Nickelic cathode material rich in lithium and preparation method thereof

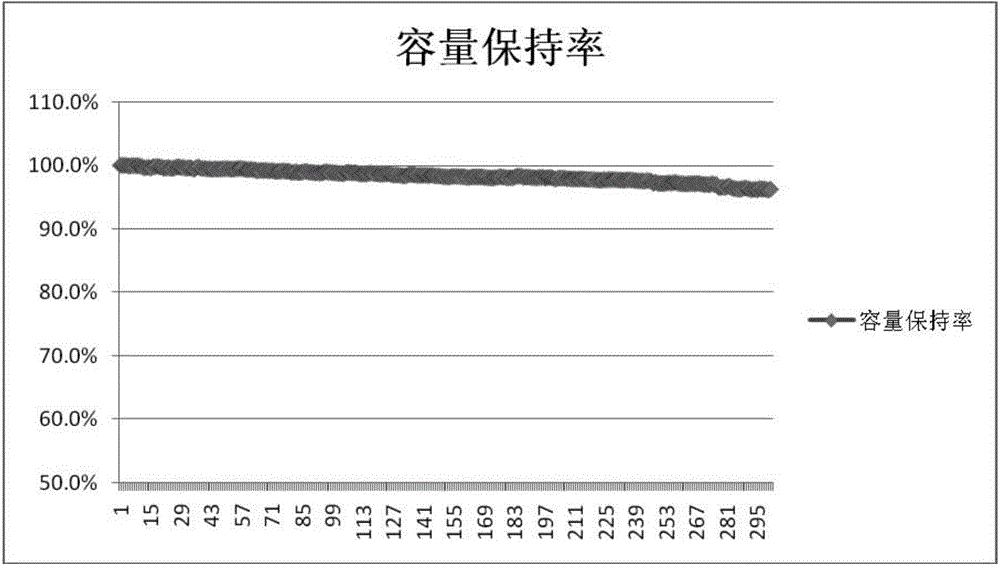

A positive electrode material, high-nickel technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of high irreversible capacity for the first time, difficulty in fully exerting performance, poor thermal stability of materials, etc., and achieve excellent anti-high temperature flatulence performance, physical and chemical properties Excellent electrical performance and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

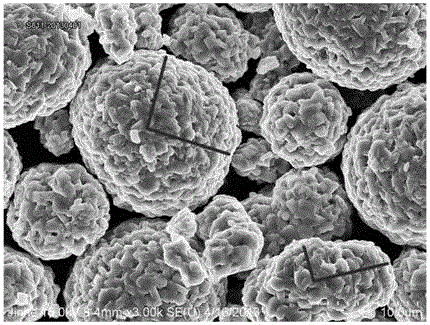

[0031](1) Preparation of nickel-cobalt-manganese precursor: Ni: Co: Mn molar ratio 0.75: 0.20: 0.05 Nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution are mixed evenly as raw materials, and the concentration of metal ions in the solution after mixing is 1.0 mol / L, and then the complexing agent solution, NaOH precipitating agent solution and the mixed solution are added together into the reaction kettle equipped with bottom liquid, heated and stirred for precipitation reaction, and the overflowing slurry is started to be treated after fully reacting Solid-liquid separation is carried out, and the separated solid product is washed and dried to obtain a spherical nickel-cobalt-manganese precursor;

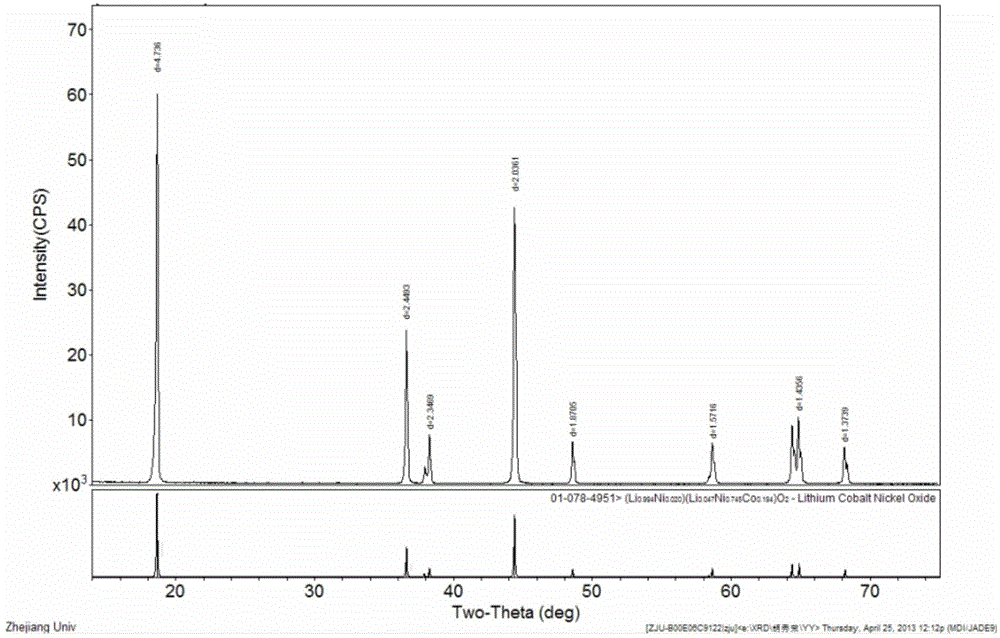

[0032] (2) Pre-oxidize and calcinate the lithium-rich and high-nickel positive electrode material precursor obtained in the above step (1) at a sintering temperature of 650°C for 12 hours. After the sintering is completed, cool in the furnace, crush and sieve;...

Embodiment 2

[0038] (1) Preparation of nickel-cobalt-manganese precursor: Ni: Co: Al molar ratio 0.77: 0.18: 0.05 Nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution are mixed evenly as raw materials, and the concentration of metal ions in the mixed solution is 1.0 mol / L, and then the complexing agent solution, NaOH precipitating agent solution and the mixed solution are added together into the reaction kettle equipped with bottom liquid, heated and stirred for precipitation reaction, and the overflowing slurry is started to be treated after fully reacting Solid-liquid separation is carried out, and the separated solid product is washed and dried to obtain a spherical nickel-cobalt-manganese precursor;

[0039] (2) The lithium-rich and high-nickel positive electrode material precursor obtained in the above step (1) is pre-oxidized and calcined at a sintering temperature of 500°C for 12 hours. After the sintering is completed, it is cooled in the furnace and crushed ...

Embodiment 3

[0045] (1) Preparation of nickel-cobalt-manganese precursor: Ni:Co:Al molar ratio 0.80:0.15:0.05 Nickel chloride solution, cobalt chloride solution, and manganese chloride solution are mixed evenly as raw materials, and the metal ions in the solution after mixing The concentration is 1.5mol / L, and then the complexing agent solution, the NaOH precipitating agent solution and the mixed solution are added together into the reaction kettle equipped with the bottom liquid, heated and stirred to carry out the precipitation reaction, and the overflowing The slurry is subjected to solid-liquid separation, and the separated solid product is washed and dried to obtain a spherical nickel-cobalt-manganese precursor;

[0046] (2) Pre-oxidize and calcinate the lithium-rich and high-nickel cathode material precursor obtained in the above step (1) at a sintering temperature of 450°C for 12 hours. After sintering, cool in the furnace and crush and sieve;

[0047] (3) Mix the sieved mixture and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com