Patents

Literature

1999results about How to "Reduce the difficulty of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

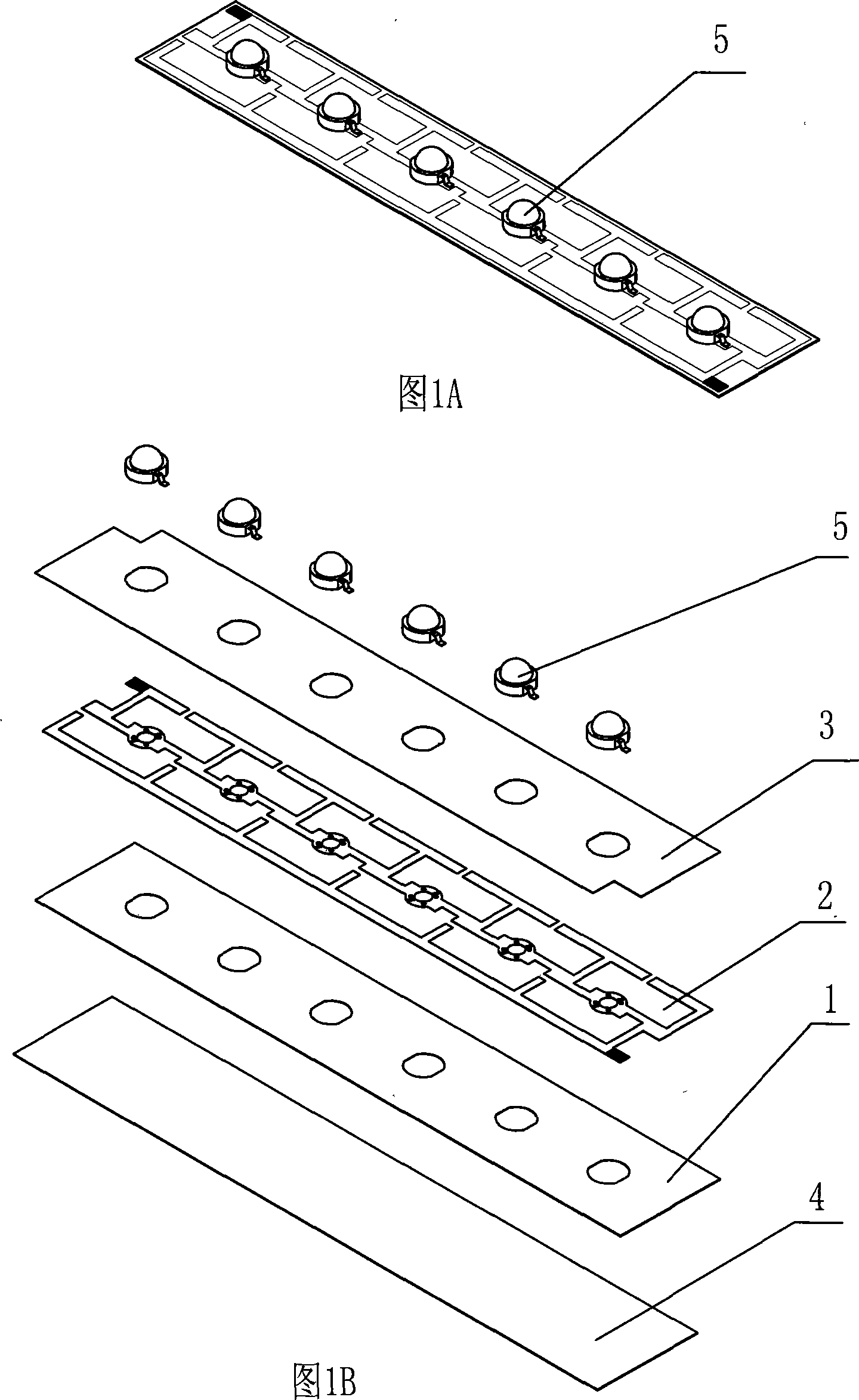

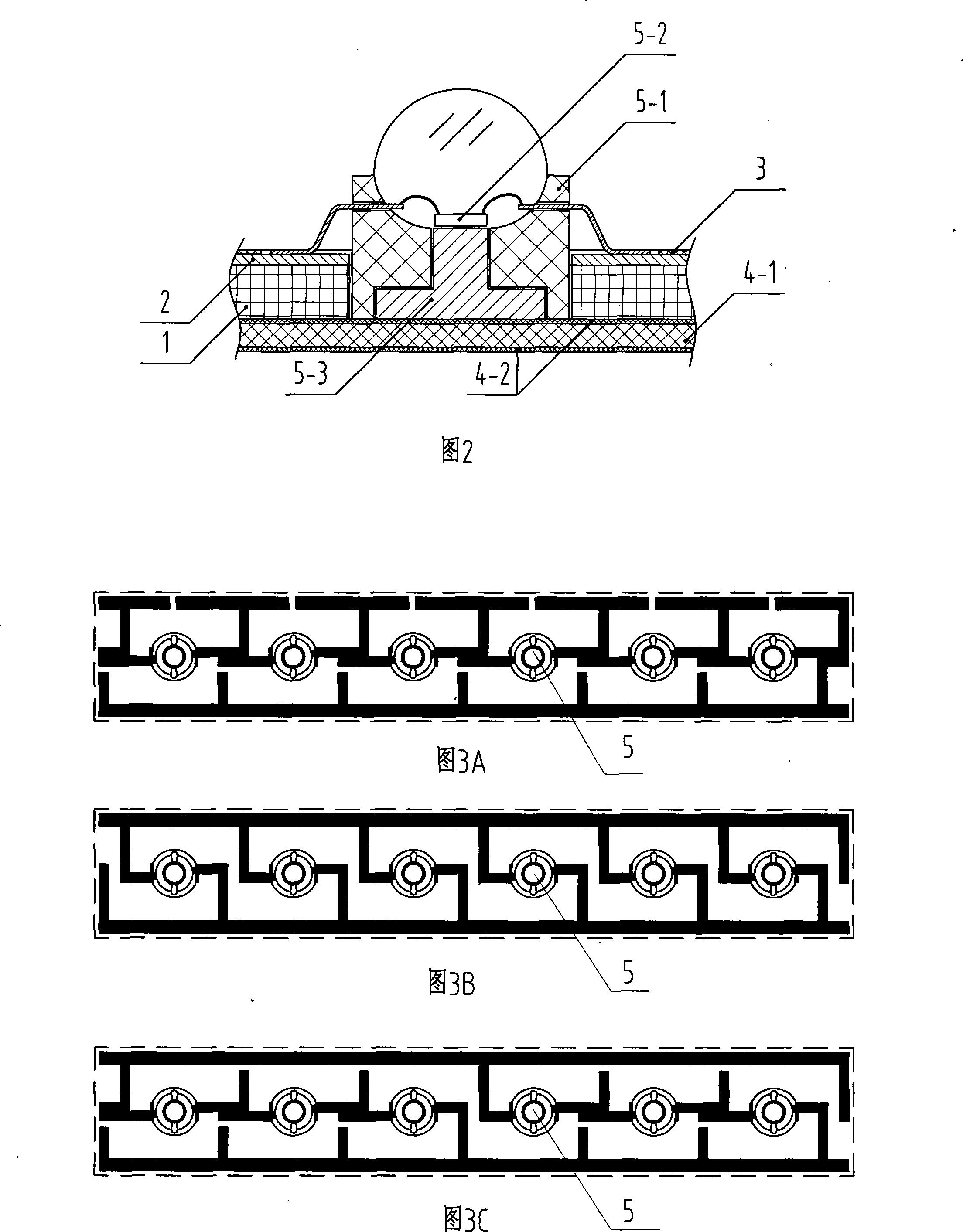

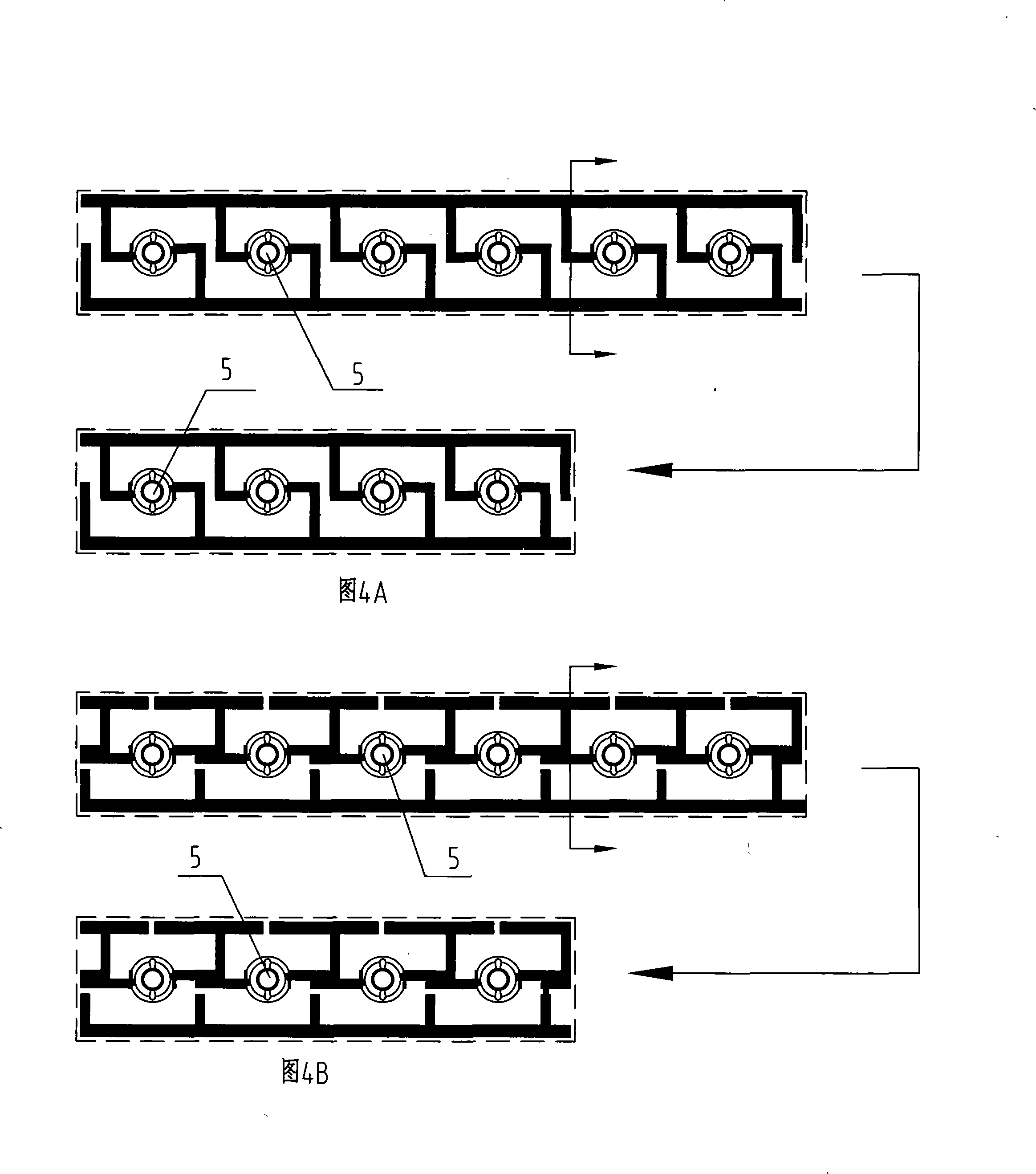

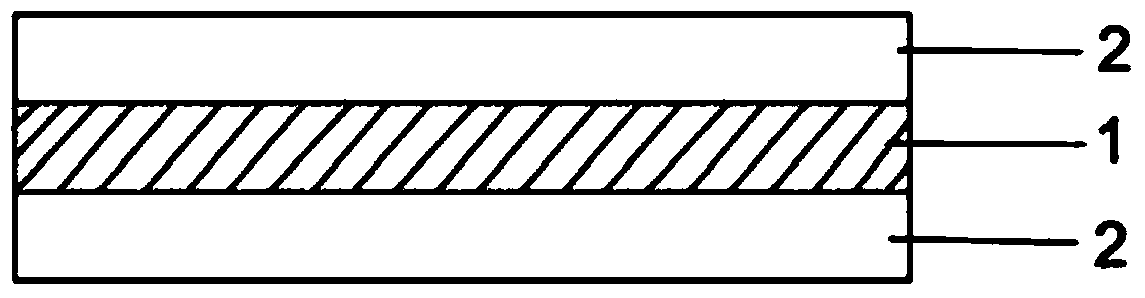

Flexible circuit board of LED illumination array

InactiveCN101198216ANovel, reasonable and compact structureEasy to producePrinted circuit detailsElectric circuit arrangementsFlexible circuitsHeat conducting

The invention discloses a flexible circuit board convenient for efficient heat dissipation and mainly used in a high-power LED illumination array, belonging to the semiconductor illumination technical field. The flexible circuit board of an LED illumination array is characterized in that: the circuit board is provided with a flexible substrate, a connection circuit, an insulating film-covered layer, a heat-conducting rubber pad and an LED light source; the connection circuit is arranged on the surface of the flexible substrate; the surfaces of the flexible substrate and the connection circuit are covered with the insulating film-covered layer to form a circuit board module; the LED light source is packaged inside the circuit board module in an array mode; the bottom surface of the flexible substrate is adhered to the surface of the heat-conducting rubber pad. Therefore, the entire flexible circuit board module has certain elasticity and flexibility and can adapt to bending, twisting and crimp deformation of certain strength; moreover, the invention can also be arranged on non-flat surfaces not more than a certain curvature such as a cylindrical surface or a spherical surface. The invention has wider application scope, better heat dissipation performance, less production cost, convenient installation and substantially increased production efficiency.

Owner:史杰

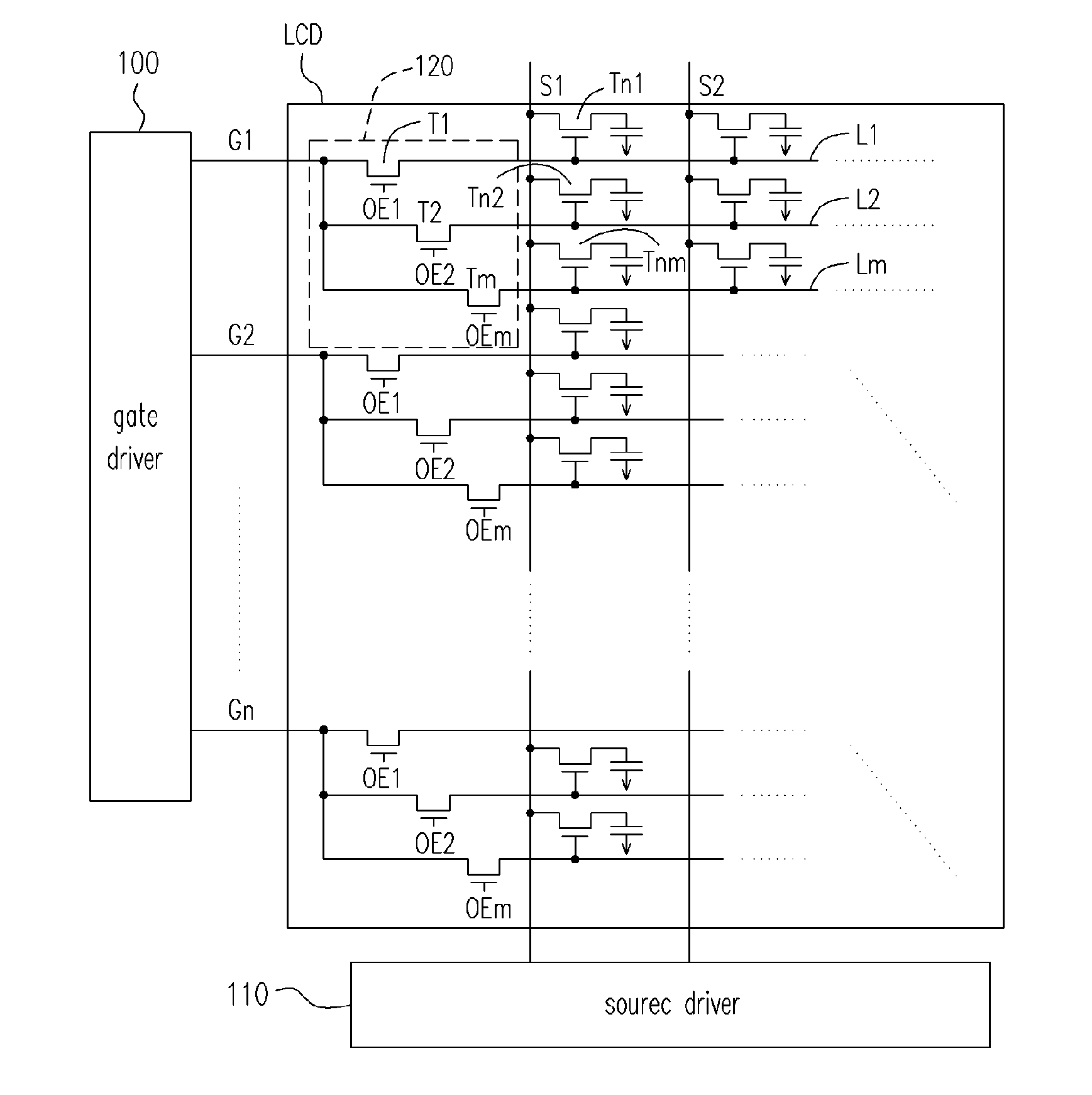

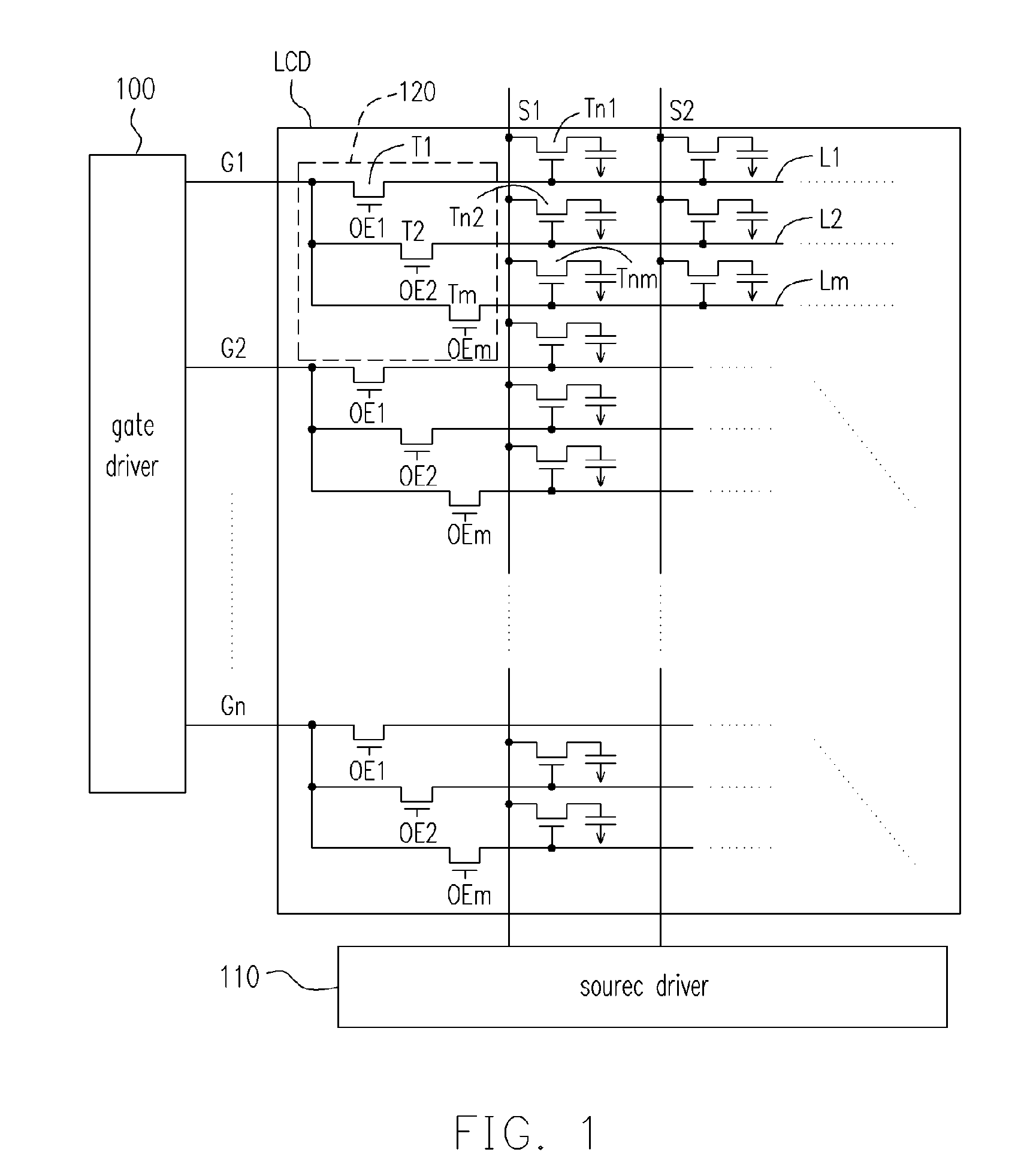

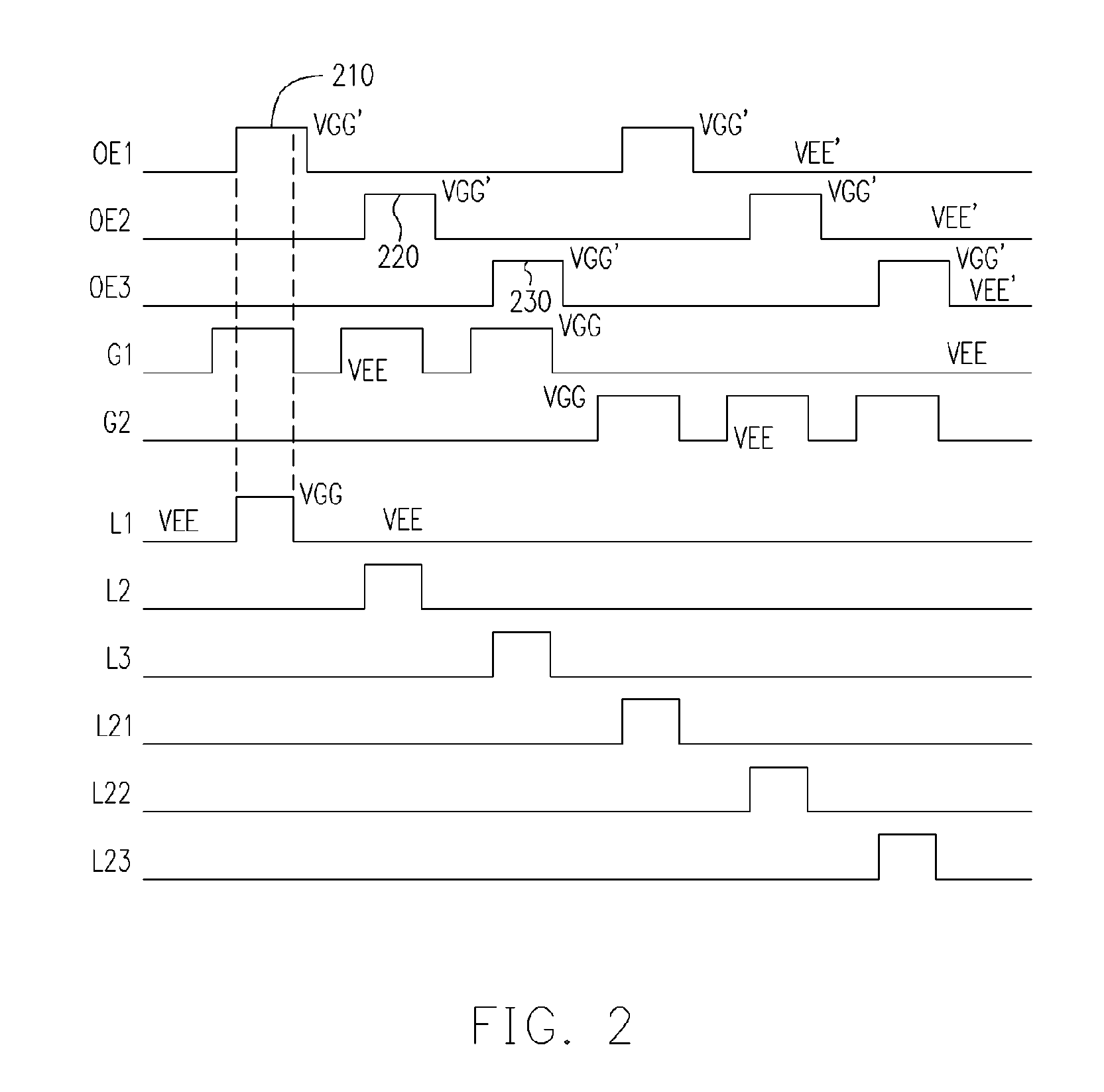

Gate switch apparatus for amorphous silicon LCD

InactiveUS20060267909A1Reduce outputCost savingCathode-ray tube indicatorsInput/output processes for data processingEngineeringDisplay device

