HB600 grade wear-resistant non-quenched and tempered steel plate and making method thereof

A wear-resistant steel plate and a manufacturing method technology, applied in the field of wear-resistant steel plates, can solve the problems of inability to guarantee the dimensional accuracy and shape accuracy of parts, increase the process production cost, and difficult to control the shape of the steel plate, and achieve excellent atmospheric corrosion resistance, good Atmospheric corrosion resistance, good shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

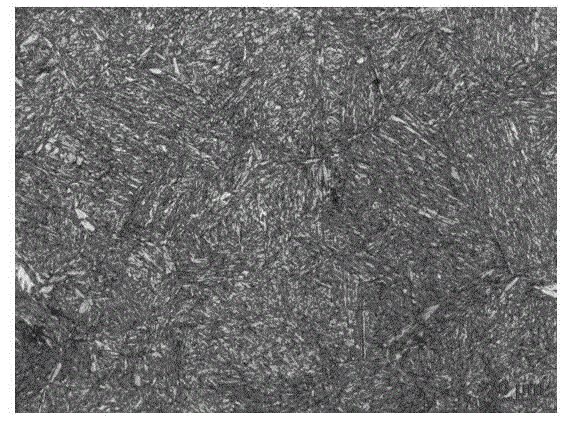

Image

Examples

Embodiment 1

[0031] Example 1: The composition ratio and manufacturing method of the HB600 grade non-tempered wear-resistant steel plate are as follows.

[0032] The chemical composition of this HB600 non-quenched and tempered wear-resistant steel plate is as follows: C 0.44%, Si 0.50%, Mn 1.5%, P 0.007%, S 0.002%, Cr 1.0%, Mo 0.15%, Ni 0.5%, Cu 1.9%, Al 0.04%, B 0.002%, rare earth 0.002%, the rest is Fe and unavoidable impurities; the thickness is 30mm.

[0033]The above chemical components are smelted according to the mass percentage and cast into ingots, and the ingots are heated before rolling. The heating temperature is 1230° C. and the heating time is 3 hours. Two-stage controlled rolling is adopted, the rough rolling start temperature is 1150°C, the finish rolling temperature is 1050°C, the cumulative reduction rate of rough rolling is 51.5%; the finish rolling start temperature is 1030°C, the finish rolling temperature is 950°C, and the finish rolling cumulative The reduction rate...

Embodiment 2

[0034] Example 2: The composition ratio and manufacturing method of the HB600 grade non-quenched and tempered wear-resistant steel plate are as follows.

[0035] The chemical composition of this HB600 non-quenched and tempered wear-resistant steel plate is: C 0.45%, Si 0.40%, Mn 1.3%, P 0.009%, S 0.002%, Cr 0.95%, Mo 0.1%, Ni 0.6%, Cu 2.0%, Ti 0.1%, Al 0.02%, B 0.003%, rare earth 0.002%, the rest is Fe and unavoidable impurities; the thickness is 8mm.

[0036] The above chemical components are smelted according to mass percentage and cast into ingots, and the ingots are heated before rolling at a heating temperature of 1225° C. for 3 hours. Using two-stage controlled rolling, the rough rolling start temperature is 1130°C, the finish rolling temperature is 1040°C, and the cumulative reduction rate of rough rolling is 72.1%; The reduction rate is 82.6%, and the reduction rate in the last three passes is not less than 10%. The thickness of the plate after finishing rolling is 8m...

Embodiment 3

[0037] Example 3: The composition ratio and manufacturing method of the HB600 grade non-quenched and tempered wear-resistant steel plate are as follows.

[0038] The chemical composition of the 600HB non-quenched and tempered wear-resistant steel plate is as follows: C 0.35%, Si 0.30%, Mn 1.6%, P 0.005%, S 0.006%, Cr 0.3%, Mo 0.3%, Ni 1.2%, Cu 1.2%, Nb 0.2%, V 0.1%, B 0.001%, rare earth 0.001%, the rest is Fe and unavoidable impurities; the thickness is 50mm.

[0039] The above chemical components are smelted according to the mass percentage and cast into ingots, and the ingots are heated before rolling. The heating temperature is 1200° C. and the heating time is 3 hours. Two-stage controlled rolling is adopted, the rough rolling start temperature is 1120°C, the finish rolling temperature is 1030°C, and the cumulative reduction rate of rough rolling is 51.5%; the finish rolling start temperature is 1000°C, the finish rolling temperature is 920°C, the finish rolling temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com