Patents

Literature

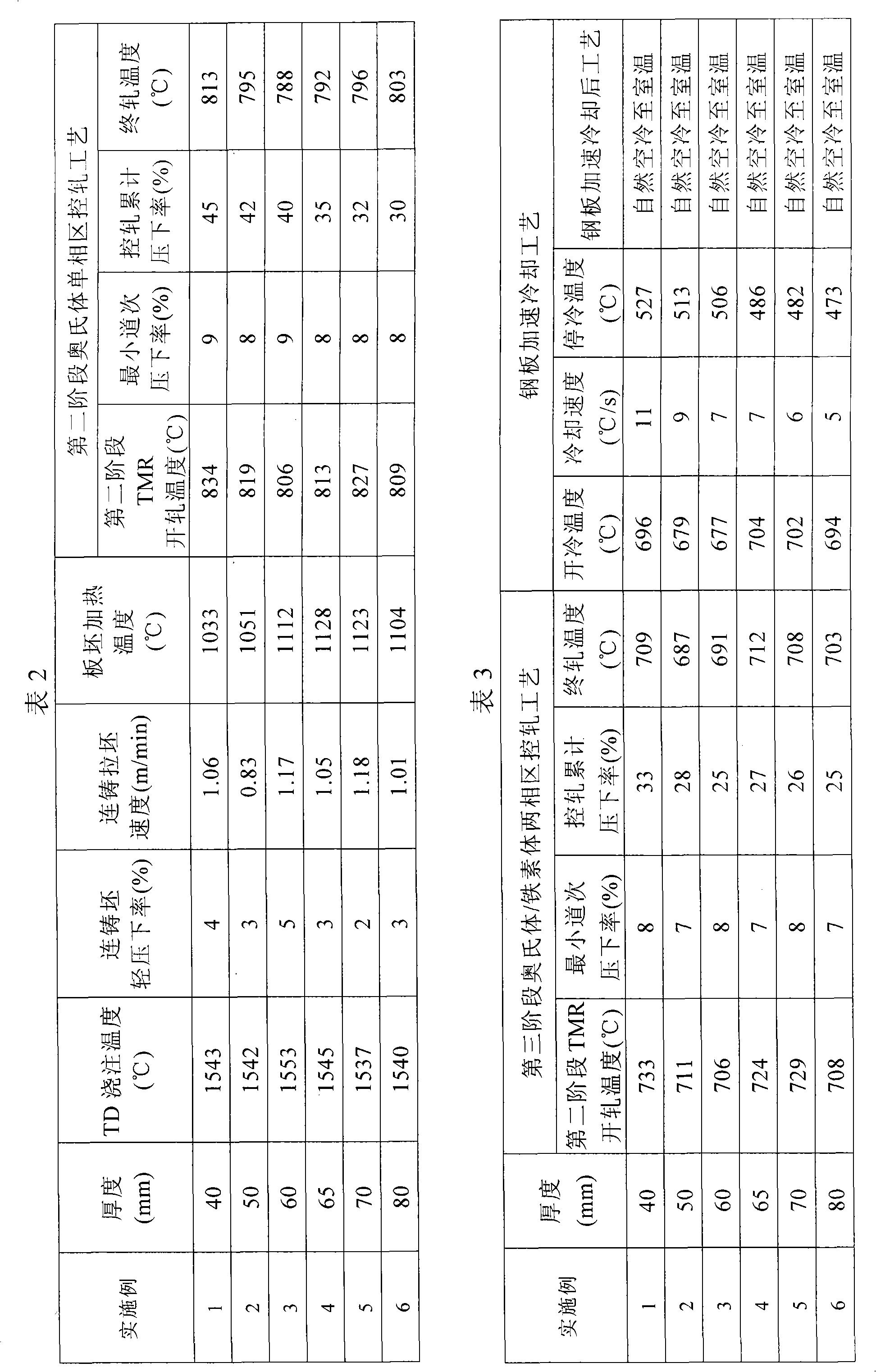

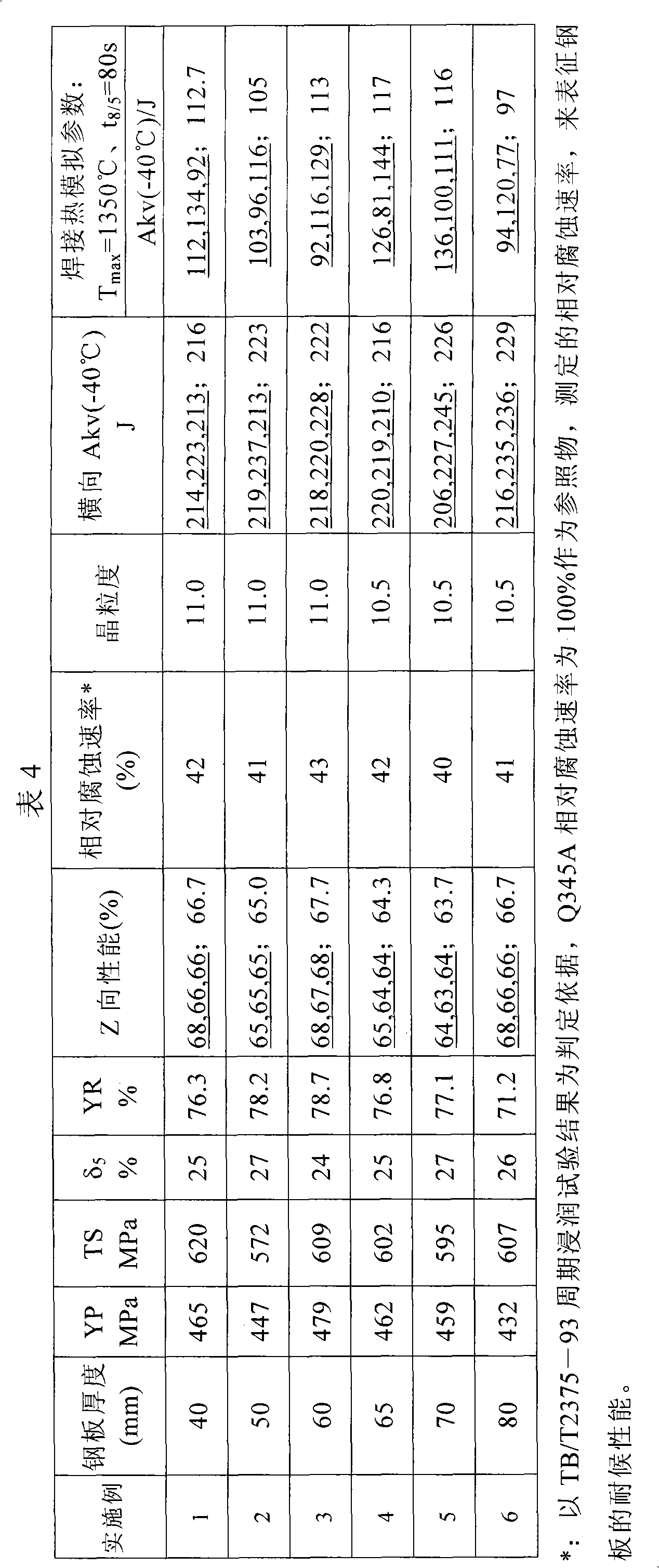

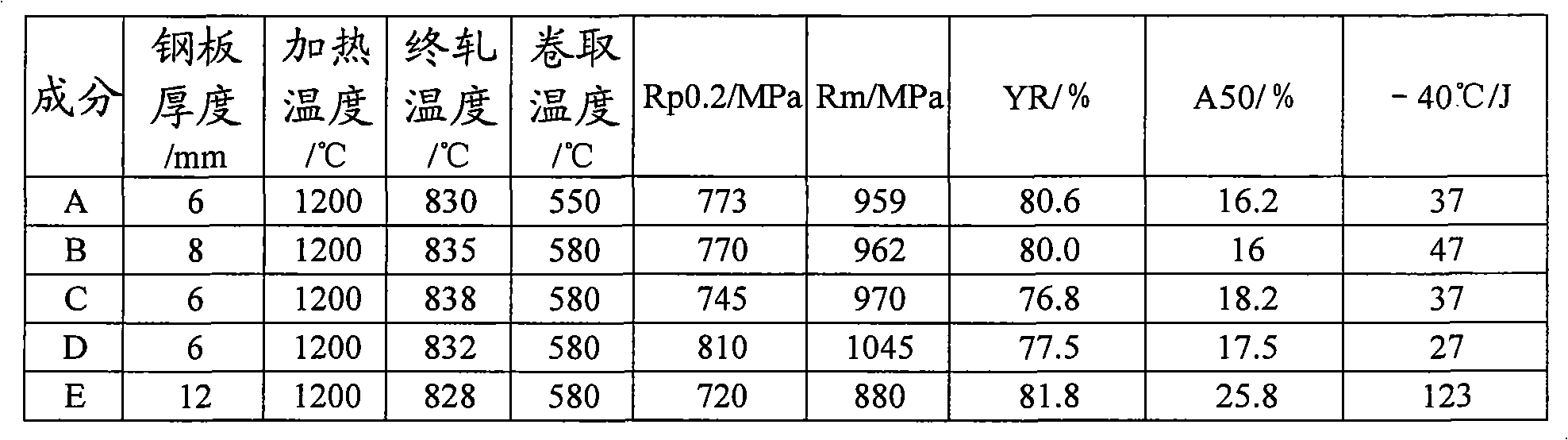

252results about How to "Good atmospheric corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

