Patents

Literature

32results about How to "Fully designed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

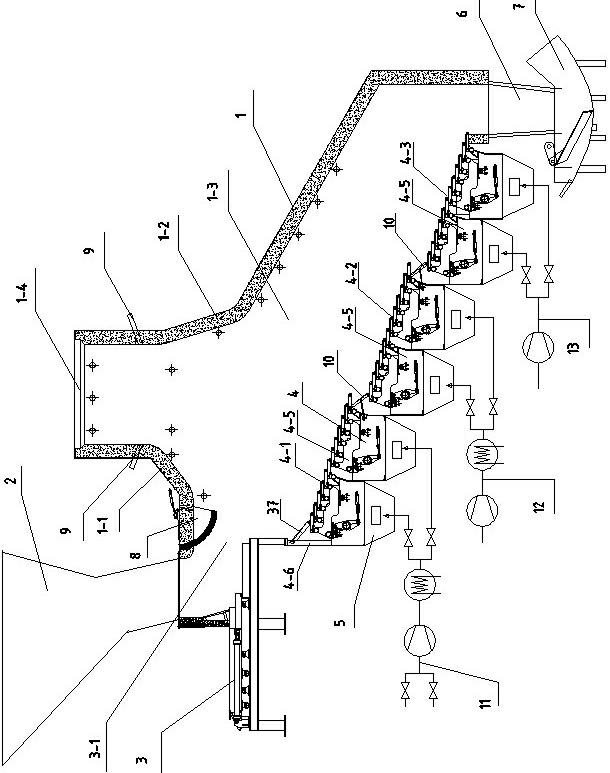

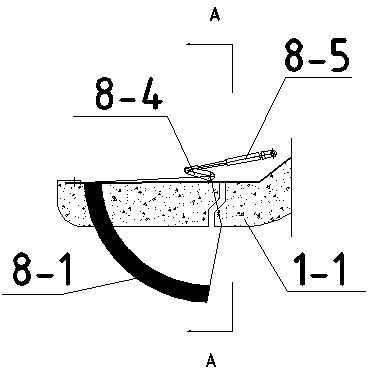

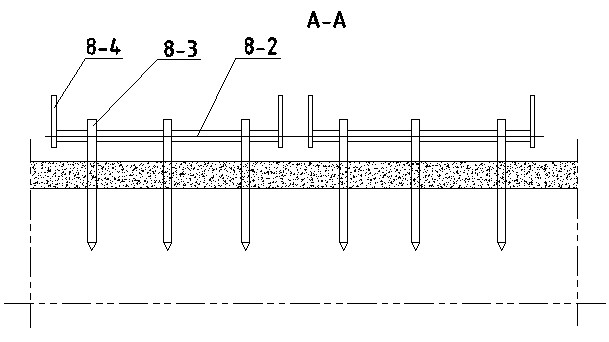

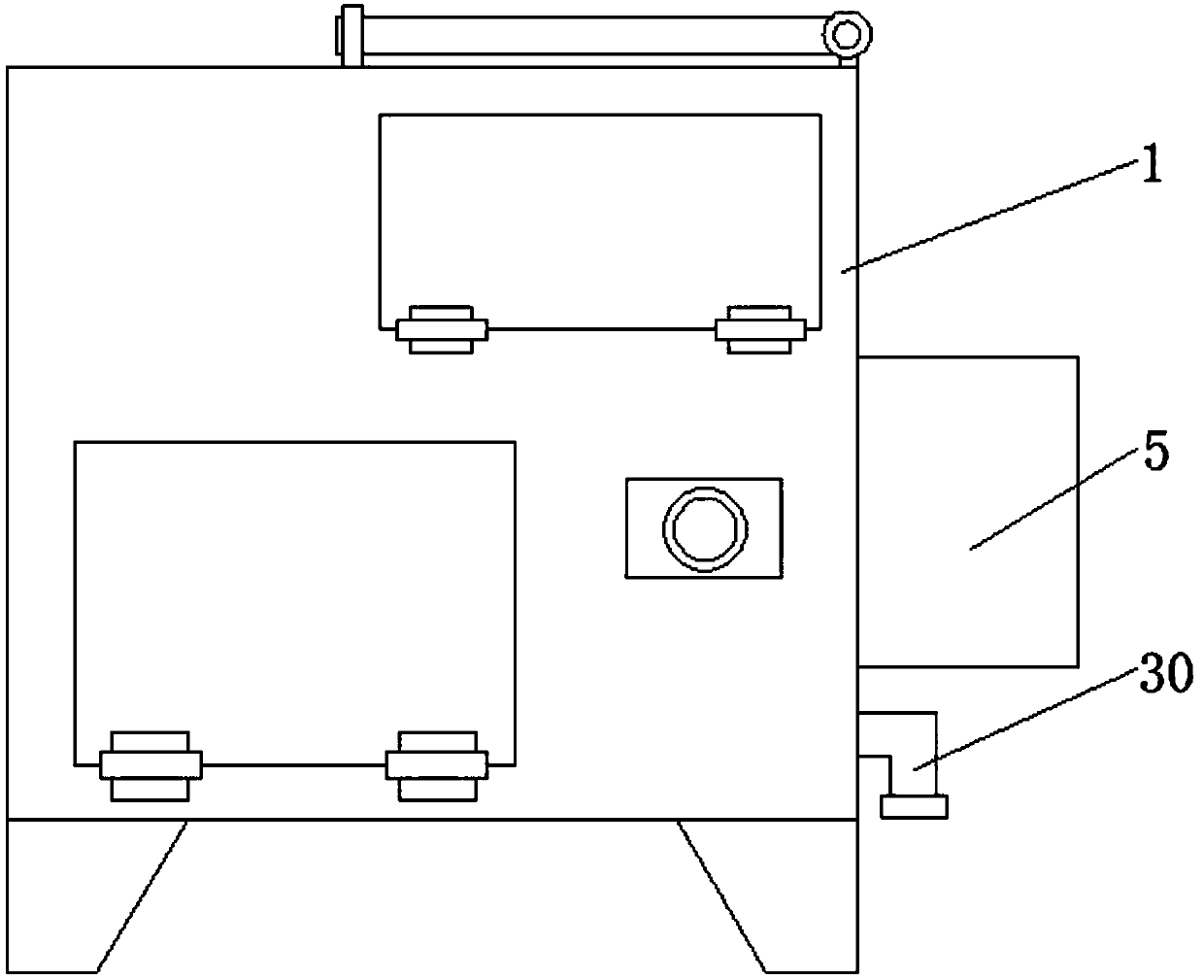

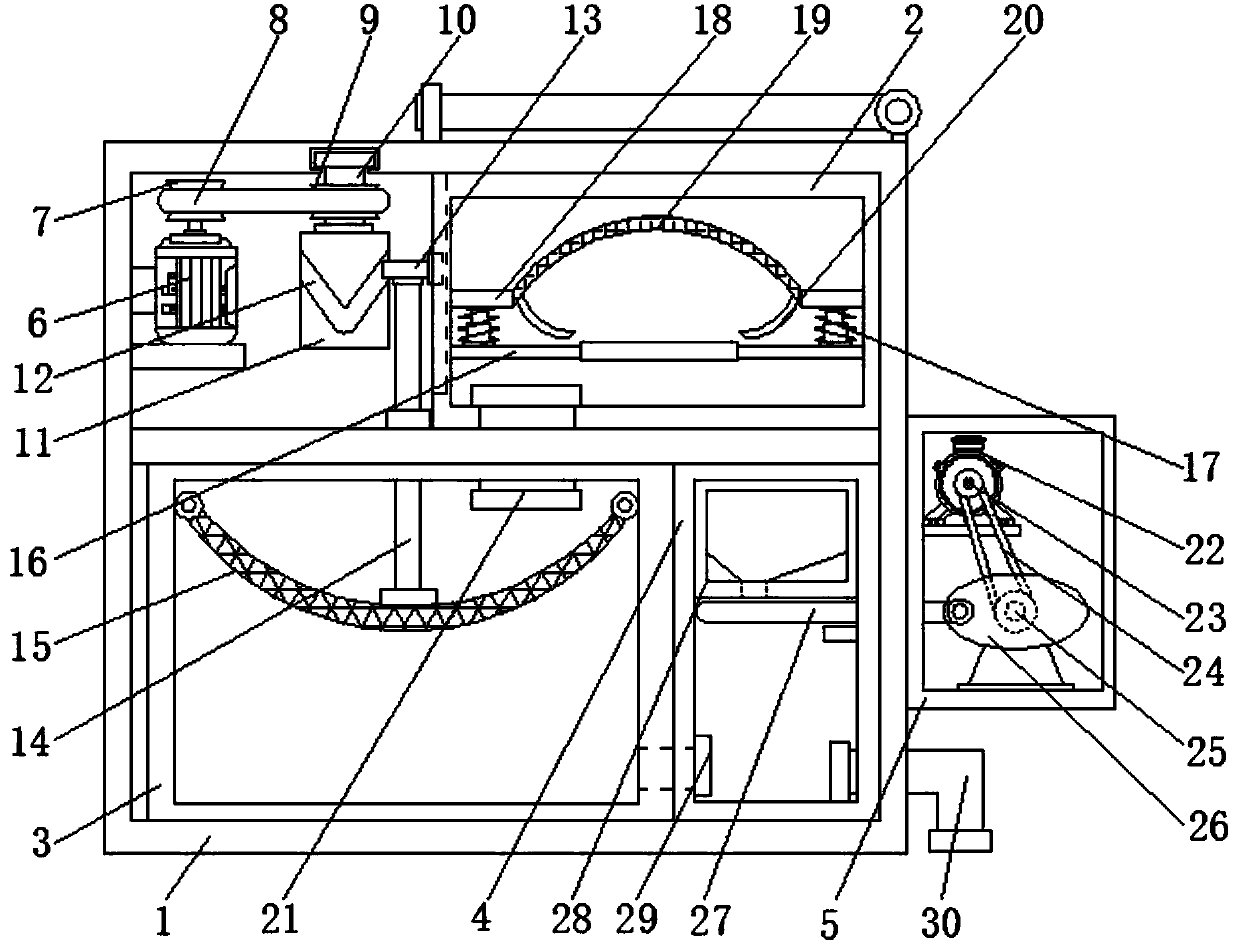

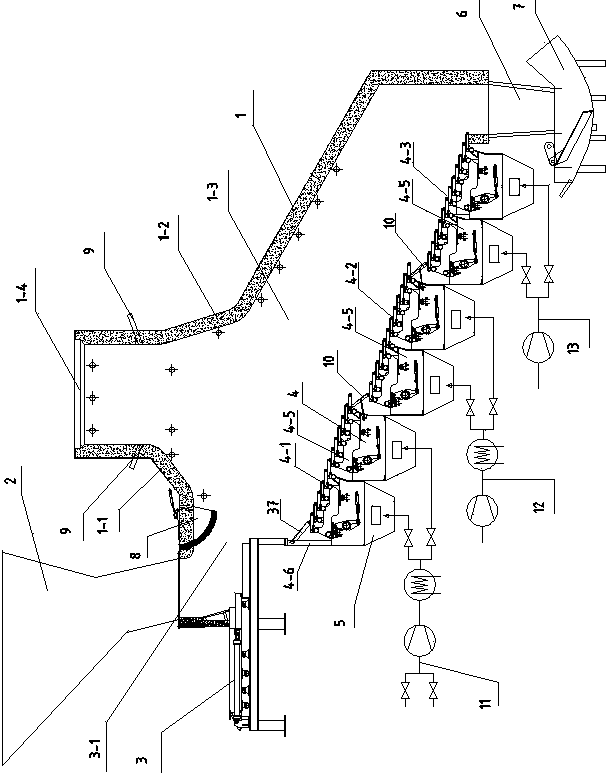

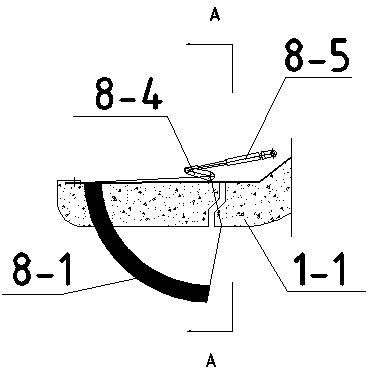

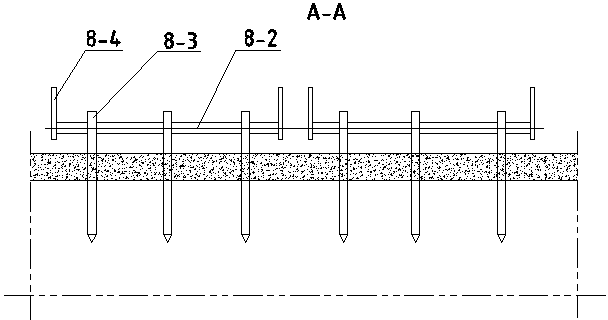

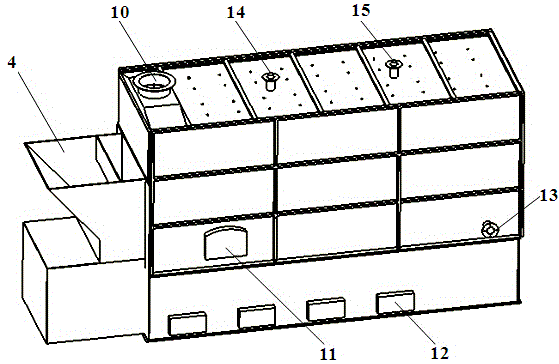

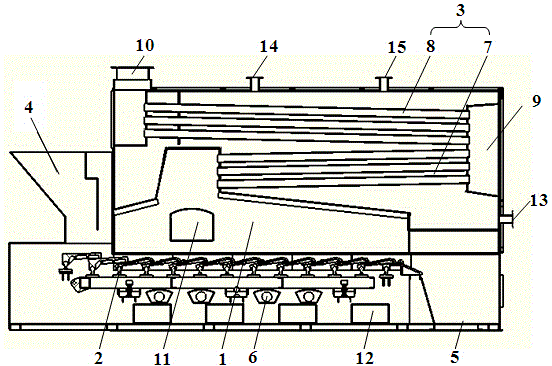

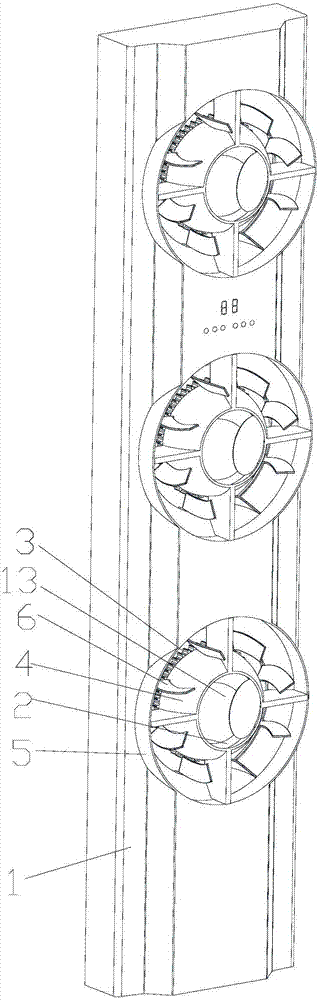

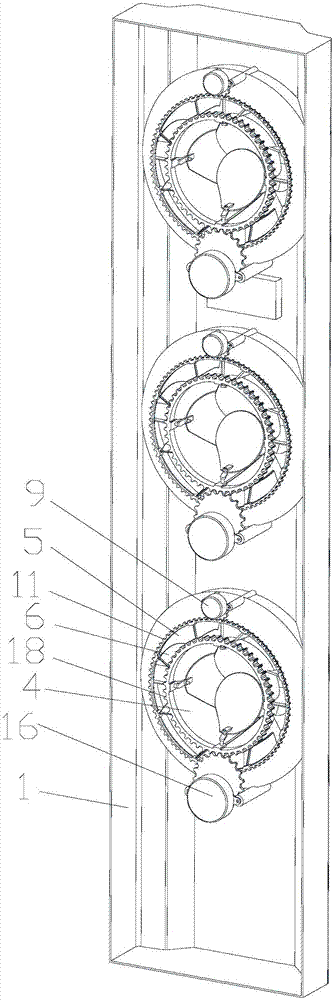

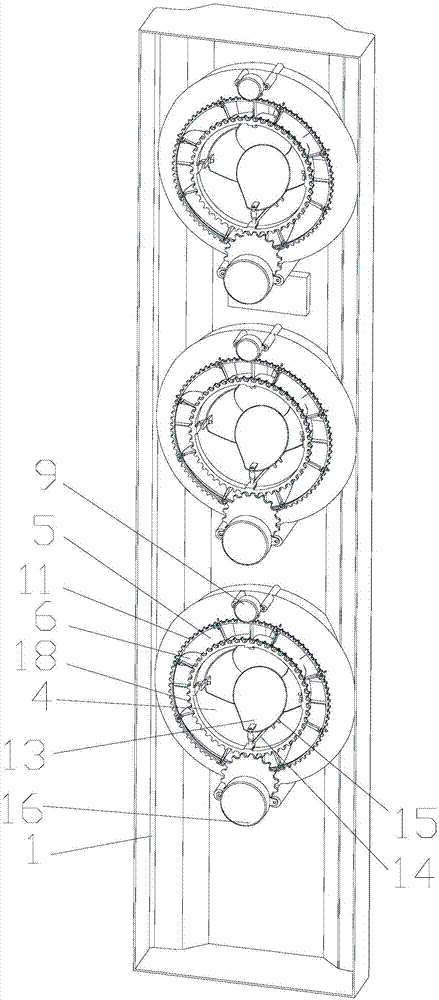

Unit modular large household refuse incineration furnace

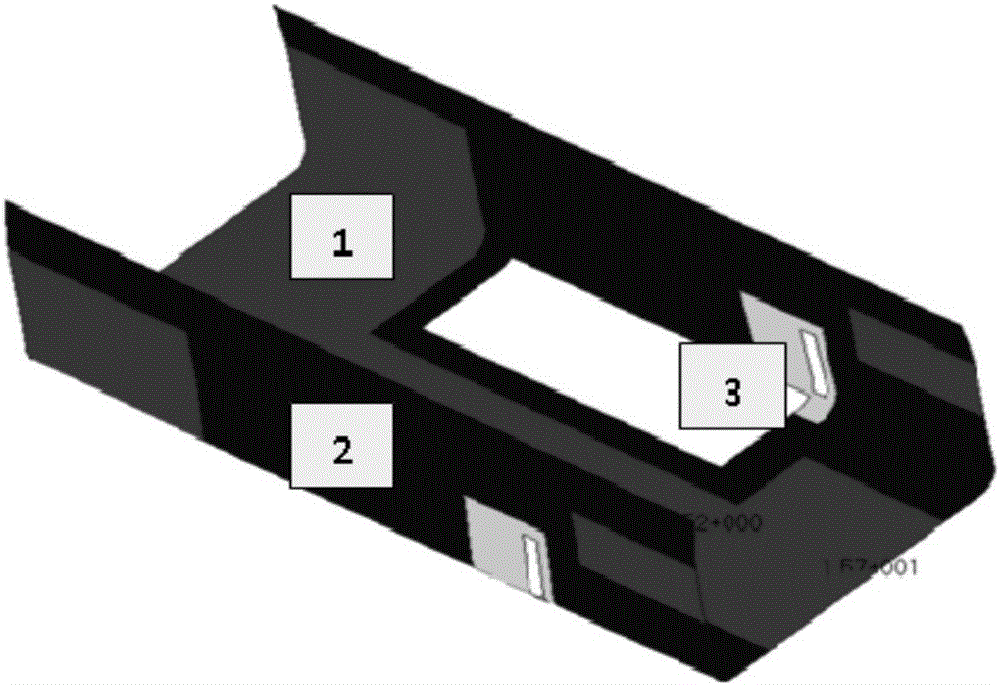

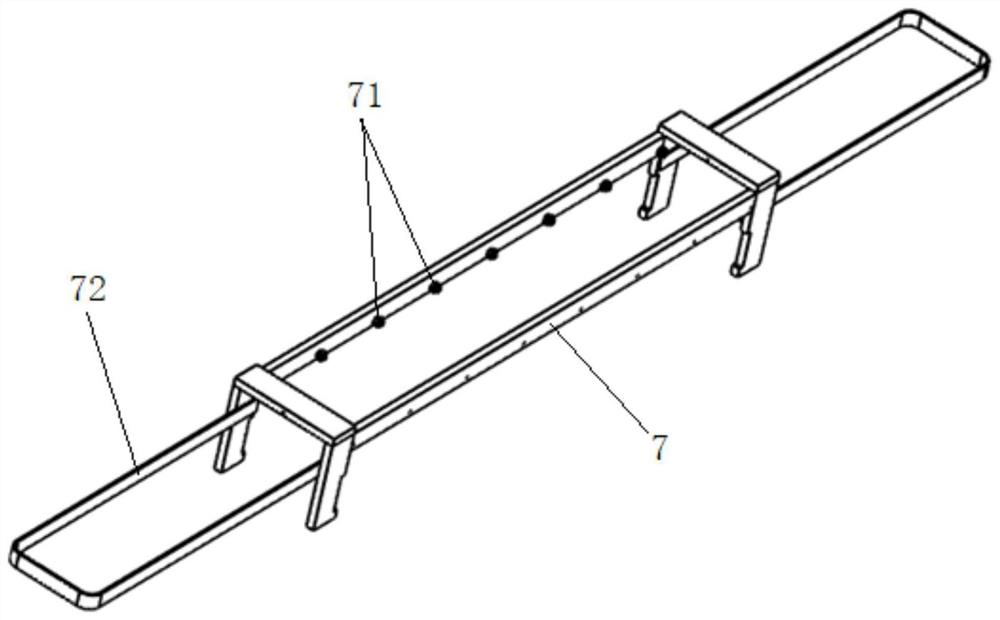

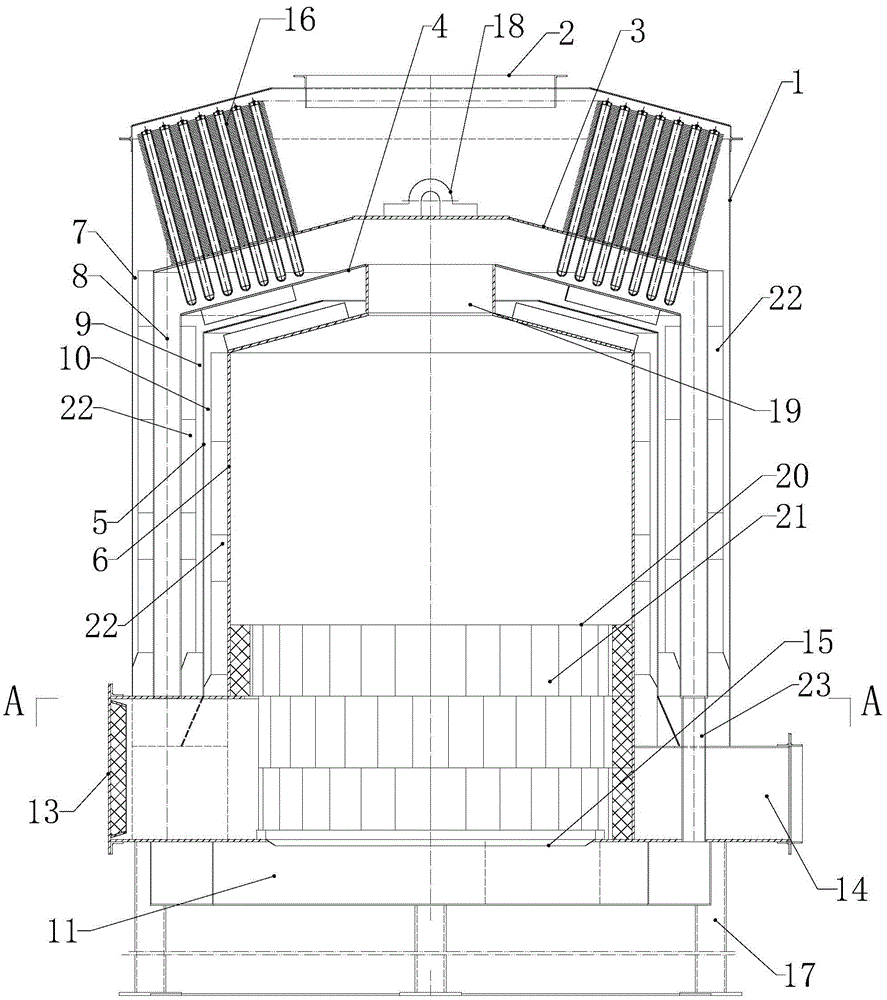

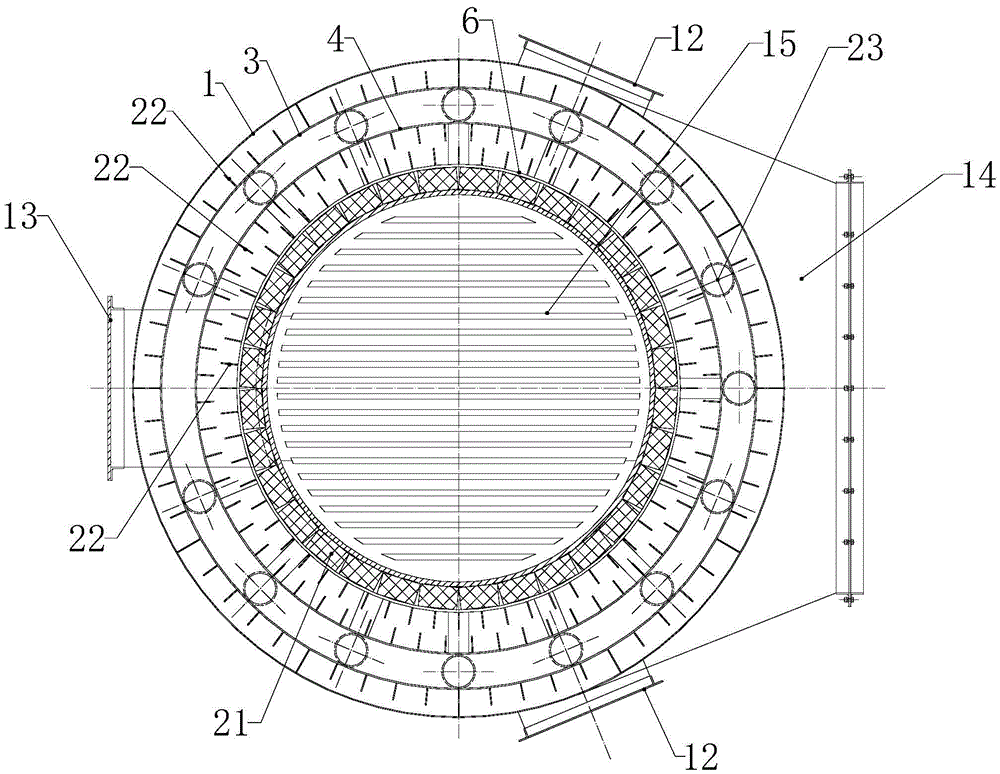

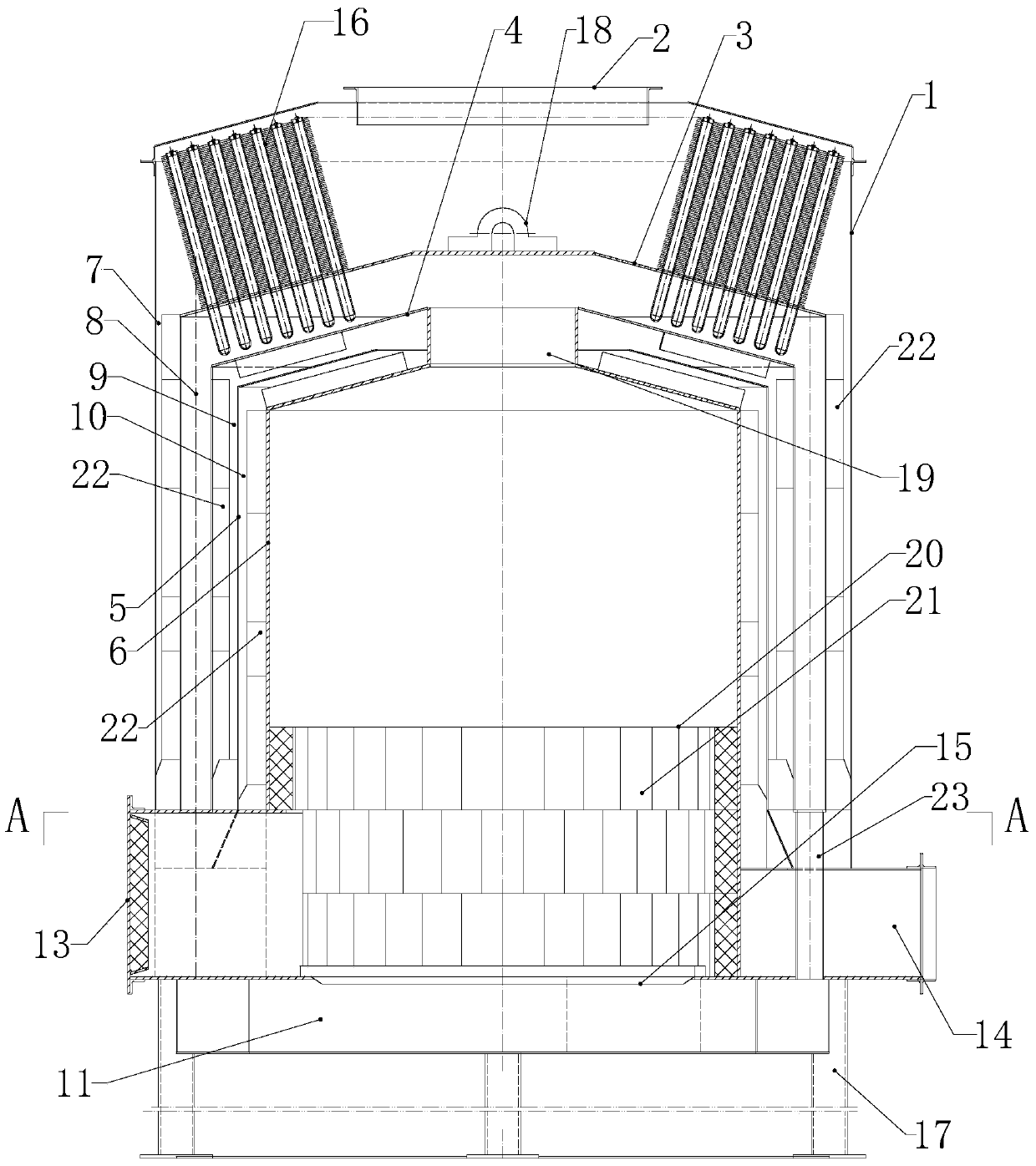

The invention discloses a unit modular large household refuse incineration furnace and relates to household refuse incineration treatment equipment. The unit modular large household refuse incineration furnace comprises an incineration grate mechanism, air chambers and air supply systems, wherein the incineration grate mechanism comprises a drying section grate, a burning section grate, a burnout section grate and a rack; the drying section grate, the burning section grate and the burnout section grate respectively comprise two groups of grate units; each group of grate units comprises a spindle, a partition plate, a front wall plate, a rear wall plate and a grate with stepped drop; each grate comprises two groups of edge modules and at least one group of middle modules; each edge module and each middle module respectively consist of a plurality of grate sheets; each group of edge modules is fixed on the corresponding rack through a sidewall protection plate device; each air chamber is formed below each middle module and each edge module; an air inlet is formed at the lower end of each air chamber and connected with the corresponding air supply system; and each air supply system comprises a drying section air supply system, a burning section air supply system and a burnout section air supply system. The unit modular large household refuse incineration furnace is stable in operation, low in energy consumption and long in service life.

Owner:江苏楹能环保科技发展有限公司

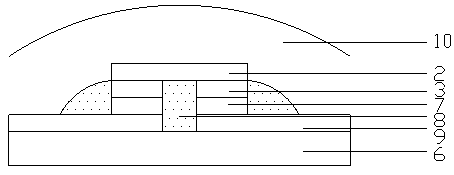

Low frequency built-in antenna used for handhold communication device

InactiveCN101483272AReduce volumeGood antenna performanceAntenna arraysSimultaneous aerial operationsLow volumeInternal layer