Owner:NOVATEK MICROELECTRONICS CORP

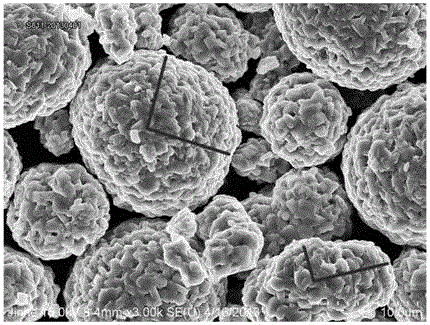

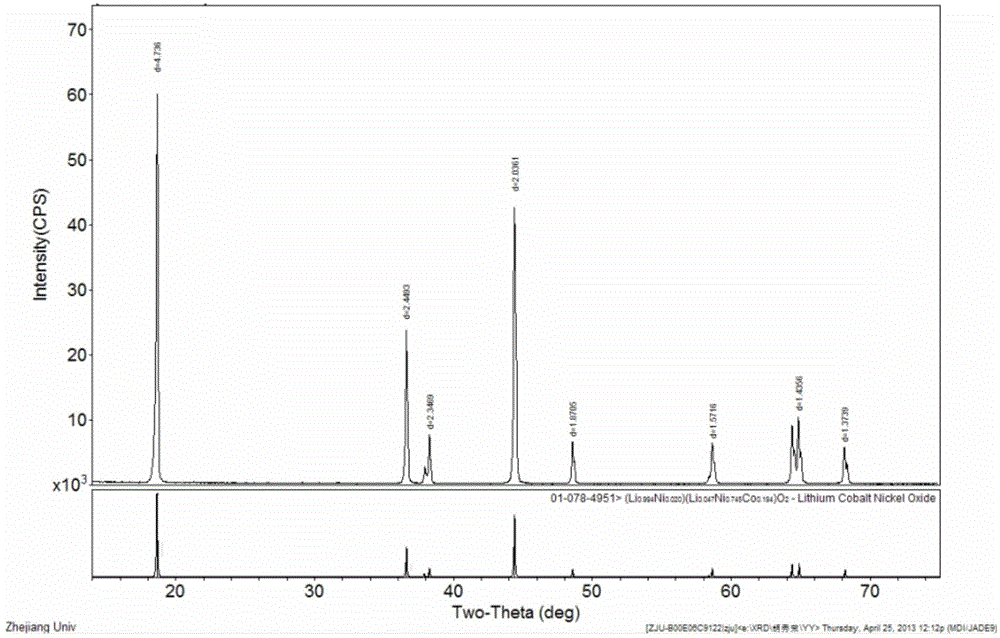

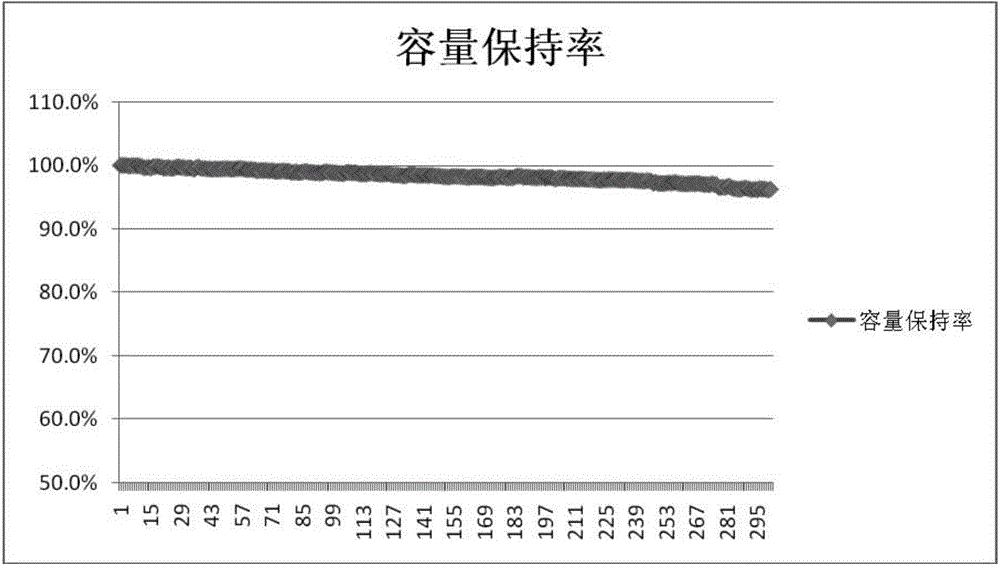

Nickelic cathode material rich in lithium and preparation method thereof

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

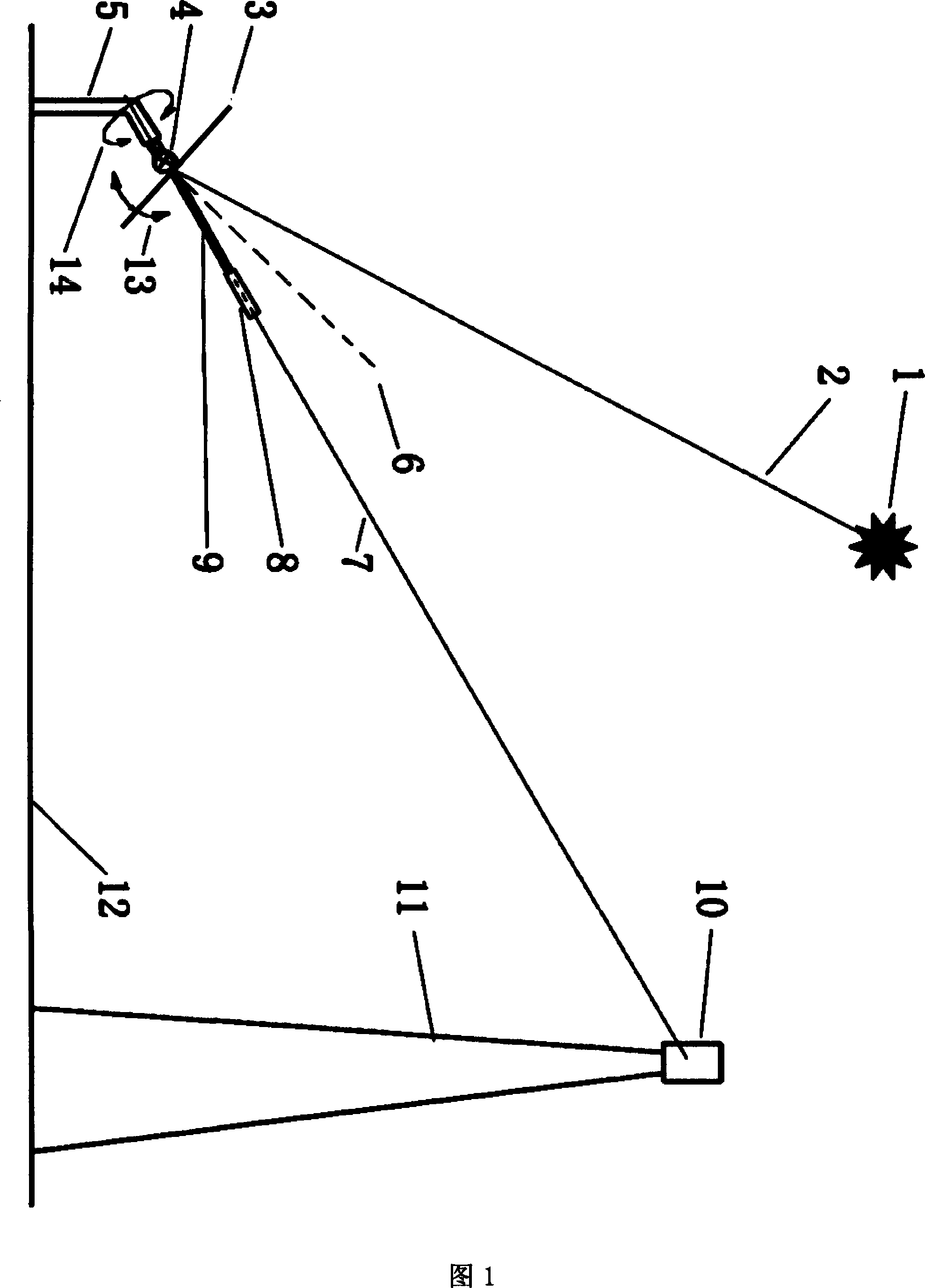

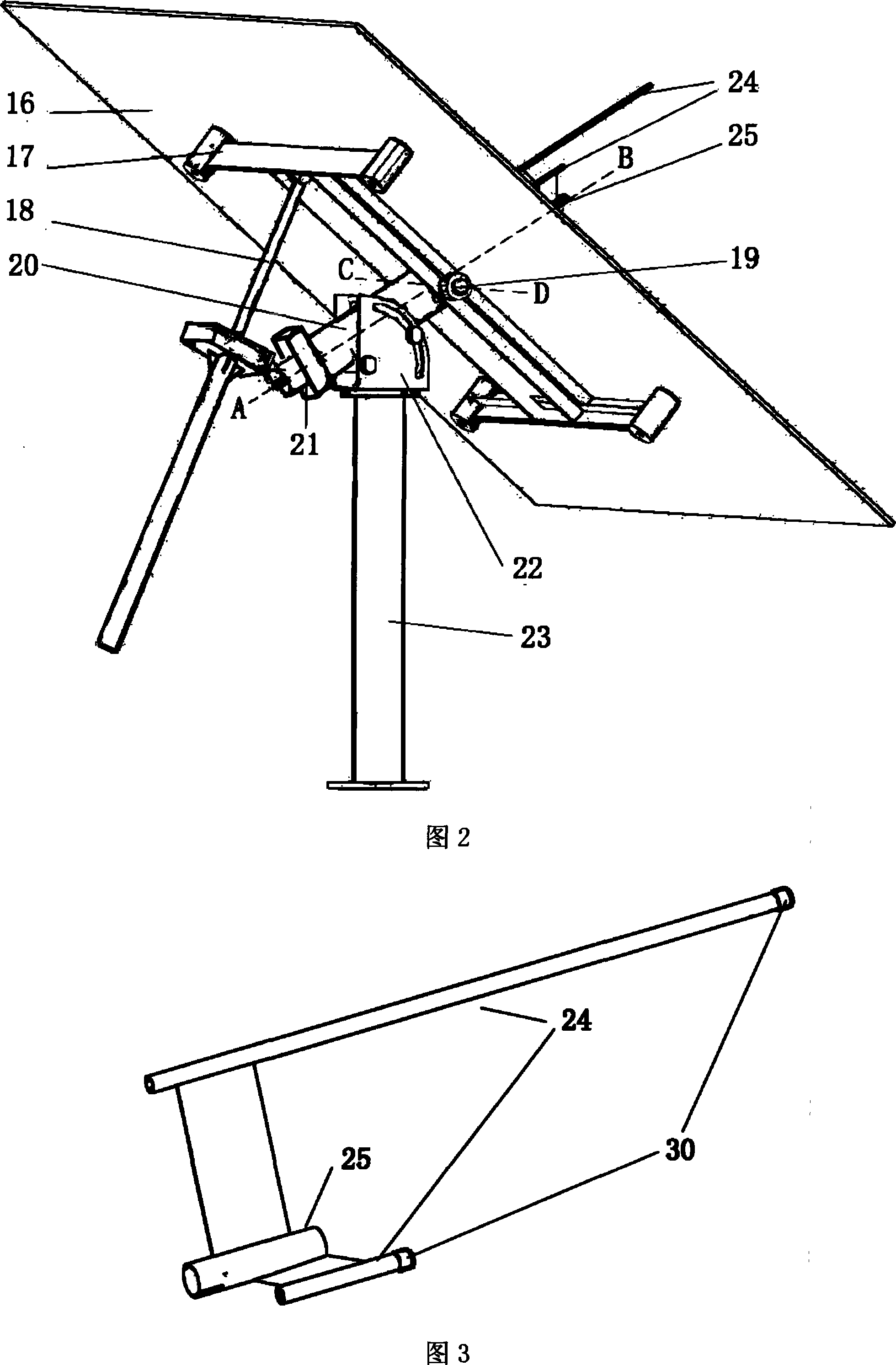

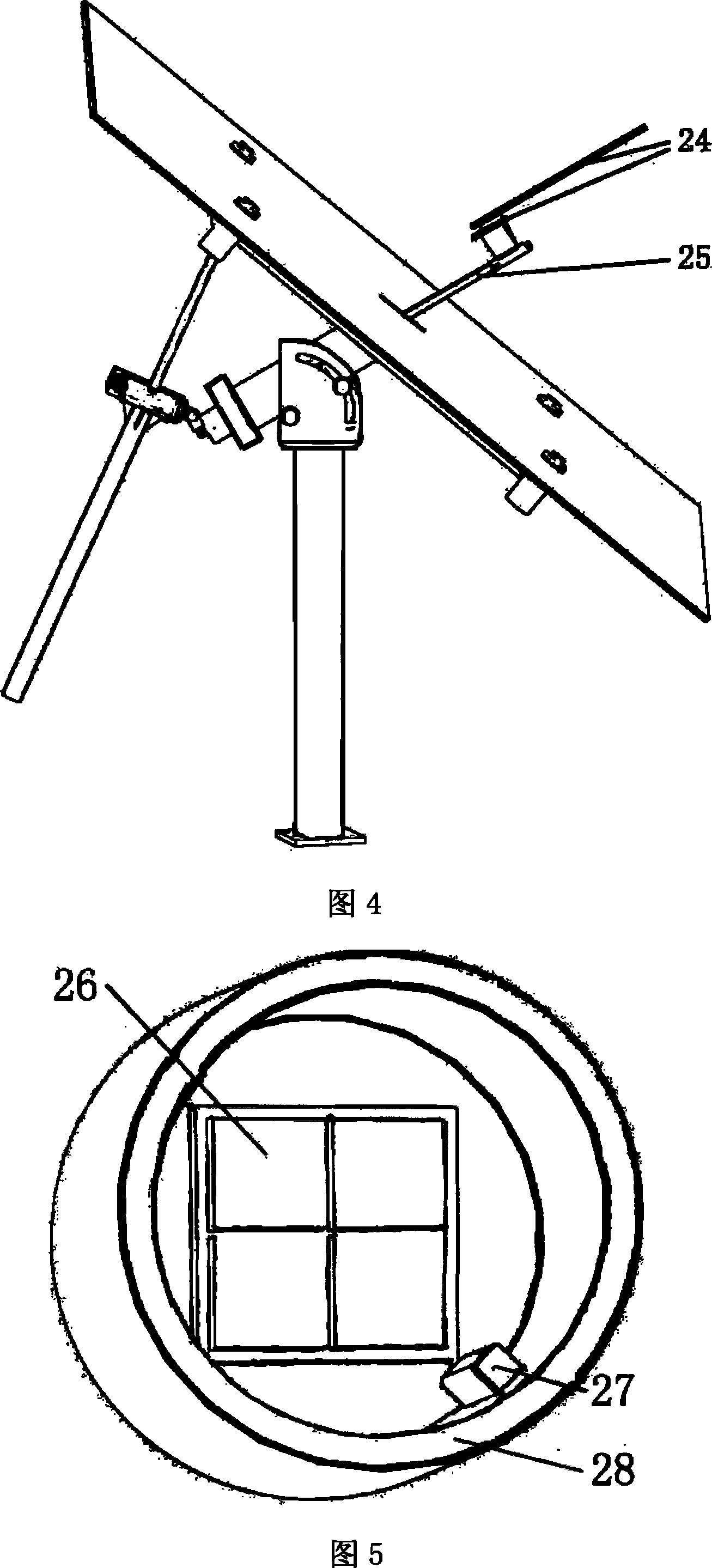

Heliostat device

InactiveCN101236287ALow costReduce the difficulty of productionSolar heating energySolar heat collector controllersFour quadrantsHeliostat

The invention relates to a plane mirror being capable of projecting sunlight directionally which is the usually-called Tingri mirror and belongs to the solar energy application technical field. In the device, positioning plus elevation tracking or auto-rotating plus elevation tracking is adopted; the device comprises a plane mirror, a frame with a dimension small enough to be formed at one time, an adjusting device, a positioning and guiding pipe arranged a center tower and the Tingri mirror, a positioning sensor and a control system which carries out control and error judgment according to signals produced by reflection light reaching a mirror surface of a four-quadrant photosensitive element through the positioning and guiding pipe. If the invention is adopted, as long as sunlight, no matter where the sun move, the reflection light of the Tingri mirror can always project into a collector. Due to the adoption of the positioning and guiding pipe, the positioning sensor and DCS (distributed control system), a mirror with a small area can be used, reducing the difficulty in production, installation and commissioning and thus reducing the cost significantly.

Owner:苏建国

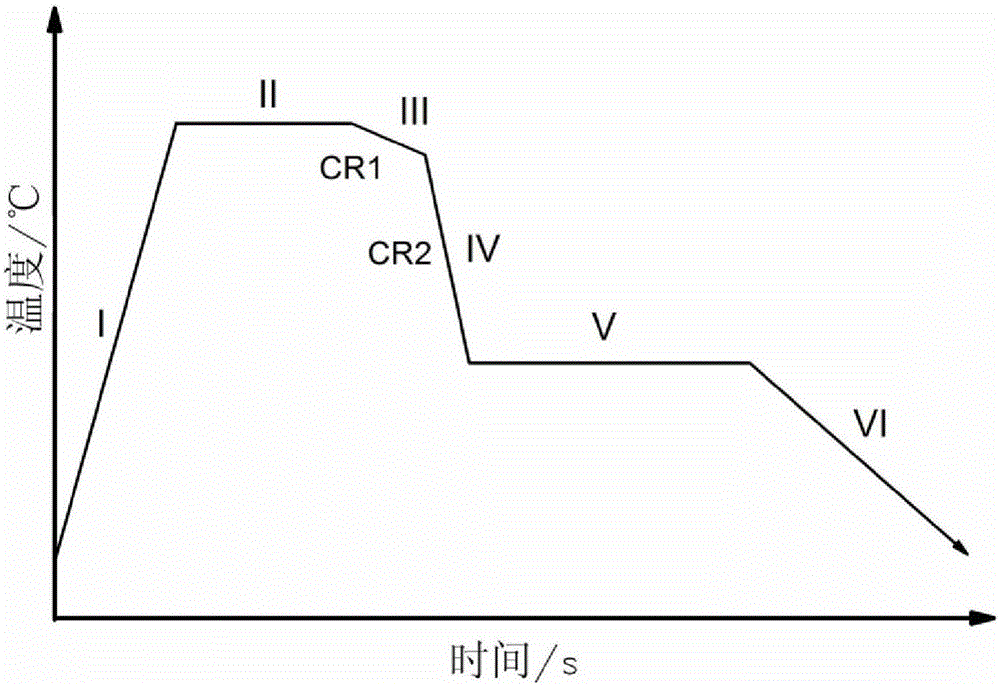

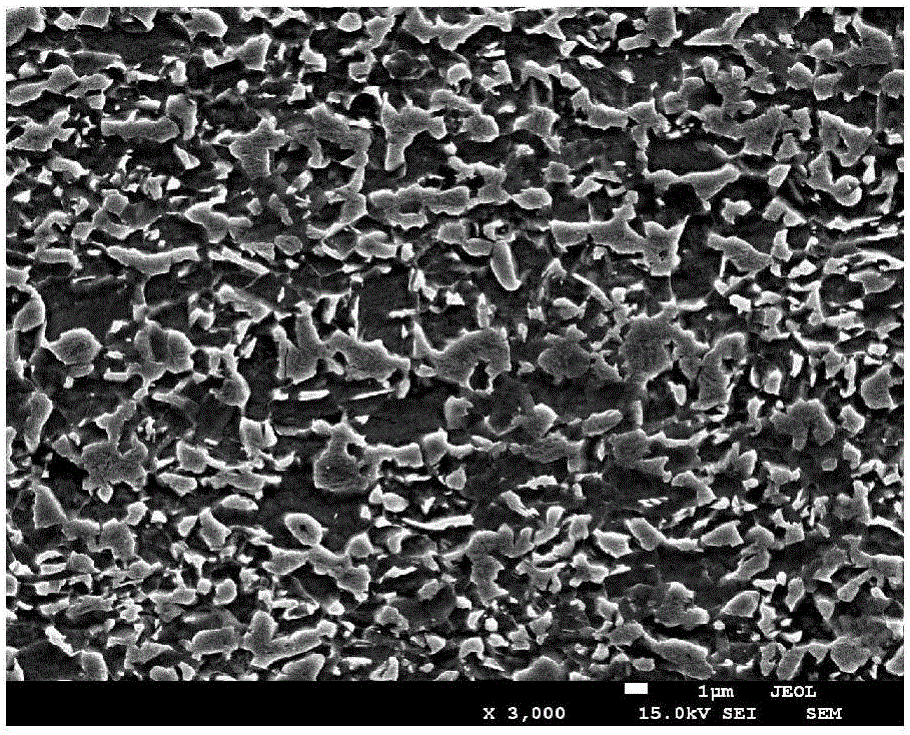

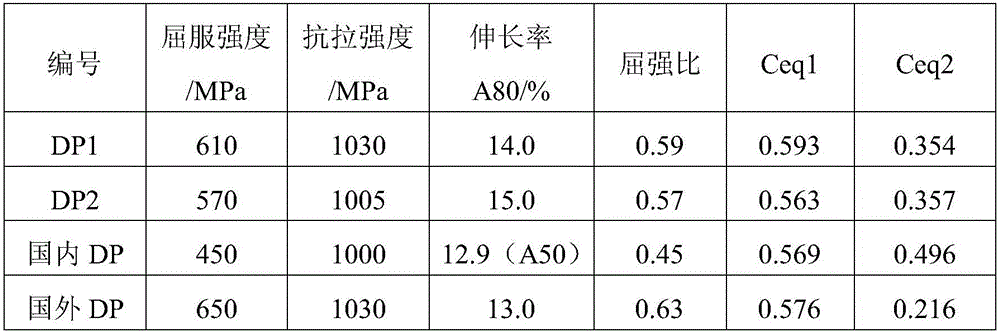

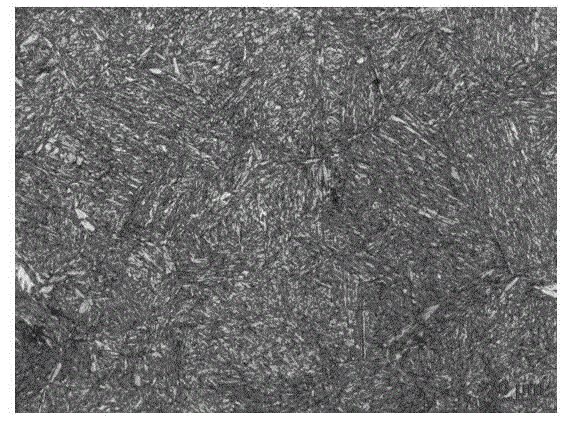

980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and preparing method thereof