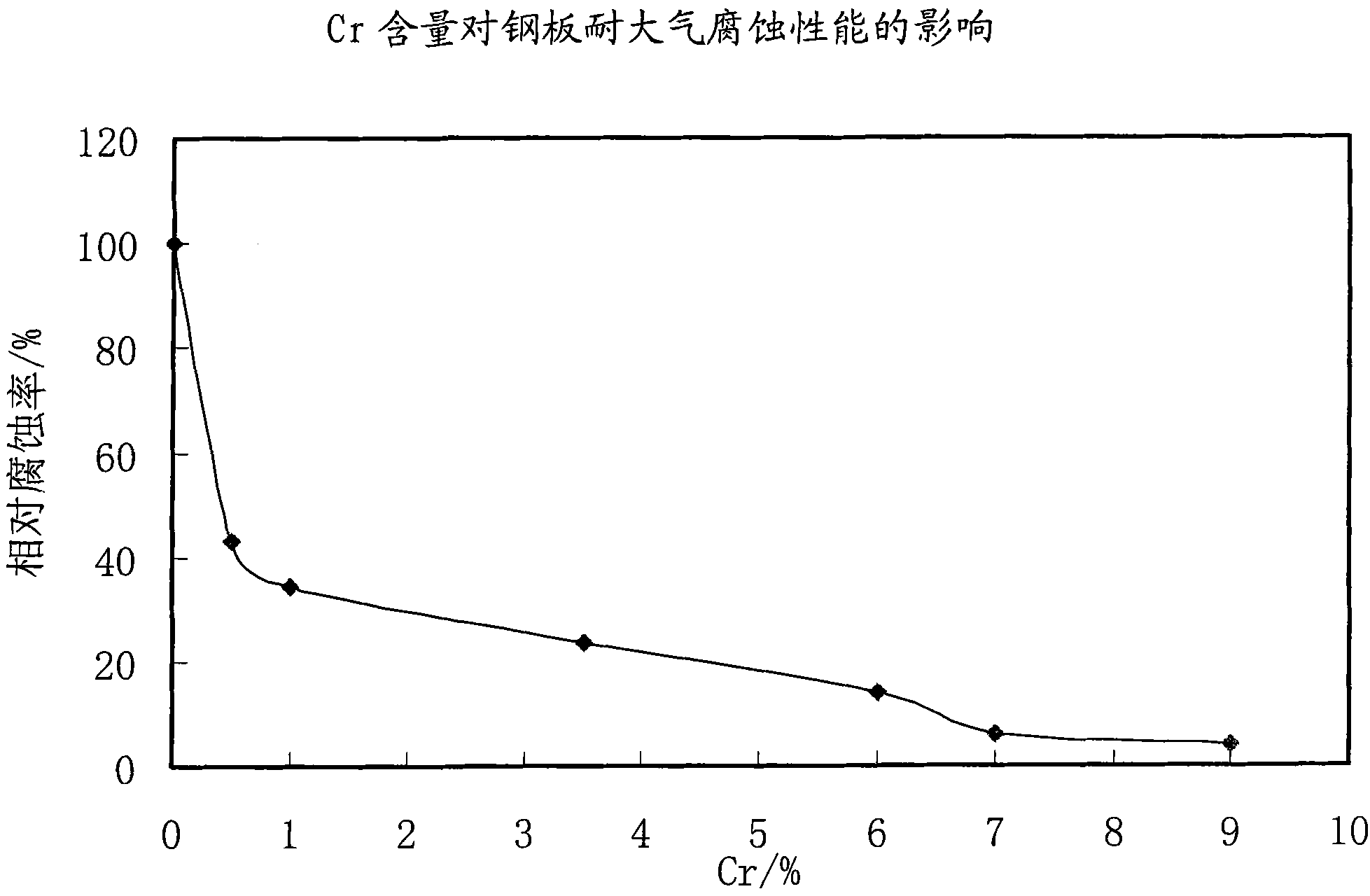

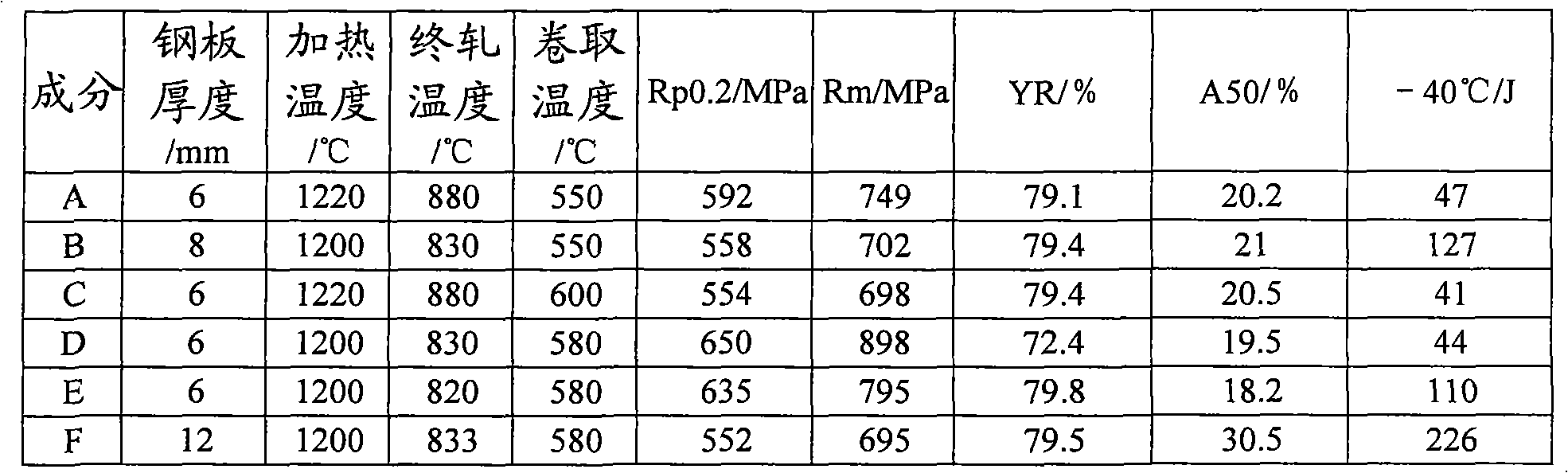

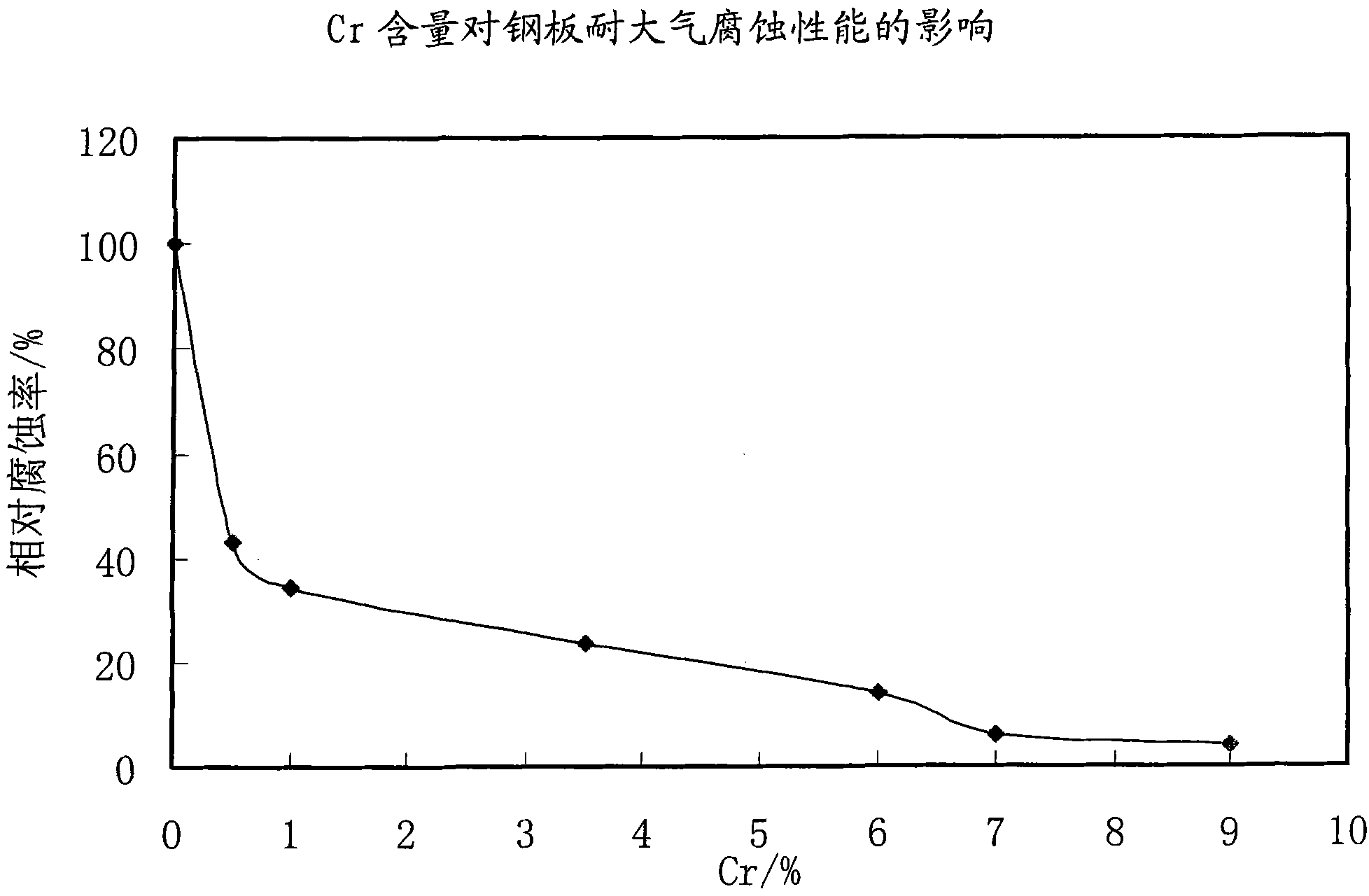

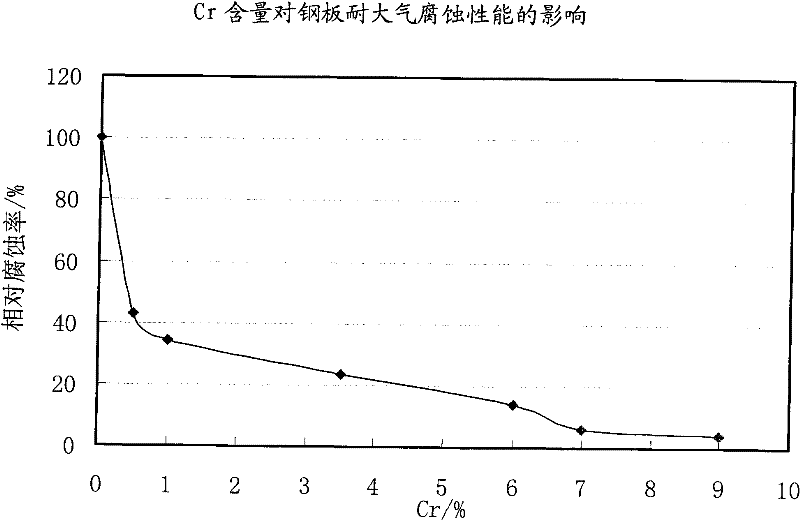

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

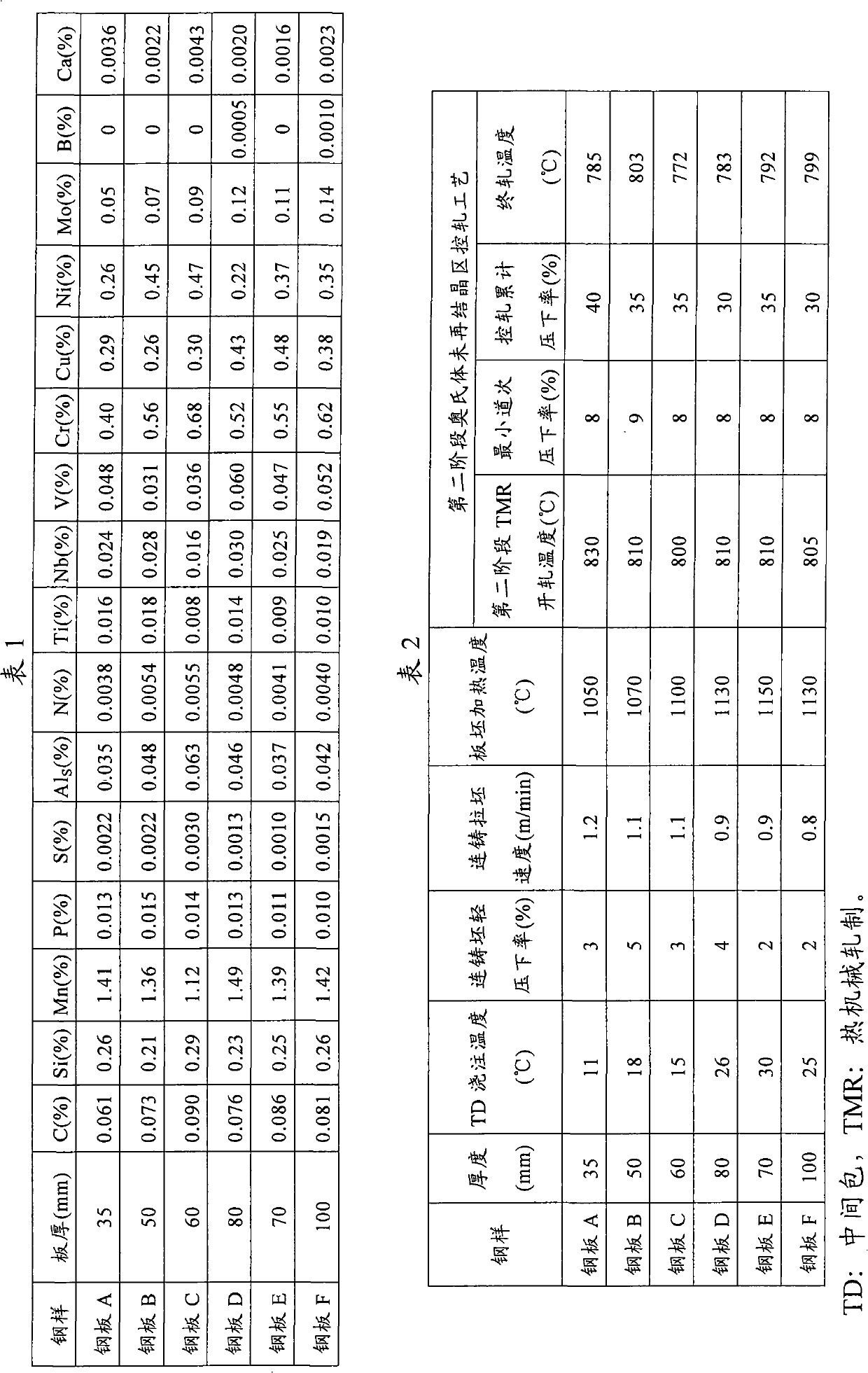

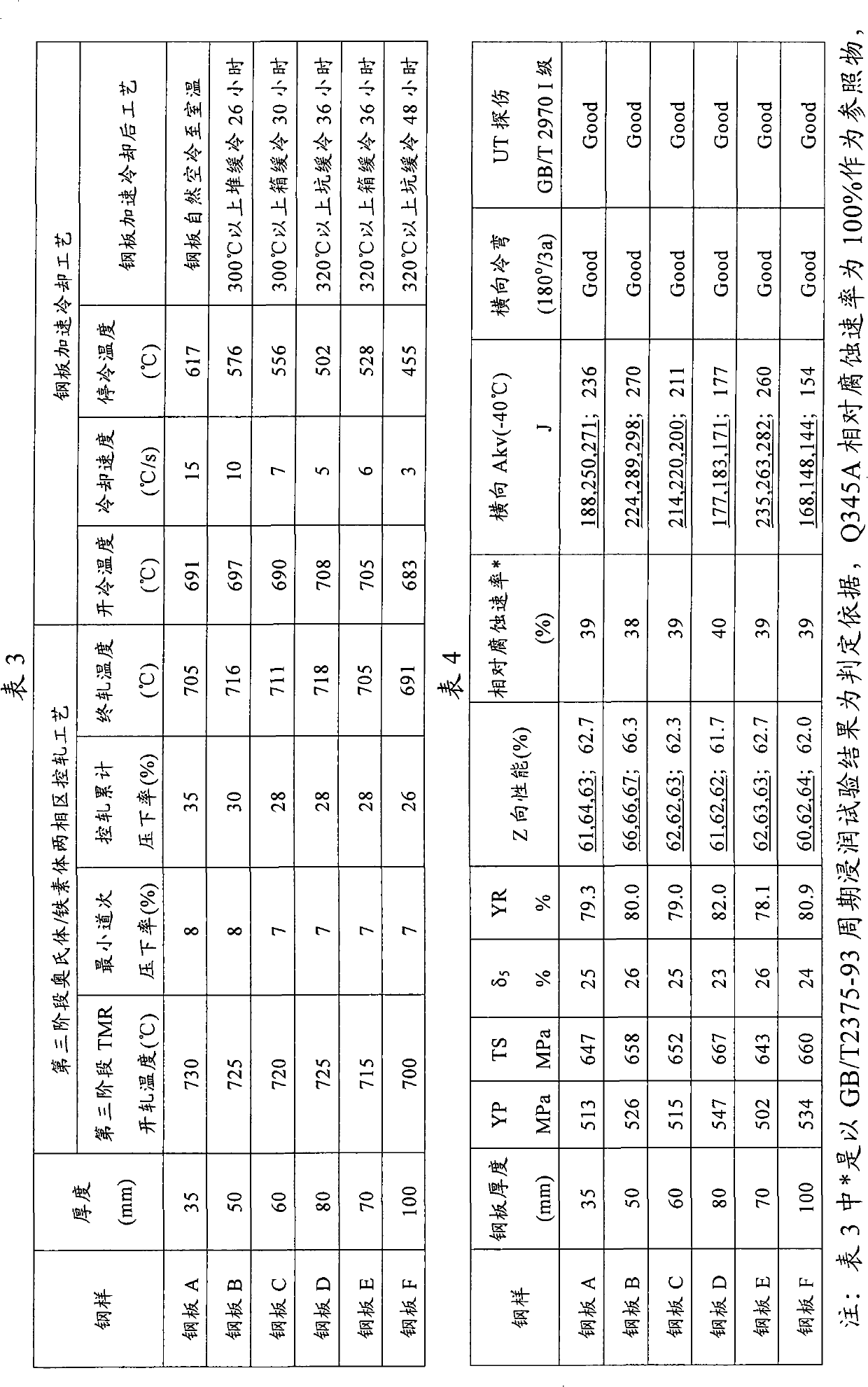

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

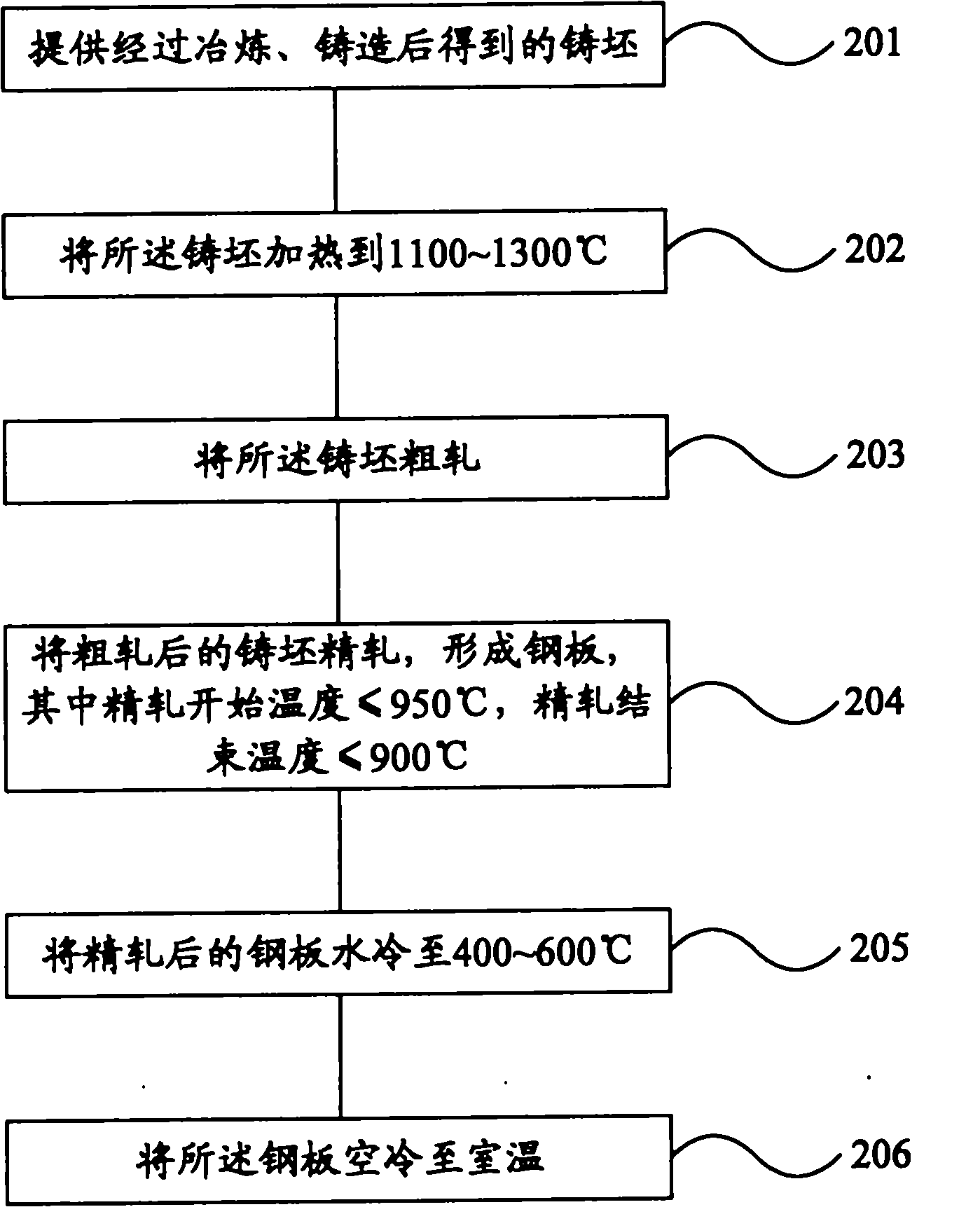

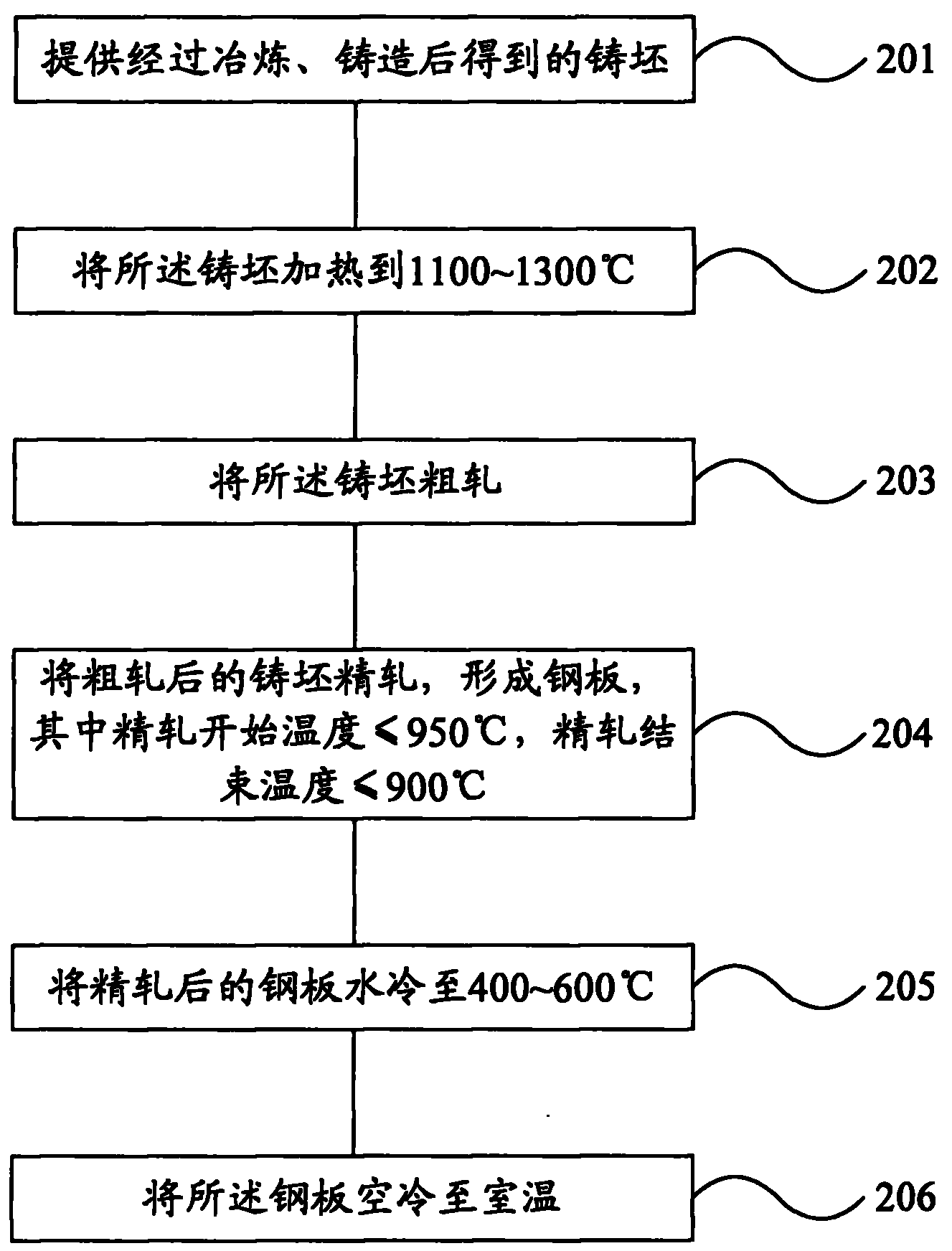

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance weather-proof building structural steel and manufacturing method thereof

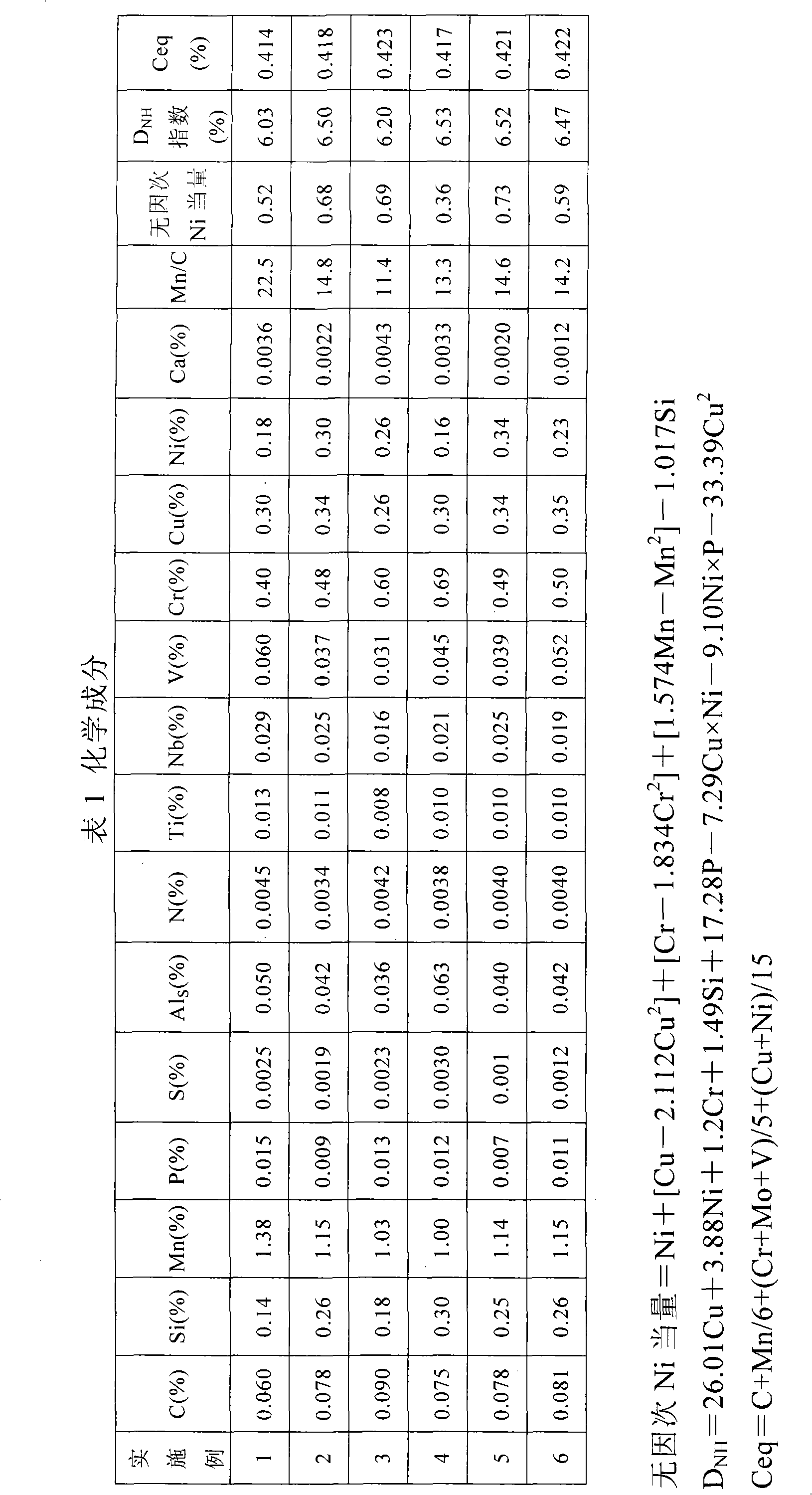

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Weathering steel with yield strength of more than 700MPa and manufacturing method thereof

InactiveCN101994063AMeet the requirements of reducing the self-weight of componentsGood atmospheric corrosion resistanceTemperature control deviceSheet steelUltimate tensile strength

The invention relates to Cr-containing weathering steel with the yield strength of more than 700MPa, good toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components in percentage by weight: 0.02 to 0.10 percent of C, 0.1 to 0.4 percent of Si, 0.3 to 1.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.2 to 0.5 percent of Cu, 2.5 to 10 percent of Cr, 0.2 to 1.0 percent of Ni, 0.02 to 0.06 percent of Nb, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.02 to 0.10 percent of Ti and the balance of Fe and inevitable impurities. A steel plate made of the steel has the yield strength of more than 700MPa and good toughness; meanwhile, the relative corrosion rate of the steel is reduced by one time compared with that of the conventional weathering steel, so the steel meets the requirement of improving the corrosion resistance of steel for railway vehicles and fulfils the aims of prolonging the service life and reducing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

