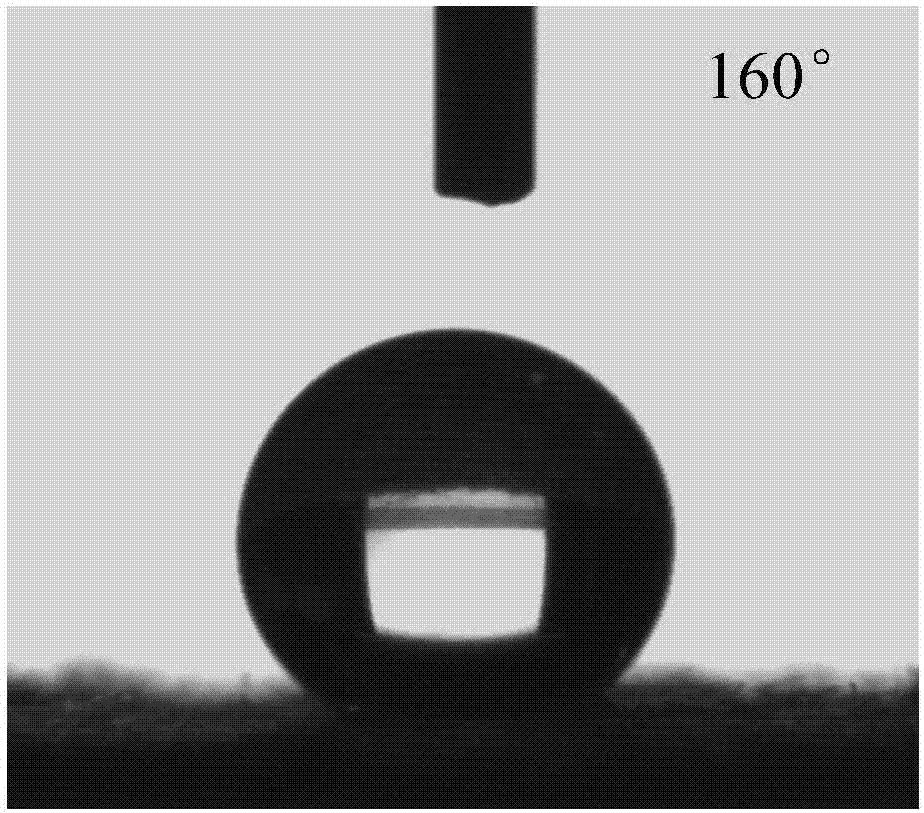

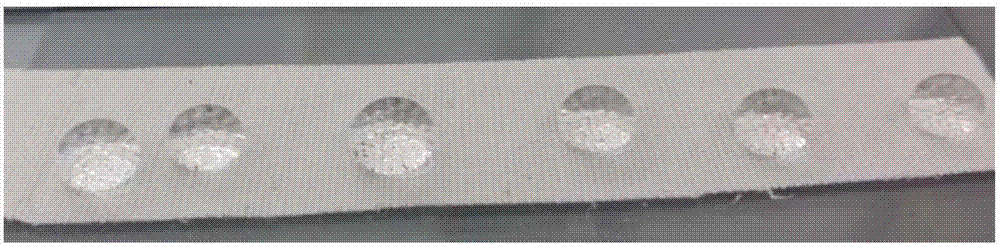

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

A textile finishing and super-hydrophobic technology, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of difficult process control, loss of super-hydrophobic properties, complicated and multi-step methods, etc., to achieve high-efficiency anti-ultraviolet and convenient The effect of large-scale production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the embodiments of the present invention provides a method for preparing a multifunctional superhydrophobic textile finishing agent, which includes:

[0026] (1) Disperse the precursor of the oxide sol and the aqueous dispersion of graphite oxide in deionized water, add an anionic surfactant, and stir at room temperature for 20-30 minutes. After uniform dispersion, add a catalyst for hydrolysis and condensation reactions to form a mixture reaction system;

[0027] (2) The mixed reaction system obtained in step (1) is heated to 30-50°C, stirred and reacted at a speed of 200-1000 rpm for 3-12 hours, followed by ultrasonic treatment for 10-20 minutes to form a hydrosol;

[0028] (3) Add a functional agent to the hydrosol obtained in step (2), and perform ultrasonic treatment for 10-100 minutes to obtain the multifunctional superhydrophobic textile finishing agent.

[0029] In some embodiments, the precursor includes any one or a combination of two or more of tetrabut...