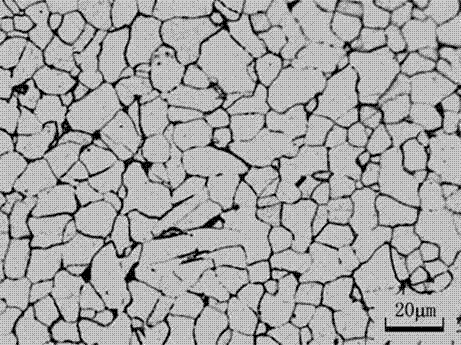

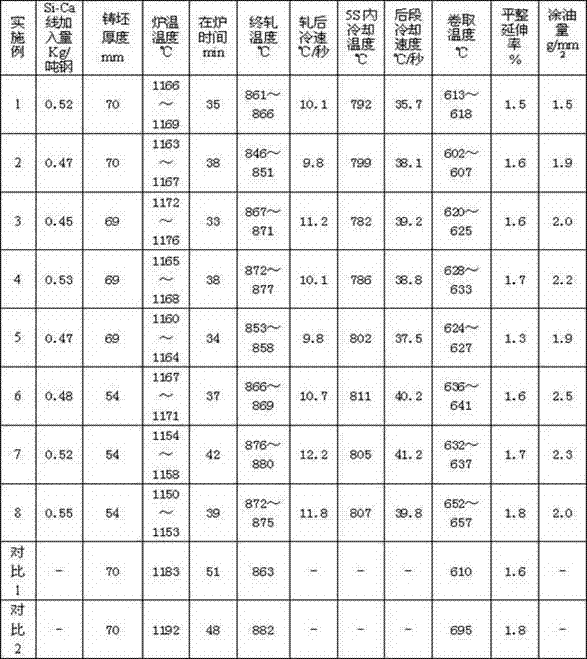

The invention provides 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and a preparing method, and belongs to the technical field of cold rolling ultrahigh strength steel for an automobile. The 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel is composed of, by weight percent, 0.10% to 0.20% of C, 0.30% to 1.00% of Si, 1.50% to 2.50% of Mn, 0.20% to 0.80% of Cr, 0.01% to 0.06% of Al, 0.05% to 0.15% of V, not larger than 0.020% of P, not larger than 0.015% of S, not larger than 0.006% of N and the balance Fe and inevitable impurities. Ferrite and martensite grains are refined through the micro amount of V; and meanwhile, VC dispersed precipitation plays a role in strengthening sedimentation, and the production cost is obviously reduced. The prepared cold rolled dual-phase steel is excellent in mechanical property, forming property and welding property, the cost advantages are obvious, and the obvious economic benefits and social benefits are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

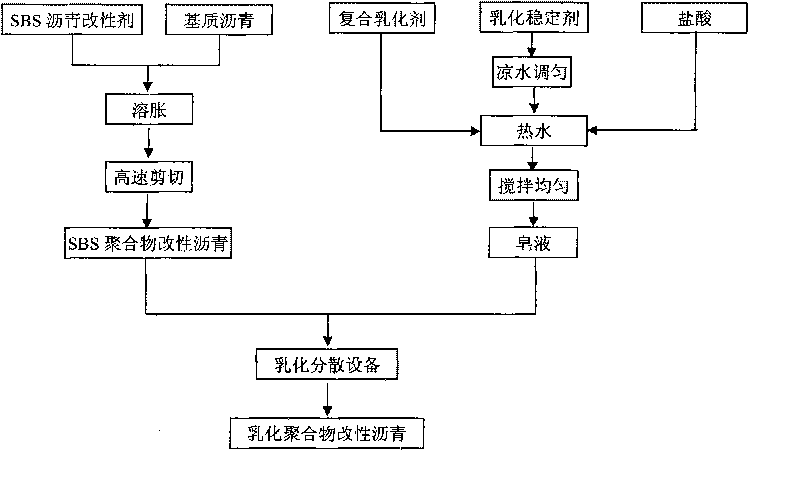

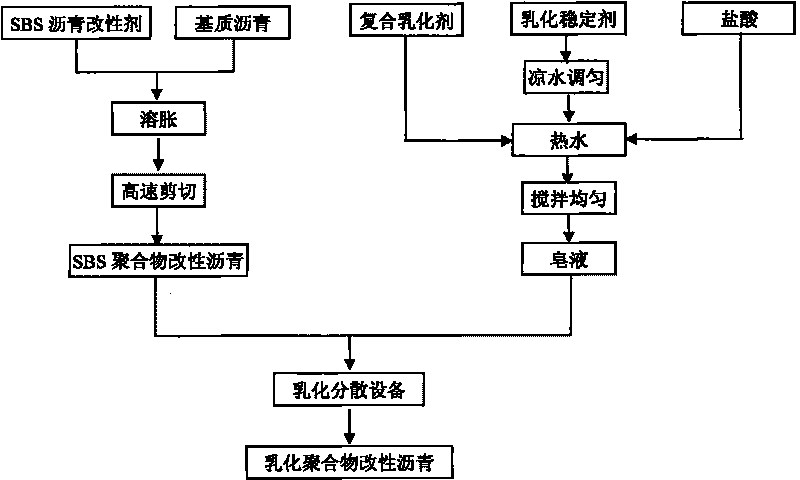

Emulsified SBS polymer modified asphalt and preparation method thereof

InactiveCN101717585AImprove performanceReduce the difficulty of productionClimate change adaptationBuilding insulationsPolymer scienceHigh-speed grinding

The invention relates to an emulsified SBS polymer modified asphalt and preparation method thereof. At present, emulsification and emulsified modified asphalt applied to surfacing is hard to produce and not stable in quality, high temperature performance improvement is not obvious. The raw materials of the invention are matrix asphalt, water, SBS asphalt modifier, compound asphalt emulsifier, emulsification stabilizer and hydrochloric acid; firstly the matrix asphalt is heated, added with SBS asphalt modifier and then stirred to be swelled, high speed grinding by colloid grinder and full dispersion are carried out, and heat preservation growth is carried out to obtain SBS modified asphalt; compound asphalt emulsifier is added into water, emulsification stabilizer smoothened by water in advance is added, and appropriate hydrochloric acid is added to adjust pH value, so as to obtain liquid soap; and finally the SBS modified asphalt is subject to temperature reduction and then mixed with the liquid soap and emulsification dispersion is carried out, thus obtaining emulsified SBS polymer modified asphalt. The invention is applicable to coat tacking, coat sealing, surface treatment, slurry sealing and asphalt pavement recycling, asphalt wet-mixing of road construction and cerement asphalt mortar layer of passenger special line plate type unballasted track.

Owner:深圳路安特沥青高新技术有限公司

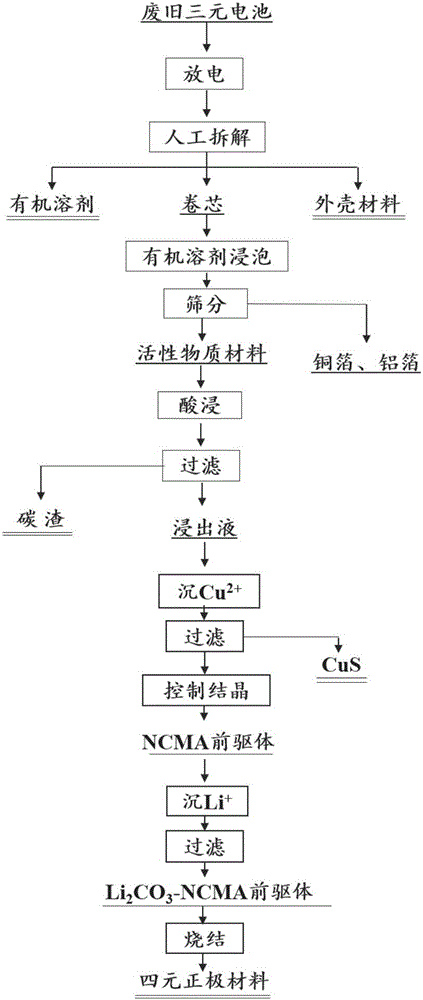

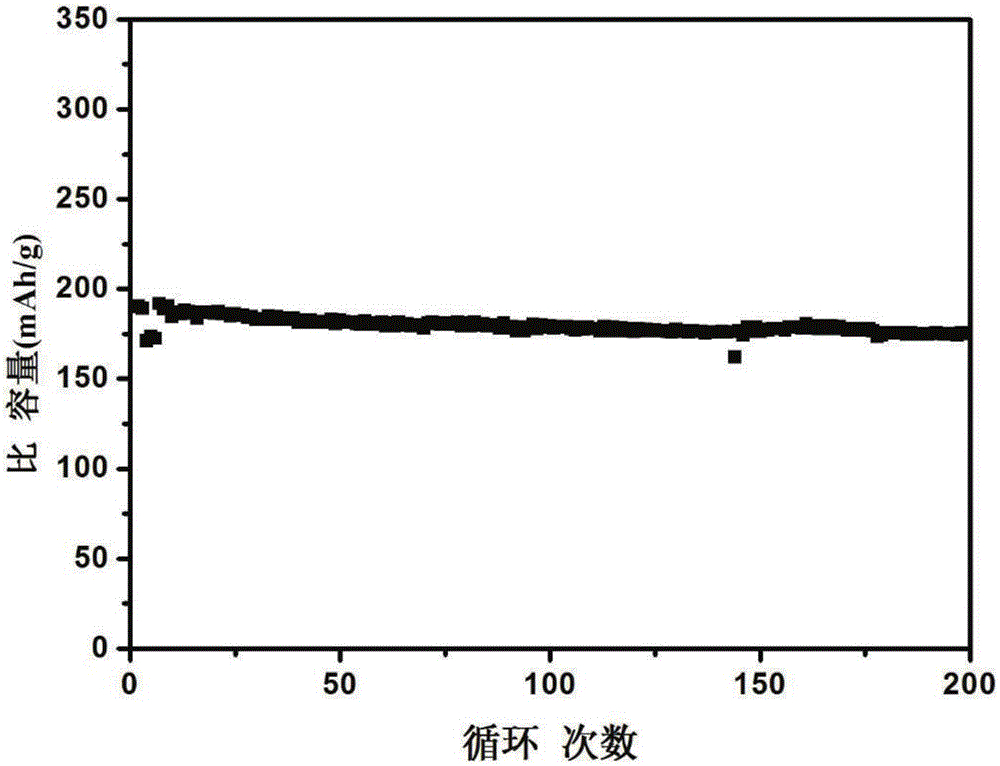

Method for recovering and preparing nickel-cobalt-manganese-aluminum quaternary positive electrode material from waste nickel-cobalt-manganese ternary lithium-ion battery

ActiveCN106785177AAvoid separationAvoid it happening againWaste accumulators reclaimingBattery recyclingManganeseLithium-ion battery

The invention discloses a method for recovering and preparing a nickel-cobalt-manganese-aluminum quaternary positive electrode material from a waste nickel-cobalt-manganese ternary lithium-ion battery. The method comprises the following steps of (1) obtaining a leach solution containing Cu<2+>, Al<3+>, Li<+>, Ni<2+>, Co<2+> and Mn<2+> from the waste ternary lithium-ion battery through manual disassembly, magnetic separation, crushing, organic solvent soaking, screening and sulfuric acid leaching, and carrying out purification (Cu<2+>) treatment on the leach solution to obtain a purified liquid; (2) adjusting the molar ratio of Al to Ni to Co to Mn in the purified liquid, adding alkali metal hydroxide, adjusting the pH of a system until the pH is greater than or equal to 10 and carrying out primary precipitation to obtain a turbid liquid in which NCM hydroxide is precipitated; (3) adding carbonate to the turbid liquid in the step (2) for secondary precipitation, and carrying out solid-liquid separation to obtain a quaternary material precursor; and (4) burning the quaternary material precursor in air to obtain an Al-doped NCM quaternary positive electrode material. The method is simple in technology, wide in raw material source and high in repeatability; the prepared quaternary positive electrode material is excellent in cycle performance; and large-scale production can be carried out.

Owner:CENT SOUTH UNIV

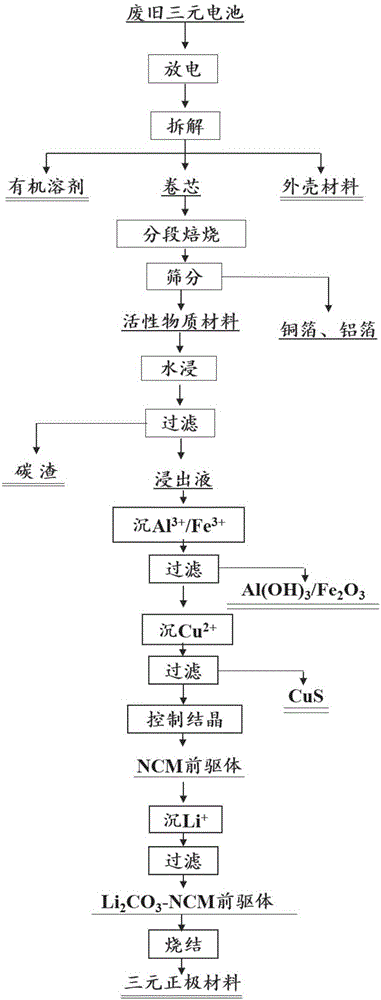

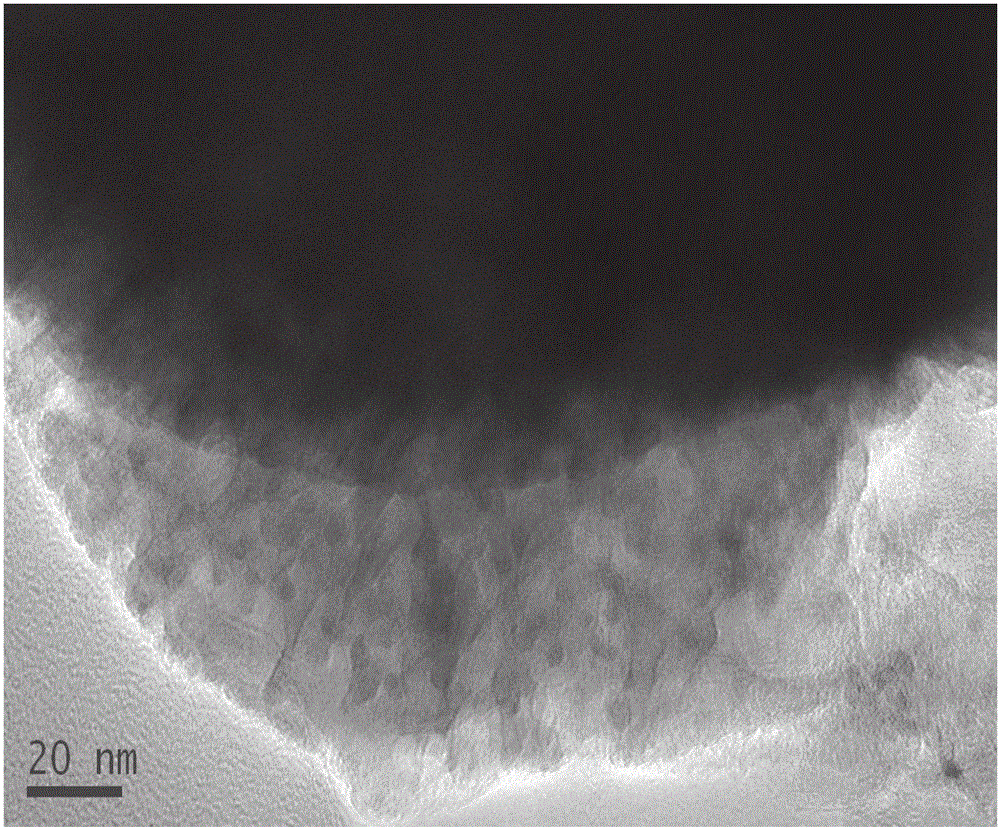

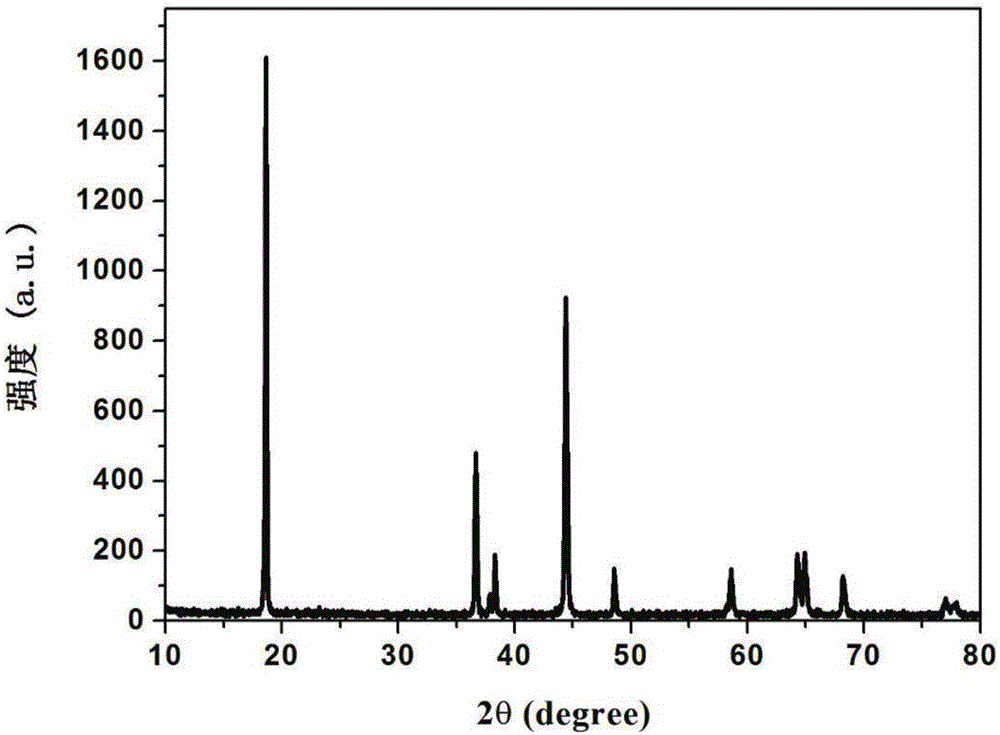

Method for preparing and recovering ternary anode material from waste nickel-cobalt-manganese ternary lithium ion batteries

ActiveCN106848470AAvoid separationShort processCell electrodesWaste accumulators reclaimingAlkali hydroxideLithium electrode

The invention discloses a method for preparing and recovering a ternary anode material from waste nickel-cobalt-manganese ternary lithium ion batteries. The method is characterized by including steps: step 1, subjecting the waste nickel-cobalt-manganese ternary lithium ion batteries to disassembling, crushing, calcining and leaching to obtain leachate which contains Li, Ni, Co and Mn, and subjecting the leachate to decontamination to obtain decontaminated liquid; step two, adjusting a molar ratio of Ni, Co and Mn in the decontaminated liquid, adding alkali metal hydroxides, adjusting system pH to be larger than or equal to 10, and performing primary precipitation to obtain turbid solution with NCM hydroxide precipitates; step 3, adding carbonates into the turbid solution obtained at the step 2 to realize secondary precipitation, and performing solid-liquid separation to obtain a ternary material precursor; step 4, calcining the ternary material precursor in air to obtain the ternary anode material. The method is simple in process, extensive in raw material source and high in repeatability, and the ternary anode material prepared according to the method is excellent in performance and available for large-scale production.