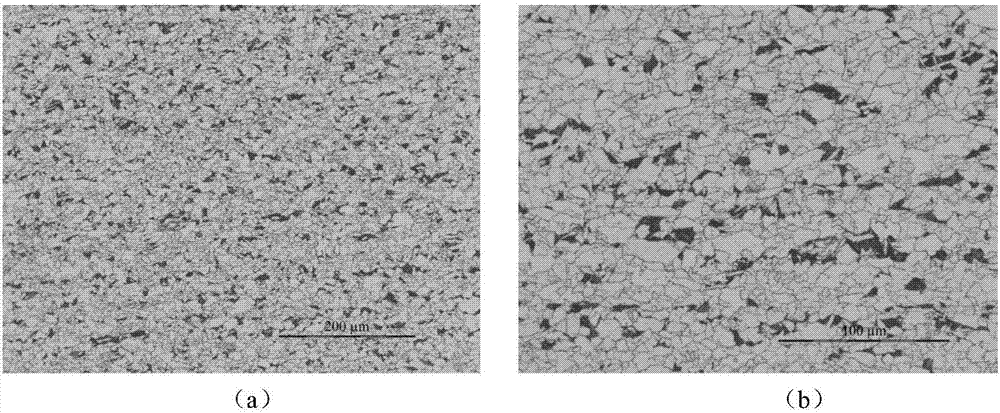

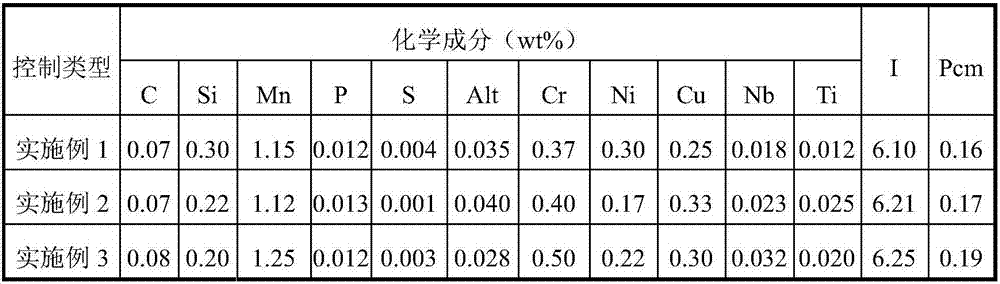

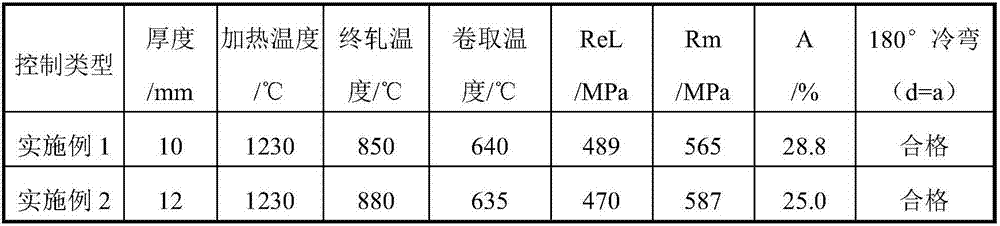

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Cr-contained weathering steel with excellent toughness and high corrosion resistance

InactiveCN102127717AGood atmospheric corrosion resistanceImprove low temperature toughnessTemperature control deviceToughnessWeathering steel

The invention relates to a Cr-contained weathering steel with high corrosion resistance and a manufacture method thereof. The weathering steel is prepared from the following components in percentage by weight: 0.01-0.06 percent of C, 0.1-0.4 percent of Si, 0.2-0.8 percent of Mn, not more than 0.01 percent of P, not more than 0.006 percent of S, 0.2-0.5 percent of Cu, 2.5-7.0 percent of Cr, 0.2-1.2 percent of Ni, 0.01-0.05 percent of Al, not more than 0.005 percent of N, 0.01-0.10 percent of Ti and the balance of Fe and inevitable impurities. The relative corrosion rate of the weathering steel is decreased twice on the basis of traditional weathering steel and can be served in atmosphere environment; the preferred weathering steel has the yield strength over 460 MPa and excellent toughness, meets the requirement of steel for railway vehicles and achieves the aims of prolonging service length and decreasing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

485MPa level TMCP+ tempering weather-proof bridge steel plate and production method

InactiveCN105779883AGood atmospheric corrosion resistanceCounteract harmful effectsSheet steelSensitive index

The invention discloses a 485MPa level TMCP+ tempering weather-proof bridge steel plate and a production method. The steel plate is formed by smelting following chemical components including, by weight percent, 0.05%-0.08% of C, 0.25%-0.50% of Si, 1.20%-1.40% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.005% of S, 0.25%-0.40% of Ni, 0.45%-0.7% of Cr, 0.25%-0.4% of Cu, 0.02%-0.08% of Mo, 0.015%-0.030% of Nb, 0.020-%-0.050% of Al, 0.040%-0.070% of V, and the balance Fe and inevitable impurities. According to the steel plate production method, molten steel is subjected to the procedures of smelting, continuous casting, heating, rolling, cooling and tempering, and then the steel plate is obtained. The large-thickness yield 485MPa level TMCP+ tempering weather-proof bridge steel plate produced through the method has the beneficial effects that the low equivalent carbon equivalent and crack sensitive indexes and the low yield ratio are achieved, the low-temperature impact strength is excellent, and the welding performance is good.

Owner:WUYANG IRON & STEEL

Refractory steel and manufacturing method thereof

The invention provides a fire resistant steel and process for preparing it, wherein C, Si, Mn, Cr and Mo are used as the primary alloy elements for the steel with added trace elements of Cu, Nb, V, Ni, Ti, Al, B and RE, wherein controlled rolling and controlled chilling processes are used, and by controlling carbon equivalent, alloy content and yield ratio, high-performance fire resistant steel with air corrosion resistance can be realized.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

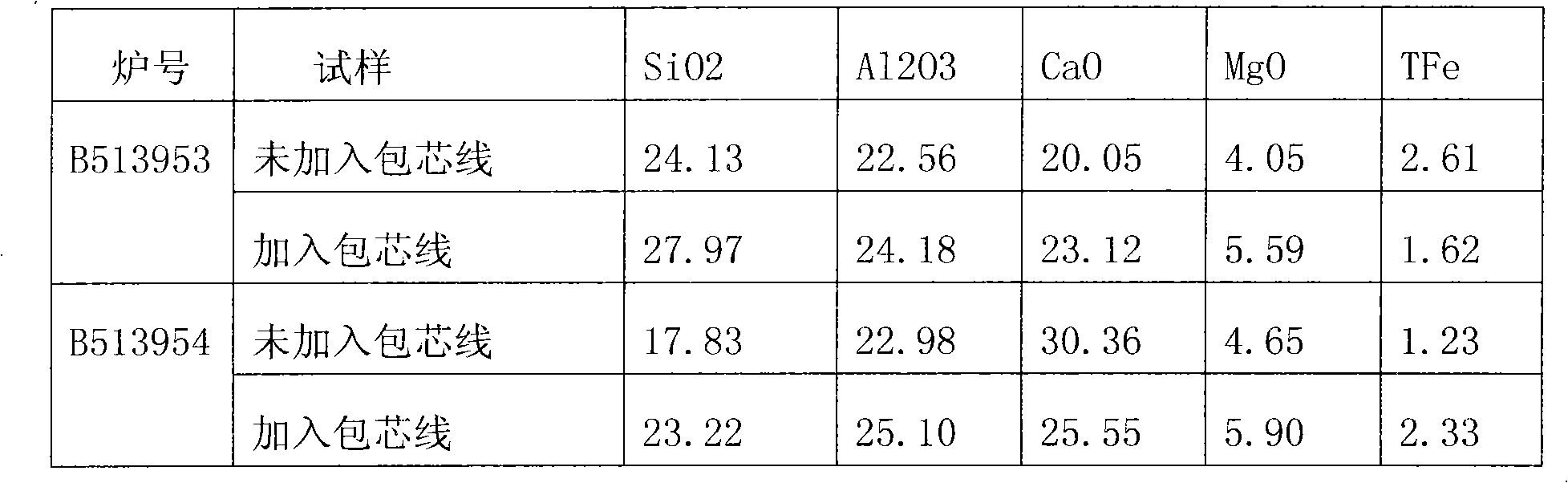

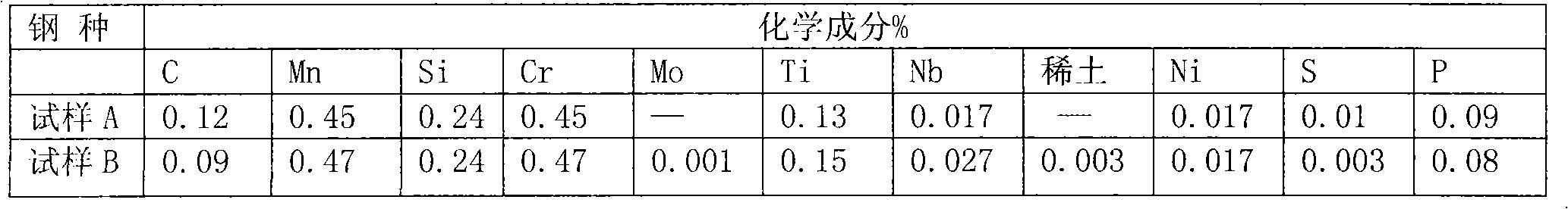

Novel weathering resistant steel microalloying compound core-spun yarn

The invention discloses a novel weathering resistant steel microalloying compound core-spun yarn comprising a steel sheath and a powdery inner core, wherein the powdery inner core is composed of the following chemical ingredients in percentage by weight: 20% of Ca, 0.5% of Mg, 38% of Si, 1.2% of Ba, 1.9% of rare-earth metal, 3.2% of Zr, 1.6% of Ti, 0.5% of B, 0.9% of Mo, 0.5% of Mn, 0.9% of Nb, 0.6% of V and the balance of Fe and inevitable impurity. The invention can obviously refine steel microstructure, improves the decay resistance of steel and lowers C, P and S content in steel by reasonably designing the chemical ingredients; and meanwhile the invention can reduce the amount of parts of alloy elements in steel so as to lower cost.

Owner:HUBEI KMK WELDING MATERIALS

HB600 grade wear-resistant non-quenched and tempered steel plate and making method thereof

ActiveCN104831189AImprove wear resistanceGood atmospheric corrosion resistanceWear resistantRare earth

The invention discloses an HB600 grade wear-resistant non-quenched and tempered steel plate and a making method thereof. The method comprises the processes of smelting, casting, heating, rolling and cooling; and the steel plate comprises, by mass, 0.35-0.45% of C, 0.20-0.50% of Si, 1.20-1.60% of Mn, 0.015% or less of P, 0.01% or less of S, 0.2-1.0% of Cr, 0.1-0.5% of Mo, 0.5-1.5% of Ni, 1.0-2.0% of Cu, 0.2% or less of Ti, 0.2% or less of Nb, 0.2% or less of V, 0.05% or less of Al, 0.005% or less of N, 0.003% or less of O, 0.001-0.005% of B, 0-0.02% of rare earth, and the balance of Fe and inevitable impurities. A carbon content micro alloying mode is adopted, Cr, Ni, Cu, B and other hardenability effect improving elements and V and other precipitating reinforcement elements are properly added, hard phase martensite is obtained under a low cooling rate by using the high hardenability, and a large amount of carbon nitride formed by carbide forming elements is precipitated to improve the content of the hard phase in order to improve the wear resistance of the steel plate; and alloy elements containing Cu and Ni make the steel plate have excellent atmosphere corrosion resistance.

Owner:HEBEI IRON AND STEEL

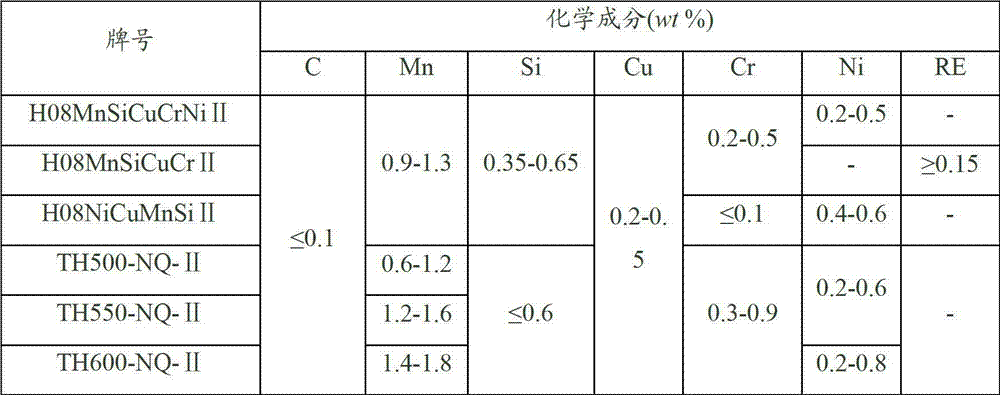

High-corrosion-resistance gas protection welding wire

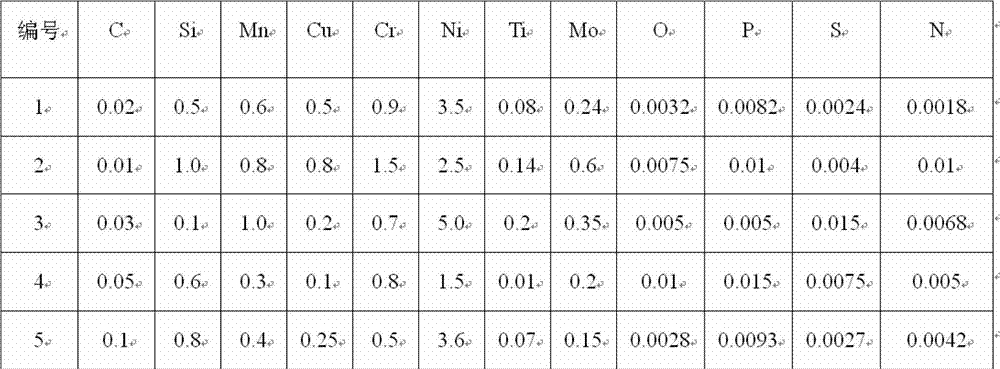

ActiveCN103028865AGood atmospheric corrosion resistanceGood comprehensive mechanical propertiesWelding/cutting media/materialsSoldering mediaCorrosionGas protection

The invention belongs to the field of welding materials, and relates to a high-corrosion-resistance gas protection welding wire. The welding wire comprises the following chemical compositions in percentage by mass: 0.01-0.1 percent of C, 0.1-1.0 percent of Si, 0.3-1.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 1.5-5 percent of Ni, 0.5-1.5 percent of Cr, 0.1-0.8 percent of Cu, 0.01-0.2 percent of Ti, 0.15-0.6 percent of Mo, less than or equal to 0.01 percent of O, less than or equal to 0.01 percent of N and the balance of ferrum. The welding wire has stable welding performance, and obtained deposited metal is matched with the corrosion resistance of parent metal; and meanwhile, the welding wire has high comprehensive mechanical performance, and is particularly suitable for novel high-weather-proof steel.