The invention provides a low frequency built-in aerial for a hand-held communication device comprising a radiation body respectively arranged on each layer of the multi-layer PCB boards. The low frequency built-in aerial for the hand-held communication device provided by the invention applies the multi-layer PCB board technology on the aerial design, uses the characteristic of the compact and low volume of the PCB board, performs the aerial radiation design on each layer, thereby guaranteeing a smaller volume of the built-in aerial device. Moreover the radiation body is mainly in the internal layer of the PCB, the final design of the aerial radiation body has a certain concealment, and is difficult to copy and produce. The stacked coupling compresses the aerial size by pressing convention. In a limited space, the invention designs the aerial by full volume and reaches best aerial property.

Owner:PULSE (SUZHOU) WIRELESS PRODUCTS CO LTD

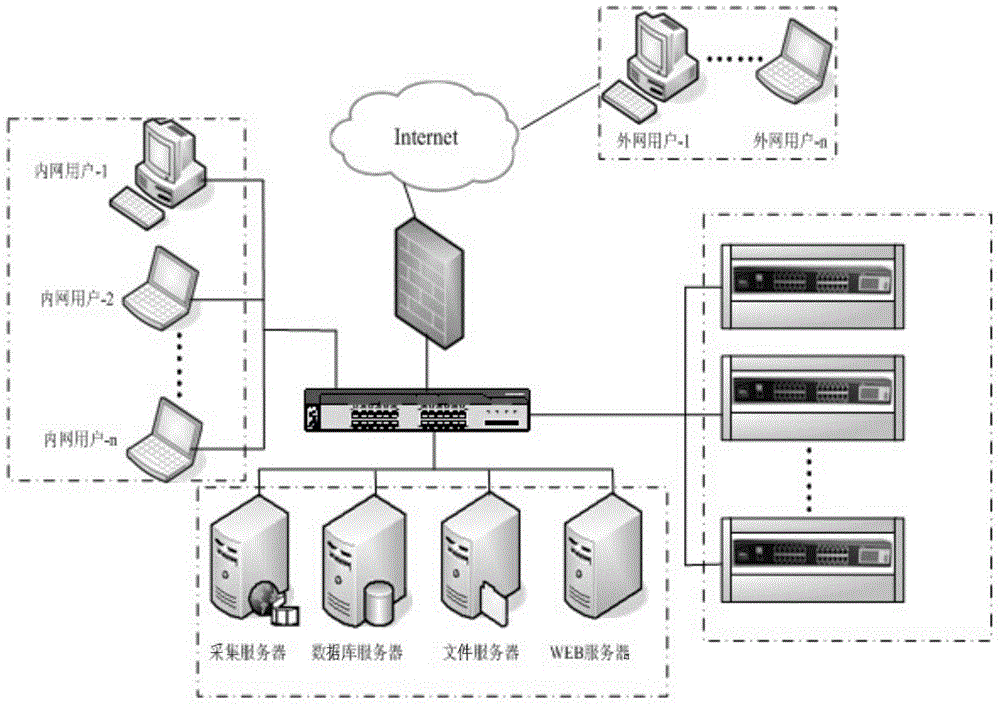

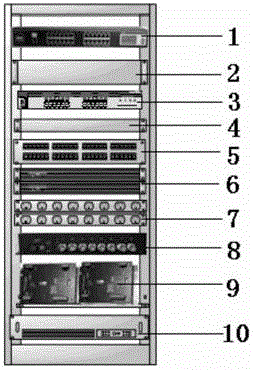

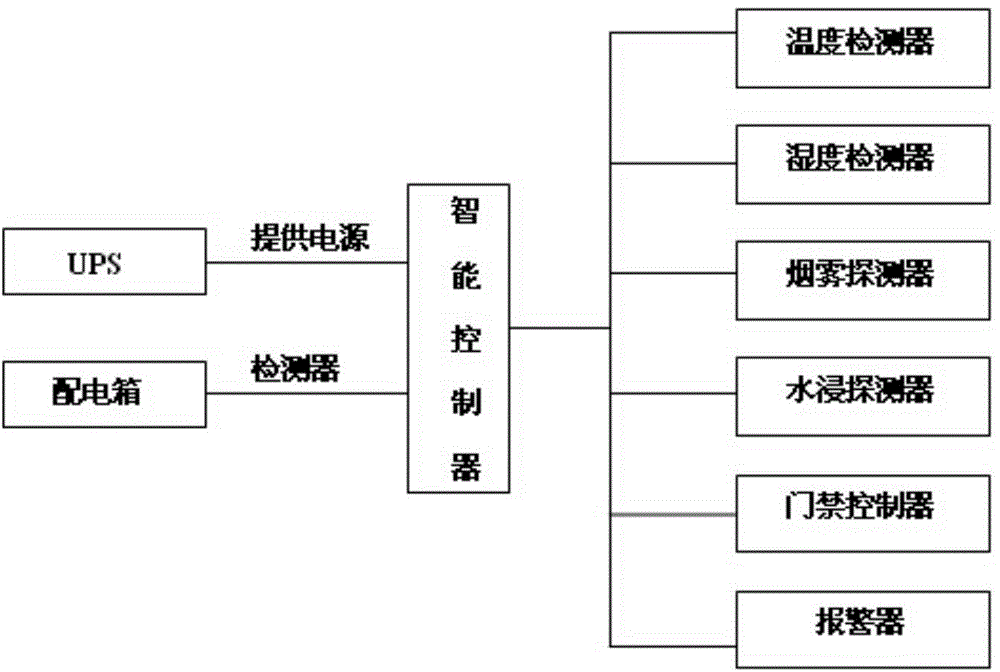

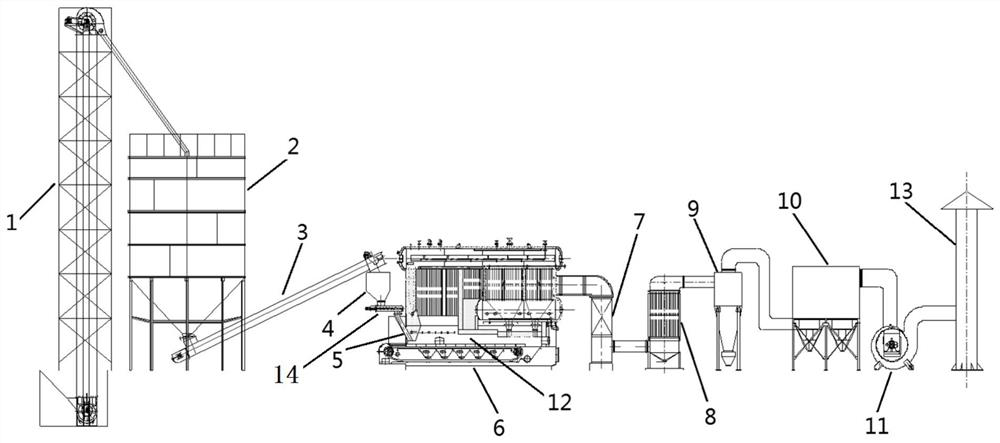

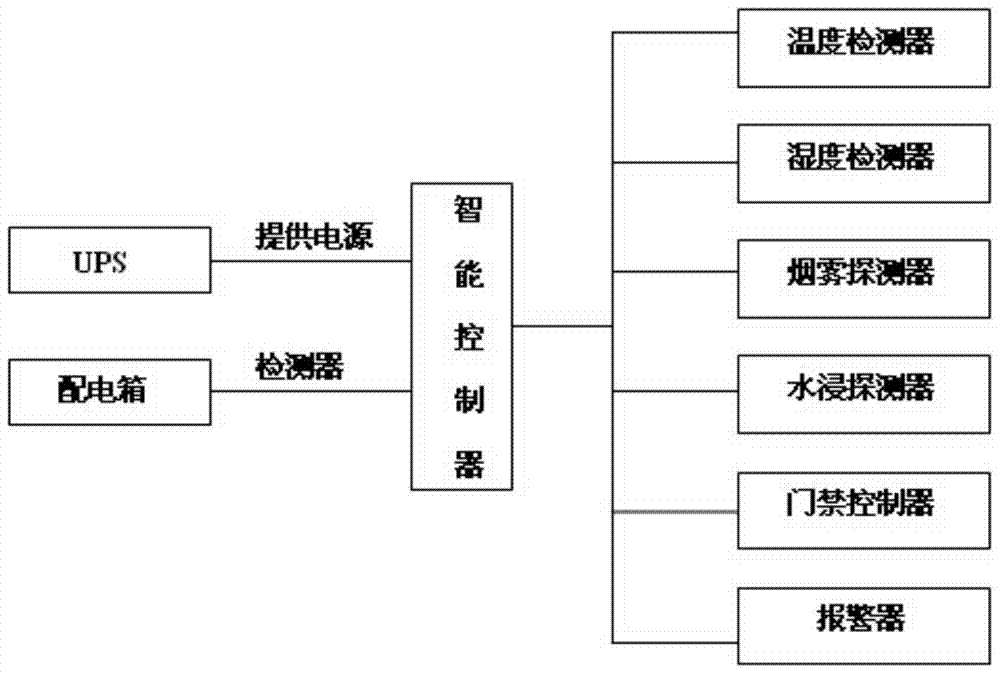

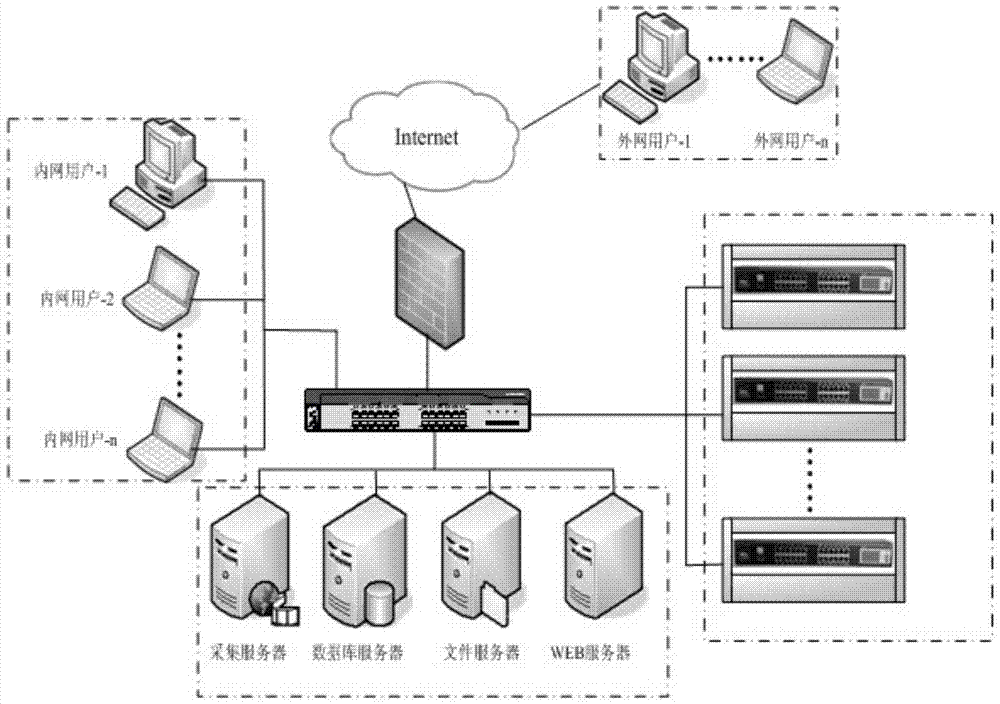

Building communication cabinet automatic control device

InactiveCN104483909ARealize anti-jammingRealize integrated self-power supplyProgramme total factory controlDistribution frameFiber

The invention discloses a building communication cabinet automatic control device which comprises a cabinet. The cabinet is internally and fixedly provided with an intelligent controller, a power distribution box, a switch, a wire arrangement frame, a distribution frame, a fibre distribution frame, a PDU, an optical transceiver, an access controller and a UPS and matching power source thereof from the top down in sequence by means of trays. The power distribution box is electrically connected with the intelligent controller through a current and voltage detector. The cabinet is further internally provided with a temperature detector, a humidity detector, a smog detector, a water logging detector and an alarm, which, together with the access controller, are electrically connected with the intelligent controller. The intelligent controller is connected with a remote monitoring system terminal through a network. The cabinet of the device is in standard design; port and device installation are increased and added as needed; sufficient redundancy design is realized; different devices are in subarea arrangement in structure; the distribution frame and the wire arrangement frame are made full use of; and therefore, anti-interference between wires is realized, the cabinet realizes UPS integrated self-powering; and the cabinets in the network are interconnected through the intelligent controller, and intelligent centralized management is realized.