Owner:CENT SOUTH UNIV

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

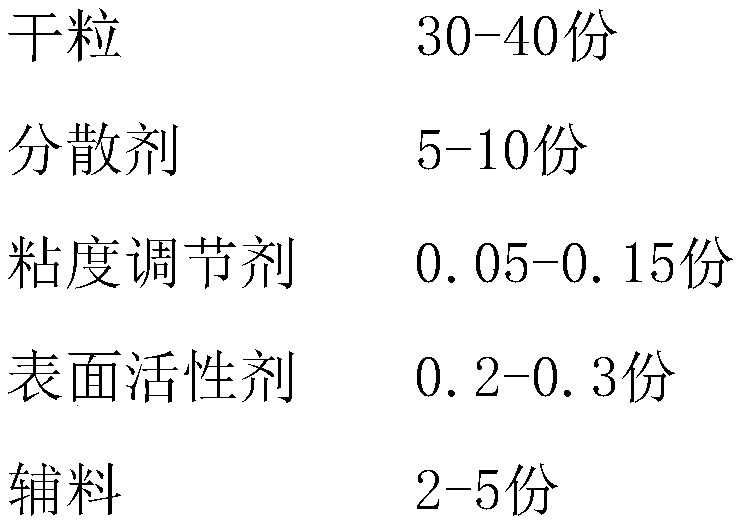

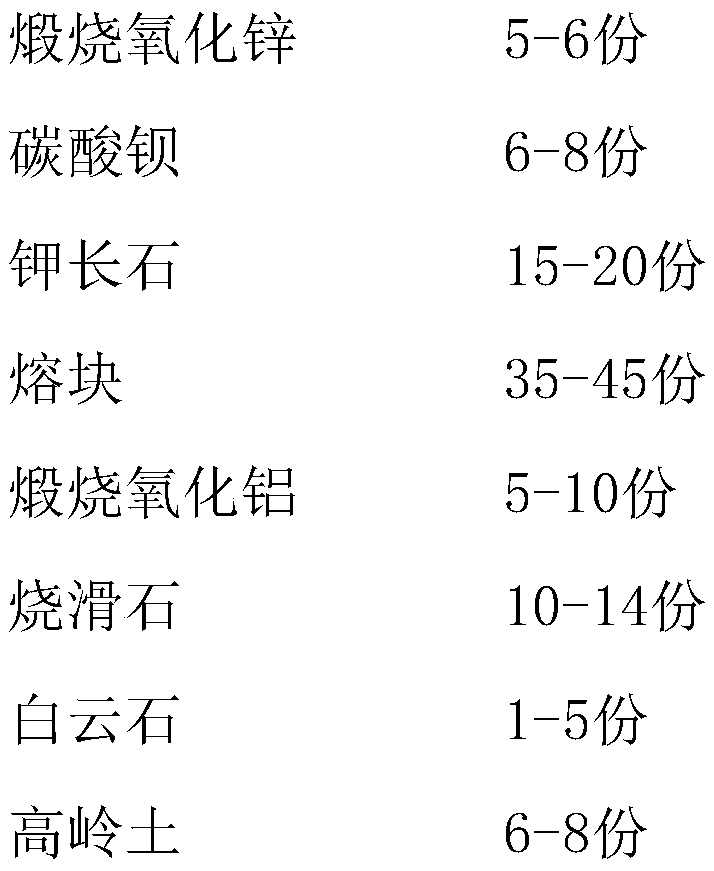

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

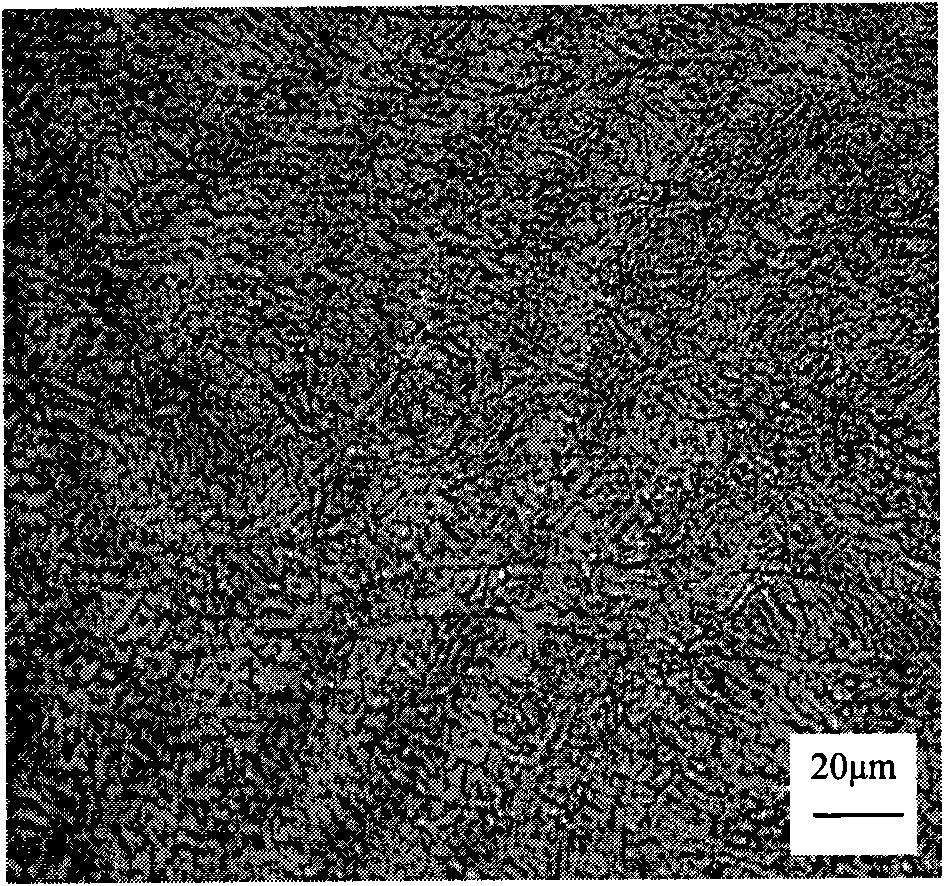

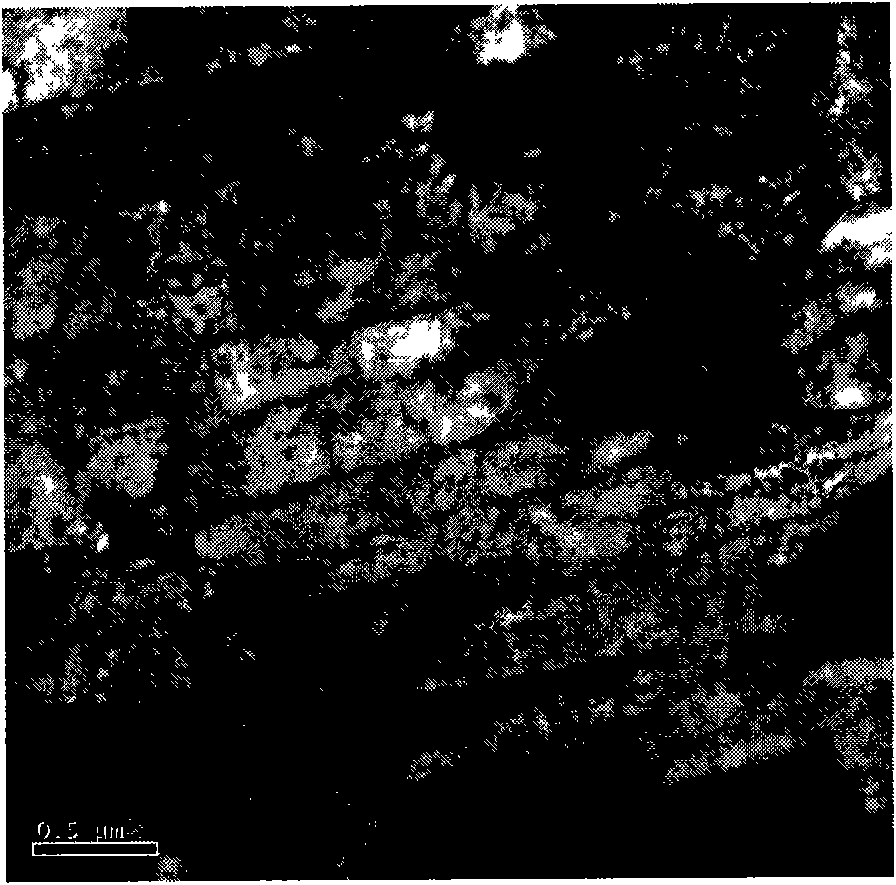

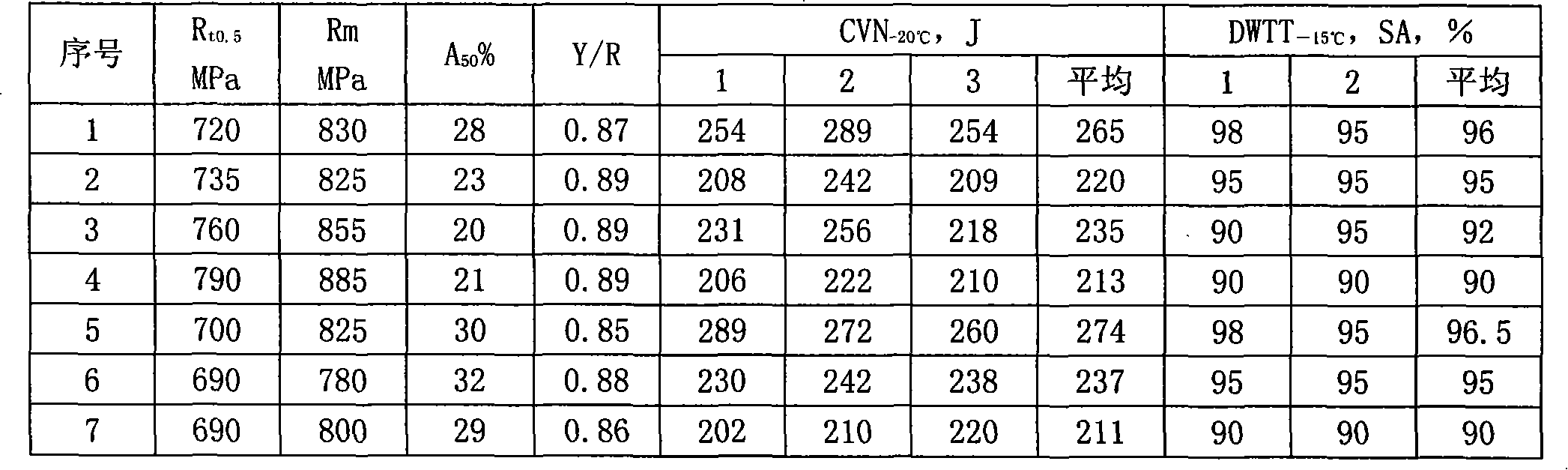

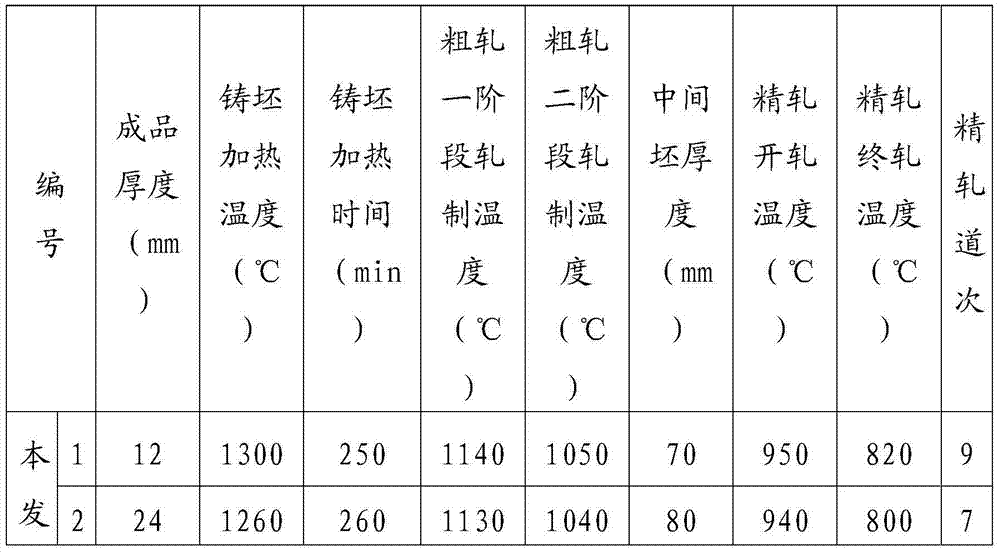

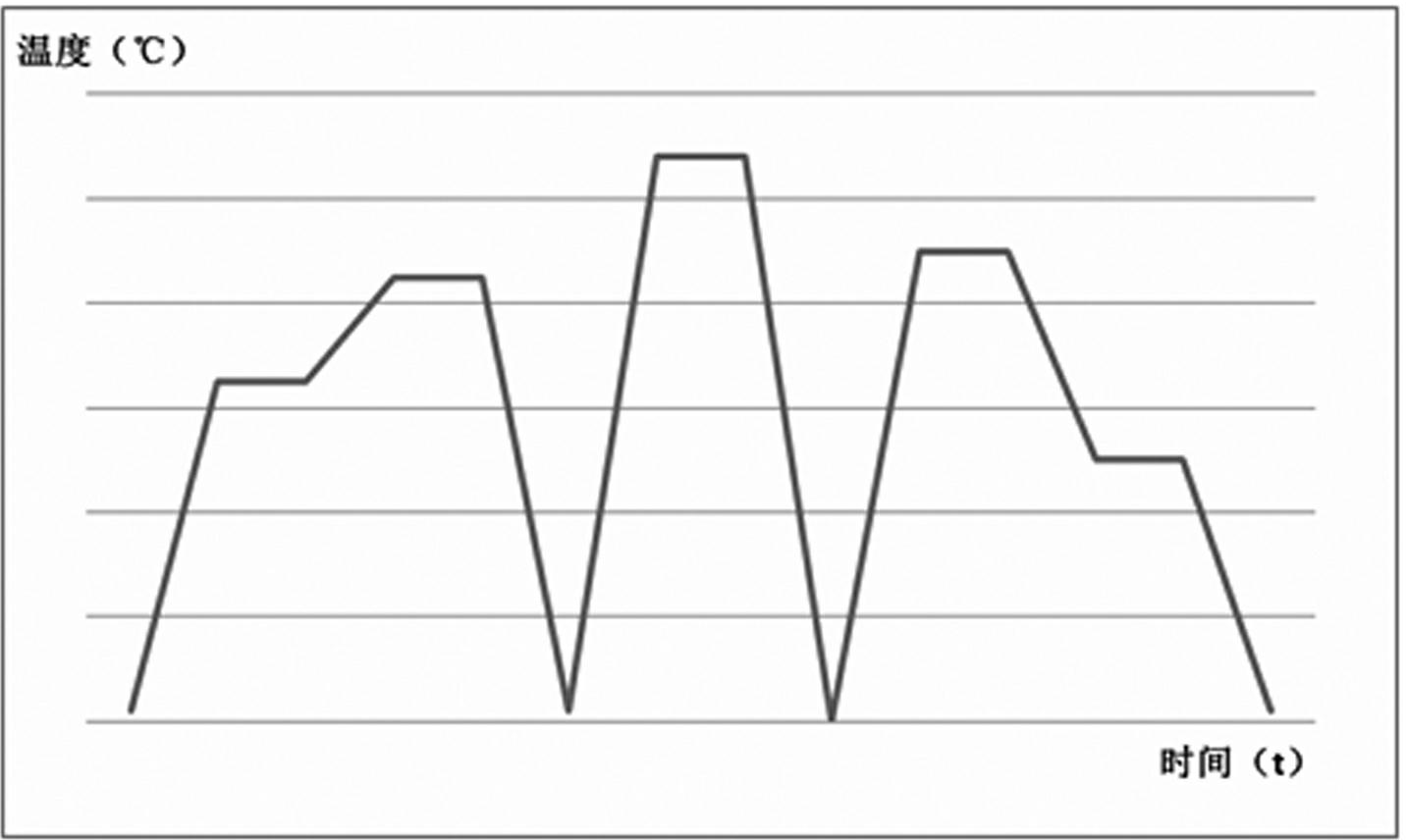

High-strength X100 pipe line steel hot rolling flat plate and method for manufacturing same

InactiveCN101619416AReduce alloy costLow carbon equivalentTemperature control deviceCooling temperatureHigh intensity

The invention discloses a high-strength X100 pipe line steel hot rolling flat plate and a method for manufacturing the same. The steel comprises the following chemical components in percentage by weight: 0.02 to 0.08 percent of C, 0.10 to 0.35 percent of Si, 1.65 to 2.20 percent of Mn, 0.005 to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.04 to 0.11 percent of Nb, 0.008 to 0.030 percent of Ti, 0.02 to 0.045 percent of Als, one or more of less than or equal to 0.60 percent of Ni, less than or equal to 0.30 percent of Mo and less than or equal to 0.30 percent of Cu, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps that: the heating temperature of a plate blank is between 1,160 and 1,280 DEG C, the rough rolling temperature is between 1,070 and 1,150 DEG C, the finish rolling temperature is between 830 and 950 DEG C, the finish cooling temperature is between 300 and 550 DEG C, and the controlled cooling speed is between 15 and 30 DEG C / S. By using the method, a complex phase structure mainly comprising the following bainites can be obtained. By adopting the complex phase structure, the yield strength of the pipe line steel hot rolling flat plate reaches 690 to 825MPa, the tensile strength reaches over 780MPa, the impact energy at a temperature of 20 DEG C below zero is more than or equal to 200J, and the shearing area of DWTT at a temperature of 15 DEG C below zero is more than or equal to 90 percent; and the rolling resistance and the straightening resistance are reduced, and the operating rates of the rolling machine and the straightening machine are improved.

Owner:ANGANG STEEL CO LTD

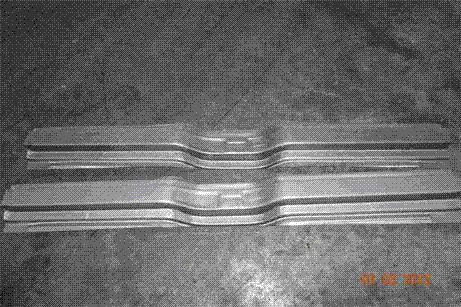

Thin hot-rolled pickled steel with good formability and production method thereof

ActiveCN102787270AReduce the difficulty of productionImprove surface qualityMetal rolling arrangementsChemical compositionHigh pressure water

The invention relates to a thin hot-rolled pickled steel with good formability, which comprises the following chemical components by weight percent (wt%): 0.04-0.07% of C, 0.10-0.30% of Si, 0.41-0.60% of Mn, 0.025% of P or less, 0.012% of S and 0.010-0.030% of Als. The preparation method of the thin hot-rolled pickled steel with good formability comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water, controlling rolling, cooling by laminar flow, curling, pickling by acid levelling and finishing adopting static oil removal. The produced hot-rolled pickled steel which has the tensile strength of 370MPa or higher and the thickness of 1.8 mm or lower, is low production difficulty and good in surface quality and is convenient to weld, oil and paint. In addition, the thin hot-rolled pickled steel has the advantages of good punch formability, high forming size accuracy, short production cycle, high yield and low cost.

Owner:武汉钢铁有限公司

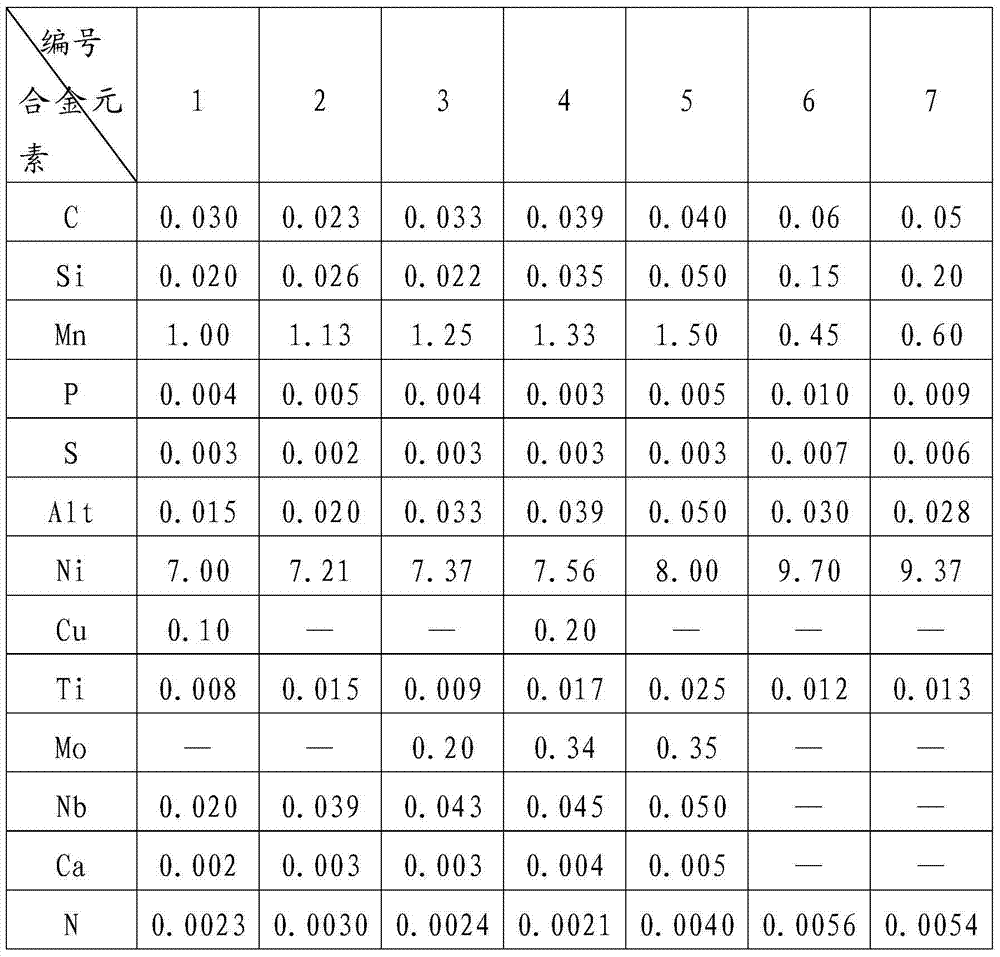

Low-Ni high-Mn economical low-temperature steel capable of being used at minus 196 DEG C and preparing method thereof

InactiveCN103498100AReduce manufacturing costImprove low temperature toughnessChemical compositionToughness

The invention discloses low-Ni high-Mn economical low-temperature steel capable of being used at minus 196 DEG C and a preparing method thereof. The low-Ni high-Mn economical low-temperature steel capable of being used at minus 196 DEG C and the preparing method thereof solve the problem that existing low-temperature steel is high in technological difficulty and high in cost. The low-temperature steel comprises, by weight, C<=0.04, Si<=0.05, Mn:1.00-1.50, P<=0.005, S<=0.003, Alt:0.015-0.050, Ni:7.00-8.00, Nb:0.02-0.05, Ti:0.008-0.025, N<=0.004, at least one of Mo<=0.35, Cu<=0.20 and Ca<=0.005, and the balance Fe and inevitable impurities. The preparing method comprises the steps of smelting, rolling and drawing. The steel prepared with the method is good in toughness and welding performance after composition design, impurity control, rolling and heat treatment and can be used for manufacturing pressure vessel equipment requiring low-temperature usage in the LNG industry, and production difficulty and cost are effectively reduced.

