Technique for preparing hydrogen gas by hydrocarbons gases

A gas preparation and hydrocarbon gas technology, applied in hydrogen, chemical recovery, inorganic chemistry, etc., to achieve the effect of solving catalyst consumption and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using methane gas as raw material, the flow rate is 220ml / min;

[0036] Ni / Al 2 o 3 As a catalyst, the metal loading is 10-35%wt;

[0037] Three-stage fixed-bed cracking reactor with a temperature of 500°C;

[0038] The heat exchange unit after cracking adopts shell and tube heat exchanger;

[0039] No gas-solid separation equipment after cracking;

[0040] No hydrogen purification equipment;

[0041] The post-combustion heat exchange unit adopts a shell-and-tube heat exchanger;

[0042] The gas-solid separation equipment after combustion adopts cyclone separator;

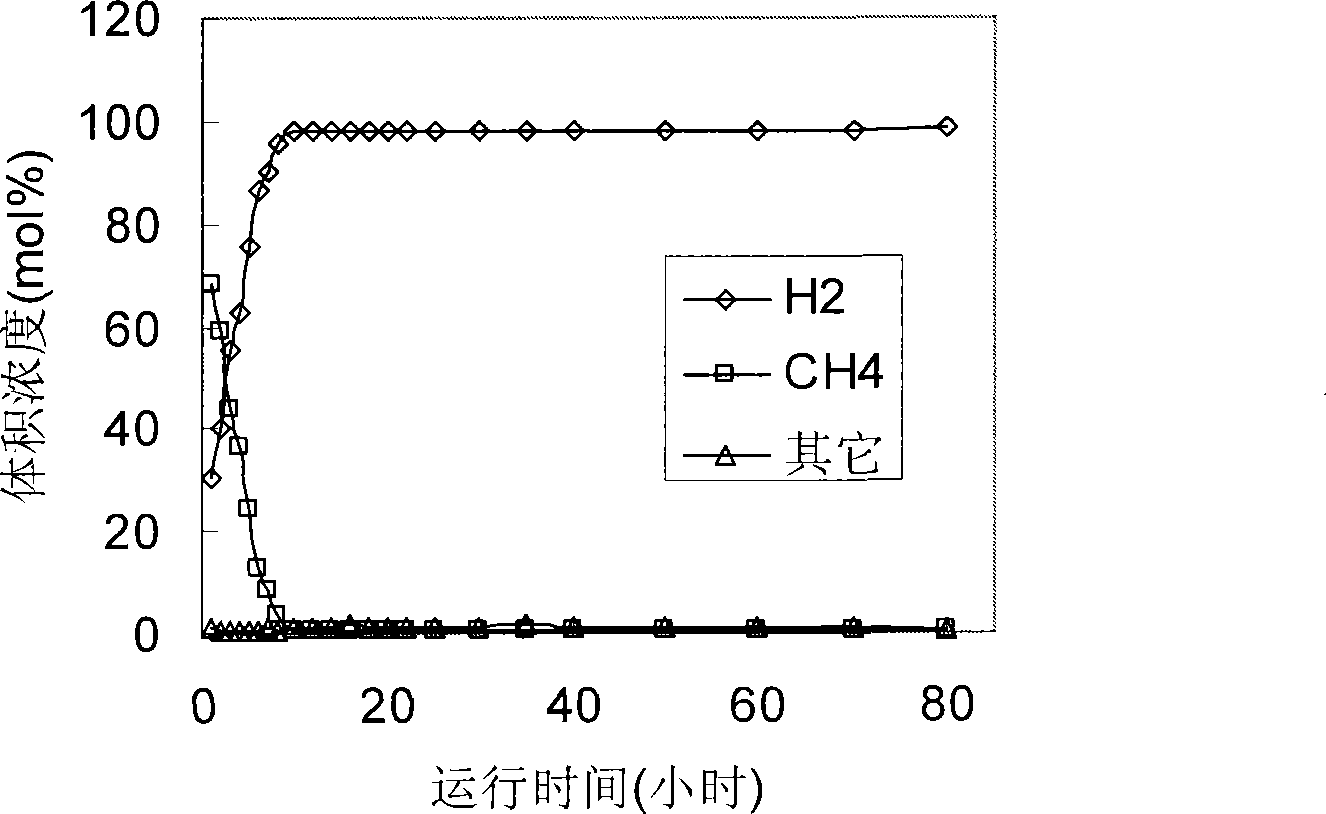

[0043] Experiment runs 80 hours, product gas composition and content measure with gas chromatography (AgilentN9608), the situation that the composition of product gas changes with time is as follows figure 1 As shown, it can be seen that once the system runs stably, the product gas composition is stable and the impurity content is very low.

