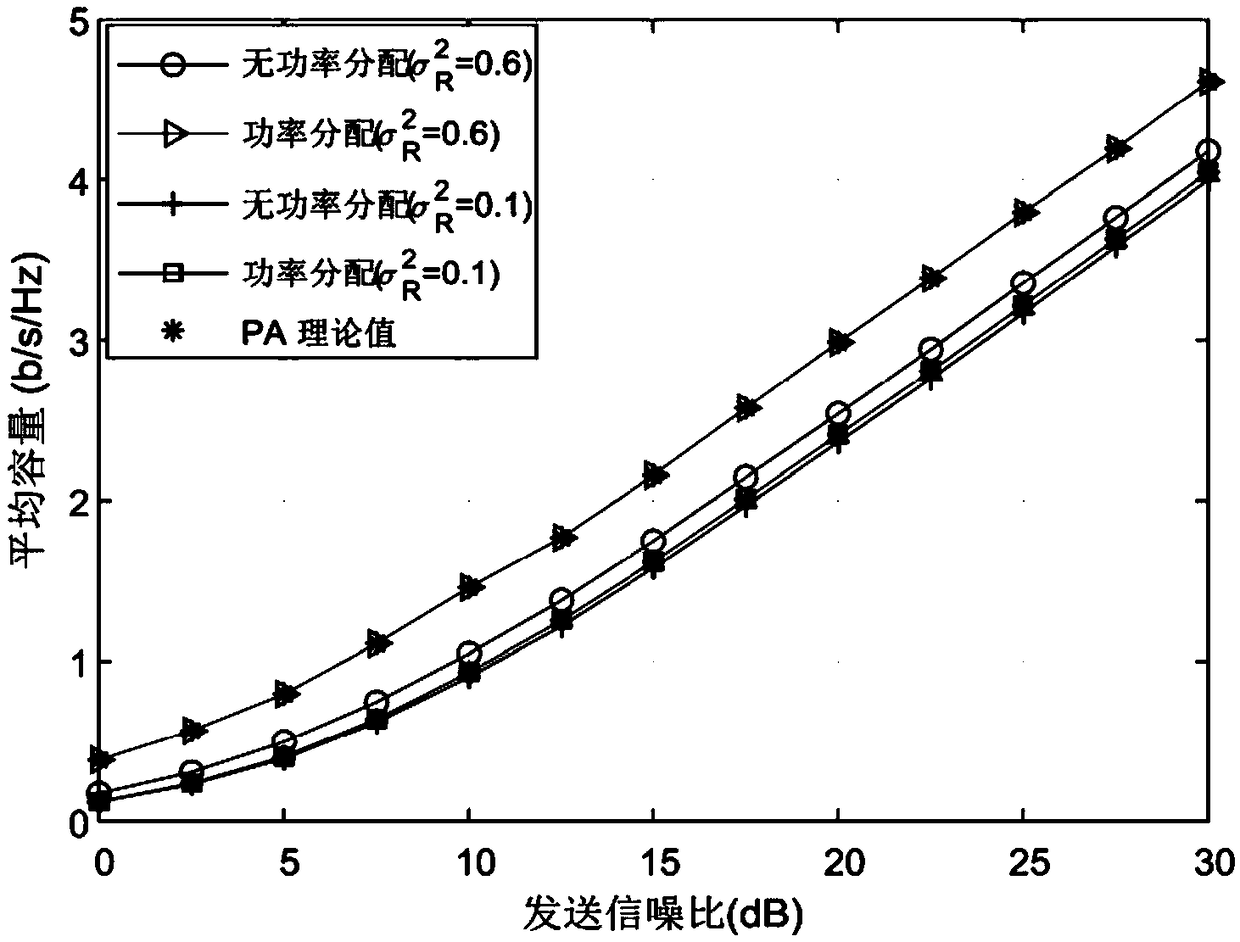

Method for performing relay selection and sending power distribution by energy transmission full-duplex relay

ActiveCN109302250ASolve consumptionImprove performanceWireless communicationDuplex signal operationChannel state informationSelf interference

The invention discloses a method for performing relay selection and sending power distribution by energy transmission full-duplex relay. The transmission process comprises two stages: a source node sends information to a relay node at the first stage, and the relay node works in a full-duplex mode at the second stage; the source node sends energy to the relay node and amplifies and forwards information to a destination node; at this time, the relay node worked under the full duplex mode regards the self-interference as the extra energy capturing source of the node, and the energy capturing utilization is performed through a channel between a sending antenna and a receiving antenna of the relay node. According to multiple relay different forward and backward channel conditions, a destination node capacity formula related to different channel state information and source node and relay node sending power is used for selecting the optimal relay which enables the system capacity to reach the maximum in multiple relays. The method disclosed by the invention further comprises performing optimization on distribution parameters of the source node S sending first power Ps1 and second powerPs2 at the first stage and the second stage, and the system performance is further improved.

Owner:XI AN JIAOTONG UNIV

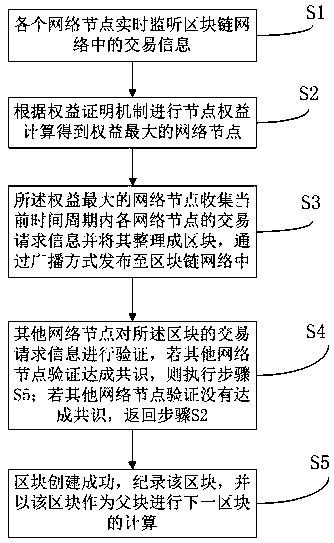

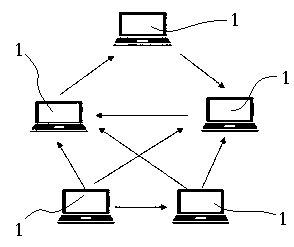

Charging company network transaction settlement method and device

InactiveCN108805567ASolve consumptionImprove transaction efficiencyFinancePayment protocolsTrusted systemDistributed computing

The invention discloses a charging company network transaction settlement method and device. The method comprises the following steps: S1, monitoring, by each network node, transaction information ina blockchain network in real time; S2, performing node equity calculation according to an equity proof mechanism to obtain the network node with the largest equity; S3, collecting, by the network nodewith the largest equity, transaction request information of the network nodes within the current time period, organizing the transaction request information into a block, and publishing the block into the blockchain network through a broadcast manner; S4, verifying, by the other network nodes, the transaction request information of the block, executing S5 if the other network nodes achieve consensus by verification, and returning to S2 if the other network nodes do not achieve consensus by verification; and S5, successfully creating the block, recording the block, and using the block as a parent block for the calculation of the next block. The device is used for implementing the method. The charging company network transaction settlement method and device disclosed by the invention are beneficial to establishing a mutual trust system, supervising the entire transaction process, and building a mutual trust transaction platform.

Owner:SHENZHEN POWER SUPPLY BUREAU

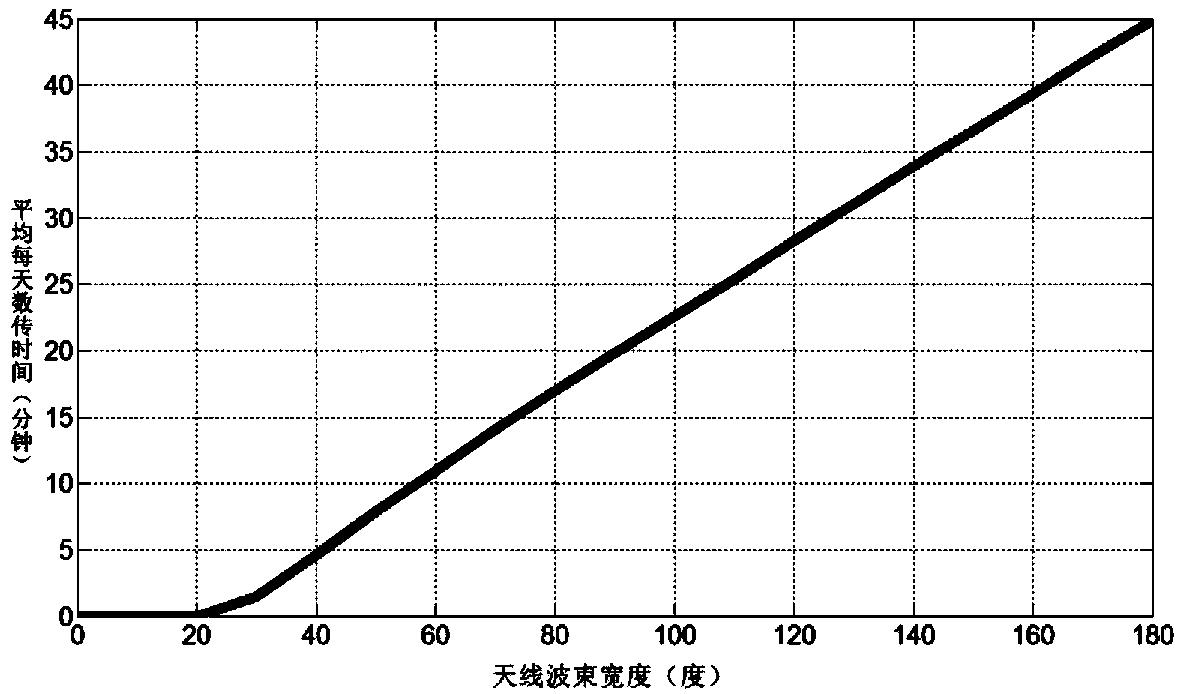

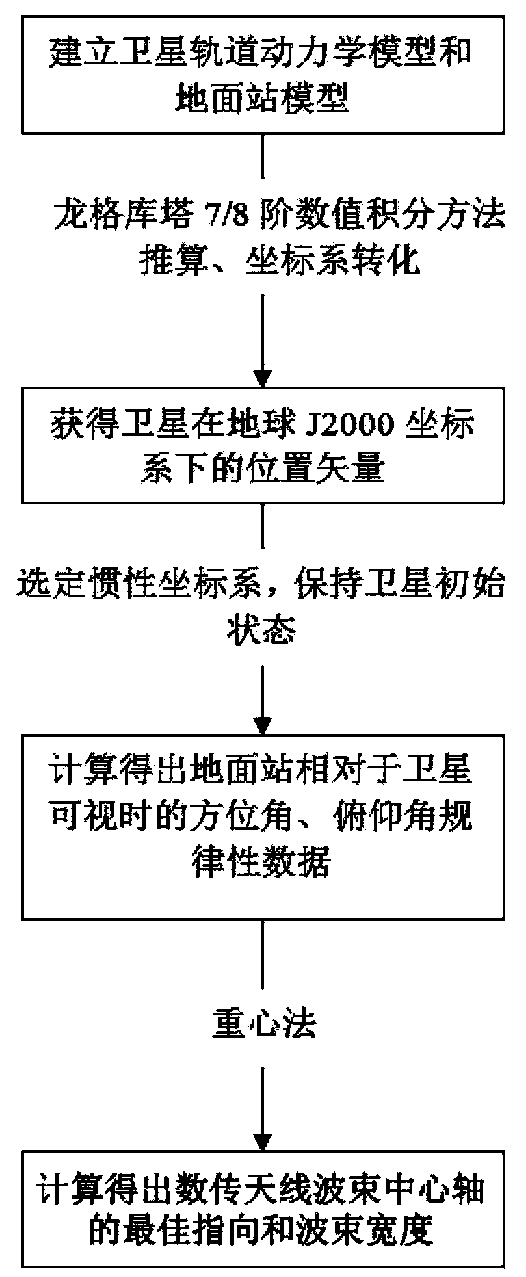

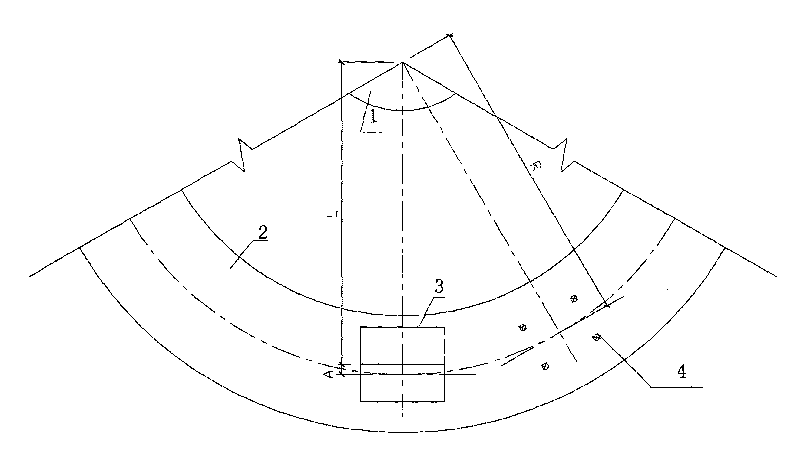

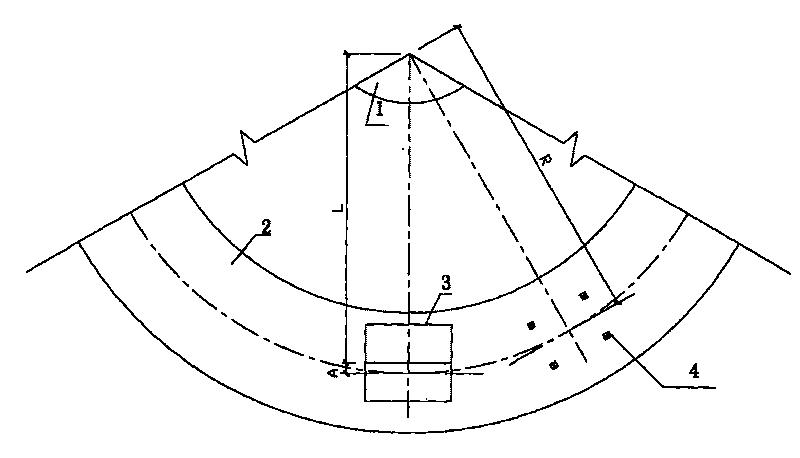

Method for designing data transmission antenna beams of space inertia oriented posture satellites

ActiveCN103413006AThe need for reduced beamwidthHigh gainSpecial data processing applicationsTransmitted powerData transmission time

The invention relates to a method for designing data transmission antenna beams of space inertia oriented posture satellites. Satellite borne data transmission antennas obtained by the method for designing the data transmission antenna beams of the space inertia oriented posture satellites can ensure that transmitted beams of the data transmission antennas can cover designated ground stations without adopting spherical omnibearing beam antennas or mechanical turntables, so that required data transmission time can be achieved, width of the data transmission antenna beams required for executing specific data transmission tasks can be reduced, and accordingly, a pair of narrow beam oriented antennas can replace the spherical omnibearing antennas without using the mechanical turntables. Therefore, the task data transmission time can be ensured, gain of the data transmission antennas can be improved, fast data transmission performance can be obtained, transmitting power is reduced, and the problem of energy consumption on satellites can be solved.

Owner:NAT SPACE SCI CENT CAS

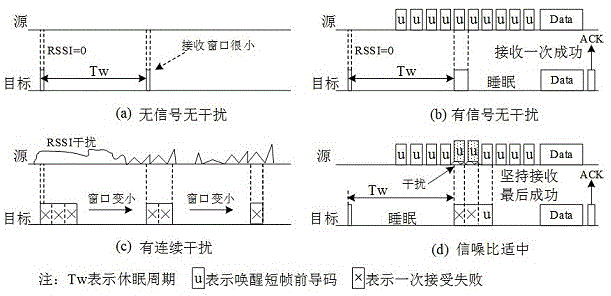

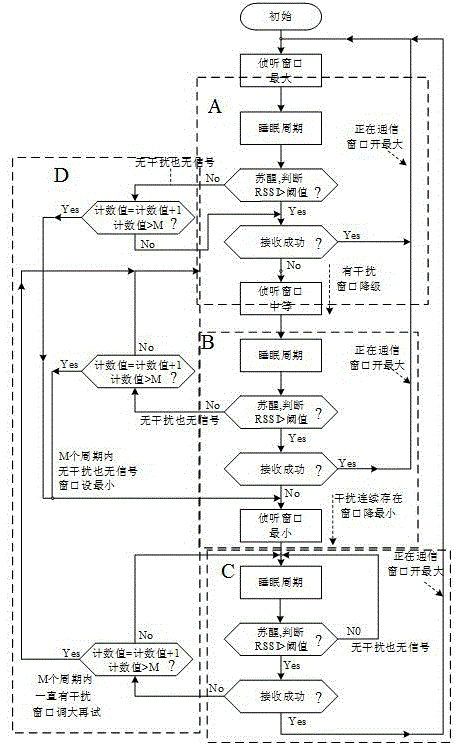

Self-adaptive monitor matching anti-interference method of wireless sensor network

InactiveCN105657804ASize adjustmentSolve consumptionPower managementNetwork topologiesCycle rateWireless mesh network

The invention discloses a self-adaptive monitor matching anti-interference method of a wireless sensor network. The self-adaptive monitor matching anti-interference method adopts a 'self-adaptive monitor matching window' flexibly adjustable in receiving window size to receive data information transmitted from a source node. A receiving monitor window is maximum in size in an initial state, and a received signal strength indicator measures the strength of wireless signals. When the signal strength is lower than a set threshold value, a cycle rate counter adds 1. When the signal strength is higher than the set threshold value, signal receiving starts. When signal receiving succeeds, a communication window is adjusted to be maximum in size and returns to the initial state. If the receiving fails, the window size is decreased. In the monitoring process, if no interference signal or normal signal is found in M cycles, the size of the receiving monitor window is minimum. When the monitor window is in a minimum state, interference signals always exist in the M cycles, and the window is adjusted to be in an intermediate state. By the adoption of the self-adaptive monitor matching anti-interference method, monitor errors between a transmitting node and a receiving node in a wireless interference environment is effectively decreased, and unnecessary energy consumption and lost data packets are reduced.