Owner:武汉钢铁有限公司

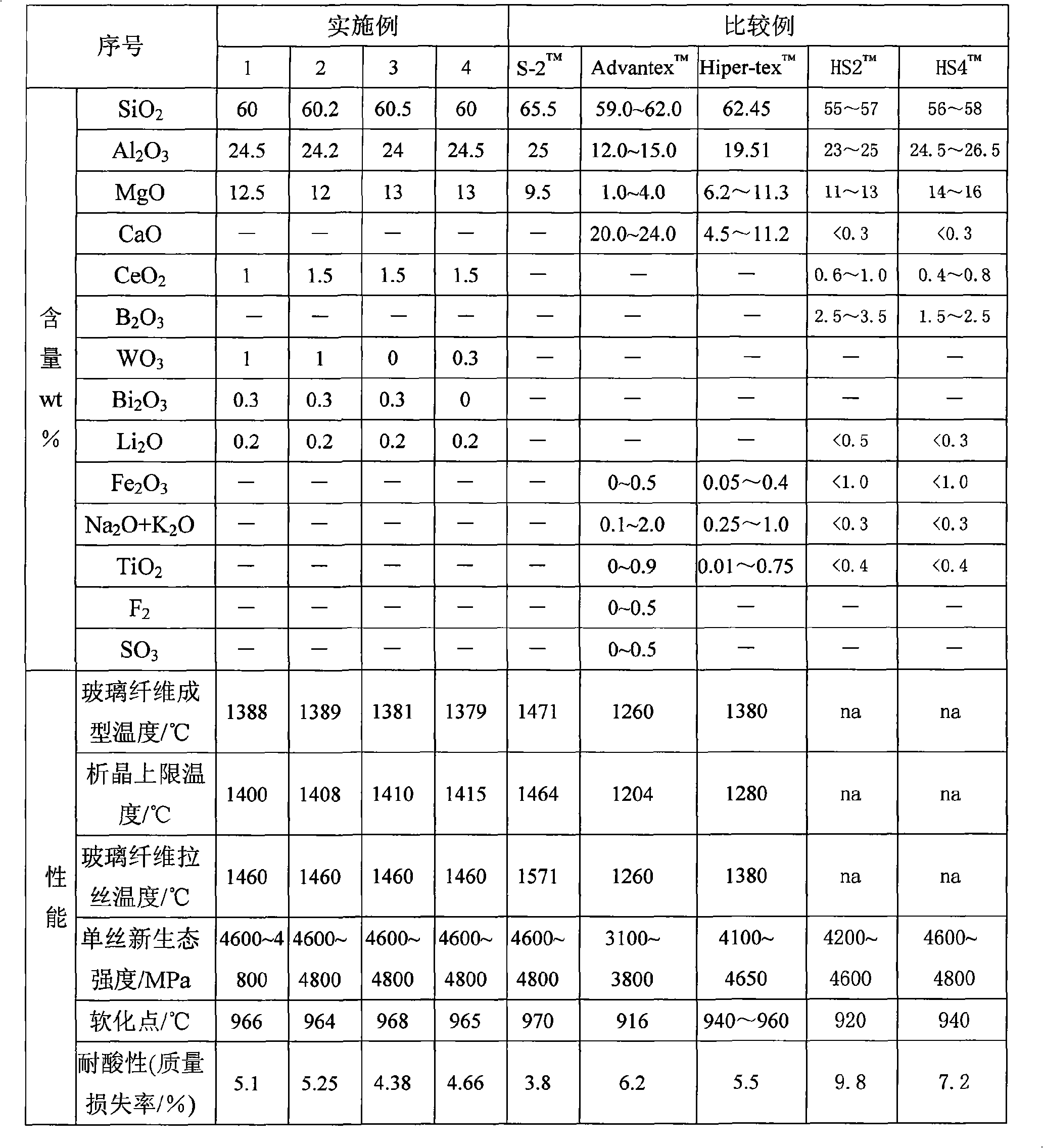

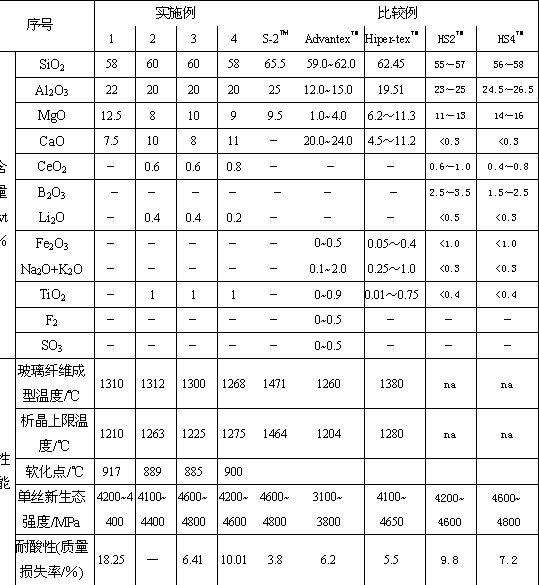

Composition for high-performance glass fiber

The invention relates to a composition for high-performance glass fiber, which comprises 55 to 63 wt percent of SiO2, 23 to 26 wt percent of Al2O3, 11.5 to 14.5 wt percent of MgO, 0.5 to 2.5 wt percent of CeO2, 0 to 0.5 wt percent of LiO2, 0 to 1.5 wt percent of Bi2O3, 0 to 1.5 wt percent of WO3, and the balance of unavoidable impurities; the contents of the Li2O, the Bi2O and the WO3 can not be zero simultaneously. By adopting the composition as a raw material, the high-performance glass fiber can be produced by using a melting furnace and a fiber drawing furnace which are made from the existing fire resisting materials to perform melting and wire drawing. With reduced production difficulty and low cost, the composition has good producibility, is suitable for industrial continuous production and can save energy source, and the produced high-performance glass fiber can be used as the reinforcing material of a resin base composite material and has the advantages of high strength, corrosion resistance, high temperature resistance and light weight.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

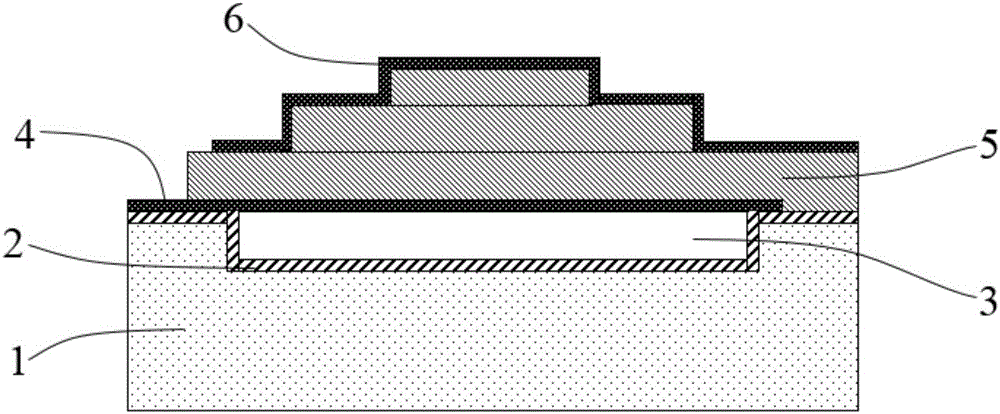

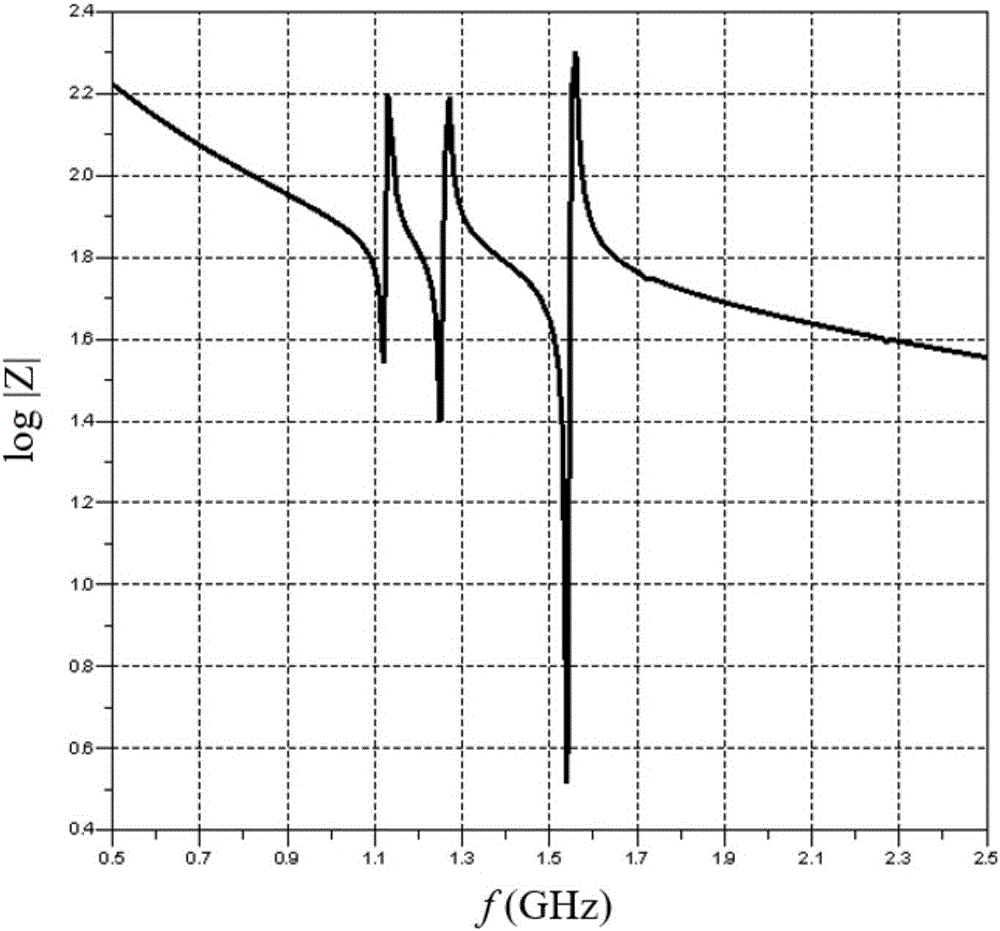

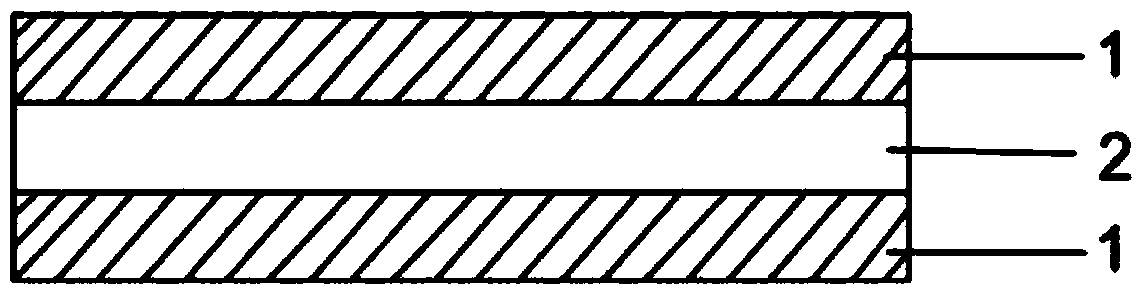

Film bulk acoustic resonator having multiple resonance modes and preparation method thereof and filter

ActiveCN105897211AReduce in quantityReduce the difficulty of productionImpedence networksElectricityResonant cavity

The invention discloses a film bulk acoustic resonator having multiple resonance modes. The film bulk acoustic resonator sequentially comprises a silicon substrate and piezoelectric stack structures; a cavity between the piezoelectric stack structures forms a resonant cavity of the film bulk acoustic resonator; and the piezoelectric stack structure comprises a bottom electrode, more than two layers of piezoelectric films and a top electrode in sequence from bottom to top. The film bulk acoustic resonator disclosed by the invention is provided with multiple resonance points; a multi-passband filter can be designed through multiple film bulk acoustic resonators in manners of cascading, bridging and the like; and thus, the number of FBAR filters on a wireless terminal can be greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH

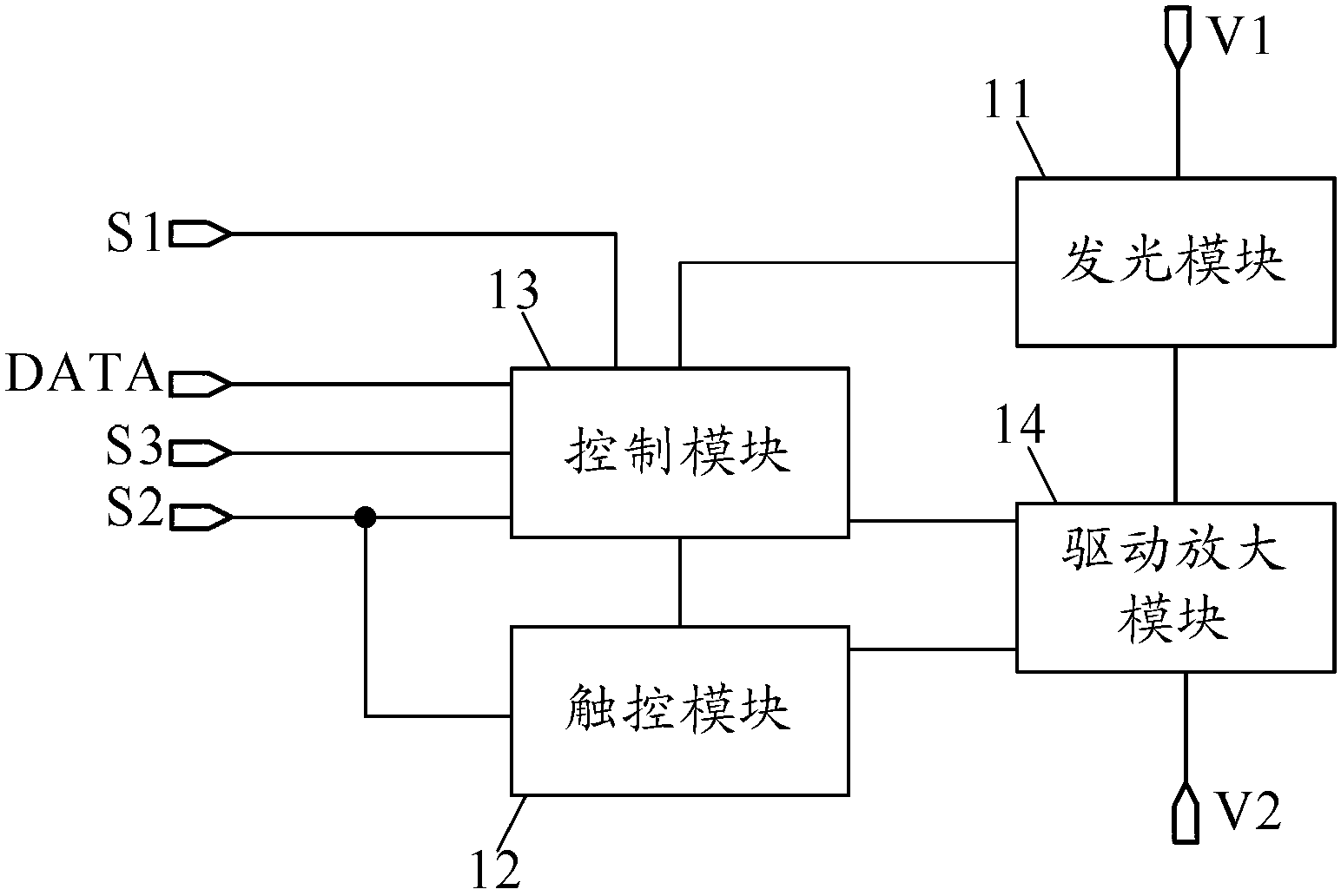

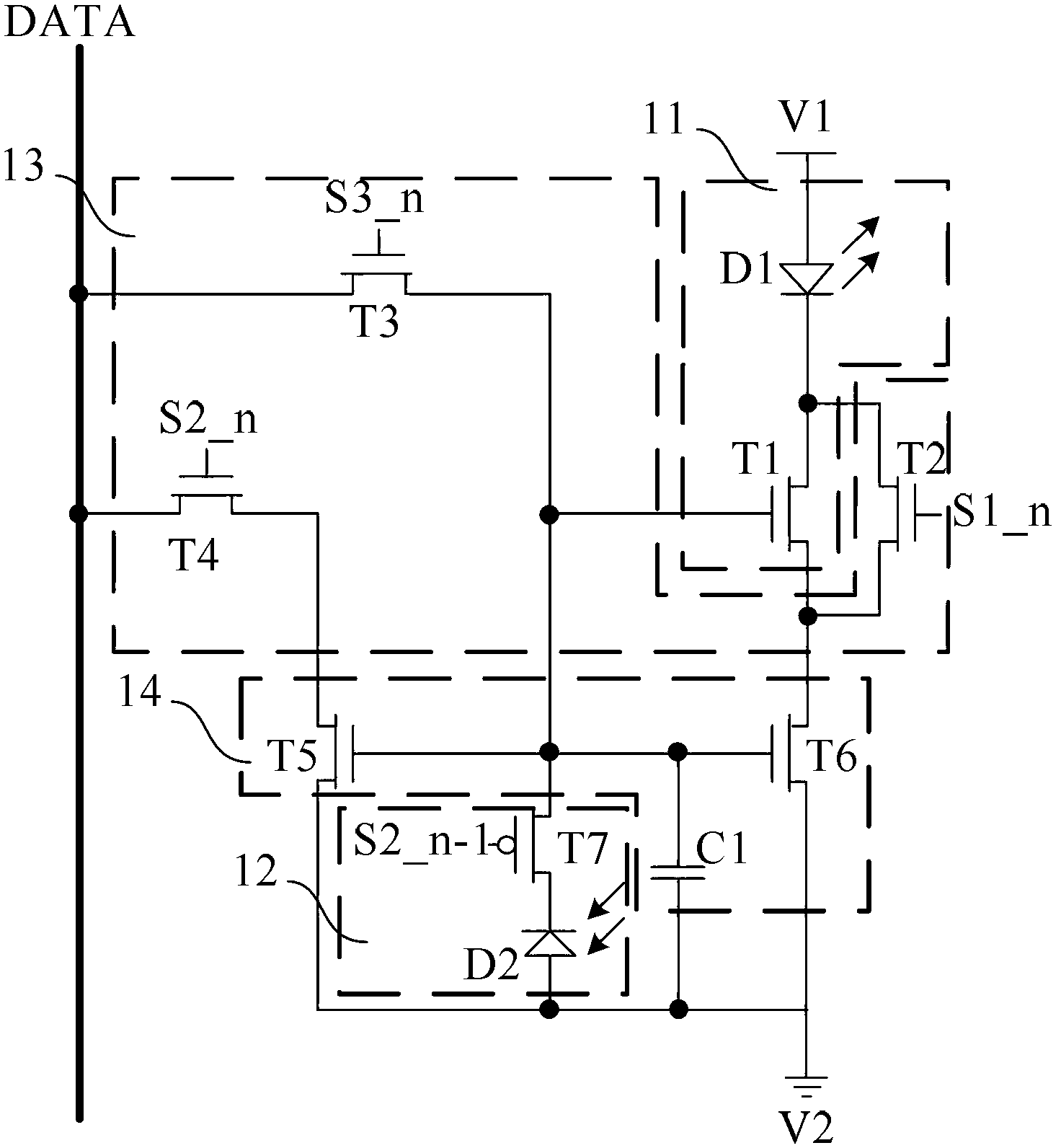

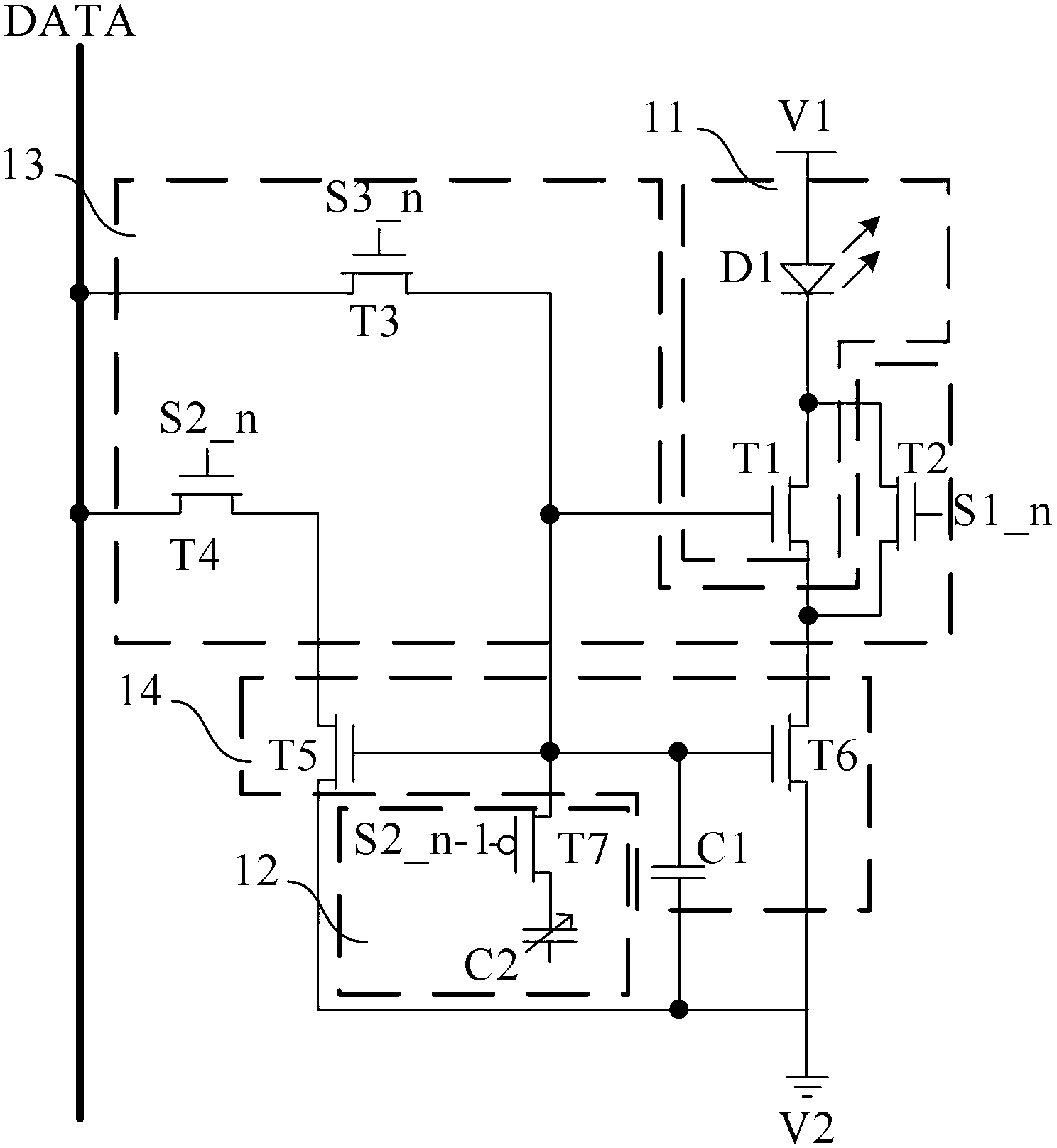

Active matrix/organic light emitting diode (AMOLED) pixel circuit, driving method thereof and display device

ActiveCN103310734AHighly integratedQuality improvementStatic indicating devicesInput/output processes for data processingActive matrixDisplay device

The invention discloses an active matrix / organic light emitting diode (AMOLED) pixel circuit, a driving method thereof and a display device and relates to the technical field of display. According to the AMOLED pixel circuit and the driving method of the AMOLED pixel circuit, the integration level of an AMOLED driving circuit and an embedded type touch circuit can be improved. The AMOLED pixel circuit comprises a light-emitting module, a touch module, a control module and a driving amplification module. The AMOLED pixel circuit and the driving method of the AMOLED pixel circuit are used for manufacturing the AMOLED display device.