Owner:SUZHOU SUNGO TECH

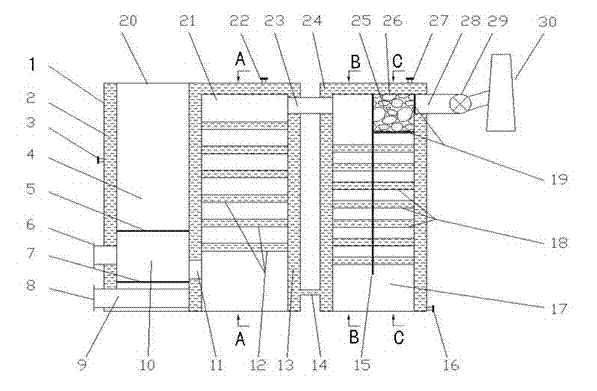

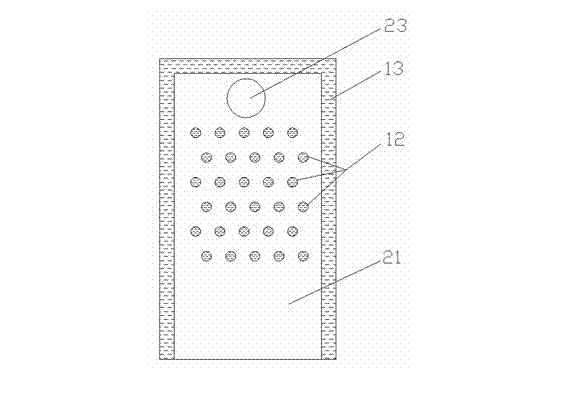

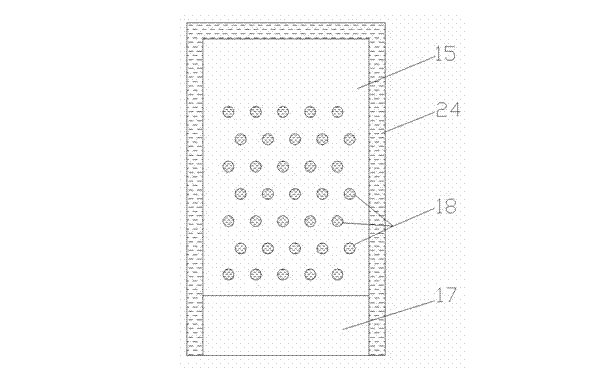

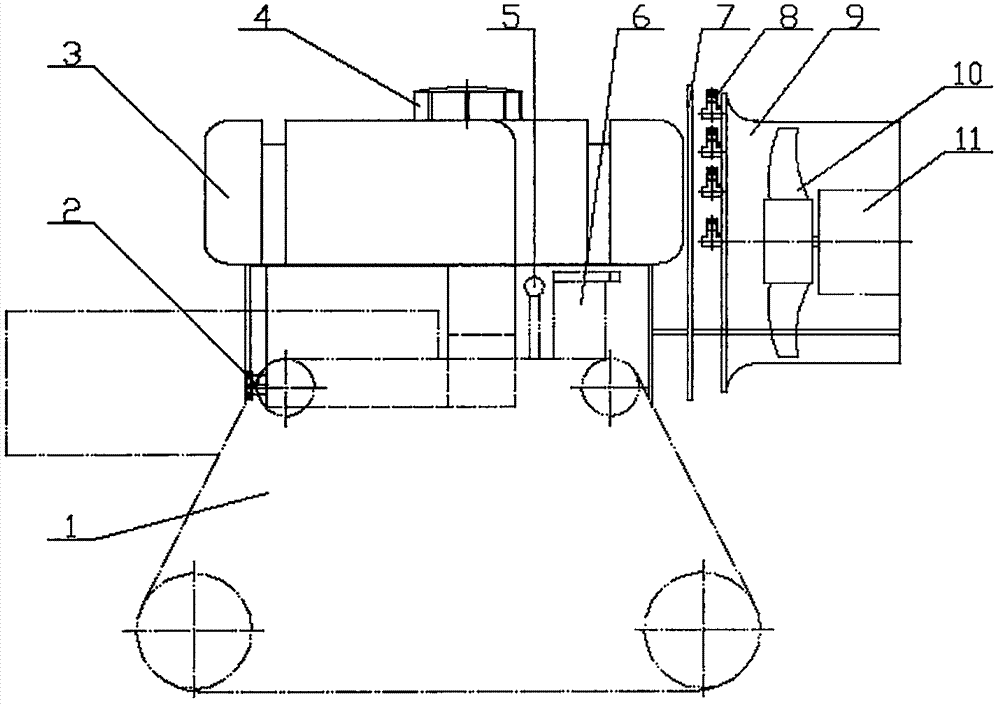

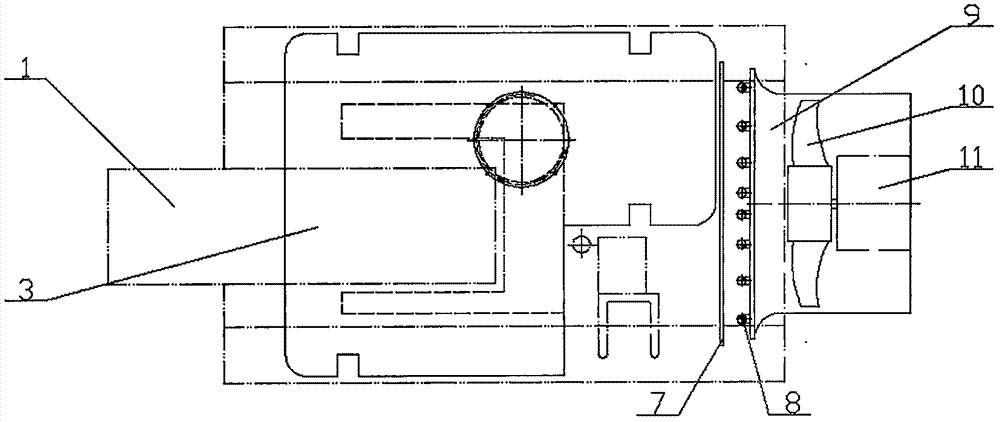

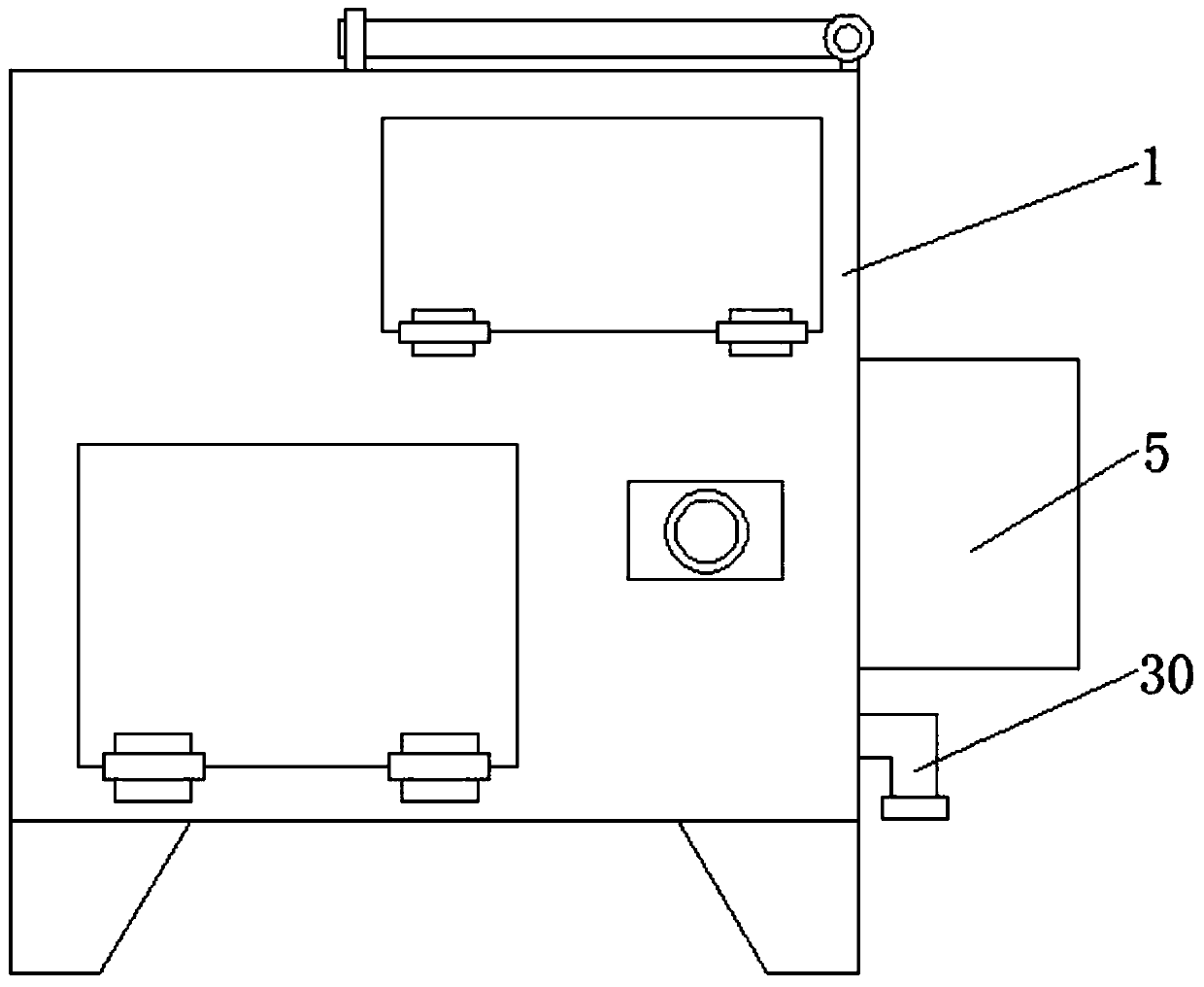

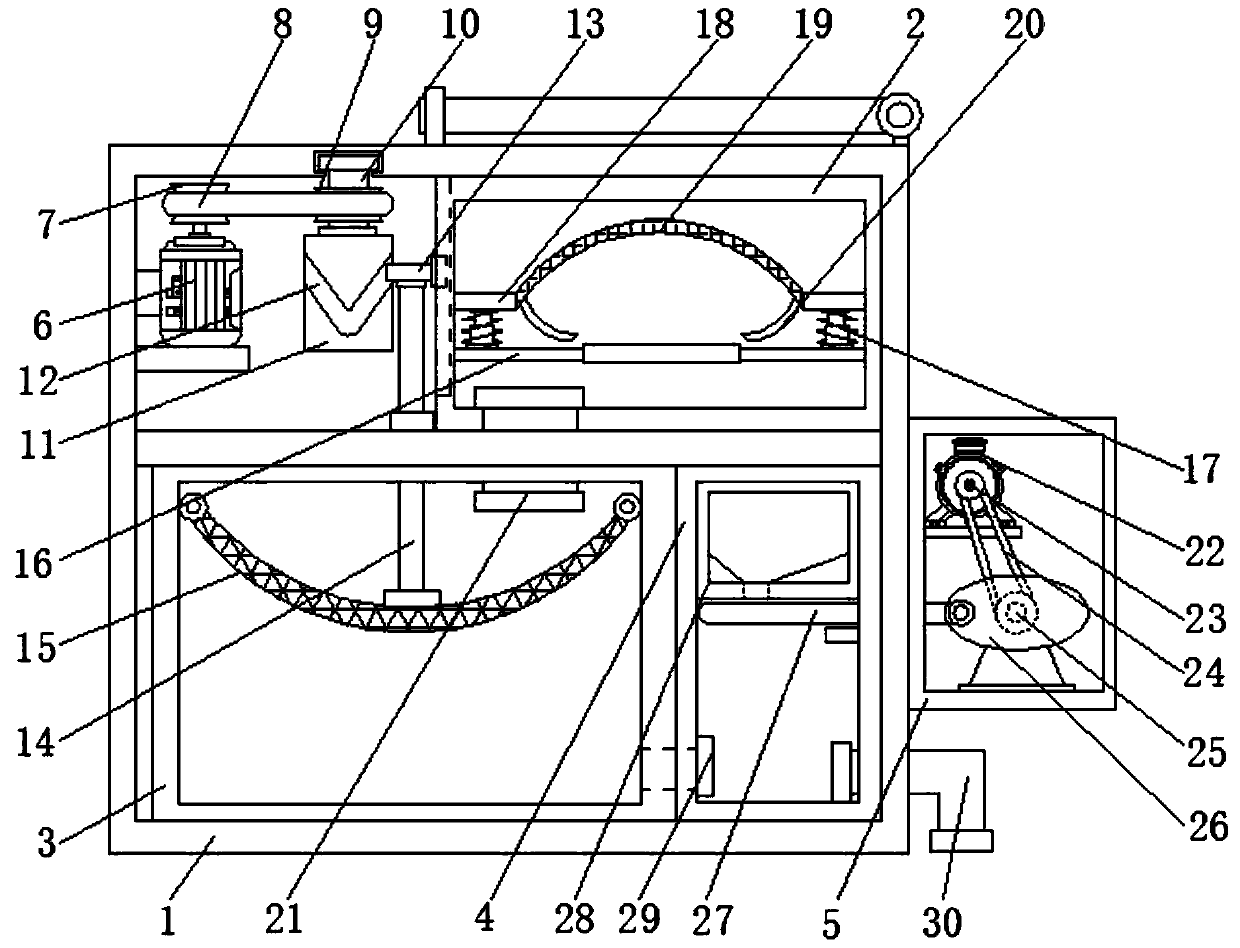

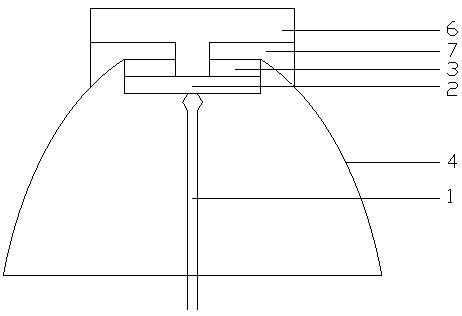

Novel biomass anti-burning type water heating boiler

The invention discloses a novel biomass anti-burning type water heating boiler. The novel biomass anti-burning type water heating boiler comprises a boiler body (1), wherein a boiler water interlayer (2) is arranged in the inner cavity of the boiler body (1); and the boiler water interlayer (2) is divided into an upper furnace cavity (4) and a lower furnace cavity (10) by using an upper fire grate (5). The novel biomass anti-burning type water heating boiler is characterized in that: a discharge flue (11) is formed in the side wall of the lower furnace cavity (10) and is communicated with the inner cavity of a boiling water tank (21); the inner cavity of the boiling water tank (21) is connected with the inner cavity, serving as a flue, of a hot water tank (17) through a communicating pipeline (14) and a boiling water tank discharge flue (23); and an exhaust port (28) formed at the upper end of the hot water tank (17) is connected to a chimney (30) through a pipeline and a draught fan (29). The novel biomass anti-burning type water heating boiler has the advantages of full combustion, high heating efficiency, energy conservation and environment friendliness. The boiler is designed to be an upper feeding mode, an air inlet and a material inlet are combined integrally, automatic feeding is realized under the action of the gravity of fuel and the draught fan, and manpower is saved. A flue gas purifier is arranged at the exhaust port of the boiler, so that tar and ash in flue gas can be removed effectively; therefore, the pollutant discharge is far below national standards.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH +1

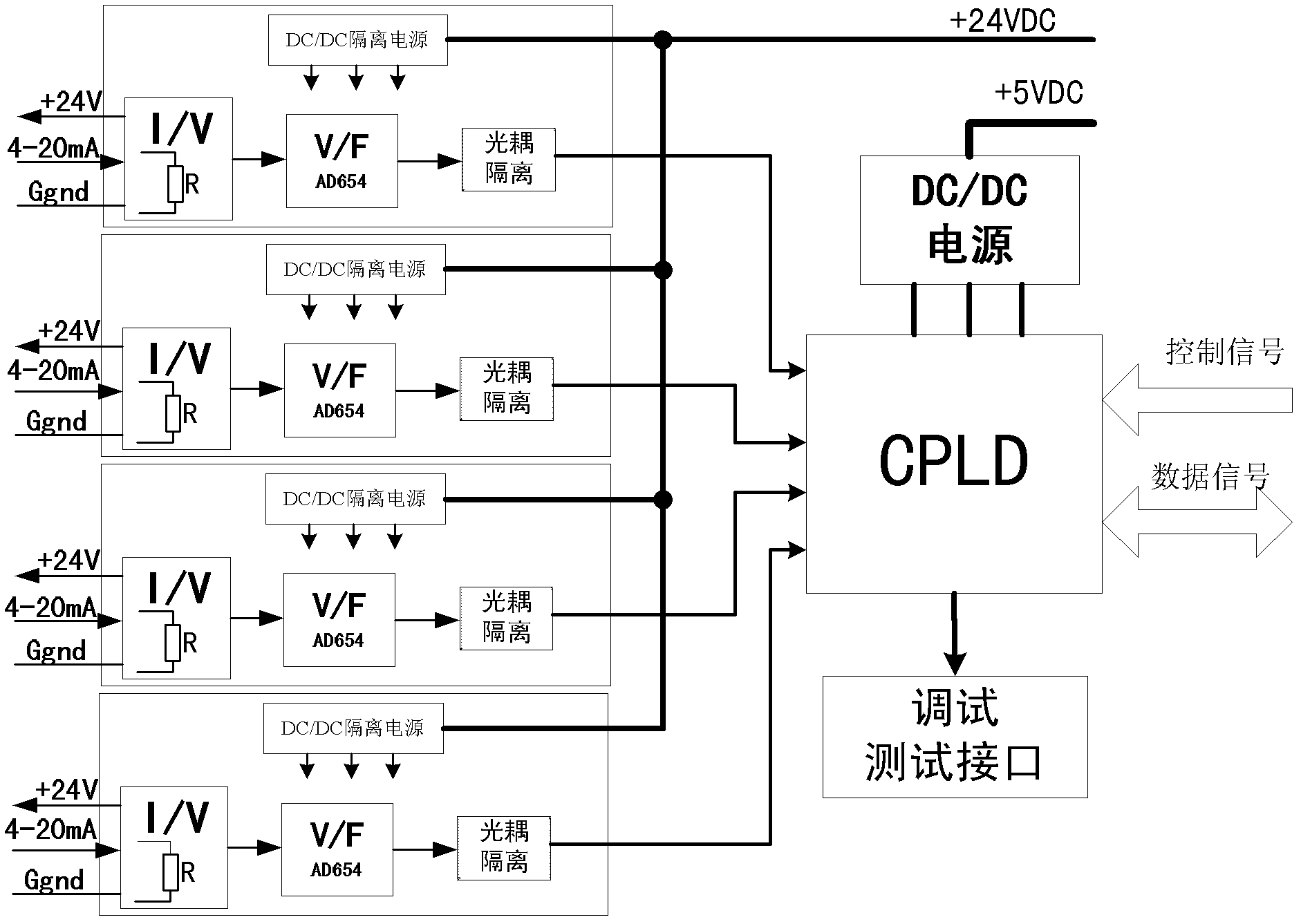

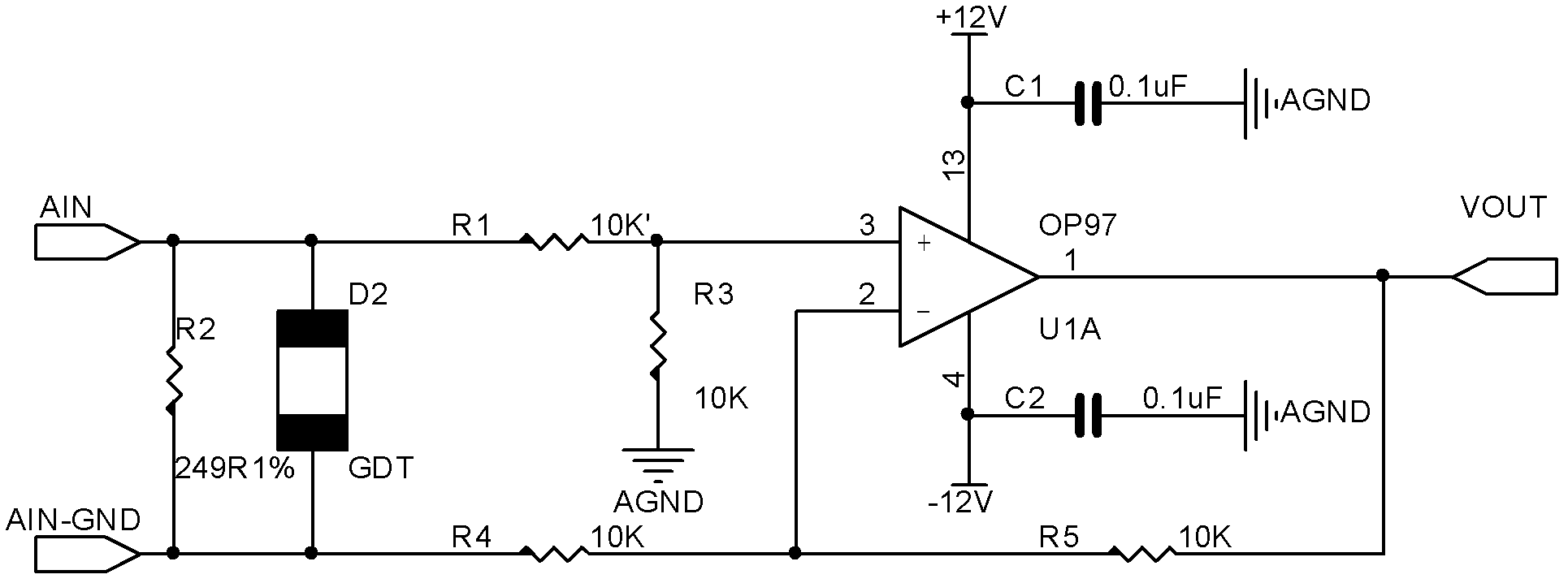

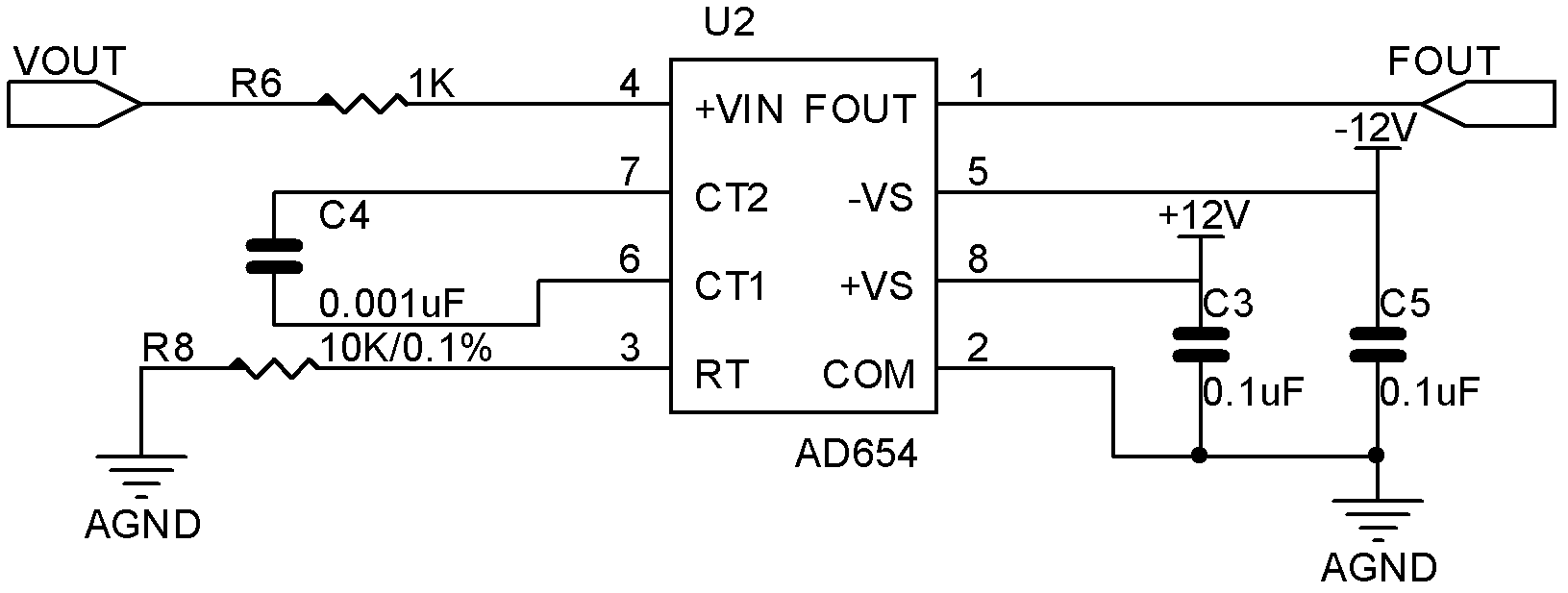

4-20ma special analogue acquisition module

InactiveCN102506909AReal-time acquisitionFully designedConverting sensor output electrically/magneticallyElectricityComputer module

The invention provides a 4-20mA special analogue acquisition module, which comprises an I / V conversion unit, a V / F conversion unit, an opto-coupler isolation unit, a CPLD (Complex Programmable Logic Device) core control unit and multiple paths of power supply units, wherein 4-20mA analogue quantity is converted into a 1-5V voltage signal through the I / V conversion unit firstly; the voltage signal is converted into a 10K-50KHz frequency signal through the V / F conversion unit; the frequency signal is isolated from the CPLD core control unit through the opto-coupler isolation unit; the CPLD core control unit is used for counting, collecting and operating the collected frequency pulse, and is connected with a background device through an I / O port of the CPLD core control unit finally; the information collected by the CPLD is uploaded; the multiple paths of power supply units supply the electricity to the analogue acquisition module; a +5V power source is converted into a +3.3V and a + / -12V power sources to supply power to the module.