Embodiment 1

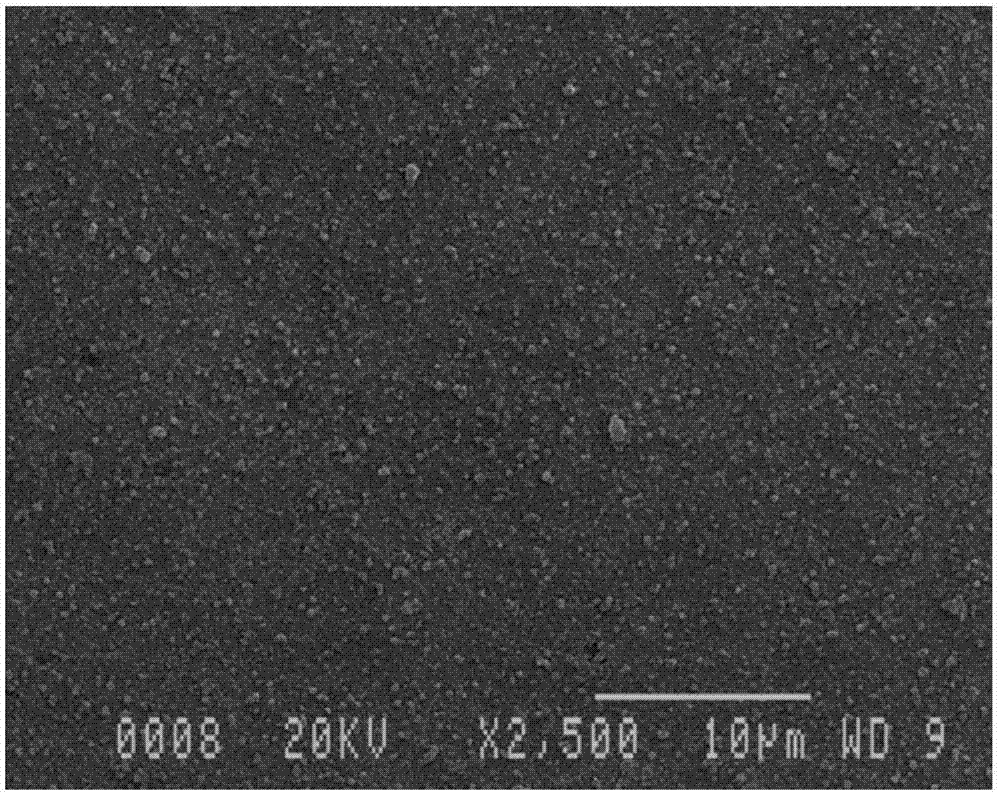

[0052] (1) Disperse 10 mL of tetrabutyl titanate and 4 mL of aqueous graphite oxide dispersion (with a concentration of 10 mg / mL) in 200 mL of deionized water, add 0.1 g of sodium dodecylbenzene sulfonate, and stir vigorously for 20 min at room temperature. After being uniformly dispersed, 5 mL of hydrochloric acid with a concentration of 0.1 mol / L is added dropwise to conduct hydrolysis and condensation reactions.

[0053] (2) The mixed reaction system obtained in step (1) is heated to 30° C., and magnetic stirring is continued at a speed of 300 rpm for 3 hours, and then ultrasonicated for 10 minutes to obtain a clear and transparent hydrosol.

[0054] (3) Add 5 mL of octyl triethoxysilane and 1 g of TiO to the hydrosol obtained in step (2) 2 It is mixed with carbon black, 0.2g polyphosphoric acid, 0.2g nano silver and 0.4g silk protein, and then subjected to ultrasonic treatment for 50 minutes to obtain a uniform and stable dispersion, which is the multifunctional superhydrophobic...

Embodiment 2

[0060] (1) Disperse 10 mL of tetraoctyl titanate and 2 mL of graphite oxide aqueous dispersion (with a concentration of 5 mg / mL) in 100 mL of deionized water, add 0.05 g of sodium dodecyl sulfonate, and stir vigorously for 30 min at room temperature to be uniform After dispersion, 3 mL of ammonia water with a concentration of 0.05 mol / L was added dropwise for hydrolysis and condensation reactions.

[0061] (2) The mixed reaction system obtained in step (1) is heated to 35° C., and magnetic stirring is continued at a speed of 500 rpm for 5 hours, and then ultrasonicated for 15 minutes to obtain a clear and transparent hydrosol.

[0062] (3) Add 3 mL of dodecyl triethoxysilane, 2 g of ZnO and kaolin, 0.1 g of melamine, 0.1 g of nano titanium oxide and 0.2 g of collagen to the hydrosol obtained in step (2), and then perform ultrasonic treatment In 20 minutes, a uniform and stable dispersion is obtained, which is the multifunctional superhydrophobic textile finishing agent.

[0063] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com