Owner:BOE TECH GRP CO LTD +1

HB600 grade wear-resistant non-quenched and tempered steel plate and making method thereof

ActiveCN104831189AImprove wear resistanceGood atmospheric corrosion resistanceWear resistantRare earth

The invention discloses an HB600 grade wear-resistant non-quenched and tempered steel plate and a making method thereof. The method comprises the processes of smelting, casting, heating, rolling and cooling; and the steel plate comprises, by mass, 0.35-0.45% of C, 0.20-0.50% of Si, 1.20-1.60% of Mn, 0.015% or less of P, 0.01% or less of S, 0.2-1.0% of Cr, 0.1-0.5% of Mo, 0.5-1.5% of Ni, 1.0-2.0% of Cu, 0.2% or less of Ti, 0.2% or less of Nb, 0.2% or less of V, 0.05% or less of Al, 0.005% or less of N, 0.003% or less of O, 0.001-0.005% of B, 0-0.02% of rare earth, and the balance of Fe and inevitable impurities. A carbon content micro alloying mode is adopted, Cr, Ni, Cu, B and other hardenability effect improving elements and V and other precipitating reinforcement elements are properly added, hard phase martensite is obtained under a low cooling rate by using the high hardenability, and a large amount of carbon nitride formed by carbide forming elements is precipitated to improve the content of the hard phase in order to improve the wear resistance of the steel plate; and alloy elements containing Cu and Ni make the steel plate have excellent atmosphere corrosion resistance.

Owner:HEBEI IRON AND STEEL

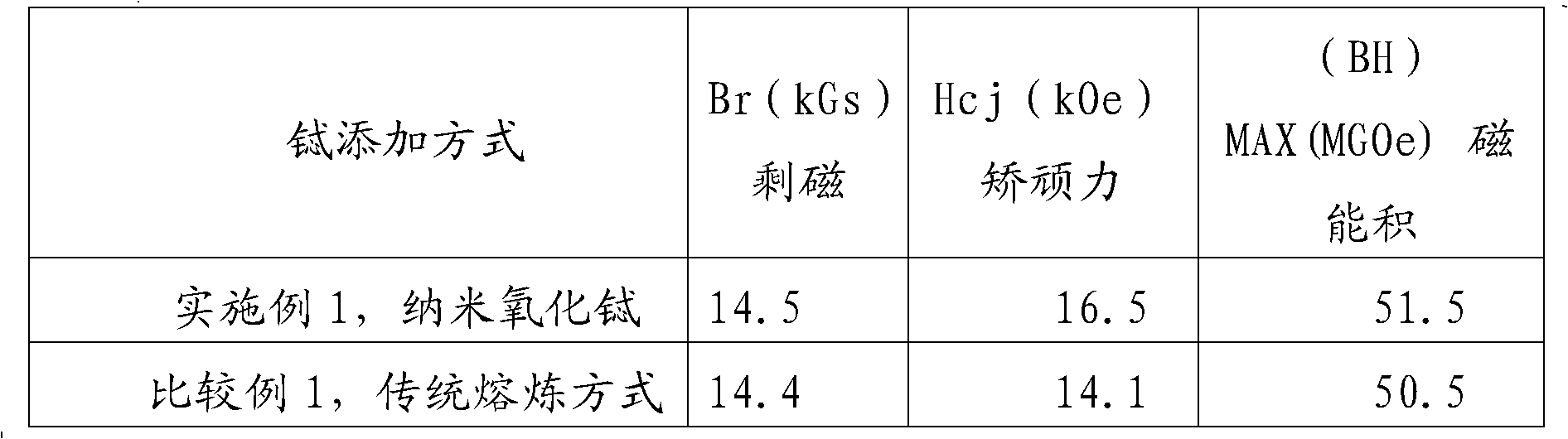

Manufacturing method of high-coercivity R-Fe-B sintered permanent magnet material

ActiveCN102534358ASimple preparation processImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureHydrogen pressureDysprosium

The invention discloses a manufacturing method of a high-coercivity R-Fe-B sintered permanent magnet material, which specifically comprises the following steps: blending raw materials according to a certain proportion and casting into an alloy plate with a thickness of 0.1-0.4mm; performing hydrogen decrepitation of the alloy plate and dehydrogenizing to a hydrogen pressure less than 10Pa at a temperature of 400-600 DEG C; sending the alloy plate after hydrogen decrepitation into a mill under the anaerobic environment protected by inert gas, grinding to a grain size less than 0.5mm, micro-grinding with an airflow mill and preparing R-Fe-B alloy powder with a grain size d being equal to 2-4 mum in a classification manner; adding at least one of nano dysprosium oxide, nano terbium oxide andnano holimium oxide with a grain size being less than 100nm into the prepared R-Fe-B alloy powder under the anaerobic environment protected by the inert gas, uniformly mixing, carrying out orientation in a magnetic field of 1.5-3T and pressing into a pressed blank; and carrying out high-temperature sintering for three times and aging treatment for two times in a vacuum sintering furnace under theanaerobic environment protected by the inert gas to prepare a high-coercivity R-Fe-B sintered permanent magnet without size limitation. The manufacturing method has the advantages of simple process and low cost.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

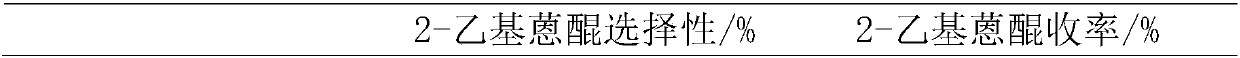

Technology for preparing 2-ethylanthraquinone

InactiveCN107746372AReduce the difficulty of productionLow costMolecular sieve catalystQuinone preparation by oxidationMolecular sieveAnthracene

The invention discloses a technology for preparing 2-ethylanthraquinone from anthracene and ethylene. The technology comprises the following steps: alkylating anthracene and ethylene by using a transition metal oxide supported MWW type molecular sieve catalyst to prepare 2-ethylanthracence; and oxidizing the 2-ethylanthracence by using a molybdena supported Y type molecular sieve catalyst to prepare the 2-ethylanthraquinone. The technology has the advantages of facilitation of the proceeding of the reactions, low cost and high yield.

Owner:QINZHOU UNIV

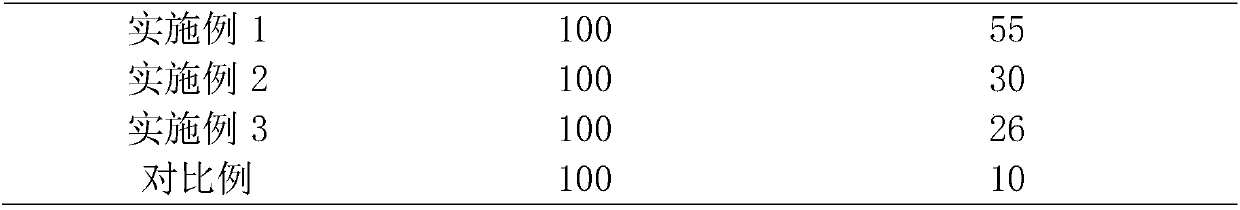

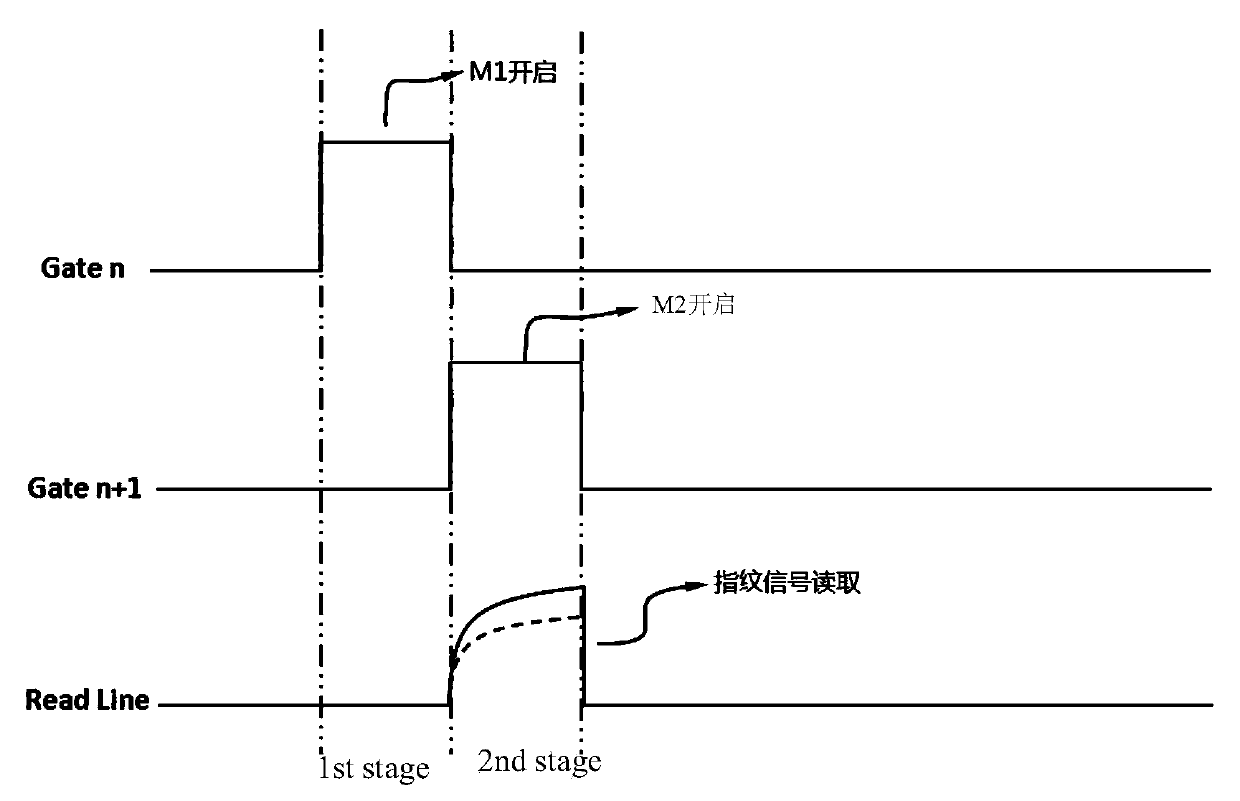

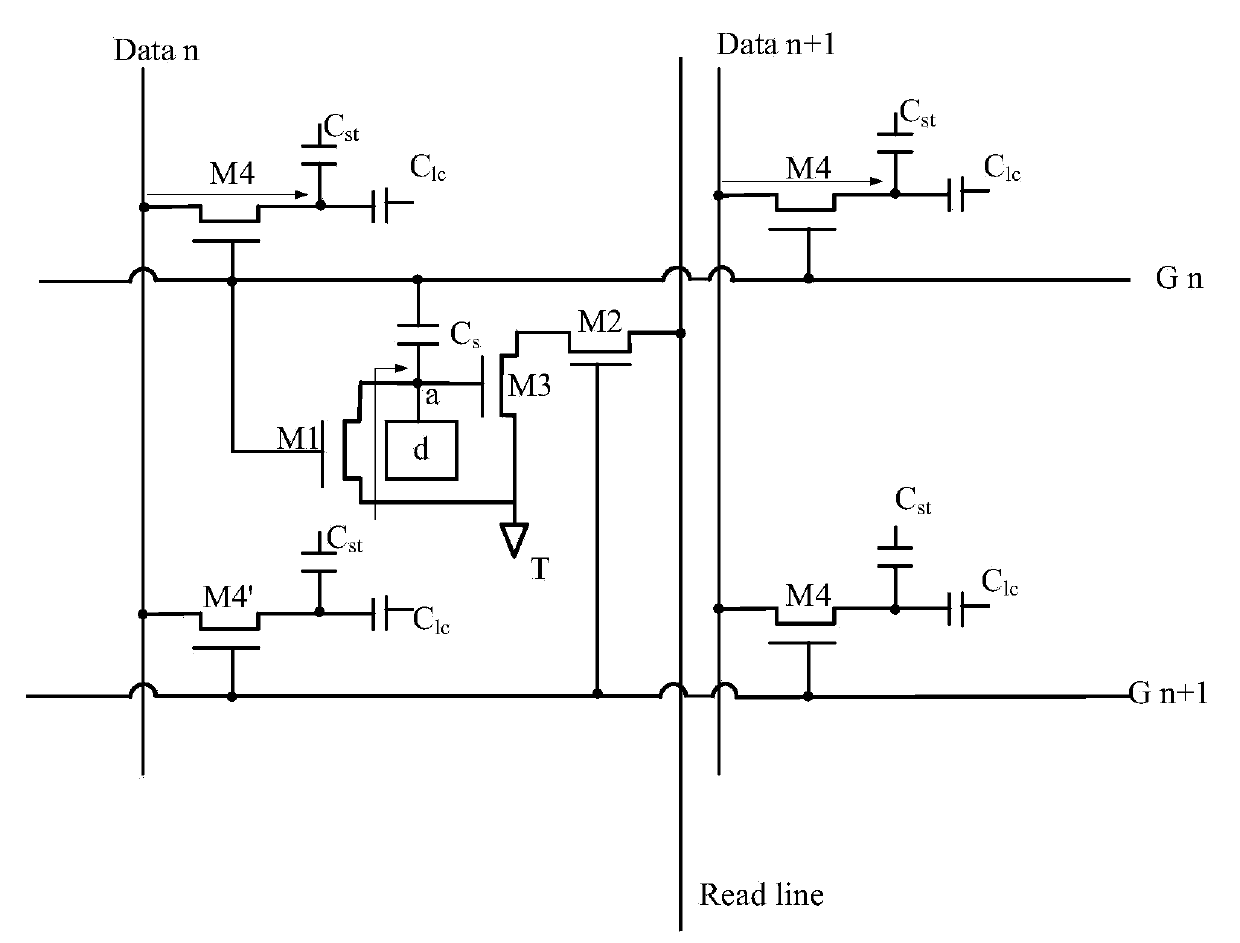

Array substrate, driving method and display device

InactiveCN104200768AReduce thicknessReduce the difficulty of productionStatic indicating devicesPrint image acquisitionFingerprintEngineering

The invention discloses an array substrate, a driving method and a display device for a fingerprint identification circuit. The array substrate comprises a substrate, wherein the fingerprint identification circuit, a fingerprint signal reading wire, an initialized signal wire, a common voltage input end and an output control signal wire are formed on the substrate. Therefore, on one hand, due to the fact that an independent film layer or face plate does not need to bear the fingerprint identification circuit, the thickness of the corresponding display device can be reduced; on the other hand, the fingerprint identification circuit and related signal wires can be formed at the same time while the array substrate is manufactured, so that the manufacturing difficulty for the corresponding display device is reduced.

Owner:BOE TECH GRP CO LTD +1

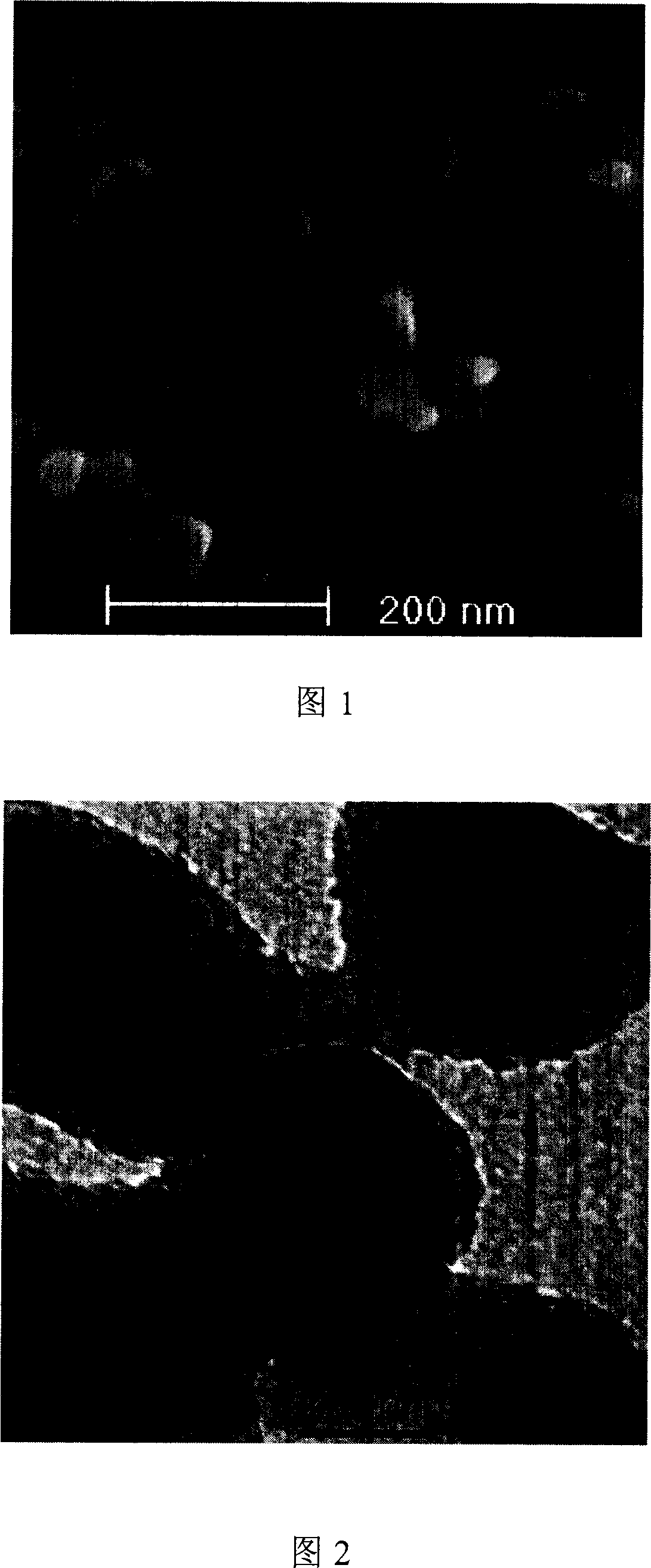

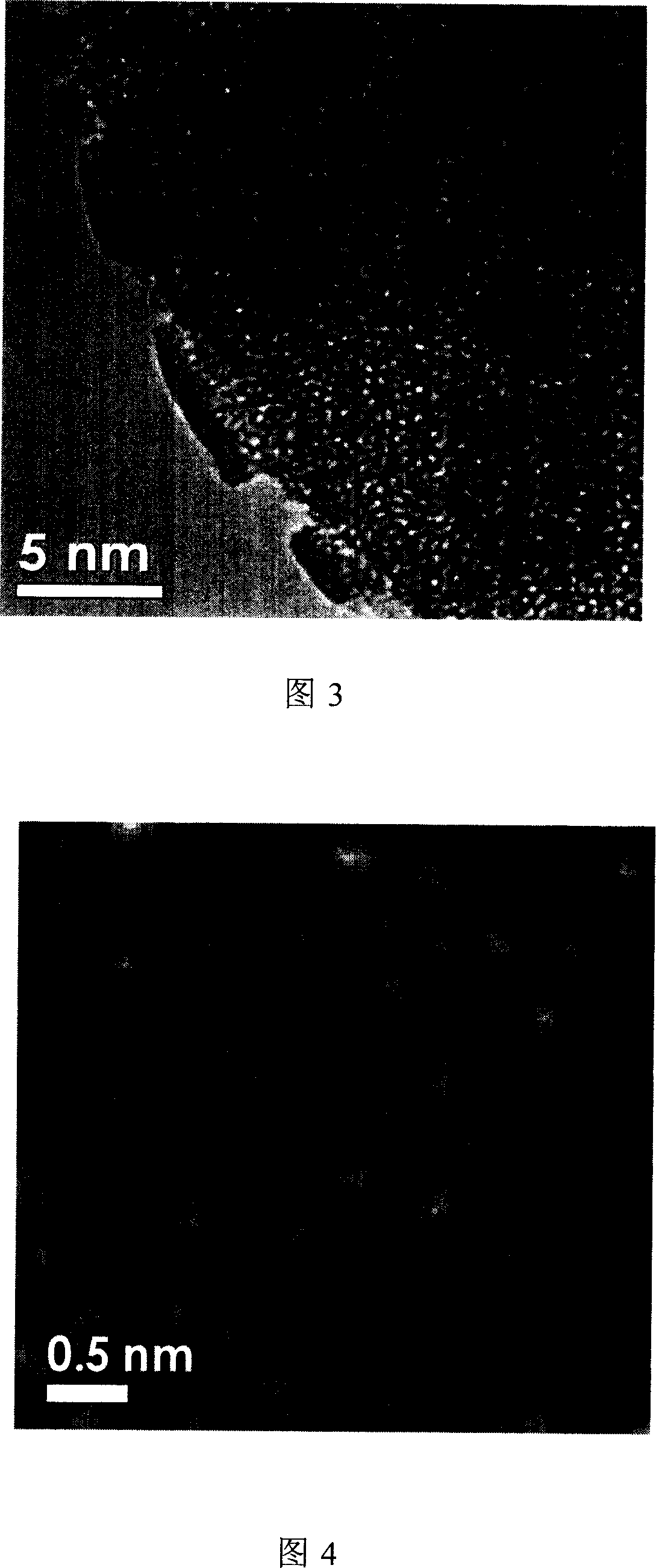

Method for preparing nano Fe-ZSM-5 zeolite molecular sieve

InactiveCN101121526ASynthetic safetyEasy to synthesizeNanostructure manufactureMolecular sieve catalystsSoluble glassPetrochemical

The present invention relates to the technical field of a zeolite molecular sieve synthesis, concretely speaking, relating to a preparation method of a zeolite molecular sieve of a nano heteroatom. A sodium silicate or a soluble glass, an inorganic acid, an inorganic ferric salt, an organic amine and deionized water serve as the material. After the steps of liquor preparation, two variable temperature crystallizations, washing-up centrifugalization, drying and roasting, the zeolite molecular sieve of nano Fe-ZSM-5 is produced with a grain size less than 100nm. The present invention can be used in the petrochemical industry, fine chemical industry and the environmental protection field.