Owner:CHINA XD ELECTRIC CO LTD

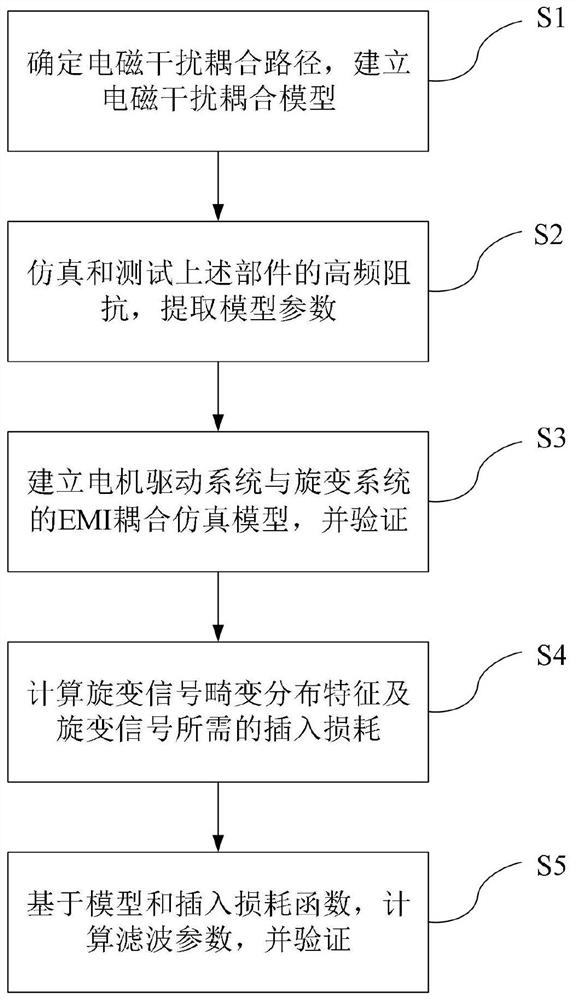

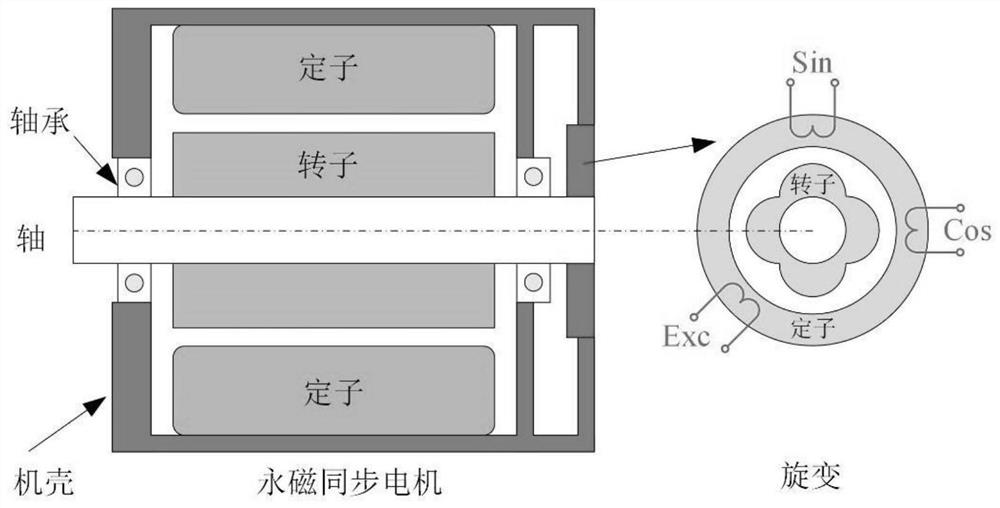

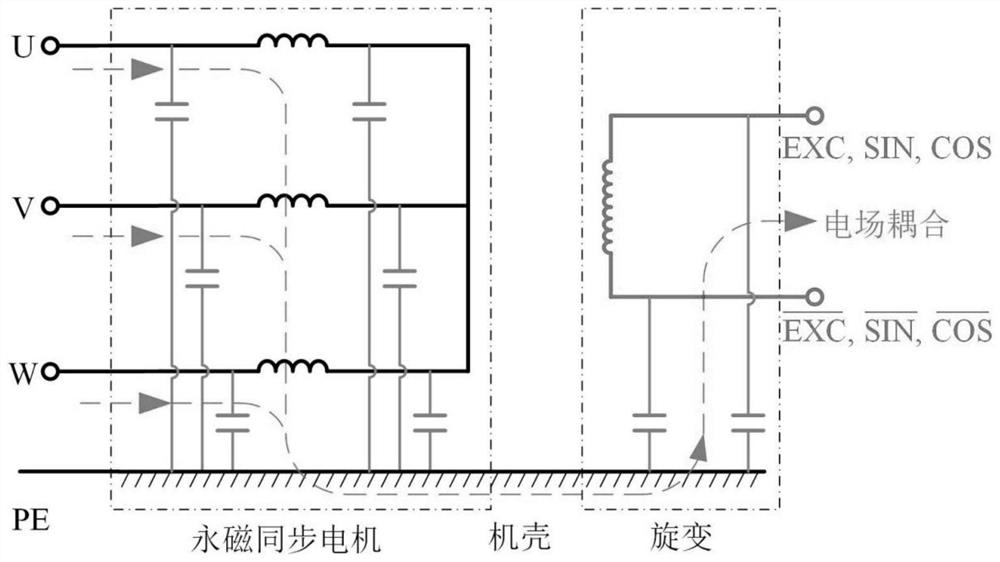

Evaluation and suppression method for electromagnetic interference noise of rotary transformer

ActiveCN111800108AAccurate assessmentQuantitative designImpedence networksInductorElectromagnetic noise

The invention discloses an evaluation and suppression method for electromagnetic interference noise of a rotary transformer, and the method achieves the accurate evaluation of the coupling electromagnetic noise of a rotary transformer system in a mode of combining testing with circuit modeling. The filter inductor of the rotary transformer circuit is quantitatively designed based on the evaluationmodel, so that the quality of input and output signals of the rotary transformer is improved. Compared with a traditional resolver noise suppression method, the electromagnetic interference couplingmodel of the motor driving system and the rotary transformer system is established, the electromagnetic interference noise coupled by the rotary transformer system can be quickly evaluated in the design stage of the new energy automobile, a noise suppression scheme can be quantitatively designed based on the model, and the design cost can be effectively reduced.

Owner:ZHEJIANG UNIV

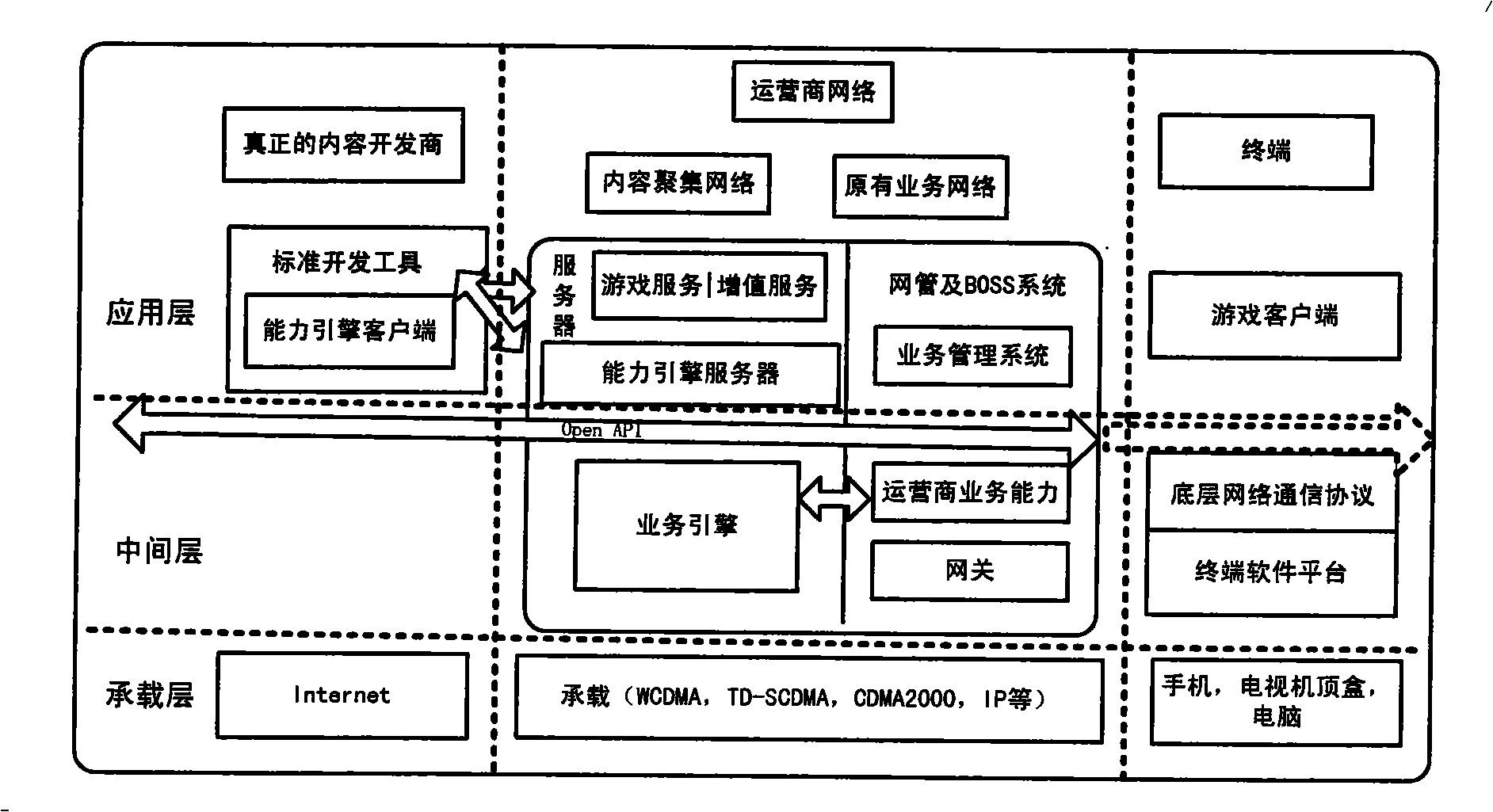

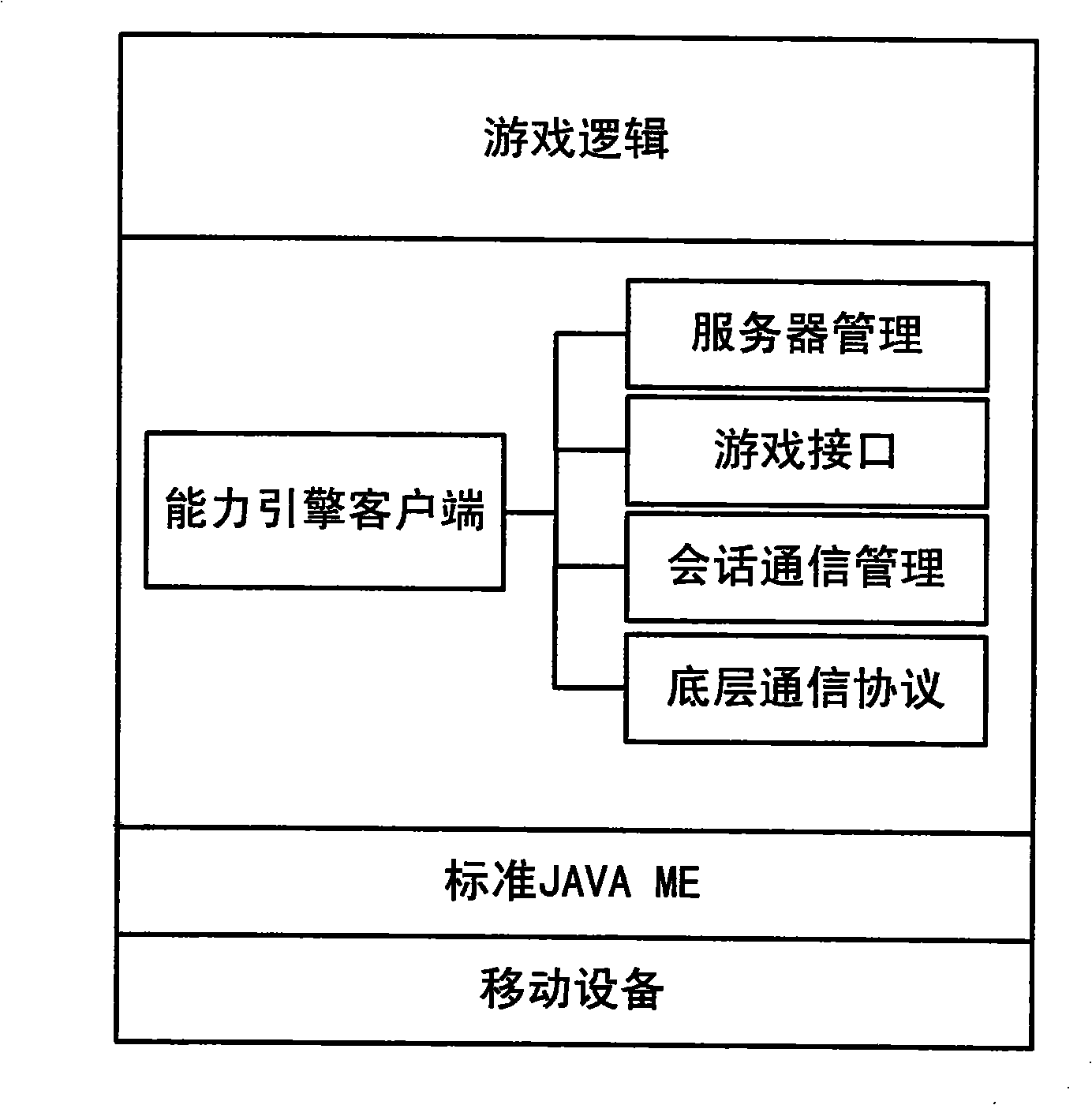

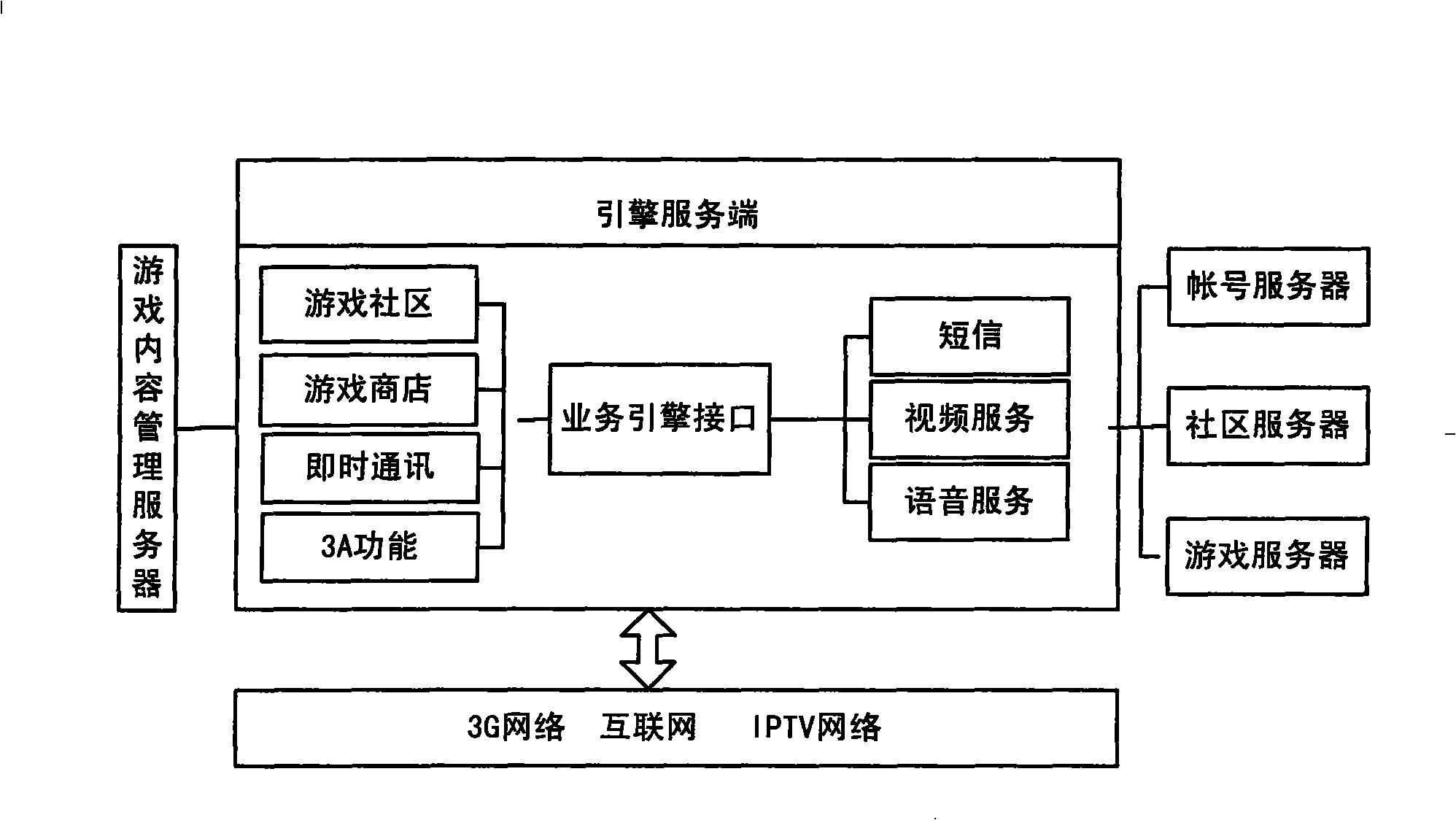

Integral ability engine of moving game

InactiveCN101344901AAchieve hiddenReduce couplingSpecial data processing applicationsSpecific program execution arrangementsPersonalizationEngineering

The invention relates to a mobile game comprehensive capacity engine of 3G network. The engine is a uniform and standard interface opened to numerous game developers, game providers and game operators for lowering the threshold of cell phone game development and operation and providing abundant cell phone network games for users by fully utilizing the resources of the game developers and the game providers. By the mobile game comprehensive capacity engine, service interfaces are developed and the platform resources of the operators are fully utilized so as to develop personalized services in the games.

Owner:CHINA YOUKE COMM TECH

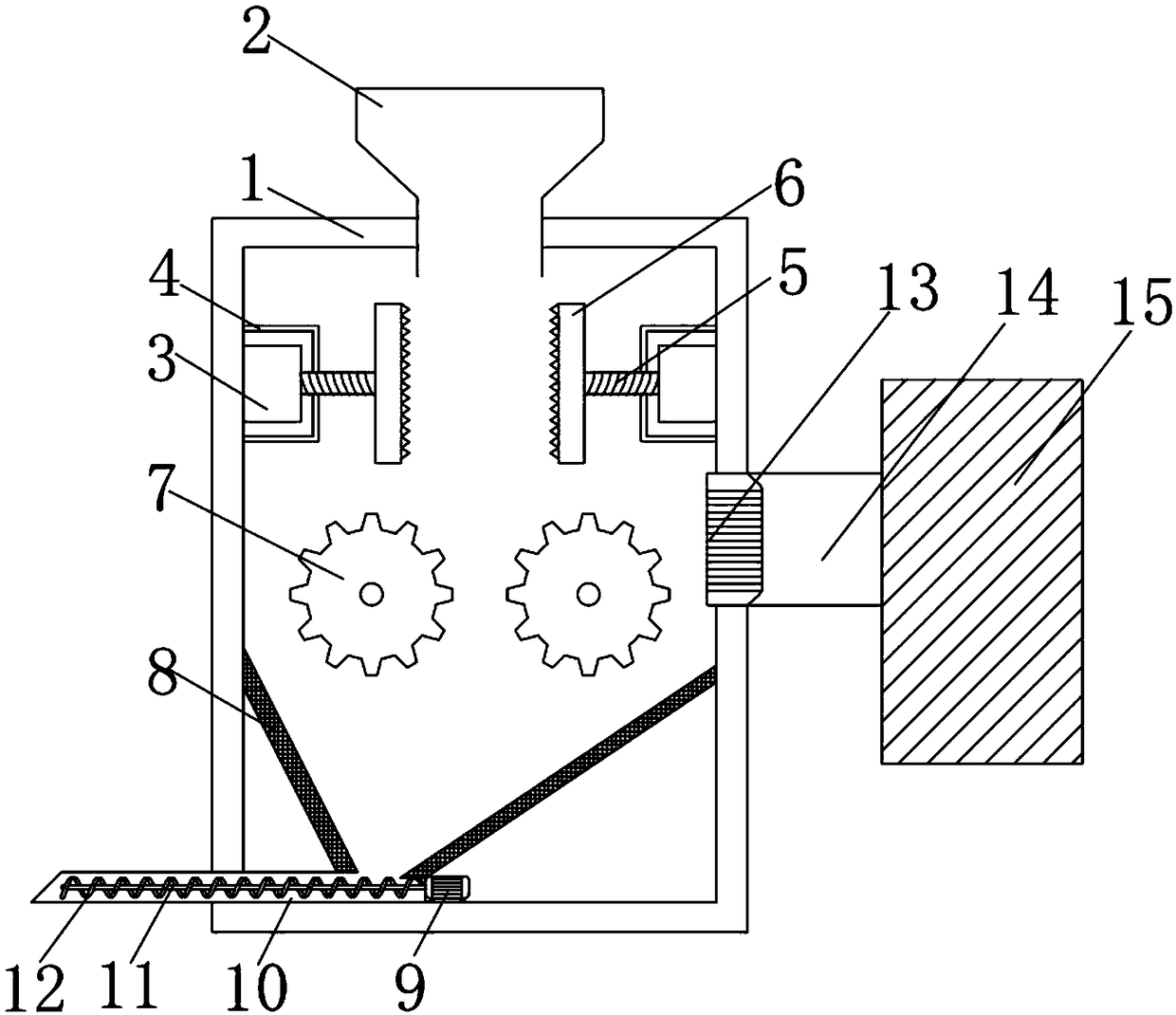

Waste asphalt reclaimed material crushing device

PendingCN109366808AImprove crushing qualityReasonable structural designUsing liquid separation agentPlastic recyclingEngineeringAsphalt

The invention discloses a waste asphalt reclaimed material crushing device. The waste asphalt reclaimed material crushing device comprises a housing and a dust cleaning device, an upright feed hopperis fixedly arranged on the top of the housing, and first motors are arranged on the upper end of the inner side of the housing, the number of the first motors is two and the height of the motors is the same. The outer sides of the first motors are provided with first motor housings, and the outer sides of first motors are connected with electric telescopic rods in horizontal direction, and one sides of the electric telescope rods which are away from the first motor are connected to rolling plates. The middle of the right side of the housing is fixedly connected to a suction fan, and the suction fan penetrates through the housing, the right side of the suction fan is connected with a dust passage, and the right side of the dust passage is provided with the dust cleaning device. The waste asphalt reclaimed material crushing device has a reasonable structural design, the waste asphalt reclaimed material crushing device can reduce the dust generated by the machine during work, the crushingquality is high, and the waste asphalt reclaimed material crushing device can meet the needs of people.