Owner:SHANGHAI UNIV

Blockchain light-weight processing method, blockchain node and storage medium

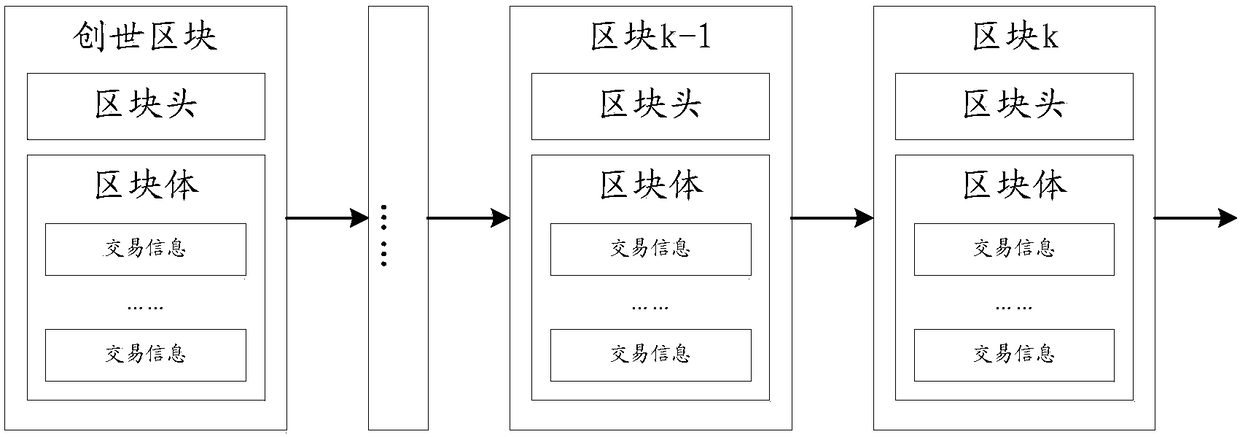

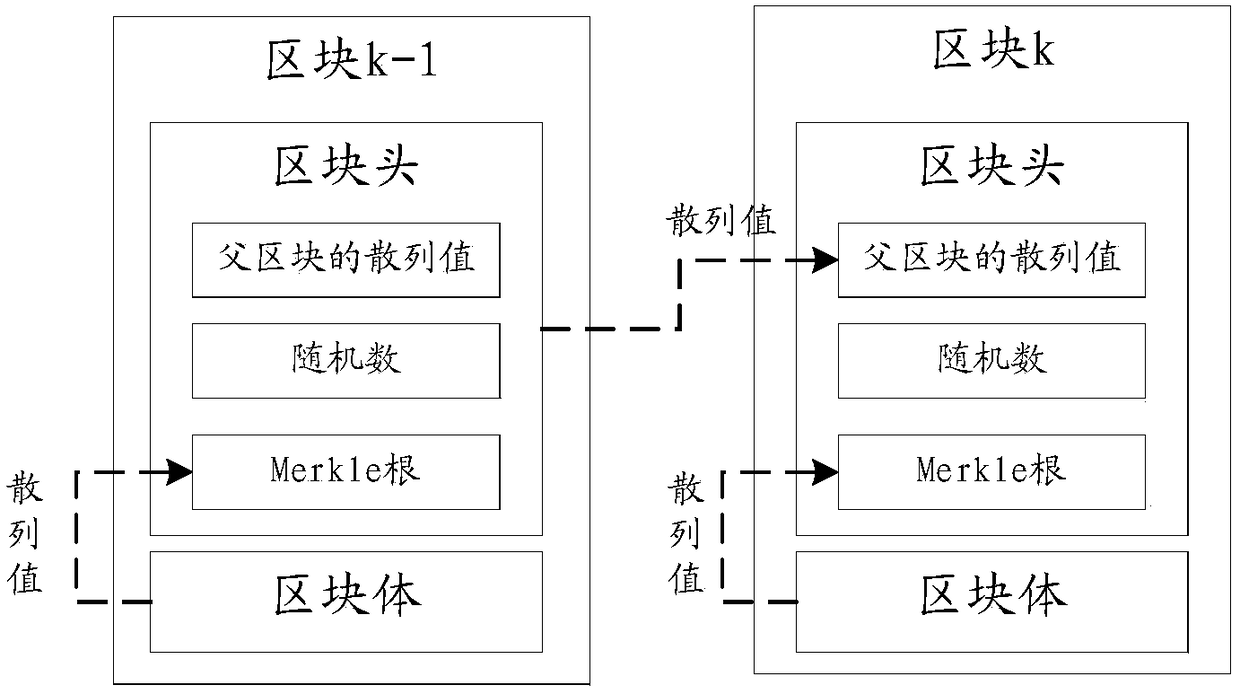

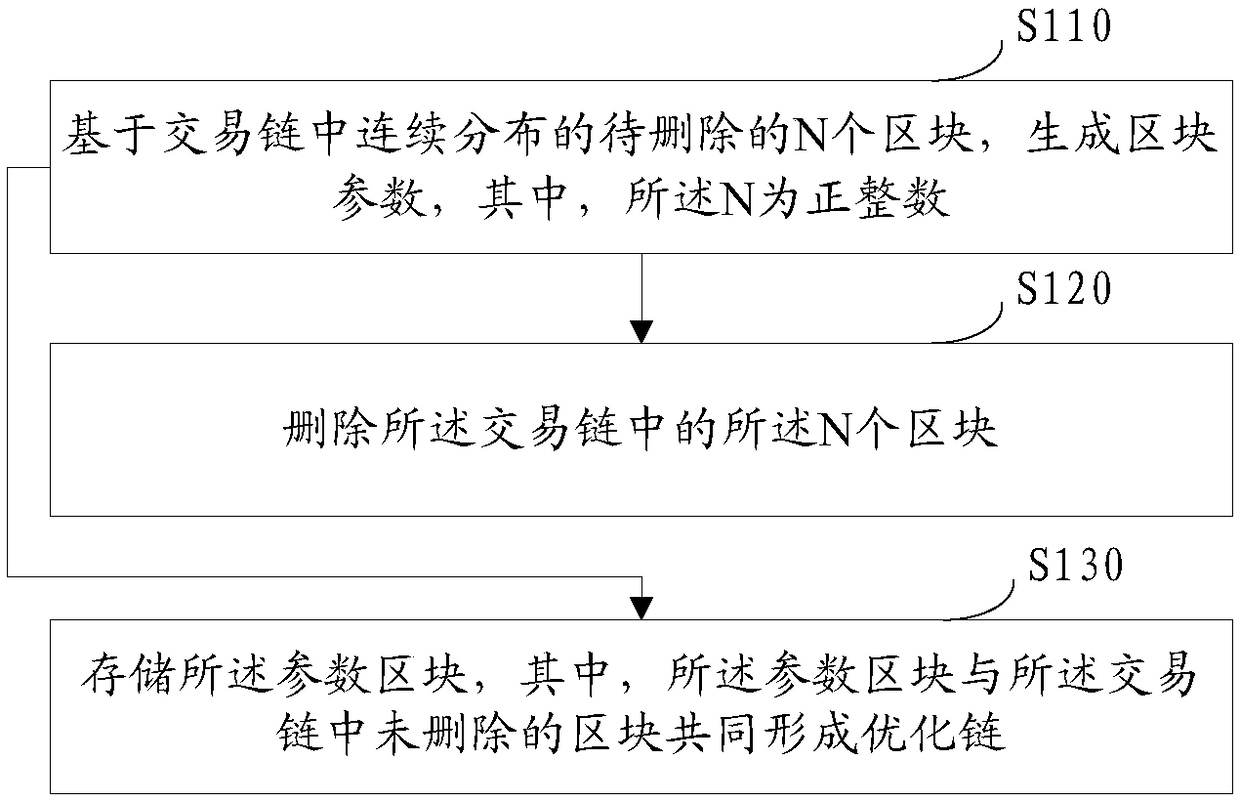

ActiveCN109391645AReduce data volumeReduce consumptionUser identity/authority verificationBuying/selling/leasing transactionsComputer hardwareBlockchain

The embodiment of the invention discloses a blockchain light-weight processing method, a blockchain node and a storage medium. The method applied in the first blockchain comprises the steps of: generating a reference block based on continuously distributed N blocks to be deleted in a transaction chain, wherein N is a positive integer; deleting the N blocks in the transaction chain; storing the parameter block, wherein the parameter block and the block without being delete in the transaction chain commonly form an optimal chain, wherein the father block of the reference block is the previous block of the deleted N blocks in the transaction chain, and the sub area of the parameter block is the next region of the deleted N blocks in the transaction chain.

Owner:CHINA MOBILE COMM LTD RES INST +1

Routing method of radio sensor network

InactiveCN1988503AEven consumptionSolve consumptionData switching by path configurationGradient directionCluster Node

The invention discloses a wireless sensor network routing method, for forming a network of the wireless sensor network and transmitting & receiving the signal, which includes the following steps: pre-allocating independent ID for each node, then creating wireless sensor network from clustering nodes to outside, increasing the gradient in turn, calculating along the nodes efficiency N on the way, and in their own routing table, recording the communicated front gradient node ID and the corresponding efficiency N. If it need to send data, the data is transmitted along the decreasing gradient direction, with the transmission path decided by the node, based on the probability P, the front gradient node in the routing table is selected as a communications target, so as to average the node working times, uniform the node energy consumption and stablish the network.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

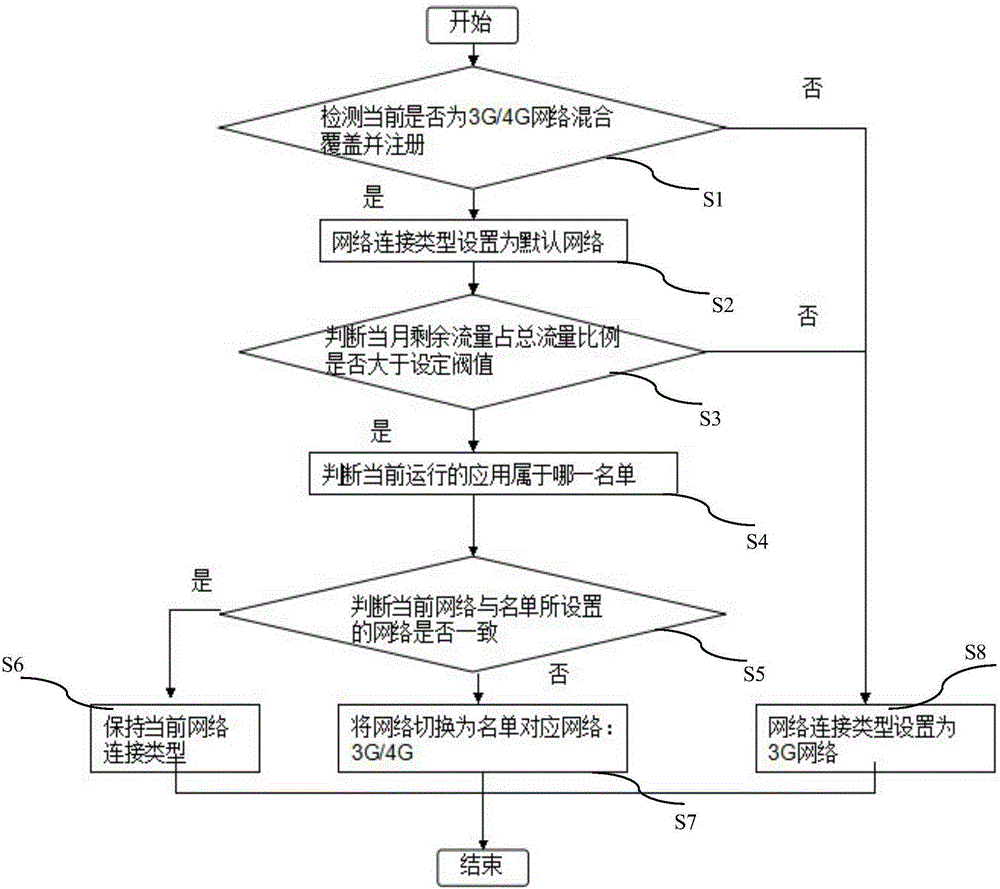

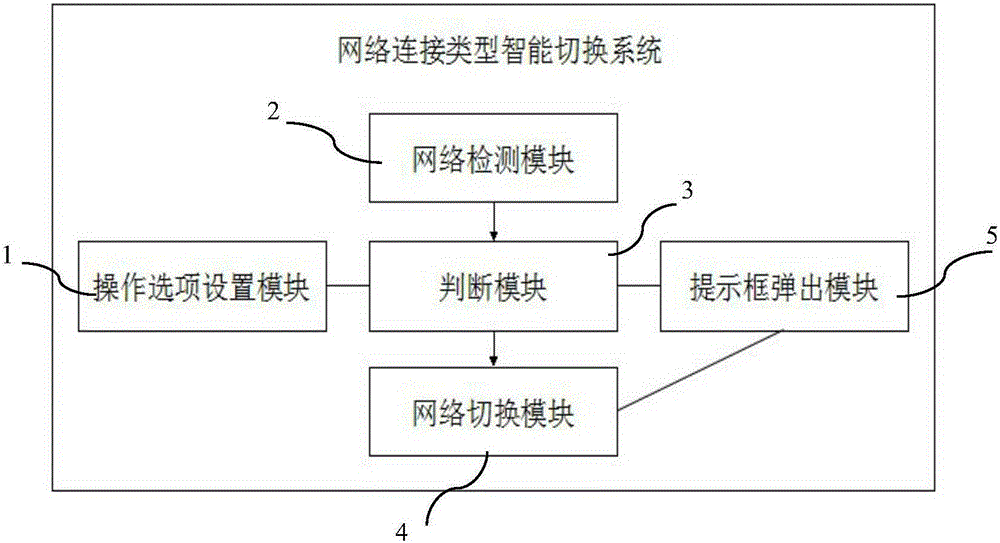

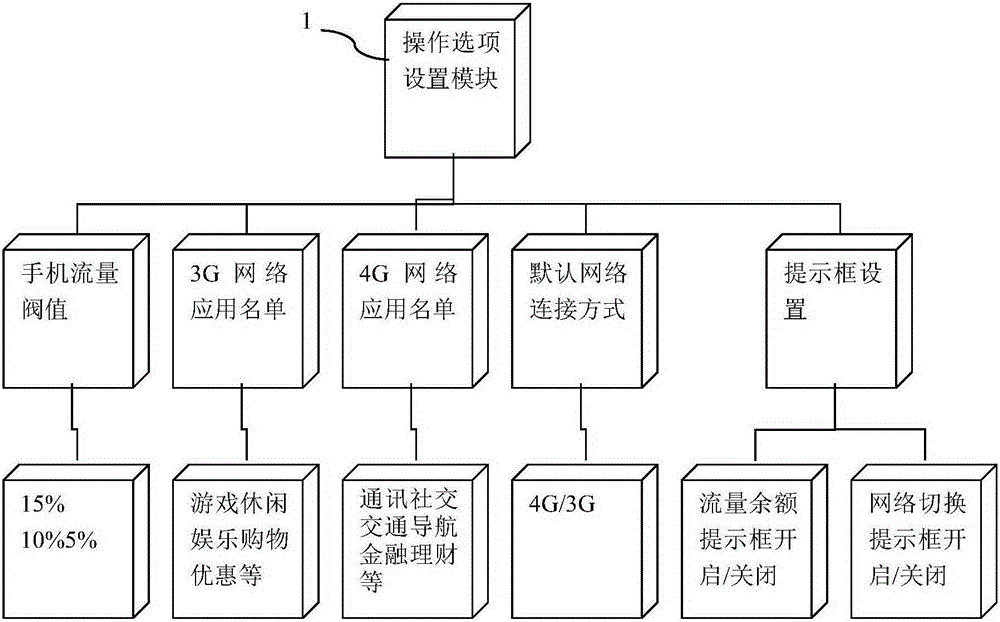

Method and system for controlling excessive consumption of mobile phone traffic

InactiveCN105245731AReduce wasteSolve consumptionAccounting/billing servicesSubstation equipmentThird generationThe Internet

The invention discloses a method and a system for controlling excessive consumption of mobile phone traffic. An operation option is provided in a mobile phone to classify applications of the mobile phone, when one specific applications are used, the mobile phone will automatically switch the connecting manner into 3G traffic even if the 4G network signal strength is strong; the operation option provides recommended classification options, when unnecessary applications with large traffic consumption are used, the mobile phone will automatically switch into a 3G network connecting manner; and a user can also self define the application classification according to his own habits and expects. By adopting the method and system disclosed by the invention, the waiting time of the user is prolonged when unnecessarily using the applications, no excessive traffic will be wasted by watching online videos and browsing pictures on the internet at leisure times, and the problem of excessive traffic caused by over fast traffic consumption is fundamentally solved. Meanwhile, the method and system disclosed by the invention are combined with the function of reminding remaining data plan and automatically switching to the 3G network to help the user to open the last line of defense, so as to avoid the use of excessive traffic to cause additional consumption.