Owner:CENT IRON & STEEL RES INST

Soft magnetic FeCo based target material

ActiveUS20080112841A1Improve corrosion resistanceImprove magnetic propertiesCellsVacuum evaporation coatingAlloyCobalt

A soft-magnetic FeCo based target material is provided which has a high saturation magnetic flux density and superior atmospheric corrosion resistance. The target material is a soft-magnetic FeCo based target material made of an FeCo based alloy. The FeCo based alloy comprises 0 to 30 at. % of one or more metal elements selected from the group consisting of B, Nb, Zr, Ta, Hf, Ti and V; and the balance being Fe and Co with unavoidable impurities. The Fe:Co atomic ratio ranges from 10:90 to 70:30. The FeCo based alloy may further comprise 0.2 at. % to 5.0 at. % of Al and / or Cr.

Owner:SANYO SPECIAL STEEL COMPANY

High ductility climate resistant solder stick with tensile strength of 600MPa

ActiveCN1923431AGood atmospheric corrosion resistanceExcellent overall performanceWelding/cutting media/materialsSoldering mediaFerromanganeseDuctility

The invention relates to a high-flexibility welding bar whose tensile strength is 600MPa. Wherein, its components comprise that marble at 6-42;derbyshire spar at 16-22;ferrotitanium at 9-12;medium-carbon ferromanganese at 4-6; ferrosilicium at 1-3;synthetic mica at 1-3;micro silicon powder at 1-3;iron powder at 12-18;chrome metal at 1-2;copper powder at 0.5-1; nickel at 1-2;molybdenum at 0.3-0.8; and titanium white at 2-5. The inventive product has better corrosion resistance, with better low-temperature impact flexibility at -40Deg. C; and its yield strength is higher than 500MPa;tensile strength is higher than 600MPa; extensibility is higher than 20%;and (-40Deg. C) Akv>=60J.

Owner:BAOSHAN IRON & STEEL CO LTD +1

High strength anti-weather burial arc welding wire

ActiveCN1714985ASimple designDesign economyArc welding apparatusWelding/cutting media/materialsMetallurgyAtmospheric corrosion

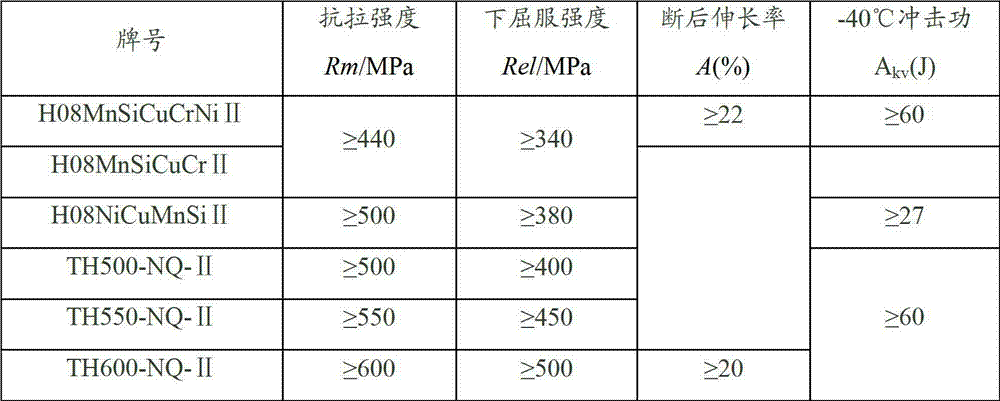

The high strength weather resisting submerged arc welding wire consists of: C 0.04-0.15 wt%, Mn 1.2-2.0 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, Cu 0.10-0.30 wt%, Cr 0.40-1.2 wt%, Ni 0.20-0.80 wt%, and Ti 0.03-0.10 wt%. The welding wire forms fused-on metal and welded joint with excellent atmospheric corrosion resistance and excellent comprehensive performance, including yield strength not lower than 450 MPa, tensile strength not lower than 550 MPa, elongation greater than 22 %, and especially low temperature impact toughness of Akv not lower than 60 J at the temperature of -40 deg c.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength and high-toughness automatic submerged arc welding wire with weathering resistance

InactiveCN101537549AGood atmospheric corrosion resistanceGood joint performanceWelding/cutting media/materialsSoldering mediaWeather resistanceChemical composition

The invention relates to a high-strength and high-toughness automatic submerged arc welding wire with weathering resistance and mainly aims at overcoming disadvantages of poor atmospheric corrosion resistance, high production cost and the like of the existing submerged arc welding materials. In term of technical measures, the welding wire is made from the following chemical components by weight percent: C: 0.05-0.12, Si: 0.01-0.10, Mn: 1.50-2.1. S: not more than 0.015, P: not more than 0.020, Ni: 0.20-0.60, Cr: 0.20-0.50, Cu: 0.25-0.50, Ti: 0.05-0.16, B: 0.002-0.010, Als: 0.001-0.015, Fe and other unavoidable impurities. The welding wire is matched with a basic sintered flux for welding, a weld joint has excellent atmospheric corrosion resistance and comprehensive mechanical properties, and a deposited metal at a weld seam has tensile strength up to 560MPa and ballistic work up to 107J at -40 DEG C and up to 87J at -50 DEG C.

Owner:武钢集团有限公司

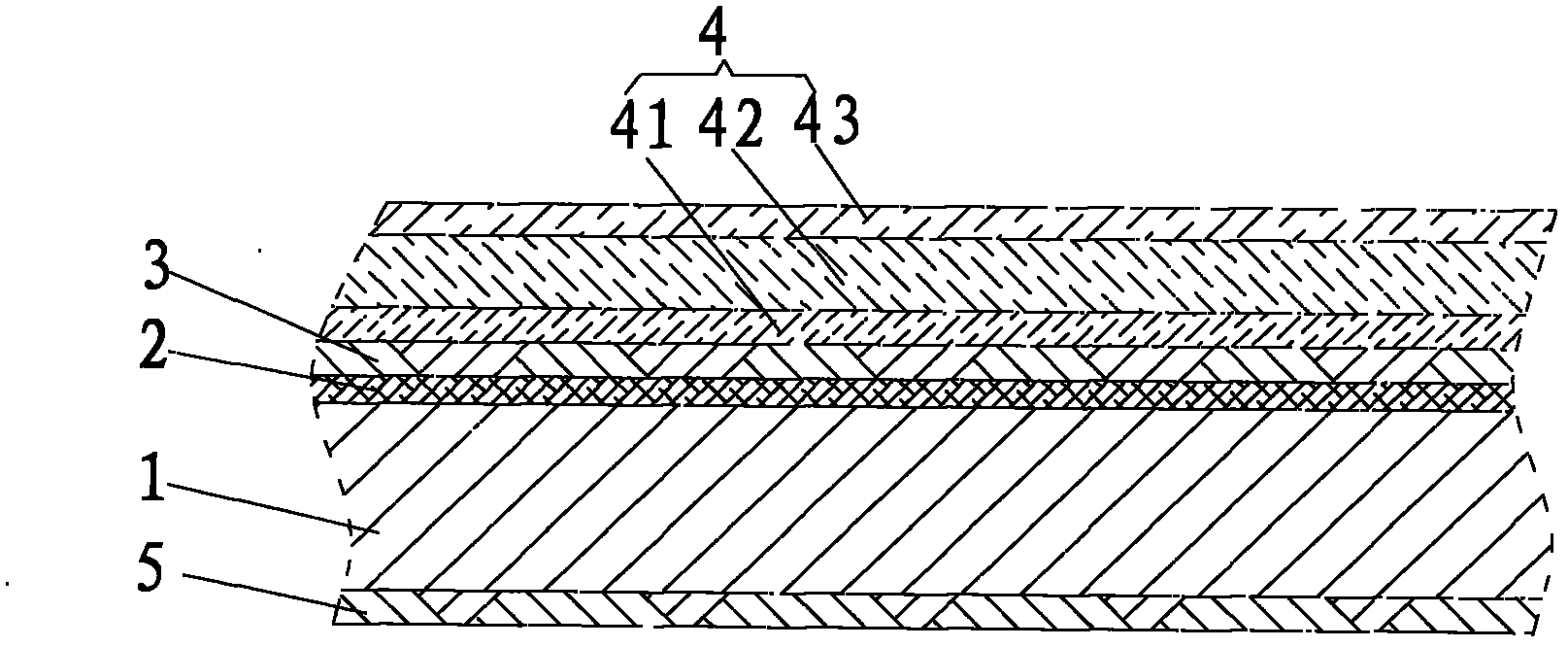

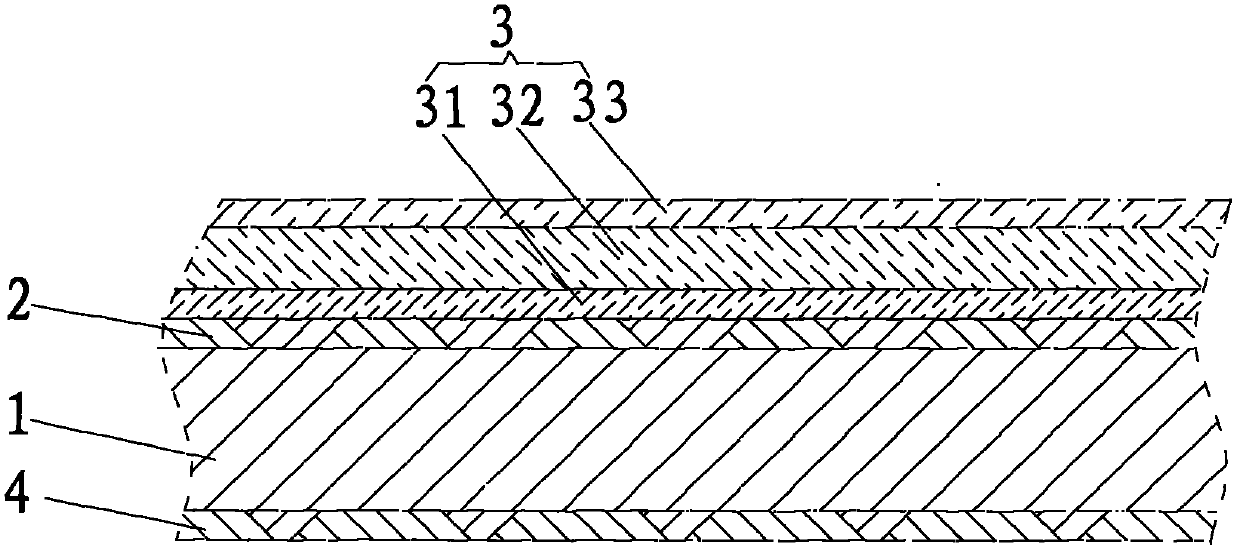

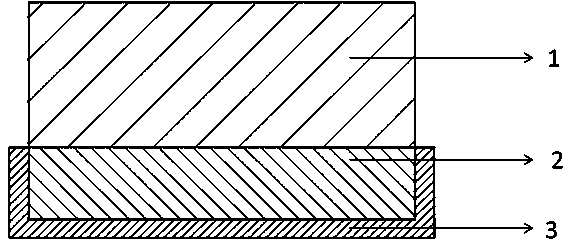

Ceramic aluminum single sheet and preparation process thereof

InactiveCN102658691AReliable and easy processImprove acid resistanceLaminationLamination apparatusCeramic coatingAlloy

The invention relates to the technical field of building materials and particularly relates to a ceramic aluminum single sheet and a preparation process of the ceramic aluminum single sheet. The ceramic aluminum single sheet comprises an aluminum alloy panel, wherein a sand-sprayed passivation layer, a chromizing pre-treatment layer and a fluorine-carbon ceramic coating are sequentially and outwardly arranged at the outer side of the aluminum alloy panel; the fluorine-carbon ceramic coating sequentially comprises a fluorine-carbon primer layer, a fluorine-carbon paint layer and a fluorine-carbon protection layer from inside to outside; a chromizing protection layer is arranged at the inner side of the aluminum alloy panel, and then the sand-sprayed passivation layer and the chromizing pre-treatment layer are arranged, and finally the fluorine-carbon ceramic coating is arranged, so that the surface of the alloy panel is cleaned and the adhesive force is strong; and the fluorine-carbon ceramic coating is firmly attached and is not easy to drop off. The preparation process of the ceramic aluminum single sheet disclosed by the invention is reliable and feasible, so that the final product ceramic aluminum single sheet has the advantages of excellent adhesive force, excellent acid resistance, excellent solvent resistance, excellent abrasion resistance, excellent impact resistance and excellent mechanical property.

