Waste iron absorption device and automatic waste iron cleaning vehicle

An automatic cleaning and absorber technology, used in road cleaning, cleaning methods, construction, etc., can solve the problems of reusable value, difficult to re-use, inability to absorb iron sheets and some heavy objects, and limited use of cleaning vehicles. , to achieve the effect of reducing maintenance cost and difficulty, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically described below in conjunction with the embodiments shown in the accompanying drawings.

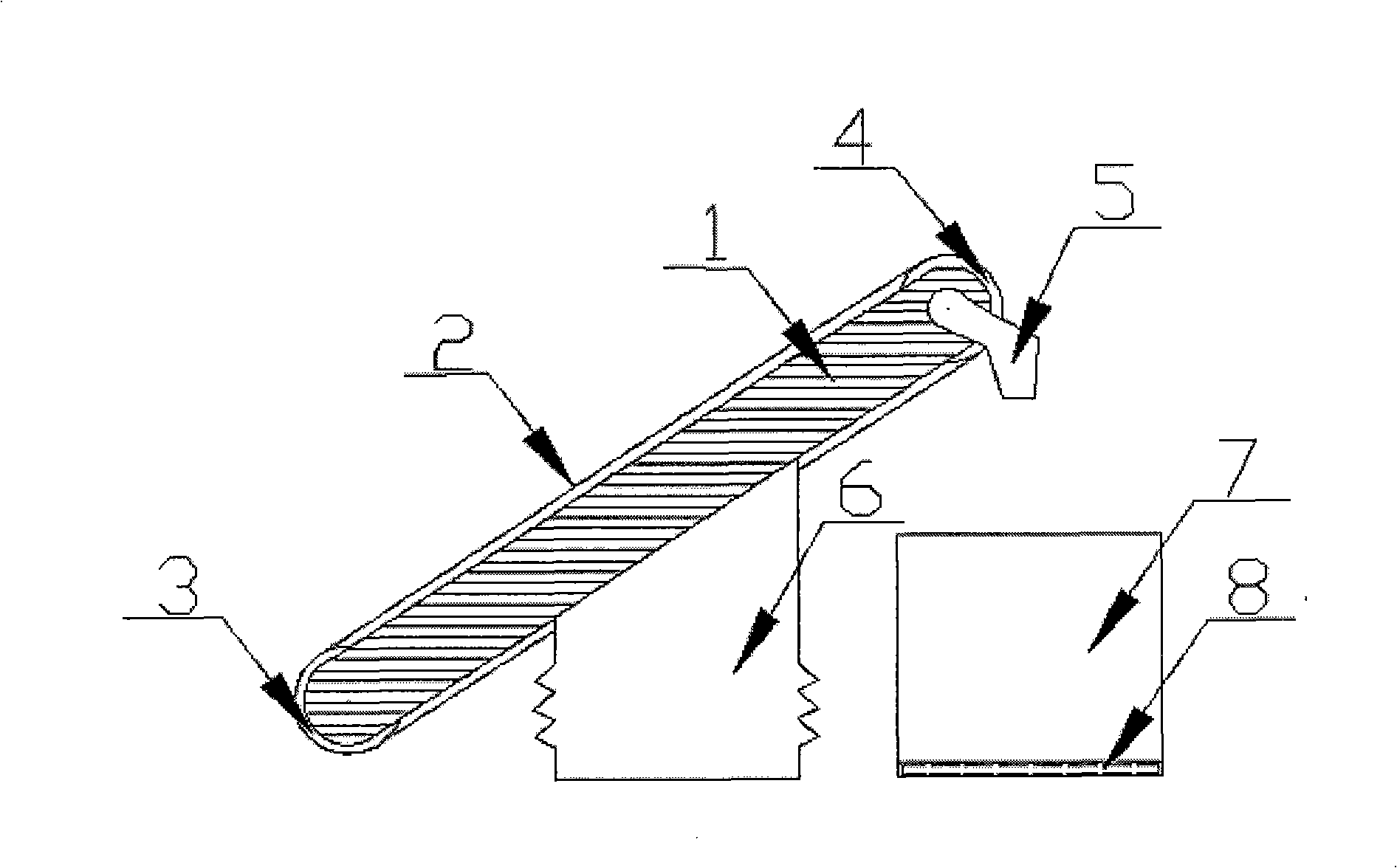

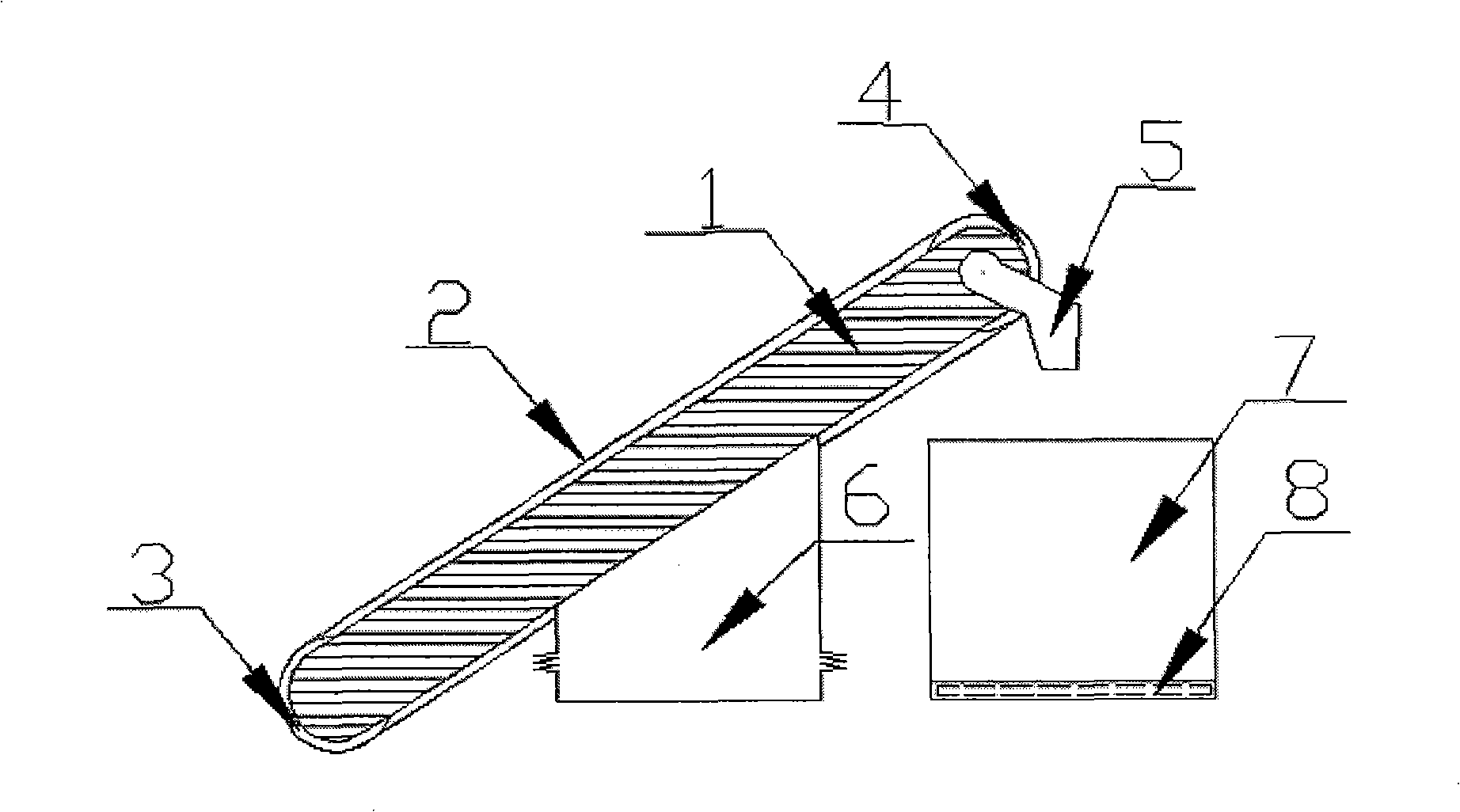

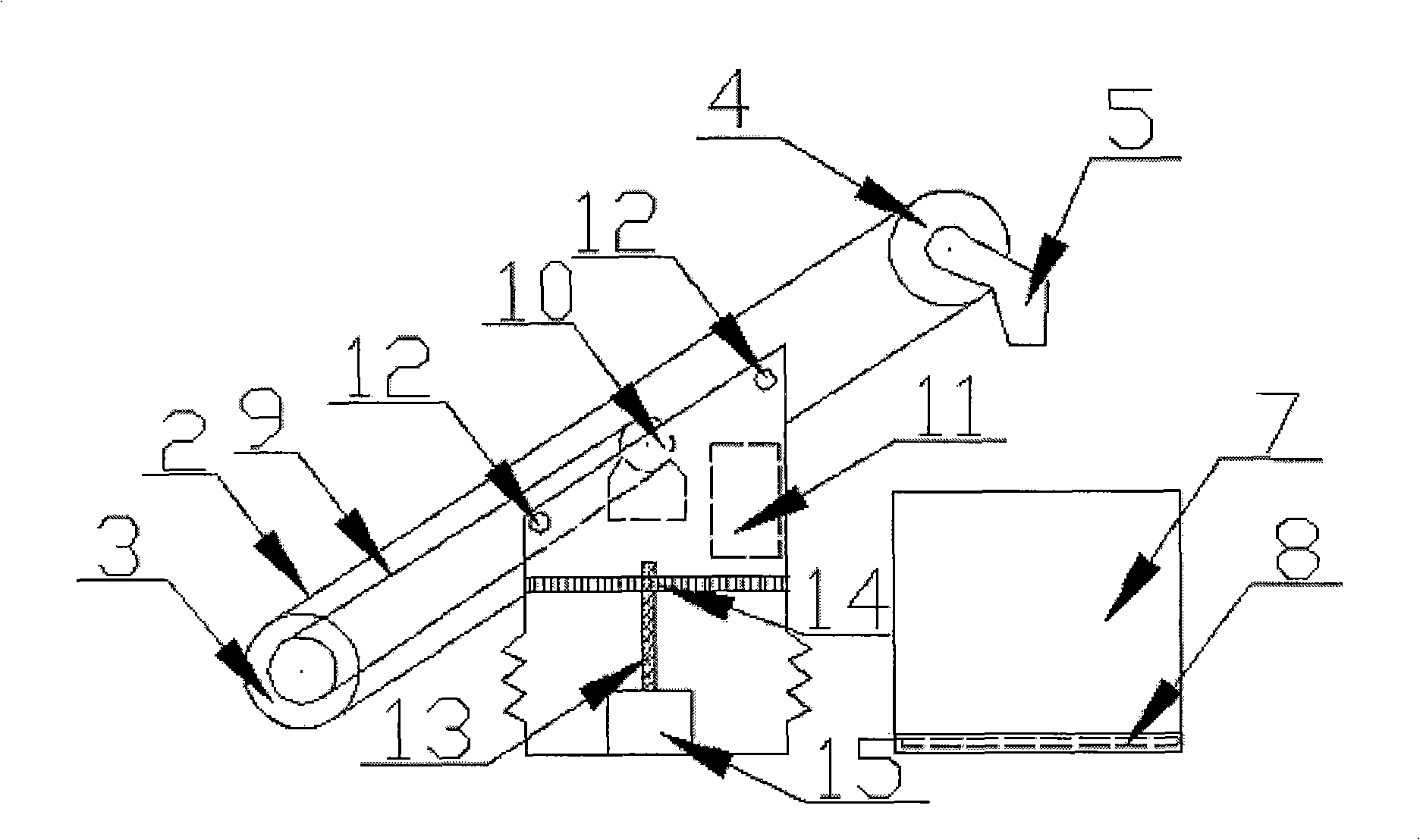

[0025] Such as Figure 1-3 As shown, the scrap iron absorber is mainly composed of two parts: the absorption area and the storage area. These are two independent areas, wherein the absorption area consists of the absorption rolling system and the control system 6 .

[0026] In the absorption rolling system, the upper roller 4 and the lower roller 3 are fixed at both ends by the roller fixing plate 1 , and the roller fixing plate 1 is fixed on the control system 6 through the roller fixing plate mounting hole 12 . The upper roller 4 and the lower roller 3 are connected by a hoisting belt 2 . The hoisting belt 2 is made up of a closed coil, a central thin iron sheet and a layer of thin rubber poured on its surface, and a row of brush layers is left on the edge for use when the electromagnetic relay power supply 11 supplies power. A blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com