Spiral stirrup continuously and synchronously machining machine and machining method

A spiral stirrup and synchronous processing technology, applied to wire processing, other household appliances, household appliances, etc., can solve the problems of small binding force and cannot effectively adapt to the building requirements of seismic strength, etc., to achieve convenient processing, production, installation and layout, and structural Simple, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

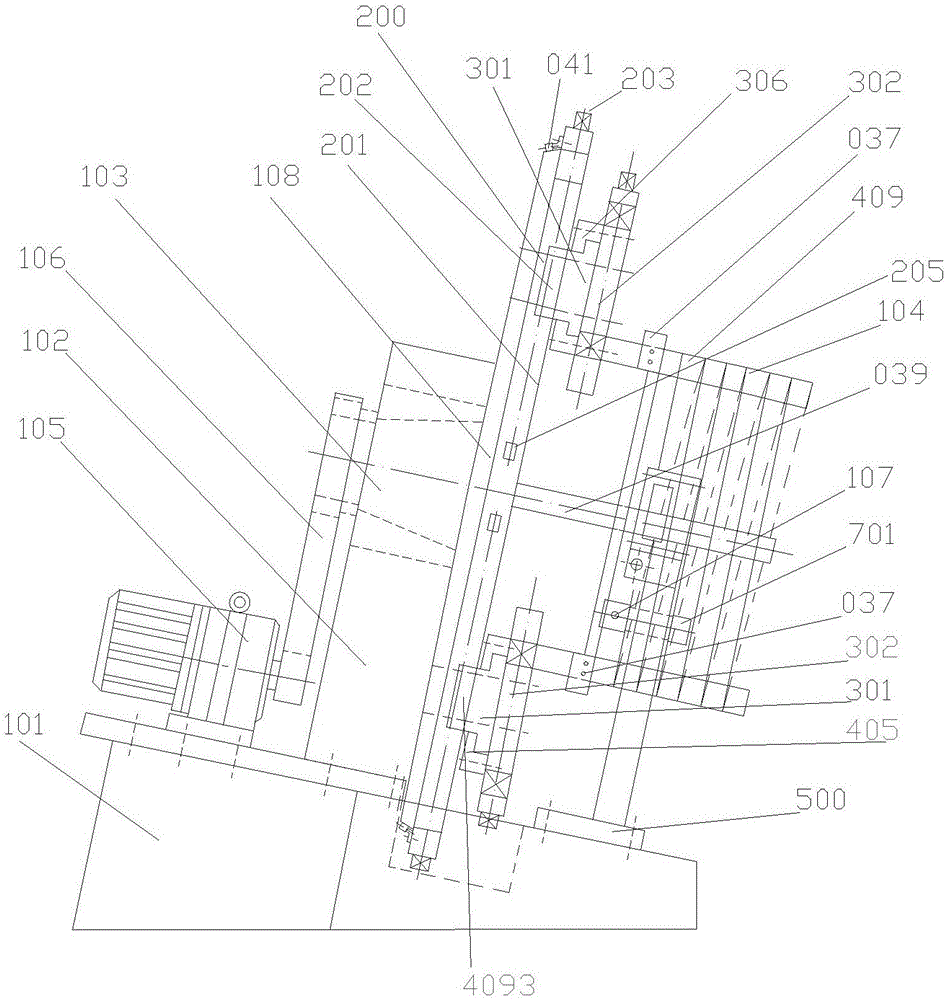

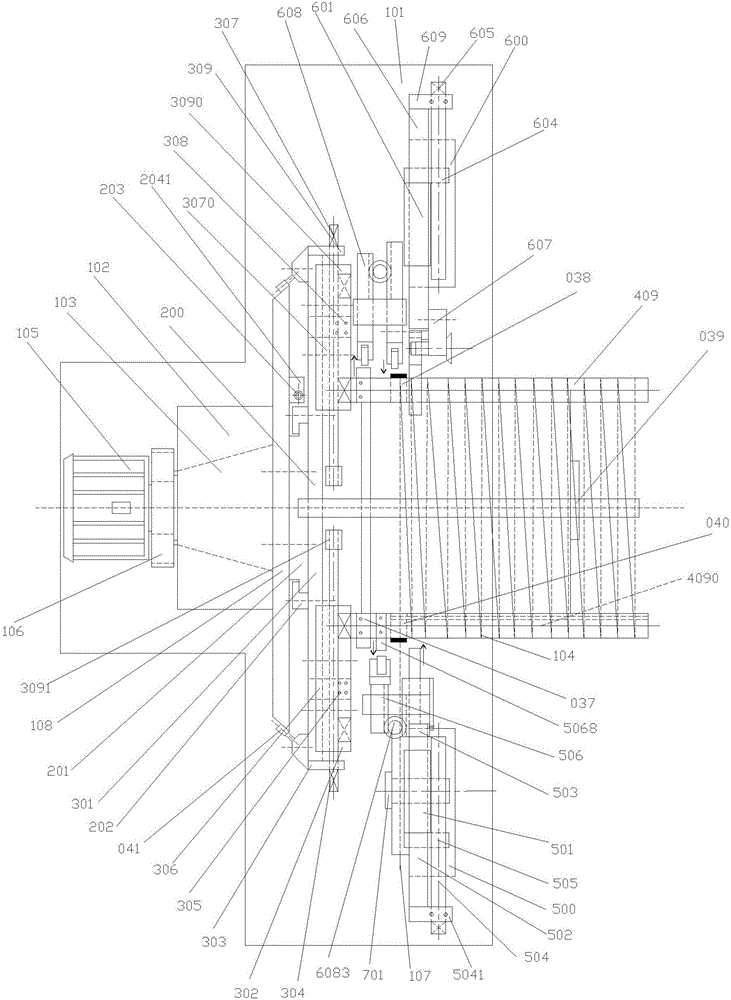

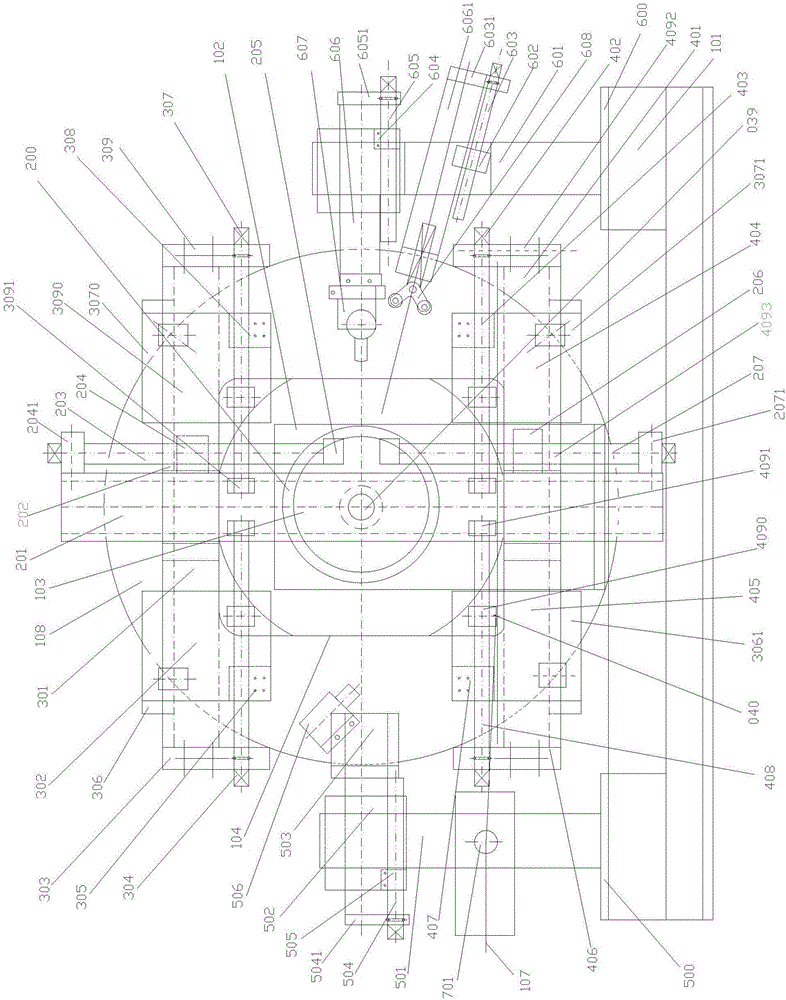

[0117] Such as figure 1 , figure 2 , image 3 and Figure 12 As shown, the present invention includes a fuselage base 101, a spiral stirrup processing device installed on the fuselage base 101 and gradually inclined downward from the rear to the front, and a monitoring device for monitoring the spiral stirrup processing device; by setting The spiral stirrup processing device is gradually inclined downward from the back to the front, so that the processed spiral stirrup can be slid and unloaded from the spiral stirrup processing device under the action of gravity, which not only reduces the manual labor, but also Production costs are reduced. The winding number and winding speed of the spiral stirrup can be monitored in real time by setting the monitoring device, so that the processing process of the spiral stirrup is easy to control and convenient to realize.

[0118] The spiral stirrup processing device includes a rotary table 200 installed on the fuselage base 101, a st...

Embodiment 2

[0221] In this example, if Figure 14 As shown, the difference between the spiral stirrup continuous synchronous processing machine and the processing method used in Embodiment 1 is that the number of the winding shafts 409 is eight. The eight winding shafts 409 are respectively the first upper left winding shaft, the second upper left winding shaft, the first right upper winding shaft, the second right upper winding shaft, the first left lower winding shaft, the Two lower left winding shafts, a first lower right winding shaft and a second lower right winding shaft.

[0222] In this way, by changing the number of winding shafts 409 and changing the processing shape of the spiral stirrup 104, polygonal spiral stirrups can be processed according to requirements, which improves the flexibility of the continuous synchronous processing machine for spiral stirrups and has a wide range of applications.

[0223] In this embodiment, the rest of the structure, connection relationship a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com