Owner:PHICOMM (SHANGHAI) CO LTD

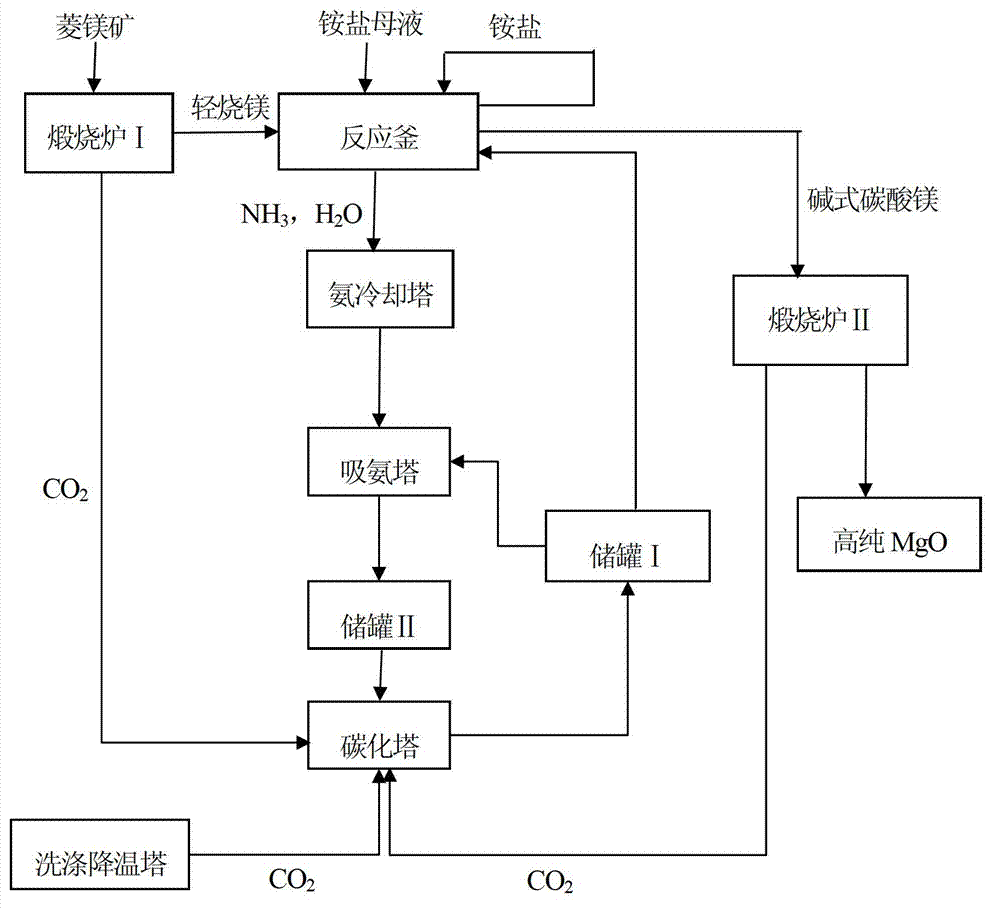

Preparation method for high-purity magnesium oxide

The invention discloses a preparation method for high-purity magnesium oxide. The preparation method for high-purity magnesium oxide comprises the following steps of: calcining magnesite to generate caustic calcined magnesite; heating the caustic calcined magnesite and ammonium salt mother liquor to boil, and distilling; absorbing the distilled mixture of ammonia gas and water by carbonated aqueous ammonia I to form carbonated aqueous ammonia II; carbonizing the carbonated aqueous ammonia II by CO2 from a calcining furnace or flue gas from a washing-cooling tower in a carbonization tower to generate the carbonated aqueous ammonia I, and conveying the carbonated aqueous ammonia I in a storage tank I; conveying a part of the carbonated aqueous ammonia I entering in the storage tank I in an ammonia absorption tower for recycling; mixing the other part of the carbonated aqueous ammonia I with the magnesium salt solution formed by distillation in a reaction kettle, so as to generate basic magnesium carbonate and ammonium salt; filtering and conveying the ammonium salt in the reaction kettle for recycling; and calcining basic magnesium carbonate to prepare high-purity magnesium oxide. According to the preparation method for high-purity magnesium oxide disclosed by the invention, by recycling CO2 and ammonia gas generated during the reaction process, the problem of high raw material consumption due to massive use for ammonium bicarbonate during the production process is solved, and the production cost is reduced; and moreover, the product is high in purity, and the production process is simple in equipment and capable of being used for industrial production for high-purity magnesium oxide.

Owner:SHAANXI NORMAL UNIV

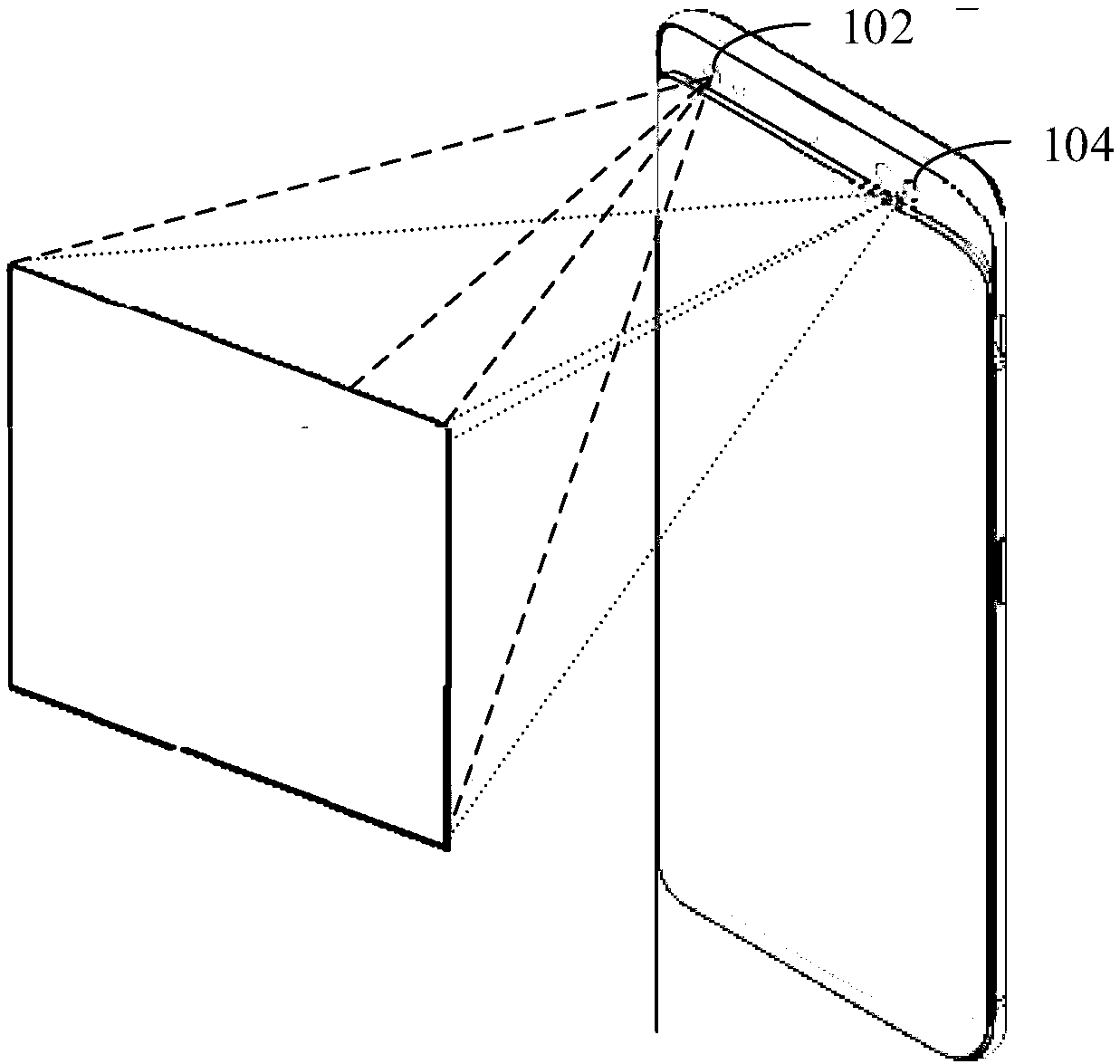

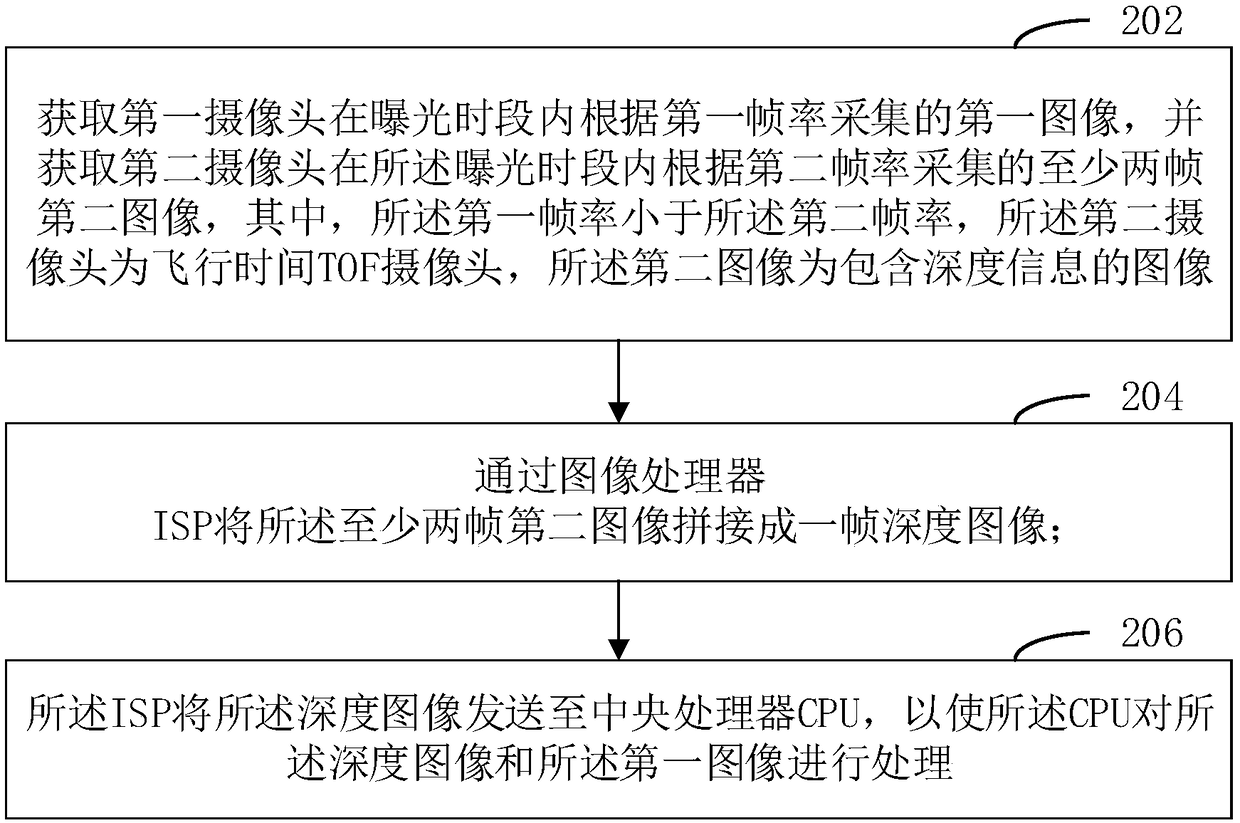

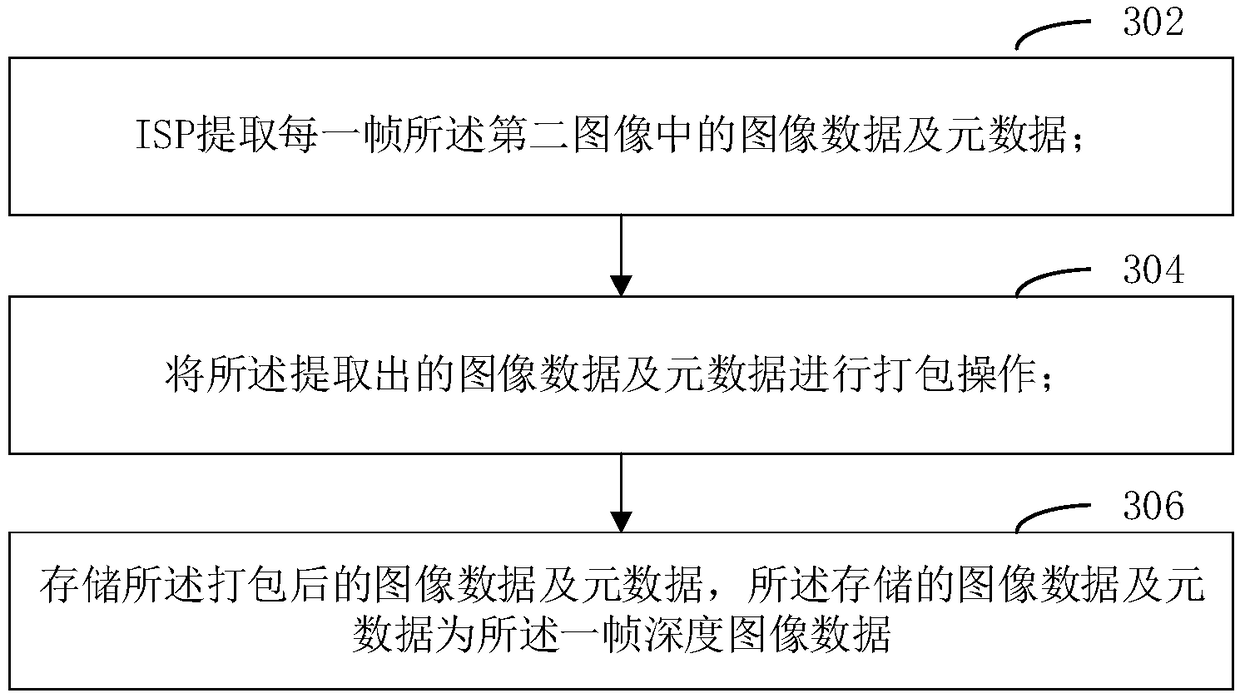

Image processing method, apparatus, computer-readable storage medium, and electronic device

ActiveCN109040591AImprove resource utilizationSolve consumptionTelevision system detailsColor television detailsExposure periodFrame rate

The present application relates to an image processing method, an apparatus, a computer readable storage medium and an electronic device. The method comprises: acquiring a first image acquired by a first camera according to a first frame rate during an exposure period, and acquiring at least two frames of second images acquired by a second camera according to a second frame rate in the exposure period, wherein the first frame rate is smaller than the second frame rate, the second camera is a time-of-flight TOF camera, and the second image is an image containing depth information; splicing at least two second image into one depth image by that ISP; The ISP sends the depth image to a central processor CPU to cause the CPU to process the depth image and the first image. The image processing method, the apparatus, the computer-readable storage medium and the electronic device can prevent the TOF image from being dropped and improve the stability of the image processing.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