Owner:徐州铭山路桥机械设备制造有限公司

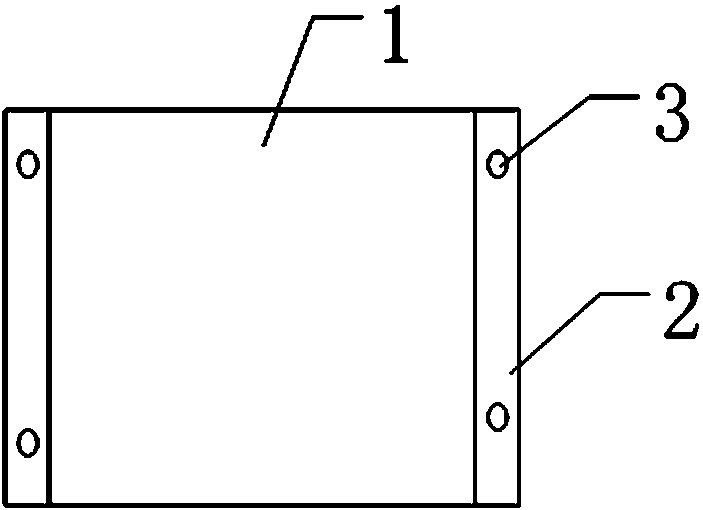

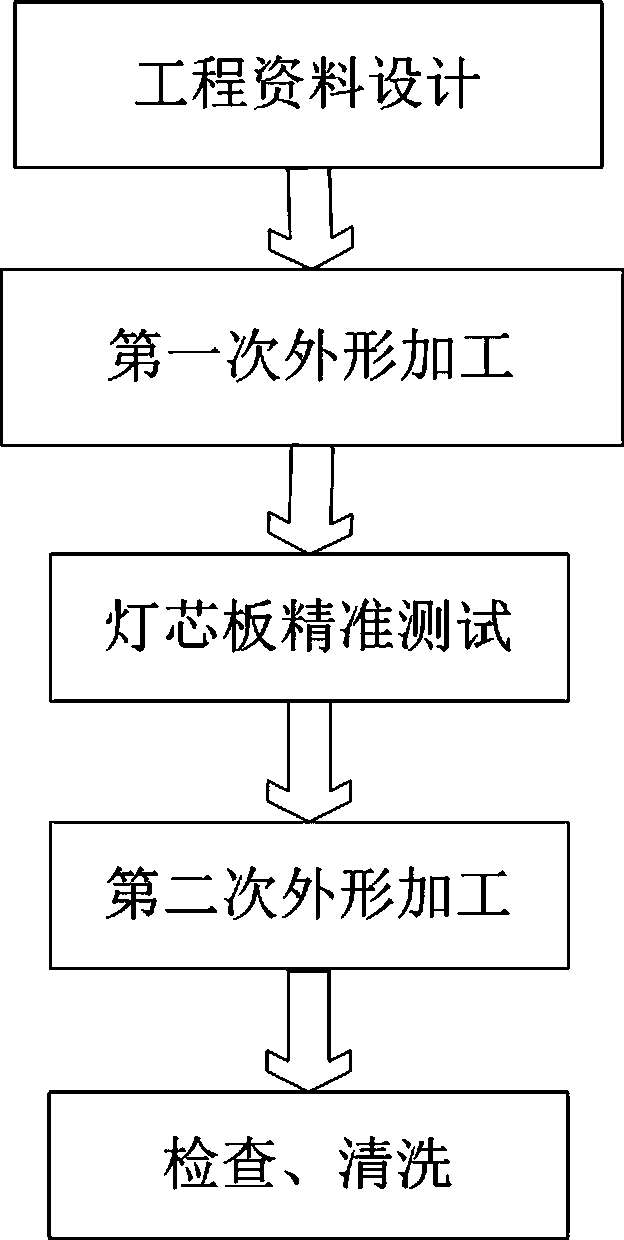

Quick testing method for opening/shortcircuit of high-density LED lamp diode product without inner positioning hole

InactiveCN107907816AReduce the difficulty of productionLow costElectronic circuit testingElectricityHigh density

The invention discloses a quick testing method for opening / shortcircuit of high-density LED lamp diode product without an inner positioning hole. Edge strips are added on two corresponding short edgesof a diode board. Furthermore two positioning holes are designed on each edge strip. The diode board without the positioning hole is converted to a routine testing product which satisfies a testing requirement. Then a universal testing method is utilized for testing the electric performance of the LED diode testing board with the positioning holes. After testing, no-positioning profile fine-milling technology is utilized for successively milling the two added edge strips, thereby realizing electric performance testing for the high-density LED lamp diode without the inner positioning hole. Thequick testing method for the high-density LED lamp diode product has advantages of low production difficulty, low cost, high operability, high production efficiency, high quality, batch inputting into production, etc.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

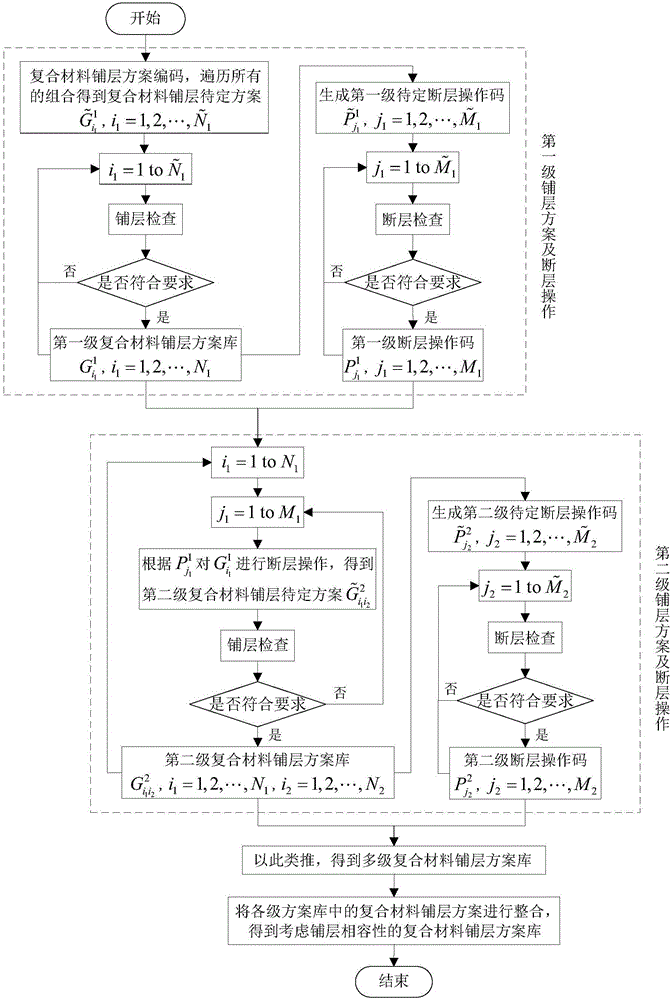

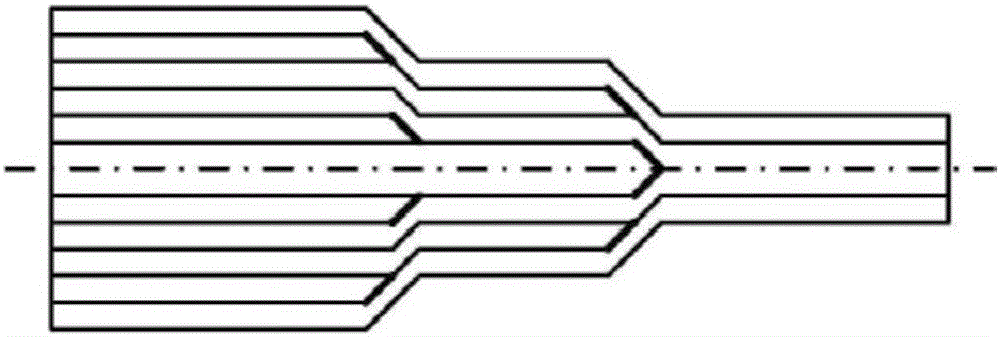

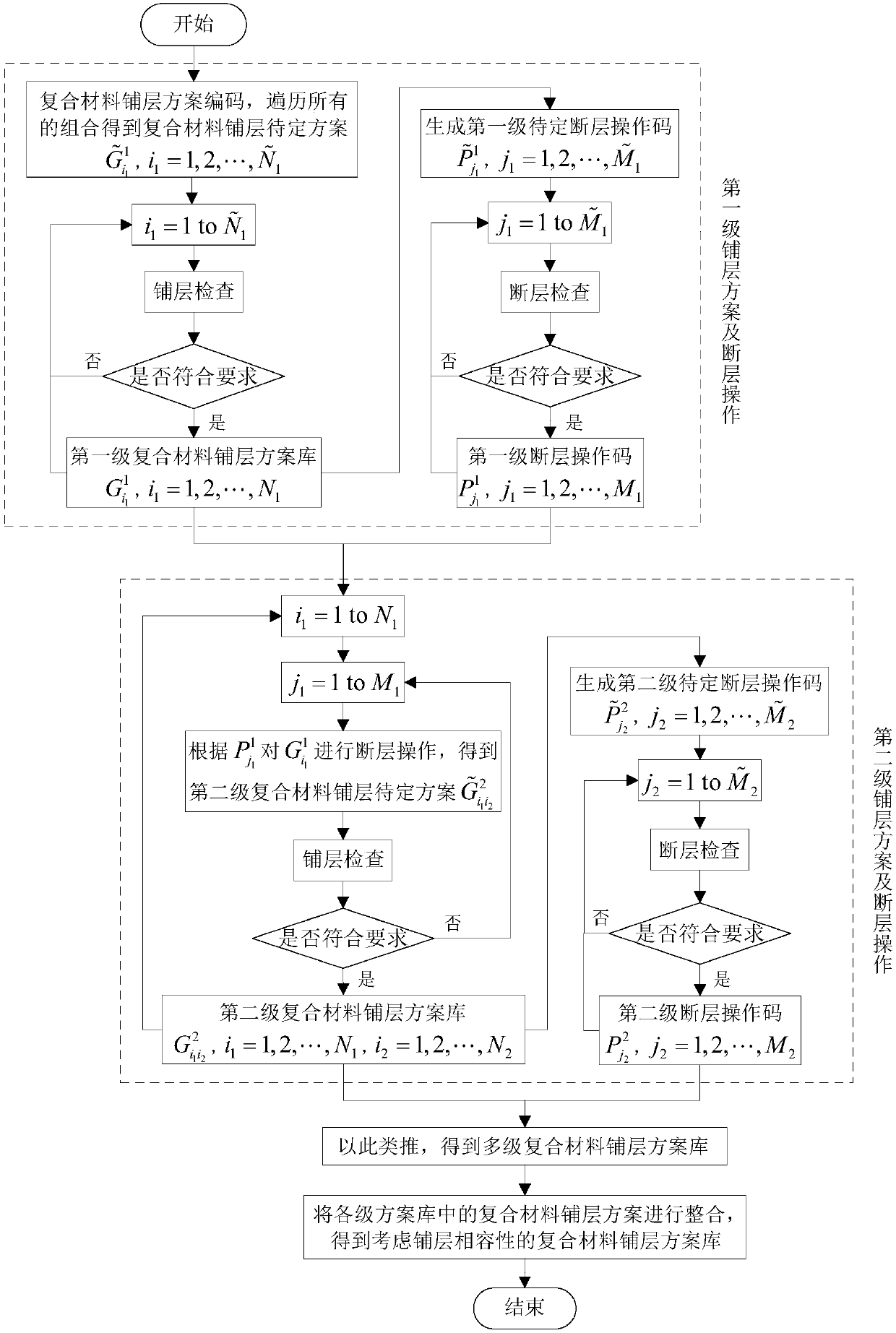

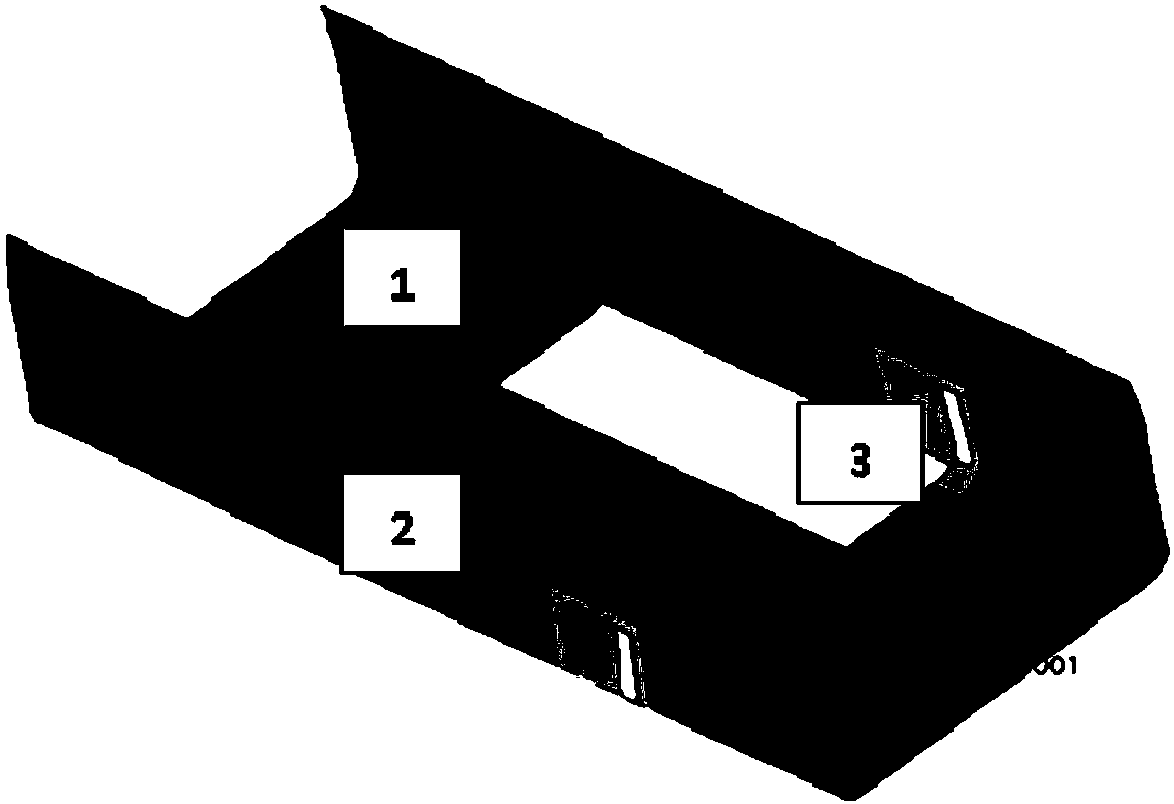

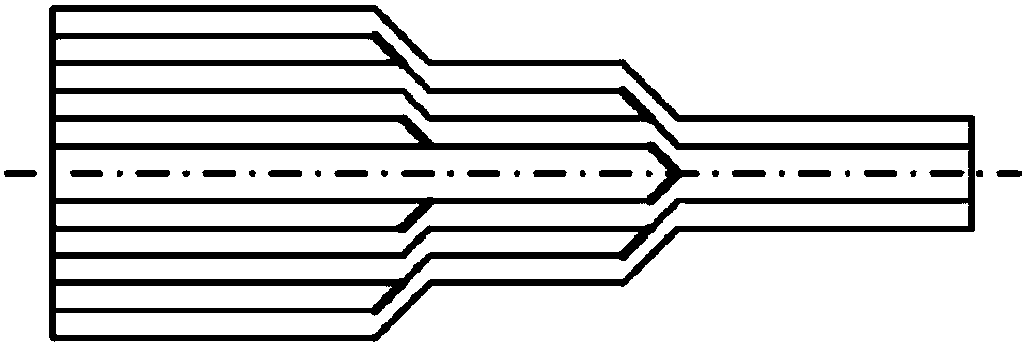

A composite material layering scheme library establishing method taking layering compatibility into account

ActiveCN106021654AAvoid complex constraintsLayup Compatibility Problem SolvingGeometric CADConstraint-based CADProcess designComputer science

The invention provides a composite material layering scheme library establishing method taking layering compatibility into account. The method comprises the steps of encoding composite material layering schemes by using integers; traversing all combinations and establishing a composite material layering basic scheme library, which is a first-stage composite material layering scheme library; using binary numbers as layer breaking operation codes, and further obtaining a second-stage composite material layering scheme library on the basis of first-stage composite material layering schemes through layer breaking operation; performing layer breaking operation successively to obtain multiple stages of composite material layering scheme libraries. With the method, a composite material layering scheme library meeting the layering compatibility requirement can be obtained; effective transition in thickness changing areas of composite material layering is realized; a feasible layering scheme is provided for composite material layering process design; and foundation is laid for composite material structure optimization design.