Owner:东莞市华轩幕墙材料有限公司

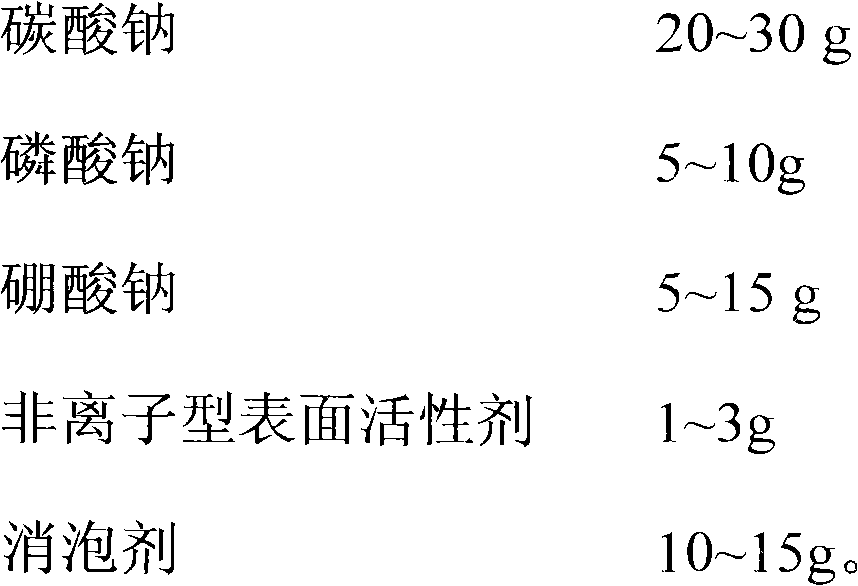

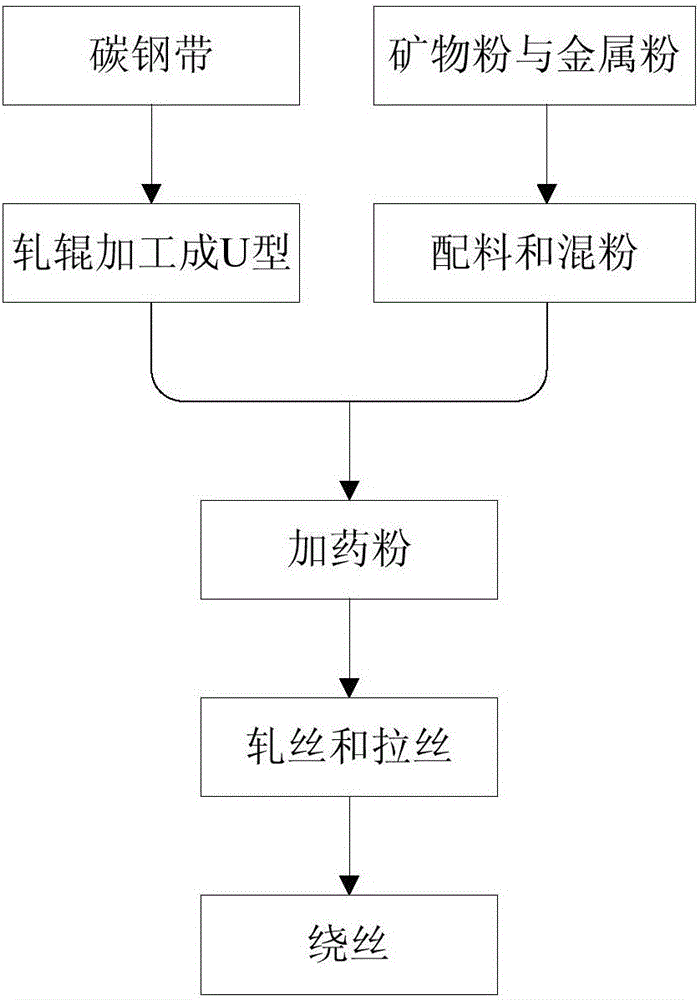

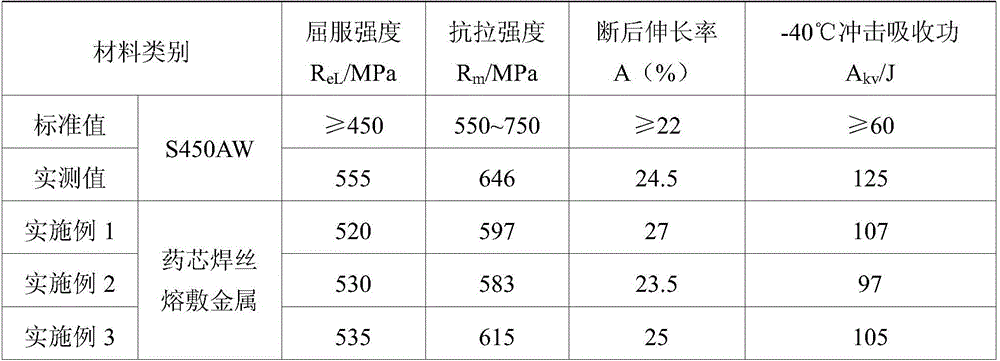

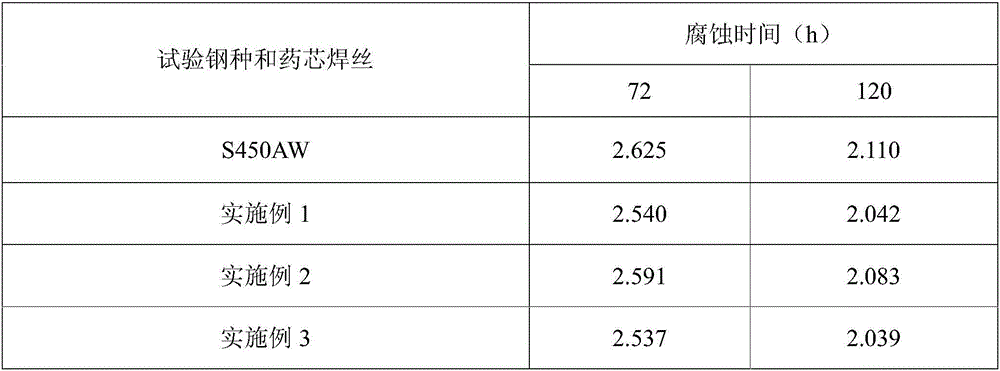

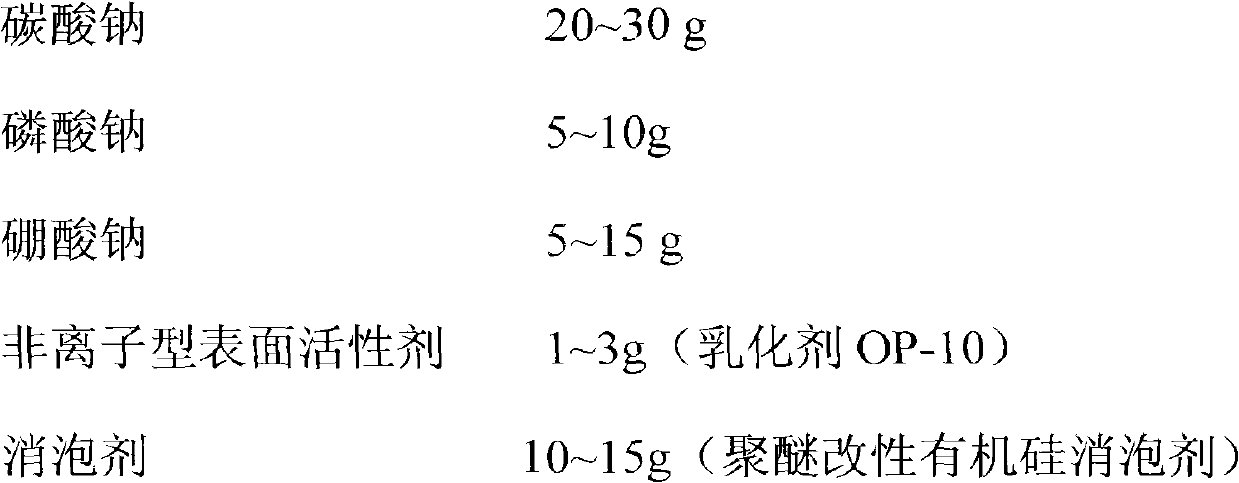

High-toughness atmosphere corrosion resistance flux-cored solder wire and preparation method thereof

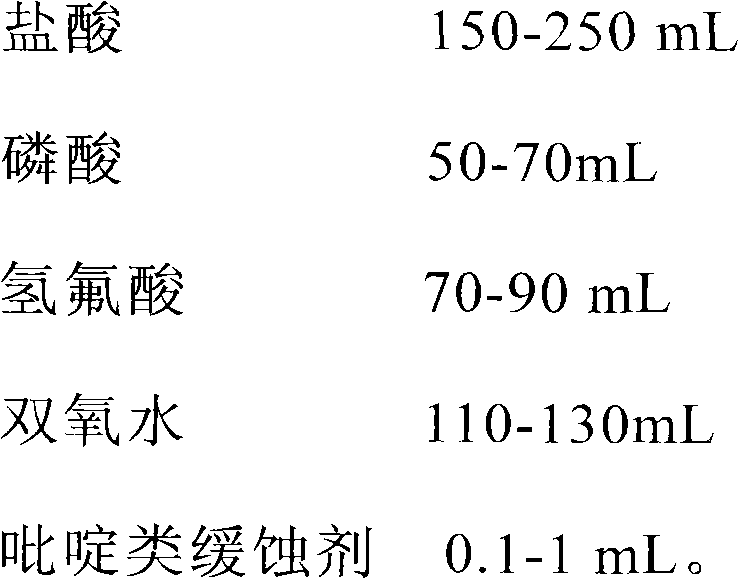

ActiveCN105728989AEnsuring Low Temperature Impact AbsorptionGood atmospheric corrosion resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconAbsorbed energy

The invention discloses a high-toughness atmosphere corrosion resistance flux-cored solder wire and a preparation method thereof. The flux-cored solder wire is made of carbon steel cold-rolled steel strip and a flux core. The flux core comprises, by mass, 25-40% of rutile, 3-7% of quartz sand, 1-3% of magnesite, 3-12% of aluminosilicate, 1-4% of sodium fluoride, 1-3% of sodium oxide, 5-15% of low-carbon ferromanganese, 3-7% of ferrosilicon, 2.5-5.5% of Ni, 2.5-7% of Cr, 1-3% of Cu, 1.5-5.5% of ferrotitanium, less than or equal to 3% of ferromolybdenum and ferrovanadium, and the balance iron powder. According to the flux-cored solder wire, welding is carried out with 100% of CO2 as protective gas, so that the flux-cored solder wire has good welding usability, and the low-temperature impact absorbing energy of the flux-cored solder wire at minus 40 DEG C is greater than 60J. Moreover, the flux-cored solder wire has good atmosphere corrosion resistance and can meet the requirements for welding of weather resistant steel with the yield strength being 450 MPa.