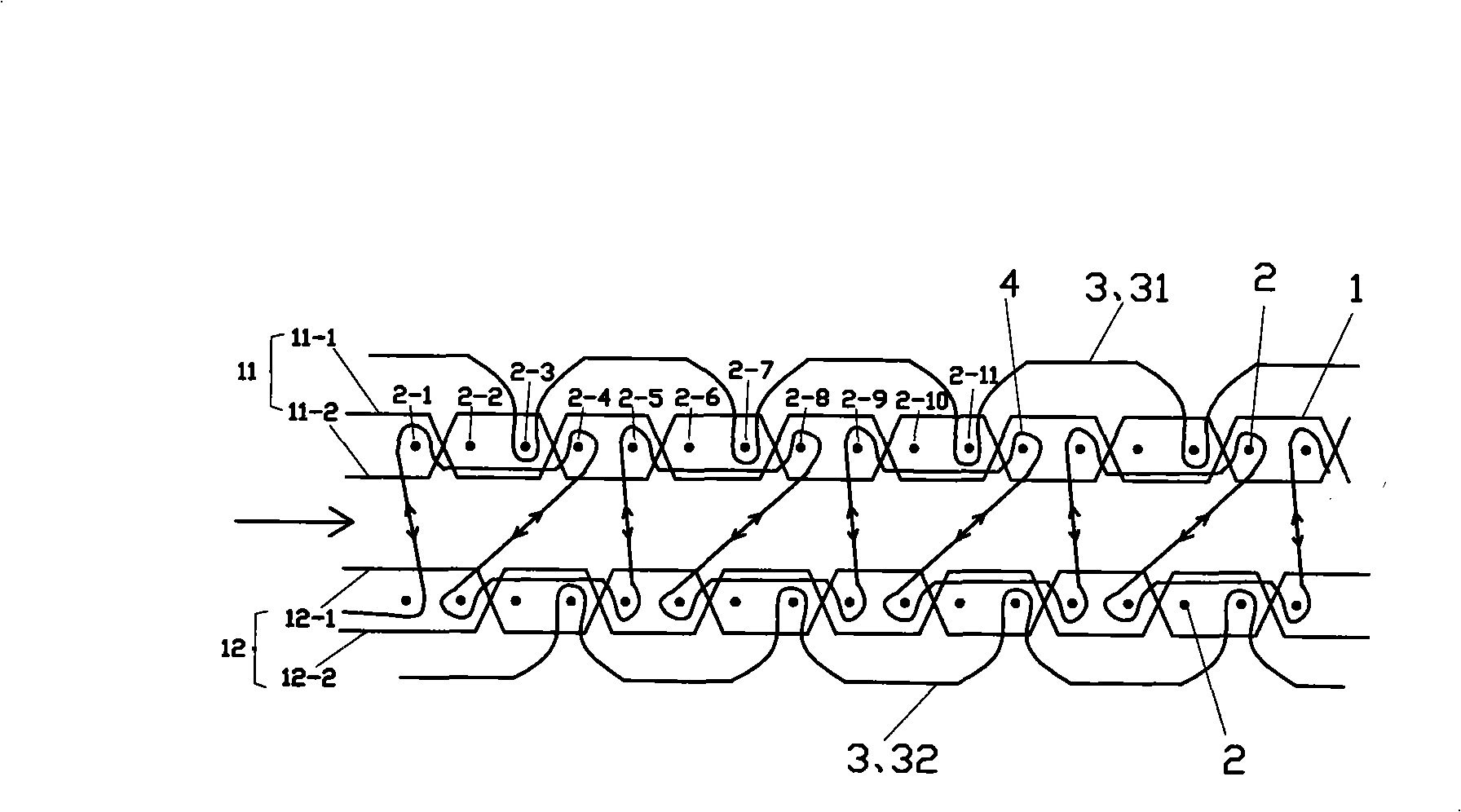

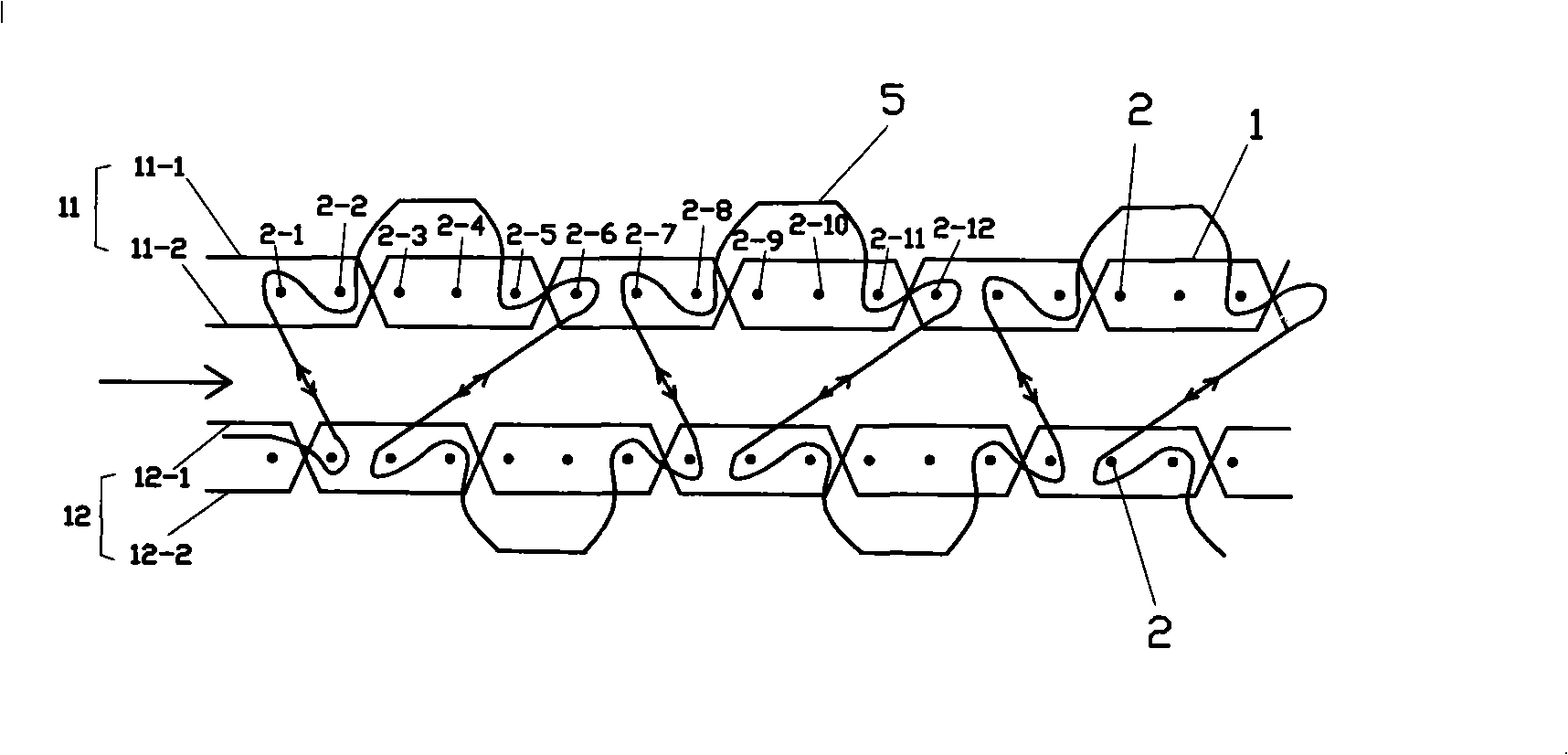

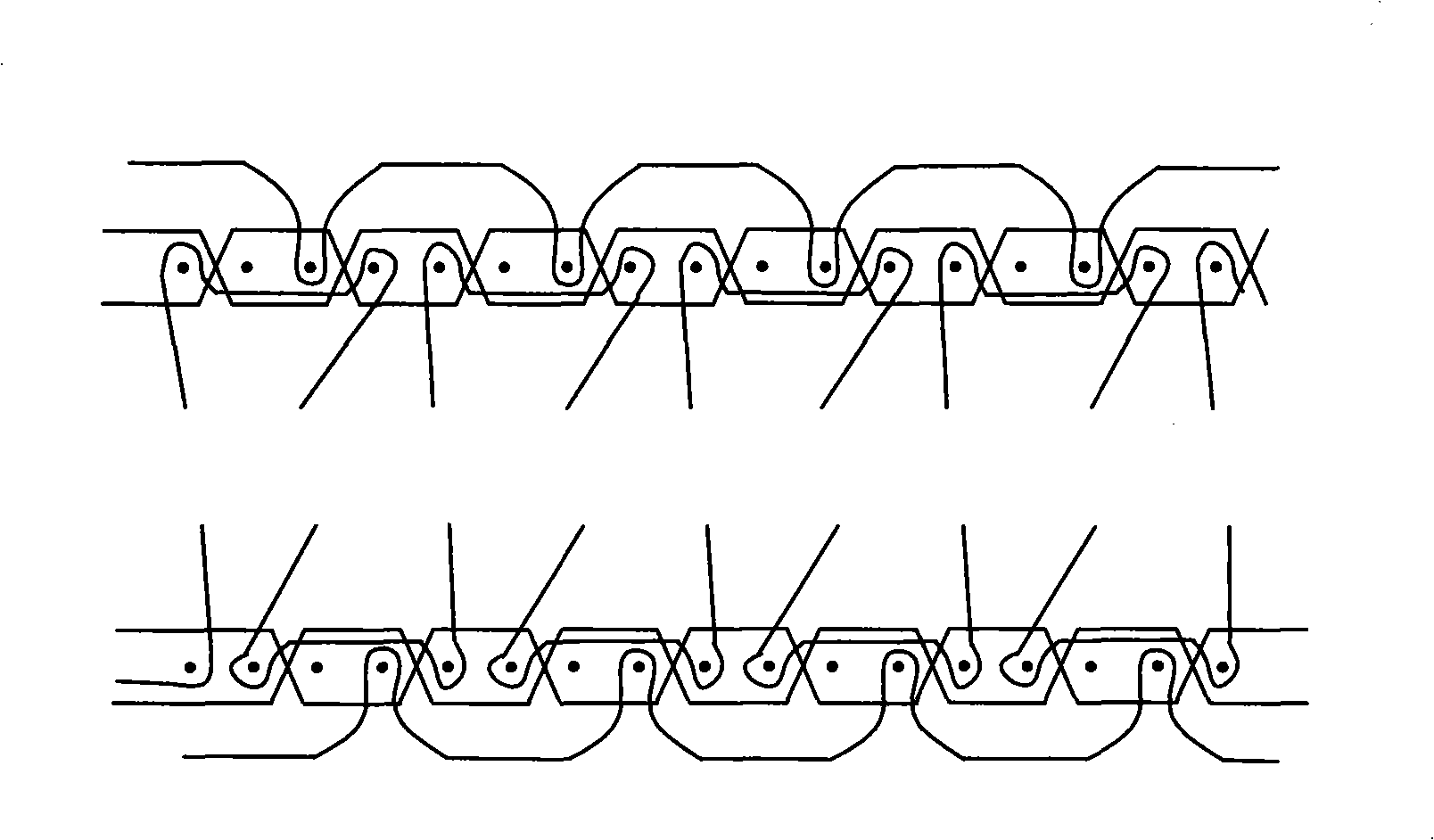

Sheared towel with one-side terry and one-side velutum

ActiveCN101343811AReasonable organizational structureRich textureWoven fabricsWater storageMoisture absorption

The invention discloses a cutting velvet towel, which comprises a two-layer bottom fabric composed of warp yarns and weft yarns, a double-layer nap fabric which is formed by alternatively interweaving worsted warp yarns which have looped piles on both surfaces of the most outside of the two-layer bottom fabric, and worsted weft yarns through which the two-layer bottom fabric is connected, and after the warp yarns are cut from the middle of the two layers of fabrics, the cutting velvet towel with two pieces, one surface of which adopts a looped pile, and the other surface of which adopts a knap surface, is formed, and the two pieces are arranged up and down and face to face, and have the identical patterns. The two-layer bottom fabric can be also woven with the knap warp yarns which have looped piles on both surfaces at the most outside of the two-layer bottom fabric and simultaneously connect the two-layer bottom fabric. The invention solves the problems existing in the prior art and caused by the cutting of the looped piles on one surface of the double surface looped pile towel that the working procedures are multiple, the raw material consumption is large, the looped pipes and knops are not firm, and the towel is easy to depilate, the manufacture procedures are reduced, the cost of raw material is reduced, the product quality is improved, and the cutting velvet towel has theadvantages that the looped piles and the knops are firm, the hand feeling are soft and the moisture absorption and water storage rate is high.

Owner:常州市悦腾机械有限公司

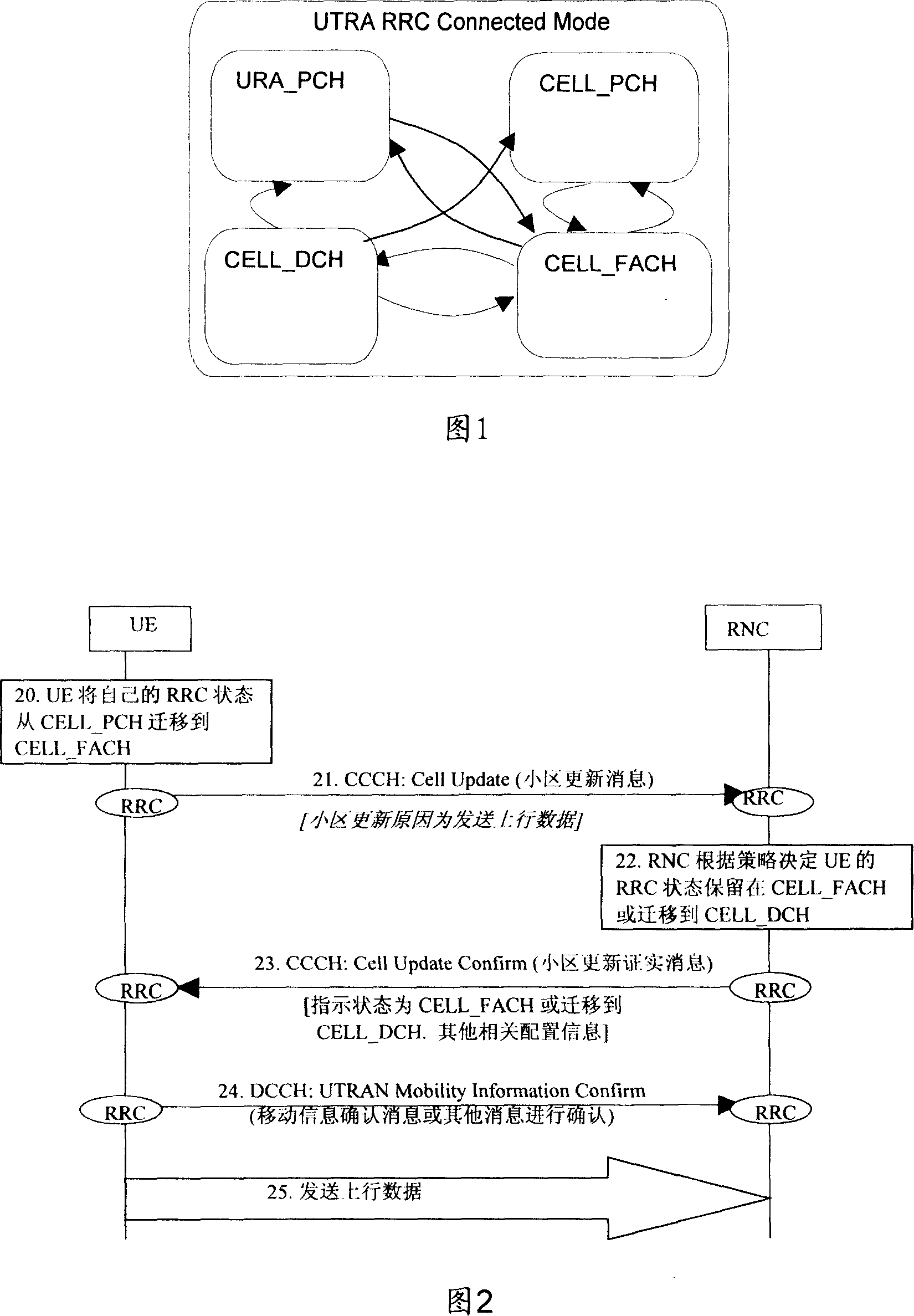

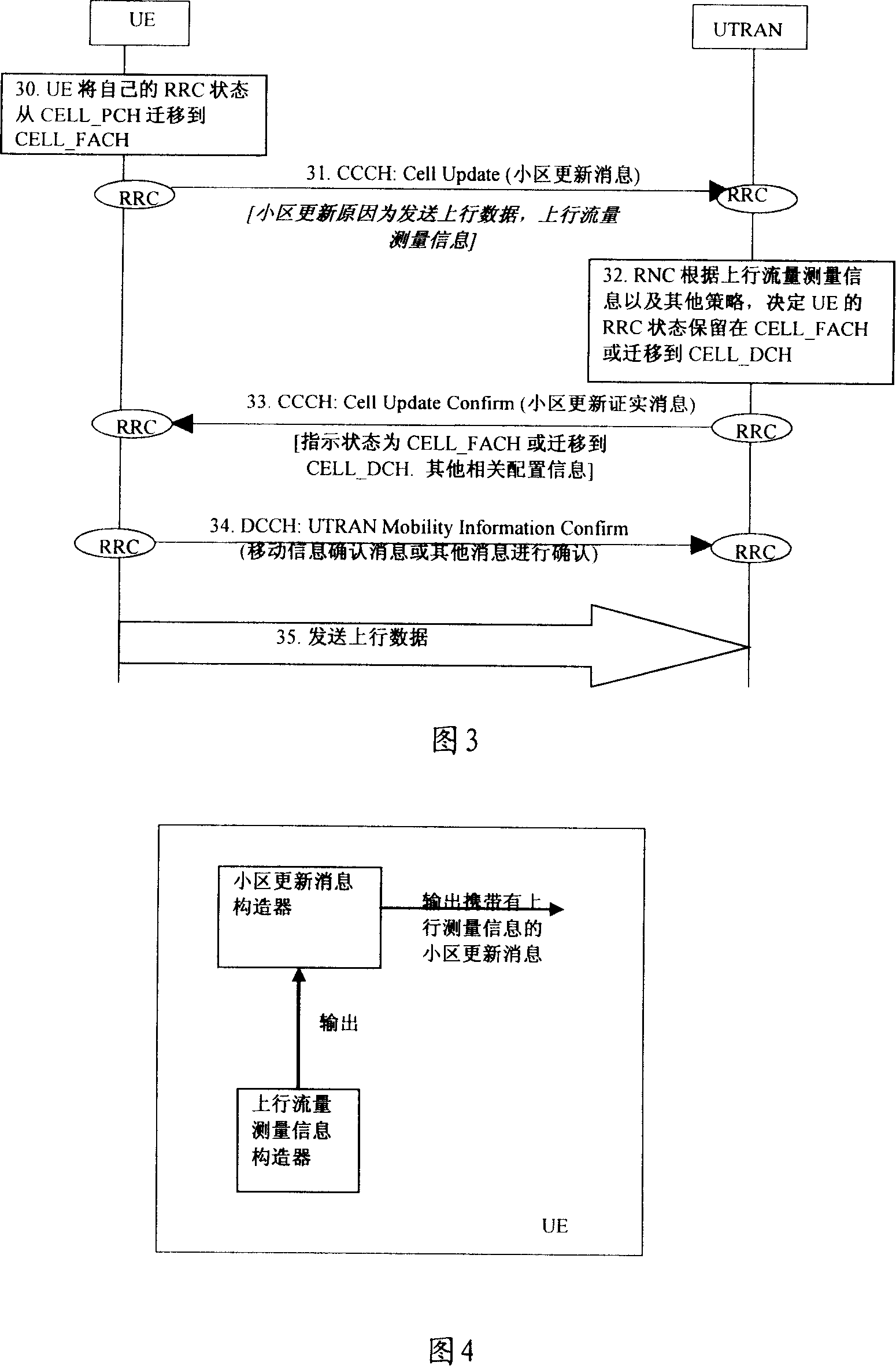

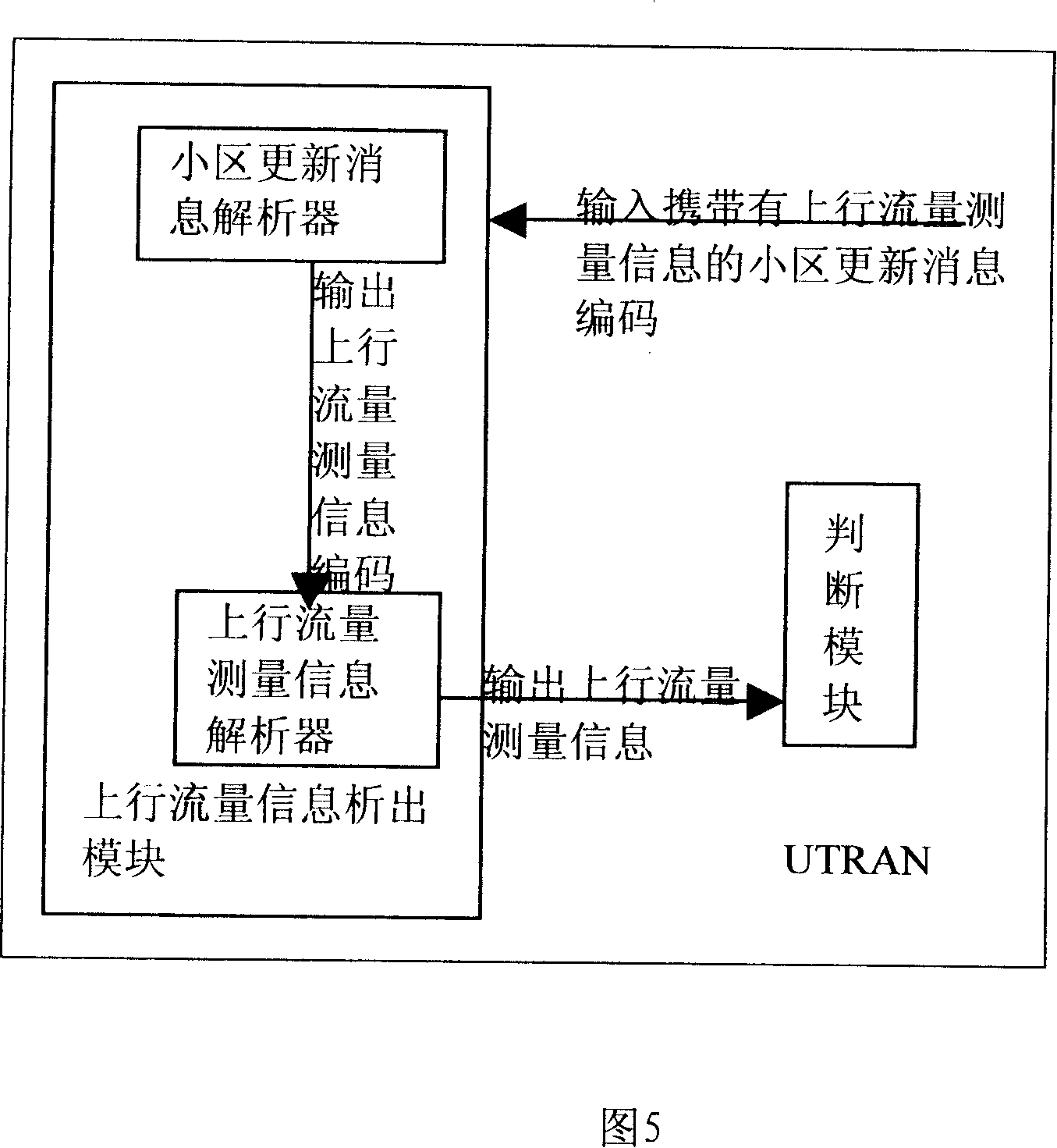

Method for switching RRC status and its user's set network appliance

InactiveCN101155413ASolve consumptionSolve capacity problemsAssess restrictionRadio/inductive link selection arrangementsProblem of timeTelecommunications

The present invention relates to communication domain, provided are a radio resource control state switching method and user equipment and network equipment. The core of the present invention is: through the method of the user equipment UE sends the information of the cell updating reason is 'sending uplink data' and the flow measuring information of the uplink data needed to be sent, to resolve effectively the problems of time delay prolonging of the state transition caused by multi-time processing UE radio resource control RRC state transition, empty ora resource superfluity consumption, system performance and capacity decreasing existing in the prior art, reducing the time delay of the RRC state transition, further reducing the time delay of UE sending uplink data; reducing the signaling interactive between the UE and the UTRAN, thereby achieving to reduce empty ora resource superfluity consumption, that is achieving the technique effect to reduce the radio resource consumption, and promoting the system performance and capacity at the same time.