Owner:BEIHANG UNIV

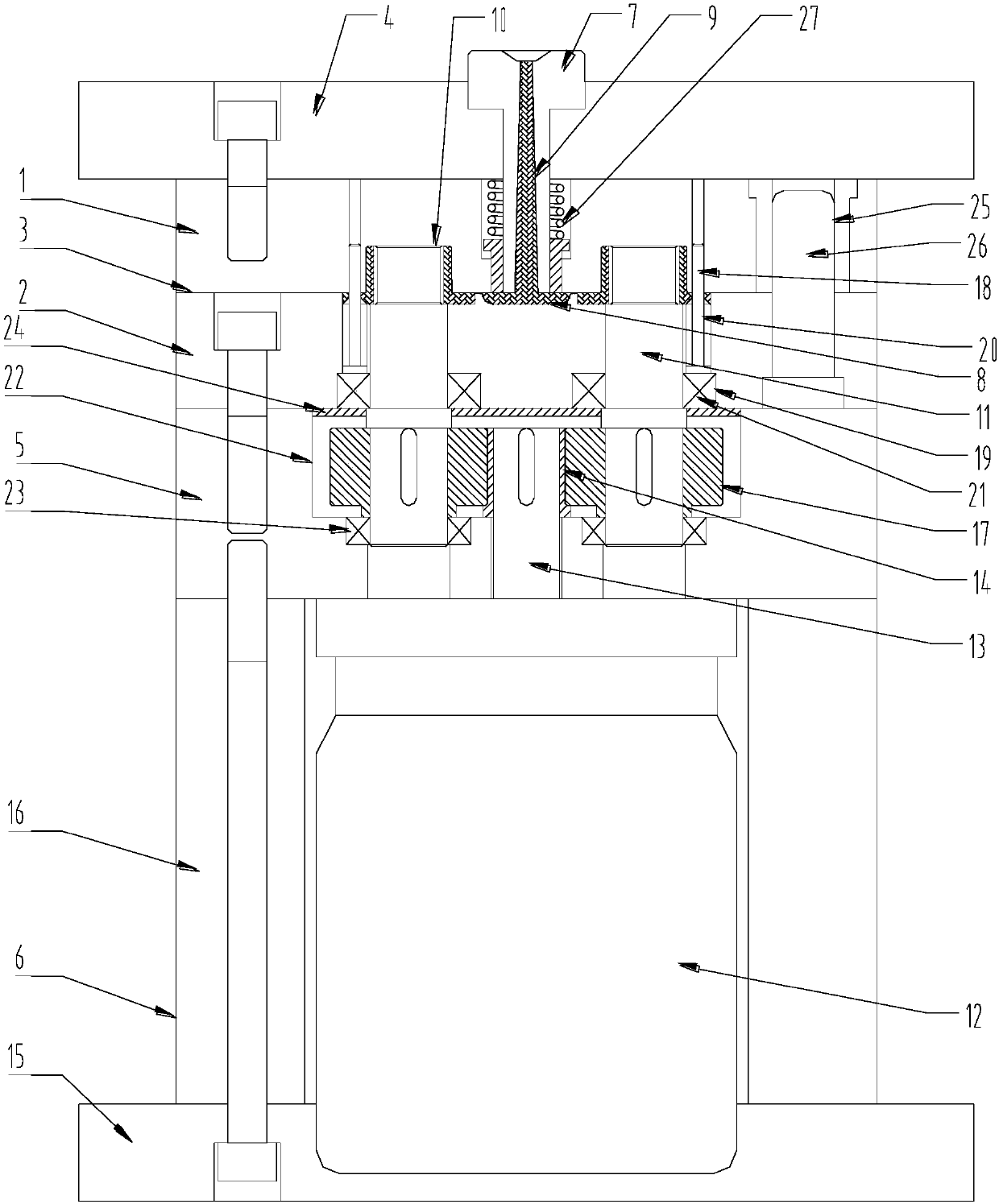

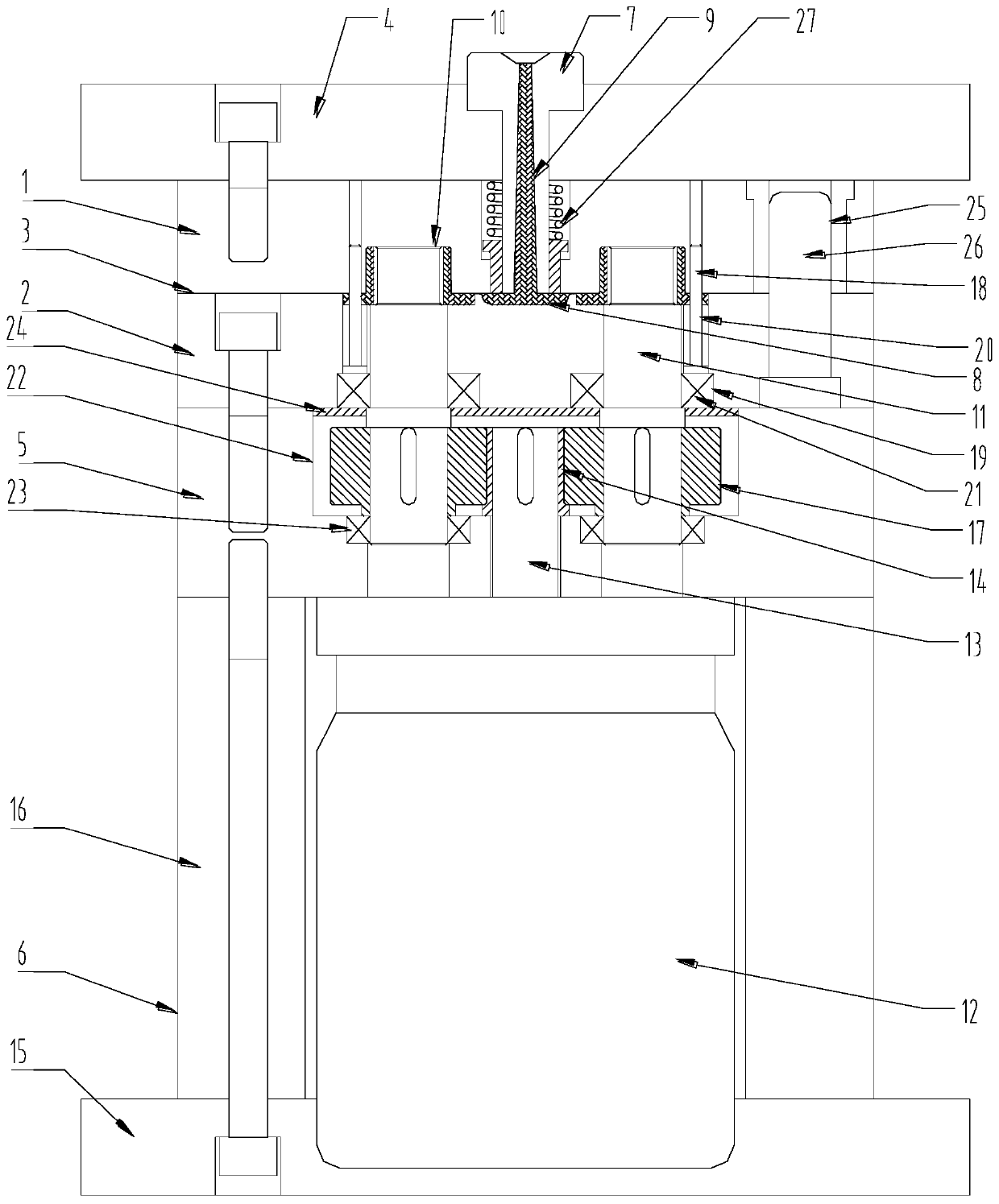

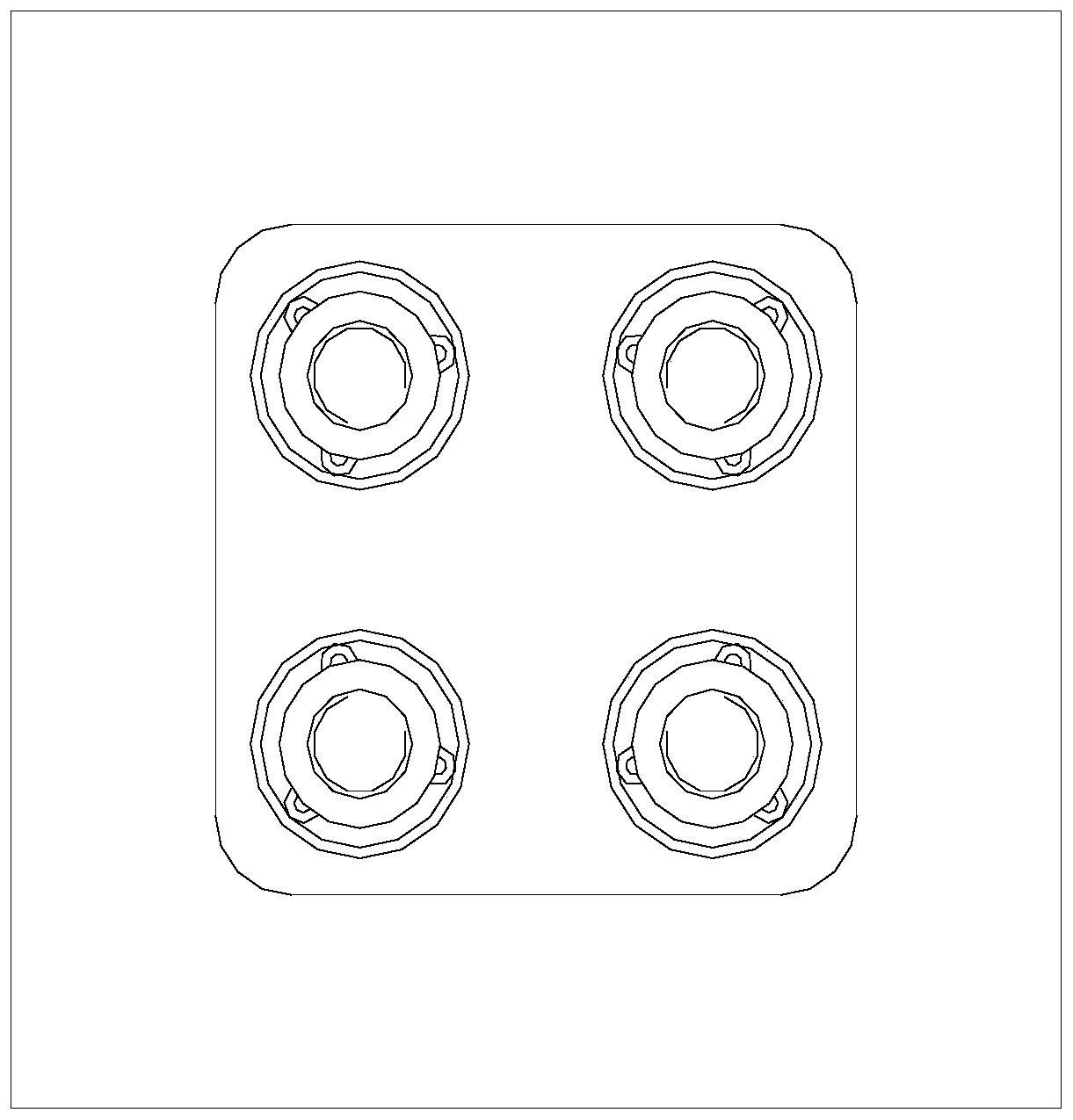

Full-automatic de-molding mould for internal thread plastic part

The invention discloses a full-automatic de-molding mould for an internal thread plastic part. The full-automatic de-molding mould comprises a fixed model chamber plate and a moveable model chamber plate, wherein a mold joint of the plastic part is arranged between the fixed model chamber plate and the moveable model chamber plate; a base plate is connected with the lower end face of the moveablemodel chamber plate; a moveable seat plate is arranged under the base plate; a pouring sleeve is arranged at the top end of a fixed seat plate; a main runner is arranged on the mold joint; a product chamber is connected with the main runner; a threaded mold core is arranged in the product chamber; the threaded mold core is penetrated through the moveable seat plate and extends into the base plate;a hydraulic motor is arranged in the moveable seat plate; the lower end of the threaded mold core is connected with the hydraulic motor through a driving mechanism; the threaded mold core is driven by the hydraulic motor to rotate. According to the invention, the hydraulic motor is placed between the base plate and the moveable mold fixing plate, so that the mold space is saved and the requirement for the tonnage of the injection molding machine is lower. A driving gear is adopted for driving a plurality of driven gears to de-mold and the chamber can be fully designed according to the template space. A rotation-stopping mechanism is adopted for guaranteeing the automatic rotation of the plastic part, a spring is adopted for pushing a stub bar and the adjustment and the repairing are convenient.

Owner:FUZHOU UNIV +1

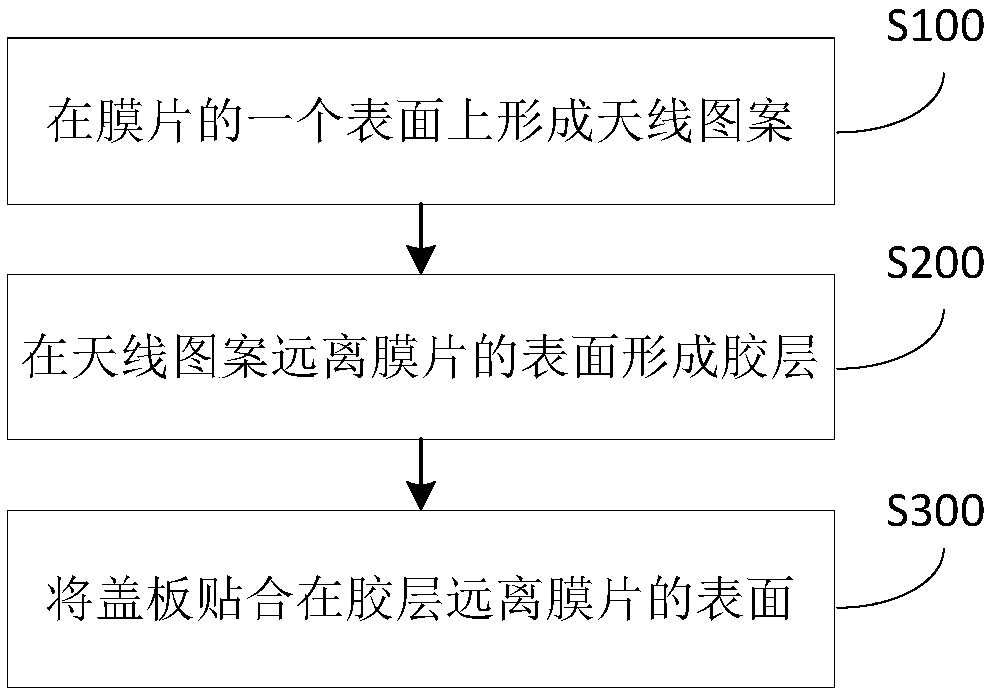

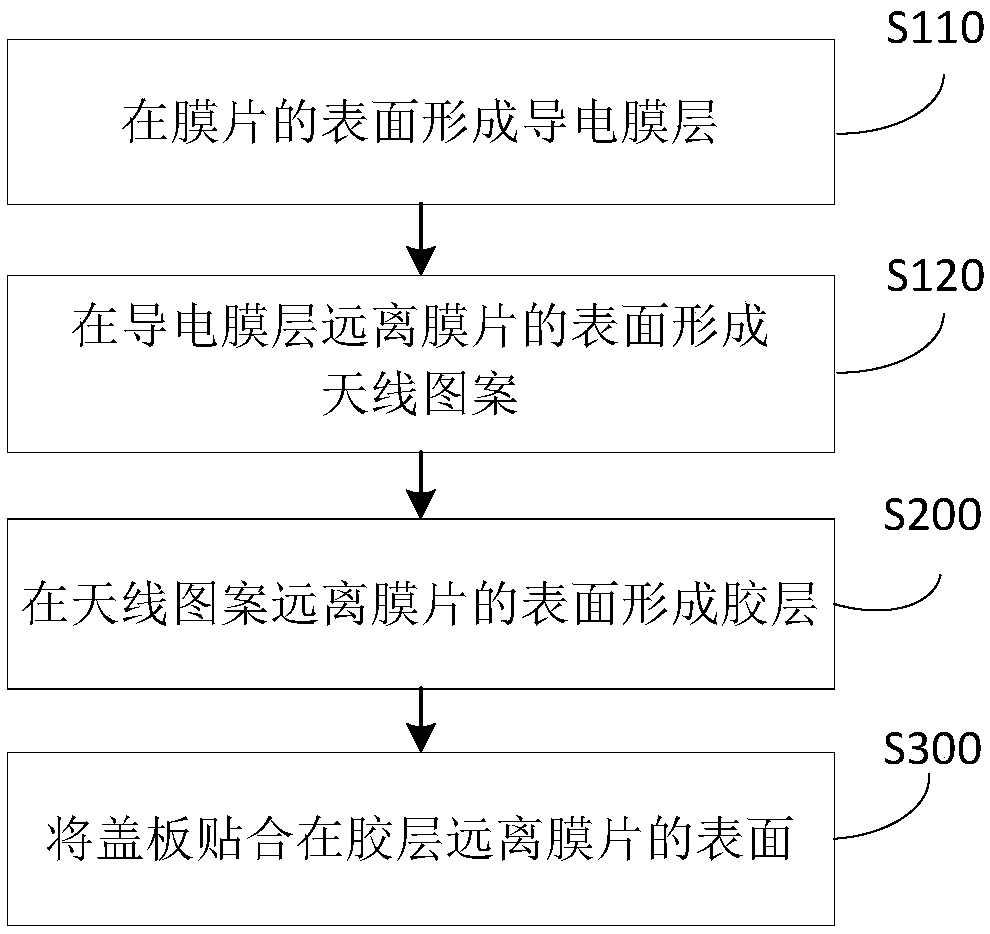

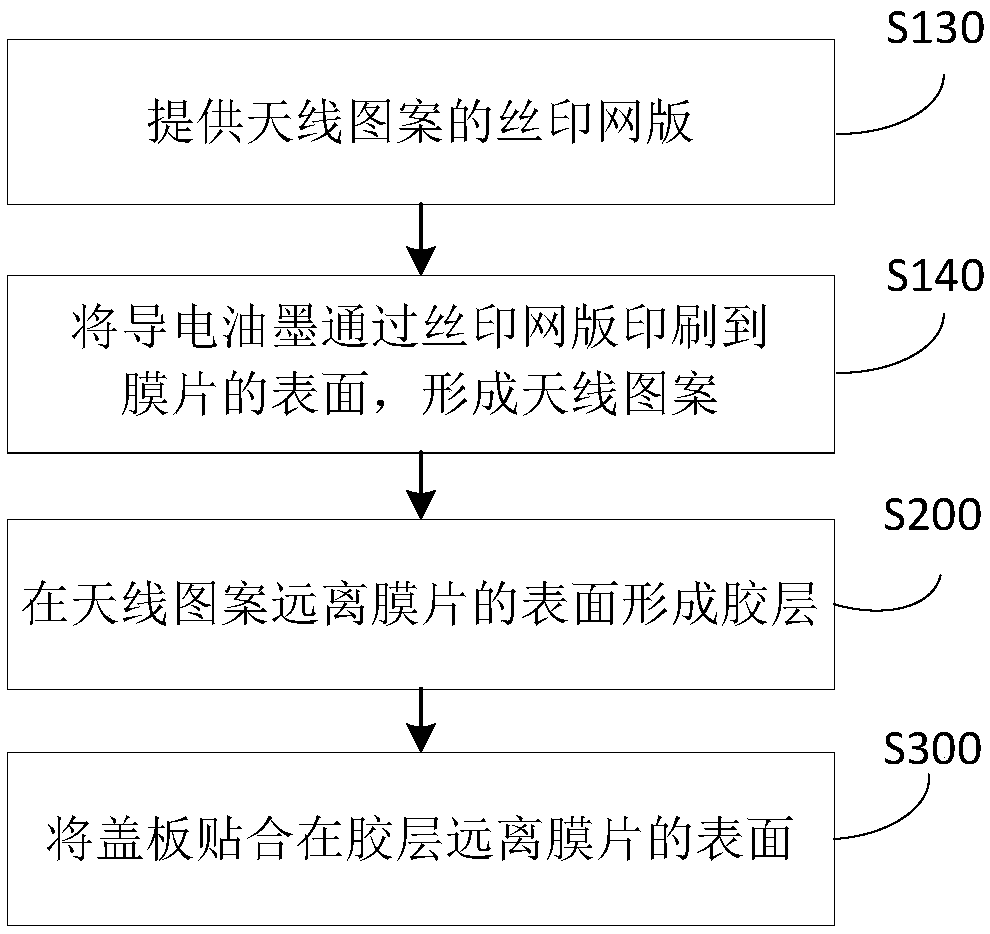

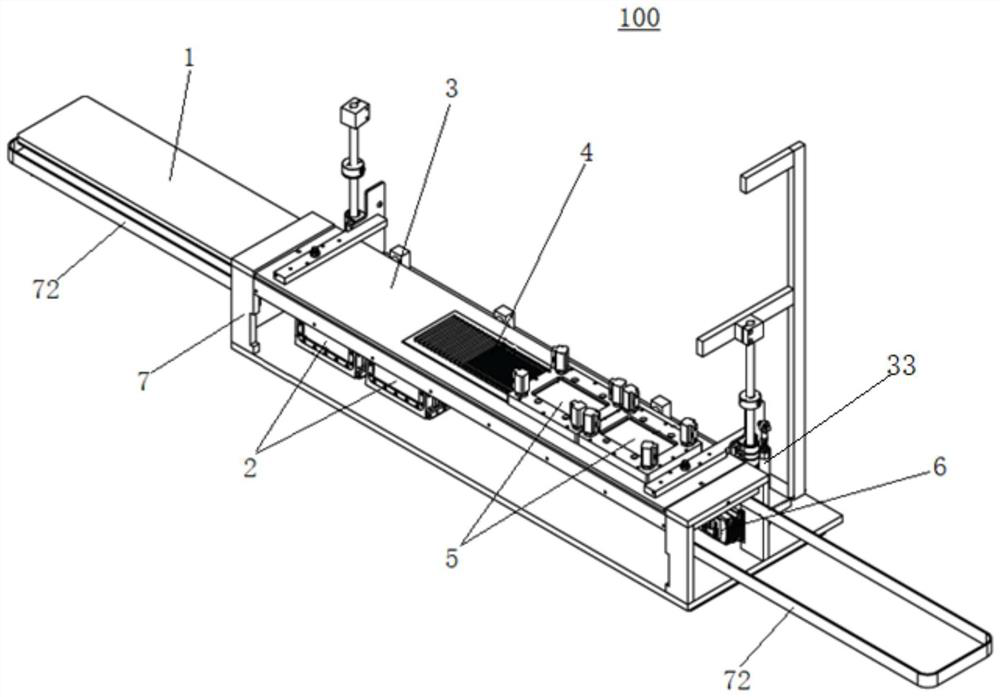

Antenna, manufacturing method thereof, and electronic device

InactiveCN109103588ASimple and fast operationSimple processAntenna supports/mountingsRadiating elements structural formsElectronElectrical and Electronics engineering

The invention provides an antenna, a manufacturing method thereof and an electronic device. The manufacturing method of the antenna comprises: forming an antenna pattern on a surface of a diaphragm; forming an adhesive layer on the surface of the antenna pattern remote from the diaphragm; attaching the cover plate to the surface of the adhesive layer away from the diaphragm. According to the invention, there is no space limitation for antenna patterning, the antenna pattern can be arranged on the diaphragm at will, and the antenna pattern can be directly bonded to the cover plate without reserving additional space on the cover plate. Moreover, the manufacturing method has the advantages of simple operation and simple process, and is suitable for manufacturing antenna patterns with complexshapes, and even can produce stereoscopic antennas on the inner edges of the curved cover plate.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

