Quick testing method for opening/shortcircuit of high-density LED lamp diode product without inner positioning hole

A technology of LED lamp wick and detection method, applied in the direction of electronic circuit testing, measuring electricity, measuring device, etc., can solve the problems of normal mass production, inability to meet customer delivery, waste of processing time, etc., to achieve low production difficulty, low cost, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

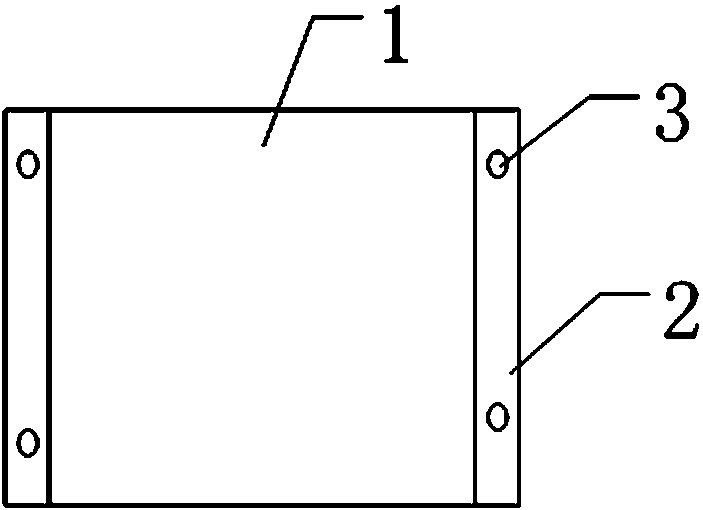

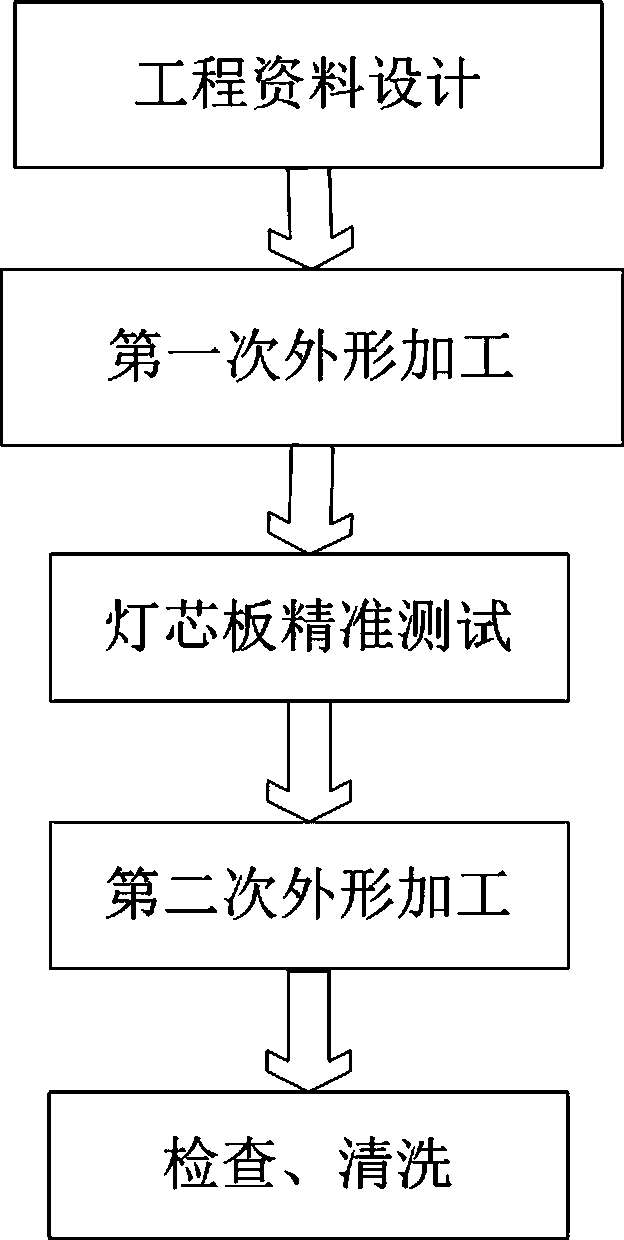

[0026] Such as figure 1 and figure 2 As shown, a quick detection method for open and short circuits of high-density LED wick products without internal positioning holes, adding side strips 2 on the two short sides of the wick board 1, and designing positioning holes 3 on the side strips, so that there are no positioning holes The wick board 1 is transformed into a conventional test board that meets the test requirements, and then the wick board 1 is tested by using the general test method of the test board with positioning holes. The rapid detection method of the high-density non-internal positioning LED wick product of the present invention is based on the non-internal positioning PCB wick board 1 data provided by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com