Owner:HUAWEI TECH CO LTD

Anti-ultraviolet transparent hard coating film for in-mold decoration (IMD)

ActiveCN101955699AGuaranteed normal formationMeet the molding tensile performance requirementsSynthetic resin layered productsCoatingsPolyesterUltraviolet

The invention relates to an anti-ultraviolet transparent hard coating film for in-mold decoration (IMD), which is formed by coating a transparent hard coating on a transparent substrate. The transparent hard coating comprises the following components in part by weight: 20 to 40 parts of polyester acrylate oligomer, 10 to 30 parts of organic-inorganic hybrid oligomer, 0.5 to 5 parts of ultraviolet absorption precursor, 1.0 to 10 parts of hydrogen proton donor, 0.5 to 7 parts of photoinitiator, 0.5 to 7 parts of active amine, 0.05 to 2 parts of leveling agent and 30 to 70 parts of solvent, wherein the thickness of the hard coating is 2 to 6mu m. The anti-ultraviolet transparent hard coating film solves the problems of ageing, yellowing, embrittlement and the like of a product irradiated by ultraviolet rays, solves the problems of oxygen inhibition and hydrogen proton consumption and ensures the formation of an ultraviolet absorbent; and the film meets the requirements of the IMD on forming and stretching by combining raw materials and controlling the thickness of the hard coating, and the stretching and forming height of the film can be 7 to 8mm at most but the film cannot be embrittled.

Owner:CHINA LUCKY FILM CORP

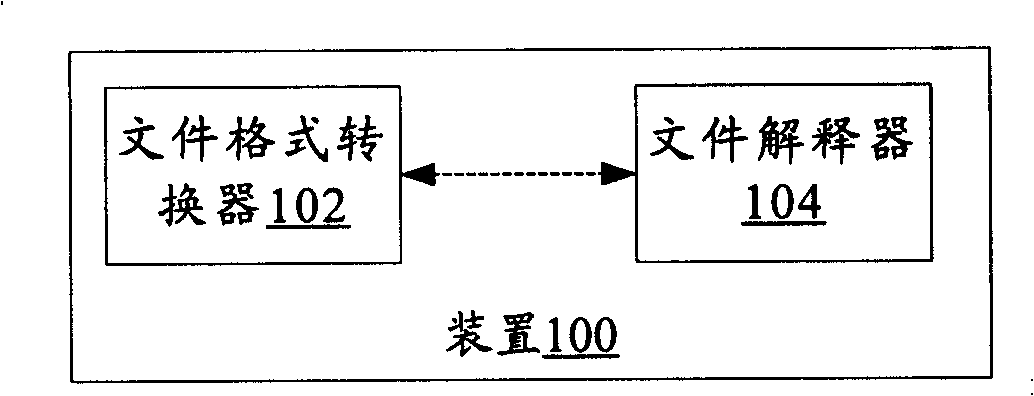

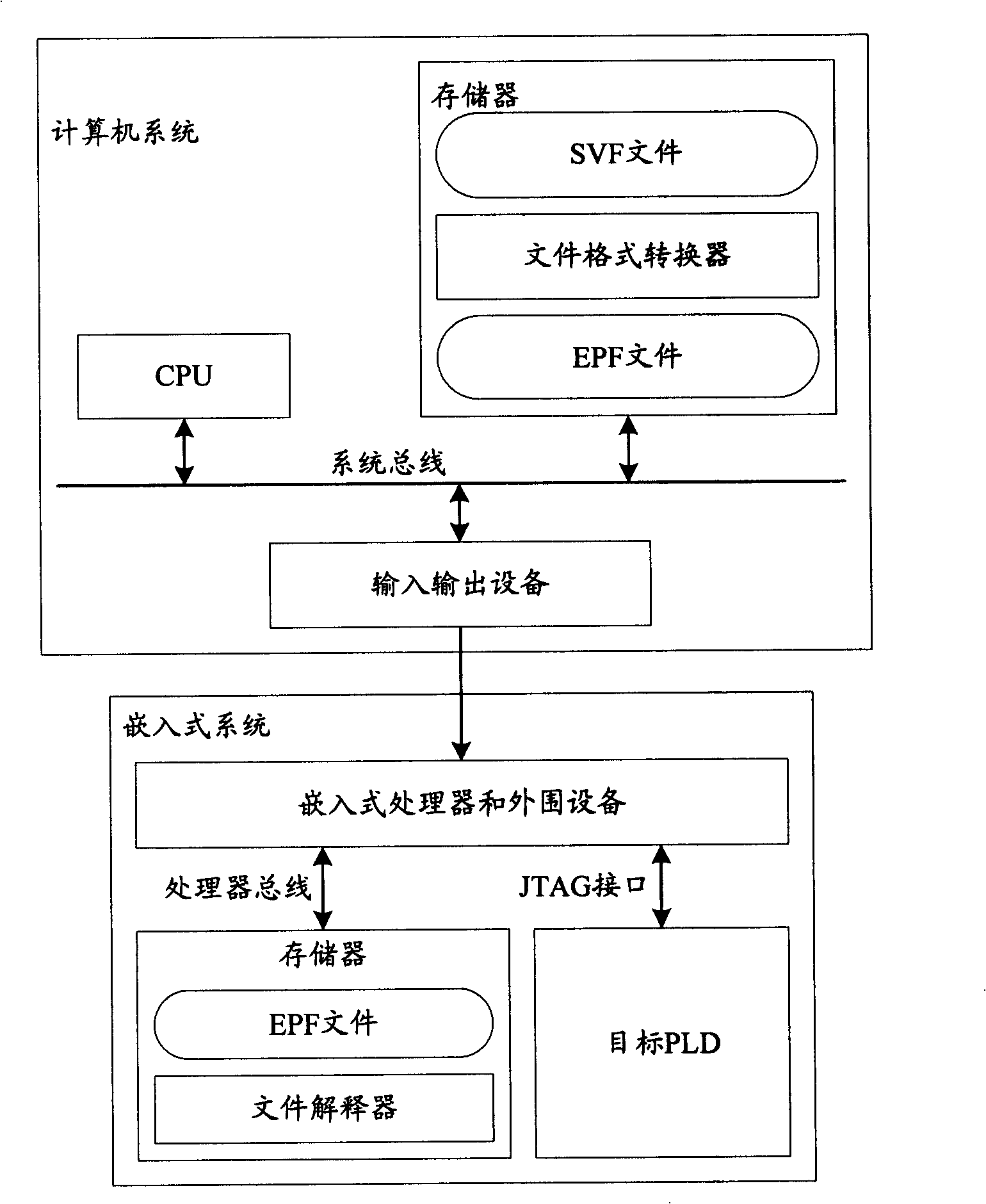

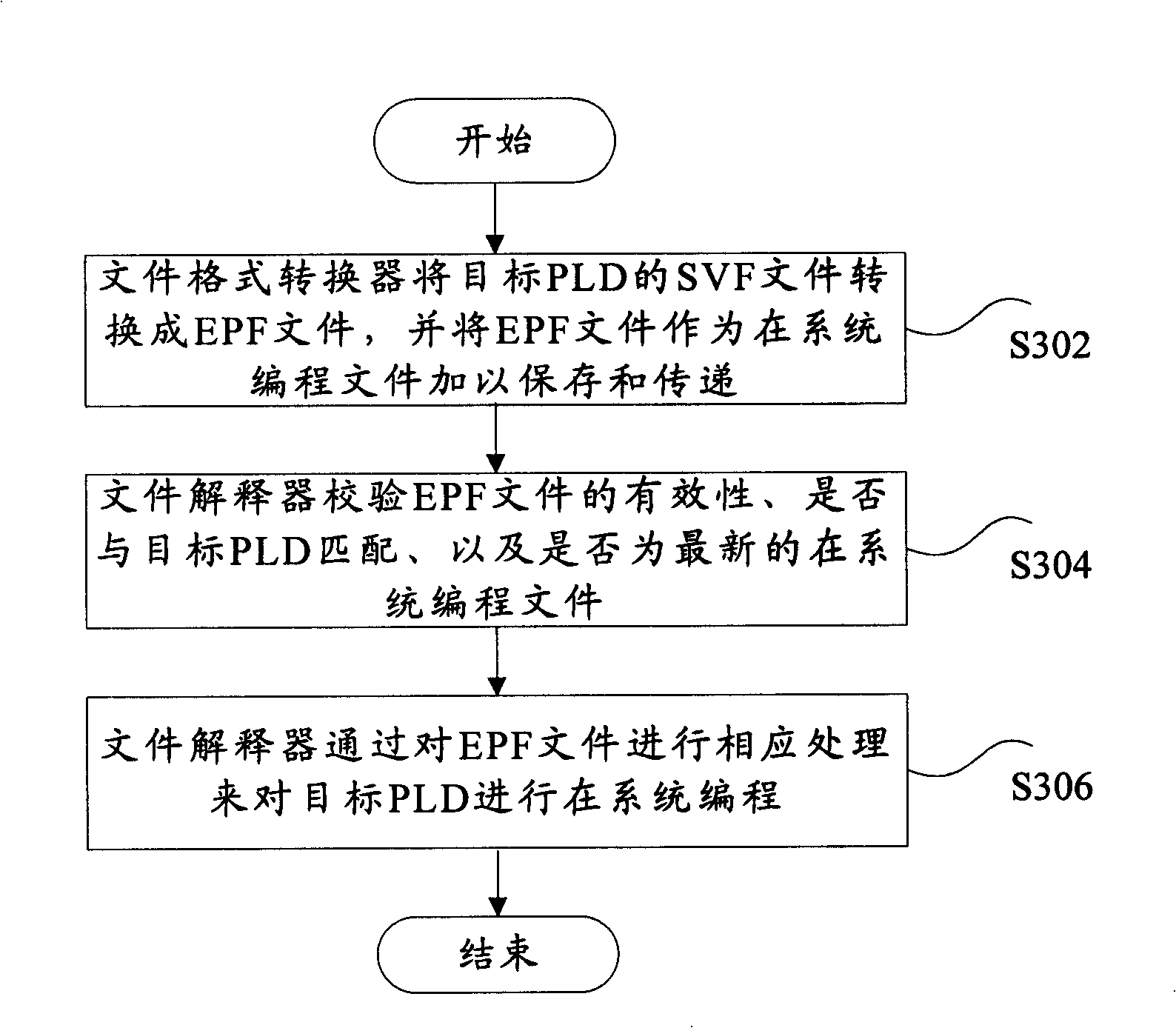

Device and method for in-system programming for programmable logic device

InactiveCN101266548ASolve consumptionResolve detectionElectrical testingProgram controlIn-system programmingResource consumption

The invention provides an installment used to carry on the in-system programming for the programmable logical component, the equipment includes: a document format converter used to convert the serial vector format file of the goal programmable logic component to an embedded programming format file as the in-system programming file of the goal programmable logic component; and a file interpreter used to analyze the input embedded programming format file to produce programming information conforming to the IEEE1149.1, and a JTAG connection signal is driven according to the programming information to carry on the in-system programming of the goal programmable logic component. In addition, the invention also provides a method used to carry on the in-system programming for the programmable logical component. The following effects are achieved through the technical program of the invention: while retaining the superiority suitable for nearly all the present programmable logical component manufacturer component, solving the problems that the memory resources consumption is big, the error detection ability is weak, and each stage in the whole in-system programming process cannot be displayed and distinguished.

Owner:ZTE CORP

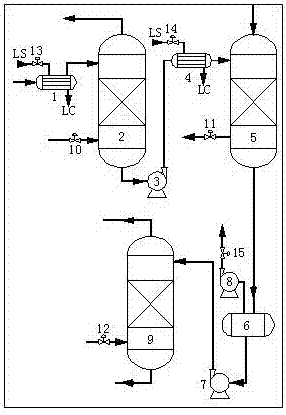

System and method for recovering methyl nitrite through coal ethylene glycol carbonyl synthesis system

InactiveCN107056582AReduce shortingReduce pollutionOrganic compound preparationHydroxy compound separation/purificationChemical reactionFluid phase

The invention relates to the field of coal ethylene glycol chemical engineering and particularly relates to a system and method for recovering methyl nitrite through a coal ethylene glycol carbonyl synthesis system. According to the method, the main target of effectively recovering a methyl nitrite gas is achieved in the coal ethylene glycol carbonyl synthesis system through the methods of combining air stripping, flash evaporation and nitric acid reduction. The recovery system mainly comprises a front air stripping system for methyl nitrite, a nitric acid reduction system and a rear air stripping system, wherein the front air stripping system is provided with a liquid-phase preheater, a front air stripping tower and a liquid-phase discharge centrifugal pump; the nitric acid reduction system is provided with a liquid-phase feeding preheater and a nitric acid reduction tower; and the rear air stripping system is provided with the flash evaporation tank, the liquid-phase feeding centrifugal pump and the rear air stripping tower. Stable content of nitric oxide and the methyl nitrite in a gas-phase component of the synthesis system is ensured through the method of combining a physical process and chemical reaction, the losses of the nitric oxide and the methyl nitrite are avoided to a great extent, the waste is changed into treasure, and resource waste and water source pollution are reduced.

Owner:安阳永金化工有限公司

Annular furnace base movable thread stand bolt positioning method

InactiveCN101748747ASolve consumptionReduce construction proceduresFoundation engineeringSteel barTotal station

The invention relates to an annular furnace base movable thread stand bolt positioning method. The method is implemented by arranging a total station at the central point of the annular base, putting the marked movable thread stand on a reinforcing steel bar fixing stand, moving the movable thread stand so that one straight line on the movable thread stand steel plate is in superposition with the straight line of the positioning bolt group, which passes through the central point of the annular base; the reinforcing steel bar fixing stand is marked; the total station is used for measuring the distance L from the central point of the annular base to central points of two mutually orthogonal straight lines on the movable thread stand, the difference value A between distance L and the radius R of the group of bolts is calculated, the position points of the group of bolts can be determined according to the difference value and marked on the reinforcing steel bar fixing stand to realize positioning the bolts. The method adopts the movable thread stand to mark on the reinforcing steel bar fixing stand, thus dispensing with quantities of steel plates or profile steel, being simple and fast, saving materials, and having precise positioning.

Owner:ANGANG CONSTR CONSORTIUM

Process of synthesizing gastrodiacin by microorganism cell biological transferring parhydroxy benzyl methylol

InactiveCN100999750AShort training timeSimple and fast operationMicroorganism based processesFermentationMicroorganismPlant cell

The present invention discloses microbe cell synthesis process of converting p-hydroxy benzyl alcohol to synthesize gastrodine. The process is one converting reaction of wet cell of rmillaria luteo-virens ZJUQH in 1-10 g / 100ml and 0.22 micron microporous film filtered p-hydroxy benzyl alcohol in 0.1-3.1 mmol / L, in the culture liquid comprising sterilized potato in 2 wt% concentration and glucose in 0.5 concentration, at temperature of 20-25 deg.c and shaking table rotation speed of 50-200 rpm for 1-3 days. Compared with available plant cell conversion process, the microbe cell synthesis process has the advantages of short period, simple operation and easy control.

Owner:ZHEJIANG UNIV

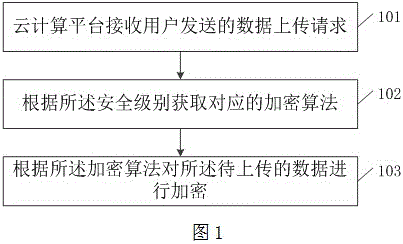

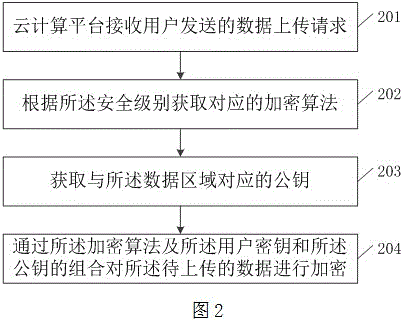

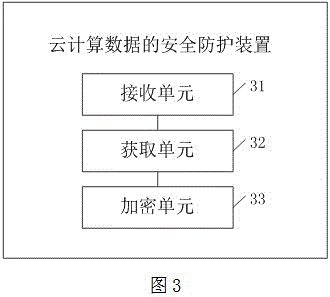

A safety protection method and apparatus for cloud computing data

InactiveCN106230776ASolve consumptionFix security issuesTransmissionResource consumptionSecurity level

The invention discloses a safety protection method and apparatus for cloud computing data, relates to the technical field of network safety and solves problems such as large system resource consumption and low data security in the prior art. The main technical scheme of the invention is that a cloud computing platform receives a data upload request sent by a user, wherein the data upload request includes the data to be uploaded and a security level and a data area corresponding to the data to be uploaded, and the data in the cloud computing platform is divided into a plurality of security levels; obtaining a corresponding encryption algorithm according to the security level; and encrypting the data to be uploaded according to the encryption algorithm. The method and apparatus of the invention are mainly used for the data in a safety protection cloud computing platform.