Owner:XIANGTAN UNIV

Large-thickness rack steel plate directly produced by continuous casting billet and manufacturing method of large-thickness rack steel plate

The invention relates to a large-thickness rack steel plate directly produced by a continuous casting billet. The steel plate takes Fe as a base component and further comprises the following chemical components by mass percent: 0.10% to 0.16% of C, 0.15% to 0.35% of Si, 0.95% to 1.25% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, greater than or equal to 2.4% and less than or equal to 3.0% of Cr+Mo+Ni+Cu, greater than or equal to 0.08% and less than or equal to 0.13% of Al+V, less than or equal to 0.007% of N and 0.001% to 0.002% of B. A manufacturing method of the large-thickness rack steel plate comprises the following steps of KR molten iron pretreatment, converter smelting, LF (ladle furnace) refining, RH refining, continuous casting, casting billet covering for slow cooling, casting billet clearing, heating, high-pressure water descaling, rolling control, straightening, accumulation slow-cooling or slow cooling under a control condition and tempering. The steel plate is high in strength, good in plasticity, high in Z-direction performance and high in low-temperature toughness. In addition, the steel plate is simple and convenient in production process and low in cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

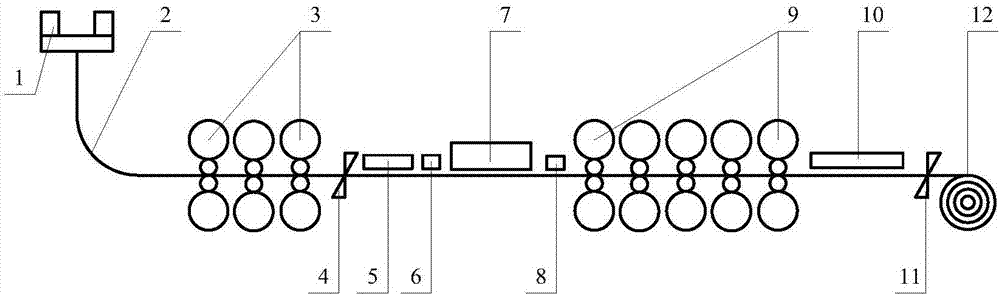

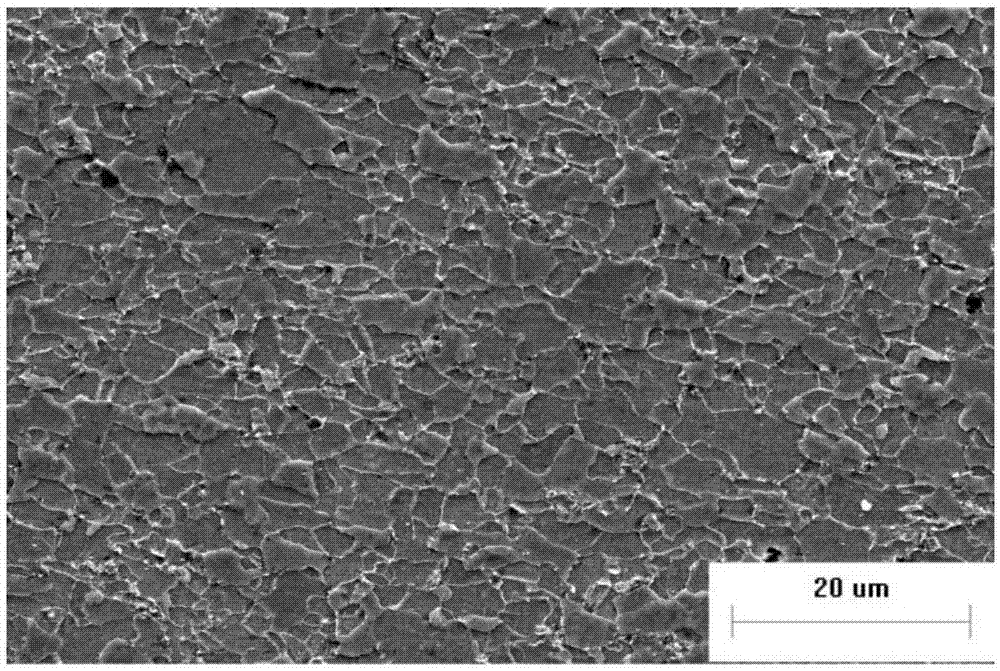

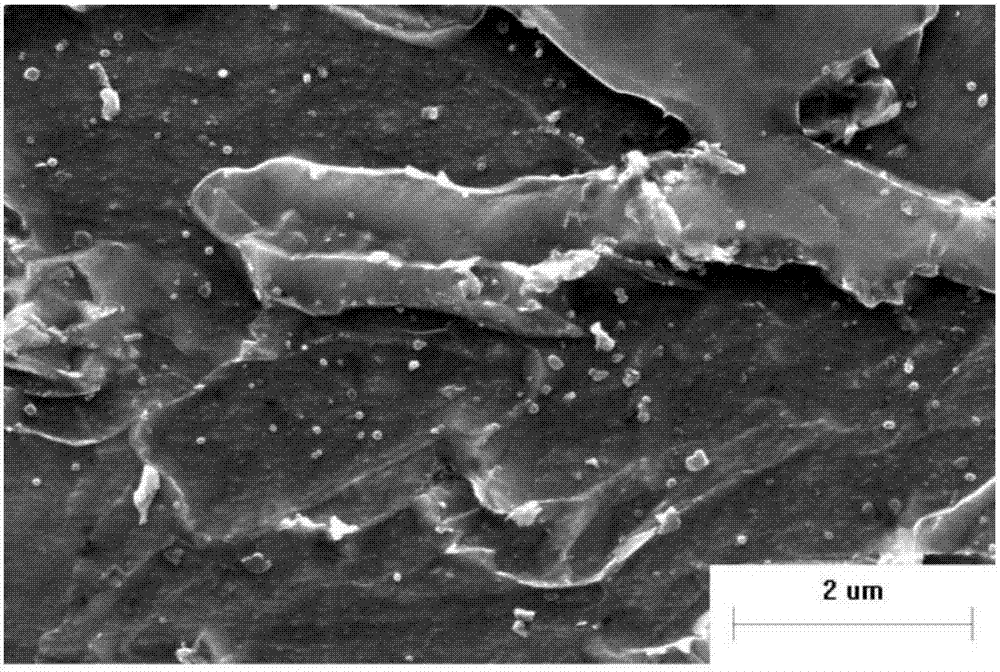

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

Submerged arc welding wire for superstrength pipeline steel and production method thereof

InactiveCN102069320AHigh strengthIncrease contentArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingCopper plating

The invention relates to a submerged arc welding wire for superstrength pipeline steel and a production method thereof. The technical scheme is that: the submerged arc welding wire comprises the following components in percentage by weight: 0.04 to 0.06 percent of C, 1.40 to 2.00 percent of Mn, 0.70 to 1.10 percent of Mo, 2.00 to 2.60 percent of Ni, 0.80 to 1.20 percent of Cr, 0.10 to 0.30 percent of Cu, less than or equal to 0.0005 percent of B, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe and inevitable impurities. The production method comprises the following steps of: adding 0.01 to 0.5 weight percent of composite additive when the components are smelted, forming a square billet in a pouring way, hot-rolling the square billet to form a steel wire rod with the diameter of Phi 5.5 to Phi 7.5mm, removing oxide skin from a surface, drawing the steel wire rod to form the welding wire with the diameter of Phi 3.2 to Phi 4.0mm and performing copper plating, wherein the composite additive is added in form of cored wire. The welding wire produced by the method is welded together with an SJ105 welding flux so as to achieve the tensile strength sigmab of more than or equal to 910MPa and the impact toughness Akv at -30 DEG C of more than or equal to 84J of a weld metal, and is suitable for the submerged arc welding of X120 pipeline steel with superstrength.

Owner:WUHAN UNIV OF SCI & TECH

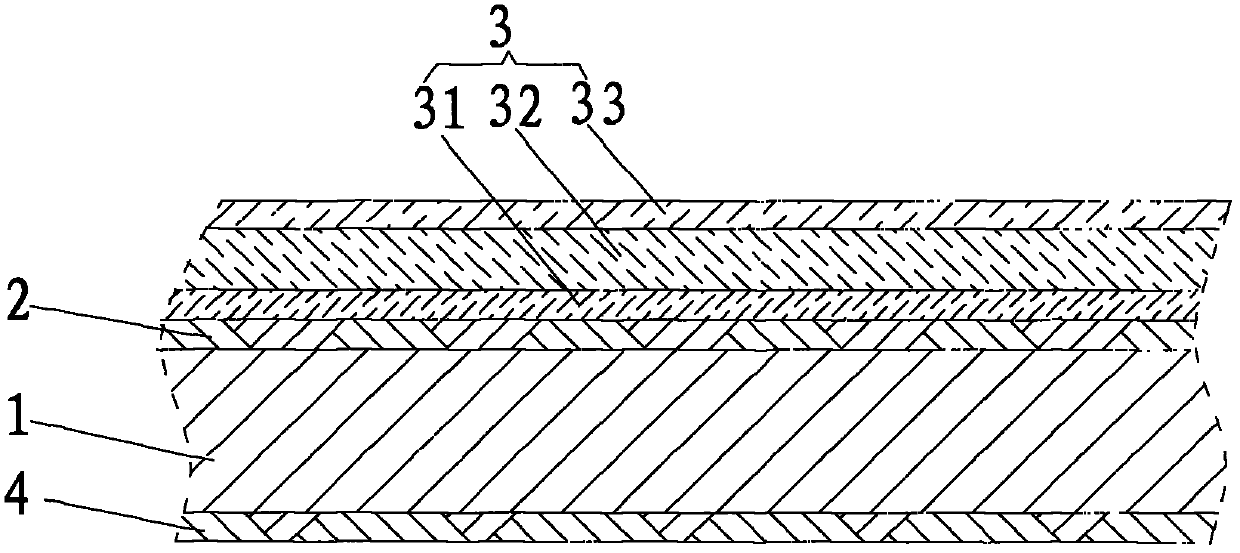

Fluorocarbon spray coating and etching aluminum veneer and preparation process of fluorocarbon spray coating and etching aluminum veneer

InactiveCN102632653AReliable and easy processImprove acid resistanceDecorative surface effectsSpecial ornamental structuresCeramic coatingSpray coating

The invention relates to the technical field of building materials, in particular to a fluorocarbon spray coating and etching aluminum veneer and a preparation process of the fluorocarbon spray coating and etching aluminum veneer. The fluorocarbon spray coating and etching aluminum veneer provided by the invention comprises an aluminum alloy panel with etching patterns at the outer side, wherein the outer side of the aluminum alloy panel is sequentially and outwards provided with a chromizing pretreatment layer and a fluorocarbon coating, the inner side of the aluminum alloy panel is provided with a chromizing protection layer, and the fluorocarbon ceramic coating is further arranged on the chromizing pretreatment layer, so the protection effect is realized on the surface of the aluminum alloy panel, and the adhesive force is strong, so the fluorocarbon coating is firmly attached and cannot easily fall off. The fluorocarbon spray coating and etching aluminum veneer has the characteristics that the light pollution is avoided, the self cleaning performance is high, the daily maintenance is convenient, the color is rich and cannot fade. The manufacture process of the fluorocarbon spray coating and etching aluminum veneer is reliable and is easy to implement, so the adhesive force, the acid resistance, the solvent resistance, the wear resistance, the impact resistance and the mechanical performance of the finished product fluorocarbon spray coating and etching aluminum veneer are good.

