Composition for high-performance heat-resistant and corrosion-resistant glass fibers

A glass fiber and high-performance technology, which is applied in the field of high-performance heat-resistant and corrosion-resistant glass fiber compositions, can solve the problems of poor acid resistance of fibers and achieve high strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

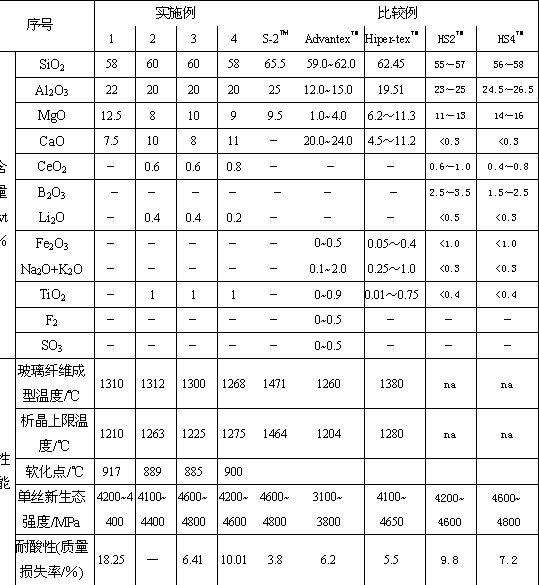

[0039] Embodiments of the present invention and S-2 ? 、Advantex ? 、Hiper-tex ? 、HS2 ? 、HS4 ? The glass fiber comparison data are shown in the table below:

[0040]

[0041] Calculate the required amount of various raw materials according to the chemical composition of the formulas listed in the above table, and mix them evenly to prepare batches after accurate weighing, and place them in a platinum-rhodium alloy melting crucible at a temperature range of 1500 ° C to 1530 ° C , melted while stirring, and melted for 20 hours to obtain clarified and homogenized molten glass. Flow the molten glass onto a heat-resistant steel plate, and obtain a glass block after cooling, and then part of the melted glass Put it into a single-hole platinum-rhodium wire drawing furnace, remelt it at 1440 ° C ~ 1450 ° C, and draw it into Continuous glass fiber with a diameter of 5-22 μm. The new eco-strength of the glass fibers of the above-mentioned embodiments with a diameter of 7-8 μm wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com