Owner:南京睦泽信息科技有限公司

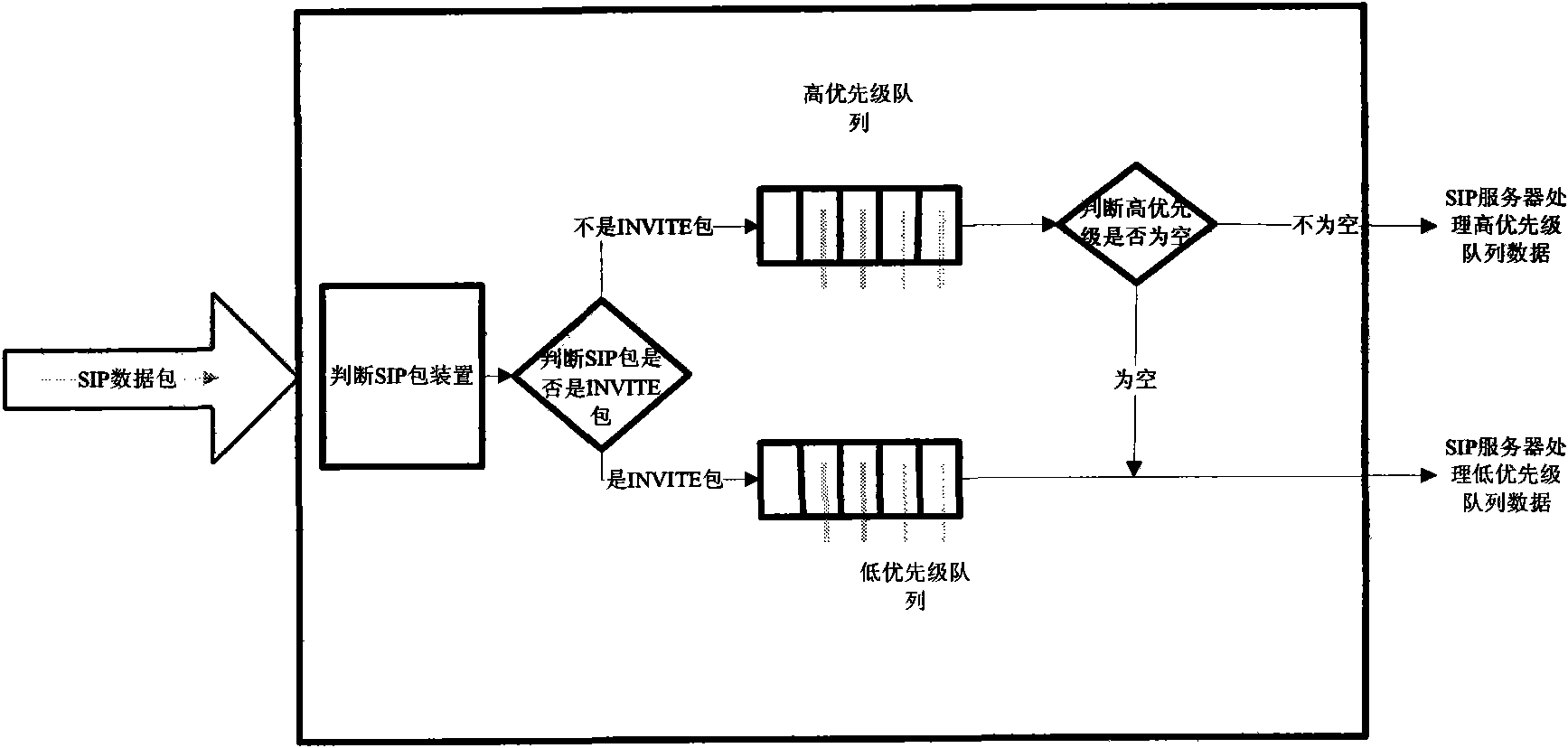

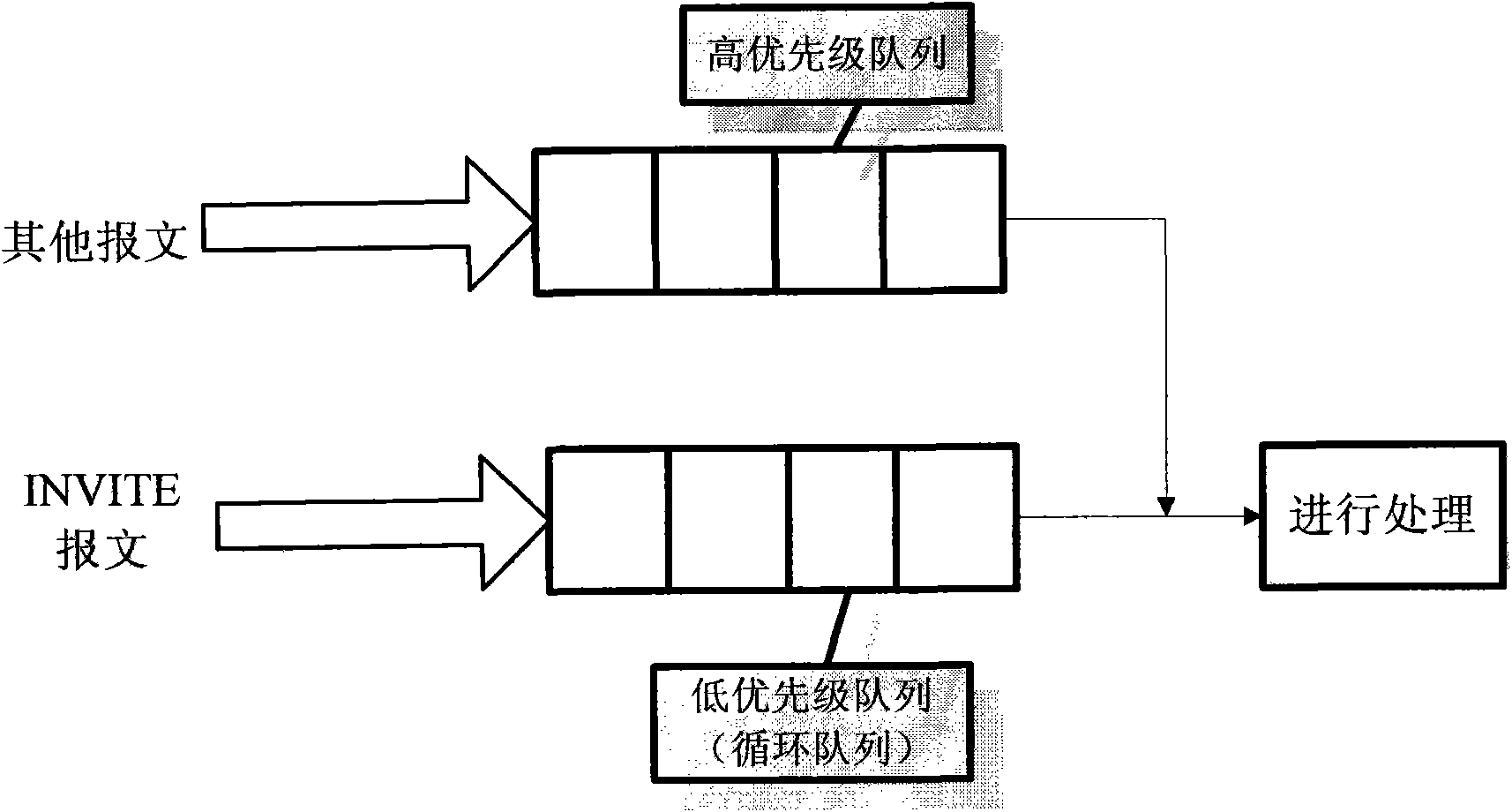

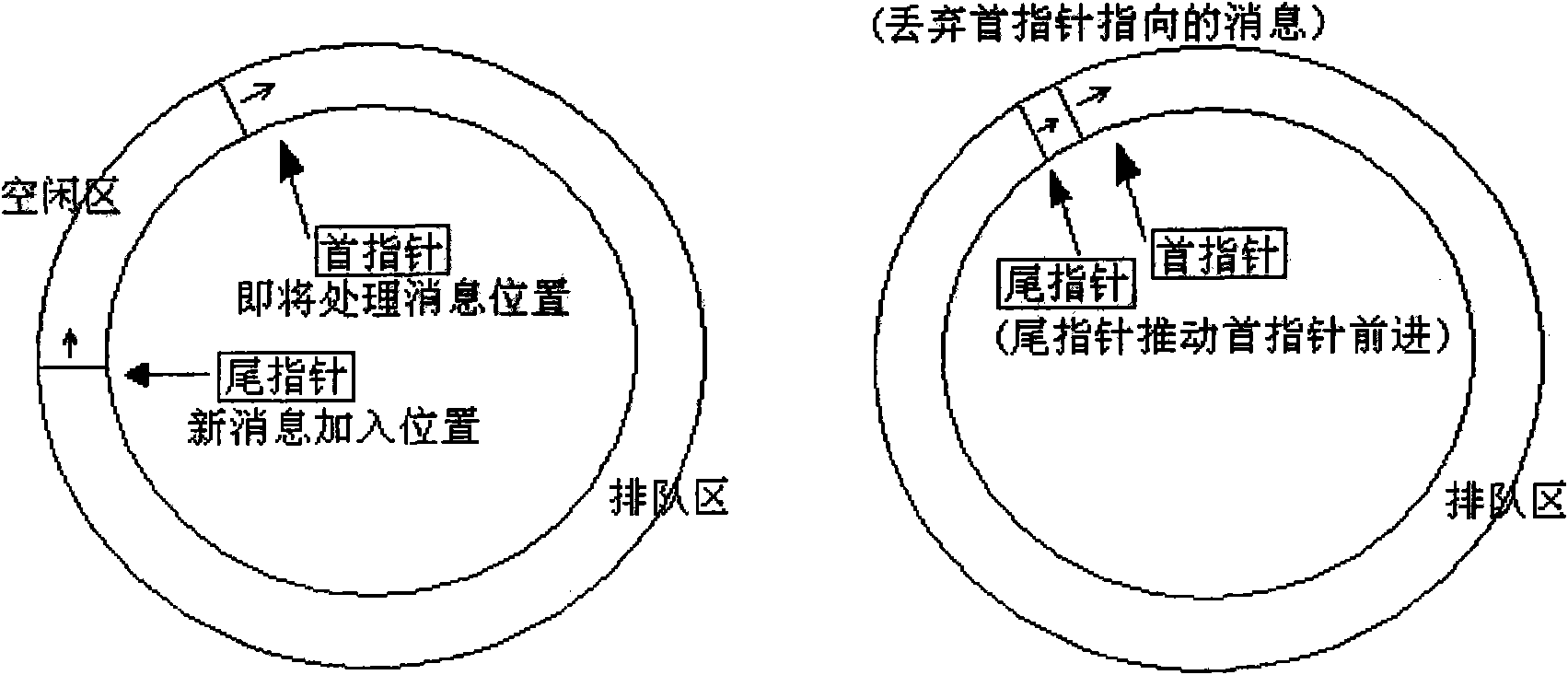

Method for preventing DOS attack by utilizing priority queue

InactiveCN102111383ASolve consumptionSolve resource consumptionTransmissionResource consumptionPriority queue

The invention discloses a method for preventing DOS (Denial of Service) attack by utilizing a priority queue. The specific protection points comprises the following steps: (1) a waiting queue adopts the priority queue method to store different data packet in a classified manner; (2) a server treats a high priority queue at first and then treats a low priority queue when the high priority queue is empty; and (3) the data packets are treated by adopting a circular queue method in the low priority queue, which is realized in the way that the circular queue of an INVITE data packet is stored, a tail pointer pushes a head pointer to advance, the data packet forwardly directed by the head pointer is rejected, and the data packet recently entering the queue is stored at the tail of the queue. The invention also discloses a device utilizing the circular queue to relieve, and solves the problem of resource consumption due to SIP (Session Initiation Protocol) DOS attack.