Owner:CHINA PETROLEUM & CHEM CORP +1

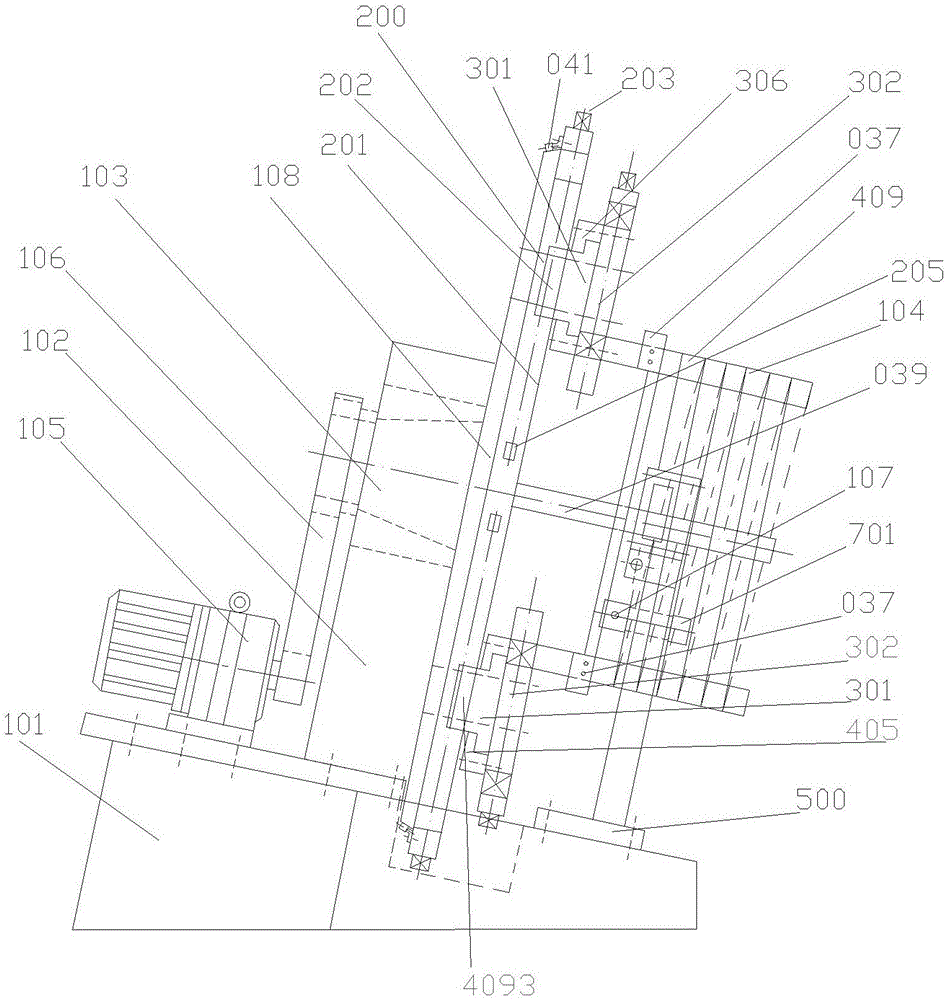

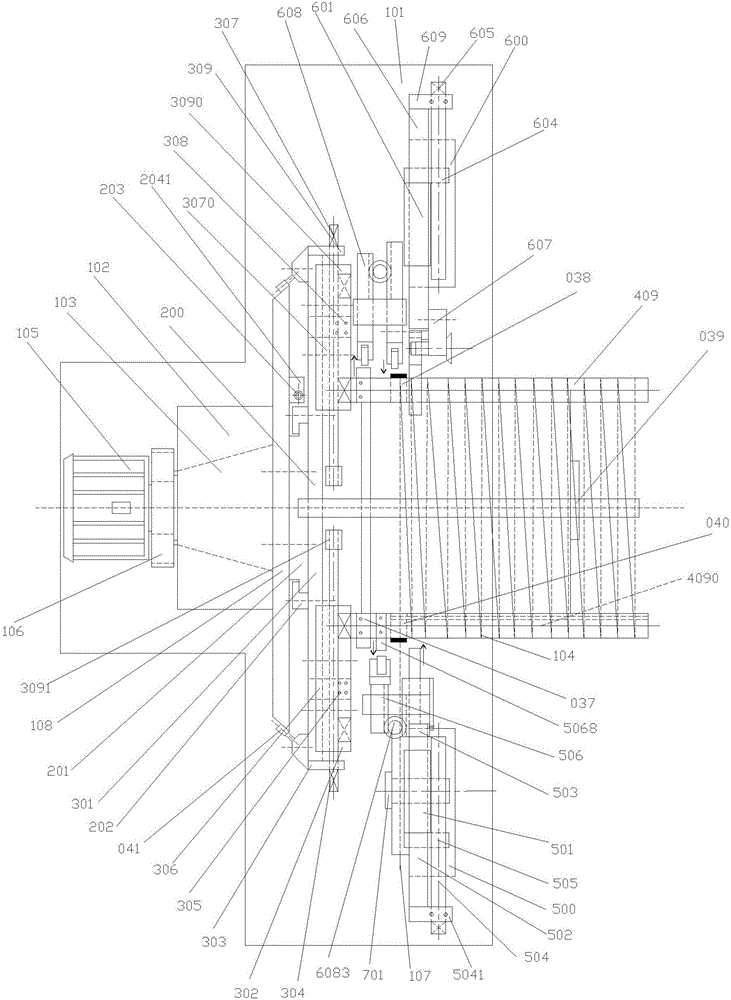

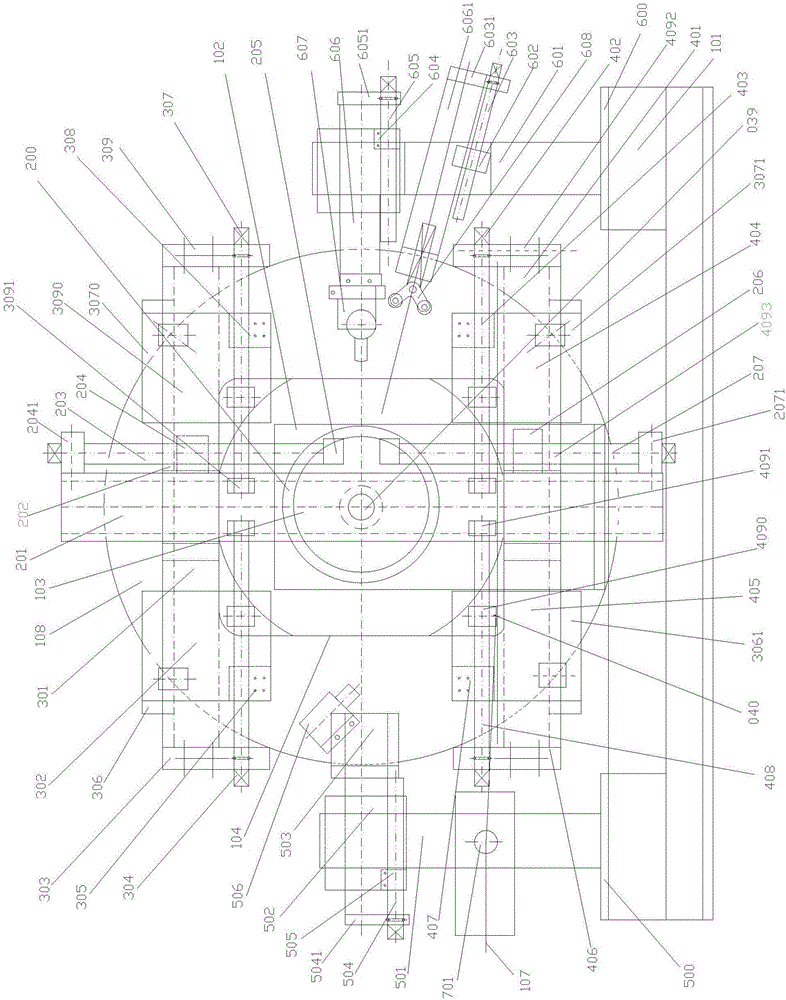

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

Composite filter material for heat-setting-free pleated filter cartridge and processing method of composite filter material

InactiveCN103908837AGood mechanical foldabilityImprove stiffnessSynthetic resin layered productsFiltration separationGlass fiberPolymer science

The invention discloses a composite filter material for a heat-setting-free pleated filter cartridge and a processing method of the composite filter material. The composite filter material is prepared by taking paper made of plant fibers, synthetic fibers and glass fibers as a base material, and compounding the base material and a polypropylene (PP) or polytetrafluoroethylene (PTFE) synthetic fiber filter film by adopting hot melt adhesive, liquid glue or an ultrasonic composite method. The paper made of the plant fibers, synthetic fiber materials and glass fibers serves as the base material, and the prepared material is a novel composite filter material which is low in airflow resistance, high in tensile strength, diversified in varieties, convenient to fold, wide in application range and excellent in overall performance.

Owner:重庆造纸工业研究设计院有限责任公司

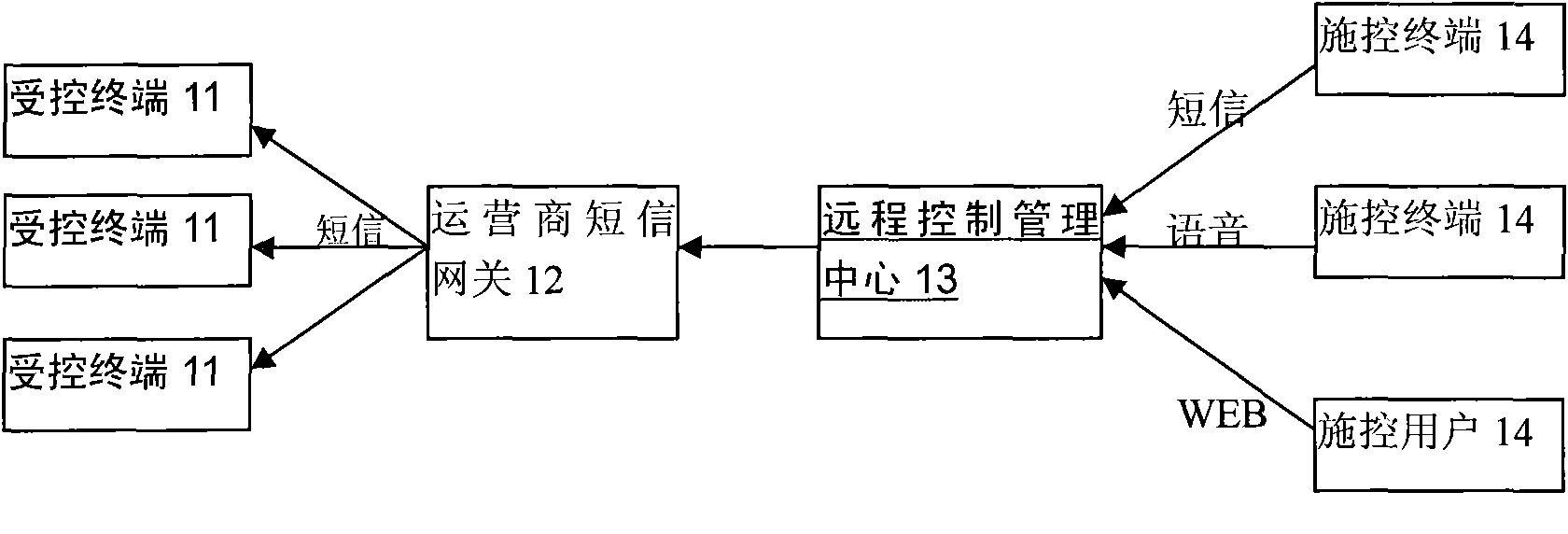

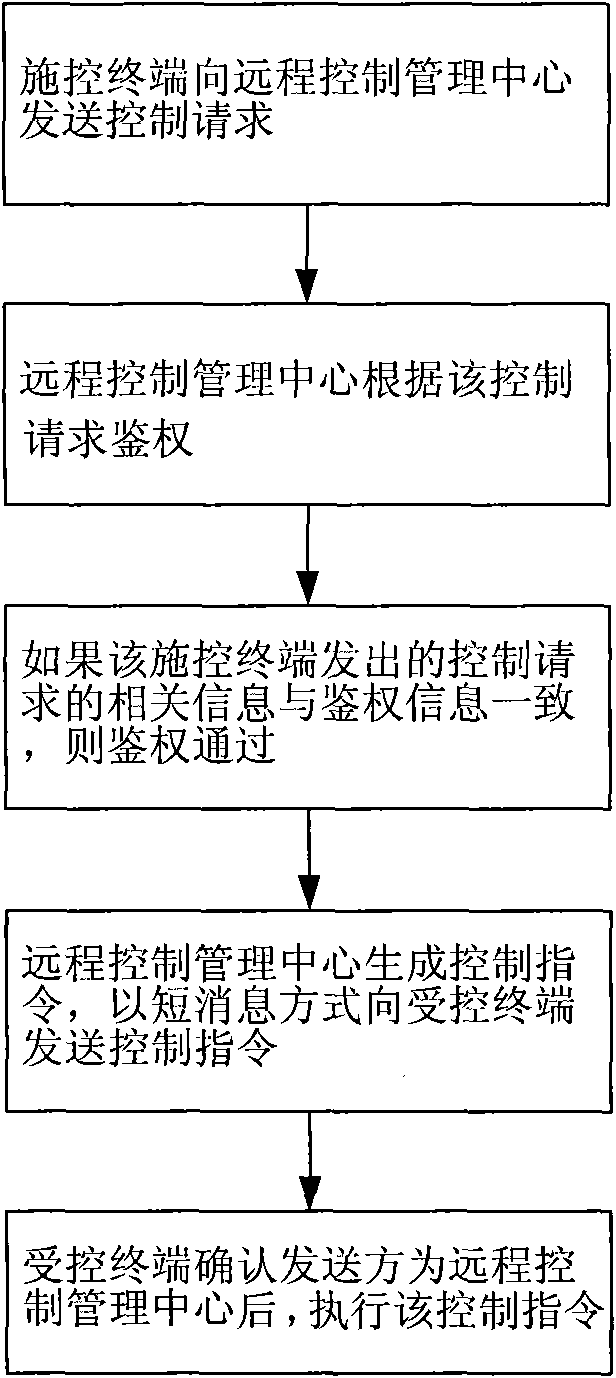

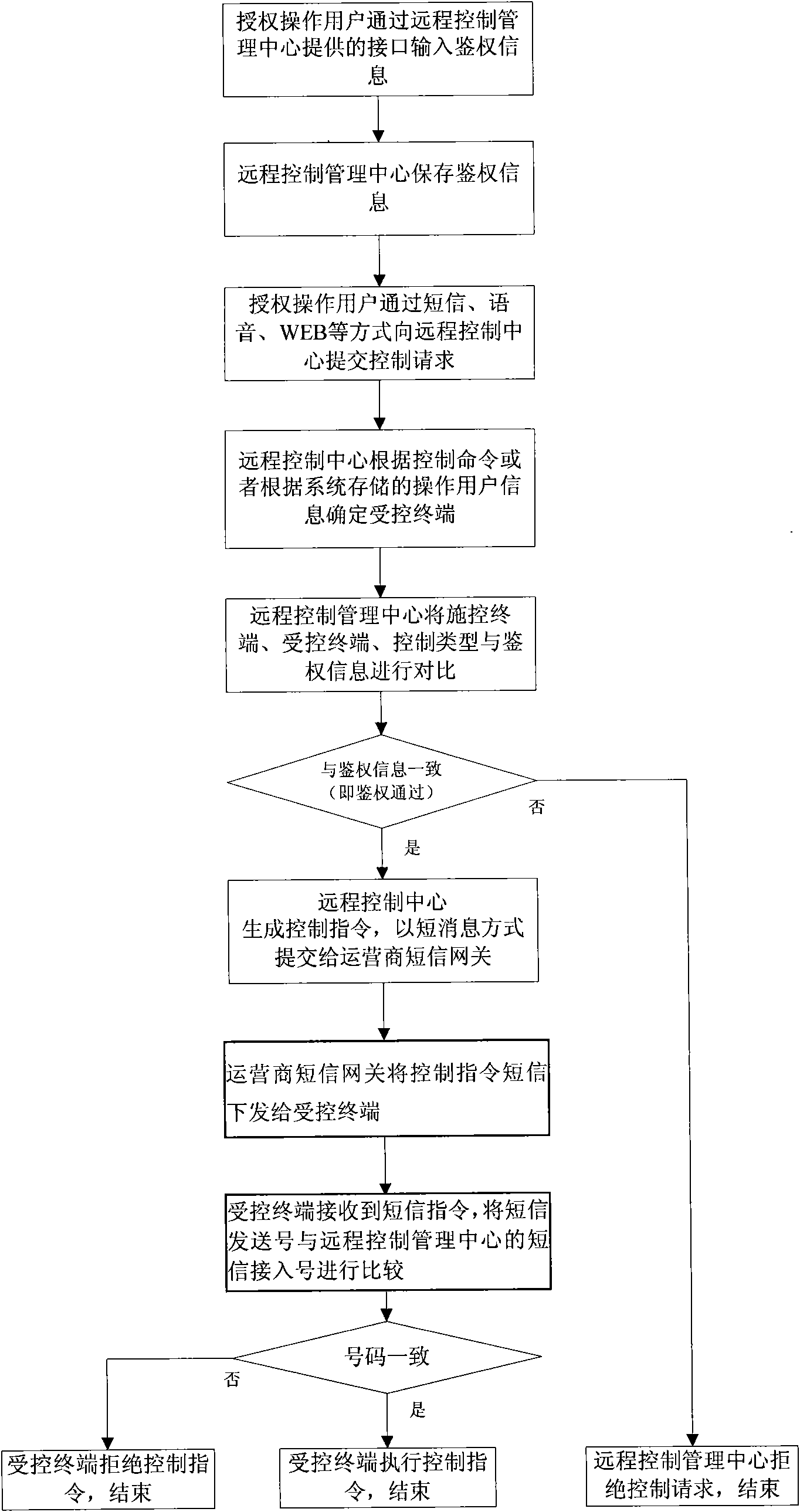

Remote control system and method based on short messages

InactiveCN101616381AReduce the difficulty of operationReduce the difficulty of productionTransmission systemsMessaging/mailboxes/announcementsControl systemRemote control

The invention relates to a remote control method and a remote control system based on short messages. The system comprises a remote control management center, a controlling terminal, a controlled terminal and an operator short message gateway. The method comprises the following steps: 1, the remote control management center is provided, and prestores authentication information; 2, the remote control management center receives a control request sent by the controlling terminal, compares the control request with the prestored authentication information for authentication, generates a control instruction and sends the control instruction to the controlled terminal through the operator short message gateway in a short message mode; and 3, if the controlled terminal judges that the control instruction is sent by the remote control management center according to a short message sending number, the controlled terminal executes corresponding action. The method and the system have the advantages of adopting a new remote control management system to process operation such as remotely controlled authentication and the like, improving the security and flexibility of remote control, reducing operating difficulty for users, reducing production difficulty of the controlled terminal, and contributing to batch production.

Owner:中国移动通信集团重庆有限公司

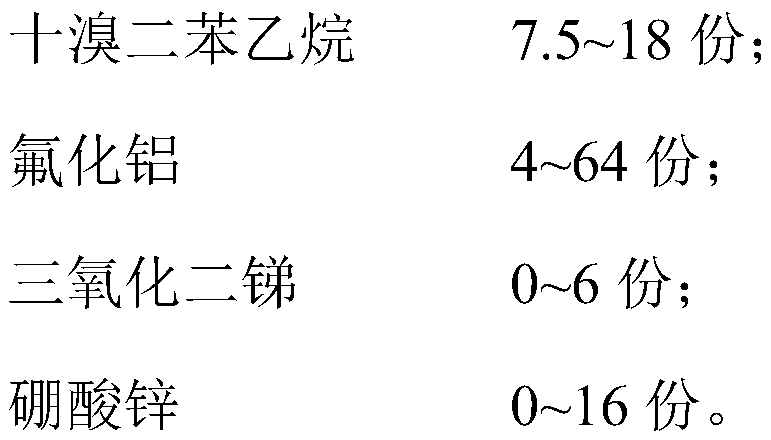

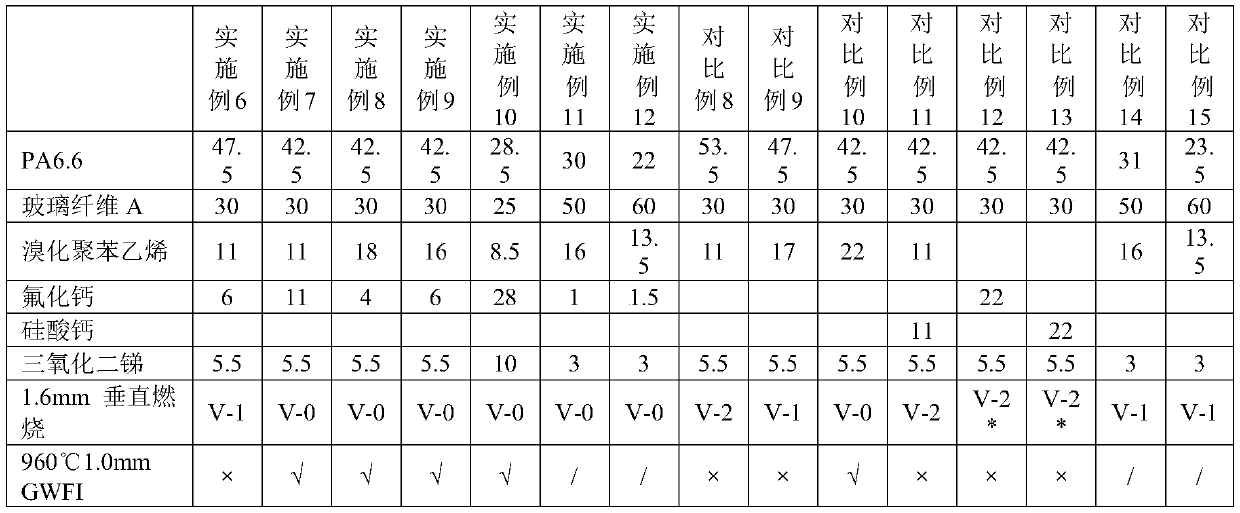

Halogen-flame retardant and application thereof

ActiveCN109836817AReduce the difficulty of productionReduce dosageCost ControlsInorganic fluorine compounds

The invention belongs to the field of flame retardant technology and provides a halogen-frame retardant. The halogen-flame retardant comprises a first component and a second component. The first component is composed of a main flame retardant and an auxiliary flame retardant. The main flame retardant is selected from a brominated flame retardant and a chlorinated flame retardant; and the auxiliaryflame retardant is a fluorine compound. The second component is a flame-retardant synergistic compound, selected from metal oxides of the group IIIA, IVA, VA metals in the periodic table of the elements or salt thereof, transition metal oxide, a silicon-based flame retardant, a phosphorus-based flame retardant and a nitrogen-based flame retardant. The invention also provides a resin composite material, an elastomer composite material and a relative formed body containing the halogen-frame retardant, a coating medium and related part or structural body, and an impregnated material. The invention has the following beneficial effects: the technical bias that fluoride cannot effectively perform the flame-retardant effectiveness and then cannot be used or is hard to be used as a flame retardant is corrected; the actual usage of the brominated flame retardant and / or the chlorinated flame retardant is reduced, and then the production difficulty of the flame retardant and the environmental pollution are reduced, and the color matching and cost control difficulty is reduced.