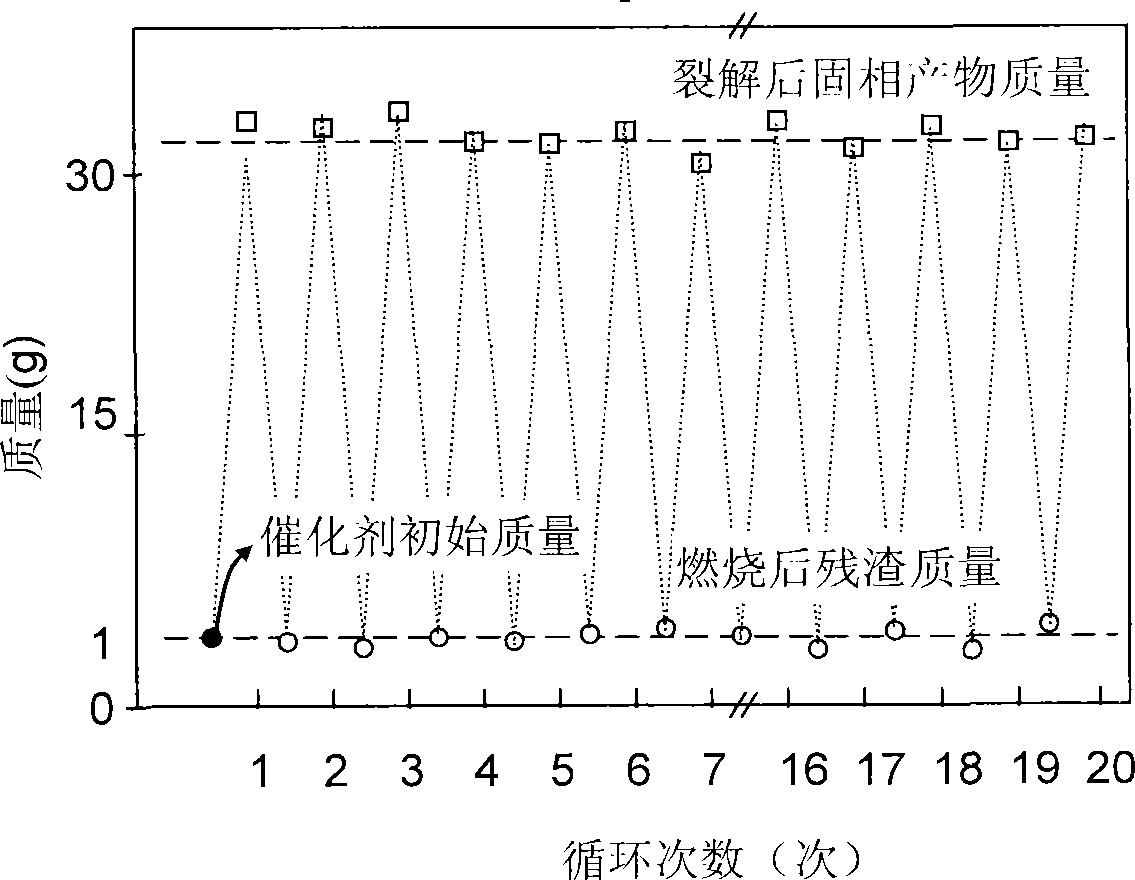

[0044] In order to verify the change of catalyst activity ...

Embodiment 2

[0047] The mixed gas of methane and hydrogen is used as the raw material, the flow rate is 350ml / min, and the volume content of hydrogen is 10%;

[0048] Fe / MgO is the catalyst, and the metal loading is 5-25%wt;

[0049] Three-stage fixed-bed pyrolysis reactor with a temperature of 650°C;

[0050] The heat exchange unit after cracking adopts shell and tube heat exchanger;

[0051] No gas-solid separation equipment after cracking;

[0052] No hydrogen purification equipment;

[0053] The post-combustion heat exchange unit adopts a shell-and-tube heat exchanger;

[0054] The gas-solid separation equipment after combustion adopts cyclone separator;

[0055] The experiment was run for 80 hours, and the gas chromatographic detection results were averaged after the stable operation, and the hydrogen-rich gas component obtained was H 2 : 99.6%, CH 4 : 0.2%, other 0.2%; no CO 2 Or CO is detected.

Embodiment 3

[0057] Using liquefied petroleum gas as raw material, the flow rate is 280ml / min;

[0058] Co / MgO is the catalyst, and the metal loading is 5-30%wt;

[0059] Three-stage fixed-bed pyrolysis reactor with a temperature of 660°C;

[0060] The heat exchange unit after cracking adopts shell and tube heat exchanger;

[0061] No gas-solid separation equipment after cracking;

[0062] No hydrogen purification equipment;

[0063] The post-combustion heat exchange unit adopts a shell-and-tube heat exchanger;

[0064] The gas-solid separation equipment after combustion adopts cyclone separator;

[0065] The experiment was run for 80 hours, and the gas chromatographic detection results were averaged after the stable operation, and the hydrogen-rich gas component obtained was H 2 : 99.2%, CH 4 : 0.1%, other 0.7%; no CO 2 Or CO is detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com