Owner:BEIJING SAFE CODE TECH

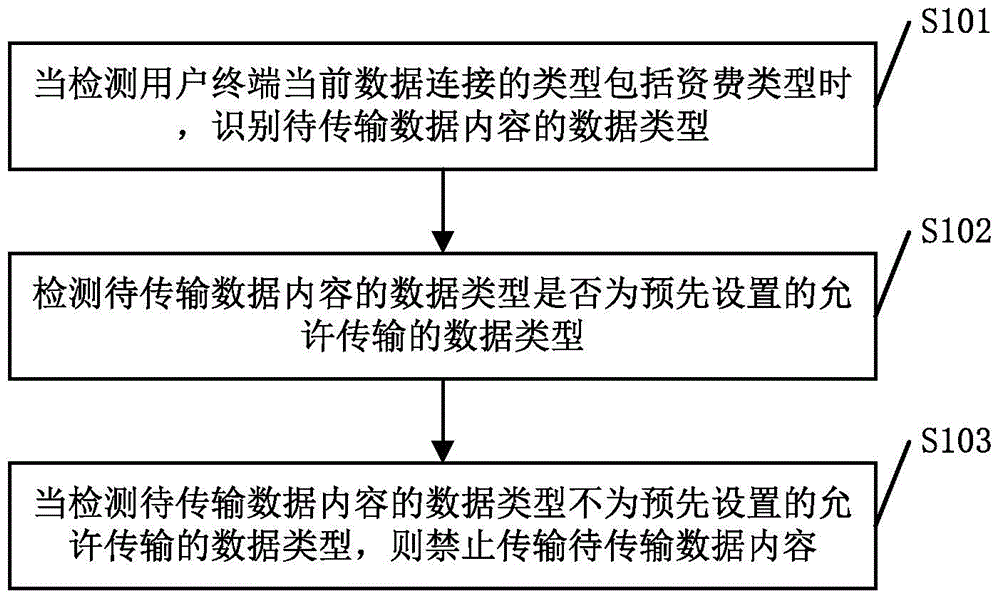

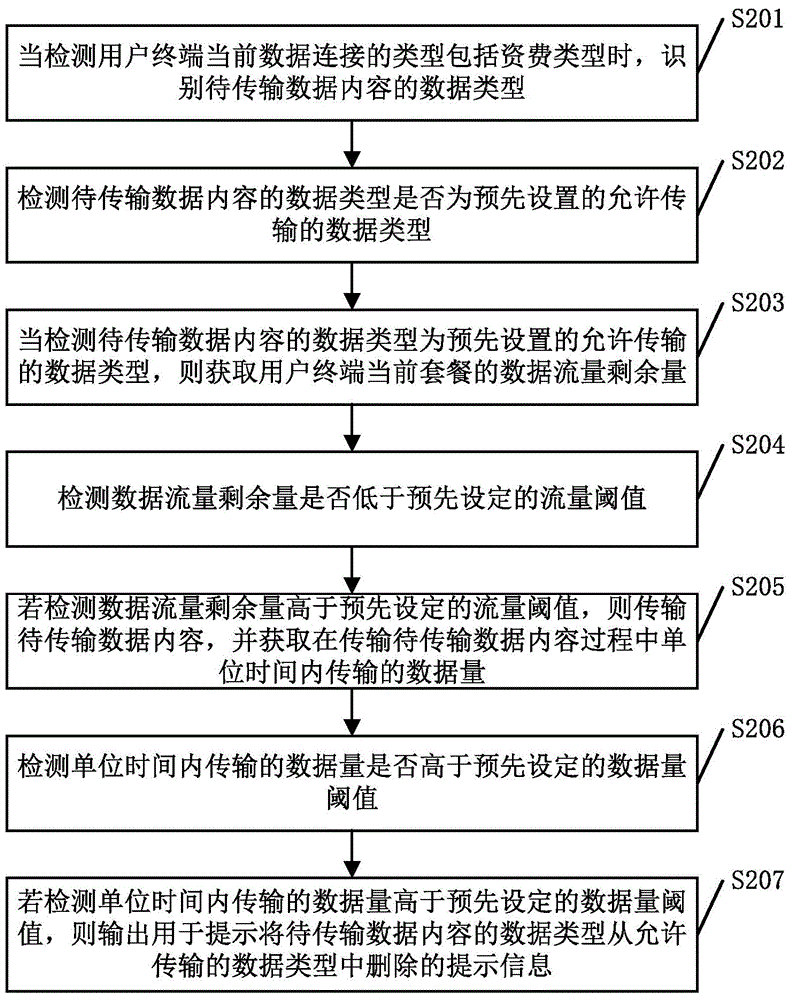

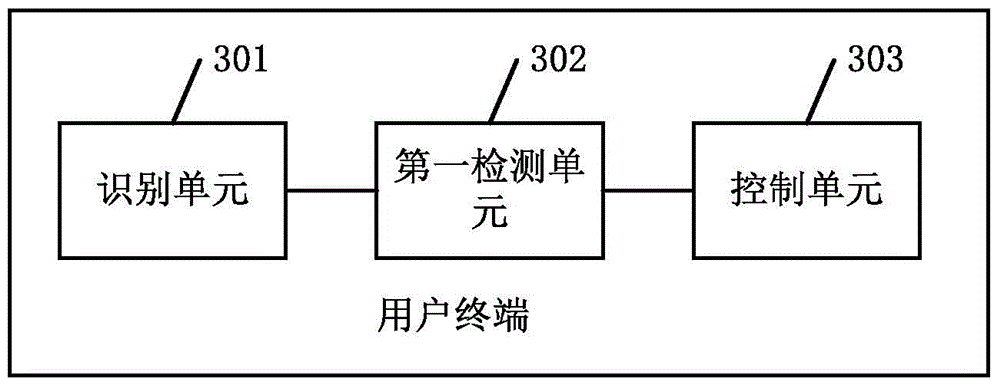

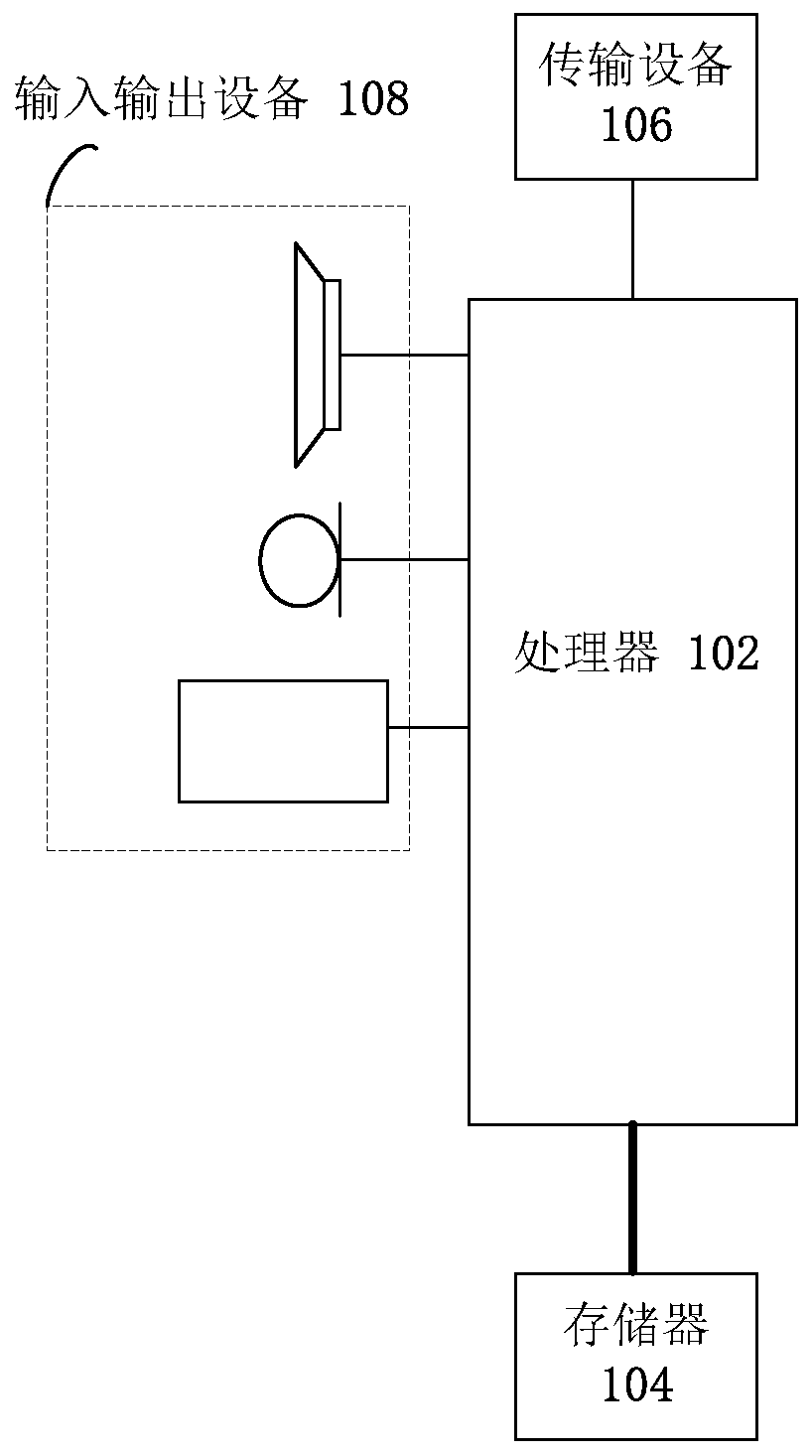

Data transmission control method and user terminal

ActiveCN104967758ASolve consumptionAccounting/billing servicesTelephonic communicationData connectionControl data

The embodiment of the invention discloses a data transmission control method and a user terminal, comprising identifying the data type of data contents to be transmitted when current data connection types of a user terminal are detected to include consumption types; detecting whether the data type of data contents to be transmitted is a preset data type allowing transmission; and prohibiting transmission of the data contents to be transmitted if the data type of the data contents to be transmitted is not a preset data type allowing transmission. The data transmission control method and user terminal can solve the problem of flow excessive consumption.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

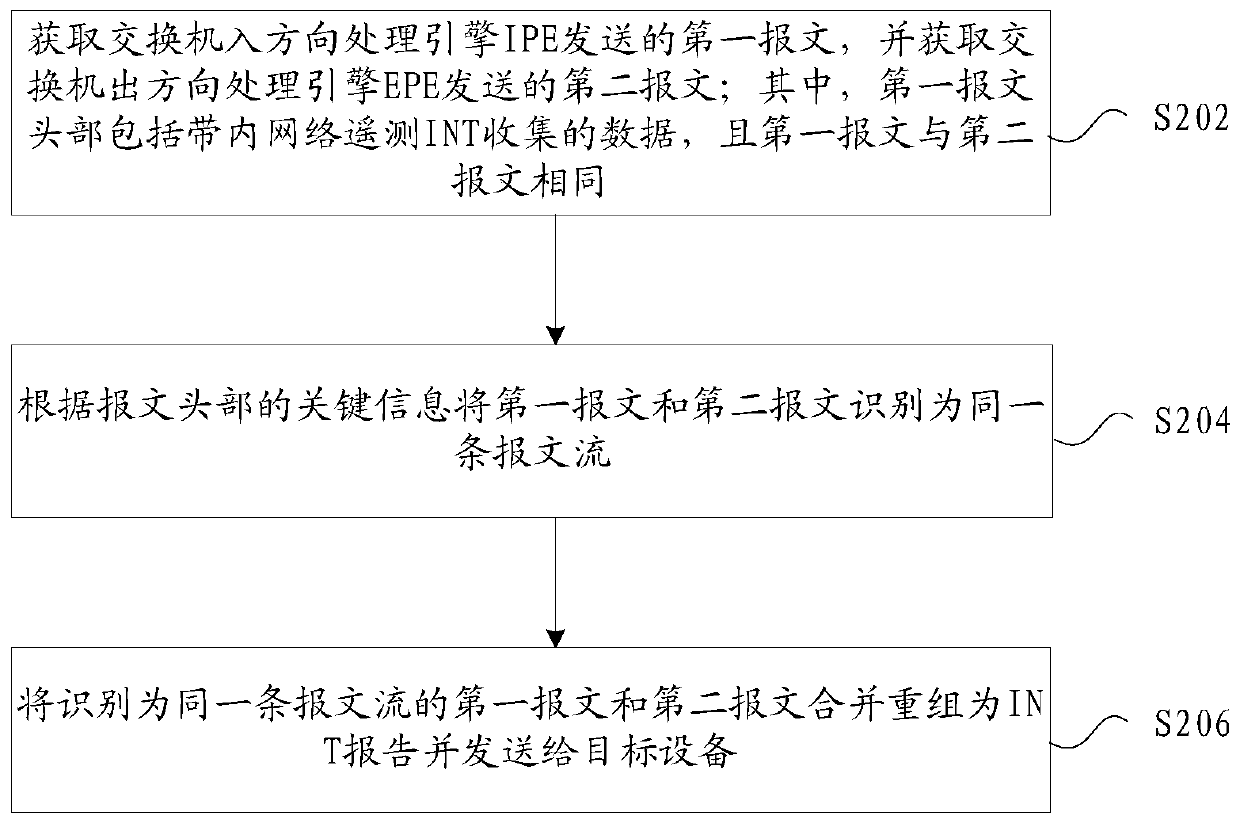

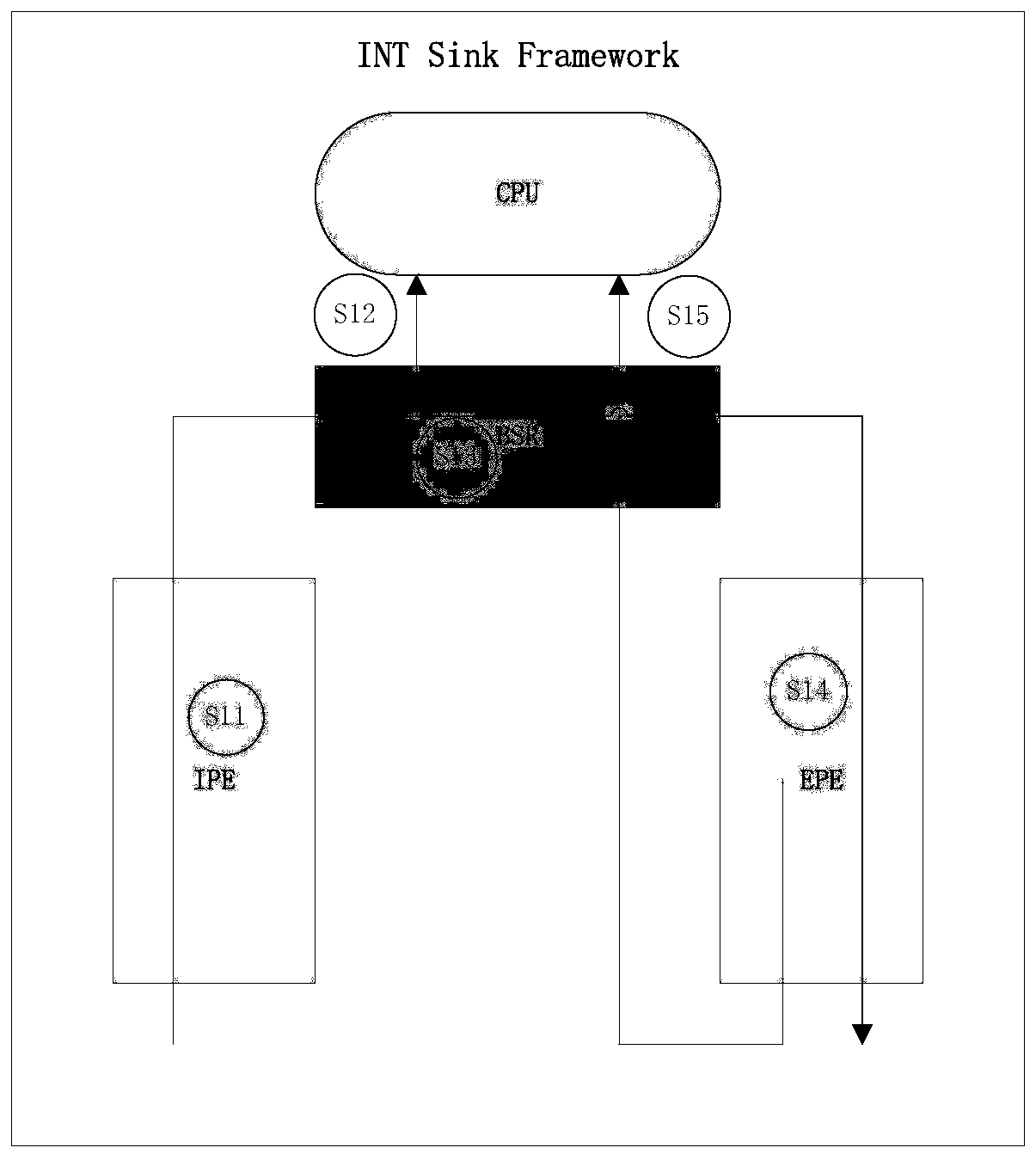

Message processing method and device, storage medium and electronic device

ActiveCN111147403ASolve consumptionReduce consumptionData switching networksComputer hardwareMessage flow

The invention provides a message processing method and device, a storage medium and an electronic device, and the method comprises the steps: obtaining a first message sent by a switch incoming processing engine IPE, and obtaining a second message sent by a switch outgoing processing engine EPE; wherein the first message header comprises data collected by in-band network telemetry INT, and the first message is the same as the second message; identifying the first message and the second message as the same message flow according to the key information of the message header; and combining and recombining the first message and the second message which are identified as the same message flow into an INT report and sending the INT report to target equipment. According to the method and the device, the problem of high network bandwidth consumption caused by realizing network state monitoring on a protocol layer in related technologies is solved.

Owner:SUZHOU CENTEC COMM CO LTD

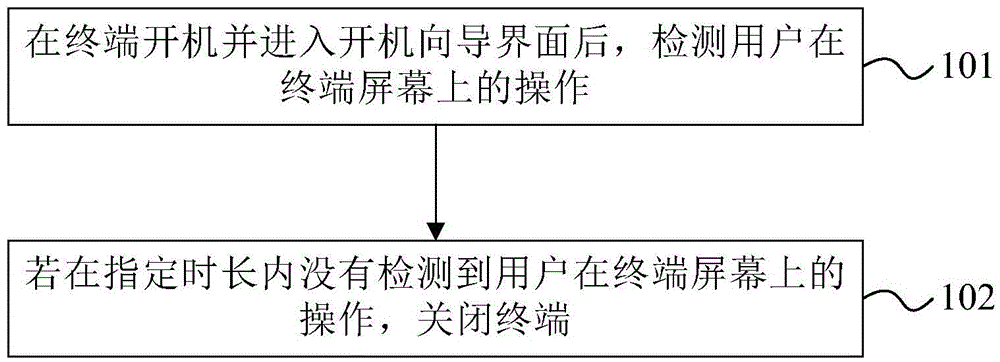

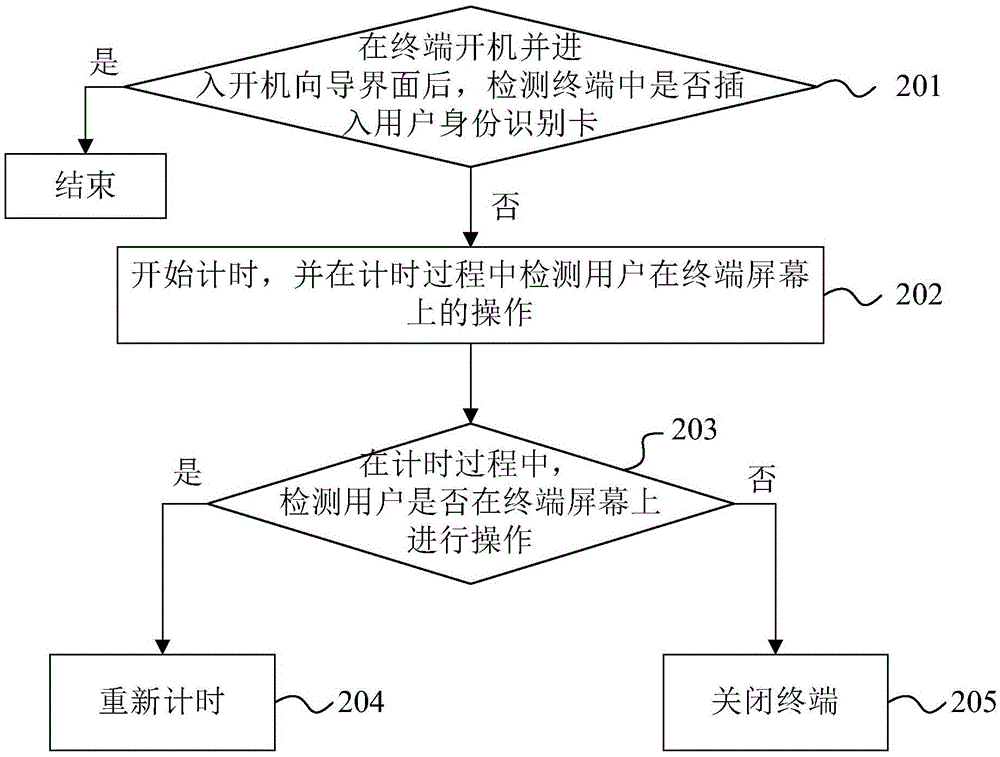

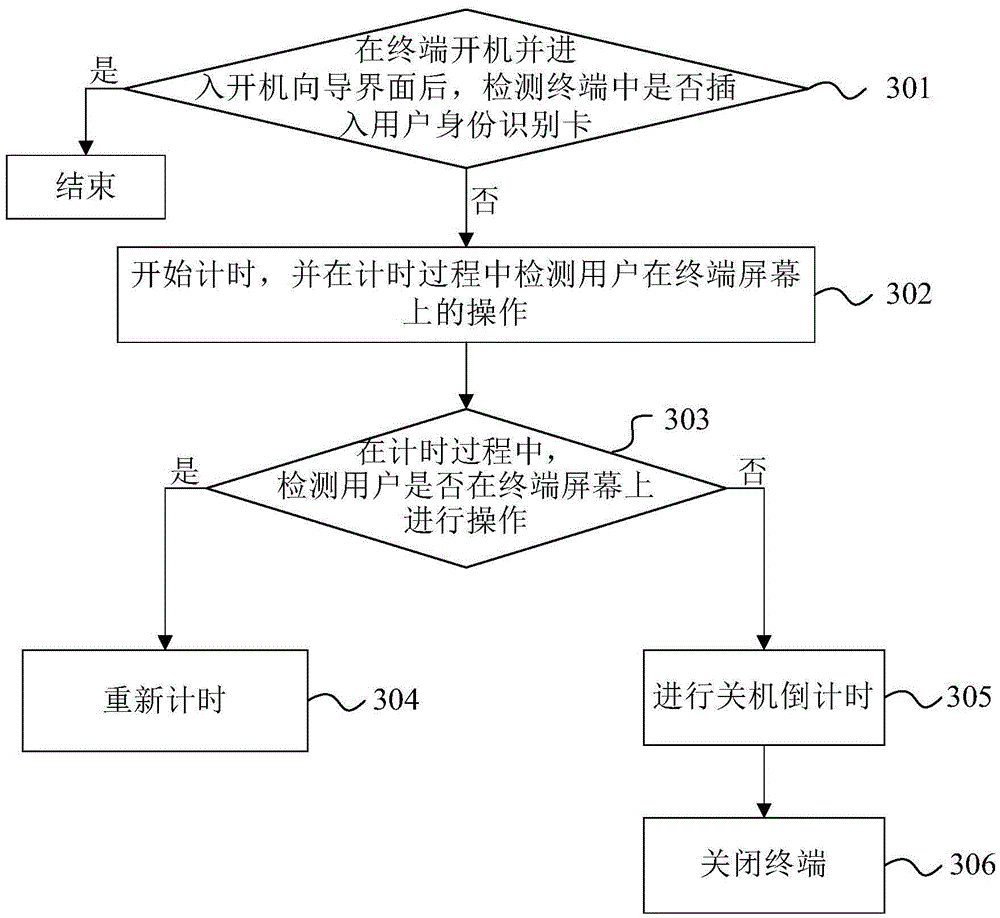

Terminal control method and apparatus as well as terminal

InactiveCN105867579AAvoid running outEnergy savingCurrent supply arrangementsPower supply for data processingElectrical batteryStart up

The invention provides a terminal control method and apparatus as well as a terminal. The terminal control method comprises the steps of after the terminal is started up and enters a startup guide interface, detecting operation of a user on a terminal screen, and if the operation of the user on the terminal screen is not detected within a specified duration, turning off the terminal. Therefore, the problem of unnecessary energy consumption caused by continuous power consumption in a false startup process of a terminal in the prior art is solved, the terminal is ensured to have sufficient power when the startup guide operation is carried out after startup, the power of a battery in the terminal is prevented from being used up before startup for the first time, and the energy-saving effect is achieved.