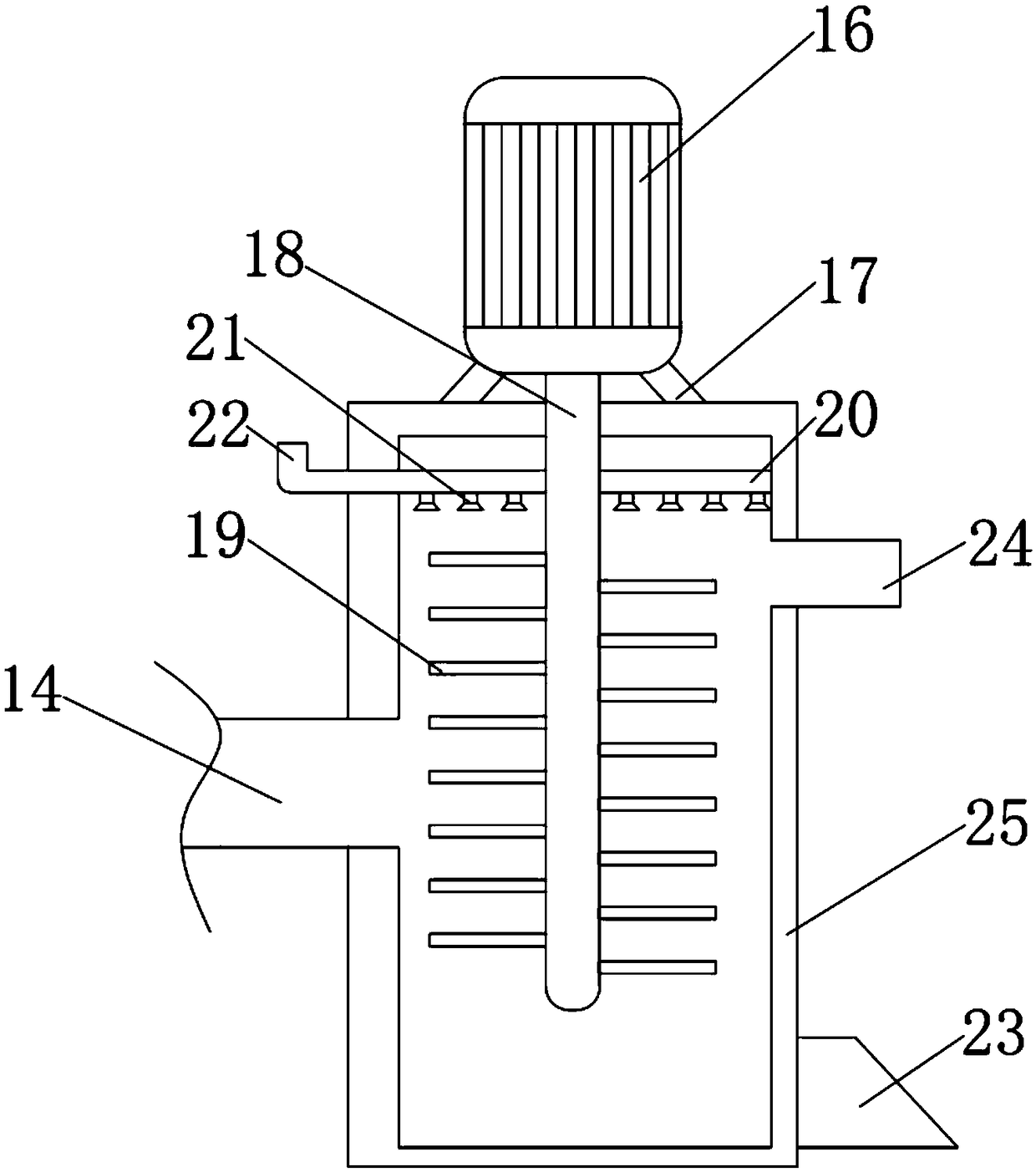

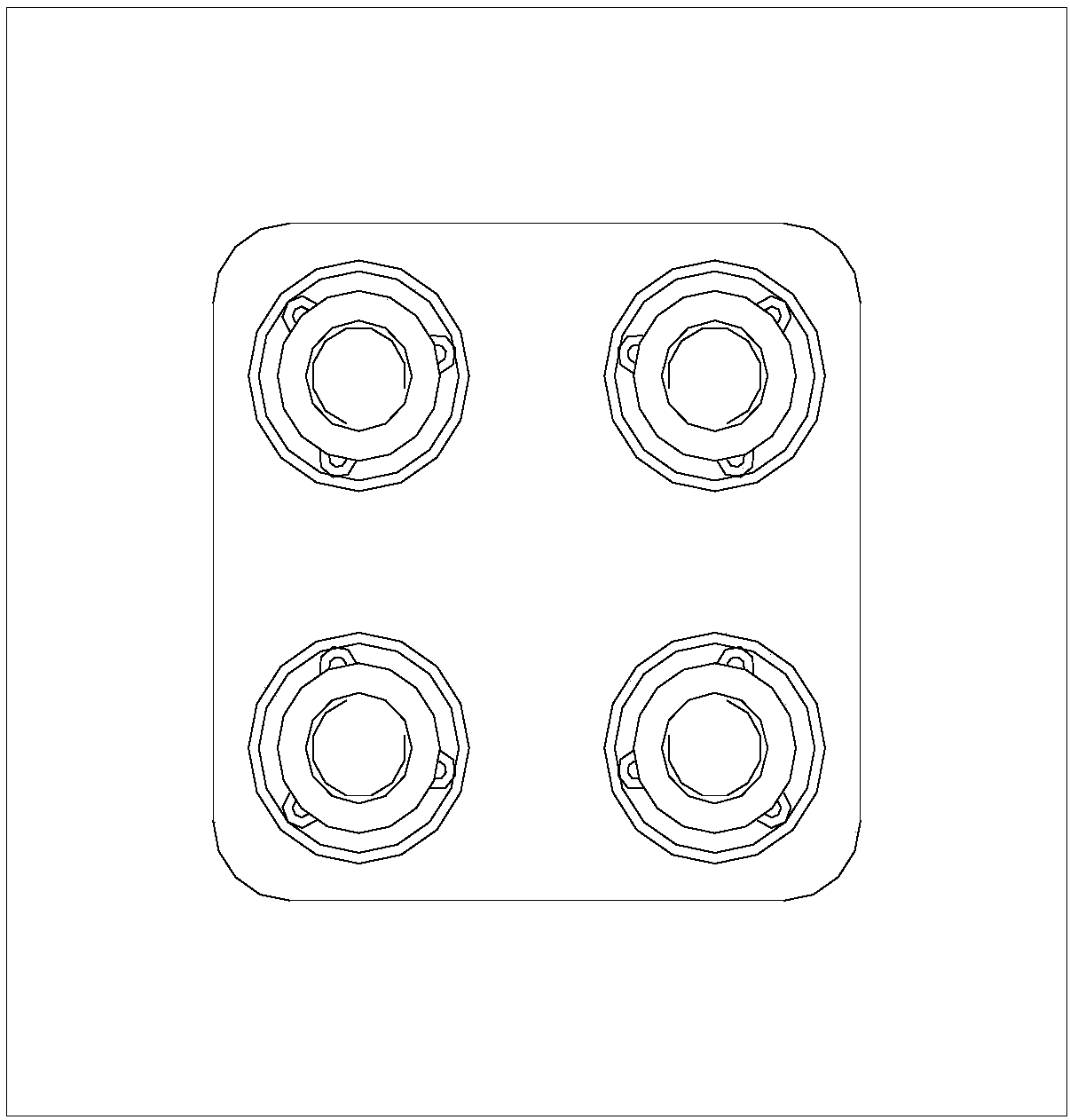

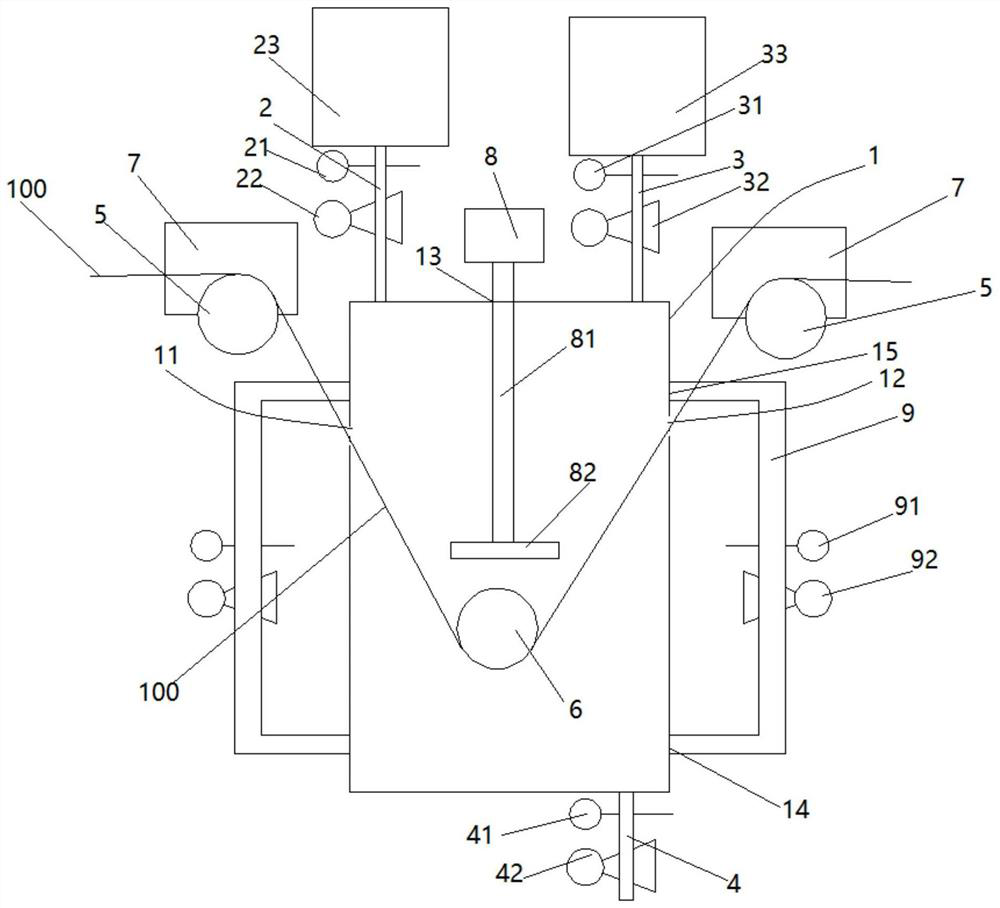

Sealed type high-flux high-efficiency full-automatic biosynthesis device

PendingCN112063494AIncrease setup densityFlexible time controlBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxSample mass

The invention discloses a sealed type high-flux high-efficiency full-automatic biosynthesis device. The sealed type high-flux high-efficiency full-automatic biosynthesis device comprises a moving plate, several synthesis cavity units, a sealing plate assembly, a sample adding unit and several pressurizing sealing units; the moving plate moves horizontally and linearly; the several synthesis cavityunits are fixed below the moving plate and form an upper opening in the moving plate; the sealing plate assembly is positioned above the moving plate and forms a sealed space with the moving plate through up-down movement; the sample adding unit is fixed on the sealing plate assembly; the several pressurizing sealing units are fixed on the sealing plate assembly and seal the upper opening; and the movable plate is driven by a driving part to move among the position of the sample adding unit and the positions of the pressurizing sealing units. According to the sealed type high-flux high-efficiency full-automatic biosynthesis device in the invention, automatic addition of the sample amount in the synthesis reaction process of a large batch of ultra-micro biological samples is realized; primers are automatically transferred into a sealed reaction cabin; furthermore, automatic pressurization and pressure maintaining are carried out; the pressure and synthesis speed required by synthesis are precisely controlled; and the biosynthesis efficiency is greatly improved.

Owner:DONGXUAN GENE TECH CO LTD

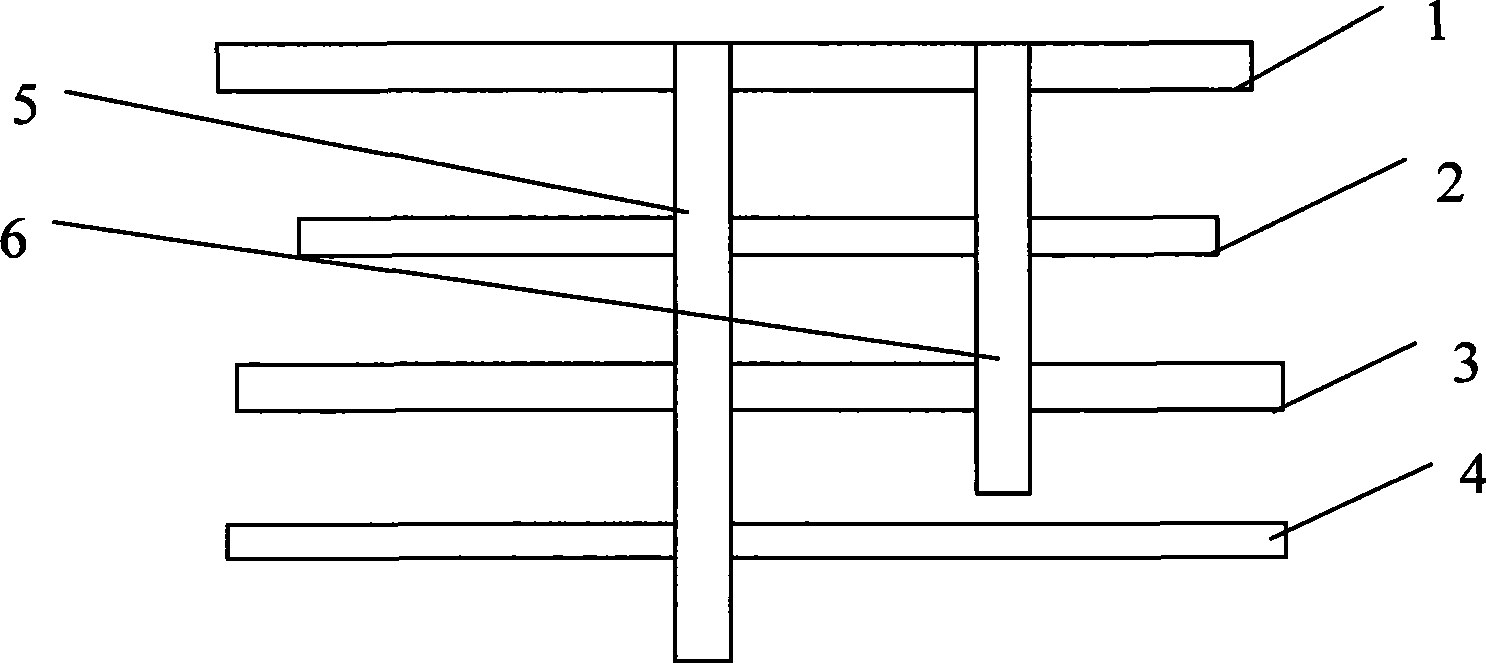

Multi-fuel indirect heating hot air stove with heat pipes

ActiveCN105466008AImprove thermal efficiencyIncrease the heat exchange areaAir heatersPlate heat exchangerProcess engineering

The invention relates to a multi-fuel indirect heating hot air stove with heat pipes. The multi-fuel indirect heating hot air stove is high in energy utilization rate and comprises an outer shield; a plate heat exchanger is arranged in the outer shield and comprises a first shell, a second shell arranged in the first shell, a third shell arranged in the second shell and a fourth shell arranged in the third shell; a first descending air flue is formed between the outer shield and the first shell, a smoke flue is formed between the first shell and the second shell, an ascending air flue is formed between the second shell and the third shell, a second descending air flue is formed between the third shell and the fourth shell, the first descending air flue is communicated with the ascending air flue, and the ascending air flue is communicated with the second descending air flue; the cavity of the fourth shell is communicated with the smoke flue, and a fire grate is arranged on the bottom surface of the cavity of the fourth shell; a hot air confluence cavity is formed in the lower part of the outer shield, a smoke box is arranged under the hot air confluence cavity, and a hot air outlet is formed in the back of the hot air confluence cavity; the multiple heat pipes are arranged on the top surface of the first shell.

Owner:SHANDONG SHUANGLI MODERN AGRI EQUIP

Environment-friendly device with impurity-collecting function

ActiveCN107601724AEffective filteringFiltering does not affectMultistage water/sewage treatmentWastewaterImpurity

The invention discloses an environment-friendly device with an impurity-collecting function. The environment-friendly device comprises a tank, wherein a top box is fixedly connected with the top of aninner wall of the tank; a limiting plate is fixedly connected with the top of a bottom box between the two sides of the inner wall of the tank; a disinfecting box is fixedly jointed between the rightside of the bottom box and the right side of the inner wall of the tank; a motor chassis is fixedly connected with the bottom on the right side of the tank; a first motor is fixedly connected with the top on the left side of the inner wall of the tank through a fixed base; a first belt pulley is fixedly connected with an output shaft of the first motor; and a second belt pulley is in driving connection with the surface of the first belt pulley through a belt. The invention relates to the technical field of environment-friendly equipment. The environment-friendly device with the impurity-collecting function is capable of effectively filtering, moving back and forth and guaranteeing the design for sufficiently purifying wastewater; the upward arc-shaped design is capable of gathering the impurities at the bottom; the wastewater filtering is not influenced; and the environment-friendly device is long in service life.

Owner:安徽上造智能设备科技有限公司

Aged apple orchard minitype air-blast sprayer

InactiveCN107251886AFully designedDeep research valueInsect catchers and killersSprayerSpatial structure

The invention discloses a miniature air-driven sprayer for old apple orchards, comprising a crawler-type car body, a drug outlet cover, a medicine box, a top cover of the medicine box, a gear position, a left and right turning handle, a baffle plate, a nozzle, a current collector, and an impeller , Conductive fluid. It is characterized in that: the medicine box is fixed on the crawler car body, the medicine outlet cover and the medicine box upper cover are installed on the medicine box, the gear position and the left and right turning handles are installed on the crawler car body, the The baffle plate is fixedly connected to the crawler car body, the collector, the impeller and the deflector form a fan, and the nozzle is fixedly connected to the collector. The invention relies on the crawler tractor as the main body to realize the mobile spraying operation, and the medicine box has a singular shape, fully utilizes the space structure of the tractor, and has strong application value for the research on the spraying of old orchards.

Owner:NORTHWEST A & F UNIV

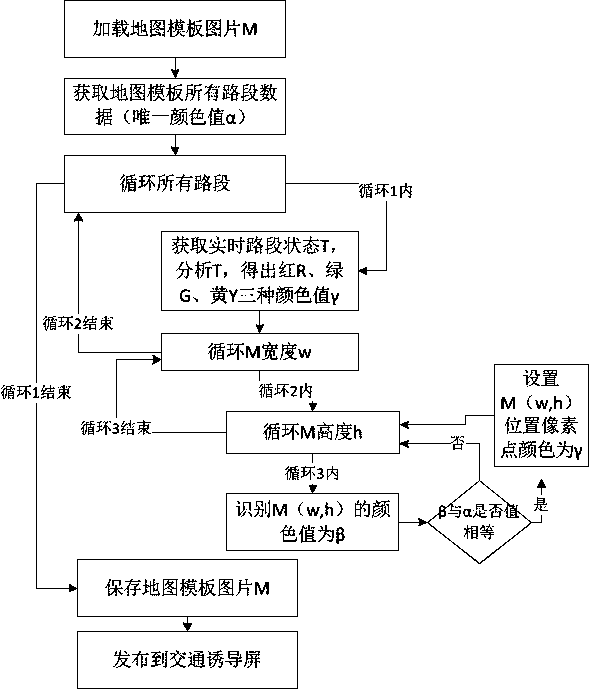

Traffic guidance map rendering method

PendingCN110176048ADoes not affect publishing resultsFully designedDrawing from basic elementsGraphicsWorkload

The invention relates to a traffic guidance map rendering method. The rendering method comprises the steps of performing data binding and re-coloring rendering according to a color value (RGB) of a map template picture. Each road is formed by splicing a plurality of road sections, and the color value (RGB) on the traffic guidance map template corresponding to each road section is absolutely unique. According to the method, various complex traffic road graphs can be rendered; the limitation by the actual road shape is avoided; a designer can fully and efficiently design the map in the early stage; a traffic guidance map template is designed in an earlier stage; after road section acquisition data and a map template road section color value (RGB) are successfully bound; the map is randomly modified in the later period, the release result of the guidance map is not influenced, the workload of redrawing the road section bound with the traffic guidance map can be reduced, the use efficiencyof the traffic guidance map template is improved, and meanwhile, the accuracy of traffic guidance is also improved.

Owner:河北瑞通公路配套设施有限公司

An environmental protection device with the function of collecting impurities

ActiveCN107601724BEffective filteringFiltering does not affectMultistage water/sewage treatmentElectric machineryWastewater

The invention discloses an environment-friendly device with an impurity-collecting function. The environment-friendly device comprises a tank, wherein a top box is fixedly connected with the top of aninner wall of the tank; a limiting plate is fixedly connected with the top of a bottom box between the two sides of the inner wall of the tank; a disinfecting box is fixedly jointed between the rightside of the bottom box and the right side of the inner wall of the tank; a motor chassis is fixedly connected with the bottom on the right side of the tank; a first motor is fixedly connected with the top on the left side of the inner wall of the tank through a fixed base; a first belt pulley is fixedly connected with an output shaft of the first motor; and a second belt pulley is in driving connection with the surface of the first belt pulley through a belt. The invention relates to the technical field of environment-friendly equipment. The environment-friendly device with the impurity-collecting function is capable of effectively filtering, moving back and forth and guaranteeing the design for sufficiently purifying wastewater; the upward arc-shaped design is capable of gathering the impurities at the bottom; the wastewater filtering is not influenced; and the environment-friendly device is long in service life.

Owner:安徽上造智能设备科技有限公司

A 3D printing packaging method for flip chips

The present invention provides a 3D printing packaging method of a flip chip. The method is characterized by comprising the following steps of S1 utilizing a computer to design a three-dimensional digital model of an LED device, programming the LED device, after the hierarchical slicing processing, introducing a 3D printer, and utilizing the computer to control the hierarchical printing; S2 utilizing a suction nozzle to absorb the flip chip, and fixing under a reflector cup; S3 carrying out the 3D printing on a solder layer and a radiating substrate, wherein the radiating substrate is equipped with a leading-out circuit in electrode connection with the chip, and further can comprises a step S4 of filling the fluorescent powder. Relative to the general packaging, according to the present invention, the die bonding wires and the eutectic solders are not needed, the packaging yield is improved, a support and a PCB or a COB do not need to purchase, the packaging cost is reduced, the packaging research and development cycle is shortened, and the packaging appearance diversity is increased, and the LED thinning and miniaturization are promoted.

Owner:GUANGDONG DELI PHOTOELECTRIC

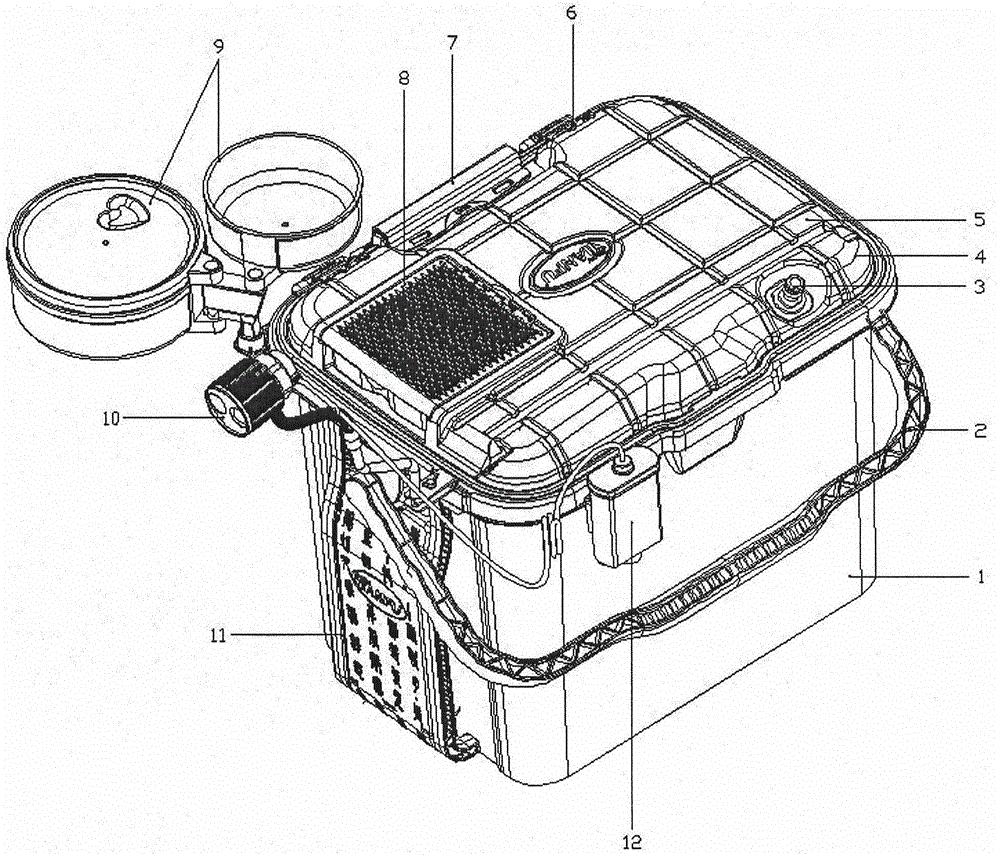

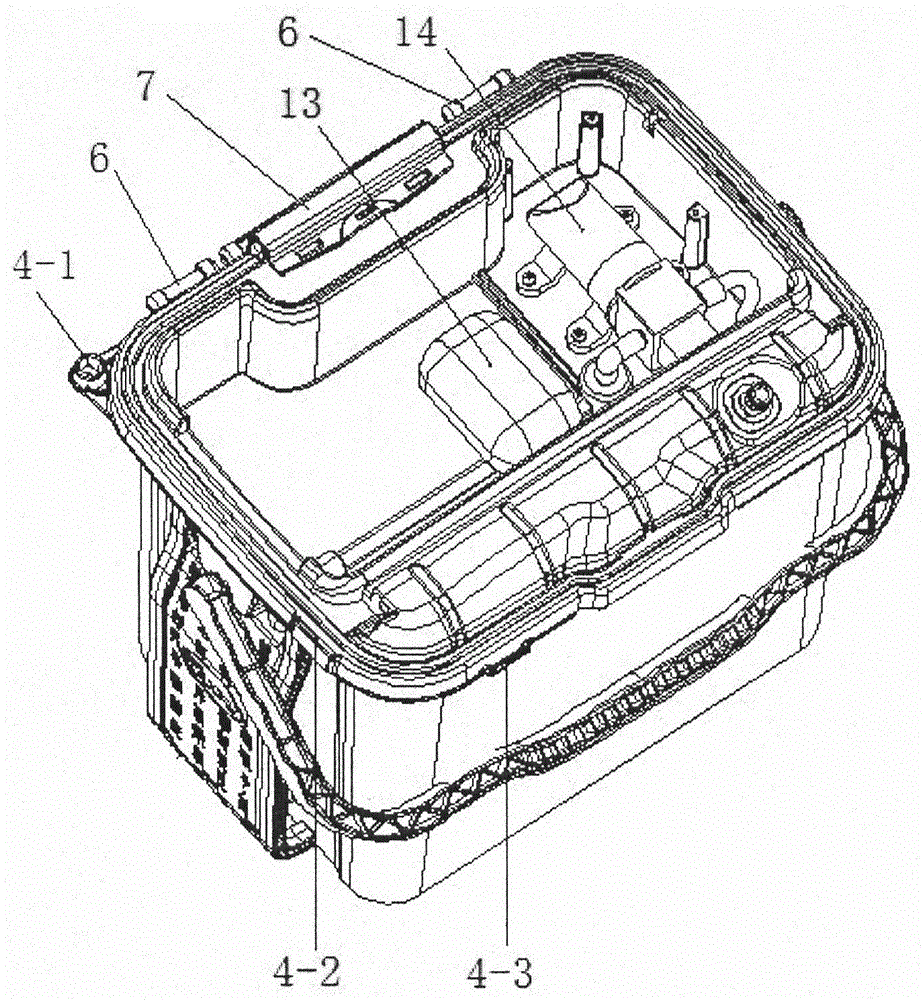

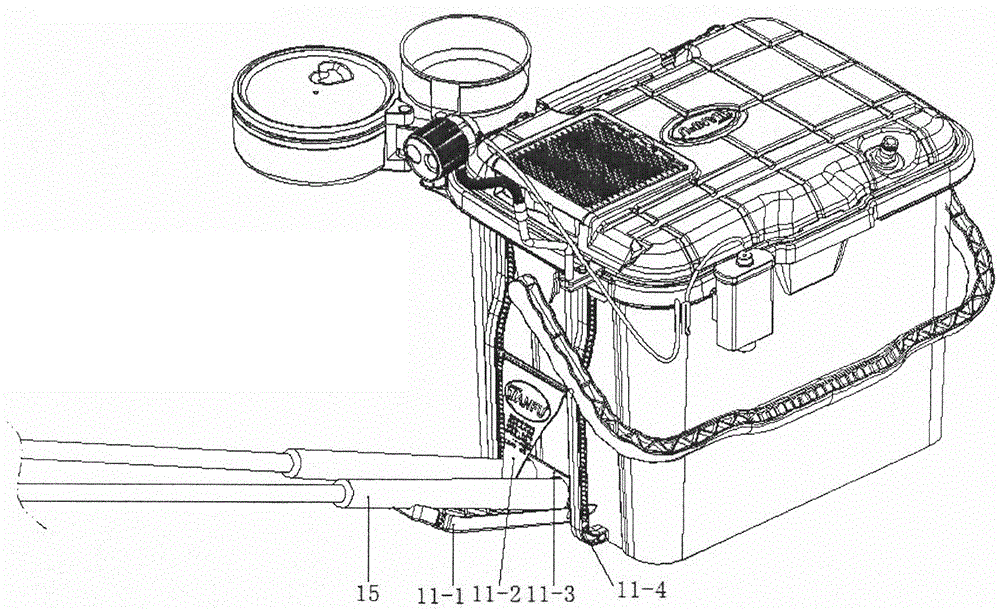

a multifunctional box

InactiveCN104396906BVersatileSave space resourcesTravelling sacksVehicle cleaning apparatusDiaphragm pumpEngineering

