Unit modular large household refuse incineration furnace

A domestic waste incineration, unit module technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of incomplete combustion, uneven air supply, insufficient contact, etc., to suppress and generate NOx, reduce NOx The effect of generating, manufacturing and maintaining low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

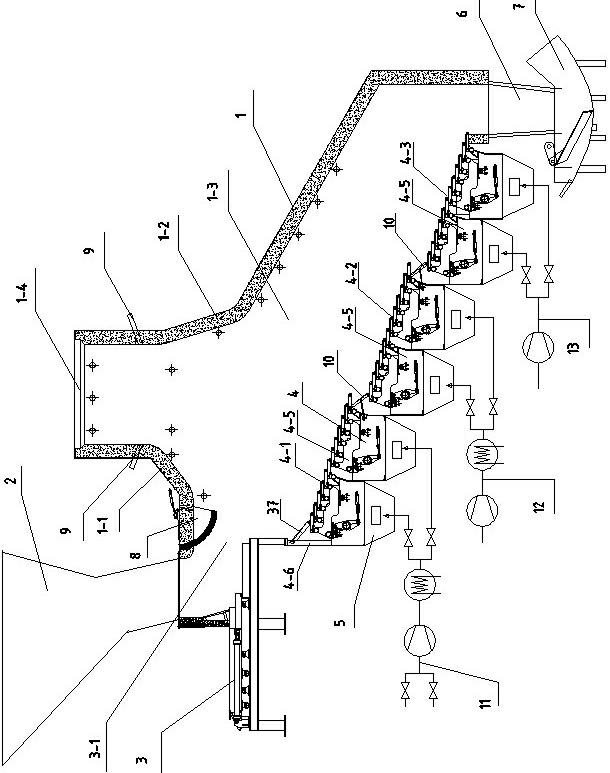

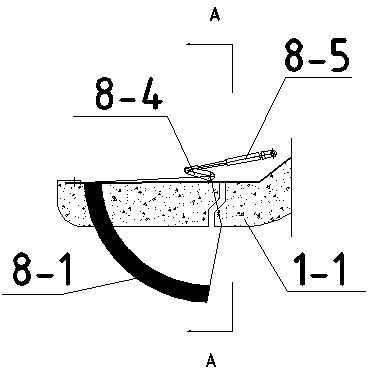

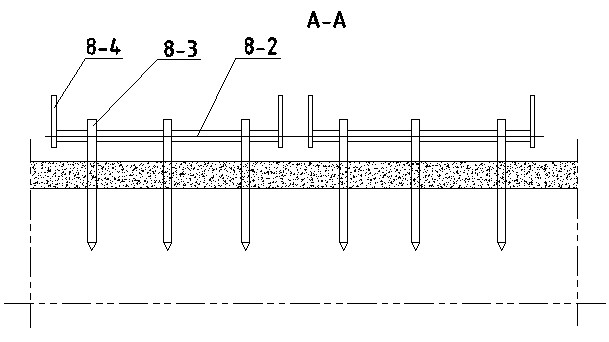

[0041] Such as Figure 1-16 As shown, the present invention is provided with a furnace 1, and the furnace 1 includes a front arch 1-1, a rear arch 1-2, a side wall 1-3, and a furnace outlet 1-4, on the side close to the front arch 1-1 A feed hopper 2 is set above the furnace 1, a feeder 3 is set below the feed hopper 2, and an incineration grate mechanism 4 is set below the feeder 3 outlet 3-1; At least one air chamber 5 is arranged below the grate mechanism 4, and an air supply system 33 is connected below the air chamber 5; a slag well 6 is arranged at the end of the incineration grate mechanism 4, and a slag well 6 is arranged below the slag well 6. Slagging machine 7; on the front arch 1-1 close to the lower end of the feed hopper 2, a homogenizing device 8 is set above the feeder outlet 3-1, and the front arch 1-1 and the rear Nozzles 9 are respectively set on the arch 1-2 and near the furnace outlet 1-4.

[0042] Described feeder 3 comprises frame 3-1, material pushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com