Owner:LEMOBILE INFORMATION TECH BEIJING

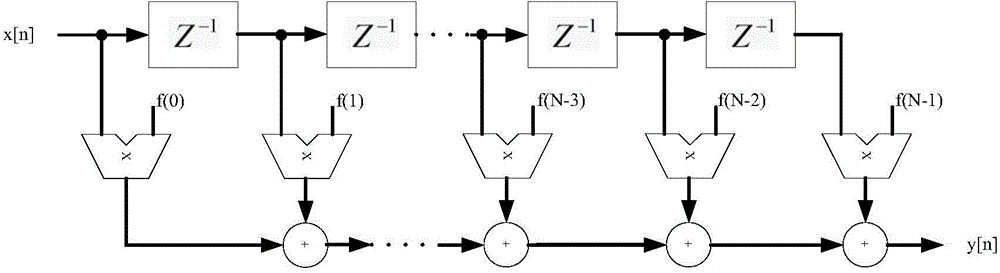

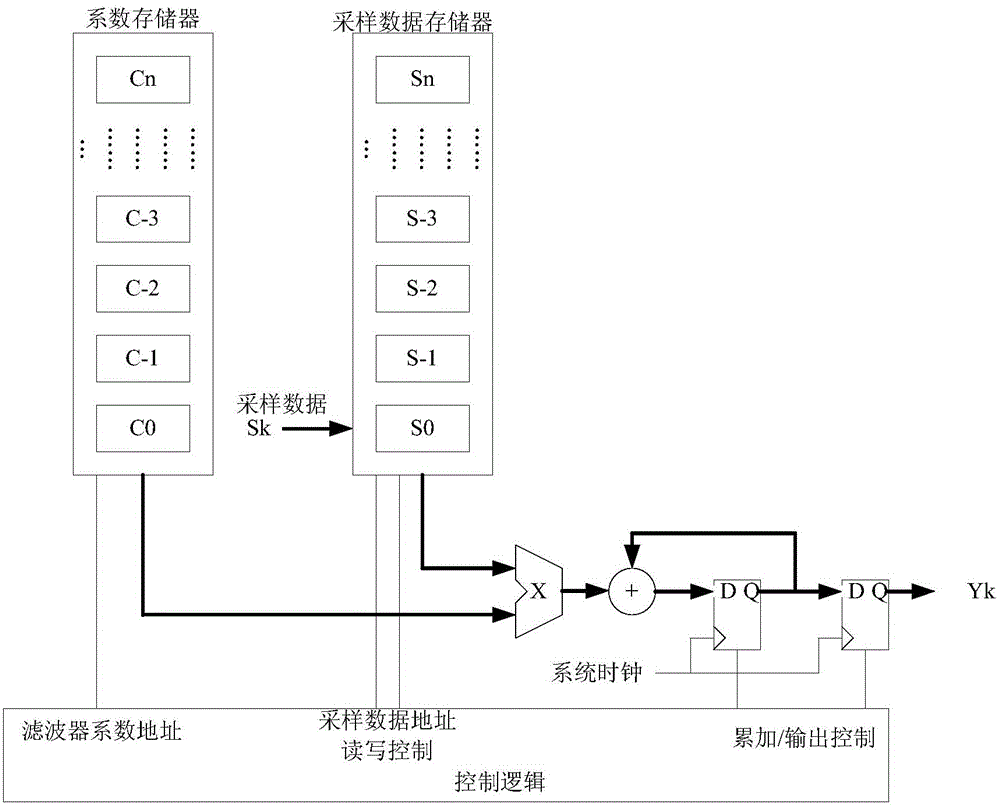

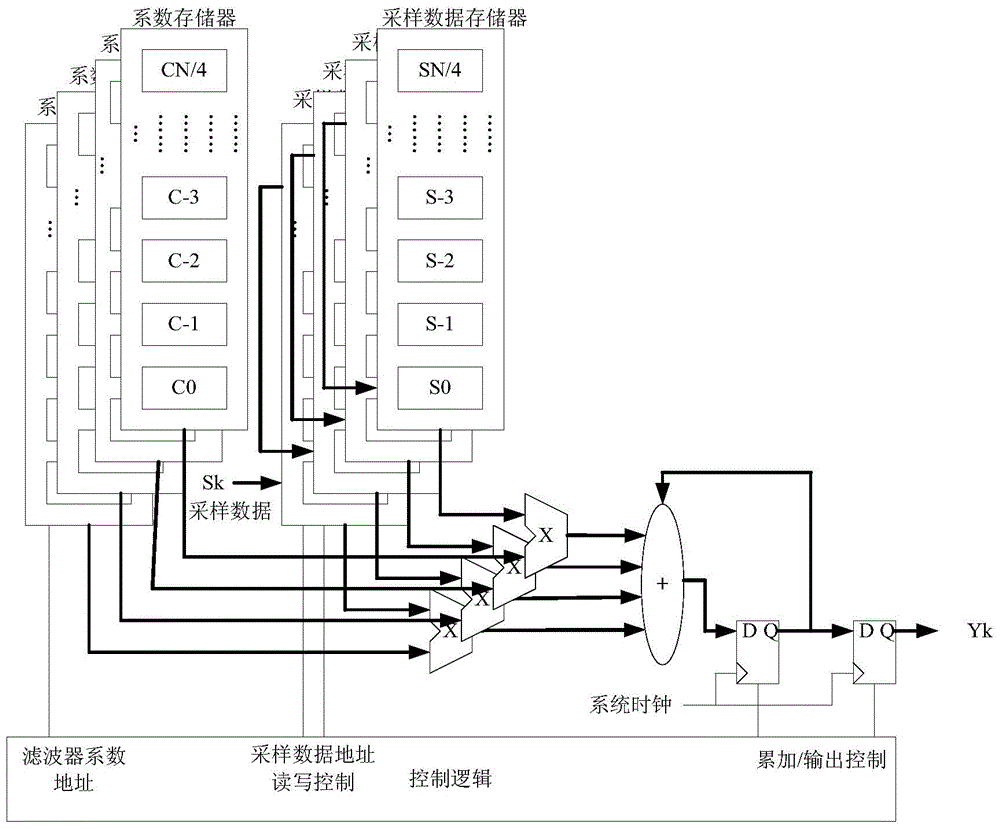

FPGA-based configurable-coefficient filter and filtering method, and electronic equipment

ActiveCN104579240ASolve consumptionSatisfy filtering processing requirementsDigital technique networkBinary multiplierElectric equipment

The invention relates to an FPGA-based configurable-coefficient filter. The FPGA-based configurable-coefficient filter is connected to an external MCU, and coefficients of the filter are updated through the external MCU. The filter comprises a control logic with a coefficient read address line and a data read and write address line, a plurality of coefficient memorizers arranged in parallel and used for storing the filtering coefficients, and a plurality of sample data memorizers, wherein filtering coefficients in each coefficient memorizer are mutually arranged in a serial manner, the filtering coefficients of the coefficient memorizers are connected end to end, the coefficient memorizers are coupled with the control logic and the external MCU, and form channels for updating of the coefficients of the filter with the external MCU, and updated coefficient address lines are arranged in the channels for updating of the coefficients of the filter; each coefficient memorizer and each sample data memorizer are coupled with the corresponding multiplier of a plurality of multipliers, and the multipliers are connected to an accumulator; under the control of the control logic, a filtering operation result is output by a trigger. According to the filter provided by the invention, the processing speed is increased.

Owner:CAPITAL MICROELECTRONICS

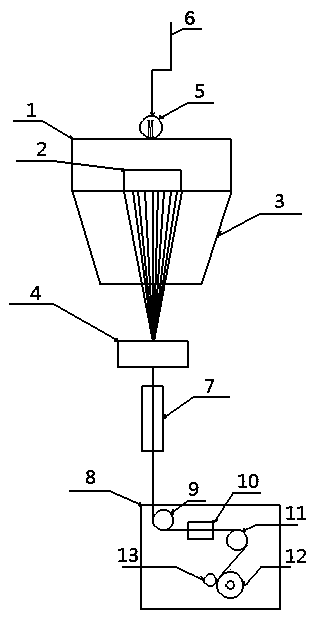

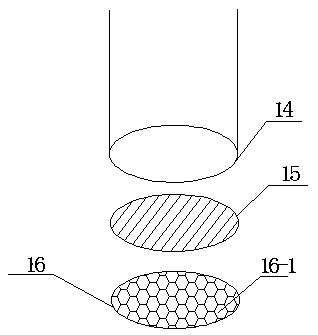

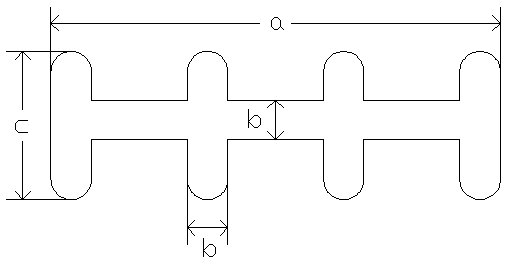

Production equipment of multi-H-shaped coarse-denier porous POY filament and manufacturing method thereof

InactiveCN109137109ANovel structural designReduce unevennessSpinning head liquid feederArtificial thread manufacturing machinesPolyesterWinding machine

The invention discloses the production equipment of a multi-H-shaped coarse-denier porous POY filament and a manufacturing method thereof. The production equipment comprises spinning box bodies, a ring blowing cooling device, an oiling device, a spinning channel, a winding machine and a plurality of heating medium pipeline system devices used for melt conveying in a spinning process, wherein the spinning box bodies, the ring blowing cooling device, the oiling device, the spinning channel and the winding machine are successively arranged from top to bottom. The manufacturing method comprises the following steps of using the above production equipment to produce; making molten polyester melt pass through the melt pipes of the heating medium pipeline system devices to enter into each spinningbox body; after passing through a metering pump and a spinning component, extruding a nascent fiber; and passing through the ring blowing cooling device, the oiling device and the spinning channel, finally winding into a spinning cake. A temperature in the spinning box bodies can be rapidly increased, and the temperature can be accurately controlled, balanced and uniformed, product quality is ensured, energy consumption is reduced, and production efficiency and the abnormity degree of products are increased, which is good for rear channel processing.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Full-biodegradable material capable of being applied to paper laminating and manufacturing method thereof

The invention discloses a full-biodegradable material capable of being applied to paper laminating and a manufacturing method thereof. The full-biodegradable material is prepared from, by weight, polylactic acid, PBAT, a compatibilizer, a coupling agent, paraffin, glycerinum and sorbitol. The manufacturing method of the full-biodegradable material comprises the following steps of 1, weighing the polylactic acid, the PBAT, the compatibilizer, the coupling agent, the paraffin, the glycerinum and the sorbitol for uniform mixing and stirring; 2, putting the raw materials which are uniformly mixedinto a pelletizer for mixing, melting, extrusion, and grain-sized dicing after cooling to prepare full-biodegradable plastic particles. The price of the full-biodegradable material is nearly the sameas that of common plastic thin film, and the material is a green material capable of being completely degraded; the material is processed into the thin film through equipment and then applied to paperlaminating.

Owner:海南海达丰实业有限公司

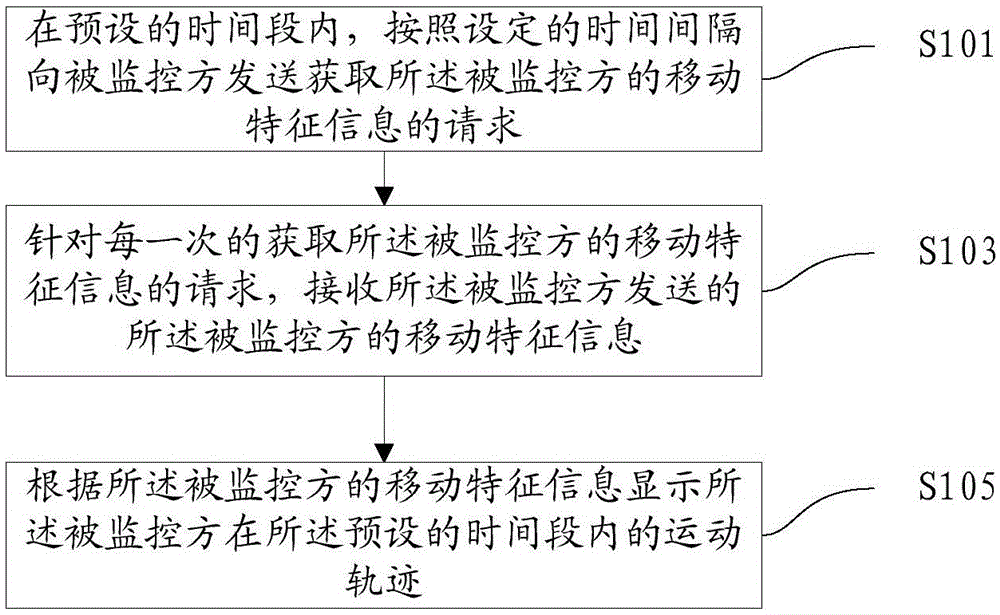

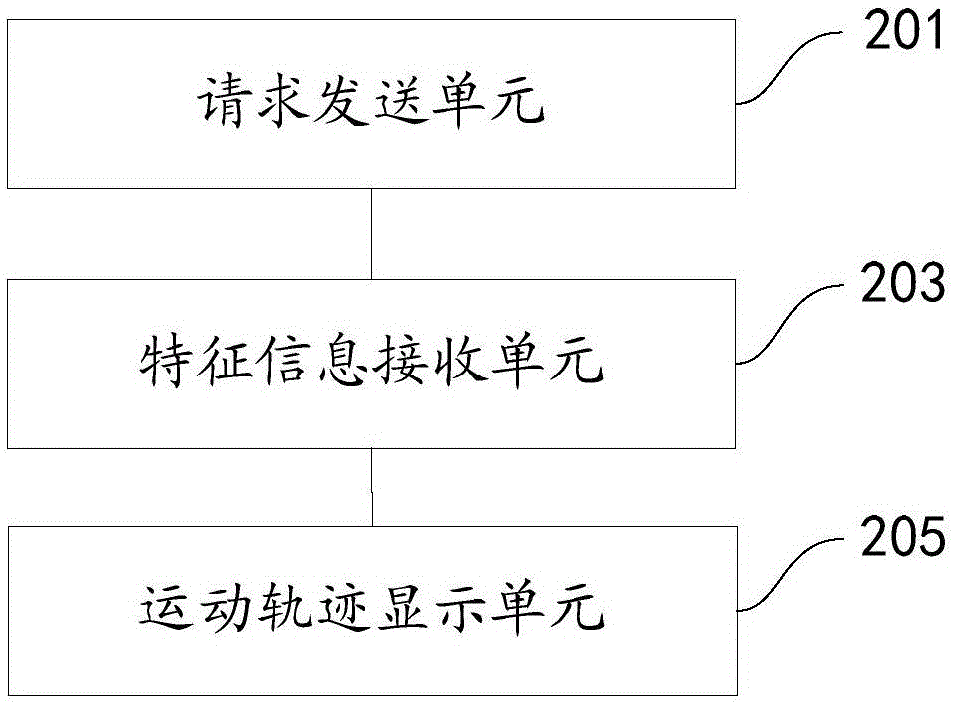

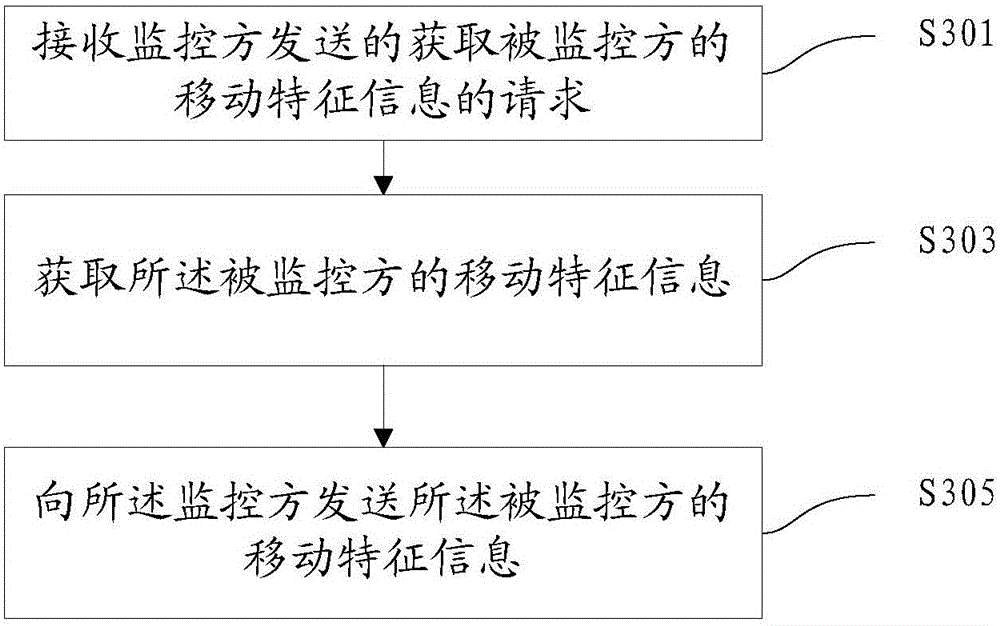

Method, apparatus, and system for monitoring position information of mobile terminal

ActiveCN105050038ASolve consumptionSolve usabilityPower managementLocation information based serviceComputer terminalReal-time computing

The application discloses a method, an apparatus, and a system for monitoring position information of a mobile terminal. The method includes: sending a request for obtaining mobile characteristic information of a monitored party to the monitored party according to a set time interval in a preset time period; receiving the mobile characteristic information of the monitored party sent by the monitored party aiming to each request for obtaining the mobile characteristic information of the monitored party; and displaying the movement track of the monitored party in the preset time period according to the mobile characteristic information of the monitored party. According to the method, the apparatus, and the system, in the preset time period, the request for obtaining the mobile characteristic information of the monitored party is sent to the monitored party according to the set time interval, the problem of high flow consumption is solved, and the problems of poor positioning and tracking effects and high usage power consumption are solved via the displayed movement track of the monitored party in the preset time period according to the mobile characteristic information of the monitored party.

Owner:SHANGHAI HAIYANG SOFTWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com