Owner:东莞市华轩幕墙材料有限公司

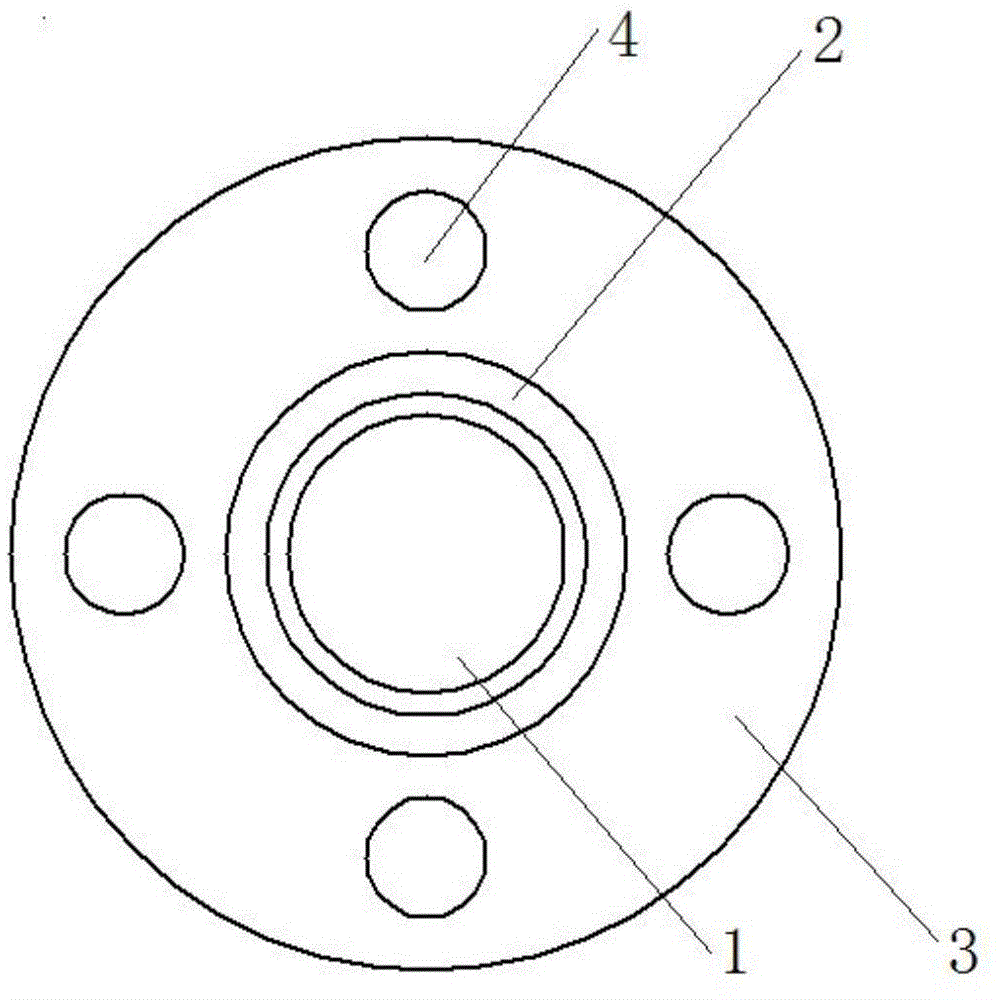

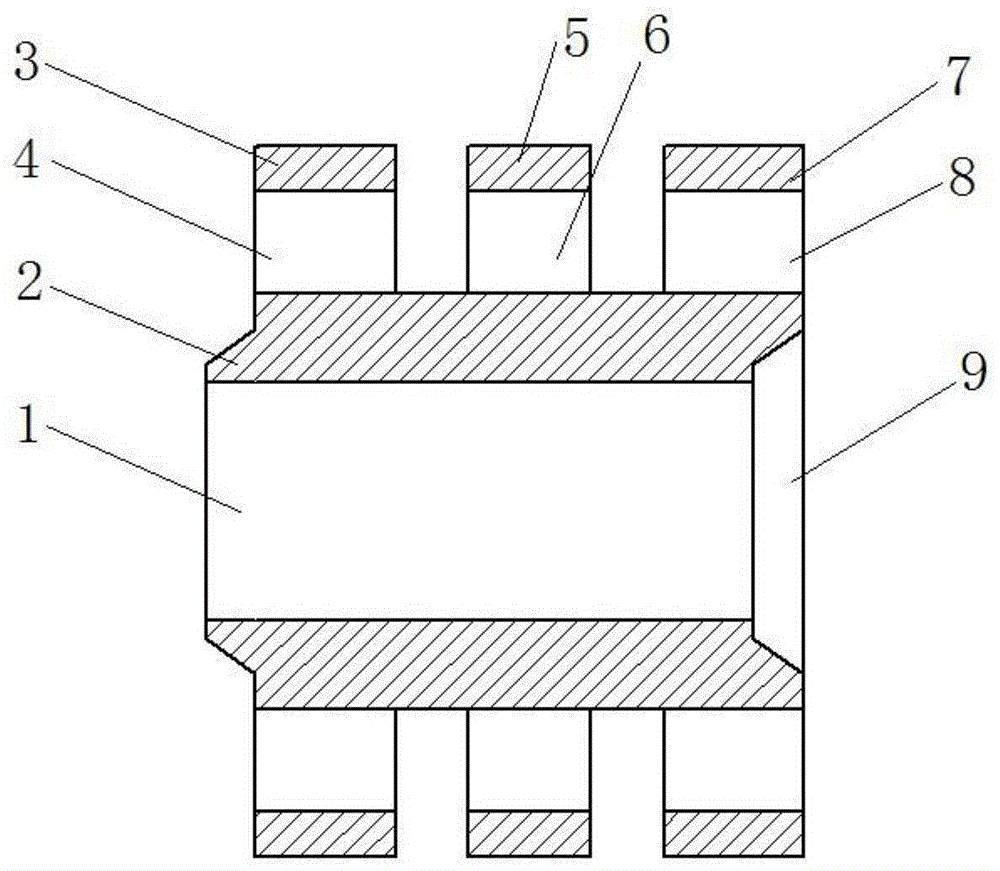

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

High-strength weather-resistant welding rod

ActiveCN1743126AGood atmospheric corrosion resistanceImprove performanceWelding/cutting media/materialsSoldering mediaIron powderFerrosilicon

A sort of strong clime-withstanding welding rod is disclosed, whose coating content as follows, marble 35-40%, fluorite 15-20%, ferrotitanium 8-11%, mid-carbon Fe-Mn 3-8%, ferrosilicon 45%, synthesized isinglass(40 mesh) 2-3%, tiny ganister sand 2-4%, iron powder 12-20%, chrome 1-2%, copper powder 0.5-1%, nickel powder 1-2%, titanium pigment 4-8%. The fused metal and welded joint obtained by the invention has the good performance of withstanding clime and comprehensive performance, especially at -40deg.C it has good low temperature impact toughness, yield strength>=450MPa, tensile strength>=550MPa, elongation rate >=22%, Akv>=100j.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Weather-resistant submerged arc welding wire for free-coating weather-resistant steel bridge

ActiveCN106001987AGood weld formabilityImprove metallurgical qualityArc welding apparatusWelding/cutting media/materialsChemical compositionAtmospheric corrosion

The invention discloses a weather-resistant submerged arc welding wire for a free-coating weather-resistant steel bridge, and belongs to the field of welding materials. According to the technical scheme, the weather-resistant submerged arc welding wire for the free-coating weather-resistant steel bridge comprises a basic chemical component Fe and the following chemical components in percentage by mass: 0.03 to 0.10% of C, 0.10 to 0.28% of Si, 1.15 to 1.55% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.25 to 0.55% of Cr, 0.25 to 0.55% of Ni, 0.20 to 0.50% of Cu, 0.005 to 0.025% of Ca, and 0.005 to 0.05% of Re. The welding wire is applied to the welding of Q345qENH-Q460qENH serial weather-resistant bridge steel, and is outstanding in atmospheric corrosion resistance, high in process performance, stable in quality, and suitable for large-scale popularization and application.

Owner:YANSHAN UNIV

Corrosion-resisting steel with yield strength of 450 MPa for coal open-boxcar and manufacturing method thereof

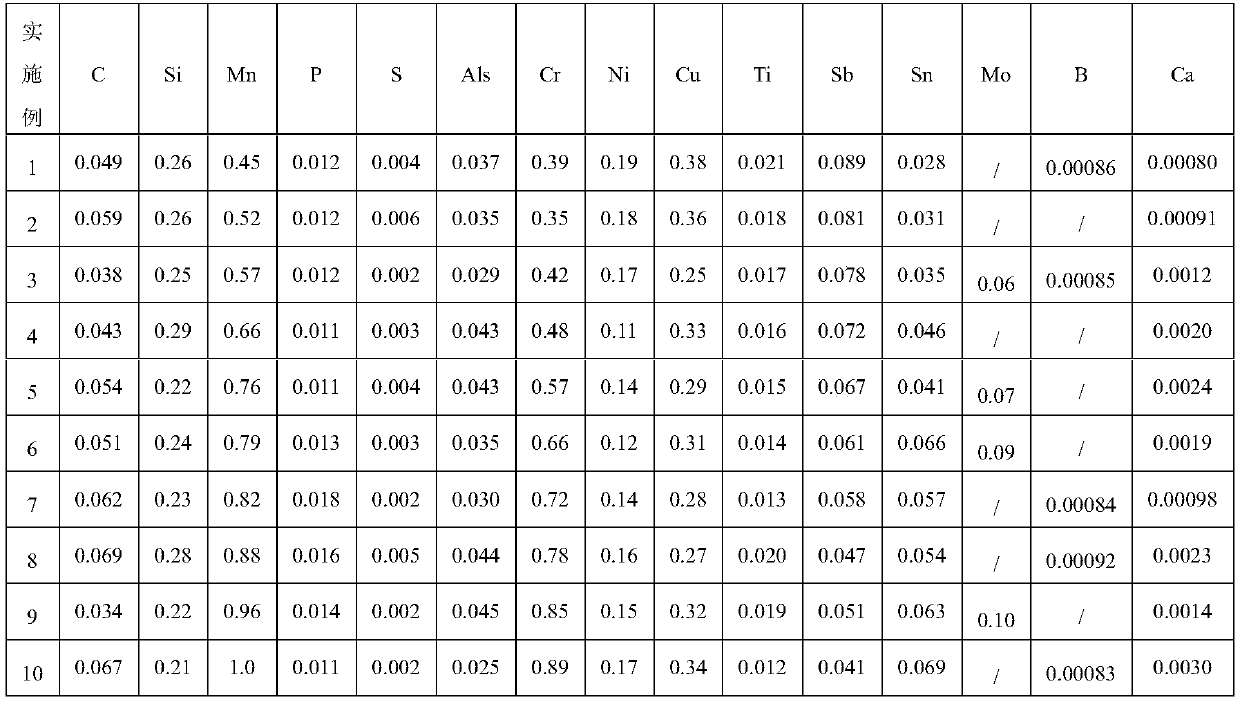

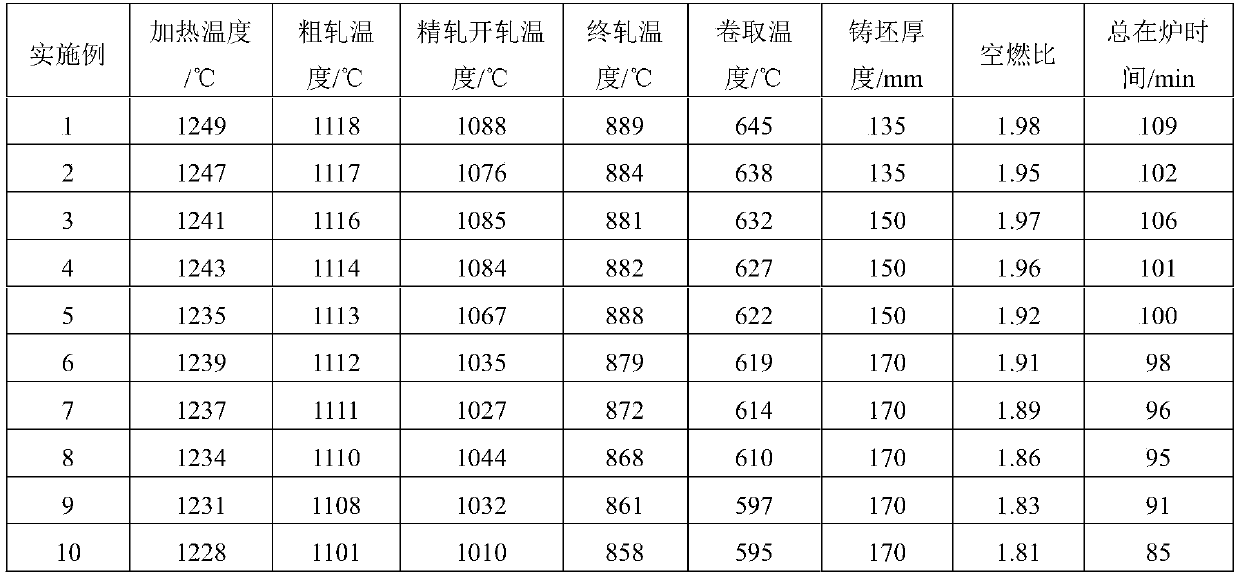

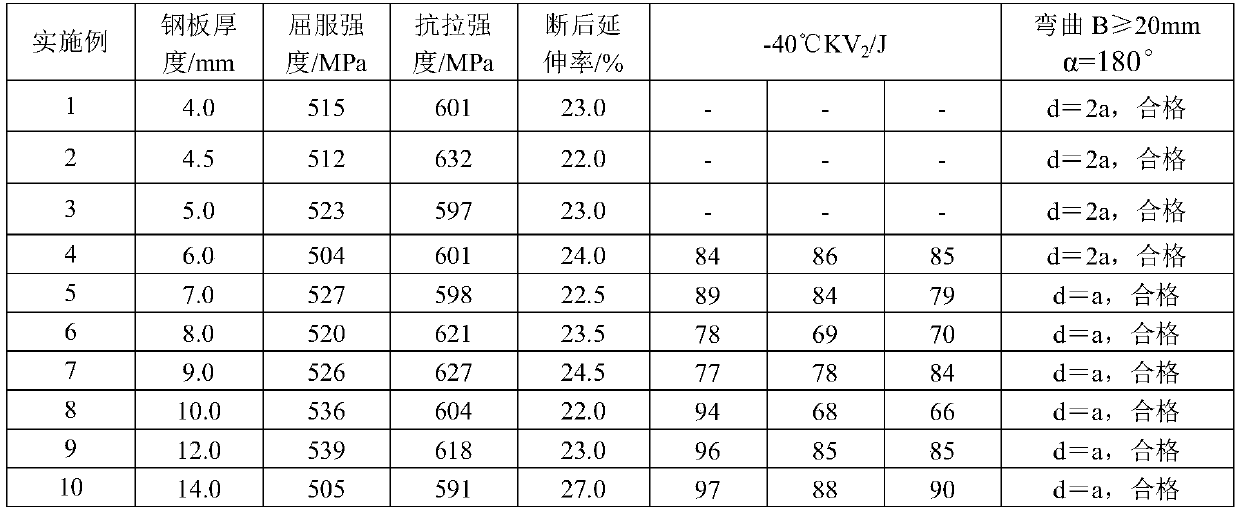

The invention discloses a corrosion-resisting steel with yield strength of 450 MPa for a coal open-boxcar and a manufacturing method thereof. The corrosion-resisting steel is prepared from 0.034%-0.069% of C, 0.21%-0.29% of Si, 0.45%-1.0% of Mn, less than or equal to 0.018% of P, less than or equal to 0.006% of S, 0.015%-0.045% of Als, 0.35%-0.89% of Cr, 0.11%-0.19% of Ni, 0.25%-0.38% of Cu, 0.012%-0.021% of Ti, 0.041%-0.089% of Sb, 0.028%-0.069% of Sn, 0-0.19% of Mo, 0-0.0019% of B, 0.0008%-0.0030% of Ca, and the balance Fe and inevitable impurities. The method includes steps of heating a plate blank being 135-170 mm thick to the temperature of 1228-1249 DEG C, rough rolling the plate blank at the temperature greater than 1100 DEG C, finish rolling the plate blank at the temperature of 1000-1100 DEG C, carrying out final rolling on the plate blank at the temperature of 830-895 DEG C, and coiling the plate at the temperature of 580-650 DEG C. The steel plate has excellent resistance tosulfuric acid and chloride ion corrosion.

Owner:ANGANG STEEL CO LTD

Plated switch contact and preparing method thereof

ActiveCN104112607AImproved arc erosion resistanceImprove reliabilityLiquid/solution decomposition chemical coatingContactsKey pressingVulcanization

The invention discloses a plated switch contact and a preparing method thereof. The switch contact is a combined body with a three-layer structure, the first layer is a hydrophobic rubber layer, the second layer is a sheet metal layer, the third layer is a plated layer, and a combination body of the first layer and the second layer is soaked in a chemical plating solution with a soluble gold compound and gold or gold alloy is selectively deposited on the surface of sheet metal in the combination body by a chemical deposit method to form the plated layer. According to the plated switch contact and the preparing method thereof, the prepared switch contact is suitable for heat vulcanization bonding and forming with rubber, and thereby, a rubber press key with the switch contact can be produced. The switch contact has the advantages that the resistance to atmospheric corrosion, contact chatter and arc erosion is good, the surface contact resistance is low, the service life is long, and the like.

Owner:NANTONG MEMTECH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com