Owner:BENSONG ENG PLASTICS HANGZHOU

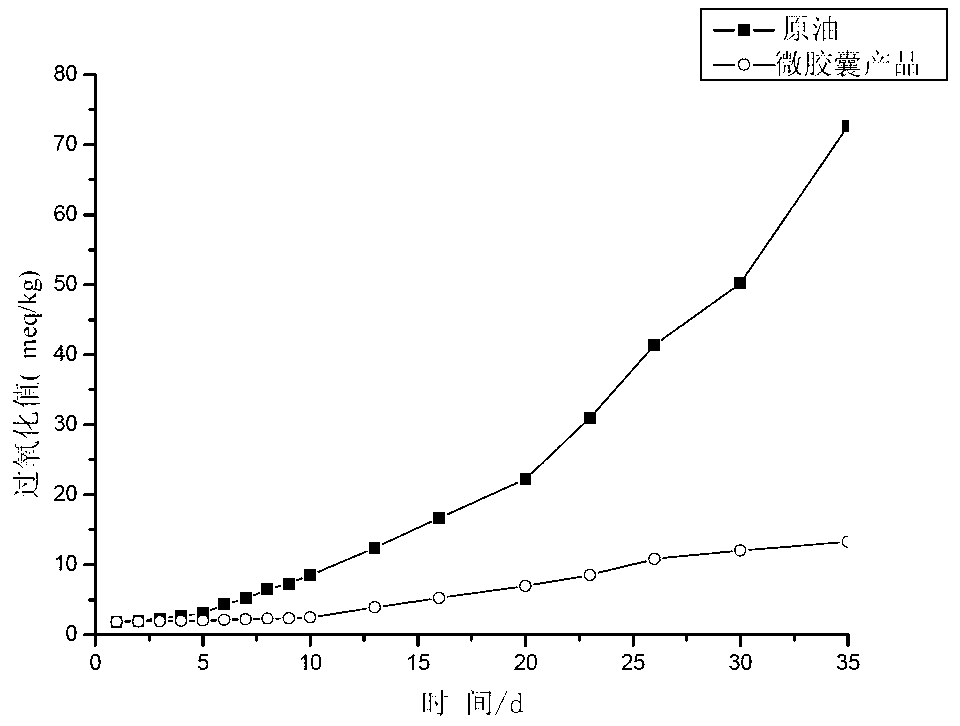

Method for preparing perilla oil powder through composite condensation microencapsulation

InactiveCN103300379AReduce the difficulty of productionLow costFood preparationProtein solutionEmulsion

The invention discloses a method for preparing perilla oil powder through composite condensation microencapsulation, and in particular provides a preparation method of a perilla oil microcapsule which is low in cost and stable in property. The preparation method comprises the following steps of: adding an emulsifying agent into a soy isolated protein solution, and stirring to dissolve the emulsifying agent; adjusting the pH value of the solution to ensure that soy isolated protein has same electric charges with sodium alginate; adding perilla oil into the obtained solution, homogenizing to obtain an emulsion, adding a sodium alginate solution into the emulsion, and uniformly stirring; adjusting the temperature of a system to 40-50 DEG C, and adjusting the pH value to ensure that the soy isolated protein has charges opposite to those of the sodium alginate and then a composite condensation product is formed in the system; diluting and reducing the temperature of the composite condensation product by adding water, putting the composite condensation product into an ice bath, and continuously stirring until the temperature is lower than 10 DEG C to ensure that the composite condensation product is gelatinized; adding glucose or pectin into the system, and curing; and filtering, washing, depositing, and performing freeze-drying to obtain a perilla oil microcapsule product. The perilla oil microcapsule product obtained by the method can be widely applied to the fields of foods, medicines and the like.

Owner:TIANJIN UNIV OF COMMERCE

Vegetable substrate nutritional soil and preparing method thereof

InactiveCN106348833ALow costStrong buffer capacityBio-organic fraction processingAnimal corpse fertilisersNutrientRiver sand

The invention discloses vegetable substrate nutritional soil and a preparing method thereof. The vegetable substrate nutritional soil is prepared from corn straws, soybean curd residues, edible mushroom waste, chicken manure, river sand, river sludge, coal residues, pig bones, urea, wood shavings, pig manure, diatomite, traditional Chinese medicine residues, peanut shells, wheat straws, soybean straws, a microbial fermentation agent and agar liquid by the following steps: putting the microbial fermentation agent into the agar liquid to cultivate; putting the chicken manure and the pig manure into the edible mushroom waste to perform fermentation cultivation; grinding and mixing the corn straws, the coal residues, the pig bones, the wood shavings, the diatomite, the peanut shells, the wheat straws and the soybean straws; mixing the soybean curd residues, the river sand, the river sludge and the traditional Chinese medicine residues; adding the microbial fermentation agent and performing fermentation; adding other raw materials and performing fermentation again. The raw materials are obtained locally and cheap, have low cost and high buffer capability, avoid contradiction between water, nutrient and supplied oxygen, can be repeatedly recycled, and avoid environmental pollution residues.

Owner:安徽省新思维农业科技股份有限公司

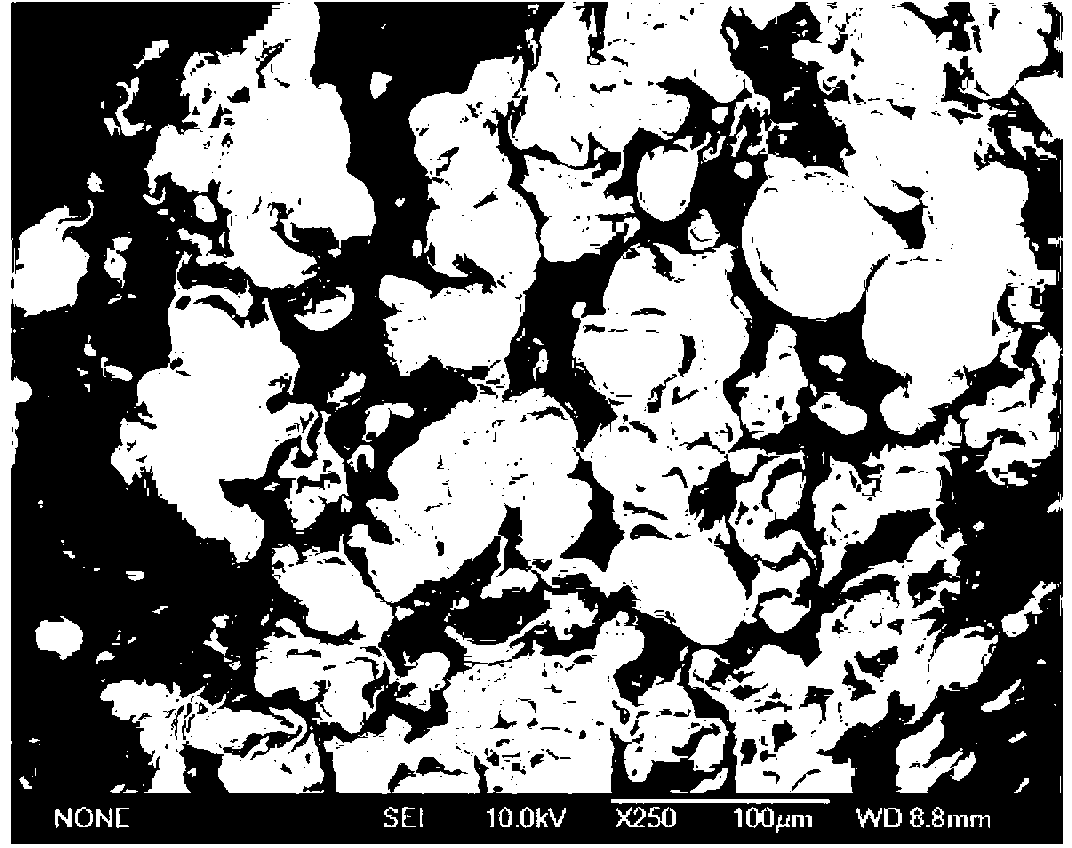

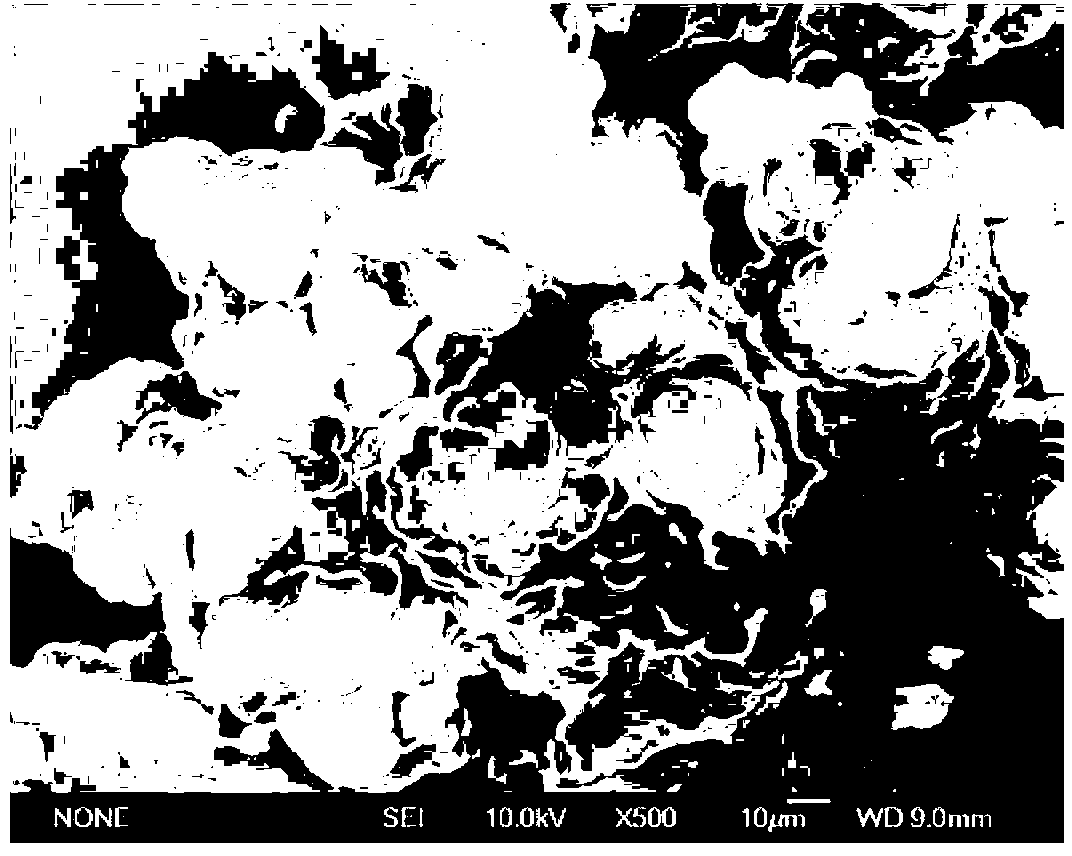

Composition for high-performance heat-resistant and corrosion-resistant glass fibers

ActiveCN102276153ASolve difficulties such as high manufacturing costsIncrease production capacityGlass fiberResin-Based Composite

The invention provides a composition for high-property heat-resisting corrosion-resisting glass fiber. The composition comprises the following components: 55-63wt% of SiO2, 18-23wt% of Al2O3, 8-16wt% of MgO, 7-13wt% of CaO, 0-1wt% of CeO2, 0-0.5wt% of Li2O, 0-0.4wt% of Fe2O3, 0-2wt% of TiO2, 0-0.5wt% of WO3 and 0-1.5wt% of Bi2O3, wherein the total content of SiO2, Al2O3, MgO and CaO is 94-98wt%; and CeO2, Li2O, Fe2O3, TiO2, WO3 and Bi2O3 are modifiers, the content of a single modifier is 0 at different times, and the total content of the modifiers is 2-6wt%. According to the invention, raw materials are adopted to produce the high-property heat-resisting corrosion-resisting glass fiber, thus the production difficulty is low, and the cost is low; and the produced glass fiber can be used as a reinforcing material and a heat-resisting heat-insulating material of a resin-based composite material and has the characteristics of high strength, corrosion resistance, high temperature resistance and light mass.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

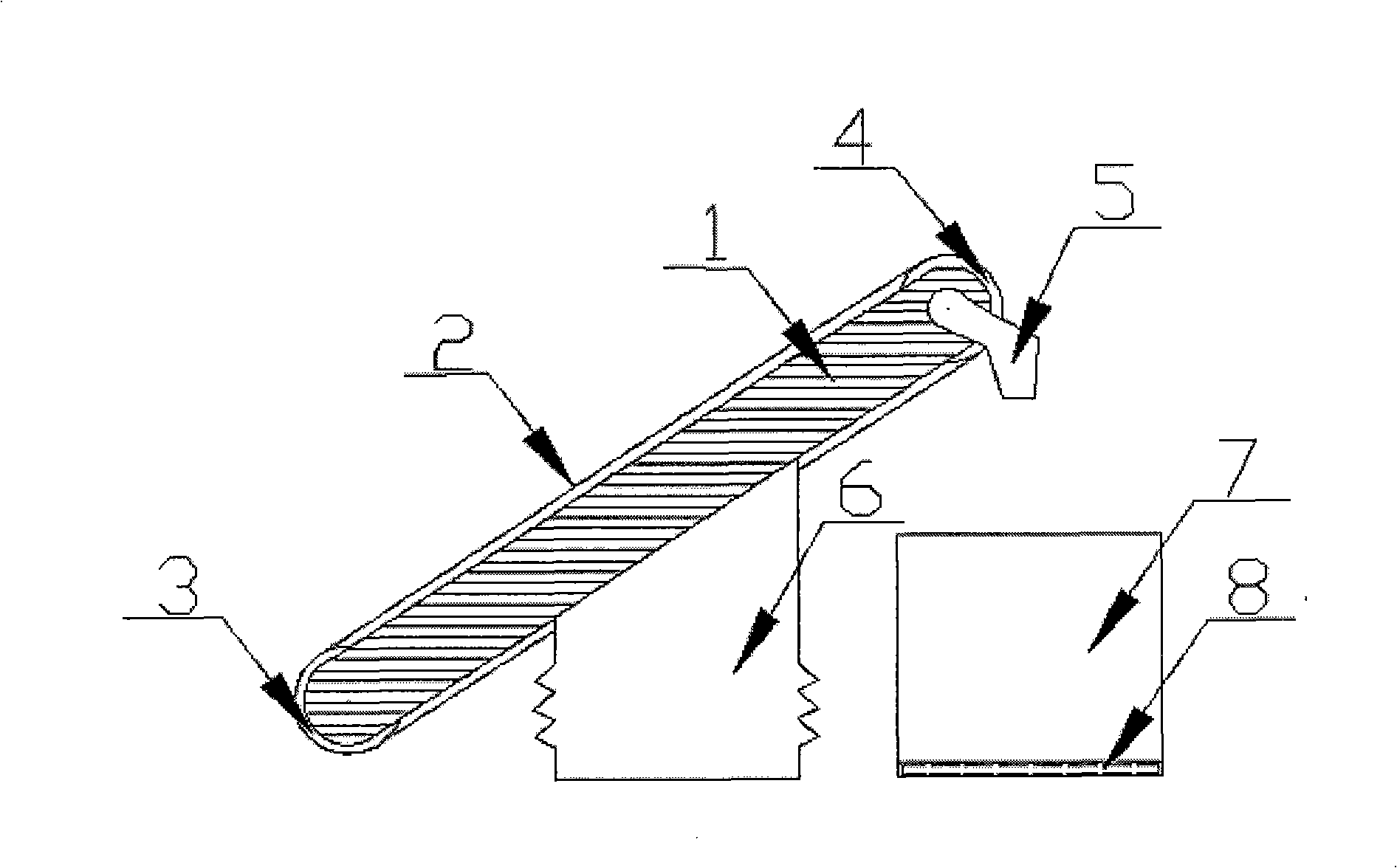

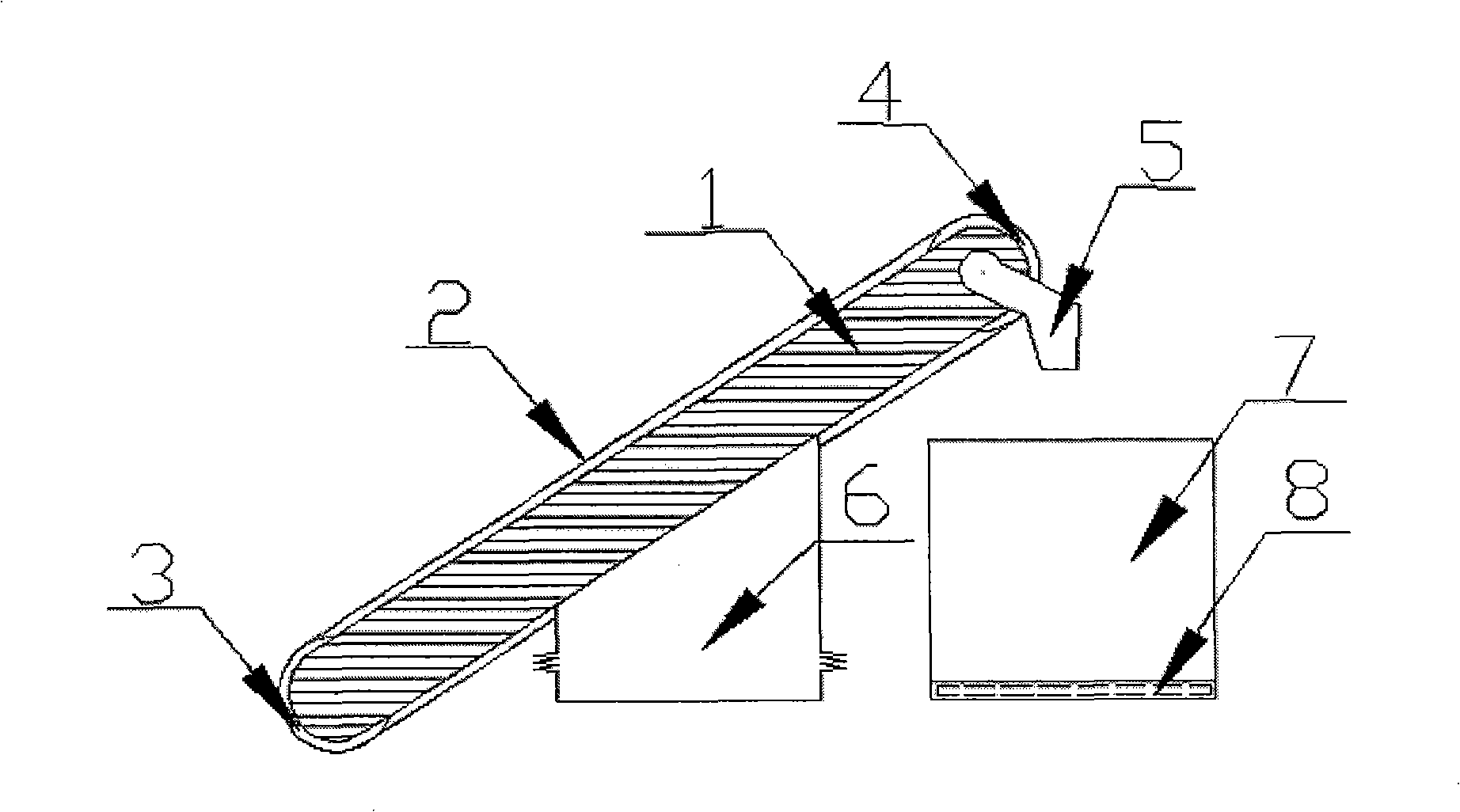

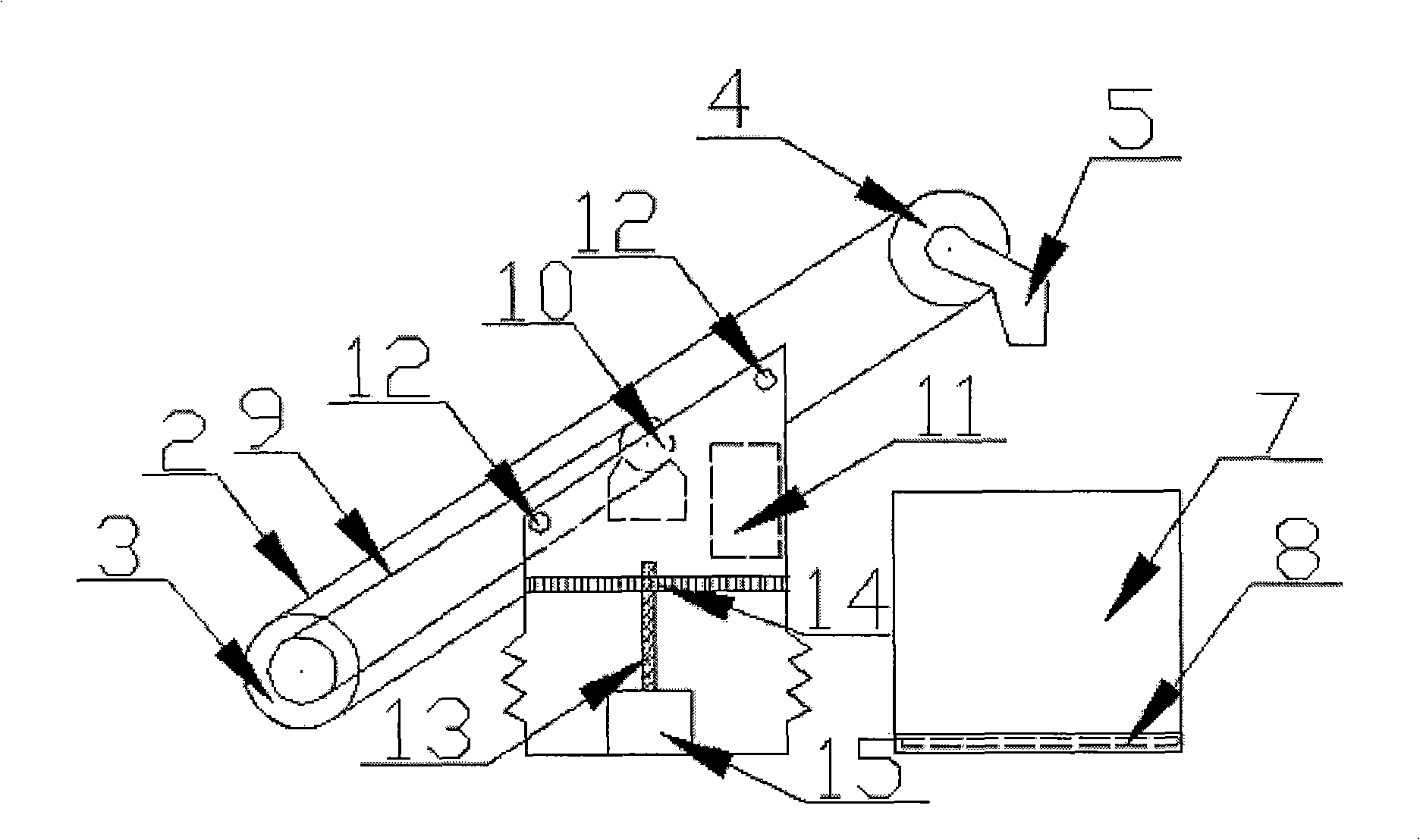

Waste iron absorption device and automatic waste iron cleaning vehicle

InactiveCN101349044AWill not affect normal useAvoid safety hazardsRoad cleaningControl systemEngineering

The invention discloses a scrap iron absorber and an automatic scrap iron cleaning vehicle provided with the scrap iron absorber. An absorption region of the scrap iron absorber comprises an absorption rolling system and a control system (6), a storage region comprises a collecting bin (7), wherein the absorption rolling system comprises an upper rolling shaft (4), a lower rolling shaft (3), a rolling shaft fixing plate (1), a hoisting belt (2) and a blanking opening (5), the upper rolling shaft (4) and the lower rolling shaft (3) are fixed at both ends of the rolling shaft fixing plate (1), the rolling shaft fixing plate (1) is fixed on the control system (6) through a fixing plate mounting hole (12), and the upper rolling shaft (4) and the lower rolling shaft (3) are connected through the hoisting belt (2); and the control system (6) consists a power driving module, a magnetization module and a lifting module. The scrap iron absorber is supported by a station transport or bucket wagon, overcomes the disadvantages of large volume and ponderosity of the prior cleaning vehicle, can collect, recover and utilize scrap iron garbage, and has a simple structure and convenient operation.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com