The invention relates to a multifunctional box. The multifunctional box comprises a box body and a large cover, wherein a receiving space is formed in the large cover and an aeration pump and an intelligent diaphragm pump are arranged in the receiving space; a small cover is arranged on the opening of the receiving space of the large cover and a receiving cover is arranged in the small cover; a water outlet nipple is arranged on the large cover; a bait disc clamping position, a night fishing lamp clamping position and a power source clamping position are defined on the frame of the opening of the box body; a bait disc is mounted at the bait disc clamping position, while a night fishing lamp is mounted at the night fishing lamp clamping position, and a power source is mounted at the power source clamping position; a hanger assembly is fixed on the front sidewall of the box body and comprises two angle chute rods arranged vertically; an angle adjusting plate is arranged on the angle chute rods and connected with the inner side of a fishing rod tray; a fishing rod fixing sleeve is arranged on the lower part of the inner side of the fishing rod tray. The multifunctional box can be applied to storing articles and also to fishing as well as washing cars, and therefore, the box is integrated with a plurality of functions; besides, the multifunctional box is portable and easy to carry, and simple to operate.

Owner:重庆建福模具制造有限公司

Unit modular large household refuse incineration furnace

Owner:江苏楹能环保科技发展有限公司

Multi-fuel heat pipe indirect heating hot air stove

ActiveCN105466008BImprove thermal efficiencyIncrease the heat exchange areaAir heatersPlate heat exchangerProcess engineering

The invention relates to a multi-fuel indirect heating hot air stove with heat pipes. The multi-fuel indirect heating hot air stove is high in energy utilization rate and comprises an outer shield; a plate heat exchanger is arranged in the outer shield and comprises a first shell, a second shell arranged in the first shell, a third shell arranged in the second shell and a fourth shell arranged in the third shell; a first descending air flue is formed between the outer shield and the first shell, a smoke flue is formed between the first shell and the second shell, an ascending air flue is formed between the second shell and the third shell, a second descending air flue is formed between the third shell and the fourth shell, the first descending air flue is communicated with the ascending air flue, and the ascending air flue is communicated with the second descending air flue; the cavity of the fourth shell is communicated with the smoke flue, and a fire grate is arranged on the bottom surface of the cavity of the fourth shell; a hot air confluence cavity is formed in the lower part of the outer shield, a smoke box is arranged under the hot air confluence cavity, and a hot air outlet is formed in the back of the hot air confluence cavity; the multiple heat pipes are arranged on the top surface of the first shell.

Owner:SHANDONG SHUANGLI MODERN AGRI EQUIP

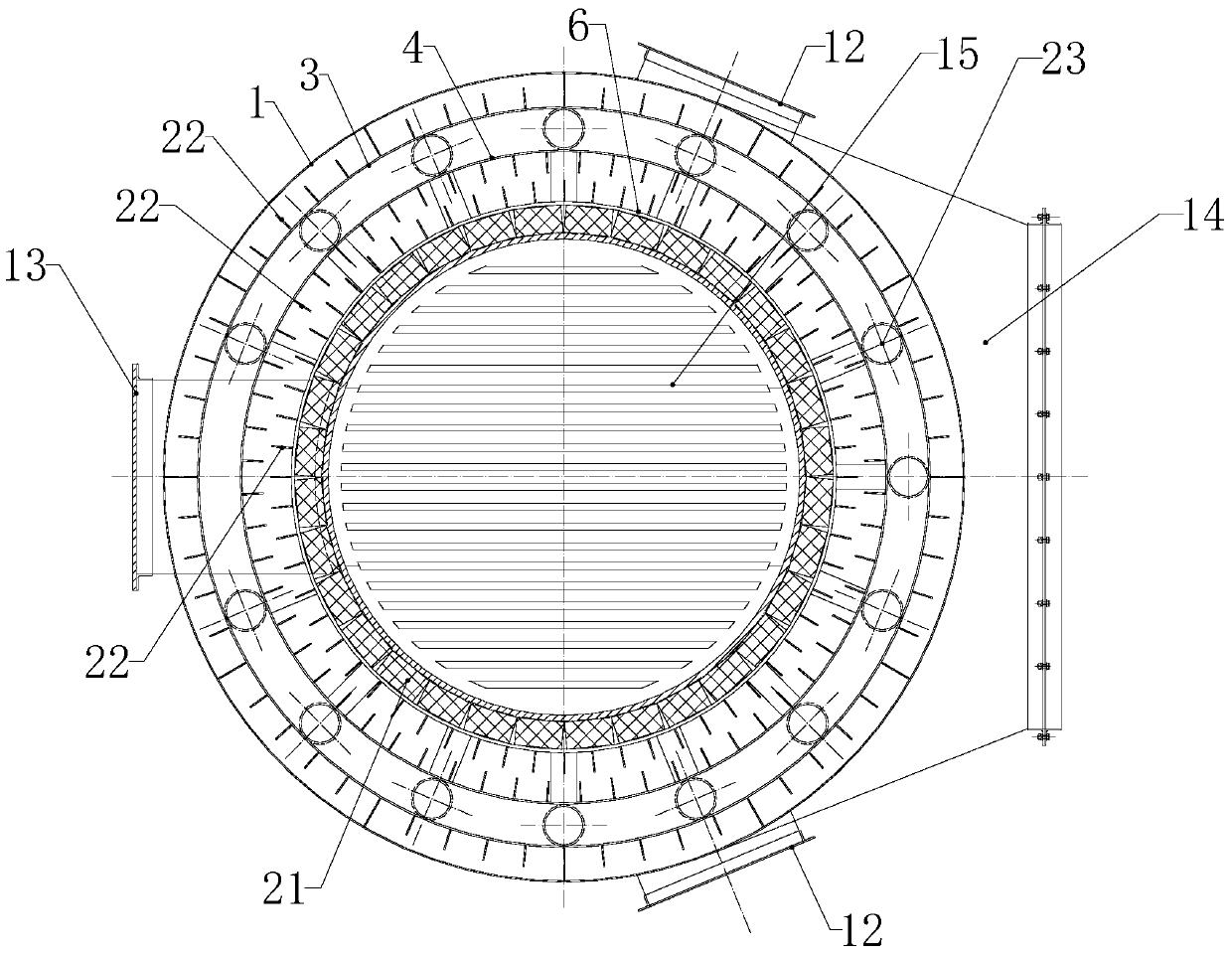

Biomass briquette combustion system

PendingCN113217908AEvenly distributedExtended service lifeFuel supply regulationFuel feeding arrangementsAir preheaterAutomatic control

The invention relates to a biomass briquette combustion system. The system comprises a feeding system, a boiler main machine, an economizer, an air preheater, a cyclone dust collector, a bag-type dust collector, an induced draft fan, a chimney and a control system; the feeding system comprises a closed bucket elevator, a closed storage bin, a closed scraper conveyer, a front daily material bin and a screw feeder; a variable-frequency motor is arranged in the screw feeder. Biomass briquette is separated from a combustion fire bed in the boiler main machine through the screw feeder, and the problem of tempering of traditional coal bucket type feeding is completely eradicated; double-layer high-pressure secondary air is designed in the boiler main machine, so that the biomass briquette can be fully combusted in a hearth; a convection section in the boiler main machine is designed to be of a wide-interval, sequential-arrangement and four-return-stroke design structure; the control system is used for automatically controlling boiler feeding, deslagging, hearth temperature, fire grate speed regulation and variable-frequency regulation of the variable-frequency motor and the induced draft fan according to set programs.

Owner:江西江右净达热能科技有限公司

An automatic control device for a building communication cabinet

InactiveCN104483909BRealize anti-jammingRealize integrated self-power supplyProgramme total factory controlFiberDistribution frame

The invention discloses a building communication cabinet automatic control device which comprises a cabinet. The cabinet is internally and fixedly provided with an intelligent controller, a power distribution box, a switch, a wire arrangement frame, a distribution frame, a fibre distribution frame, a PDU, an optical transceiver, an access controller and a UPS and matching power source thereof from the top down in sequence by means of trays. The power distribution box is electrically connected with the intelligent controller through a current and voltage detector. The cabinet is further internally provided with a temperature detector, a humidity detector, a smog detector, a water logging detector and an alarm, which, together with the access controller, are electrically connected with the intelligent controller. The intelligent controller is connected with a remote monitoring system terminal through a network. The cabinet of the device is in standard design; port and device installation are increased and added as needed; sufficient redundancy design is realized; different devices are in subarea arrangement in structure; the distribution frame and the wire arrangement frame are made full use of; and therefore, anti-interference between wires is realized, the cabinet realizes UPS integrated self-powering; and the cabinets in the network are interconnected through the intelligent controller, and intelligent centralized management is realized.

Owner:SUZHOU SUNGO TECH

Normal-pressure clean coal water heating boiler

The invention provides an atmospheric clean coal-fired hot water boiler, which comprises a combustion chamber, a fire grate and a return smoke pipe. The front end of the furnace is connected to the hopper, and the rear end is connected to the slag outlet. There are 4 blowers under the grate. The return smoke pipe includes the first return smoke pipe and the second return smoke pipe. One end of the first return smoke pipe is connected to the combustion chamber The top is connected, the other end is connected to the smoke chamber, one end of the second return smoke pipe is connected to the smoke chamber, and the other end is connected to the smoke outlet. The boiler of the invention uses clean briquette coal as the main fuel, has the advantages of sufficient combustion, high heat energy utilization rate, and small smoke and dust, has wide application fields, can replace bulk coal boilers, and is beneficial to environmental protection.

Owner:天津市双鑫锅炉辅机有限公司

A fully automatic demoulding mold for internal thread plastic parts

The invention discloses a full-automatic de-molding mould for an internal thread plastic part. The full-automatic de-molding mould comprises a fixed model chamber plate and a moveable model chamber plate, wherein a mold joint of the plastic part is arranged between the fixed model chamber plate and the moveable model chamber plate; a base plate is connected with the lower end face of the moveablemodel chamber plate; a moveable seat plate is arranged under the base plate; a pouring sleeve is arranged at the top end of a fixed seat plate; a main runner is arranged on the mold joint; a product chamber is connected with the main runner; a threaded mold core is arranged in the product chamber; the threaded mold core is penetrated through the moveable seat plate and extends into the base plate;a hydraulic motor is arranged in the moveable seat plate; the lower end of the threaded mold core is connected with the hydraulic motor through a driving mechanism; the threaded mold core is driven by the hydraulic motor to rotate. According to the invention, the hydraulic motor is placed between the base plate and the moveable mold fixing plate, so that the mold space is saved and the requirement for the tonnage of the injection molding machine is lower. A driving gear is adopted for driving a plurality of driven gears to de-mold and the chamber can be fully designed according to the template space. A rotation-stopping mechanism is adopted for guaranteeing the automatic rotation of the plastic part, a spring is adopted for pushing a stub bar and the adjustment and the repairing are convenient.

Owner:FUZHOU UNIV +1

Anti-corrosion antibacterial spinning cleaning device

PendingCN111621862AGood anti-corrosion and anti-bacterial effectExtended service lifeArtificial thread manufacturing machinesArtificial filament washing/dryingSpinningEngineering

The invention provides an anti-corrosion antibacterial spinning cleaning device. The anti-corrosion antibacterial spinning cleaning device comprises a cleaning box, two outer wire guide rollers, at least one inner wire guide roller, at least one driving motor, a stirring motor and a PLC, wherein the cleaning box is provided with a spinning inlet and a spinning outlet, a stirring opening is formedin the upper surface of the cleaning box, a cleaning liquid inserting pipe and a clean water inserting pipe are inserted into the upper surface of the cleaning box at intervals, and a liquid discharging pipe is inserted into the bottom surface of the cleaning box; the two outer wire guide rollers are erected on the outer side of the cleaning box; the at least one inner wire guide roller is erectedat the lower part of the inner side of the cleaning box; the output end of the driving motor is connected with the outer wire guide roller located on the outer side of the spinning outlet; the stirring motor is erected on the upper surface of the cleaning box, the output end of the stirring motor is connected with a stirring shaft, the stirring shaft extends into the inner side of the cleaning box from the stirring opening and is connected with a stirring paddle, the stirring paddle is located above the inner wire guide roller, and the outer side end of the stirring paddle is located on the inner side of a V-shaped silk thread structure;. The cleaning device can fully clean silk threads, is good in cleaning effect, can save water sources, and is good in anti-corrosion and anti-bacterial effects, long in service life and low in cleaning cost.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

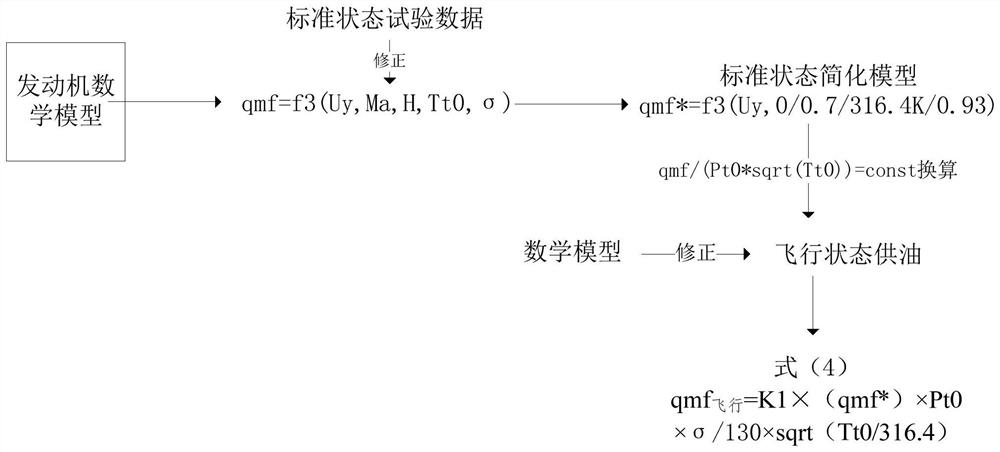

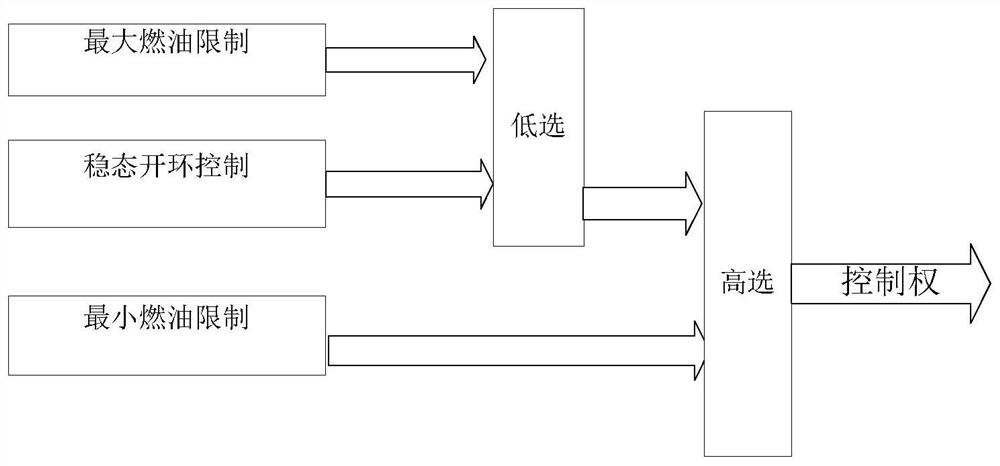

Open-loop turbine engine steady state control method

PendingCN114458400AFully designedEasy to useMachines/enginesDesign optimisation/simulationModel engineLoop control

The open-loop turbine engine steady state control method does not depend on a rotating speed signal of the engine, and when the rotating speed signal of the engine breaks down, it can still be guaranteed that the engine works safely and reliably, preset thrust is given out, and use of an aircraft is met. According to the method, through engine thrust bridging, a mathematical model of engine throttle voltage and fuel flow in flight is established, and when it is detected that an engine rotating speed signal is abnormal and rotating speed closed-loop control cannot be adopted, the engine is controlled to work in an open-loop mode, so that the engine can still complete preset functions. Due to the fact that the rotating speed signal is abnormal, the maximum rotating speed and the minimum rotating speed of the engine cannot be limited, the oil supply boundary of the working area of the engine is designed through a mathematical model, and the oil supply boundary is corrected through the difference between the actual performance of the engine and the model engine.

Owner:BEIJING POWER MACHINERY INST

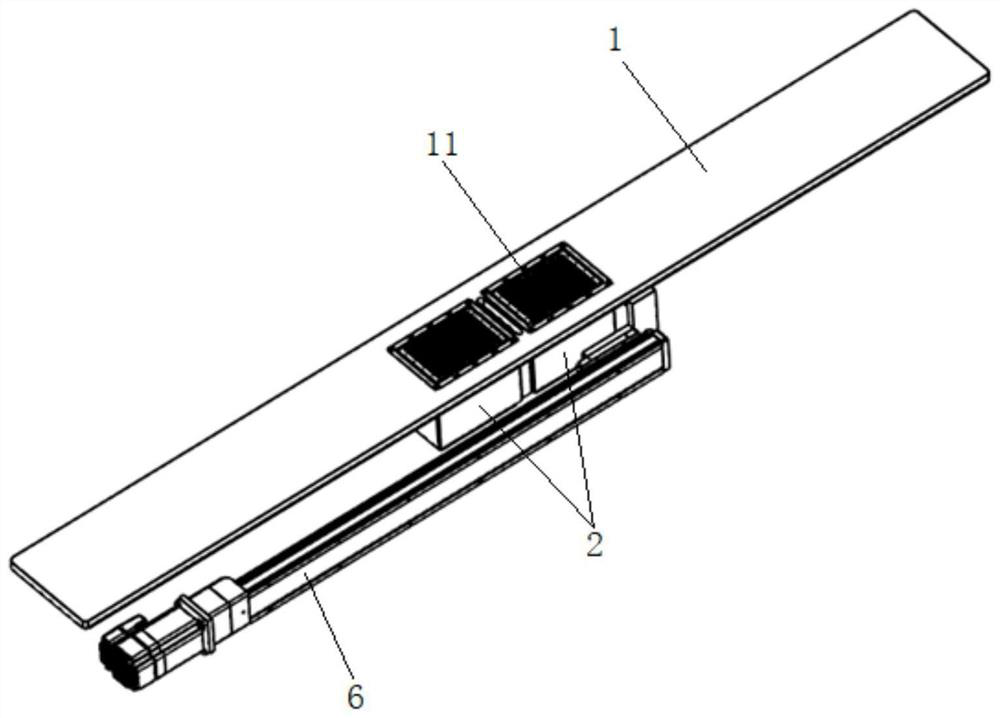

Air conditioner panel and air conditioner

PendingCN107152775AGood lookingImprove consistencyHeating and ventilation casings/coversInterior spaceEngineering

The invention provides an air conditioner panel and an air conditioner. The air conditioner panel comprises a main body frame (1); the main body frame (1) is provided with an arc inner wind guide surface; an inner ring exhaust port (2) is formed in an outlet of the inner wind guide surface, and is provided with door sheets (13); and multiple door sheets (13) are movably arranged along the inner wind guide surface to open or close the inner ring exhaust port (2). According to the air conditioner panel, the overall appearance effect of the air conditioner can be improved; the design is simple; the internal space of the air conditioner can be effectively used; and the design cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

A Composite Material Layup Scheme Database Construction Method Considering Laminate Compatibility

ActiveCN106021654BAvoid complex constraintsLayup Compatibility Problem SolvingGeometric CADConstraint-based CADComposite laminatesComputer science

The invention provides a composite material layering scheme library establishing method taking layering compatibility into account. The method comprises the steps of encoding composite material layering schemes by using integers; traversing all combinations and establishing a composite material layering basic scheme library, which is a first-stage composite material layering scheme library; using binary numbers as layer breaking operation codes, and further obtaining a second-stage composite material layering scheme library on the basis of first-stage composite material layering schemes through layer breaking operation; performing layer breaking operation successively to obtain multiple stages of composite material layering scheme libraries. With the method, a composite material layering scheme library meeting the layering compatibility requirement can be obtained; effective transition in thickness changing areas of composite material layering is realized; a feasible layering scheme is provided for composite material layering process design; and foundation is laid for composite material structure optimization design.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com